Patents

Literature

365results about How to "Save shipping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass spectrometer

ActiveUS7759638B2Avoid restrictionsFast switching speedTime-of-flight spectrometersSamples introduction/extractionMass spectrometricSpectrometer

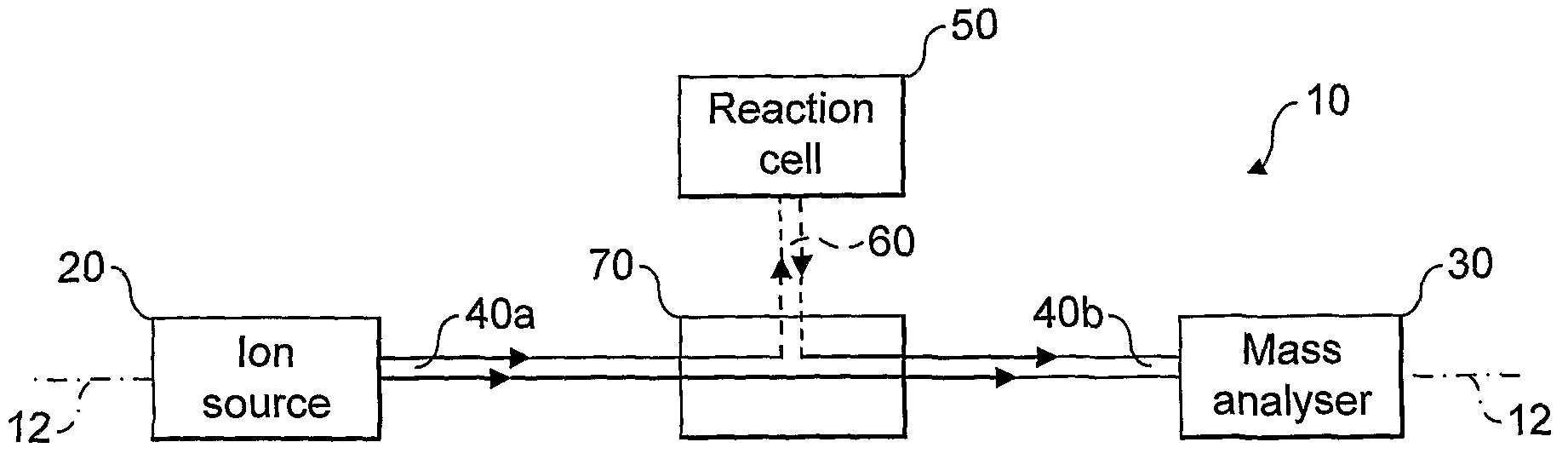

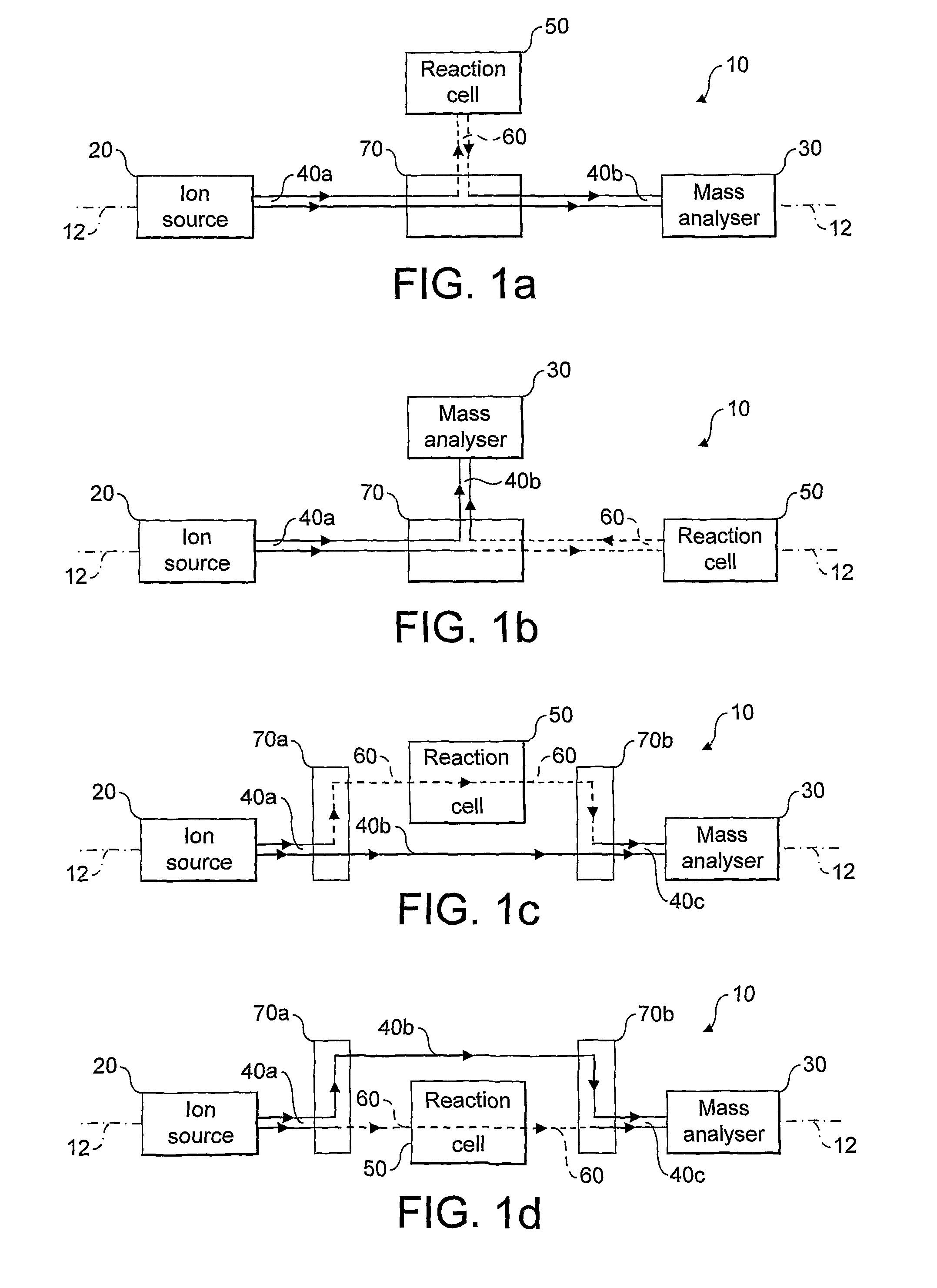

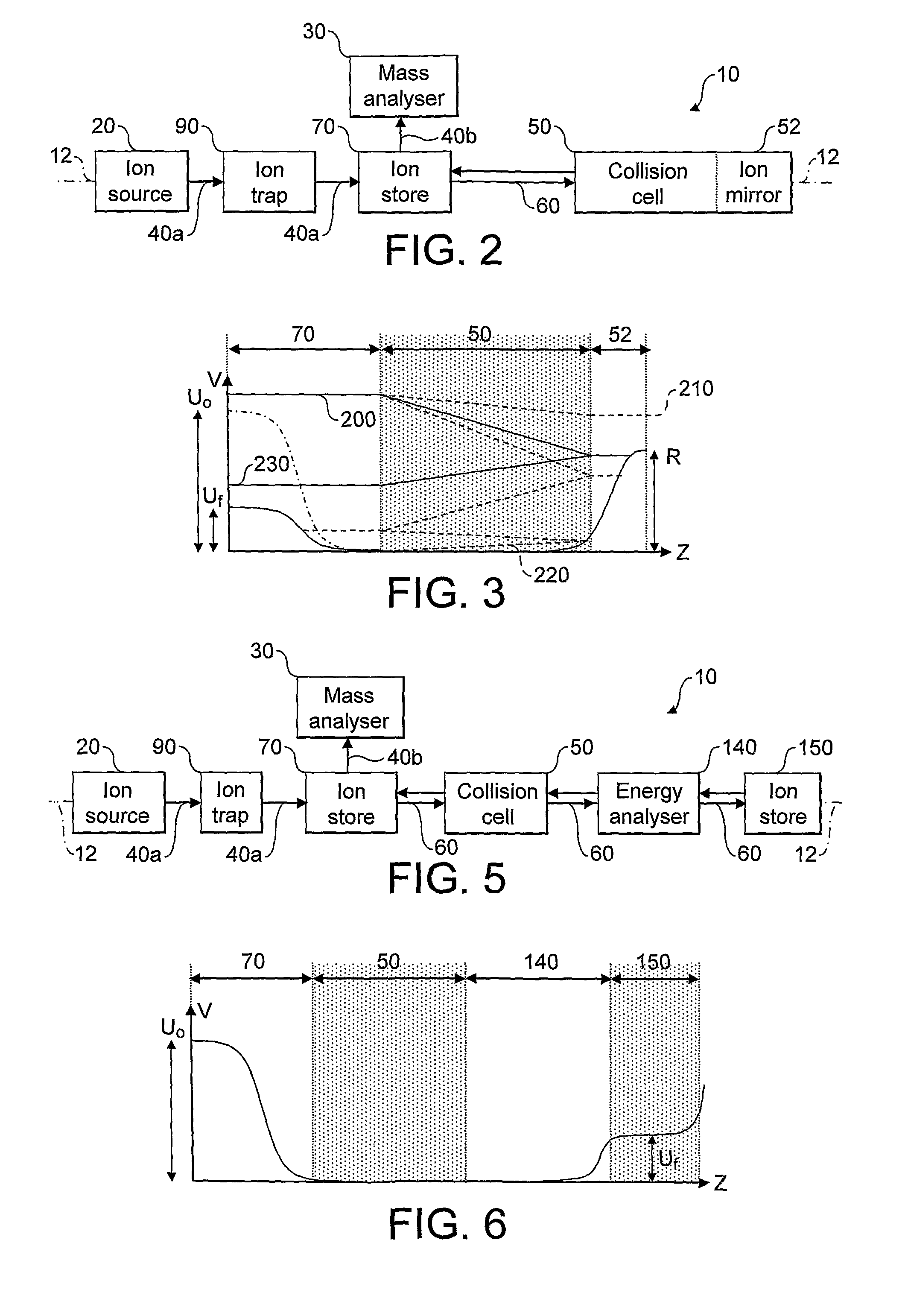

This invention relates to mass spectrometers comprising a reaction cell and where mass spectra are collected both from unreacted ions and also from reaction product ions. In particular, although not exclusively, this invention finds use in tandem mass spectrometry where mass spectra are collected from precursor and fragment ions. The present invention provides an arrangement where ions may be sent to a reaction cell for fragmentation or other processing before onward transport to a mass analyser. Alternatively, ions may be passed directly to a mass analyser along a bypass path.

Owner:THERMO FINNIGAN

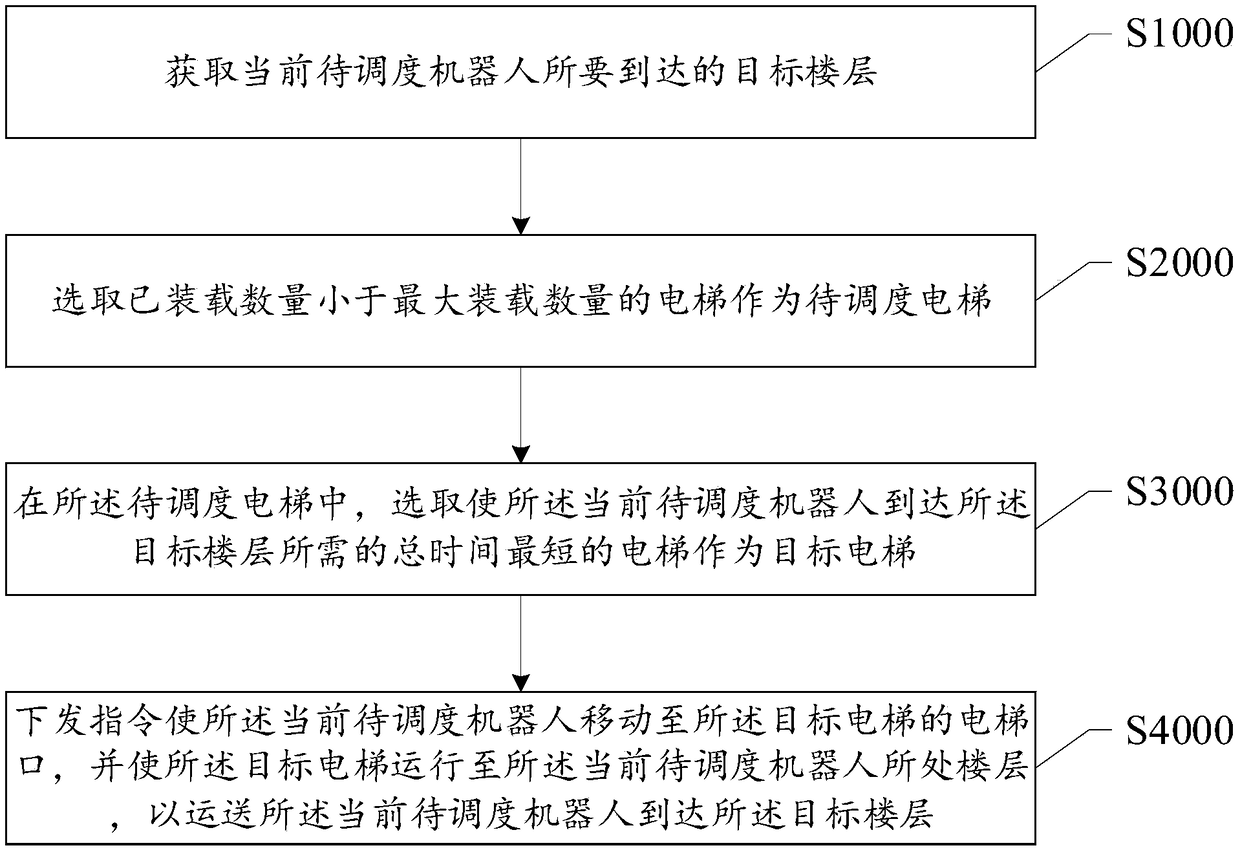

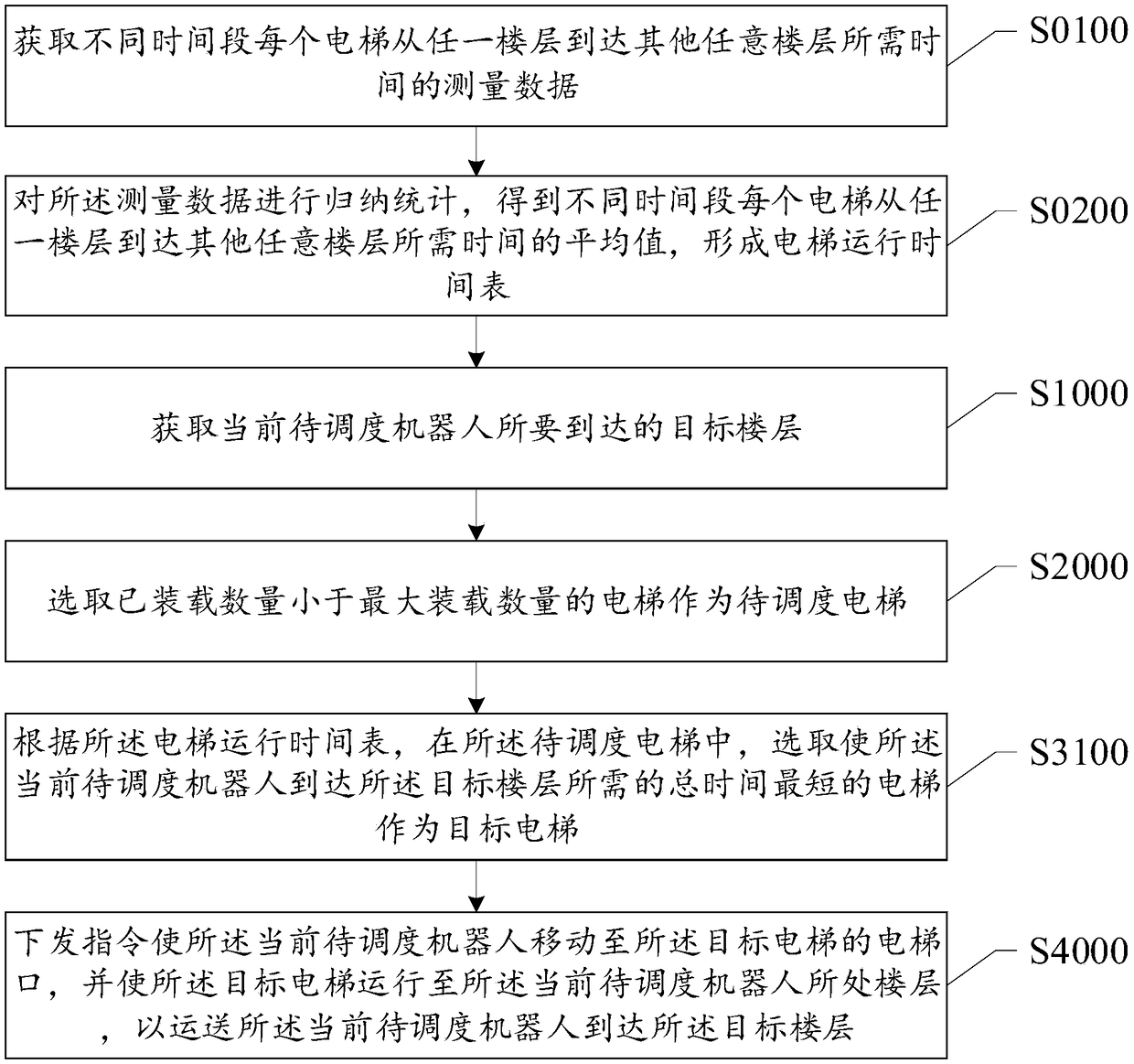

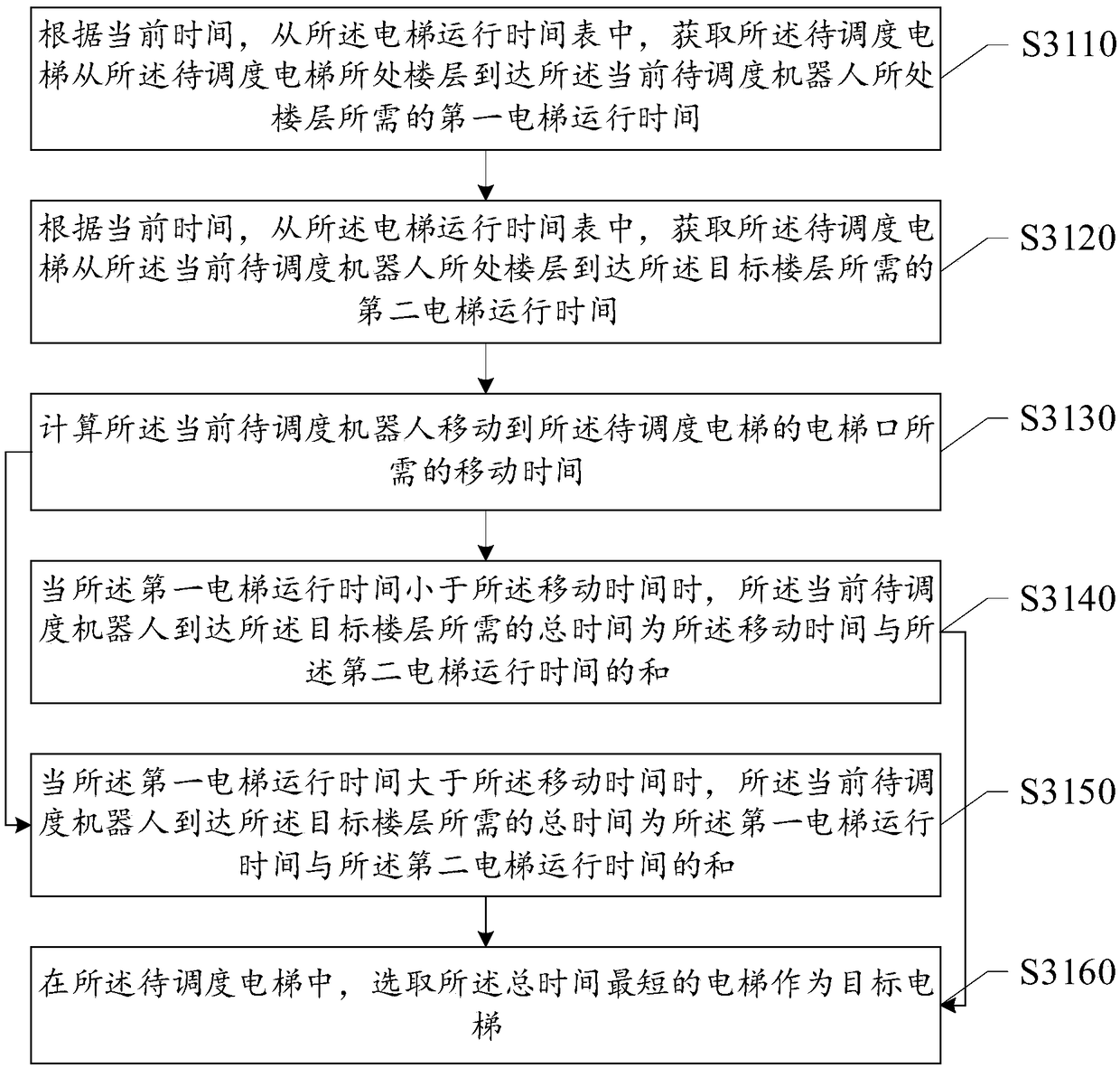

Scheduling method and system for multi-robots and multi-elevators

ActiveCN109250593ASave shipping timeImprove transportation efficiencyElevatorsTransport timeSimulation

The invention belongs to the field of the intelligent control, and discloses a scheduling method and system for multi-robots and multi-elevators. The method comprises the following steps: to obtain atarget floor to be arrived by a current robot to be scheduled; selecting elevators of which a loaded number is smaller than a maximum loading number as elevators to be scheduled; in the elevators to be scheduled, selecting the elevator of which needed total time of the current robot to be scheduled arriving the target floor is shortest as the target elevator; issuing an instruction, and enabling the current robot to be scheduled to be moved to an elevator landing opening of the target elevator, and enabling the target elevator to be moved to the floor on which the current robot to be scheduledis positioned, and conveying the current robot to be scheduled to the target floor. The method is capable of firstly selecting multiple elevators of which the loading numbers do not reach an upper limit as the elevators to be scheduled, and selecting the elevator of which the needed time of arriving the target floor is shortest as the target elevator from the elevators to be scheduled, and conveying the current robot to be scheduled, thereby reducing conveying time of the current robot to be scheduled, and improving conveying efficiency of the robots.

Owner:上海木木聚枞机器人科技有限公司

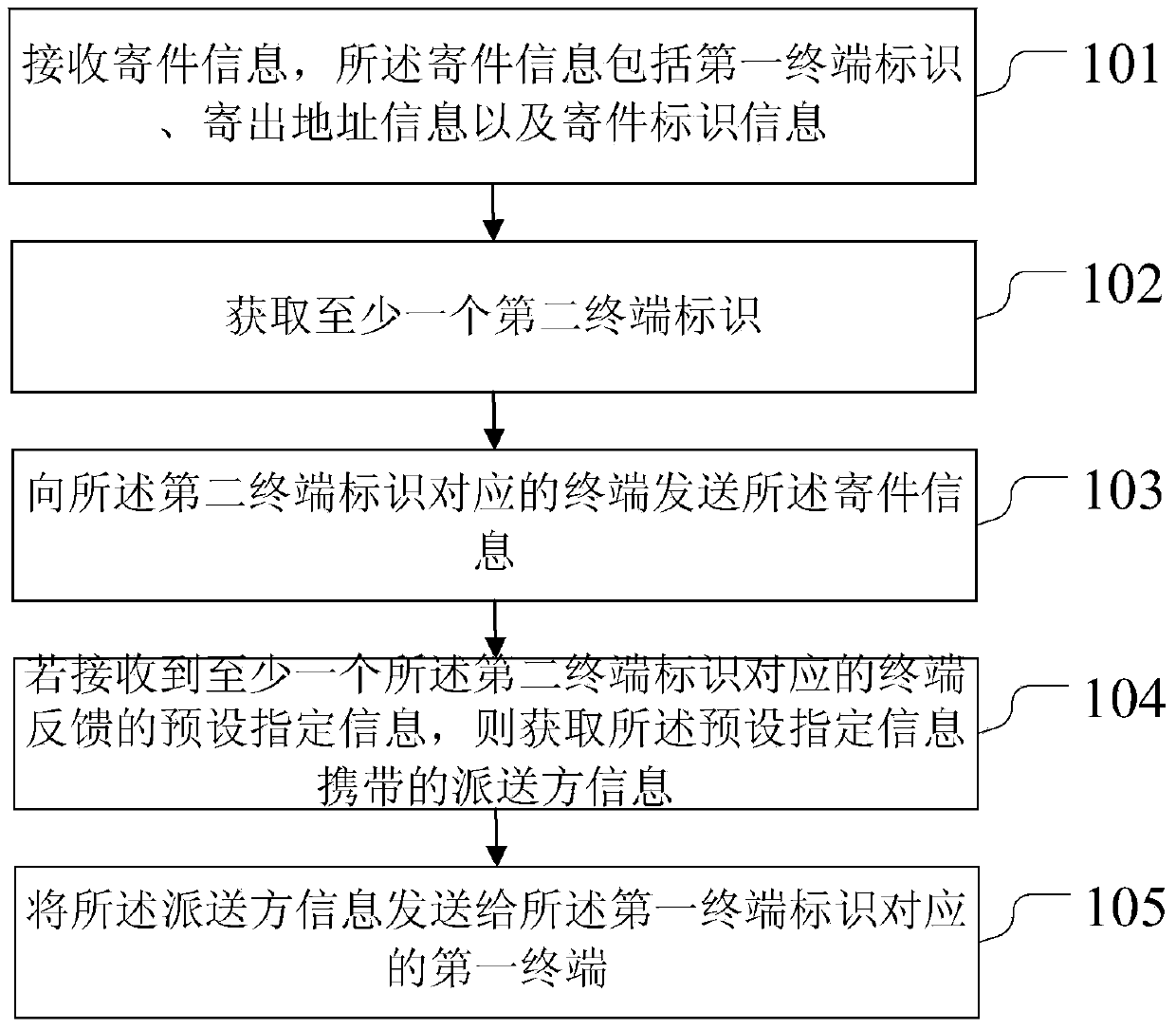

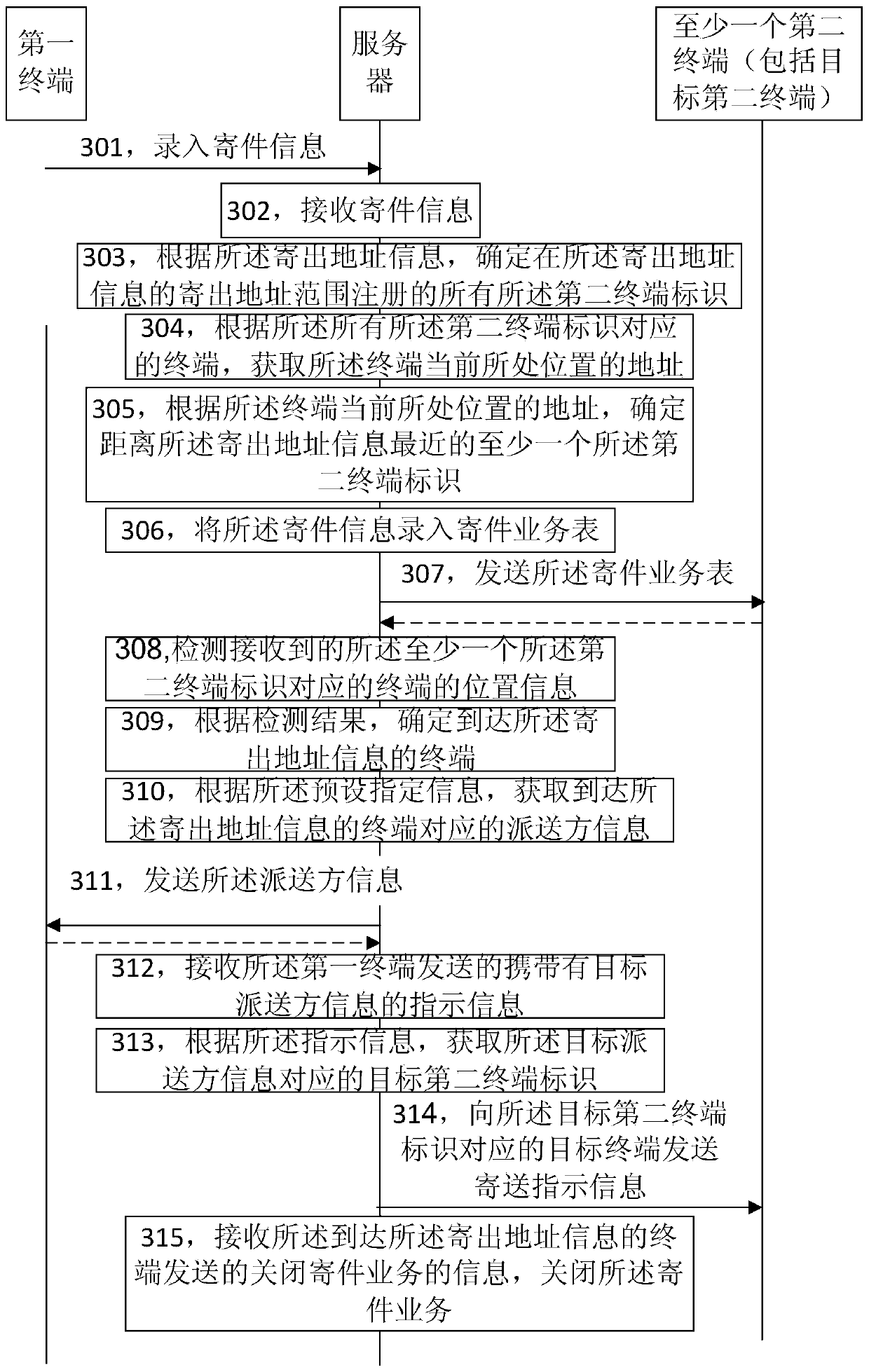

Logistics business processing method and device

InactiveCN103793801AAddresses issues that require a single notification recipientSave shipping timeLogisticsLogistics managementComputer terminal

The invention discloses a logistics business processing method and device, and relates to the logistics business technical field. The logistics business processing method provided by the embodiment of the invention includes the following steps that: delivery information is received, wherein the delivery information includes a first terminal identifier, a delivery-out address information and a delivery identifier information; at least one second terminal identifier is obtained; the delivery information is transmitted to a terminal corresponding to the second terminal identifier; if preset specified information fed back by the terminal corresponding to the least one second terminal identifier is received, delivery party information carried by the preset specified information is obtained; and the delivery party information is transmitted to a first terminal corresponding to the first terminal identifier, such that effective information of a delivery party can be queried. The logistics business processing method and device of the embodiment of the invention are suitable for being adopted in the implementation of e logistics business.

Owner:BEIJING QIHOO TECH CO LTD +1

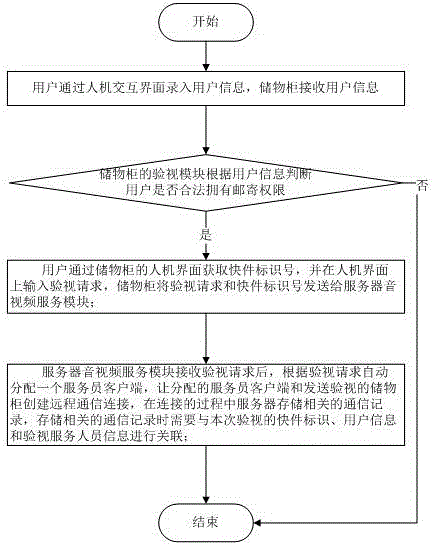

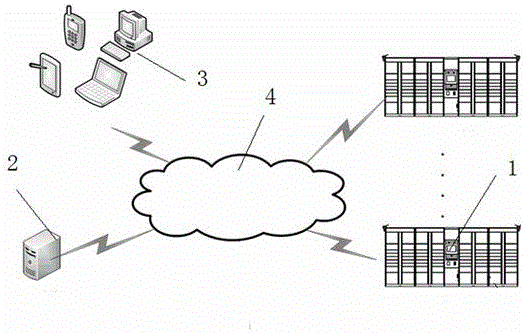

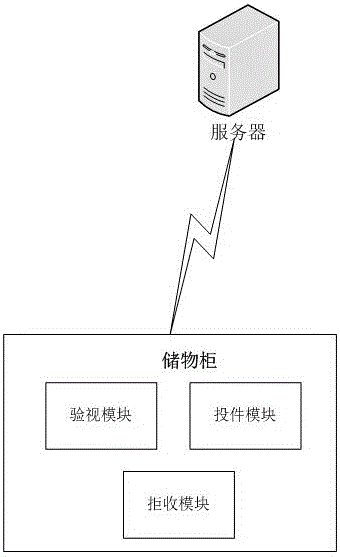

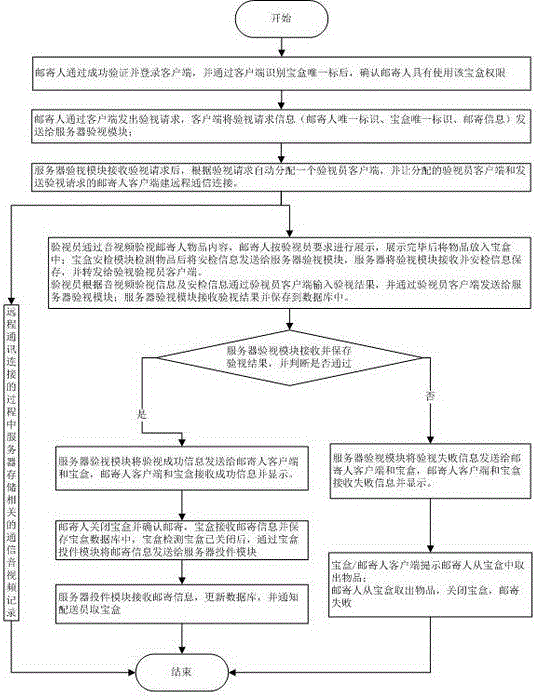

Storage cabinet inspection system and storage cabinet inspection method

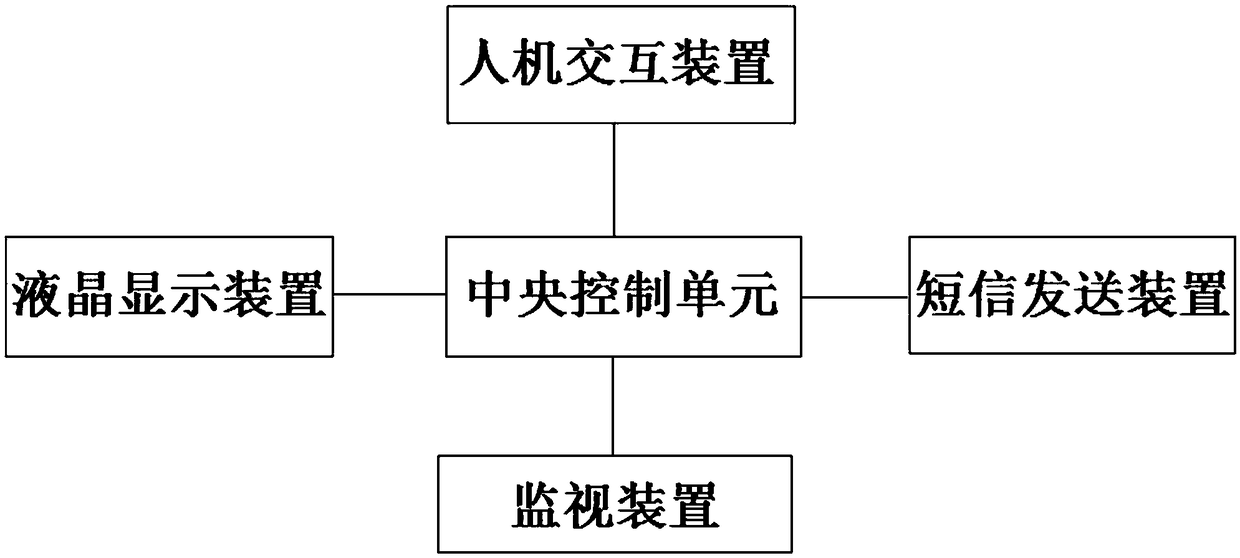

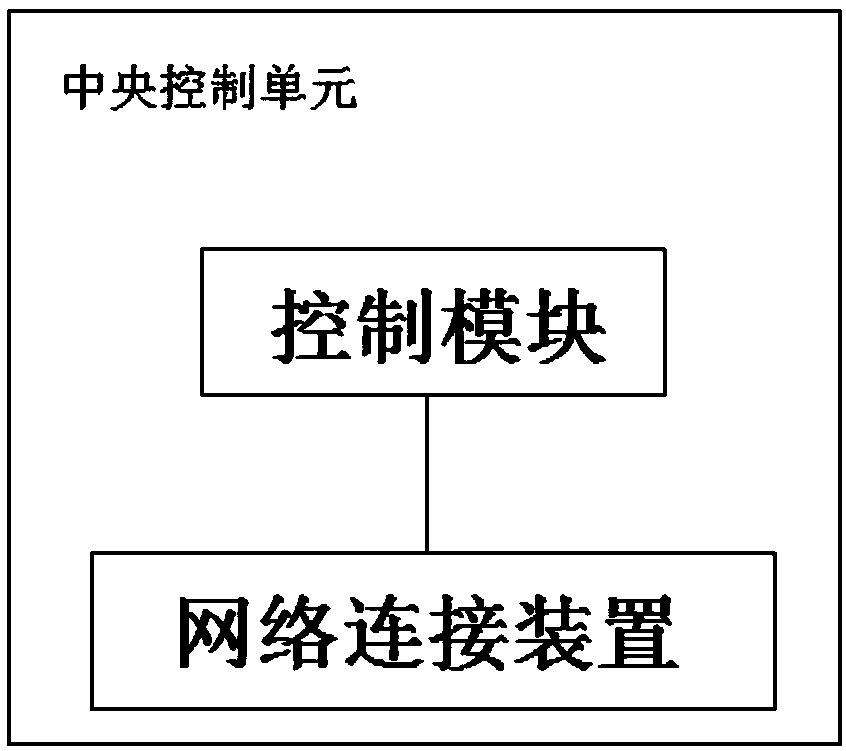

ActiveCN105719403AExperienceLow probability of error detectionApparatus for meter-controlled dispensingTransmissionComputer hardwareControl unit

The invention discloses a storage cabinet inspection system and a storage cabinet inspection method. The storage cabinet inspection system comprises a server, a plurality of storage cabinets and a plurality of waiter clients, wherein each storage cabinet comprises a central control unit, a camera and a plurality of box compartments; and the central control unit comprises a mail delivery module and an inspection module. The waiter clients remotely inspect whether mails meet delivery requirements or not, so that the labor consumption is reduced while couriers and senders perform inspection personally, the mail sending time of the senders is shortened, and mail sending of the senders is facilitated.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

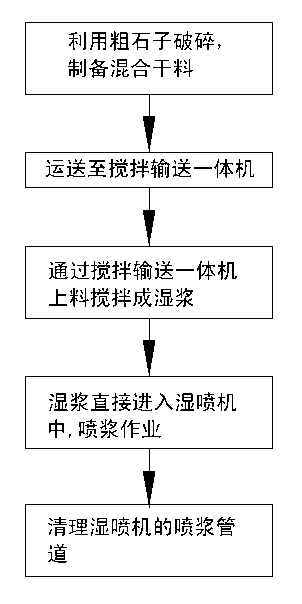

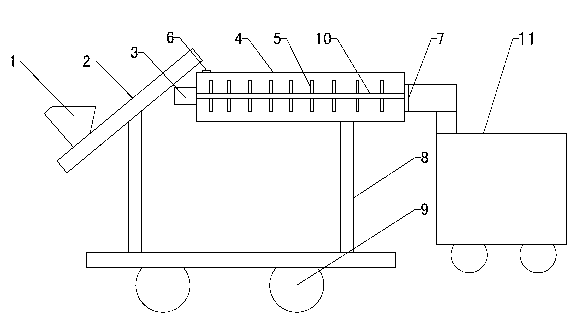

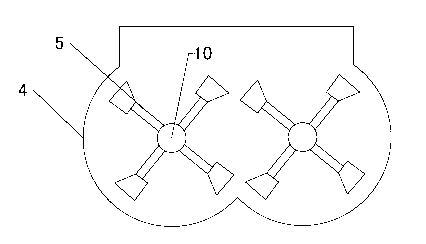

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

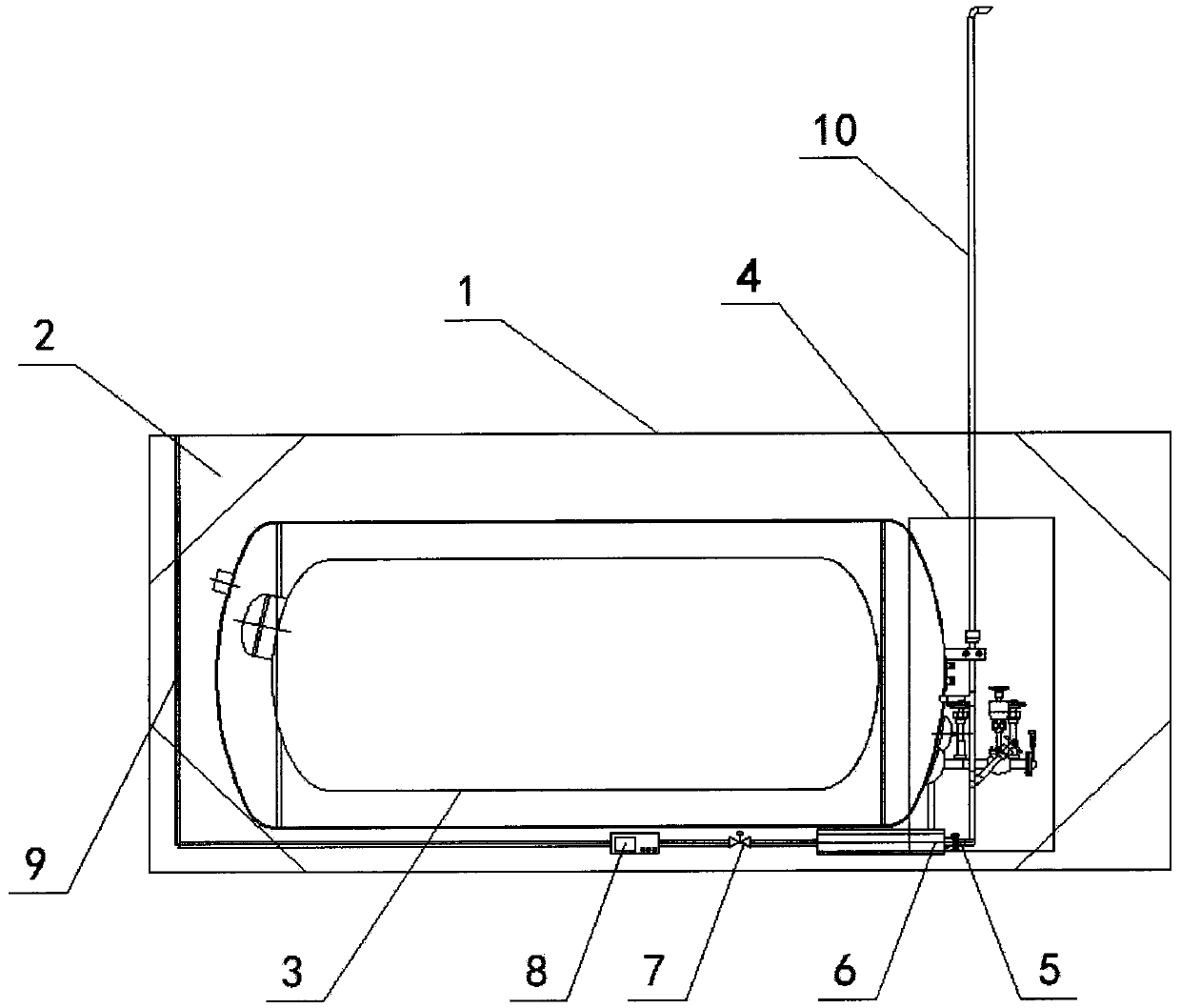

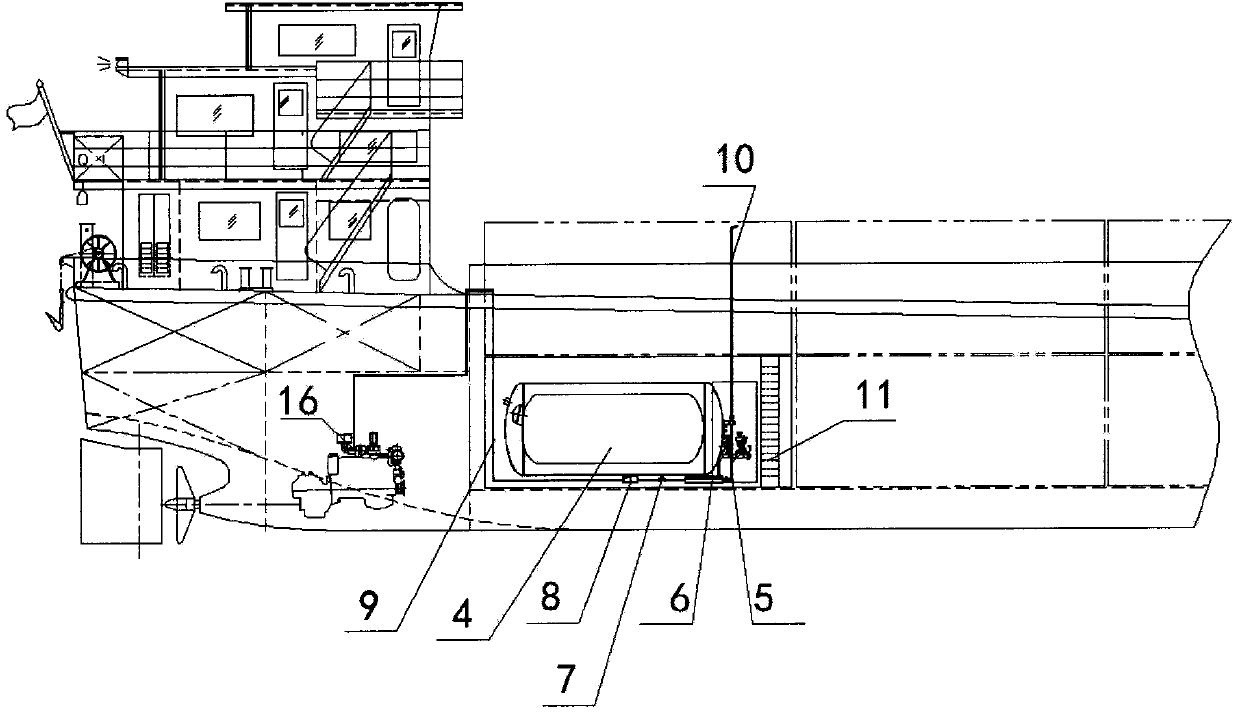

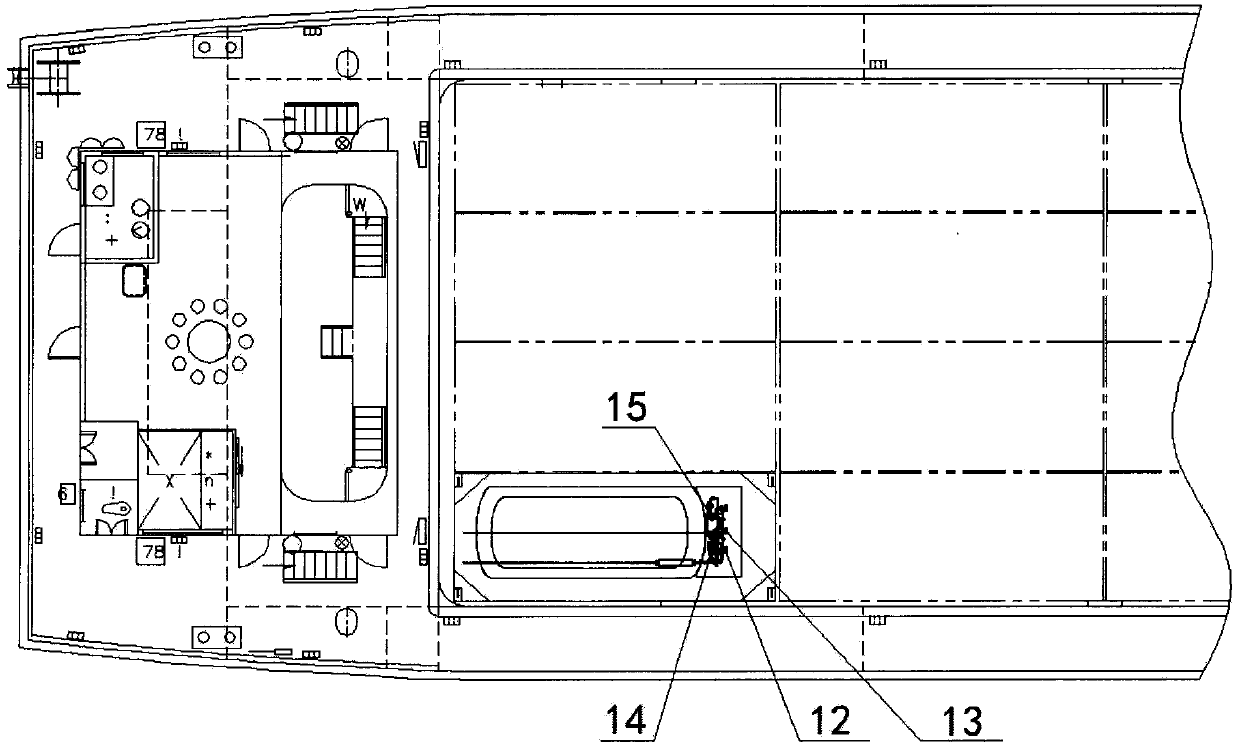

Novel LNG gas-feeding integrated module device

InactiveCN103867888AEasy refillGas filling station is fixed and easy to fillContainer filling methodsPressure vesselsGas phaseControl system

The invention discloses a novel LNG gas-feeding integrated module device, and belongs to the field of ship transportation. The device is designed according to the standards of ISO shipping containers, and comprises a liquefied natural gas gas-feeding device case and a case frame; wherein the liquefied natural gas gas-feeding device case comprises a liquefied natural gas storage tank, an operation valve case, a liquid transportation pipeline, a gasifying device, an emergency cut-off device, a gas flowmeter, a gas transportation pipeline, a pressure releasing pipe, and a vertical ladder; the case frame comprises a front end frame, a rear end frame, a upper side beam, a lower side bean, a diagonal brace, an upper diagonal member, a lower diagonal member, a bottom plate, and a bearer; the operation valve case comprises a liquid-phase operation pipeline, a gas-phase operation pipeline, a backup pipeline, and a control system, and the liquid-phase operation pipeline, gas-phase operation pipeline, backup pipeline, and control system are concentratedly arranged through low-temperature stainless steel pipes. The device solves the problems of difficult gas feeding for a diesel oil-LNG bi-fuel source ship. A gas-feeding station can utilize the integrated module device to safely butt-join a diesel oil-LNG bi-fuel source diesel engine, provide gas for the ship to be fueled, and control the gas volume. The transportation cost is reduced, and the transportation efficiency is improved.

Owner:JIANGSU MODERN SHIPBUILDING TECH

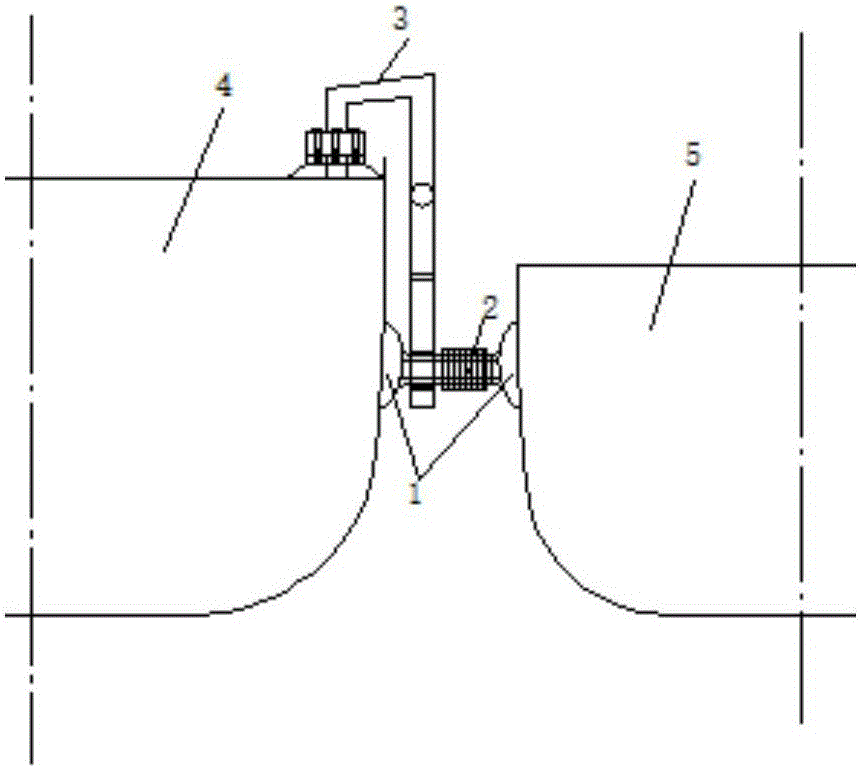

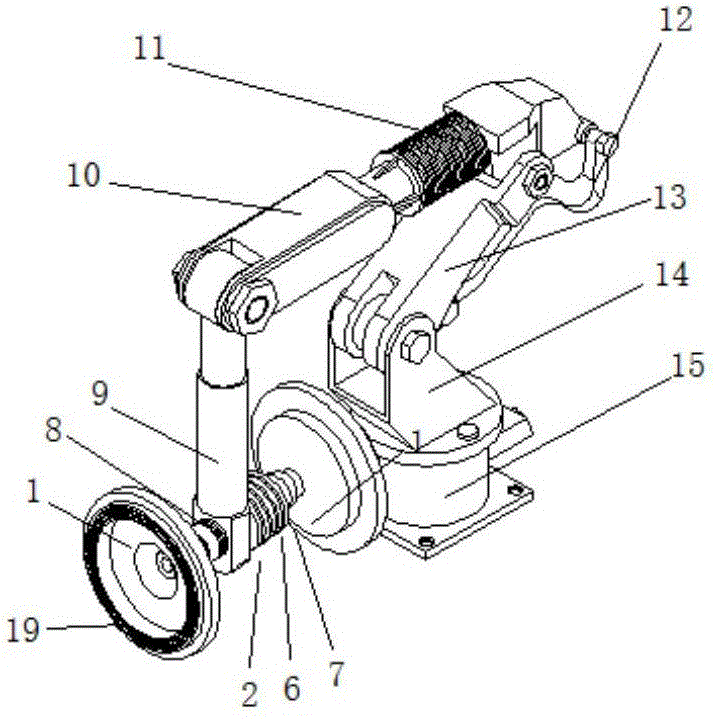

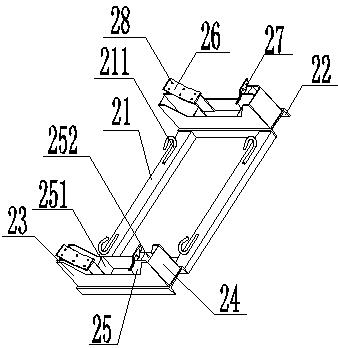

Mechanical adsorbing device for improving ship abreast supply stability

ActiveCN105947113ASafe and reliable structureReduce time spentVessel cleaningHullsMarine engineering

The invention provides a mechanical adsorbing device for improving ship abreast supply stability. The mechanical adsorbing device for improving the ship abreast supply stability mainly comprises vacuum suckers (1), a hydraulic buffering mechanism (2) and a mechanical arm (3), wherein during working, the mechanical adsorbing device provides restraining forces, buffering forces and pushing forces for two ships at supplying work and can exert the abreast supply process of the two ships to be smoothly finished. According to the invention, by using the double-face suckers to adsorb and fix ship bodies, the supply is stable; due to adoption of the hydraulic buffering mechanism between the suckers, the ship abreast buffering and pushing forces can be provided so that the ship abreast supply stability and safety are improved; and through adoption of a folding type mechanical arm design, the device is easy to mount and operate and deck spaces are saved.

Owner:WUHAN UNIV OF TECH

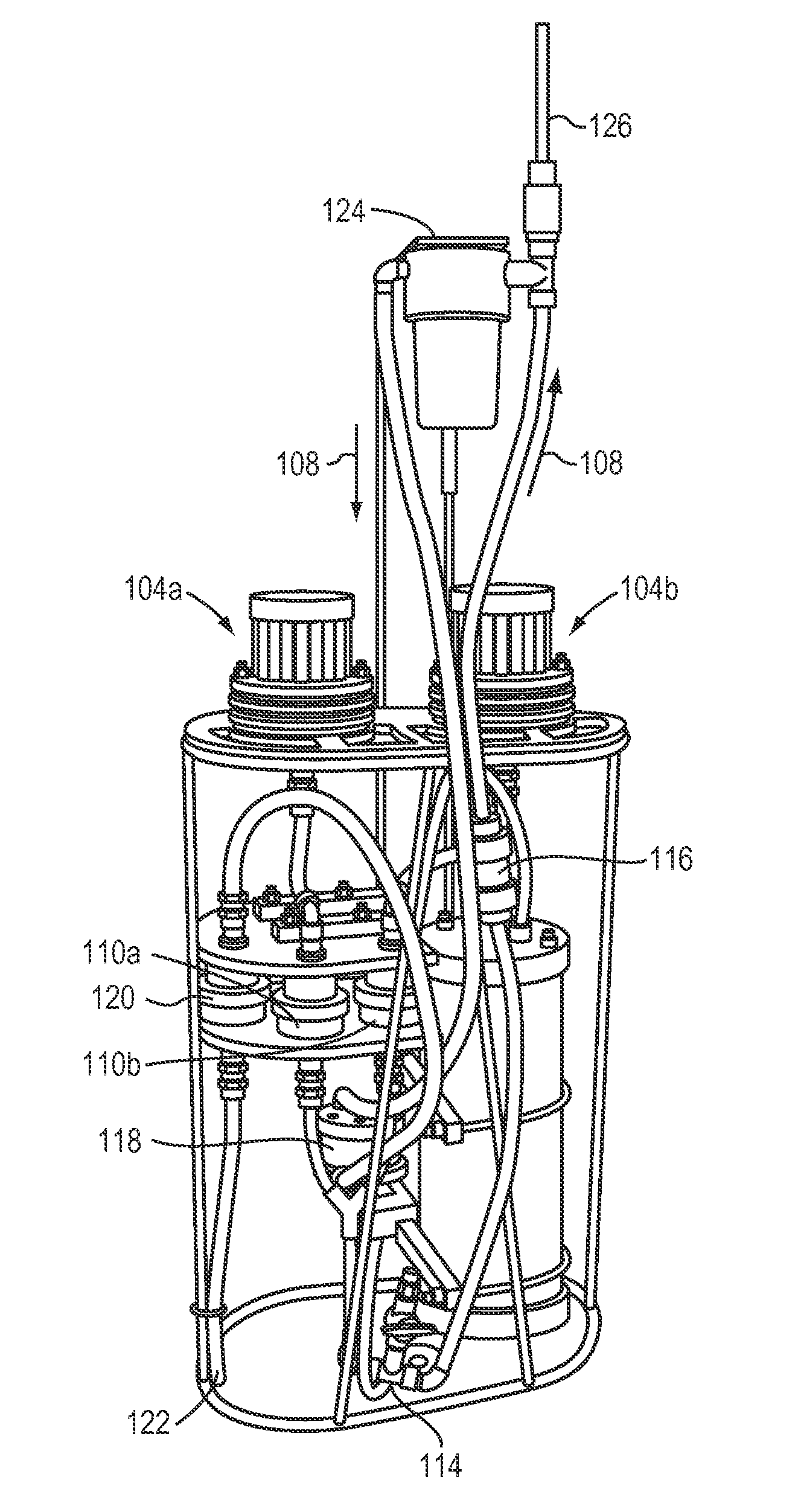

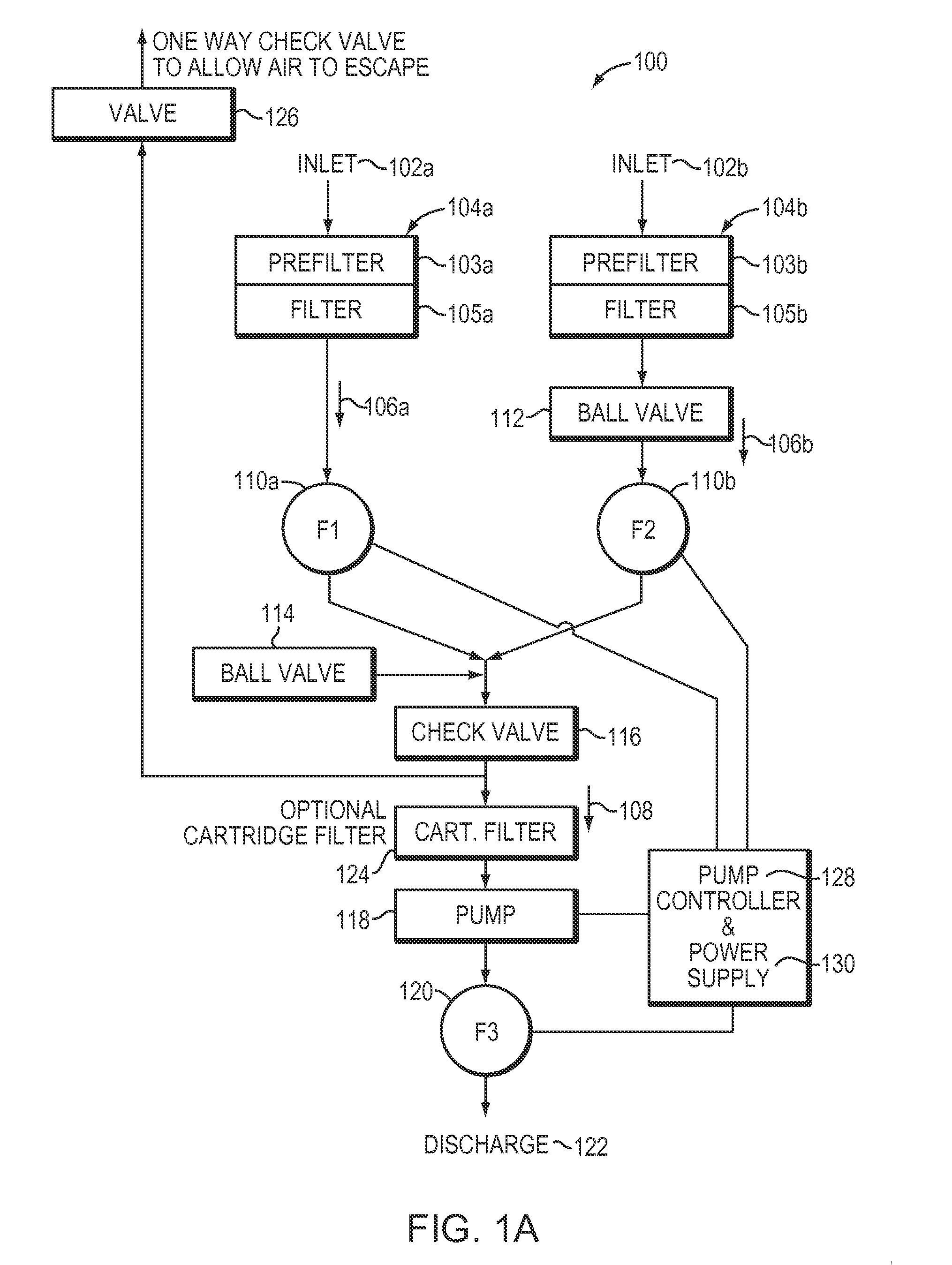

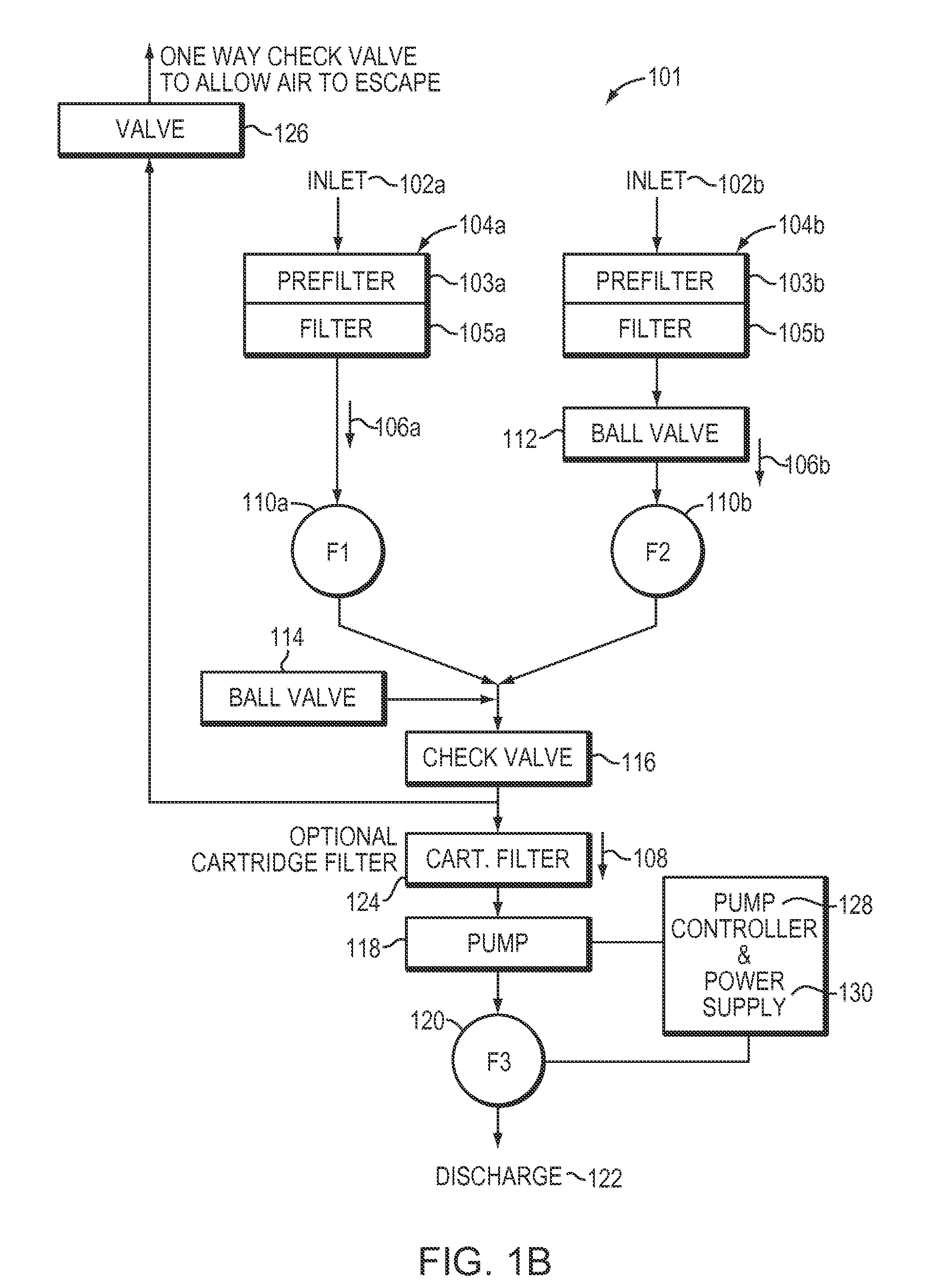

In situ marine sample collection system and methods

InactiveUS20130298702A1Save shipping timeEasy to collectWithdrawing sample devicesSample collectionCollection system

According to one aspect, the invention relates to a marine sample collection system adapted for in situ use. The system includes a first filter head and a second filter head for filtering material of interest from ambient marine fluid passing therethrough and a respective filter flow meter disposed downstream of each of the filter heads for measuring volumetric flow through each filter head. The system also includes a pump downstream of the filter heads for inducing flow through the filter heads and an outlet flow meter disposed downstream of the pump for measuring volumetric flow through the pump. An optional controller compares a sum of an output of the flow meters associated with the first and second filter heads and an output of the outlet flow meter to determine if there is leakage in the system.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

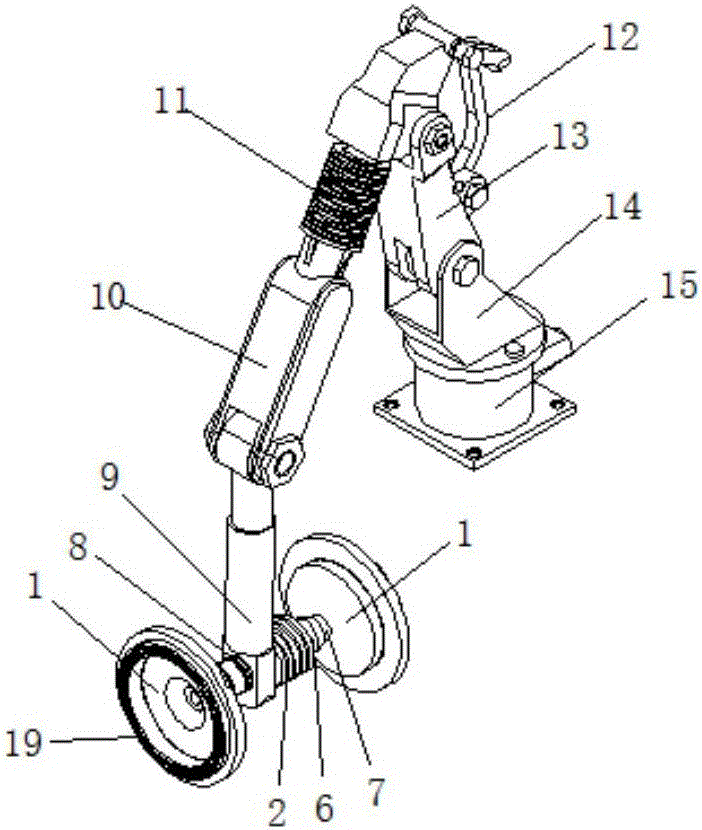

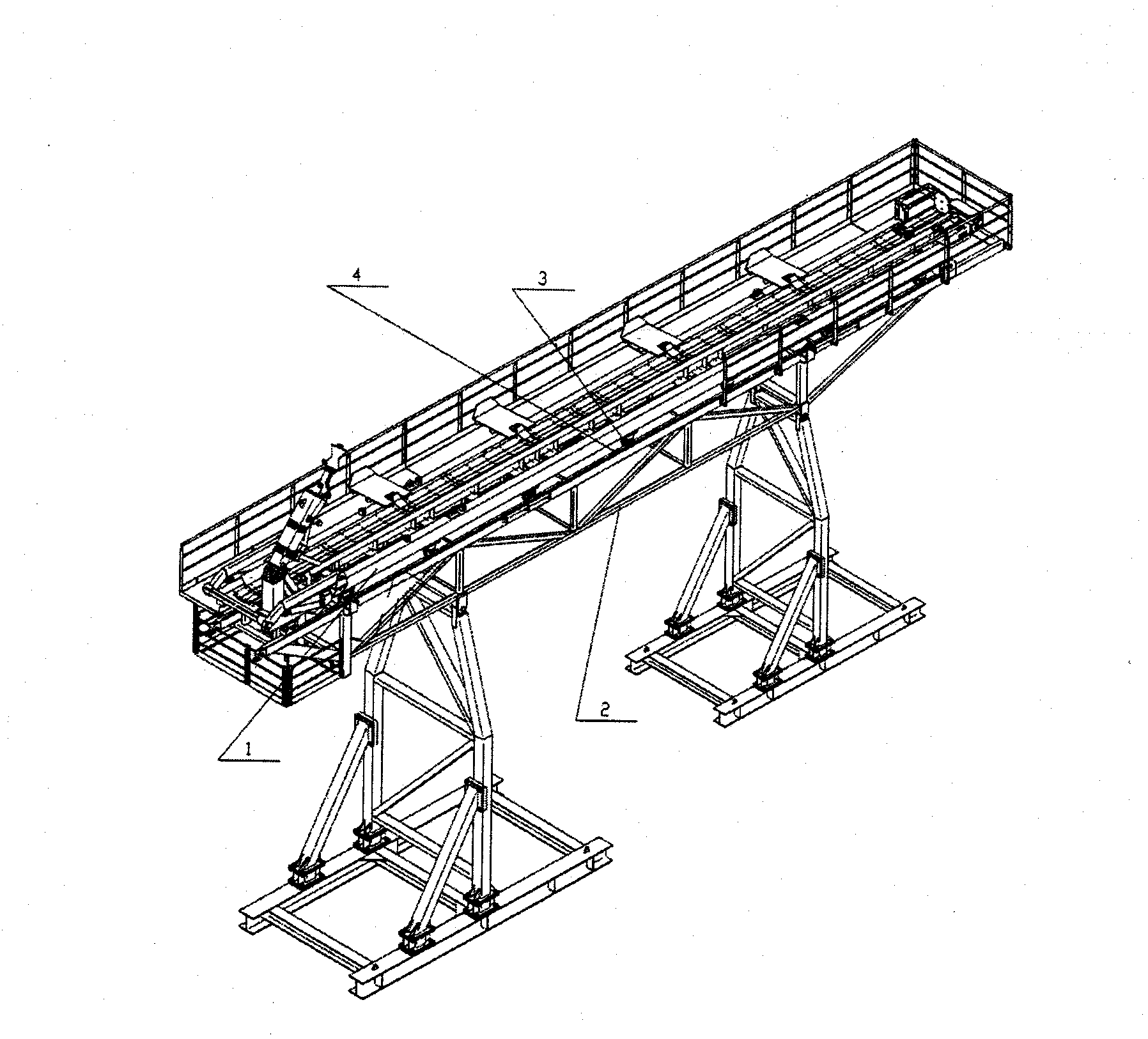

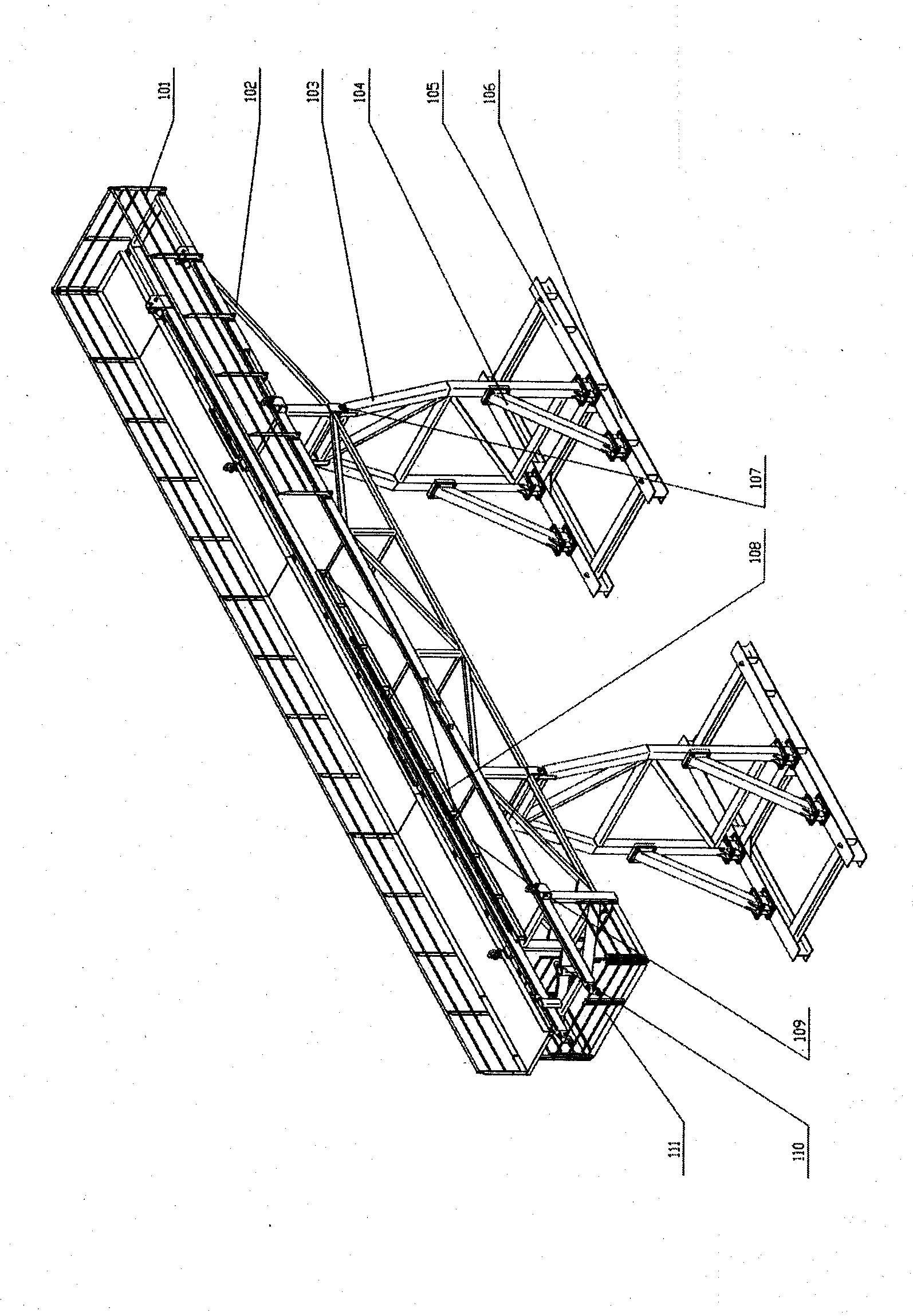

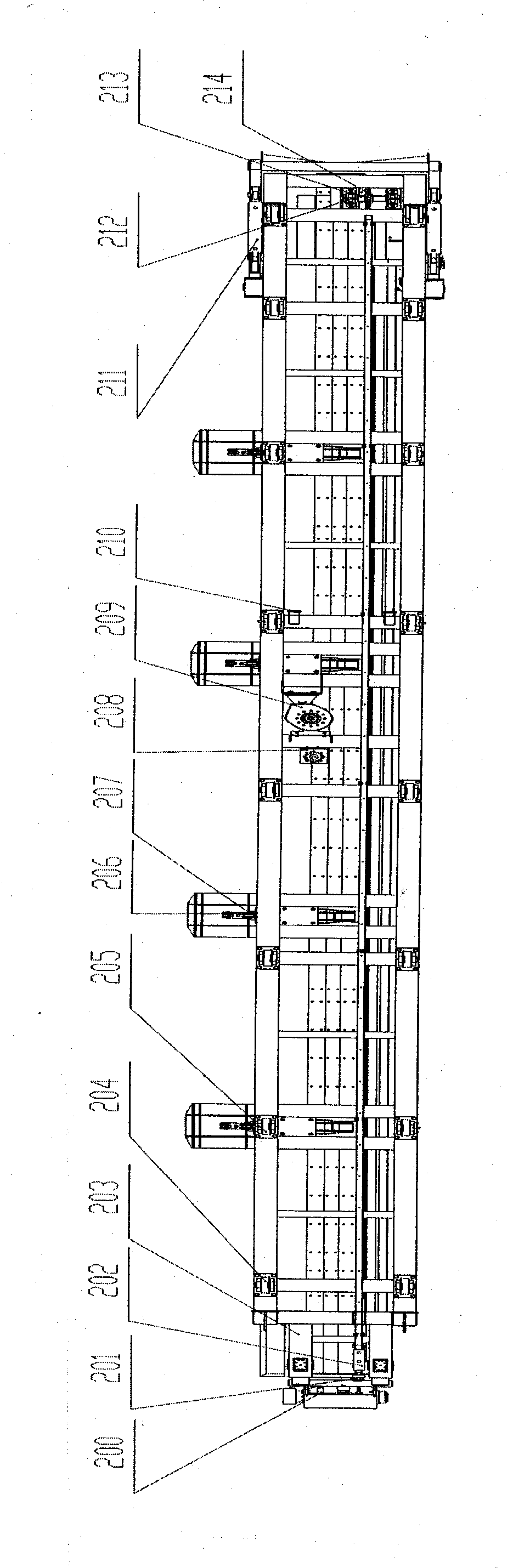

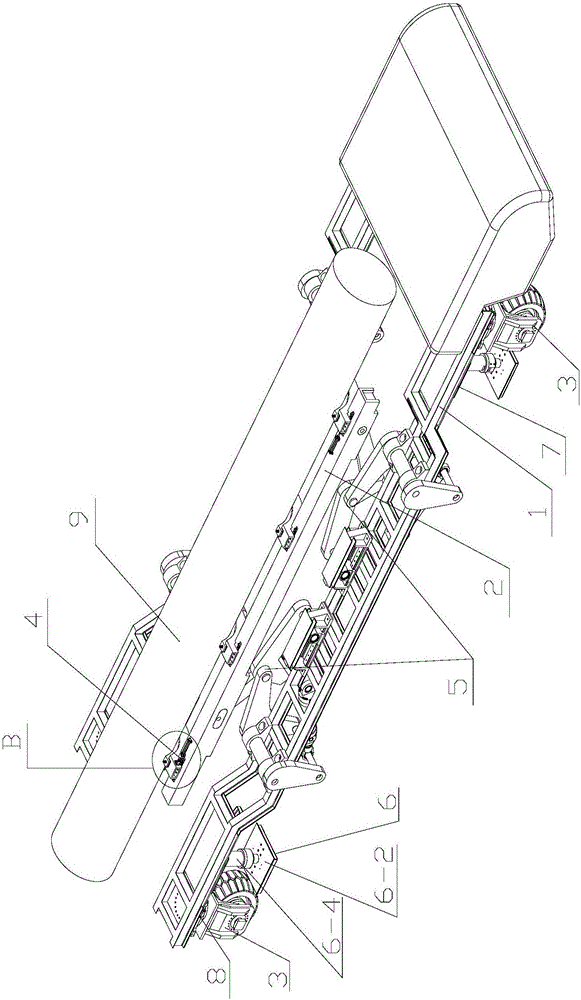

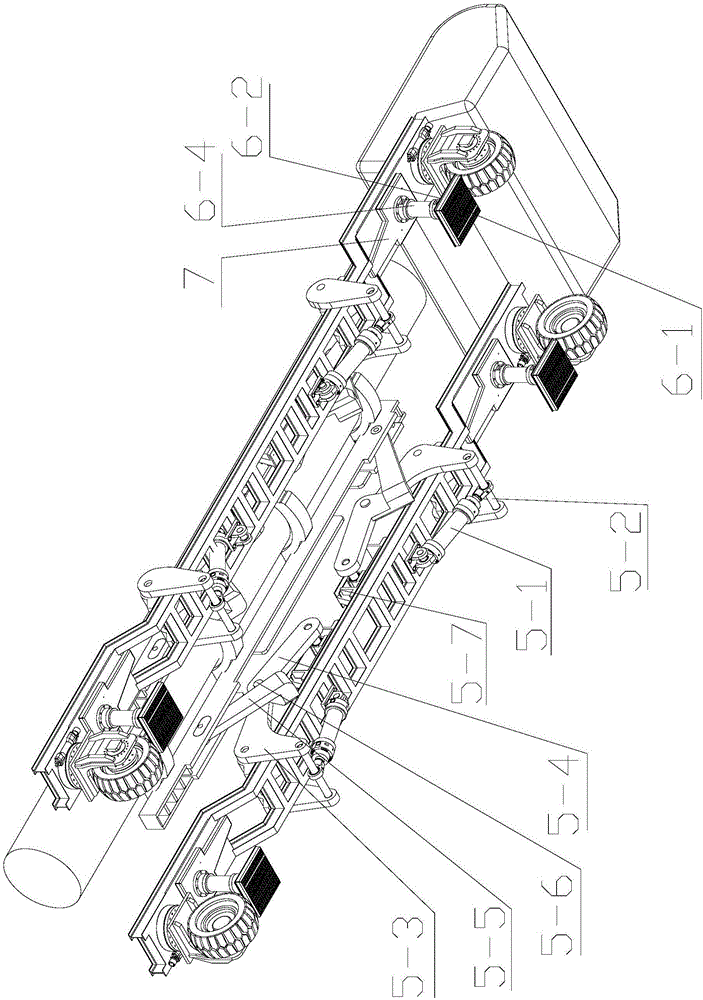

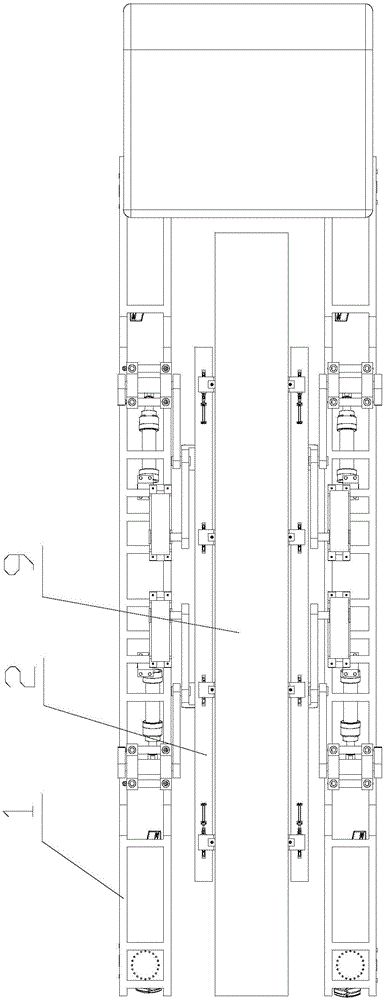

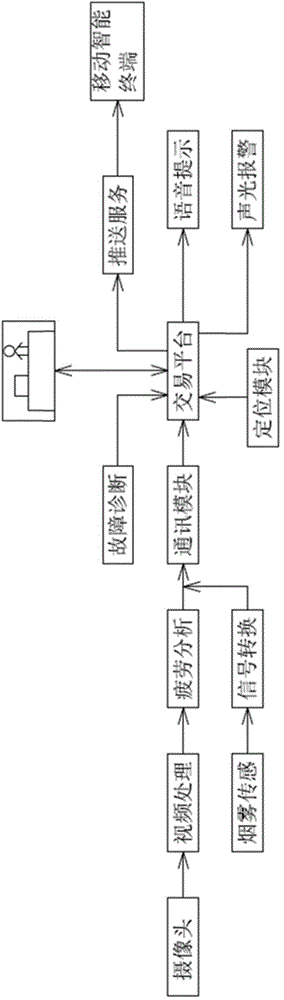

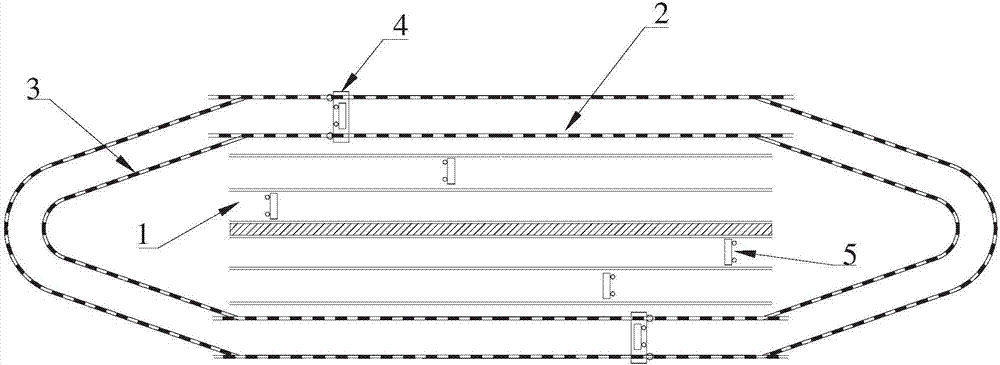

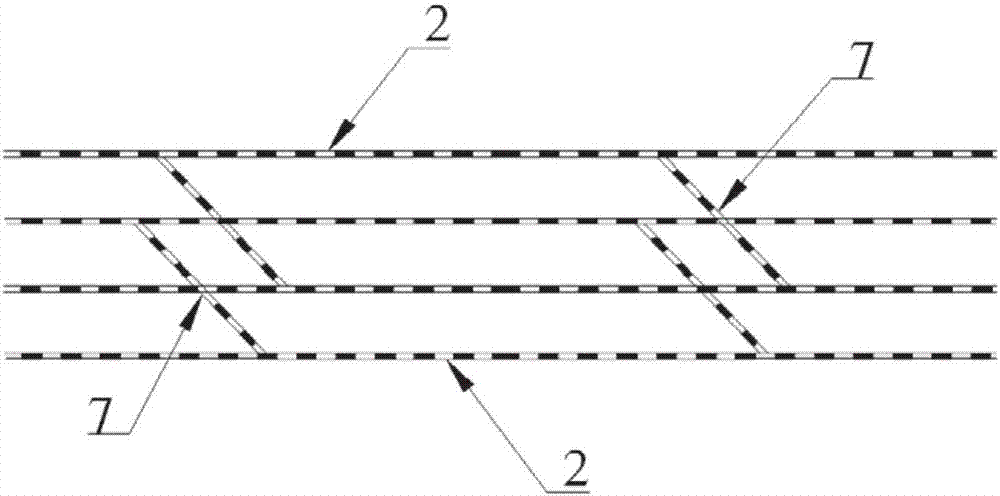

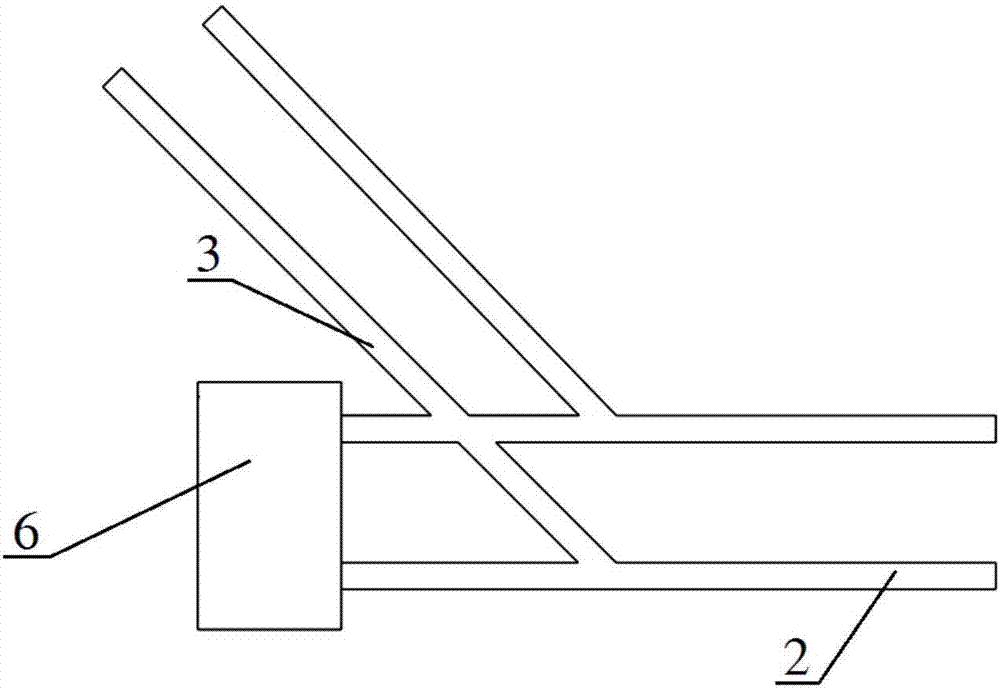

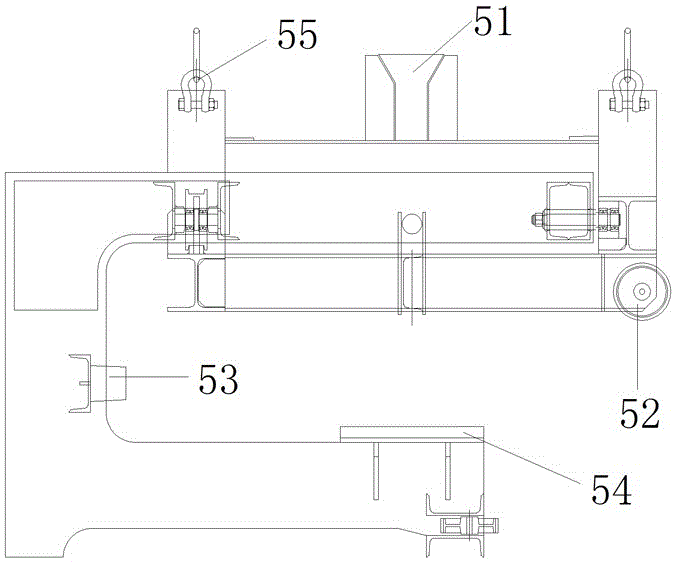

An intelligent power catwalk

InactiveCN102278082AHigh degree of intelligenceReduce labor intensityDrilling rodsDrilling casingsModularityModular design

The invention provides an intelligent power catwalk which consists of a bracket, a track, a wheel set, a mechanical arm assembly and a catwalk main body, wherein the catwalk main body is arranged on the track of the bracket through the wheel set; and the mechanical arm assembly is arranged on the catwalk main body. The catwalk main body runs on the track through a general wheel and a wind-resistant wheel. According to the intelligent power catwalk disclosed by the invention, the automation of the transportation process for work of the power catwalk is realized, the labor intensity of workers is reduced and occurring probability of accidents and the loss caused by unexpected accidents are reduced. According to the intelligent power catwalk disclosed by the invention, by adopting a coder structure, the intelligent degree of the power catwalk is improved, further labor saving in the work process is realized, the work efficiency is improved and the transportation time of a drill rod is shortened. With the modular design, the intelligent power catwalk has a quickly-changing function and can be used for eliminating faults in time and ensuring stable and continuous production. The application range of the intelligent power catwalk is widened by using a catwalk platform; and the intelligent level of the intelligent power catwalk is improved by using different implementation schemes.

Owner:深圳市欧佩亚海洋工程有限公司

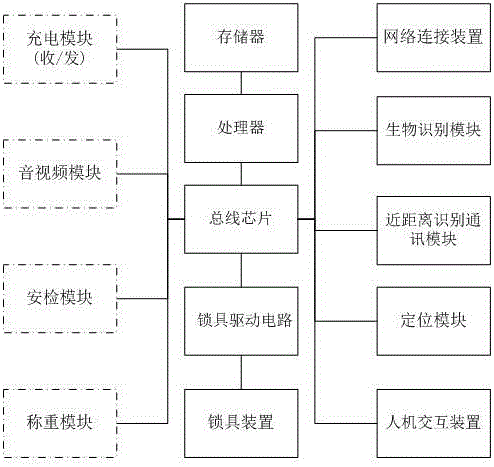

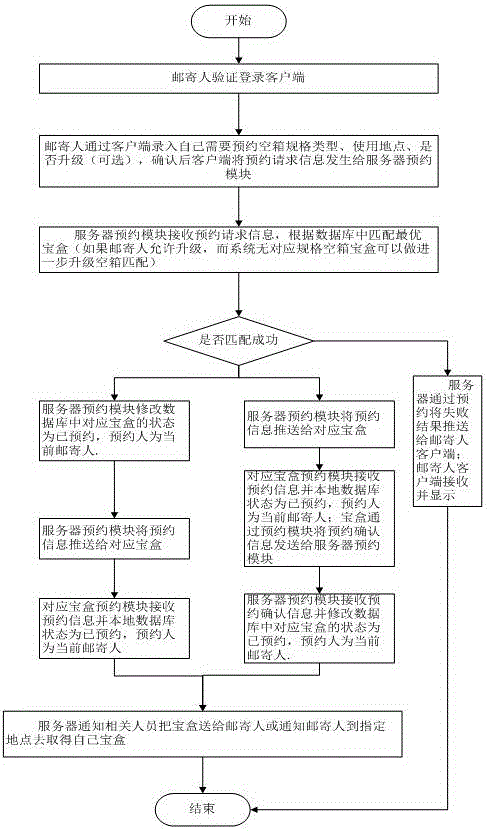

Treasure box mailing system and method

InactiveCN106203899AImprove securityCommunication is convenient and simpleApparatus for meter-controlled dispensingIndividual entry/exit registersWorkloadData library

The invention discloses a treasure box mailing system and method. The mailing system comprises a client, a treasure box and a server, the client and the treasure box communicate with the server via the network, the server comprises a user module, a mail inspection module, a mail sending module, a mail taking module and a database, and the treasure box comprises a safety check module, an audio and video module and a treasure box database. The mailing method comprises a treasure box booking step, a mail sending step and a mail taking step, and remote inspection is needed when a mail is sent. According to the invention, onsite inspection is not needed when the fast mail is sent, convenience is provided for senders, and the workload of delivery staff is reduced at the same time.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

Aluminum chip recovery and smelting process

InactiveCN110172582ASimple recovery and smelting processSave shipping timeProcess efficiency improvementSmelting processEnergy consumption

The invention provides an aluminum chip recovery and smelting process. The process is to perform screening, crushing, oil removal, drying, iron separation, preheating and melting on recovered waste aluminum in sequence to obtain recovered molten aluminum; and the specific steps are as follows: the recovered aluminum is vibrated and screened for crushing; then, an oil remover is used for oil removal and drying; iron is separated; and separated aluminum chips are preheated to enter a smelting furnace for smelting to obtain the recovered molten aluminum. The aluminum chip recovery and smelting process is simple and low in energy consumption, can recycle high-temperature waste gas generated in the process to achieve the purposes of energy conservation and emission reduction, and meanwhile, canshorten the smelting time to further reduce the energy investment.

Owner:襄阳恒德汽车配件有限公司

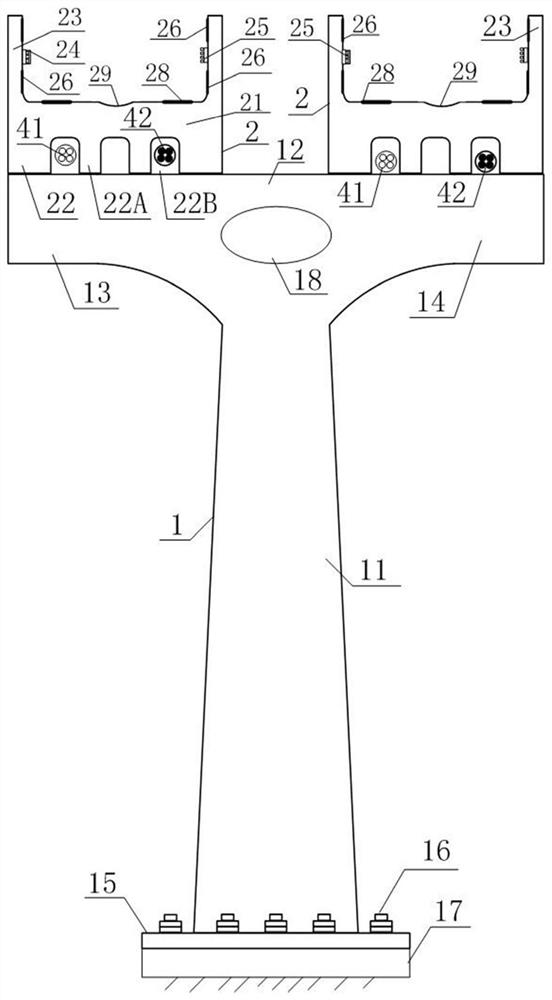

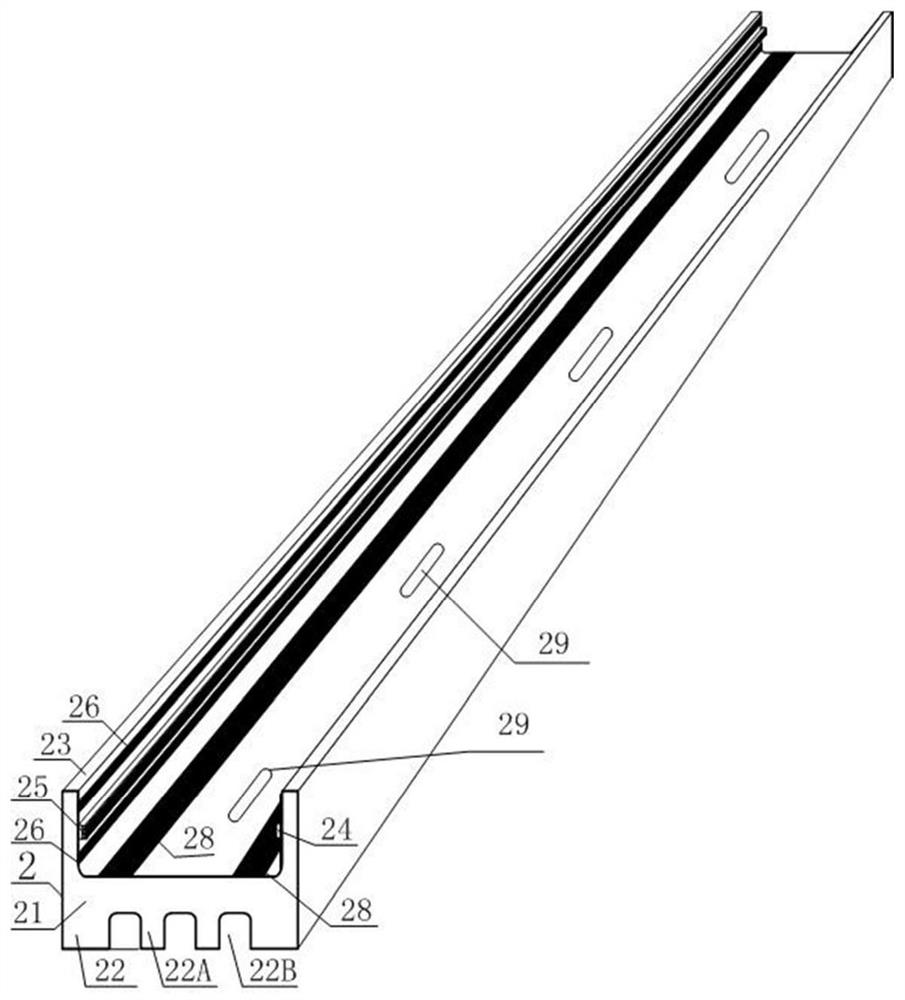

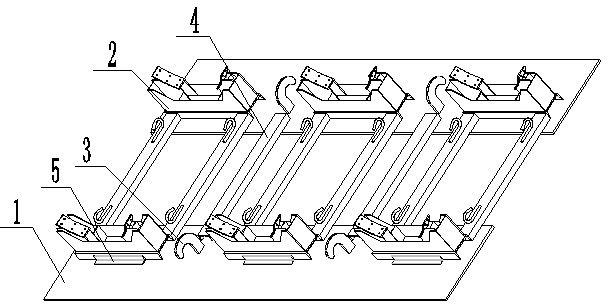

Multi-mode combined transportation composite rail transport system

ActiveCN112109736AImprove efficiencyFlexible choiceRoadwaysRailway tunnelsTransport systemCommunications system

The invention relates to a multi-mode combined transportation composite rail transport system. The system can run on overhead rails in the air, ground rails and underground tunnel rails, can be transported on ferryboats and railways and can also be used for communicating with ports, airports, trains, logistics distribution centers and production bases to directly reach users. The system is composed of a multi-mode combined transportation rail beam, pier columns, a power supply system, a signal communication system and a suspension rail beam. The multi-mode combined transportation rail system is adopted, a new energy unmanned multi-mode combined transportation vehicle, an unmanned suspension rail vehicle, the 5G Internet of Things, the artificial intelligence technology and the like are matched, the system directly reaches the user from the production place or the port, the whole process is transparent and visible, the efficiency is high, the speed is high, the cost is low, energy is saved, the environment is protected, the all-weather operation planning rate is high, and safe and reliable effects can be achieved. The multi-mode combined transportation rail utilizes road slopes or green belts or underground tunnels, is less in demolition, saves land, is low in construction cost, does not increase congestion, and is an important component of future urban intelligent logistics newecology.

Owner:SHANDONG QIHE CLOUD SHUTTLE LOGISTICS TECH CO LTD

Intelligent scheduling system based on multi-station AGV and scheduling method thereof

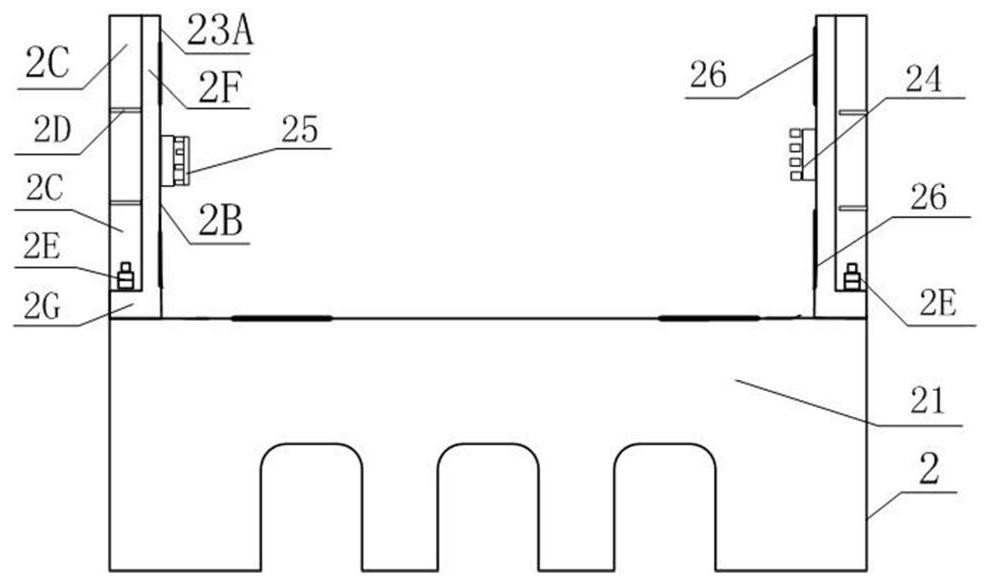

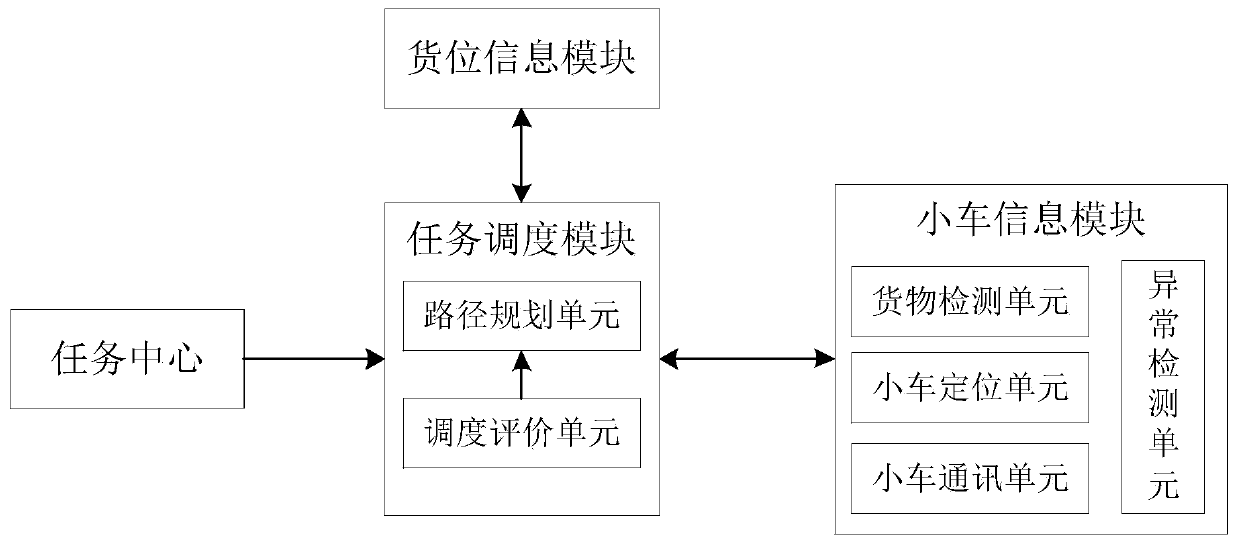

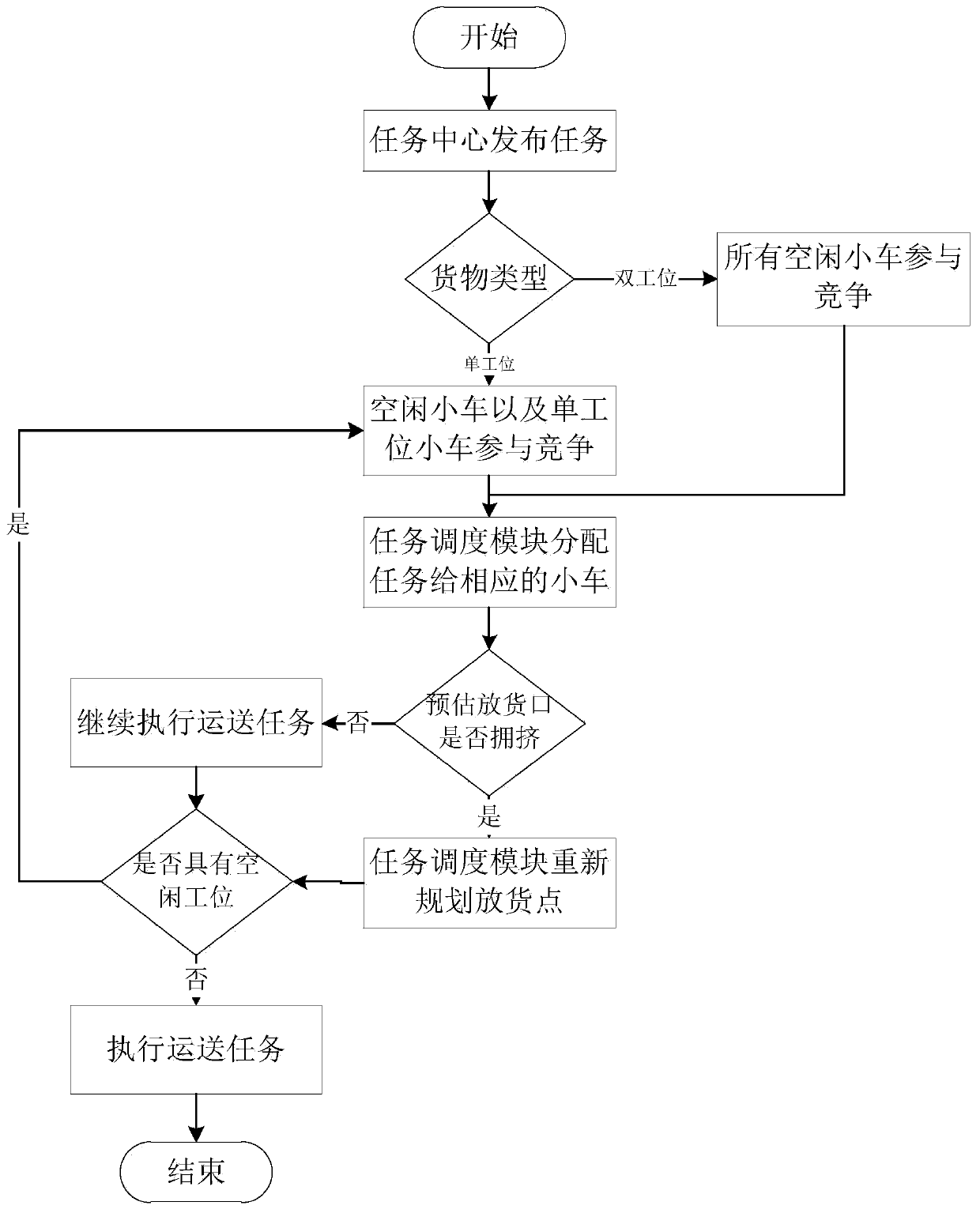

PendingCN110598928AReal-time adjustment of delivery pointsReal-time adjuster delivery orderForecastingResourcesComputer scienceUtilization rate

The invention provides an intelligent scheduling system based on a multi-station AGV and a scheduling method thereof. The intelligent scheduling system comprises a task center, a task scheduling module, a goods allocation information module and a trolley information module, wherein the task scheduling module schedules an optimal trolley according to a goods taking point and a goods placing point of a task, position information and goods carrying information of each trolley and crowding degree information of a goods port of each goods allocation, and associates different tasks, so that the empty running rate of the trolley without goods is reduced; meanwhile, the task scheduling module can give an optimal advancing path according to the information, the transportation time is shortened, crowding of a goods taking and placing opening can be avoided, and the loading and unloading efficiency of goods is improved; and, in addition, the trolley comprises a plurality of stations, a pluralityof tasks can be executed at the same time, and the utilization rate of goods allocation of the trolley is increased.

Owner:四叶草(苏州)智能科技有限公司

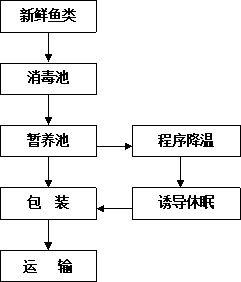

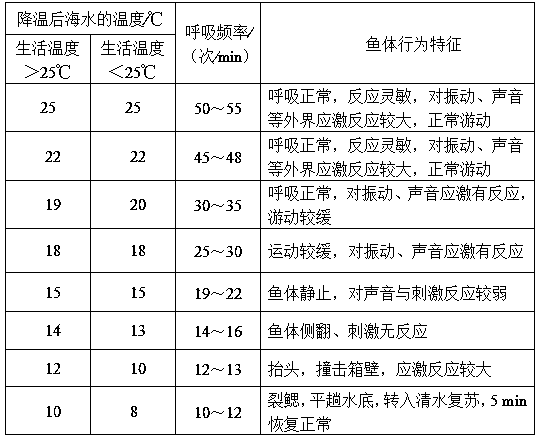

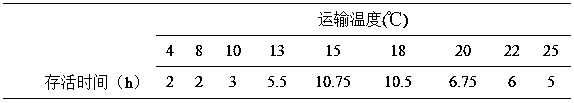

Method for waterless transportation of sea groupers

InactiveCN107853236ALower respiratory rateReduce transportation lossPisciculture and aquariaE-commerceOxygen

The invention provides a method for waterless transportation of sea groupers. The method comprises the following steps that S1, the live sea groupers are not fed and placed in seawater for temporary raising, and then the seawater is subjected to programmed cooling to a temperature of 13 to 14 DEG C; and S2, the seawater groupers treated with S1 are placed in an anhydrous alive-keeping bag having ahumidity of 90% or more, and the bag is filled with oxygen, then sealed and transported in a transport box at a temperature of 15 to 18 DEG C. The programmed cooling method in step S1 includes the steps that, when the seawater temperature is 20 DEG C or above, the cooling rate is 2-3 DEG C / h; when the seawater temperature is 15-20 DEG C, the cooling rate is 1-2 DEG C / h; and when the seawater temperature is below 15 DEG C, the cooling rate is 0.5-1 DEG C / h. The waterless transportation method is suitable for the development of the e-commerce logistics industry in modern cities, and achieves the direct transportation from the factory to the home. Compared with the water-containing transportation of groupers on the current market, the method greatly reduces the transportation cost and is conducive to the development of the grouper market.

Owner:GUANGDONG OCEAN UNIVERSITY

Six-freedom-degree heavy loading vehicle used for conveying and installing heavy components

ActiveCN106515544ATroubleshoot special installation issuesReduce construction costsVehicle to carry long loadsLoad securingVehicle frameRolling angle

The invention discloses a six-freedom-degree heavy loading vehicle used for conveying and installing heavy components. The six-freedom-degree heavy loading vehicle comprises a U-shaped vehicle frame and a bracket platform. The bracket platform is arranged on the U-shaped vehicle frame, and a travelling wheel mechanism is arranged at the bottom of the U-shaped vehicle frame. Y-axis translation mechanisms and XZ-plane rotary mechanisms are arranged on the bracket platform, Z-axis translation mechanisms are arranged between the bracket platform and the U-shaped vehicle frame, and X-axis translation mechanisms, XY-plane rotary mechanisms and YZ-plane rotary mechanisms are arranged on the U-shaped vehicle frame. According to the six-freedom-degree heavy loading vehicle used for conveying and installing the heavy components, multi-direction conveying can be conducted in the narrow space, and accurate positioning installation can be conducted under the circumstance of multi-dimension fine adjustment of X-axis translation, Y-axis translation, Z-axis translation, pitching angle, rotary angle and rolling angle; and compared with a traditional conveying vehicle of the same kind, more quick and accurate multi-angle conveying can be achieved, considerations of vehicle back up judgment and driving tracks are avoided, efficiency of conveying a bridge is greatly improved, conveying time is shortened, and social benefits are obvious.

Owner:SOUTH CHINA UNIV OF TECH

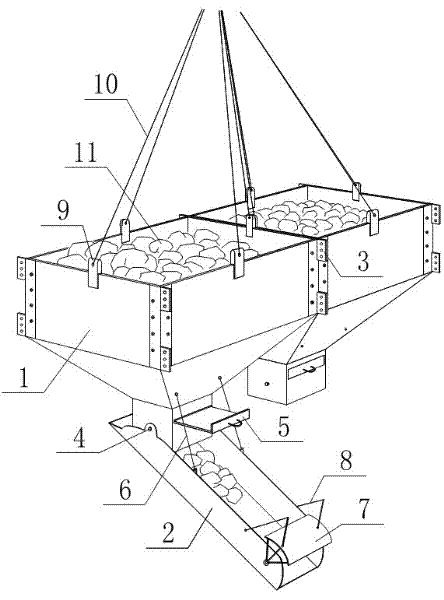

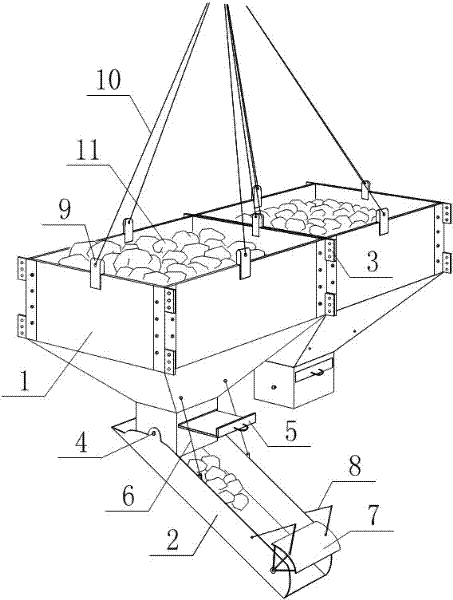

Construction device capable of blanking mixed materials of block-shaped waste concrete

ActiveCN102383604AImprove pouring efficiencySave shipping timeBuilding material handlingLifting capacityMixed materials

The invention discloses a construction device capable of blanking mixed materials of block-shaped waste concrete, which comprises a row type hopper, a chute and ear plates. Hoppers are connected through the ear plates to form the row type hopper, lugs are arranged at the upper portion of the row type hopper and connected with steel wire ropes of a lifting device, and a drawer type baffle is arranged at the lower portion of the row type hopper. The chute is connected with the bottom of the row type hopper in hanging mode through round hinges, the inclined angle of the chute can be changed through stretching out and drawing back of adjusting ropes, and the lower end of the chute is provided with a lifting type baffle to control the blanking. The block-shaped waste concrete or mixed materials formed by cast-in-place concrete and the block-shaped waste concrete are filled in the row type hopper, the number of the hoppers can be determined accordingly to casting requirements and lifting capacity, and casting materials are accurately conveyed to casting operation places through the construction device. The construction device capable of blanking the mixed materials of the block-shaped waste concrete is simple in structure, flexible in use, convenient in installation and dismounting, safe in operation, low in cost and capable of playing a positive role on operation of the project forpromoting the block-shaped waste concrete in large area.

Owner:SOUTH CHINA UNIV OF TECH

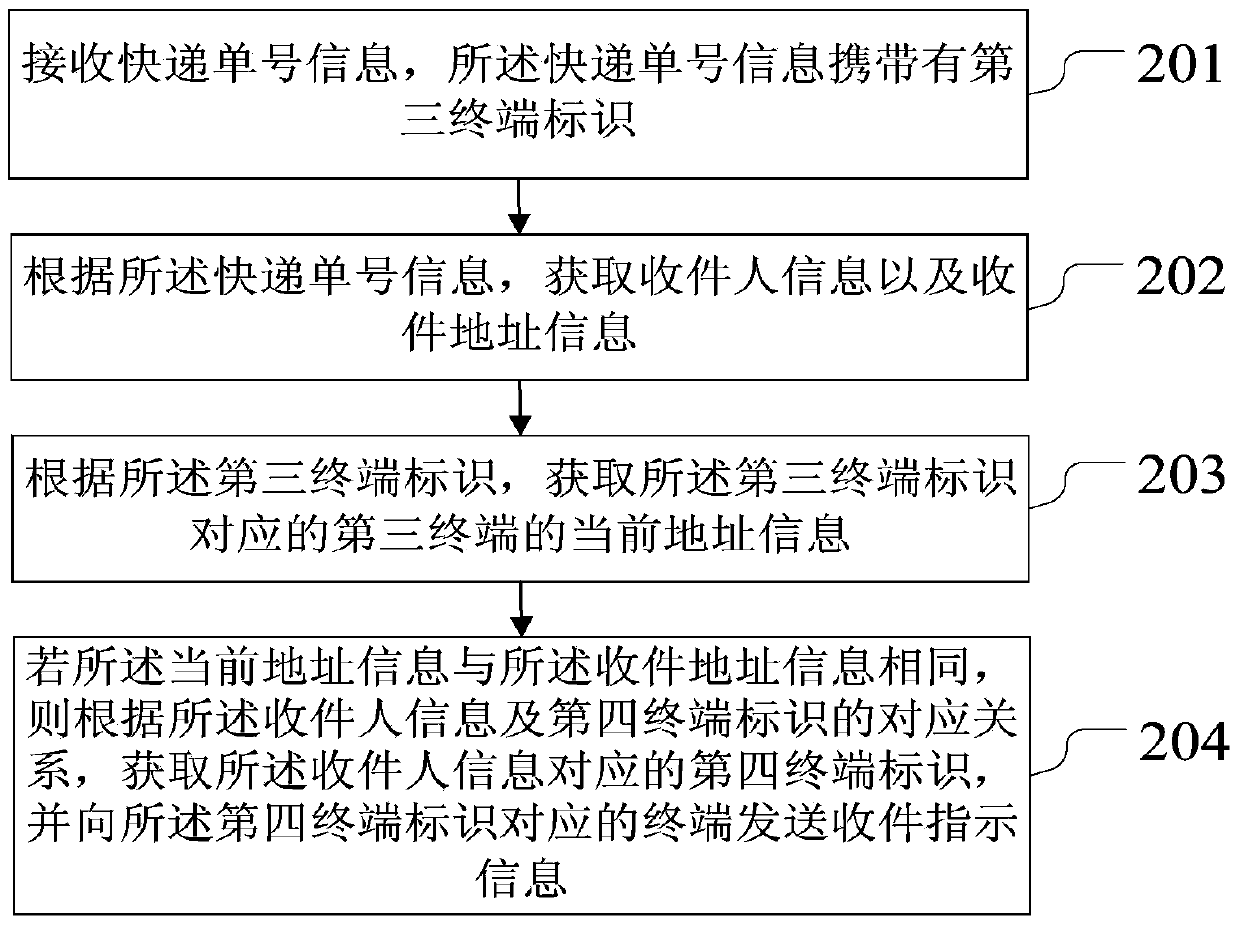

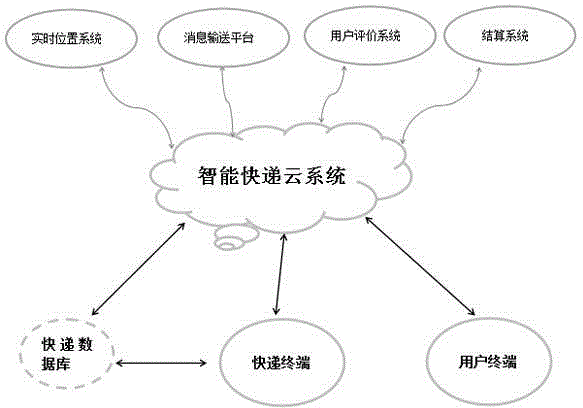

Intelligent express processing method and intelligent express cloud system

InactiveCN104951914ASave shipping timeImprove work efficiencyLogisticsReal-time computingFunctional module

The invention discloses an intelligent express processing method and an intelligent express cloud system implementing the method. The intelligent express cloud system comprises a user terminal, an express terminal, a real-time position system, a user evaluation system, a settlement system and a message transmission platform, the user terminal and the express terminal are connected with the intelligent express cloud system, an express database is placed in the intelligent express cloud system, and the express terminal and the user terminal are directly in communication connection with the real-time position system, the user evaluation system, the settlement system and the message transmission platform. Different from a traditional express receiving and delivering mode, delivering time is saved, the working efficiency of a courier is improved, the intelligent express cloud system has a price comparison function, corresponding prices can be automatically calculated according to the number of delivered goods and distances, and the goods can be sequentially arranged from high to low according to prices. The intelligent express cloud system is reasonable in system architecture, complete in functional module and wide in communication coverage.

Owner:章凯

Cleaning device for hardware product machining

InactiveCN107855308AShorten the timeImprove work efficiencyDrying solid materials without heatDrying gas arrangementsMotor driveCoupling

The invention discloses a cleaning device for processing five pieces of products, which comprises a cleaning box, both sides of the lower surface of the cleaning box are fixedly equipped with supporting legs, and a fixing plate is arranged inside the cleaning box, and both ends of the fixing plate are arranged There is a connecting shaft, a protective net is fixedly installed on the lower surface of the fixed plate, and a motor is fixedly installed on the right side plate of the cleaning box. The rotating shaft of the motor runs through the right side plate of the cleaning box and extends to the inside of the cleaning box. One end inside the box is connected with the connecting shaft at the right end of the fixed plate through a coupling. The invention uses the first water pump to flush the workpiece, which can quickly wash away the debris and oil stains on the surface of the workpiece, and then the motor drives the fixed plate to rotate to move the workpiece to the top of the inner cavity of the cleaning box, and then passes through the drying box. The workpiece is dried, and then the first electric telescopic plate and the second electric telescopic plate are opened, which can save a lot of time, thereby improving work efficiency.

Owner:无锡永锋科技有限公司

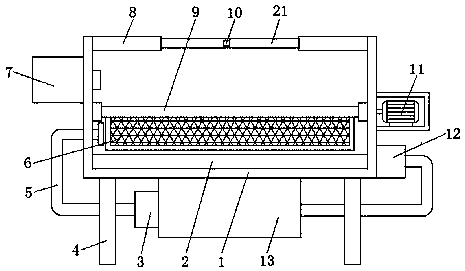

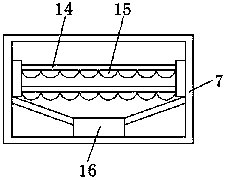

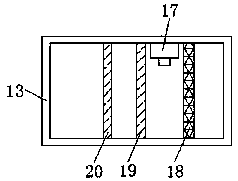

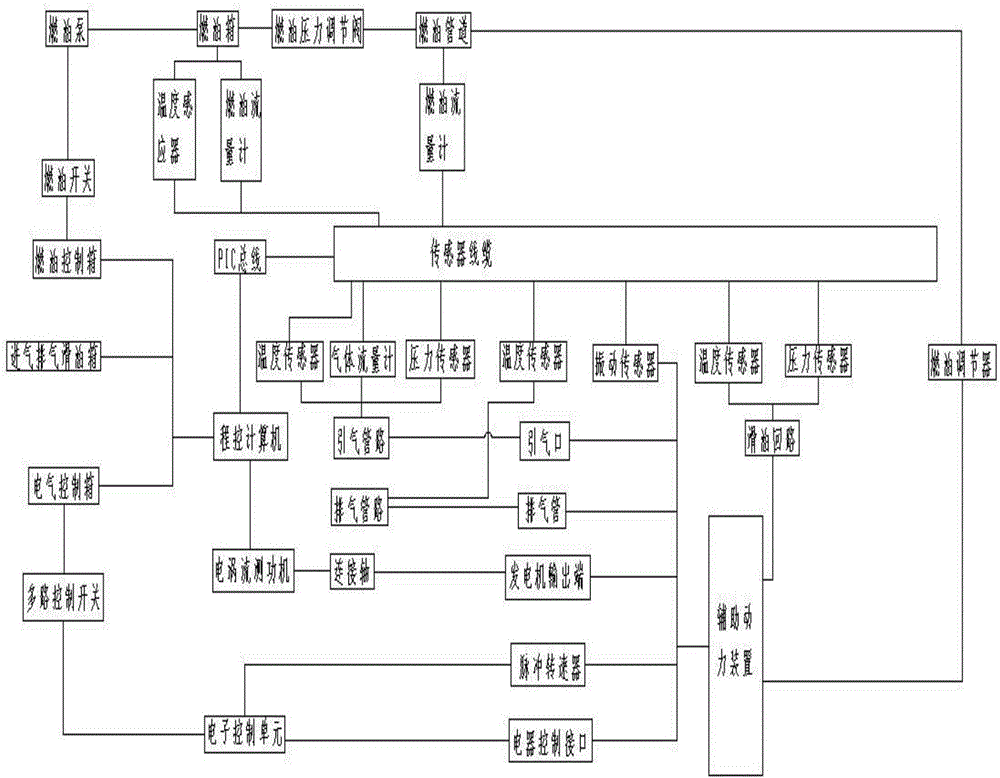

Testing system for aircraft auxiliary power unit

The invention discloses a testing system for an aircraft auxiliary power unit, which comprises a console, an electronic control unit, a fuel tank, a test bench, a vibration sensor, and an auxiliary power unit, wherein the console comprises a program control computer, an electric control box, a fuel control box and an air intake and exhaust oil tank; the test bench mainly comprises a mounting base, a dynamometer system, an exhaust pipeline and a bleeding pipeline; a temperature sensor, a pressure sensor and a gas flowmeter are arranged on the bleeding pipeline; the dynamometer system comprises an eddy current dynamometer and a connection shaft; and the eddy current dynamometer is connected with the auxiliary power unit via the connection shaft. Vacancy of domestic aircraft auxiliary power unit testing devices is remedied, the technology blockage in the field by oversea factories is broken, and the flight punctuality rate and the flight safety are ensured. Meanwhile, a large amount of transportation time and detection and maintenance costs are saved for airlines, the real-time performance and the accuracy of the test are ensured, and the labor intensity of a testing operator is lessened.

Owner:成都飞亚航空设备应用研究所有限公司

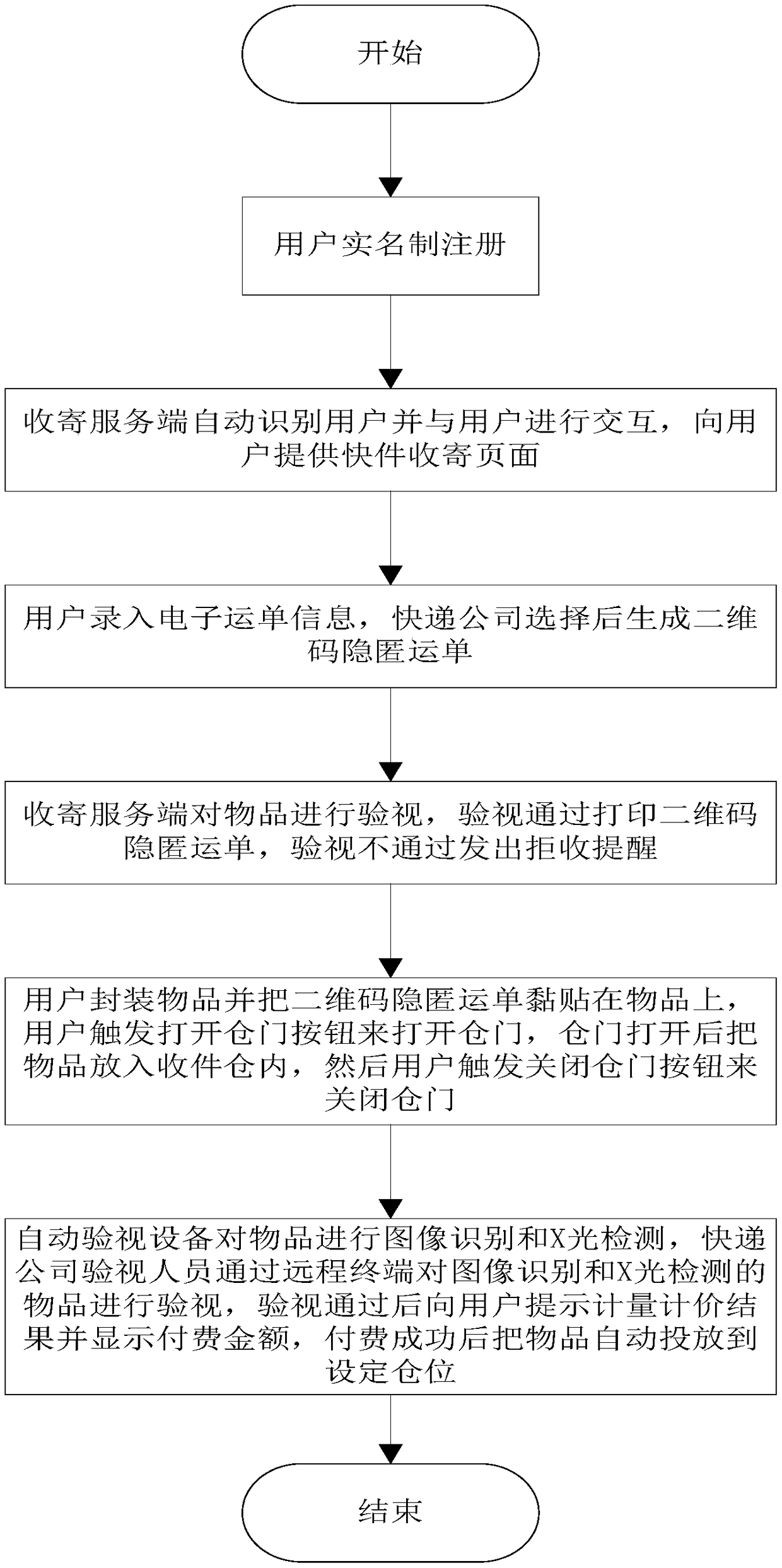

Method for safe self-service receiving and sending of expresses

The invention discloses a method for the safe self-service receiving and sending of expresses, and the method comprises the steps that a user carries out the real-name registration; a receiving and sending server actively recognizes the information of the user when the user completing the real-name registration carries out the self-service receiving and sending and delivery of expresses; the receiving and sending server carries out the voice interaction with the user, so as to remind the use of selecting a receiving and sending function; the user inputs the electronic waybill information intothe receiving and sending server, and selects an express company to generate and display a QR code hiding waybill; the receiving and sending server carries out the inspection of articles and allows the article to pass, and then the receiving and sending server prints the QR code hiding waybill for the user; the user packages the articles and then pastes the QR code hiding waybill; the user opens an express receiving cabin door and then puts the articles into an express receiving cabin, and closes the express receiving cabin door; an automatic inspection device in the express receiving cabin carries out the image recognition and X-ray detection of the articles, gives a prompt of a metering and pricing result and displays a to-be-paid amount; and the articles is put at a set cabin position after successful payment. The method saves a large amount of manpower, and reduces the operation cost.

Owner:王俊杰

Novel shopping electronic commerce platform integrating live video and entertainment

PendingCN105719170AIncrease purchase intentionIncrease salesAdvertisementsBuying/selling/leasing transactionsWeb siteThird party

The invention discloses a novel shopping electronic commerce platform integrating live video and entertainment and relates to electronic network business shopping platforms. The implementation processes are of establishing an overall framework of the whole shopping platform; adding 5H exhibition shows to a door opening wide video on the home page in a circulating manner; adding a 5H layout to home classification by using a small live video and inserting product advertisements; subdividing each region station in units of a city, adding local station stores and adding a 5H layout to the video; using a Linux mainstream operation system; operating an Apache server; adopting a PHP programming language on a website; and introducing a WOWZA or CC third-party video platform into the video and adopting a video shopping and local purchasing mode combining entertainment and consumption on the platform. According to the invention, transportation time is shortened; transportation cost is reduced; it is convenient for clients to go shopping; purchasing experience of the clients is improved; benefit of the clients and the stores is protected; and the platform is easy to promote and use.

Owner:苏汉东

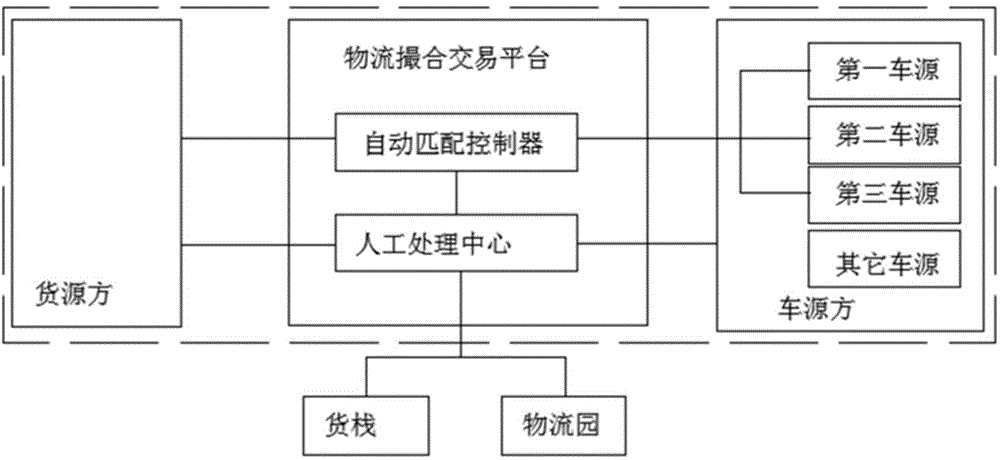

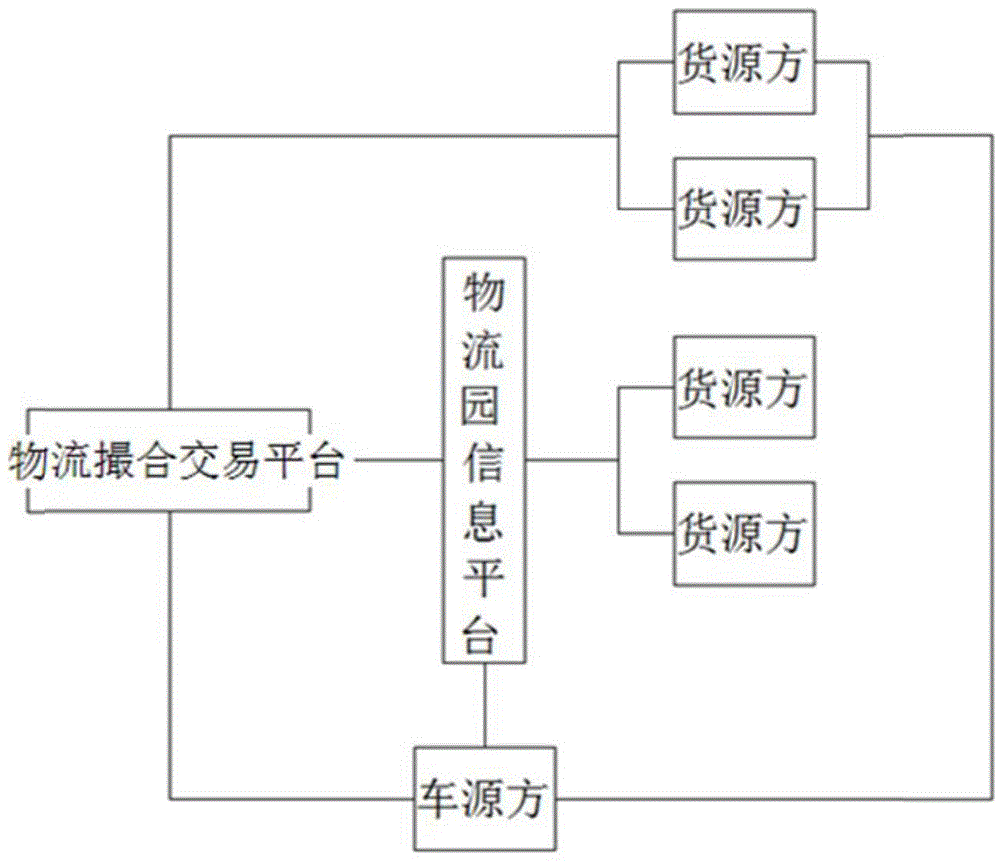

Intelligent logistics trading platform matching vehicle sources with goods sources

The invention provides an intelligent logistics trading platform matching vehicle sources with goods sources. The intelligent logistics trading platform matching the vehicle sources with the goods sources comprises a vehicle source side, a goods source side and a logistics matching trading platform, wherein the logistics matching trading platform is connected to the vehicle source side and the goods source side respectively. The logistics matching trading platform comprises an automatic matching controller and a manual processing center. The vehicle source side comprises a first vehicle source, a second vehicle source, a third vehicle source and other vehicle sources. The goods source side is respectively connected to the automatic matching controller and the manual processing center. Both the automatic matching controller and the manual processing centers are connected to the vehicle source side. The manual processing center is connected to the automatic matching controller through a visual interface or an information network. According to the intelligent logistics trading platform matching the vehicle sources with the goods sources, the vehicle sources and the goods sources can be fully matched, resources are saved, and the problems of monitoring safety and early warning road congestion in a logistics process are solved.

Owner:天津正易物通网络科技有限公司

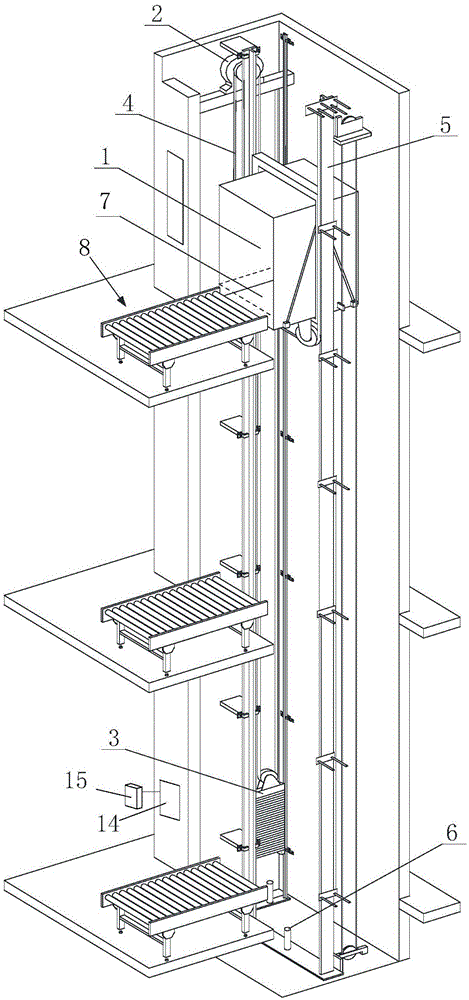

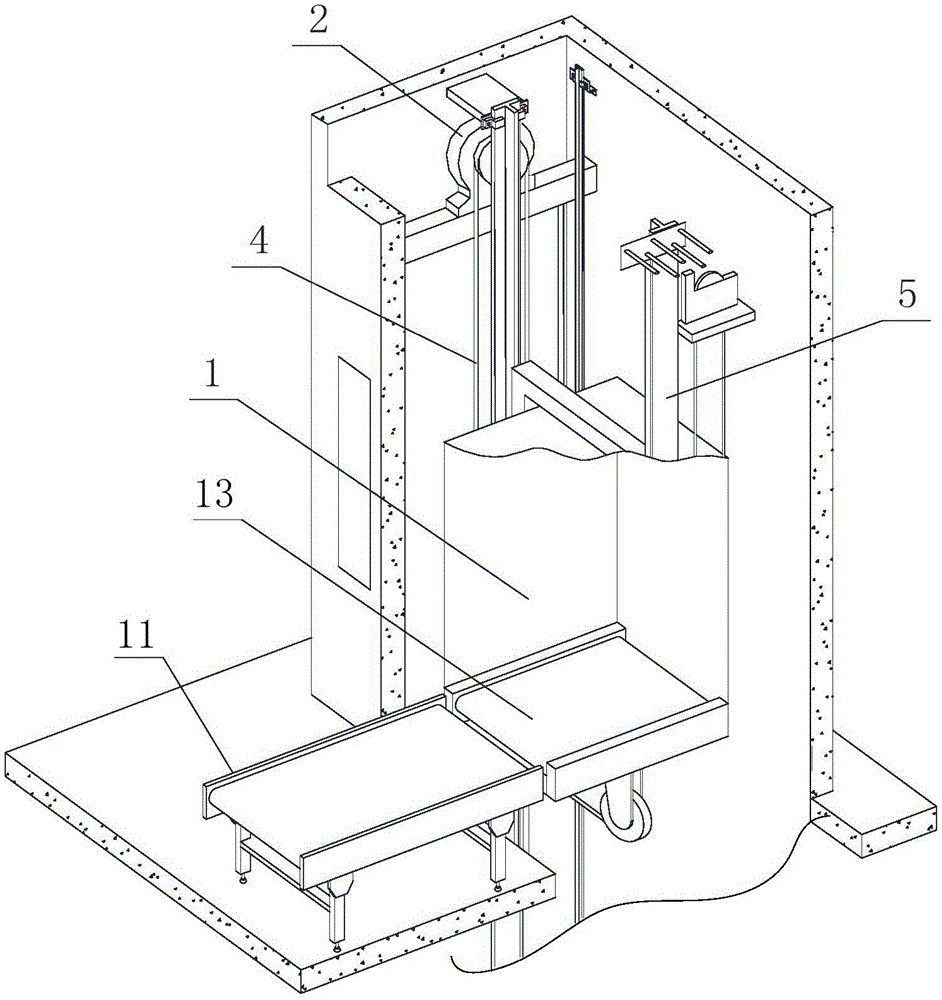

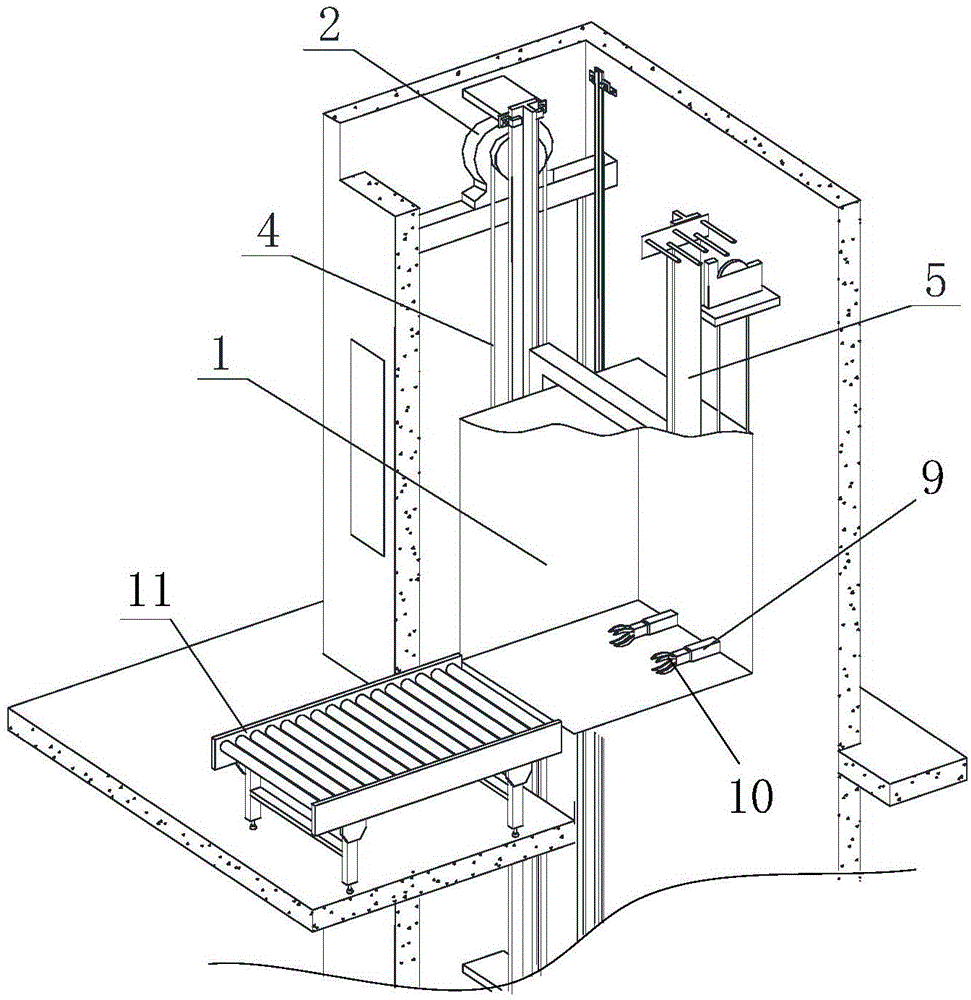

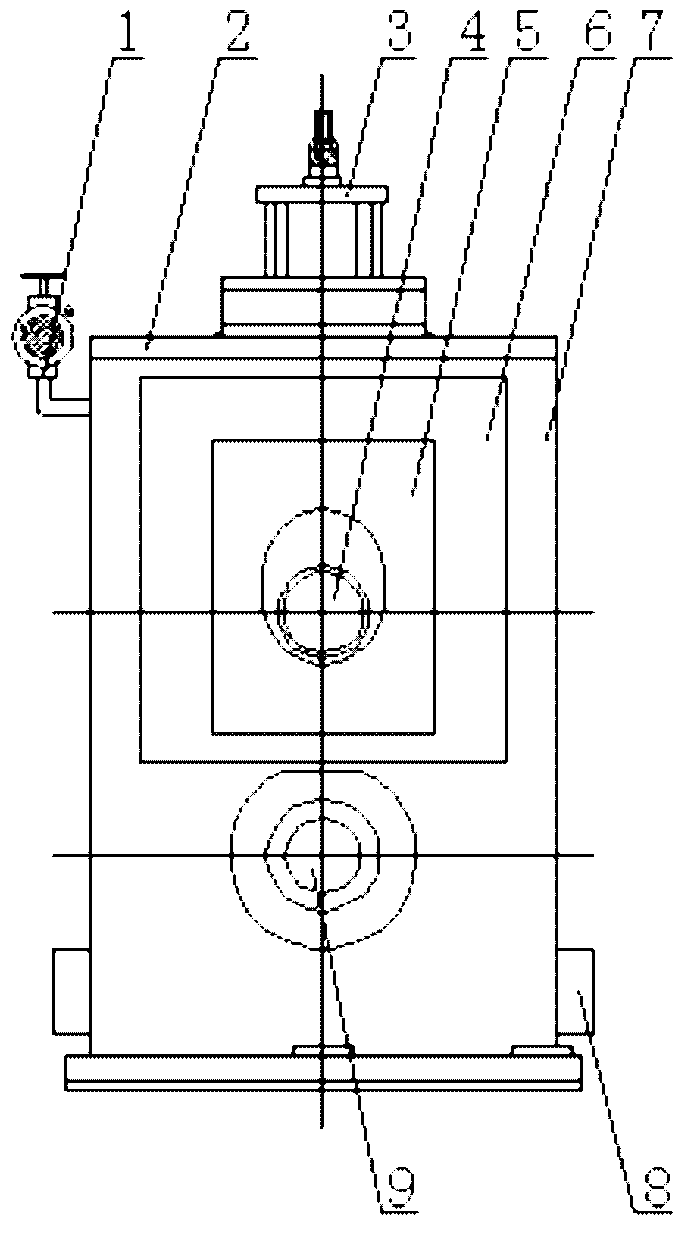

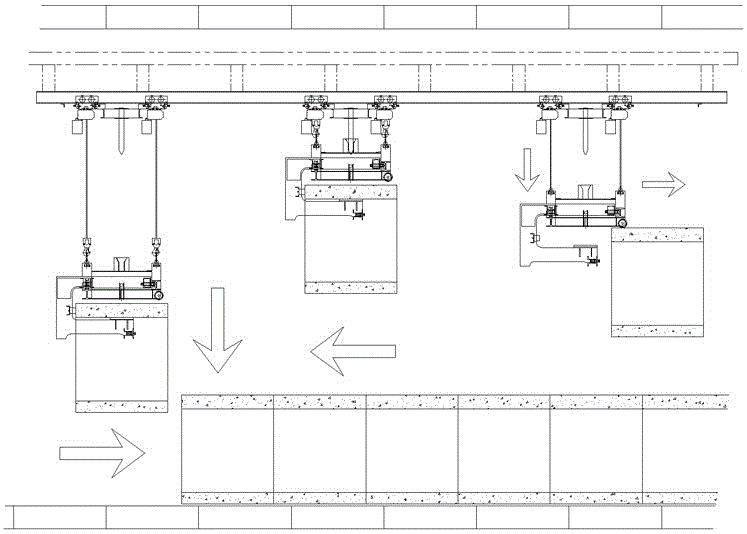

Medical dragging type vertical sorting machine with horizontal transporting function

InactiveCN106429281AFulfill transportation needsTransportation is fully automated and fastMechanical conveyorsLogistics managementEngineering

The invention relates to a medical dragging type vertical sorting machine with a horizontal transporting function. The medical dragging type vertical sorting machine comprises a sorting machine body provided with a lift car; and the medical dragging type vertical sorting machine is characterized in that an internal horizontal transporting device is arranged in the lift car, and external horizontal transporting devices are arranged at the positions, corresponding to the internal horizontal transporting device, of an outlet and an inlet of the lift car. In this way, the transportation demand of materials formed by multiple medical objects such as boxes, medicine chests and bagged medicines in all floors in the vertical direction and the horizontal direction can be met. Meanwhile, full-process automation and rapid transportation can be achieved, and manpower-free carrying is achieved to the maximum degree. More importantly, a dragging drive type lifter is adopted, and the characteristics of being low in energy consumption, high in speed, stable in running, low in noise and free of limitation in lifting height as for human buildings are achieved; and in addition, control is achieved in cooperation with a code scanning manner, the transmission route is optimized, and the transportation time is further saved. As the better using effect is achieved, so that the medical dragging type vertical sorting machine can be applied to the medical field and can also be applied to other logistics transportation fields.

Owner:ESSENIOT INTELLIGENT MEDICAL EQUIP SUZHOU LTD INC

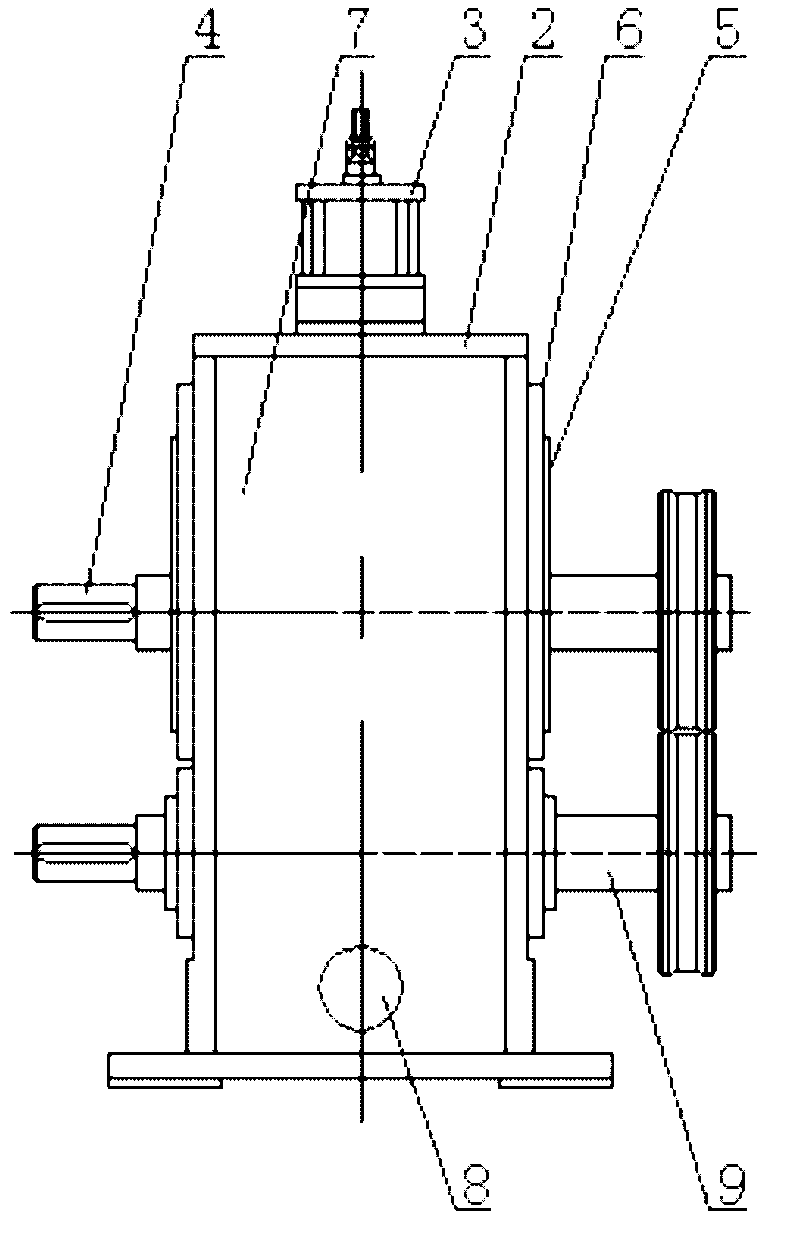

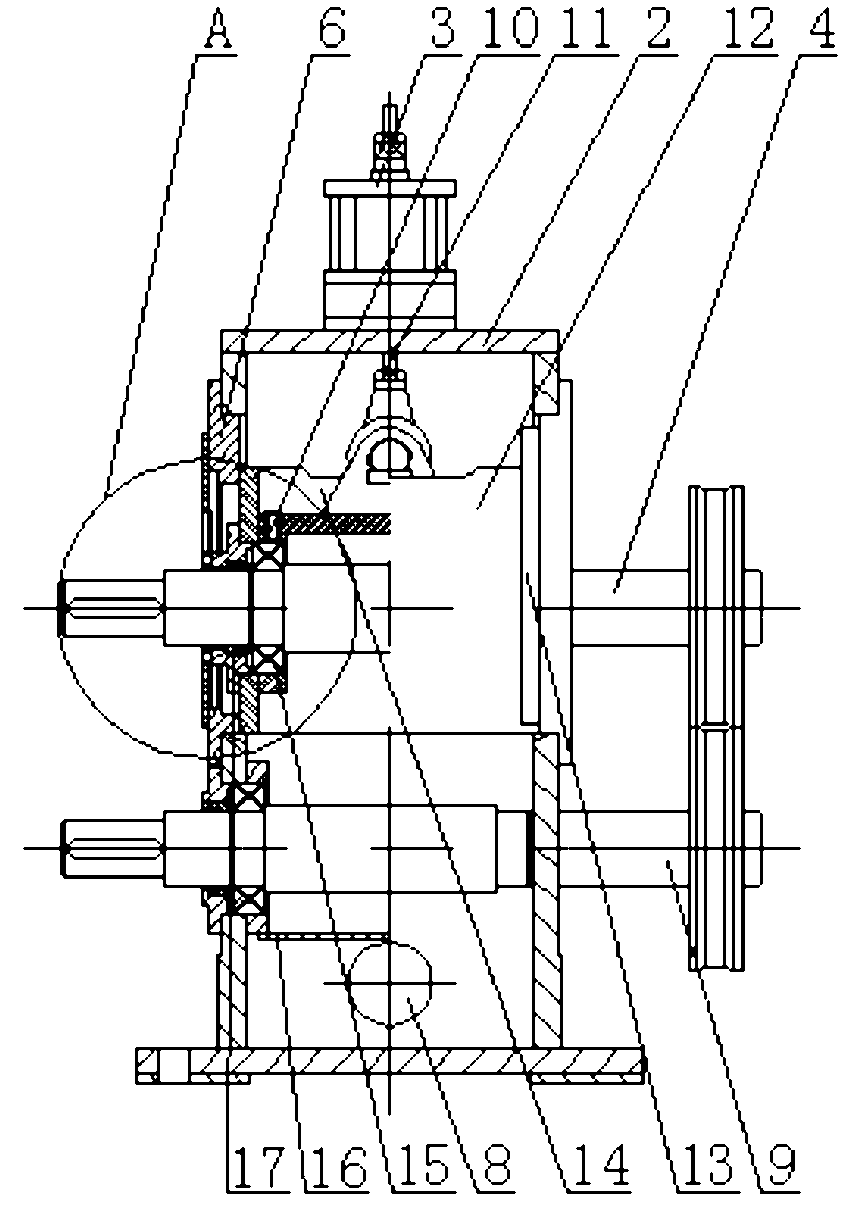

Clamping and conveying device for conveying steel bars

InactiveCN102319822ASave shipping timeImprove transportation efficiencyMetal-working feeding devicesPositioning devicesEngineeringRebar

The invention relates to a clamping and conveying device for conveying steel bars. The device comprises a main box, a secondary box, an upper roller, a lower roller and a cylinder, wherein the secondary box is glidingly arranged in the main box at the upper part of the lower roller; the secondary box is driven by the cylinder fixedly arranged at the top of the main box; the main box at two ends of the upper roller is provided with symmetrical end covers respectively; each end cover is provided with an upper roller sliding hole and an oil return baffle plate; the lower part of the oil return baffle plate is provided with an oil return oil; an oil baffle cover plate is fixedly arranged at the outer side of the end cover; the oil baffle cover plate is provided with a cover plate through holecorresponding to the upper roller sliding hole; and a dustproof oil baffle cover is fixedly arranged on the upper roller bearing end cover between the oil baffle cover plate and the oil return baffleplate. The device has compact structure, scientific and reasonable design, low manufacturing cost, small volume and high clamping accuracy, and can adapt to the steel bars of different specifications; the lubricating mode is circulating oil reinforced lubrication; and the device is reliable in sealing and high in transport velocity, improves the production efficiency of the steel bars, prolongs the service life of the steel bars, and is safe and reliable.

Owner:王丽燕

Expressway intelligent operation system through coordination of automobiles and pathways and using method

The invention discloses an expressway intelligent operation system through coordination of automobiles and pathways and a using method. The system comprises two pathways which are arranged at the ascending side and the descending side of an expressway in the same direction, and at least one veering rail is connected between the pathways at the two sides, the veering rail is communicated with the pathways, and the system further comprises transportation carts which can load automobiles and run on the pathways, control panels, control chips, locating devices, and a central running system, wherein the control panels, control chips, and locating devices are arranged on the corresponding transportation carts, and the central running system is used for regulating and controlling all the transportation carts. Through the method of combining the automobiles with the pathways, the purpose of conducting door-to-door transportation can be achieved, and the transportation time is saved; the central running system is utilized to intelligently regulate and control all the transportation carts, and thus unmanned driving is achieved; after getting rest in one transportation cart and getting off the transportation cart, a driver keeps a better mental state to drive on a common expressway, and thus an car accident caused by fatigue driving is avoided; it is guaranteed that green-hand drivers can be helped to safely drive on the expressway.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

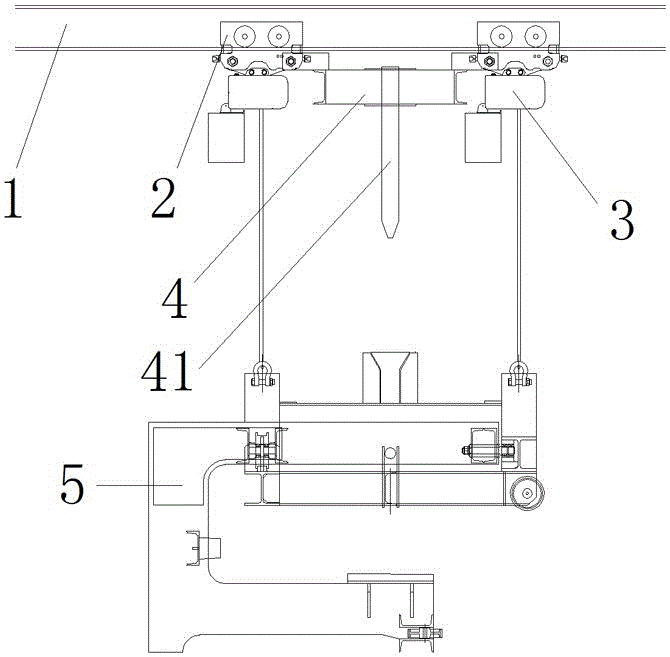

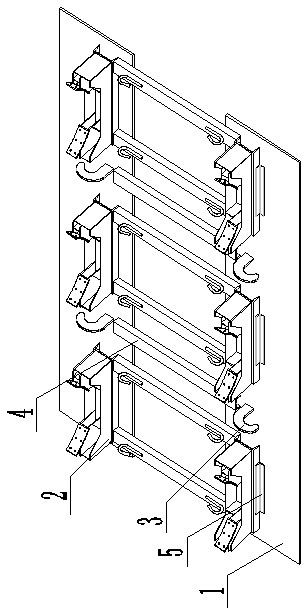

Road element crane used for shield tunneling machine synchronous box culvert construction

ActiveCN106761856AEasy to installShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringShield tunneling

The invention relates to a road element crane used for shield tunneling machine synchronous box culvert construction. The road element crane comprises a crane traveling beam, traveling trolleys, lifting devices, a positioning support and a box culvert bracket. The two sets of traveling trolleys are arranged on the crane traveling beam and connected through the positioning support. The box culvert bracket is connected with the traveling trolleys through the lifting devices and is of a U-shaped structure. By adoption of the structure, box culverts can be mounted while a shield tunneling machine performs tunneling, and accessories of the box culverts are easy to mount; and meanwhile, mounting of the accessories is not limited to the mounting speed of the box culverts any more, the construction period of the whole project is greatly shortened, and the efficiency is improved.

Owner:XCMG KAIGONG HEAVY IND NANJING

Locomotive steering frame transportation base for railways

ActiveCN102424186ASimple structurePractical and convenientPackaging vehiclesContainers for machinesBogieMode of transport

The invention relates to the technical field of a base, in particular to a locomotive steering frame transportation base for railways, which comprises a bottom plate, wheel pair transportation devices, hanging hooks, first long channel steel and angle steel, wherein three wheel pair transportation devices are arranged on the bottom plate, two hanging hooks are arranged among the wheel pair transportation devices, the first long channel steel is arranged between the hanging hooks, and two sides of the wheel pair transportation devices are fixed on the bottom plate through the corner steel. The locomotive steering frame transportation base for railways has the advantages that the structure is simple, practical and convenient, the steel frame transportation adopts the railway transportation mode, the safety and the reliability are improved, and higher speed and greater convenience are realized. Compared with the original transportation mode, the locomotive steering frame transportation base for railways has the advantages that the cost is saved by 40 percent to the furthest degree, the transportation cost is greatly reduced, simultaneously, the transportation time is reduced, the transportation efficiency is improved, and the application and the popularization are favorably realized.

Owner:CRRC QISHUYAN CO LTD

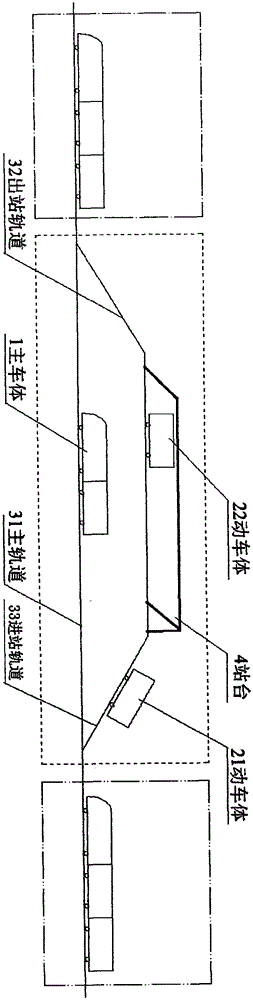

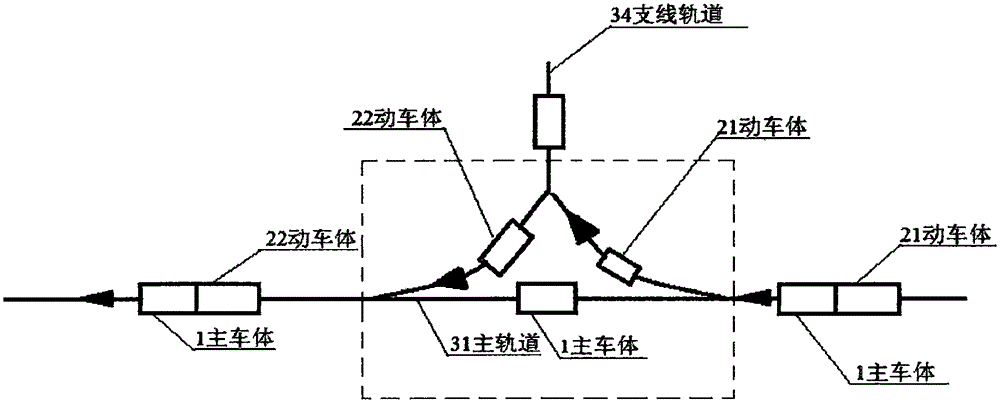

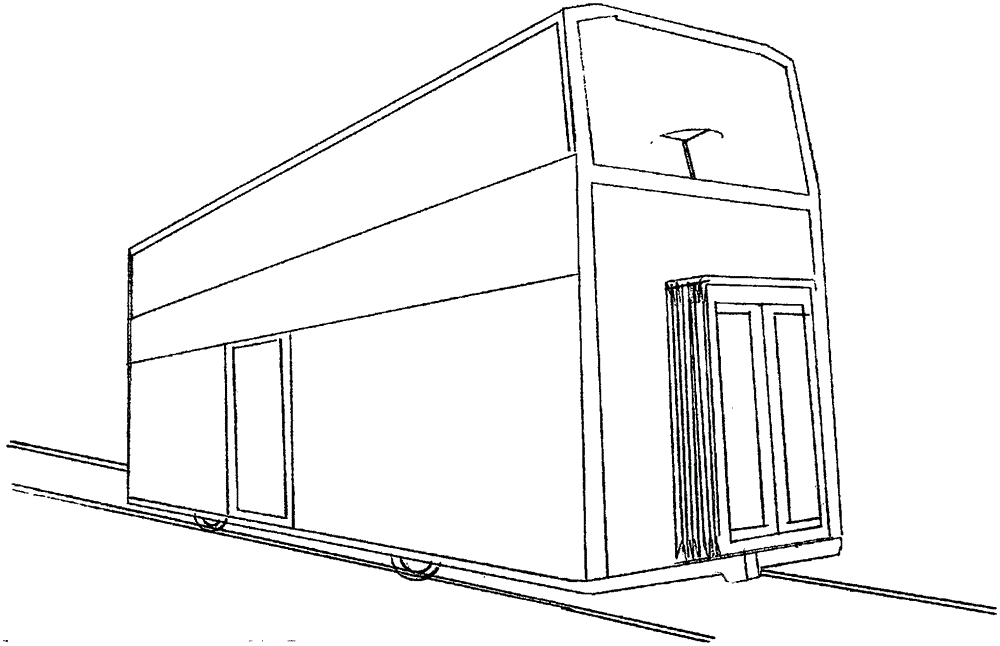

Docking type rail transit system and operation method thereof

InactiveCN105292132AWaste less timeImprove overall work efficiencyRailway componentsRailway stationTransit timeAutomotive engineering

The invention provides a docking type rail transit system and an operation method thereof. The docking type rail transit system comprises a main train body, a moving train body and a track, wherein the main train body and the moving train body are both track type train sets and move on the track; the main train body is connected with the moving train body through a connecting ring; the main train body and the moving train body can be electrically controlled to realize hard connection or disconnection; and doors for passengers to get on and off the trains are arranged on both left and right sides of the main train body and the moving train body in an advancing direction. According to the invention, the passengers can get on and off the train through the moving train body without stopping the main train body so that the time is saved for the passengers; and meanwhile, the train braking opportunity is reduced so that energy waste is reduced and the utilization rate of the energy is increased. According to the invention, the number of small stations of the train running route can be integrally reduced, economic expenditures of the passengers are reduced, the local economic benefits are increased, the traditional transportation cost is reduced, and the transportation time is also reduced. The docking type rail transit system provided by the invention has the advantages of immeasurable economic values and wide application range; and a technical problem of high cost is solved from the perspective of low cost.

Owner:邸本健

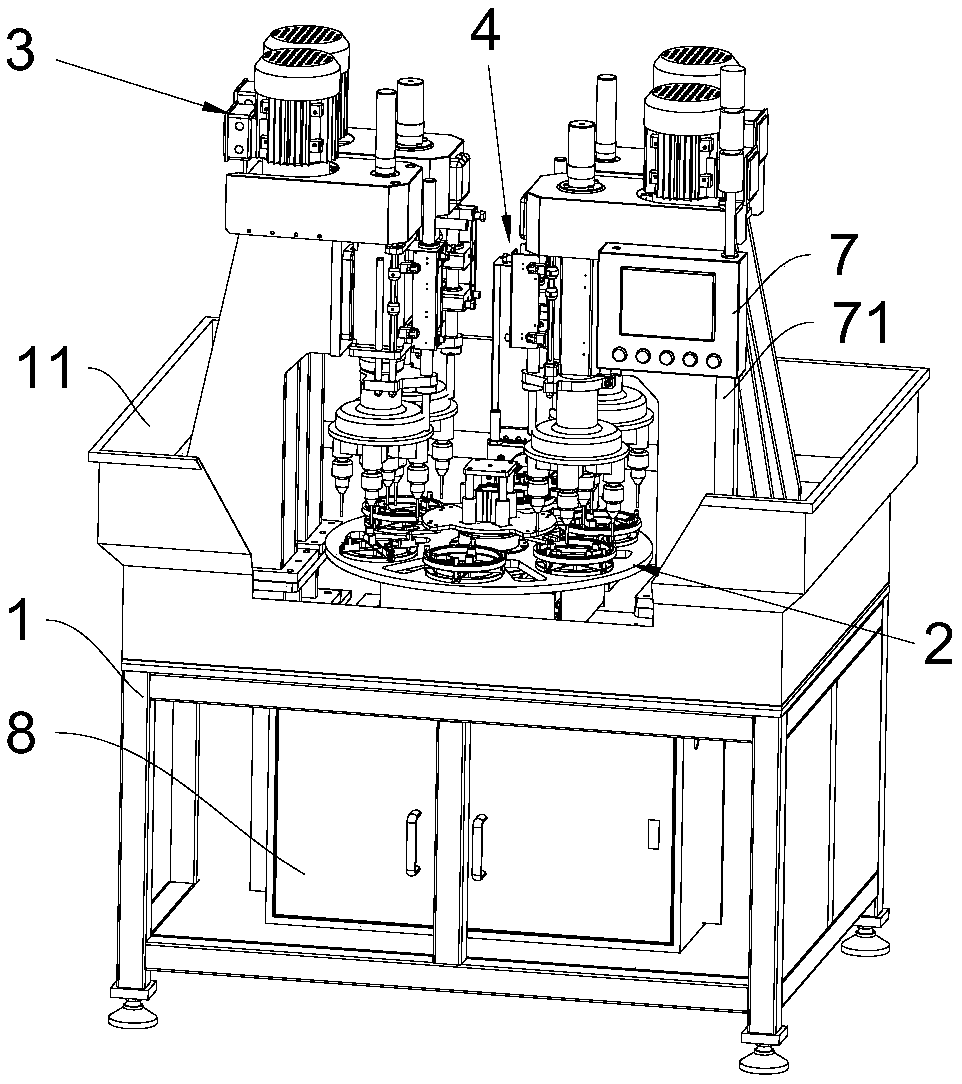

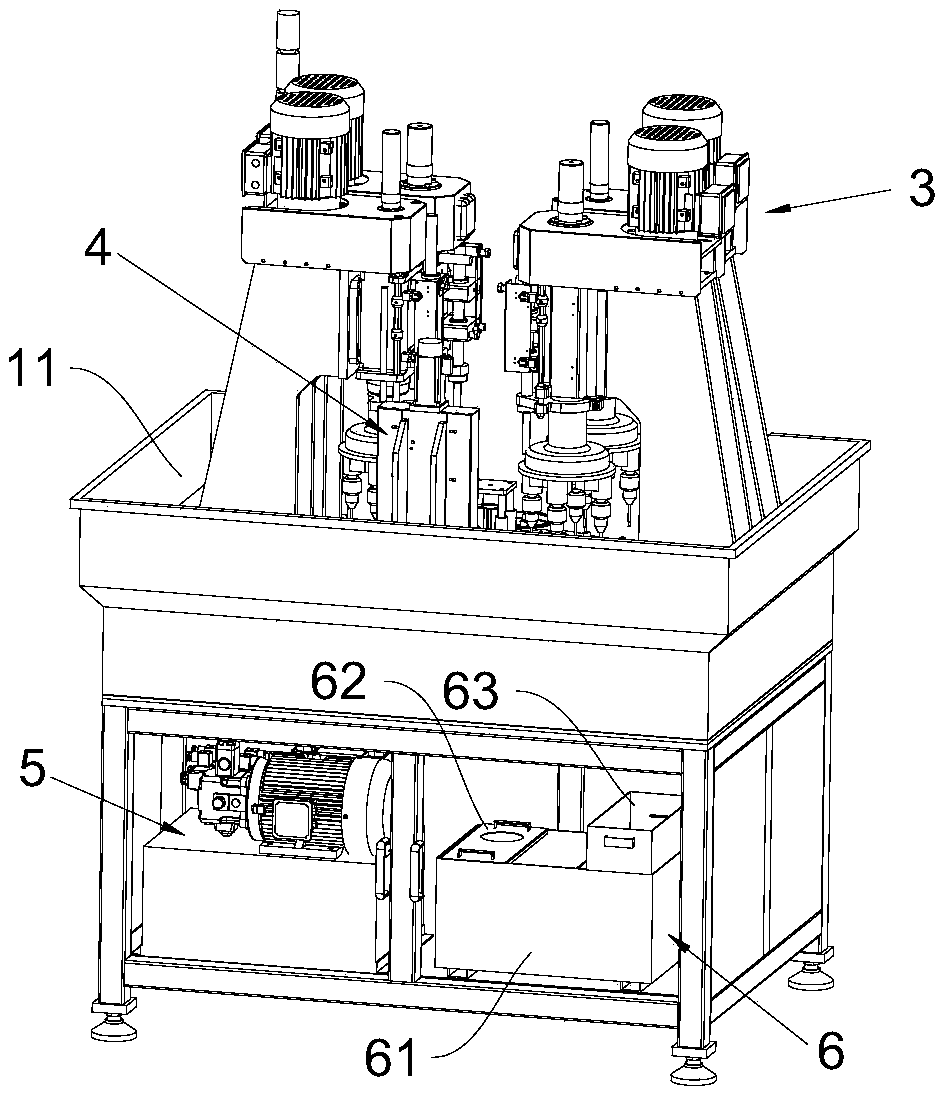

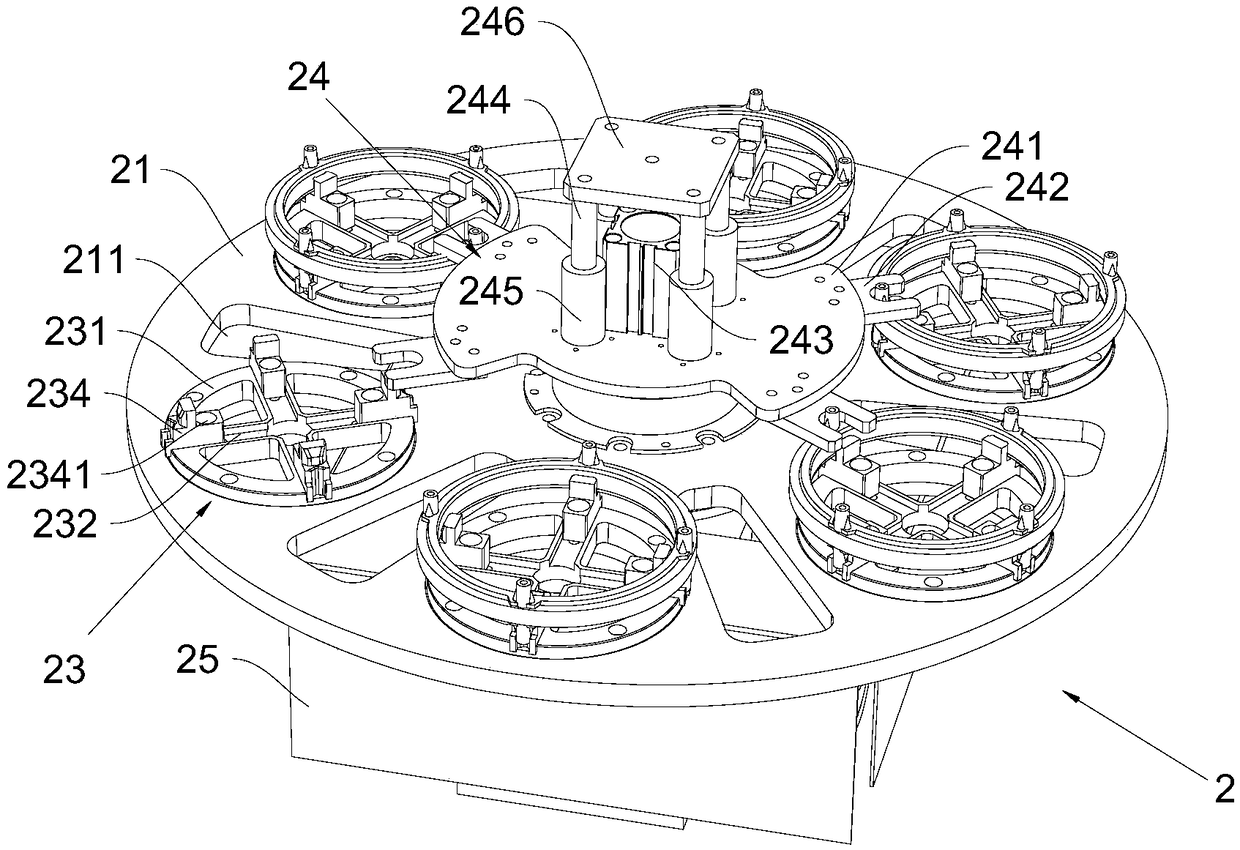

Drilling-tapping all-in-one machine

PendingCN109454457AReduce dependenceImprove processing efficiencyPrecision positioning equipmentOther manufacturing equipments/toolsTransport timeWorking environment

The invention provides a drilling-tapping all-in-one machine which solves the problem that an existing motor ring processing process is complex. According to the technical scheme, the key point is that the drilling-tapping all-in-one machine comprises a rack and an oil supply system, wherein an indexing positioning device which is rotatably connected with the rack is arranged on the rack; a turnover device for turning over workpieces is arranged on the rack; processing devices are arranged on the positions, at the two sides of the turnover device, of the rack; and each processing device comprises a drilling device and a tapping device. The indexing positioning device, the processing devices and the turnover device are arranged on the rack, so that the workpieces are transported to each station through the indexing positioning device, one workpieces is clamped once and processing of positive and negative surfaces is accomplished, multi-time calibration is not needed, processing time isshortened, and processing efficiency is improved; and moreover, the turnover device can automatically turn over the workpiece, equipment processing speed is increased, transportation time is saved, workpiece collision is avoided, working environment of a worker is improved, working strength is reduced, fatigue of the worker is reduced, and processing quality of the workpiece is guaranteed.

Owner:广东顶固集创家居股份有限公司

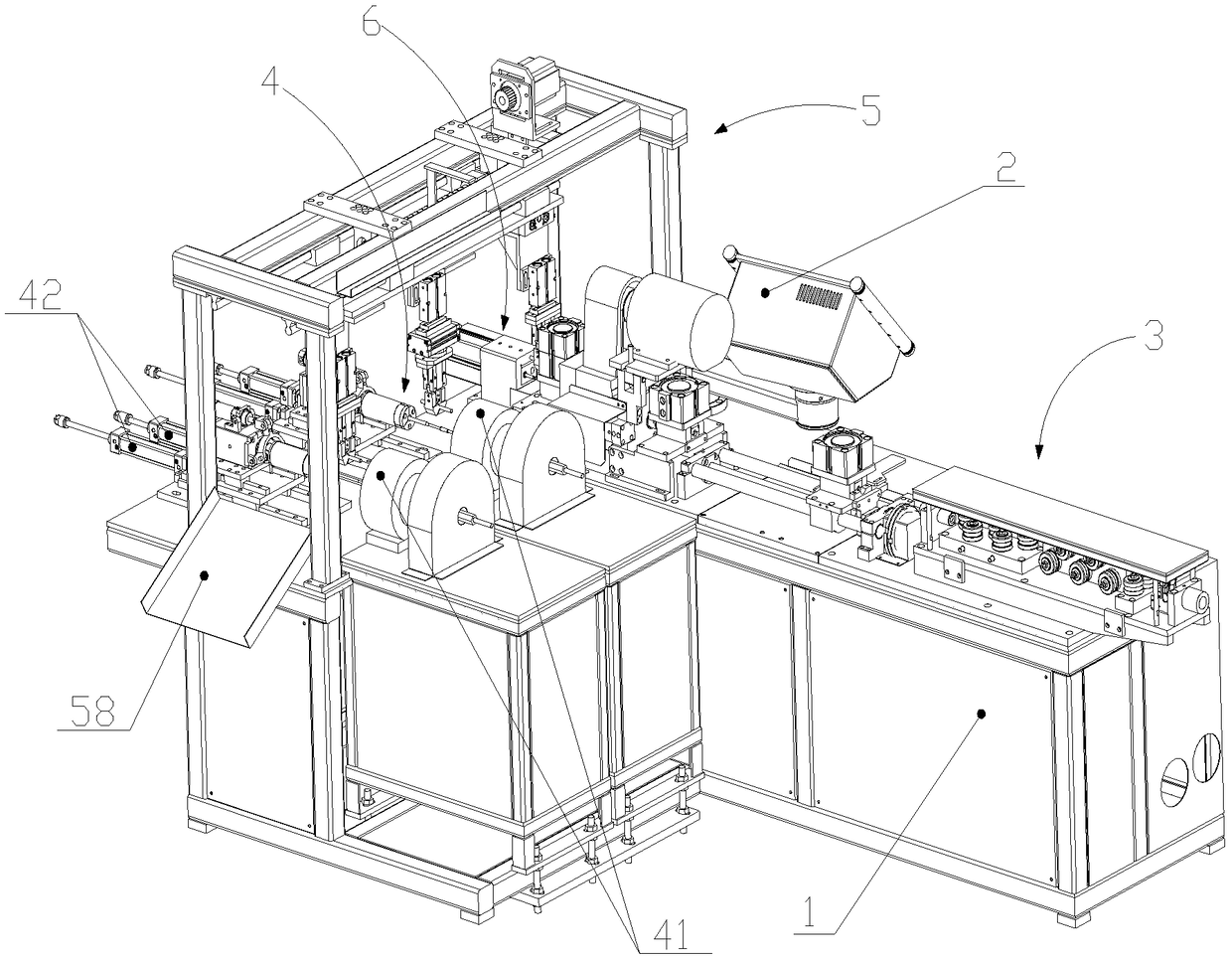

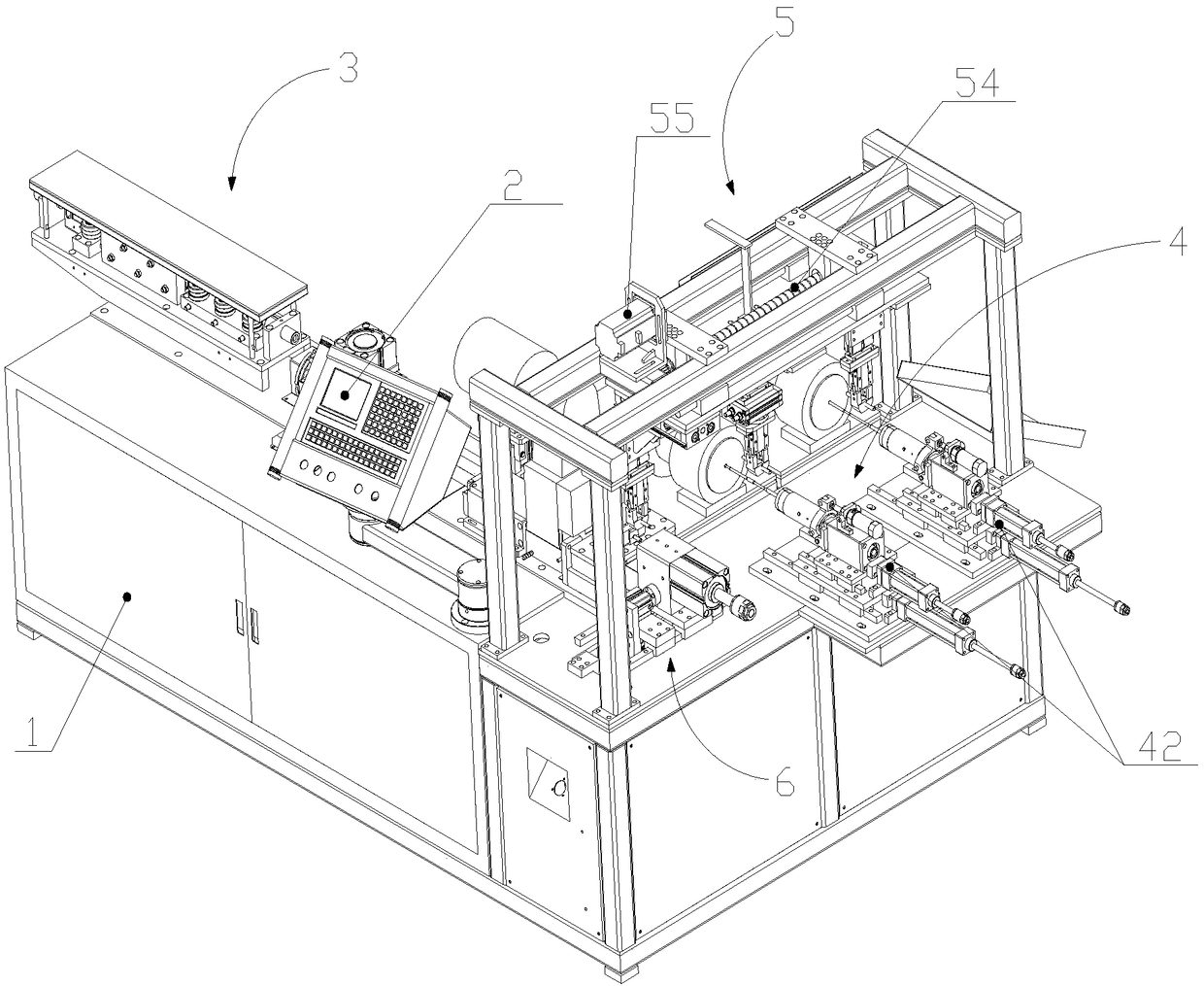

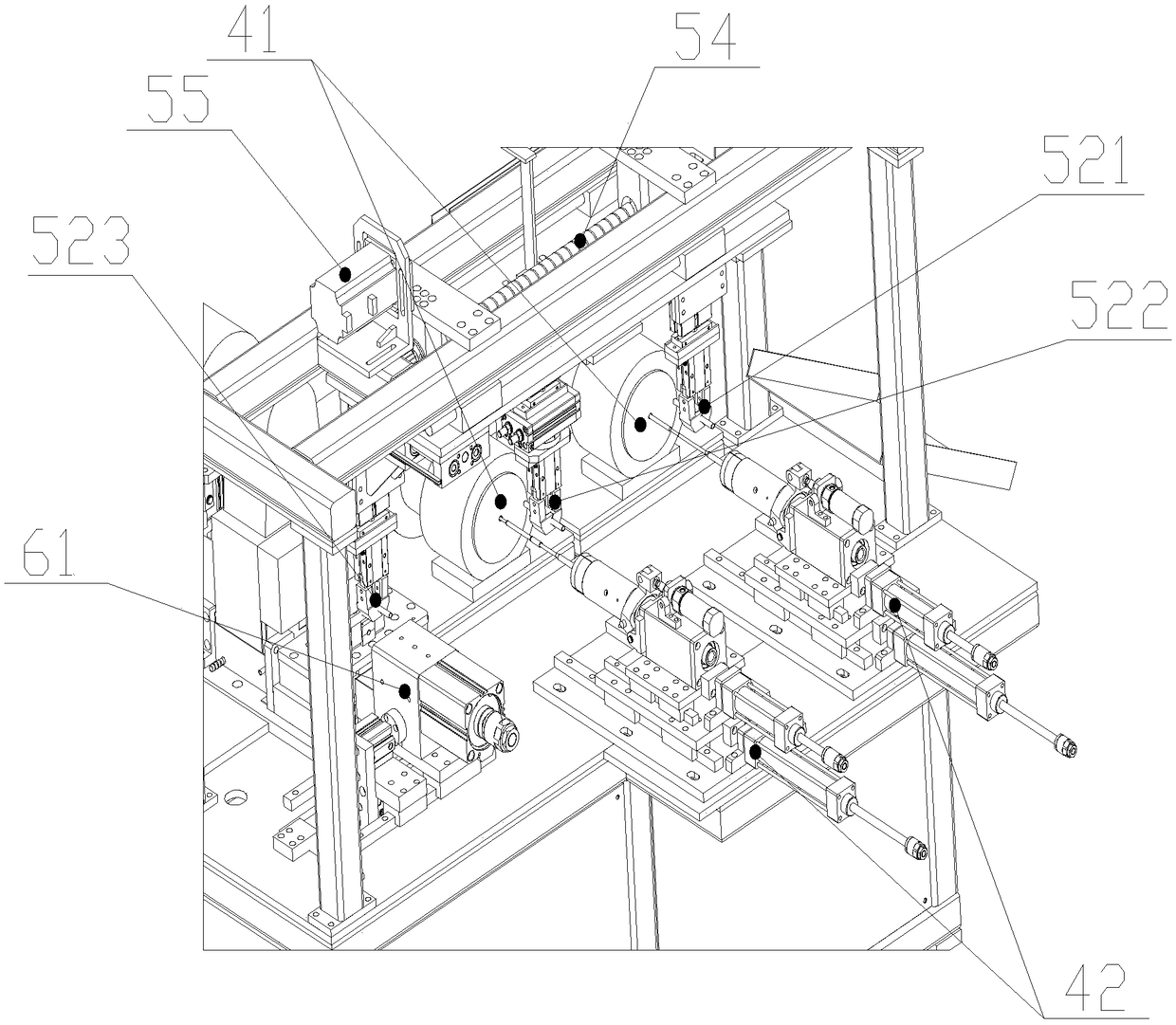

Copper pipe automatic cutting and double-end pipe end processing equipment

PendingCN109366188ASimple structureReasonable designOther manufacturing equipments/toolsEngineeringPipe fitting

The invention discloses copper pipe automatic cutting and double-end pipe end processing equipment comprising a machine table and a controller. The machine table is provided with a cutting device, anopening shrinking device and a transverse movement device; the cutting device is used for conducting straightness and roundness correction on a copper pipe and conducting cutting according to the setspecification to form a pipe fitting to be processed; the opening shrinking device is arranged on one side of the cutting device and is used for conducting opening shrinking machining on the head endsof the pipe fitting; and the transverse movement device is used for clamping the pipe fitting and transferring the pipe fitting from the cutting device to the opening shrinking device. The copper pipe automatic cutting and double-end pipe end processing equipment in the above technical scheme is simple in structure, reasonable in design, high in efficiency, high in safety factor and high in accuracy, the depth accuracy of the pipe ends can be ensured, the problem that the hand is scalded is well solved, the time for transporting materials is saved due to the fact that cutting and pipe end assembling are carried out on the same machine, and the work efficiency is improved.

Owner:彭华斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com