Road element crane used for shield tunneling machine synchronous box culvert construction

A technology of shield machine and box culvert, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., which can solve the problems of time-consuming and labor-intensive, longer transportation distance, and low construction efficiency, so as to expand transportation channels, reduce construction period, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

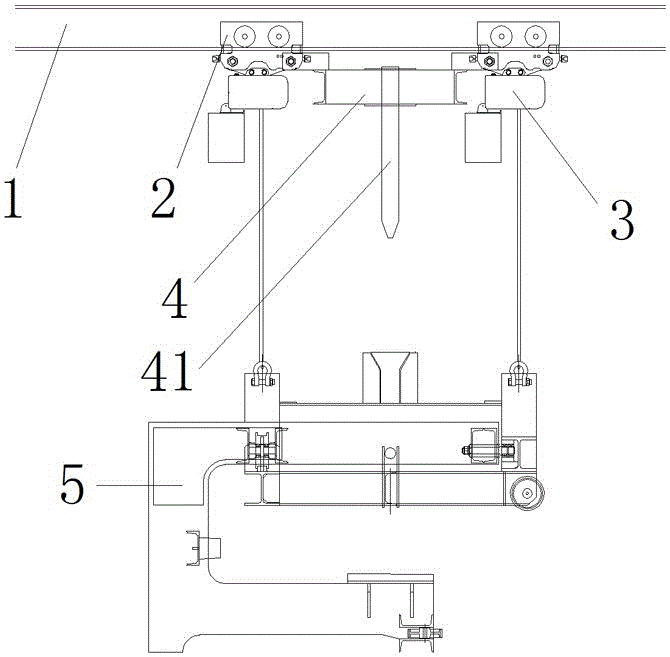

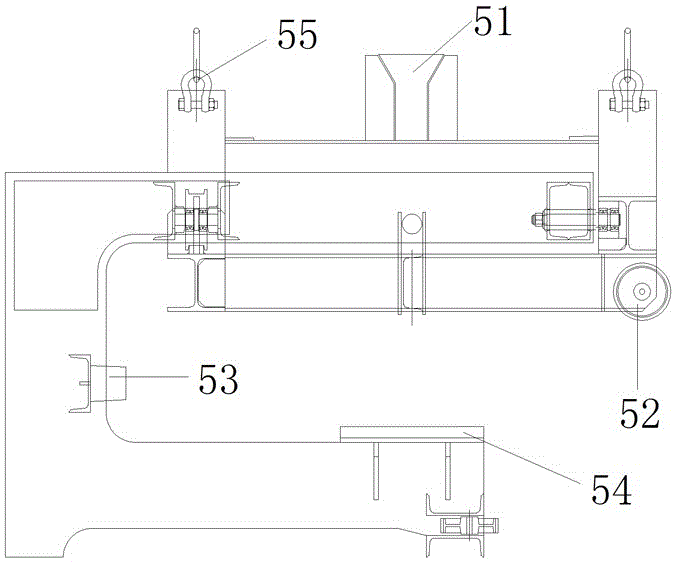

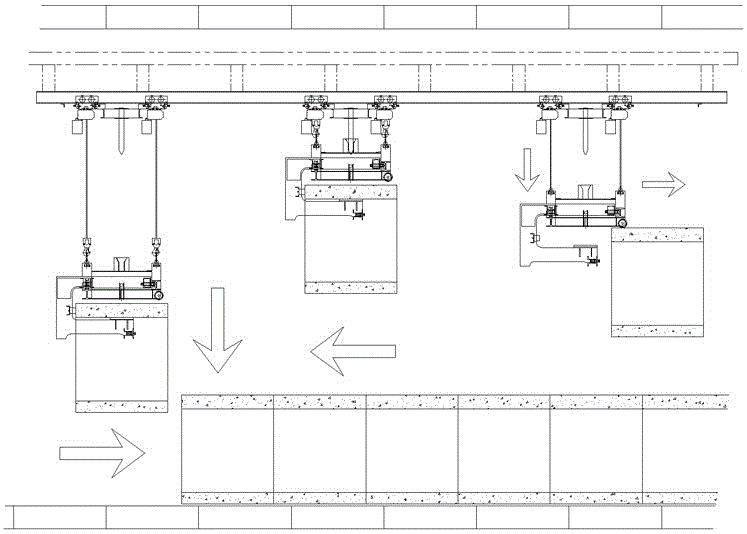

[0019] combine Figure 1-Figure 4 , an embodiment of the present invention is as follows: a box culvert crane for shield machine synchronous box culvert construction, including crane walking beam 1, walking trolley 2, lifting device 3, positioning bracket 4 and box culvert bracket 5 , there are two groups of walking trolleys 2, which are arranged on the crane walking beam 1, and the two walking trolleys are connected through the positioning bracket 4, and the box culvert bracket 5 is connected with the walking trolley 2 through the lifting device 3, and the box culvert bracket 5 is U type structure.

[0020] When using the present invention, a beam structure is added at the position of the supporting trailer behind the shield machine, so as to install two walking beams required for the walking of the box culvert crane. Two groups of walking trolleys 2 are connected together by positioning brackets 4 , each group on the left and right sides. The box culvert is transported by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com