Patents

Literature

269results about How to "Extended seal life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

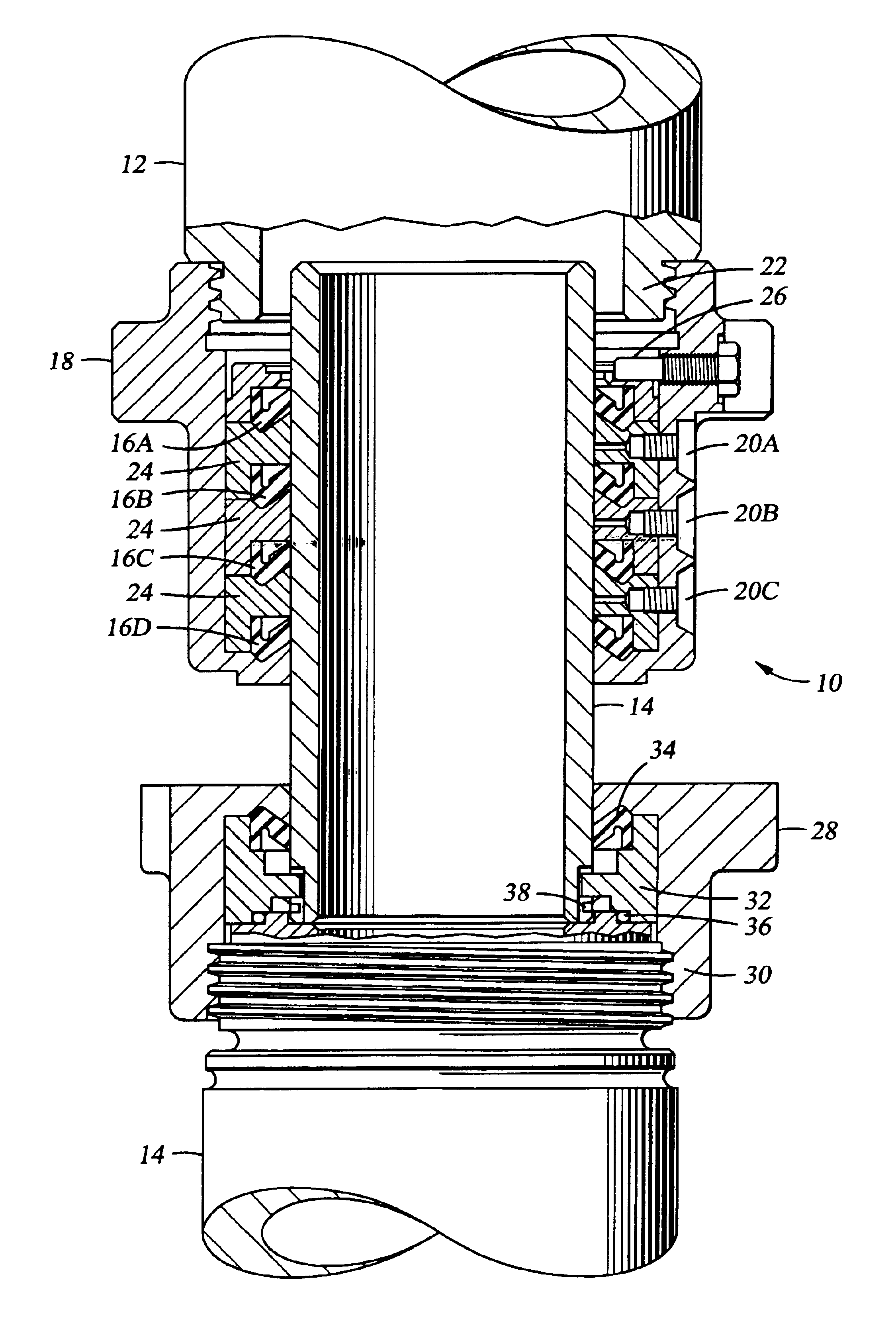

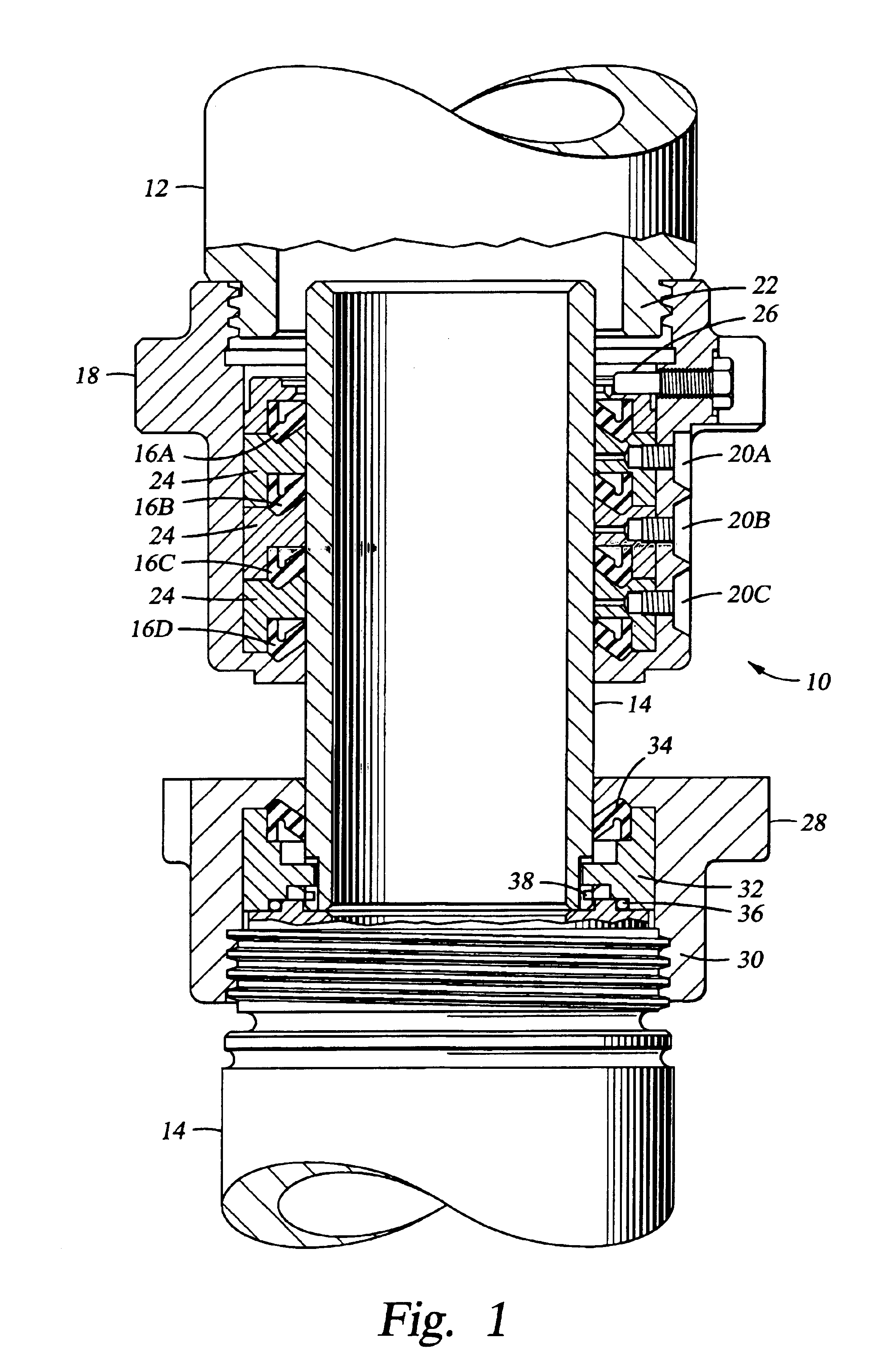

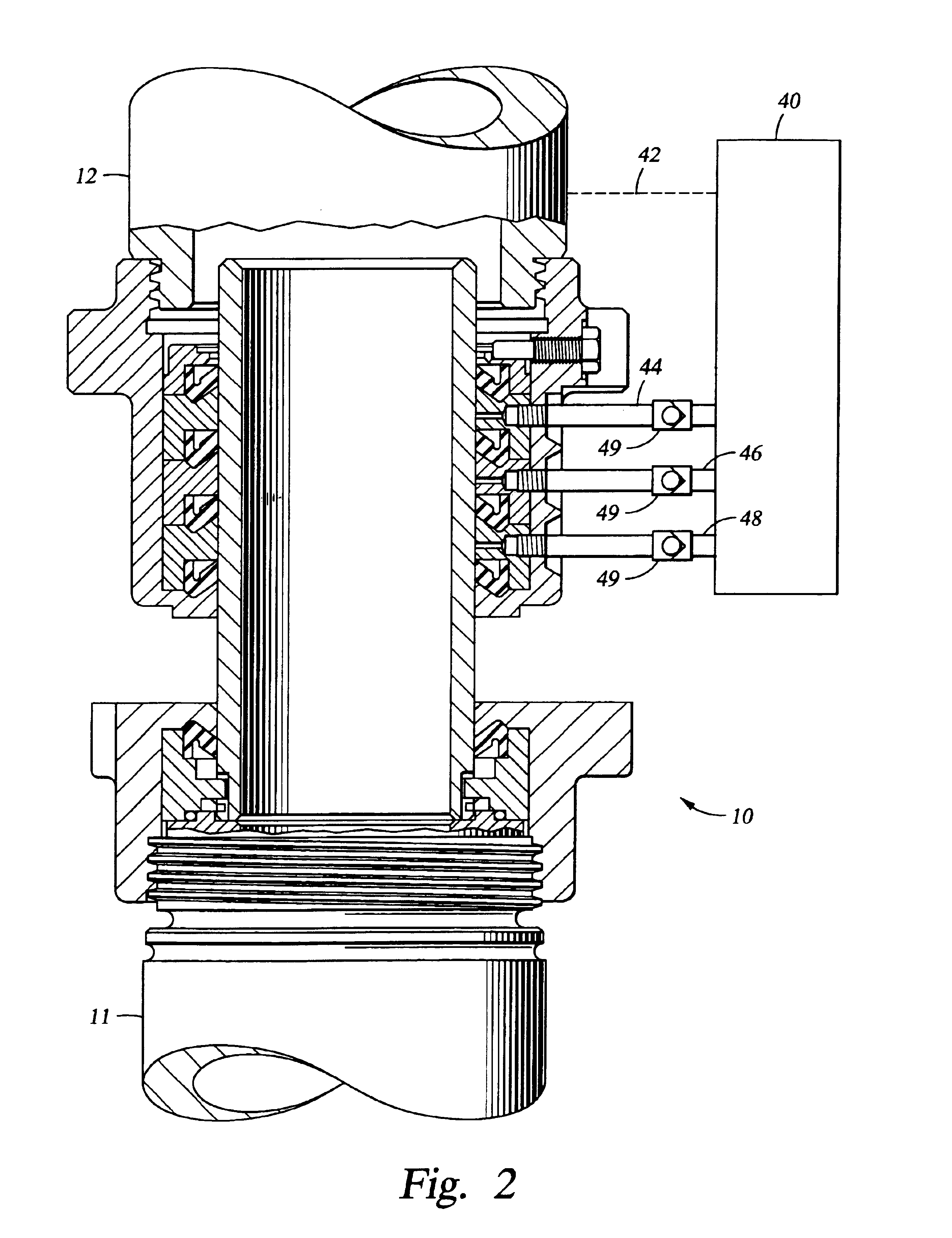

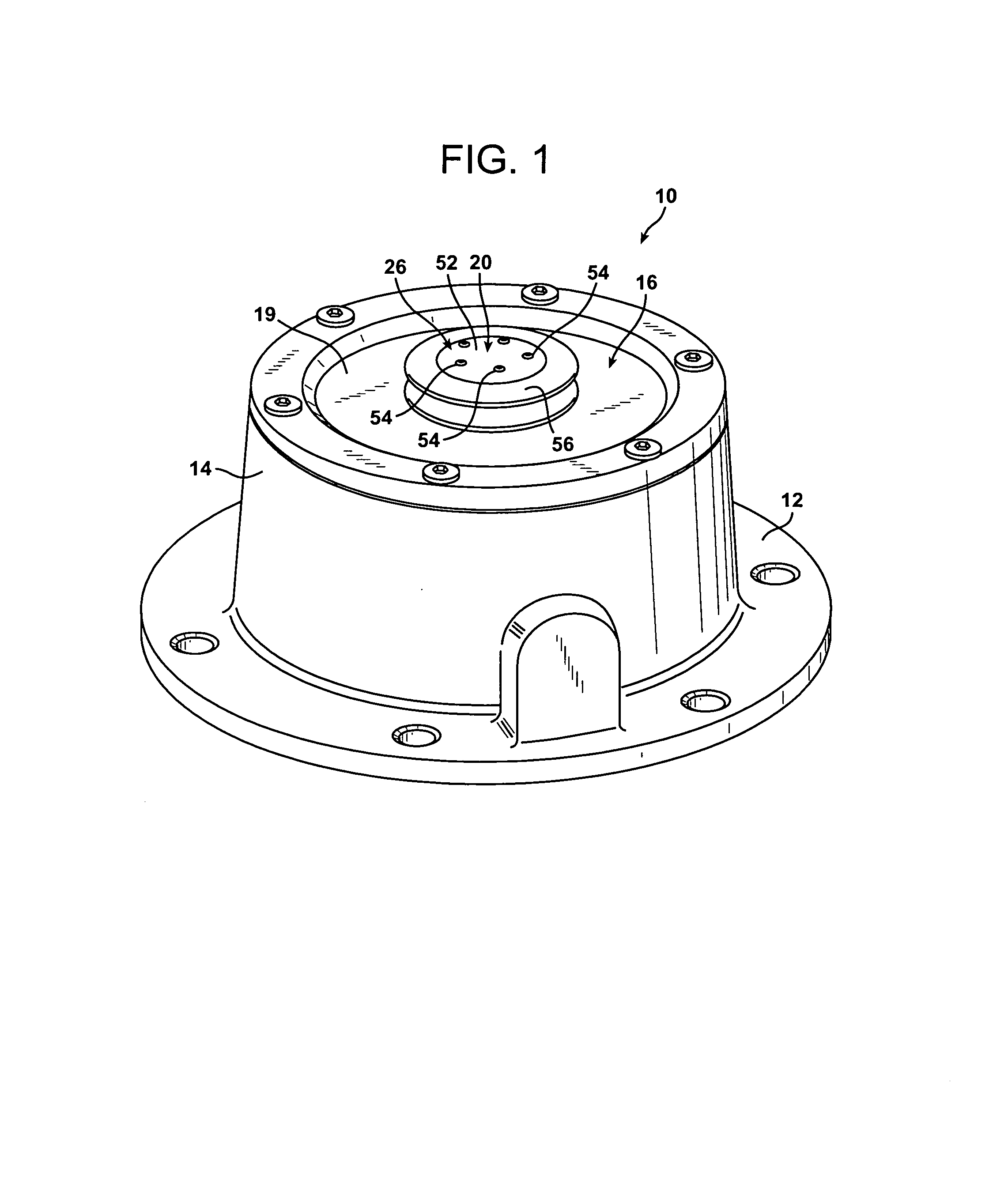

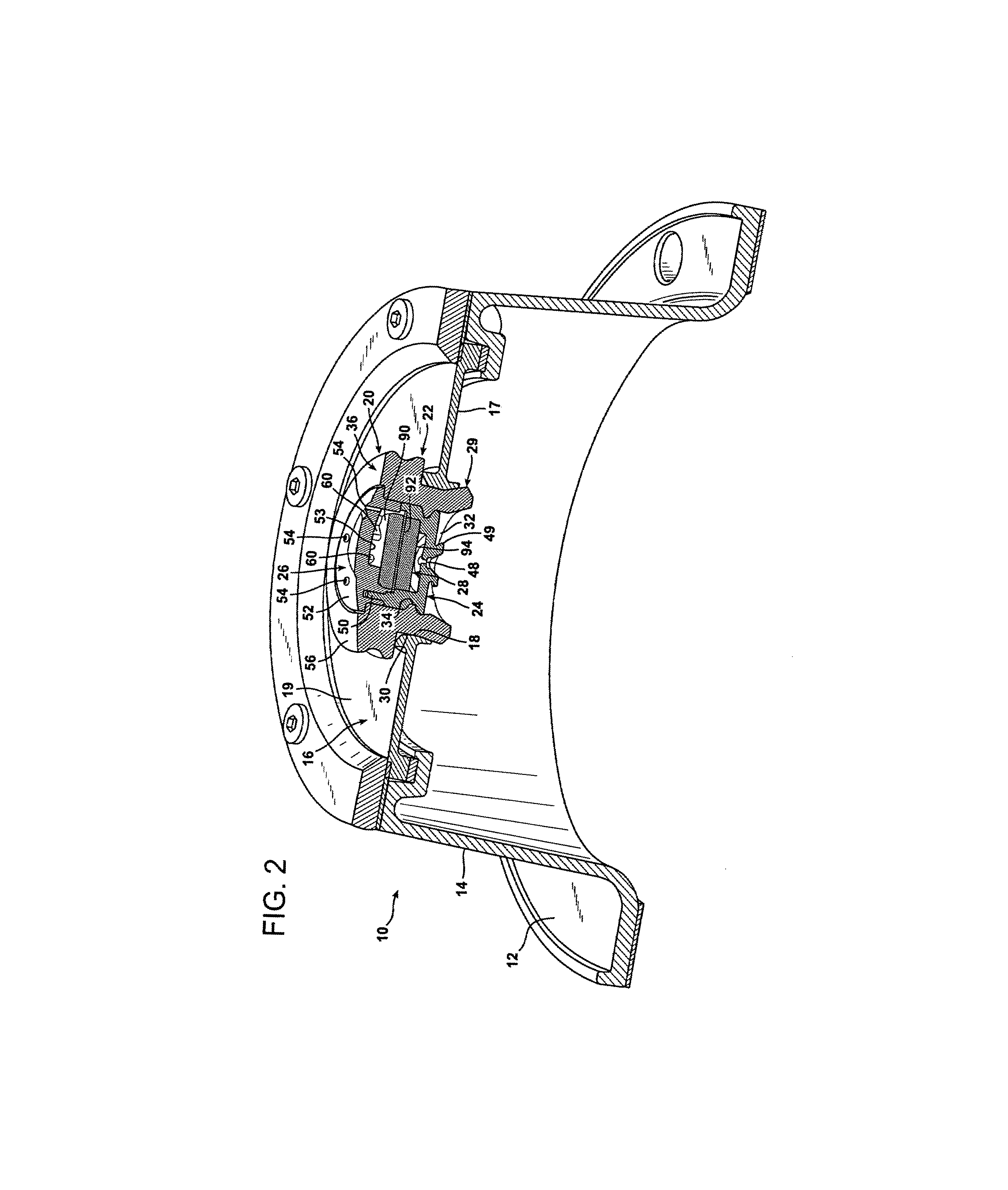

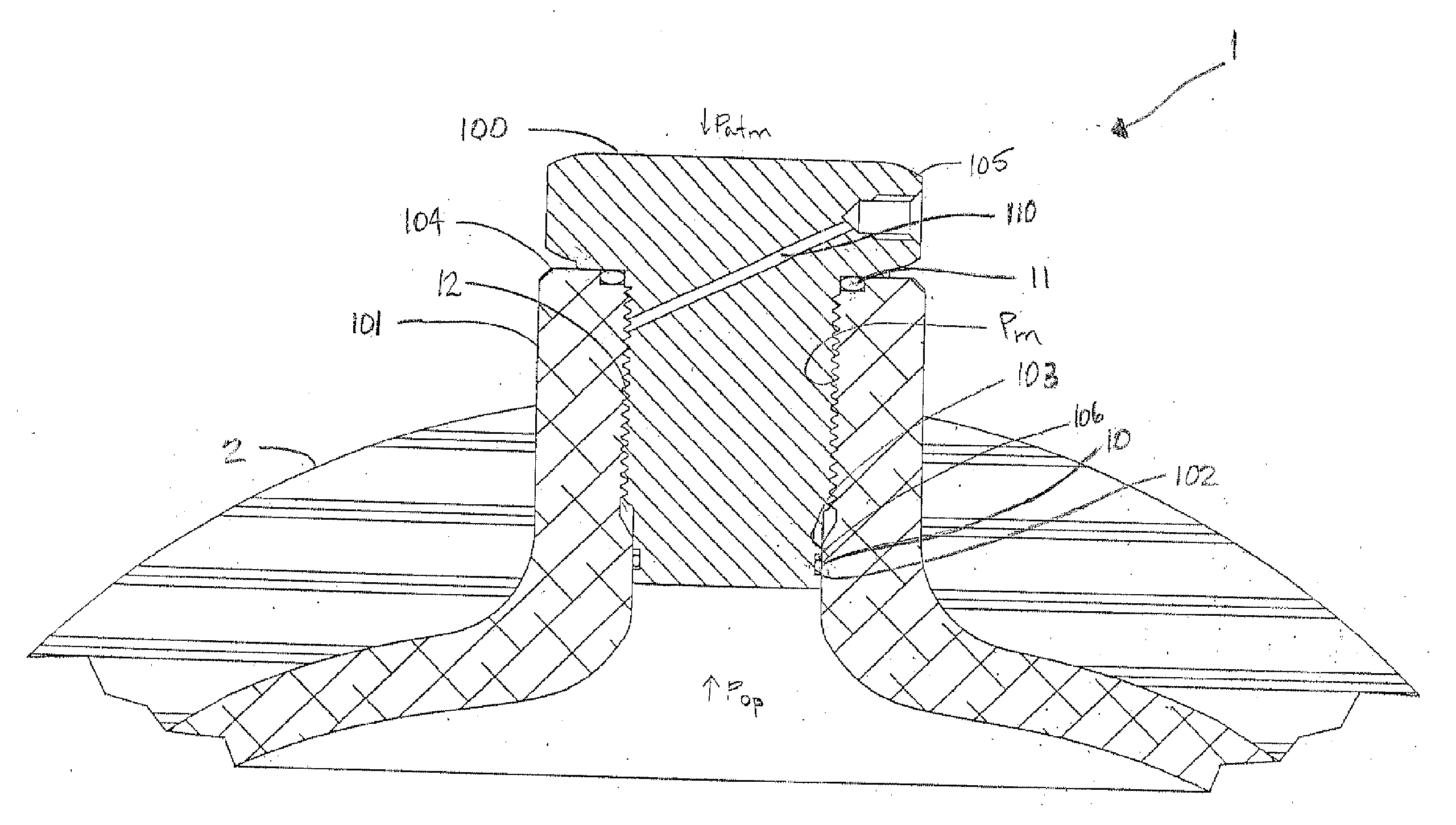

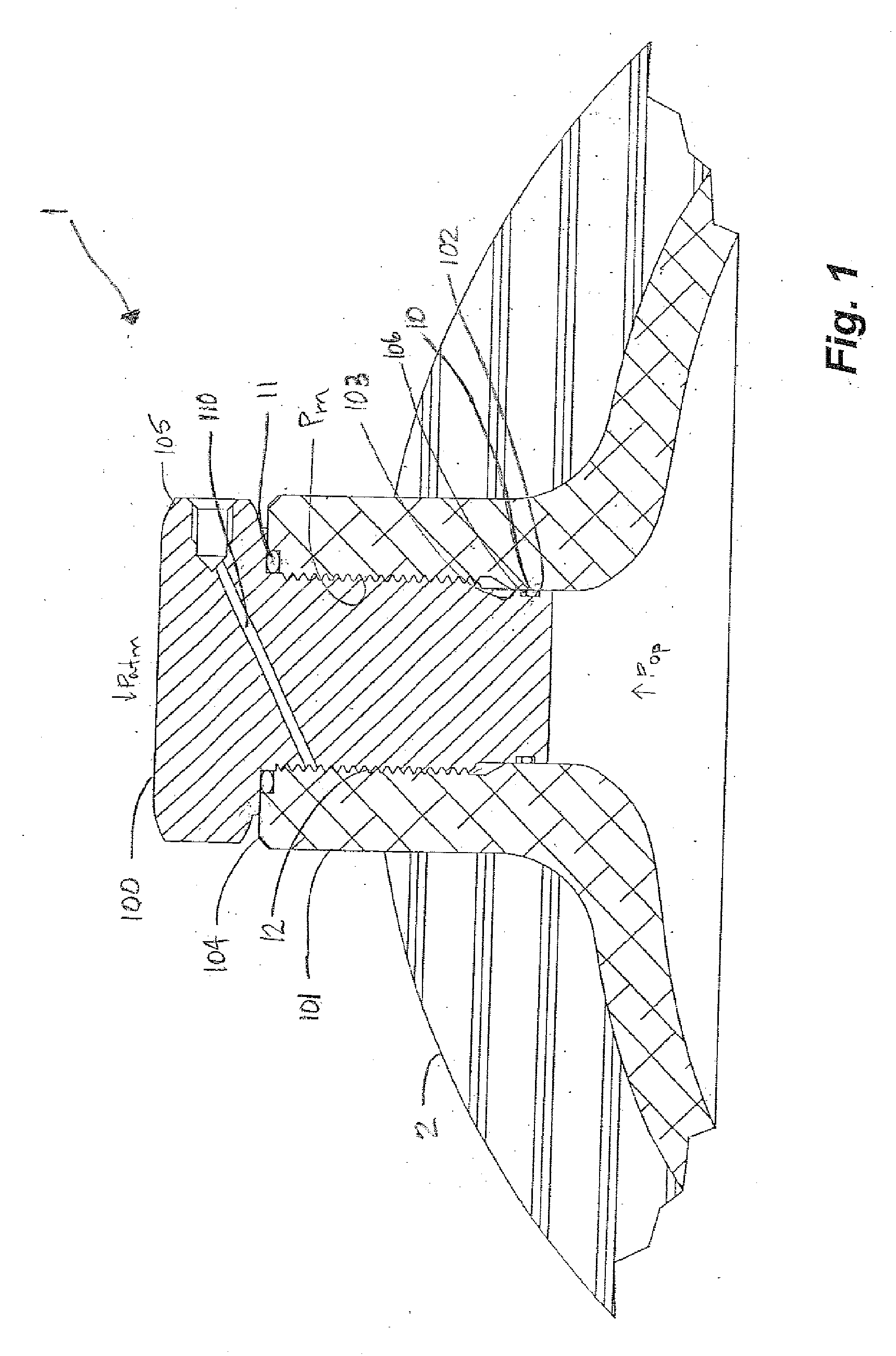

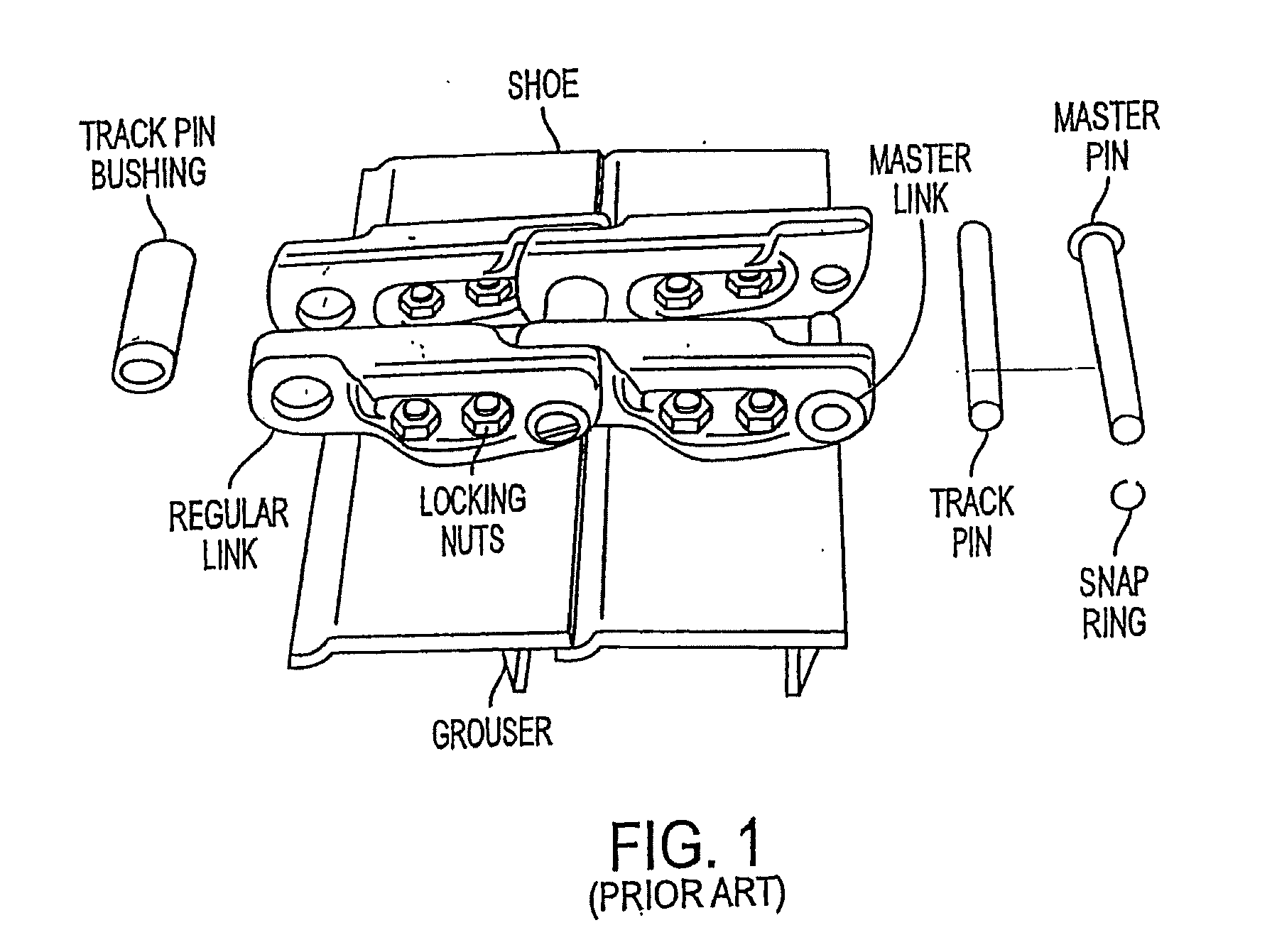

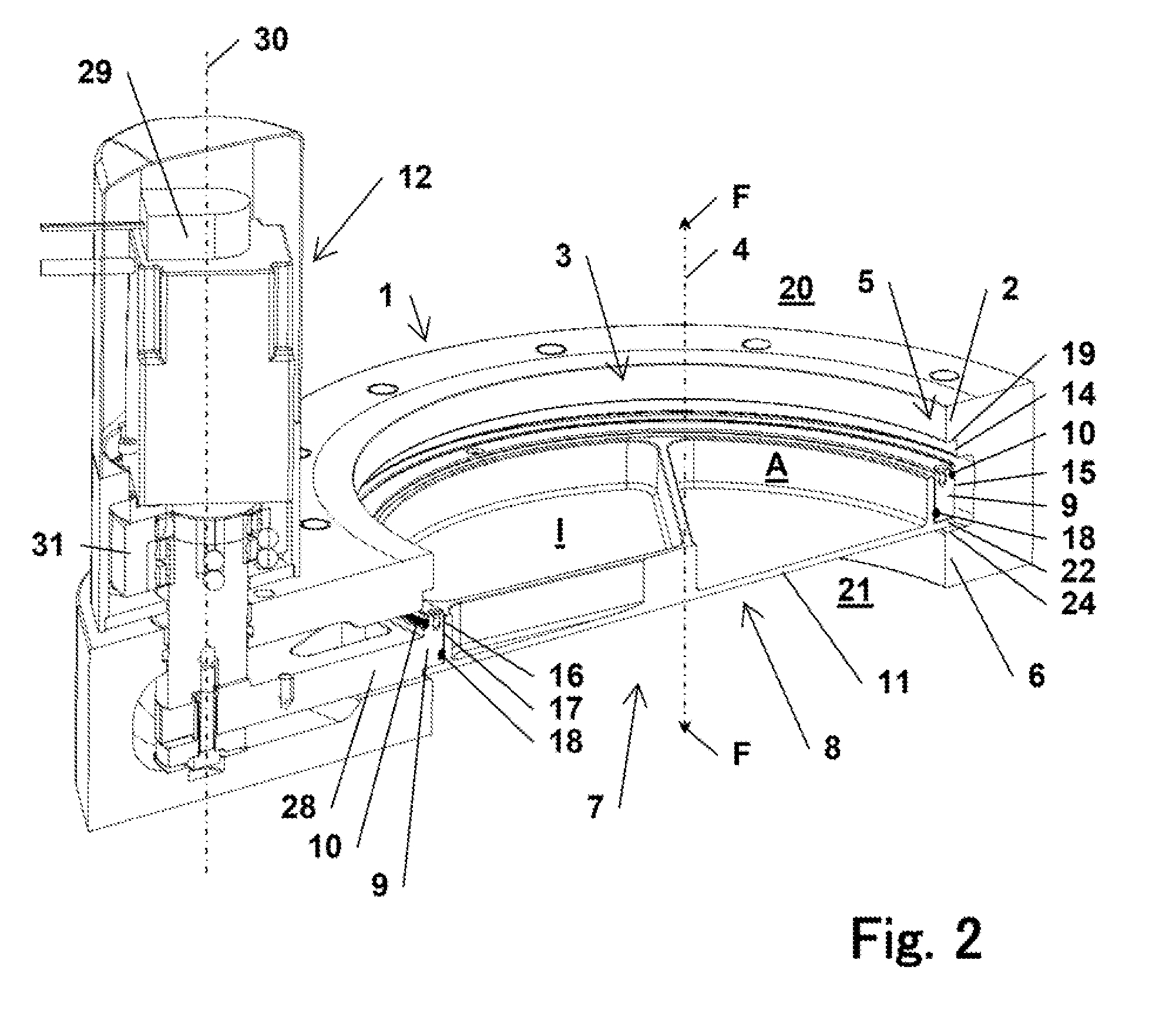

Washpipe apparatus

InactiveUS6923254B2Prolong lifeExtended seal lifeEngine sealsDrilling rodsControl systemDifferential pressure

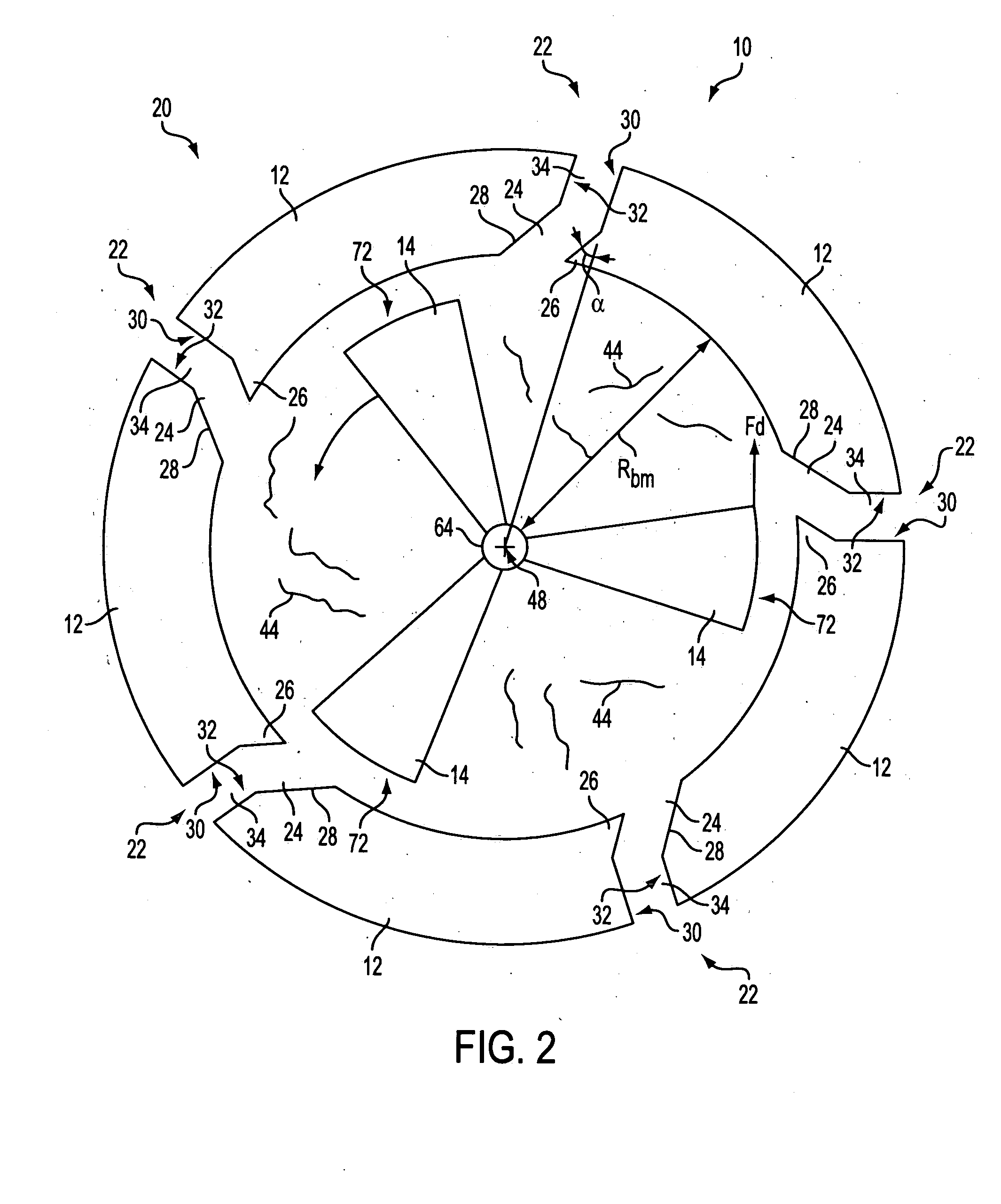

Methods and apparatus for providing enhanced seal life of a swivel seal assembly by decreasing the effective differential pressure across a given rotating seal. The differential pressure is decreased by providing a pressurized fluid on the low-pressure side of the seal at a predetermined fraction of the operating pressure of the swivel seal assembly. A preferred swivel seal assembly utilizes a washpipe and packing box that are rigidly affixed to their respective conduits such that misalignment and dynamic run-out is compensated for in the gap between the washpipe and the packing box. A control system monitors and regulates the pressurized fluid supplied to the assembly.

Owner:NAT OILWELL DHT

Hubcap filter

ActiveUS7156890B1Effective preventionExtended seal lifeCombination devicesGas treatmentMobile vehicleBreather

A hubcap breather assembly is provided for a hubcap housing lubricated wheel bearings in an automotive vehicle. The breather assembly includes a resilient, annular collar that fits into an access opening in a hubcap end wall, a filter cartridge cup, and a filter cartridge lid which fit together to hold a filter therebetween in a filter cartridge chamber. The filter is a hydrophobic, gas-permeable, particular matter filter that is disposed within and extends entirely across the filter cartridge chamber. Ambient air entering the hubcap through the hubcap breather assembly is filtered to exclude both particulate matter and water before entering the wheel bearing chamber. The filter is preferably formed of three layers, including an outboard porous layer of sintered polypropylene plastic, an intermediate hydrophobic layer of polytetrafluoroethylene, and an inboard porous layer of sintered polypropylene plastic. The filter can be replaced by separating the filter cartridge lid from the filter cartridge cup.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

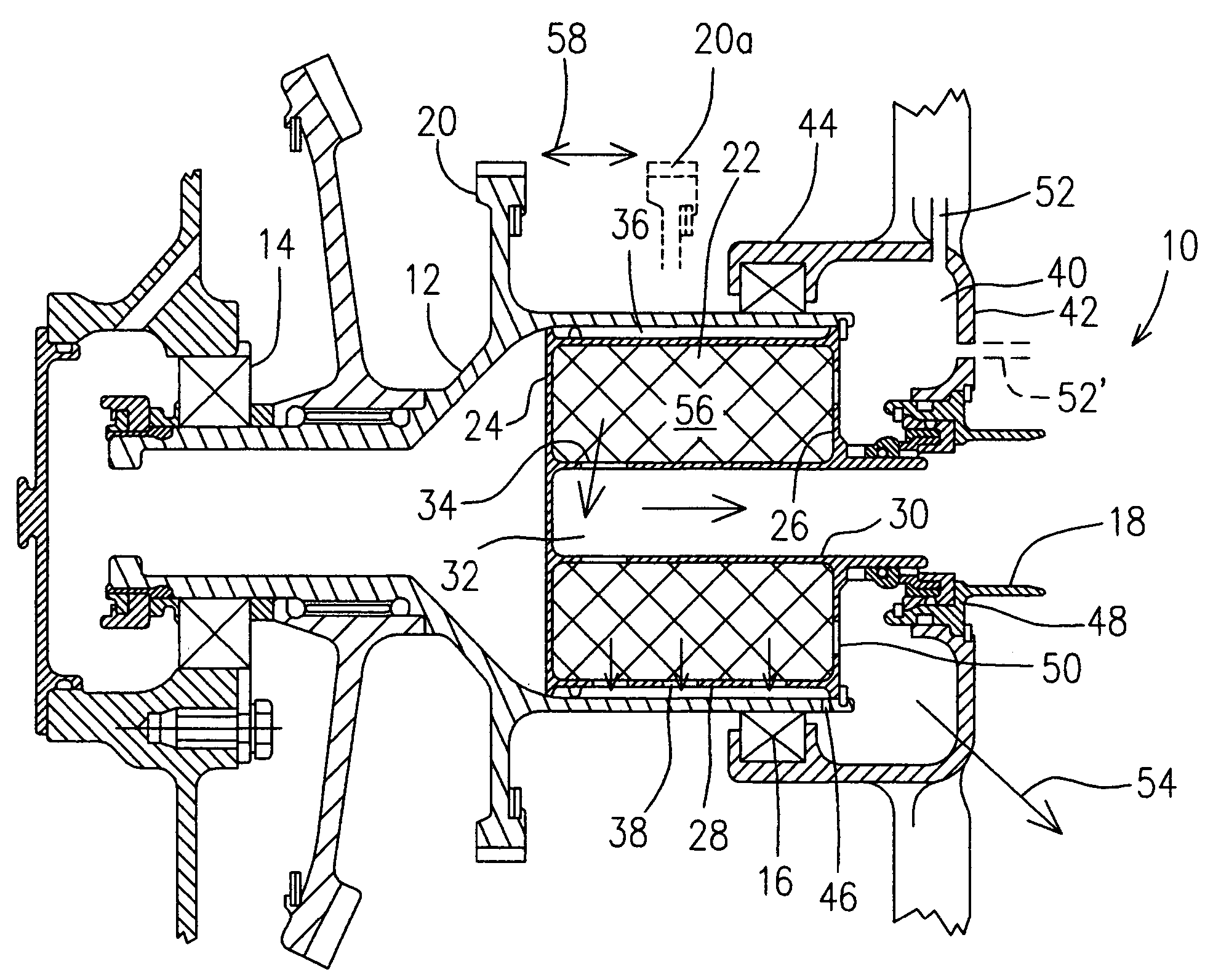

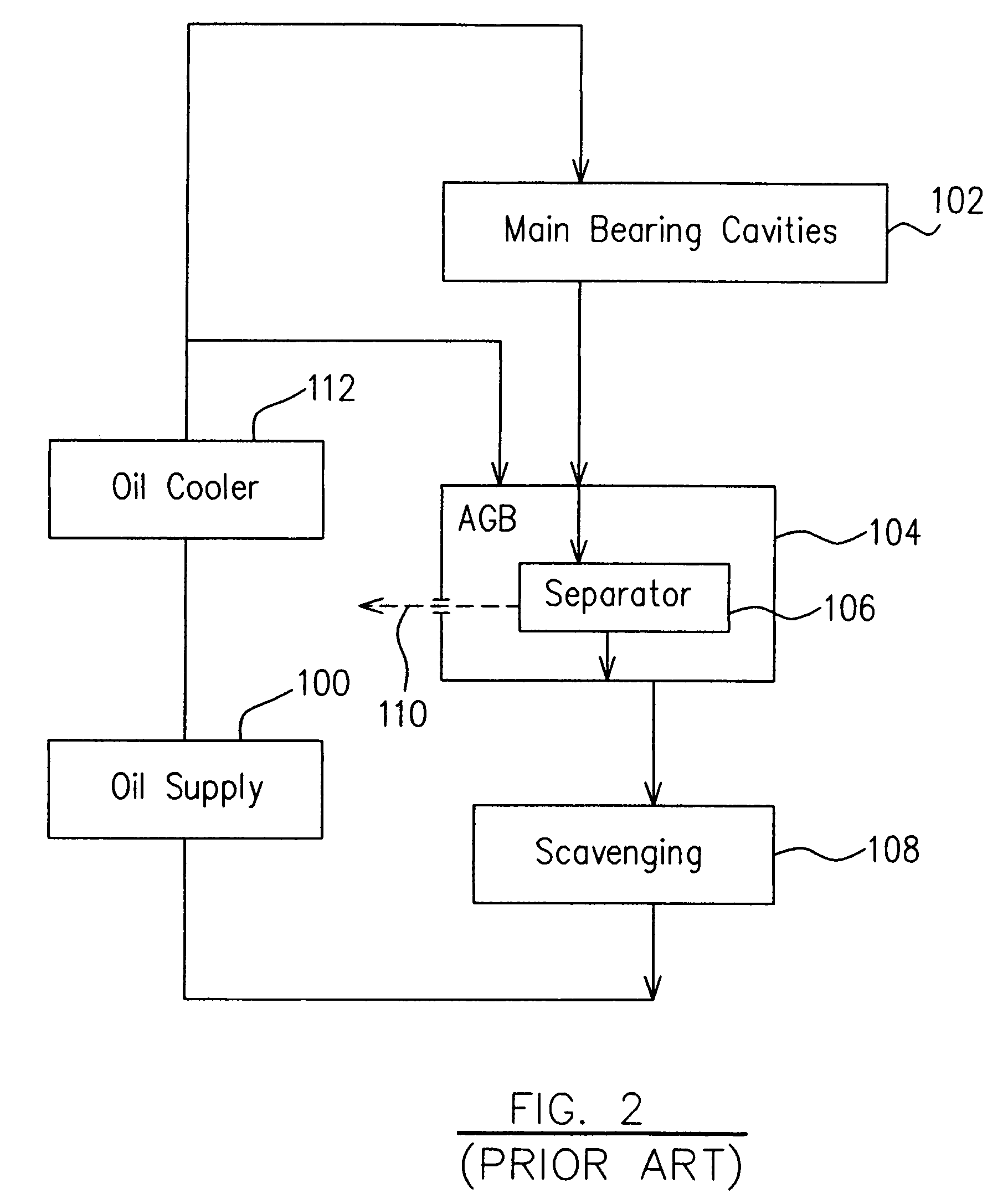

Air/oil separation system and method

ActiveUS7063734B2Extended seal lifeCombination devicesLiquid degasificationOil separationEngineering

A centrifugal air / oil separation system communicates with bearing cavities of the engine and substantially isolates separated oil from contacting the gearbox.

Owner:PRATT & WHITNEY CANADA CORP

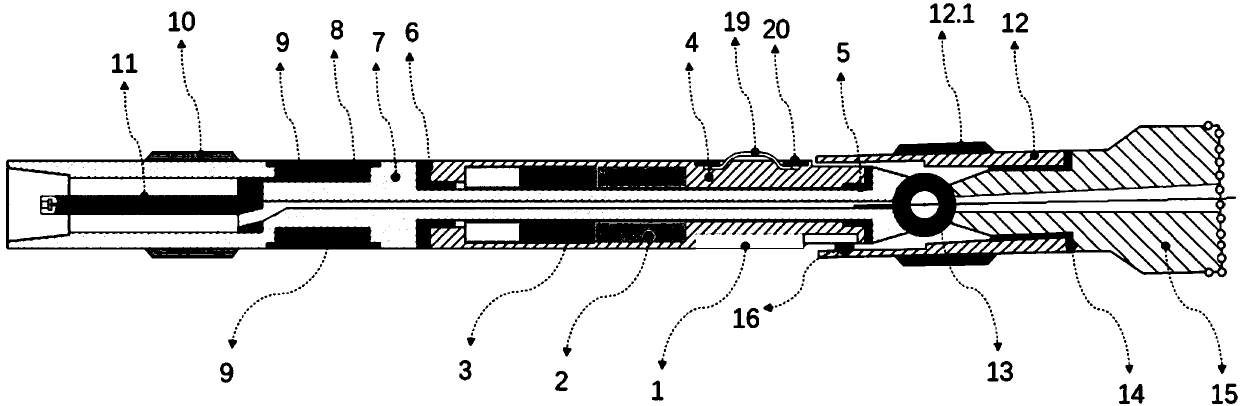

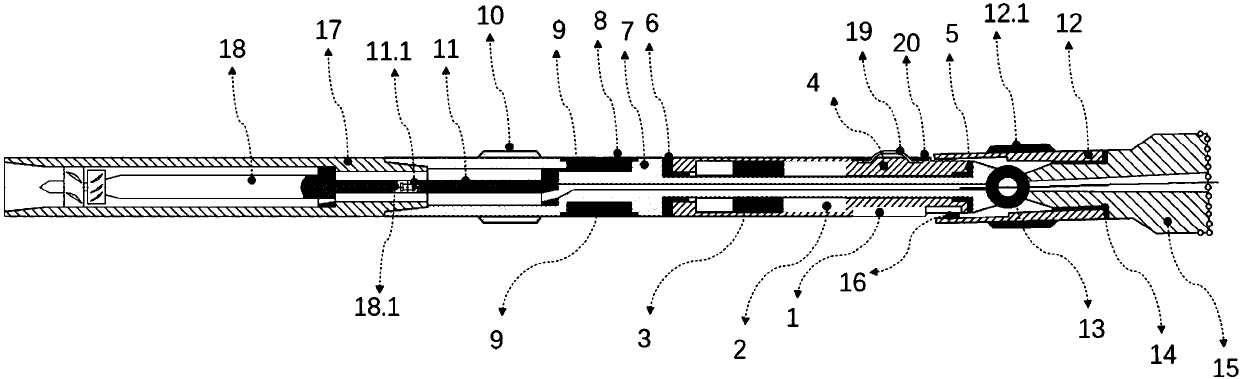

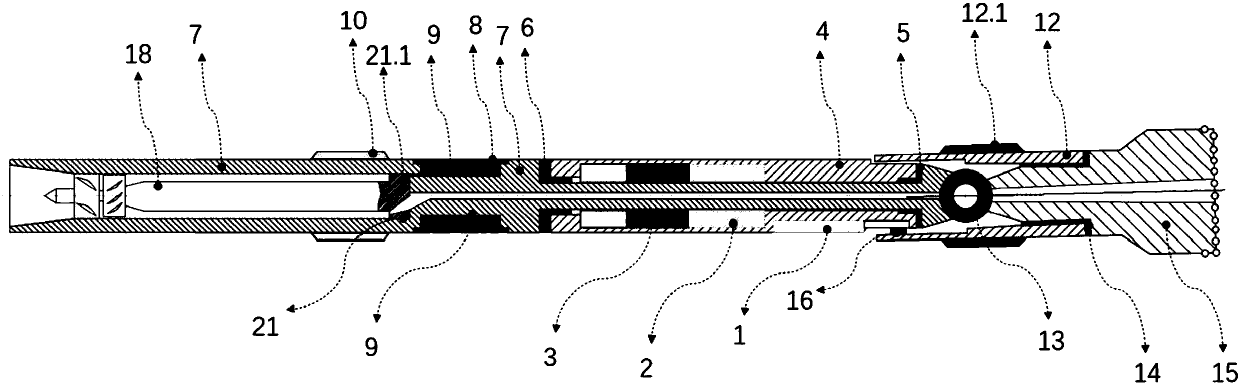

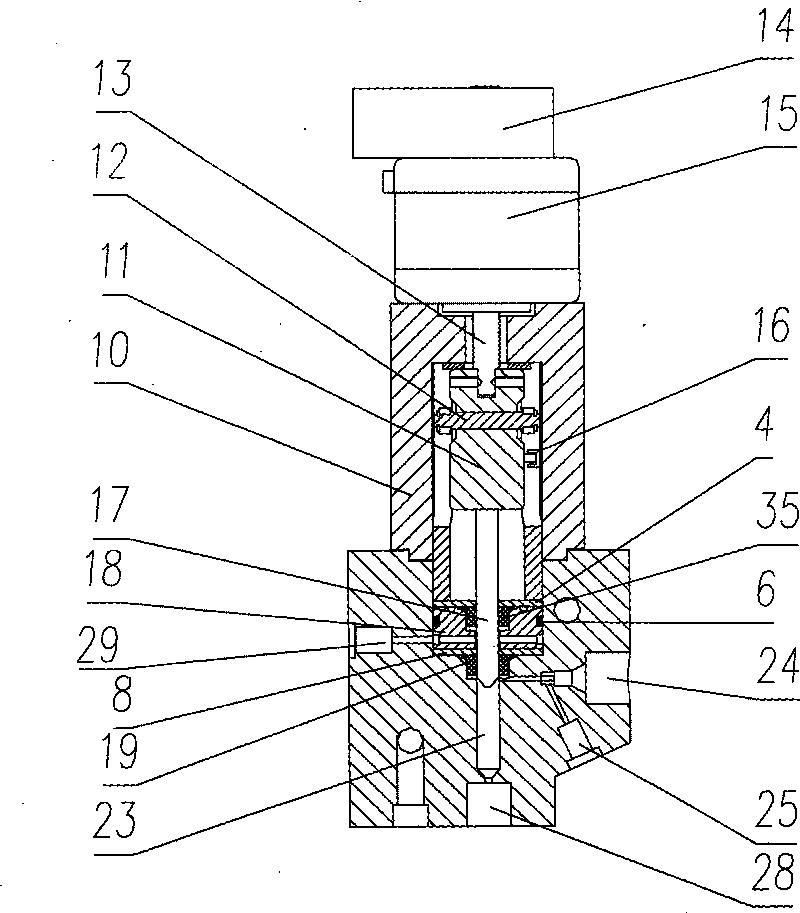

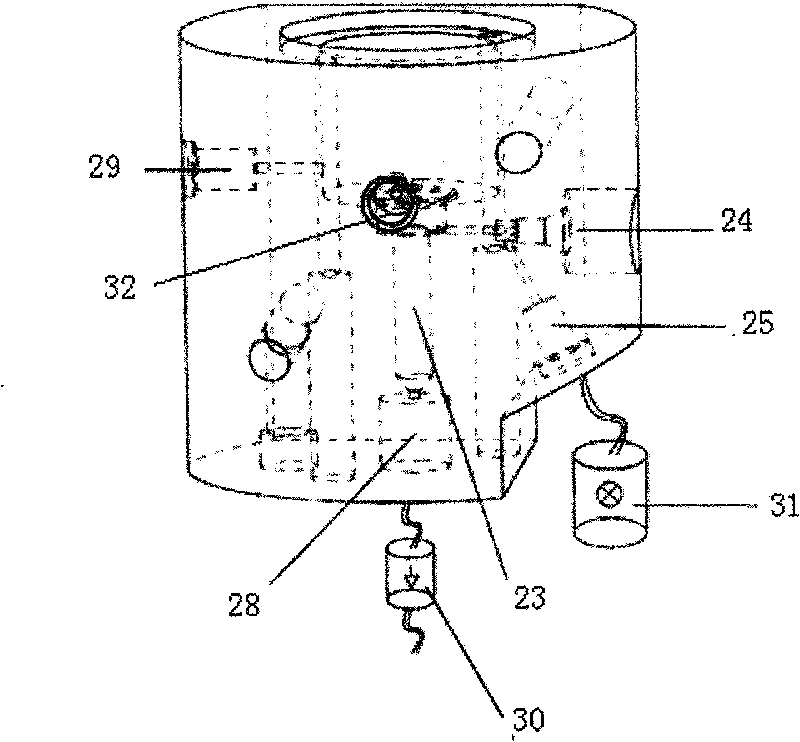

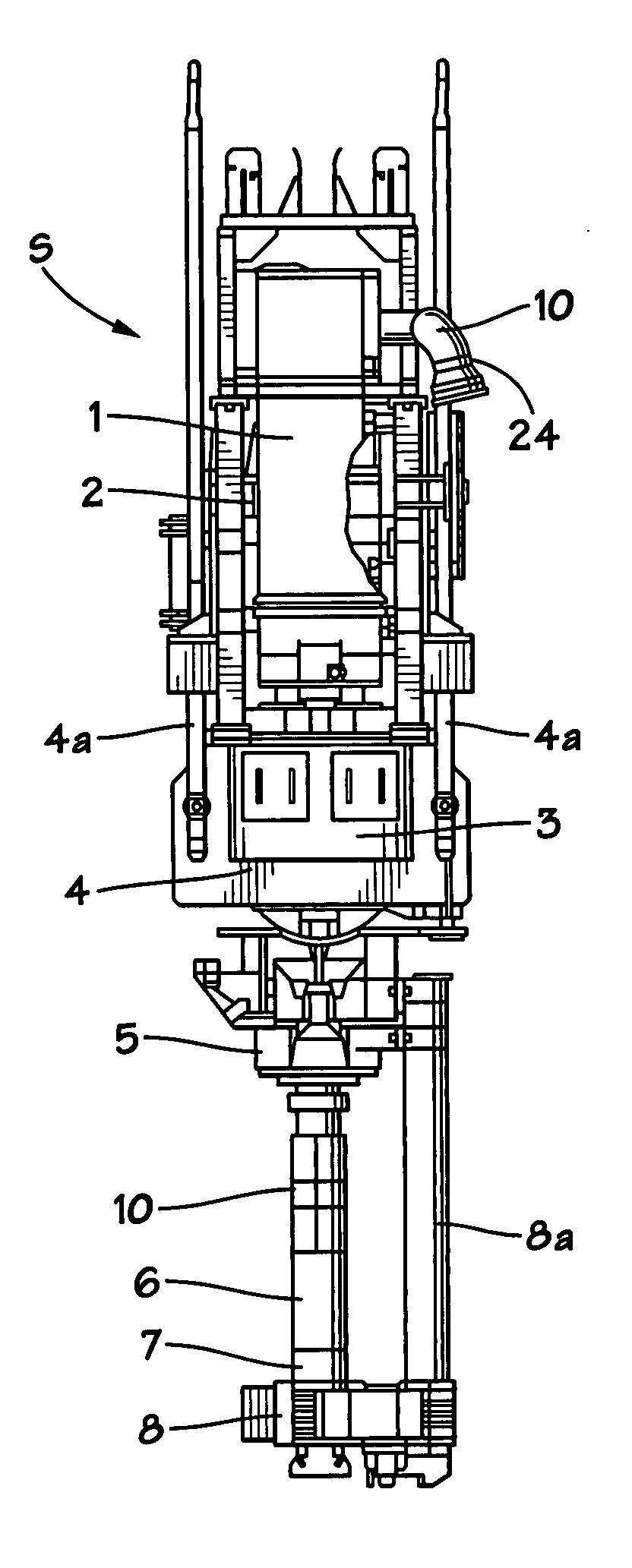

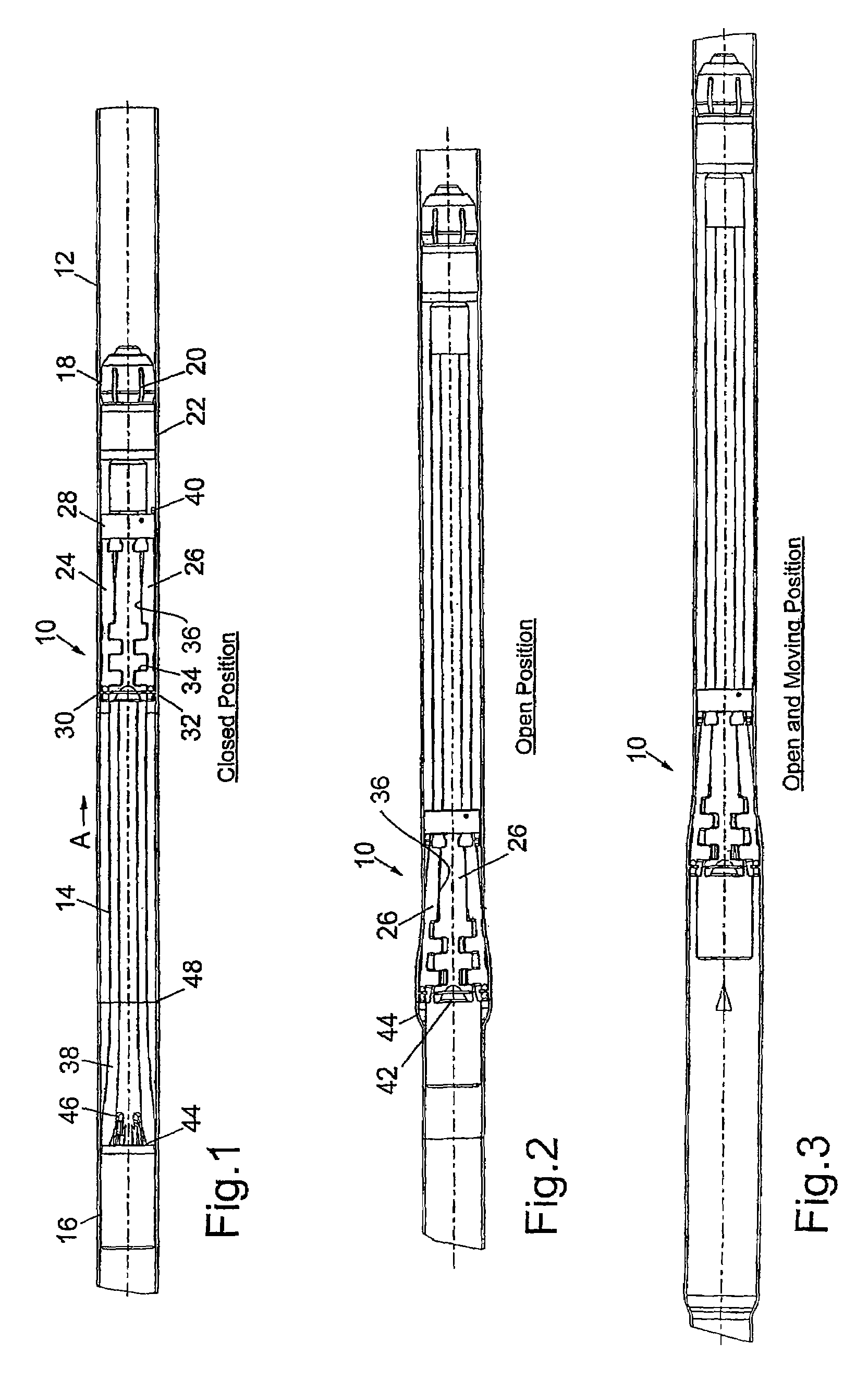

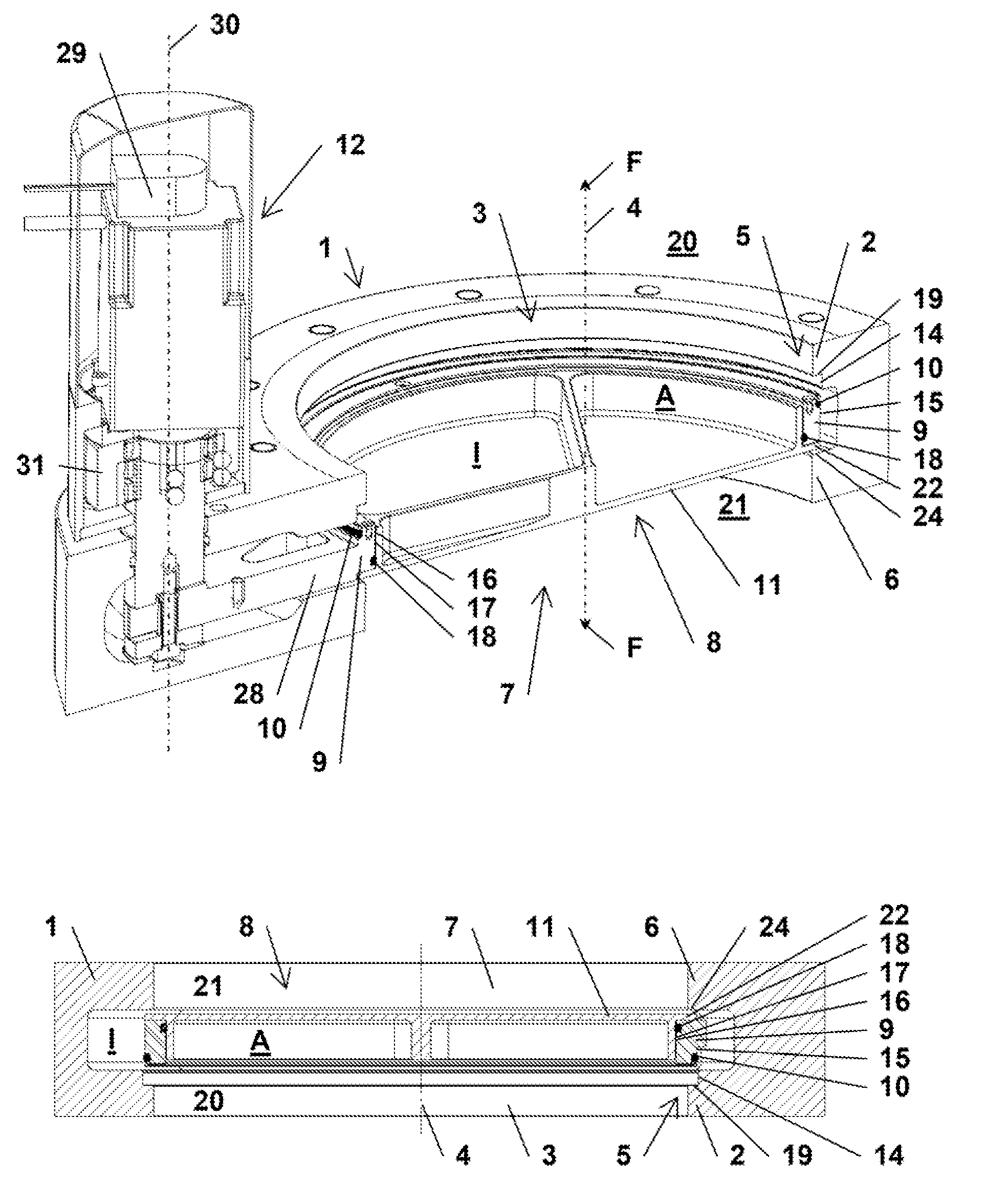

Static internal pushing hinged-type high-deflecting-rate rotary guiding tool and control method

ActiveCN107701107AEasy to bendReduce bending stressDirectional drillingAutomatic control for drillingWell drillingPressure difference

The invention mainly belongs to the technical field of rotary guiding systems and particularly relates to a static internal pushing hinged-type high-deflecting-rate rotary guiding tool and a control method thereof. According to the static internal pushing hinged-type high-deflecting-rate rotary guiding tool, static internal pushing hinged-type design is adopted, a non-rotation measurement and control body and a non-rotation executing mechanism body are hinged, and a non-integral-type structure is achieved; and a drilling tool is prone to bending in a well, the bending stress on the upper portion of the guiding tool is small, and consumption of pushing force used for drilling tool bending deformation reaches the minimum. Rotary friction does not exist between a bearing executing mechanism body outer sleeve and the well wall, and only axial sliding exists, so that the service life is long; meanwhile, the mode of the hydraulic pressure instead of the mud pressure difference is adopted toact on a piston to form the pushing force, the pushing force is greatly increased, and the sealing service life of the piston is also prolonged; and thus, the higher deflecting rate is easy to achieveon the guiding tool, and the advantage that the well drilling service life is long is achieved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

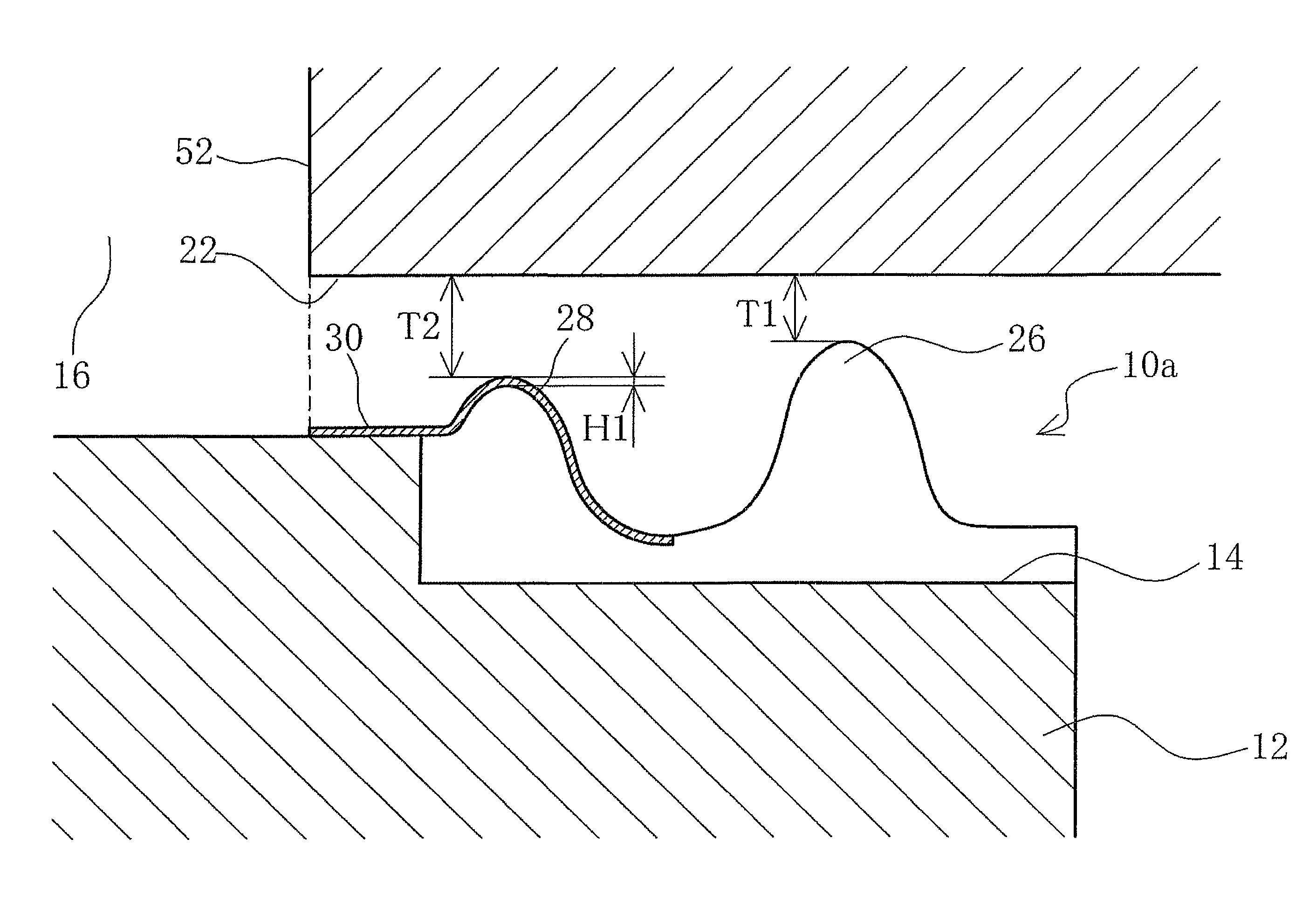

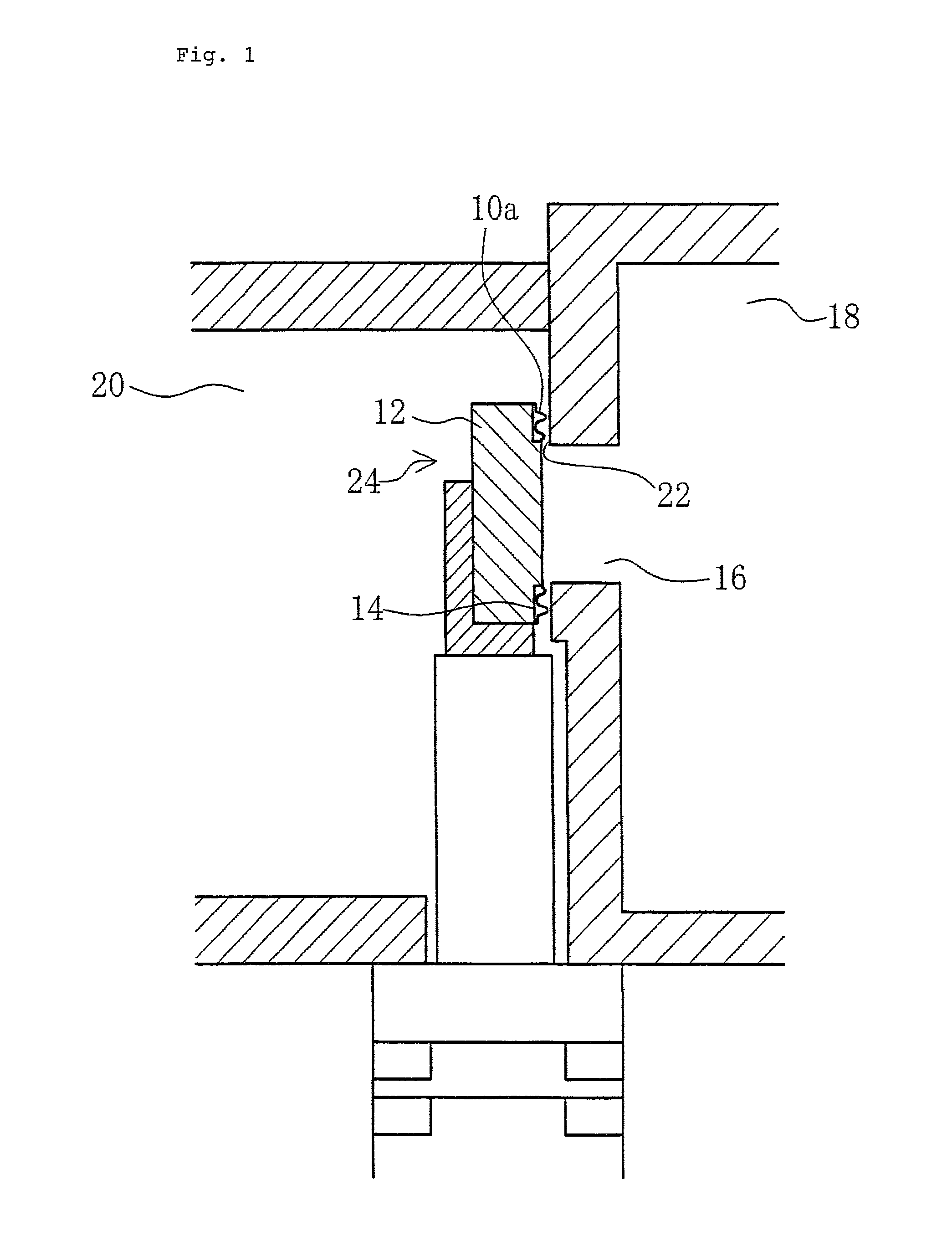

Bonded slit valve door seal with thin non-metallic film gap control bumper

The present invention provides a thin film spacer for maintaining a gap between a slit valve door and a sealing surface of a slit valve, such as a metallic insert. The film spacer can extend the life of a seal by limiting the line of sight exposure of the seal to corrosive gases within a wafer processing chamber, for example, and by controlling the compression percentage of the seal. The spacer may be located on an outer ambient side of the slit valve away from any corrosive gasses that may exist in the chamber.

Owner:PARKER INTANGIBLES LLC

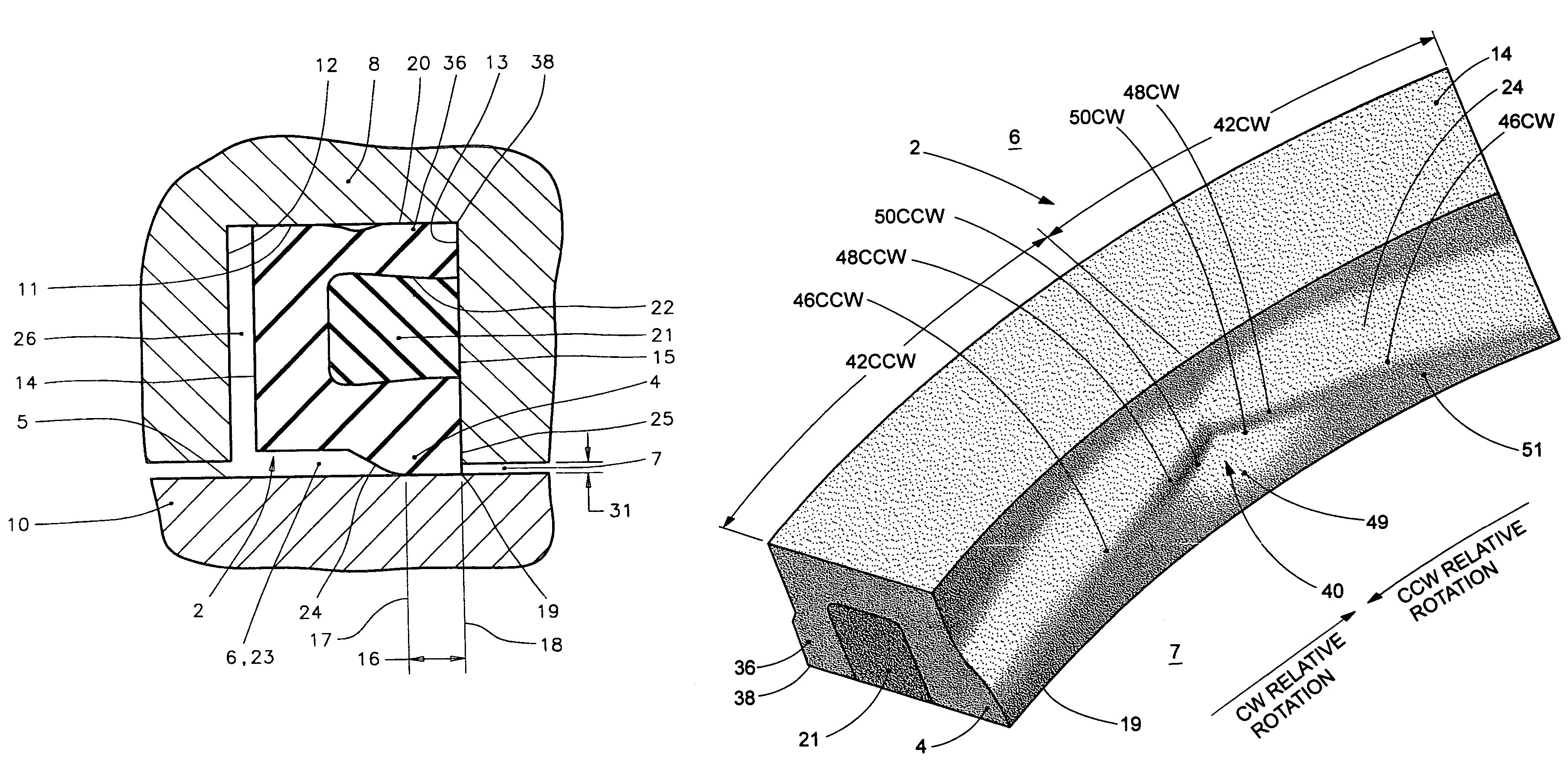

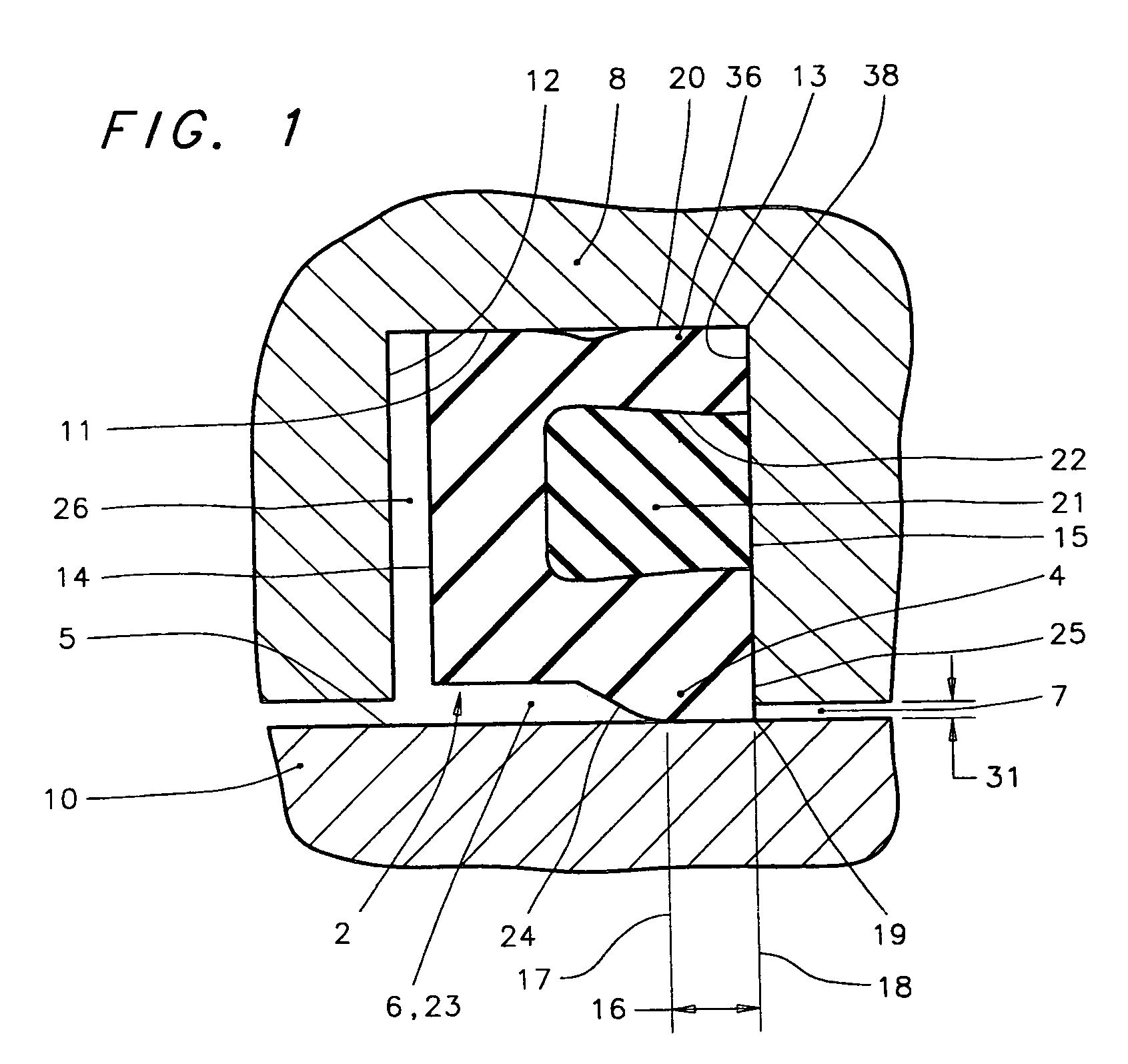

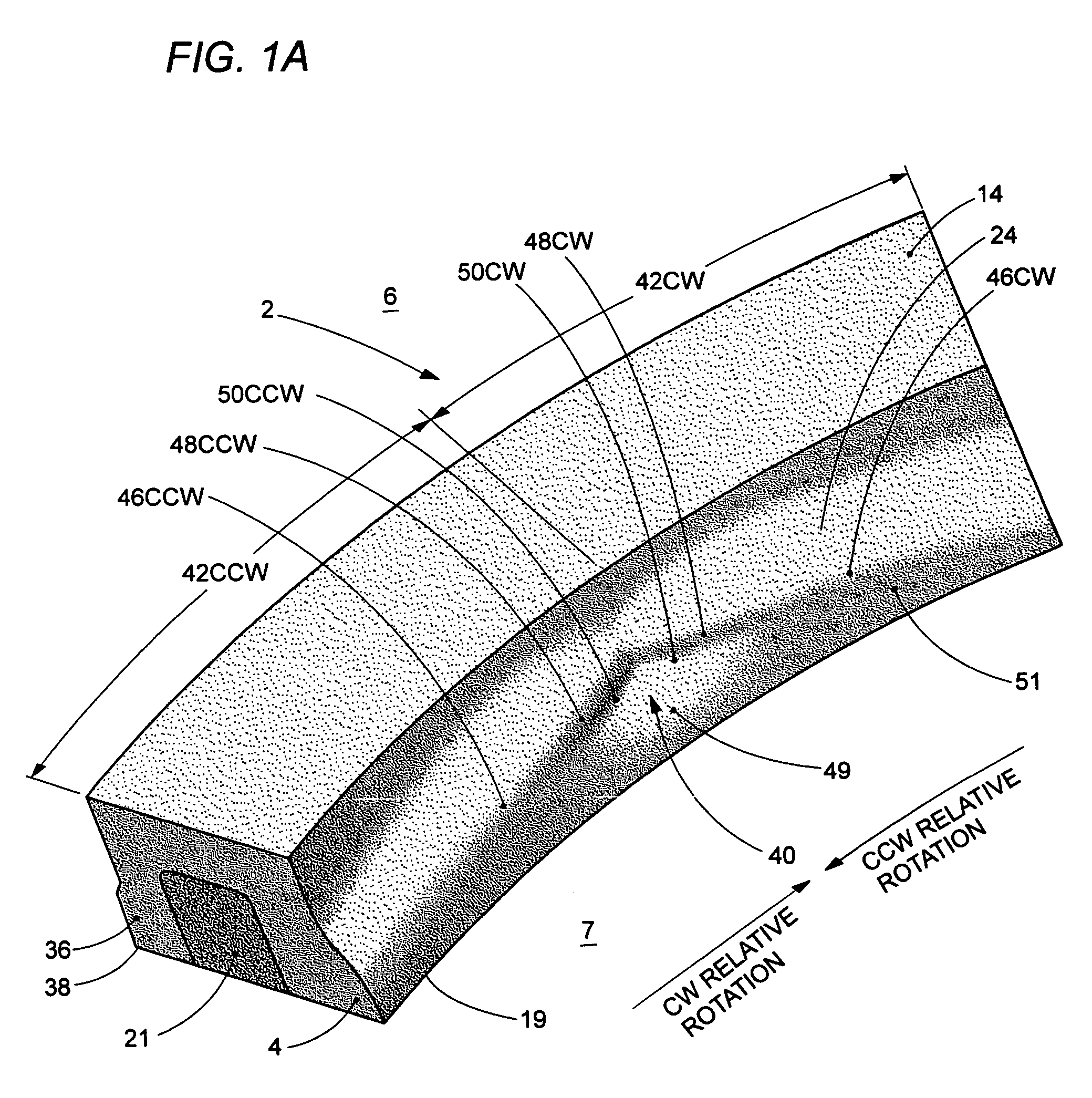

Low torque hydrodynamic lip geometry for bi-directional rotation seals

A hydrodynamically lubricating geometry for the generally circular dynamic sealing lip of rotary seals that are employed to partition a lubricant from an environment. The dynamic sealing lip is provided for establishing compressed sealing engagement with a relatively rotatable surface, and for wedging a film of lubricating fluid into the interface between the dynamic sealing lip and the relatively rotatable surface in response to relative rotation that may occur in the clockwise or the counter-clockwise direction. A wave form incorporating an elongated dimple provides the gradual convergence, efficient impingement angle, and gradual interfacial contact pressure rise that are conducive to efficient hydrodynamic wedging. Skewed elevated contact pressure zones produced by compression edge effects provide for controlled lubricant movement within the dynamic sealing interface between the seal and the relatively rotatable surface, producing enhanced lubrication and low running torque.

Owner:KALSI ENG

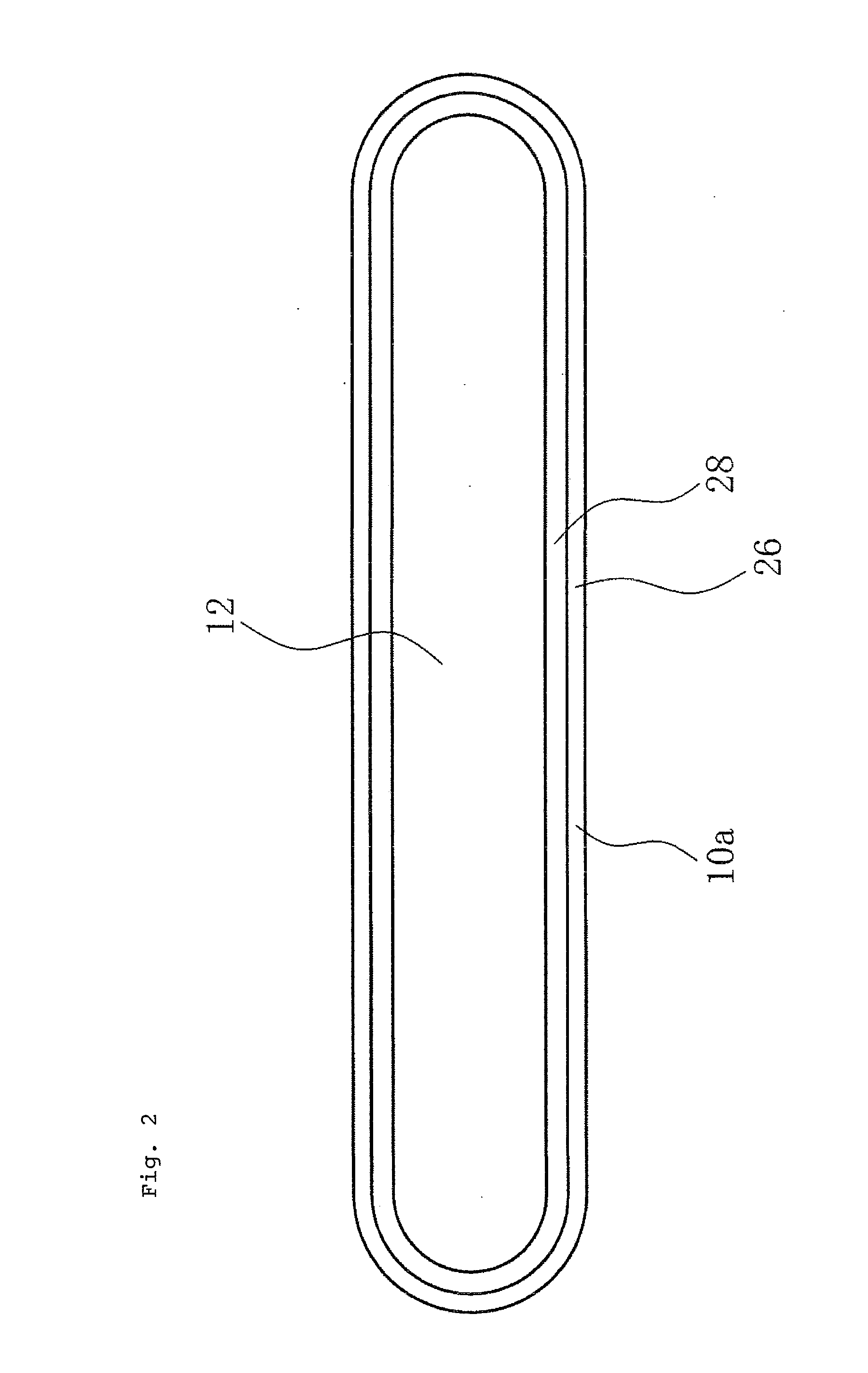

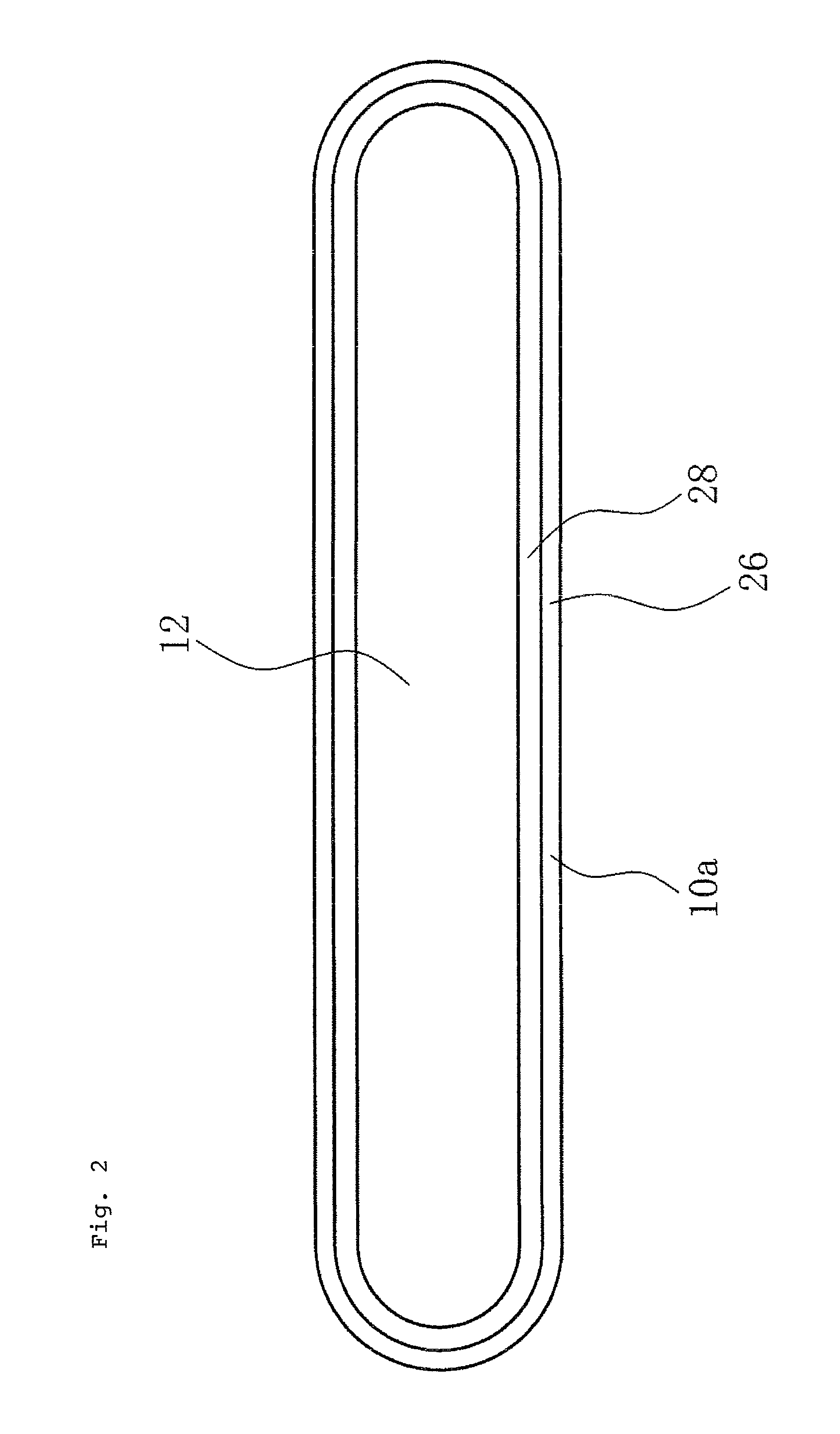

Seal Plate, Seal Member that is Used in Seal Plate, and Method for Manufacturing the Same

In a vacuum gate valve, a seal member for sealing a gate opening part is bonded to an outer edge part of a planar seal plate that is disposed in such a manner that the planar seal plate is opposed to a valve seat surface of the gate opening part and comes into contact with the valve seat surface. The seal member includes a vacuum seal part that is located on a side farther from the gate opening part and maintains the sealability of the gate opening part when the gate opening part is closed, and also includes a radical seal part that is located on a side closer to the gate opening part and that prevents the seal member from being affected by a treatment gas in the gate opening part when the gate opening part is closed. The vacuum seal part is made of a rubber elastic body, and the radical seal part is configured by providing a radical resistant body that is provided with an excellent radical resistance on the rubber elastic body.

Owner:VALQUA LTD

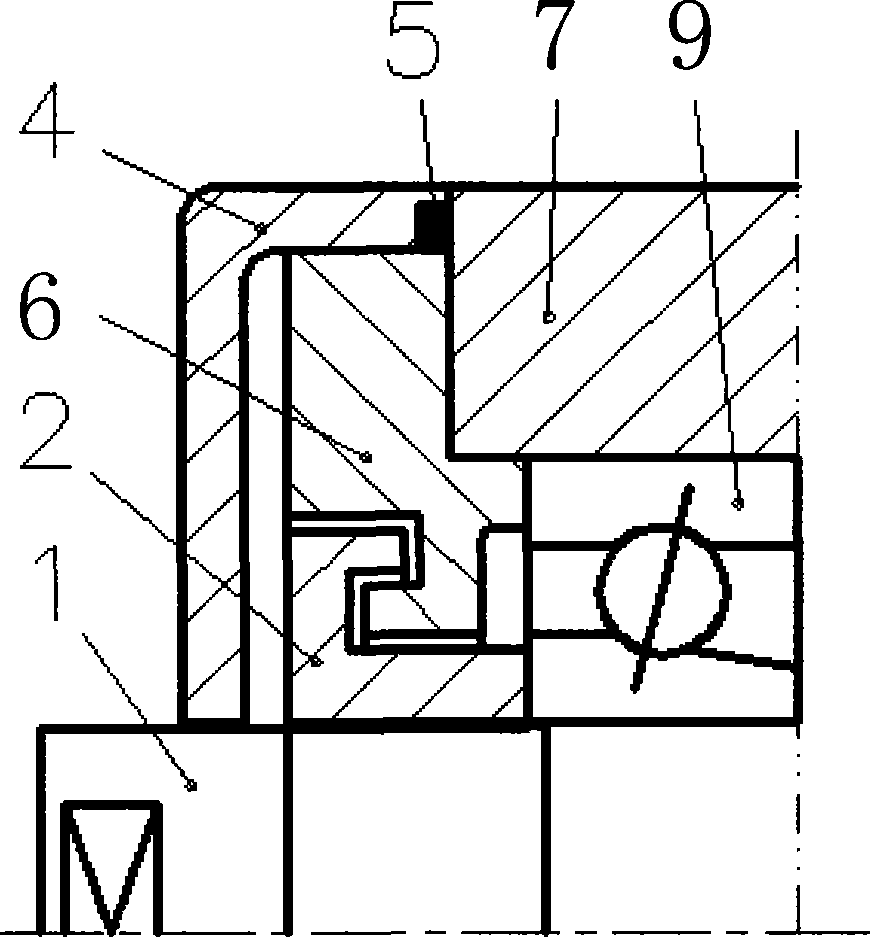

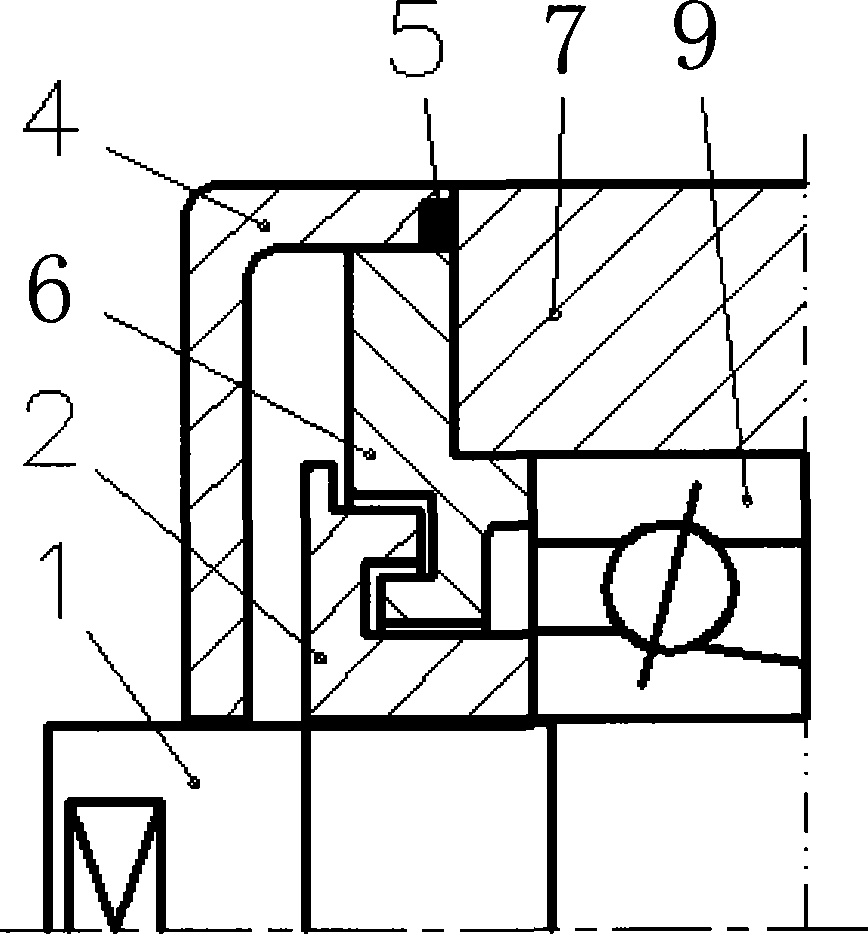

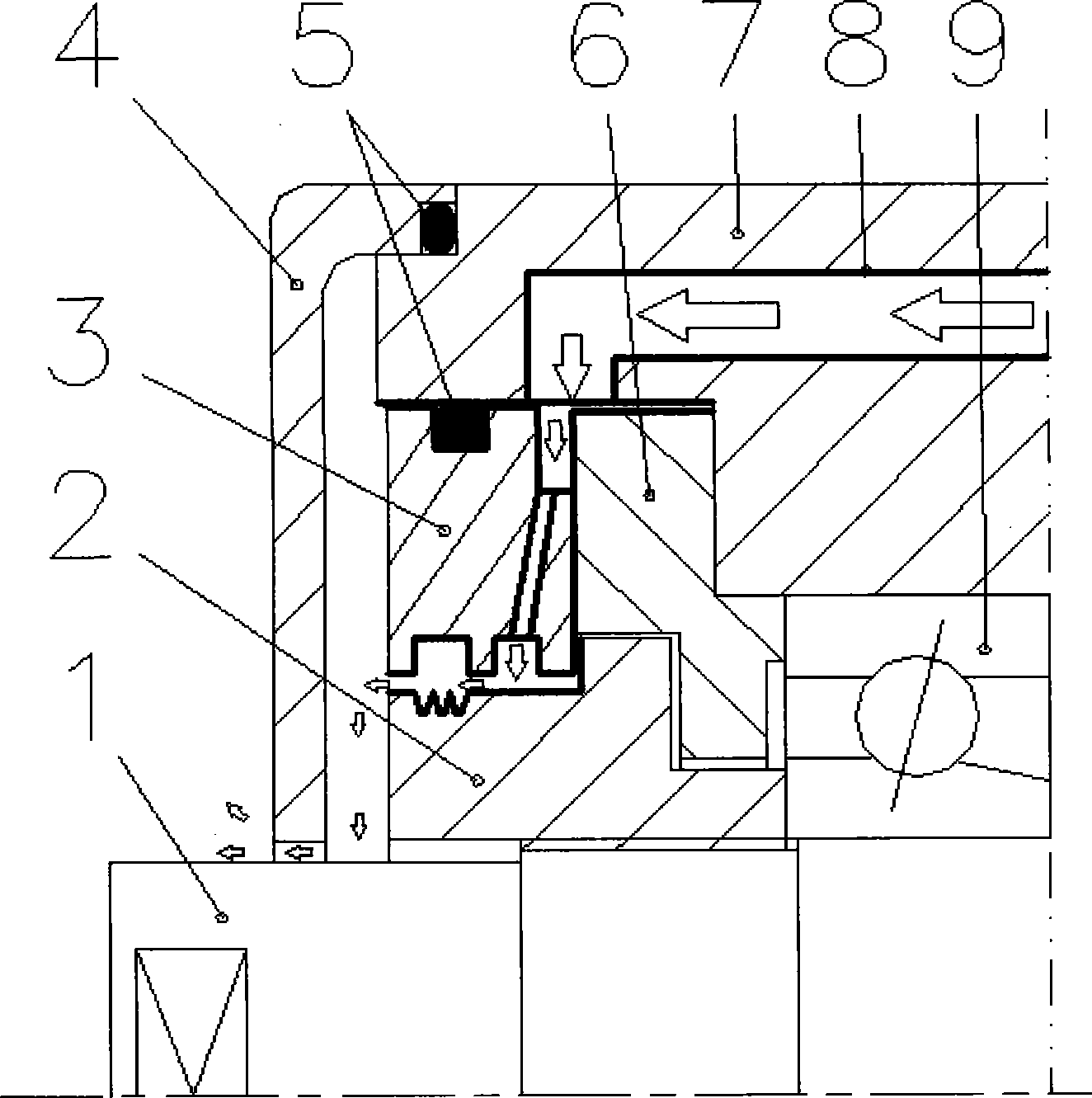

Air sealing construct design for electric main shaft of oil grease mill

ActiveCN101478190AExtended seal lifeGuaranteed uptimeEngine sealsSupports/enclosures/casingsEngineeringAir tightness

The invention relates to a design of an air seal structure of an electric spindle used for a grease film. The air with a certain pressure enters in an annular cavity between a baffle plate 3 and a front small cover 6 through an air passage 8 arranged on a front bearing seat 7 and then reaches an annular groove through a radial slant hole, a clearance is formed between the inner circle of the baffle plate and the outer circle of a front screw cap 2, a sawtooth-shaped groove is designed on the front screw cap and corresponds to the other annular groove of the baffle plate, the pressure air forms pressure air sealing rings in the clearance and the two grooves along with the rotation of the rotating axle at high speed, and the pressure air sealing rings are used for preventing the cooling fluid and the foreign impurities from entering in the rotating axle; an O-shaped sealing ring is sealed at the sealing point among the baffle plate, a dust cap and the front bearing seat for ensuring the air tightness of running of the pressure air in the air passage; and the sawtooth shape of the front screw cap can prevent a small amount of cutting solution from infiltrating, the small amount of the cutting solution can be thrown into the other annular groove of the baffle plate along with the rotation of the front screw cap, and then is discharged outside the electric spindle through the baffle plate and a guide groove or guide hole for the dust cap, so that the reliable air tightness is provided for the high-precision running of a bearing 9.

Owner:LUOYANG BEARING RES INST CO LTD

Dynamic and static pressure mixing lubricating end face sealing structure

ActiveCN108757945AMeet the requirements of positive and negative rotationIncrease stiffnessEngine sealsImpellerMultiple forms

The invention discloses a dynamic and static pressure mixing lubricating end face sealing structure which comprises a dual-end-face sealing structure, a single end face sealing structure and a seriesconnection sealing structure. The dual-end-face sealing structure feeds buffering gas to carry out zero leakage sealing on toxic and dangerous technological gas and comprises a static ring and a movable ring; the static ring has the axial degree of freedom and is provided with a lubricating gas passage, a lubricating gas pressure stabilization cavity, a porous medium friction pair and a high-precision displacement sensor and other structure; and the movable ring rotates along with a rotary shaft. Lubricating gas with adjustable pressure is fed to generate controllable gas static pressure; oneor more annular cavities penetrating through the circumferential direction are formed in the radial direction of the lubricating gas pressure stabilization cavity; the end face of the movable ring canbe a smooth end face, or a dynamic pressure groove structure is processed on the end face of the movable ring; and the groove type of the dynamic pressure groove has multiple manners including a traditional spiral groove, T-shaped groove or a novel rhombus groove structure. Under the extreme conditions including high temperature, high pressure, high rotating speed, ultralow temperature and the like, frequent start and halt and sealing of the mechanical shaft end of an impeller operating under variable working conditions can be realized.

Owner:XI AN JIAOTONG UNIV

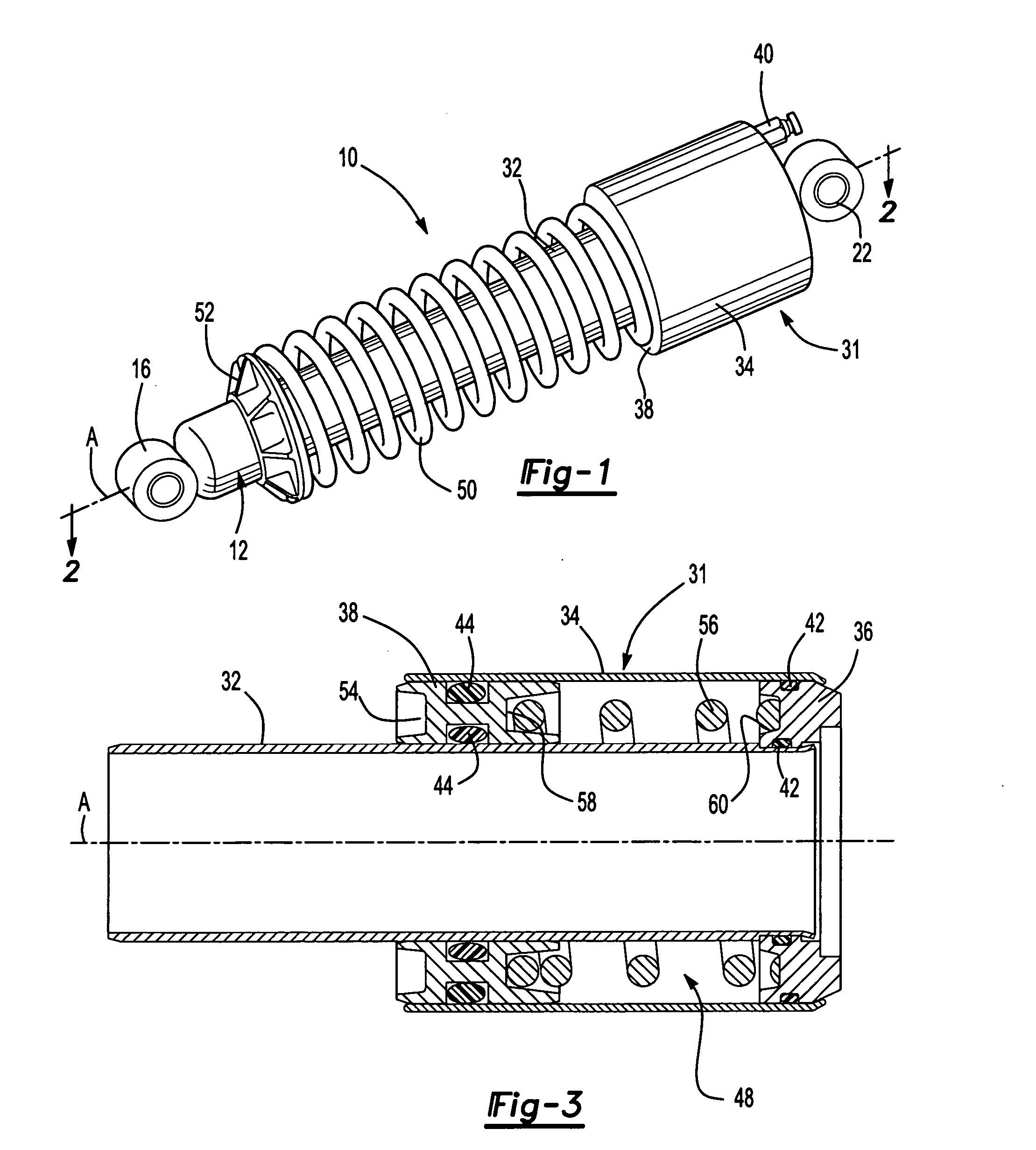

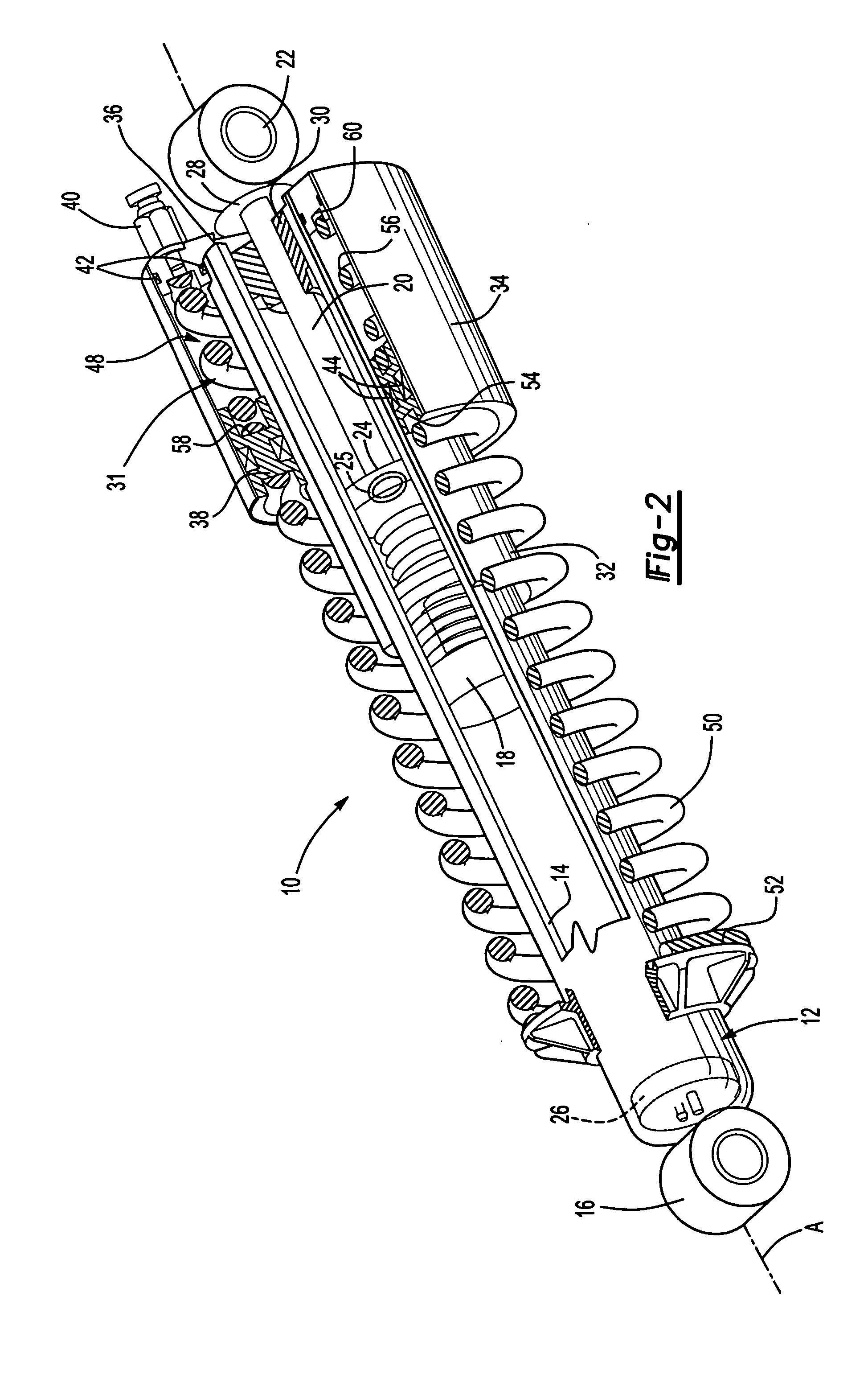

Dual spring rate preload module with air adjustment

InactiveUS20050189685A1Avoid lostShorten the lengthMultiple spring combinationsResilient suspensionsHydraulic cylinderCylinder head

A preload shock absorber assembly includes a shock absorber having a hydraulic cylinder. The cylinder includes a rod slideably supported by a cylinder head having a seal at one end of the hydraulic cylinder. A preload air chamber is arranged radially outwardly of the rod seal to provide a first spring having a first spring rate. The pressurized preload air chamber is separated from the rod seal to prevent loss of pressurized from the preload air chamber to the hydraulic cylinder. The pressurized air chamber uses a movable separator that seals the air chamber and isolates the air chamber from the outside environment. A second spring is supported by a seat secured to the hydraulic cylinder outer wall and is arranged between the seat and the separator. A third spring is arranged within the air chamber to supplement the spring rate provided by the pressurized air chamber.

Owner:ARVINMERITOR TECH

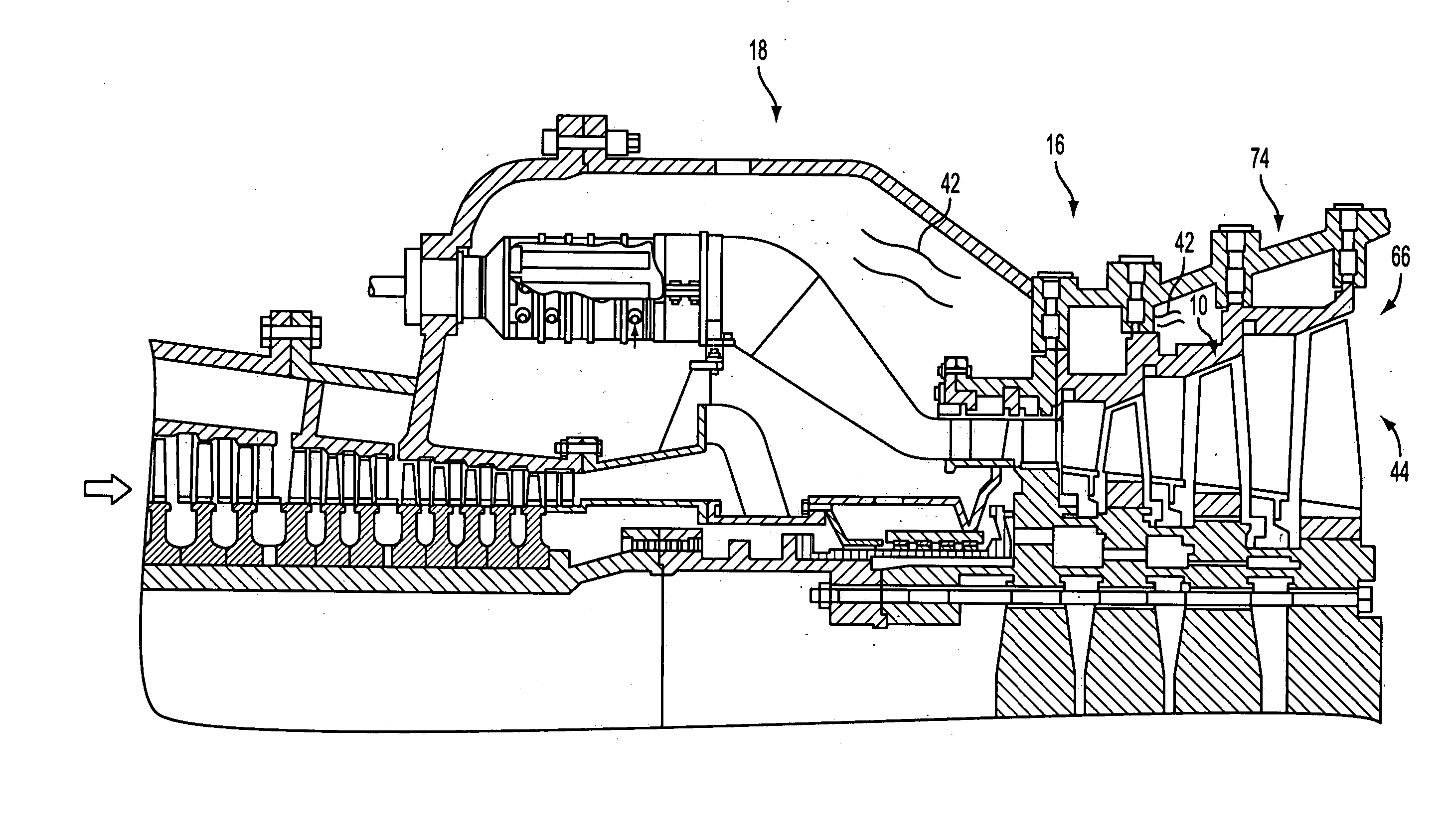

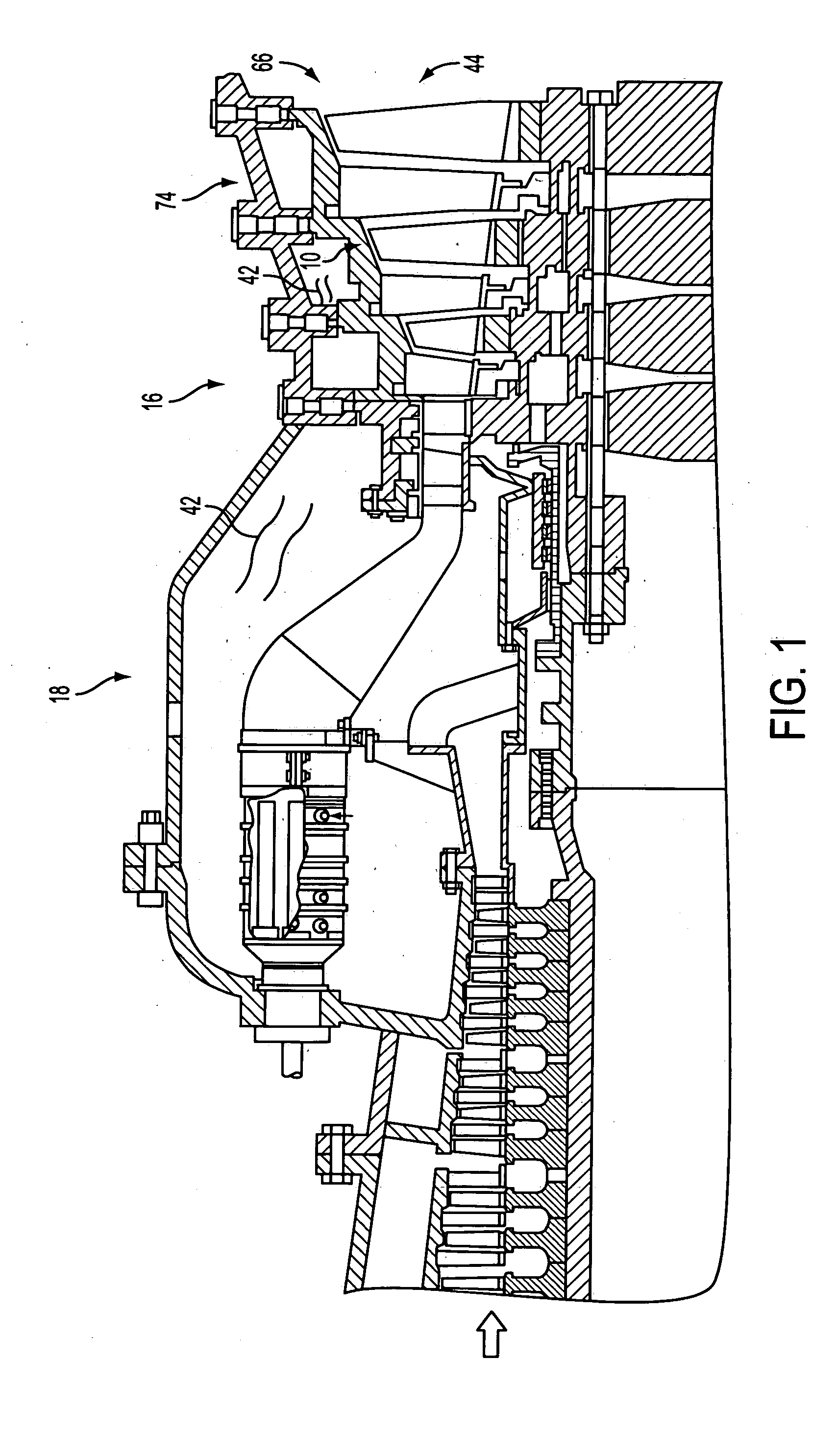

Outer air seal assembly

InactiveUS20050067788A1Reduced Radial LeakageExtended service lifeEngine sealsLeakage preventionTurbineCooling fluid

An outer air seal assembly for use around rotating fluid guide components, such as rotating blades within a turbine engine, is disclosed. The seal includes features that reduce radially-directed leakage while increasing operational life of the seal and providing additional turbine section cooling without reducing engine performance. The seal employs boundary members that cooperatively prevent leakage within the turbine section of an associated gas turbine engine. The boundary members are spaced apart by interface gaps having radially-skewed portions that protect blocking panels disposed within the gap and extends the life of seal. The interface gap may also include a radially-aligned portion, and partition members may extend into the gap to form a flow-slowing serpentine-shaped pathway within the gap. Conduits disposed within the boundary members allow cooling fluid to enter the interface gap, providing supplemental cooling benefits without reducing engine operating efficiency. Multiple sets of boundary members may be used in an axially-extending orientation, with interface gaps being disposed between boundary members of each set.

Owner:SIEMENS ENERGY INC

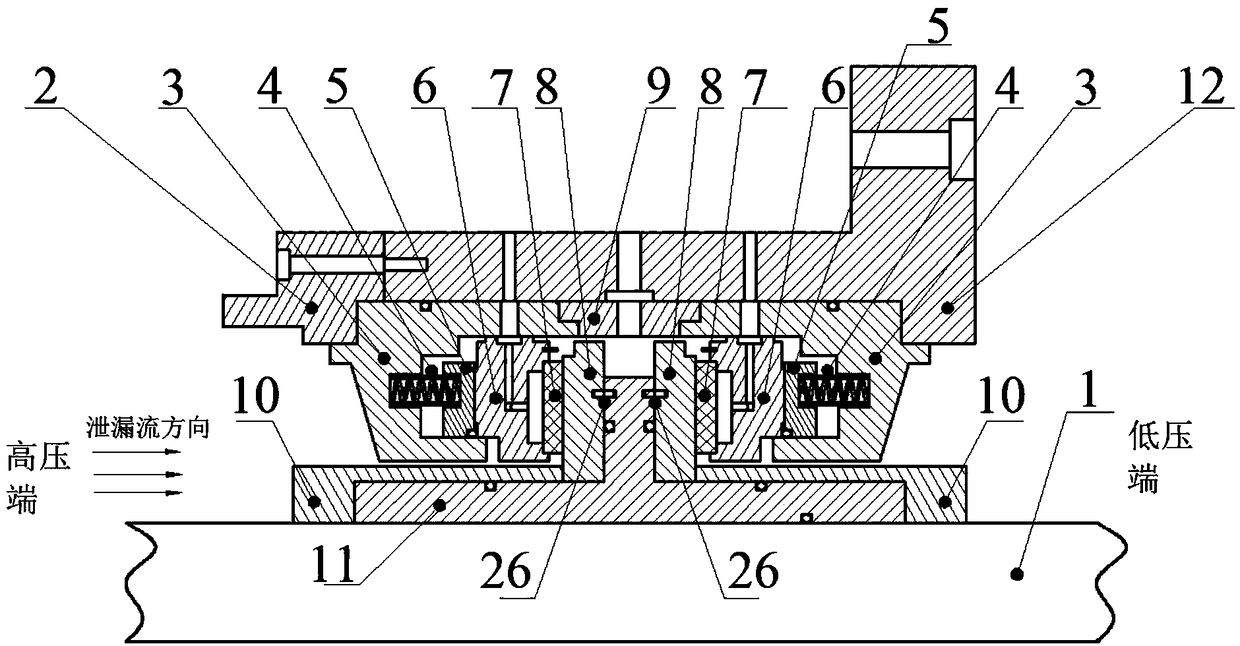

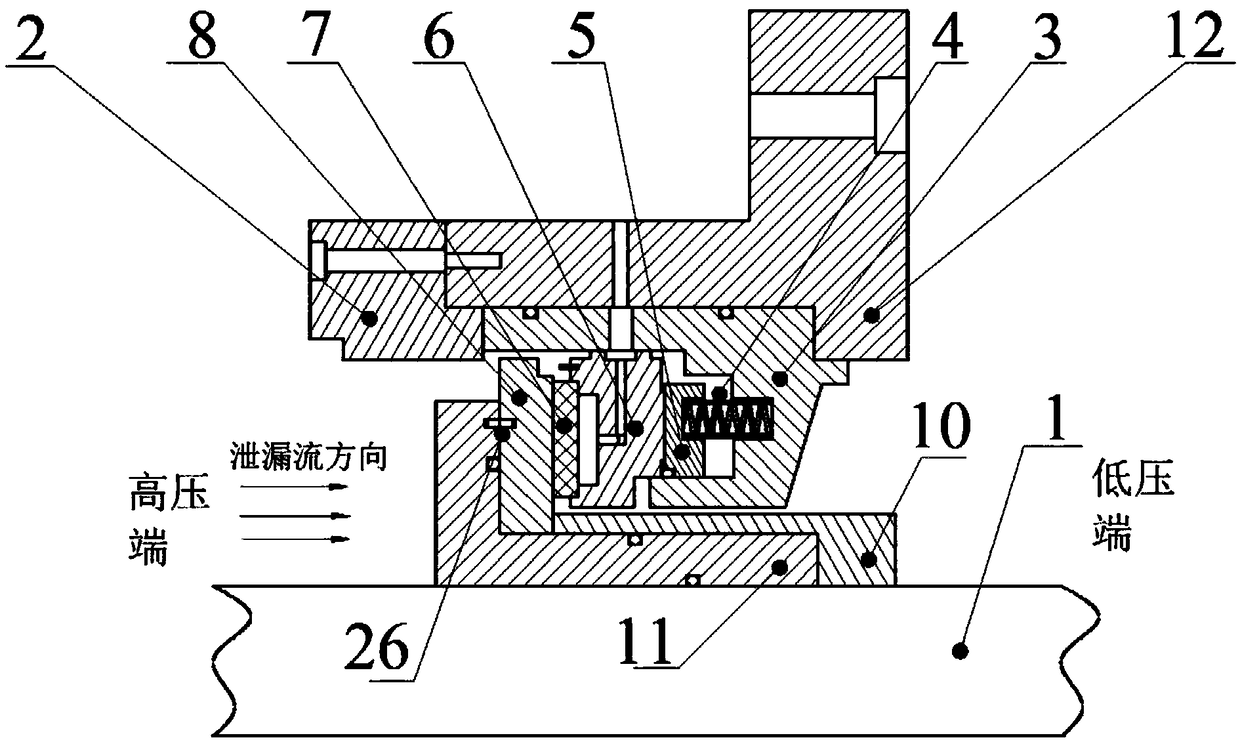

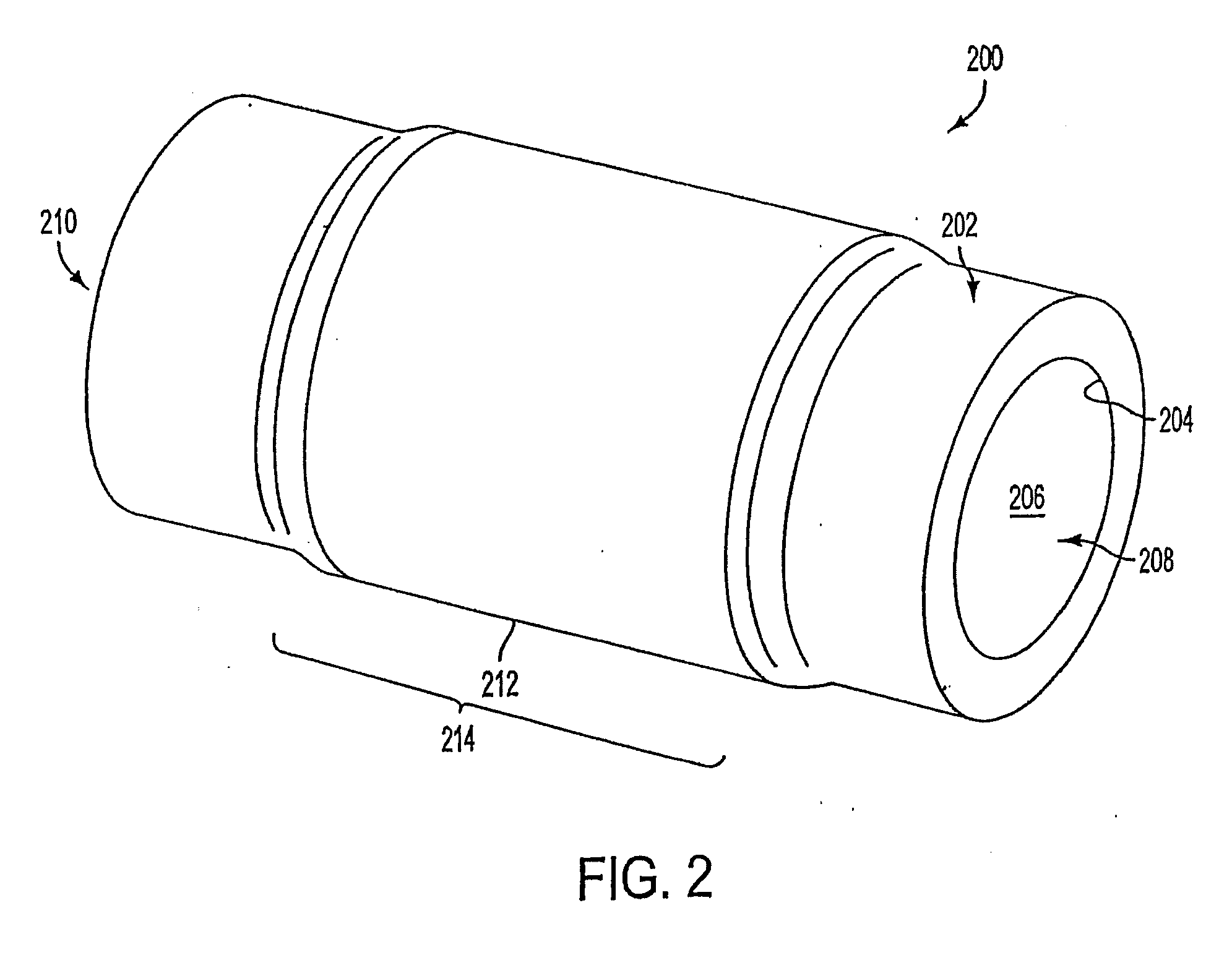

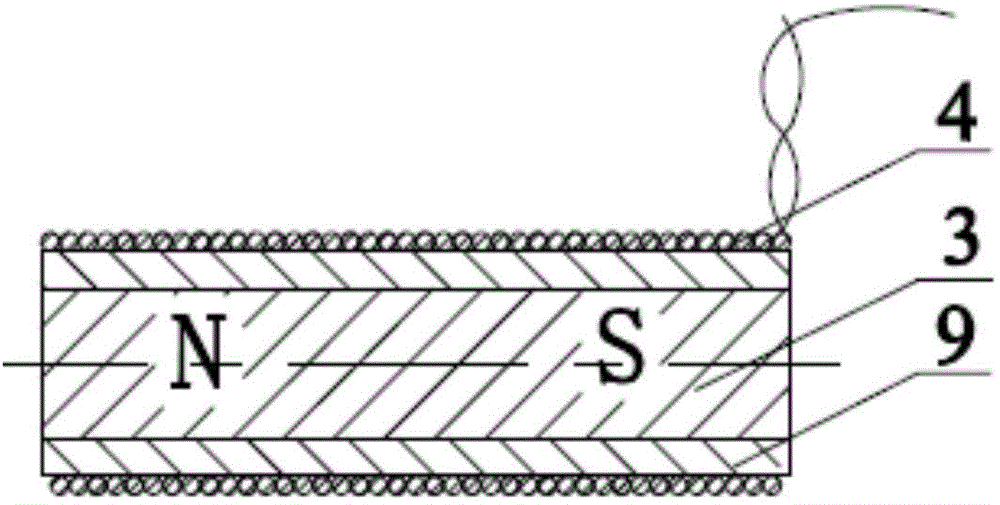

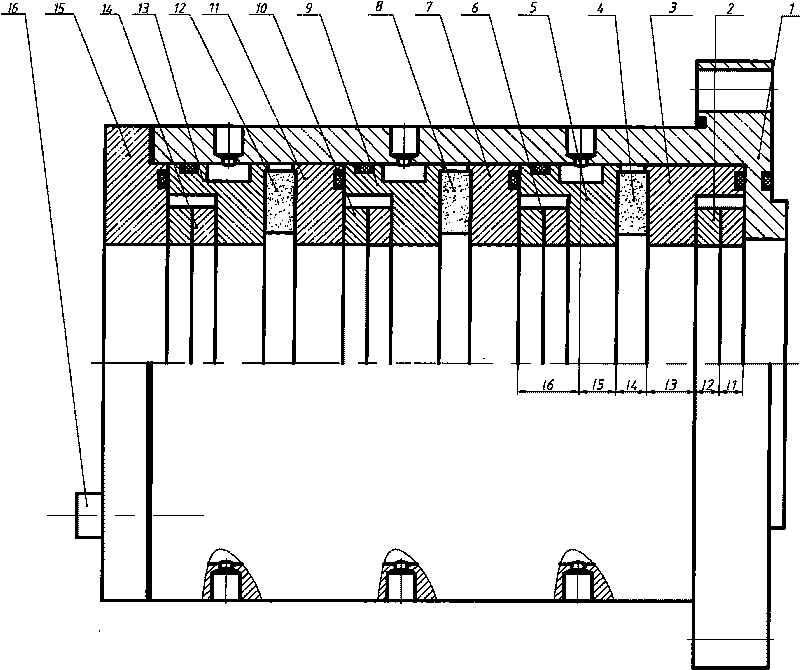

Reciprocating shaft magnetic liquid sealing structure

InactiveCN101776151AAvoid churnReduce leak rateEngine sealsBearing componentsMagnetic liquidsPole piece

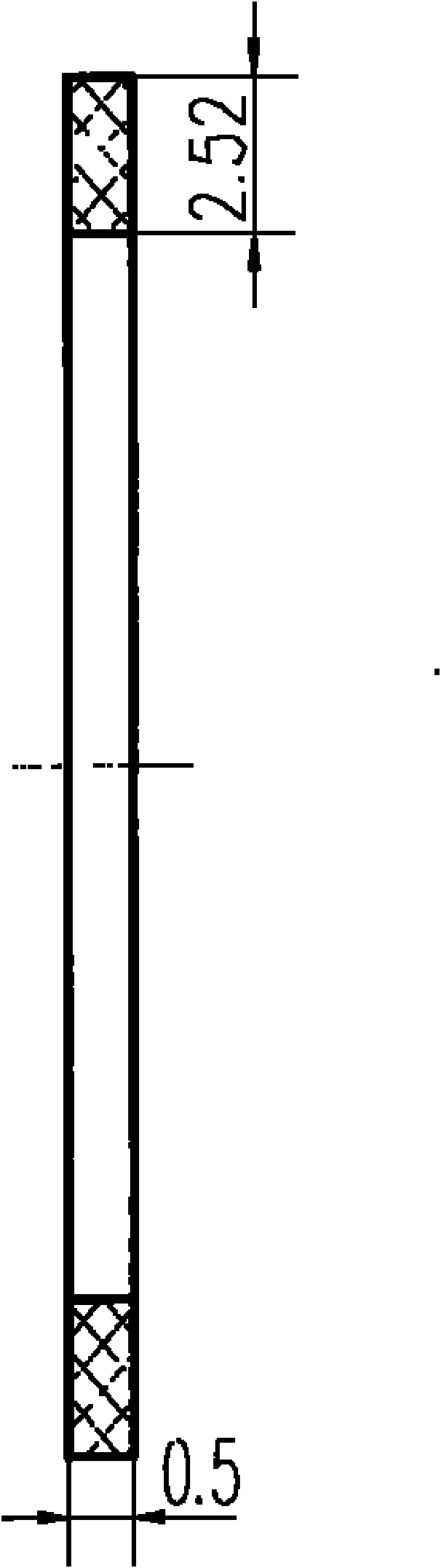

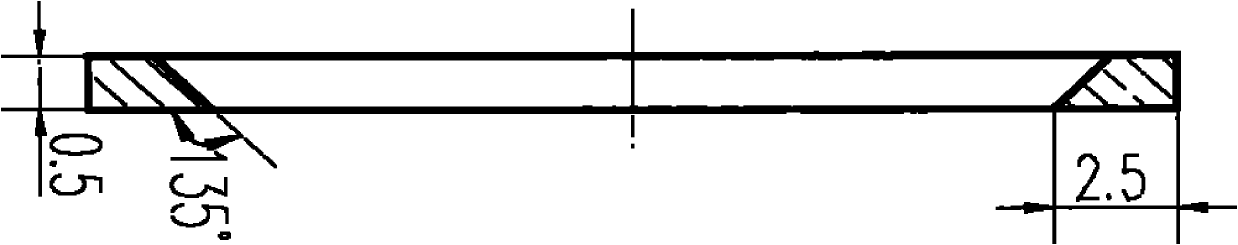

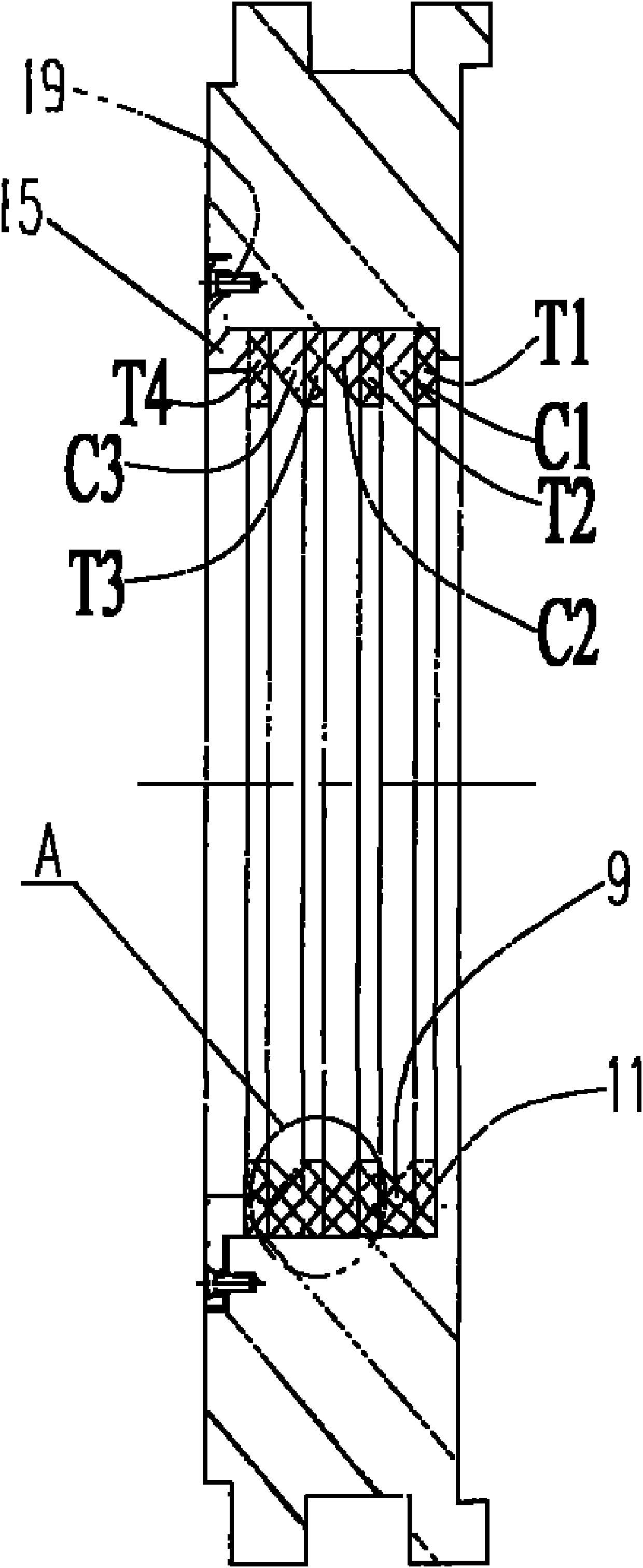

The invention relates to a reciprocating shaft magnetic liquid sealing structure, which comprises a first bearing, a first magnetic-isolated ring, a first pole piece, a first O-shaped rubber gasket ring, a permanent magnet, a second O-shaped rubber gasket ring, a second pole piece, a second magnetic-isolated ring and a second bearing, which are sequentially and closely propped against an external nested inner lug boss, wherein an end cover is fixed on an outer jacket through a bolt, and the second bearing is compressed. The inner annular surface of the second pole piece (13) is provided with a left, a middle and a right counter bores, elastic rings (T) with the quantity of N+1 and trapezoid sealing gears (C) are arranged at intervals from each other to be closely arranged inside the middle counter bore, N is a positive integer of 1 to 8, the trapezoid sealing gears and the elastic rings, which are closely lined at intervals, are fixedly connected with the second pole piece in a threading way through bolts and retainer rings (15), and the trapezoid sealing gears with the quantity of N are lined up in the expansion direction of the identical inner holes; and the structure of the first pole piece (7) is completely identical to that of the second pole piece. The problems of the conventional reciprocating shaft magnetic liquid sealing structure that the magnetic liquid runs off, the sealing service life is shortened, and the leakage rate is increased can be solved.

Owner:BEIJING JIAOTONG UNIV

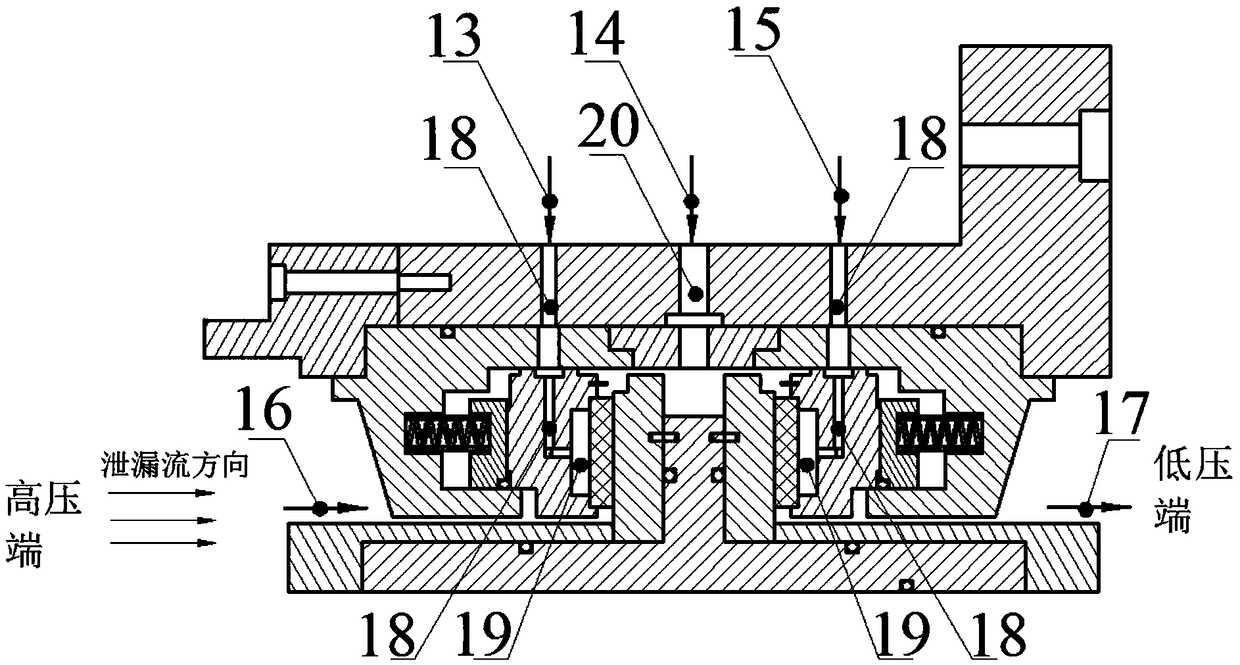

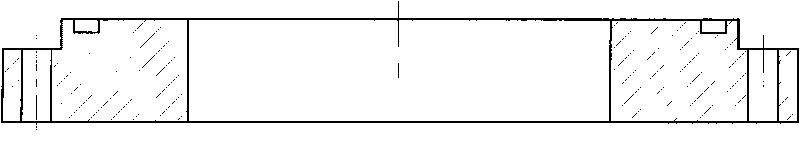

Combined reciprocating sealing device of magnetic liquid, C-shaped slip ring and Y x type seal ring

The invention relates to a combined reciprocating sealing device of magnetic liquid, a C-shaped slip ring and a Y x type seal ring. The connection of the components of the device is as follows: a first O-shaped rubber sealing ring (3), the Y x type seal ring for a first shaft (4) and a first C-shaped slip ring (5) are respectively arranged into a circular groove provided on a first permanent seat(2); a second O-shaped rubber sealing ring (15), the Y x type seal ring for a second shaft (14) and a second C-shaped slip ring (13) are arranged into a circular groove provided on a second permanentseat (16); and the first permanent seat, a first pole piece (7) with the O-shaped rubber sealing ring, a permanent magnet (10), a second pole piece (11) with the O-shaped rubber sealing ring and the second permanent seat are successively arranged at the bottom of the cavity of a sealing socket (1) with the O-shaped rubber sealing ring and are in threaded connection with the sealing socket throughbolts, and an end cover compresses the above components tightly. Before installation, the magnetic liquid is injected. The combined reciprocating sealing device solves the leakage problem of the piston rod of a reciprocating compressor.

Owner:BEIJING JIAOTONG UNIV

Precision plunger metering pump

InactiveCN101709693AHigh surface hardnessImprove cylindricityPumpsPositive-displacement liquid enginesRubber ringEngineering

The invention relates to a precision plunger metering pump, comprising three parts, including a driving mechanism, a sealing mechanism and a pump head, wherein by utilizing a photoelectric encoder, the driving mechanism accurately controls the movement of a stepper motor, thereby effectively preventing the error of pump output caused by the falling out of step or the idling of the motor from being generated; a sealing ring in the sealing mechanism is matched with a plunger piston to realize precision fit, and the sealing ring based on a stainless steel spring enclasping mechanism solves the problems of low enclasping force and easy aging of a traditional rubber ring and prolongs the service life; the pump head has the design of water washable airtight cabin, realizes the washing and sealing functions of the plunger piston and the sealing ring and prolongs the sealing life; the technic level of processing the plunger piston and slab rubber achieves the purpose that a miniature precision plunger metering pump can provide 20MPa pressure intensity; and the slab rubber has good polishing performance, extremely high transparency, compact structure, small volume and delicate appearance. The precision plunger metering pump can be applied to the precise metering of fluid in the fields of medication, sanitation, biology and chemistry.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

Sealing system and method of determining seal integrity

InactiveUS20050236778A1Reduce differential pressureExtended seal lifeVessel mounting detailsEngine sealsIntermediate spaceEngineering

A sealing system for a high pressure fuel cylinder has an inner seal and an outer seal sealing an insert into a boss of the cylinder. Permeation rates as a result of the differential pressures across the seals are balanced across both the inner and outer seals to maintain a constant pressure in an intermediate space between the seals. Permeation is balanced by selecting suitable seal materials or by seal geometry or by providing a pressure relief device to the intermediate space to release excess pressure built up in the intermediate space beyond a desired intermediate pressure. Maintaining the intermediate pressure lower than the cylinder pressure and higher than atmospheric pressure results in lower pressure differentials across the seals, extending the seal life. A pressure switch or gauge is provided to monitor the pressure in the intermediate space. Changes in the pressure are indicative of a leak in one or both of the seals.

Owner:DYNETEK INDS

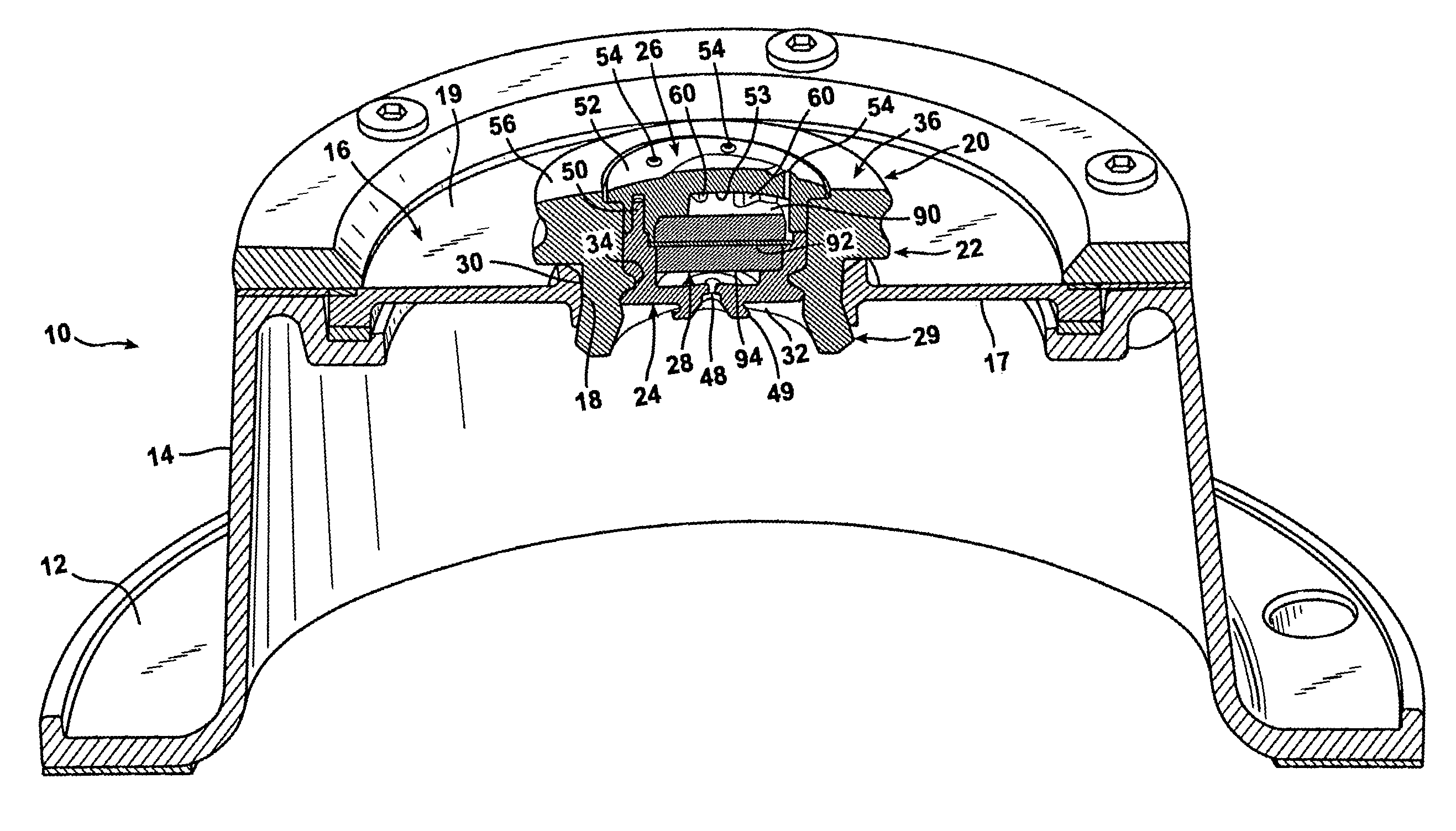

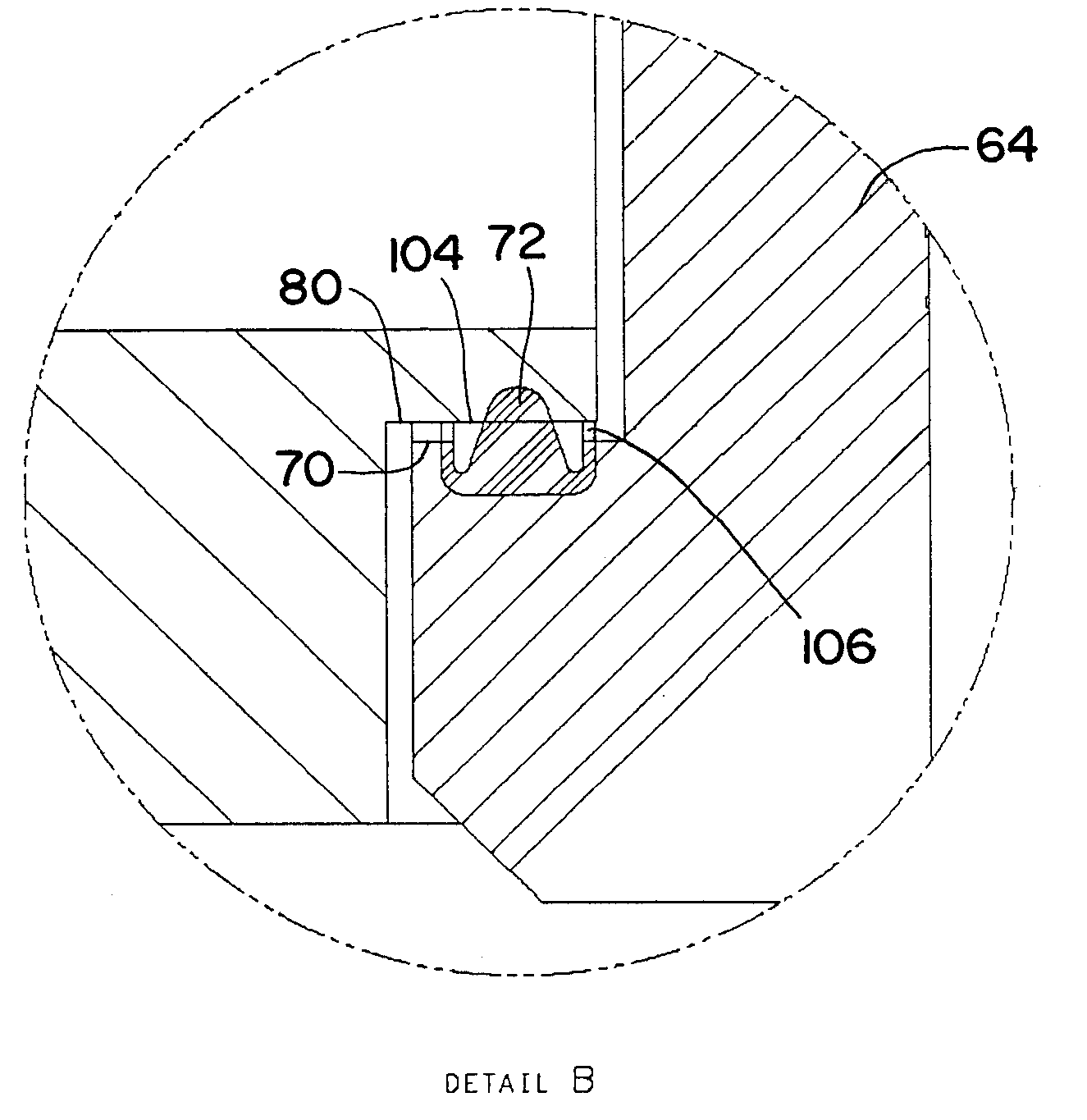

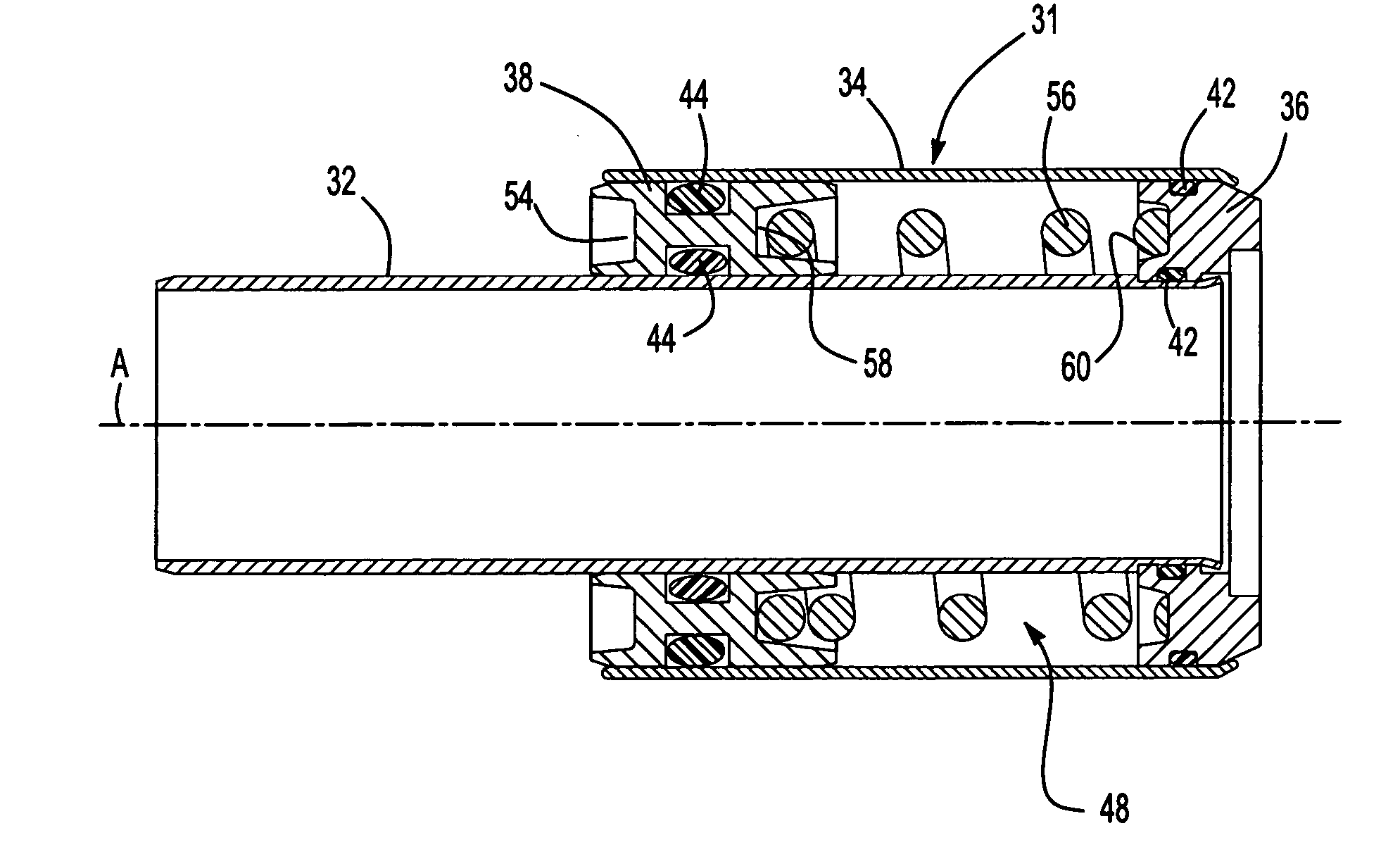

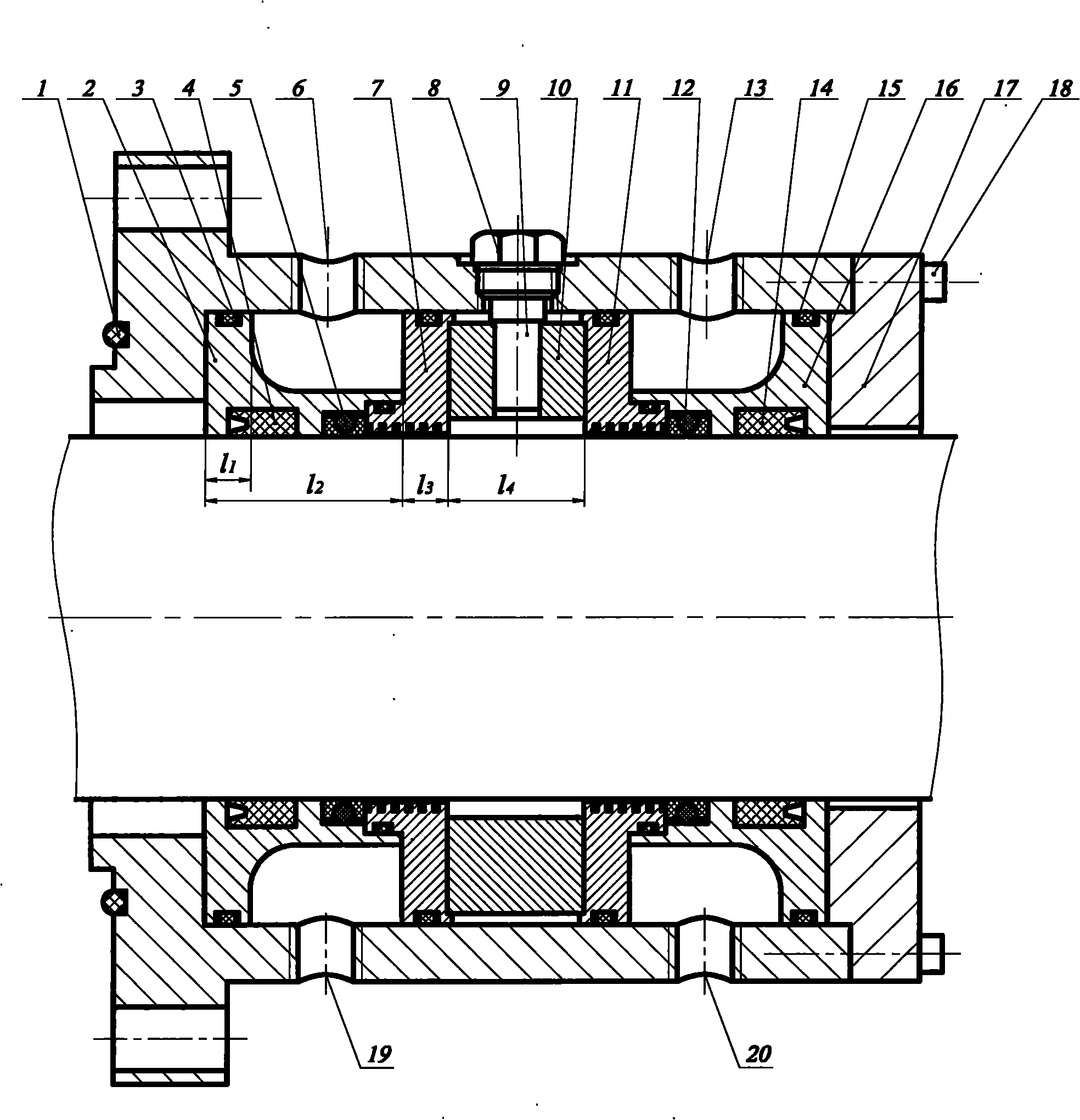

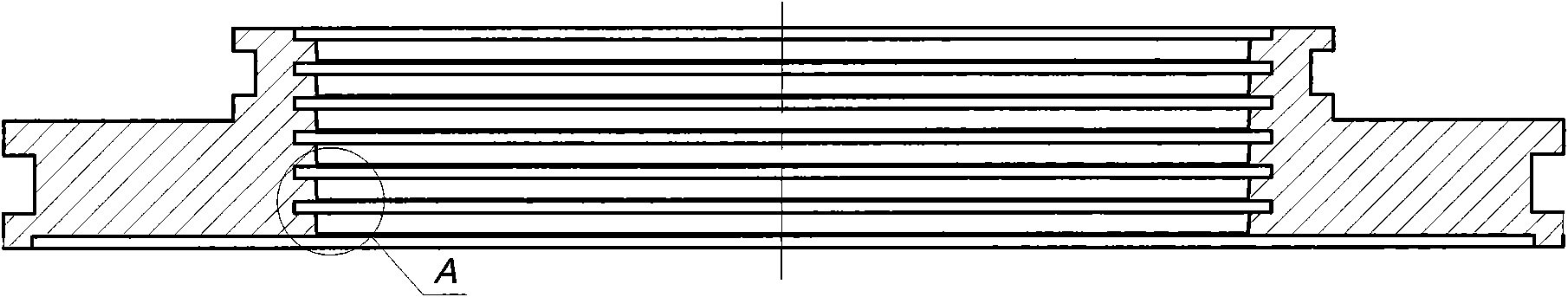

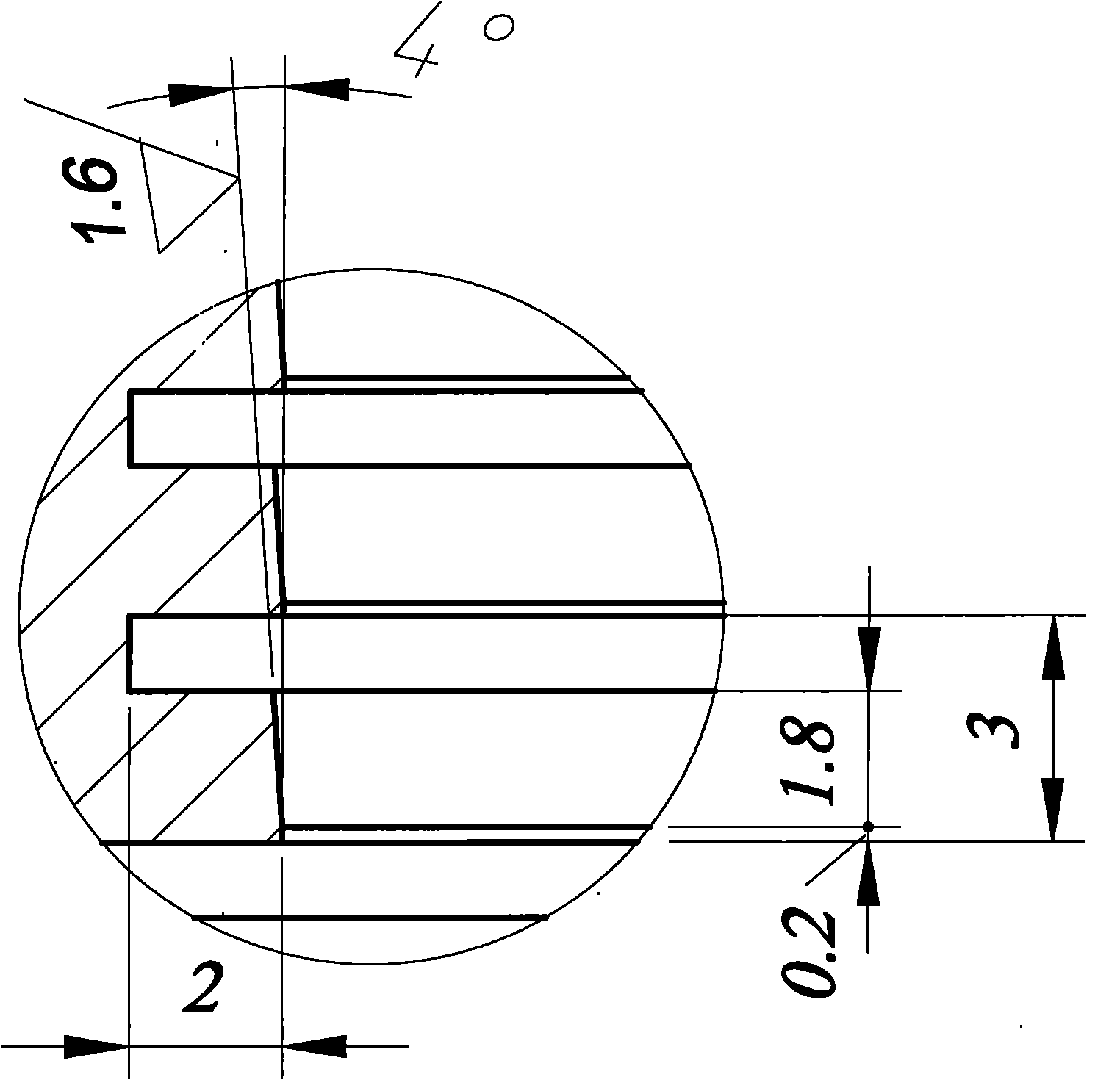

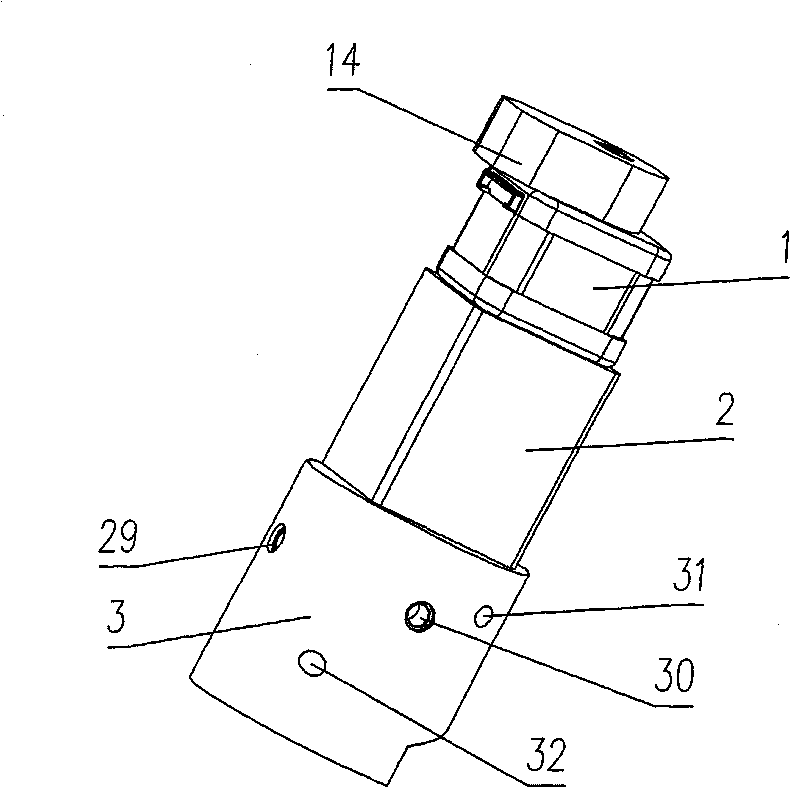

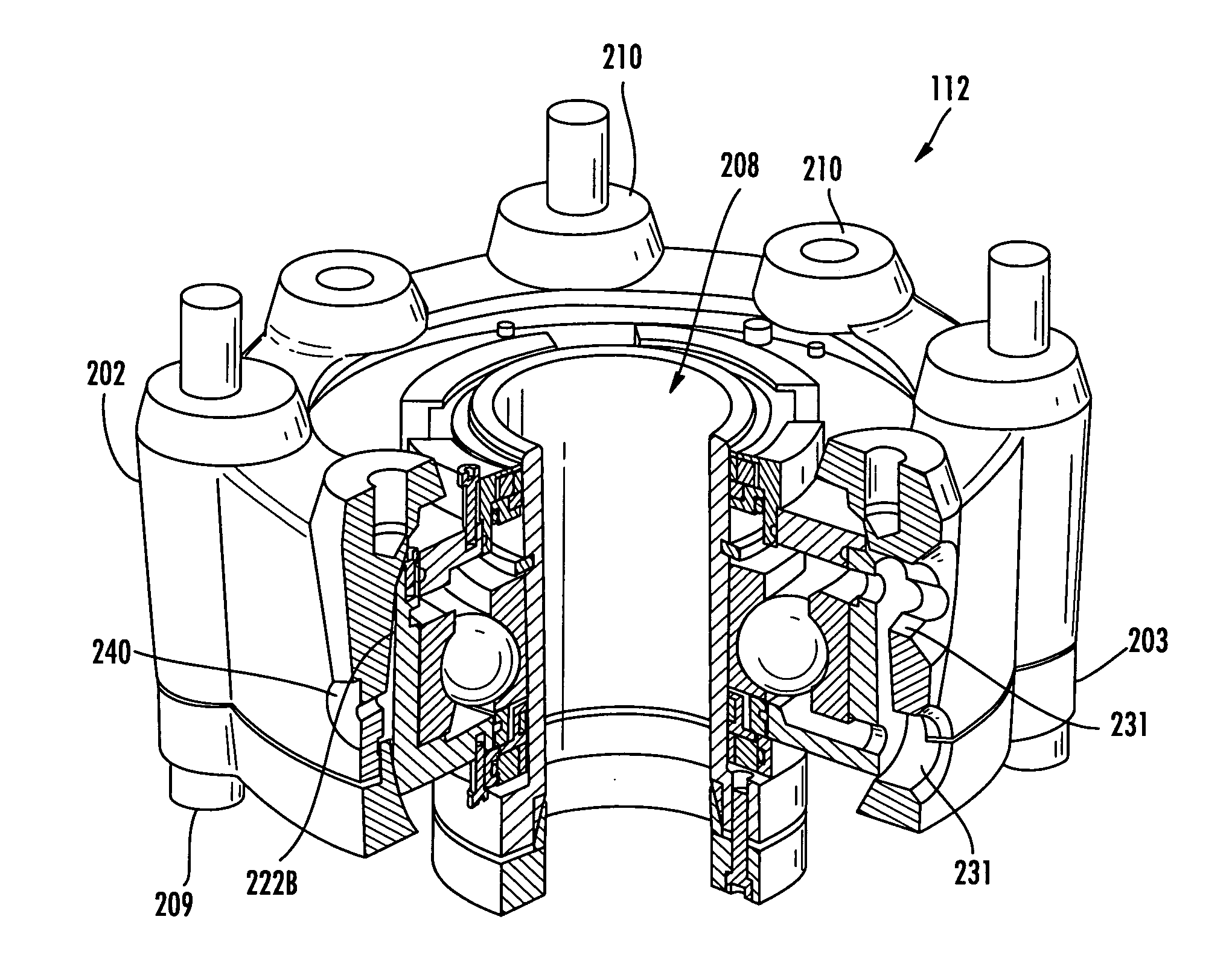

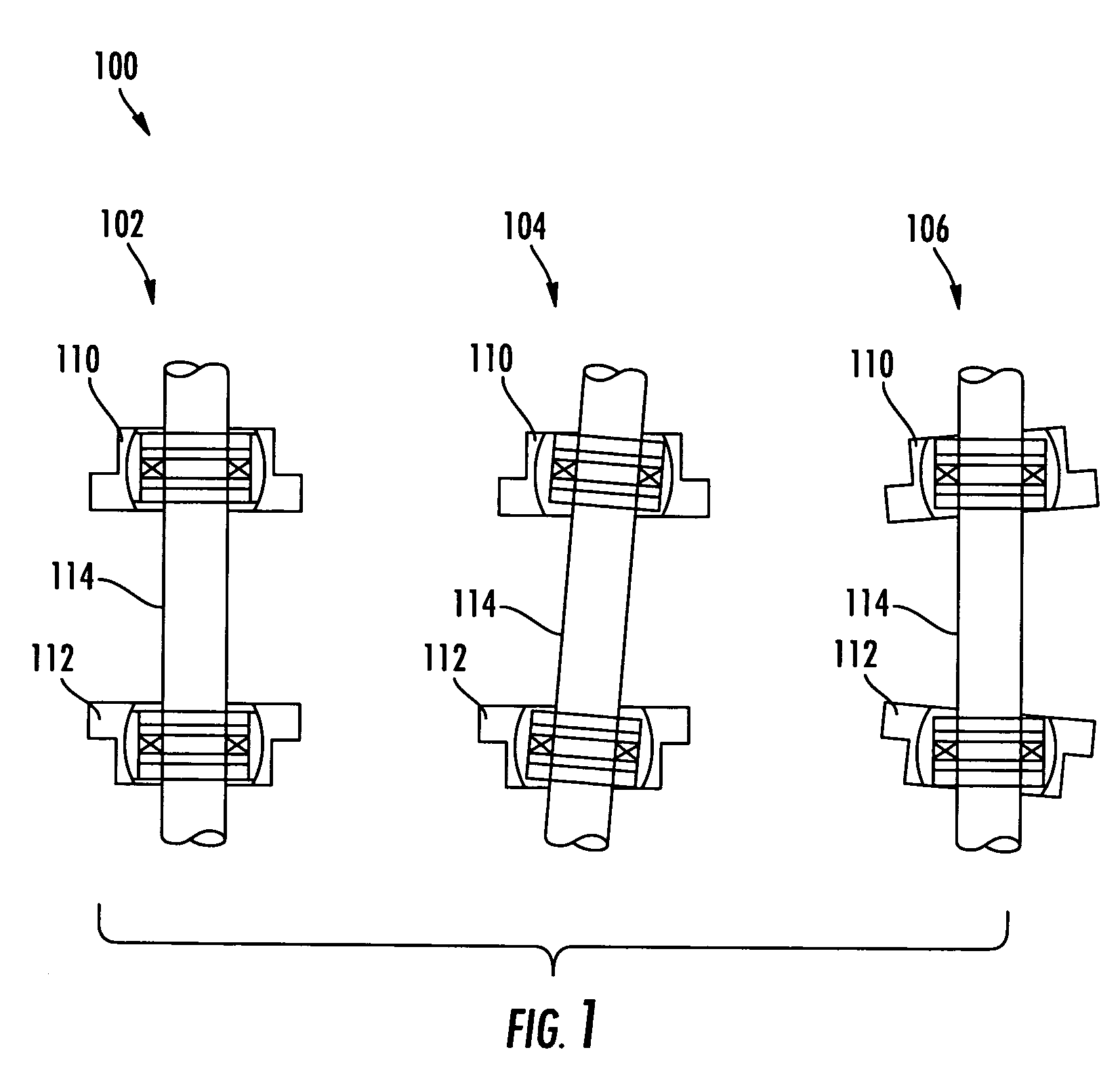

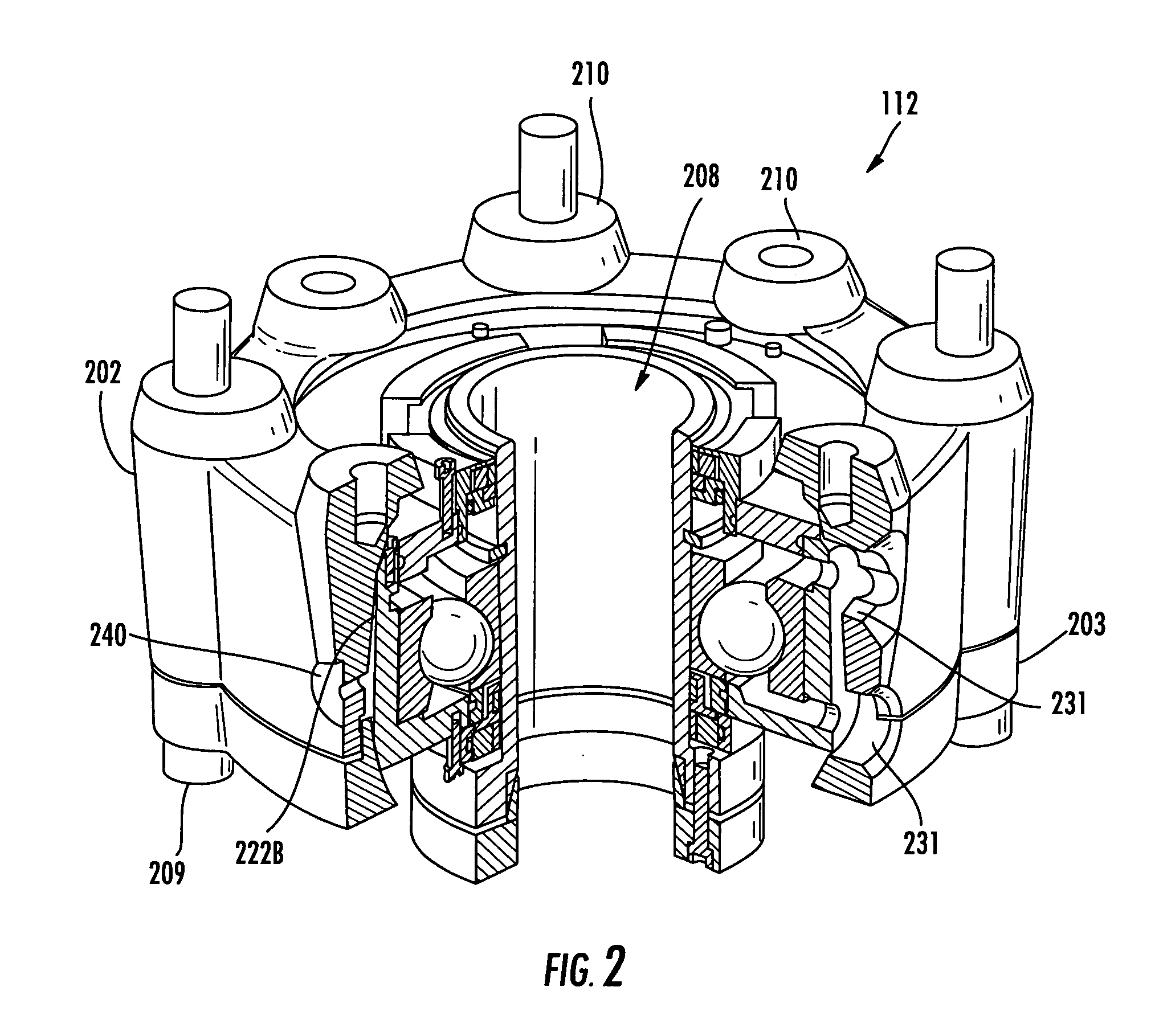

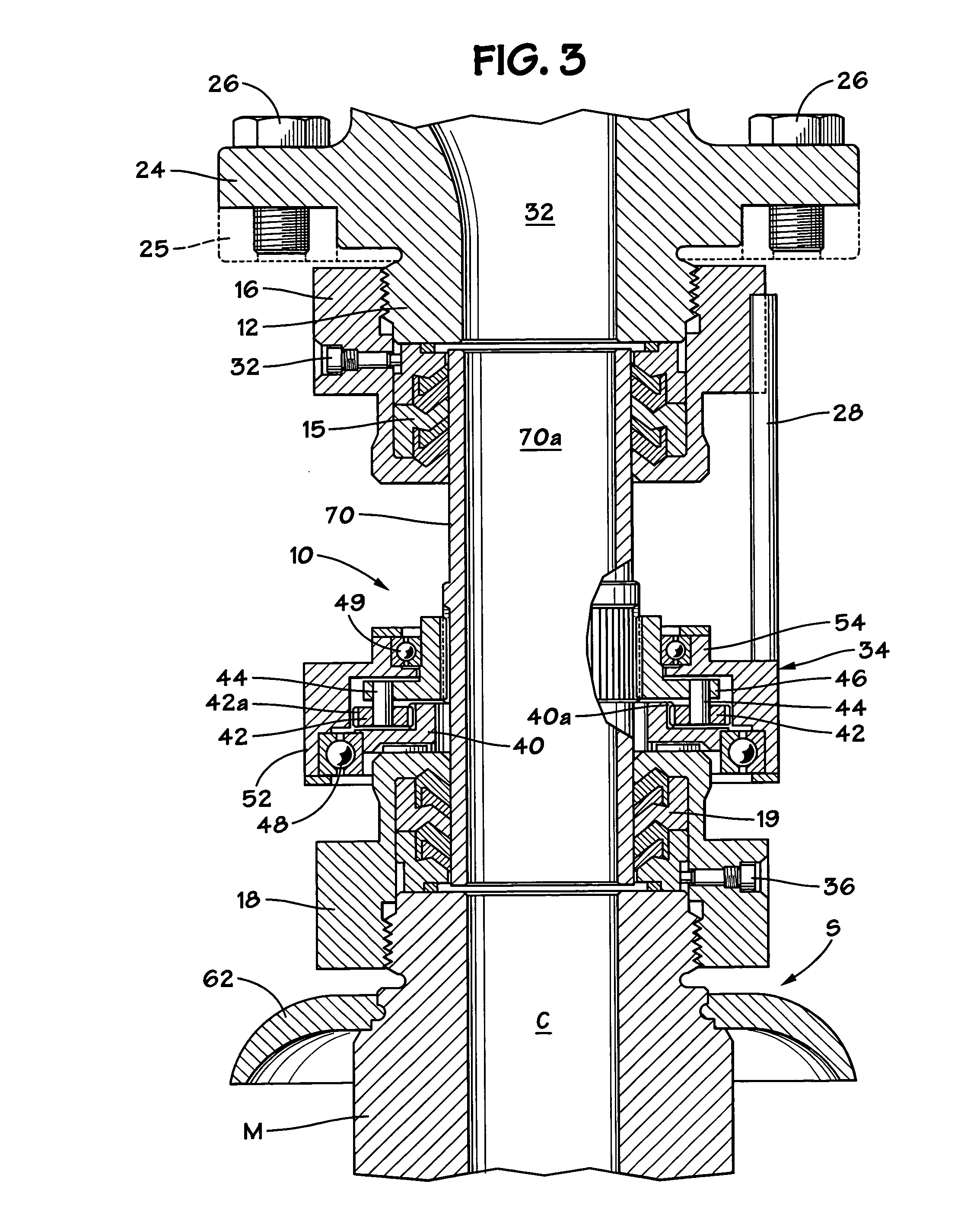

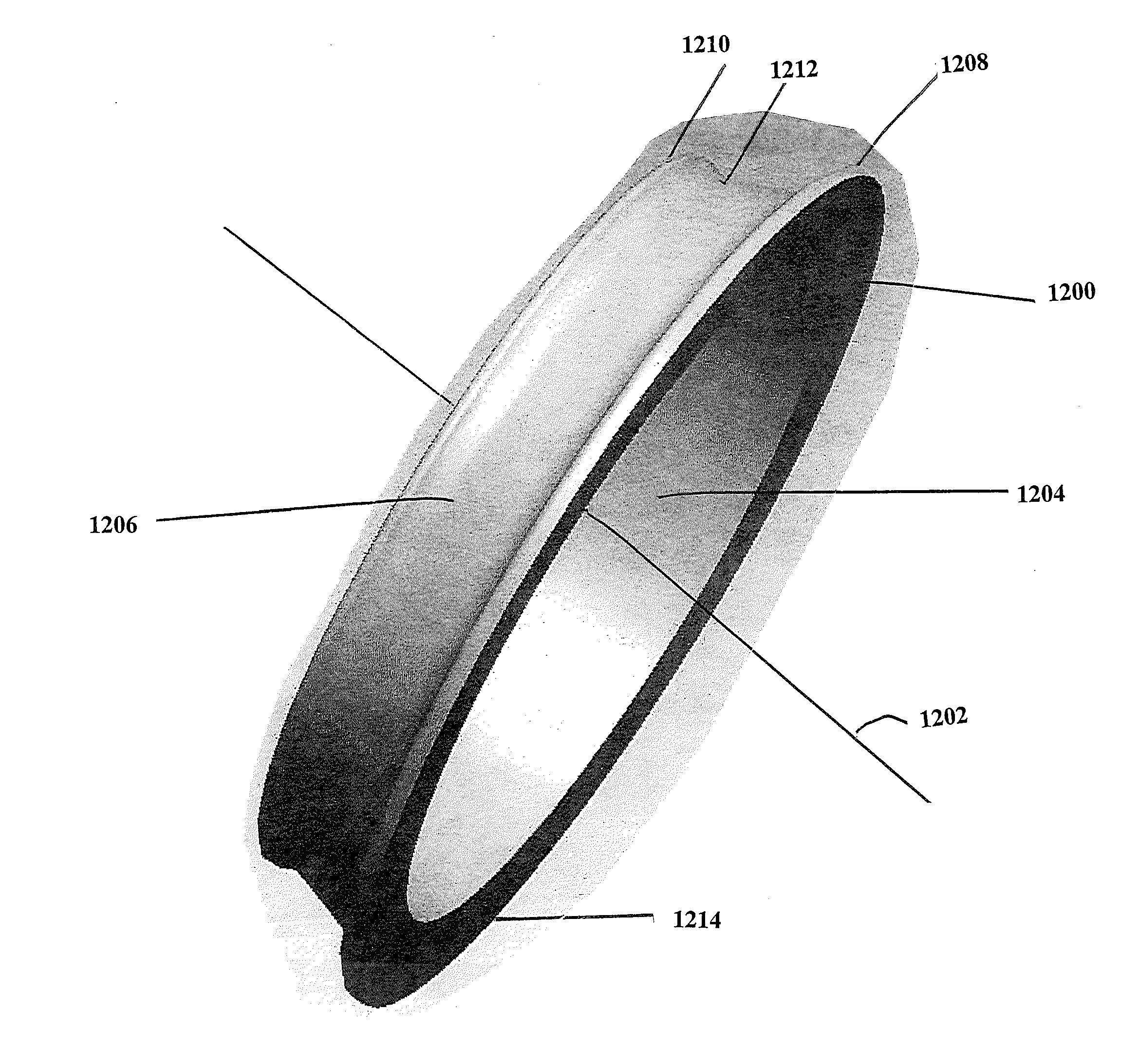

Self aligning bearing and seal assembly

ActiveUS20100135606A1Reduce frictionExtended seal lifeBall bearingsSliding contact bearingsEngineeringMechanical engineering

A self aligning bearing and seal assembly including a bearing housing operable to mount to a surface, a bearing unit seated within the bearing housing and having an outer race, an inner race, and at least one ball intermediate the outer and inner race. The self aligning bearing and seal assembly also includes a pivot assembly having a shaft sleeve operable for receiving and maintaining a rotatable shaft and being disposed in the bearing housing and in operational contact with the inner race of the bearing unit. The pivot assembly allows for a degree of angular misalignment between the surface and the shaft greater than three degrees.

Owner:RELADYNE RELIABILITY SERVICES INC

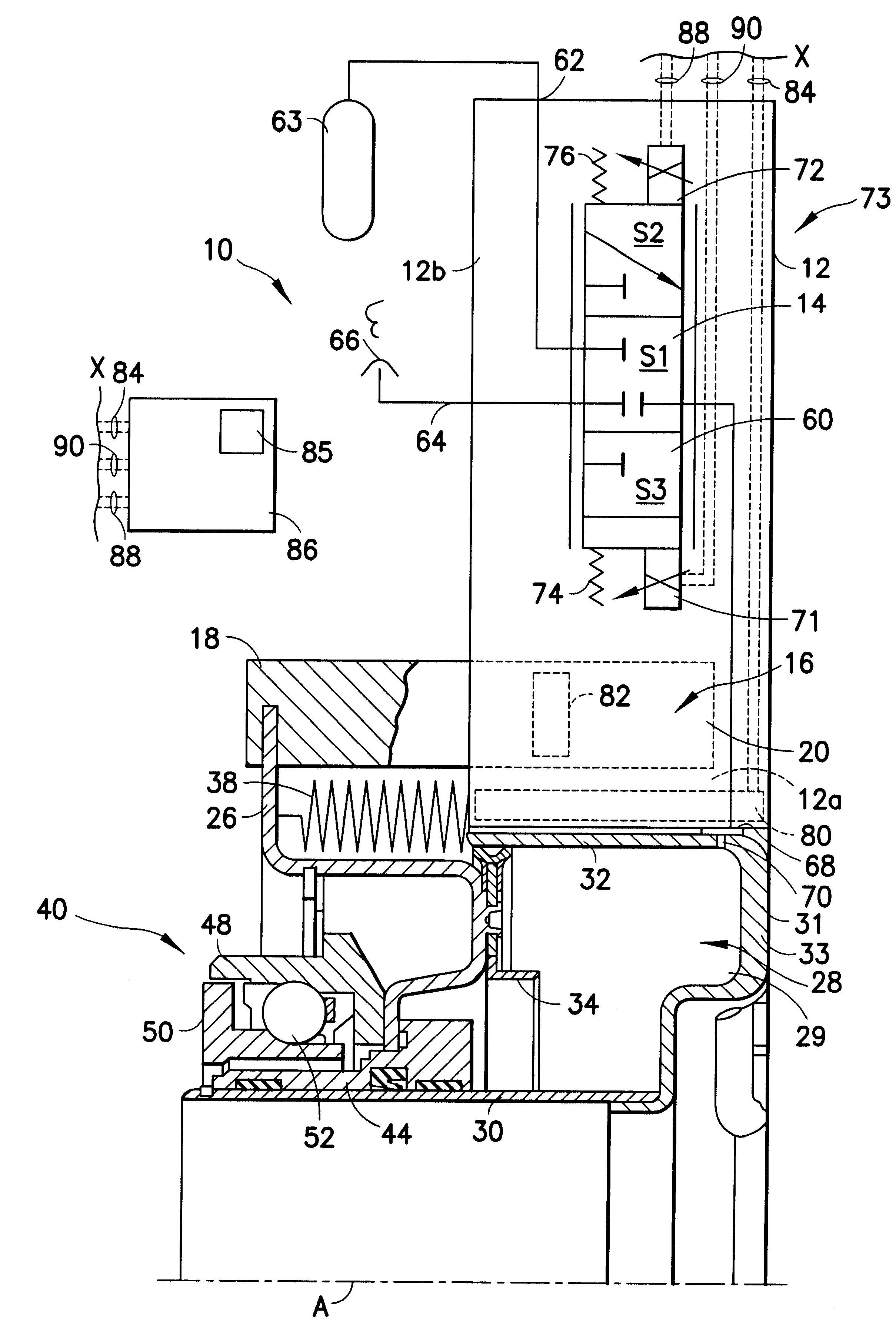

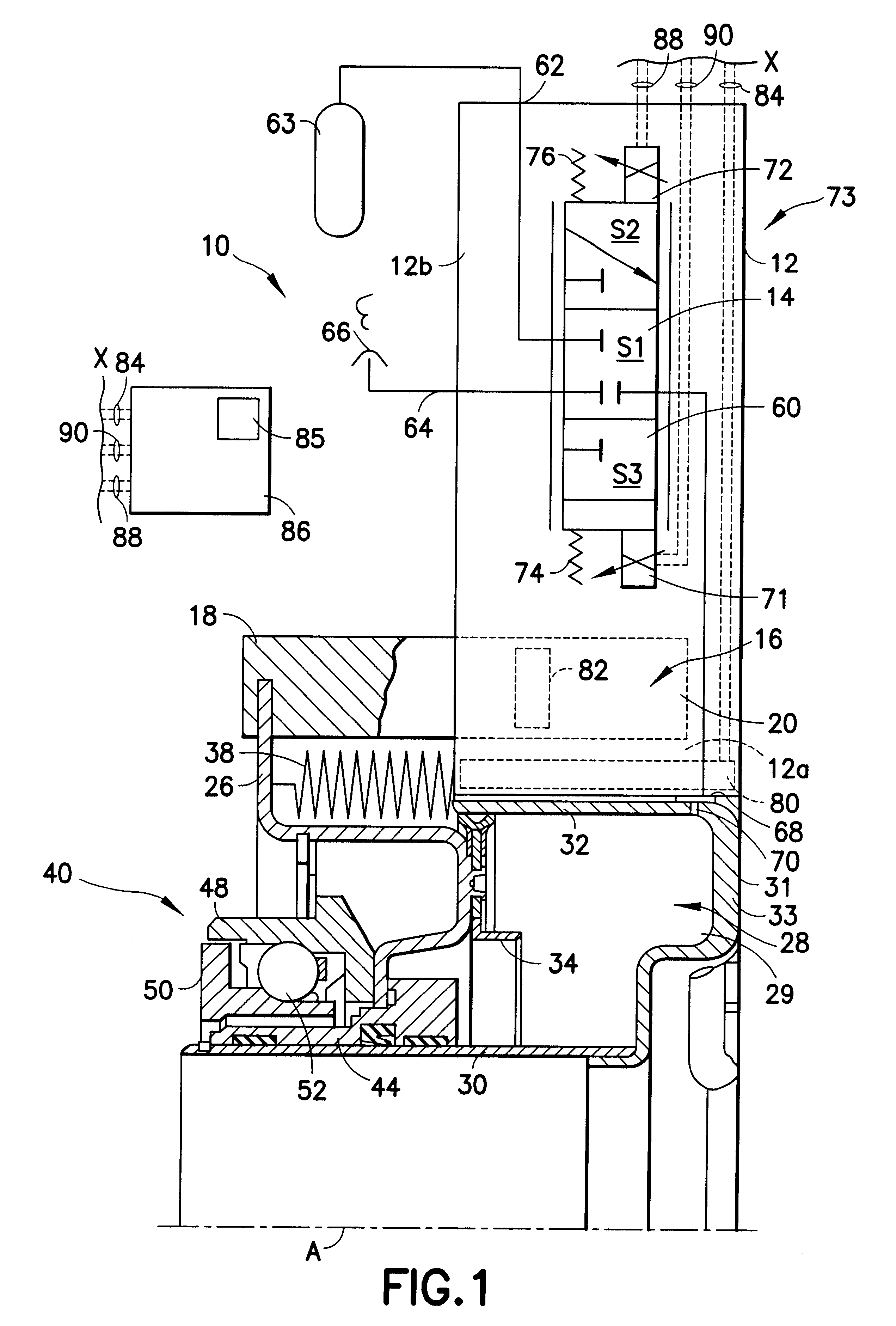

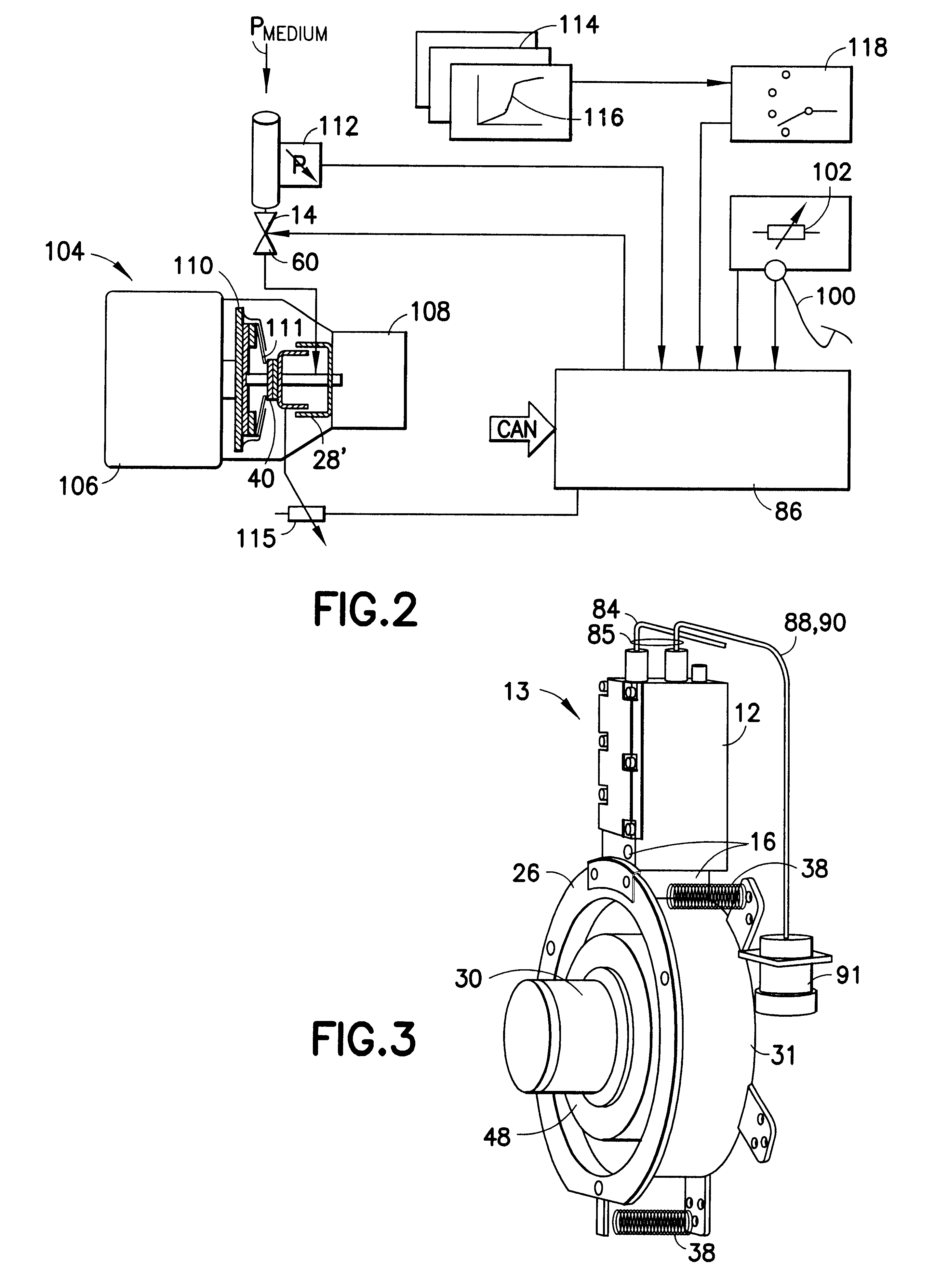

Actuation device for a friction clutch in a motor vehicle

InactiveUS6540059B2Avoid excessive wearMore reliableFluid actuated clutchesMagnetically actuated clutchesMobile vehicleDrivetrain

An actuation device for a friction clutch which is arranged in the drivetrain of a motor vehicle between a drive unit and a transmission arrangement includes a pressure medium force cylinder arrangement for actuating the friction clutch via a release member having a release bearing arrangement. A measuring arrangement detects an actual release state, i.e., an instantaneous position of the release member. A control / regulating valve arrangement is connected with a pressure medium source, a pressure compensation opening, and with the pressure medium force cylinder arrangement. The pressure medium force cylinder arrangement is actuated depending on the actual release state and on a desired release state. The actuation device is adjustable in a defined manner between a non-actuation state and an actuation state, wherein the release bearing arrangement is decoupled from an associated release force receiving arrangement of the friction clutch in the non-actuation state and is coupled with the release force receiving arrangement in the actuation state.

Owner:ZF FRIEDRICHSHAFEN AG

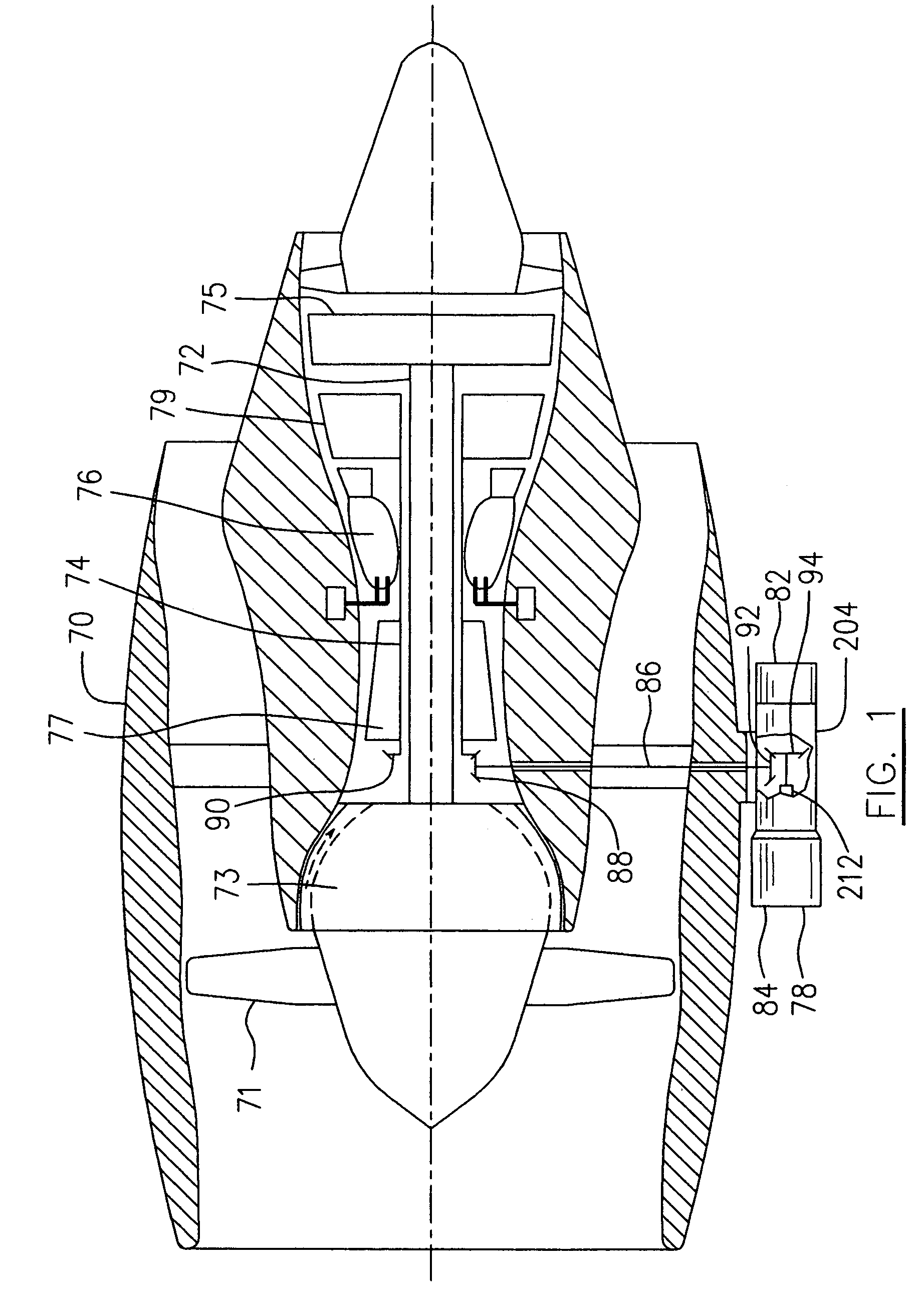

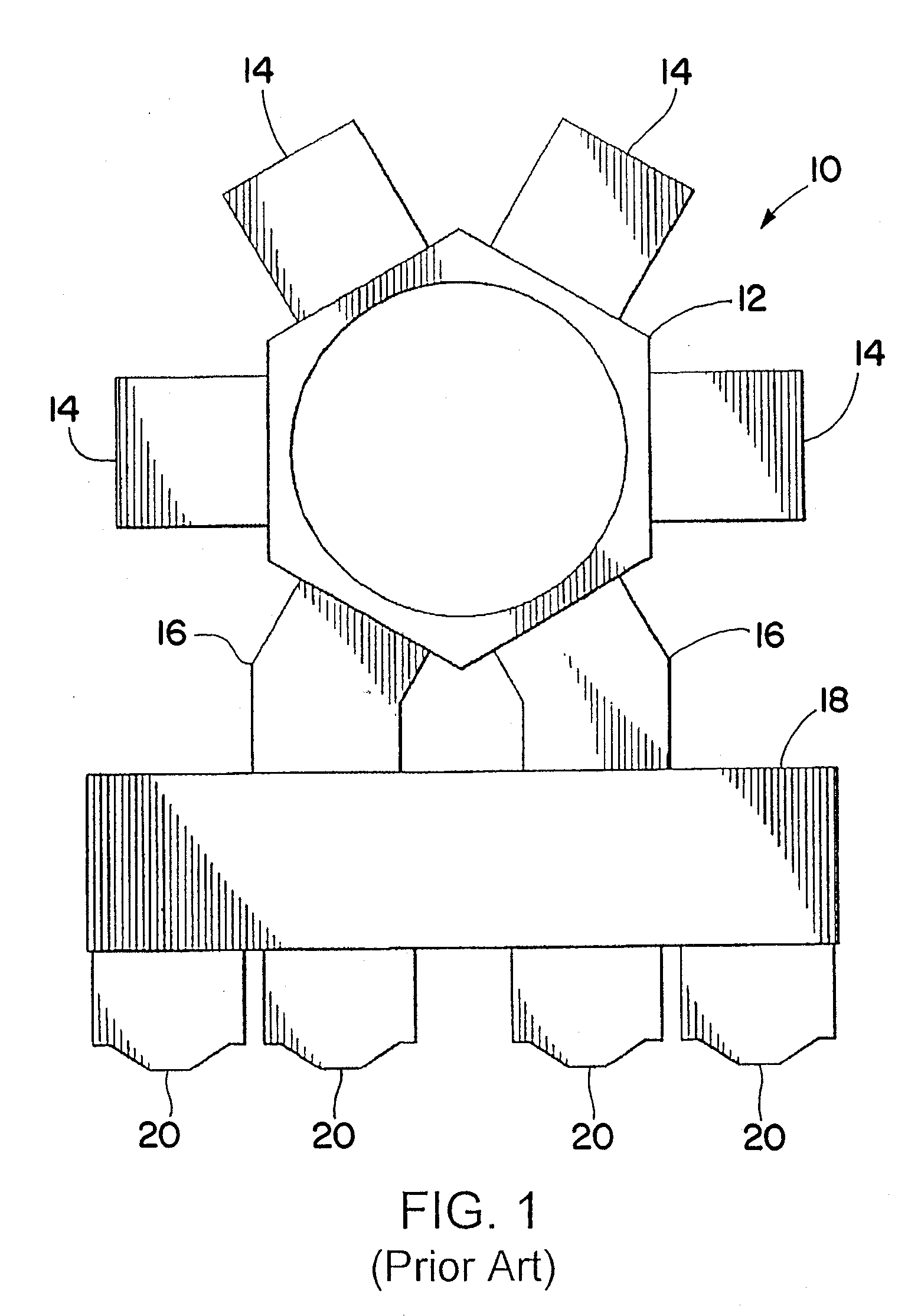

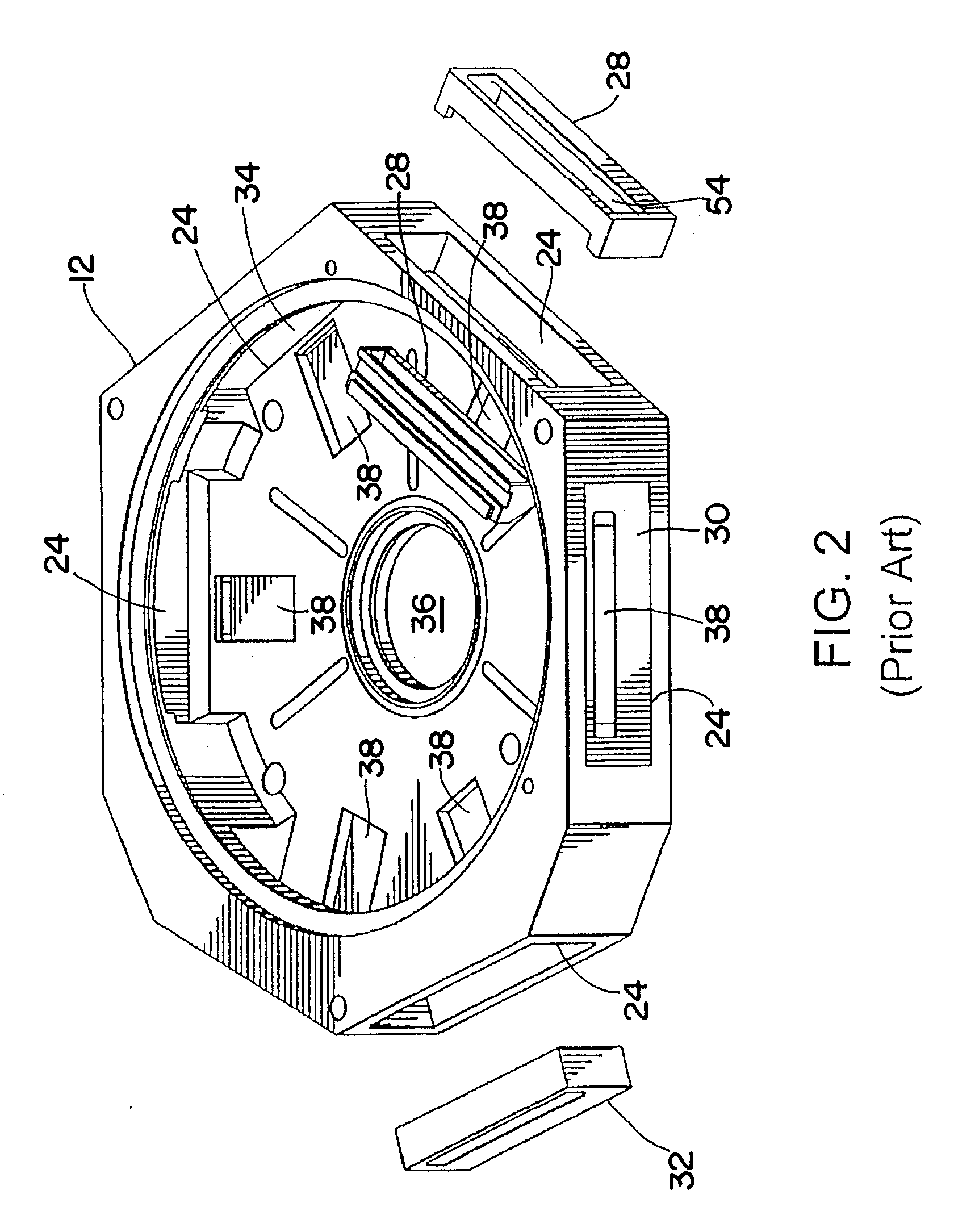

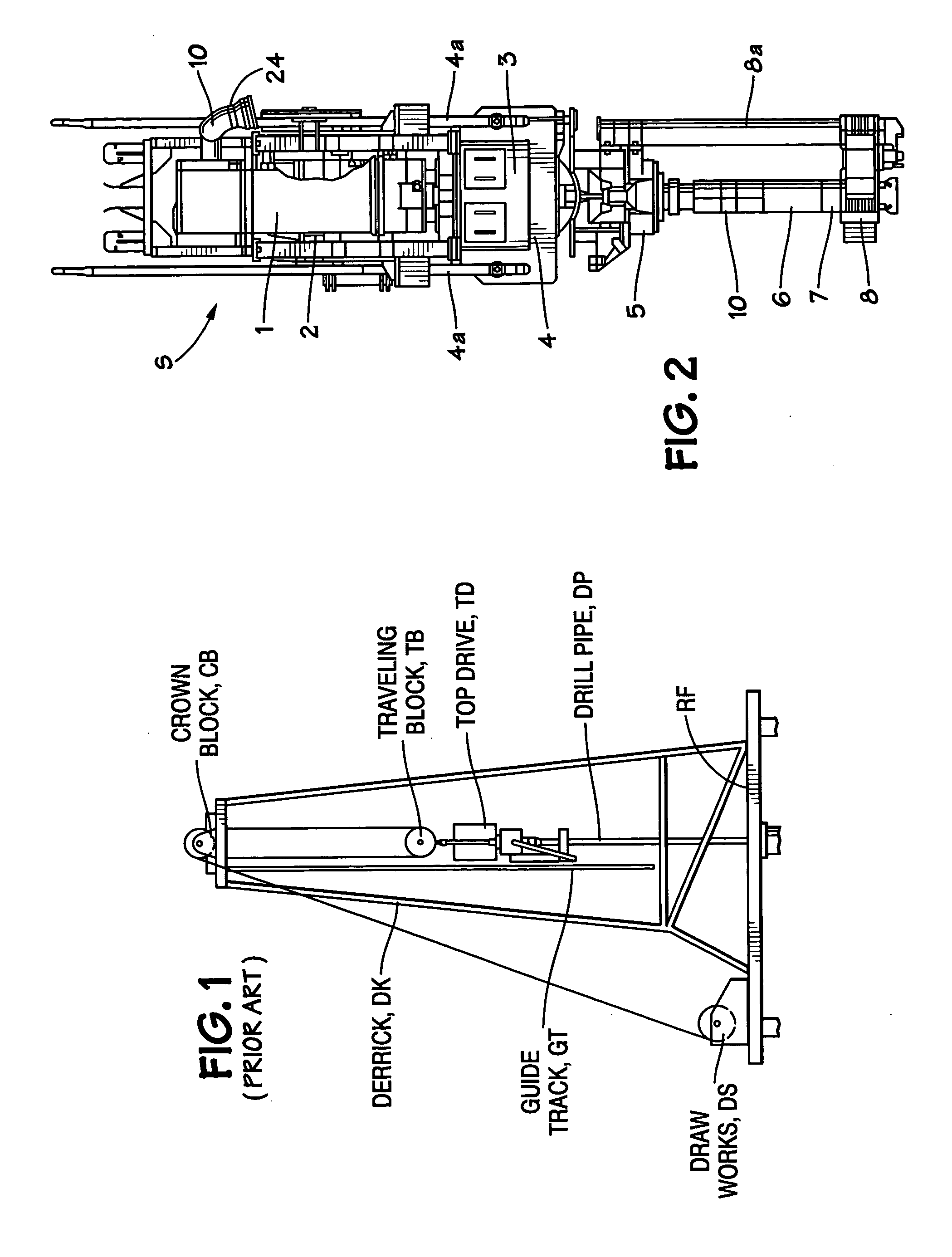

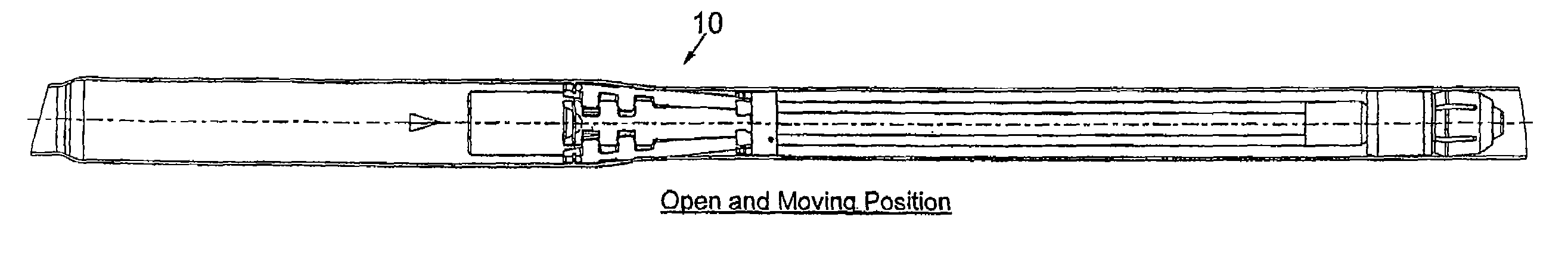

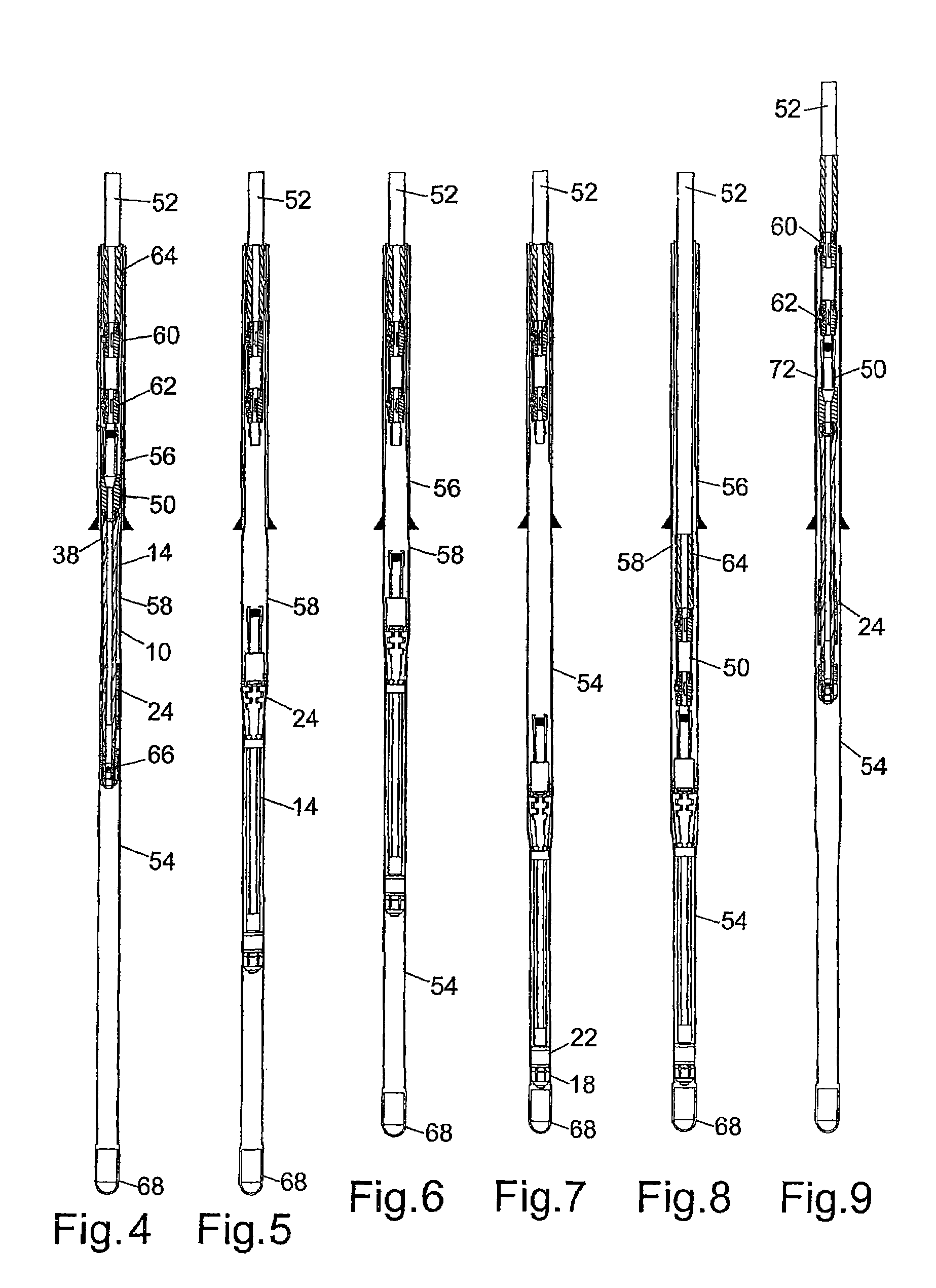

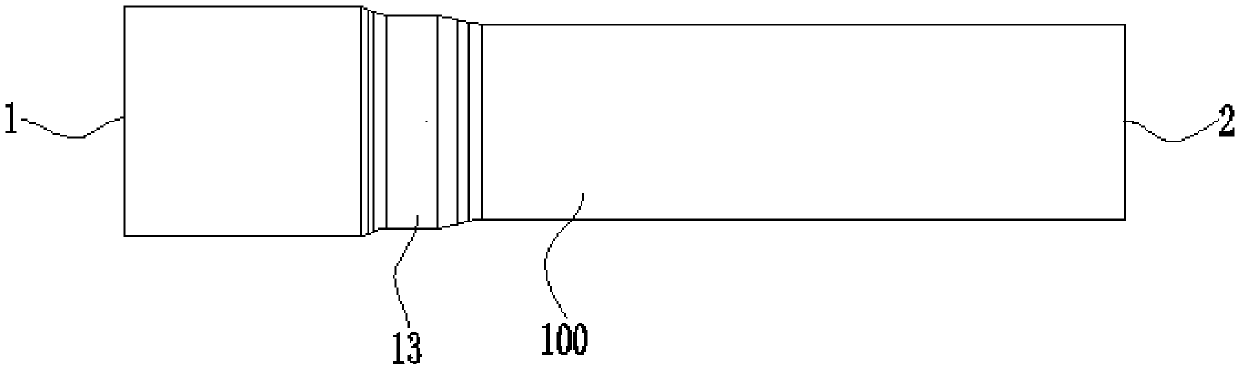

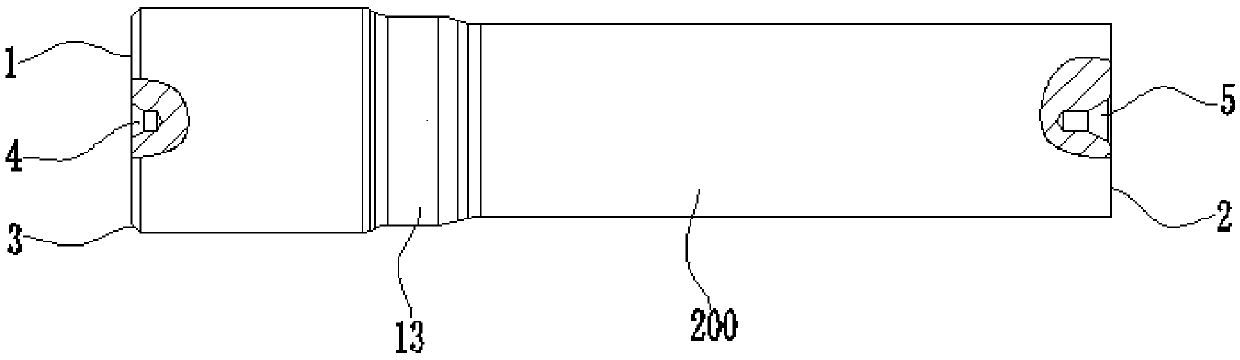

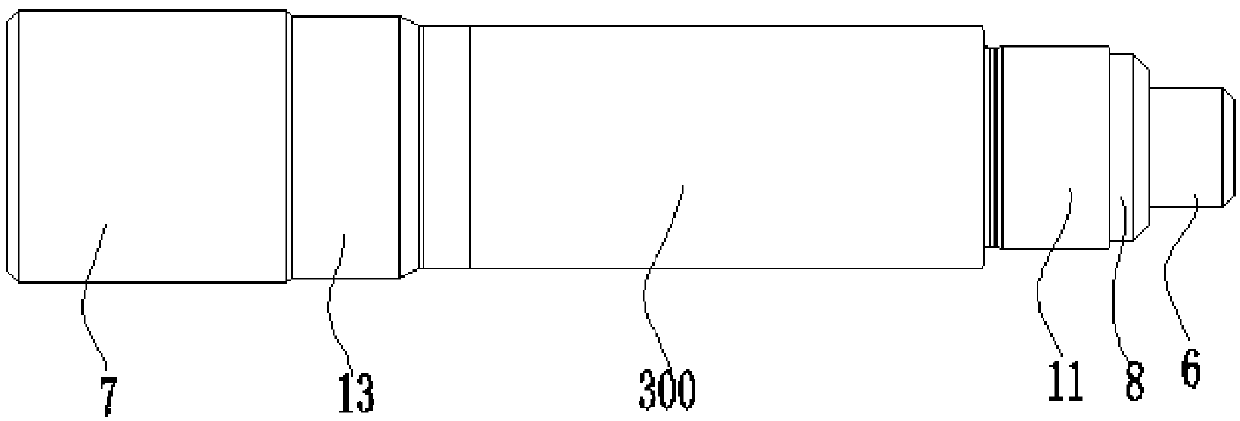

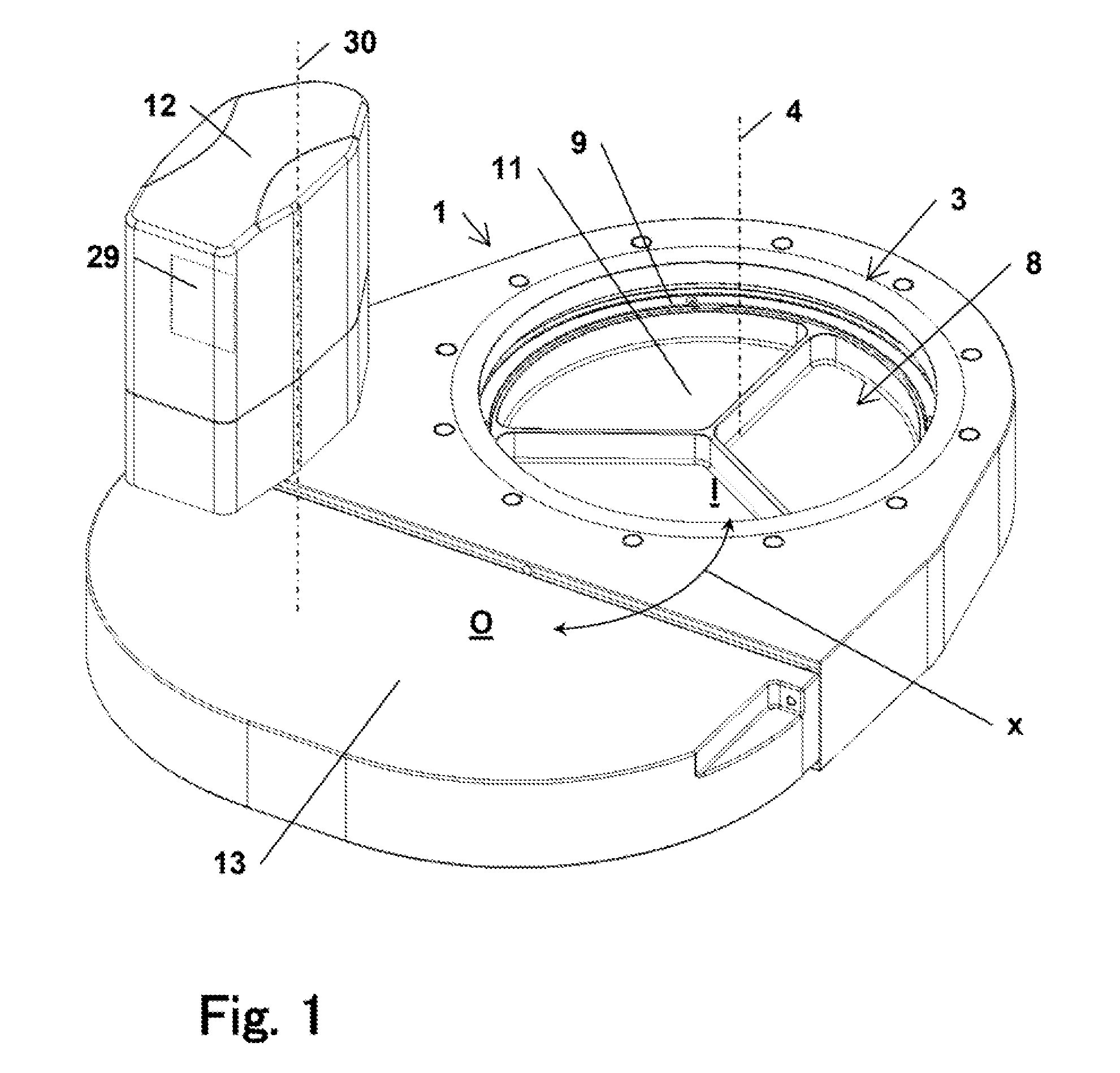

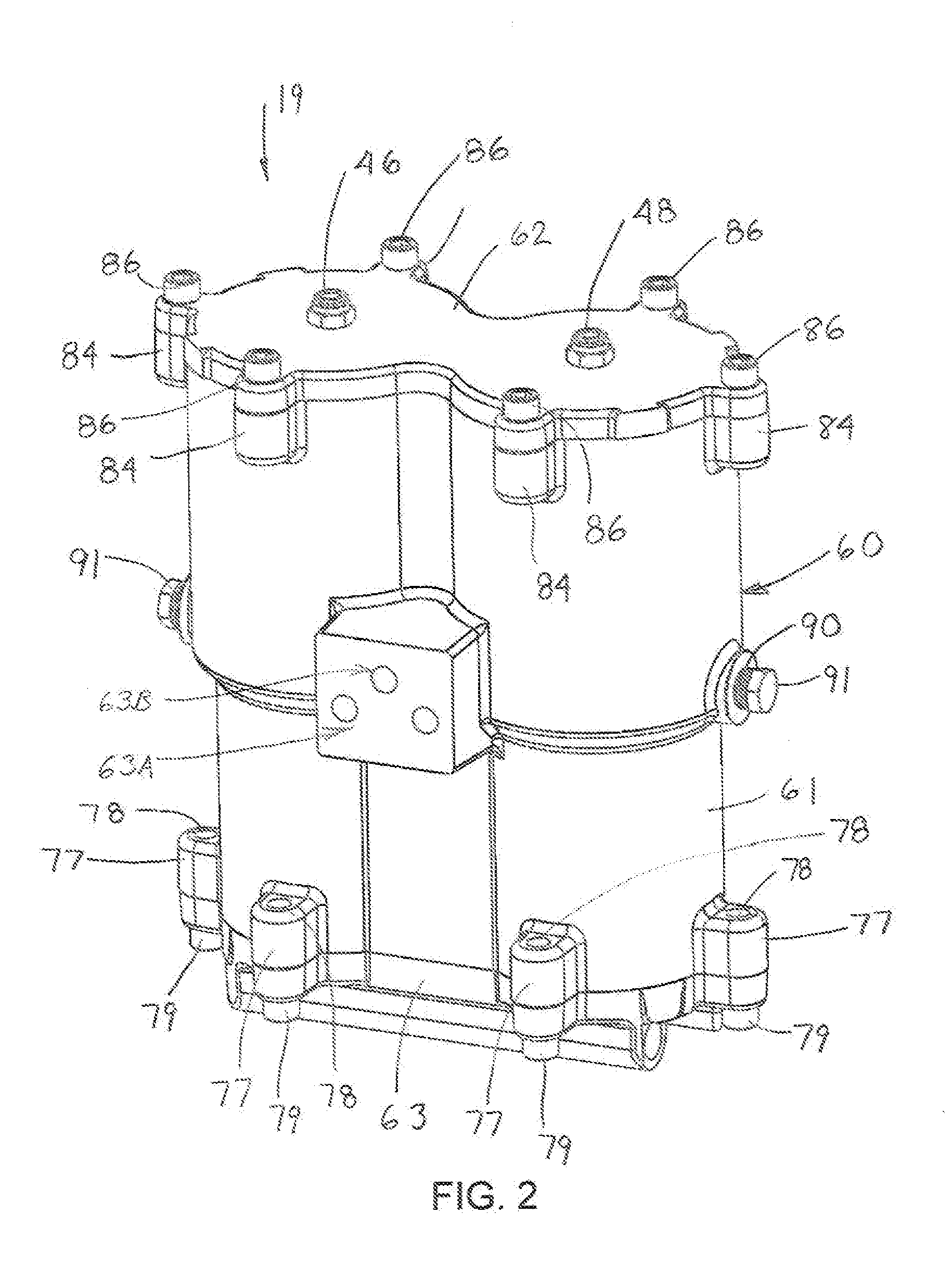

Top drive washpipe system

A top drive system for wellbore operations, the top drive system, in at least certain aspects, including a motor, a main shaft driven by the motor, the main shaft having a top end and a bottom end, a speed reduction system interconnected with the main shaft, a washpipe shaft interconnected with the speed reduction system for driving the washpipe shaft at a speed of rotation less than a speed of rotation of the main shaft. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.P.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

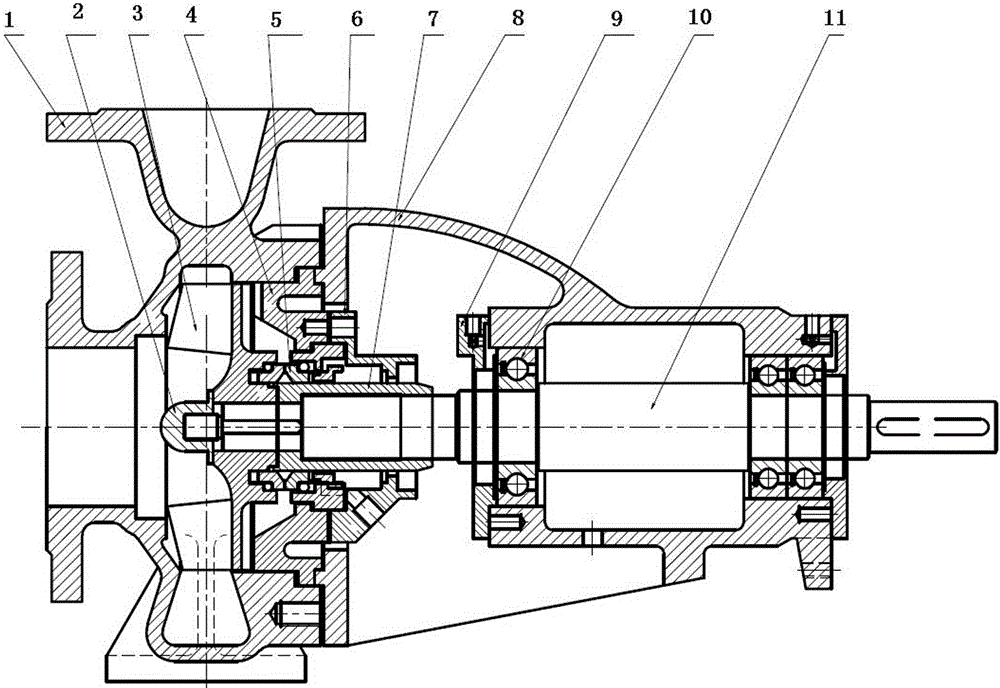

Anti-corrosive wearproof chemical centrifugal pump

The invention provides an anti-corrosive wearproof chemical centrifugal pump. The anti-corrosive wearproof chemical centrifugal pump comprises a pump body, an impeller nut, an impeller, a pump cover, a mechanical sealing set, a sealing box, a shaft sleeve, a carrier, a bearing gland, a bearing, a shaft and a suspension support. The pump body and the suspension support are connected with a base through bolts. The pump body is fixed to the carrier through bolts. The mechanical sealing set comprises a mechanical sealing moving ring and a mechanical sealing stationary ring. The mechanical sealing moving ring is arranged on the impeller. The pump cover, the sealing box and the mechanical sealing set are arranged on the pump shaft jointly. The pump cover is connected with the sealing box through bolts. The mechanical sealing stationary ring, a stationary ring seat and a spring are arranged between the pump cover and the sealing box. The shaft sleeve sleeves the shaft, and the bearing gland is connected to the carrier through bolts. The shaft is detachably connected with the carrier. The pump has the advantages of wide application range, long service life in sealing, wear resistance, corrosion resistance, no clogging and the like, and can be applicable to acid, alkali and / or salt media with any concentration and solid content smaller than or equal to 40%, wherein the hardness or softness degree of particles of the media is unlimited.

Owner:JIANGSU YAMEI PUMP IND GRP

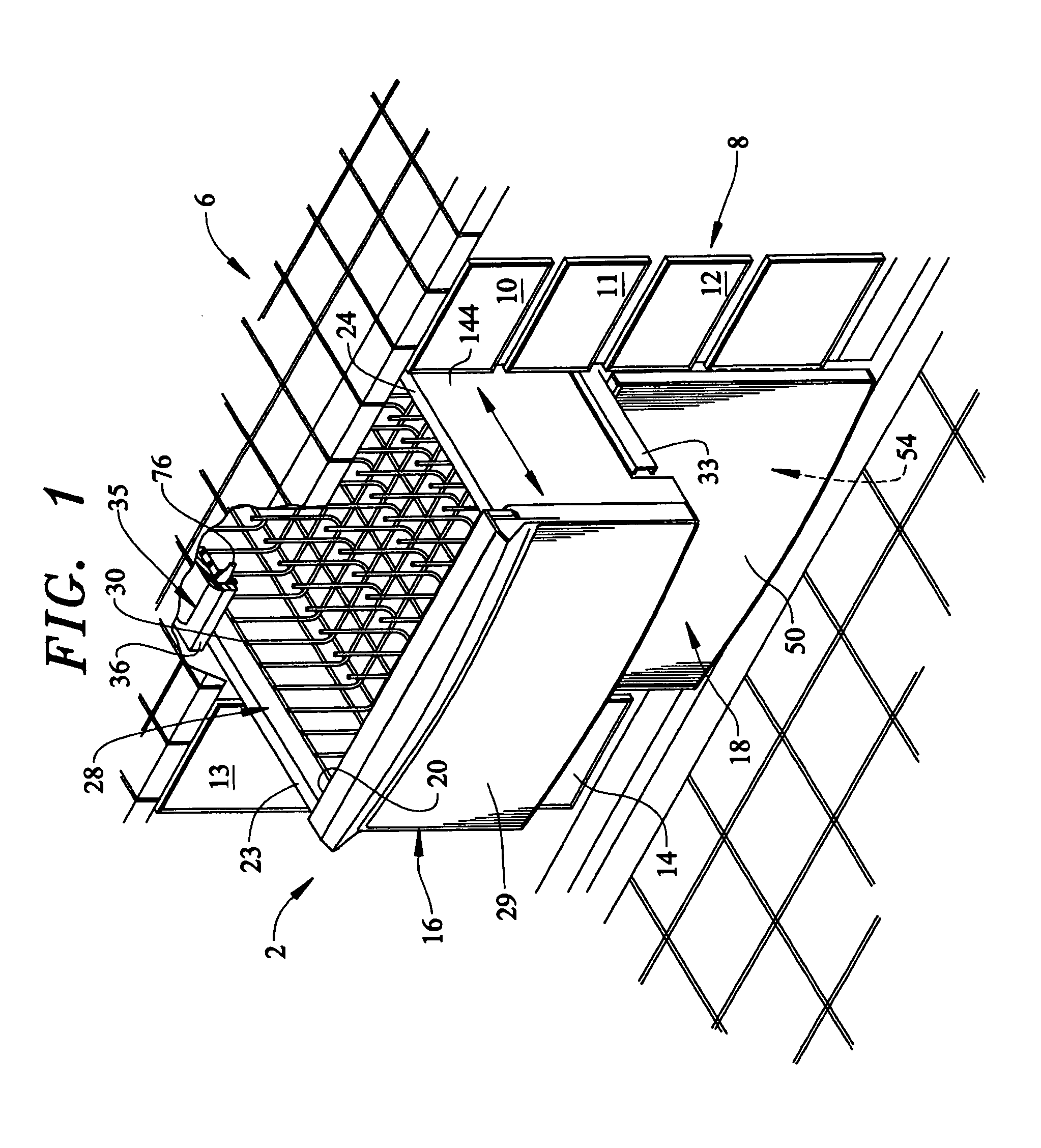

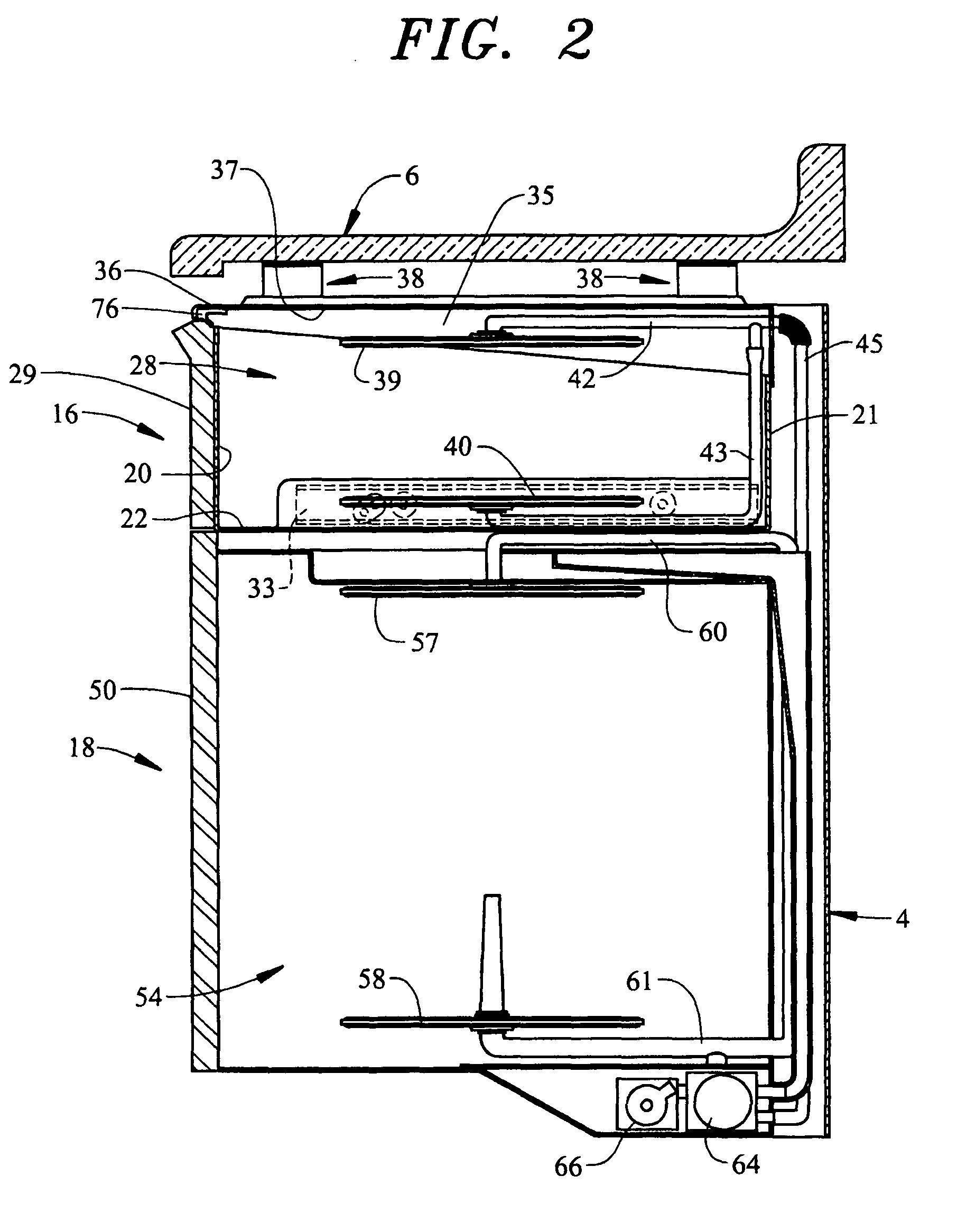

Lid seal for a drawer-type dishwasher

InactiveUS7850784B2Prevent escapeExtended seal lifeEngine sealsTableware washing/rinsing machine detailsEngineeringMechanical engineering

A drawer-type dishwasher includes a frame assembly, a wash tub slidably mounted in the frame assembly, and a lid member. The lid member can be lowered onto the wash tub when the wash tub is shifted into the frame assembly, and raised when the wash tub is shifted out of the frame assembly. The lid member includes a seal element that abuts the wash tub when the lid member is lowered. The seal element includes a base portion, an angled, deflecting finger portion and a flat pad portion which projects from the base portion. When the seal element is urged against the wash tub, a compressive force is applied to the flat pad portion causing the deflecting finger to seal against the wash tub in a manner that substantially shields the deflecting finger from excessive compressive forces.

Owner:MAYTAG

Tubing expansion

InactiveUS7322420B2Promote formationExtended seal lifeFluid removalBearing surfaceBiomedical engineering

An apparatus and a method for expanding a downhole tubular. The apparatus includes a mandrel defining at least one curved support surface. The apparatus further includes an expansion member defining a curved bearing surface for contact with the support surface and corresponding to the mandrel support surface. The expansion member is movable relative to the mandrel, whereby the surfaces are in contact and movable over one another to move the expansion member from a smaller diameter first configuration towards a larger diameter second configuration.

Owner:WEATHERFORD TECH HLDG LLC

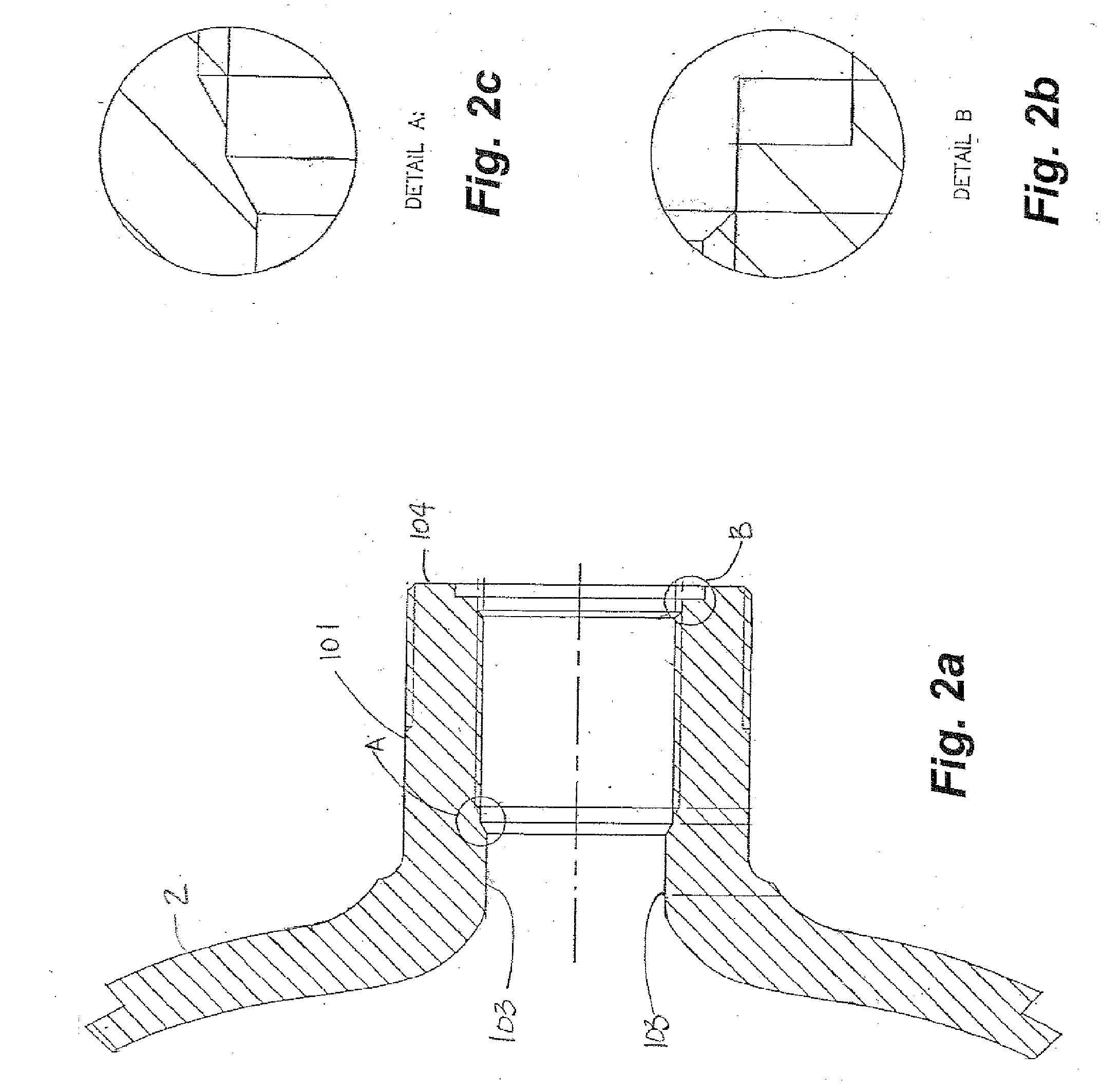

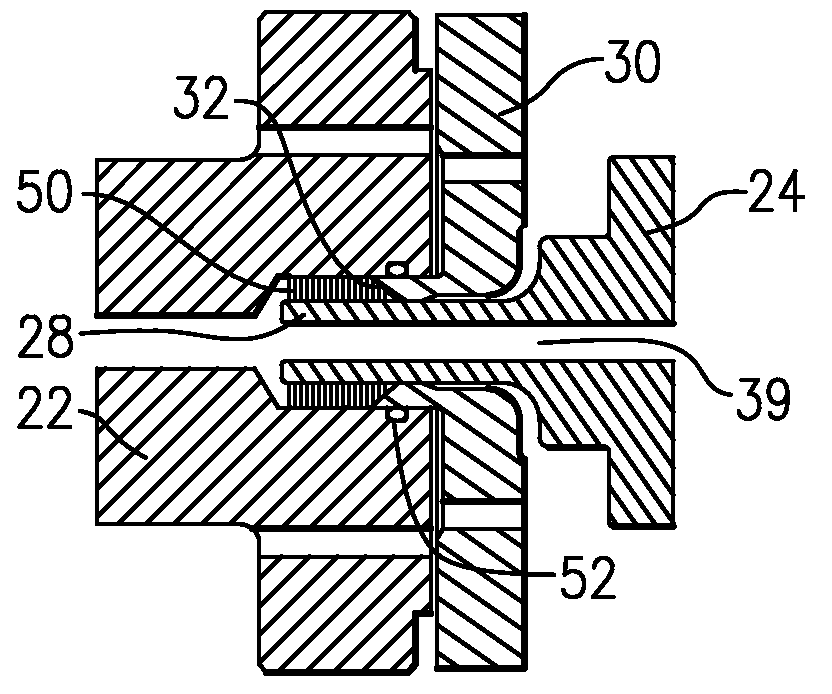

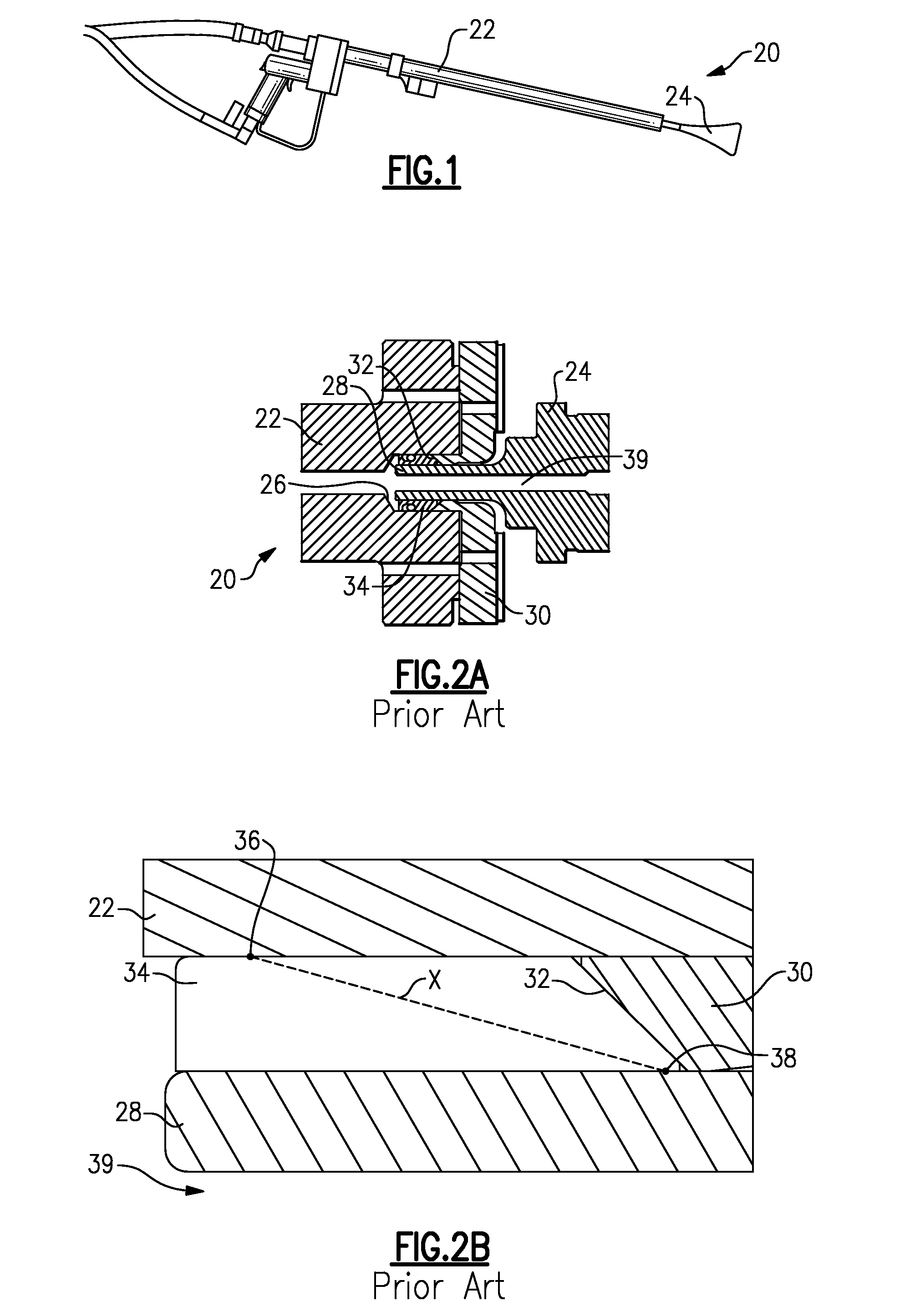

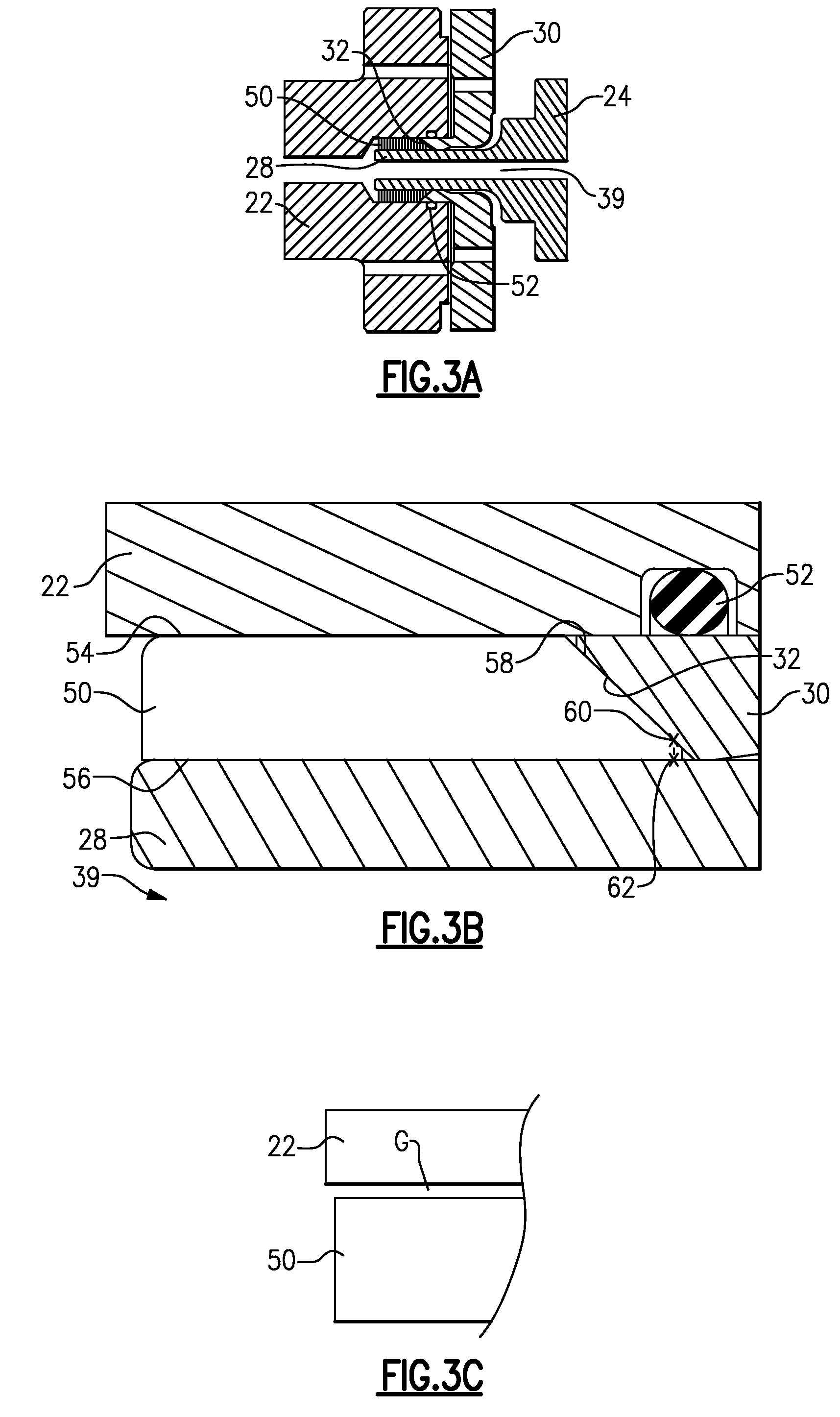

Rotating fluid jet with improved rotary seal

ActiveUS7600700B2Extended seal lifeReduce areaEngine sealsMovable spraying apparatusEngineeringMechanical engineering

An improved seal for use in fluid systems such as a water jet system includes an outer seal point that is very close to an inner seal point. By spacing these two seal points very close together, the force on the seal is greatly reduced compared to the prior art. In the disclosed embodiment, the outer seal point is on an angled forward face of the seal that abuts a back-up ring angled face. The inner seal point is between the seal and an internal shaft which rotates relative to a housing.

Owner:NEW LANTAO BUS

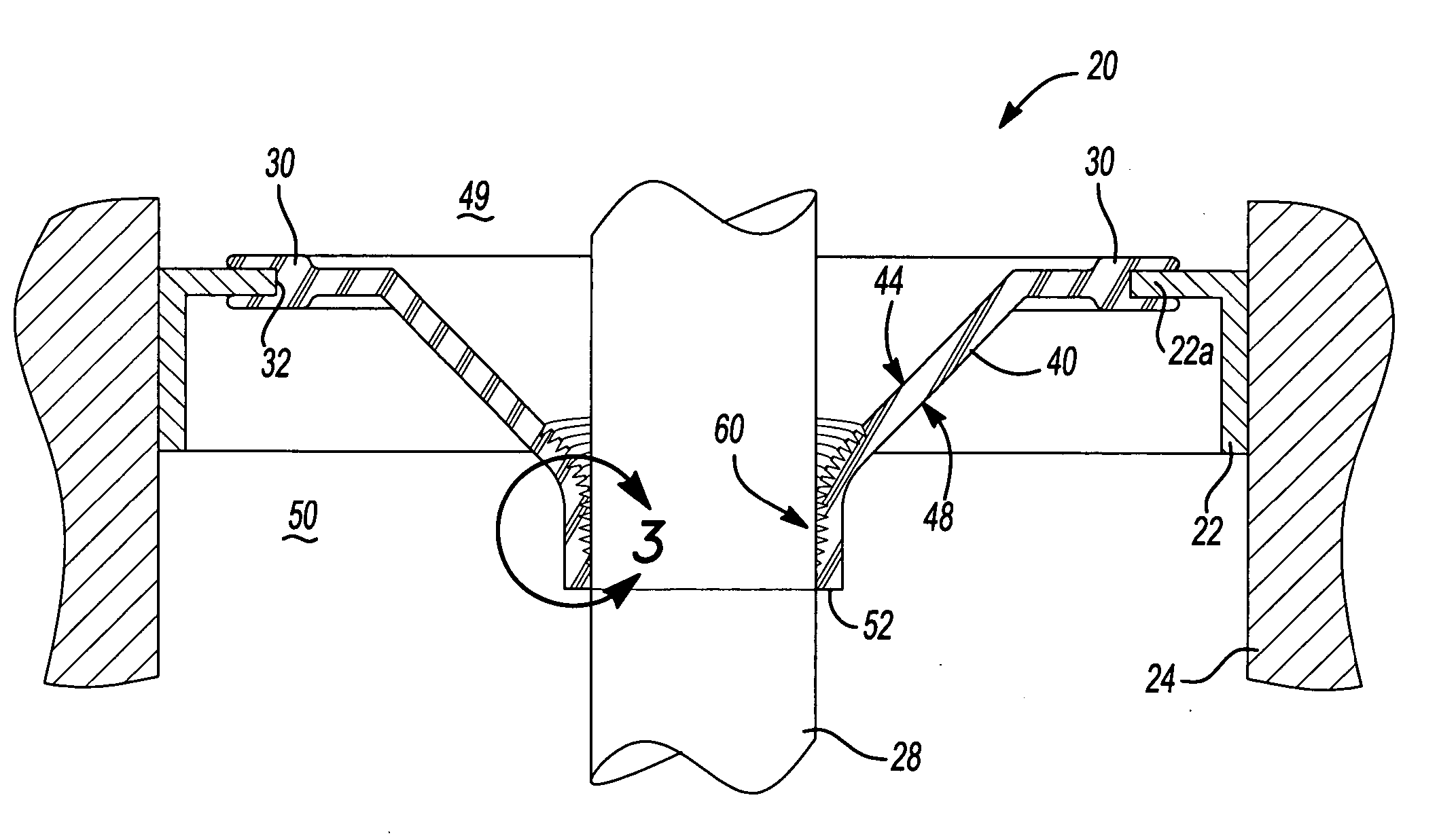

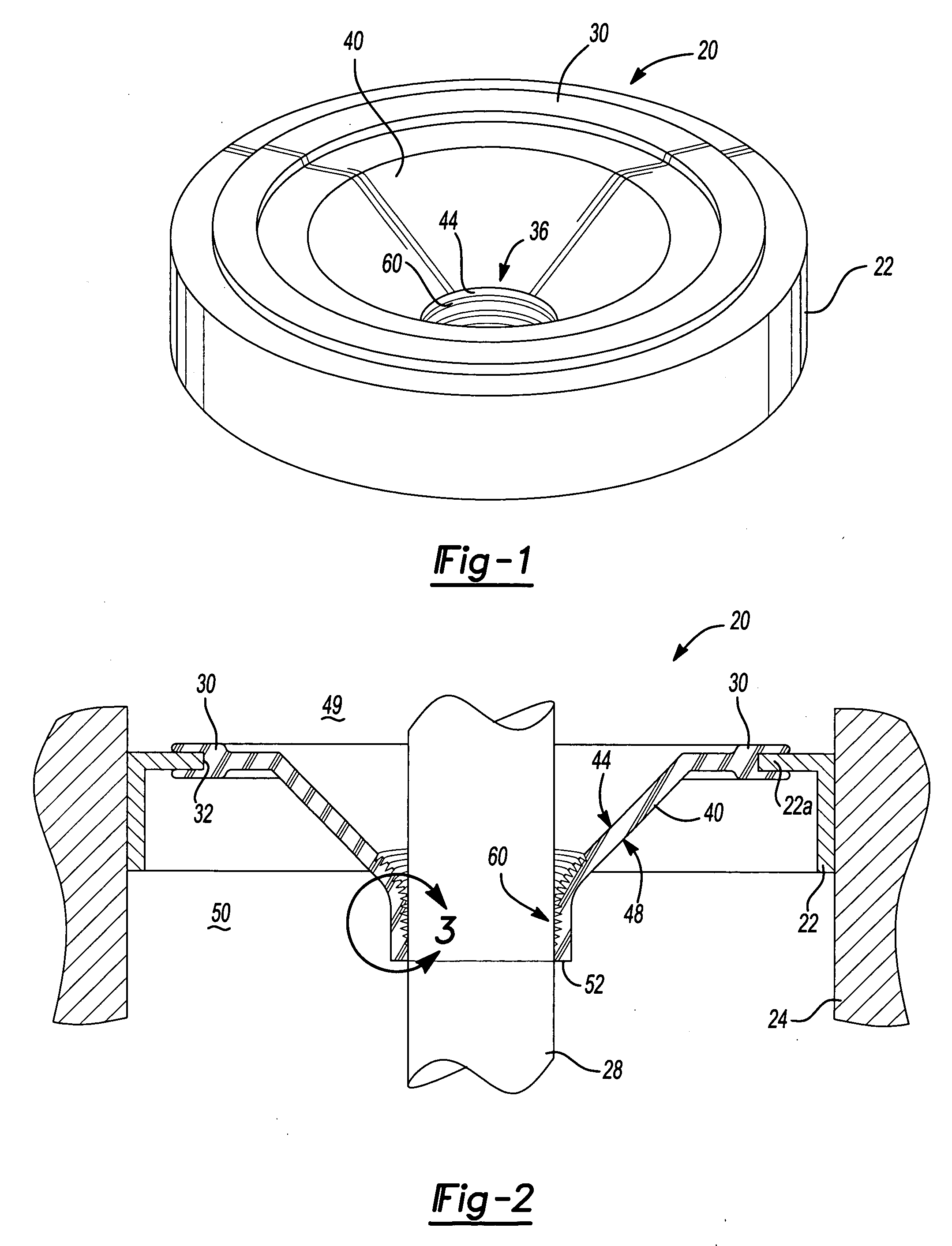

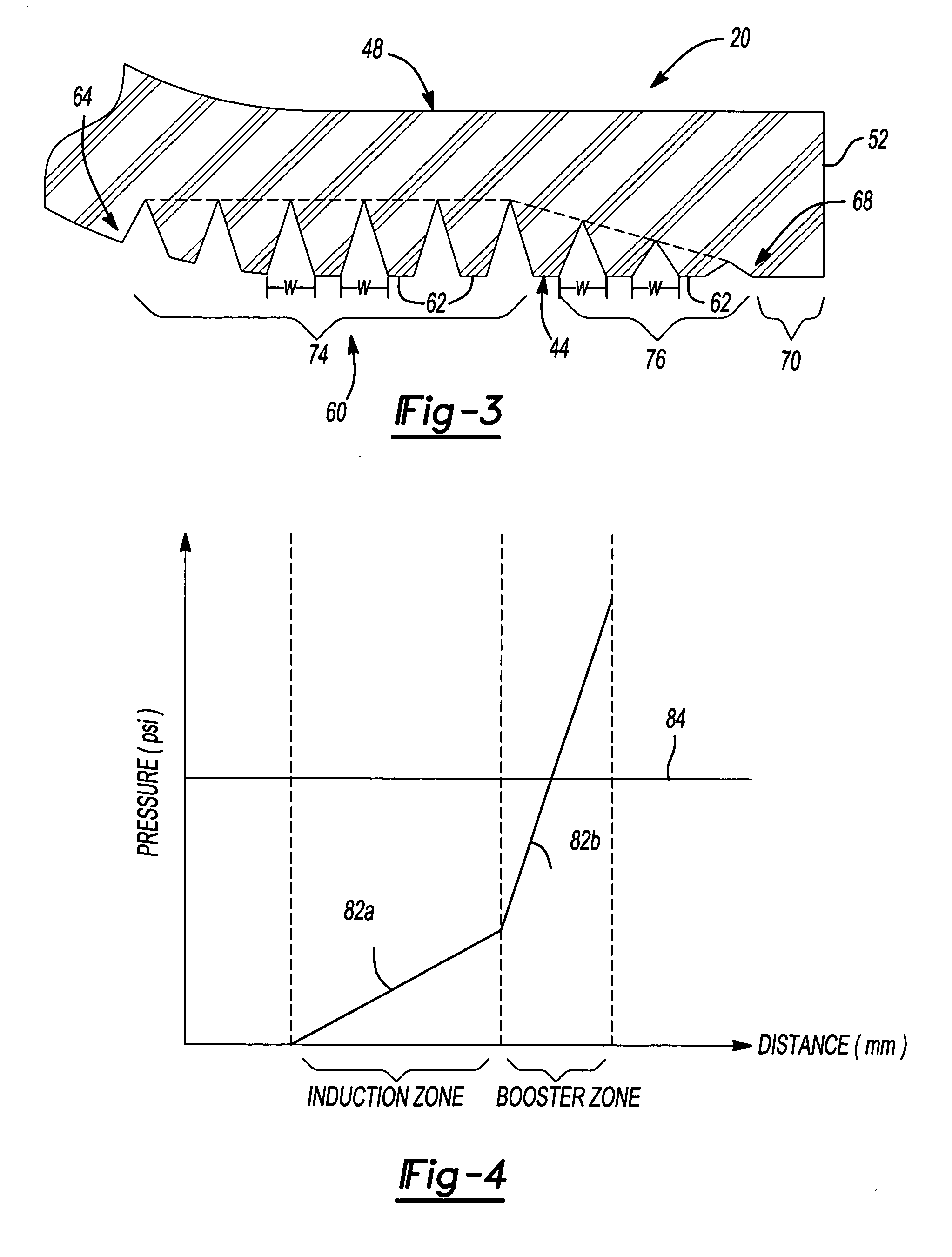

Seal with controllable pump rate

A dynamic seal advantageously utilizes a groove on the active side or surface of the seal to capture a leaked lubricant and hydrodynamically pump the lubricant back into the lubricated side of the seal. The groove stops short of the leading edge of the seal that faces the lubricant side thereby forming a static dam between the termination point of the groove and the seal edge. When the fluid pressure within the groove adjacent the static dam exceeds the opening pressure for the seal lip, the lubricant within the groove is pumped back into the lubricant side of the seal. The groove can have an induction zone wherein the fluid pressure rise is gradual and a booster zone wherein the fluid pressure rise is relatively faster than in the induction zone. The booster zone is disposed adjacent the static dam.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Method for Applying Wear Resistant Coating to Mechanical Face Seal

InactiveUS20110285091A1Extended seal lifeLow costEngine sealsPretreated surfacesWear resistantSlurry

Mechanical face seal rings having a metallurgically bonded wear-resistant coating on the wear surfaces thereof and methods for forming such coated components is taught herein. The face seal rings, which can be formed of a relatively inexpensive base metal or alloy, have a hard metal alloy slurry disposed on the wear surfaces and then fused to form a metallurgical bond with the iron-based alloy. The wear-resistant coating comprises a fused, metal alloy comprising at least 60% iron, cobalt, nickel, or alloys thereof.

Owner:DEERE & CO

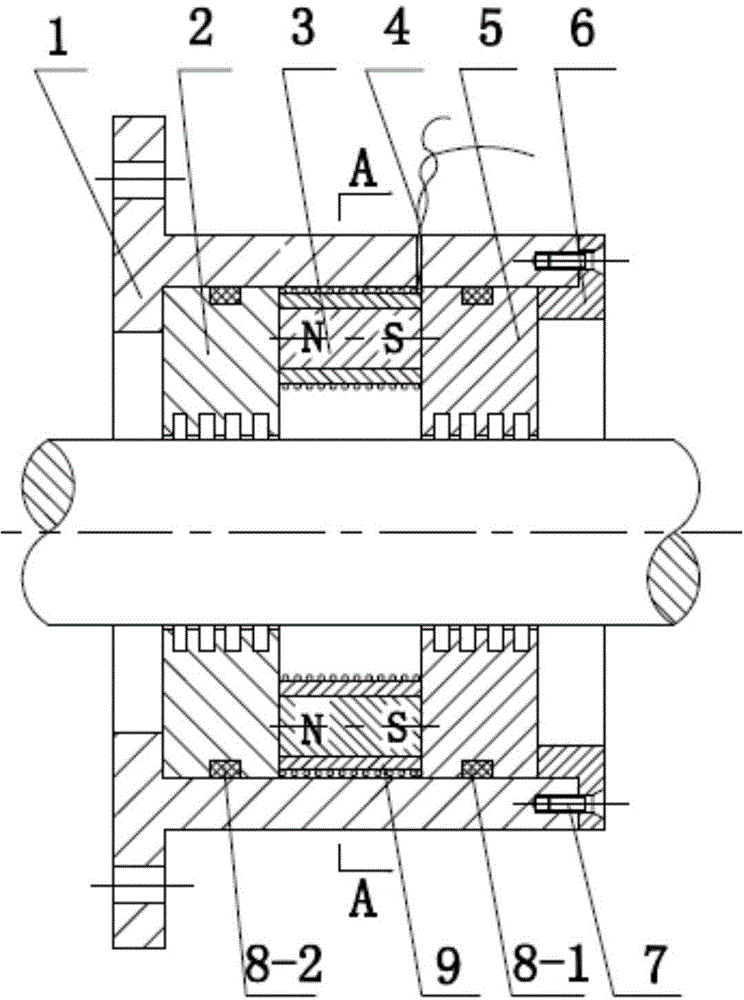

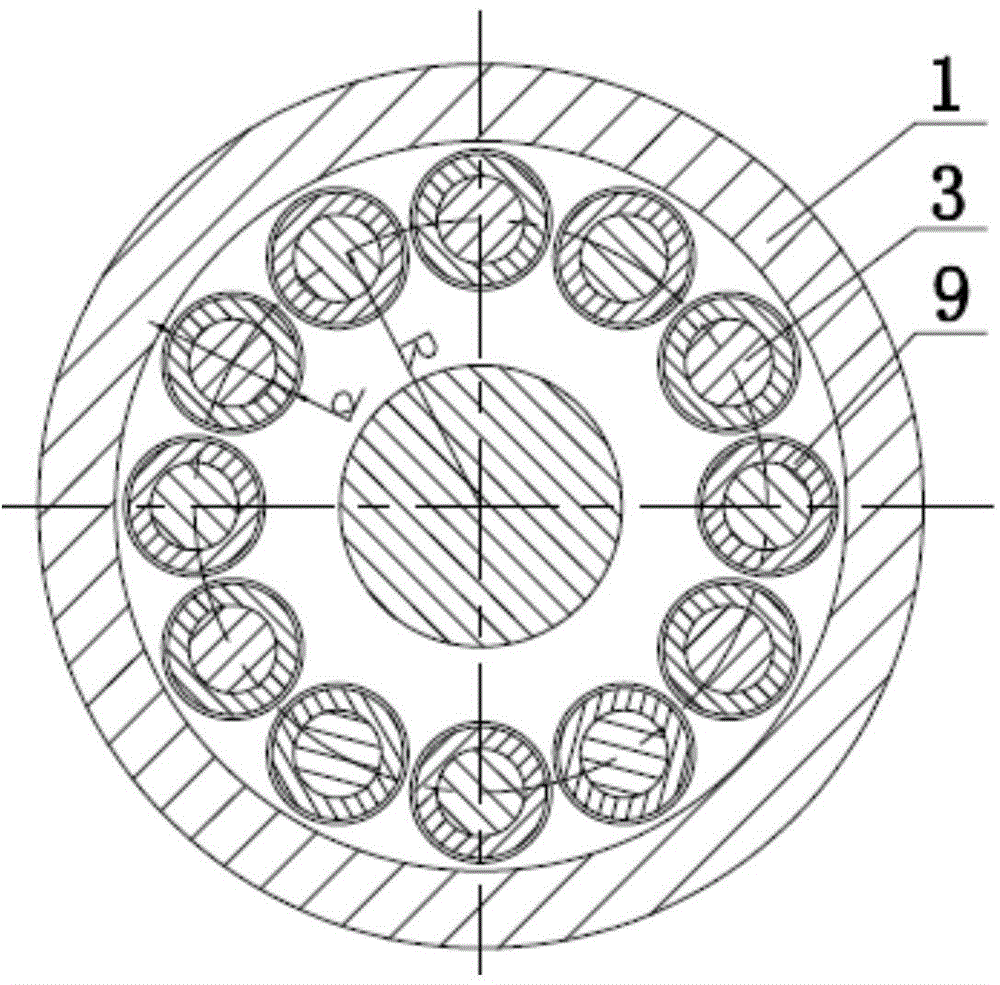

Novel method for increasing high linear speed and prolonging sealing life of static magnetic liquid

InactiveCN104534100AGuaranteed sealing conditionIncrease the magnetic field strengthEngine sealsPower flowEngineering

The invention provides a novel method for increasing high linear speed and prolonging the sealing life of static magnetic liquid, and belongs to the field of mechanical engineering sealing. The method solves the problem that the calorific value of magnetic liquid in a sealing gap of an existing magnetic liquid rotary sealing device is too high and accordingly service life is lowered, and solves the problem that in the static sealing process, a magnetic liquid agglomeration phenomenon occurs due to the action of a long-time stable strong magnetic field, and accordingly sealing performance is reduced. According to the method, outer cylindrical faces of N cylindrical permanent magnets (3) are sleeved with N iron core rings (9), and electromagnetic coils are wound around the outer cylindrical faces of the N cylindrical permanent magnets provided with the iron core rings. The electromagnetic coils are connected with an external power supply to generate an electromagnetic field; by changing the direction and the size of current and changing the magnetic field intensity applied to the magnetic liquid, problems existing when the magnetic liquid is used in rotation sealing of the high linear speed and static sealing can be solved; the iron core structure can increase the intensity of the electromagnetic field, improves the magnetism gathering effect and further prolongs the service life of the magnetic liquid.

Owner:BEIJING JIAOTONG UNIV

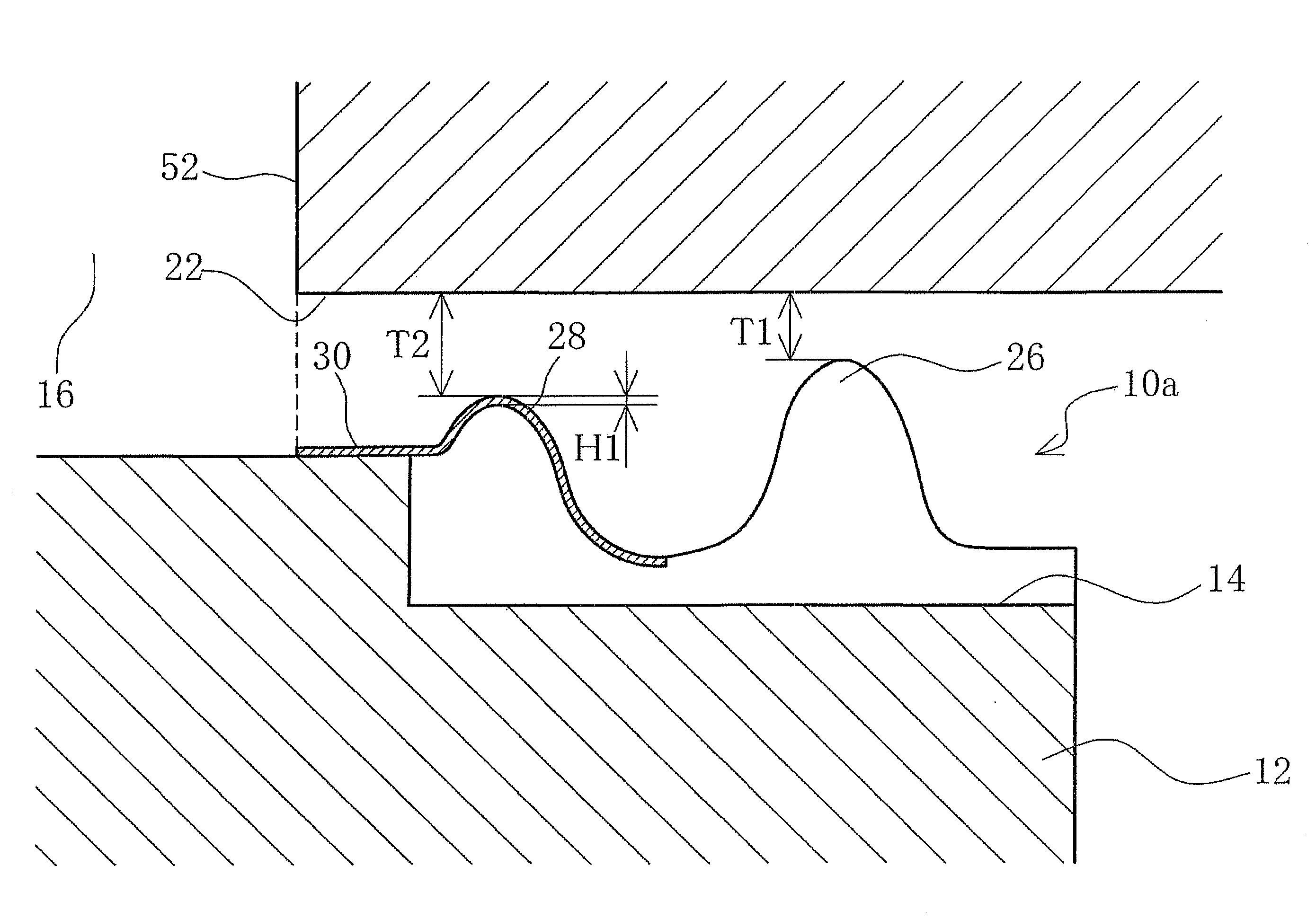

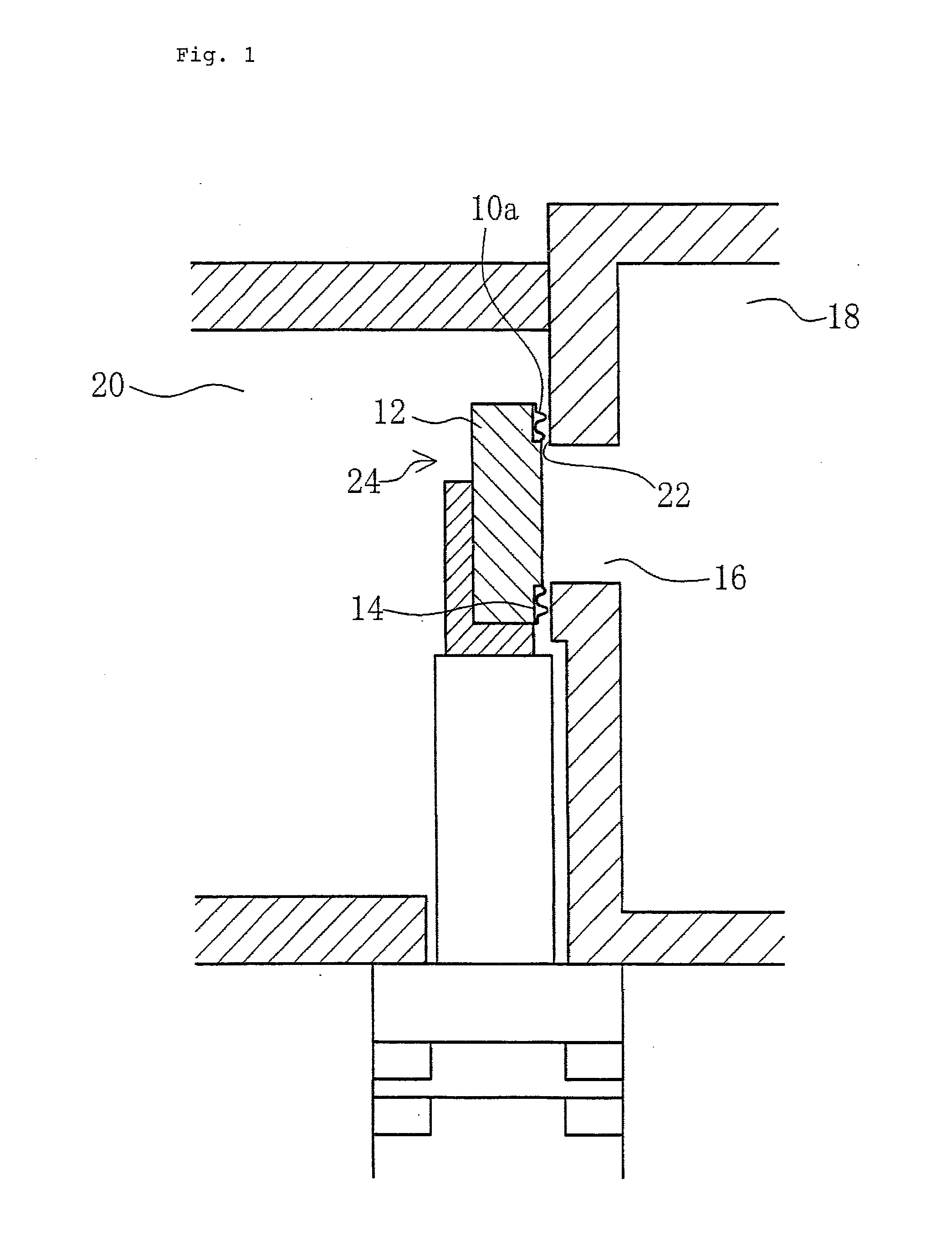

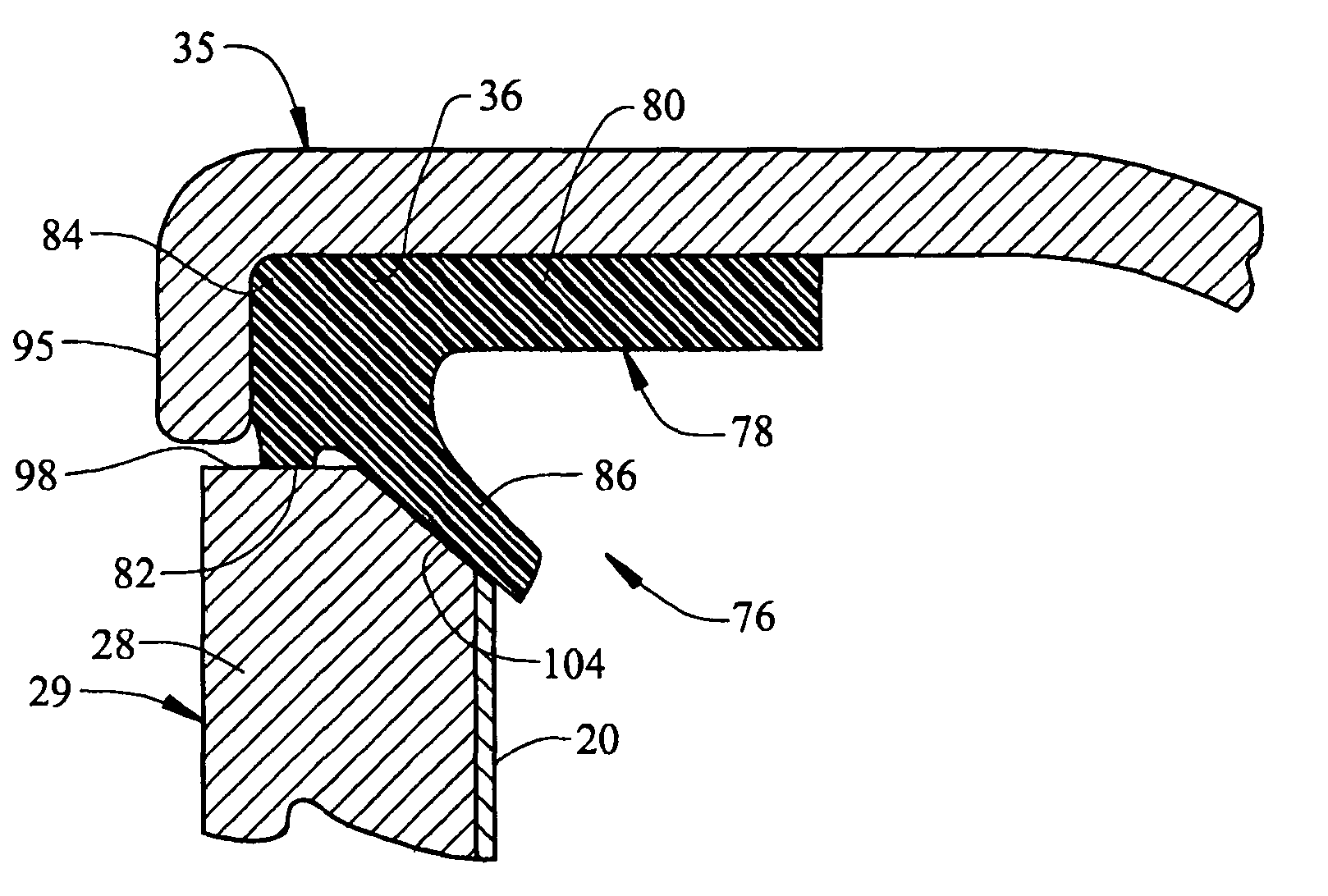

Seal plate, seal member that is used in seal plate, and method for manufacturing the same

ActiveUS8888106B2Extended seal lifeProlong lifeEngine sealsFluid pressure sealed jointsEngineeringGate valve

In a vacuum gate valve, a seal member for sealing a gate opening part is bonded to an outer edge part of a planar seal plate that is disposed in such a manner that the planar seal plate is opposed to a valve seat surface of the gate opening part and comes into contact with the valve seat surface. The seal member includes a vacuum seal part that is located on a side farther from the gate opening part and maintains the sealability of the gate opening part when the gate opening part is closed, and also includes a radical seal part that is located on a side closer to the gate opening part and that prevents the seal member from being affected by a treatment gas in the gate opening part when the gate opening part is closed. The vacuum seal part is made of a rubber elastic body, and the radical seal part is configured by providing a radical resistant body that is provided with an excellent radical resistance on the rubber elastic body.

Owner:VALQUA LTD

Washing machine shaft and machining method thereof

ActiveCN109623298ALow costImprove organizationOther washing machinesTextiles and paperPulp and paper industryMachining

The invention discloses a washing machine shaft and a machining method thereof, and belongs to the technical field of shaft machining. The machining method is characterized in that a cold extrusion process is adopted to machine a rod material to enable the rod material to be formed into a stepped shaft, for the stepped shaft obtained after milling and drilling machining, the two end faces are milled, chamfering is performed, and a center hole is punched so that the stepped shaft can be clamped by adopting a double-centre tool method. According to the washing machine shaft and the machining method thereof, through the unified positioning reference, the machining precision is improved, in addition, the production cost is also reduced, the production efficiency is improved, the operation is simple and convenient, the machining quality is stable, and the batch production is facilitated.

Owner:安徽一众精密轴业有限公司

Valve for the substantially gas-tight interruption of a flow path

ActiveUS8550430B2Reduced seal wearHigh pressure loadingSlide valveLift valveEngineeringPressure difference

A valve for the gastight interruption of a flow path is disclosed. A valve housing includes a first opening and a valve seat. A valve disk includes an inner disk portion, which is linearly movable relative to an outer disk portion so that, in a closed setting, a pressure differential acts substantially upon the movable inner disk portion, which is supported on the valve housing. The valve seat has a radially inward pointing first inner face and the outer disk portion has a radially outward pointing first outer face, wherein in the closed setting there exists a radial sealing contact with the first inner face. The outer disk portion has a radially inward pointing second inner face and the inner disk portion has a radially outward pointing second outer face, having a radially sealing contact with the second inner face.

Owner:VAT HLDG AG

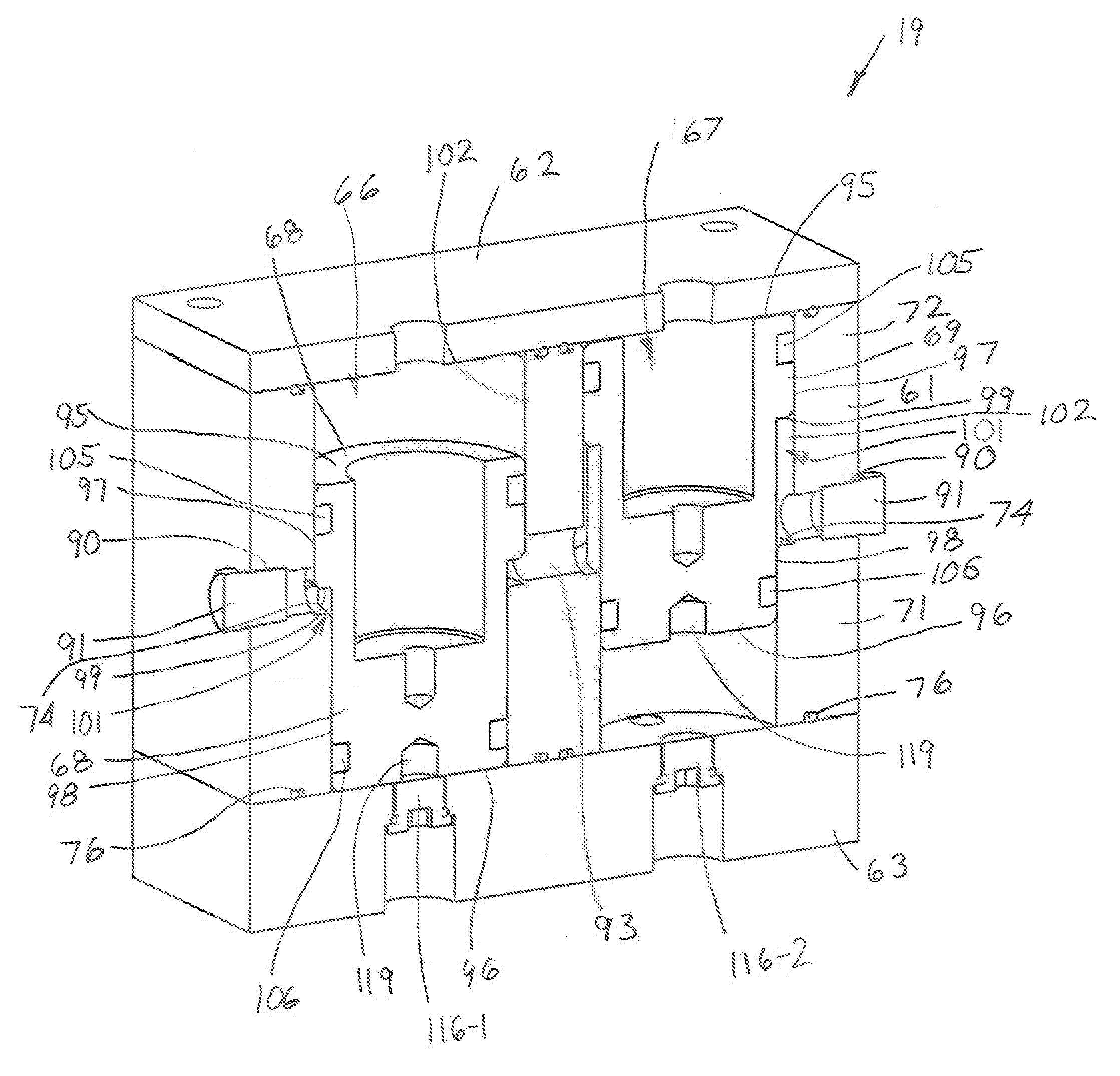

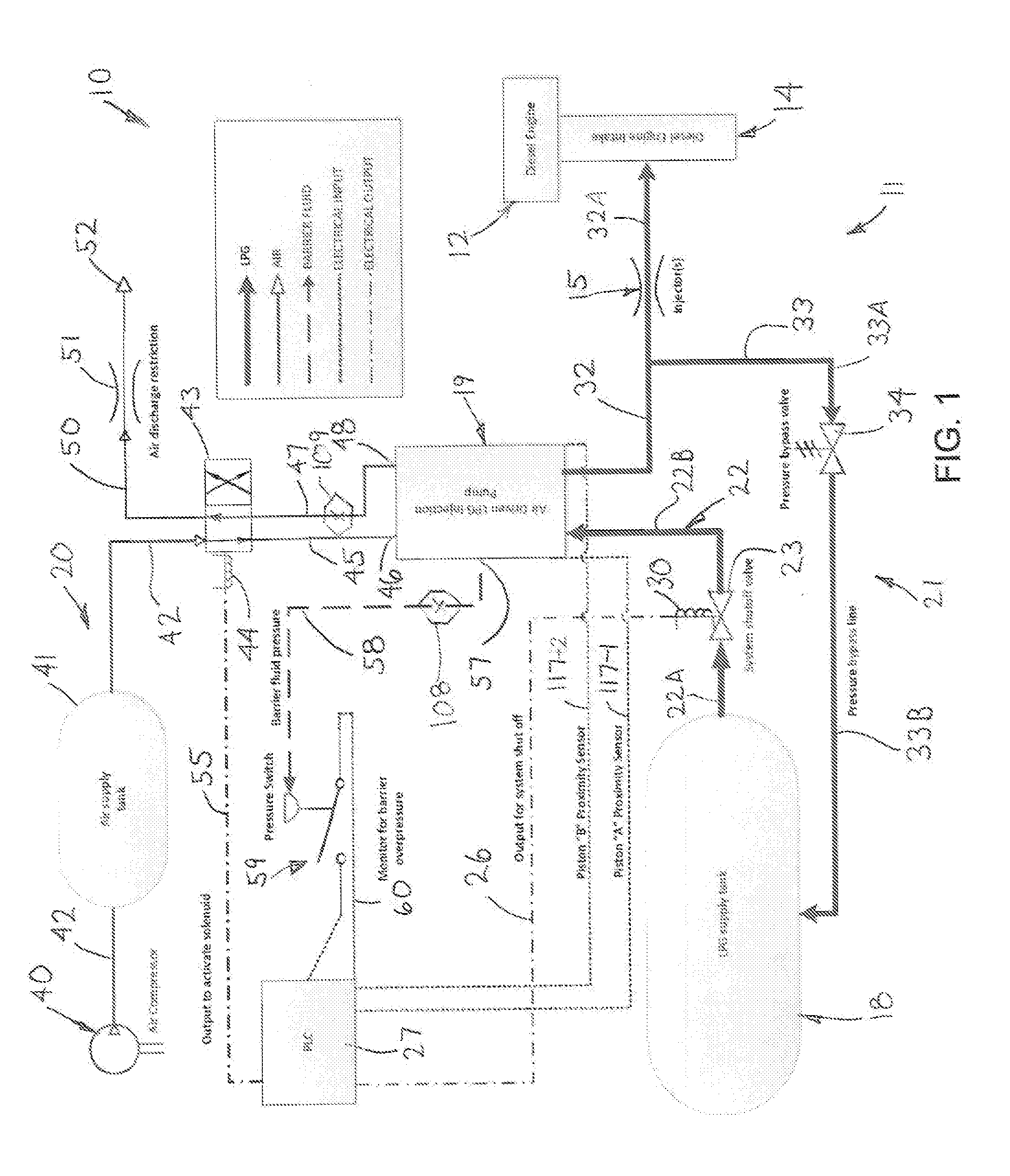

Piston pump for liquefied gas

InactiveUS20140023530A1Increase volumeLower the volumeFlexible member pumpsPiston pumpsEngineeringLiquid gas

A fuel supply system for a vehicle uses a multi-piston LPG injunction pump which pumps fluid from a storage tank to an engine. The multi-piston pump uses the vehicle's pneumatic air system, wherein the pressurized air of this system alternatingly drives at least two pistons of the piston pump. Each piston moves through a pumping stroke and a return stroke wherein one piston moves through a pumping stroke, while the opposite piston moves through a return stroke. The pump includes barrier fluid chambers surrounding each of the pistons wherein during a pumping stroke of one piston, a first barrier fluid chamber associated with the one piston decreases in volume as the piston displaces through its pumping stroke. This reduction in volume of the barrier chamber drives the barrier fluid out of the first barrier fluid chamber into a second barrier fluid chamber associated with the second piston. By driving the barrier fluid into this second chamber, this pressurizes the second chamber and effects the displacing movement of the second piston through its return stroke as the barrier fluid chamber increases in volume through the movement of the second piston.

Owner:DELAWARE CAPITAL FORMATION

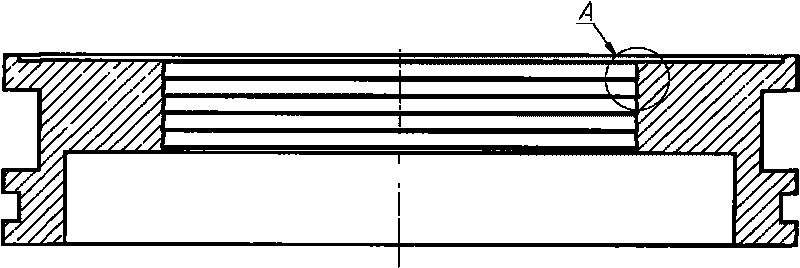

Magnetic liquid and triclinic mouth packing ring combined reciprocating shaft sealing device

InactiveCN101737497AAvoid deformationReduce surface temperatureEngine sealsEngineeringMagnetic liquids

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com