Alarming type automatic control material-dripping machine

A technology of drop material and alarm switch, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of uneven feeding, troublesome cleaning, easy deposition, etc., to prolong the liquid supply time and avoid loss of workpieces , to avoid the effect of dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

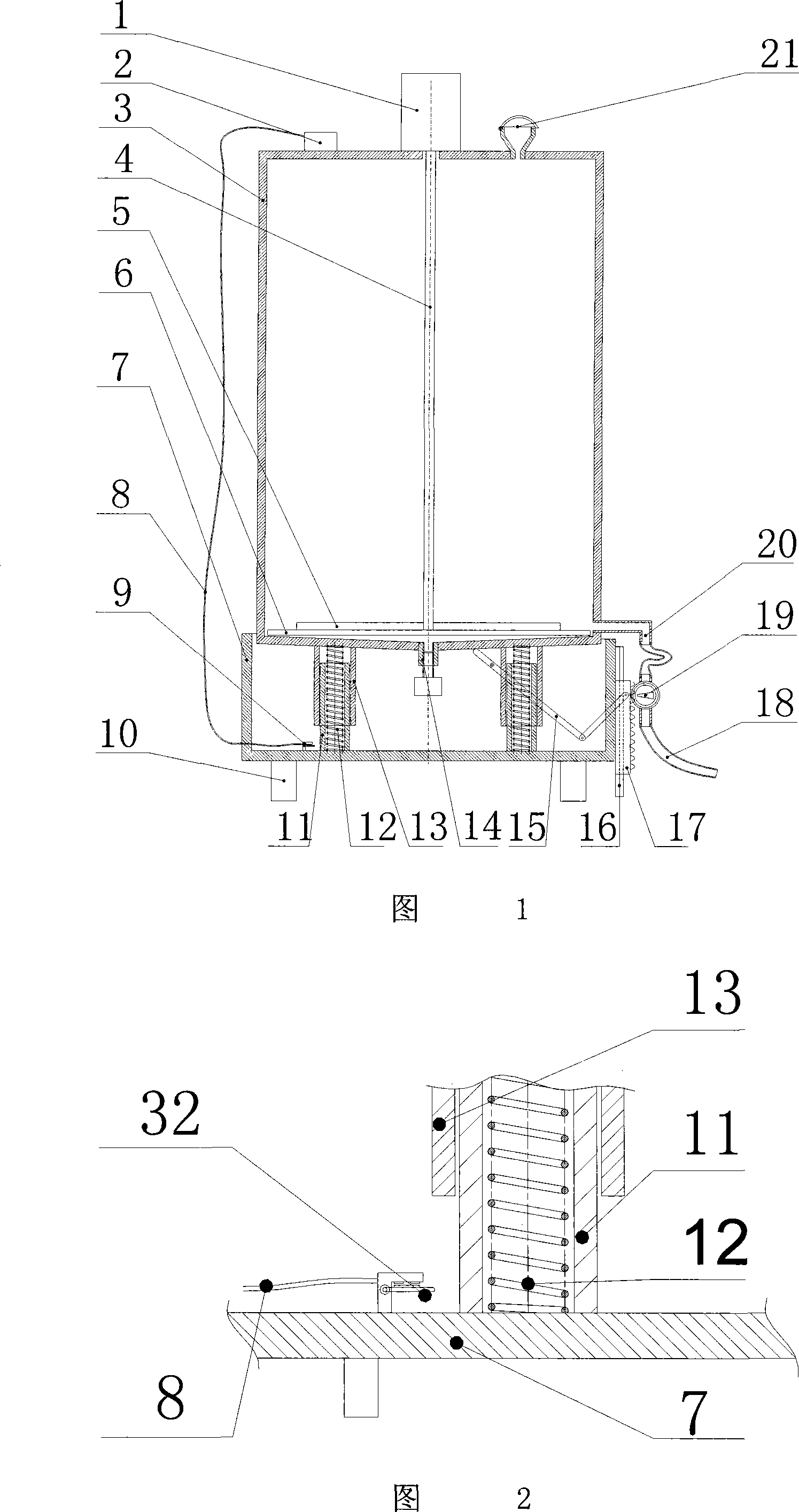

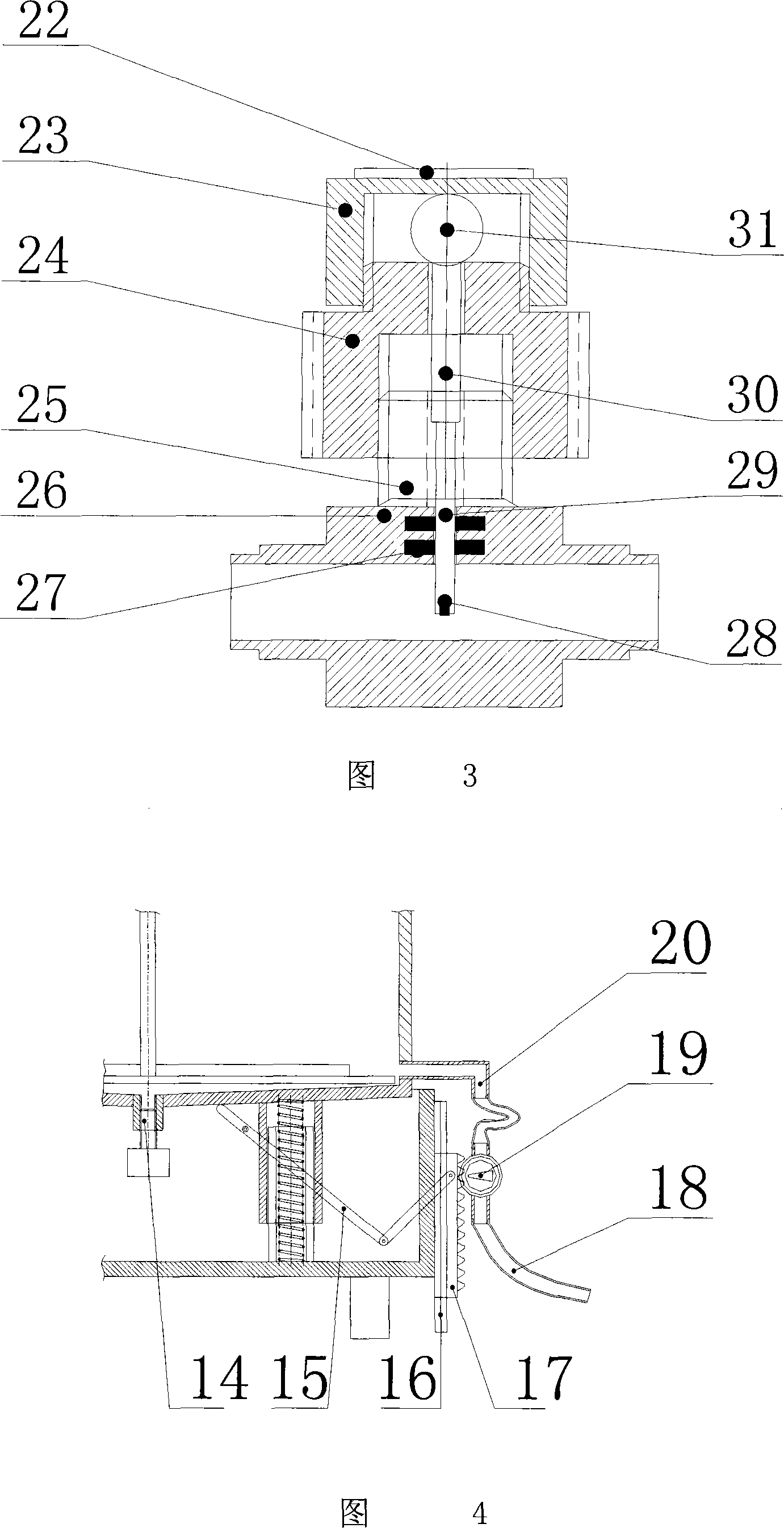

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Referring to Figures 1 to 4, an alarm-type automatic control dripping device includes a base 7 and a barrel 3 installed on the base 7. The barrel 3 is connected to the base 7 through at least three spring mechanisms, and the spring The mechanism includes an upper spring sleeve 13, a lower spring sleeve 11 and a compression spring 12. The upper spring sleeve 13 is fixedly installed on the bottom of the barrel 3, the lower spring sleeve 11 is fixedly installed on the base 7, and the upper spring sleeve 11 is fixedly installed on the upper The spring sleeve 13 is sleeved on the lower spring sleeve 11, the compression spring 12 is installed in the upper spring sleeve 13 and the lower spring sleeve 11, the alarm switch 9 is installed on the base 7, the upper spring sleeve The lower end of the barrel 13 cooperates with the trigger end 32 of the alarm switch 9 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com