Large-span steel arch frame

A steel arch frame and large-span technology, applied in arch bridges, erection/assembly bridges, bridge materials, etc., can solve the problems of poor adjustment accuracy and achieve good adjustment accuracy, good visibility, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

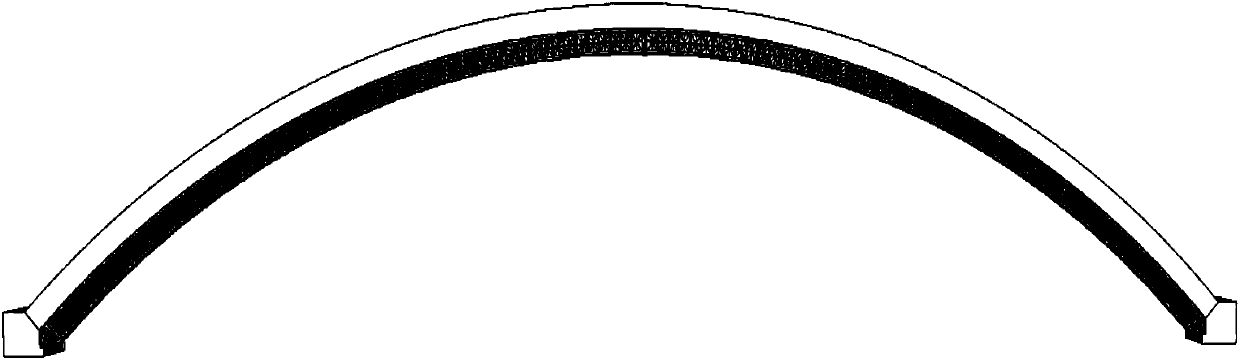

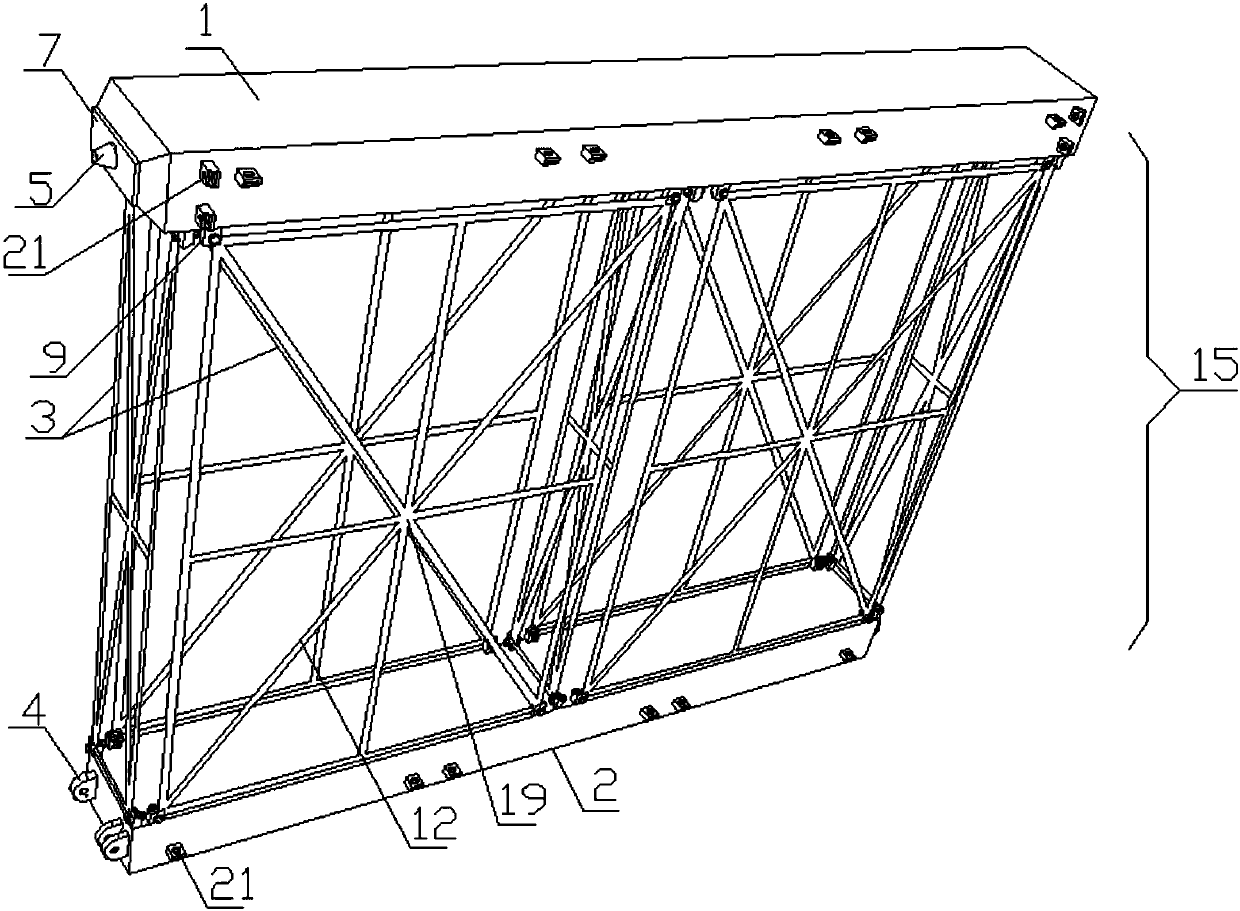

[0034] A long-span steel arch frame, which is mainly composed of arch foot segments, standard segments, adjustment segments, closing segments and closing devices. In addition to the closing devices, the lower chords of adjacent segments are connected by pin-type hinges , the upper chords of the adjacent segments are connected by chords with multi-sided bolts to form an arch frame.

[0035] Furthermore, wedges are arranged between the transverse end faces of the upper chords of adjacent segments to realize the adjustment of the arc of the arch and meet the arc requirements of the constructed reinforced concrete main arch.

[0036] In order to improve the stability of the steel arch, the above-mentioned wedges are limited axially and radially between the transverse end surfaces of adjacent segments.

[0037] In order to further improve the stability of the steel arch, the above-mentioned wedge fits with the installation hole through the cone and is axially and radially limited b...

Embodiment 2

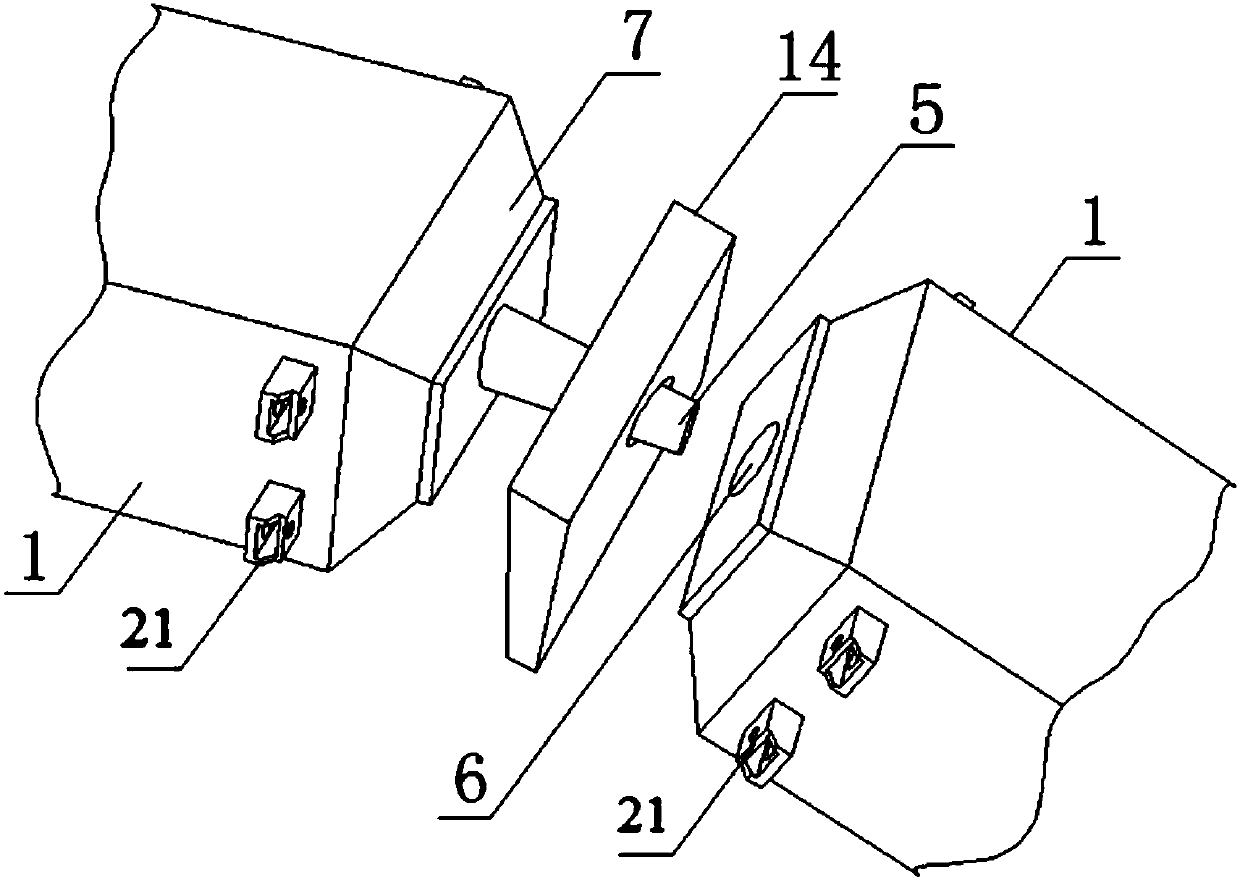

[0042] A long-span steel arch, such as Figure 1 to Figure 11 As shown, it is mainly composed of arch foot segment 18, standard segment 15, adjustment segment 16, closing segment 17 and closing device 8; except for closing device 8, the lower chords 2 of all adjacent segments adopt the pin-through type Hinged connection, in this example, a hinged assembly 4 is provided at the transverse section of the lower chord 2, and a through hole is provided on the hinged assembly 4, and pins are inserted in the through hole to realize the hinged connection of the lower chord of adjacent segments. The upper chord 1 of the adjacent segment is connected by chord multi-side bolted to form an arch frame. In this example, a plurality of connecting bolt fixing seats 21 are arranged on the side of the end of the upper chord 1, and the connecting bolts of the adjacent segment Locking bolts 22 are pierced on the fixing seat 21 to realize the multi-side bolted double-pull connection of the chords. ...

Embodiment 3

[0067] A long-span steel arch frame, refer to Example 2. Among them, the truncated cone is a truncated cone fixed in the middle of the upper chord transverse end face of the segment, the installation hole is a circular hole set in the middle of the upper chord transverse end face of the segment, the wedge is set on the truncated cone, and the truncated cone can be inserted into the circular hole A small gap fit of 1-3mm is formed to realize the axial and radial limit of the wedge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com