Patents

Literature

294results about How to "Easy refill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

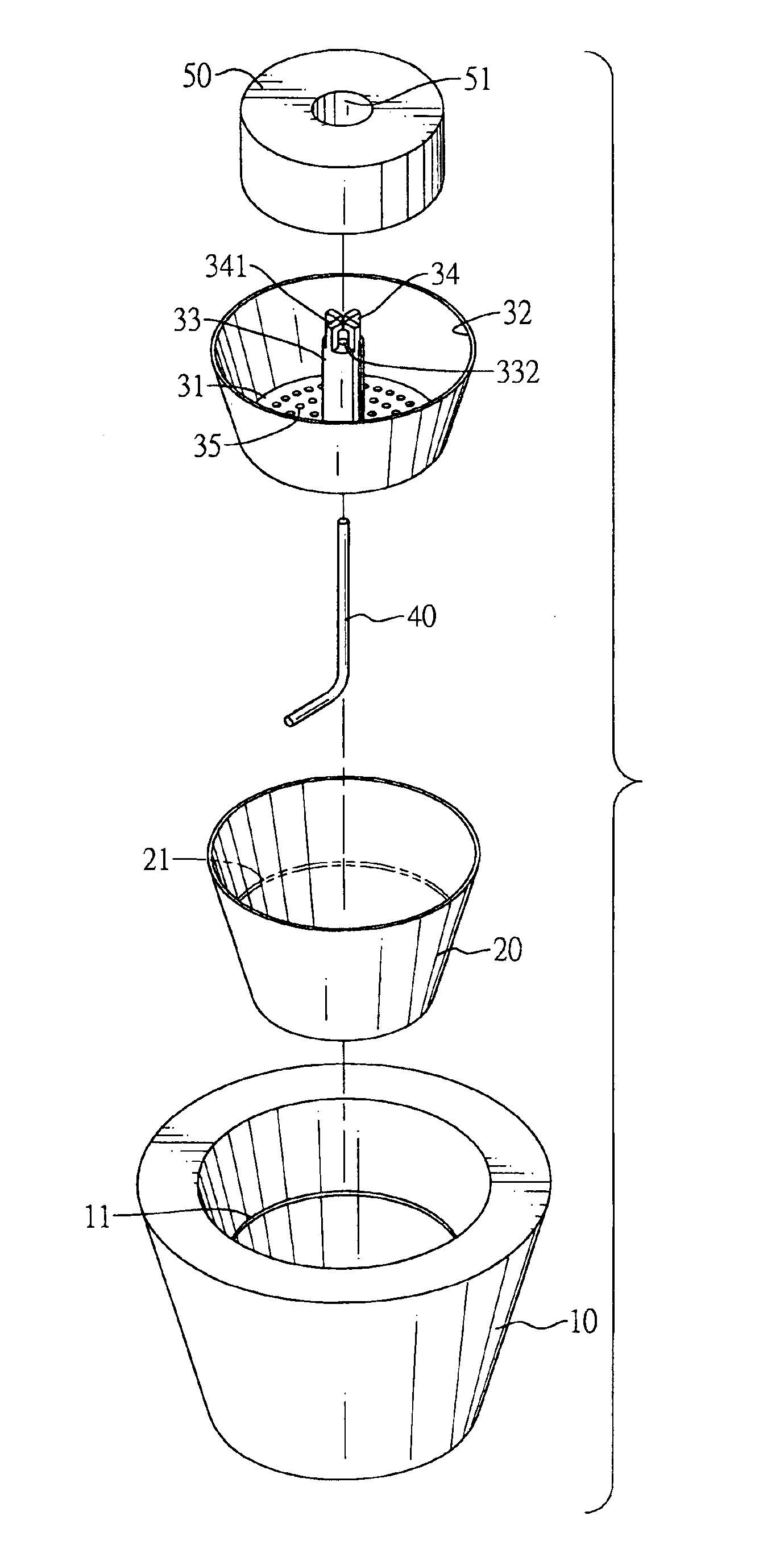

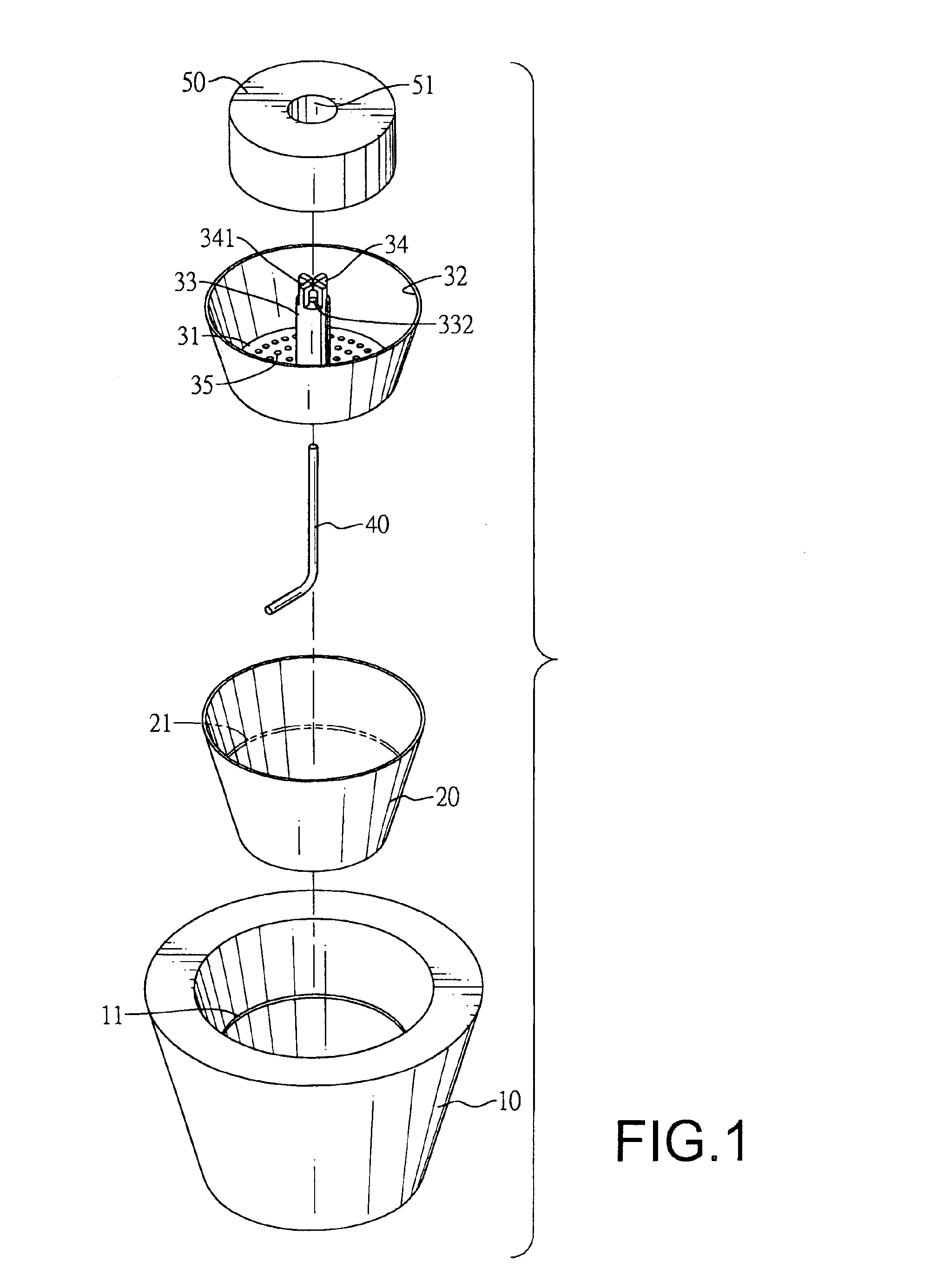

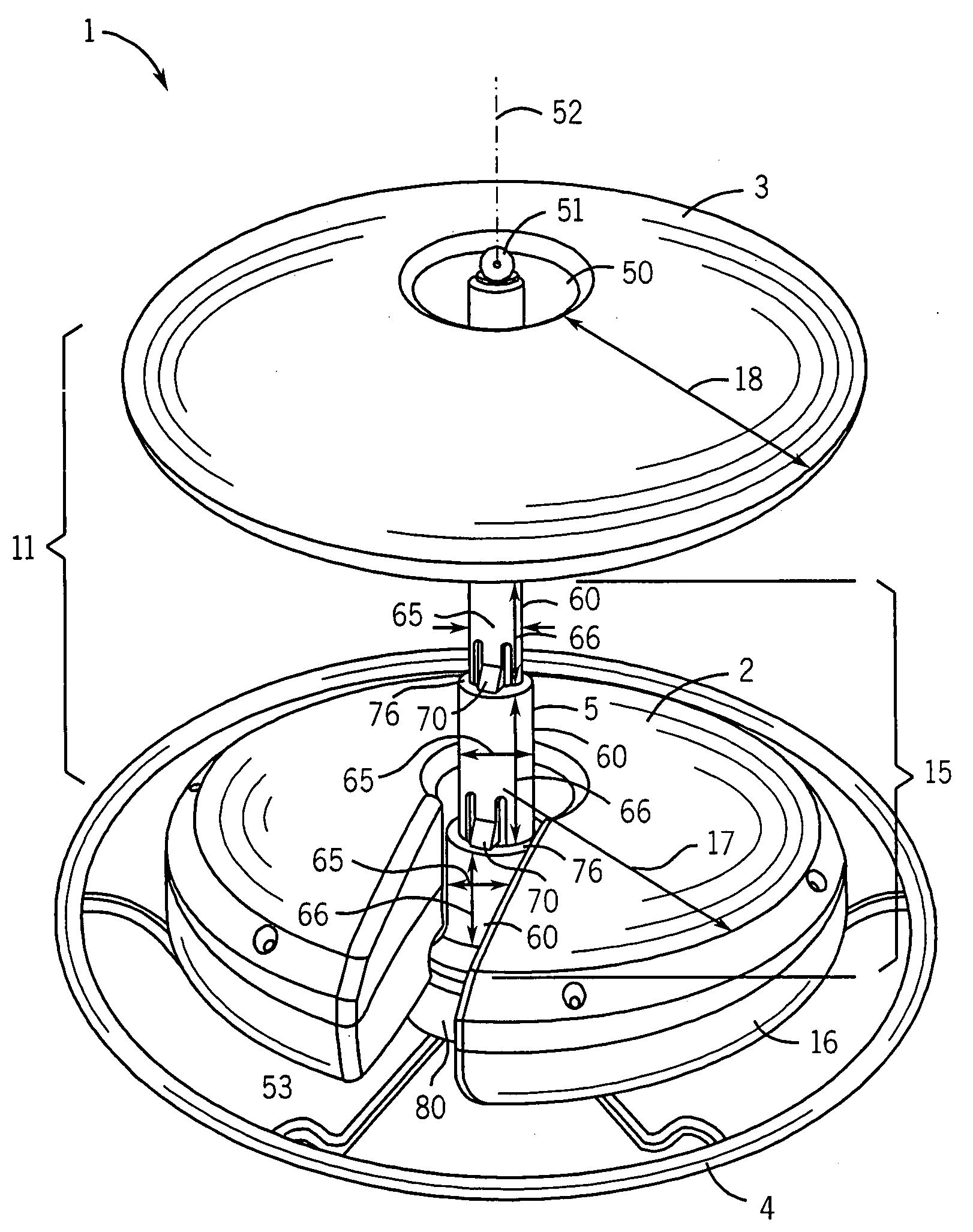

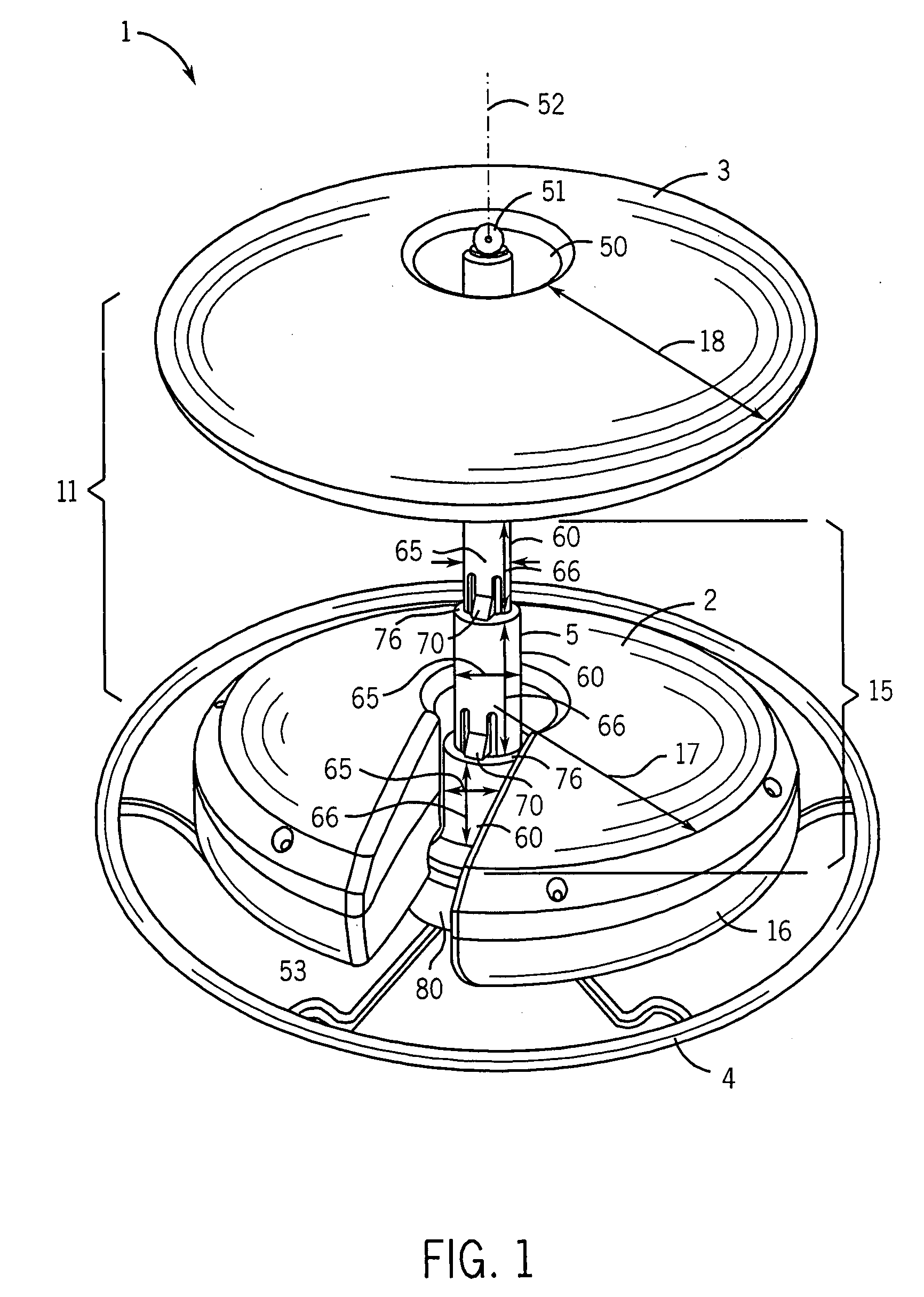

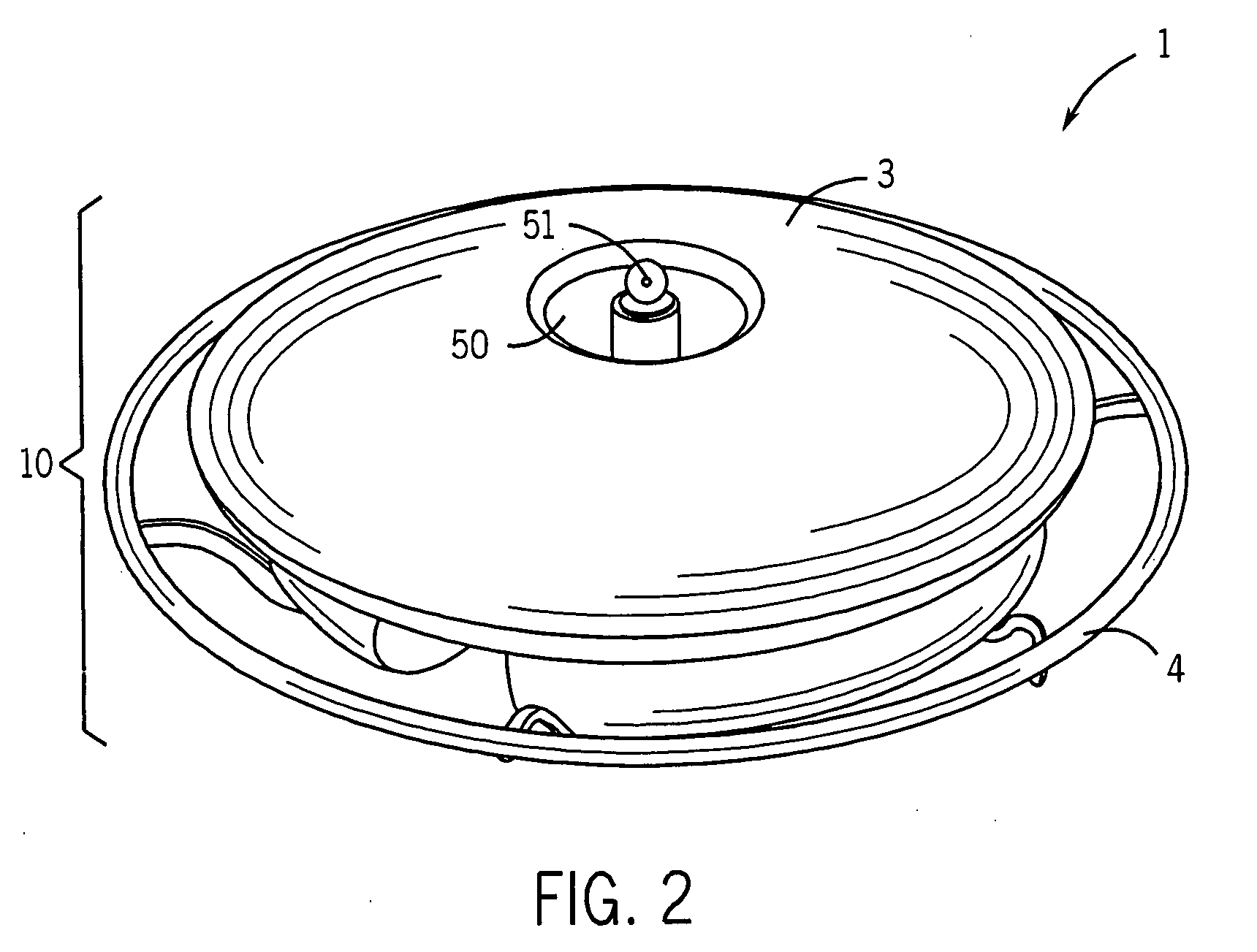

Refillable candle stand

A candle stand includes a container and a bowl supported by an inner periphery of the container and having a hollow column formed on top of the bowl. The hollow column has multiple pawls each having a bend formed on a free end of the pawl and extending toward a central axis of the hollow column so as to clamp a wick. Multiple through holes are defined through a base of the bowl, wherein a space is defined between a bottom face of the container and the base of the bowl for receiving liquefied wax.

Owner:SUN CHENG SEU

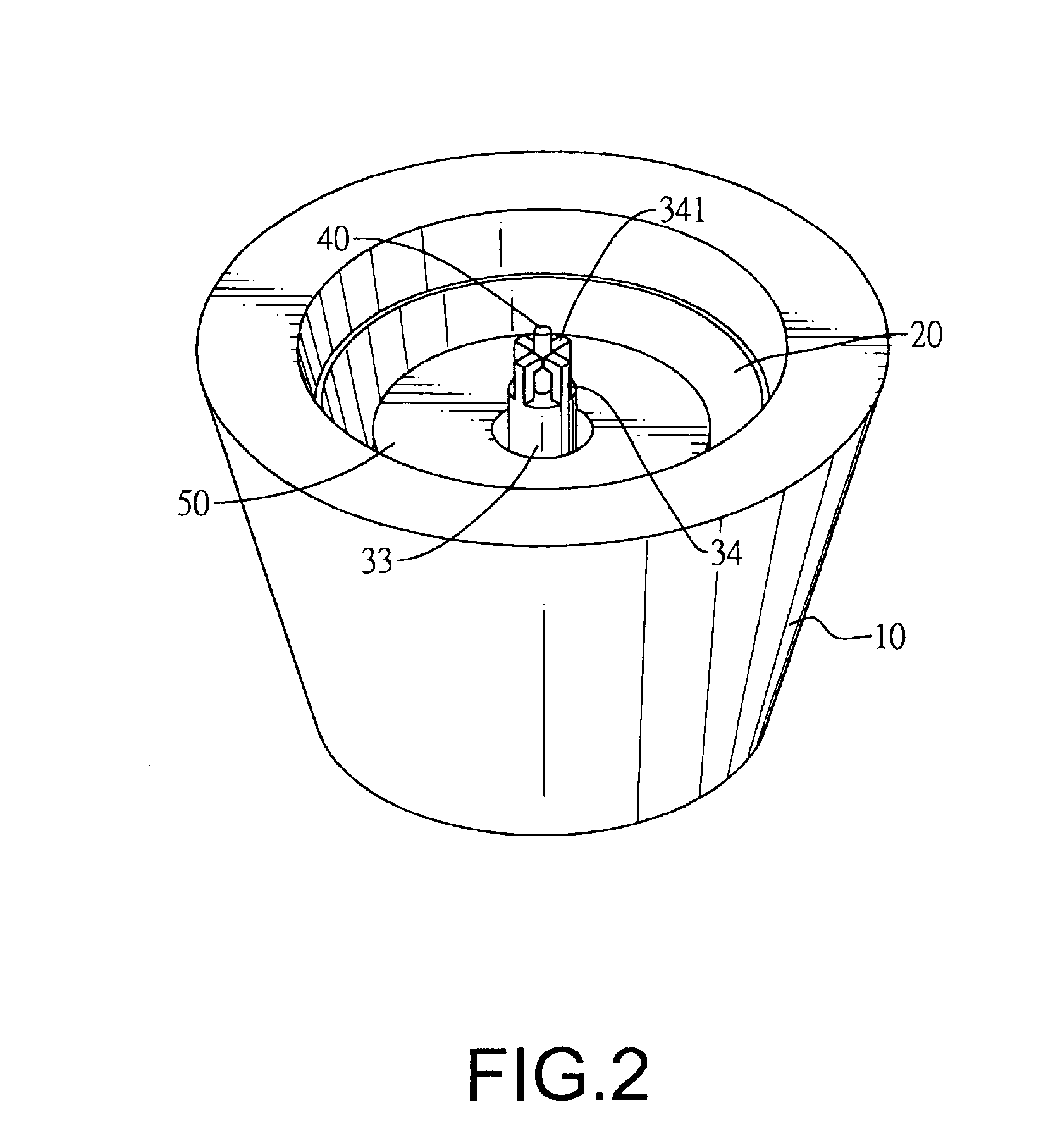

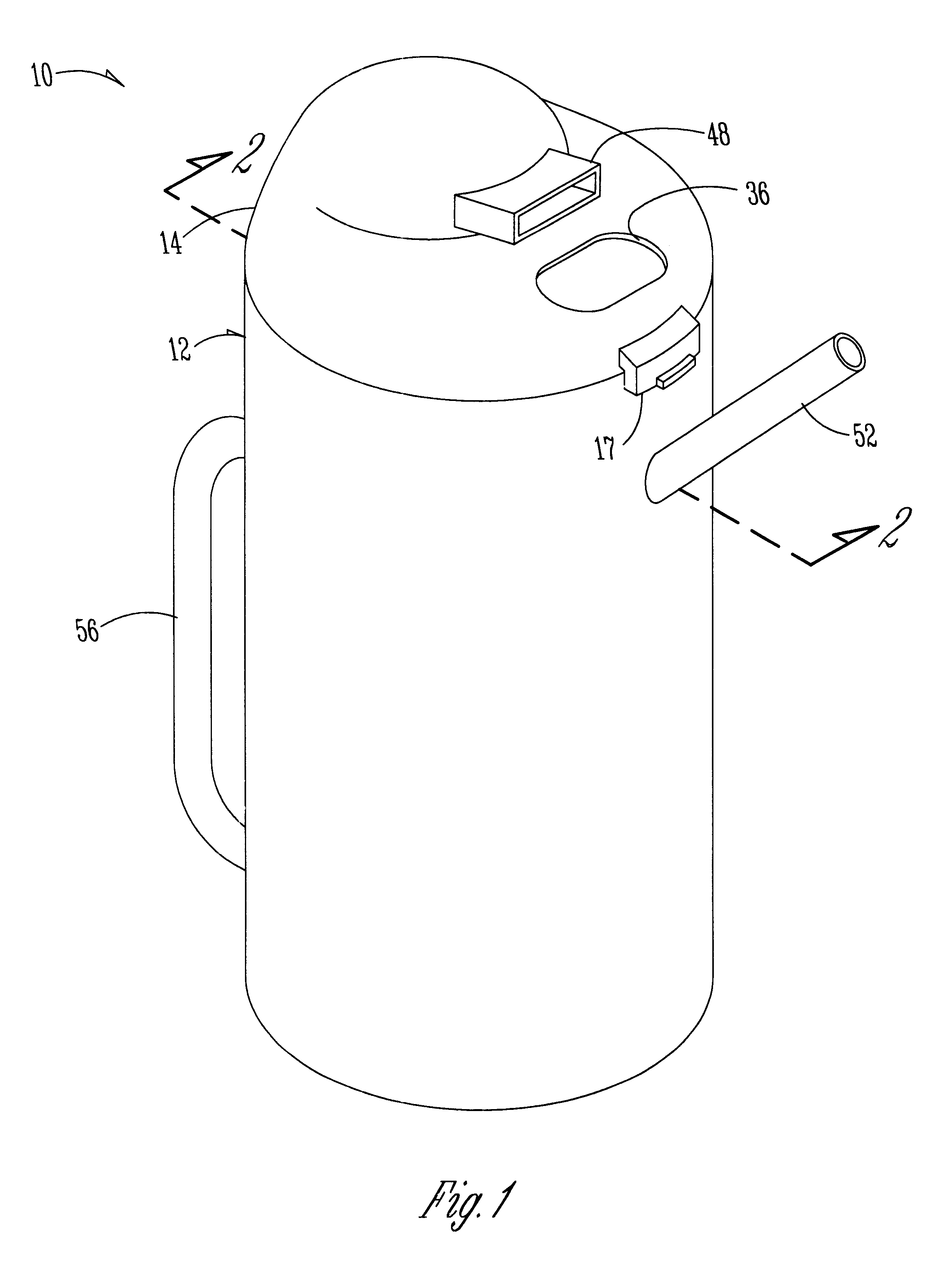

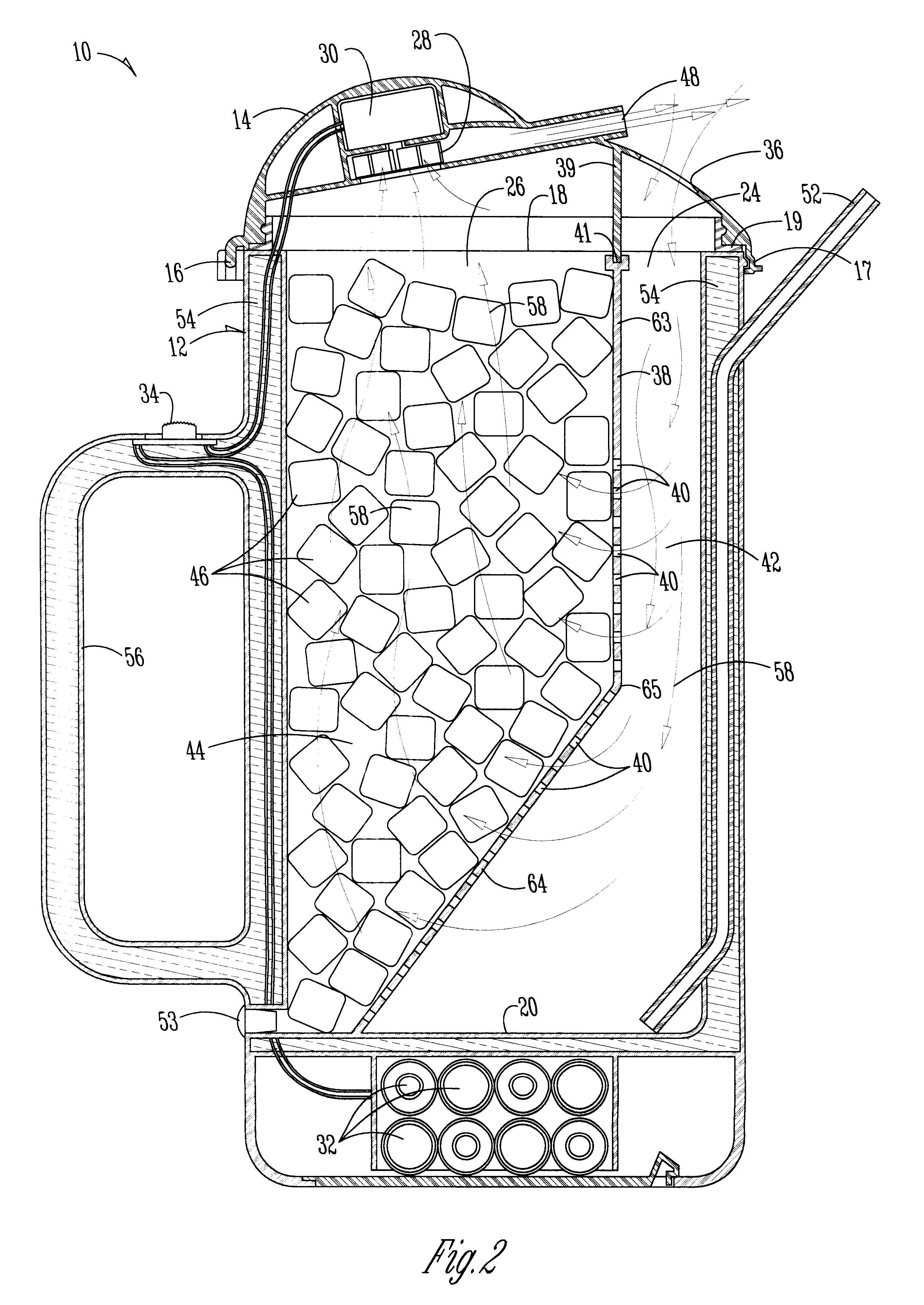

Portable air conditioner/beverage container

InactiveUS6227004B1Easy to cleanEasy to useLighting and heating apparatusDrinking vesselsCold airWaste management

Owner:COOL GUYZ

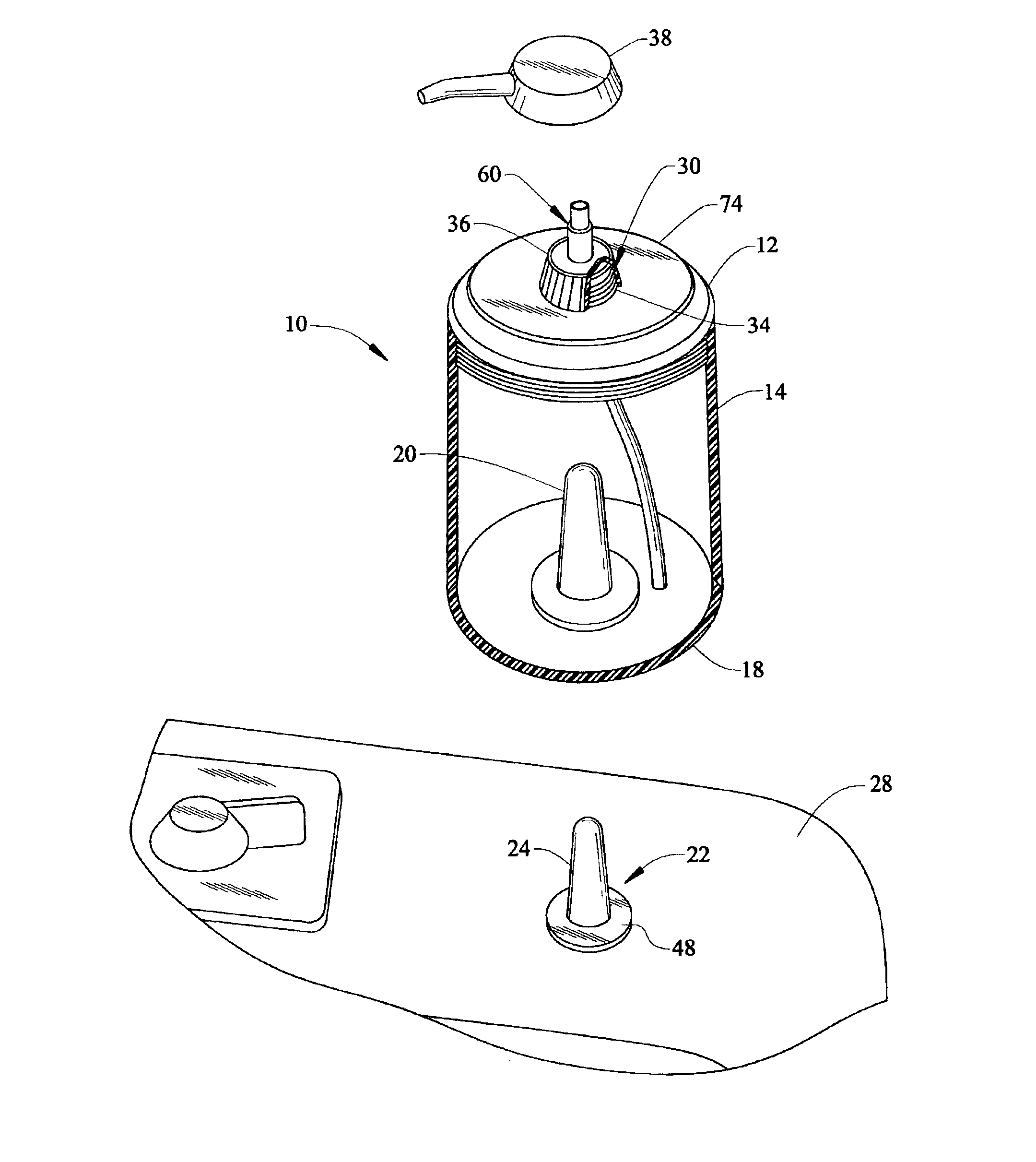

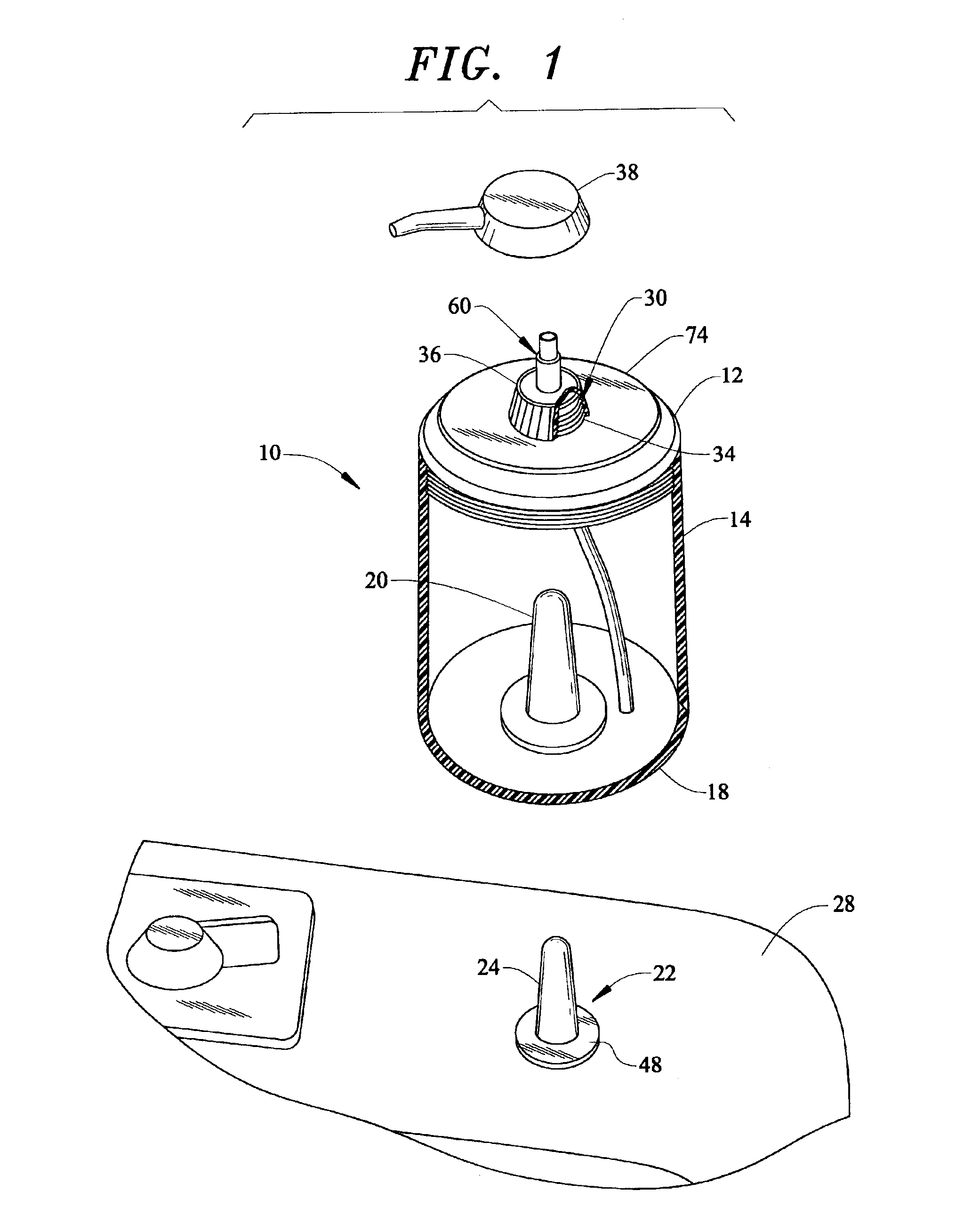

Kitchen sink top-mounted rigid stem-portable dispenser soap system

InactiveUS6910604B2Convenient teachingEasy refillLarge containersHolders and dispensersEngineeringMechanical engineering

The present invention provides a liquid soap dispensing apparatus having a counter-top mounting system that makes it possible to securely anchor the liquid dispensing device to a surface such as a counter-top and still allow easy removal for portability, so the dispenser can be transported and used in other areas. The apparatus also allows the soap reservoir to be easily refilled and utilizes readily available pump components.

Owner:GUGLIOTTI CARMINE +1

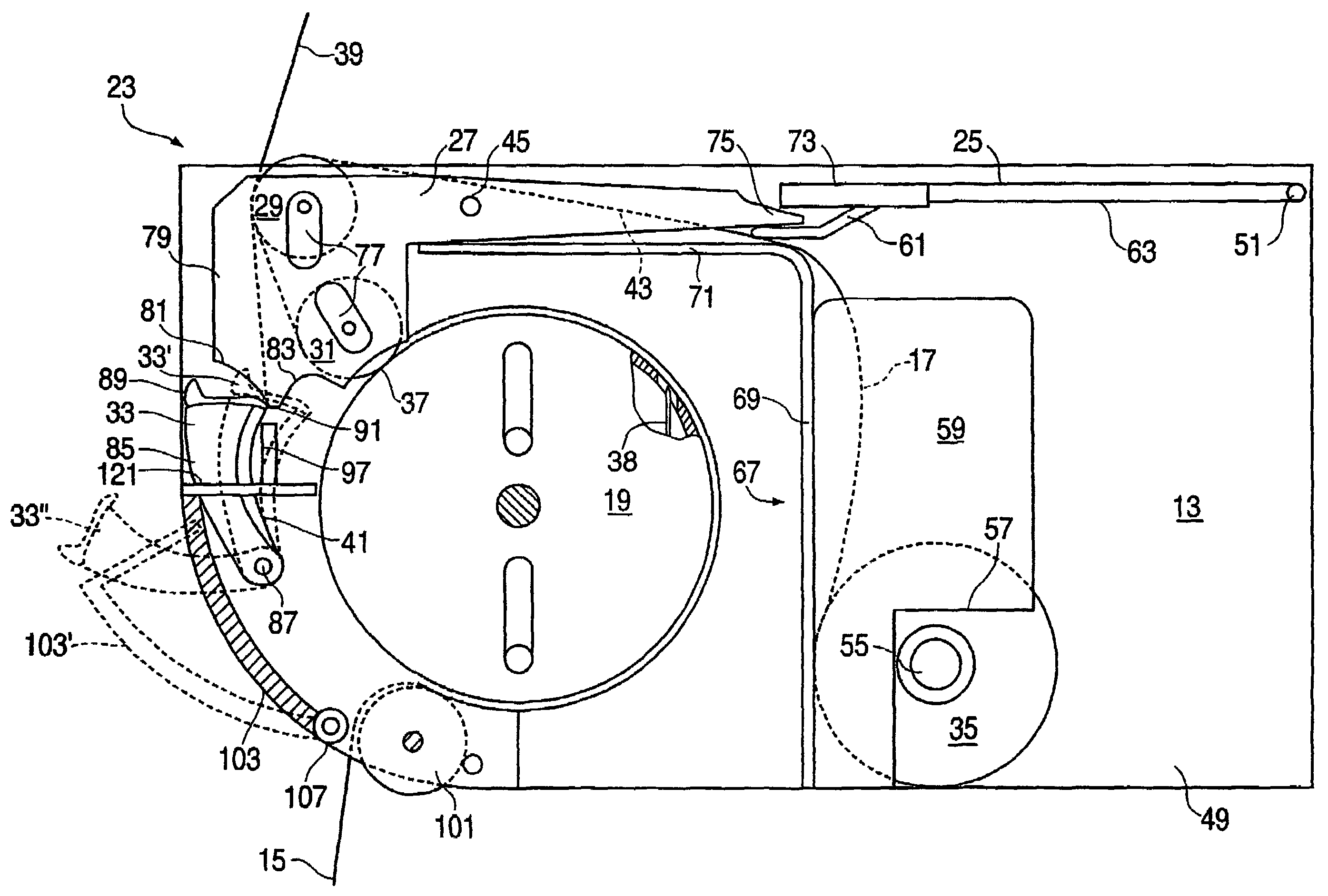

Web transfer mechanism for flexible sheet dispenser

InactiveUS7270292B2Eliminate health risksEasy refillFilament handlingDomestic applicationsLeading edgeEngineering

An automatic web transfer mechanism in a flexible sheet material dispenser includes a web-sensing member operatively coupled with a transfer arm. The member senses the absence of web from a stub roll at a pre-feed portion between the stub roll and a feed roll nip to activate a transfer of feed to the web of a reserve roll. The transfer is initiated by a transfer arm that advances the reserve web into the proximity of the feed roller nip. In a second aspect, a movable front shield opens automatically upon opening of the outer dispenser cover, presenting an opening for pre-transfer placement and retention of a leading edge of web material from the reserve roll. Upon closure of the dispenser cover, the front shield returns to a closed position placing the transfer arm in a pre-transfer set position.

Owner:GPCP IP HLDG LLC

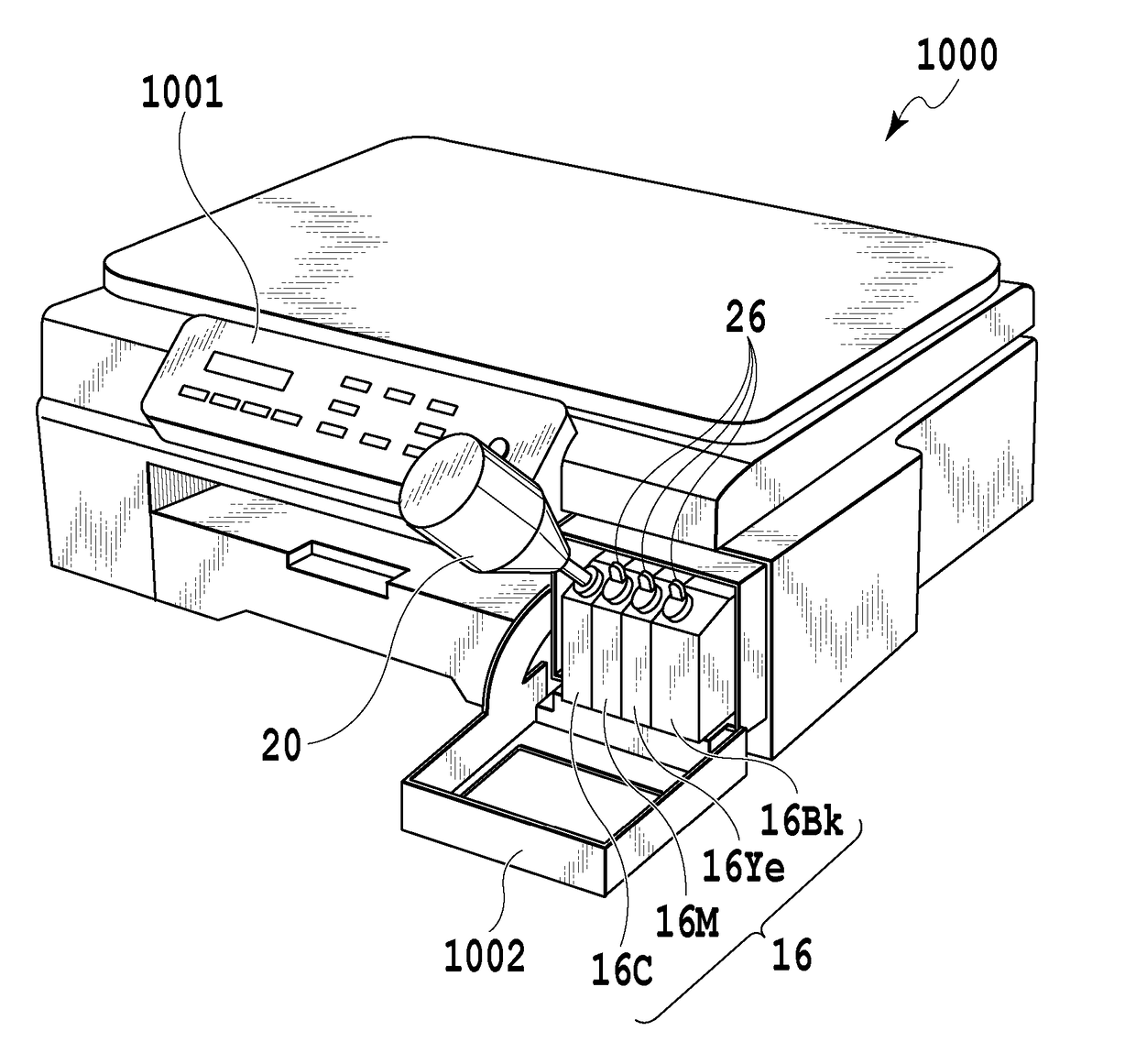

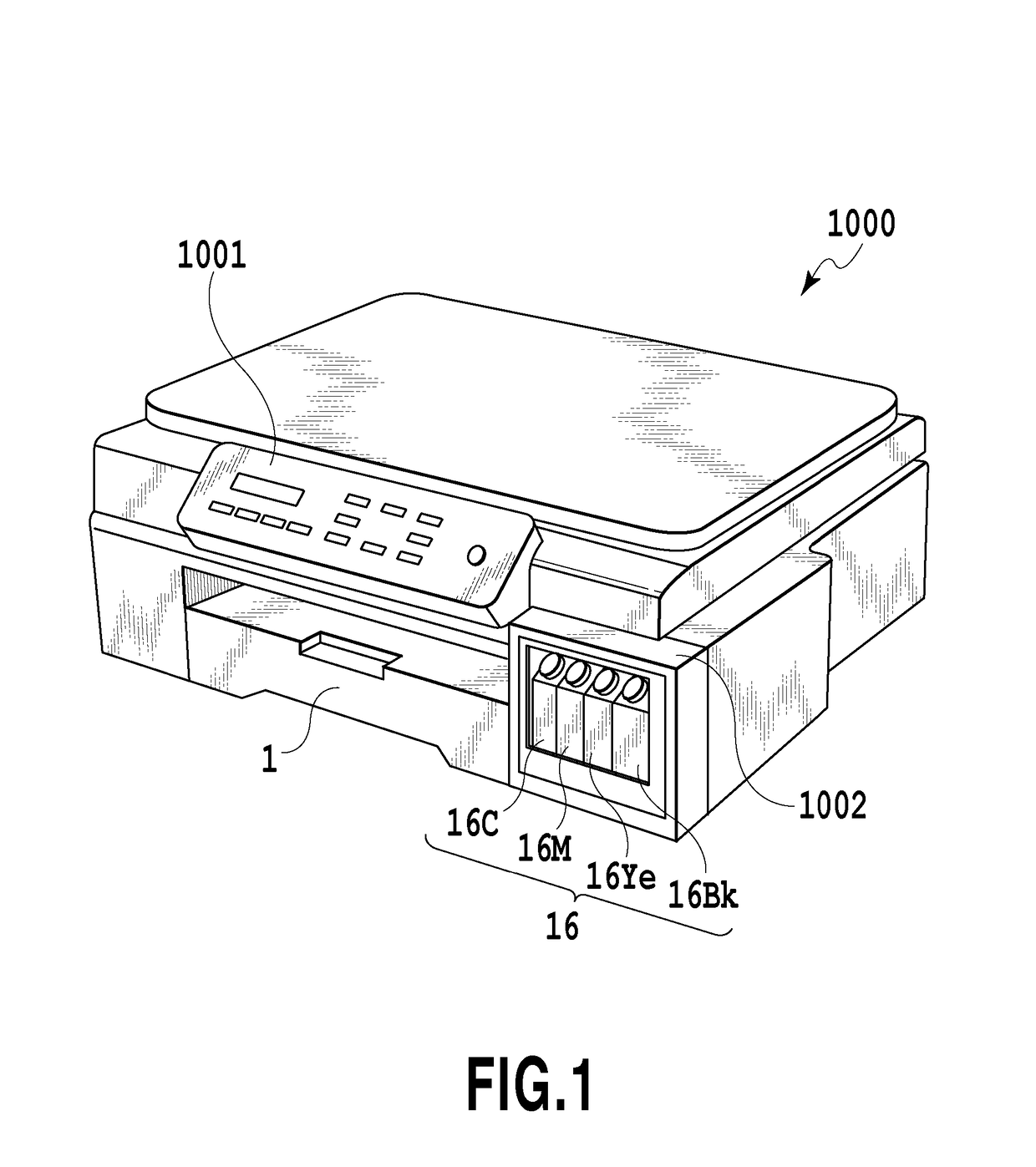

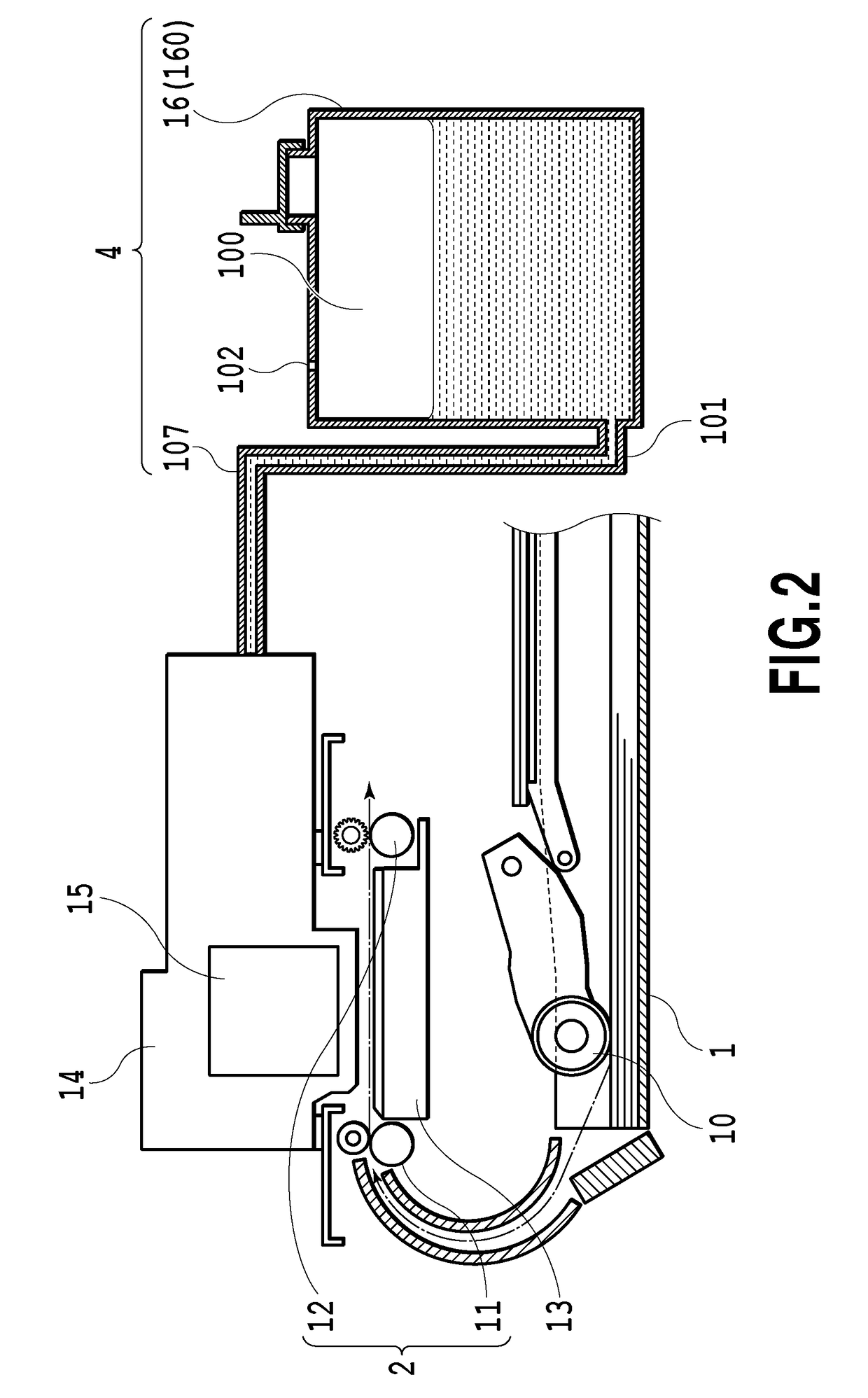

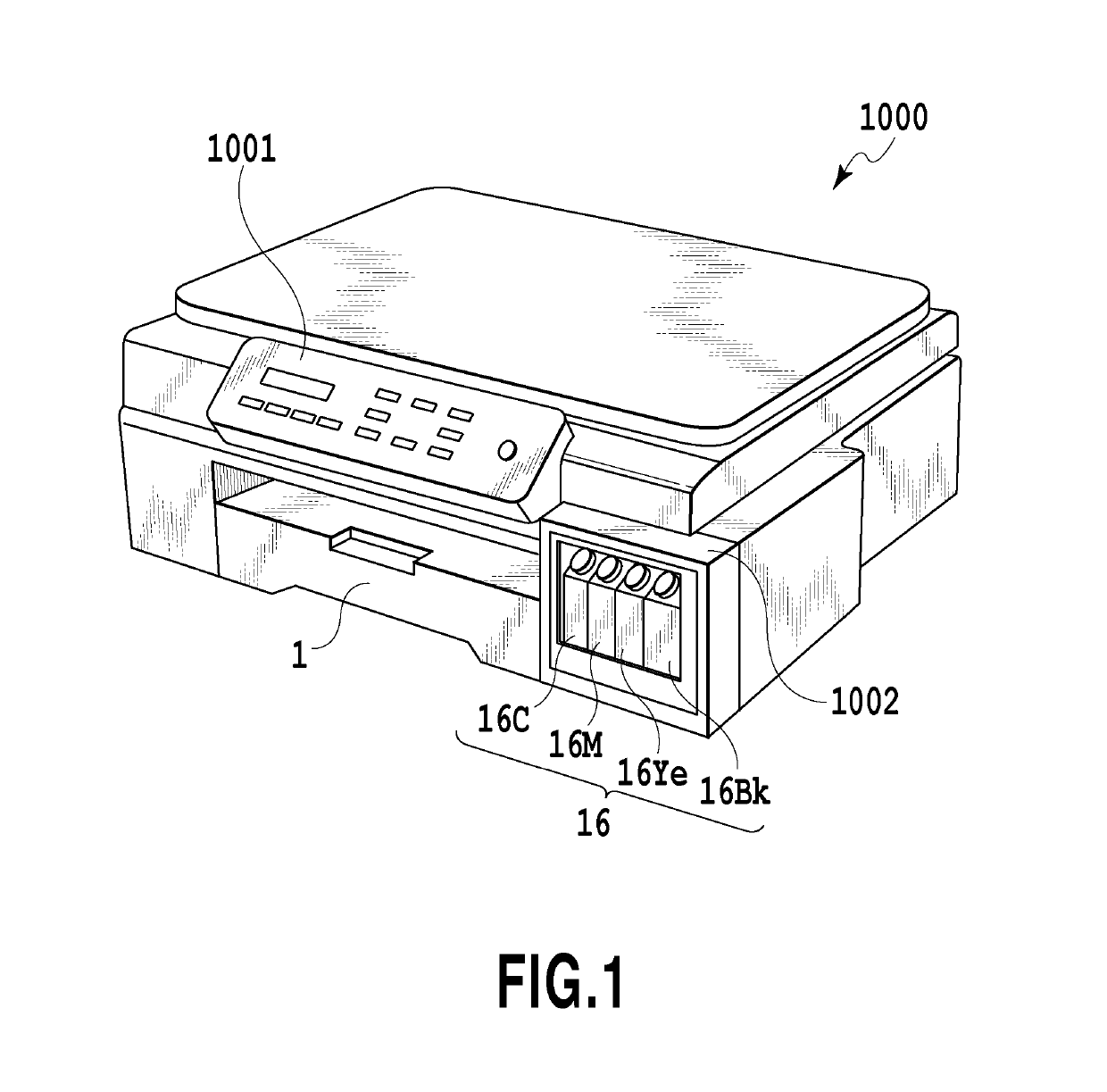

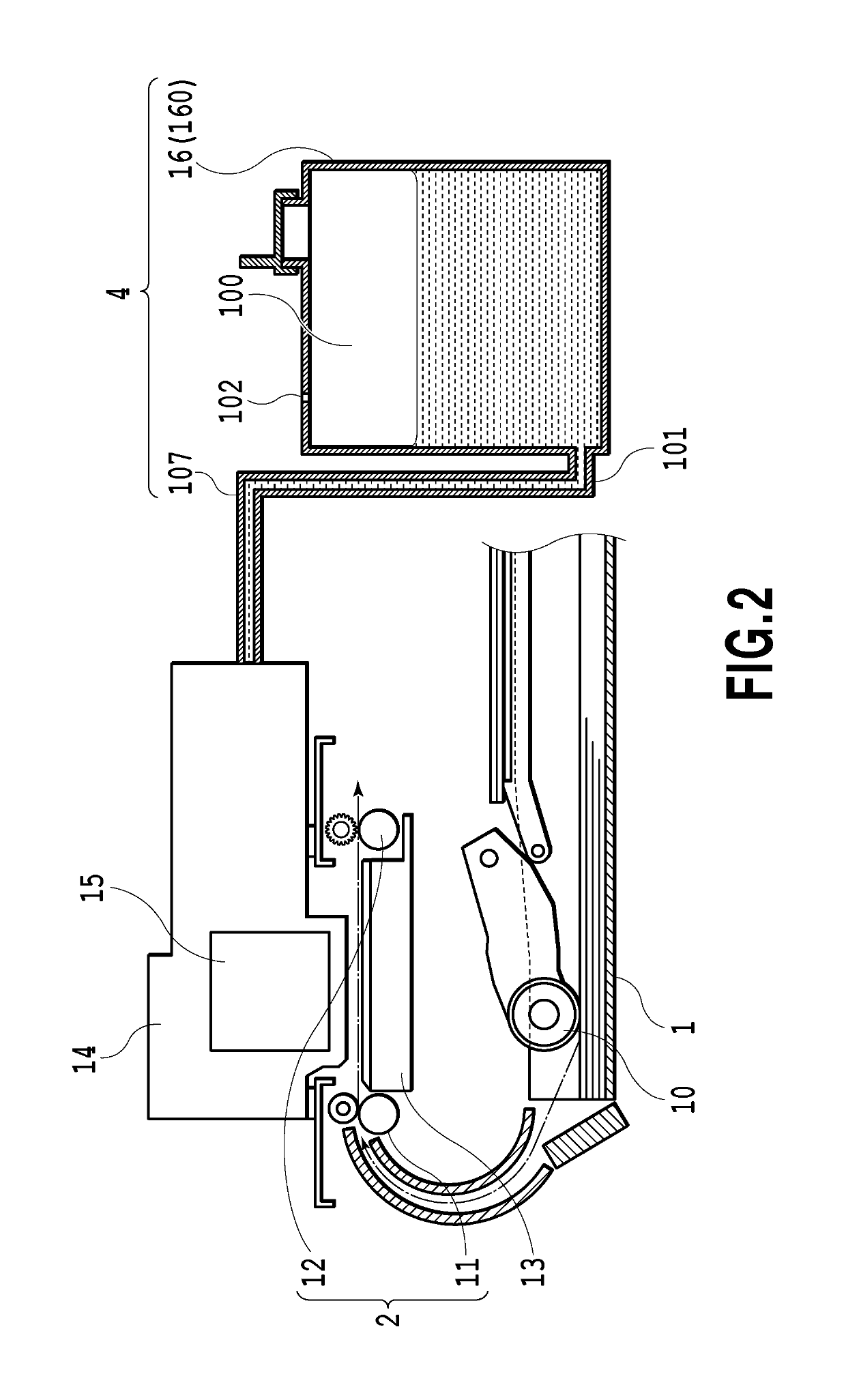

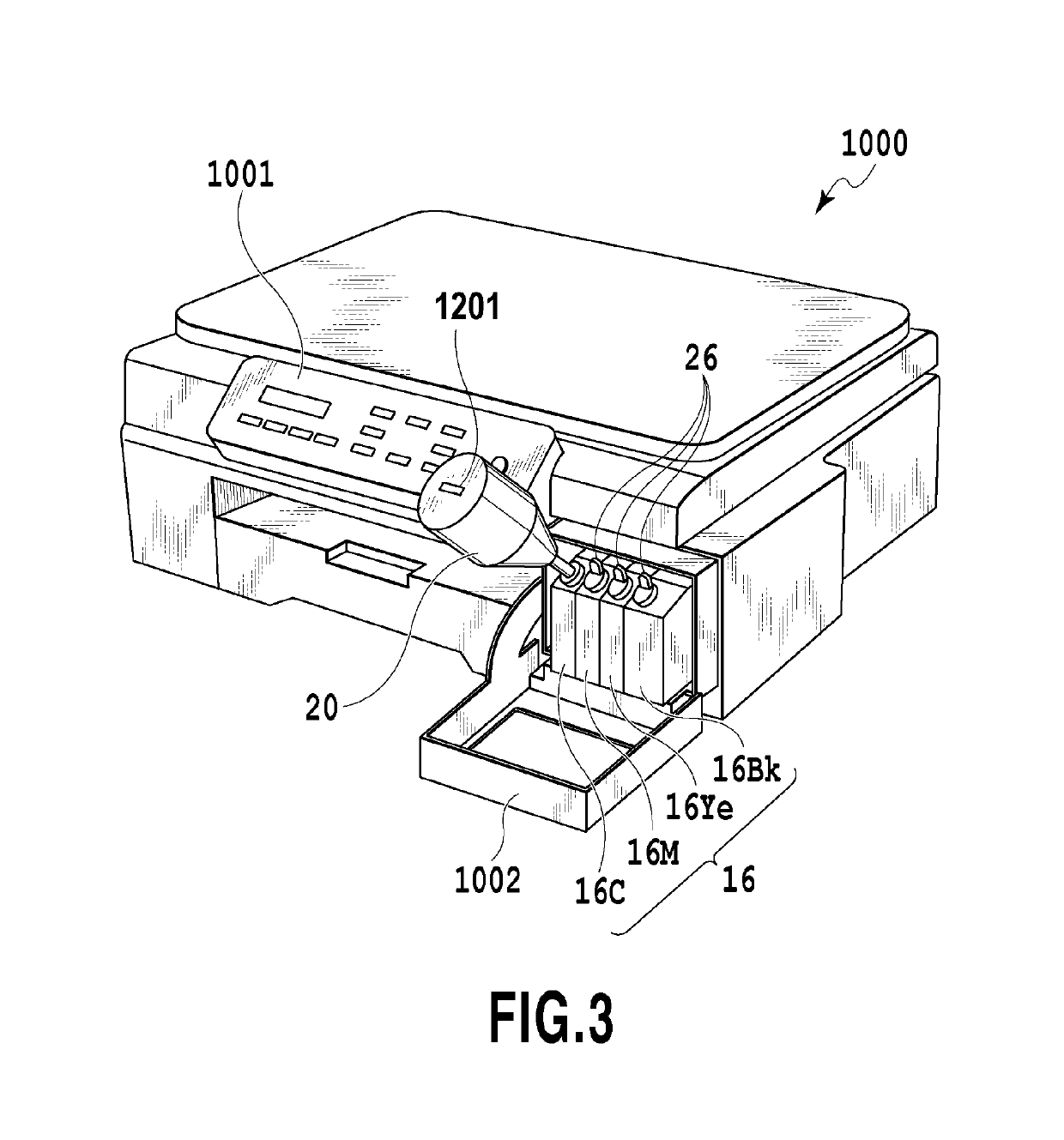

Liquid ejecting apparatus and liquid refilling container

An object is to provide a liquid ejecting apparatus that enables a liquid storage container to be properly and easily refilled with a liquid from a liquid refilling container without causing color mixture in the liquid storage container. The liquid ejecting apparatus includes liquid storage containers each configured to feed the liquid to a liquid ejecting portion and liquid refilling containers each configured to refill the liquid storage container with the liquid. A first fitting unit is provided around a liquid injection port in each of the liquid storage containers. A second fitting unit is provided around a liquid pour-out port in each of the liquid refilling containers. The second fitting unit is fitted to the first fitting unit to enable the liquid to be delivered from the liquid pour-out port to the liquid injection port.

Owner:CANON KK

Fabric cleaning

InactiveUS6883353B2Minimize redepositionEasy to useHand rubbing apparatusBathroom accessoriesBiomedical engineeringEngineering

A device for spot cleaning a fabric with a liquid cleaning composition, said device comprising[0001]i) at least one absorbent means for absorbing at least some of said composition from the fabric; and[0002]ii) mesh means for rubbing the fabric so that the liquid absorbed by the absorbent means from the fabric passes through the mesh means.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

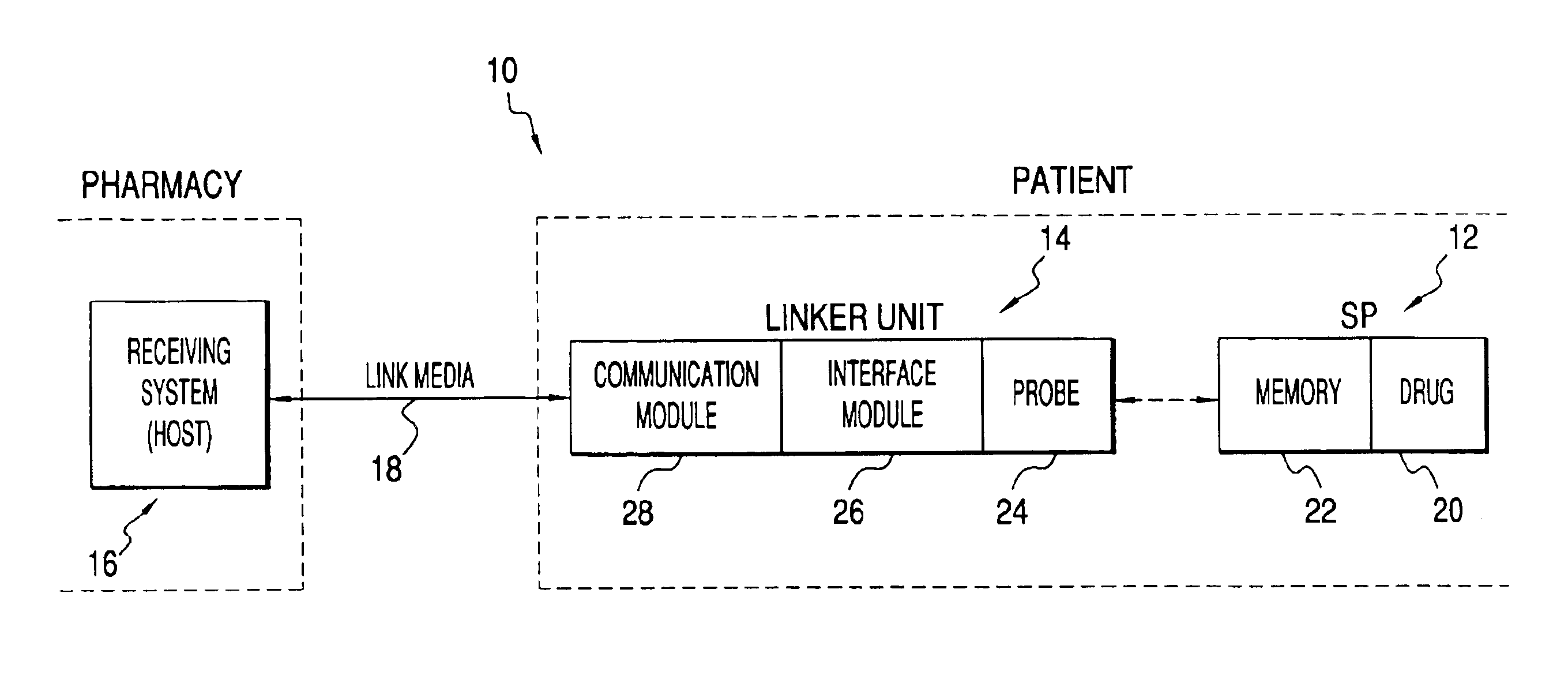

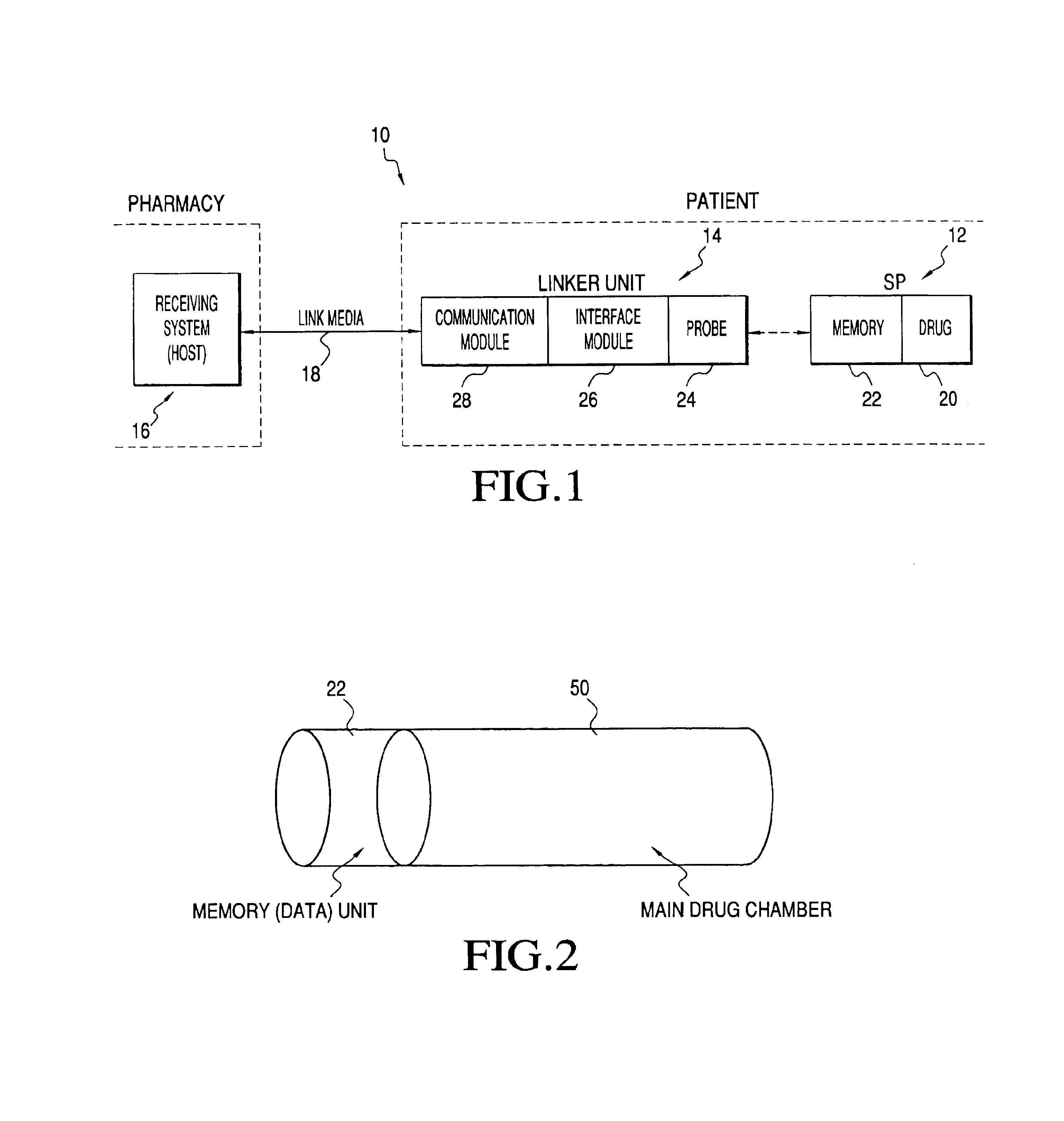

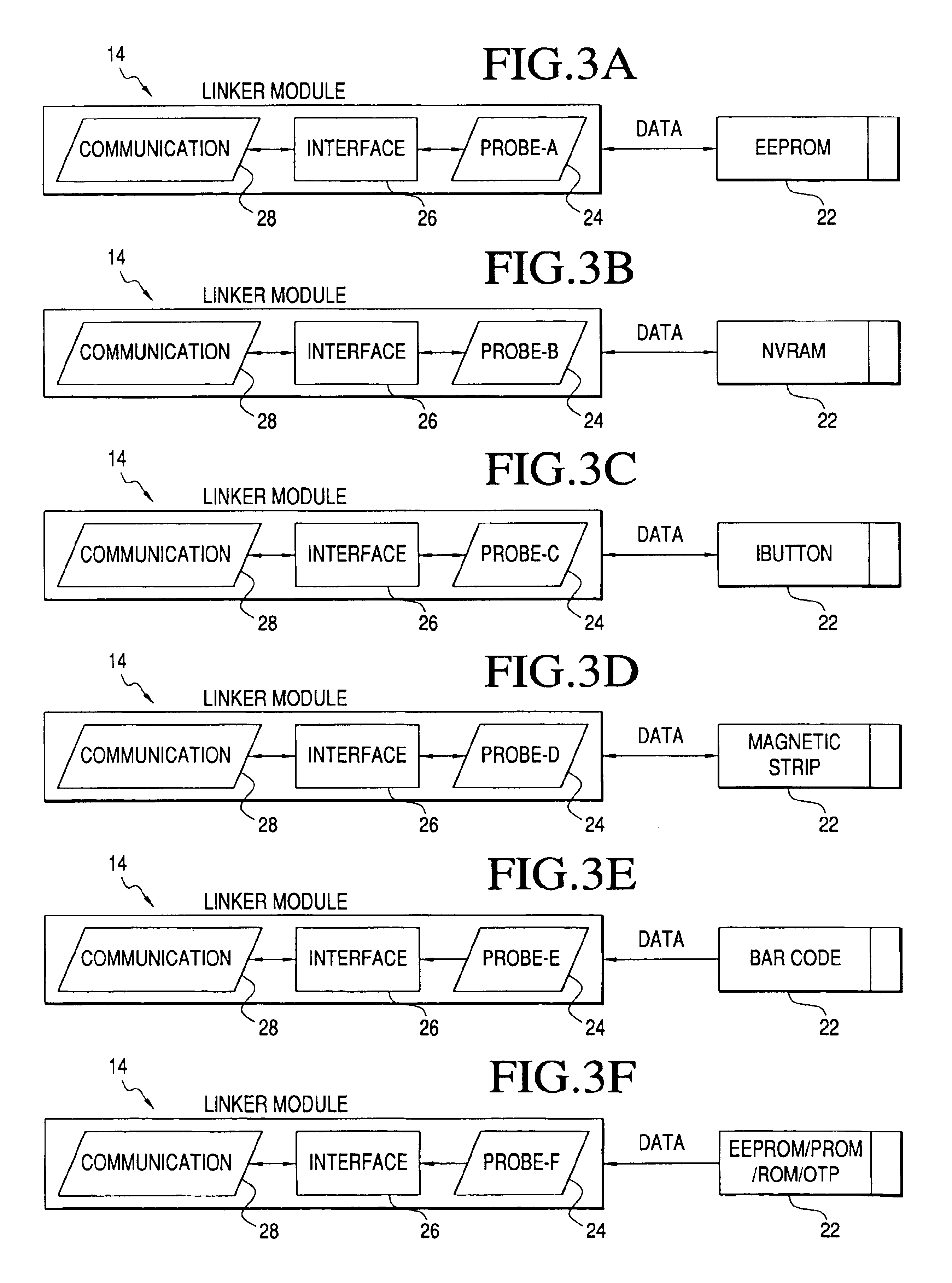

Method and system for ordering services or products, including prescriptions

InactiveUS6973435B1Easy to getEliminate errorsDrug and medicationsDiagnostic recording/measuringPharmacyEngineering

A method and system for transmitting information included in a memory device to a remote location. The information included in the memory device could take the form of patient information as well as a prescription dosages and the remote location could be a pharmacy or a physician's office. The memory device could be fixedly attached to a drug container and a linker module would read the information contained in the memory device and automatically contact a pharmacy located at a remote location to fill a particular prescription. Information relating to the patient or the prescription which is filled can also be transferred from the remote location directly into the memory device through the linker module. In addition, the method and system can be used to order or purchase any products or services from a vendor.

Owner:S K SCRIPT

Cart Handle Dispenser

InactiveUS20090199360A1Improve sanitationMinimum logistic effortWing handlesKitchen equipmentCartEngineering

A cart handle with an integral wipe dispenser for storing and dispensing sanitary wipes which consists of a hollow cylindrical canister portion with two ends and an operatively-sized main chamber, two coupling end portions one each attached to each of the two ends of the canister portion, a lid portion hingedly coupled to the main chamber and having an operatively sized and positioned opening, whereby individual sanitary wipes can be dispensed and used for sanitizing the cart handle.

Owner:MADANAT AZMIE K

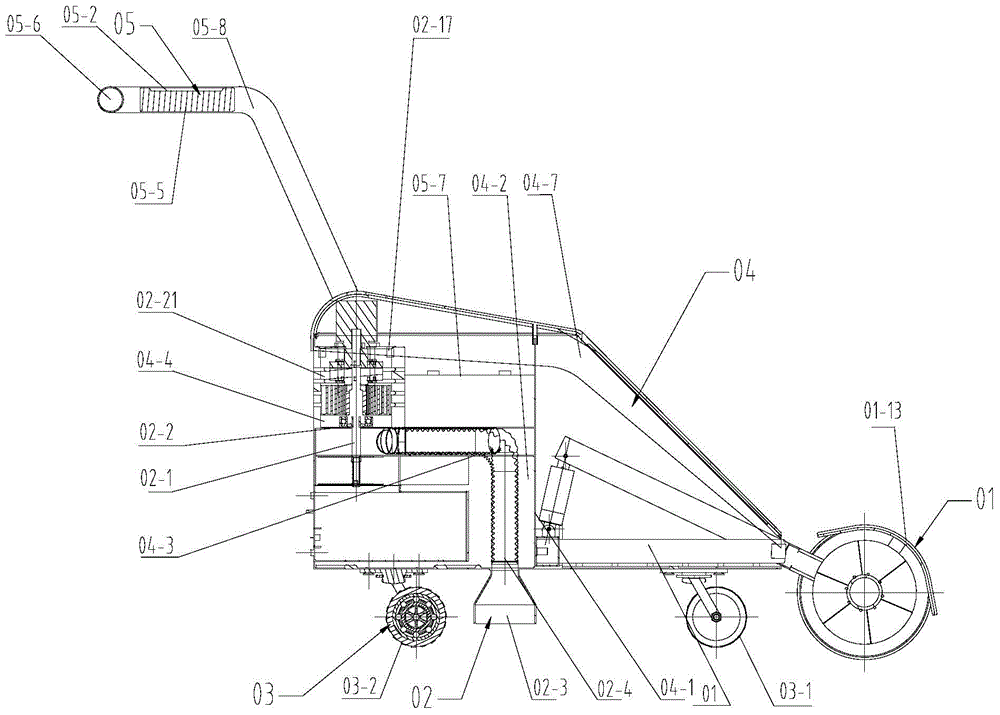

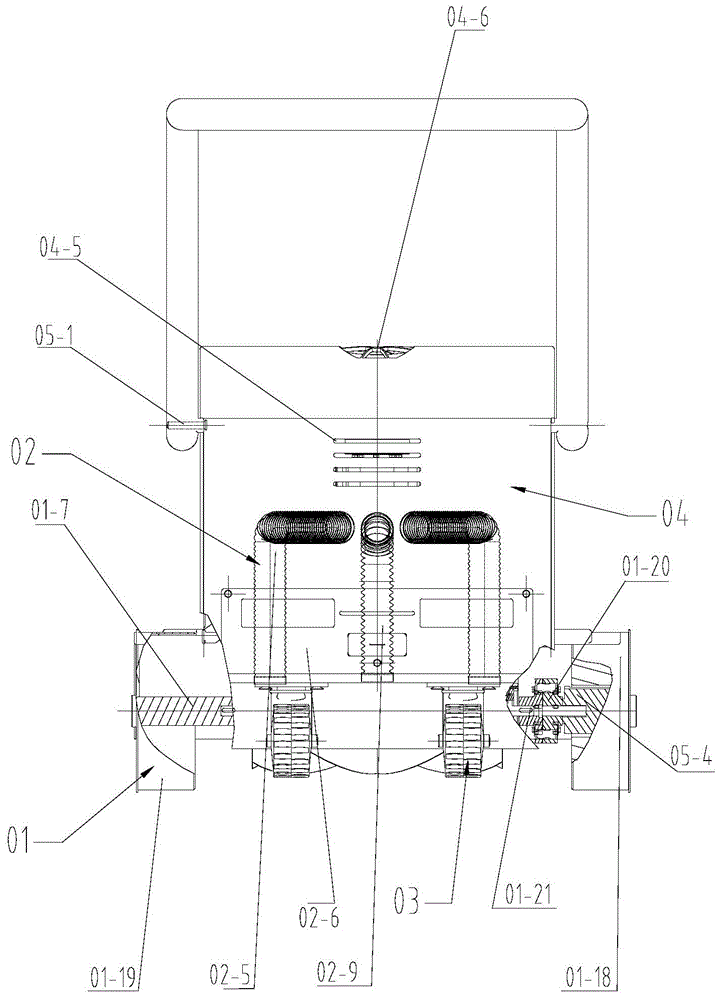

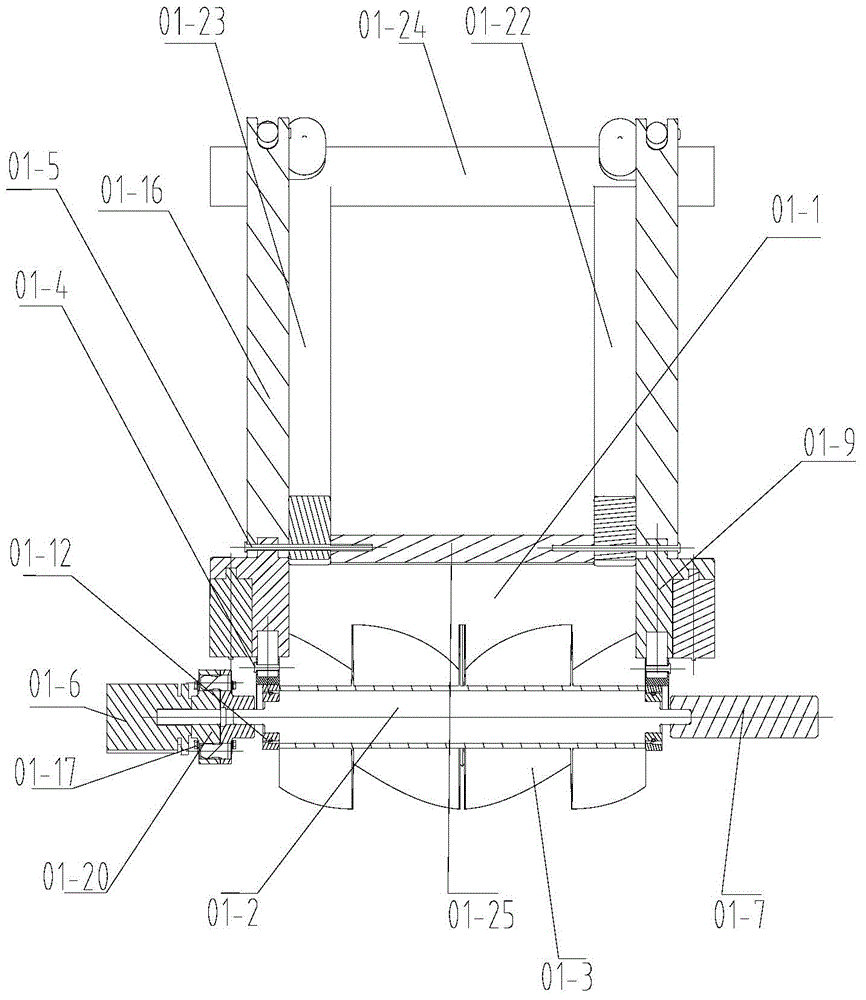

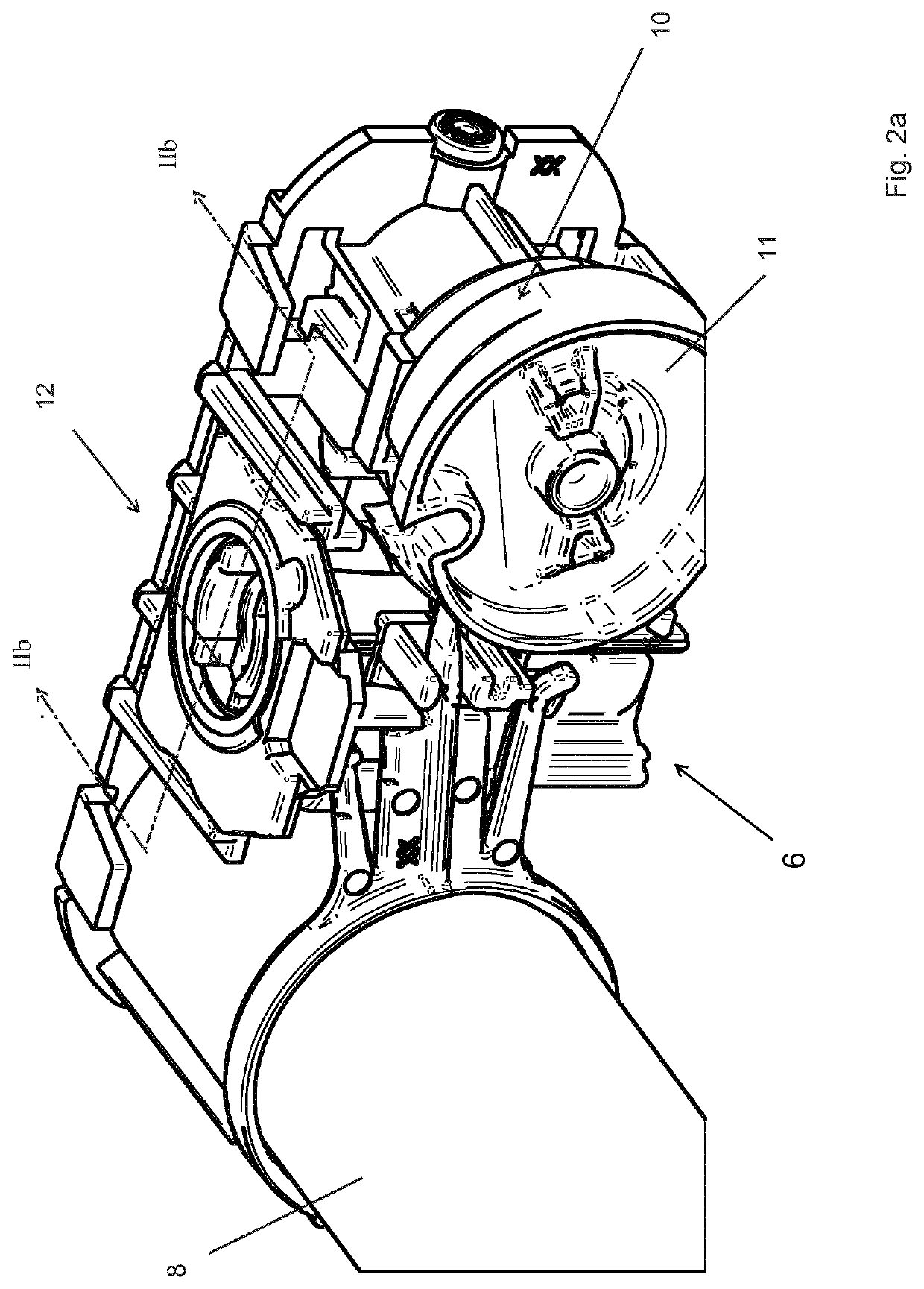

Sweeping and smashing integrated machine for fallen leaves

The invention discloses a sweeping and smashing integrated machine for fallen leaves. The sweeping and smashing integrated machine for the fallen leaves comprises a sweeping device, a dust smashing collecting device, four castors, a case, an outer casing, a control handrail, a storage battery and a control system; the cleaning device is installed on the front portion of the case; the dust smashing collecting device is installed on the middle rear portion of the case; the four castors are symmetrically installed at the bottom end of the case; the outer casing is installed at the top of the case; the control handle is connected to the rear portion of the case; the storage battery which is installed in the middle of the case is used for providing electric energy for the sweeping device, the dust smashing collecting device and the control system; the control system which is arranged inside an interior component of the case is used for controlling the sweeping device and the dust smashing collecting device. The sweeping and smashing integrated machine for the fallen leaves is mainly used for sweeping operation of fallen leaves in urban street green belt, a park and a campus lawn greenbelt, the fallen leaves form into leaf fragments after sweeping, collecting and smashing, the space utilization rate of a collection box is improved, and convenience is provided for follow-up processing.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

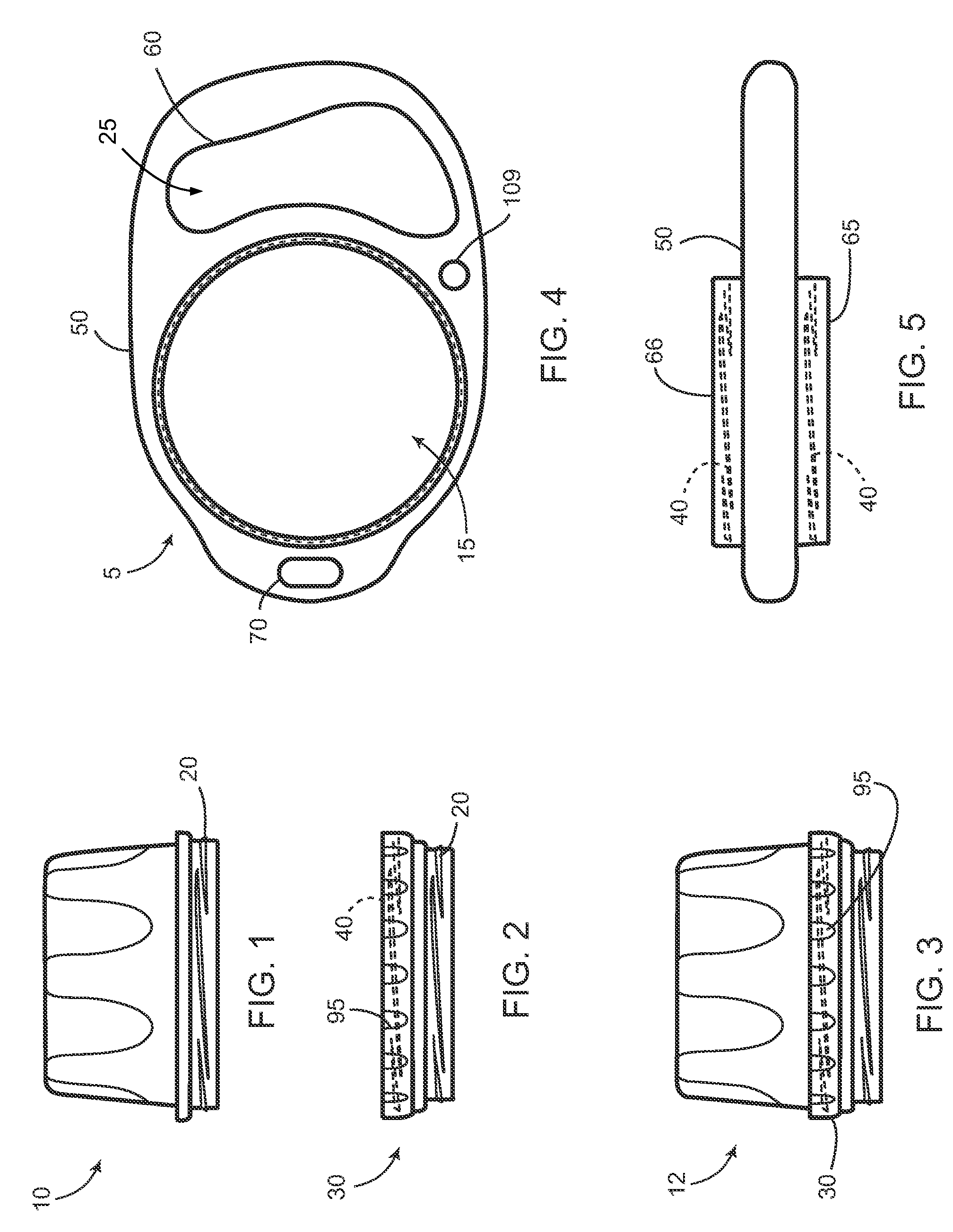

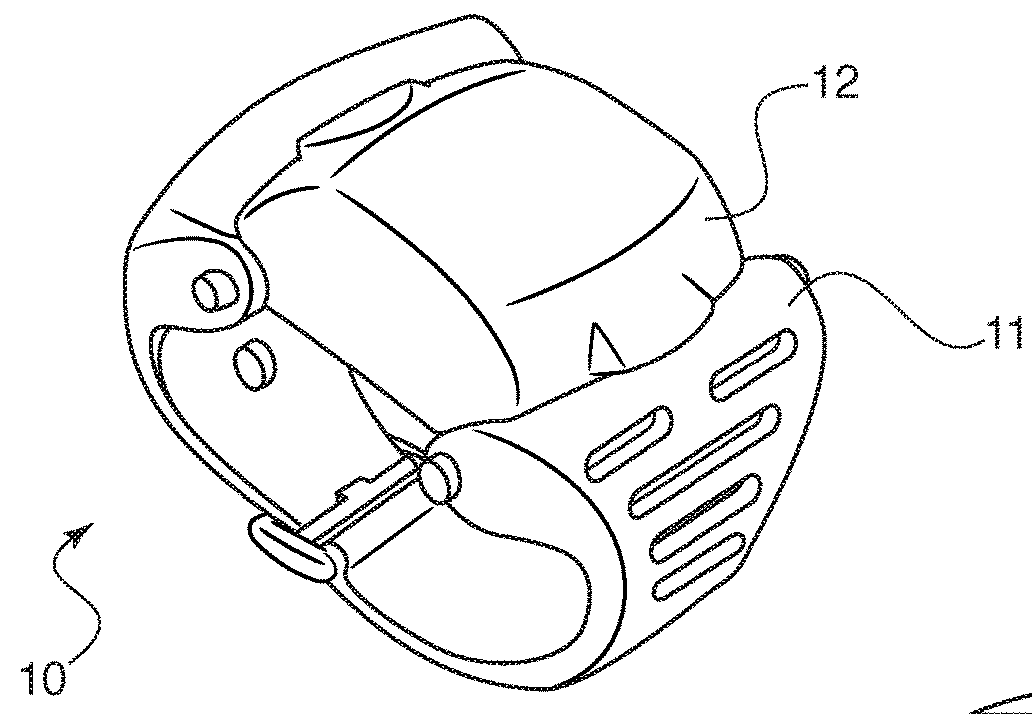

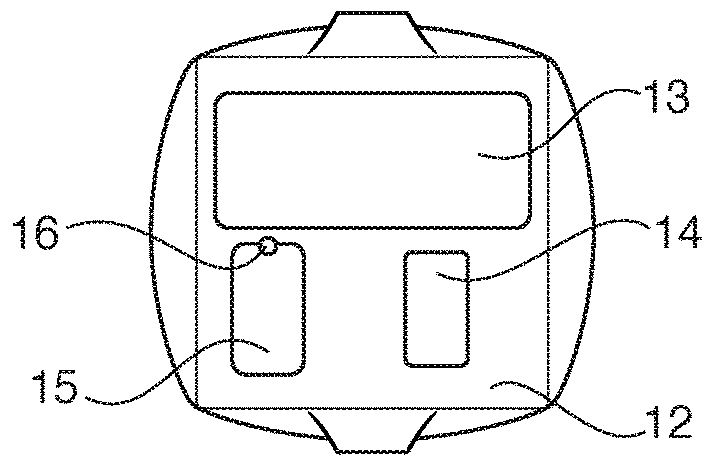

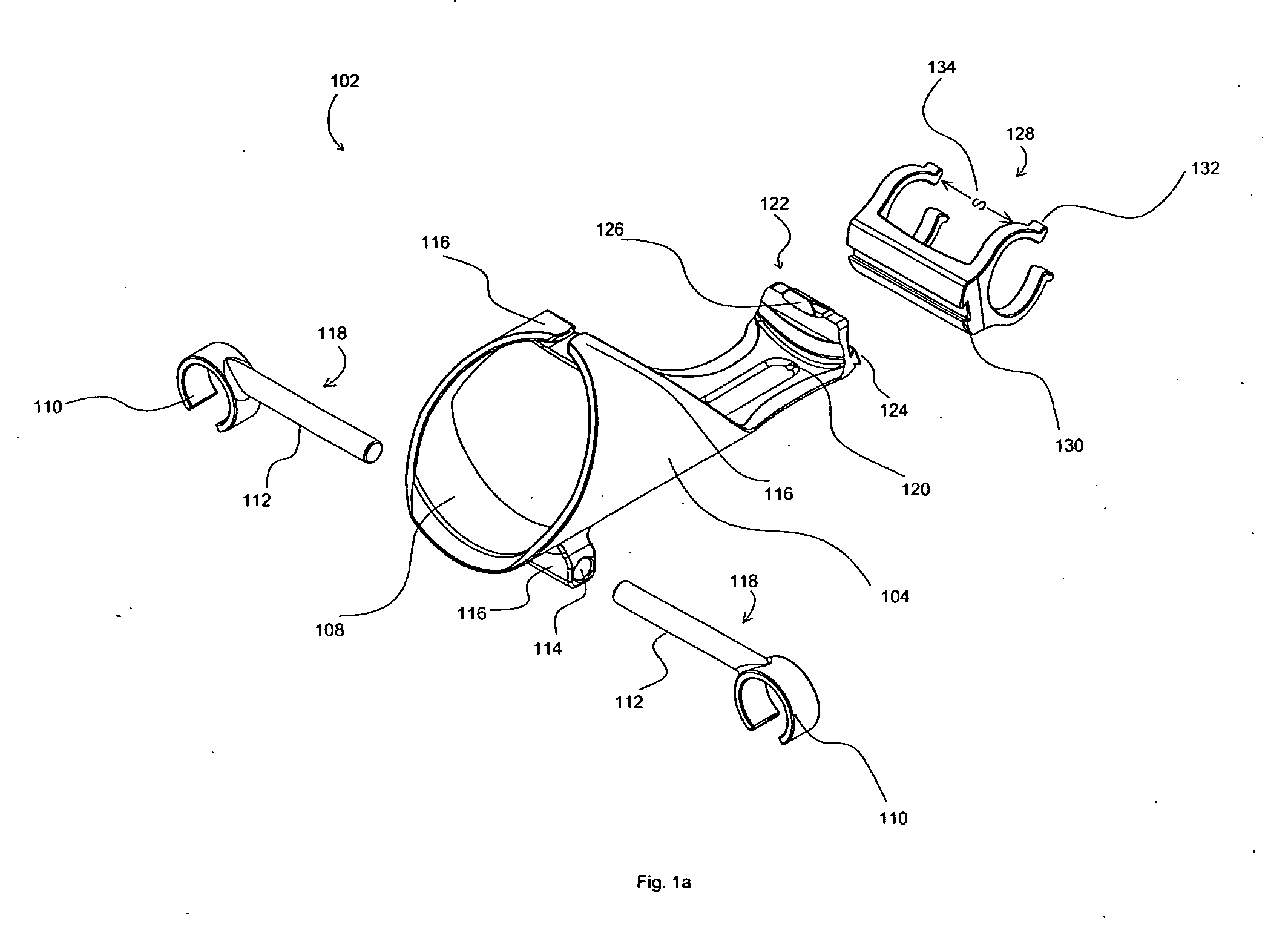

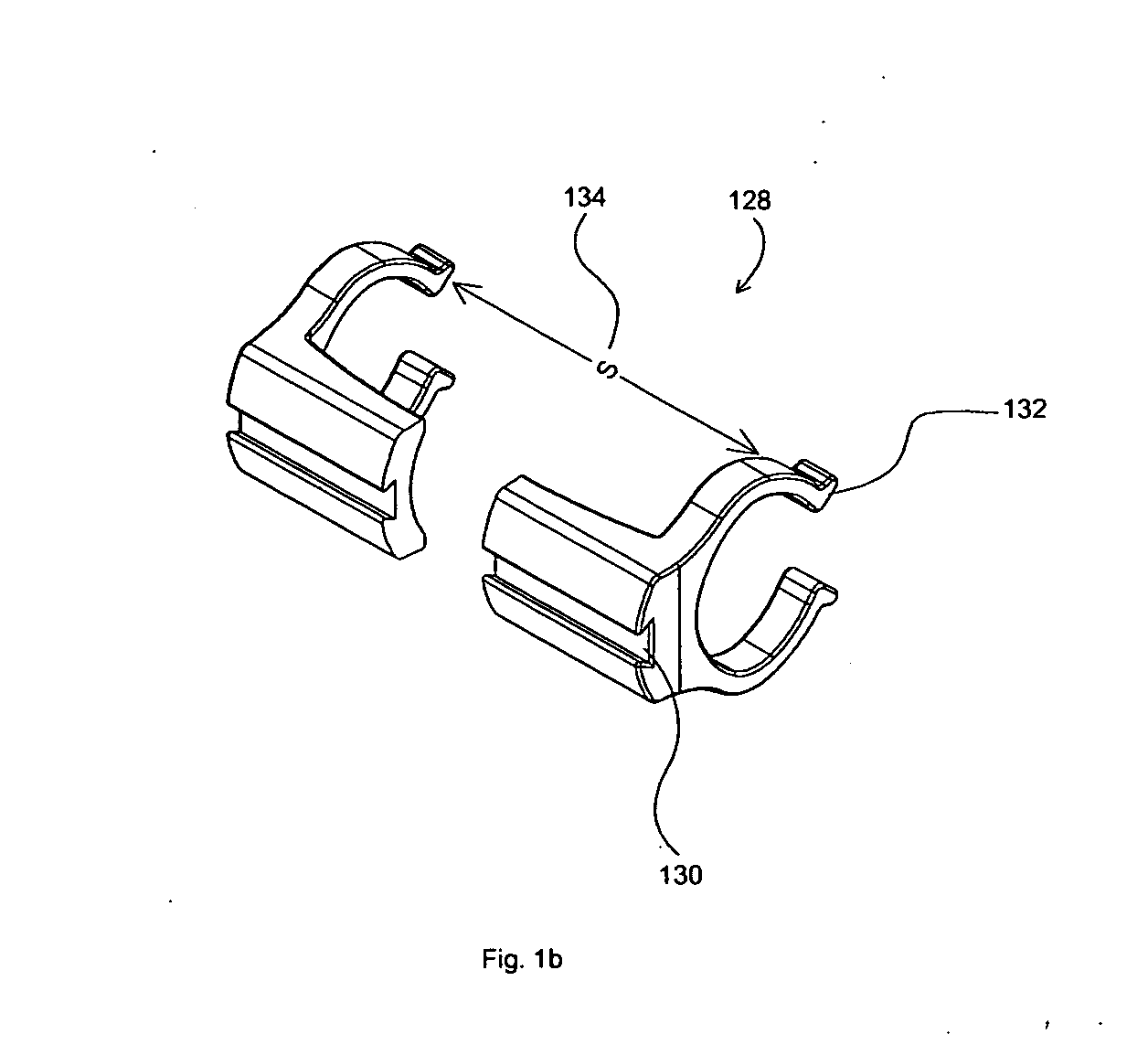

Dog leash assembly with removable containers

InactiveUS20100018468A1Easy refillEasily refilledAnimal feeding devicesAnimal housingEngineeringLeather belt

A dog leash handle assembly is provided with containers for dog food and water which are removeably attached to the assembly. Thus, the dog owner has a single assembly including the leash and provisions for the dog which are readily transported. The assembly also provides a place for the storage of clean up bags and other items. The handle assembly further includes has a mechanism for attaching to the loop handle of a typical dog leash but may also be used with a retractable leash.

Owner:RABELLO BILLY PAK

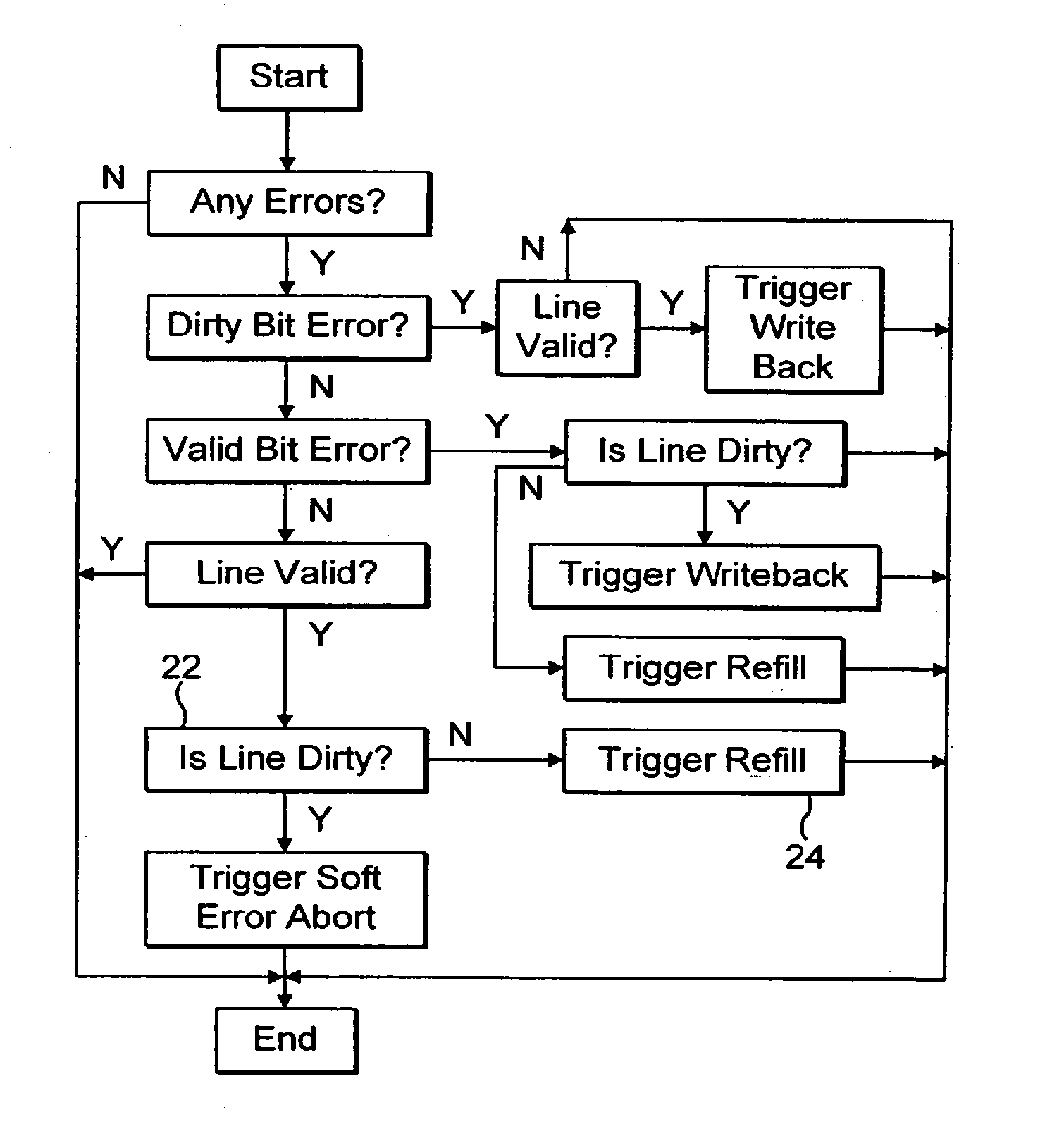

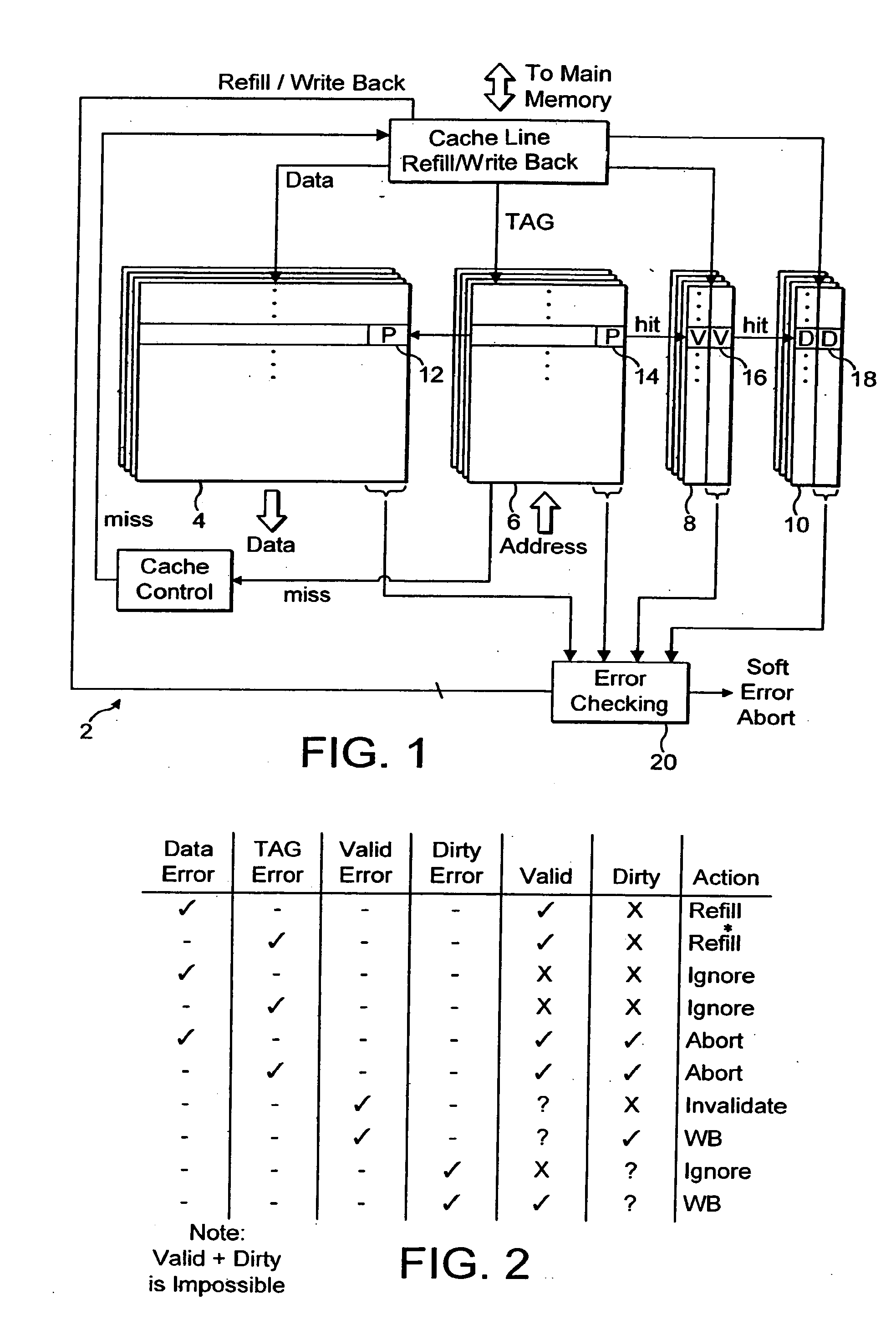

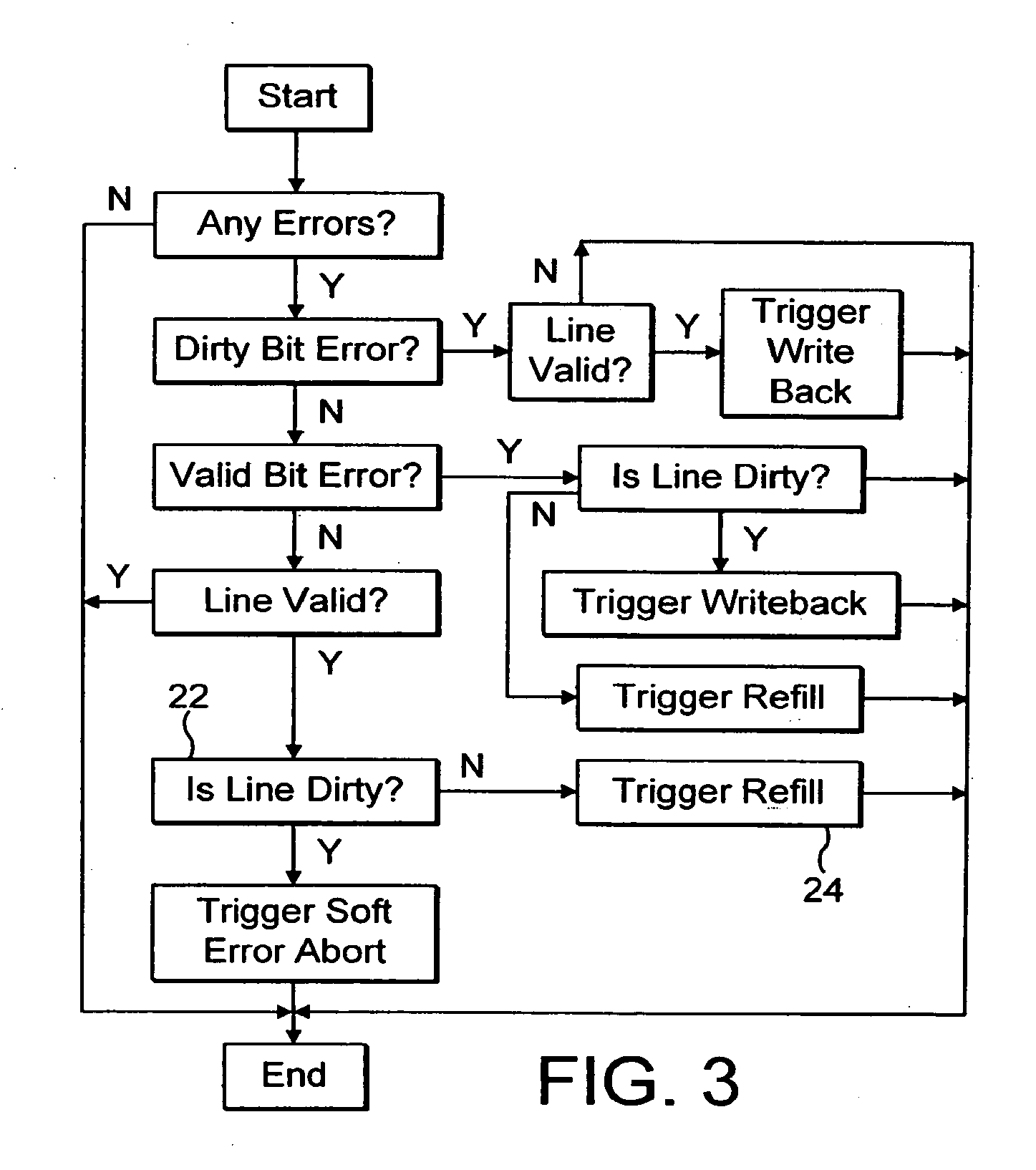

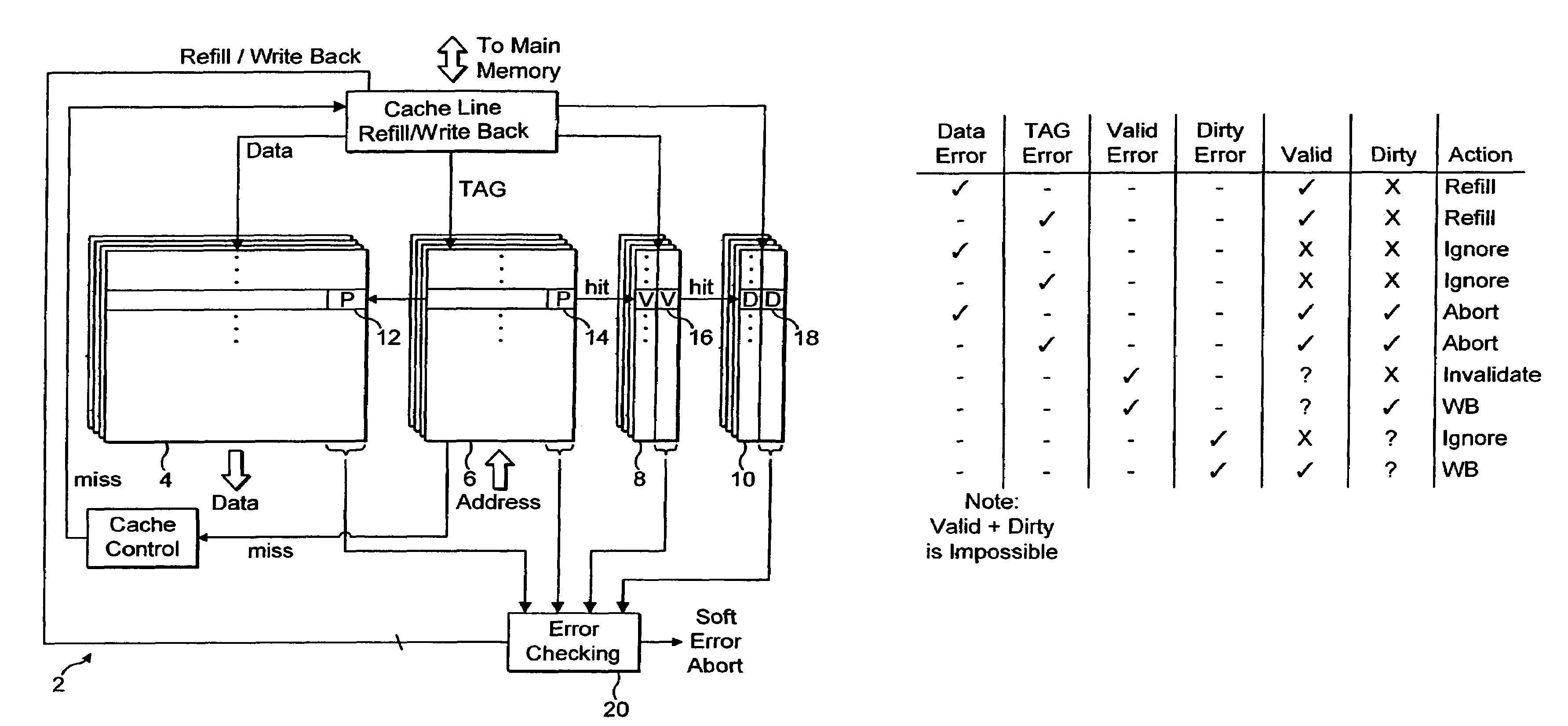

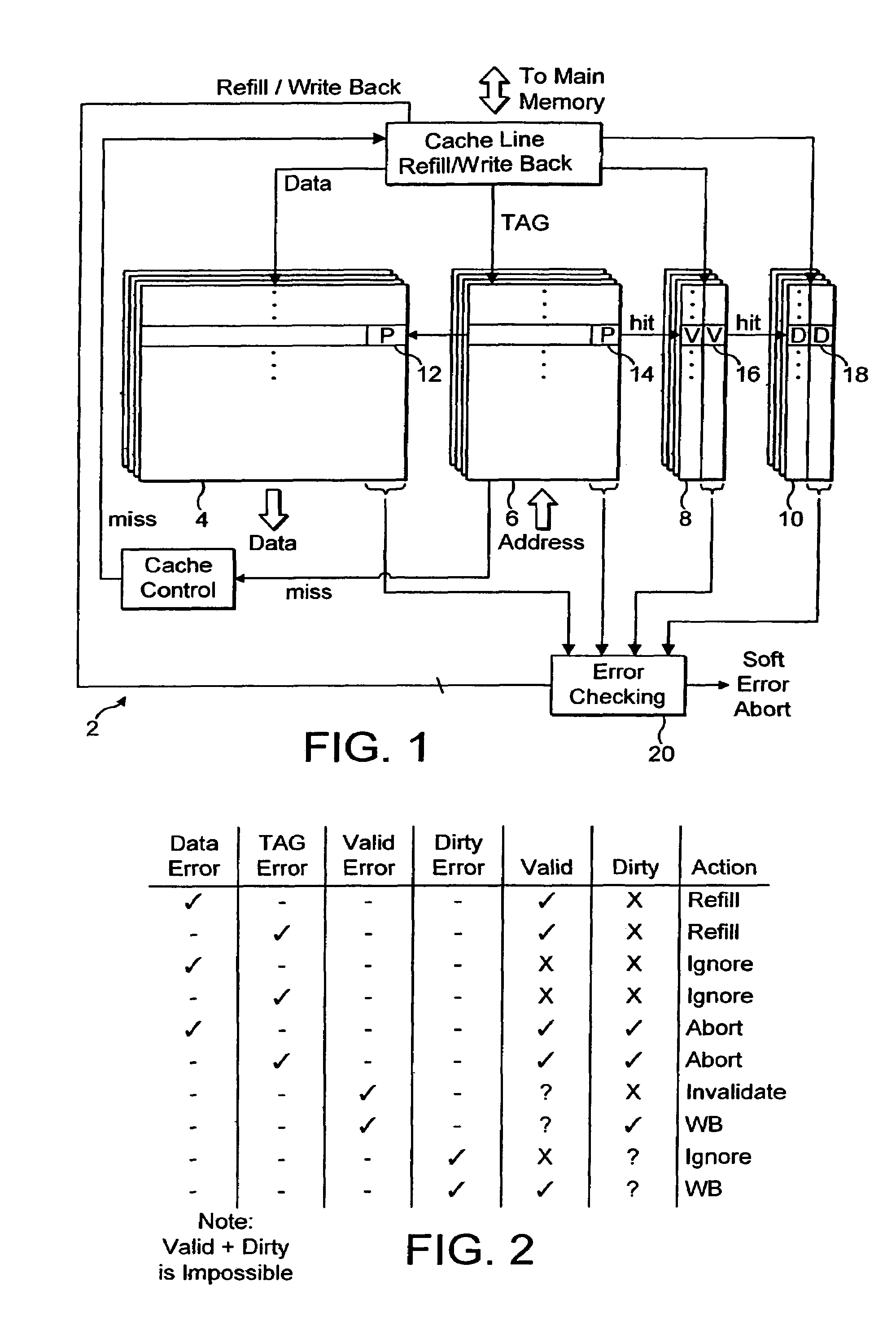

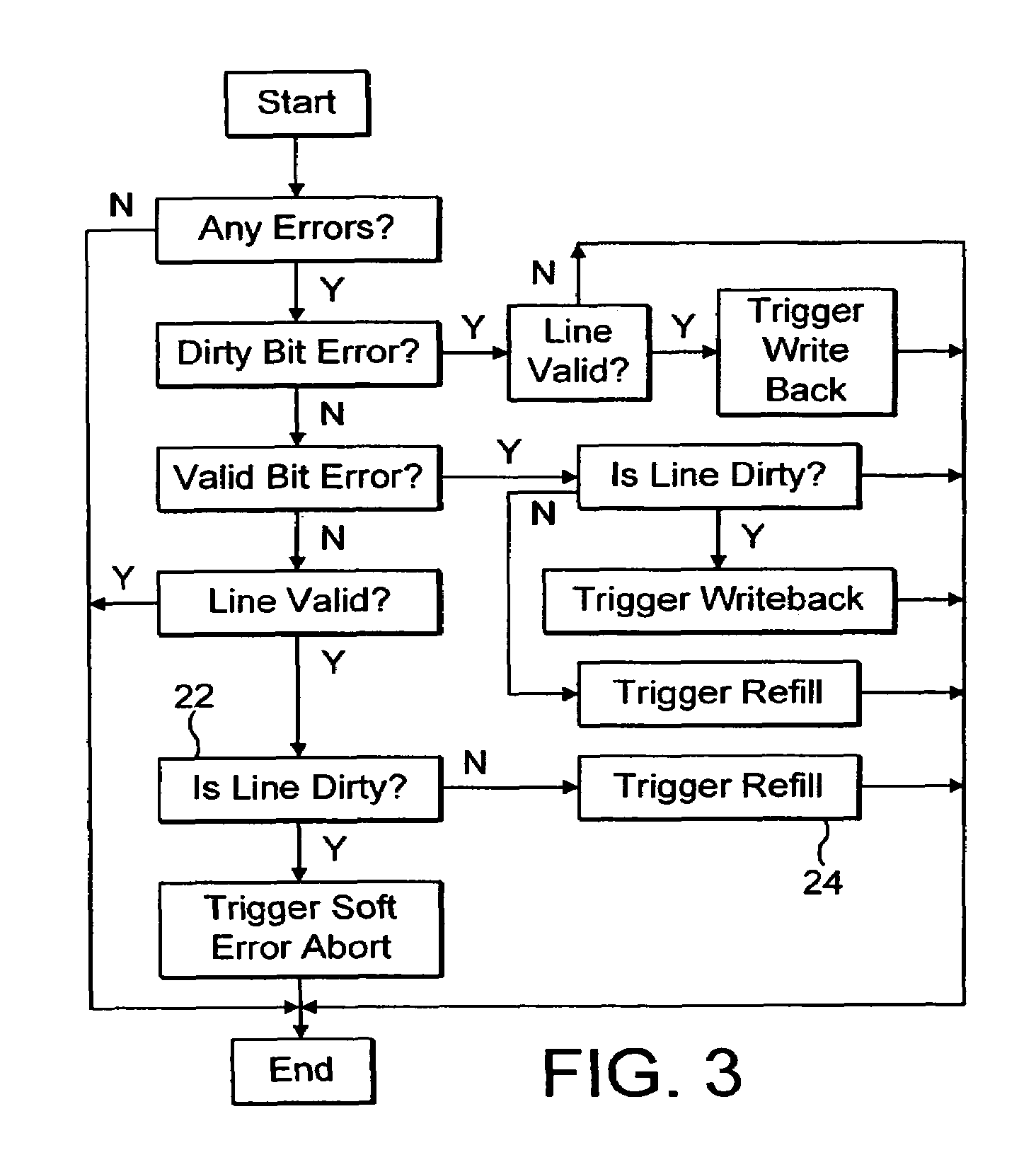

Error correction within a cache memory

ActiveUS20050188249A1Easy refillEfficient repairMemory loss protectionMemory adressing/allocation/relocationComputer hardwareSoft error

A cache memory 2 includes error bits corresponding to each line of data. An error detecting circuit uses these error bits 12, 14, 16, 18 to detect if a soft error has occurred within the data of a cache line. If such an error has occurred, then the line may be refilled from the main memory or some other action taken, such as a write back or generation of a soft error abort signal.

Owner:ARM LTD

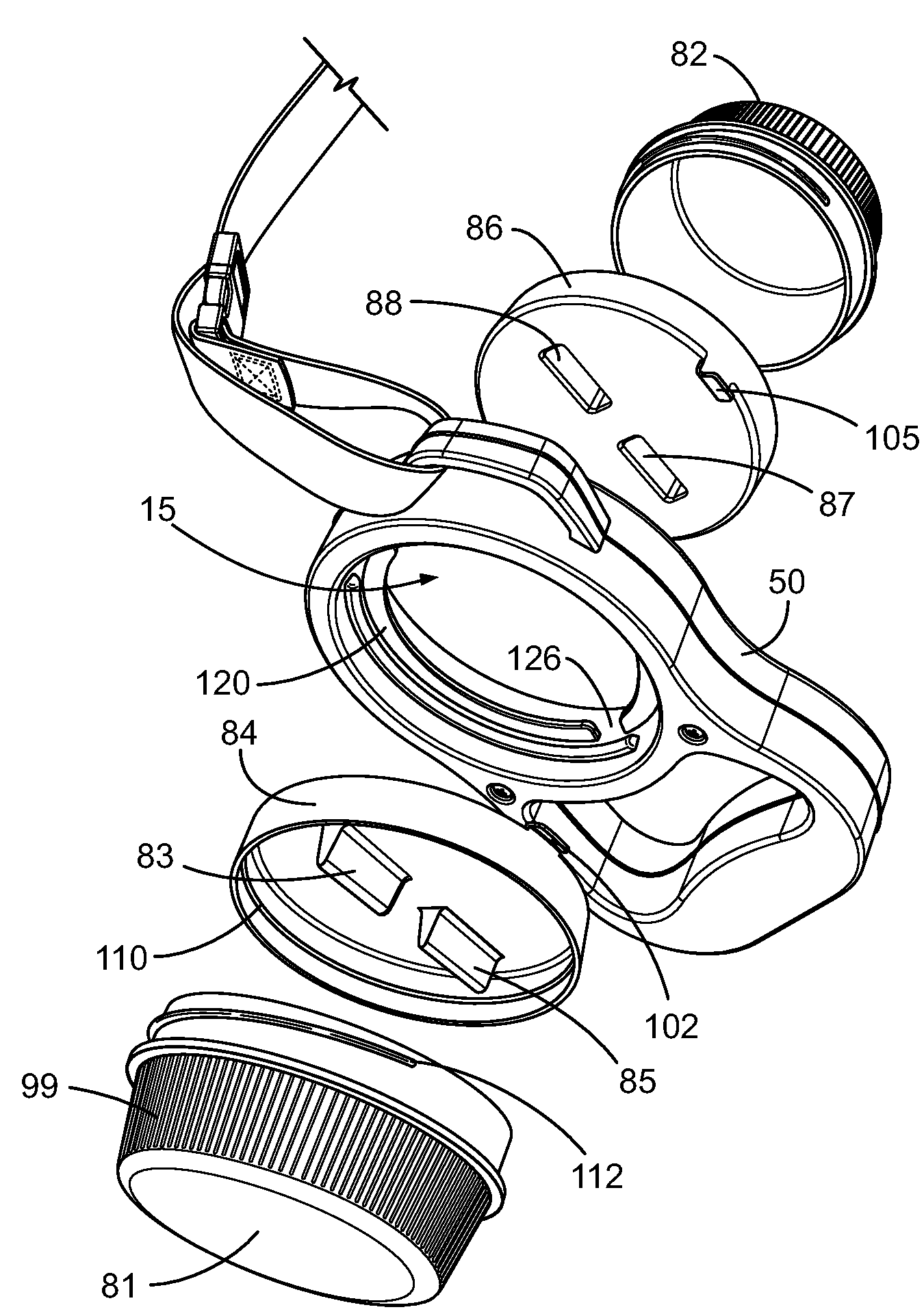

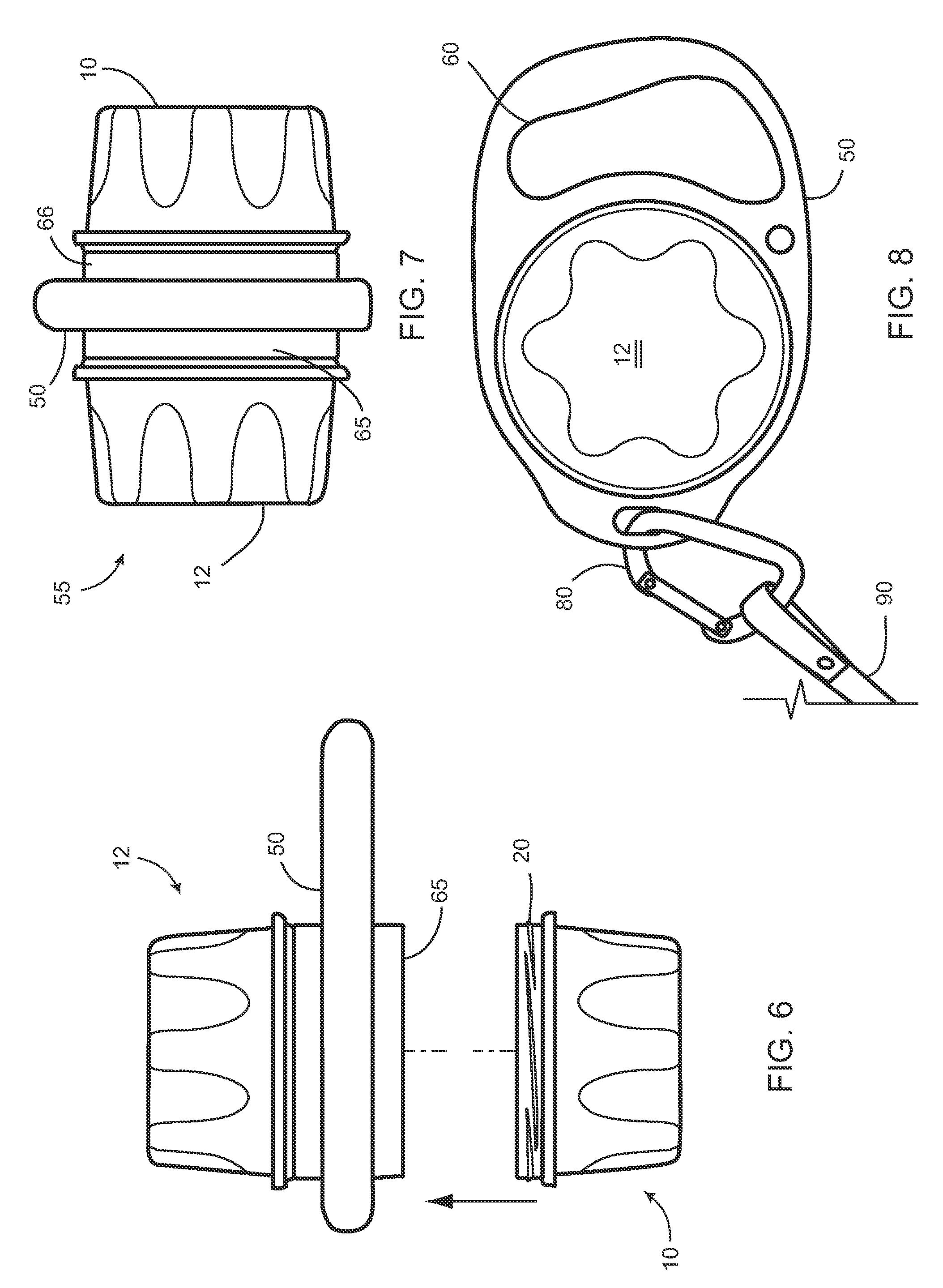

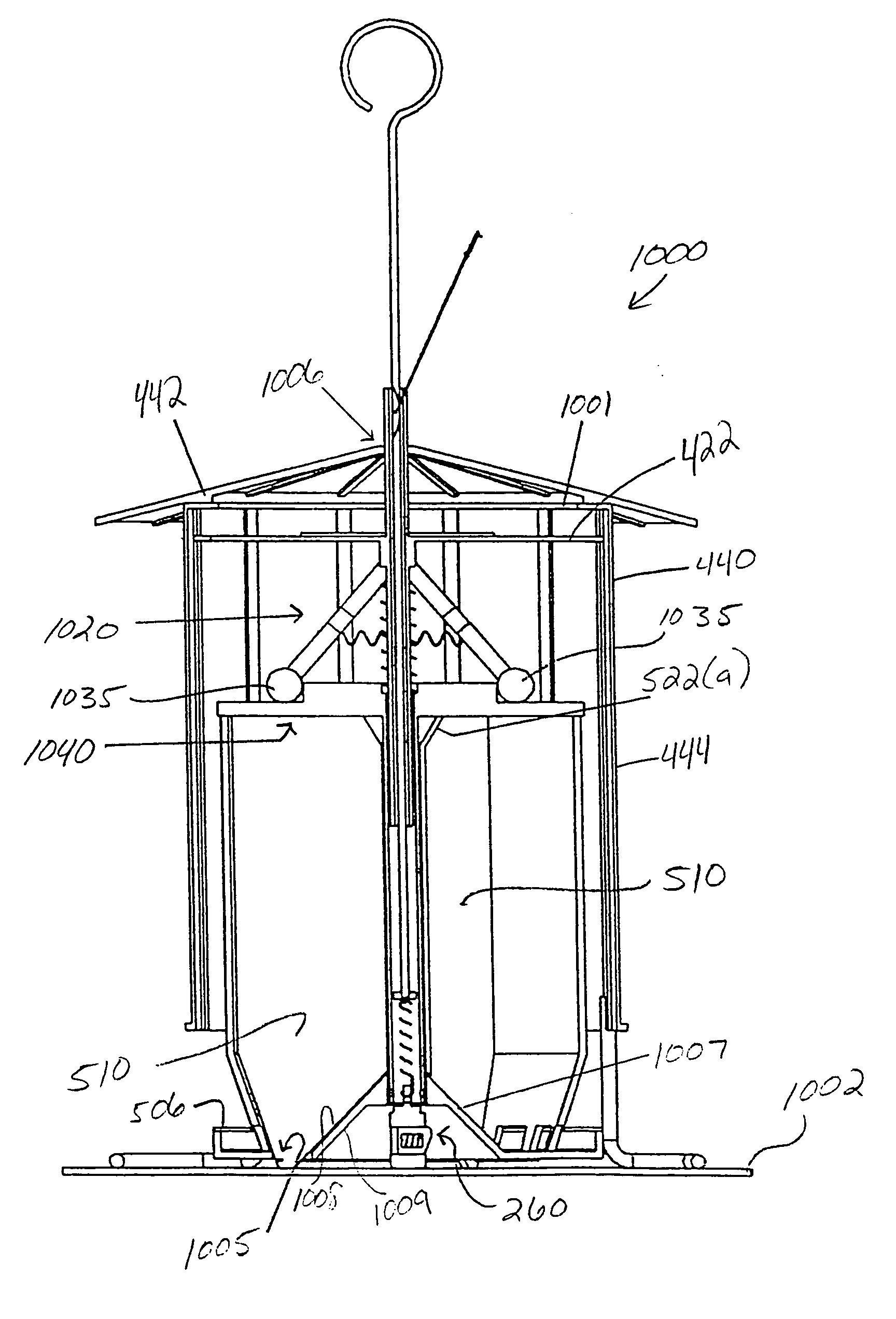

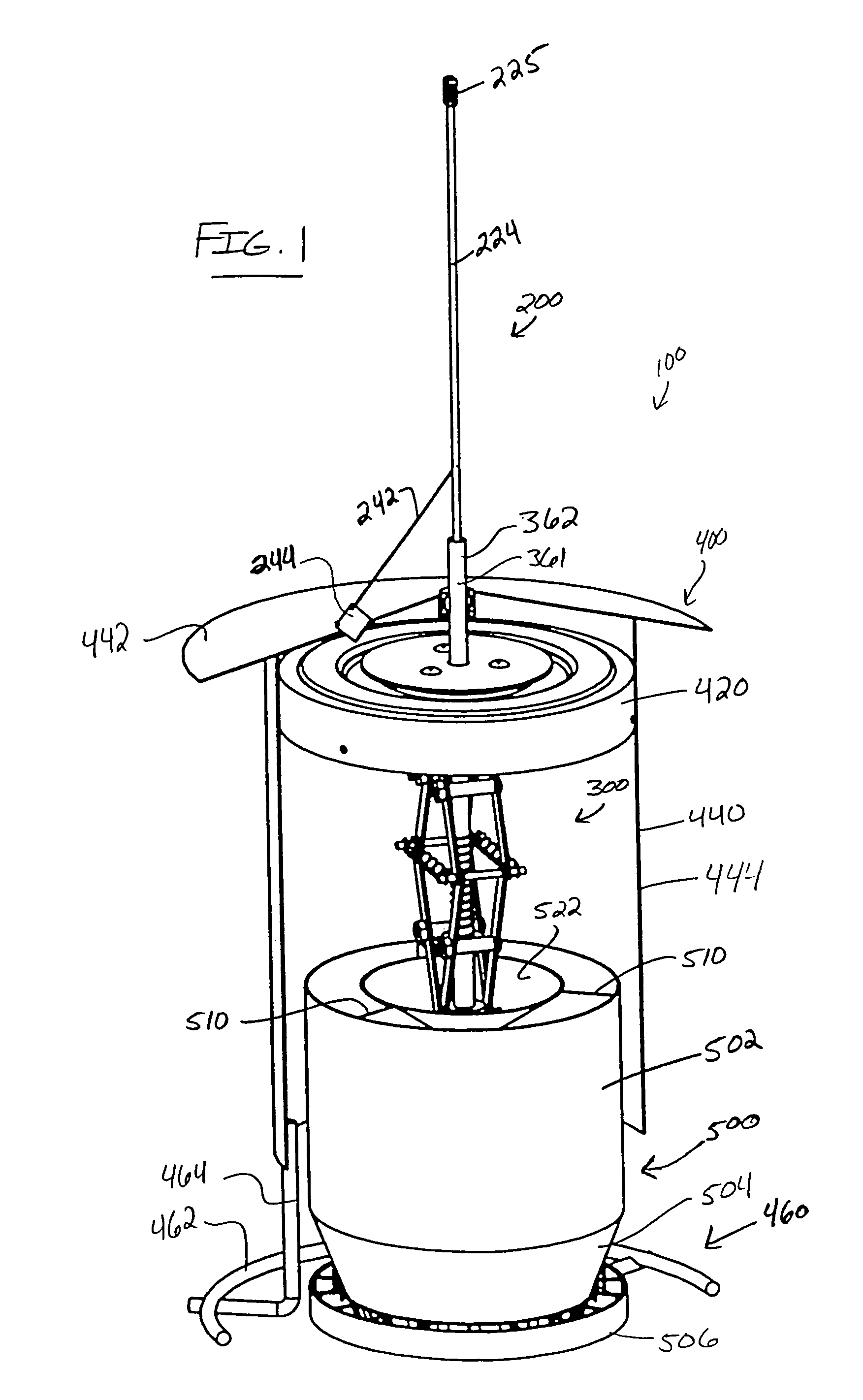

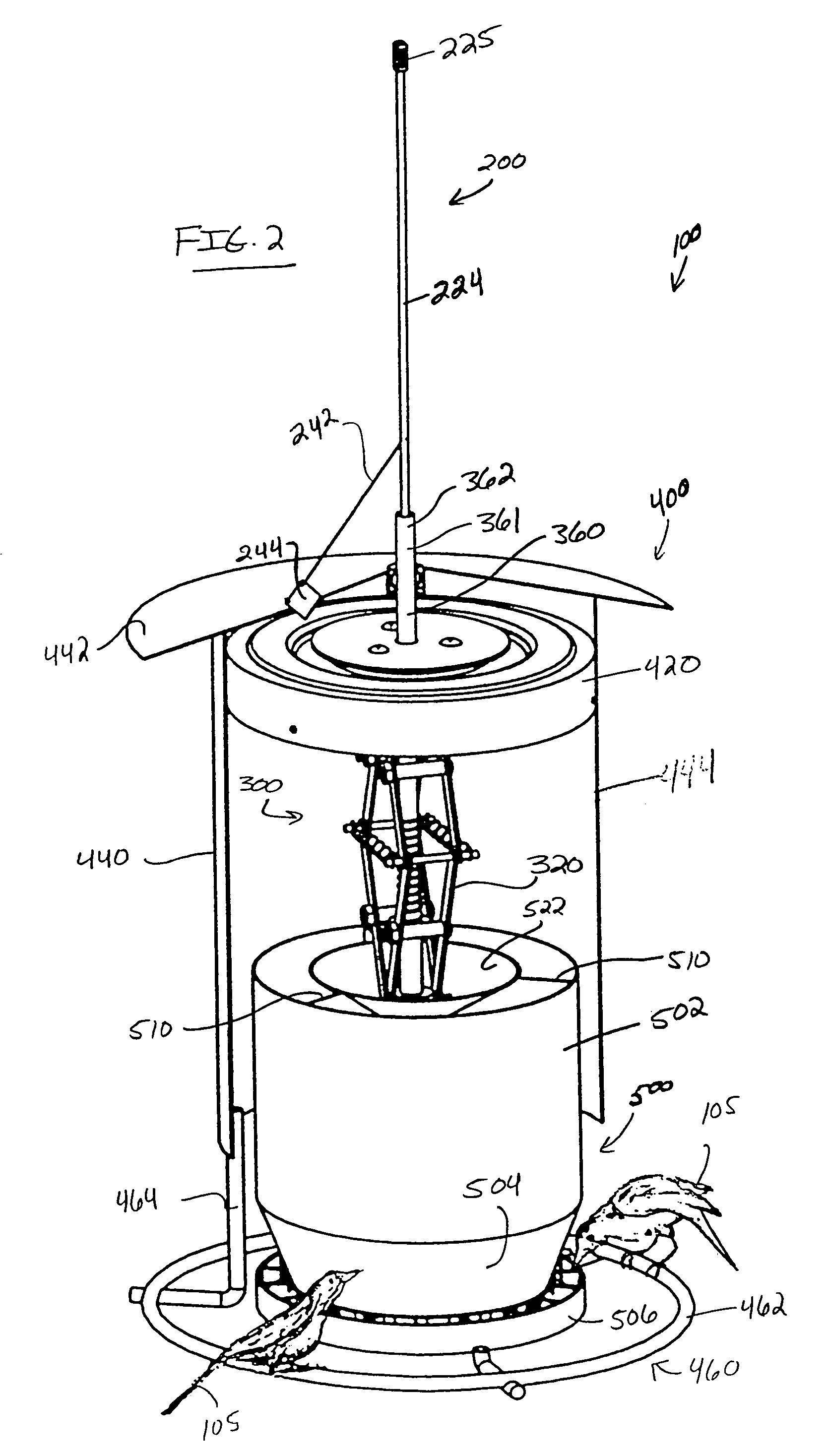

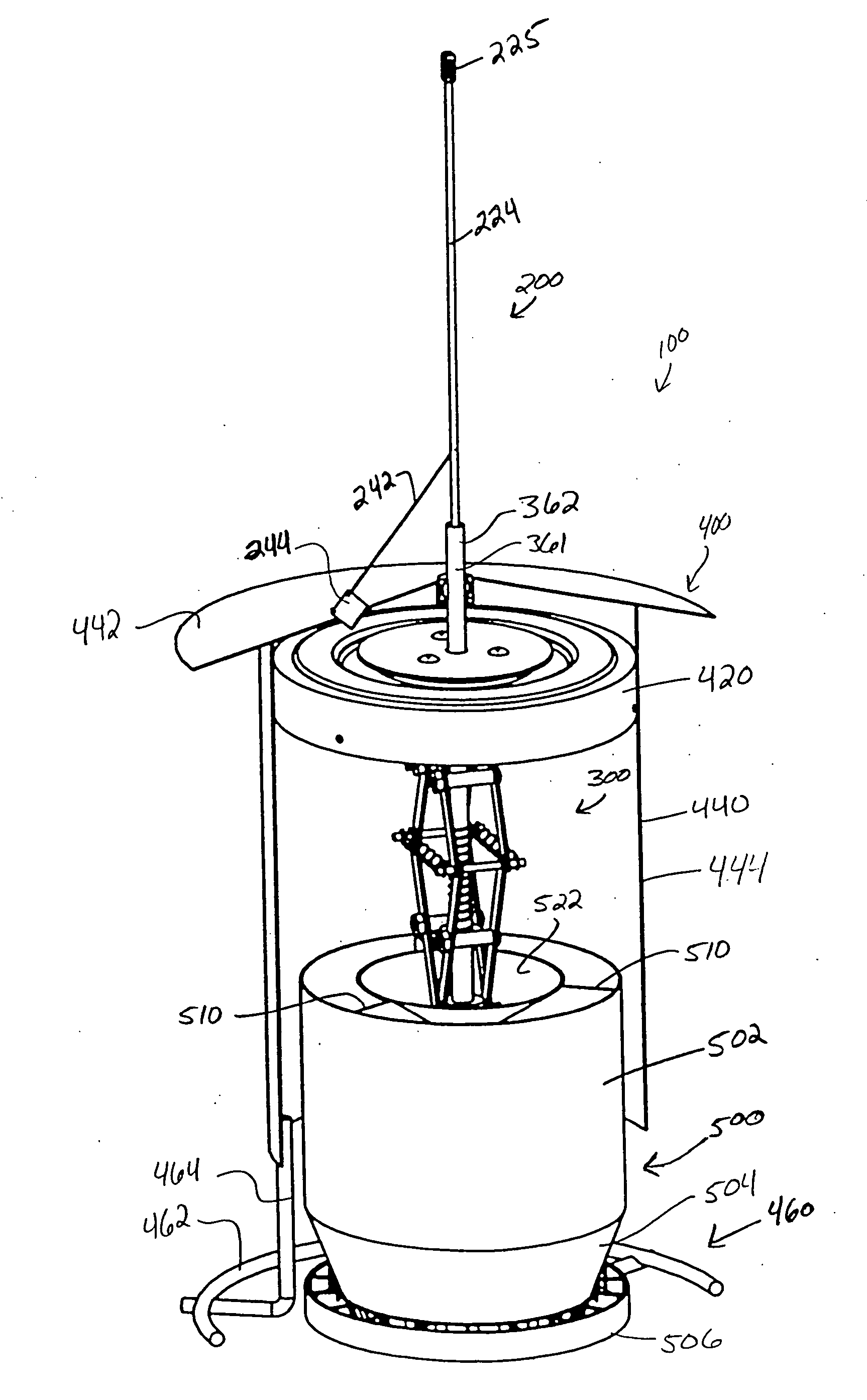

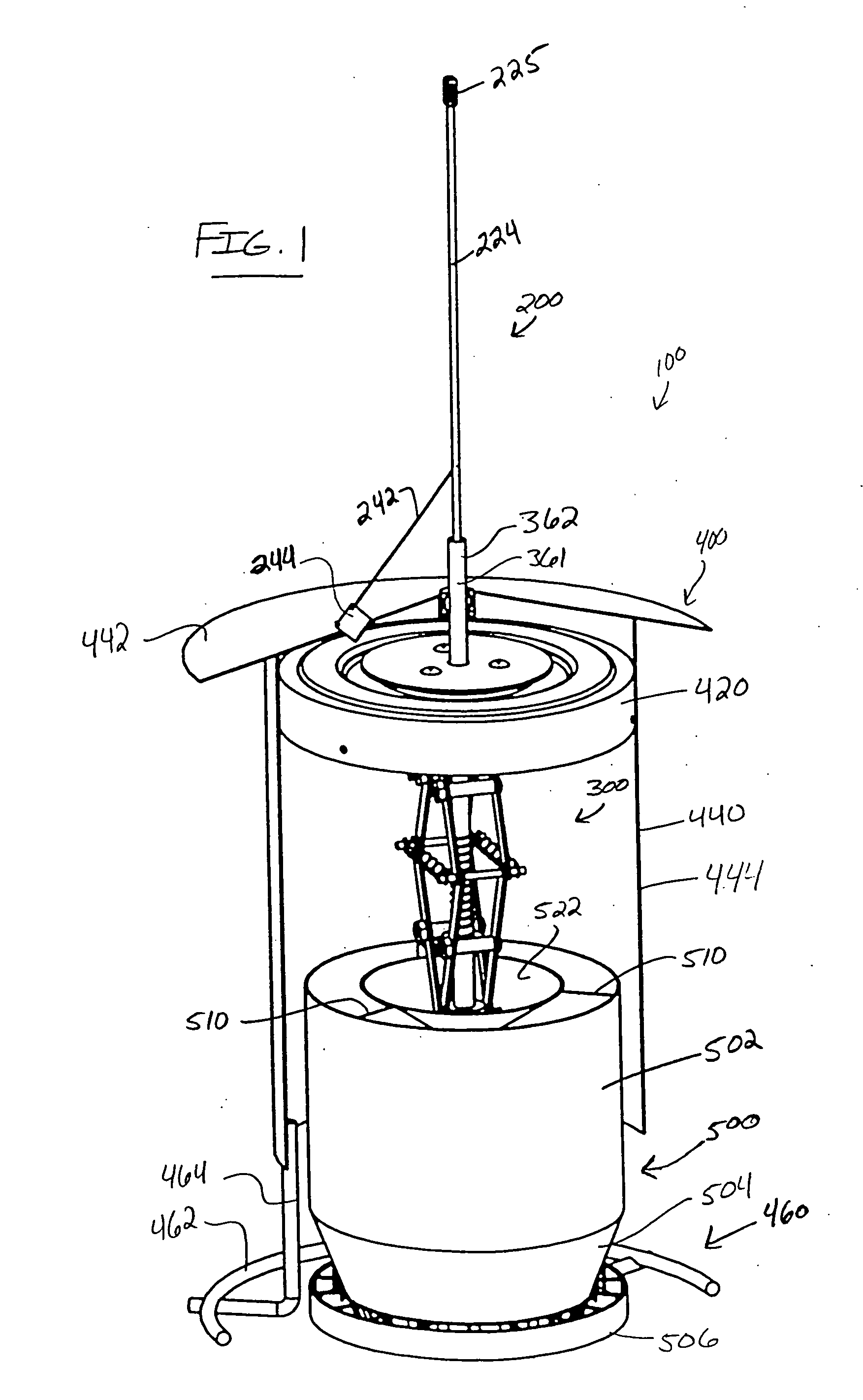

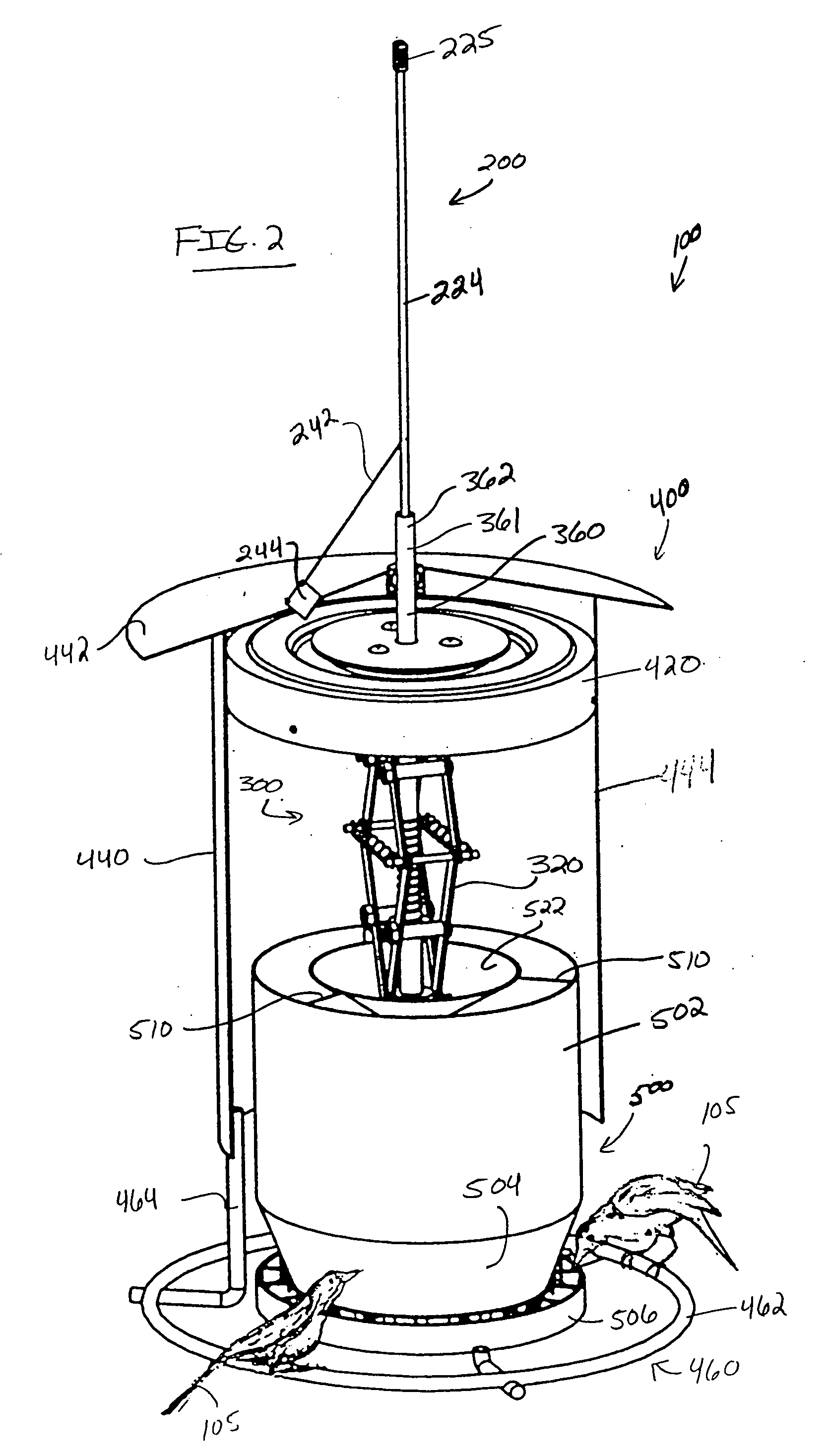

Anti-squirrel bird feeder

ActiveUS7219621B2Easy to cleanImprove viewing effectAnimal feeding devicesAnimal housingSebastesBird feeder

The present invention provides a bird feeder apparatus for providing a readily available supply of feed for birds. The apparatus comprises a telescopic-operational assemblage, a shroud assembly, and a hopper assembly. The telescopic-operational assemblage provides a nonlinear, geometrically-based closure mechanism for effectively closing the bird feeder when a large load is placed upon the shroud assembly such as when a squirrel attempts to gain access to feed outlets of the hopper assembly by positioning itself upon the apparatus. Further, the apparatus provides a partitioned, selectively removable (drop out-type) hopper for enabling easy refills; a feed-level status flag assembly for indicating to the user whether the hopper assembly is full or empty; and at least one surround perch assembly for accommodating birds of various sizes.

Owner:CORONEOS DONALD L

Error correction within a cache memory

ActiveUS7328391B2Easy refillEfficient repairMemory loss protectionMemory adressing/allocation/relocationComputer hardwareForward error correction

A cache memory includes error bits corresponding to each line of data. An error detecting circuit uses these error bits to detect if a soft error has occurred within the data of a cache line. If such an error has occurred, then the line may be refilled from the main memory or some other action taken, such as a write back or generation of a soft error abort signal.

Owner:ARM LTD

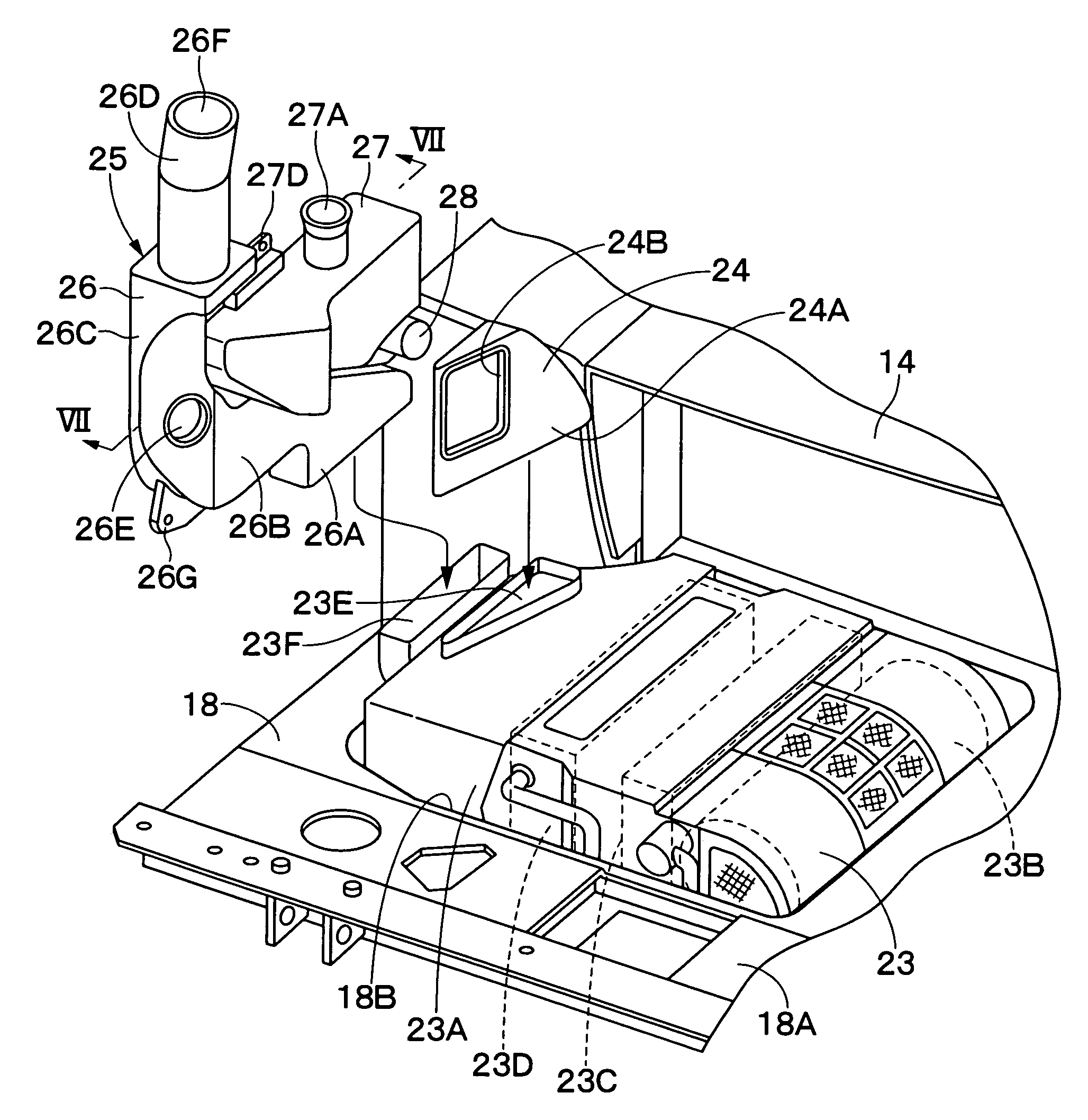

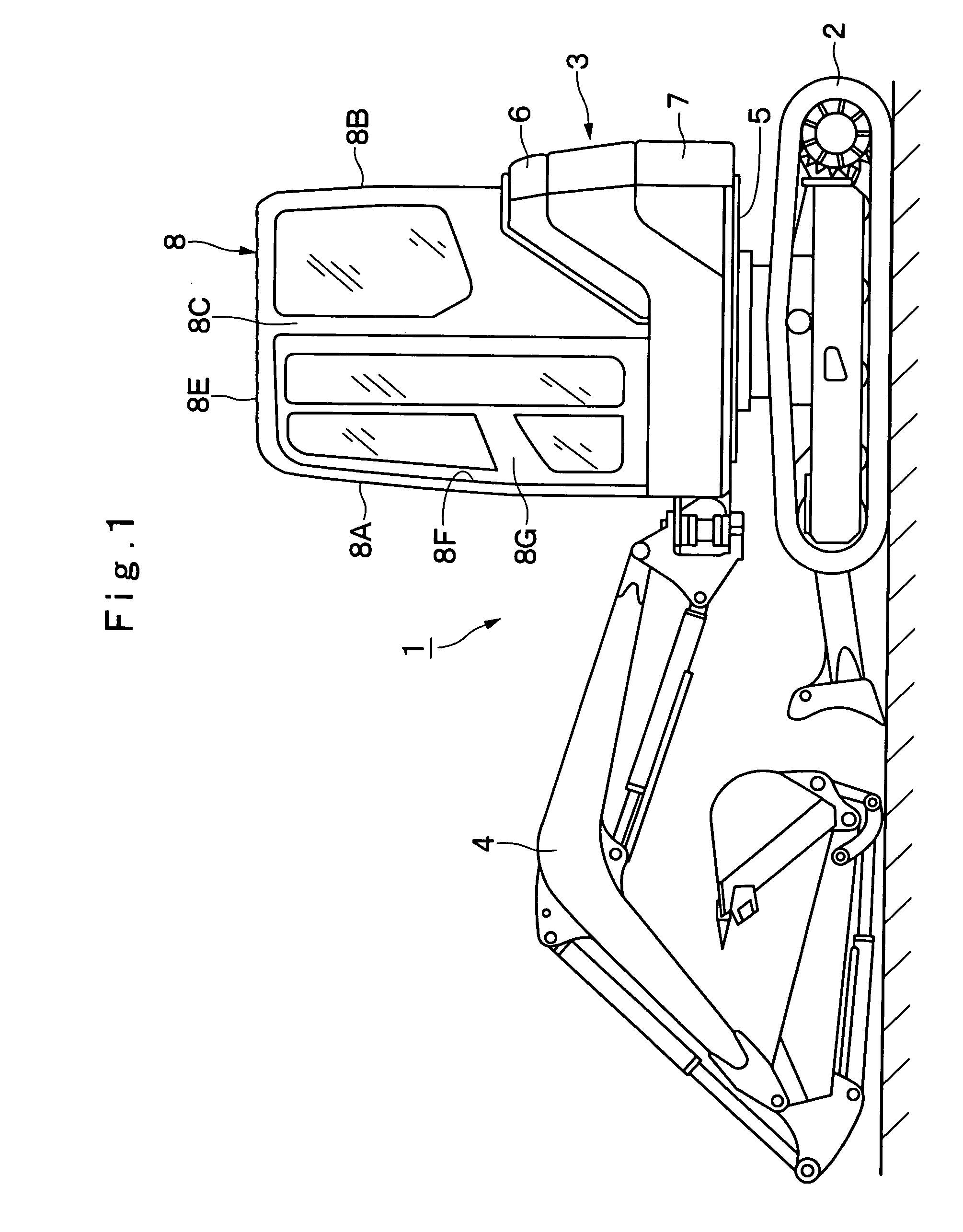

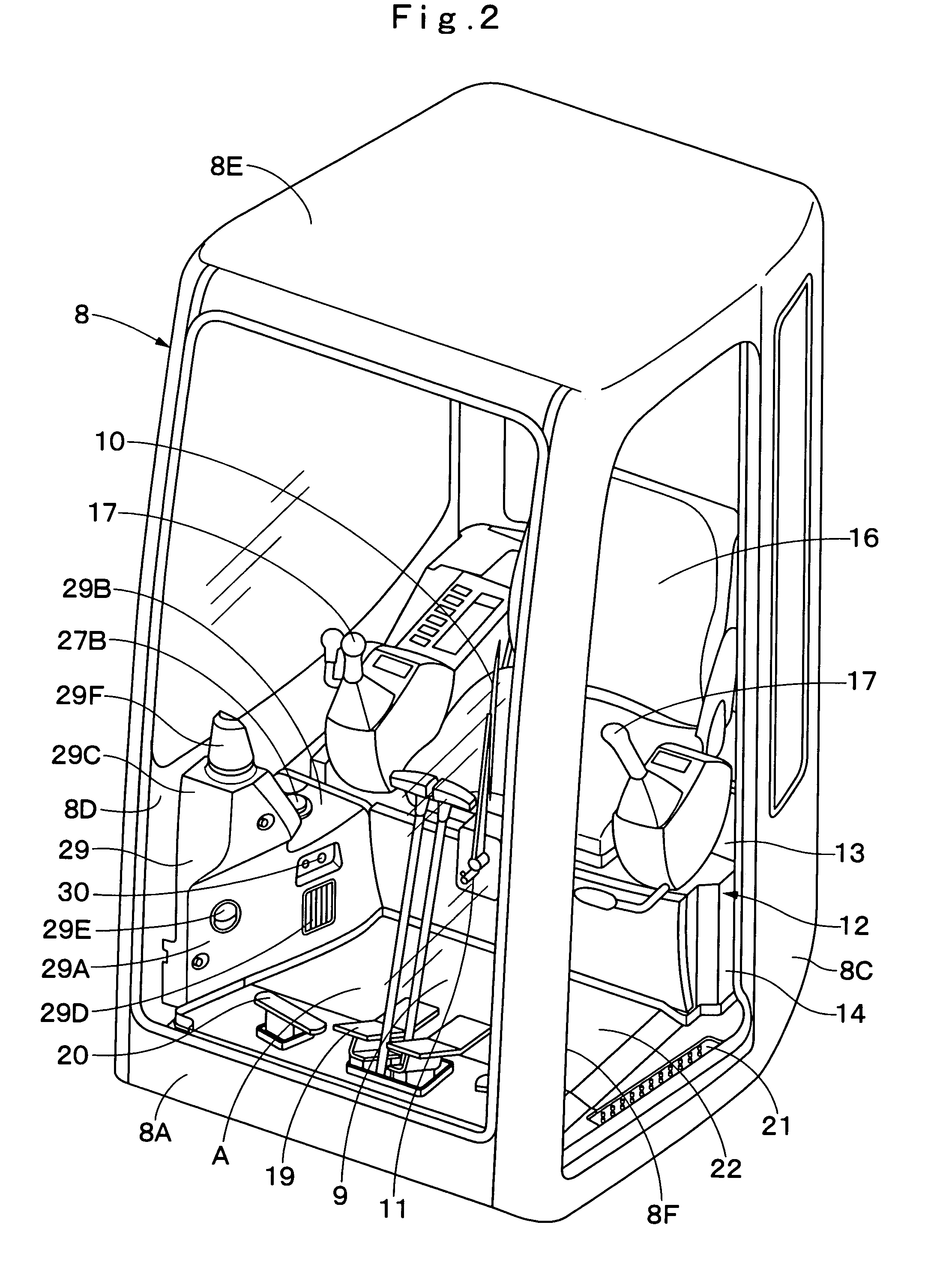

Construction machine

ActiveUS7537074B2Improve reliabilityGuarantee efficiencyVehicle seatsSoil-shifting machines/dredgersScrubberBuilding construction

A washer tank is integrally formed with a front air duct, and the washer tank and the front air duct are installed within a cab. Thus, the washer tank can be installed within the cab by the use of spaces around the air duct. This arrangement makes it possible to install the washer tank within the cab in an unintrusive way and in the vicinity of a washer liquid spout nozzle without necessitating to provide an installation space exclusively for the washer tank.

Owner:NIHON KENKI CO LTD

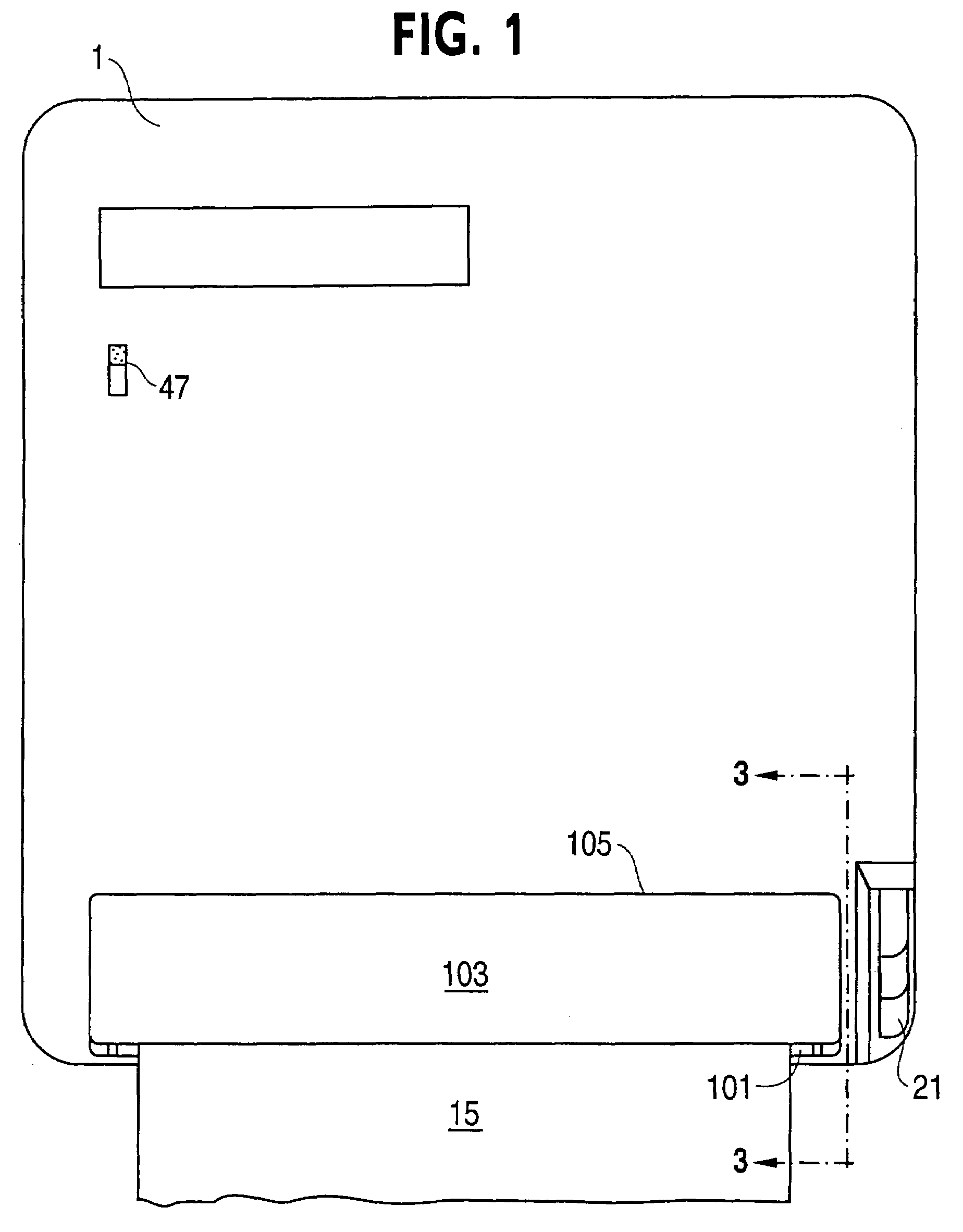

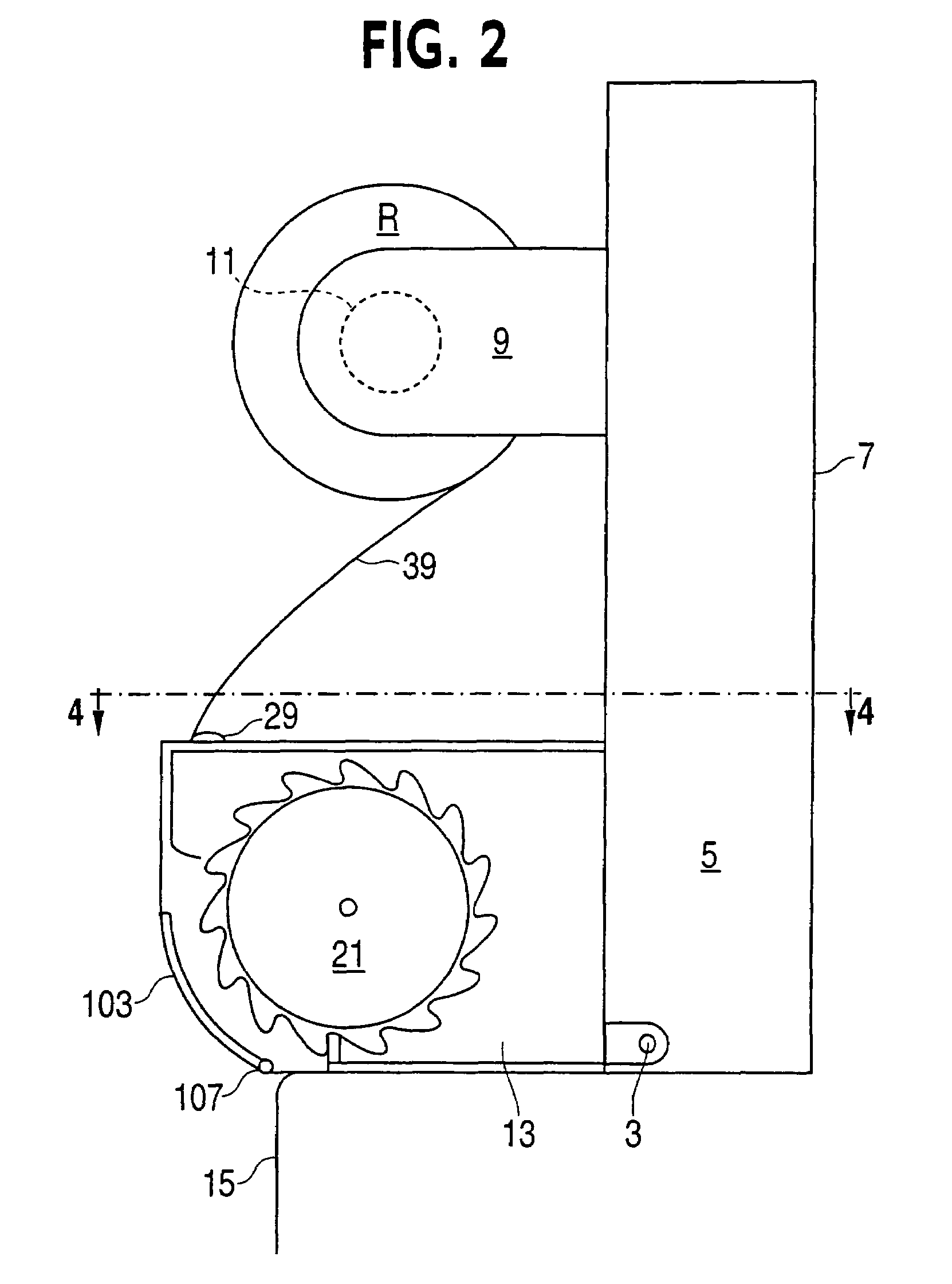

Collapsible bird feeder with a removable tray

InactiveUS20090031962A1Easy to cleanEasy refillAnimal watering devicesAnimal feeding devicesBird feederEngineering

The present invention generally relates to a bird feeder having a removable tray. The removable tray may be generally circular and may have an opening that wraps around a telescoping support section. Further, the removable tray may have a convex portion which acts to counter-balance the bird feeder. The removable tray is especially useful for cleaning and / or refilling the bird feeder. The bird feeder may be collapsed in a first position for storage or transportation or may be opened telescopically in a second position for use. The bird feeder may further have a perch to allow a bird to rest while visiting the bird feeder and / or may have a concave portion on the top surface which may be used to prevent insects or other animals from accessing the bird food.

Owner:AKERUE INDS

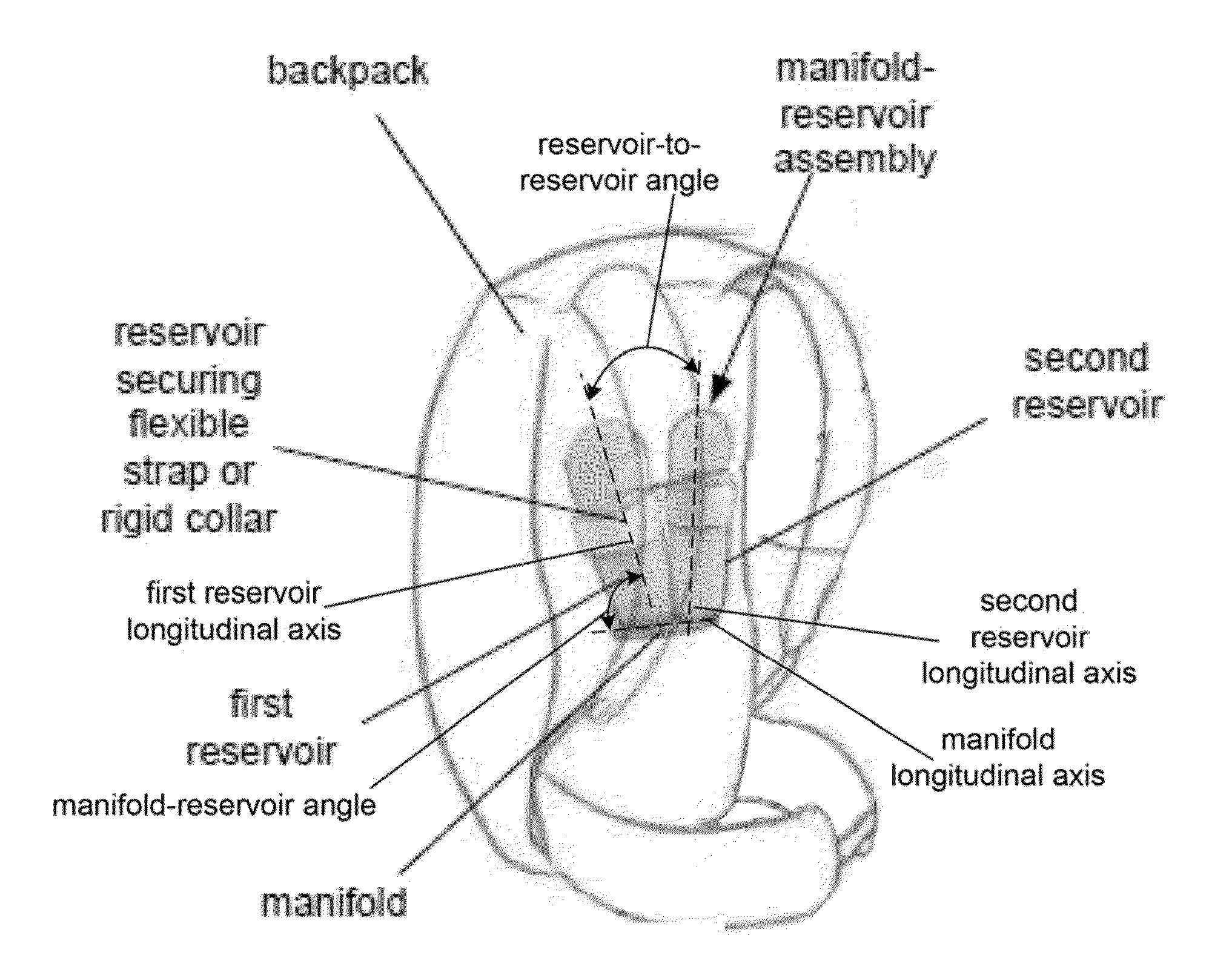

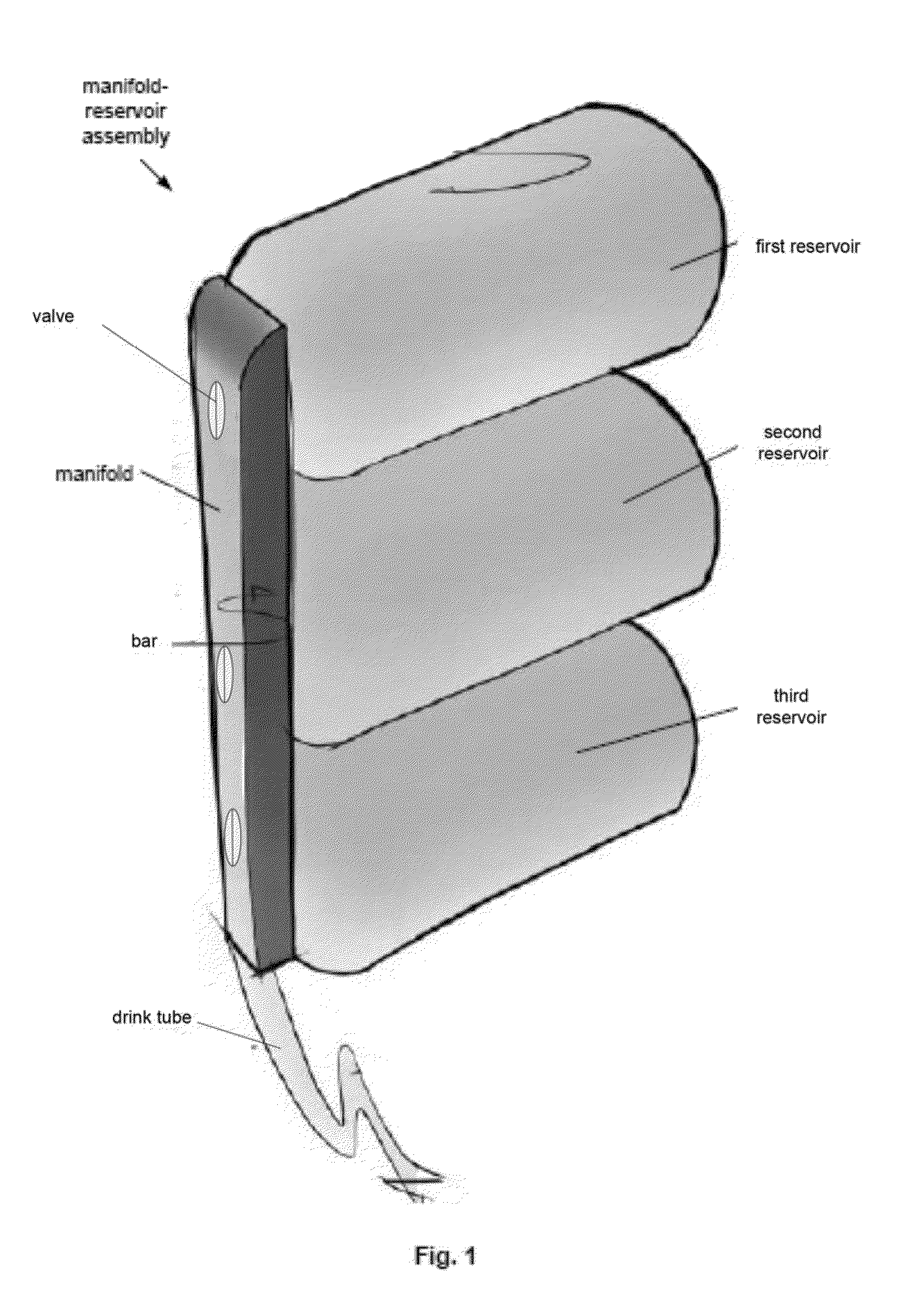

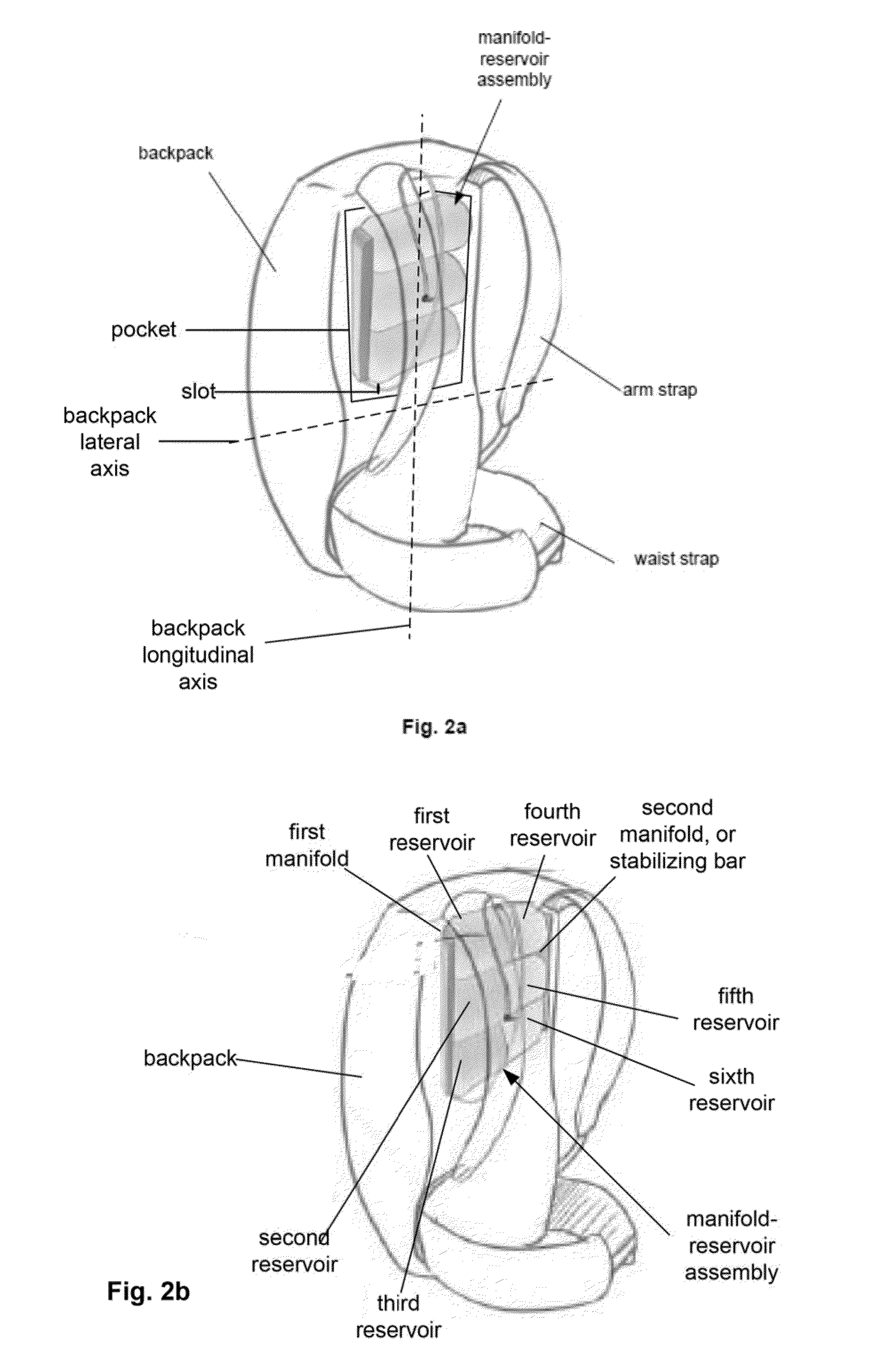

Reservoir system and method of making

InactiveUS20150053718A1Maximize comfortMaximize usability-whileTravelling sacksClosuresEngineeringReservoir system

A reservoir system is disclosed that can have two or more reservoirs attached to a manifold. The manifold can direct or control the flow of liquids from the reservoirs and deliver the liquids to a drinking tube extending from the manifold. The reservoirs and manifold can be in a backpack. Some or all of the reservoirs can be positioned on other parts of the body outside of the backpack.

Owner:HYDRAPAK LLC

Anti-squirrel bird feeder

ActiveUS20050263083A1Easy to cleanImprove viewing effectPisciculture and aquariaAvicultureSebastesBird feeder

The present invention provides a bird feeder apparatus for providing a readily available supply of feed for birds. The apparatus comprises a telescopic-operational assemblage, a shroud assembly, and a hopper assembly. The telescopic-operational assemblage provides a nonlinear, geometrically-based closure mechanism for effectively closing the bird feeder when a large load is placed upon the shroud assembly such as when a squirrel attempts to gain access to feed outlets of the hopper assembly by positioning itself upon the apparatus. Further, the apparatus provides a partitioned, selectively removable (drop out-type) hopper for enabling easy refills; a feed-level status flag assembly for indicating to the user whether the hopper assembly is full or empty; and at least one surround perch assembly for accommodating birds of various sizes.

Owner:CORONEOS DONALD L

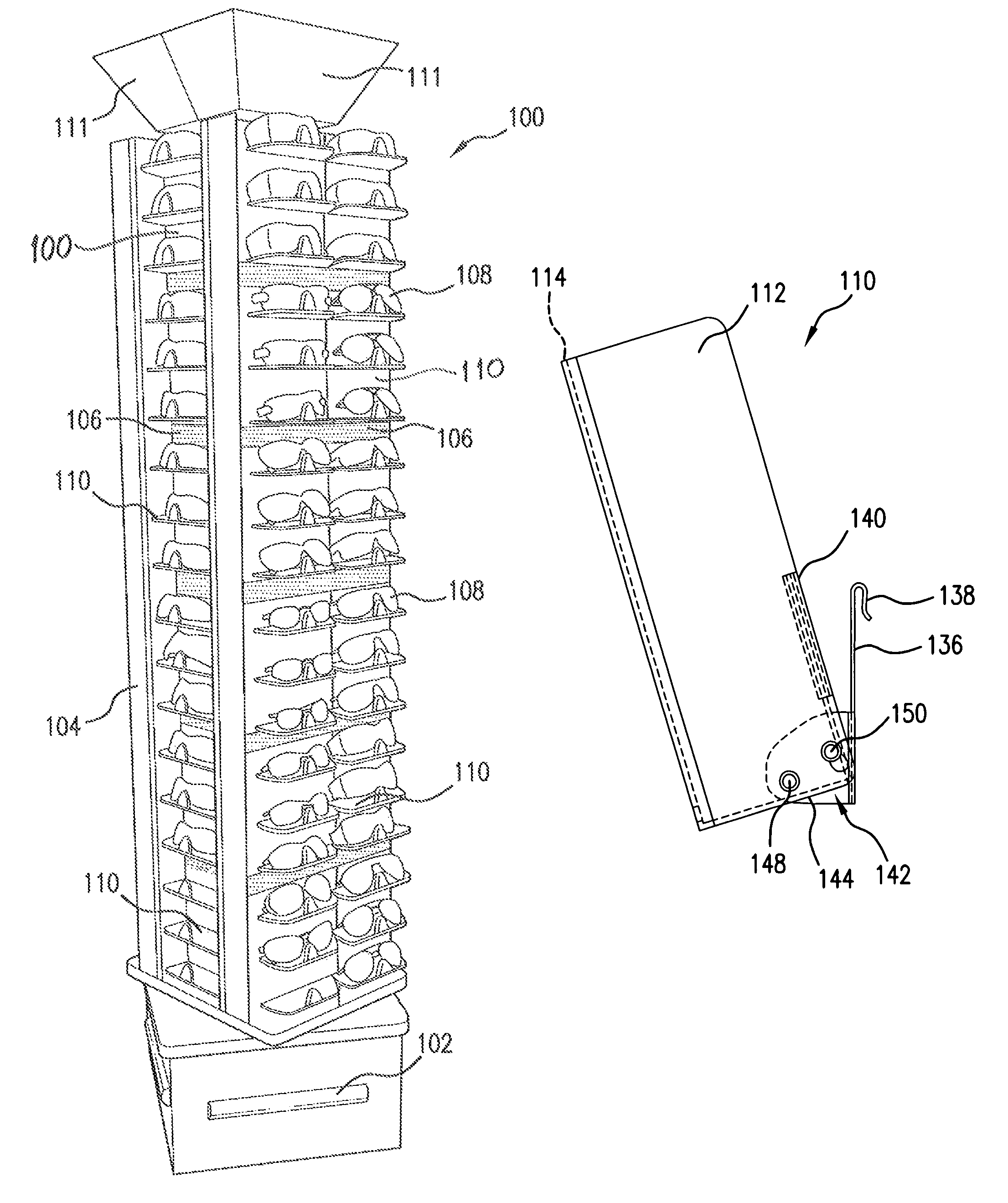

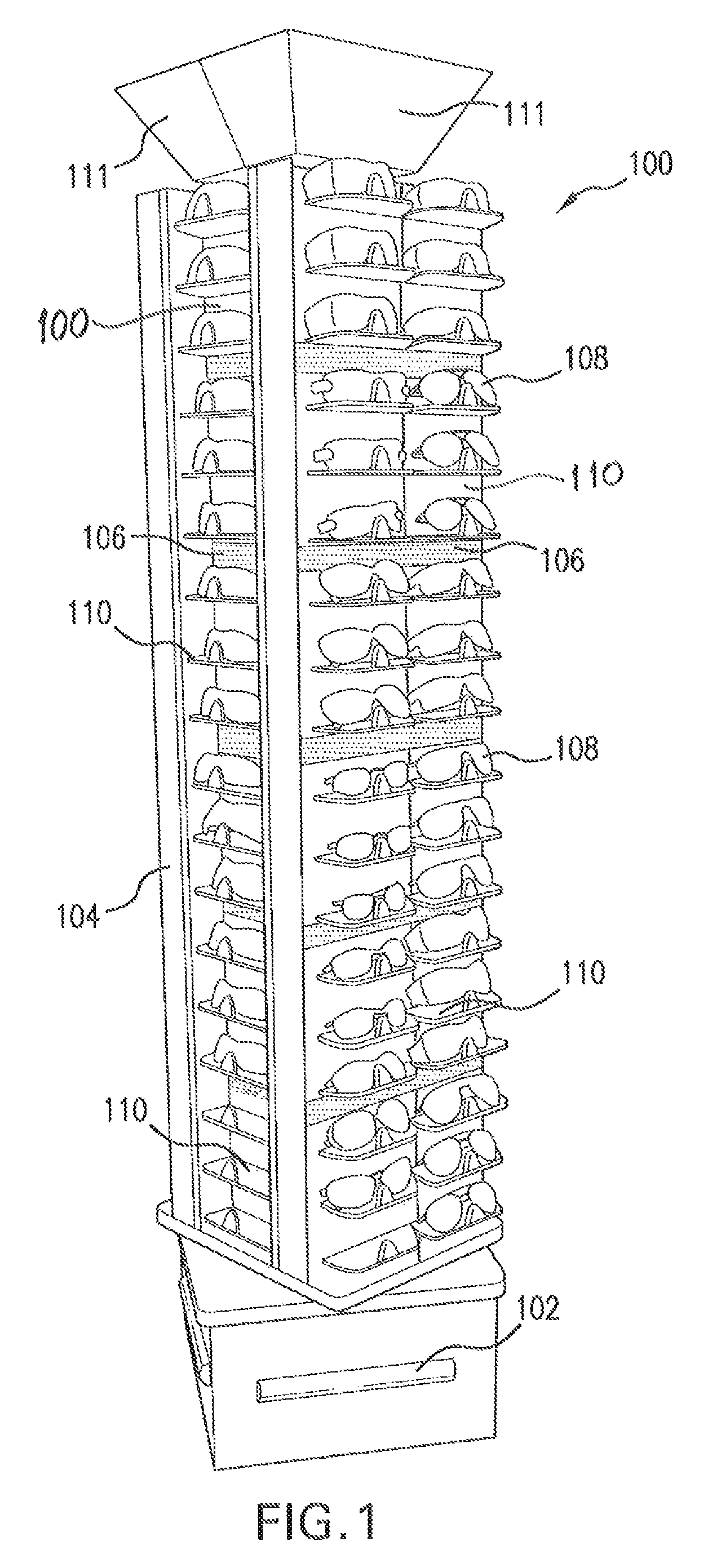

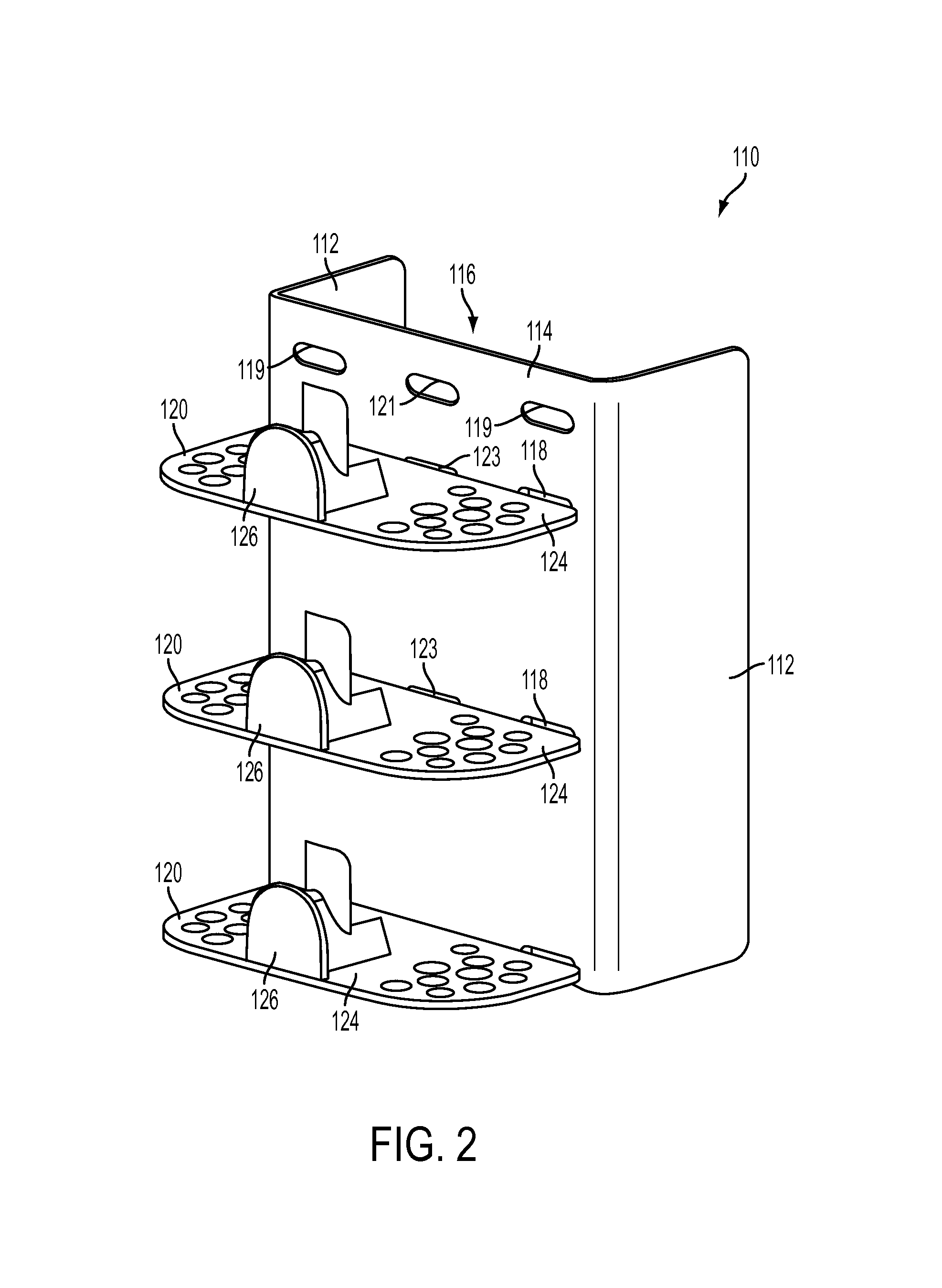

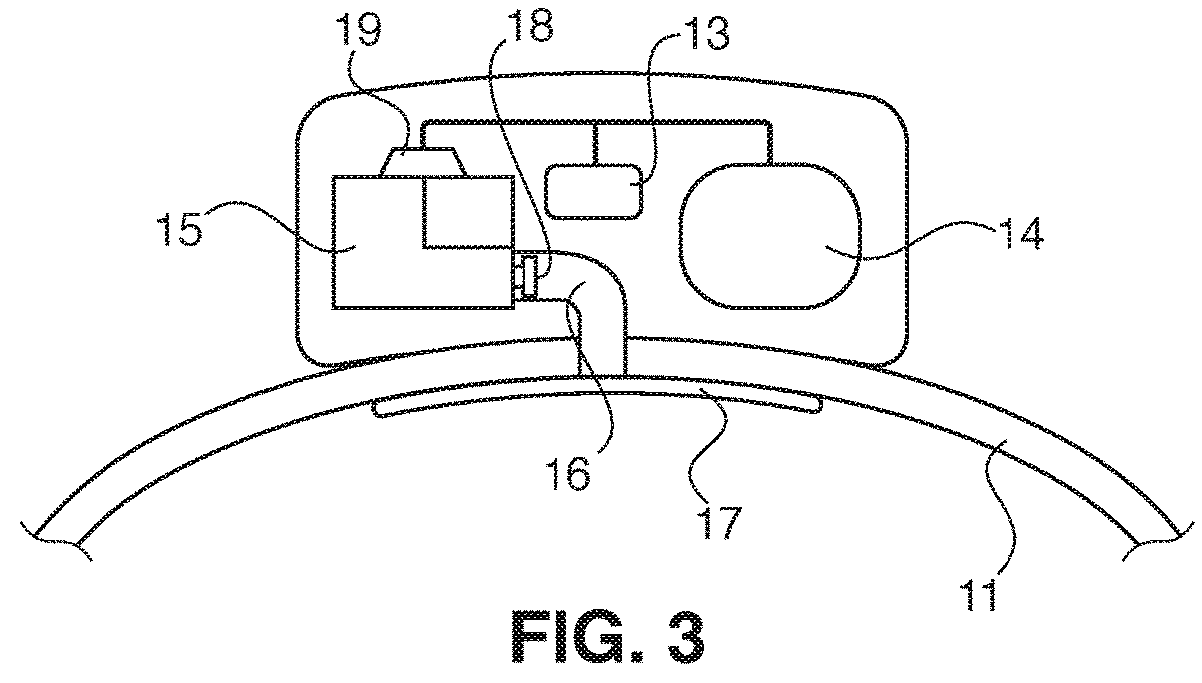

Eyewear display and modules for same

An eyewear display including a plurality of pods. Each pod includes a pair of opposing sidewalls, a back wall, and a front wall to form a proximal opening. The front wall defines a plurality of apertures for receiving eyewear support fixtures. A base wall encloses a distal end of the pod to form a storage space for holding eyewear stock accessible by the proximal opening. A mounting mechanism attaches to the back wall by a hinge and has at least one mounting clip for coupling the pod to the display mounting fixture. Each pod is selectively pivotable away from the display mounting fixture to provide access to the storage space for restocking the eyewear display. Preferably, in a display position, the plurality of pods are arranged so that at least one of the proximal openings is at least partially blocked by an adjacent.

Owner:FGX INT

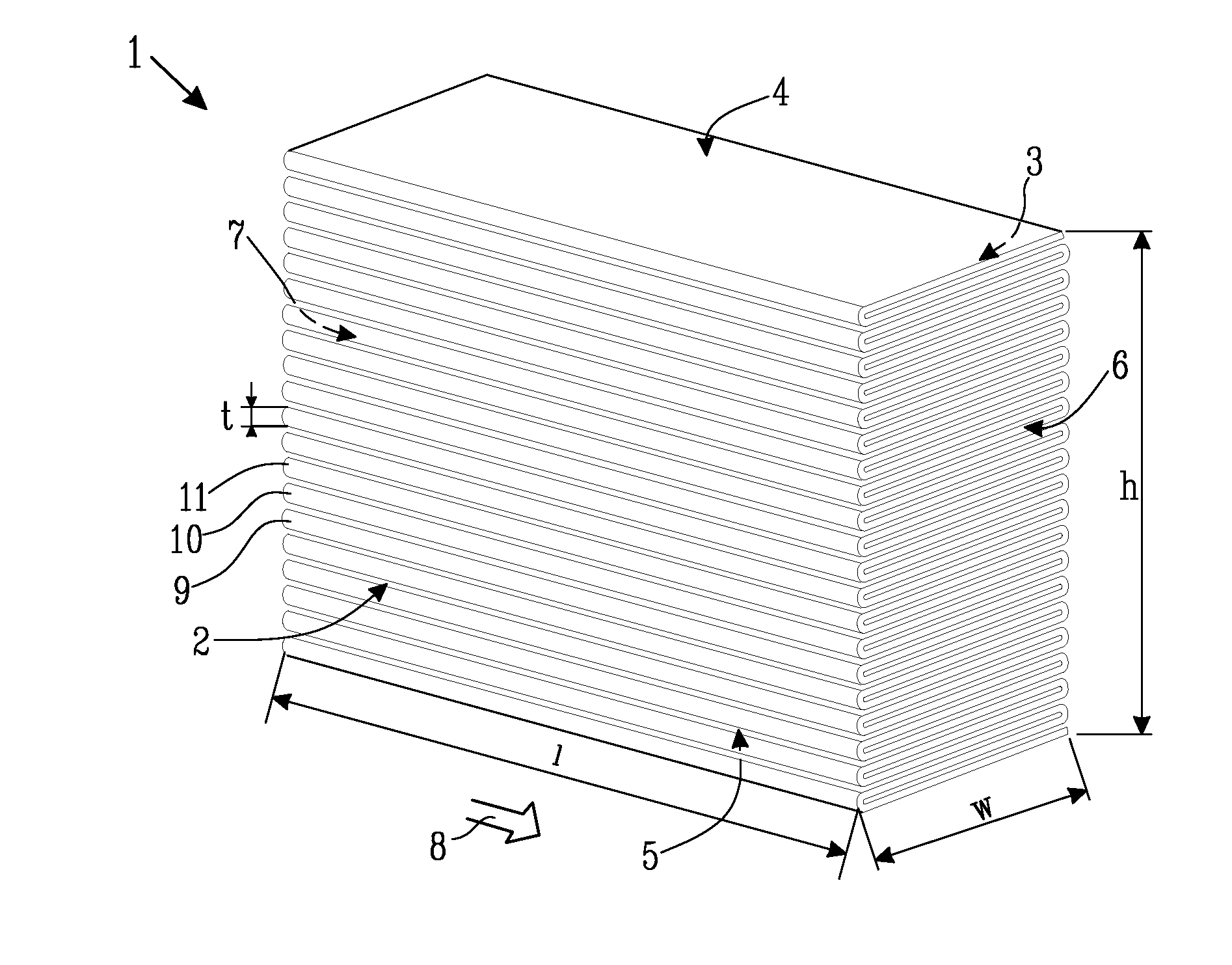

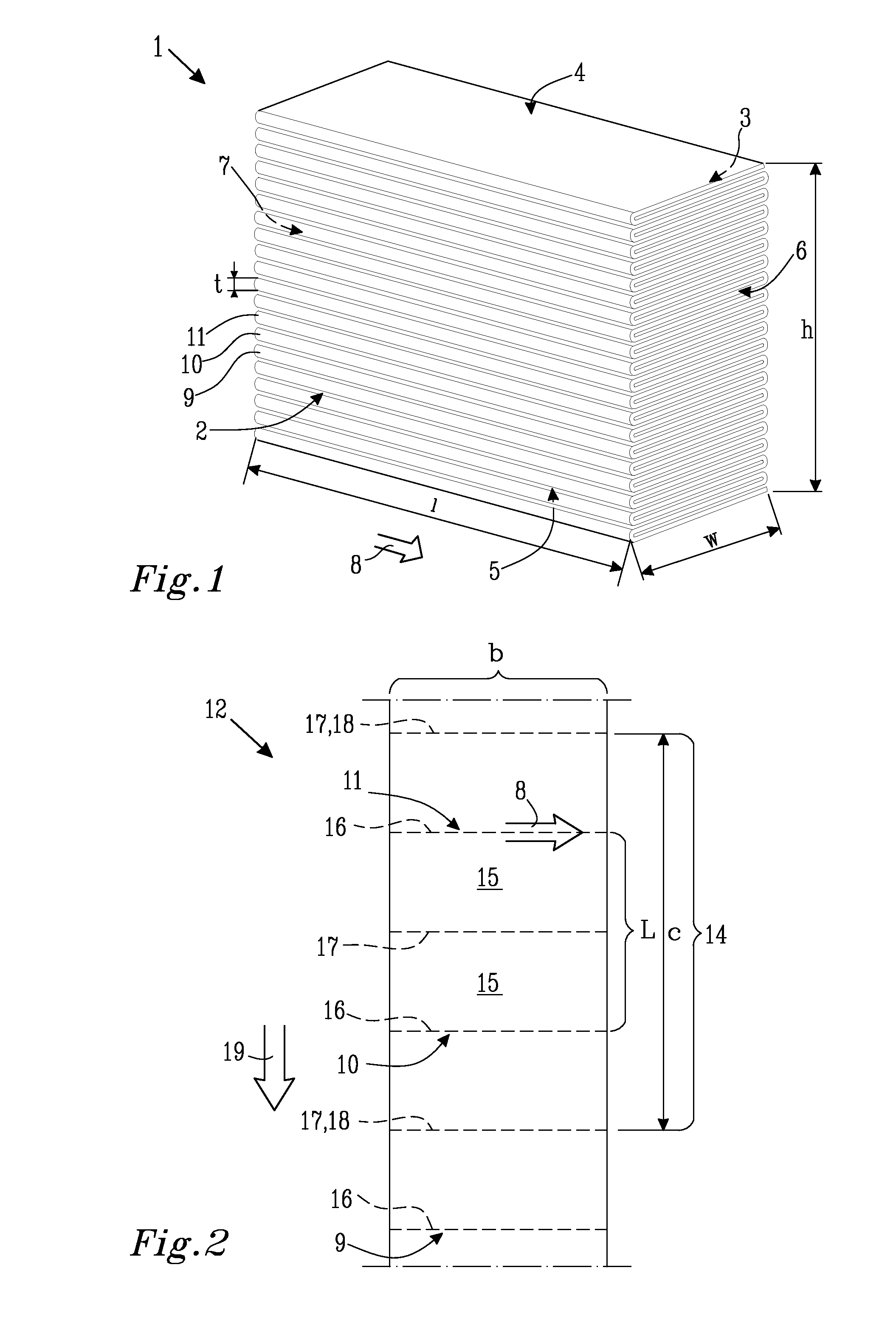

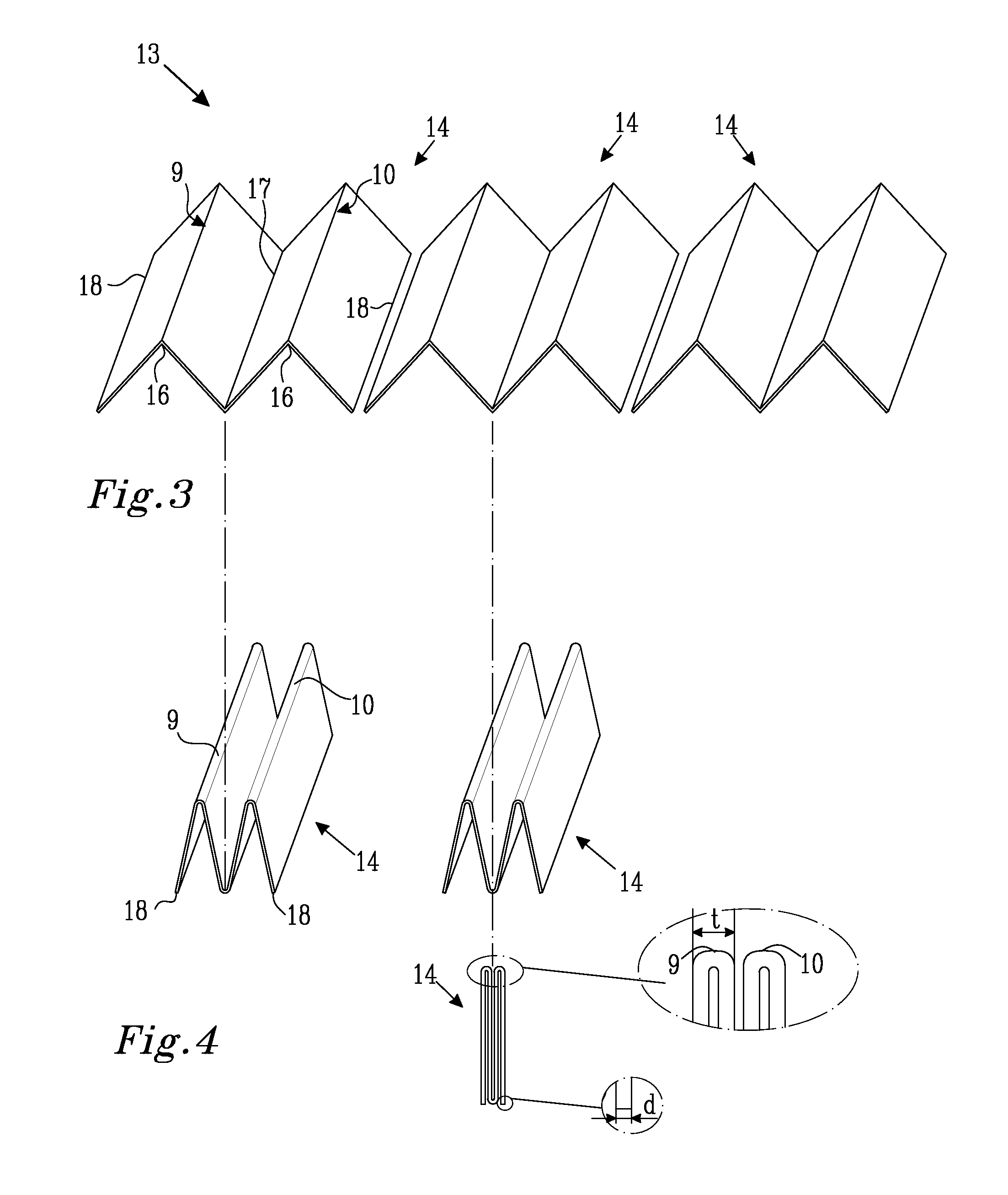

Stack of folded material

Owner:SCA HYGIENE PROD AB

Ground water back pouring cyclic utilization method

InactiveCN101298945ACreate pollutionIncrease pressureOther heat production devicesGeothermal energy generationFlushing timeGroundwater recharge

The invention belongs to the technical field of the groundwater recharge cyclic utilization method, particularly discloses a groundwater recharge cyclic utilization method, which is characterized by determining the depth of the pumping well and drilling a recharge well borehole having the same depth with the pumping well in the precipitation action radius of the pumping well, according to the local hydrogeology. The well pipe is fixed in the borehole according to the sequence of a sedimentation pipe, a strainer and a case pipe, then filter material, the killing well and the flushing are filled in turn, finally a pumping device and a recharging device are arranged, which forms a circular loop in the water pumping and recharging process. In the flow process of the groundwater, the temperature rises or lowers; and flushing is performed again after killing well, the flushing time is short and complete, and the groundwater does contact with the outside, which does not pollute the groundwater after recharging. The invention not only is suitable for the puaternary system stratal configuration, also suitable for the tertiary stratal configuration of the pottery and the Minghua town.

Owner:刘娇娜

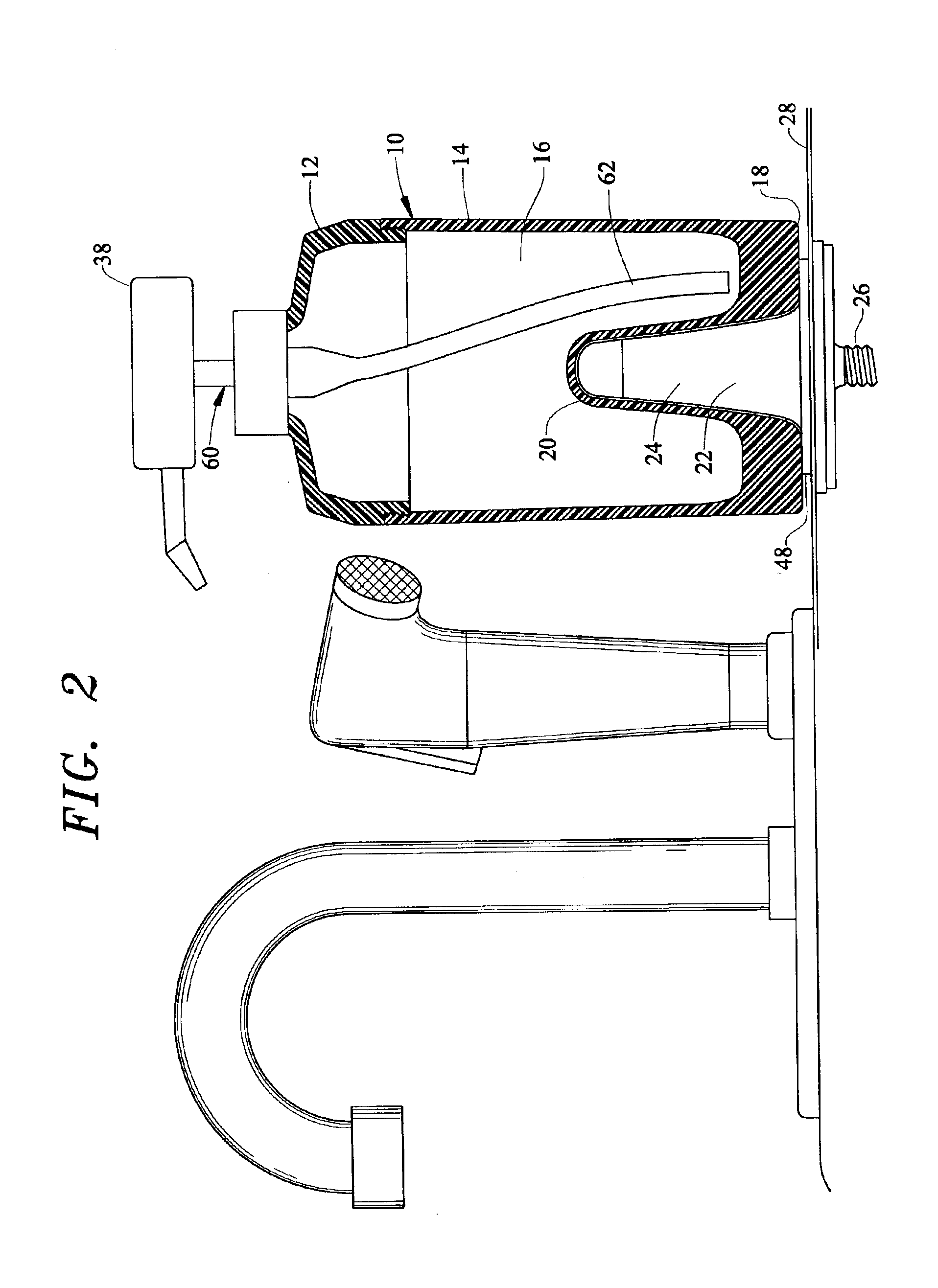

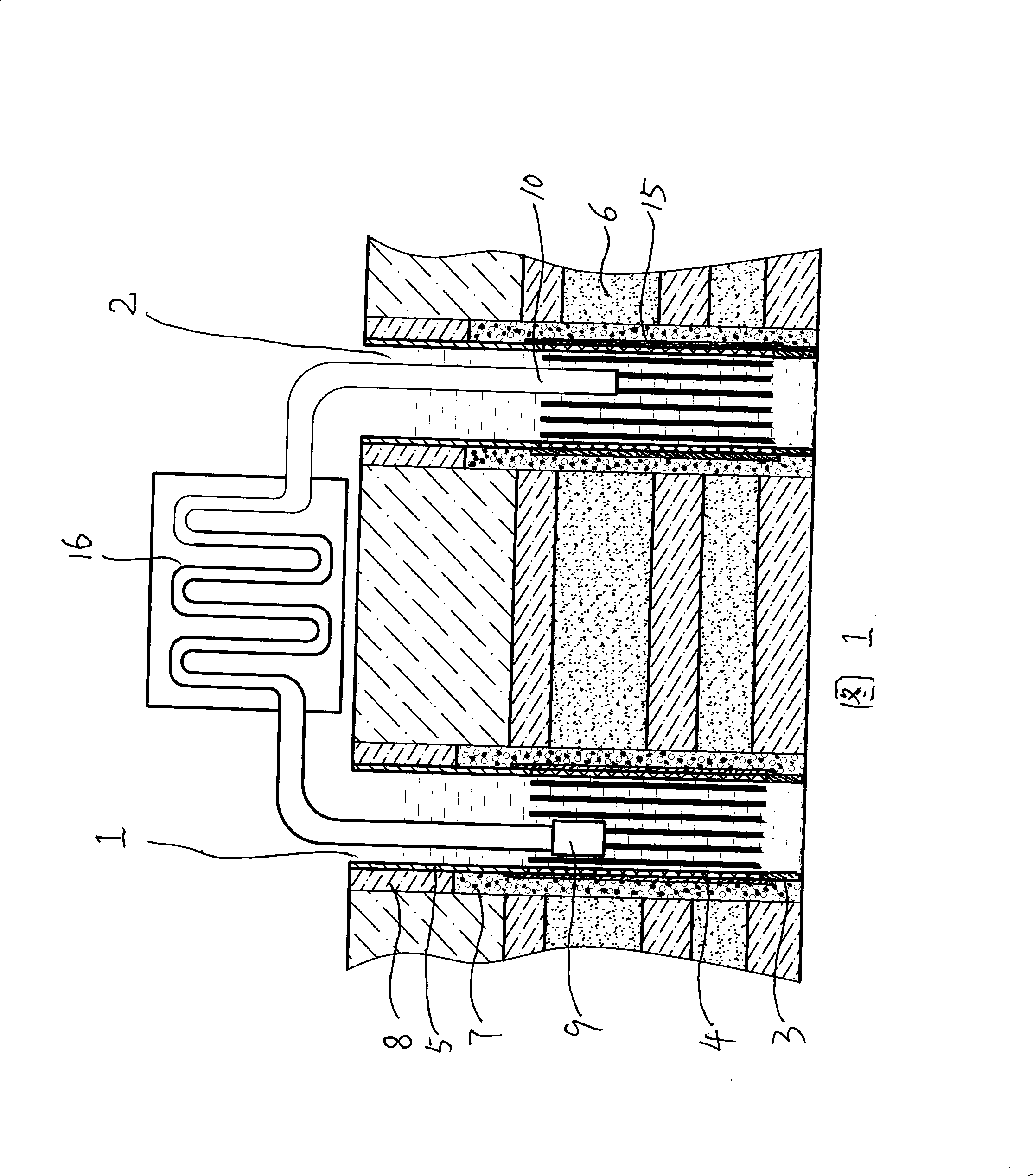

Device for releasing a pharmaceutical onto the skin of a patient

InactiveUS20180264242A1Dangerous situationEasy to useElectrocardiographyMedical devicesEngineeringCatheter

A wearable device for administering a pharmaceutical has a housing, a heart monitor disposed in the housing, a microprocessor connected to the heart monitor, a receptacle for holding a pharmaceutical disposed in the housing, the receptacle being in communication with a conduit leading out of the housing, an actuator connected to the receptacle and being configured to release the contents of the receptacle into the conduit upon a command from the microprocessor, and a power source disposed in the base body and being configured to power the microprocessor, the heart monitor and the actuator. The microprocessor is programmed to actuate the actuator to release the contents of the receptacle when a heart rate measured by the heart monitor falls outside a preprogrammed range.

Owner:AM NOD INC

Liquid ejecting apparatus and liquid refilling container

An object is to provide a liquid ejecting apparatus that enables a liquid storage container to be properly and easily refilled with a liquid from a liquid refilling container without causing color mixture in the liquid storage container. The liquid ejecting apparatus includes liquid storage containers each configured to feed the liquid to a liquid ejecting portion and liquid refilling containers each configured to refill the liquid storage container with the liquid. A first fitting unit is provided around a liquid injection port in each of the liquid storage containers. A second fitting unit is provided around a liquid pour-out port in each of the liquid refilling containers. The second fitting unit is fitted to the first fitting unit to enable the liquid to be delivered from the liquid pour-out port to the liquid injection port.

Owner:CANON KK

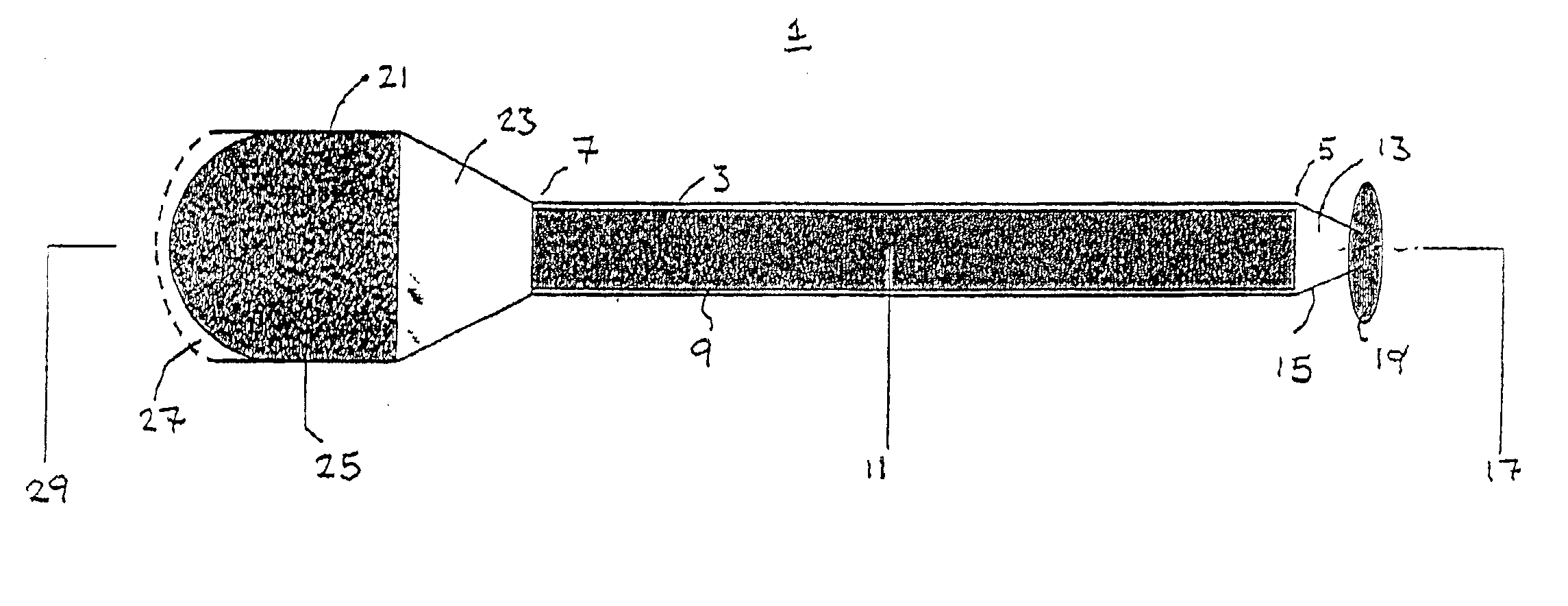

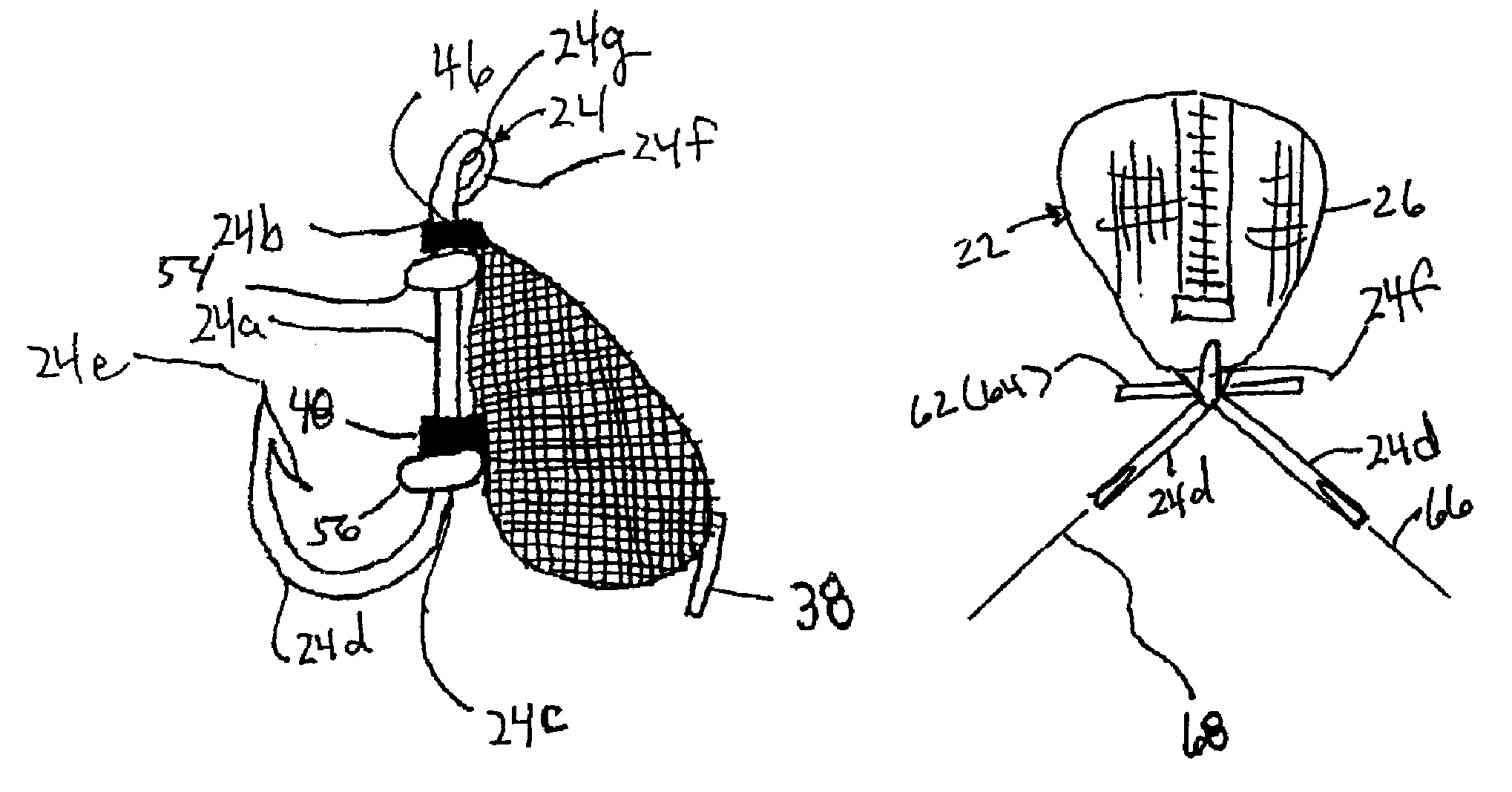

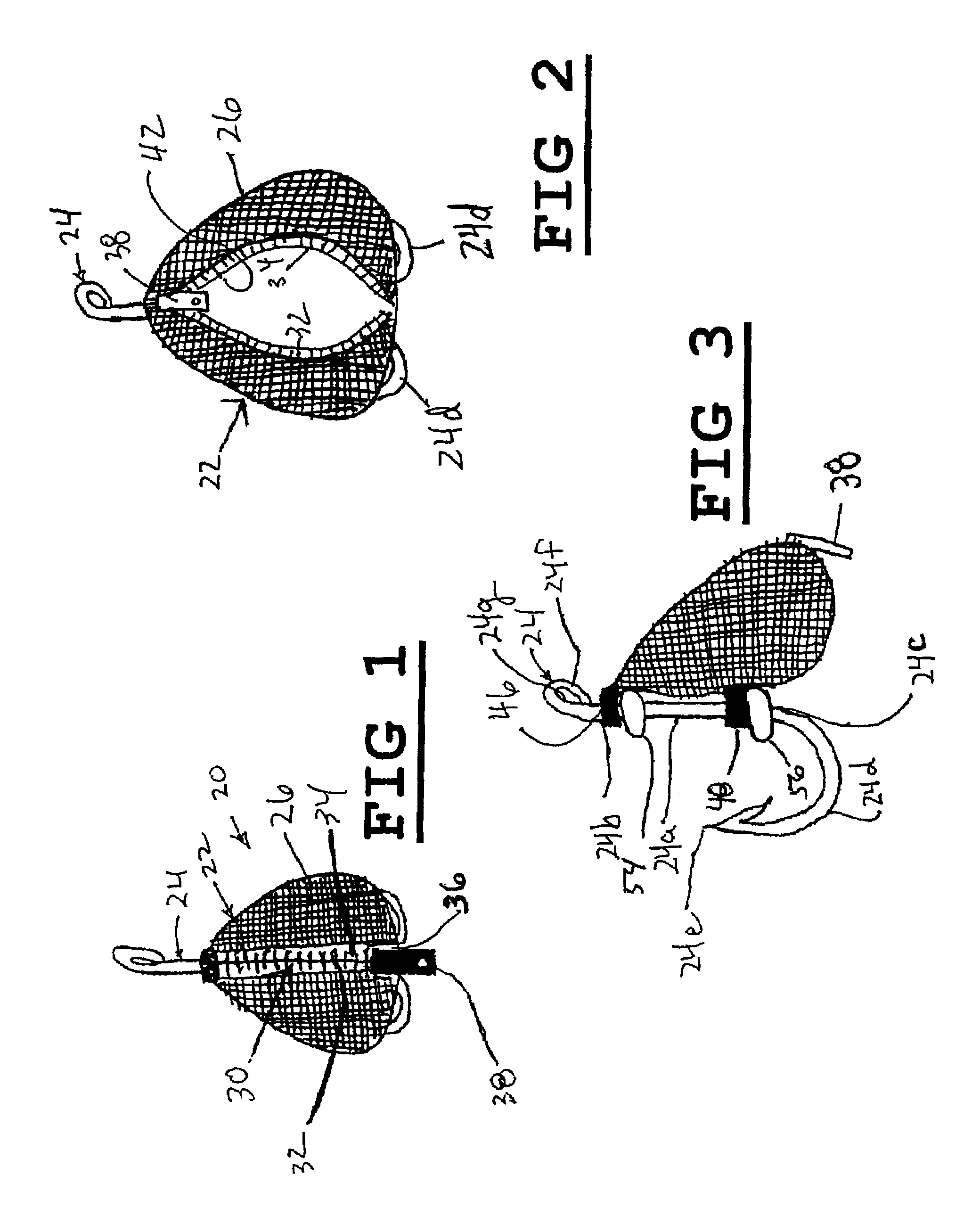

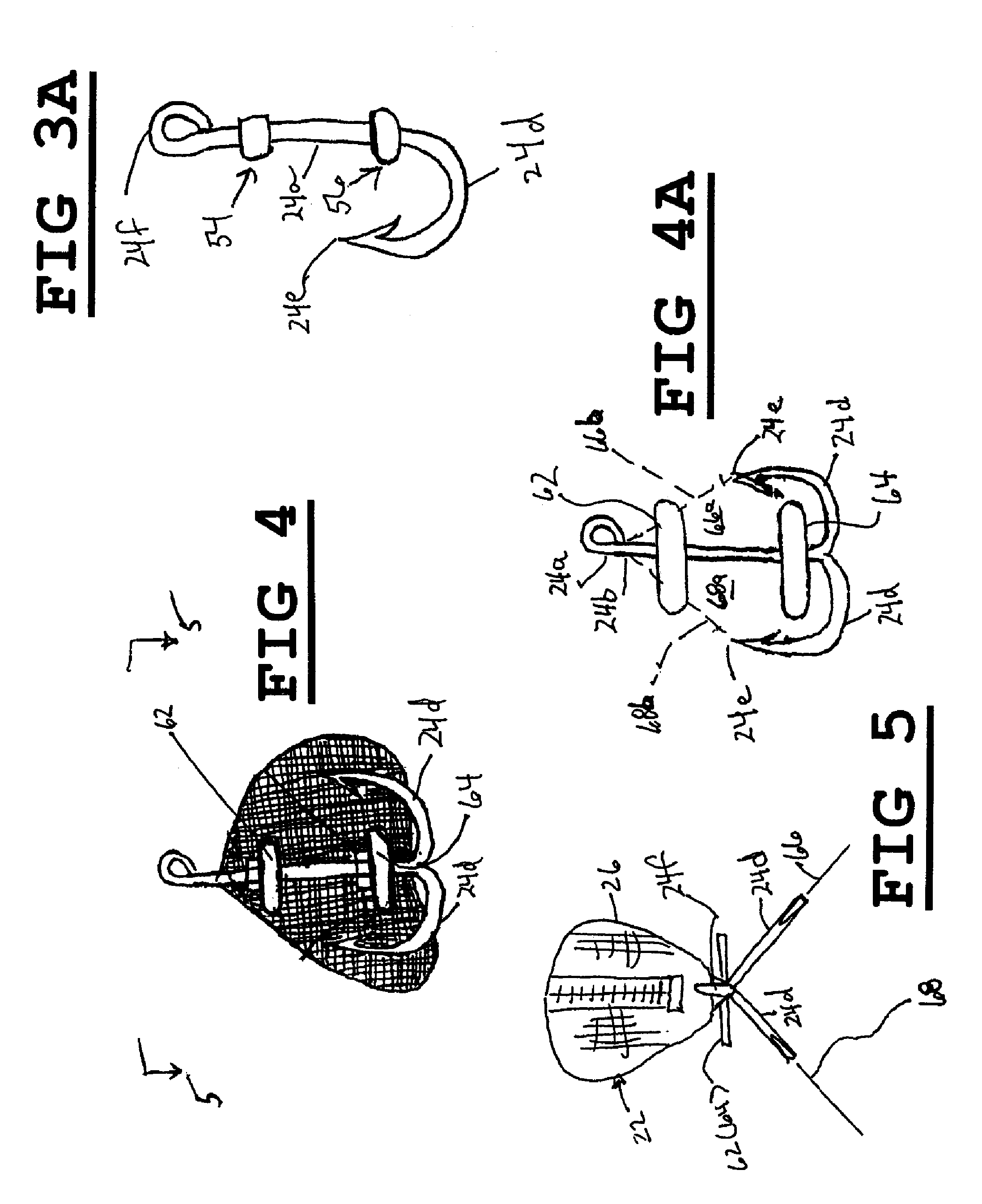

Refillable bait bag and integrated hook

A bait bag and hook combination is provided for use in fishing. The bait bag and hook combination includes a bag that is fixedly mounted on the hook in such a way that the bag does not hinder the hooks ability to impale game fish. The bag includes an easy-opening and re-closing apparatus for efficient refilling of the bag. In addition, the bag is made up of material that is durable enough to withstand the underwater environment, but is also permeable enough to release the scent of the bait contained inside.

Owner:GILLIHAN MICHAEL A

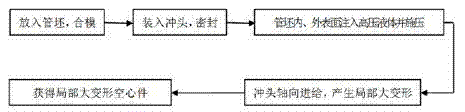

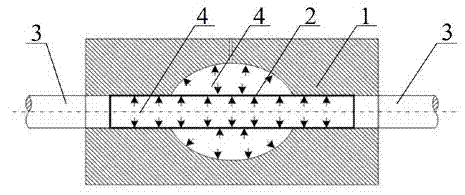

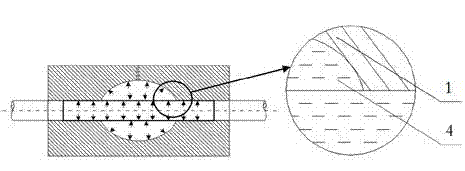

Differential pressure forming method for local large-deformation hollow pieces

InactiveCN103920788AImprove the lubrication effectSimple structureHydraulic cylinderStructural engineering

The invention discloses a differential pressure forming method for local large-deformation hollow pieces and belongs to the technical field of manufacturing of metal hollow members. The differential pressure forming method includes steps of firstly placing a pipe billet into a rear die, loading a punch into the pipe billet and sealing; injecting high-pressure liquid to the inner and outer surfaces of the pipe billet at the same time, keeping pressure in the pipe billet larger than the pressure of the outer surface of the pipe billet and forming controllable pressure difference; pushing the punch to axially feed to realize material supplement by the aid of a hydraulic cylinder, and enabling the pipe billet to generate local large deformation under the action of inside and outside hydraulic differential pressure; finally, discharging the high-pressure liquid and obtaining a local large-deformation hollow piece. By controlling inside and outside pressure difference of the pipe billet, stress state during local expansion of the pipe billet can be improved, expansion can be sufficiently realized and expansion limit is increased. Hydraulic oil is injected onto the outer surface of the pipe billet, lubricating between the outer surface of the pipe billet and a form cavity of the die is evidently improved, friction is reduced, and axial supplement and final forming are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

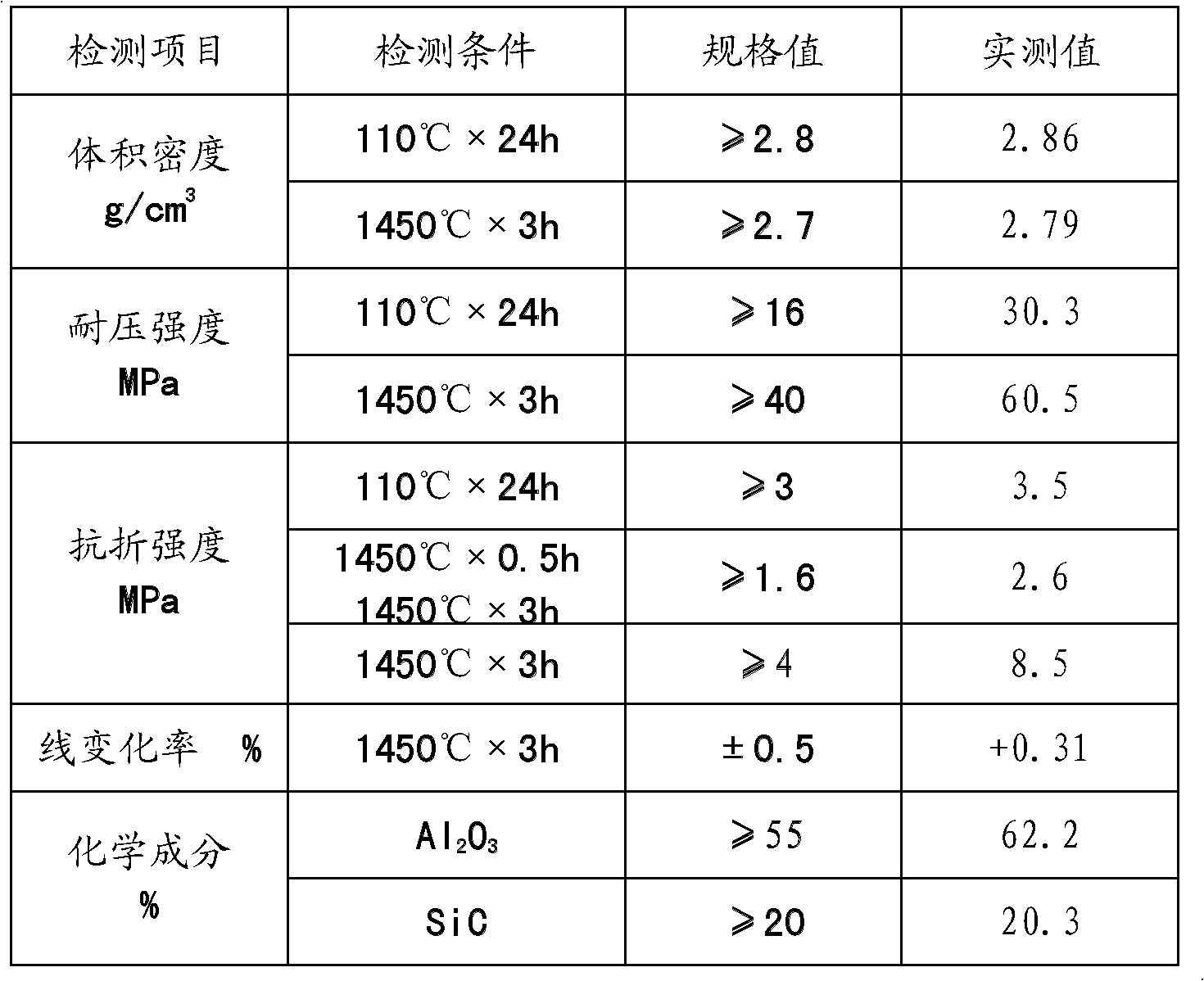

Fast-setting castable for main runner for COREX furnace and production technology thereof

The invention aims to provide a fast-setting castable for a main runner for a COREX furnace and a production technology thereof. The fast-setting castable for the main runner for the COREX furnace can be used for repairing the main runner within a short time in the thermal state as well as for tapping recovery, further ensures the consistency of production, is long in service life and convenient for repairing operation and reduces the labor intensity of workers. To achieve the effects, the fast-setting castable for the main runner for the COREX furnace is characterized in that the fast-setting castable comprises the following components: aluminas, silicon carbide, carbonaceous materials and additives. Through the technical scheme, the aluminas different in nature and grain size are mixed according to the specific percentage, and since the extra additives and the novel processing technique are adopted, the newly cast runner can allow 80,000 tons iron to be output; the service life of the fast-setting castable is more than twice of that of the former ordinary low cement castable; and furthermore, the fast-setting castable is particularly outstanding in fast-setting, can meet the requirements of on-site tapping within 8-hour operating time and has remarkable effect as a repairing material.

Owner:长兴煤山新型炉料有限公司

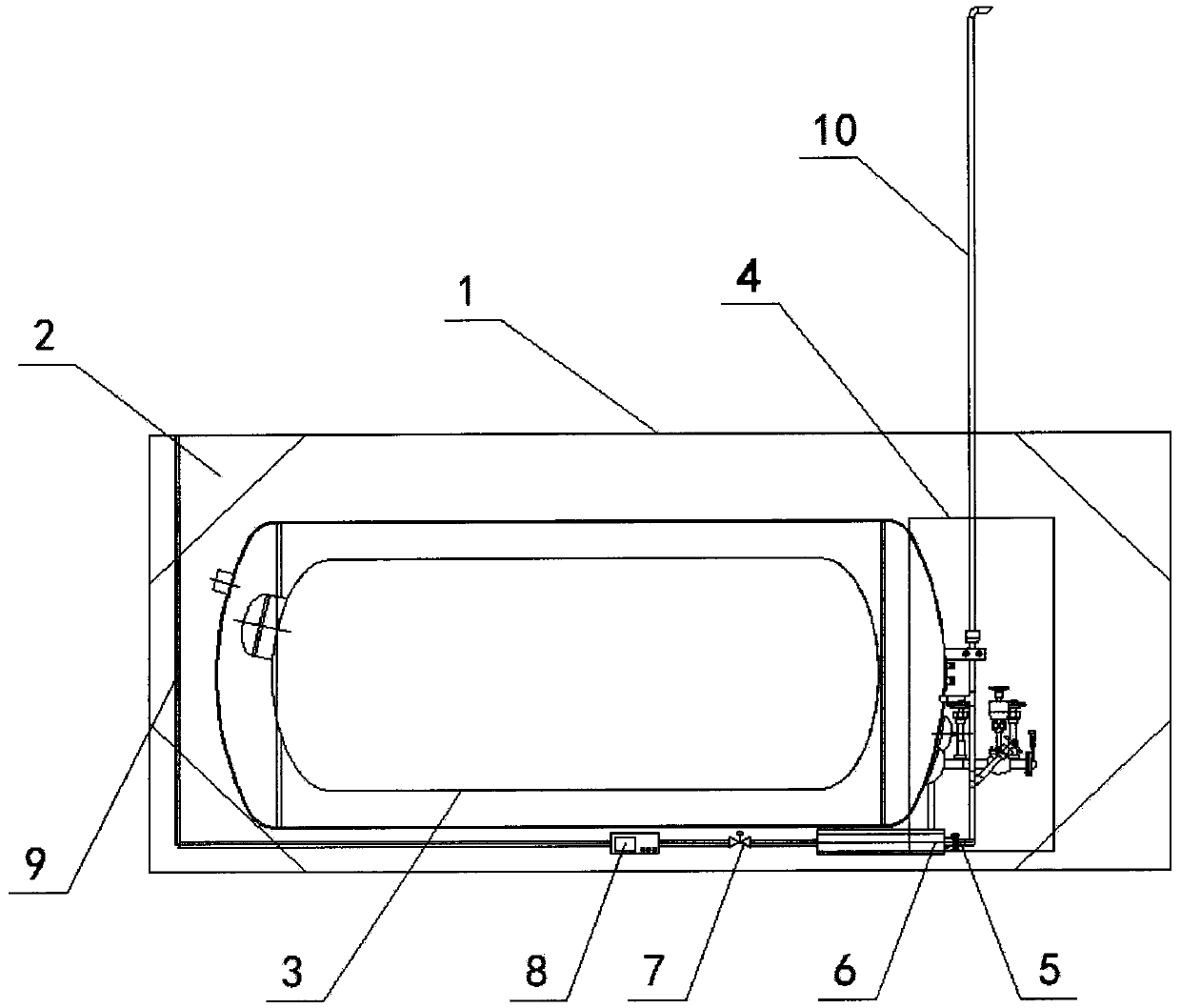

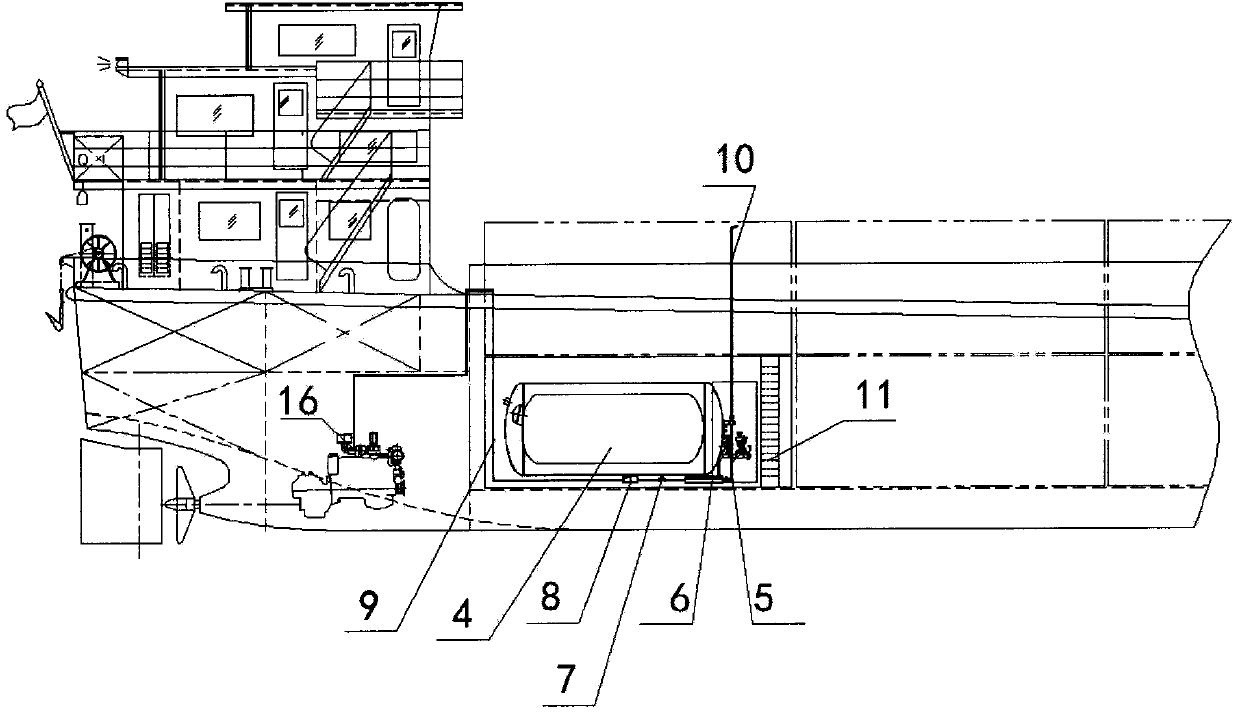

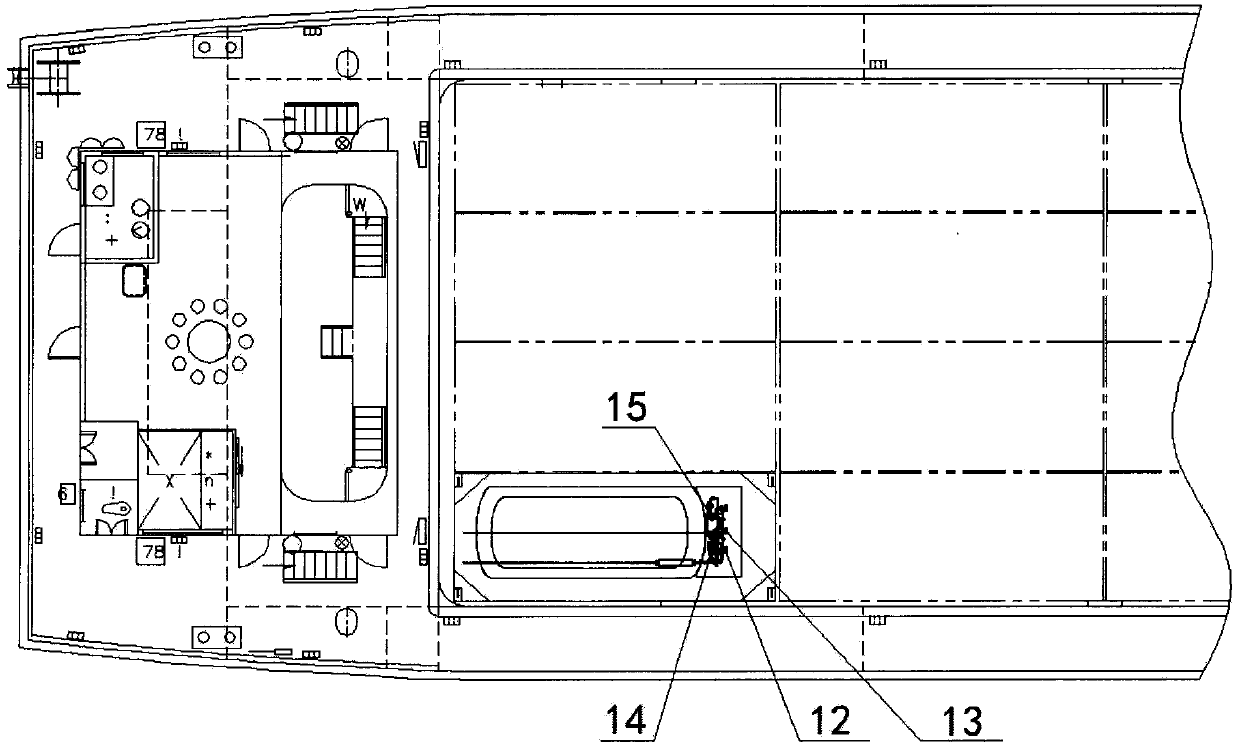

Novel LNG gas-feeding integrated module device

InactiveCN103867888AEasy refillGas filling station is fixed and easy to fillContainer filling methodsPressure vesselsGas phaseControl system

The invention discloses a novel LNG gas-feeding integrated module device, and belongs to the field of ship transportation. The device is designed according to the standards of ISO shipping containers, and comprises a liquefied natural gas gas-feeding device case and a case frame; wherein the liquefied natural gas gas-feeding device case comprises a liquefied natural gas storage tank, an operation valve case, a liquid transportation pipeline, a gasifying device, an emergency cut-off device, a gas flowmeter, a gas transportation pipeline, a pressure releasing pipe, and a vertical ladder; the case frame comprises a front end frame, a rear end frame, a upper side beam, a lower side bean, a diagonal brace, an upper diagonal member, a lower diagonal member, a bottom plate, and a bearer; the operation valve case comprises a liquid-phase operation pipeline, a gas-phase operation pipeline, a backup pipeline, and a control system, and the liquid-phase operation pipeline, gas-phase operation pipeline, backup pipeline, and control system are concentratedly arranged through low-temperature stainless steel pipes. The device solves the problems of difficult gas feeding for a diesel oil-LNG bi-fuel source ship. A gas-feeding station can utilize the integrated module device to safely butt-join a diesel oil-LNG bi-fuel source diesel engine, provide gas for the ship to be fueled, and control the gas volume. The transportation cost is reduced, and the transportation efficiency is improved.

Owner:JIANGSU MODERN SHIPBUILDING TECH

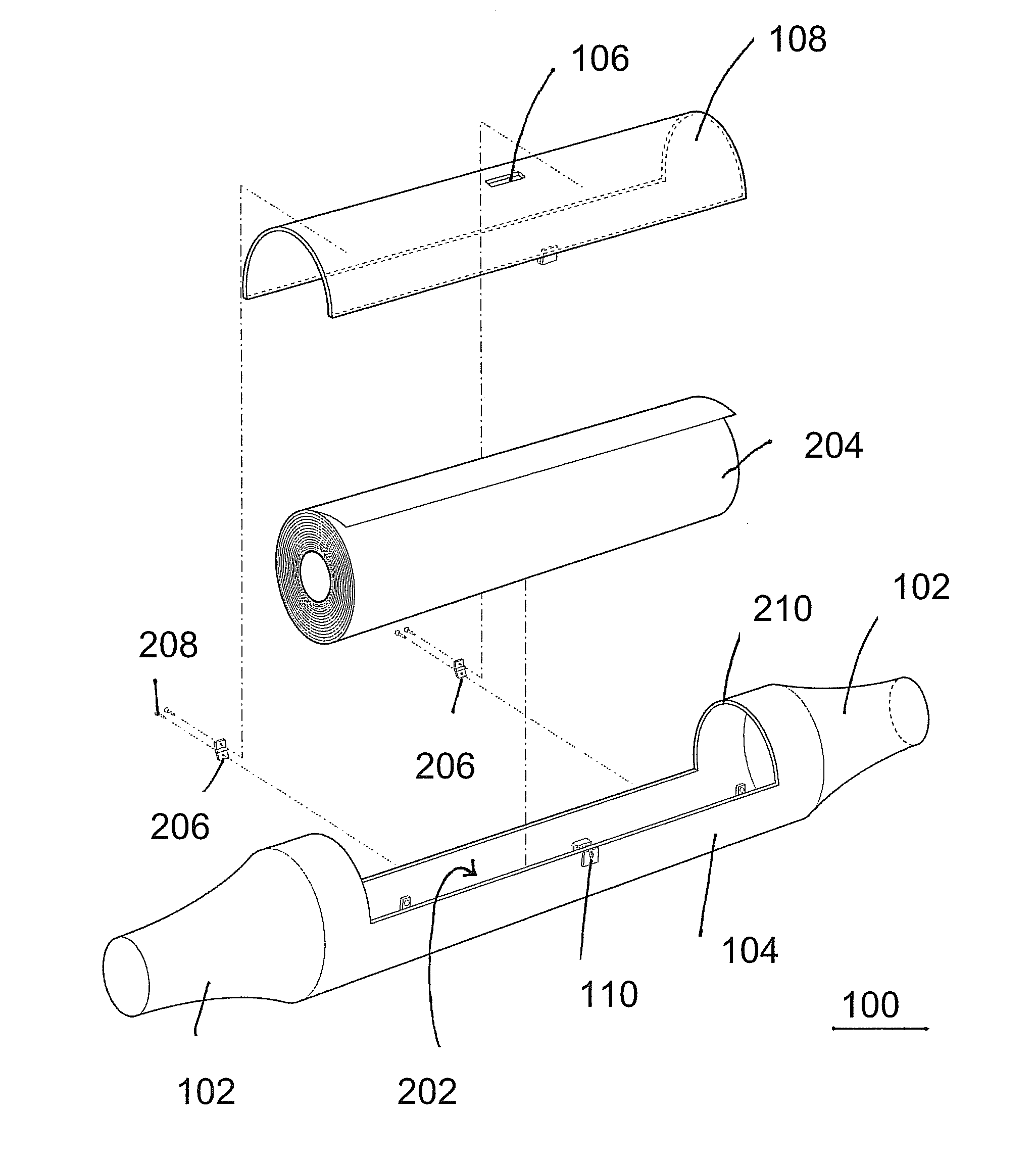

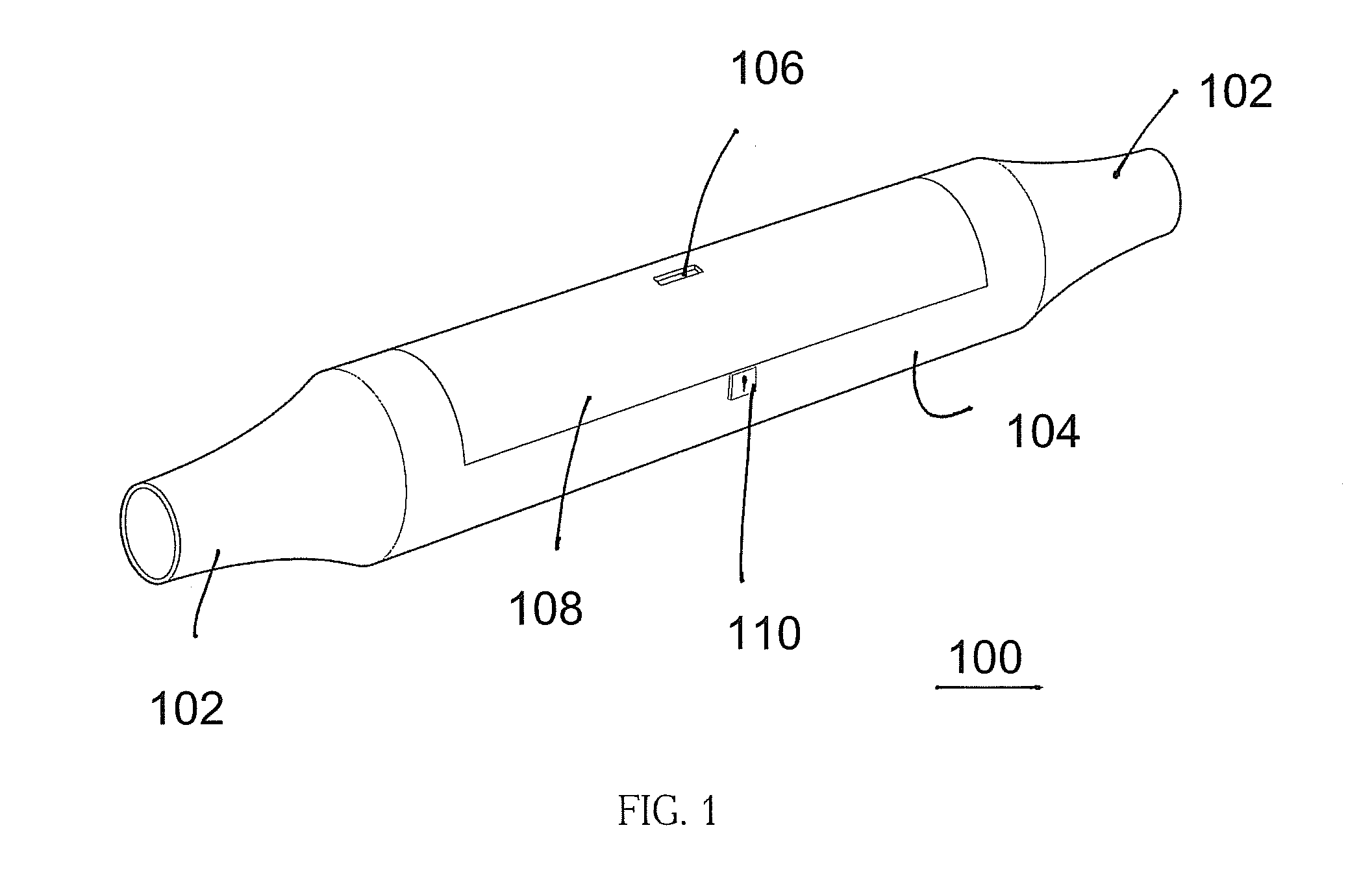

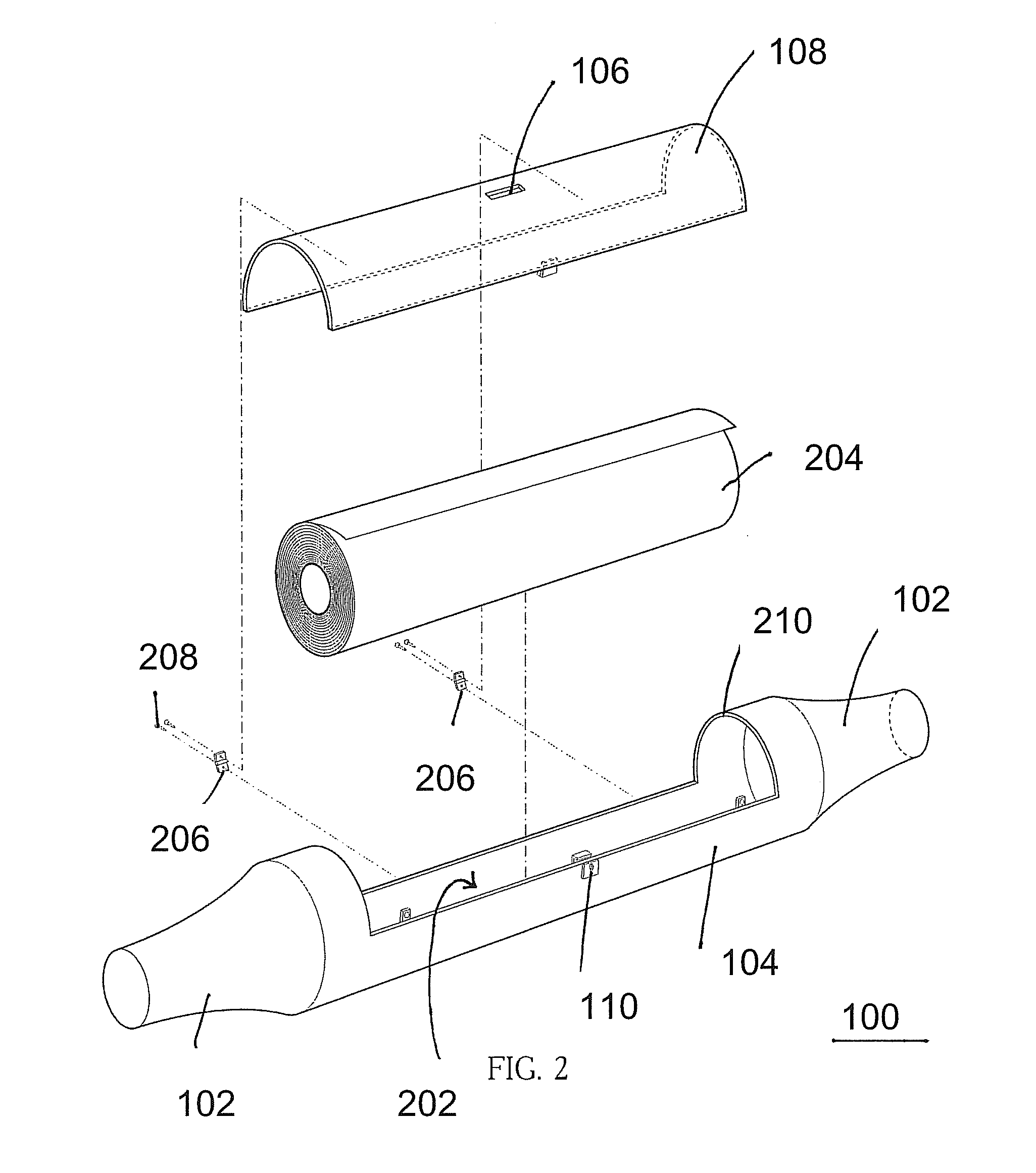

Aerodynamic bottle support cage for bicycles

InactiveUS20120104063A1Reduces the aerodynamic drag on the bicyclePrevent overflowTravelling sacksTravelling carriersEngineeringHands free

An aerodynamic, hands free liquid containment system for mounting on to a bicycle handlebar and aerobars. The water bottle and the bottle cage are aerodynamically shaped and positioned between a rider's arms to eliminate turbulence and reduce drag on the bicycle and rider. The cage typically clips to both the aerobar extensions and the horizontal sections of the handlebars. The water bottle includes an opening for filling the container and another opening for receiving a flexible drinking tube. The opening for filling the container can be closed with a removable cover and includes a splash flap to avoid spilling of the reservoir contents.

Owner:SWEIGART TODD E

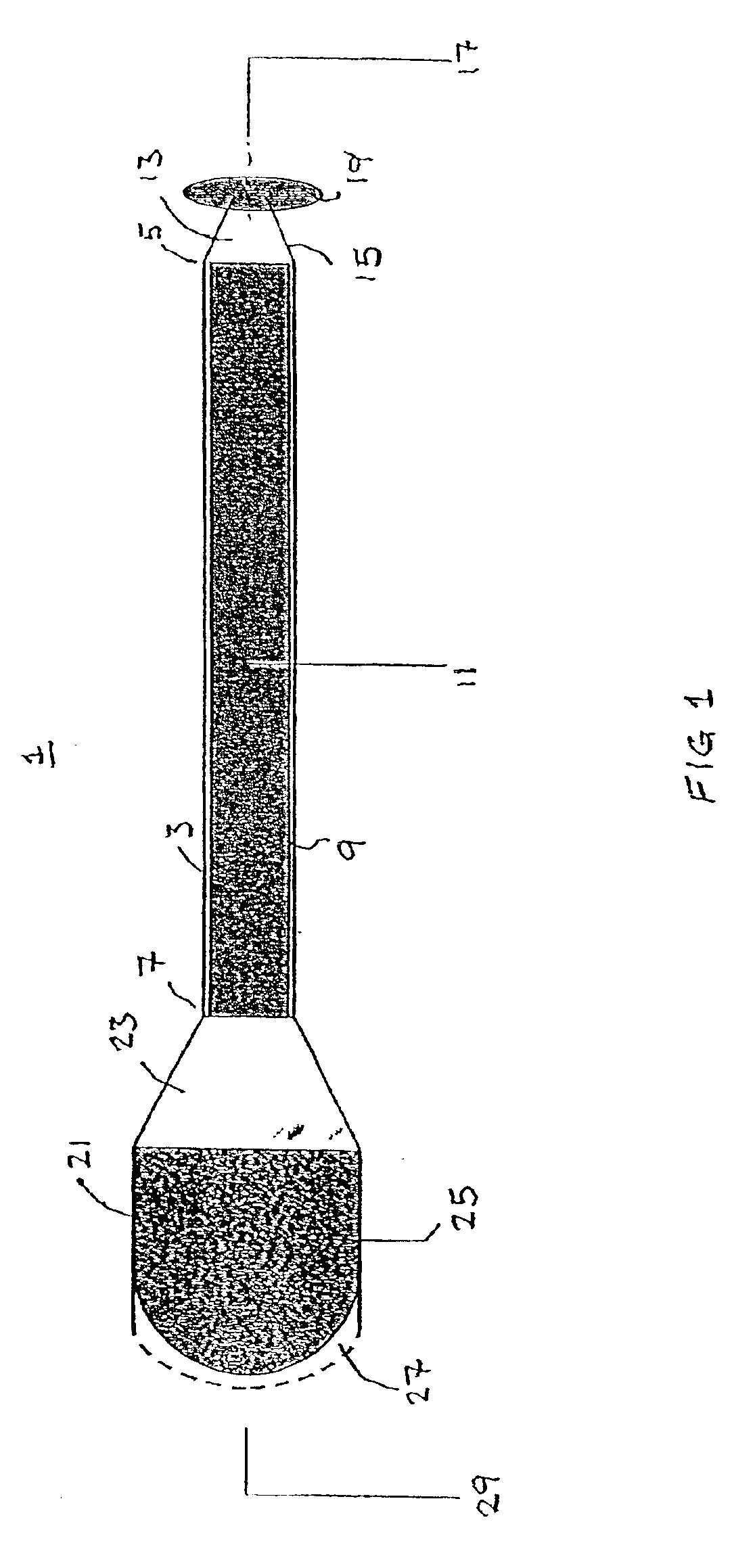

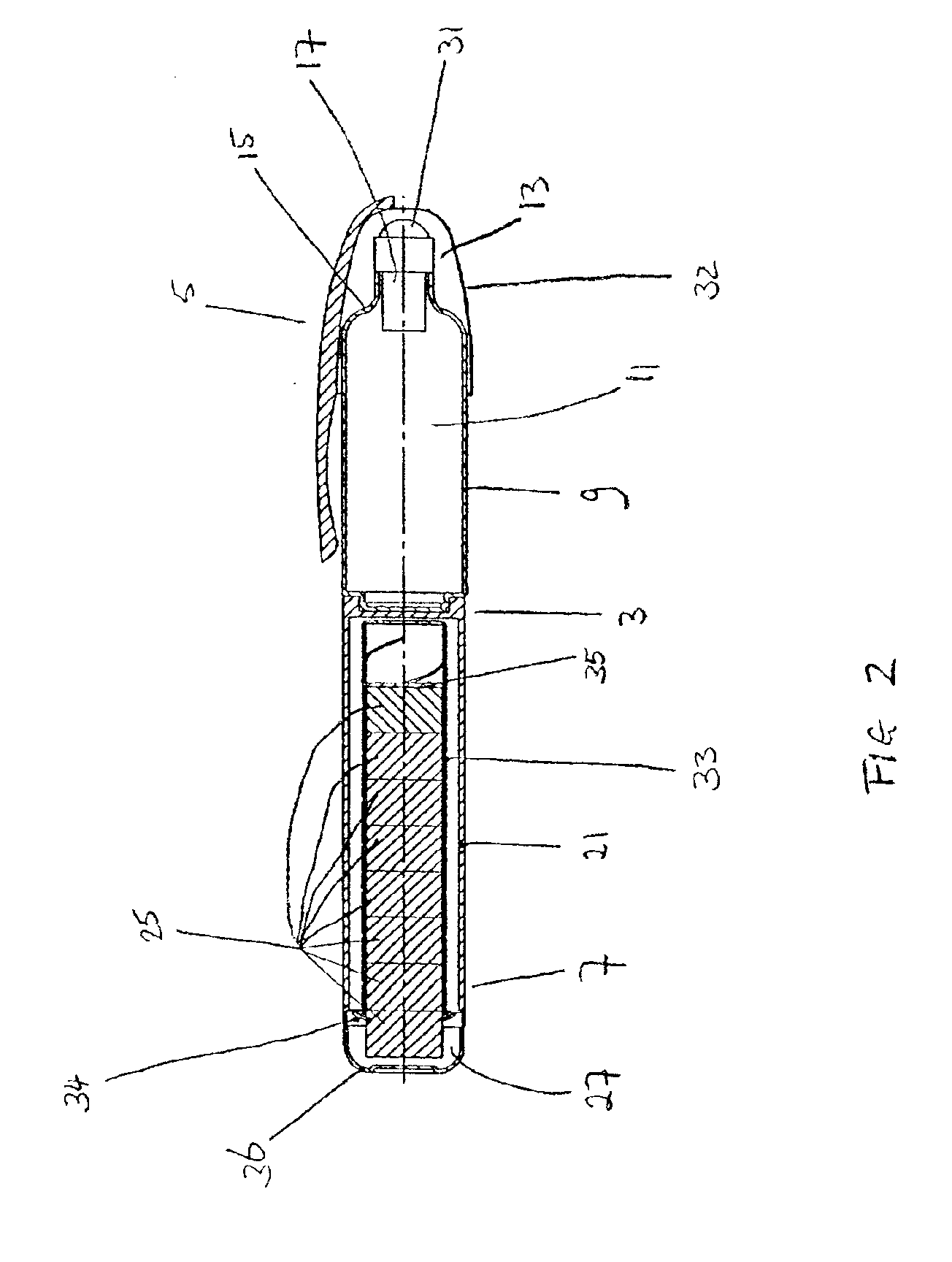

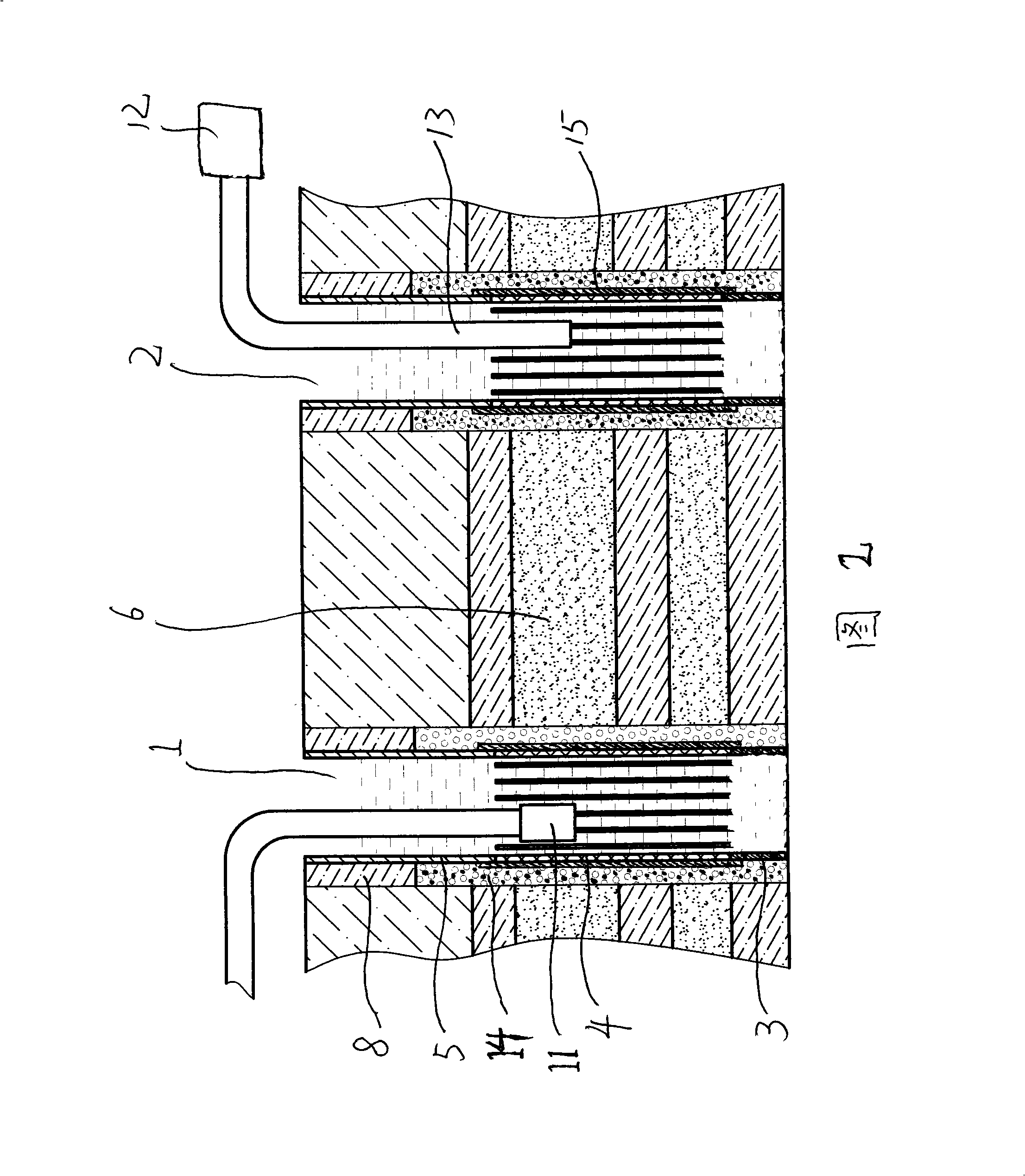

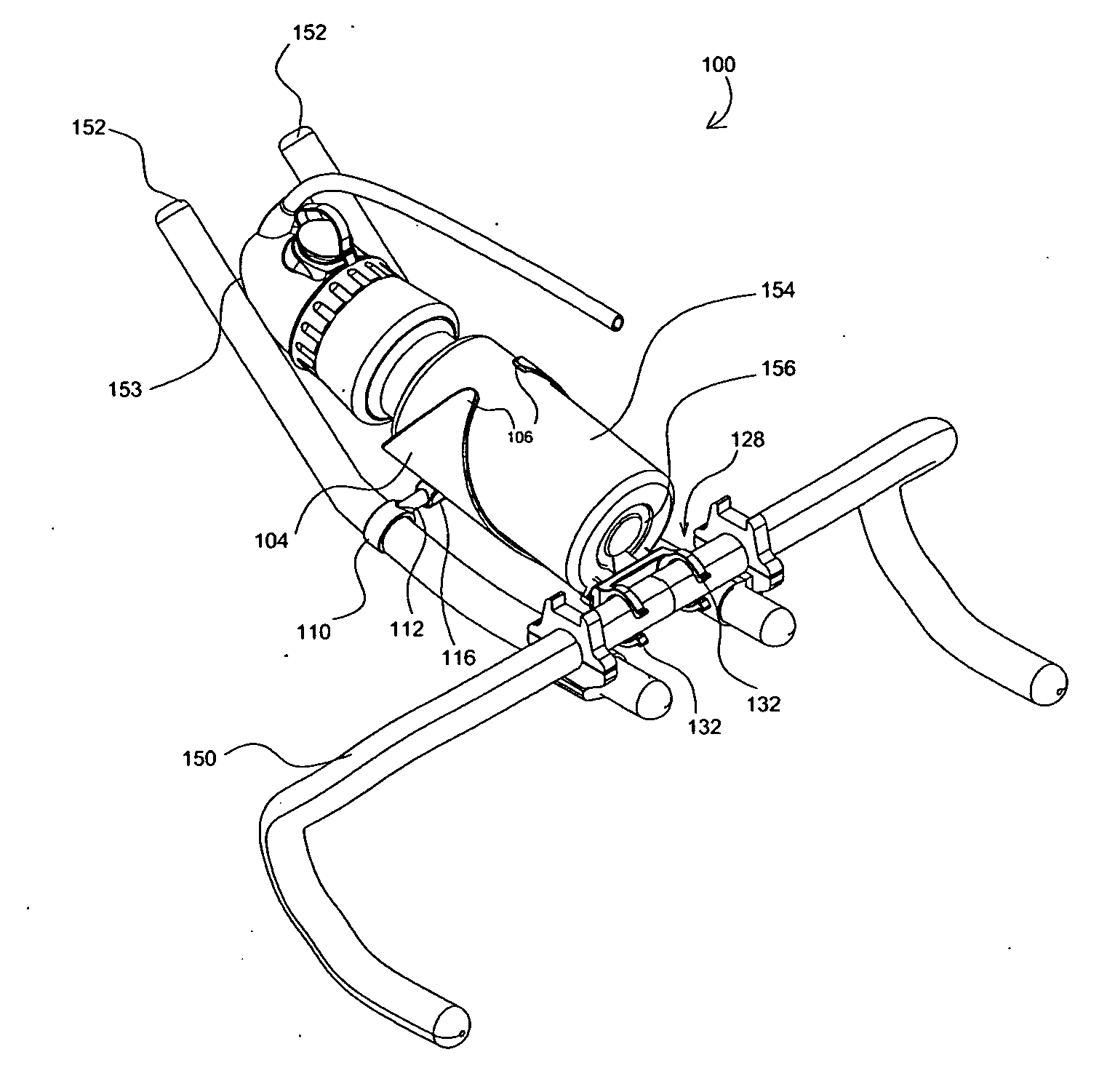

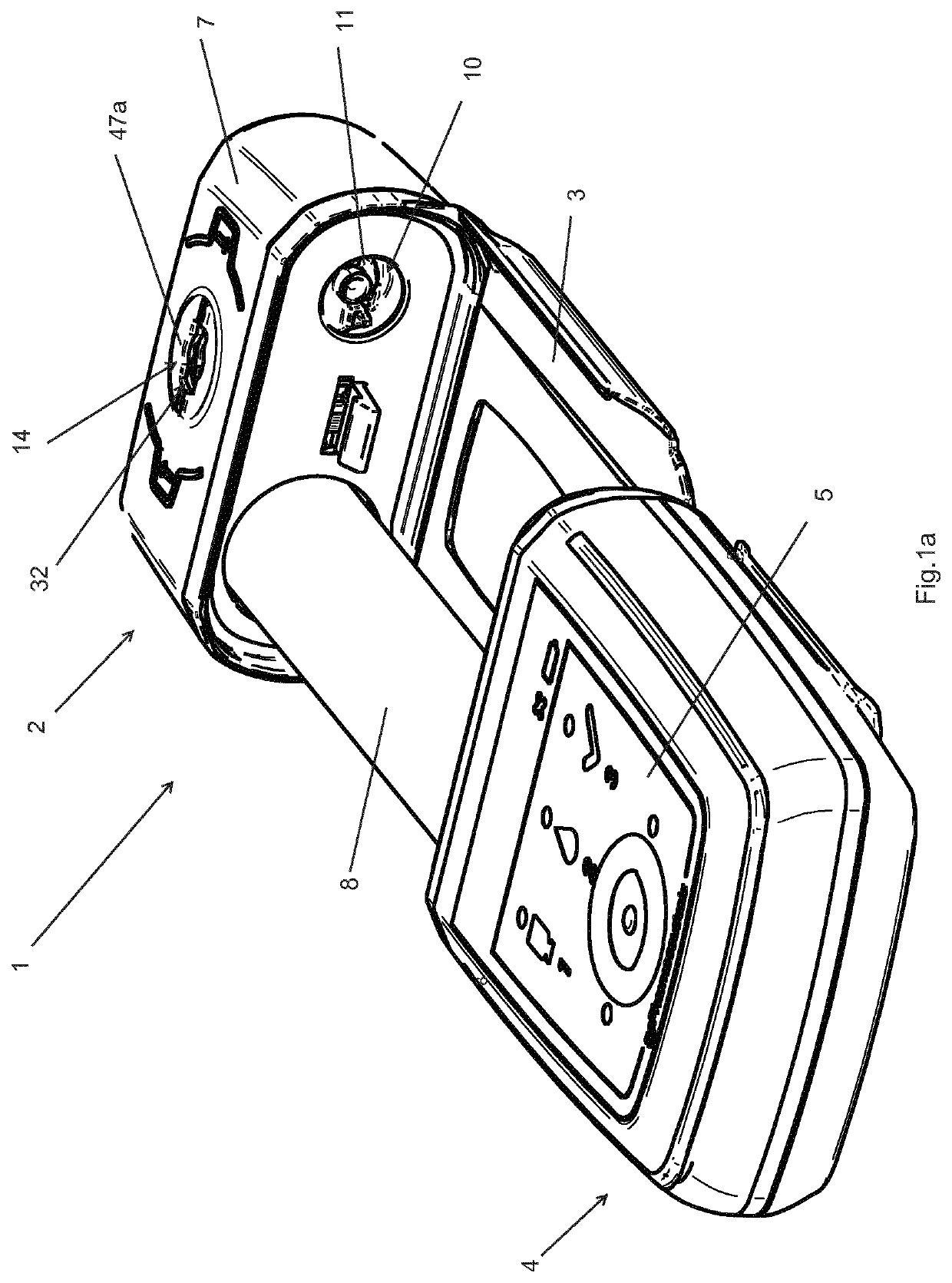

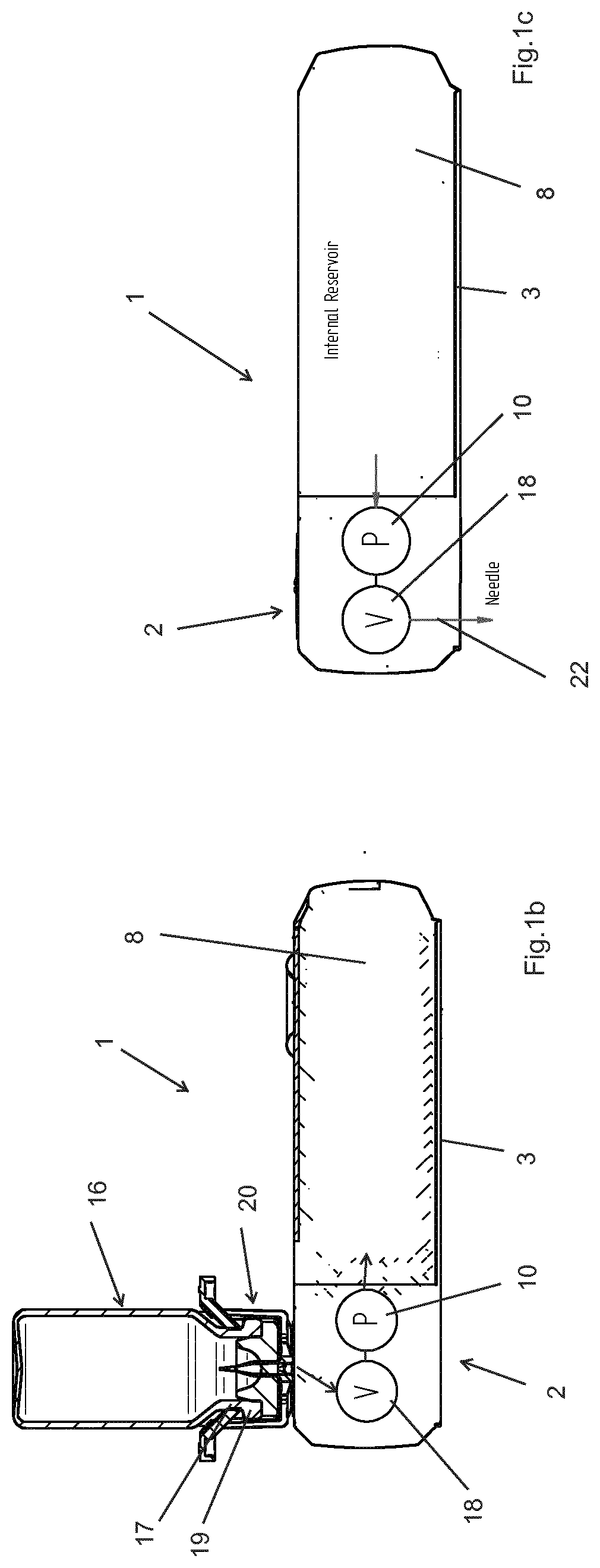

Drug delivery device

ActiveUS20190358393A1Easy to useEasy refillInfusion syringesPharmaceutical containersDelivery systemBiomedical engineering

A drug delivery device comprising a delivery unit (2) including an internal reservoir (8), a subcutaneous delivery mechanism (6), a pump for pumping liquid from the internal reservoir to the subcutaneous delivery system, and a liquid filling mechanism (12) configured for injecting liquid from an external vial (16) or reservoir into the internal reservoir. The liquid filling mechanism comprises a filling port (14) and a valve mechanism (18) selectively operable to: open a first fluid path (54) extending from the filling port to the internal fluid reservoir and close a second fluid path (56) extending from the internal reservoir to the subcutaneous delivery member, or close the first fluid path and open the second fluid path. The valve mechanism comprises a valve housing (48) fixedly mounted in relation to a housing of the drug delivery device and a valve stem (50) rotatably received within the valve housing, whereby the first fluid path and the second fluid path are selectively operated by the rotational position of the valve stem in relation to the valve housing, such that when the valve stem is in a first position, the first fluid path is open while the second fluid path is closed, and when the valve stem is in a second position, the second fluid path is open while the first fluid path is closed.

Owner:SENSILE MEDICAL AG

Sugar-free soft-sweets and hard-sweets made of spirulina for replenishing nutrient elements, and its prepn. method

InactiveCN1860902AHas the ability to clear directlyImprove immunityConfectionerySweetmeatsHard candySugar free

A saccharide-free hard or soft spirulina candy for supplementing nutrients to human body is disclosed. Said hard candy is prepared from spirulina, maltose, xylitol, sweetening agent, citric acid, malic acid, potassium sorbate, sodium chloride, apple essence and glycerin. Said soft candy is prepared from spiruline, chitosan, sweetening agent, xylitol, refined konjak starch, citric acid, malic acid, potassium sorbate, sodium chloride, apple essence and glycerin.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

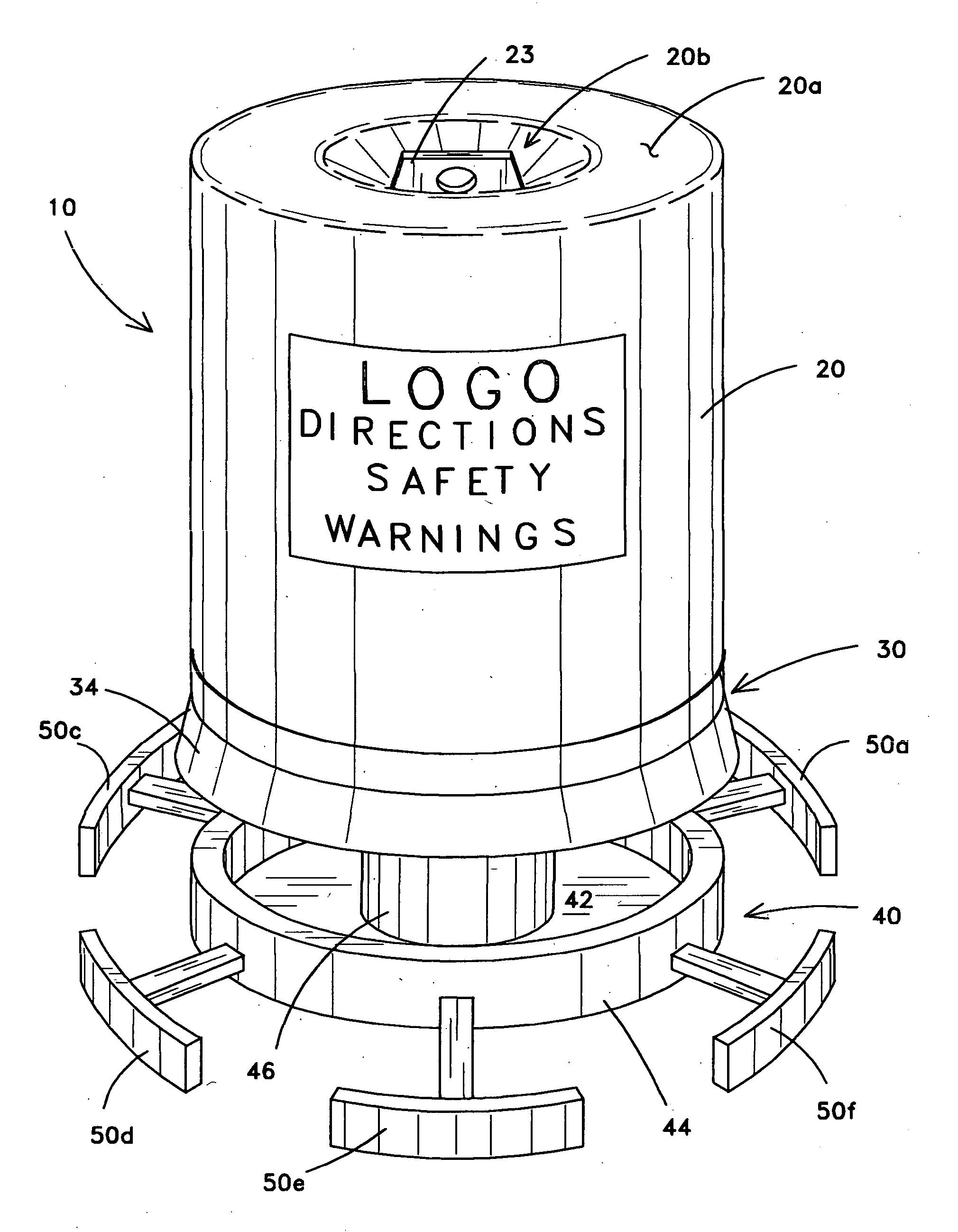

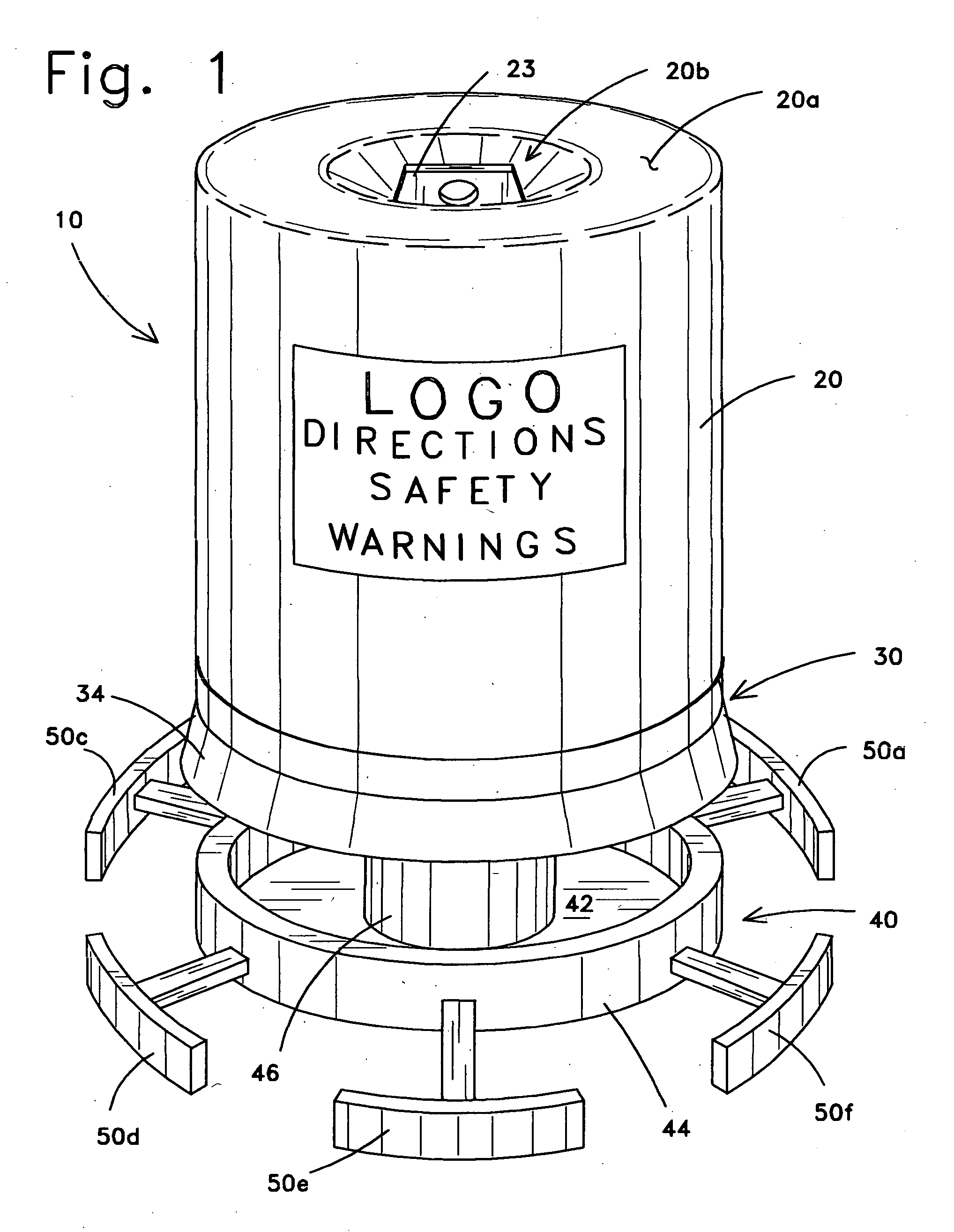

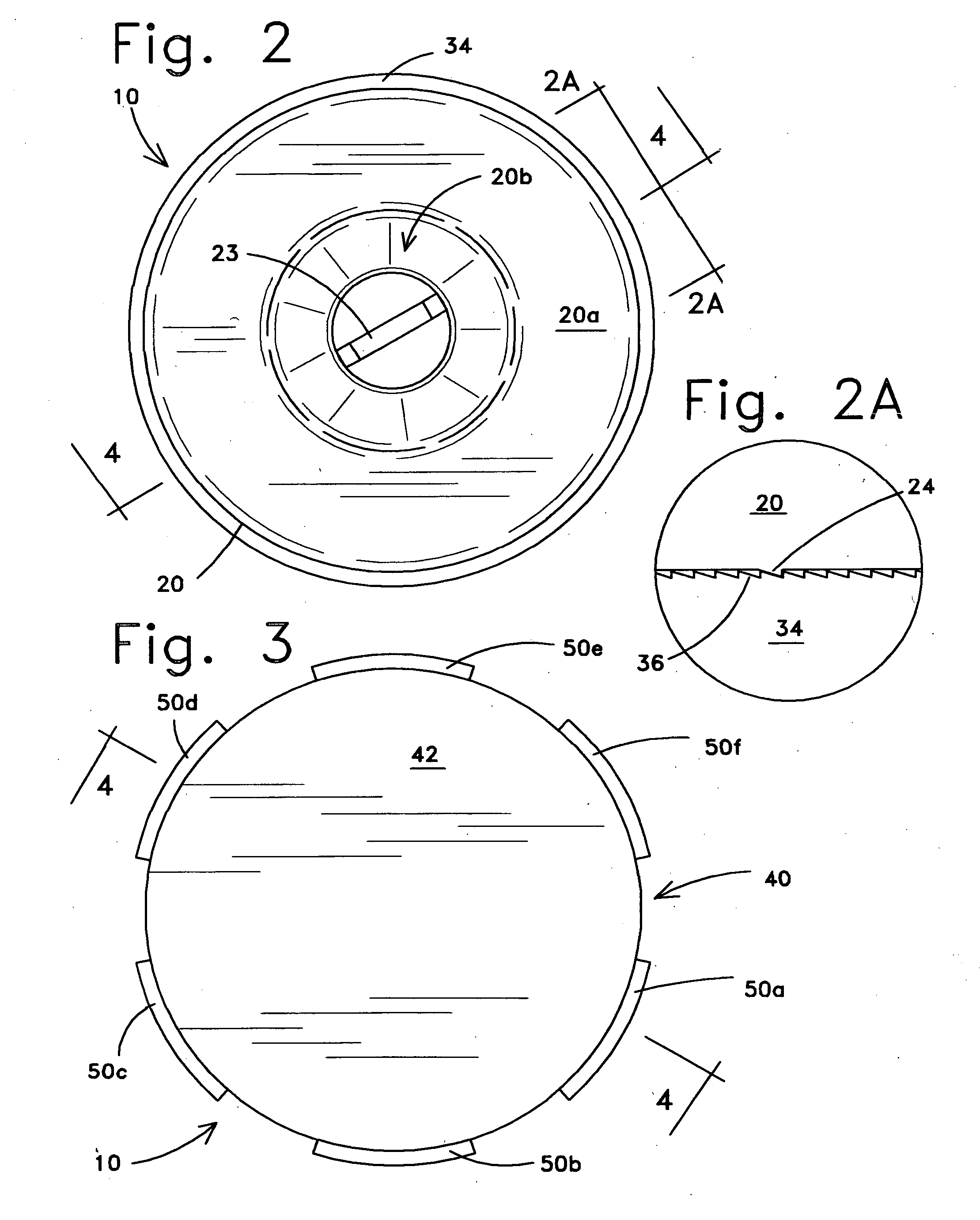

Disposable wild bird feeder

InactiveUS20090188432A1Easy to useResistant being reusedPisciculture and aquariaAvicultureBird feederEngineering

The present invention is a wild bird feeder with the features that make it safe and easy to use but protected from being reused. A reservoir containing bird seed is connected with a feeding base using an adaptor. The feeding base is threaded to the adaptor which in turn is threaded to the reservoir. A stop attached to the feeding base and a locking adaptor seat keeps the assembled wild bird feeder from being taken apart and refilled. The wild bird feeder converts from a first storage position to a second feeding position by partially unthreading the feeding base from the adaptor so bird seed is supplied to the bottom portion of the feeding base. A plurality of perches are supported by the feeding base. The perches are moved from a stored position to a properly deployed position when second feeding position is realized. A label is placed on the reservoir to provide a logo, directions for use and bird seed data.

Owner:NATRIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com