Fluid discharge gun

A fluid and cylinder technology, used in the field of leaking fluid equipment, can solve the problems of affecting the leaking speed, easy oil leakage, poor sealing effect, etc., and achieve the effect of preventing oil leakage, easy to use, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

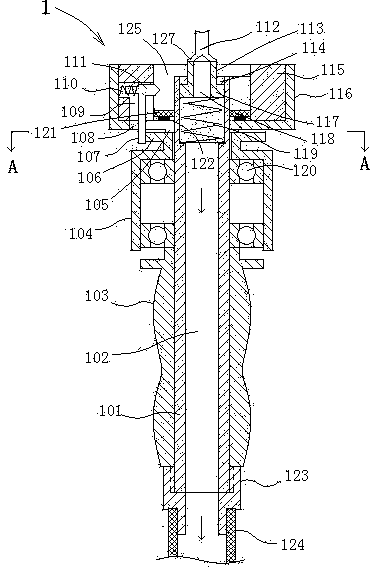

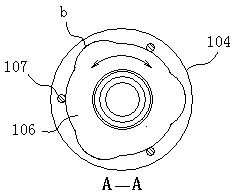

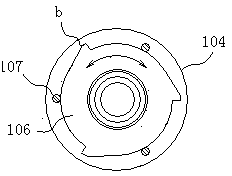

[0028] see figure 1 -2, Figure 4 The fluid leaking gun 1 provided by the present invention includes a tubular central rod 101 with a through hole 102, an elastic thimble, a connecting cover, and an unlocking wheel; the elastic thimble is movable in the front end of the central rod 101 and can move axially, and the elastic thimble Comprising a thimble, a spring 119 between the barrel 113 and the center rod 101, the thimble (see Figure 6 ) includes a needle 112 and a cylinder 113 with a through hole 118 at the rear of the needle 112. The needle 112 is connected to the cylinder 113 through a herringbone bracket 127 to increase the flow area c of the fluid entering the cylinder 113. The central rod 101 A fixed ring 114 is provided in the front end of the cylinder, the needle head 112 passes through the fixed ring 114, and the rear end of the cylinder 113 is provided with a limit flange 117 to cooperate with the fixed ring 114; The cover includes an outer shell 116, a lock body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com