Novel LNG gas-feeding integrated module device

A technology of integrated modules and refueling devices, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of shipping companies and difficulties in refueling, and achieve easy popularization and refilling Convenience and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

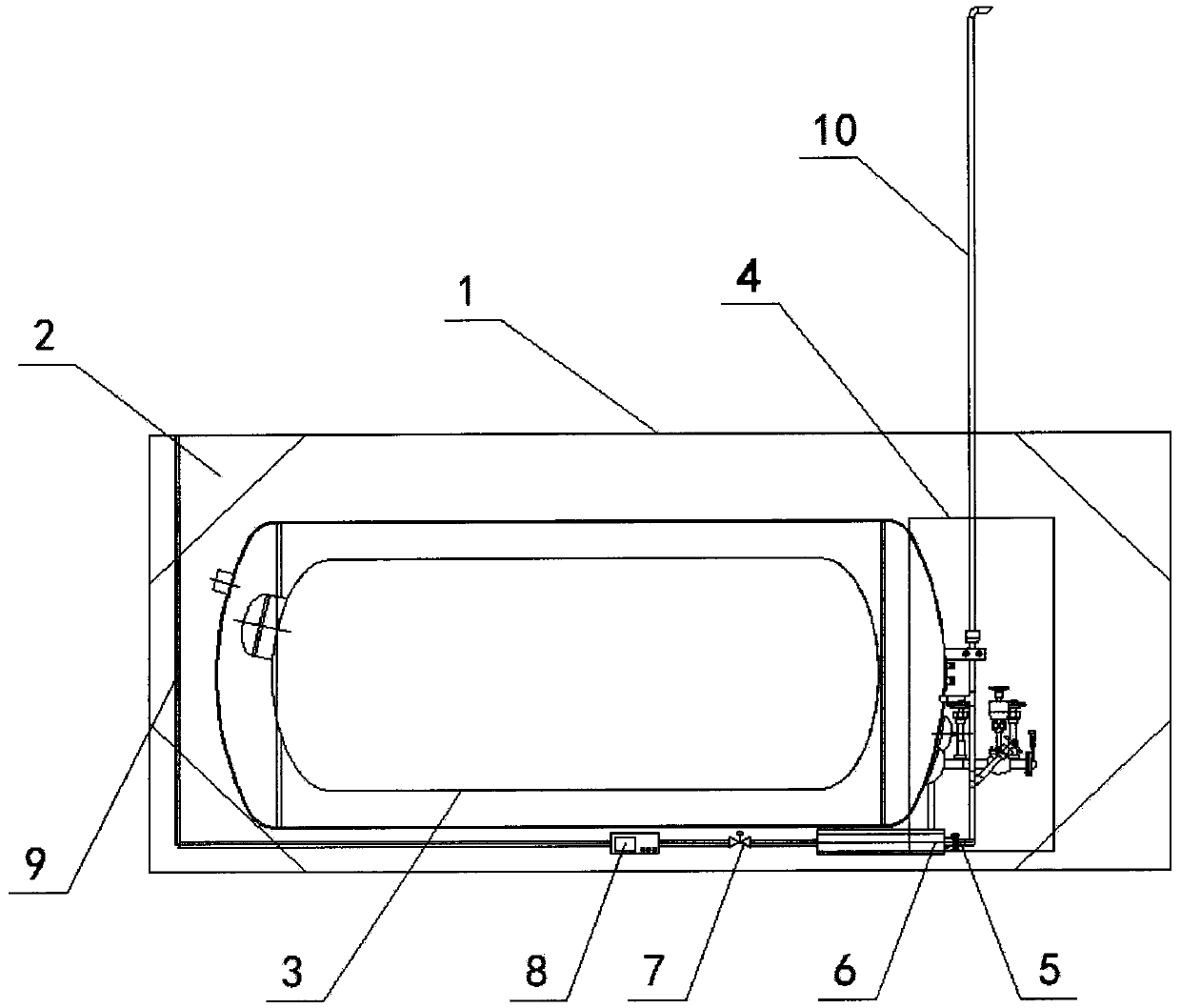

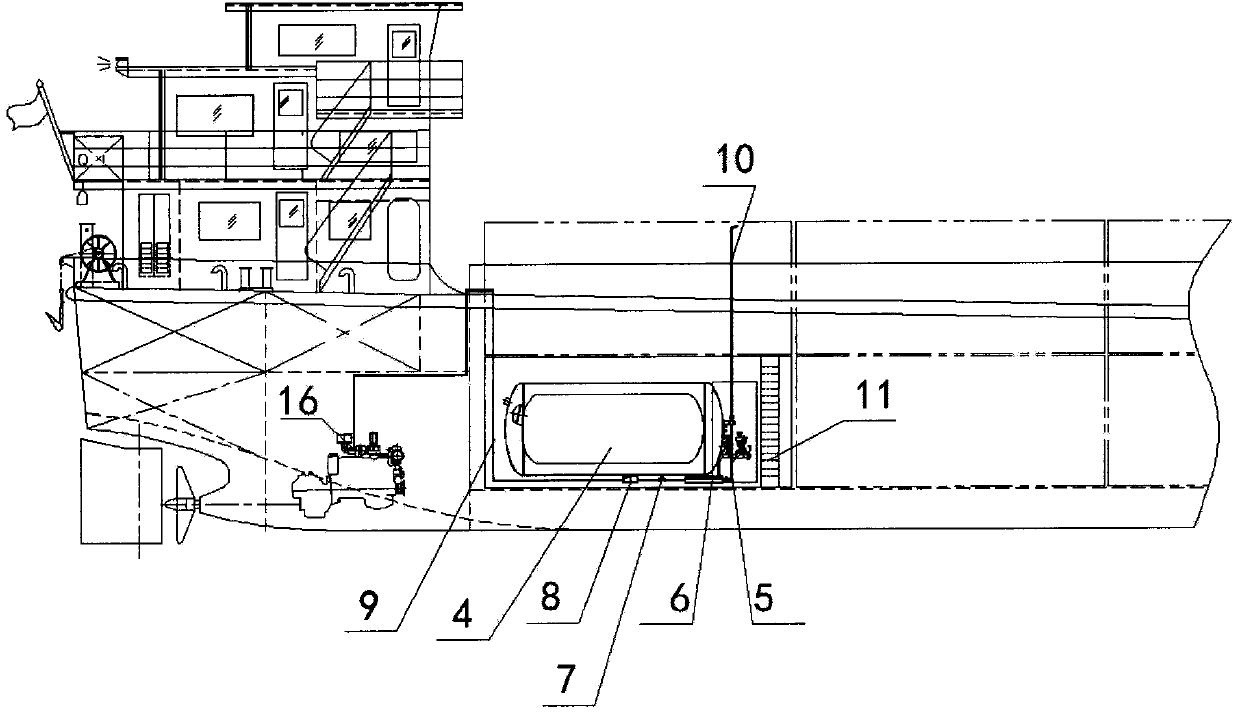

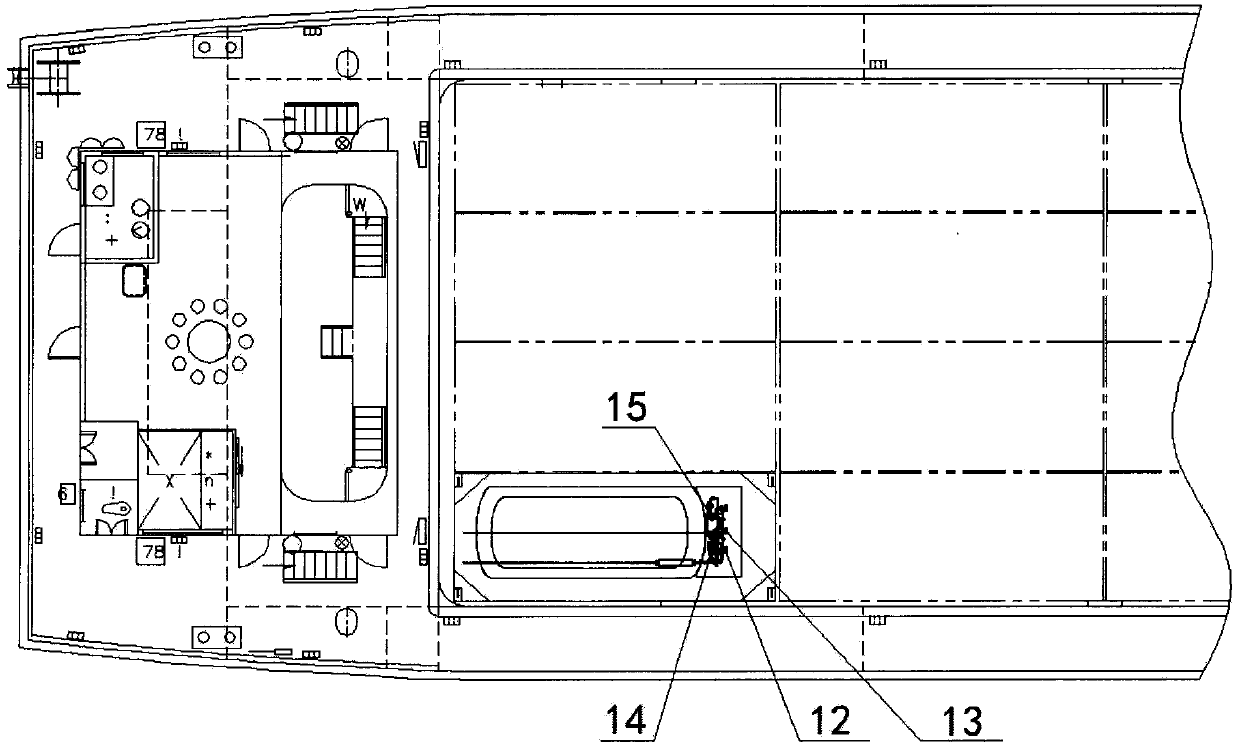

[0021] Such as Figure 1 to Figure 5 As shown, the LNG gas supply integrated modular device of the present invention consists of two major parts, the LNG refueling device box 1 and the box frame 2 . Wherein, the liquefied natural gas filling device box 1 includes a liquefied natural gas storage tank 3, an operating valve box 4, a liquid delivery pipeline 5, a vaporizer 6, an emergency shut-off device 7, a gas flow meter 8, a gas delivery pipeline 9, and a pressure release pipe 10 , straight ladder 11; the box frame 2 includes a front end frame, a rear end frame, an upper side beam, a lower side beam, a brace, an upper corner piece, a lower corner piece, a bottom plate and a support; the operation valve box 4 includes a liquid Phase operation pipeline 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com