Top drive washpipe system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

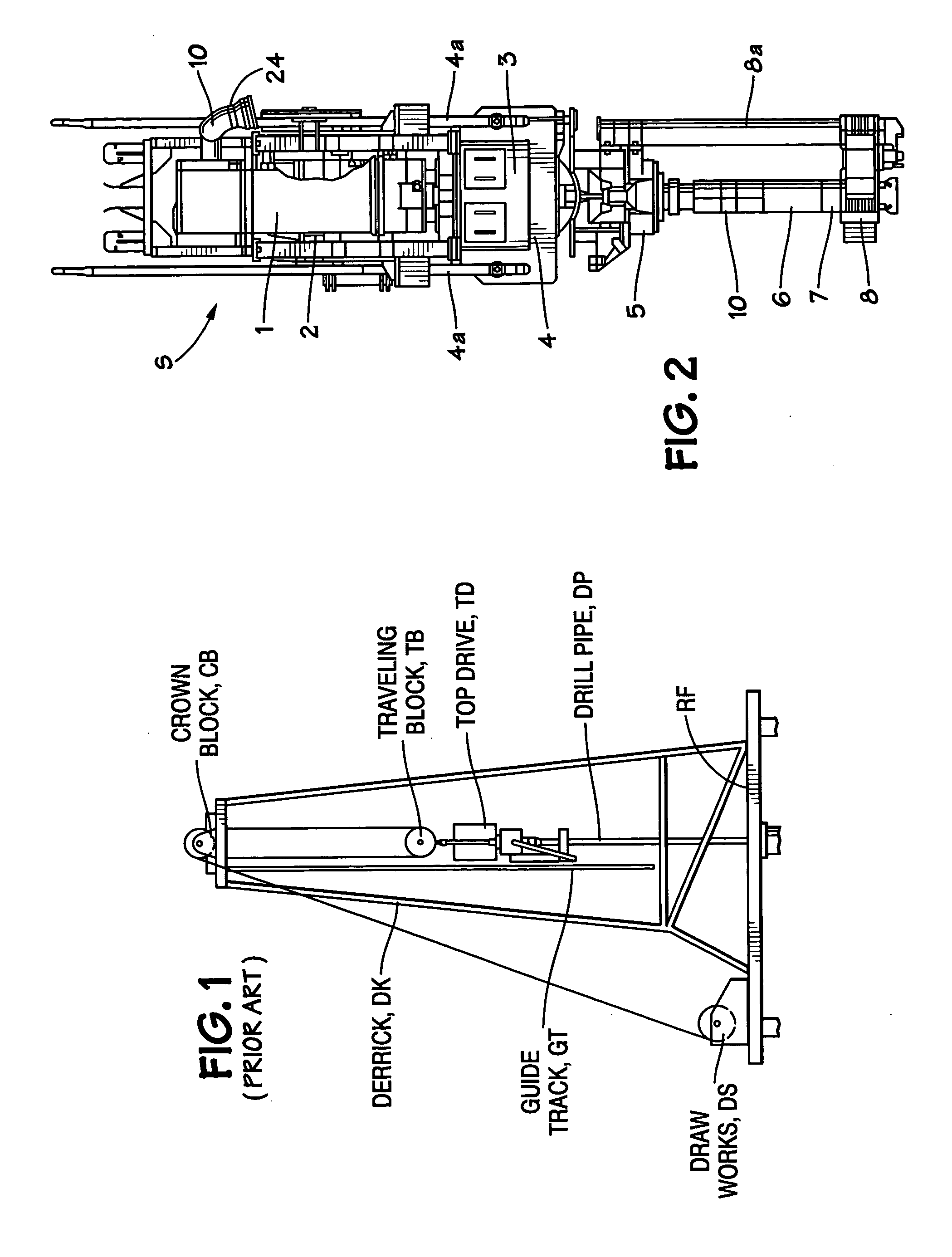

[0027]FIG. 1 shows a typical prior art drilling system with a derrick DK supporting a top drive TD which rotates drill pipe DP. The top drive is supported from a travelling block TB beneath a crown block CB. A drawworks, DS, on a rig floor RF raises and lowers the top drive. The top drive moves on a guide track GT.

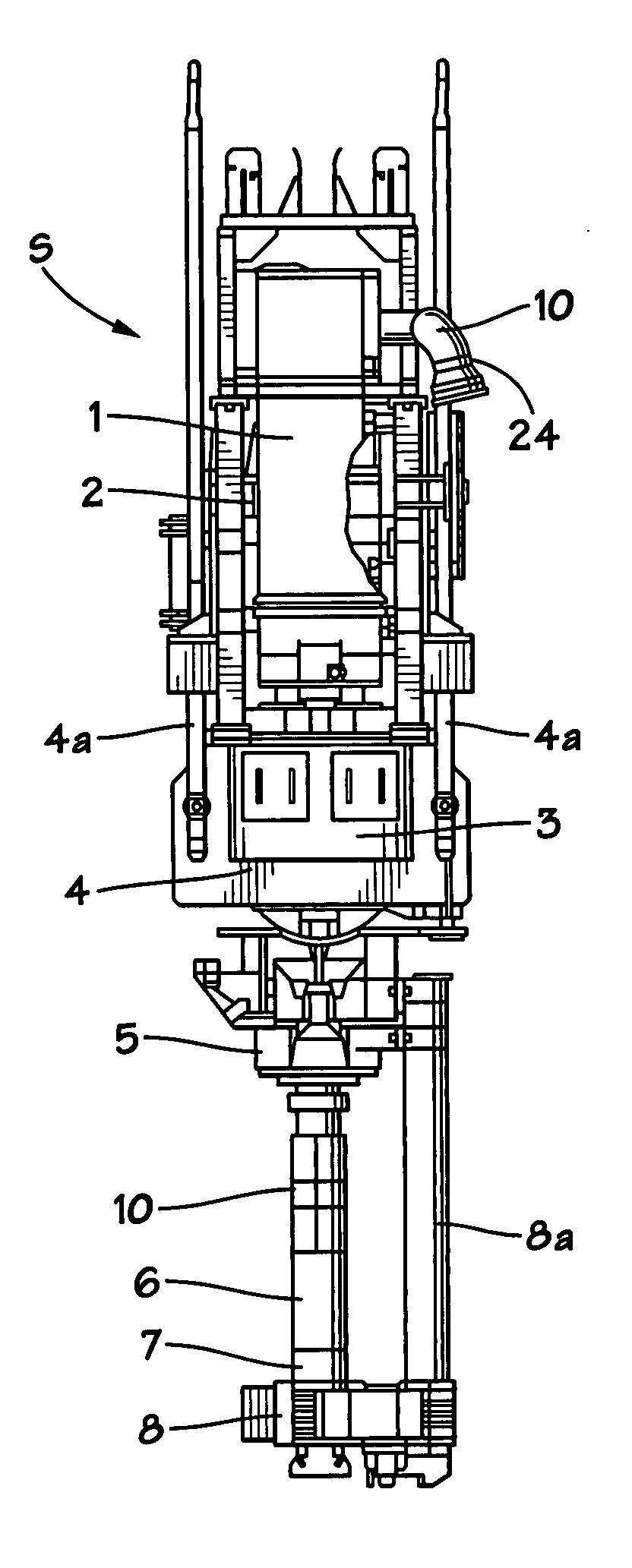

[0028]FIG. 2 shows a system S according to the present invention with a top drive 1 with a drive motor 2; a gear system 3 coupled to the top drive 1 with a bearing support 4 and support links 4a; a washpipe apparatus 10 with a washpipe shaft according to the present invention; an elevator load ring 5; a mud saver system 9; a lower internal blowout preventer 6; a saver sub 7; a gooseneck 24; and a pipe gripper 8 with supports 8A connected to the elevator load ring 5.

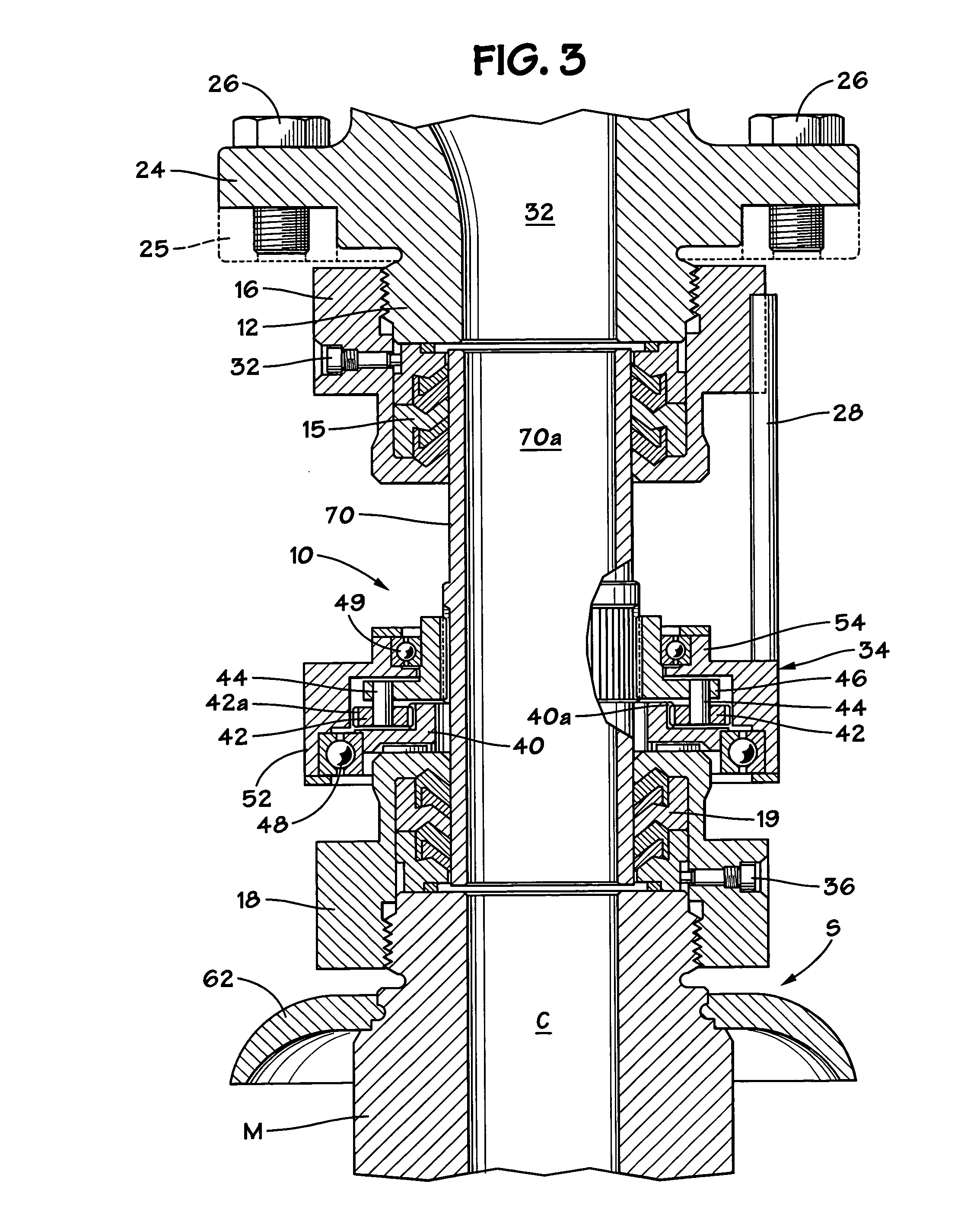

[0029]The present inventors have recognized the problems associated with the rotation of a shaft with respect to packing or seals and have realized that effective reduction of the speed of shaft rotation can enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com