Multifunctional scrapping type single-component thermal insulation coating, multifunctional scrapping type bi-component thermal insulation coating and preparing methods of multifunctional scrapping type single-component thermal insulation coating and multifunctional scrapping type bi-component thermal insulation coating

A thermal insulation and batch scraping technology, which is applied in the direction of reflection/signal coating, coating, filling slurry, etc., can solve the problems of complex color, dark color and poor decorative feeling of thermal insulation coating, and achieve good weather resistance, excellent Long-lasting flexibility, good whiteness and hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

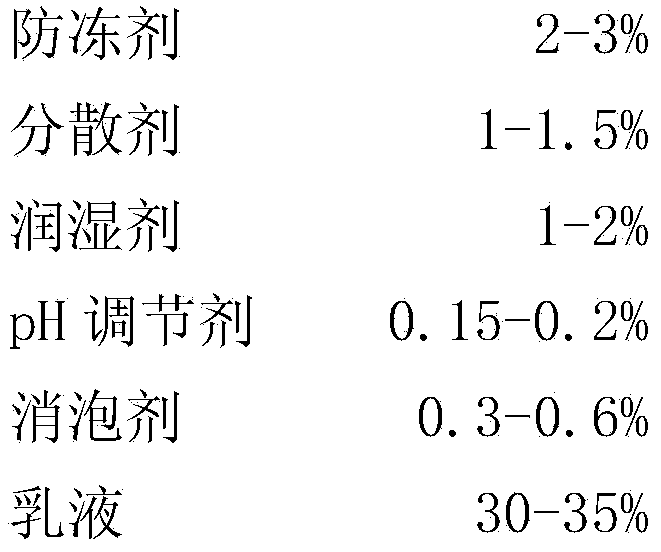

[0040] Embodiment 1: A multi-functional batch-scraping type single-group thermal insulation coating, which is composed of a main paint, and the main paint is prepared from the following components according to the following weight percentages:

[0041]

[0042]A preparation method for preparing multi-functional batch-scratch type one-component thermal insulation coating, wherein the main paint is prepared according to the following preparation method: first, 27% of water, 3% of antifreeze, 1.2% of dispersant, 1.5% of After mixing wetting agent, 0.2% defoamer 1 and 0.2% pH regulator, disperse at 300 rpm for 10 minutes, then add 33% emulsion and disperse for 8 minutes, then add 22% hollow glass Microbeads, 8% expandable microspheres, 0.6% lignocellulose, 0.3% antifungal agent and 0.5% antibacterial agent, increase the speed to 900 rpm for 15 minutes, then reduce the speed to 600 rpm , then add 0.2% preservative, 1.2% coalescent 1, 0.8% coalescent 2 and 0.3% defoamer 2 in sequ...

Embodiment 2

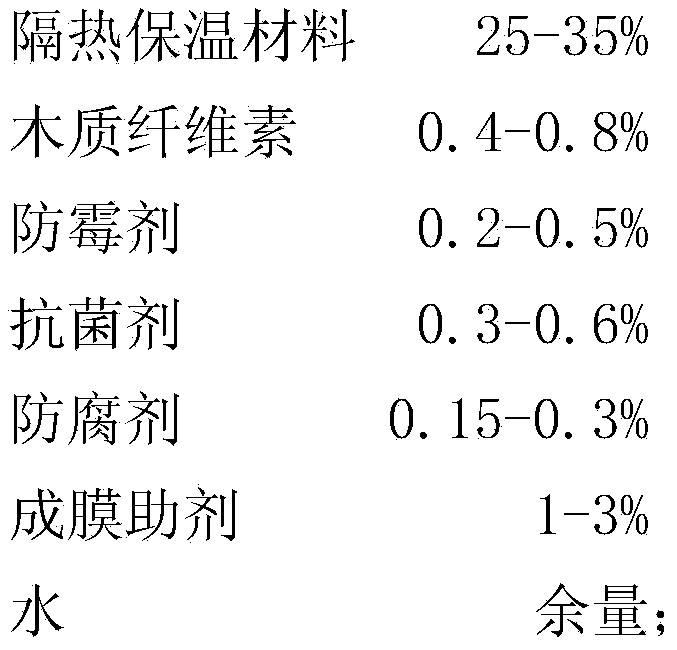

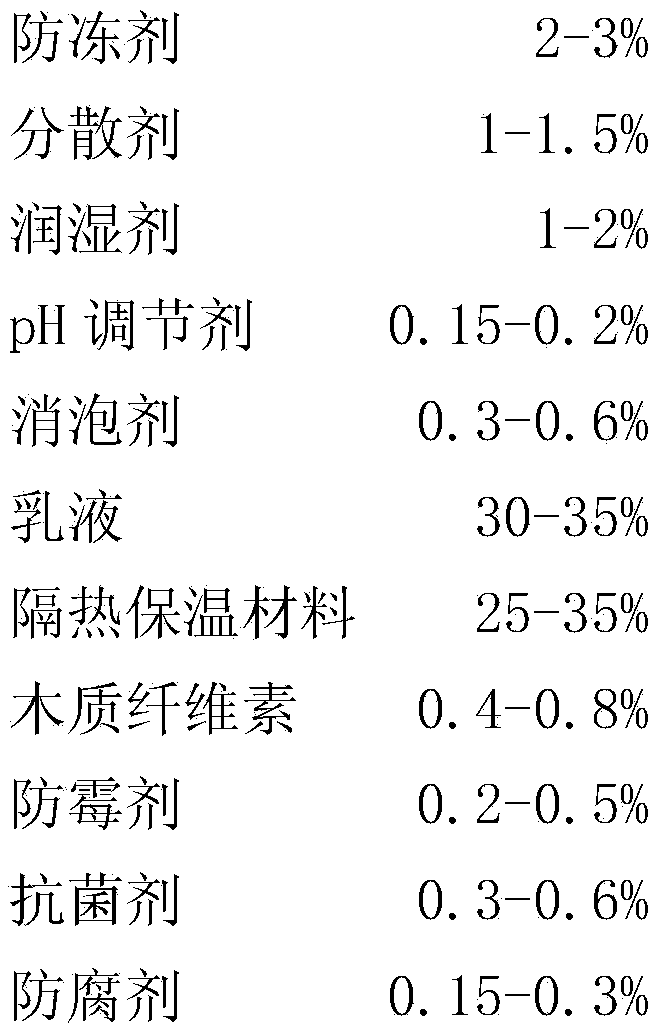

[0050] Embodiment 2: A multi-functional batch-scraping single-group thermal insulation coating, which is composed of a main paint, and the main paint is prepared from the following components according to the following weight percentages:

[0051]

[0052]

[0053] A preparation method for preparing multifunctional batch-scraping single-component heat-insulating coating, wherein the main paint is prepared according to the following preparation method: first, 20% of water, 2.5% of antifreeze, 1.5% of dispersant, 2% of After mixing wetting agent, 0.2% defoamer 1 and 0.2% pH regulator, disperse at 400 rpm for 6 minutes, then add 35% emulsion and disperse for 10 minutes, then add 20% hollow ceramic Microbeads, 6% hollow glass microspheres, 8% expandable microspheres, 0.8% lignocellulose, 0.3% antifungal agent and 0.5% antibacterial agent, increase the speed to 1000 rpm to disperse for 12 minutes, Then reduce the speed to 700 rpm, then add 0.2% preservative, 1.3% coalescent 1...

Embodiment 3

[0063] Embodiment 3: A multi-functional batch-scraping single-group thermal insulation coating, which is composed of a main paint, and the main paint is prepared from the following components according to the following weight percentages:

[0064]

[0065] A preparation method for preparing a multifunctional batch-scraping single-component thermal insulation coating, wherein the main paint is prepared according to the following preparation method: first, 31% of water, 3% of antifreeze, 1% of dispersant, 2% of After mixing wetting agent, 0.15% defoamer 1 and 0.2% pH regulator, disperse at 250 rpm for 10 minutes, then add 30% emulsion and disperse for 5 minutes, then add 20% hollow ceramic Microbeads, 8% expandable microspheres, 0.8% lignocellulose, 0.5% antifungal agent and 0.3% antibacterial agent, increase the speed to 800 rpm for 20 minutes, then reduce the speed to 500 rpm , and then sequentially add 0.3% preservative, 1.3% coalescent 1, 1.2% coalescent 2 and 0.25% defoa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com