Patents

Literature

272results about How to "High clamping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

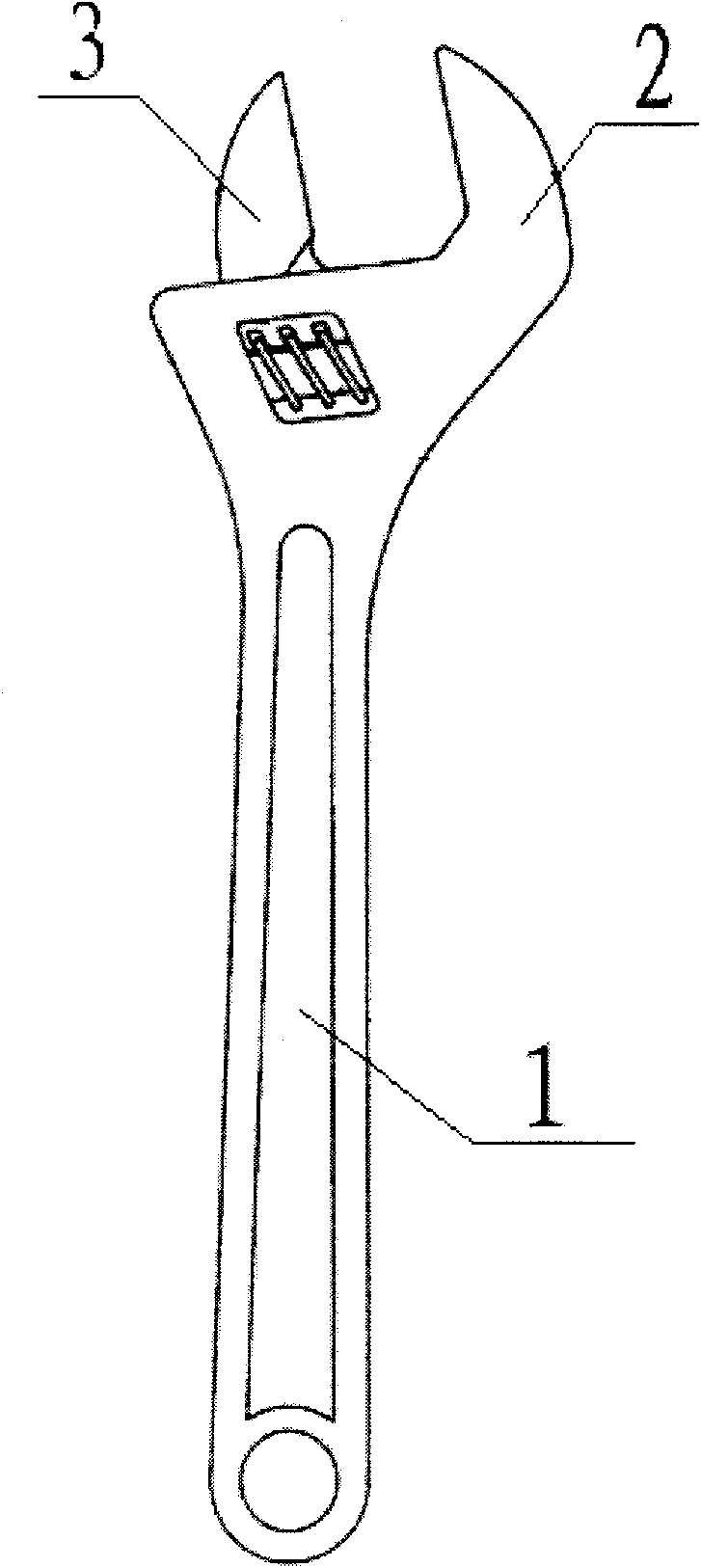

Movable spanner

Owner:鲁宏

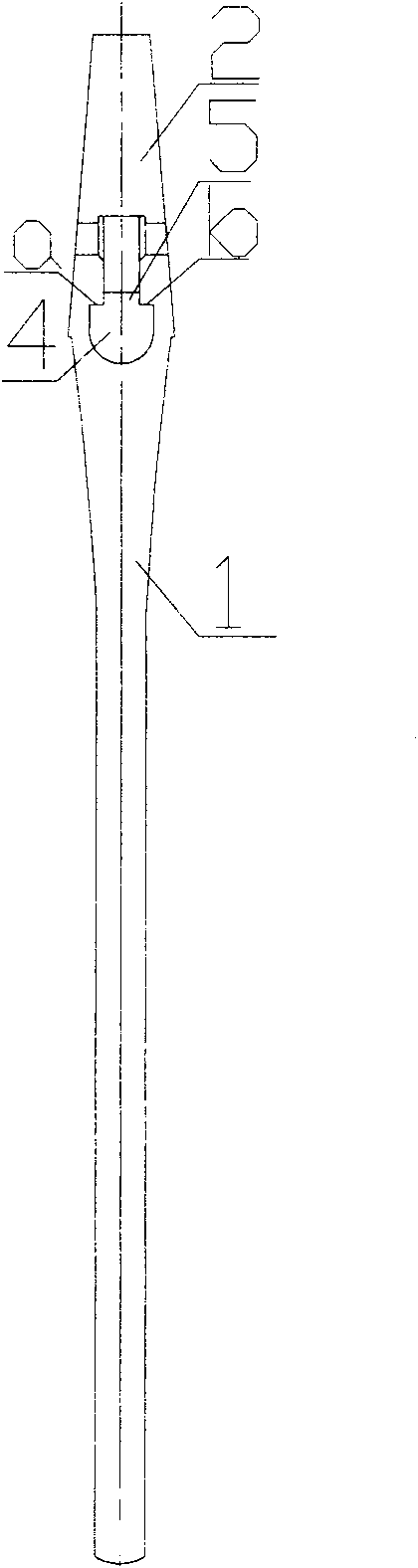

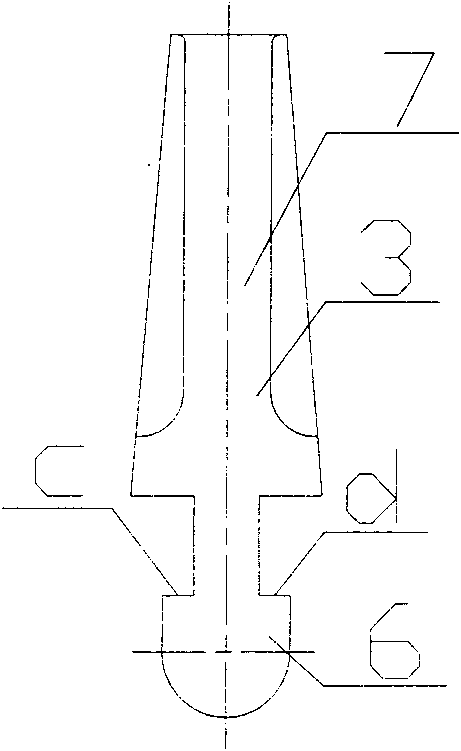

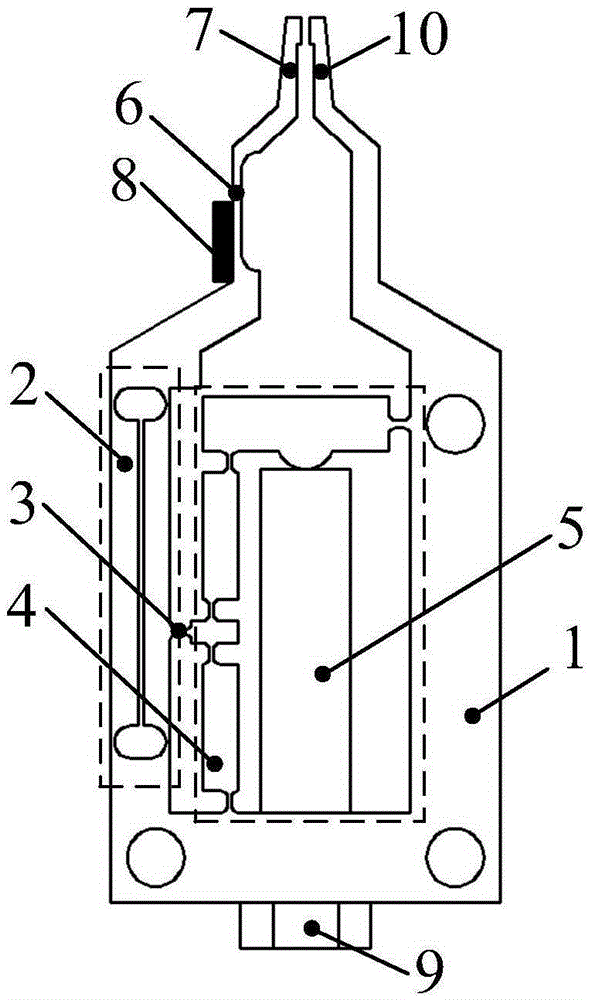

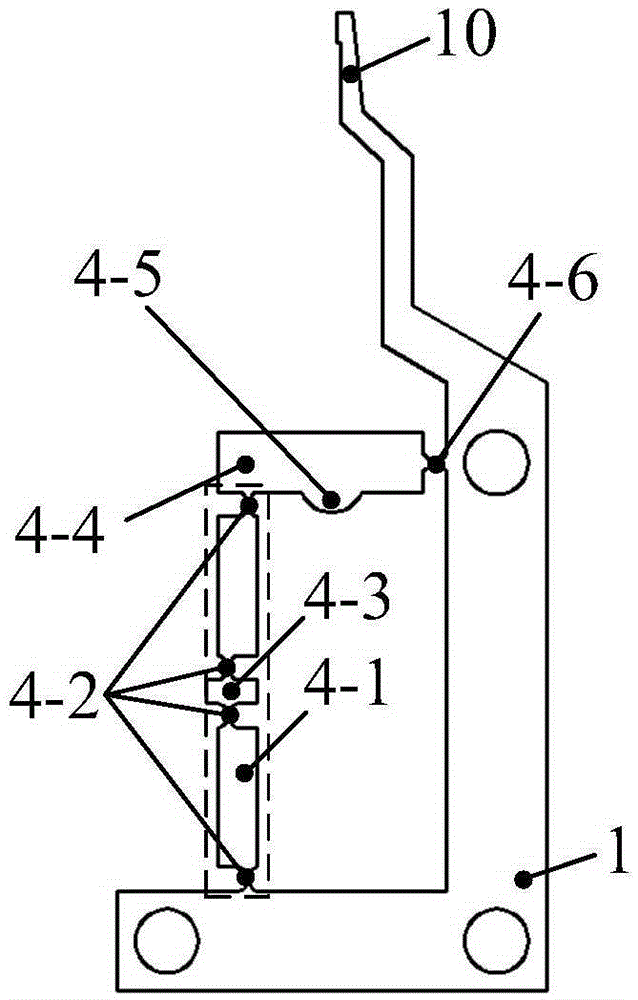

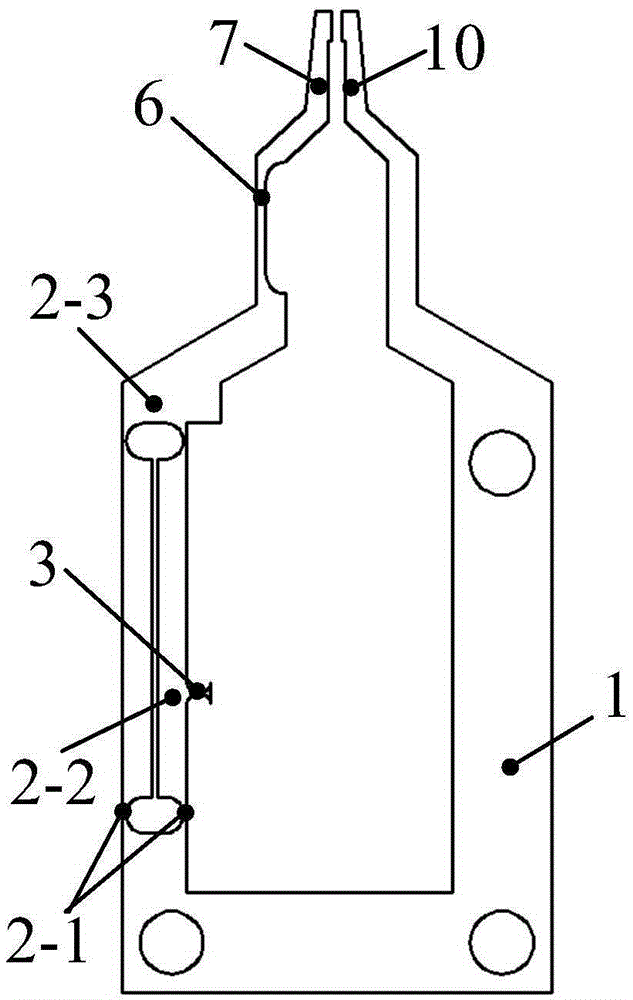

Medical portable syringe needle recoverer for clinical usage

ActiveCN107485765AEasy to useHigh degree of automationInfusion needlesSyringe needleBiomedical engineering

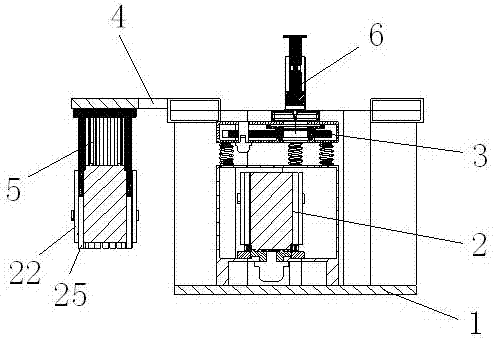

The invention discloses a medical portable syringe needle recoverer for clinical usage. The recoverer includes a splint device, a syringe needle pulling device and a syringe needle collecting device, wherein the splint device includes a rack base, two support plates symmetrically arranged above the rack base and two splint fixing mechanisms which are symmetrically and fixedly arranged on the inner sides of the upper portions of the two support plates respectively and used for fixing and clamping a needle cap in a syringe needle assembly; the rack base is successively provided with the syringe needle pulling device and the syringe needle collecting device which are positioned under the two splint fixing mechanisms from top to bottom, the syringe needle pulling device is used for clamping and pulling out a metal syringe needle fixedly inserted in the bottom of the needle cap, and the syringe needle collecting device is used for collecting the metal syringe needles pulled out by the syringe needle pulling device. The medical portable syringe needle recoverer for the clinical usage has the advantages of being small in overall occupied space, convenient to carry, high in automation degree, convenient to operate and use, environment-friendly and capable of well recovering the medical syringe needles alone.

Owner:李奇元

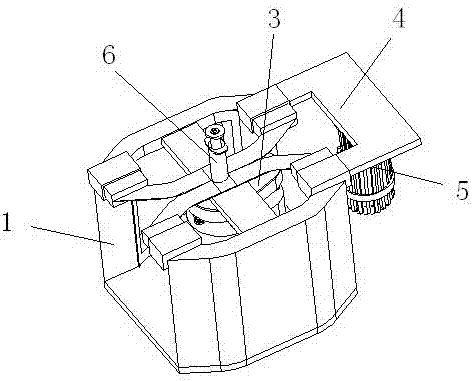

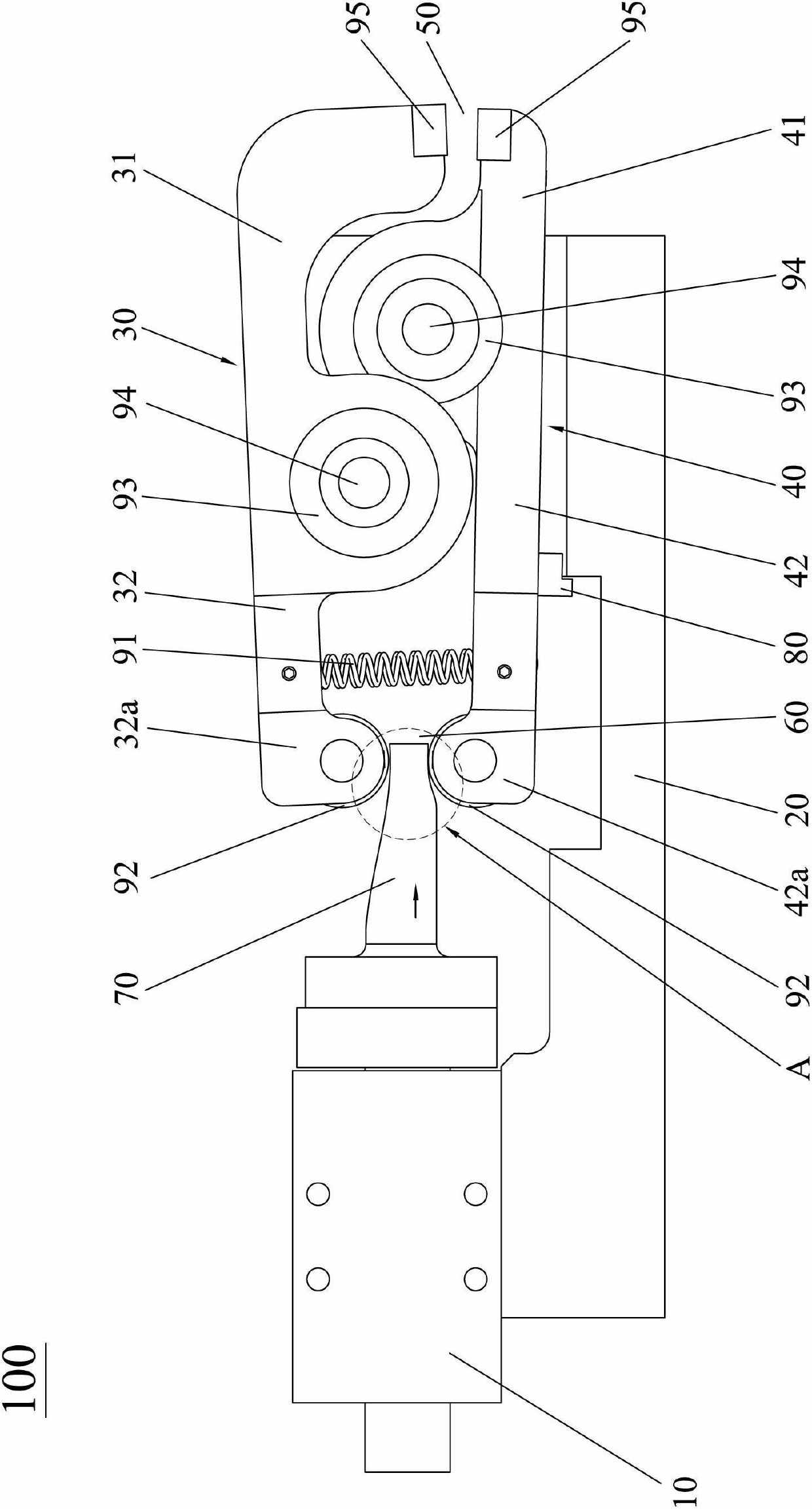

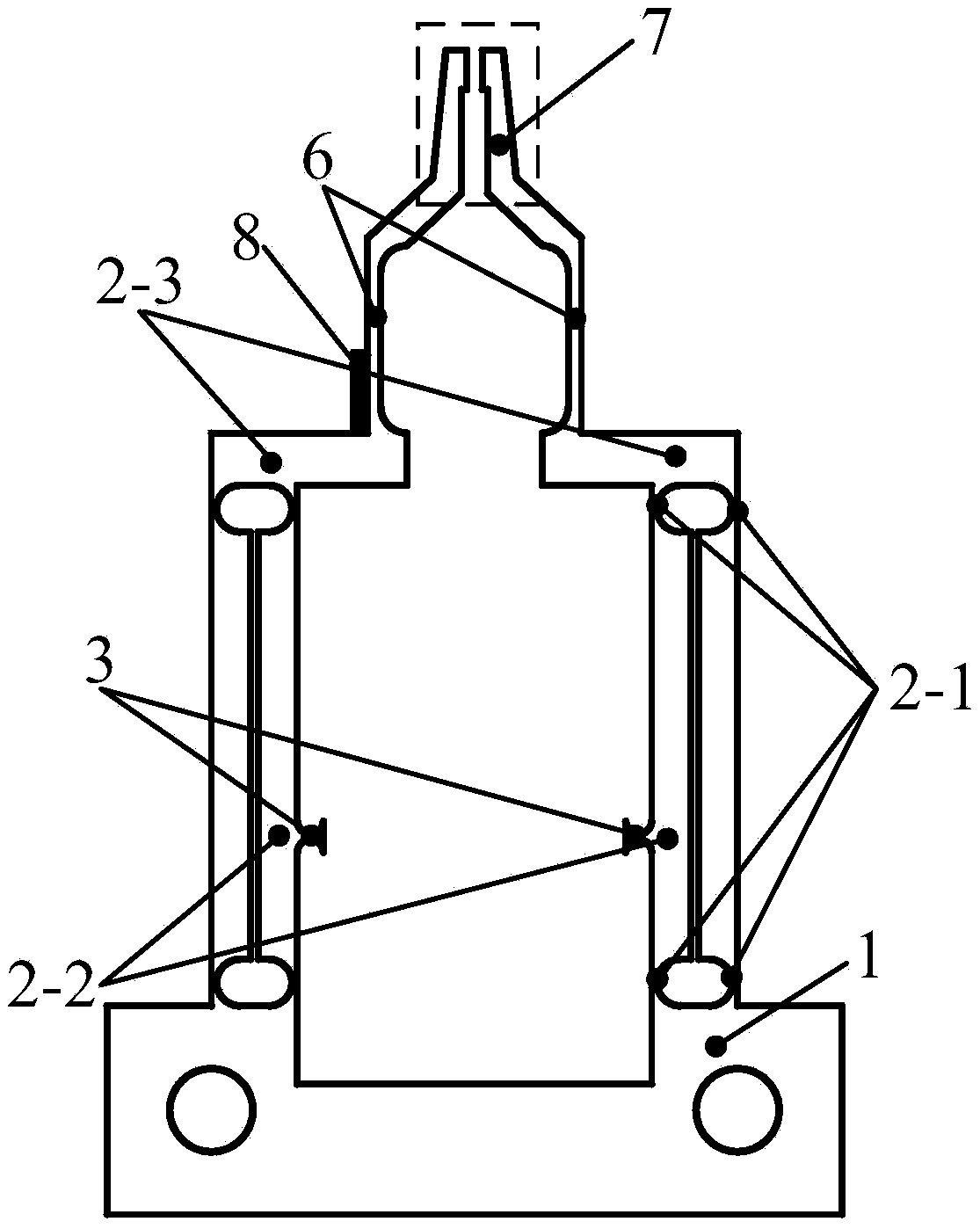

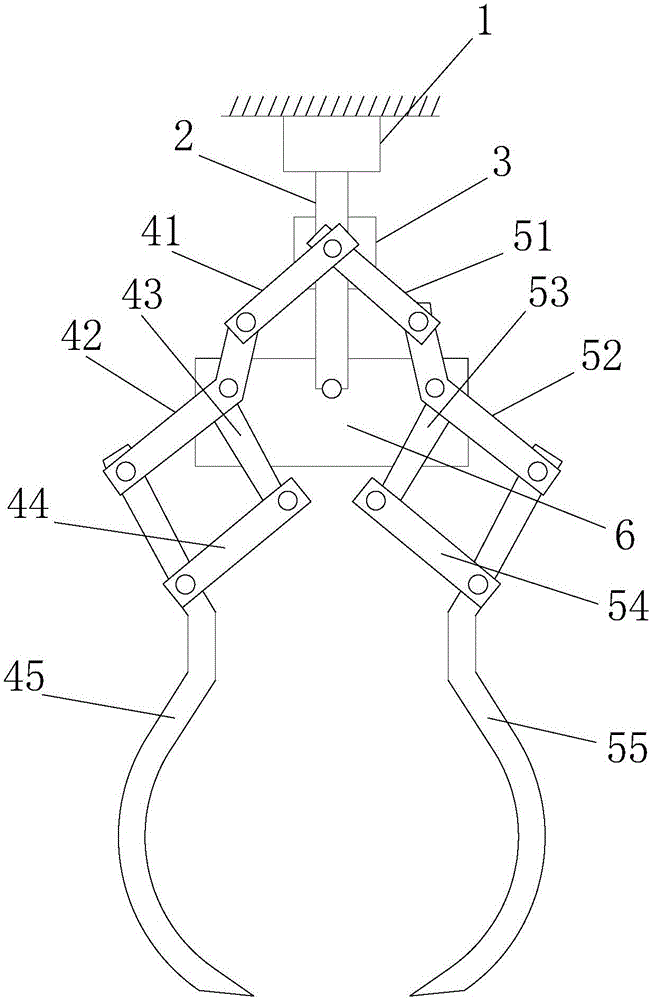

Double-linkage manipulator

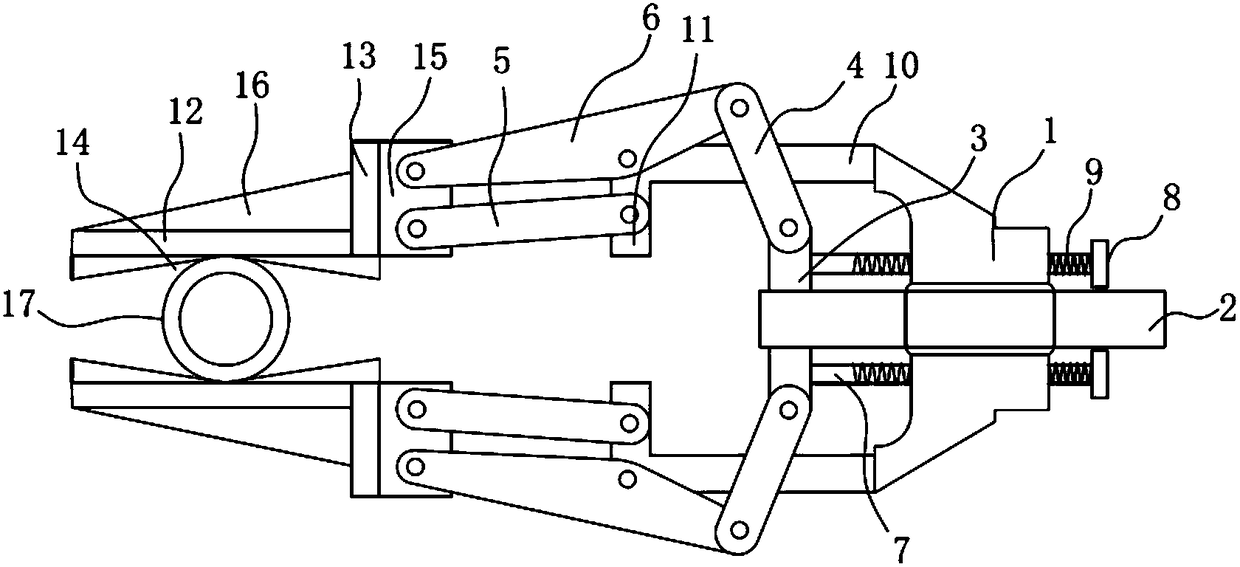

The invention discloses a double-linkage manipulator. The double-linkage manipulator comprises a bracket, a piston rod, a driver board, a pair of driving connecting rods, a pair of linkage connectingrods, a pair of claw connecting rods and a pair of claws, and the driving connecting rods, the linkage connecting rods, the claw connecting rods and the claws are separately and symmetrically arranged. The piston rod penetrates through the bracket and is in sliding fit with the bracket. Connecting arms are arranged at the positions, on both sides of the piston rod, of the brackets, and the driverboard is located between the connecting arms and fixedly connected with the free end of the piston rod. The two ends of the linkage connecting rods are separately hinged to the rear ends of the clawsand the connecting arms, and the claw connecting rods are located outside the linkage connecting rods. The front ends of the claw connecting rods are hinged to the rear ends of the claws, and the middle portions of the claw connecting rods are hinged to the connecting arms. One ends of the driving connecting rods are hinged to the driver board, and the other ends of the driving connecting rods arehinged to the rear ends of the claw connecting rods. A guiding mechanism for preventing the piston rod from being displaced is disposed between the driver board and the bracket. The double-linkage manipulator has simple structure, no movement gap, accurate clamping of workpiece, stable and reliable use and great popularization and application value.

Owner:余云丰

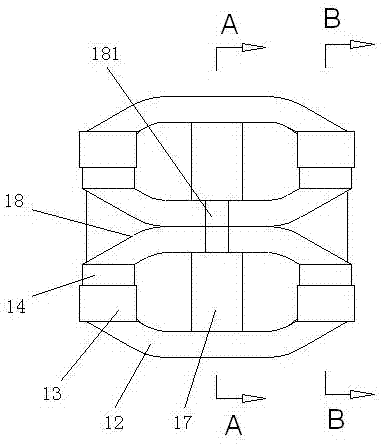

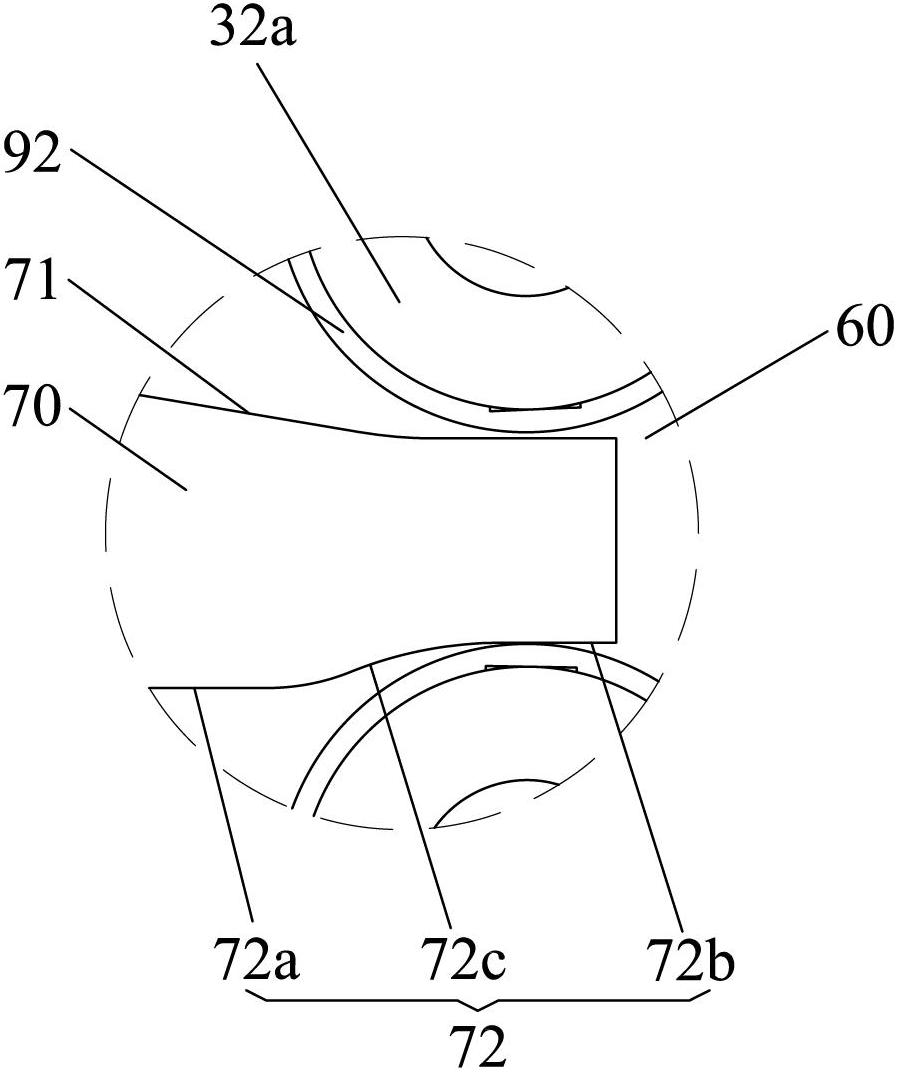

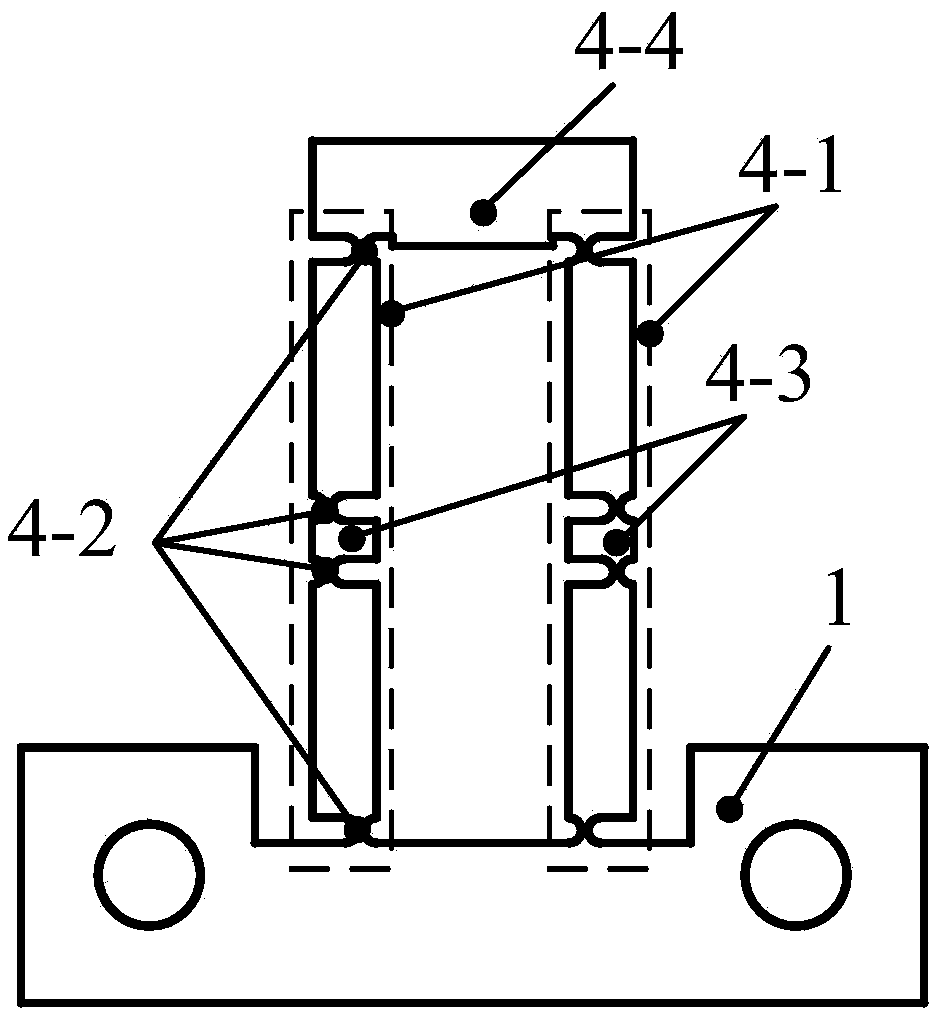

Clamping mechanism

InactiveCN104552076AWon't shakeEven by forceWork holdersPositioning apparatusDevices fixationEngineering

Owner:浙江和良智能装备有限公司

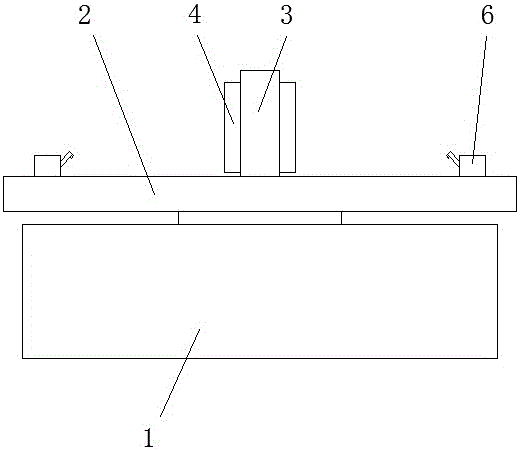

Clamp for detecting of automobile covering part

InactiveCN108015693AAvoid damageHigh clamping accuracyVehicle testingWork holdersEngineeringAutomation

The invention discloses a clamp for detecting of an automobile covering part. The clamp comprises a fixing seat, wherein two fixing rods are welded to the top end of the fixing seat; a connecting rodthrough hole is formed in each fixing rod; connecting rods are mounted into the connecting rod through holes in a sliding manner, and two ends of the connecting rods extend out of the connecting rod through holes; fixing blocks are arranged at two sides of the fixing seat; a connecting rod groove which is in sliding connection with each connecting rod is formed in one side, close to the corresponding fixing rod, of each fixing block; one end of each connecting rod extends out of the corresponding connecting rod groove; a rotating shaft groove is formed in one side, in the corresponding connecting rod groove, of each connecting rod; first rotating shafts are rotatably mounted in the rotating shaft grooves. The clamp is simple in structure, and convenient to use; the clamping accuracy of theclamp is improved; the fine adjusting can be carried out, so that the clamping work can be conveniently performed; the automation degree is high; the clamp is capable of damping, so that the damage to the automobile covering part is reduced; the time is saved; and the working efficiency is improved.

Owner:柳州市钜嘉机械有限公司

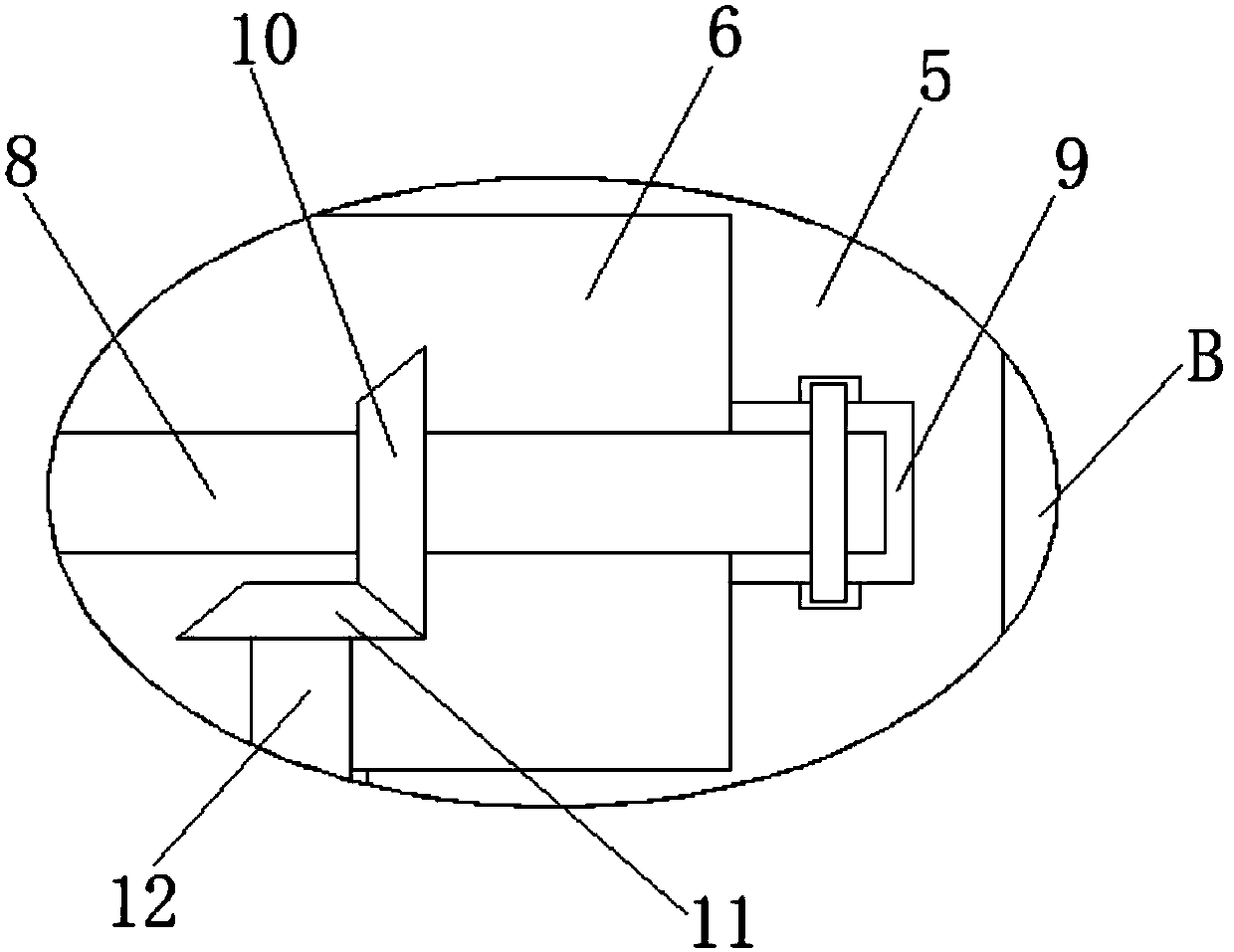

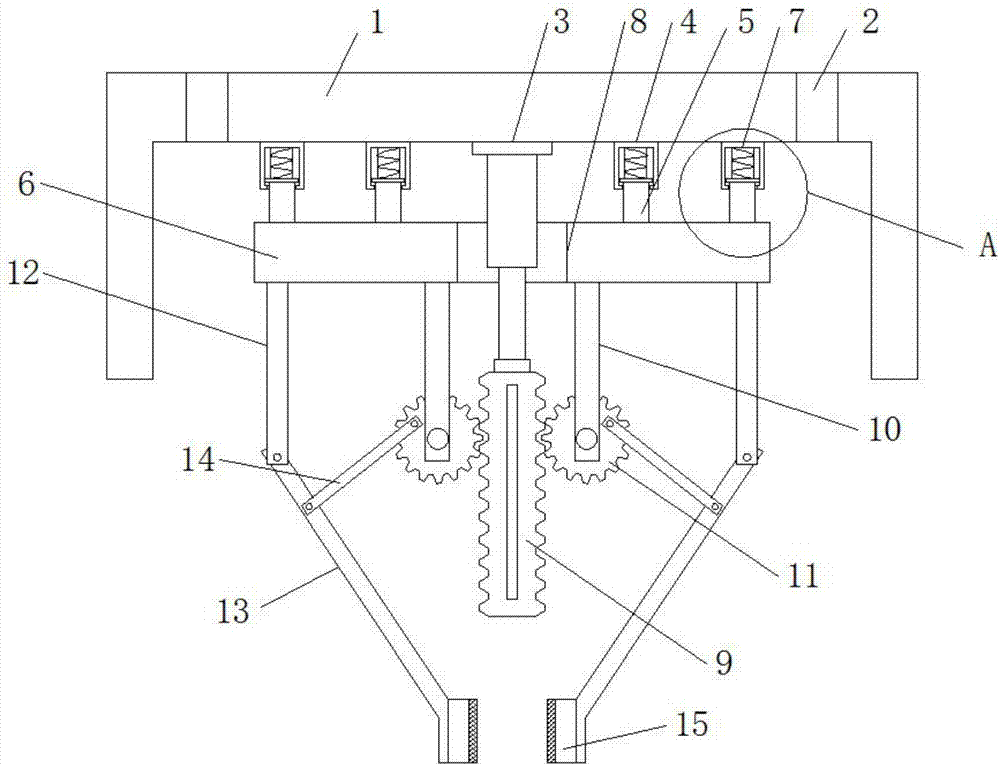

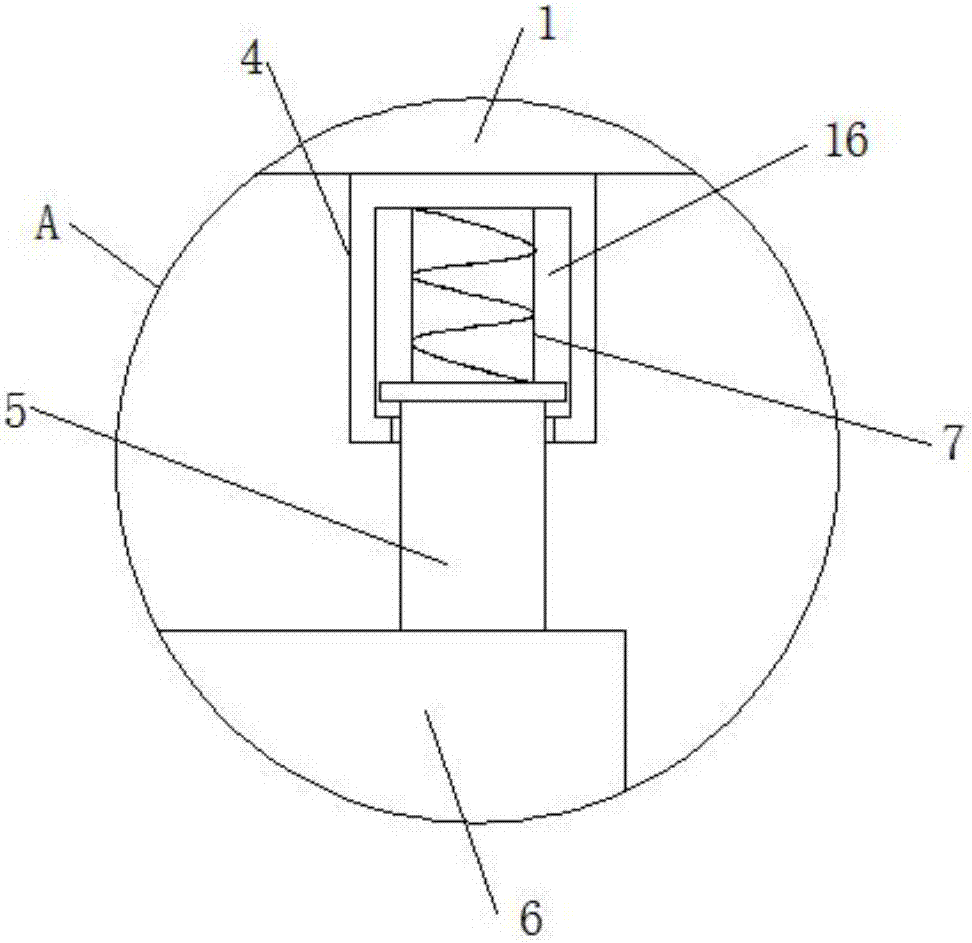

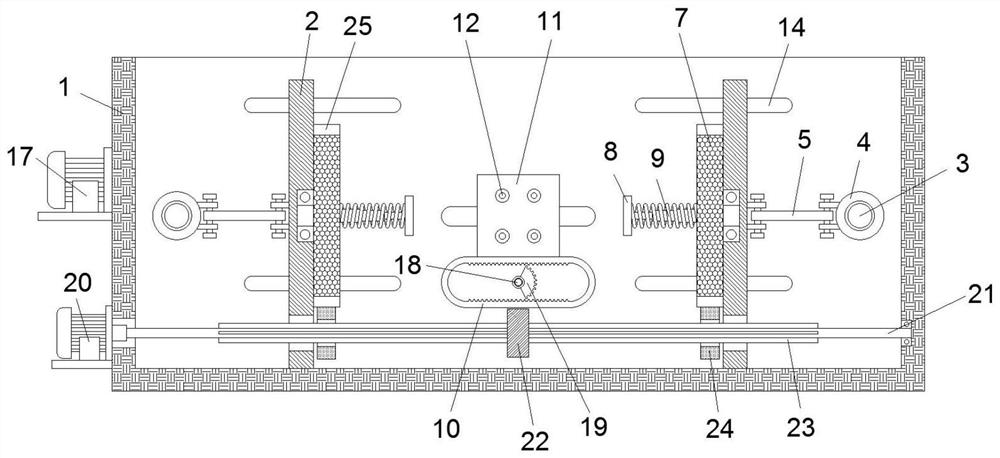

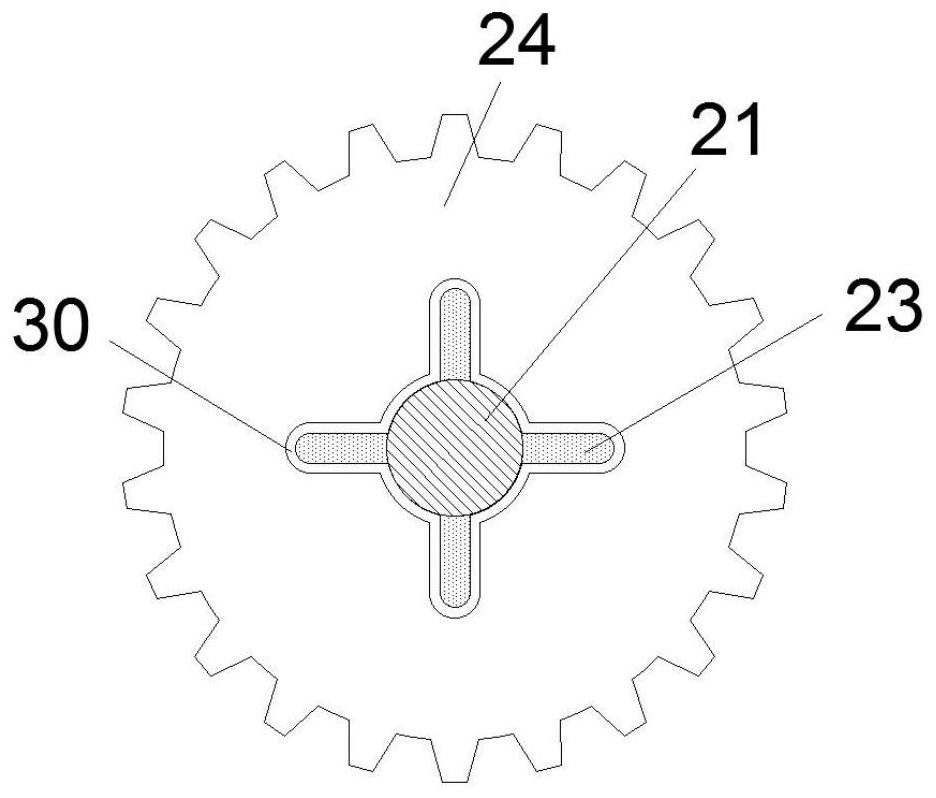

Clamping device of walking agricultural machine

InactiveCN107336254AEasy to holdReduce vibration forceGripping headsWork holdersAgricultural engineeringPiston rod

The invention discloses a clamping device of a walking agricultural machine. The clamping device comprises a fixed base. A plurality of mounting holes are formed in each of the two sides of the fixed base. An air cylinder and supporting rods are fixedly mounted at the bottom of the fixed base. The supporting rods are located on the two sides of the air cylinder. Buffering rods and buffering plates are arranged under the supporting rods correspondingly. A storage groove is formed in the side, close to the corresponding buffering rod, of each supporting rod. The inner wall of the top end of each storage cavity is fixedly connected with one end of a spring. The other end of each spring is connected with one end of the corresponding buffering rod. The other end of each buffering rod is perpendicularly connected with the corresponding buffering plate. A through hole is formed in the middle of each buffering plate. A rack is arranged at the bottom of the air cylinder and fixedly connected with a piston rod of the air cylinder. Supports are arranged on the two sides of the rack correspondingly and fixedly welded to the bottom ends of the buffering plates. The bottoms of the supports are sleeved with gears, and the gears are engaged with the racks. The clamping device is reasonable in design and high in clamping precision, and the operating quality of the machine is effectively improved.

Owner:HEFEI XIONGCHUAN MACHINERY SALE CO LTD

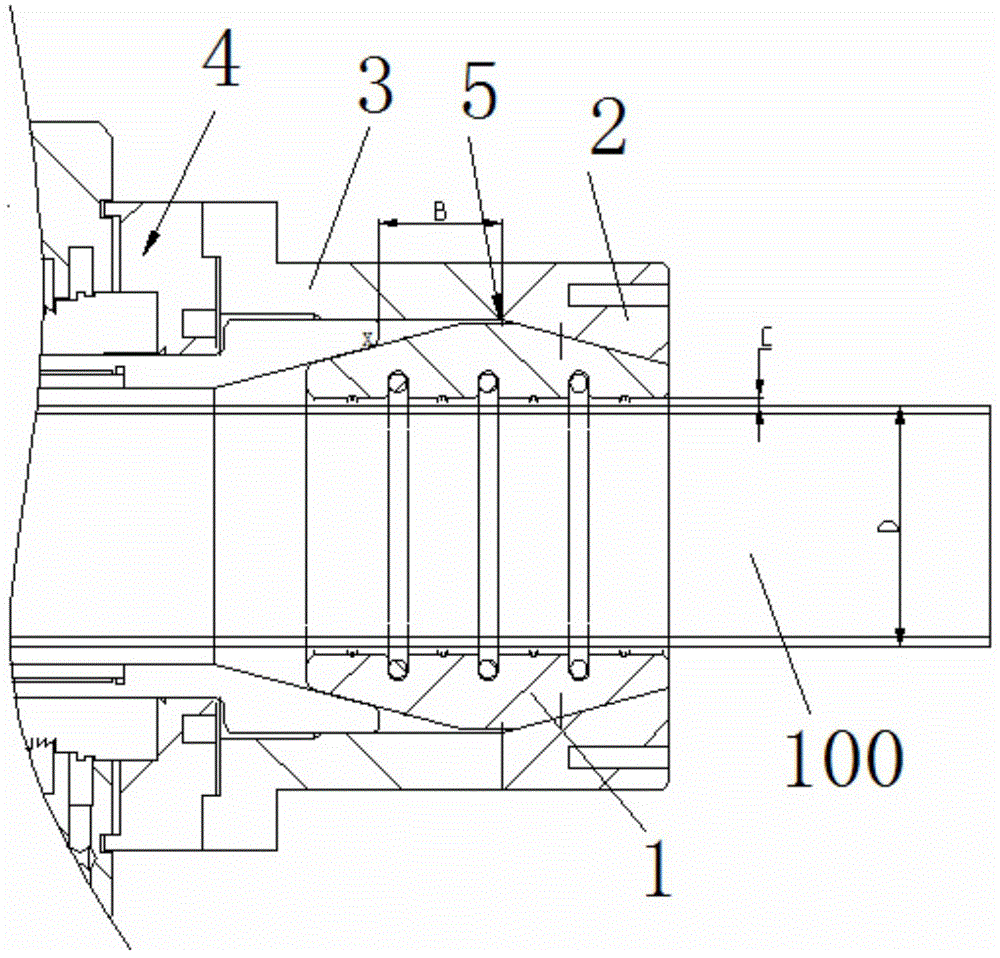

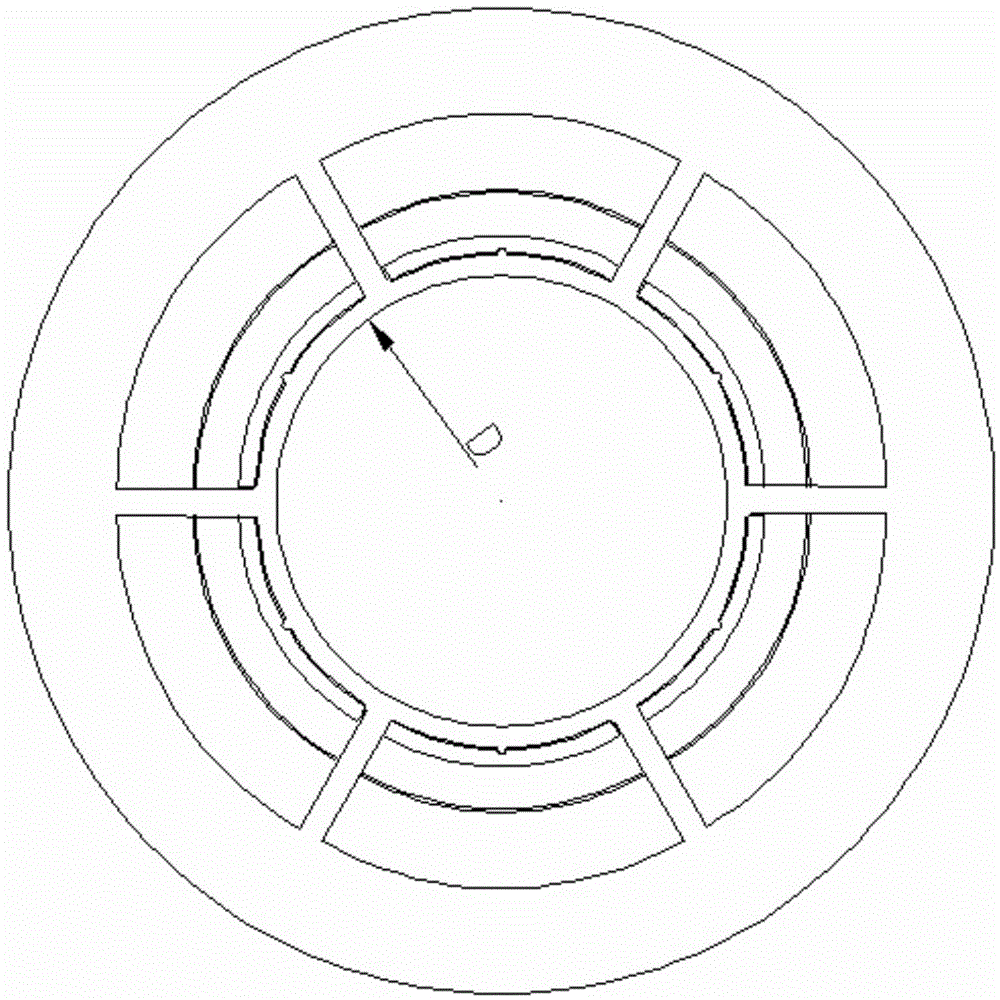

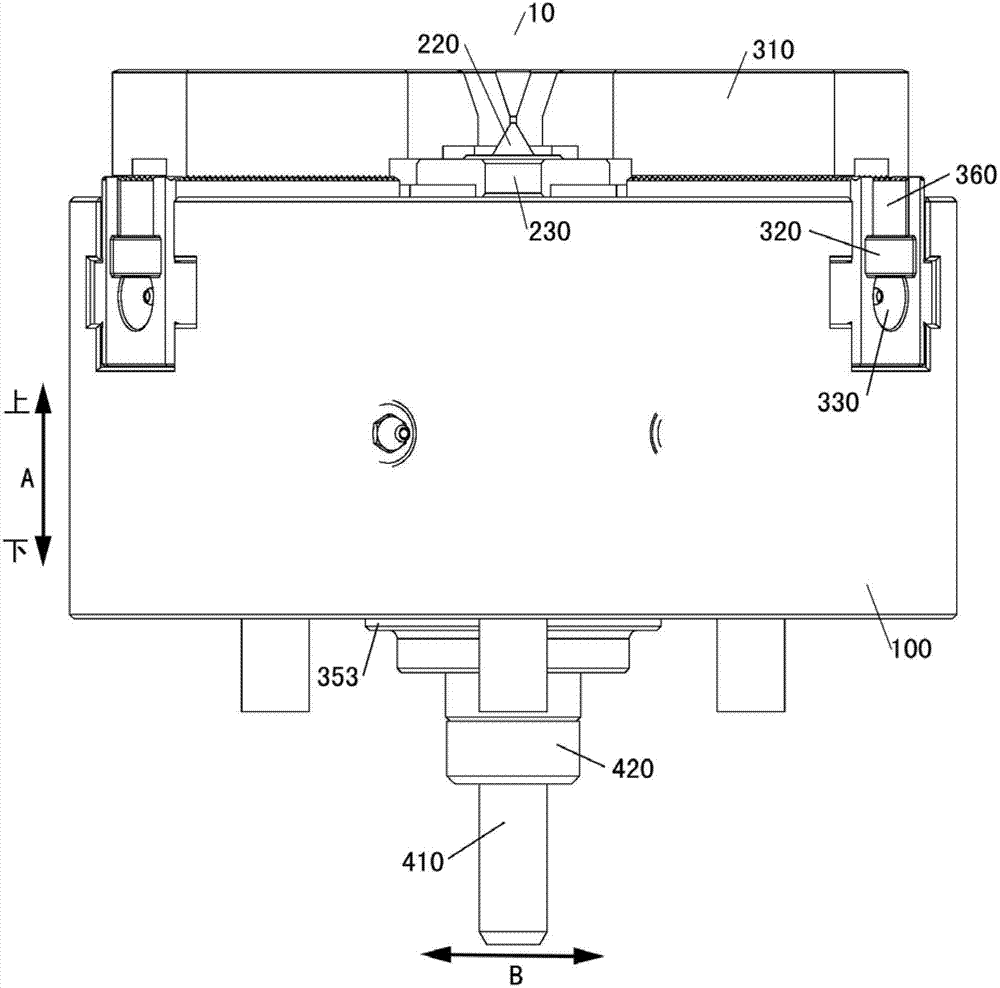

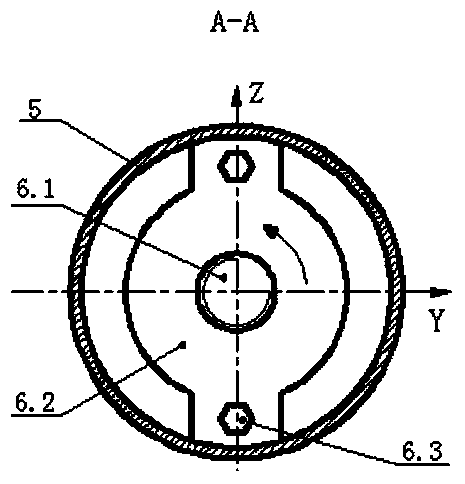

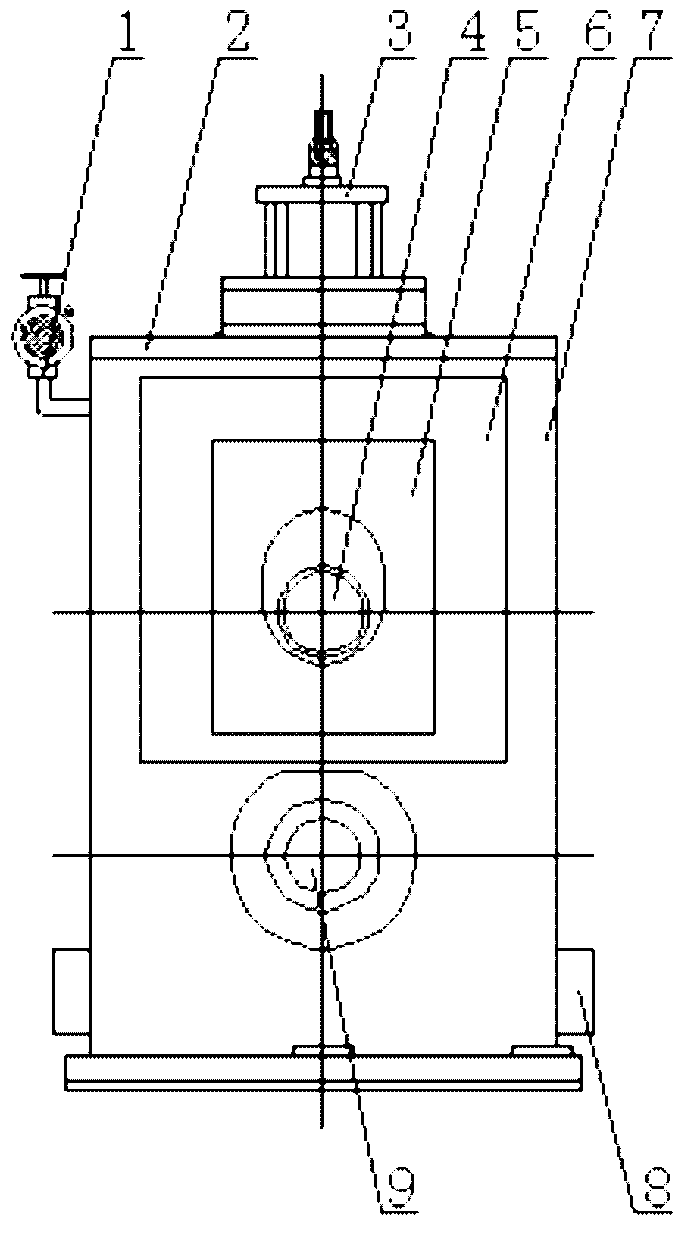

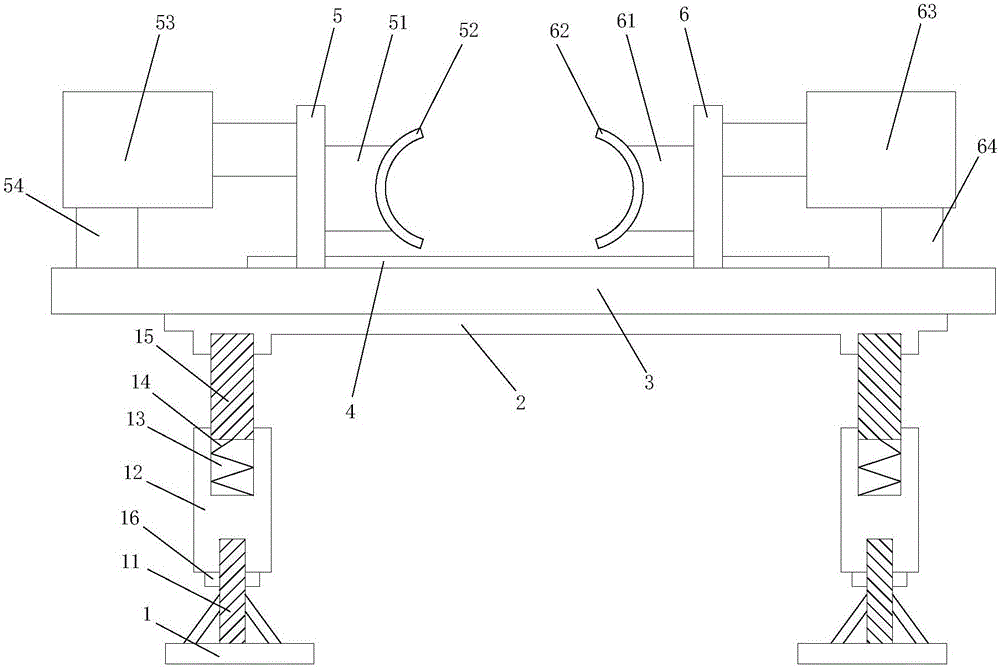

Center floating type chuck

ActiveCN103111647AHigh clamping accuracyEasy to installTailstocks/centresChucksEngineeringMechanical engineering

Owner:TSINGHUA UNIV

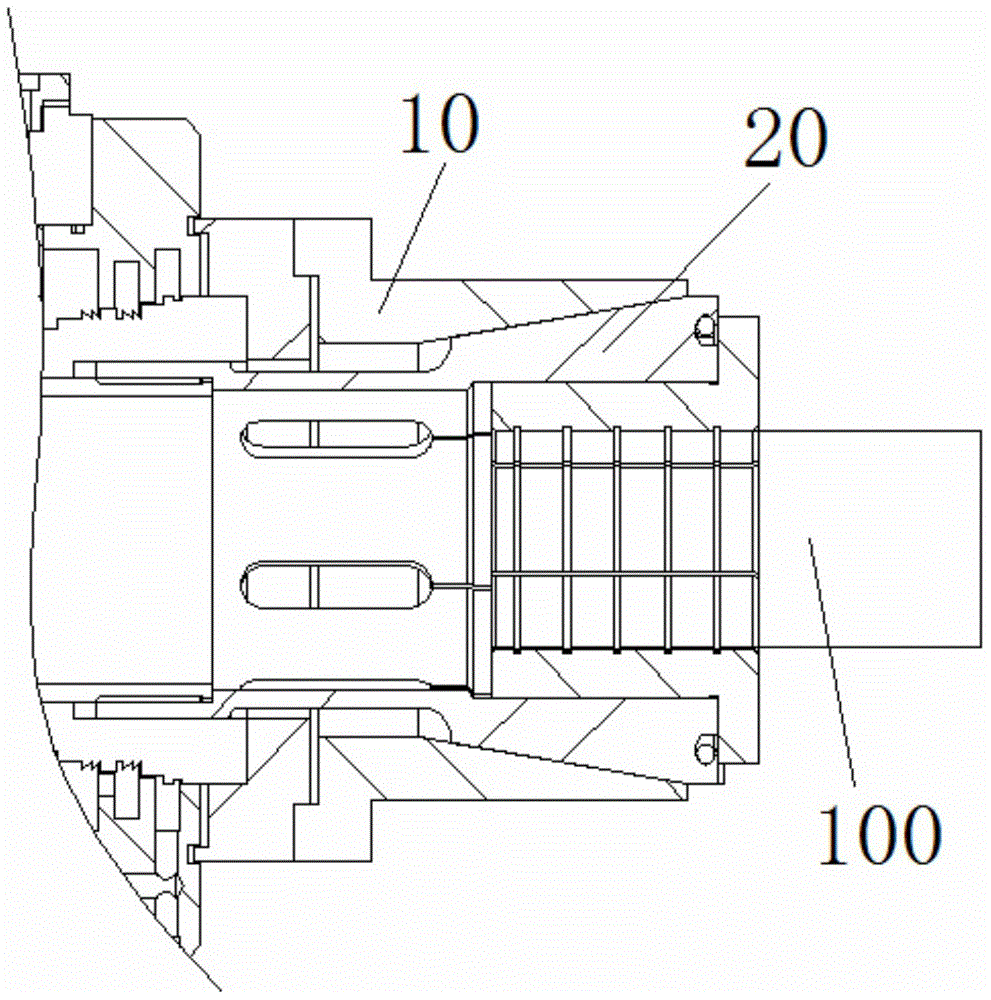

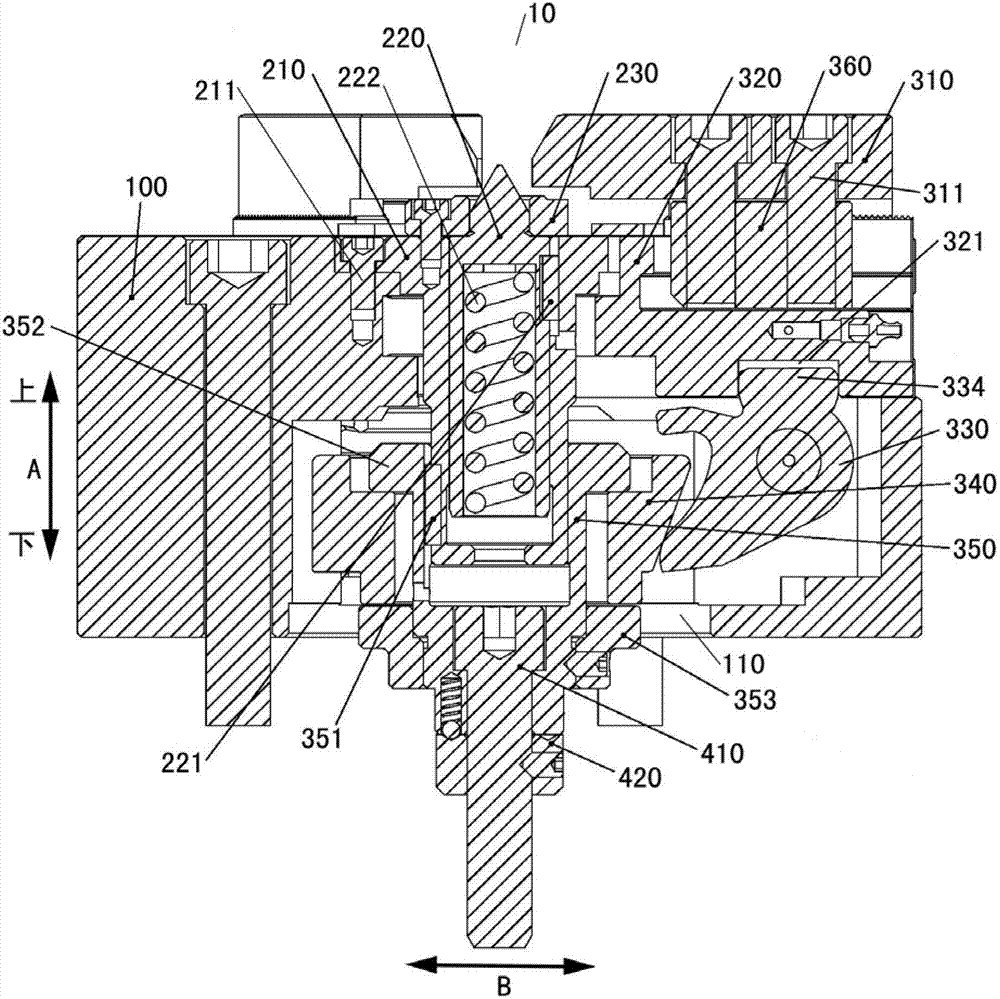

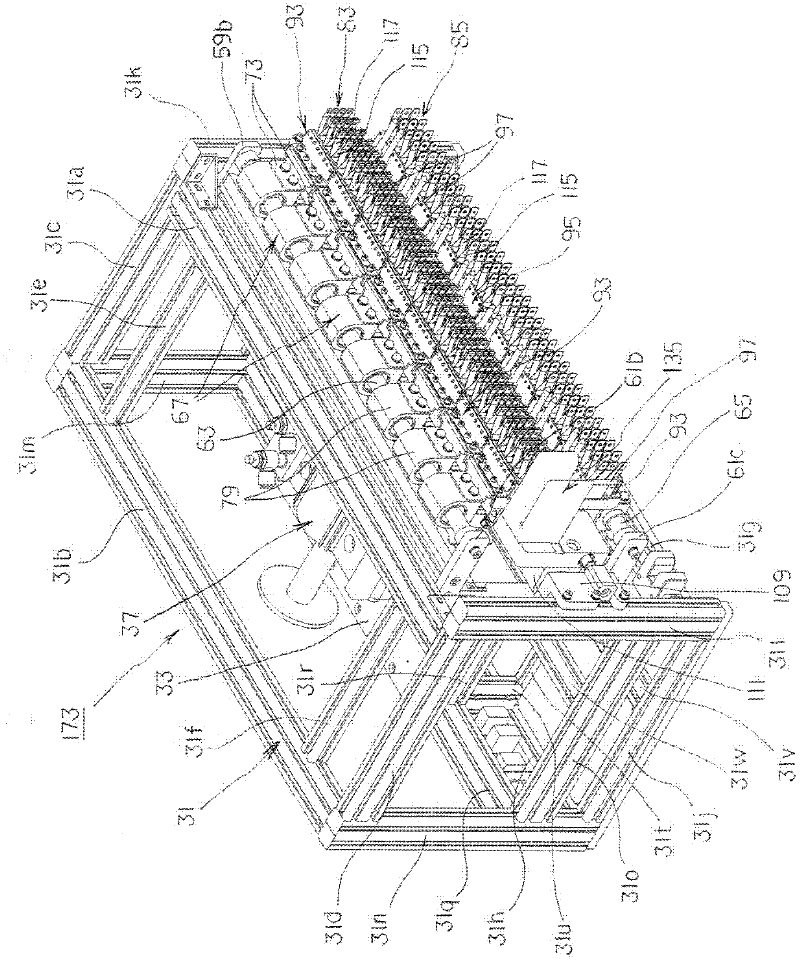

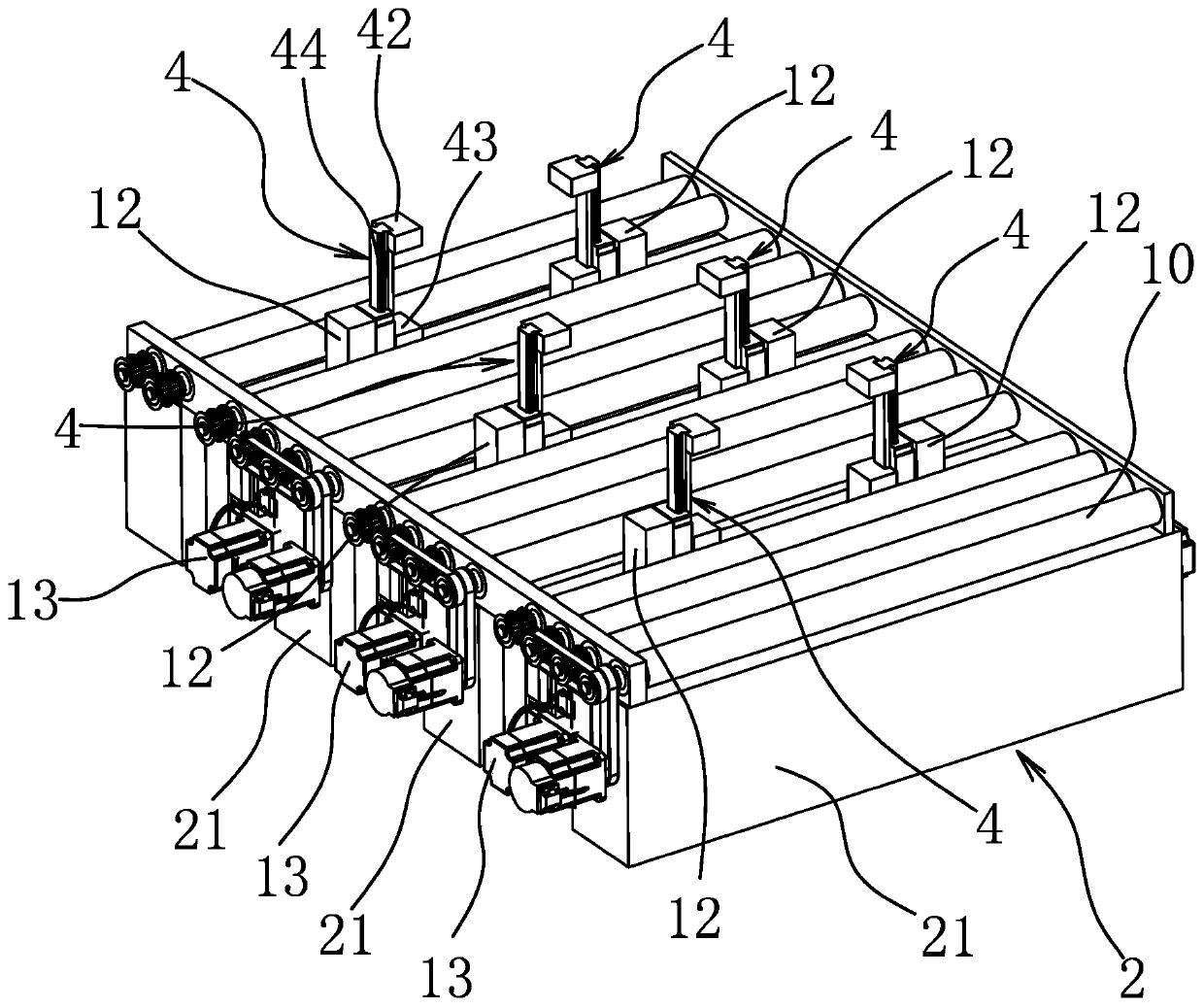

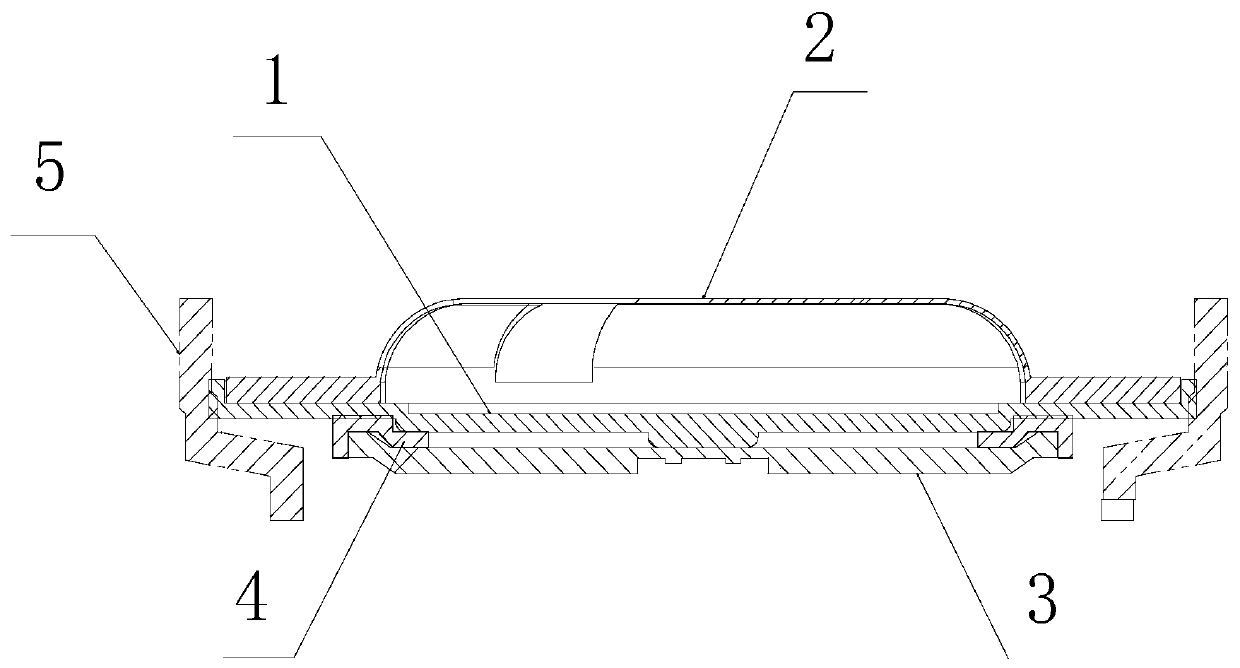

Clamping mechanism of charge-discharge test device for thin secondary battery

ActiveCN102290615APrecise clampingCorrectly and well clampedFinal product manufactureCurrent conducting connectionsBattery chargeElectrical battery

The present invention relates to a chuck mechanism of a charge / discharge testing device for flat-rechargeable batteries and has a proposition to provide a chuck mechanism that makes it possible to lighten conventionally needed troublesome works, that is, for example, works of storing and fixing a large number of flat-rechargeable batteries in a container, and that is capable of surely chucking the flat-rechargeable batteries (electrodes). The chuck mechanism includes a first guide couplable with a battery storage retaining a plurality of flat-rechargeable batteries arranged in parallel, and a plurality of chuck units continuously joined with the first guide and resiliently arranged in parallel, wherein the chuck units each have a second guide resiliently positioning each of the chuck units with a predetermined number of corresponding flat-rechargeable batteries in the battery storage.

Owner:TOKYO SEIMITSU +1

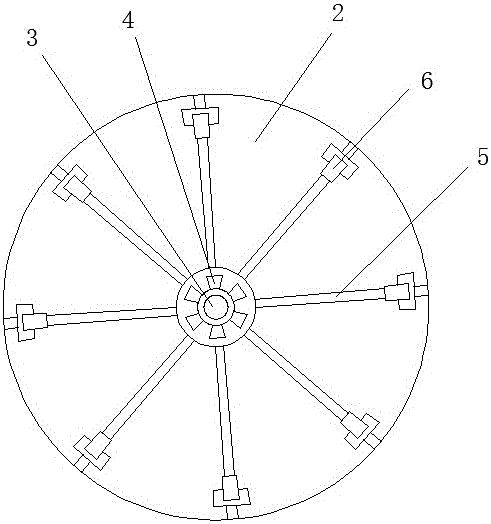

Automobile hub clamping fixture with automatic centering function

InactiveCN106624931AImprove general performanceHigh positioning and clamping accuracyPositioning apparatusMetal-working holdersProgrammable logic controllerEngineering

The invention patent discloses an automobile hub clamping fixture with an automatic centering function, and belongs to the technical field of clamping fixtures. The automobile hub clamping fixture comprises a machine body and a rotary worktable arranged above the machine body; a PLC (Programmable Logic Controller) control unit and an electric control unit for driving the rotary worktable to rotate are arranged in the machine body; a pneumatic expansion shaft is fixedly arranged at the center of the rotary worktable; circumferentially uniformly distributed pneumatic blocks are arranged on the pneumatic expansion shaft; radially uniformly distributed positioning slots are arranged on the upper surface of the rotary worktable; a pressing module is arranged on the positioning slot; and the pneumatic expansion shaft and the pressing module are both connected with the PLC control unit. The automobile hub clamping fixture disclosed by the invention is simple in structure, reasonable in design, strong in university, and wide in applicable range. The automatic centering positioning can be realized, the processing efficiency of the product is greatly improved, the processing period is shortened, and the processing cost is saved.

Owner:太仓市夏米粒信息技术有限公司

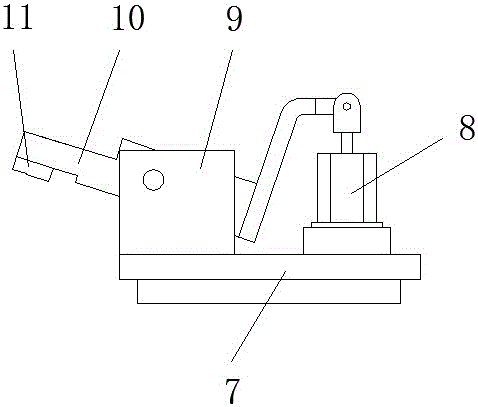

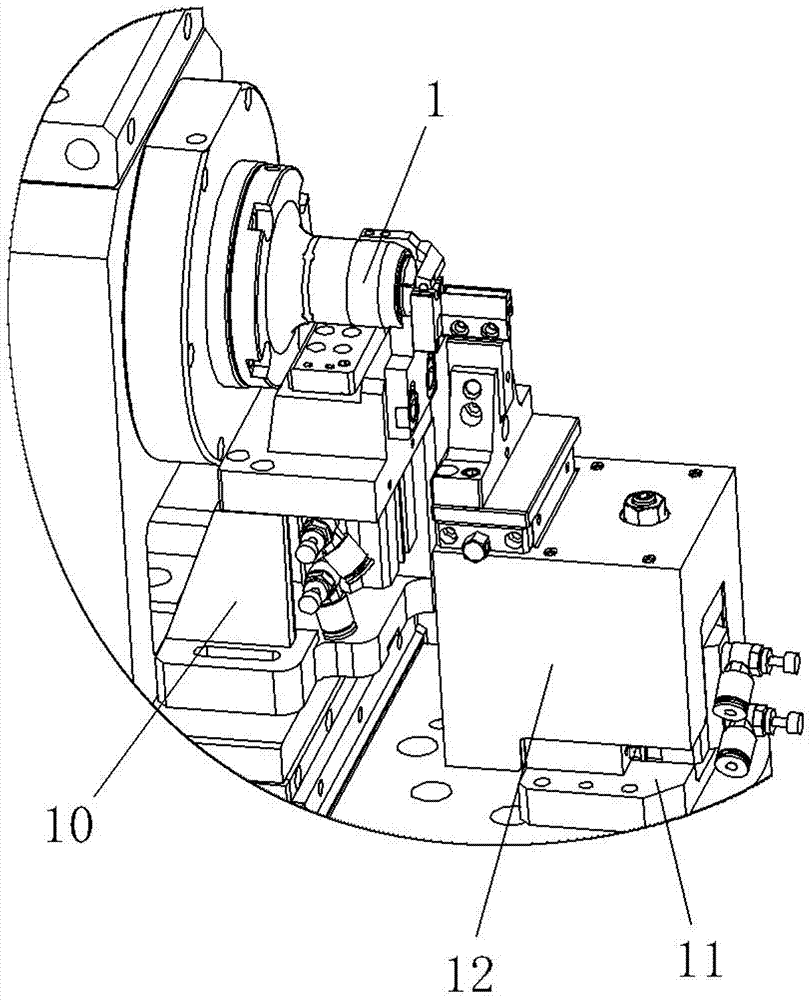

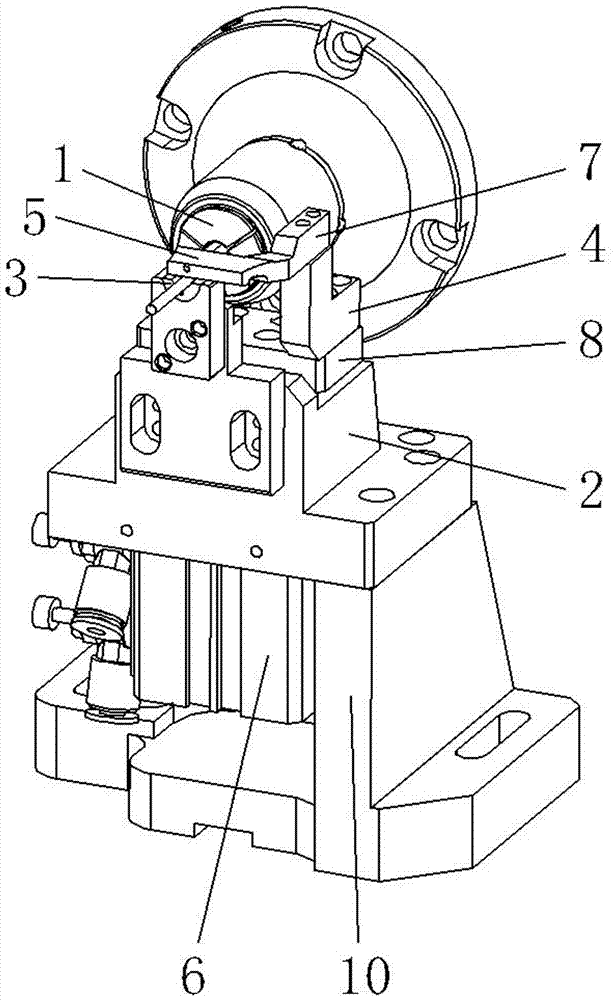

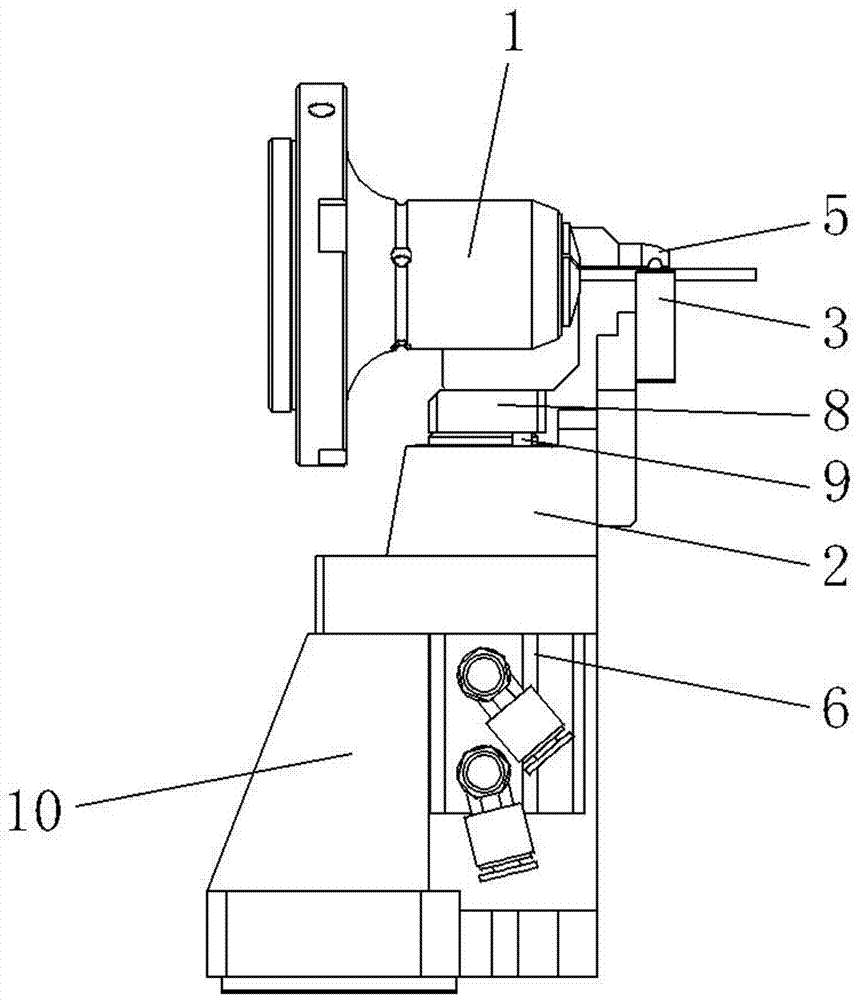

Clamping assisting mechanism for tool grinder

InactiveCN105437075AGuaranteed accuracyGuaranteed rigidityOther manufacturing equipments/toolsGrinding work supportsPerpendicular directionCollet

The invention provides a clamping assisting mechanism for a tool grinder, and belongs to the technical field of machinery. The problem that a conventional clamping assisting mechanism for the tool grinder can only perform movement and adjustment in a horizontal direction and a perpendicular direction, so that the supporting precision is difficult to guarantee is solved. The mechanism comprises a supporting seat I and a V-shaped block I arranged on the supporting seat I, wherein a V-shaped slot I is formed in the top of the V-shaped block; a supporting seat II is arranged on the supporting seat I, a pressing plate is arranged on the supporting seat II, and a driving unit I is also arranged on the supporting seat I; the mechanism further comprises a fixing seat II, wherein a supporting seat III is arranged on the fixing seat II, a regulating assembly is arranged on the supporting seat III, a V-shaped block II is arranged on the regulating assembly, a V-shaped slot II is formed in the V-shaped block II, and a driving unit II is arranged on the fixing seat II. According to the clamping assisting mechanism disclosed by the invention, the rigidity of a collet is improved through the pressing plate and the V-shaped block I at a near clamping end, the grinding rigidity and the grinding precision during the grinding of a cutter are improved through the V-shaped block II at a far clamping end, and the clamping assisting mechanism has the advantages that the clamping precision is high, and the processing precision and the stability of the tool grinder can be effectively guaranteed.

Owner:TAIZHOU BEIPING MASCH TOOL CO LTD

Under-actuated ingenious multifunctional space robot hand claw

InactiveCN103921271AImprove work efficiencyGreat effortProgramme-controlled manipulatorGripping headsRobot handBall screw

Provided is an under-actuated ingenious multifunctional space robot hand claw. A body composed of a front sleeve and a tail sleeve is arranged, and a motor seat is connected with the front sleeve. A ball screw is arranged in the body, a screw rod is in transmission connection with a motor rotary shaft through a coupling, and a supporting piece is arranged outside the screw. An upper driving block and a lower driving block are fixed to the rear end of a nut seat in screw fit with the screw rod. Tail fingers fixedly provided with an upper finger and a lower finger are arranged on the inner surfaces of the driving blocks, and joints are arranged at the front ends of the fingers. Replacement connectors fixed to the tail sleeve through pin columns are formed in the front ends of the tail fingers. The tail fingers are connected with the clamping structure of the replacement connectors through the joints to achieve finger replacement. The driving blocks axially move to push the fingers to open and close two fingertips. The under-actuated ingenious multifunctional space robot hand claw is simple and compact in structure, large in grasping force, high in efficiency, easy to manufacture and reliable in work. One hand claw is arranged and can be replaced with multiple fingers, and the functions of capturing and clamping are achieved. Space screw turning, experimental instrument clamping, floating object grabbing and other space production assembling, scientific experiments and maintenance can be completed at the same time.

Owner:SICHUAN UNIV

Heavy-load precise flexible adsorption mechanical arm

ActiveCN104742112AIncrease stiffnessImprove adaptabilityProgramme-controlled manipulatorGripping headsHeavy loadOrthogonal plane

The invention discloses a heavy-load precise flexible adsorption mechanical arm. The overloading precise flexible adsorption mechanical arm comprises a locating assembly, an adsorption arm used for main locating and a side arm for end face locating and auxiliary locating. The adsorption arm comprises a first branched adsorption arm body and a second branched adsorption arm body, and the tail end of the first branched adsorption arm body and the tail end of the second branched adsorption arm body are detachably connected. The locating assembly comprises a locating plate, a first locating base and a second locating base; a guide groove is formed in the locating plate, and the first locating base and the second locating base are arranged in cooperation with the guide groove in a manner of making linear back-and-forth movements in the direction of the guide groove; and the first branched adsorption arm body, the second branched adsorption arm body and the side arm can make linear back-and-forth movements in a direction perpendicular to the direction of the guide groove. The clamping at different positions in an orthogonal plane of the locating plate can be performed, and the clamping locating position of the main locating adsorption arm can be effectively adjusted according to the shape and size of a part required to be clamped, so that it can be ensured that the heavy-load precise flexible adsorption mechanical arm is adaptive to mechanical parts in irregular shapes, and is high in clamping precision and suitable for the heavy-load condition.

Owner:CHONGQING JIAOTONG UNIVERSITY

Piezoelectric driving single-arm type high-speed lead wire clamp

ActiveCN105355572AReduced overall mass and moment of inertiaReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingAmplification factorHinge angle

The invention discloses a piezoelectric driving single-arm type high-speed lead wire clamp. The wire clamp is integrally formed by cutting board wires. The wire clamp comprises an L-shaped base body, wherein a parallelogram mechanism and a bridge-type displacement amplifying mechanism are formed on the inner side of the L-shaped base body; a piezoelectric ceramic driver is arranged between the input end of the bridge-type displacement amplifying mechanism and the L-shaped base body; the parallelogram mechanism is provided with an output end and an input end, a connecting beam vertical to the parallelogram mechanism is formed on the output end of the parallelogram mechanism, a movable jaw is formed on the end part, far away from the L-shaped base body, of the connecting beam, the movable jaw is provided with a corresponding fixed jaw, and the fixed jaw is formed on the top of the L-shaped base body; and the output end of the bridge-type displacement amplifying mechanism is connected with the input end of the parallelogram mechanism through a flexible hinge III. The piezoelectric driving single-arm type high-speed lead wire clamp is small in size, compact in structure, stable and reliable in clamping force and low in manufacturing cost, has a bigger displacement amplification factor, can realize measurement and feedback of clamping force, and is applicable for lead wire bonding packaging equipment.

Owner:TIANJIN UNIV

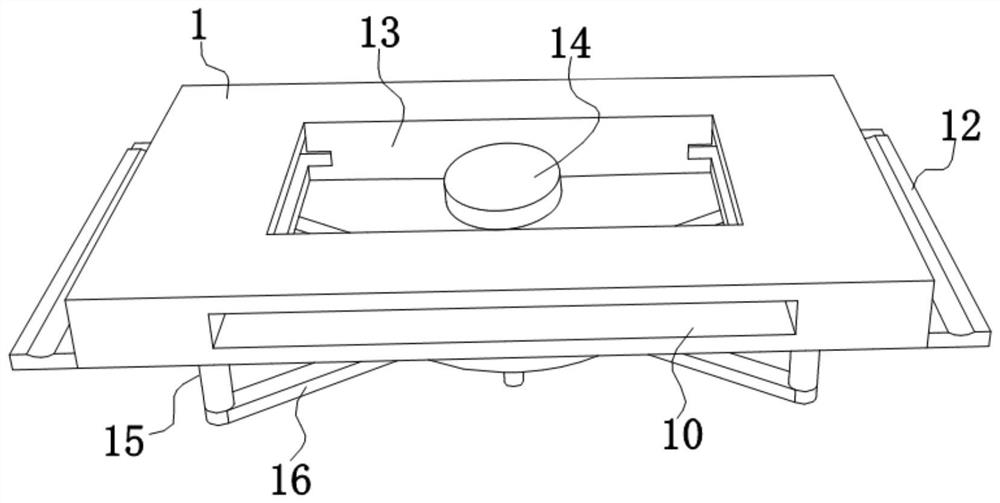

Substrate clamping device

PendingCN102683257ACompact structureReduce transmission energy consumptionSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention discloses a substrate clamping device for clamping substrates in an organic light-emitting display and a solar cell panel. The substrate clamping device comprises a driver, a bottom plate, a first clamping piece and a second clamping piece, wherein the first clamping piece and the second clamping piece are matched with each other. Both the first clamping piece and the second clamping piece are pivoted at one end of the bottom plate and are provided with clamping parts and pushing parts; a clamping region is formed between the clamping parts of the first clamping piece and the second clamping piece; a pushing region is formed between the pushing parts of the first clamping piece and the second clamping piece; the driver is arranged at the other end of the bottom plate; the output end of the driver is provided with a pushing piece corresponding to the pushing region; the driver drives the pushing piece to stretch into the pushing region to eject the pushing parts to rotate along an expanding direction; and the rotating pushing parts drive the clamping parts to rotate along a direction of reducing the clamping region so as to clamp the substrate in the clamping region. The substrate clamping device can overcome the disadvantages of the conventional manipulator that the manufacturing difficulty is great and the manufacturing cost is high; and the substrate clamping device has the advantages of compact structure, convenience for installation and easiness for maintenance.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

Rapid fixing clamp for aluminum alloy machining

InactiveCN112846874ASolve the problem of centering clampingQuick fixPositioning apparatusMetal working apparatusHydraulic cylinderElectric machinery

The invention belongs to the technical field of aluminum alloy machining auxiliary devices, and discloses a rapid fixing clamp for aluminum alloy machining. The rapid fixing clamp comprises a fixing table and an aluminum alloy plate, the fixing table is symmetrically provided with two clamping assemblies, each clamping assembly comprises a fixing plate, a hydraulic cylinder is arranged in the interior of each fixing plate in a penetrating mode, a movable plate is arranged at the output end of each hydraulic cylinder, a first sliding groove is formed in the interior of each movable plate, a lead screw is rotationally connected to the interior of each first sliding groove through a bearing, a supporting plate is arranged on one side of each movable plate, a motor is arranged on one side of each supporting plate, an output shaft of each motor penetrates through each movable plate to be fixedly connected with each lead screw, and two receding grooves are formed in one side of each movable plate. According to the rapid fixing clamp for aluminum alloy machining, through the arrangement of a feeding frame, the two clamping assemblies and a lifting plate, the aluminum alloy plate can be quickly centered and fixed, the conditions of clamping deformation and cutting stress deformation of the aluminum alloy plate in the machining process are avoided, the good shock absorption effect is achieved, and the clamping effect and the working efficiency of the device are improved.

Owner:陈云

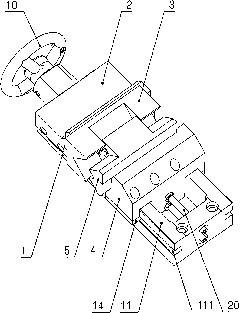

Clamping and conveying device for conveying steel bars

InactiveCN102319822ASave shipping timeImprove transportation efficiencyMetal-working feeding devicesPositioning devicesEngineeringRebar

The invention relates to a clamping and conveying device for conveying steel bars. The device comprises a main box, a secondary box, an upper roller, a lower roller and a cylinder, wherein the secondary box is glidingly arranged in the main box at the upper part of the lower roller; the secondary box is driven by the cylinder fixedly arranged at the top of the main box; the main box at two ends of the upper roller is provided with symmetrical end covers respectively; each end cover is provided with an upper roller sliding hole and an oil return baffle plate; the lower part of the oil return baffle plate is provided with an oil return oil; an oil baffle cover plate is fixedly arranged at the outer side of the end cover; the oil baffle cover plate is provided with a cover plate through holecorresponding to the upper roller sliding hole; and a dustproof oil baffle cover is fixedly arranged on the upper roller bearing end cover between the oil baffle cover plate and the oil return baffleplate. The device has compact structure, scientific and reasonable design, low manufacturing cost, small volume and high clamping accuracy, and can adapt to the steel bars of different specifications; the lubricating mode is circulating oil reinforced lubrication; and the device is reliable in sealing and high in transport velocity, improves the production efficiency of the steel bars, prolongs the service life of the steel bars, and is safe and reliable.

Owner:王丽燕

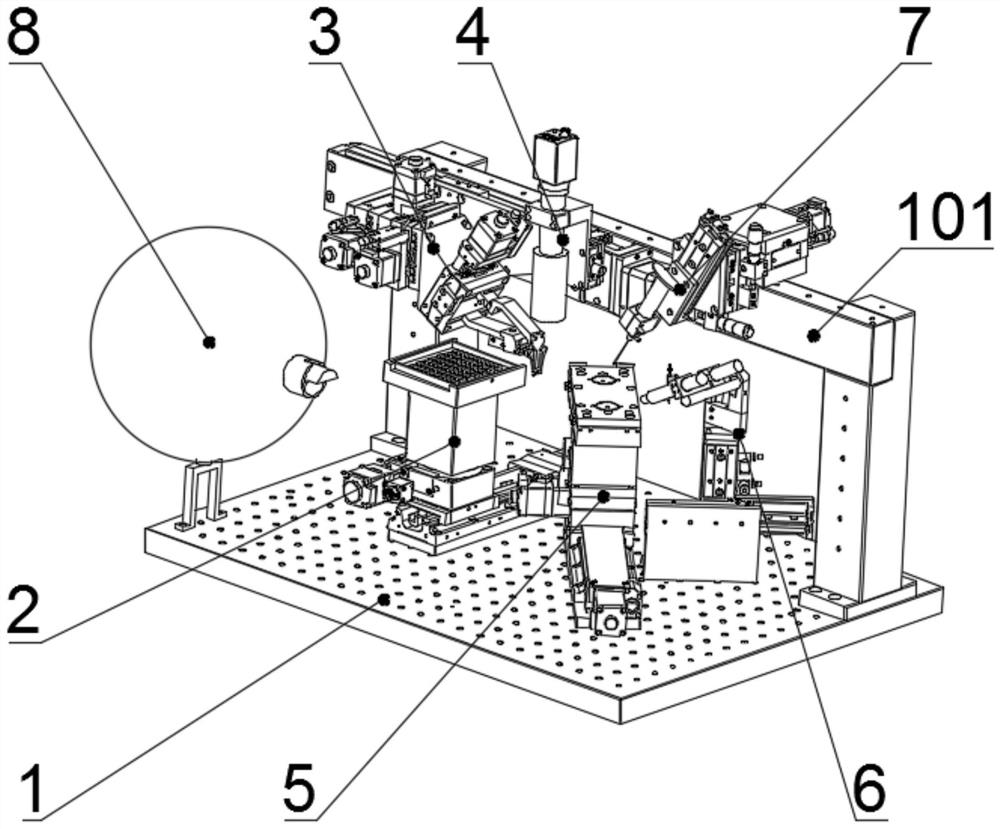

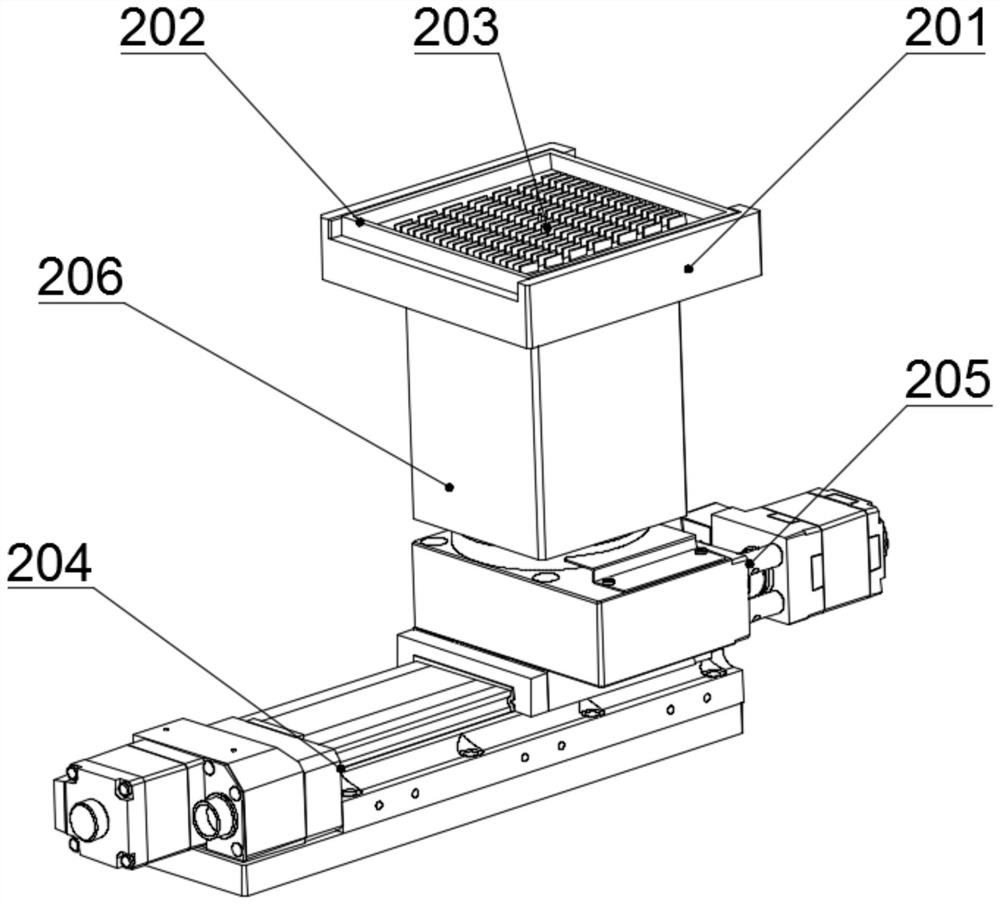

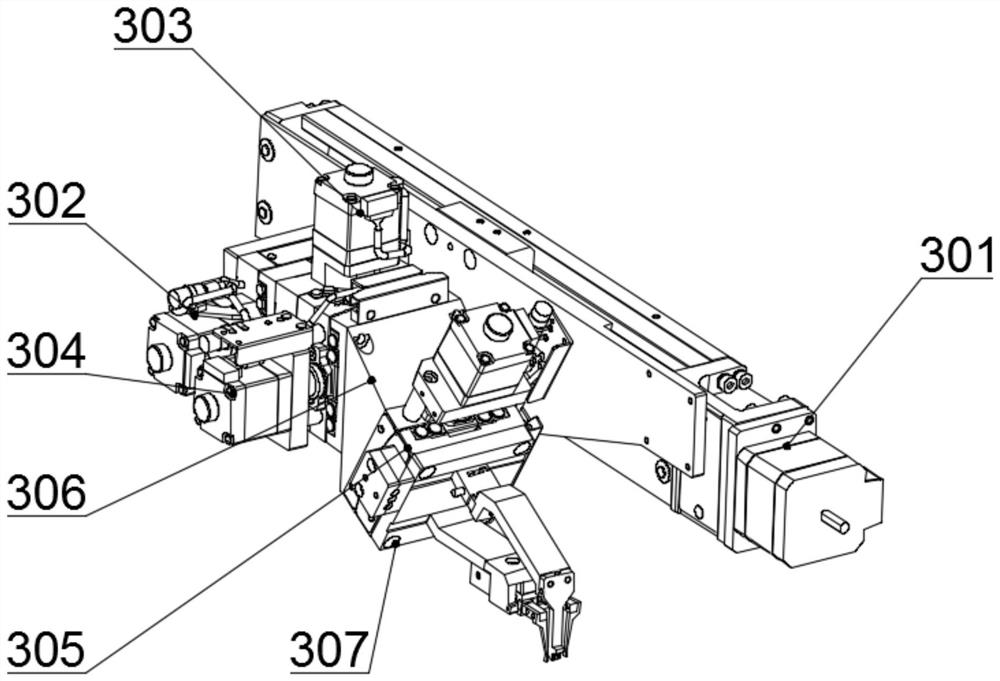

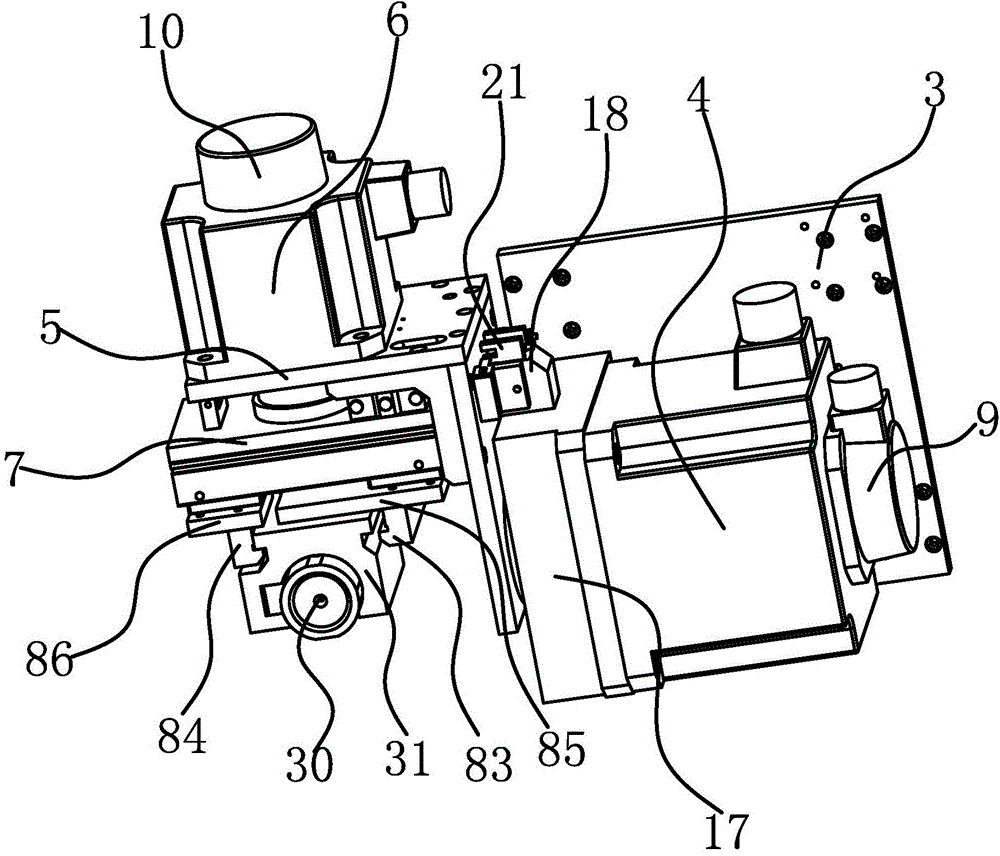

Semiconductor laser array reflector coupling device based on power detection

InactiveCN112387542AAchieve installationAccurate clampingMaterial gluingPretreated surfacesVisual monitoringLaser array

The invention provides a semiconductor laser array reflector coupling device based on power detection, comprising a device bottom plate, a tray unit, a clamp unit, a visual monitoring unit, a materialunit, a probe unit, a dispensing unit and an integrating sphere. The probe unit can power on a laser chip to emit light; the clamp unit clamps a reflector from the tray unit and transports the reflector to the coupling position of the material unit; the reflector is fixed to the coupling position through dispensing and curing of the dispensing unit; a clamp movement mechanism of the clamp unit can drive a clamp mechanism to move freely to implement precise displacement; the clamp mechanism can implement precise clamping through the double effects of clamping and adsorption; and finally, the integrating sphere can determine whether coupling is completed or not according to reflector reflected light received by a light receiving probe. The device is reasonable in structural design, high inautomation degree, capable of implementing automatic coupling and installation of the reflector, high in clamping precision and capable of effectively improving the coupling efficiency.

Owner:CENT SOUTH UNIV

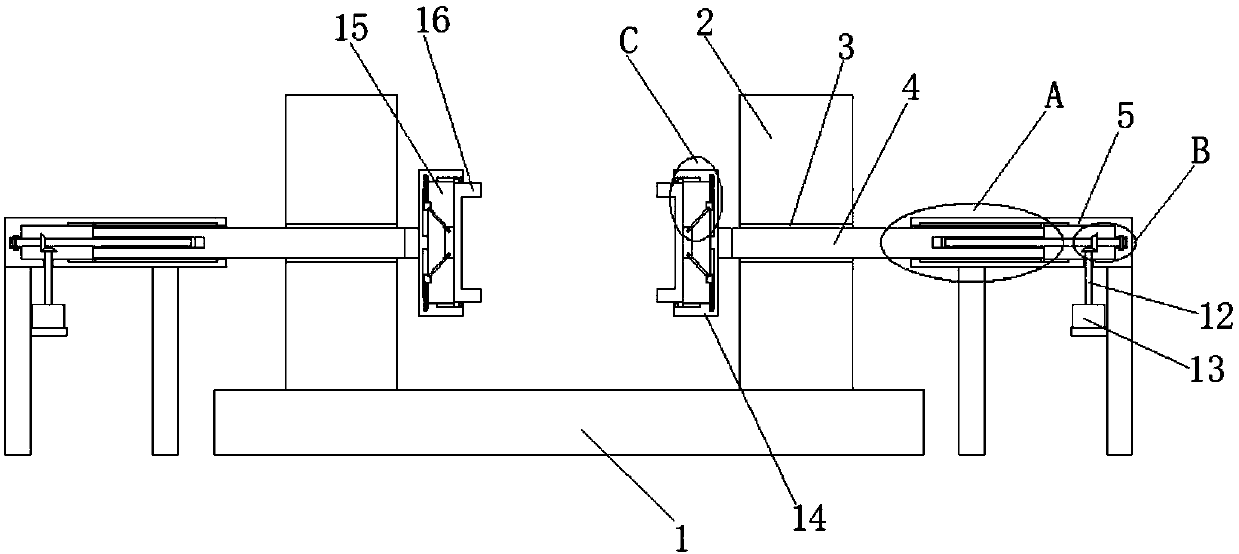

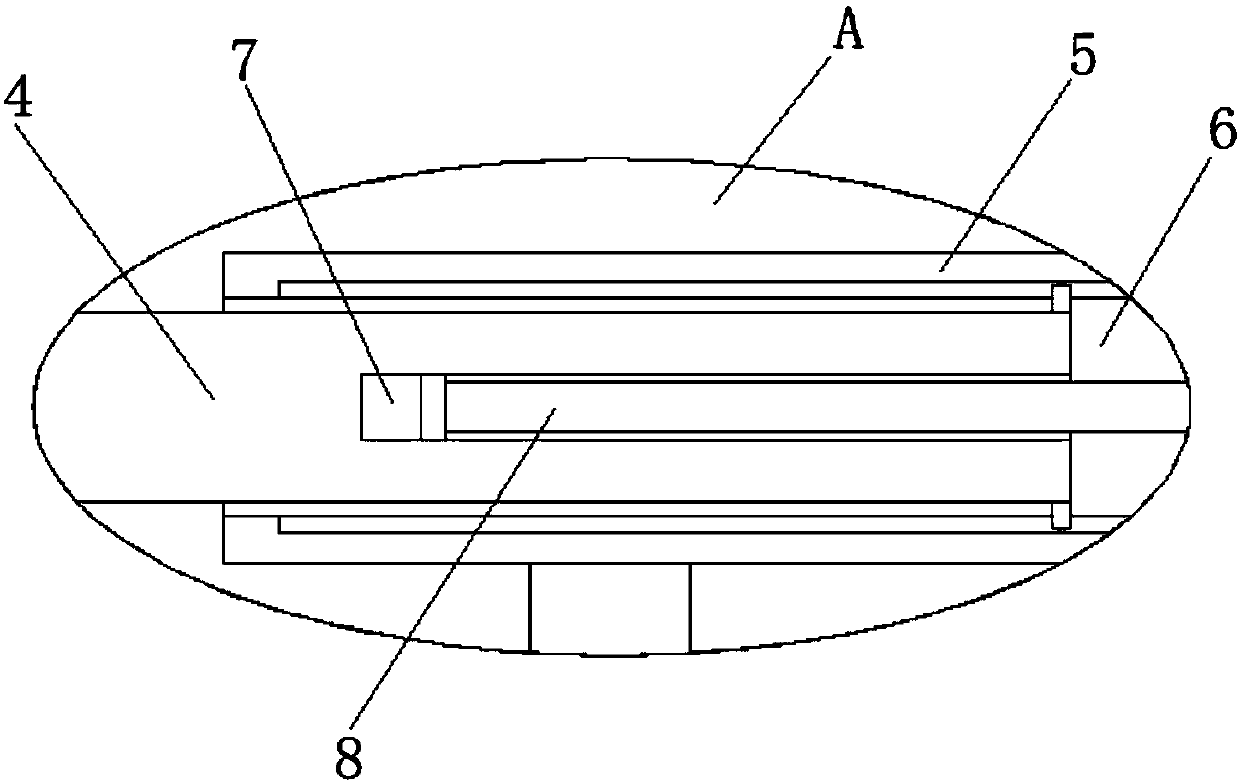

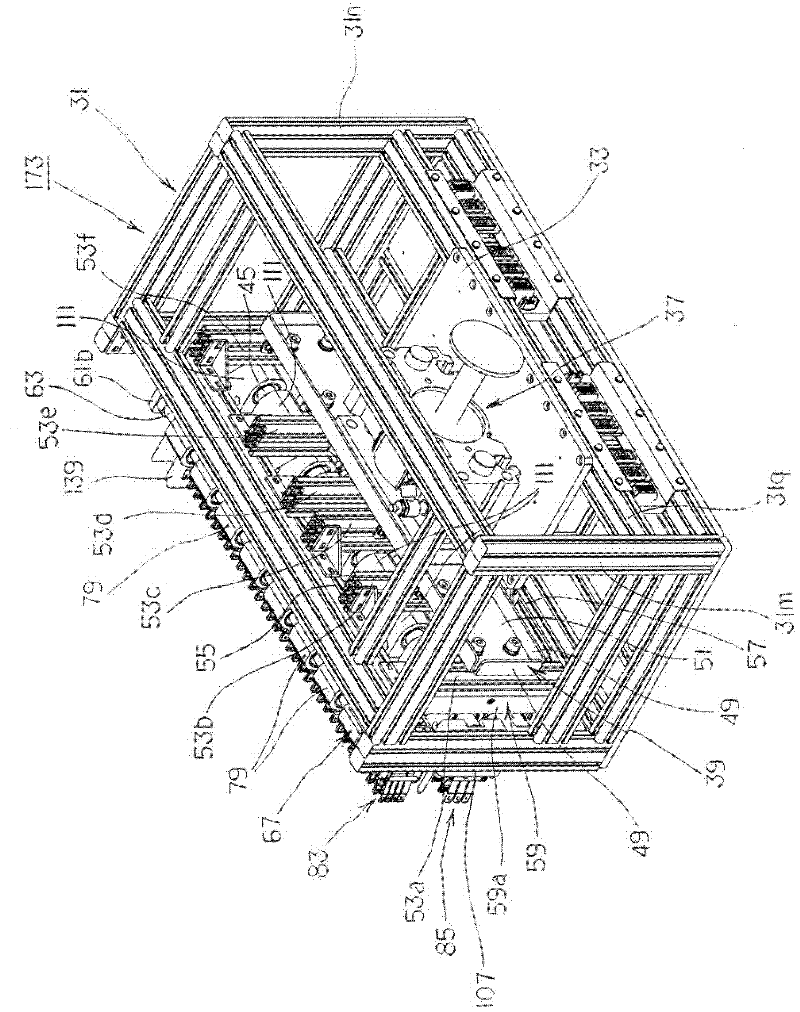

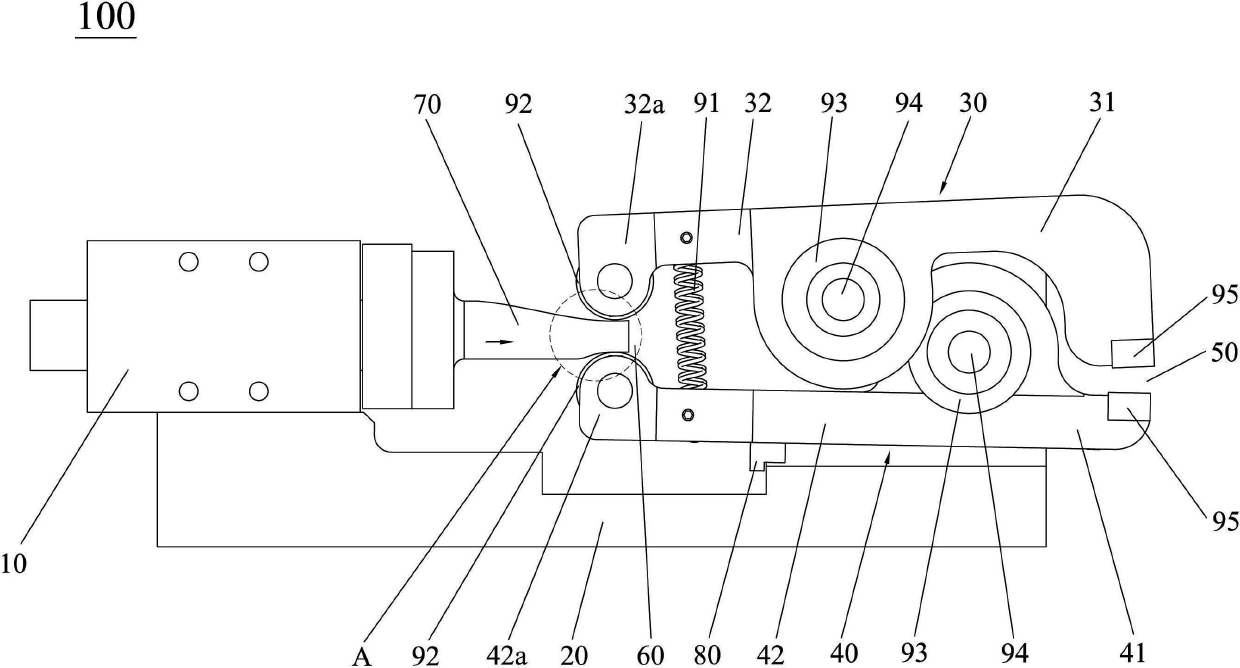

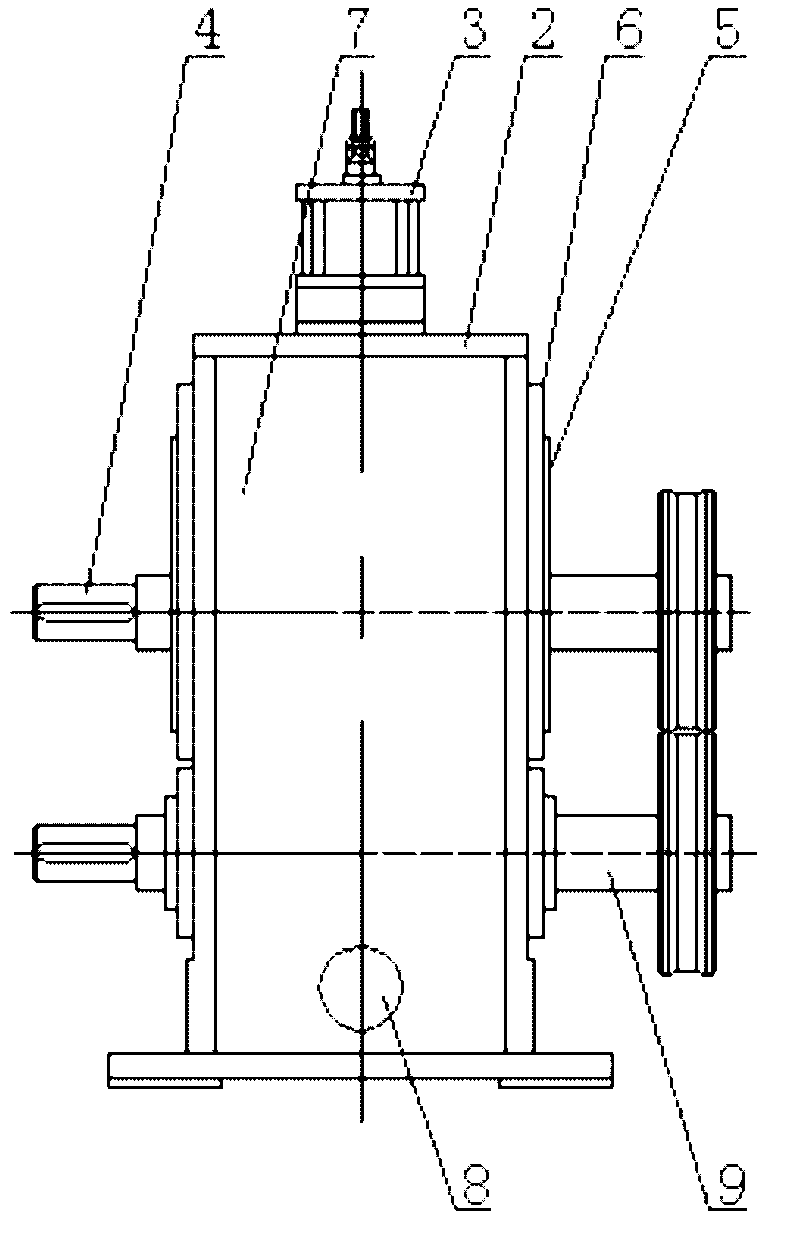

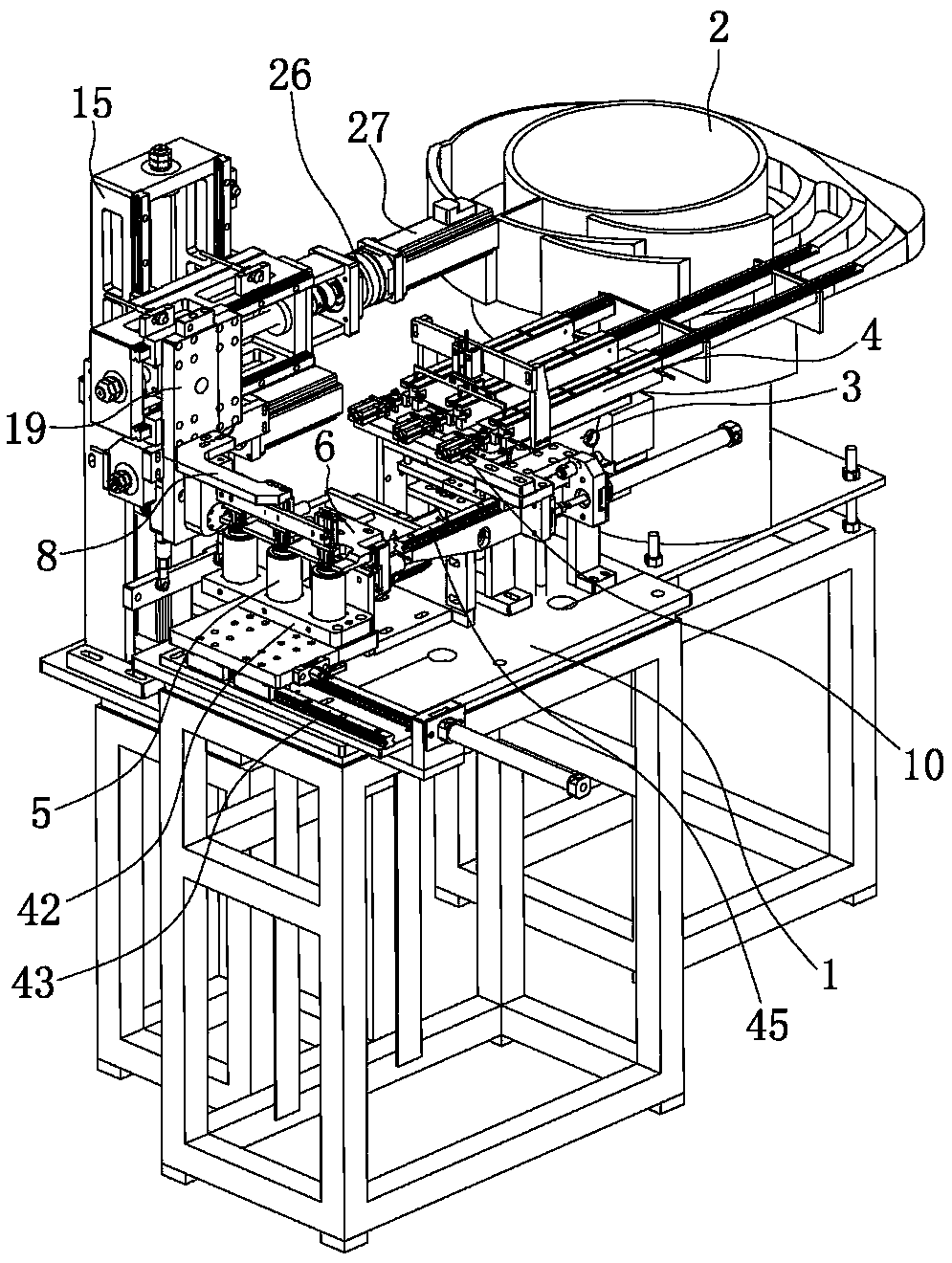

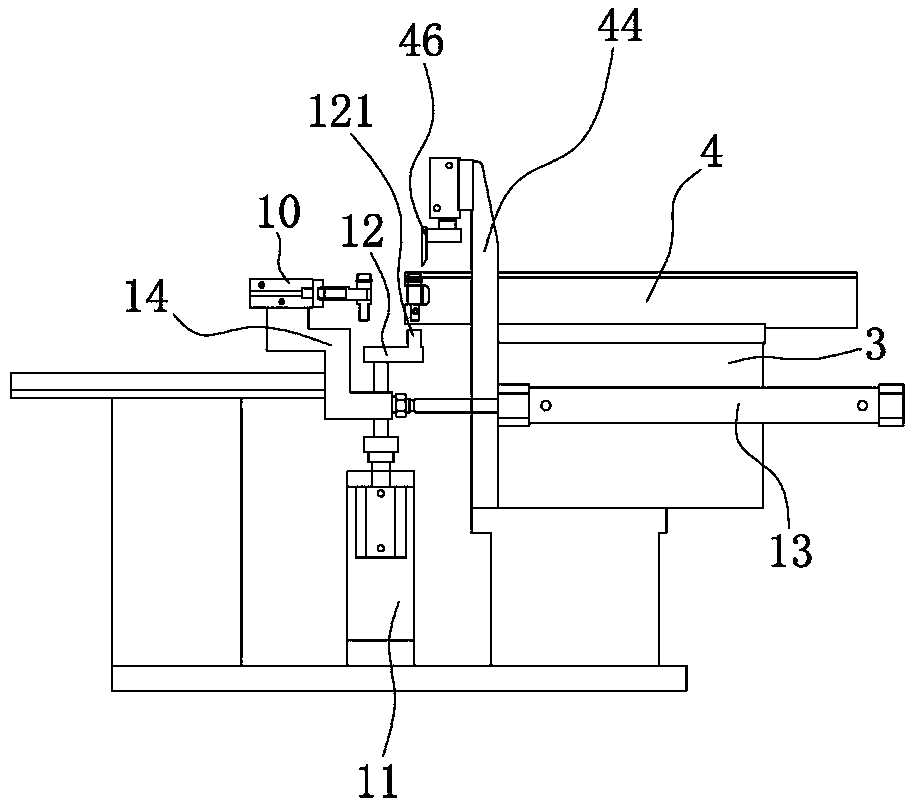

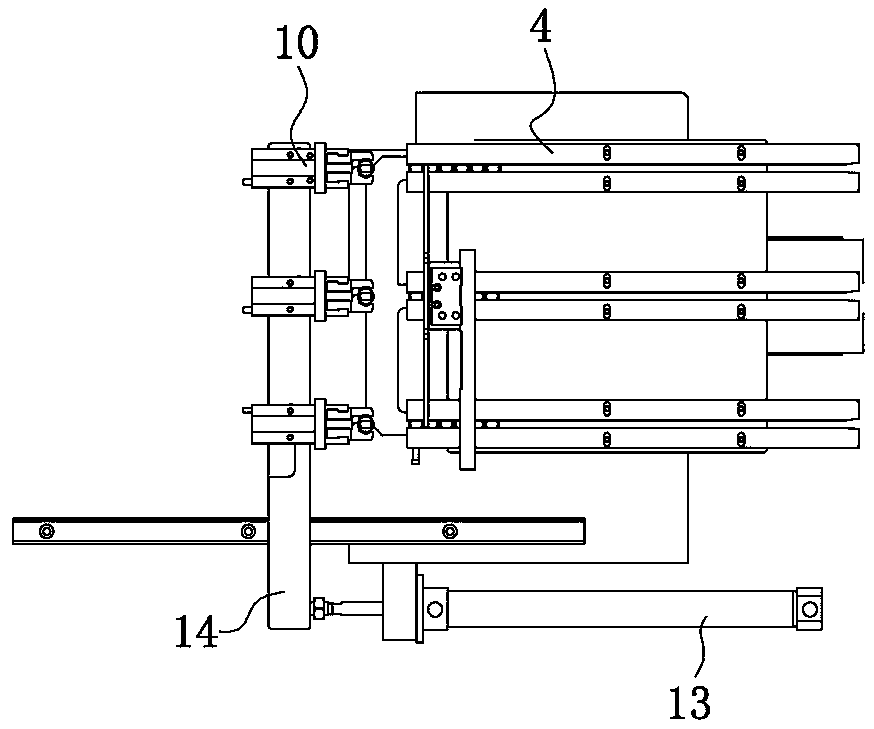

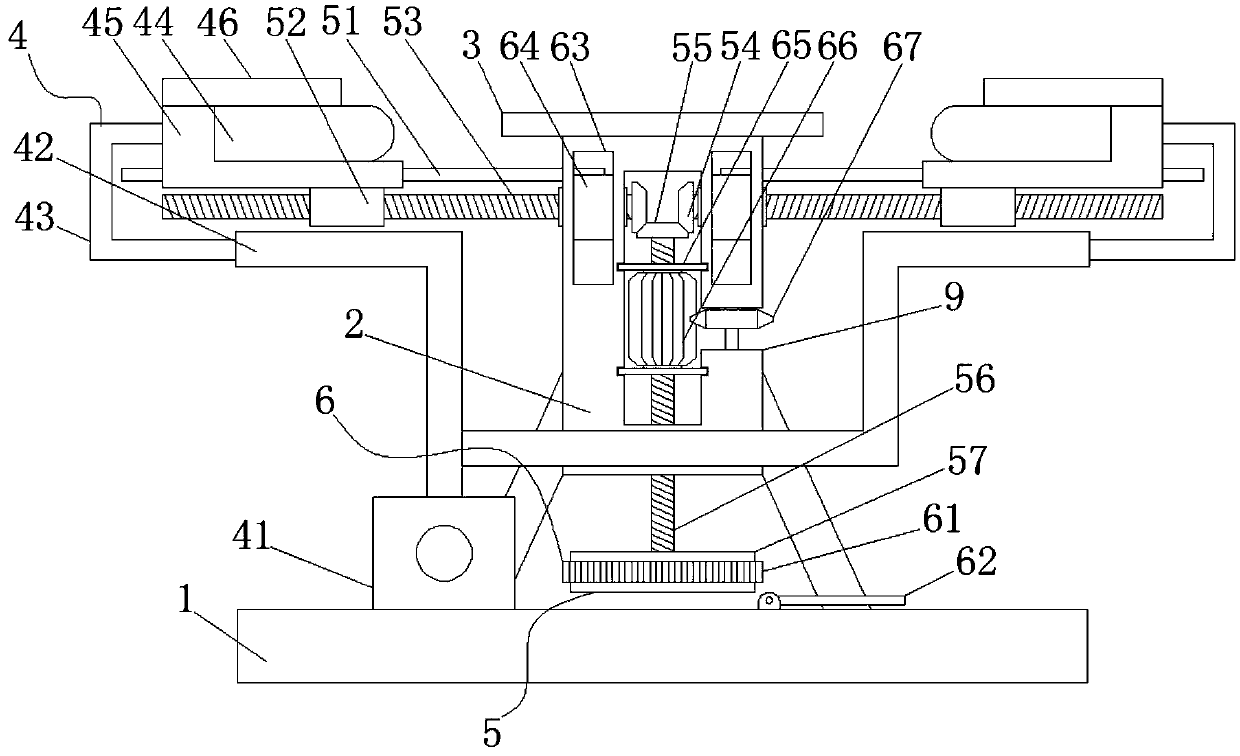

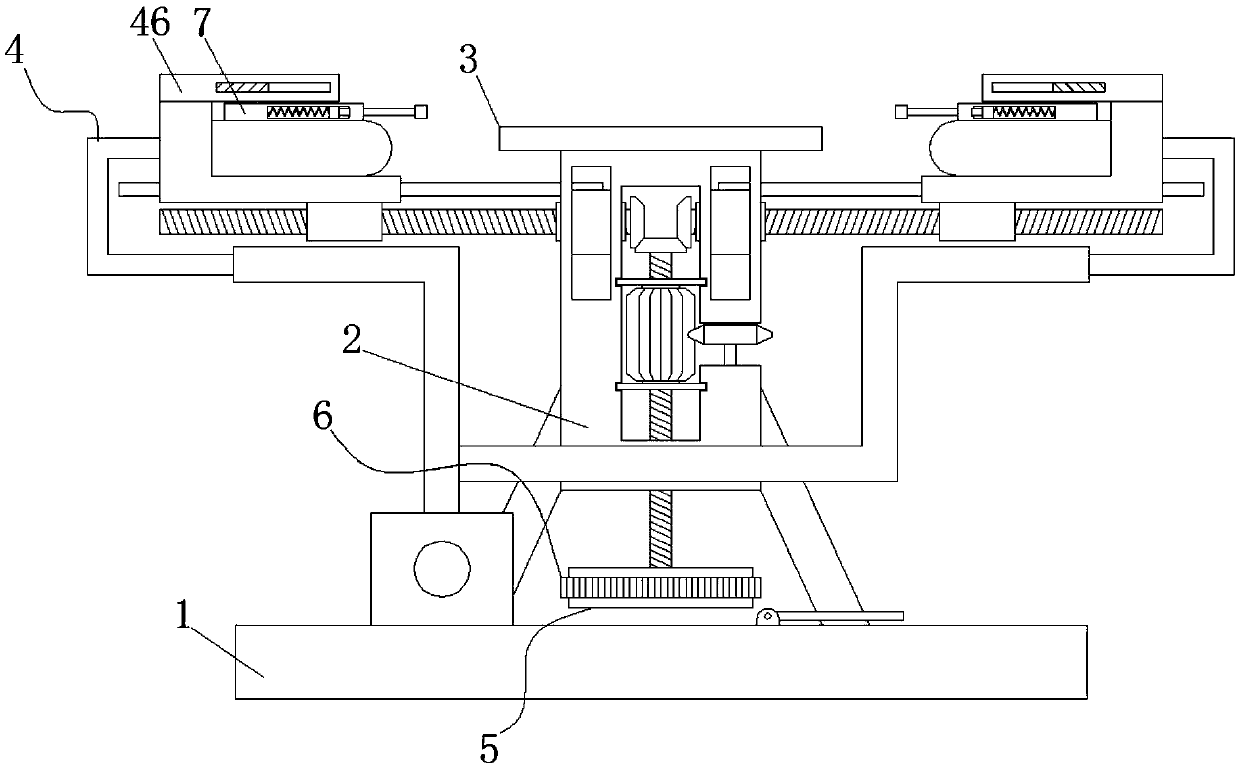

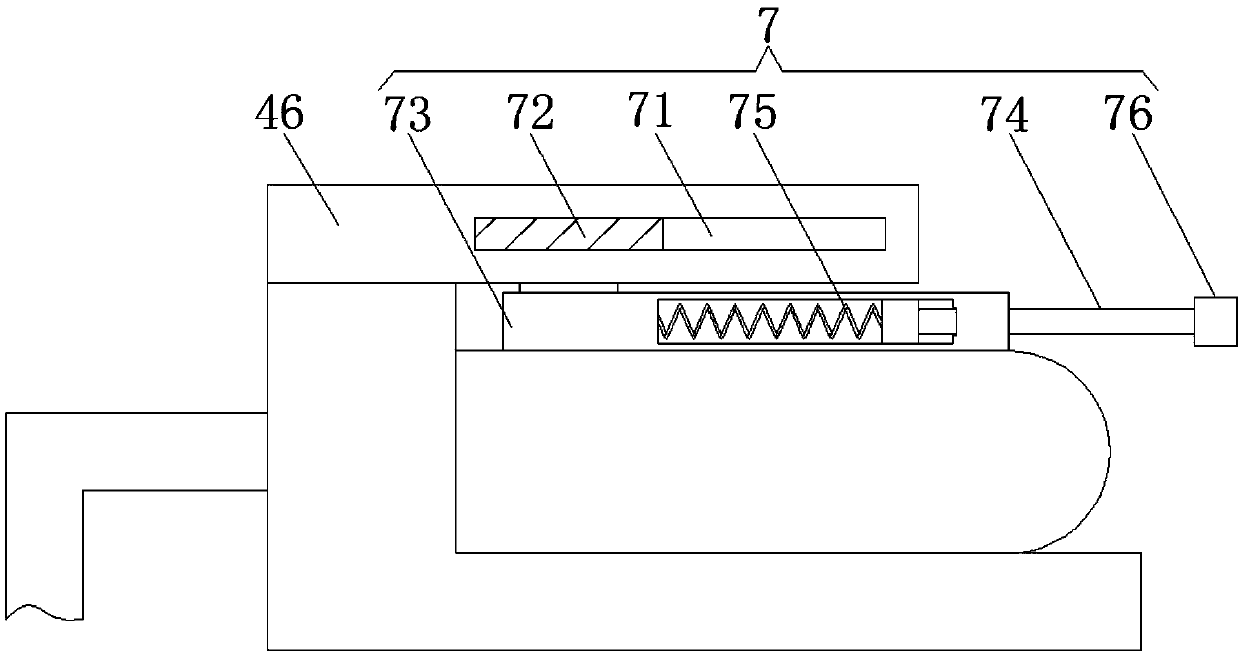

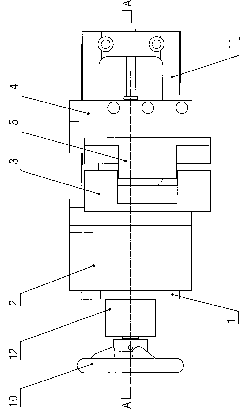

Valve rod and valve body assembling machine

PendingCN109304589AHigh positioning accuracyHigh clamping accuracyMetal working apparatusEngineeringVALVE PORT

The invention provides a valve rod and valve body assembling machine, and belongs to the technical field of machines. The problem that an existing valve rod and valve body assembling machine is low inassembling success rate is solved. The valve rod and valve body assembling machine comprises a workbench, a die base is provided with a notch for a valve rod hole of a valve body to be exposed, a positioning plate is located at the opening part position of an installing cavity for jacking contact of a valve port of the valve body, and the positioning plate is provided with an arranging port. Theworkbench is provided with a supporting structure and a positioning structure, and the die base and / or the positioning plate are / is driven by a displacement mechanism to move. A valve rod arranging device comprises a drive structure, a rotation shaft and a rotation base, the rotation shaft is located at the front end of the drive structure and driven by a rotation mechanism to rotate around the axis of the rotation shaft, the rotation base is fixedly connected to the rotation shaft and fixedly connected with a gas claw, and the distance is formed between the clamping end of the gas claw and the axis of the rotation shaft. After the gas claw clamps the valve rod, the circle center line of the bottom face of the valve rod is basically located at the extension line of the axis of the rotationshaft. The valve rod and valve body assembling machine has the advantages that the assembling precision is high, and the success rate is high.

Owner:台州中通智能科技有限公司

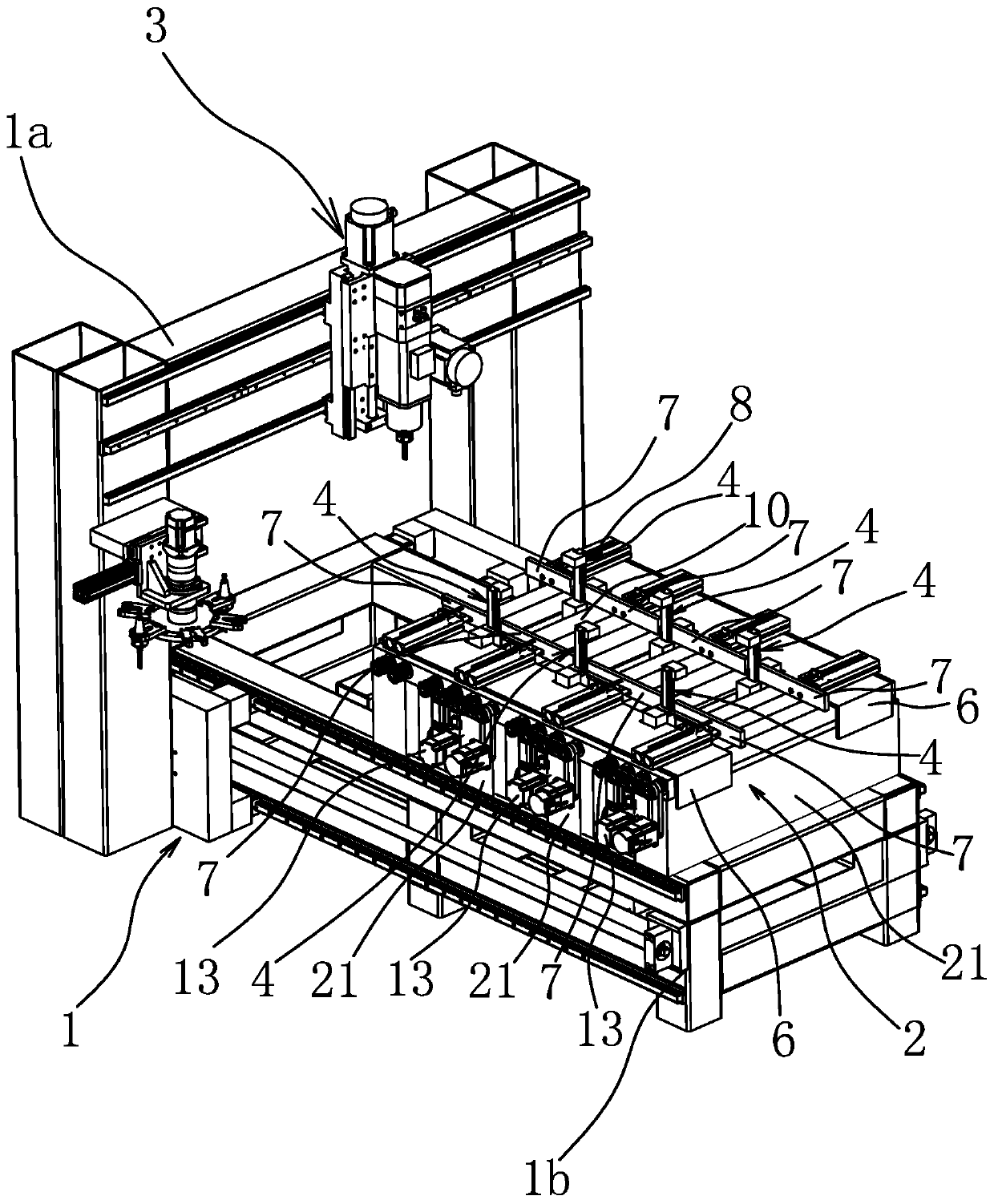

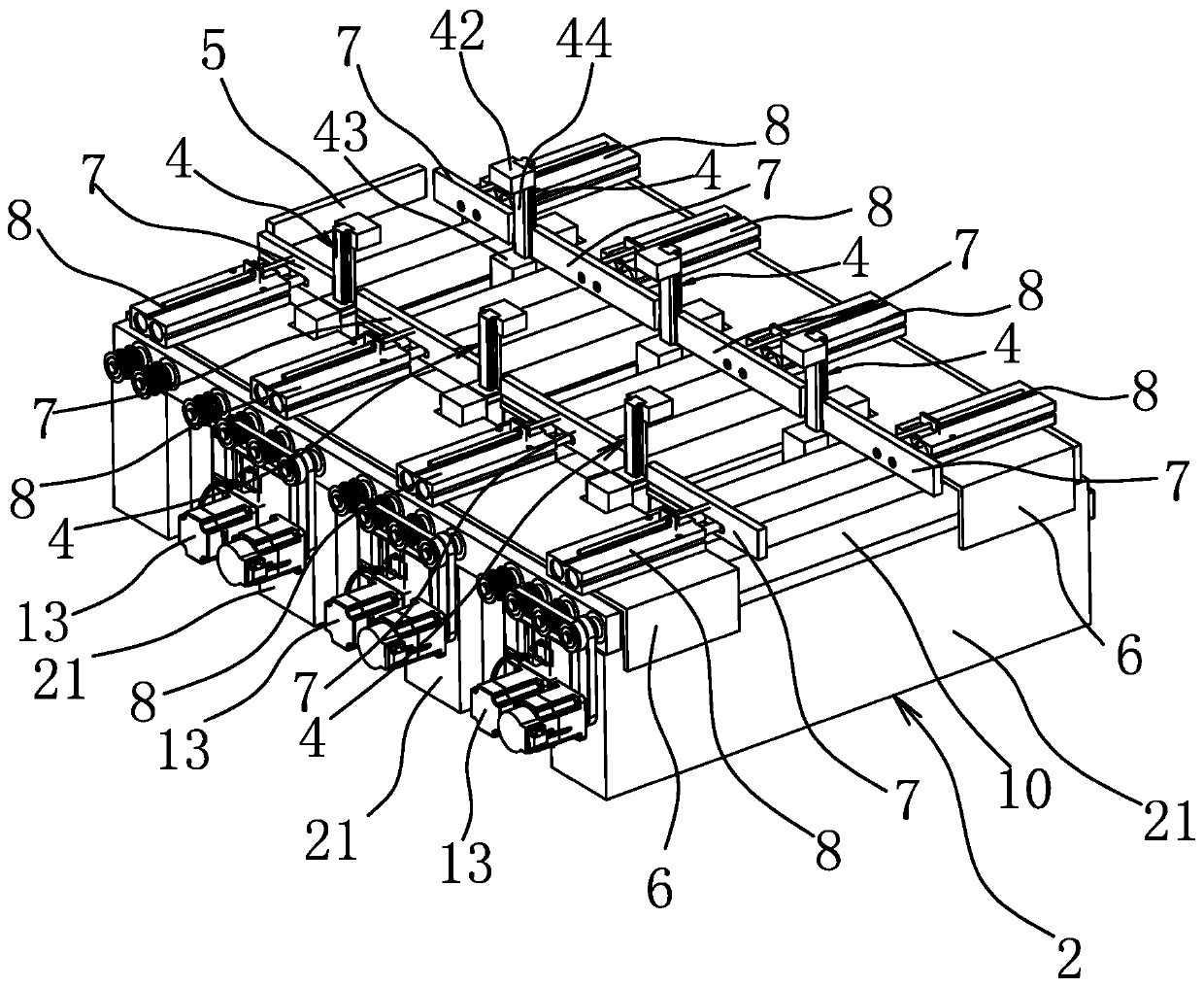

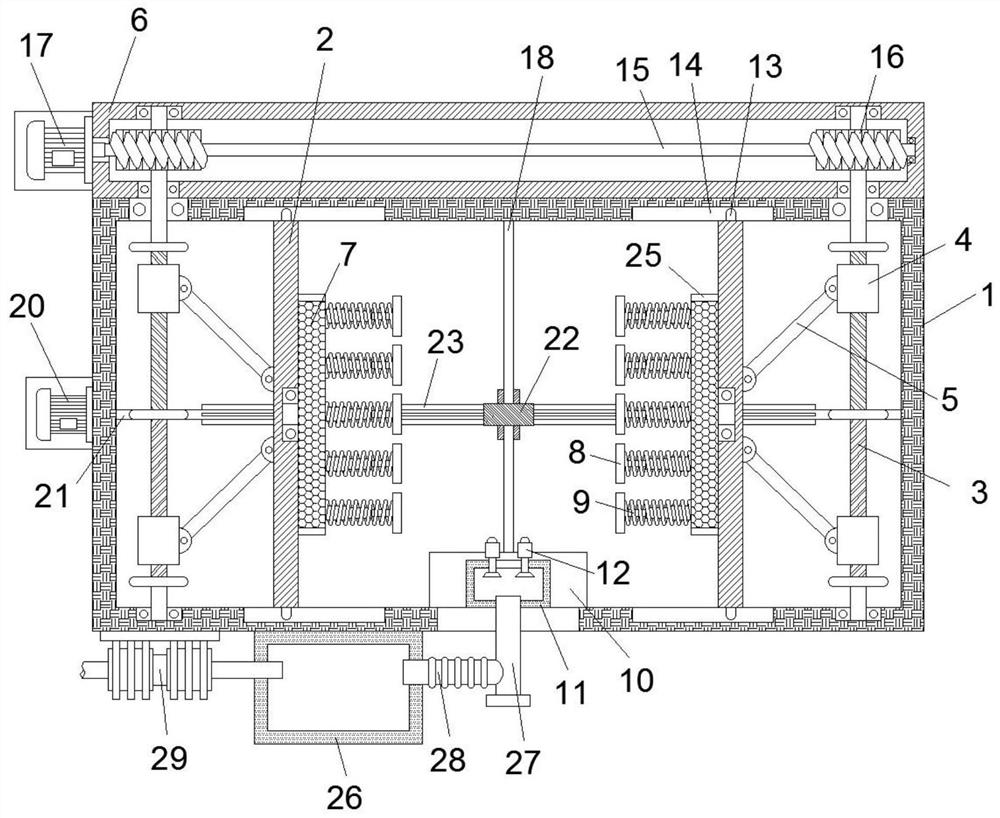

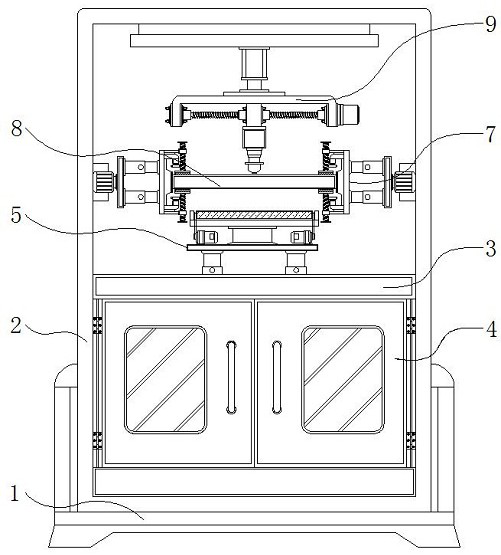

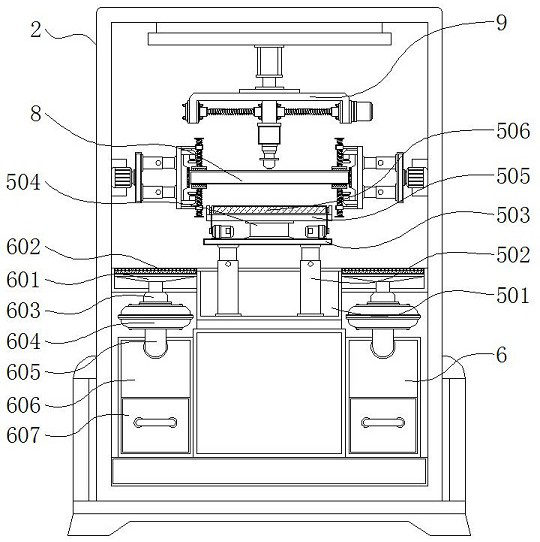

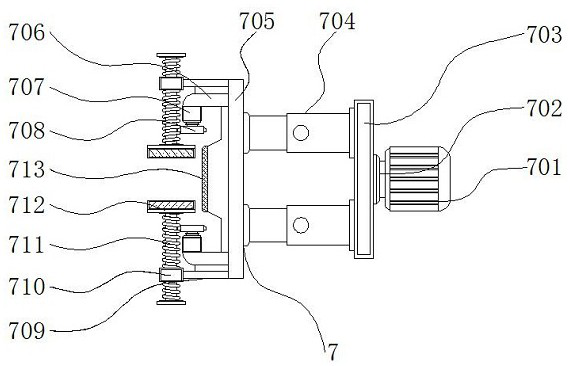

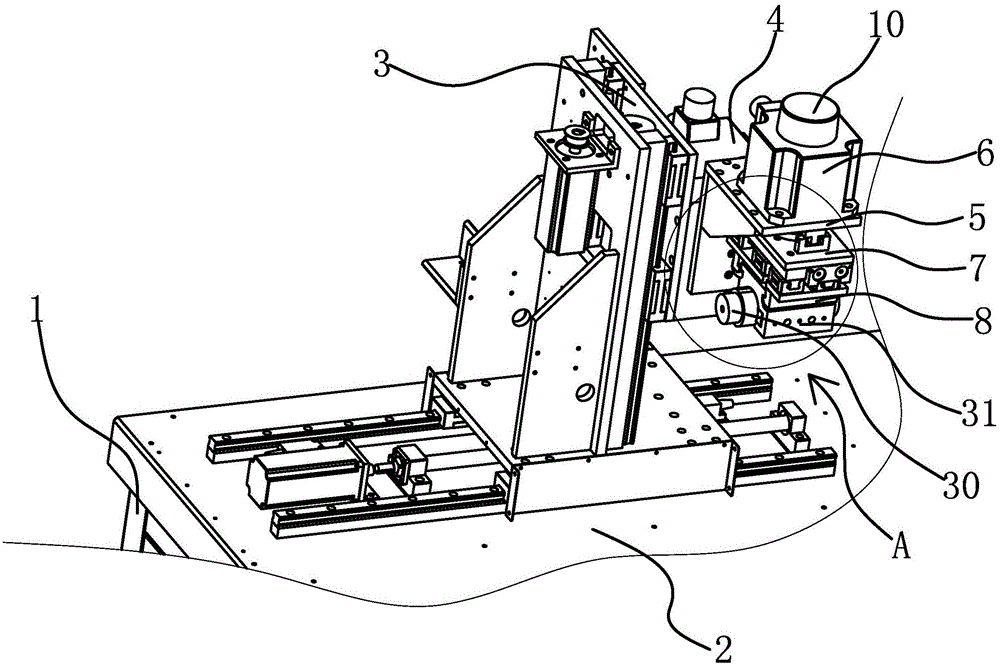

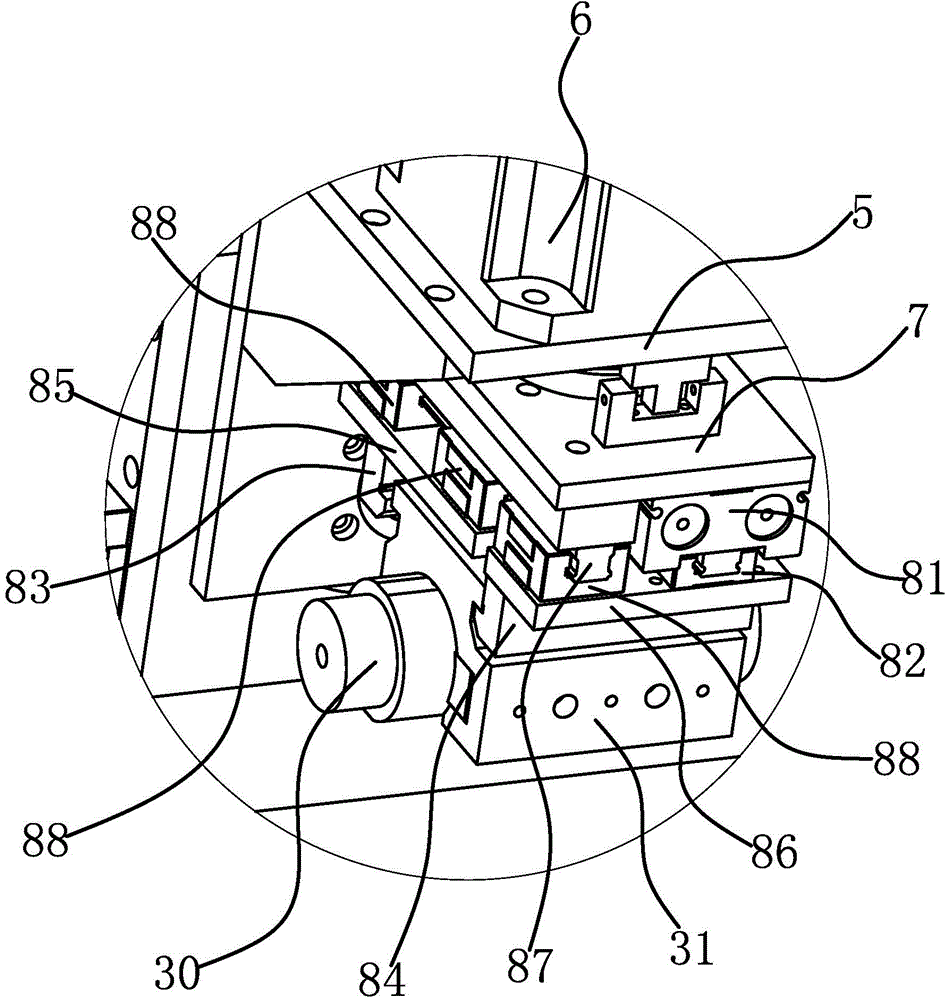

Engraving and milling machine

PendingCN110480377ARealize multi-point clampingImprove stabilityWork clamping meansOther manufacturing equipments/toolsEngineeringMachining

The invention provides an engraving and milling machine, belongs to the technical field of engraving equipment, and solves the problem that it is hard for engraving and milling machines to perform high-precision machining on specially-shaped workpieces in the prior art. The engraving and milling machine comprises a rack and a working platform which is arranged on the rack and used for placing a workpiece; an engraving component which can perform three-dimensional translation relative to the working platform is further arranged on the rack; three or more clamping pieces are arranged on the working platform; any clamping piece is located on one side of the workpiece and can move independently relative to the working platform; and any clamping piece can move in the direction far away from theworkpiece, so that the engraving component can machine contact part, acted by the clamping piece, of the workpiece. The engraving and milling machine has the advantage of high machining precision forthe specially-shaped workpiece.

Owner:吴善旺

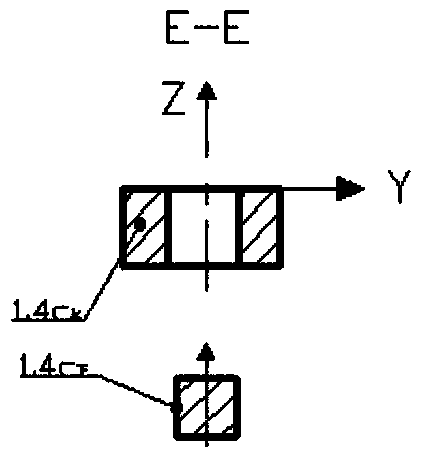

Steel tube clamping device

The invention discloses a steel tube clamping device. The steel tube clamping device comprises a supporting base, a screw rod is arranged on the supporting base, the screw rod is arranged in a threaded hole which is located at the lower end of a sleeve rod, a blind hole is formed in the upper end of the sleeve rod, a spring is arranged in the blind hole, a mandril is arranged in the blind hole, and the upper end of mandril is arranged in a groove of a top plate; a supporting plate is arranged above the top plate, a slide rail is arranged above the supporting plate, a sliding column A and a sliding column B are slidably arranged on the slide rail, one side of the sliding column A is provided with a fixed column A, one side of the fixed column A is provided with a clamping device A, one side of the sliding column B is provided with a fixed column B, one side of the fixed column B is provided with a clamping device B, the other side of the sliding column A is provided with an actuator A, the actuator A is arranged on a support body A, the support body A is arranged above the supporting plate, the other side of the sliding column B is provided with an actuator B, an actuator B is arranged on a support body B, and the support body B is arranged above the supporting plate.

Owner:黄斌

Precision casting part surface sand blasting polishing device

ActiveCN112476252AStable clampingImprove clamping accuracyBlast gunsAbrasive feedersSlide plateReciprocating motion

The invention discloses a precision casting part surface sand blasting polishing device, which comprises a sand blasting box with an opening formed in the upper end; two sliding plates are arranged inthe sand blasting box; the sliding plates are slidably connected to the inner side wall of the sand blasting box; threaded rods are arranged between the two sliding plates and the inner side wall ofthe sand blasting box; the threaded rods are provided with two sections of threads opposite in rotating direction; the two sections of threads are connected with threaded sleeves in a threaded and sleeved mode; the ends, close to the sliding plates, of the threaded sleeves are rotatably connected with pushing rods; the pushing rods are rotatably connected to the side walls of the sliding plates; and a driving box is fixedly connected to the outer side wall of the sand blasting box, and a driving mechanism is arranged in the driving box. By arranging the driving mechanism, the clamping precision can be improved, and subsequent machining treatment is facilitated; and by arranging a rotating disc, a casting part can be driven to rotate at the same time, and complete and efficient sand blasting and polishing treatment is conducted on the surface of the casting part in cooperation with continuous sand blasting and reciprocating motion of a spray head.

Owner:和县华林精密铸造有限公司

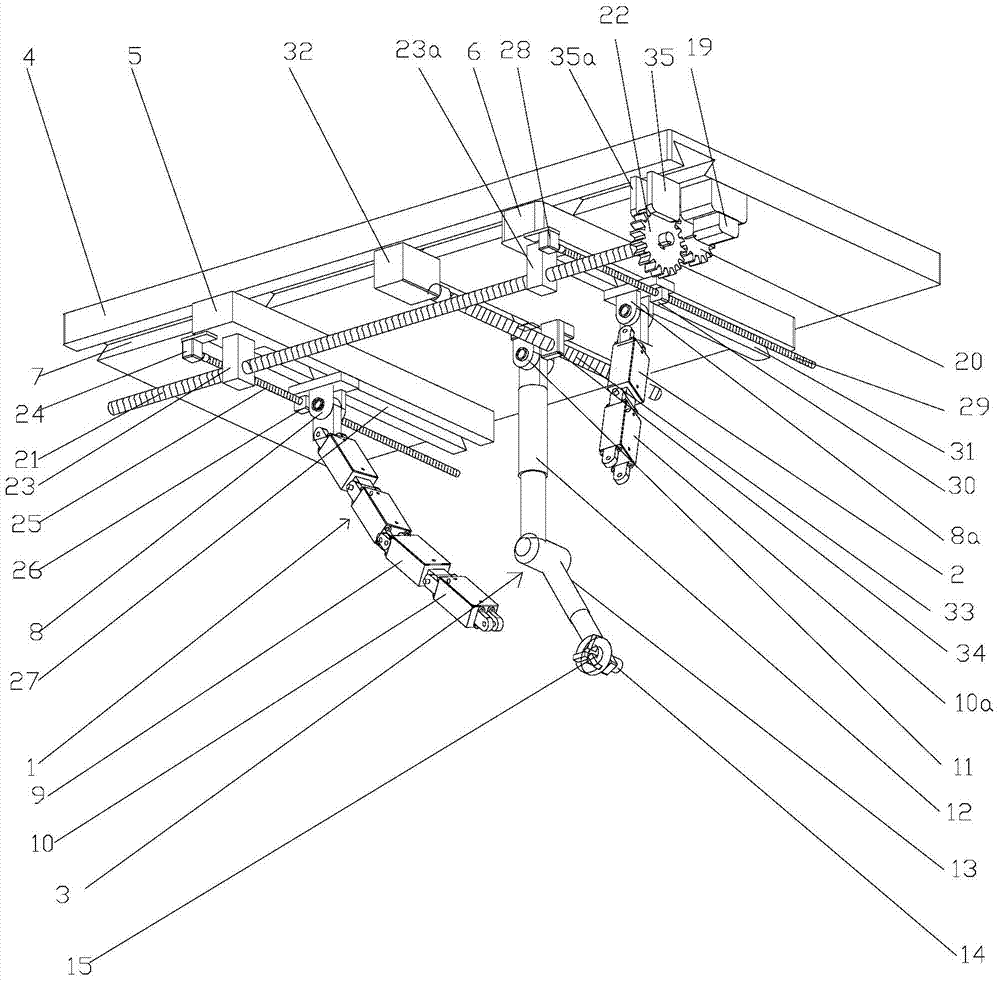

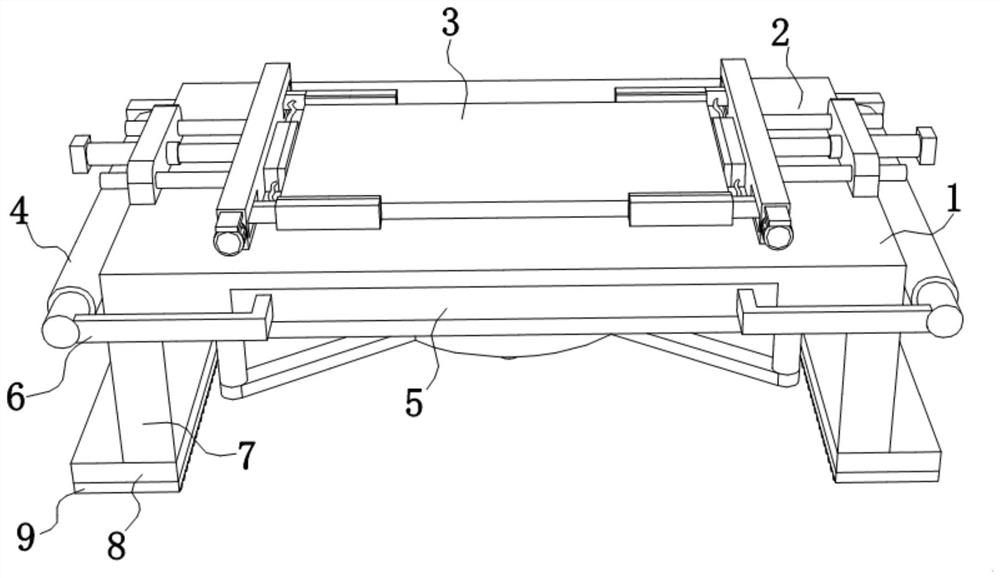

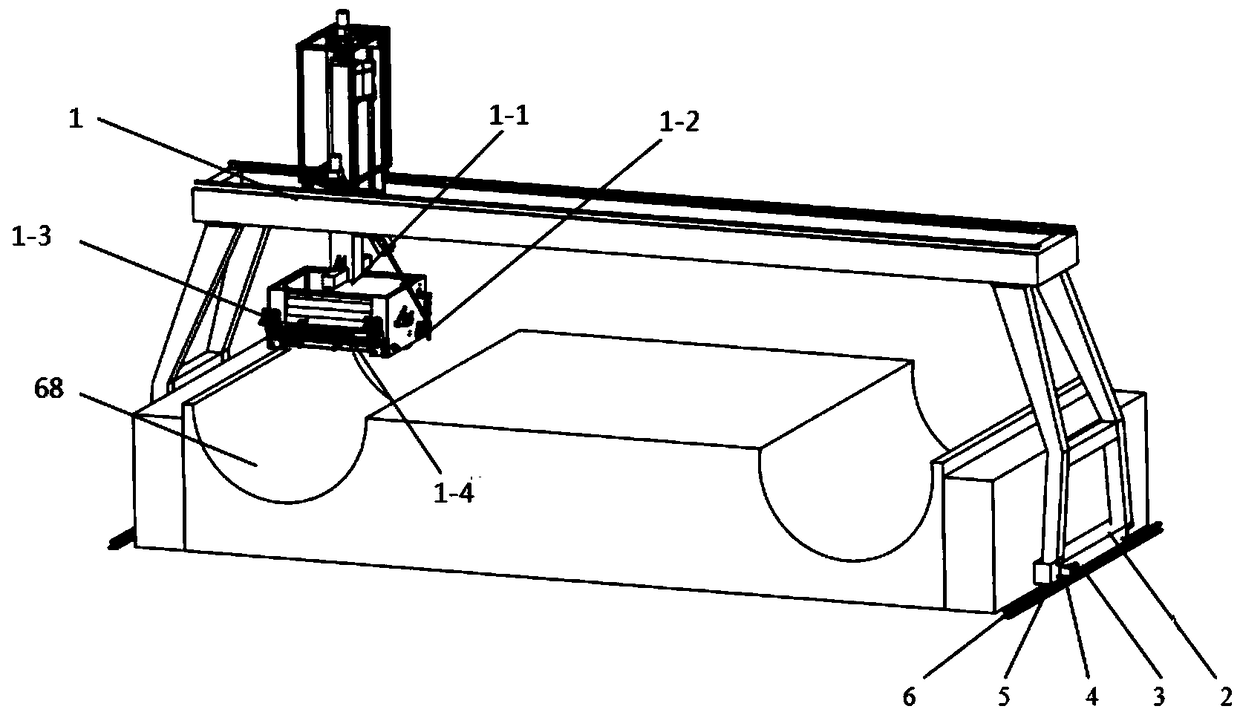

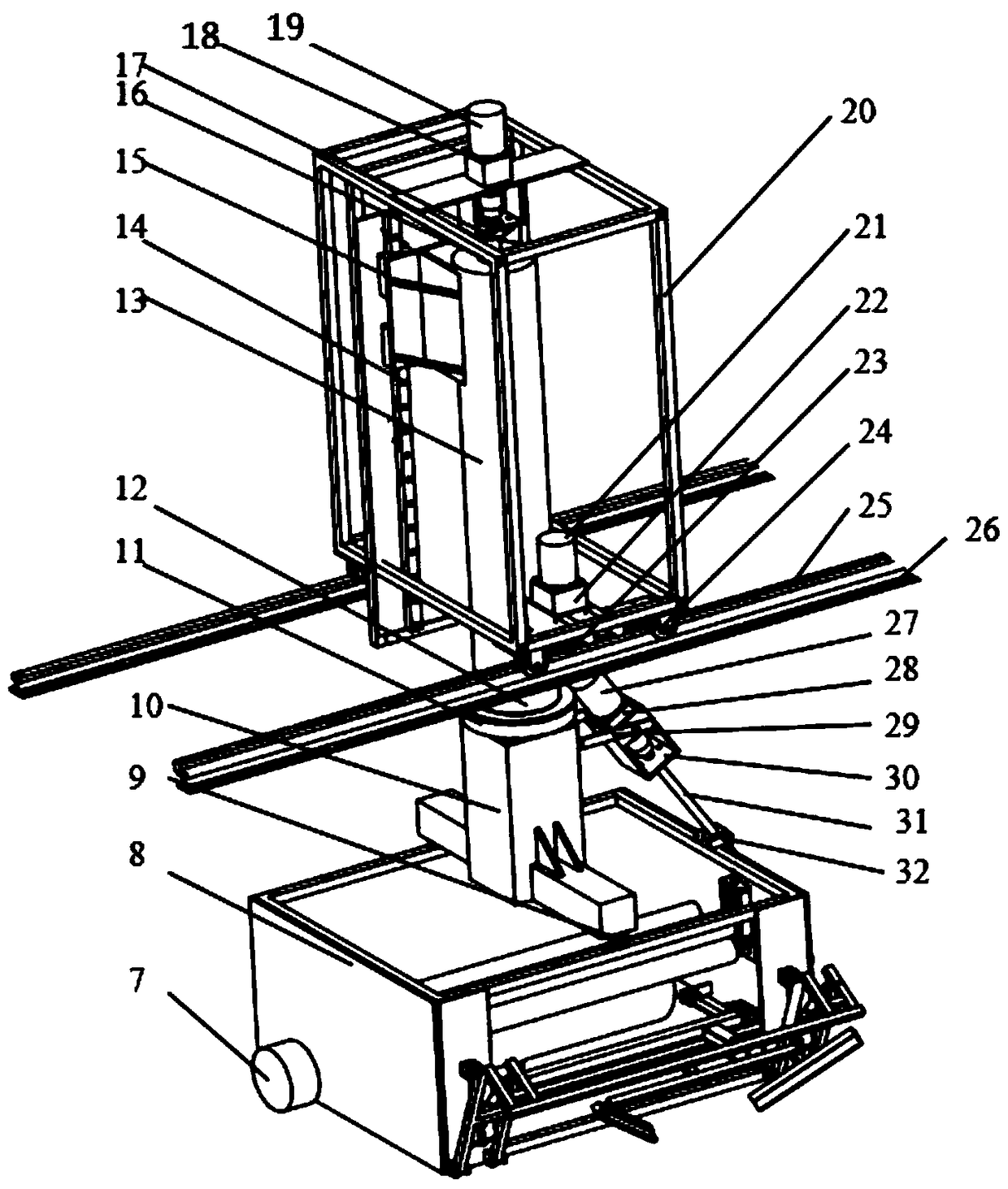

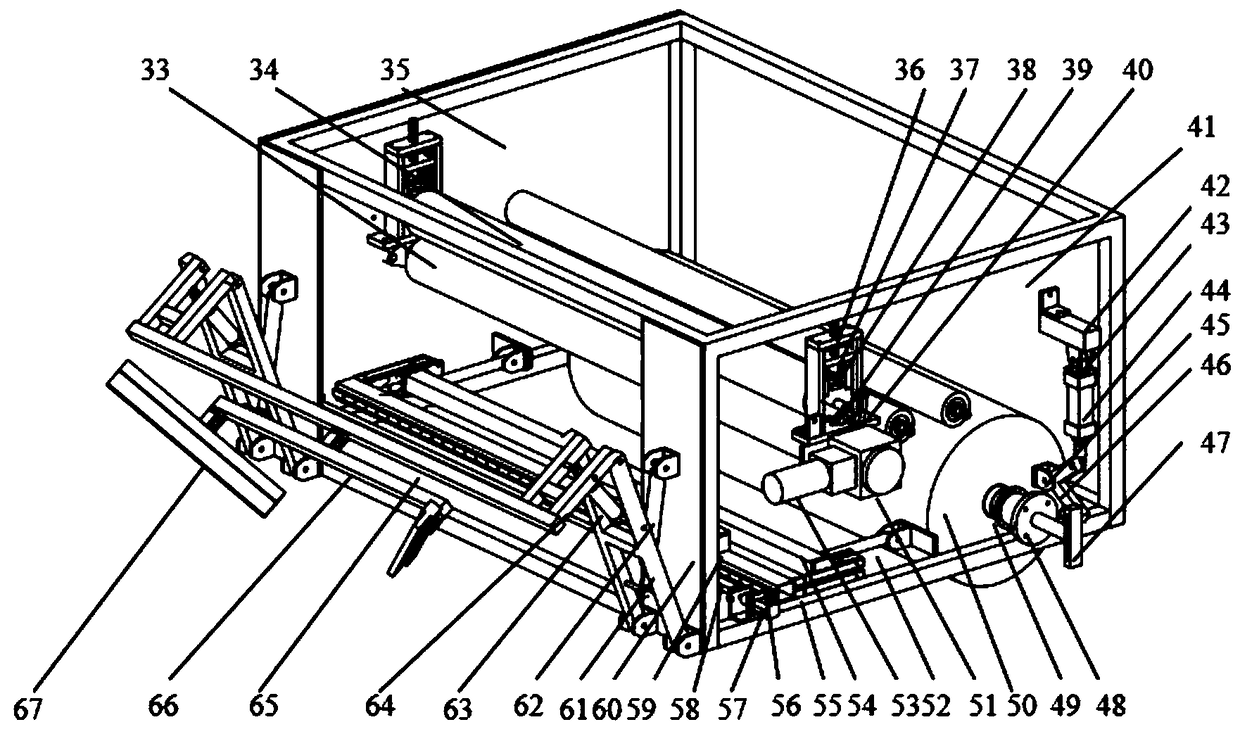

Full-automatic wind turbine blade glass fabric cloth laying device and method

The invention provides a full-automatic wind turbine blade glass fabric cloth laying device and method. The full-automatic wind turbine blade glass fabric cloth laying device structurally mainly comprises a gantry frame. Two end of the gantry frame are mounted on an electric base beam. A servo motor is mounted at the electric base beam. The servo motor is connected with a sheave I by a planetary decelerator I and a servo motor I. The sheave I is located at a ground rail. Two light rails perpendicular to the ground rail are mounted at the gantry frame. A laying device is arranged at the light rails. The bottom of the laying device is connected with a feed device, a cloth pressing device and a cutting device. According to the full-automatic wind turbine blade glass fabric cloth laying deviceand method, the problems that in a manual wind turbine blade glass fabric cloth laying and cutting mode, production efficiency is low, random error is large, and labor intensity is high are solved.

Owner:SHANDONG UNIV OF TECH

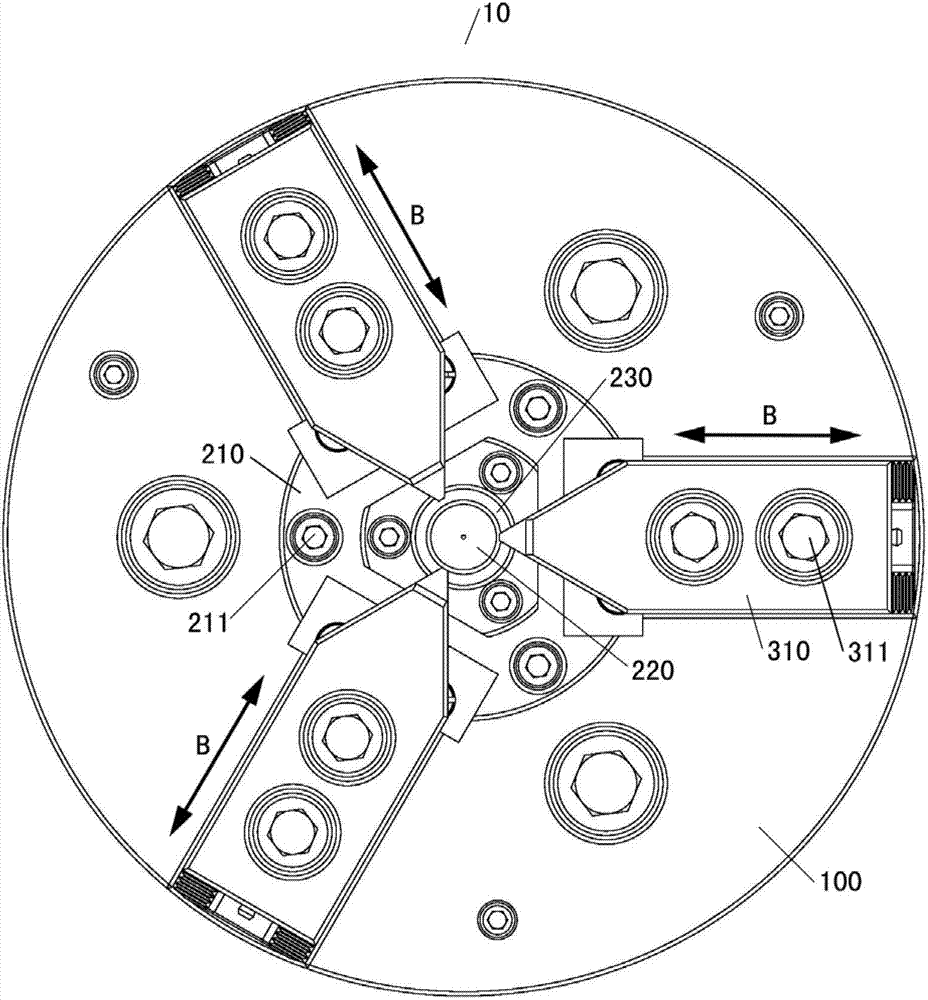

High-accuracy intelligent feeding tool

InactiveCN109607197ANo distractionGuaranteed clamping accuracyCharge manipulationConveyor partsEngineeringCentral symmetry

The invention relates to the technical field of optical lens polishing tool equipment, and discloses a high-accuracy intelligent feeding tool. The high-accuracy intelligent feeding tool comprises a base plate and a supporting column, wherein the supporting column is fixedly installed on the upper end face of the base plate. A supporting platform is fixedly installed on the upper end face of the supporting column, and a window is formed in the right side face of the supporting platform. The high-accuracy intelligent feeding tool further comprises four clamping mechanisms, a horizontal movementmechanism and a vertical movement mechanism. The four clamping mechanisms are arranged on the periphery of the supporting column in a central symmetry distribution mode and used for clamping materialsin the four directions. The horizontal movement mechanism is arranged on the lower end faces of the clamping mechanisms, installed on the supporting column, and used for moving the clamping mechanisms in the horizontal direction and adjusting the clamping force. The vertical movement mechanism is arranged inside the supporting column, and used for adjusting the clamping mechanisms in the verticaldirection and adjusting the clamping height. By the adoption of the high-accuracy intelligent feeding tool, the clamping position can be adjusted according to the size and the thickness of an opticallens, and the clamping accuracy is improved. In addition, flexible clamping operation can be utilized to replace rigid clamping operation, and the lens is better protected.

Owner:武汉安比克科技有限公司

Forming equipment with positioning structure for computer graphics card backboard machining

InactiveCN113172370AEasy to adjustLoad stabilityWelding/cutting auxillary devicesDirt cleaningGear wheelElectric machinery

The invention discloses forming equipment with a positioning structure for computer graphics card backboard machining, and relates to the technical field of computer graphics card backboard machining. The forming equipment comprises an equipment outer frame, a positioning clamping mechanism and a welding forming mechanism, a base is arranged under the equipment outer frame, and a workbench is fixed in the middle of the interior of the equipment outer frame; and an opening and closing door is mounted on the outer side of the lower portion of the equipment outer frame and connected with the equipment outer frame through hinges, and a feeding mechanism is arranged on the upper portion of the middle of the workbench and comprises a mounting frame, hydraulic push rods, a supporting plate, a bearing column, a bearing plate and a conveying belt. The forming equipment has the beneficial effects that the positioning clamping mechanism of the forming equipment is provided with gears and threaded rods, the gears are conveniently driven to rotate through a micro motor, the gears and the threaded rods are of an engaged structure so that the rotating gears can drive the threaded rods to move up and down, the positions of positioning plates at one ends of the threaded rods can be conveniently adjusted, and attaching gaps of the positioning plates is reduced.

Owner:长沙市熊亮机电设备有限公司

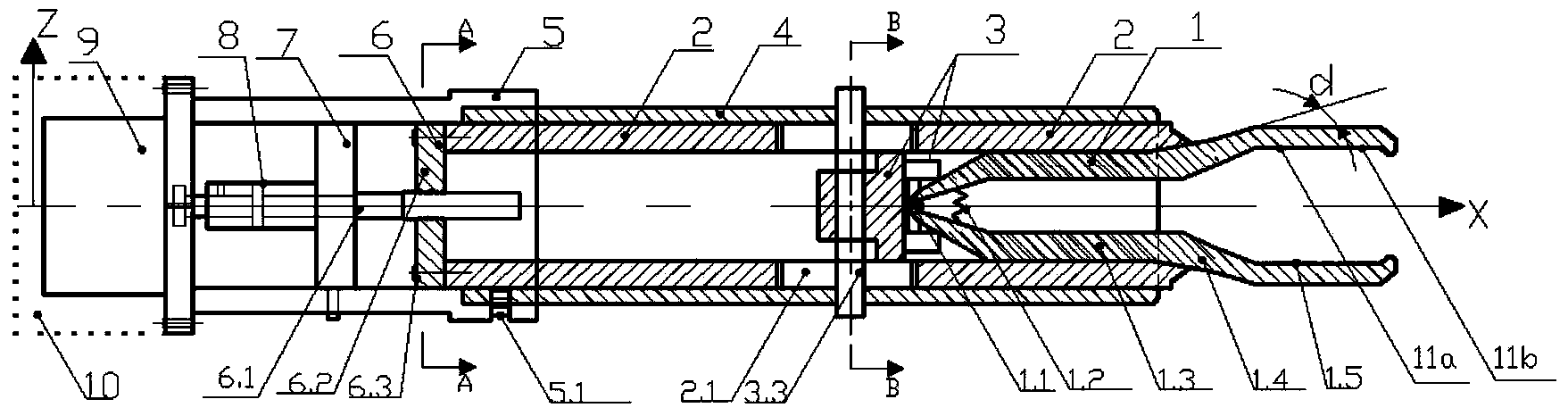

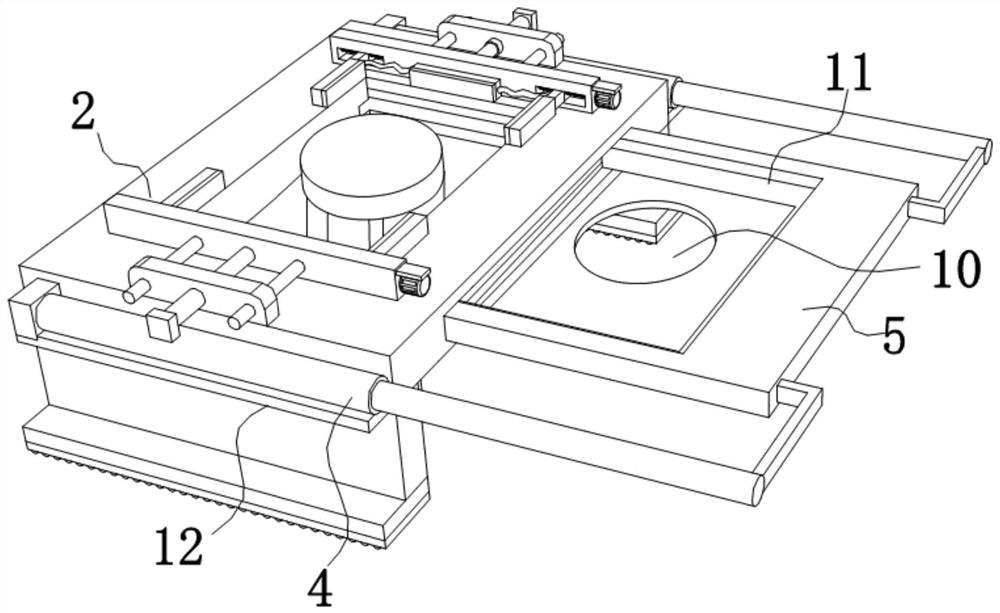

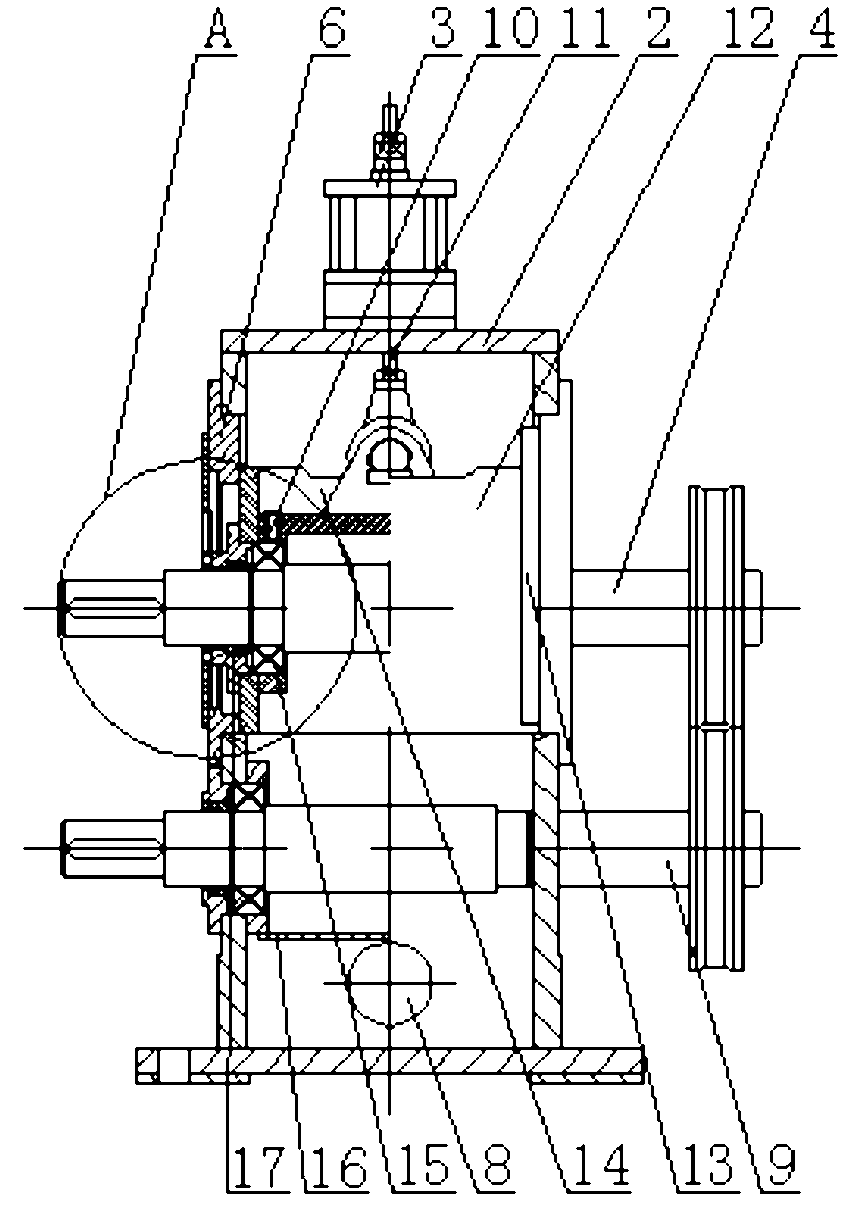

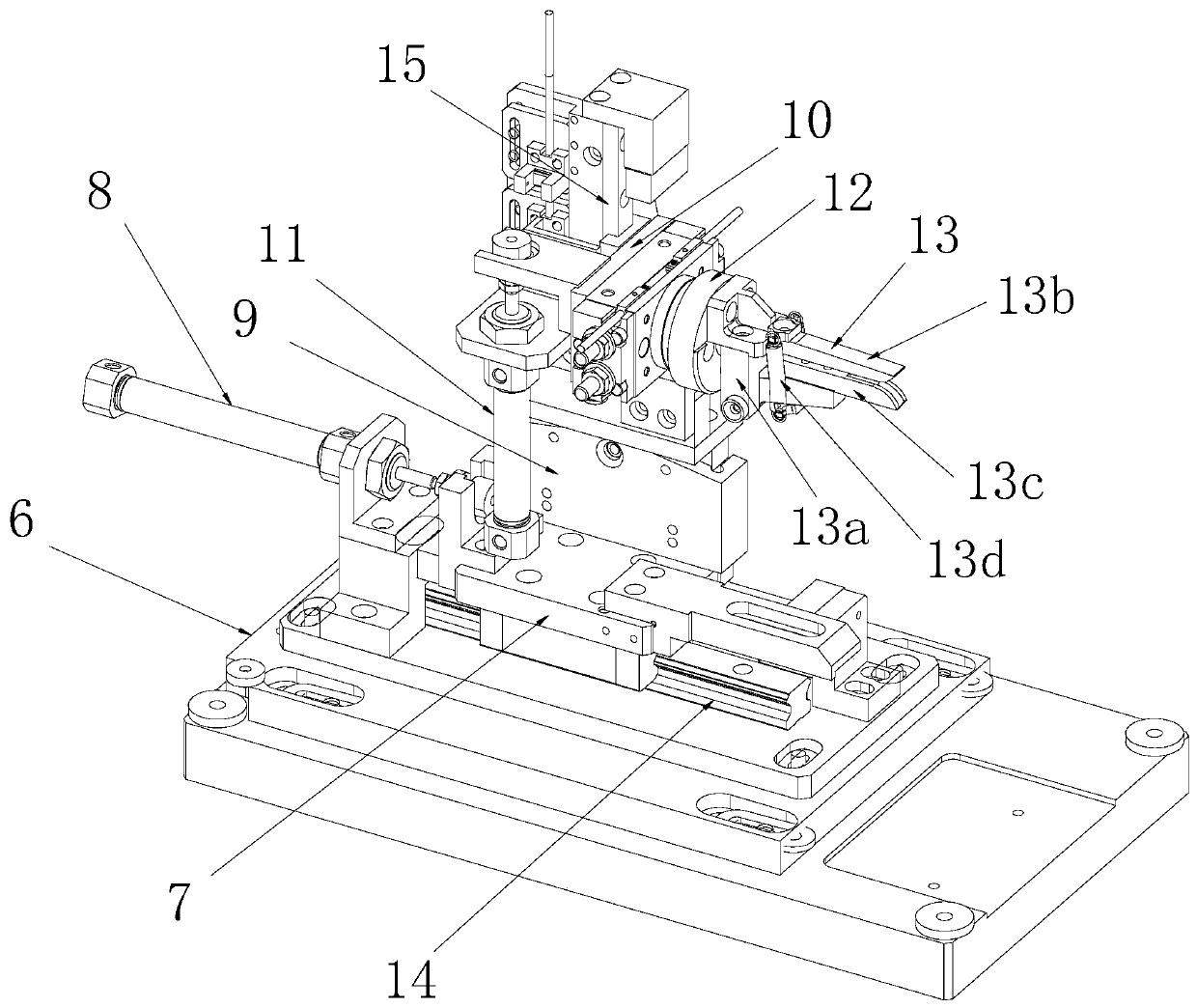

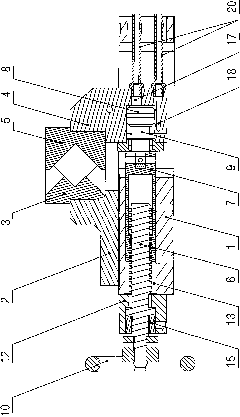

Crystal angle adjusting mechanism of automatic X-ray directional bonding machine of round-bar crystals

ActiveCN104458779AHigh orientation accuracyAccurate collectionMaterial analysis using radiation diffractionX-rayDrive motor

The invention provides a crystal angle adjusting mechanism of an automatic X-ray directional bonding machine of round-bar crystals and belongs to the technical field of measuring equipment. By adoption of the crystal angle adjusting mechanism, the problem that the crystal angle adjustment of an existing automatic directional bonding machine is troublesome and is low in accuracy is solved. The crystal angle adjusting mechanism comprises an installing plate I, wherein a vertical-rotation driving motor is fixedly arranged on the installing plate I; a main shaft of the vertical rotation driving motor is positioned at the horizontal position; an installing plate II is fixedly arranged at the front end of the vertical rotation driving motor; a horizontal rotation driving motor is fixed on the installing plate II; a main shaft of the horizontal rotation driving motor is downward; an installing plate III is fixedly arranged at the front end of the horizontal rotation driving motor and is provided with a pneumatic clamping claw; and an encoder I is connected with the rear end of the main shaft of the vertical rotation driving motor, and an encoder II is connected with the rear end of the main shaft of the horizontal rotation driving motor. The crystal angle adjusting mechanism provided by the invention has the advantage of high adjusting accuracy.

Owner:台州昌泓机器人有限公司

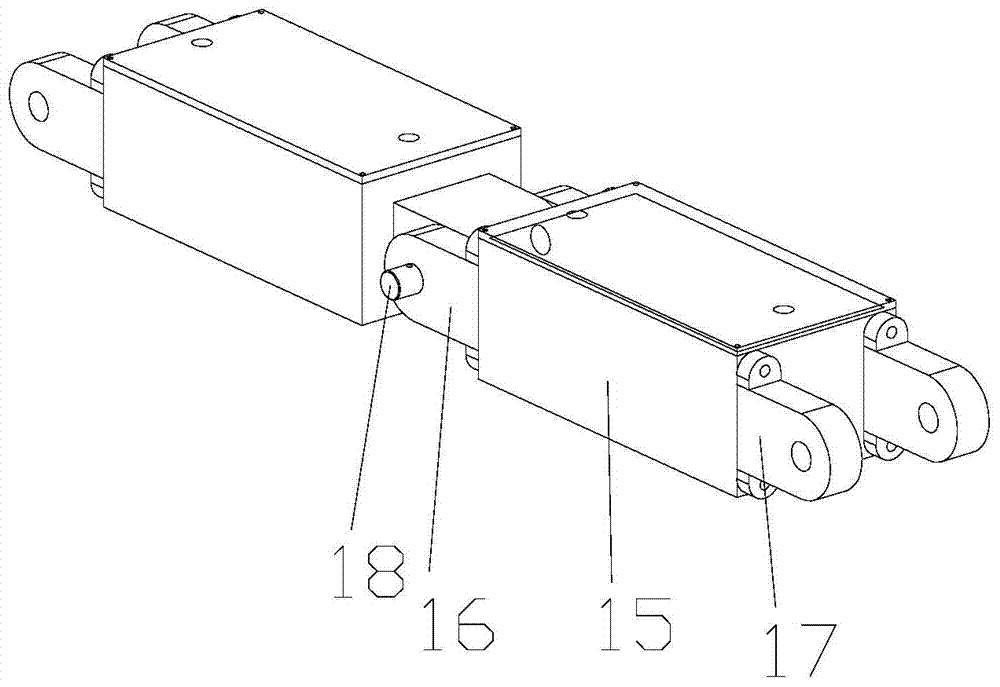

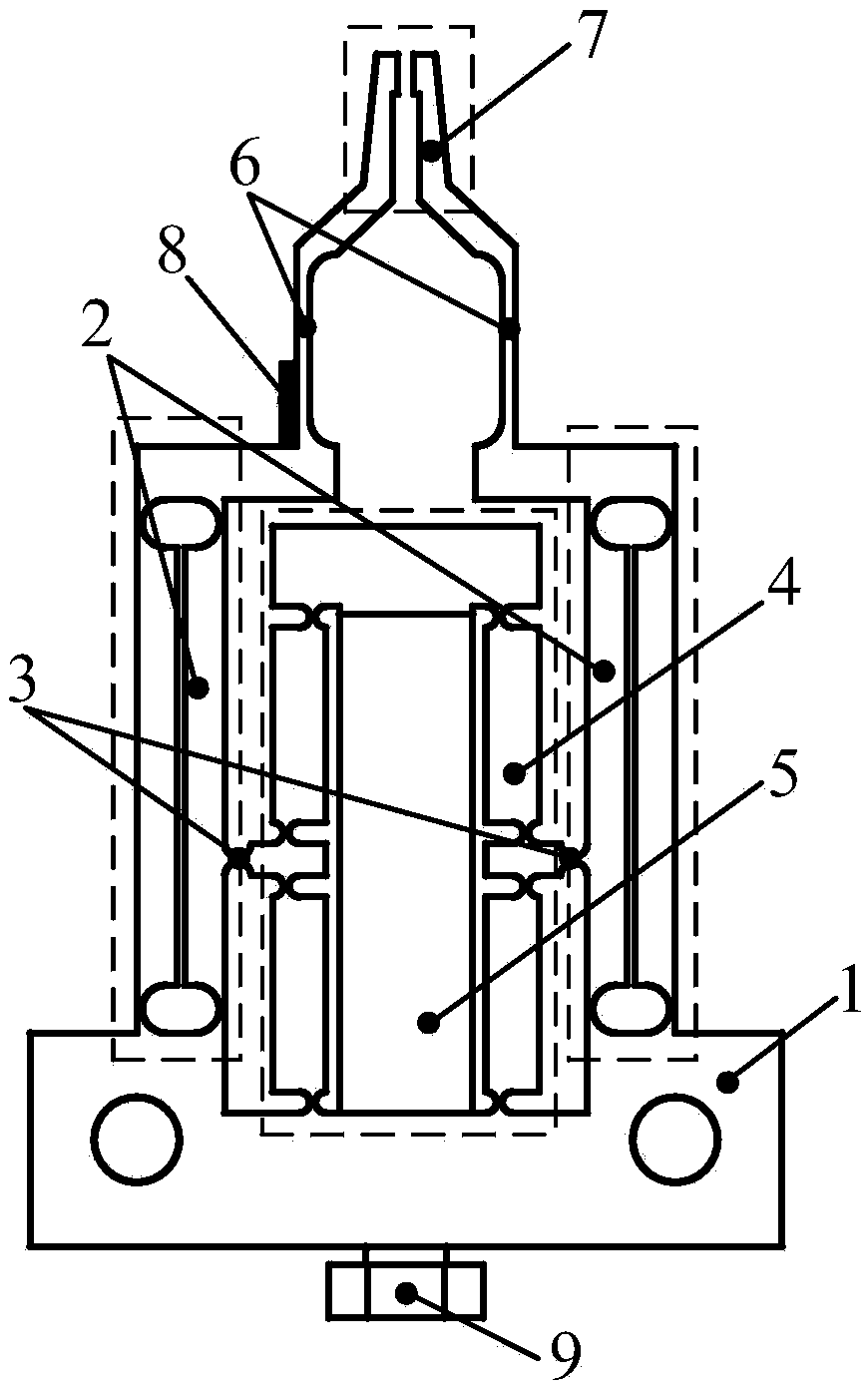

Automatic turnover device for welding cylindrical lithium ion battery cap assembly

PendingCN110216395AImprove assembly efficiencyReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention discloses an automatic turnover device for welding a cylindrical lithium ion battery cap assembly. The automatic turnover device comprises a base, a translation block, a translation driving device, a supporting vertical frame, a lifting block, and a lifting driving device; wherein the translation block is arranged on the base through a horizontal guide mechanism; the translation driving device is connected with the translation block and drives the translation block to move forwards and backwards along the horizontal guide mechanism; the supporting vertical frame is fixed on the horizontal moving block; a lifting block is arranged on the supporting vertical frame through a longitudinal guide mechanism; the lifting driving device is connected with the lifting block and drives the lifting block to move up and down along the longitudinal guide mechanism; the lifting block is provided with a rotary driving device; and the rotary driving device is connected with an elastic chuck driven by the rotary driving device to rotate. The turnover of the battery cap assembly between two welding can be implemented by the automatic turnover device instead of workers, so that the assembly efficiency of a battery cap is greatly improved by matching with an assembly line, the labor intensity of the workers is reduced, and the labor cost is reduced.

Owner:伊欧激光科技(苏州)有限公司

Piezoelectric actuated two-arm type high-speed lead wire clamp

InactiveCN105366634AReduced overall mass and moment of inertiaReduce volumeDecorative surface effectsSolid-state devicesElectricityHinge angle

The invention discloses a piezoelectric actuated two-arm type high-speed lead wire clamp. The piezoelectric actuated two-arm type high-speed lead wire clamp is molded integrally through linear cutting of a board and comprises a base body; two parallelogram mechanisms which are in forward-backward symmetry and a bridge-shaped displacement amplification mechanism are formed at one side of the base body; a piezoelectric ceramic actuator is arranged in the bridge-shaped displacement amplification mechanism; each parallelogram mechanism is provided with an output end and an input end; a connecting beam which is vertical to each parallelogram mechanism is formed at the output end of the parallelogram mechanism; a jaw is formed at the end part, far away from the base body, of the connecting beam; and the output end of the bridge-shaped displacement amplification mechanism is connected with the input end of the parallelogram mechanism at the outside through a flexible hinge III. The piezoelectric actuated two-arm type high-speed lead wire clamp is small in volume, compact in structure, steady and reliable in clamping force and low in manufacturing cost, has relatively great displacement amplification times, can realize measurement and feedback of the clamping force, and can be applicable for a lead bonding and packaging device.

Owner:TIANJIN UNIV

Clamp

ActiveCN101797730ACompact structureMove straight and stableWork holdersEngineeringMechanical engineering

The invention discloses a clamp which has compact structure and high clamping strength and precision. The clamp comprises a pedestal, a fixed clamp jaw base and a movable clamp jaw base. The fixed clamp jaw base is fixed on the pedestal; the movable clamp jaw base is movably arranged on the pedestal; a fixed clamp jaw body is arranged on the fixed clamp jaw base; a movable clamp jaw body which matches with the fixed clamp jaw body is arranged on the movable clamp jaw base; a screw rod adjusting device is arranged in the pedestal; a piston cavity is arranged in the movable clamp jaw base; a piston is arranged in the piston cavity, and the piston cavity is divided into a front oil cavity and a rear oil cavity by the piston; two oil channels which are respectively communicated with the frontoil cavity and the rear oil cavity are arranged in the movable clamp jaw base; oil pipe joints are arranged at the oil channels; one side of the piston is provided with a piston rod; and the piston rod is connected with the screw rod adjusting device. The clamp adopts internally-mounted oil cylinder, thereby having very compact structure. In addition, the clamp can clamp the workpiece tightly without supporting the internally-mounted oil cylinder by adopting a long guiding rod. Moreover, the point of the application of the hydraulic force is close to the jaw of the clamp, thus the clamp has higher clamping strength and precision.

Owner:SUZHOU KINKALTECK MACHINERY TECH

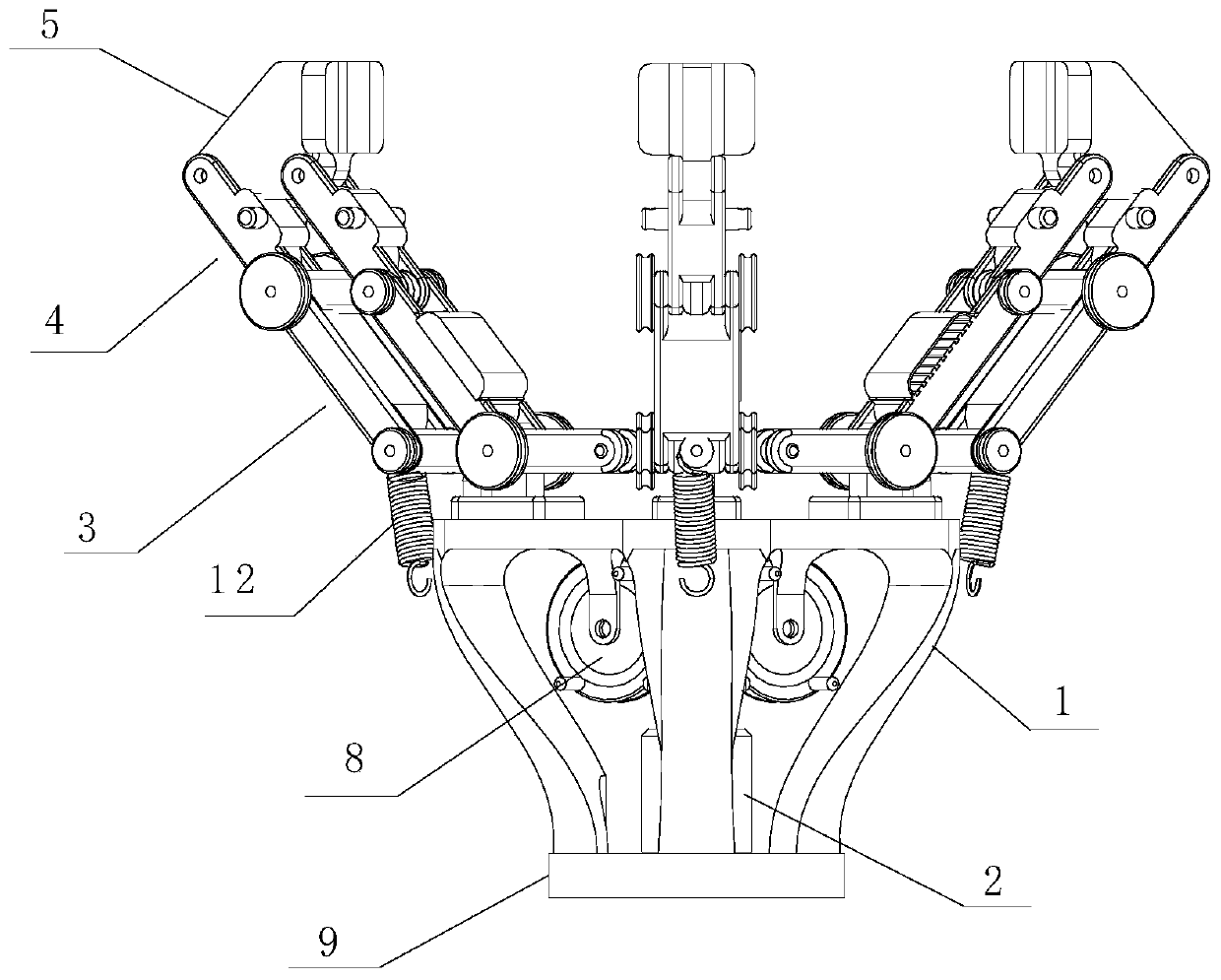

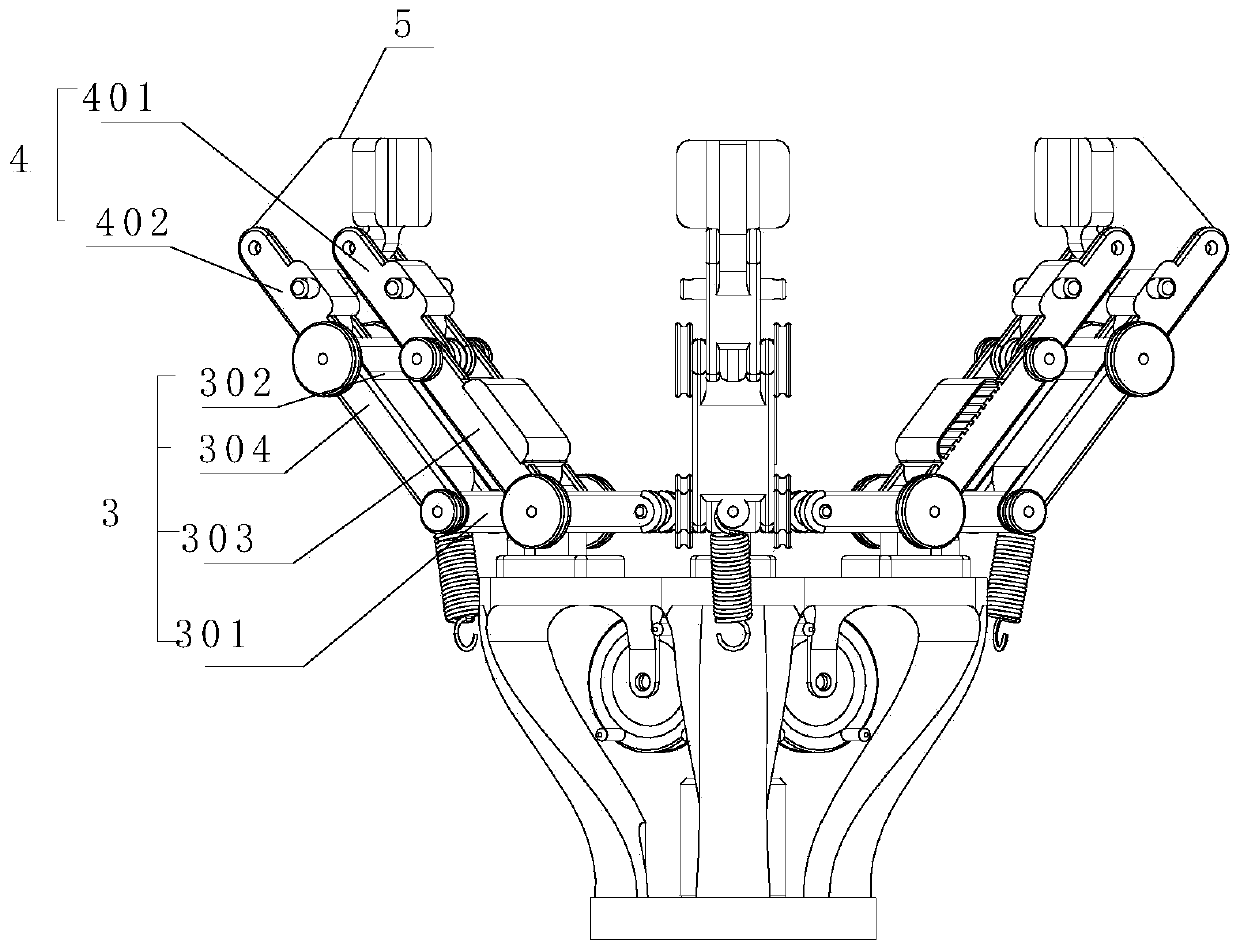

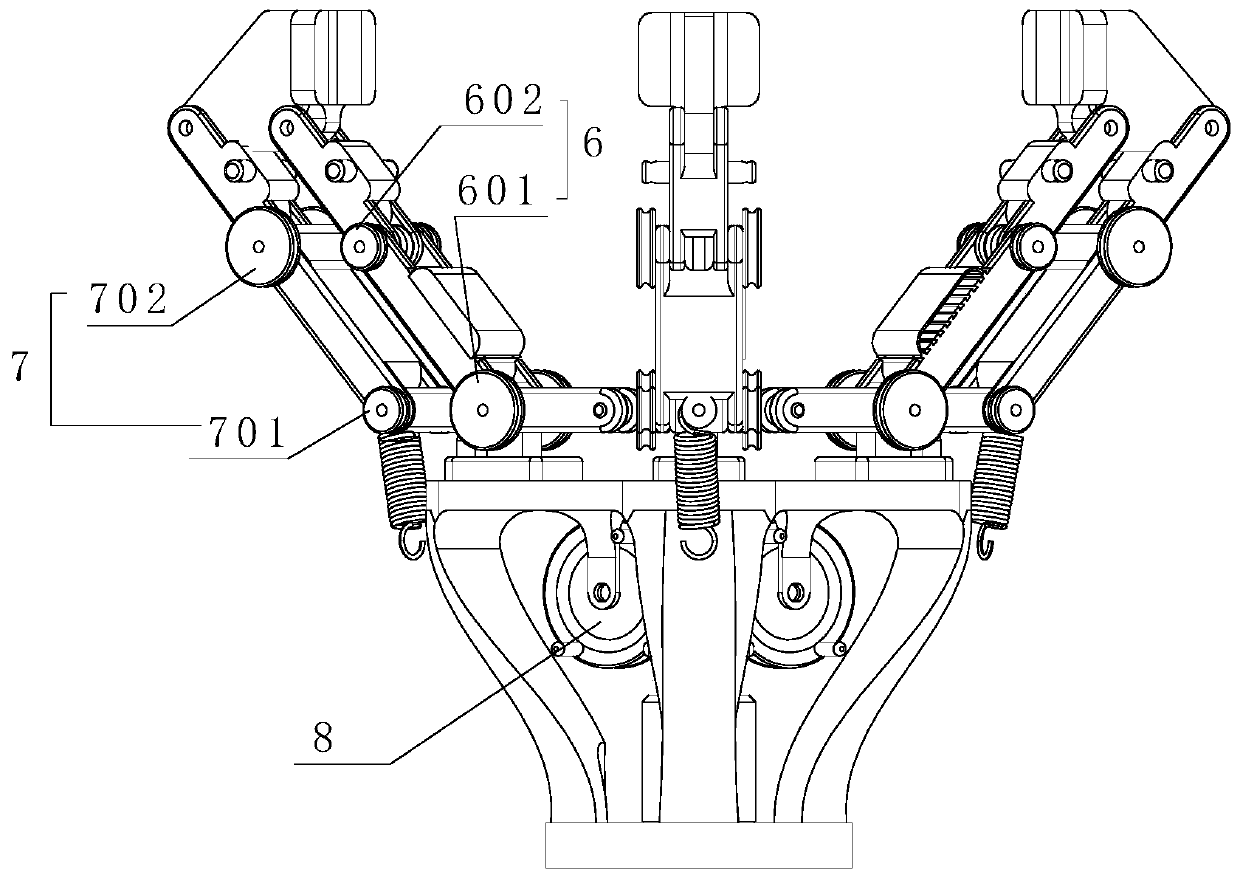

Robot end dexterous underactuated bionic gripper

InactiveCN111496828AQuick responseBalanced grip and holding forceJointsGripping headsKnuckleFlexible cable

The invention discloses a robot end dexterous underactuated bionic gripper. The bionic gripper comprises a base, a driving mechanism and at least two bionic fingers circumferentially distributed on the base, wherein any one bionic finger comprises a proximal knuckle, a middle knuckle, a front fingertip joint, a first pulley block, a second pulley block, a winch, an imitative flexor cable, an imitative extensor cable and a tension spring; the middle knuckles, the proximal knuckles and the front fingertip joints are flexibly and pivotally connected in sequence; the imitative flexor cables and the imitative extensor cables are flexible cables and are connected to the winches by the corresponding pulley blocks. During operation, the winches are driven to rotate forward and backward by controlling the driving mechanism, so that clamping, expanding and clamping positions and clamping force of parallel manipulators. Compared with a plurality of dexterous hand products in the current market, the structure has the advantages that responding is fast during gripping and expansion, gripping and clamping force is more balanced, and the structure is compact.

Owner:ANHUI SANLIAN UNIV

Clamping device based on connecting rod transmission mechanism

InactiveCN106393090APrevent clamping failureHigh clamping accuracyProgramme-controlled manipulatorGripping headsEngineering

Owner:周末

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com