Patents

Literature

418results about How to "Guarantee efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

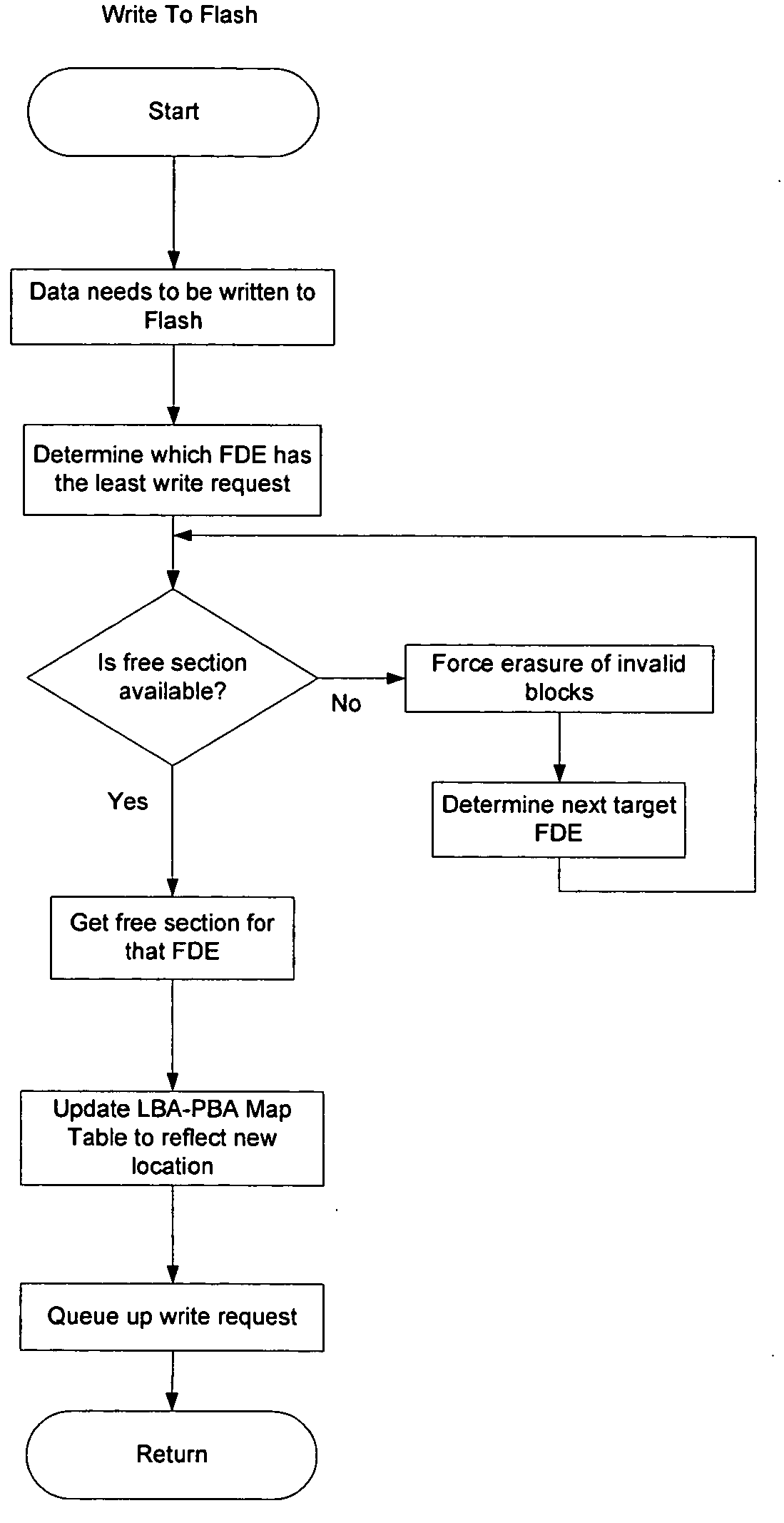

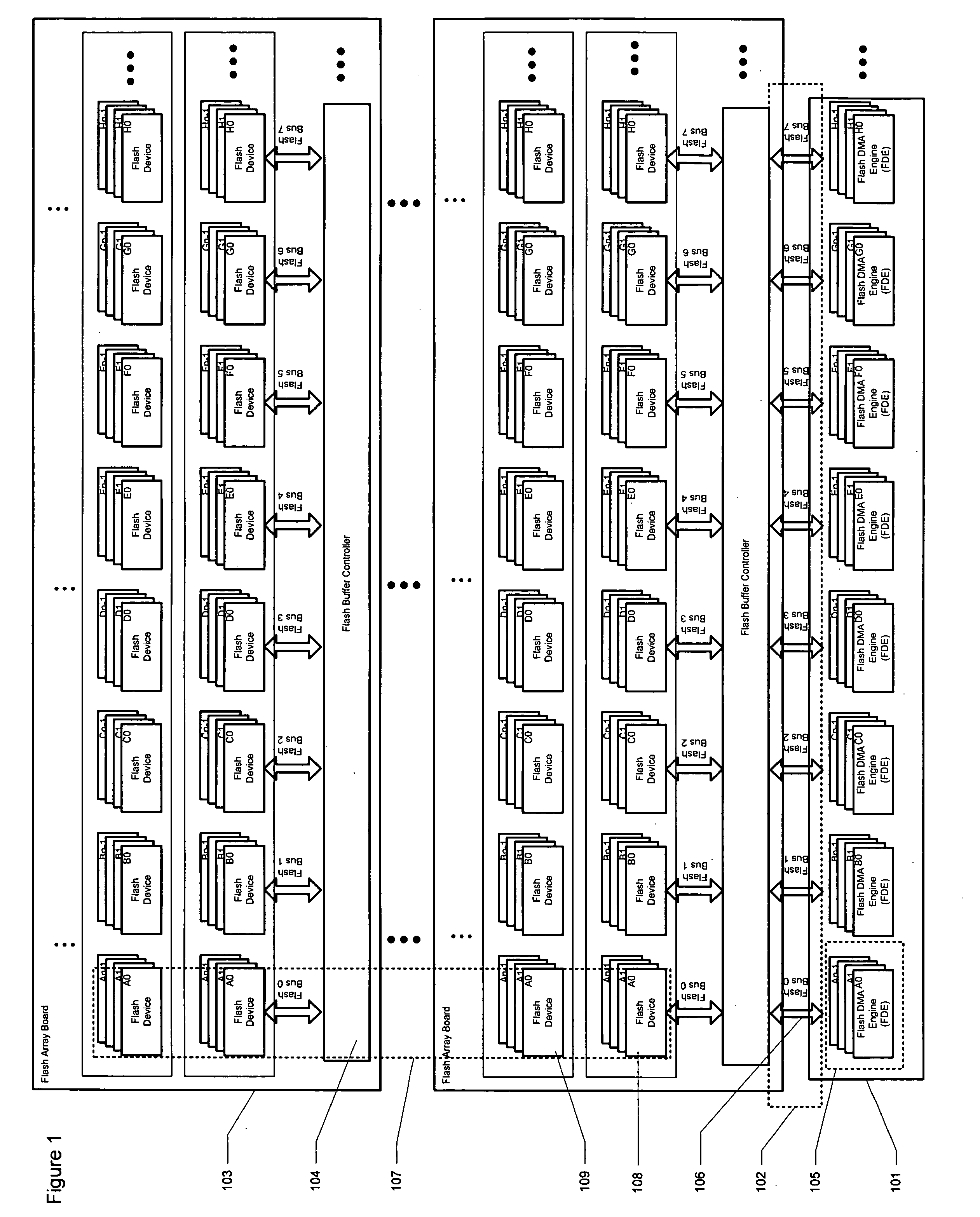

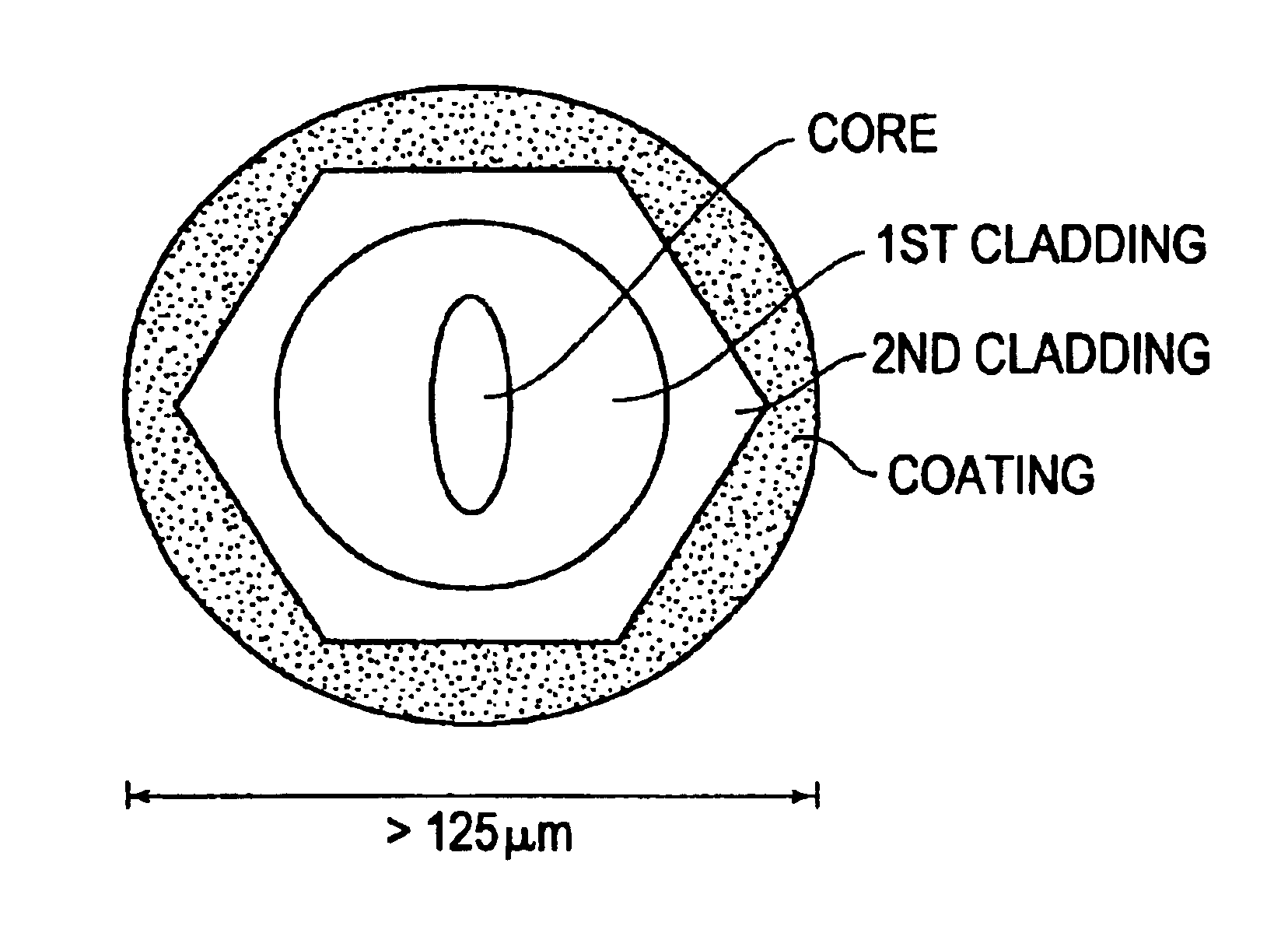

Optimized placement policy for solid state storage devices

InactiveUS20070288686A1Evenly loadedGuarantee efficiencyMemory architecture accessing/allocationMemory systemsSolid-state storageCurrent load

A data storage system is provided comprising several flash arrays in a board and stacking these boards to attain a high-capacity solid state hard drive. A remap table is used to map all logical addresses from a host system to the actual physical addresses where data are stored. The assignments of these physical locations are done in such a way that the load of the system is evenly distributed to its available resources. This would ensure that the storage system will run at its utmost efficiency utilizing its resources properly. To achieve this, the system would make sure that the physical location of data be evenly distributed according to the current load of the system.

Owner:BITMICRO LLC

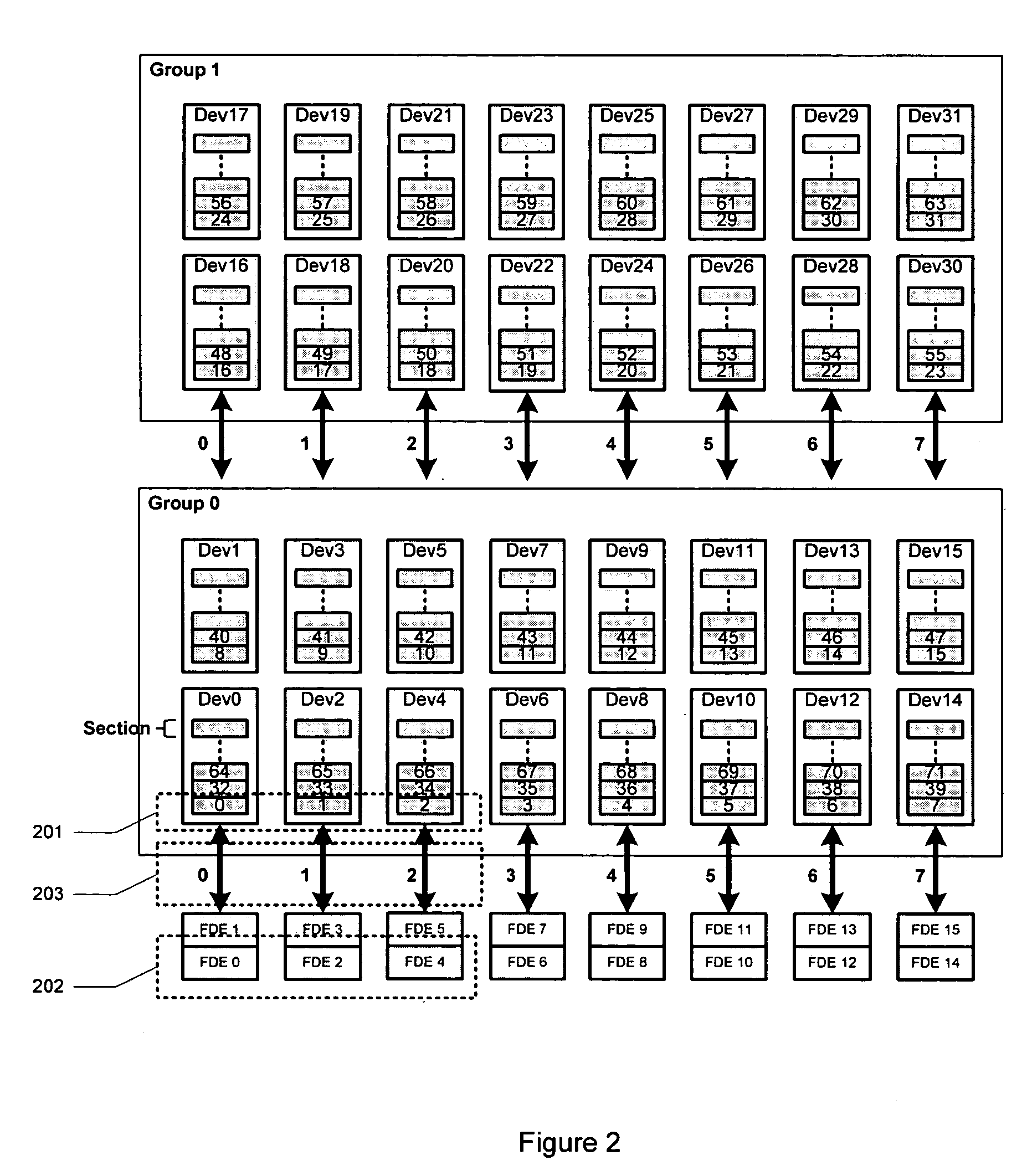

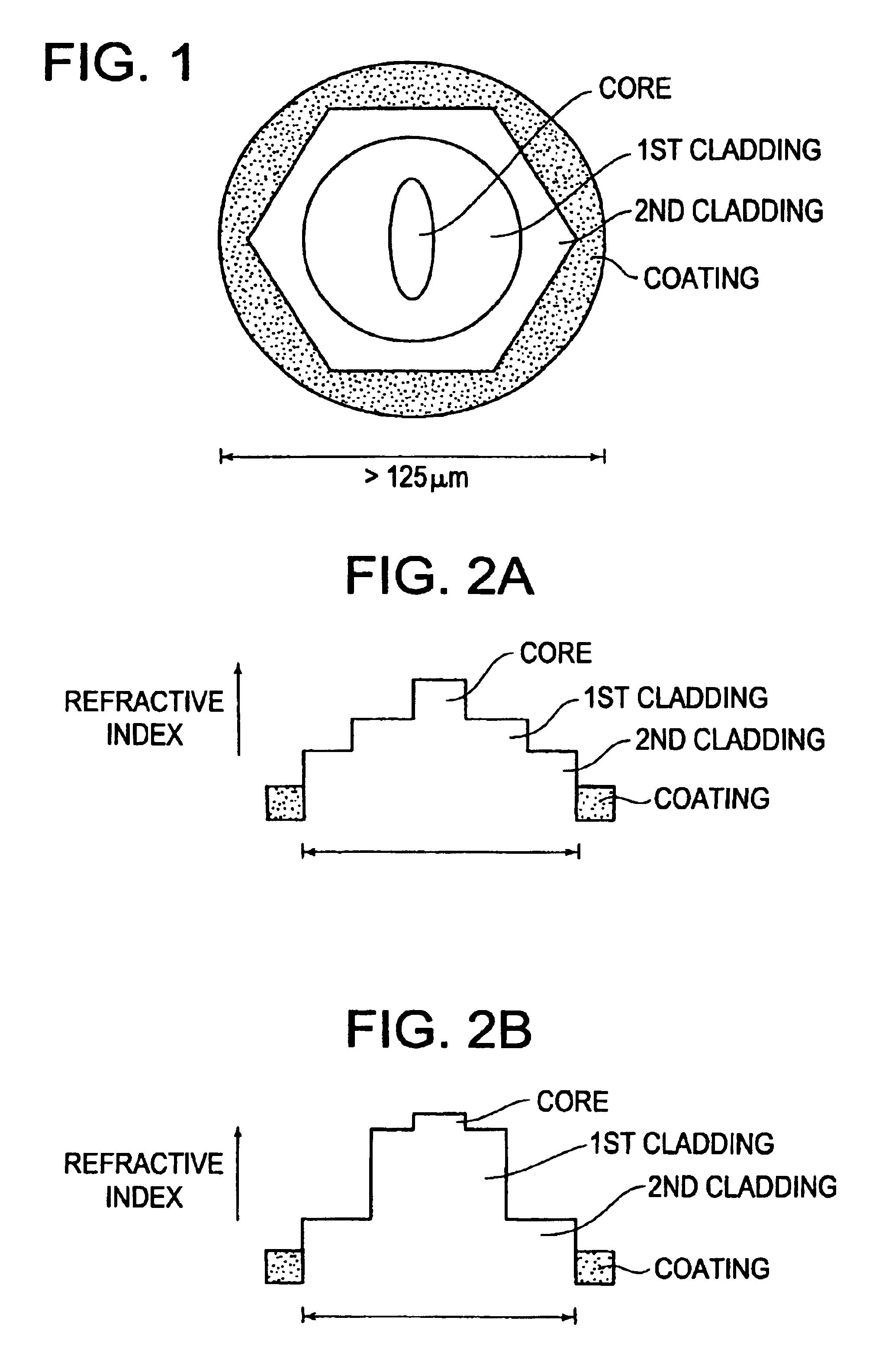

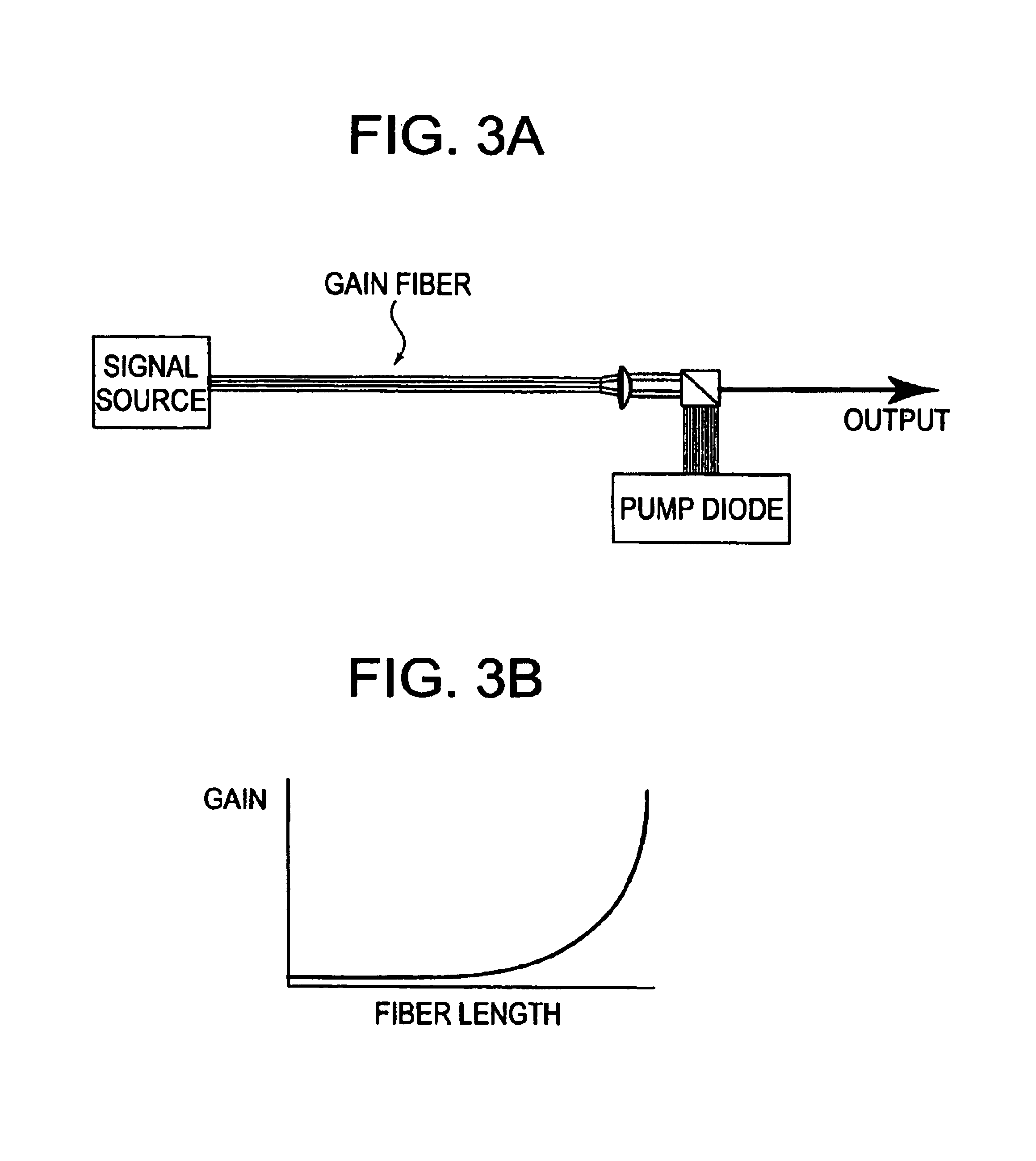

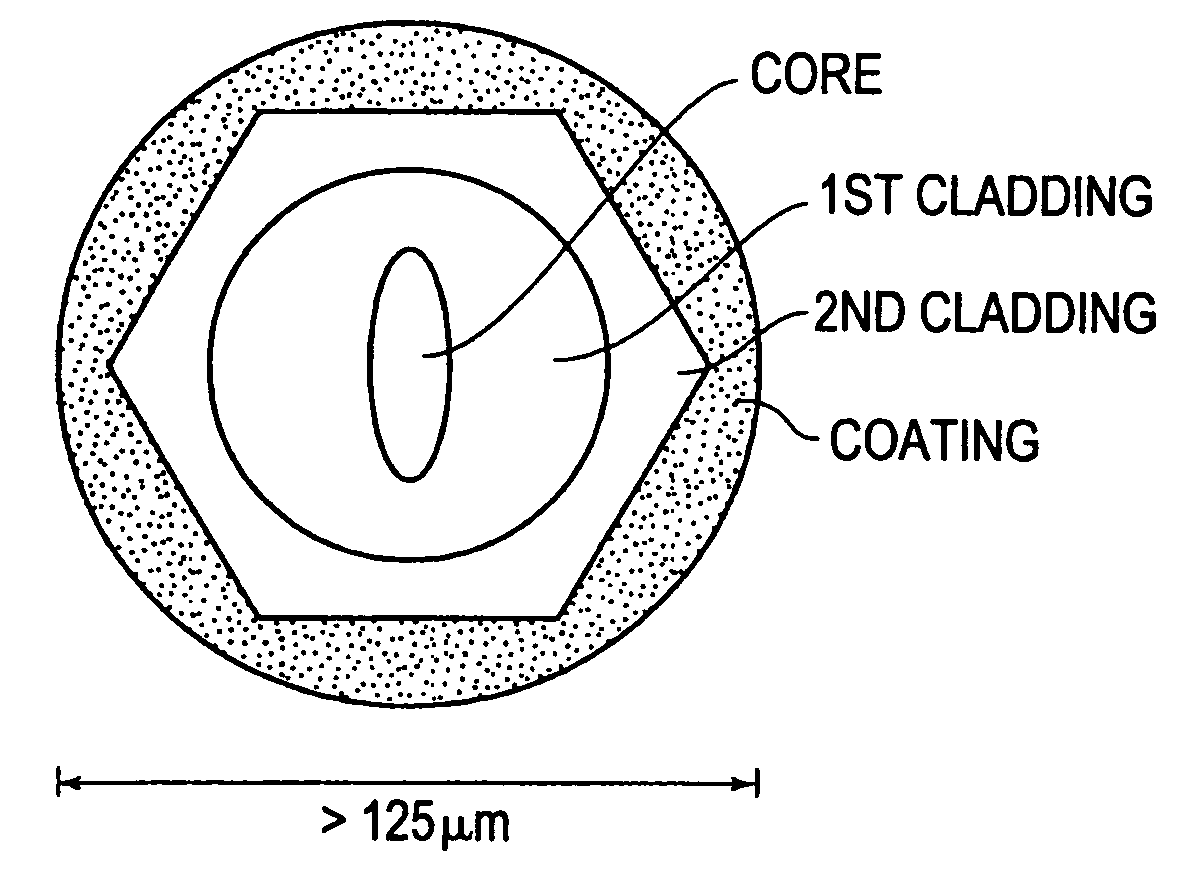

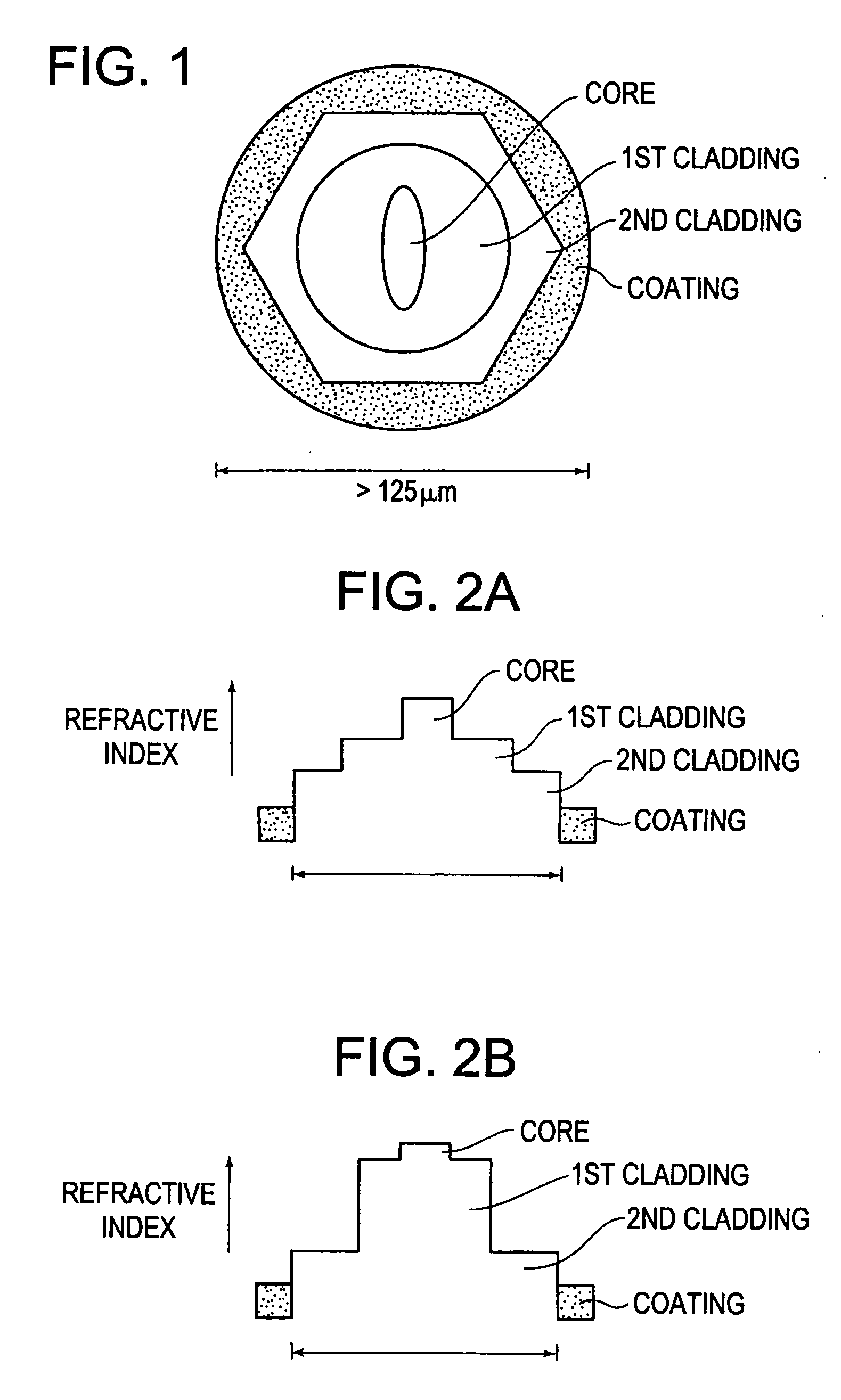

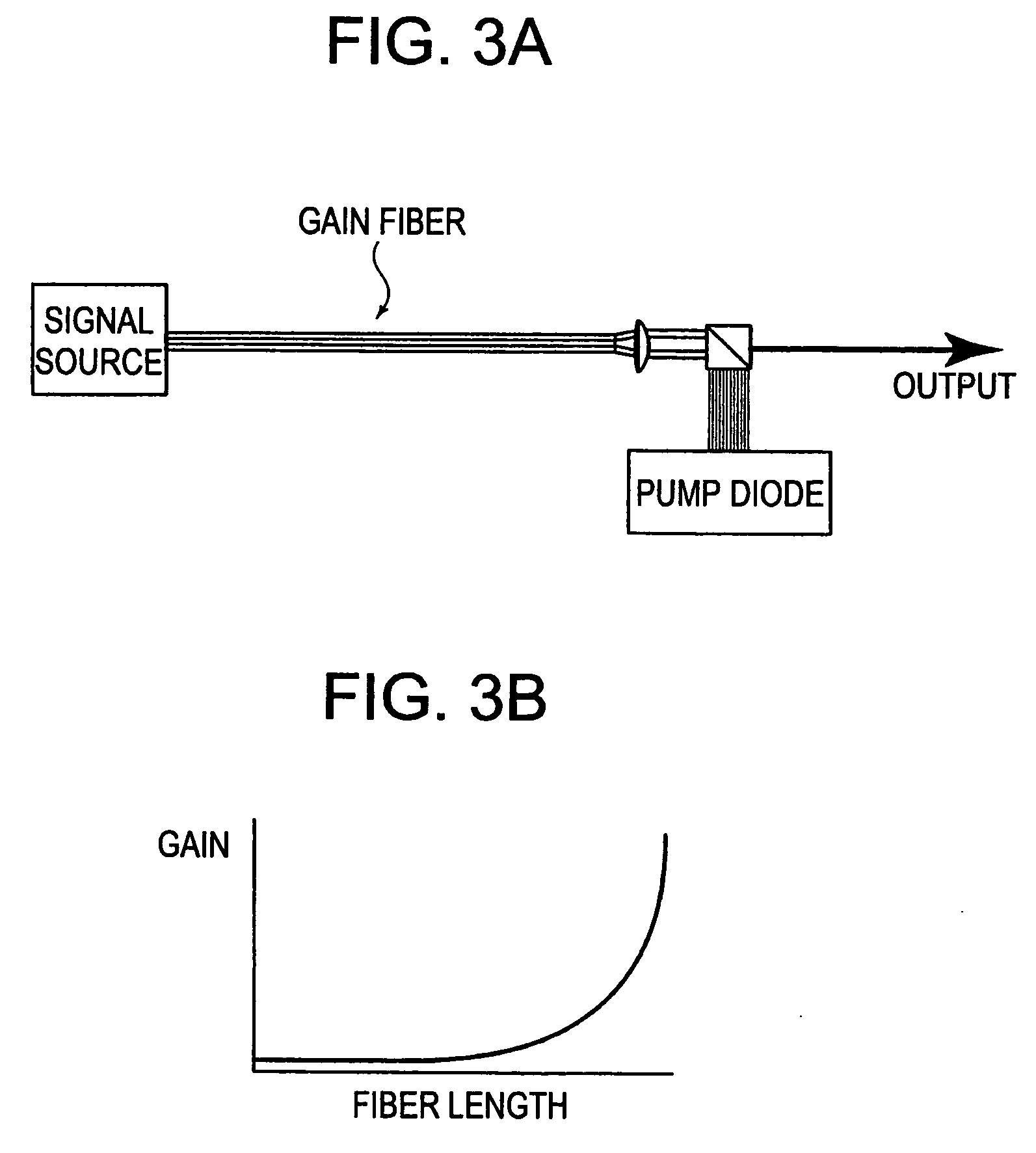

Single-polarization high power fiber lasers and amplifiers

InactiveUS6954575B2Modelocking stabilityPulse stabilizationLaser using scattering effectsOptical fibre with polarisationSingle polarizationFibre coating

A novel polarization maintaining optical fiber, which can be used as a high-power polarization maintaining fiber laser or amplifier, is described. Insensitivity of the polarization state to external fiber bending and temperature changes is accomplished by minimizing polarization mode-coupling via reducing stresses inside the fiber core via increasing the fiber diameter. Alternatively, polarization mode-coupling can be minimized by an optimization of the fiber coating to minimize stresses at the interface between the fiber and the coating. As a result insensitivity to polarization mode-coupling is obtained at greatly reduced values of birefringence compared to small-diameter fibers. The fiber is of significant use in any application where polarization stability is important, and will be useful in telecommunications applications in particular for reducing polarization mode dispersion. An implementation in a parabolic pulse-producing fiber laser is also described as one specific high power example.

Owner:IMRA AMERICA

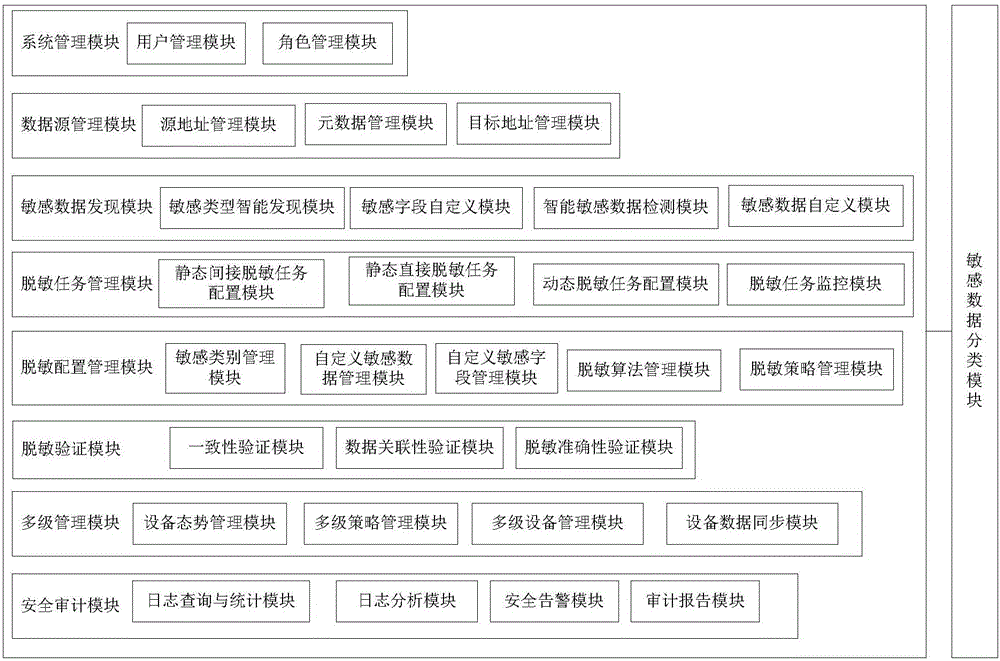

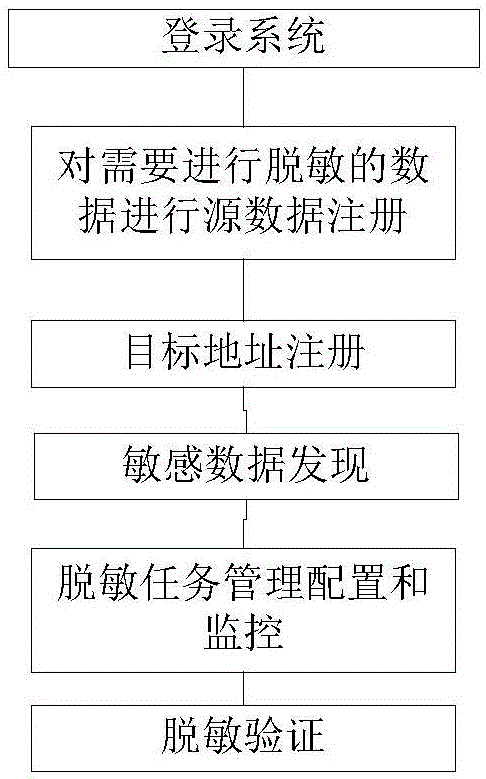

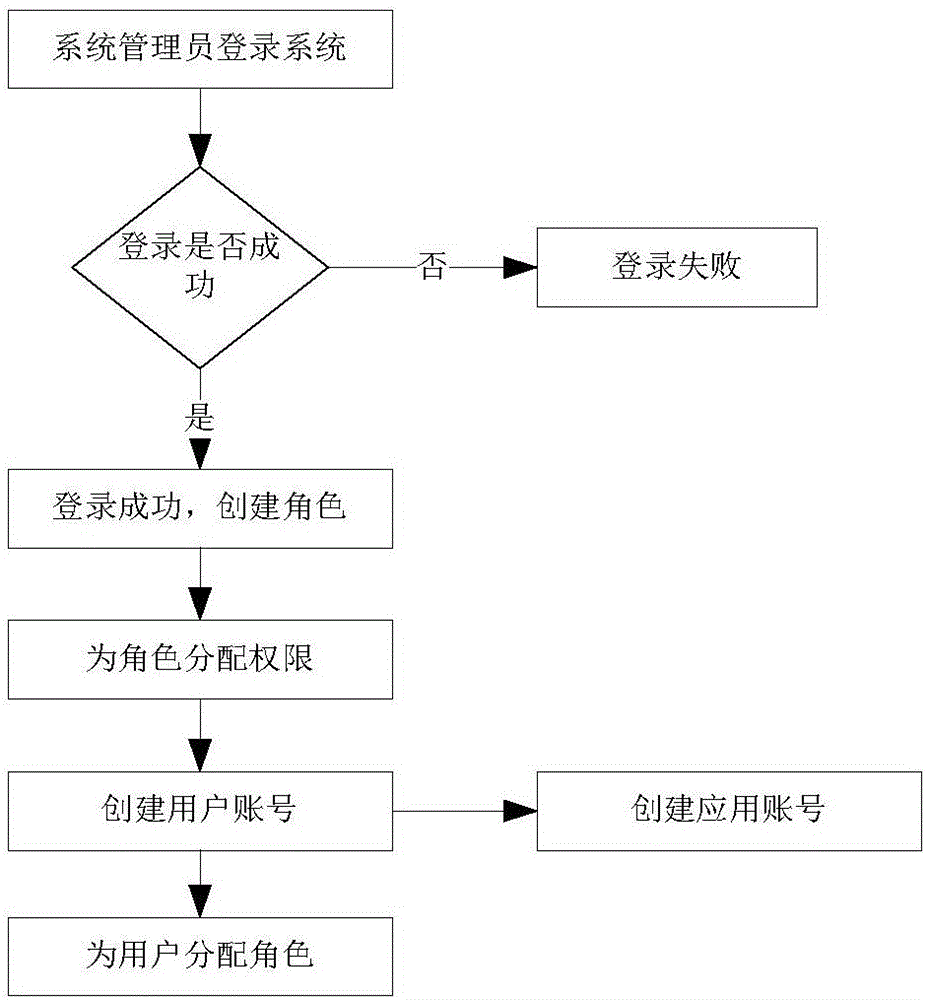

Database masking system and method based on big data

ActiveCN106599713AImprove accuracySolve unrecognizedDigital data protectionData synchronizationReal time analysis

The invention discloses a database masking system based on big data. The system comprises a system management module for constructing a role for the database masking system, and performing function authorization and management on the role, a data source management module for providing data source management for the database masking system, a sensitive data discovery module for automatically discovering sensitive data in the database and submitting the sensitive data to a user to adjust and confirm, a masking task management module for configuring and managing the masking task of the database masking system; a masking configuration management module for managing and defining the sensitive data and performing masking algorithm and masking strategy management, a masking verification module for verifying the masking by comparing data before the masking with data after the masking, a multi-stage management module for realizing the status monitoring and strategy issuing and data synchronization of multi-stage masking equipment, and a security auditing module for analyzing the acquired masking log data in real time to guarantee the security of the database masking system. The invention further discloses a database masking method based on the big data.

Owner:CHINA ELECTRONICS TECH CYBER SECURITY CO LTD

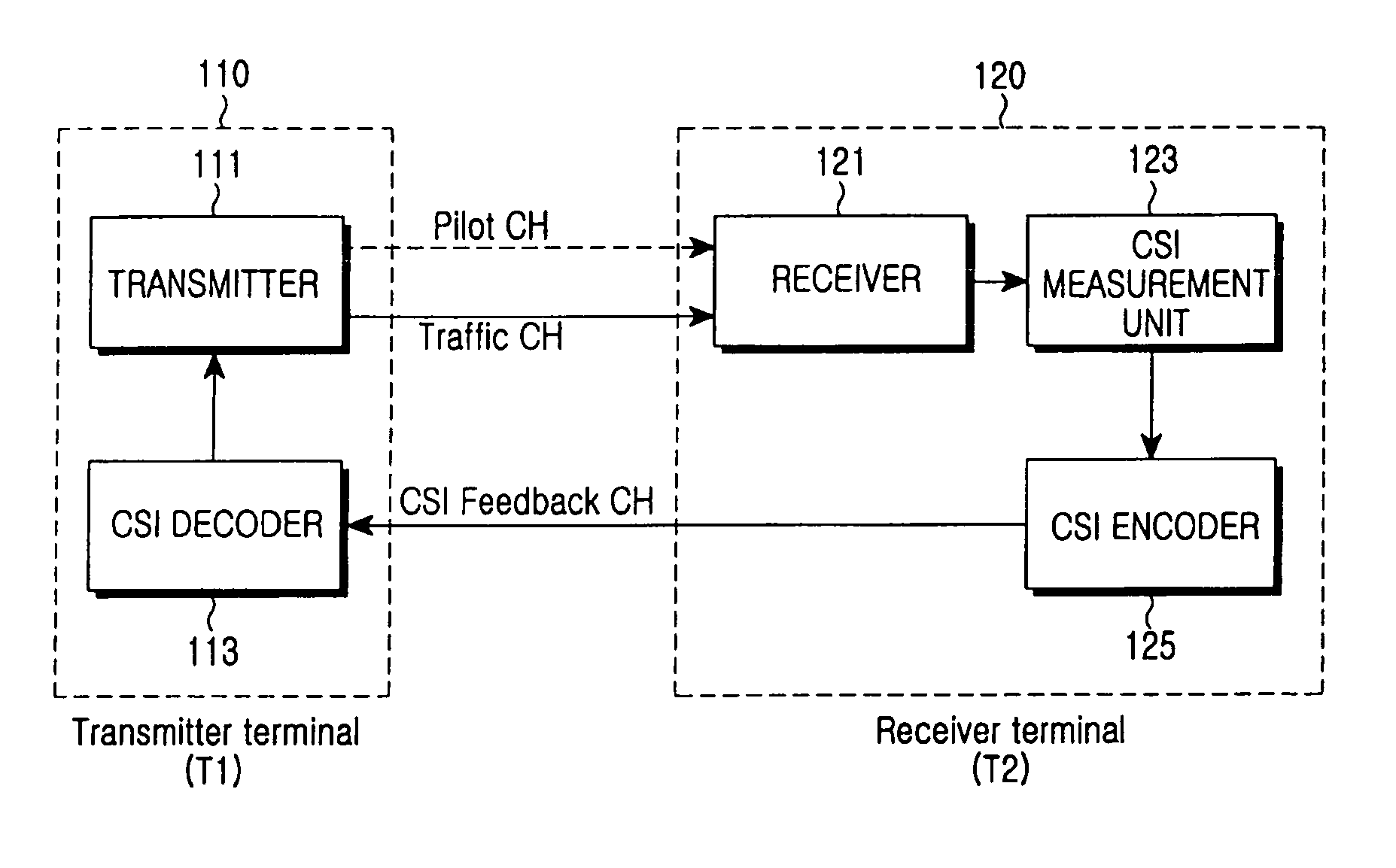

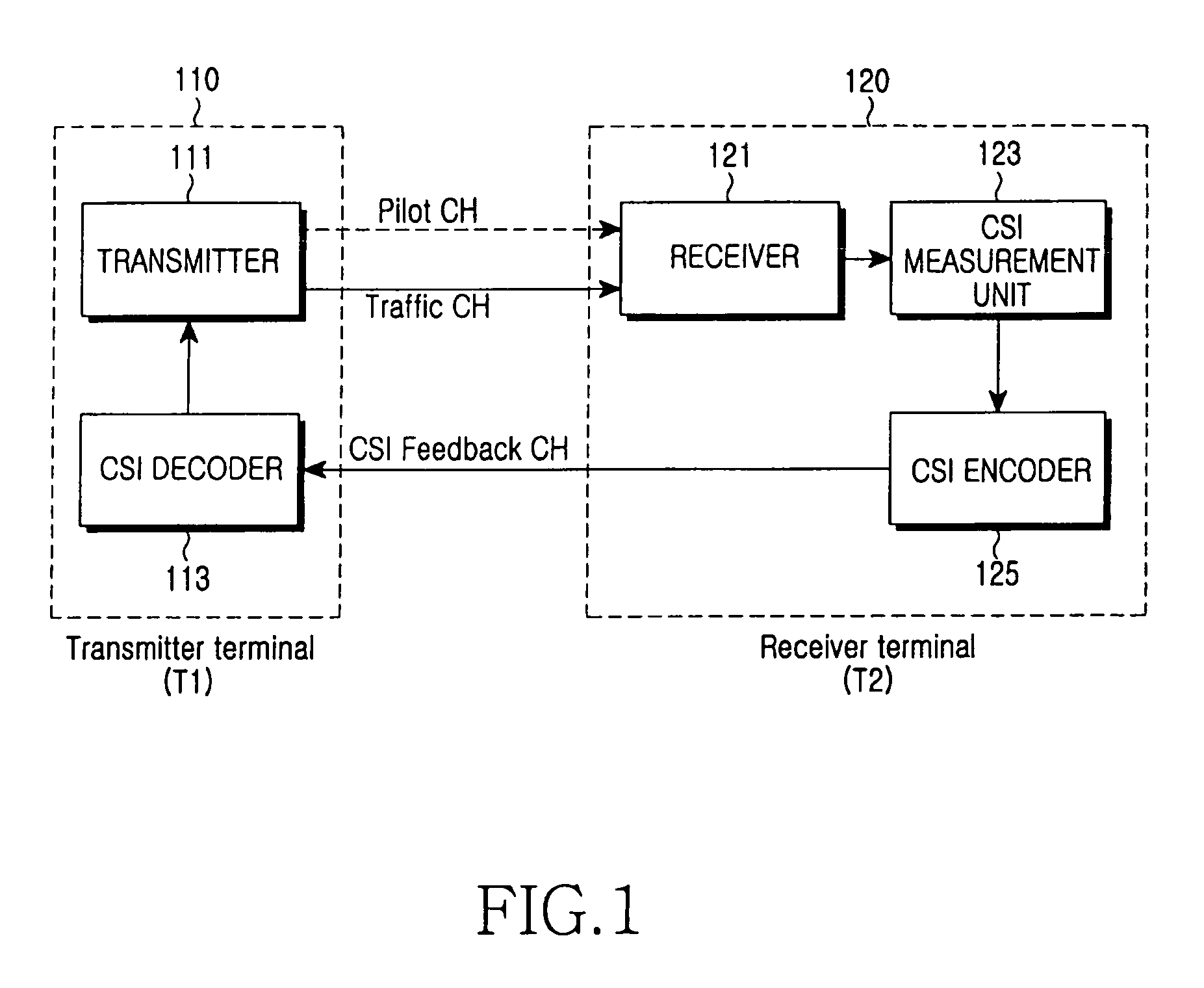

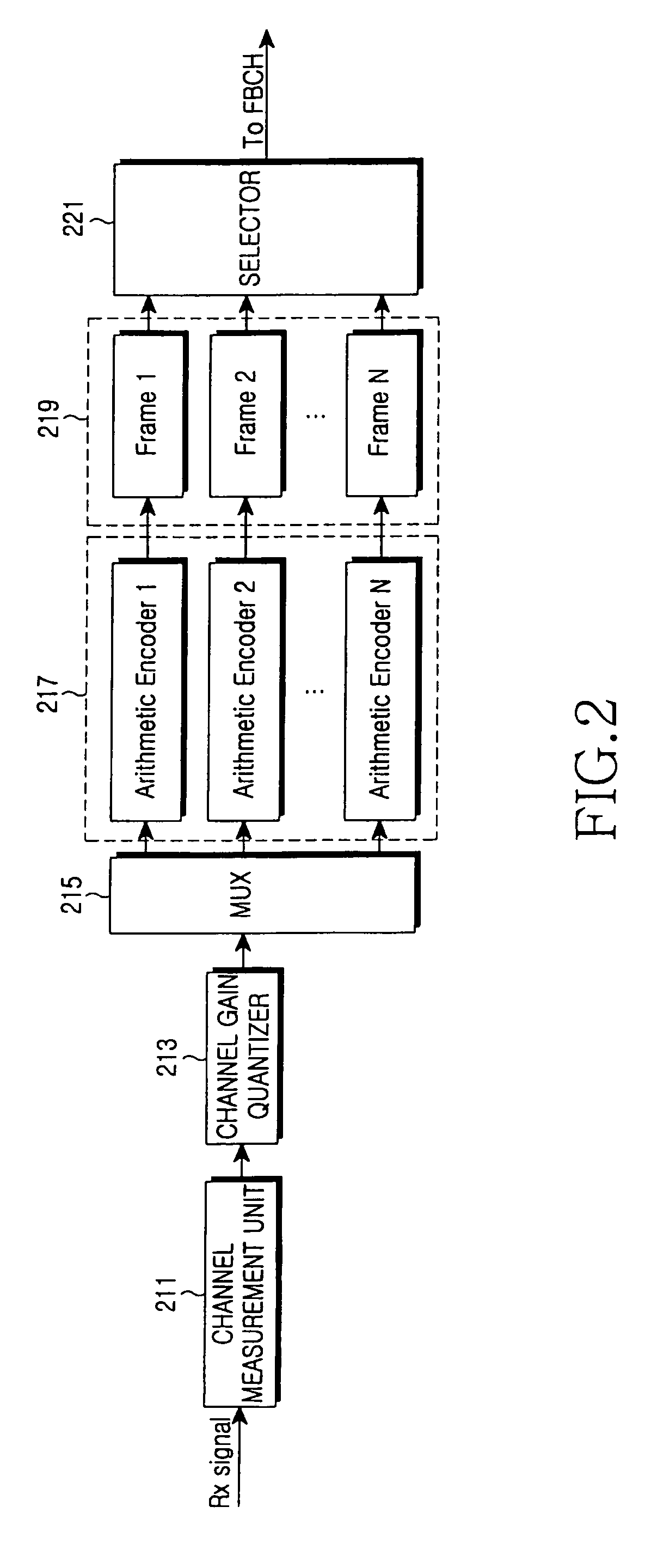

Method and apparatus for channel state feedback using arithmetic coding

ActiveUS7746802B2Reduce impactImprove system performanceFrequency-division multiplex detailsModulated-carrier systemsCommunications systemEngineering

Disclosed are the design and implementation of a CSI feedback channel in a multi-carrier wireless communication system. An apparatus and a method for channel state feedback using arithmetic coding are provided to ensure efficiency and reliability of a system by transmitting the CSI while compressing the CSI with a predetermined compression rate selected depending on a channel state. The apparatus for CSI feedback in a wireless communication system performing channel estimation at a transmitter or a receiver by using a communication channel includes a transmitter terminal transmitting a signal for CSI measurement by using the communication channel, and a receiver terminal receiving the signal from the transmitter terminal, checking a channel state based on the received signal, and transmitting the signal to the transmitter terminal after compressing the signal according to the channel state.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Single-polarization high power fiber lasers and amplifiers

InactiveUS20050232313A1Reduce absorptionMinimize nonlinearityLaser using scattering effectsOptical fibre with polarisationAudio power amplifierPolarization-maintaining optical fiber

A novel polarization maintaining optical fiber, which can be used as a high-power polarization maintaining fiber laser or amplifier, is described. Insensitivity of the polarization state to external fiber bending and temperature changes is accomplished by minimizing polarization mode-coupling via reducing stresses inside the fiber core via increasing the fiber diameter. Alternatively, polarization mode-coupling can be minimized by an optimization of the fiber coating to minimize stresses at the interface between the fiber and the coating. As a result insensitivity to polarization mode-coupling is obtained at greatly reduced values of birefringence compared to small-diameter fibers. The fiber is of significant use in any application where polarization stability is important, and will be useful in telecommunications applications in particular for reducing polarization mode dispersion. An implementation in a parabolic pulse-producing fiber laser is also described as one specific high power example.

Owner:IMRA AMERICA

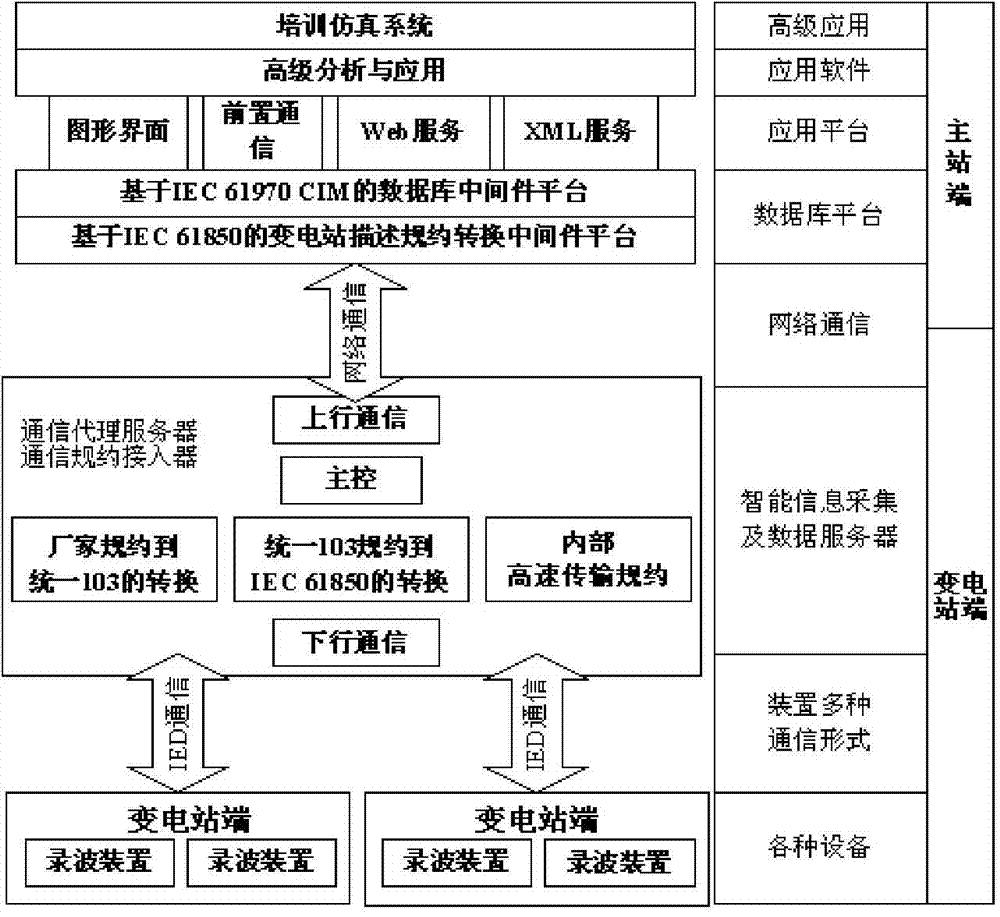

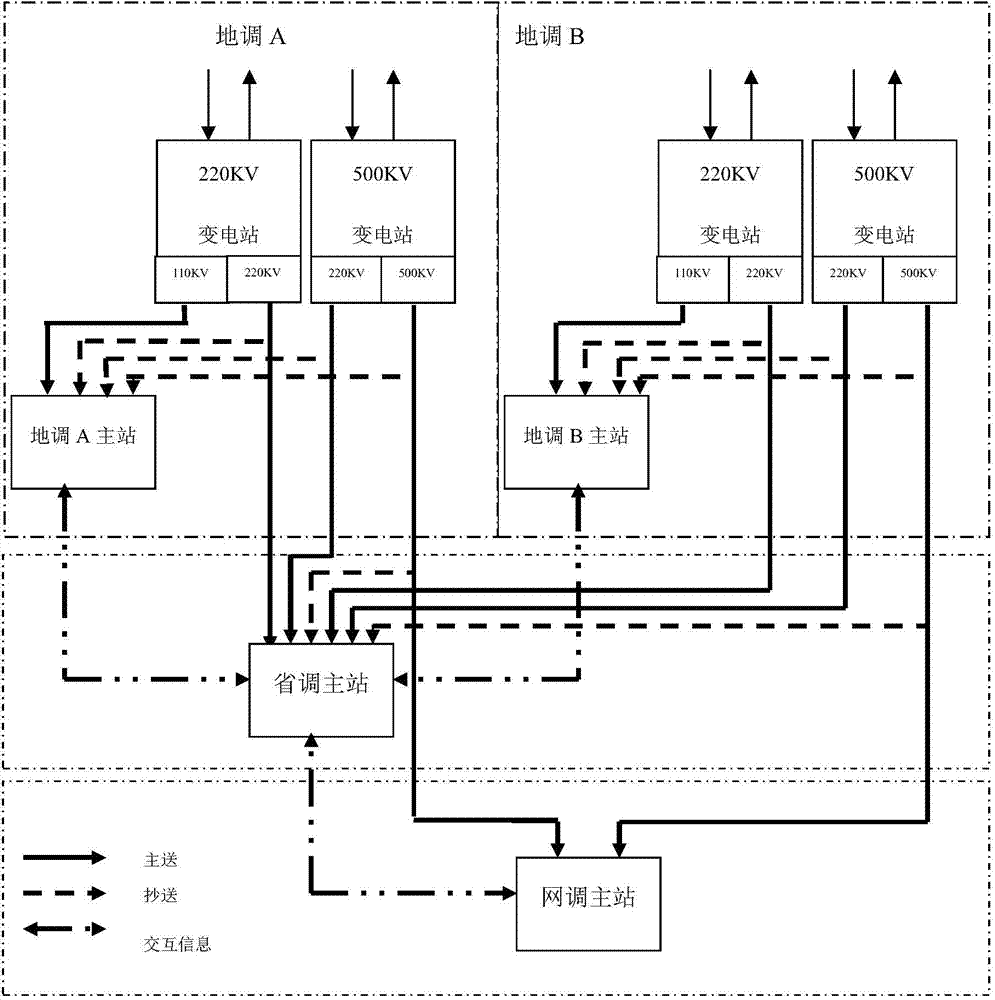

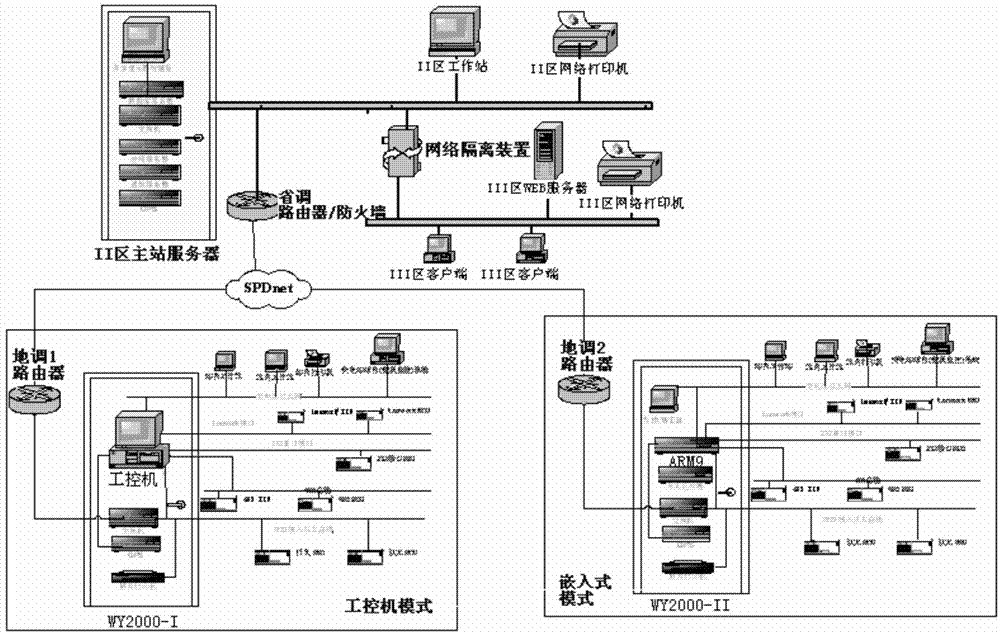

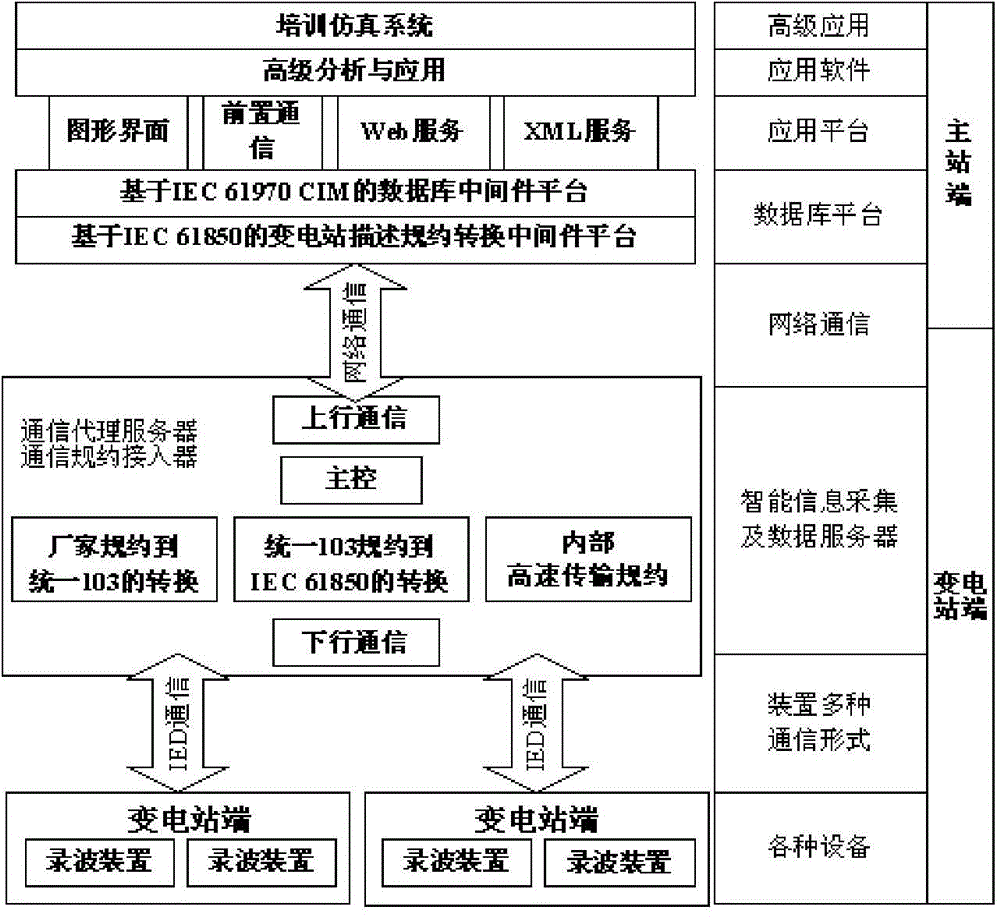

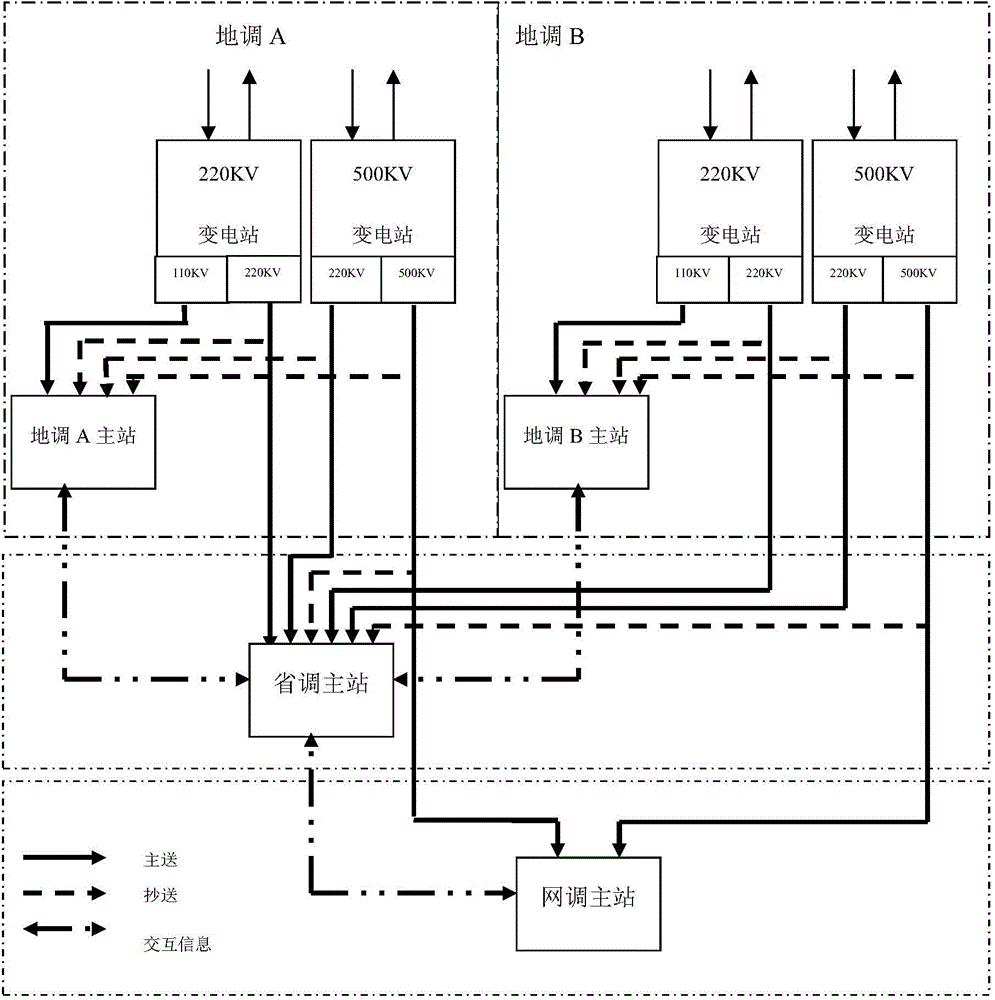

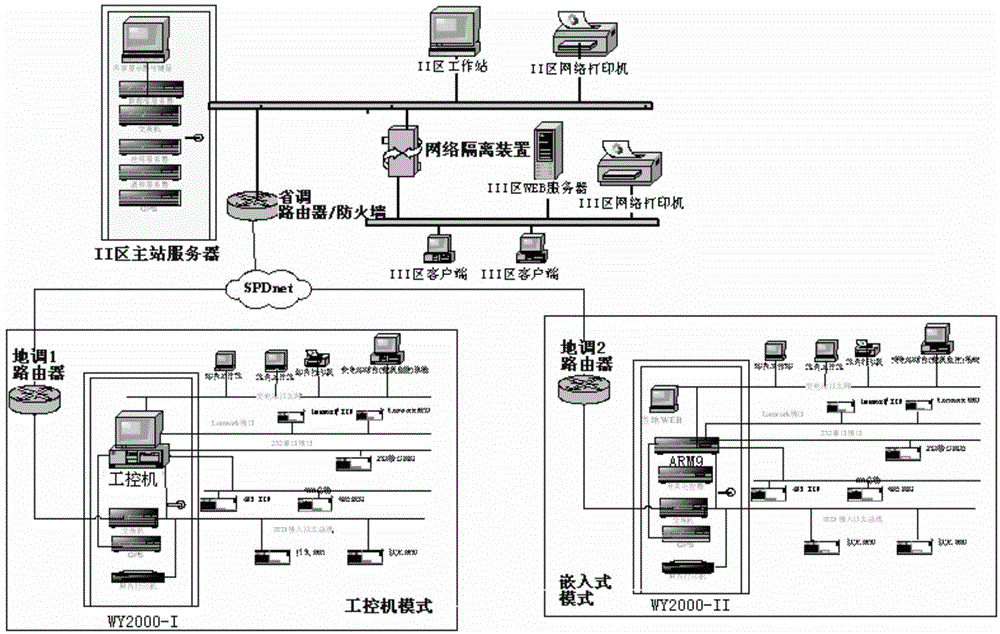

Intelligent fault wave recording main station information management system

The invention discloses an intelligent fault wave recording main station information management system, which comprises a main system and a plurality of sub systems, wherein each sub system is provided with a fault wave recording device used for automatic recording waves and sending wave recording files to the main system when a fault occurs, the main system is provided with a management unit, a configuration unit, an operation unit, a monitoring unit, an integration unit and a retrieval unit, the configuration unit is used for configuring the fault wave recording device, the management unit is used for automatically searching or passively updating an accessed fault wave recording device, and carrying out the management operation on the fault wave recording device, the operation unit is used for obtaining the wave recording files, the standard wave recording information is obtained after the protocol conversion through the analysis, a fault report is automatically analyzed and generated, the monitoring unit is used for carrying out state monitoring and electric network monitoring, the integration unit is used for carrying out wave recording analysis on data according to the time and the version for outputting editable or printable wave recording analysis reports, and the retrieval unit is used for carrying out data retrieval according to the retrieval conditions.

Owner:YUNNAN ELECTRIC POWER DISPATCH CONTROL CENT +1

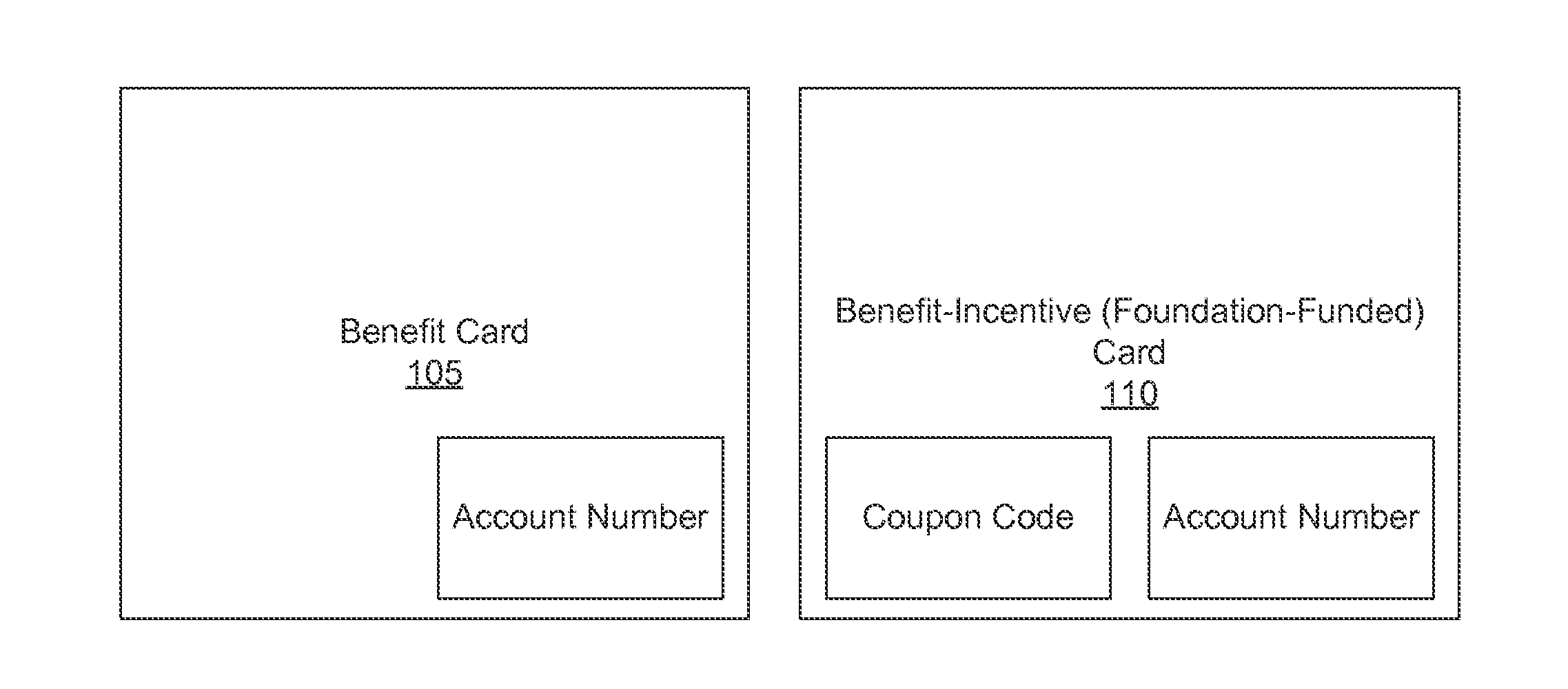

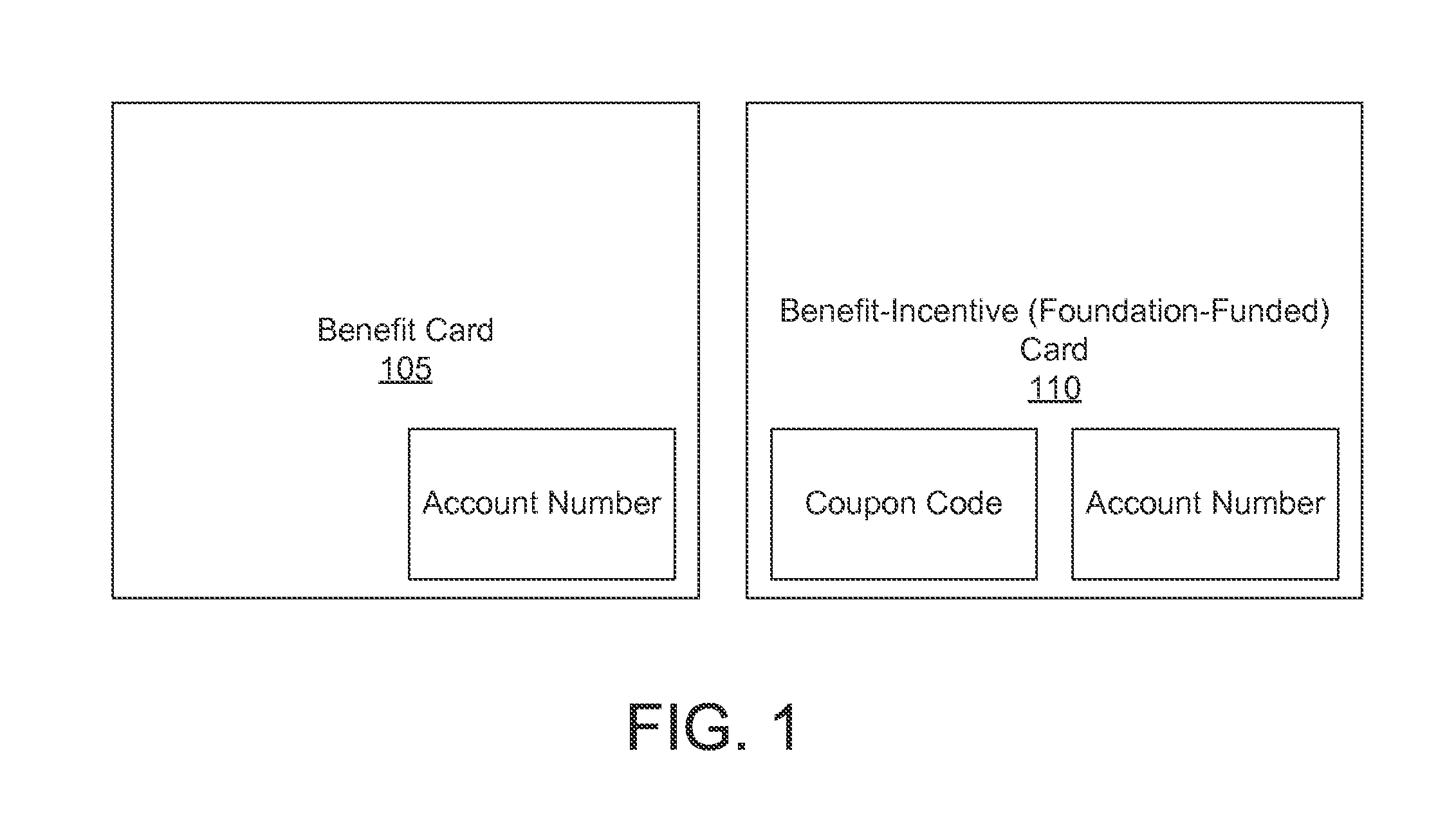

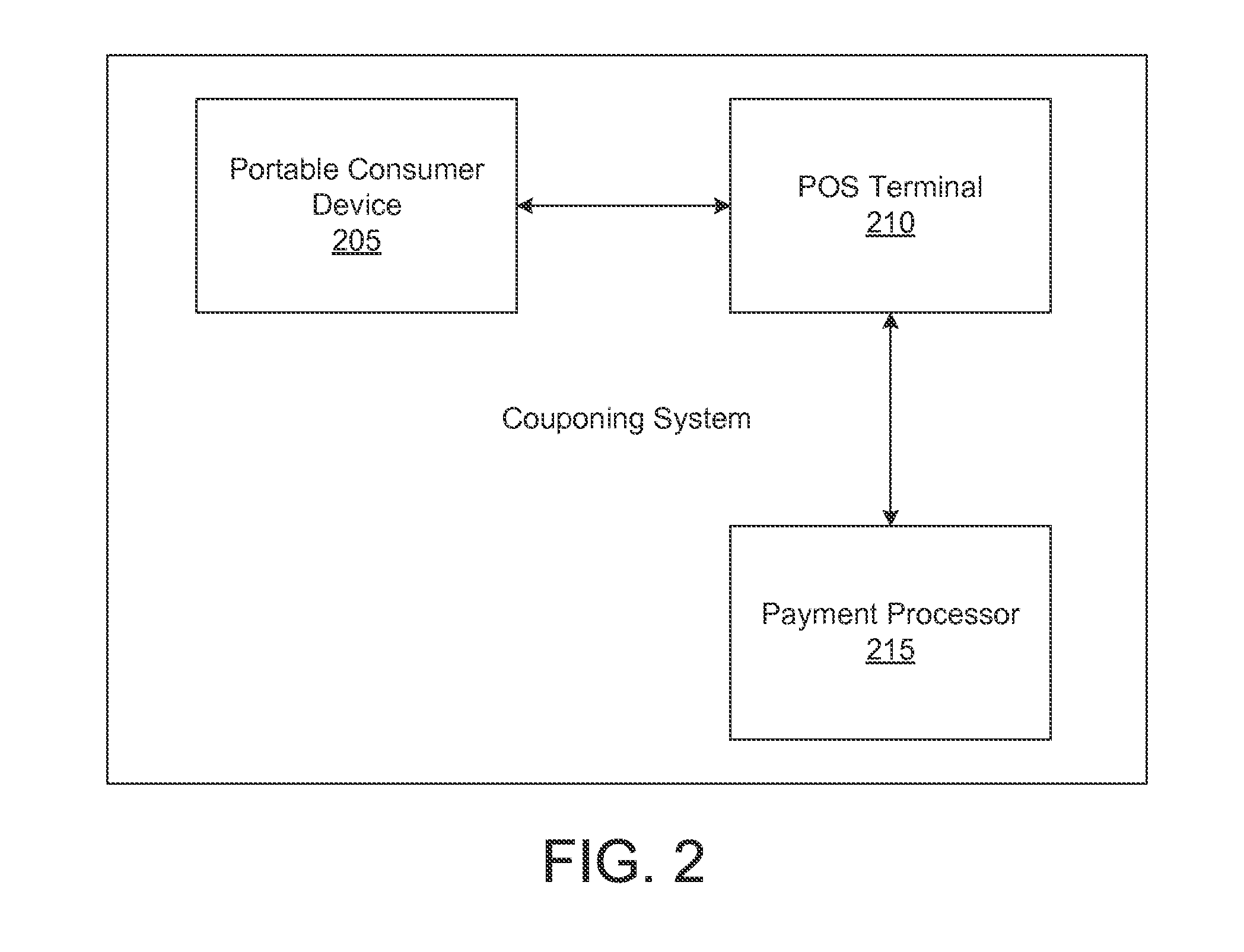

Payment Processing For Qualified Transaction Items

ActiveUS20130339167A1Guarantee efficiencyEnsure convenienceHand manipulated computer devicesPayment protocolsHealthy foodFood item

Systems, methods, and apparatuses for providing a portable consumer device (e.g., a plastic card) that includes a coupon code and an account number (e.g., embedded on a magnetic stripe or a chip) where the portable consumer device is configured to apply a coupon to goods and services purchased at a merchant (e.g., store). Upon identifying the goods and services under a particular category specified by the coupon code (e.g., healthy food category), a user may pay for a predetermined portion (e.g., 50%) of the goods and services under the particular category using the portable consumer device. The user may pay for the remaining portion using a benefits card (e.g., state benefits card). As such, by allowing the user to pay for the predetermined portion using the portable consumer device, the user has incentive to purchase goods and services that fall under the particular category.

Owner:VISA INT SERVICE ASSOC

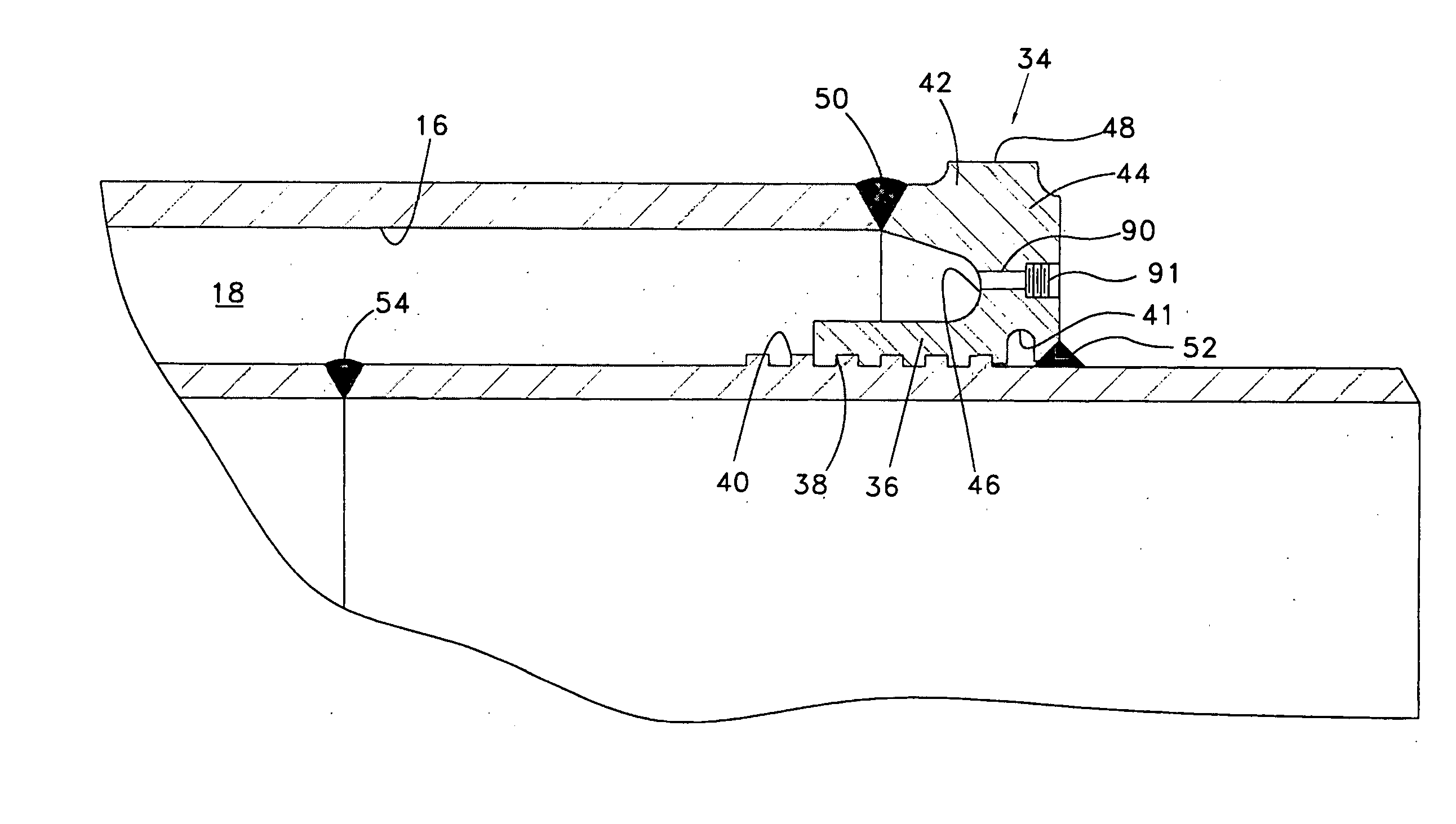

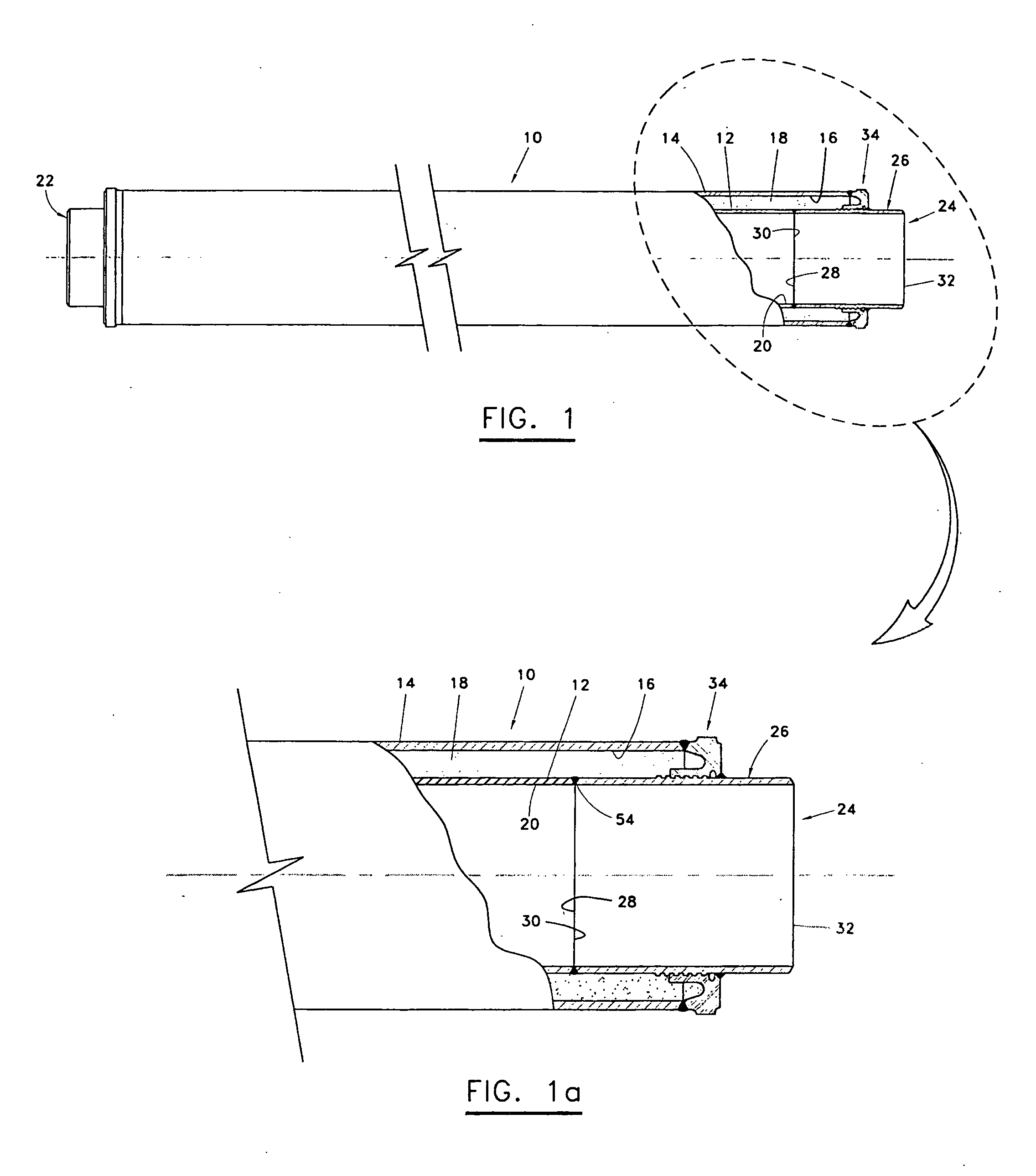

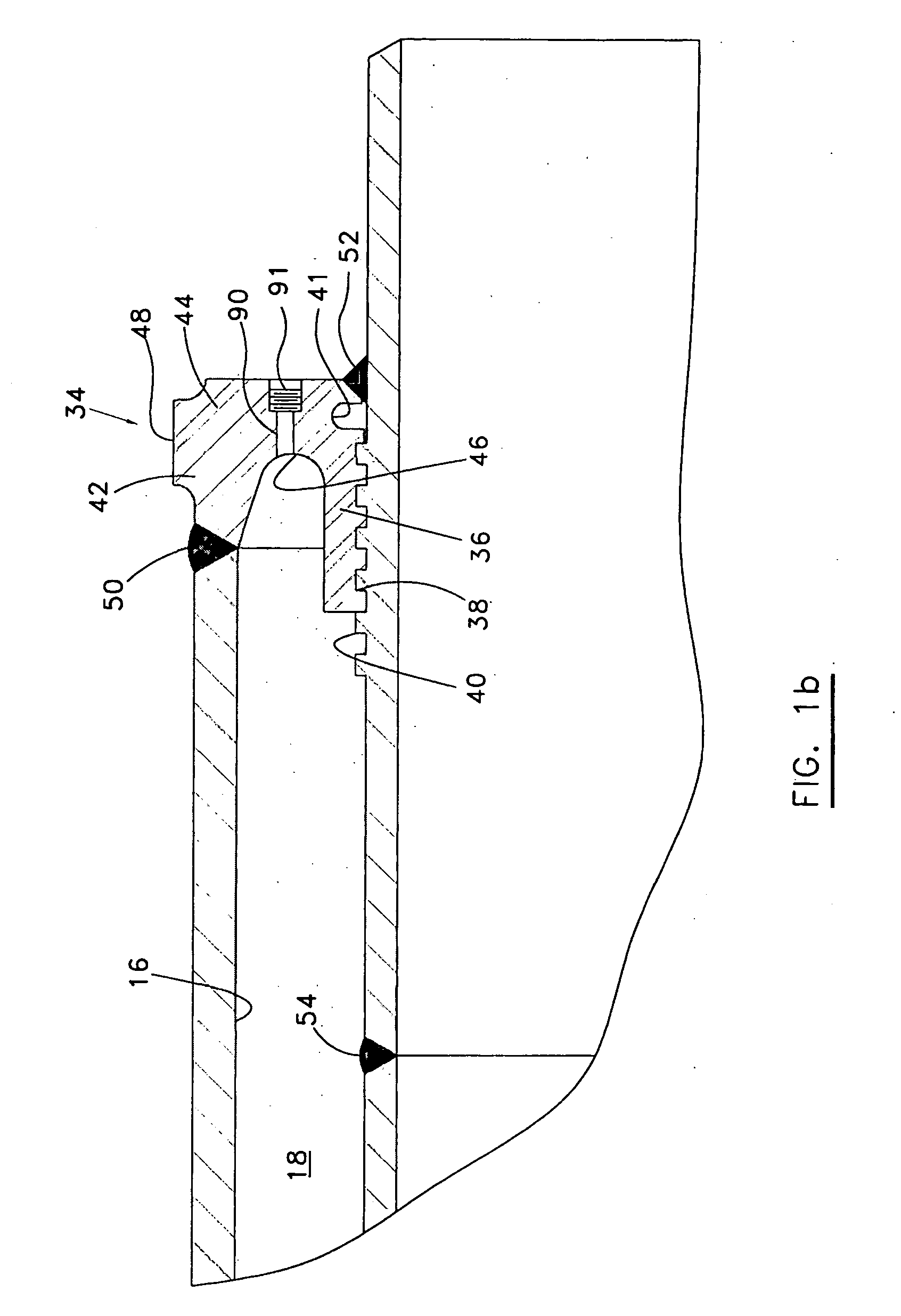

Dual-walled piping system and methods

InactiveUS20050212285A1Improved load transfer controlRelieve pressurePipe supportsThermal insulationCompound (substance)Axial force

Dual-walled piping segments and pipelines are described that use an annular bulkhead to secure the jacket pipe radially outside of the carrier pipe near the axial ends of the piping segment. Pup joints are welded to each end of the carrier pipe, and the bulkheads are welded to the pup joints. The bulkheads have a number of features that provide improved load path control for axial forces induced by temperature differentials. There is a mechanical load-sharing interlock mechanism provided between the bulkhead and the interior pup joint and field joint closure joints designed to transmit stress loading to a plurality of ridges or threads, that may be enhanced by thermal contraction, and preclude axial movement between the jacket pipe and pup joint. A number of methods are described for creating the load-sharing interlock. Additionally, the bulkhead has a generally arcuate cross-section that defines an interior channel. The arcuate cross-section allows the bulkhead to be somewhat flexible to absorb axial and radial loading while reducing the available heat transfer rate. The bulkhead also contains several ports for pressure equalization and plugged ports for the pressure-thermal-chemical conditioning of the annular spaces.

Owner:OPE INT

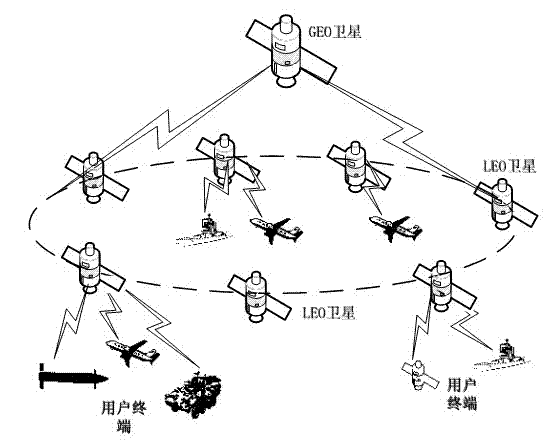

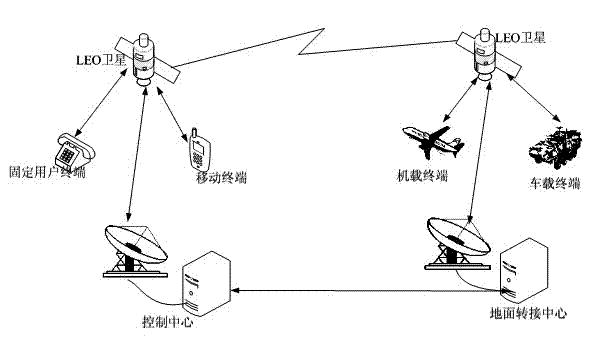

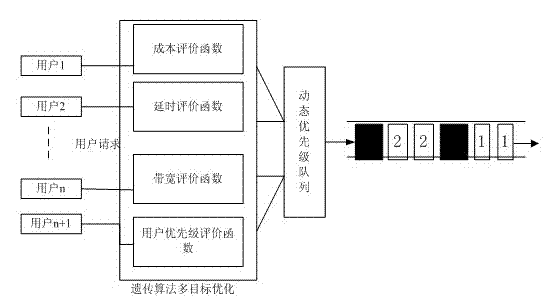

Resource management method suitable for multilayer satellite system

InactiveCN103079273AGuarantee fairnessGuarantee efficiencyRadio transmissionWireless communicationQuality of serviceTime delays

The invention relates to a resource management method suitable for a multilayer satellite system. The resource management method adopts the following design principle that high altitude satellites are used as reserved resources and are specially used for distributing resources for users with high priorities and high QOS (Quality of Service) requirements and distributing the resources for the user as required in a real-time manner; and meanwhile, low earth orbit satellites are combined and are used as ground network supplements, the characteristics of high-speed motion and the like of the low earth orbit satellites are considered and a method for dynamically distributing the resources for users with low priorities by using efficiency, cost and user publicity as evaluation indexes is designed. According to the design, the characteristics of the high altitude satellites and the low earth orbit satellites are combined; the priorities of the users are considered; the resources are distributed for the users with high priorities as required; a multi-target evaluation function is designed for the users with low priorities; and the multi-target evaluation function is nondimensionalized, so that in the resource management process, the evaluation indexes of other targets are not ignored due to an excessive function value of a certain index, and thus, a multi-target optimization method which has the advantages of short time delay, high bandwidth utilization rate and balanced resource distribution is integrally implemented.

Owner:NANJING UNIV OF POSTS & TELECOMM

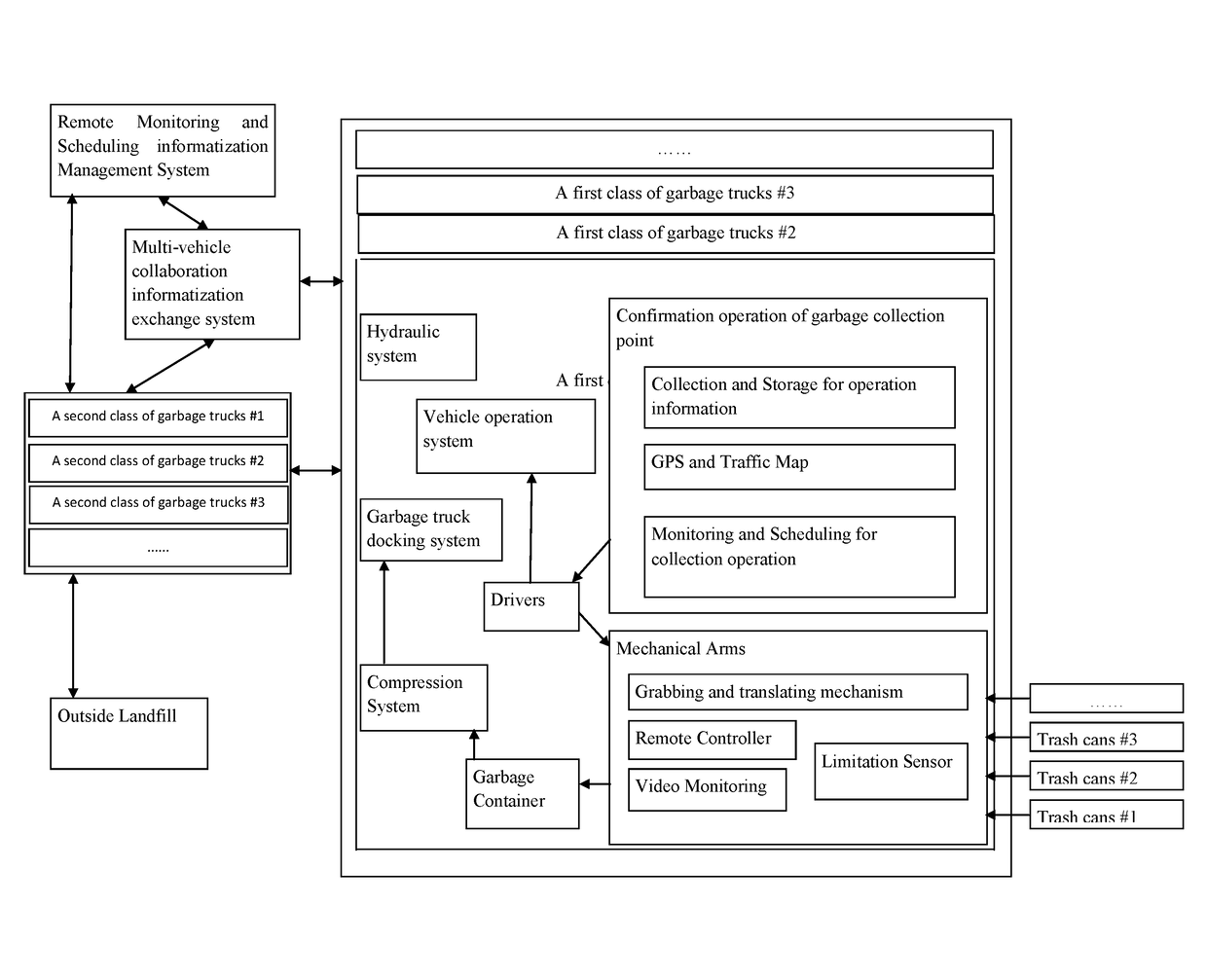

Intelligent and Informatized Multi-Vehicle Collaboratively Operating Municipal Refuse Collection and Transfer System and Method

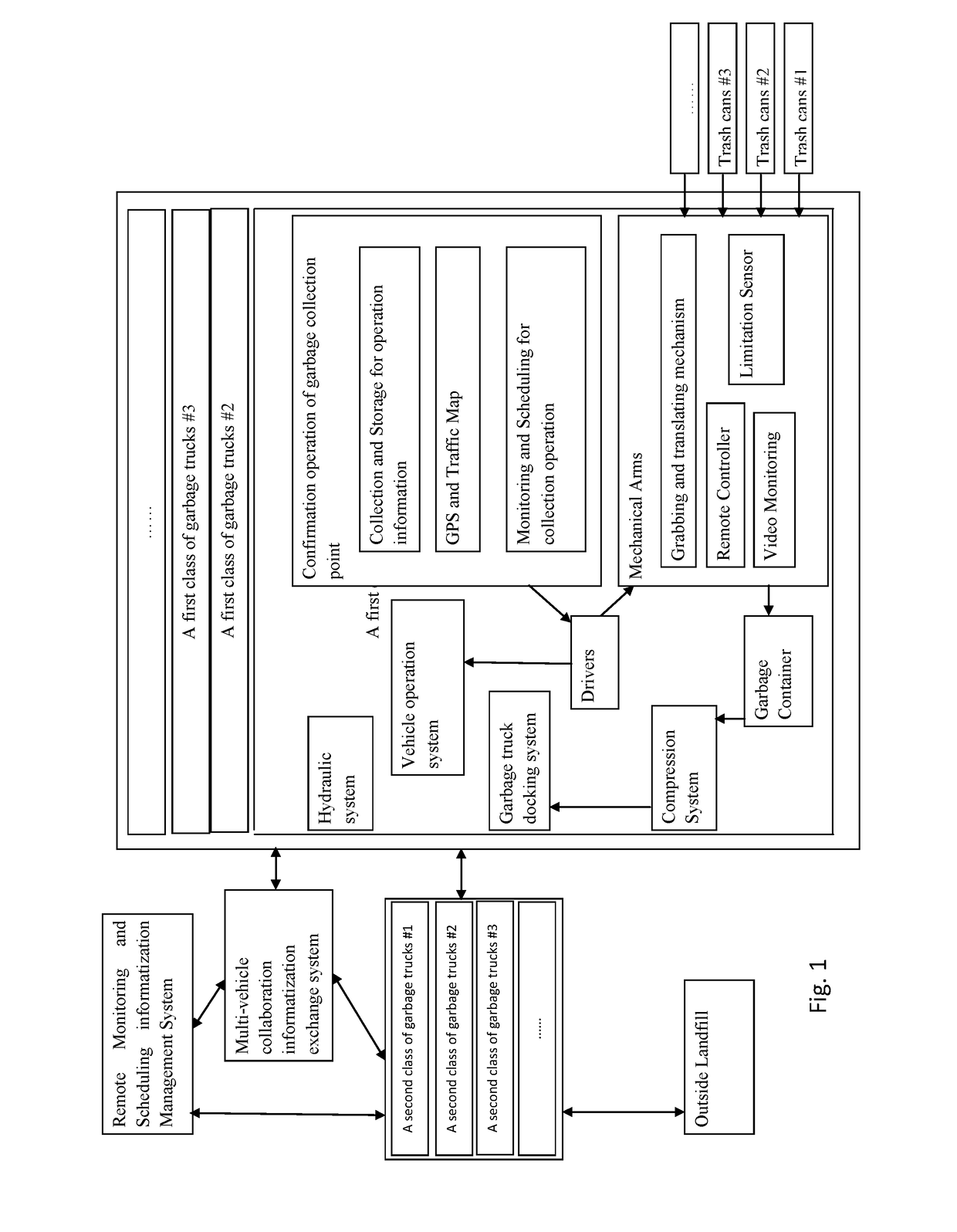

ActiveUS20170081120A1Improve mobilityImprove IQRefuse transferringLoading/unloadingRefuse collectionTransfer system

An intelligent and information multi-vehicle collaboratively operating municipal refuse collection and transfer system and method are provided. The system comprises an automated system with multiple-degree of freedom intelligent dustbin grabbing, an operating system with two types of refuse vehicles collaborating, a multi-vehicle collaborative operation information system, and a fixed-point refuse collection operation confirmation and remote monitoring information management system for coordinating overall operation of the systems. The automated system with multiple-degree of freedom intelligent dustbin grabbing system is used for the refuse vehicles to automatically collect dustbins; the operating system with two types of refuse vehicles collaborating comprises a plurality of small- and medium-sized refuse vehicles and large capacity refuse vehicles. The small- and medium-sized refuse vehicles collect refuse in the dustbins according to multi-vehicle collaborative operation information with the support of the multi-vehicle collaborative operation information system, and the large capacity refuse vehicles are used to dock with the collected refuse and transport the refuse out of town with the support of the multi-vehicle collaborative operation information system. The method is the implementation of the above system. The system and method have good operability and high degree of intelligence and provide good results of refuse disposal.

Owner:HUNAN UNIV

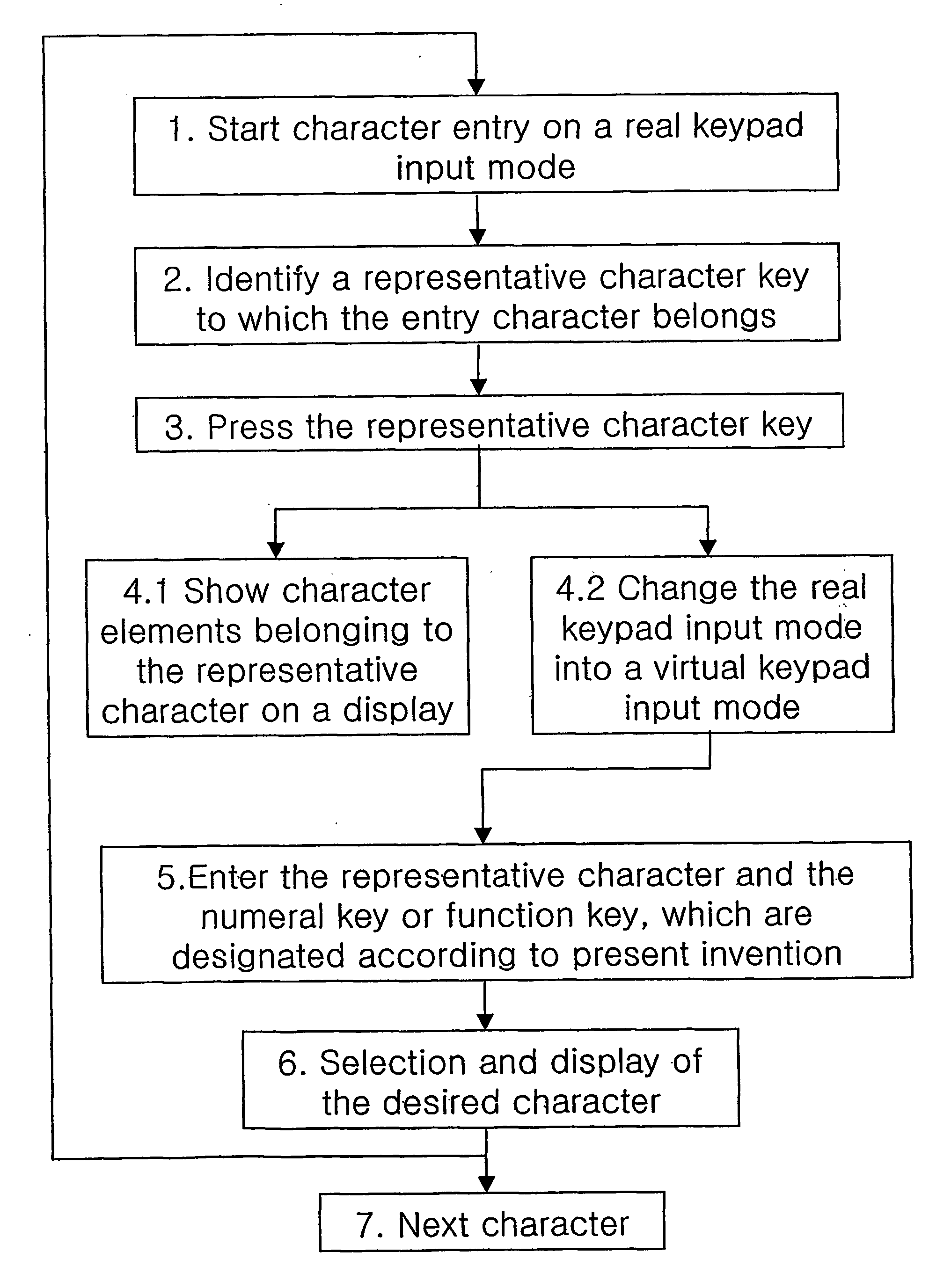

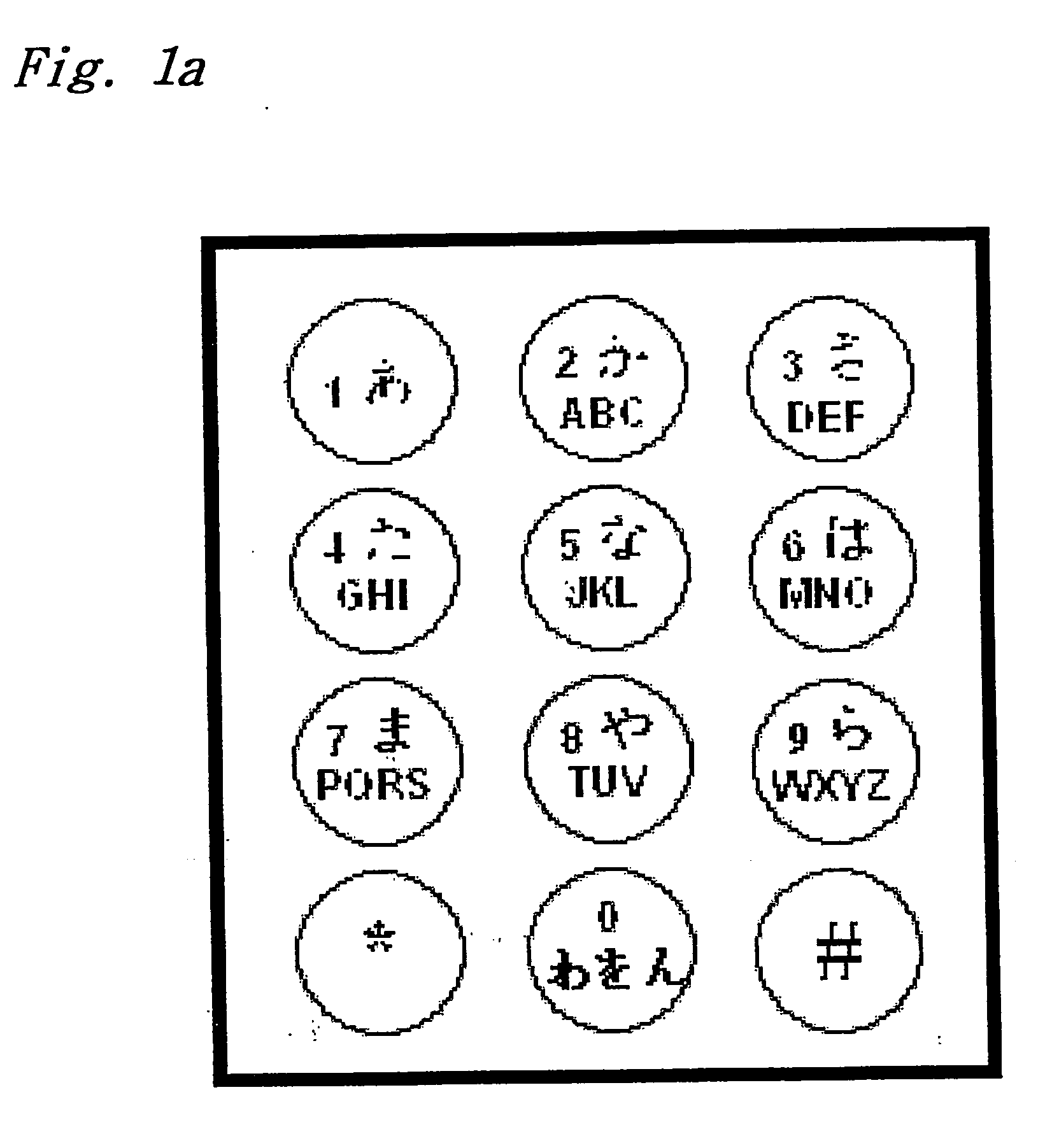

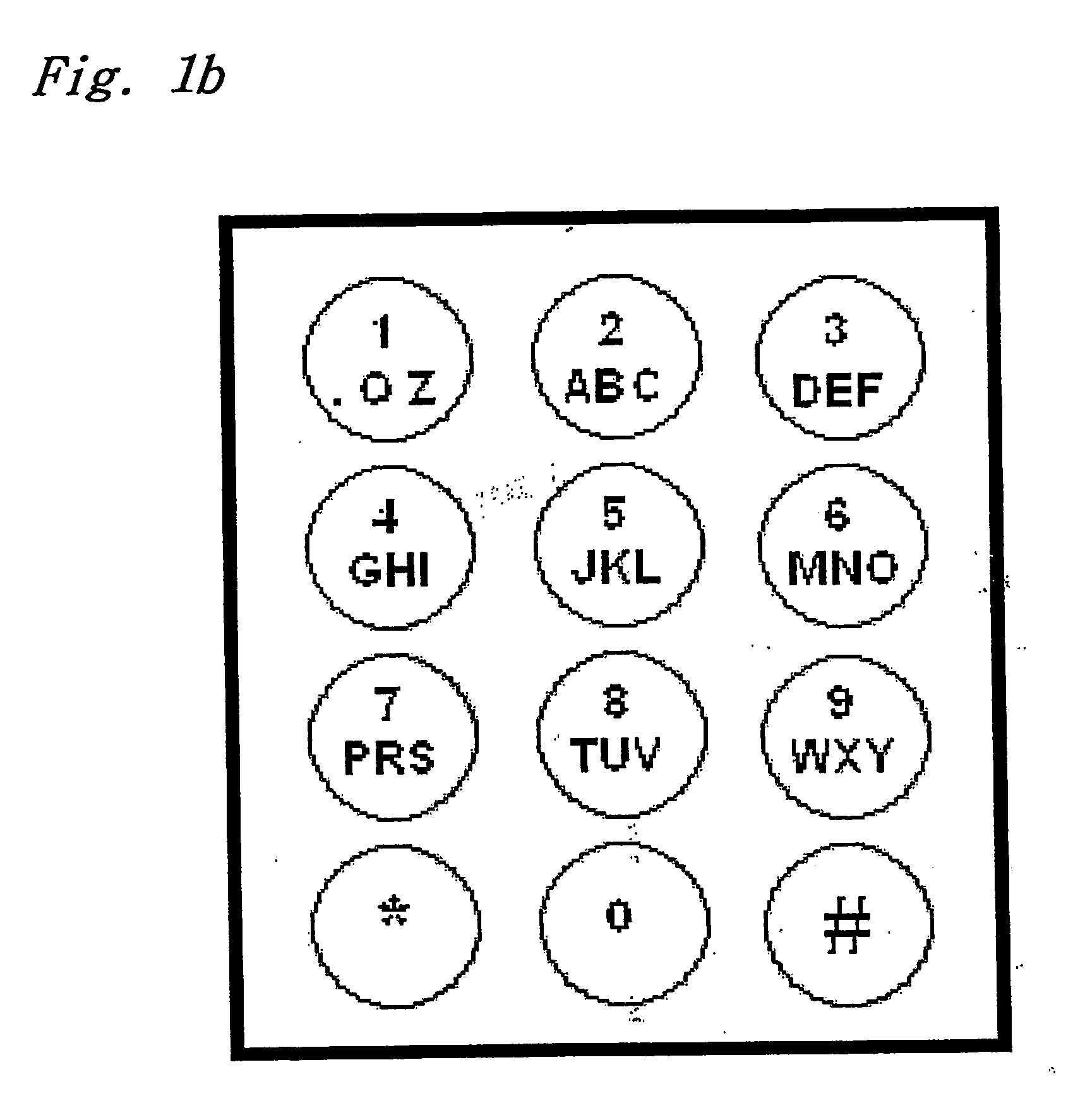

Creation method for characters/words and the information and communication service method thereby

InactiveUS20050104869A1Expandability and adaptabilityEfficiencyInput/output for user-computer interactionAlphabetical characters enteringLiquid crystalInformation appliance

This invention relates to a method for entering characters into a small keypad with a limited number of keys or information appliances with a liquid crystal panel such as PDA. The object of the present invention is to provide a character entry method to ensure the efficiency of letter entry, the expandability and adaptability of information services, and the information and communication service method thereby, which substantially obviates problems due to limitations and disadvantages of the multi-tap and single-tap method. The distinctive features of the present invention are representative character keys, a virtual keypad, and virtual key entry method on the viral keypad mode, in entering multiple characters by means of a keypad with about 12 keys. Moreover, the present invention provides a character entry method ensuring the input efficiency of various characters. The present invention can be utilized as an interface in the mobile info-communication services.

Owner:NEOPAD

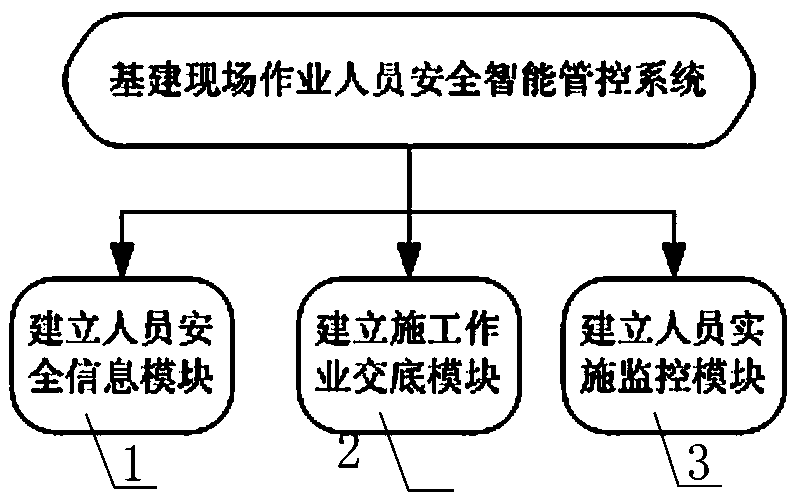

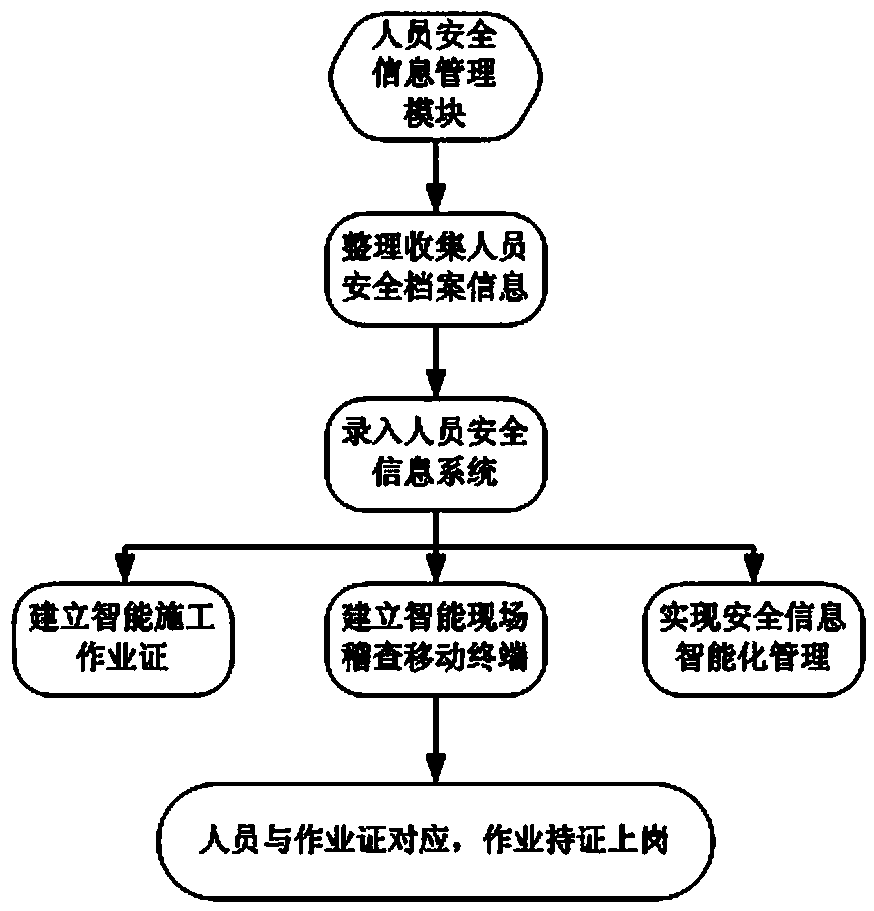

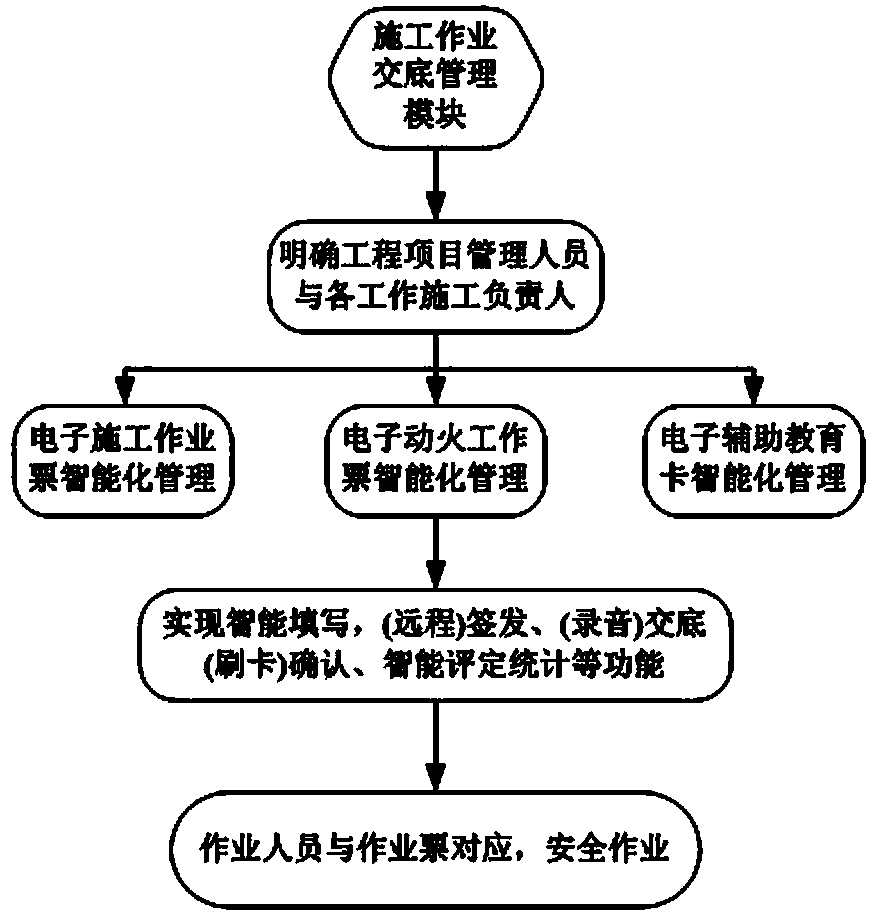

Intelligent security control method of electric power field operating personnel

InactiveCN103729712AAchieve normalizationRealize intelligent construction safety inspectionResourcesControl engineeringHot work

An intelligent security control method of electric power field operating personnel is mainly established based on the following three modules of a constructor safety information module, an intelligent construction operation disclosure module and a construction operating personnel real-time monitoring module. The constructor safety information module is used for achieving intelligent management of operating personnel safety information. The intelligent construction operation disclosure module is used for achieving intelligent compiling, signing and issuing, disclosing and statistic making of construction operation tickets, hot work operation tickets, auxiliary personnel education cards and the like. The construction operating personnel real-time monitoring module is used for achieving real-time monitoring of working site images, real-time monitoring of entrance and exit of the operating personnel and real-time positioning of the operating personnel. The constructor safety information management module mainly comprises a server including construction enterprise unit information, construction enterprise personnel information and labor subcontracting personnel information. The intelligent construction operation disclosure module carries out the following three sorts of intelligent management, namely construction operation ticket intelligent management, hot work operation ticket intelligent management and auxiliary education card establishing intelligent management. The construction operating personnel real-time monitoring module comprises two modes, one mode is that power transformation engineering is performed at a closed construction site so that directional recognizing and monitoring can be conducted, and the other mode is that a line project is performed at an opened construction site so that omni-directional recognizing and monitoring can be conducted.

Owner:STATE GRID CORP OF CHINA +2

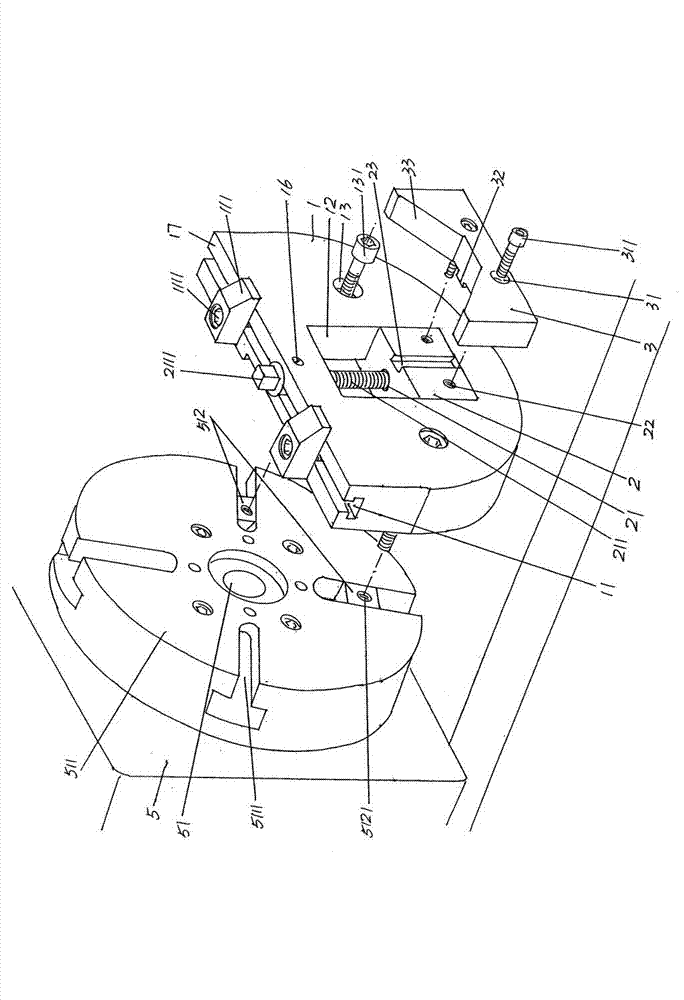

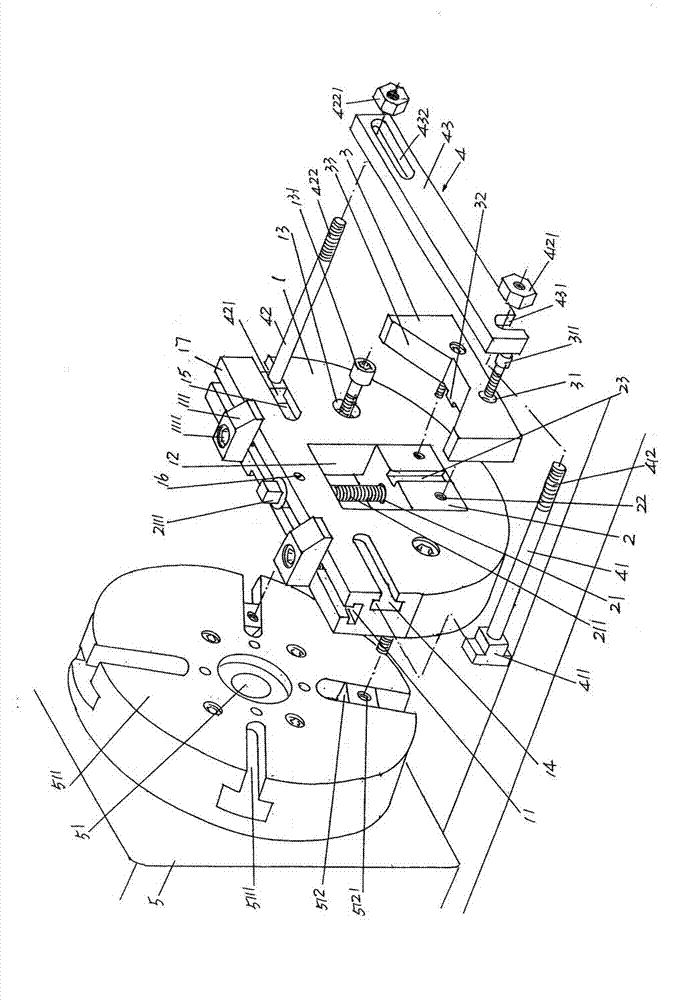

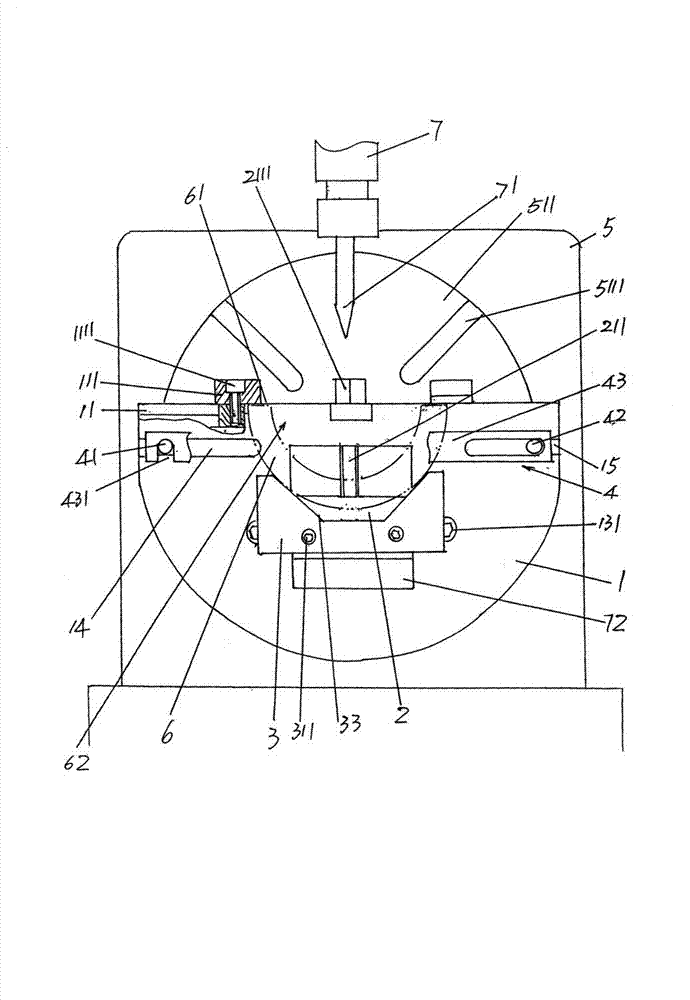

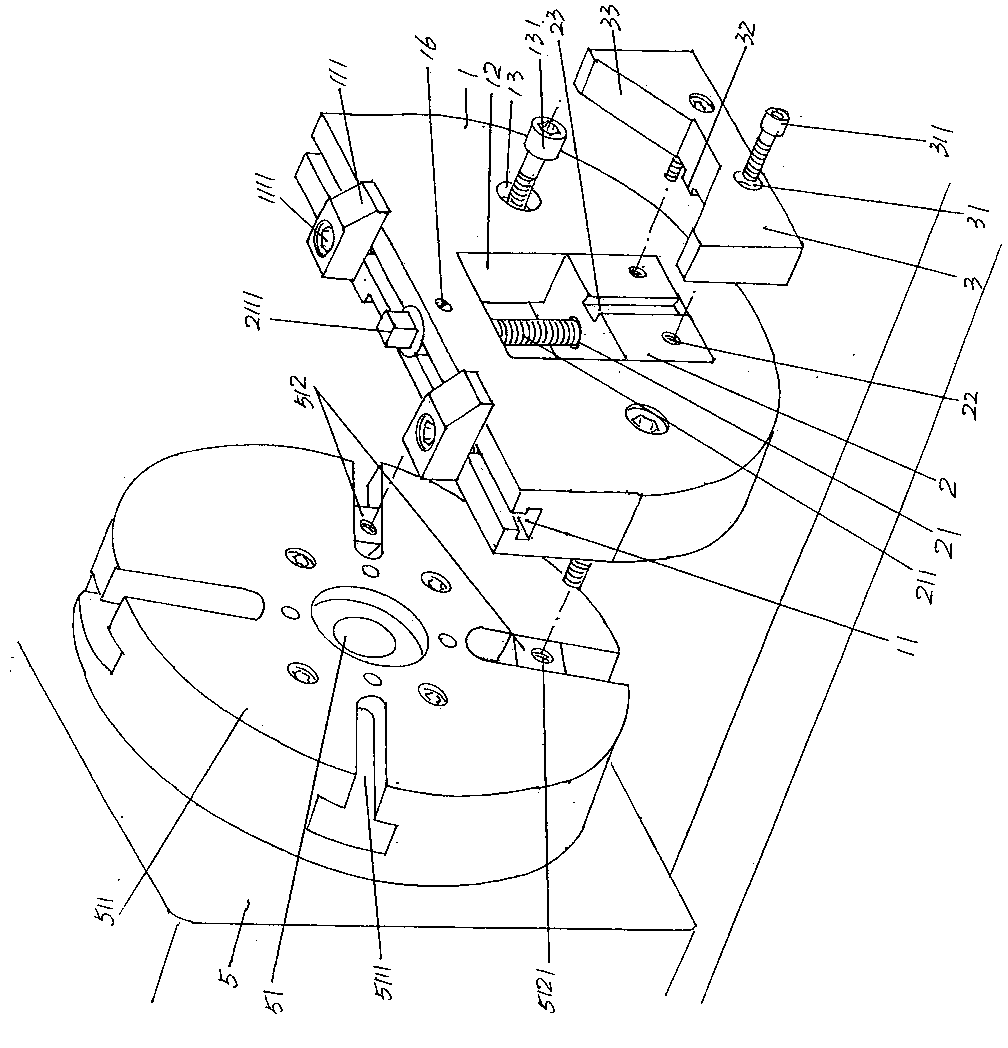

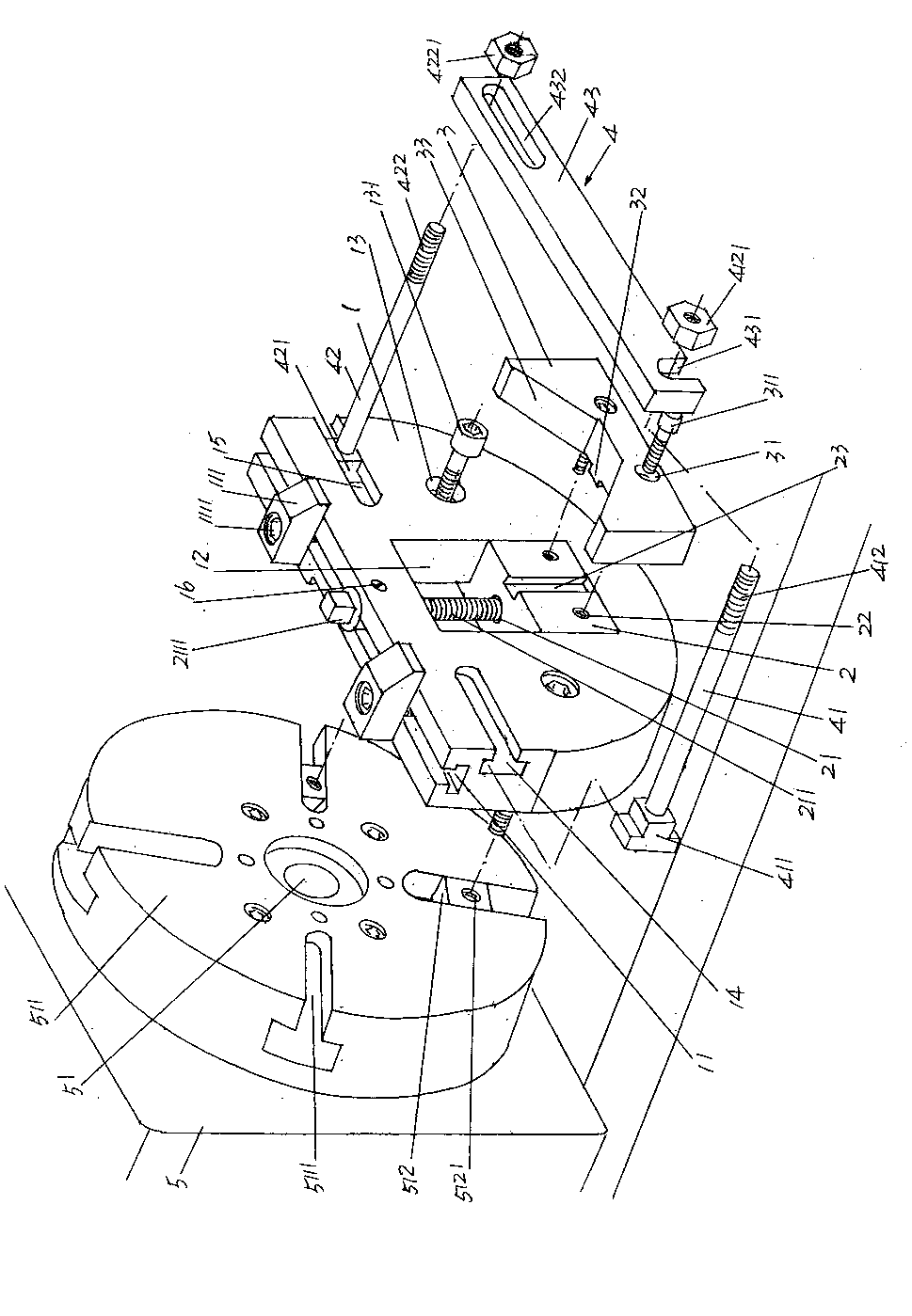

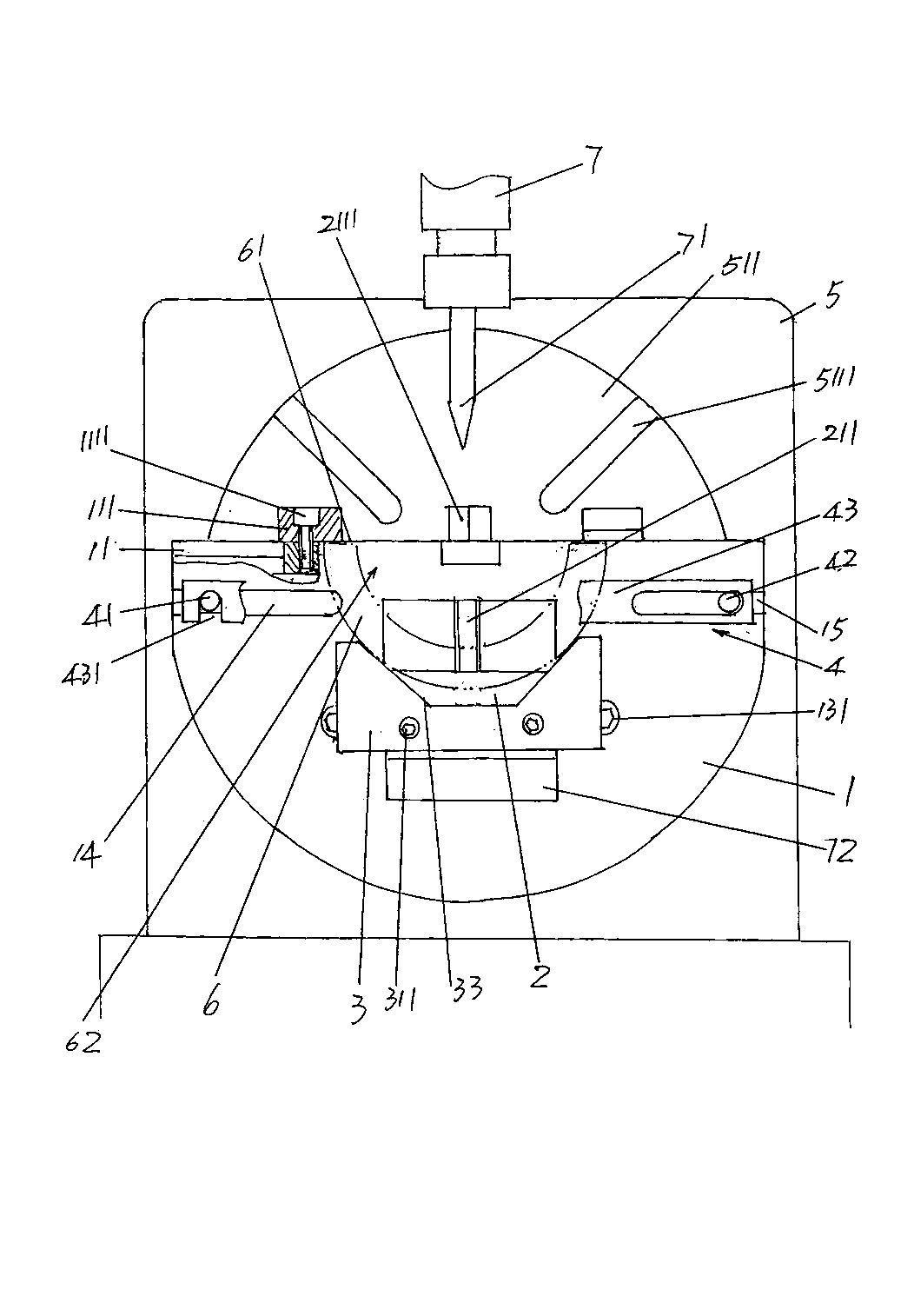

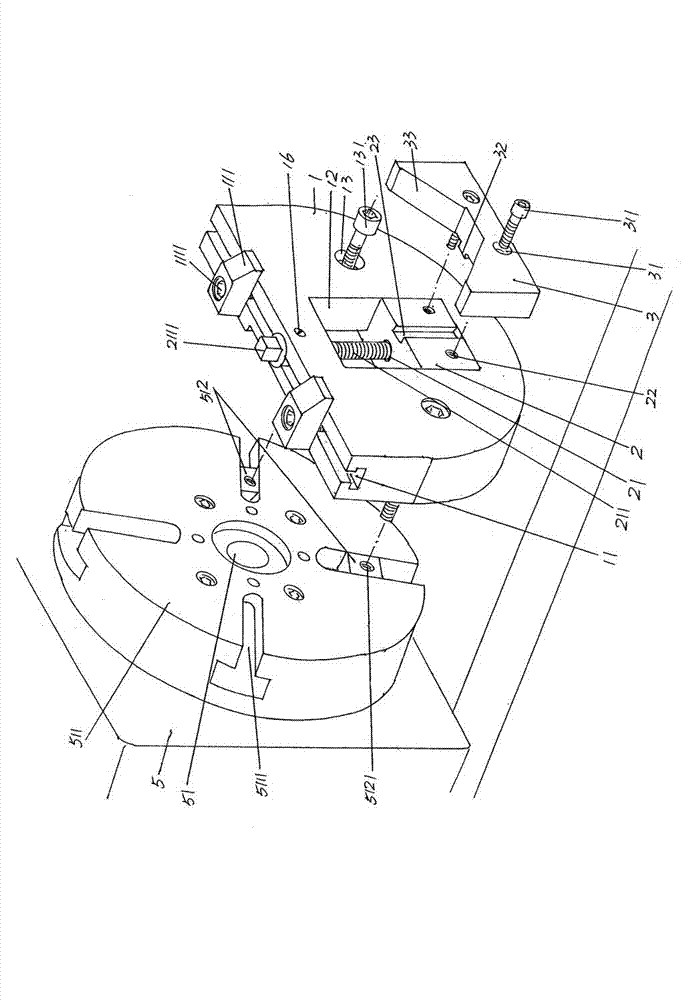

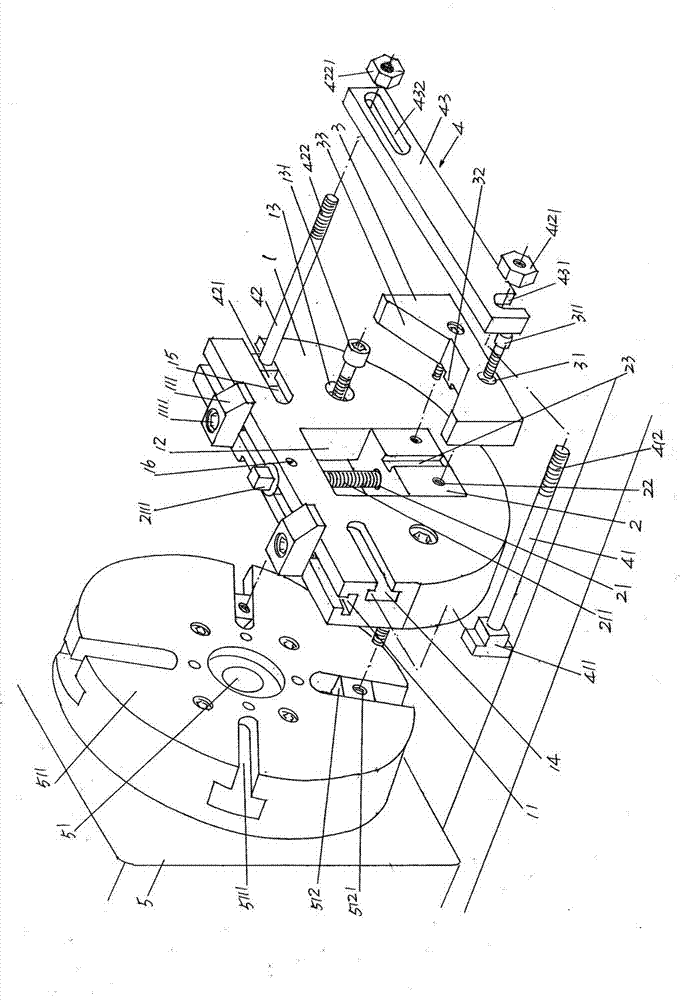

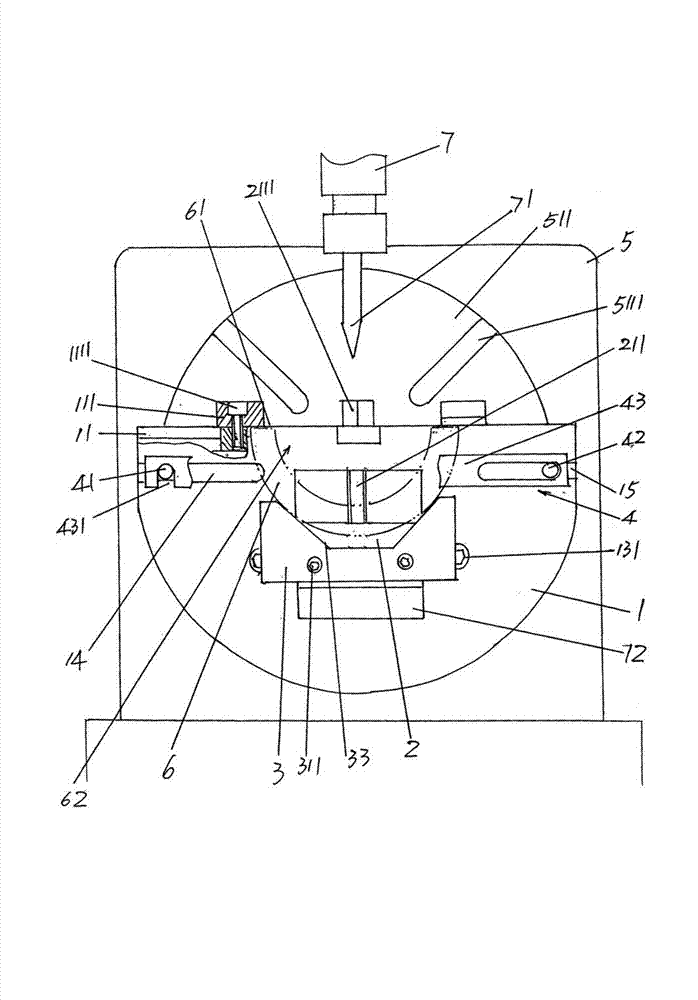

Clamping mechanism for machining glass die

ActiveCN102848245AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringCarving

The invention discloses a clamping mechanism for machining a glass die and belongs to the field of frock clamps. The clamping mechanism comprises a base, a support module fixing seat and a support module, wherein a pressure foot sliding chute is formed in a flat surface; a pressure foot is arranged in the pressure foot sliding chute; a support module fixing seat sliding cavity is formed in the base; the support module fixing seat is matched with a support module sliding cavity; a support module fixing seat nut is matched and arranged on the support module fixing seat; one end of a support module fixing seat lifting screw is connected onto the support module fixing seat nut; the other end of the support module fixing seat lifting screw is supported on the flat surface; the support module is fixedly connected with one side of the support module fixing seat; one end of the pressure foot extends out of the surface of one side of the base; a first guide sliding chute and a second guide sliding chute are formed in one side of the base; and a bottle die end surface positioning mechanism is matched and arranged on the other side of the base. The clamping mechanism has the advantages that the carving machining for an inner cavity of the glass die is realized without adopting a traditional an electric spark mode; the carving quality and efficiency are ensured; the clamping mechanism is convenient and quick in operation and is favorable in clamping adaptability; resources are saved and the interference influence on the die cavity is avoided.

Owner:CHANGSHU JIANHUA MOLD TECH

Fixture structure for glass mould machining

ActiveCN102837213AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringMachining

The invention belongs to the field of a tool fixture and provides a fixture structure for glass mould machining. The fixture structure comprises a base seat, a pressure foot slide groove is arranged on the surface of one side of the base seat along the length direction of the surface, pressure feet are arranged on the pressure foot slide groove in a matched mode, a supporting mould block fixing seat and a supporting mould block slide cavity are arranged on the base seat, and the positions on the base seat where the supporting mould block fixing seat and the supporting mould block slide cavity are arranged correspond to the lower portion of the center position of the length direction of the pressure foot slide groove; the supporting mould block fixing seat is matched with the supporting mould block slide cavity, a supporting mould block fixing seat nut is arranged on the supporting mould block fixing seat in matched mode, the supporting mould block fixing seat nut is connected with one end of a lifting screw rod of the supporting mould block fixing seat, and the other end of the lifting screw rod of the supporting mould block fixing seat is arranged on the pressure foot slide groove in a supporting mode; a supporting mould block is fixed with one side of the supporting mould block fixing seat, one end of each pressure feet stretches out the surface of one side of the base seat, wherein the end and the surface both face towards the supporting mould block. The fixture structure for the glass mould machining has the advantages that the fixture structure breaks away from a traditional electric spark mode that flower engraving machining is used for a cavity of the glass mould, the flower engraving quality and efficiency are ensured, and the operation is convenient and fast.

Owner:CHANGSHU JIANHUA MOLD TECH

Work fixture for glass mould machining

ActiveCN102848246AGood clamping adaptabilityQuality assurancePositioning apparatusMetal-working holdersEngineeringBottle

The invention discloses a work fixture for glass mould machining, belonging to the technical field of the work fixture. The work fixture comprises a base, a support mould block fixed seat and a support mould block, wherein the surface of one side of the base is provided with a pressure pin sliding chute; a pressure pin is arranged on the pressure pin sliding chute in a matching manner; the base is provided with a support mould block fixed seat sliding cavity; the support mould block fixed seat is matched with the support mould block sliding cavity and provided with a support mould block fixed seat nut in a matching manner; the support mould block fixed seat nut is connected with one end of a support mould block fixed seat lifting screw rod; the other end of the support mould block fixed seat lifting screw rod is supported on the pressure pin sliding chute; the support mould block is fixed with one side of the support mould block fixed seat; one end of the pressure pin stretches out of the surface of one side of the base; one side of the base is provided with a first guide sliding chute and a second guide sliding chute; and the other side of the base is provided with a bottle mould end face locating mechanism in a matching manner. The work fixture for glass mould machining disclosed by the invention has the advantages that the conventional electric sparking method for carving the inner cavity of a glass mould is gotten rid of, the carving quality and efficiency are ensured, the operation is convenient and rapid, the work fixture has good clamping adaptability, and resources are saved.

Owner:CHANGSHU JIANHUA MOLD TECH

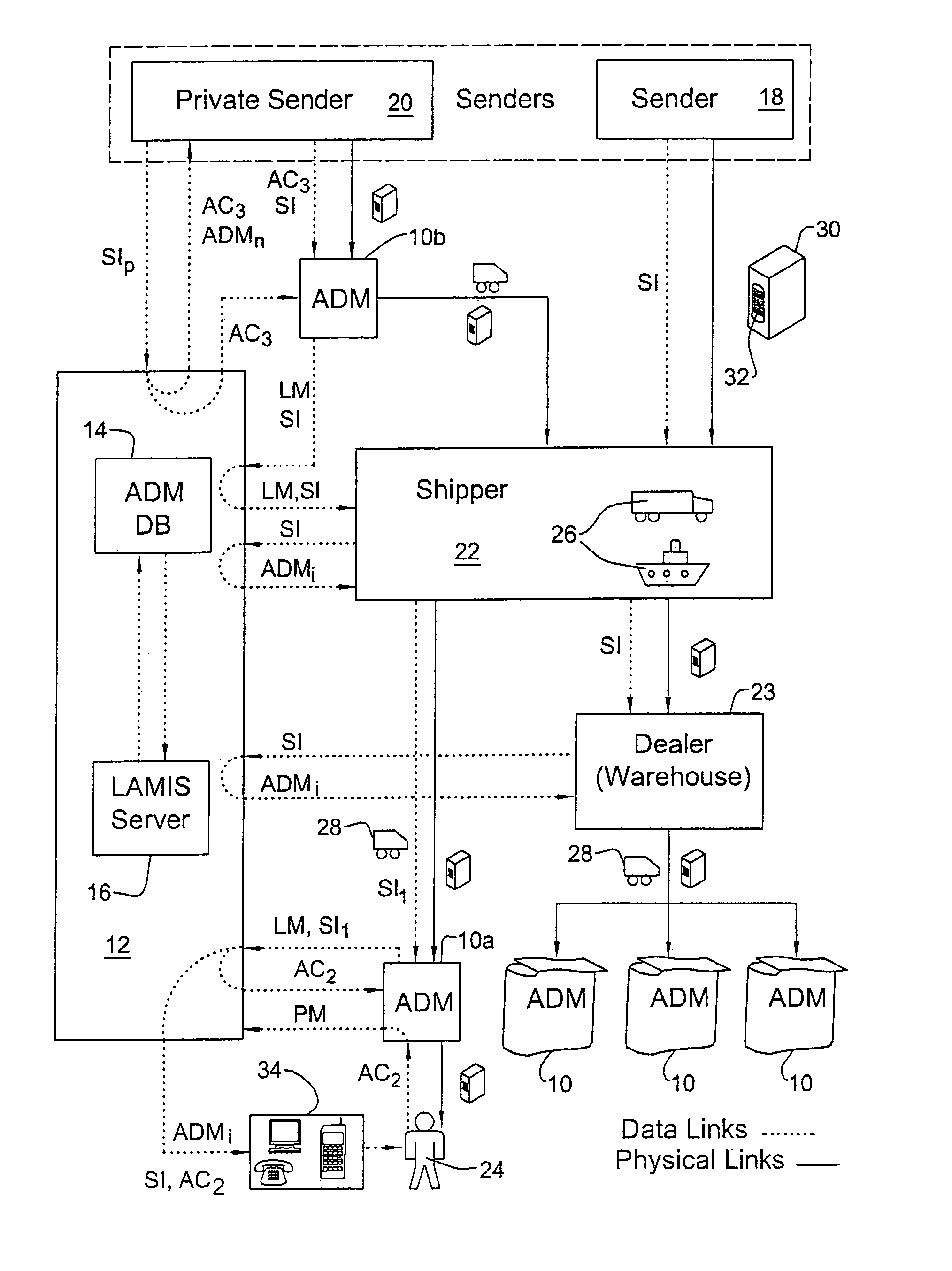

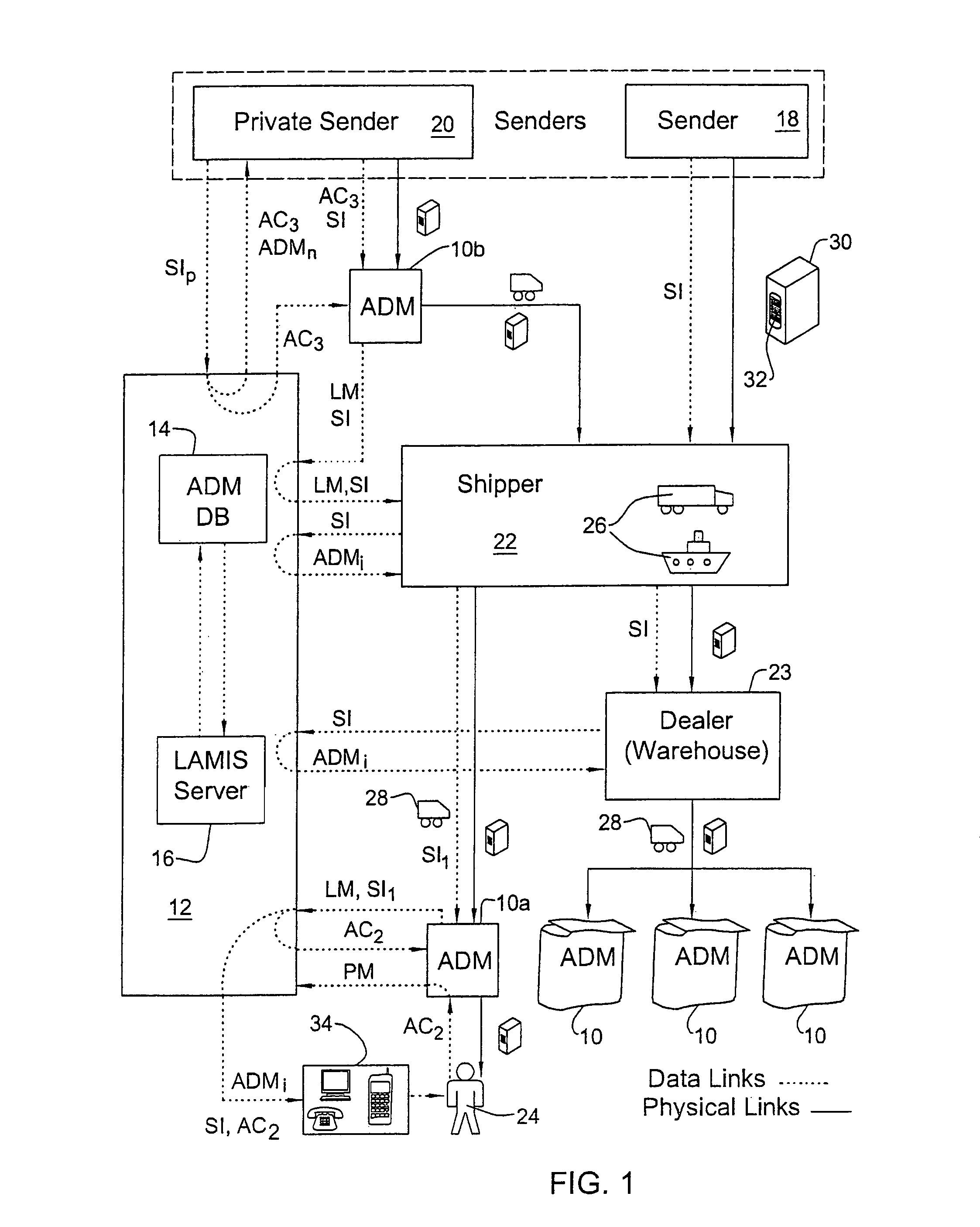

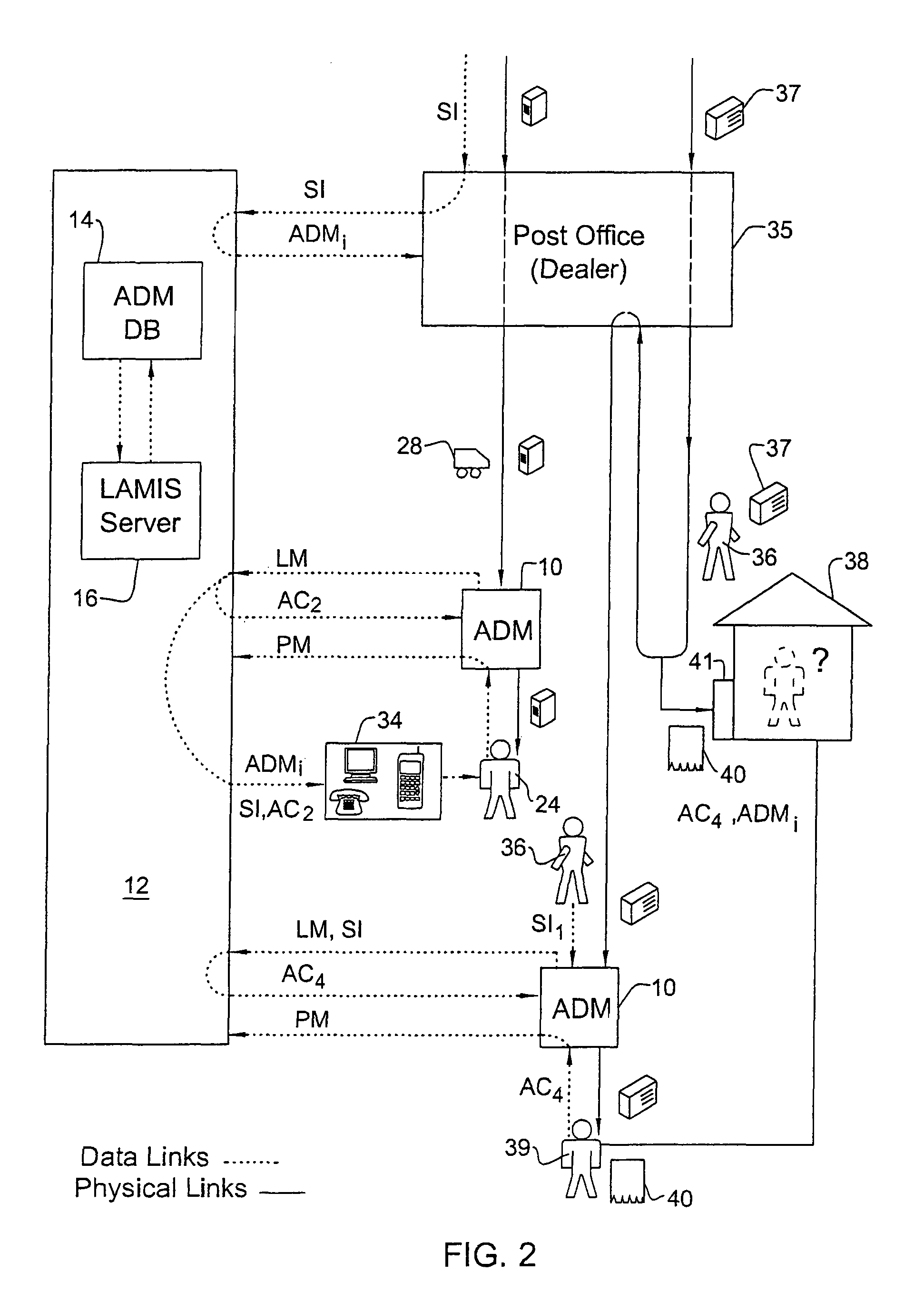

System for delivery and receipt of dispatches especially useful for e-commerce

InactiveUS8010462B2Convenient for consumerShorten delivery timeCoin-freed apparatus detailsApparatus for meter-controlled dispensingPublic placeNetwork connection

Owner:SIEMENS AG

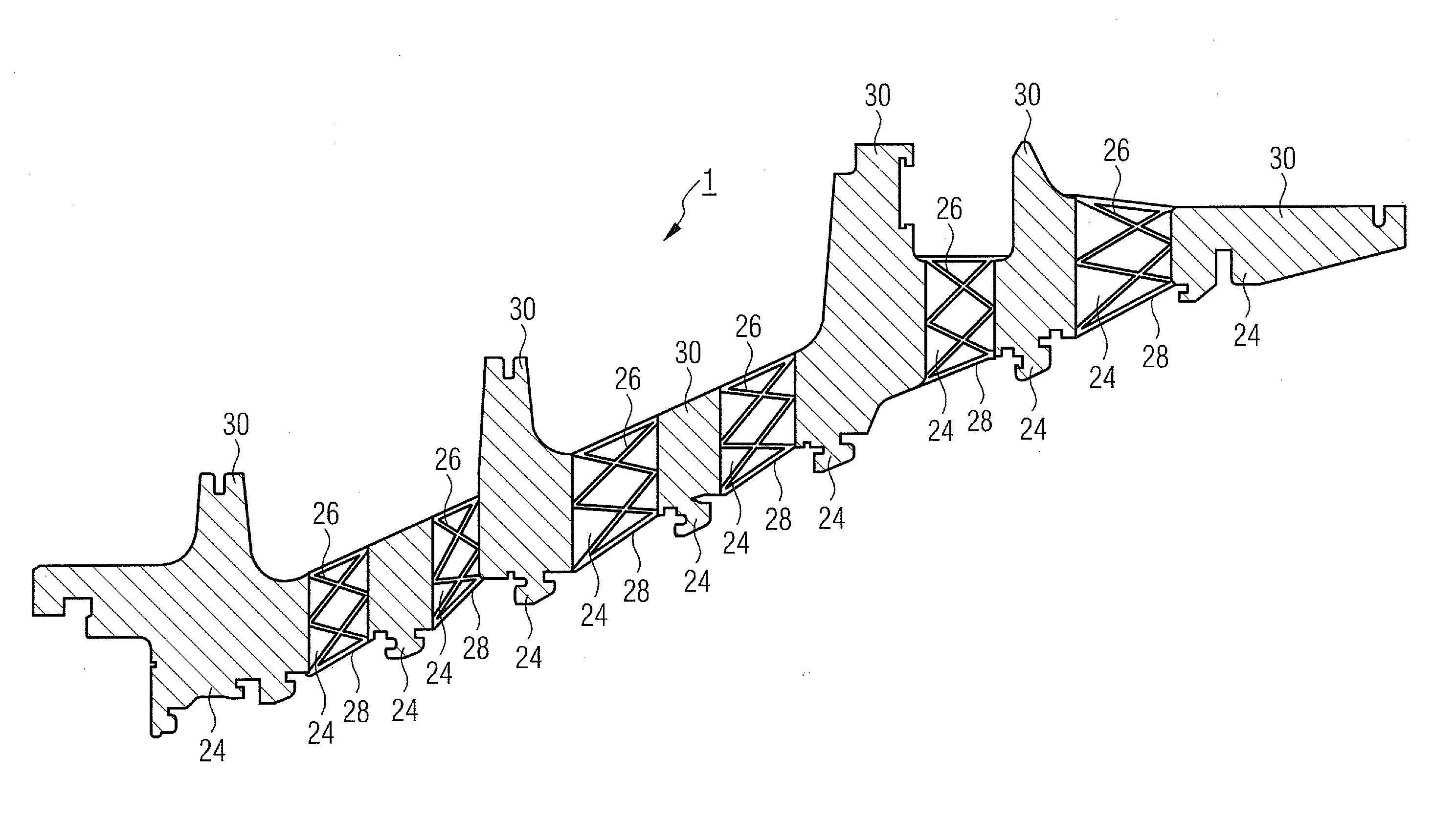

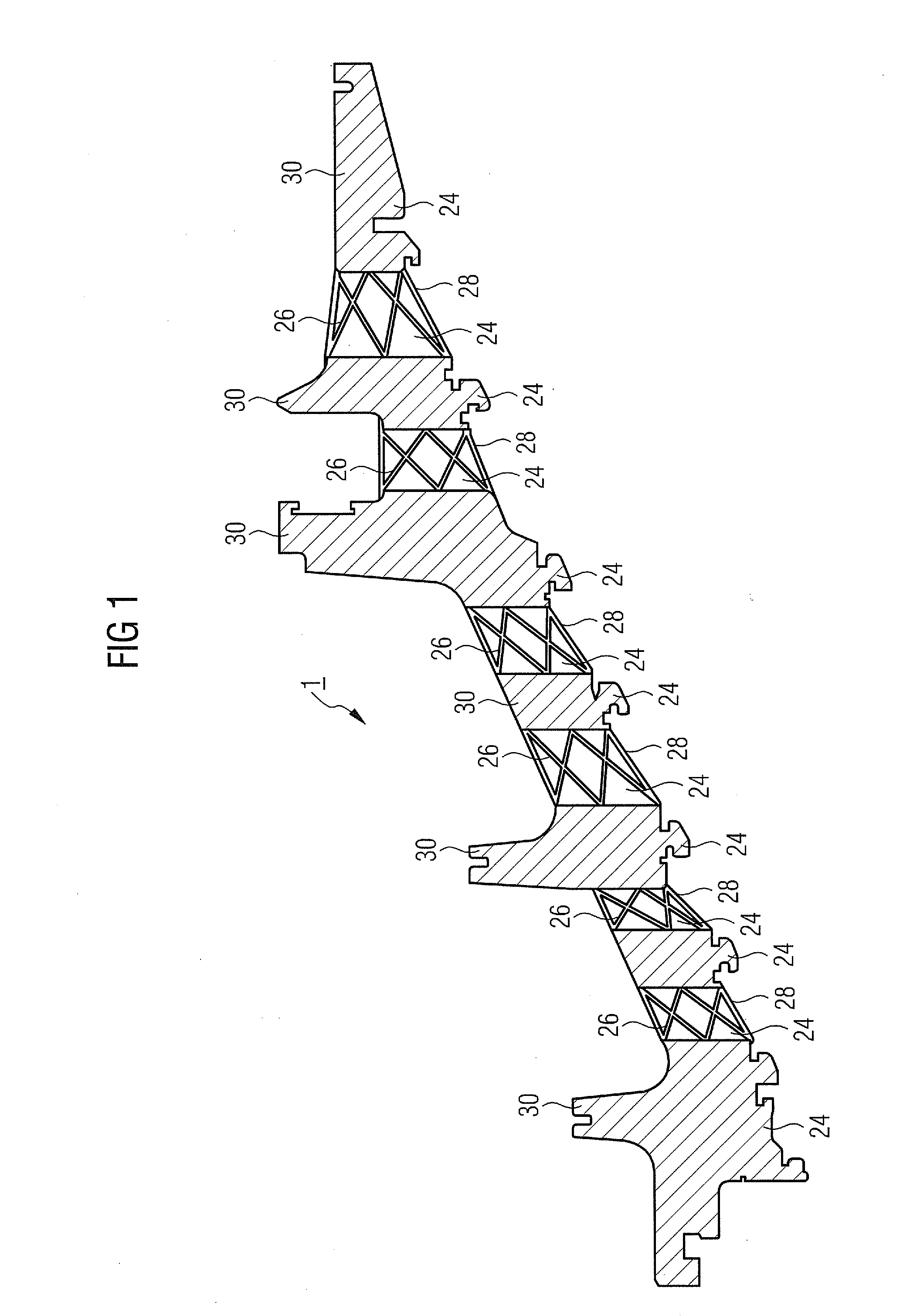

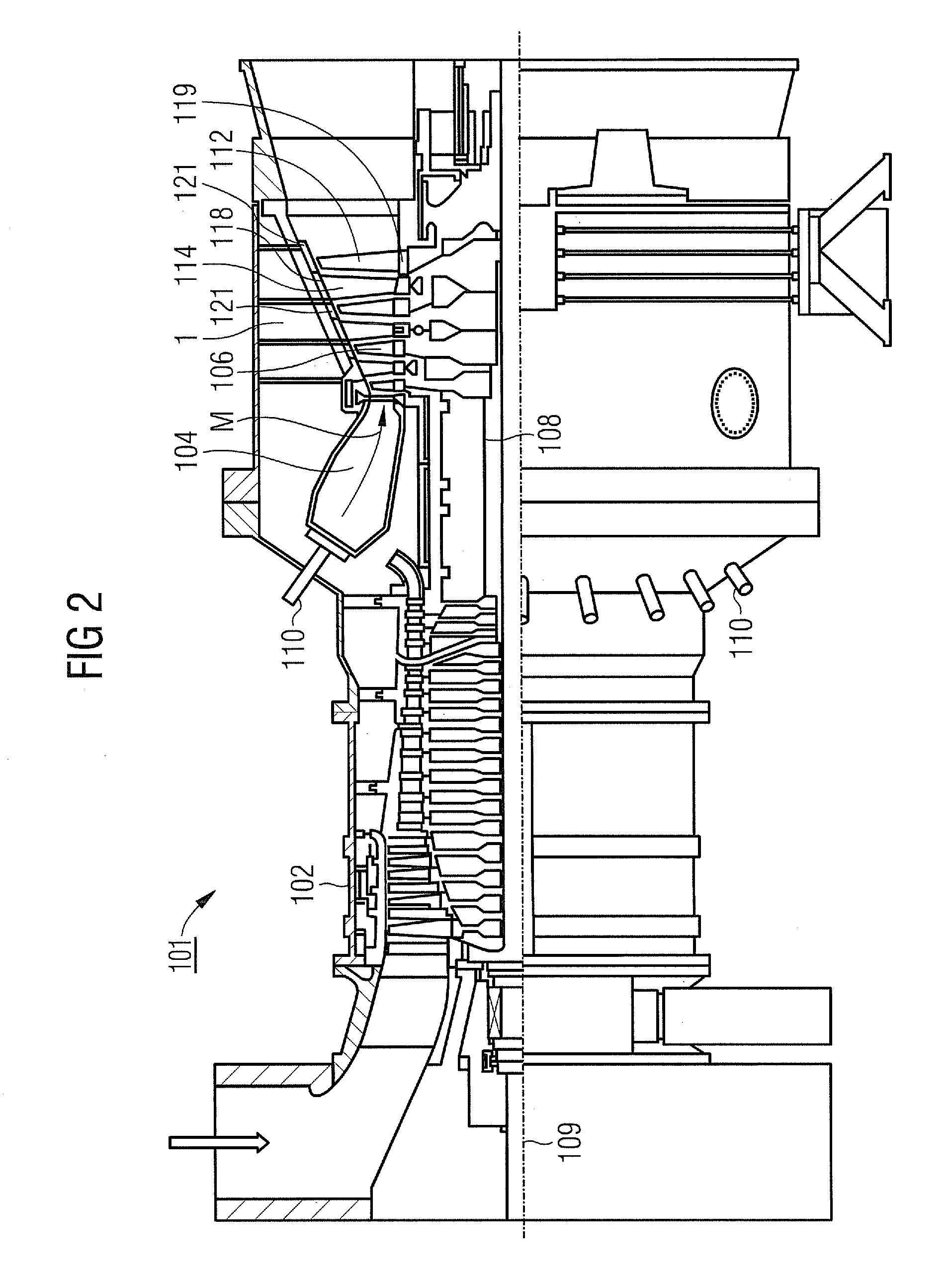

Axially segmented guide vane mount for a gas turbine

InactiveUS20110268580A1Temperature impactEasy constructionPump componentsStatorsEngineeringOperational safety

A stator blade carrier for a gas turbine is provided. The stator blade carrier includes a plurality of axial segments. At least one axial segment is designed as a tubular lattice structure. This allows a simpler design technically and a more flexible adaptation to the temperature profile present on the stator blade carrier to maintain operational safety.

Owner:SIEMENS AG

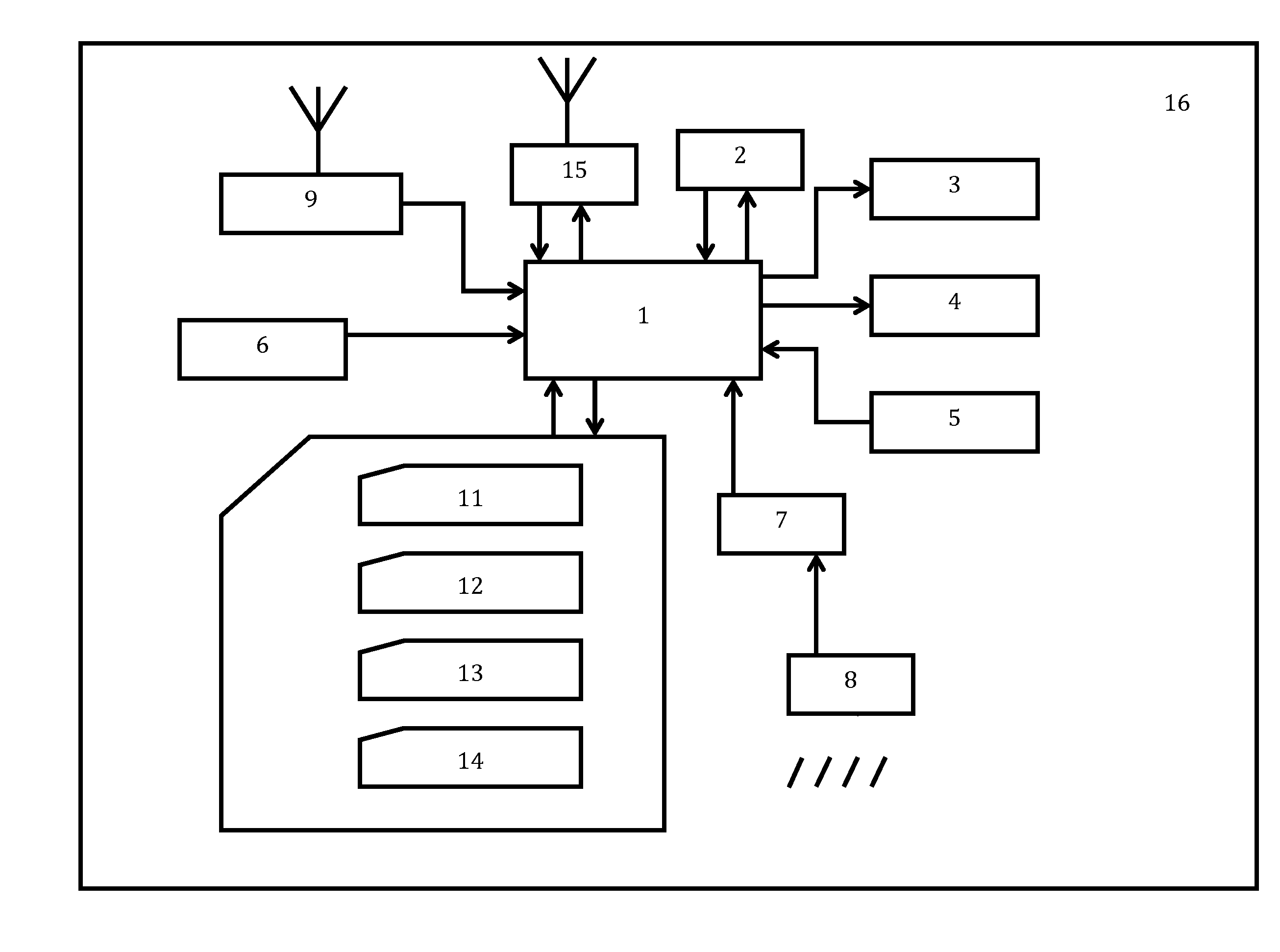

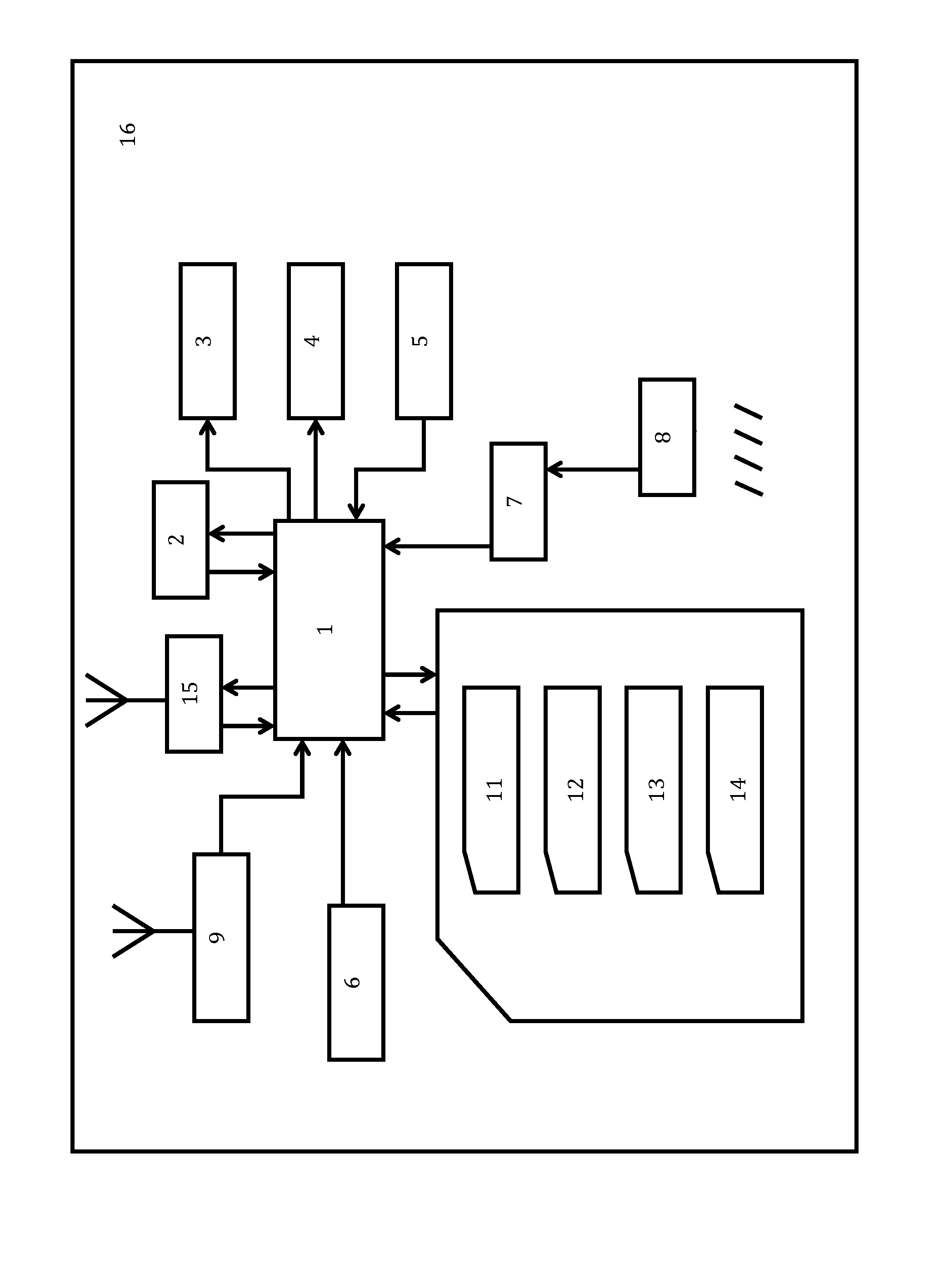

Mobile radio unit with a dosimeter-radiometer

InactiveUS20120329517A1Increase rangeGuarantee efficiencyDevices with GPS signal receiverRadiation measurementNeutron emissionTransceiver

The mobile radio unit (phone, smartphone) comprises body 16 with an incorporated processor 1. The processor 1 is connected with memory 2, display 3, audible alarm aids 4, keyboard 5, power unit 6, navigator 9, and transceiver 15. The radio unit is equipped with radiation detector 8, electronic amplifier 7 and interface 10 connected to the processor 1. The detector 8 provides measuring alpha-, beta-, gamma- and neutron emissions and solar radiation levels. The processor 1 is provided with software, which ensures both communication functions and control, warning of exposure levels, measuring background radiation, building diagrams illustrating state of human organs. The keyboard 5 comprises keys for dosimeter and / or radiometer mode control. The detector 8, the interface 10 and the amplifier 7 can be placed in the mobile unit body 16 or in separate detachable unit. Thus, there was constructed an efficient mobile unit, which ensures an extended functionality.

Owner:ELIN VLADIMIR ALEKSANDROVICH

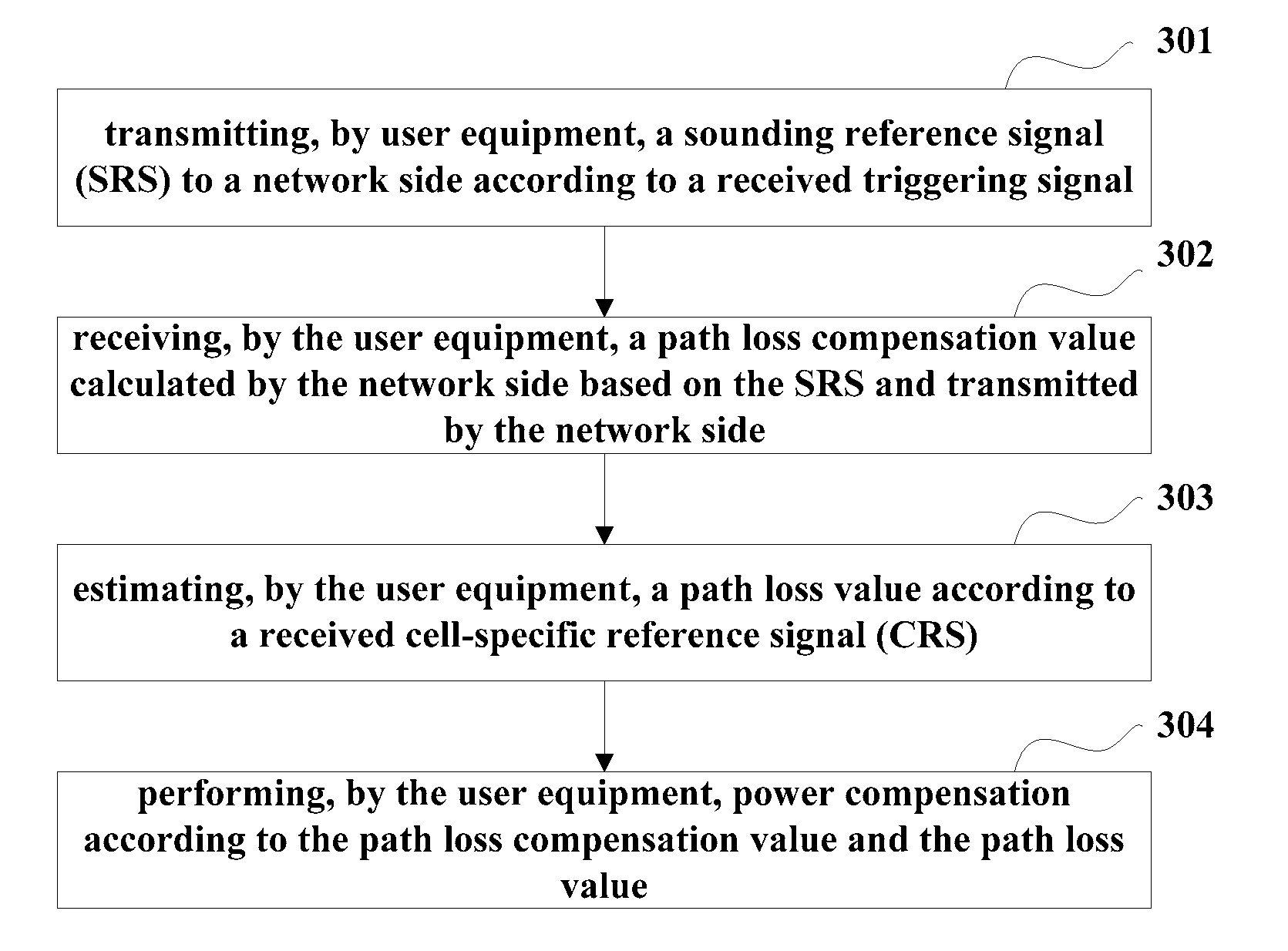

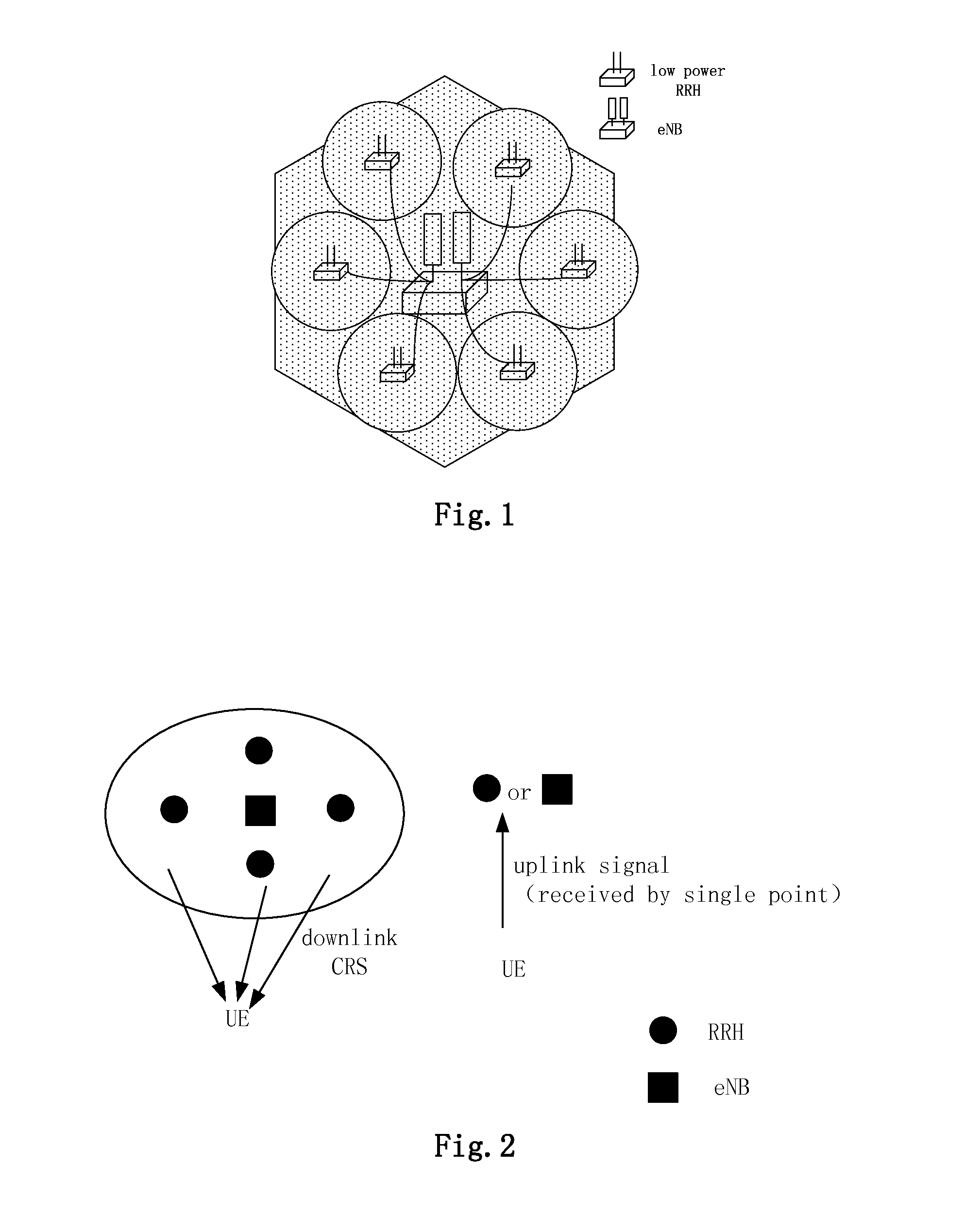

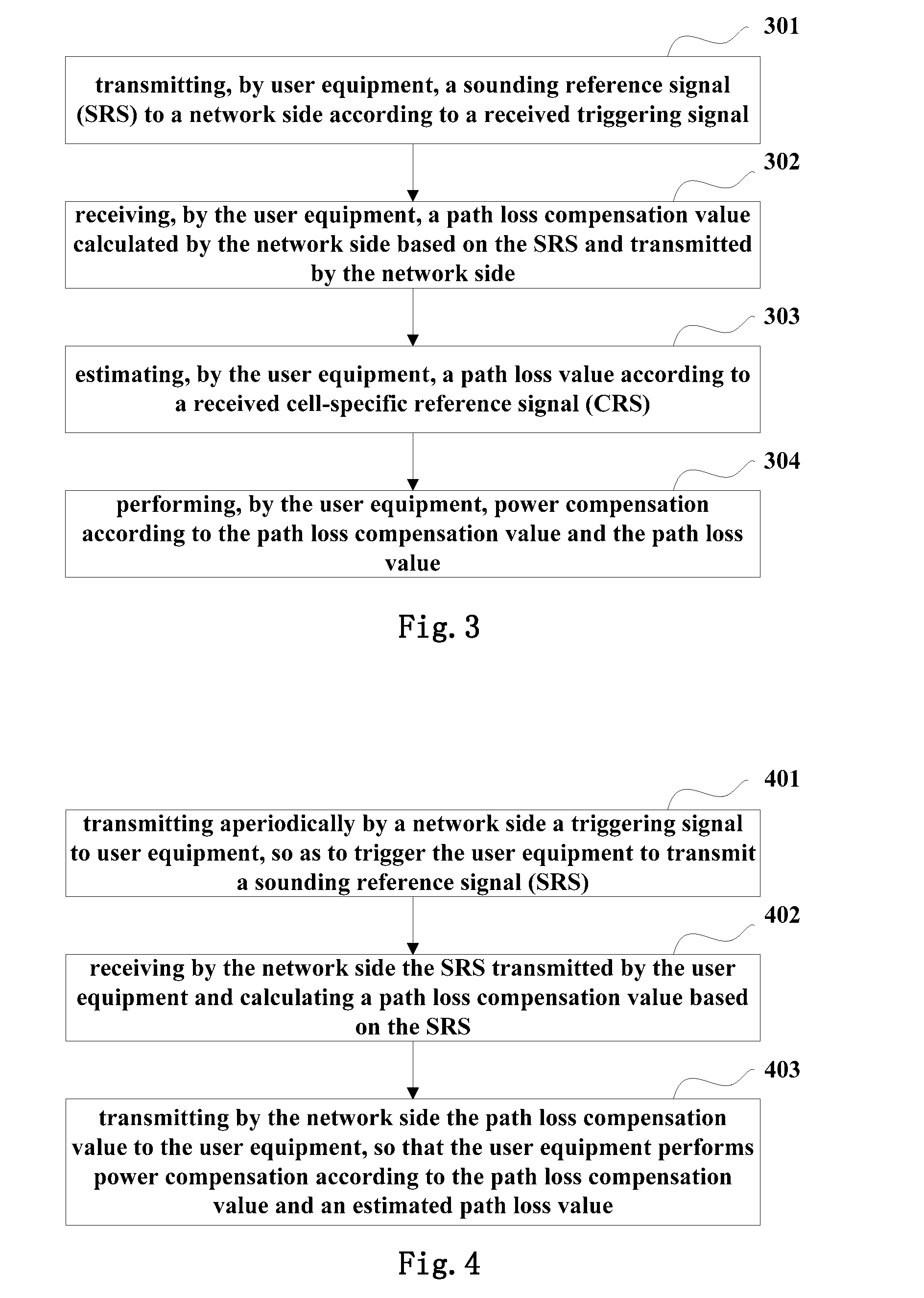

Method and apparatus for uplink power control

InactiveUS20140133448A1Guarantee efficiencyPower managementCriteria allocationPower compensationSounding reference signal

A method and apparatus for uplink power control, including: transmitting, by user equipment, a sounding reference signal (SRS) to a network side according to a received triggering signal; receiving, by the user equipment, a path loss compensation value calculated based on the SRS and transmitted by the network side; estimating, by the user equipment, a path loss value according to a received cell-specific reference signal (CRS); and performing, by the user equipment, power compensation according to the path loss compensation and path loss values. On the basis of the original uplink power control performed according to the path loss estimated based on the downlink CRSs, the network side estimates the path loss compensation value of the UE by triggering the RRH UE to transmit aperiodic SRSs, and informs the UE in a semi-static manner, compensating for the inaccuracy of estimation of path loss and ensuring the efficiency of power control.

Owner:FUJITSU LTD

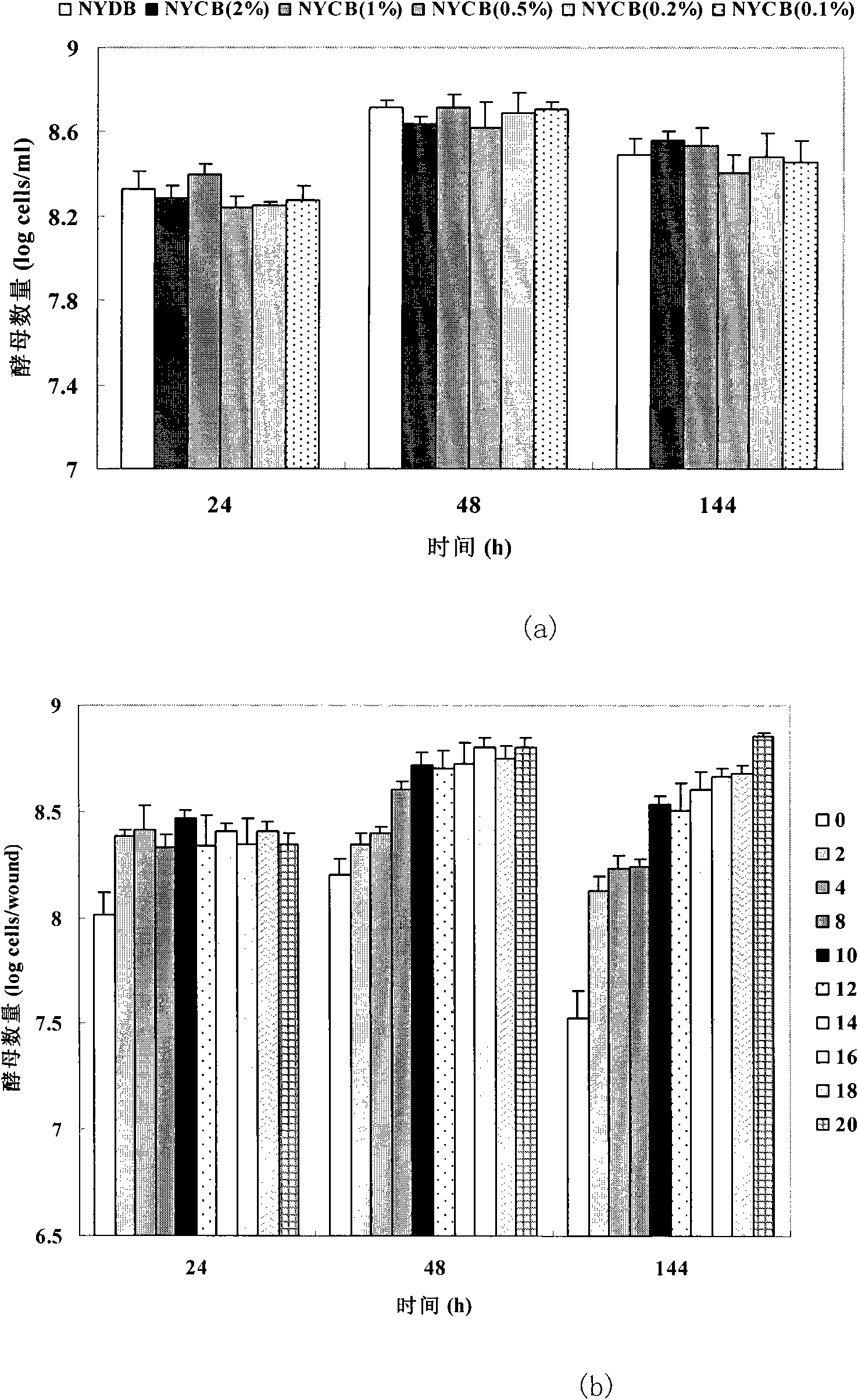

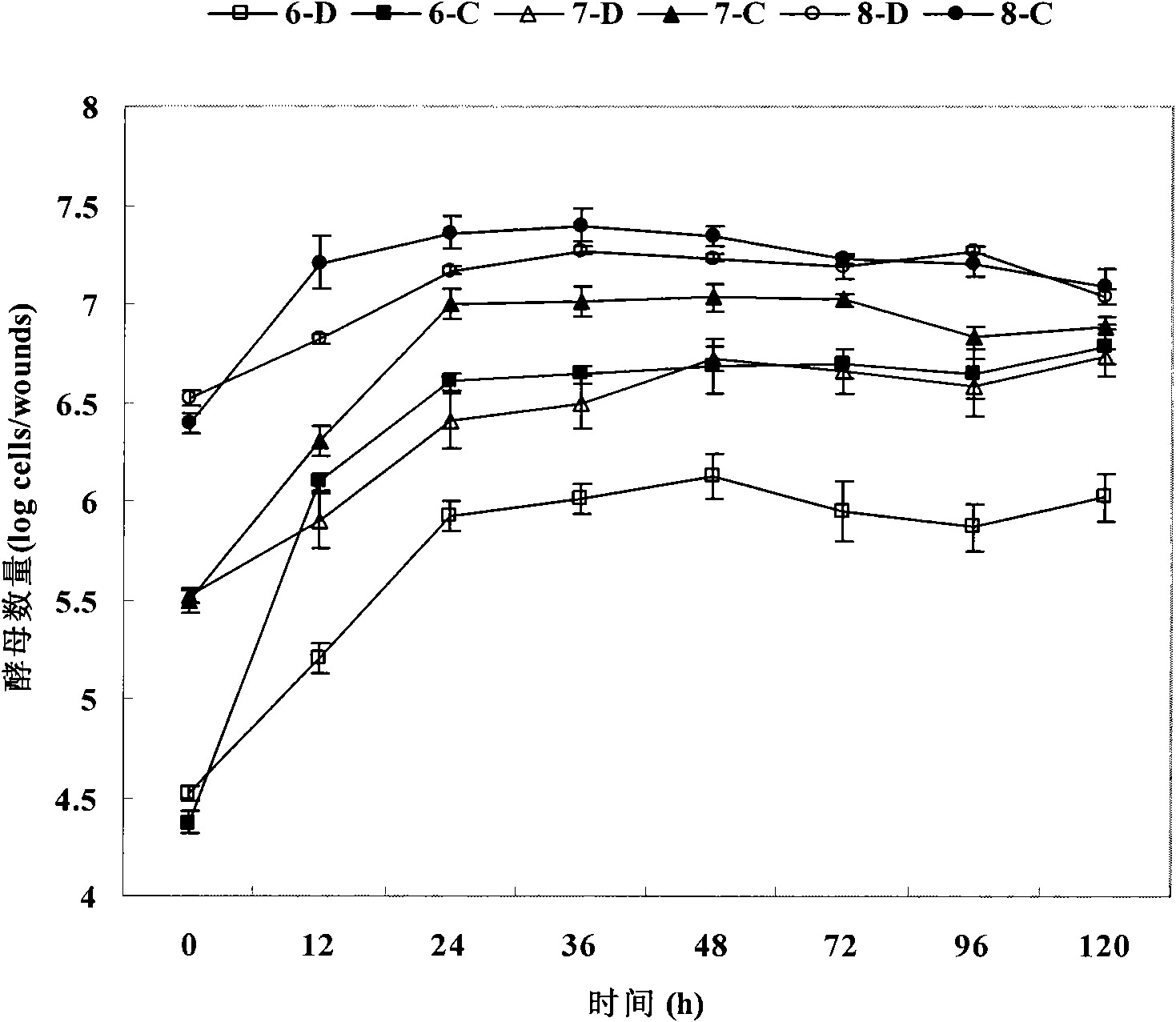

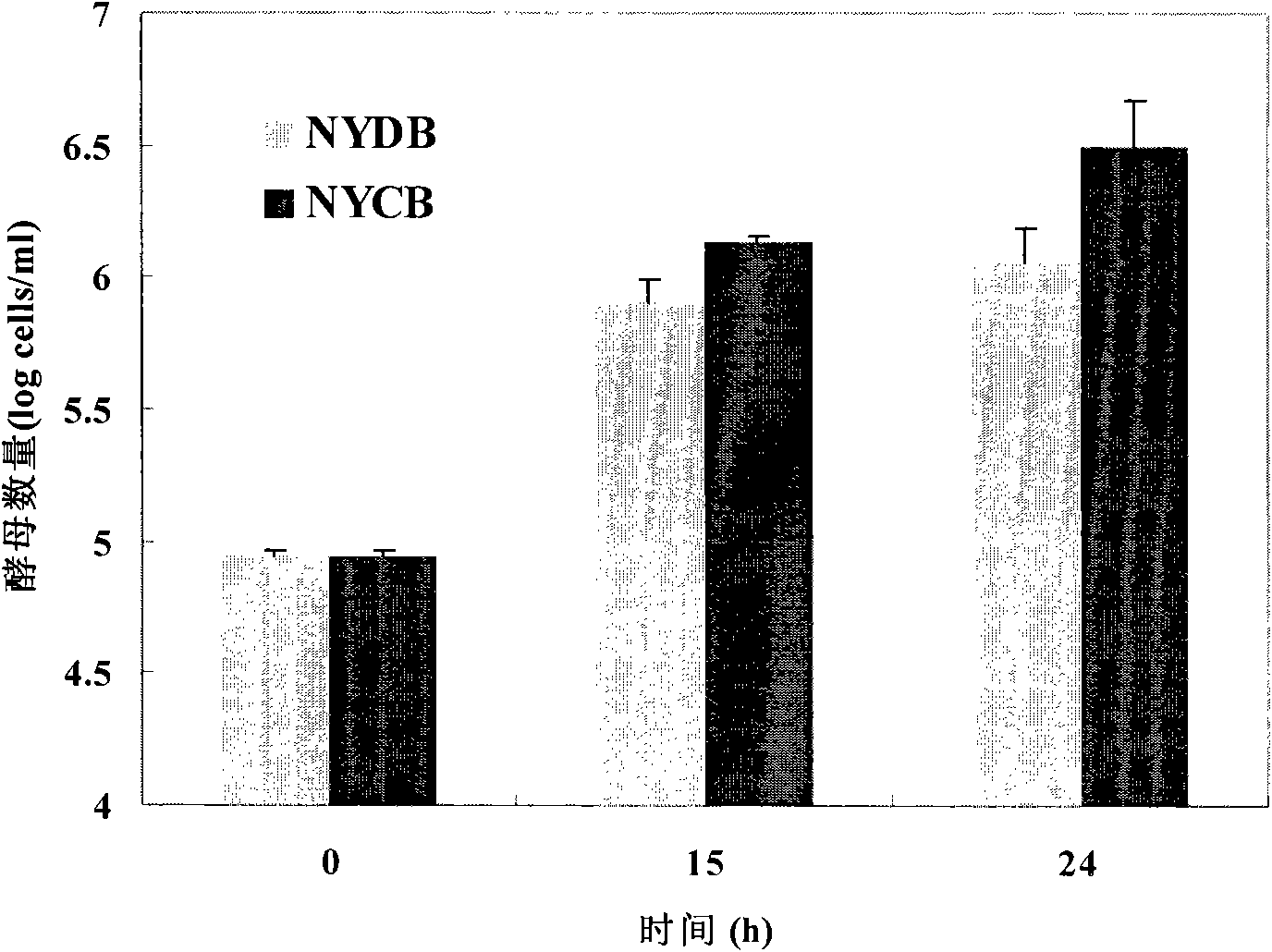

Method for improving prevention and control effects of biological control yeast on fruit diseases by induction and used culture medium

InactiveCN101857843AGood anti-corrosion and fresh-keeping effectControl PenicilliumFungiFruit and vegetables preservationBiotechnologyDisease

The invention discloses a culture medium for improving prevention and control effects of biological control yeast on fruit diseases by induction, which comprises an activation culture medium and a seed culture medium, wherein the activation culture medium is prepared into NYCA activation culture medium from 8 grams of beef extract, 5 grams of yeast powder, 2 to 30 grams of glucose, 20 grams of agar and 1 to 50 grams of chitin by fixing volume to 1,000 milliliters with water and sterilizing the mixture under high pressure; and the seed culture medium is prepared into NYCB seed culture medium from 8 grams of beef extract, 5 grams of yeast powder, 2 to 30 grams of glucose and 1 to 50 grams of chitin by fixing volume to 1,000 milliliters with water and sterilizing the mixture under high pressure. The invention also discloses a method for improving the prevention and control effects of the biological control yeast on the fruit diseases by induction by using the culture medium at the same time. The method comprises steps of performing activation and liquid culture and the like on cryptococcus laurentii CGMCC No.3590.

Owner:ZHEJIANG UNIV

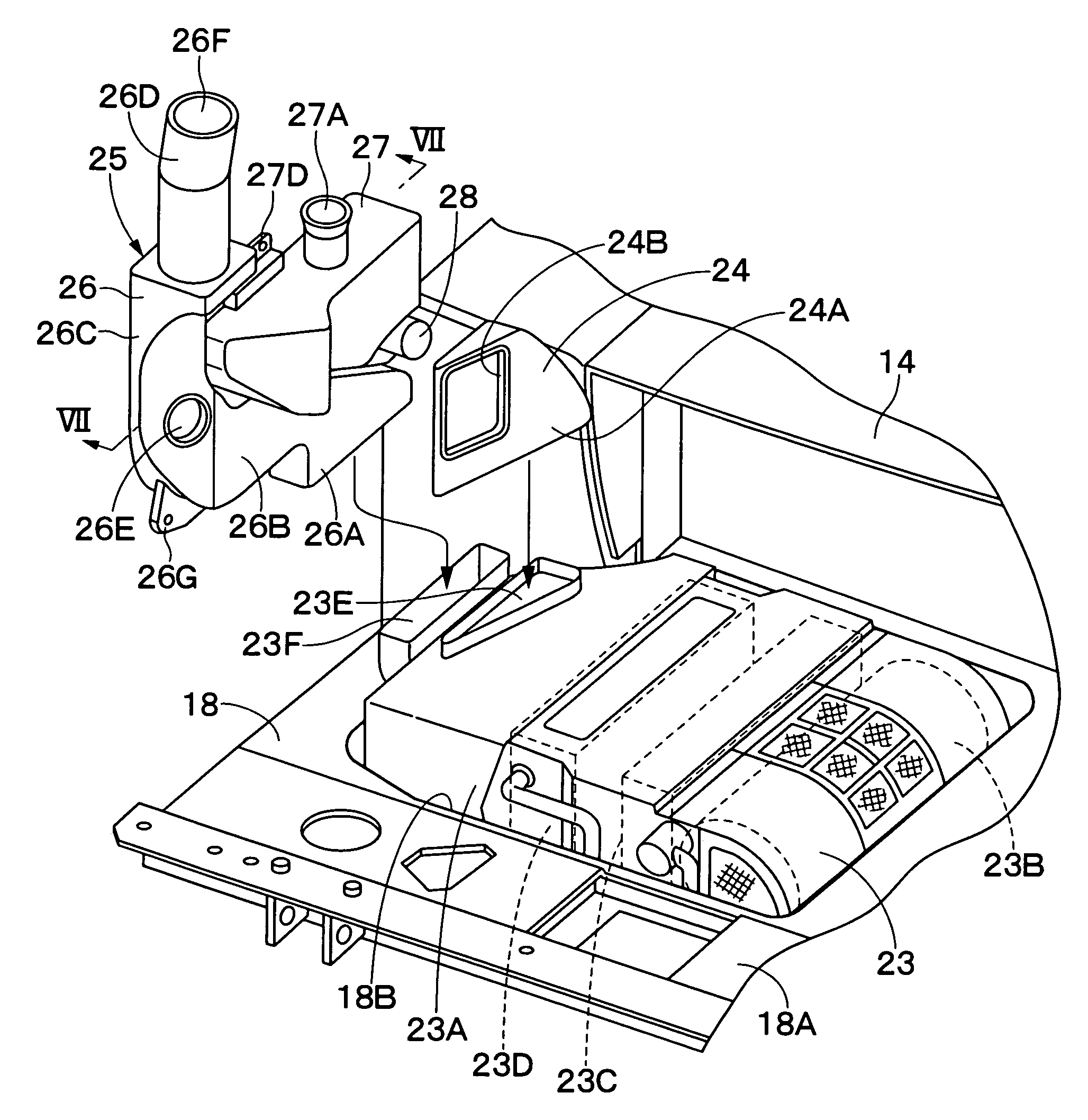

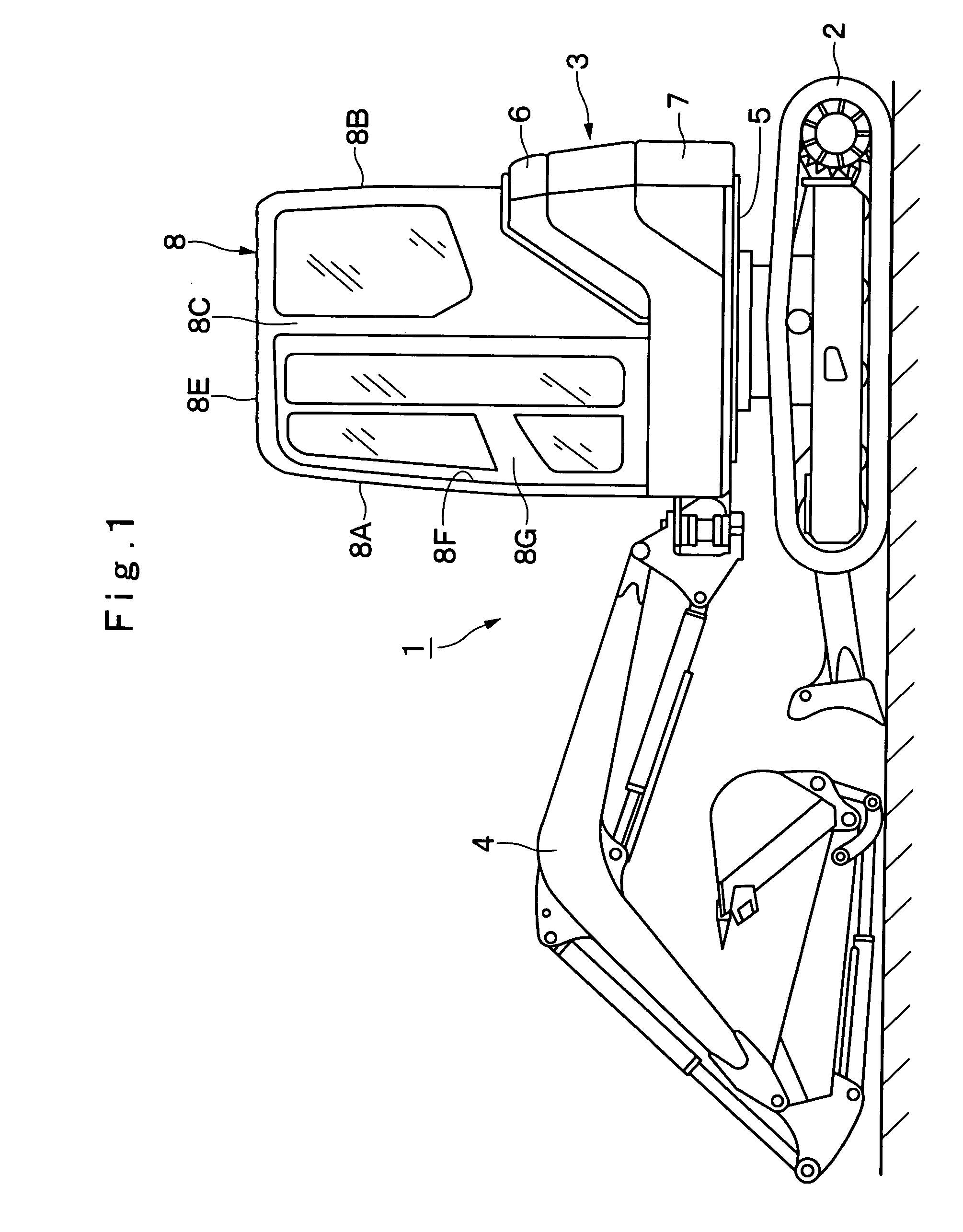

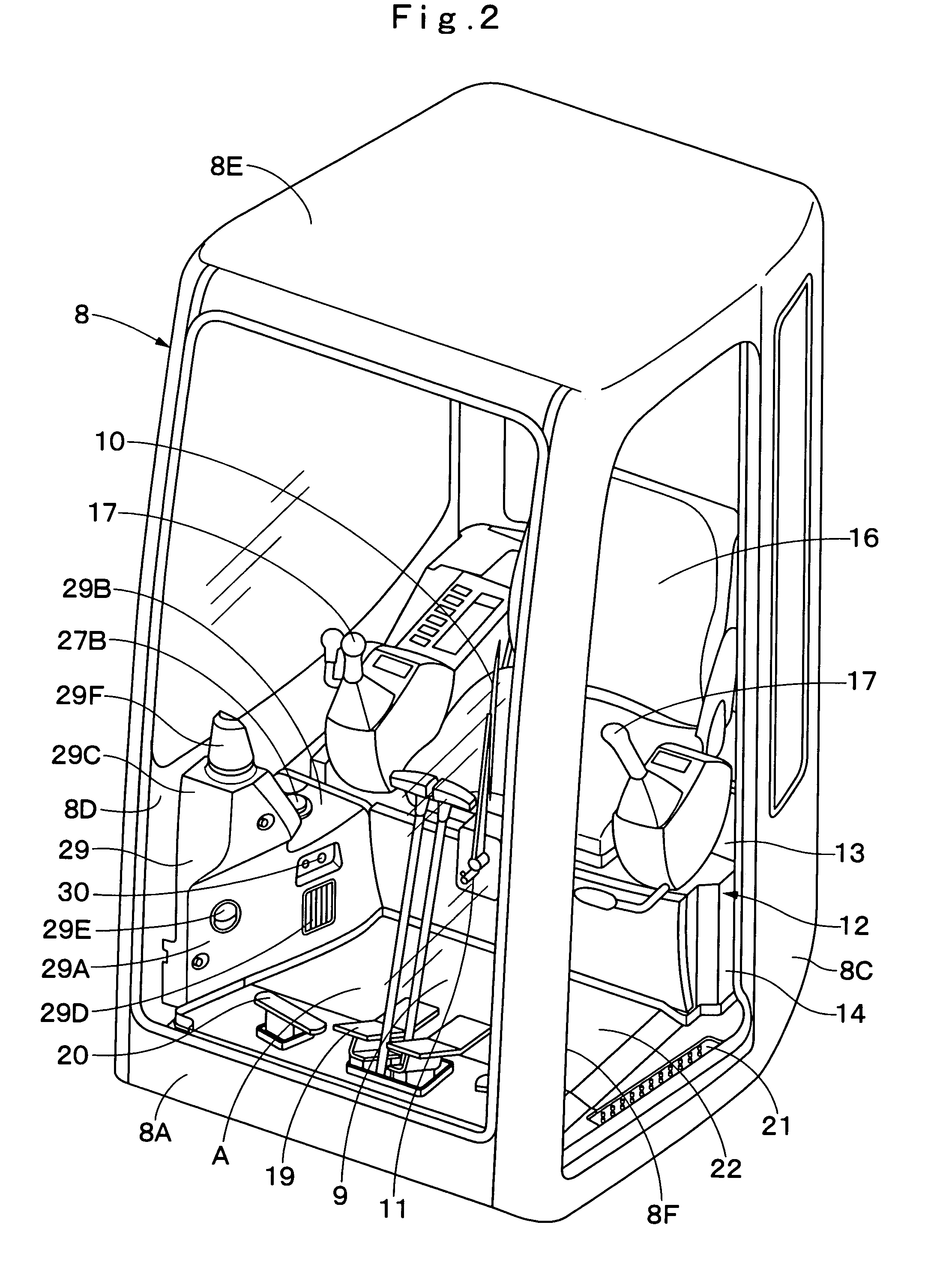

Construction machine

ActiveUS7537074B2Improve reliabilityGuarantee efficiencyVehicle seatsSoil-shifting machines/dredgersScrubberBuilding construction

A washer tank is integrally formed with a front air duct, and the washer tank and the front air duct are installed within a cab. Thus, the washer tank can be installed within the cab by the use of spaces around the air duct. This arrangement makes it possible to install the washer tank within the cab in an unintrusive way and in the vicinity of a washer liquid spout nozzle without necessitating to provide an installation space exclusively for the washer tank.

Owner:NIHON KENKI CO LTD

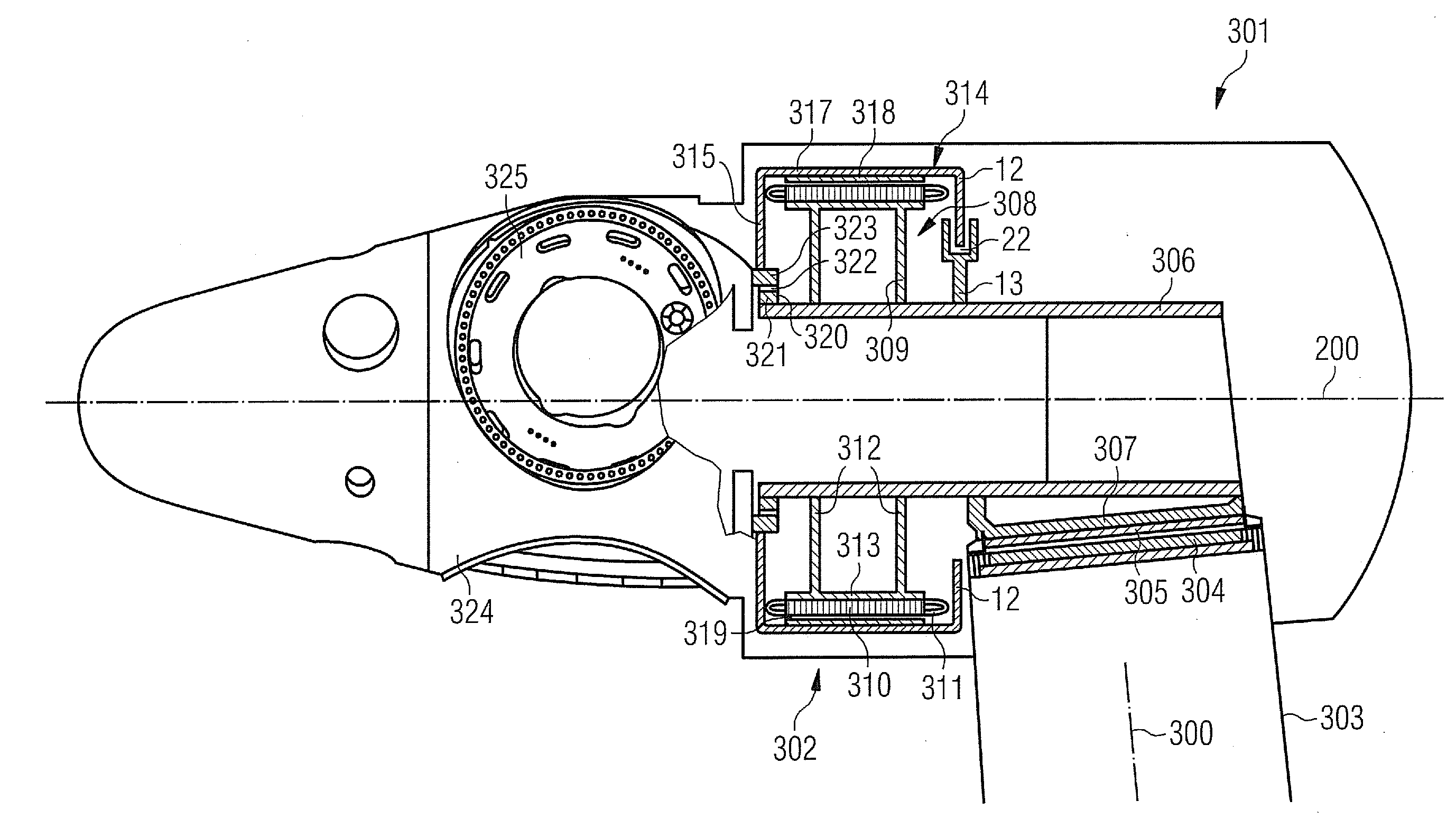

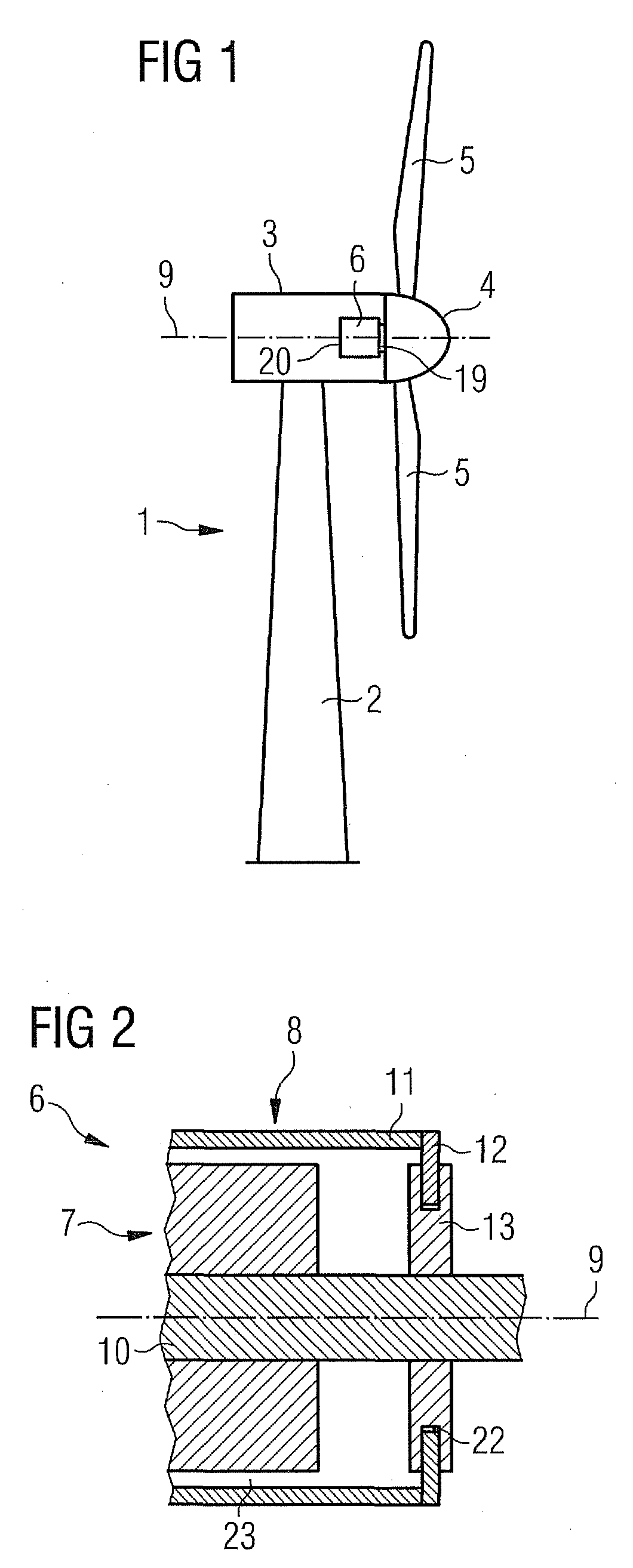

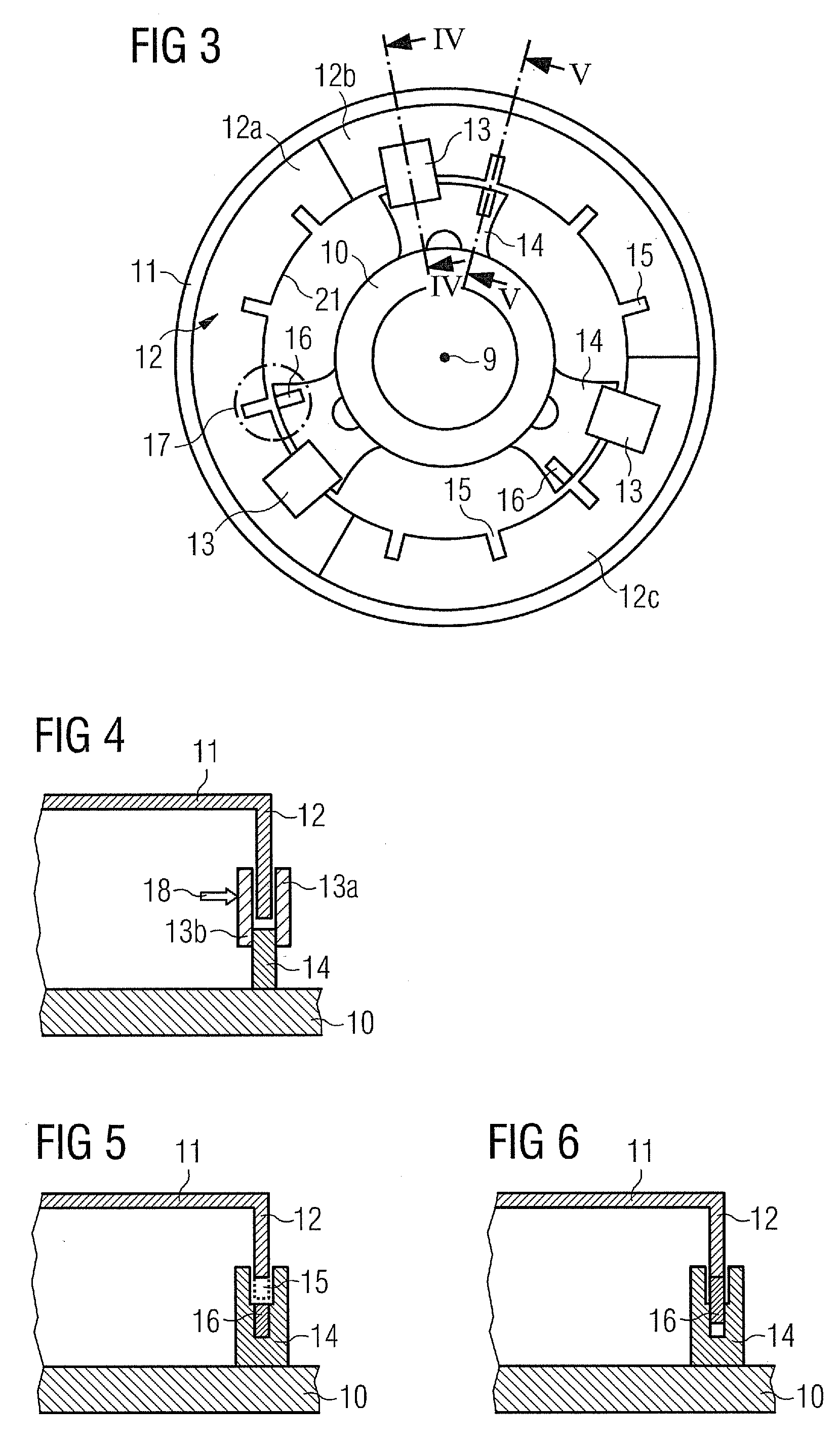

Brake system, generator and wind turbine

ActiveUS20110121579A1Absorption of heatImprove braking efficiencyWind motor controlAxially engaging brakesEngineeringTurbine

A brake system, especially for a generator, including a rotor assembly, a stator assembly and a rotation axis is disclosed. The rotor assembly includes an outer portion which is located radially outward of the stator assembly. The outer portion includes a brake disc, and the stator assembly comprises at least one frictional member operatively configured for frictionally engaging at least a portion of the brake disc.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

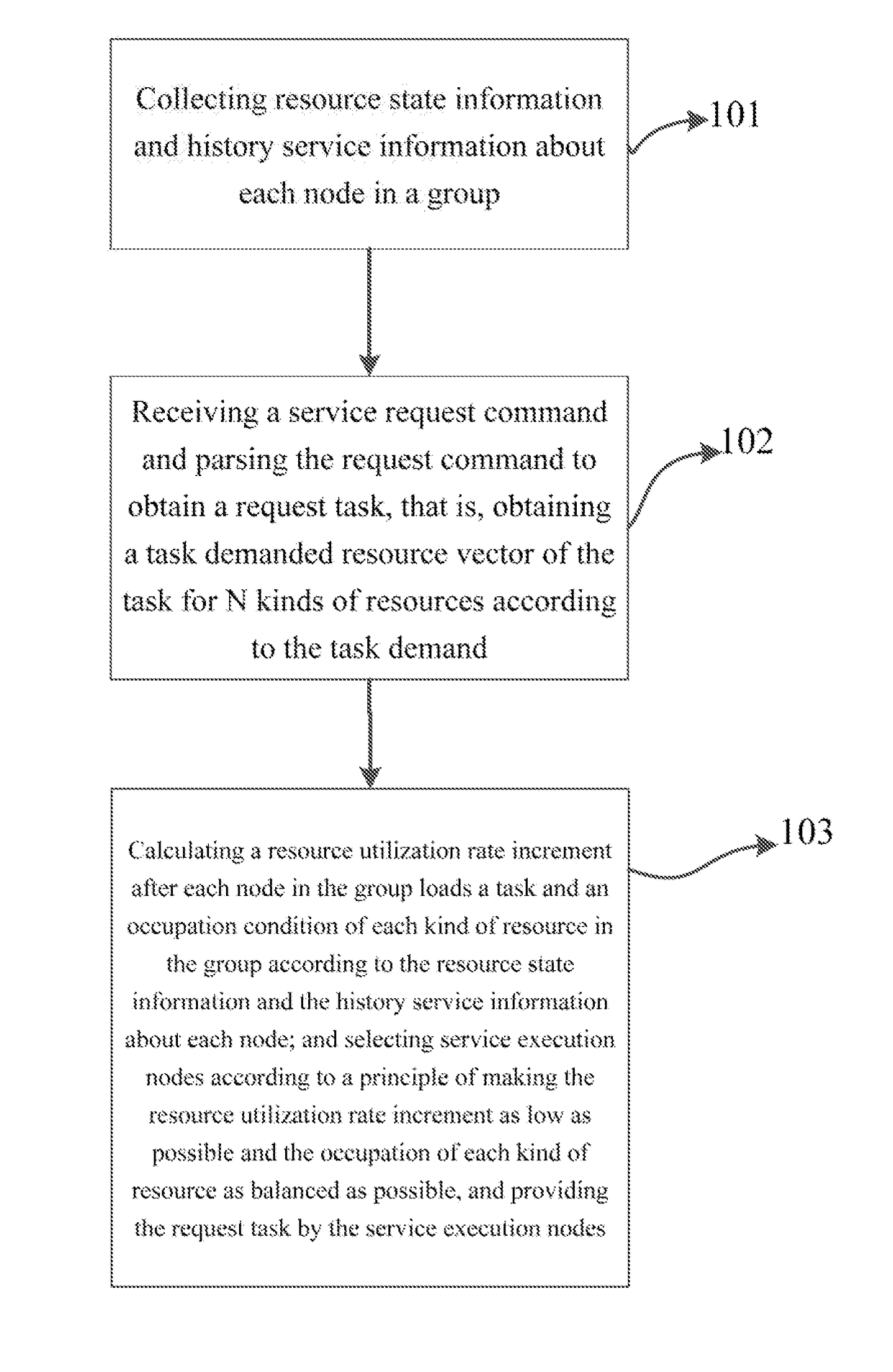

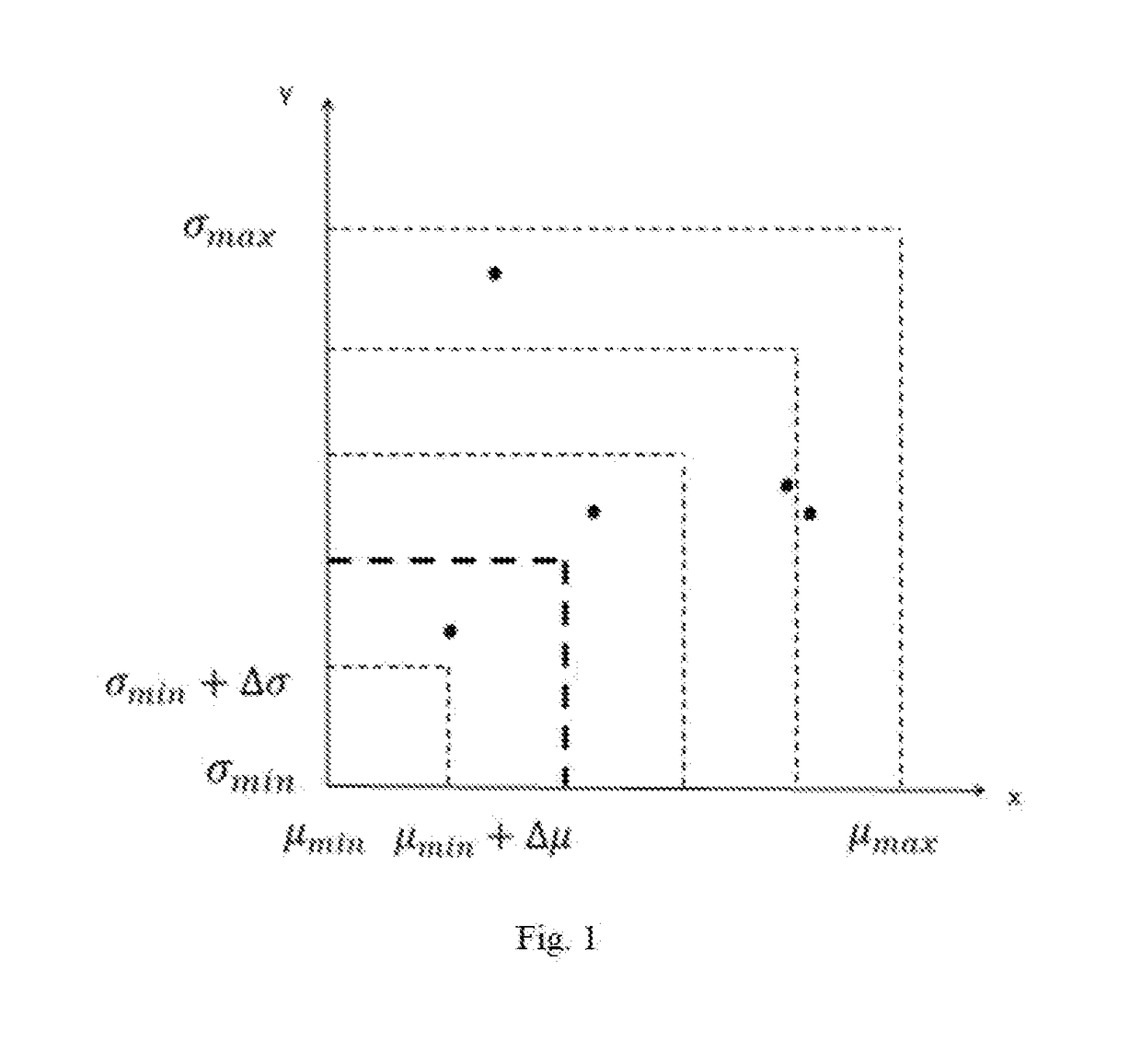

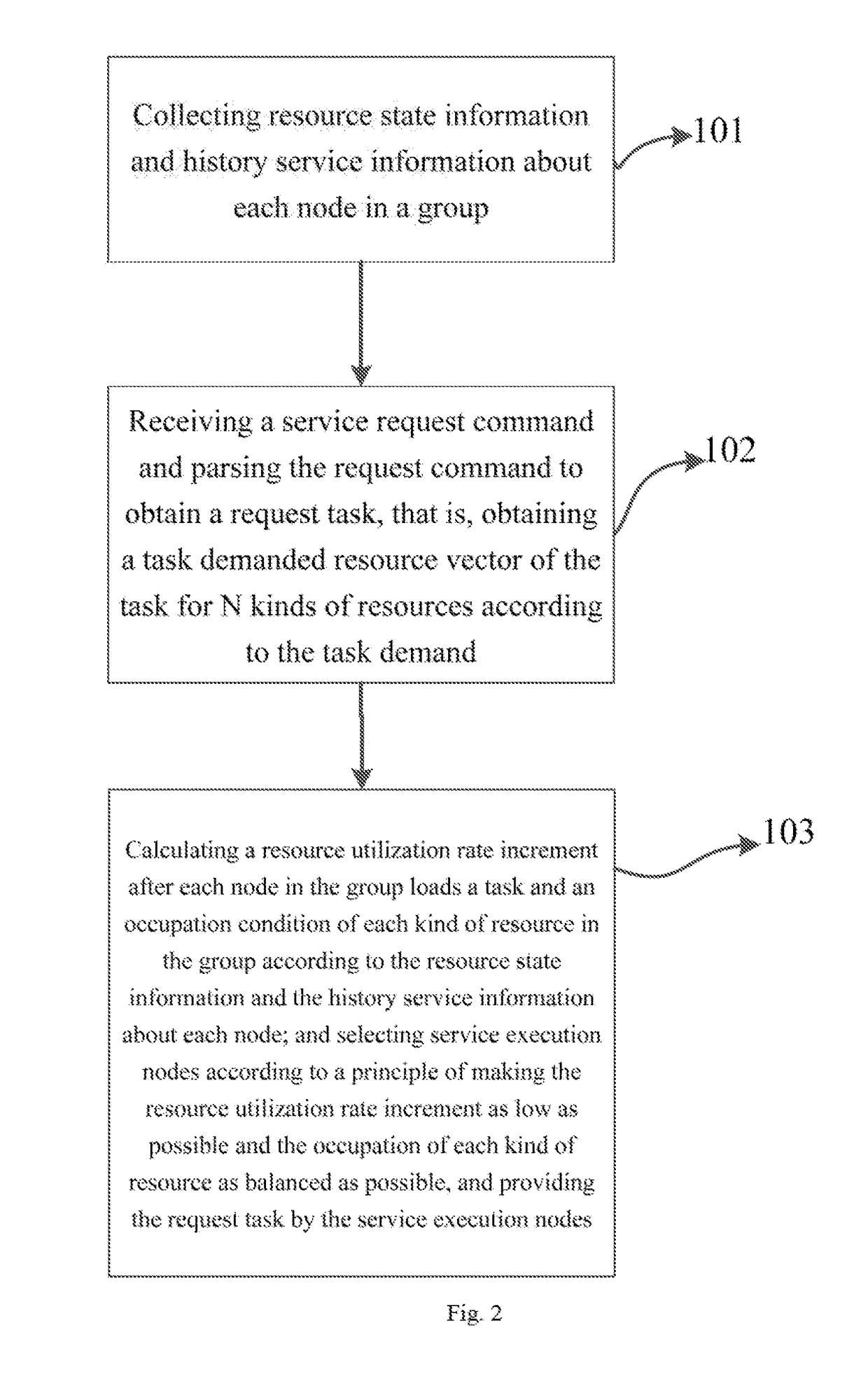

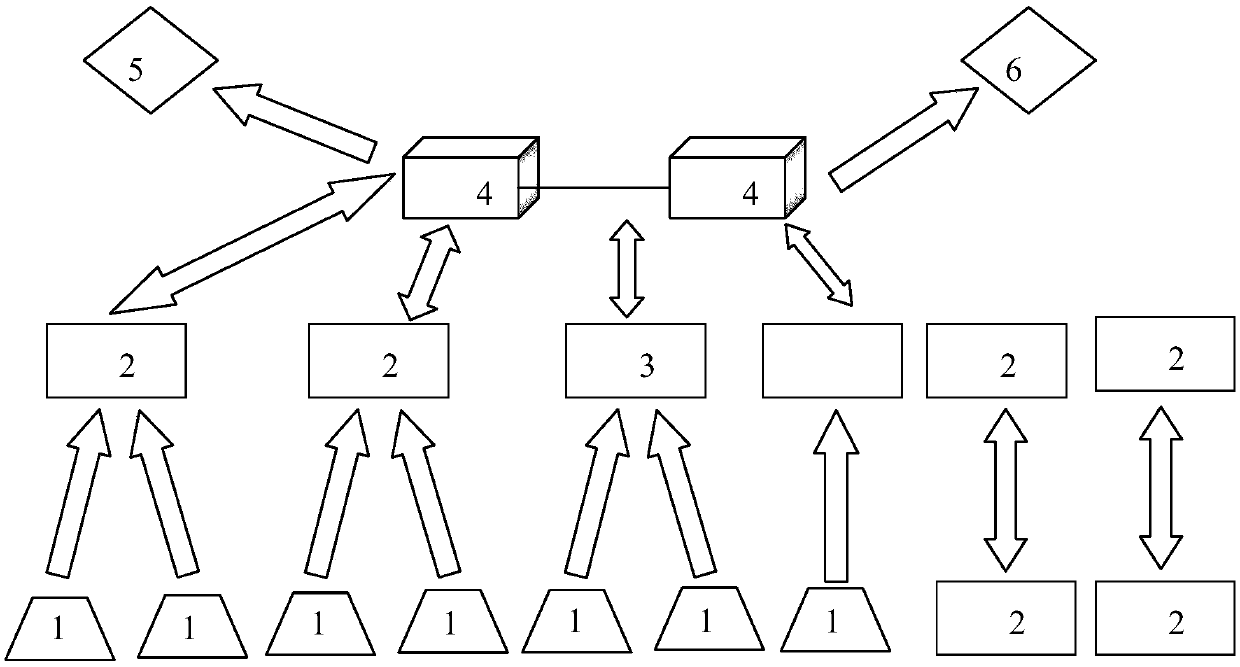

Distributed node intra-group task scheduling method and system

ActiveUS20170329643A1Guarantee efficiencyService performance be improveResource allocationSecuring communicationData packDistributed computing

An SSH protocol-based session parsing method and system. The method includes: step 101) receiving an SSH protocol-based session data packet and respectively preprocessing the received data packet as follows: when one data packet contains several complete messages, extracting each complete message from the data packet; when the data packet contains an incomplete message, firstly caching the incomplete message contained in the current data packet, then receiving the subsequent data packet, and finally splicing the message contained in the subsequent data packet with content of the cached message until a complete message is spliced; and step 102) extracting a content associated with log generation from each obtained complete message, packaging the content associated with the log according to a set format, and then obtaining a parsed log and finishing the session parsing.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +2

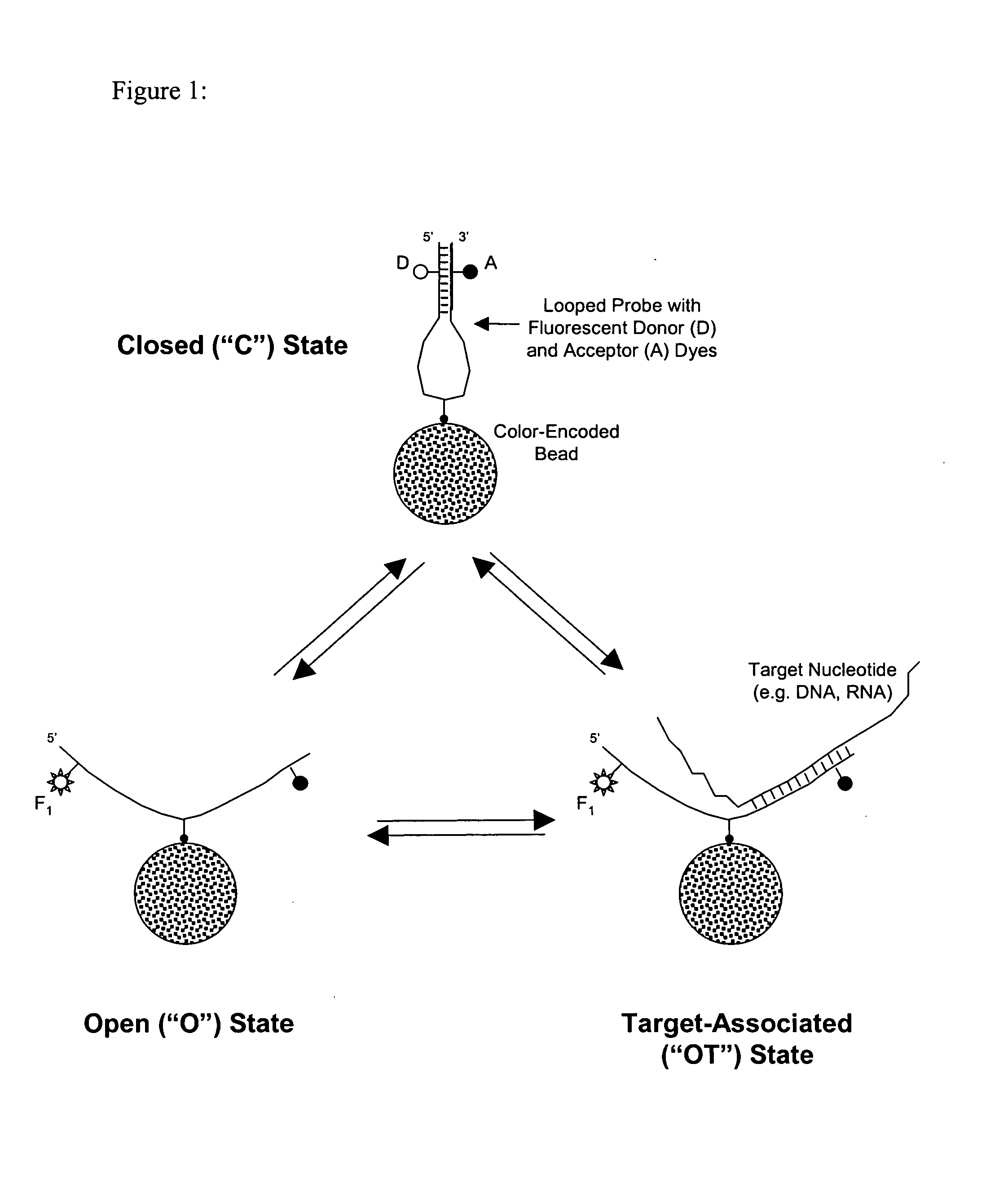

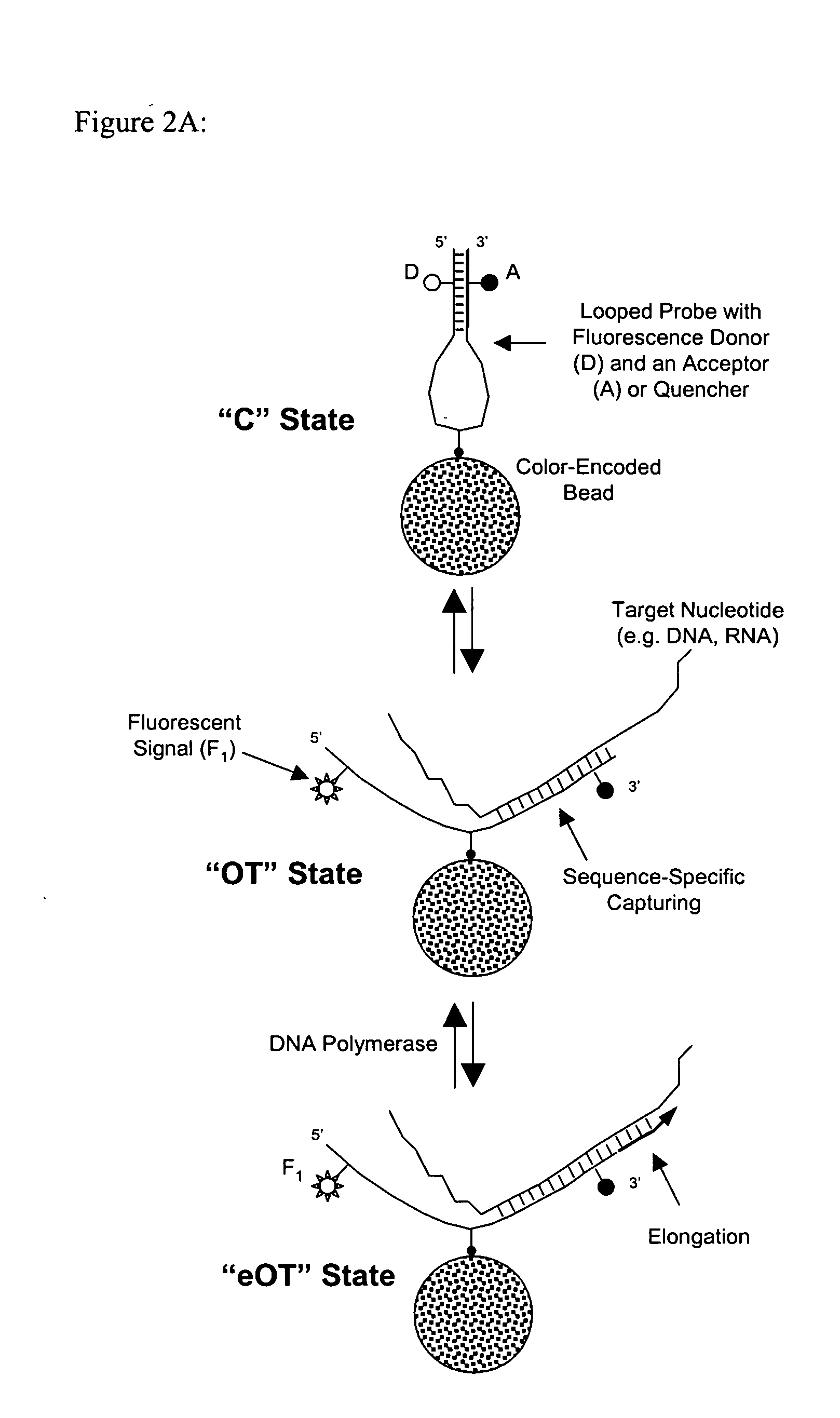

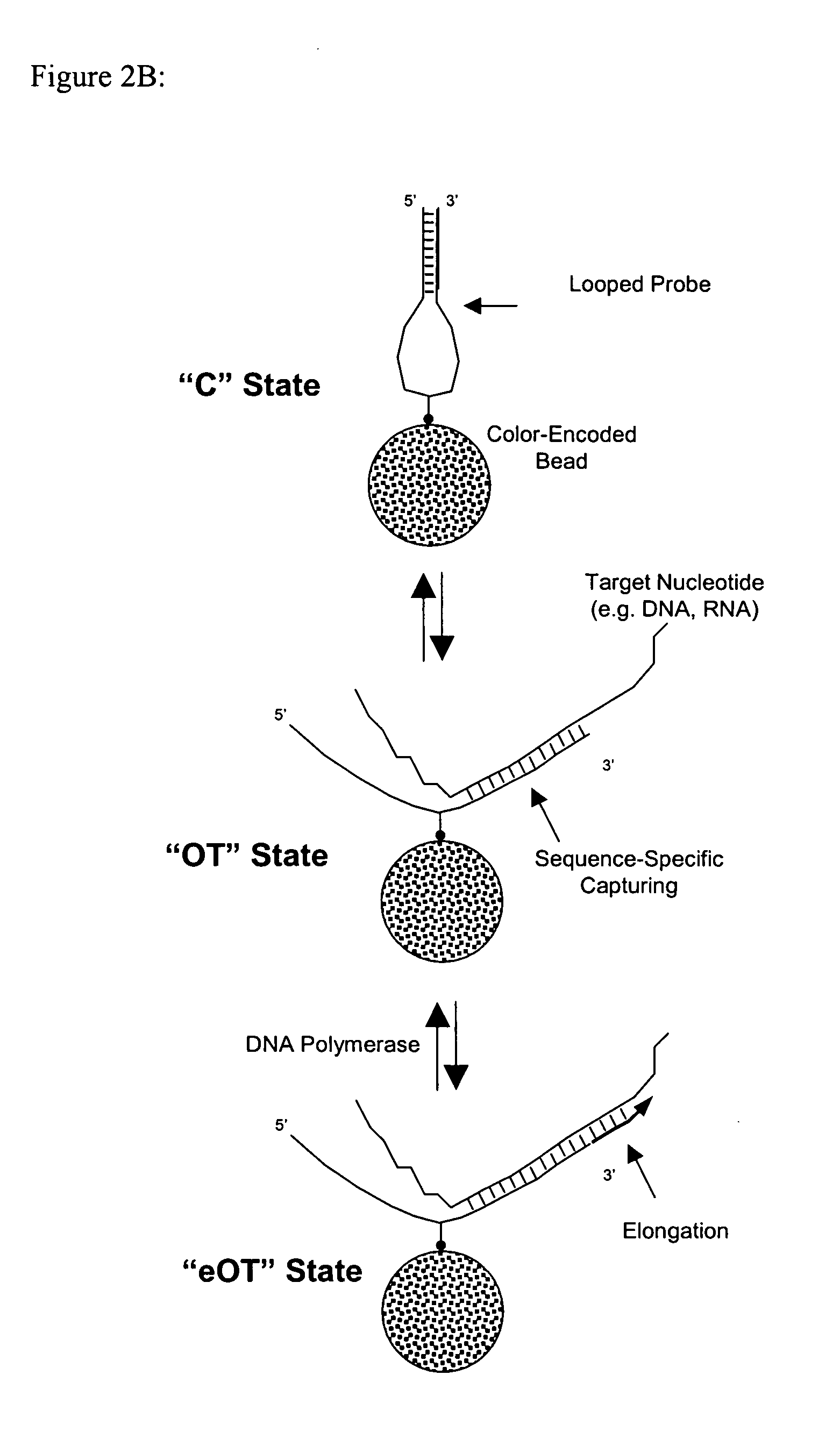

Probe density considerations and elongation of self-complementary looped probes where probes are attached to a solid phase

InactiveUS20070243534A1High detection sensitivityIncrease rangeBioreactor/fermenter combinationsBiological substance pretreatmentsIonic strengthAssay

In a multiplexed assay method carried out in solution, wherein the solution contains nucleic acid targets and, wherein several different types of oligonucleotide probes, each type having a different sequence in a region designated as a target binding domain, are used to detect the nucleic acid targets, said assay method including a method for increasing the effective concentration of the nucleic acid targets at the surface of a bead to which the oligonucleotide probes are bound, by one or more of the following steps: adjusting assay conditions so as to increase the effective concentration of the targets available for binding to the probes, by one or more of the following: (i) selecting a particular probe density on the surface of the bead; (ii) selecting a solution having an ionic strength greater than a threshold; (ii) selecting a target domain of a size less than a threshold; or (iii) selecting target domains within a specified proximity to a terminal end of the targets.

Owner:SEUL MICHAEL +4

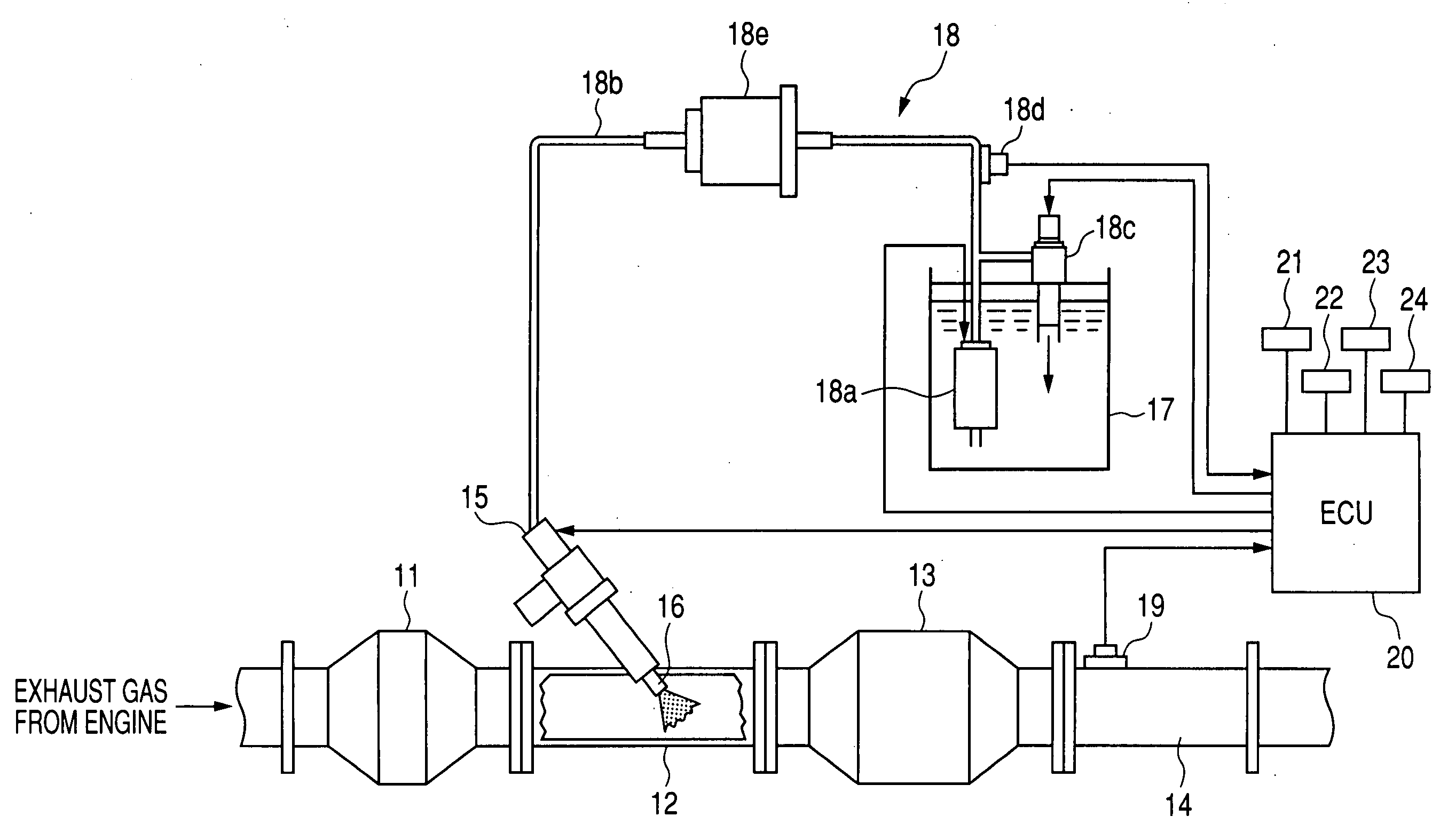

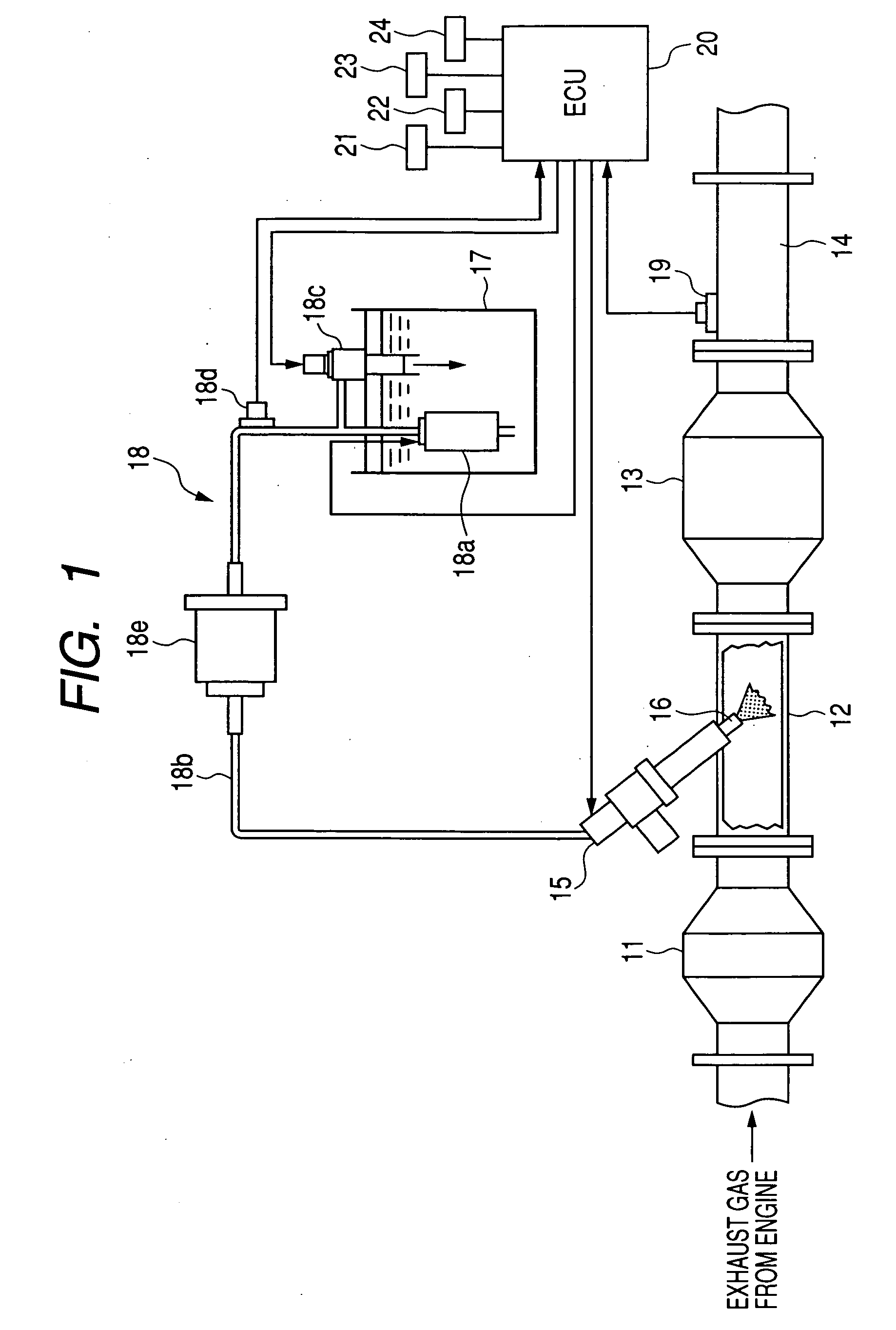

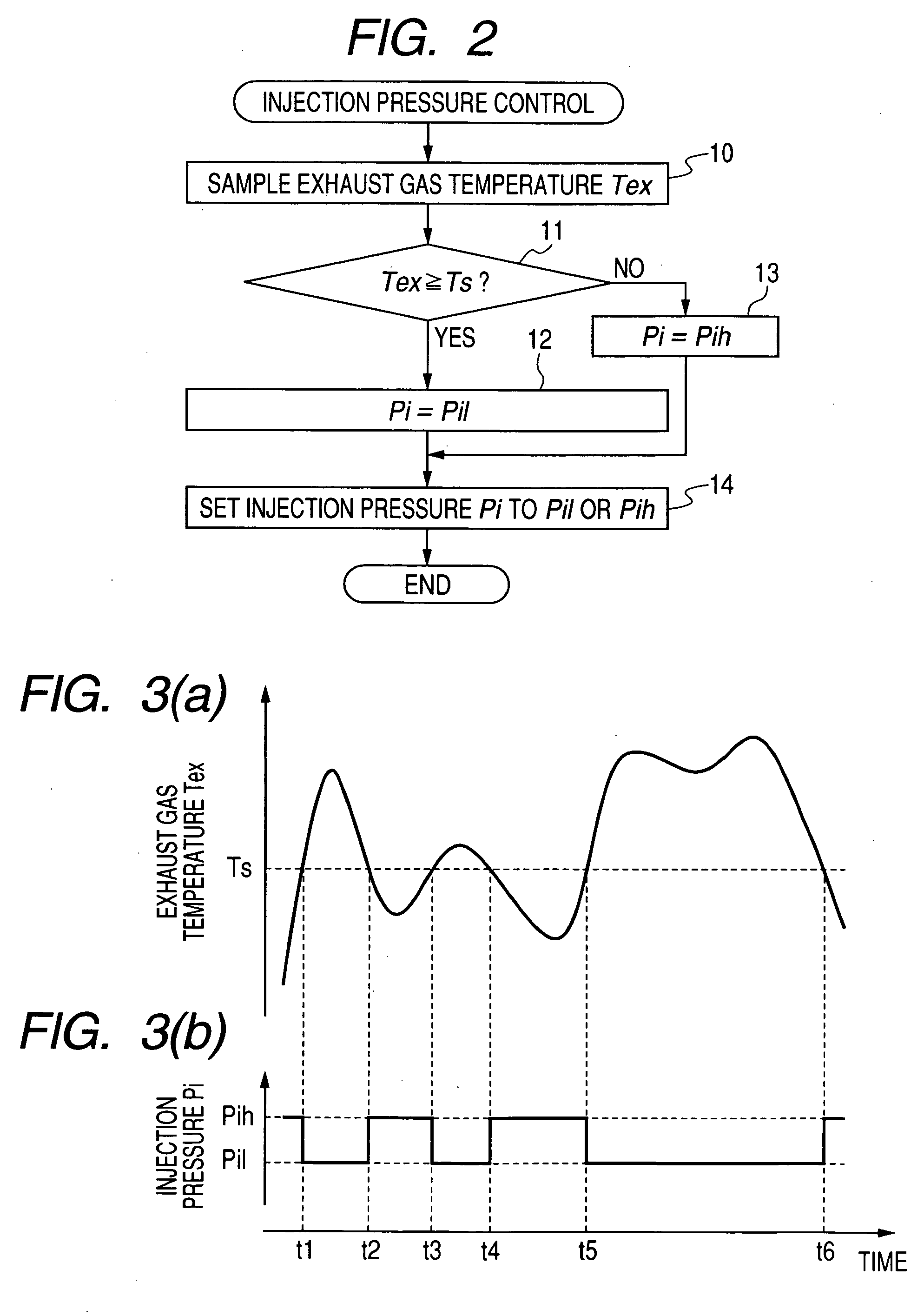

Reducing agent spray control system ensuring operation efficiency

InactiveUS20090104085A1Improve responseIncrease pressureInternal combustion piston enginesExhaust apparatusCombustionControl system design

A reducing agent spray control system designed to control an exhaust emission control device such as a urea SCR device for automotive internal combustion engines. The exhaust emission control device includes an injector injecting a spray of a reducing agent into an exhaust pipe of the engine to reduce a selected component such as NOx in exhaust gas to purify the exhaust gas and a pump regulating the pressure of the reducing agent to be sprayed by the injector. The system works to control the pump so as to bring the pressure of the reducing agent to be sprayed by the injector into agreement with a target value, as determined based on the state of the exhaust gas, to ensure the efficiency of purification of the exhaust gas without sacrificing the service life of the pump.

Owner:DENSO CORP

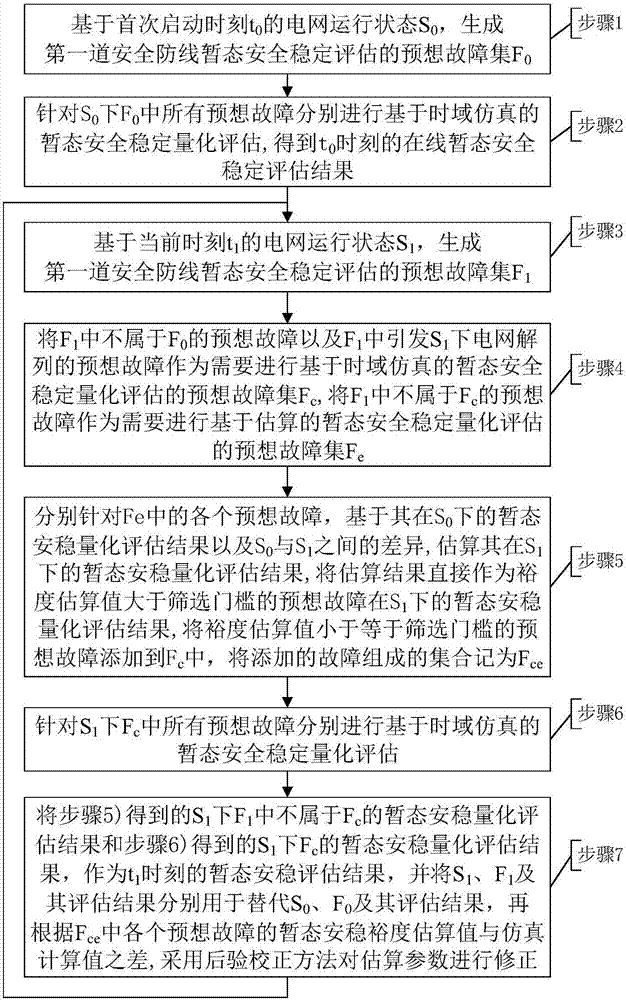

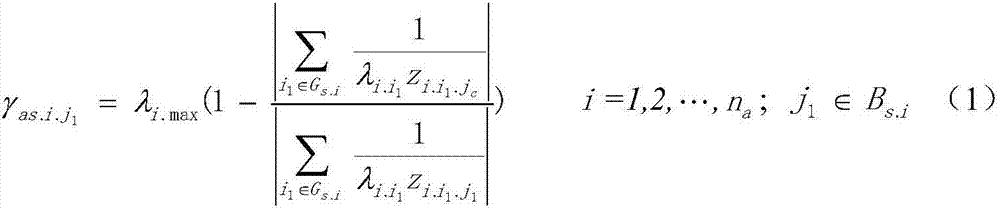

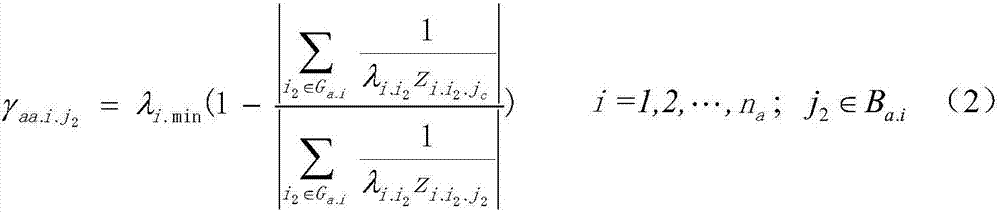

Online transient safety stabilization evaluation method based on automatic expected fault set filtering

ActiveCN107093895AShorten the timeAvoid hidden dangersPower oscillations reduction/preventionEvaluation resultTime domain

The invention discloses an online transient safety stabilization evaluation method based on automatic expected fault set filtering and belongs to the electric power system safety stabilization analysis technology field. According to the method, a participation factor of a node active power for transient power angle stabilization is calculated based on a transient power angle stabilization participation factor of a generator and mutual impedance between a node and a generator inner node, weak node voltage sensitivity of a node reactive power for transient voltage safety stabilization is taken as a participation factor for transient voltage safety stabilization, a participation factor of the node active power for transient frequency safety is calculated based on mutual impedance between the node and a transient frequency safety weak node, a transient safety stabilization quantification evaluation result is estimated based on a previous transient safety stabilization quantification evaluation result and present node power injection change, an estimation parameter is corrected through a posteriori correction method according to the transient safety stabilization quantification evaluation result based on time domain simulation and difference of estimated values. The method is advantaged in that automatic expected fault set filtering of online transient safety stabilization evaluation can be realized.

Owner:YUNNAN ELECTRIC POWER DISPATCH CONTROL CENT +2

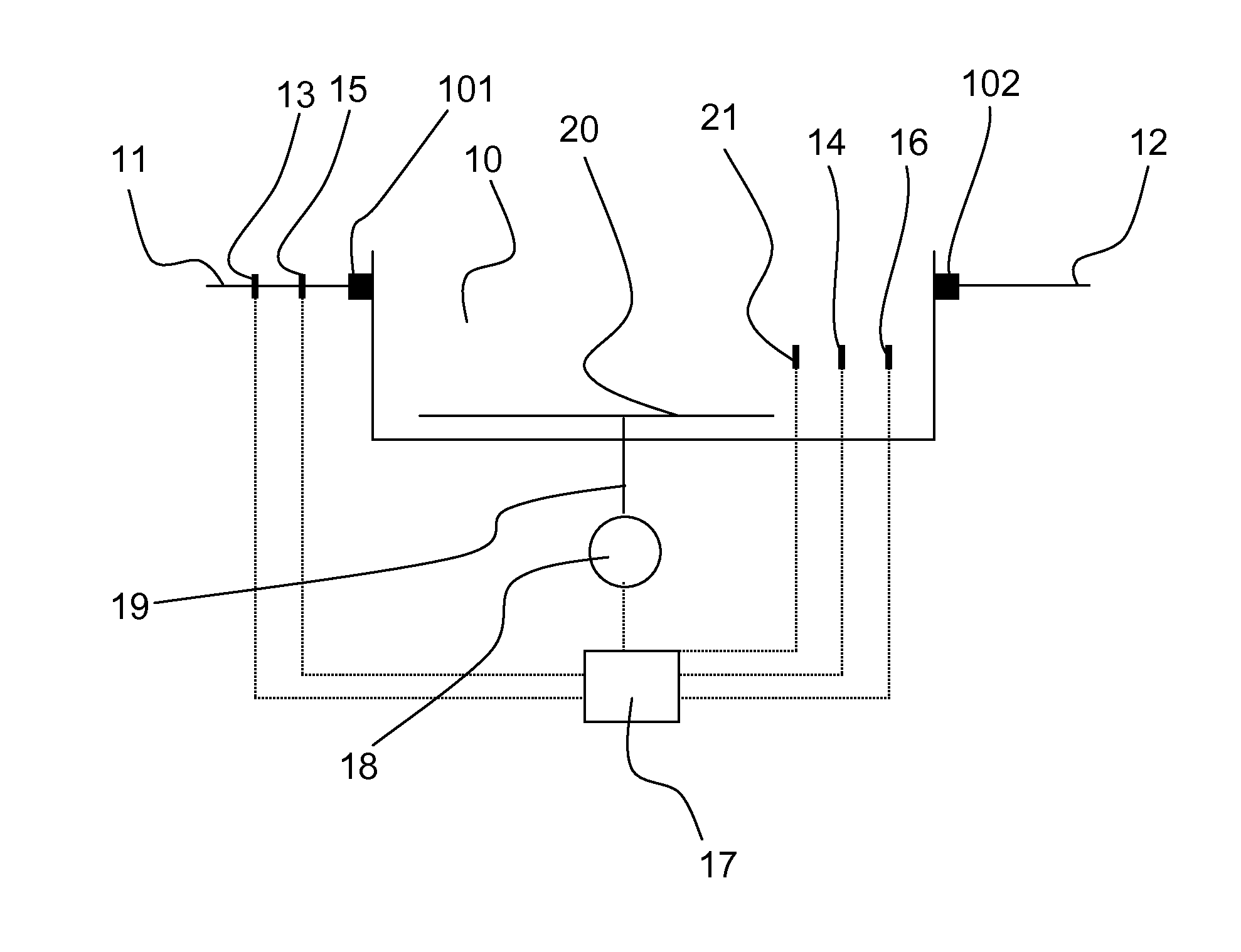

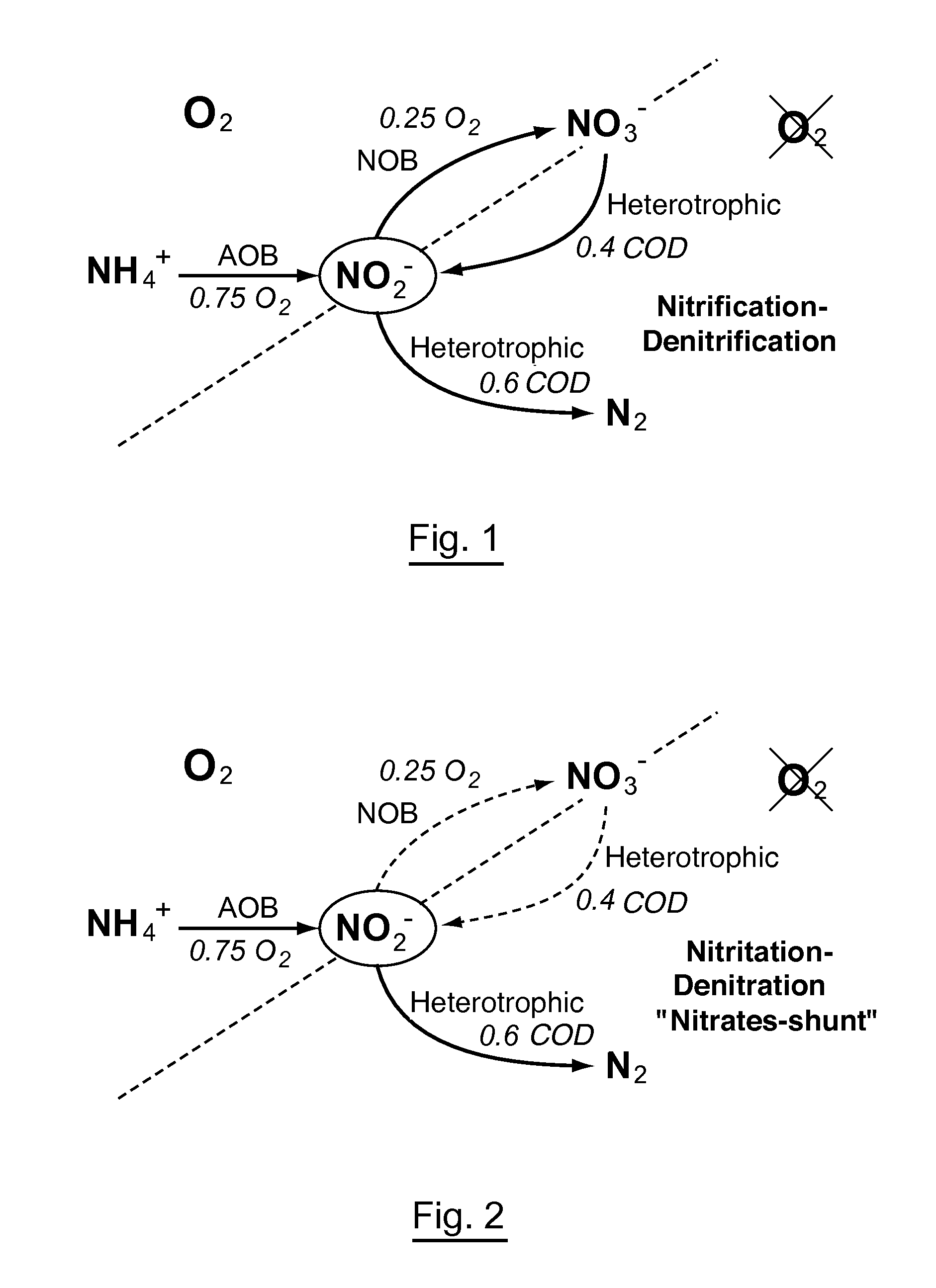

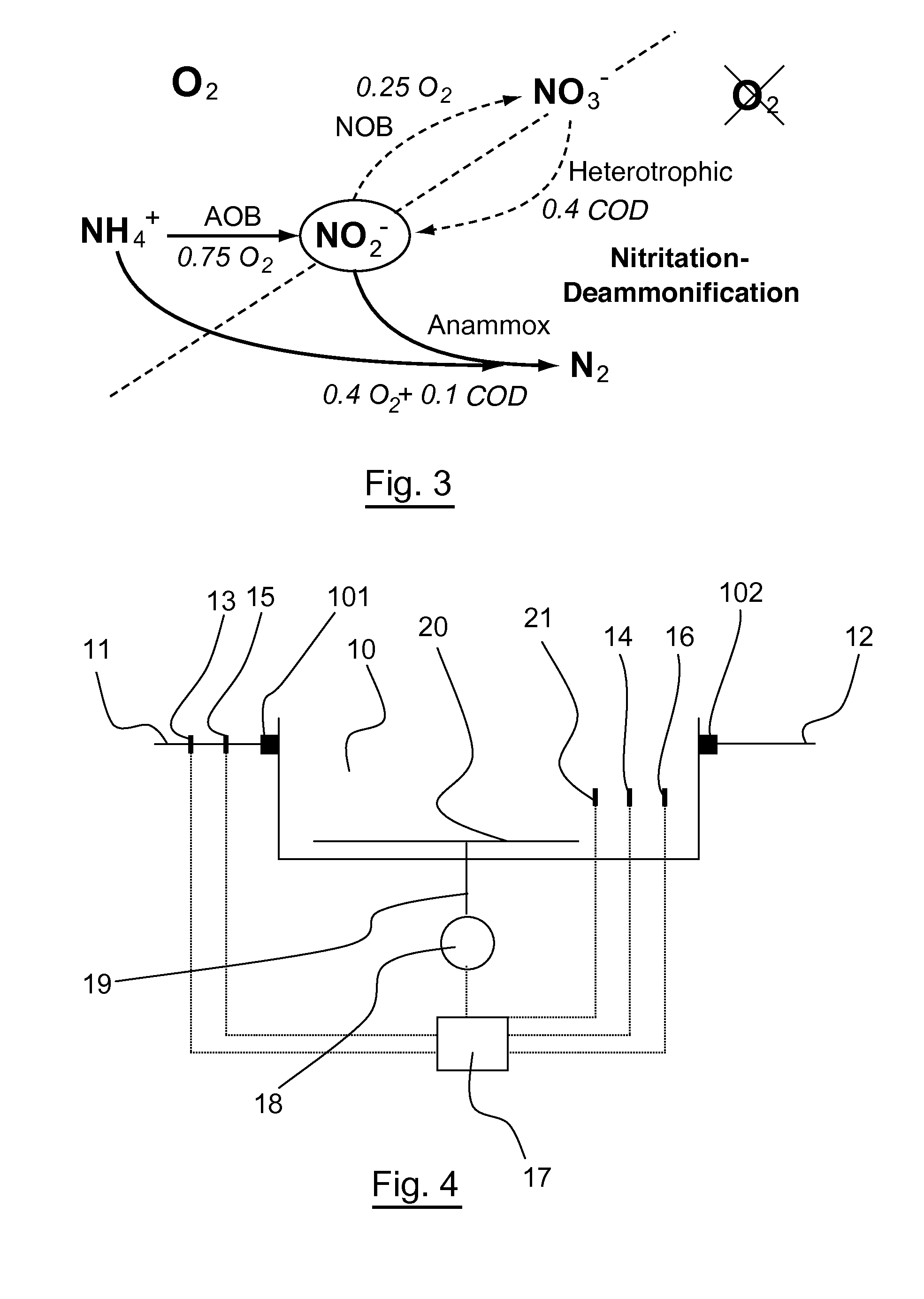

Process for Treating Water by Nitritation-Denitration Comprising at Least One Aerated Step and One Step for Controlling the Oxygen Input During the Aerated STep

ActiveUS20130256217A1Production is limitedAdequate ammonium reductionWater treatment parameter controlTreatment using aerobic processesNitrateOxygen

A process for treating water that includes ammonium. The water is directed to a biological reactor and the quantity of nitrates formed in the reactor and the quantity of ammonium reduced in the reactor is determined. A ratio of the quantity of nitrates formed to the quantity of ammonium reduced is determined. Further, the percentage of ammonium reduced is also determined. The water in the biological reactor is aerated by injecting oxygen into the reactor where the amount of oxygen injected is a function of the ratio and the percentage of ammonium reduced in the reactor.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

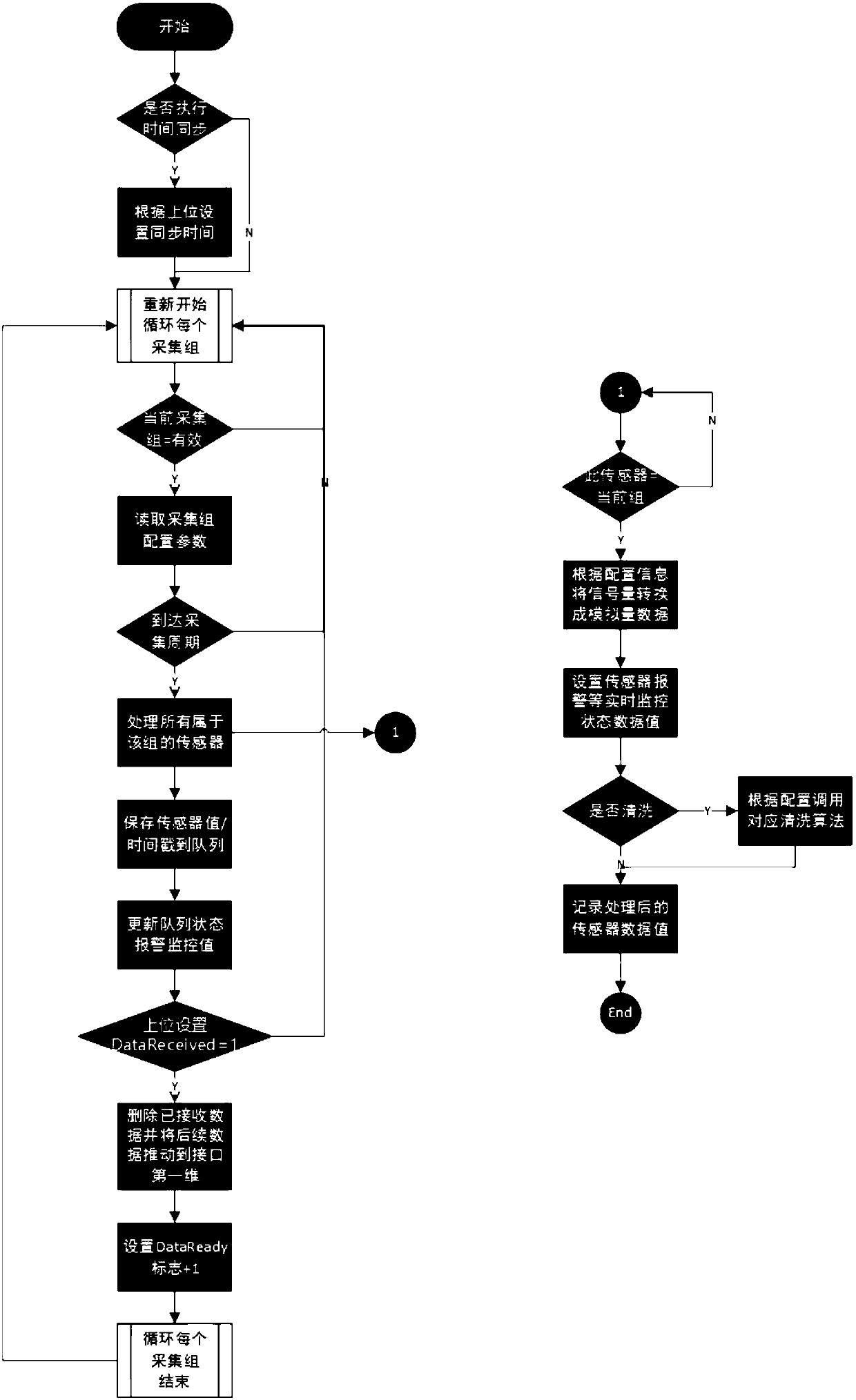

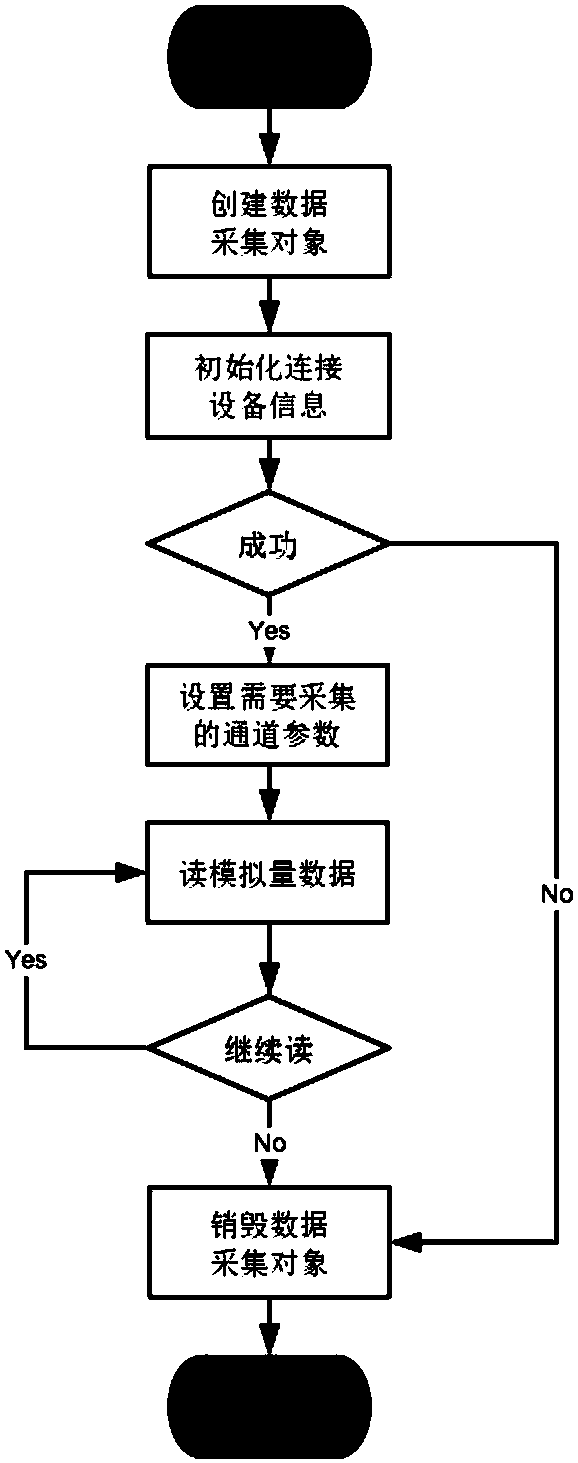

Automobile manufacturing MES data acquisition system based on industrial Internet

ActiveCN107908166AEasy to manageHigh speed acquisitionTotal factory controlProgramme total factory controlData acquisitionThe Internet

The invention discloses an automobile manufacturing MES data acquisition system based on the industrial Internet. Data acquisition and data transmission are included. The data acquisition comprises sensor data acquisition, high speed acquisition card data acquisition, PLC-to-PLC data acquisition, PLC-to-PC data acquisition, and data acquisition from an industrial personal computer to a data server. The data transmission is set to be in the way that the acquired data is transmitted to a big data platform. According to the invention, data acquisition is normalized; by use of the high speed dataacquisition technology, the sensing technology and the buffering technology, by use of the distributed acquisition mode, each system data in a workshop currently and data of production devices are acquired by use of the microsecond-grade and millisecond-grade high frequency acquisition technology; wide-coverage and high-frequency data acquisition is achieved; and by use of the big data technology,stability and efficiency of system operation are ensured.

Owner:上海亚太计算机信息系统有限公司

Fault recording master station information management system

ActiveCN103559570AComplete system solutionLong-term information integration goalsTechnology managementResourcesCommunications serverApplication server

The invention discloses a fault recording master station information management system which comprises a master station and at least one substation. The master station comprises an application server, a communication server and a database server. The substation is provided with a fault wave recording device and used for automatically carrying out wave recording and sending a wave recording file to the communication server when a fault occurs; the communication server is provided with a wave recording access unit and a protocol conversion unit; the protocol conversion unit is used for achieving unified input or output of information; the recording access unit is used for receiving the wave recording file and transmitting standard wave recording information to the application server; the application server is provided with a storage unit, a strategy setting unit, an information processing unit and a display unit; the storage unit is used for temporarily storing the standard wave recording information and transmitting the standard wave recording information to the database server to be stored; the strategy setting unit is used for setting processing strategies; the information processing unit processes the standard wave recording information according to the processing strategies, and the standard wave recording information is dynamically displayed through the display unit in real time.

Owner:NORTHEAST CHINA GRID +2

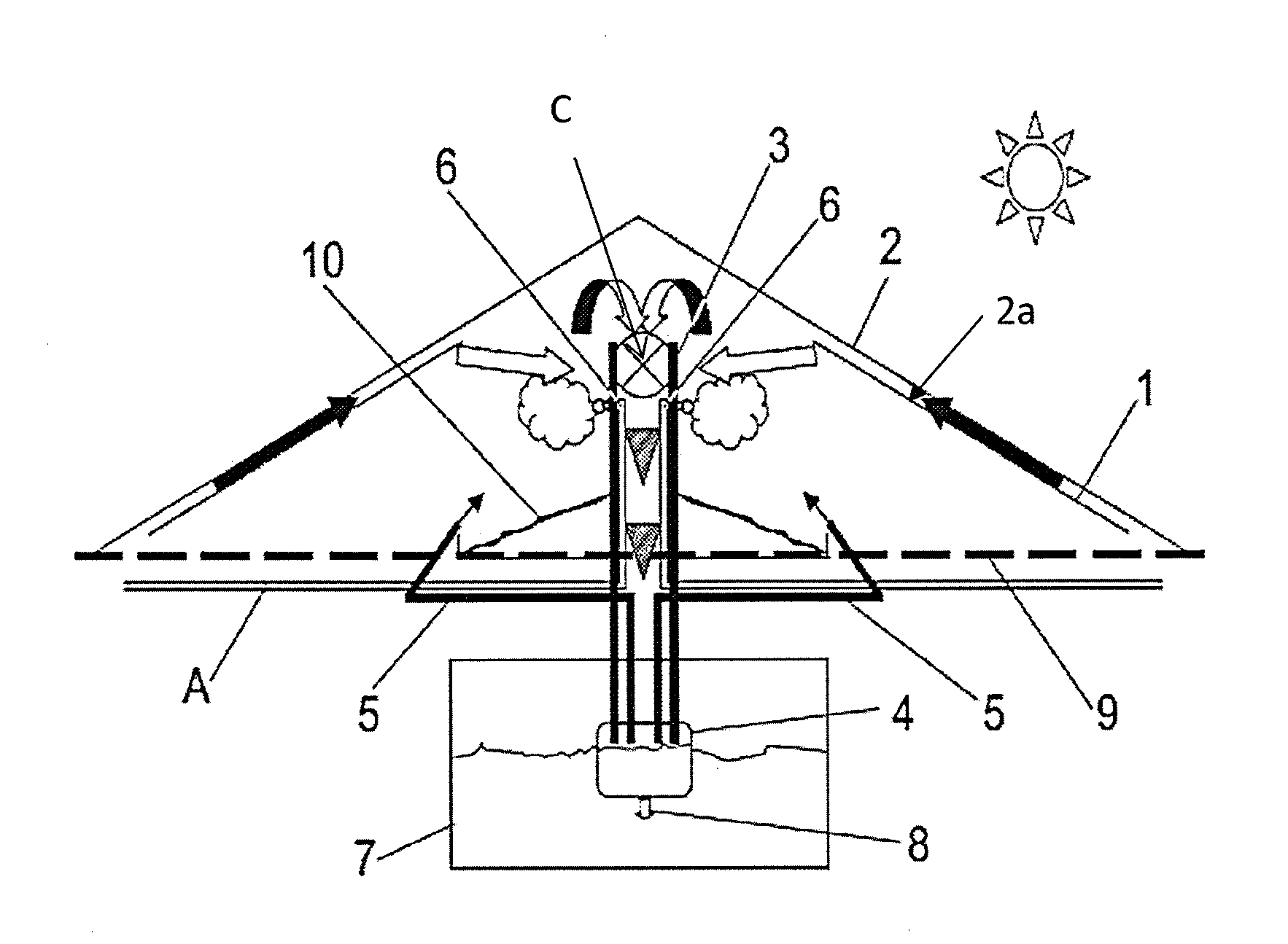

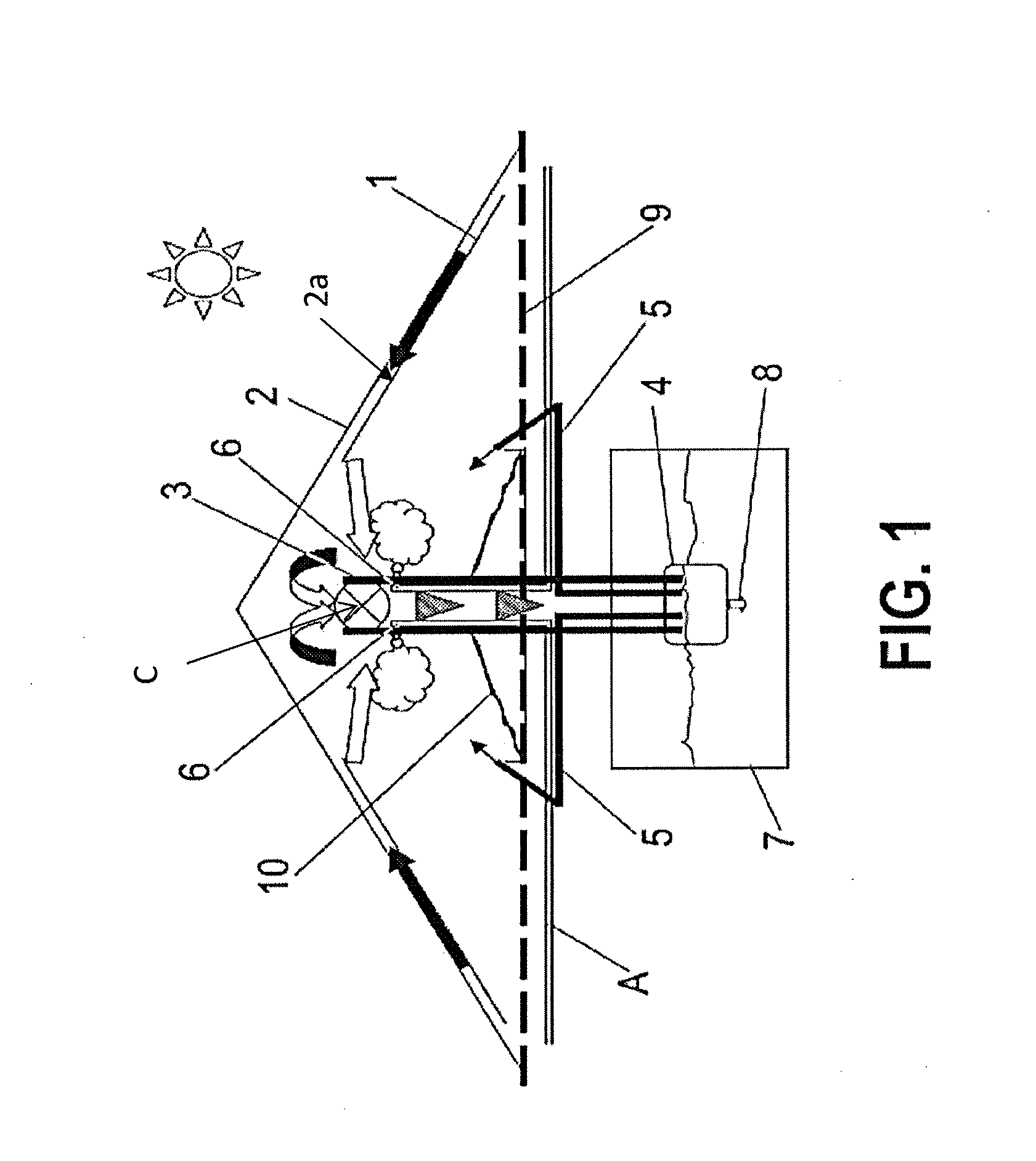

Seawater, brine or sewage solar desalination plant, and desalination method

InactiveUS20140054159A1Comfortable environmentReduce energy consumptionAuxillariesGeneral water supply conservationSaline waterDistillation

A tent or covering with a pyramid-shaped structure, with an inner dark-coloured sheet and an outer transparent sheet, installed on a supporting base anchored to the ground or on floats on the surface of the sea, wherein in the apex of the pyramid there are included vaporizers with micronebulisers for nebulising the water to be treated, a device for capturing humid air through a continuous or sectioned condensation column and for subsoil distillation and heat dissipation in the smaller, water-collecting tank and recirculation of the air devoid of humidity into the enclosure. In addition, it includes a computerised control system of the processes includes controls of the air and nebulised water flow rates and of the working regime of the facility.

Owner:UNIV POLITECNICA DE CATALUNYA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com