Cyclone pile

A cyclone and pile driver technology, which is applied to sheet pile walls, buildings, and infrastructure engineering, can solve the problems of large amount of labor, slow overall work efficiency, and environmental pollution, and achieve improved hole-forming efficiency and dependence on resources and the environment small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

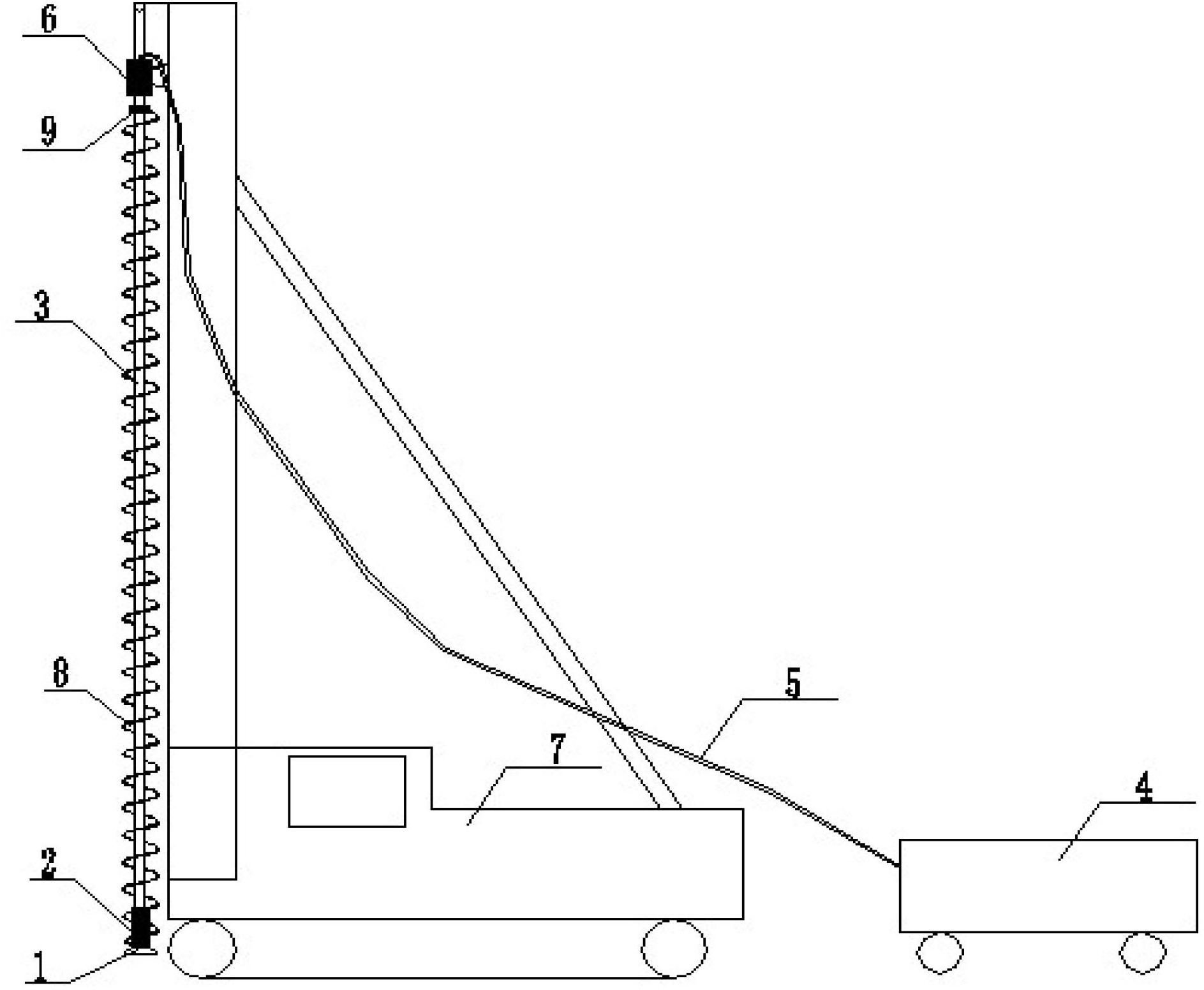

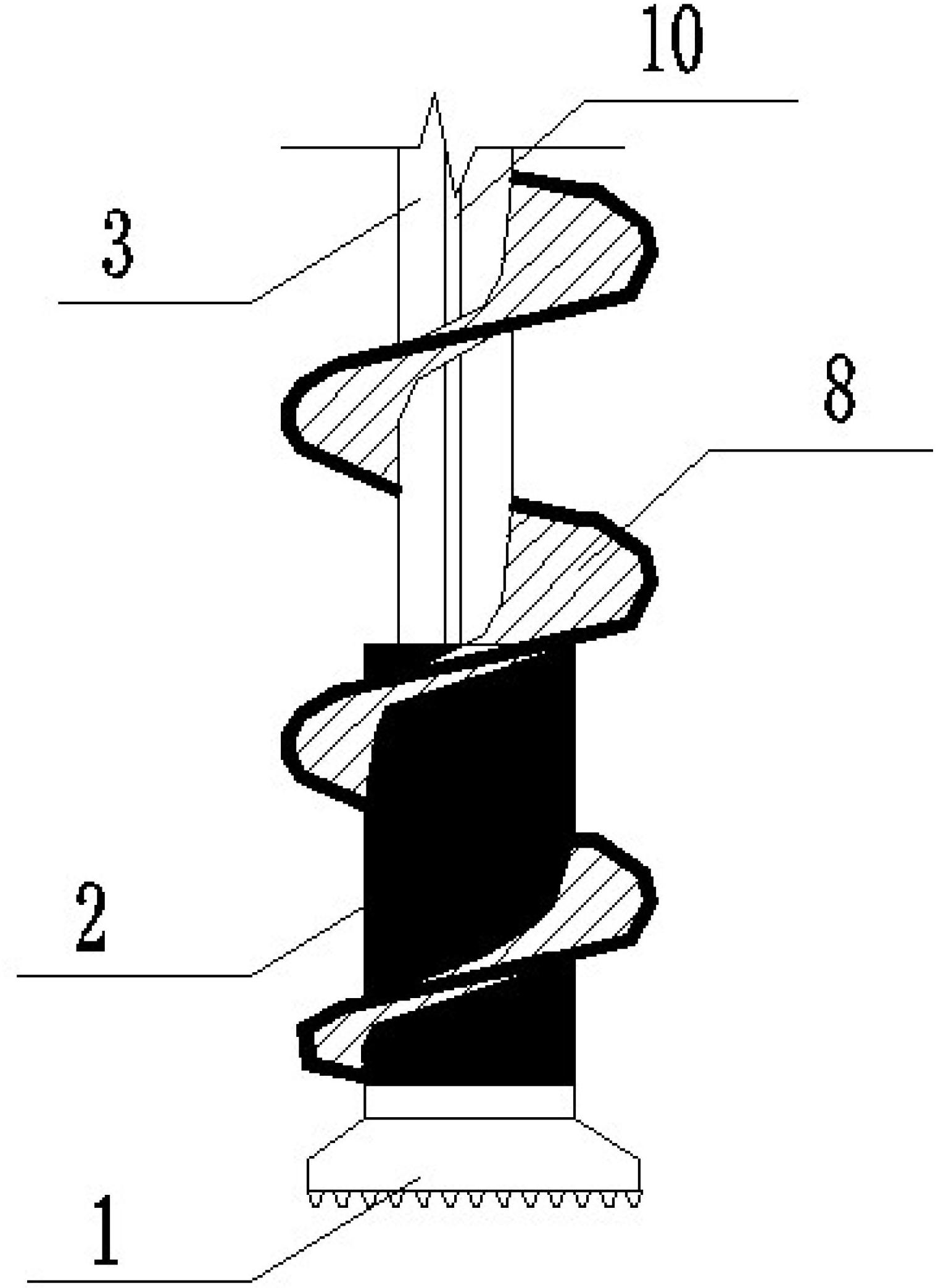

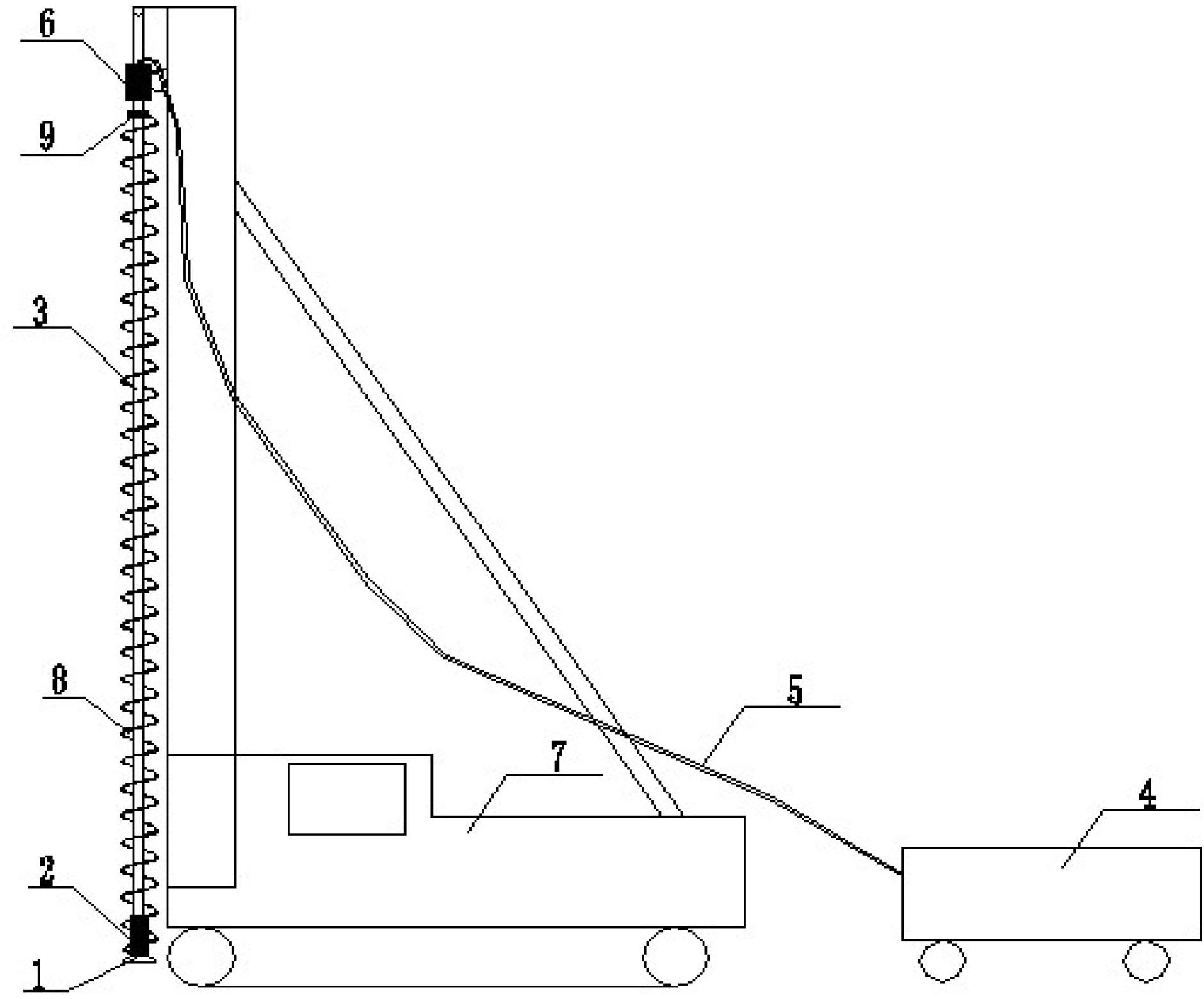

[0015] The cyclone pile of the present invention consists of a long auger frame 7 that moves as a pile driver, a long auger rod 3 placed on the long auger frame 7, a hammer head 1 placed at the lower end of the long auger rod 3 and a down-the-hole impactor 2. The blade 8 placed on the long auger rod 3, the shock absorber 9 and the power head 6 placed on the upper end of the long auger rod 3, the air compressor 4 connected to the power head 6 through the air supply pipe 5, placed in the long auger rod 3 The inner air pipe 10 in the auger rod 3 is composed.

[0016] The present invention is prepared by conventional methods using commercially available products and materials.

[0017] Working process of the present invention is:

[0018] The long auger drill frame 7 of the present invention carries the main equipment to move to the working place and locate it; turn on the power supply, the air compressor 4 generates wind pressure, and the compressed air is transmitted through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com