Patents

Literature

123results about How to "Improve pore forming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

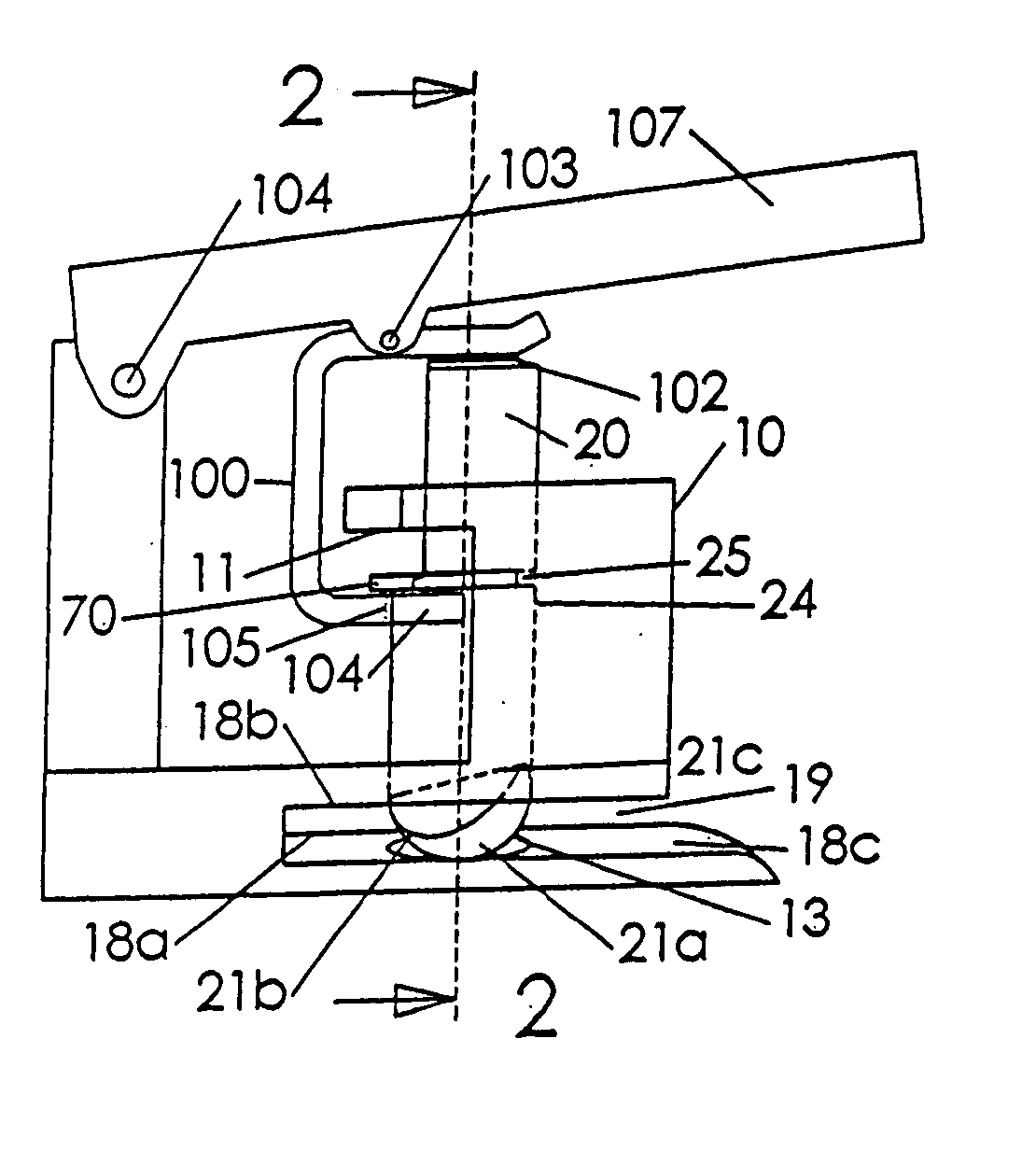

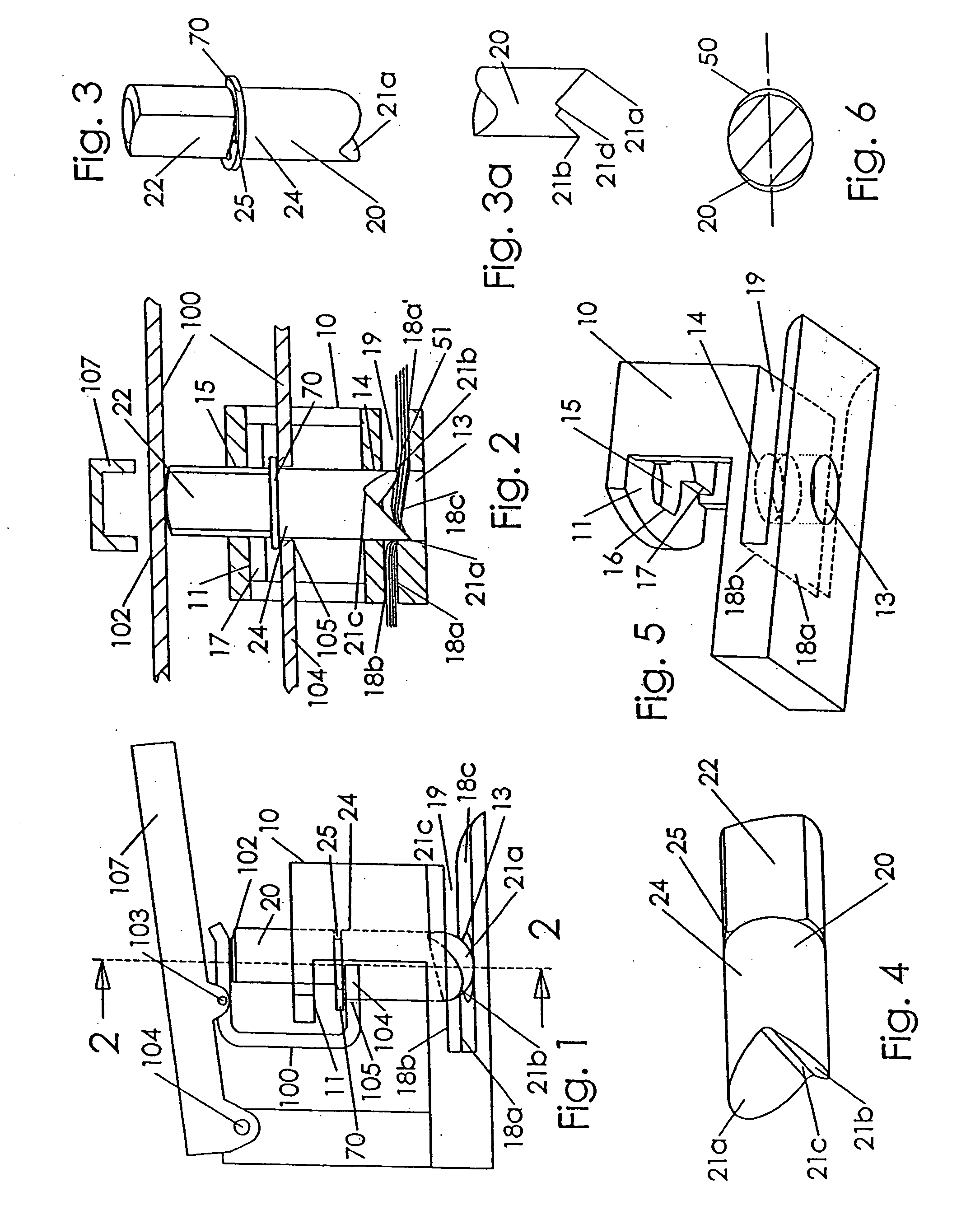

Hole punch element

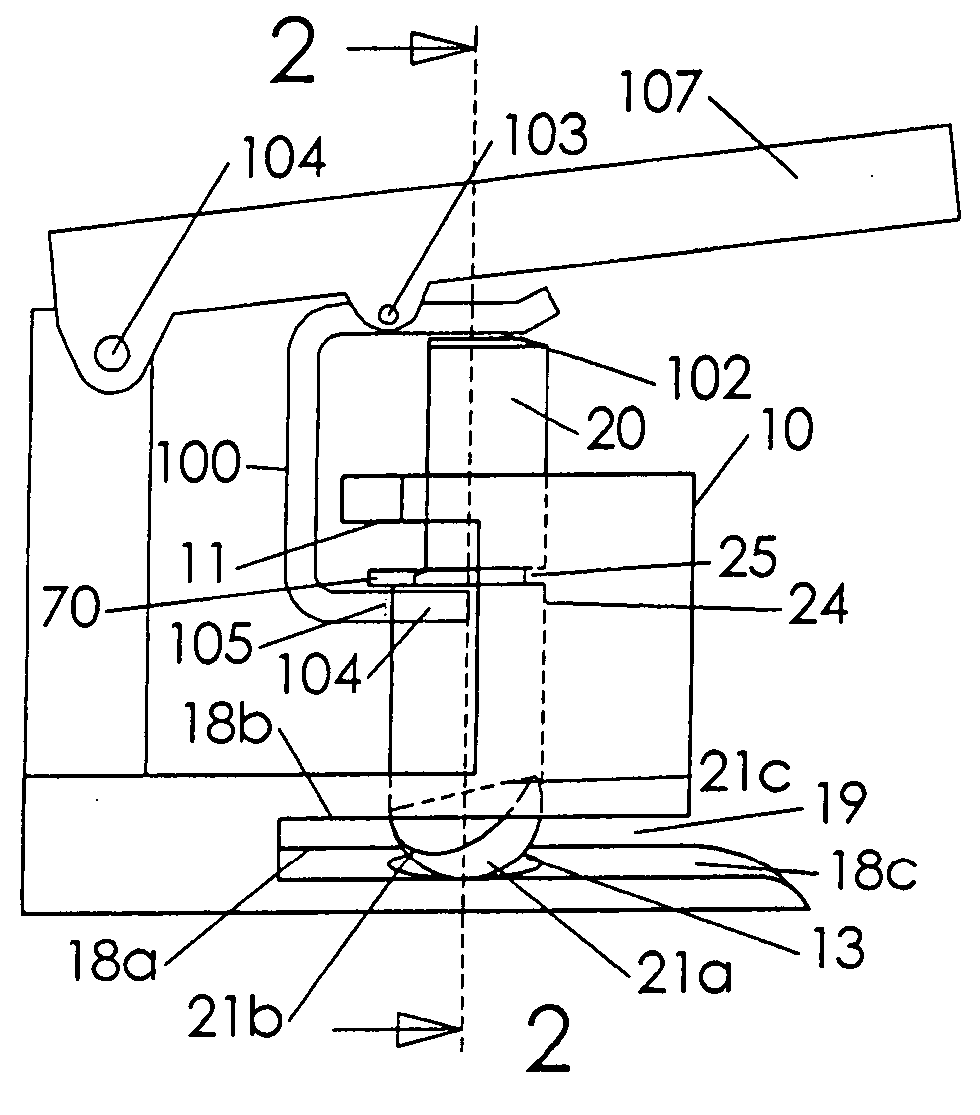

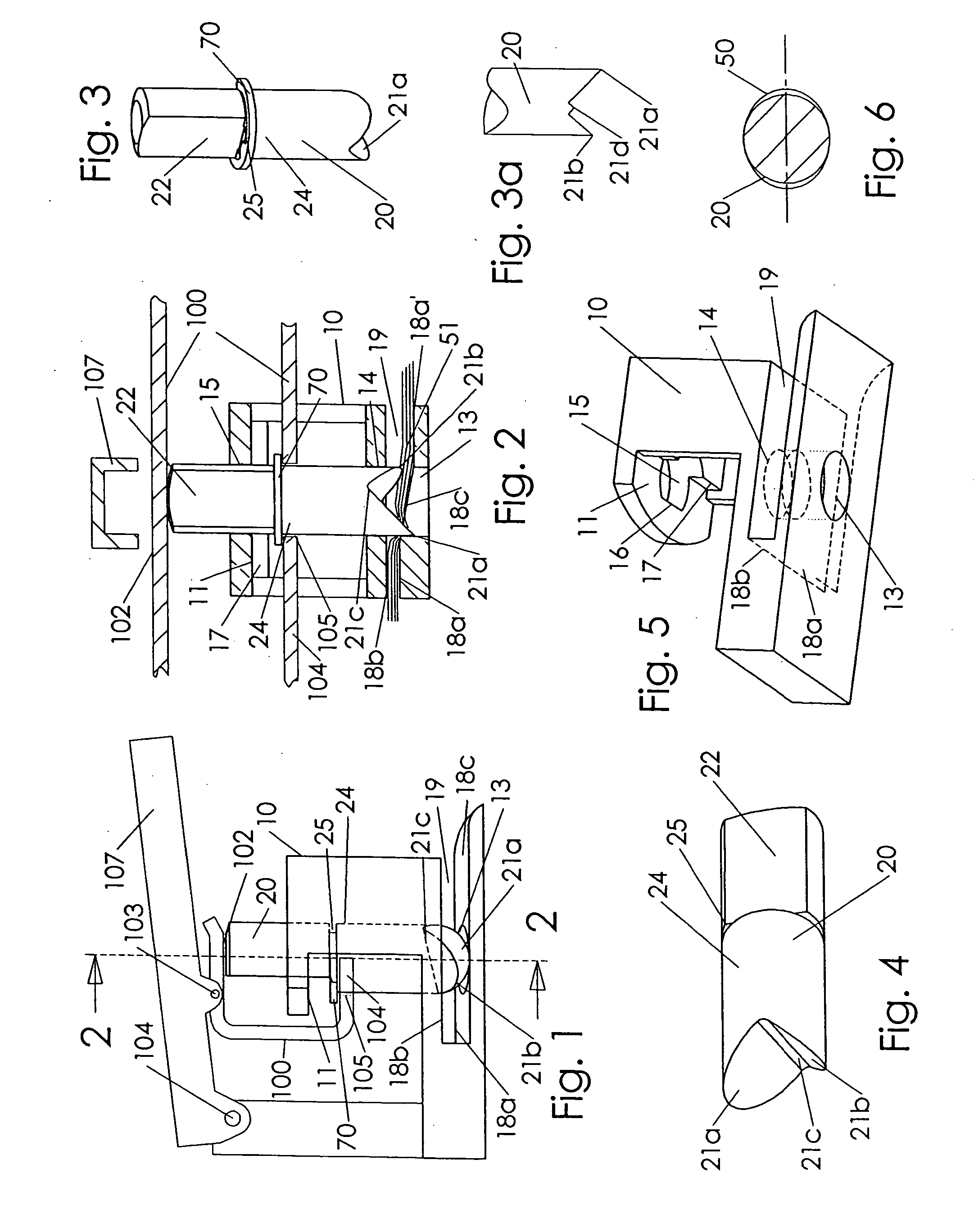

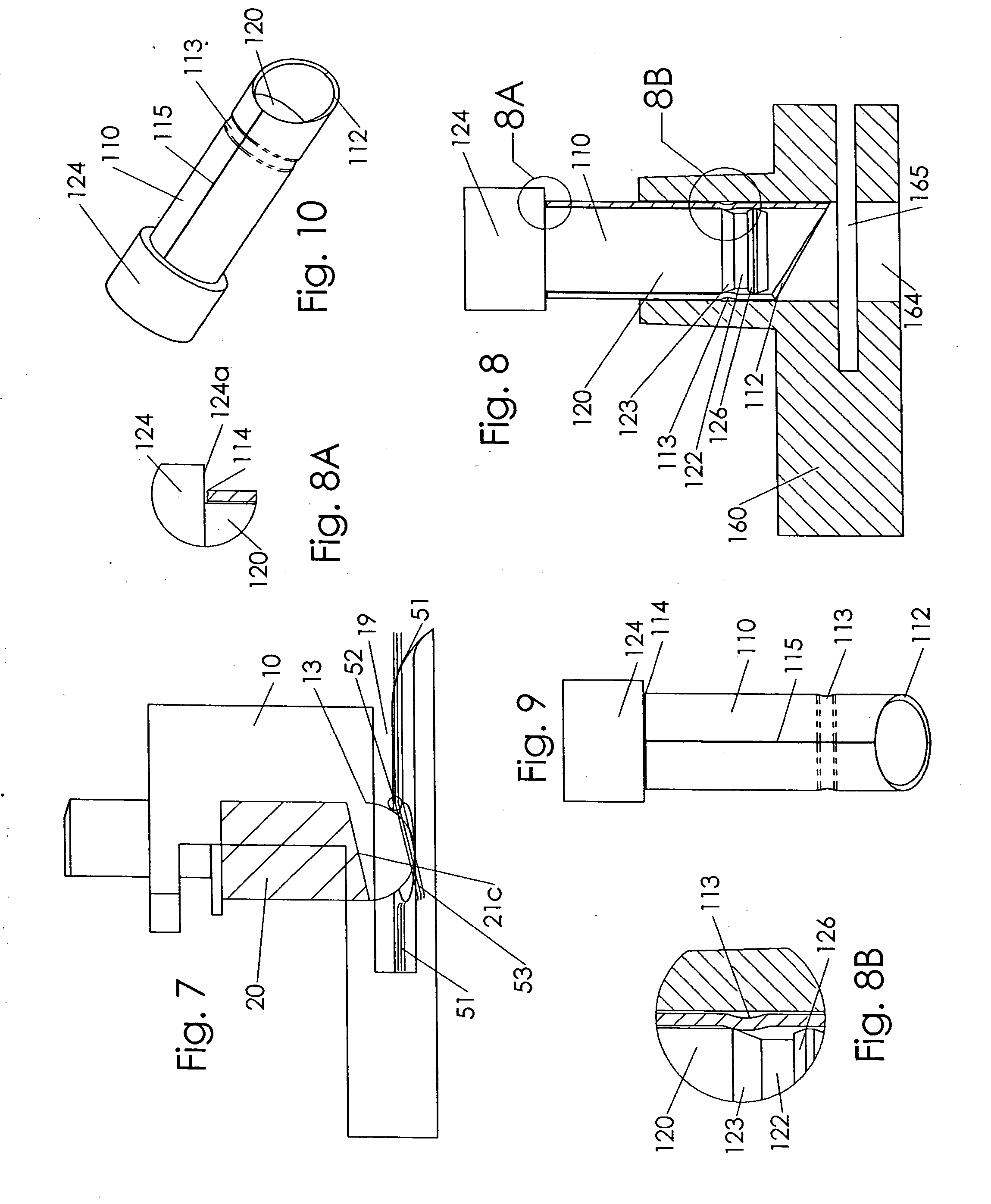

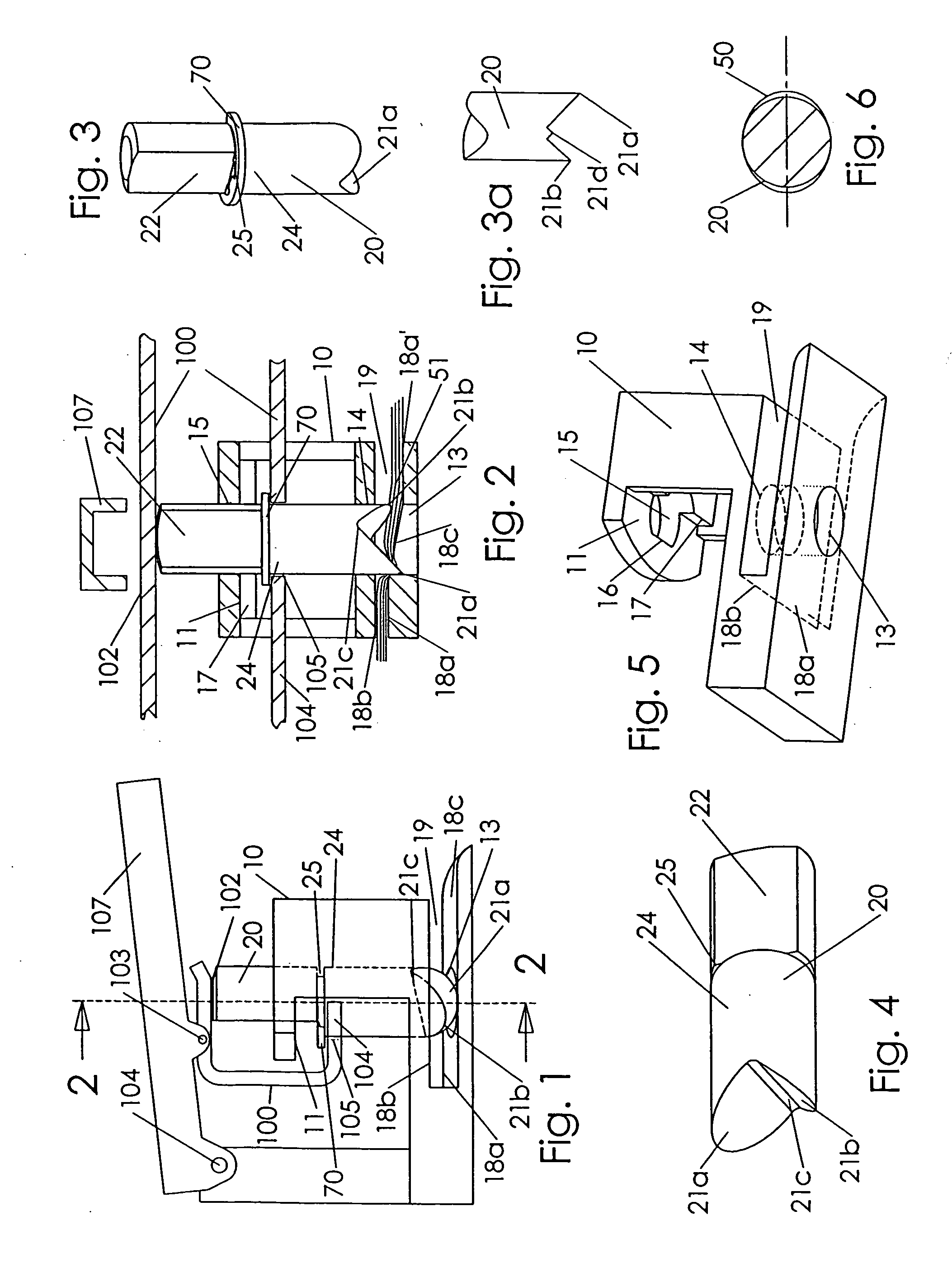

InactiveUS20070044618A1Reduce punching effortMinimize return spring forceMetal working apparatusClassical mechanicsStructural engineering

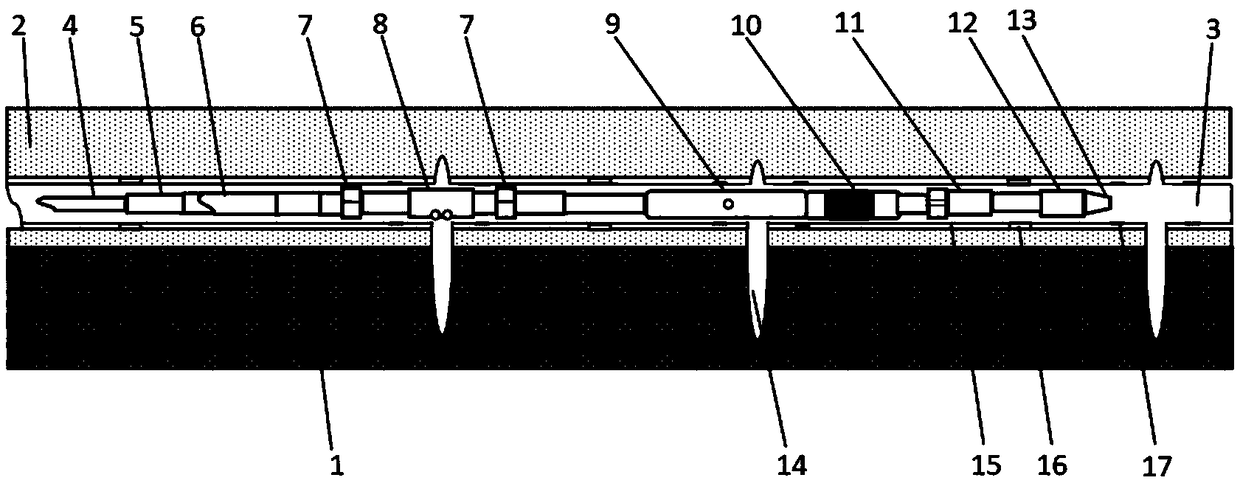

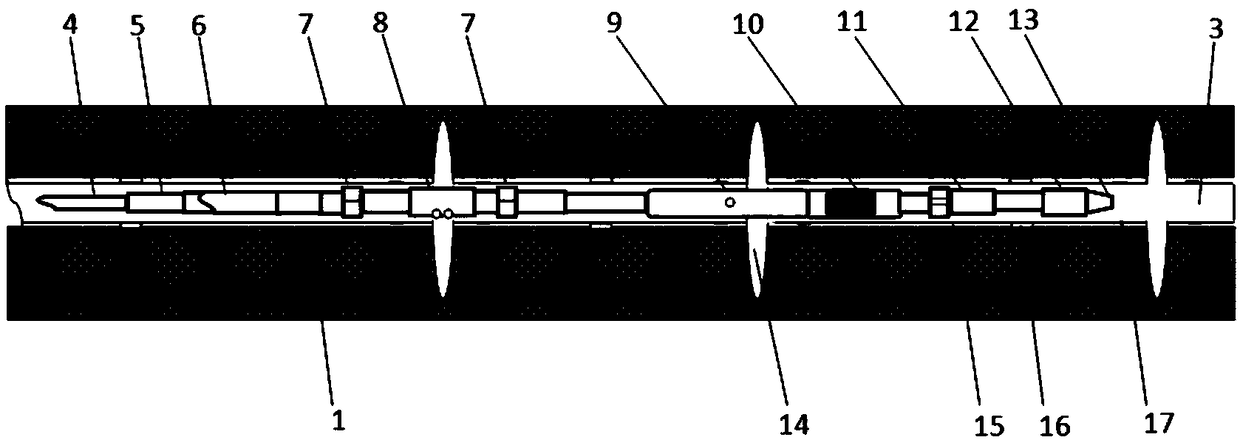

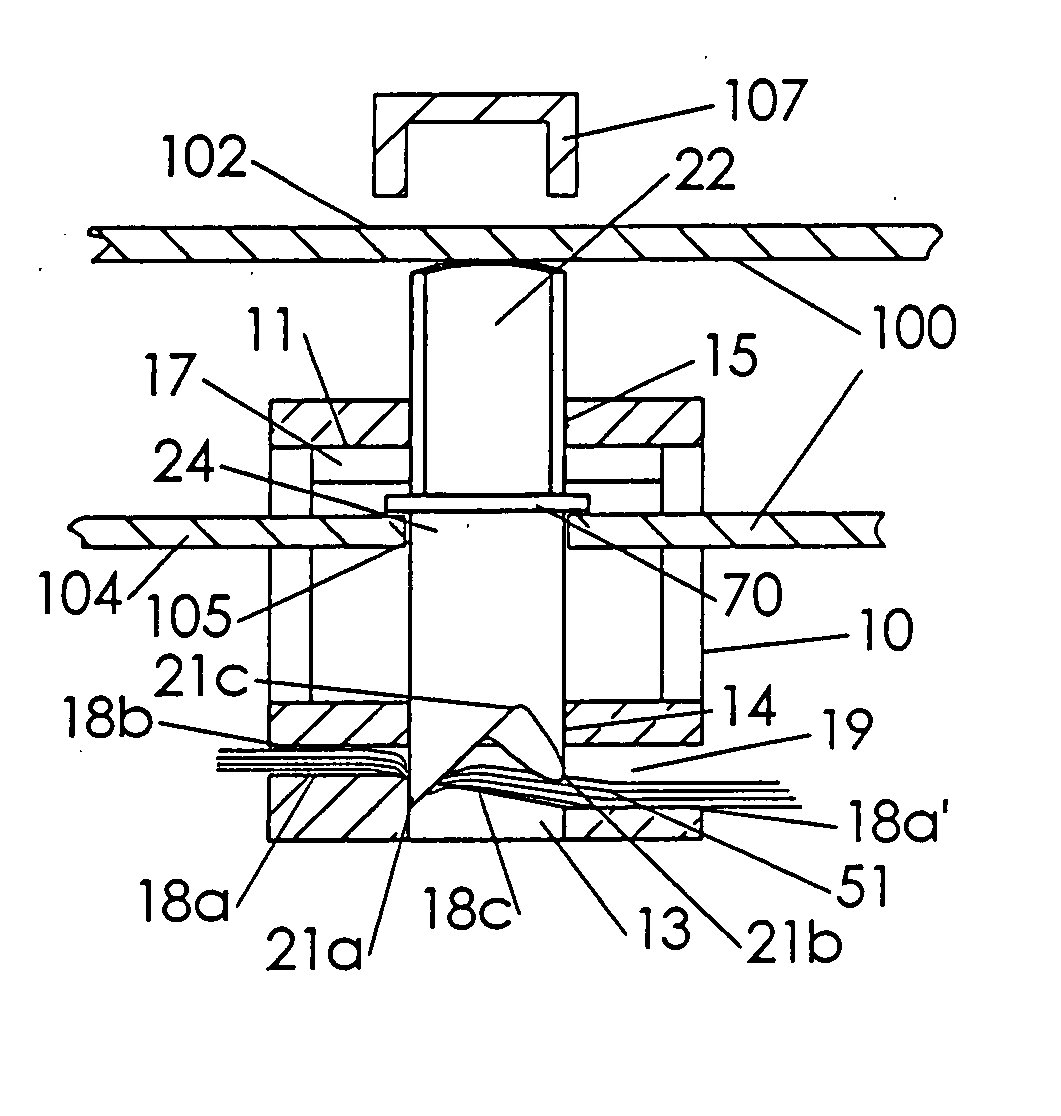

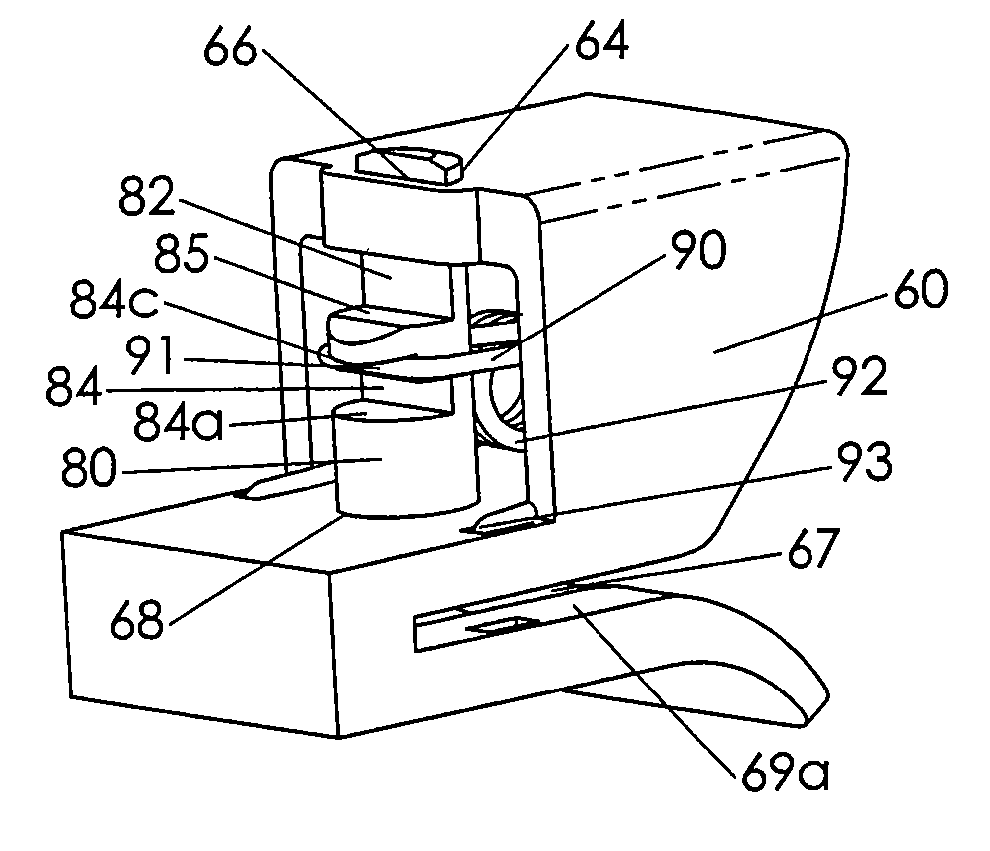

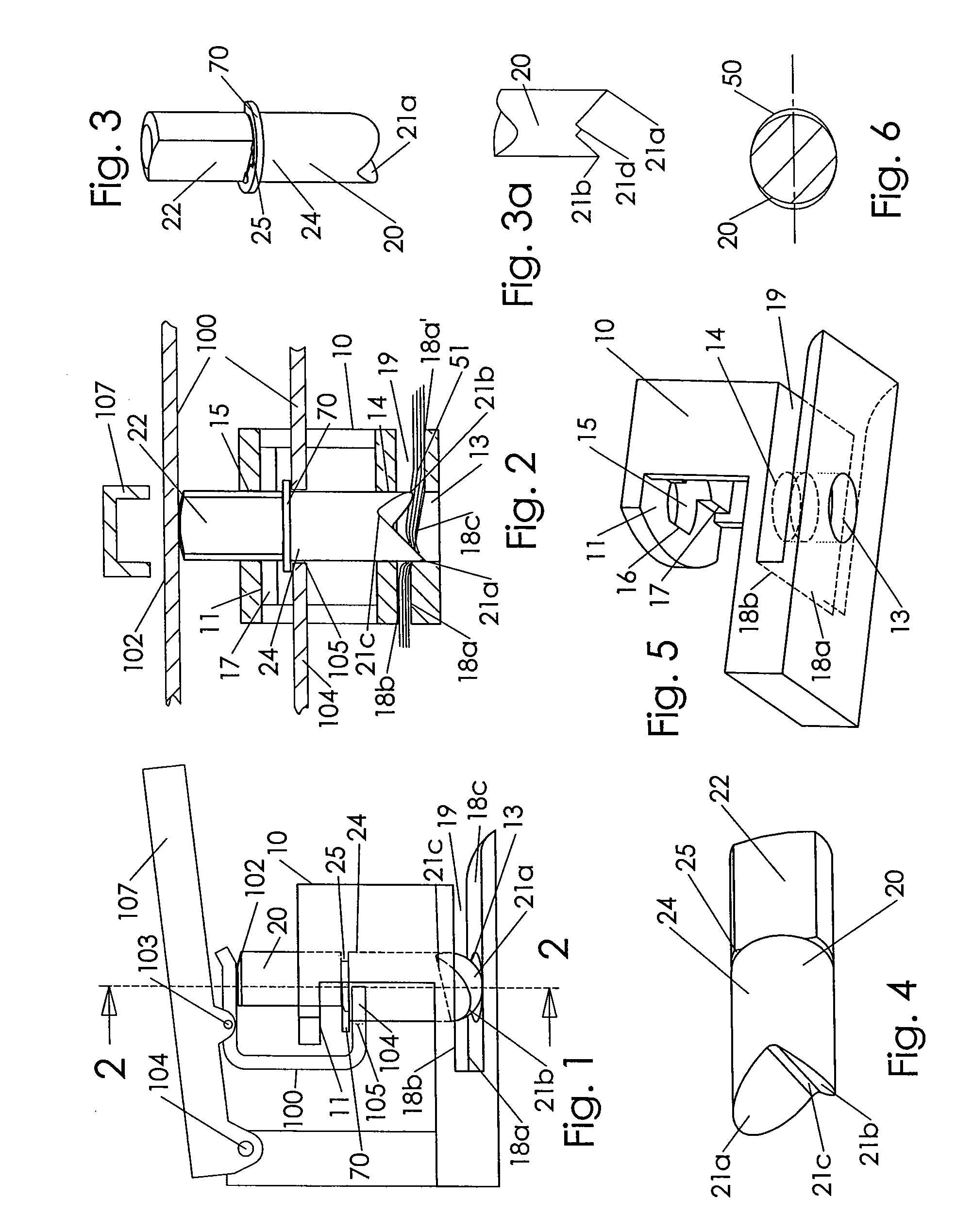

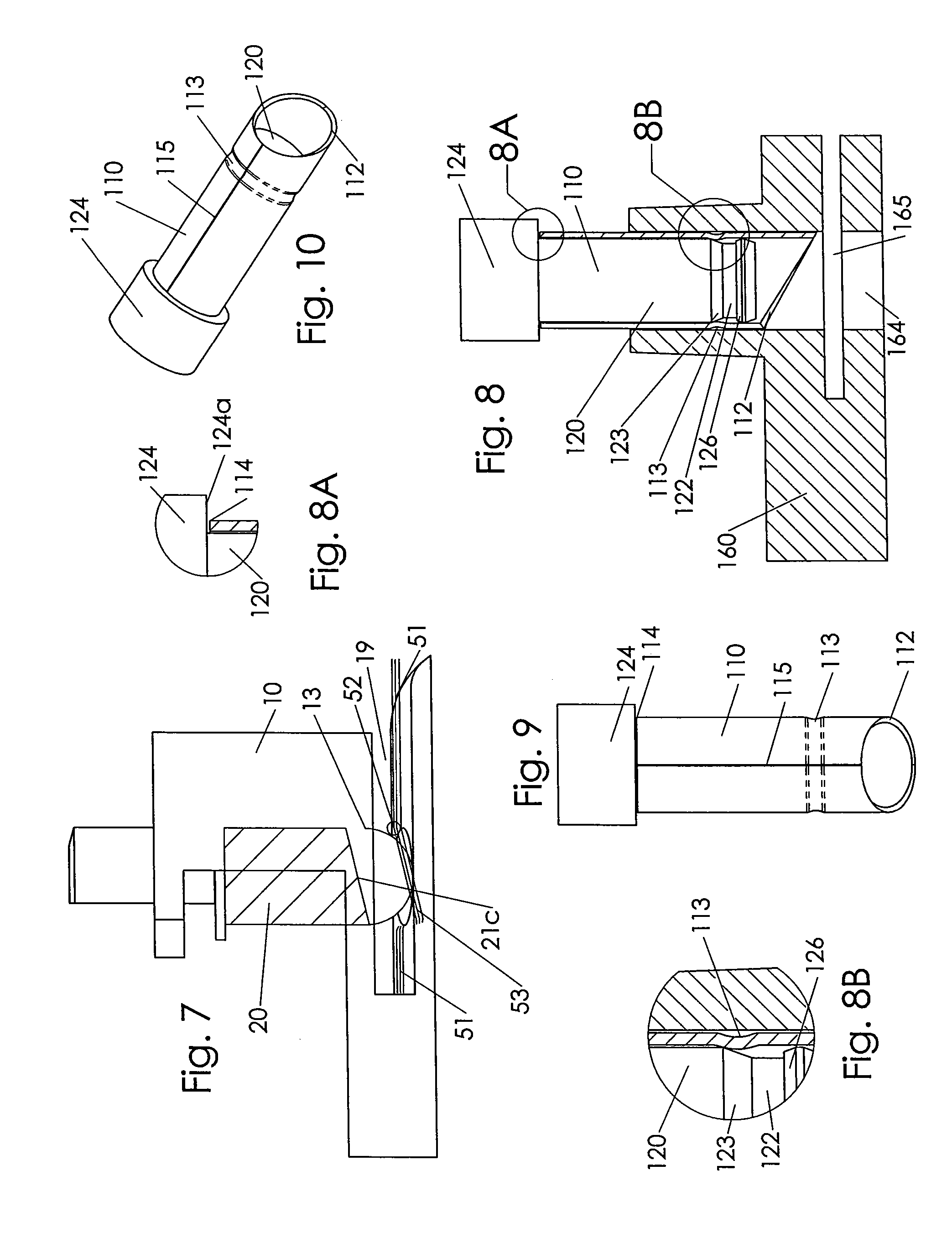

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create a bend in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. A long lead-in surface in the frame helps installing sheet media into the feed slot of the punch element.

Owner:WORKTOOLS

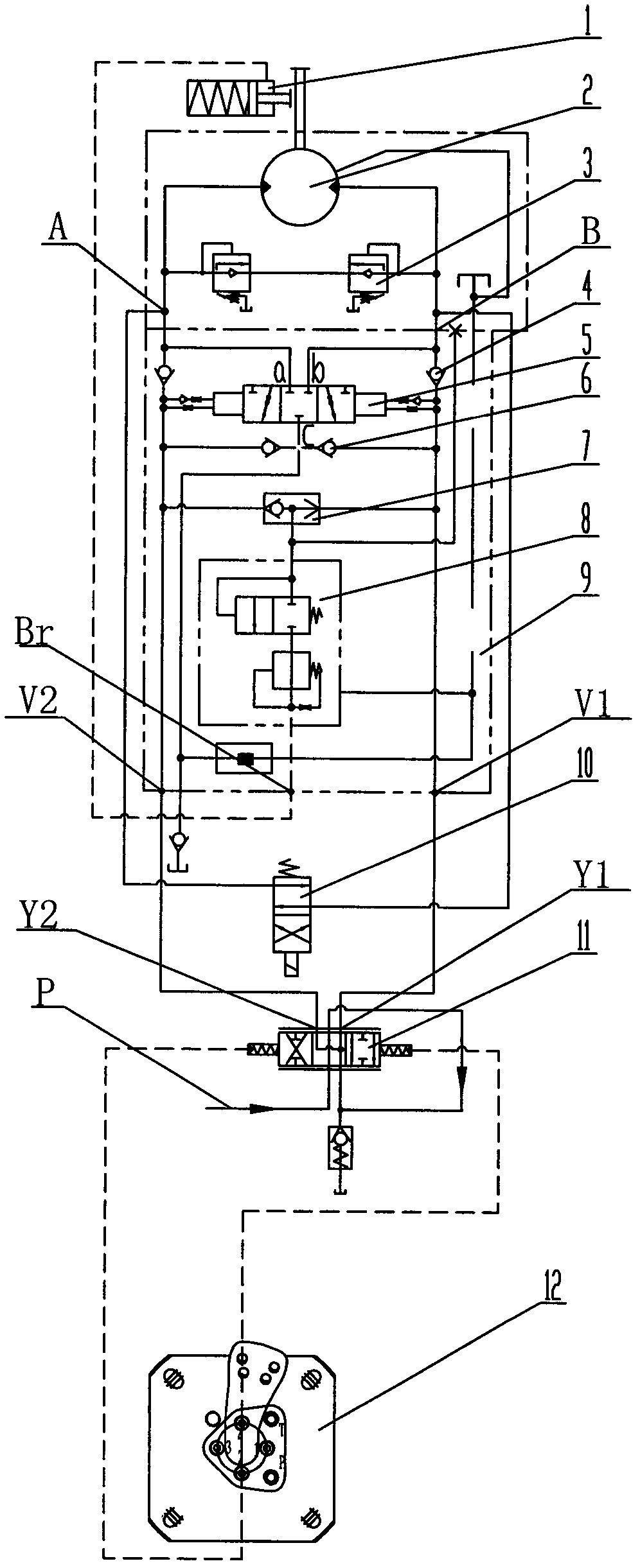

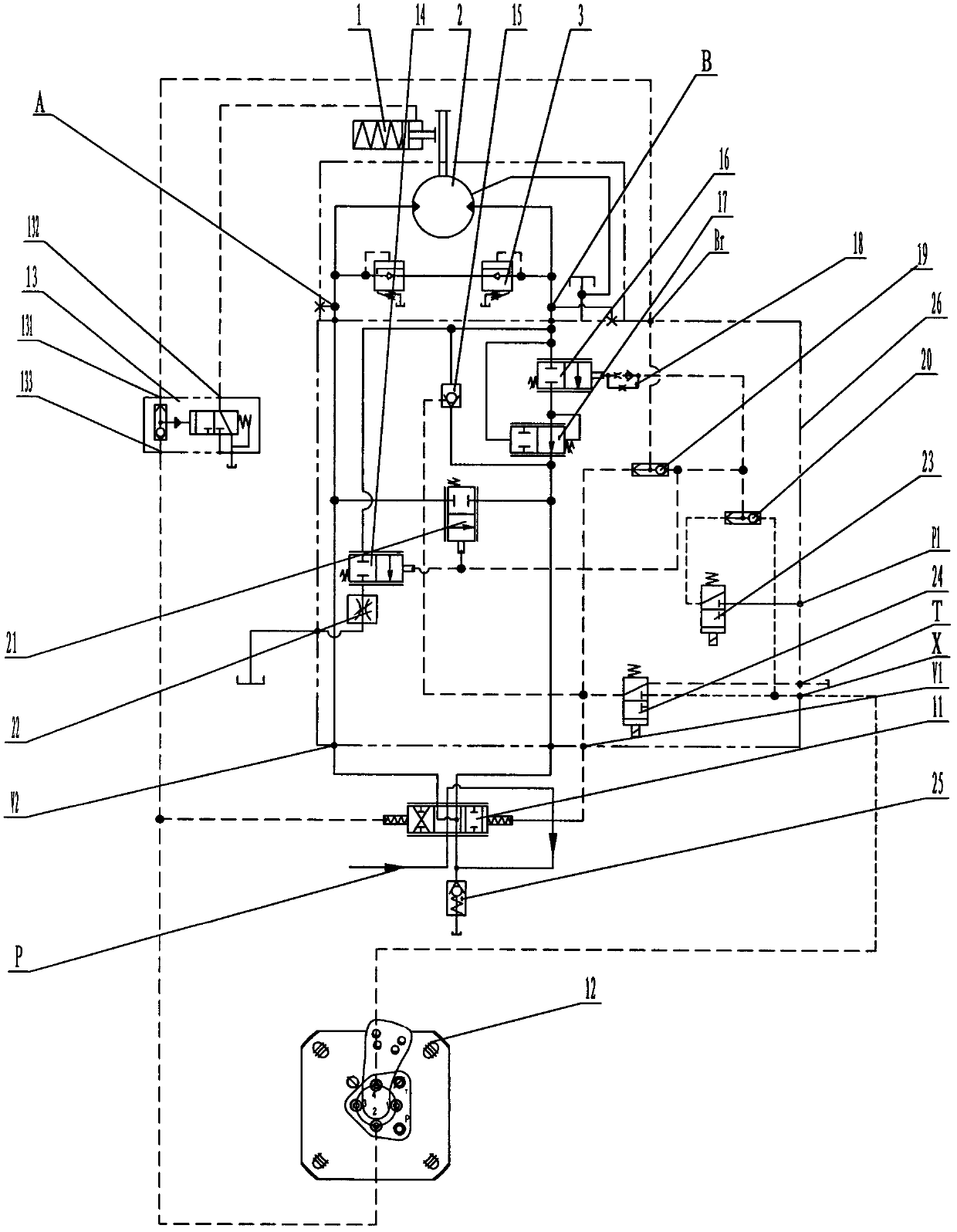

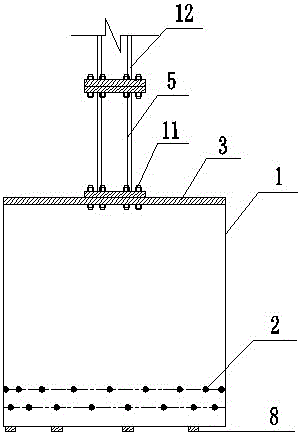

Main winch rapid-descent and confluent return oil regeneration system of rotary drilling rig

ActiveCN102167266ASpeed up the descentReduce auxiliary work timeDrilling rodsWinding mechanismsControl signalIdle speed

The invention discloses a main winch rapid-descent and confluent return oil regeneration system of a rotary drilling rig, which includes a main winch motor, a brake, a main valve and a pilot handle, wherein the pilot handle is communicated with the main valve through an oil path, and a special balance valve block for return oil regeneration is connected between the main winch motor and the main valve through pipelines and is controlled and adjusted by a control device. The invention improves the efficiency, accelerates the descent of the main winch, shortens the pore-forming subsidiary operation time, and improves the pore-forming efficiency. The main winch utilizes the own gravity to do work in the descent process, so that an engine is not required to run with full power but run at an idle speed, thereby saving the fuel oil and reducing the CO2 emission from a main unit; braking and speed adjusting control signals come from the pilot handle, so that the system controllability is better in comparison with the original form that motor +BVD balance valve control signals come from the inside of a BVD balance valve, the problem that the winch slides downwards in a stalled state is basically solved, and the damage to a drilling stem and a drilling rig caused by the fall-off of the drilling stem can be effectively prevented.

Owner:QINGDAO LOVOL EXCAVATOR

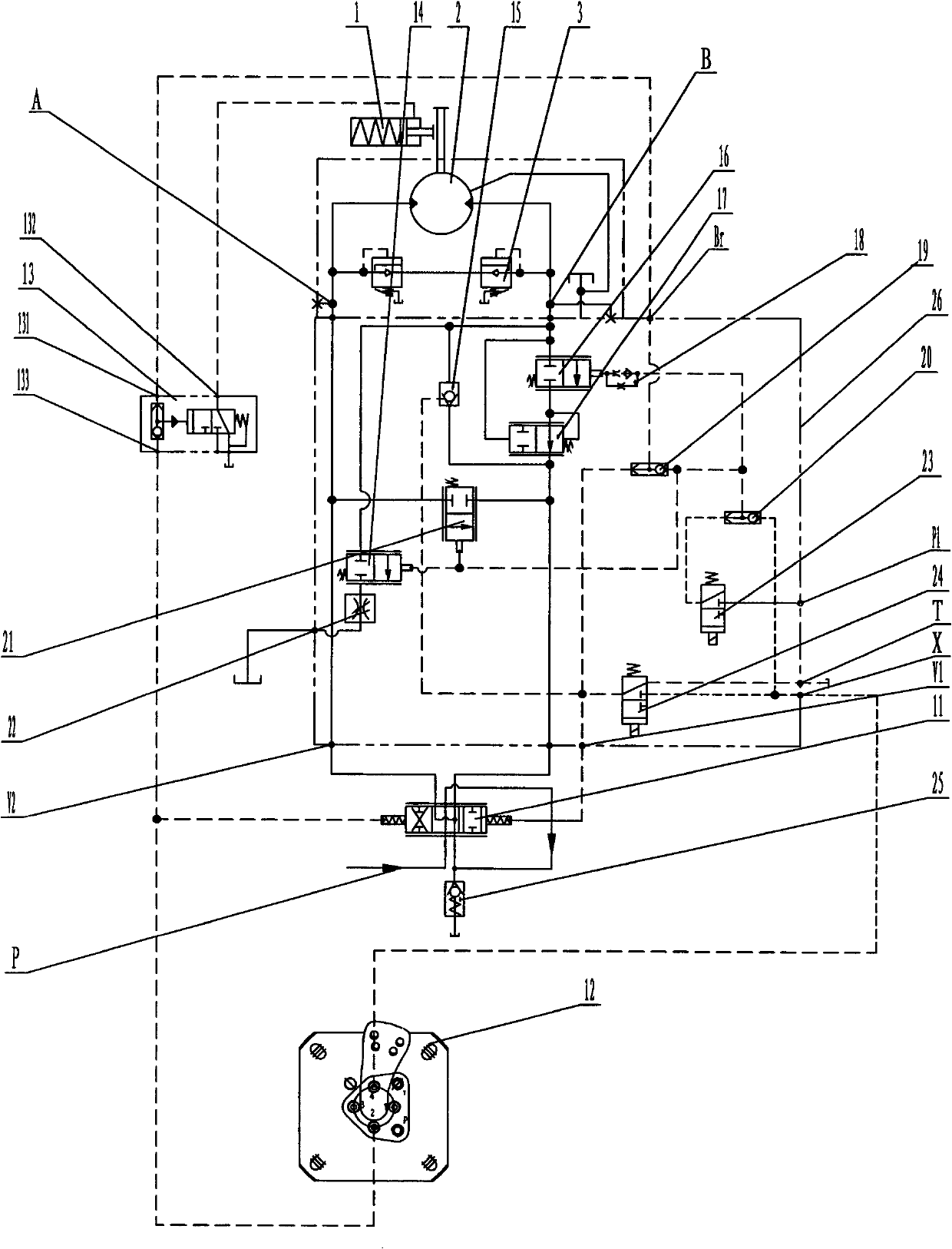

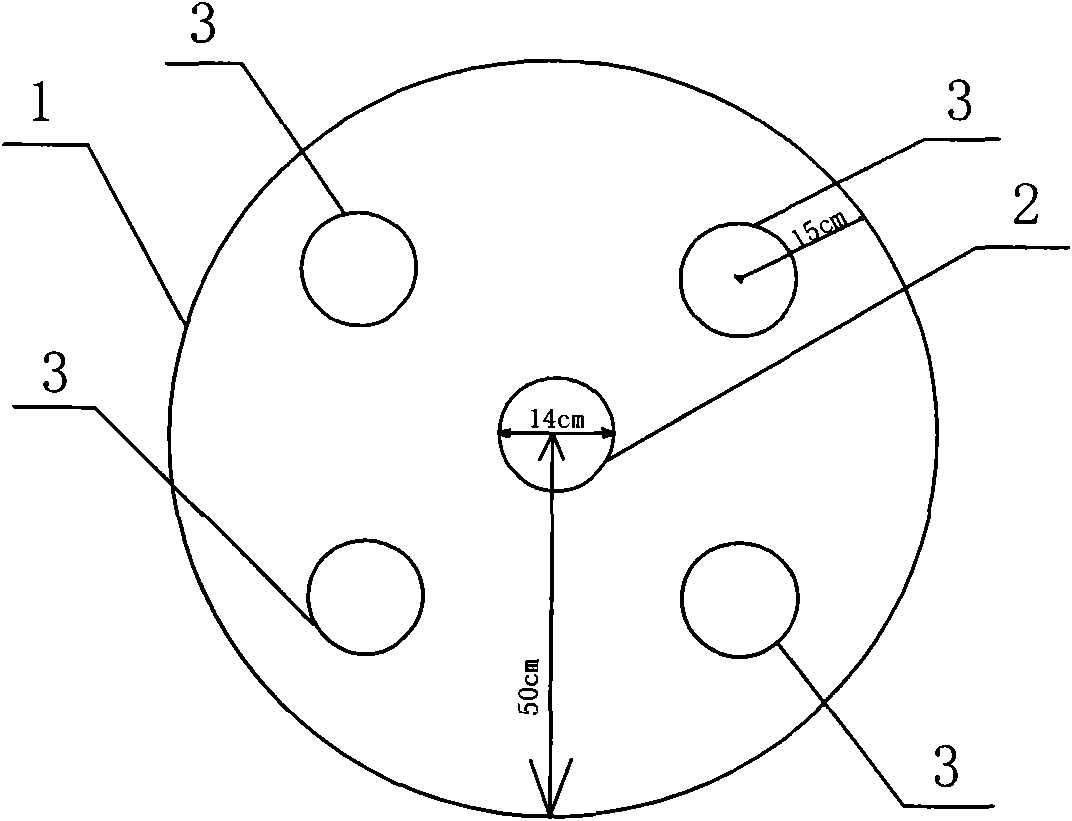

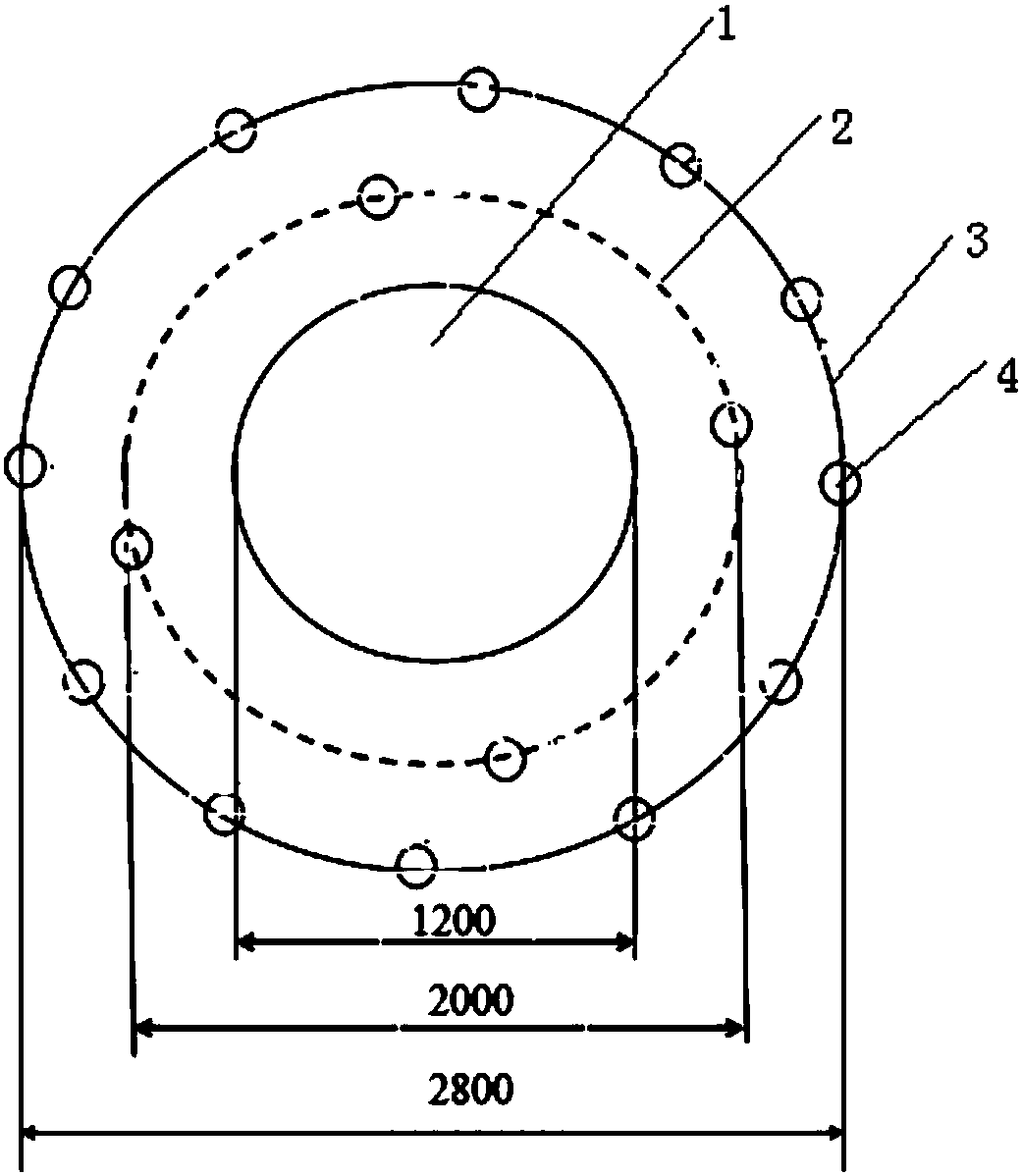

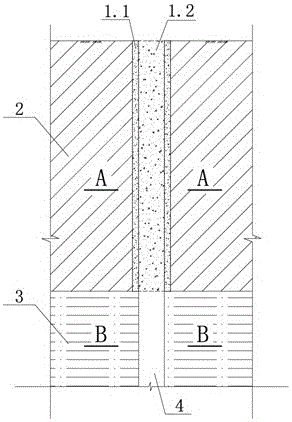

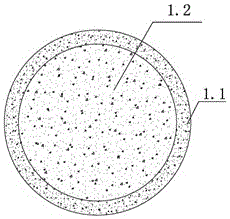

Rock mass pile foundation pore-forming preboring construction method

ActiveCN101570971AReduce the difficulty of correctionImprove pore forming efficiencyReciprocating drilling machinesFoundation engineeringPunchingModel Number

The invention relates to a rock mass pile foundation pore-forming preboring construction method, including: five hole sites are arranged at a drilled pile site, a center hole sit is arranged in the center of the drilled pile site, four surrounding hole sites are evenly distributed outside the center hole site, the distance between the center of each surrounding hole and the margin of the drilled hole site is equal, and an in-the-hole drill with a drill model number of Phi 140mm is used for drilling on the center hole site and the surrounding hole site. Another hole distribution mode includes: three hole sites are arranged at the drilled pile site, the distance between the center of each hole site and the center of the drilled hole pile site is equal and the connection lines of two adjacent hole site and the center form a 120 degrees angle, the distance between the center of the hole site and the margin of the drilled hole pile site is equal, and an in-the-hole drill with the model number of Phi 220mm is used for punching on the hole site. The method of the invention realizes that pore-forming efficiency of a punching drill is high, slant rock correction difficulty is reduced, construction quality is high, construction period is short and construction cost is low when rock bearing capacity at the foundation pile site of a bridge pile is more than 1000kPa or a slant rock is existed.

Owner:SINOHYDRO ENG BUREAU 4 +1

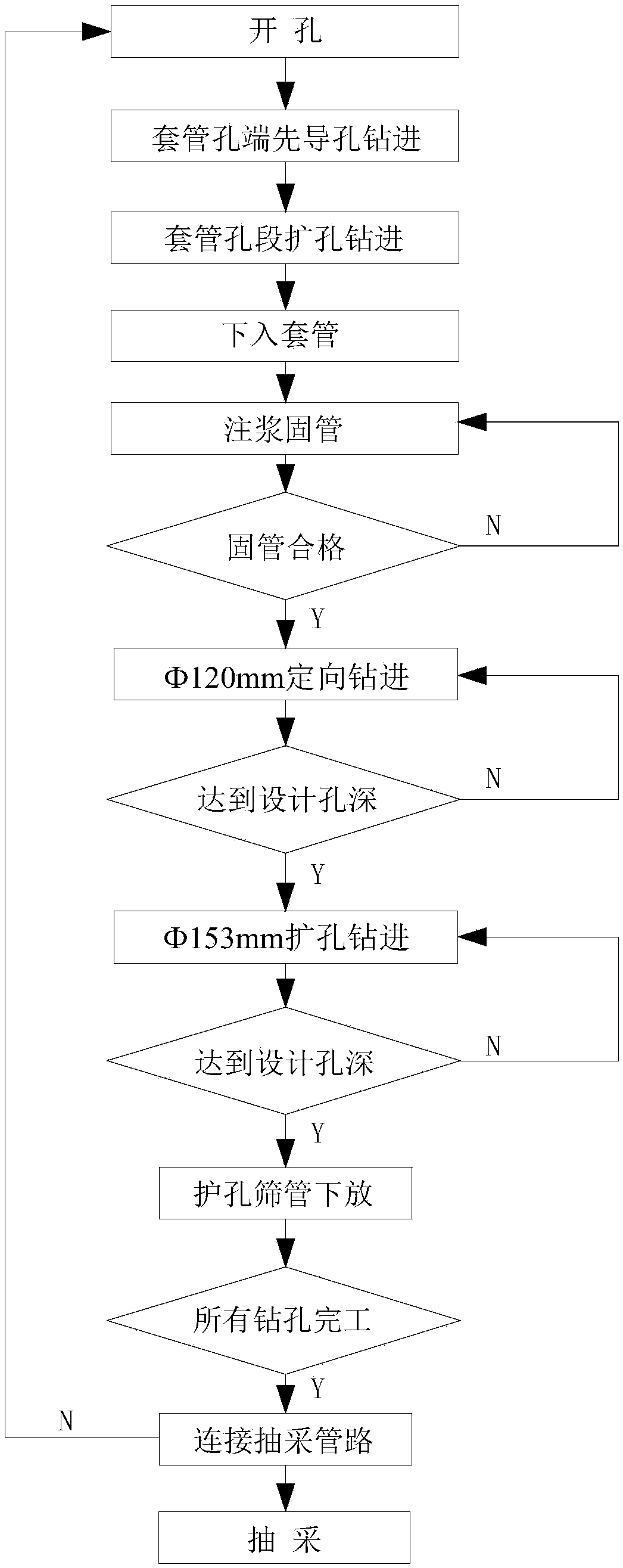

Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

ActiveCN109339855AAvoid prone to collapse holesAvoid problems such as drill stickingFluid removalGas removalSand blastingCoiled tubing

The invention relates to a coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method. The method includes the steps that first, a gas extraction long drilled hole is constructed in a mudstone or sandstone roof with a certain distance to the top boundary of a broken soft coal seam or a hard layer of the broken soft coal seam or a hard coal seam with a good coal body structure; second, a guiding shoe and a rigid casing are lowered; third, cement paste blocking is carried out on annular space between the gas extraction long drilled hole and the rigid casing so as to solidify the hole; fourth, packing staging is carried out through a mode of dragging a packer by coiled tubing, an ejector carries out sand blasting perforation, and fracturing is carried out on the annulus between the coiled tubing and the casing; fifth, a fracturing tool is lifted out, and uniform blowout of fracturing fluid is carried out. The method can solve the problems that in existing gas extraction hole-drilling, hole forming is difficult, the crack initiation position of fracturing cracks is not determined, the fracturing cracks extend short, the fracturing modification effect is poor, the extraction affecting range is small and nonuniform, and extraction duration is short, and realizes gas extraction long drilled hole forming and multi-level precise staged fracturing.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

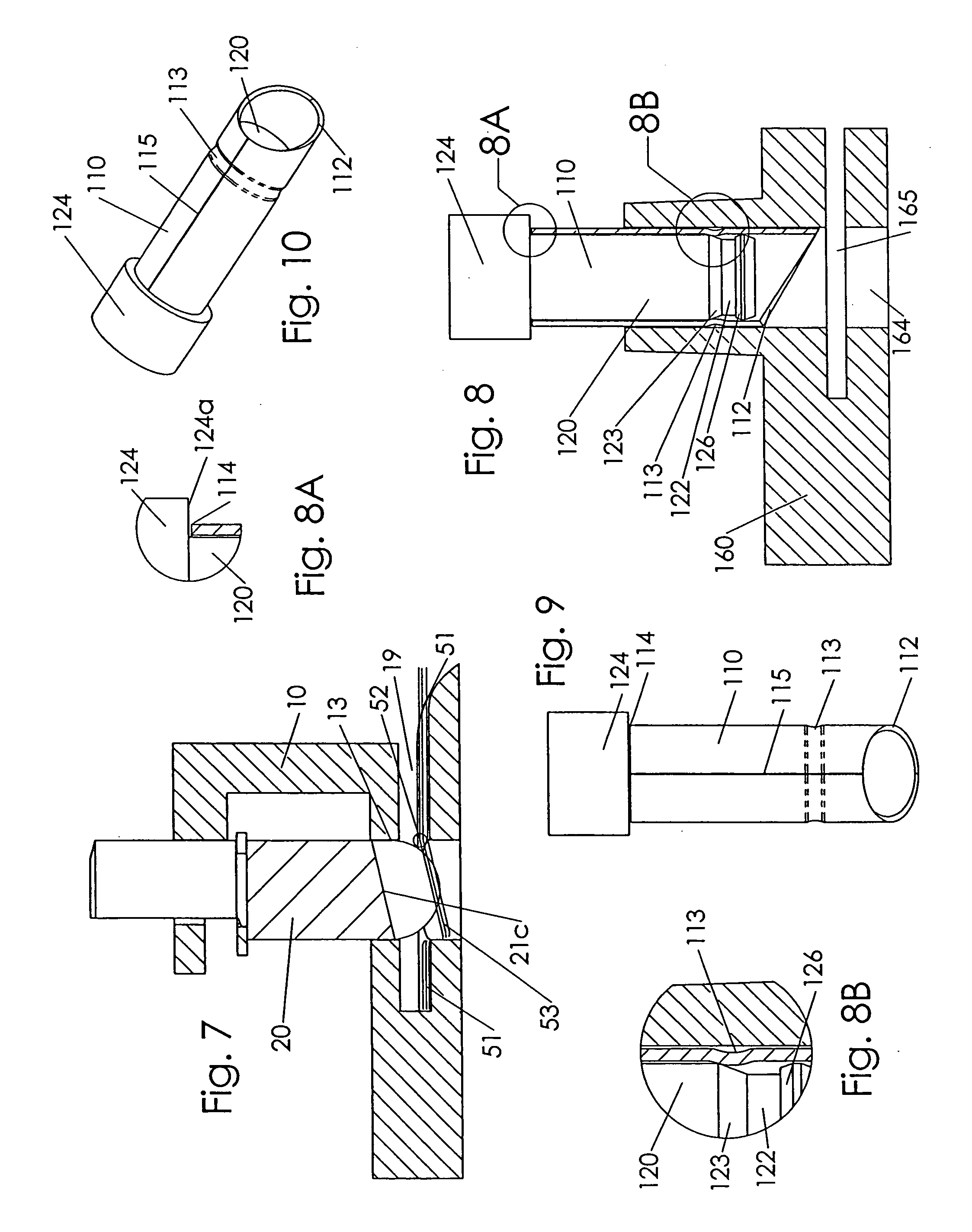

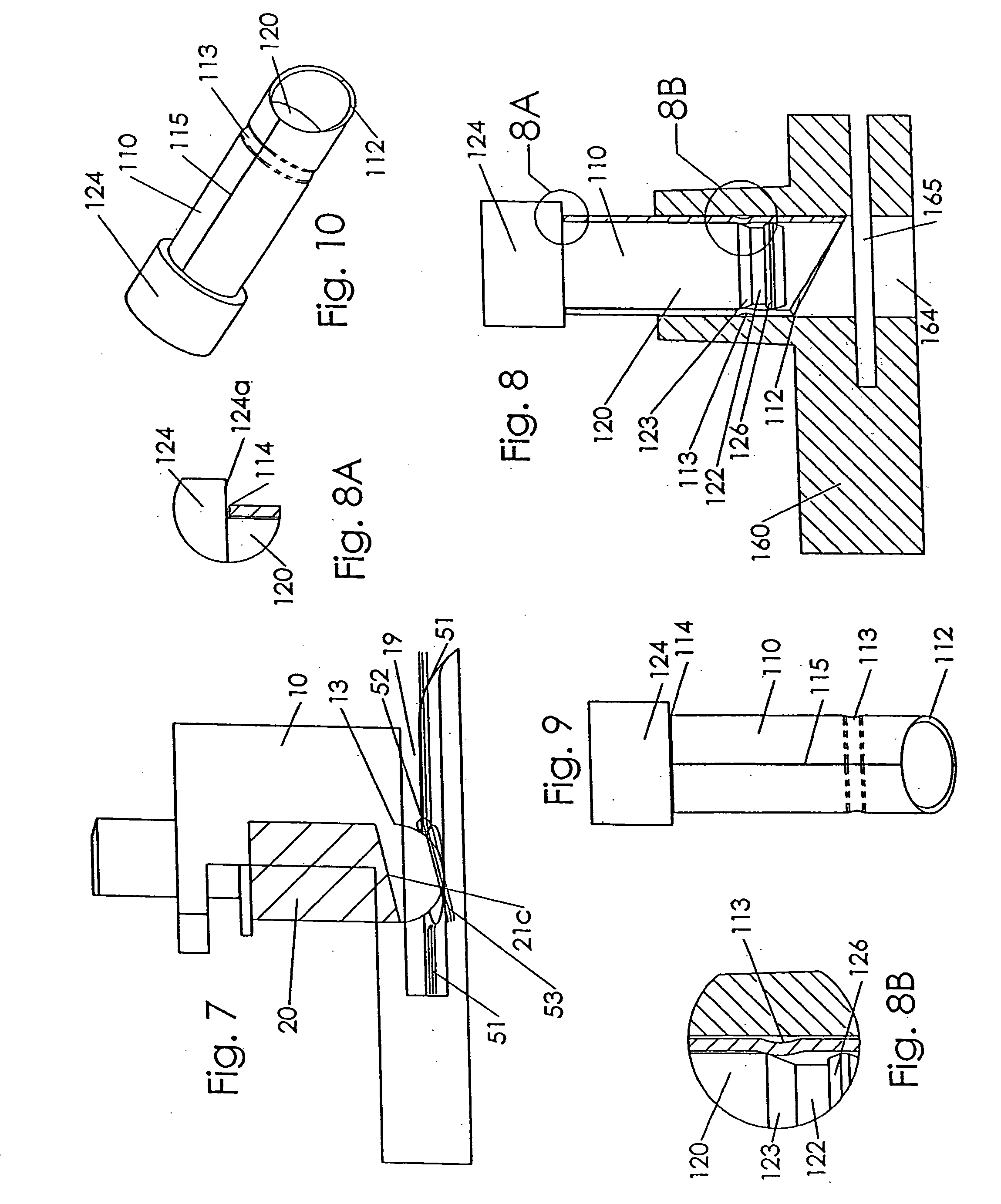

Low friction hole punch element

InactiveUS20070044623A1Reduce punching effortMinimize return spring forceMetal working apparatusElectroless nickelCutting force

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create a bend in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. The pin and / or other components optionally include electroless nickel plating to reduce friction and wear at the component or pin sliding and cutting surfaces.

Owner:WORKTOOLS

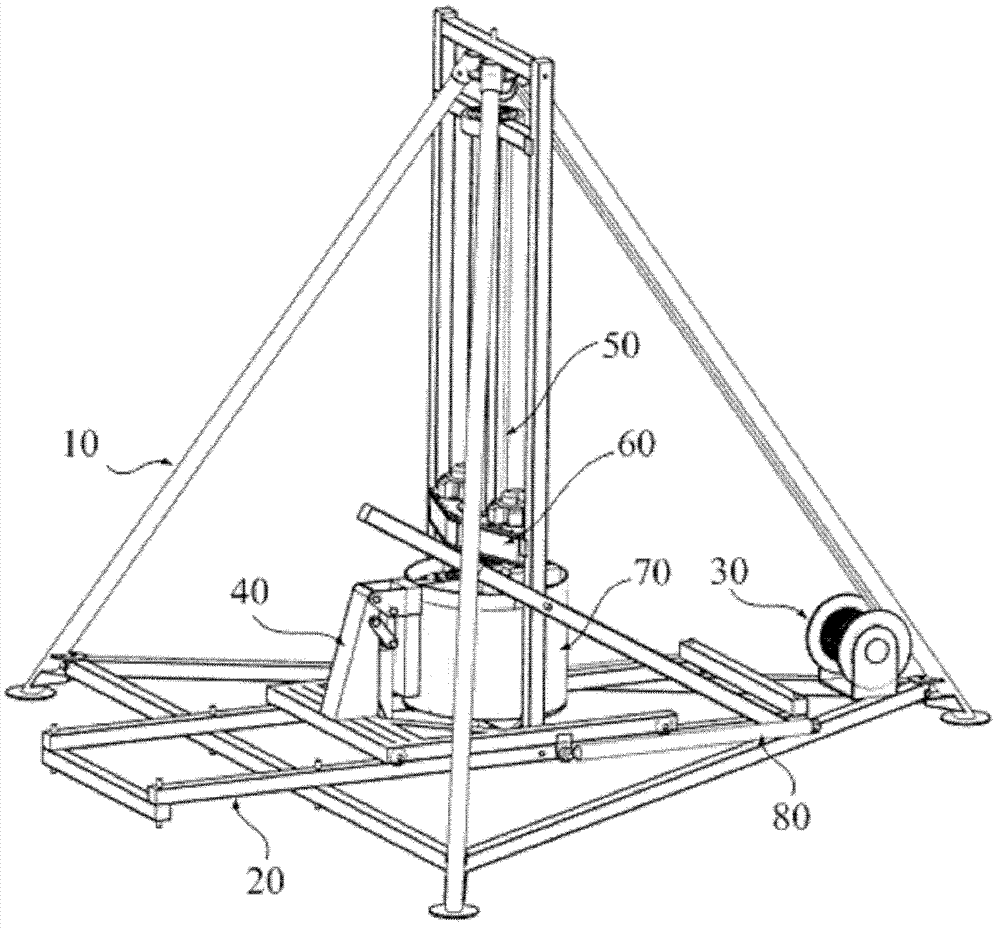

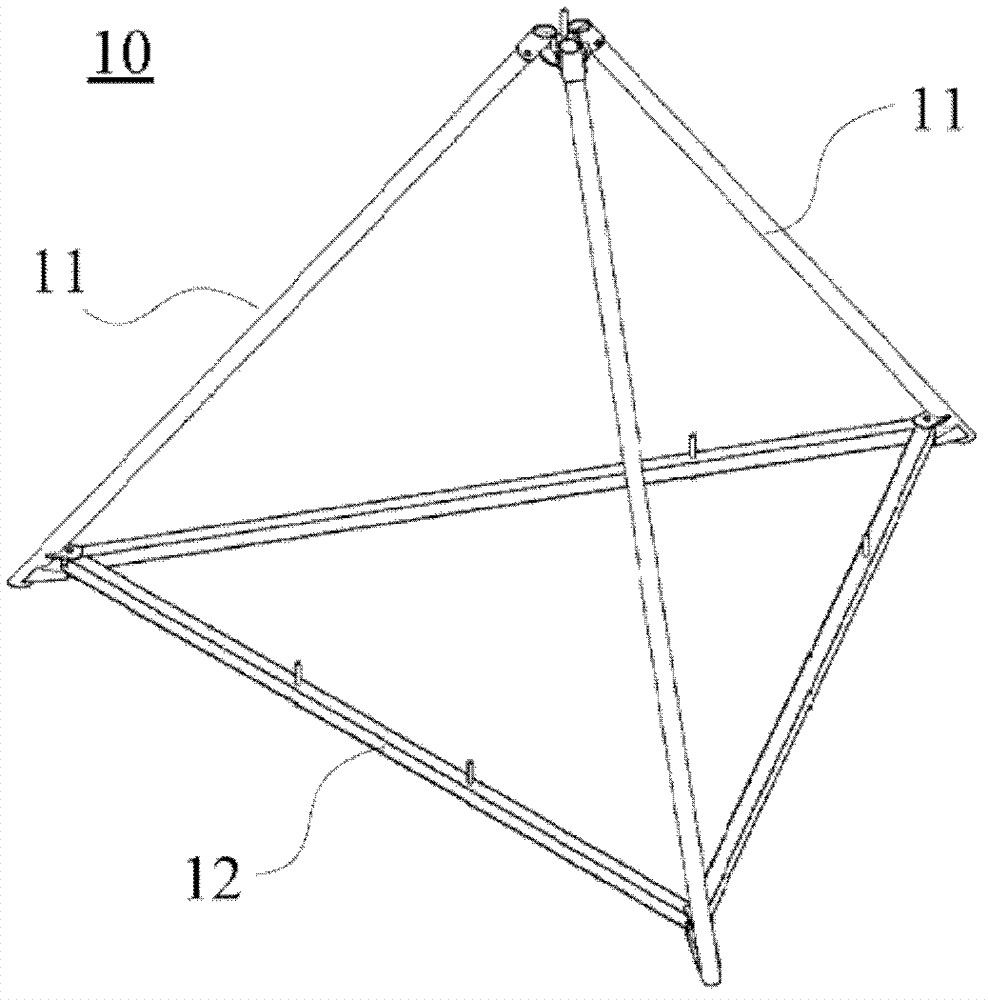

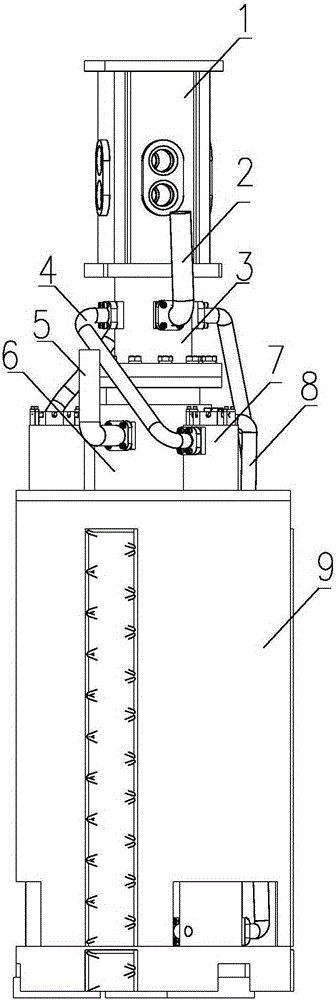

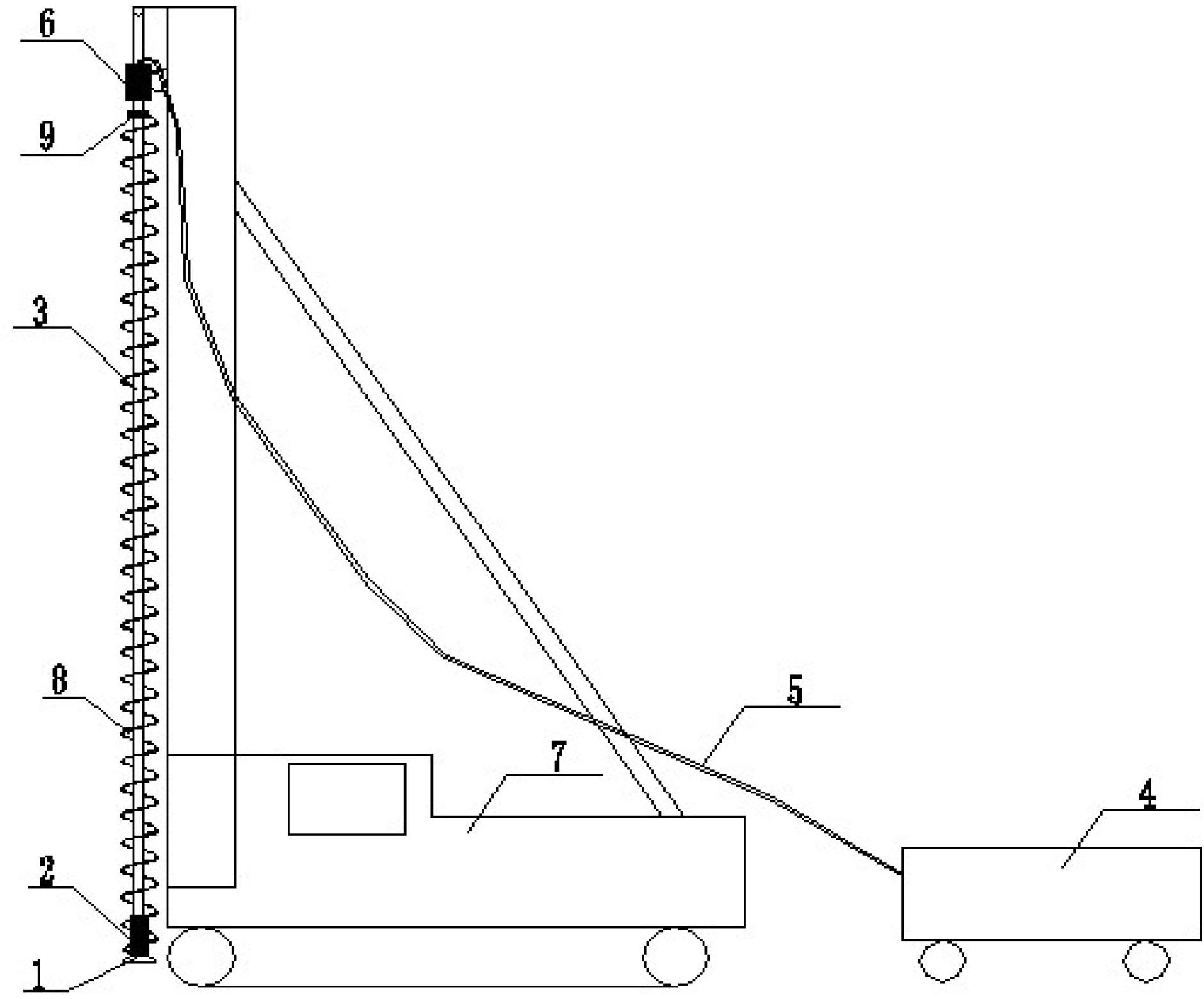

Combined type digging and drilling machine

ActiveCN102900360AHigh degree of mechanizationImprove pore forming efficiencyDrill bitsConstructionsHydraulic cylinderTerrain

The invention relates to a combined type digging and drilling machine. The combined type digging and drilling machine comprises a support, slide rails, a soil discarding mechanism, a drilling rod, a power head, a drilling head, a winch and two hydraulic cylinders. The slide rail is fixedly connected on the support and comprises a horizontal rail and a vertical rail. The soil discarding mechanism is arranged on the slide rail and driven to run on the slide rail via the hydraulic cylinder. The drilling rod is connected on the slide rail and penetrates through the power head. Two ends of the power head are slidingly connected to the vertical rail. The drilling head is detachably connected at the lower end of the drilling rod. The winch is arranged on the support and connected to the top end of the drilling rod via a steel cable. One ends of the two hydraulic cylinders are respectively connected with a longitudinal beam of a slide frame, and the other ends are connected on the support or on the slide rail. The combined type digging and drilling machine is convenient to move on the scene, has no special requirement on terrain and is applicable to plains, hills and ordinary mountain areas.

Owner:STATE GRID CORP OF CHINA +2

Hole punch element

InactiveUS20070044624A1Reduce punching effortMinimize return spring forceMetal working apparatusEngineeringCutting force

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create an angle in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. The punch elements and punch pins may be configured so that the punch pins cut into the sheet media sequentially.

Owner:MARKS JOEL S

Construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles

ActiveCN104264689AQuick breakHole forming efficiencyExcavationsBulkheads/pilesSlurry wallSurface layer

The invention discloses a construction method for forming grooves and holes and replacing large-diameter piles with small-diameter piles. The method mainly includes the steps of forming the grooves in an underground continuous wall with the aid of a DTH hammer, forming the holes in the large-diameter piles with the aid of the DTH hammer and replacing the large-diameter piles with the small-diameter piles equivalently through the DTH hammer. Compared with a conventional groove and hole forming method, the construction method has the advantages that the defects that rock entering efficiency is low, holes are deviated, the hammer is stuck and even holes are difficult to form in the construction process under the comprehensive complicated geological conditions such as high-rock surface layers, hard stratums and slope stratums can be effectively overcome, the rock entering construction efficiency during grooving of the underground continuous wall and hole forming of the large-diameter piles can be greatly improved, the technical problems of the rock entering groove and hole forming construction under the complicated geological conditions such as high rock surface layers and hard stratums are solved, the construction quality is stable and reliable, the requirements for safety civilization and environmental construction are met, and economic loss and construction time loss of a project can be effectively avoided.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Quick cleaning device for boulders in cast-in-place pile and construction process thereof

The invention discloses a quick cleaning device for boulders in a cast-in-place pile. The quick cleaning device comprises a drilling cylinder and steel wire comb teeth, a top plate is arranged on the upper portion of the drilling cylinder, a second flange is connected in the middle of the top plate, the middle of the second flange is connected with stress rods, grouting holes are formed in the middle of the stress rods, the upper portions of the stress rods are connected with drilling rods through a first flange, and the lower portions of the stress rods extend downwards to the interior of the drilling cylinder. Rib plates are arranged between the side face of the top plate and the inner wall of the drilling cylinder, and 4-10 alloy drilling heads are arranged at the bottom of the drilling cylinder. The steel wire comb teeth are arranged on the lower portion inside the drilling cylinder, the steel wire comb teeth are divided into an upper layer and a lower layer, each layer of steel wire comb teeth is composed of 10-30 steel wire ropes, and stone filling holes are formed between the steel wire comb teeth. According to the quick cleaning device, quick boulder cleaning is achieved, significant effects are achieved particularly on the boulders with small volumes and numbers, manufacturing cost is low, and operation is easy. The drilling cylinder needs to be replaced instead of a drilling machine when used, so that compared with a punching piling machine, pore forming efficiency is greatly improved, the construction period is shortened, efficiency is improved, and practicability is strong.

Owner:CCCC THIRD HARBOR ENG +1

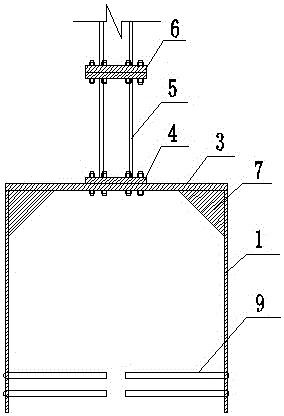

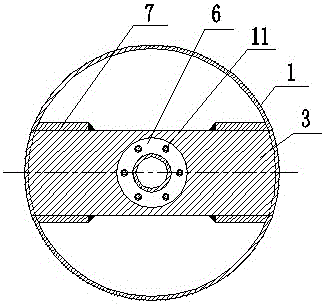

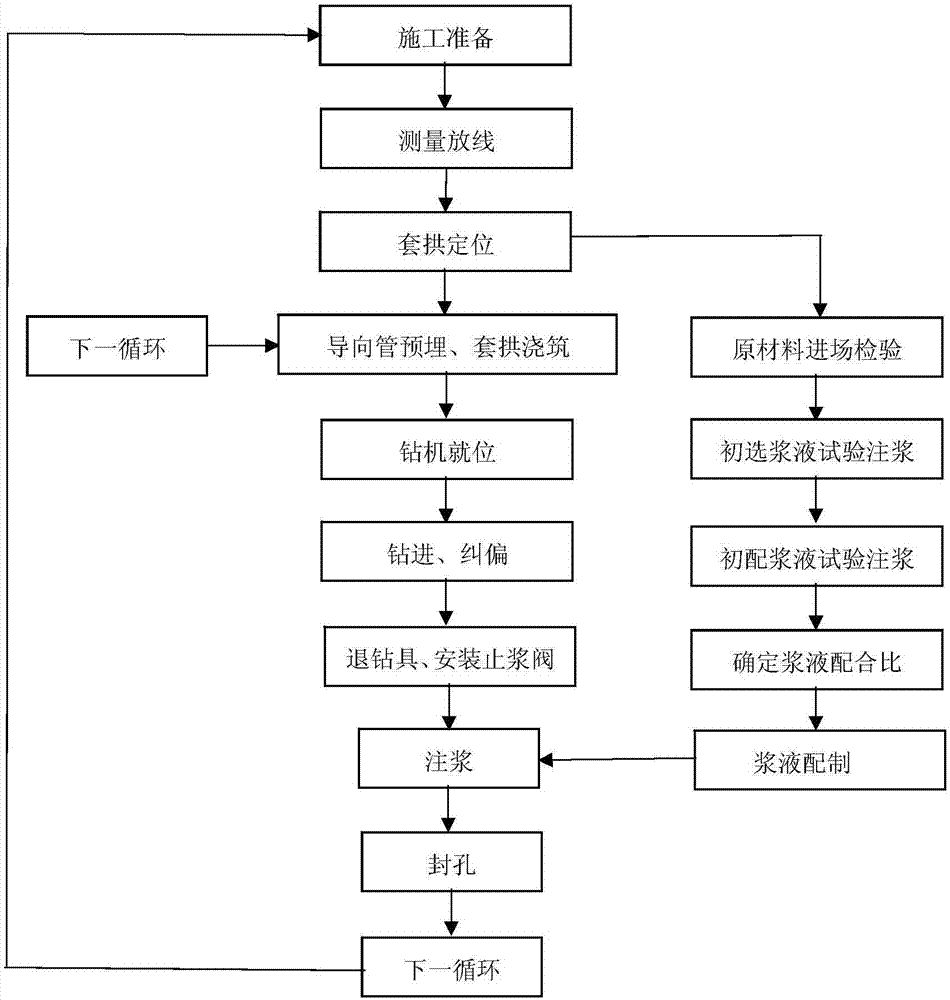

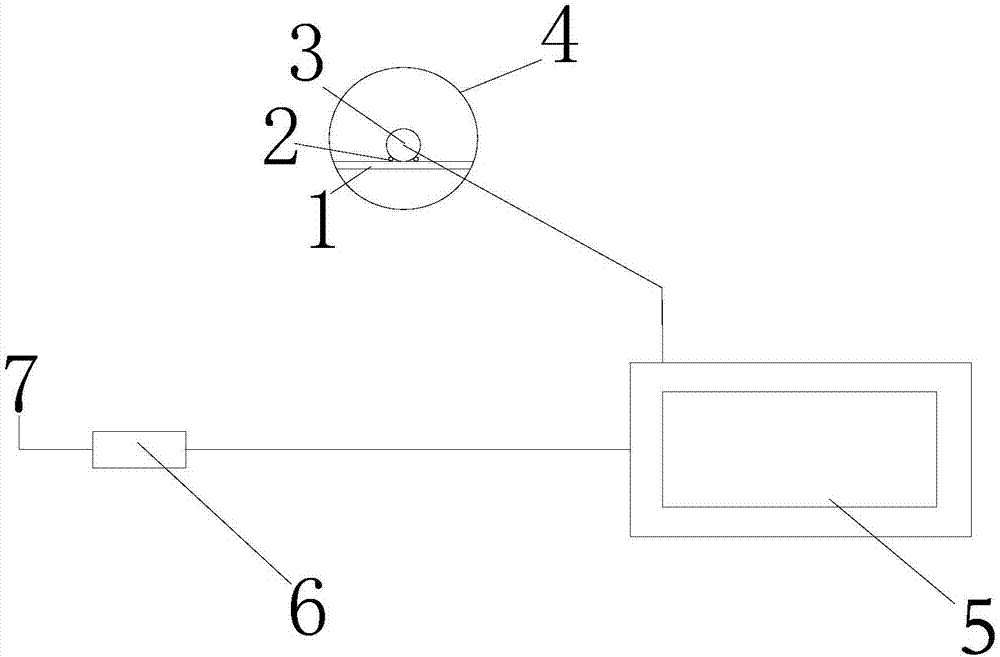

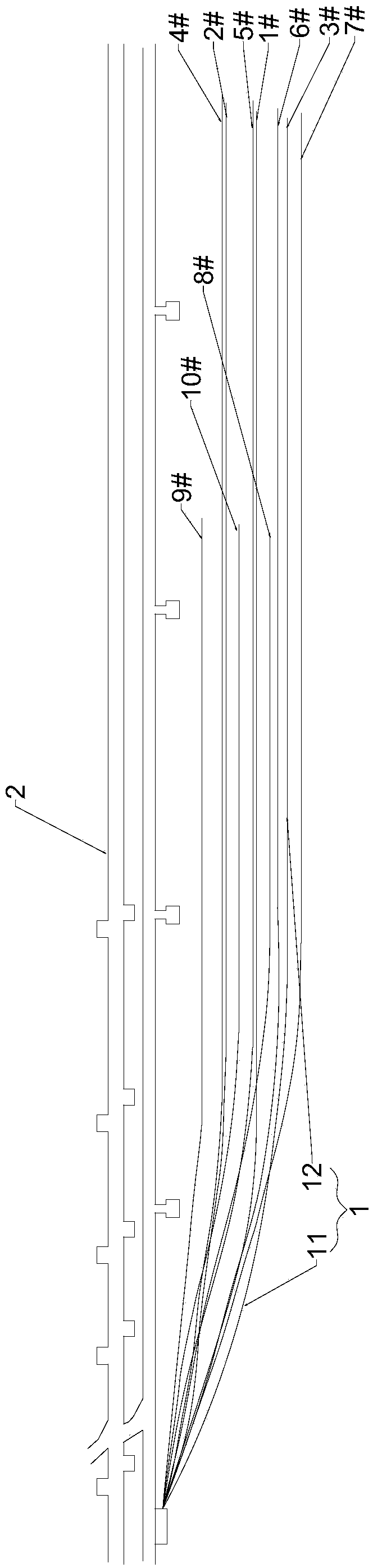

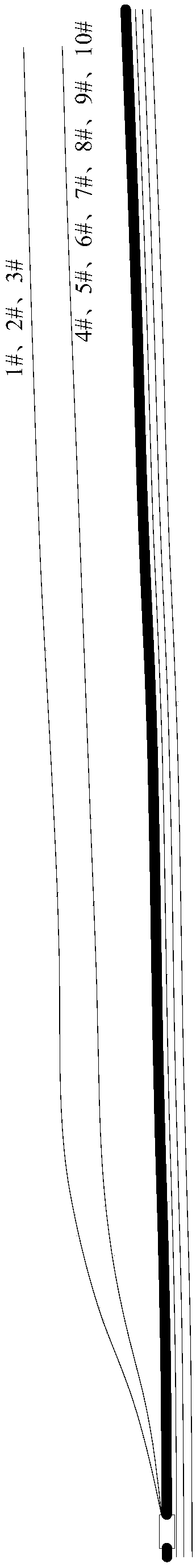

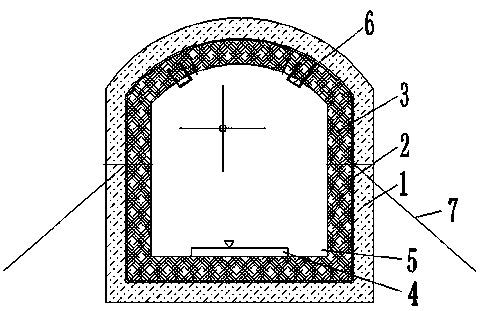

Construction method of super long pipe shed in soft surrounding rock section of tunnel portal

PendingCN106988755APrecise drilling processImprove pore forming efficiencyUnderground chambersDirectional drillingStructural engineeringAir compressor

The invention discloses a construction method of a super long pipe shed in a soft surrounding rock section of a tunnel portal. The accuracy of the construction of the pipe shed is ensured through utilizing a guiding technology, the drilling process records the geography and provides a reference for tunnel excavation, and effective advance support provides technical support for tunnel excavation. Before tunnel excavation and entering the portal, a front slope on the edge of the portal is excavated in place, a pipe shed guiding wall is applied, a guiding pipe is pre-embedded, meanwhile, a drill pipe is machined, a high-speed air compressor is arranged, after a drilling machine is in place, a positioning device is mounted in a drill pipe head for positioning, deviation is rectified in time in the drilling process according to the drilling bias of a rod body, meanwhile, the power is adjusted according to the drilling length and soil layer geological conditions, the depth and the location of the drilling machine are ensured, and after drilling is completed, the drilling machine and the drill pipe are separated and grouting is conducted; and construction of the next pipe shed is started, and a stable arch ring outside excavation is formed. According to the construction method of the super long pipe shed in the soft surrounding rock section of the tunnel portal, the phenomena of hole shifting and hole collision do not exist, the hole-forming efficiency is high, and the construction method is suitable for environments such as complex geological conditions, a loose sand layer and a clay layer.

Owner:THE FIFTH ENGEERING OF CHINA RAILWAY 5TH BUREAU GROUP

Method for forming holes in long and large anchor cables in karst region

InactiveCN107503681AHole forming efficiency guaranteeGuarantee the quality of hole formationDirectional drillingBulkheads/pilesWork periodKarst

The invention provides a method for forming holes in long and large anchor cables in a karst region, and relates to the field of construction of drilling. The method for forming holes in long and large anchor cables in the karst region comprises the following steps: step one, placing a drilling machine at a suitable position; step two, carrying out exposed drilling for the first time; step three, carrying out primary pipe-following construction; and step four, carrying out secondary exposed drilling. By the method for forming holes in long and large anchor cables in the karst region, the technical problem that existing anchor cable hole forming construction is low in hole forming efficiency, high in cost and long in working period is solved.

Owner:CCFEB CIVIL ENG

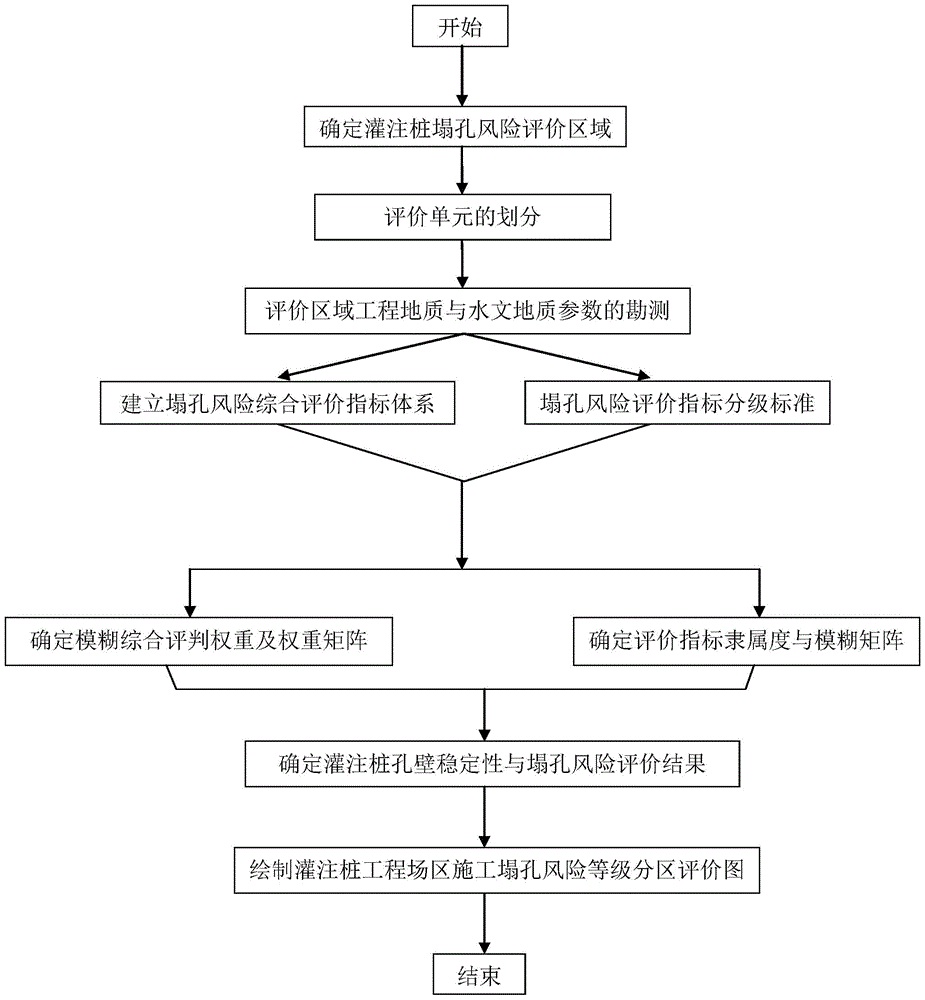

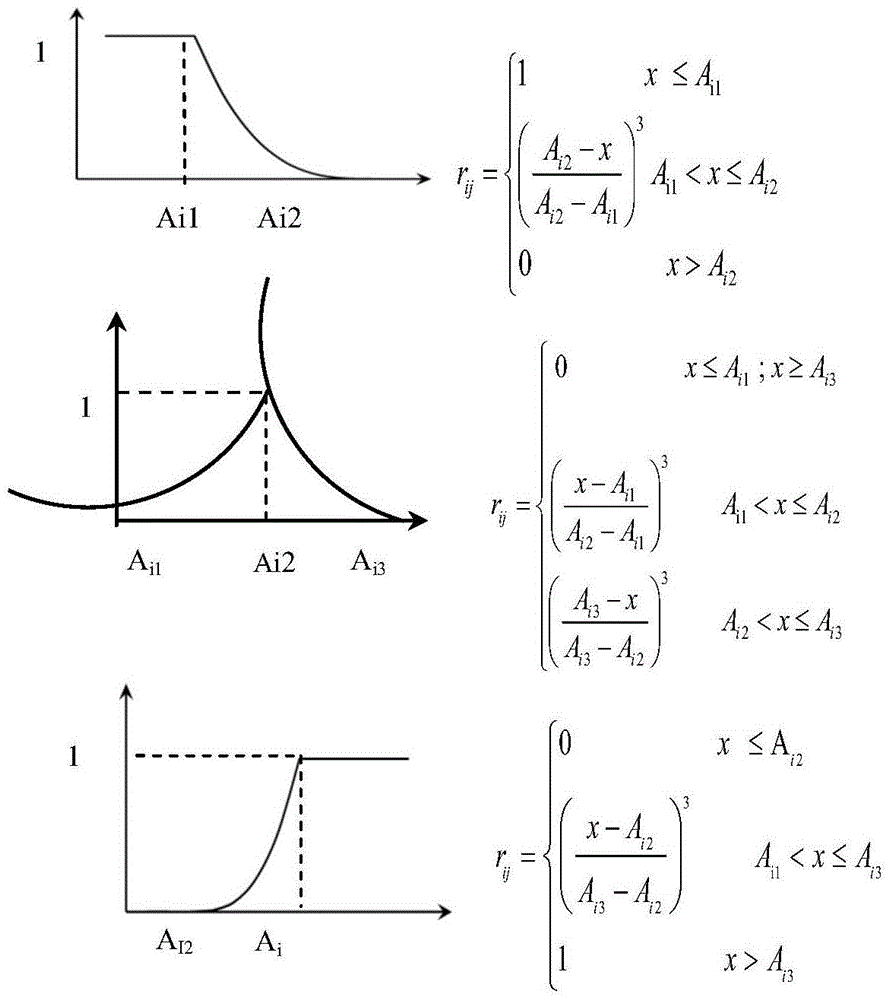

Evaluation method for hole collapse risk of foundation of cast-in-situ bored pile and application

ActiveCN105701345AImprove pore forming efficiencyImprove hole qualitySpecial data processing applicationsInformaticsMultiple factor analysisInformation quantity

The invention discloses an evaluation method for a hole collapse risk of a foundation of a cast-in-situ bored pile and application. On the basis of the basic principle of a fuzzy mathematic theory, the method is a fuzzy synthetic evaluation method for carrying out analysis and evaluation on the stability of a hole wall of the cast-in-situ bored pile and the hole collapse risk through multiple-factor analysis and evaluation. The fuzzy evaluation method not only evaluates and sorts evaluation objects according to the comprehensive scores, but evaluates the order of evaluation of the evaluation objects according to values on a fuzzy evaluation set and a maximum membership principle. The method overcomes the defect of oneness of a result of the conventional mathematical method, and the result contains abundant information quantity. The method is simple and feasible, and as for problems which cannot be subjected to number analysis from some traditional views, the problems of fuzziness and uncertainty of stability evaluation of many projects can be well solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

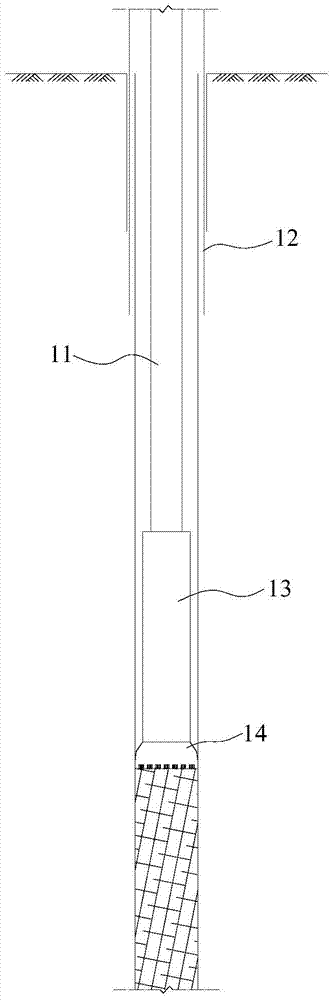

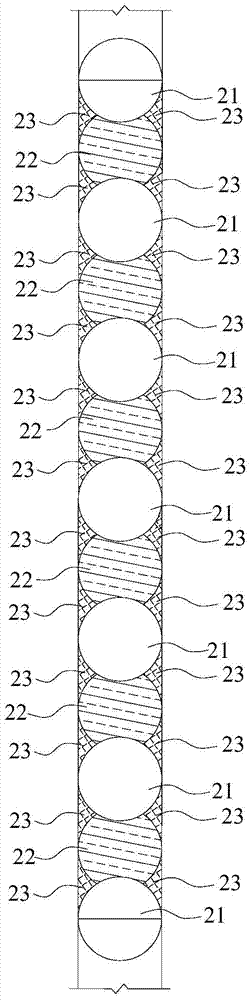

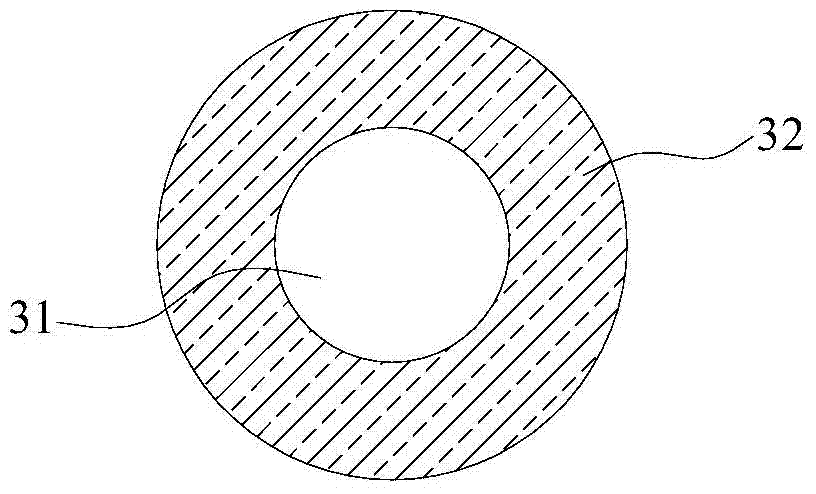

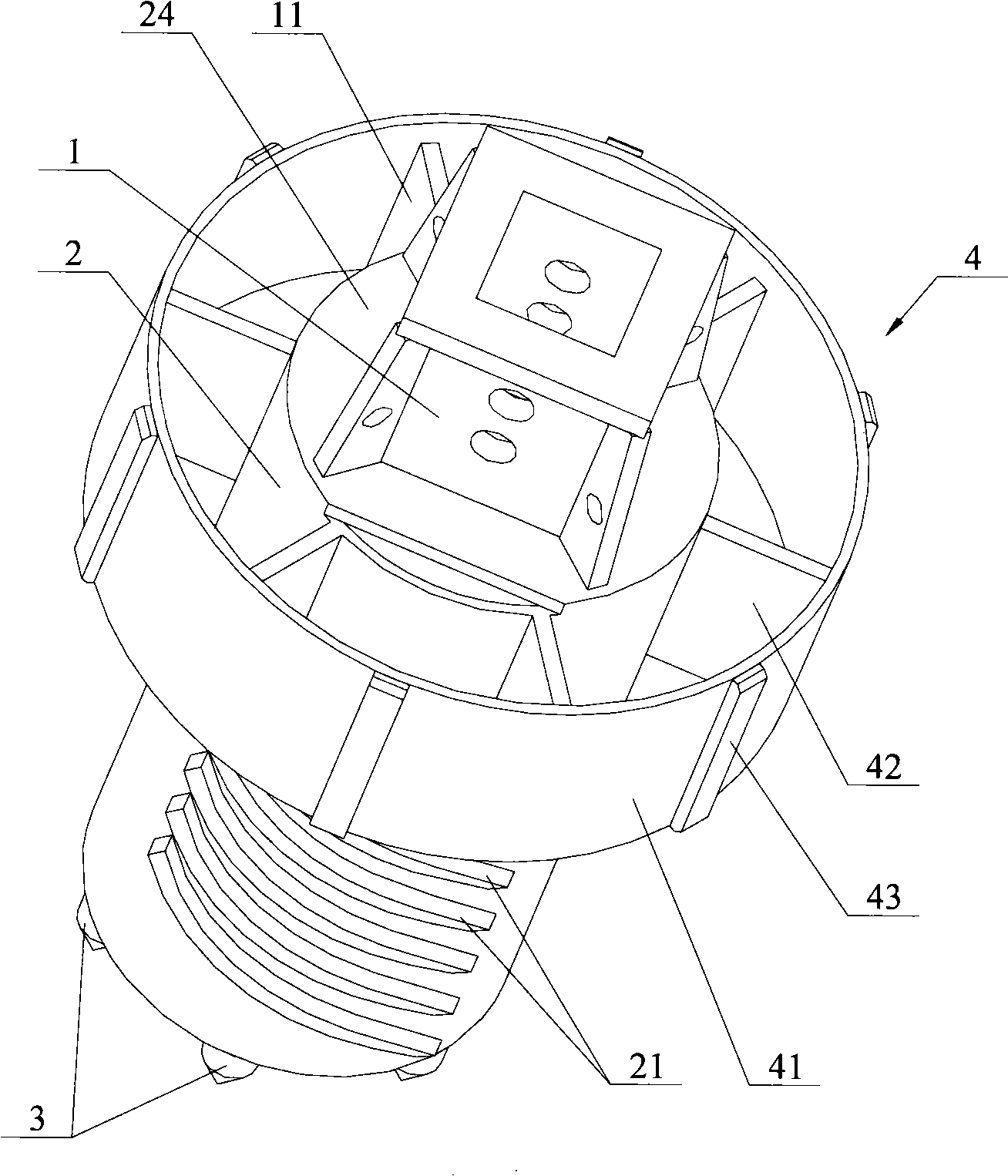

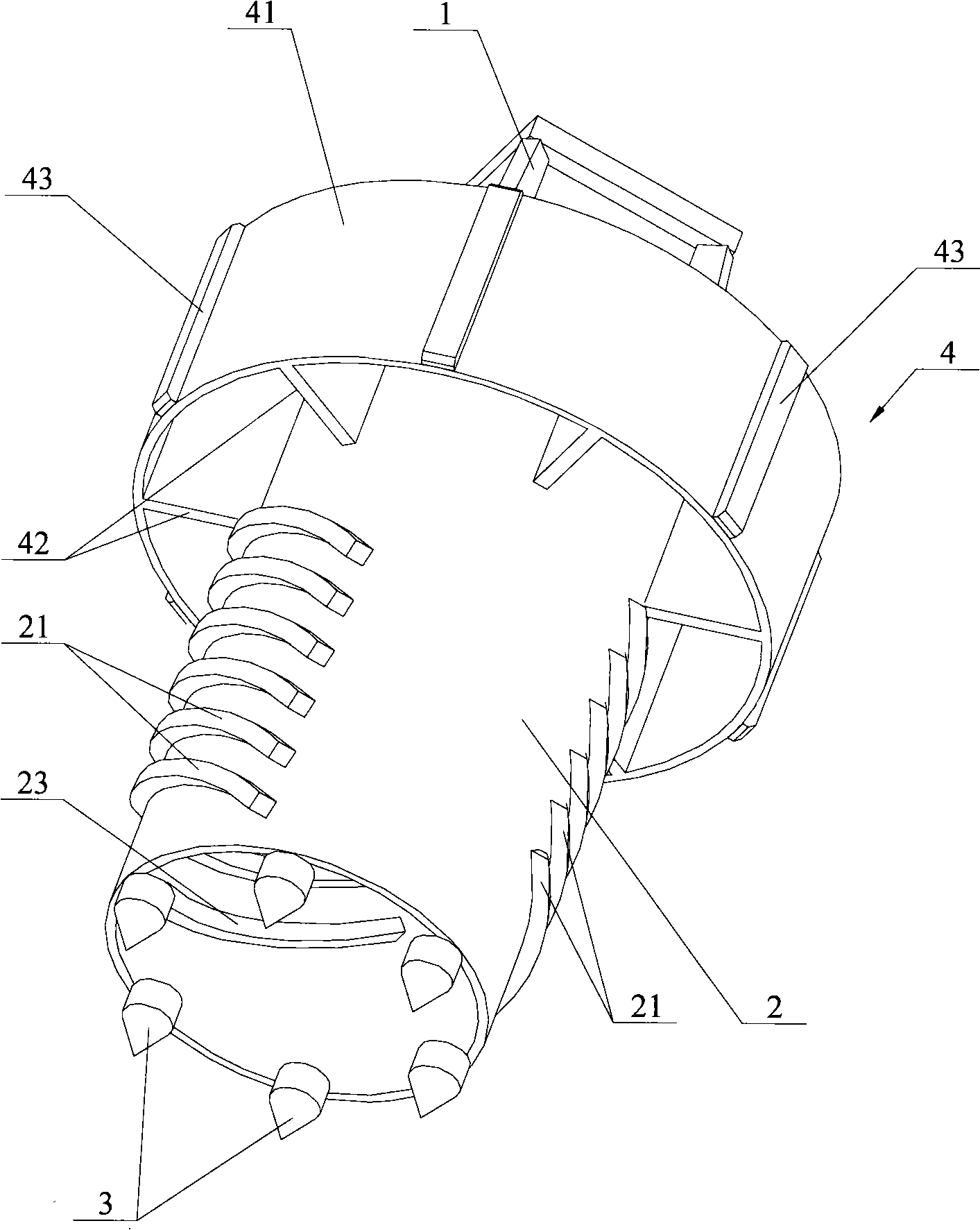

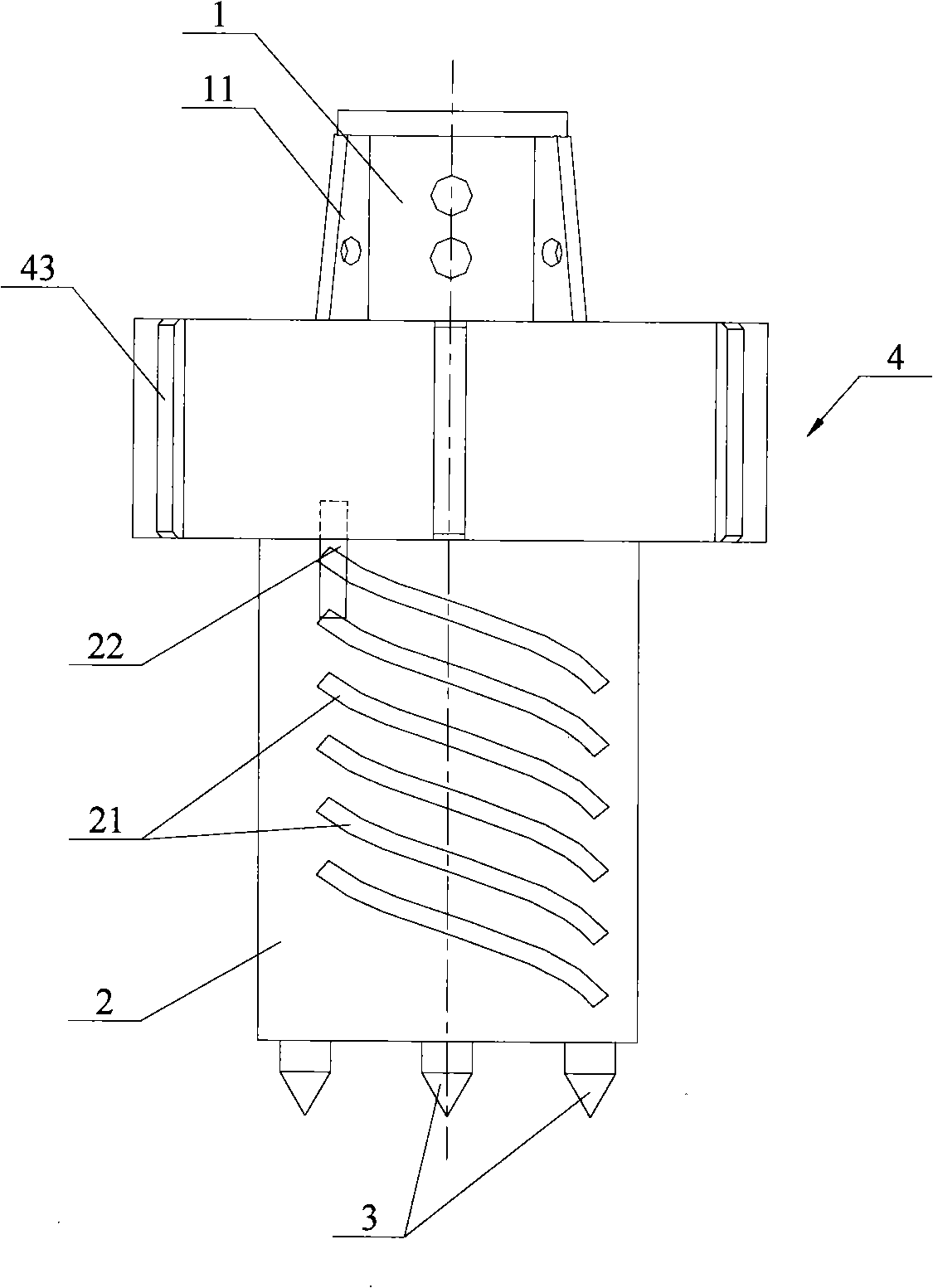

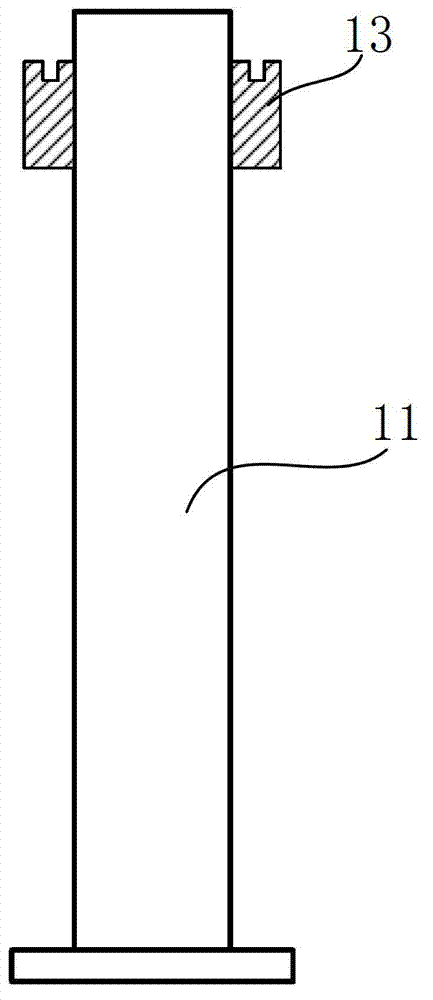

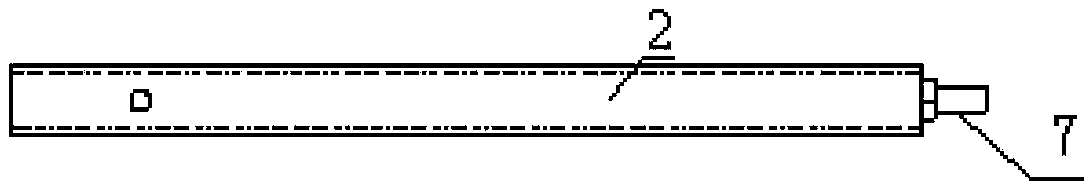

Barrel type drilling tool

The invention discloses a tubular drilling tool, which comprises connecting parts, a tube body and a cutting tool which are arranged sequentially from top to bottom. The tubular drilling tool also comprises a righting part which is fixedly arranged at the outer side of the upper end part of the tube body, and the revolution external diameter of the righting part is identical with the aperture of a pile hole. Preferably, the righting part comprises a righting sleeve and a plurality of connecting pieces; the righting sleeve is nested at the outer side of the upper end of the tube body; and the plurality of connecting pieces are respectively and fixedly arranged between the righting sleeve and the tube body. The righting part arranged at the upper end part of the tube body butting against the inner wall of the pile hole is adopted in the tubular drilling tool to guarantee the righting of the tubular drill, and the diameter of the tubular drill can be designed into a smaller size. The deep drilling resistance during the graded drilling construction process can be reduced, thereby enhancing the hole forming efficiency; in addition, the defects of pressure and torque insufficiencies can be made up. The tubular drilling tool can be used for rotary drilling rigs or other pile work machinery and can be particularly used for the graded drilling process on hard rock formation under the condition that the pressure of the drilling rig is insufficient.

Owner:BEIJING SANY HEAVY MASCH CO LTD

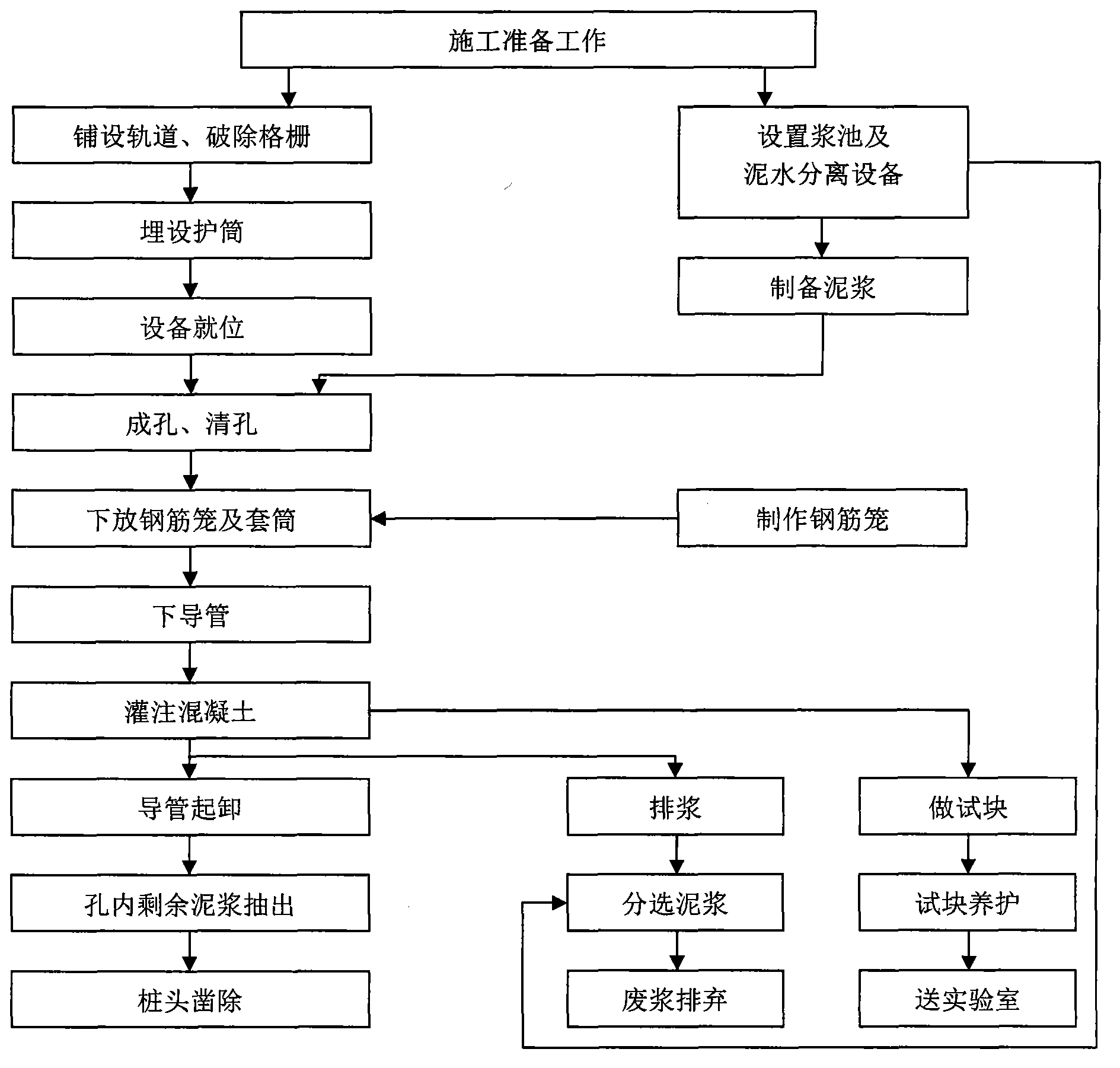

Construction method of minor diameter pile inside city underground construction underground excavation pilot tunnel

InactiveCN103174132AImprove pore forming efficiencyImprove hole qualityFlushingBulkheads/pilesSocial benefitsEconomic benefits

The invention discloses a construction method of a minor diameter pile inside a city underground construction underground excavation pilot tunnel. The construction method of the minor diameter pile inside the city underground construction underground excavation pilot tunnel comprises the following steps: surveying and setting out, pile test, reinforcement cage machining, track laying, equipment lifting, pile casing construction, drill hole construction, reinforcement cage installing and concrete pouring, wherein a drill hole construction equipment system can be divided into four sub systems, namely a drilling system, a slagging system, a mud-water separation system and a slurry filling system. Based on an existing construction method of the minor diameter pile inside a pilot tunnel, surrounding environment requirements are taken into overall consideration, the construction method of the minor diameter pile inside city underground construction underground excavation pilot tunnel is put forward, pile forming efficiency and pile forming quality of construction of the minor diameter pile in a narrow space are guaranteed, influence on city underground construction on surrounding buildings, earth surface traffic and an underground pipeline is effectively reduced, and remarkable social benefit and economic benefit are possessed.

Owner:BEIJING CONSTR ENG GRP CO LTD

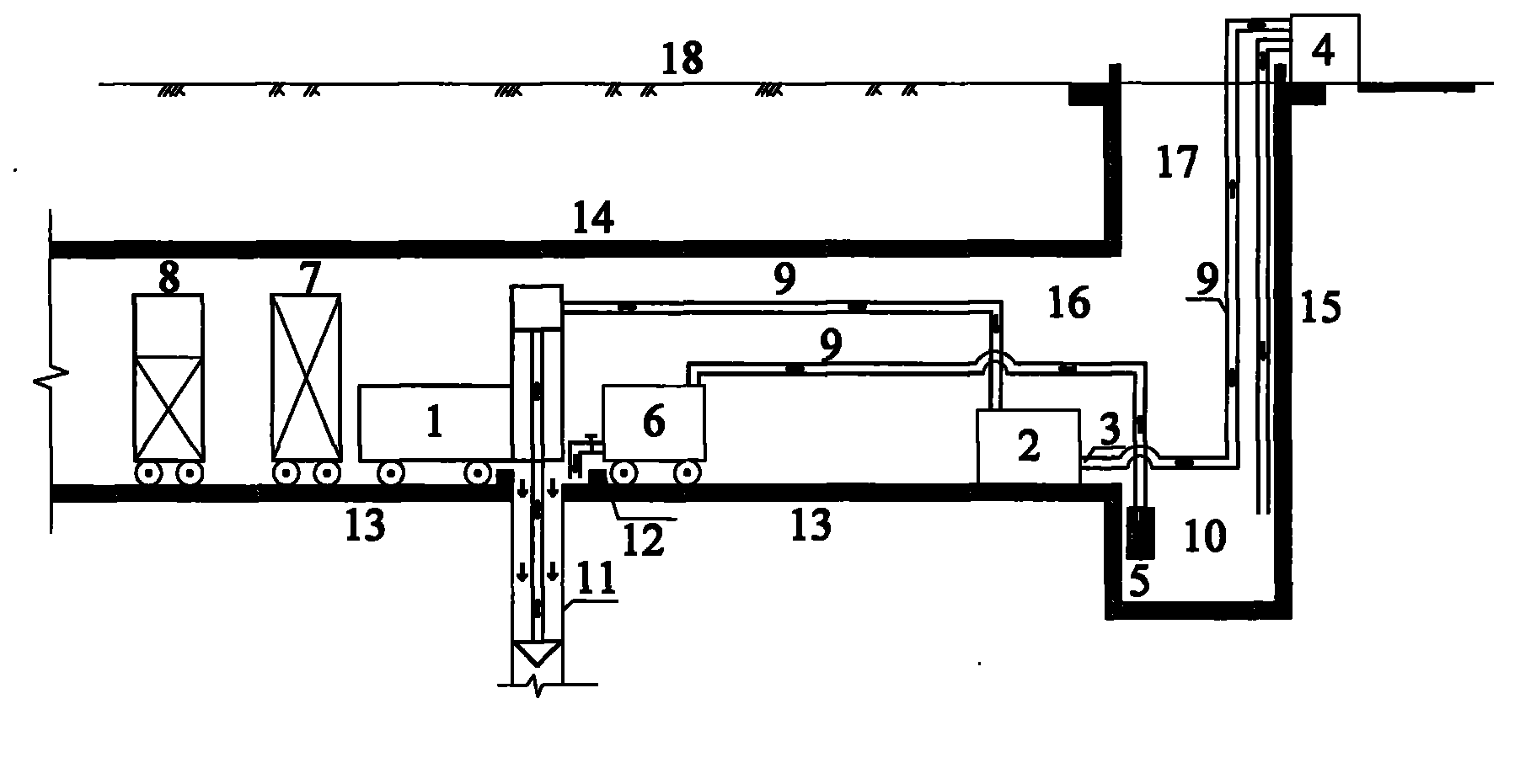

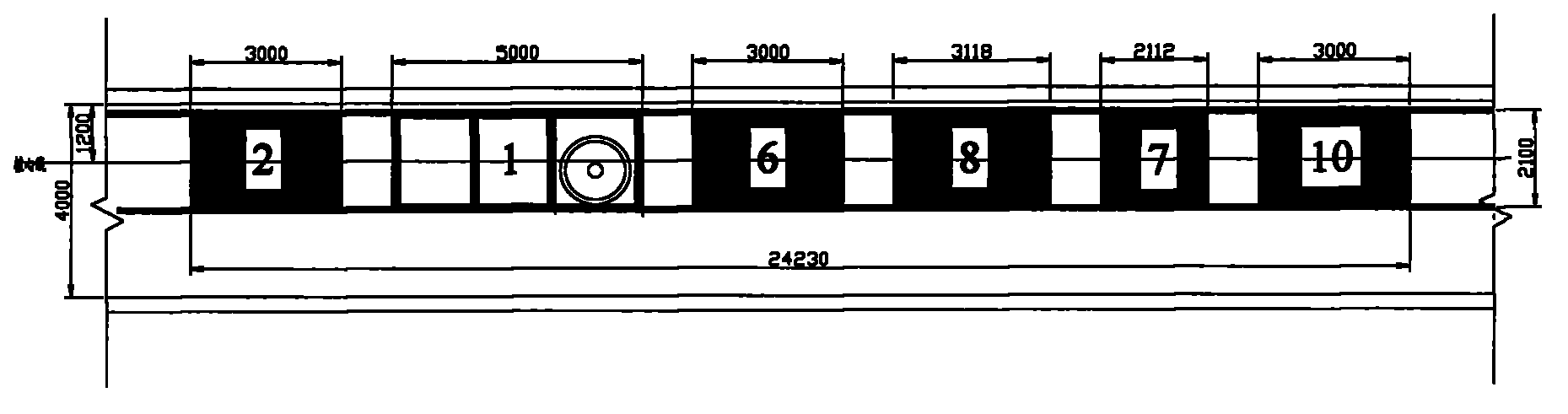

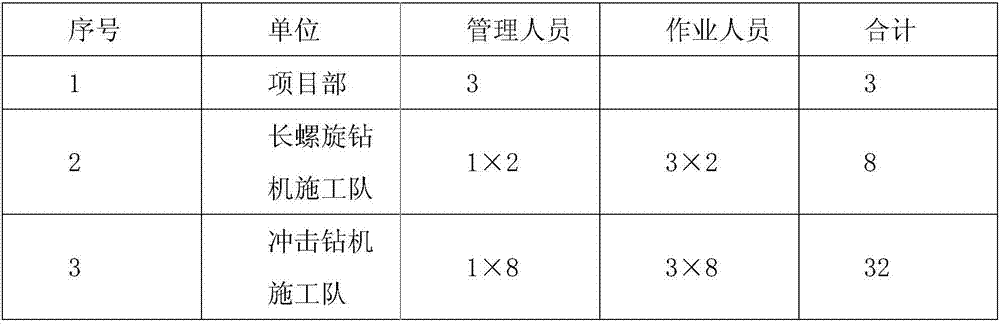

Long spiral drilling and percussion drilling dual-machine composite pore-forming grouting pile construction method

ActiveCN107130592ALow costImprove hole qualityBulkheads/pilesComposite constructionEnvironmental resistance

The invention discloses a long spiral drilling and percussion drilling dual-machine composite pore-forming grouting pile construction method. The method comprises the following steps of (1) construction preparation, (2) long spiral drilling primary pore forming, (3) percussion drilling machine secondary chambering and rock entering, (4) the from-inside-to-outside one-spiral multi-percussion dual-machine joint construction technology, and (5) reinforcement cage placement and concrete pouring. According to the method, under the condition of guaranteeing the pore-forming quality, the pore-forming efficiency and rock-entering depth are greatly improved through the construction technology, and the construction efficiency is greatly improved; spiral and percussion composite construction is achieved, the noise and vibration duration is short, and the phenomena of pile breaking, virtual piles, necking down, hole collapse and repeated construction are avoided; and several devices carry out construction at the same time, the foundation treatment speed is increased, a user can use a foundation in advance, and social and environment protection benefits are remarkable.

Owner:荣泰建设集团有限公司

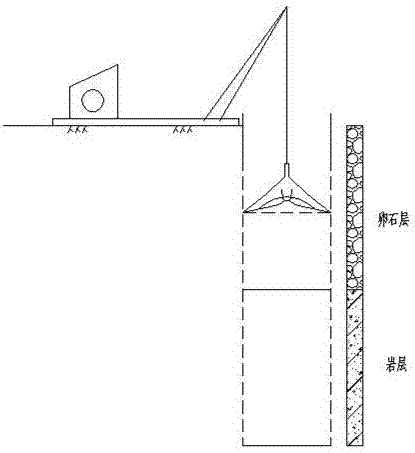

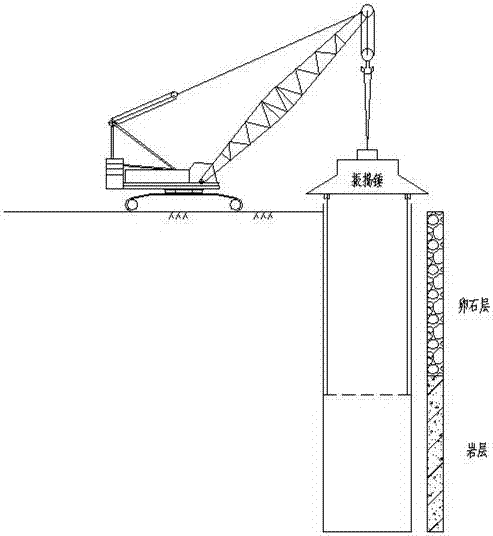

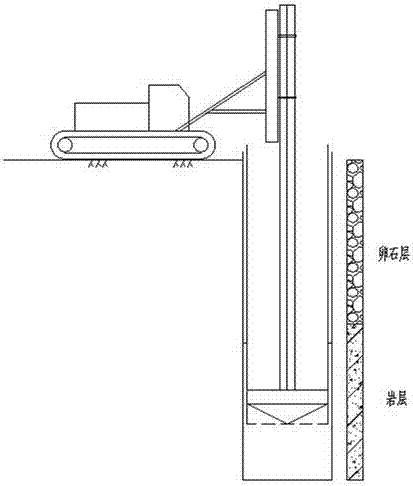

Large-diameter super-thick pebble bed hole forming method

InactiveCN107237323AGuaranteed pore forming efficiencyGuarantee the construction qualityReciprocating drilling machinesRotary drillingEngineeringDrill hole

The invention discloses a large-diameter super-thick pebble bed hole forming method. The large-diameter super-thick pebble bed hole forming method is characterized by comprising the following steps that a construction site is leveled firstly, a foundation is compacted, lofting and outer protection cylinder burying are carried out, construction in an outer protection cylinder is carried out through an impact drill, after the impact drill enters a pebble covering layer, the impact drill penetrates the pebble covering layer and enters the rock and then stops drilling, an inner protection cylinder is lowered in the drilled hole, and a rotary drilling rig is used for drilling in the inner protection cylinder until a hole is formed. The large-diameter super-thick pebble bed hole forming method is high in hole forming efficiency, stable in hole wall, capable of shortening the working period and high in flexibility.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 1ST ENG

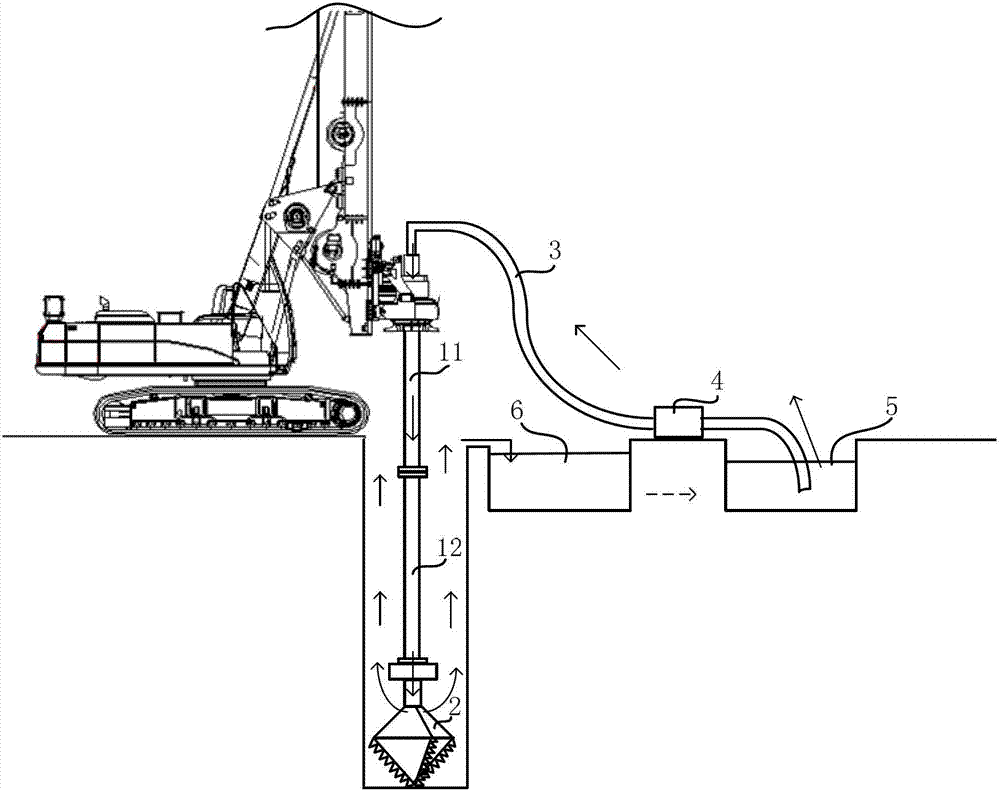

Rotary drilling rig and bittern collecting method

InactiveCN102877782APlay the role of wallNo need to take out and unload soil frequentlyDrilling rodsConstructionsTorque transmissionSlurry

The invention discloses a rotary drilling rig and a bittern collecting method. The rotary drilling rid is provided with a torque transmission drill pipe and a drill bit, wherein the torque transmission drill pipe is connected with a power head of the rotary drilling rig and can transmit torque of the power heat, a slurry injection passage is arranged in the torque transmission drill pipe, and the drill bit is mounted at the bottom end of the torque transmission drill pipe. The slurry injection passage where slurry can be injected and discharged is arranged in the torque transmission drill pipe of the rotary drilling rig, and during hole forming, the slurry is injected into the slurry injection passage and can be discharged from the torque transmission drill pipe and can rise together with drill slags of the drill bit, and meanwhile, part of slurry can cover the hole wall and has a function of protection the hole wall. The rotary drilling rig has the advantages of high drilling efficiency, simple structure and capability of realizing deep-hole drilling. The bittern collecting method includes utilizing the rotary drilling rig to drill a permeable hole by the positive-circulating rotation drilling method and collecting bittern permeated into the permeable hole. By the bittern drilling method, deep-layer bittern can be extracted.

Owner:SANY HEAVY IND CO LTD (CN)

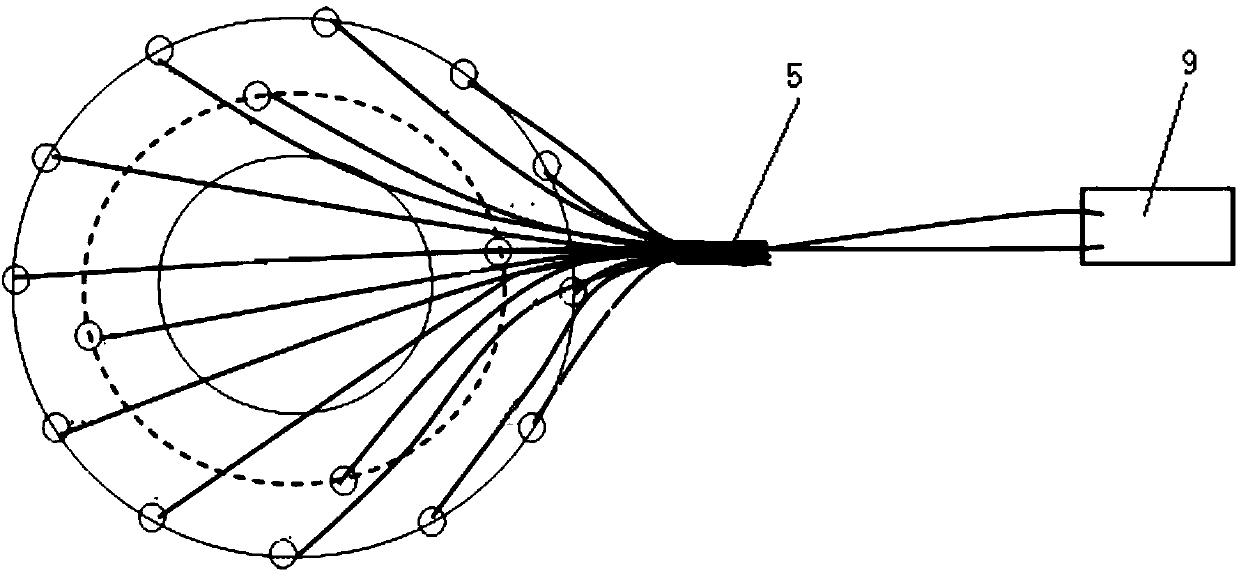

Deep-layer one-time hole forming construction method through matching of blasting and rotary drilling rig

InactiveCN107762399ALarge difference in lithologyImprove pore forming efficiencyDrilling using explosivesConstructionsTime delaysDrill bit

The invention discloses a deep-layer one-time hole forming construction method through matching of blasting and a rotary drilling rig. The deep-layer one-time hole forming construction method comprises the following steps that (1) coring is conducted on the center of a pile foundation to the pile bottom through the rotary drilling rig to form a free face; (2) a plurality of blastholes are drilledin the peripheral direction of concentric circles correspondingly through a down-the-hole hammer, and the depth of each blasthole is consistent with an empty hole; (3) the blastholes are charged withexplosives correspondingly in sequence, and an in-hole millisecond time-delay detonating cord priming system is used for detonation; and (4) after blasting, a drill bit of the rotary drilling rig is used for deslagging hole-flushing. According to the one-time hole forming construction method, the drilling defect of a traditional drilling rig in a high-strength rock region is overcome, meanwhile, the hole forming efficiency is high, and the construction progress is accelerated greatly.

Owner:CCCC SECOND HARBOR ENG +1

Re-drilling concrete wall protecting method for hole formation of rock-socketed pile in karst region

The invention relates to a re-drilling concrete wall protecting method for hole formation of a rock-socketed pile in a karst region. Firstly, a plain concrete bored pile comprising a retaining concrete thin-wall tubular pile and a concrete solid pile capable of being extracted from the plain concrete bored pile as the core of the plain concrete bored pile and located inside the retaining concrete thin-wall tubular pile is constructed in overlaying soil, the pile diameter of the plain concrete bored pile is larger than the hole diameter of a pile hole of a rock-socketed pile of underlying bedrock, the pile length of the plain concrete bored pile is the depth from the natural ground to the top surface of the underlying bedrock, after the age of concrete of a pile body reaches 3-7 d, the core (namely the concrete solid pile) of the plain concrete bored pile is extracted by a rotary drilling rig, after the concrete solid pile is taken out, a re-drilling concrete wall protecting structure is formed by the wall protecting concrete thin-wall tubular pile, then the underlying bedrock is exposed, and hole formation construction of the rock-socketed pile of the underlying bedrock is conducted in a bedrock stratum. The method has the advantages of simplicity, easiness in operation, stability, reliability, high hole formation efficiency, large wall protecting depth, wide application range, environment-friendliness and the like and can provide a reference for hole formation construction of rock-socketed piles in similar strata.

Owner:BEILONG CONSTR GRP

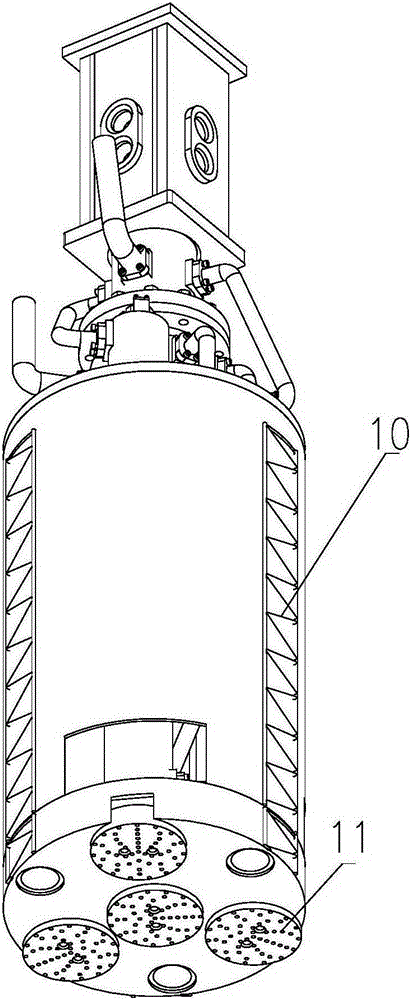

Energy-saving bundled combined hammer

ActiveCN105350909AReduced air consumptionReduce air volumeConstructionsBorehole drivesAir volumePulp and paper industry

The invention provides an energy-saving bundled combined hammer which comprises a square connecting head, a main air inlet pipe, an air inlet chamber, an air dividing pipe, a main exhaust pipe, an exhaust chamber, connectors, an exhaust pipe branch, a barrel and an impactor. The square connecting head, the air inlet chamber, the exhaust chamber and the barrel are sequentially fixed from top to bottom. The connectors are arranged at the top of the barrel and the side face of the exhaust chamber, and the impactor is mounted at the bottom of the barrel. The square connecting head is communicated with the air inlet chamber through the main air inlet pipe, the air inlet chamber is communicated with the connectors through the air dividing pipe, and the connectors are communicated with the impactor. The impactor is further communicated with the exhaust chamber through the exhaust pipe branch, and the main exhaust pipe is arranged on the exhaust chamber. Blast consumption is reduced, and under the same condition, at least two fifths of blast volume is saved. The pore forming efficiency is high, pore bottom back pressure is small, and therefore the problem that due to too large treatment back pressure, work efficiency is low is avoided. Comprehensive cost is low, and the manual labor intensity is lowered.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

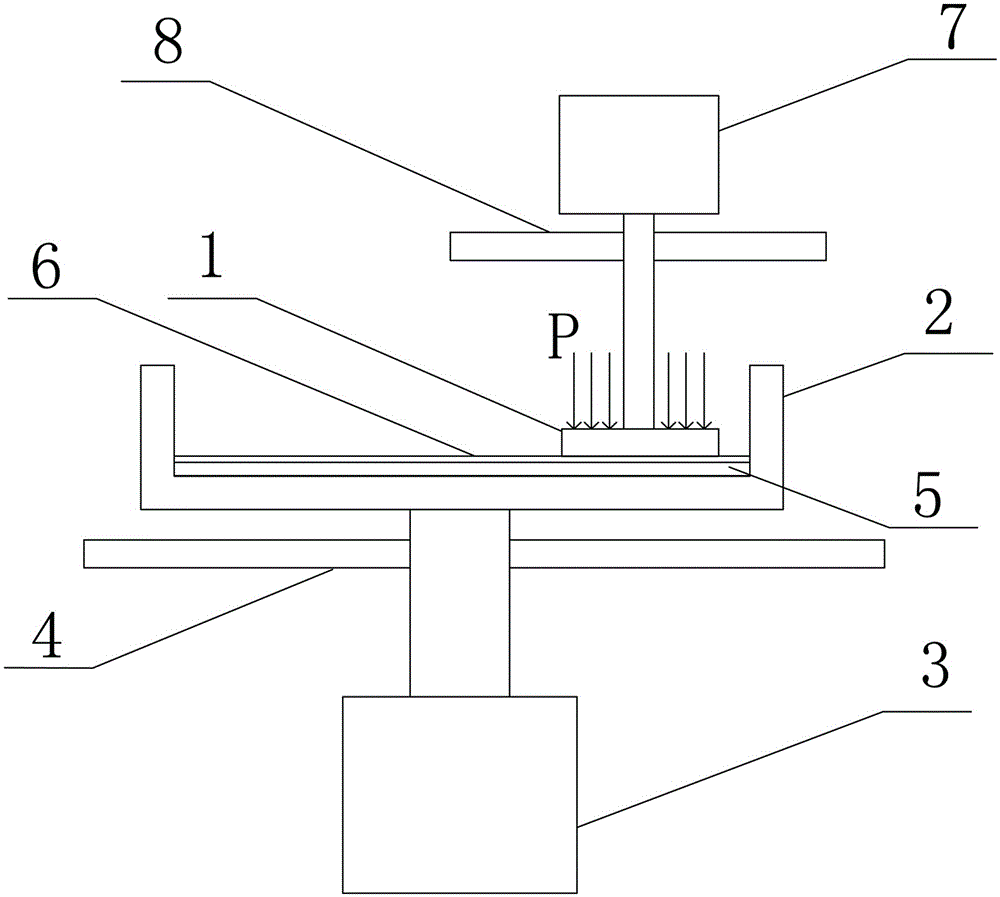

Forming method for metal surface micro-nano holes through mechanical lapping and lapping and polishing machine

ActiveCN105033838AShorten molding timeAvoid ablative damageLapping machinesMicro nanoStress concentration

The invention provides a forming method for metal surface micro-nano holes through mechanical lapping. The forming method comprises the steps that a lapping and polishing solution containing lapping particles and a metal workpiece with defects formed on the surface are provided; under the action of the lapping and polishing solution, mechanical lapping is carried out on the surface, with the defects, of the metal workpiece, the lapping and polishing solution is made to coerce the lapping particles to constantly carry out eddy lapping movement in the defects, lapping chips are generated by lapping the walls of the defects, the lapping particles and the lapping chips in the defects are flushed out constantly, and thus the micro-nano holes are formed in the defects. The invention further provides a lapping and polishing machine used in the forming method. Due to the fact that by means of the forming method, the micro-nano holes with the aperture capable of reaching the submicro dimension can be quickly formed in the defects, the forming time of the micro-nano holes is greatly shortened, the peripheries of the holes are in smooth transition, the phenomenon of stress concentration does not exist, the inner surfaces of the holes are regular and smooth, and the holes are hemispherical holes or cylindrical holes with the hemispherical bottoms.

Owner:ZHENGZHOU UNIV

Hole punch element

ActiveUS20070267472A1Improve scalabilityImprove pore forming efficiencyMetal working apparatusDigital marking by punchingEngineeringCutting force

Owner:WORKTOOLS

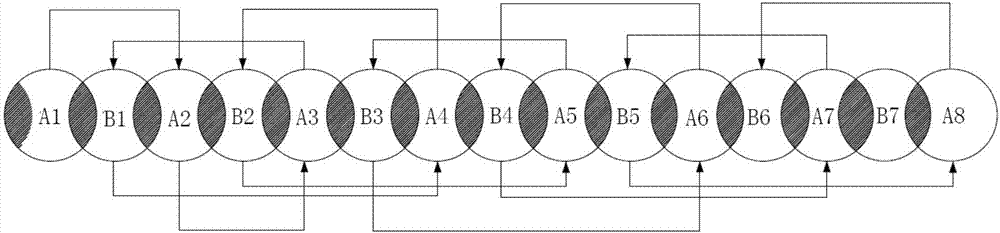

Biting pile construction method and biting pipe applied to method

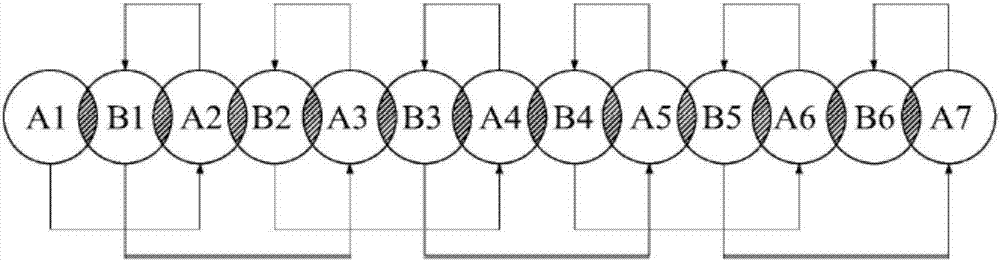

The invention relates to a biting pile construction method and a biting pipe applied to the method. The biting pile construction method is completed mainly by repeatedly mounting and demounting the biting pipe on the intersection portion of a plain concrete pile and a reinforced concrete pile. The biting pipe is formed by one or more biting pipe bodies. Each biting pipe body is of an integrally-formed structure formed by welding two arc steel plates. The pipe opening shape of each biting pipe body is the same as the shape of the intersection portion of the plain concrete pile and the reinforced concrete pile. According to the brand-new biting pile construction method, the multiple defects brought by cutting of concrete on intersection parts of an A1 pile, an A2 pile and an A3 pile in the prior art are overcome.

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST

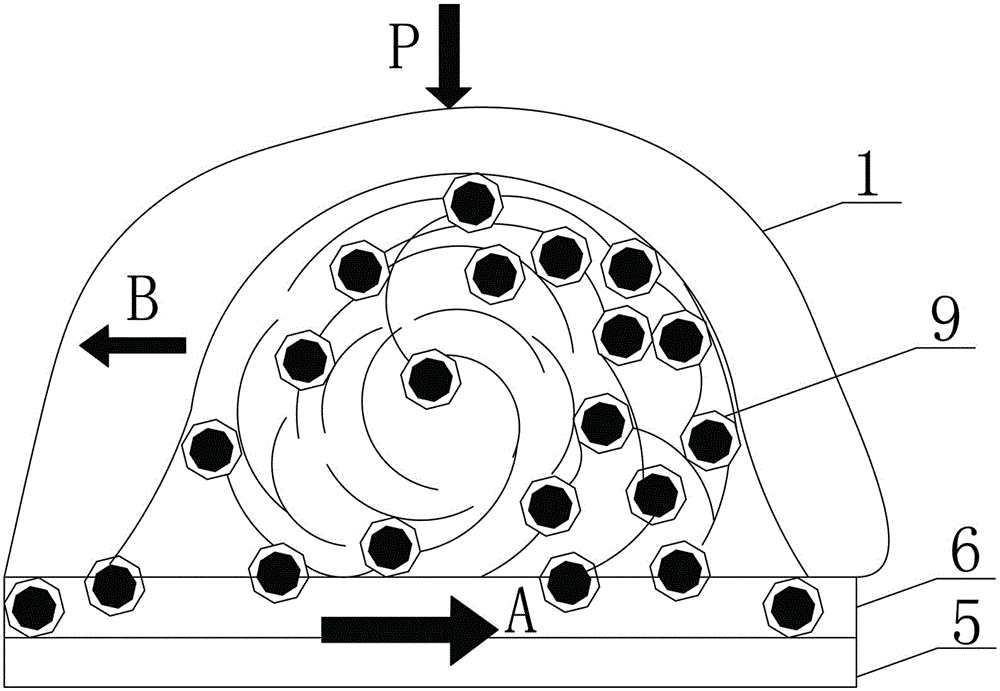

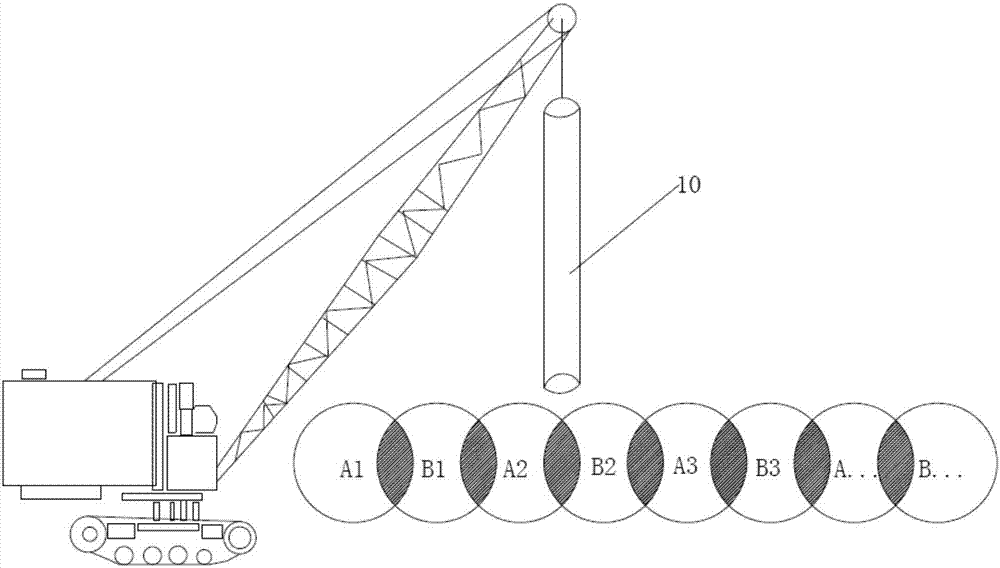

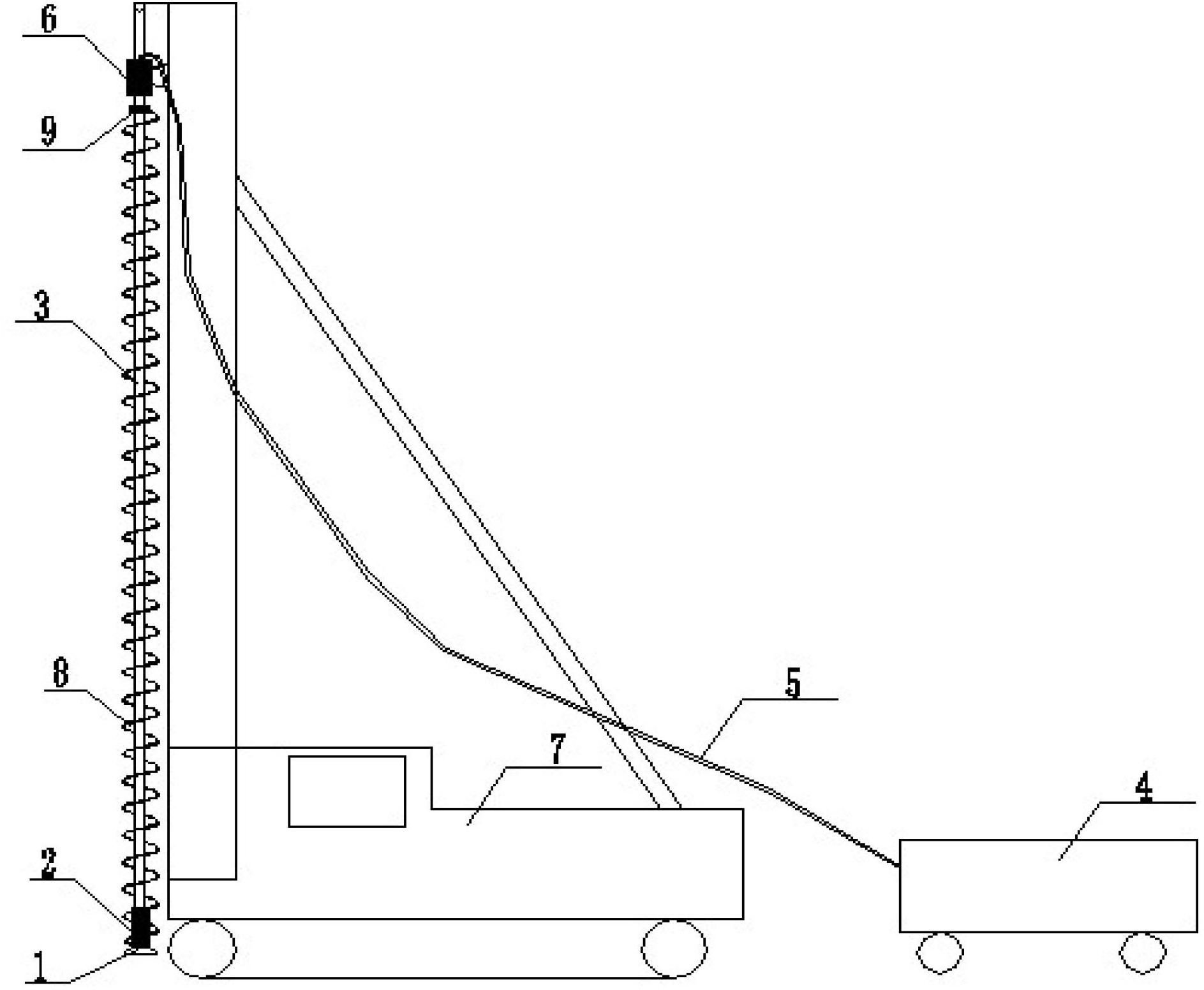

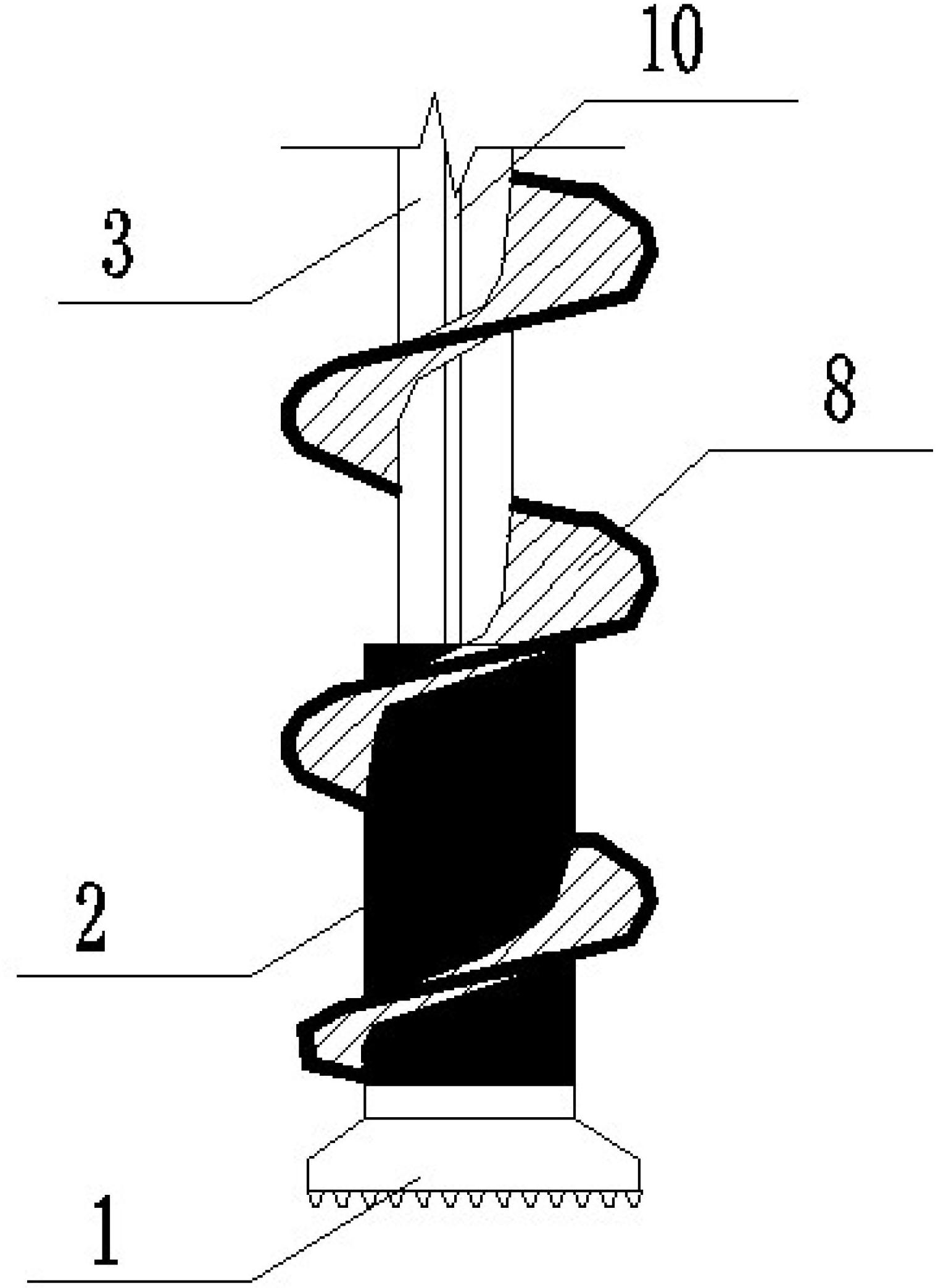

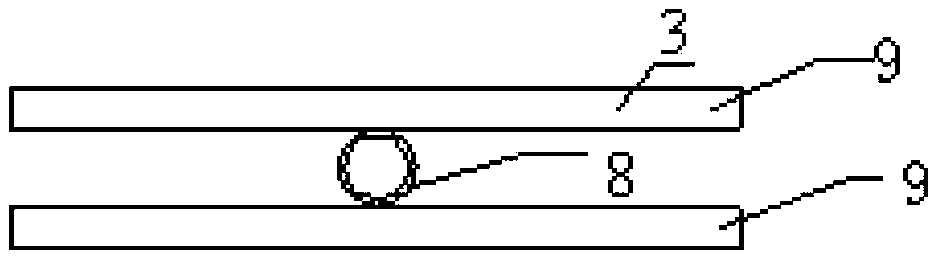

Cyclone pile

InactiveCN102628268AImprove pore forming efficiencyLess dependent on resources and environmentBulkheads/pilesEngineeringCyclone

The invention relates to a cyclone pile, which belongs to the technical field of geotechnical engineering. The cyclone pile comprises a movable long-spiral drilling rig (7) as a pile driver, a long-spiral drill stem (3), a hammerhead (1), a down-hole hammer (2), a blade (8), a shock absorber (9), a power head (6), an air compressor (4) and an inner air pipe (10), the long-spiral drill stem (3) is arranged on the long-spiral drilling rig (7), the hammerhead (1) and the down-hole hammer (2) are arranged on the lower end of the long-spiral drill stem (3), the blade (8) is arranged on the long-spiral drill stem (3), the shock absorber (9) and the power head (6) are arranged on the upper end of the long-spiral drill stem (3), the air compressor (4) is connected with the power head (6) through an air pipe (5), and the inner air pipe (10) is arranged in the long-spiral drill stem (3). The cyclone pile has the advantages that: the cyclone pile solves the problems of muck removal and difficult rock entry after hole formation on a unconsolidated formation by the air-pressure down-hole hammer; the overall efficiency of the cyclone pile is 10 to 15 times as the overall efficiency of the conventional equipment, and the hole formation efficiency of the rock-entering pile in a rocky region is greatly increased; and the cyclone pile does not have slurry, water and other conventional auxiliary materials, is energy-saving and environment-friendly, and has little dependence on resources and the environment.

Owner:KUNMING PROSPECTING DESIGN INST OF CHINA NONFERROUS METALS IND

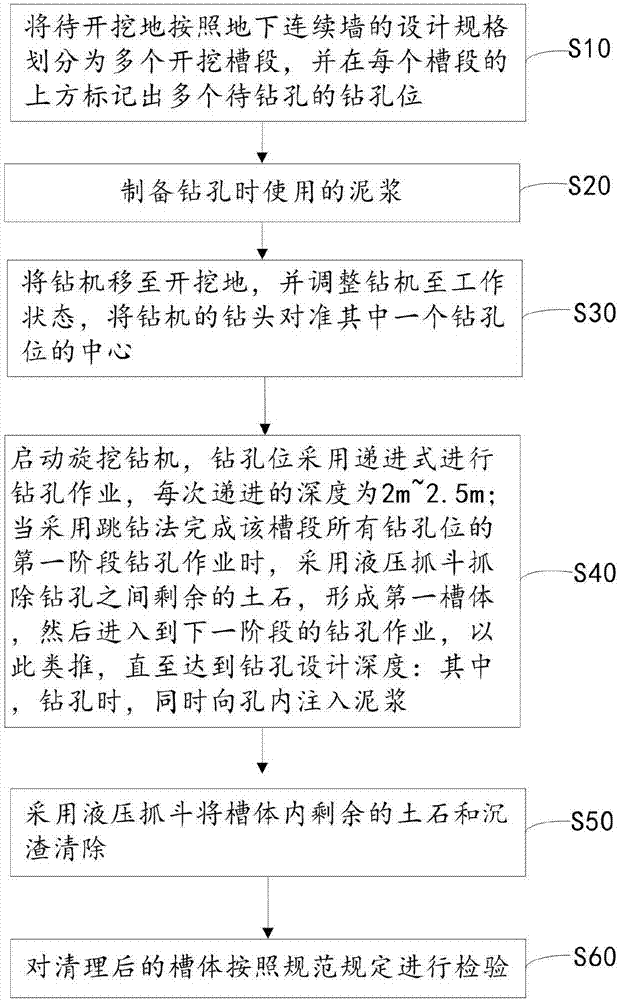

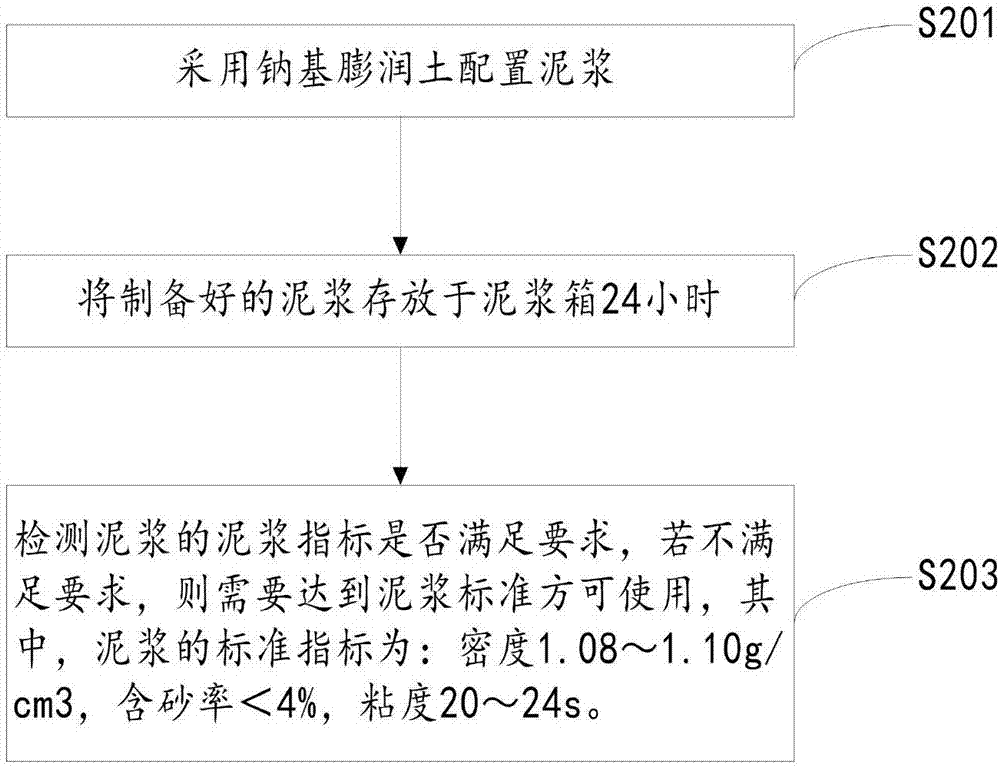

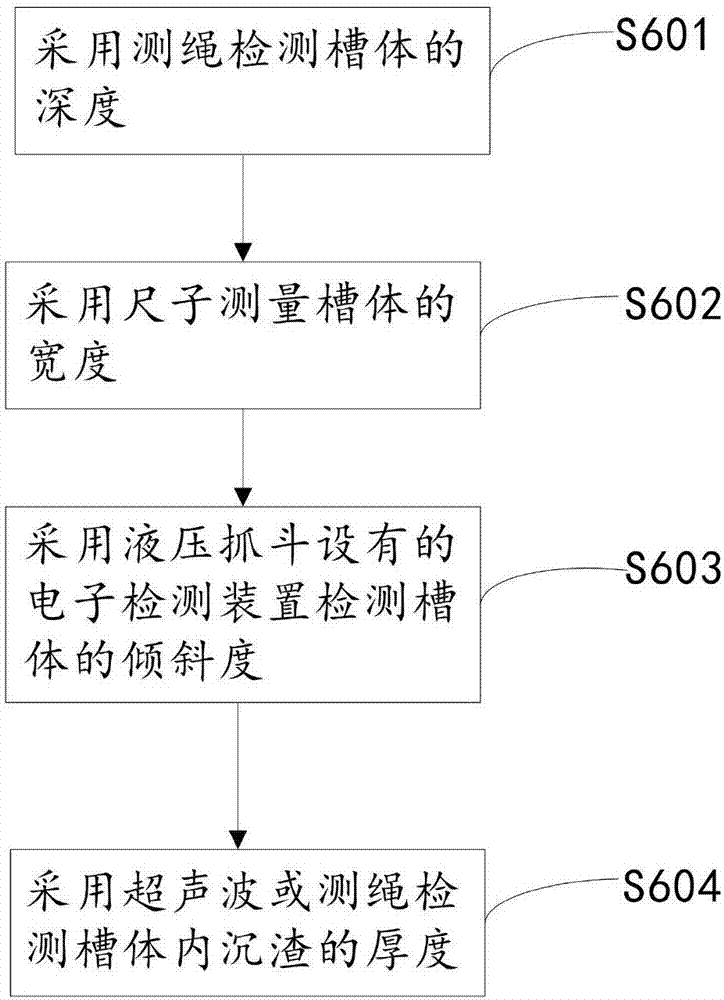

Underground diaphragm wall grooving construction method

The invention discloses an underground diaphragm wall grooving construction method. The method comprises the following steps: dividing a to-be-excavated ground into a plurality of box cut sections according to a design specification of an underground diaphragm wall and marking a plurality of to-be-drilled drilling positions on each section; preparing mud used for drilling; moving a rotary drillingrig to the to-be-excavated ground and adjusting the rotary drilling rig to a working state, and aligning the drill of the rotary drilling rig to the center of one drilling position; starting the rotary drilling rig, wherein the drilling operation is carried out progressively in the drilling position and the progressive depth every time is 2-2.5m; and when the drilling operations in the first stage of all drilling positions of the section are finished by adopting a drilling selective method, grabbing residual earth and stones among the drill holes by using a hydraulic grab bucket to form a first groove body, and then entering the drilling operation in the next stage and so on till the designed depths of the drill holes are reached. The underground diaphragm wall grooving construction method disclosed by the invention improves the drilling efficiency and the drilling precision.

Owner:中铁十局集团城市轨道交通工程有限公司

Directional long-hole group for gas extraction and construction method of directional long-hole

InactiveCN108894728AImprove efficiencyImprove pore forming efficiencyDirectional drillingGas removalEngineeringCost savings

The invention discloses a gas extraction directional long drill hole group, comprising a plurality of staggered directional long drill holes, wherein the orifices of the directional long drill holes are located at the same height, and the orifices are located on the bad stratum at the top plate of the coal seam; the orifices of the directional long drill holes are located at the same height. Eachdefinite long hole comprises a first hole section and a second hole section, wherein the first hole section extends from an orifice to a good formation to a junction of a bad formation and a good formation, and the first hole section and a roof are at an included angle, and the angle range is 0-90 degrees; The second hole section is connected with the first hole section and is located in a good formation, and the second hole section is arranged in parallel with the top plate. The invention also discloses a construction method of a directional long drill hole. The invention has the advantages of high hole forming efficiency, fast construction speed, good gas drainage effect and cost saving.

Owner:HUAINAN MINING IND GRP

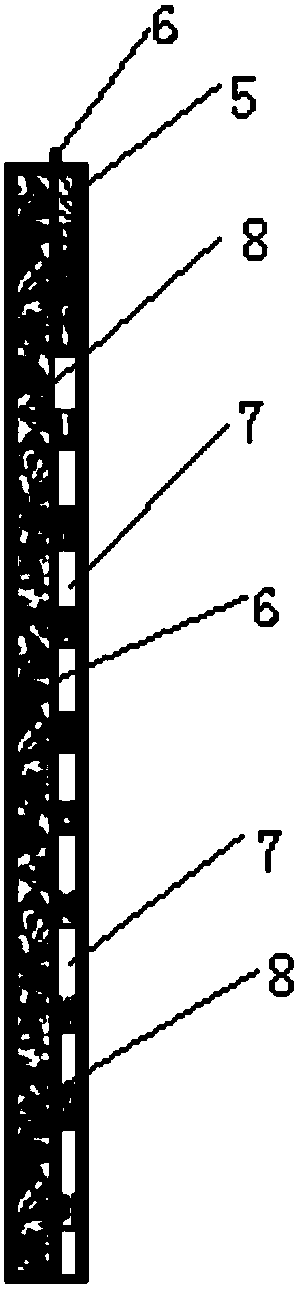

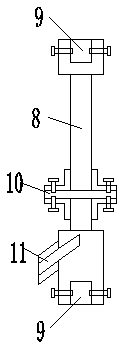

Device and method for improving roadway base plate anchor rod anchor cable pore-forming efficiency and anchoring performance

InactiveCN103410542AImprove pore forming efficiencyImprove the anchoring effectAnchoring boltsSlurryDrilling machines

The invention discloses a device and a method for improving pore-forming efficiency and anchoring performance of a roadway base plate anchor rod anchor cable. The device comprises a special drill rod, a connecting rod and a rod taking device. The special drill rod is successively utilized to perform twice drilling operations and reserved in a hole after the operations of the special drill rod are finished, then a common drill rod is inserted into the inner cavity of the special drill rod to continue to perform drilling till the designed depth is reached, the common drill rod is taken out, an anchoring agent is placed into the hole, an anchor rod or the anchor cable is installed, and finally the special drill rod is taken out through the rod taking device. When the device and the method are adopted to perform drilling and installation of the anchor rod or the anchor cable, the special drill rod is always reserved in the hole so that hole collapse can be effectively prevented. The smooth mud return of an anchor rod anchor cable drilling machine is ensured in the drilling process, water in mud is prevented from entering a loose fractured rock mass at the shallow portion of a base plate, accordingly rock soil is prevented from depositing at the drilling bottom, and borer clamping is avoided. The device for improving the pore-forming efficiency and the anchoring performance of the roadway base plate anchor rod anchor cable is simple in structure and convenient to use, the drilling rate reaches to 100%, the anchoring effects of the anchor rod and the anchor cable are good, the borer clamping is effectively prevented in the drilling process, and the construction efficiency is improved remarkably.

Owner:CHINA UNIV OF MINING & TECH

Deformation control construction method for shallow-buried underground excavation foundation of power tunnel in cobble stratum

ActiveCN111119931AImprove pore forming efficiencyImprove hole qualityUnderground chambersMaterial fill-upDeformation controlGroundwater

The invention belongs to the technical field of power tunnel construction, discloses a deformation control construction method for a shallow-buried underground excavation foundation of a power tunnelin the cobble stratum, and aims to solve the problem that the existing shallow-buried underground excavation construction cannot meet the requirement of the coble stratum. Through the adoption of thedeformation control construction method for the shallow-buried underground excavation foundation of the power tunnel in the cobble stratum, a stratum area constructed by dense cobble stratums can be effectively avoided. Rocks are complex in composition and different in particle sizes, and even include boulders and solid rock stratums, the underground water volume is large, and even local areas have the phenomena of diameter expansion and hole collapse in the presence of cavities, so that the method effectively improves the pore formation efficiency and the pile base quality.

Owner:CHINA MCC5 GROUP CORP

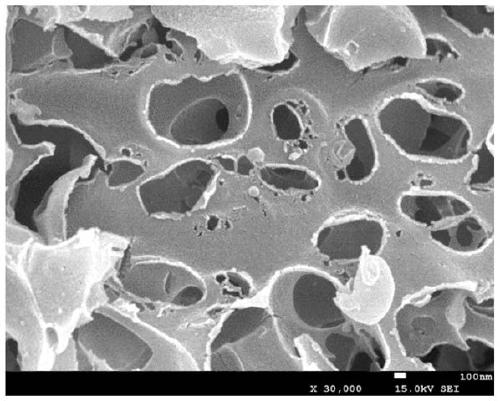

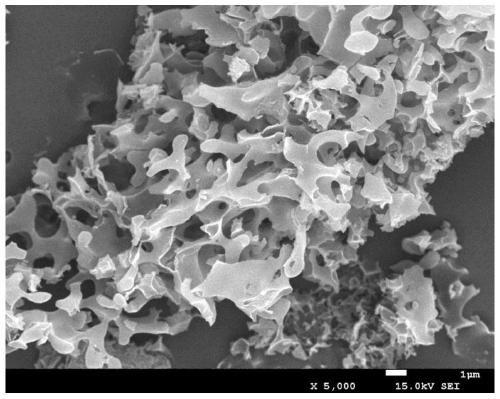

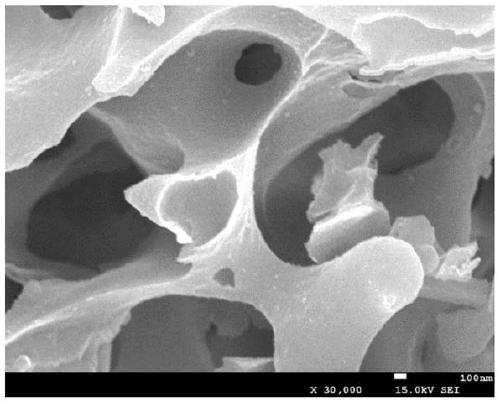

Tobacco matrix activated carbon and preparation method thereof

InactiveCN111137889ASimple componentsSimple processCarbon compoundsLow-density polyethyleneActivated carbon

The invention discloses tobacco matrix activated carbon and a preparation method thereof. The tobacco matrix activated carbon is obtained by mixing anhydrous K2CO3, tobacco waste powder and low-density polyethylene powder and performing high-temperature carbonization in a protective gas environment. The methylene blue adsorption capacity of the activated carbon is as high as 806 mg / g and is far higher than the standard methylene blue adsorption capacity of first-grade products. Low-density polyethylene plastic is added, so activation process is more sufficient, activation effect is uniform, and the prepared activated carbon has a more developed pore structure. Potassium carbonate is used as an activating agent, generated K<+> can break a carbon chain to form a complex salt, and the catalytic process of repeated ring opening, cracking and ring opening enriches the microstructure of the activated carbon. CO2 is also a good physical activating agent, so the pore volume and the pore-forming efficiency of the activated carbon can be increased.

Owner:SICHUAN BRANCH OF CHINA TOBACCO +1

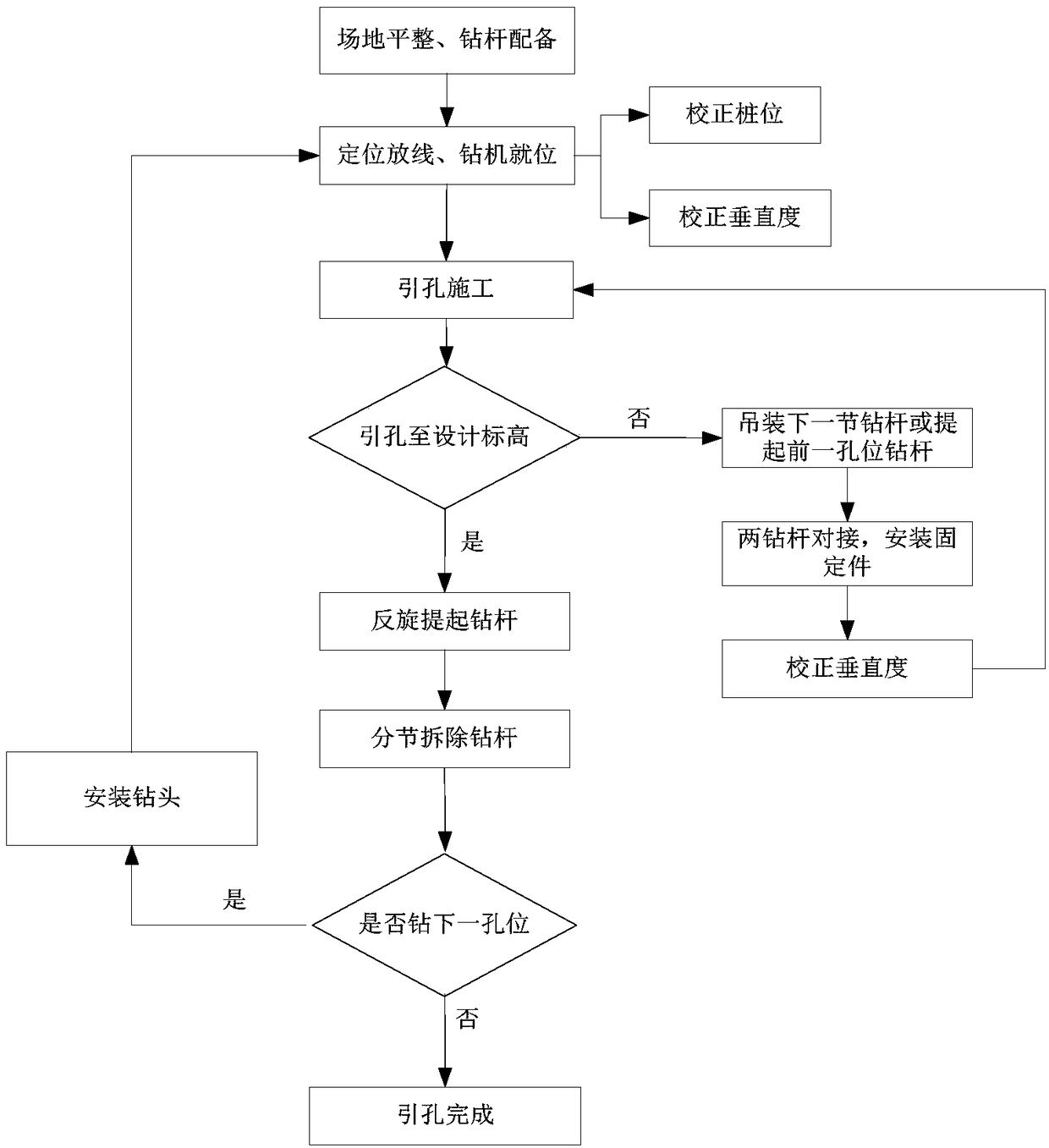

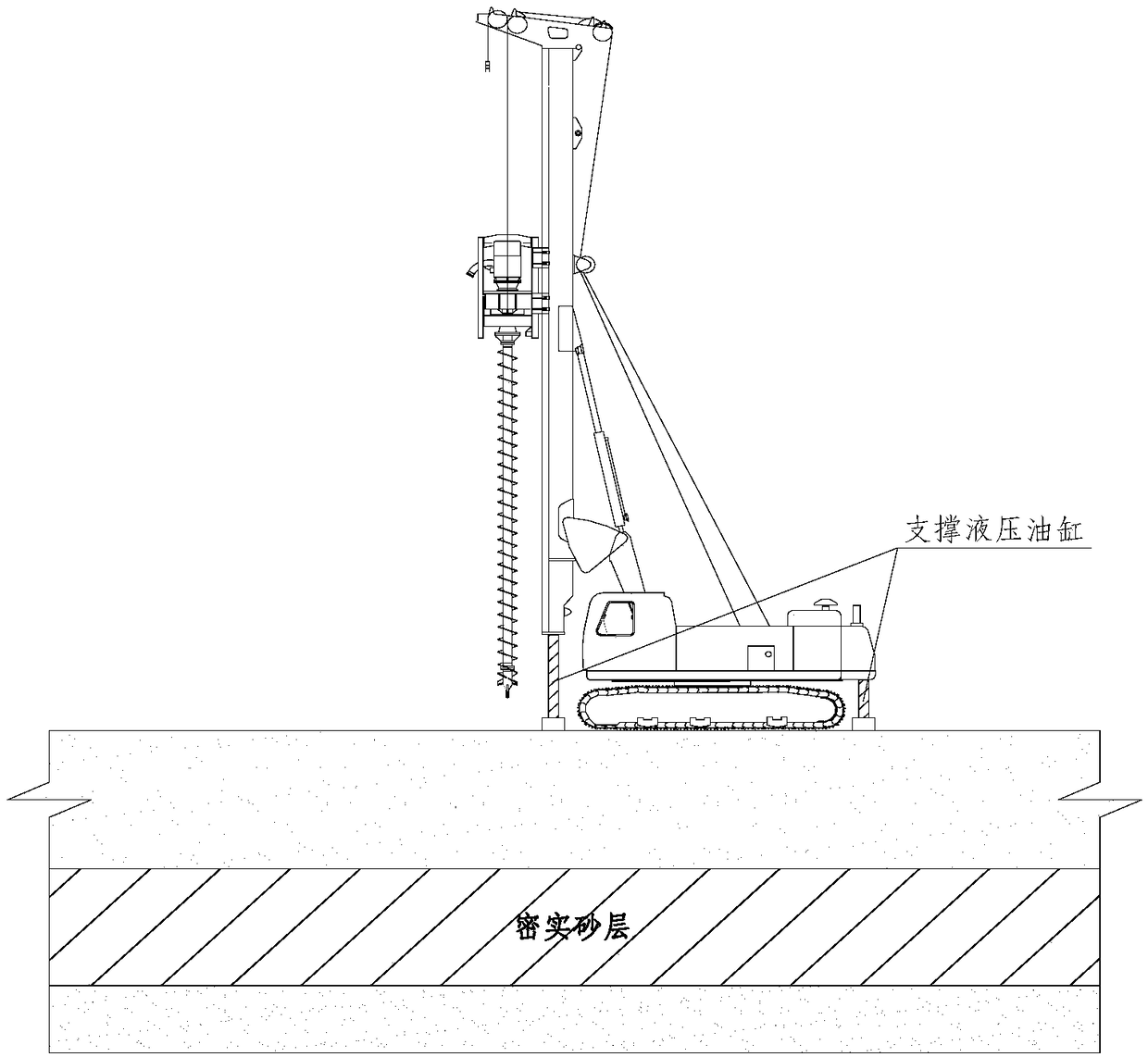

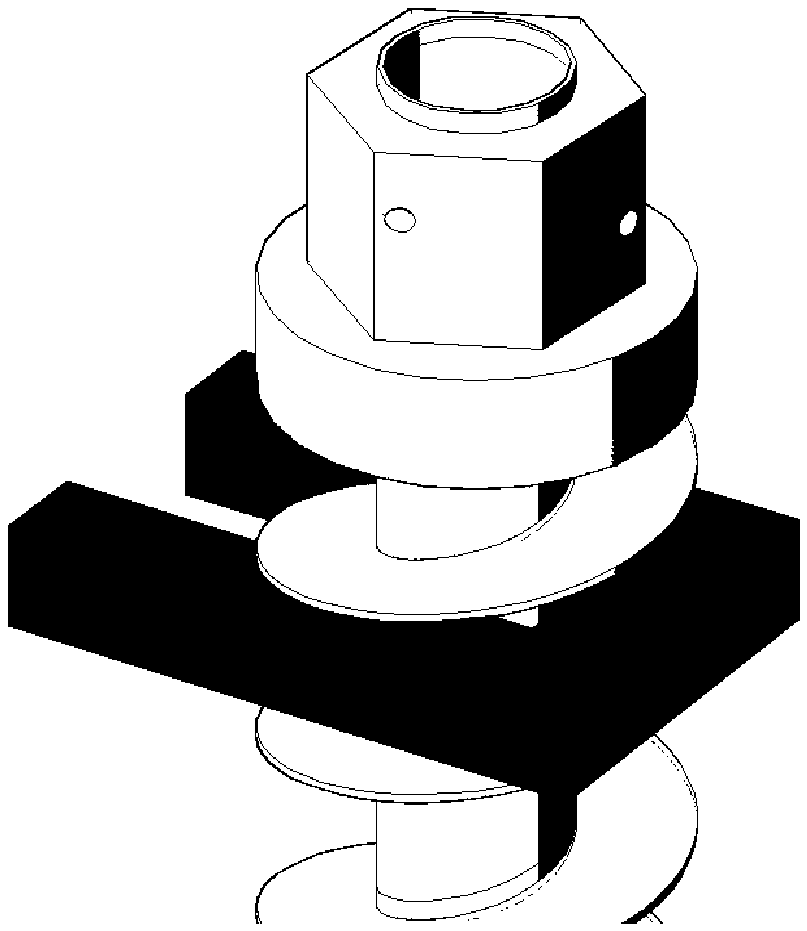

Ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method

ActiveCN109025816AFirmly connectedMeet the constructionDrilling rodsDirectional drillingTotal stationEngineering

The present invention discloses an ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method. The method comprises the following steps of: S1: siteformation and drill stem equipping: performing leveling and compaction for a site prior to place taking, or bedding a steel plate to facilitate place taking of a pile machine, and regulating equippingof the corresponding quantity of drill stems according to the depth of the lead holes to ensure the lead hole operation flow construction, wherein two lead hole drills are arranged on the site; and S2: location, paying-off and place taking of the pile machine: employing a total station to perform laying-off for preset lead hole stake positions, taking a drill machine in place to complete correction of the vertical degree of the drill stem and the centering of the center of the drill, and after location, putting down a support oil cylinder at the lower portion of a front-end mast and two support oil cylinders at the tail portion of the machine body of the drill machine. The ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method can extend the drill stem at will through connection according to pore-forming demands by employing a design of the hexagonal joint of the drill stem, can effectively ensure the reliable connection of the drill stem by only using a dual-way fixed plug pin after the drill stem is inserted when being connected and can meet the construction of an overlength pile hole.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com