An Improved Back Suction Anticorrosion Pump

A pump casing and pump cover technology, which is applied in the field of centrifugal pump manufacturing, can solve the problems of poor wear resistance of solid materials, high fluid pressure in the shaft seal cavity, and high fluid pressure at the shaft seal, so as to overcome the problem of particle wear resistance, Good sealing performance, overcoming the effect of non-wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

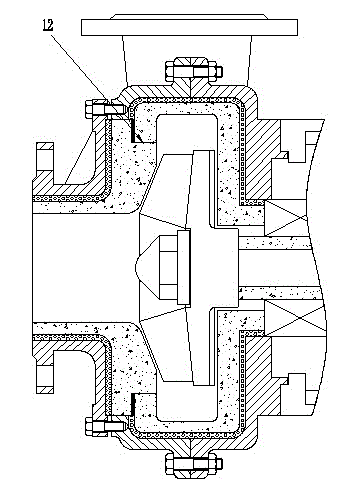

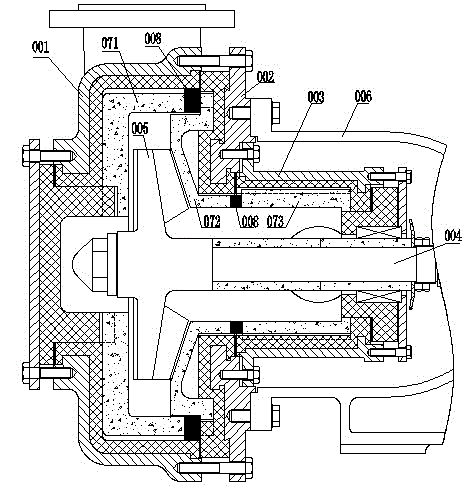

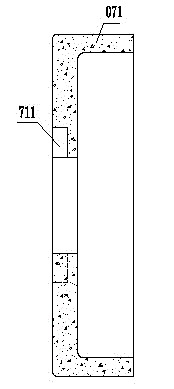

[0033] Embodiment 1: as Figure 2~6As shown, an improved back-suction anti-corrosion pump includes a plastic-lined pump casing 001, a plastic-lined pump cover 002 installed at one end of the pump casing 001, and a liner installed on the center hole of the pump cover 002 and communicated with the inner cavity of the pump casing 001. The plastic suction port tee 003, the pipe connecting the suction port tee 003 and the inner cavity of the pump casing 001 is provided with a main shaft 004, and the main shaft 004 extends into the inner cavity of the pump casing 001, and an impeller 005 is installed at one end, extending out of the suction port One end of the tee 003 is connected to the bearing bracket 006 fixed on the pump cover 002. The inner wall of the chamber formed by the inner wall of the pump housing 001 and the pump cover 002 and the inner wall of the suction inlet tee 003 are inlaid with a wear-resistant lining. The grinding lining body 071 is in the shape of a dome match...

Embodiment 2

[0034] Embodiment 2: as Figure 7 As shown, referring to Example 1, an improved back-suction anti-corrosion pump is molded with ultra-high molecular weight polyethylene to form an all-plastic pump casing 001, and then combined with a plastic-lined pump cover 002 and a plastic-lined suction inlet tee 003 The joint surface of the pump cover 002 and the pump casing 001 is provided with a positioning sleeve 009 to prevent the radial displacement of the wear-resistant liner 072 of the pump cover 002. The wear-resistant liner 072 of the pump cover is set in the positioning sleeve 009, and the pump cover 002 Press the positioning sleeve 009 on the pump casing 001 to fix it. The connection between the wear-resistant liner 071 of the pump casing and the positioning sleeve 009 is provided with an elastic buffer ring 008. The shape of the buffer ring 008 can be "O" shape, square, etc. , the above-mentioned wear-resistant liner is glass-ceramic or silicon carbide, and the outer diameter o...

Embodiment 3

[0035] Embodiment 3: as Figure 8~10 As shown, referring to Example 1, an improved back-suction anti-corrosion pump, the positioning layer 010 is poured between the lining plastic and the wear-resistant lining body. This implementation method is more suitable for good wear resistance, high brittleness, and manufacturing The fixing of the high-cost silicon carbide wear-resistant lining is also suitable for wear-resistant linings that are combined in blocks. The wear-resistant lining 071 in the pump casing 001 is spliced by several wear-resistant linings 071. The positioning layer 010 can be made of various resins such as epoxy resin, liquid rubber, cast nylon, cement, etc.

[0036] In order to save production cost, the material of the lining plastic in the present invention can be ultra-high molecular weight polyethylene, polyethylene, polyvinyl fluoride, polypropylene, PO, polyphenylene sulfide and other materials. The lining molding process can also be any one of molding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com