Mechanical seal leakage rate online monitoring system

A technology of mechanical seal and monitoring system, applied in control/adjustment system, liquid level control, non-electric variable control and other directions, can solve the problems of seal failure, inability to realize automatic replenishment of blocking liquid, dry friction of sealing end face, etc., to avoid problems such as The effect of dry friction, improving reliability and reducing production loss of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

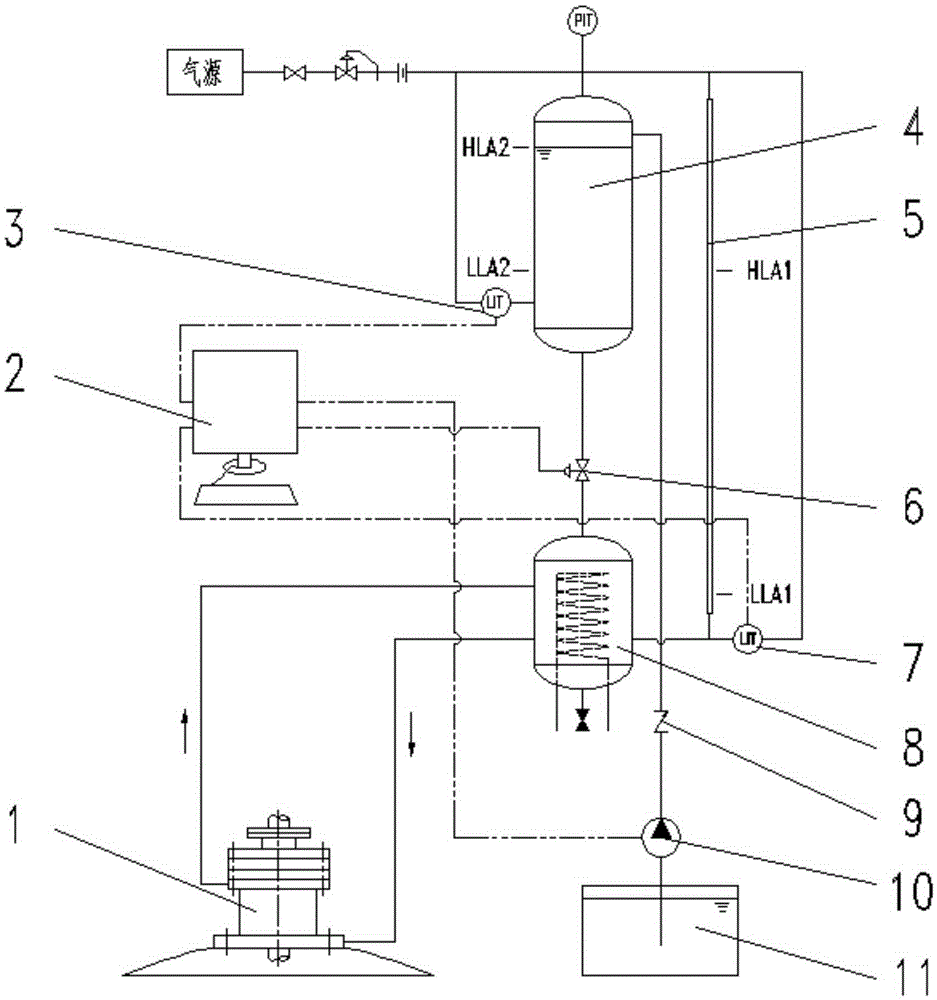

[0022] An on-line monitoring system for the leakage rate of a mechanical seal, comprising a leakage sensitive tube 5, a liquid replenishment tank 4, a circulation tank 8, a data processor 2, a liquid level transmitter 1 7, a liquid level transmitter 2 3, and an automatic control switch valve 6 , Rehydration pump 10, one-way valve 9, mechanical seal structure 1, water tank 11.

[0023] The connecting pipe at the bottom of the liquid replenishment tank 4 is connected to the top pipe of the circulating tank 8 through the automatic control switch valve 6, and the bottom of the liquid replenishing tank 4 is higher than the top of the circulating tank 8 at a certain height. There is a certain liquid level change space;

[0024] The leakage sensitive tube 5 is vertically installed, the lower end of the leakage sensitive tube 5 is connected with the side wall connection pipe of the circulation tank 8, and the upper end of the leakage sensitive tube 5 is connected with the gas pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com