Clamping and conveying device for conveying steel bars

A technology for steel bars and main boxes, applied in the field of pinch devices, can solve the problems of increased maintenance frequency and cost, poor clamping and separation accuracy, and large space occupation in the factory area, so as to reduce maintenance costs and accurately limit positions , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

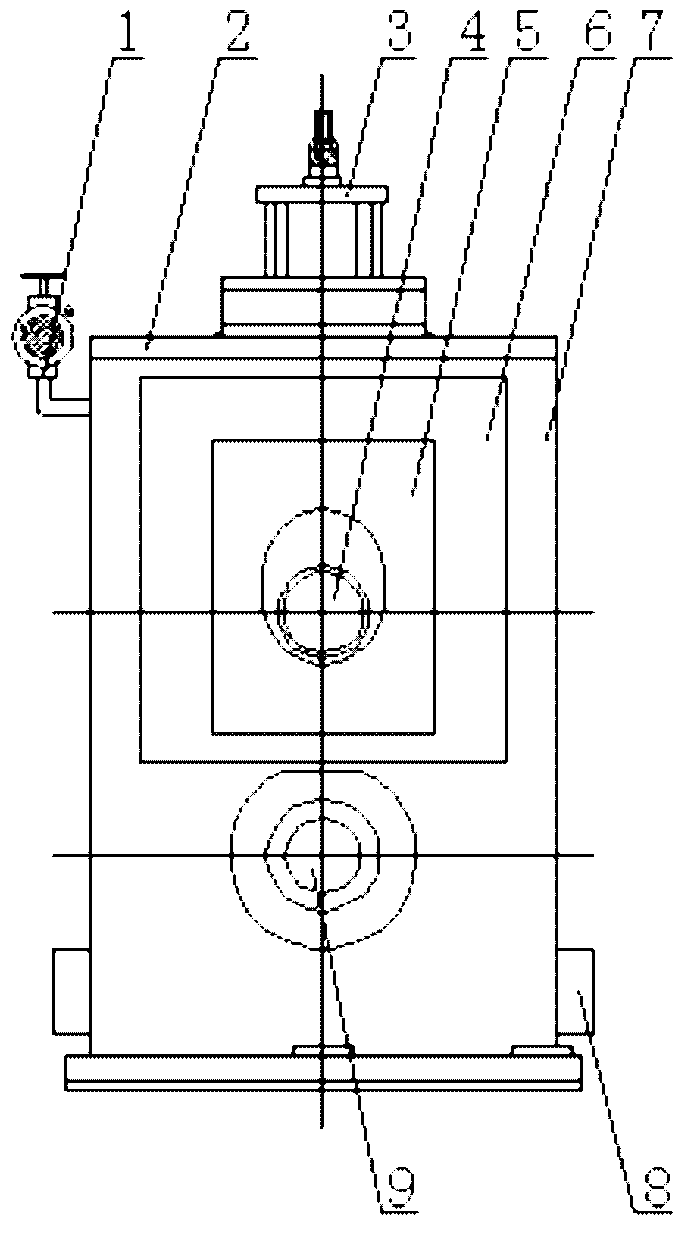

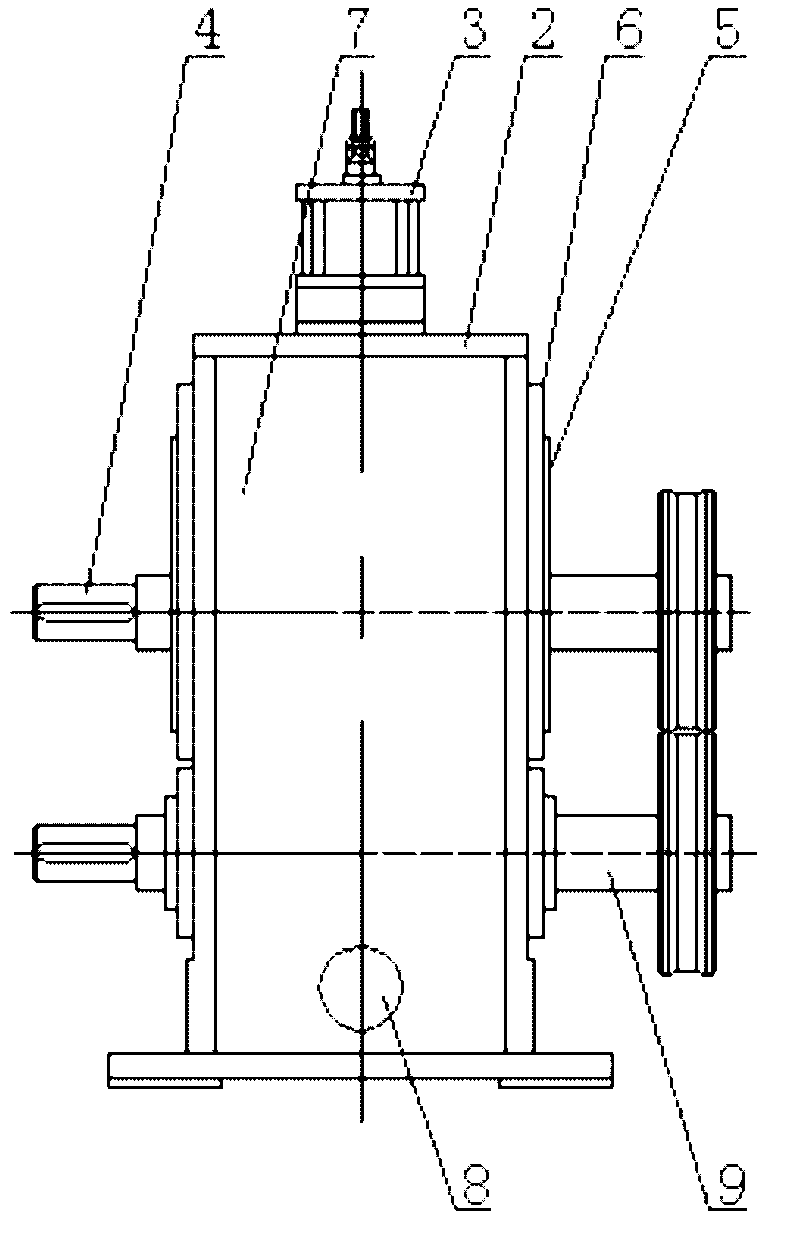

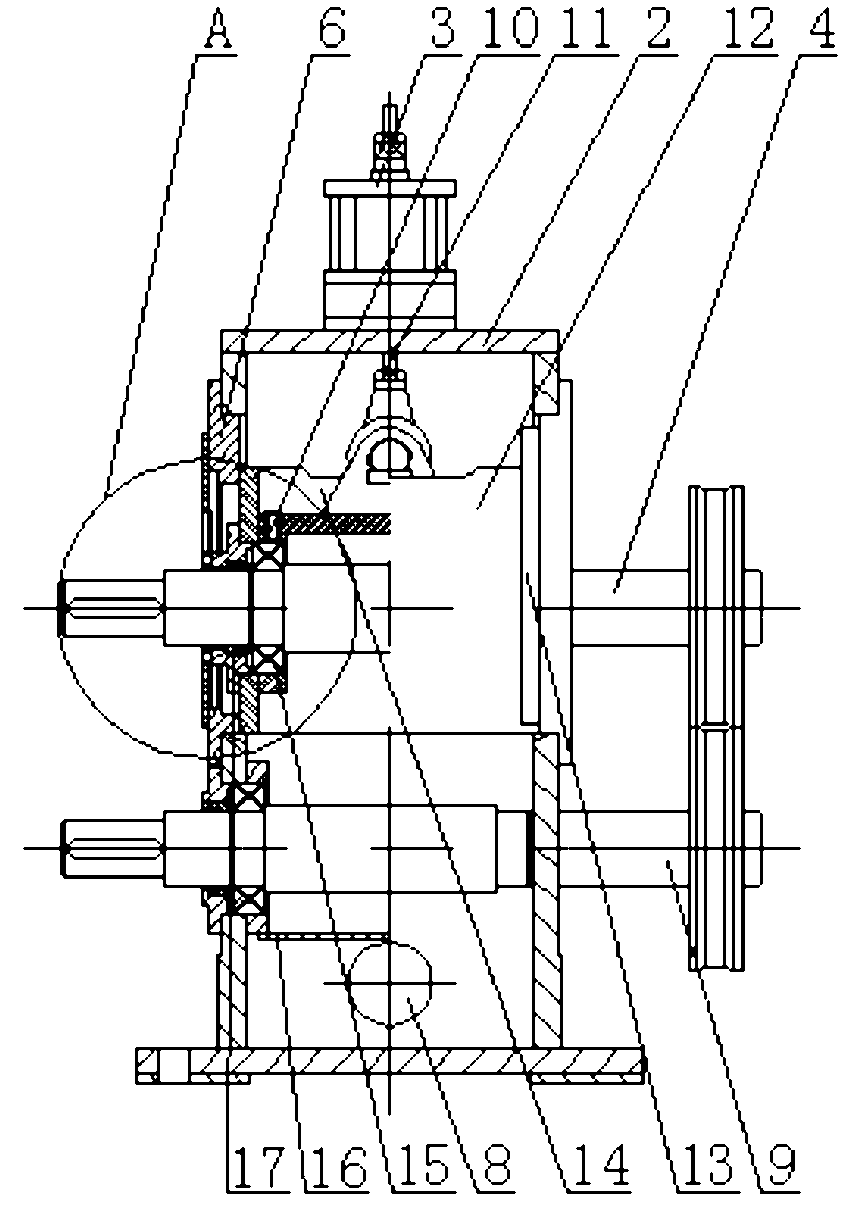

[0025] A pinch device for conveying steel bars, comprising a main box body 7, an auxiliary box body 12, an upper roller 4, a lower roller 9 and an air cylinder 3, and the lower roller is rotatably installed at the lower part of the main box body, as shown in the drawings of this embodiment The lower roller shown in the figure is installed on the main box through bearings and gaskets, the upper roller is rotatably installed on the auxiliary box, the upper roller is installed on the auxiliary box through bearings 15 and gaskets 17, and an oil tank 14 is arranged on the top of the auxiliary box. , an oil supply hole 10 is formed on the auxiliary box above the upper roller, the upper roller and the lower roller are arranged in parallel, the upper part of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com