Ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method

A technology of prestressed pipe piles and construction methods, which is applied in the direction of drilling equipment and methods, drill pipes, casings, etc., and can solve the unfavorable site civilized construction of mud holes, high comprehensive cost of rotary drilling holes, and side friction of pipe piles Unfavorable force and other problems, to achieve the effect of low overall cost of hole introduction, improve mechanical utilization rate, and high efficiency of hole introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Although the embodiments of the present invention have been shown and described, those skilled in the art can understand that various changes, modifications and substitutions can be made to these embodiments without departing from the principle and spirit of the present invention. and modifications, the scope of the invention is defined by the appended claims and their equivalents.

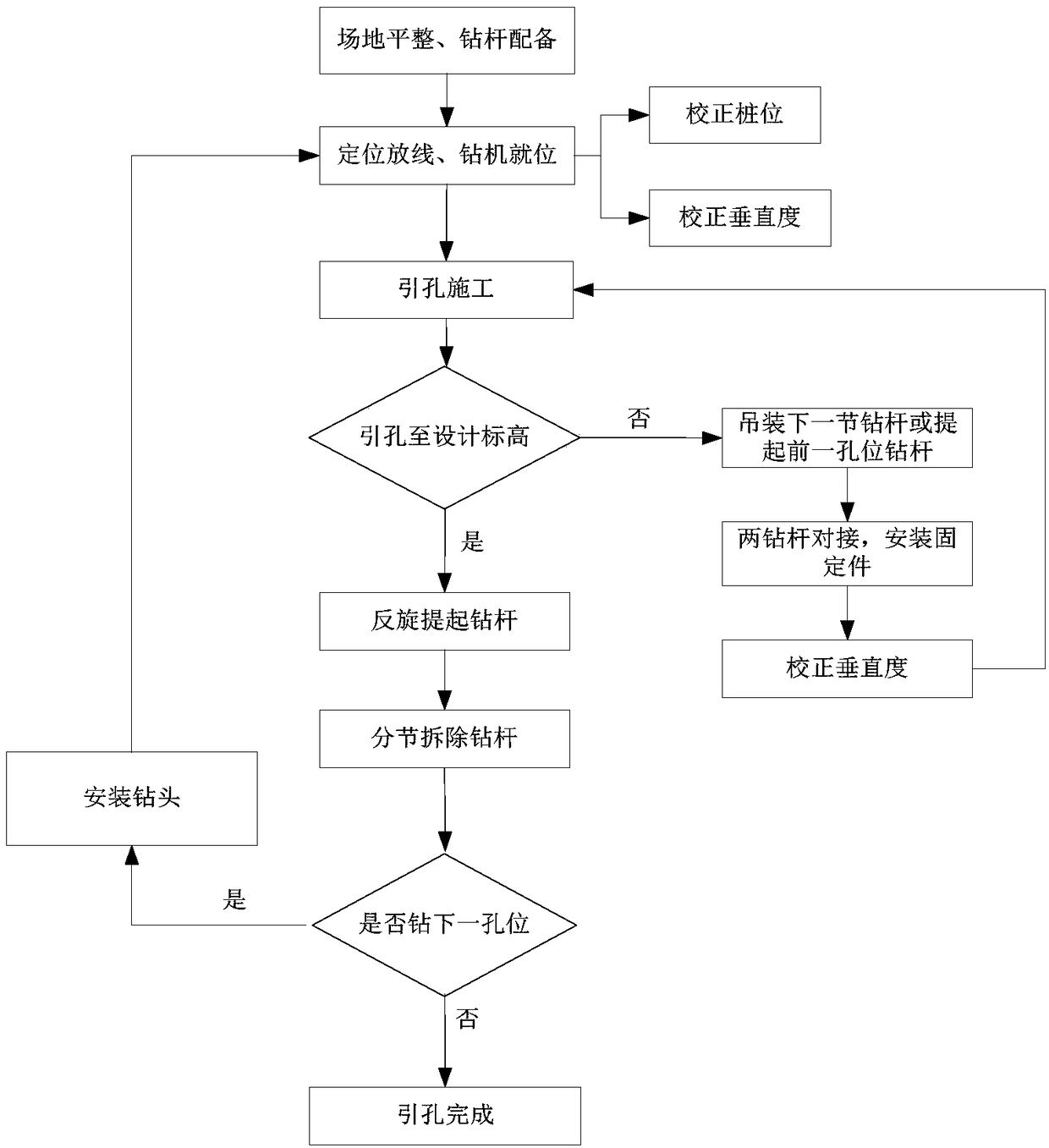

[0027] refer to Figure 1-2 , a construction method for super-deep and super-thick dense sand layer prestressed pipe pile long spiral pilot hole construction method, comprising the following steps:

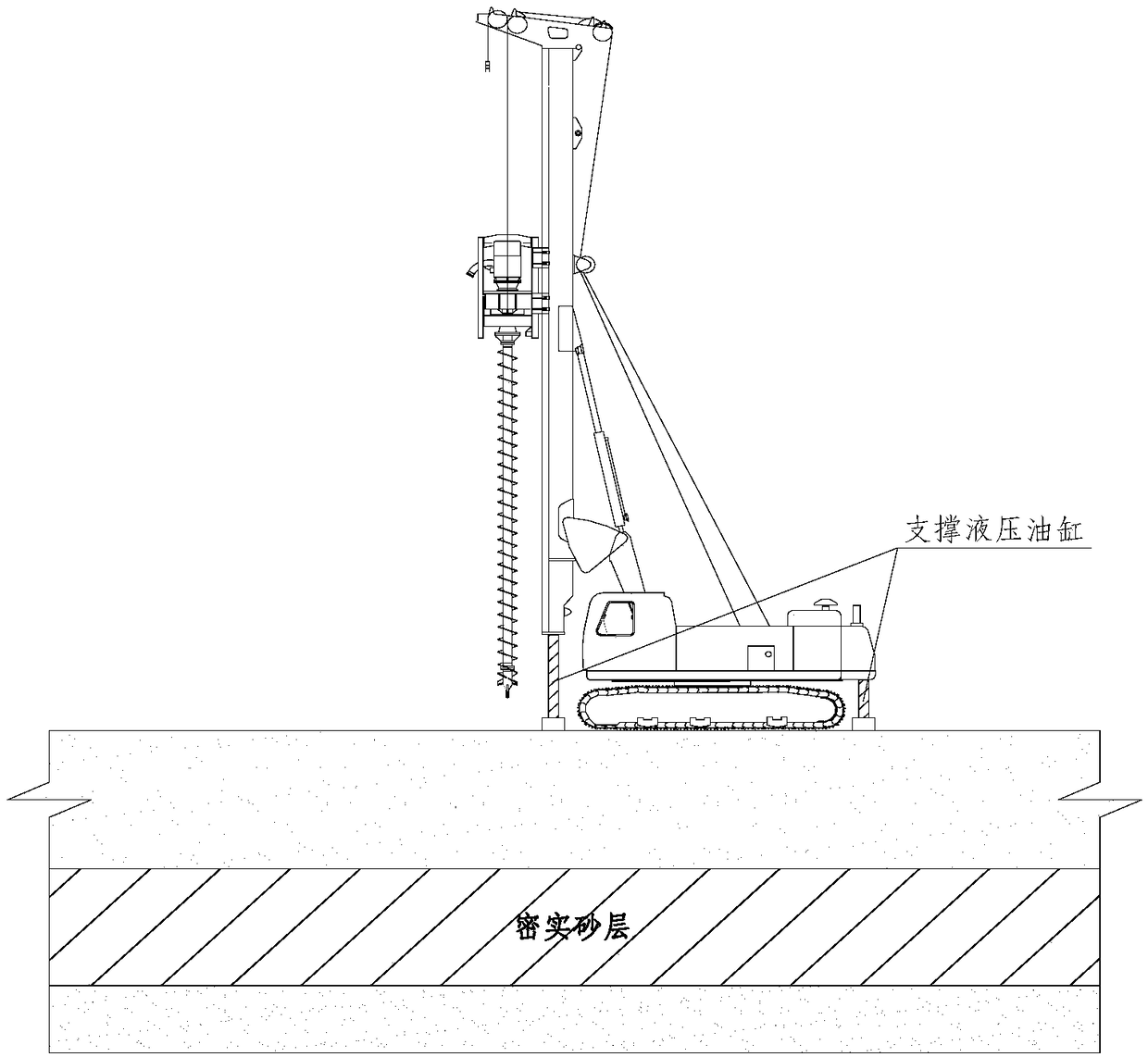

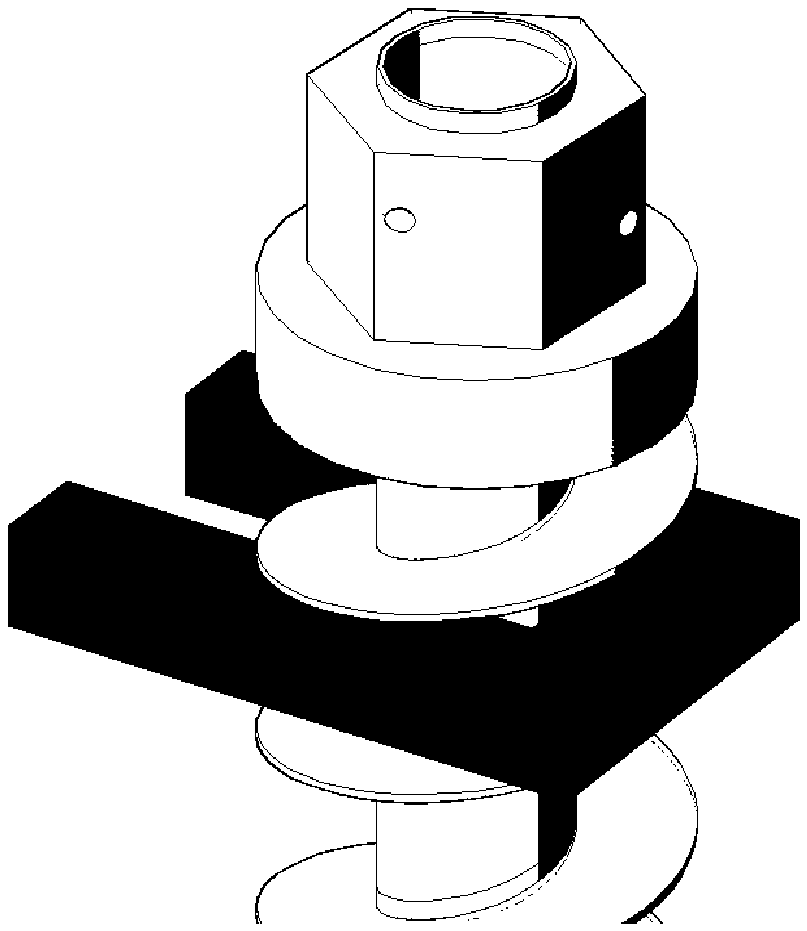

[0028] S1: Site leveling and drill pipe equipment: Level and compact the site before placing in place, or lay steel plates so that the pile driver can be in place, and adjust the corresponding number of drill pipes according to the depth of the pilot hole to ensure the smooth construction of the pilot hole operation , equipped with two pilot drill bits on site;

[0029] S2: Positioning and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com