Ceramic atomizing core and atomizer formed thereby

An atomizing core and atomizer technology, applied in the field of atomizers, can solve the problems of easy oil leakage, easy generation of debris in fiber cotton, high temperature resistance, etc., and achieve clean and hygienic atomization steam and good atomization taste. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

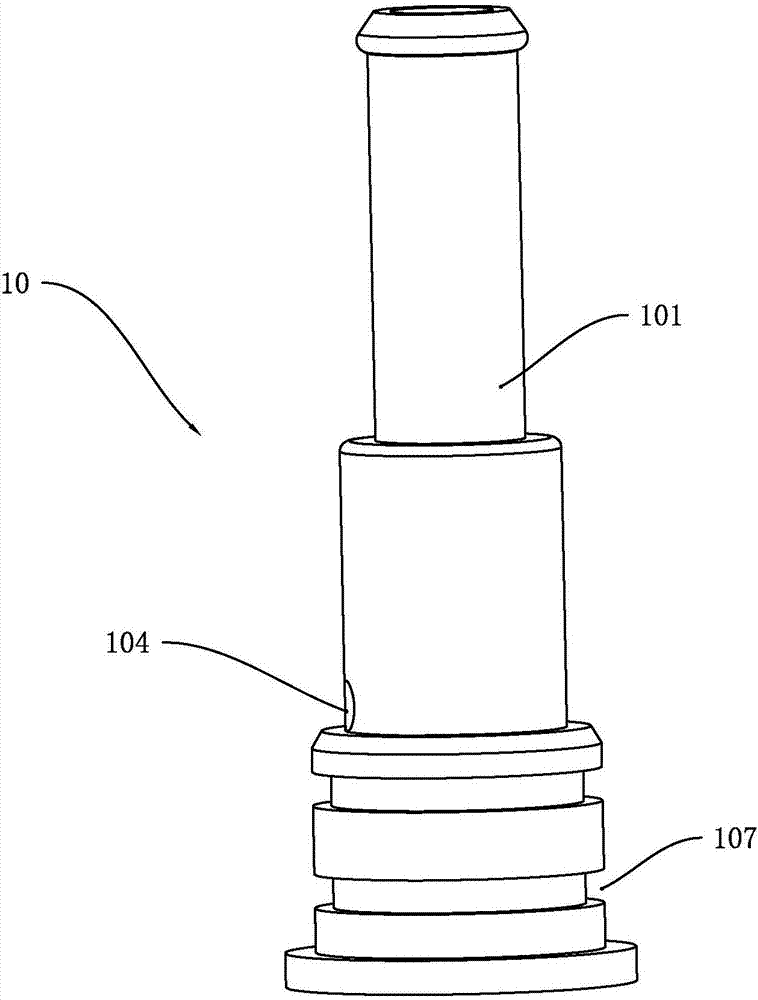

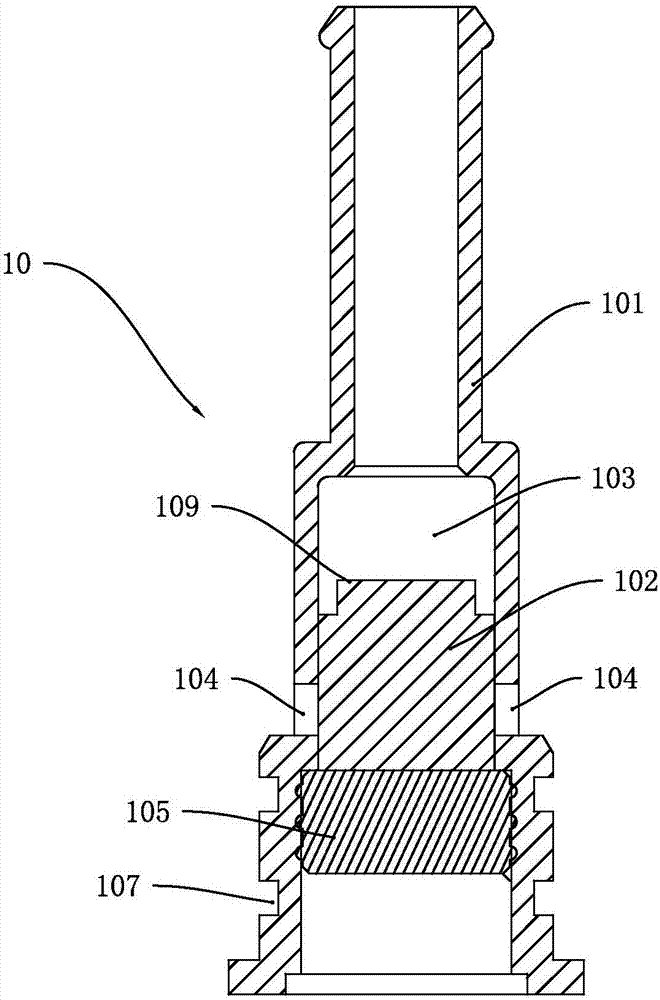

[0024] The first embodiment, such as figure 1 and figure 2 As shown, a ceramic atomizing core 10 includes a ceramic tube 101 and a microporous ceramic heating element 102. The microporous ceramic heating element 102 is located in the ceramic tube 101 and is sintered with the ceramic tube 101. The upper surface and the inner cavity of the ceramic tube 101 form an atomization chamber 103 , and the side wall of the ceramic tube 101 is provided with an oil inlet hole 104 connected with the microporous ceramic heating element 102 .

[0025] Such as figure 1 and figure 2 As shown, the external liquid passes through the oil inlet hole 104 and penetrates into the microporous ceramic heating element 102, and the microporous ceramic heating element 102 heats and atomizes the liquid. The liquid can be e-liquid. Since the microporous ceramic heating element 102 is a high-temperature-resistant material, and there is no need to add oil-conducting cotton in the ceramic atomizing core 10...

no. 3 example

[0030] The third embodiment, such as figure 1 , figure 2 and Figure 5 As shown, an atomizer includes a suction nozzle 201, a fixed seat 202, a casing 203 and an electrode assembly 211; the upper end of the casing 203 is sealed and fixedly connected with the fixed seat 202, and the fixed seat 202 penetrates an air inlet 204; the outer casing 203 The lower end is sealed and fixedly connected with the electrode assembly 211, and also includes an air guide tube 205, and a ceramic atomizing core 10. The ceramic atomizing core 10 is arranged in the shell 203 and forms an oil storage tank 206 between the inner wall of the shell 203, and one end of the air guide tube 205 Insert it into the ceramic tube 101, and the other end is docked with the suction nozzle 201. An air intake channel 207 is formed between the air guide tube 205 and the inner wall of the ceramic tube 101. External air enters from the air inlet 204 and enters the atomization chamber 103 along the air intake channel ...

no. 4 example

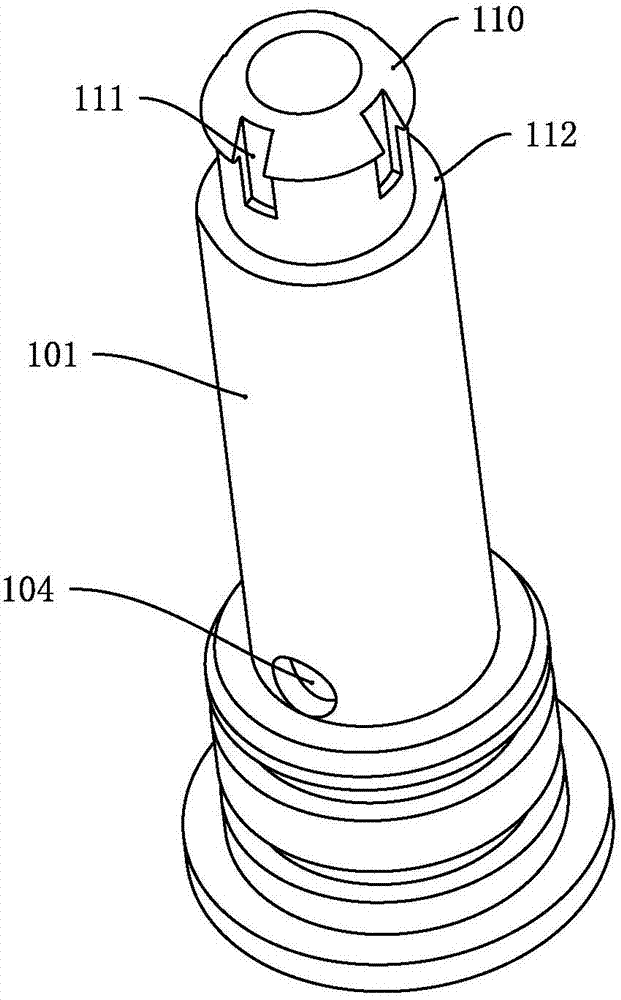

[0034] The fourth embodiment, the difference between this embodiment and the third embodiment is: if image 3 , Figure 4 and Figure 6 As shown, the atomizer also includes an annular oil sealing plug 208, the upper end of the ceramic tube 101 is inserted into the oil sealing plug 208 and the annular groove 113 of the ceramic tube 101 is in sealing connection with the inner wall of the oil sealing plug 208, and the outer wall of the oil sealing plug 208 is in contact with the oil sealing plug 208 The inner wall of the fixing seat 202 is sealed and connected. When assembling, insert the upper end of the ceramic atomizing core 10 into the oil sealing plug 208. At this time, there is a gap between the pressure relief groove 111 and the inner wall of the oil sealing plug 208, so the gas in the oil storage tank 206 can flow out from the pressure relief groove 111. The discharge prevents the air pressure from squeezing the smoke oil in the oil storage bin 206, thereby preventing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com