A multi -function batch scraping single, dual -component heat insulation coating and preparation method

A thermal insulation and multi-functional technology, applied in the direction of reflection/signal coatings, coatings, filling pastes, etc., can solve the problems of complex colors, poor decorative feeling, and dark colors of thermal insulation coatings, and achieve good weather resistance and excellent durability The effect of flexibility, good whiteness and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

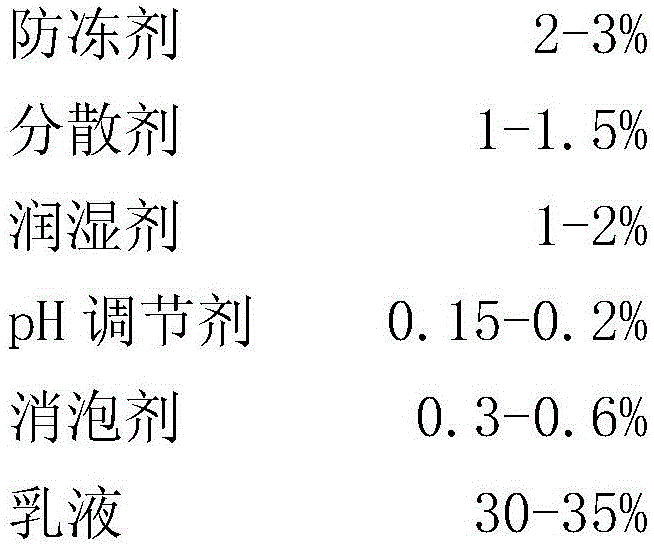

[0040] Embodiment 1: a multifunctional batch scraping type single-component thermal insulation coating, consisting of a main paint, the main paint is prepared from the following components according to the following weight percentages:

[0041]

[0042]A preparation method for preparing a multifunctional batch scraping type single-component thermal insulation coating, wherein the main paint is prepared according to the following preparation method: firstly, 27% of water, 3% of antifreeze, 1.2% of dispersant, 1.5% of Wetting agent, 0.2% defoamer 1 and 0.2% pH adjuster were mixed and dispersed at 300 rpm for 10 minutes, then 33% emulsion was added for 8 minutes, followed by 22% hollow glass Microbeads, 8% expandable microspheres, 0.6% lignocellulose, 0.3% mildew inhibitor and 0.5% antibacterial agent, increase the speed to 900 rpm for 15 minutes, then reduce the speed to 600 rpm , and then add 0.2% preservative, 1.2% film-forming aid 1, 0.8% film-forming aid 2 and 0.3% defoam...

Embodiment 2

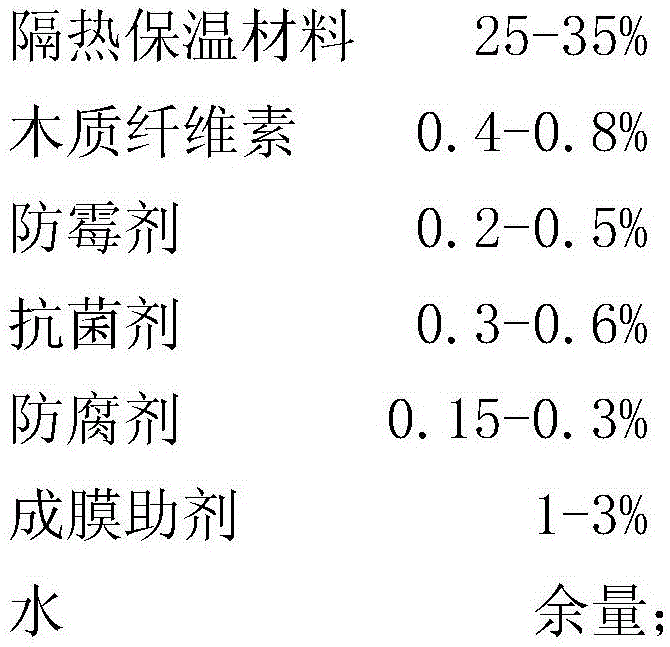

[0050] Embodiment 2: a multifunctional batch scraping type single-component thermal insulation coating, which is composed of main paint, and the main paint is prepared from the following components according to the following weight percentages:

[0051]

[0052]

[0053] A preparation method for preparing a multifunctional batch scraping single-component type thermal insulation coating, wherein the main paint is prepared according to the following preparation method: first, 20% of water, 2.5% of antifreeze, 1.5% of dispersant, 2% of After mixing wetting agent, 0.2% defoamer 1 and 0.2% pH adjuster, disperse at 400 rpm for 6 minutes, then add 35% emulsion for 10 minutes, then add 20% hollow ceramic Microspheres, 6% hollow glass microspheres, 8% expandable microspheres, 0.8% lignocellulose, 0.3% mildew inhibitor and 0.5% antibacterial agent, increase the speed to 1000 rpm for 12 minutes, Then reduce the speed to 700 r / min, then add 0.2% preservative, 1.3% film-forming aid 1...

Embodiment 3

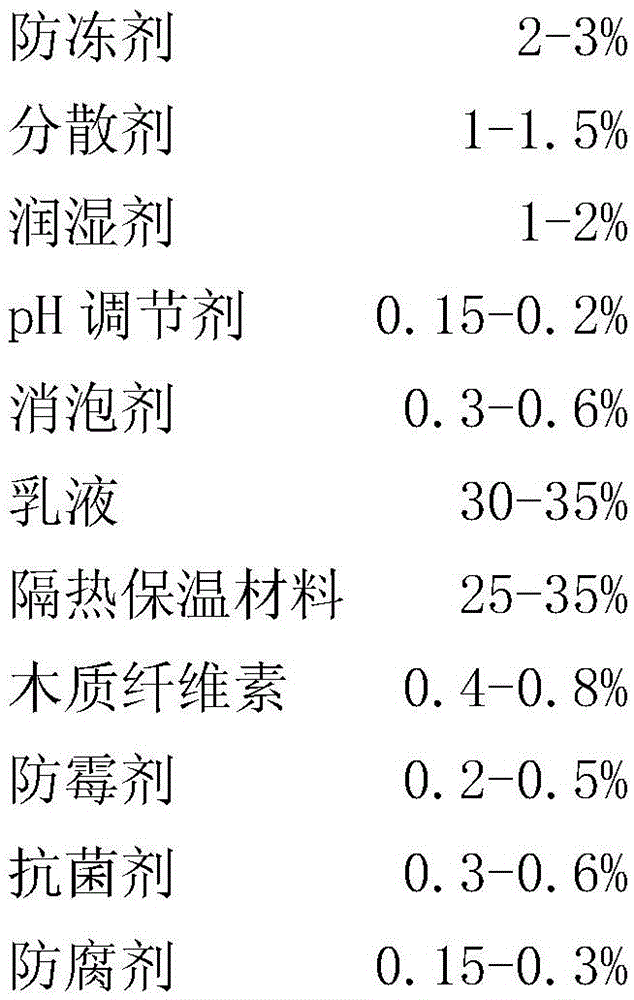

[0063] Embodiment 3: a kind of multifunctional batch scraping type single-component thermal insulation coating, which is composed of main paint, and the main paint is prepared from the following components according to the following weight percentages:

[0064]

[0065] A preparation method for preparing a multifunctional batch-scraping single-component thermal insulation coating, wherein the main paint is prepared according to the following preparation method: first, 31% of water, 3% of antifreeze, 1% of dispersant, 2% of Wetting agent, 0.15% defoamer 1 and 0.2% pH adjuster were mixed and dispersed at 250 rpm for 10 minutes, then 30% emulsion was added for another 5 minutes, followed by 20% hollow ceramic Microbeads, 8% expandable microspheres, 0.8% lignocellulose, 0.5% mildew inhibitor and 0.3% antibacterial agent, increase the speed to 800 rpm for 20 minutes, then reduce the speed to 500 rpm , and then add 0.3% preservative, 1.3% film-forming aid 1, 1.2% film-forming aid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com