Atomizer of electronic cigarette and atomizing core

A technology of electronic cigarettes and atomizers, applied in the field of electronic cigarettes, can solve the problems of long oil conduction time, time-consuming, dripping of smoke oil, etc., and achieve the effects of preventing oil leakage, responsiveness, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

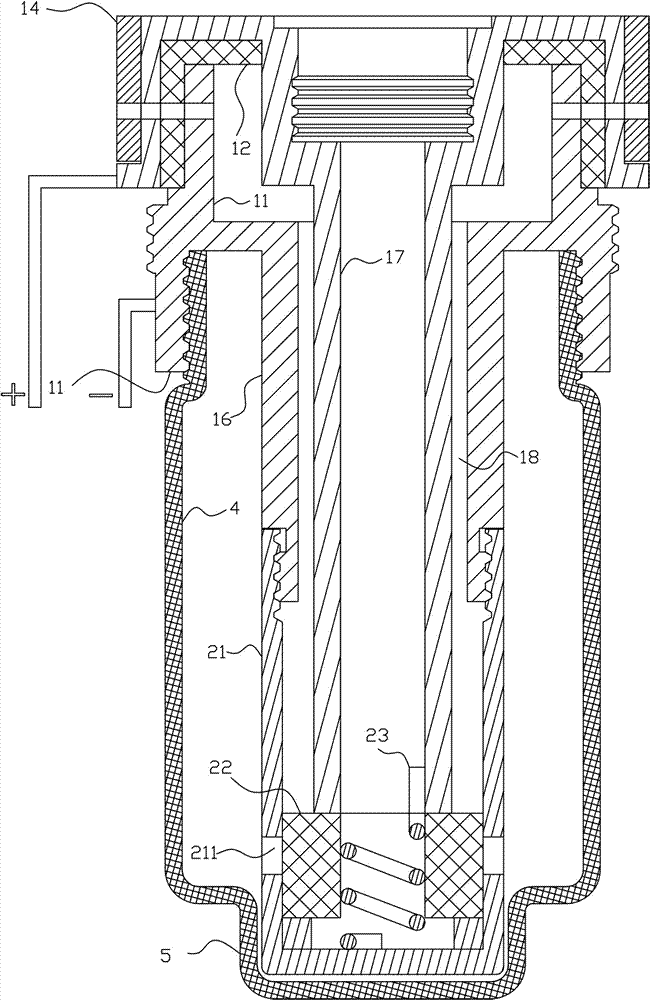

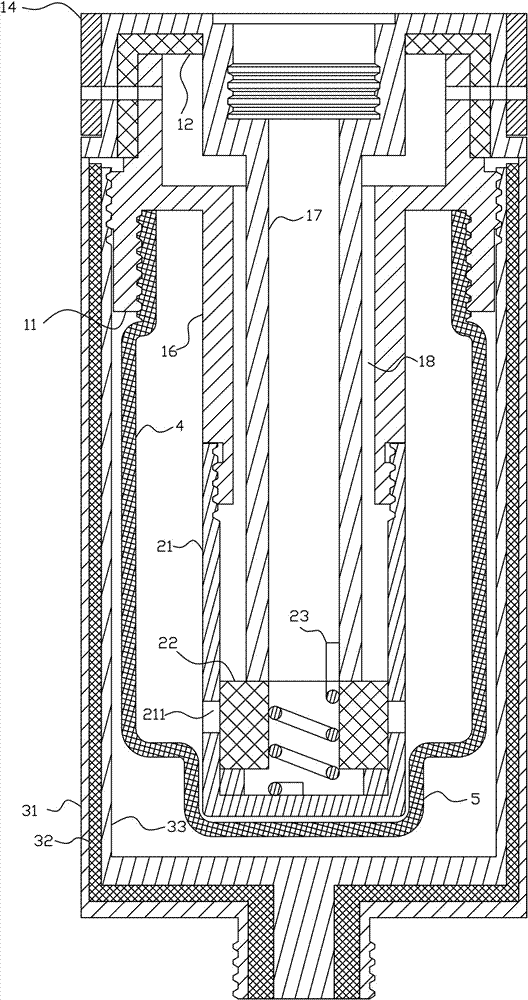

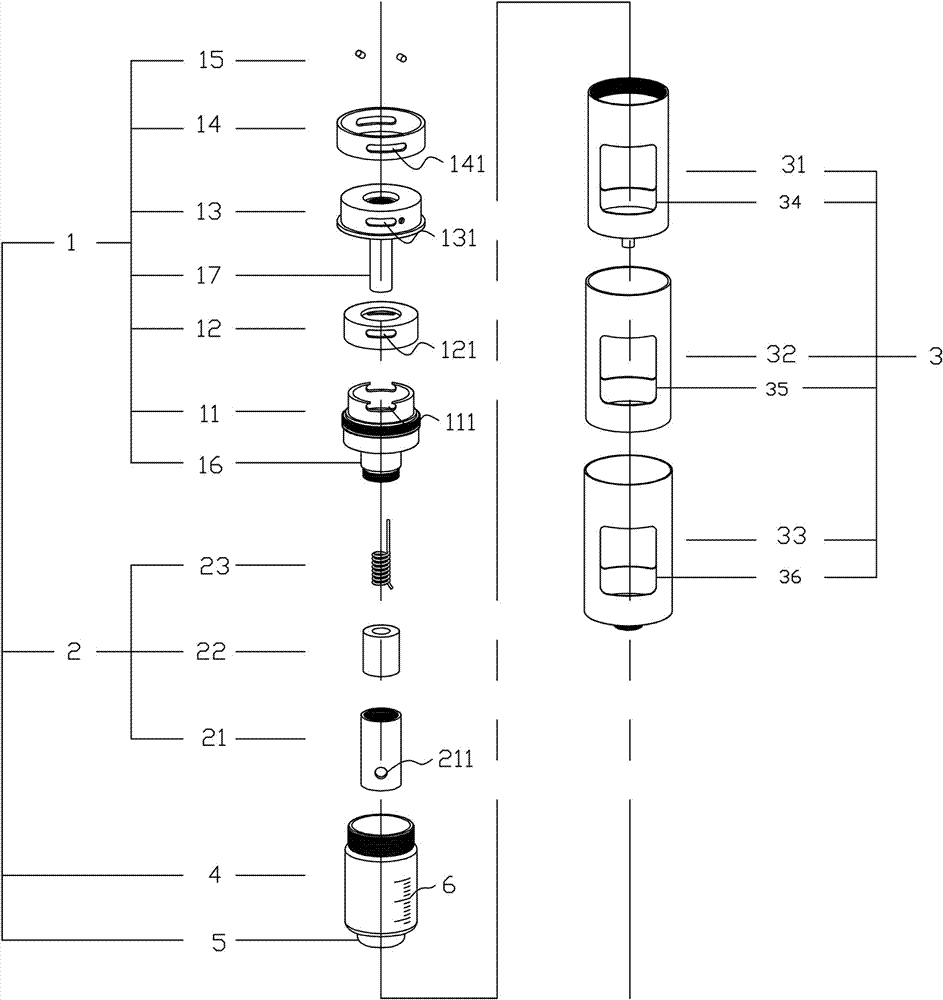

[0036] like figure 2 and image 3 As shown in the figure, the difference between this embodiment and Embodiment 1 is that a cylinder shell 3 is also provided under the bottle cap 1, the oil storage bottle 4 is arranged in the cylinder shell 3, and a joint 7 is provided under the cylinder shell 3. , the cylindrical shell includes an outer cylindrical shell 33, an inner cylindrical shell 31, an insulating tube 32, the insulating tube 32 is arranged between the outer cylindrical shell 33 and the inner cylindrical shell 31, and the conductive circuit includes the outer cylindrical shell 33 , the inner cylinder shell 31, the cover outer shell 13, the cover inner shell 11, the outer cylinder shell 33, the inner cylinder shell 31, the cover outer shell 13, and the cover inner shell 11 are all made of conductive materials, and the outer cylinder shell 33 The inner cylinder shell 31 is electrically connected to the connector 7, one end of the outer cylinder shell 33 is electrically c...

specific Embodiment 3

[0041] The difference between the simulated cigarette in this embodiment and the specific embodiment 2 is that the air flow channel is provided with a negative pressure sensor 8. The function of the negative pressure sensor 8 is that when a person is smoking, a negative pressure will be generated on the air flow channel. If the pressure is high, the negative pressure sensor 8 will be connected to the power supply voltage, so that the electric heating body 23 will be heated, so that people can experience the feeling of smoke as soon as it is smoked.

specific Embodiment 4

[0043] The difference between this embodiment and the specific embodiment 1 is that the airflow channel of the electronic cigarette is no longer provided with an air intake end 131 , a second air intake end 121 , and a third air intake end 111 , such as Figure 5 As shown, an inner air inlet end 112 is provided on the inner shell 11 of the cover, and an outer air inlet end 71 is provided on the joint 7, and the outer air inlet end 71 is connected to the inner air inlet end 112, so the The inner air inlet end 112 is communicated with the air flow passage. It can be seen from this embodiment that the arrangement of the airflow channel in the bottle cap 1 is diverse, and is not limited to being arranged at any position of the bottle cap 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com