Motive power and fluid power driving device based on motor and torque converter integration unit

A transmission device and integrated unit technology, applied in the field of power hydraulic transmission device, can solve the problems of low concentricity accuracy, low transmission efficiency, large vibration, etc., and achieve the elimination of low concentricity accuracy, good acceleration characteristics, and space occupation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

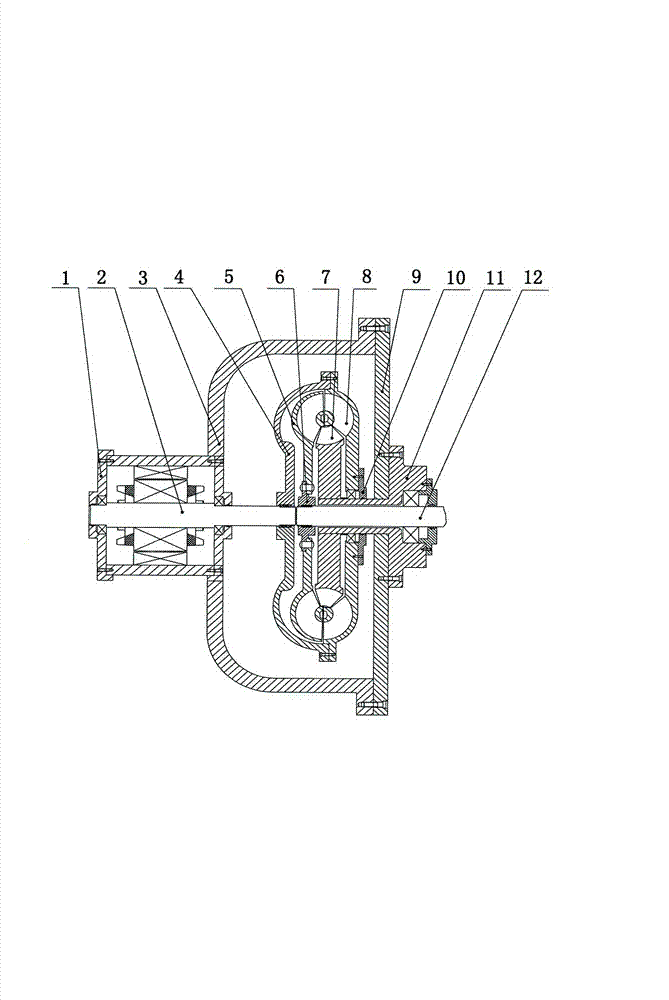

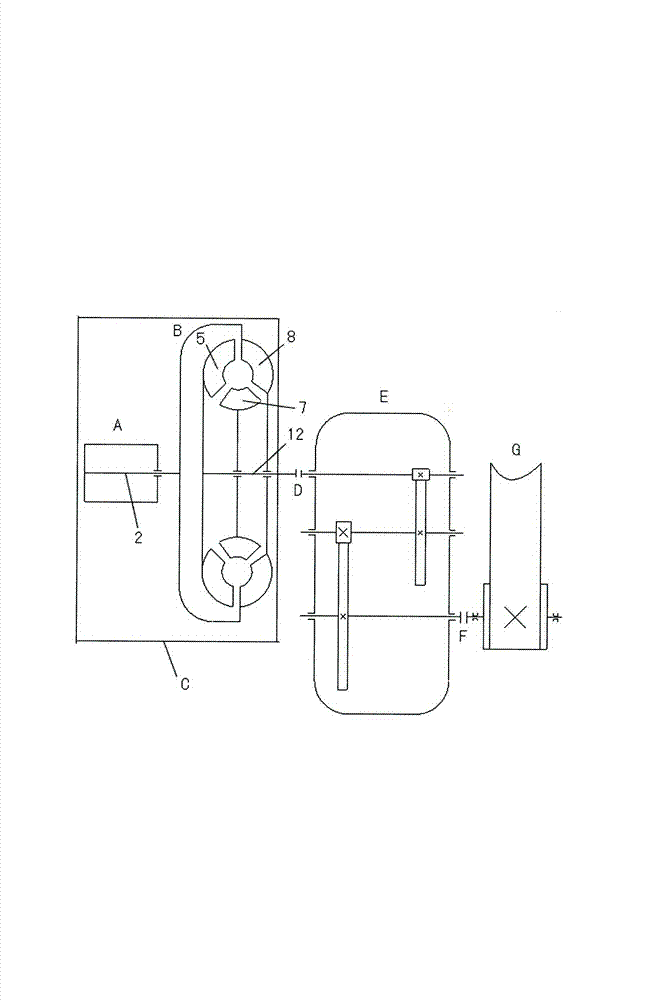

[0012] Taking the inner rotor motor as an example, such as figure 1 with figure 2 As shown, the motor rotating shaft 1 of the present invention is connected with the cover plate 4 of the hydraulic torque converter by a spline, and the cover plate 4 is connected with one end of the pump wheel 8 through a screw. The motor front end cover 2 and the hydraulic torque converter shell 3 are connected as an integral structure by welding, and the hydraulic torque converter shell end is fixed and connected to the flange through the front cover 9 set on the flange 11 shaft sleeve. On the plate 11, the flange plate 11 is slidingly fitted on the output shaft 12, and the other end of the pump wheel 8 is fixed on the flange plate bushing through the bearing and the pump hub 10 with a spline, and can rotate freely. A sealing ring is installed between the contact surfaces of the disc shaft sleeve to prevent oil leakage. The guide wheel 7 of the hydraulic torque converter is fixed on the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com