Patents

Literature

40results about How to "Reduced seal wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

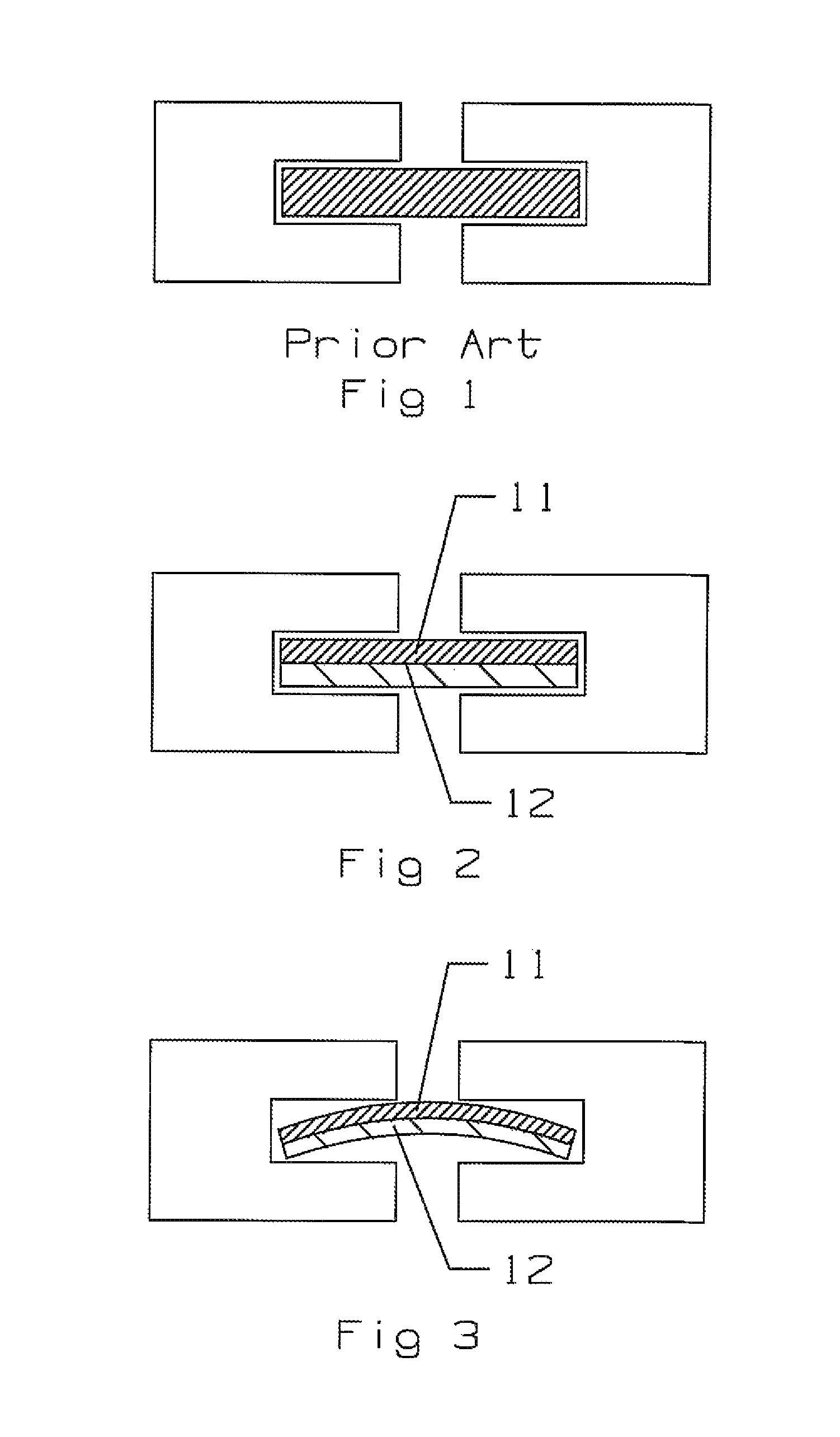

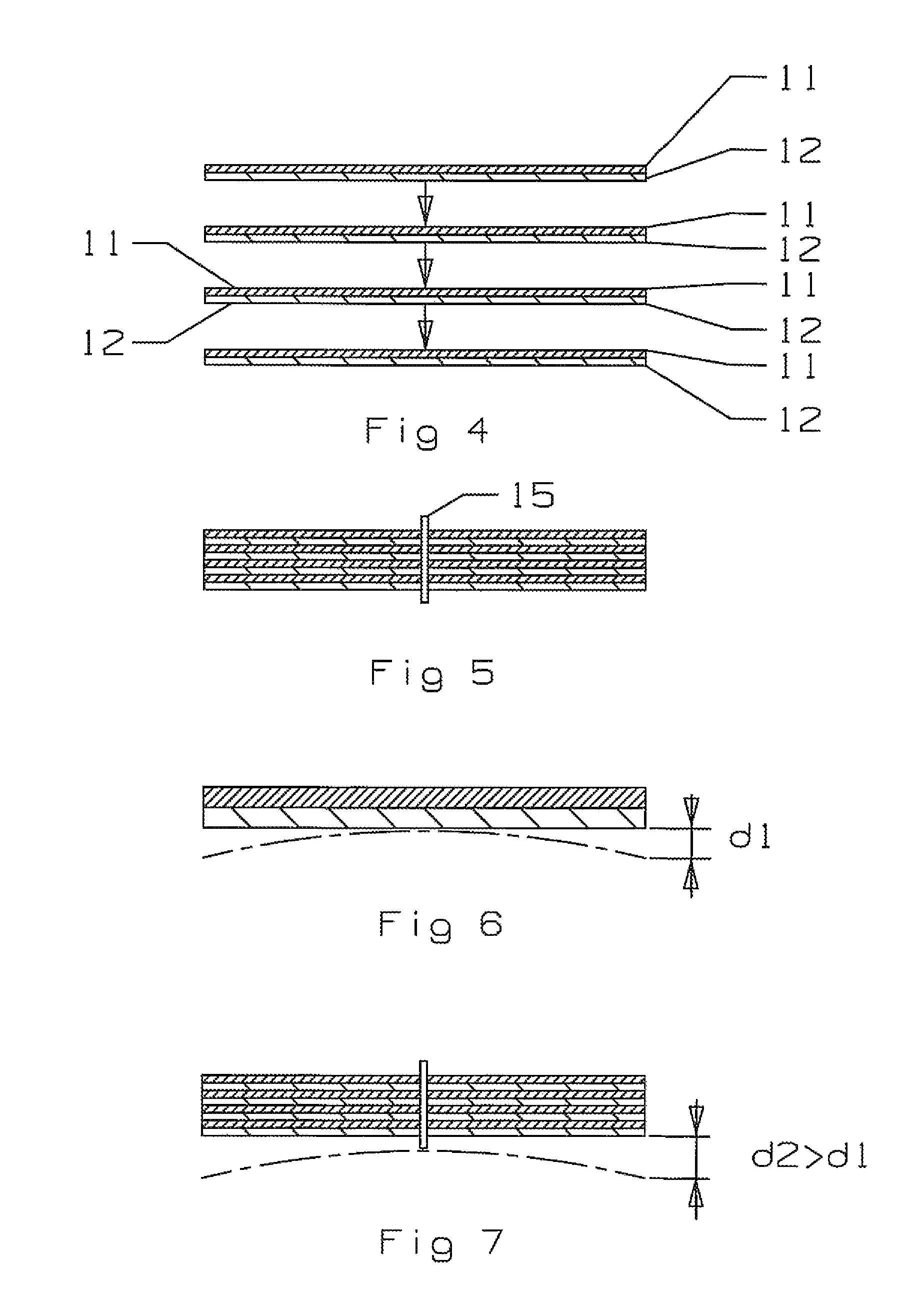

Bi-metallic strip seal for a turbine shroud

ActiveUS8210799B1Easily instalSufficient sealEngine sealsPump componentsGas turbinesMetallic materials

A bi-metallic strip seal used to seal the gap between adjacent shroud segments in a gas turbine engine. The bi-metallic strip seal is formed from one or more layers of bi-metallic materials with different coefficients of thermal expansion. In a cold state the bi metallic strip seal will fit within the slot easily, while in the hot state the strip seal will expand to fit tightly within the slot and block leakage flow. The strip seal can be formed with the bi-metallic layers oriented similarly or oppositely in order to control the seal force and deflection properties. In one embodiment, the strip seal is formed from four bi-metallic layers in which the middle is bonded while the adjacent layers are free from shear.

Owner:FLORIDA TURBINE TECH

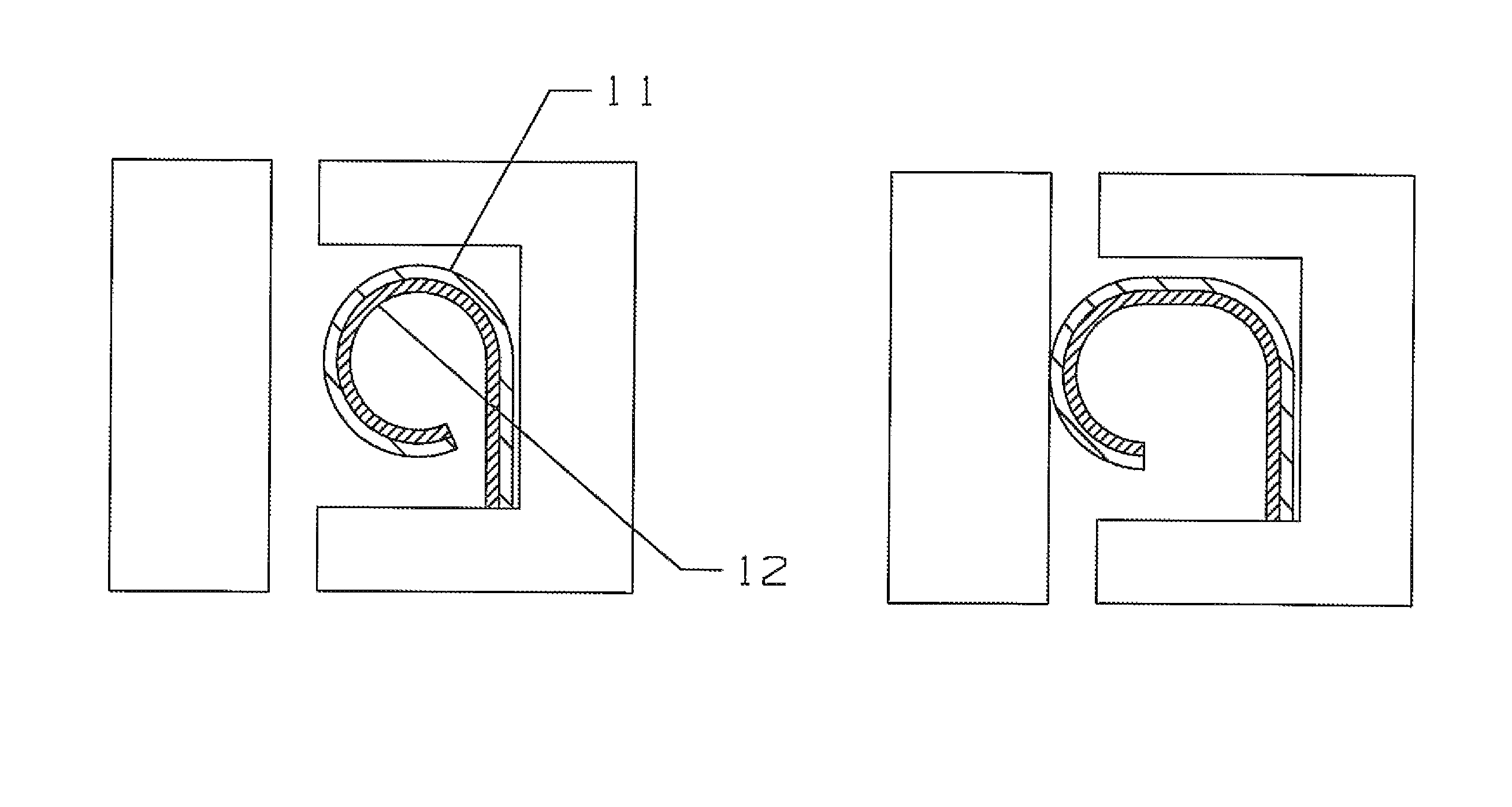

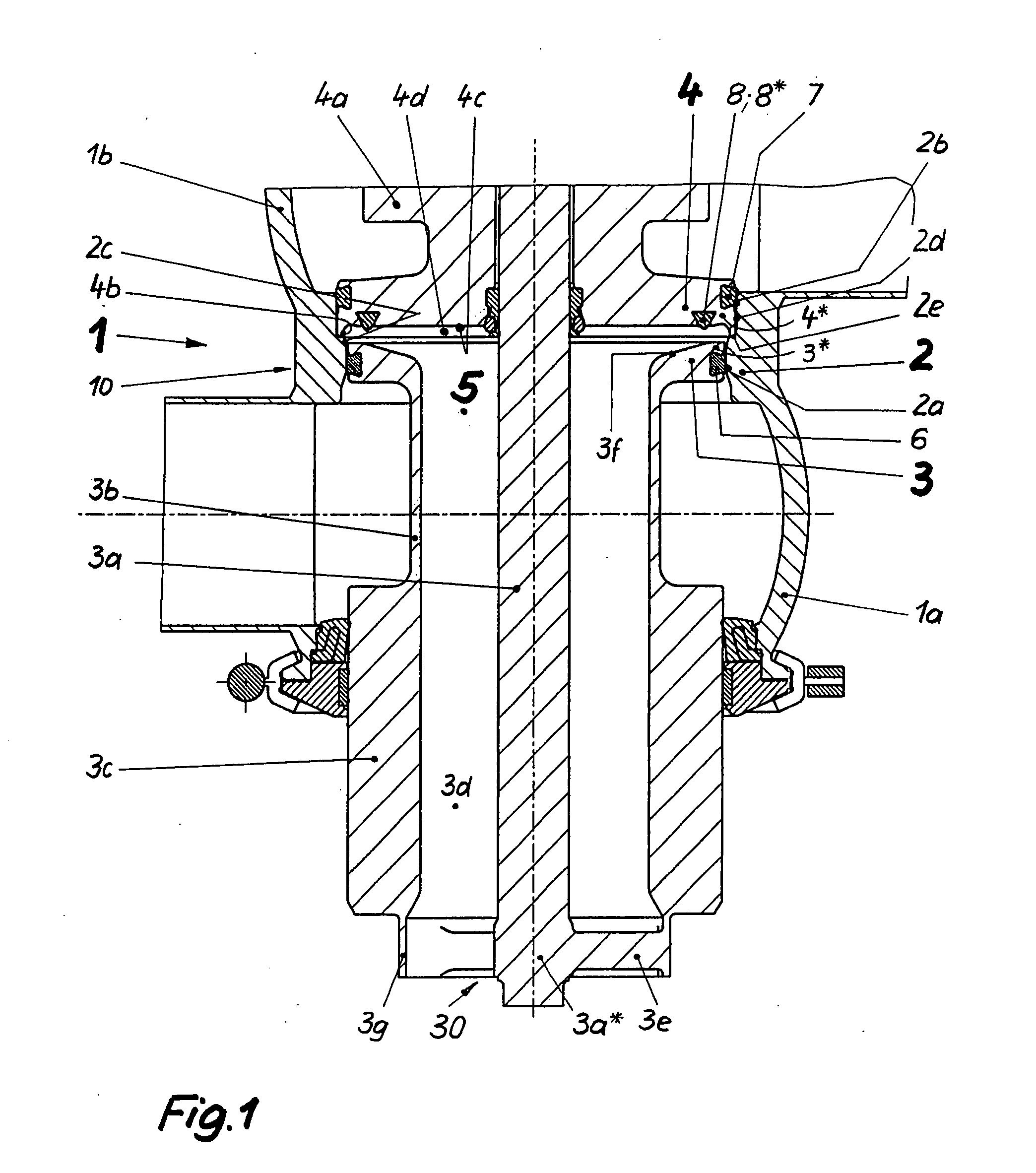

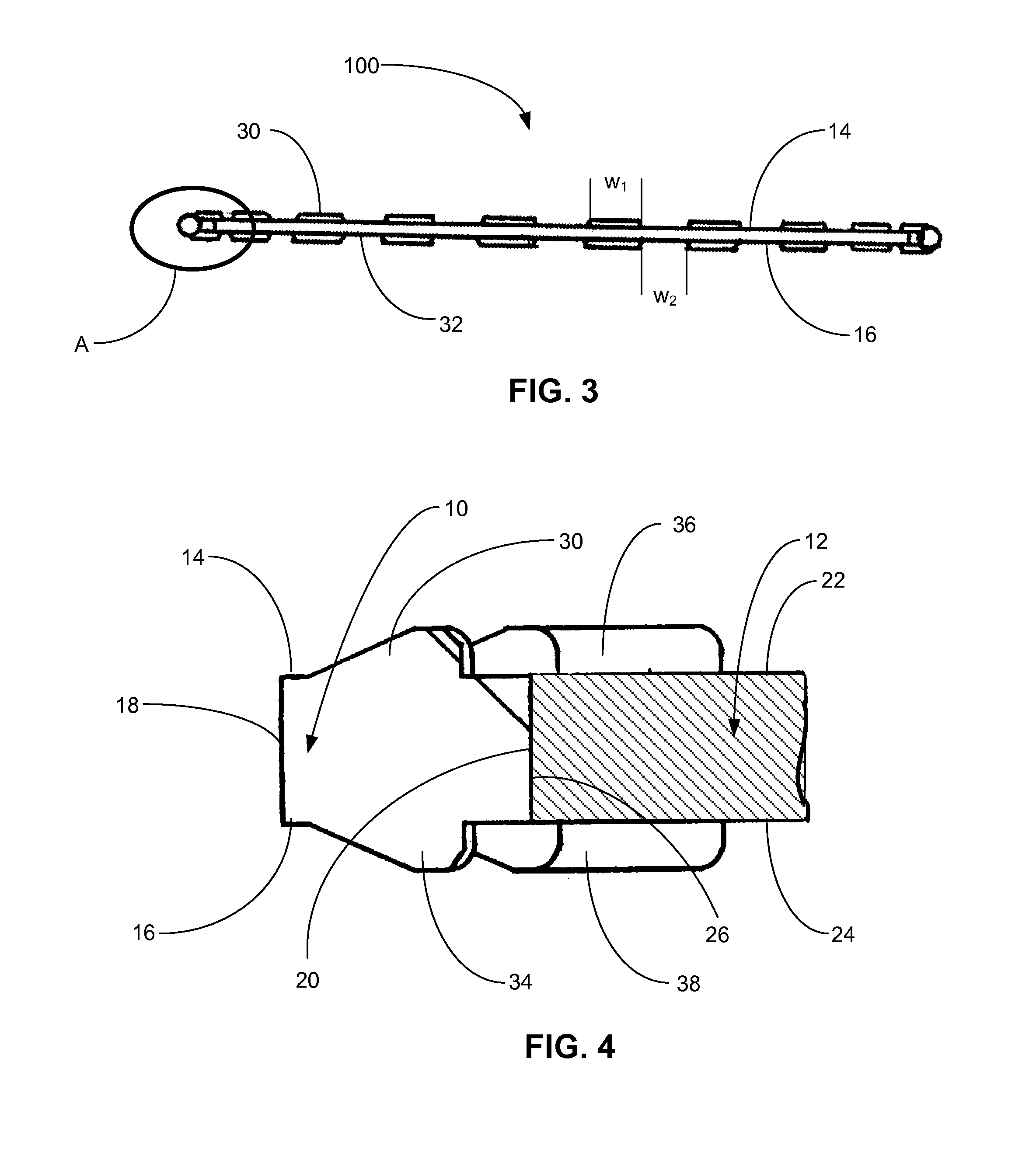

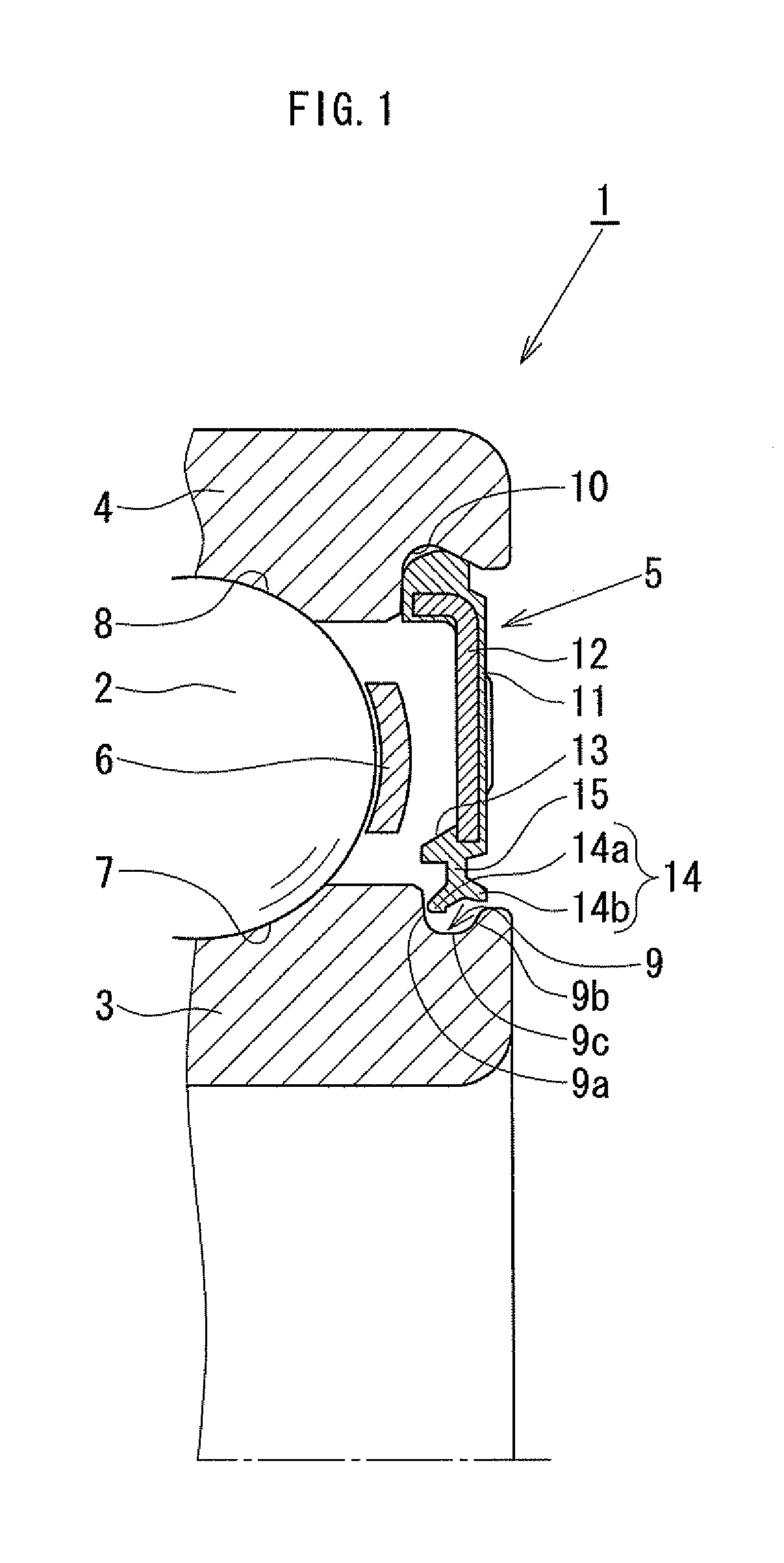

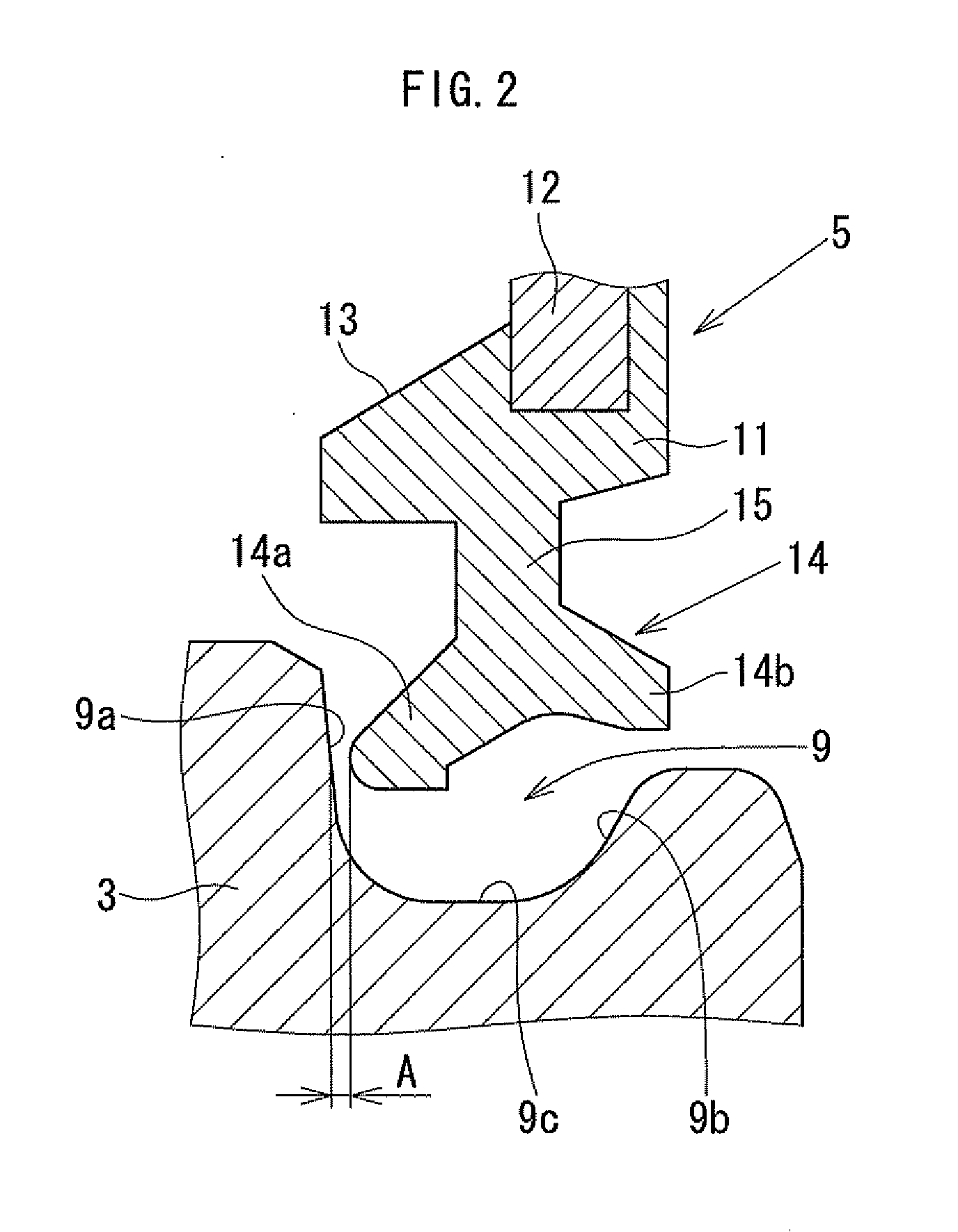

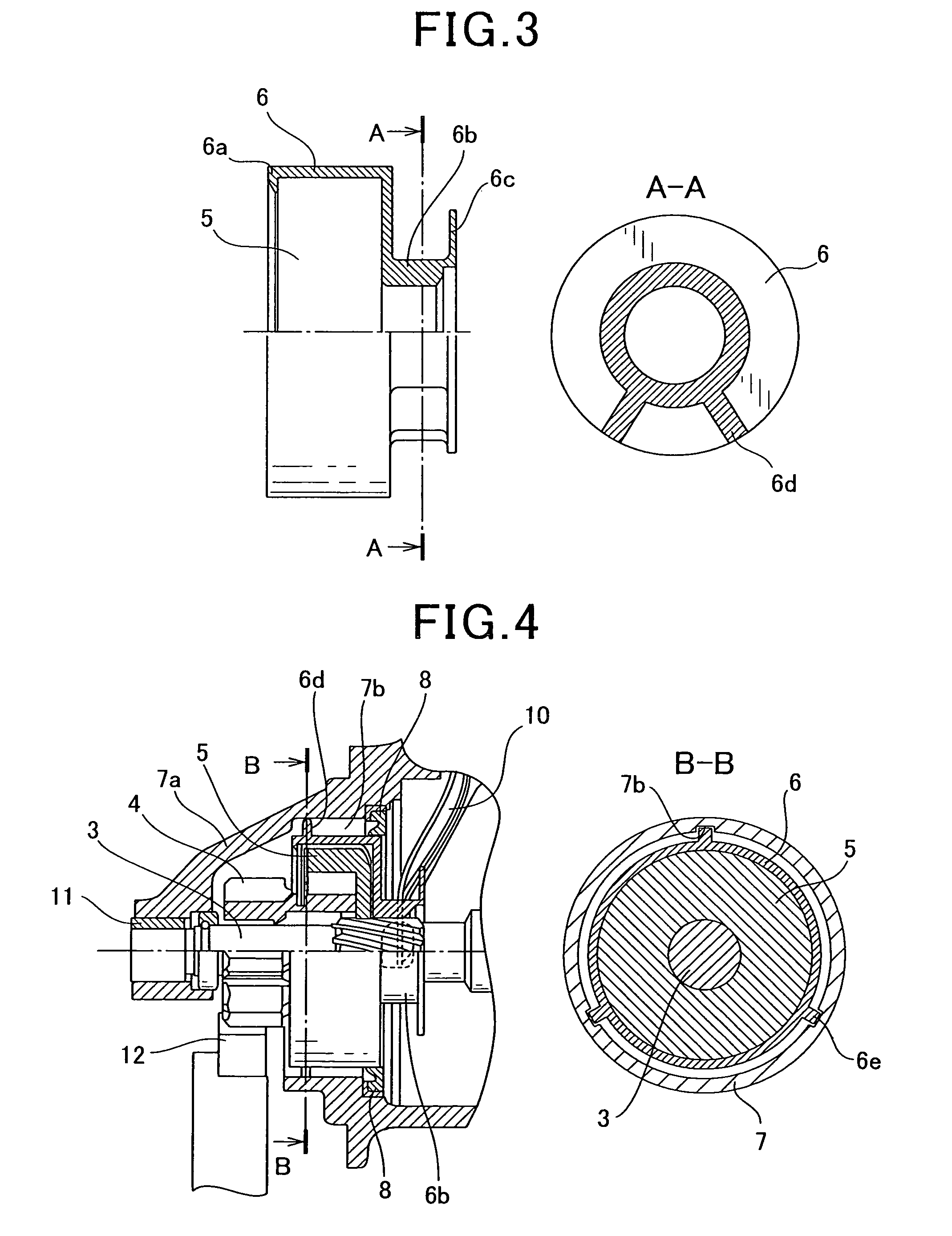

Annular seal assembly for insertion between two relatively rotatable members, in particular a tub and a rotating shaft of the drum of a washing machine

ActiveUS20080272557A1Improve performanceSlight frictionEngine sealsOther washing machinesRotational axisRadial plane

A seal assembly including a first rigid shield having an annular sealing member of elastomeric material, and a second rigid shield mounted facing the first and having respective sliding surfaces for a first and second annular sealing lip of the annular sealing member, which extend towards the second rigid shield to exert axial sealing pressure and radial sealing pressure, respectively; wherein the first annular sealing lip has a radial seat facing the opposite way to the second annular sealing lip and housing a toroidal spring, which exerts a radial thrust on the first annular sealing lip eccentrically with respect to an elastic hinge defined by a root portion common to the first and second annular sealing lip, and having a centre of rotation located along a line extending through a V-shaped sealing edge of the first annular sealing lip and forming a 20° to 60° angle with a radial plane; the root portion being defined between two opposite annular recesses of the annular sealing member, which have a U-shaped radial section and bottom walls facing each other and substantially aligned along the aforementioned line; and the second annular sealing lip having a V-shaped sealing edge defined by an undulated, circumferential groove.

Owner:AB SKF

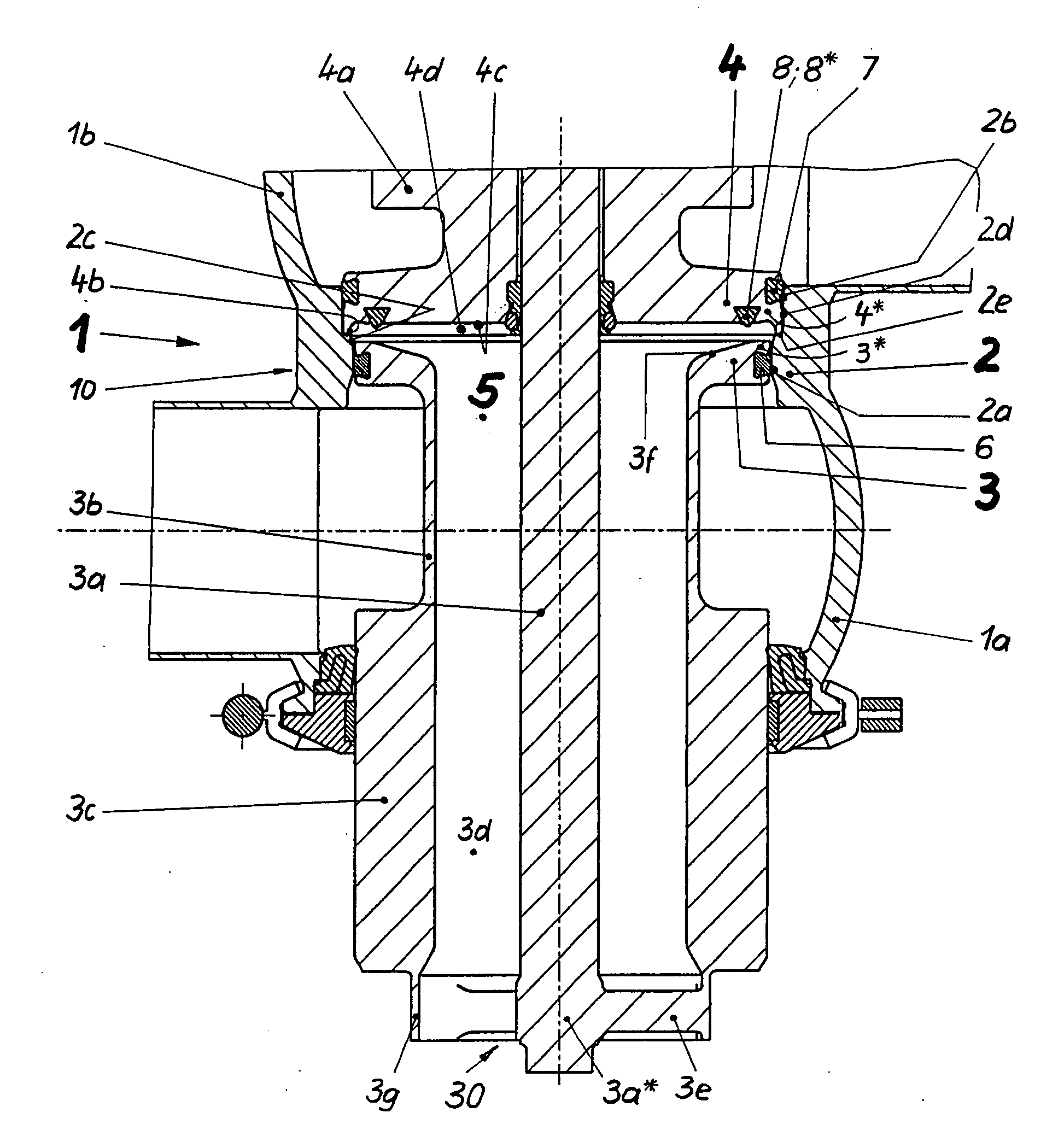

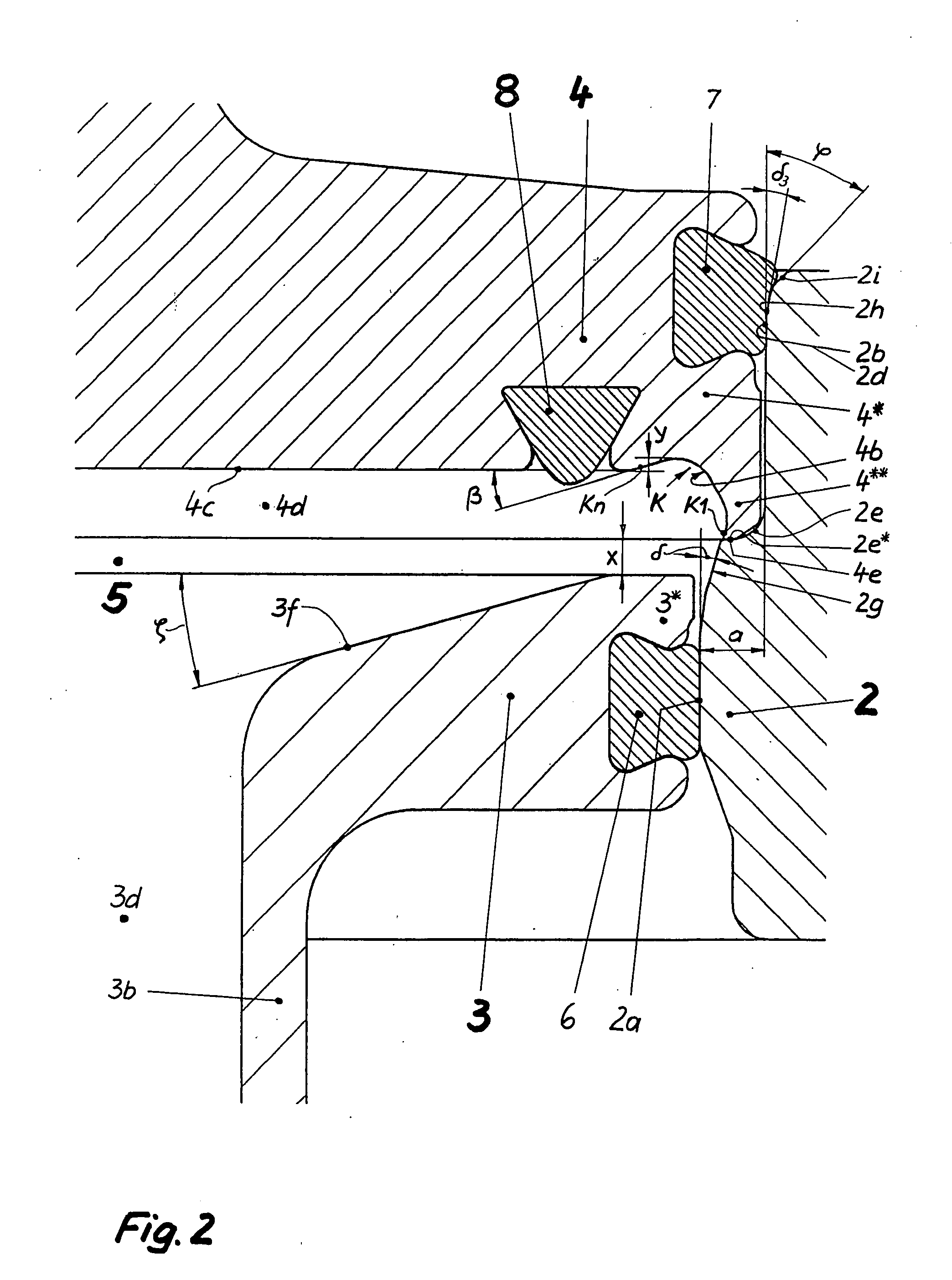

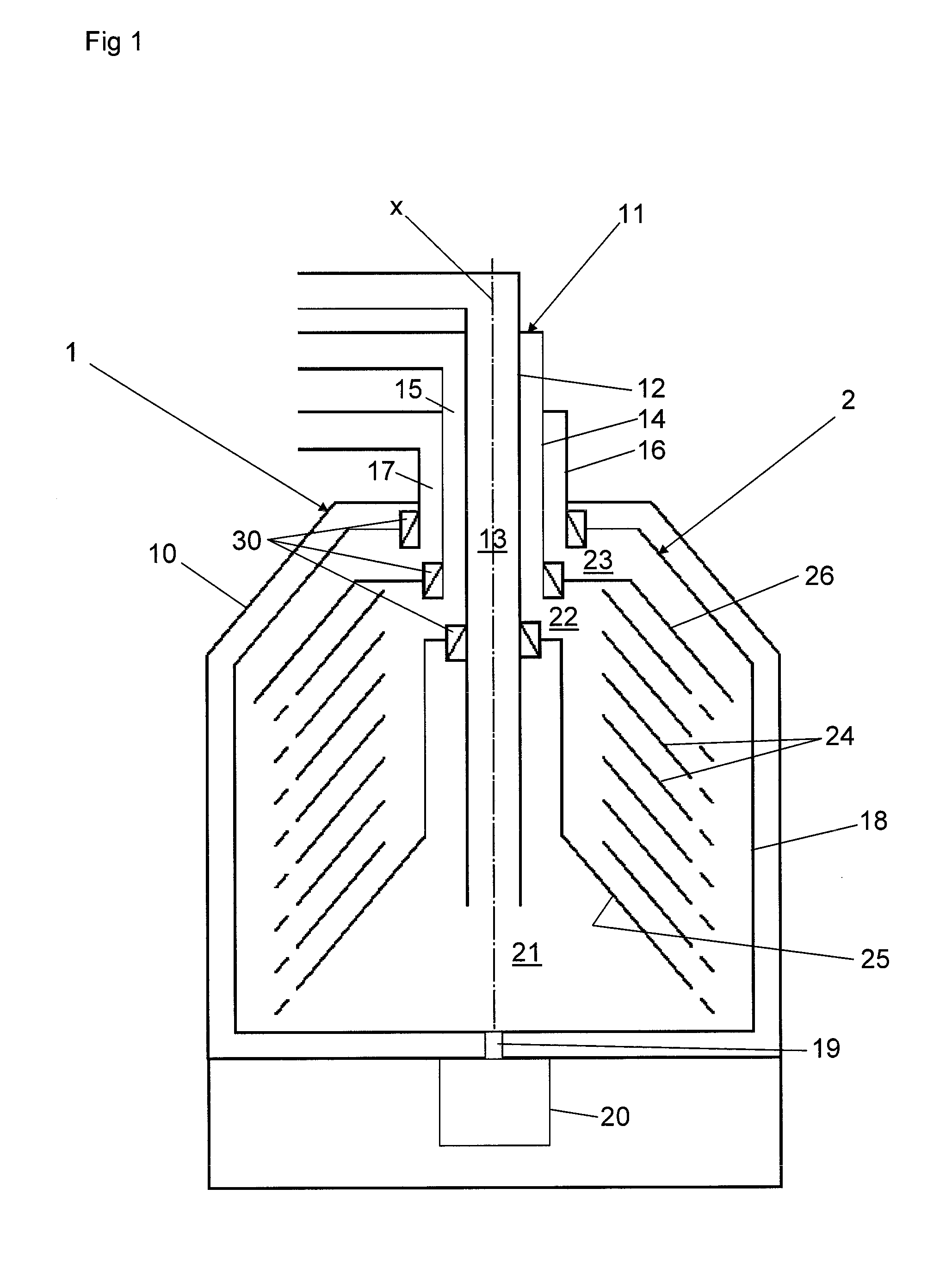

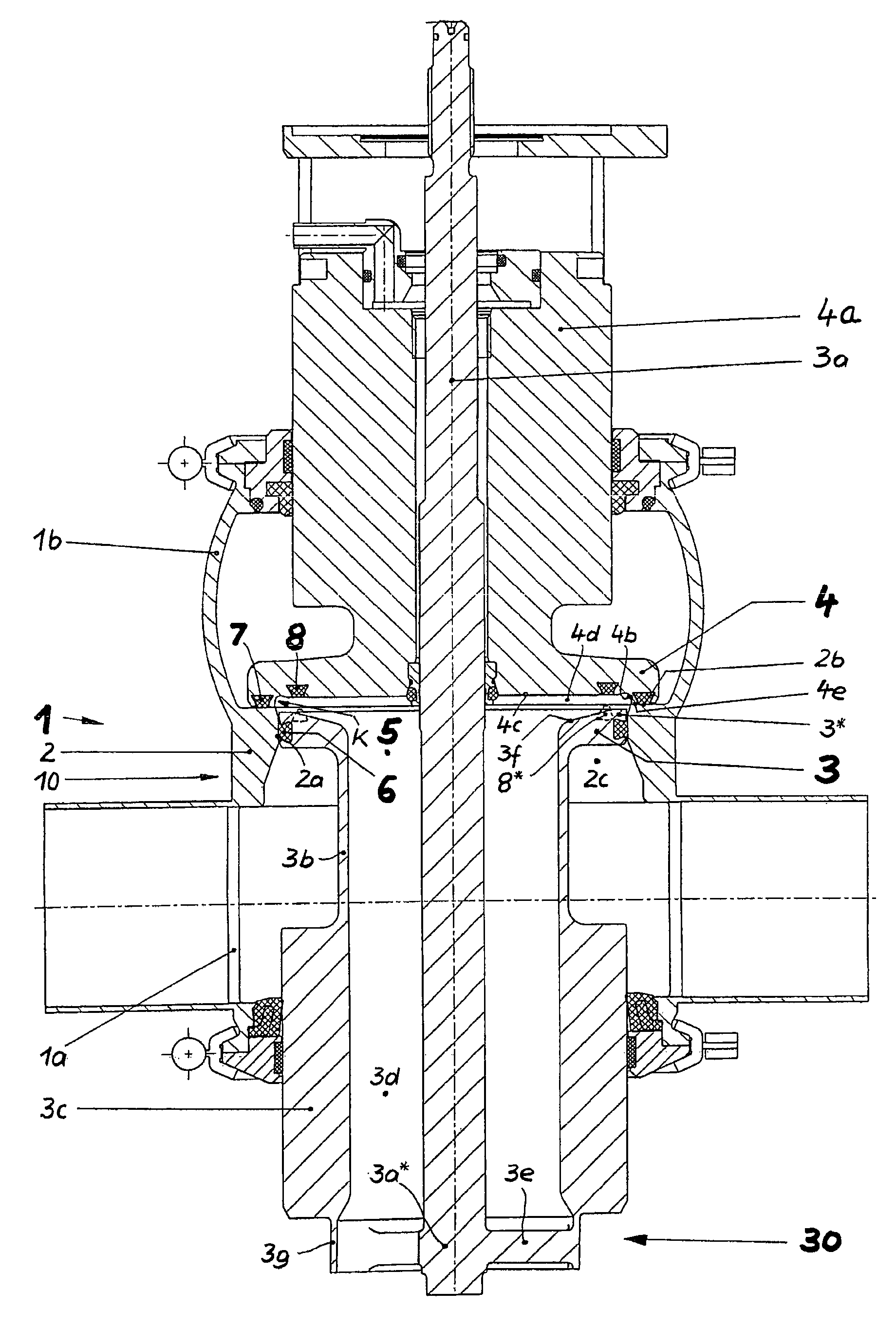

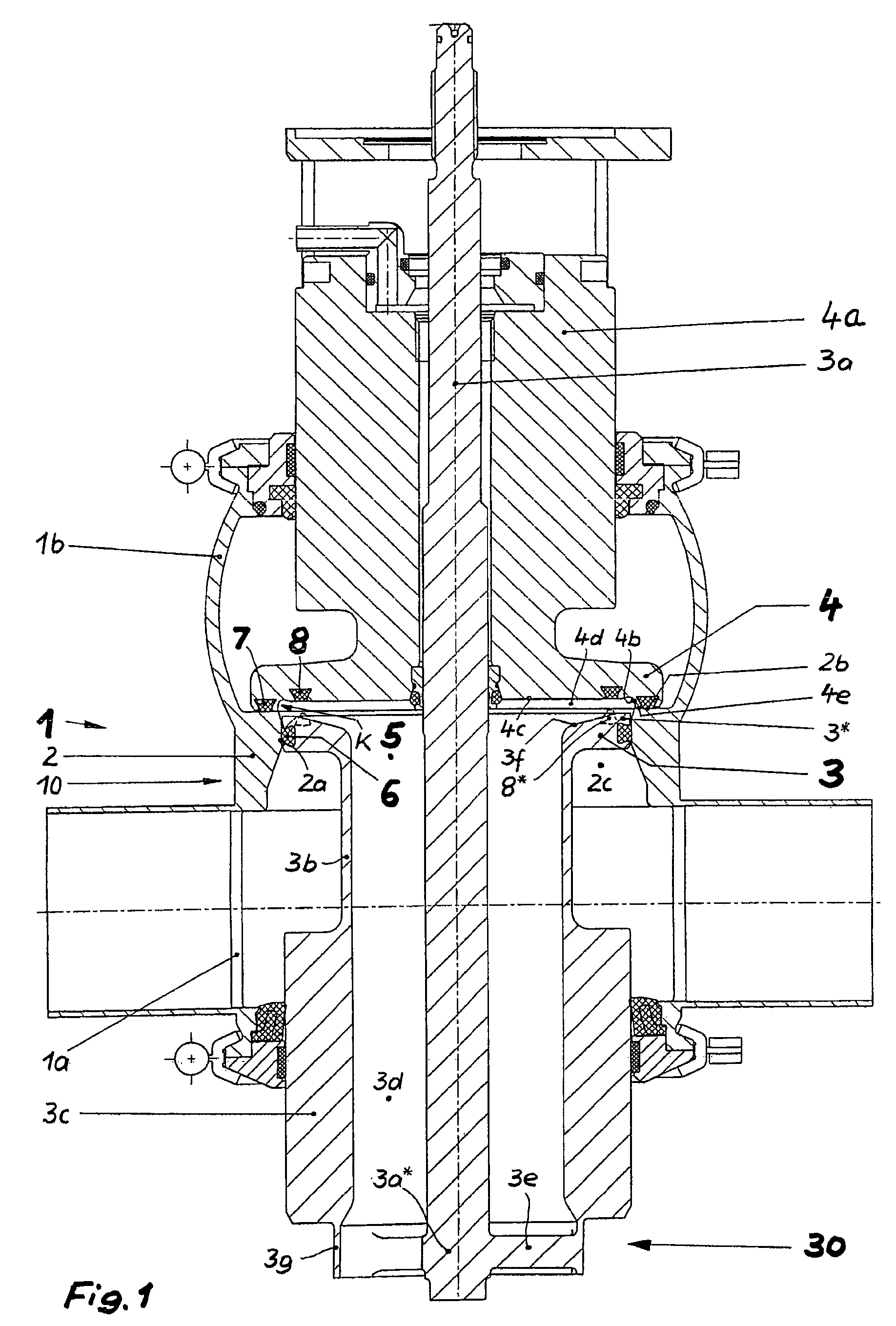

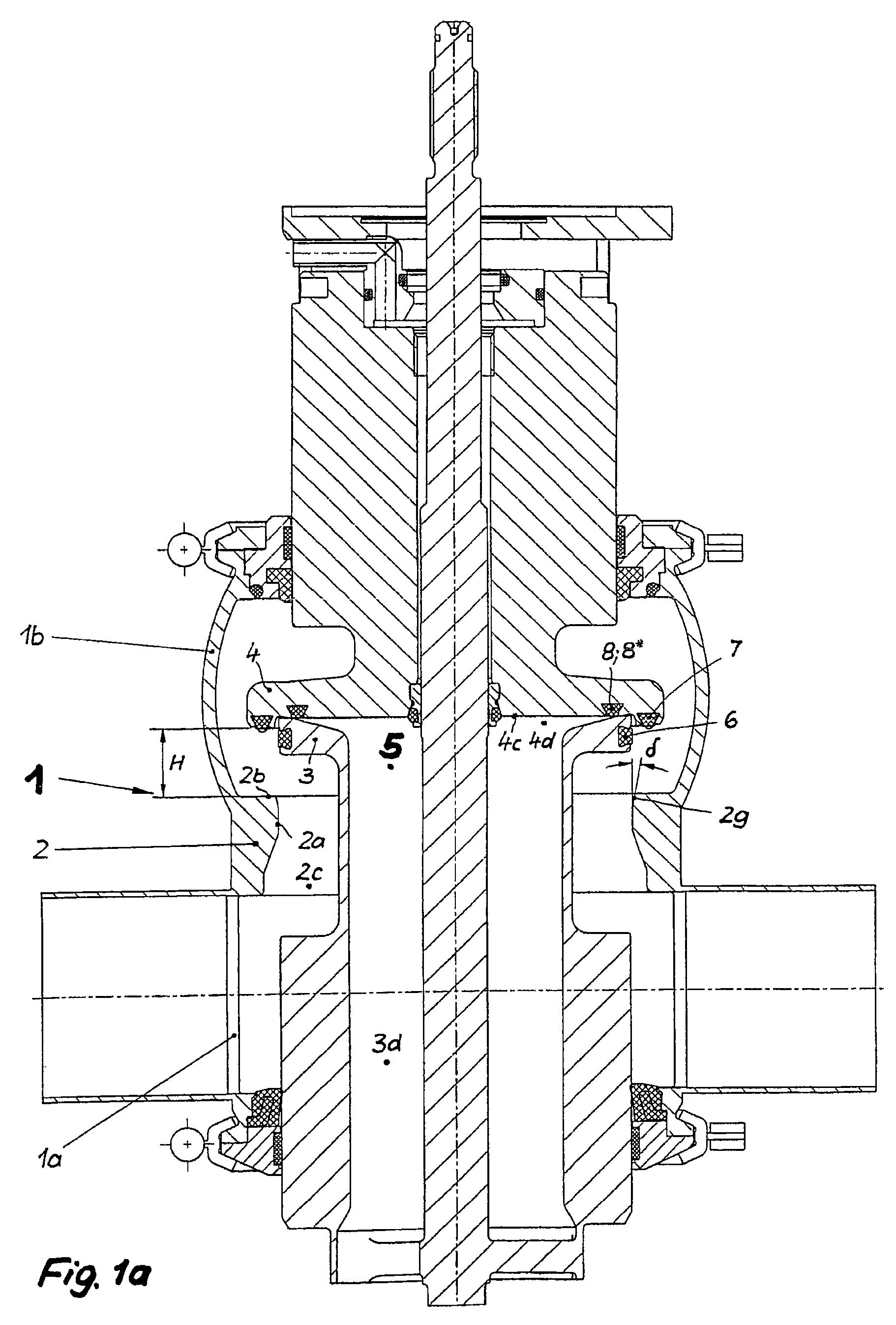

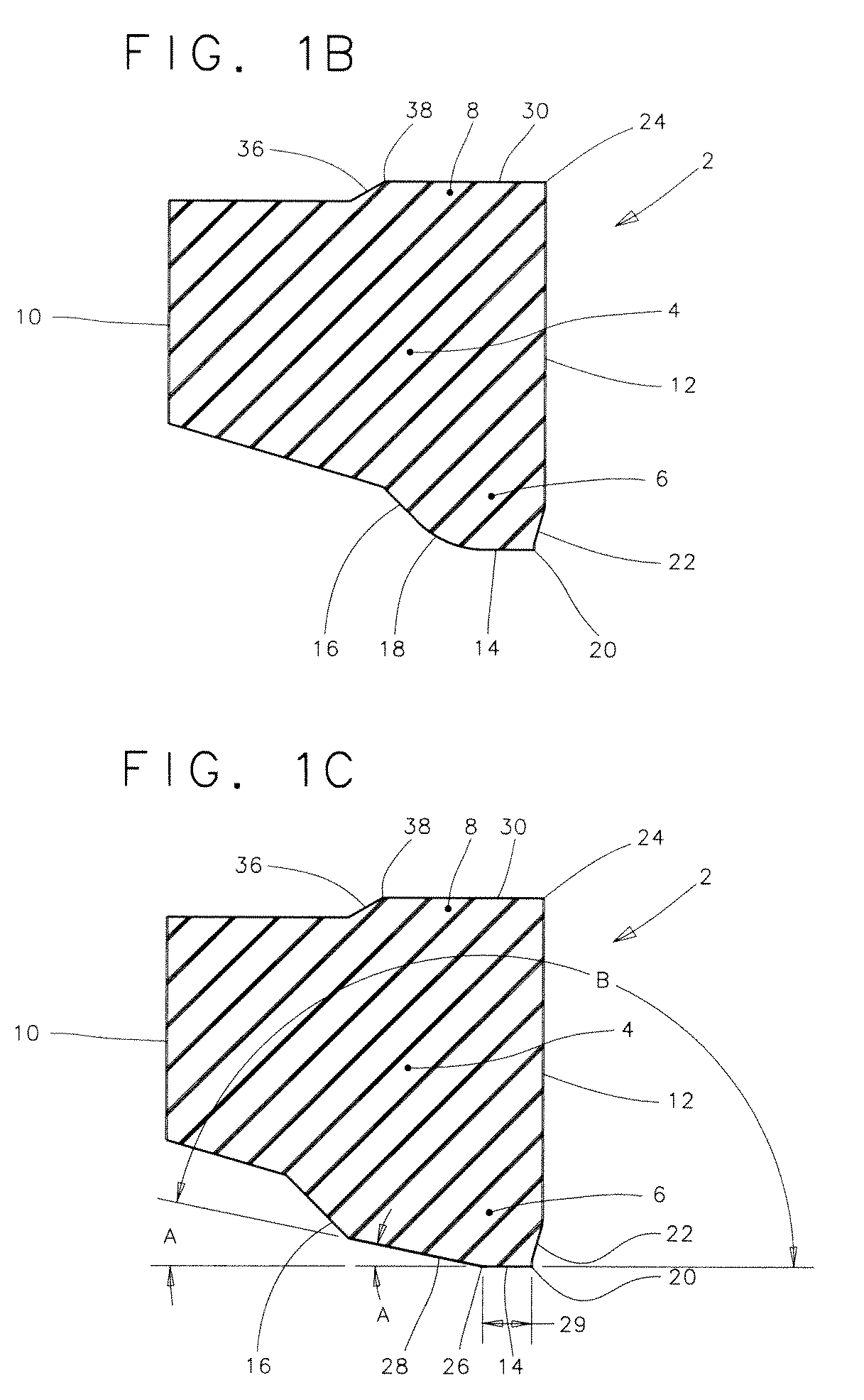

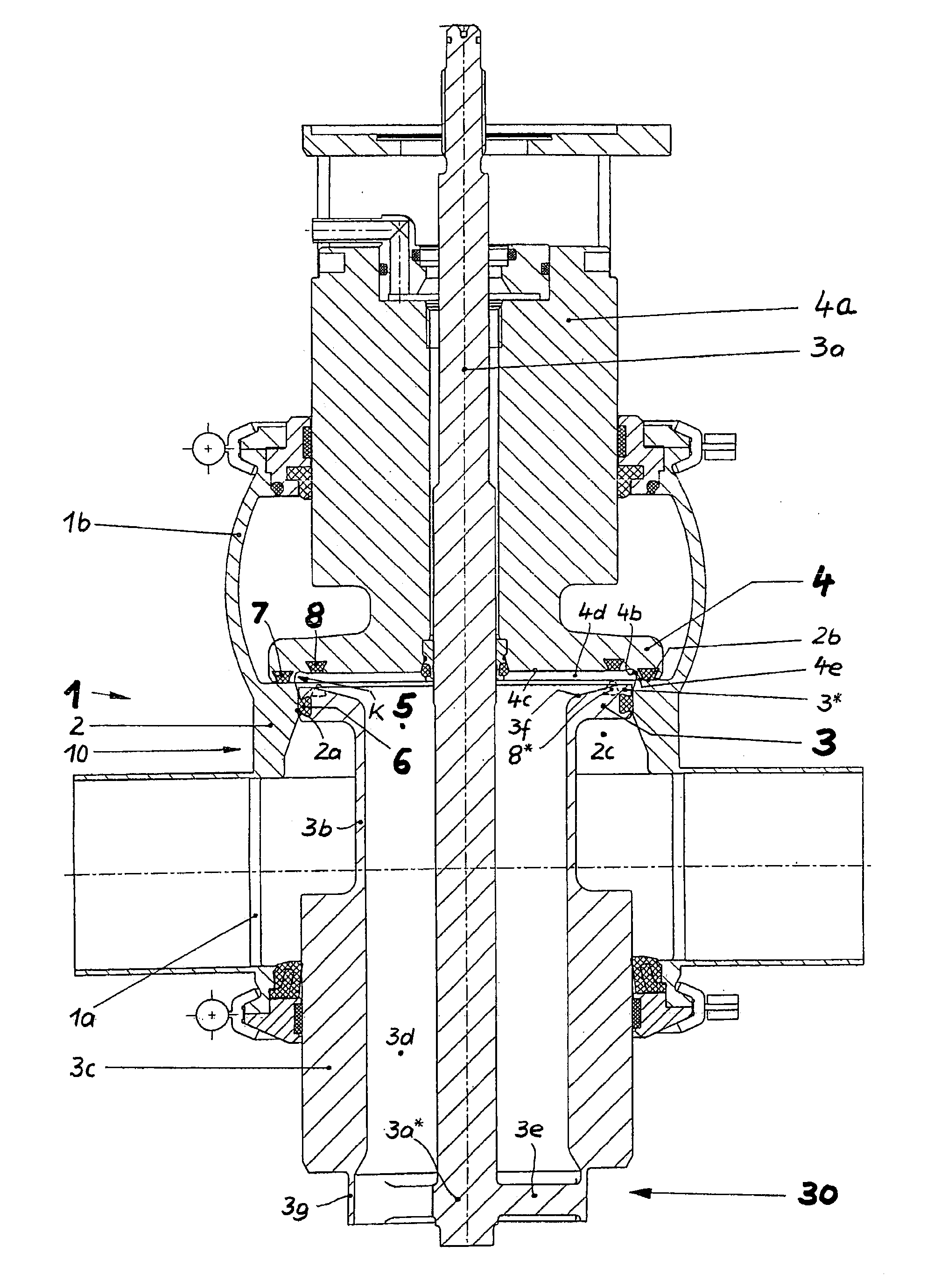

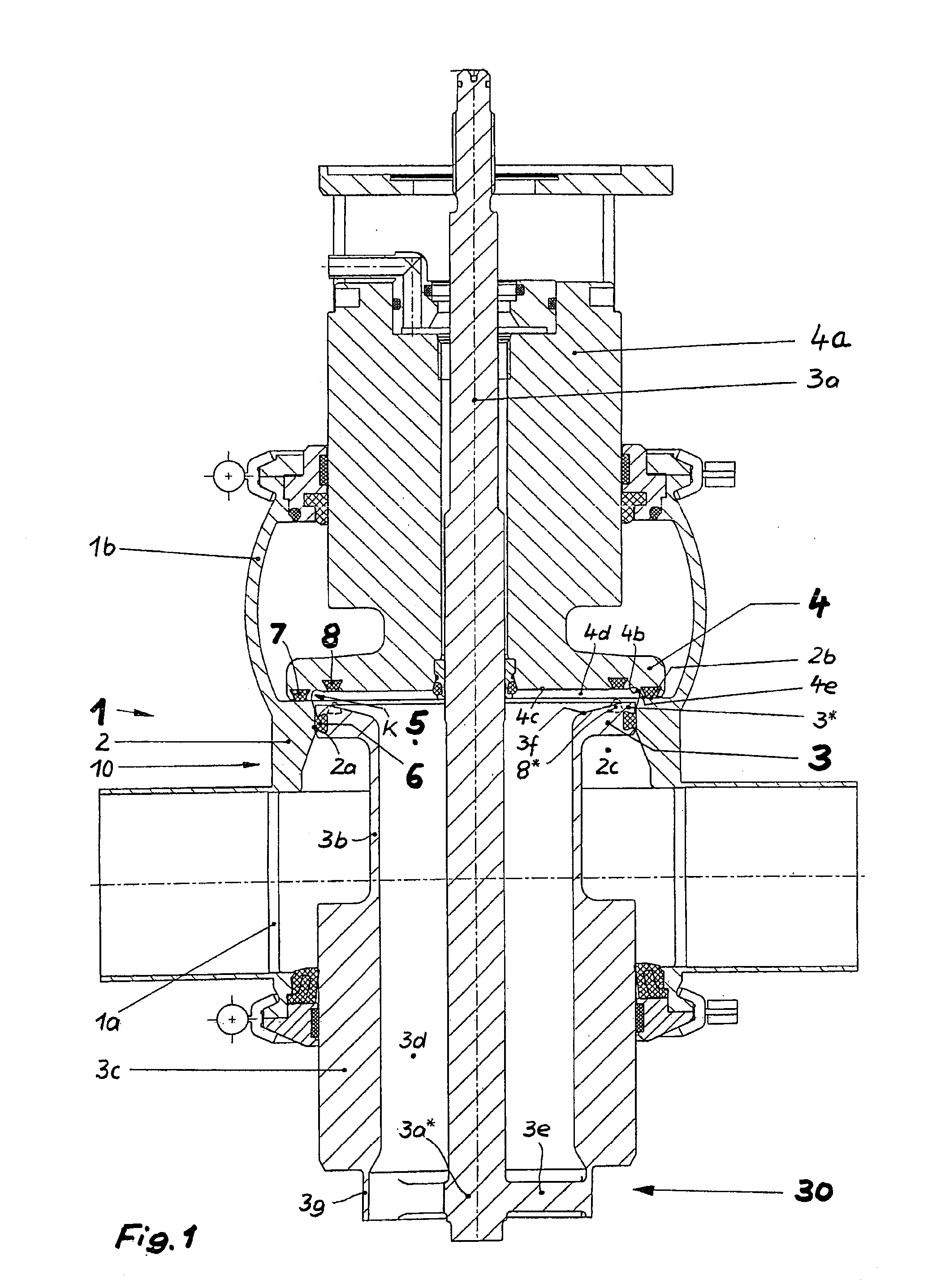

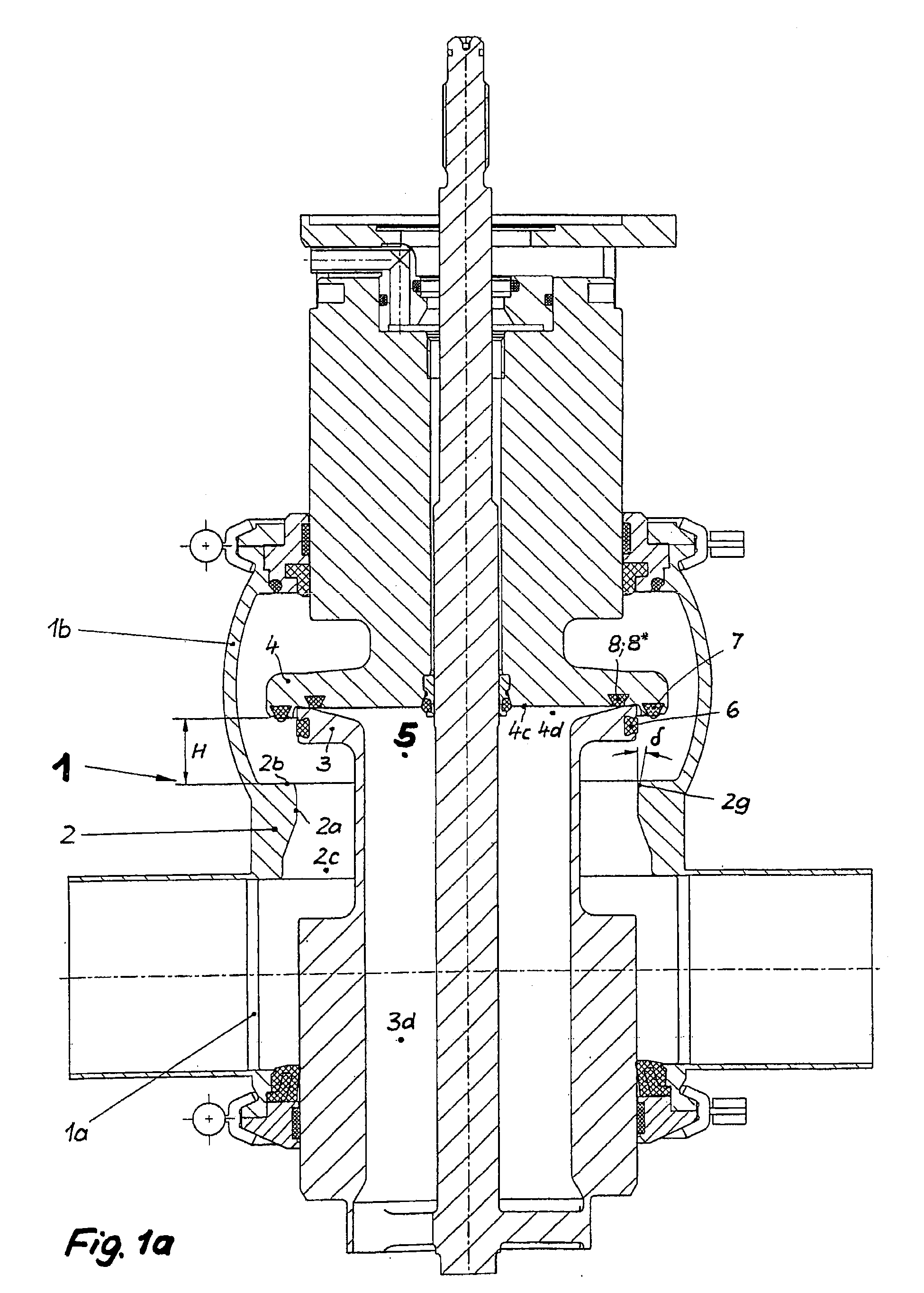

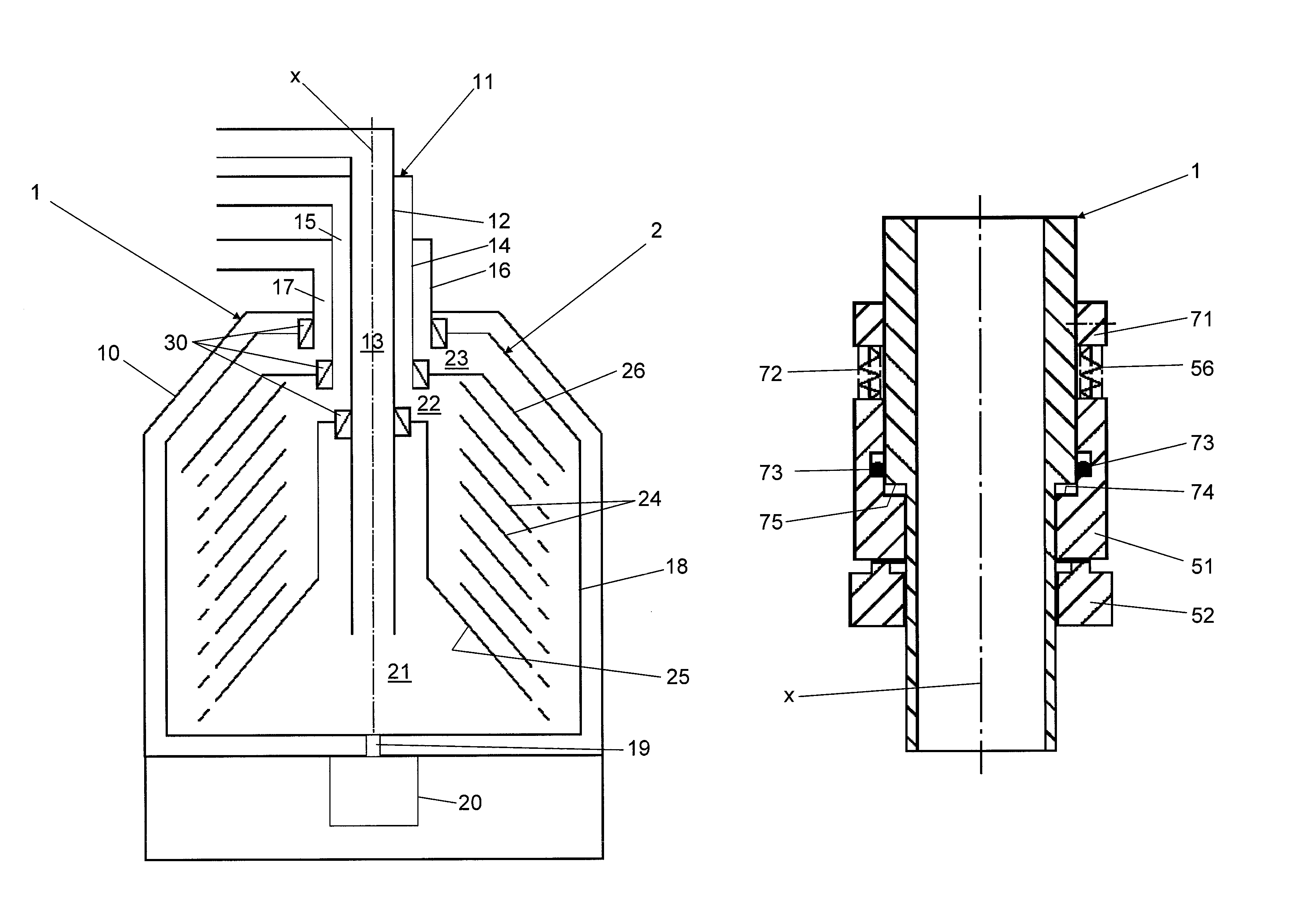

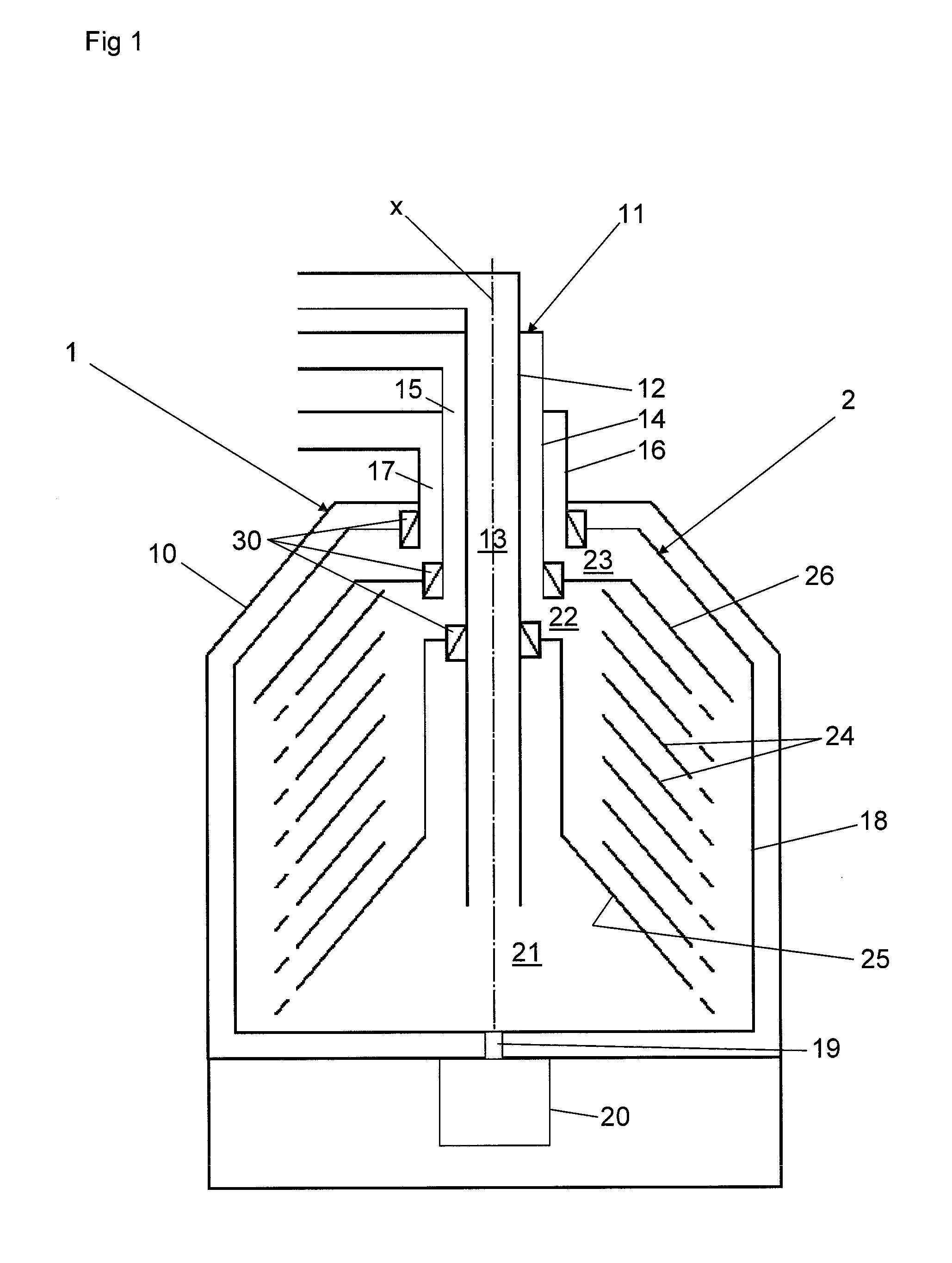

Double seat valve

ActiveUS20090008594A1Reduce trafficSmooth diversionPlug valvesMultiple way valvesEngineeringMechanical engineering

The invention relates to a double seat valve with cleanable seats, which is improved with regard to the prior art in that a discharge possibly free of turbulence of the seat cleaning flow into and out of the leakage cavity is ensured and a direct admission of the seat areas, which would increase pressure, is safely avoided. This is achieved in that the second closing element (4) abuts in its closed position at the transition area (2e; 2e*) with a stop face (4e) arranged at a front face of its cylindrical lug (4*) and that directly adjacent to the first seat (2a, 2g), that a central recess (4d) is provided in the front face of the second cylindrical lug (4*), which starts radially on the outside with a rotationally symmetrical diversion area (4b) (starting point of the contour (K)) and is bounded at the front by a front face (4c) oriented substantially vertically towards the longitudinal axis of the second closing element (4), the diversion area (4b) leading out into the front face (4c) (leading out point of the contour (K)), that the diversion area (4b) and the stop face (4e) form a second circumferential edge (U2), which is directly adjacent to a first end section (2g) of the first seat (2a) in the closed position of the second closing element (4), that, viewed in vertical centre section, the diversion area (4b) comprises a contour (K) with unbent shape, wherein a direction vector in the leading out point of the diversion area (4b) points into a discharge bore (3d) centrally arranged in the first closing element (3), without colliding with the first closing element (3) in the area of its areas bounding the leakage cavity (5) or of the intermediate seal (8; 8*) and without forming impact pressure thereby, and that a frontal boundary of the first closing element (3) directed towards the leakage cavity (5) has an axial safety distance (x) from the direction vector at an outlet point of the transition area (2e) formed as a first circumferential edge (U1) into the first end section (2g).

Owner:TUCHENHAGEN GMBH

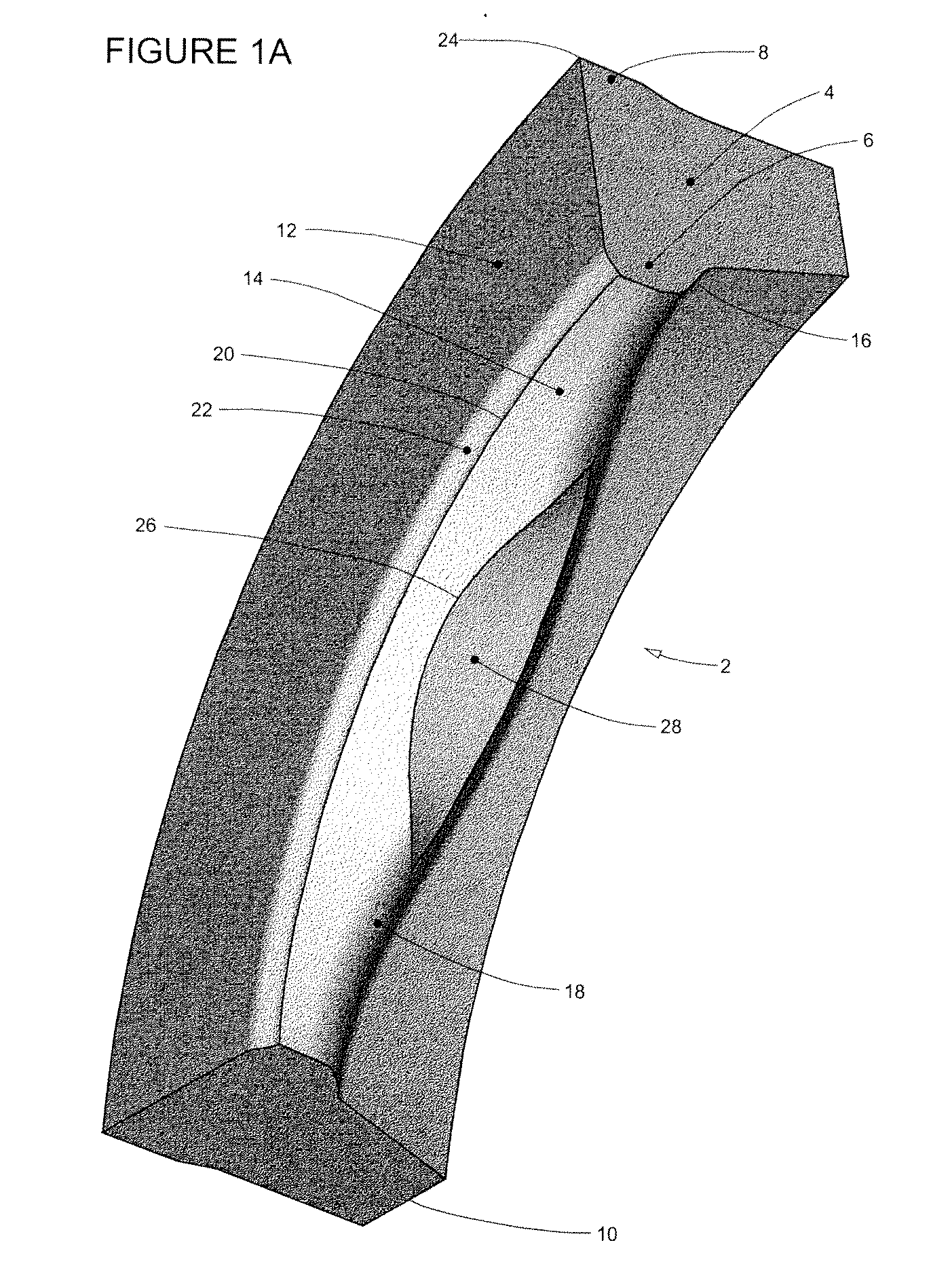

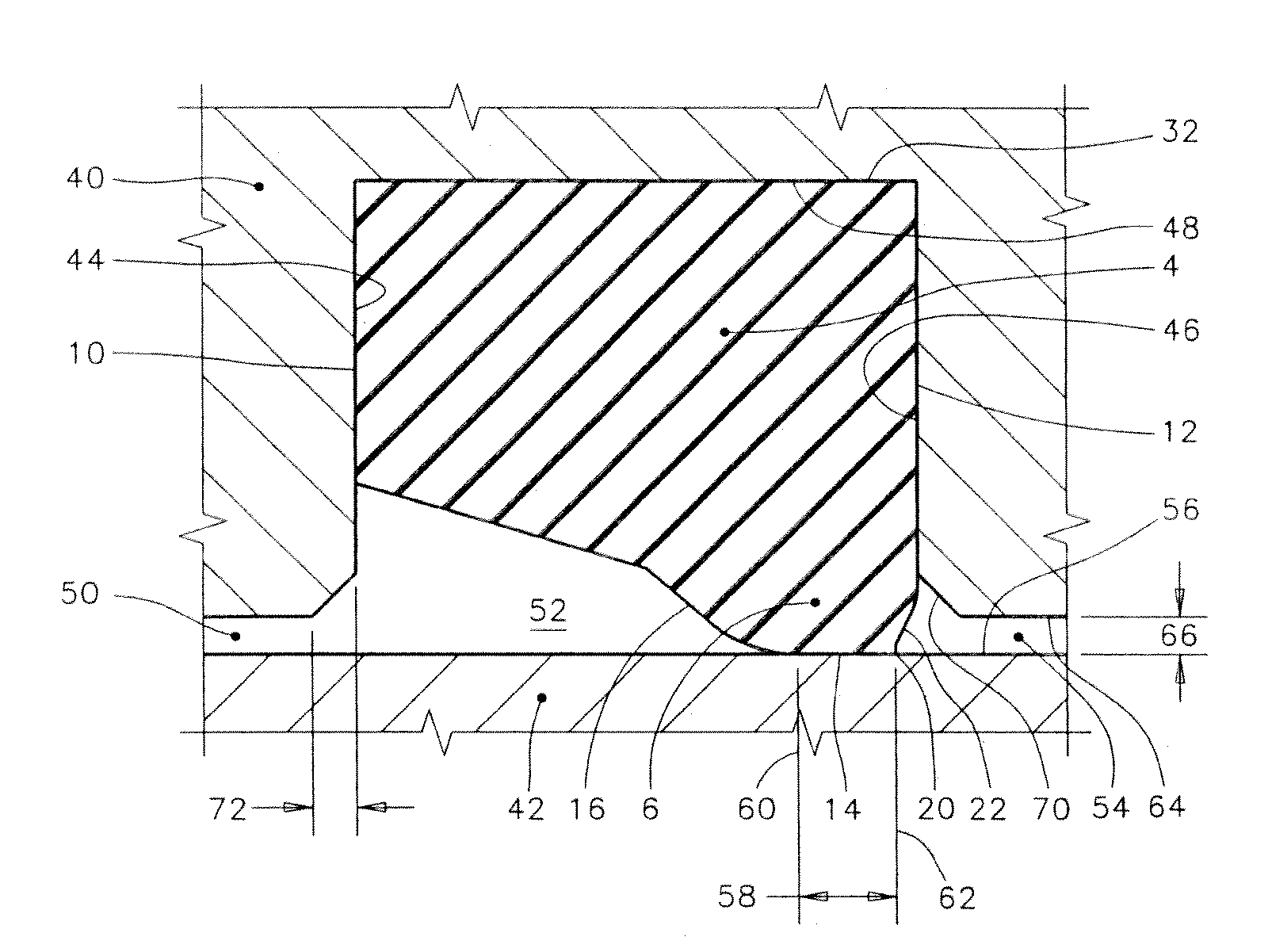

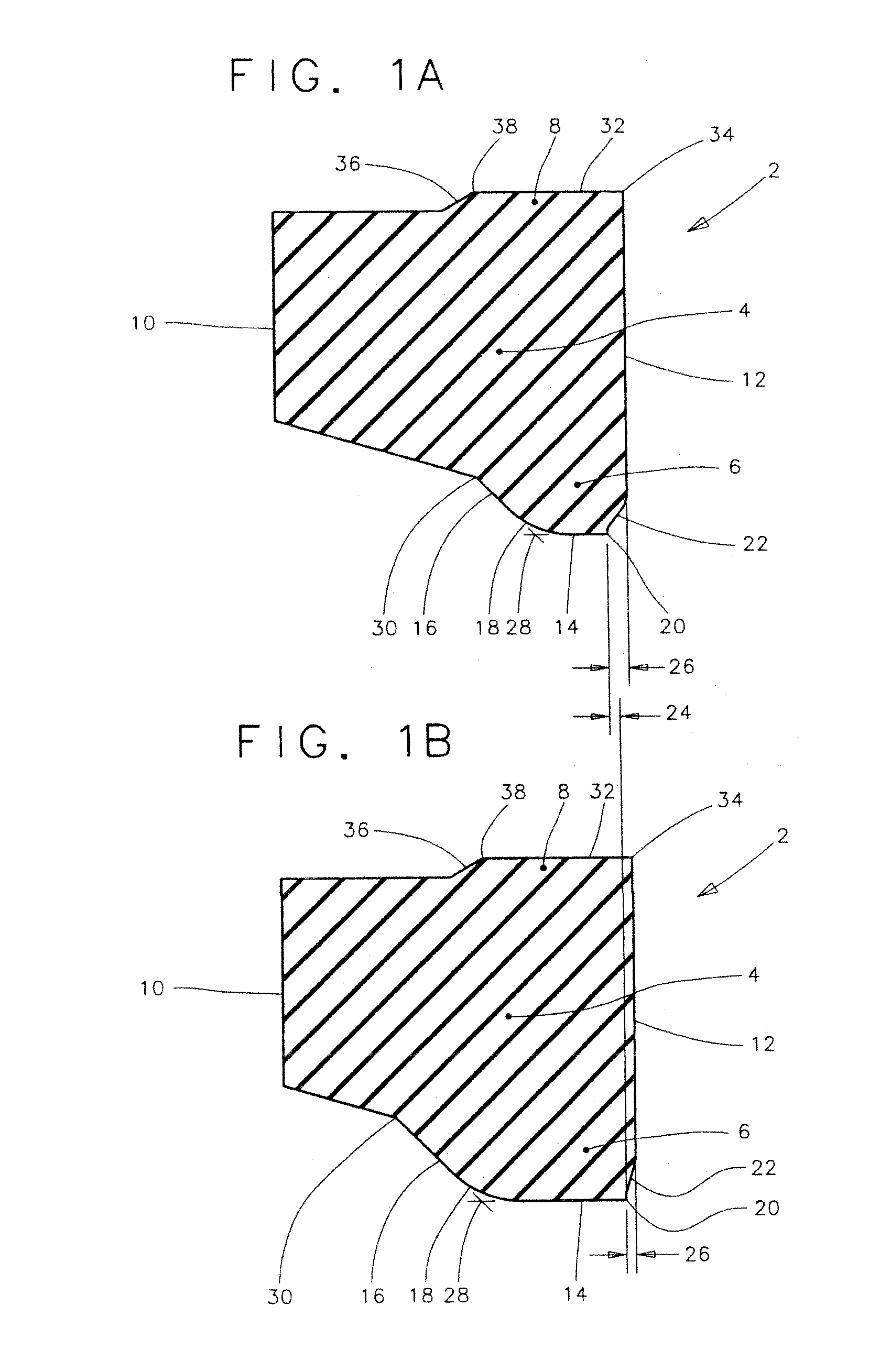

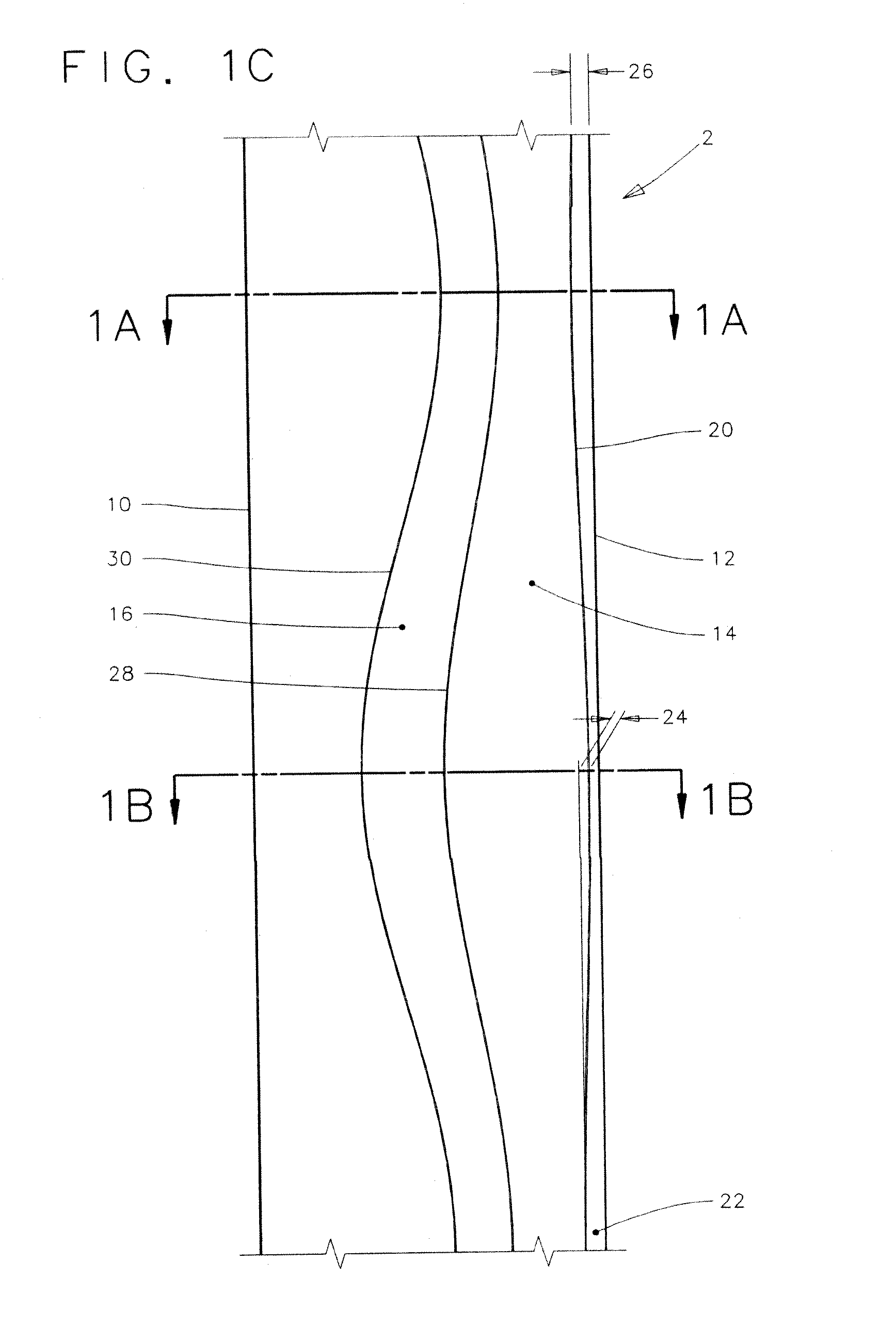

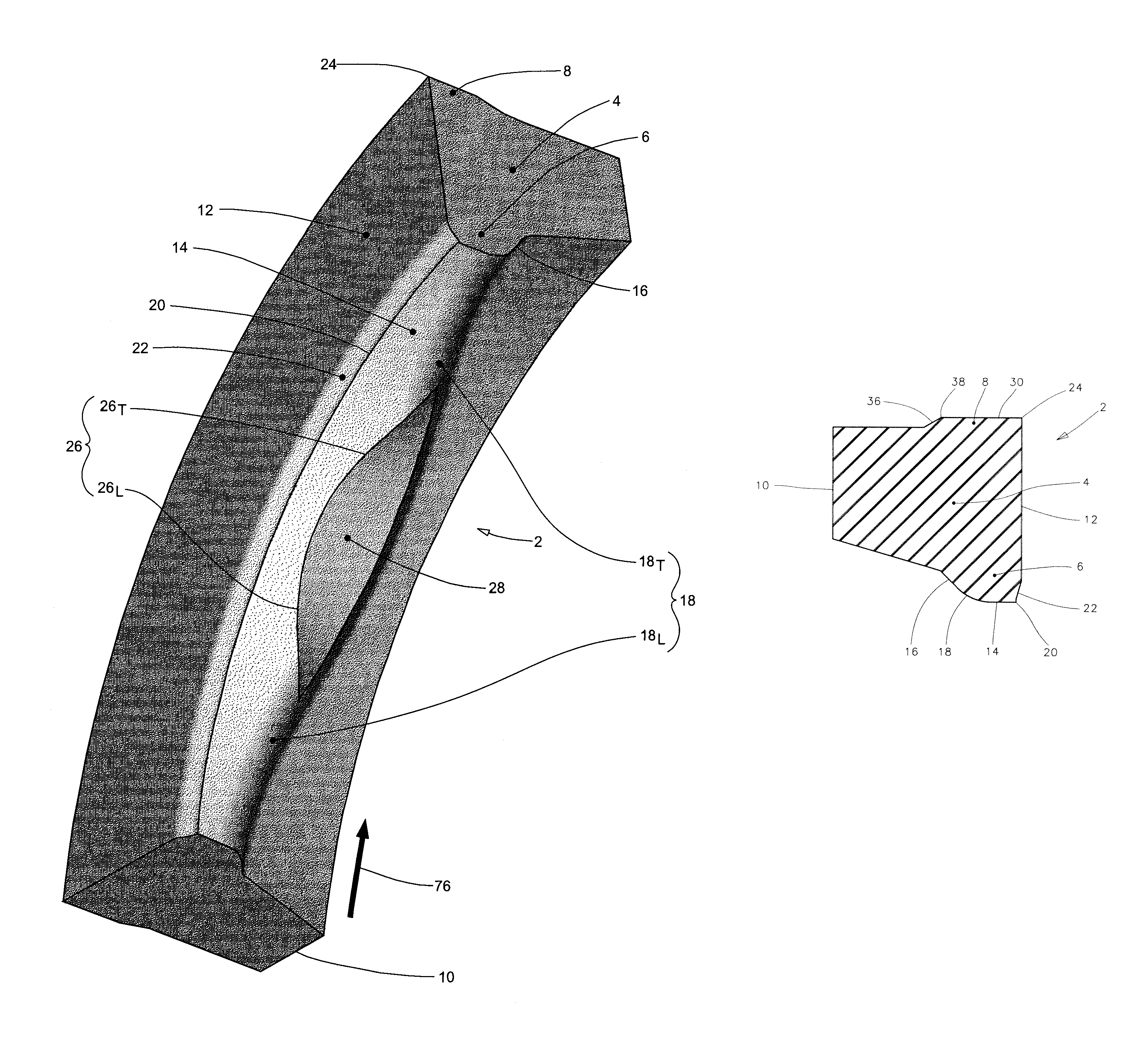

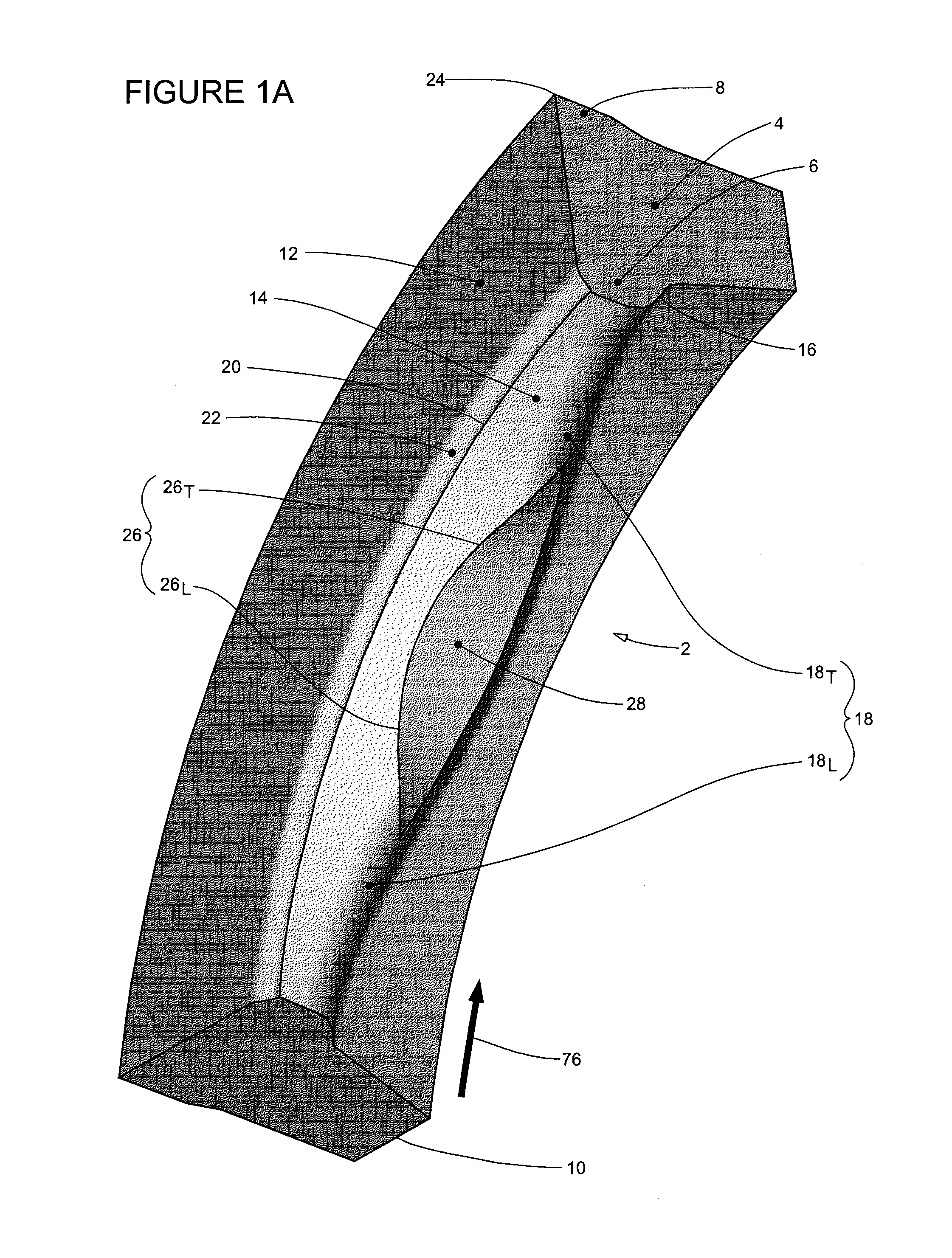

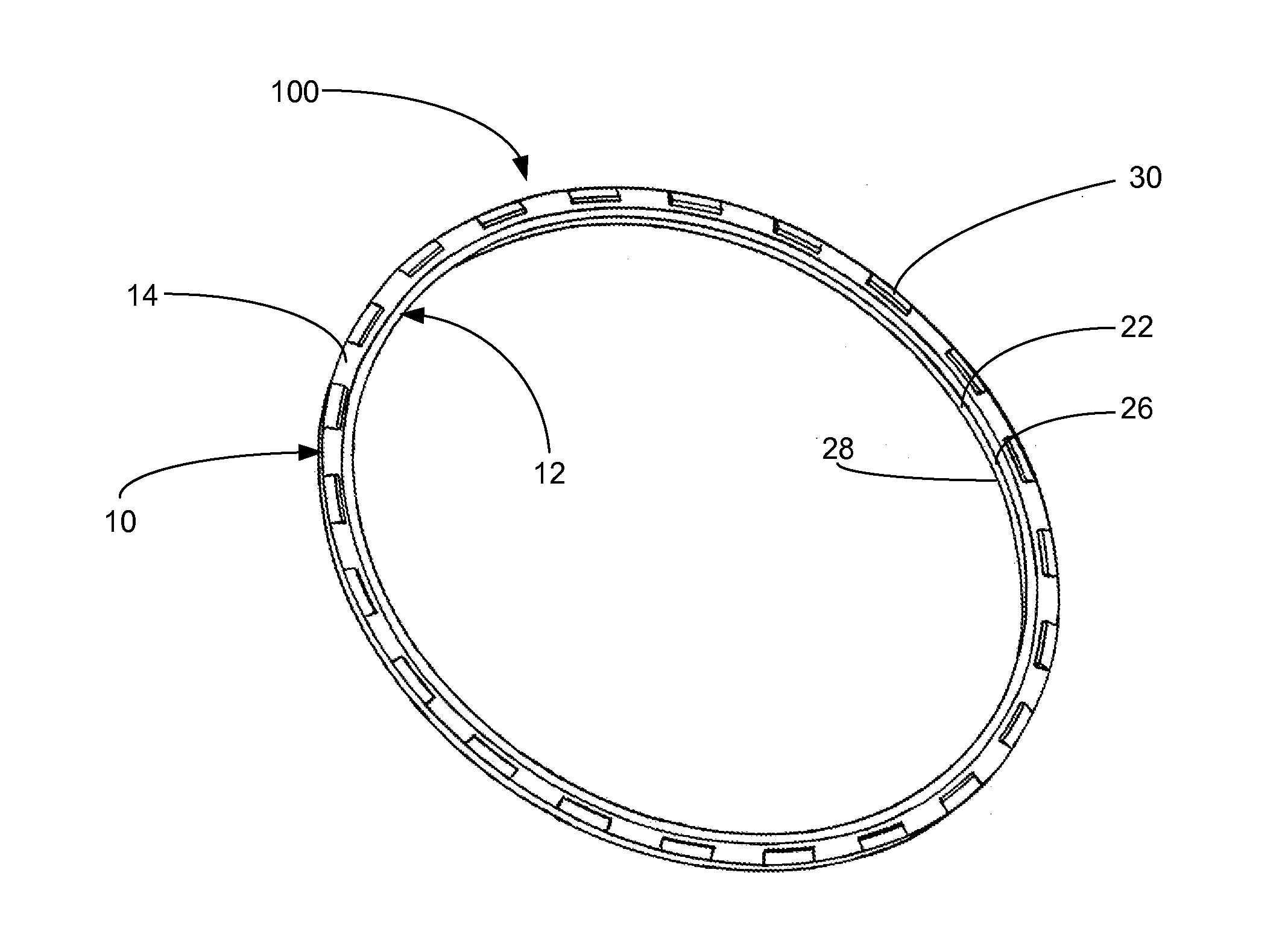

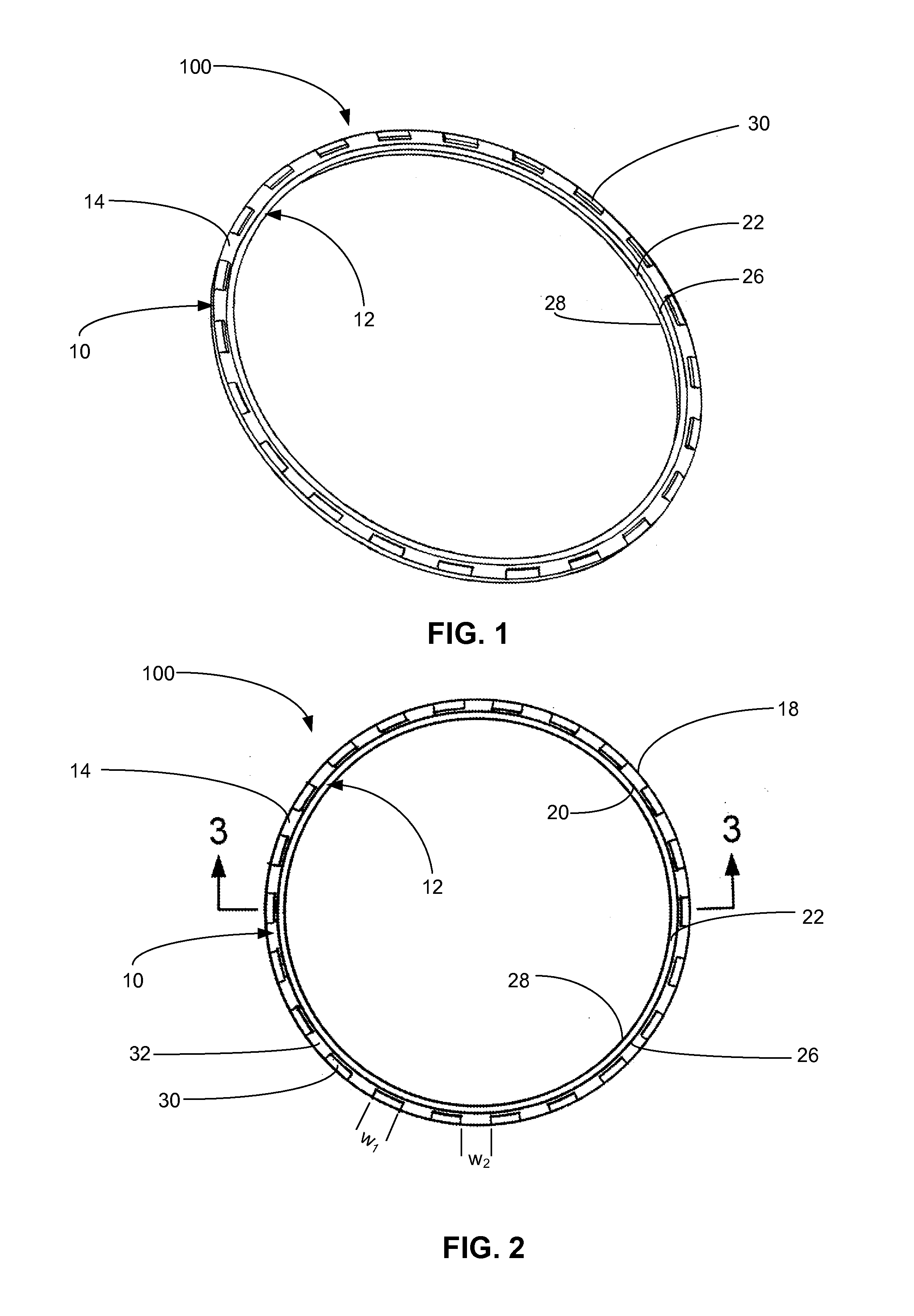

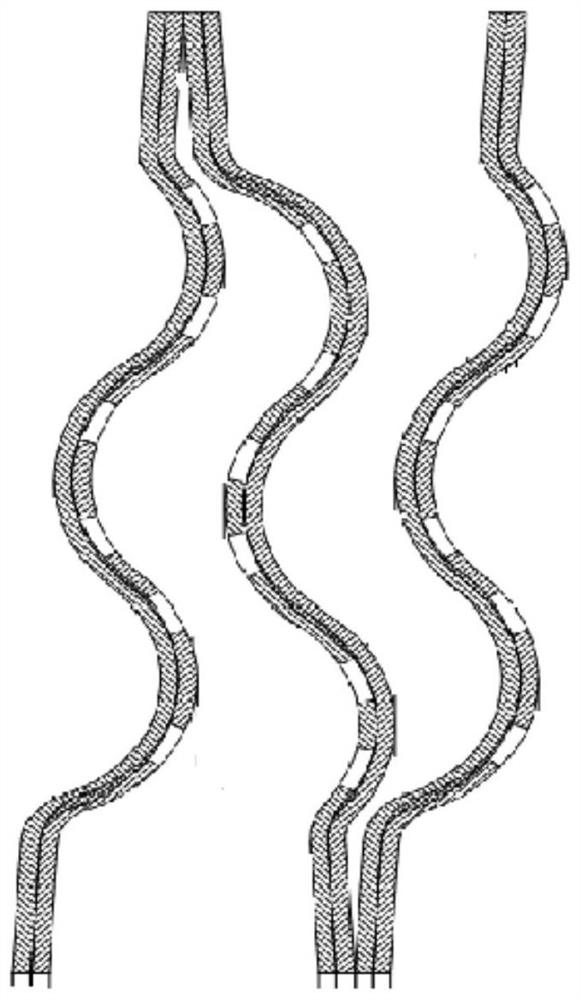

Rotary seal with truncated wave form

The present invention is a generally circular rotary seal that establishes sealing between relatively rotatable machine components for lubricant retention and environmental exclusion, and incorporates seal geometry that interacts with the lubricant during relative rotation to distribute a lubricant film within the dynamic sealing interface. A preferably curved elevated contact pressure zone serves to maximize interfacial lubrication in critical areas during severe operating conditions by utilizing lubricant that would otherwise escape at the trailing edge of the hydrodynamic waves. The zones are produced by geometry that serves to minimize lubricant shear area, seal torque, seal volume, and wear, while ensuring retrofitability into the seal grooves of existing equipment.

Owner:KALSI ENG

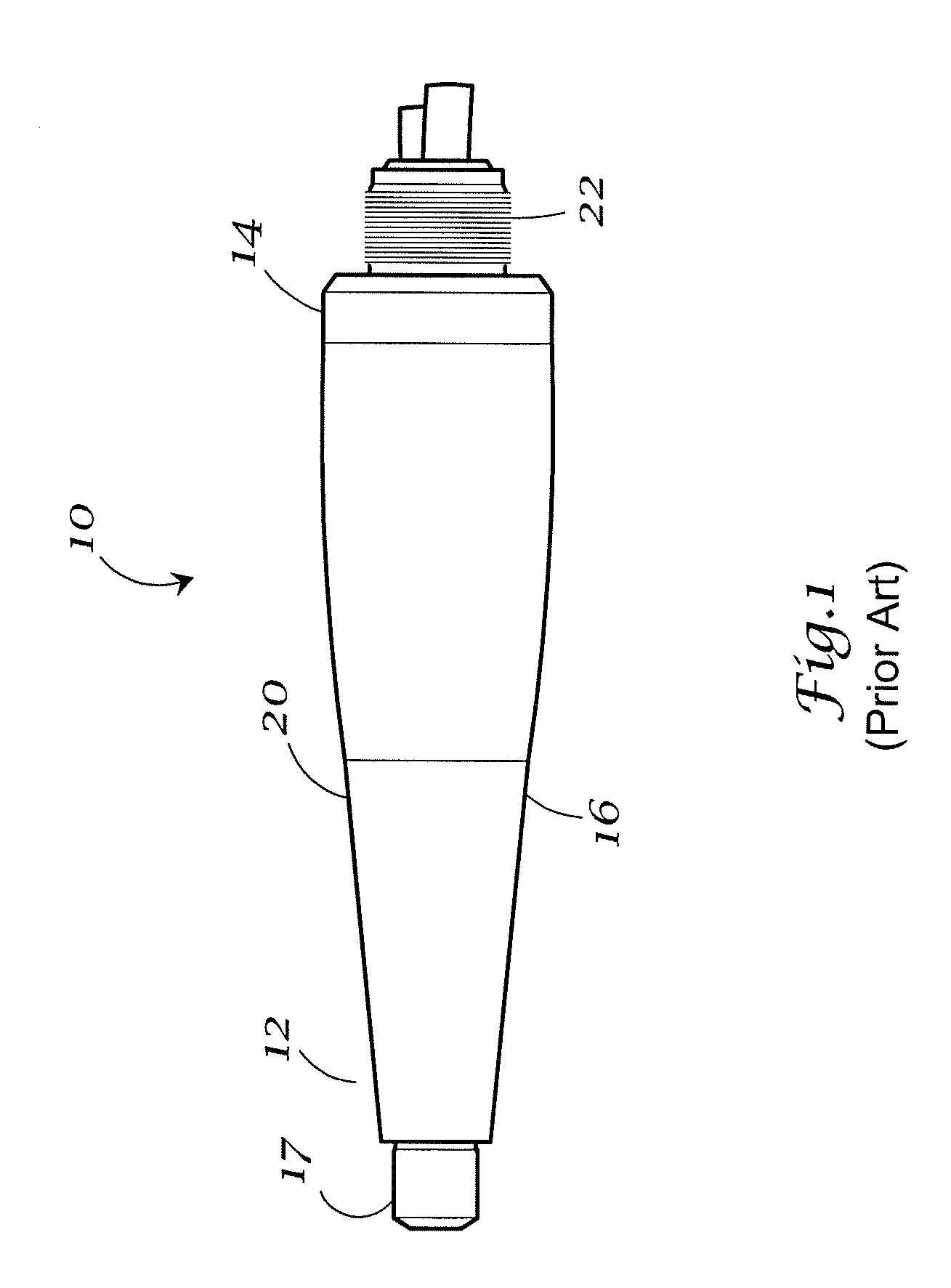

Centrifugal separator

InactiveUS20090280974A1Improve mechanical sealingProlong lifeEngine sealsRotary centrifugesCentrifuge rotorMechanical engineering

In a centrifugal separator comprising a first and second separator part having a centrifuge rotor and rotates during operation relative to the first separator part. A space connecting the first and second separator parts houses a rotating liquid body during operation. A mechanical sealing device is provided at the space and includes a first sealing element on the first separator part having a first contact surface, and a second sealing element on the second separator part having a second contact surface. The liquid body on the first sealing element or the second sealing element and displaces the same axially so that the first and second contact surfaces are pressed against each other. A pre-tensioning element exerts force on the sealing element which acts to displace the first contact away from the second contact surfaces so that a gap is formed, forming a throttling.

Owner:ALFA LAVAL CORP AB

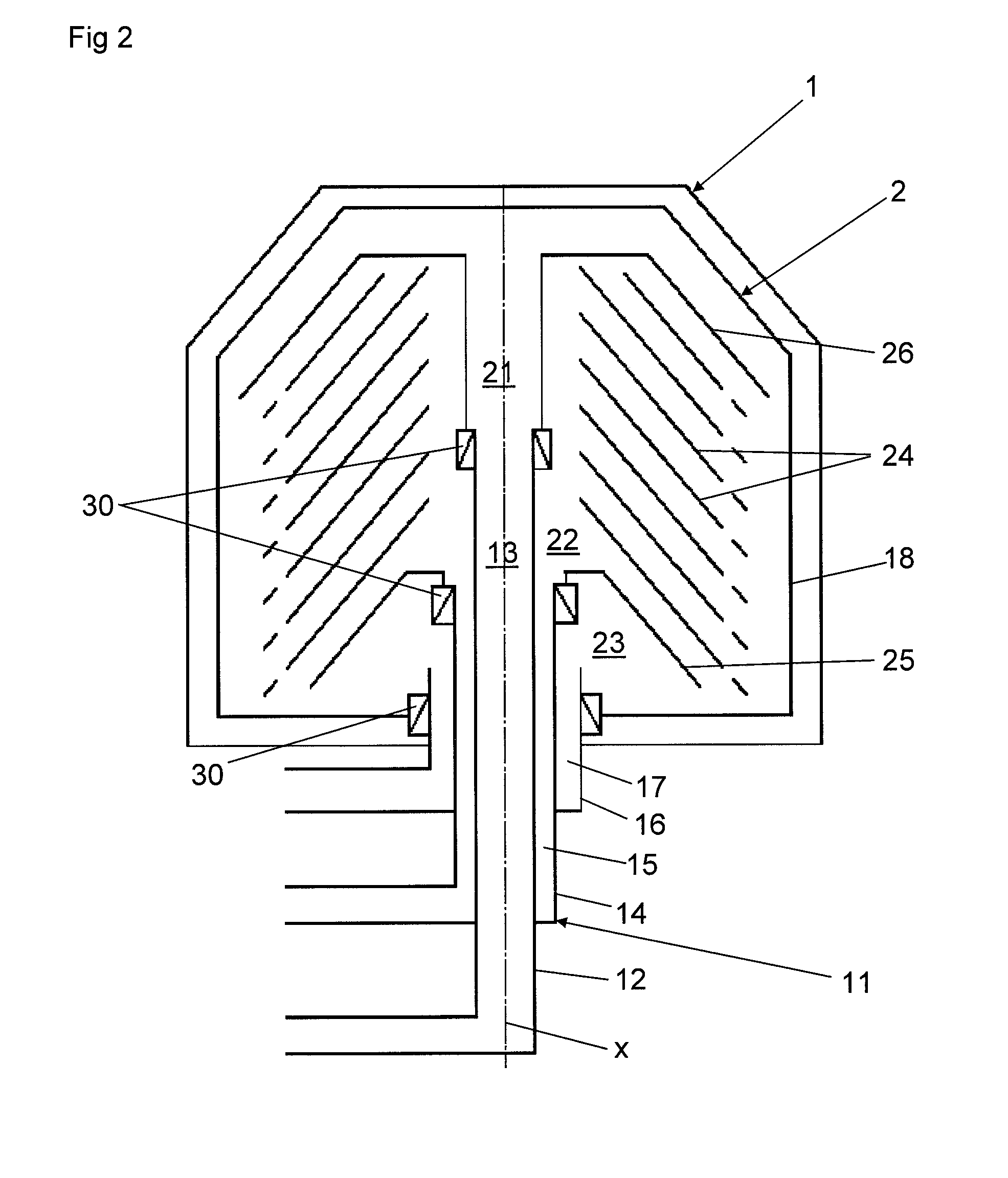

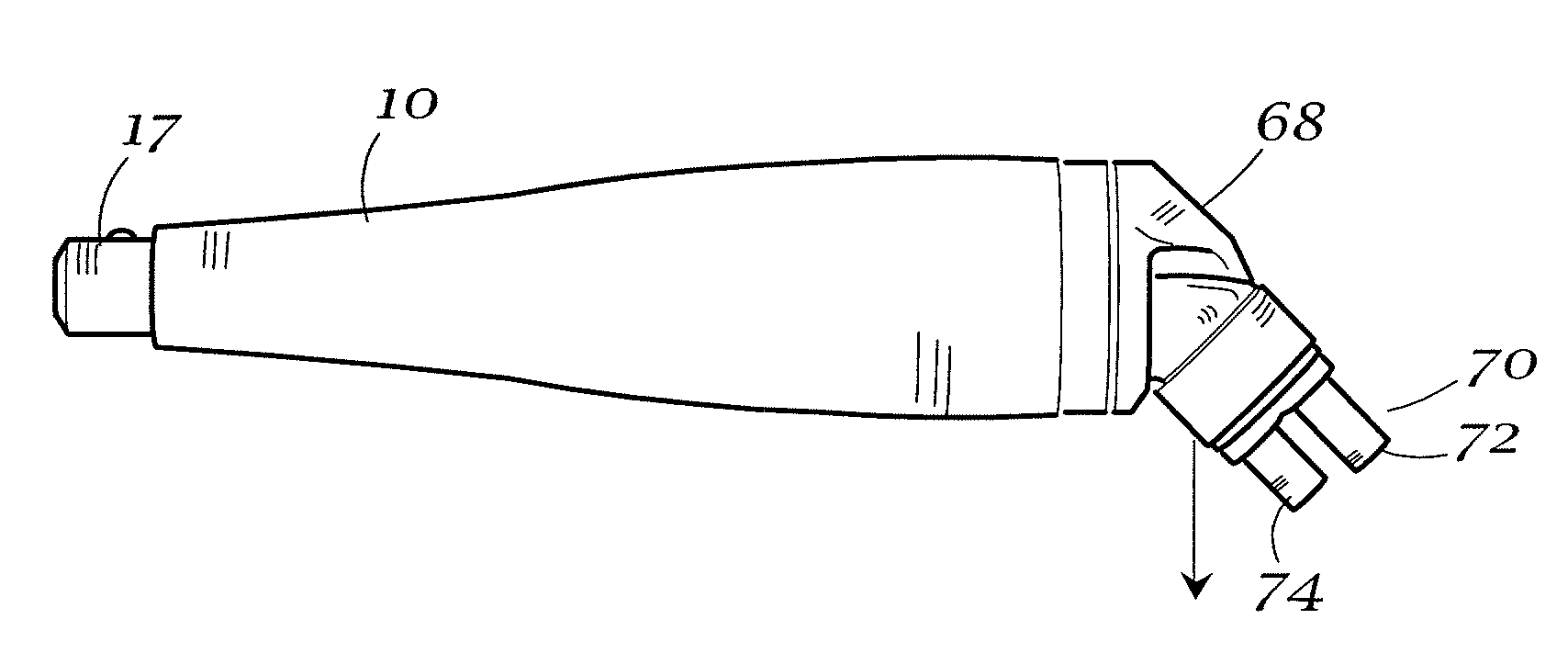

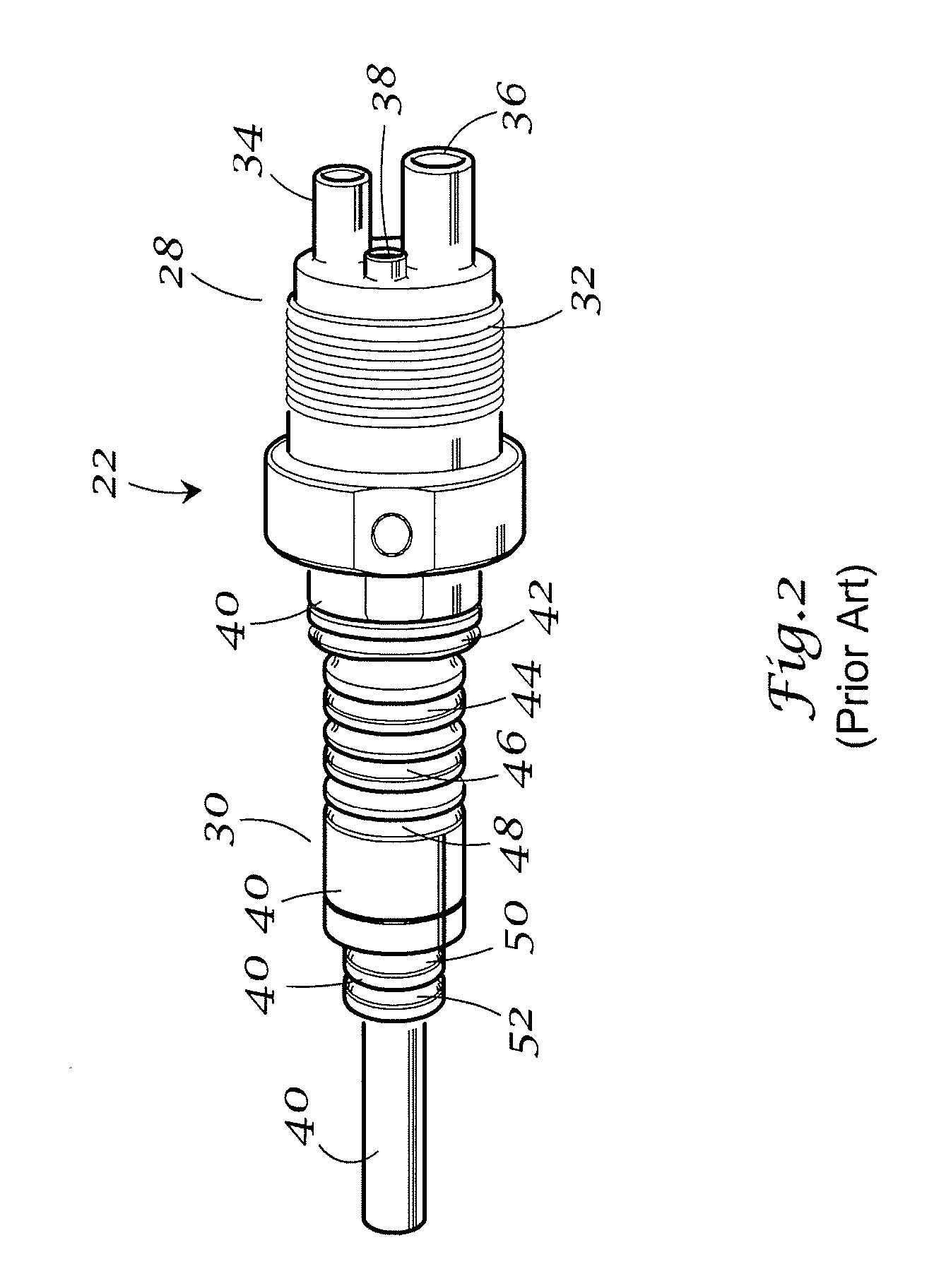

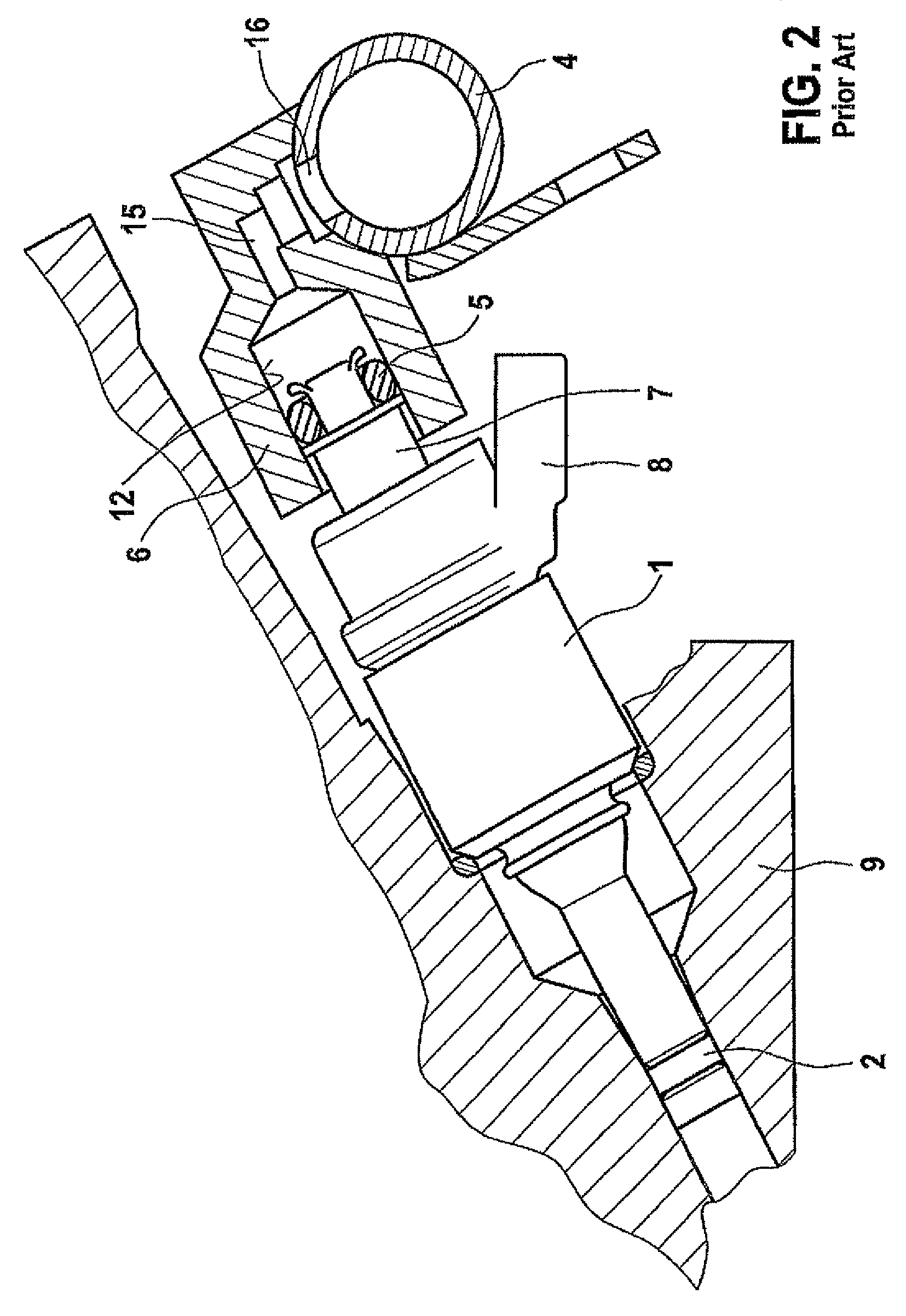

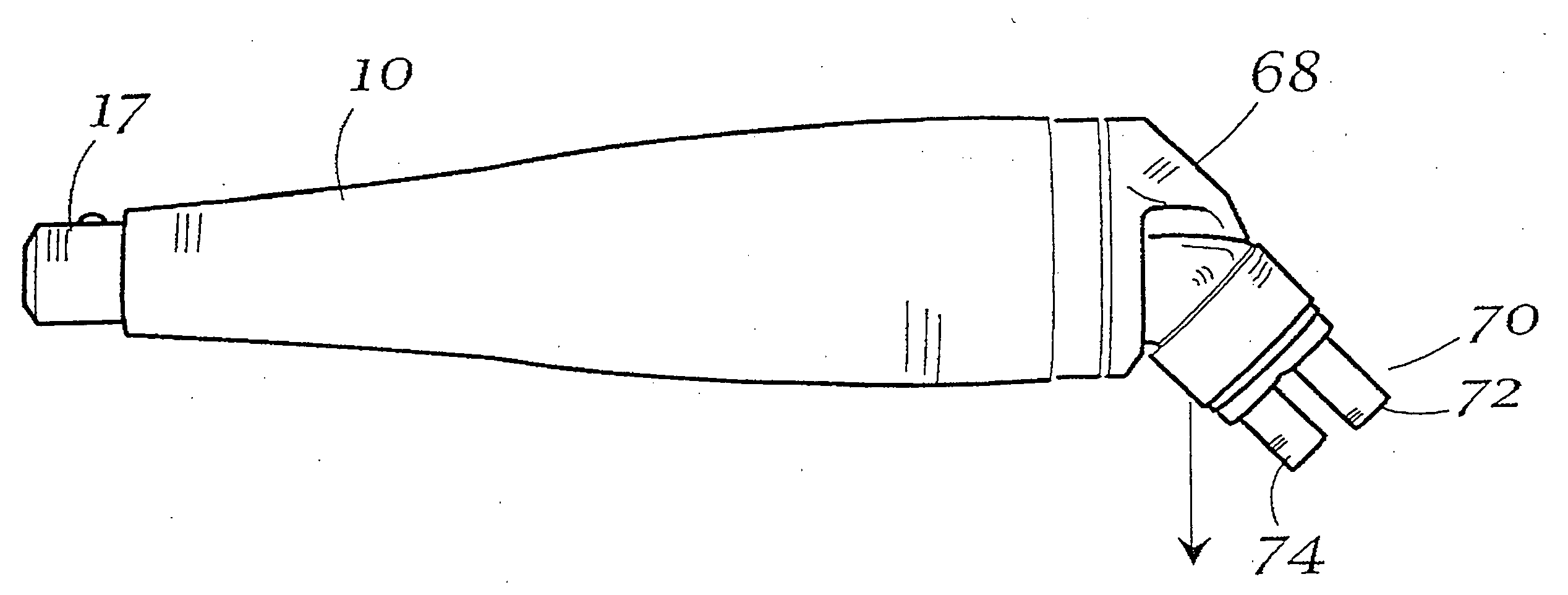

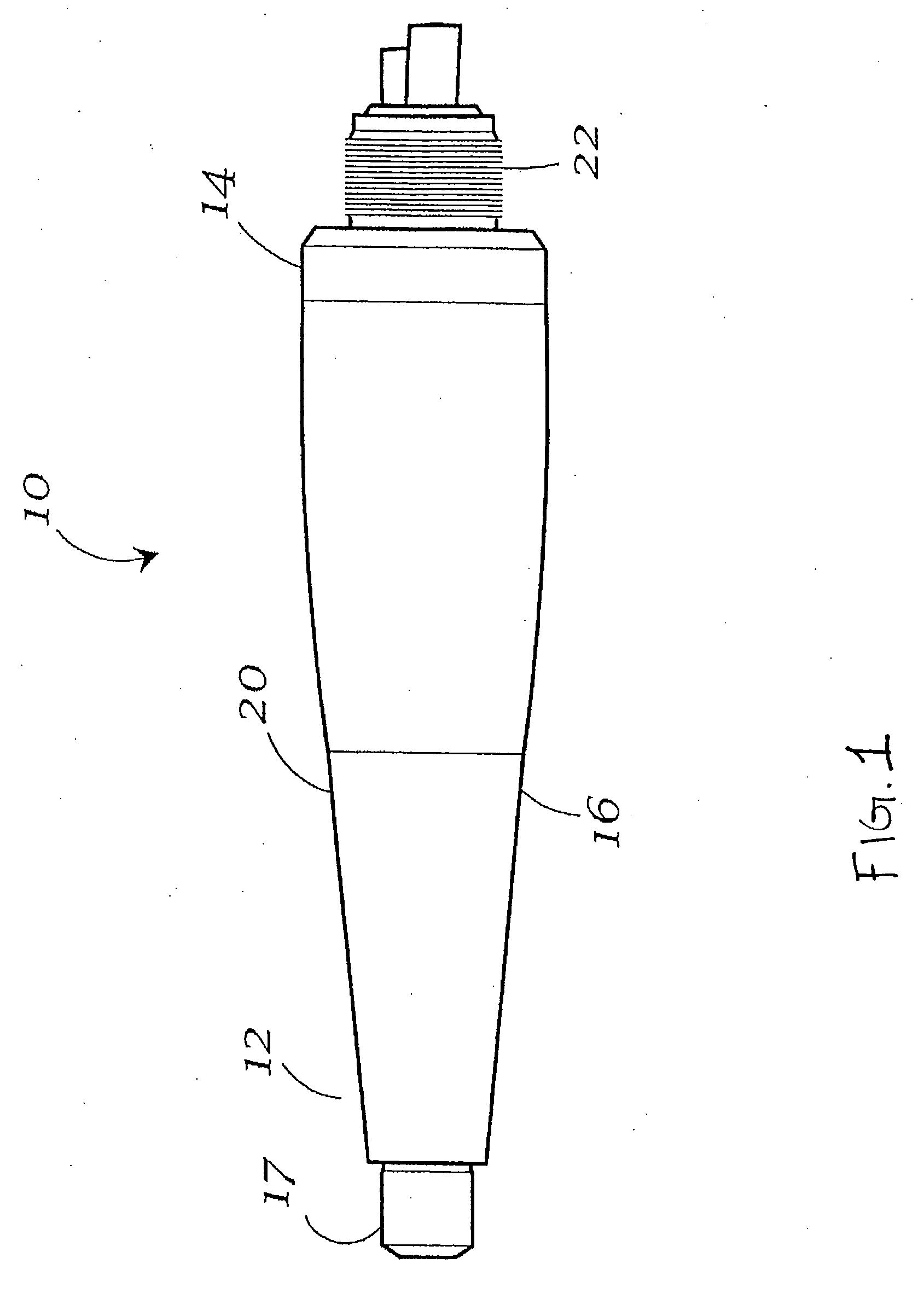

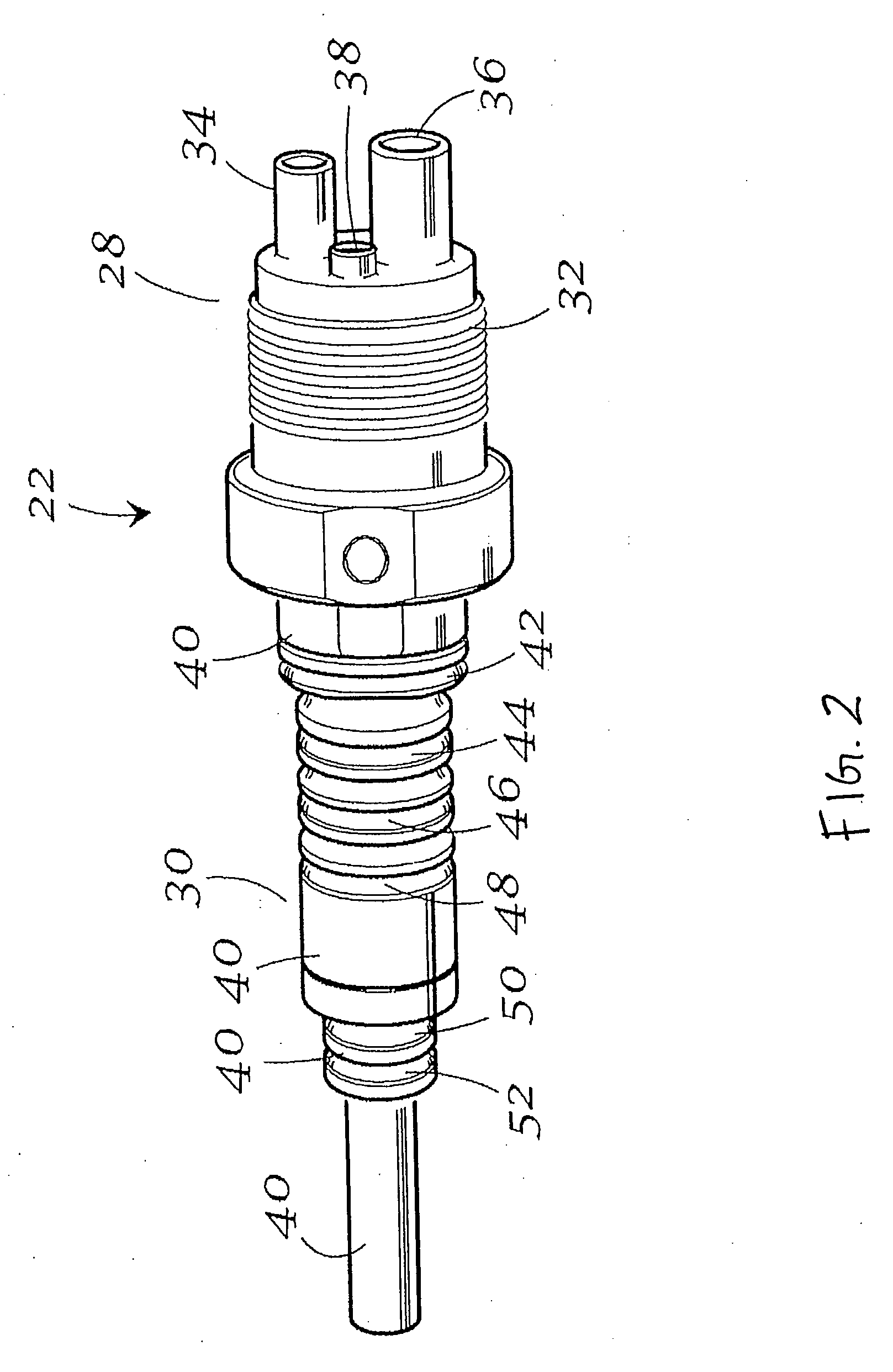

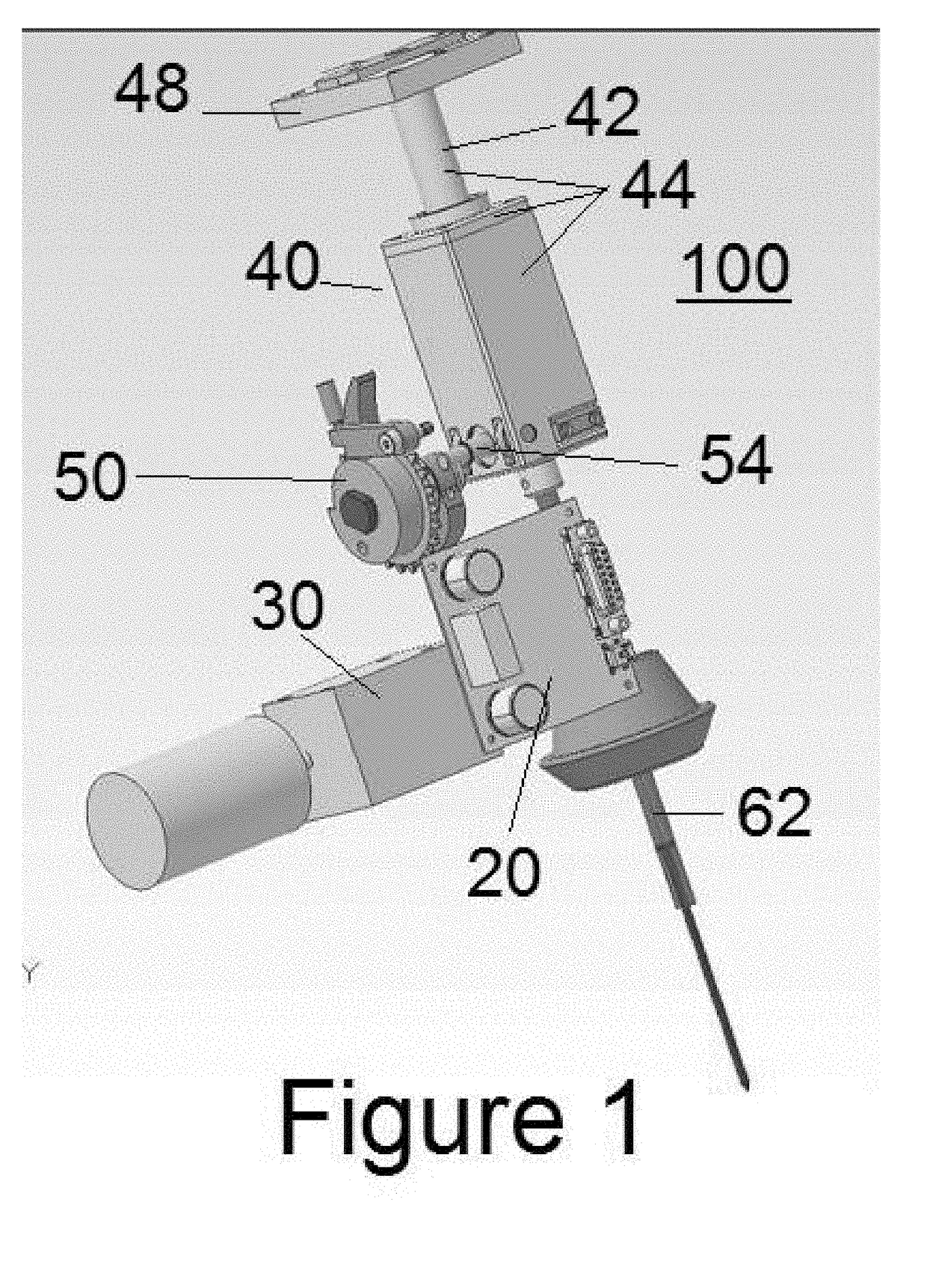

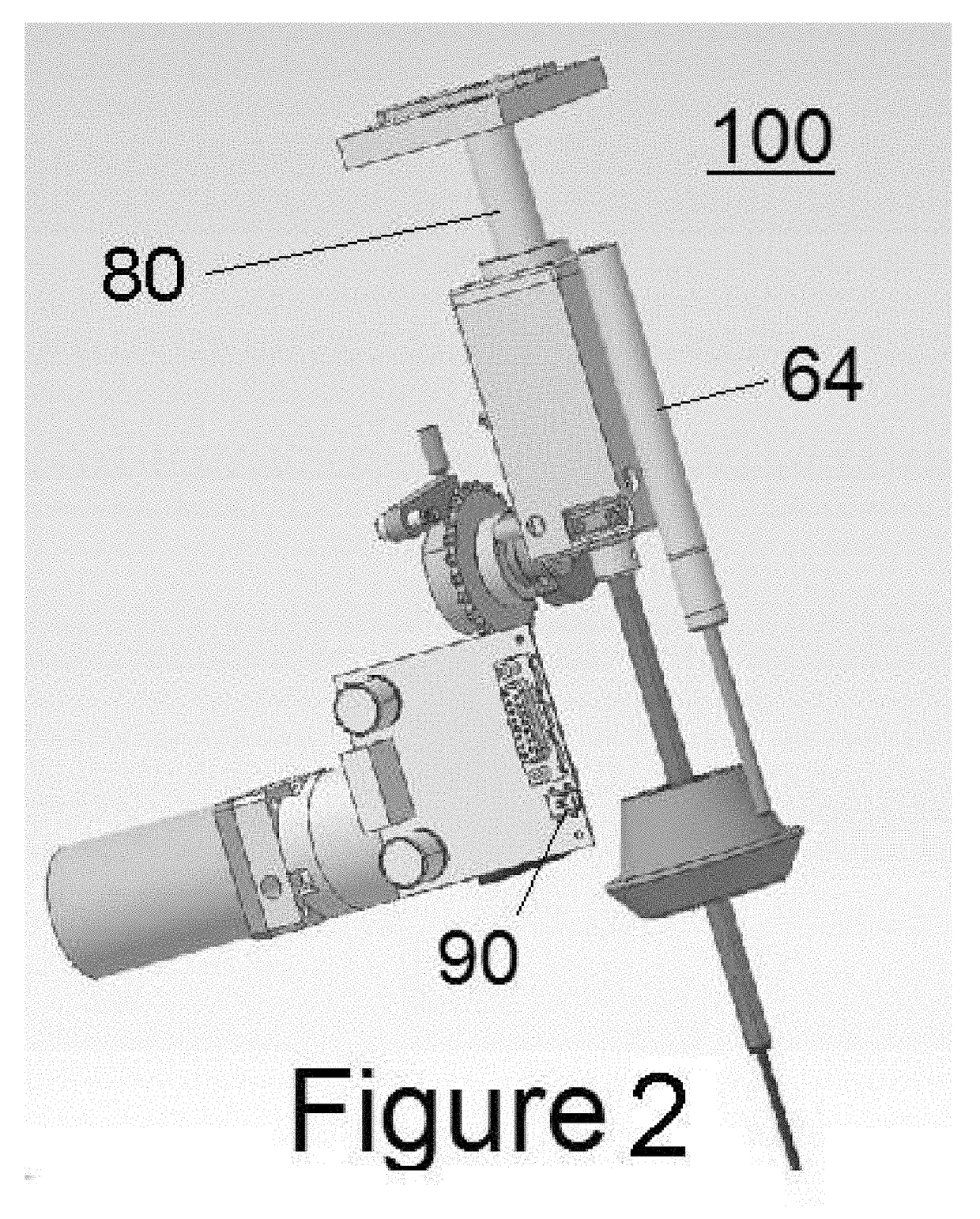

Angled hose connection for dental handpiece

A dental handpiece having a distal end including an attachment for assembly of a removable workpiece and a handpiece body intermediate a proximal end and the distal end. The handpiece extends in a substantially axial direction. A coupler is included having a cylinder portion and a supply-end portion, the cylinder portion being assembled into the handpiece extending in the axial direction toward the distal end. The cylinder portion includes at least one seal that interfaces with an interior of the body so as to isolate a portion of the body interior into at least one distinct chamber. The supply-end portion of the coupler extends from the proximal end of the handpiece body at an angle from the axis. The supply-end portion also includes a plurality of outlets, the at least one distinct chamber in fluid communication with one of the outlets of the plurality of outlets.

Owner:DENTSPLY SIRONA INC

Hydrodynamic seal with improved exclusion and lubrication

InactiveUS20100259015A1Improved environmental exclusionReduce torqueEngine sealsEngineeringLubrication

A hydrodynamic sealing assembly including a first machine component defining a seal groove and a second machine component having a rotatable surface that is rotatable relative to the first machine component. A hydrodynamic seal including a seal body of generally ring-shaped configuration having a circumference and the seal body includes a sealing lip having a sealing surface contacting the relatively rotatable surface to establish a sealing interface between the sealing lip and the relatively rotatable surface. The sealing lip includes an exclusion edge of abrupt substantially circular form that is substantially aligned with a direction of relative rotation between the sealing lip and the relatively rotatable surface in a compressed, installed condition of the seal and wherein the exclusion edge is non-circular and slightly wavy in an uncompressed, uninstalled condition of the hydrodynamic seal.

Owner:KALSI ENG

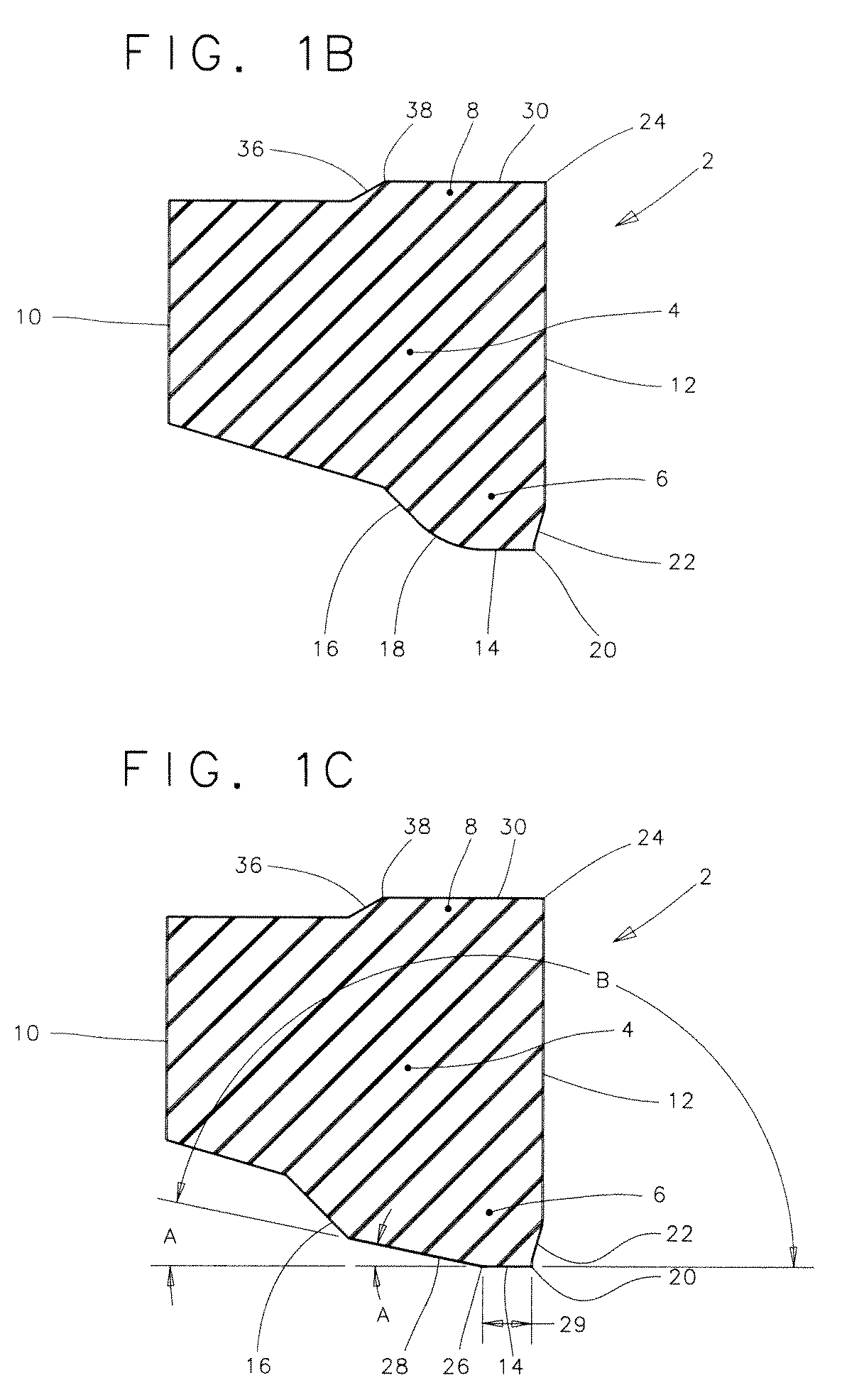

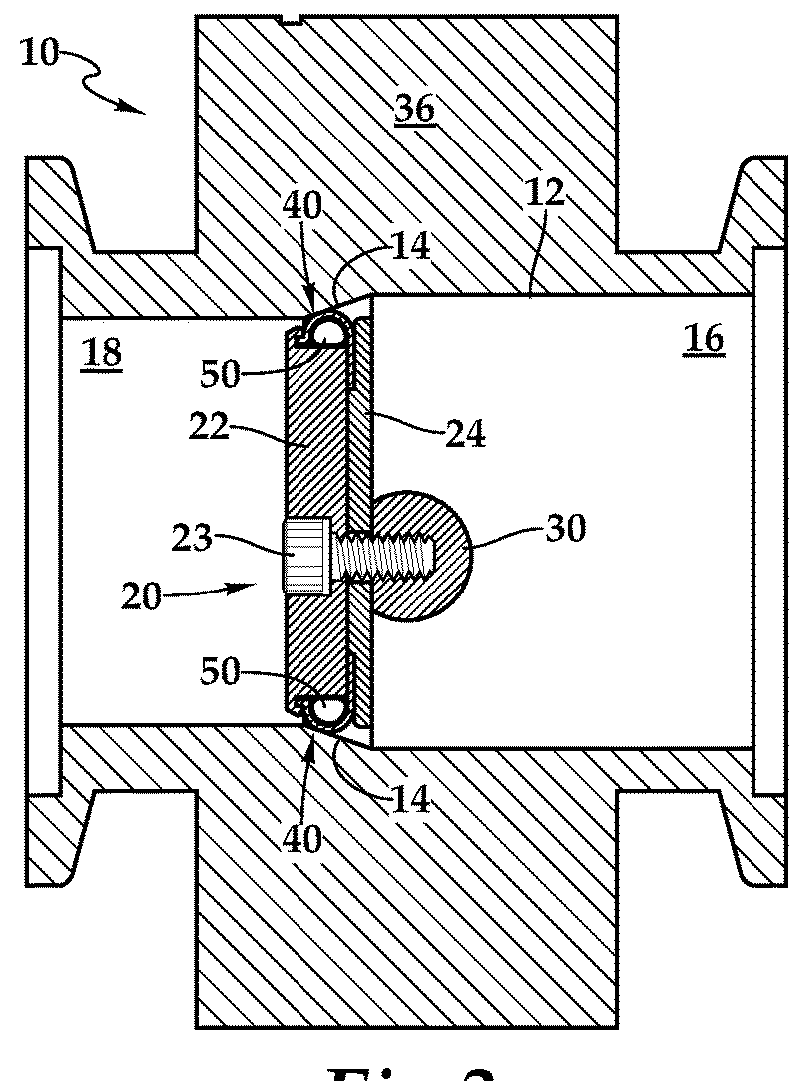

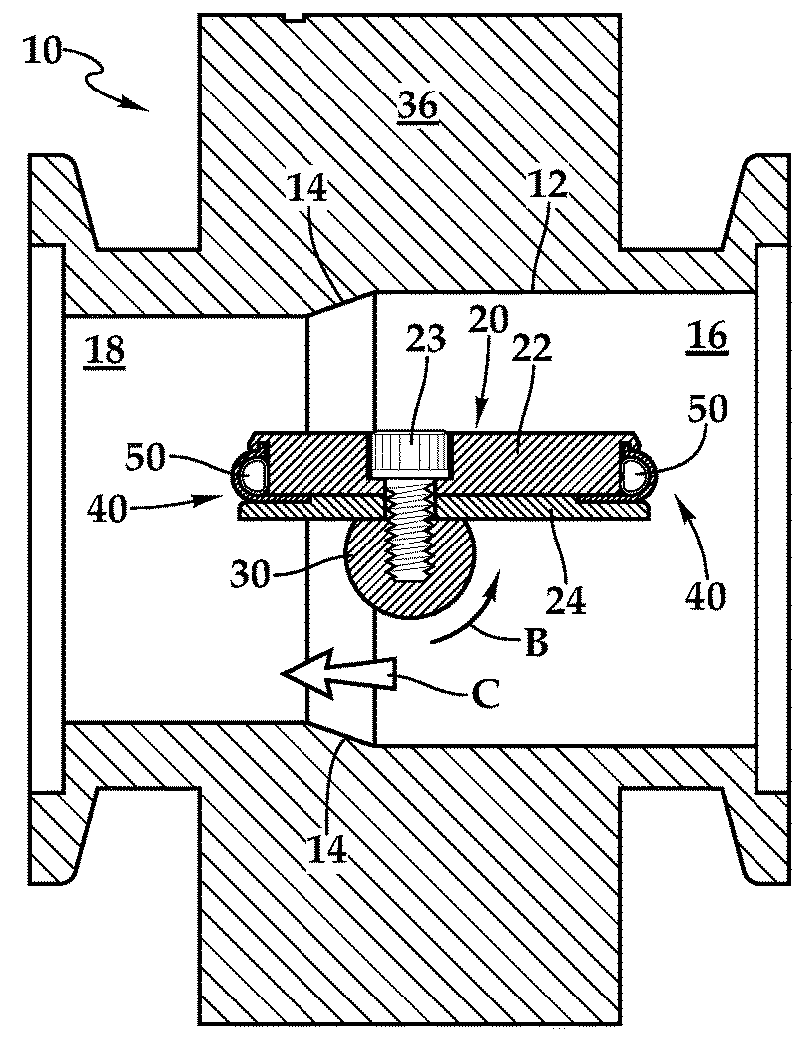

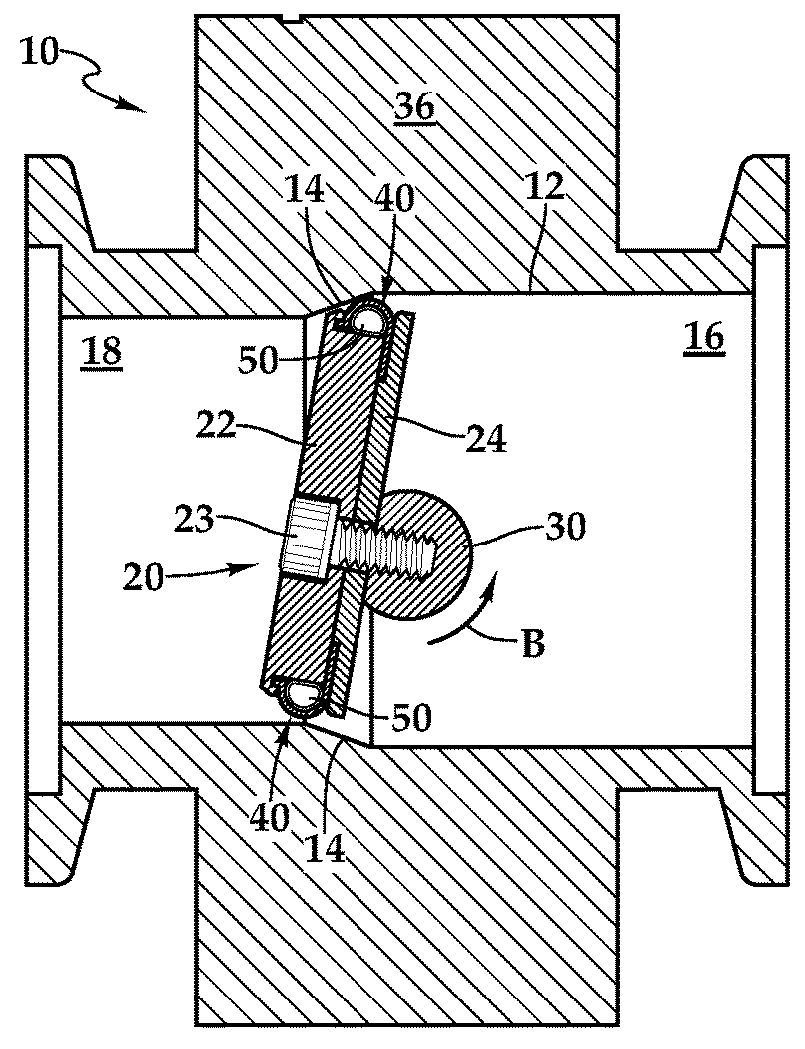

Energized PTFE seal for butterfly valve

InactiveUS20180266567A1Minimize seal wearReduced seal wearEngine controllersMachines/enginesEngineeringButterfly valve

A plate within the valve pivots about a shaft to cause the plate to transition between an open position and a closed position within a bore passing through the housing of the valve. The plate has a perimeter seal thereon which abuts against a tapering seat of the bore when the throttle plate is in a closed orientation. The seal has a curving form over a recess and an energy source, such as the toroidal spring in the recess, to energize the seal and allow it to maintain secure contact against the seat. The shaft is offset from the centerline of the bore and the plate is mounted to the shaft at a location offset from the center point of the plate, so that rotation of the plate causes the plate to swing somewhat into a closed position, minimizing abrasive contact between the seat and seal during closing.

Owner:NOR CAL PRODS

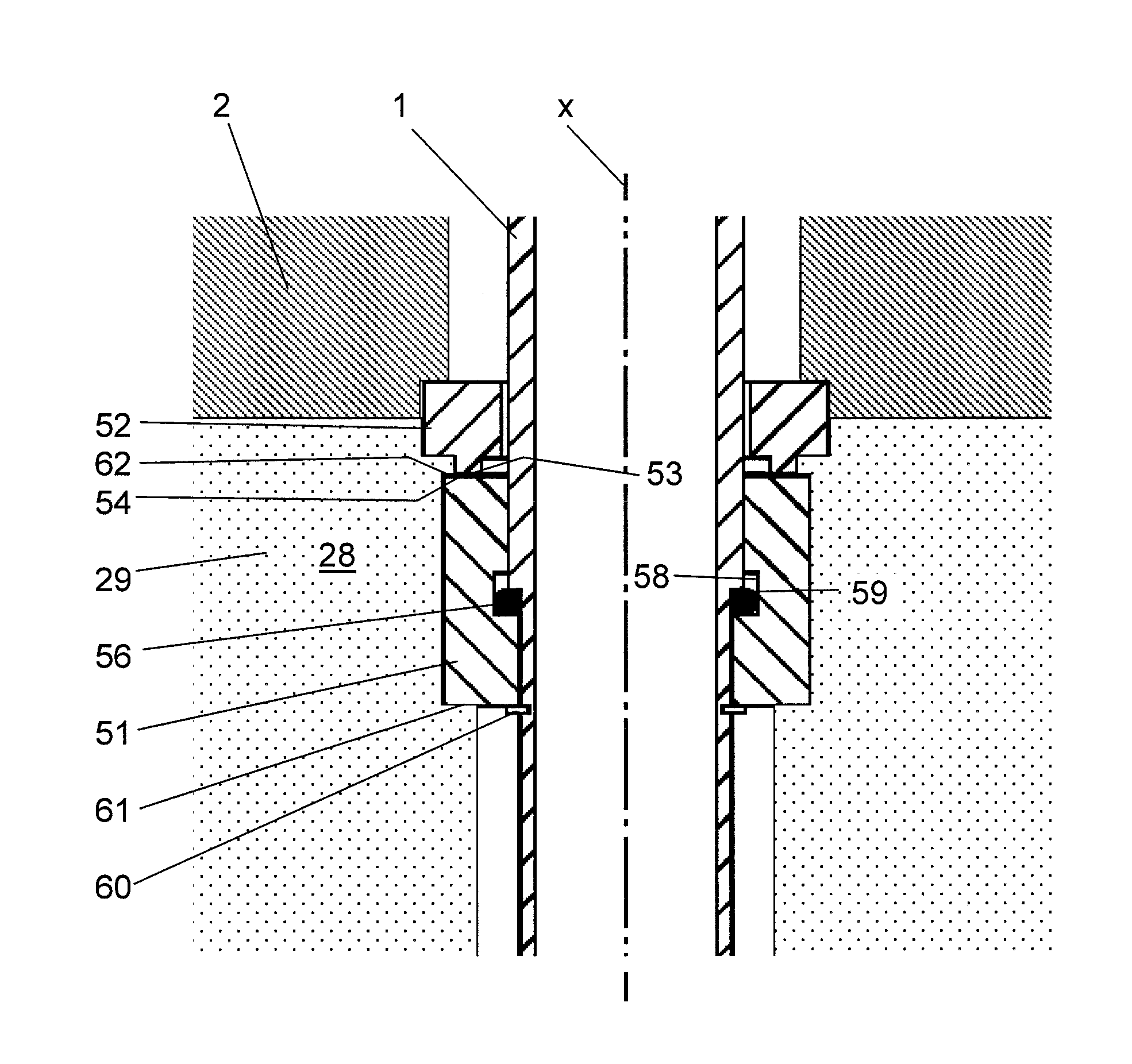

Double seat valve with seat cleaning

ActiveUS8336572B2Reduced seal wearImprove sealingPlug valvesOther washing machinesEngineeringMechanical engineering

Owner:GEA TUCHENHAGEN GMBH

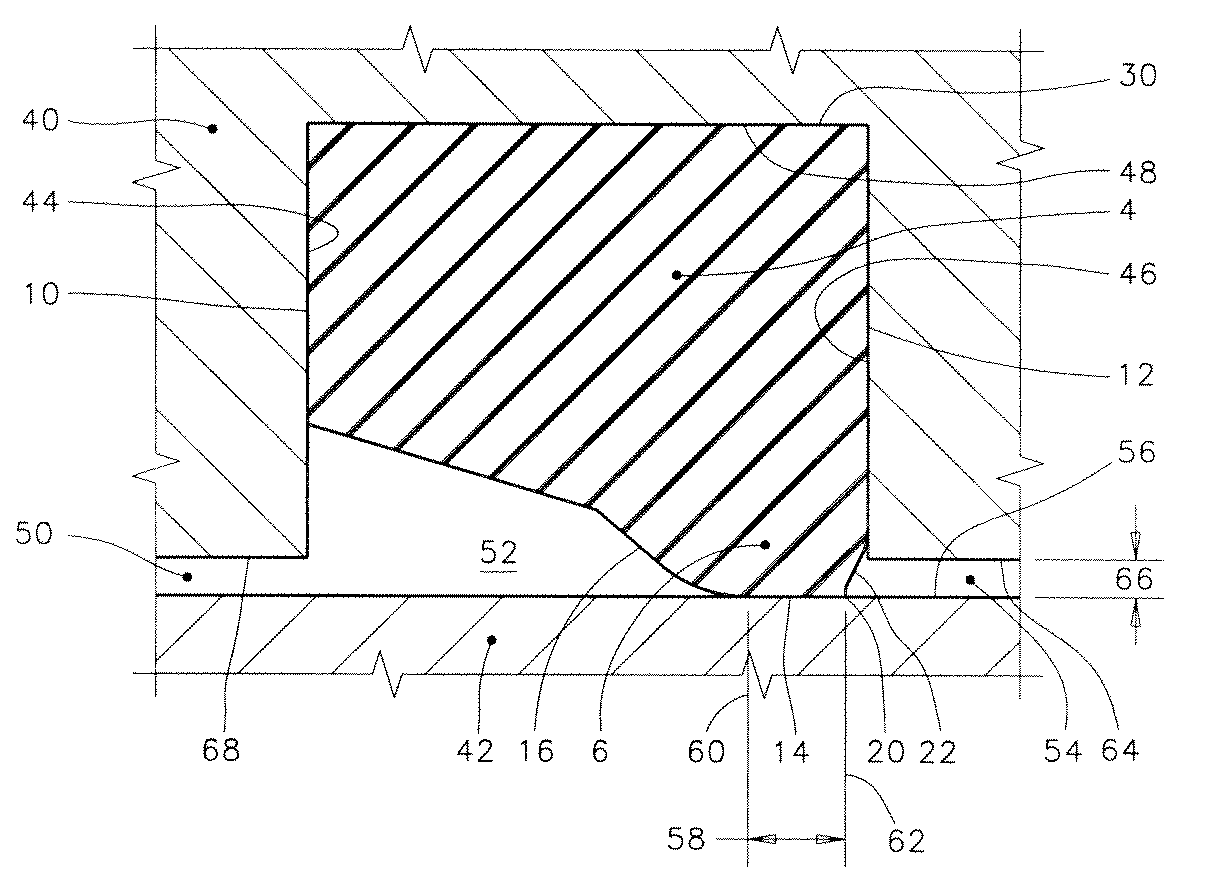

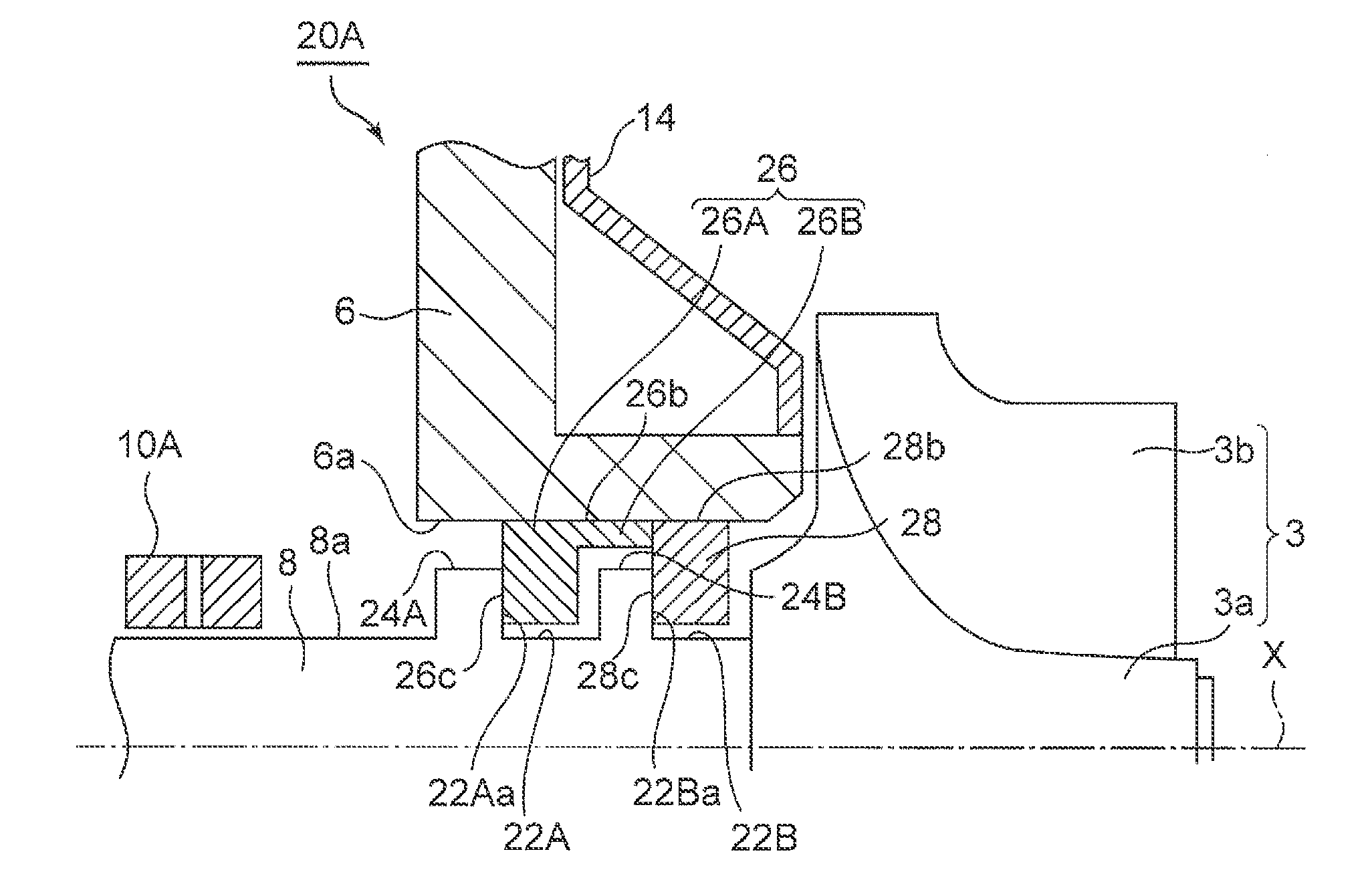

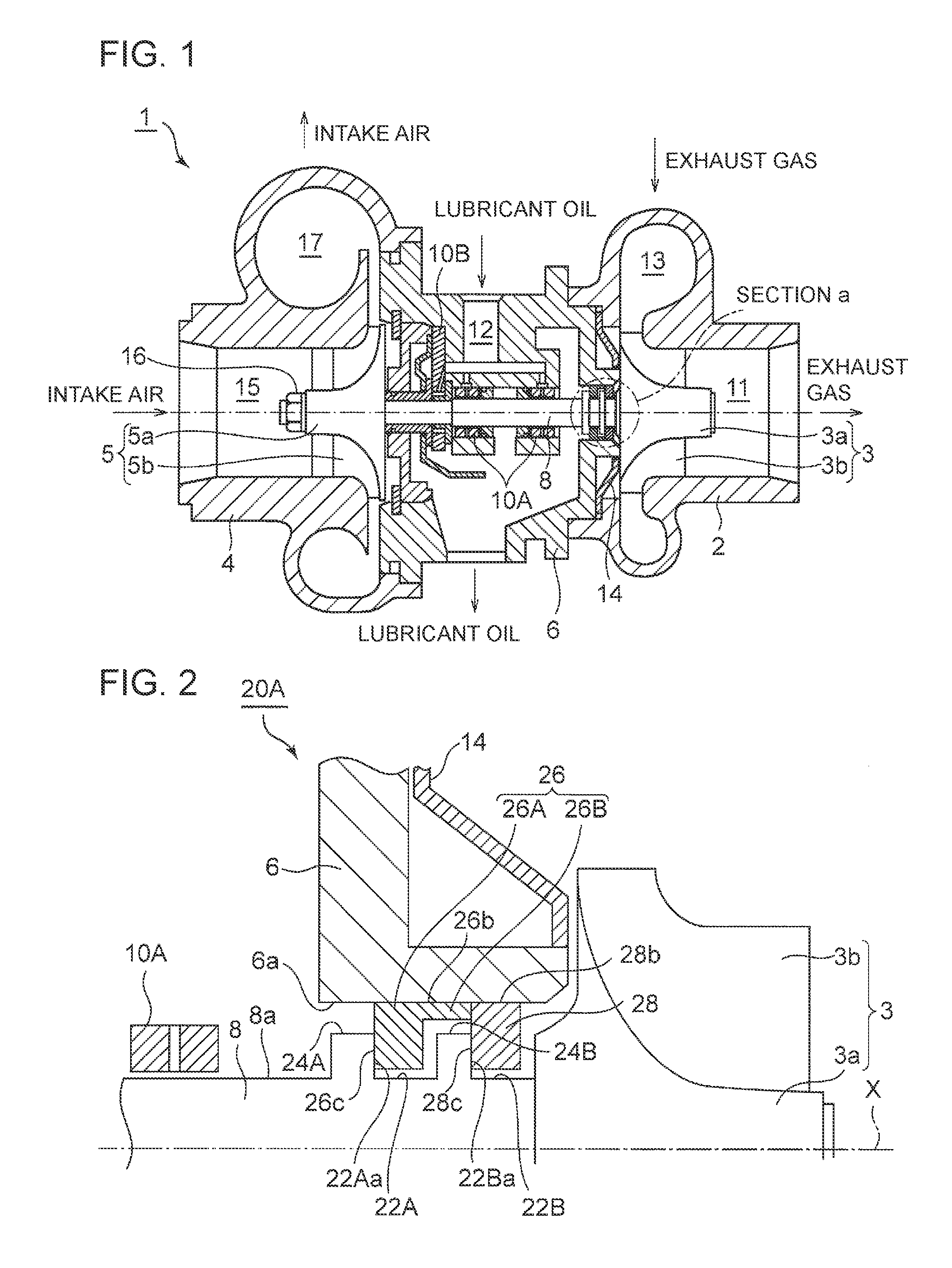

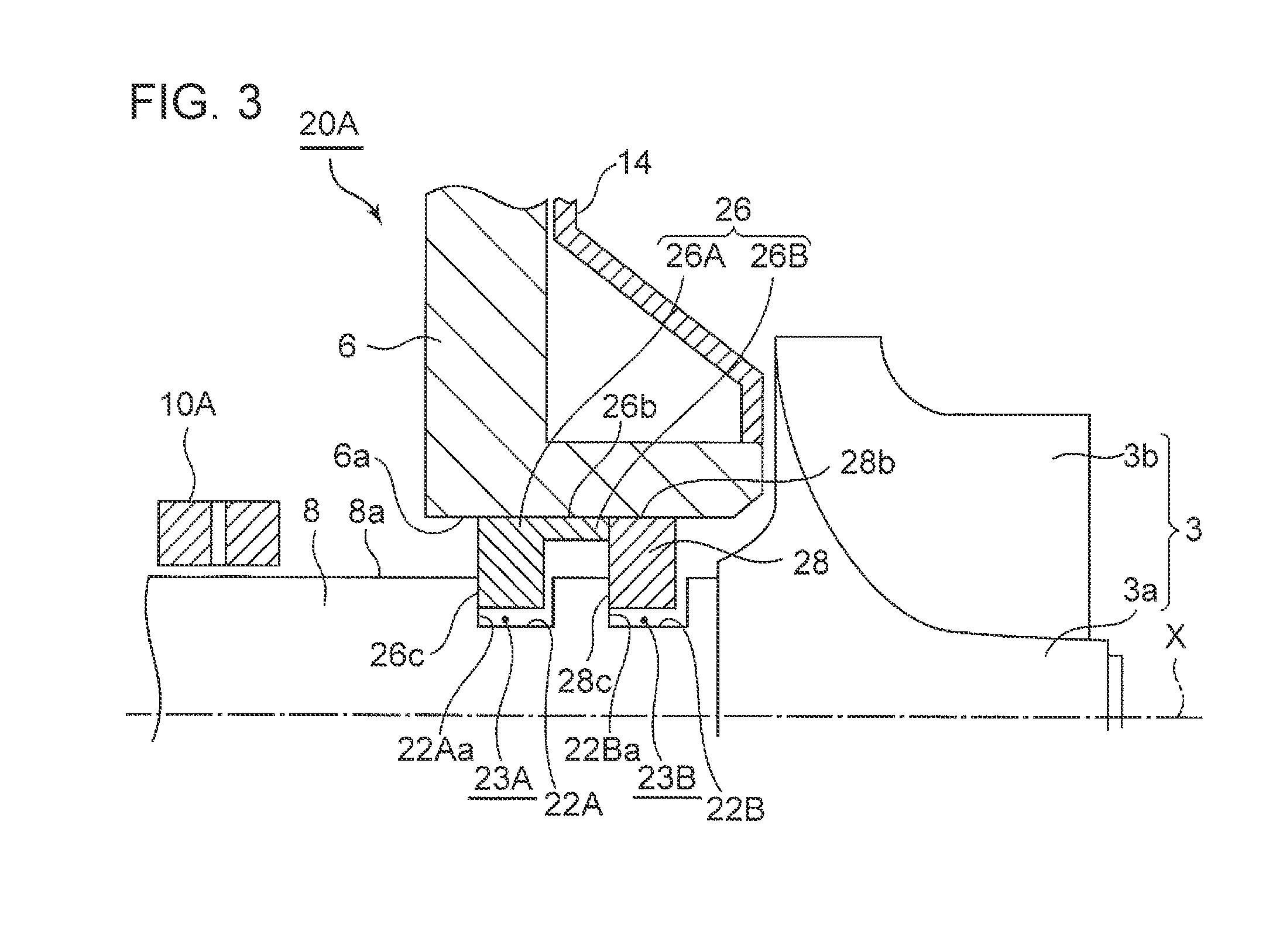

Seal structure and supercharger provided with the seal structure

An object is to provide a seal structure capable of reducing abrasion of a seal ring without increasing the number of components and of minimizing generation of abrasion powder. A seal structure to seal clearance between an outer peripheral surface 8a of a rotary shaft 8 and an inner peripheral surface 6a of a bearing housing 6 includes: a first seal groove 22A formed on the outer peripheral surface 8a of the rotary shaft 8; a second seal groove 22B disposed between the first seal groove and the impeller; a first seal ring 26 to be mounted to the first seal groove; and a second seal ring 28 to be mounted to the second seal groove. The first seal ring 26 includes a first-seal body portion 26A mounted to the first seal groove, and a first-seal protruding portion 26B protruding from the first-seal body portion toward the second seal ring 28, and being configured to be in contact with the second seal ring contacting a bearing-side wall surface 22Ba of the second seal groove, in a state in which the first-seal body portion is in contact with a bearing-side wall surface 22Aa of the first seal groove.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

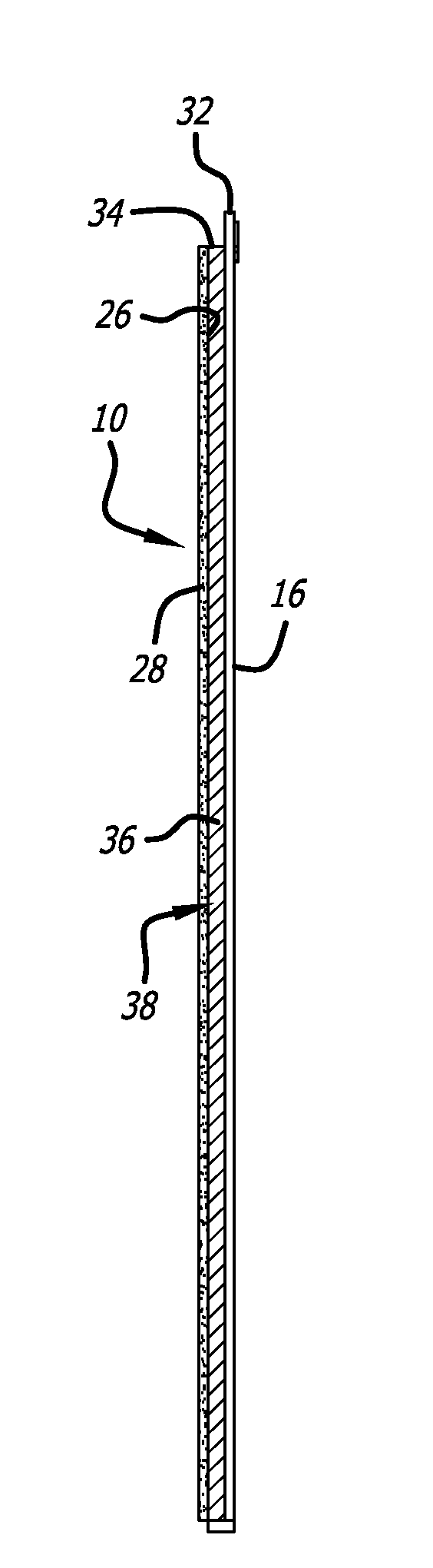

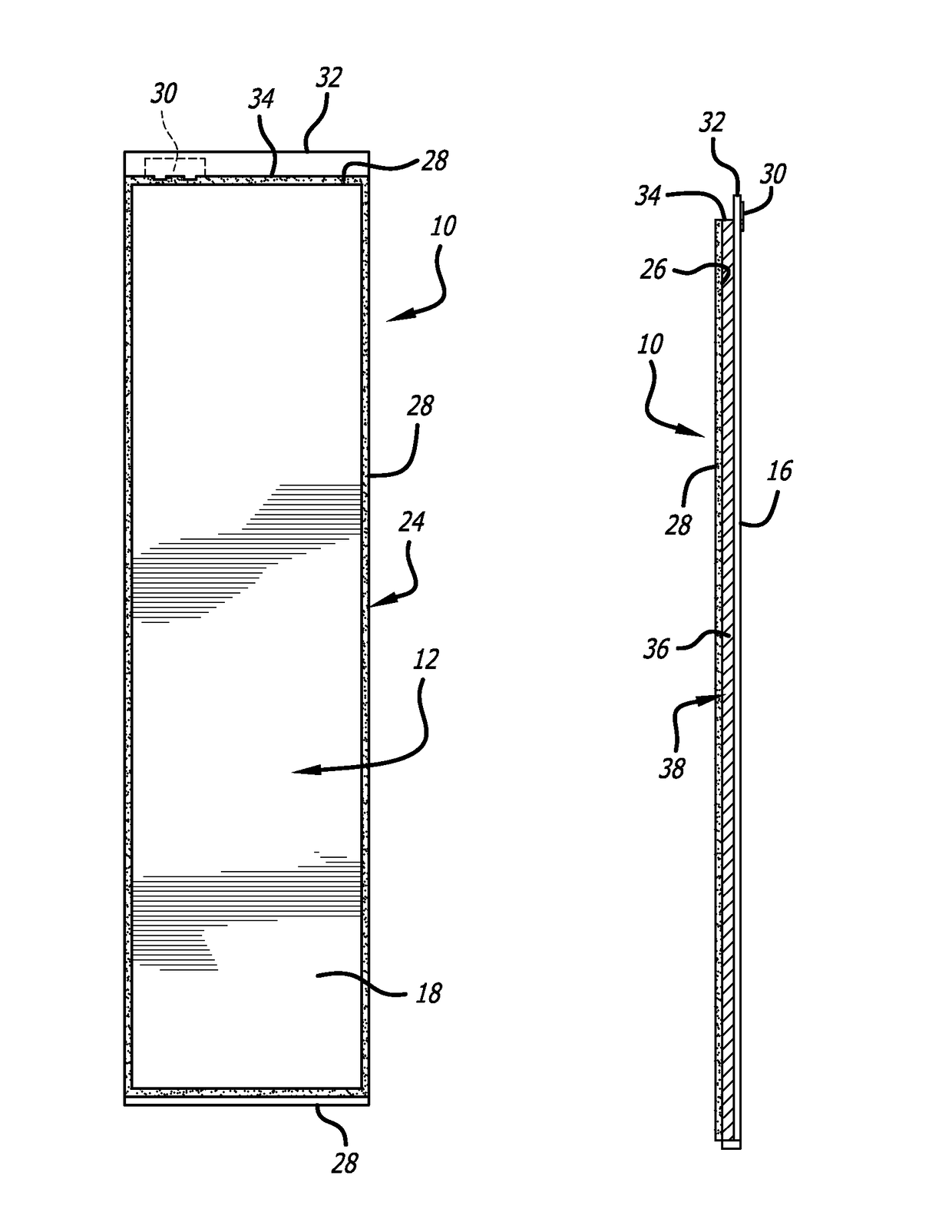

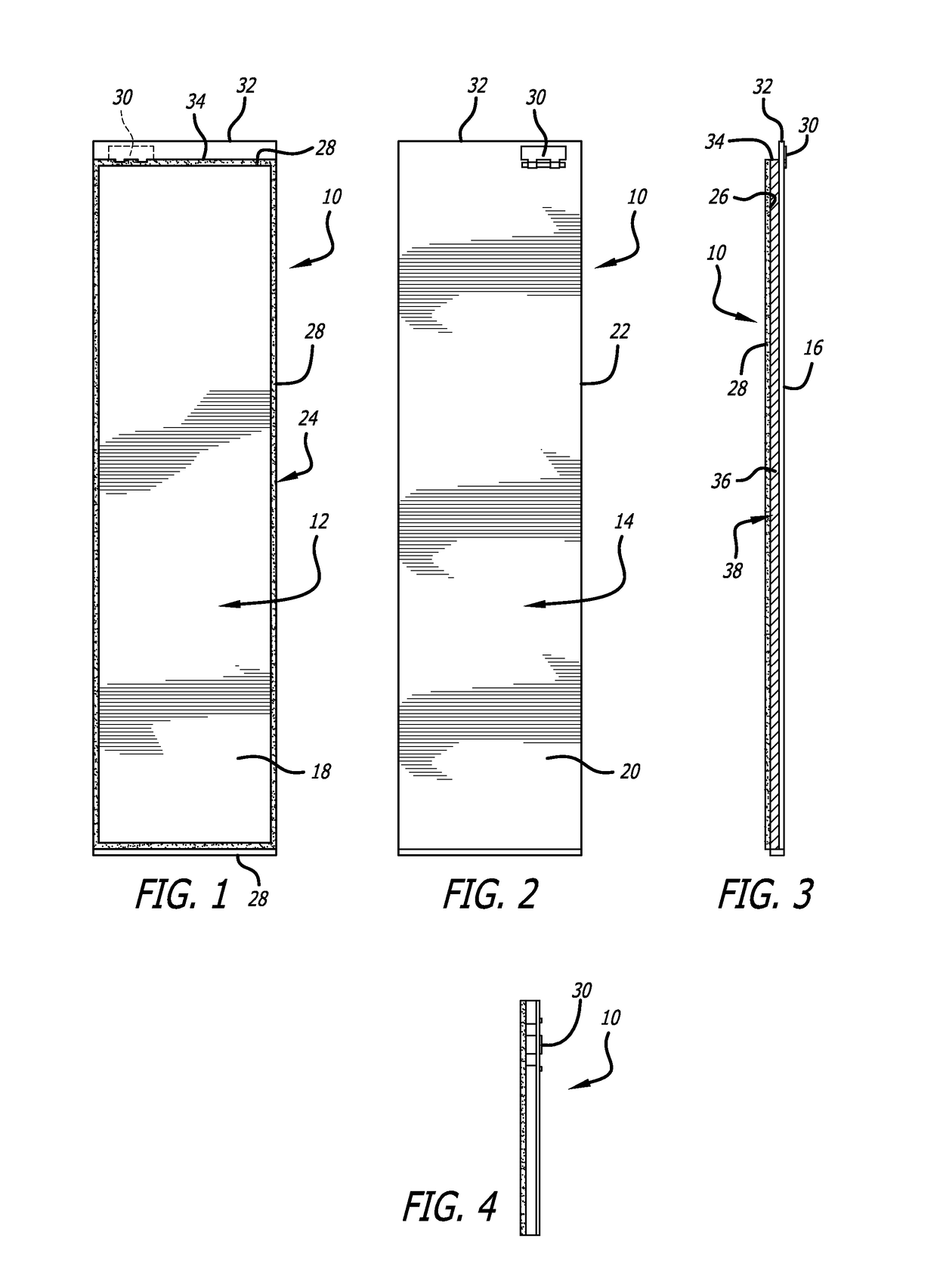

Aircraft galley cart bay door

ActiveUS20140366454A1Improve sealingReduced seal wearGalleysAircraft accessoriesEngineeringHigh intensity

An aircraft galley cart bay door includes a door main structure having an inwardly facing peripheral inner edge with an inner surface, and a surface seal on the inner surface of the inwardly facing peripheral inner edge of the inner wall. A substantial majority of the main structure of the door is formed from a high strength molded carbon fiber composite material. The door main structure may optionally define a recess, and insulation material can be disposed in the recess defined by the main structure of the door.

Owner:BE AEROSPACE INCORPORATED

Rotary seal with truncated wave form

The present invention is a generally circular rotary seal that establishes sealing between relatively rotatable machine components for lubricant retention and environmental exclusion, and incorporates seal geometry that interacts with the lubricant during relative rotation to distribute a lubricant film within the dynamic sealing interface. A preferably curved elevated contact pressure zone serves to maximize interfacial lubrication in critical areas during severe operating conditions by utilizing lubricant that would otherwise escape at the trailing edge of the hydrodynamic waves. The zones are produced by geometry that serves to minimize lubricant shear area, seal torque, seal volume, and wear, while ensuring retrofitability into the seal grooves of existing equipment.

Owner:KALSI ENG

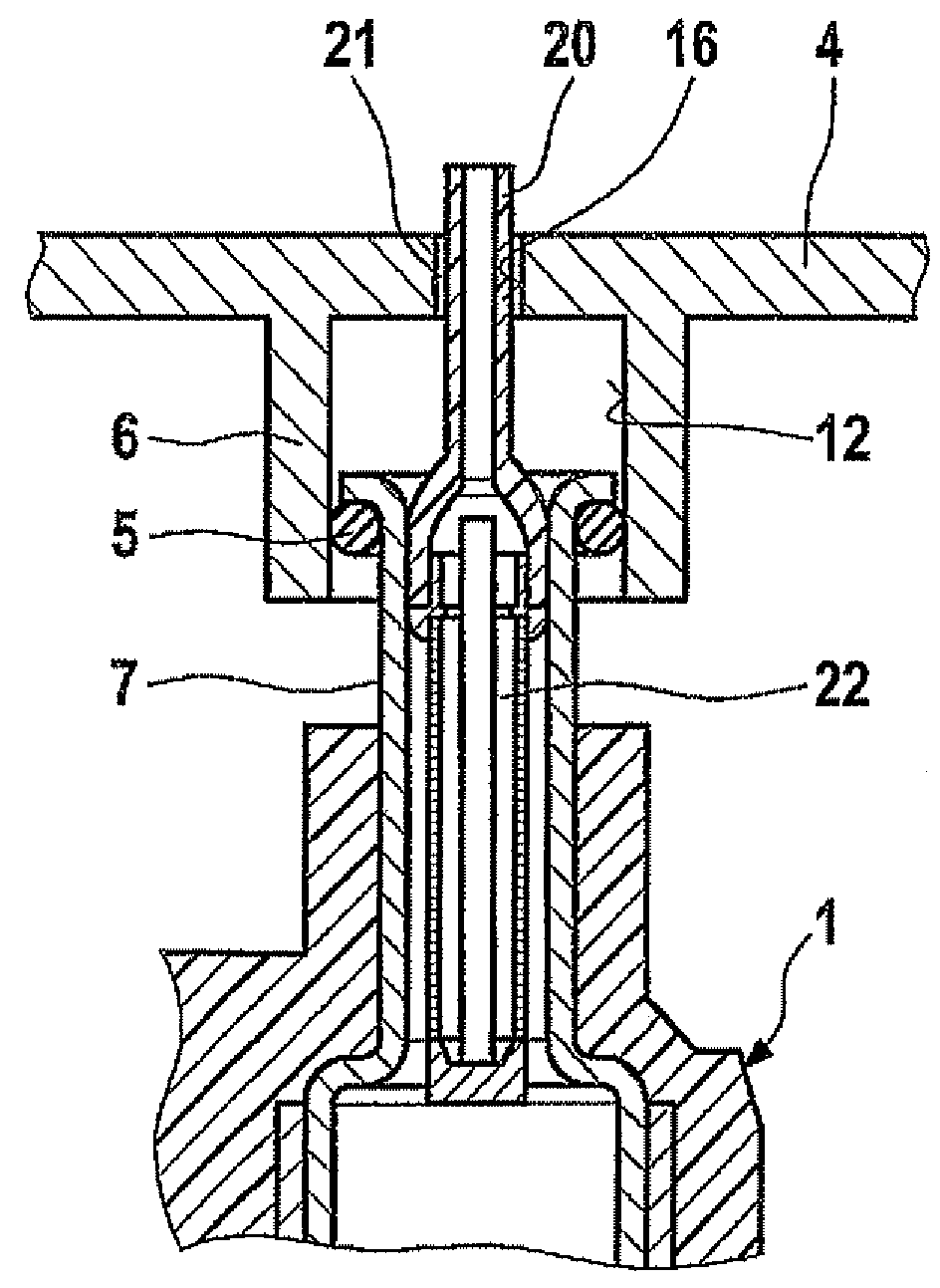

Fuel-injection device

InactiveUS7931007B2Improve sealingReduce generationLow-pressure fuel injectionMachines/enginesCombustion chamberInlet manifold

The fuel-injection device is characterized by an especially low-noise design. The fuel-injection device includes at least one fuel injector and a fuel rail having at least one pipe connection, the fuel injector being introduced into a receiving bore of the pipe connection, and the fuel rail having a discharge opening to supply fuel to the fuel injector. Provided between the fuel injector and the fuel rail is a pressure-wave guide connecting both, in such a way such that dynamic pressure fluctuations in the fuel injector are able to be routed largely past the volume of the receiving bore of the pipe connection. The fuel-injection device is especially suitable for the direct injection of fuel into a combustion chamber of a mixture-compressing internal combustion engine having external ignition, but it is also suitable for the injection of fuel into an intake manifold.

Owner:ROBERT BOSCH GMBH

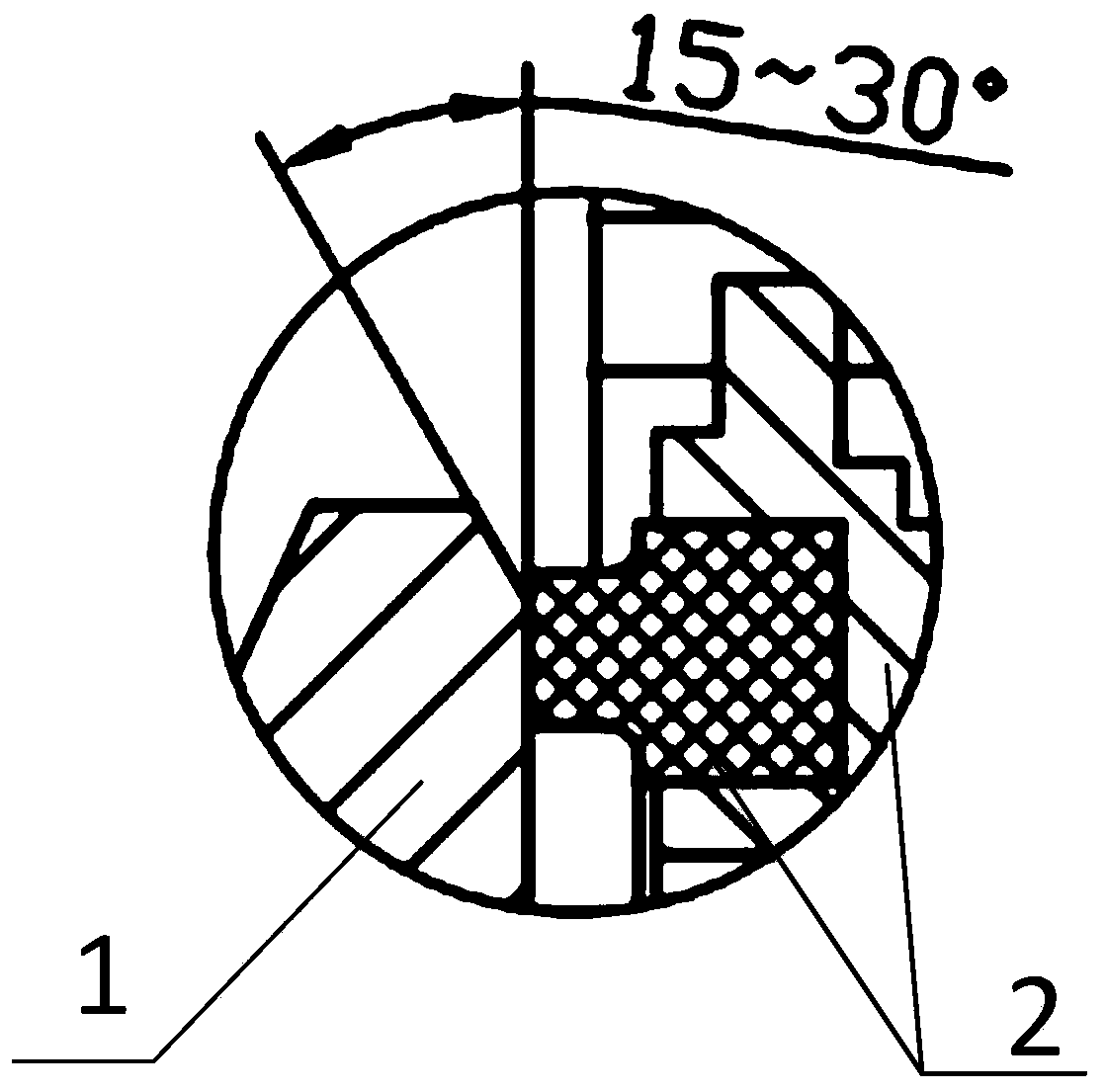

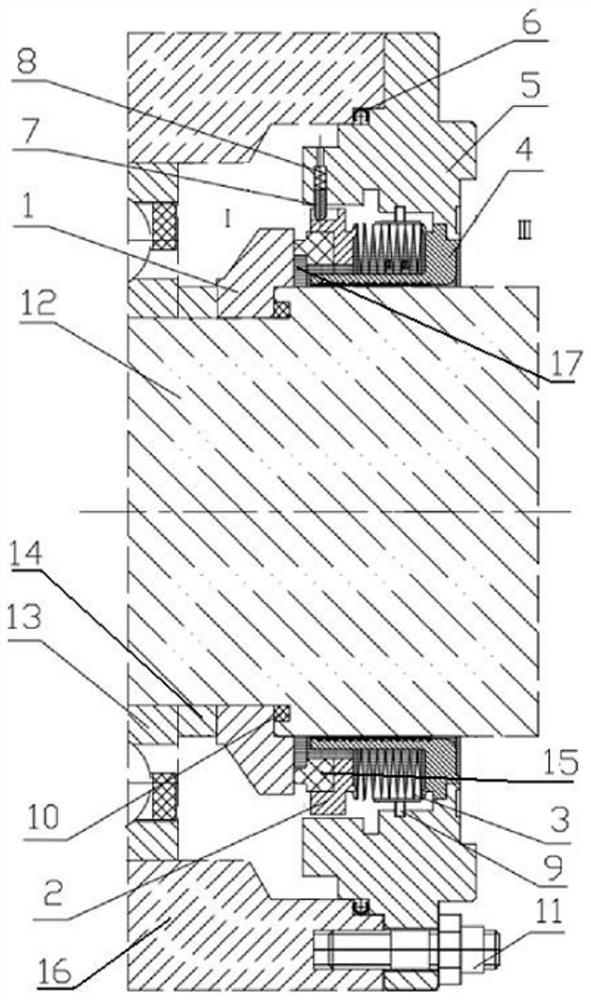

Dynamic sealing device suitable for low-temperature and high-speed repeated use

The invention relates to a dynamic sealing device suitable for low-temperature and high-speed repeated use. The dynamic sealing device is applied to a liquid rocket engine turbopump. The liquid rocketengine turbopump comprises a shaft (18) and a bearing (9) sleeving the shaft (18). The dynamic sealing device comprises a main sealing structure. The main sealing structure comprises a dynamic ring (1), a static ring assembly (2), a corrugated pipe (3), a rear ring (4), a sealing shell (5) and a shaft sleeve (14). The dynamic sealing device comprises the main sealing structure, so that low-temperature media can easily enter a dynamic ring and static ring assembly joint surface, dry friction on the sealing surface is avoided, sealing wear is reduced, the sealing service life is prolonged, andrequirements for long service life and repeated use under severe working conditions such as high rotating speed, high pressure and large radial runout of the turbopump are met.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Double seat valve with seat cleaning

ActiveUS20100180958A1Avoid creatingReduced seal wearPlug valvesOther washing machinesEngineeringVALVE PORT

The invention relates to a double seat which is capable of cleaning the seat and which is improved compared to that of the prior art, whereby a delivery as free from turbulence as possible of the seat cleaning flow into and out of the leakage cavity is ensured, and a pressure-increasing direct action upon the seat areas is reliably prevented. This is achieved in that: the second closing element (4), when in its closed position rests with a stopping surface (4e), arranged on the boundary surface thereof radially adjacent on the inner side to the second seal (7), on the second seating surface (2b) and directly adjacent to the first seating surface (2a, 2g) with a central recess (4d) provided in the front face of the second closing body (4) facing the leakage cavity (5), beginning on the radial outside with a rotationally symmetrical deflector surface (4b) (starting point for the contour (K)) and frontwardly defined on the front face (4c) oriented essentially perpendicular to the longitudinal axis of the second closing body (4) wherein the deflector surface (4b) opens in the front face (4c) (opening point of the contour (K)), the deflector surface (4b) and the stop surface (4c) form a second circumferential edge (U2) directly adjacent to a first end section (2g) f the first seat surface (2a) in the closed position of second closing body (4), viewed in meridional section the deflector surface (4b) has a contour (K) with a bend-free curve, a directional vector in the opening point of the deflector surface (4b) faces a drain drilling (3d) arranged centrally in th first closing body (3), without coming into contact with the first closing body (3) in the vicinity of the regions thereof around the leakage cavity (5) or with the middle seal (8; 8*) such as to form a back pressure and a front face boundary of the first closing body (3) facing the leakage cavity (5) has an axial security separation (x) form the directional vector to a outlet point on the second seating surface (2b) in the first end section (2g) designed as a first deflector edge (U1).

Owner:GEA TUCHENHAGEN GMBH

Shaft seal ring with Anti-rotation features

A shaft seal includes an elastomeric component that includes a plurality of anti-rotation features spaced intermittently about a circumference of the elastomeric component, and a seal contact component that is bonded to the elastomeric component. Each of the plurality of anti-rotation features is a rib structure. The rib structure of each of the plurality of anti-rotation features may extend from adjacent the outer diameter face and widen toward the inner diameter face, or may extend from adjacent the inner diameter face and widen toward the outer inner diameter face, to form substantially a tear drop shape. A shaft seal assembly includes the described shaft seal, and an application housing structure including a bore that receives at least a portion of the shaft seal. The seal contact component is received within the bore, and the application housing structure is configured to rotate relative to the shaft seal.

Owner:PARKER HANNIFIN CORP

Annular seal assembly for insertion between two relatively rotatable members and method for its use

ActiveUS7926814B2Slight frictionLow cost manufacturingEngine sealsOther washing machinesRadial planeEngineering

A seal assembly including first and second rigid shields and a sealing member carried by the first shield and having a first and second annular sealing lip in sealing engagement with respective sliding surfaces of the second shield. The first sealing lip carries in a radial seat thereof a toroidal spring exerting a radially eccentric thrust on the first sealing lip with respect to an elastic hinge defined by a common root portion of the lips, having a center of rotation located along a line extending through a V-shaped sealing edge of the first lip and forming a 20° to 60° angle with a radial plane. The root portion is defined between two opposite annular recesses having a U-shaped cross-section and bottom walls facing each other, substantially aligned along the aforementioned line.

Owner:AB SKF

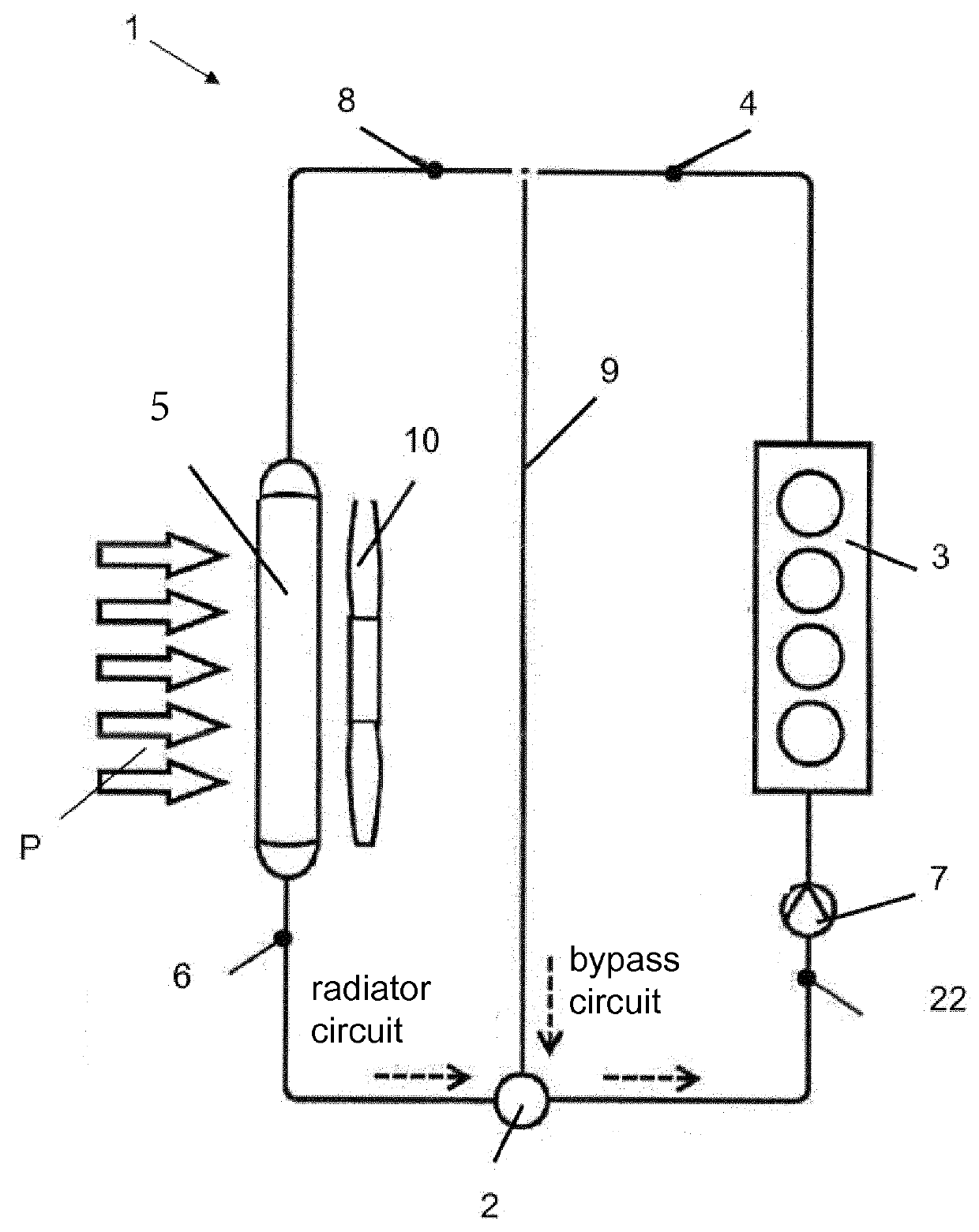

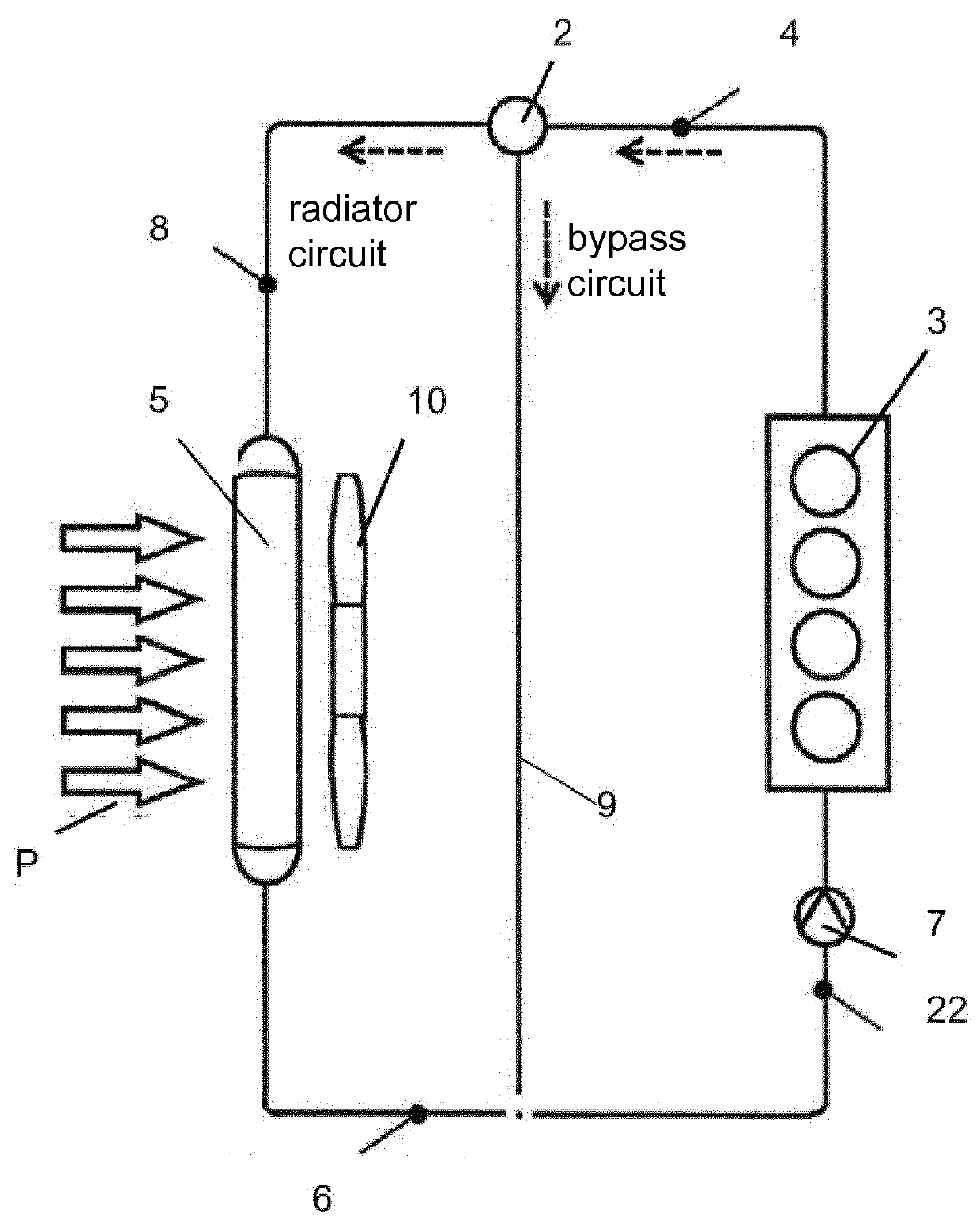

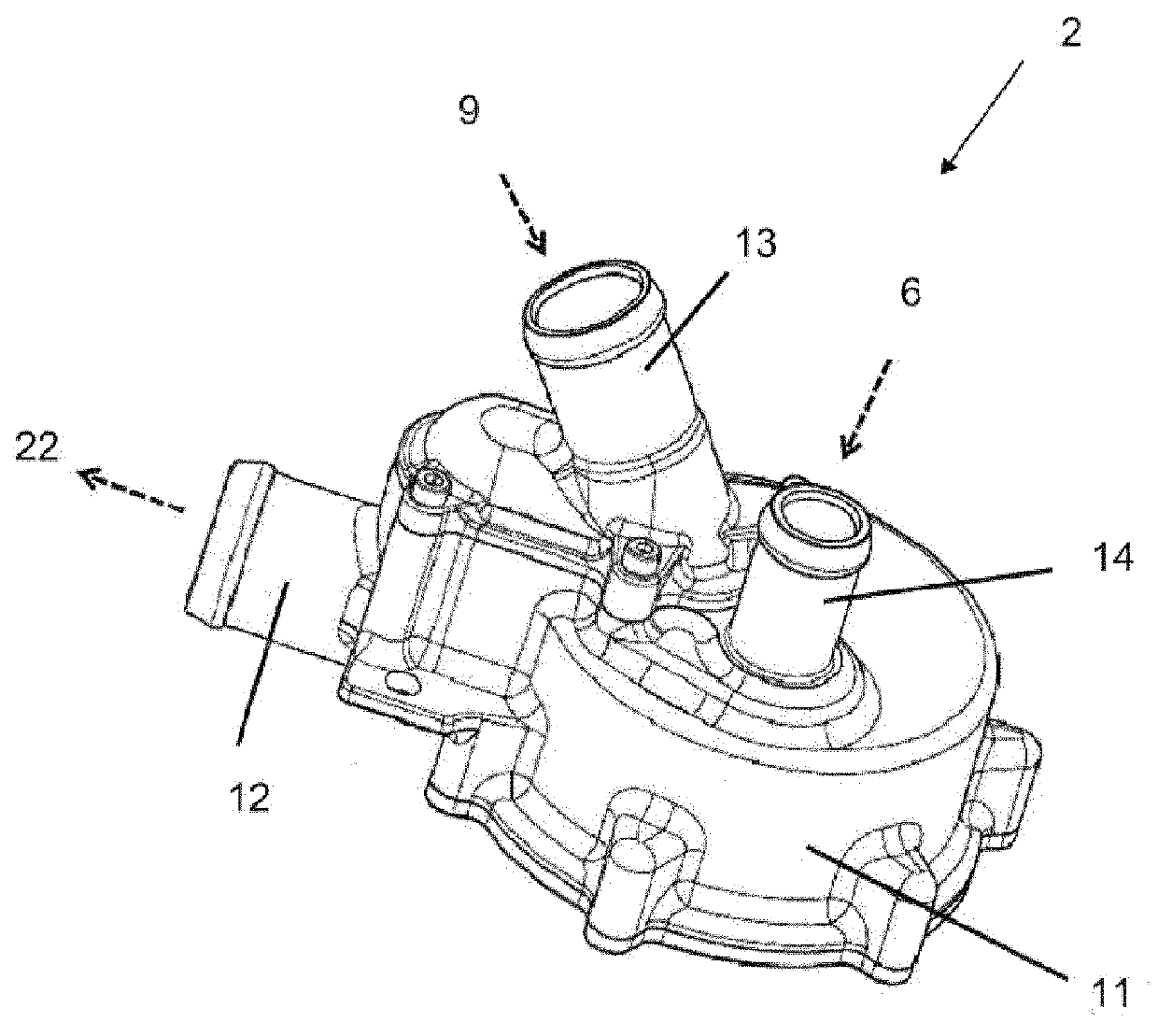

Electrically drivable valve for controlling volumetric flows in a heating and/or cooling system of a motor vehicle

ActiveUS20160053911A1Simple designLong life-timeOperating means/releasing devices for valvesMultiple way valvesElectricityEngineering

An electrically drivable valve for controlling volumetric flows in a heating and / or cooling system of a motor vehicle, including a housing, from which at least two channels, preferable an inlet channel and an outlet channel, branch off, wherein a disk-shaped valve body is arranged in the housing, which valve body can be rotated about an axis of a drive shaft and has a control contour. For a valve that is simple to produce in regard to the design of the valve, the single control contour of the valve body controls a bypass circuit and a cooler circuit of the heating and / or cooling system.

Owner:MAHLE INT GMBH

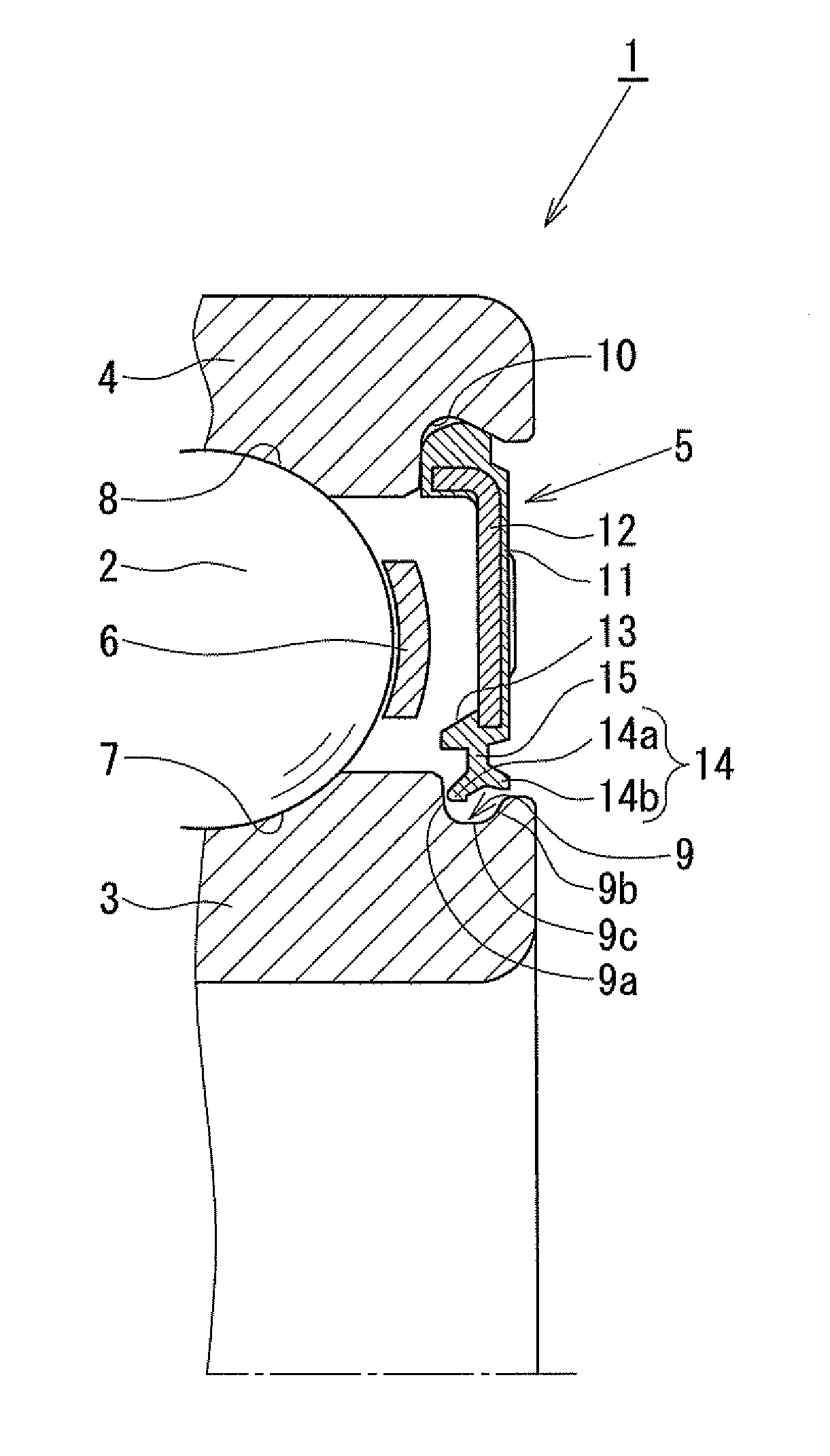

Rolling bearing

ActiveUS20130163907A1Reduce wearAvoid vibrationShaftsBall bearingsRolling-element bearingEngineering

A rolling bearing has an inner ring; an outer ring; a seal fixing groove provided at either the inner ring or the outer ring; a seal contact groove provided at either the inner ring or the outer ring on a side where the seal fixing groove has not been provided; and a sealing member with two ends. One end of the sealing member is fitted into the seal fixing groove, and the other end of the sealing member is configured not to contact the seal contact groove in a non-preloaded state but to contact the seal contact groove in an axial direction in a preloaded state. Further, a central line average roughness Ra of a contact surface of the seal contact groove to which the sealing member contacts is Ra≦0.6 μm.

Owner:MINEBEAMITSUMI INC

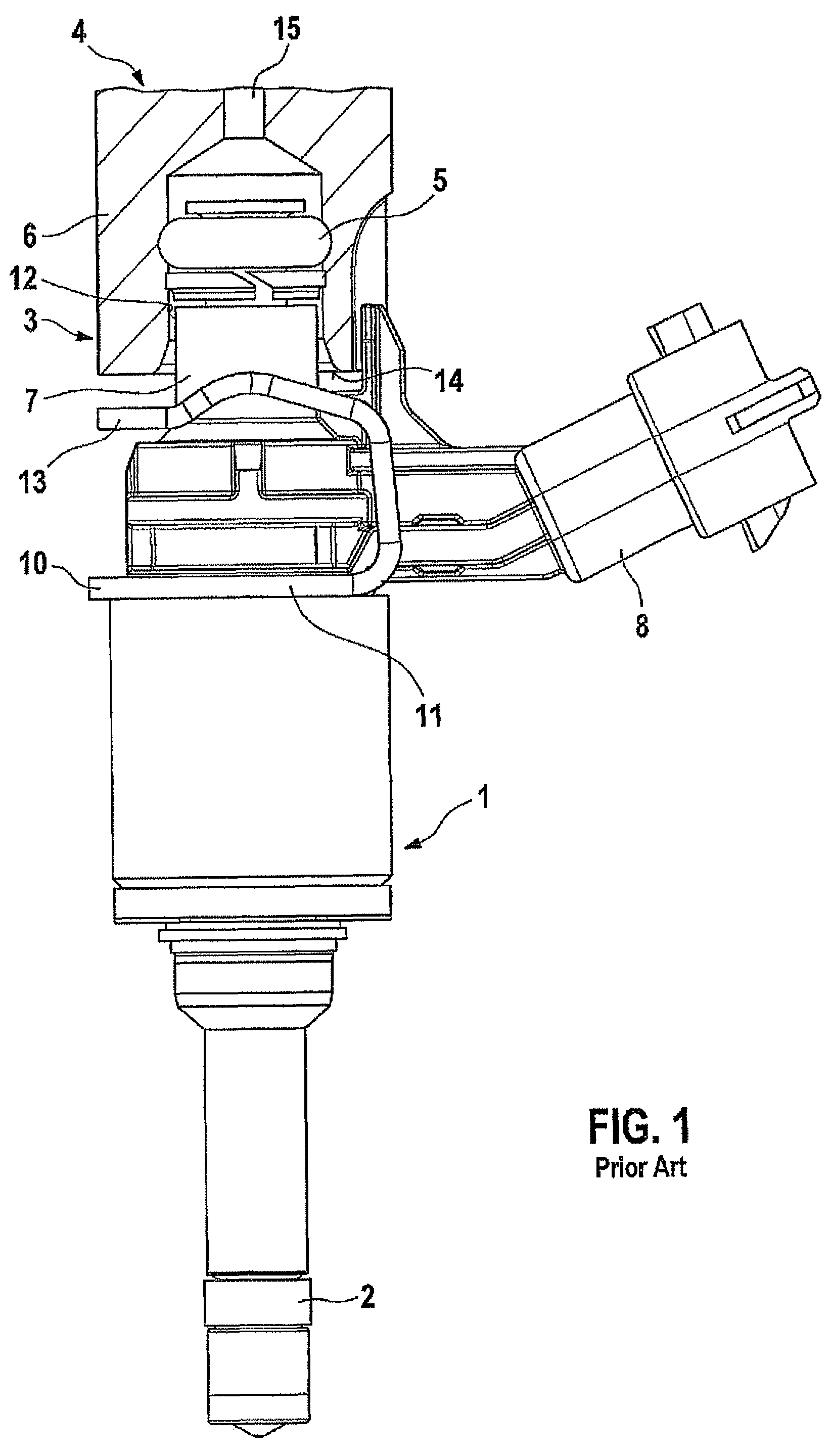

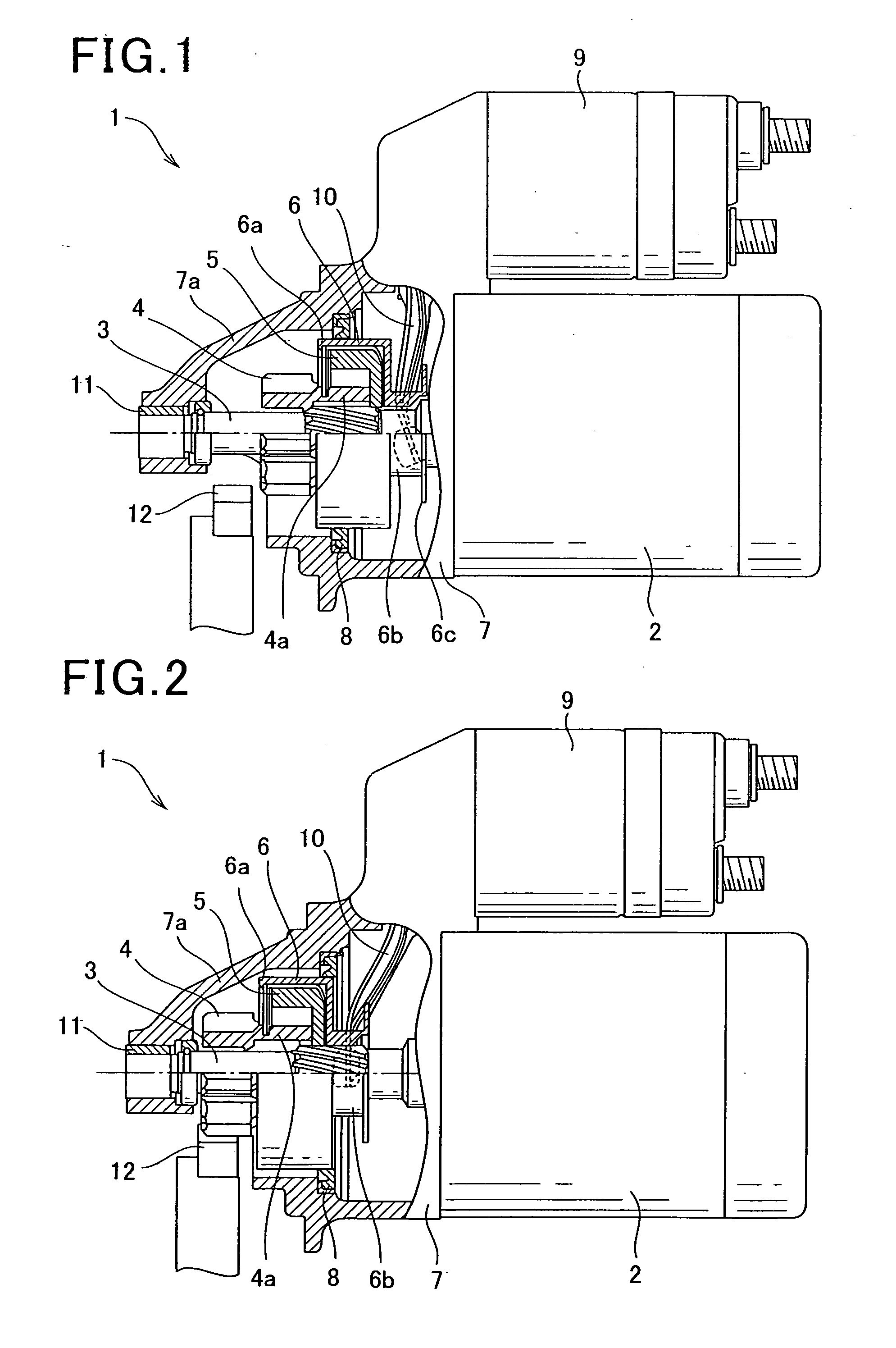

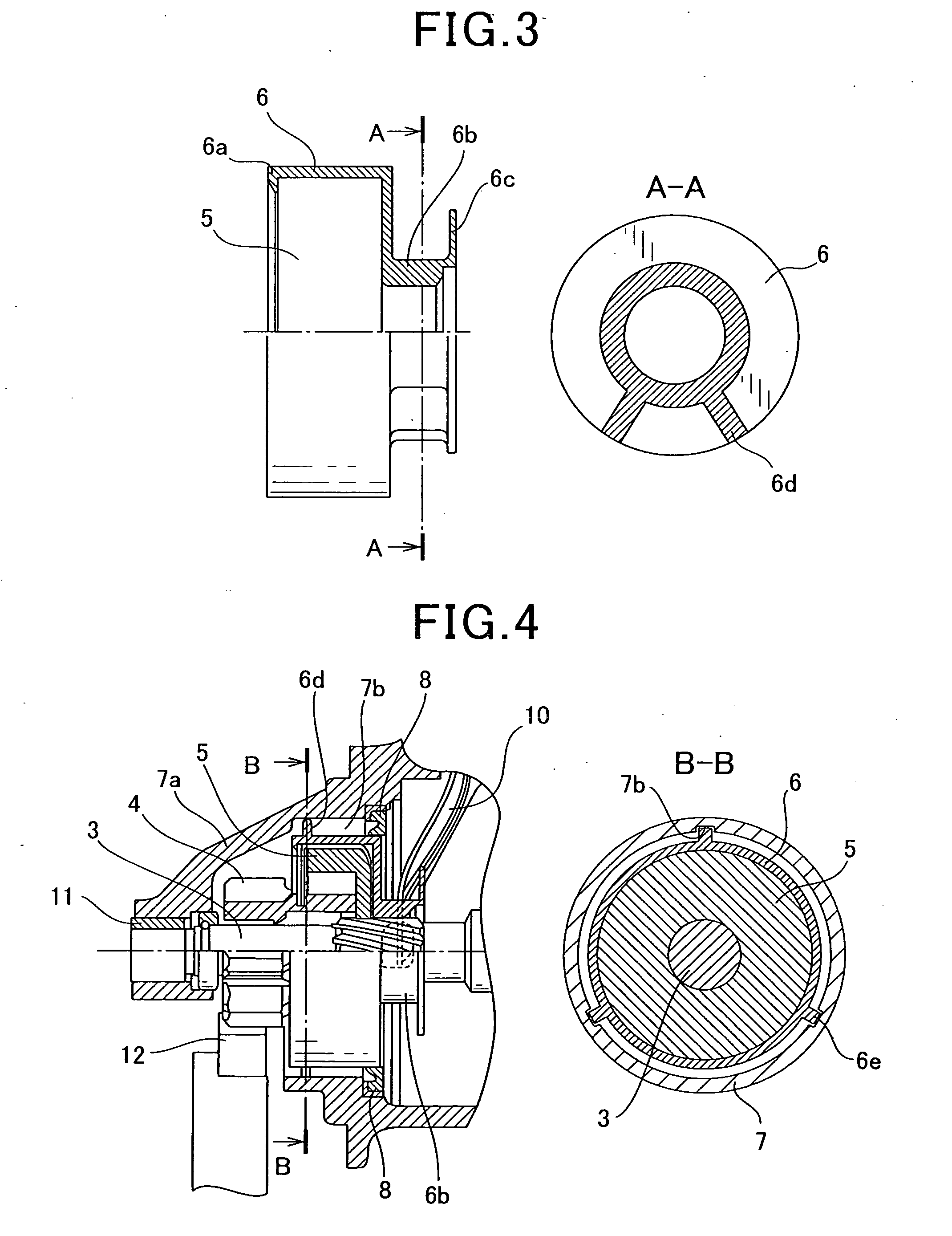

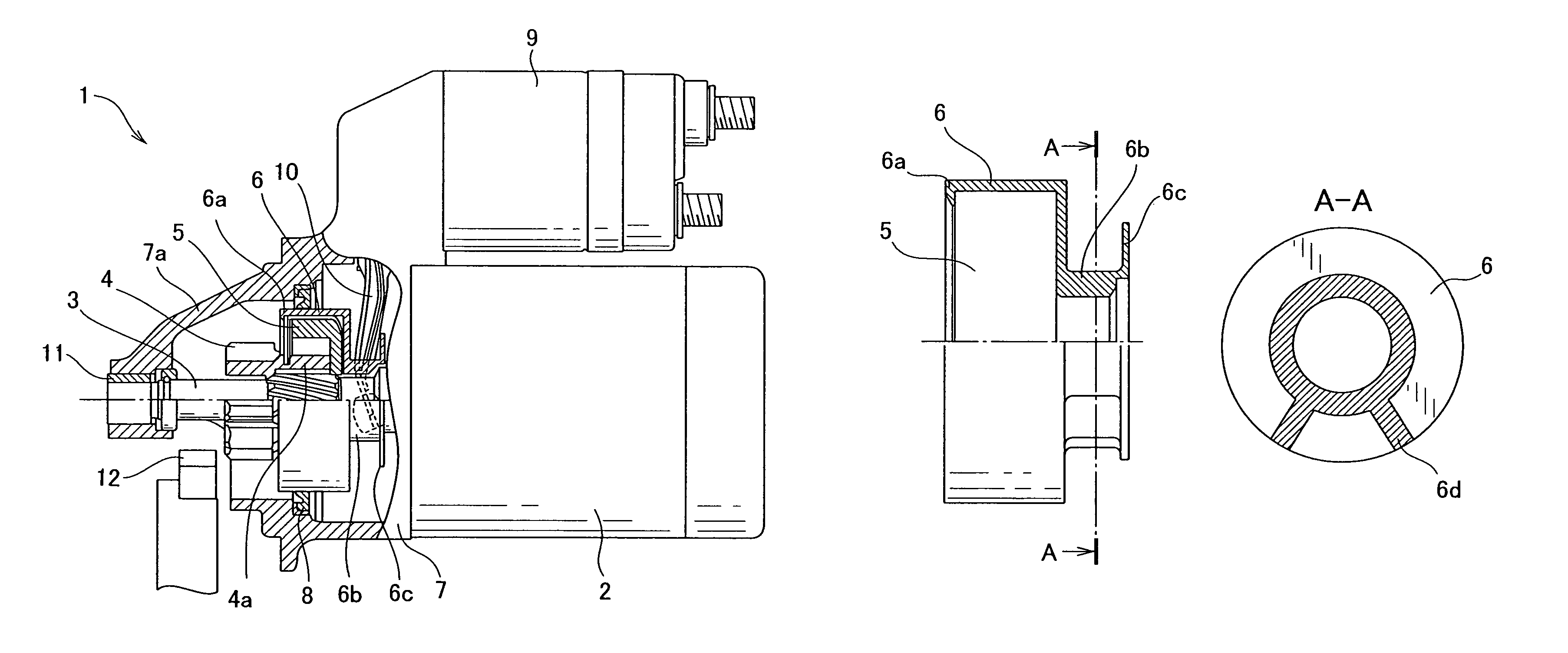

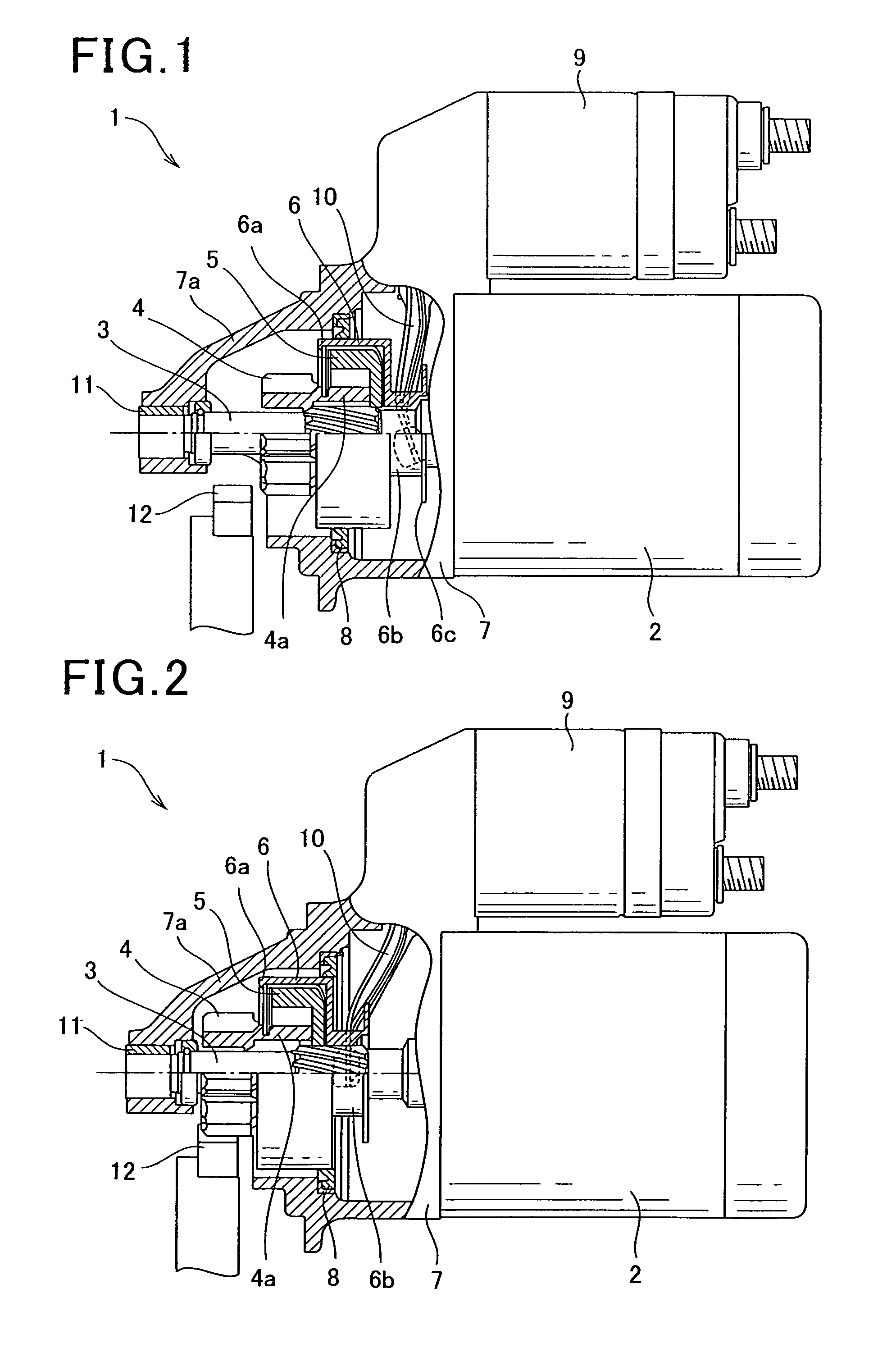

Starter

ActiveUS20100225189A1Reduce rotationReduce wearPower operated startersMachines/enginesEngineeringPinion

In a starter with which a pinion movable body with which a pinion gear and a one-way clutch were united moves on an output shaft, a holder is attached to the one-way clutch. A seal component having the shape of a ring is provided so that an end of an outer circumference of the seal component is fixed to a nose part of a housing and an end of an inner circumference of the seal component slidably contacts an outer circumferential surface of the holder. The holder is provided so that relative rotation to the one-way clutch is possible. Since the holder doesn't rotate relative to the housing, wear of a seal component is reduced compared with the case where the seal component contacts the one-way clutch which rapidly rotates whereby the sealability preventing a foreign substance or water from infiltrating into the inside of the starter can be maintained.

Owner:DENSO CORP

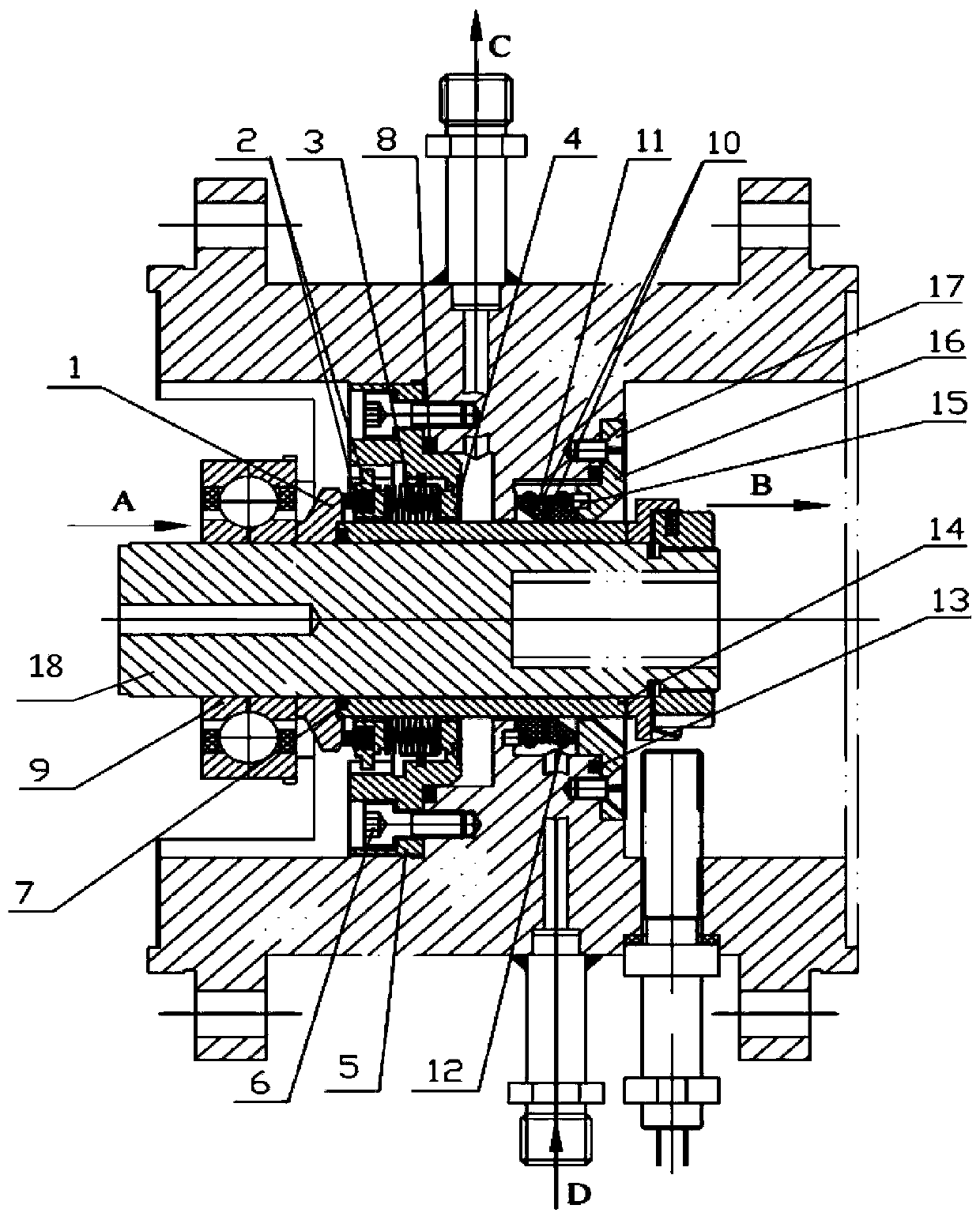

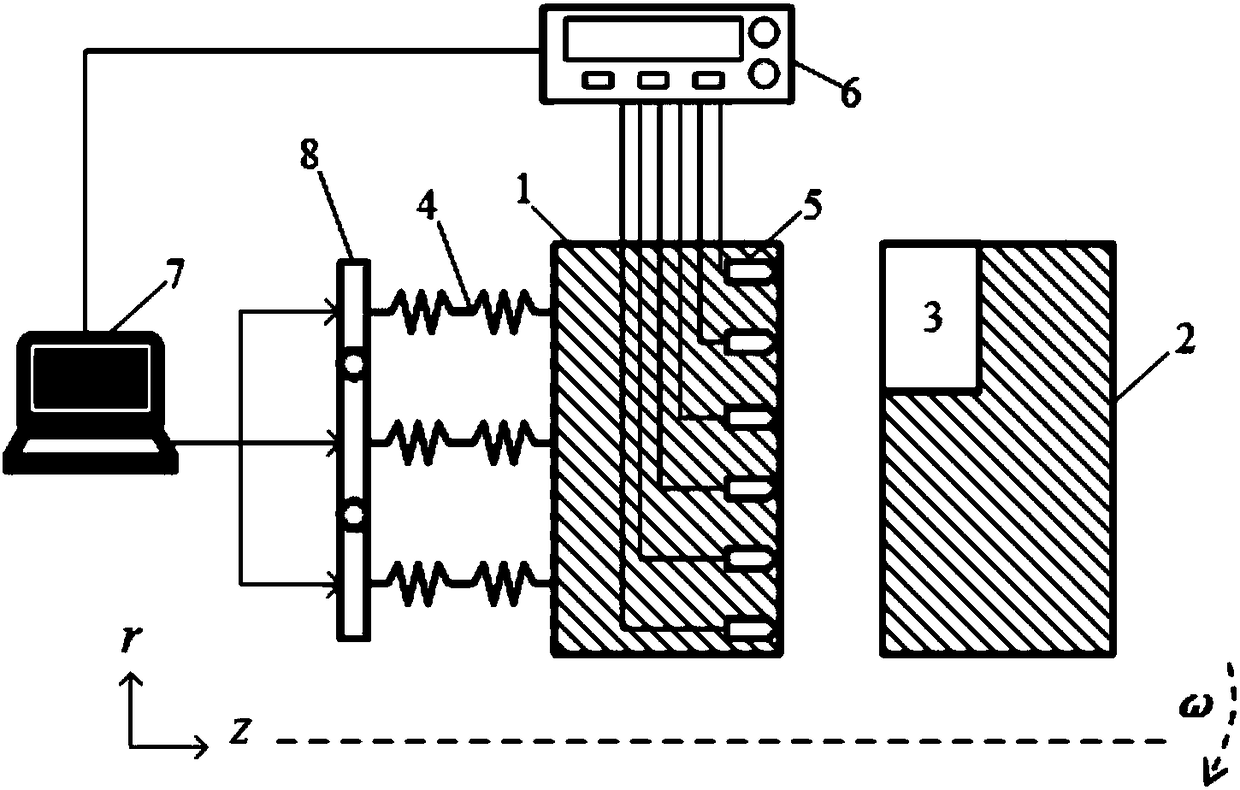

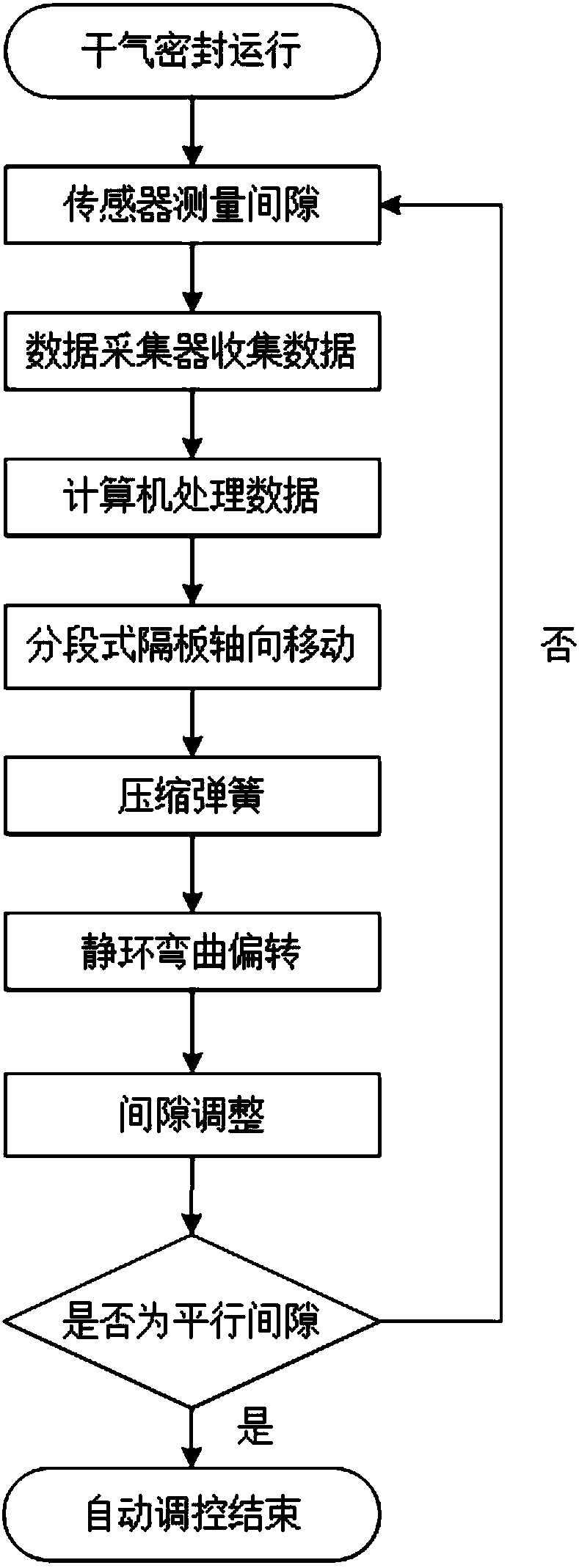

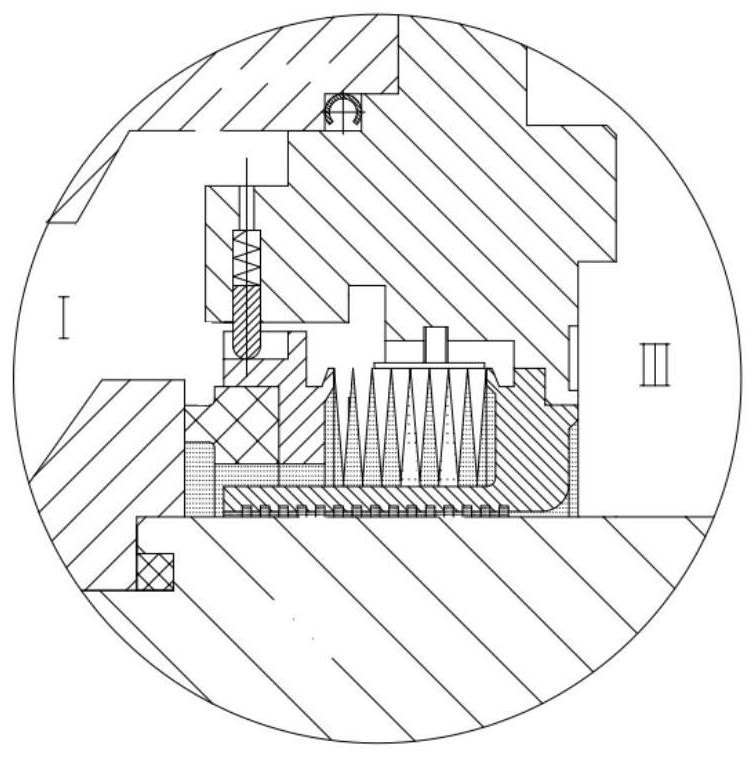

Dry gas seal system capable of automatically regulating clearance, and regulating method thereof

The invention discloses a dry gas seal system capable of automatically regulating a clearance, and a regulating method thereof. The system comprises a static ring, a moving ring, springs, a sensor, adata acquisition unit, a computer and a sectional type clapboard. The sensor is arranged on the sealed end surface of the static ring; the sensor is connected to an input end of the data acquisition unit; an output end of the data acquisition unit is connected with an input end of the computer; an output end of the computer link-controls the sectional type clapboard; the multiple springs are fixedly arranged between the sectional type clapboard and the non-sealed end surface of the static ring; a plurality of dynamical pressure slots are uniformly formed in the sealed end surface of the movingring along the circumferential direction; and the static ring sealed end surface and the moving ring sealed end surface are matched to form dry gas seal. The sensor transmits acquired data to the computer, the data is processed so as to obtain a sealed end surface gas film clearance value, a signal is provided to drive the sectional type clapboard to move, the springs are compressed, and the static ring bends and deflects for compensating the deformation of the end surfaces, so that the sealed end surfaces are tend to be parallel, the influence of the deformation on sealing is reduced, the stable operation of sealing is maintained, and the risk of seal failure is reduced.

Owner:XI AN JIAOTONG UNIV

Starter

ActiveUS8215194B2Increased durabilityImprove reliabilityPower operated startersElectric motor startersEngineeringPinion

Owner:DENSO CORP

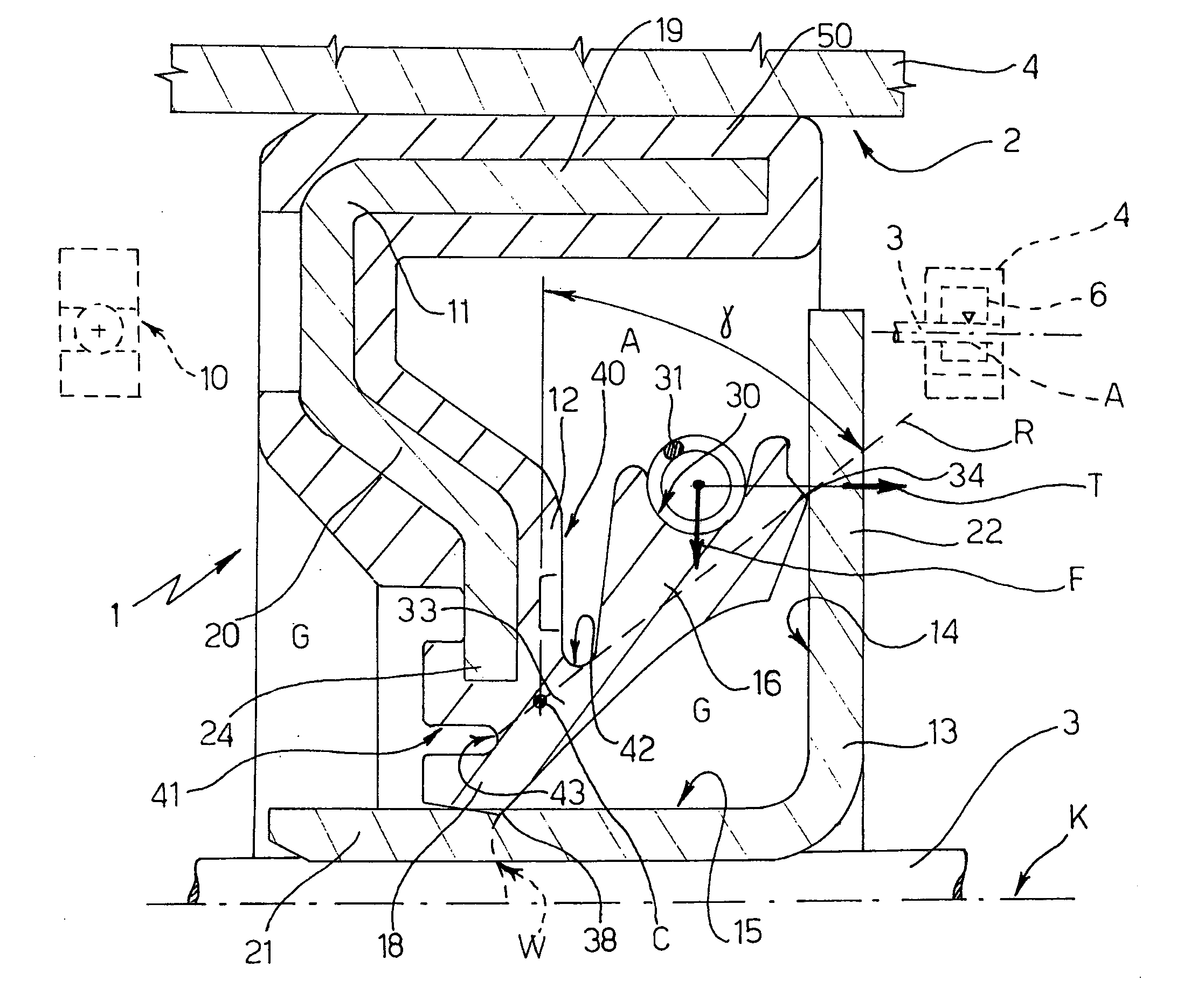

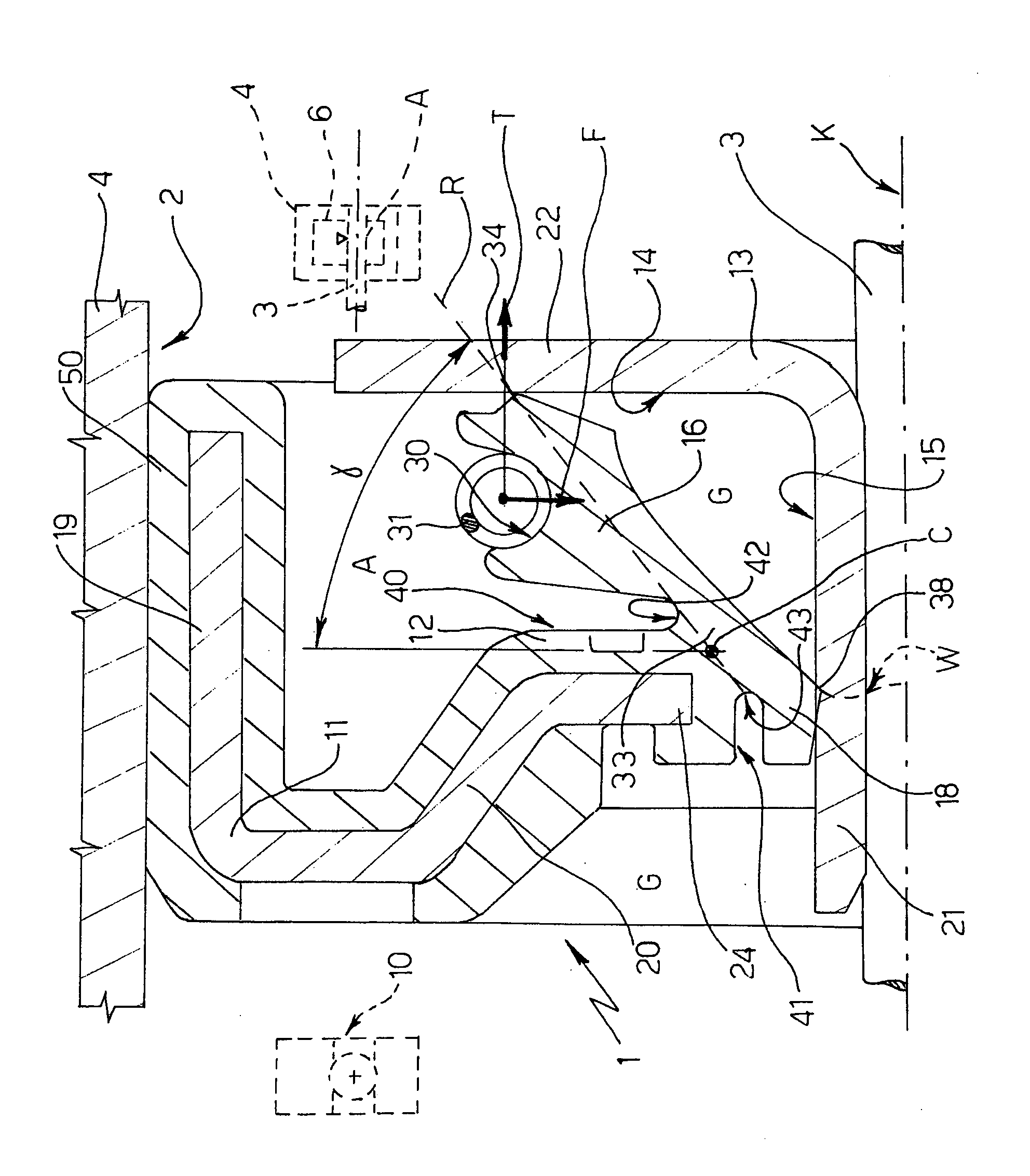

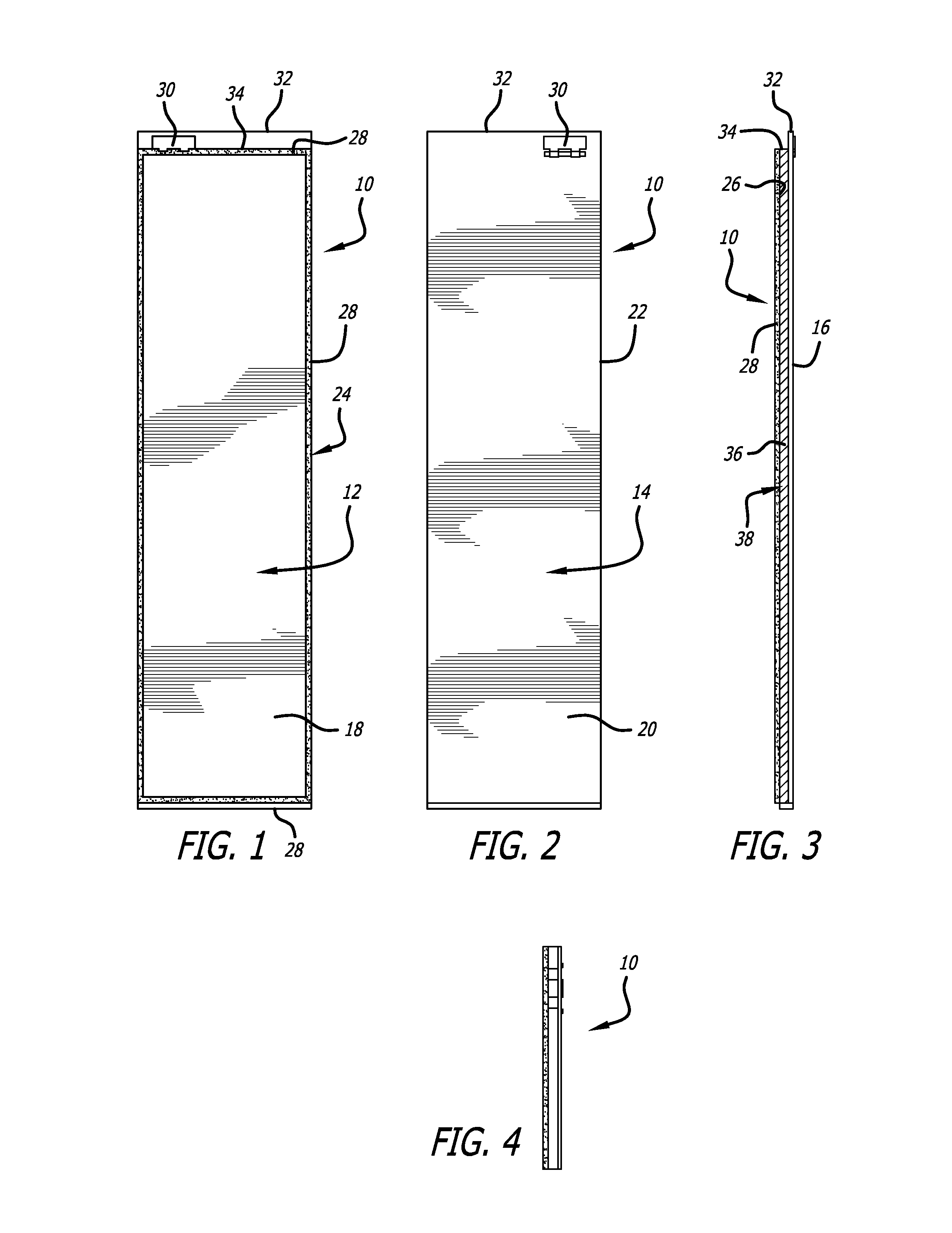

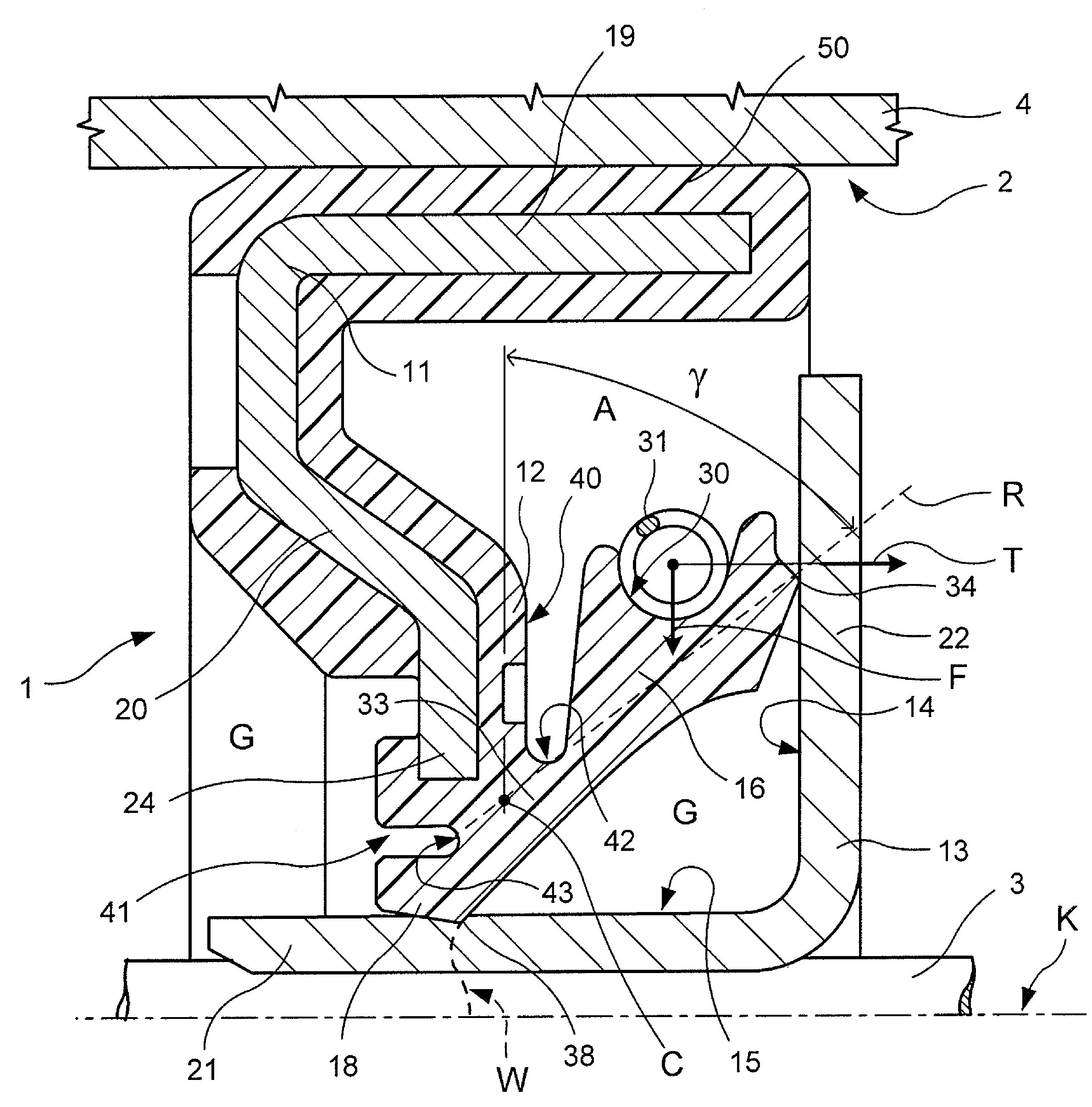

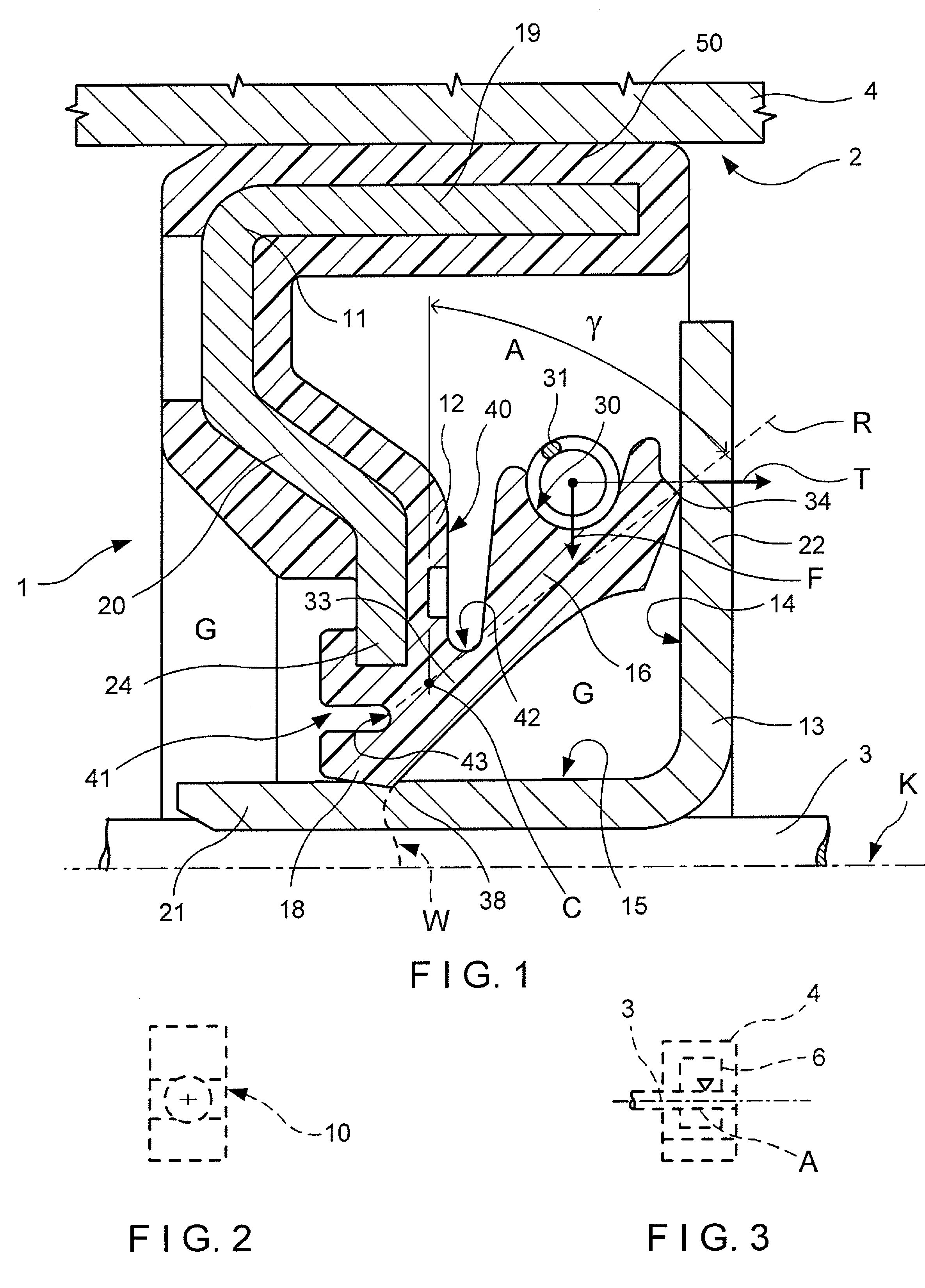

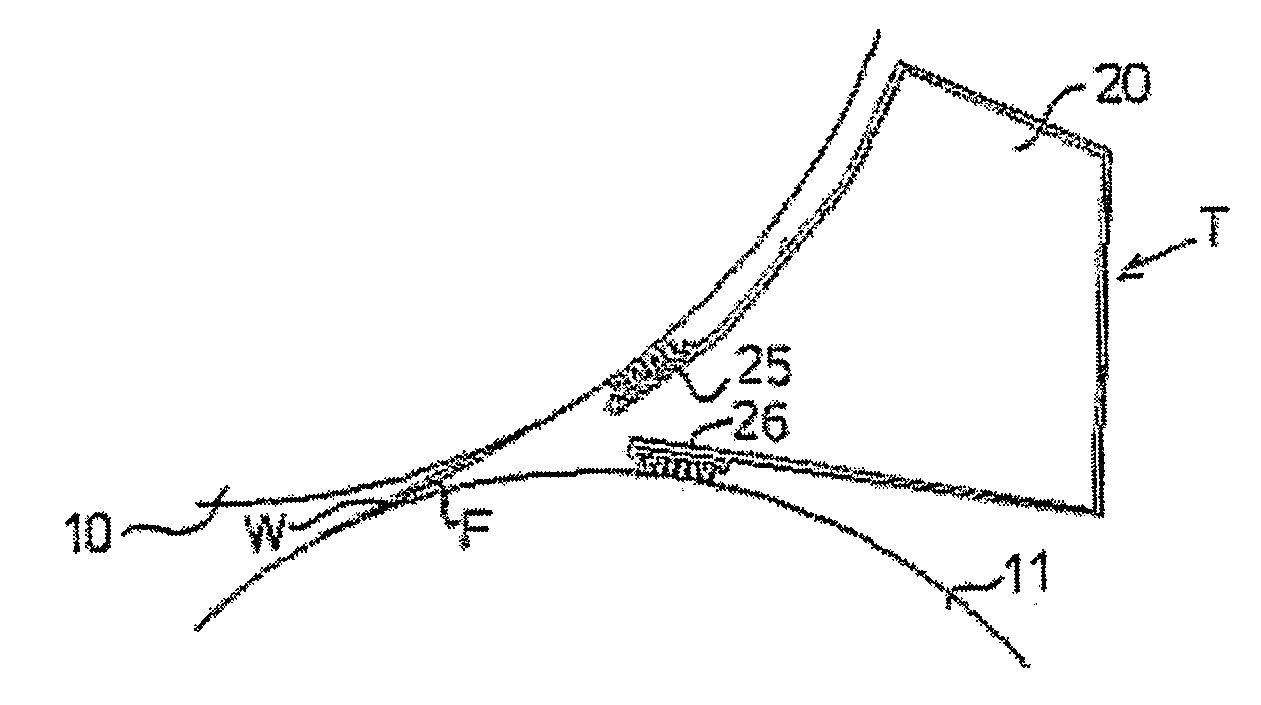

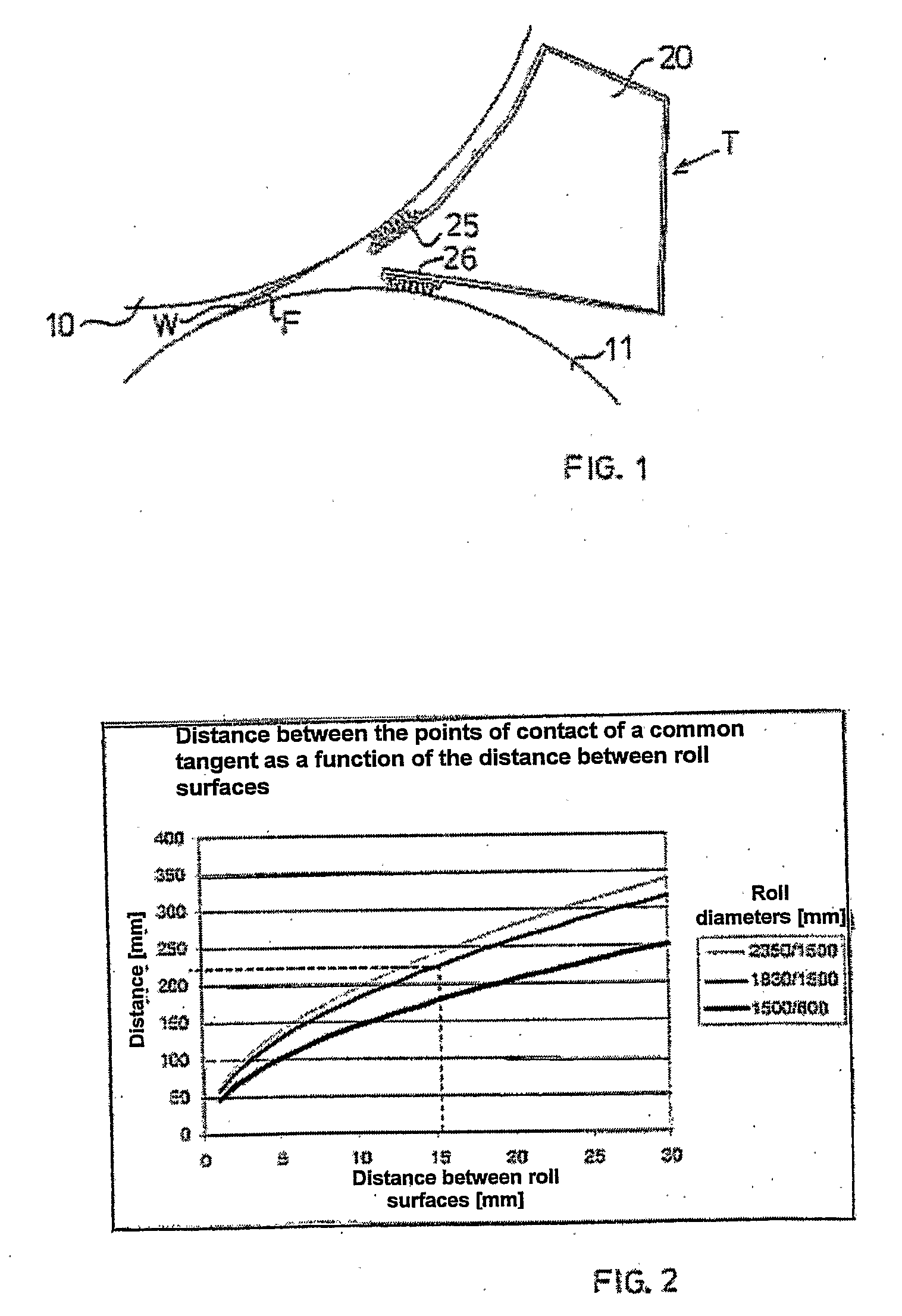

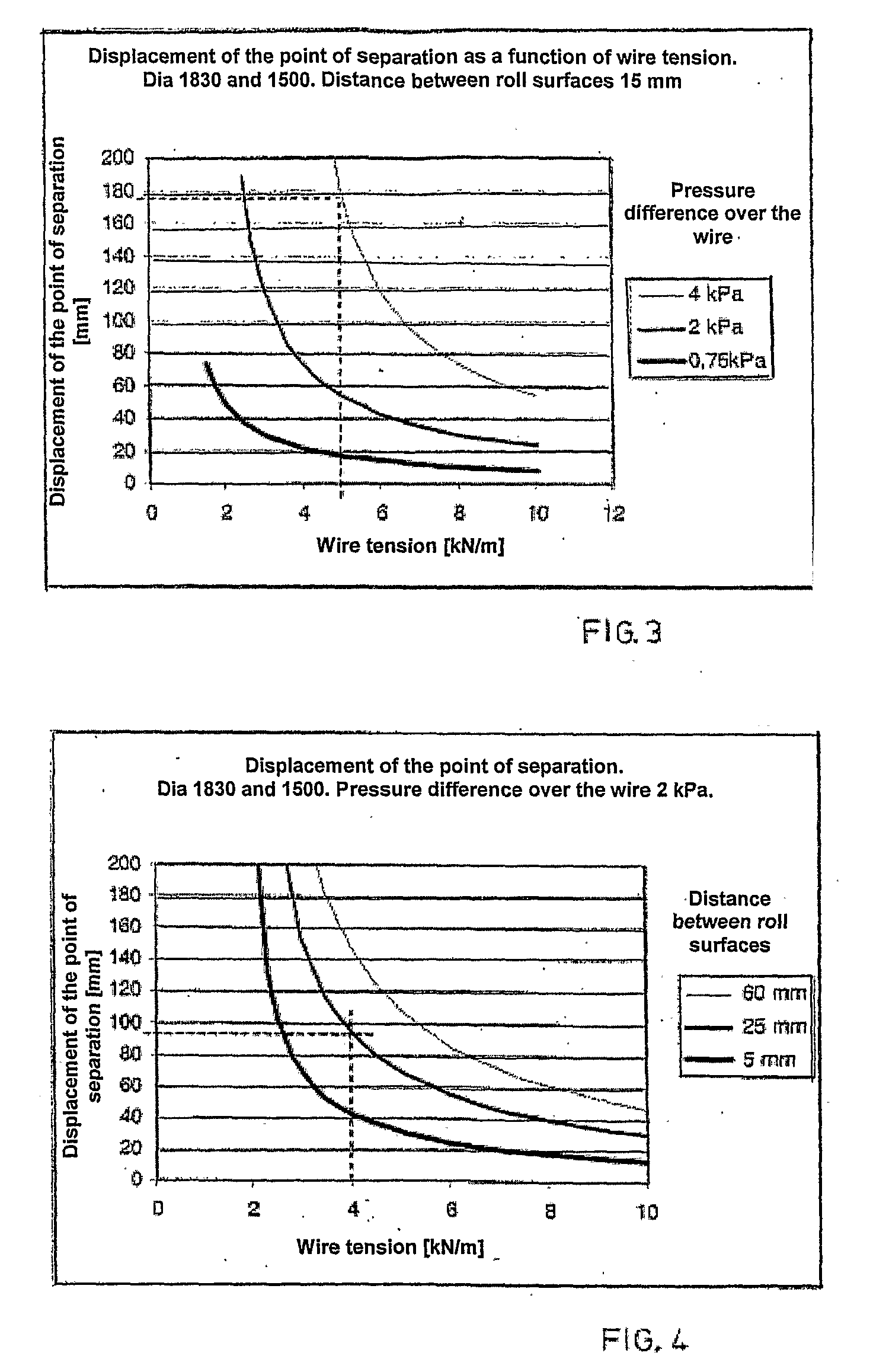

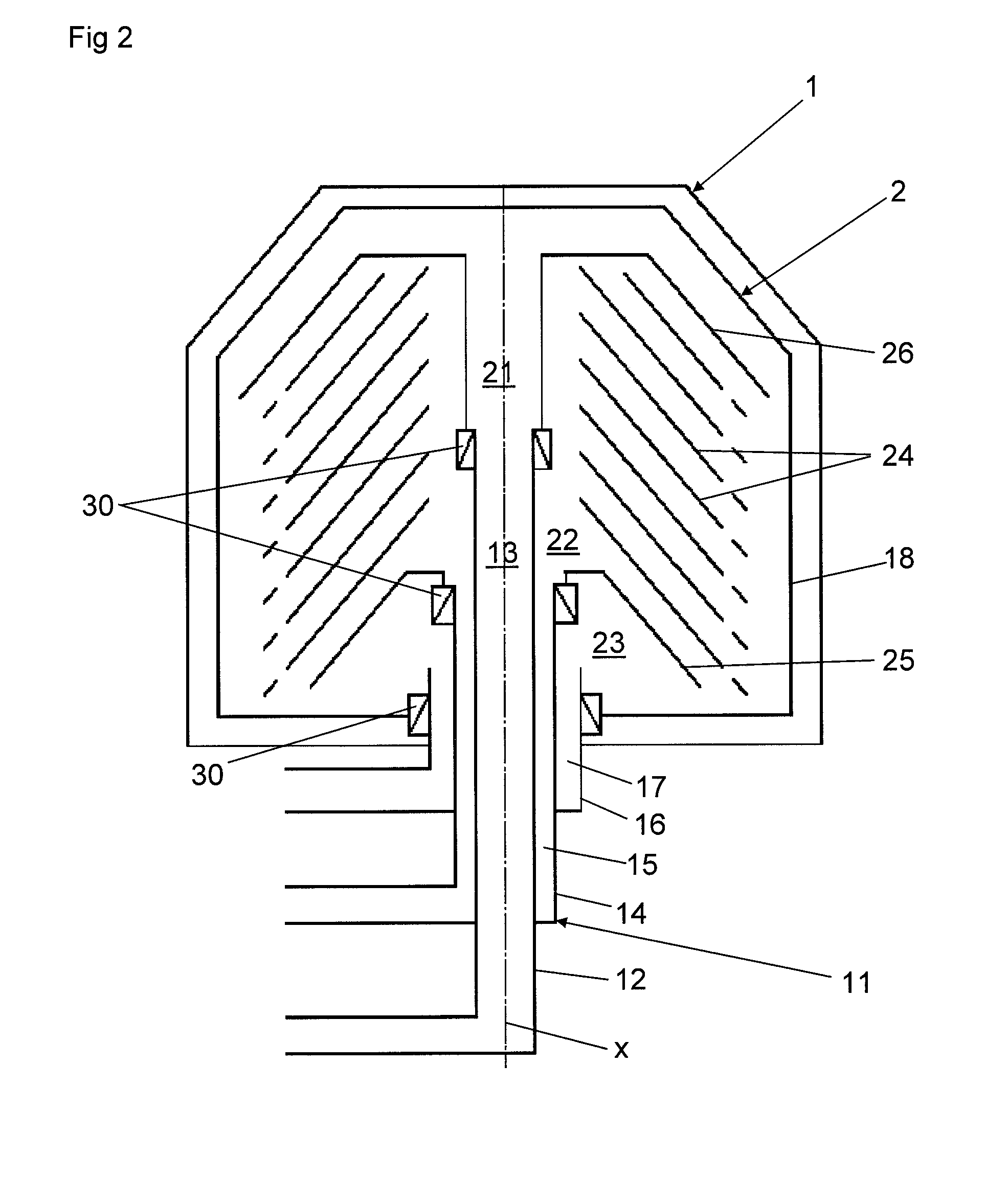

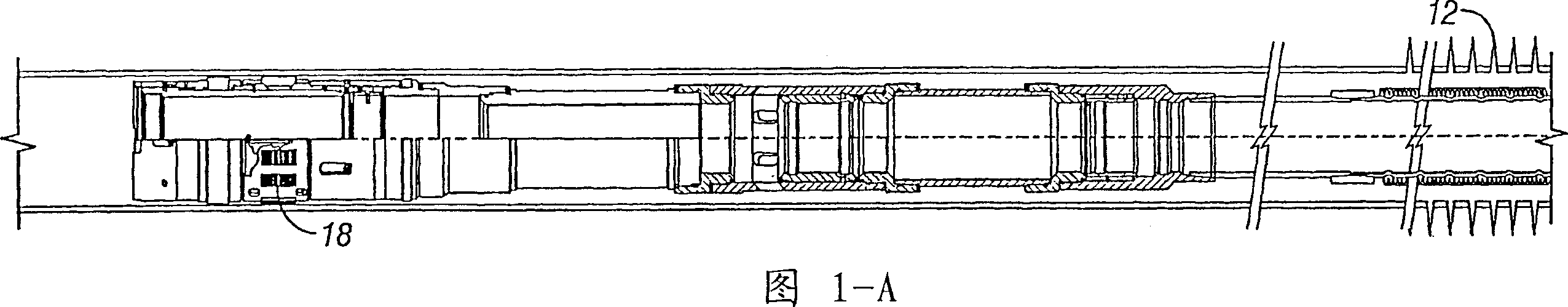

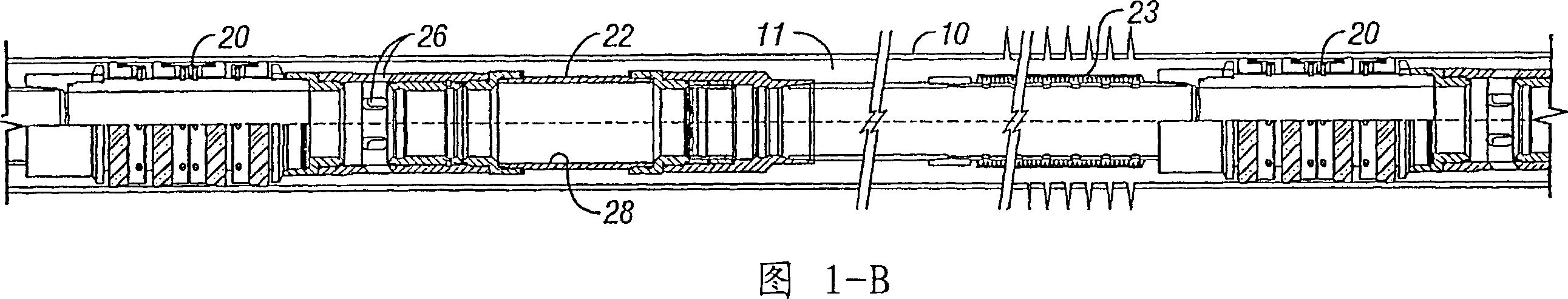

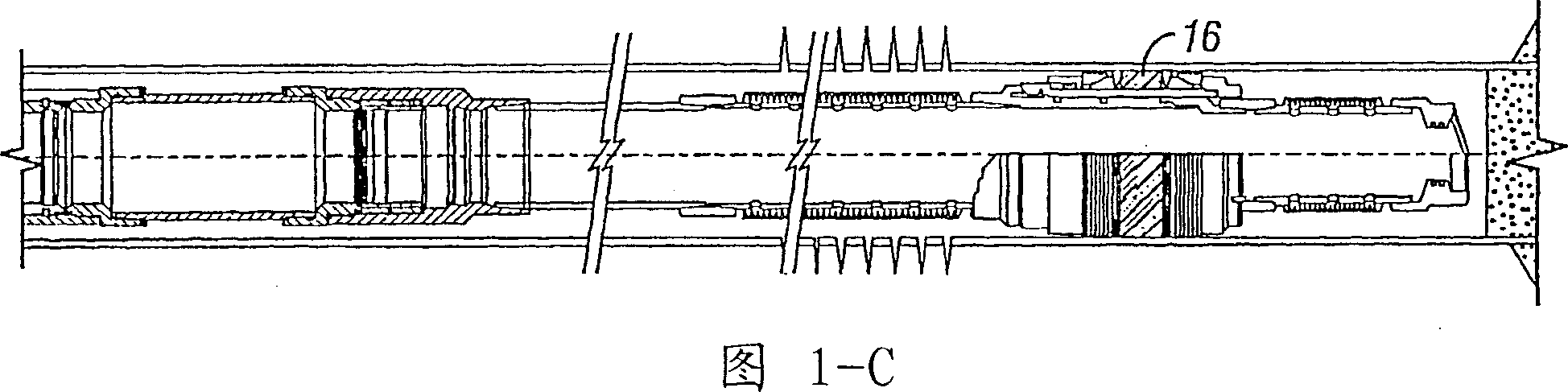

Method and Device in a Dryer Section of a Fibre-Web Machine, Such as a Paper or Board Machine

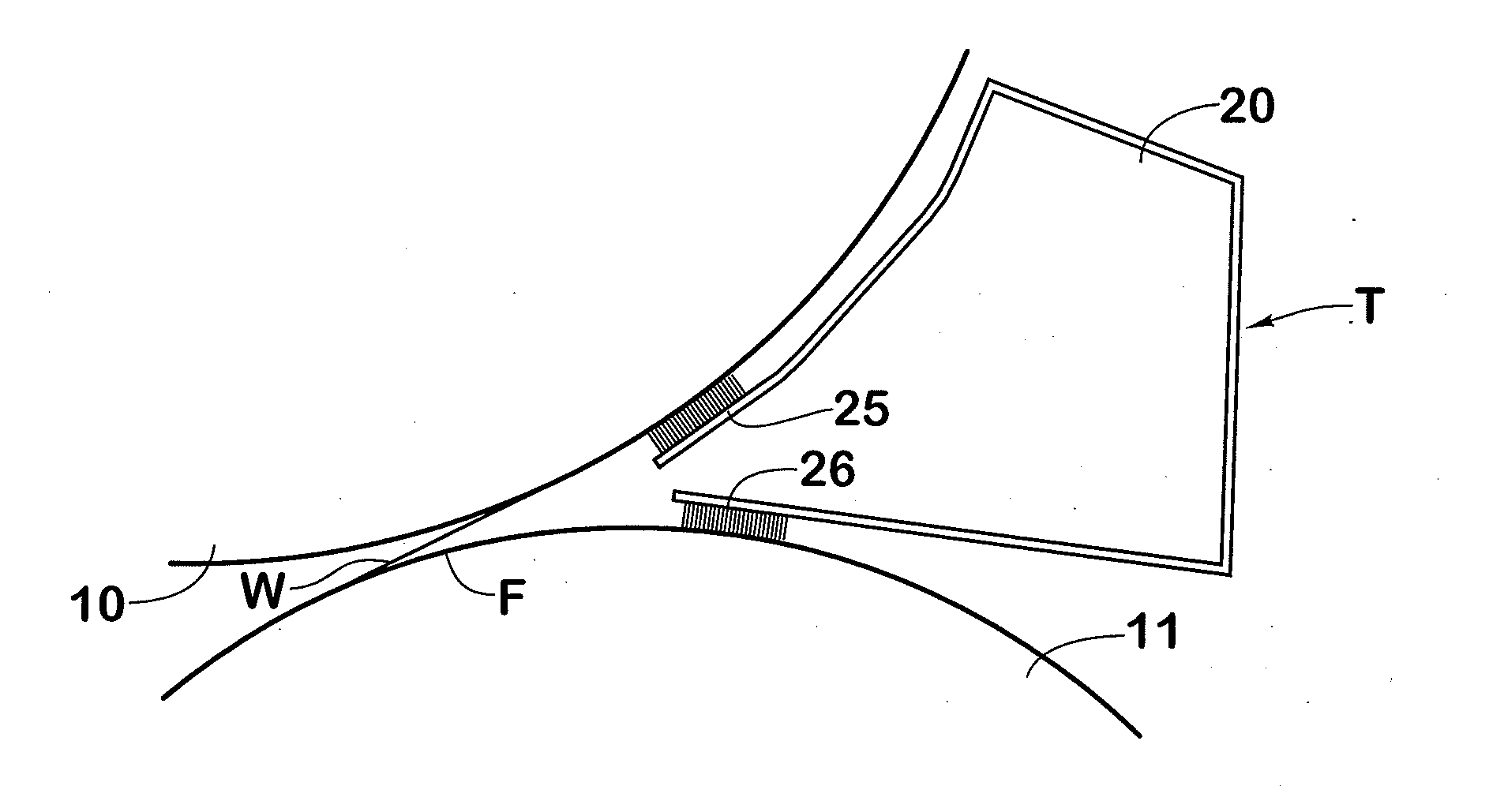

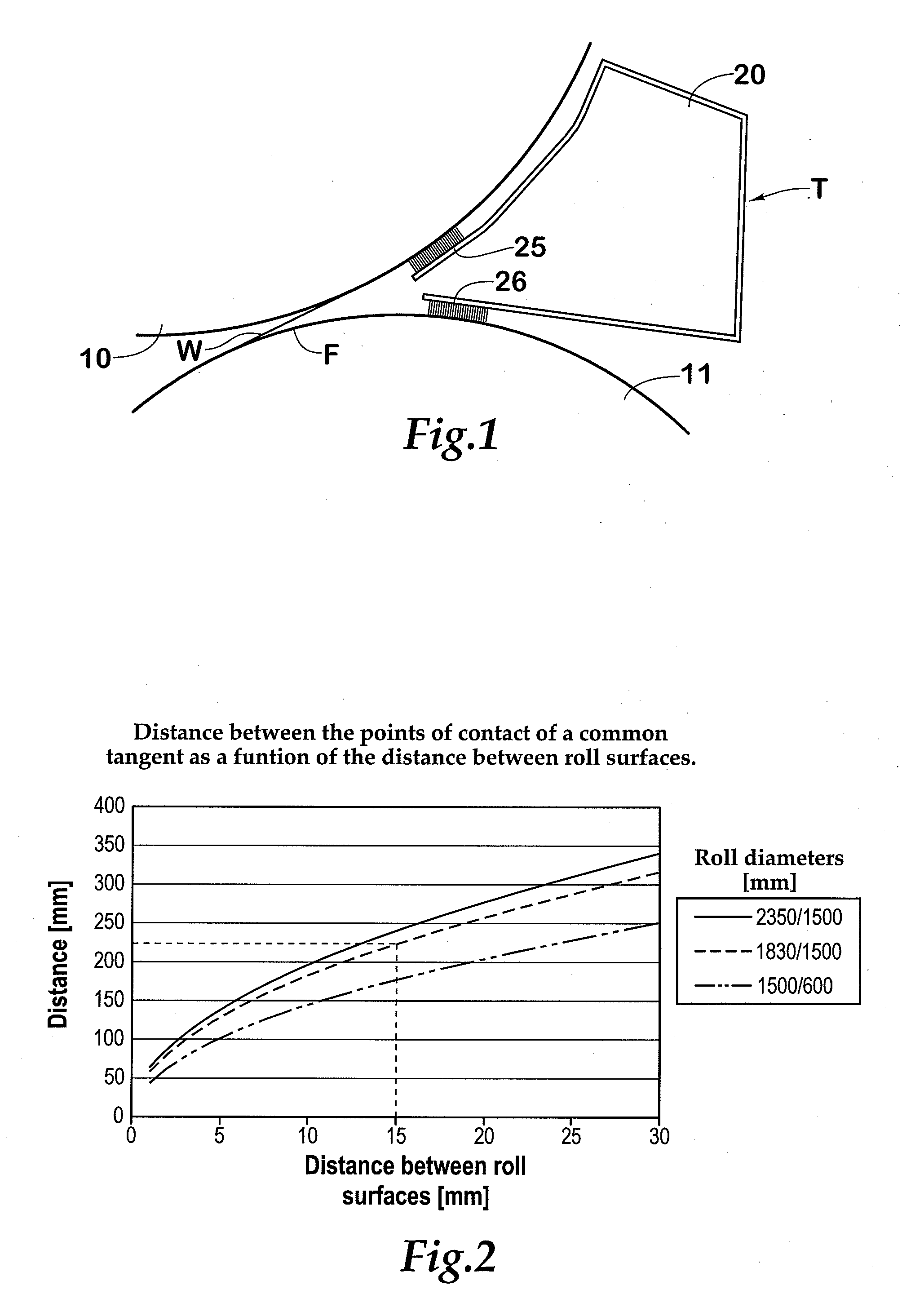

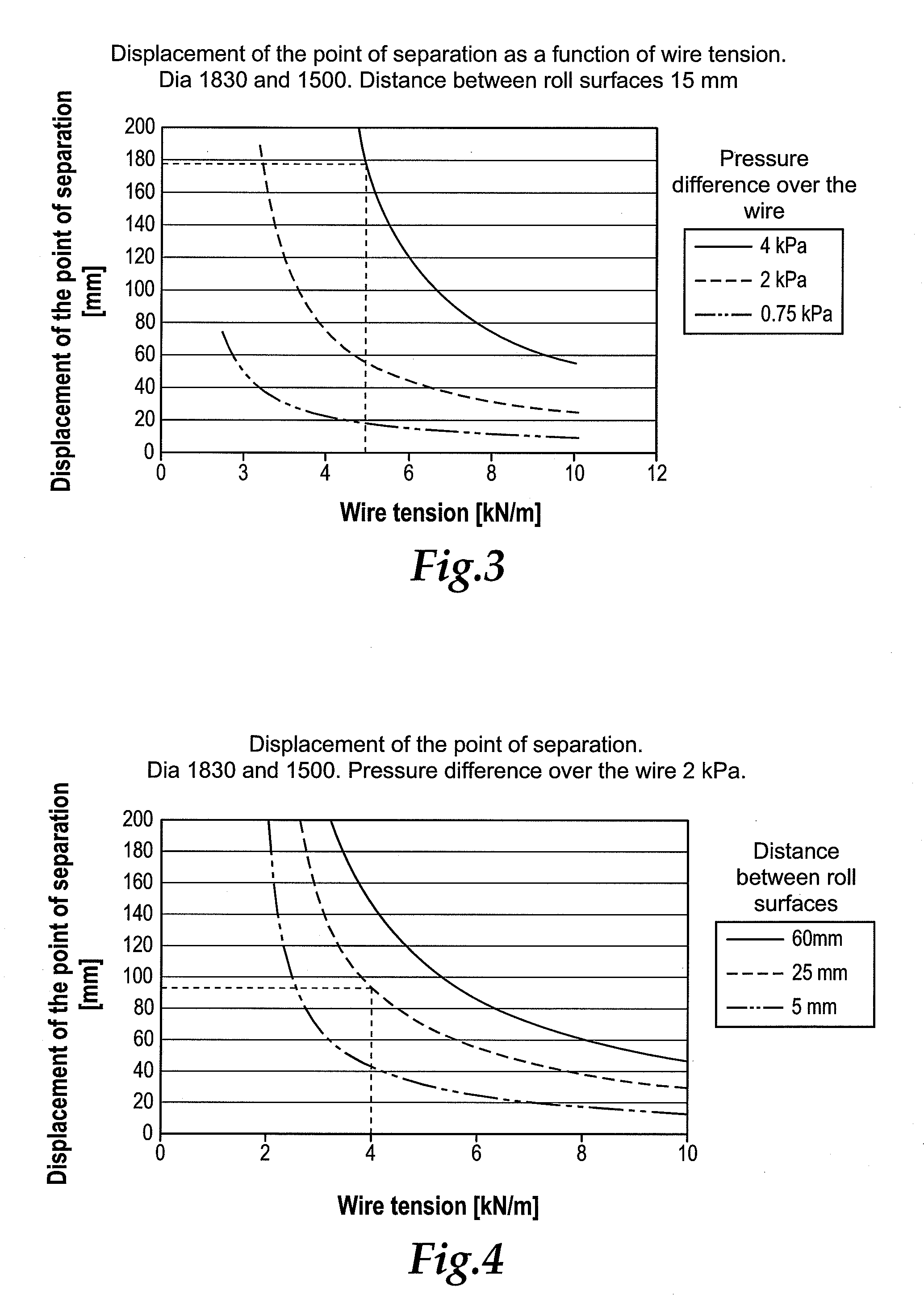

InactiveUS20090025249A1Guaranteed uptimeEliminate and minimizeDrying solid materials with heatDryer sectionPaper sheetFiber

A fiber-web machine dryer section has a drying group with single-wire draw. A drying wire (F) presses the web (W) on a drying cylinder (10) against heated cylinder surfaces, and the web (W) remains at the side of the outside curve of reversing cylinders (11) situated between drying cylinders (10). For enhancing runnability of the web (W), a runnability component (20) is in a pocket space (T) confined by two adjacent drying cylinders (10) and a reversing cylinder (11) situated between them and by the drying wire (F). The web (W) passes from the drying cylinder (10) to the reversing cylinder (11) as a short transfer of 80-400 mm, where a negative pressure effect produced by the runnability component (20) is applied and confined by seals of the runnability component (20) against the surfaces of the drying cylinder (10) and reversing cylinder (11).

Owner:VALMET TECHNOLOGIES INC

Angles hose connection for dental handpiece

Owner:DENTSPLY SIRONA INC

Aircraft galley cart bay door

An aircraft galley cart bay door includes a door main structure having an inwardly facing peripheral inner edge with an inner surface, and a surface seal on the inner surface of the inwardly facing peripheral inner edge of the inner wall. A substantial majority of the main structure of the door is formed from a high strength molded carbon fiber composite material. The door main structure may optionally define a recess, and insulation material can be disposed in the recess defined by the main structure of the door.

Owner:BE AEROSPACE INCORPORATED

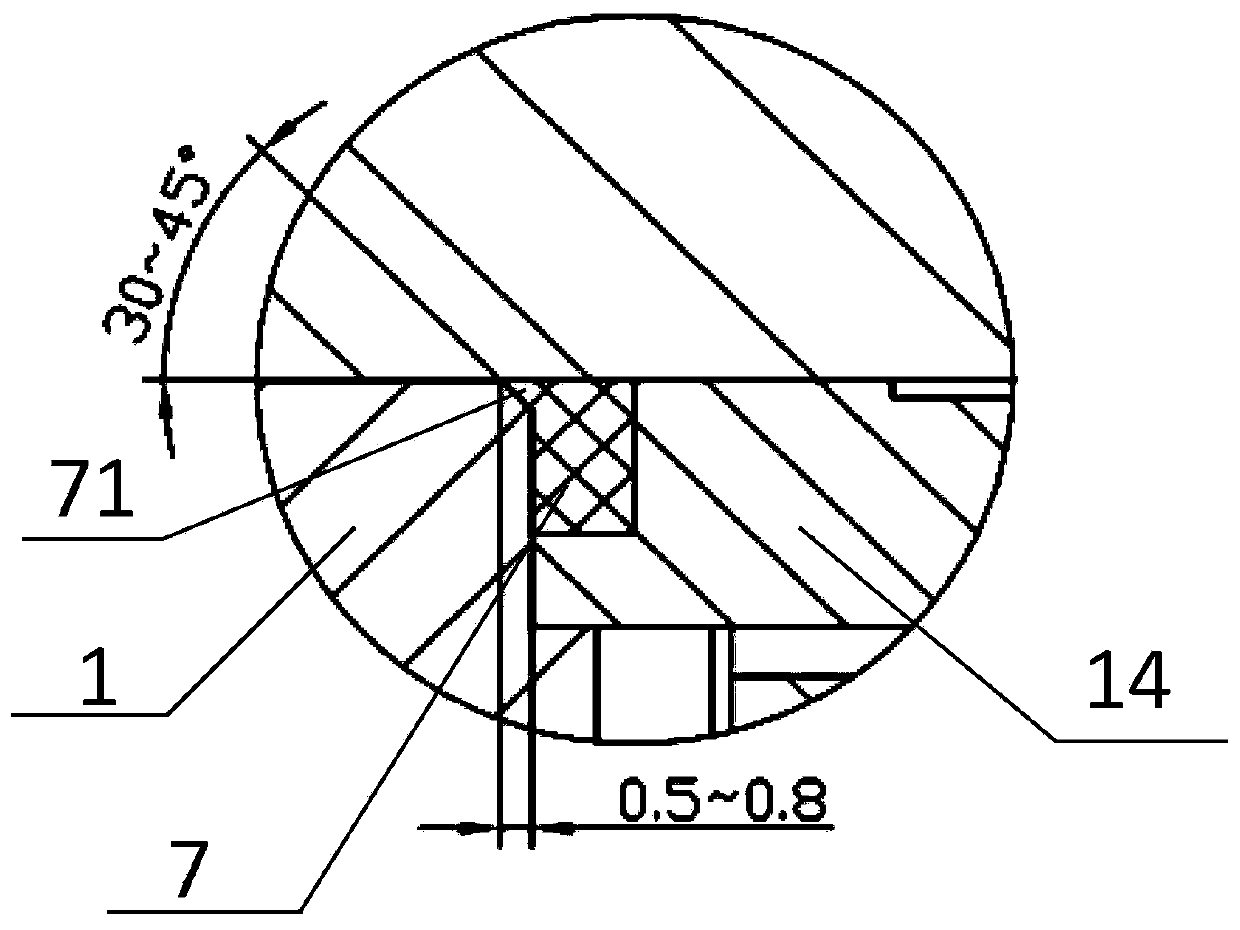

Turbine pump sealing mechanism and turbine pump

ActiveCN112012954ASmall overall deformationReduce deformationPump componentsPumpsEngineeringTurbopump

The invention discloses a turbine pump sealing mechanism and a turbine pump applying the same. The turbine pump sealing mechanism comprises a moving ring, a static ring, a double-layer corrugated pipe, an isolating ring, a sealing shell and a rotating shaft; the sealing shell is suitable for being connected with a turbine pump shell of the turbine pump; the isolating ring is arranged on the rotating shaft in a sleeving mode and forms a seal with the contact surface of the rotating shaft; the end face of an outer ring of the isolating ring abuts against the inner wall of the sealing shell to form a seal, the moving ring is arranged on the end surface of one side of the rotating shaft in a sleeving mode and attached to the end surface of one side of the static ring to form a seal; the staticring is welded to the isolating ring in a sleeving mode, and the end face of one side of the static ring is attached to the moving ring to form a seal; the end face of the other side of the static ring is connected with the end face of one side of the isolating ring through the double-layer corrugated pipe; the two ends of the double-layer corrugated pipe are connected with the static ring and the isolating ring correspondingly; and small holes are uniformly formed in the side, in contact with leaked media, of the double-layer corrugated pipe. The turbine pump sealing mechanism is high in sealing reliability, small in loss in a high-pressure environment and suitable for being used in a high-speed and high-pressure medium environment easy to vaporize.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +2

Centrifugal separator with sealing device

InactiveUS7998051B2Improve mechanical sealingAccurate abilityEngine sealsRotary centrifugesCentrifuge rotorEngineering

In a centrifugal separator comprising a first and second separator part having a centrifuge rotor and rotates during operation relative to the first separator part. A space connecting the first and second separator parts houses a rotating liquid body during operation. A mechanical sealing device is provided at the space and includes a first sealing element on the first separator part having a first contact surface, and a second sealing element on the second separator part having a second contact surface. The liquid body on the first sealing element or the second sealing element and displaces the same axially so that the first and second contact surfaces are pressed against each other. A pre-tensioning element exerts force on the sealing element which acts to displace the first contact away from the second contact surfaces so that a gap is formed, forming a throttling.

Owner:ALFA LAVAL CORP AB

Fastener Driving Apparatus

A fastener driving apparatus includes a spring anvil assembly and an elastomer. The elastomer is capable of being energized under tension or under compression. A drive mechanism acts on the spring anvil assembly and / or anvil to store potential energy in the spring. The drive mechanism thereafter ceases acting on the spring anvil assembly and / or anvil and the potential energy accumulated in the elastomer is released, causing the spring anvil assembly and / or anvil move and to separate from the drive mechanism for a period of free flight of the spring anvil assembly, the anvil thereafter moving to strike a fastener to drive the fastener into a substrate.

Owner:TRICORD SOLUTIONS

Method and apparatus for treating a subterranean formation

A service / completion liner having a plurality of downhole selectable indicating tools and being used in sand control (gravel pack) placement systems in conjunction with a straddle packer service tools or with conventional crossover type service tools. Each indicating collar has a downhole selectable indicating collar providing a robust, landing profile for precisely locating and maintaining service tool position during well treatment operations. The landing collars accommodate hydraulic and / or thermal effects commonly referred to as tubing move effects which are the principle cause of tool position error and excessive seal wear. The landing collar is downhole convertible between a pass through (Go) and non pass through (No-go) condition by simple upward and downward cycling via the tool running and treatment fluid tubing and a shifting tool, which may also be referred to as a set down collet. The shifting / set down collet is also used to open and close a downhole sliding sleeve valve and may be an integral part of an injection tool or a tool for gravel or fracture packing. A sliding sleeve valve design and a straddle packer configuration that protects the primary PBRs in the gravel pack system and also protects the sliding sleeve while sand is placed in the screen casing annulus.

Owner:SCHLUMBERGER TECH LTD BV

Paper or Board Machine Employing a Single-Wire Draw Dryer Section

ActiveUS20110162230A1Guaranteed uptimeBending of the wire is reducedDrying solid materials with heatDryer sectionPulp and paper industryPaper sheet

A paper or board machine having a machine dryer section with a drying group with single-wire draw. A drying wire (F) presses the web (W) on a drying cylinder (10) against heated cylinder surfaces, and the web (W) remains at the side of the outside curve of reversing cylinders (11) situated between drying cylinders (10). For enhancing runnability of the web (W), a runnability component (20) is in a pocket space (T) confined by two adjacent drying cylinders (10) and a reversing cylinder (11) situated between them and by the drying wire (F). The web (W) passes from the drying cylinder (10) to the reversing cylinder (11) as a short transfer of 80-400 mm, where a negative pressure effect produced by the runnability component (20) is applied and confined by seals of the runnability component (20) against the surfaces of the drying cylinder (10) and reversing cylinder (11).

Owner:VALMET TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com