Patents

Literature

727results about How to "Prevent oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

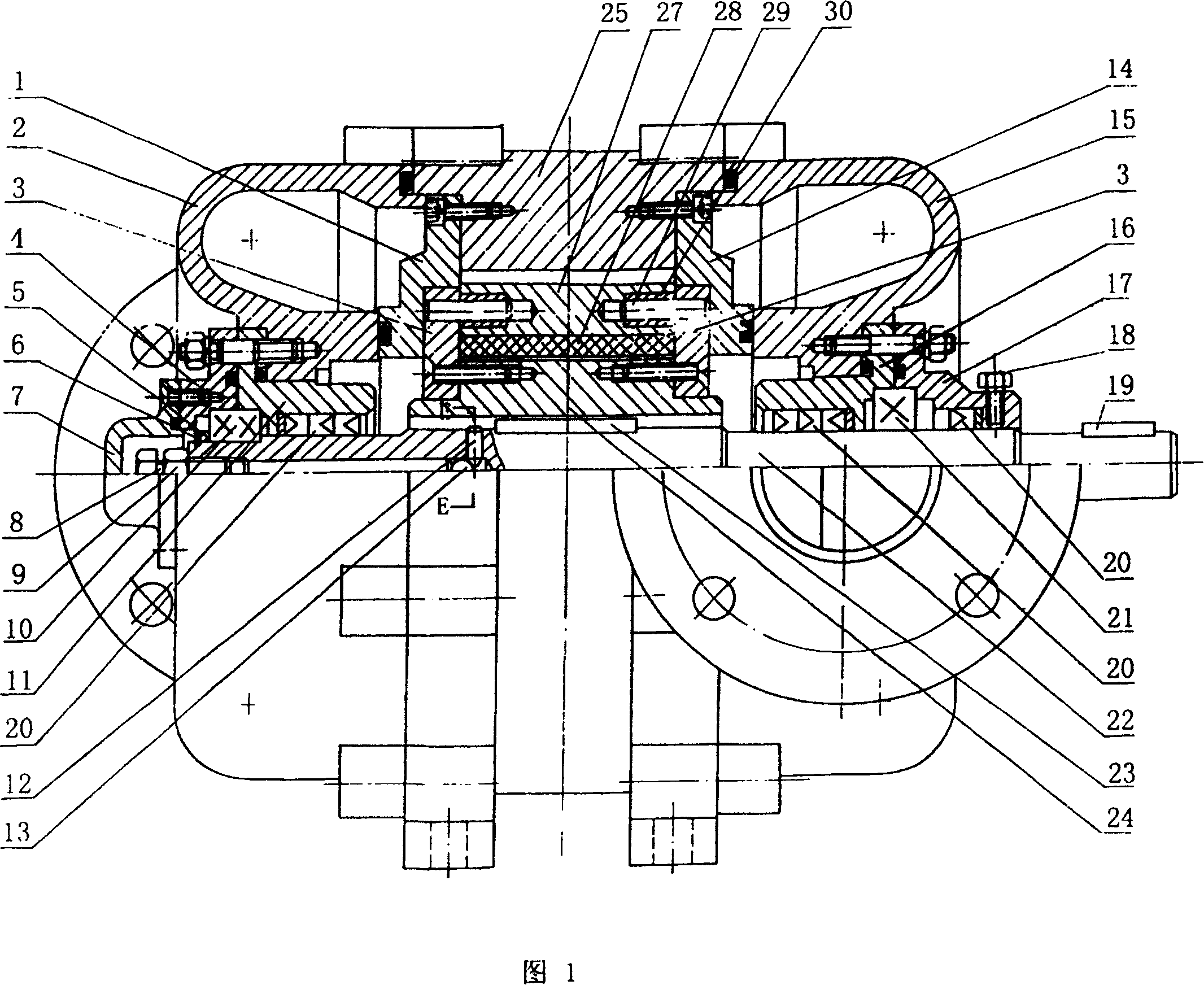

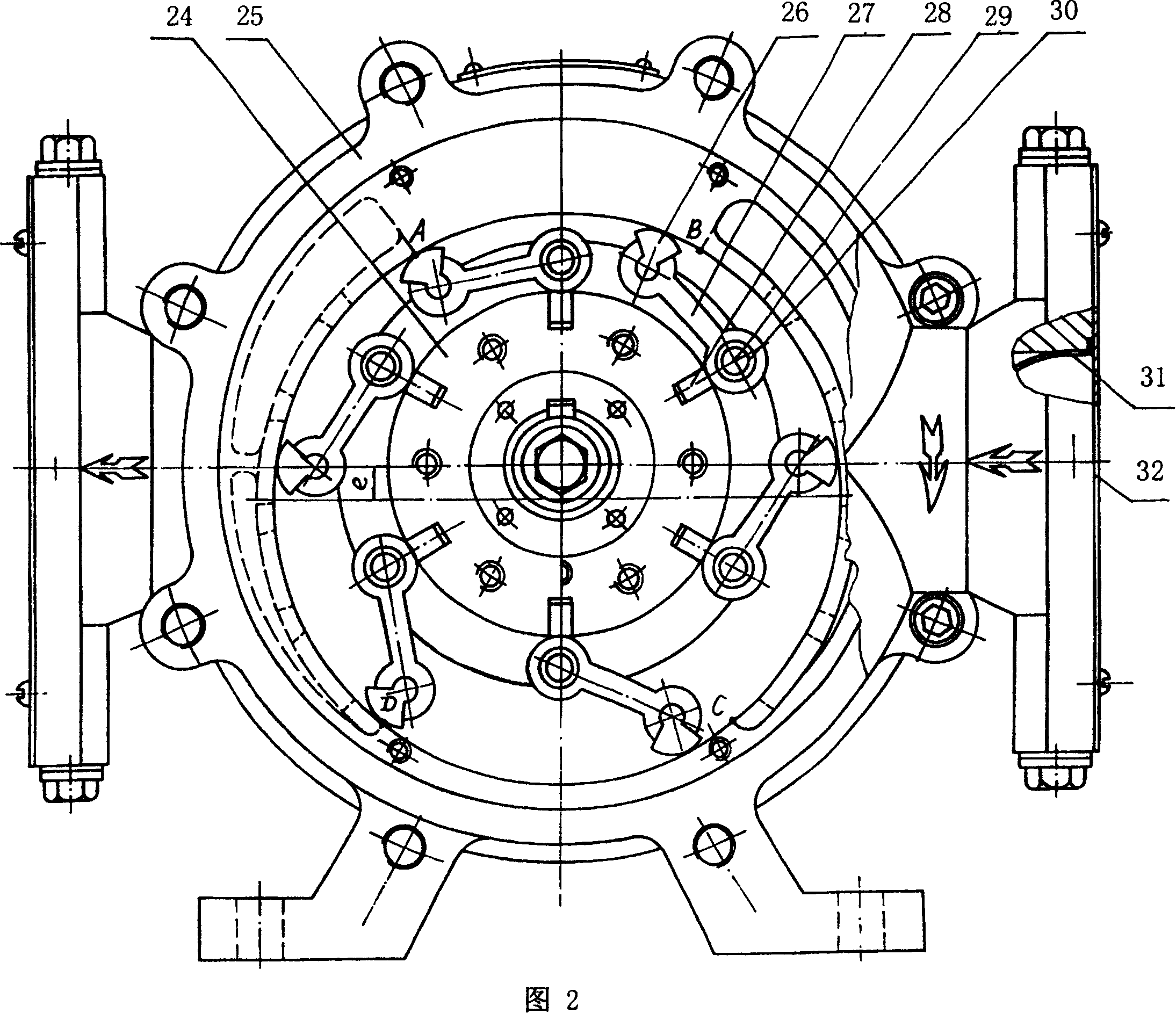

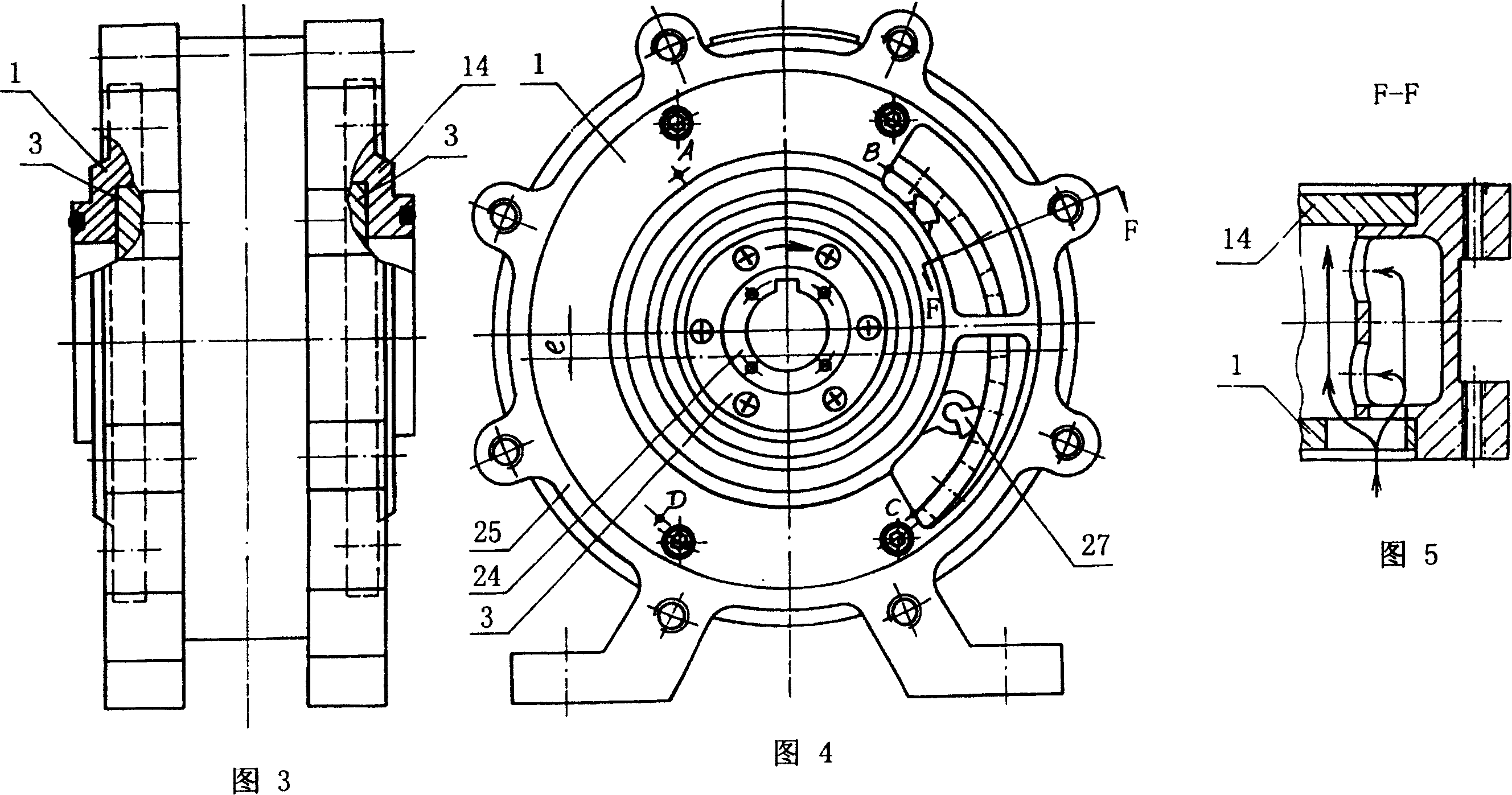

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

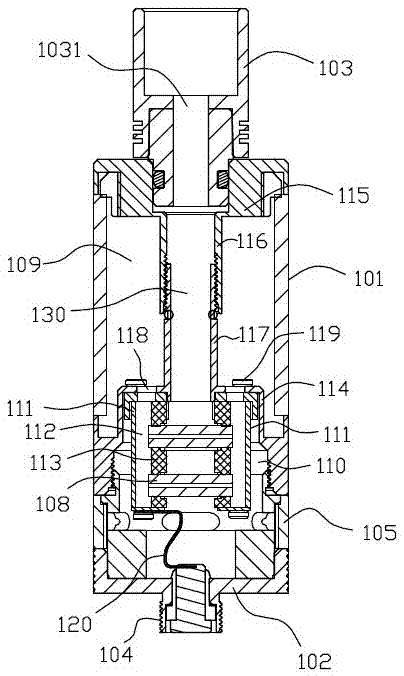

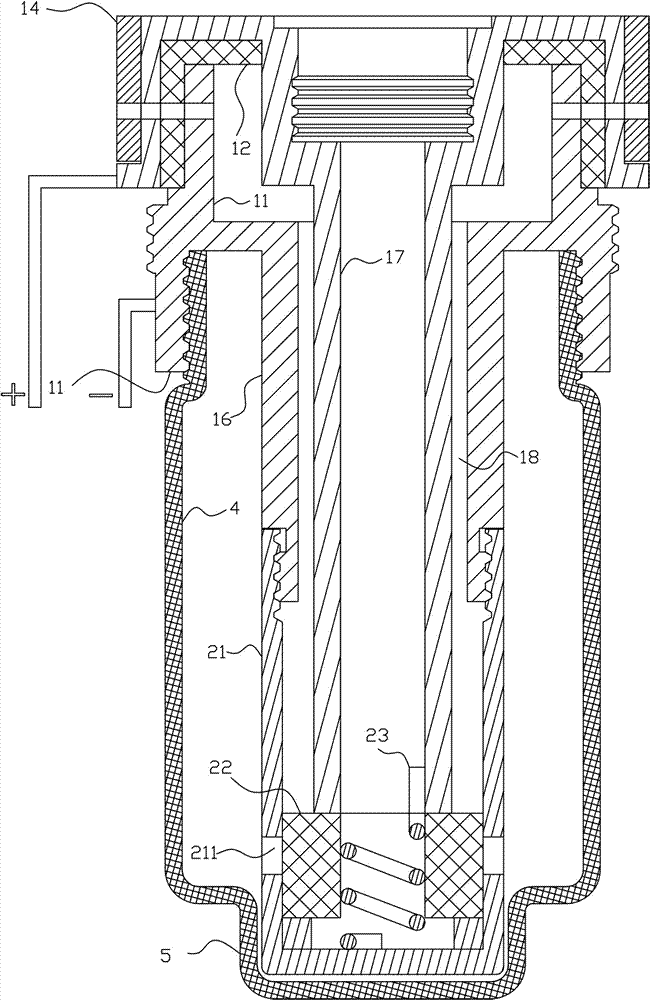

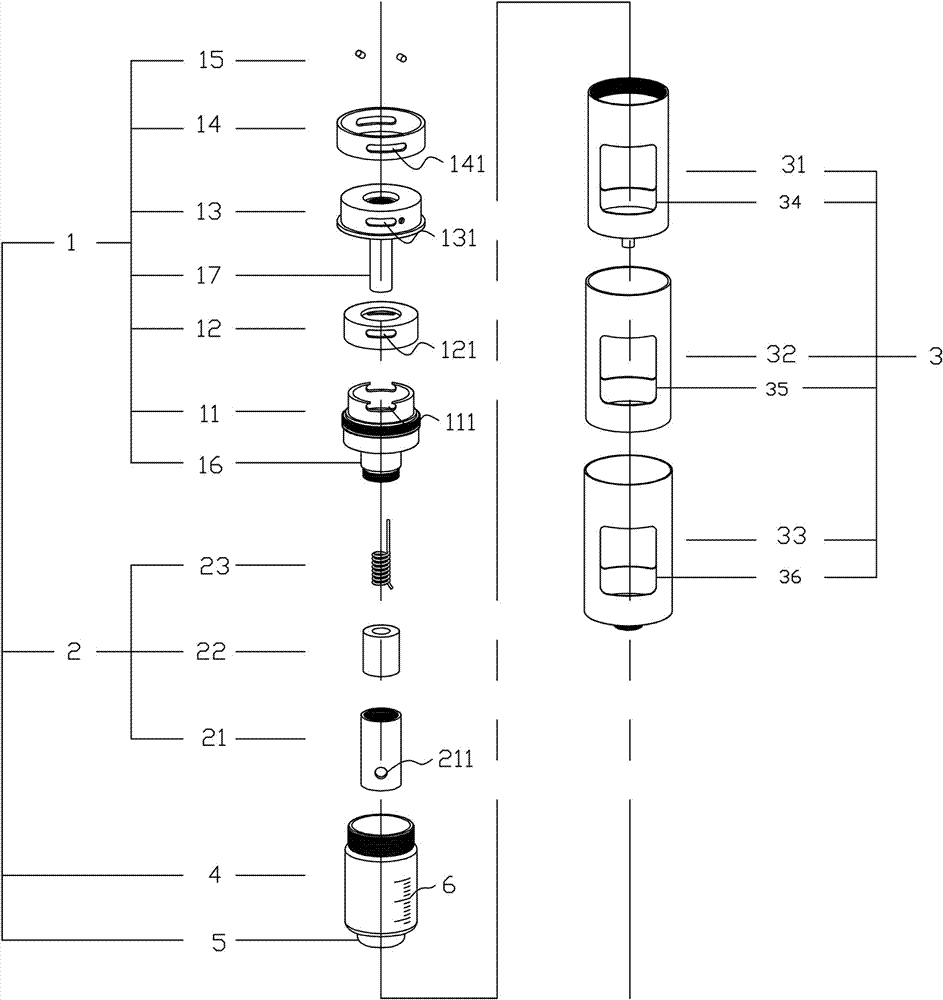

Atomizer and electronic smoking device

PendingCN105433443AWith heating functionEasy to assembleAdditive manufacturingOhmic-resistance waterproof/air-tight sealsCapillary actionLiquid storage

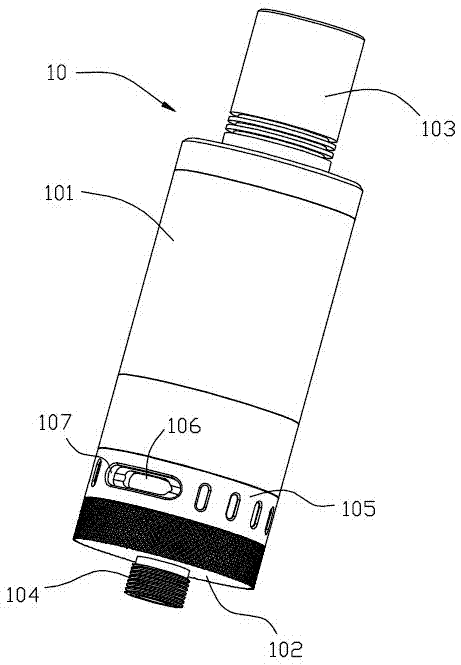

The invention discloses an atomizer and an electronic smoking device. The atomizer comprises a shell, an electric conduction part arranged on the shell and a suction nozzle with a gas outlet, a liquid storage cavity used for containing tobacco liquid is formed in the interior of the shell, the shell is further internally provided with at least one heating element which is electrically connected with the electric conduction part, each heating element comprises a liquid conduction carrier with a micropore structure and a heating part which forms an integral structure with the liquid conduction carrier, and the liquid conduction carrier can make contact with the tobacco liquid; the heating elements heat and atomize the tobacco liquid sucked by the liquid conduction carrier through the capillary action. The heating elements in the atomizer have the functions of sucking the tobacco liquid and heating simultaneously, and the atomizer is simple in structure and capable of being applied to high-power electronic smoking devices.

Owner:SHENZHEN FIRST UNION TECH CO LTD

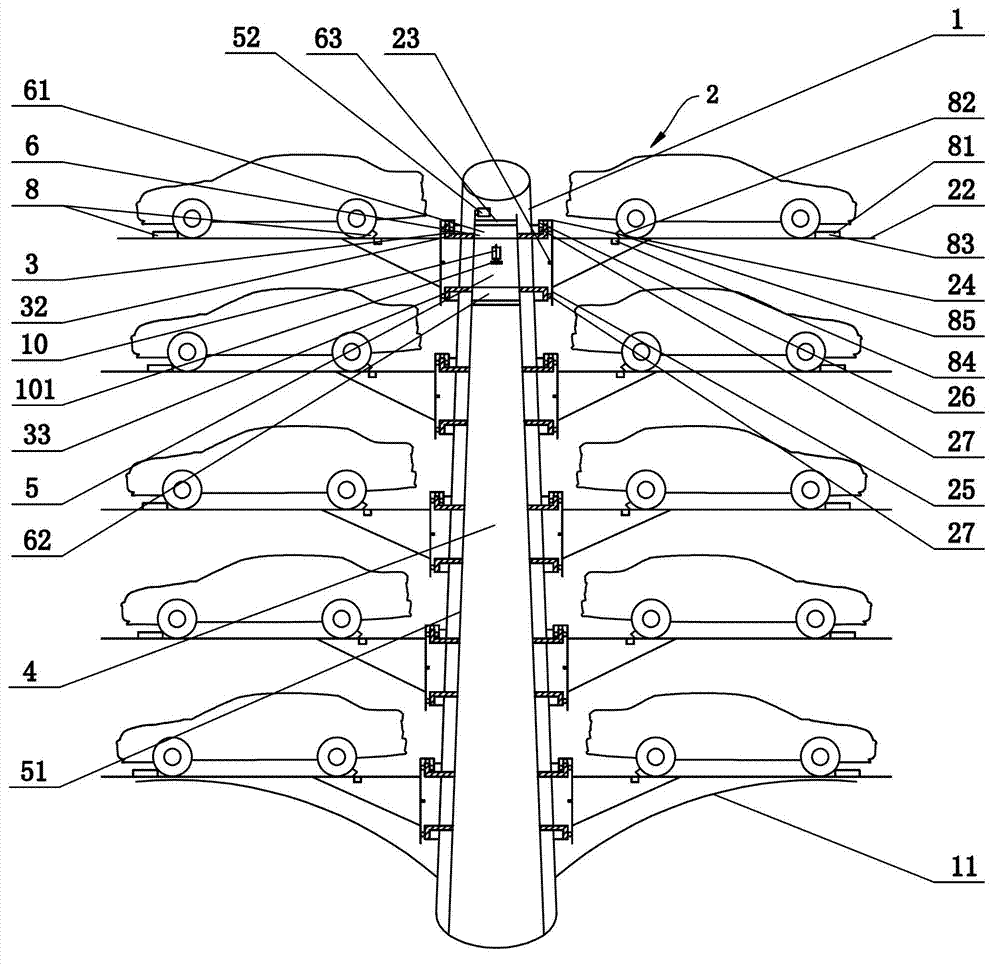

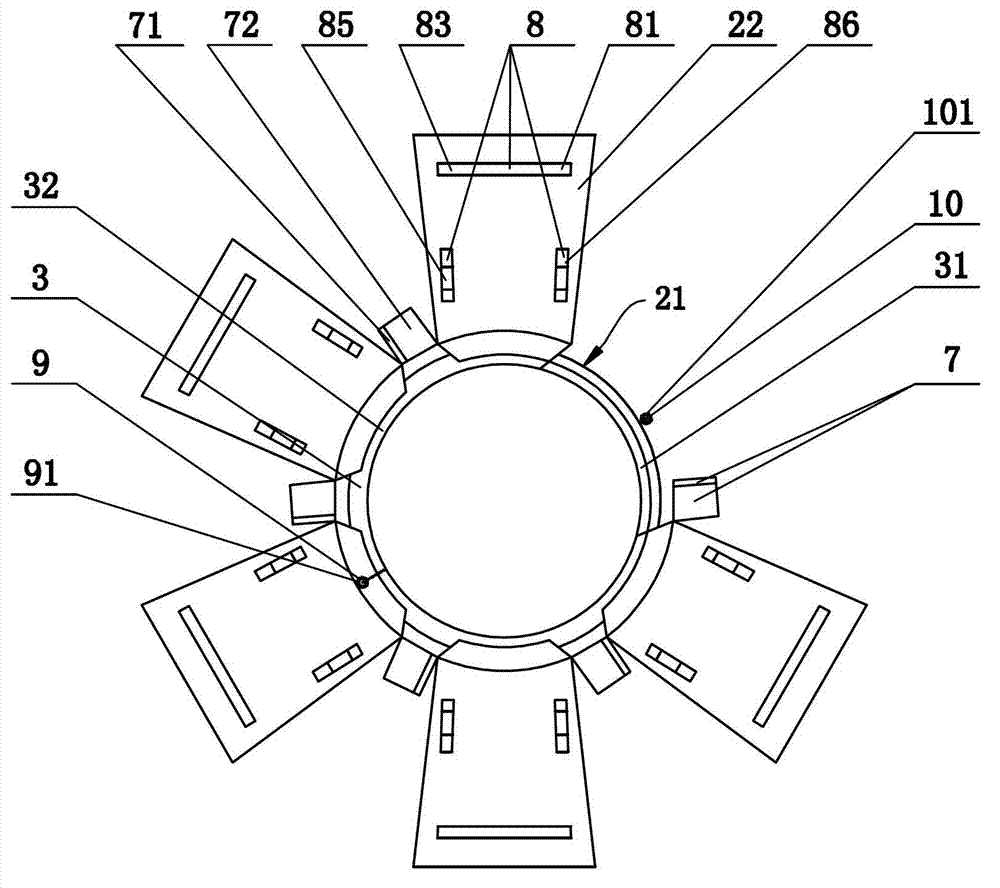

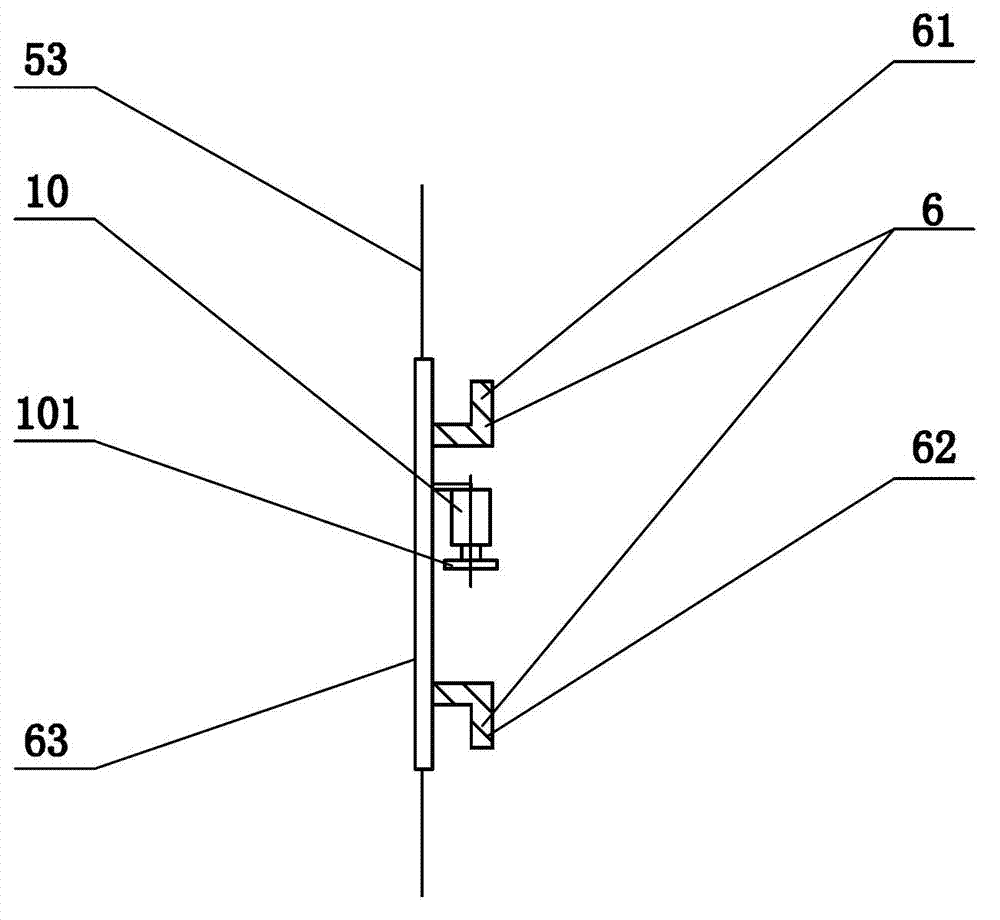

Stereoscopic parking lot

The invention belongs to the technical field of parking equipment and provides a stereoscopic parking lot. The stereoscopic parking lot comprises a tower column and a plurality of layers of parking units arranged on the tower column; each layer of the parking unit comprises a vacant site and a plurality of parking spaces; a pushing device is arranged between the adjacent two parking spaces; the parking spaces are slidingly mounted on a first rail under the driving of a first power device; a hoisting channel is internally provided with a second rail which is connected with the hoisting device; and the second rail is provided with a second power device which is used for driving the parking spaces to slide on the second rail. With the adoption of the stereoscopic parking lot provided by the embodiment of the invention, the ground space of a plurality of the parking spaces which are arranged around the tower column and one tower column is occupied and a plurality of overhead parking spaces are realized; the occupied area is small, more vehicles are parked and the space can be sufficiently utilized; the framework design in a trunk shape is adopted so that the shielding to peripheral buildings is small and the lighting is not influenced; and the time for parking and taking the vehicle is 2-3 minutes so that the stereoscopic parking lot is rapid, safe and efficient and is suitable for middle-small-sized parking lots.

Owner:日照未来水处理设备有限公司

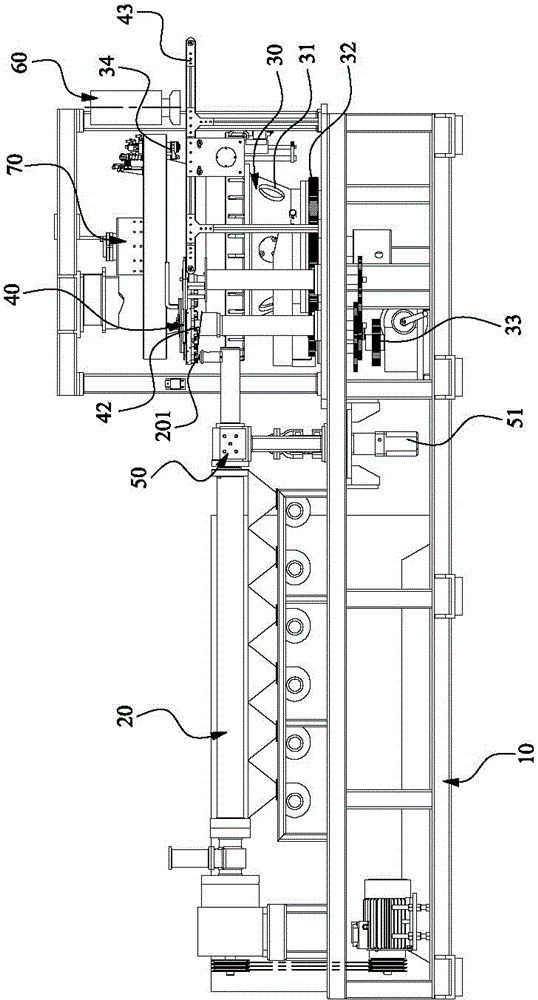

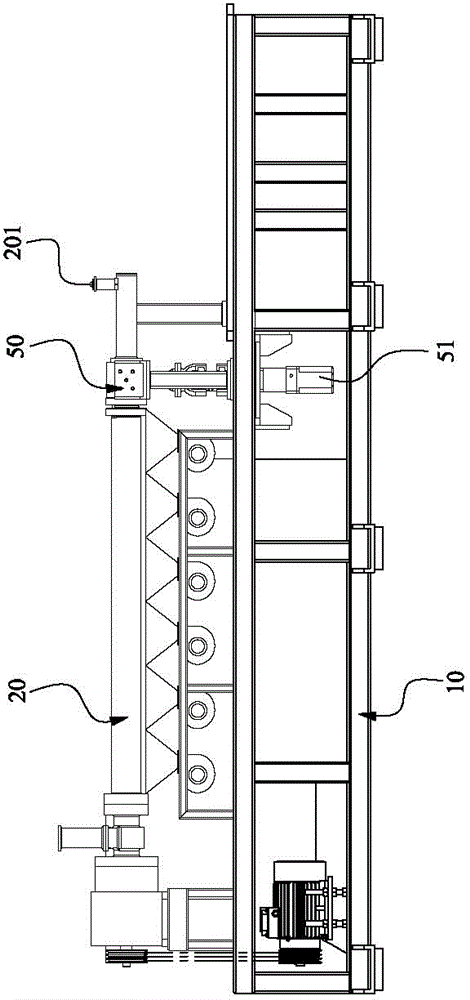

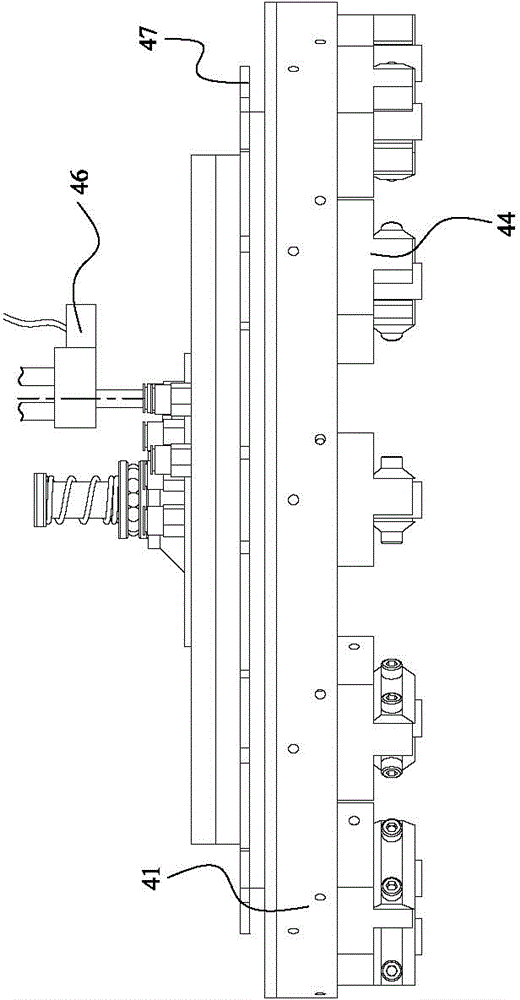

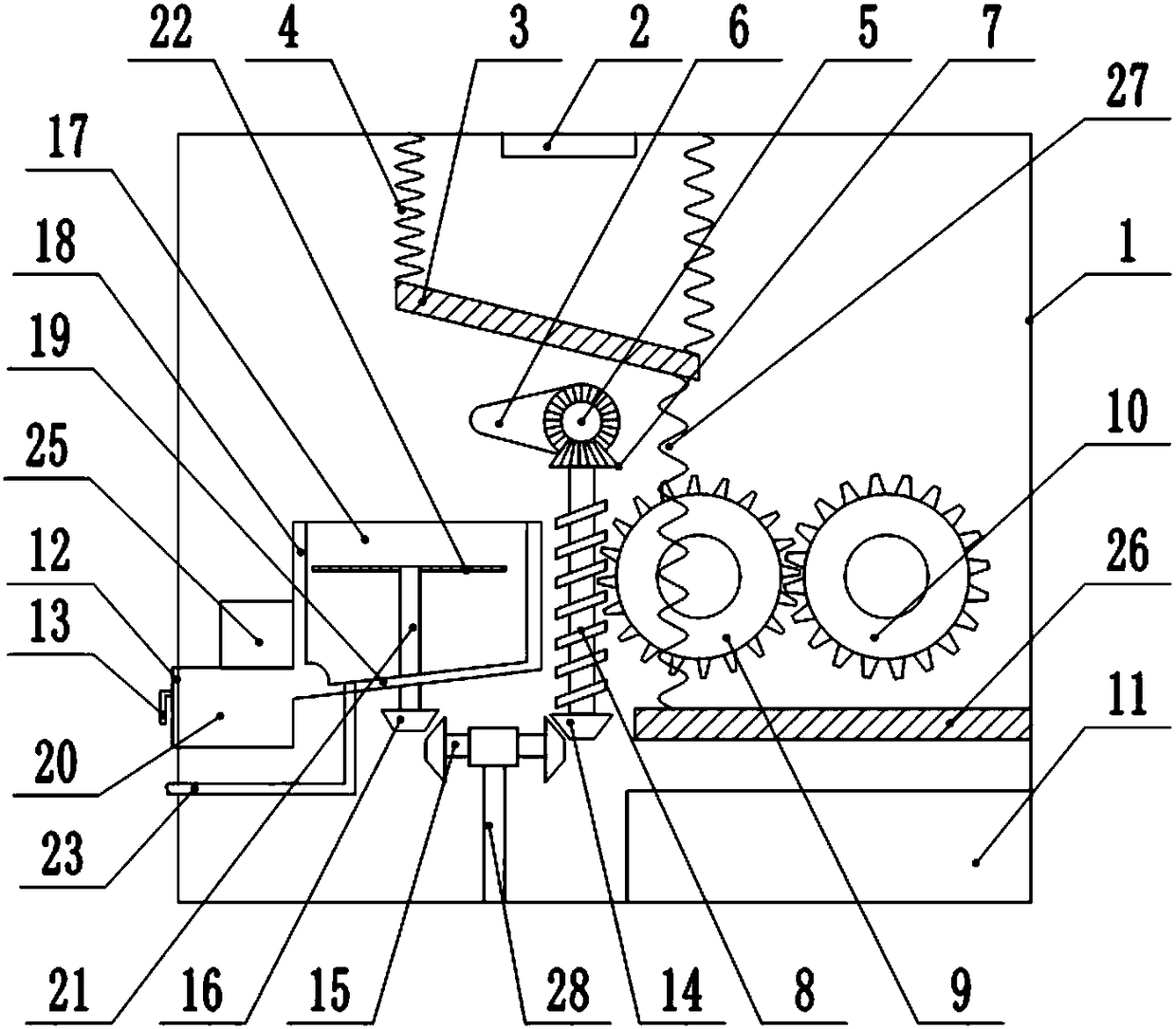

Fully-automatic die pressing lid maker

InactiveCN102862296ASmooth rotationGuarantee molding qualityDomestic articlesSortingEconomic benefitsEngineering

The invention discloses a fully-automatic die pressing lid maker, which comprises a rack, an extrusion module, a pressing module and a feeding and discharging module. The extrusion module is provided with an extrusion port. A metering pump is arranged on the extrusion module. The pressing module comprises a rotating main body, a rotating support and a driving device. A high-speed forming mold is arranged on the rotating main body. The rotating support is arranged between the rack and the rotating main body. The feeding and discharging module is arranged between the extrusion module and the pressing module. In such a way, the metering pump is used for accurately controlling feeding, and a high-frequency valve is matched to drive a piston head to move to accurately feed a blank. In addition, the rotating support is arranged between the rack and the rotating main body, and is used for enlarging the support area of the rotating main body, so that the rotating main body can rotate more stably. The fully-automatic die pressing lid maker is particularly applied to a heavy large-sized machine. Therefore, the forming quality of a bottle lid is ensured, a defective rate is lowered, and more economic benefits are created for an enterprise.

Owner:GUANGZHOU JEEPINE INTELLIGENT COMPRESSION MOLDING MACHINE CO LTD

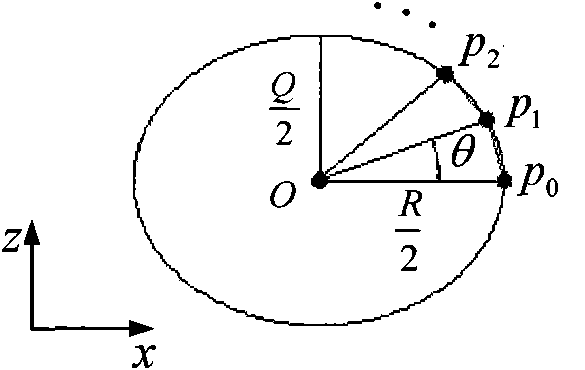

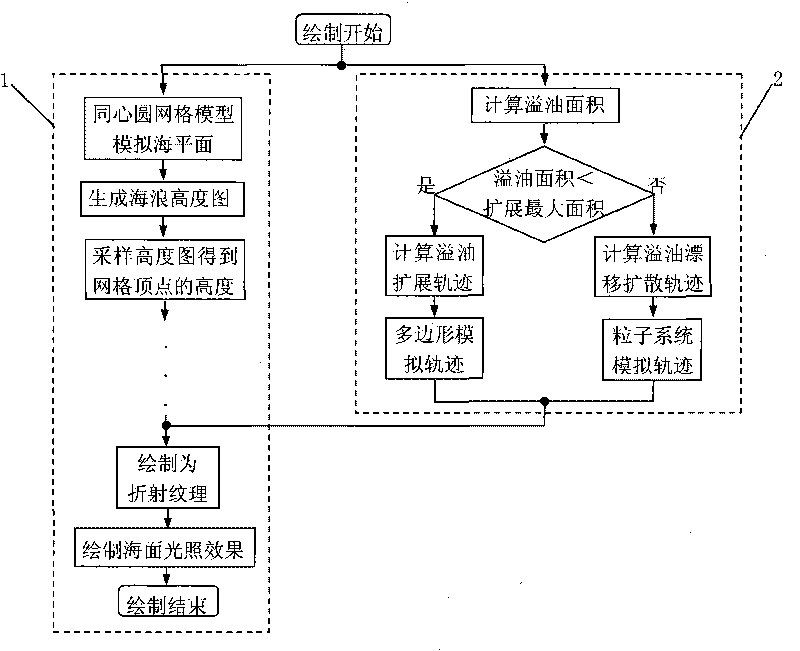

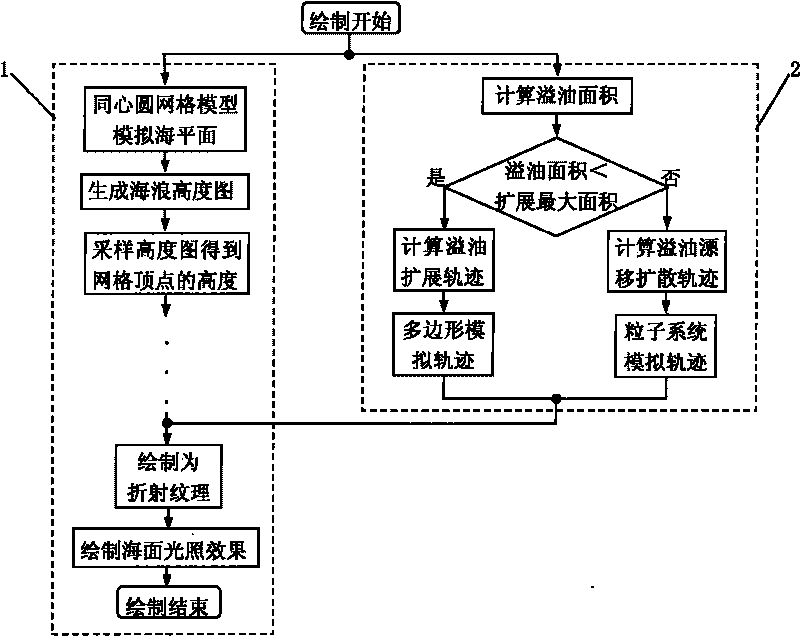

Three-dimensional visualized algorithm for maritime oil spill

InactiveCN101706972ARealize visualizationSimulation is accurate3D-image rendering3D modellingOil spillSea level

The invention relates to a three-dimensional visualized algorithm for maritime oil spill, which is realized in a way that: on the basis of drawing a large-scale sea level scene, dividing an oil spill process within a short time scale into an oil film self-spreading stage and an oil film drift diffusion stage, and calculating the oil spill loci of the two stages respectively by selecting an Lehr model and an oil particle model; simulating the oil particle model by using a particle system; and visualizing the oil spill loci on the simulated sea level by utilizing a planar refraction technology, accessing the veins in a fragment shader of a GPU by projecting vein coordinates, and simulating and reproducing the three-dimensional scene of maritime oil spill while drawing the sea level refraction effect. The algorithm solves the problems of simulation of the oil particle model, visualization of the oil spill loci on the simulated sea level, and the like, and realizes the vivid and visual simulation of the three-dimensional movement change process of oil spill within a short time scale.

Owner:DALIAN MARITIME UNIVERSITY

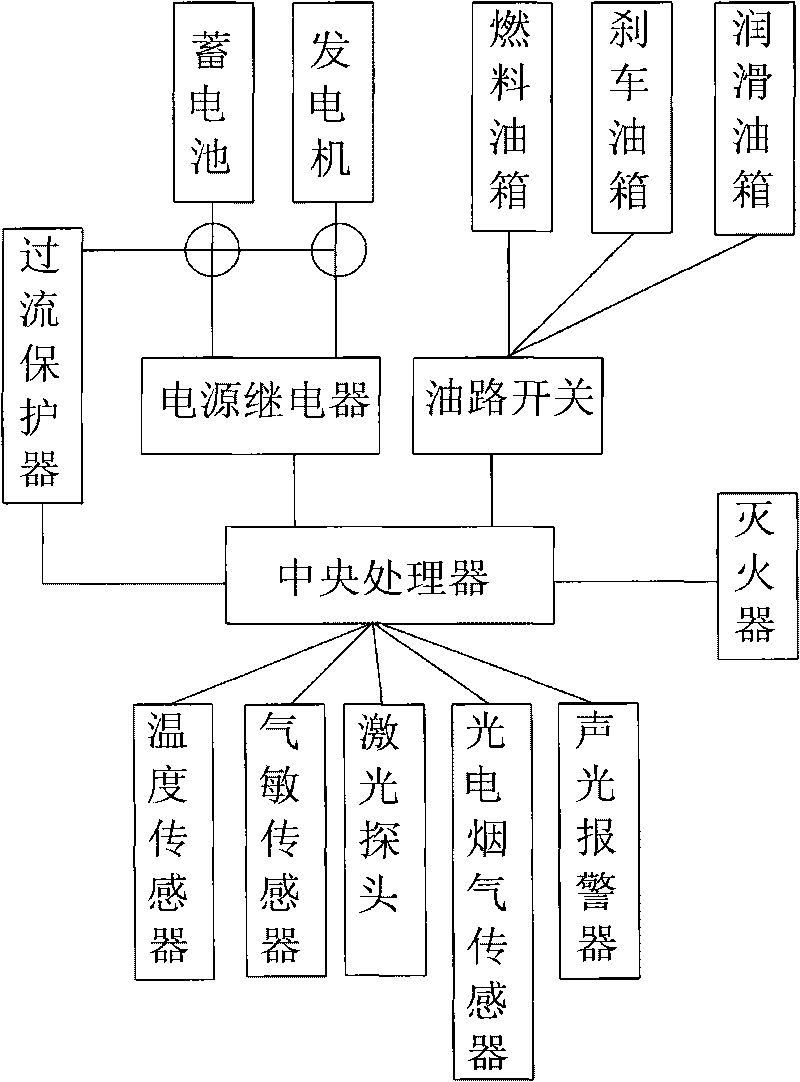

Automatic early warning fire extinguishing method for preventing vehicle from spontaneously combusting

InactiveCN101737186APrevent oil spillsAvoid short circuitElectrical controlInternal combustion piston enginesSpontaneous combustionLaser probe

The invention provides an automatic early warning fire extinguishing method for preventing a vehicle from spontaneously combusting. The inside of an engine case is provided with a central processing unit, a temperature sensor, a gas sensitive sensor, a laser probe, a photoelectric smoke sensor, a direct current over-current protector, a power relay, an oil circuit switch and a fire extinguisher. The central processing unit is connected with the temperature sensor, the gas sensitive sensor, the laser probe, the photoelectric smoke sensor, the direct current over-current protector, the power relay, the oil circuit switch and the fire extinguisher through a data wire to form a detection early warning fire extinguishing system; the outside of an oil supply pipeline which is connected with an engine is covered with a transparent plastic pipe; an oil absorption discoloration flame retardant material is filled between the oil supply pipeline and the transparent plastic pie to form an oil supply pipeline protection structure; and a brake oil tank and an engine oil tank which are arranged at the periphery of the engine are isolated through a flame retardant plate. The automatic early warning fire extinguishing method has the advantages that: the design is scientific and rational; the method gives priority to preventing the pipeline from oil leakage and short circuit, and is supplemented by the passive fire extinguishing; and even though the spontaneous combustion is caused by the fire of the circuit after the oil leaks, the central processing unit can cut off the power relay and the oil circuit switch as soon as possible, so the loss of the spontaneous combustion is minimized.

Owner:寇春祥

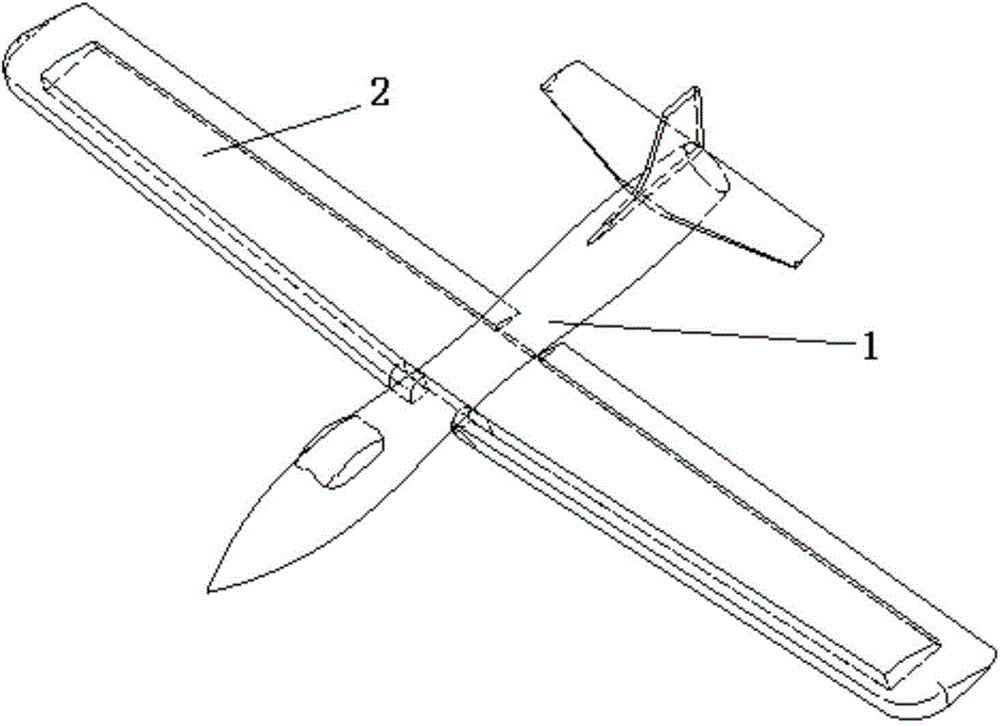

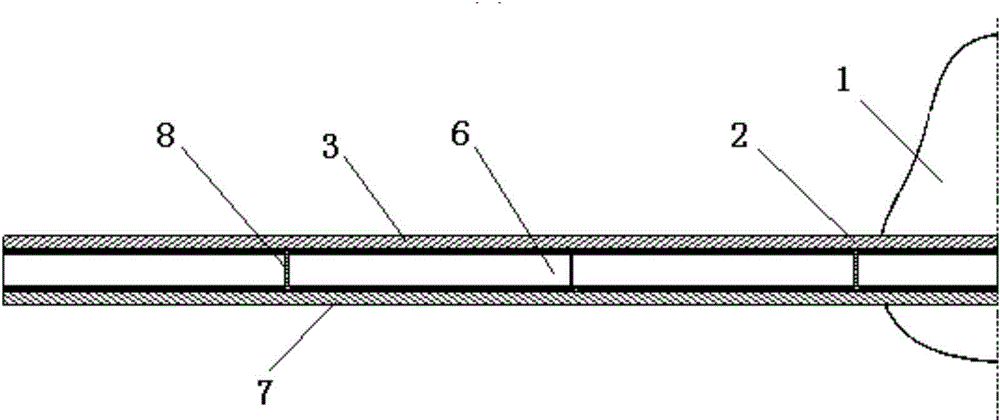

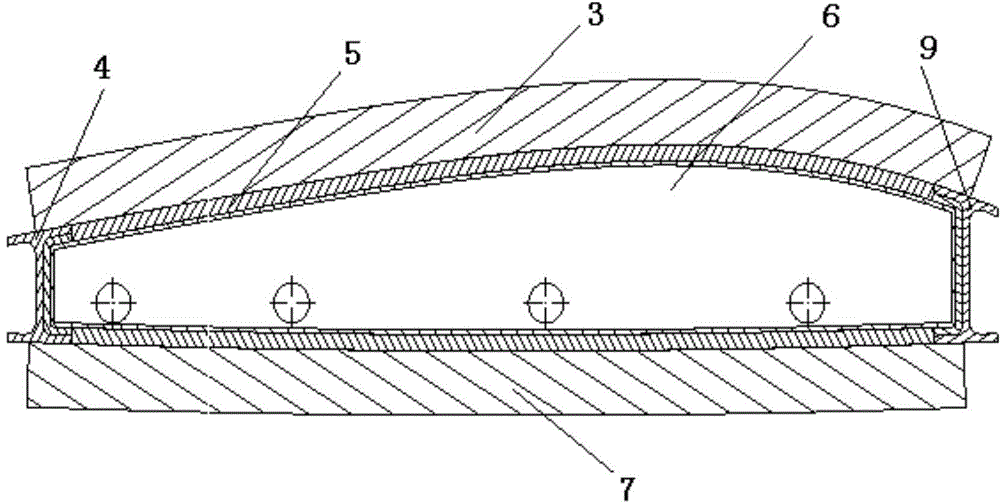

Whole oil tank structure of airplane

InactiveCN104369857AConducive to maximum strengthAccording to the failure principleWingsInternal fittingsFuel tankFront edge

A whole oil tank structure of an airplane comprises a plurality of oil tank inner containers made of composite materials, a front beam, a rear beam, an upper wall board and a lower wall board; the oil tank inner containers are arranged between the upper wall board and the lower wall board; the front beam and the rear beam are connected with the front edges and rear edges of the upper wall board and the lower wall board respectively; adjacent walls among the oil tank inner containers are bonded to structural ribs of a wing; the oil tank inner containers are sealed containers prefabricated through composite materials; and the outer walls of the oil tank inner containers are in bonding curing with the adjacent upper wall board, the lower wall board, the front beam and the rear beam.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

Cigarette tar atomizing device and electronic cigarette

ActiveCN103960780AIncrease storage capacityIncrease the number of mouthsTobacco devicesUser needsTar

Owner:SHENZHEN FIRST UNION TECH CO LTD

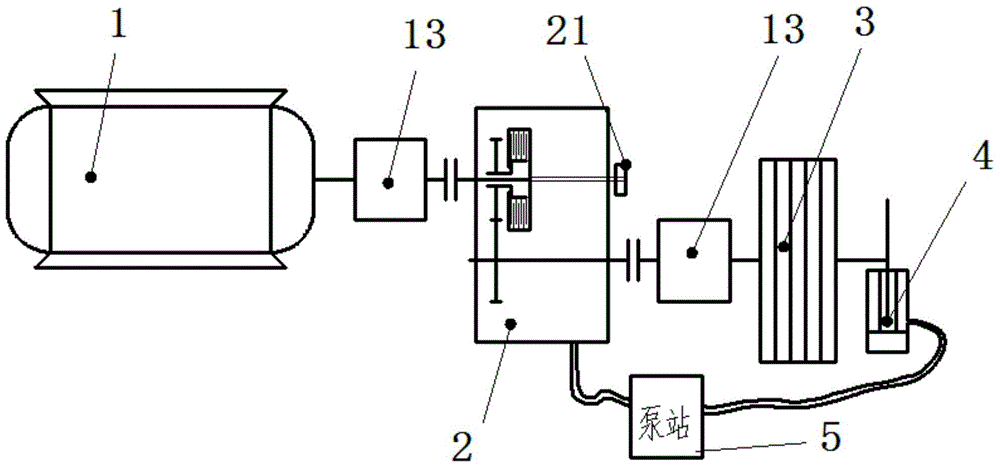

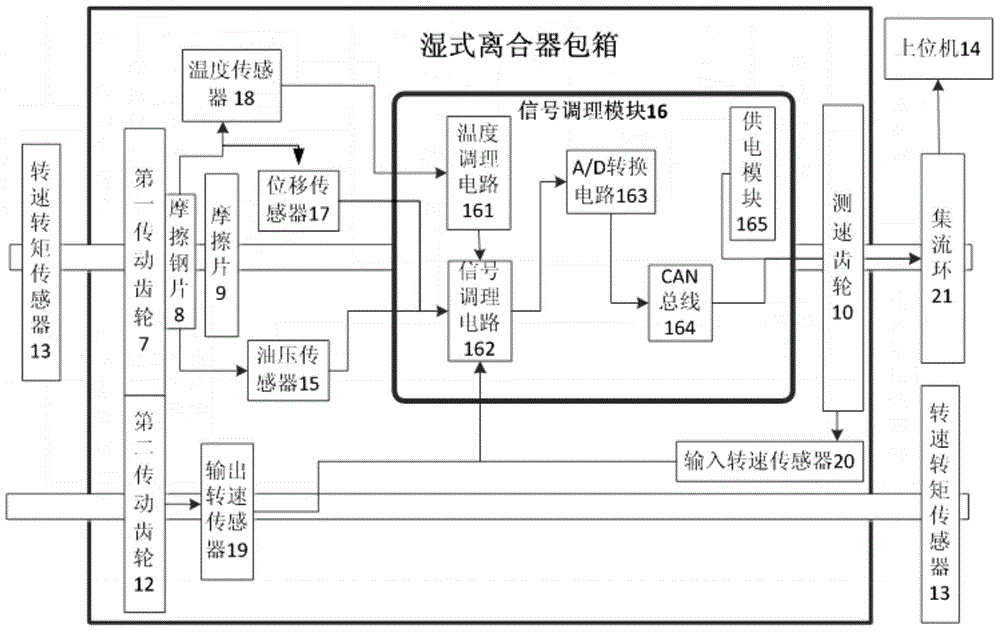

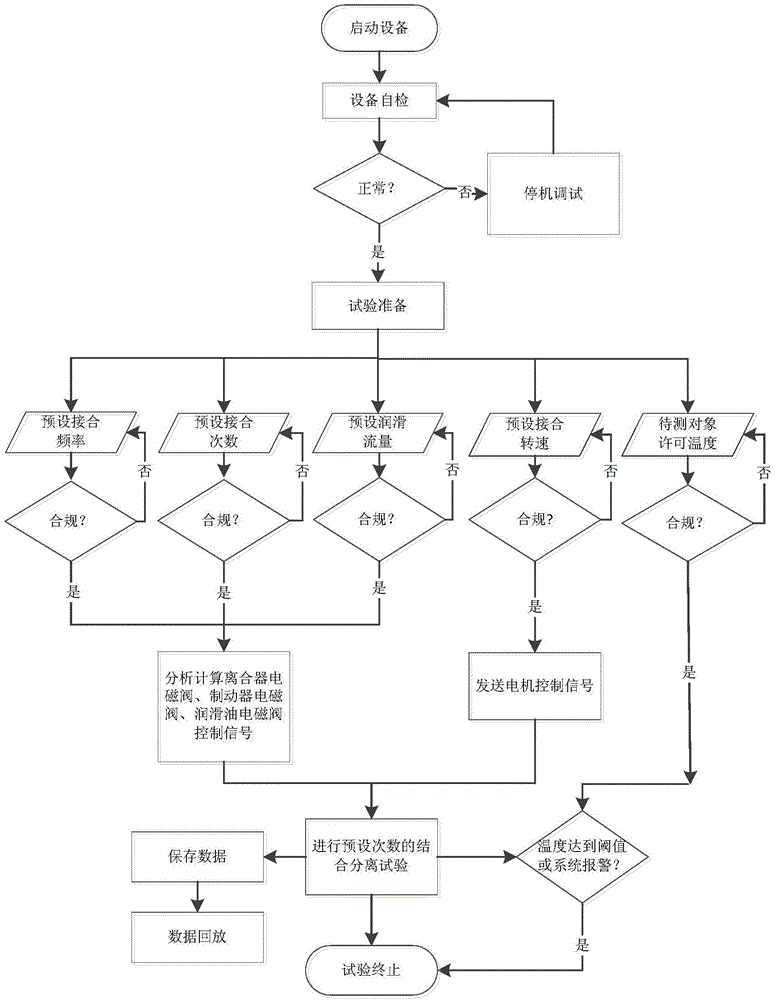

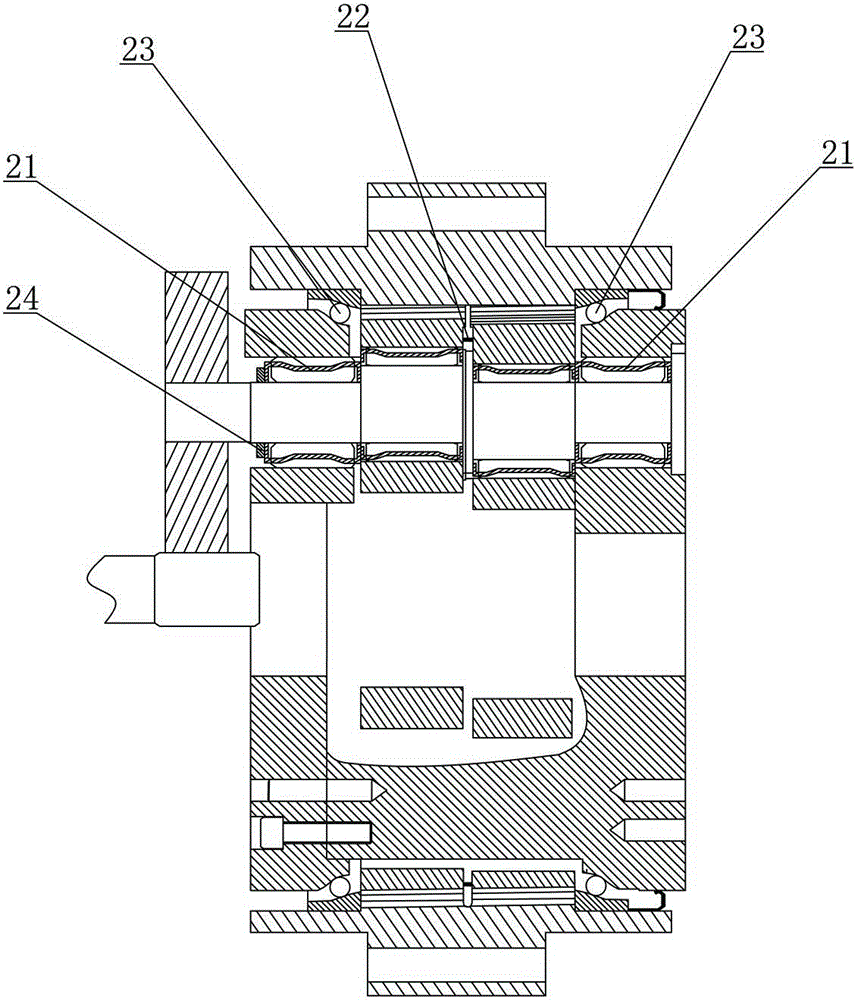

System and method for measuring temperature of friction pair of wet clutch

ActiveCN104949835AAvoid failureAccurate measurementMachine gearing/transmission testingElectric machineDrive shaft

The invention relates to a system and a method for measuring the temperature of a friction pair of a wet clutch. A motor output shaft of a power transmission system is connected with an input end of a first transmission shaft of a wet clutch box, a first transmission gear is arranged at the input end of the first transmission shaft, a steel friction plate and a friction plate are sequentially arranged at the input end of the first transmission shaft, and a speed measuring gear is arranged at an output end of the first transmission shaft; the first transmission gear is meshed with a second transmission gear arranged on a second transmission shaft, power is transmitted to the second transmission shaft through the second transmission gear, and an output end of the second transmission shaft is sequentially connected with an adjustable inertia group and a hydraulic brake; a pump station is located between the wet clutch box and the hydraulic brake; a motor is used as a power source to output the rotating speed and the torque, and the wet clutch box controls output and cutting off of the power of the second transmission shaft in the wet clutch box. The system and the method effectively solve the problem about measurement of the temperature of the friction pair of the wet clutch in a high-speed rotating state and realize prevention of failures of the wet clutch and real-time accurate detection of the combination state.

Owner:BEIJING INFORMATION SCI & TECH UNIV

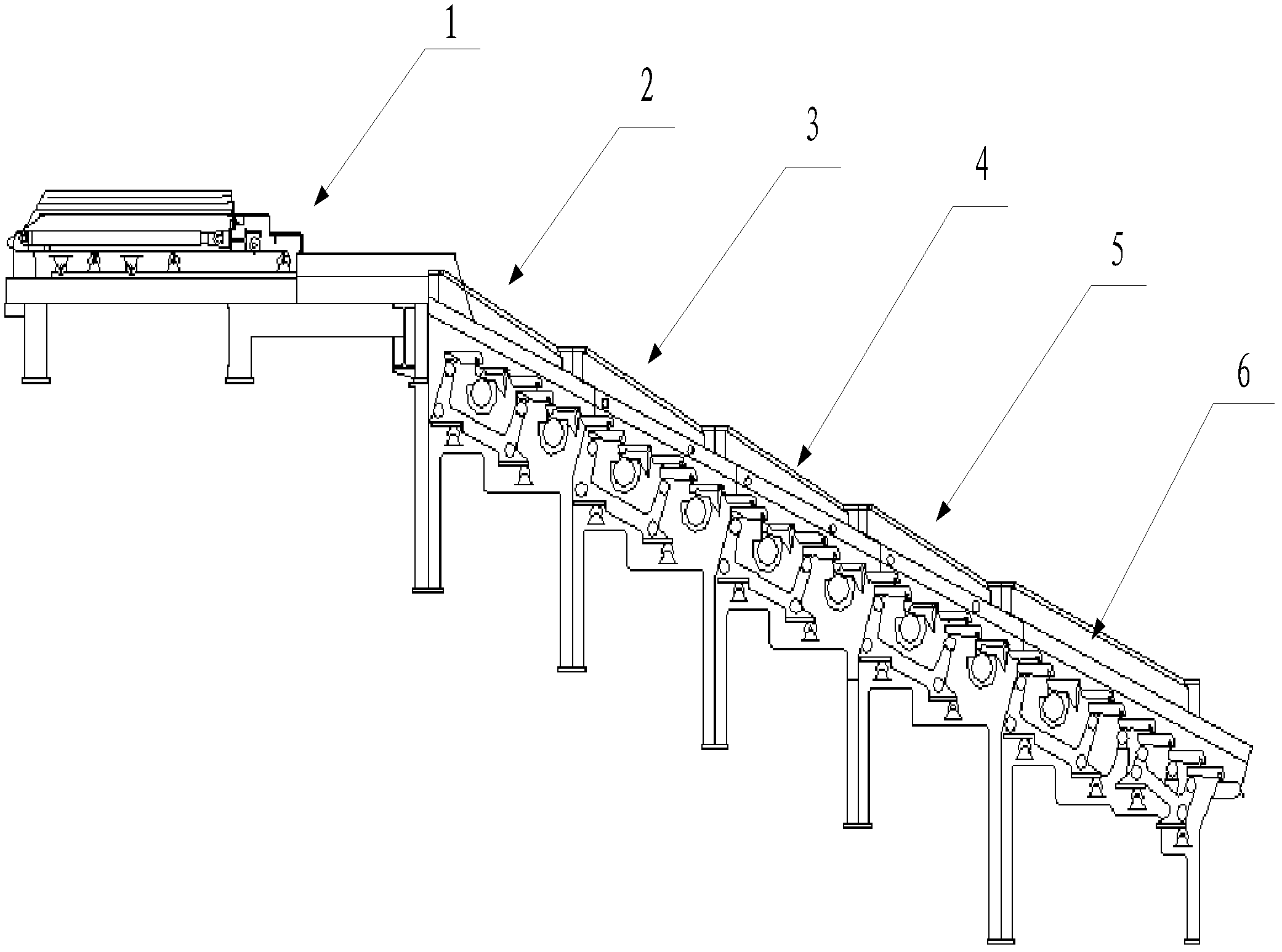

Multistage hydraulic mechanical garbage incinerator and control method for same

ActiveCN102607037AImprove combustionImprove burnout rateHollow bar grateInclined grateHydraulic machinerySteel frame

The invention provides a multistage hydraulic mechanical garbage incinerator and a control method for the same. The multistage hydraulic mechanical garbage incinerator comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally and longitudinally divided into a drying section, a burning section and a burnout section by the five units. The multistage hydraulic mechanical garbage incinerator is characterized in that the fire grate segments in each row of the incinerating fire grate are transversely driven by a shaft and transversely supported by a steel frame at three positions at the least. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

Water intake preventing automobile exhaust pipe utilizing tesla valve

ActiveCN111963290AImprove athletic abilityHigh speedExhaust apparatusSilencing apparatusWater flowEngineering

The invention relates to the technical field of automobile exhaust and discloses a water intake preventing automobile exhaust pipe utilizing a tesla valve. The water intake preventing automobile exhaust pipe comprises an exhaust pipe; a shunt pipe is rotatably connected into the exhaust pipe; a turbine rod is fixedly connected into the shunt pipe; a radiating pipe is connected with the external part of the exhaust pipe in a sleeving manner; a rear radiating shell is movably connected with the external part of the radiating pipe; an exhaust cover is fixedly connected with the external part of the exhaust pipe; an anti-reflux pipe is fixedly connected into the exhaust cover; and the tesla valve is arranged in the anti-reflux pipe. Through cooperative application of the anti-reflux pipe, thetesla valve, a movable block, a ventilating opening, a reset spring and a sealing plate, external water is effectively prevented from entering the exhaust pipe to realize a waterproof effect, and automobile safety is ensured; and under the action of the tesla valve, gas backward flow is effectively avoided, so that the possibility that an engine leaks oil due to gas backward flow is avoided, the automobile safety is further ensured and the using effect of the water intake preventing automobile exhaust pipe is effectively improved.

Owner:克康湘潭排气控制系统有限公司

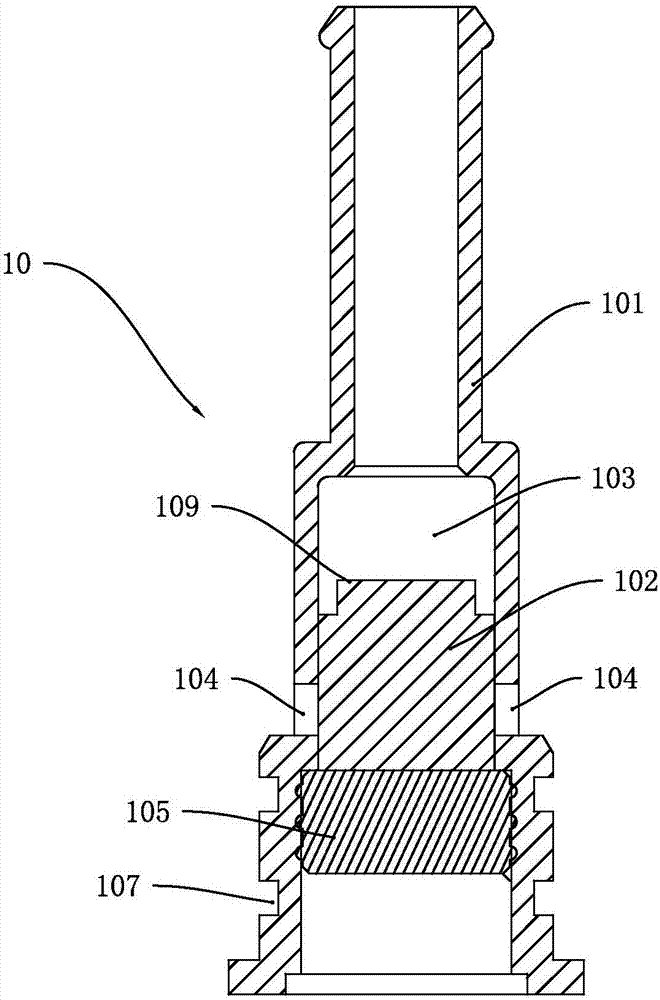

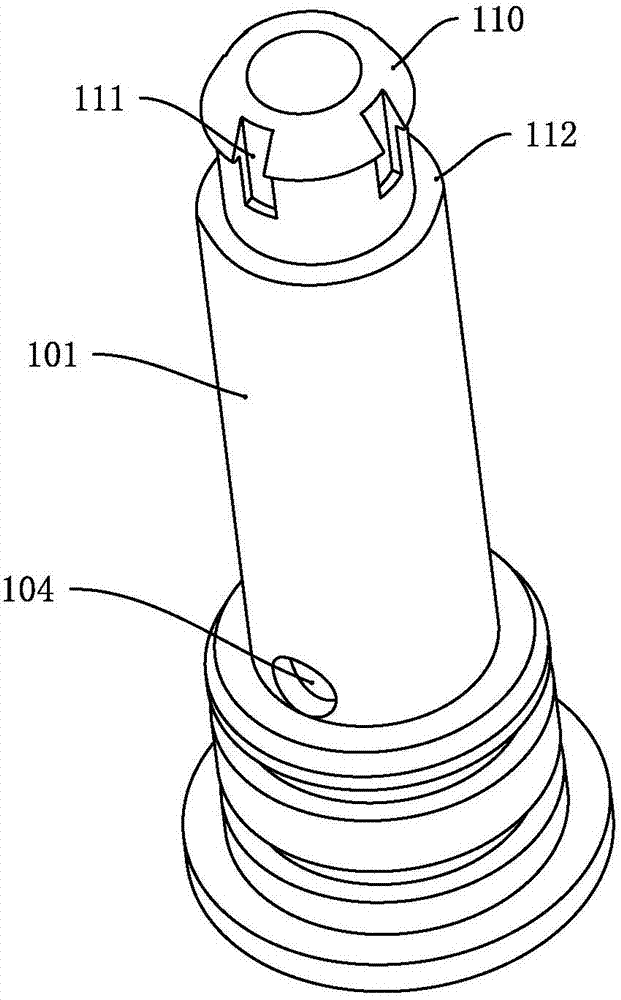

Vehicle gap adjustable conical brake device

ActiveCN106523550AAchieve separation releaseTravel piston stationaryFluid actuated brakesBrake actuating mechanismsBrake torqueVehicle frame

The invention relates to a vehicle gap adjustable conical brake device. The vehicle gap adjustable conical brake device comprises a barrel. The barrel is provided with a first end port and a second end port. A parking end cover is arranged in the first end port. A running end cover is arranged in the second end port. The parking end cover, the running end cover and the barrel define a cavity. A parking piston and a running piston are arranged in the cavity. One end of the parking piston can abut against the parking end cover, and the other end of the parking piston can abut against the running piston. The running piston can abut against the running end cover. A set of spring positioning grooves extending axially are evenly distributed in the parking piston. Parking springs are arranged in the spring positioning grooves and tightly abut against the parking end cover. The running piston is hollow, and a transmission shaft which is in sliding fit with the running piston is arranged in the hollow interior of the running piston. The vehicle gap adjustable conical brake device has the advantages that large brake torque can be achieved in a small mounting space, the brake effect is better, by adopting the nesting integral design of running and parking brakes, a parking brake does not need to be arranged independently, a vehicle frame space is saved, and great convenience is provided for overall vehicle arrangement.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

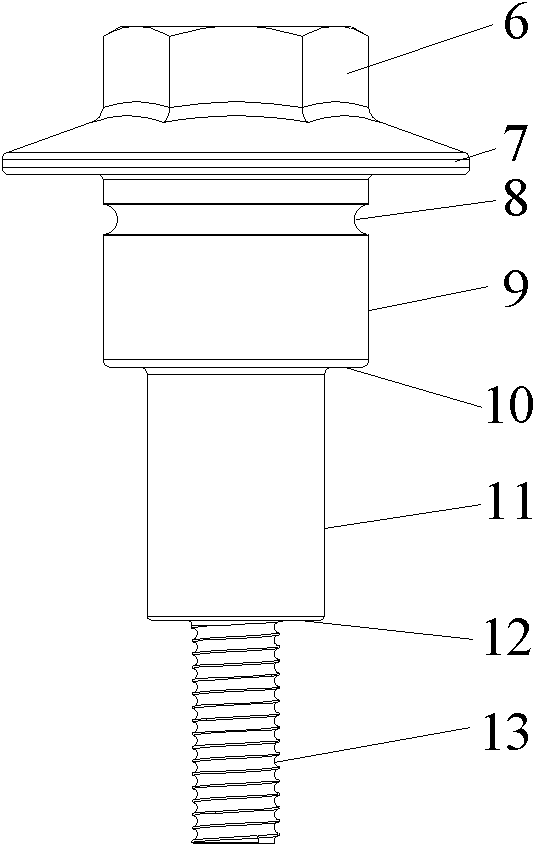

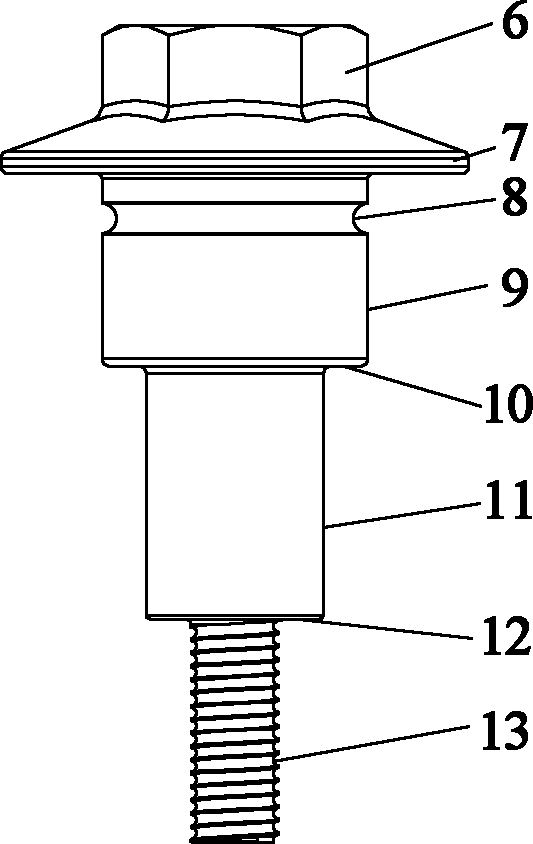

Standing bolt for fixed rail of timing chain

InactiveCN102072235AGuaranteed uptimePrevent oil spillsValve arrangementsScrewsEngineeringScrew thread

The invention discloses a standing bolt for a fixed rail of a timing chain, which comprises a bolt head and screw rods, wherein the screw rods are divided into a first screw rod, a second screw rod and a third screw rod; an annular groove is formed on the first screw rod; a first step is arranged between the first screw rod and the second screw rod; the diameter of the first screw rod is greater than that of the second screw rod; a second step is arranged between the second screw rod and the third screw rod; and full threads are formed on the third screw rod. The standing bolt has high sealing effect, and can clamp the fixed rail on an engine easily.

Owner:CHERY AUTOMOBILE CO LTD

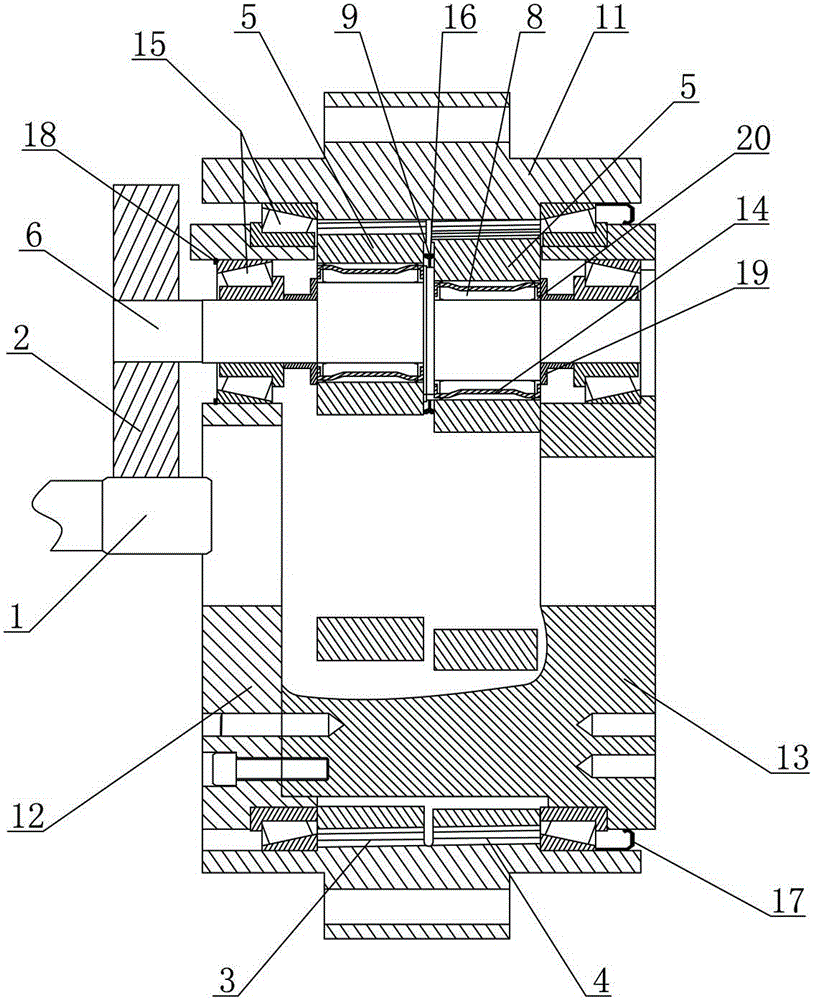

Planetary gear transmission mechanism, robot joint reducer and robot

ActiveCN105221669ARealize deceleration and torque increaseReduce machining accuracyJointsToothed gearingsReduction driveInvolute gear

The invention provides a planetary gear transmission mechanism which comprises a sun wheel, planet wheels and a few-tooth-difference transmission mechanism. In order to improve the precision, gear teeth of two inner gear rings and gear teeth of two few-tooth-difference gears are variable-tooth-thickness involute gear teeth; the rotation directions of the helix angles of the two inner gear rings are opposite, and a clearance-eliminating elastic body is arranged between a pair of few-tooth-difference gears. The planetary gear transmission mechanism has the advantages of being high in rigidity and precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty. The invention further provides a robot joint reducer which comprises the planetary gear transmission mechanism. The robot joint reducer has the advantages of being scientific in design, small in size, high in precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty. The invention further provides a robot which comprises the robot joint reducer. The robot has the advantages of being scientific in design, high in precision, large in transmission ratio and torque, and capable of greatly lowering machining difficulty.

Owner:吴建红

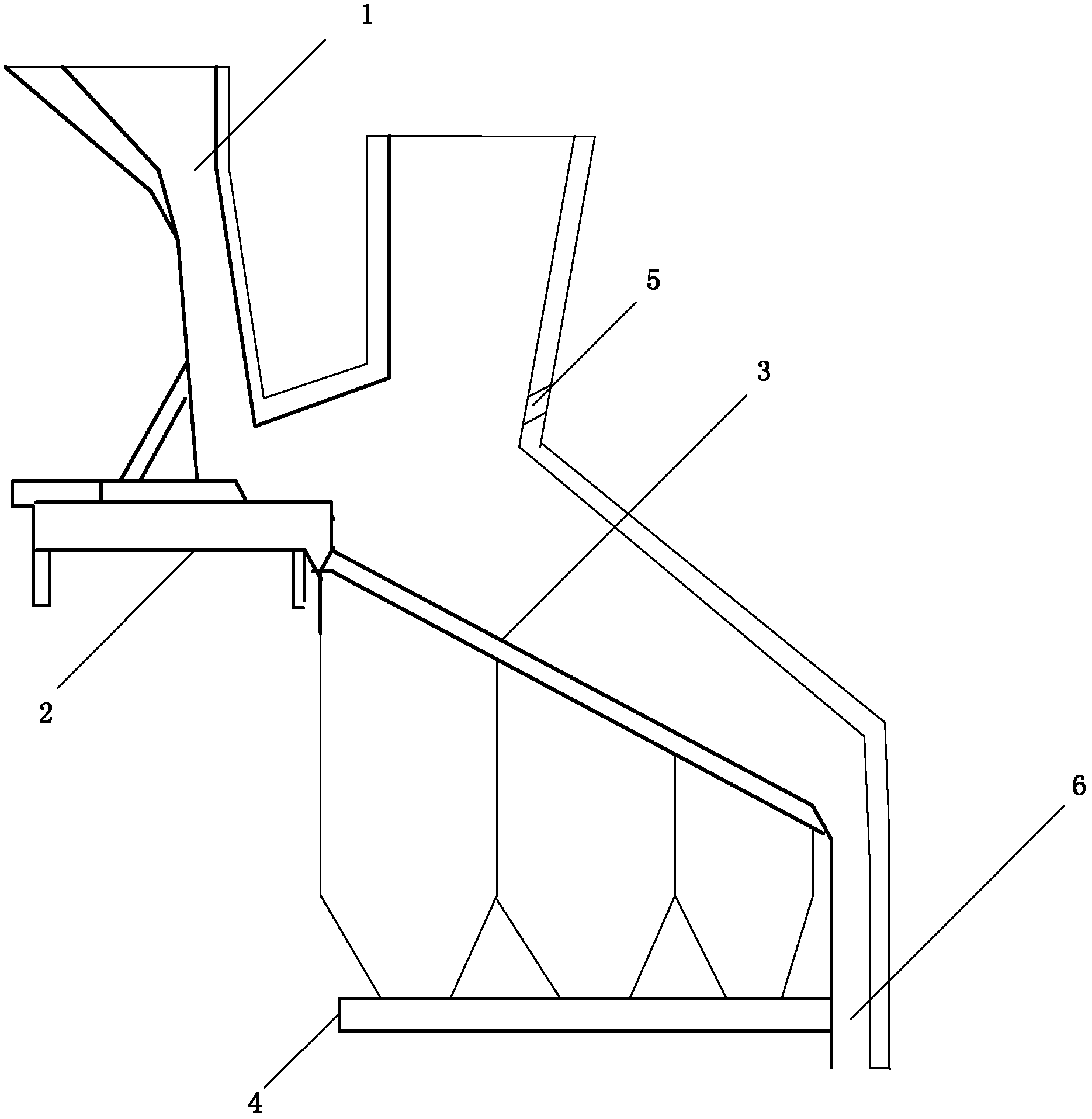

Kitchen wastewater treatment device

ActiveCN108483779AAvoid cloggingAvoid dischargeWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesDrive shaftFiltration

The invention relates to the field of sewage treatment, and discloses a kitchen wastewater treatment device. The kitchen wastewater treatment device comprises a shell below a sink. An oblique filtration screen is connected into the shell slidably. Extensible springs are fixedly connected between two ends of the filtration screen and the top wall of the shell respectively. A driving switch is arranged on the side wall of the shell. The filtration screen can be abutted against the driving switch. A driving shaft is arranged below the filtration screen. A cam is fixedly connected with the drivingshaft coaxially. A first bevel gear is fixedly connected to the driving shaft coaxially, and is meshed with a second bevel gear. A threaded rod is fixedly connected to the second bevel gear coaxially. A first runner wheel is meshed with one side of the threaded rod and a second runner wheel. A vertical shaft is fixedly connected with the bottom end of the threaded rod through the bevel gear set.An oil-water separation box is arranged on the other side of the threaded rod. An oil collection groove is formed in the inner wall of the oil-water separation box. The vertical shaft is located in the oil-water separation box, and a filtration plate is fixedly connected to the top end of the vertical shaft. By the kitchen wastewater treatment device, the problems of sewer line being blocked by grease and of inconvenience in manual collection and operation, of conventional wastewater treatment devices, are solved.

Owner:宁波清智环保科技有限公司

Permeation resisting composite film

ActiveCN105922690AImprove penetration resistanceImprove sealingSynthetic resin layered productsDomestic containersLow-density polyethylenePolyester

The invention discloses a permeation resisting composite film. The permeation resisting composite film comprises a polyester layer, a first polyethylene layer, a polyester aluminum coated layer and a second polyethylene layer from outside to inside in sequence. The second polyethylene layer is composed of a composite layer, a middle layer and a heat sealing layer, wherein the composite layer is composed of low-density polyethylene and linear low-density polyethylene according to the weight ratio of 1:3, the middle layer is composed of low-density polyethylene, linear low-density polyethylene and high-density polyethylene according to the weight ratio of 1:1:1, and the heat sealing layer is composed of low-density polyethylene and metallocene polyethylene according to the weight ratio of 2:1. By improving the formula of the second polyethylene layer and using 2050 glue between the polyester aluminum coated layer and the second polyethylene layer, barrier property and medium resistance of the product are improved greatly while the requirement for heat sealing strength is met; meanwhile, pollution resistance is high, and the permeation resisting composite film is especially suitable for packaging oily substances such as gluten.

Owner:永新股份(黄山)包装有限公司

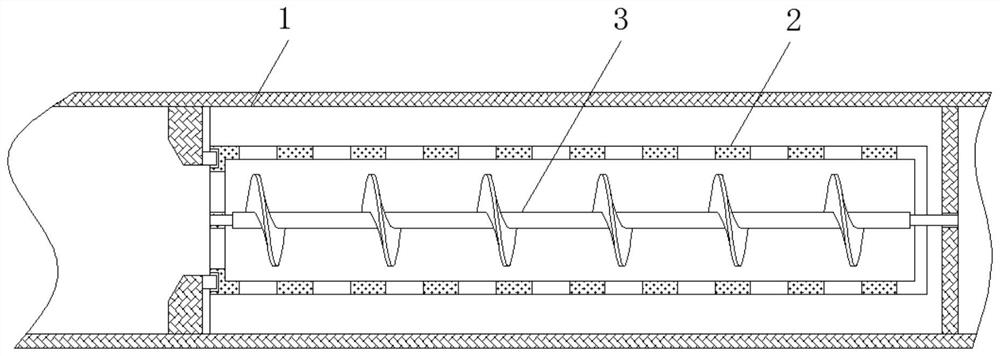

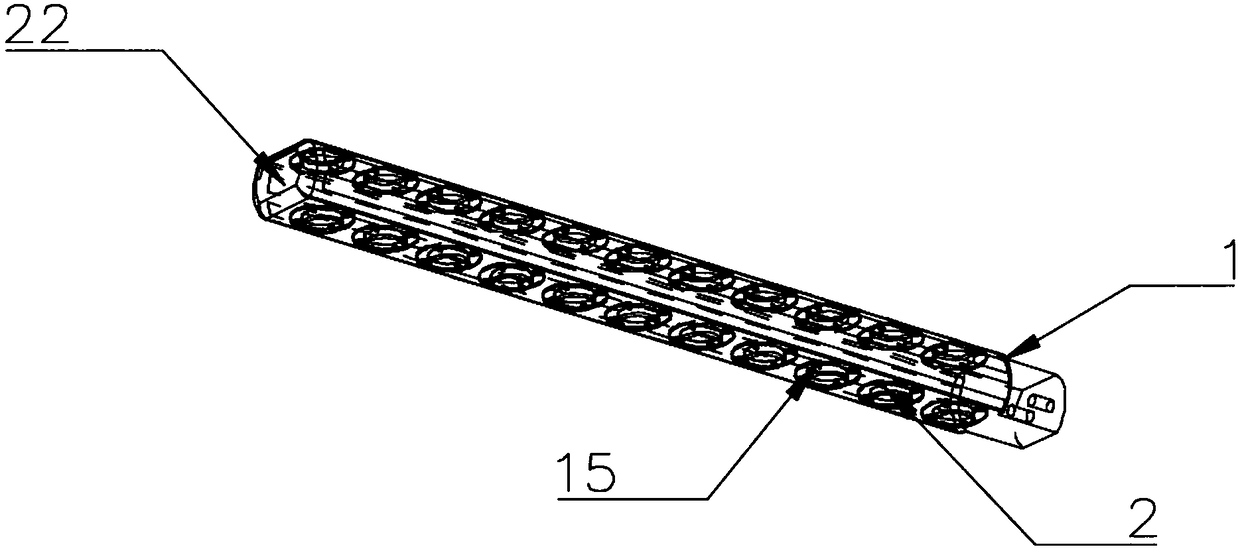

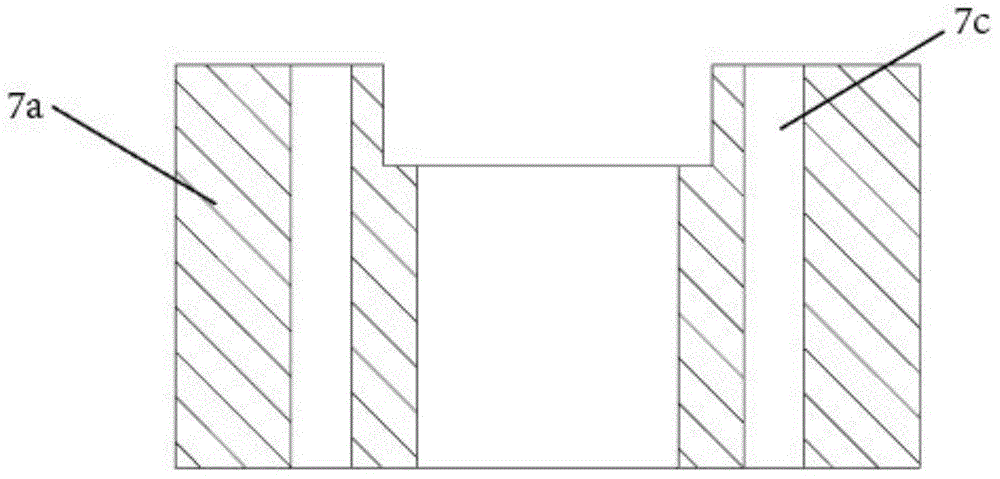

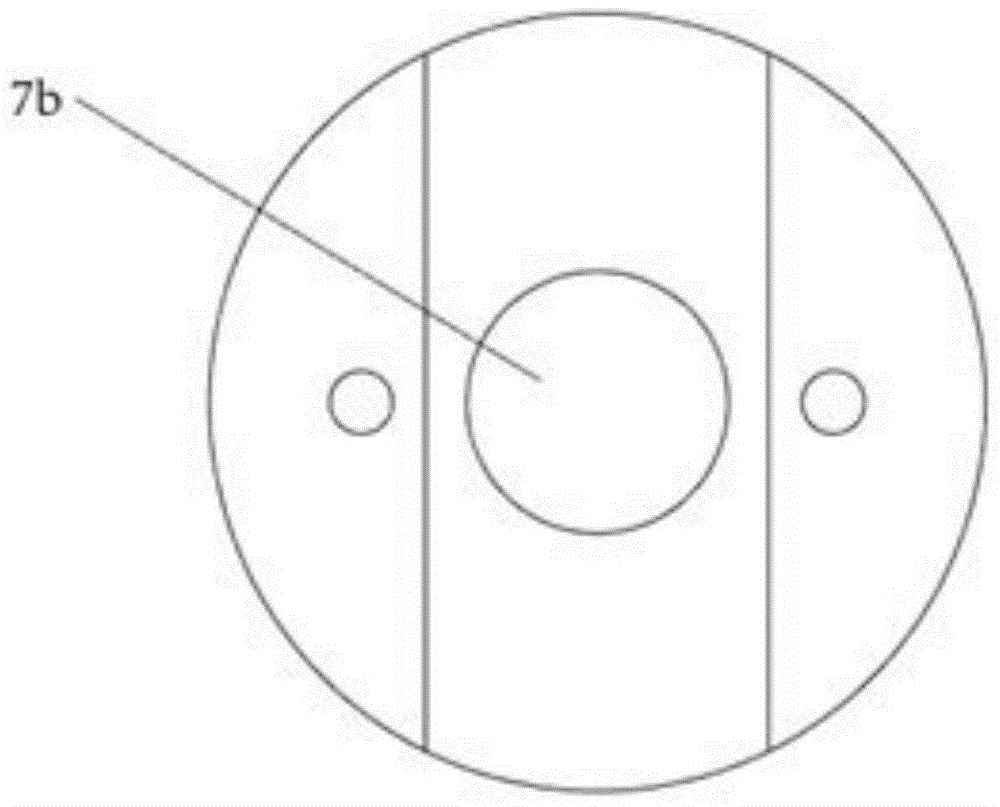

Hydraulic two-way splitting rod

InactiveCN108591170AAvoid damageShorten the lengthDisloding machinesFluid-pressure actuatorsHydraulic cylinderInlet channel

The invention discloses a hydraulic two-way splitting rod. Multiple two-way hydraulic cylinders are longitudinally arranged in a rod shell; each two-way hydraulic cylinder is connected with the adjacent two-way hydraulic cylinders end to end; all the two-way hydraulic cylinders in the rod shell share the same oil inlet channel and the same oil return channel; the two-way hydraulic cylinders comprise cylinder blocks, cylinder jackets, piston rods and sealing pieces; piston cavities are formed between first piston rods and second piston rods; the oil inlet channel is arranged on one sides of thepiston cavities, and communicates with the piston cavities through oil inlet holes; and the oil return channel is arranged on the other sides of the piston cavities, and communicates with the pistoncavities through oil return holes. Compared with a traditional splitting rod, the splitting rod is uniformly stressed in non-uniform cylinder holes through two-way piston systems, so that the damage to the splitting rod by reactive force of rocks can be prevented, and the service life is prolonged; and the splitting rod is large in travel, improves the splitting efficiency, simple and compact in overall structure and convenient to install and maintain.

Owner:CHINA UNIV OF MINING & TECH

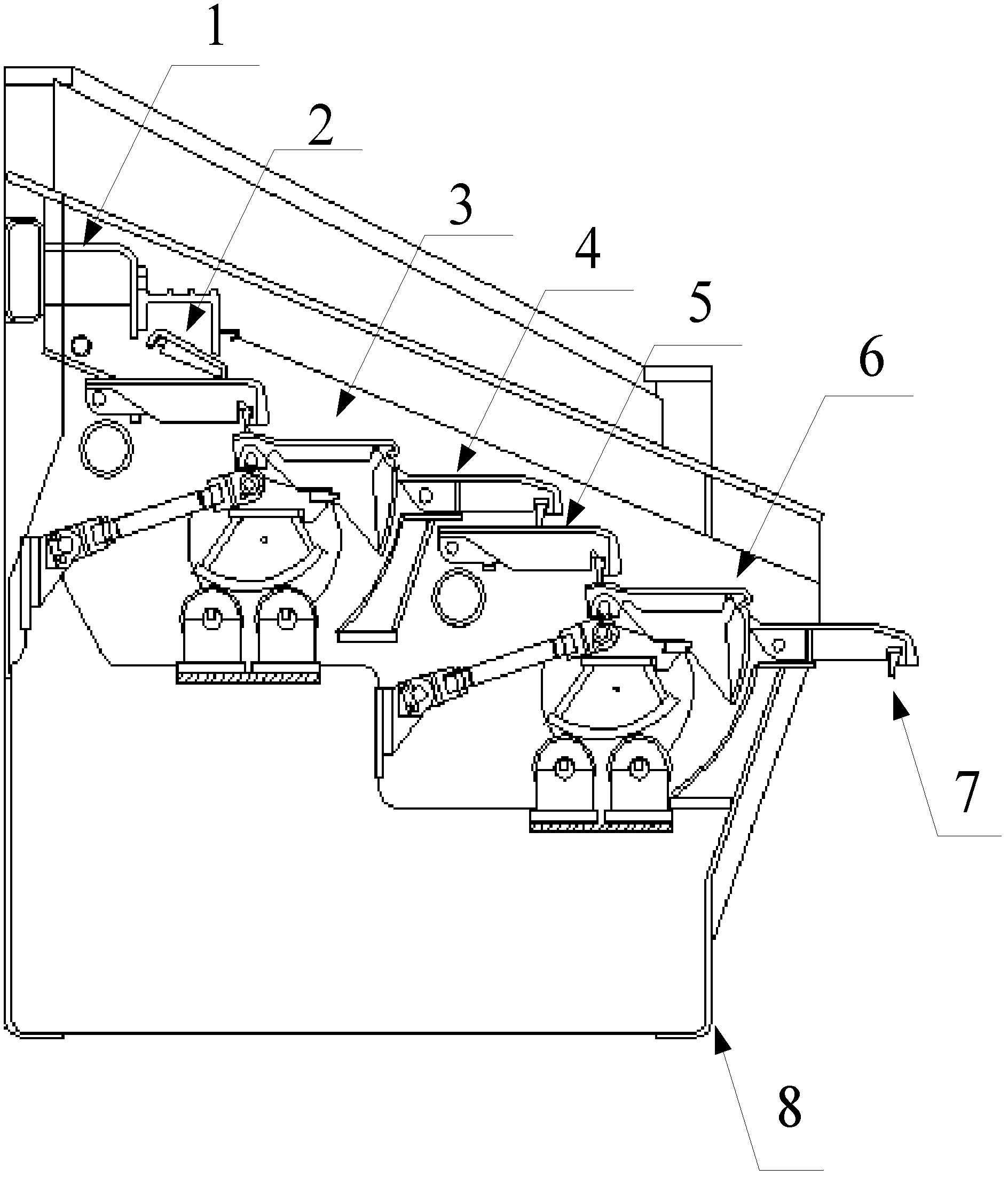

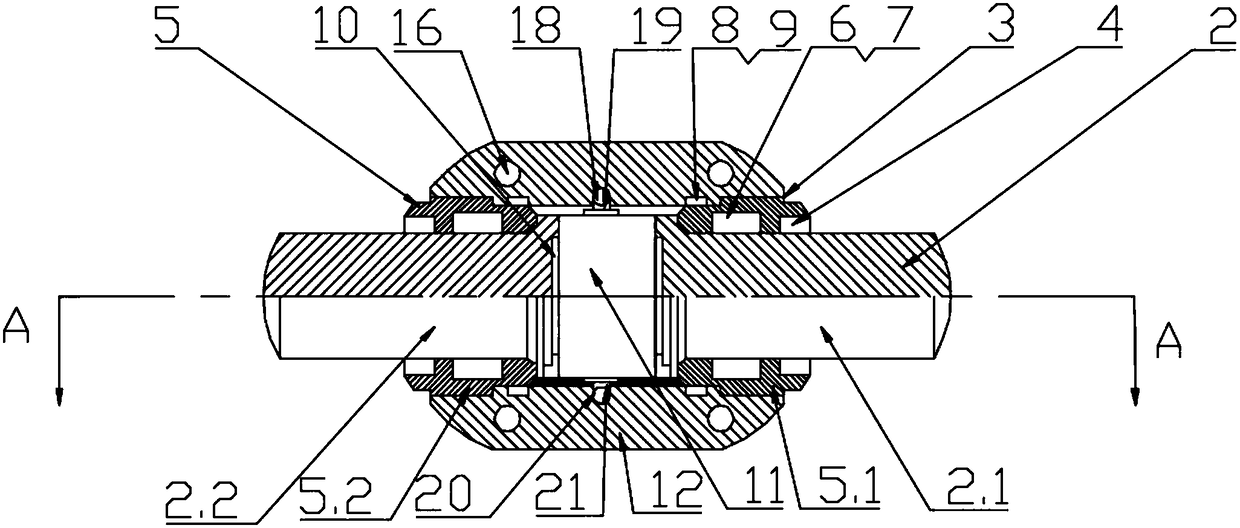

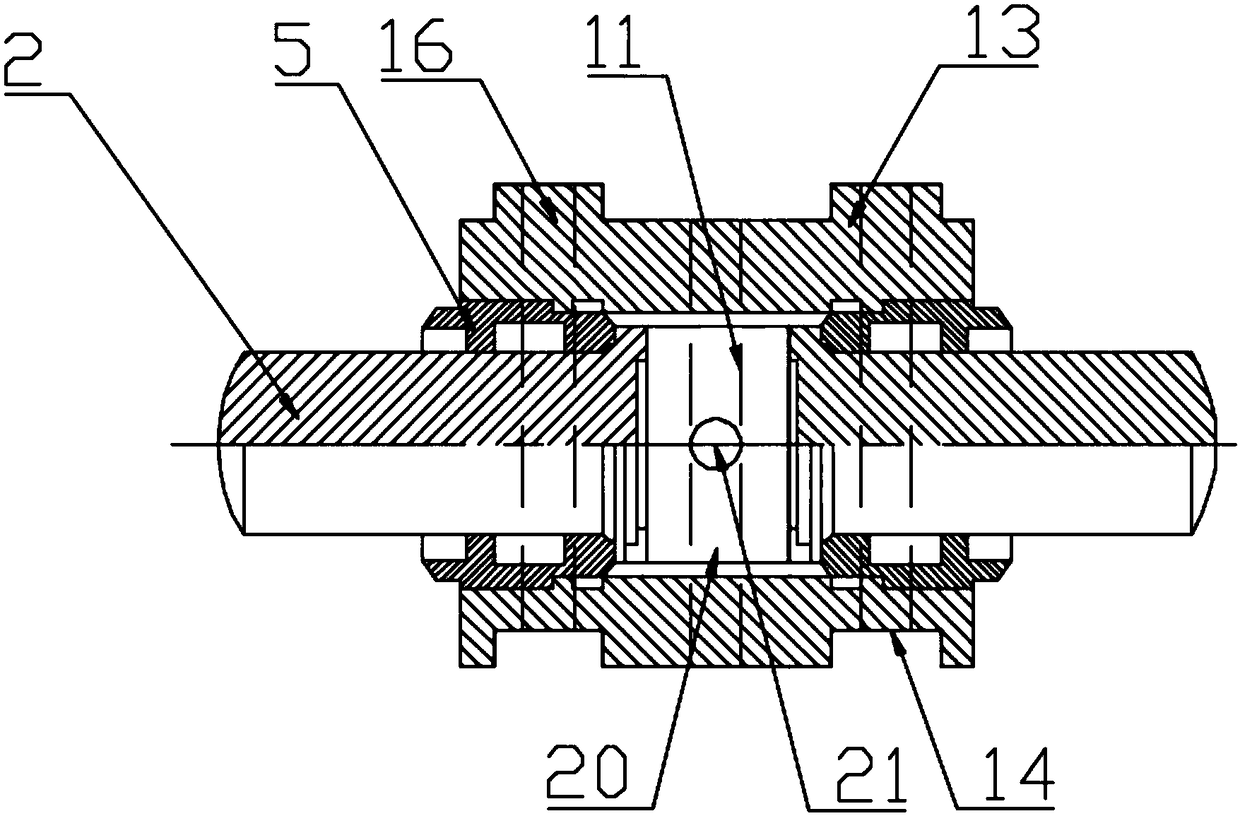

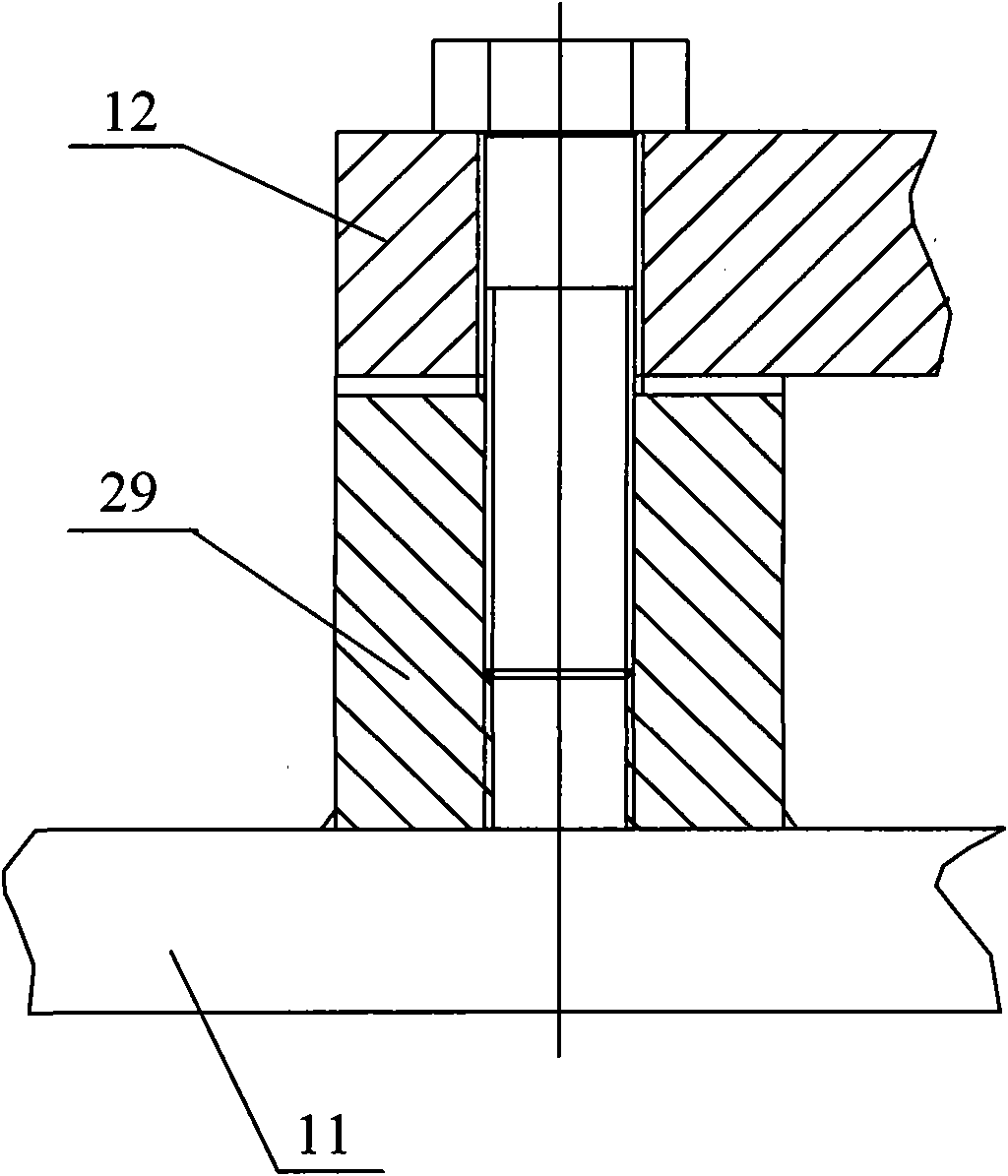

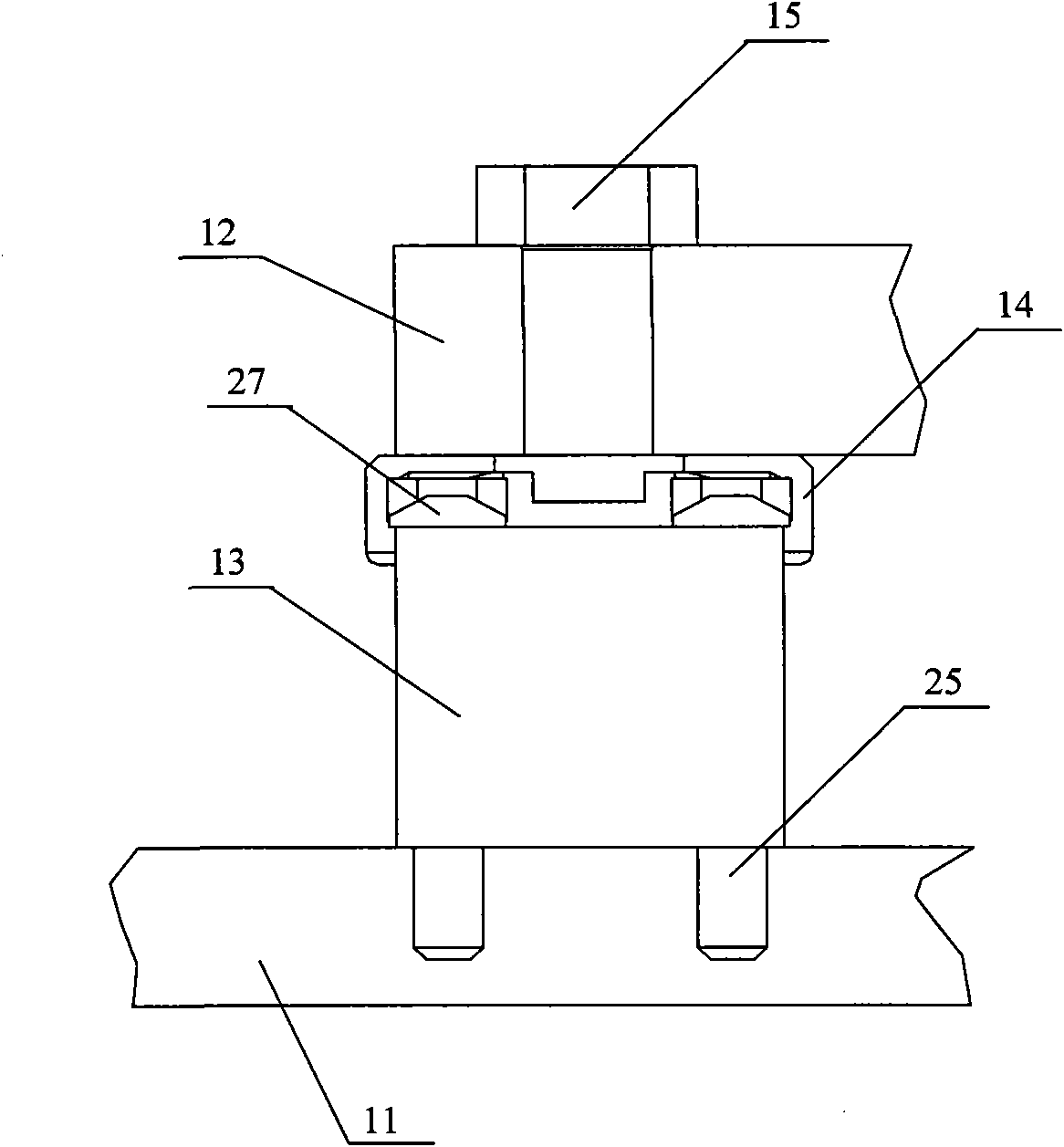

Railway locomotive and gear box and axel-hung box coupling device thereof

InactiveCN102039909APrevent oil spillsSafe and reliableElectric motor propulsion transmissionAxle-boxes mountingEngineeringCoupling

The invention provides a railway locomotive and a gear box and axel-hung box coupling device thereof. The coupling device comprises a gear box and an axel-hung box, wherein a rubber coupler is fixed to the gear box; the rubber coupler comprises an outer body, a rubber pad and an inner shaft sleeve, wherein a central hole is reserved on the outer body; the inner shaft sleeve penetrates through the central hole; the rubber pad is arranged between the outer wall of the inner shaft sleeve and the inner wall of the central hole; a positioning card is arranged between the axel-hung box and the rubber coupler; a positioning hole and a positioning edge are reserved on the positioning card; the positioning hole is opposite to the shaft hole of the inner shaft sleeve; the outer wall of the outer body of the rubber coupler is locked by the positioning edge; and a coupling bolt penetrates through a first bolt hole on the axel-hung box, the positioning hole on the positioning card and the shaft hole in the inner shaft sleeve of the rubber coupler for coupling and fixing the axel-hung box and the gear box. The railway locomotive prevents the gear box from generating structure crackles to cause oil leakage.

Owner:CRRC DALIAN CO LTD

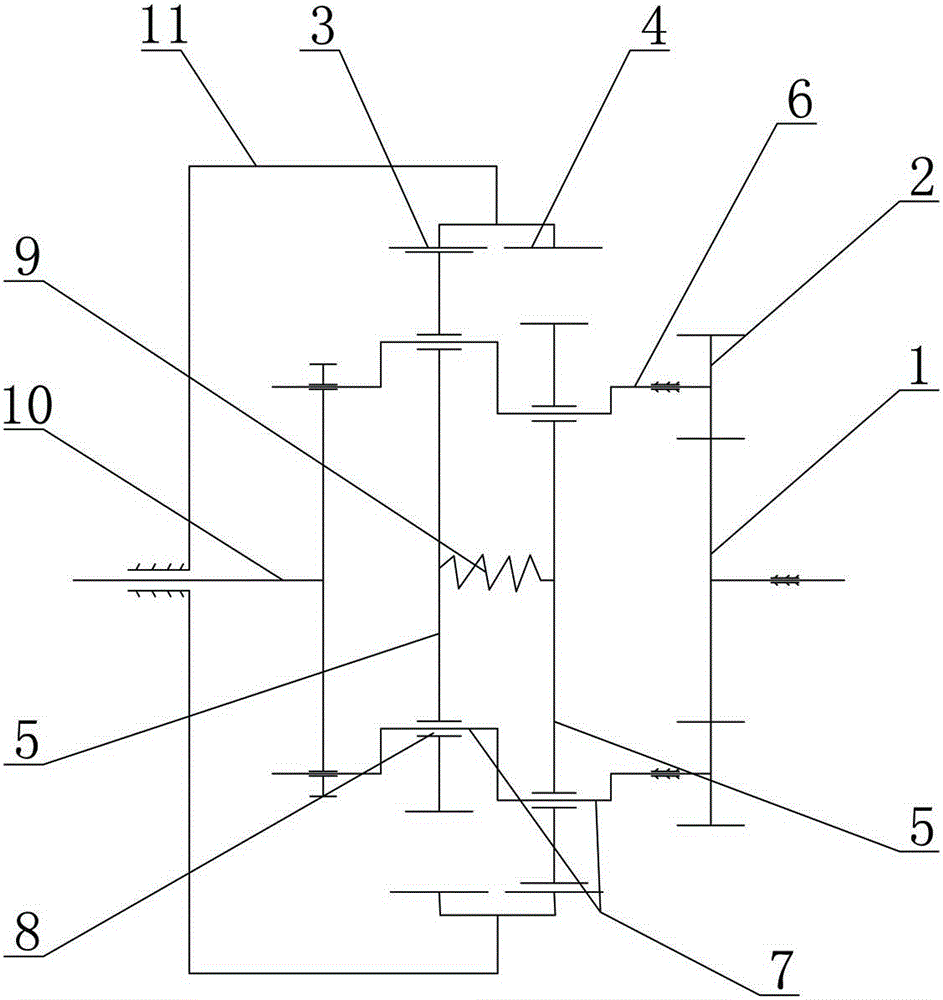

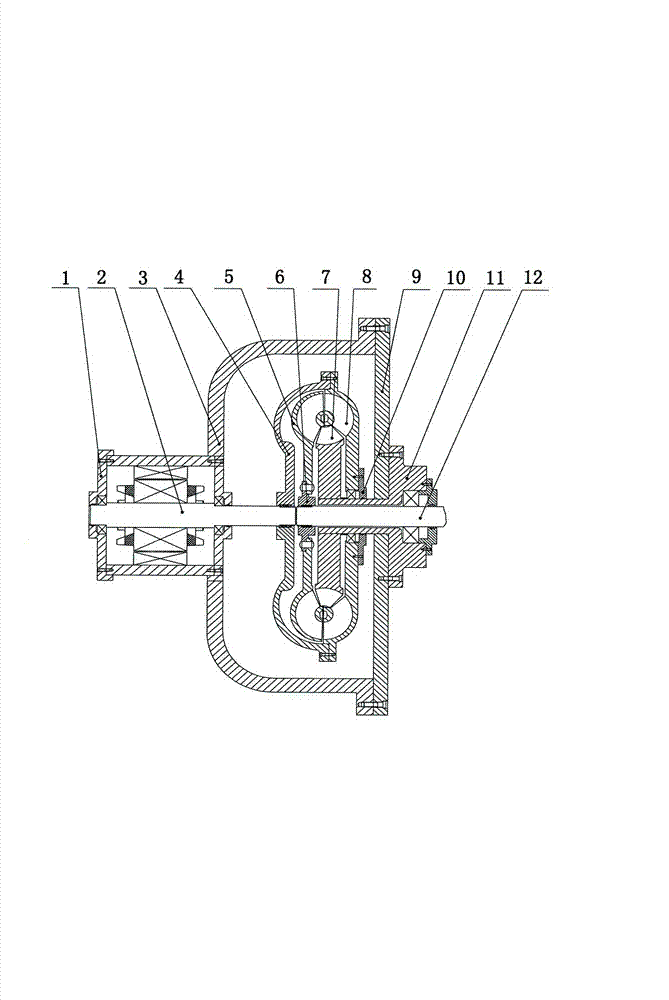

Motive power and fluid power driving device based on motor and torque converter integration unit

The invention discloses a motive power and fluid power driving device based on a motor and torque converter integration unit. The motive power and fluid power driving device based on the motor and torque converter integration unit is characterized in that a front end cover of a motor and a housing of a fluid power torque converter are fixedly connected into a whole, one end of a fluid power torque converter pump wheel is connected with a rotating shaft of the motor through splines and a cover disk, the other end of the fluid power torque converter pump wheel is fixed on a flange plate shaft sleeve through splines on and a bearing and a pump wheel hub, a guide wheel is fixed on the flange plate shaft sleeve through splines, a flange plate is fixedly connected with a front cover of a torque converter through threads, a worm wheel is connected with an output shaft through splines and a worm wheel hub, and the motor can be an inner rotor motor or an external rotor motor. Compared with the prior art, a coupler is removed, the rotating shaft of the motor and the input shaft of the torque converter is the same shaft, and accordingly the problem that concentricity precision of two side shafts of the coupler is low is solved, impacts among connections are reduced, and furthermore the motive power and fluid power driving device based on the motor and torque converter integration unit is stable in running, low in noise, high in driving efficiency, compact in structure, and small in occupying space, and can replace a motor fluid power torque converter which can only use the coupler for integration.

Owner:YANSHAN UNIV

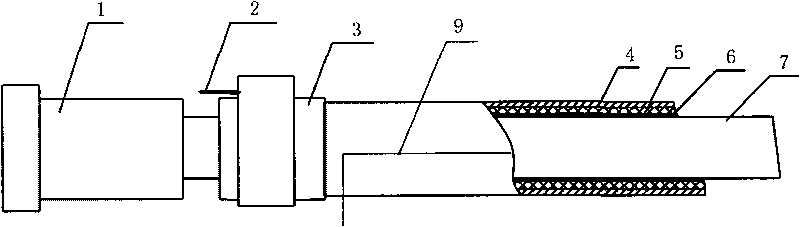

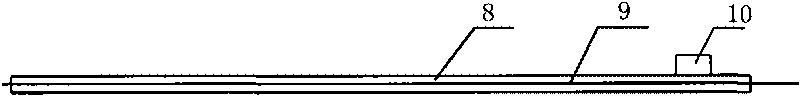

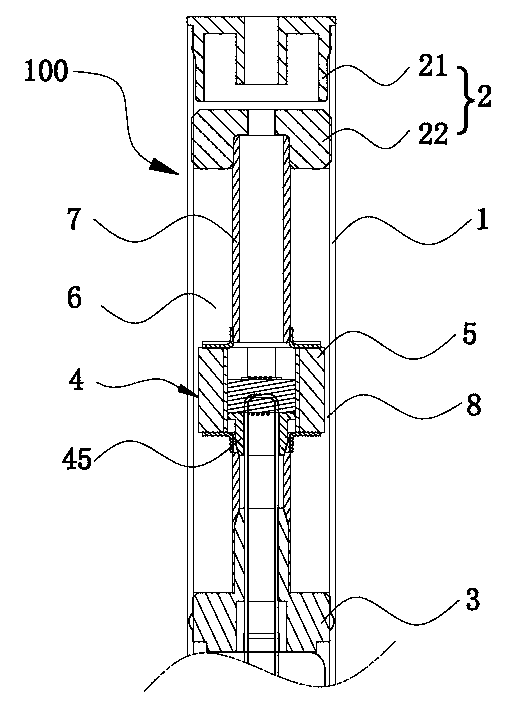

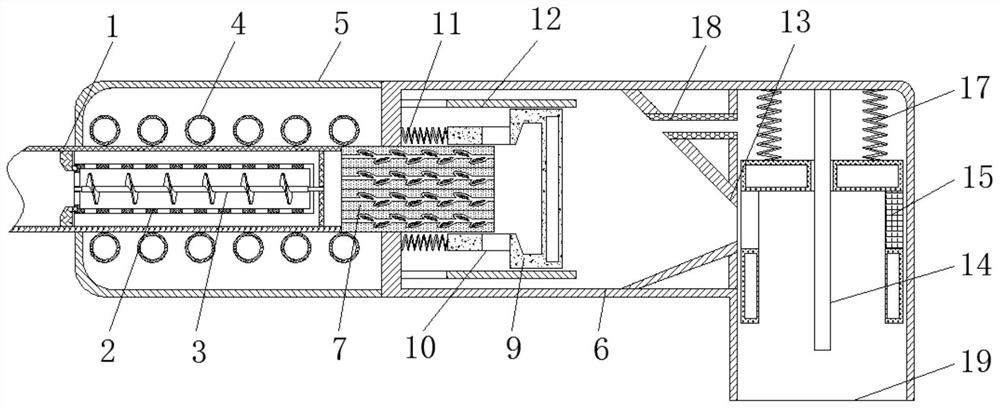

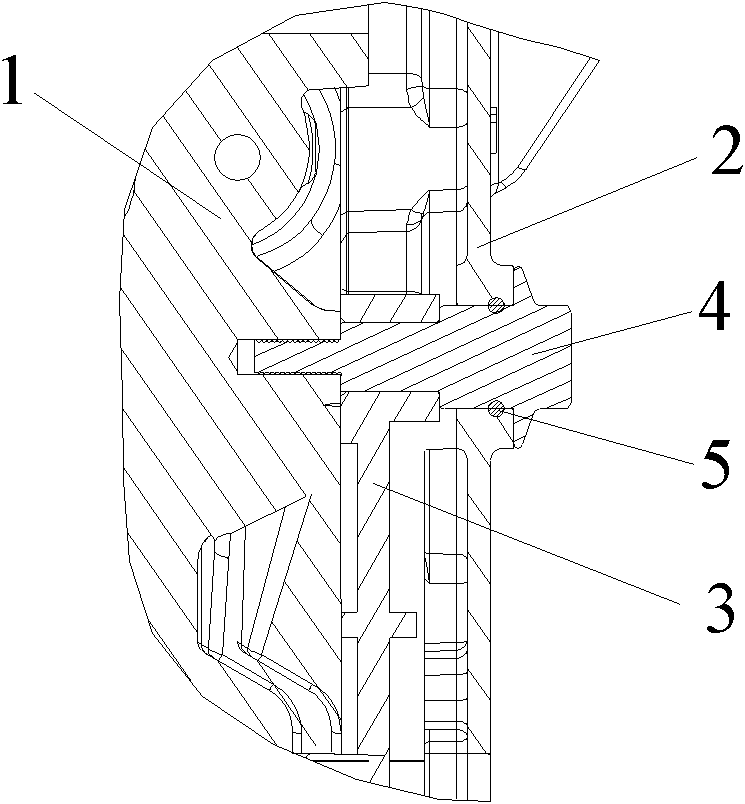

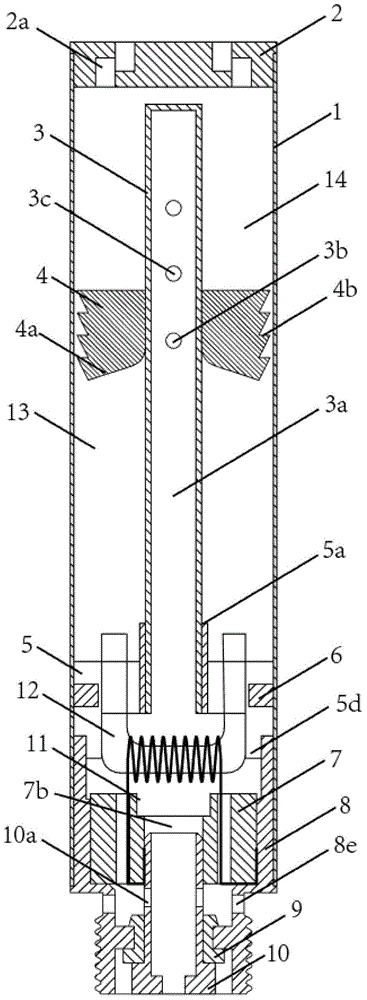

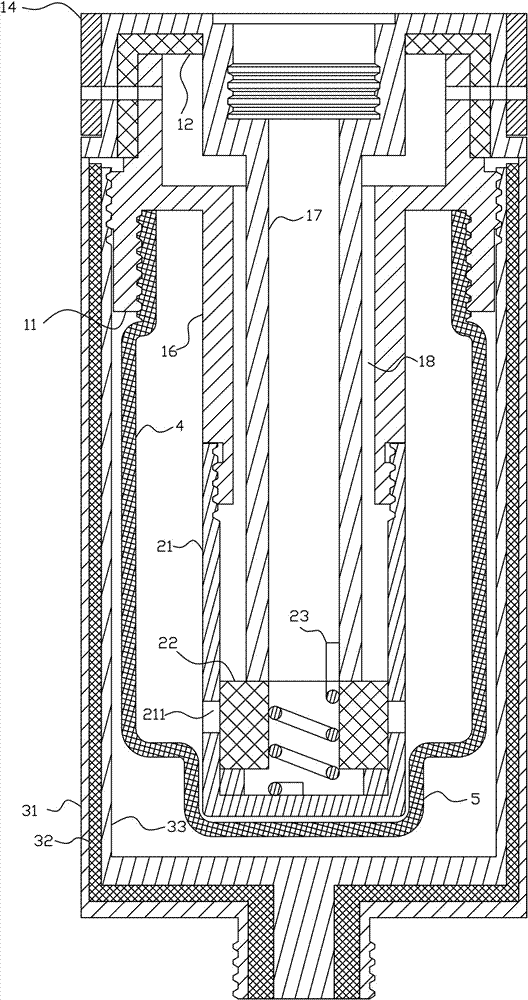

Disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage

A disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage comprises a round-tube-shaped casing (1), an axial smoke tube (3), a cigarette holder cover (2), a tobacco tar isolation rubber gasket (4) and an atomizer assembly, wherein the axial smoke tube (3) is arranged in the inner center of the casing, the cigarette holder cover (2) covers the top of the casing, vent holes (2a) are formed in the cigarette holder cover (2), the tobacco tar isolation rubber gasket (4) is arranged at the middle-upper part in the casing and mounted on the smoke tube in a sleeving manner, and the atomizer assembly is arranged at the lower end of the smoke tube; the tobacco tar isolation rubber gasket divides an inner cavity of the casing into an upper annular cavity (14) for accommodating filtration or flavoring materials and a lower tobacco tar storage cup (13) for storing tobacco tar. No tobacco tar storage cotton is used, bacterium breeding can be effectively avoided, air in the annular tobacco tar storage cup can be completely removed, the problem of tobacco tar leakage is effectively solved, the tobacco tar utilization rate is high, the smoke quantity is large, tobacco tar can be prevented from being sucked into the mouth, and the smoking experience is better.

Owner:云南拓宝科技有限公司

Fluid discharge gun

ActiveCN103775815AQuick releaseEasy to useGear lubrication/coolingLubrication check valvesRadial motionFuel tank

The invention discloses a fluid discharge gun. The fluid discharge gun comprises a tubular center rod, an elastic ejection pin, a connecting cover and an unlocking wheel, wherein the elastic ejection pin is movably arranged at the front end of the center rod and capable of moving axially, the connecting cover is fixedly arranged on the outer wall of the front part of the center rod, and the unlocking wheel is movably arranged on the outer wall of the middle of the center rod, located behind the connecting cover and capable of rotating; a clamping groove is formed between the connecting cover and the center rod, and an elastic locking bolt extending into the clamping groove for radial motion is arranged on the inner wall of the connecting cover; and a shifting block is arranged on the unlocking wheel and matched with the elastic locking bolt in the radial direction to realize radial motion of the elastic locking bolt. The fluid discharge gun can be matched with an oil drainage device of an oil tank for use, quick connection and disassembly with the oil drainage device can be realized during usage, and the gun is convenient to use; and complete sealing can be realized, oil leakage can be prevented, and quick discharge of fluids can be realized.

Owner:HUNAN ZIWEI AUTOMOBILE ENVIRONMENTAL PROT CO LTD

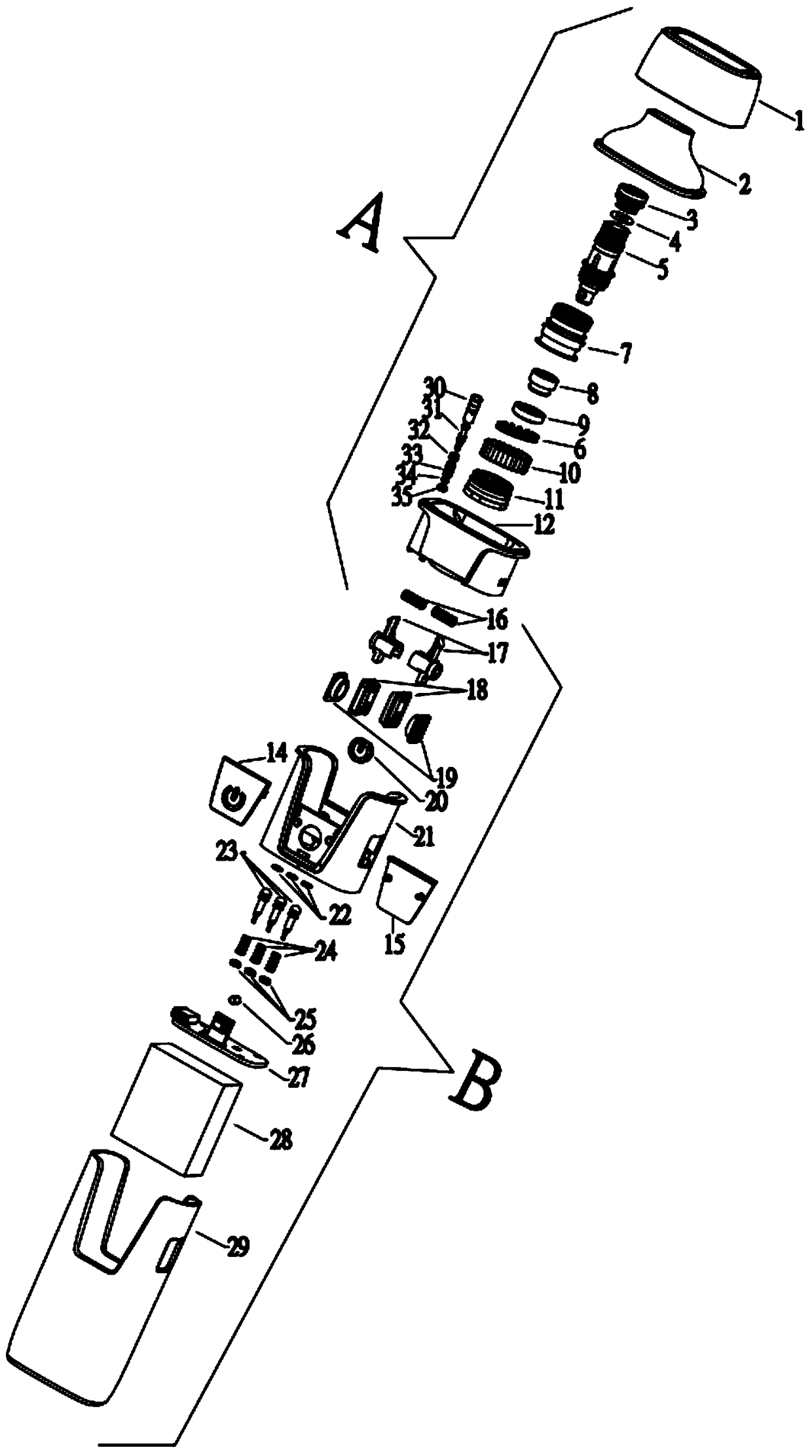

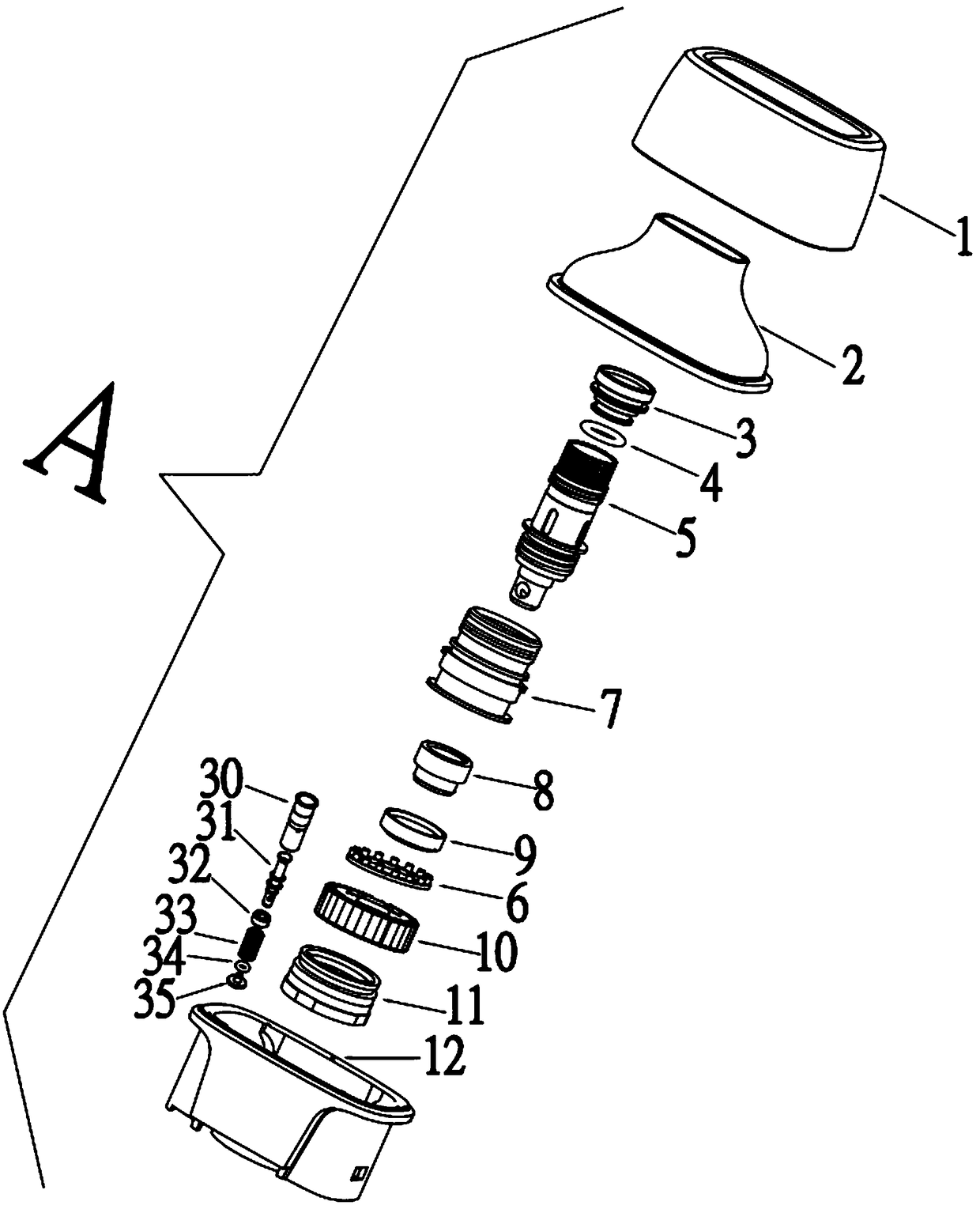

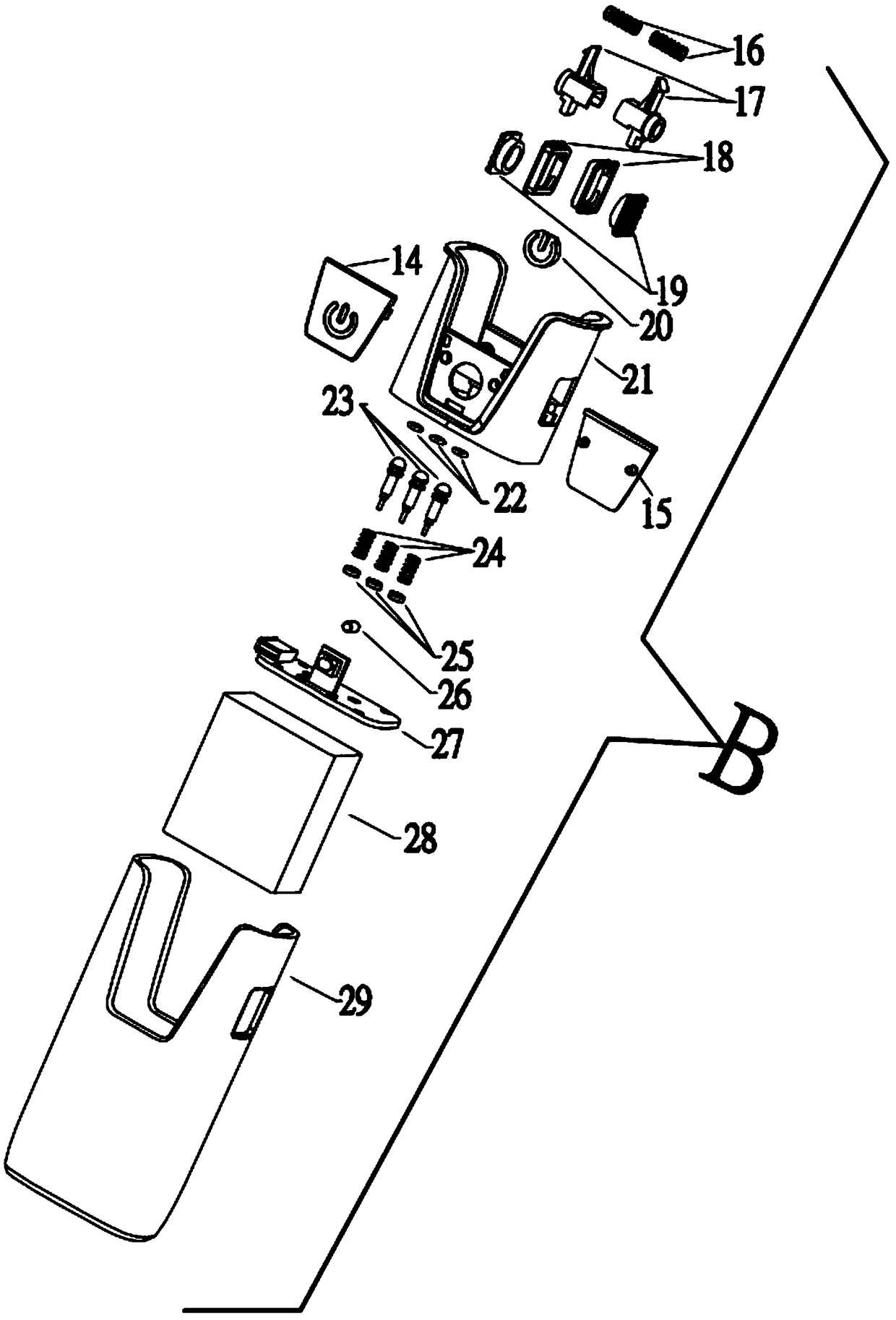

Electronic cigarette

InactiveCN109007991APrevent unscrewingEasy to separateTobacco devicesElectronic cigaretteEngineering

An electronic cigarette comprises an atomizer assembly (A) and a battery assembly (B), wherein the atomizer assembly is positioned above the battery assembly, and the atomizer assembly is tightly buckled with the battery assembly through the left and right switch keys (17) on the battery assembly, when the atomizer is detached, the press key caps (19) on the left and the right sides of the batteryassembly can be pressed at the same time, so that the atomizer can be ejected out and the atomizer can be separated from the battery, and the outer shape of the separated battery body is like a V shape. According to the invention, the battery and the atomizer can be separated from each other by pressing the key caps (19) on the left and right sides of the battery, and the opening and closing of the oil inlet hole and the child lock device are controlled by means of elastic force so as to prevent the heating core from being screwed out.

Owner:刘团芳

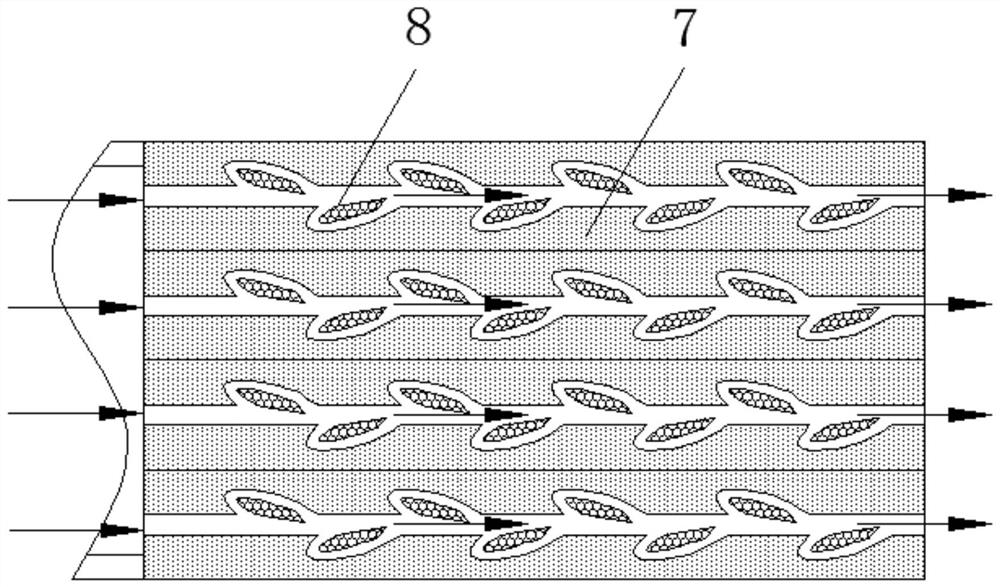

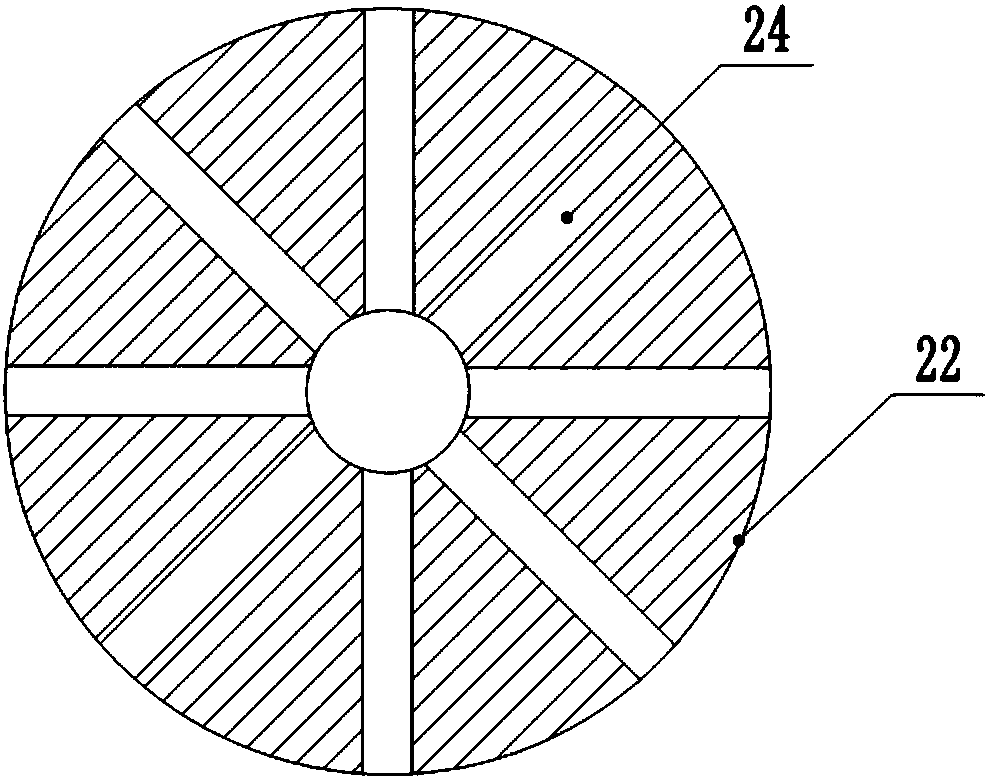

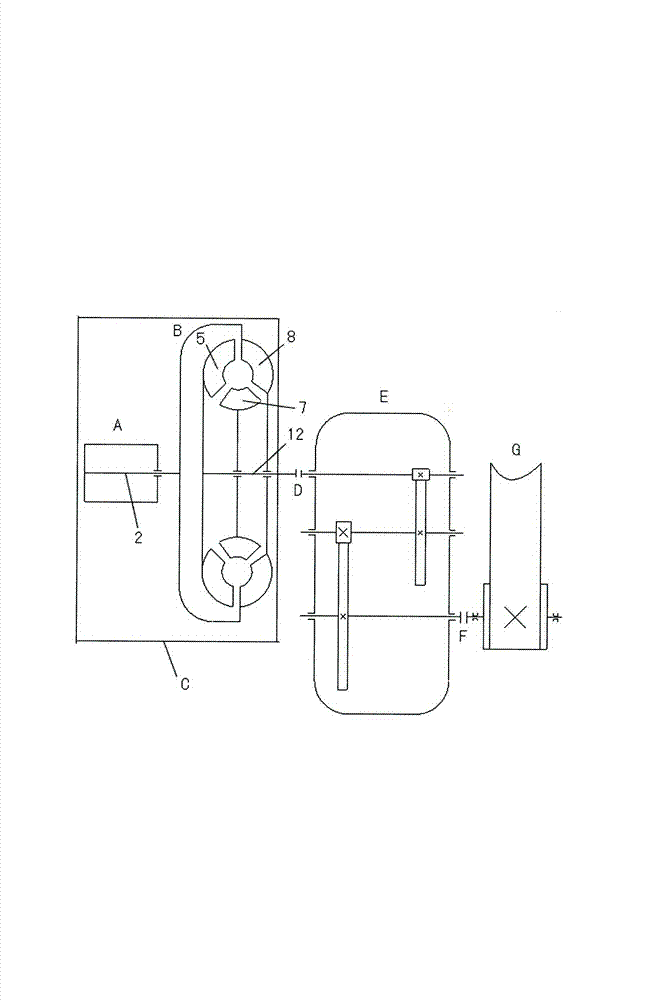

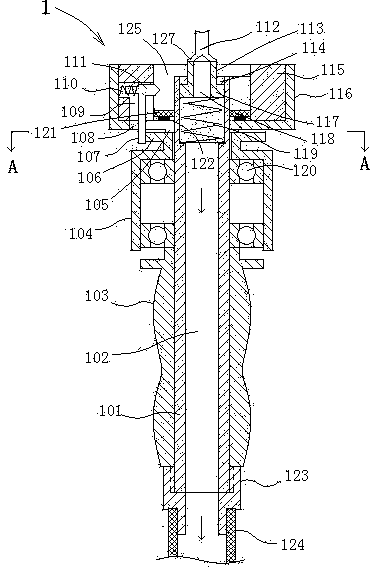

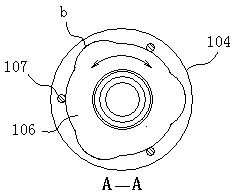

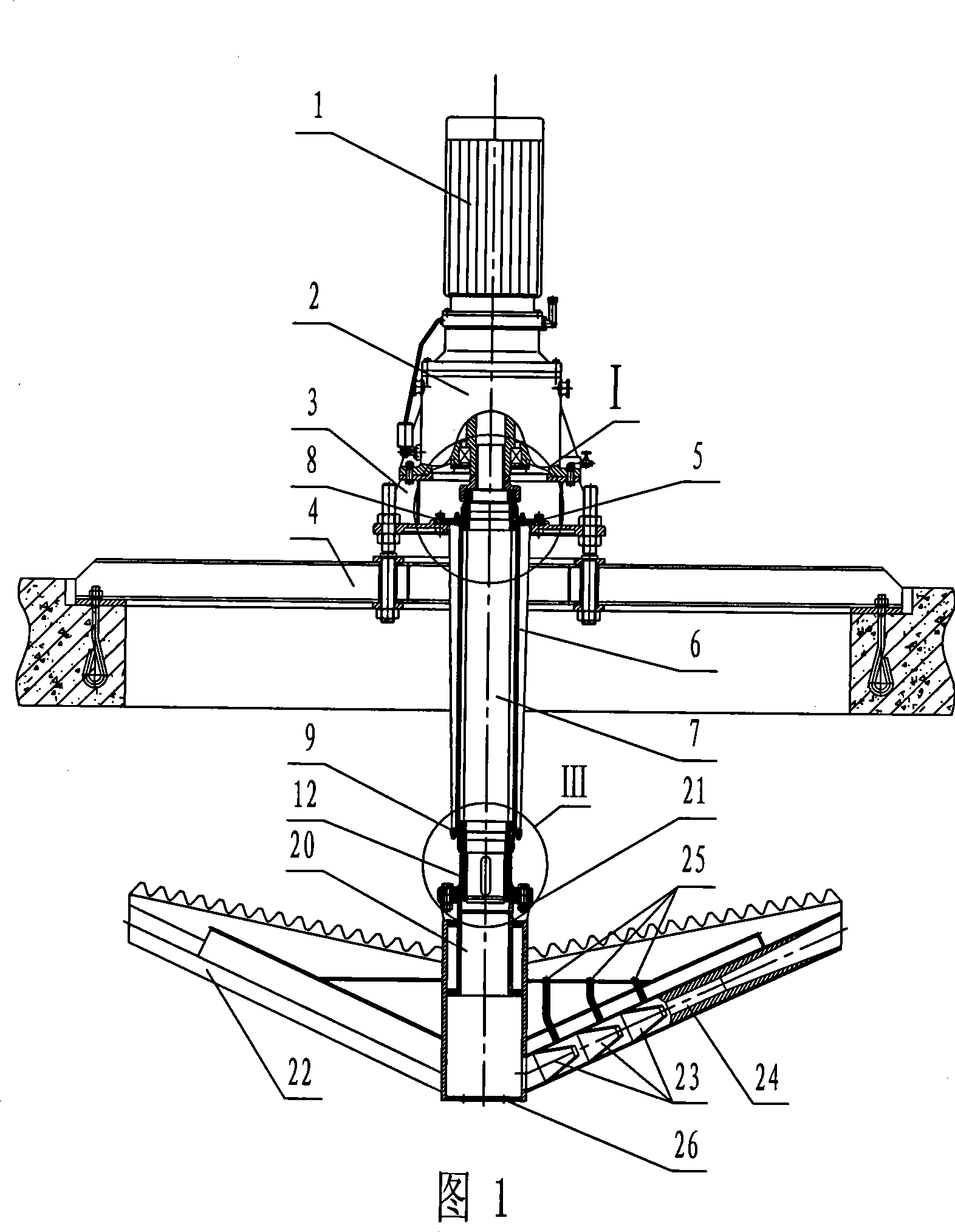

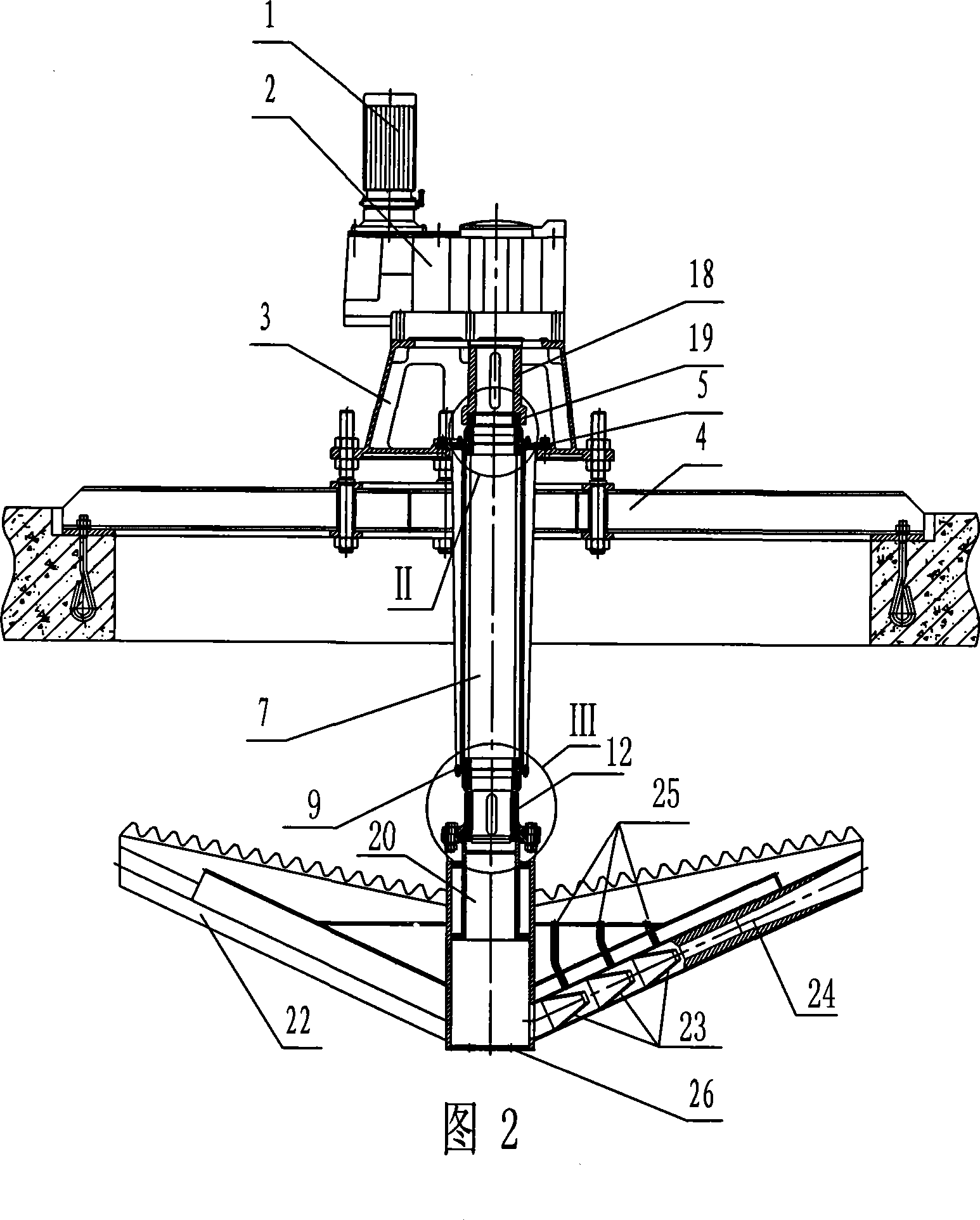

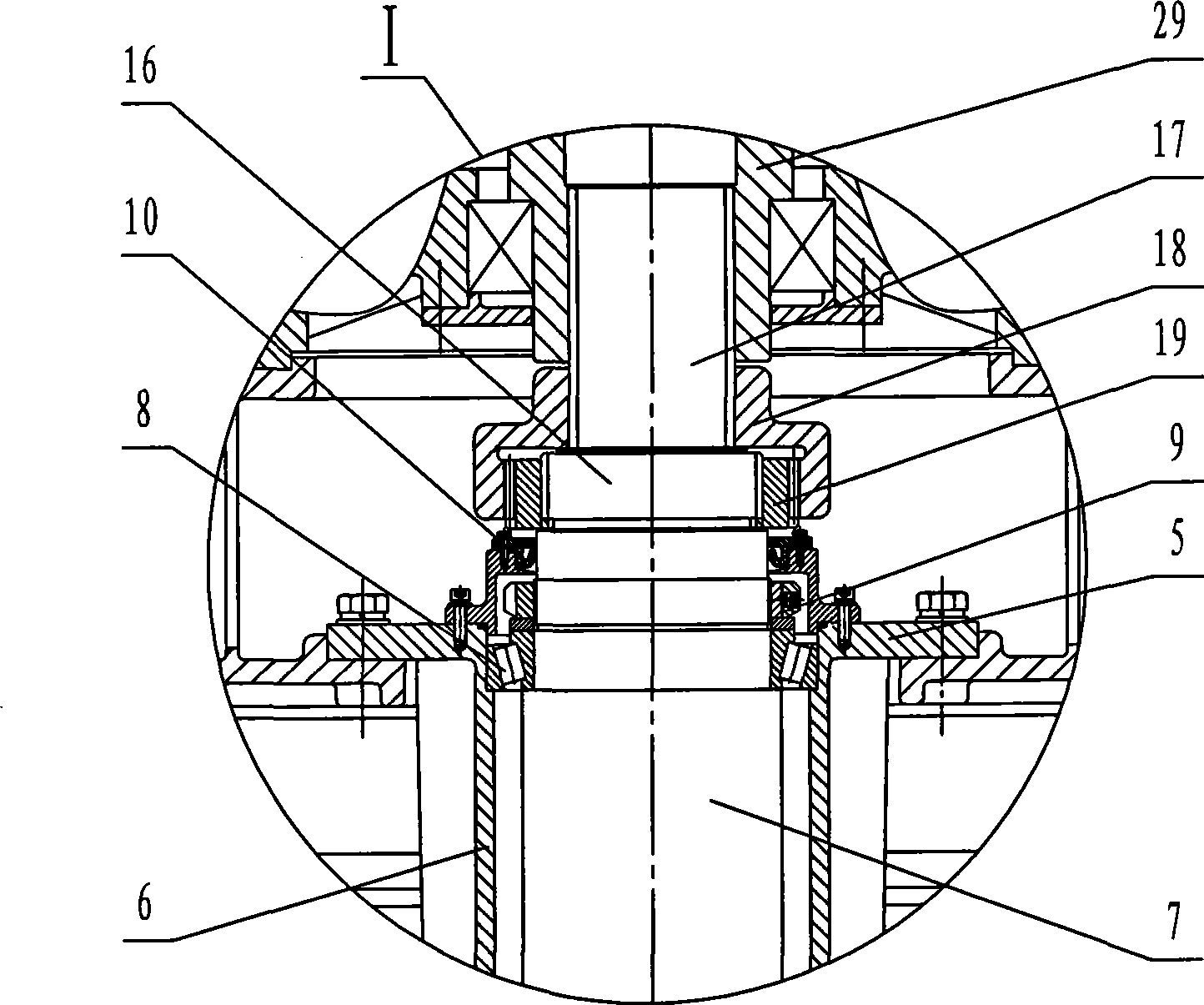

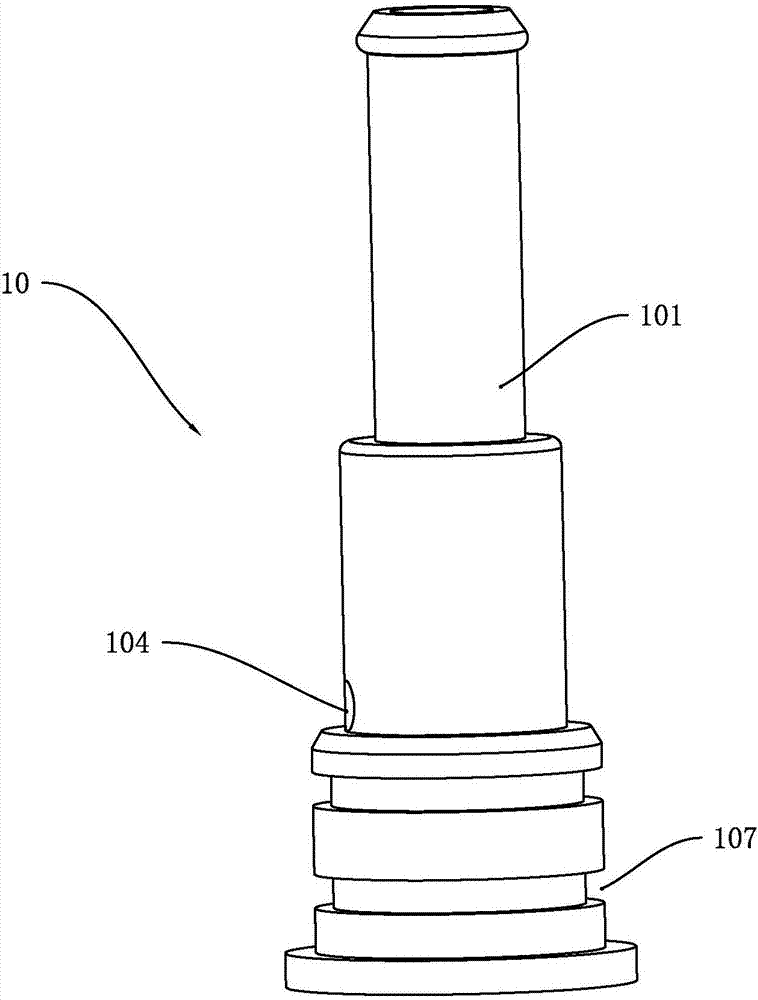

Combined jet impeller underwater aeration machine

InactiveCN101376539AReduce labor intensityReduce purification costsWater aerationSustainable biological treatmentImpellerUnderwater

The invention discloses a combined jet blade wheel underwater aerator which comprises a motor (1), a reductor (2), a mounting frame (4), a transmission mechanism and a blade wheel (20). The motor (1) is fixedly connected with the reductor (2). Blades (20) are radially fixed on the blade wheel (20). A water inlet hole (26) is formed at the bottom of the blade wheel (20). The combined jet blade wheel underwater aerator is characterized in that a pedestal (3) is arranged at the bottom of the reductor (2); the upper surface of the pedestal (3) is fixedly connected with the reductor (2) and the lower surface thereof is fixedly mounted on the mounting frame (4); and the upper end of the transmission mechanism passes through the pedestal (3) and then is connected with the output shaft of the reductor (2) in a sliding manner and the lower end thereof is fixedly connected with the blades (20). The combined jet blade wheel underwater aerator can be mounted on a pond with convenience in installation, connection, maintenance and repair and low labor intensity of the operating staff, and can ensure uniform distribution of dissolved oxygen in water in three layers, increase the dynamic efficiency and reduce the cost of purifying various sewages.

Owner:张鑫珩 +2

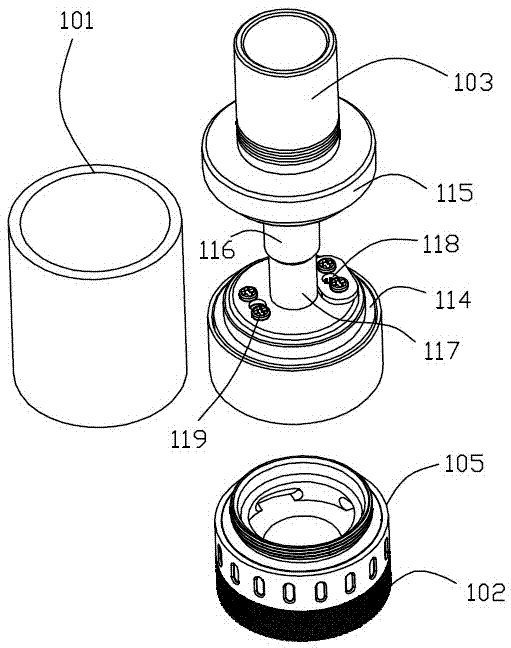

Ceramic atomizing core and atomizer formed thereby

PendingCN107874323AImprove performanceImprove the taste of atomizationTobacco devicesNebulizerMetallurgy

The invention discloses a ceramic atomizing core and an atomizer formed thereby. The ceramic atomizing core comprises a ceramic tube and a micro-porous ceramic heating body, wherein the ceramic tube and the micro-porous ceramic heating body are sintered into a whole; an atomizing chamber is formed between the upper surface of the micro-porous ceramic heating body and the inner cavity of the ceramic tube; an oil inlet hole butted with the micro-porous ceramic heating body is formed in the side wall of the ceramic tube; the atomizer comprises a suction nozzle, a fixing seat, a shell, an electrode assembly, a gas-guide tube and the ceramic atomizing core; the upper end of the shell is fixedly sealed with the fixing seat; the fixing seat penetrates through the air inlet; the lower end of the shell is fixedly sealed with the electrode assembly; an oil storage bin is formed between the ceramic atomizing core and the inner wall of the shell; one end of the gas guide tube is inserted into theceramic tube, and the other end of the gas guide tube is butted with the suction nozzle; an air inlet channel is formed between the gas guide tube and the ceramic tube; air enters the atomizing chamber from the air inlet and the air inlet channel; and atomization steam in the atomizing chamber enters the suction nozzle along the gas guide tube. The ceramic atomizing core has the advantages of being simple in structure, oil leakage proof and clean and sanitary in atomization steam.

Owner:SHENZHEN ECAP TECH CO LTD

Clamping and conveying device for conveying steel bars

InactiveCN102319822ASave shipping timeImprove transportation efficiencyMetal-working feeding devicesPositioning devicesEngineeringRebar

The invention relates to a clamping and conveying device for conveying steel bars. The device comprises a main box, a secondary box, an upper roller, a lower roller and a cylinder, wherein the secondary box is glidingly arranged in the main box at the upper part of the lower roller; the secondary box is driven by the cylinder fixedly arranged at the top of the main box; the main box at two ends of the upper roller is provided with symmetrical end covers respectively; each end cover is provided with an upper roller sliding hole and an oil return baffle plate; the lower part of the oil return baffle plate is provided with an oil return oil; an oil baffle cover plate is fixedly arranged at the outer side of the end cover; the oil baffle cover plate is provided with a cover plate through holecorresponding to the upper roller sliding hole; and a dustproof oil baffle cover is fixedly arranged on the upper roller bearing end cover between the oil baffle cover plate and the oil return baffleplate. The device has compact structure, scientific and reasonable design, low manufacturing cost, small volume and high clamping accuracy, and can adapt to the steel bars of different specifications; the lubricating mode is circulating oil reinforced lubrication; and the device is reliable in sealing and high in transport velocity, improves the production efficiency of the steel bars, prolongs the service life of the steel bars, and is safe and reliable.

Owner:王丽燕

Chlorinated polyethylene rubber material

The invention discloses a chlorinated polyethylene rubber material. The chlorinated polyethylene rubber material contains the following raw materials in percentage by weight: 36-39% of chlorosulfonated polyethylene, 29-35% of carbon black, 12-16% of triisooctyl trimellitate, 6.5-11.5% of vulcanizing agent, 2-3% of processing additive, 7-8.5% of magnesium oxide and 1.5-2% of silicon-oxygen activating agent. According to the chlorinated polyethylene rubber material, the compression set is 63% and is greatly reduced, so that good buffer performance is gained.

Owner:浙江久运汽车零部件有限公司

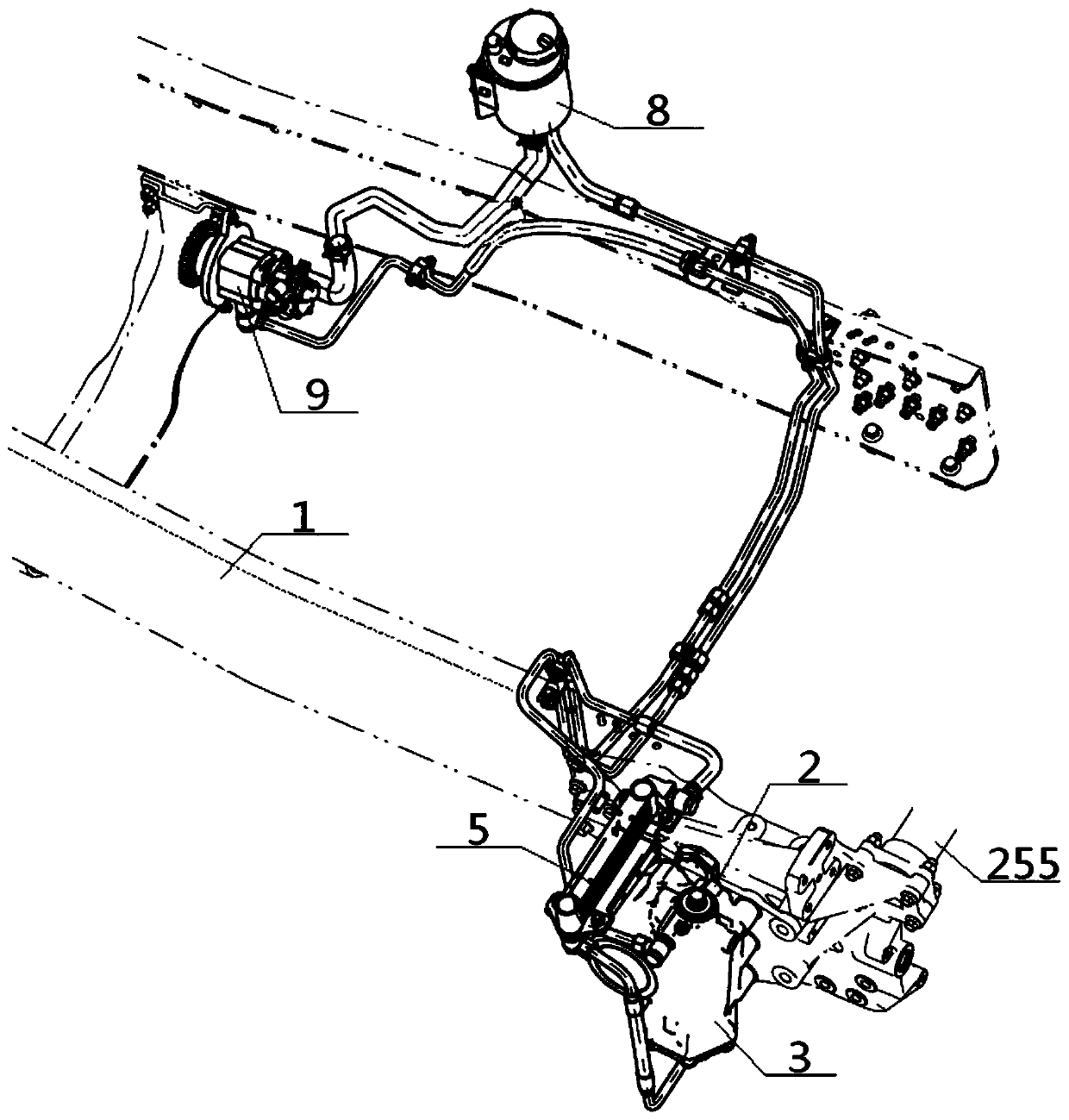

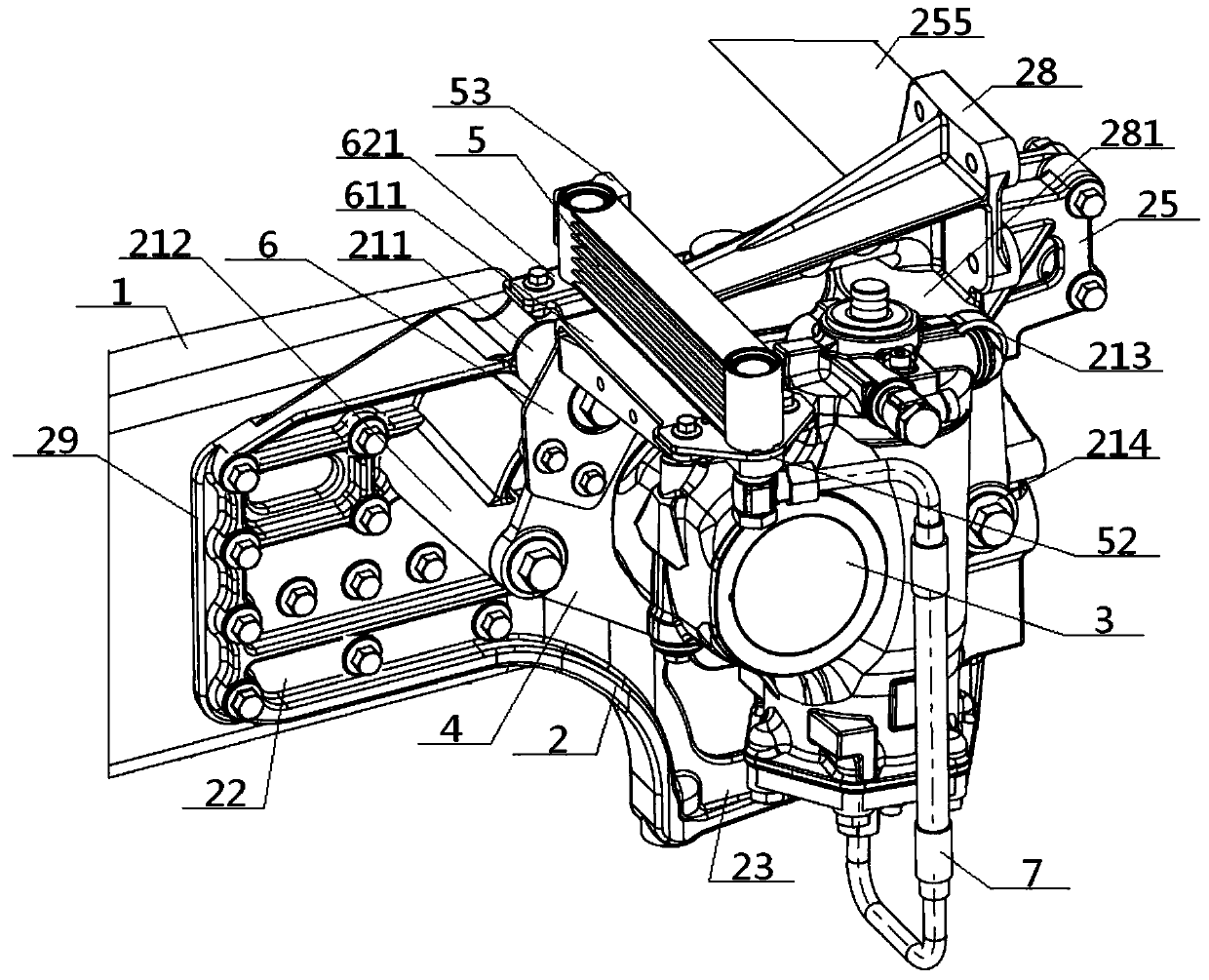

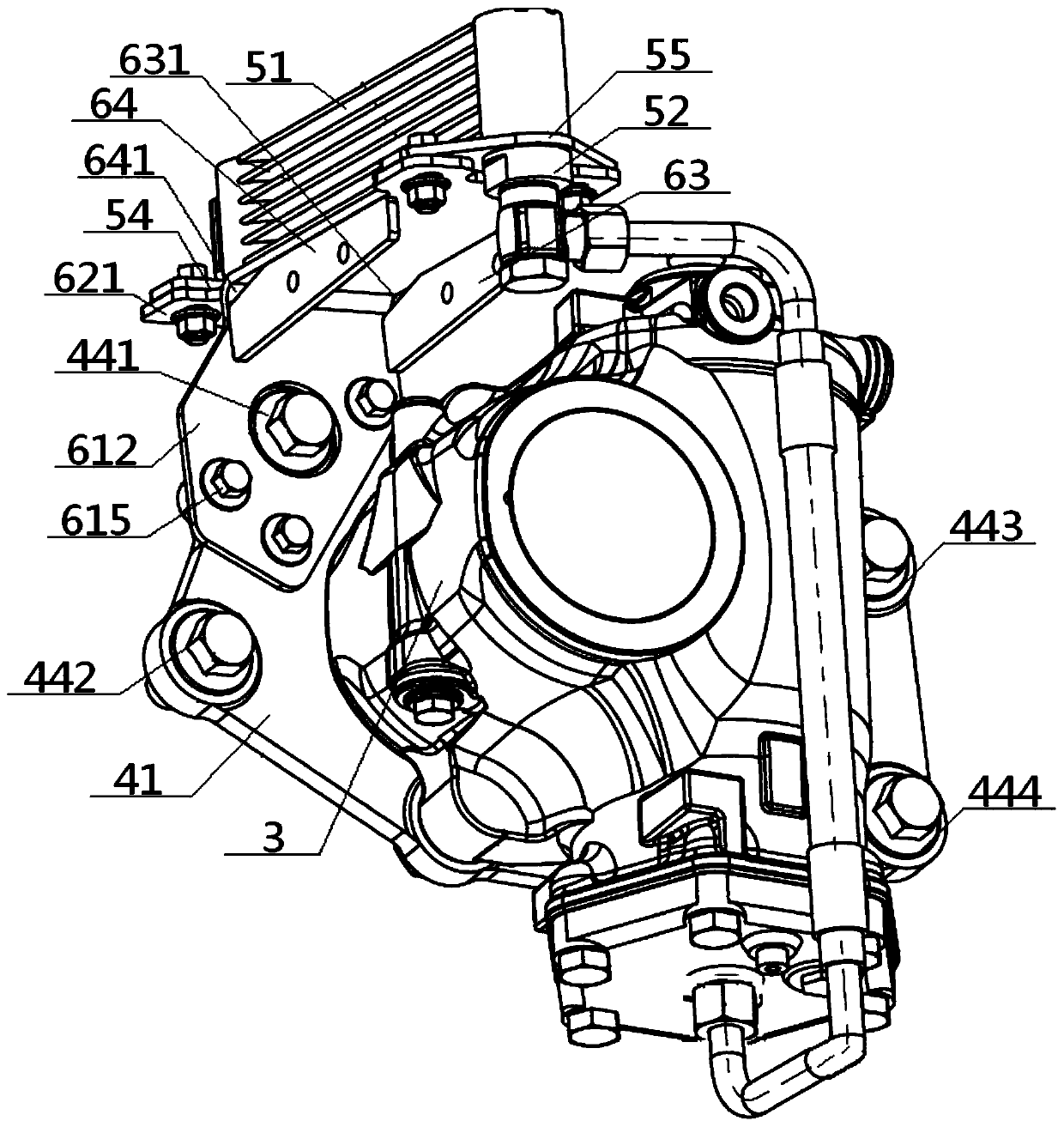

Hydraulic steering system and assembling method thereof

ActiveCN110667696AImprove stabilityGuaranteed normal operationFluid steeringVehicle frameEngineering

The invention discloses a hydraulic steering system. The hydraulic steering system comprises a comprehensive connecting support, a steering machine, a radiator, a steering oil tank and a steering pump, wherein the comprehensive connecting support comprises a beam casting slave plate, a casting machine slave plate and a cross beam connecting plate which are sequentially connected, the back surfaceof the beam cast slave plate is connected to a frame longitudinal beam through a beam casting flat plate, the cross beam connecting plate is connected to a frame transverse beam, the front surface ofthe casting machine slave plate is connected to the bottom ends of casting pillars, the top ends of the casting pillars are connected to support-support connecting holes in a steering machine support,an auxiliary connecting hole is connected to the bottom of a radiating support, the top of the radiating support is connected to the bottom of the radiator and the top of the casting machine slave plate, support-machine connecting holes are connected to the steering machine, a steering machine output shaft on the steering machine penetrates through an output shaft hole and then is connected to asteering vertical arm, the steering vertical arm is arranged in a vertical arm moving cavity in a suspended mode, and the vertical arm moving cavity is defined by the comprehensive connecting support,the steering machine support and the casting pillars together. The hydraulic steering system is not only strong in stability effect, but also high in assembly efficiency.

Owner:DONGFENG COMML VEHICLE CO LTD

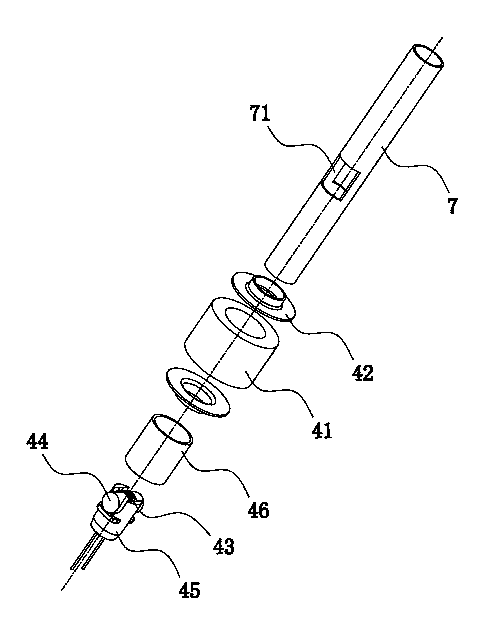

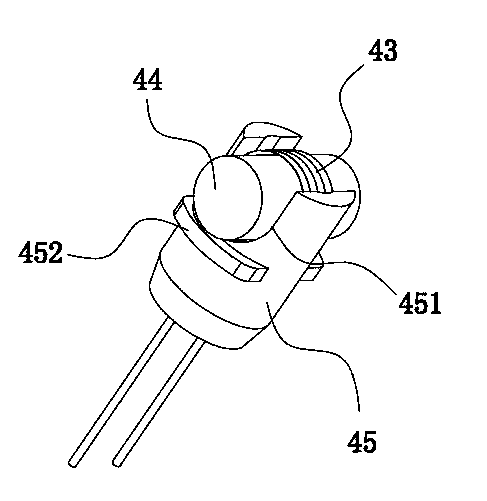

Atomizer of electronic cigarette and atomizing core

PendingCN107080289APrevent oil spillsEasy to useTobacco devicesOhmic-resistance heatingThermodynamicsEngineering

The invention belongs to the technical field of electronic cigarettes. An atomizer of an electronic cigarette comprises an airflow channel, a conductive line, oil storage equipment and an atomizing core; the atomizing core comprises a liquid seepage part, an electric heating body and an atomizing core shell; the liquid seepage part and the electric heating body are arranged in the atomizing core shell; the liquid seepage part is communicated with the oil storage equipment; the airflow channel is communicated with the atomizing core; the oil storage equipment is an oil storage bottle; the oil storage bottle is integrally formed; a bottle cover comprises a gas guide conductive pipe arranged under the bottle cover and is arranged on the oil storage bottle; the atomizing core is detachably connected with the gas guide conductive pipe; the atomizing core is arranged in the oil storage bottle; the conductive line is conducted to the electric heating body from the bottle cover. The atomizer and the atomizing core have the benefits that the oil storage bottle can be taken as a disposable product for timely replacement; the atomizing core integrates conduction, gas guide and oil guide, and oil guide cotton and other longer oil paths are concealed, so that and the reaction is more sensitive; after oil replacement, the atomizing core can be immediately used, and meanwhile, oil is more conveniently saved.

Owner:冷朝阳

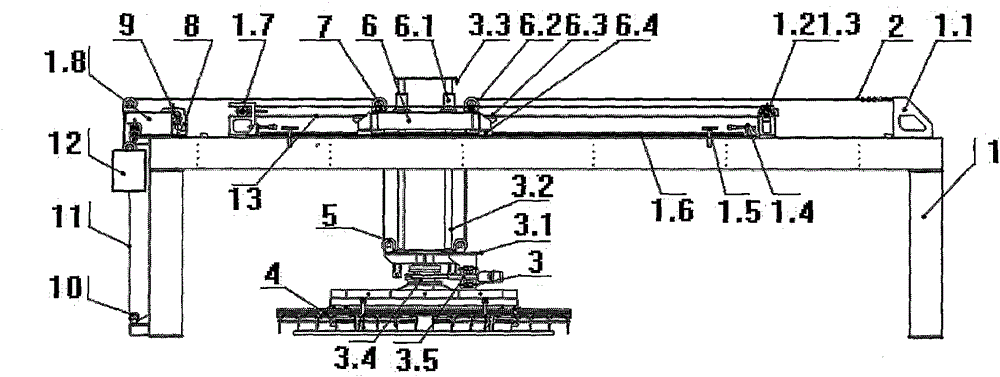

Full-automatic setting machine

InactiveCN105347050AReduce loosenessLean structureStacking articlesDe-stacking articlesBrickFrequency conversion

The invention provides a full-automatic setting machine. A frequency conversion gear motor (8) is arranged on a front support (1.8), and a transmission chain wheel (9) is arranged on the frequency conversion gear motor (8). One end of a transmission chain (11) is connected to a balance weight (12), and the other end of the transmission chain (11) penetrates a middle chain wheel (10) arranged below a rack (1) and is connected to the position below the balance weight (12). One end of a steel wire rope (2) is connected with a rear support (1.1), and the other end of the steel wire rope (2) sequentially penetrates a synchronous belt riding wheel (6.2), a movable pulley (5) and a fixed pulley (7) to be connected with the balance weight (12). An upper wheel line of a synchronous belt driving wheel and an upper wheel line of a synchronous belt driven wheel are located in the same plane, stable operating is achieved, and no shaking or vibration is generated. The brick falling frequency is reduced, and the problems that a connecting screw is loosened and a structure piece cracks due to vibration are reduced. Meanwhile, pure mechanical transmission is adopted, so that the faults of oil leakage, control valve blocking (valve clamping) and the like are completely eradicated, hydraulic oil does not need to be replaced, and maintenance cost is low.

Owner:洛阳润信机械制造有限公司

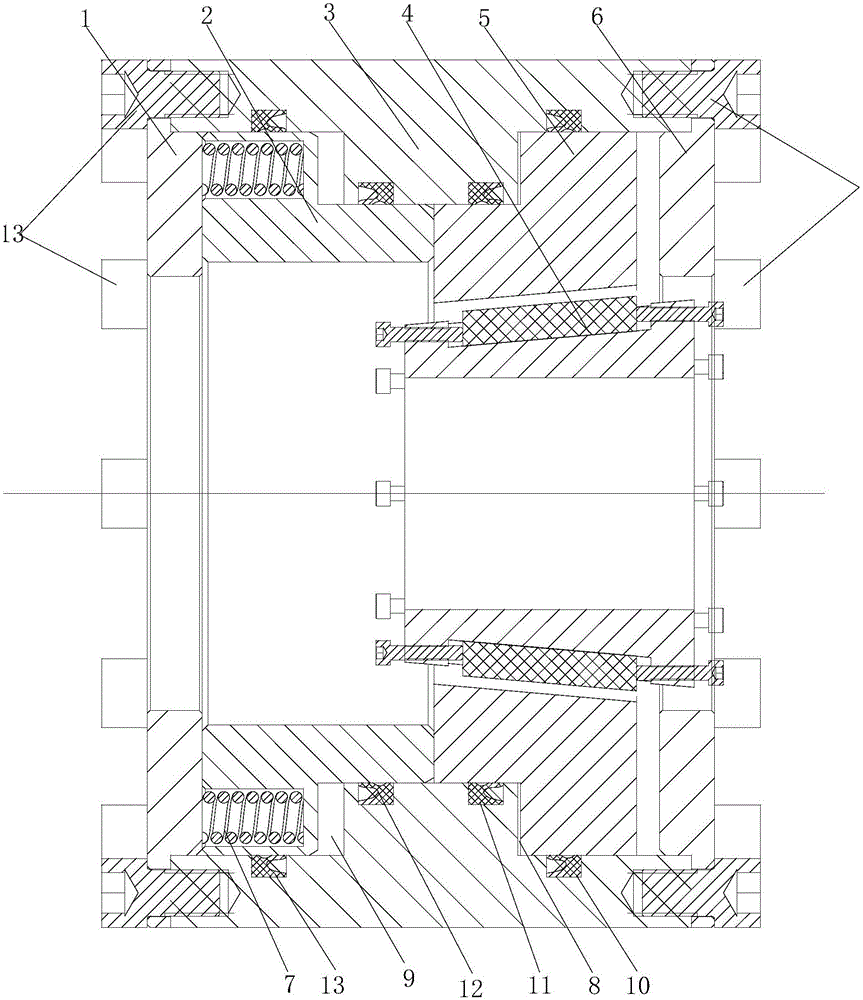

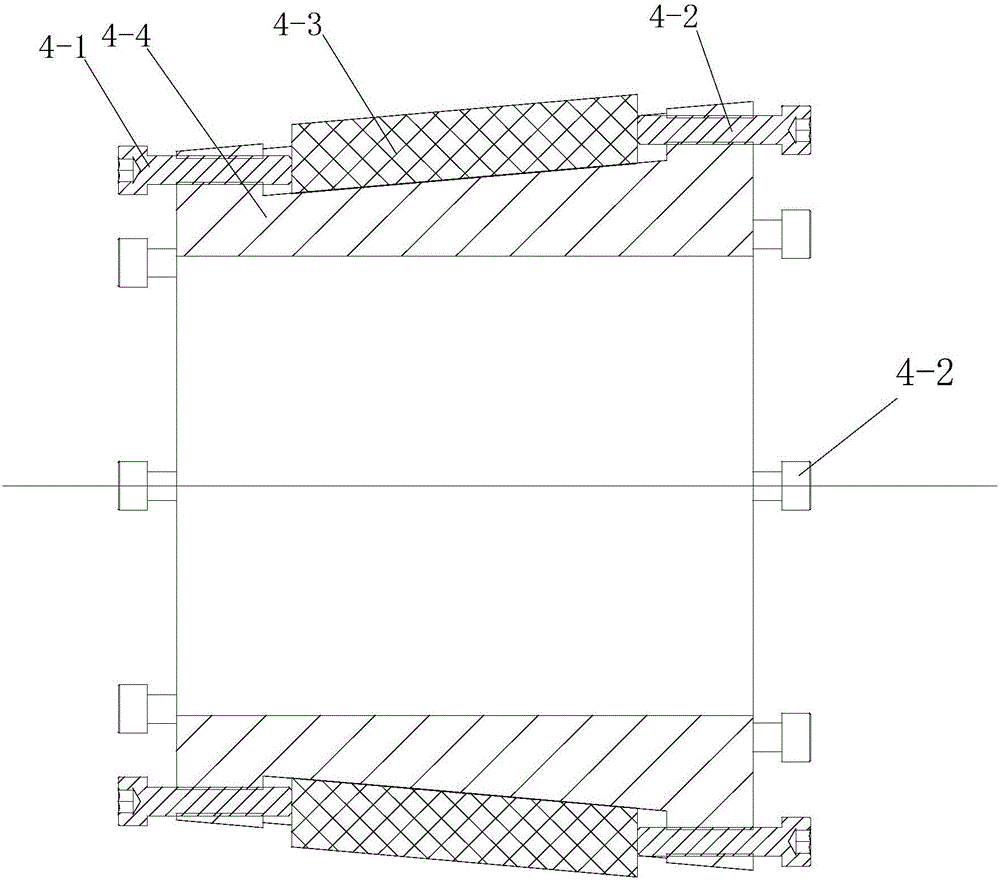

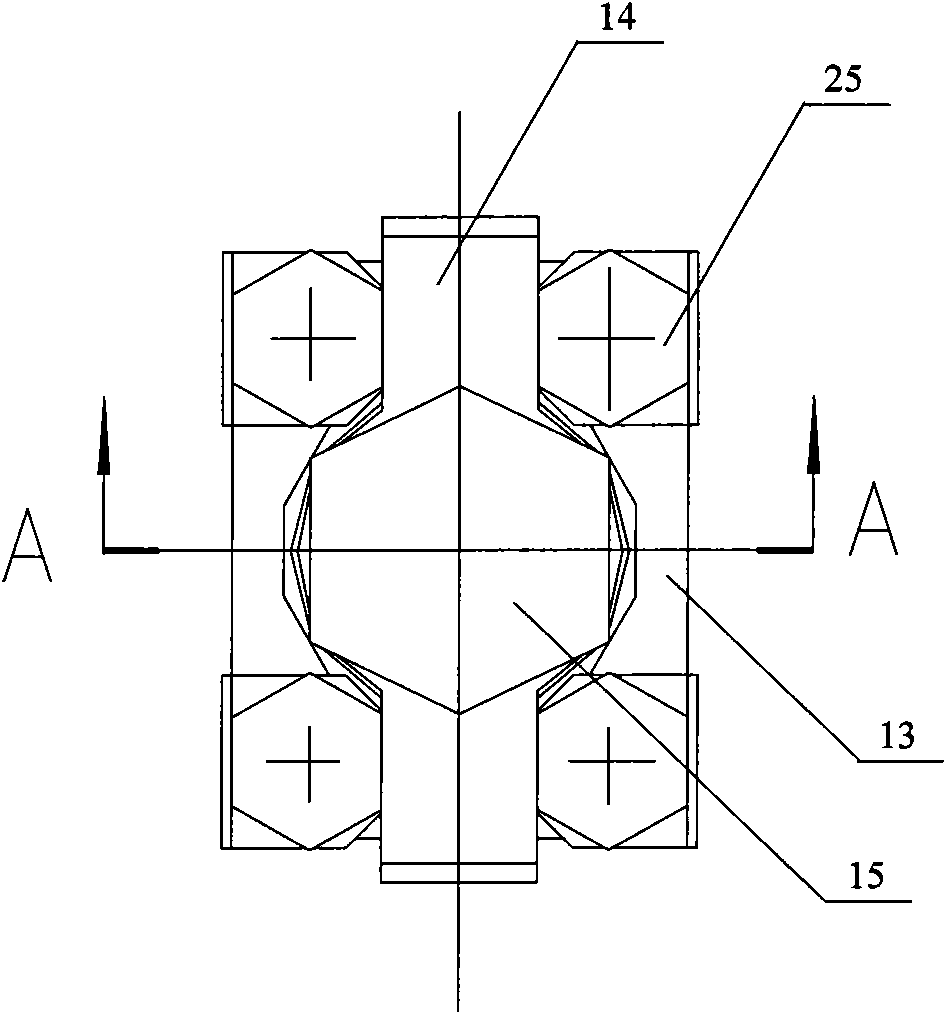

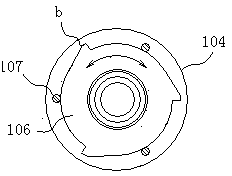

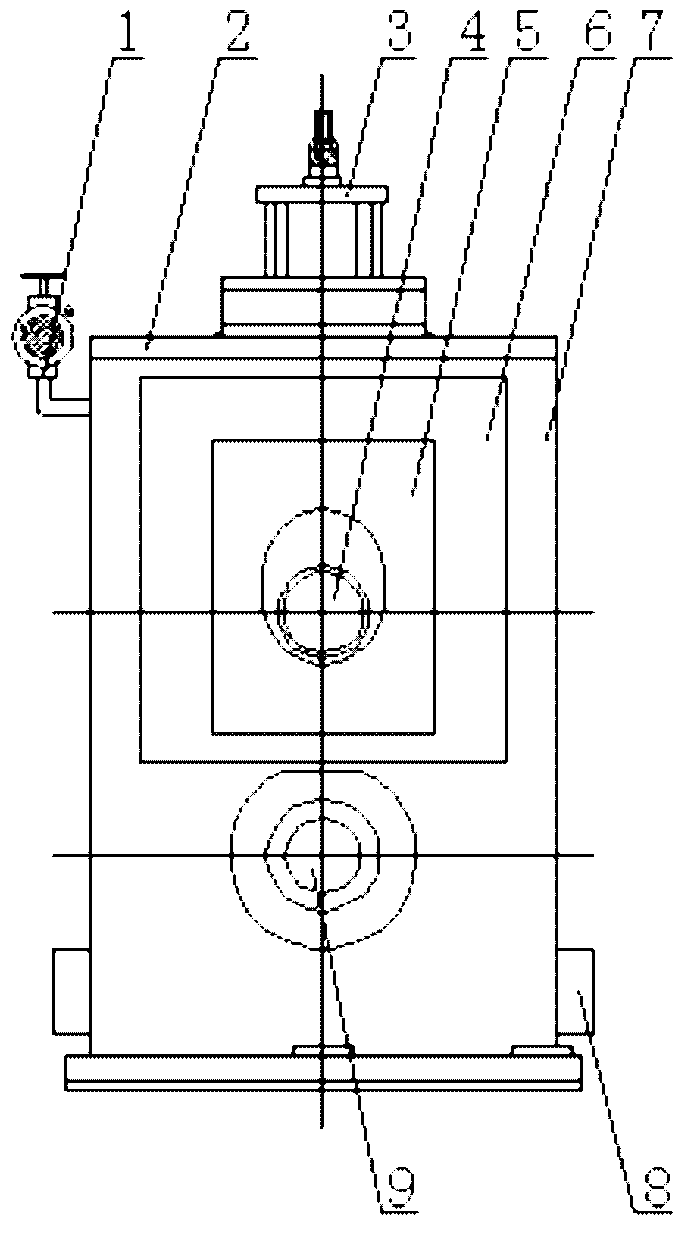

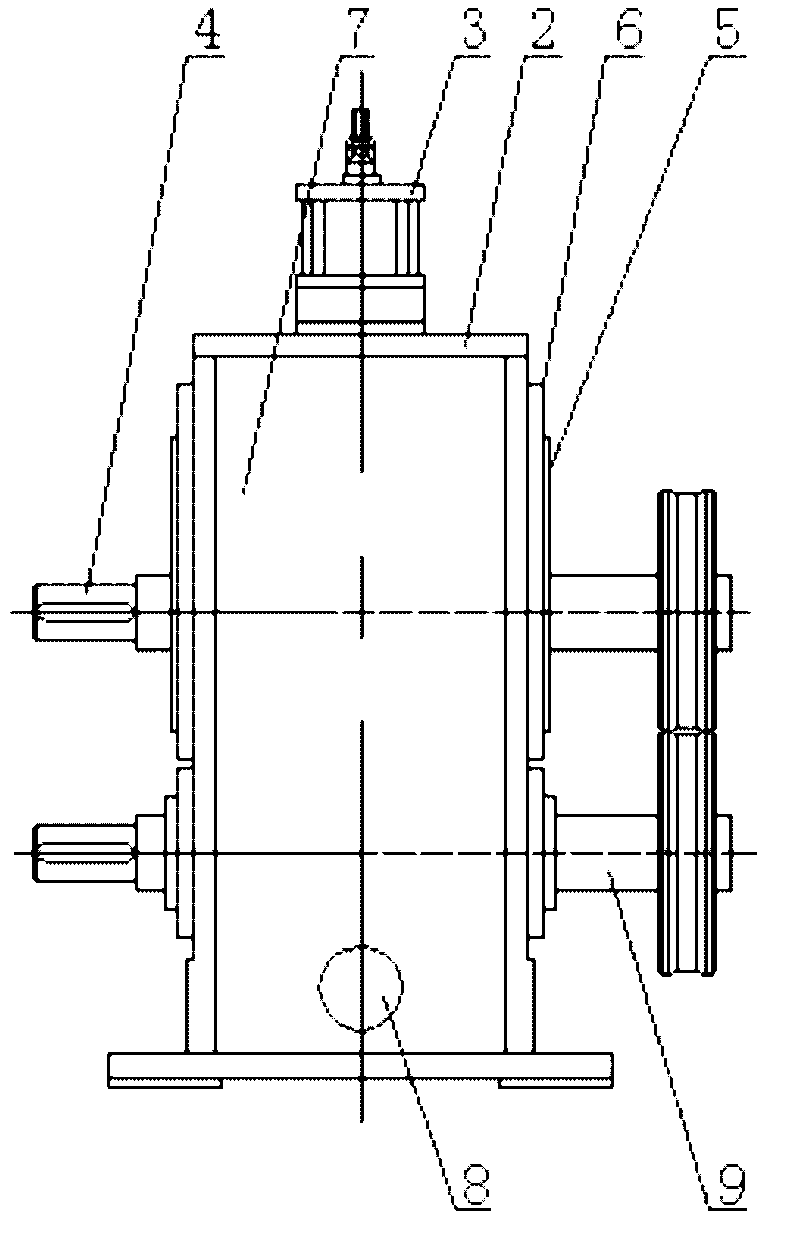

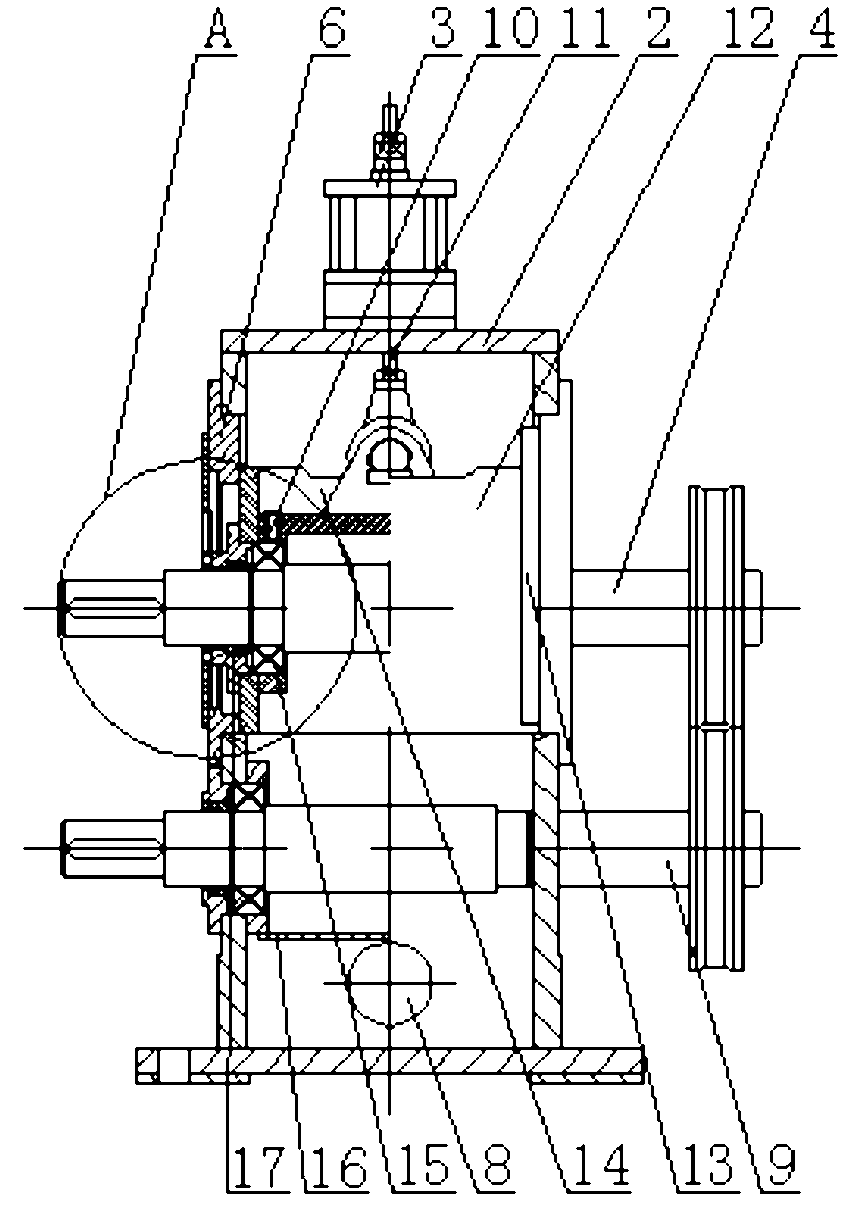

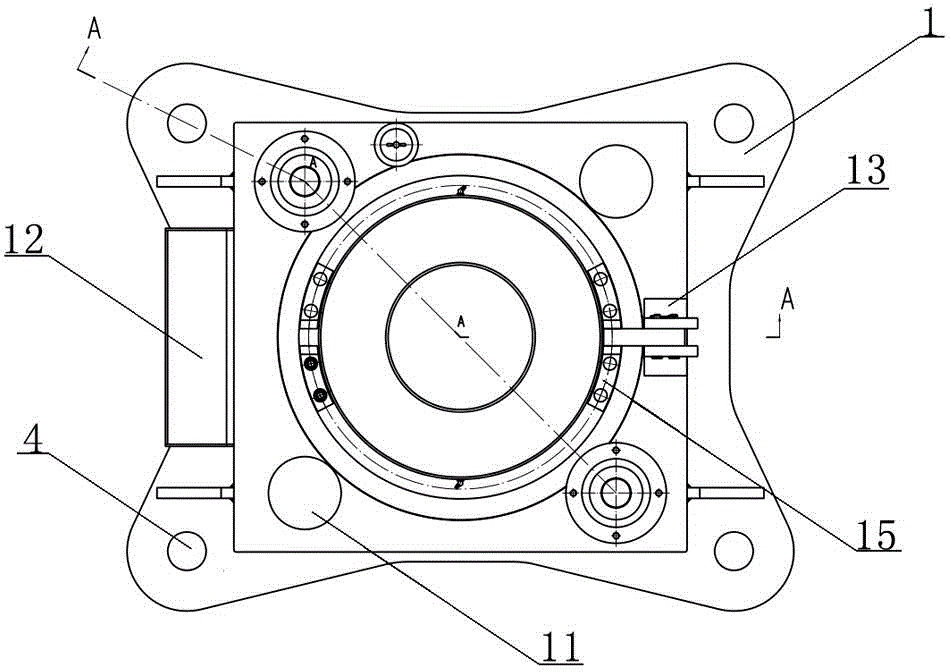

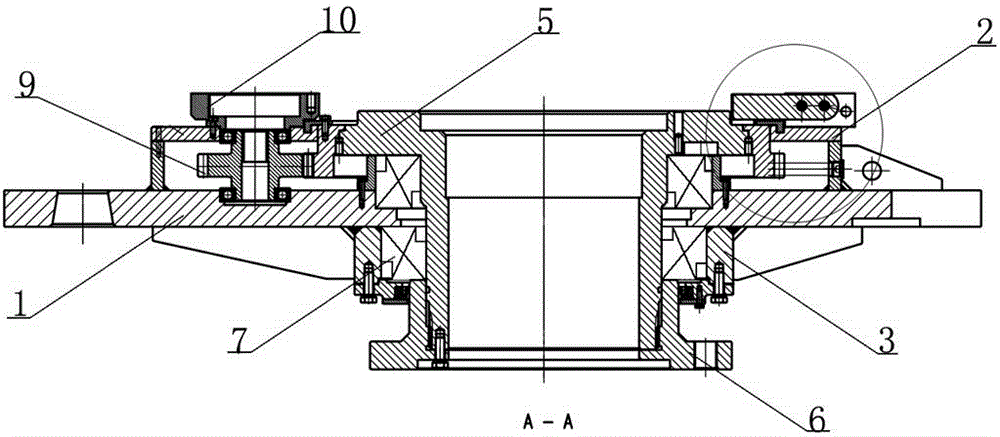

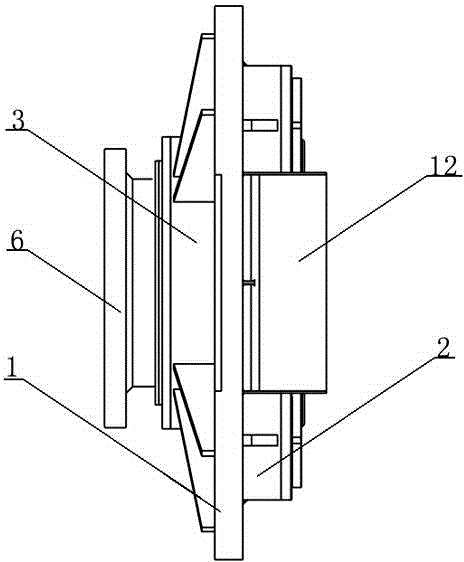

Hydraulic turntable for pressure balance workover rigs

ActiveCN103982133AJob preparation cycle shortenedImprove securityConstructionsRotary drillingMarine engineeringPressure balance

The invention relates to a hydraulic turntable for pressure balance workover rigs, which comprises a box, an upper box cover, a lower box cover, an output assembly and an input assembly; the output assembly comprises an output gear shaft, an output flange and self-aligning thrust roller bearings, the output gear shaft runs through the upper box cover, the box and the lower box cover, the self-aligning thrust roller bearings are sleeved on the output gear shaft in both the upper box cover and the lower box cover, and the lower end of the output gear shaft is connected with the output flange through splines; the input assembly comprises an input gear shaft and an input flange, the upper box cover is provided with a plurality of input flange holes, the input flange is fixed in the input flange holes, the input gear shaft is arranged on the input flange, and the output gear shaft is transmissively connected with the input gear shaft. The hydraulic turntable can ensure that a pressure balance workover rig has both the drilling function and the workover function; the pressure balance workover rig can be prepared for operation without needing other equipment after arriving at a well site, and thereby the operation preparation period is shortened by about 25 percent; moreover, the safety performance is high, and the service life is long.

Owner:LUOYANG REASTAR TRANSMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com