Patents

Literature

59results about How to "Meet the construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

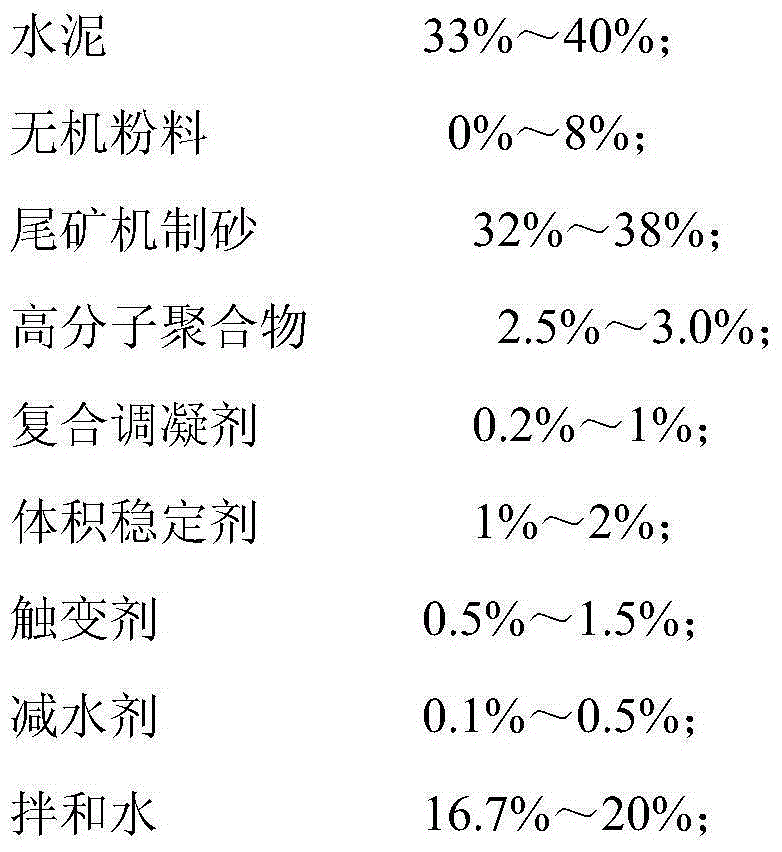

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

High fluidity grouting material and production method thereof

ActiveCN101798208AImprove mobilityEasy to pump over long distancesSolid waste managementNeutral phPortland cement

The invention discloses a high fluidity grouting material and a production method thereof. The high fluidity grouting material comprises the following components in percentage by weight: on the basis of 100 percent of total amount, 60 to 96 percent of conventional portland cement, 1 to 20 percent of calcite powder, 1 to 20 percent of a mineral modifying component, and 2 to 18 percent of swelling agent, wherein measuring on the basis of using the total amount of four substances as base number, 0.01 to 4 weight percent of high efficiency slushing agent and 0.0005 to 1 weight percent of plasticity swelling agent are added in the mixture of the four substances. The high fluidity grouting material can be made of raw materials mixed by adopting a dual-shaft paddle non-gravity high-efficiency mixer. The material has simple industrialized production process and stable product quality, adopts the water-cement ratio of between 0.24 and 0.28, is evenly blended by water with neutral pH value, and has the advantages of high fluidity, no bleeding, no segregation or layering, slight swelling, easy pump delivery, good durability and the like after the material is uniformly mixed by water.

Owner:HUBEI CHIDGE TECH

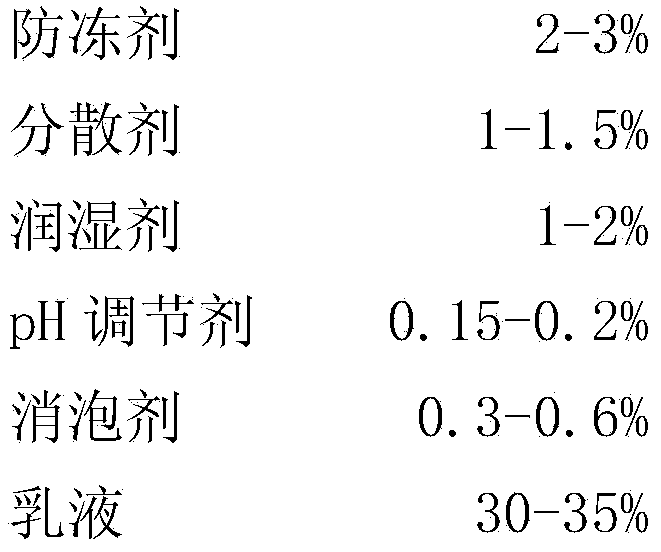

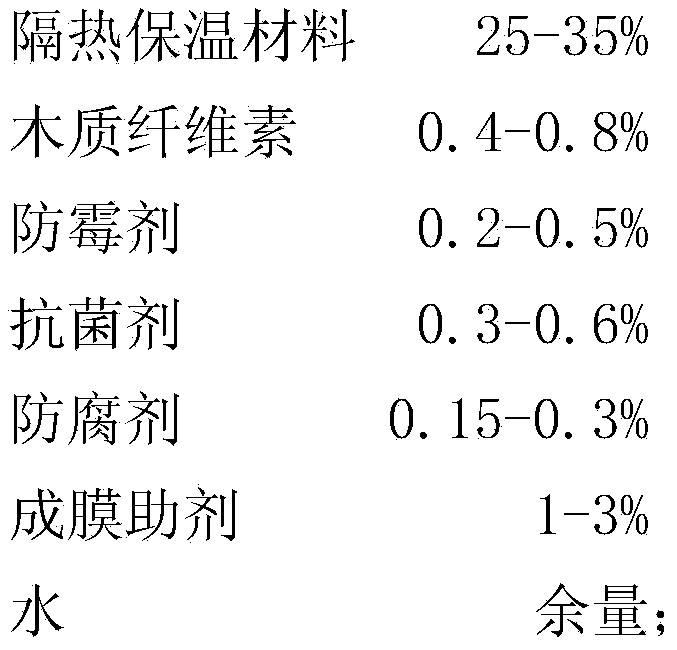

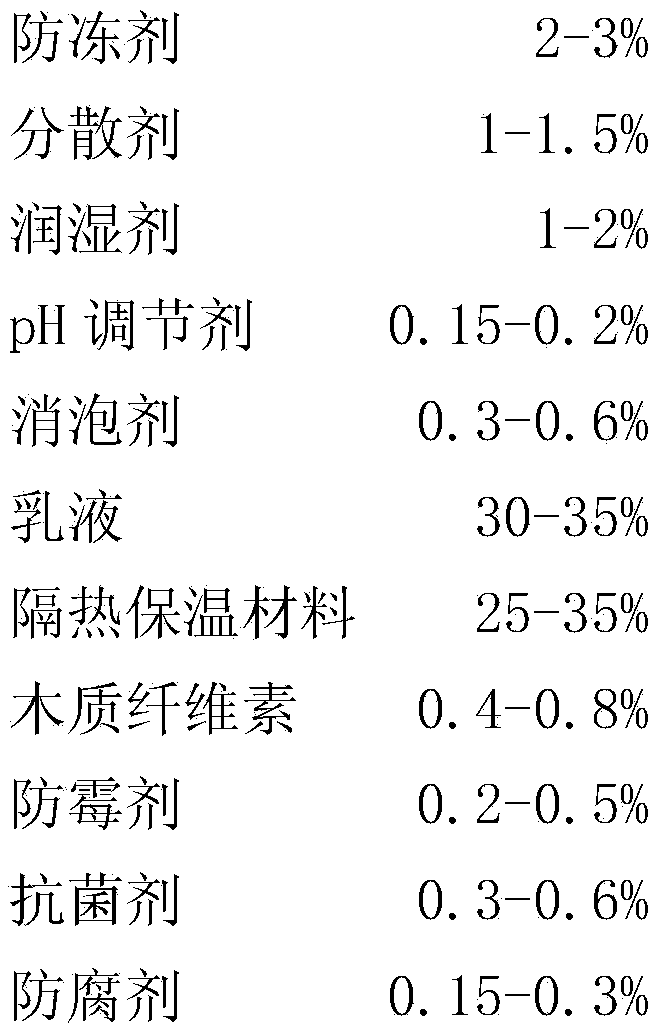

Multifunctional scrapping type single-component thermal insulation coating, multifunctional scrapping type bi-component thermal insulation coating and preparing methods of multifunctional scrapping type single-component thermal insulation coating and multifunctional scrapping type bi-component thermal insulation coating

ActiveCN103483963AOvercome the disadvantage of poor decorative feeling and not suitable for top coatingOvercome the disadvantage of easy crackingFilling pastesReflecting/signal paintsCelluloseThermal insulation

The invention relates to a multifunctional scrapping type single-component thermal insulation coating, a multifunctional scrapping type bi-component thermal insulation coating and preparing methods of the multifunctional scrapping type single-component thermal insulation coating and the multifunctional scrapping type bi-component thermal insulation coating. The multifunctional scrapping type single-component thermal insulation coating is formed by main paint. The main paint is prepared from, by weight, 2-3% of anti-freezing agent, 1-1.5% of dispersing agent, 1-2% of wetting agent, 0.15-0.2% of pH regulator, 0.3-0.6% of defoaming agent, 30-35% of emulsion, 25-35% of thermal insulation material, 0.4-0.8% of lignocellulose, 0.2-0.5% of mildew preventive, 0.3-0.6% of antibacterial agent, 0.15-0.3% of preservative and 1-3% of film-forming additive, the balance being water. The multifunctional scrapping type bi-component thermal insulation coating is formed by mixing main paint and white cement according to the weight ratio of 8-12:1. The multifunctional scrapping type single-component thermal insulation coating and the multifunctional scrapping type bi-component thermal insulation coating which are prepared with the methods are extremely low in heat conductivity coefficient, high in solar emissivity, good in thermal insulation function, free of cracking in impasto and capable of bringing a strong sense of decoration.

Owner:SKSHU PAINT

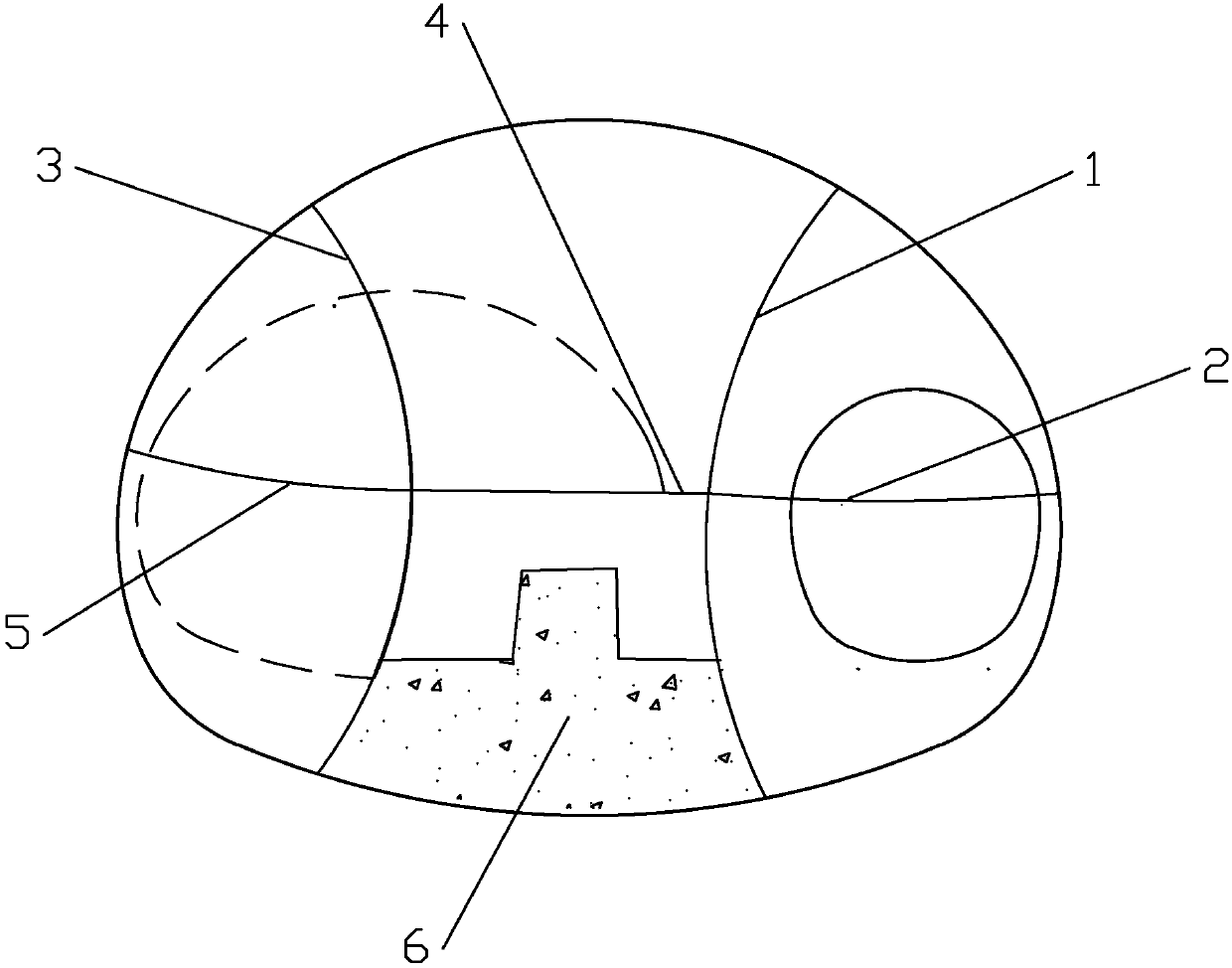

Construction conversion technology of double side walls of single-hole large section tunnels

The invention discloses a construction conversion technology of double side walls of single-hole large section tunnels. The method comprises following steps: 1. a left middle partition wall of a double-side-wall tunnel moves to the left and a temporary invert gradually moves downward to be respectively coincident with a middle partition wall and a temporary invert of CRD; 2. excavation and supportare carried out for the upper steps and the lower steps of drift heading at two sides of the two side walls and the upper step in the middle, and a middle lower step core soil is reserved; 3. small section step method of excavation and support for the upper step and the lower step is carried out; 4. excavation and support are carried out for the upper step at two sides of the middle section CRD and the lower step at the right side; 5. excavation and support are carried out for the lower step at the middle of the double side walls and for the lower step at right side of the CRD. The inventionuses the method of double-side wall drift heading and combines the moving of the partition wall and the reserved core soil for construction. The construction safety is guaranteed; the cost is reduced;the construction progress is accelerated; the construction scheme is flexible; surrounding rock deformation is rarely developed and strict deformation requirements for project construction can be met.

Owner:CCCC SECOND HARBOR ENG

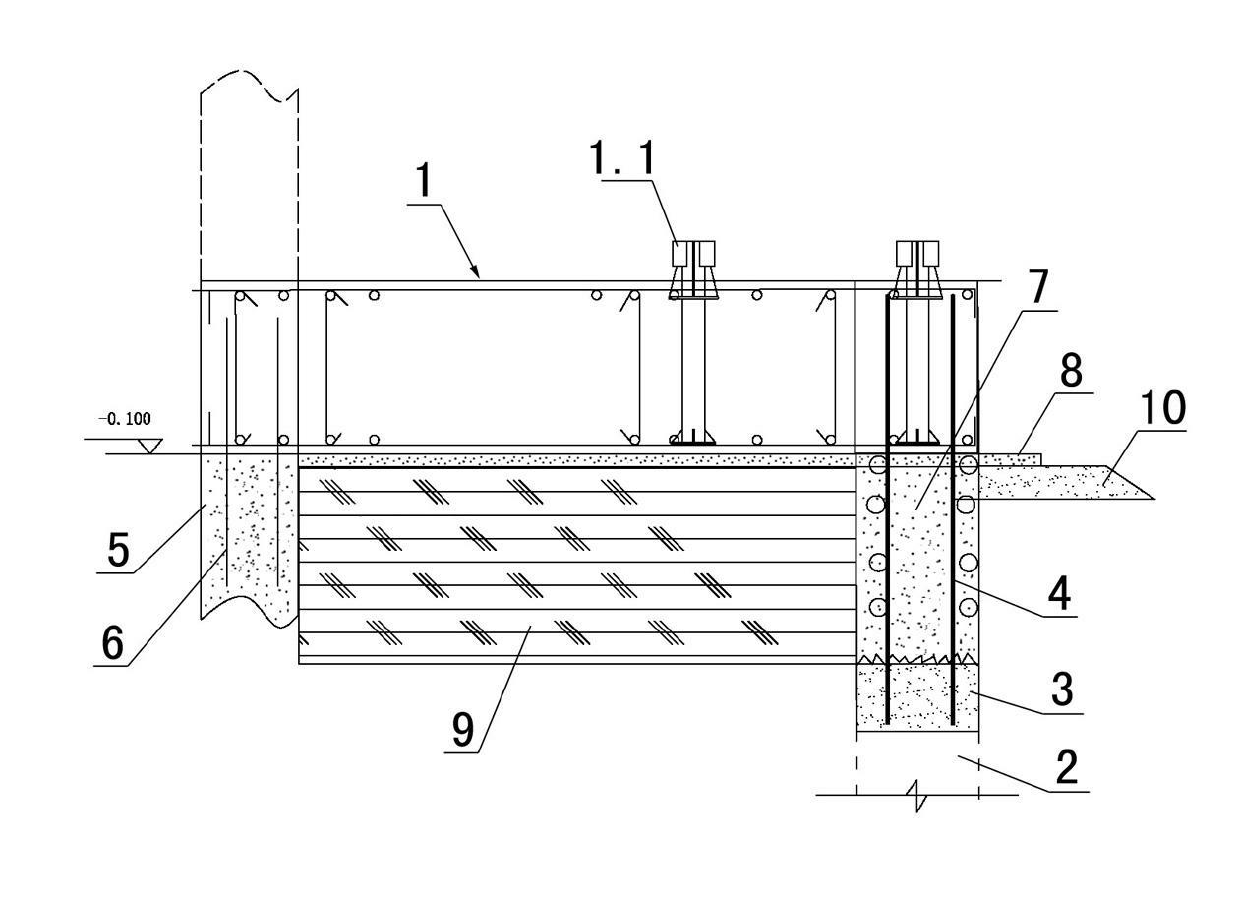

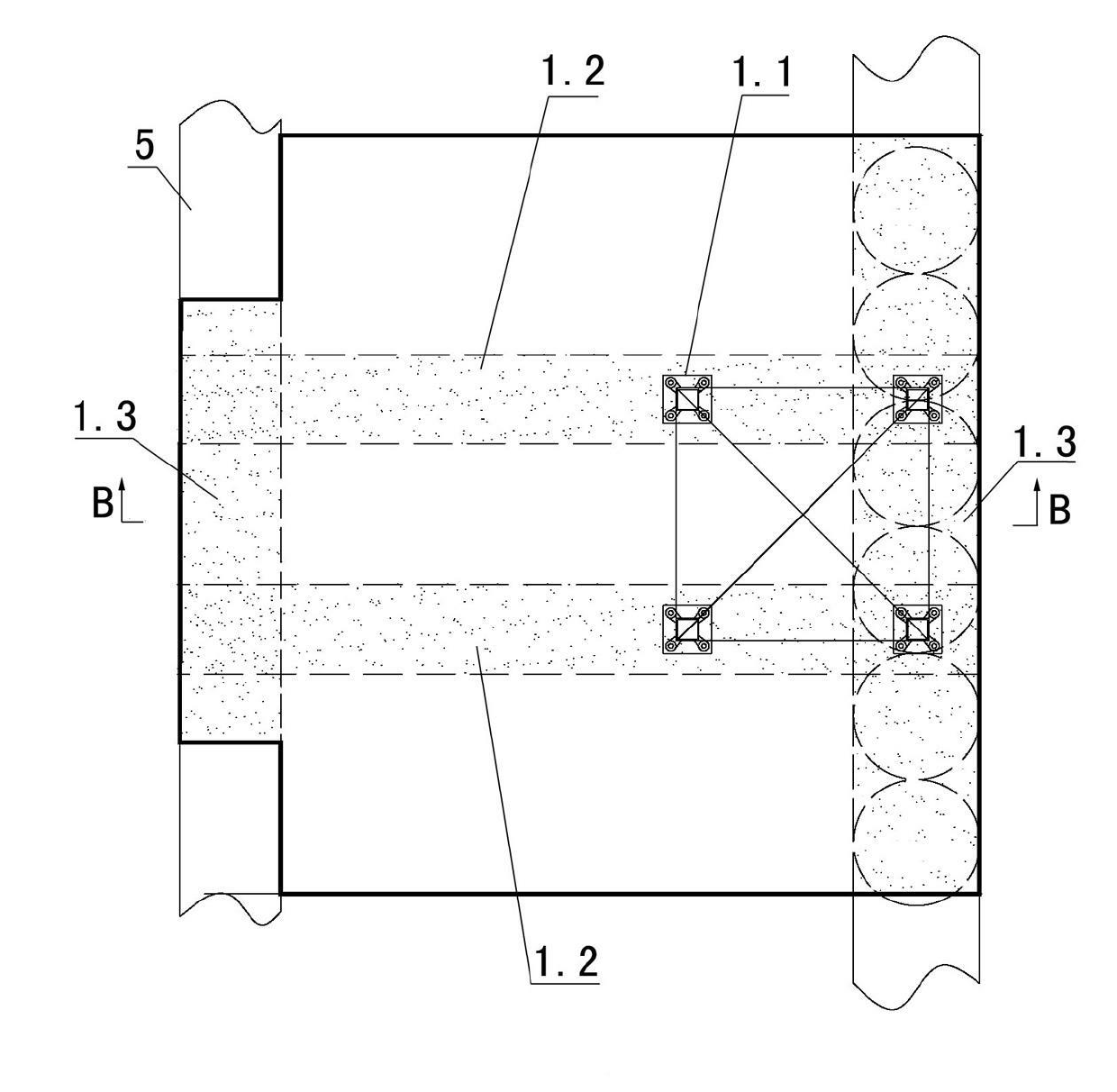

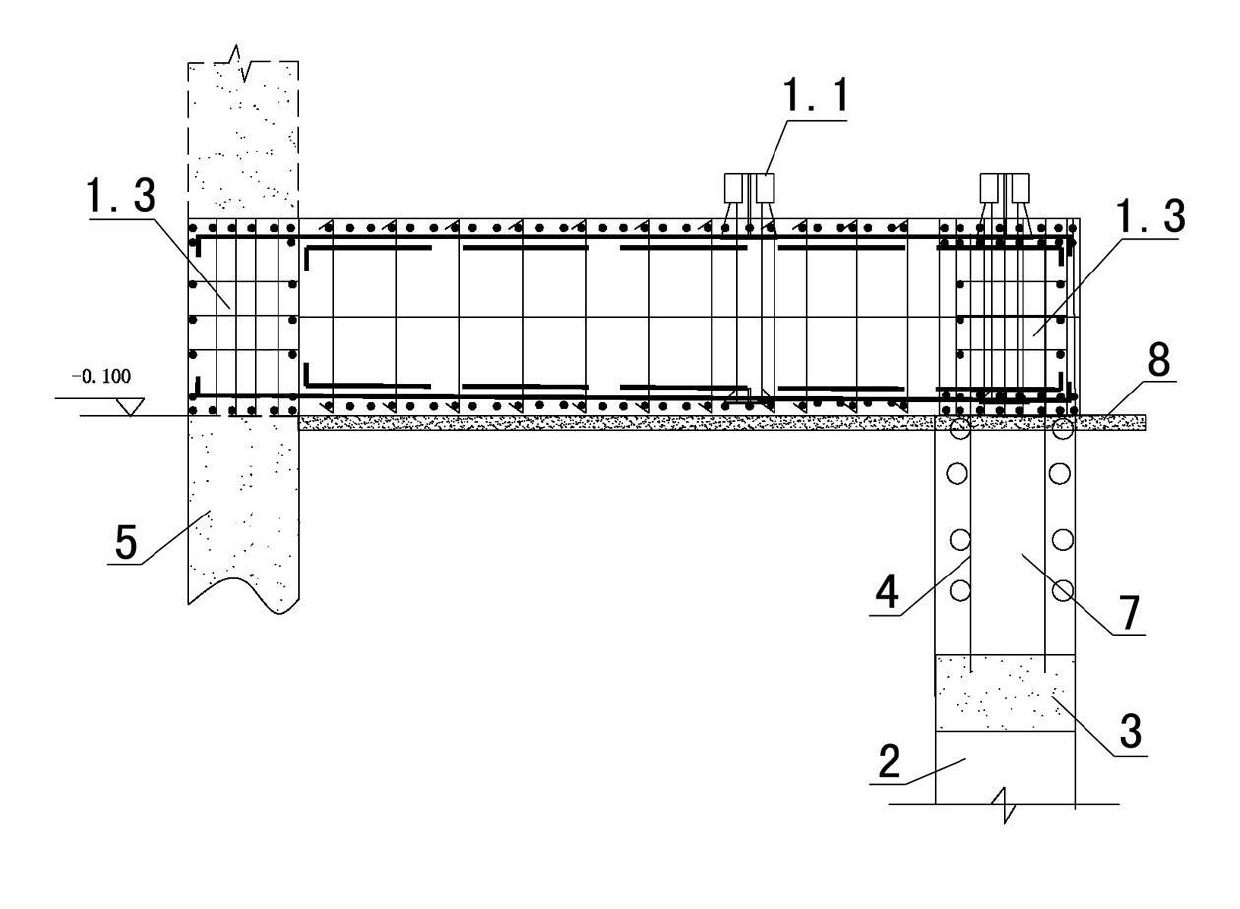

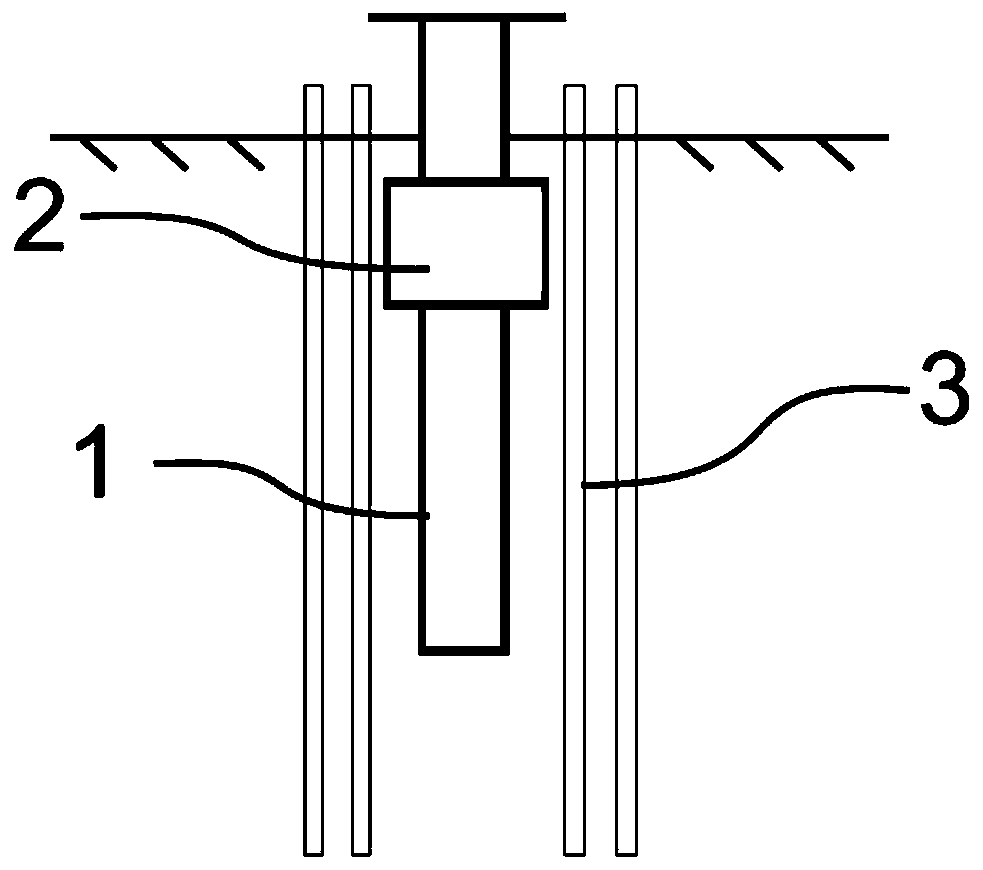

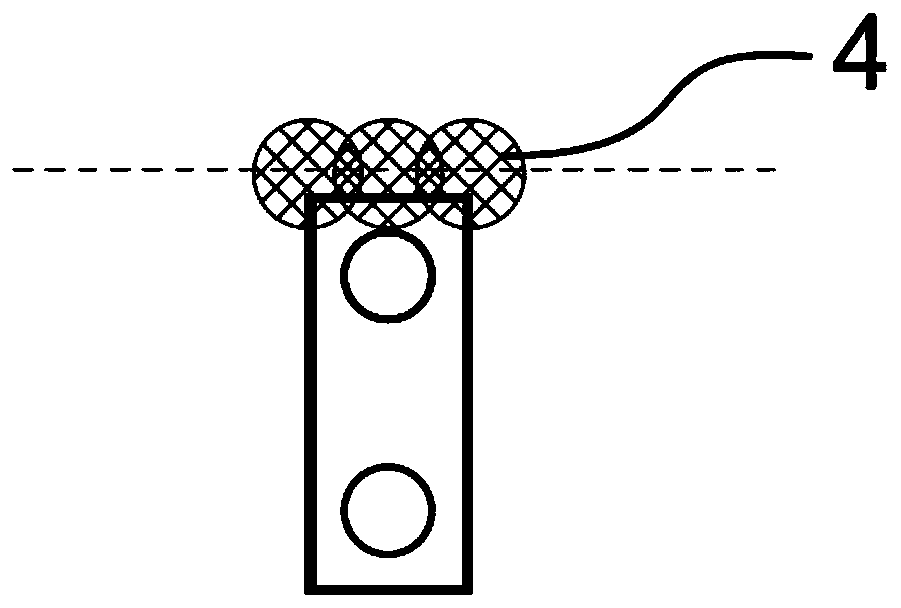

Tower crane foundation formed by using external walls of basement and supporting piles of foundation pit

InactiveCN102535505AReasonable arrangementLayout scienceFoundation engineeringBasementReinforced concrete

The invention discloses a tower crane foundation formed by using external walls of a basement and support piles of a foundation pit. The tower crane foundation comprises a tower crane foundation raft, wherein one side of the tower crane foundation raft is erected on the external walls of the basement, and external wall embedded bars of the basement are arranged between the tower crane foundation raft and the external walls of the basement; upper parts of the external wall embedded bars of the basement are arched into the tower crane foundation raft, and lower parts of the external wall embedded bars of the basement are embedded into the external walls of the basement; the other side of the tower crane foundation raft is erected on top beams of the support piles at the side slope of the foundation pit through a reinforced concrete wall; the reinforced concrete wall is internally provided with top beam embedded bars; moreover, upper parts of the top beam embedded bars are anchored into the tower crane foundation raft and lower parts of the top beam embedded bars are embedded into the top beams of the supporting piles. The tower crane foundation is used for successfully solving a difficulty that a tower crane cannot be directly arranged in the deep foundation pit of the foundation in a foundation construction stage; and the tower crane foundation is quite applicable to a large project which has higher requirements on side slope load of the foundation pit, is smaller in site and has the supporting piles and the external walls of the basement.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

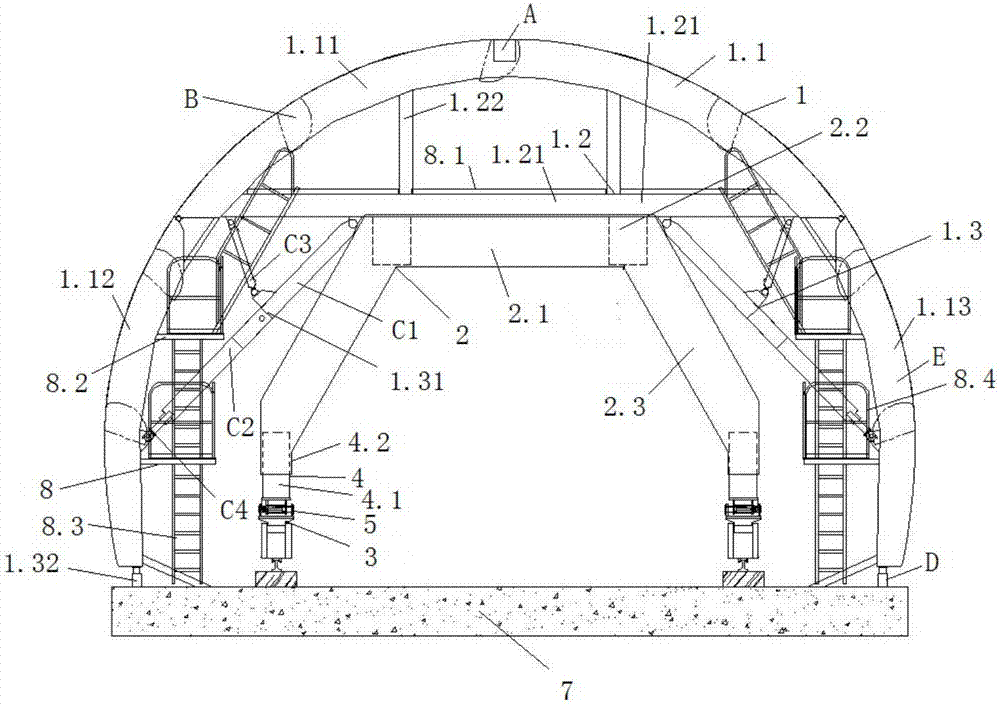

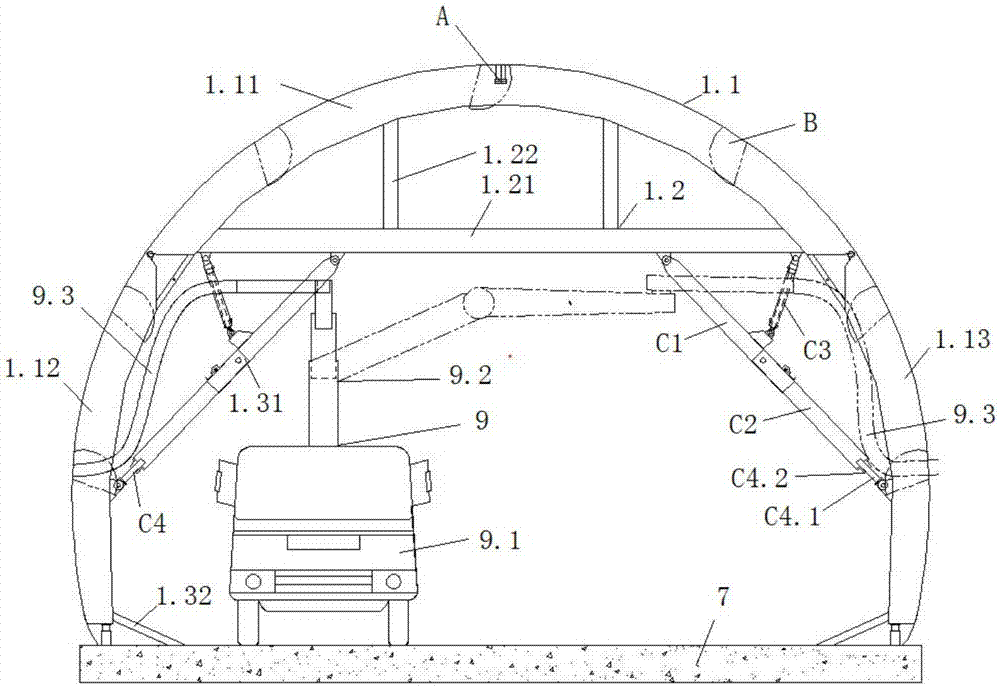

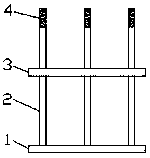

Lining construction method and lining trolley thereof

PendingCN107965337AReduce typesReduce in quantityUnderground chambersTunnel liningArchitectural engineeringPortal frame

The invention provides a lining construction method. The lining construction method includes equipment of a lining trolley and a concrete pumping mechanism, wherein the lining trolley comprises a formwork system, a portal frame system and a walking mechanism. The lining construction method comprise the following steps that the walking mechanism drives the portal frame system to convey formwork system single pieces to a construction site; the portal frame system splits the formwork system single pieces; the concrete pumping mechanism conveys concrete into pouring gates or working windows of theformwork system single pieces for lining construction; after lining construction of the construction site is completed, the walking mechanism drives the portal frame system to convey the formwork system single pieces to a next construction site. During application of the lining construction method, the combination of the portal frame system and the walking mechanism can serve as a standard component, which can be combined with a number of sets of formwork systems simultaneously to achieve simultaneous construction of multiple sets of formwork system single pieces, thereby greatly improving the construction efficiency. The invention also provides the lining trolley. The lining trolley is concise in structure and small in the number of parts; the formwork system single pieces serve as majorload bearing parts and accordingly are less prone to deformation and shifting during a pouring process.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

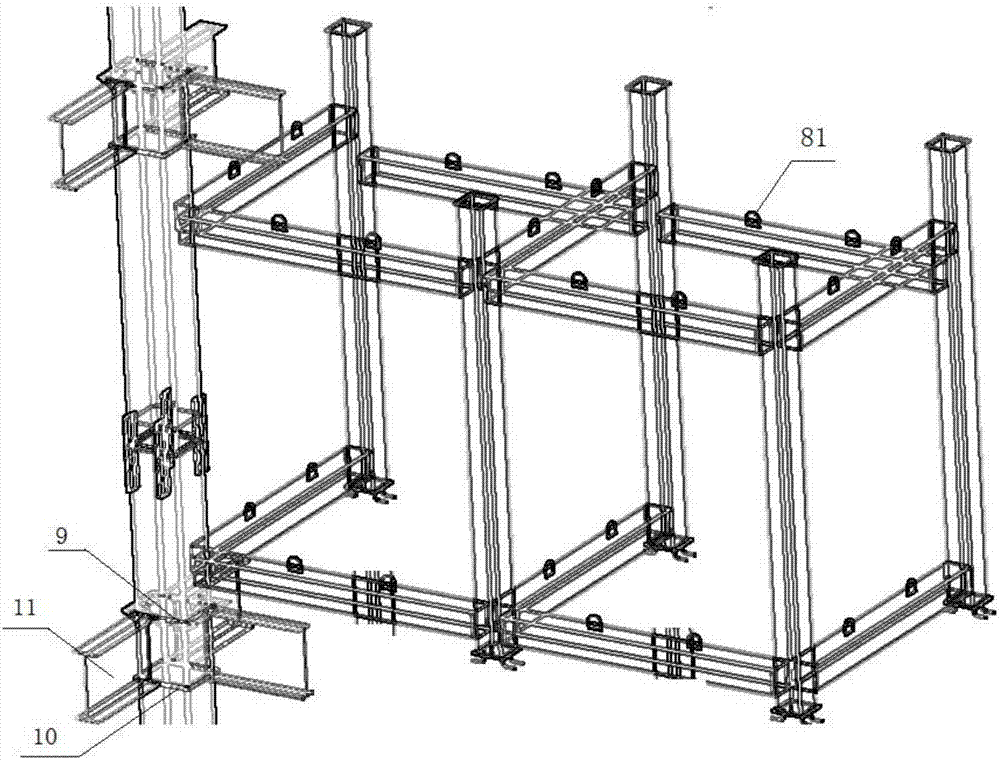

Safe crush-resistance assembly-type steel-structure elevator well

The invention discloses a safe crush-resistance assembly-type steel-structure elevator well. The elevator well comprises a frame column, a floor and an elevator well body, wherein the frame column is connected to the floor through an embedded part, and the frame column and a top board are directly welded to a top beam through an end sealing plate; the elevator well body is internally provided with an elevator girder and a frame girder, the elevator girder is provided with a first ring beam according to the height of an elevator door, and one side of the elevator girder, where the elevator door is not arranged, is provided with a second ring beam; the well wall of the elevator well body is provided with a light-steel keel plasterboard. According to the safe crush-resistance assembly-type steel-structure elevator well, by using an assembly-type steel structure to replace original concrete cast-in-place constructional columns and the ring beams and adding a brick well wall, a close well is formed, so that the construction is greatly accelerated, and the workload of staff is reduced; since the elevator girder is provided with the first ring beam according to the height of the elevator door and the side of the elevator girder, where the elevator door is not arranged, is provided with the second ring beam, the structure of the elevator well body is optimized; by arranging the plasterboard on the well wall, an effect of a partition wall is taken, and not only can a sealing effect be taken, but the properties of wind resistance and crush resistance can be improved.

Owner:JIANGSU HUNING STEEL MECHANISM +1

Cement-based composite material for 3D printing technology and its preparation method and use

ActiveCN104310918BEasy to get materialsLow costSolid waste managementComputer printingHouse building

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

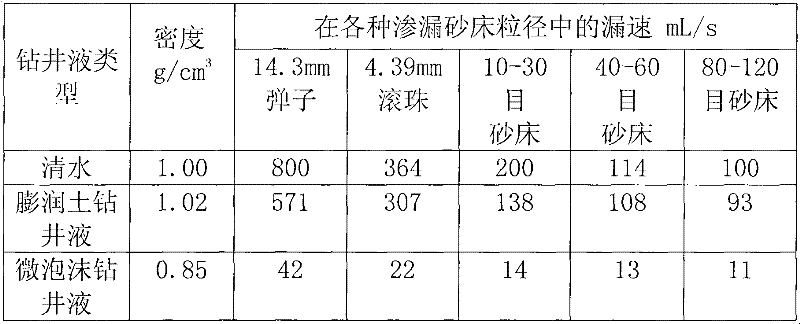

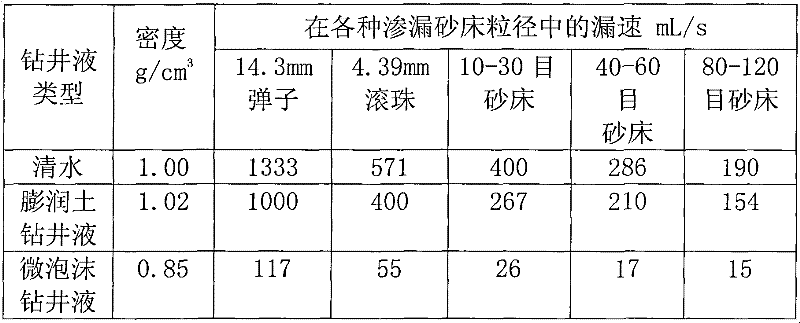

Micro-foam drilling fluid

The invention discloses a micro-foam drilling fluid. The micro-foam drilling fluid comprises the following compositions: 40 to 50 grams of bentonite, 3 to 5 grams of composite foaming agent, 2 grams of xanthan, 3 grams of high-viscosity carboxymethyl cellulose, 3 grams of sodium carbonate, 2 to 3 grams of strong zwitterionic coating agent, 5 grams of partially-hydrolyzed polyacrylonitrile ammonium salt, 5 grams of organic silicon humic acid kalium, 5 grams of lignite resin and 1 grams of viscosity reducer for the drilling fluid in each liter of the drilling fluid, wherein the composite foaming agent consists of lauryl sodium sulfate and sodium dodecyl benzene sulfonate according to mass ratio of 7:3. The drilling fluid has low density, good shielding effect and remarkable anti-leaking effect of a low-pressure easy-to-leak layer and can effectively improve the quality of well cementation.

Owner:DAQING PETROLEUM ADMINISTRATION +1

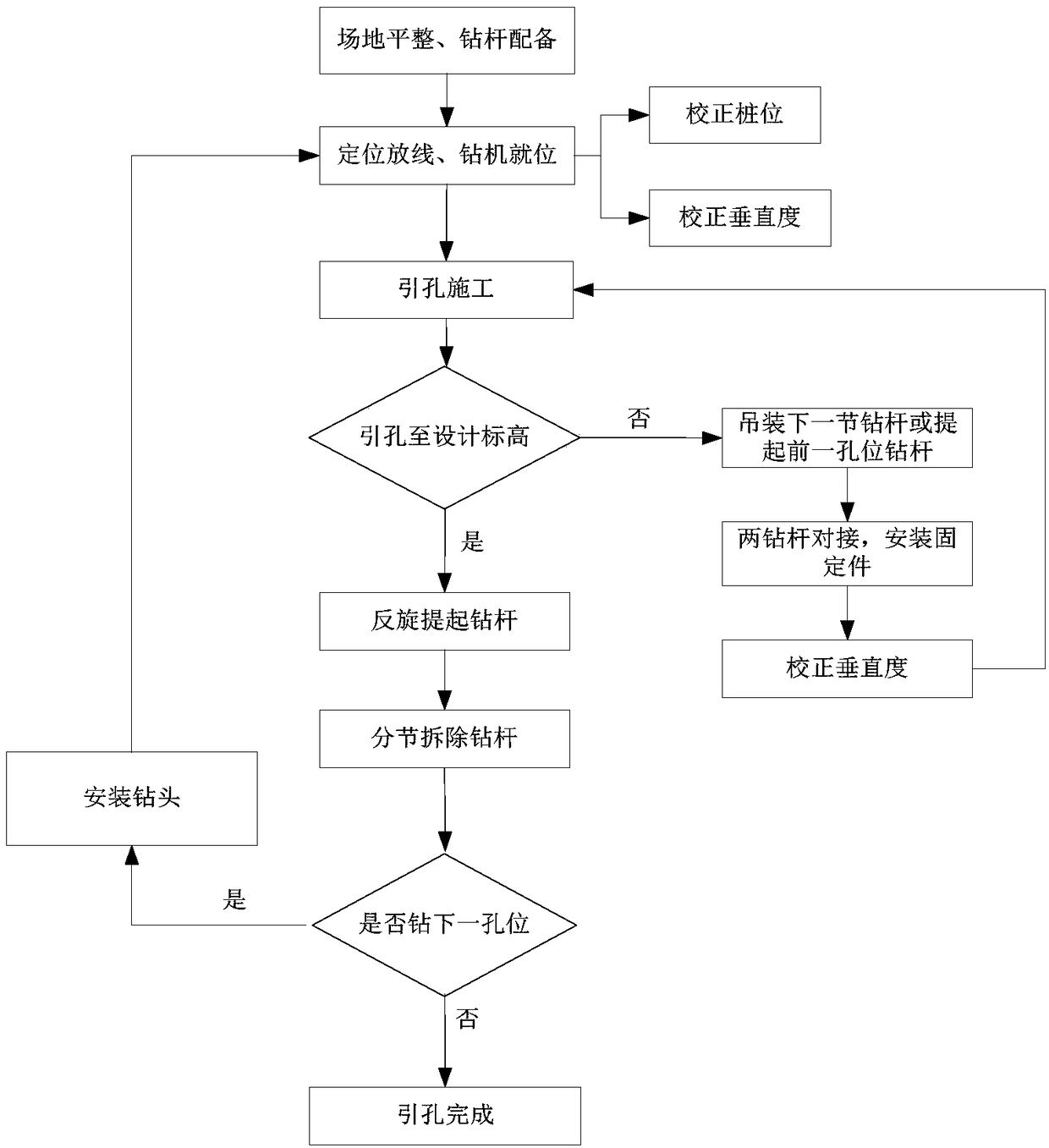

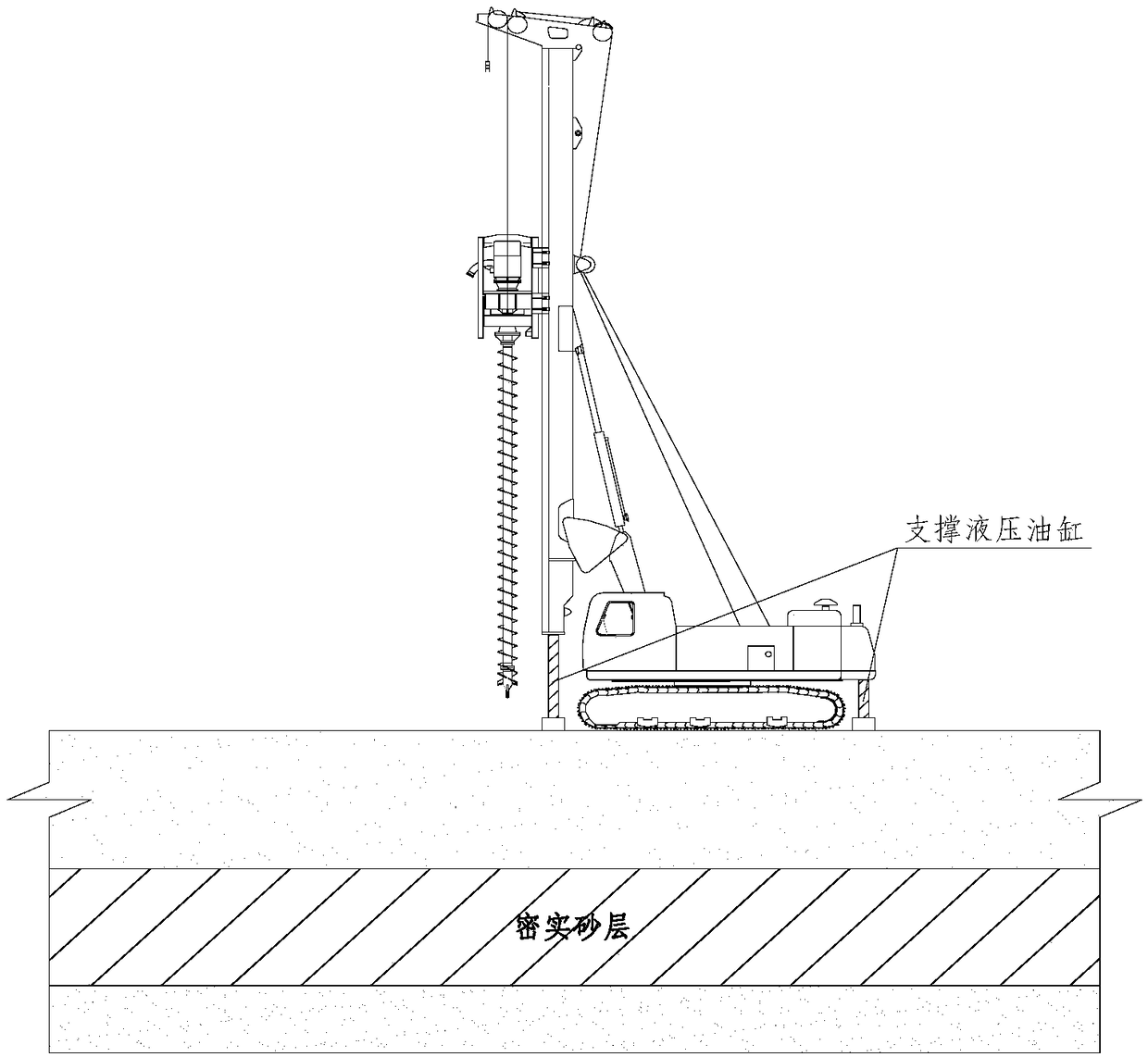

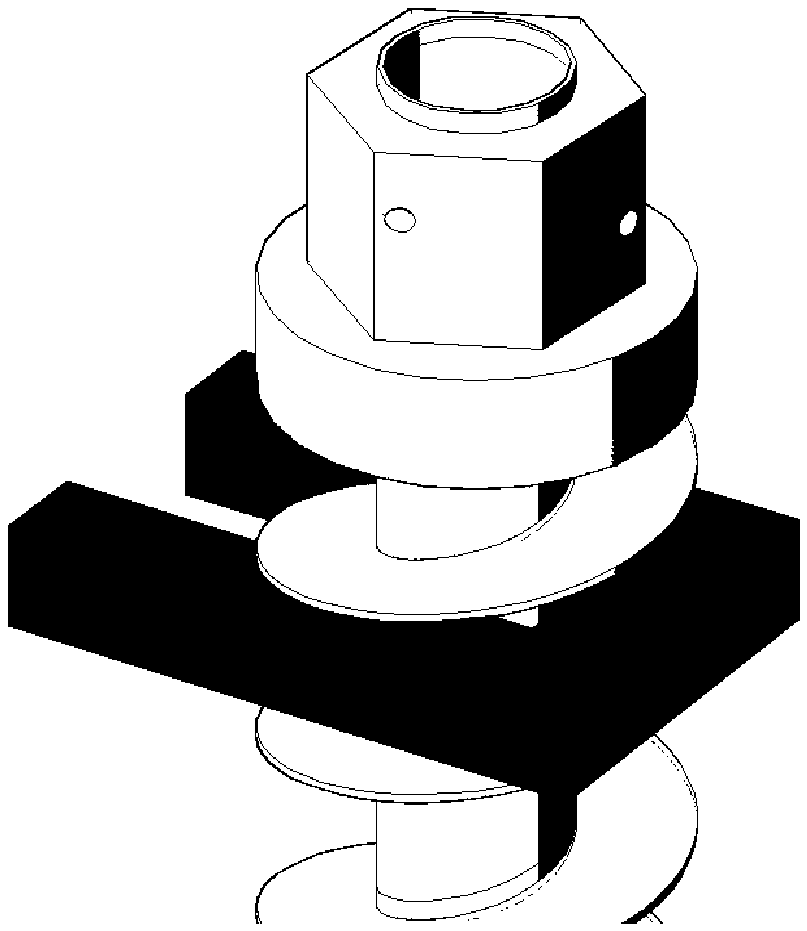

Ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method

ActiveCN109025816AFirmly connectedMeet the constructionDrilling rodsDirectional drillingTotal stationEngineering

The present invention discloses an ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method. The method comprises the following steps of: S1: siteformation and drill stem equipping: performing leveling and compaction for a site prior to place taking, or bedding a steel plate to facilitate place taking of a pile machine, and regulating equippingof the corresponding quantity of drill stems according to the depth of the lead holes to ensure the lead hole operation flow construction, wherein two lead hole drills are arranged on the site; and S2: location, paying-off and place taking of the pile machine: employing a total station to perform laying-off for preset lead hole stake positions, taking a drill machine in place to complete correction of the vertical degree of the drill stem and the centering of the center of the drill, and after location, putting down a support oil cylinder at the lower portion of a front-end mast and two support oil cylinders at the tail portion of the machine body of the drill machine. The ultra-deep and extra-thick dense sand stratum prestressed pipe pile long spiral lead hole construction method can extend the drill stem at will through connection according to pore-forming demands by employing a design of the hexagonal joint of the drill stem, can effectively ensure the reliable connection of the drill stem by only using a dual-way fixed plug pin after the drill stem is inserted when being connected and can meet the construction of an overlength pile hole.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

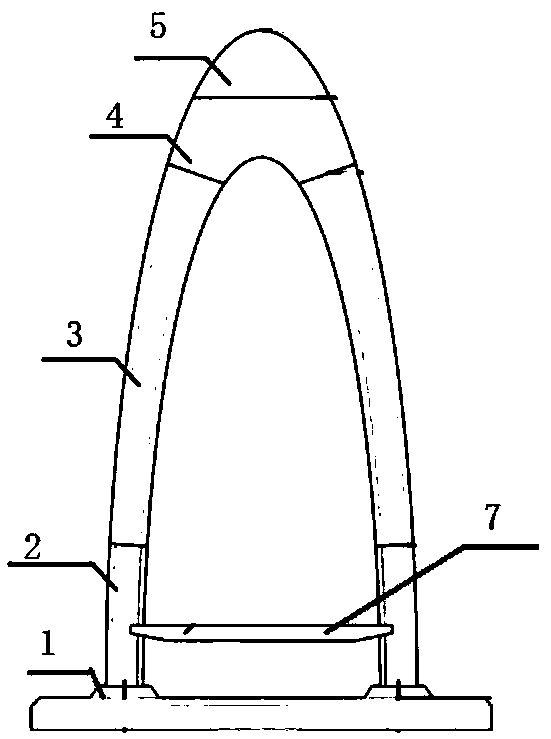

Safe and stable suspension bridge and construction technology thereof

ActiveCN109505225ASimple construction processGuarantee the construction qualitySuspension bridgeBridge erection/assemblyTowerBuilding construction

The invention discloses a safe and stable suspension bridge and a construction technology thereof. The construction technology specifically includes the following steps that 1, firstly, the whole suspension bridge is divided into a steel arch foot bearing platform, a steel mixing joint section, a pure steel structure section, a cross beam section and a tower crown decoration section according tothe different structure composition; 2, embedded parts are set in a designated position, and pouring is conducted on the embedded parts to prepare the steel arch foot bearing platform; 3, the steel mixing joint section is constructed on the steel arch foot bearing platform; 4, after the steel mixing joint section is constructed, the pure steel structure section is constructed; 5, the cross beam section is constructed on the pure steel structure section, and fixation is then conducted; 6, finally, the tower crown decoration section is built and fixed on the upper portion of the cross beam section. On the basis that the construction quality is guaranteed, the construction technology of the bridge is optimized, the whole construction process is relatively simple, the whole construction speedis increased and the construction period is shortened.

Owner:JIANGSU HUNING STEEL MECHANISM

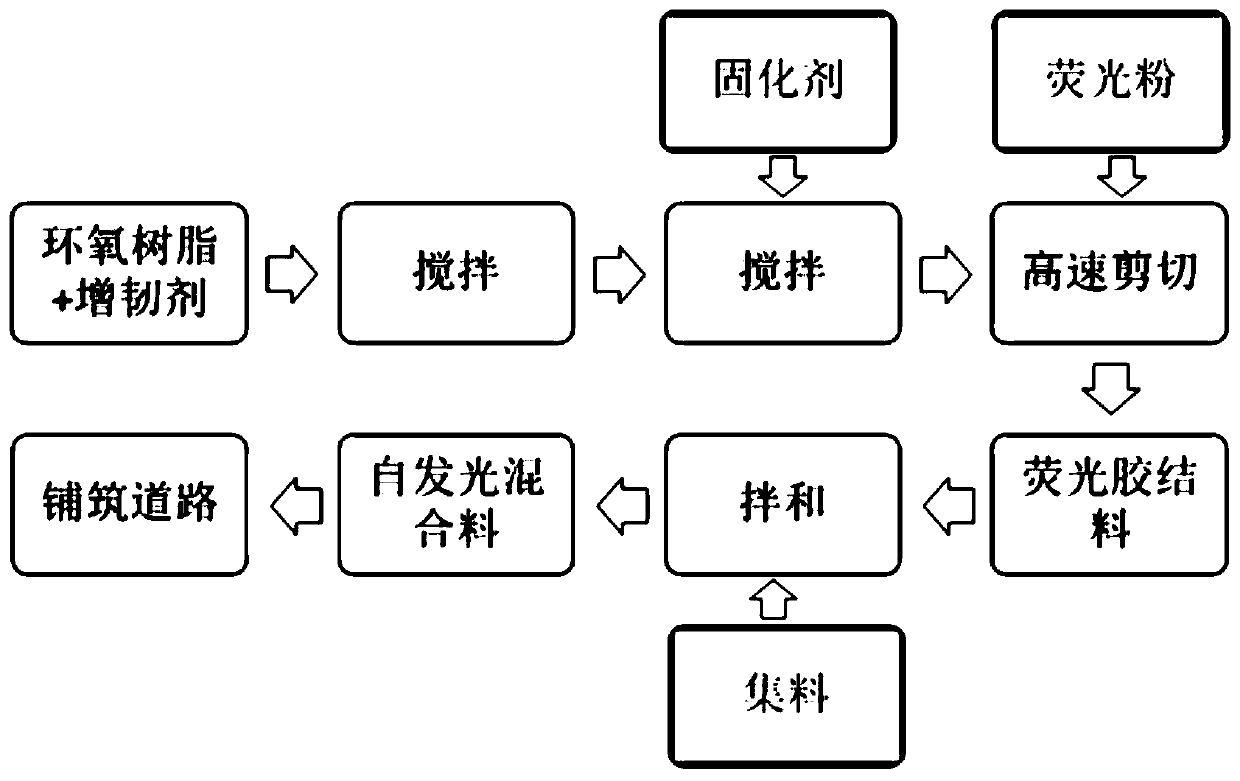

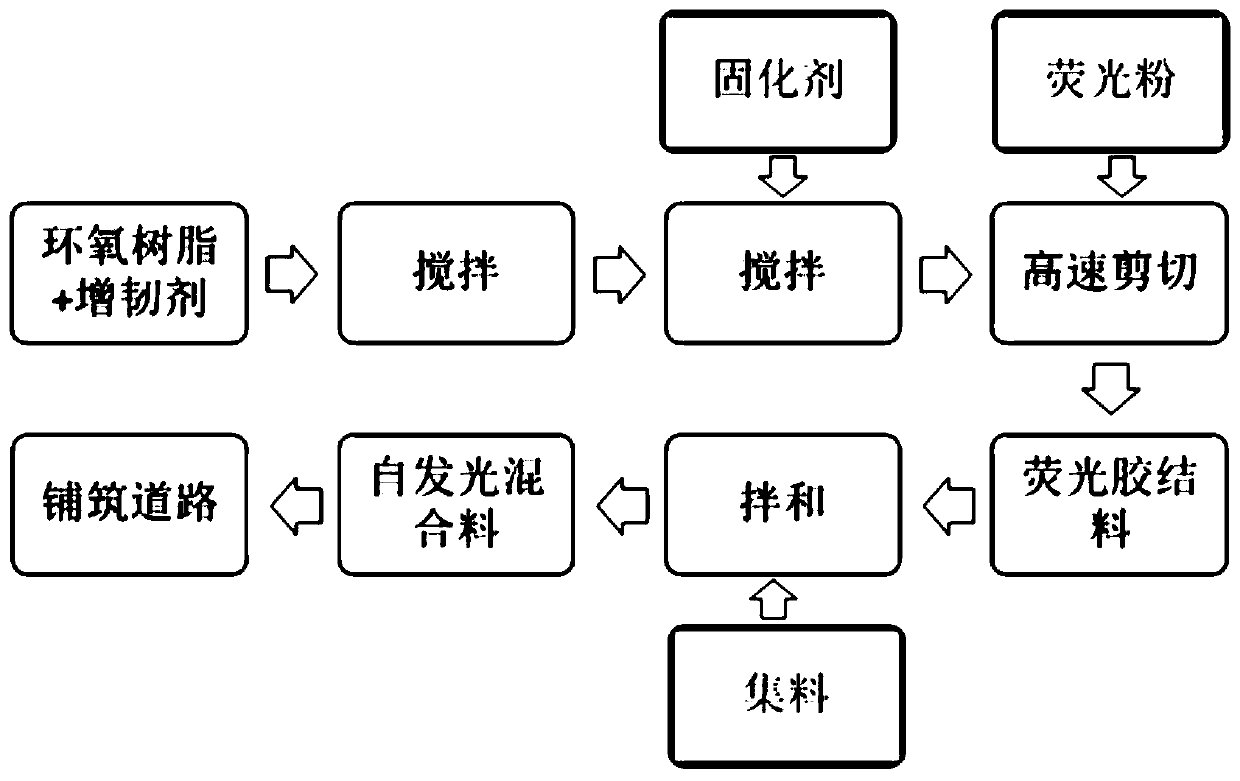

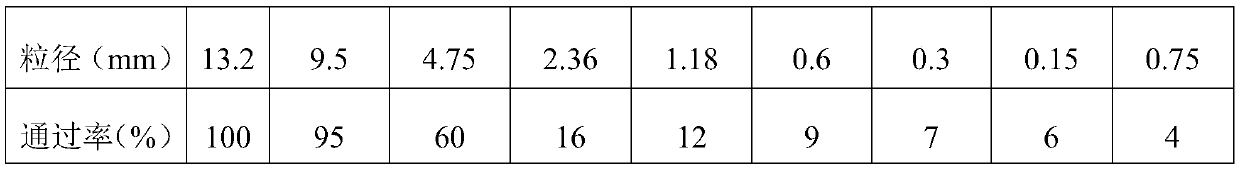

Energy-storage self-luminous epoxy resin mixture for road, preparation method and application

ActiveCN111138114AFully protect the luminosityIncrease stickinessIn situ pavingsPolymer scienceFirming agent

The invention discloses an energy-storage self-luminous epoxy resin mixture for roads as well as a preparation method and application thereof. The energy-storage self-luminous epoxy resin mixture comprises the following components: coarse aggregate, fine aggregate, epoxy resin, a toughening agent, a curing agent and fluorescent powder, wherein the nominal particle size of the coarse aggregate is greater than 2.36 mm, the nominal particle size of the fine aggregate is 0.15-2.36 mm, and the nominal particle size of the fluorescent powder is less than 0.15 mm; wherein the epoxy resin accounts for6.0%-10.0% of the total mass of the coarse aggregate and the fine aggregate, the flexibilizer accounts for 0.4%-1.0% of the total mass of the coarse aggregate and the fine aggregate, the curing agentaccounts for 1.0%-2.5% of the total mass of the coarse aggregate and the fine aggregate, and the fluorescent powder accounts for 5.0%-10.0% of the total mass of the coarse aggregate and the fine aggregate. The advantages of the fluorescent powder are achieved by applying the colorless and transparent epoxy resin, so that the epoxy resin mixture is good in light transmission and ideal in luminouseffect, and the proportion of the epoxy resin can meet the requirement of pavement performance and has a protection effect on the fluorescent powder; the fluorescent powder with the nominal particle size smaller than 0.15 mm is adopted for replacing fine aggregate with the particle size smaller than 0.15 mm, so that the mechanical property of the pavement structure is not affected, and the beneficial effects of energy storage and light emitting are achieved.

Owner:CHANGAN UNIV

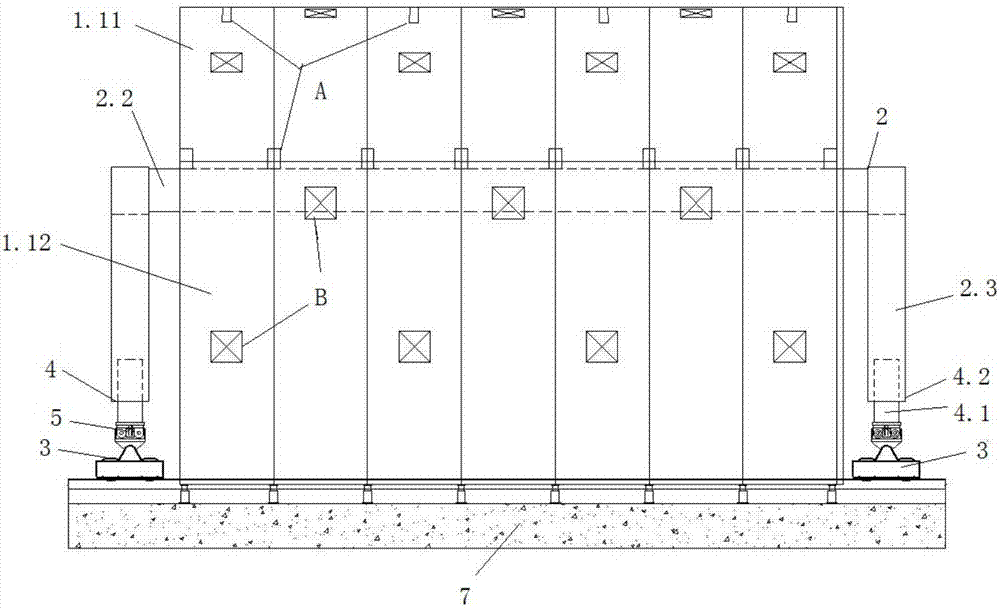

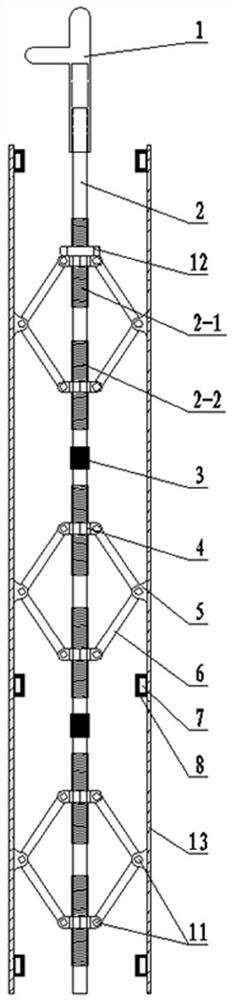

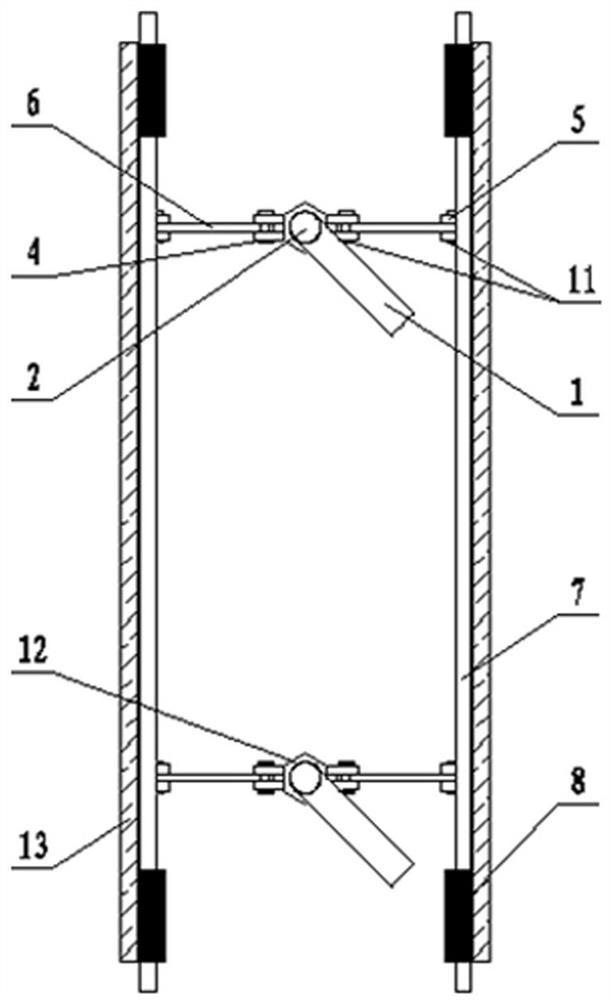

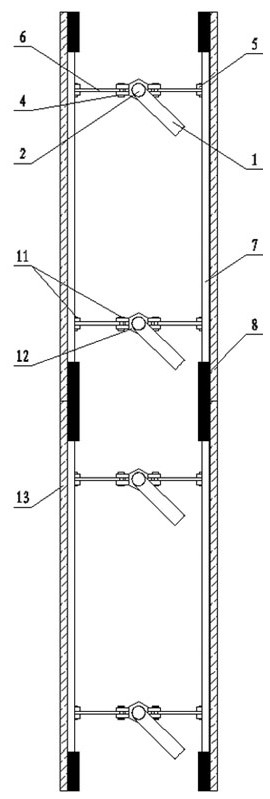

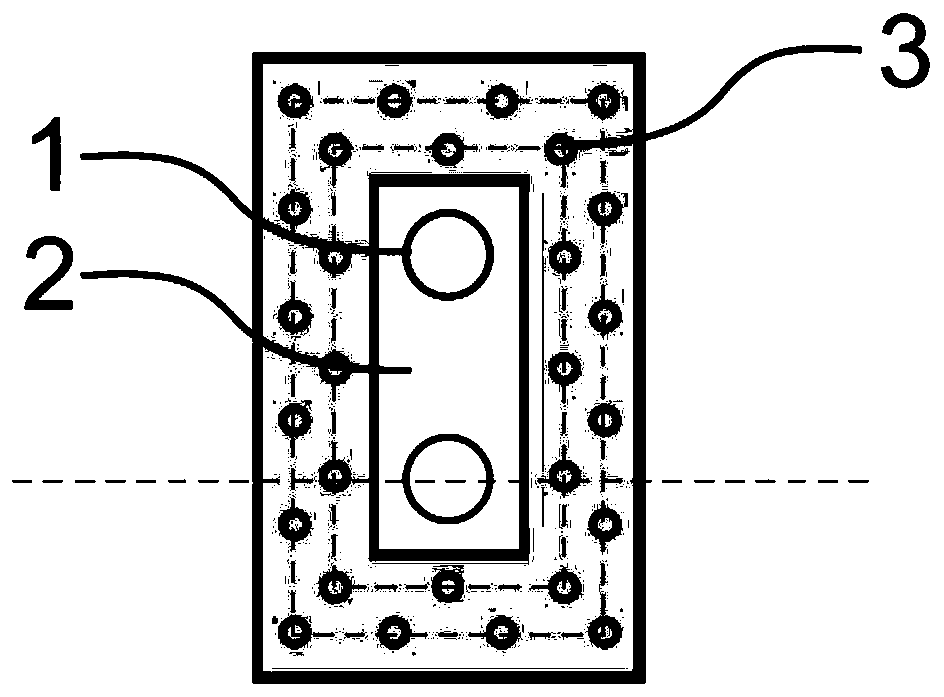

Adjustable formwork system for small-size deformation joint construction

PendingCN112412005AReduce spacingSolve the installationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringScrew thread

The invention discloses a small-size deformation joint construction adjustable formwork system which is characterized in that forward thread sections and reverse thread sections are arranged on screwsat intervals in the axial direction, connecting sleeves are fixed to the vertically adjacent screws, and handles are arranged at the tops of the screws at the top ends. The nuts are respectively arranged on the forward thread section and the reverse thread section of the same screw and internally provided with corresponding threaded holes, the steel formworks are parallelly arranged on two sidesof the screw respectively, the lug plates are fixed on the steel formworks at intervals along the axial direction of the screw, and the nuts are hinged with one ends of the two pull plates on two sides corresponding to the steel formworks respectively. The other ends of the two pull plates hinged with the screw on the adjacent forward-rotating or reverse-rotating thread section of the screw rod are respectively hinged with the lug plates. The forward and reverse thread sections are arranged on the screw rods, so that the nuts, the lug plates and the pull plates form an openable shear type structure, the distance between the steel formworks can be conveniently adjusted, the problem that the formworks are difficult to mount and dismount in small-size deformation joint construction is solved,and the device has the advantages of being convenient to mount and dismount, flexible in adjustment, high in supporting strength and capable of being repeatedly used.

Owner:CCFED THE FIGTH CONSTR & ENG

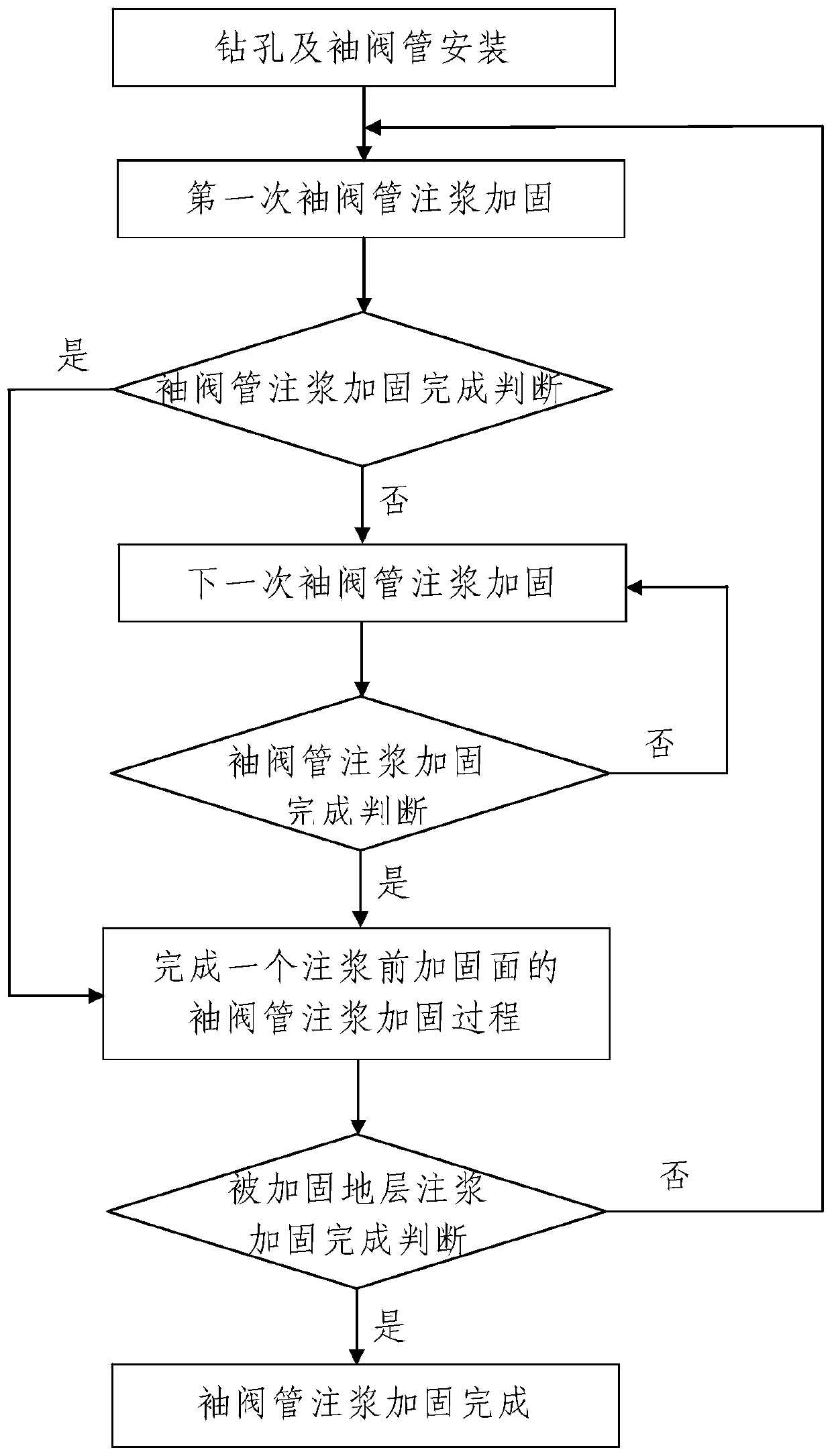

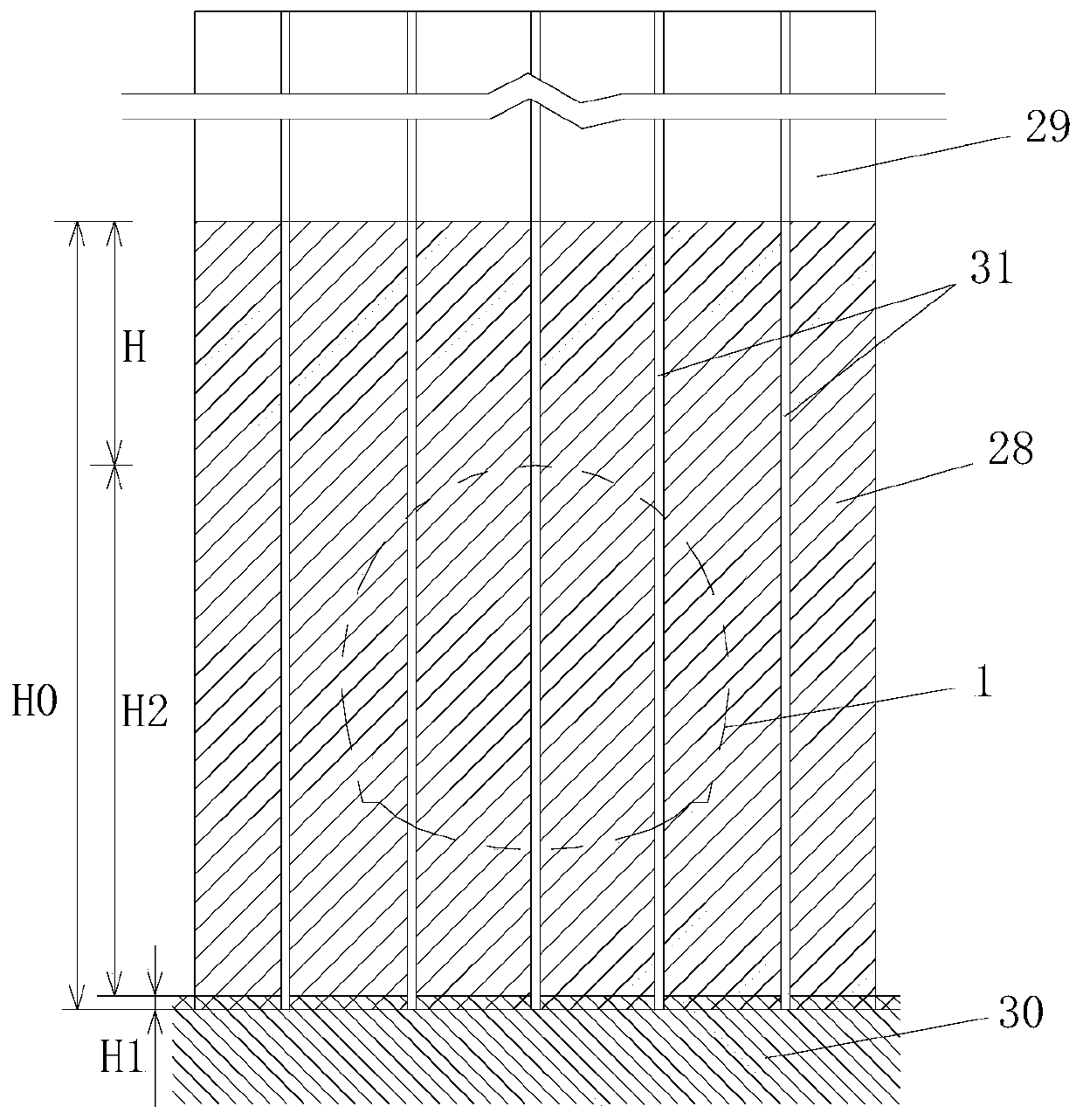

Construction method for RJP utilized reversely built enclosure structure

InactiveCN111456021AMeet the constructionMeet the reinforcement strength requirementsExcavationsBulkheads/pilesReinforced concreteArchitectural engineering

The invention relates to the field of foundation pit engineering enclosure structure construction, in particular to a construction method for a RJP utilized reversely built enclosure structure. The method comprises the following steps that grouting reinforcement treatment is conducted on surrounding stratums of an existing pile foundation and an existing bearing platform within the foundation pitengineering influence range through sleeve valve pipes; RJPs are constructed on the side, invading the enclosure structure, of the existing pile foundation; secant pile enclosure structures on the twosides of the existing pile foundation are constructed, and it is ensured that reinforced concrete piles are occluded with the RJPs; a soil body around the existing pile foundation is excavated, and anewly-added pile foundation and a newly-added bearing platform are constructed; and the site is restored, and other secant piles and foundation pit side walls are constructed. The construction of thefoundation pit enclosure structure can be completed under the condition of intrusion of the adjacent existing pile foundation, the stratum reinforcing strength requirement is met, the waterproof andstress problems are solved, the pile forming quality can be effectively guaranteed, disturbance to an existing building (structure) can be effectively reduced, and sedimentation and deviation of surrounding stratums and pipelines are effectively controlled.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

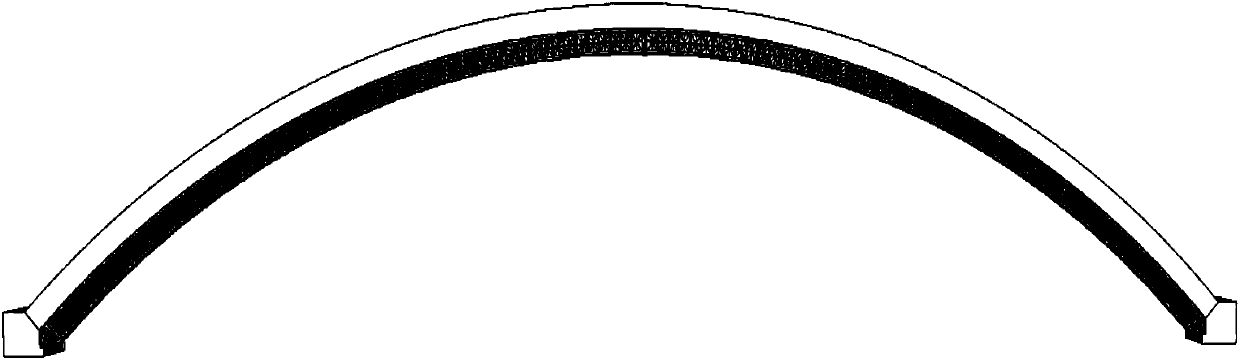

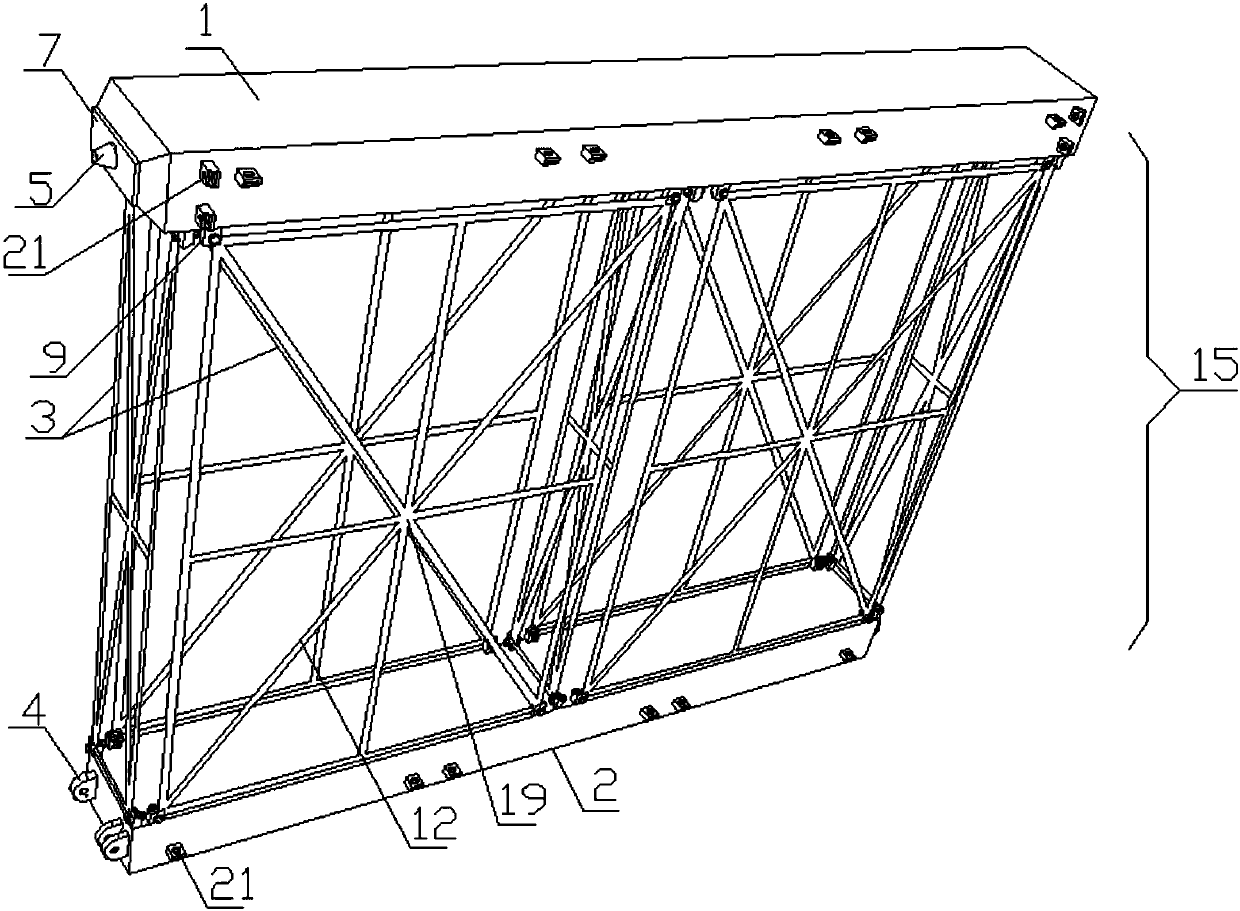

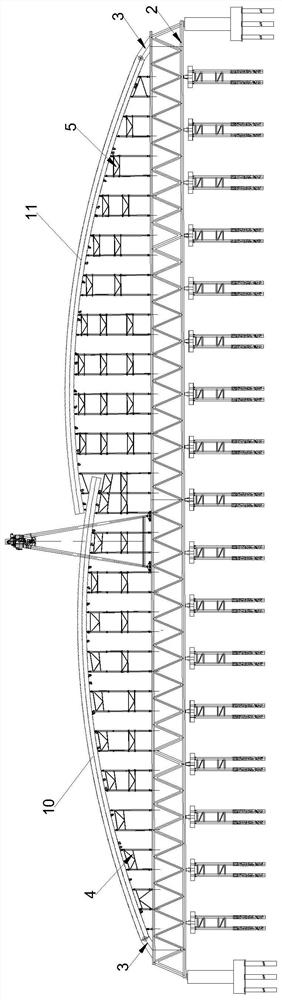

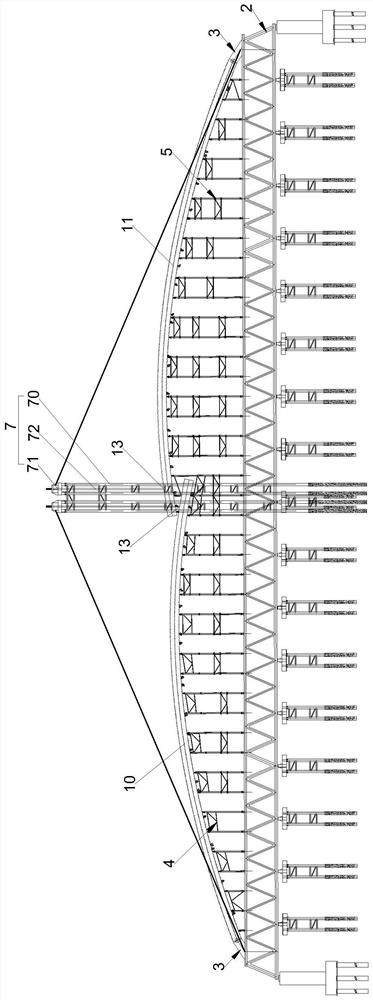

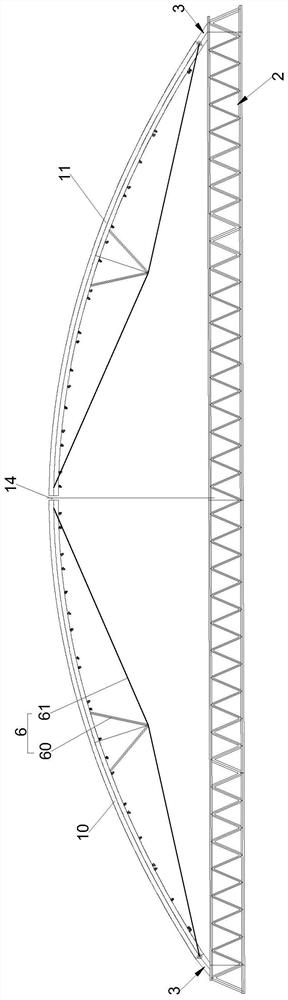

Large-span steel arch frame

PendingCN110106773AHigh adjustment accuracyImprove visibilityBridge erection/assemblyArch-type bridgeReinforced concreteArch bridge

The invention provides a large-span steel arch frame. The large-span steel arch frame is mainly composed of arch foot segments, standard segments, adjusting segments, closing segments and closing devices in an assembled mode, except the closing devices, lower chords of the adjacent segments are in hinged connection through penetrating pins, and upper chords of the adjacent segments are in opposite-pulling connection through bolts on the multiple side faces of chord members, so that the arch frame is formed; and wedge blocks are arranged between the transverse end faces of the upper chords of the adjacent segments, and the wedge blocks are axially and radially limited between the transverse end faces of the adjacent segments. The large-span steel arch frame is adjustable in rise span ratio,adjustable in span and especially suitable for construction of a main arch ring of a cast-in-place reinforced concrete arch bridge with the span being greater than 150 meters; and the rise span ratioand the span of the large-span steel arch frame are adjusted ingeniously, the force transfer effect is good, stability is good, and the force transfer effect is quite excellent.

Owner:CHONGQING BIAOWANG MACHINERY EQUIP CO LTD

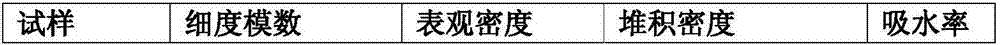

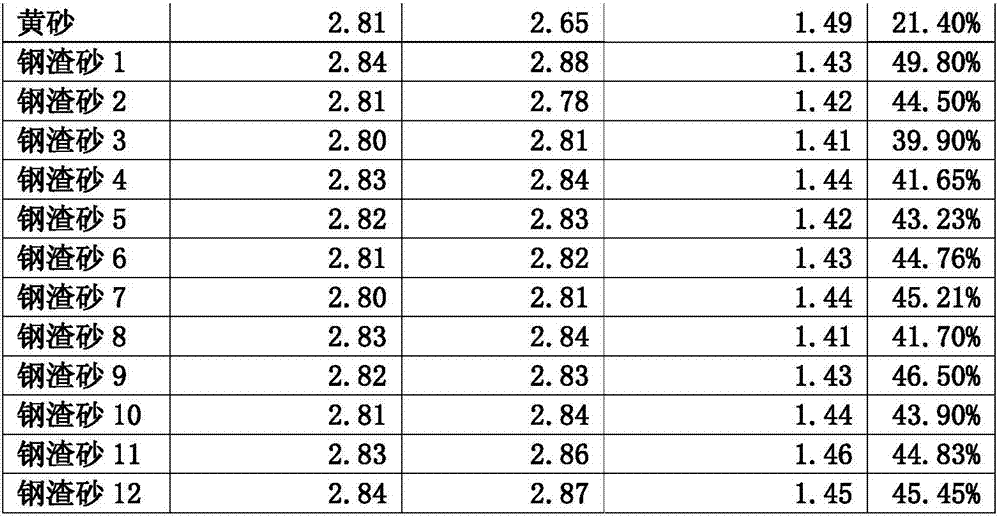

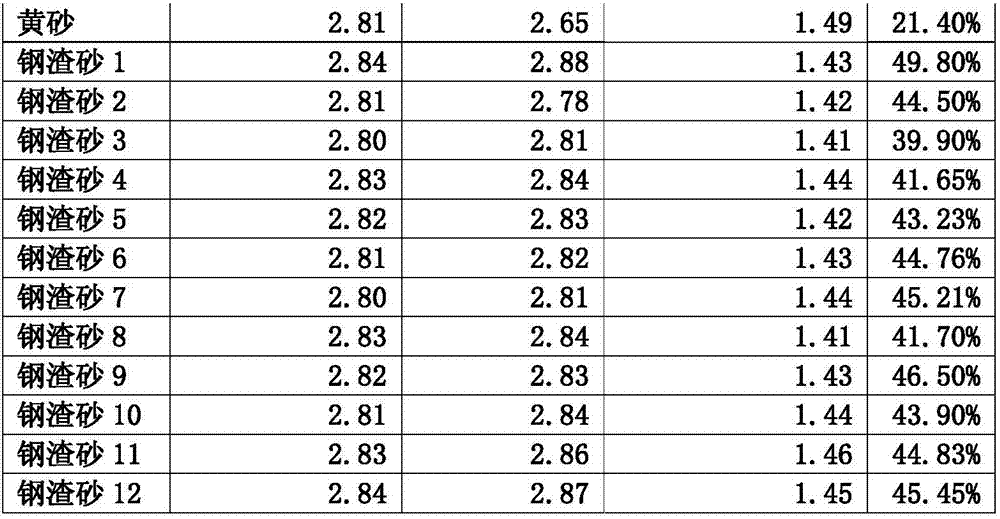

C40-grade steel slag sand self-compacting concrete and preparation method and prefabricated component thereof

The invention provides C40-grade steel slag sand self-compacting concrete, wherein the water-binder ratio is controlled between 0.3 and 0.7; the C40-grade steel slag sand self-compacting concrete is prepared from the following components in parts by weight: 2-10 parts of steel slag sand, 2-10 parts of glass beads, 2-10 parts of cement, 7-10 parts of natural coarse aggregates, 2-6 parts of recycled coarse aggregates, 2-10 parts of sand, 0.5-1.1 parts of coal ash and 2-10 parts of water. The obtained self-compacting concrete has good mobility, gap passing ability and segregation resistance, and meets the strength requirements. The production cost of the concrete is reduced while construction is facilitated, and the preparation method is simple and suitable for industrial production.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

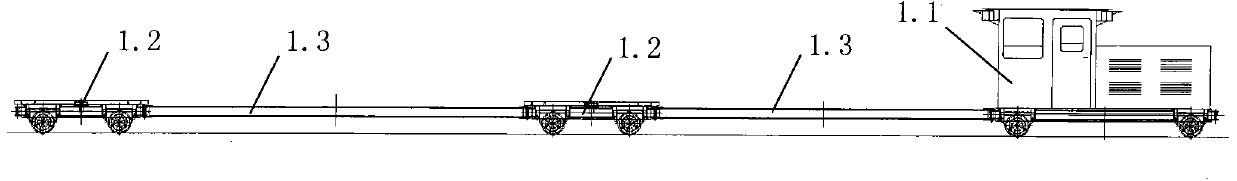

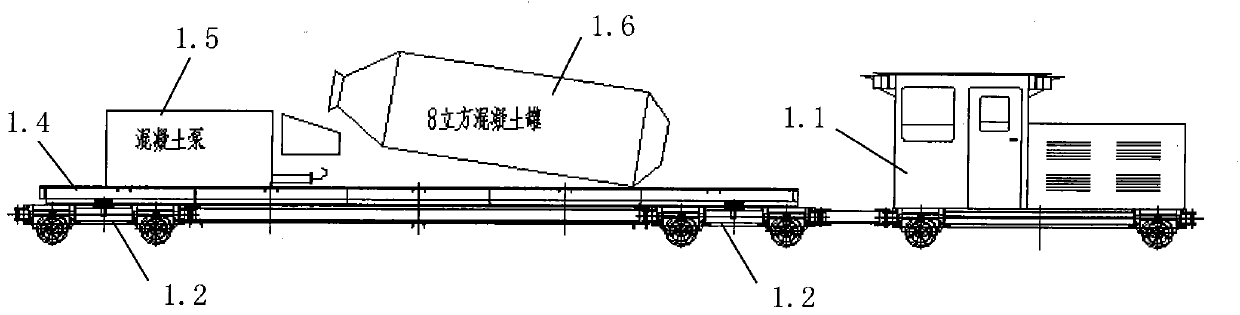

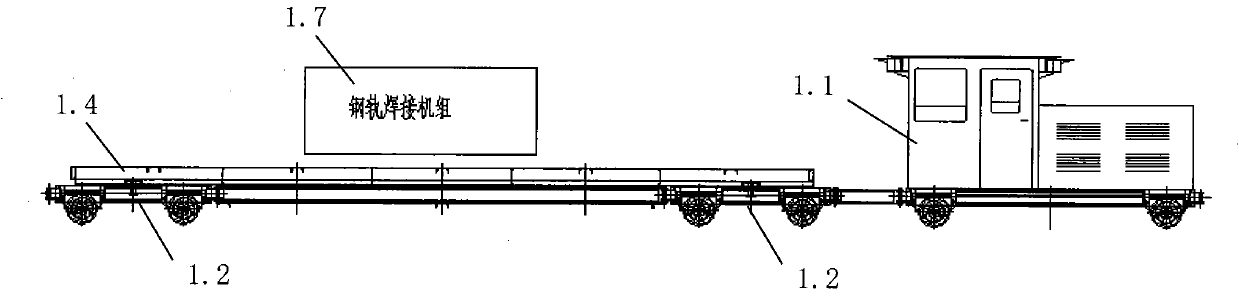

Technology of laying transport rails with track skeletons

InactiveCN104195897AHigh Order EfficiencyMeet the constructionRailway track constructionEngineeringMaterial transport

The invention relates to a technology of laying transport rails with track skeletons. The technology is characterized in that the track skeletons are laid step by step from the starting point A to the finishing point B, then ballast bed construction, steel rail welding and ballast bed arrangement are carried out step by step from the finishing point B to the starting point A, and the steel rails with the track skeletons are used for logistics transportation. The technology includes the steps of track skeleton assembly, track skeleton loading and transport, track skeleton laying, ballast bed construction, steel rail welding and ballast bed arrangement, and relates to at least five devices, namely the first device of a rail material transport railway car, the second device of a track skeleton laying unit, the third device of a track skeleton assembly pull rod, the fourth device of a track skeleton connector connection clamp and the fifth device of a split type steel rail support. The technology has the advantages that the related devices can move by means of the steel rails of the track skeletons, a gantry crane does not need to be arranged and the waling rails are high in mechanical degree, and efficient and orderly construction of ballastless tracks is guaranteed.

Owner:北京奚仲能源发展有限公司

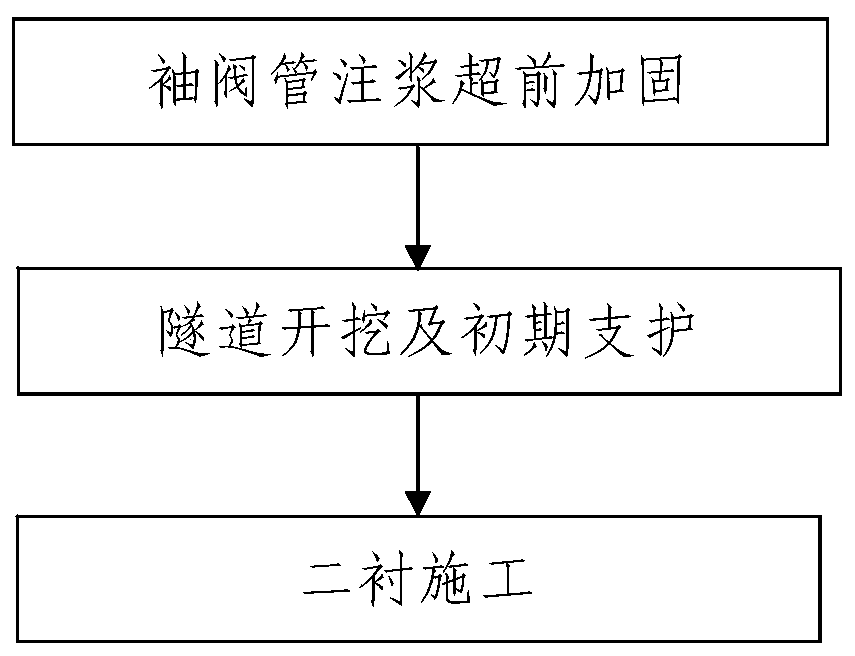

Construction method of shallow-buried tunnel in loess gully

ActiveCN110761795AThe method steps are simpleReasonable designUnderground chambersTunnel liningEarth surfacePipe

The invention discloses a construction method of a shallow-buried tunnel in a loess gully. The construction method comprises the following steps: 1, grouting a sleeve valve pipe for advancing reinforcement: carrying out sleeve valve pipe grouting for reinforcement on a stratum in the construction area of the constructed shallow-buried tunnel; 2, carrying out tunnel excavation and preliminary bracing; and 3, constructing a second lining. The construction method is simple in step, reasonable in design, simple and convenient in construction and excellent in using effect; the sleeve valve pipe isadopted and a plurality of rows of grouting holes are adopted to grout the reinforced stratum for reinforcement; the range of the reinforced stratum is specifically limited; both the tunnel hole bodyand the tunnel base can be reinforced, and the reinforcement effect is reliable; the shallow-buried tunnel construction method is particularly suitable for advancing reinforcement and excavation construction of the shallow-buried tunnel section which is positioned in a loess gully and is adjacent to an earth and stone interface, and the earth's surface of the shallow-buried tunnel is a silting-upland layer. The construction method can effectively ensure safety and reliability of the excavation process of the shallow-buried tunnel in the loess gully, can effectively improve the stability of the excavated tunnel hole and can effectively improve the bearing force of the tunnel base.

Owner:CHINA RAILWAY 20 BUREAU GRP

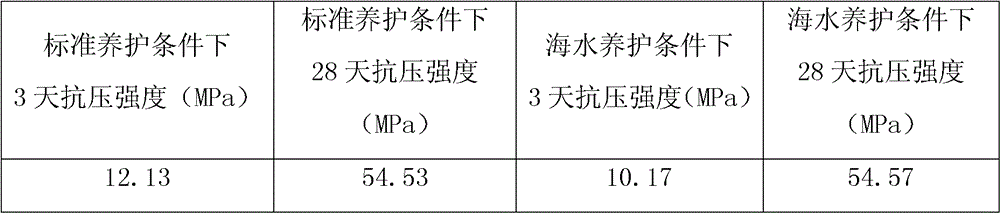

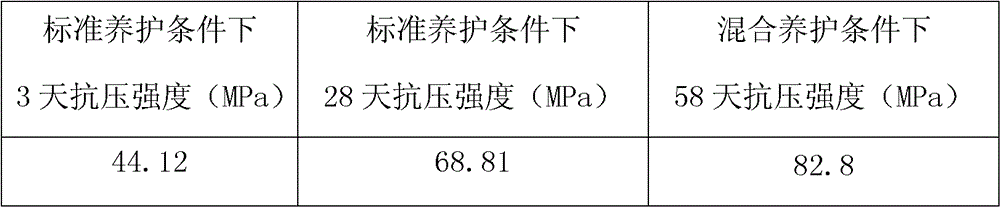

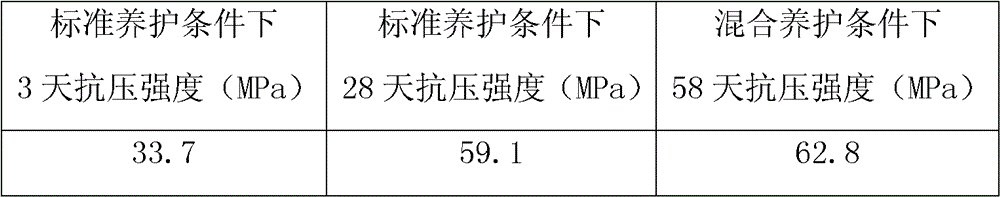

A kind of preparation method of artificial reef concrete material with steel slag as main raw material

The invention relates to the technical field of slag machining, the field of marine environmental protection, and the field of fishery industry basic facilities, in particular to a preparation method for an artificial fish reef concrete material with slag as a main raw material. The preparation method for the artificial fish reef concrete material with the slag as the main raw material is characterized in that the slag which is machined through a tightly-closed method technology is respectively used in rough aggregate, fine aggregate and binding material raw materials, and mineral waste residues, cement clinker, and flue gas desulfurization gypsum are mixed into binding materials. Compared with the prior art, the preparation method has the advantages that infiltration quantity of the slag is not lower than 75% and the slag is suitable for construction of an artificial fish reef with a large volume, a large hole rate and a complex structure, the strength of the slag can reach to 54-82MPa so that construction of the artificial fish reef can be satisfied and compact of sea tide and sea waves is resisted; the difficulties that the slag is deposited in a bulk mode, land is occupied and environment is polluted are resolved; solid waste such as the mineral waste residues and the desulfurization gypsum are further applied, and the use ratio of the solid waste can reach above 97%, and the preparation method for the artificial fish reef concrete material with slag as the main raw material has obvious resource benefits, environmental benefits, economical benefits and social benefits.

Owner:鞍钢绿色资源科技有限公司

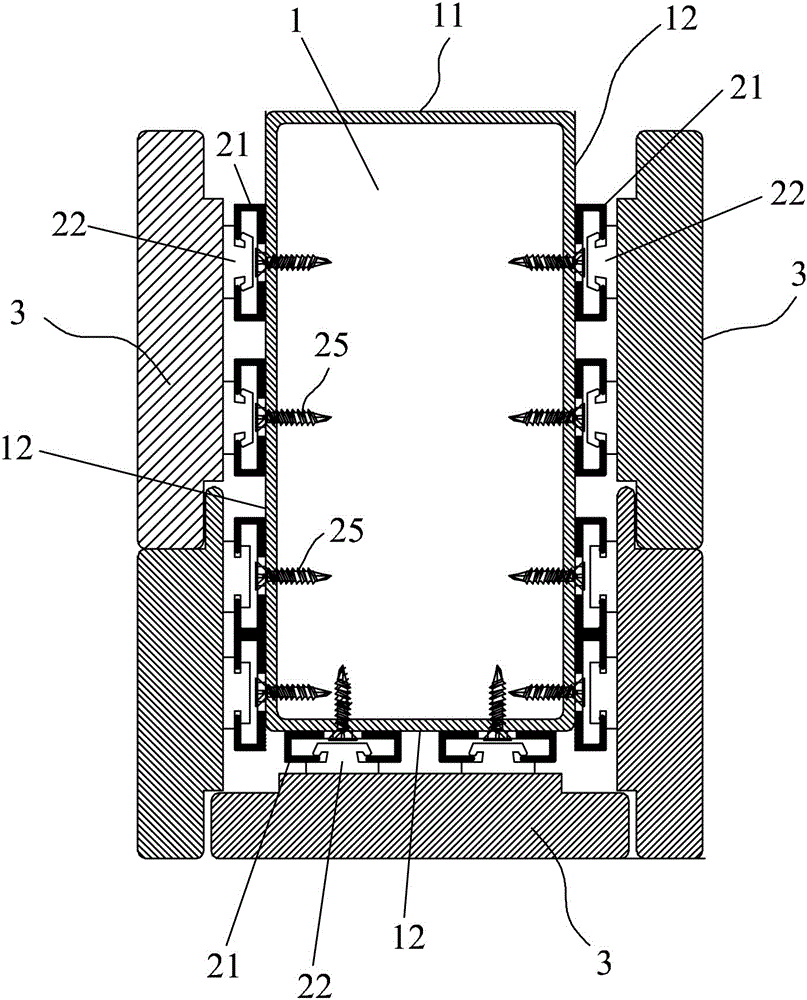

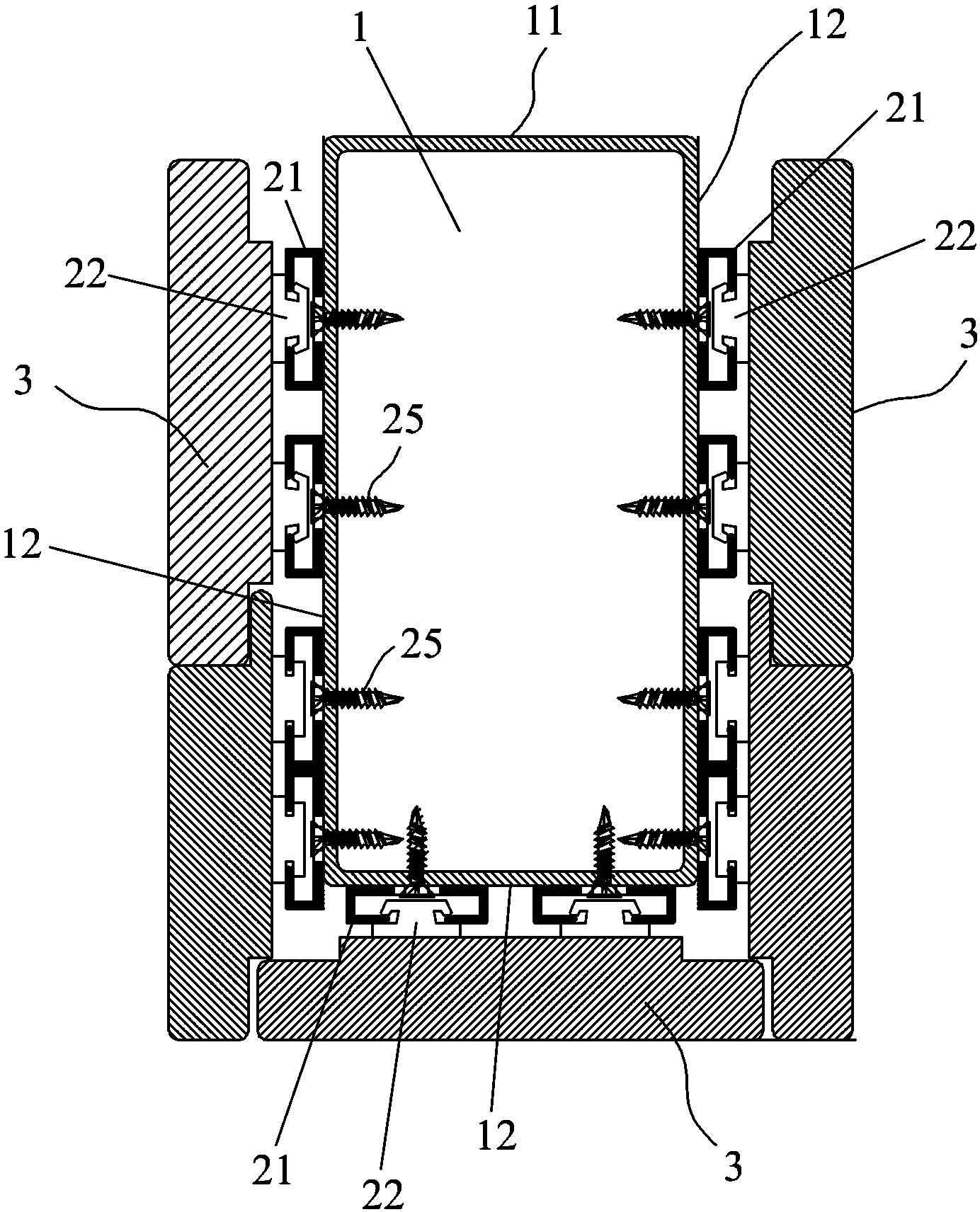

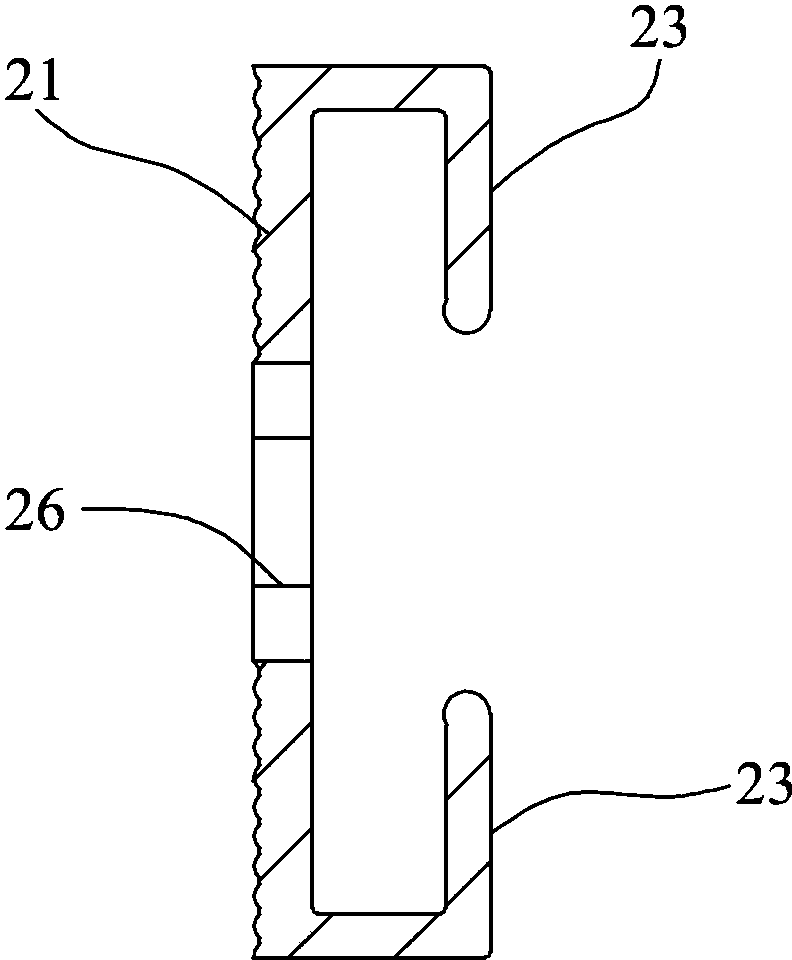

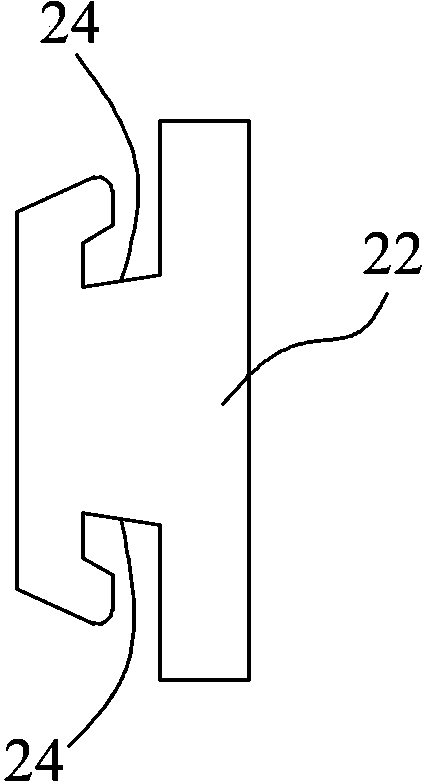

Sun room special structure and corresponding sun room

ActiveCN103590530BFirmly connectedGuaranteed service lifeWindow/door framesSmall buildingsEngineeringMechanical engineering

The present invention discloses a special structure material and the corresponding sun room. Among them, the special structure of the sun room includes a hollow steel pipe.The decoration and installation surface of the installation surface is combined. The decorative surface is connected to the decorative surface with a decorative plate on the decoration surface. The glass is installed with the glass, and the decoration surface is used to install the decorative board.The special structure material for the sun room of the present invention uses hollow steel pipes as the main support structure, which can ensure that it has a high structural strength and a long period of useful life; the use of decorative boards can decorate the hollow steel pipes, which improves the aesthetic effect; the lock is used;The deduction connecting the decorative board can ensure the reliable connection of the decorative board, and at the same time to meet the construction of the house construction site.Special structures for sunshine rooms of the present invention are suitable for building various types of sun rooms.

Owner:石家庄昱泰门窗有限公司

High-strength epoxy sealing adhesive for watertight connectors and preparation method thereof

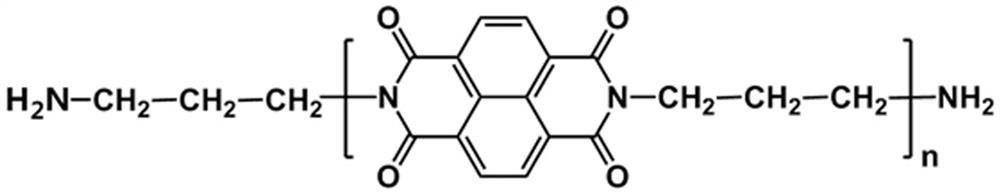

PendingCN112574708AImprove ductilityImprove toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention relates to a high-strength epoxy sealing adhesive for watertight connectors and a preparation method thereof, the adhesive is composed of a component A and a component B, and the mass ratio of the component A to the component B is (2.5-3.5):1; the component A is prepared from the following raw materials in parts by weight: 70-80 parts of epoxy resin, 15-25 parts of reinforcing filler, 0.1-0.5 part of coloring filler, 0-2 parts of a silane coupling agent, 0.5-1 part of a dispersing aid, 0.5-1 part of a defoaming agent and 0.5-1 part of a thixotropic agent; and the component B is apolyimide reinforced amine curing agent. The excellent mechanical property and excellent connecting property of a polyimide structure are utilized, the polyimide structure is compounded with epoxy resin, and when the polyimide structure is applied to a watertight connector, a high-strength epoxy sealing adhesive material suitable for the marine environment with the water depth larger than 2,000 mand the environment with the pressure larger than 20 MPa is expected to be obtained.

Owner:胡清波

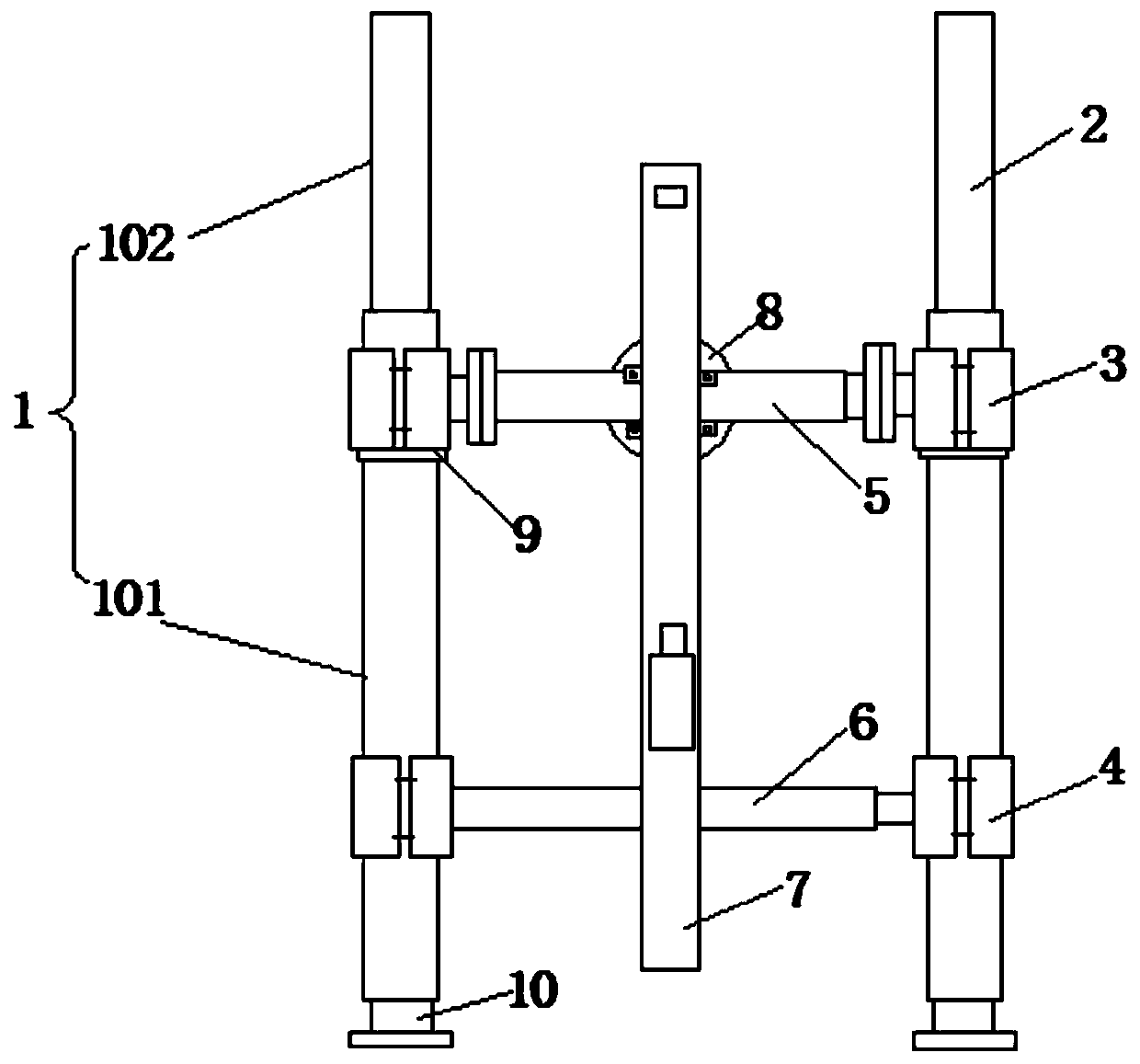

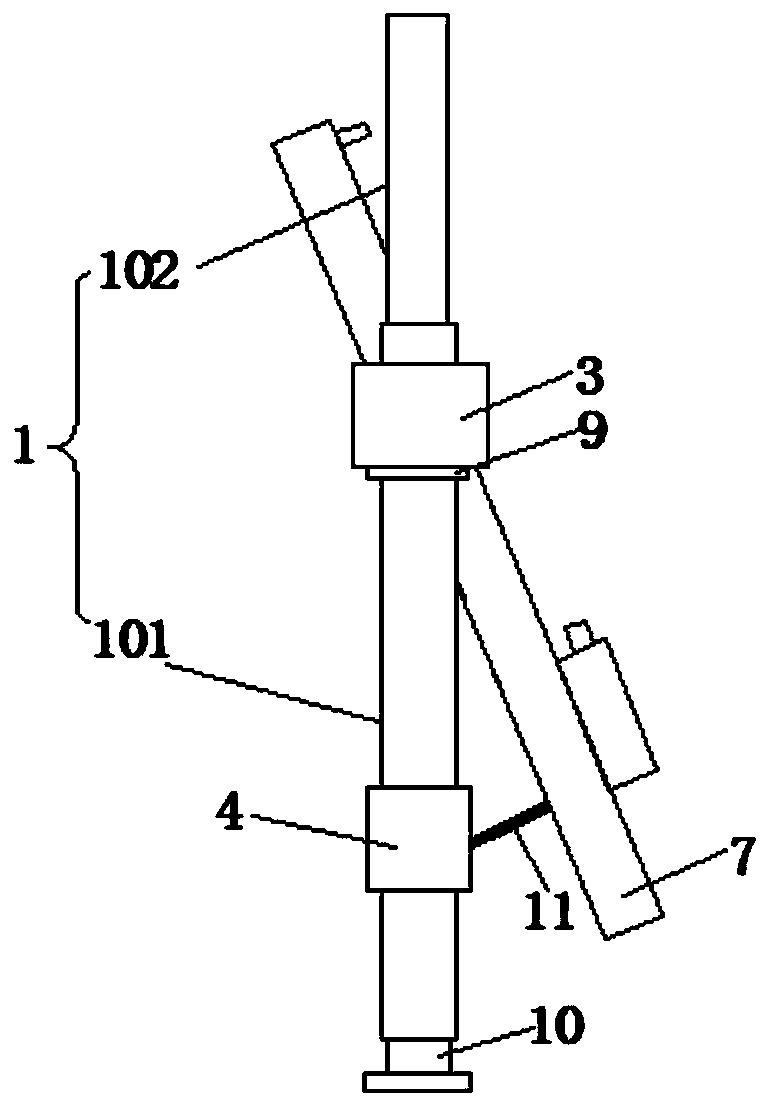

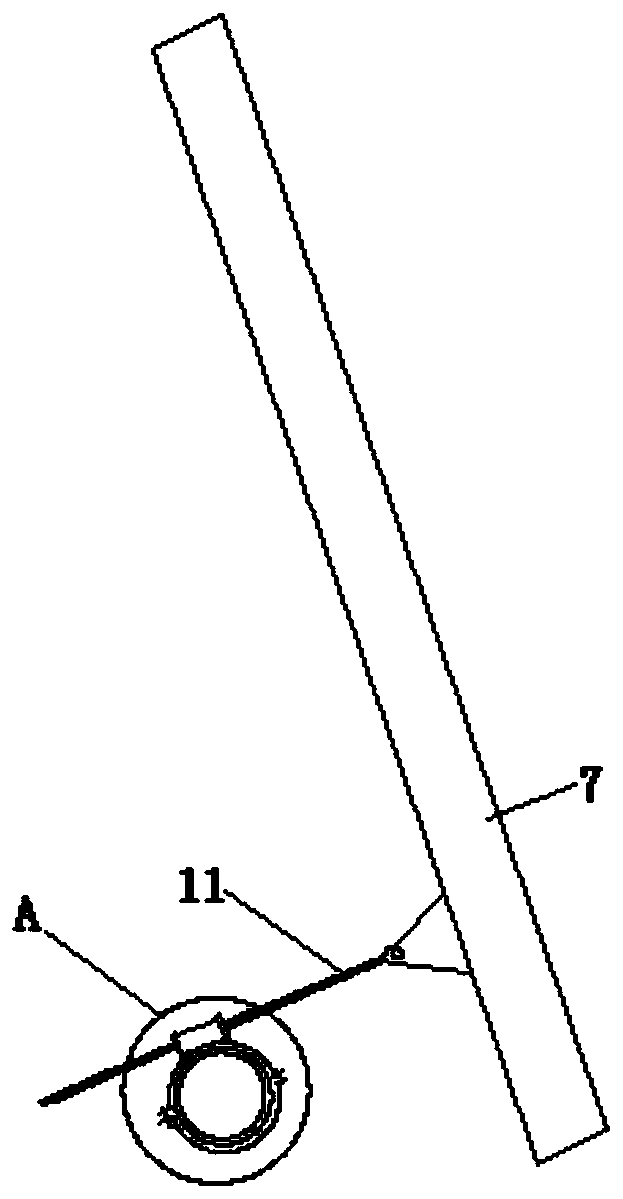

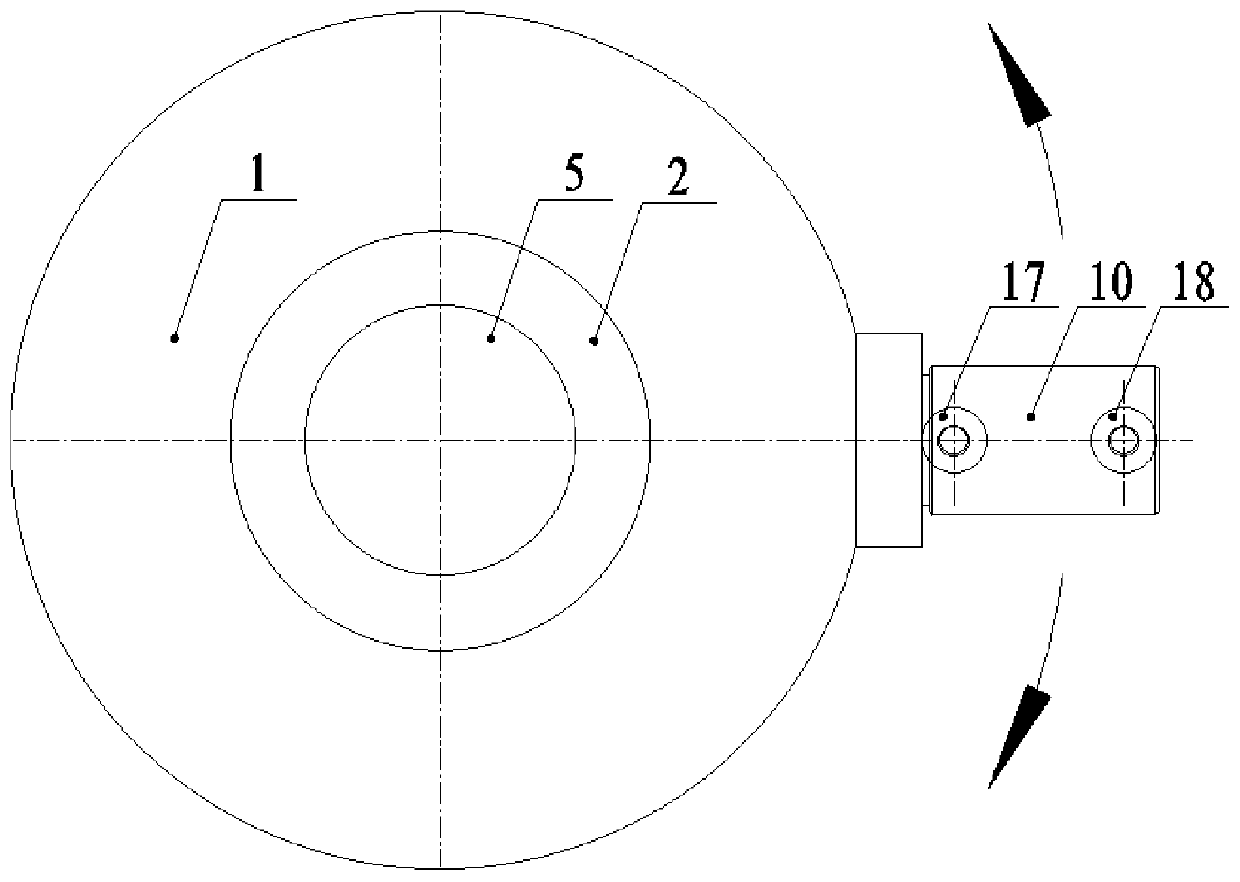

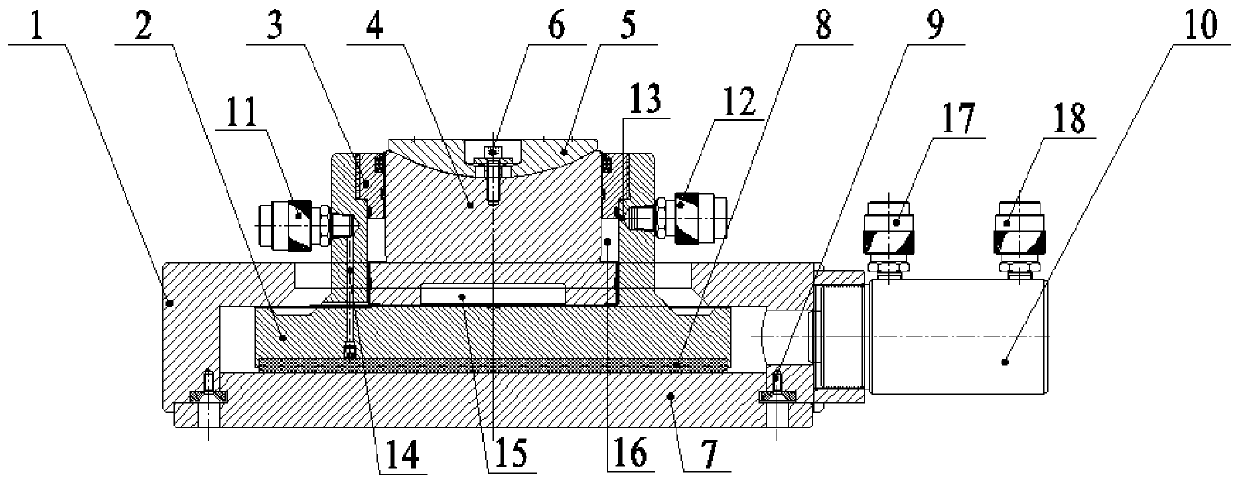

Mining roof cutting drilling rig combined step device and use method thereof

The invention belongs to the technical field of mining machinery equipment, and particularly provides a mining roof cutting drilling rig combined step device and a use method thereof. Two pillars areused for supporting, and the two pillars are connected by a transverse oil cylinder and a transverse sleeve; the two pillars are mutually supporting points, and free expansion and contraction of the transverse oil cylinder drives the synchronous expansion and contraction of the transverse sleeve; cyclic expansion and contraction of extension rods of the two pillars realizes the step forward movement of a roof cutting drilling rig; and the front section of a drilling rig guide rail is connected to a cylinder block of the transverse oil cylinder, the rear section of the drilling rig guide rail is connected to the transverse sleeve, and the inclination angle of the drilling rig guide rail is adjusted by changing the length of an inclined supporting screw rod between the drilling rig guide rail and the transverse sleeve. According to the mining roof cutting drilling rig combined step device and the use method thereof, the structure is simple, the movement is convenient, adaptability is high, and labor intensity is greatly reduced; and the turning angle of the drilling rig guide rail is large, rapid and accurate positioning of the drilling rig is facilitated, and the work efficiency isimproved; and the construction of roof cutting drilling in straight-line shape small drilling spacing and various complex geological conditions can be met, and construction of roof cutting holes for narrow spaces inside belts can be further met.

Owner:河南力行科创矿山技术开发有限公司

Arch rib construction method

InactiveCN112709154ALower the altitudeImprove working accuracyBridge erection/assemblyArch-type bridgeArchitectural engineeringTower

The invention relates to the technical field of bridge construction, in particular to an arch rib construction method which comprises the following steps that a support is erected on a main beam, a first half arch and a second half arch are subjected to low-position assembly on the support to form a half arch, and the near-shore ends of the two half arches are hinged to arch feet at the two ends of the main beam through temporary rotating hinge devices; the first half arch and the second half arch are lifted to the set height at the far shore end, and a closure gap is formed; a closure section is lifted to the closure gap from the main beam; and the first half arch and the second half arch are fixedly connected with the arch feet to form arch ribs. The arch ribs are assembled through a low-position assembling support, the height of a gantry crane can be reduced, the assembling speed is high, and the operation precision is high; the single lifting mechanism is arranged in the midspan, the number of the lifting tower frame is one, the number of the closure gap is one, the arch rib can be rapidly lifted and accurately positioned, investment of extra lifting equipment is reduced, and the construction efficiency of an arch rib structure which is large in span, high in rise and complex in structure can be effectively improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

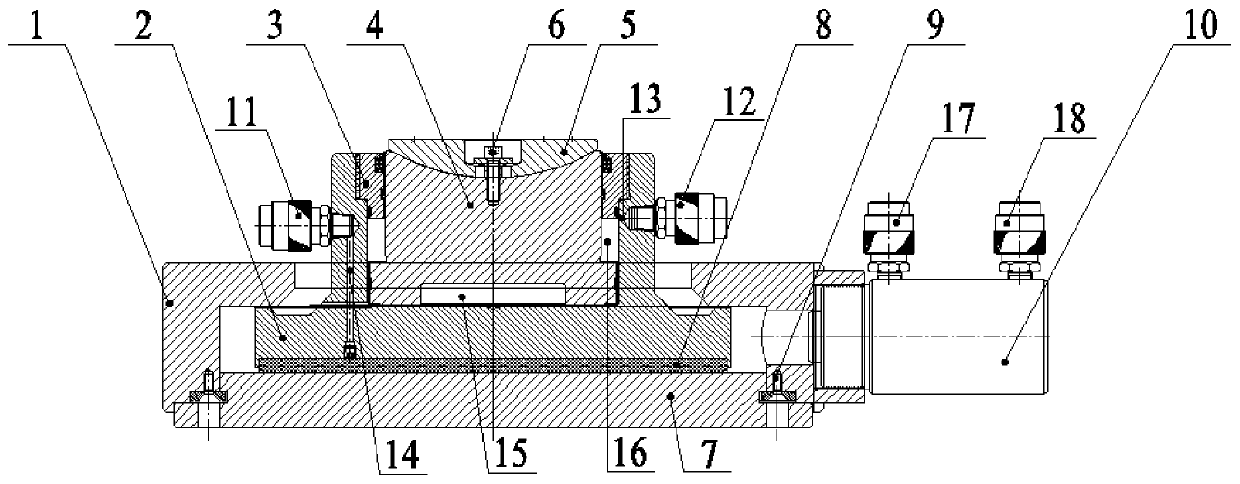

Bridge multi-dimensional deviation rectifying device

PendingCN111119077ASmall form factorCompact structureBridge erection/assemblyBridge strengtheningJackscrewTranslation system

The invention discloses a bridge multi-dimensional deviation rectifying device which comprises a jacking system and a translation system, wherein the translation system is arranged around the periphery of the jacking system, and the translation system applies an acting force to the jacking system and enables the jacking system to slide; the translation system comprises a bottom plate, a rotating body and a pushing jack, the rotating body is rotatably connected to the periphery of the bottom plate, the pushing jack is installed on the rotating body, the piston end of the pushing jack penetratesthrough the rotating body and extends to the inner side, and the pushing direction of the pushing jack is adjusted in a 360-degree rotating mode through the rotating connection; the jacking system isconnected to the bottom plate in a sliding mode, and the jacking system slides relative to the bottom plate under the pushing effect of the pushing jack. Through mutual cooperation of the jacking system and the translation system, vertical jacking and three-dimensional deviation rectifying adjustment in the horizontal direction can be achieved, and the rotating body and the jacking system arranged on the rotating body can achieve 360-degree deviation rectifying adjustment in the circumferential direction by rotating the jacking jack.

Owner:SHANGHAI XIANWEI CIVIL ENG

C30-level steel slag sand self compact concrete and preparing method thereof and prefabricated part

The invention provides C30-level steel slag sand self compact concrete. The water-binder ratio of the concrete is controlled between 0.3-0.7, and is prepared from, by weight, 2-10 parts of steel slag sand, 2-10 parts of glass beads, 2-10 parts of cement, 5-7 parts of natural coarse aggregate, 2-5 parts of recycled coarse aggregate, 2-10 parts of sand, 1.3-1.7 parts of coal ash and 2-10 parts of water. The obtained C30-level steel slag sand self compact concrete is good in fluidity, passing performance through gaps and segregation resistance, and meets the intensity requirement; construction is convenient, and meanwhile the production cost of the concrete is reduced, and the preparing method is simple and suitable for commercial process.

Owner:张家港市华诚混凝土构件有限公司

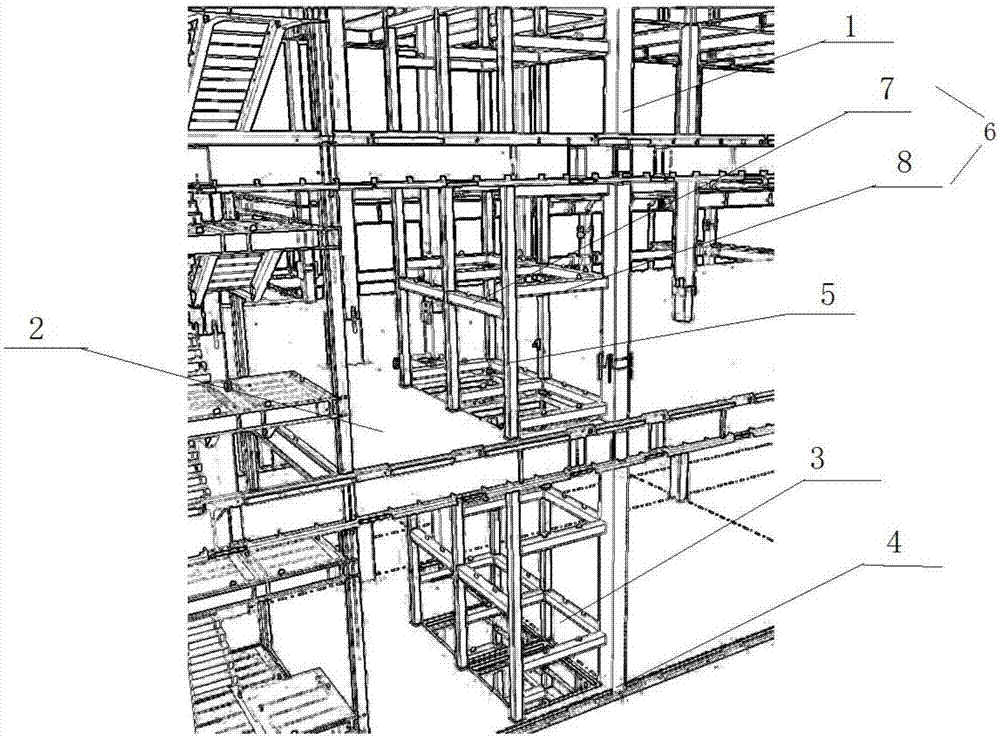

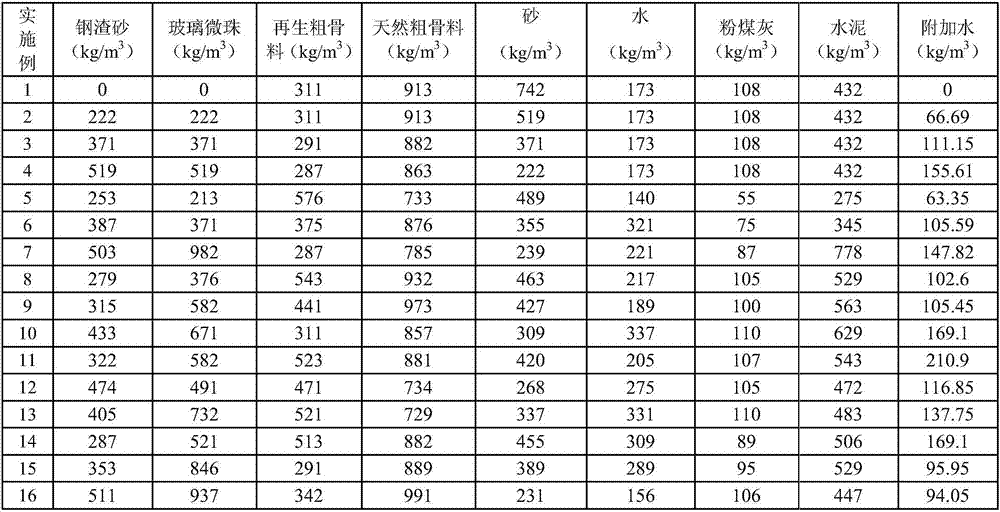

Hanging cage frame for high-sky large-size flue box body heat preservation construction

ActiveCN108118883ASimple structureEasy to manufactureScaffold accessoriesBuilding support scaffoldsFalseworkSky

The invention provides a hanging cage frame for high-sky large-size flue box body heat preservation construction. The hanging cage frame comprises an outer hanging frame and several jumping plates (7); the hanging cage frame is characterized in that the outer hanging frame comprises several square steel structure frameworks, the square steel structure frameworks surround the periphery of a flue box body at intervals, and each square steel structure framework comprises rectangular frames at the top, linear side trusses at the two sides and linear bottom trusses at the bottom, so that each jumpplate is arranged between the two adjacent square steel structure frameworks to form the hanging cage frame for the high-sky large-size flue box body heat preservation construction. The hanging cage frame has the advantages that the hanging cage frame is simple in structure and convenient to manufacture, through a hanging cage frame construction mode, construction on other majors in a limited space is satisfied, setting up of scaffolds is omitted, high-sky large-size flue construction requirements are also met, the problems of the limitation of a narrow site and the crossed majors are solved,the construction speed is increased, the construction cycle is shortened, and the engineering cost is lowered.

Owner:MCC5 GROUP CORP SHANGHAI

High fluidity grouting material and production method thereof

ActiveCN101798208BImprove mobilityEasy to pump over long distancesSolid waste managementTO-18Neutral ph

Owner:HUBEI CHIDGE TECH

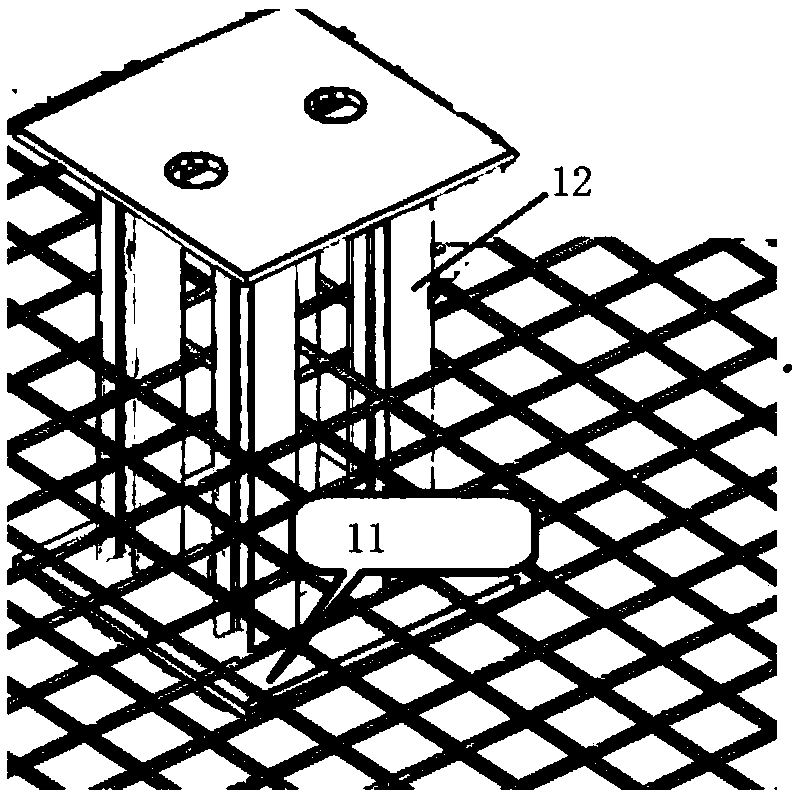

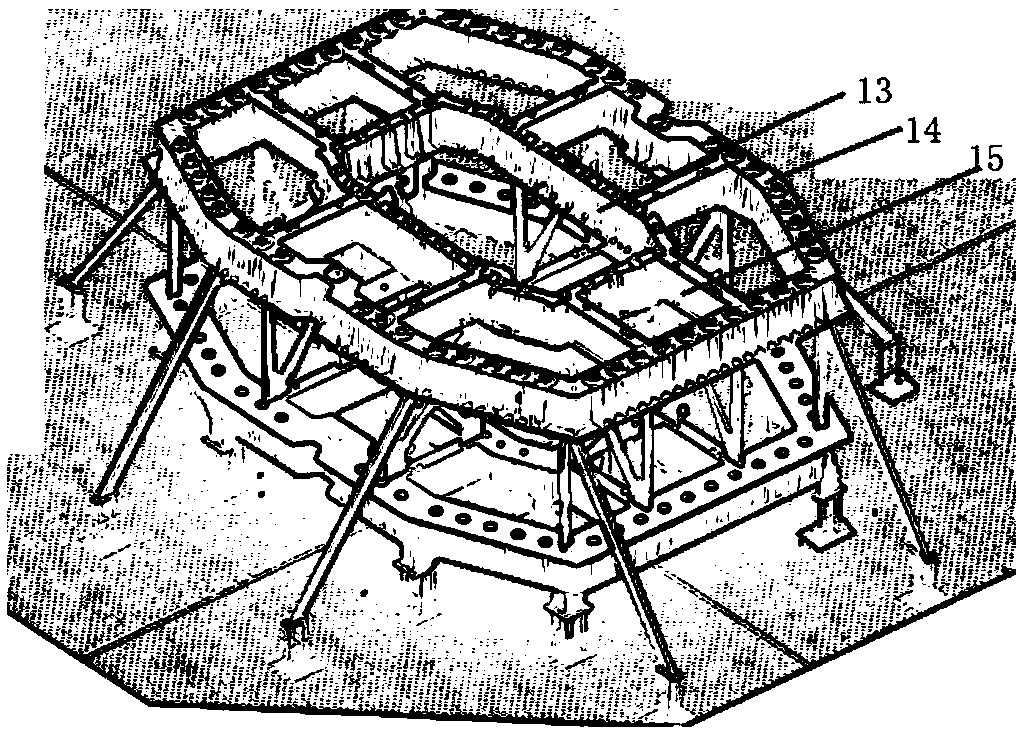

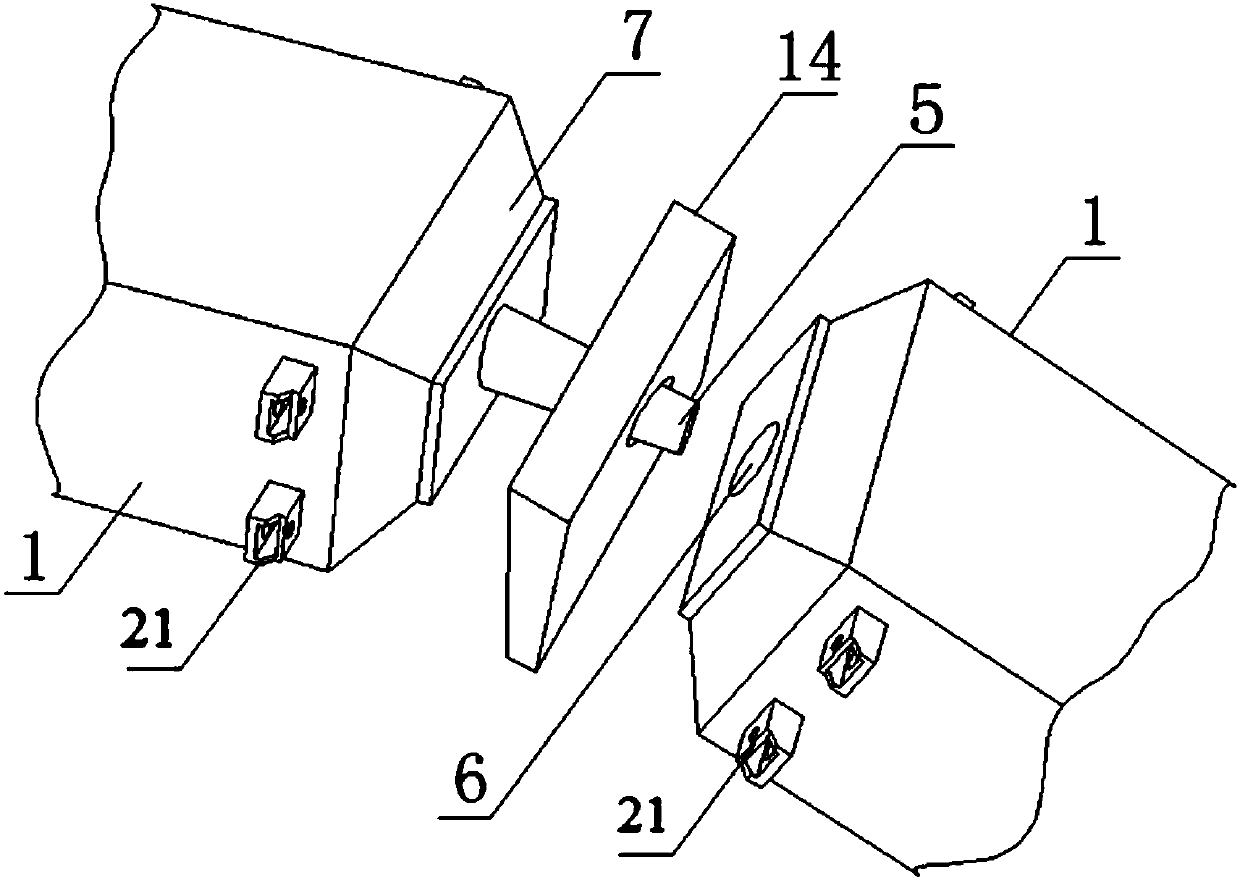

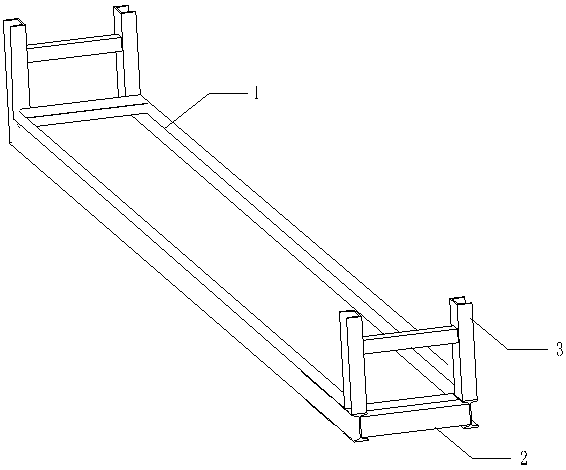

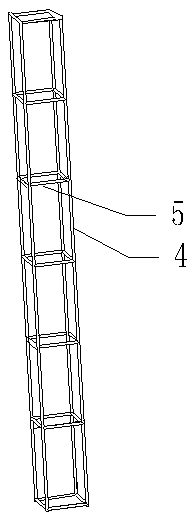

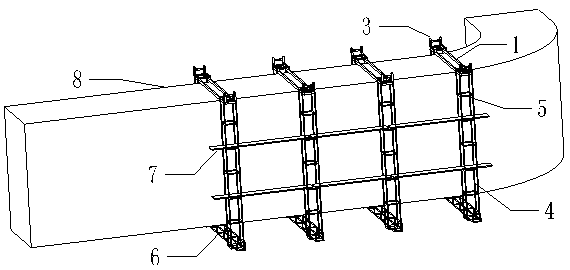

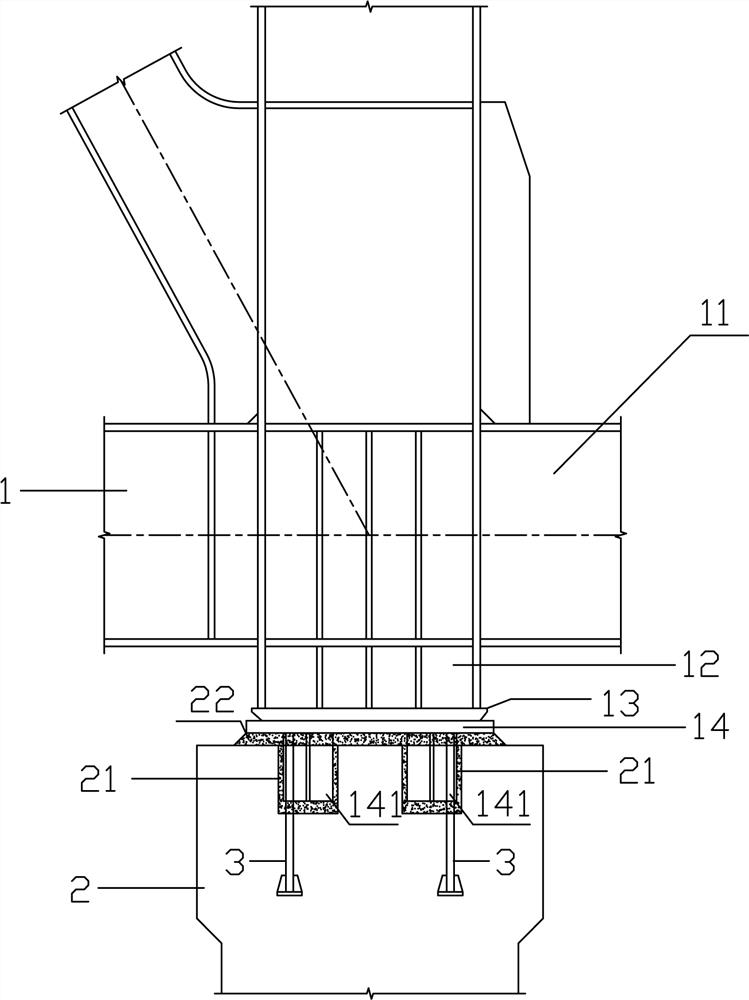

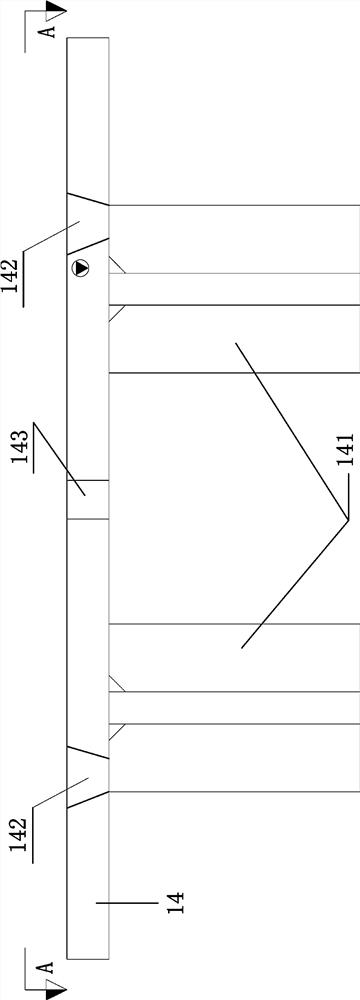

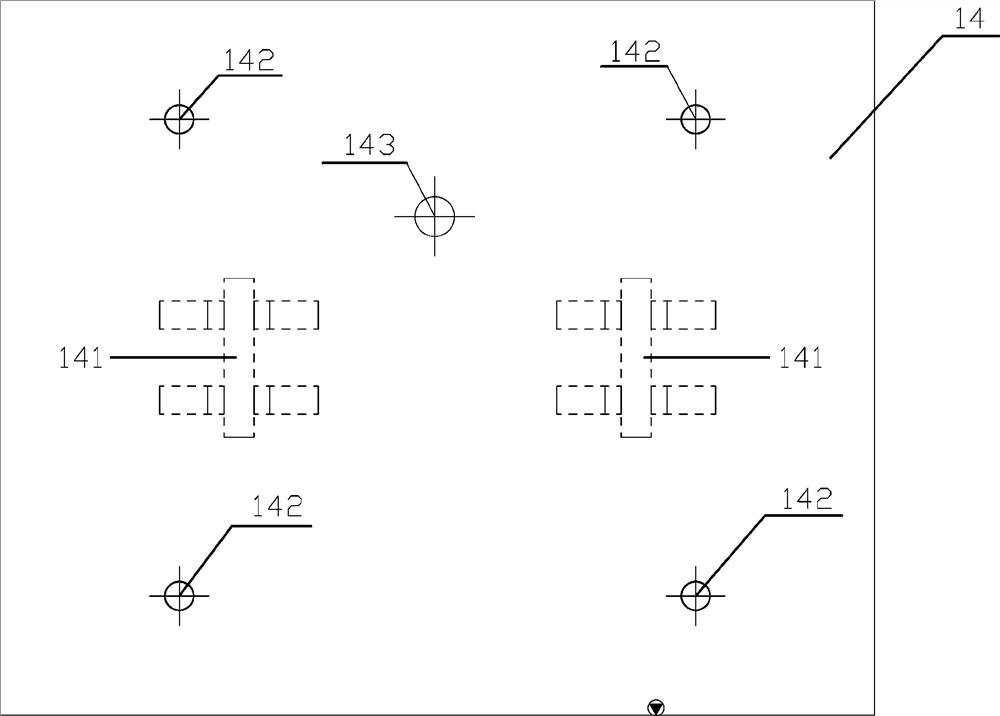

Roll-on/slide-off mounting method of large steel structure truss

InactiveCN112144872AMeet the constructionEasy constructionBuilding material handlingClassical mechanicsSteel columns

The invention relates to the field of on-site preparation, carrying or machining of building materials or building components, in particular to a roll-on / slide-off mounting method of a large steel structure truss. The roll-on / slide-off mounting method of the large steel structure truss comprises the steps that a steel truss (11) and a steel column (12) are welded to form a truss component (1), a first column foot plate (13) is fixed to the bottom end of the steel column (12), and the roll-on / slide-off mounting method is characterized by sequentially comprising the following steps that 1, at least four embedded bolts (3) are vertically mounted in the top face of a concrete column (2); 2, a second column foot plate (14) is laid on a secondary grouting layer (22) on the top face of the concrete column (2); 3, the truss column component (1) slides to the second column foot plate (14) through the first column foot plate (13) at the bottom end of the steel column (12); and 4, each truss column component (1) is mounted in a sliding mode one by one according to the steps 1-3. The roll-on / slide-off mounting method is convenient to construct, safe and reliable.

Owner:SHANGHAI BAOYE GRP CORP

Bridge deck steel guardrail embedded part positioning structure

PendingCN111005314AEasy to fixAccurately control the relative positionBridge structural detailsBridge erection/assemblyRebarTransverse reinforcement

The invention discloses a bridge deck steel guardrail embedded part positioning structure. The structure comprises steel guardrail embedded parts on the left side and the right side, the steel guardrail embedded parts on the left side and the right side are located on the two sides in a transverse pouring groove, a longitudinal pouring groove is vertically formed in the middle of the transverse pouring groove, a transverse reinforcement cage is arranged in the transverse pouring groove, and a longitudinal reinforcement cage is arranged in the longitudinal pouring groove; each steel guardrail embedded part comprises a steel guardrail embedded part bottom plate, three screws are arranged on each of the two sides of the upper end face of the steel guardrail embedded part bottom plate, and positioning blocks are movably arranged on the three screws on the same side. According to the invention, the steel guardrail embedded parts are simple to fix, the relative position of the steel guardrail embedded parts can be accurately controlled, construction similar to that of the guardrail embedded parts can be met, the quality problem that a bridge deck steel guardrail cannot be installed subsequently or the guardrail line type is not straight due to insufficient installation accuracy of the embedded parts is solved, and the bridge deck steel guardrail embedded part has the beneficial effects of being good in overall stability and easy to operate.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

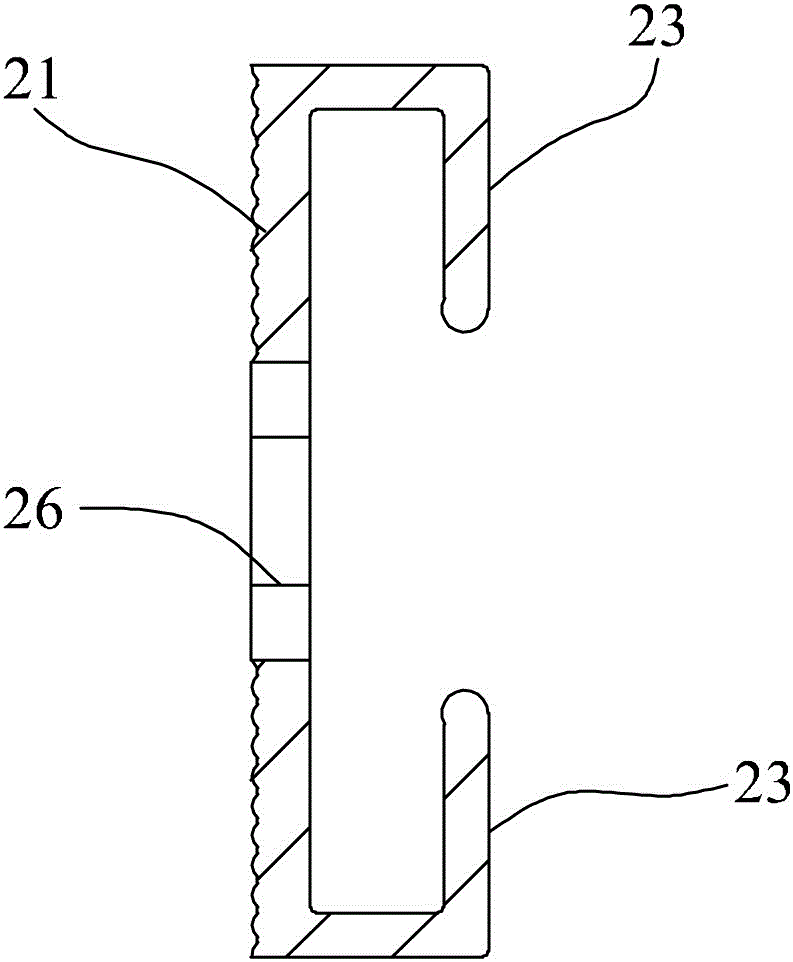

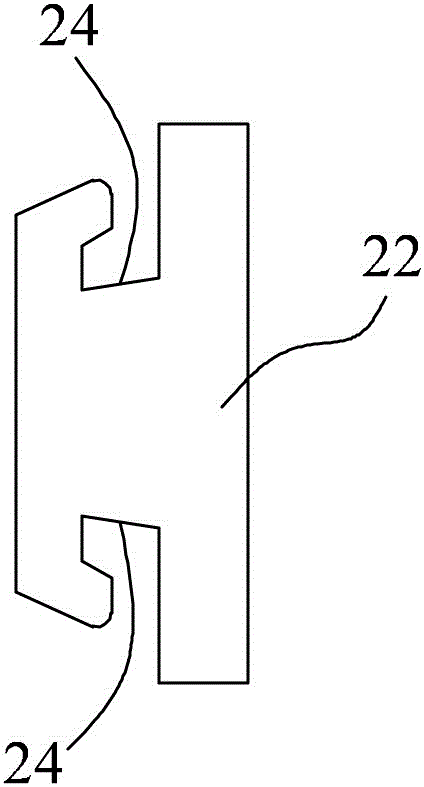

Special construction material for sunlight room and corresponding sunlight room

ActiveCN103590530AFirmly connectedGuaranteed service lifeWindow/door framesSmall buildingsEngineeringHollow core

The invention discloses a special construction material for a sunlight room and the corresponding sunlight room. The special construction material for the sunlight room comprises a hollow steel tube, wherein the outer wall surface of the hollow steel tube is surrounded by at least one planar glass mounting surface used for mounting glass and decoration mounting surfaces connected with the glass mounting surface; the decoration mounting surfaces are connected with decoration boards through buckle pieces; and the glass mounting surface is used for mounting the glass, and the decoration mounting surfaces are used for mounting the decoration boards. According to the special construction material for the sunlight room, the hollow steel tube is taken as a main support structure, so that the construction material can have higher structure strength and longer service life; the decoration boards are used for decorating the hollow steel tube, so that the attractive effect is improved; and the buckle pieces are used for connecting the decoration boards, so that the decoration boards can be connected reliably, and at the same time, the requirement of room site construction can be met. The special construction material for the sunlight room is suitable for constructing various sunlight rooms.

Owner:石家庄昱泰门窗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com