Intelligent scheduling system based on multi-station AGV and scheduling method thereof

An intelligent scheduling, multi-station technology, applied in data processing applications, forecasting, instruments, etc., can solve problems such as the inability of the AGV system to guarantee, and achieve the effect of reducing the empty running rate, improving the loading and unloading efficiency, and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

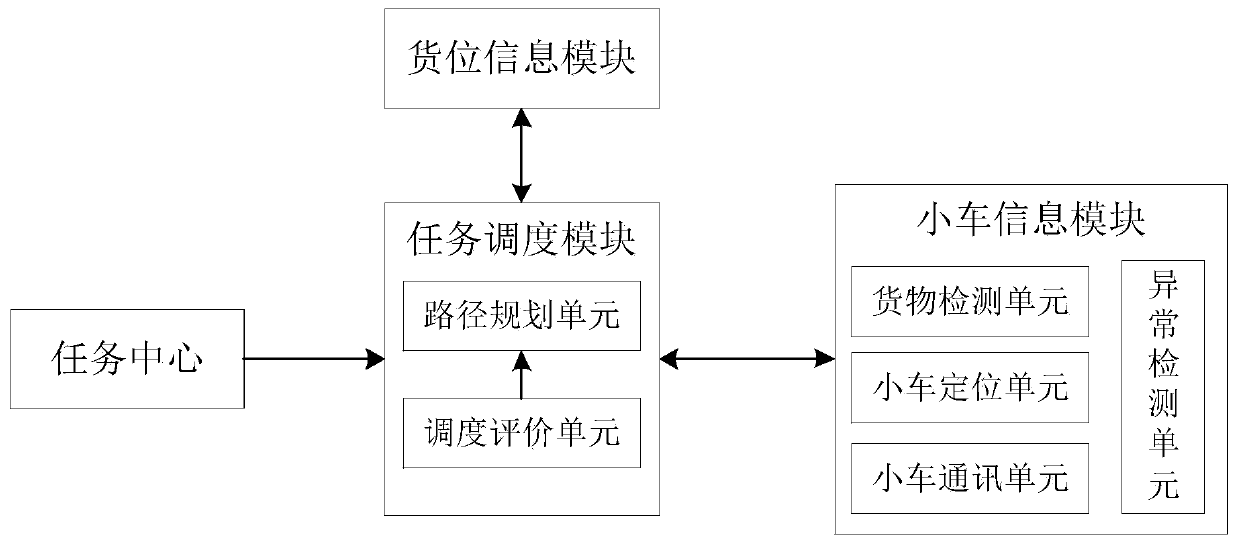

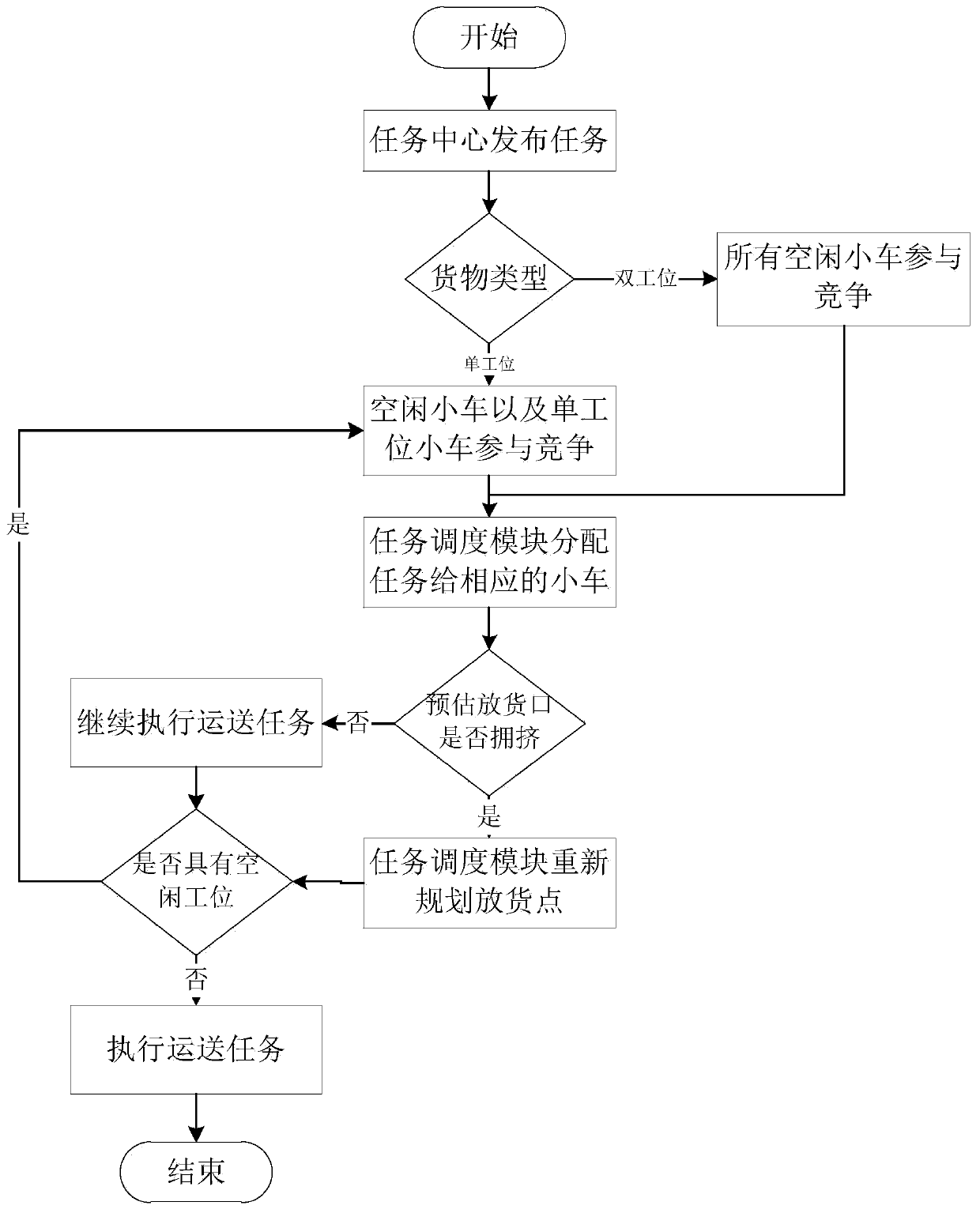

[0016] Please refer to Figure 1 to Figure 2 . The present invention proposes an intelligent scheduling system based on a multi-station AGV, which mainly includes a task center, a task scheduling module, a cargo location information module, and a trolley information module; wherein, the task center releases tasks to be completed; the task scheduling The module assigns the task to be completed to the optimal car, and plans the driving path of the car; the cargo space information module records the position information of each cargo space, the cargo information of each cargo space, and the information of the cars within a certain range of each cargo space. Quantity; the trolley information module records the real-time position information of each trolley and the loading data of each trolley.

[0017] In this embodiment, the AGV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com