Patents

Literature

129results about How to "Avoid dry rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

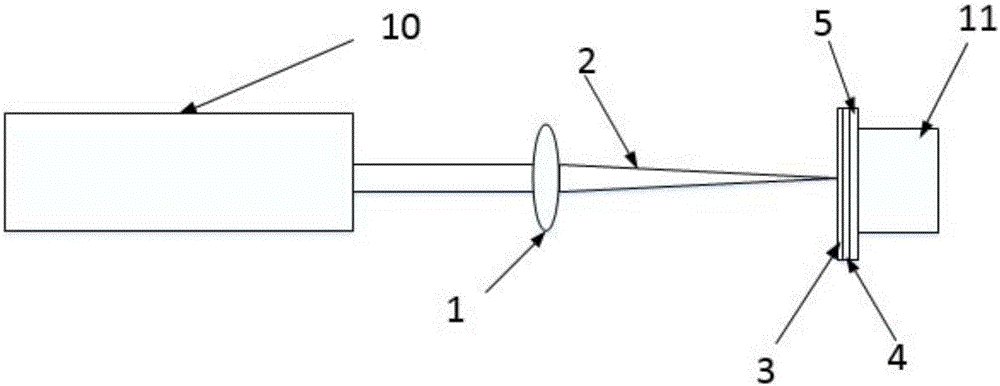

Gear surface laser shock texturing method

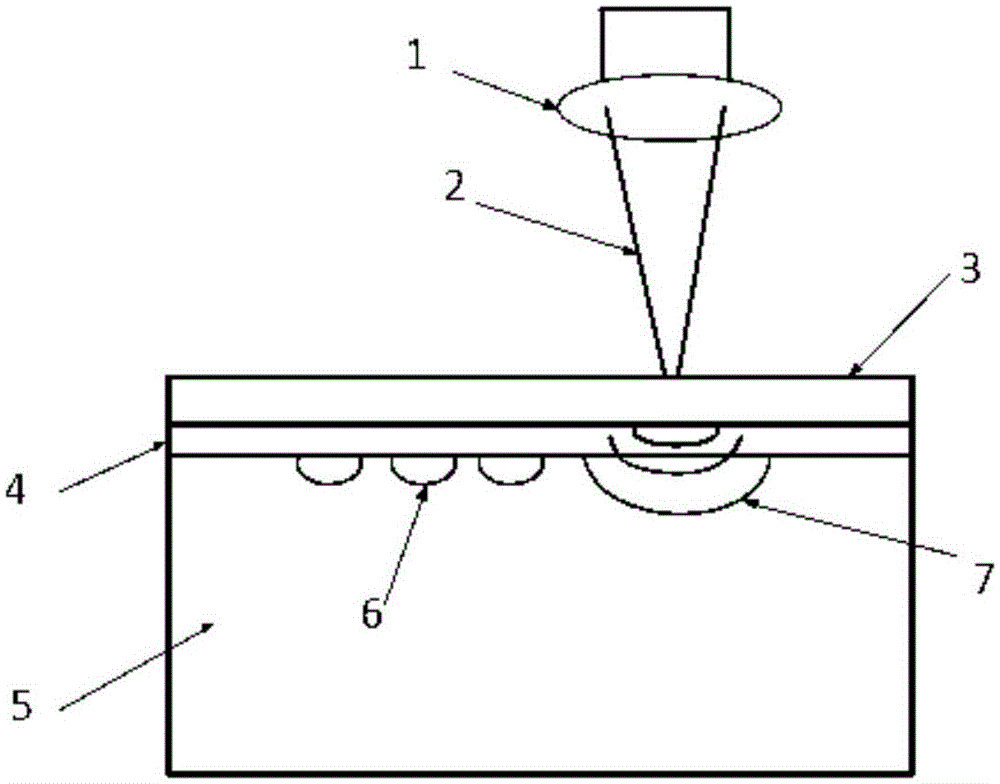

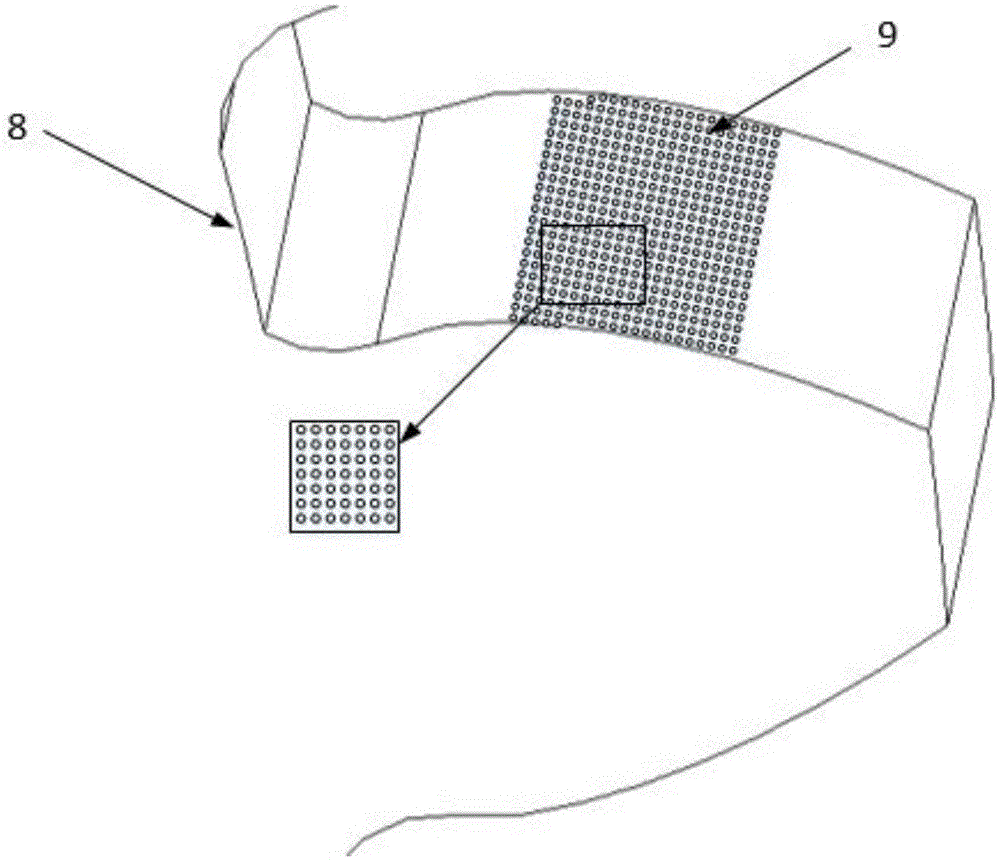

The invention discloses a gear surface laser shock texturing method. The method comprises the following steps: (1) polishing and cleaning a gear tooth surface, air-drying the gear tooth surface and uniformly spraying a black paint in the area near to 1 / 3 of the tooth top surface and 1 / 3 of tooth root surface of a pitch line; (2) mounting a gear on a workbench to position and clamp, setting parameters of a laser, allowing the laser beam to illuminate the pre-treated gear tooth surface through a focus lens and forming a micro concave pit; (3) processing a series of micro pit arrays on the gear surface by combining the numerical controlled workbench; (4) removing the black paint on the gear tooth surface by using acetone and cleaning the gear tooth surface by using ultrasonic wave. The laser shock texturing method belongs to the cold processing surface treatment and has no heat effect on the tooth surface; the size of the pit is in micro level and the strength of the gear teeth is not affected. Compared with the existing common gear, the friction coefficient of the gear tooth surface of the gear processed by the laser shock texturing is obviously reduced, and the hardness and the abrasion resistance are obviously increased.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

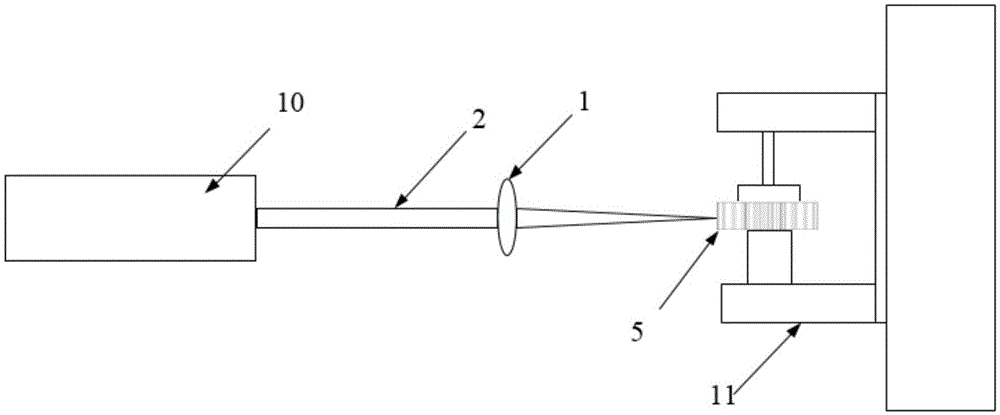

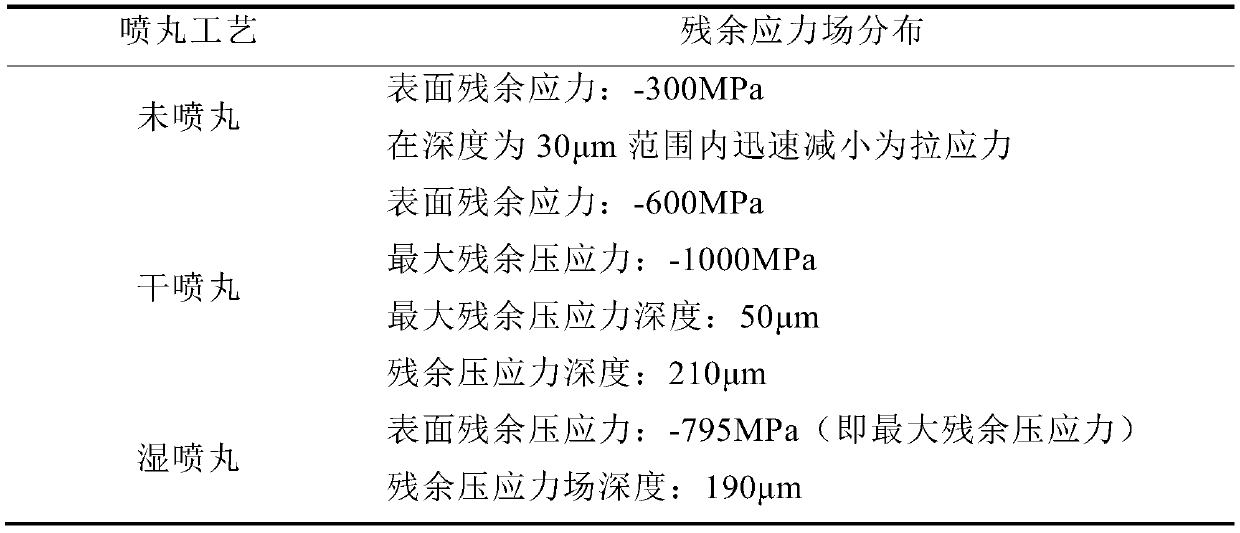

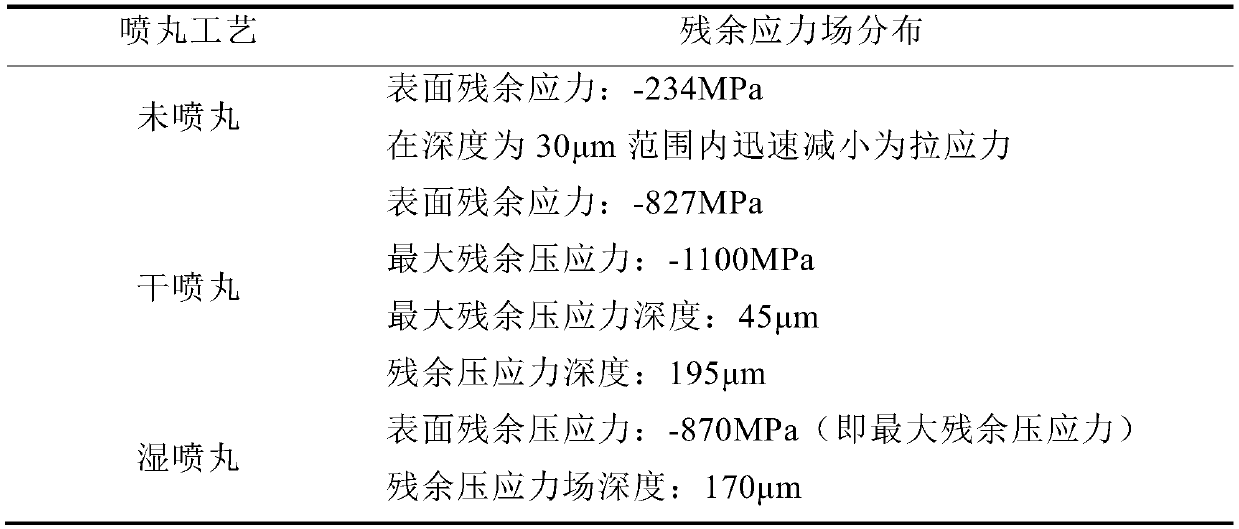

Wet shot peening surface modification treatment method suitable for nickel-based high-temperature alloy

The invention relates to a wet shot peening surface modification treatment method suitable for a nickel-based high-temperature alloy. The method comprises the following treatment methods of pre-treatment before shot peening, wherein the surface cleaning is carried out on nickel-based high-temperature alloy parts, no pollutants exist on the surface of the parts, and the parts which cannot be shot-peened are wrapped and plugged; wet shot peening treatment, wherein the wet shot peening treatment is carried out on the nickel-based high-temperature alloy parts by using ceramic shots and water, andthe water to ceramic shots is 4:1 by mass ratio; and post-treatment of shot peening, the nickel-based high-temperature alloy parts after conducting wet shot peening are dried at room temperature to finish surface modification treatment. According to the wet shot peening surface modification treatment method, the structure of materials is adjusted and controlled through the optimization of technological parameters, thus improving the universality of the method, and by utilizing the lubricating and buffering effects of water, the strain rate of plastic deformation during the process of shot peening can be reduced, the surface defects such as microcracks and peeling on the surface of the nickel-based high-temperature alloy are avoided, thus enhancing the surface integrity level of the materials and perfecting the fatigue performance of the materials.

Owner:TONGJI UNIV

Process for processing space ring of double-section drive axle for automobile

InactiveCN101700613AImprove machining accuracyExtended service lifeSolid state diffusion coatingFurnace typesEngineeringCorrosion resistant

The invention relates to a process for processing a space ring of a double-section drive axle for an automobile, comprising the following steps: the end surface and the excircle of a blank are roughly lathed with a lathe, and the end surface, the inner hole and the excircle of the blank are finely lathed; the processed work piece is quenched under high frequency, and the quenched work piece is loaded in a furnace so that the quenched work piece is glowed and compact and uniform corrosion-resistant white bright layer is formed on the surface of the glowed work piece; the excircle of the glowed work piece is firstly roughly ground and then finely ground with a grinder with the roughness of the work piece being controlled between Ra 0.3 and Ra 0.5 until the space ring is produced. The process can improve the processing precision of the space ring and the assembling precision of the space ring and an oil seal, further save the energy, enhance the work efficiency and facilitate the operation and is particularly suitable for deep hole and slit nitridation.

Owner:青岛元通汽车法兰有限公司

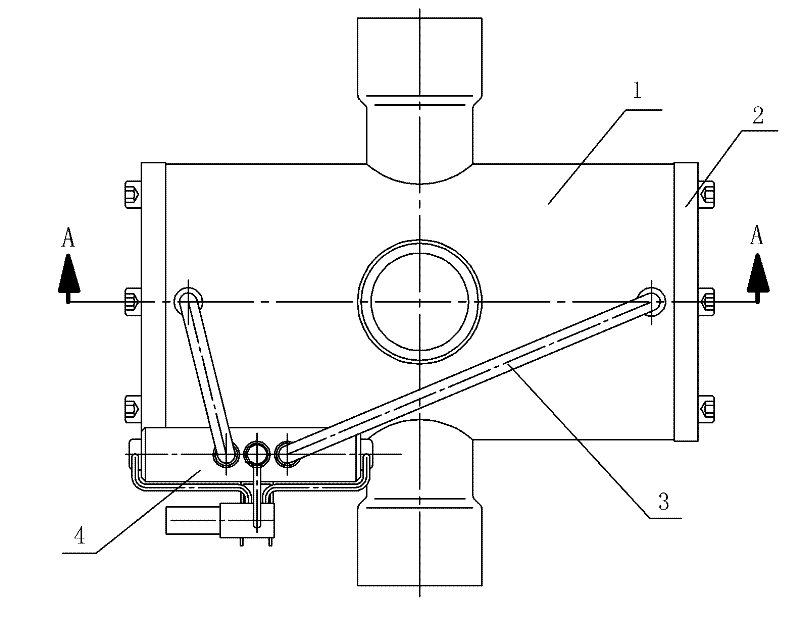

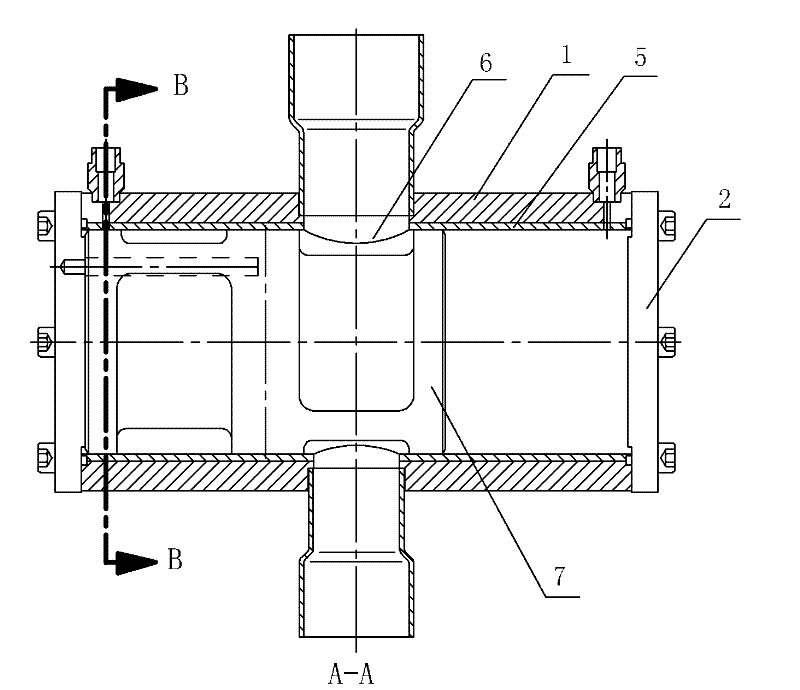

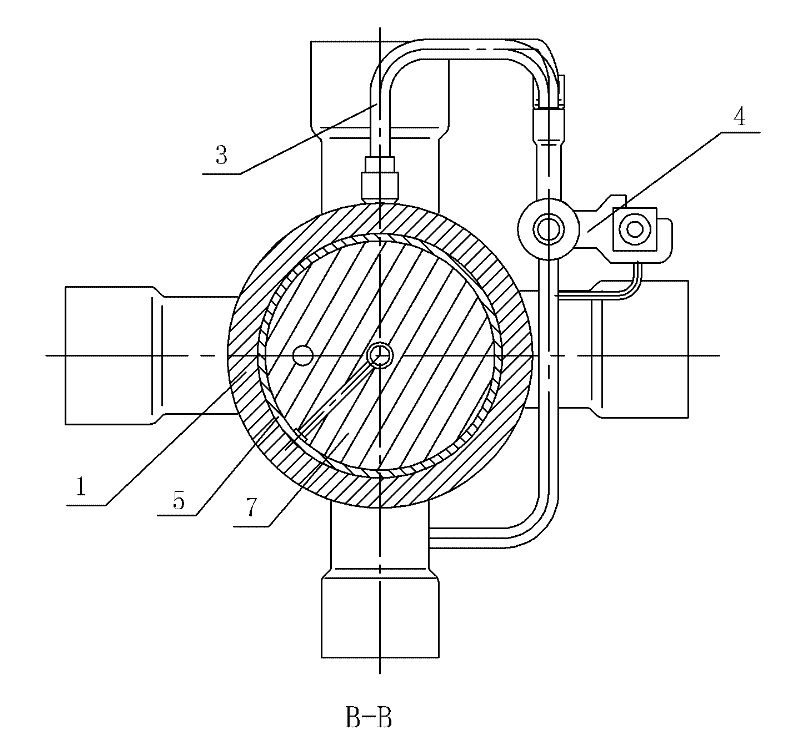

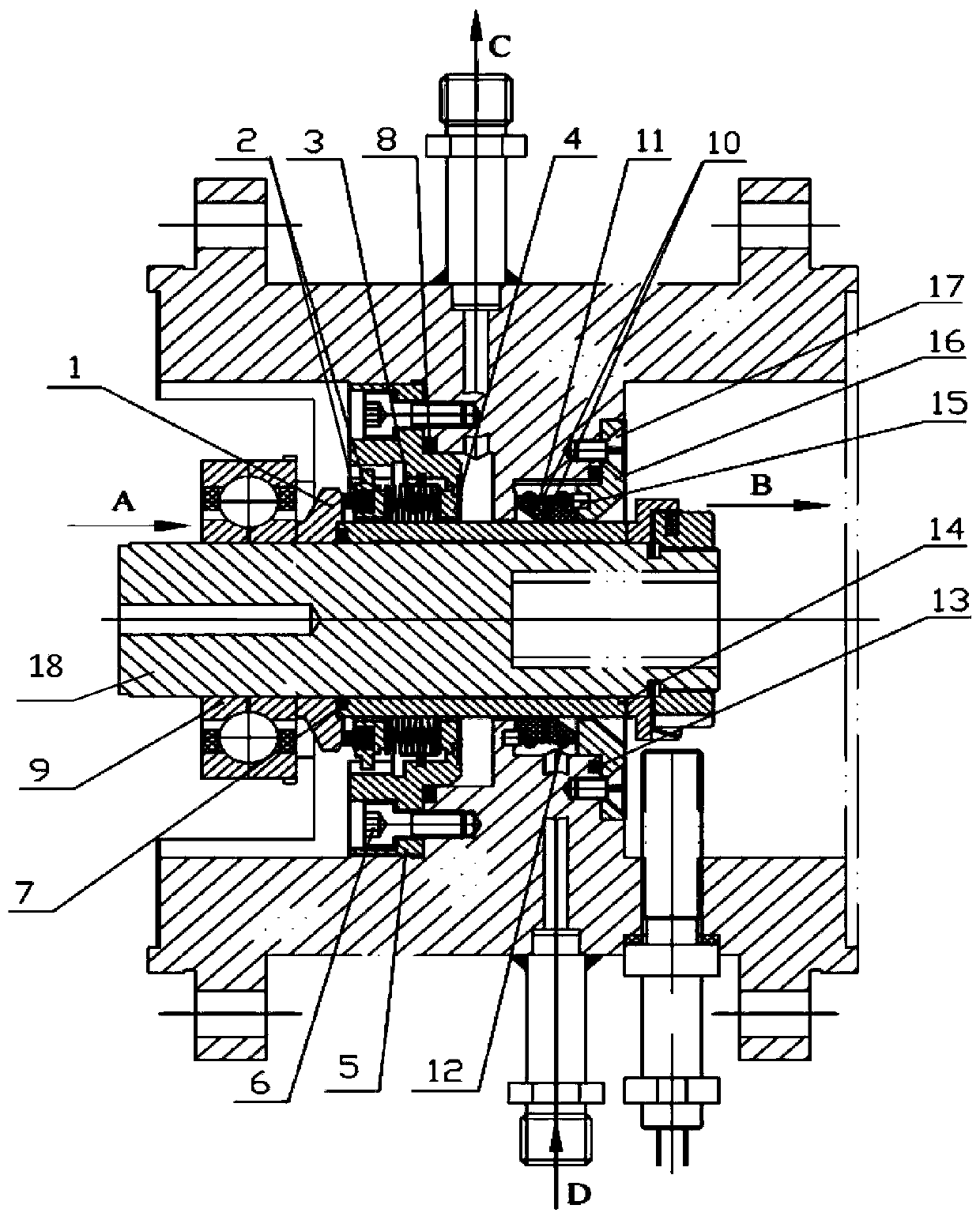

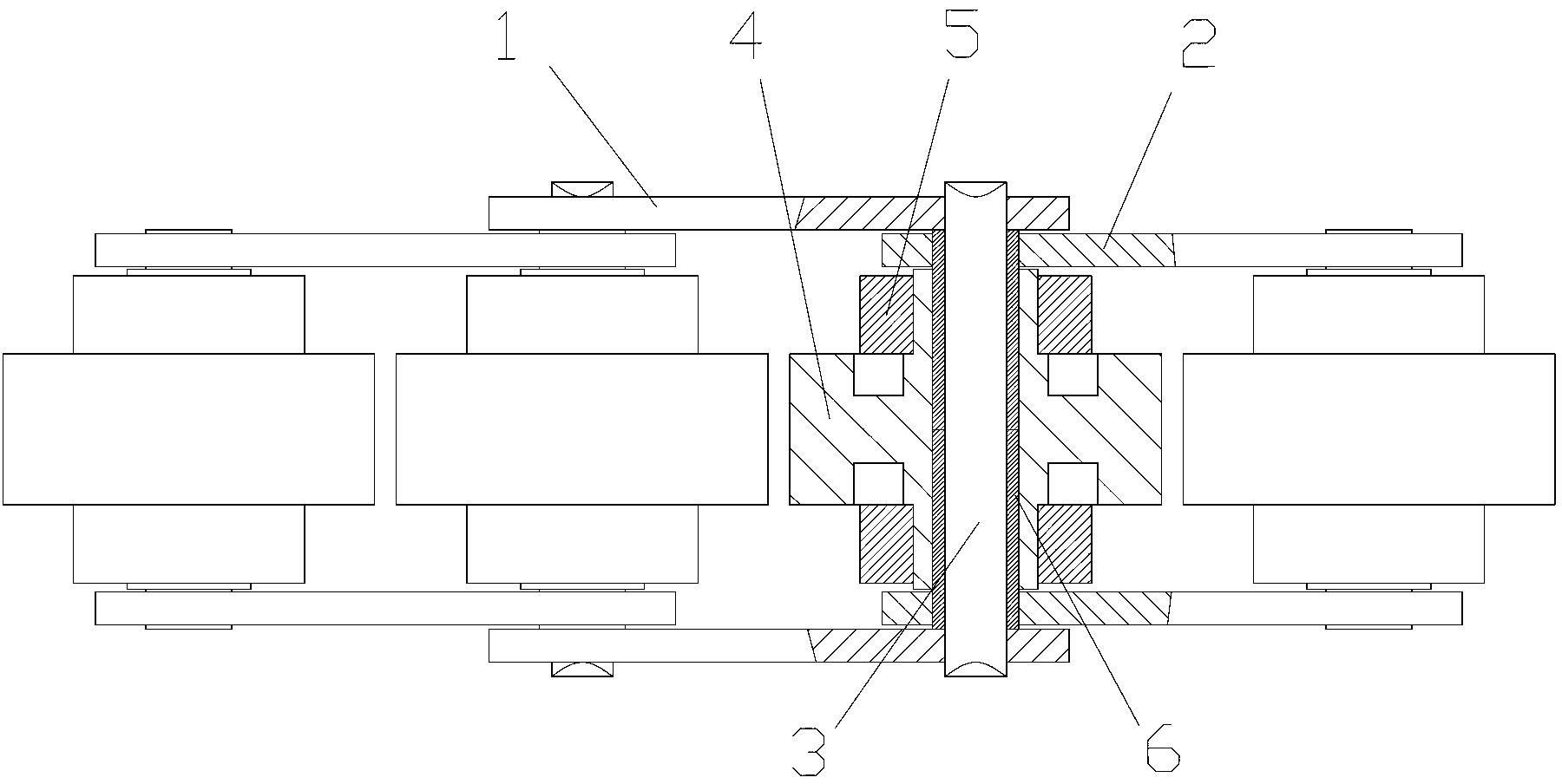

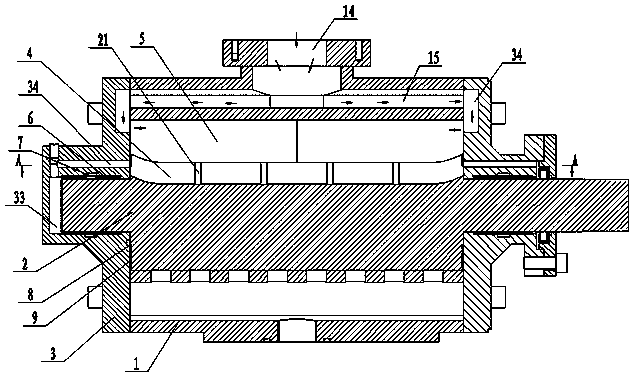

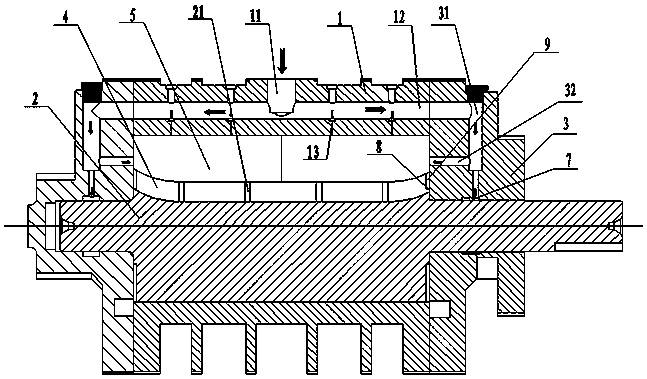

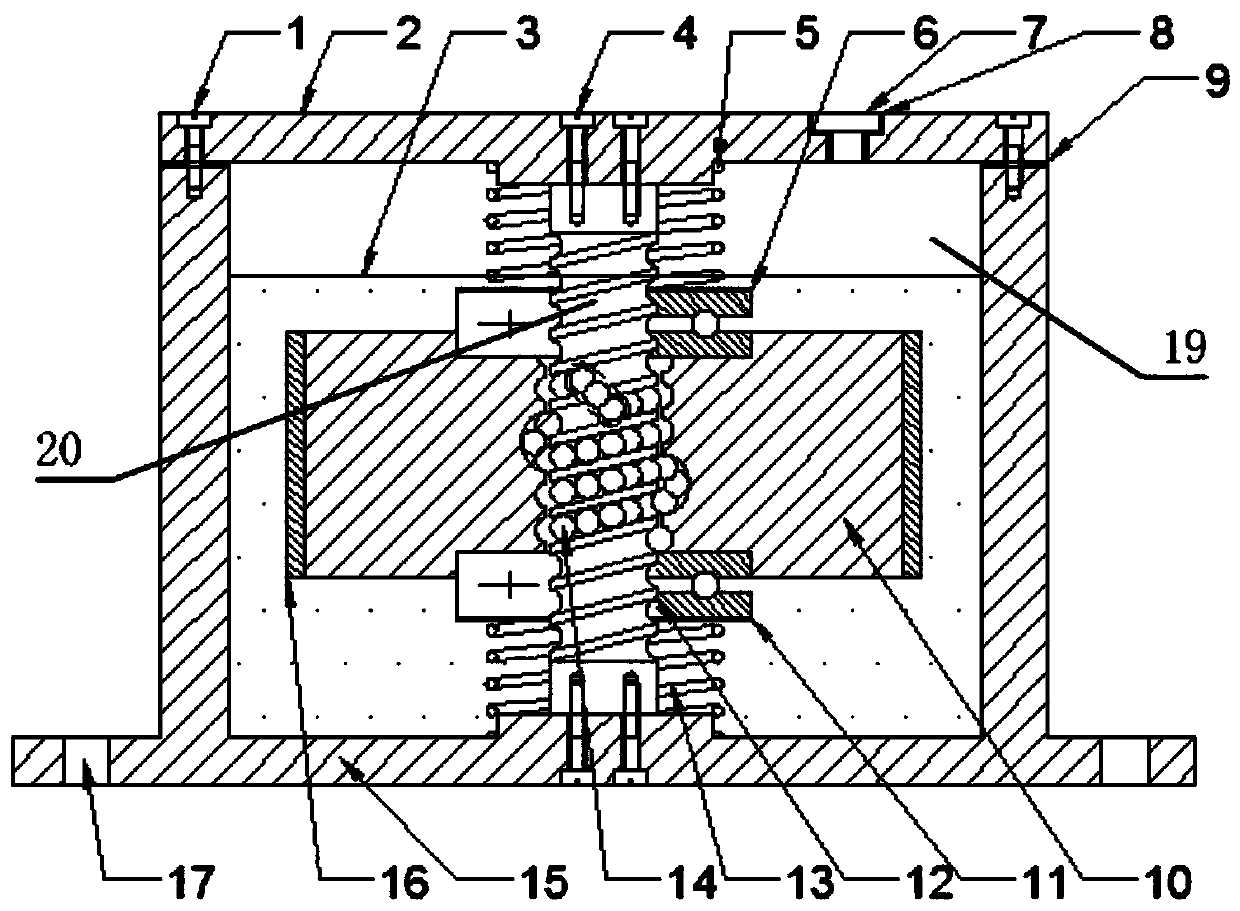

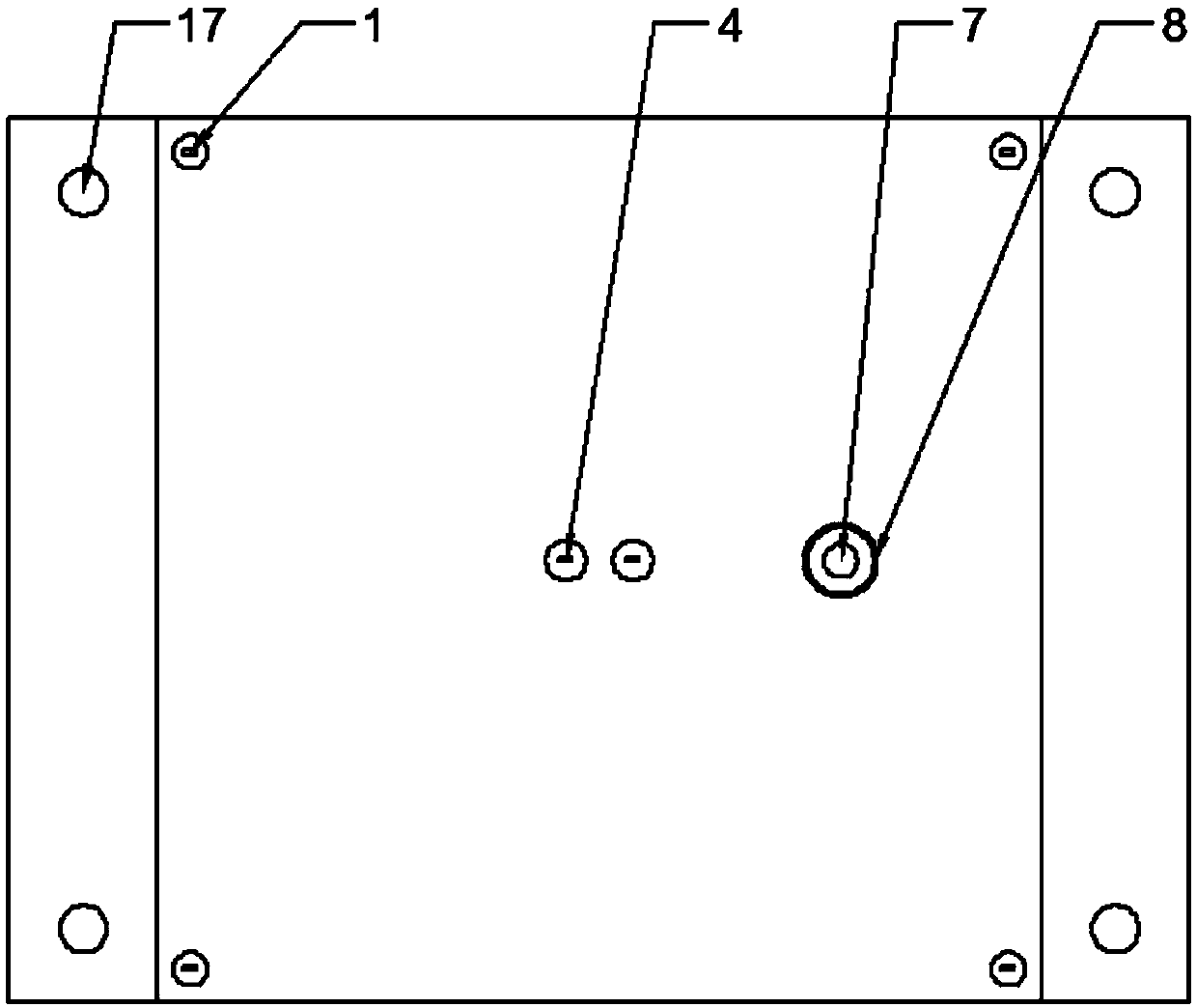

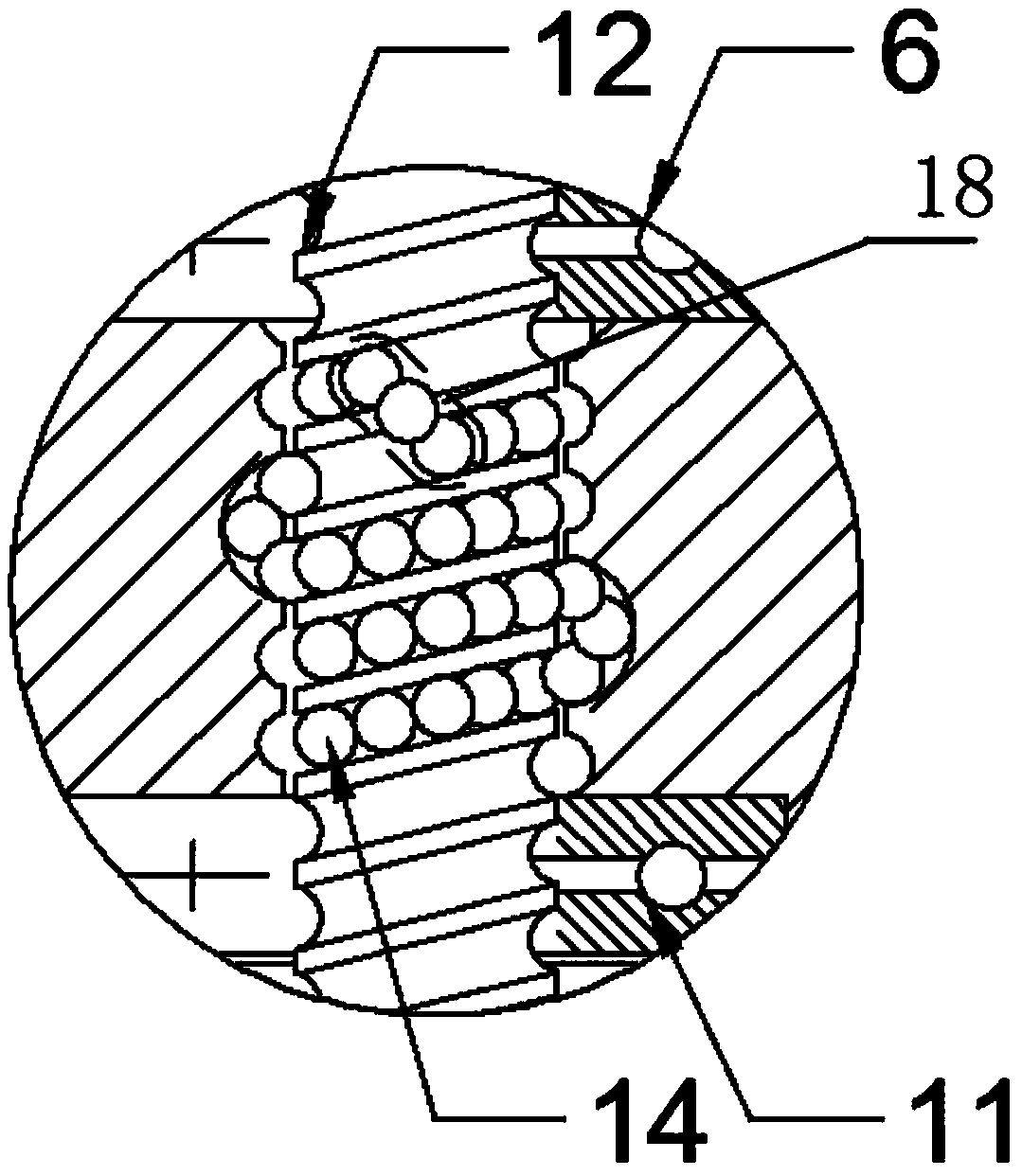

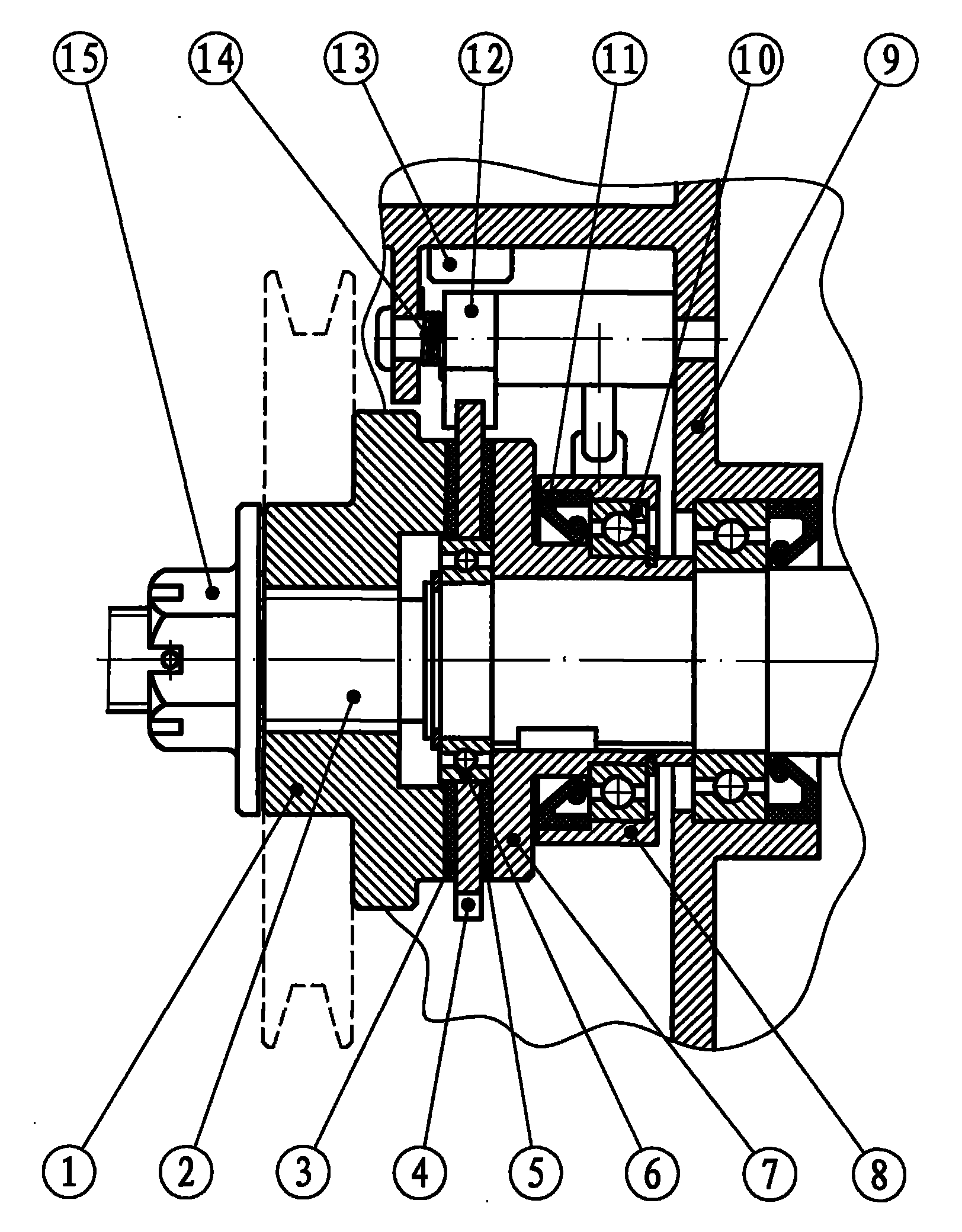

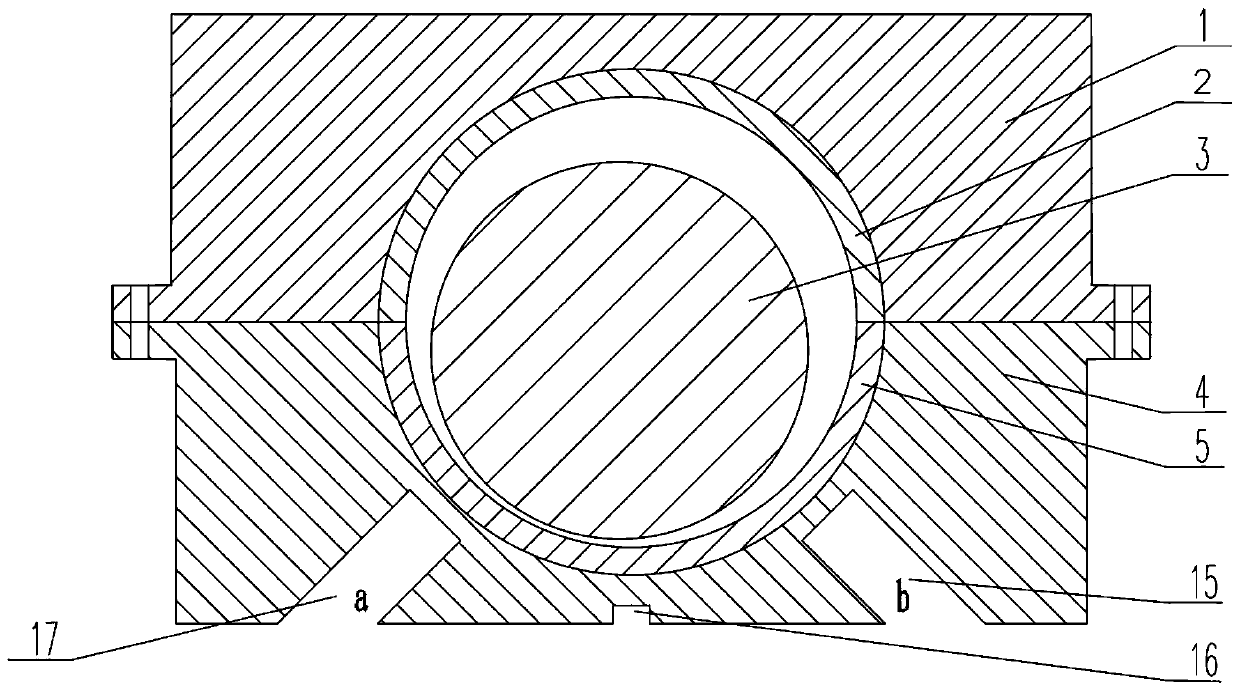

Piston four-way reversing valve for refrigerating system

InactiveCN102226482AAvoid dry rubbingWon't get stuckOperating means/releasing devices for valvesEngineeringAlloy

The invention discloses a piston four-way reversing valve for a refrigerating system and belongs to a valve which can be used for changing the flow direction of refrigerants. The existing four-way reversing valve in a stopped status has the defect that the piston is easily deadlocked due to lack of the lubricating oil when the oil film is easily washed and moved away by the refrigerating fluid. According to the invention, the piston four-way reversing valve is mainly composed of a main valve and a pilot valve, wherein the pilot valve is communicated with the cavity of the main valve through a gas-guide pipe; the main valve comprises a valve body, a piston which is arranged in the valve body and two end caps which are arranged on the two ends of the valve body; the valve body is provided with four valve ports, a lubricating sleeve is arranged between the inner surface of the valve body and the piston, the lubricating sleeve is fixedly connected with the valve body; a through hole which corresponds to and is communicated with the valve port is arranged on a lubricating sleeve body; the lubricating sleeve is divided into a steel substrate layer, a copper substrate alloy powder layer and a solid lubricating layer in the radial direction from outside to inside; and the first layer and the second layer are sintered into a whole, the third layer is rolled on the surface of the second layer, a solid lubricating material can play a role in lubricating the piston so as to ensure the piston to flexibly move in the valve body without being deadlocked, thus the service life can be prolonged.

Owner:ZHEJIANG XINSANRONG REFRIGERATION CO LTD

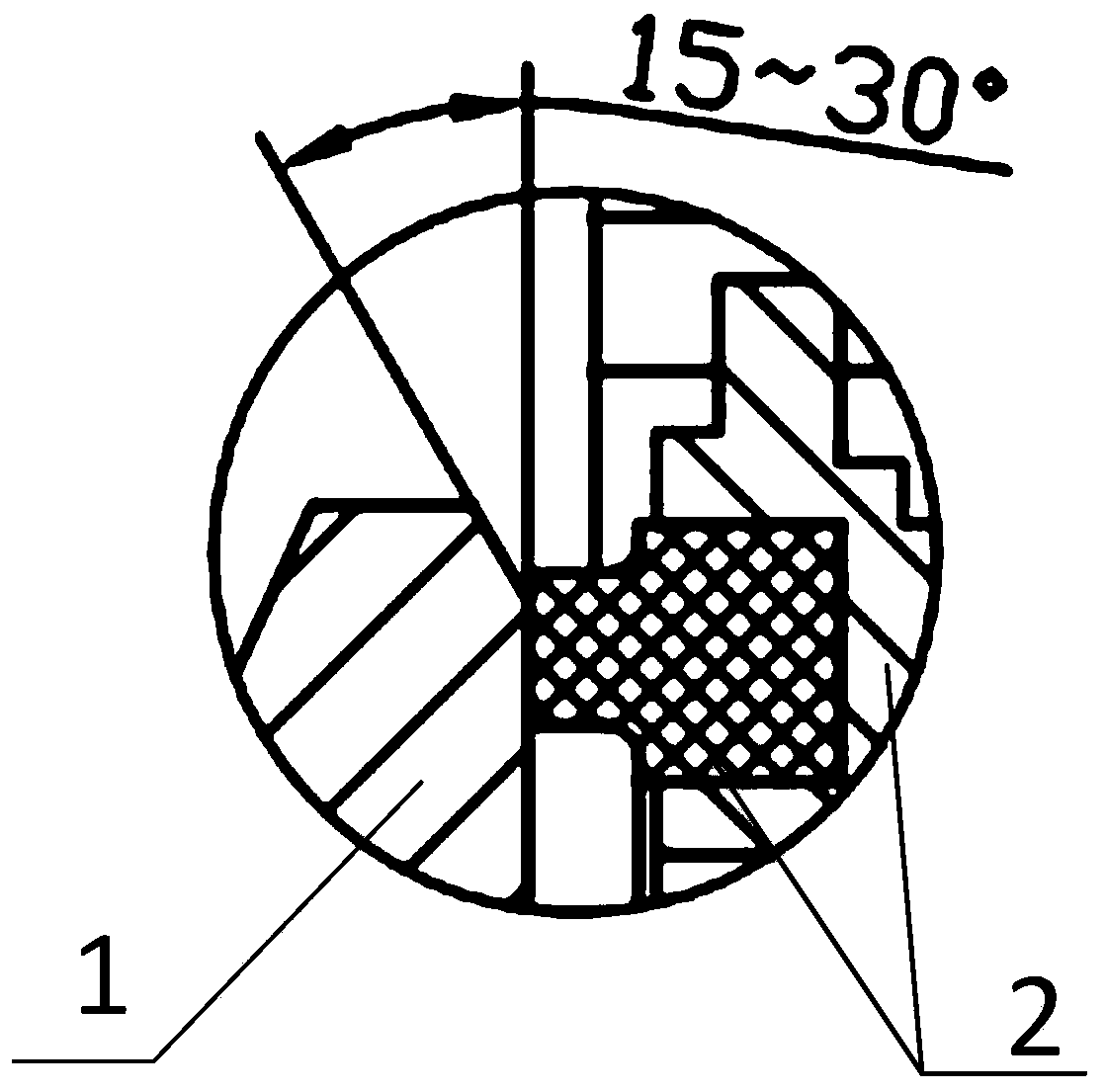

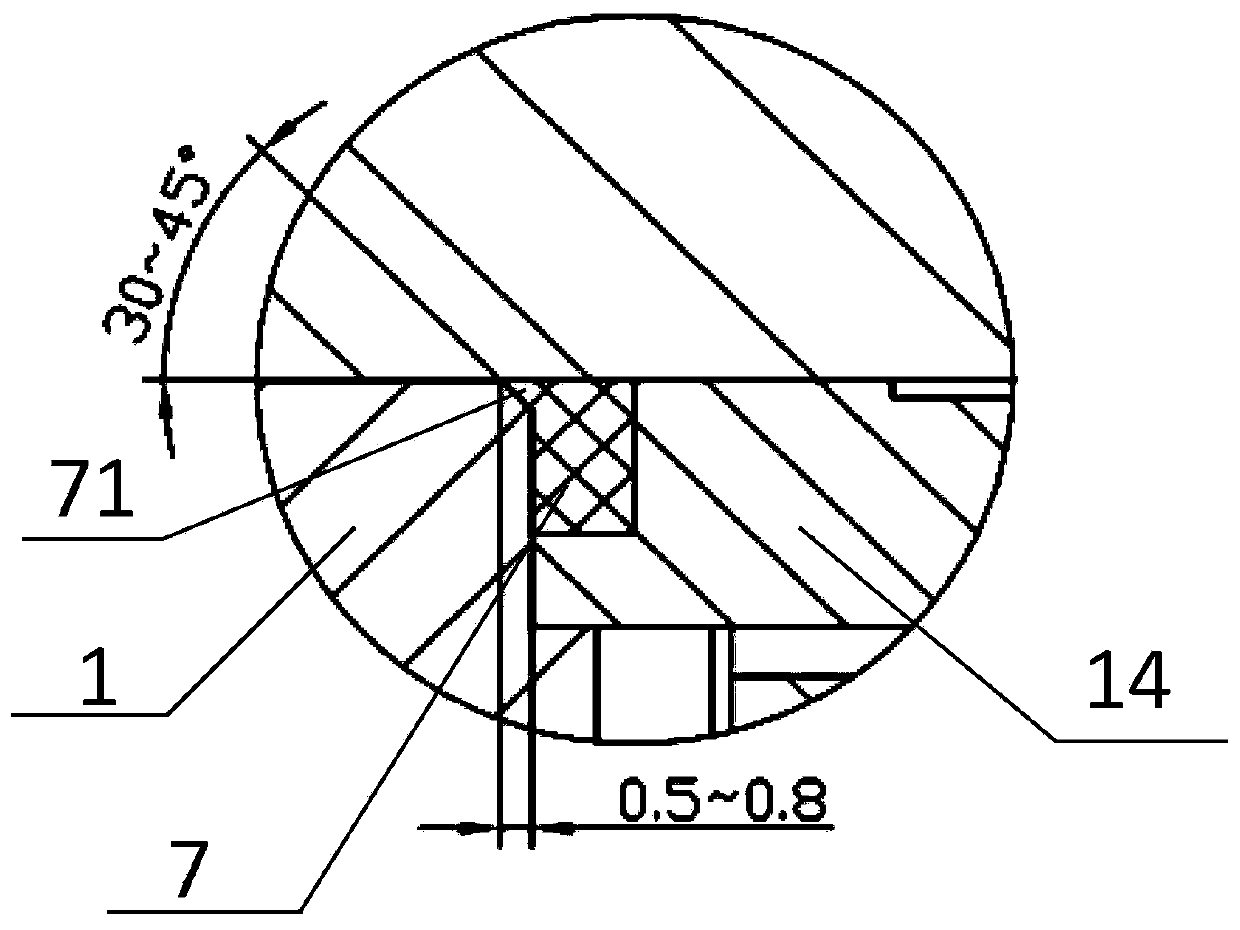

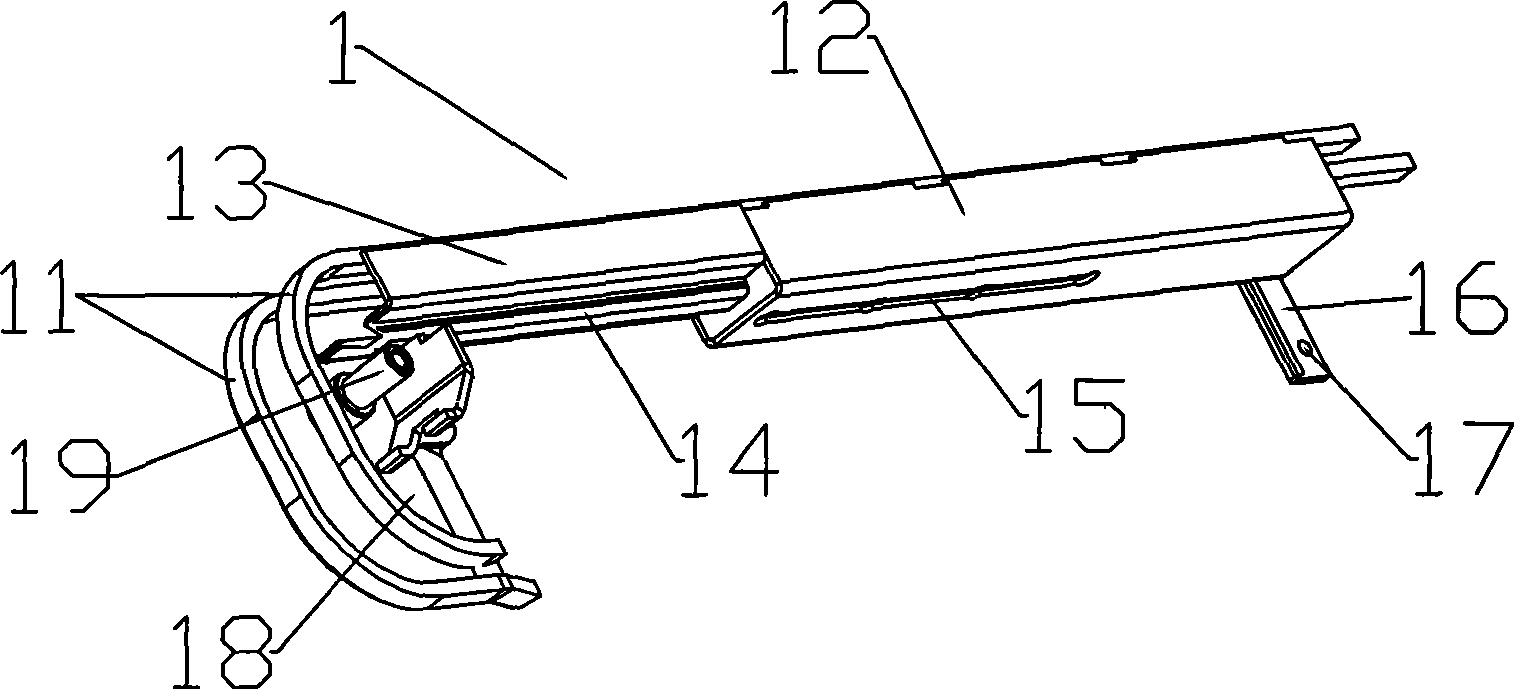

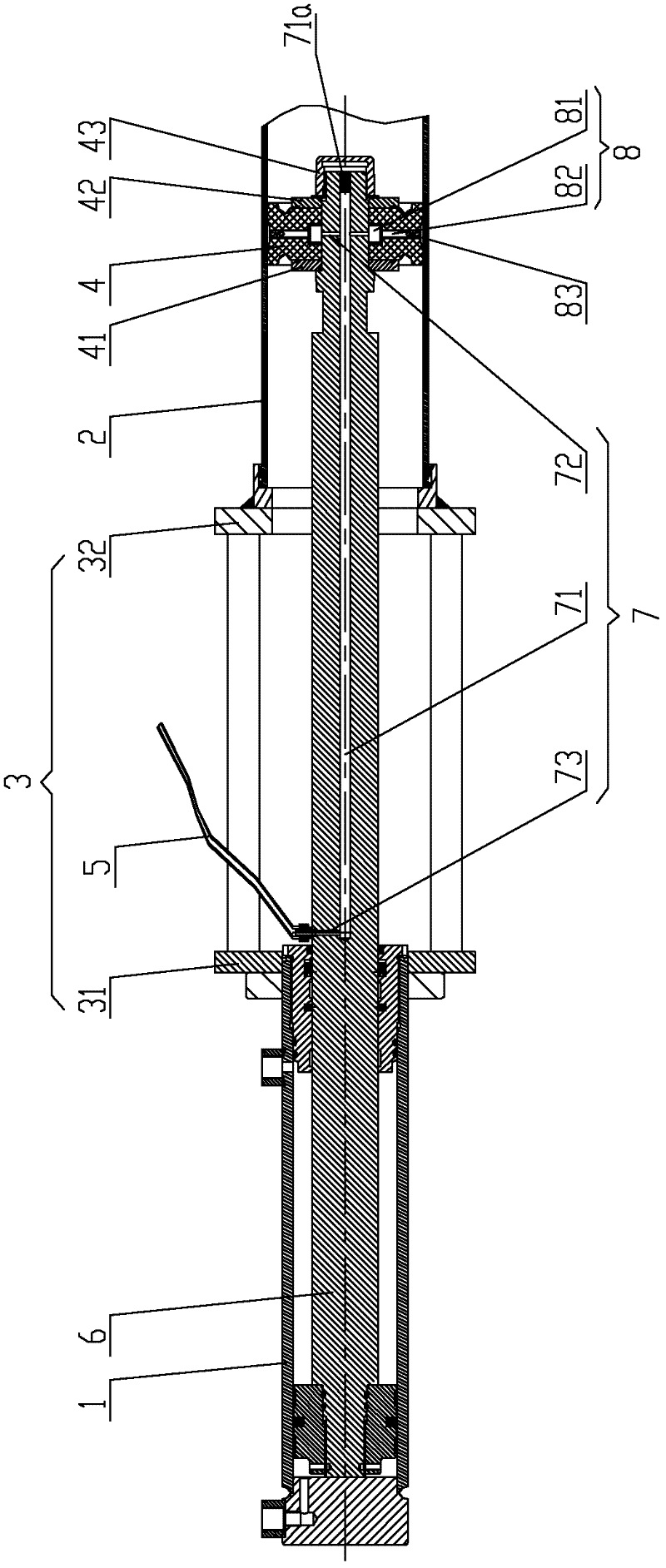

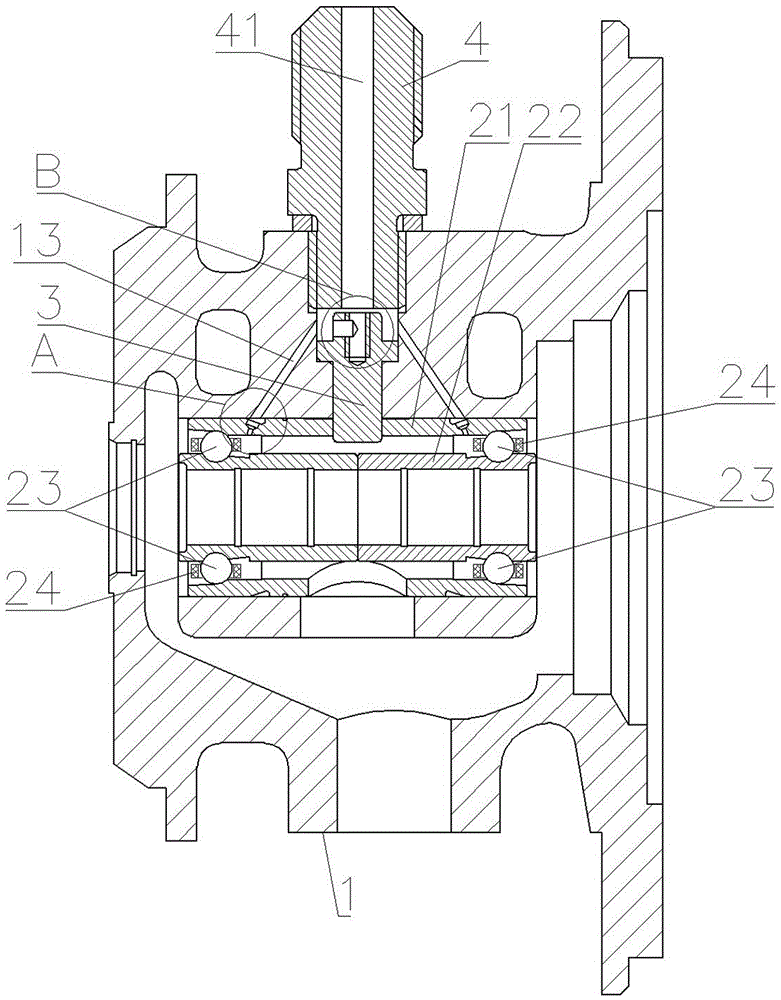

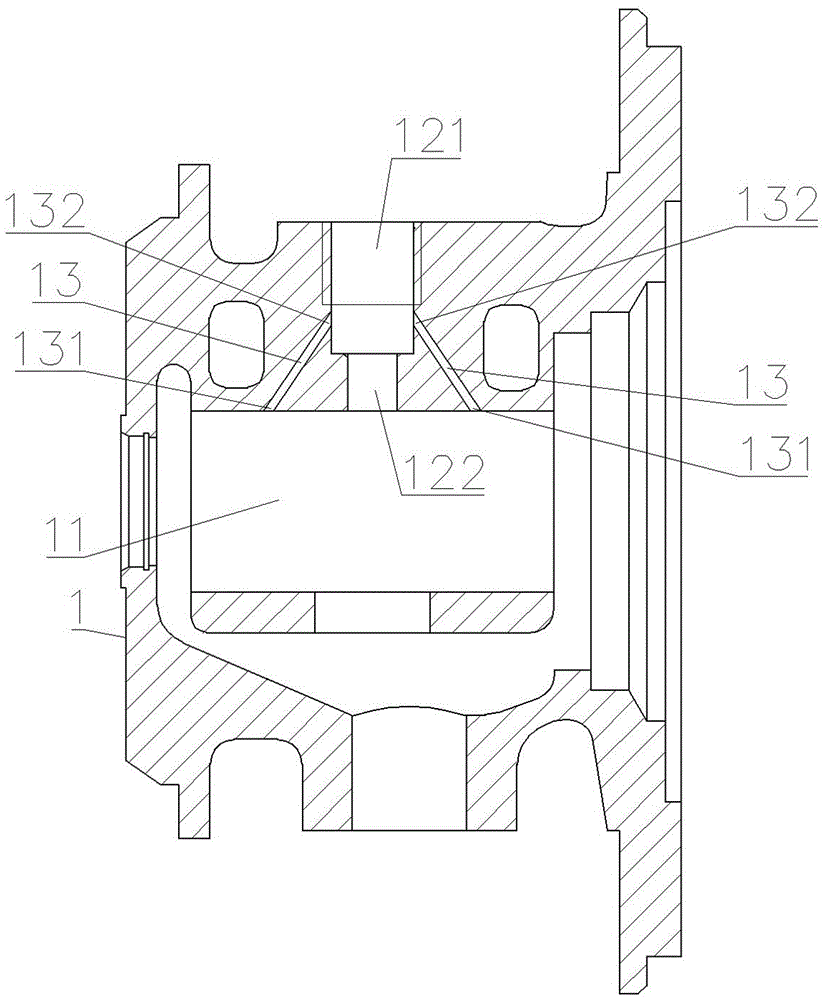

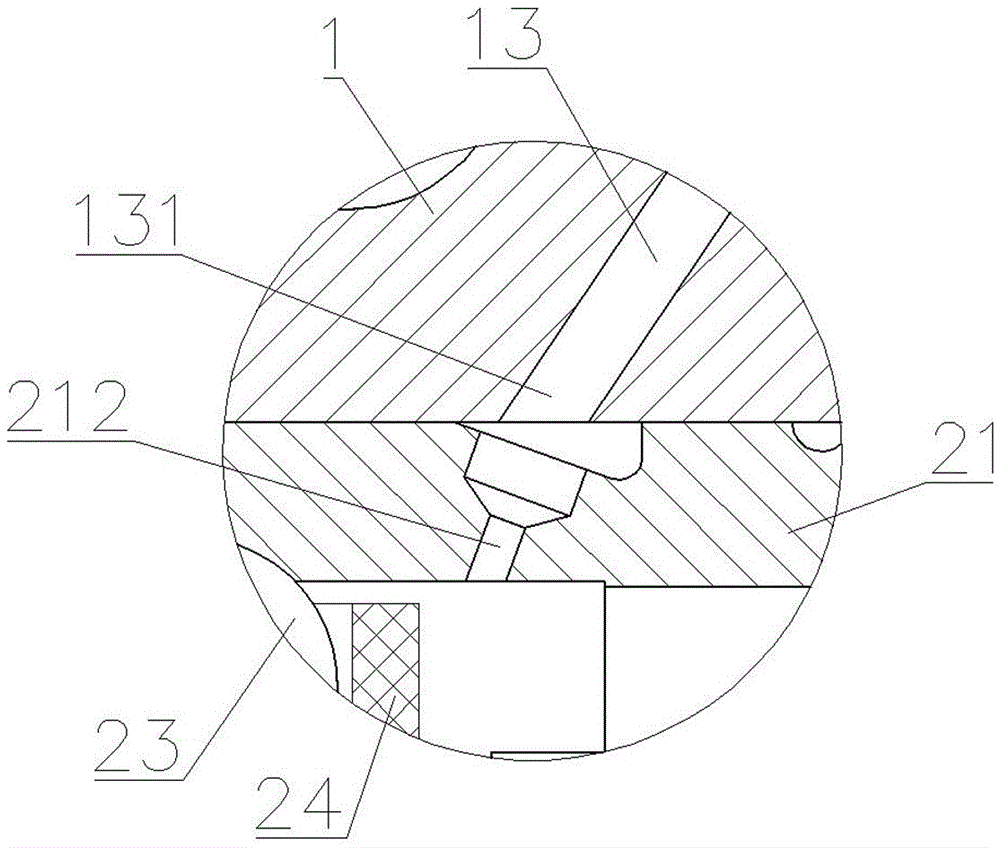

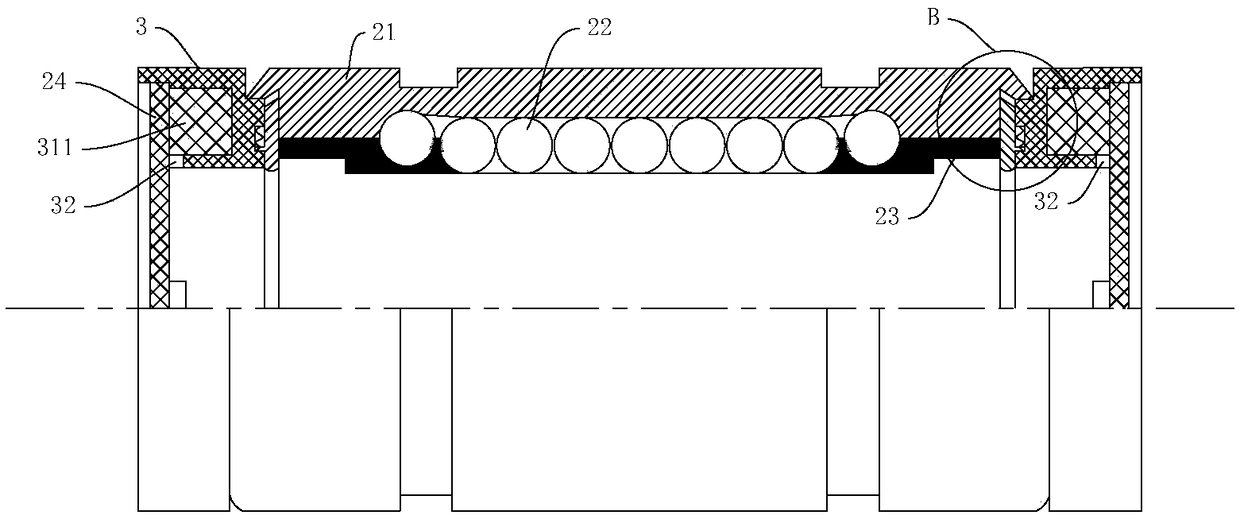

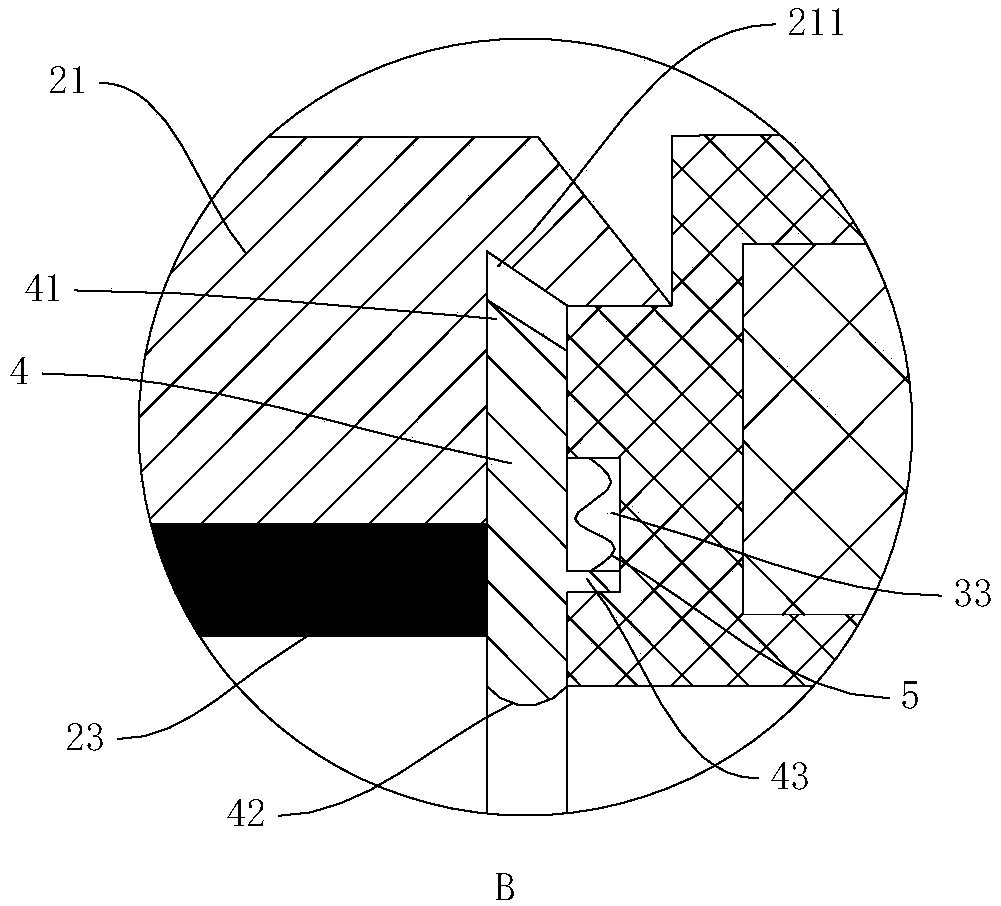

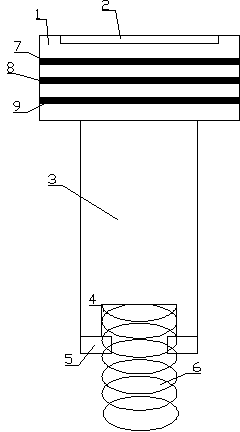

Dynamic sealing device suitable for low-temperature and high-speed repeated use

The invention relates to a dynamic sealing device suitable for low-temperature and high-speed repeated use. The dynamic sealing device is applied to a liquid rocket engine turbopump. The liquid rocketengine turbopump comprises a shaft (18) and a bearing (9) sleeving the shaft (18). The dynamic sealing device comprises a main sealing structure. The main sealing structure comprises a dynamic ring (1), a static ring assembly (2), a corrugated pipe (3), a rear ring (4), a sealing shell (5) and a shaft sleeve (14). The dynamic sealing device comprises the main sealing structure, so that low-temperature media can easily enter a dynamic ring and static ring assembly joint surface, dry friction on the sealing surface is avoided, sealing wear is reduced, the sealing service life is prolonged, andrequirements for long service life and repeated use under severe working conditions such as high rotating speed, high pressure and large radial runout of the turbopump are met.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

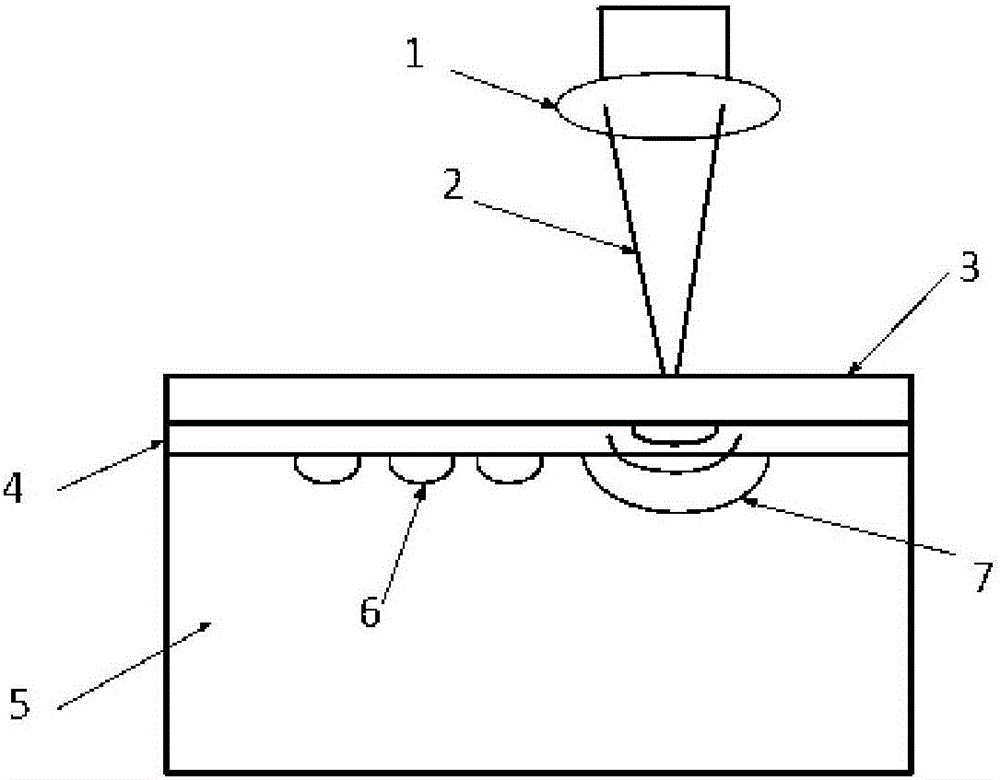

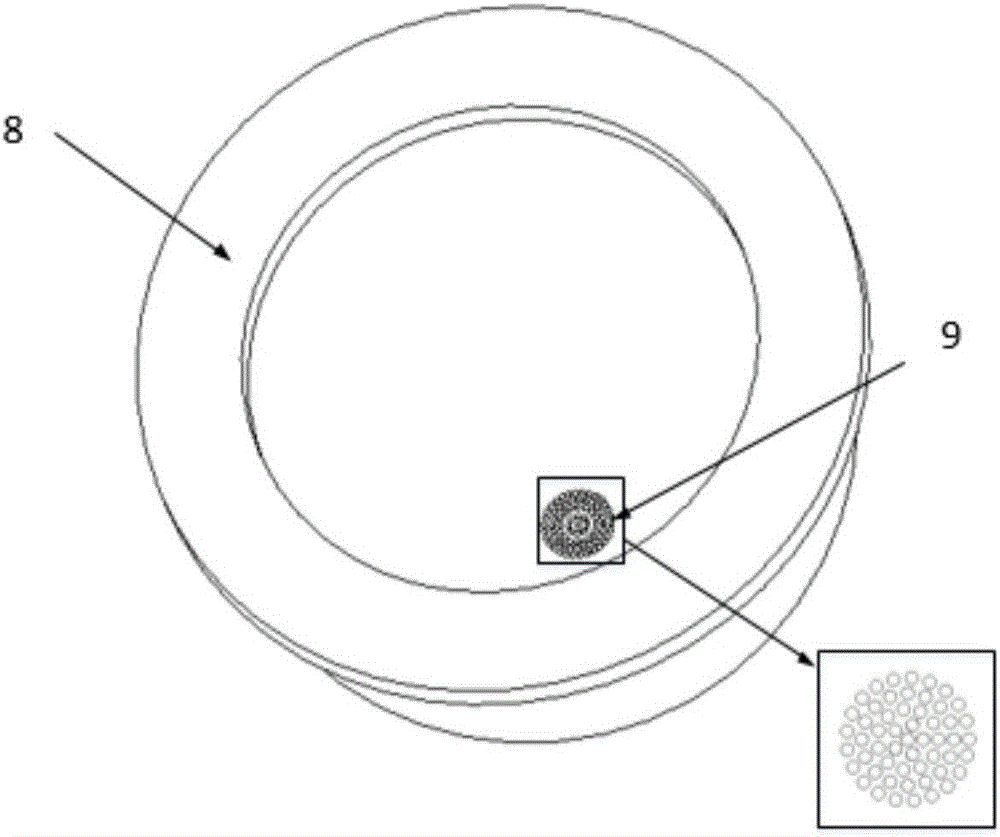

Method for conducting laser shock micro-shaping on titanium alloy artificial acetabular cup

InactiveCN104983487ANo side effectsImprove wear resistanceJoint implantsAcetabular cupsSide effectEnergy absorption

The invention discloses a method for conducting laser shock micro-shaping on a titanium alloy artificial acetabular cup. The method includes the following steps that (1) the region prone to wear of the bottom of the titanium alloy acetabular cup is polished, cleaned with alcohol and dried, and a layer of black paint is sprayed on the region prone to wear to serve as an energy absorption layer; (2) the titanium alloy acetabular cup is arranged on a workbench, parameters of a laser device are set, and the region prone to wear of the bottom of the titanium alloy acetabular cup is irradiated with laser beams through a focusing lens, and micro pits are formed; (3) micro pit arrays are machined in the bottom face of the titanium alloy acetabular cup through the laser device by moving the workbench; (4) the black paint on the surface of the titanium alloy acetabular cup is removed, and the micro-shaping surface is cleaned through ultrasonic waves. According to the method, the adopted laser shock micro-shaping technology belongs to cold machining surface treatment, no other chemical components need to be introduced, and no side effect on people exists; compared with current artificial acetabular cups, the wear resistance of the bottom of the titanium alloy artificial acetabular cup obtained through laser shock micro-shaping is improved remarkably.

Owner:JIANGSU UNIV OF SCI & TECH

Horizontal vortex air compressor for oil injection

ActiveCN102748282AEliminate tiny gapsContinuous and stable oil supplyRotary piston pumpsRotary piston liquid enginesChillerAir compressor

The invention discloses a horizontal vortex air compressor for oil injection, which comprises an oil gas barrel, a cooler, an oil filter and a host part, wherein the oil gas barrel is connected with the host part, the cooler is connected with the oil gas barrel, the cooler is connected with the host part through the oil filter, the host part comprises a frame, a spindle, a rotary vortex part and a fixed vortex part, the fixed vortex part is provided with an exhaust passage and an air suction passage, the horizontal vortex air compressor for oil injection is characterized in that a supporting component capable of supporting the rotary vortex part movably is arranged between the opposite side of a scroll of the rotary vortex part and the frame, the supporting component pushes the rotary vortex part to be always tightly jointed with the fixed vortex part in a moving process under the action of the pressure at the back side, and the rotary vortex part and the fixed vortex part are axially sealed through the supporting component. According to the invention, the leakage phenomenon of a compression chamber through a tiny clearance can be completely solved, efficiency and performance of the compressor are improved, the quality of the air at the air outlet is enhanced, and the environmental pollution is reduced.

Owner:湖北和丰机电有限公司

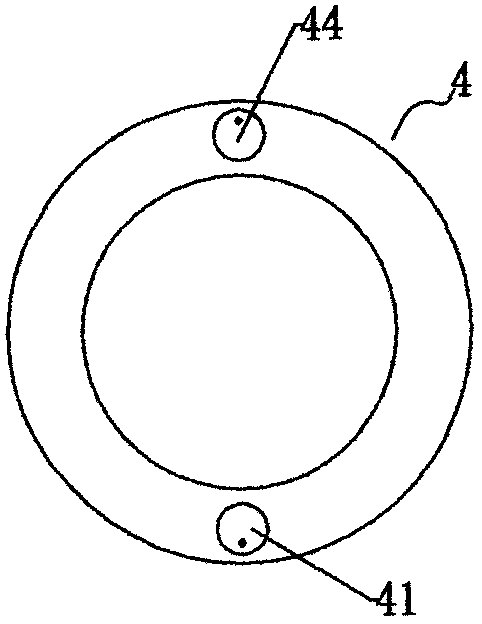

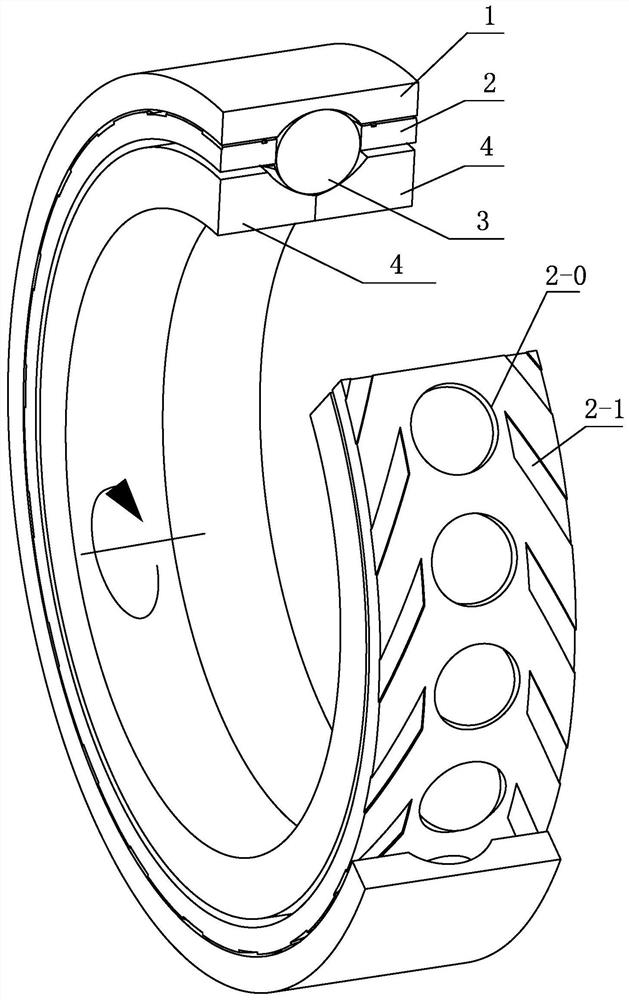

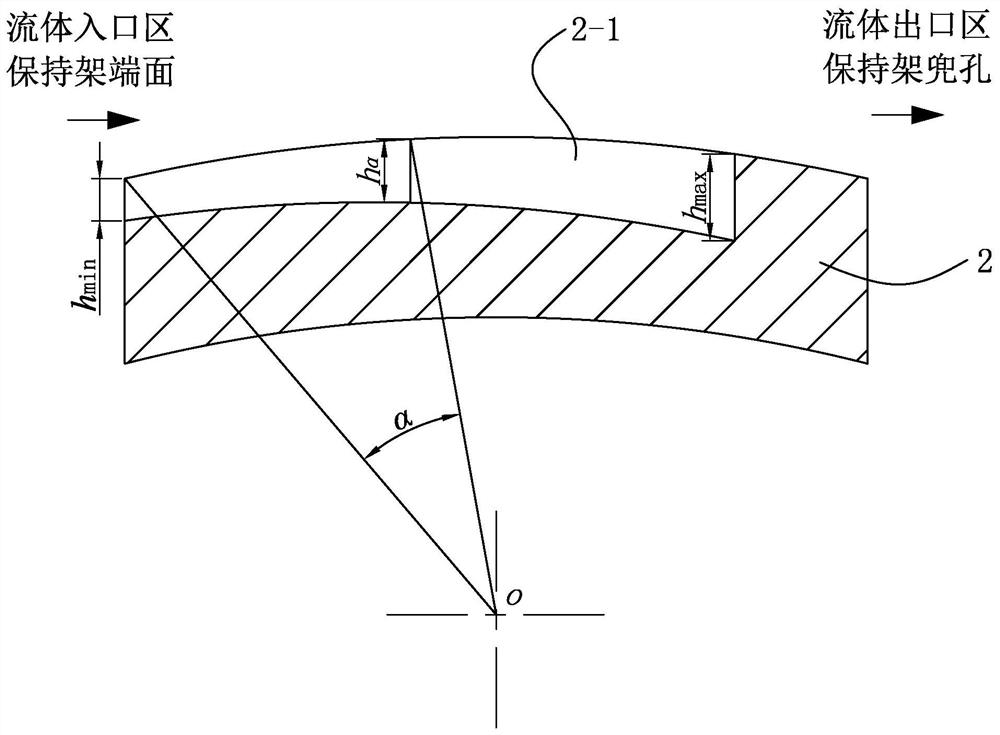

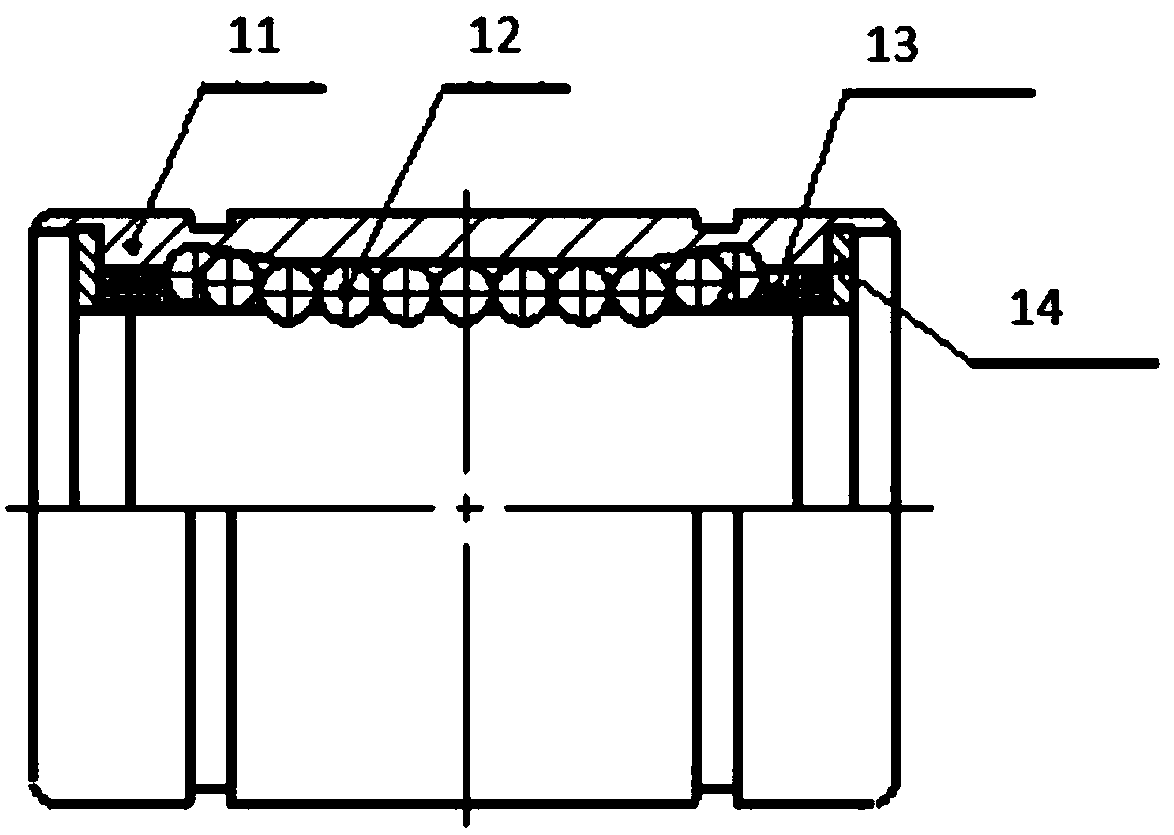

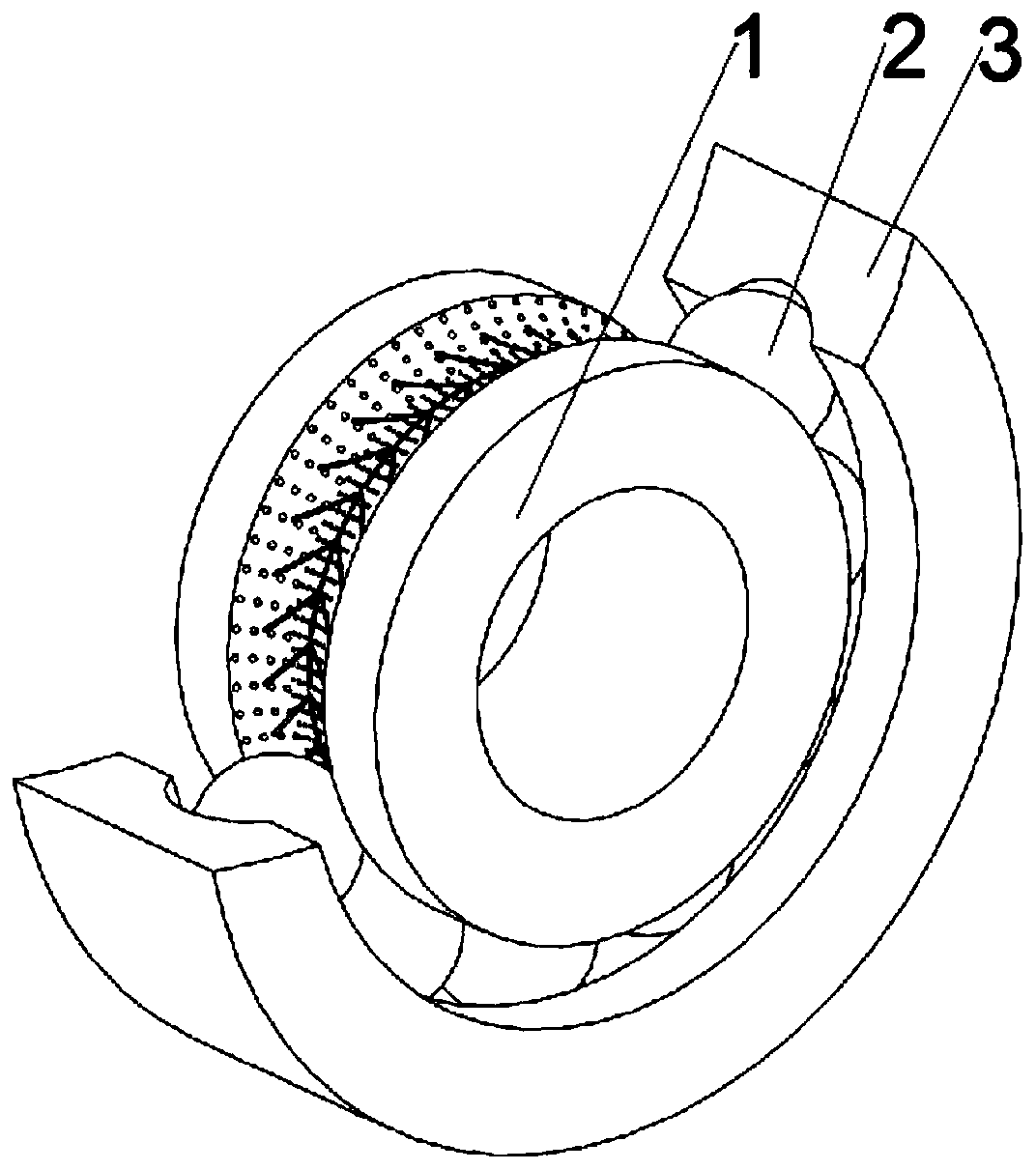

Double-half-inner-ring angular contact ball bearing with spiral grooves in outer surface of retainer

ActiveCN112283240AIncreasing the thicknessHigh movement precisionBall bearingsBearing componentsBall bearingRetainer

The invention discloses a double-half-inner-ring angular contact ball bearing with spiral grooves in the outer surface of a retainer. The bearing comprises an outer ring, the retainer, rolling bodiesand an inner ring. The inner ring is a double-half inner ring; the retainer is arranged between the inner ring and the outer ring; and the rolling bodies are arranged in pockets of the retainer and are in rolling contact with the inner ring and the outer ring respectively. The outer surface of the retainer is provided with two groups of grooves; the two groups of grooves are arranged at two sidesof the pockets of the retainer; each group of the grooves comprises multiple grooves; each groove extends from the end surface of the retainer to the pockets of the retainer; the multiple grooves arespirally arranged along the circumferential direction; and the rotating directions of the two groups of grooves are opposite. According to the double-half-inner-ring angular contact ball bearing withthe spiral grooves in the outer surface of the retainer, based on the dynamic pressure effect and the pumping function of the spiral groove microstructure, the micro-dynamic pressure effect is formedthrough the spiral groove structure between the retainer and a guide ferrule, and fluid is pumped into the contact surface, so that the multiple positive effects of increasing the thickness of a lubricating film on the contact surface, improving the bearing capacity, stabilizing the movement of the retainer and enhancing heat dissipation are achieved, and support is provided for the improvement ofaero-engine performance.

Owner:HARBIN INST OF TECH

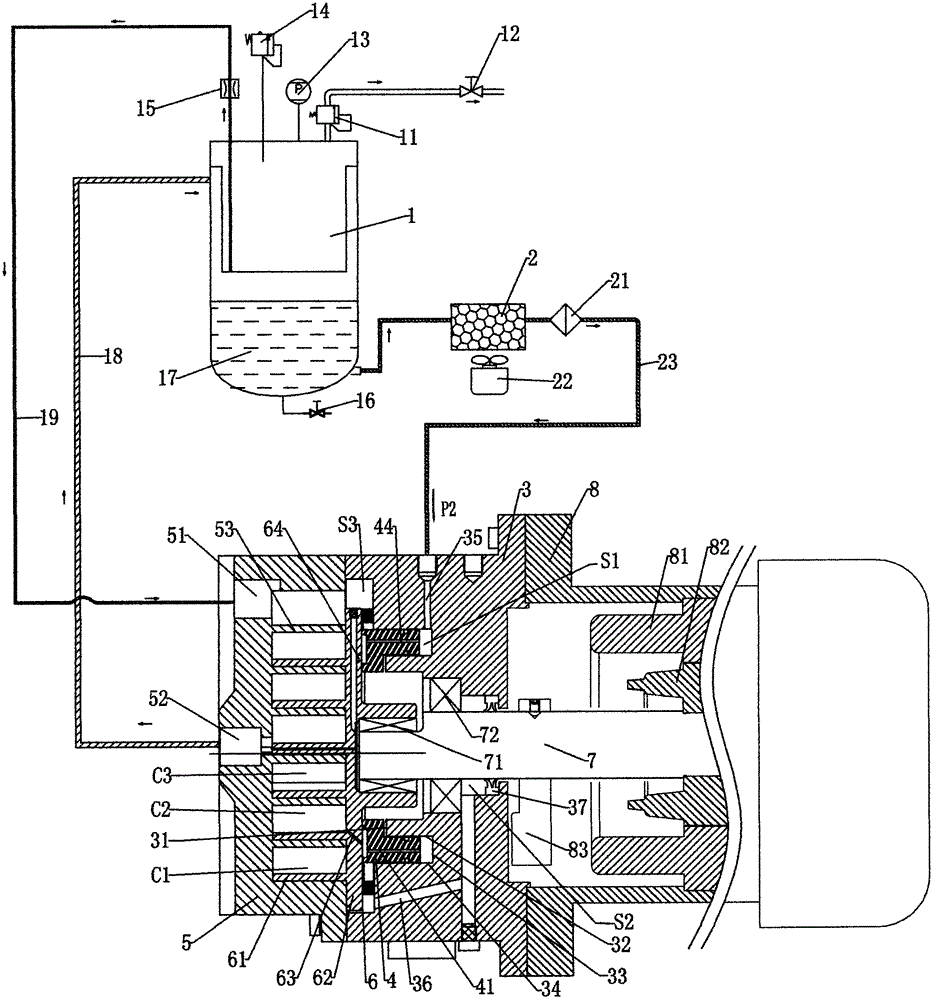

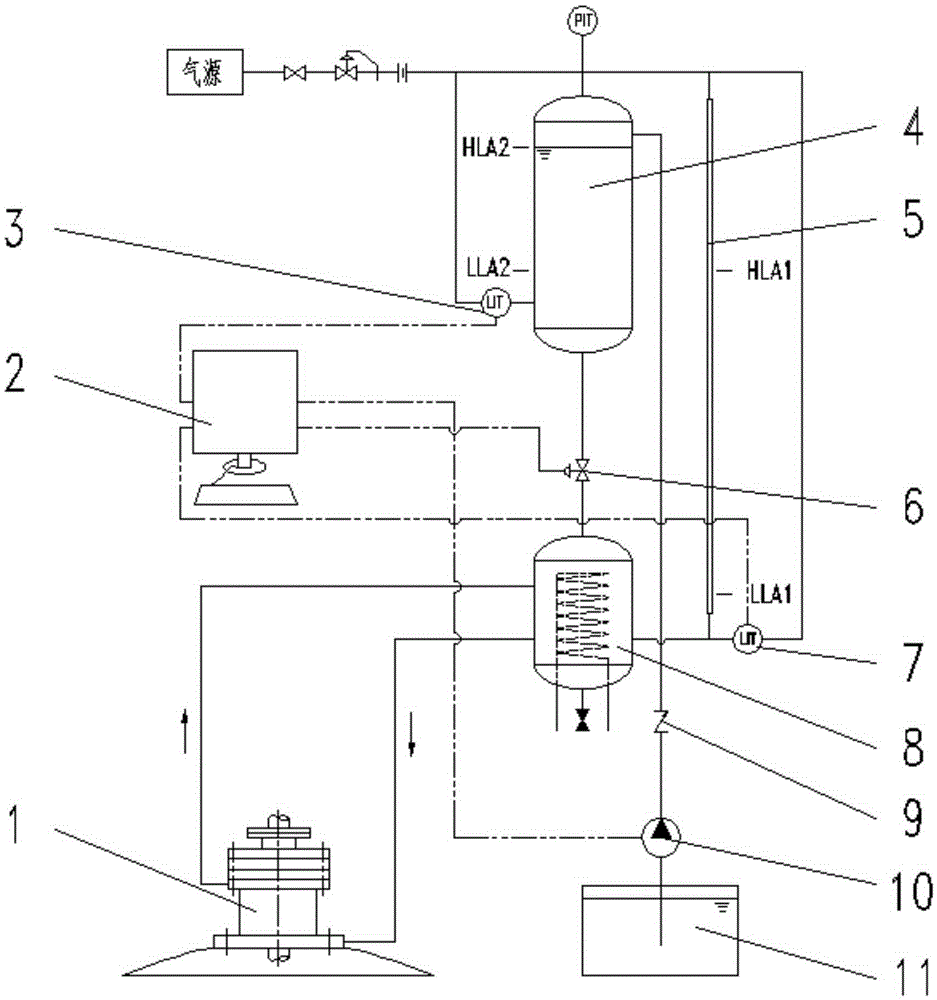

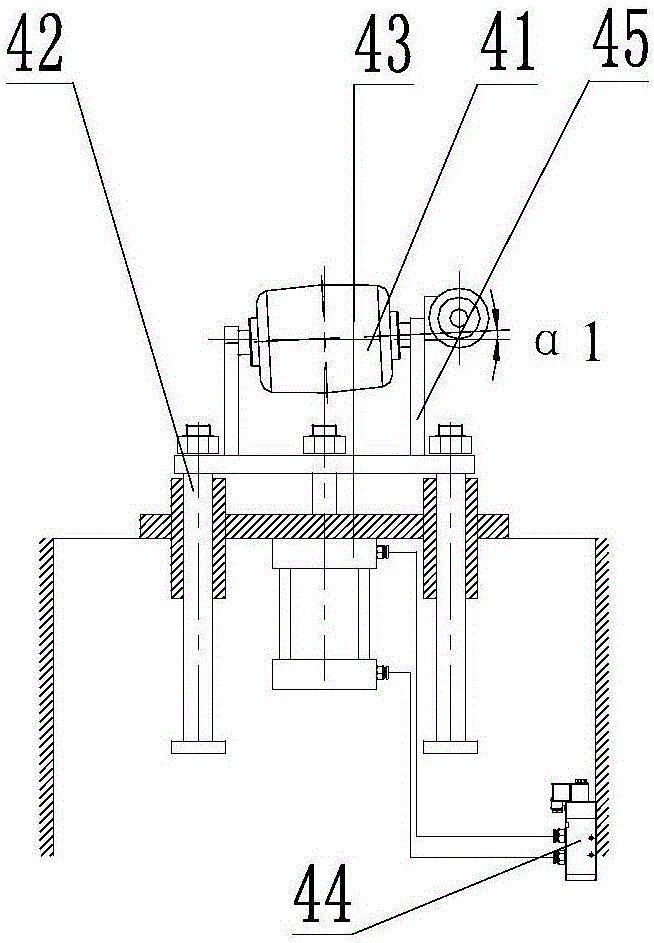

Mechanical seal leakage rate online monitoring system

ActiveCN105425842AAvoid dry rubbingReduce production lossLevel controlAutomatic controlMonitoring system

The invention discloses a mechanical seal leakage rate online monitoring system, and belongs to the field of a mechanical seal monitoring system. The mechanical seal leakage rate online monitoring system comprises a leakage-sensitive pipe, a fluid infusion tank, a circulation tank, a data processor, a first liquid level transmitter, a second liquid level transmitter, an automatic control switch valve, a fluid infusion pump, a non-return valve, a mechanical seal structure and a water tank. In case of normal work, the automatic control switch valve is normally-closed, the circulation tank communicates with the leakage-sensitive pipe, and liquid level change of the leakage-sensitive pipe sensitively reflects the leakage rate of the mechanical seal structure; when the liquid level of the leakage-sensitive pipe is reduced to a certain degree, the automatic control switch valve is open, the fluid infusion tank, the circulation tank and the leakage-sensitive pipe form a communicating vessel so as to realize automatic fluid infusion of the leakage-sensitive pipe; and when the liquid level of the fluid infusion tank is reduced to a certain degree, the fluid infusion pump is started, and thus automatic fluid infusion of the fluid infusion tank is realized. The monitoring system provided by the invention can sensitively monitor the leakage rate of a mechanical seal in real time and output early warning signals when the leakage rate exceeds a standard; and when a seal blocking liquid is insufficient, the seal blocking liquid can also be automatically supplemented.

Owner:BEIJING UNIV OF CHEM TECH

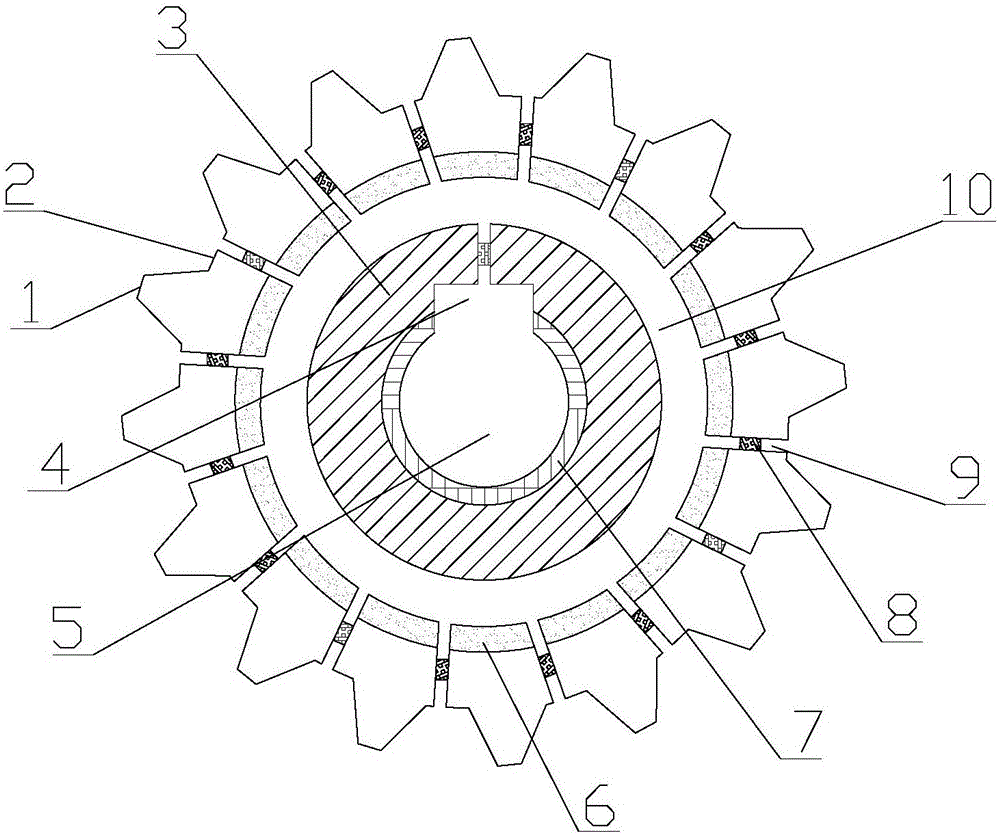

Noise elimination vibration reduction gear

InactiveCN105805273AReduced sound insulationExtended service lifeGear lubrication/coolingPortable liftingEngineeringCavity wall

The invention discloses a noise elimination vibration reduction gear which comprises a gear body, and further comprises an oil storage cavity, an elastic pressing piece and a foamed aluminium noise elimination layer, wherein teeth are arranged on the outer contour of the gear body; tooth grooves are formed between the adjacent teeth; a shaft hole is formed in the central position of the gear body; a keyway is formed in the inner wall of the shaft hole in the radial direction of the gear body; the oil storage cavity is formed inside the gear body; oil ducts are formed in the inner cavity wall of the oil storage cavity; the oil ducts are distributed on all the tooth grooves, and communicate with the upper surfaces of the tooth grooves; oil suction devices are arranged in the middle parts of the oil ducts; the elastic pressing piece is mounted around the inner wall of the shaft hole; and the foamed aluminium noise elimination layer is arranged on the inner wall of the oil storage cavity. According to the noise elimination vibration reduction gear, through the arranged elastic pressing piece, the oil ducts and the foamed aluminium noise elimination layer, when the gear runs, the elastic pressing piece reduces the friction of the shaft hole and a bearing, the oil ducts prevent the teeth from having dry friction, and the foamed aluminium noise elimination layer has a sound insulation effect.

Owner:蒙泽喜

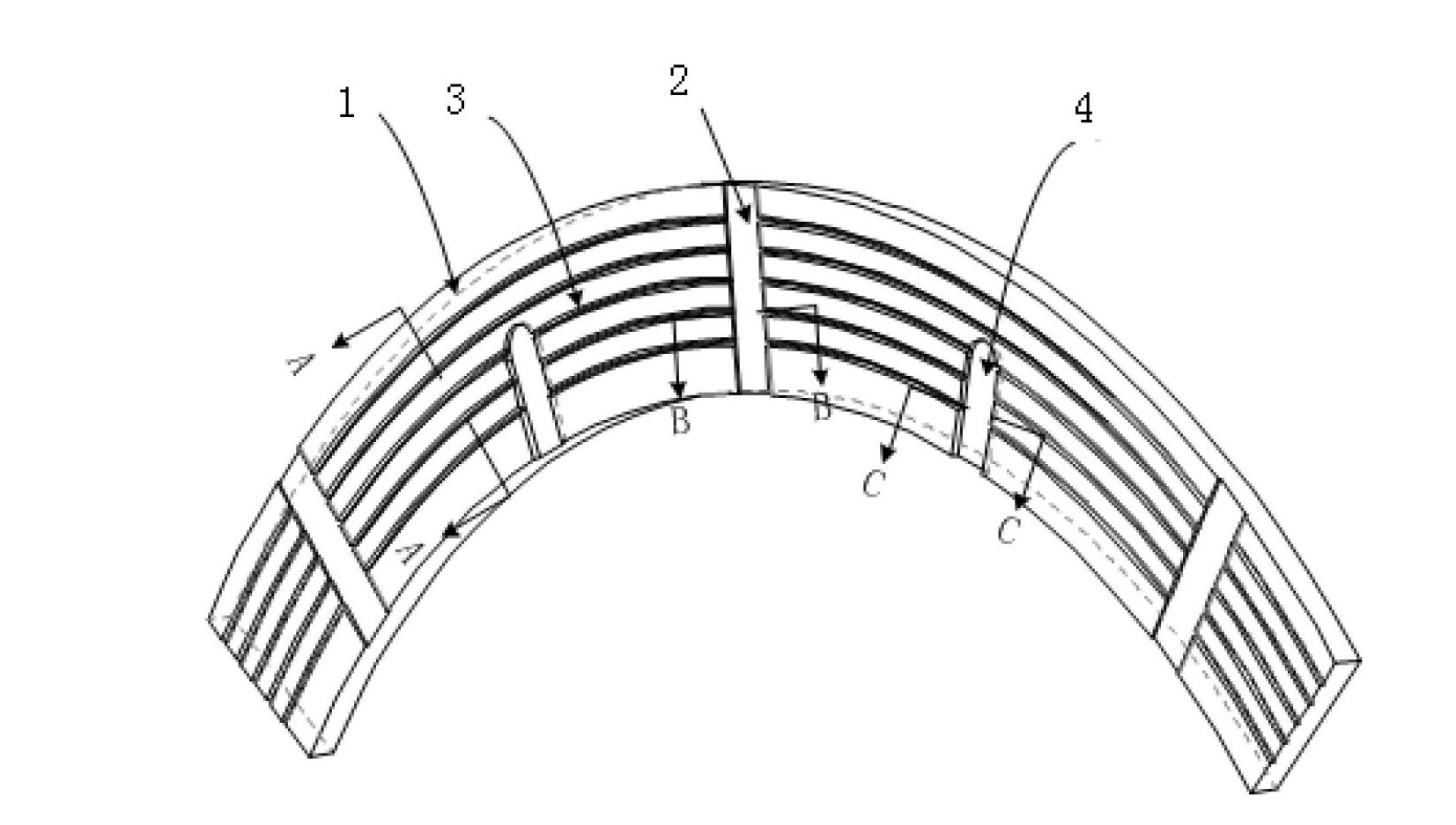

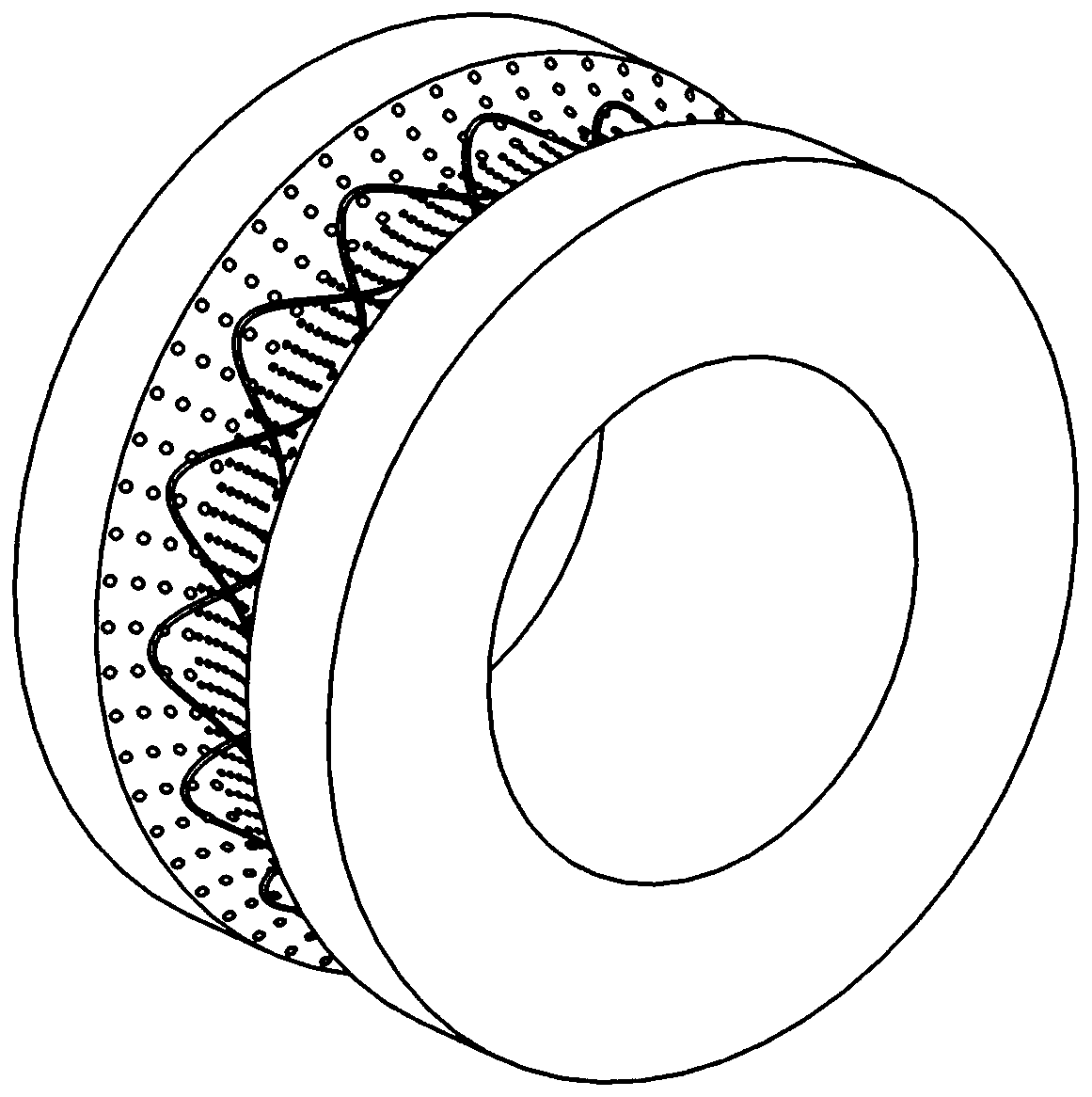

High/low-speed groove clutch friction plate

The invention belongs to the technical field of vehicle gearboxes and relates to a clutch friction plate, in particular to a high / low-speed groove clutch friction plate. Spiral grooves are formed on a circular ring surface of the clutch friction plate along the circumferential direction in equal distance; through grooves are formed along the radial direction of the clutch friction plate in equal distance; semi-through grooves are formed along the radial direction of the clutch friction plate in equal distance; and the through grooves and the semi-through grooves are formed at intervals and are communicated with the spiral grooves. In the joint process, the clutch friction plate has a lubricating function, large-area dry friction of the friction plate is avoided, and wear of the friction plate is reduced; and during an empty load, radial flow of oil is accelerated, and the probability of forming a complete oil film is reduced, so that the clutch friction plate has the advantage of reducing the drag torque at low speed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Right and left ear terminal grain-holding claw conveying chain guide device

The invention discloses a guide rail device of a conveyor chain for crop-supporting claws used for supporting an ear at the left and the right ends thereof. The guide rail device comprises backwardly inclining transportation guide rails arranged at the left and the right sides of the face of the front end of a reaper. The guide rail device is characterized in that each transportation guide rail comprises two square bar metal bodies which are bent into the shape of an L; the two L-shaped solid square bar metal bodies are stacked with spacing; the leaning sections of the two square bar metal bodies are fixed with metal plates which are bent into grooves; the openings of the grooves face the sides of the two L-shaped solid square bar metal bodies which are stacked; a cover plate which is shaped by one-time pressing is installed on each transportation guide rail; the metal plates which are used for the installation of the transportation guide rails are arranged at the upper part and the lower part of the transportation guide rails; installation holes are formed on the metal plates; the metal plates which are bent into the grooves and used for the installation of the transportation guide rails are fixed in the welding manner. The invention has the advantages of convenient dismounting in the assembly and the maintenance, strong rigidity, high strength, abrasion resistance, and long service life.

Owner:广州市科利亚农业机械有限公司

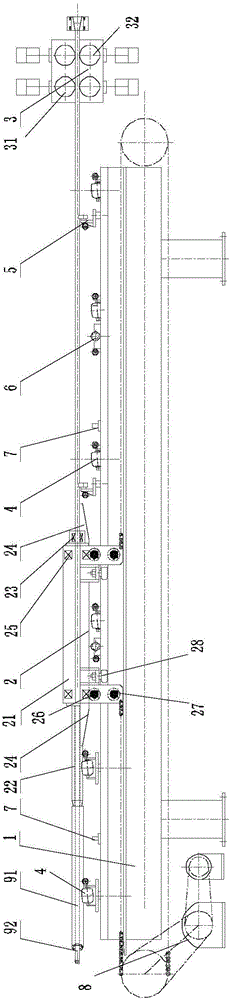

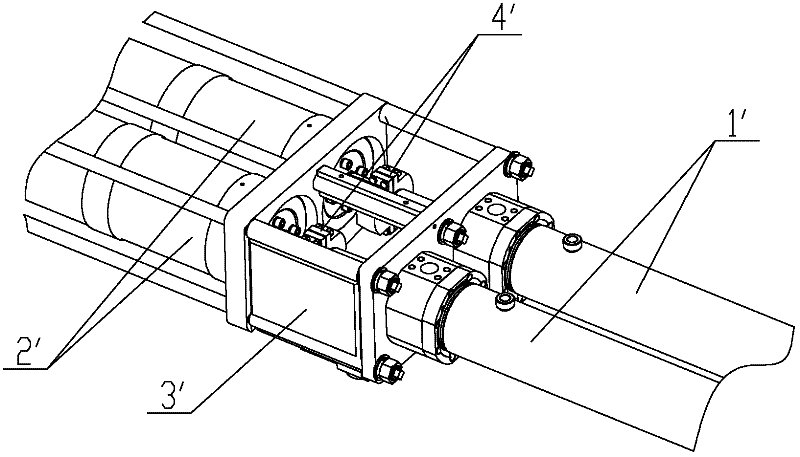

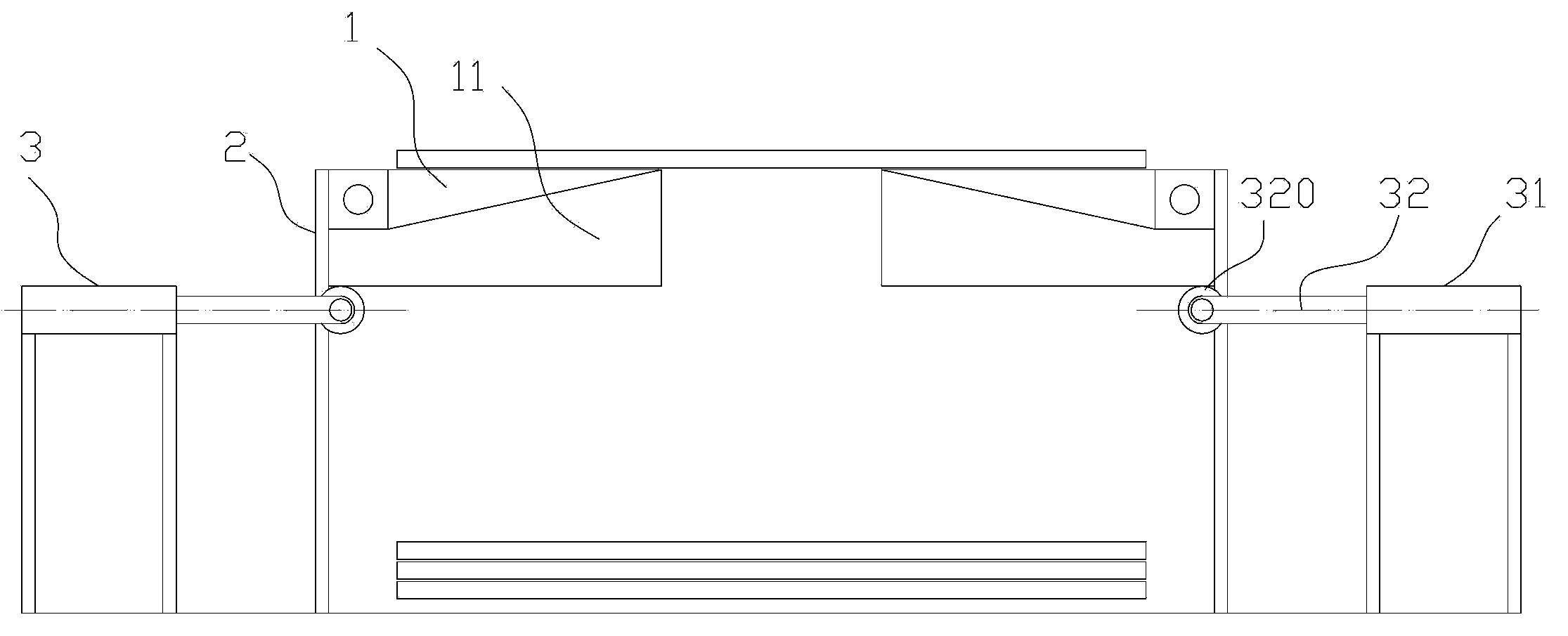

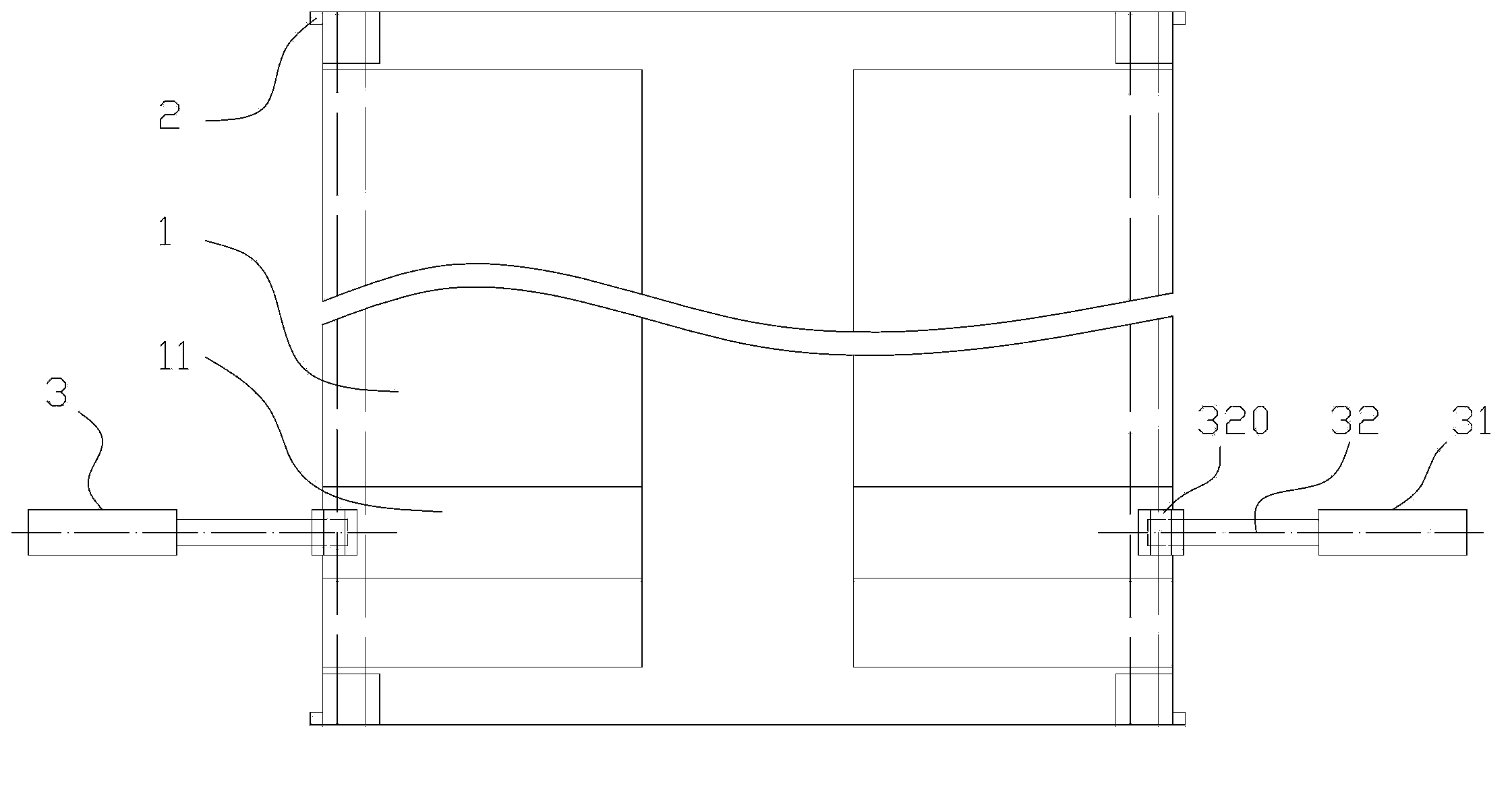

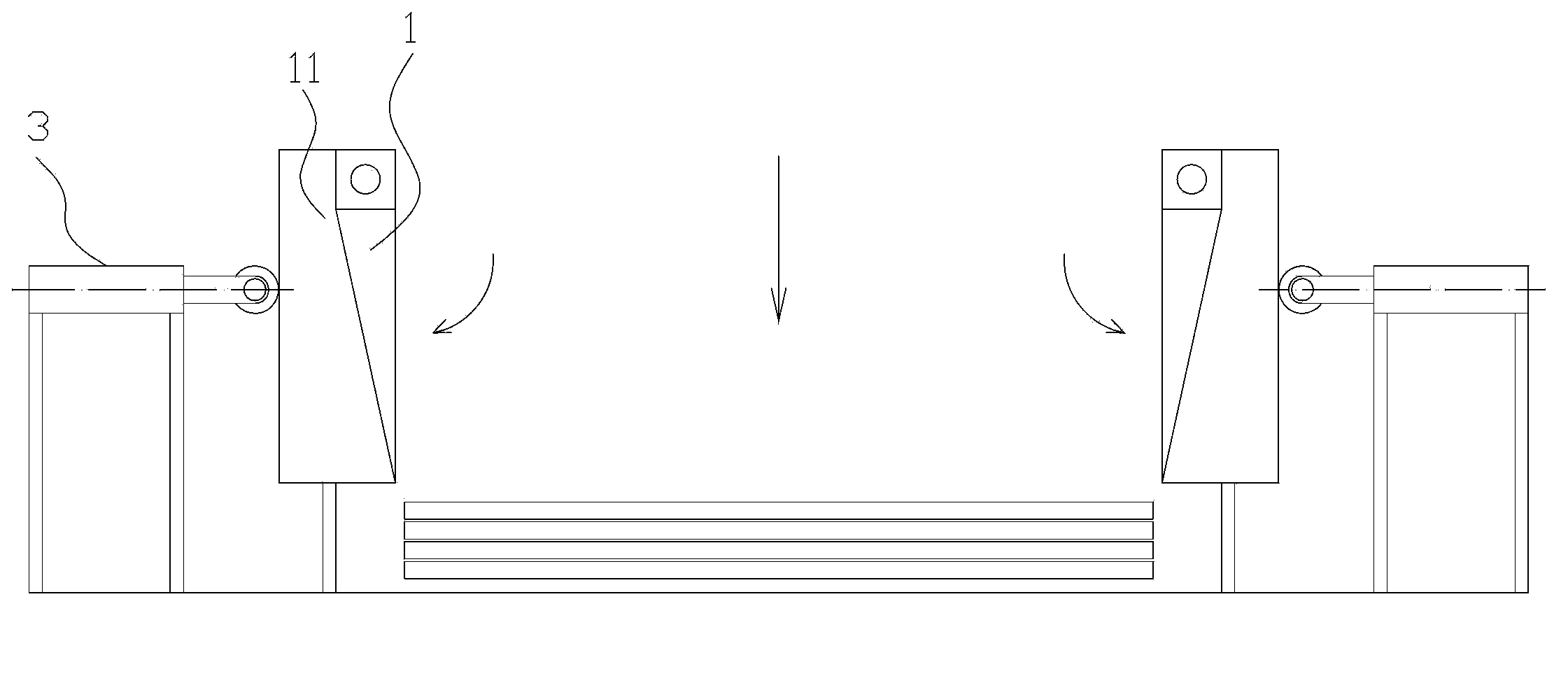

Feeding device for rolling mill

ActiveCN106140834AHigh positioning accuracyAvoid wear and tearGuiding/positioning/aligning arrangementsWork manipulationRolling mill

The invention provides a feeding device for a rolling mill. The feeding device for the rolling mill is characterized by comprising a machine frame, a core rod, a core rod feeding mechanism, a tube blank feeding trolley, a plurality of core rod supporting mechanisms and a plurality of tube blank supporting mechanisms, wherein the tube blank feeding trolley is connected with the machine frame through a tube blank feeding mechanism so that the tube blank feeding trolley can achieve reciprocation movement in the rolling direction, all the core rod supporting mechanisms and all the tube blank supporting mechanisms are arranged on the machine frame in the rolling direction, each tube blank supporting mechanism comprises a tube blank supporting portion and a first lifting module, each tube blank supporting portion is connected with the corresponding first lifting module so that the tube blank supporting portion can ascend and descend, each core rod supporting mechanism comprises a core rod supporting portion and a second lifting module, and each core rod supporting portion is connected with the corresponding second lifting module so that each core rod supporting portion can ascend and descend. The feeding device for the rolling mill can effectively support a tube blank and a core rod, improve the locating accuracy of the tube blank and the core rod and avoid the situation that because the tube blank and the core rod generate dry friction with a bearing component, the tube blank and the core rod are worn.

Owner:广东科莱博科技有限公司

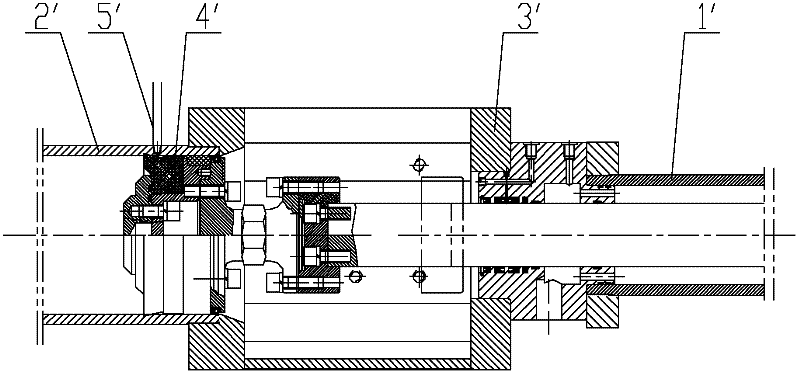

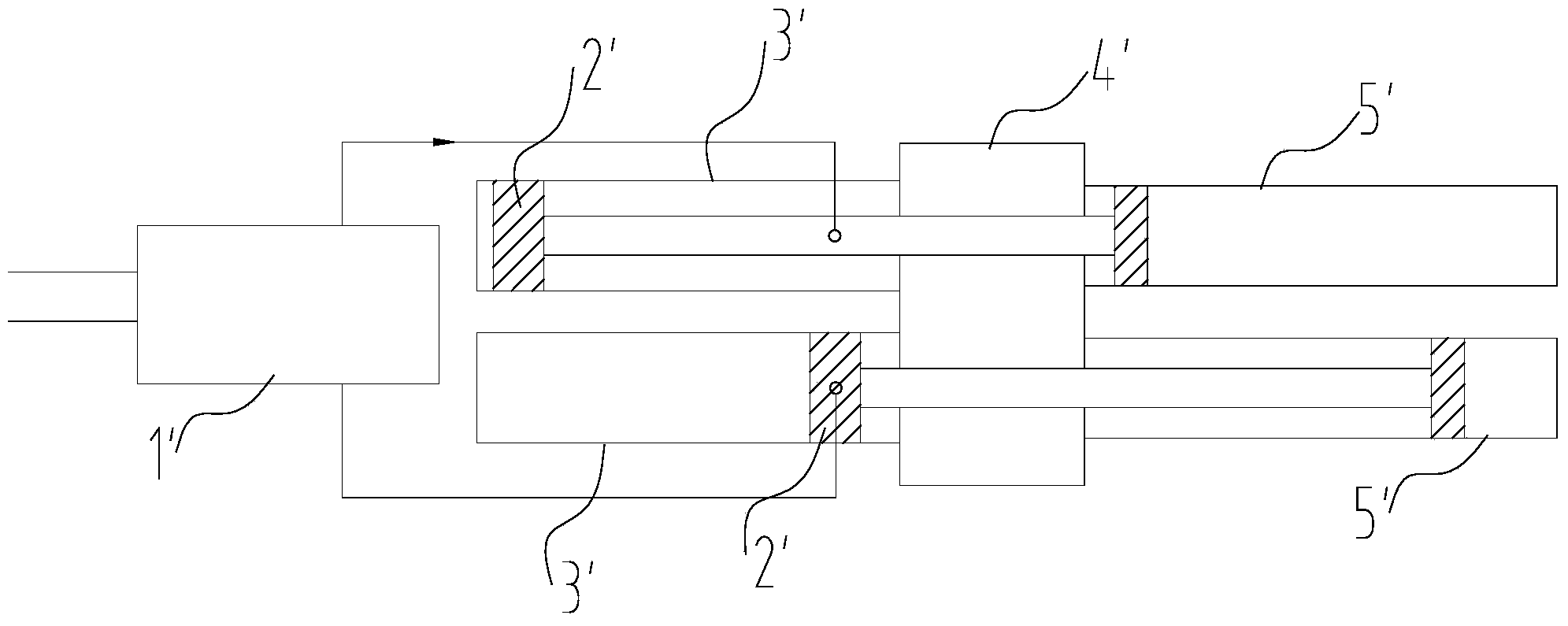

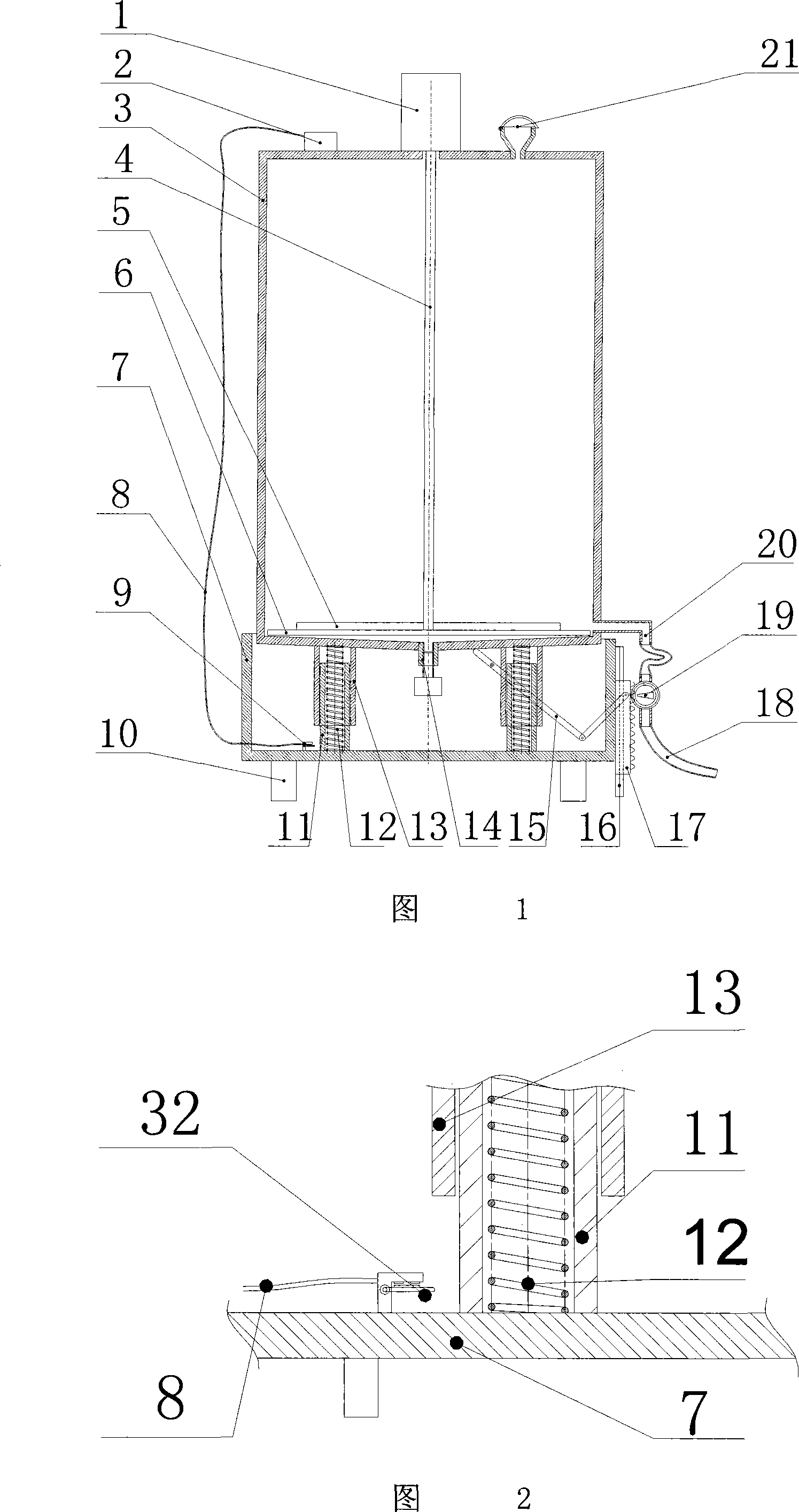

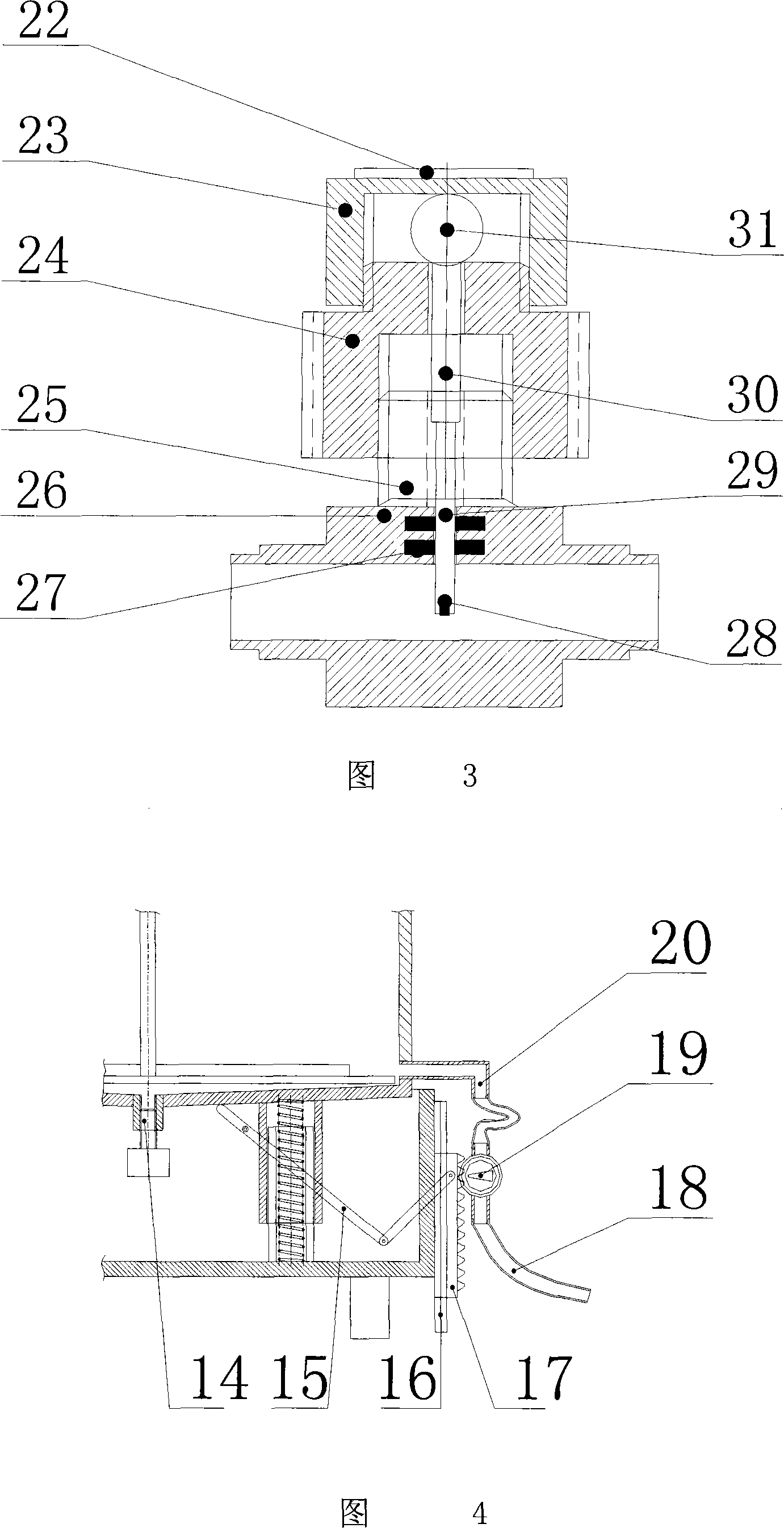

Thick slurry pump and pumping system thereof

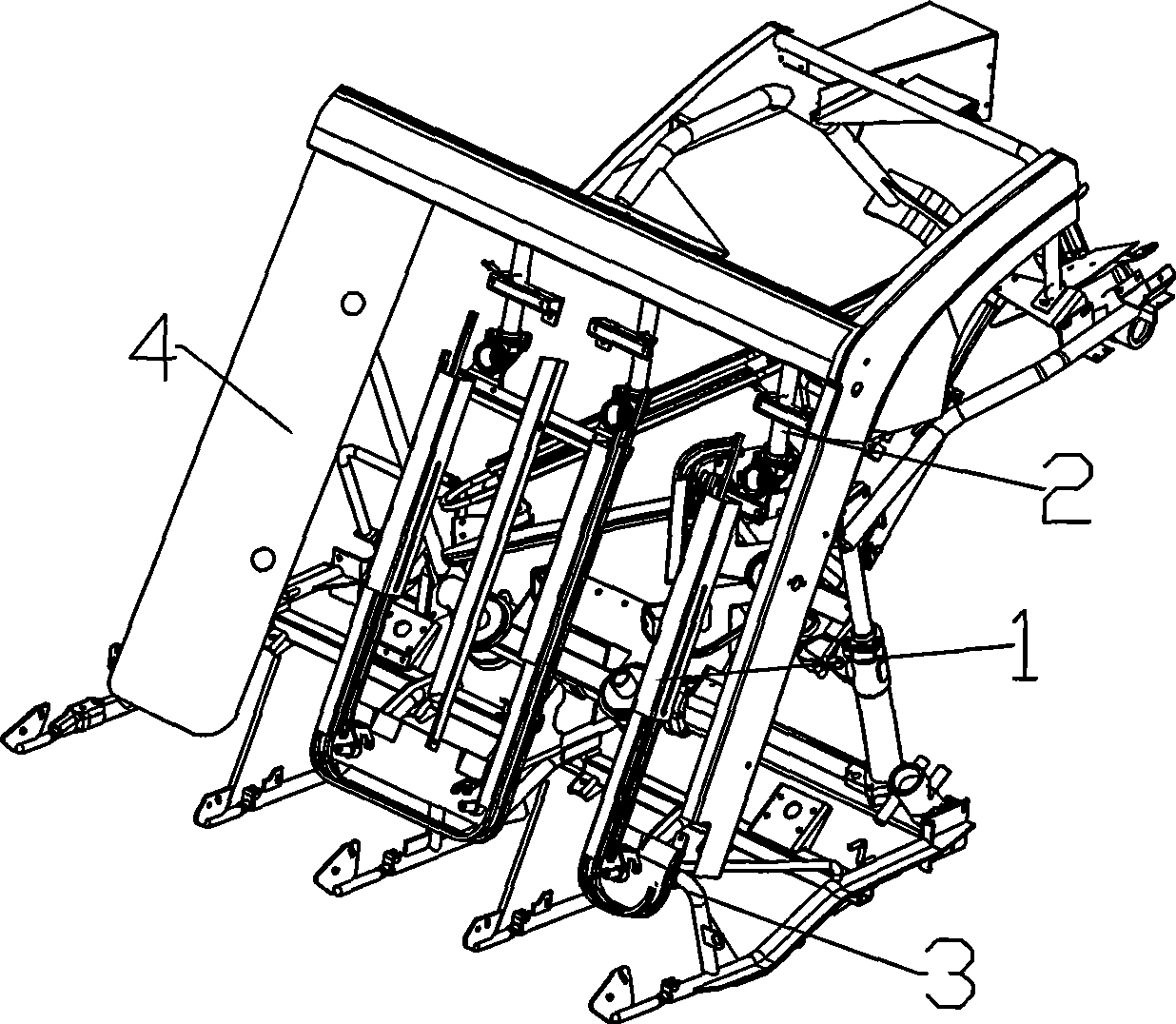

ActiveCN102330651AExtended service lifeImprove reliabilityPositive displacement pump componentsPumpsEngineeringMechanical engineering

The invention discloses a pumping system which comprises a power cylinder (1), a conveying cylinder (2), a support bracket (3), a piston rod (6) and a concrete piston (4), wherein the piston rod (6) is provided with a first oil duct (7), the concrete piston (4) is provided with a second oil duct (8) which is communicated with the first oil duct (7) and runs through the outer circumferential wall of the concrete piston (4); a lubricating oil tube (5) which is communicated with the first oil duct (7) and moves with the piston rod (6) is arranged on the piston rod (6) between a first vertical plate (31) of the support bracket (3) and a second vertical plate (32) of the support bracket (3). The structural design of the thick slurry pump can enable the concrete piston (4) to be lubricated by the lubricating oil in the conveying cylinder (2) in the whole moving process, thus the lubricant reliability can be improved and then the service life of the concrete piston (4) and the conveying cylinder (2) can be improved. Besides, the invention also discloses a thick slurry pump with the pumping system.

Owner:SANY AUTOMOBILE MFG CO LTD

Self-lubricated speed-doubling chain

InactiveCN103016614AImprove wear resistanceAvoid dry rubbingDriving chainsAgricultural engineeringWear resistance

The invention discloses a self-lubricated speed-doubling chain, which comprises an outer chain plate, an inner chain plate and a pin shaft. The outer chain plate is arranged on the inner side of the inner chain plate; the pin shaft horizontally penetrates through the inner chain plate and the outer chain plate and is fixed on the outer side of the outer chain plate; the outer side of the pin shaft is provided with a large roller, and two sides of the large roller are respectively provided with a small roller; two sleeves are arranged between the large roller and the pin shaft and are mutually contacted; the outer sidewalls of the other ends of the sleeves are contacted with the inner chain plate; and the sum of the length of the two sleeves is equal to the distance between two symmetric inner side faces of the outer chain plate. When the self-lubricated speed-doubling chain is used, dry friction caused by direct contact between the pin shaft and the inner chain plate can be avoided, and the wear resistance of the pin shaft can be improved. Moreover, since the sum of the length of the two sleeves is equal to the distance between the two symmetric inner side faces of the outer chain plate, the smoothness of a chain framework can be conveniently ensured, direct contact between the outer chain plate and the inner chain plate can be avoided, and the service life of the chain can be greatly prolonged.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

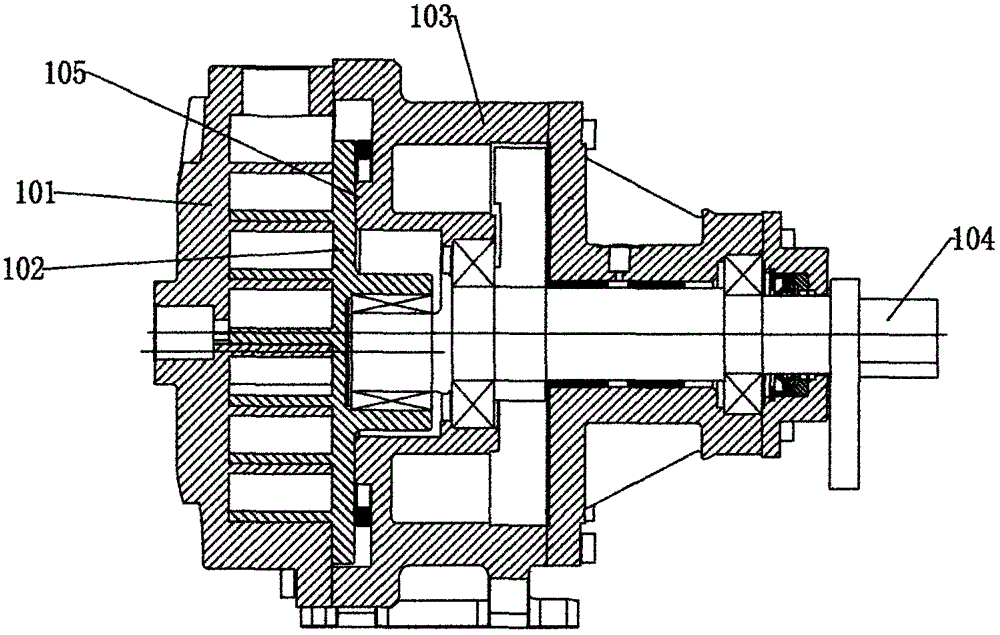

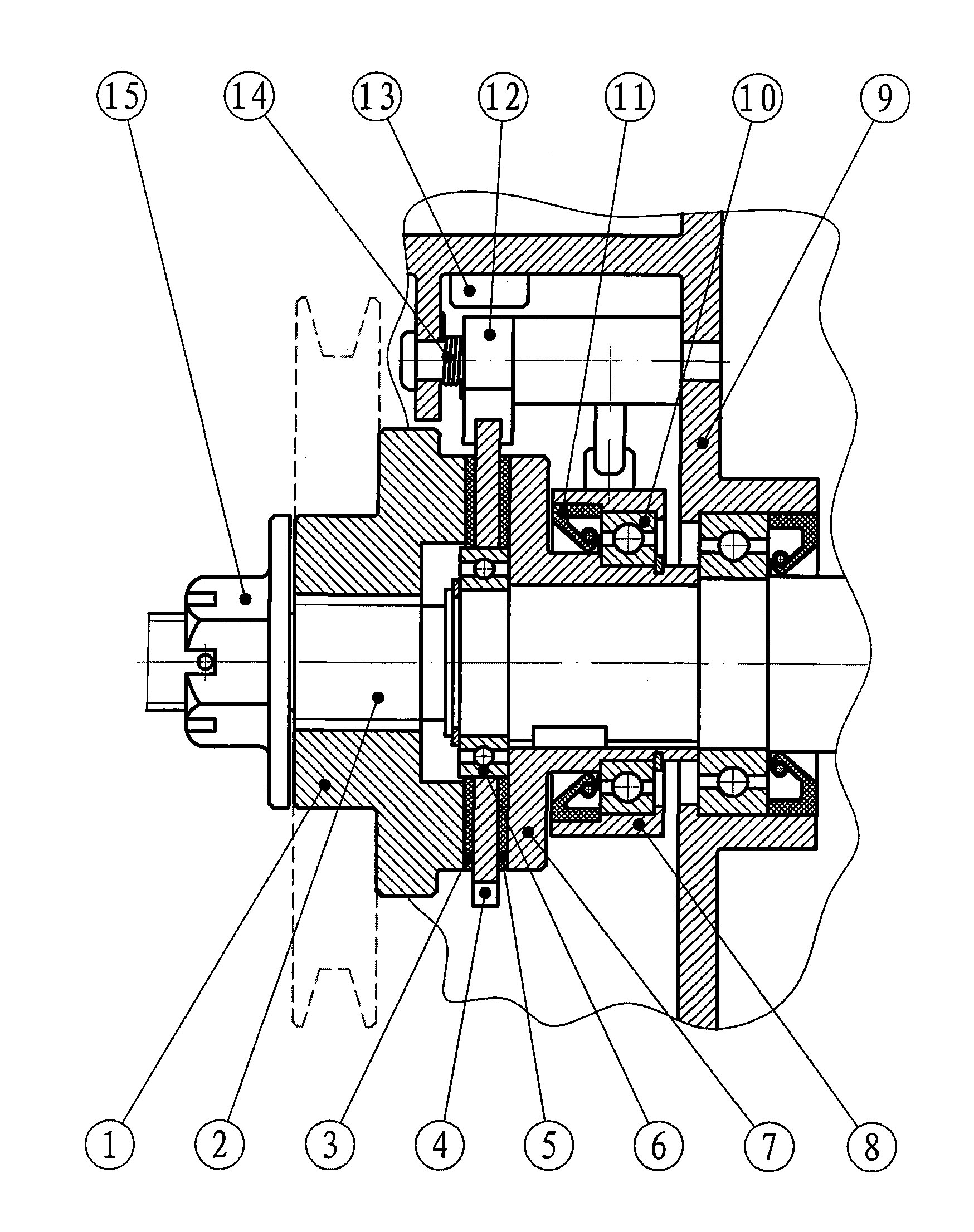

Turbocharger bearing body structure with integral ball bearing

PendingCN107524480ASimple structureEasy to assembleMachines/enginesEngine componentsBall bearingTurbocharger

The invention discloses a turbocharger bearing body structure with an integral ball bearing. The turbocharger bearing body structure comprises a bearing body, the integral ball bearing, a positioning pin and an oil inlet bolt; the integral ball bearing is arranged in a bearing hole of the bearing body; the upper end of the positioning pin is arranged in a pin hole A of the bearing body; the lower end of the positioning pin is inserted into a pin hole B of an outer ring of the integral ball bearing so as to fixedly connect the outer ring of the integral ball bearing with the bearing body; the lower end of the oil inlet bolt is connected to an inner threaded hole of the bearing body in a threaded mode; and the upper end of the oil inlet bolt is located outside the bearing body. Compared with the prior art which adopts the structure of two floating bearings, the turbocharger bearing body structure has the advantages that only one single integral ball bearing is adopted in the inner hole of the bearing body, and therefore the structure can be simpler, and the assembly can be more convenient; and an annular oil storage cavity is formed among the lower end surface of the oil inlet bolt, the outer wall of the positioning pin and the hole wall of a stepped hole, and therefore the problem that lubricating oil supply lags when an engine is started can be solved, and dry friction of the integral ball bearing in the initial rotation process can be avoided.

Owner:HUNAN TYEN MACHINERY

Linear bearing with oil storage cabins

The invention discloses a linear bearing with oil storage cabins. The linear bearing comprises an outer ring, a ball arranged in the outer ring and a retaining rack. The circular oil storage cabins with oil storage cavities are separately arranged at two ends of the outer ring, clamping mechanisms detachably connected to the outer ring are arranged on the sides, opposite to the outer ring, of theoil storage cavities, the oil storage cabins are formed in the sides, far away from the outer ring, of the oil storage cabins, the oil storage cavities on the side deviated from the outer ring are infit clamping to seal rings, and when the oil storage cabins are matched with the seal rings, an oil via hole is formed in the direction of center of circle, toward the oil storage cabins, of the oil storage cavities in a conducting manner. By arranging the oil storage cabins, the oil storage capability of the bearing is improved and the linear bearing is convenient to detach and mount.

Owner:宁波美亚特精密传动部件有限公司

Host structure of sliding-vane air compressor

PendingCN108980039AFit tightlyImprove sealingSealing arrangement for pumpsRotary piston pumpsLinear compressorPulp and paper industry

The invention discloses an enhanced sealing structure for a sliding-vane air compressor with a simple structure and a good sealing effect. The enhanced sealing structure comprises a rotor arranged ina cylinder block, wherein the cylinder block is taken as a stator; bearing seats are arranged on both sides of the cylinder block; a plurality of sliding chutes are uniformly formed in the middle of the rotor; two sliding vanes are arranged in the sliding chutes matched with the sliding vanes in a sliding way; the two ends of the rotor are rotationally arranged in the bearing seats through slidingbearings respectively; an oil inlet and a main oil inlet passage are formed in the cylinder block; a plurality of oil inlet small passages are uniformly formed in the cylinder block between the mainoil inlet passage and the sliding vanes; lubricating oil is injected directly into the cylinder block through the plurality of oil inlet small passages, so that an oil film layer is formed between therotor and the sliding vanes as well as between the two sliding vanes; the two ends of the main oil inlet passage are provided with sliding bearing lubricating oil supply passages formed in the bearing seats respectively.

Owner:盐城中德劲博机电有限公司

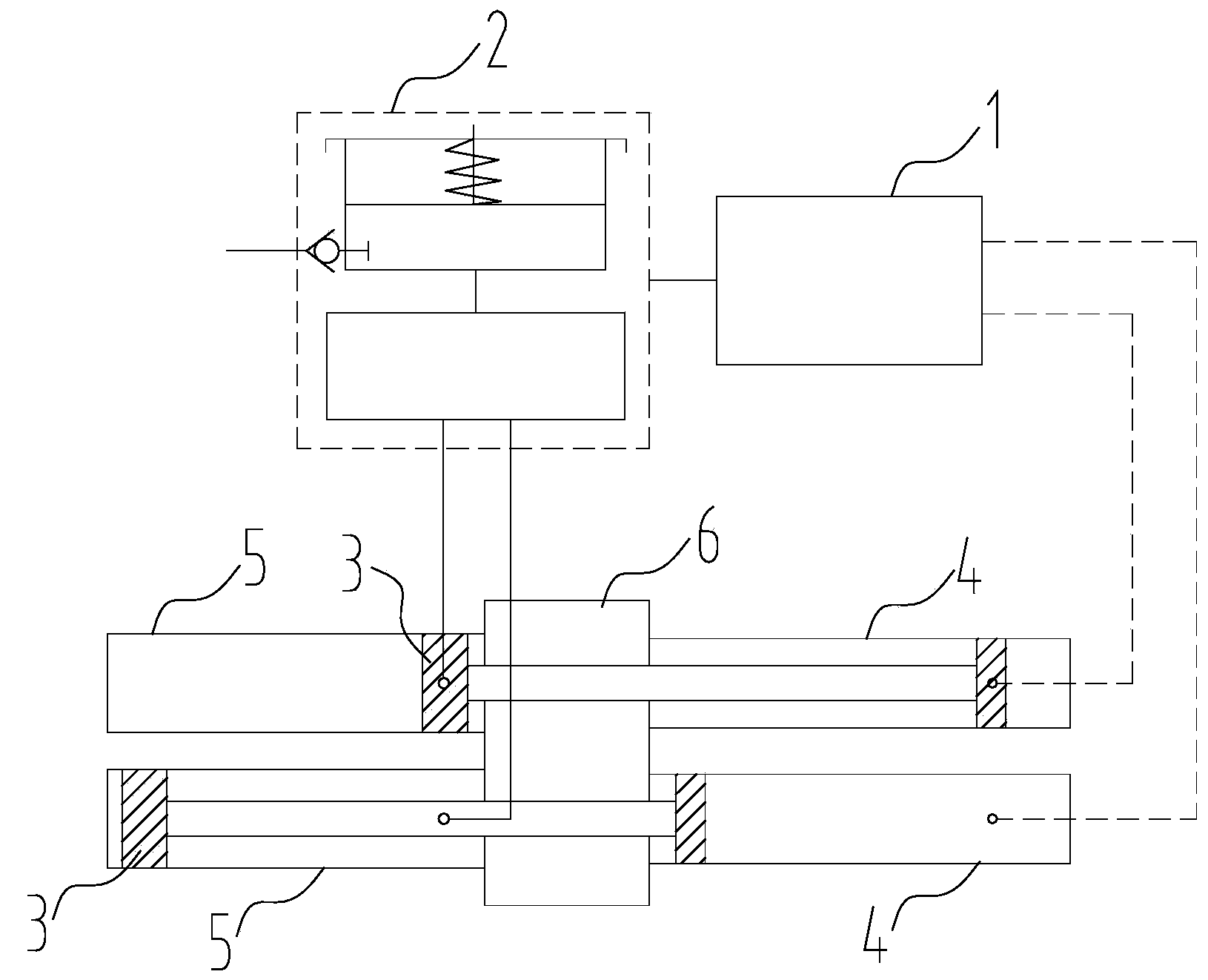

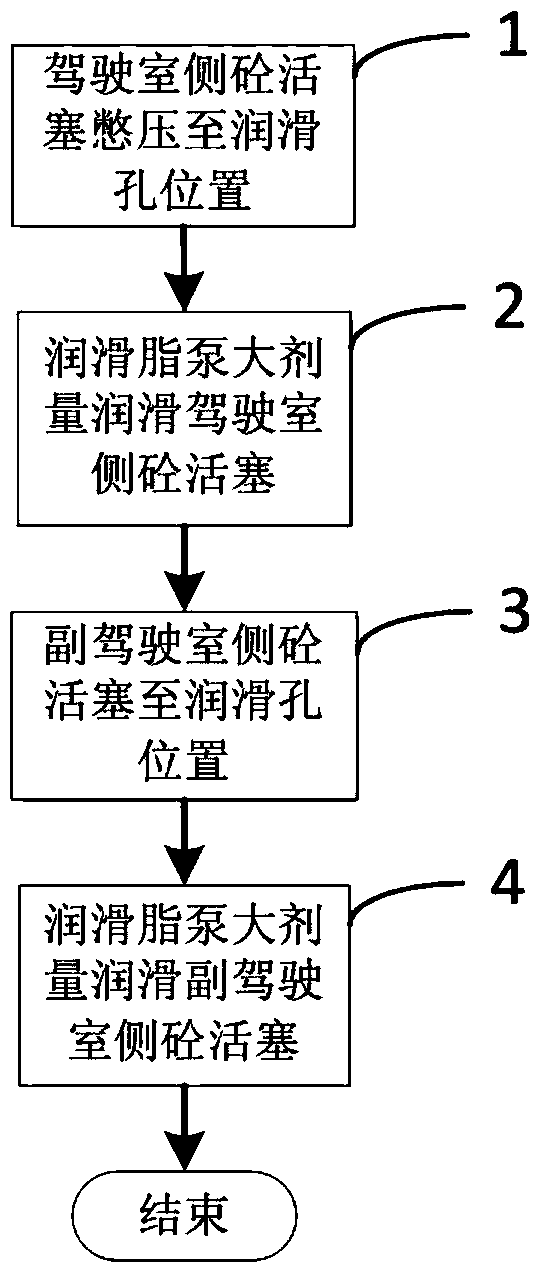

Concrete pump and concrete piston lubricating system thereof

ActiveCN103967772APrevent flow to one sidePrevent the situationPositive displacement pump componentsPumpsStructural engineeringConcrete pump

The invention discloses a concrete pump and a concrete piston lubricating system of the concrete pump. The concrete piston lubricating system comprises a position detection device, a control device and a lubricant distribution device. The position detection device is used for detecting the position of a concrete piston. The control device is connected with the position detection device and the lubricant distribution device. The lubricant distribution device is connected with a lubricating hole corresponding to the concrete piston. In the process of lubrication, the control device controls a main oil cylinder to move to retract the concrete piston. After the position detection device detects that the concrete piston returns in place, the control device controls the lubricant distribution device to make lubricant flow to the lubricating hole, so that an oil groove of the concrete piston is filled with the lubricant. By the adoption of a concentrated lubrication mode, a large amount of lubricant can be injected into the concrete piston and the concrete piston lubricating system has the advantages of being good in lubricating effect, low in lubricating cost, small in environmental pollution and the like.

Owner:SANY AUTOMOBILE MFG CO LTD

Piston for cabin wall vibration air hammer

The invention discloses a piston for a cabin wall vibration air hammer. The piston for a cabin wall vibration air hammer comprises a piston head and a piston rod; the front end of the piston head is provide with a magnet groove; a magnet is arranged inside the magnet groove; the rear end of the piston head is connected with one end of the piston rod; the other end of the piston rod is provided with a spring groove; a spring is arranged inside the spring groove. According to the piston for the cabin wall vibration air hammer, timely reset during the piston movement process is guaranteed due to the magnet and further timely reset is guaranteed, meanwhile the piston plays a role in buffering during the piston operation process, and damage to the piston is reduced due to the spring which is arranged inside the spring groove. The piston for the cabin wall vibration air hammer is simple in structure and strong in practicability and can be applied to the cabin wall vibration air hammer.

Owner:PUYANG YALI MACHINERY MFG

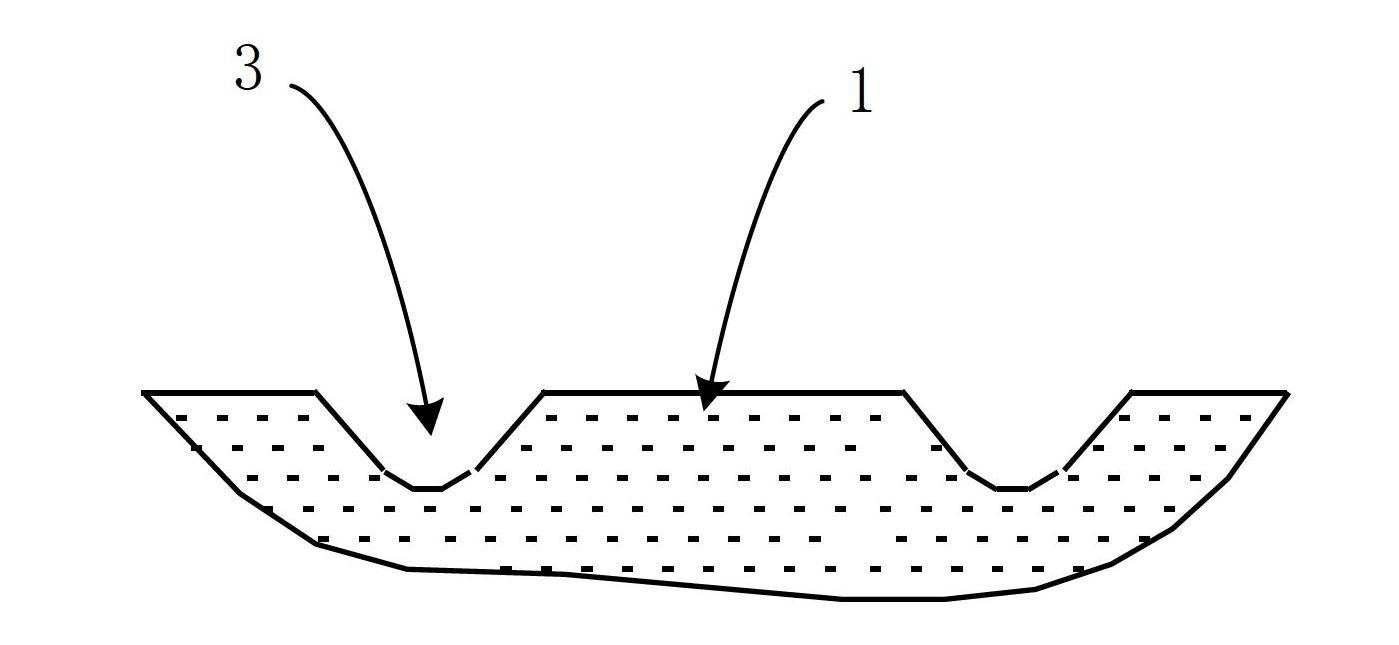

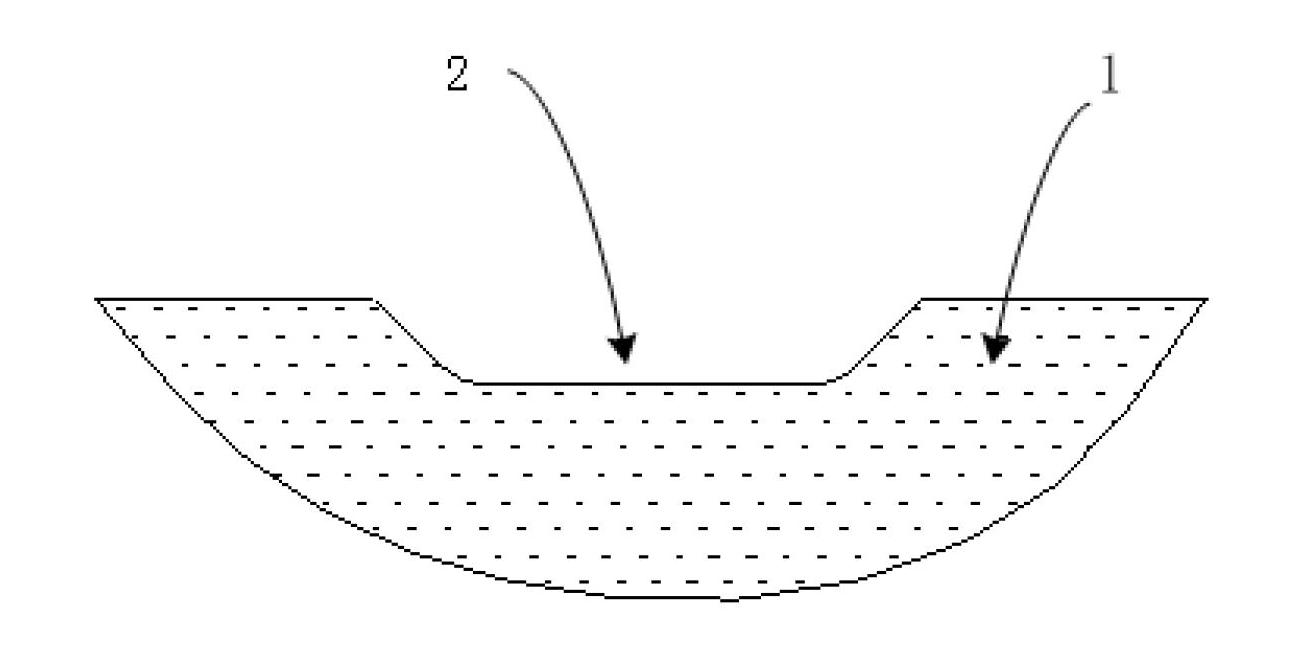

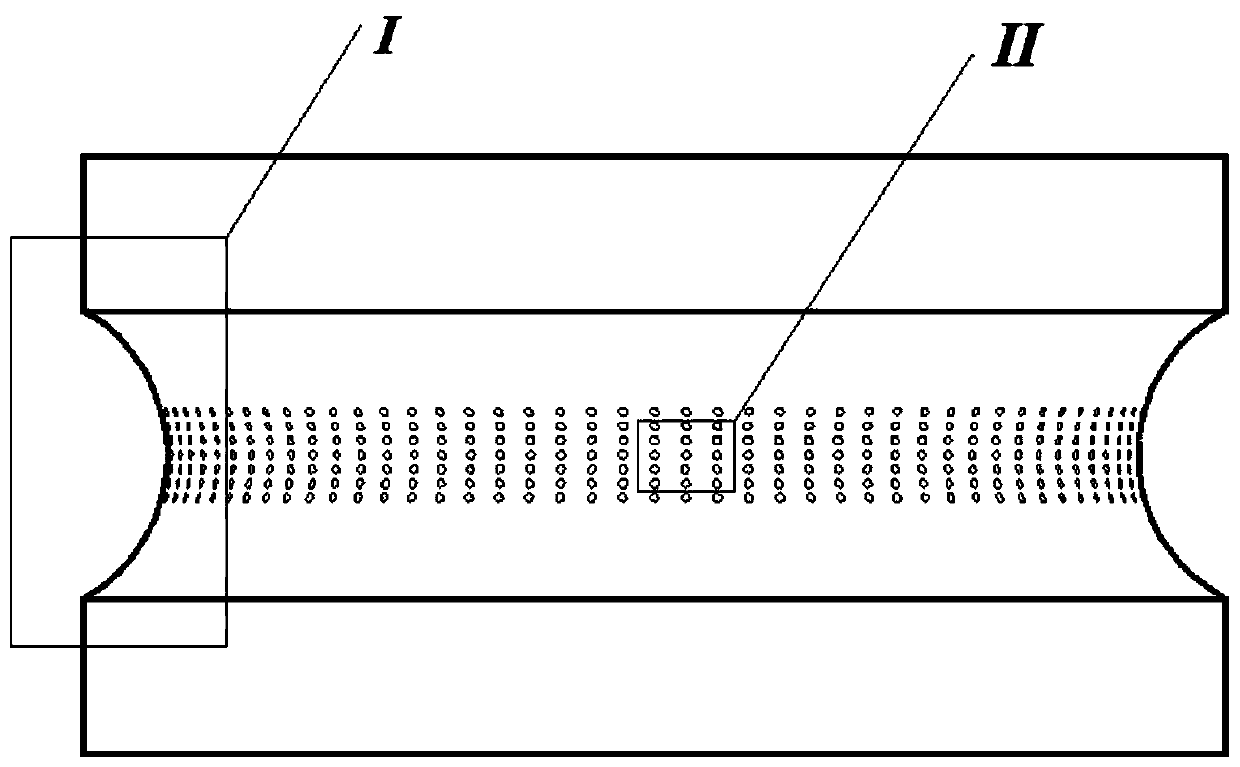

Rolling bearing inner ring raceway and rolling bearing

ActiveCN110645264AImprove lubrication conditionsGuaranteed stabilityBall bearingsBearing componentsThermodynamicsRolling-element bearing

The invention provides a rolling bearing inner ring raceway and a rolling bearing. A dynamic lubrication texture is arranged in the central area of the raceway surface of a rolling bearing inner ring,and the dynamic lubrication texture is used for separating the raceway surface from the surface of a rolling body so as to avoid generating of dry friction; the side edge area of the raceway surfaceis provided with an oil storage texture, and the side edge area of the raceway surface is a symmetrical area on the two sides of the central area of the raceway surface and is used for forming a continuous oil film under high load; and an oil distribution texture is arranged on the raceway surface, partially overlapped with the dynamic lubrication texture and the oil storage texture and used for enabling lubrication oil to move in the moving direction of the rolling body. The running stability and lubrication condition can be jointly improved through the dynamic lubrication texture, the oil storage texture and the oil distribution texture.

Owner:JIANGSU UNIV

Liquid mass double-tuned shock absorber and assembly method thereof

The invention discloses a liquid mass double-tuned shock absorber, which comprises a base, a top cover, a rubber-metal composite part and a ball screw inerter component. The inerter component comprises a screw bolt, and one end of the screw bolt penetrates a center hole of the top cover to extend upwards while the other end is positioned in a step hole of the base. A ball screw portion of the screw bolt is provided with a screw nut through a ball, a rotating flywheel and a rolling bearing externally sleeve the screw nut, the inner periphery of the rolling bearing and a convex shoulder of the rotating flywheel are positioned through a convex shoulder of the screw nut, and the outer periphery of the rolling bearing is mounted in the step hole of the base. The ball screw inerter component isdesigned in the rubber-metal composite part to form a parallel support effect along with the same, the compact structure is realized, and the ball screw inerter component has an excellent performanceof low-frequency vibration absorption and overcomes the defect of the poor performance of a rubber shock absorber in low-frequency vibration absorption.

Owner:JIANGSU UNIV OF SCI & TECH

Spiral load brake

The invention discloses a spiral load brake and relates to the field of hoisting and transporting machines. The spiral load brake comprises a machine body, a driving friction disk, a transmission shaft, a ratchet wheel, a pawl, two friction plates, a driven friction disk, a bearing, a resistance ring, a thumb wheel, a pawl return spring, a pawl limiting seat and an adjusting nut. The driving friction disk is assembled on a multi-head external thread of the transmission shaft; the driven friction disk and the transmission shaft are connected together; the ratchet wheel is mounted on the transmission shaft and between the driving friction disk and the driven friction disk, a bearing is assembled between the ratchet wheel and the transmission shaft, and the ratchet wheel is free sheathed on a housing of the bearing;and the two friction plates are respectively arranged on two sides of the ratchet wheel between the driving friction disk and the driven friction disk; the pawl is hinged with the machine body; the thumb wheel is mounted on the transmission shaft through the bearing, the resistance ring and the driven friction disk; the pawl return spring is clamped on the pawl; the pawl limiting seat is mounted on the machine body; and the adjusting nut is mounted on one side on the transmission shaft in which the driving friction disk is located. The spiral load brake has the advantages of energy conservation, high efficiency, good braking property and safety in use, and can be widely applied in the hoisting and transporting machines.

Owner:翟贵才

Blanking device

Owner:YANGZHOU HAICHUANG PLASTIC PROD

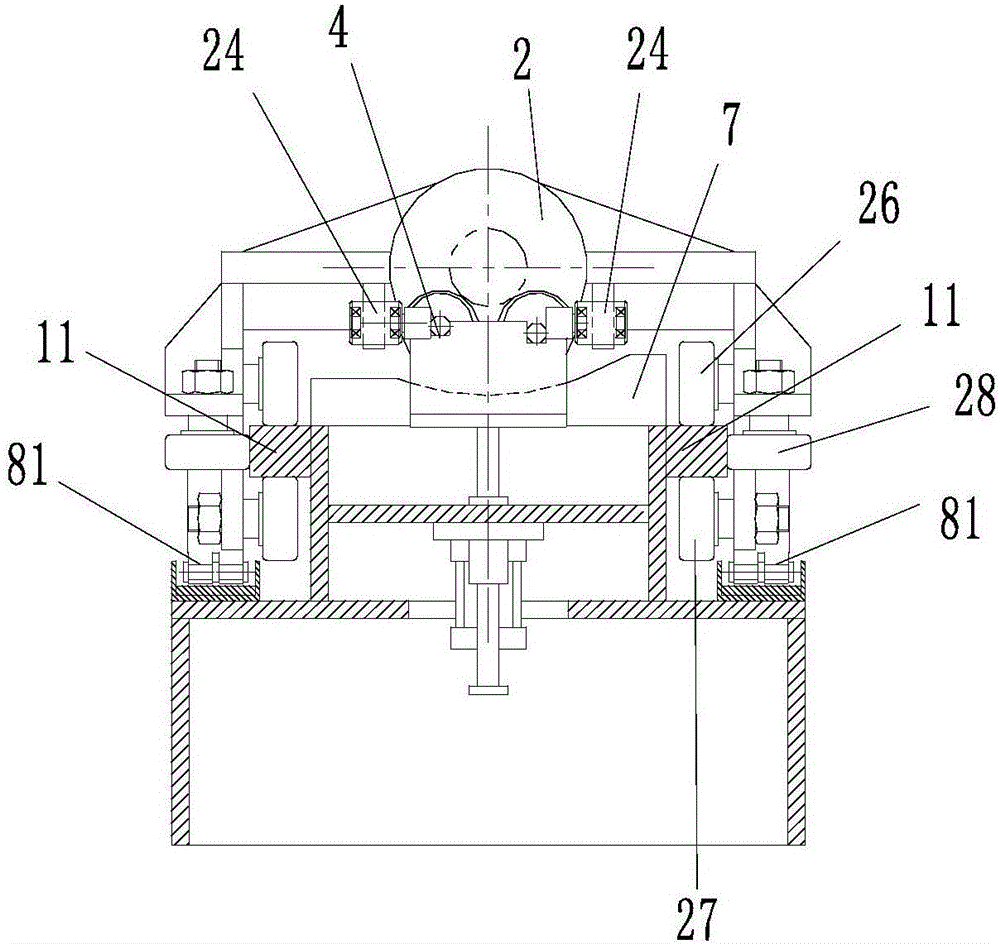

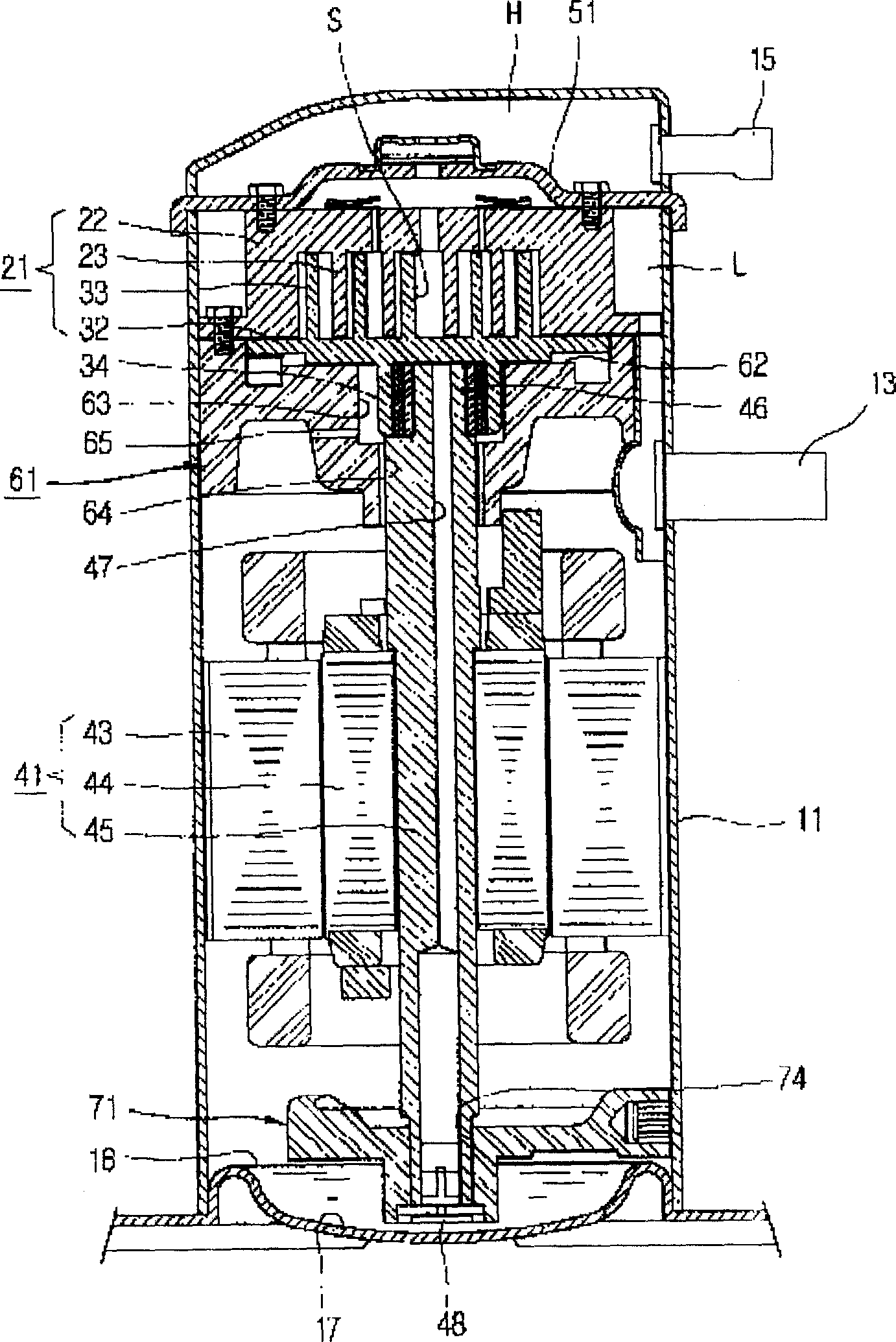

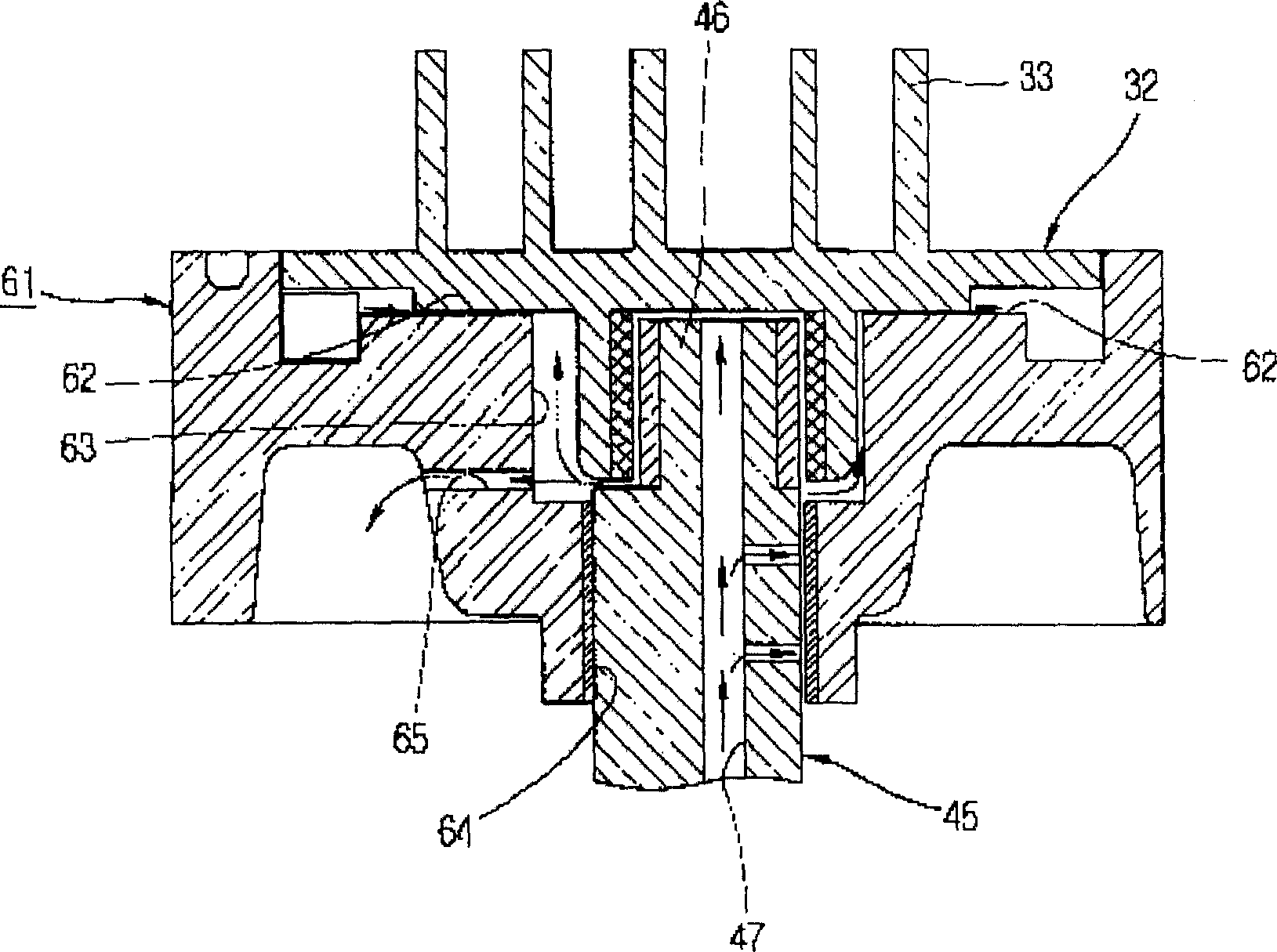

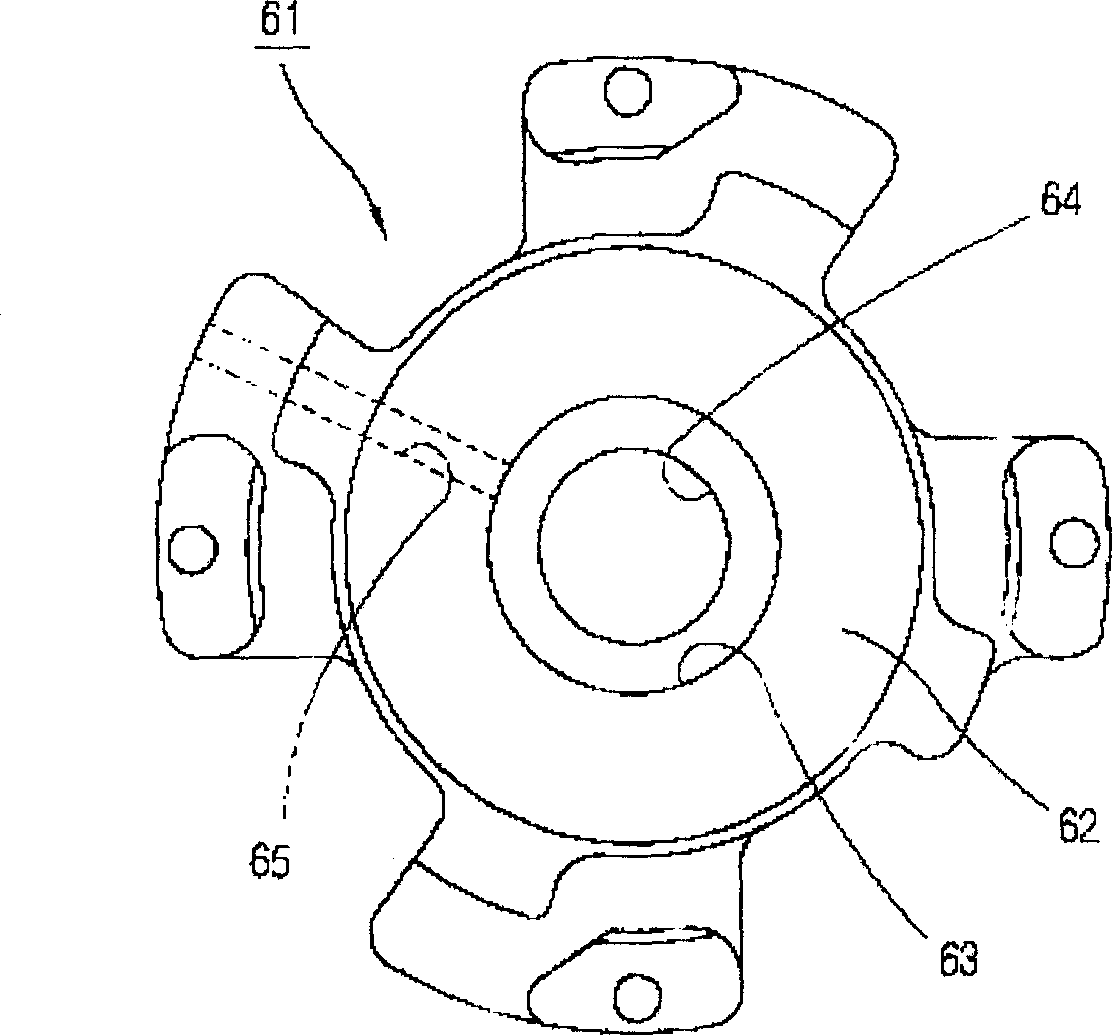

Screw compressor

InactiveCN1510302AAvoid dry rubbingExtend your lifeRotary piston pumpsRotary piston liquid enginesContact formationEngineering

A helical-lobe compressor is composed of a sealed casing, a static vortex disk with fixed involute wing, a moving vortex disk with rotary involute wing, and a main frame for supporting the moving vortex disk to do eccentrical movement and contacting with its bottom surface to form a bearing inserting surface. At least one of said bottom surface of moving vortex disk and said bearing inserting surface has an internal oil recepting part for preventing the dry friction between metallic parts.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

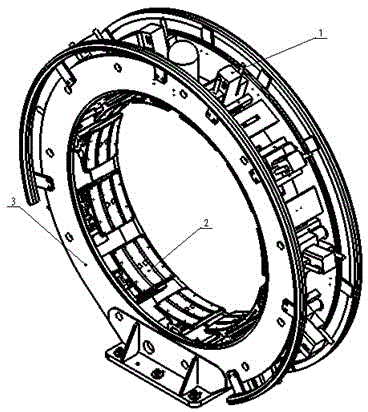

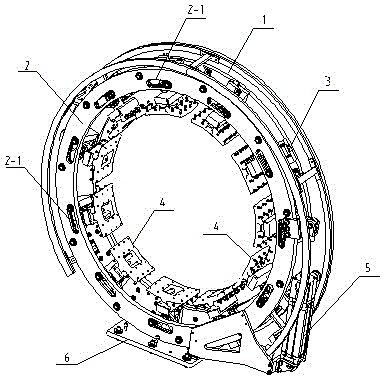

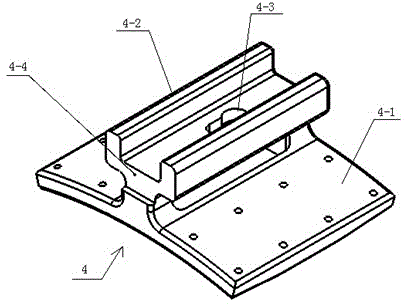

Belted layer transferring ring

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

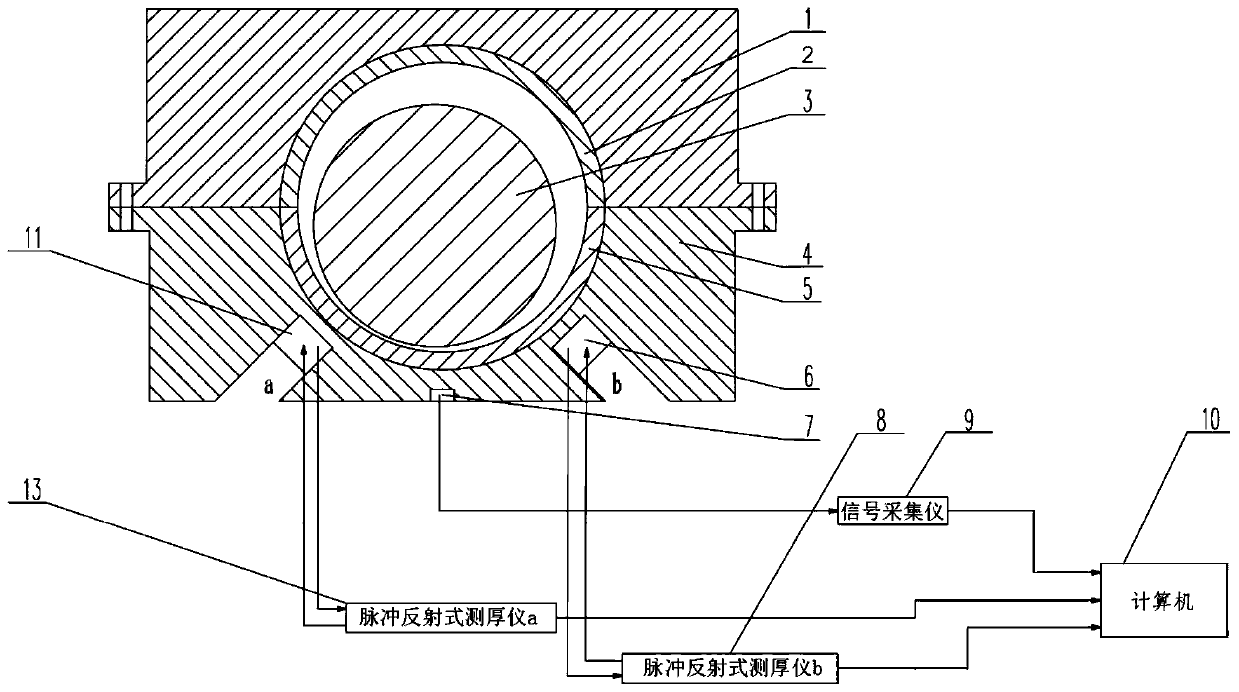

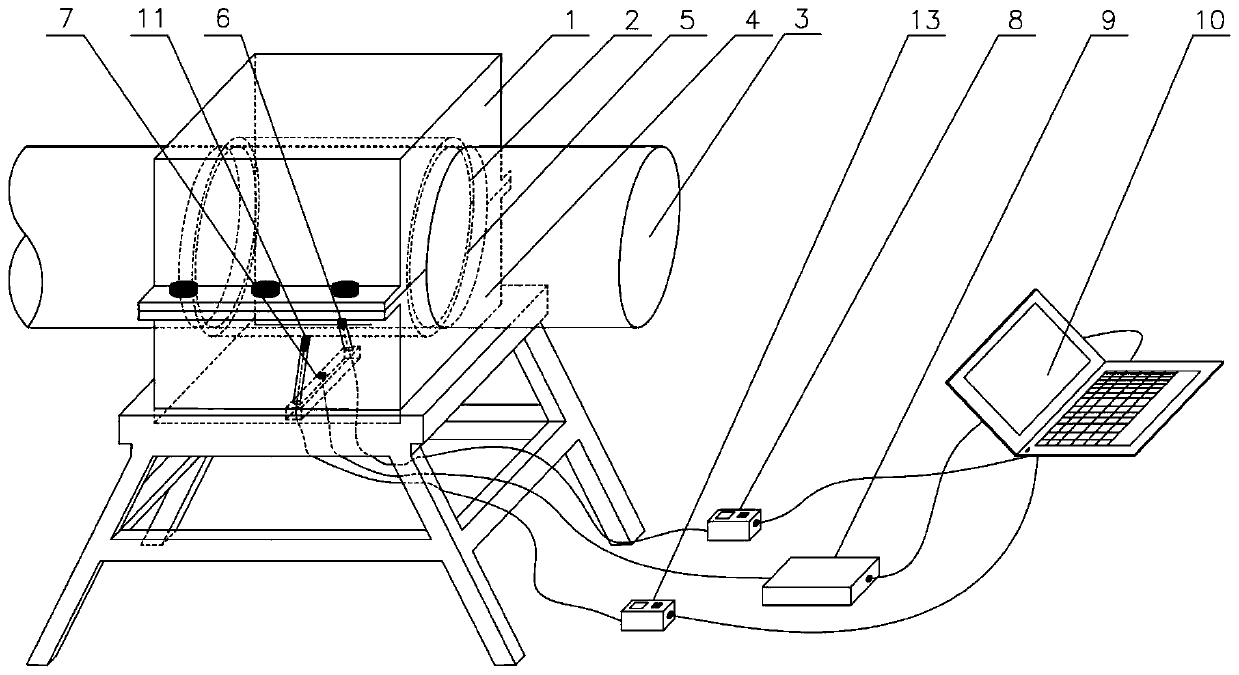

Lubricating wear state monitoring device and method for main bearing of diesel engine

InactiveCN111473750AAvoid dry rubbingSimple structureMachine part testingUsing subsonic/sonic/ultrasonic vibration meansMain bearingEngineering

The invention discloses a lubricating wear state monitoring device for a main bearing of a diesel engine. The device comprises an upper bearing bush, a lower bearing bush, a main bearing seat and a main bearing cover. A counter bore is formed in the center line of the main bearing cover, a blind hole a and a blind hole b are formed in the two sides of the center line at an included angle of 45 degrees respectively, and an ultrasonic sensor probe a is arranged in the blind hole a and sequentially connected with a pulse reflection type thickness gauge a and a computer through wires. An ultrasonic sensor probe b is arranged in the blind hole b. The ultrasonic sensor probe b is sequentially connected with a pulse reflection type thickness gauge b and a computer through wires. An acceleration sensor is arranged in the counter bore and is sequentially connected with a signal acquisition instrument and a computer through leads. The device is simple in structure and easy to install and operate. The lubricating state of the main bearing can be monitored in real time, the abrasion degree of the main bearing is obtained, safe operation of a diesel engine is guaranteed, and maintenance time and labor cost are saved.

Owner:JIANGSU UNIV OF SCI & TECH

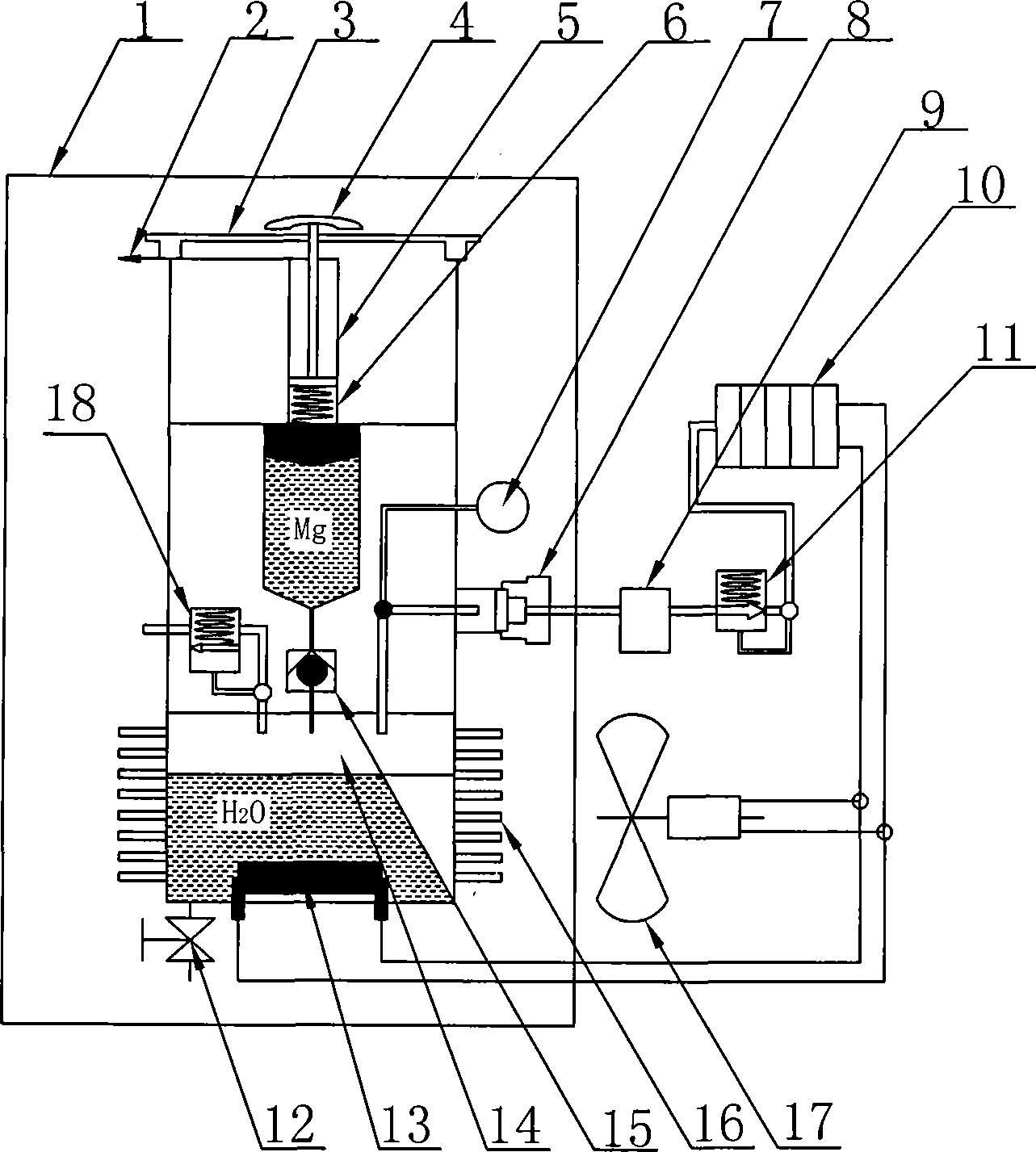

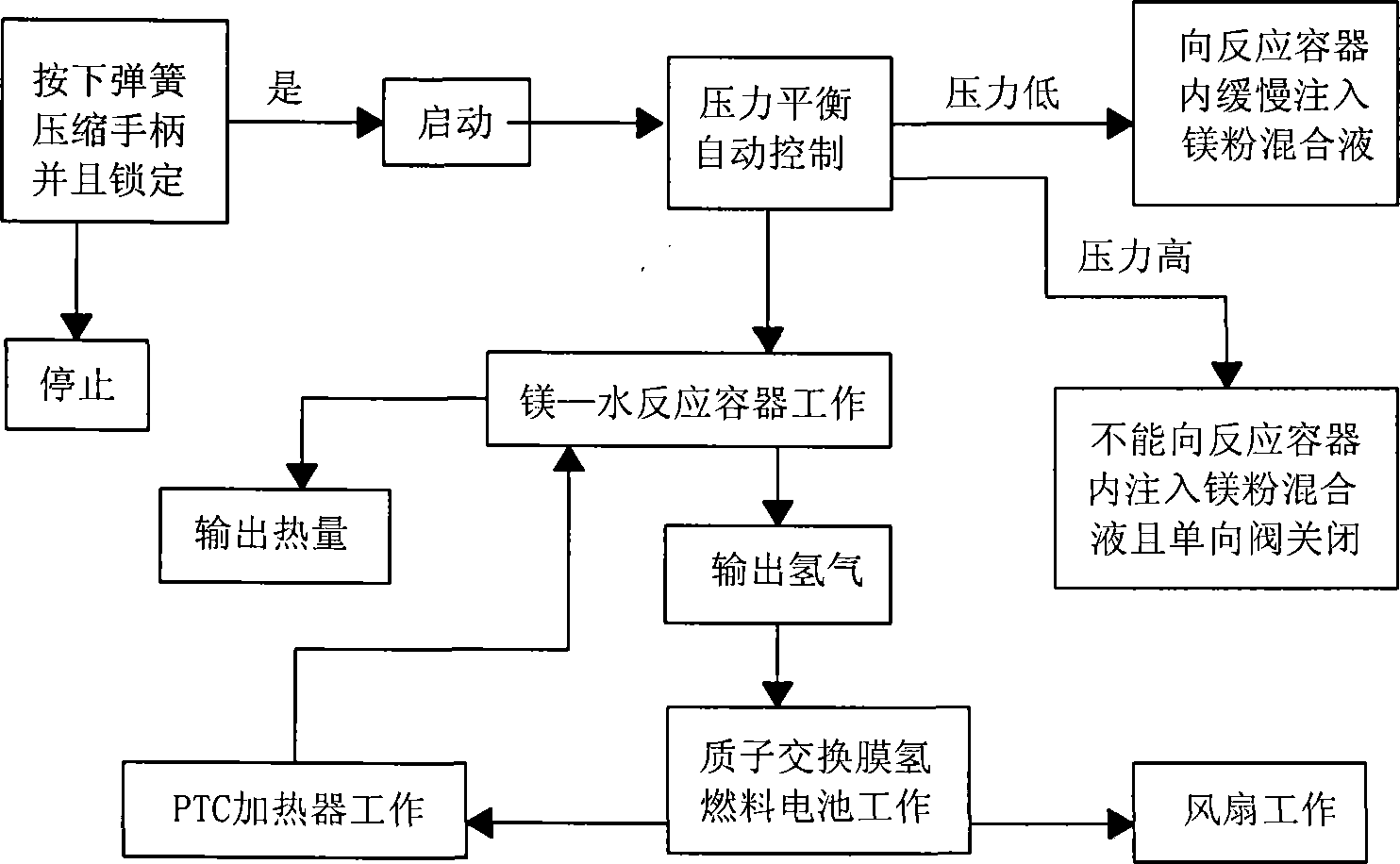

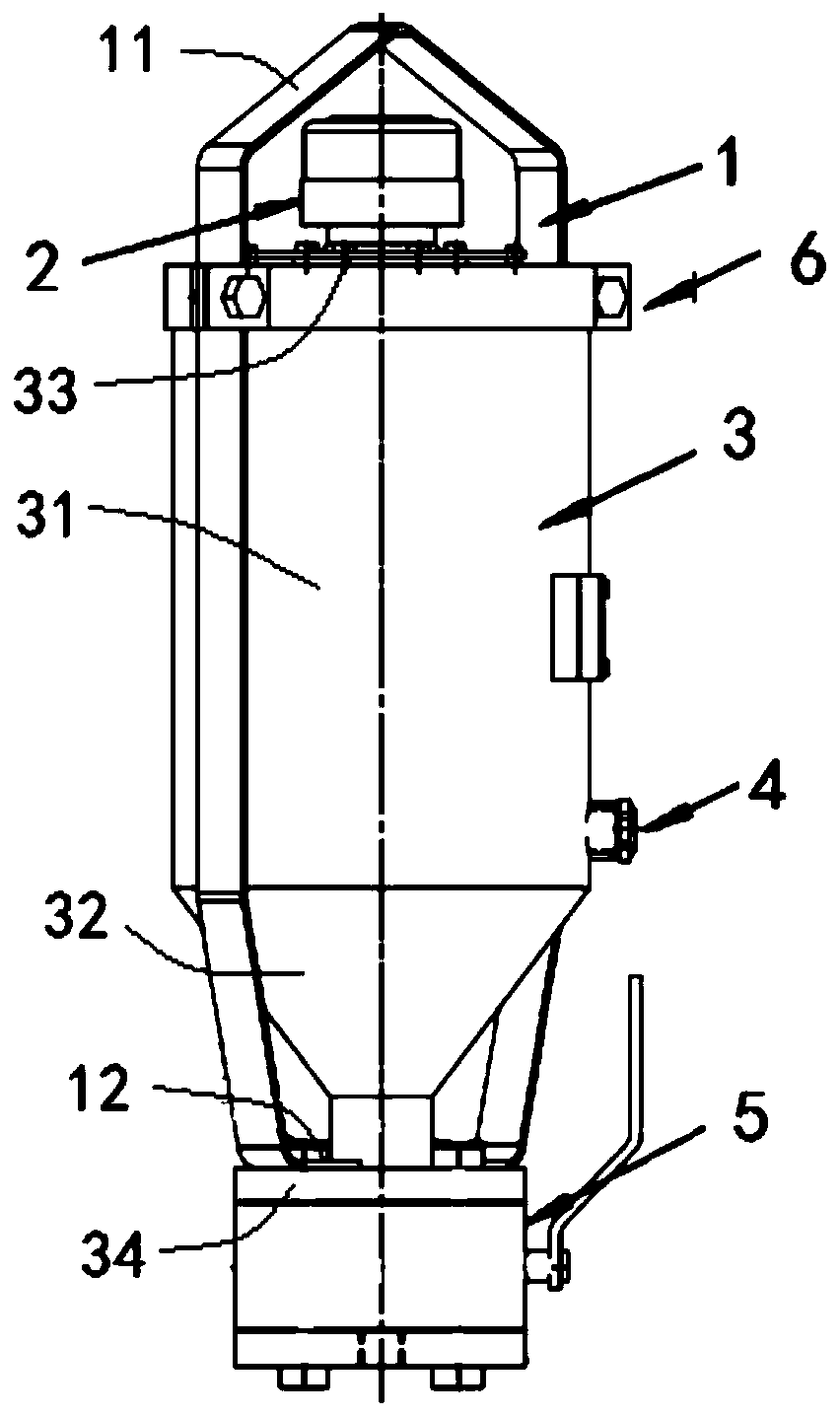

Magnesium-water heating equipment and technology of all-electric automobile

InactiveCN104228522ASolve the problem that heating affects driving mileageEnergy saving and environmental protectionAir-treating devicesFuel cell auxillariesCar drivingHydrogen fuel cell

The invention discloses a magnesium-water heating equipment and technology of an all-electric automobile and belongs to the technical field heating equipment and technology of all-electric automobiles. Magnesium powder and an inert lubricant are mixed according to a proportion to form a thick suspended state magnesium powder liquid mixture; an injecting pump safely conveys the suspended state magnesium powder liquid mixture to a reaction container for reaction with water in the reaction container so as to produce hydrogen as required in a controllable, continuous and uniform-speed manner; a heat energy generated by the reaction between the magnesium powder and the water directly heats the automobile, the generated hydrogen is supplied to a proton exchange membrane hydrogen fuel cell for power generation, and the electric energy sent out by the proton exchange membrane hydrogen fuel cell then drives a PTC (Positive Temperature Coefficient) heater for heating. The beneficial effects of the invention are that: the magnesium-water heating equipment and technology of the all-electric automobile have the advantages of being energy-saving, environment-friendly, simple and convenient in installation, safe to use, reliable in work, high in work efficiency, low in running cost, long in service life and the like; no pollutant discharge exists; the problem of influence from heating of current domestic all-electric automobile driving cab to travel distance is solved.

Owner:BEIJING HUATAI TIANCHENG TECH DEV

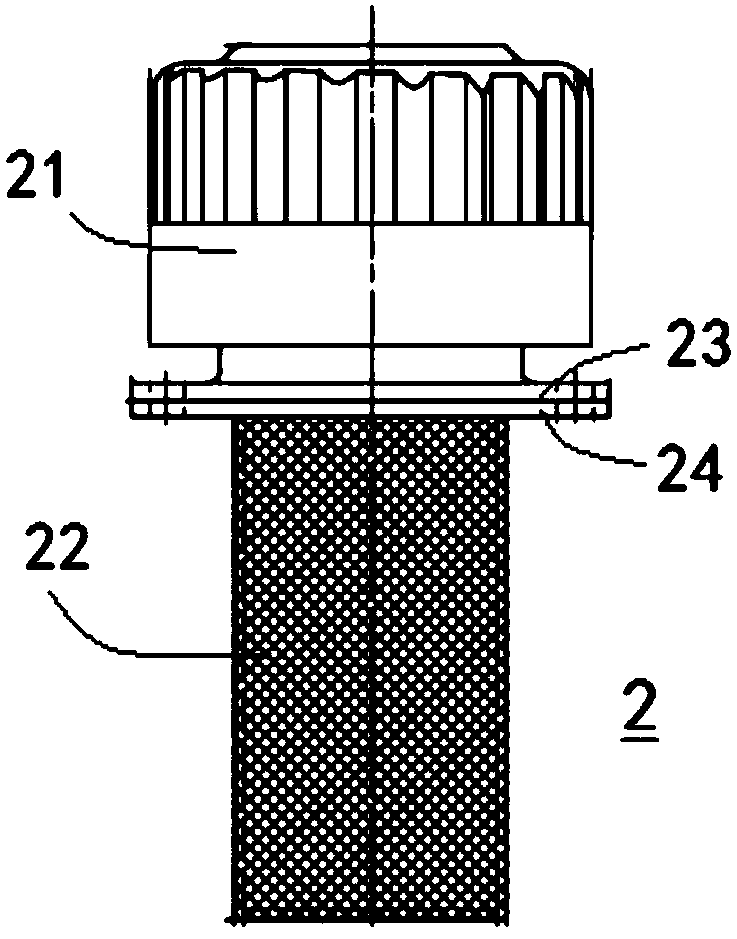

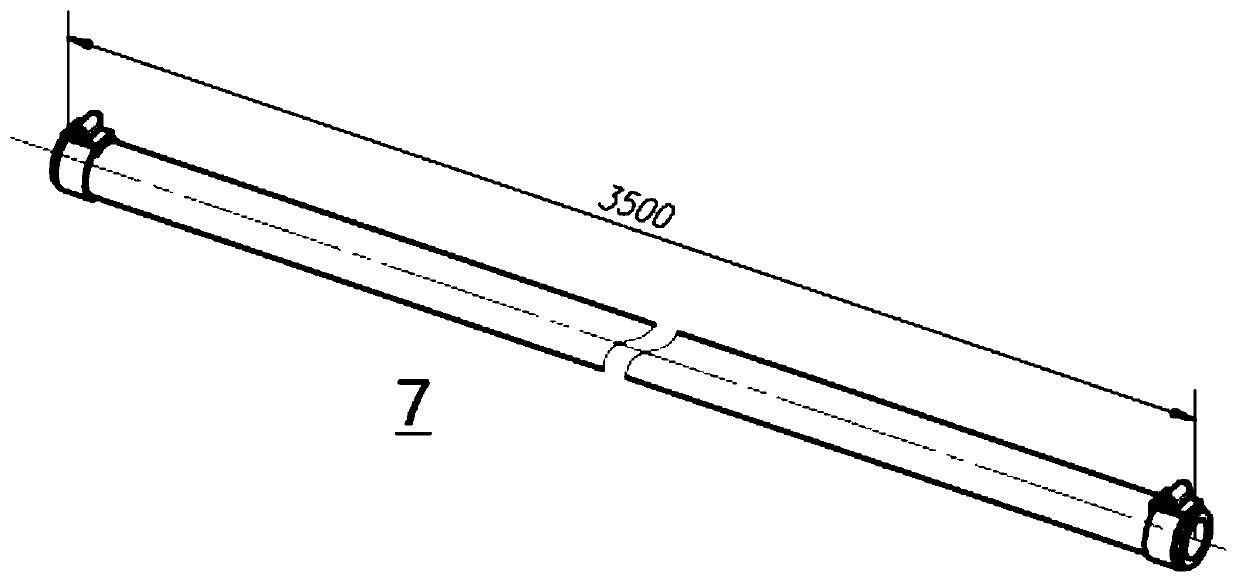

Oil supply and injection equipment for marine diesel engine

PendingCN110761871AAvoid dry rubbingAvoid wastingMachines/enginesLubricant filling/drainingBall valveInjection equipment

The invention discloses oil supply and injection equipment for a marine diesel engine. The oil supply and injection equipment comprises a bracket, an oil filter, a tank body, an observation window anda ball valve, wherein the tank body is a tapered structure which comprises an upper barrel body and a lower necking tube; the oil filter comprises a top cover and a filter screen; the top cover of the oil filter is covered by the bracket; the filter screen is inserted into the tank body from the top center of the tank body; the tank body is fixedly supported in the bracket; the ball valve is mounted on the lower part of the tank body; and the observation window is arranged on the peripheral wall of the barrel body of the tank body. The oil injection equipment can guarantee that enough lubricating oil can be injected into an oil supply unit motion part through simple gravitational potential energy action, guarantees the oil supply unit motion part to be lubricated sufficiently, avoids dryfriction, and avoids waste caused by lubricating oil leakage. The oil supply and injection equipment can be widely popularized to various lubricating fields of low-speed marine diesel engine main bearings, cam shaft bearings, and the like.

Owner:HUDONG HEAVY MACHINERY

Alarming type automatic control material-dripping machine

InactiveCN101157202AAvoid lostAvoid dry rubbingGrinding/polishing safety devicesAutomatic controlAgricultural engineering

The invention relates to a warning type automatic control drooling machine which comprises a base seat and a barrel installed on the base seat. The barrel is connected with the base seat though at least three spring devices; the spring device comprises an upper spring sleeve, a lower spring sleeve, and a compression spring; the upper spring sleeve is fixed and installed at the bottom of the spring device, the lower spring sleeve is fixed and installed on the base seat, the upper spring sleeve is sleeved with the lower spring sleeve, the compression spring is installed inside the upper spring sleeve and the lower spring sleeve, a warning switch is installed on the base seat, the lower end of the upper spring sleeve is matched with a triggering tip of the warning switch, and the warning switch is connected with a warner. The invention provides the warning type automatic control drooling machine which can warn automatically if the barrel volume is small.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com