Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Absorption of heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

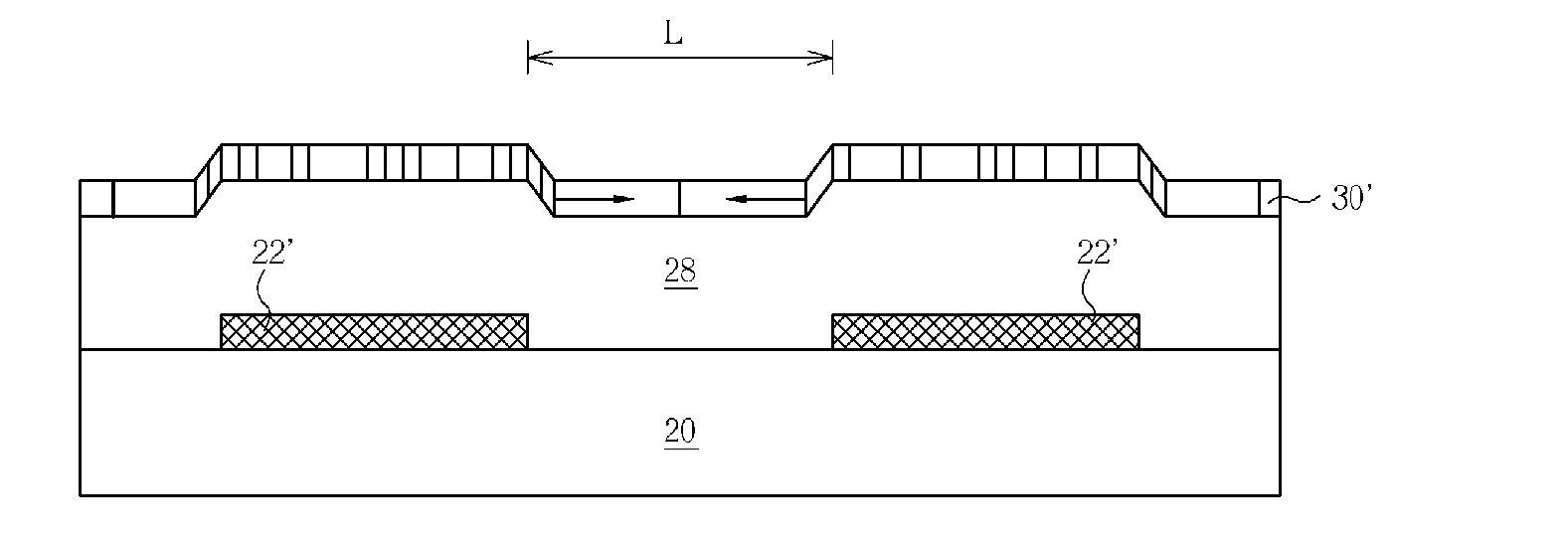

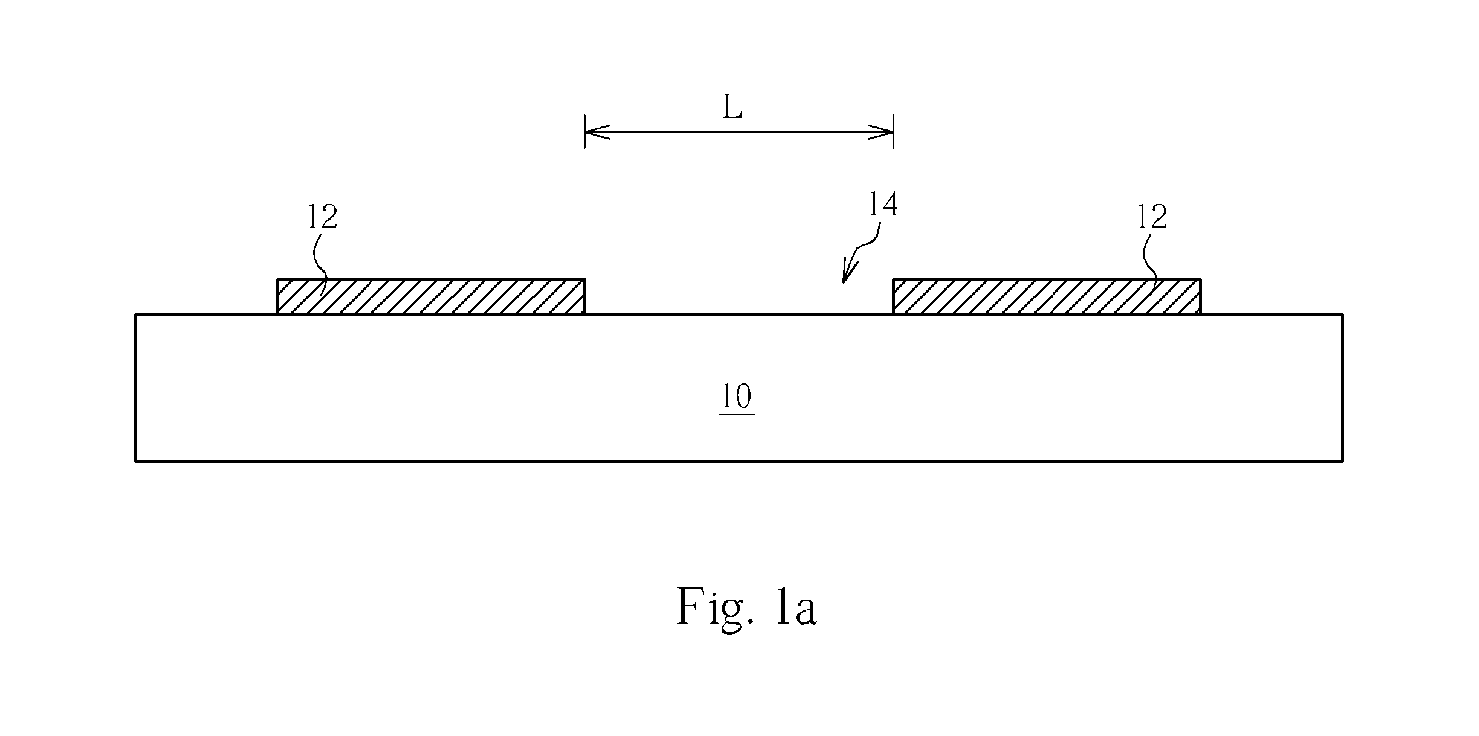

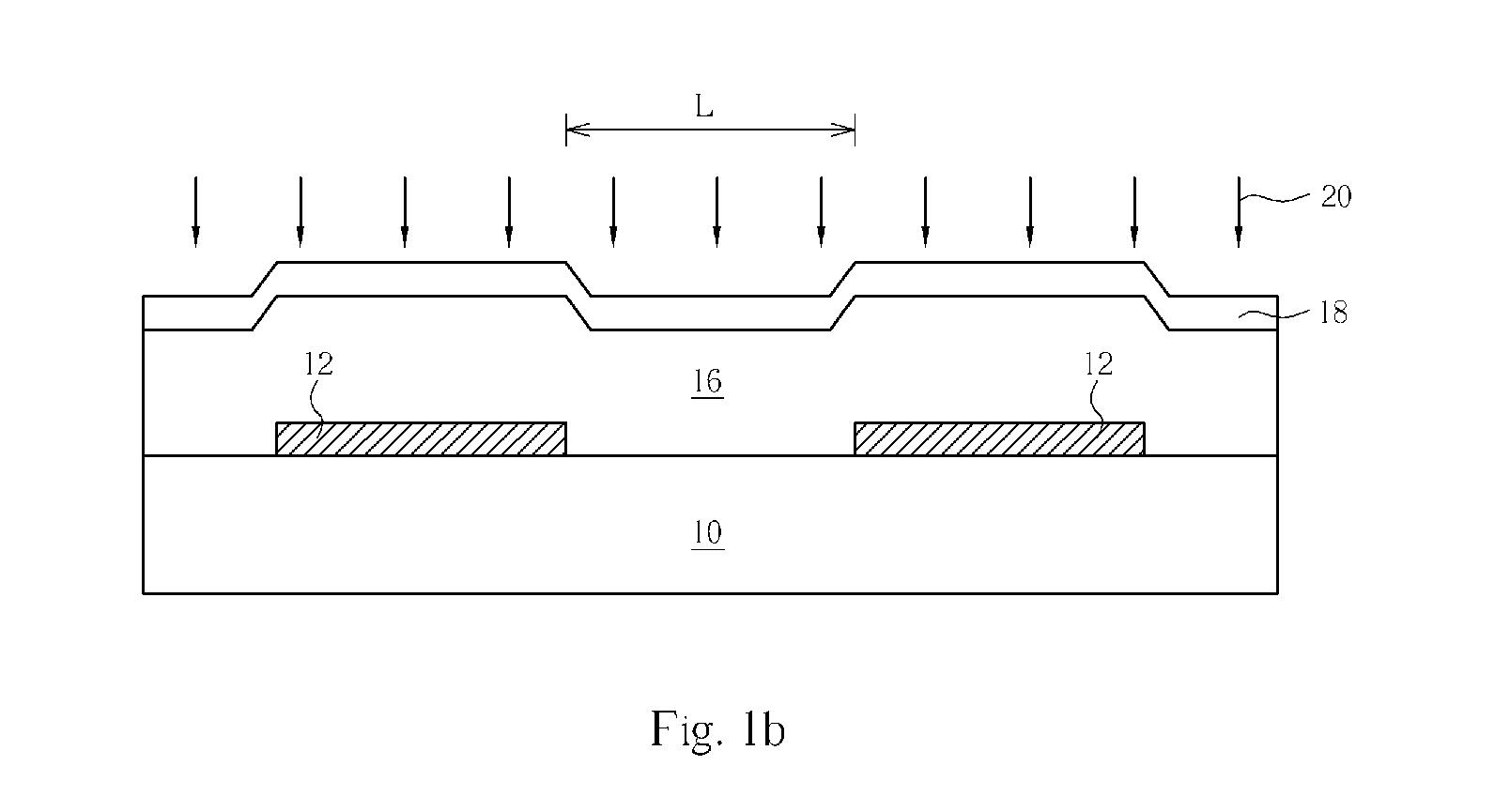

Semiconductor device and method of fabricating a low temperature poly-silicon layer

InactiveUS20060043367A1Promotes lateral growthHighly practicalTransistorSemiconductor/solid-state device detailsDevice materialAmorphous silicon

A method of fabricating a low temperature poly-silicon (LTPS). A plurality of semiconductor heat sinks are formed over a substrate. A buffer layer and an amorphous silicon layer are formed over the substrate and the semiconductor heat sinks. Following that, a laser crystallization process is performed to transform the amorphous silicon layer into a poly-silicon layer.

Owner:AU OPTRONICS CORP

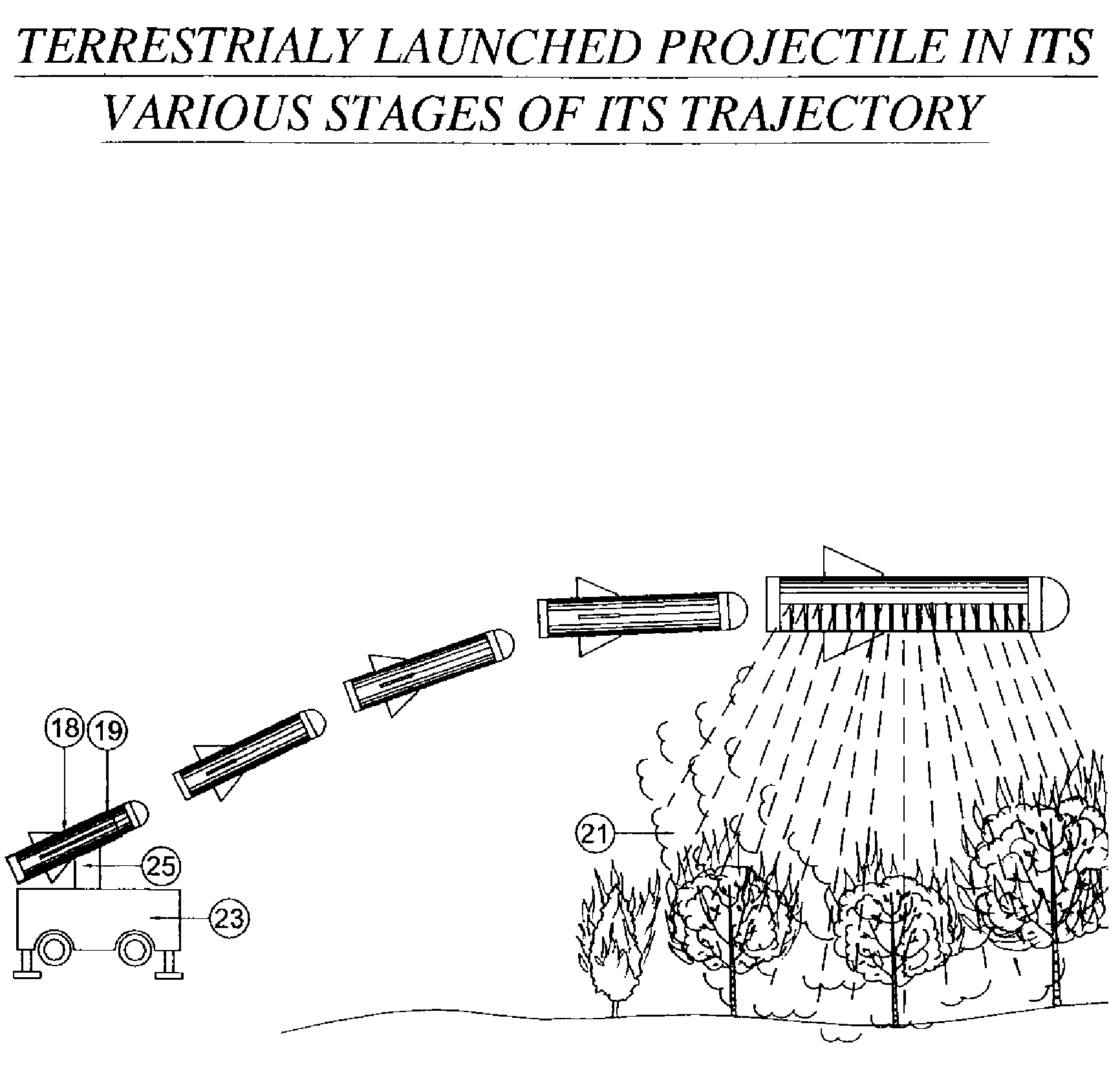

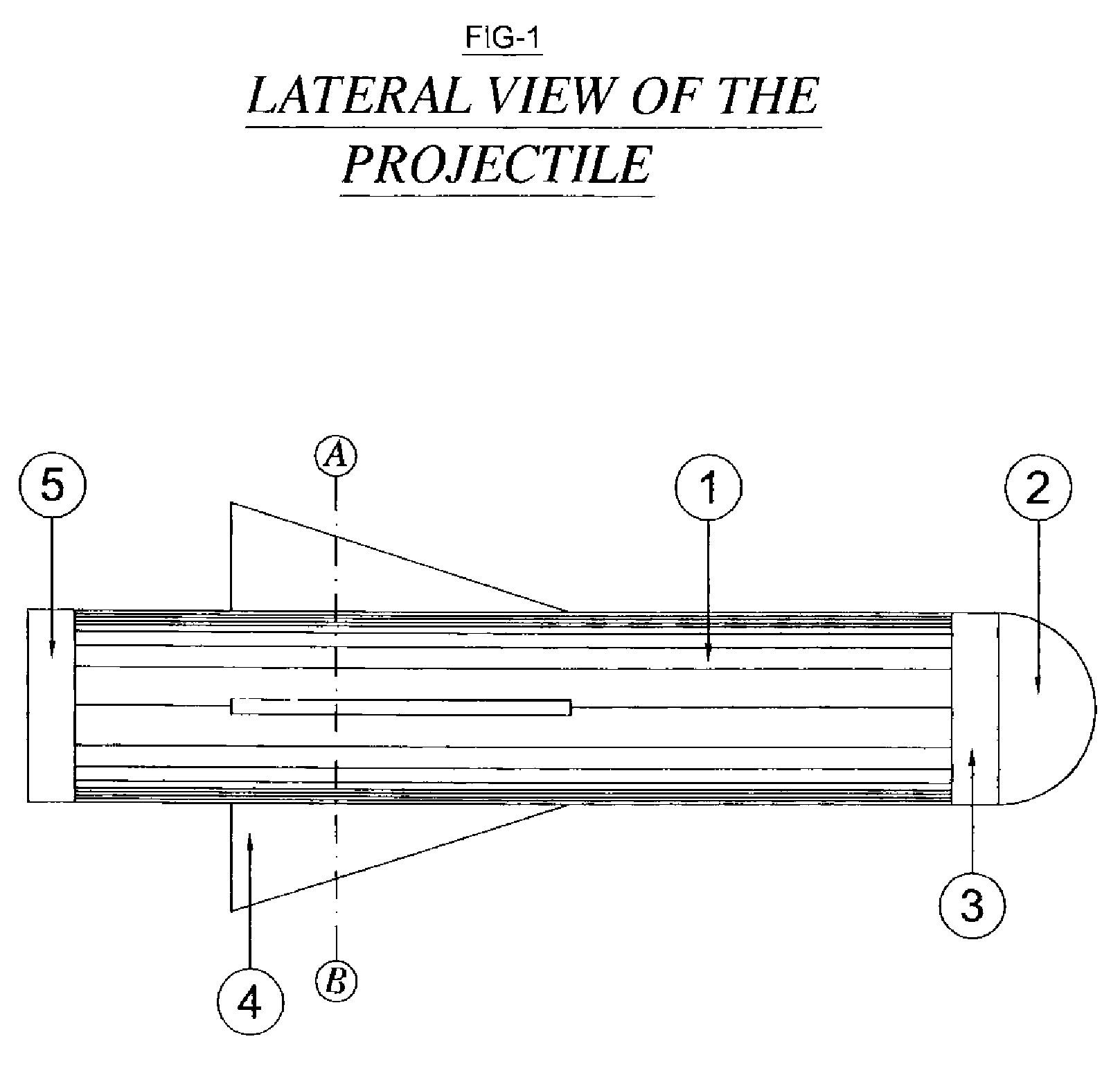

Fire extinguishing by explosive pulverisation of projectile based frozen gases and compacted solid extinguishing agents

InactiveUS7478680B2Enhance state artRate of successful fire intervention, containment and effective extinguishing is veryAmmunition projectilesFire rescueTerrainEngineering

Owner:SRIDHARAN VINAYAGAMURTHY +1

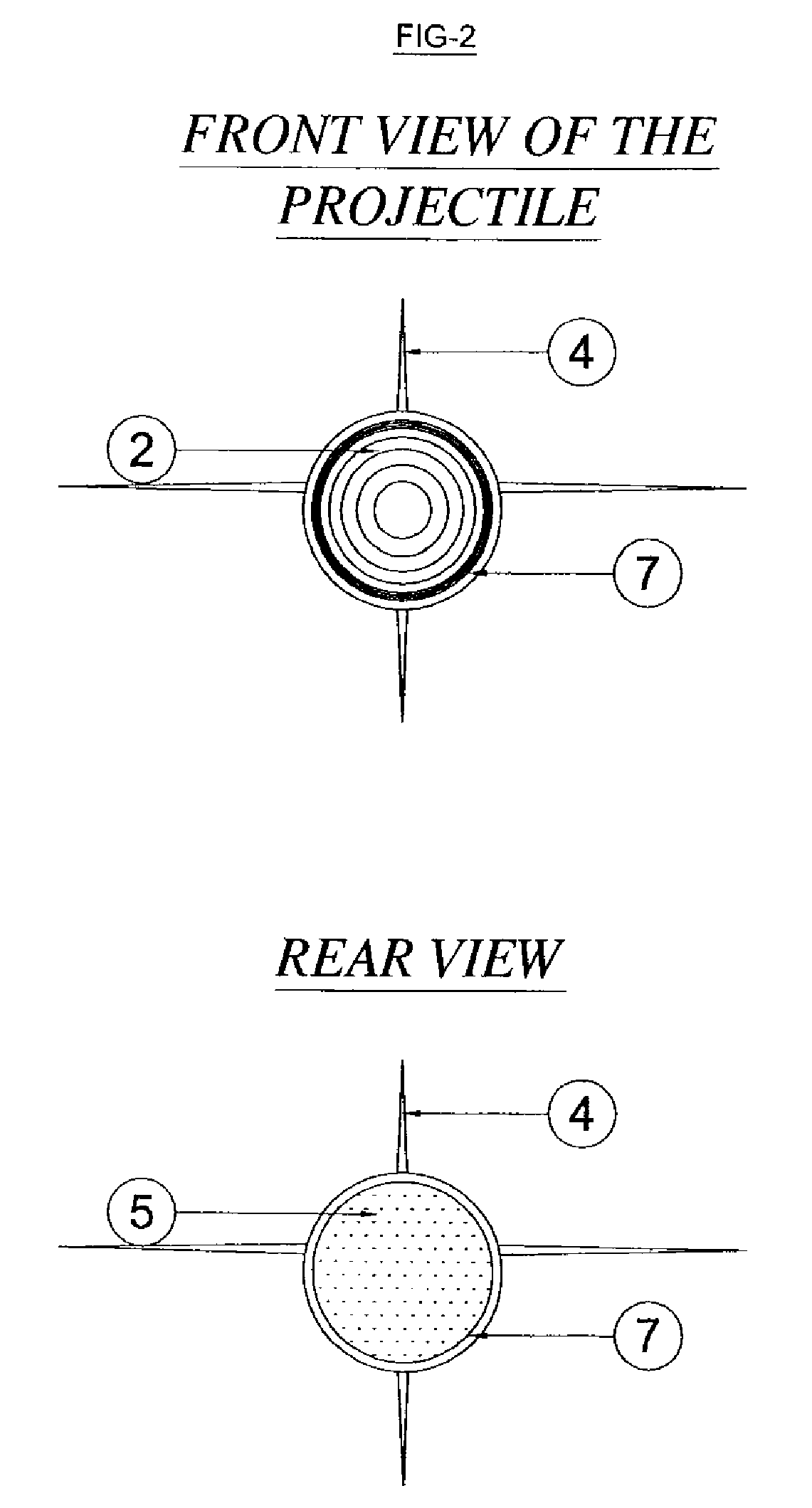

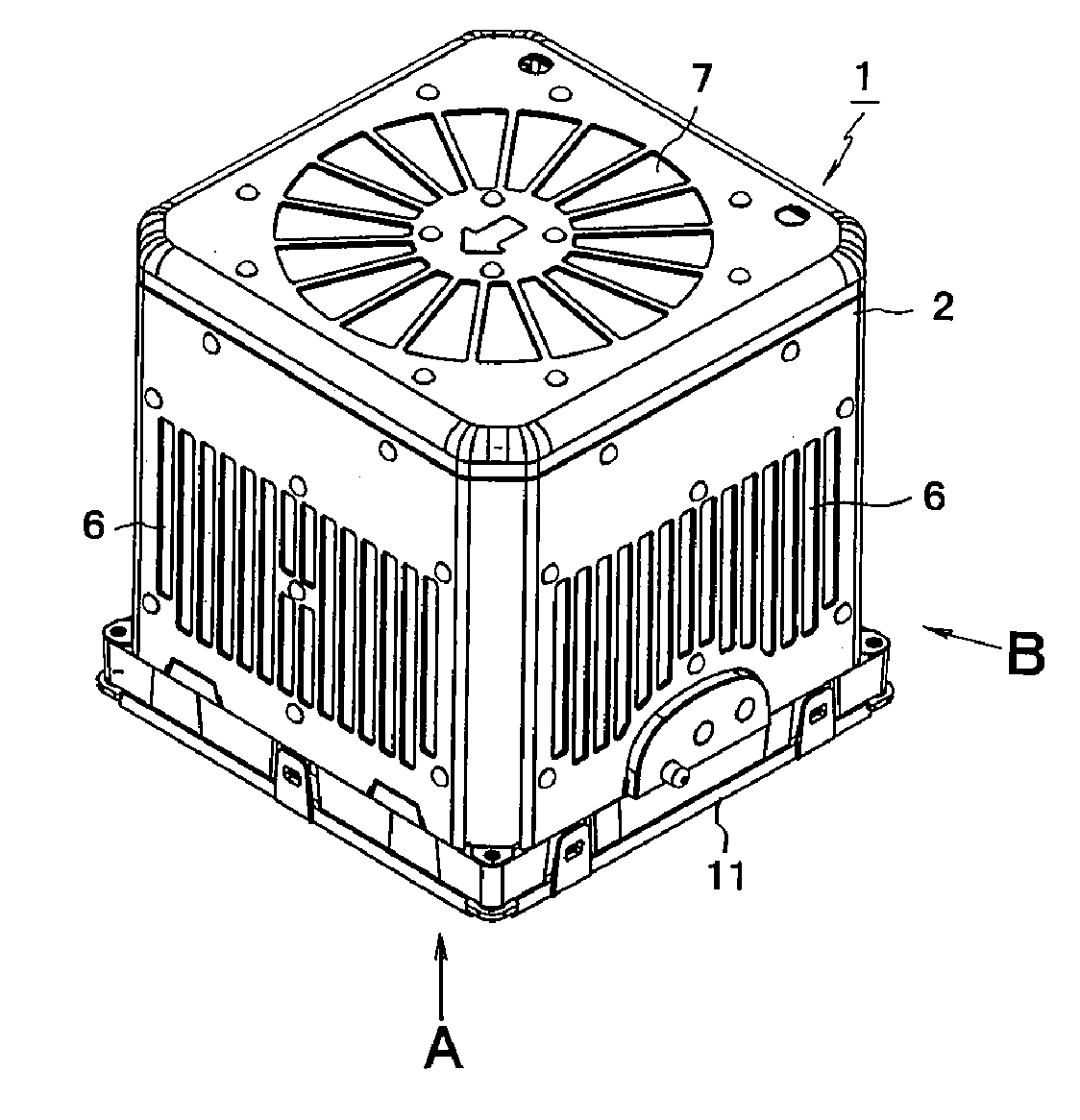

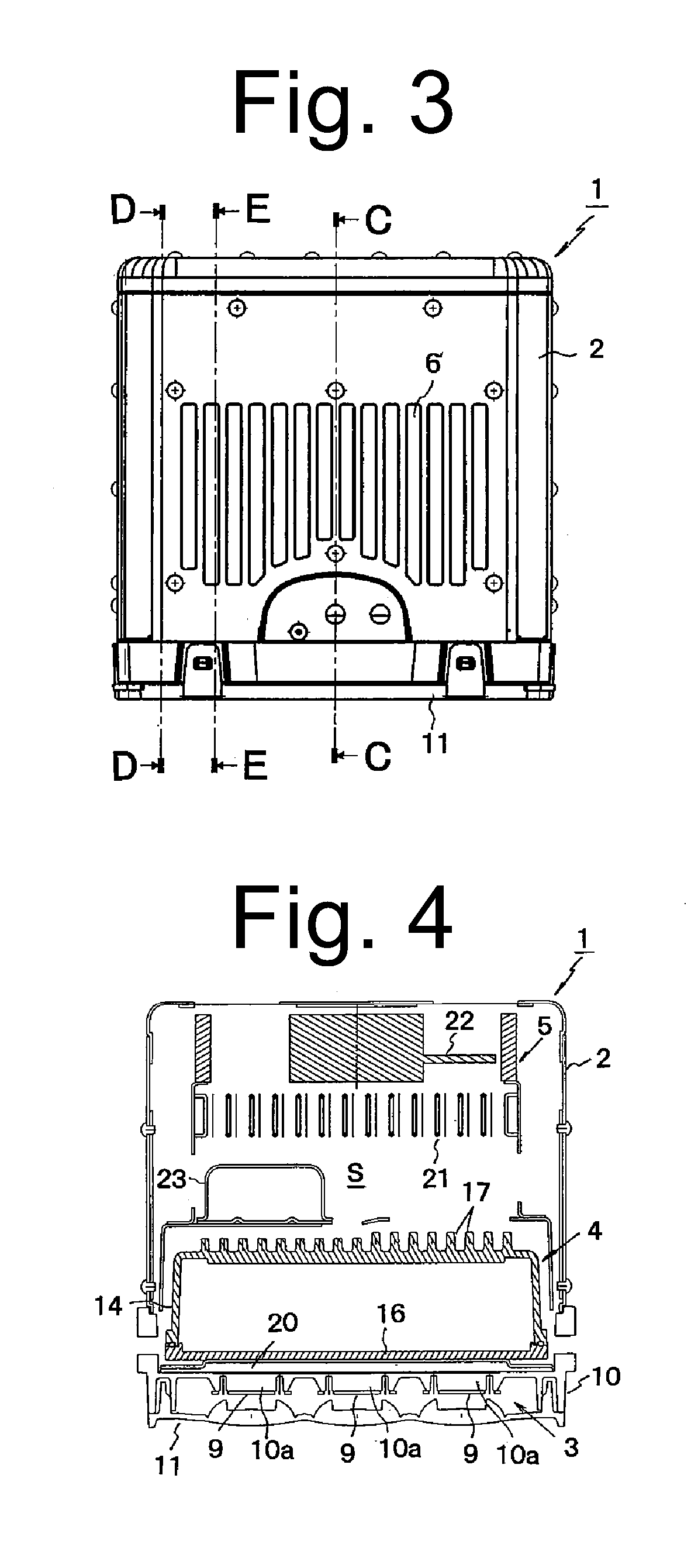

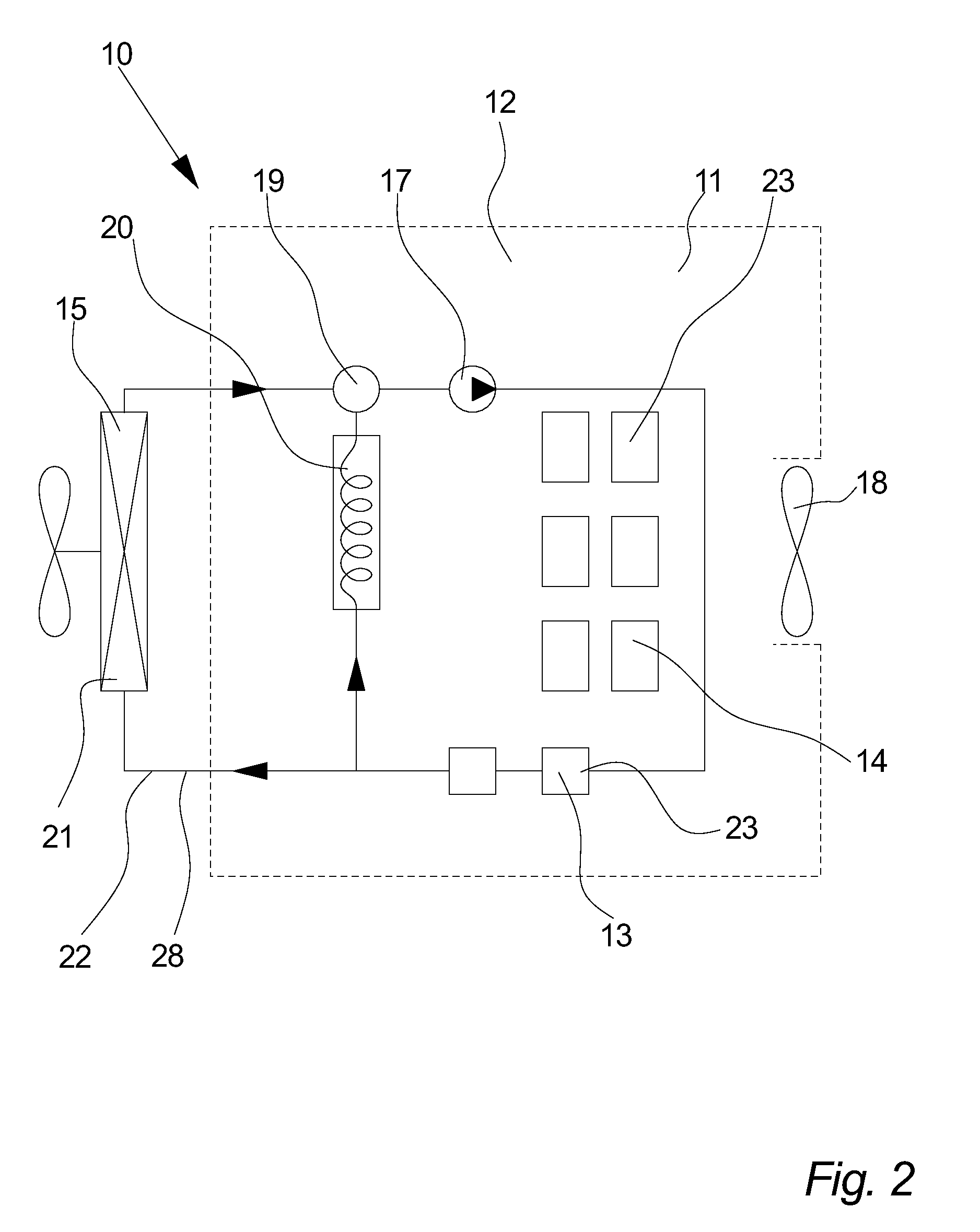

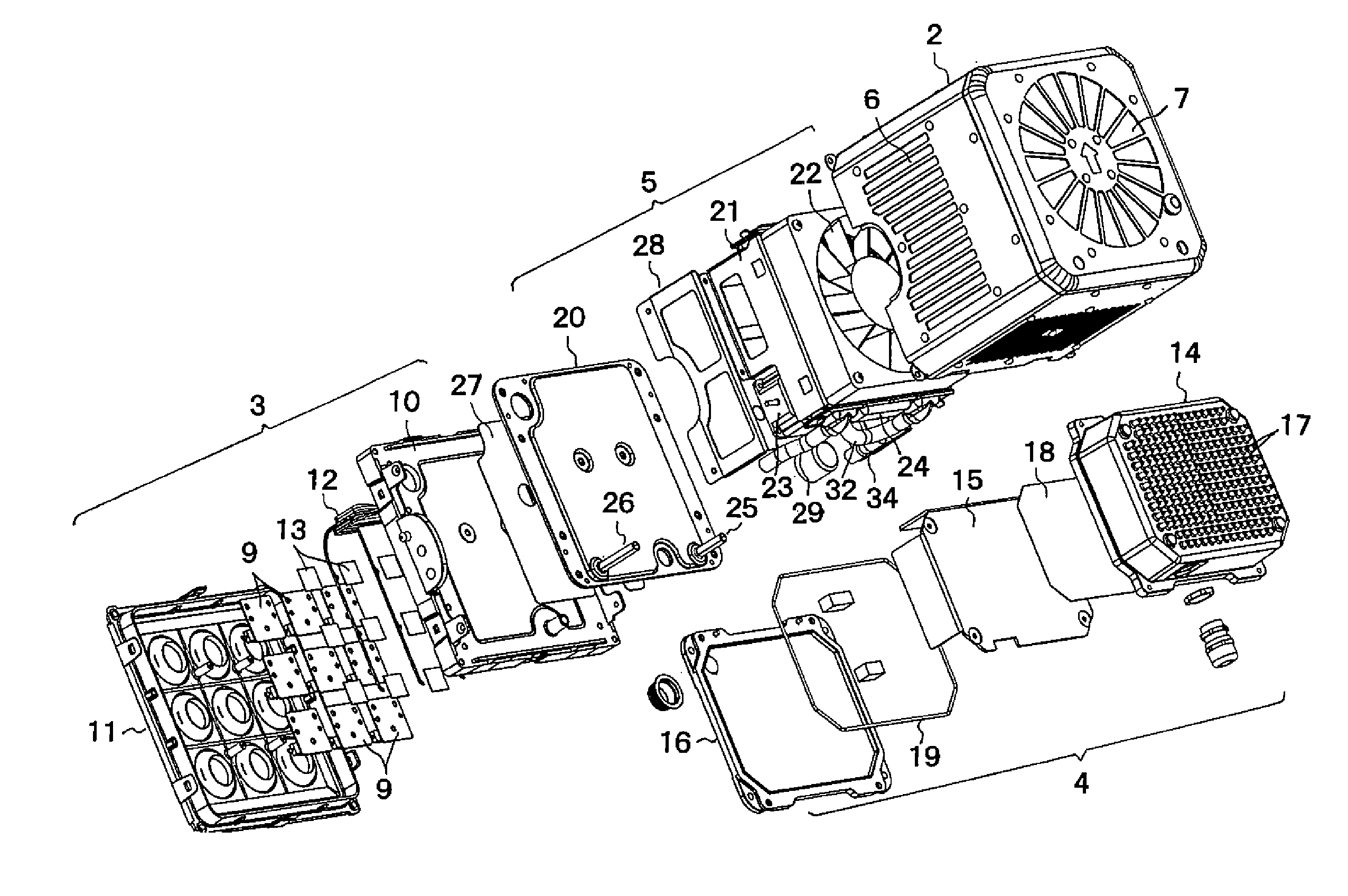

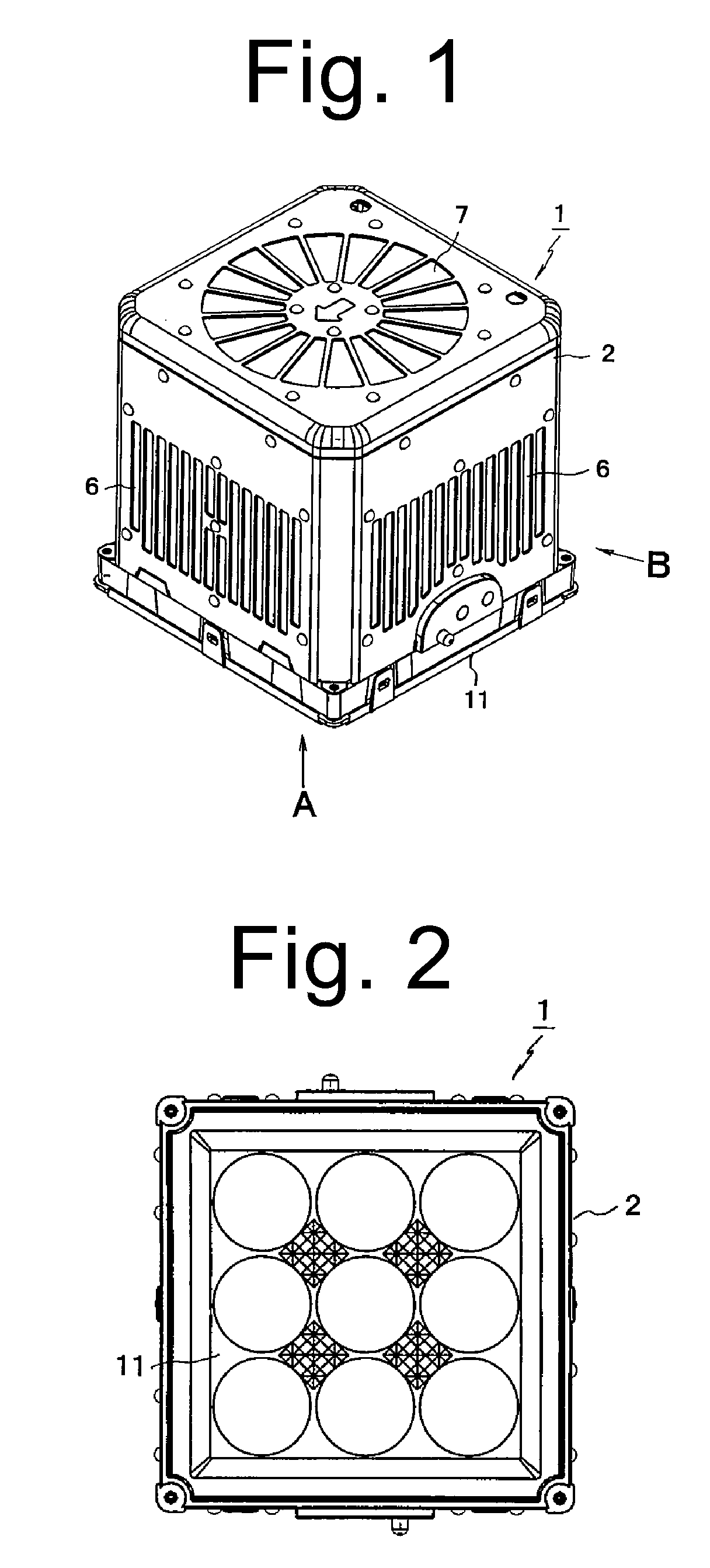

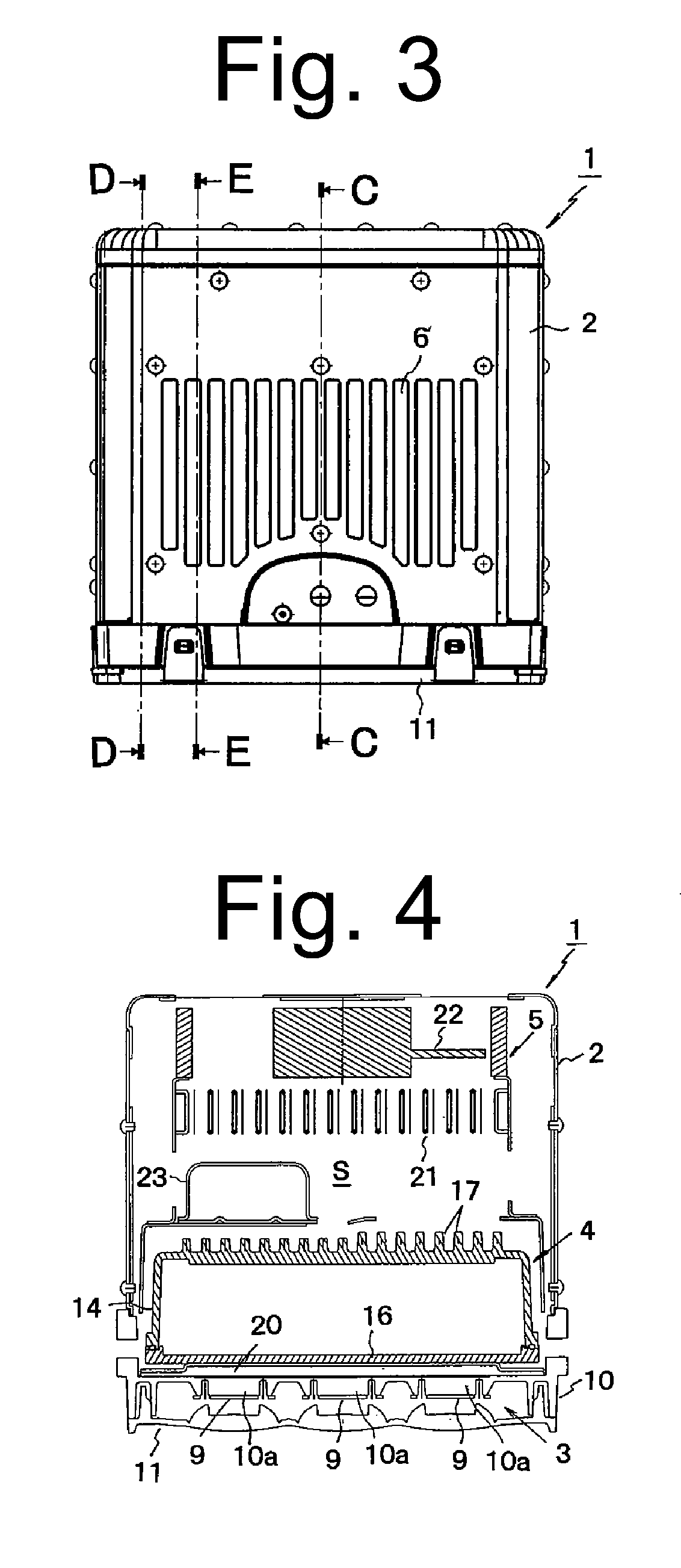

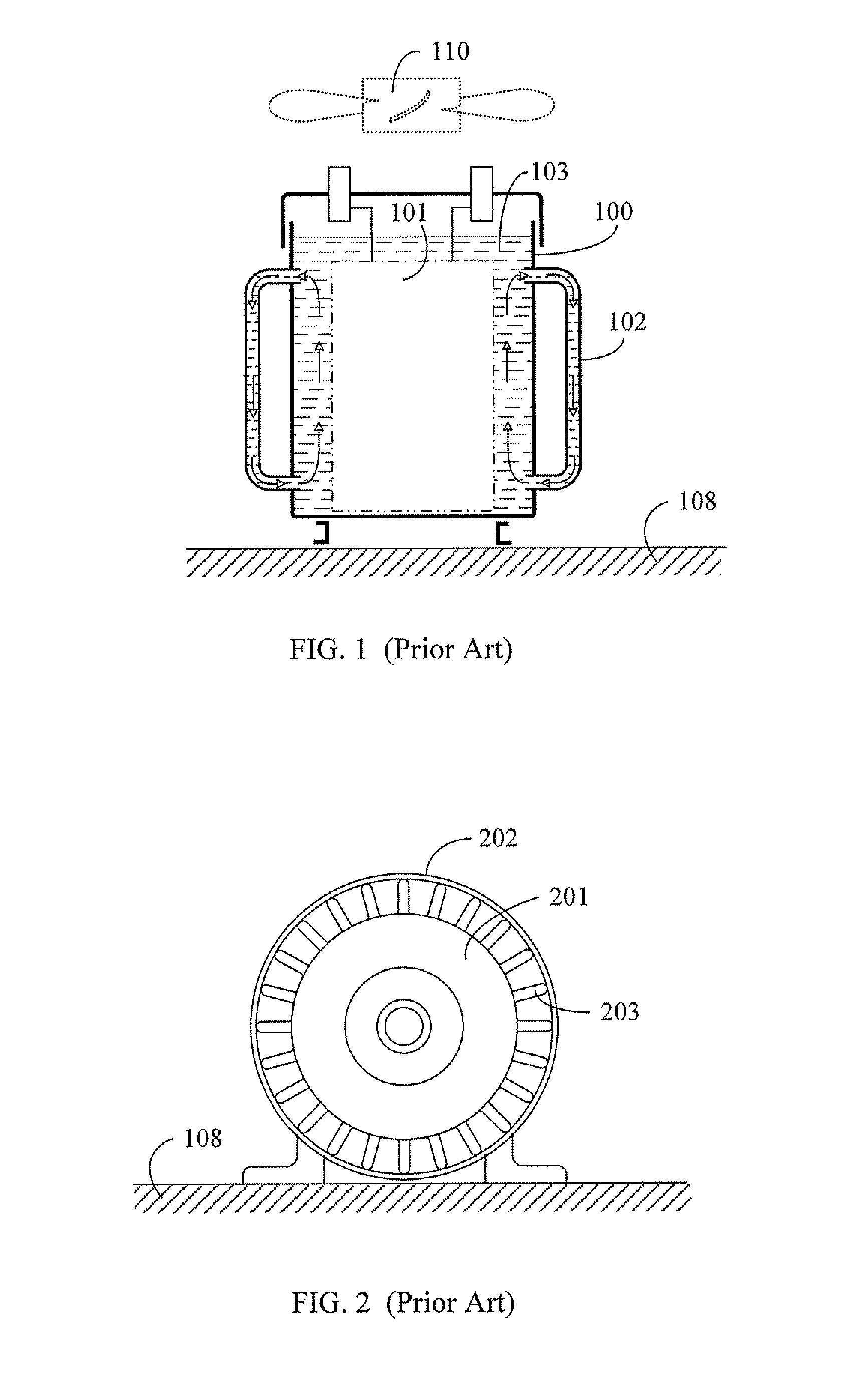

Liquid-cooled LED lighting device

ActiveUS20100264826A1Improve cooling effectEasy to limitLighting support devicesPoint-like light sourceEffect lightLiquid cooling system

A cooling liquid can be circulated in a liquid cooling system, so that a light source unit and a control unit can be forcedly cooled by the cooling liquid. Thus, a temperature increase in these components can be suppressed, thereby achieving an increase in the output power of a liquid-cooled LED lighting device. The liquid-cooled LED lighting device can include a housing, a light source unit having LEDs as light sources, a liquid cooling system, and a control unit to control the light source unit to be turned on. The liquid cooling system can include a heat receiving jacket, a radiator, a circulation pump and a fan. The light source unit and the control unit can be disposed with the heat receiving jacket of the liquid cooling system interposed therebetween. Further, one surface of the control unit can be brought in close contact with the heat receiving jacket while a heat radiation portion (e.g., fins or pins) can be provided at an other surface of the control unit.

Owner:STANLEY ELECTRIC CO LTD

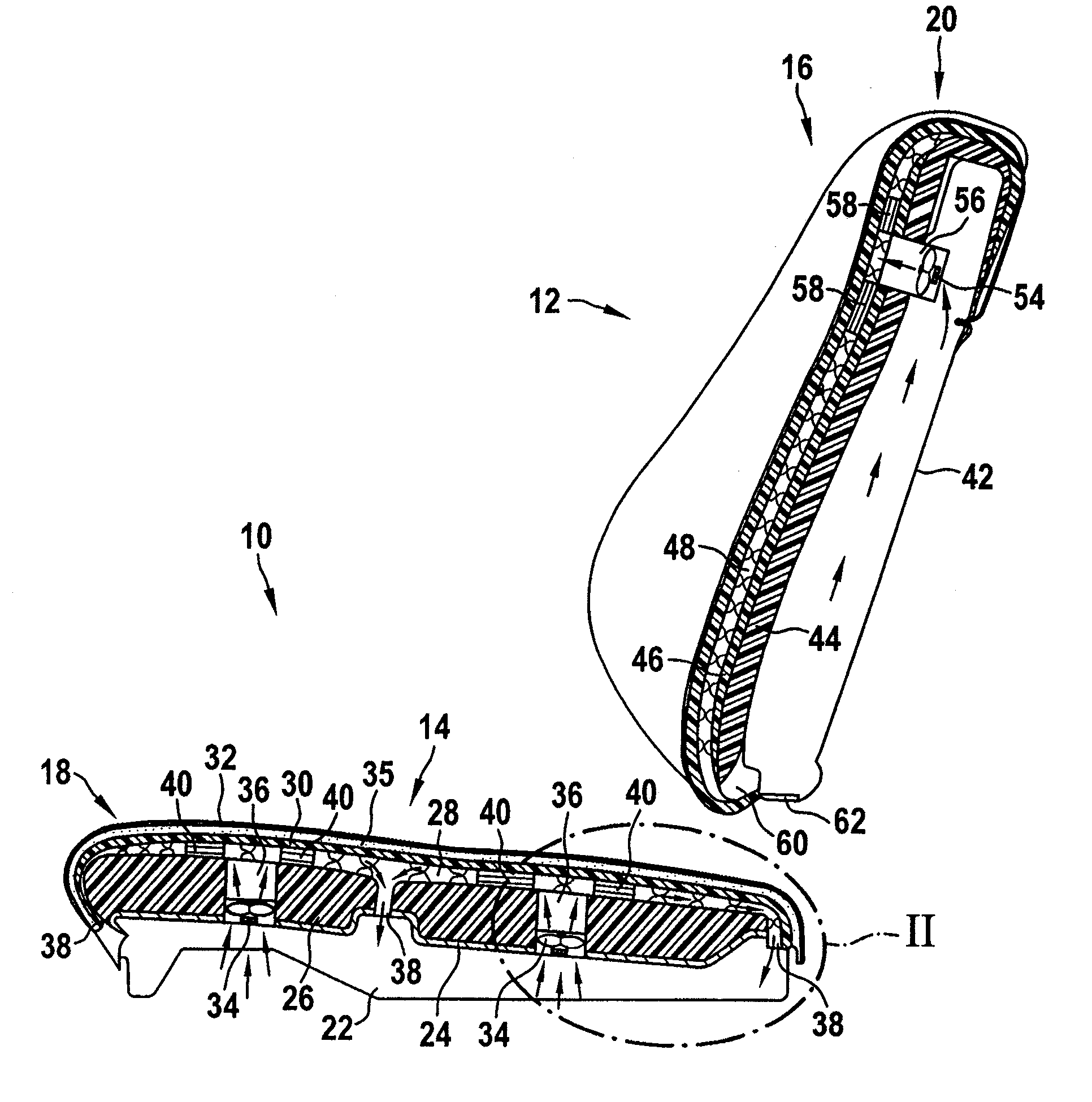

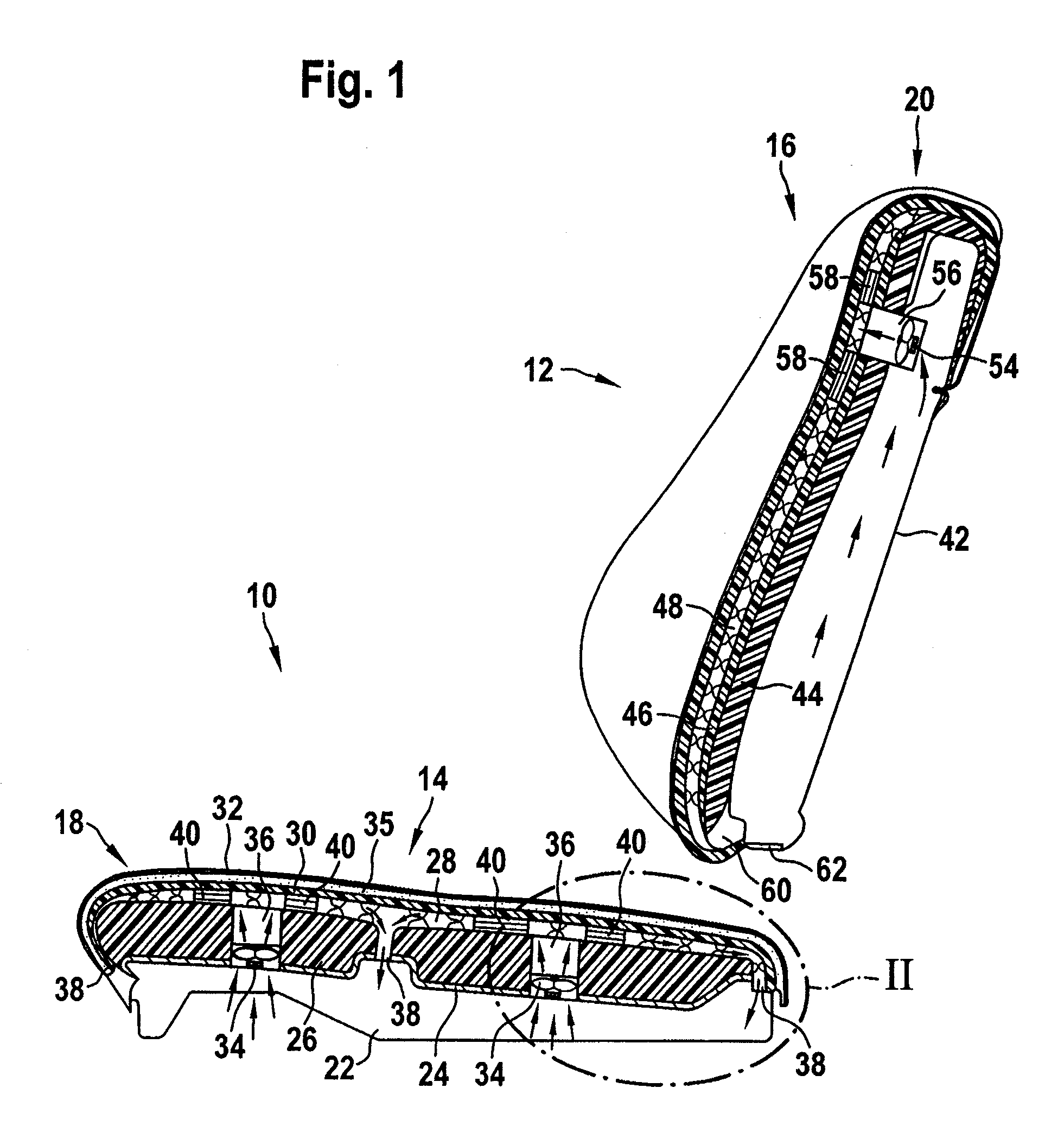

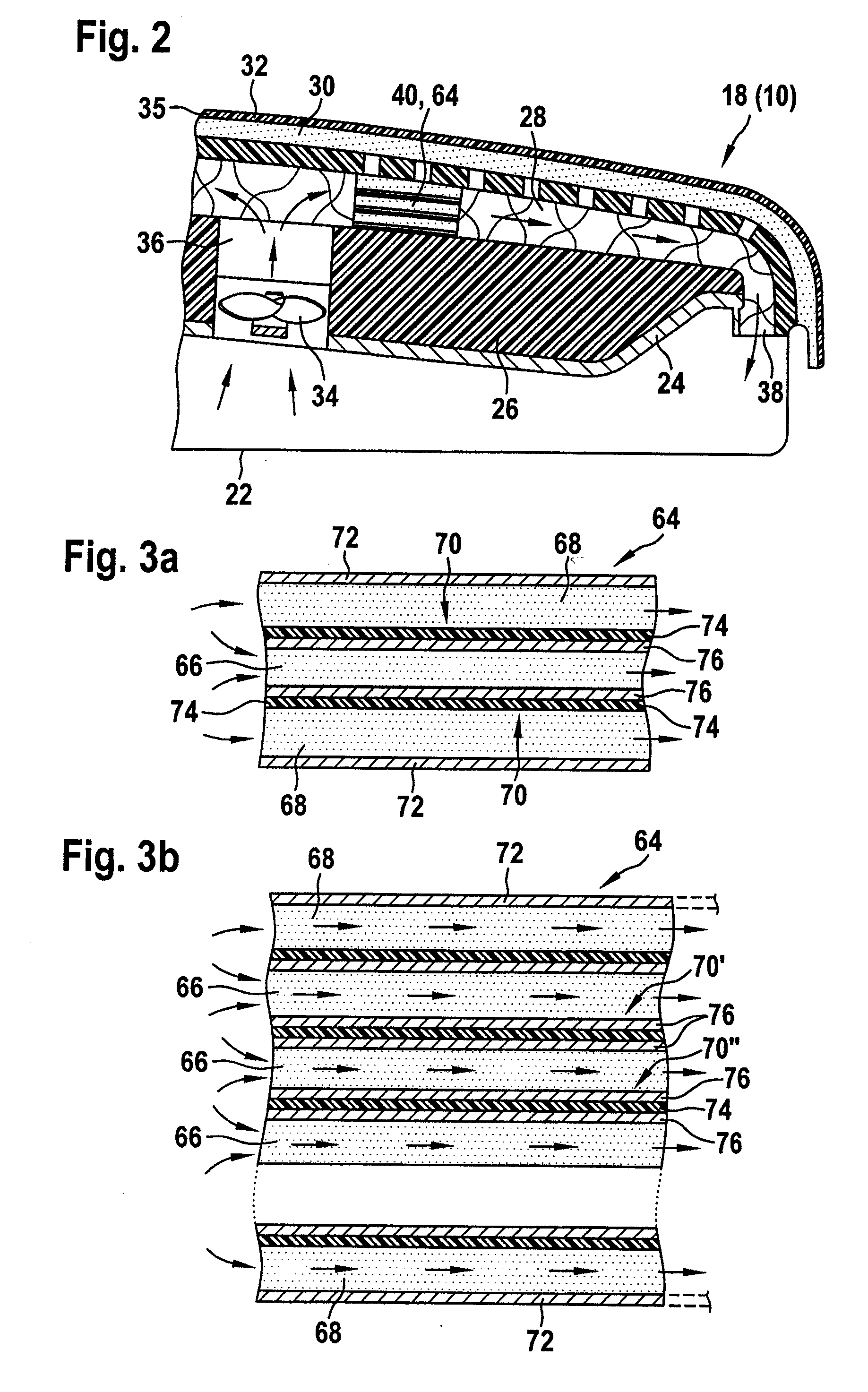

Motor Vehicle Seat Provided With a Ventilation Device

InactiveUS20090134675A1EffectiveDissipating heatAir-treating devicesSeat heating/ventillating devicesMobile vehicleCold air

The backrest and / or seat cushion part of a motor vehicle seat include / includes padding with a ventilation device including a ventilation layer and a device for heating and / or cooling the air flowing through the ventilation layer. The padding can be heated and / or cooled by the ventilation device in an improved manner by a warm or cold air flow for heating the seat or ventilating the seat. The heating and / or cooling device forms a sandwich with at least one heating and / or cooling layer and at least one air-permeable layer. The air-permeable layer has a structure by which the air flow can be converted into a turbulent and / or diffuse flow.

Owner:DAIMLER AG

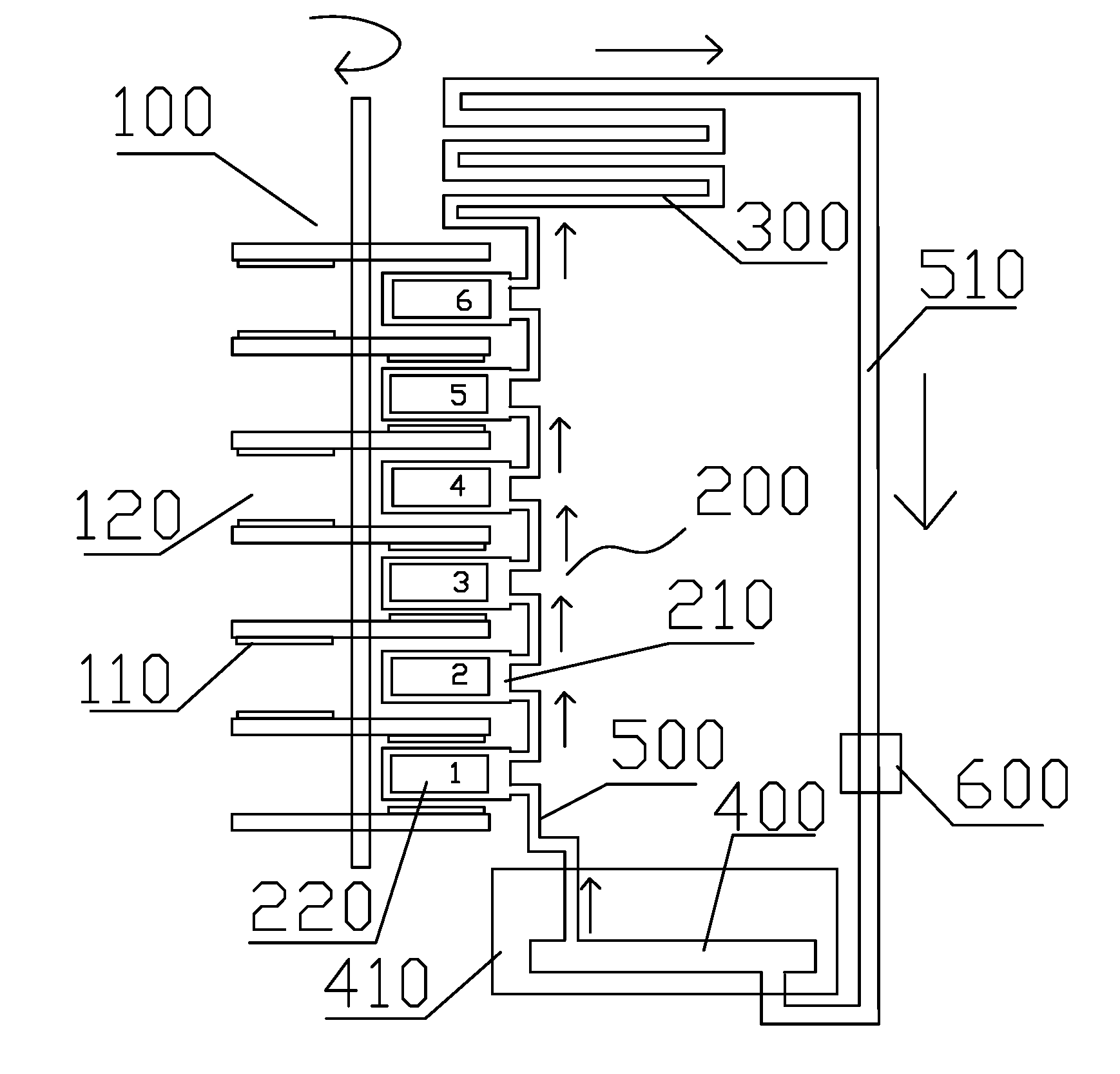

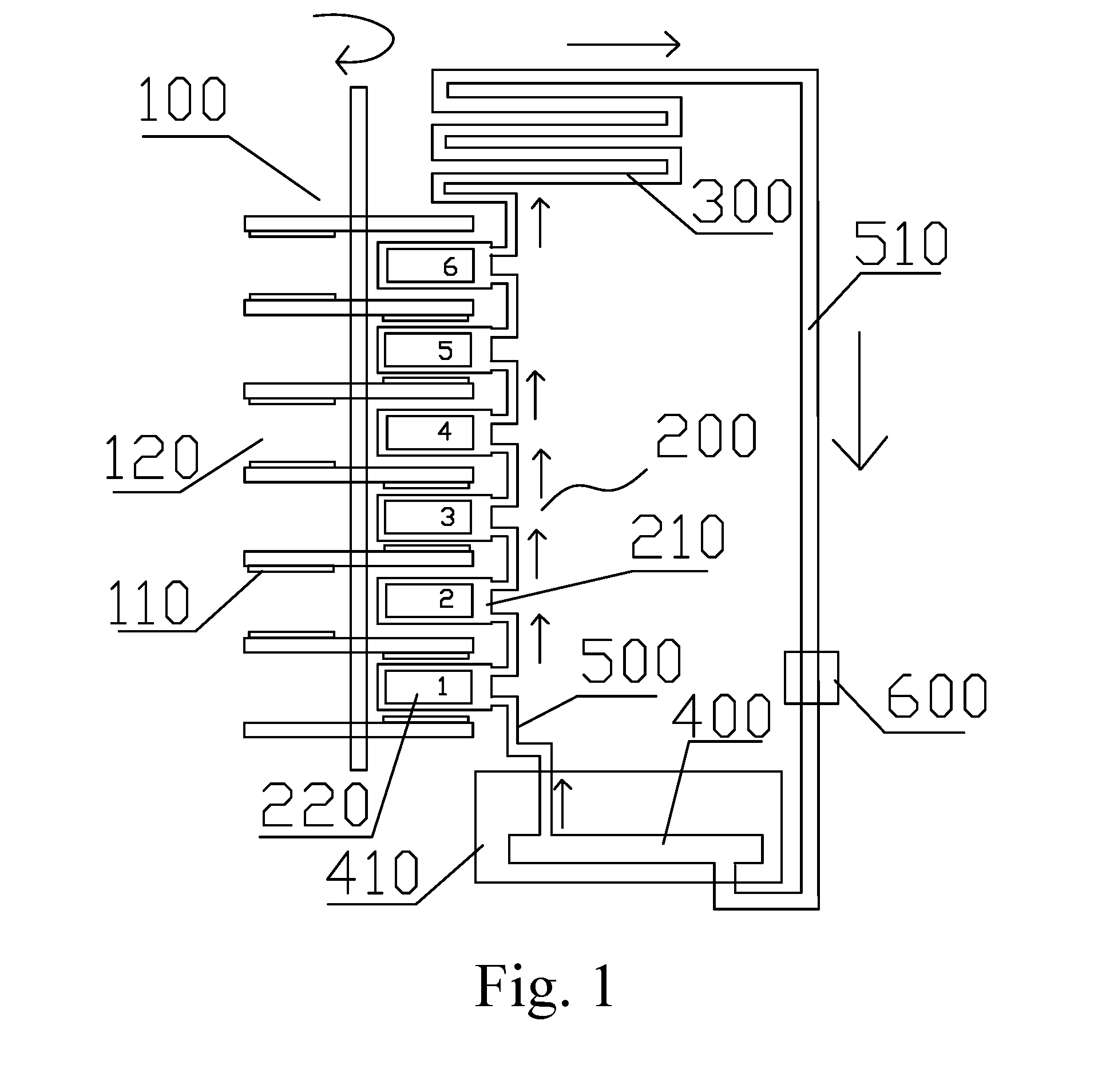

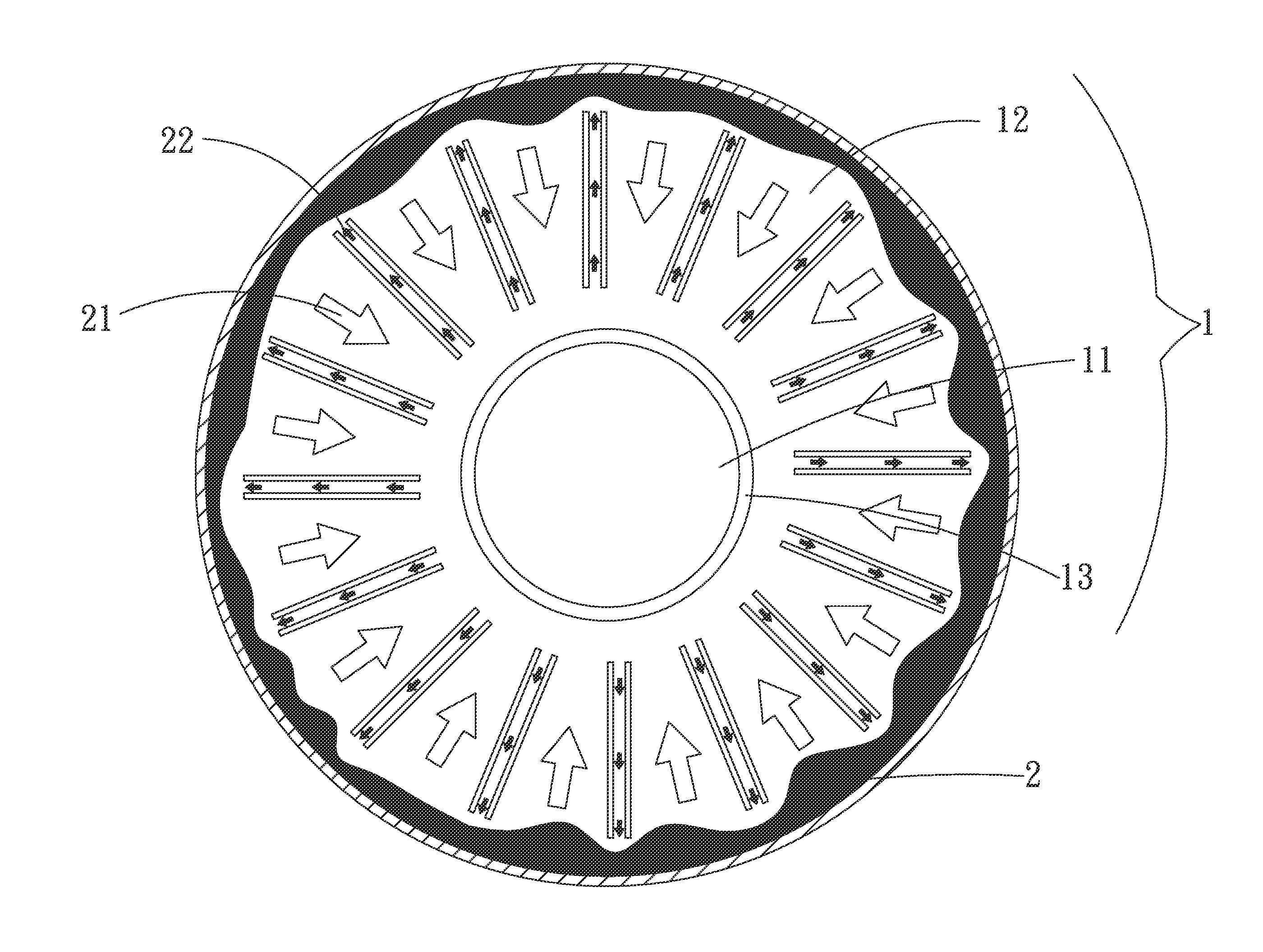

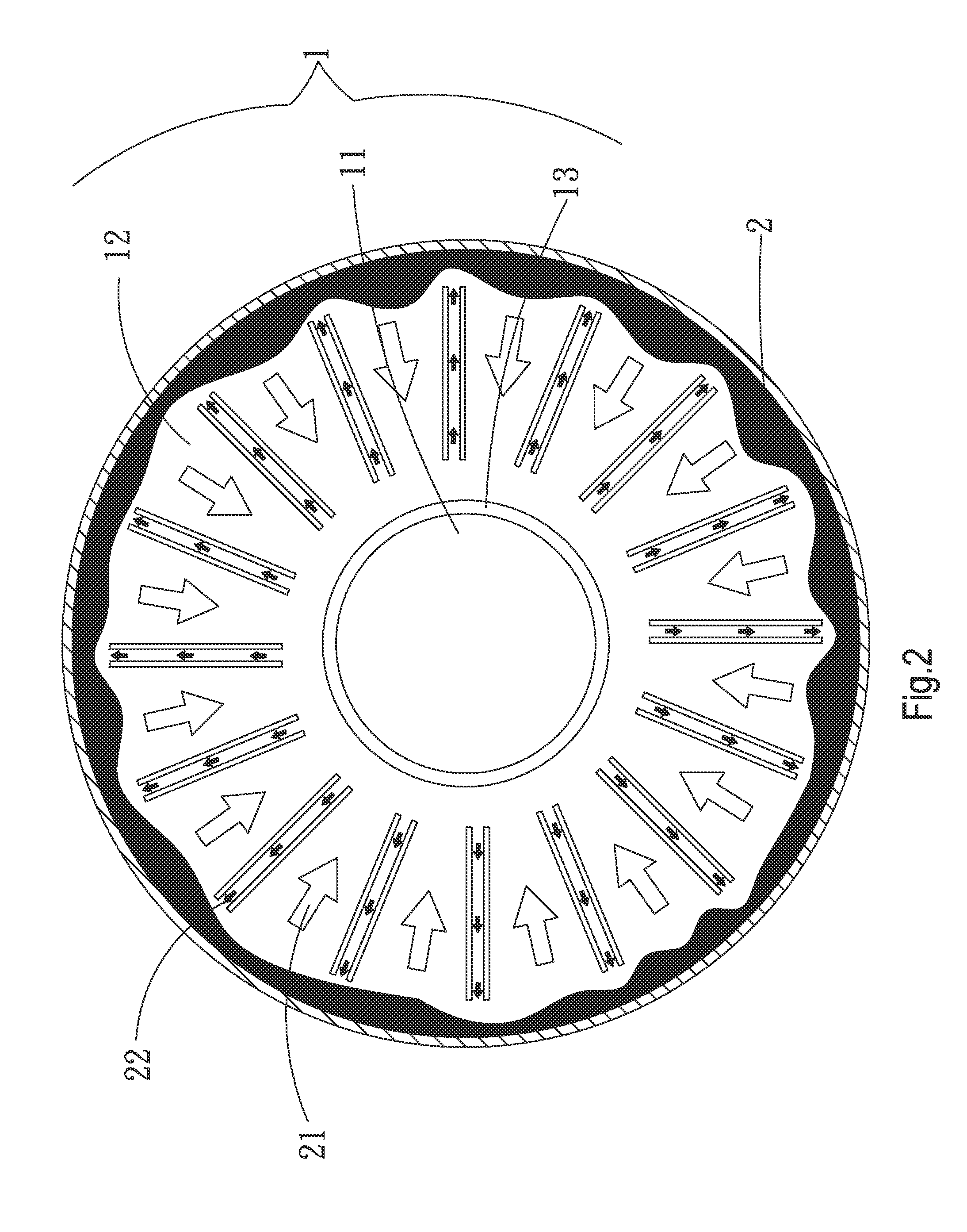

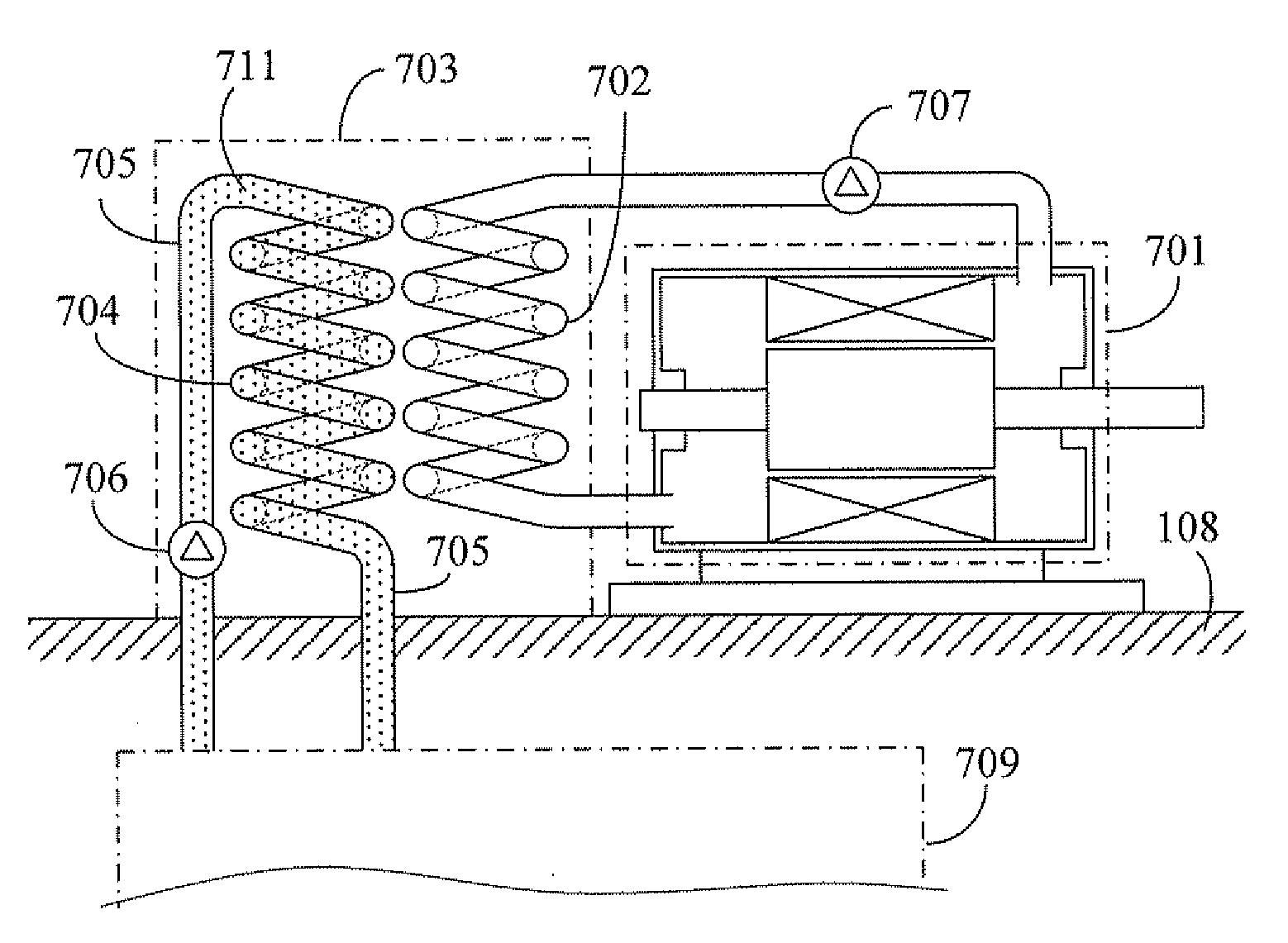

A rotatory series-pole magnetic refrigerating system

ActiveUS20160282021A1Heat dissipationAbsorption of heatMachines using electric/magnetic effectsSustainable buildingsHeat flowEngineering

The present invention relates to a rotatory series-pole magnetic refrigerating system, comprising a moving magnetic body and at least one vertically-disposed magnetic series, wherein the magnetic series further comprising a plurality of heat insulated cavities, wherein the heat insulated cavities are interconnected in series successively, wherein the interior of the heat insulated cavities are provided with magnetic working mediums, and wherein the moving magnetic body is capable of magnetizes and demagnetizes the magnetic working mediums in a crossing pattern, wherein the upper and lower magnetic working mediums which are adjacent to any magnetic working medium in demagnetizing state in the same magnetic series must be in a magnetizing state, wherein the system further comprising a heat-flow structure, which assists the internal heat energy in the magnetic series to flow in one direction.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

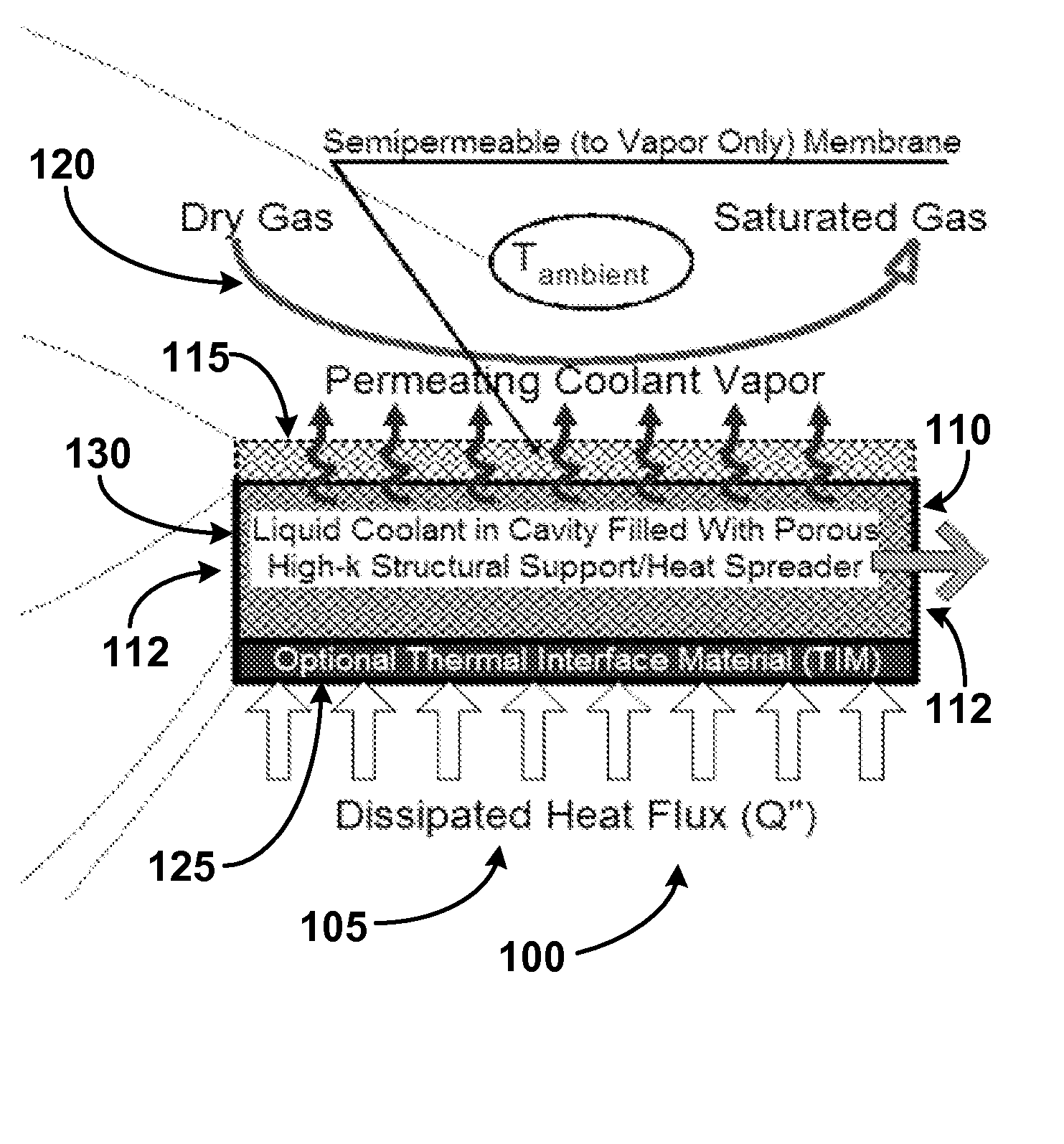

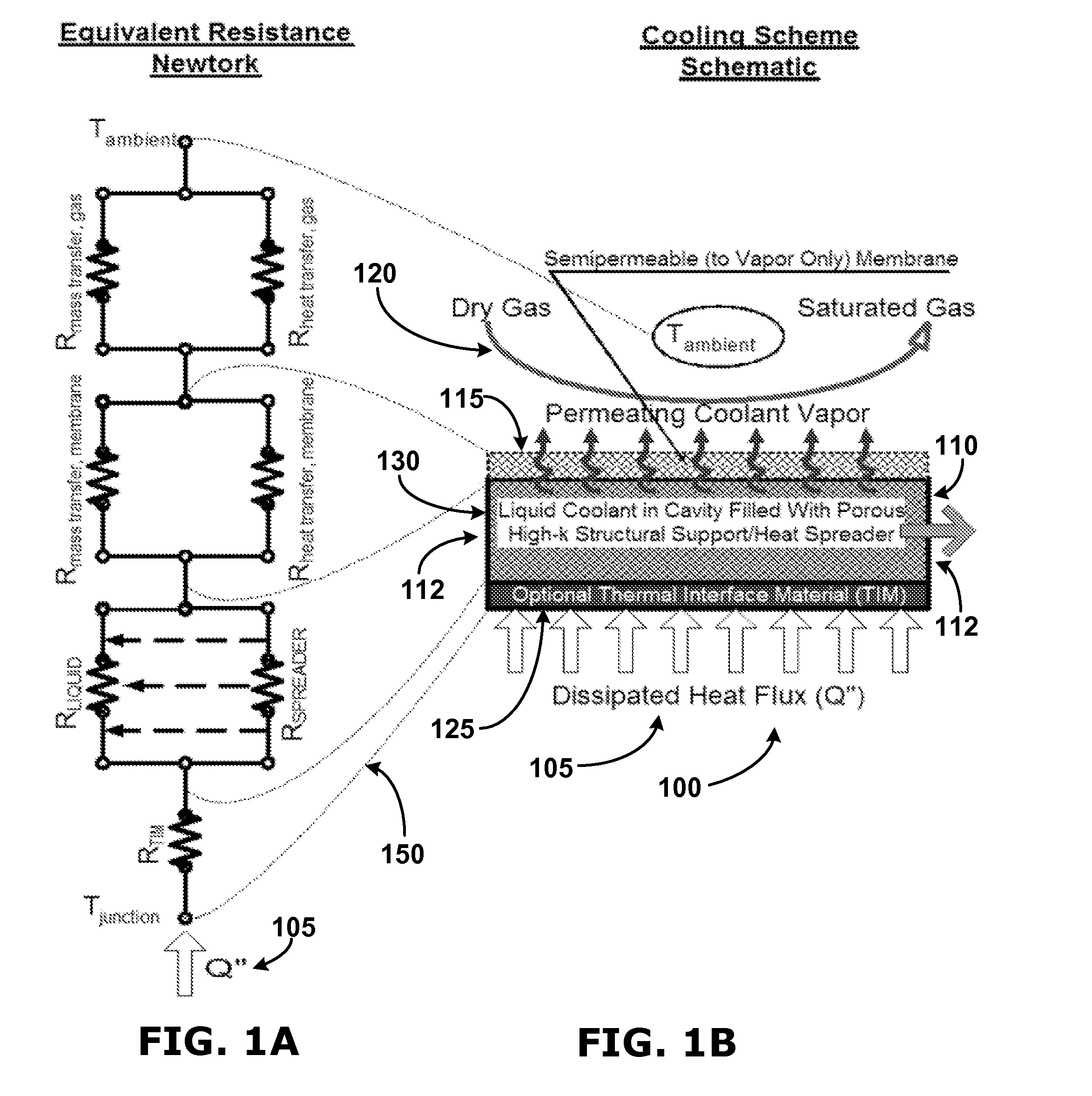

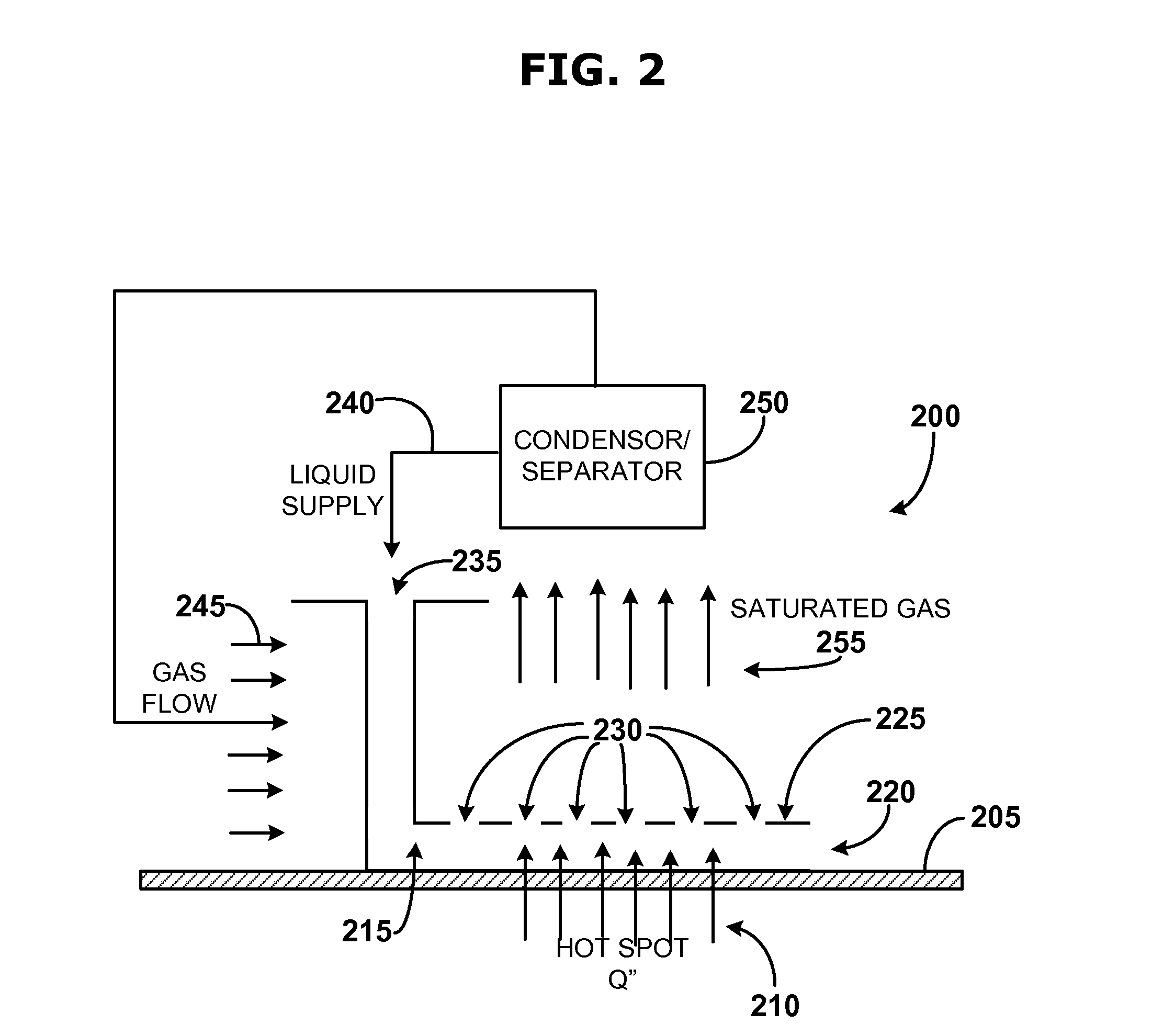

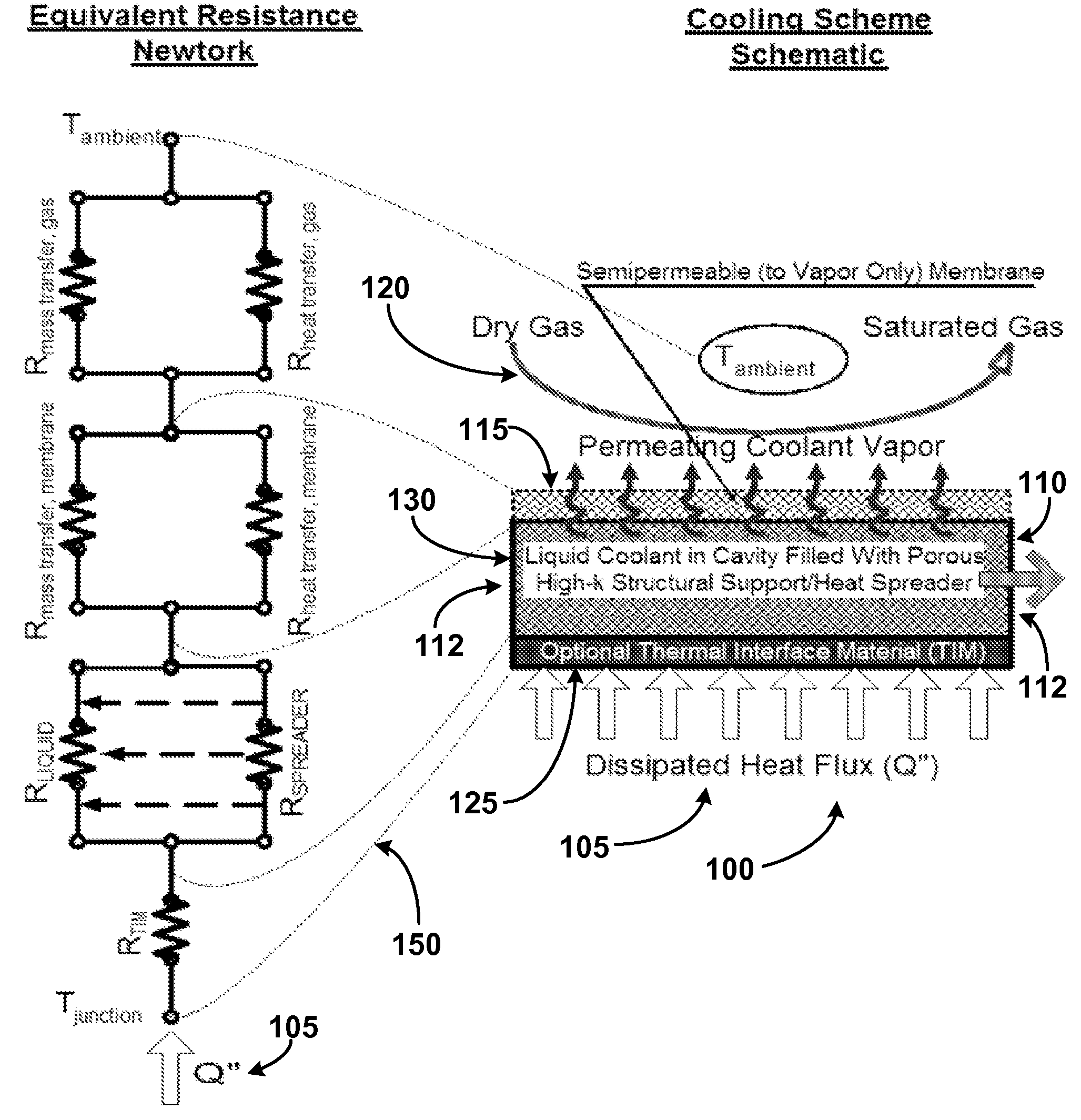

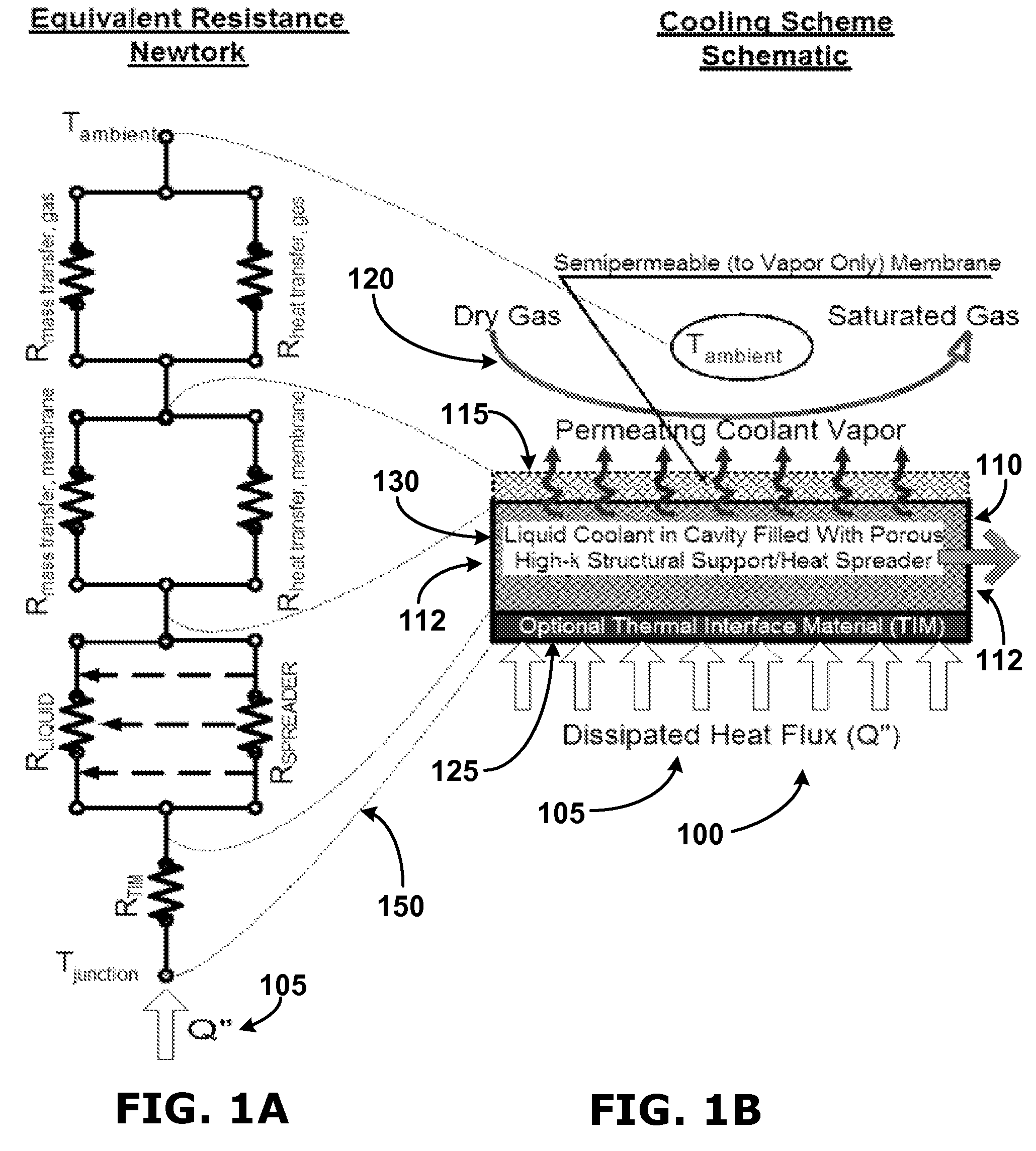

Nano-patch thermal management devices, methods, & systems

InactiveUS20080043440A1Reduce the temperatureAbsorption of heatSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

Nano-scale thermal management devices, methods, and systems are provided. According to some embodiments, a thermal management device configured to remove heat from a heated area can comprise an inlet port and a cavity. The cavity can be positioned intermediate a heat source and an opposing surface spaced apart from the heat source. The inlet port can receive a liquid (such as a coolant or cooling fluid) and direct the liquid to the cavity. The cavity can be configured to control the thickness of the liquid within the cavity. Liquid within the cavity can be heated by the heat source, and the opposing surface can comprise openings to allow evaporated liquid to exit the openings. A gas flow proximate the opposing surface can be used to carry vapor and be used to enhance liquid evaporation. Movement of the evaporated liquid enables heat from the heat source to be removed. The opposing surface can be a perforated membrane having micro-sized and nano-sized perforations. Other embodiments are also claimed and described.

Owner:GEORGIA TECH RES CORP

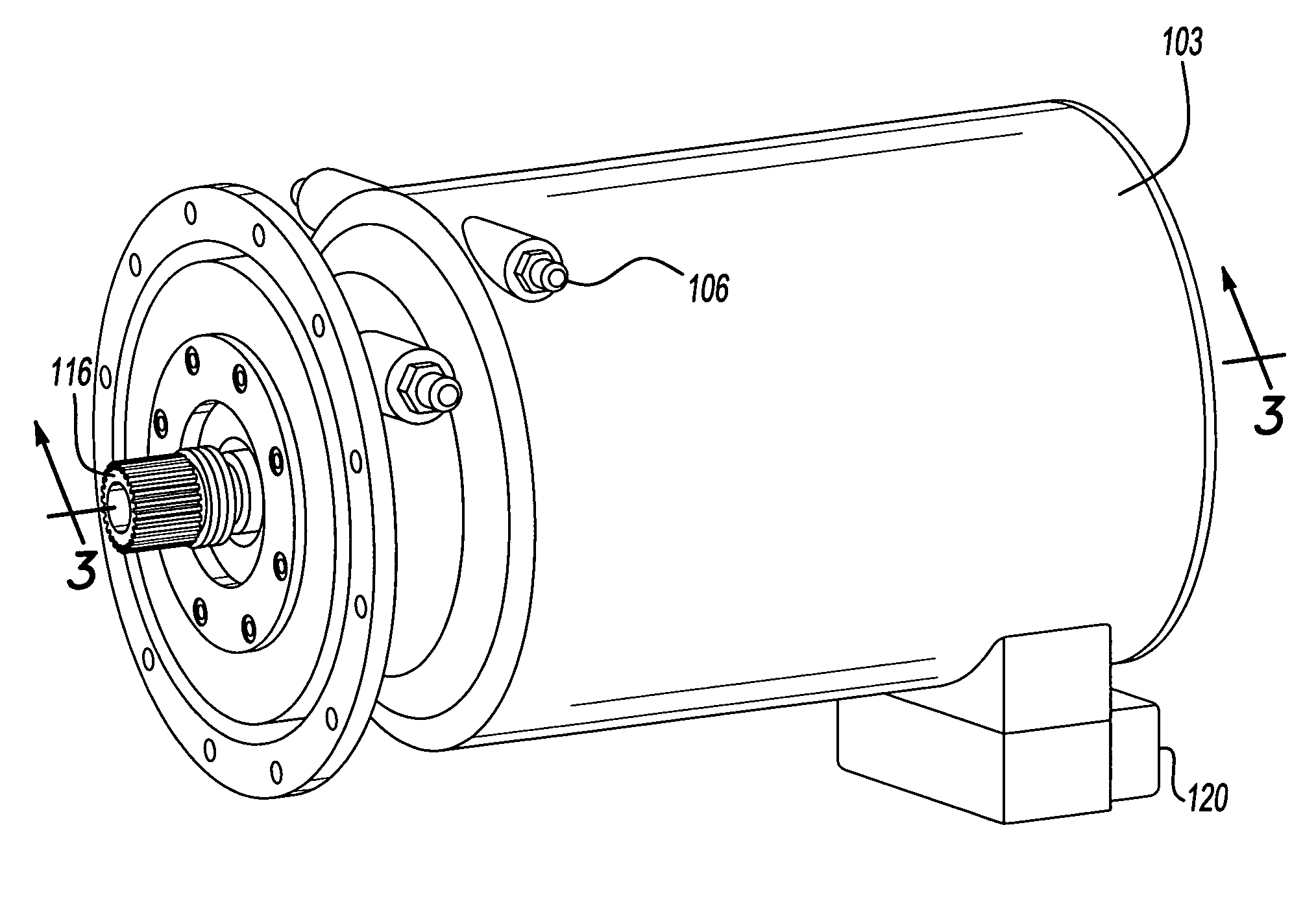

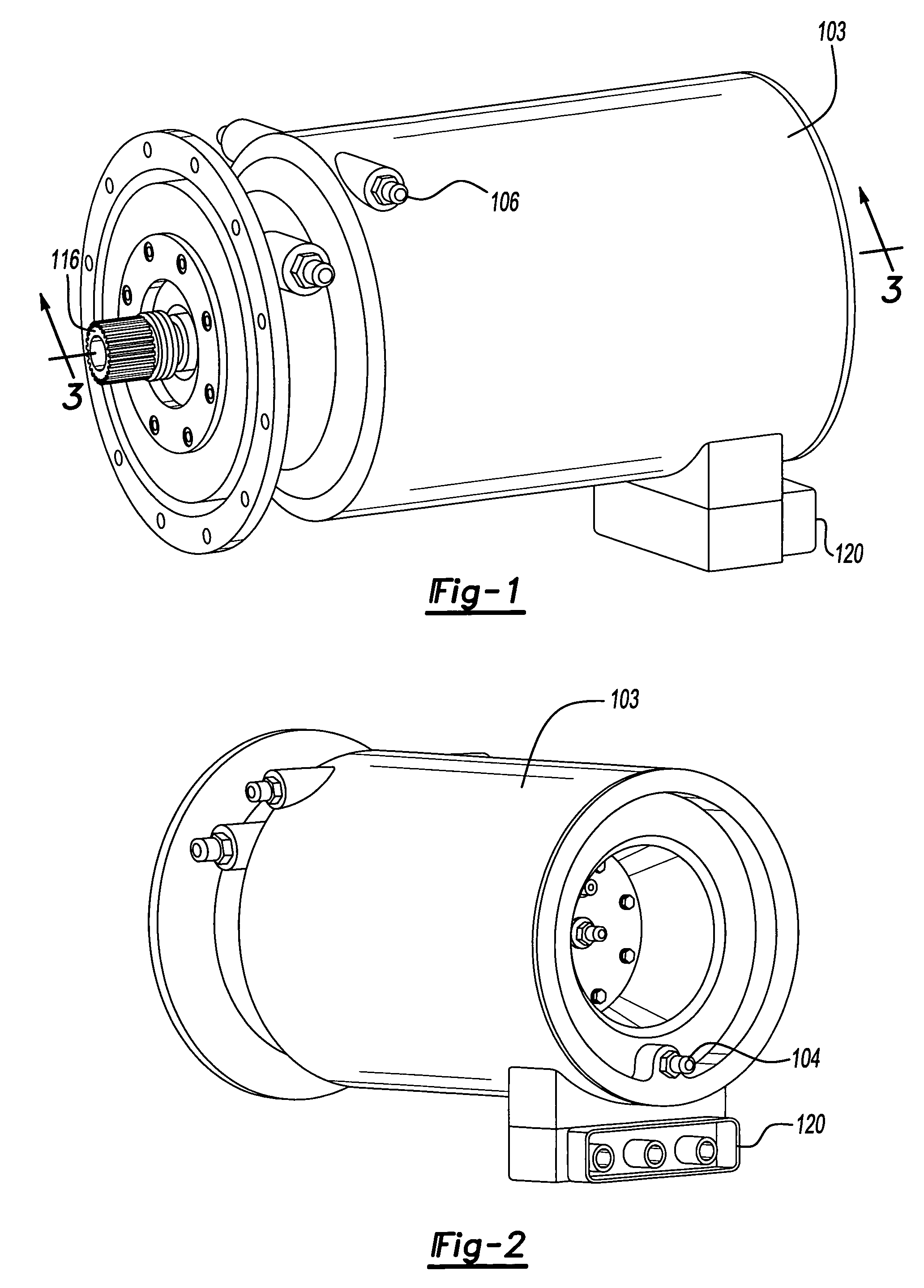

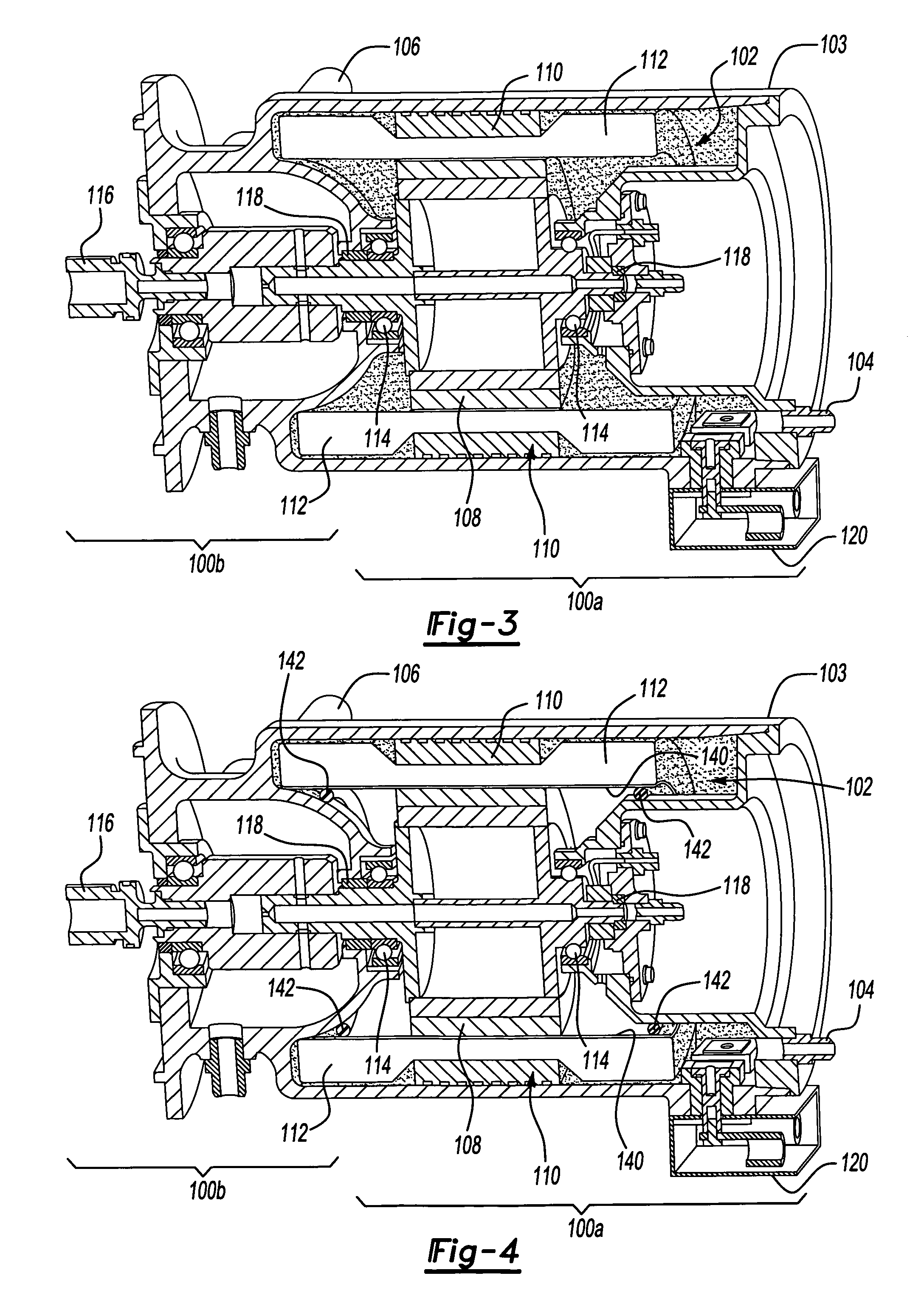

Fluid-submerged electric motor

ActiveUS7352090B2Improve cooling effectAbsorption of heatPiston pumpsMechanical energy handlingEngineeringCooling fluid

An electric motor has at least one component that is submerged in a cooling fluid held in a fluid-filled cavity. The stator, rotor, and rotor shaft bearings are all possible components that may be submerged. The cooling fluid floods the stator, rotor, and / or bearings to cool the components. The fluid may have a high electrical resistance to isolate the motor components from any contact with flammable gasses as well as prevent arcs or sparks. The cavity holding the fluid also ensures continuous lubrication by preventing fluid from leaking or evaporating out of the motor.

Owner:HAMILTON SUNDSTRAND CORP

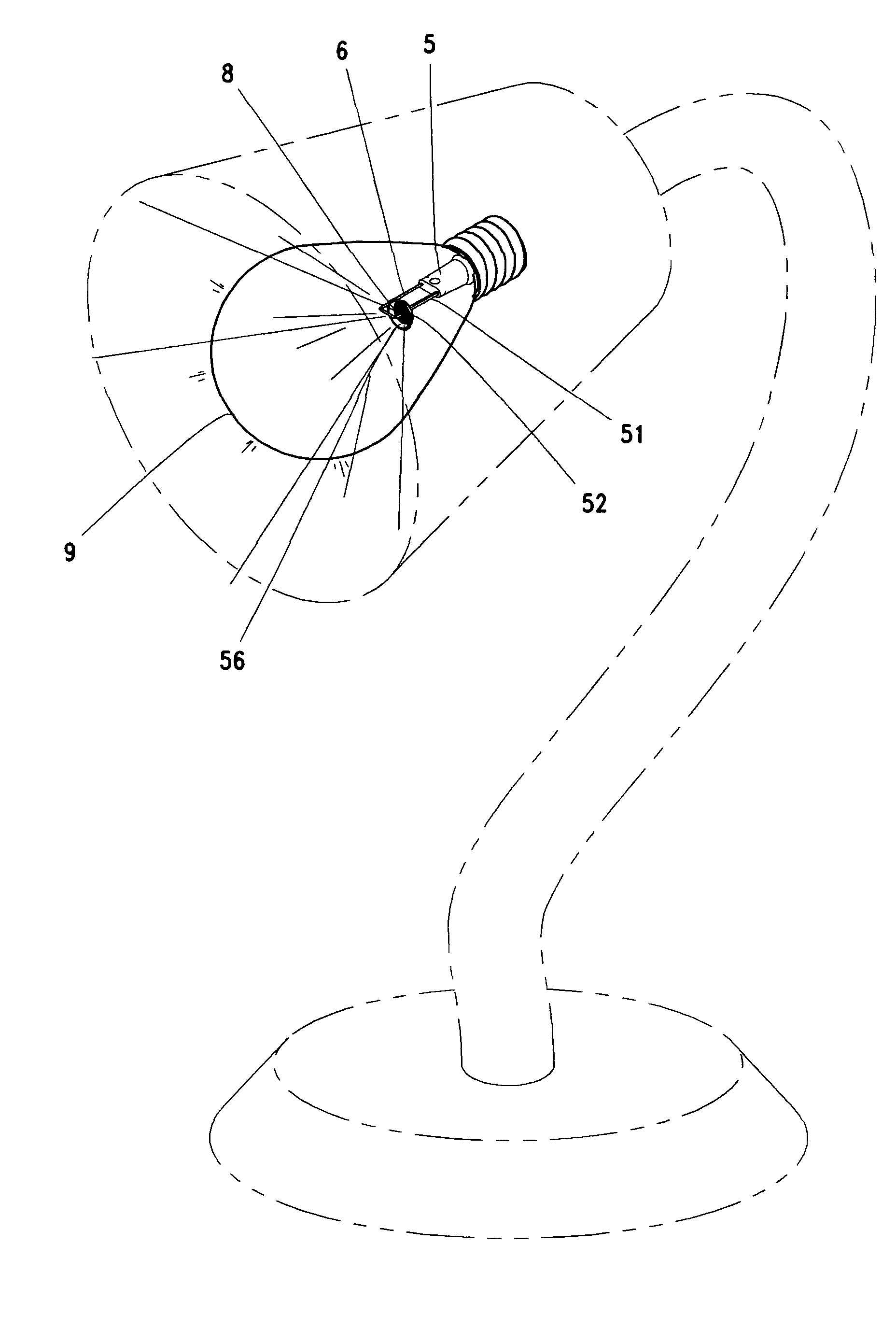

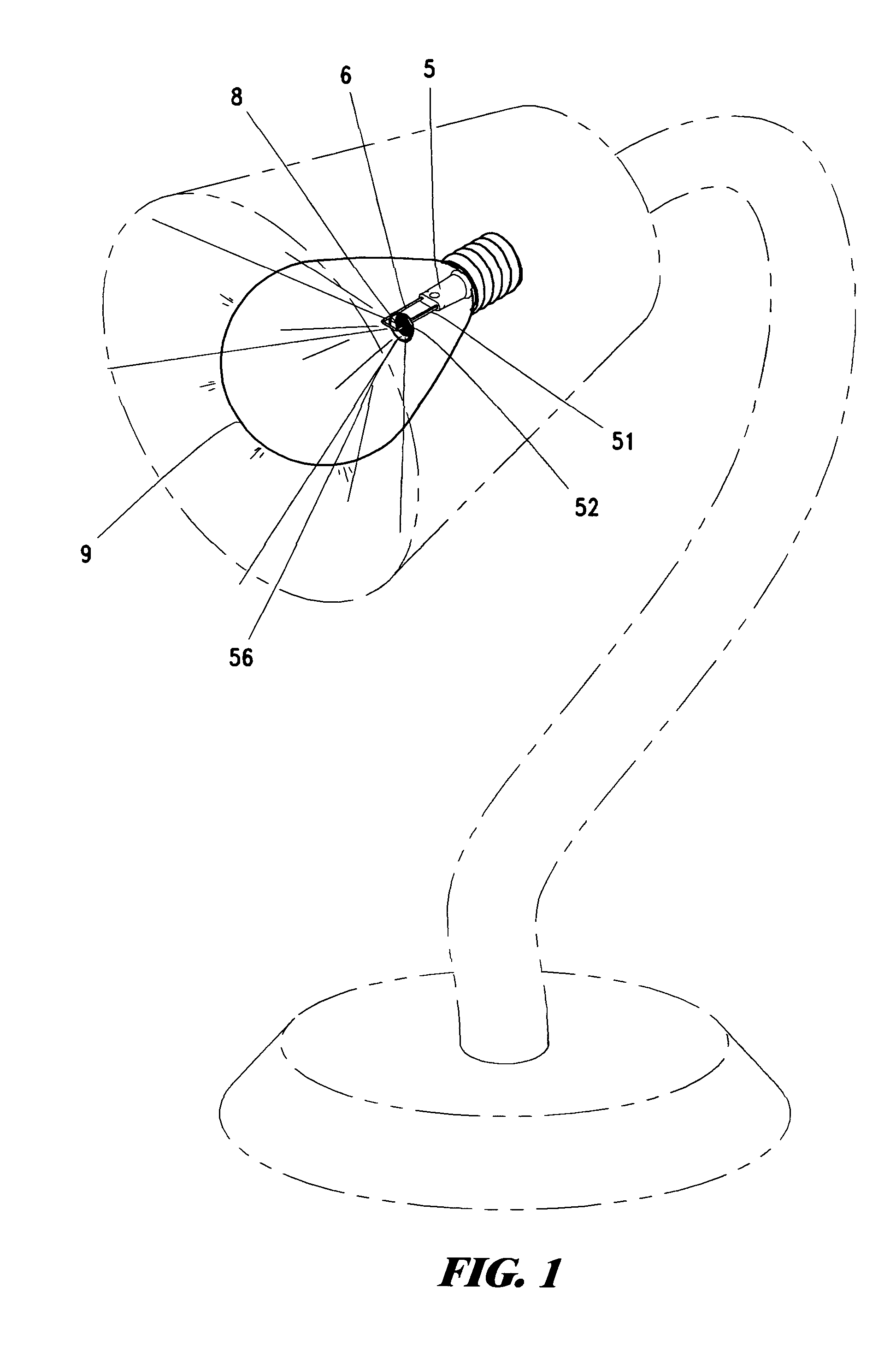

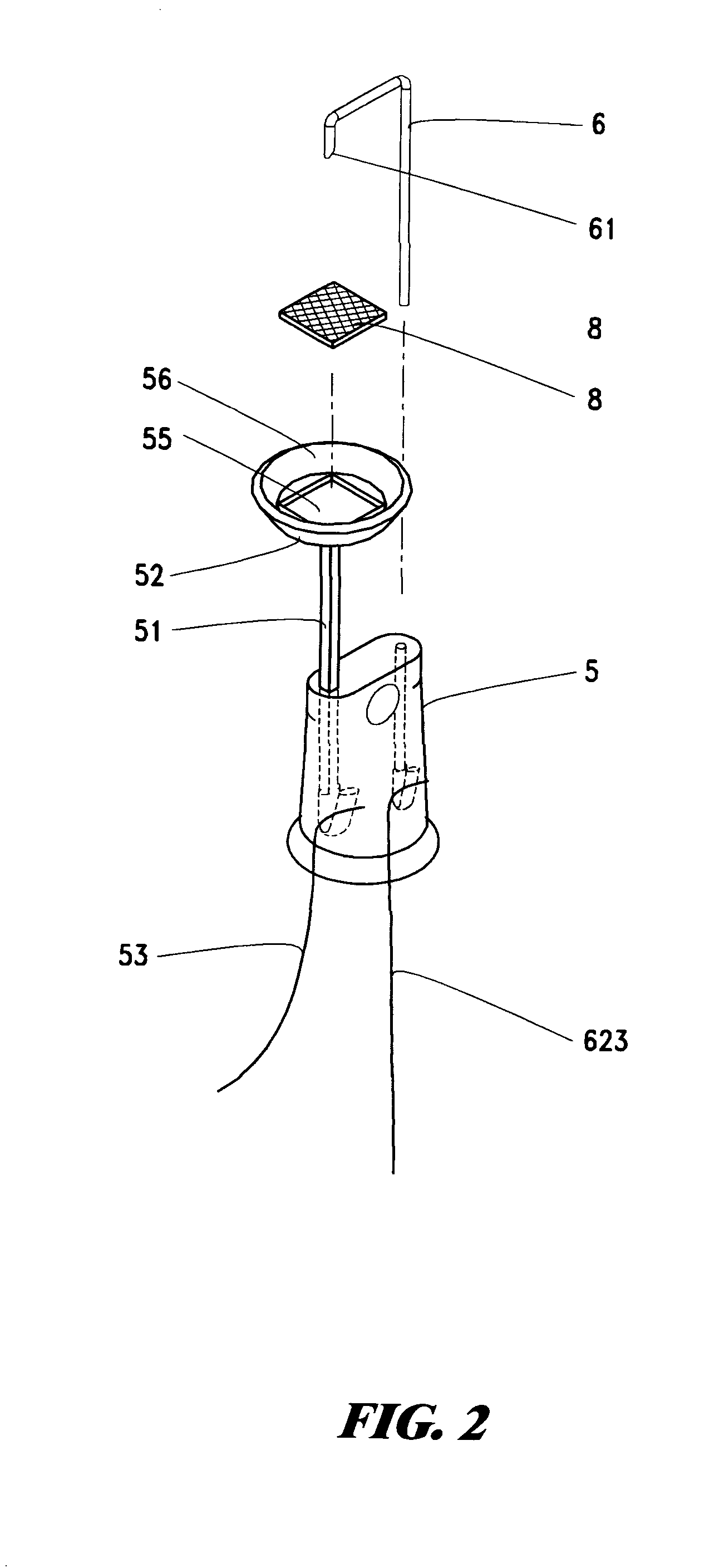

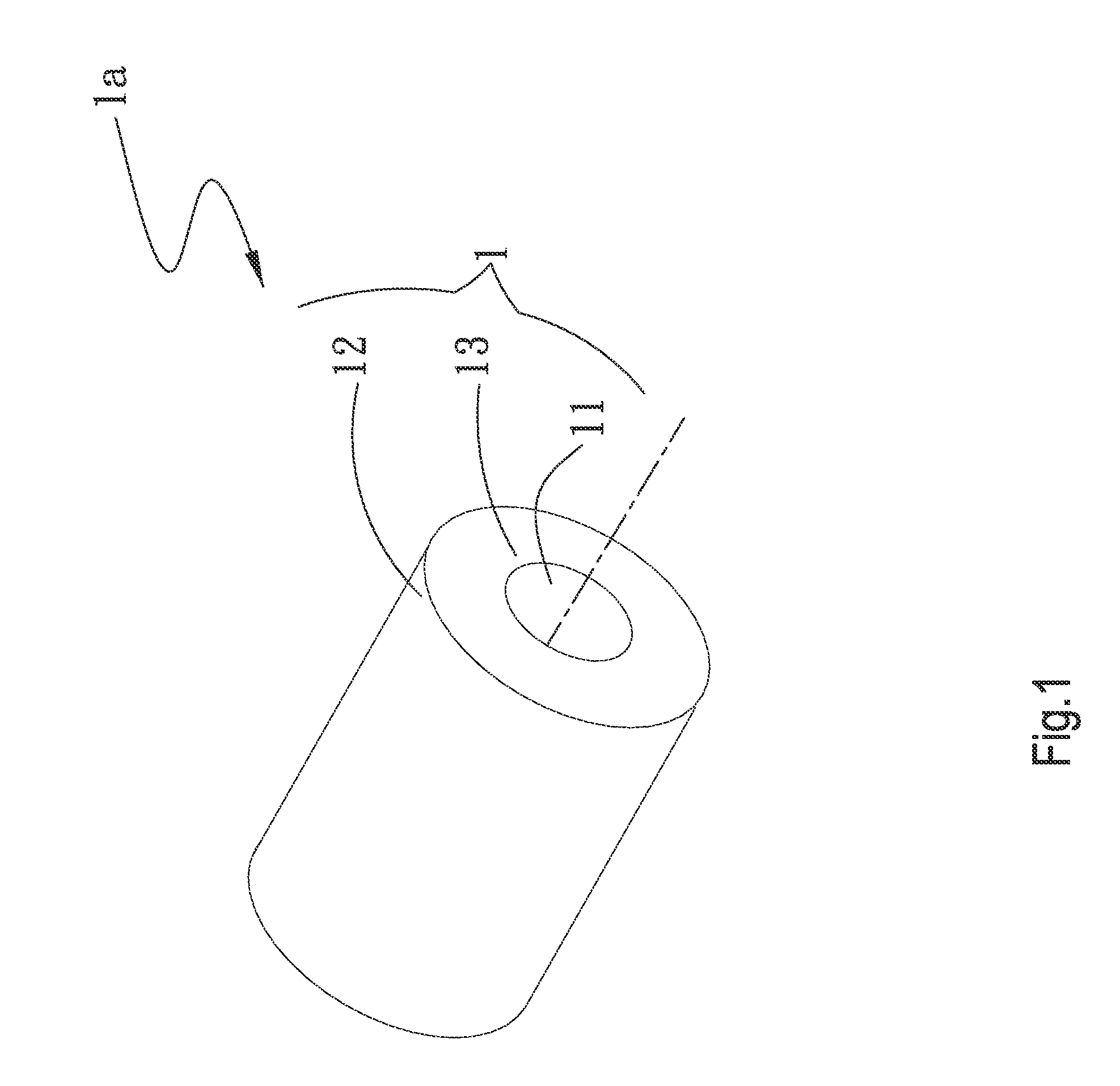

Structure of the stem of LED chip unit bulb

InactiveUS20050007010A1Facilitates efficient circulationProlong lifeDischarge tube luminescnet screensPoint-like light sourceAlloyNormal state

The present invention is related to a new structure of the stem of LED Chip Unit bulb, which comprises a cup disk, a chip, a stand, a molybdenum alloy wire and a stem. Essentially, the brace-end of the stem is connected to a supportive chip cup disk. The center of the disk is concave so as to form a holding chamber whose inner diameter is open, arc-shaped and circular. The molybdenum alloy wire is tapered off to a point and thus it takes a turn of 180°, hooking and pressing against the chip. Given the elastic coefficient of the barb-turning angle, the tip of the molybdenum alloy wire may point-press against the chip in a normal state in response to the temperature-dependent expansion-contraction feature of the chip. The gradient of the arc-shaped, circular wall of the disk enables the chip to generate light that refracts at different angles, giving rise to a wide-angle, open, homogeneous light source. The vacuum inside the bulb facilitates efficient circulation and therefore heat absorption. As a result, despite the heat dissipation of the chip, the temperature of the bulb does not increase, prolonging the life of the bulb. Hence, the new structure of the stem of LED chip unit bulb does have a practical utility.

Owner:LEE HAN MING

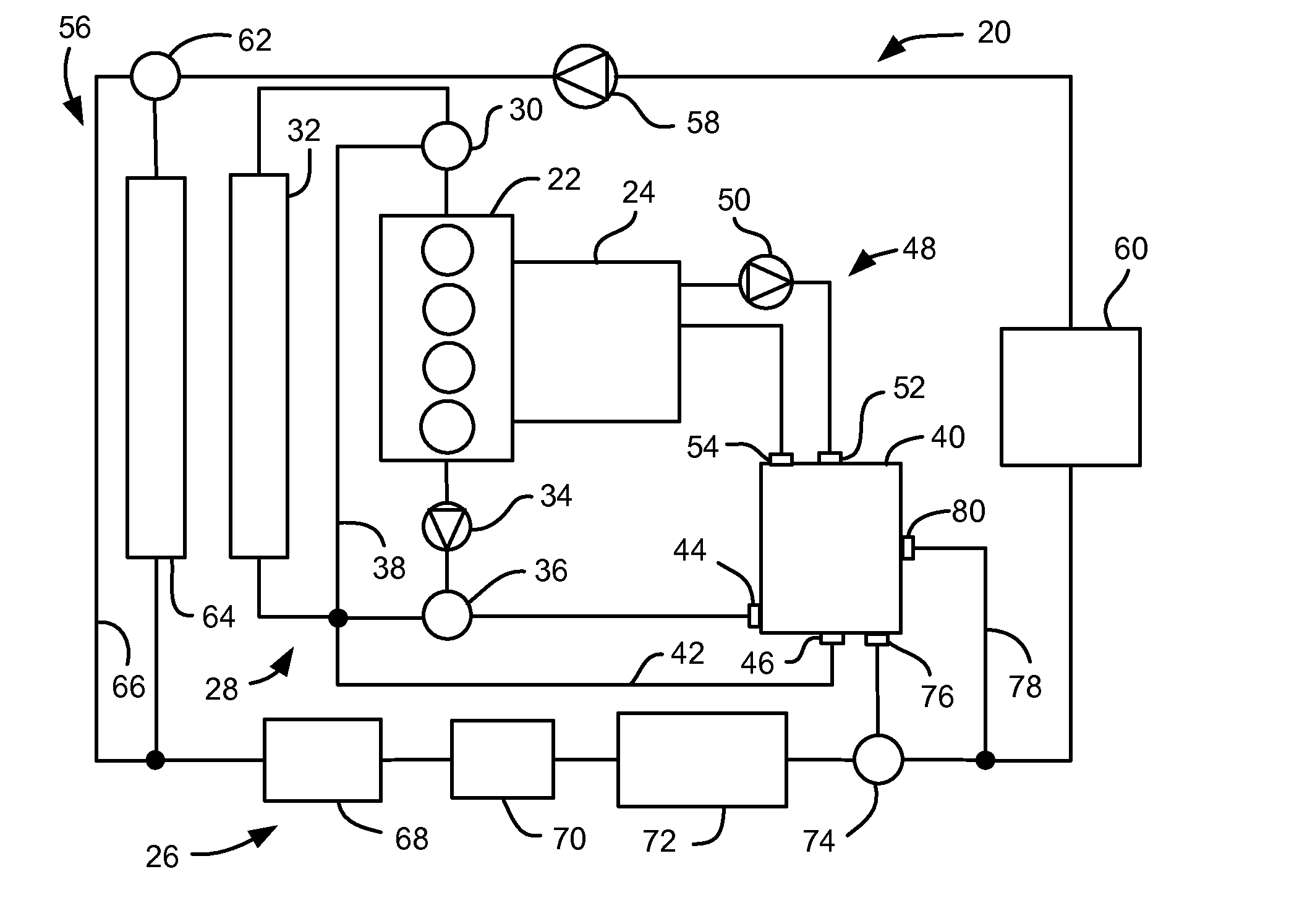

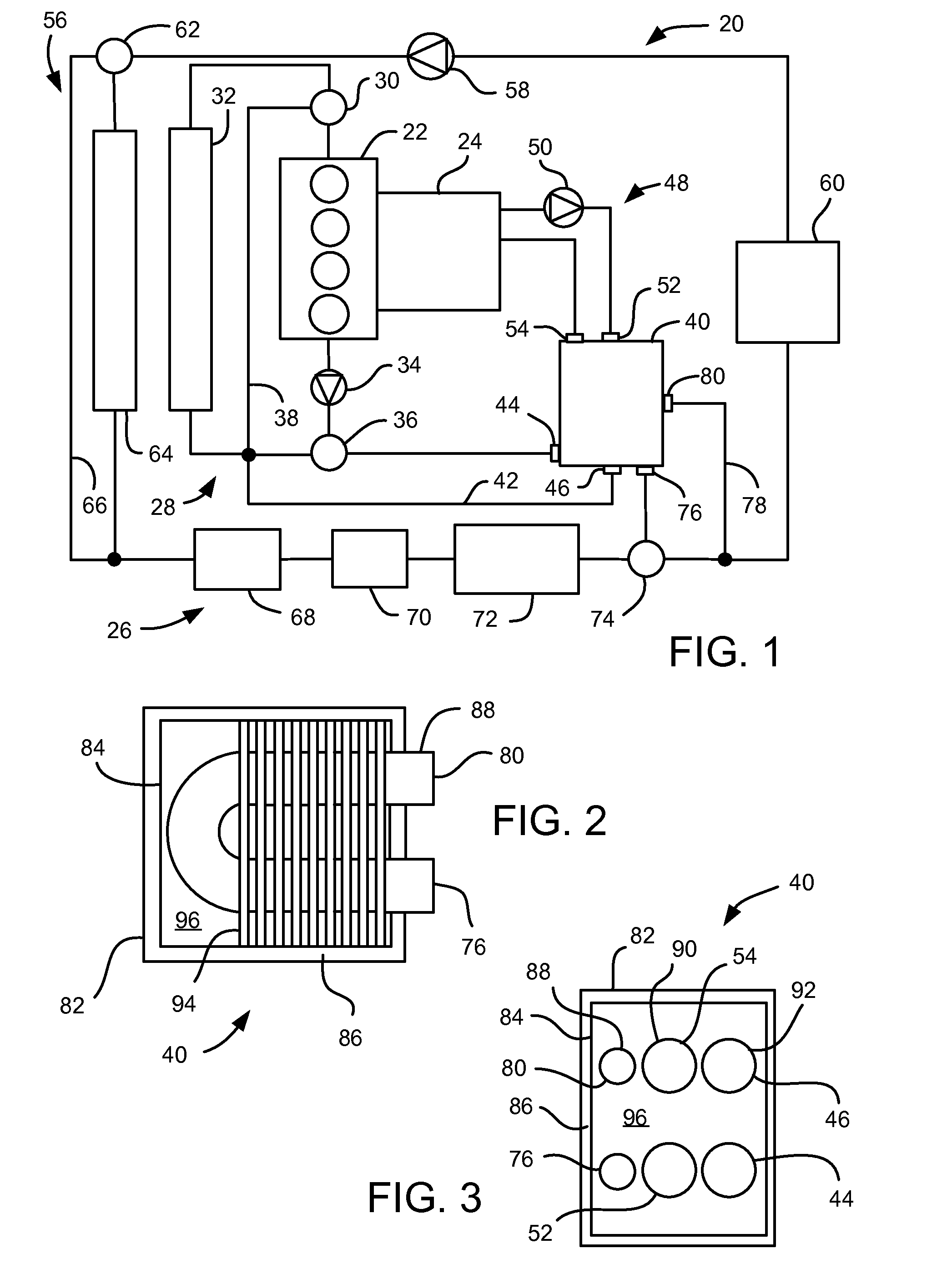

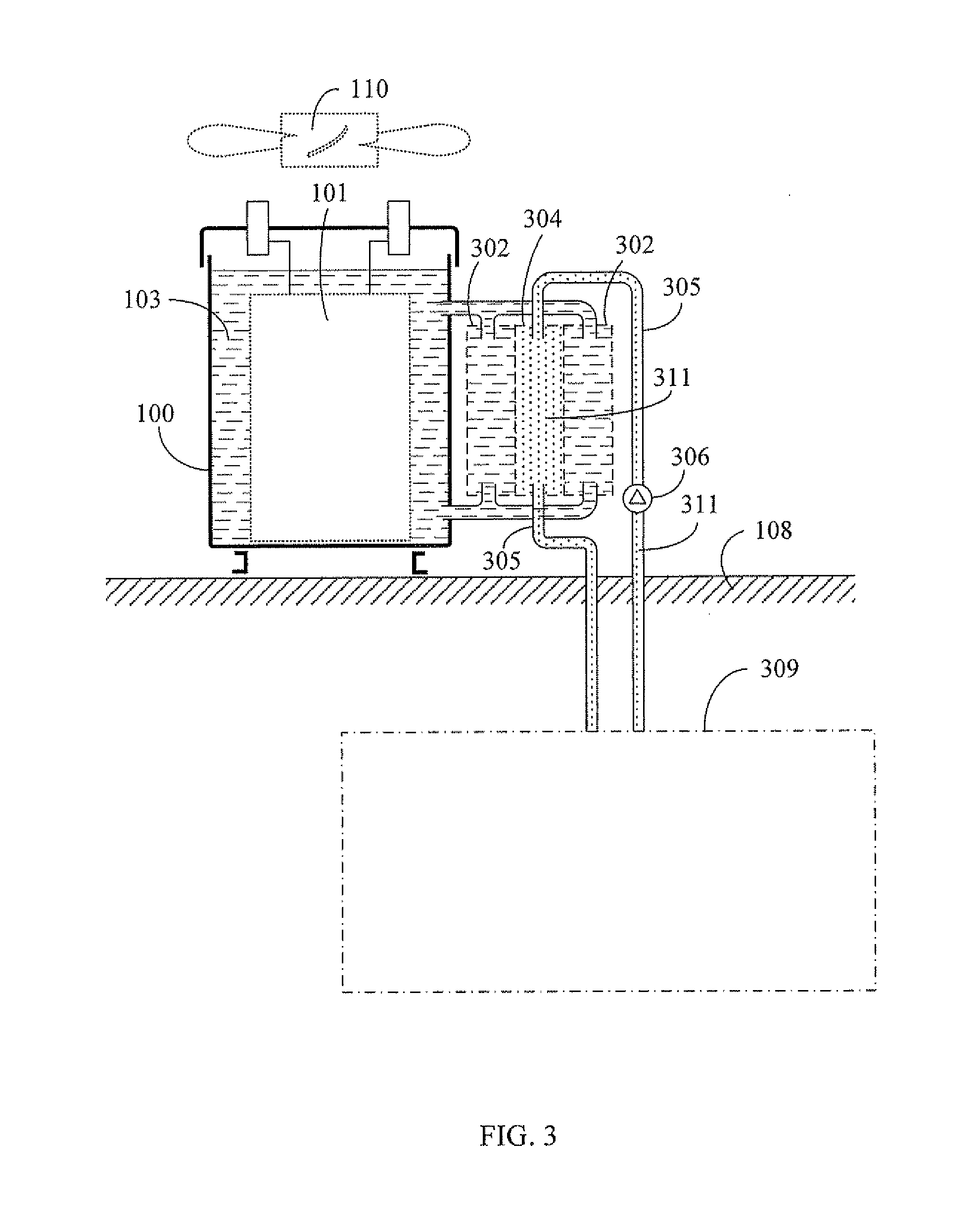

Waste Heat Accumulator/Distributor System

ActiveUS20110214629A1Absorption of heatImprove fuel economyLiquid coolingPower plant cooling arrangmentsElectronic systemsCoolant flow

A waste heat accumulator / distributor system for use in a vehicle. The system includes an engine coolant loop directing engine coolant through a power plant, a powertrain electronics coolant loop directing electronics coolant through a powertrain electronics system; and a transmission fluid loop directing transmission fluid through a transmission. The system includes a multi-fluid heat exchanger including an engine coolant inlet receiving the engine coolant from the engine coolant loop, an electronics coolant inlet receiving the electronics coolant from the powertrain electronic coolant loop, and a transmission fluid inlet receiving the transmission fluid from the transmission fluid loop; a first valve controllable to cause engine coolant to flow into the engine coolant inlet or to bypass the engine coolant inlet; and a second valve controllable to cause electronics coolant to flow into the electronics coolant inlet or to bypass the electronics coolant inlet.

Owner:GM GLOBAL TECH OPERATIONS LLC

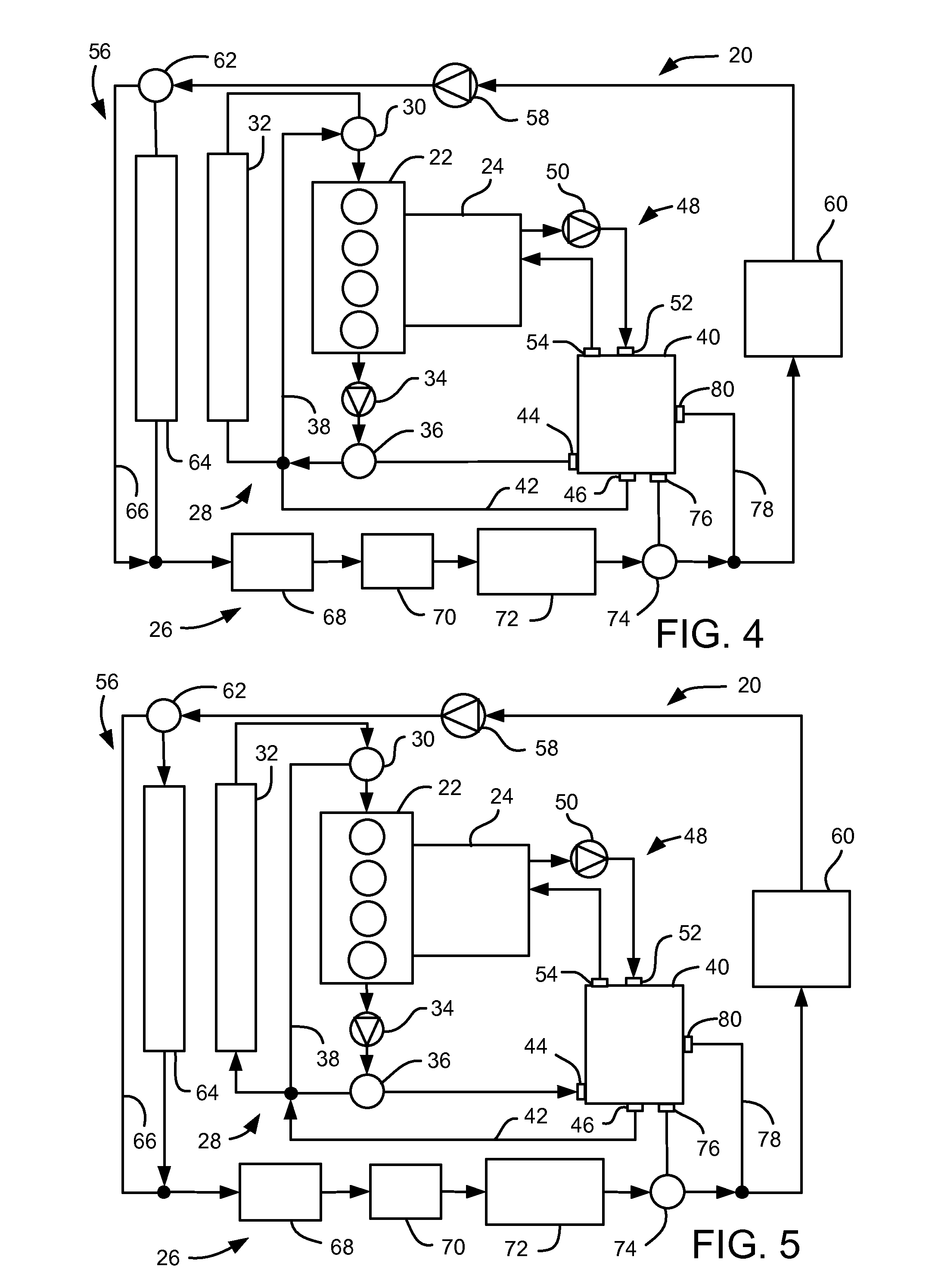

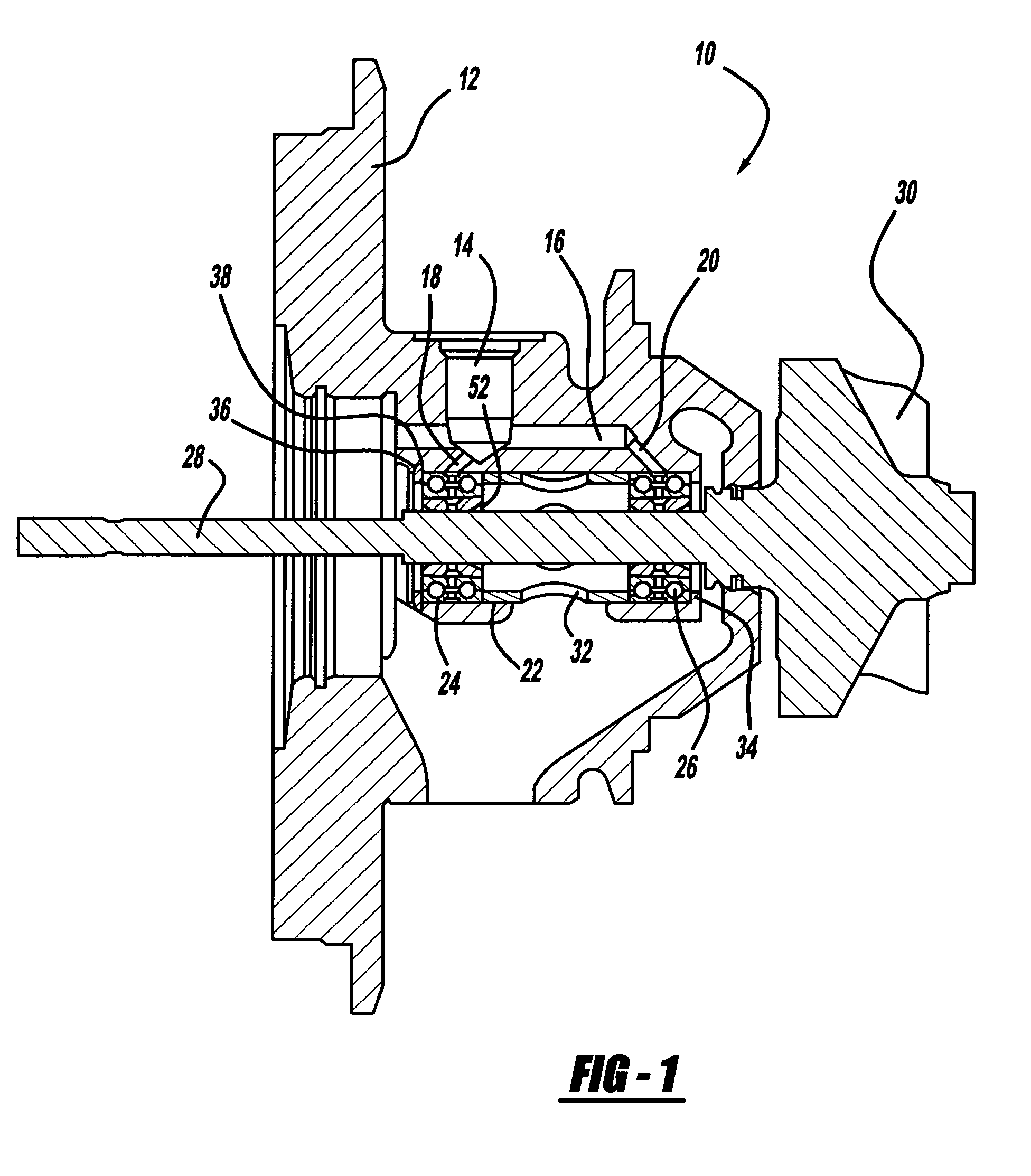

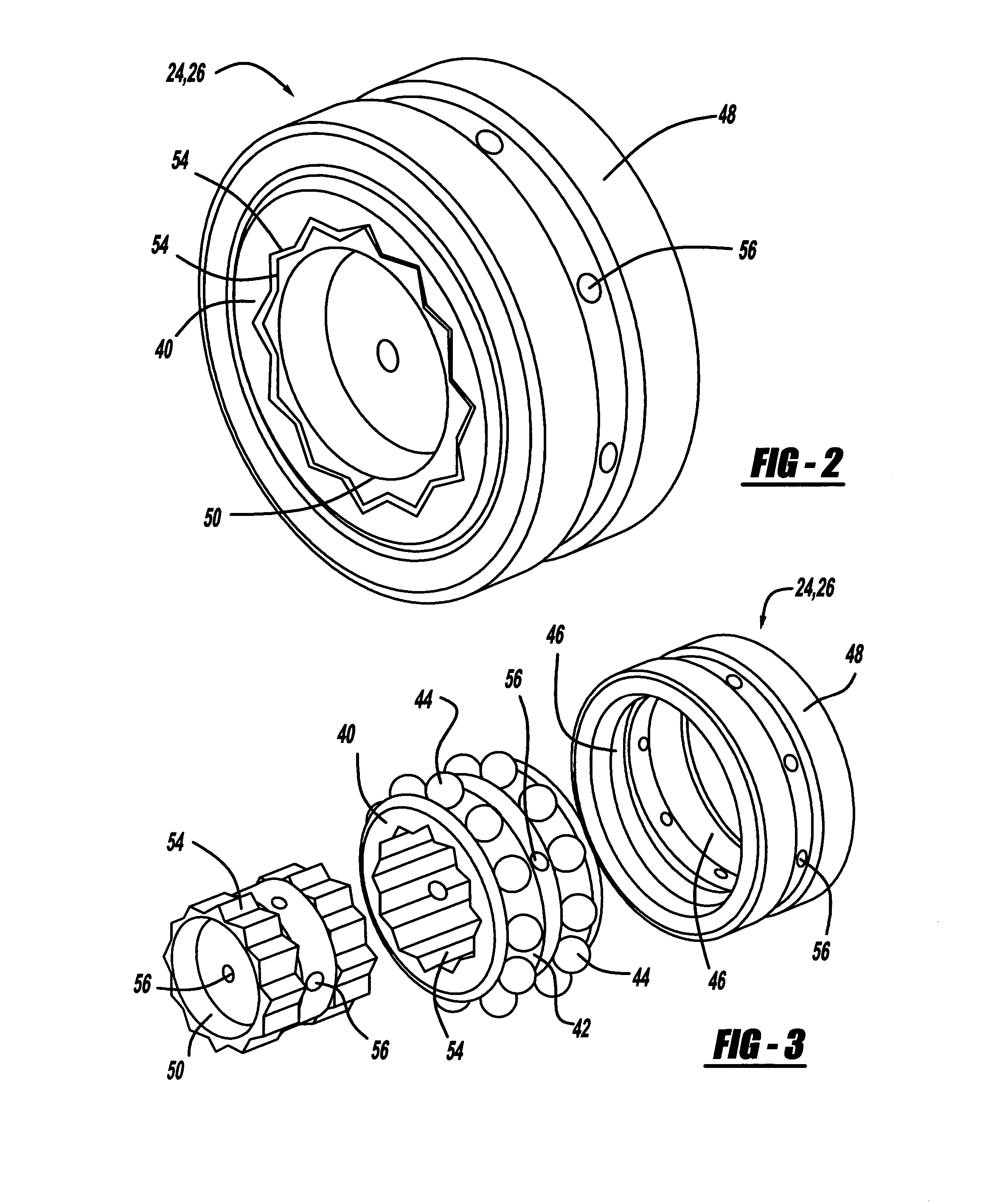

Combination hydrodynamic and rolling bearing system

InactiveUS8016554B2Compensate for misalignmentAbsorption of heatRotary combination bearingsPump componentsRolling-element bearingTurbocharger

The present invention is directed toward a hybrid bearing which will have the advantages of ball bearings as well as hydrodynamic oil films. The present invention is a hybrid bearing assembly for a turbocharger unit, having an inner race track with a series of grooves, and one or more roller balls located in the grooves of the inner race track. There is also an outer race track having a series of grooves for receiving the one or more roller balls, where the outer race track circumscribes the inner race track. The hybrid bearing also includes a sleeve made from an established tribological material located inside the inner race track, with a shaft located inside the sleeve. A hydrodynamic oil film is located between the sleeve and the shaft, wherein the hydrodynamic oil film allows the shaft to spin at greater speeds than the inner race track.

Owner:BORGWARNER INC

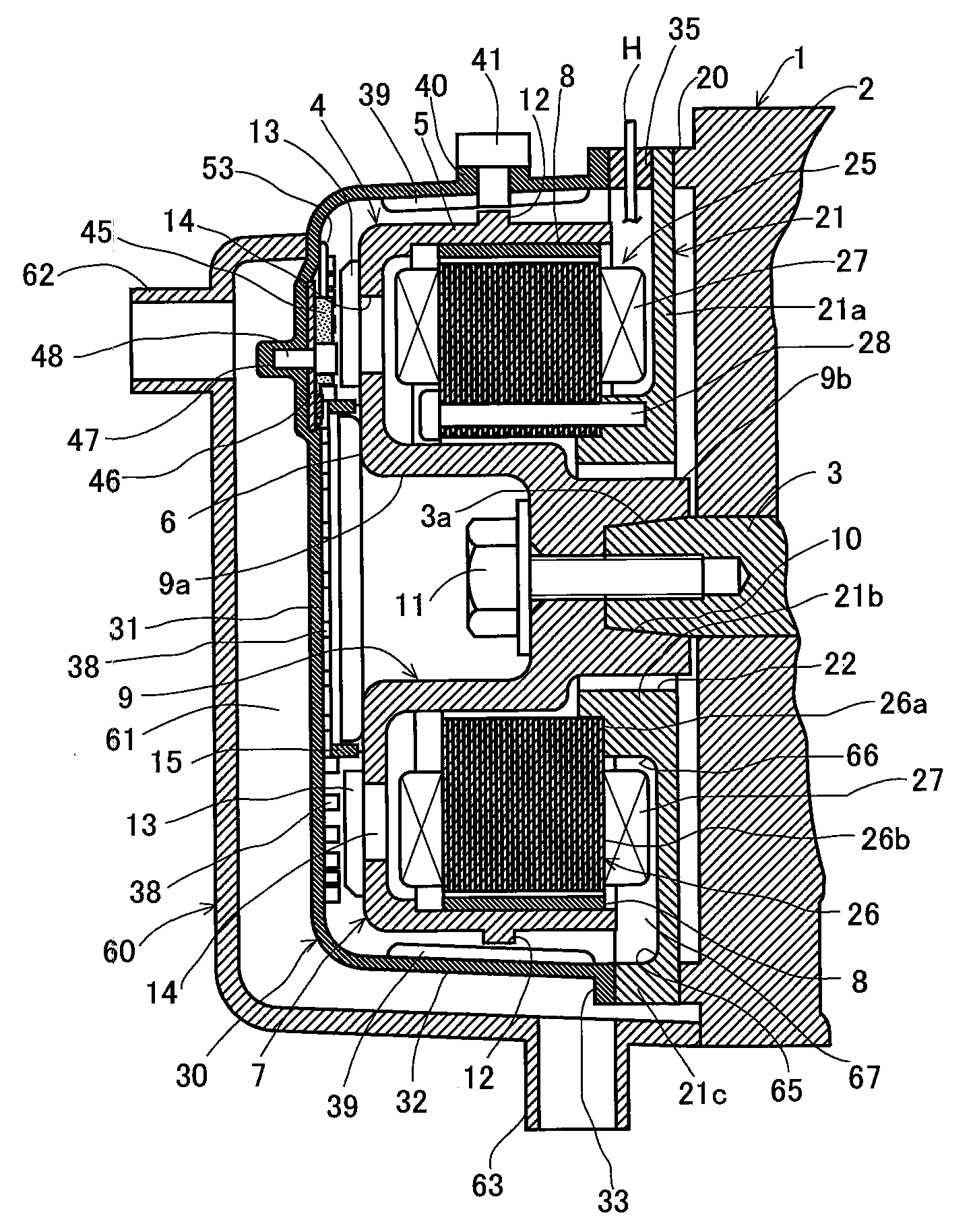

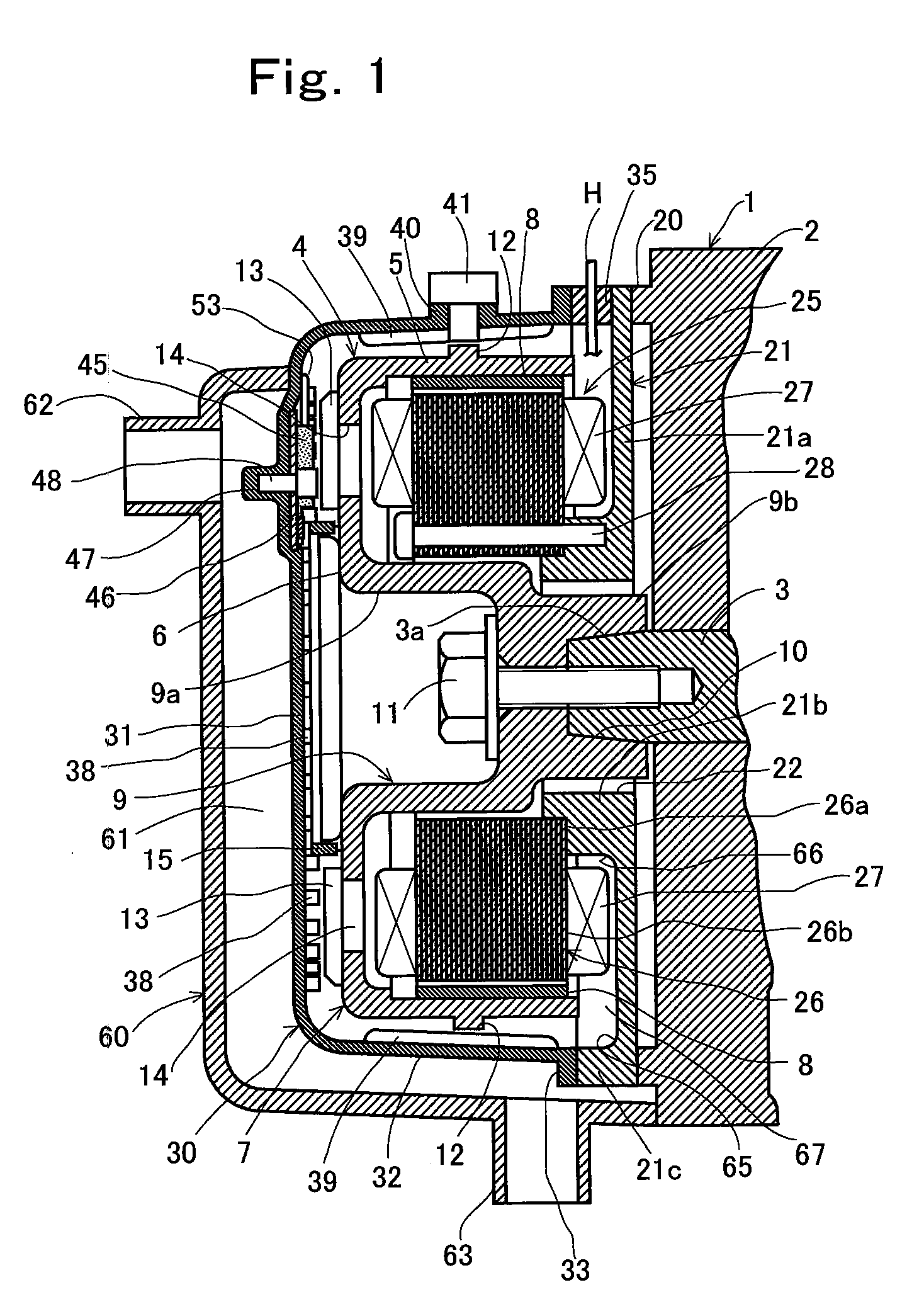

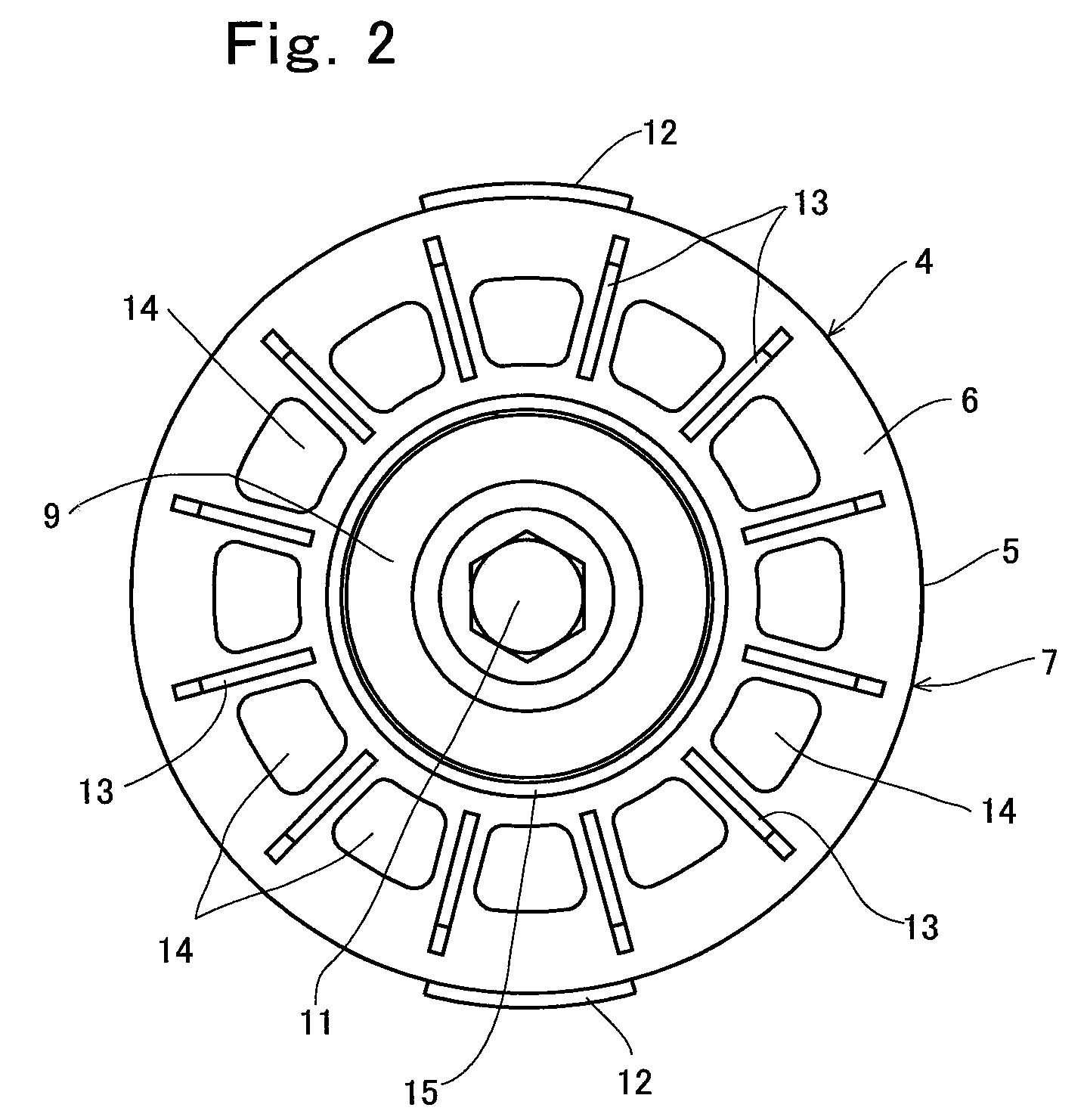

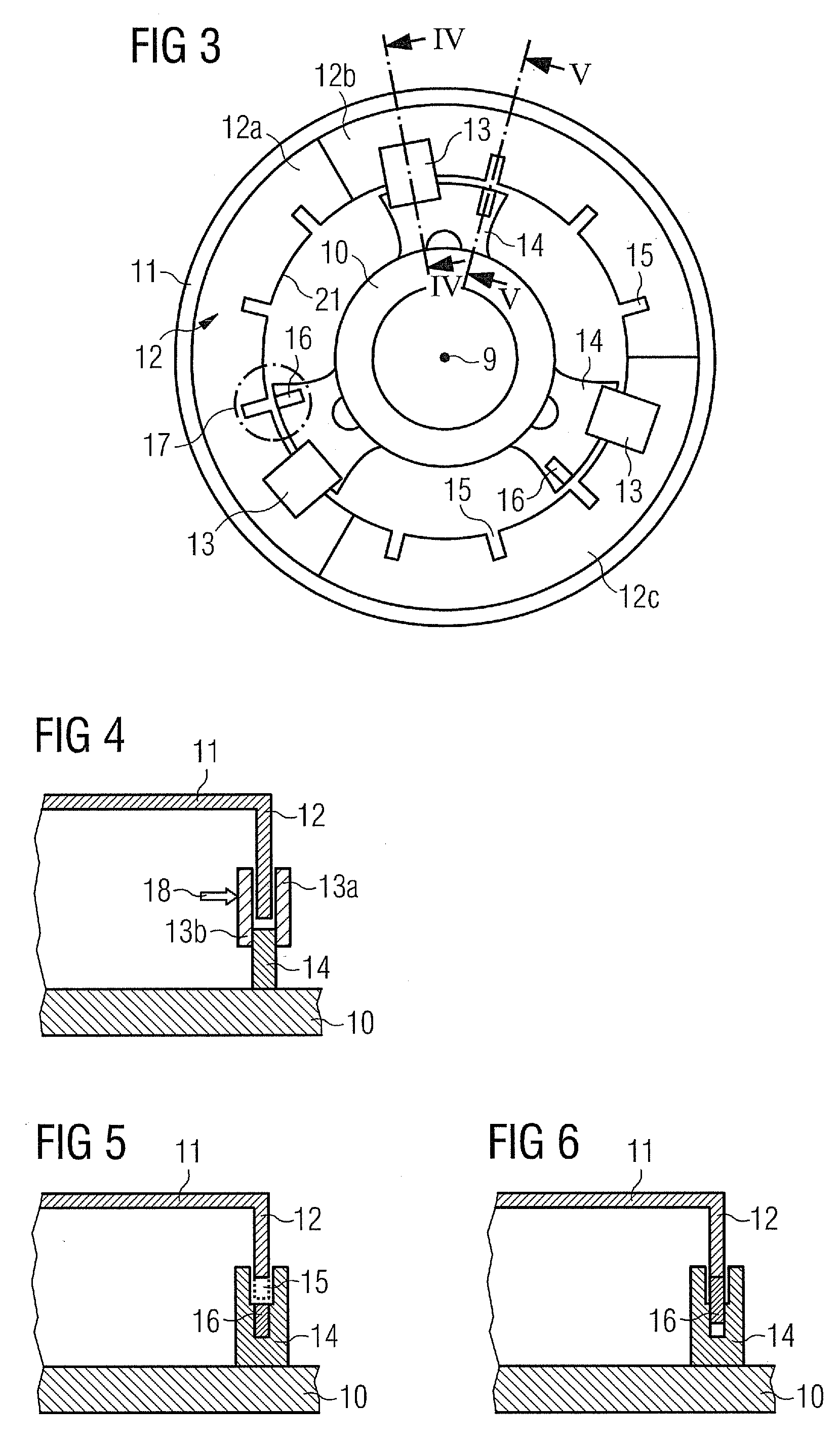

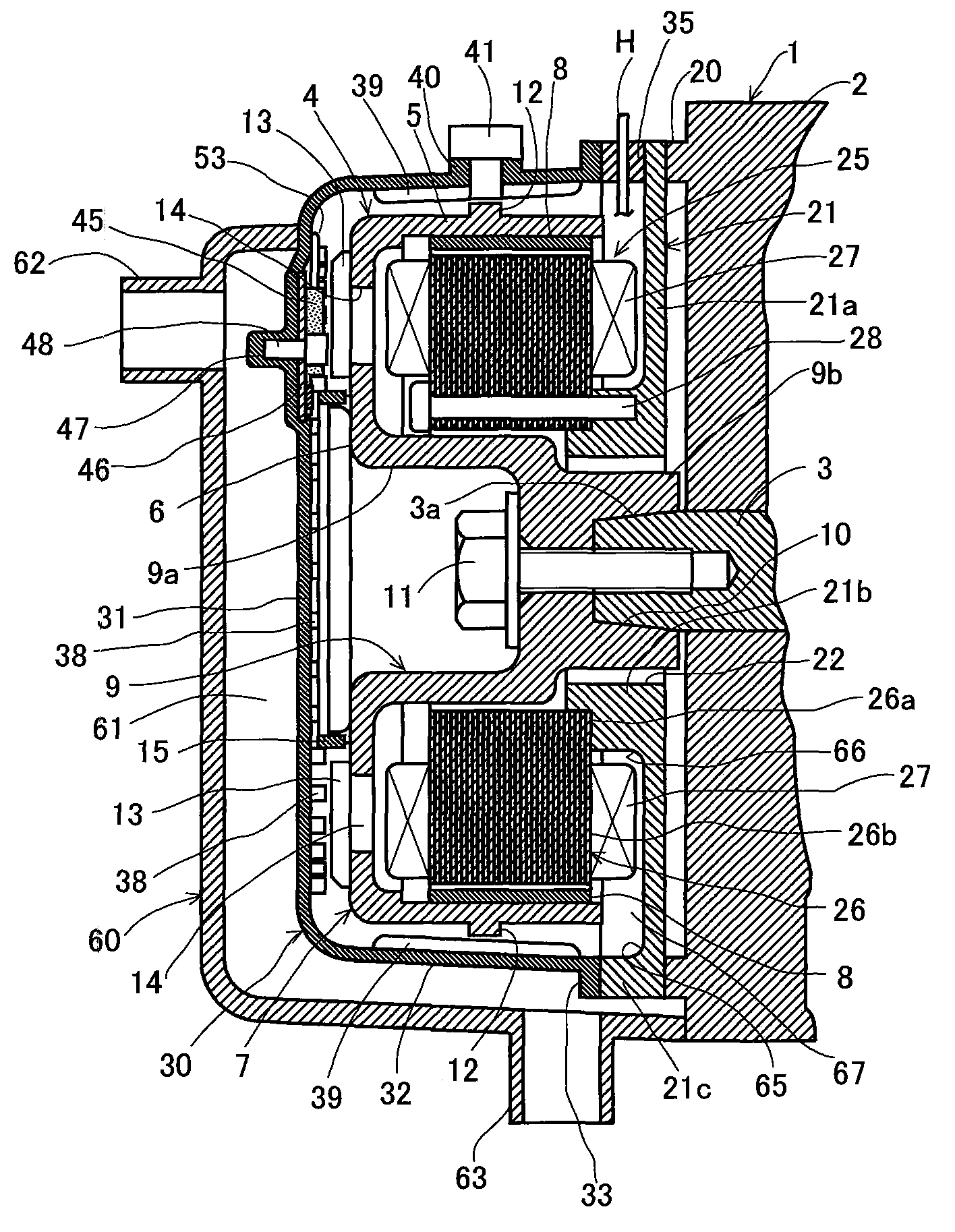

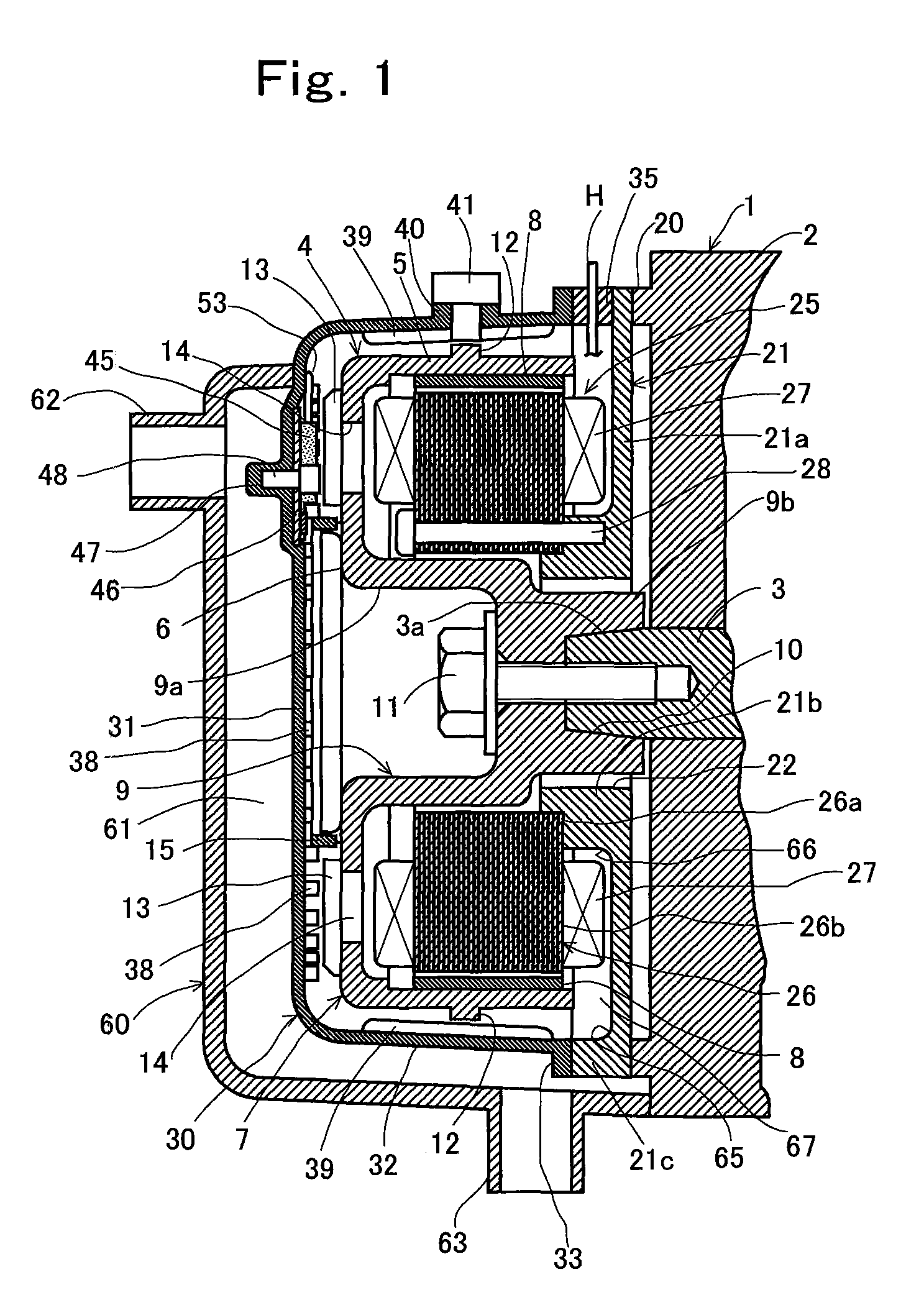

Starter generator

InactiveUS20090284087A1Avoid coolingAbsorption of heatMagnetic circuit rotating partsMechanical energy handlingStarter generatorCentrifugal fan

A starter generator which comprises a rotor having a cuplike-shaped rotor yoke and magnets attached to an inner periphery of the rotor yoke, a stator mounted on a stator bracket and a protecting cover covering said rotor and stator, in which a hermetically sealed casing is constituted by said protecting cover and stator bracket, wherein a plurality of fans are provided on an outer surface of a bottom wall portion of said rotor yoke, a plurality of vent holes are provided through said bottom wall portion, said plurality of fans constitute a centrifugal fan which draws out air inside the rotor yoke through said vent holes and sends the air to an outer periphery of the rotor yoke, and a guide surface which guides the air sent to the outer periphery of the rotor yoke to a space inside the rotor yoke is provided on the stator bracket.

Owner:KOKUSAN DENKI CO LTD

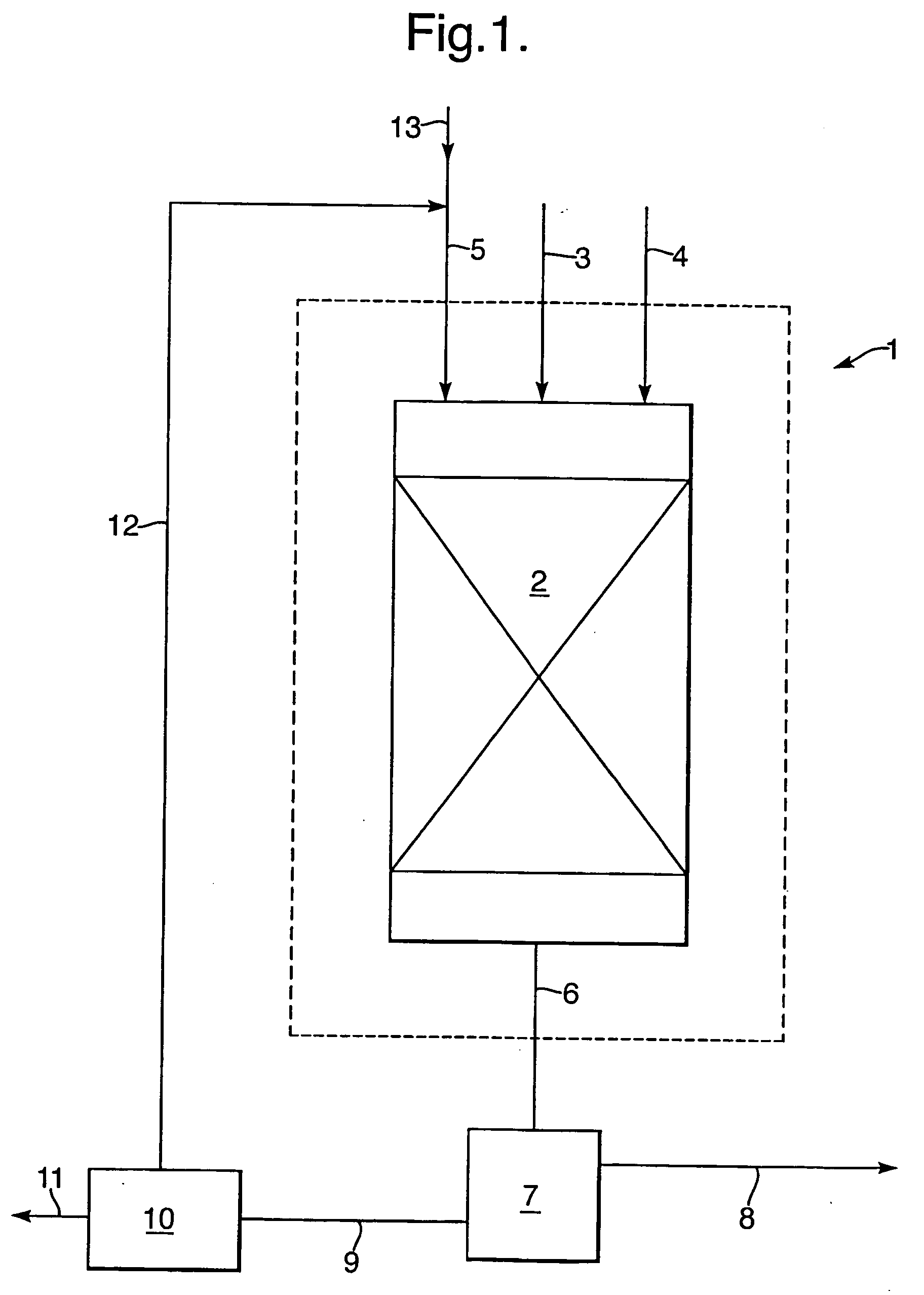

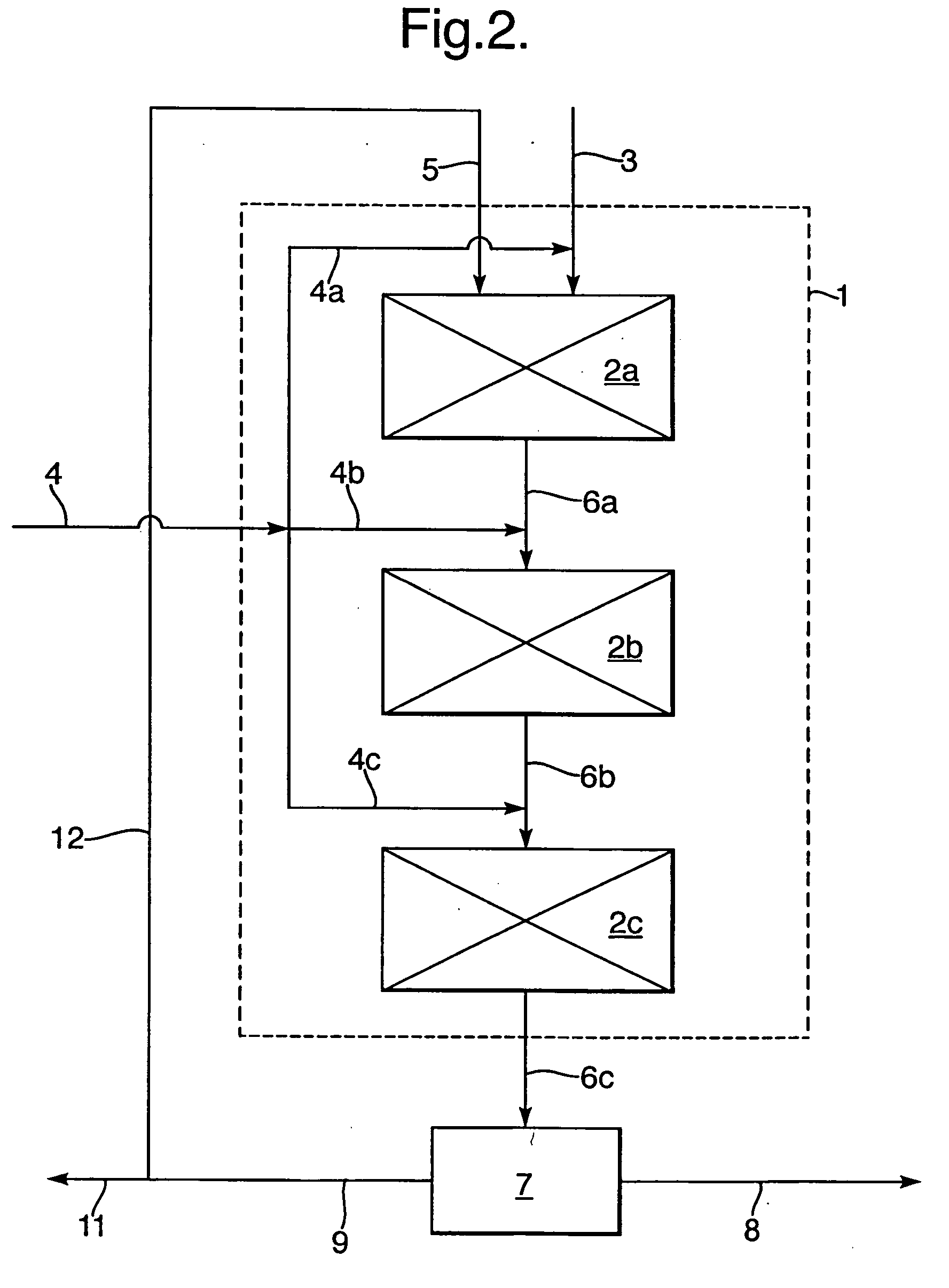

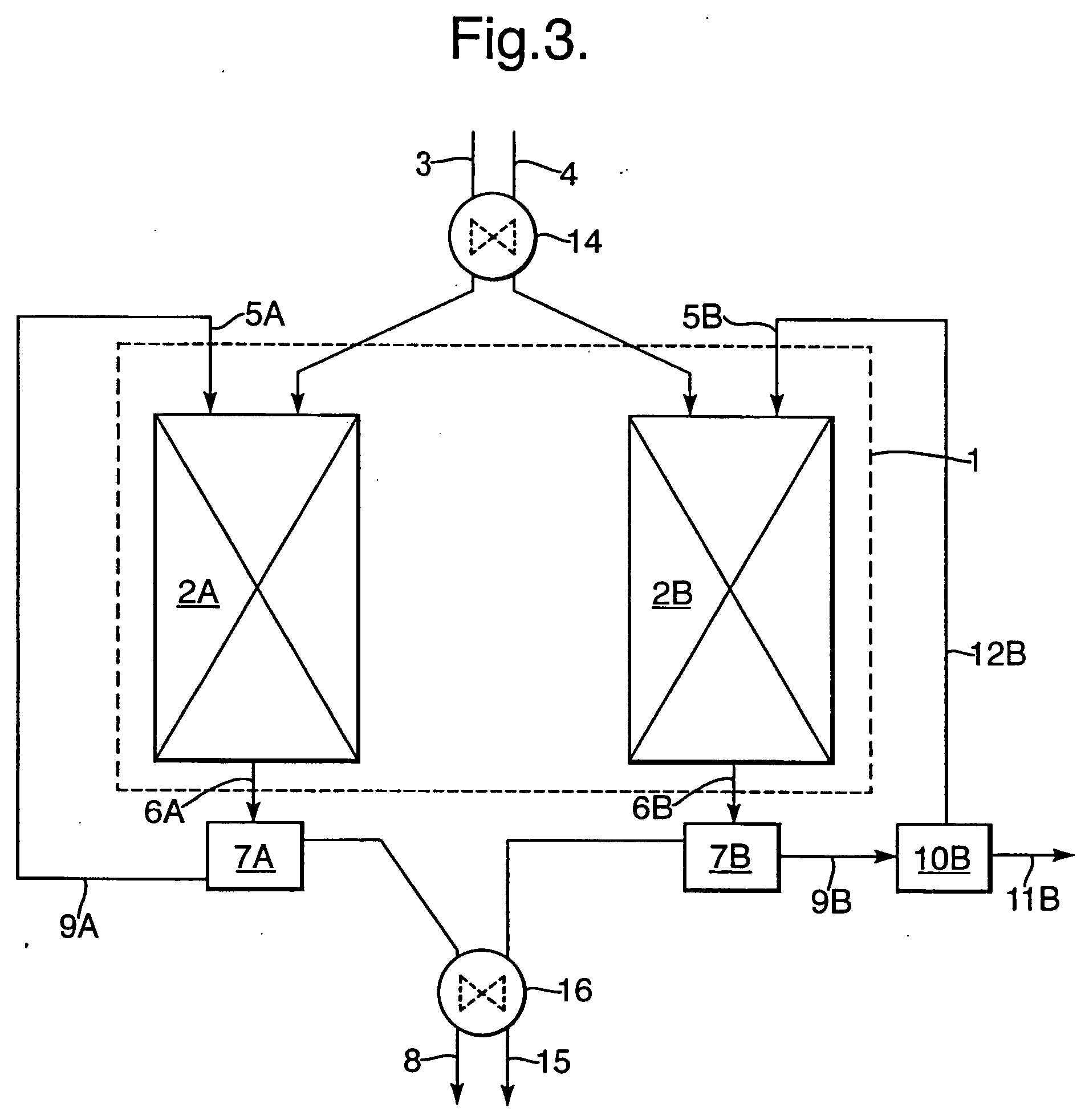

Process for the selective oxidation of hydrogen sulfhide

InactiveUS20050100504A1Hardly be formAbsorption of heatHydrogen sulfidesSulfur preparation/purificationChemistryHydrogen sulfide

A process for the selective oxidation of hydrogen sulphide in a hydrogen sulphide containing feed gas to elemental sulphur, wherein the hydrogen sulphide containing feed gas (3), an inert liquid medium (5), and a molecular-oxygen containing gas (4) are supplied to a reaction zone (1) comprising at least one catalytic zone (2) comprising an oxidation catalyst to form elemental sulphur and a gaseous stream depleted in hydrogen sulphide (8), in which process the oxidation catalyst of each catalytic zone (2) is contacted with hydrogen sulphide and / or molecular-oxygen in the presence of inert liquid medium at a temperature in the range of from 120 to 160° C., under such conditions that the elemental sulphur formed is essentially in liquid form and is removed from the reaction zone with the inert liquid medium.

Owner:SHELL OIL CO

Nano-patch thermal management devices, methods, & systems

InactiveUS7545644B2Reduce the temperatureAbsorption of heatSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

Nano-scale thermal management devices, methods, and systems are provided. According to some embodiments, a thermal management device configured to remove heat from a heated area can comprise an inlet port and a cavity. The cavity can be positioned intermediate a heat source and an opposing surface spaced apart from the heat source. The inlet port can receive a liquid (such as a coolant or cooling fluid) and direct the liquid to the cavity. The cavity can be configured to control the thickness of the liquid within the cavity. Liquid within the cavity can be heated by the heat source, and the opposing surface can comprise openings to allow evaporated liquid to exit the openings. A gas flow proximate the opposing surface can be used to carry vapor and be used to enhance liquid evaporation. Movement of the evaporated liquid enables heat from the heat source to be removed. The opposing surface can be a perforated membrane having micro-sized and nano-sized perforations. Other embodiments are also claimed and described.

Owner:GEORGIA TECH RES CORP

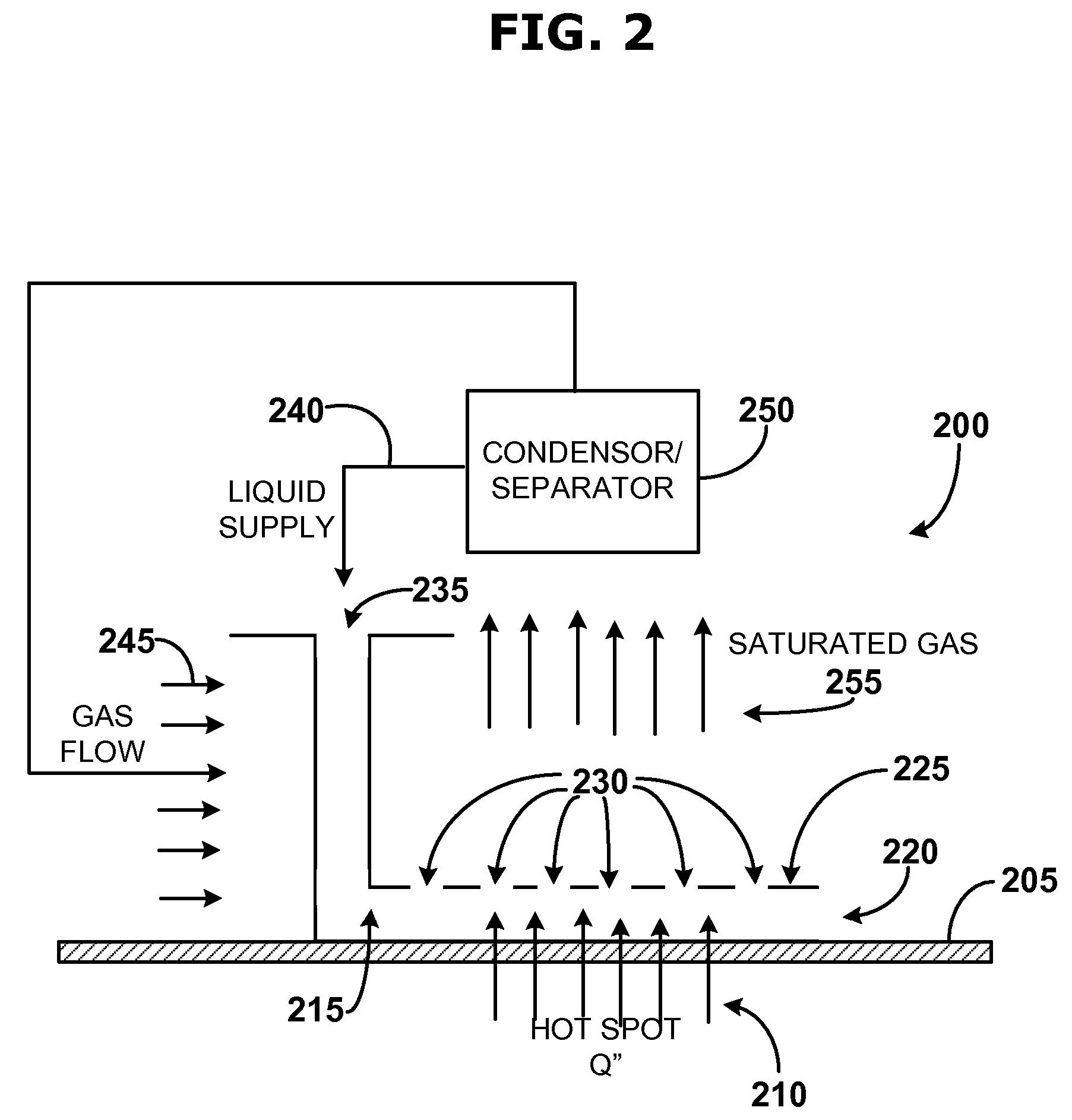

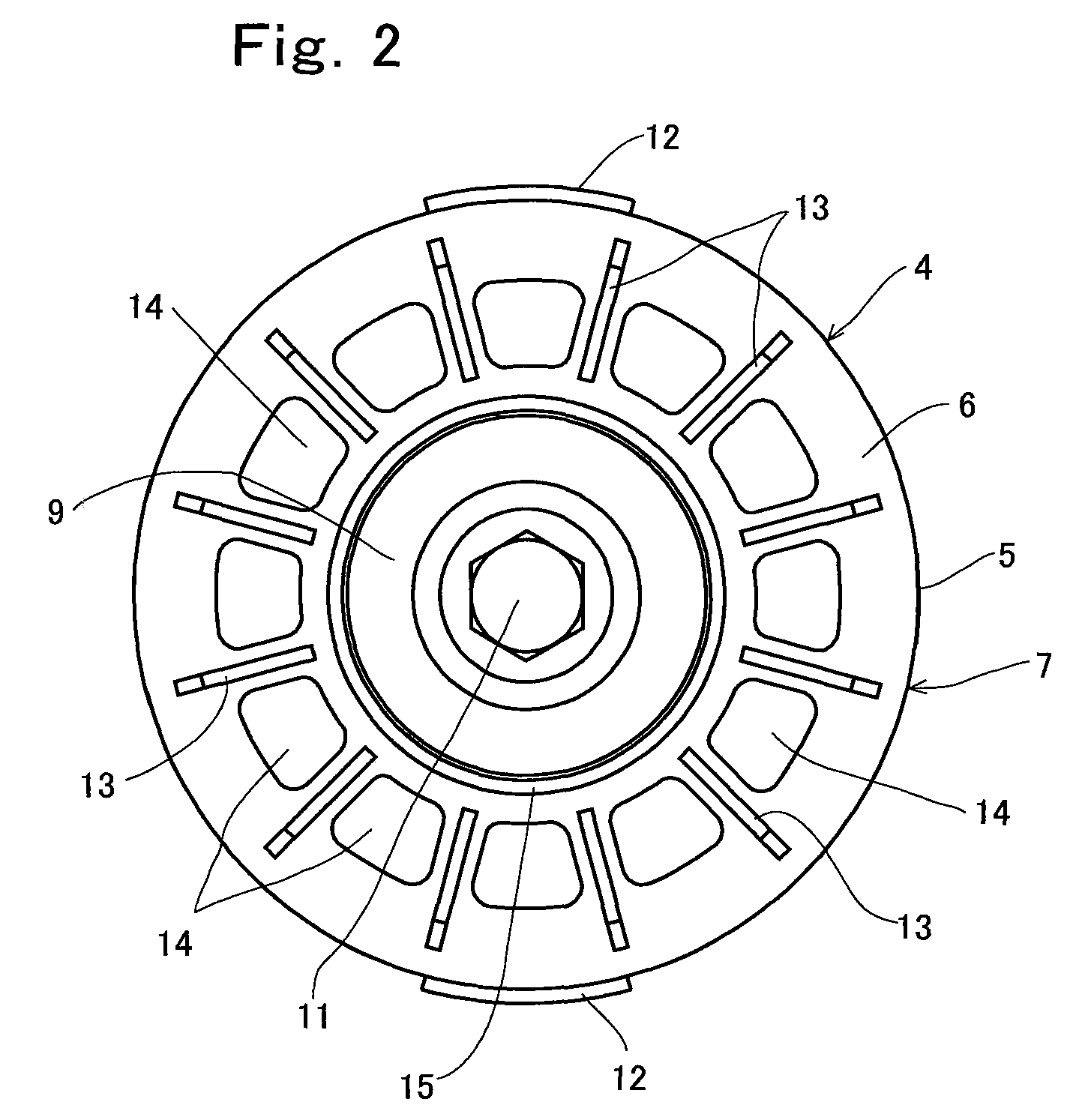

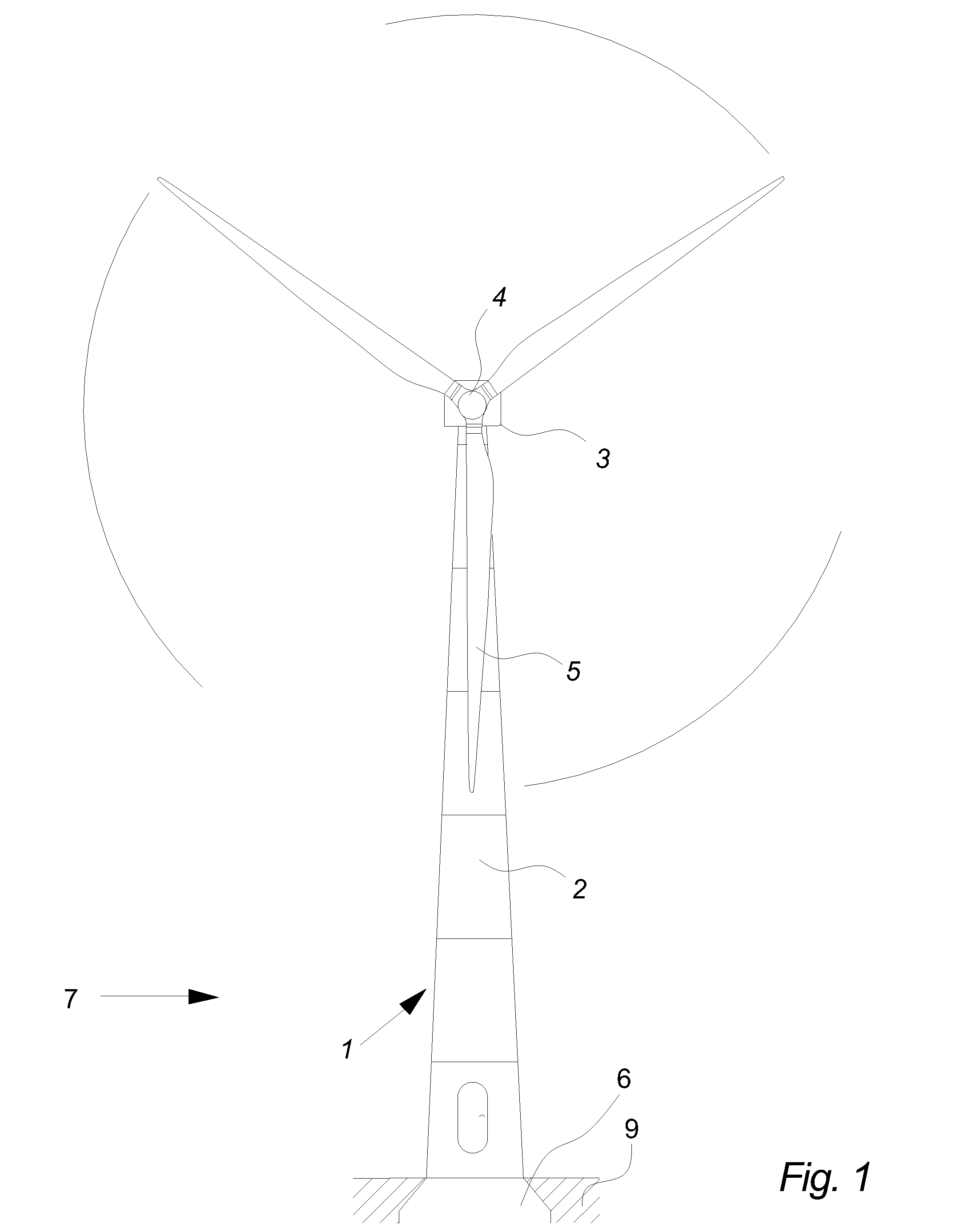

Brake system, generator and wind turbine

ActiveUS20110121579A1Absorption of heatImprove braking efficiencyWind motor controlAxially engaging brakesEngineeringTurbine

A brake system, especially for a generator, including a rotor assembly, a stator assembly and a rotation axis is disclosed. The rotor assembly includes an outer portion which is located radially outward of the stator assembly. The outer portion includes a brake disc, and the stator assembly comprises at least one frictional member operatively configured for frictionally engaging at least a portion of the brake disc.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

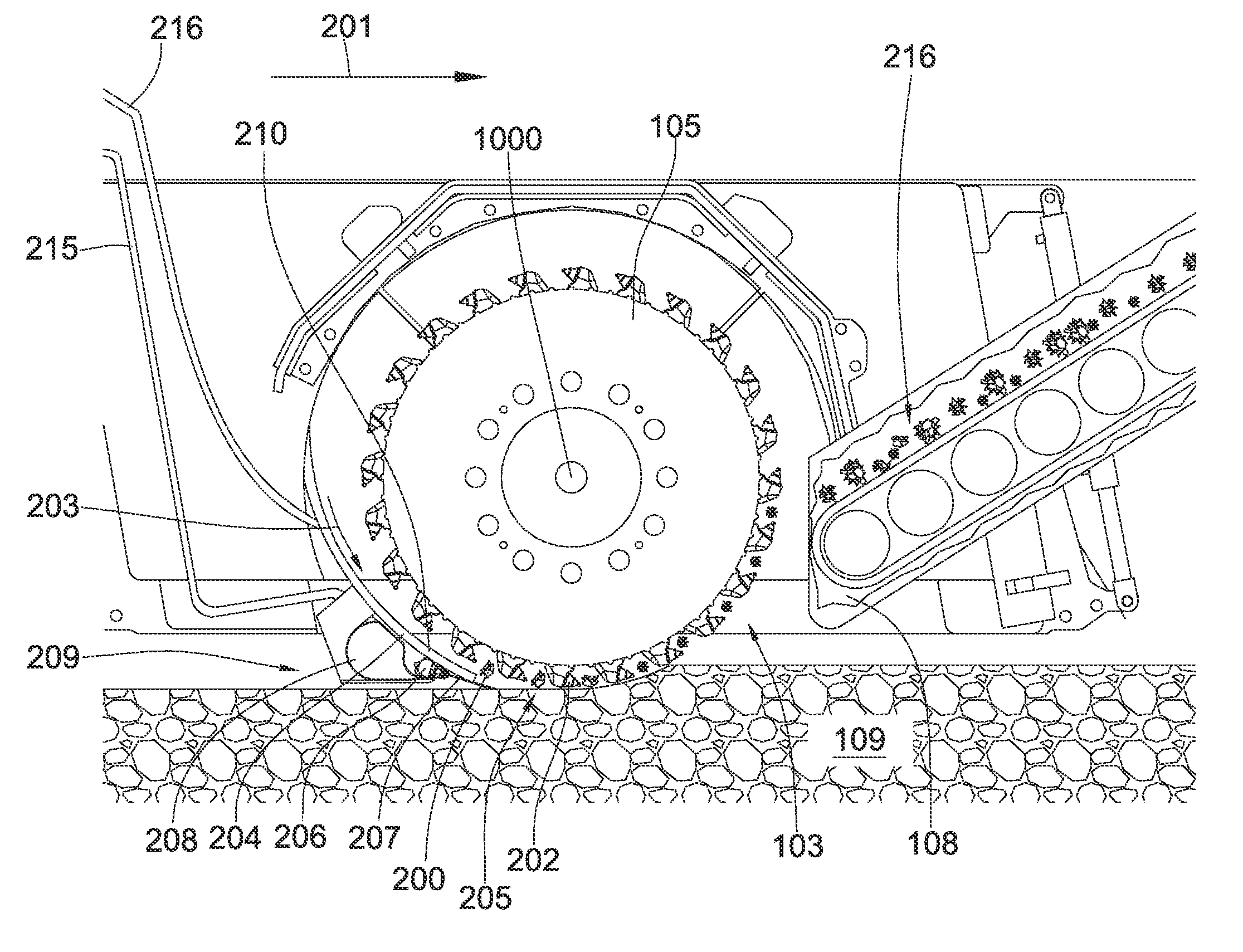

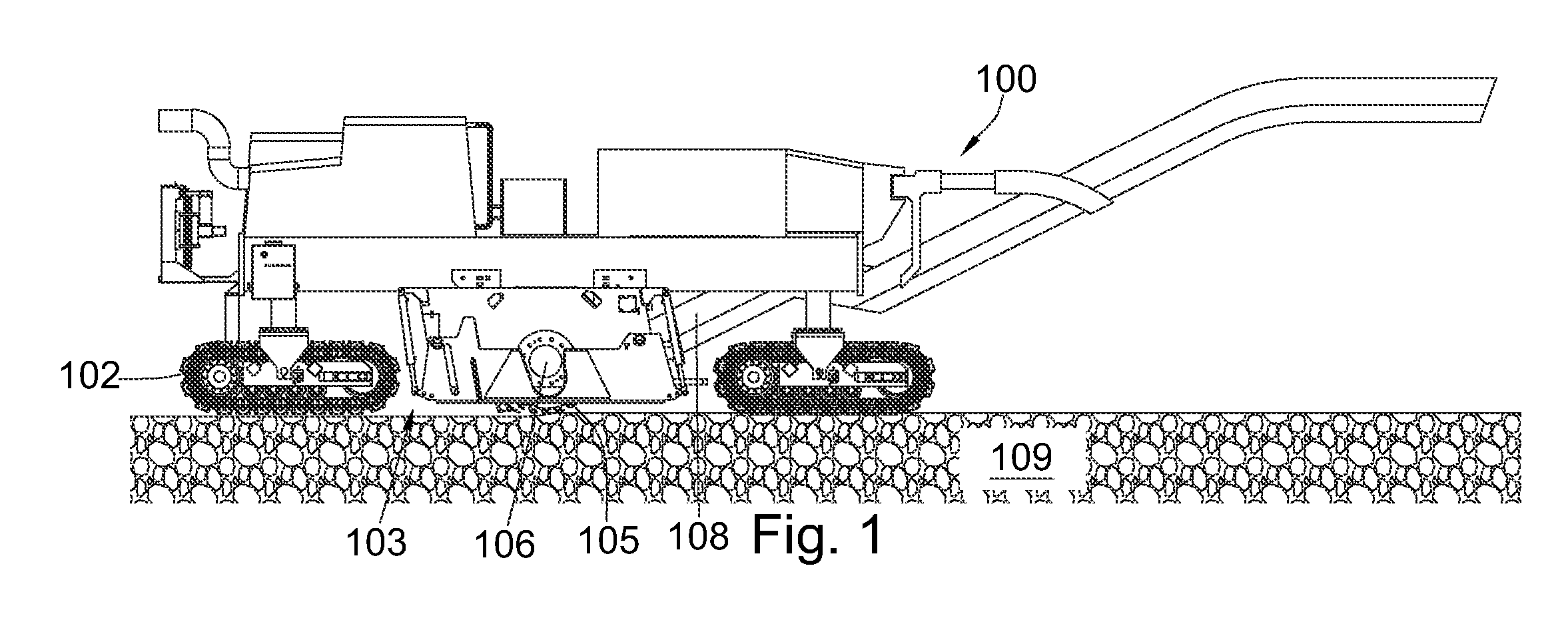

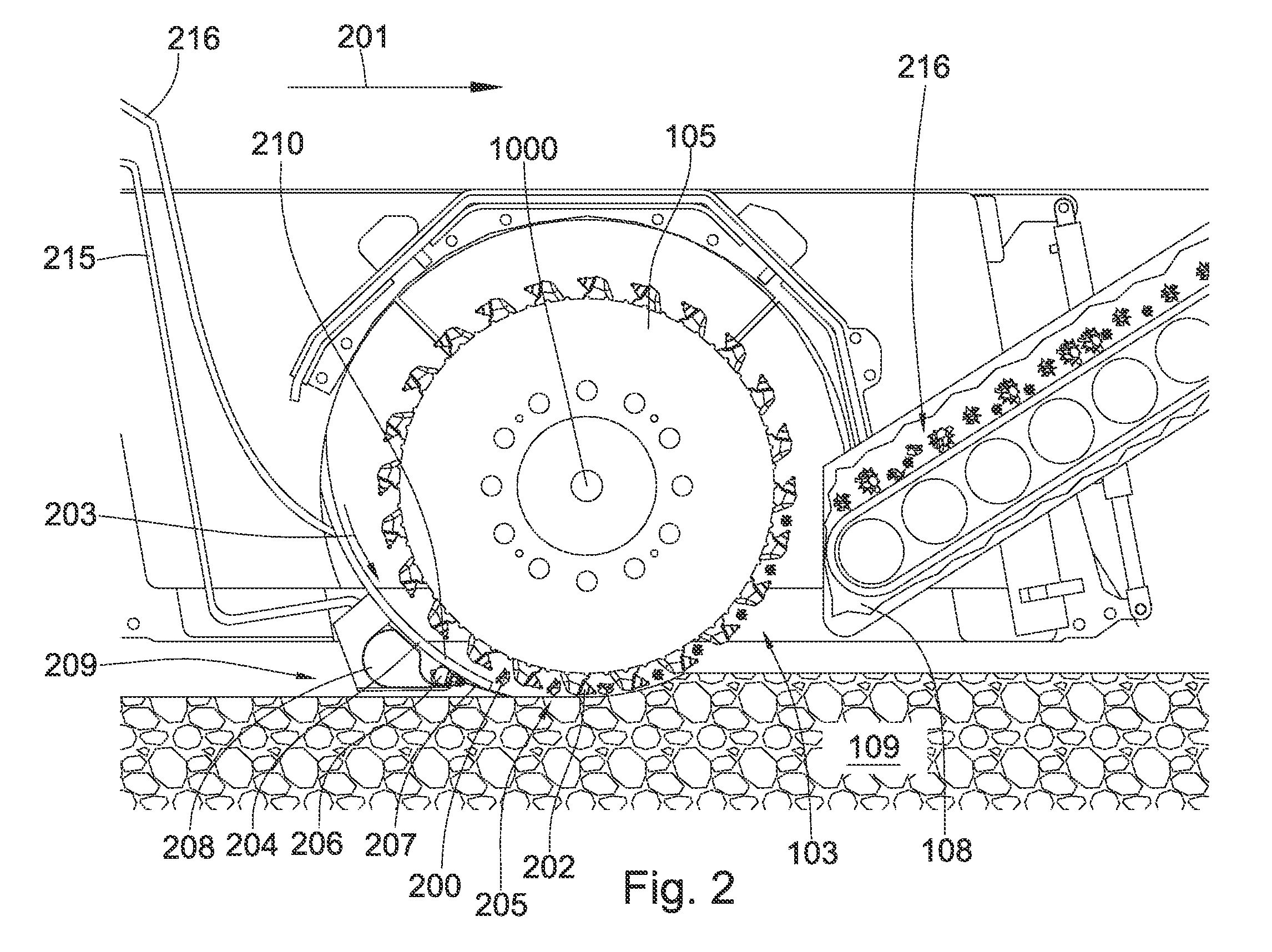

End of a moldboard positioned proximate a milling drum

InactiveUS7976239B2Avoid excessive accumulationLimit proximityRoads maintainenceCutting machinesMobile vehicleEngineering

In one aspect of the present invention, the present invention is a system for removing aggregate from a paved surface. The system includes a motorized vehicle with a degradation drum that is connected to the underside of the vehicle. The degradation drum is enclosed by a milling chamber. The milling chamber is defined by having a plurality of plates, including a moldboard positioned rearward of the milling drum. The moldboard comprises an end that is disposed opposite the underside. The end comprises a section that is proximate the milling drum.

Owner:CATEPILLAR SARL +1

Starter generator

InactiveUS7888828B2Avoid coolingAbsorption of heatMagnetic circuit rotating partsMechanical energy handlingStarter generatorEngineering

A starter generator which includes a rotor having a cuplike-shaped rotor yoke and magnets attached to an inner periphery of the rotor yoke, a stator mounted on a stator bracket and a protecting cover covering said rotor and stator, in which a hermetically sealed casing is constituted by said protecting cover and stator bracket, wherein a plurality of fans are provided on an outer surface of a bottom wall portion of said rotor yoke, a plurality of vent holes are provided through said bottom wall portion, said plurality of fans constitute a centrifugal fan which draws out air inside the rotor yoke through said vent holes and sends the air to an outer periphery of the rotor yoke, and a guide surface which guides the air sent to the outer periphery of the rotor yoke to a space inside the rotor yoke is provided on the stator bracket.

Owner:KOKUSAN DENKI CO LTD

Process for formulating a liquid animal feed ingredient containing sugar and neutralized carboxylic acid

InactiveUS6126986AReduce needAbsorption of heatConfectioneryAnimal feeding stuffAdditive ingredientCarboxylic acid

The present invention provides a process that can utilize aqueous sugar-bearing sources, including food commodities, food-processing by-products, fermentation by-products, or other industrial by-products, in the making of a liquid animal feed ingredient that contains sugar and carboxylic acid salt. In general, the process according to the invention comprises mixing: (a) an aqueous sugar-bearing source characterized by having: (i) a total monosaccharide and disaccharide sugar content of at least 5.0 weight percent based on the amount of the aqueous sugar-bearing source, and more preferably, an invert sugar content of at least 5.0 weight percent based on the amount of the aqueous sugar-bearing source; and (ii) a water content of at least 10 weight percent; (b) carboxylic acid having in the range of 1-8 carbon atoms; and (c) inorganic base; wherein the step of mixing the carboxylic acid and the inorganic base is at least partially performed in the presence of the aqueous sugar-bearing source, and wherein the proportions of the aqueous sugar-bearing source, carboxylic acid, and inorganic base are selected such that: (i) the total monosaccharide and disaccharide sugar concentration is at least 3.0 weight percent of the resulting mixture; (ii) the carboxylic acid equivalent concentration is at least 0.5 equivalent per 1,000 g of the resulting mixture; (iii) the pH of the resulting mixture is at least 3.5; and (iv) the viscosity of the resulting mixture is less than about 40,000 centipoise when measured at about room temperature and at about standard atmospheric pressure. The inorganic base at least partially neutralizes the carboxylic acid to form the carboxylic acid salt in the resulting animal feed ingredient and the aqueous sugar-bearing source absorbs at least some of the heat of neutralization.

Owner:WESTWAY FEED PRODS

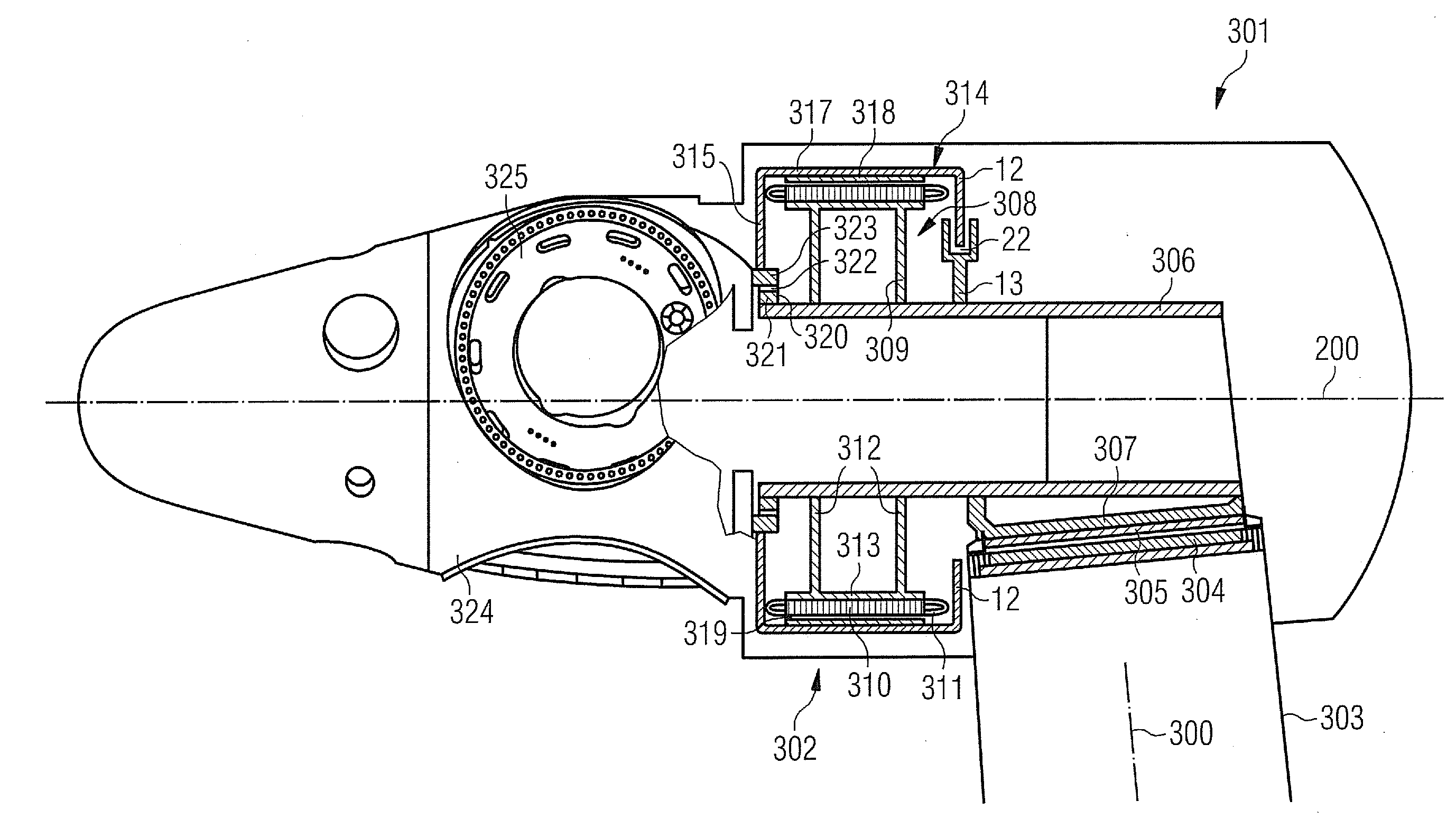

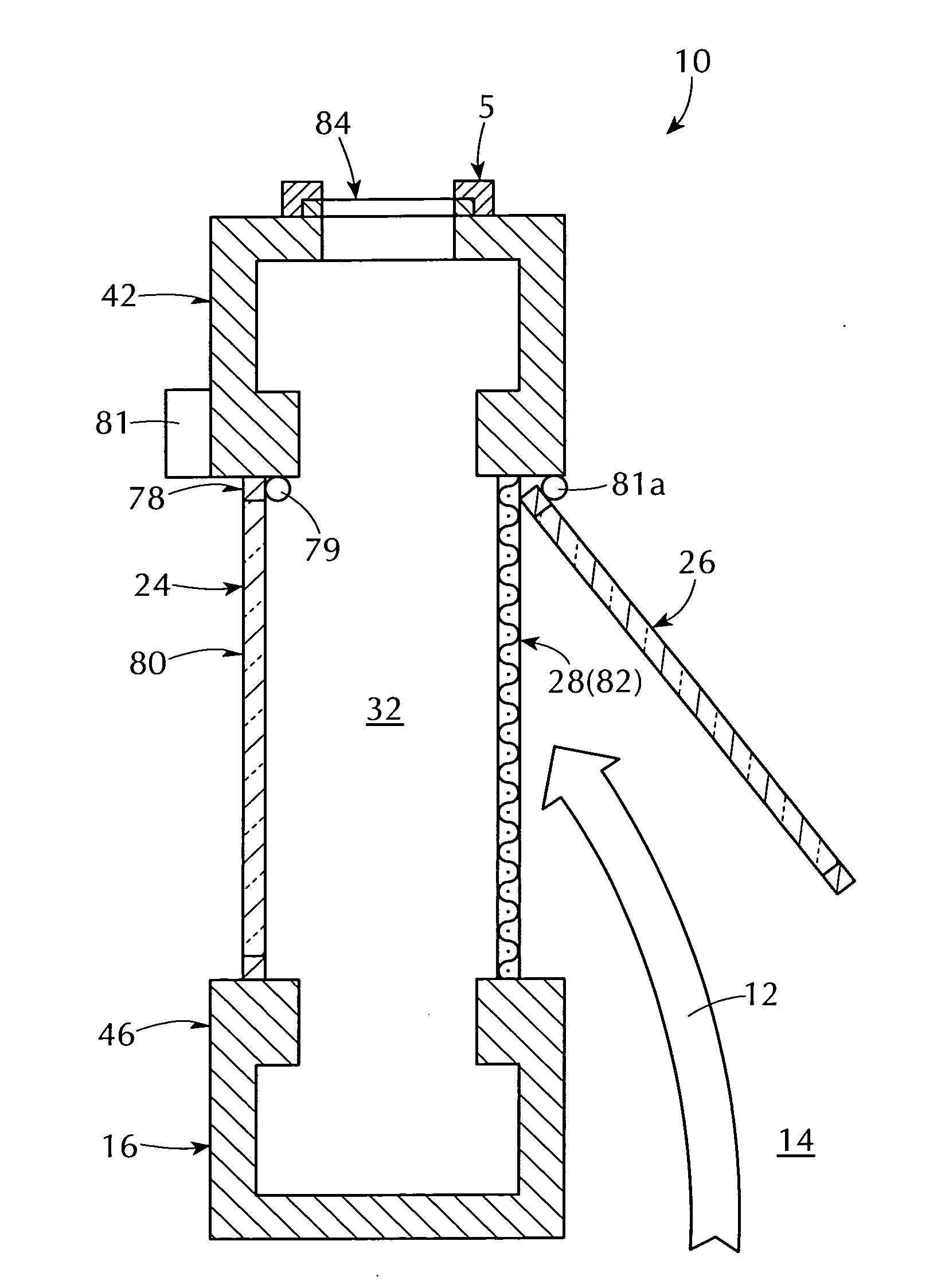

Wind Energy Converter, A Method And Use Hereof

InactiveUS20100008776A1Simple and cost-efficientAbsorption of heatPropellersPump componentsEnergy converterEngineering

A wind energy converter includes a wind turbine, a wind turbine foundation and a temperature control mechanism for controlling the temperature of one or more areas of the wind turbine. The temperature control mechanism including a mechanism for exchanging heat. The wind energy converter is characterized in that the mechanism for exchanging heat is positioned in the ground outside the foundation. Also contemplated is a method for controlling the temperature of one or more areas of a wind energy converter and use thereof.

Owner:VESTAS WIND SYST AS

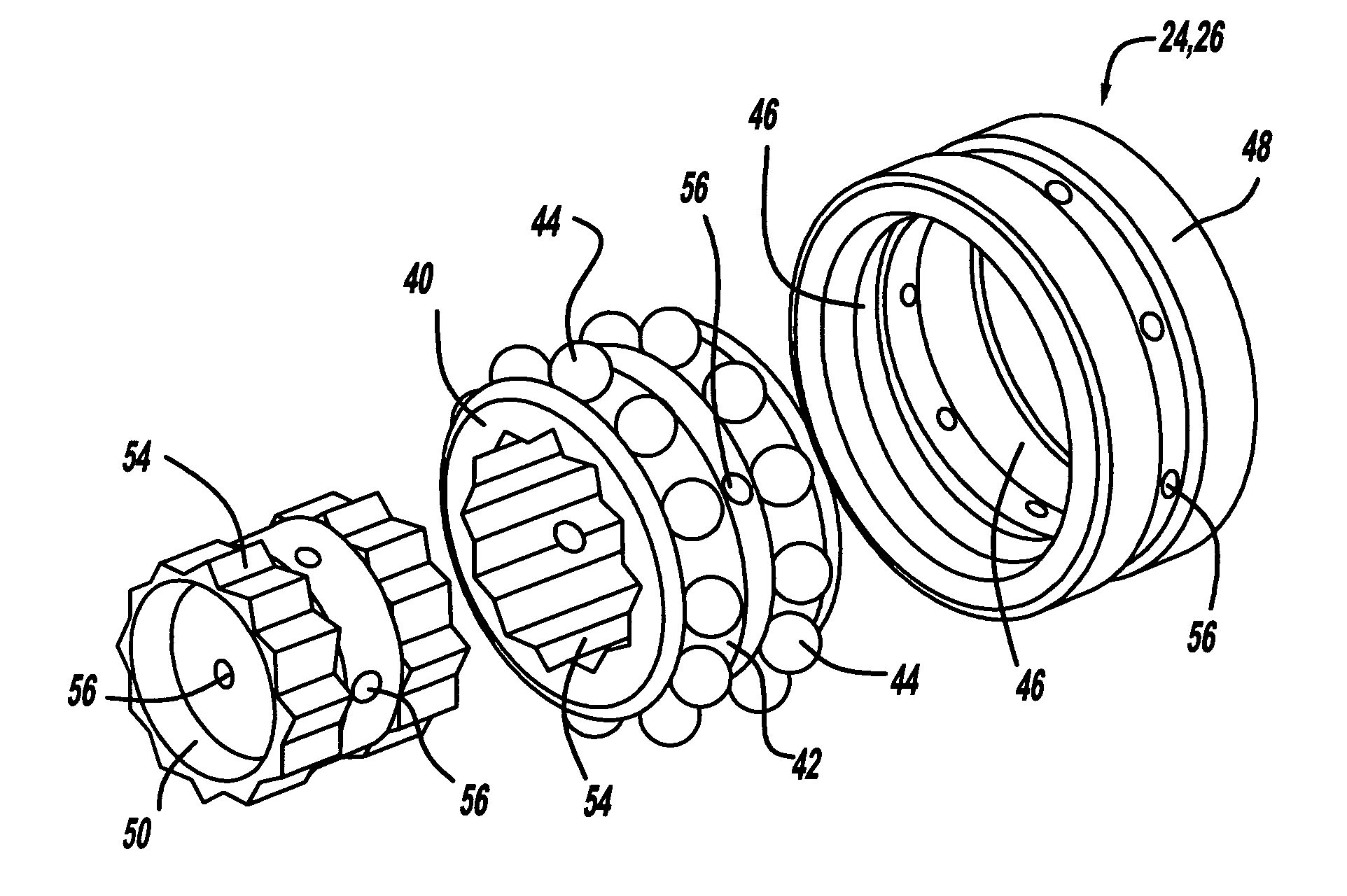

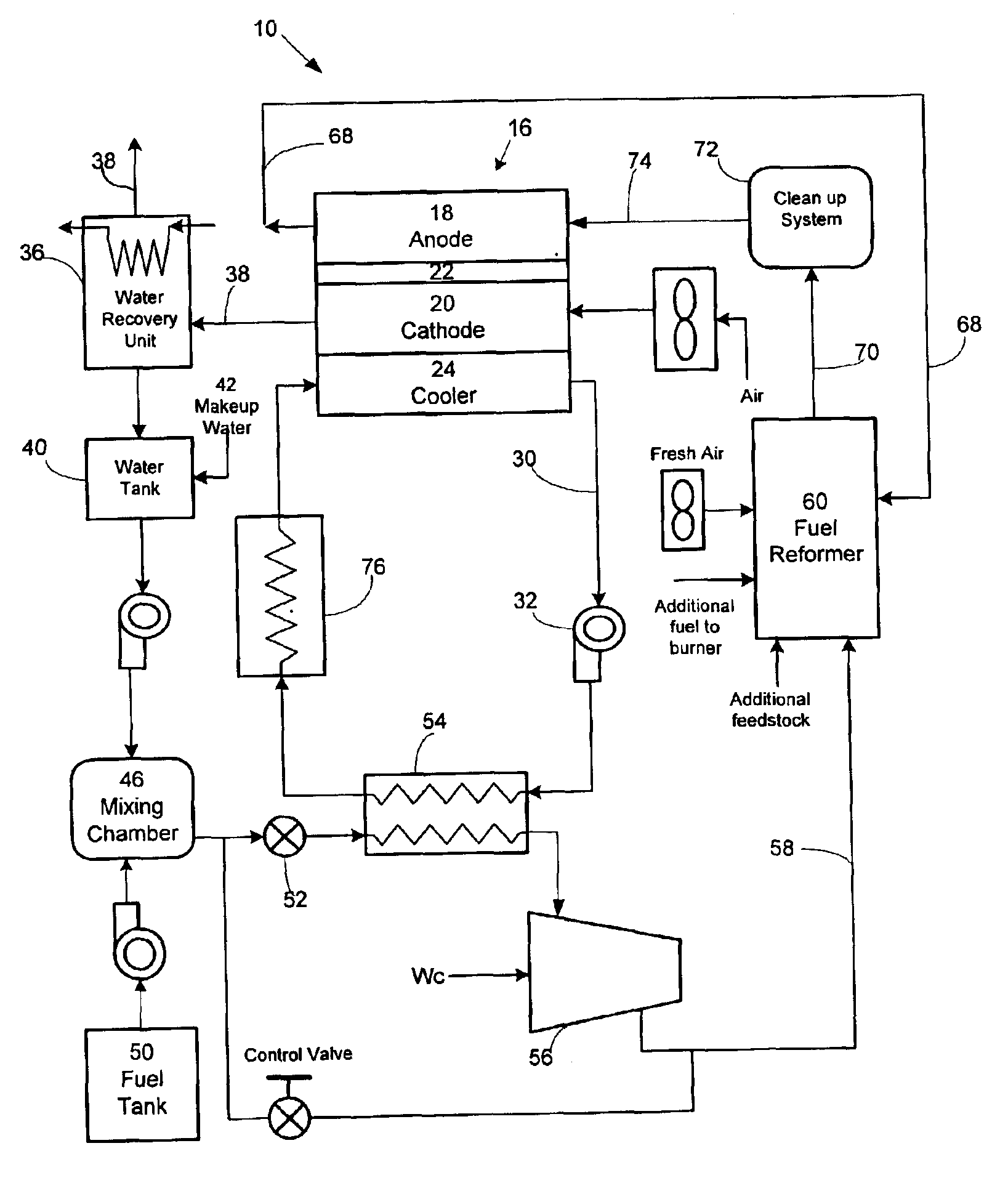

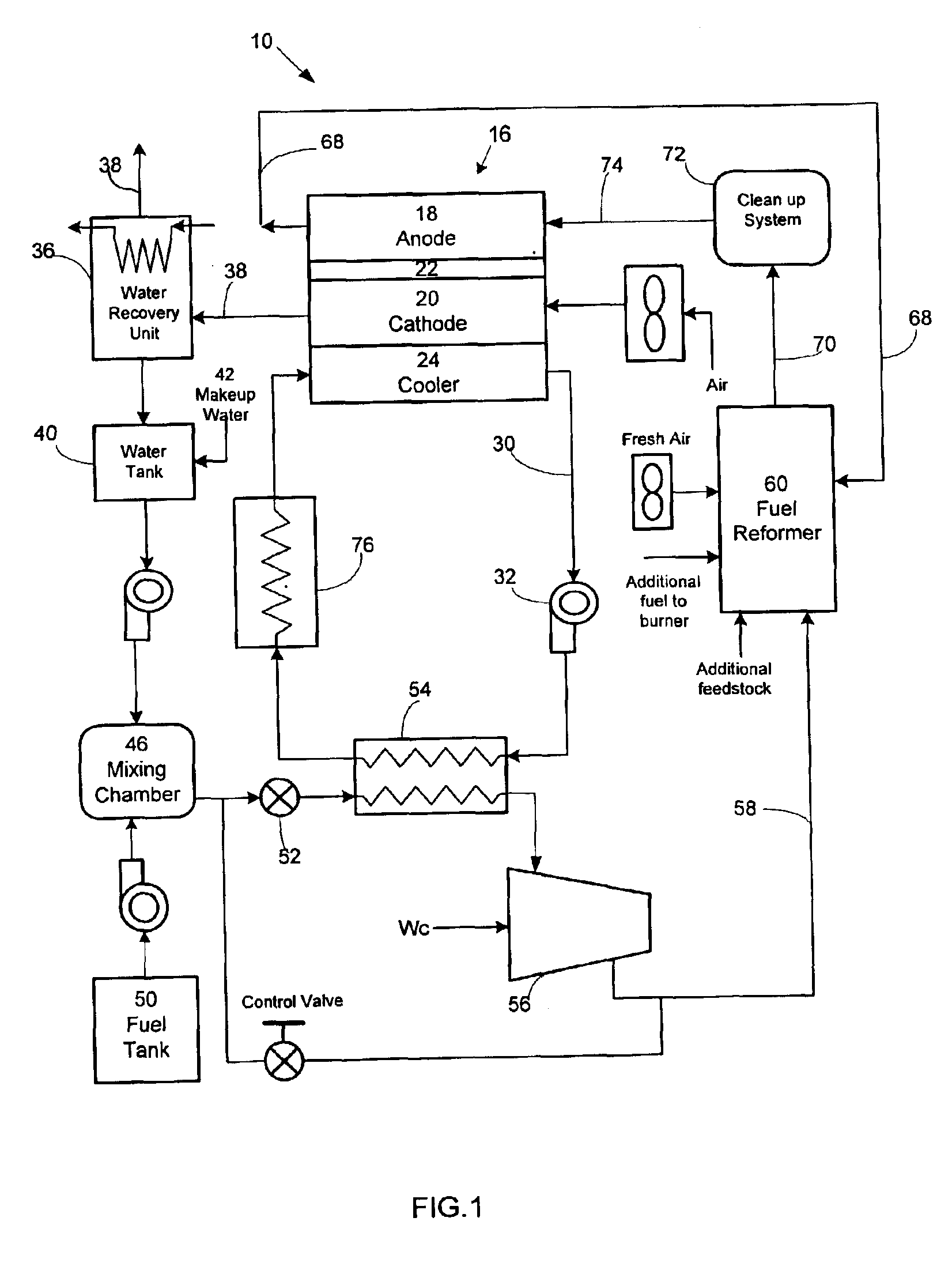

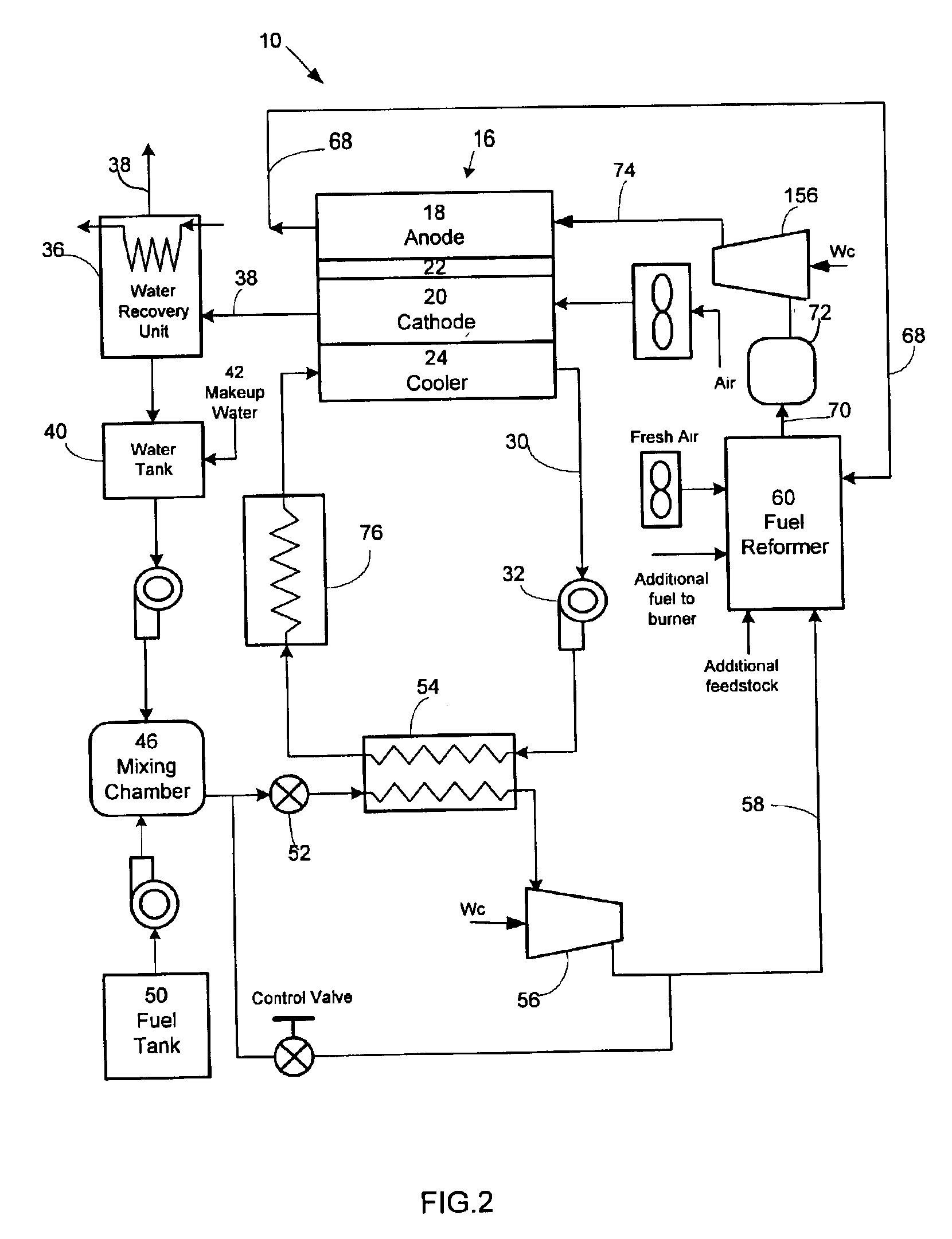

Waste heat recovery means for fuel cell power system

InactiveUS6926979B2Improve heat transfer performanceReduce thermal energyFuel cells groupingFuel cell auxillariesWaste heat recovery unitPlate heat exchanger

A fuel cell power system includes at least a fuel cell stack, a cooling means which removes the waste heat generated within the fuel cell stack, a fuel reformer which reforms a hydrocarbon for the fuel supply to the fuel cell stack, and an energy recovery system, which includes an expansion valve for reducing the pressure of the feedstock to the energy recovery system, a heat exchanger for facilitating the heat transfer from the cooling means of the fuel cell stack to the feedstock of the energy recovery system, and at least a compressor for raising the pressure of the feedstock to a sufficiently high level and delivering the feedstock to the fuel reformer, thereby a substantially large portion of the waste heat is recovered and used to vaporize the feedstock. As a result, the fuel utilization of the fuel cell power system is significantly improved due to a reduced heat input to the fuel reformer, and the size of the radiator and the associated power consumption for dissipating the waste heat into the surroundings is substantially reduced.

Owner:CAO YIDING

Liquid-cooled LED lighting device

ActiveUS8419249B2Increase pressureIncrease temperatureLighting support devicesPoint-like light sourceEffect lightEngineering

A cooling liquid can be circulated in a liquid cooling system, so that a light source unit and a control unit can be forcedly cooled by the cooling liquid. Thus, a temperature increase in these components can be suppressed, thereby achieving an increase in the output power of a liquid-cooled LED lighting device. The liquid-cooled LED lighting device can include a housing, a light source unit having LEDs as light sources, a liquid cooling system, and a control unit to control the light source unit to be turned on. The liquid cooling system can include a heat receiving jacket, a radiator, a circulation pump and a fan. The light source unit and the control unit can be disposed with the heat receiving jacket of the liquid cooling system interposed therebetween. Further, one surface of the control unit can be brought in close contact with the heat receiving jacket while a heat radiation portion (e.g., fins or pins) can be provided at an other surface of the control unit.

Owner:STANLEY ELECTRIC CO LTD

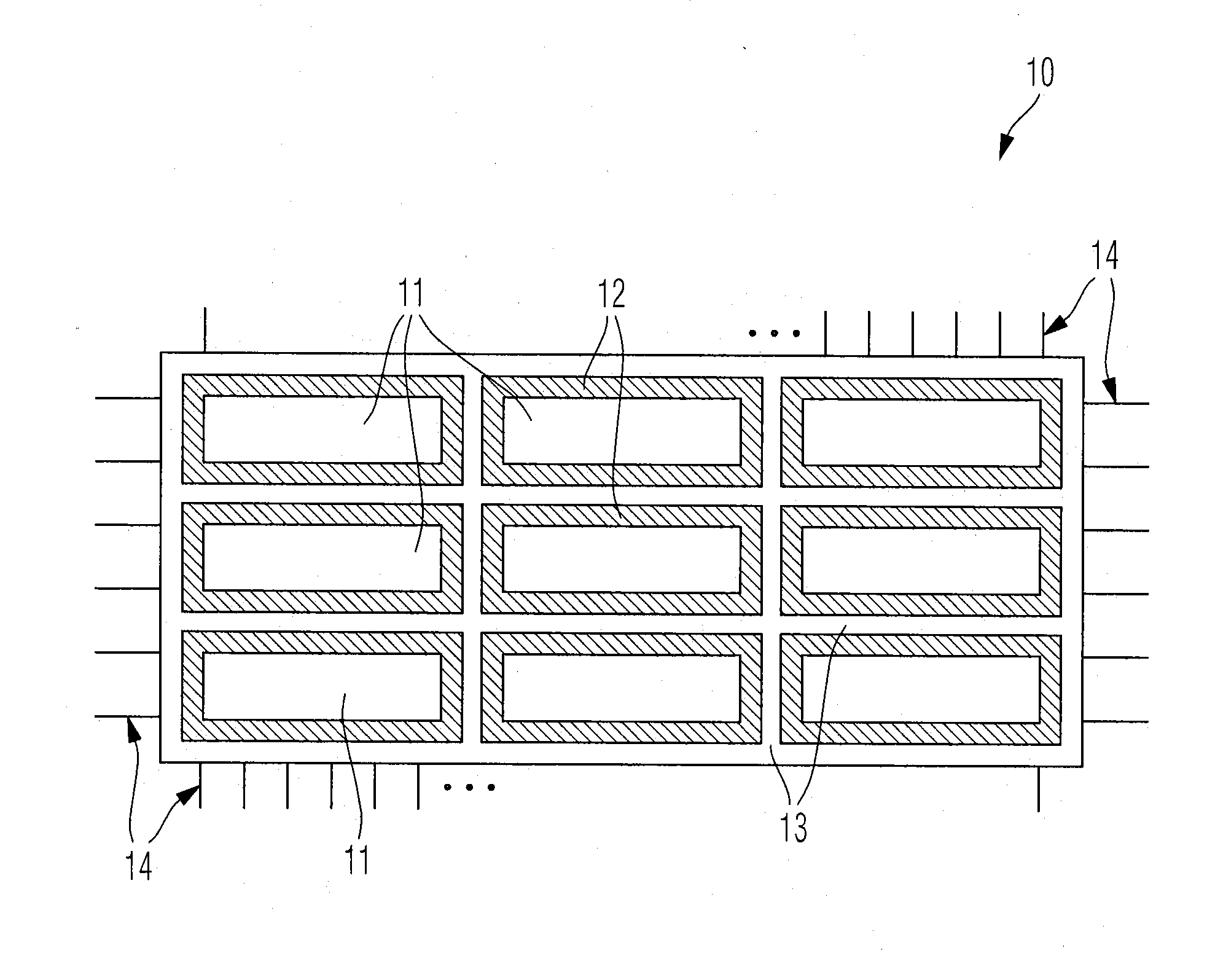

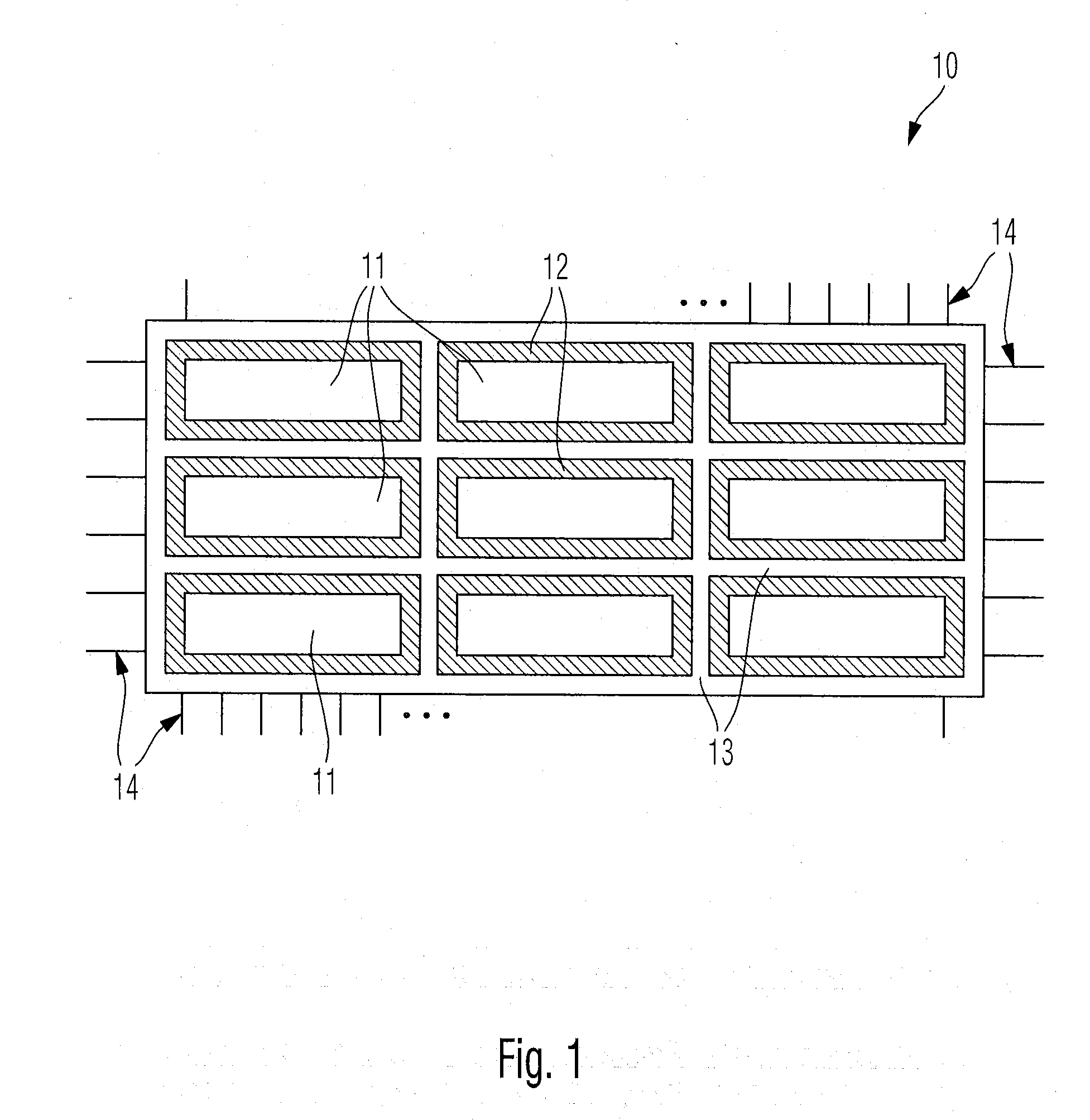

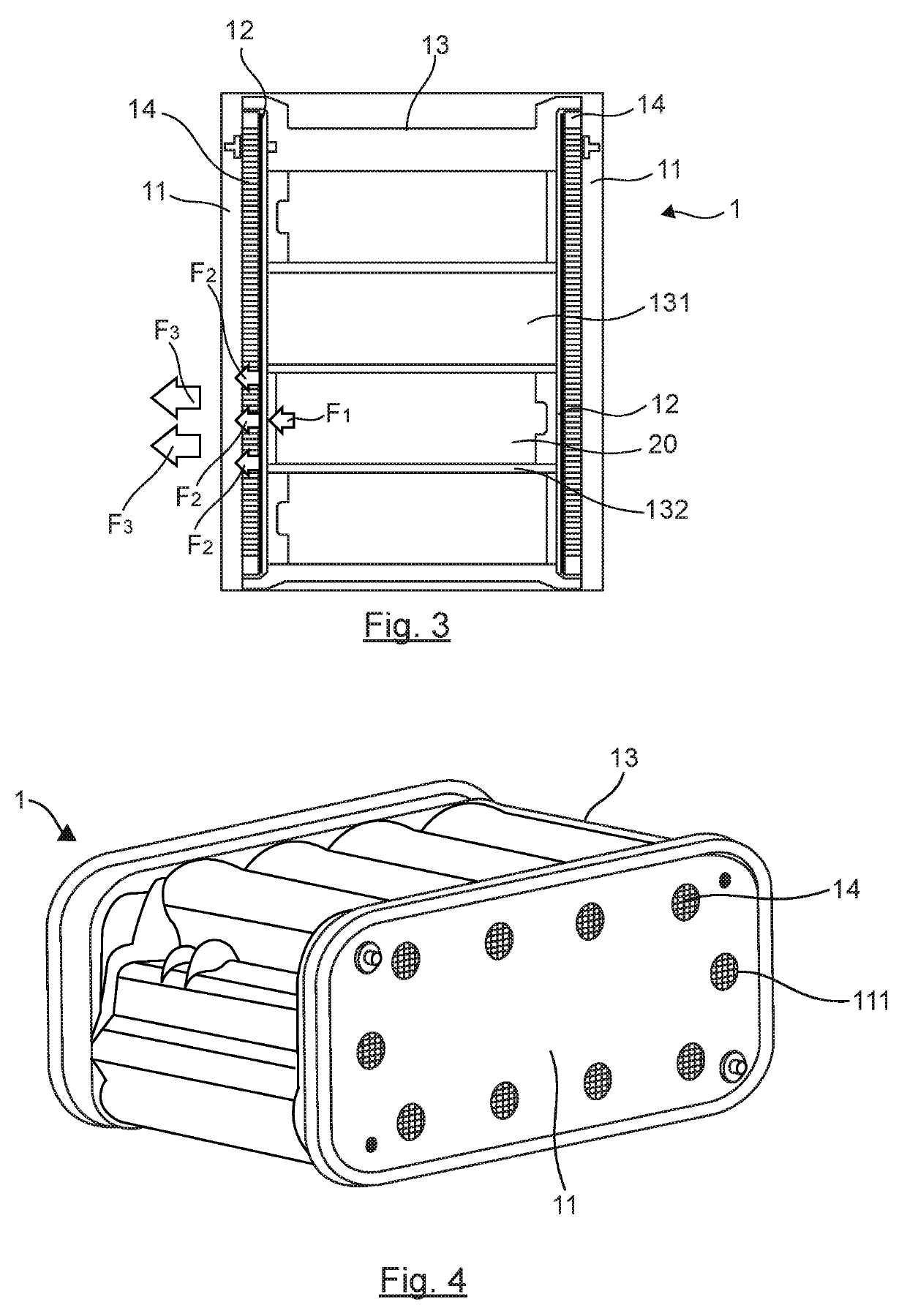

Energy store for a motor vehicle

ActiveUS20110236741A1Simple and reliable processIncrease heating capacityCell temperature controlJackets/cases materialsMotorized vehicleBattery cell

An energy store for a motor vehicle for storage and emission of electrical energy as required, having a multiplicity of cells which are positioned one above the other and / or alongside one another like an array, wherein each cell is surrounded by a first material, wherein a second material is positioned between the cells which are surrounded by the first material and form a cell array, and wherein heat exchanging ribs are positioned at edges of the cell array.

Owner:DR ING H C F PORSCHE AG

Centrifugal heat dissipation device and motor using same

InactiveUS20120248907A1Increase loopImprove cooling effectMagnetic circuit rotating partsIndirect heat exchangersVapor liquidWorking fluid

A centrifugal heat dissipation device and a motor using same are disclosed. The centrifugal heat dissipation device includes a main body having a shaft hole, a heat-absorption zone and a heat-transfer zone. The heat-transfer zone has a radially outer side connected to the heat-absorption zone and a radially inner side connected to the shaft hole. The shaft hole axially extends through the main body for receiving a shaft of a motor therein. A centrifugal force generated by the rotating shaft and accordingly, the heat dissipation device enables enhanced vapor-liquid circulation of a working fluid in the heat dissipation device, so that heat generated by the operating motor is absorbed by the centrifugal heat dissipation device and transferred to the shaft for guiding out of the motor, allowing the motor to have largely upgraded heat dissipation performance.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

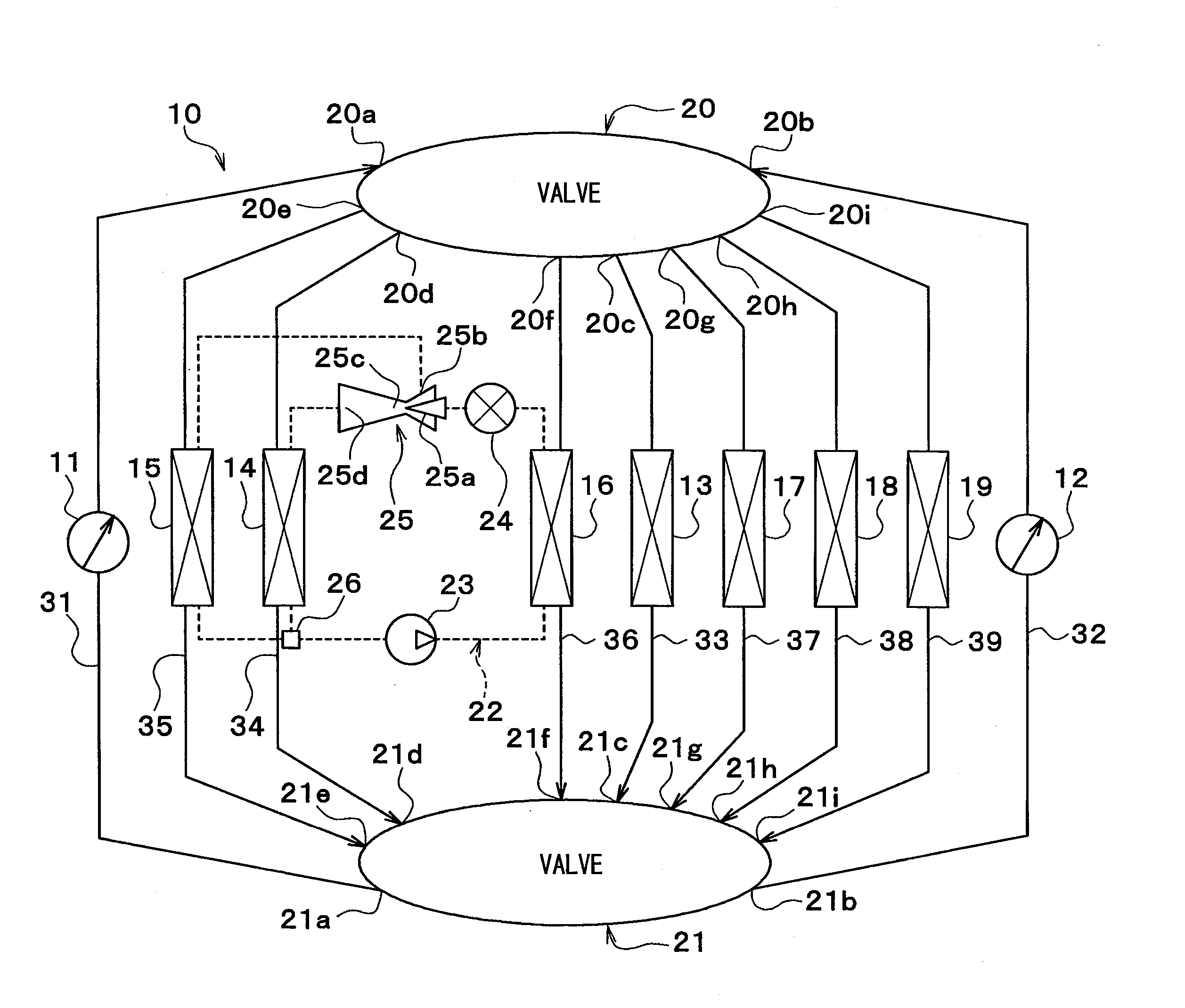

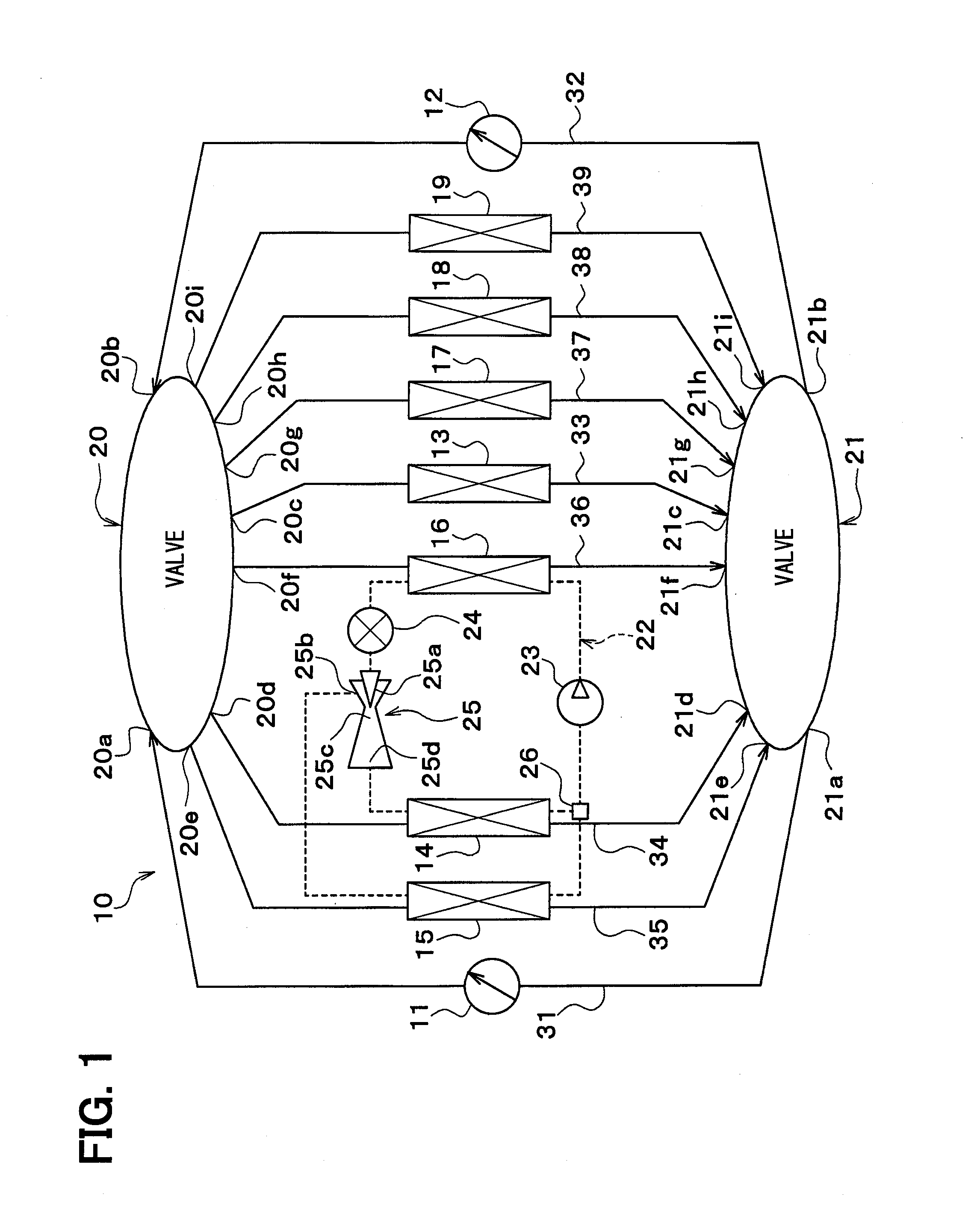

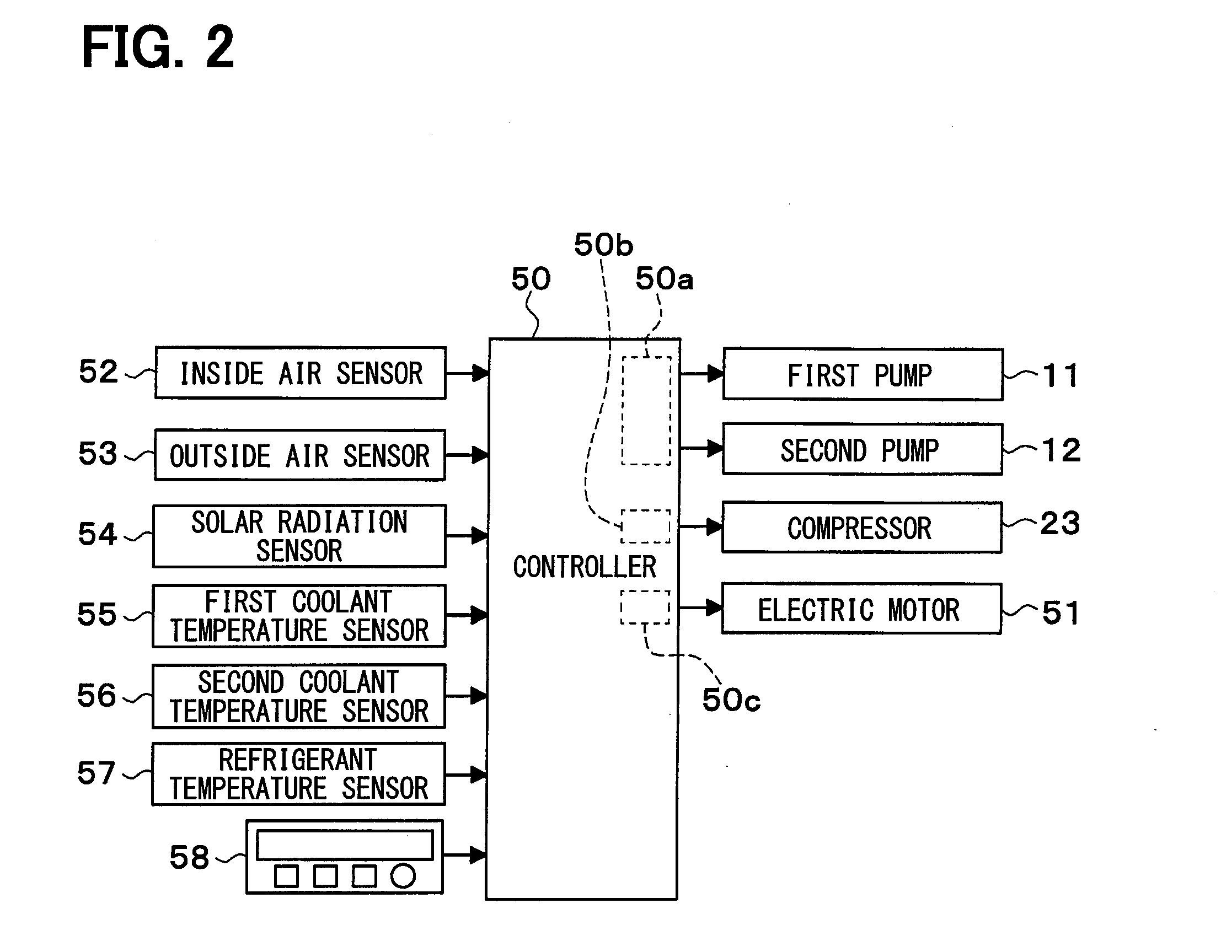

Air conditioning device for vehicle

ActiveUS20160178253A1Improve the heating effectLow densityHeat pumpsCompression machines with non-reversible cycleEngineeringAir conditioning

An air conditioning device for a vehicle has a compressor that supplies a high-pressure refrigerant by drawing and discharging a refrigerant, an air heating heat exchanger heating air that is to be blown into a vehicle cabin by using heat of the high-pressure refrigerant, a pressure reduction part expanding and decompressing the high-pressure refrigerant and supplying as an intermediate-pressure refrigerant and a low-pressure refrigerant, a first low-pressure side heat exchanger exchanging heat between the intermediate-pressure refrigerant and a heating medium other than the air, a second low-pressure side heat exchanger cooling the heating medium by exchanging heat between the low-pressure refrigerant and the heating medium, a first heating medium circuit through which the heating medium cooled in the second low-pressure side heat exchanger circulates, and a heating medium-air heat exchanger causing the heating medium to absorb heat by exchanging heat between the air and the heating medium circulating through the first heating medium circuit. The heating medium heated in the high-pressure side heat exchanger is capable of being introduced to the first low-pressure side heat exchanger.

Owner:DENSO CORP

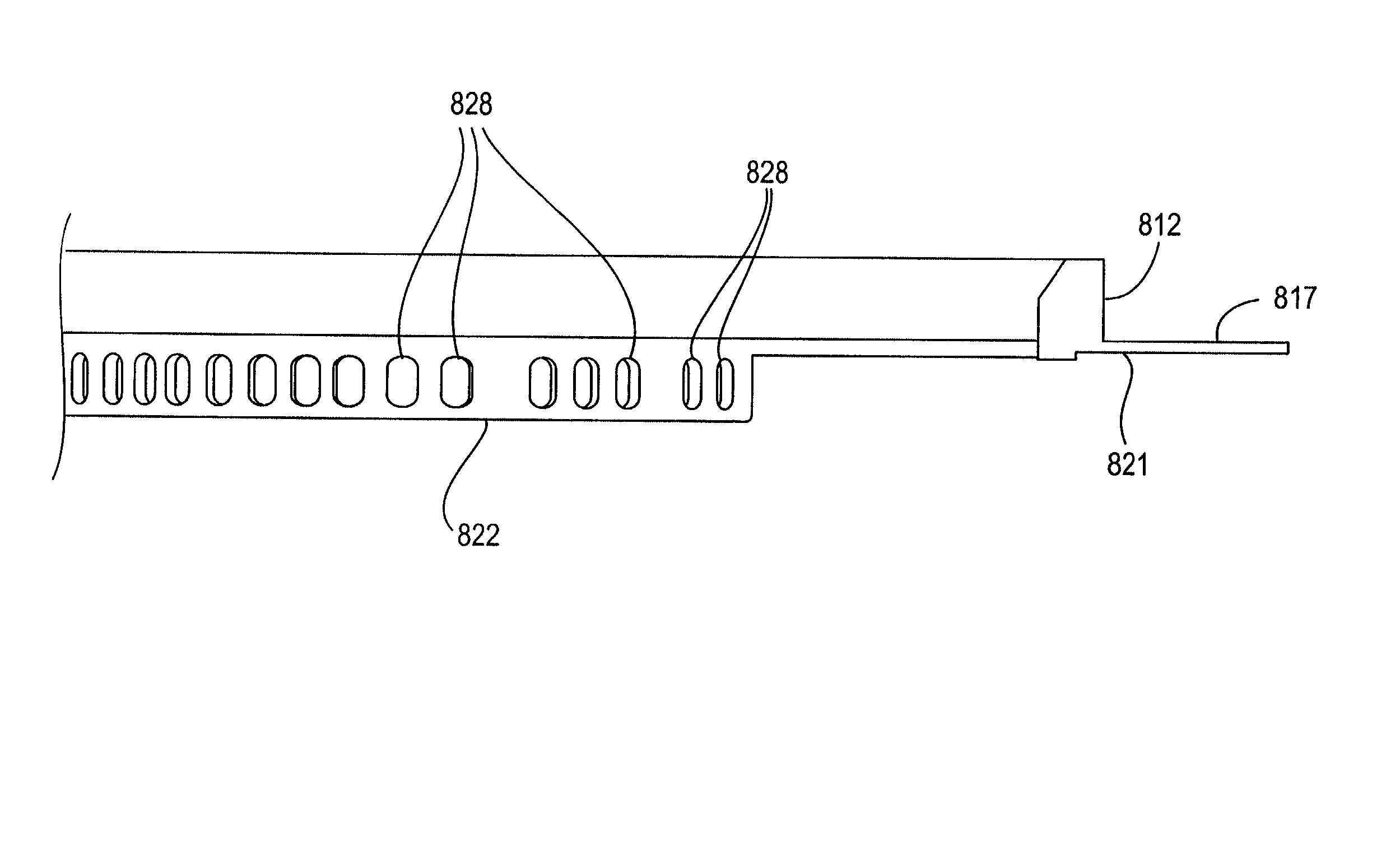

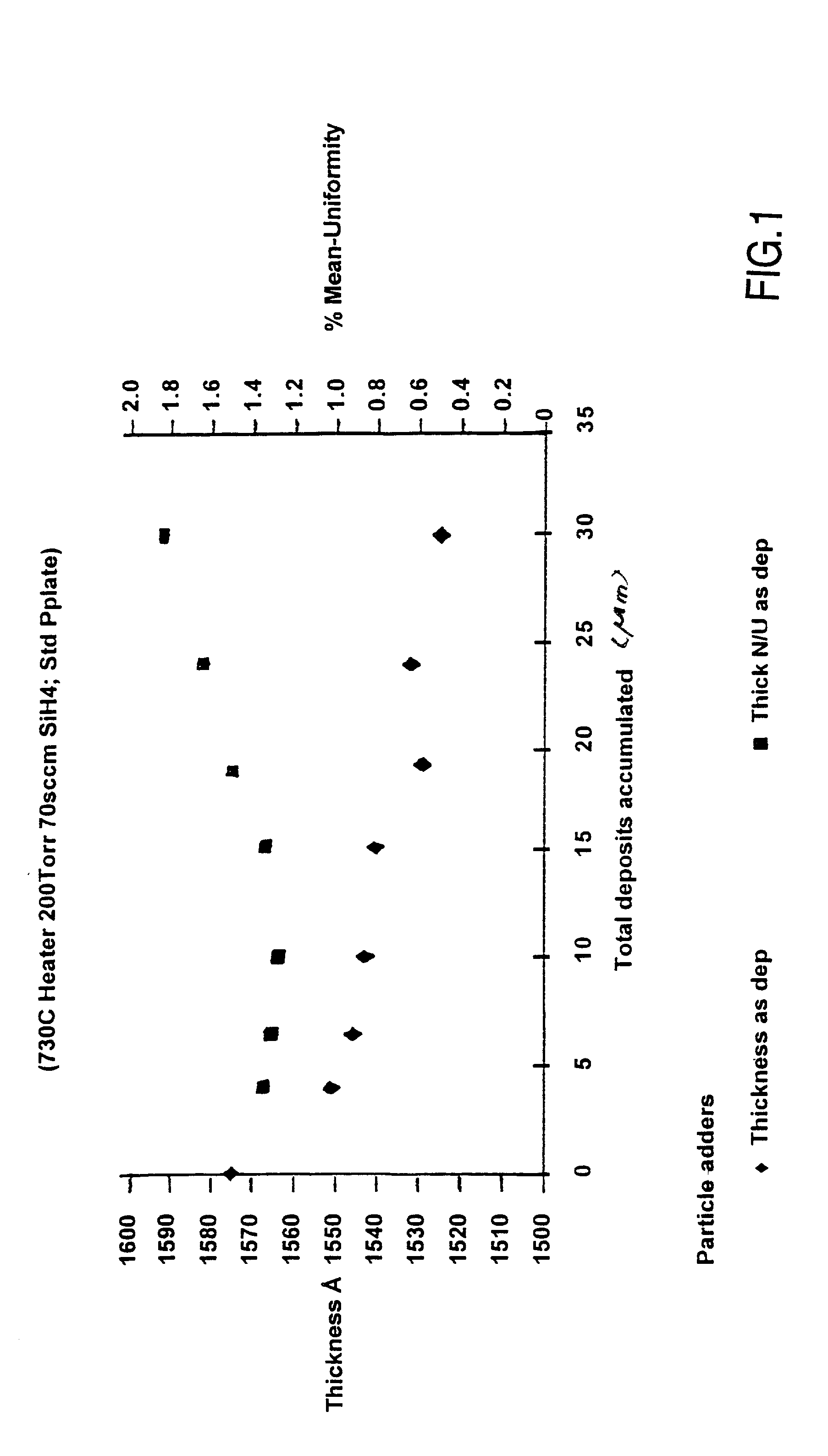

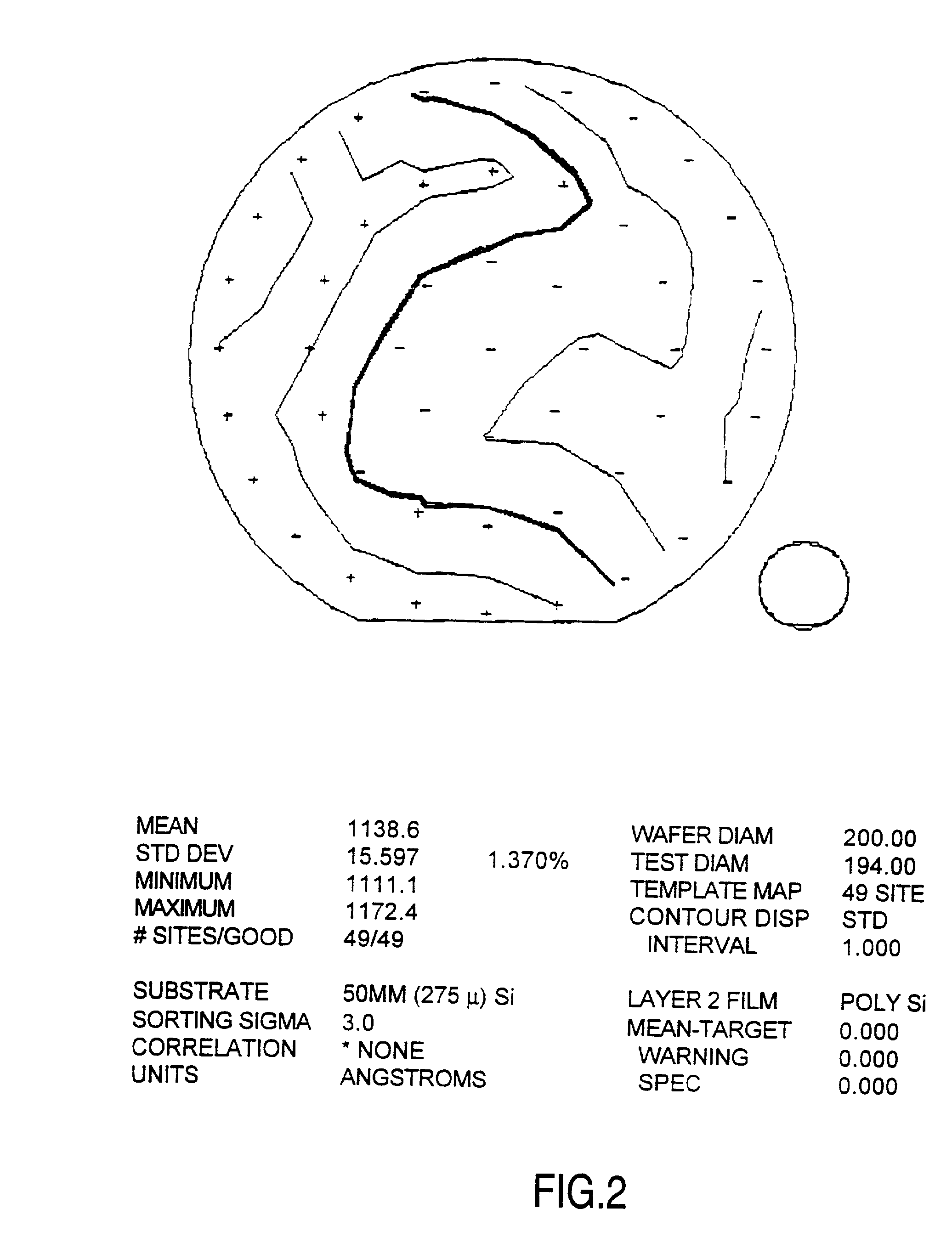

Emissivity-change-free pumping plate kit in a single wafer chamber

InactiveUS20020127508A1Preventing emissivity changeReduce powder formationFurnace componentsSemiconductor/solid-state device manufacturingSusceptorEmissivity

Owner:APPLIED MATERIALS INC

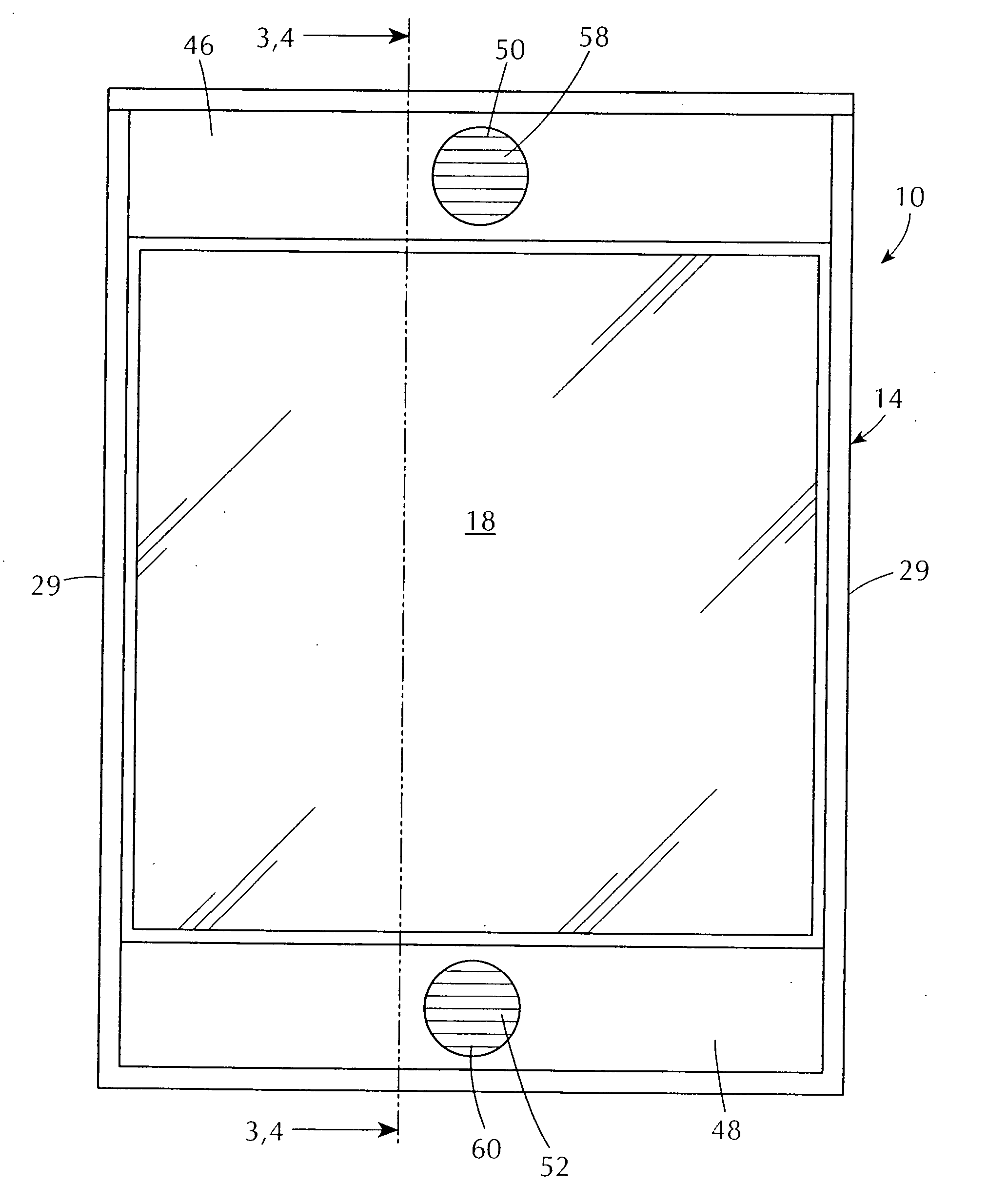

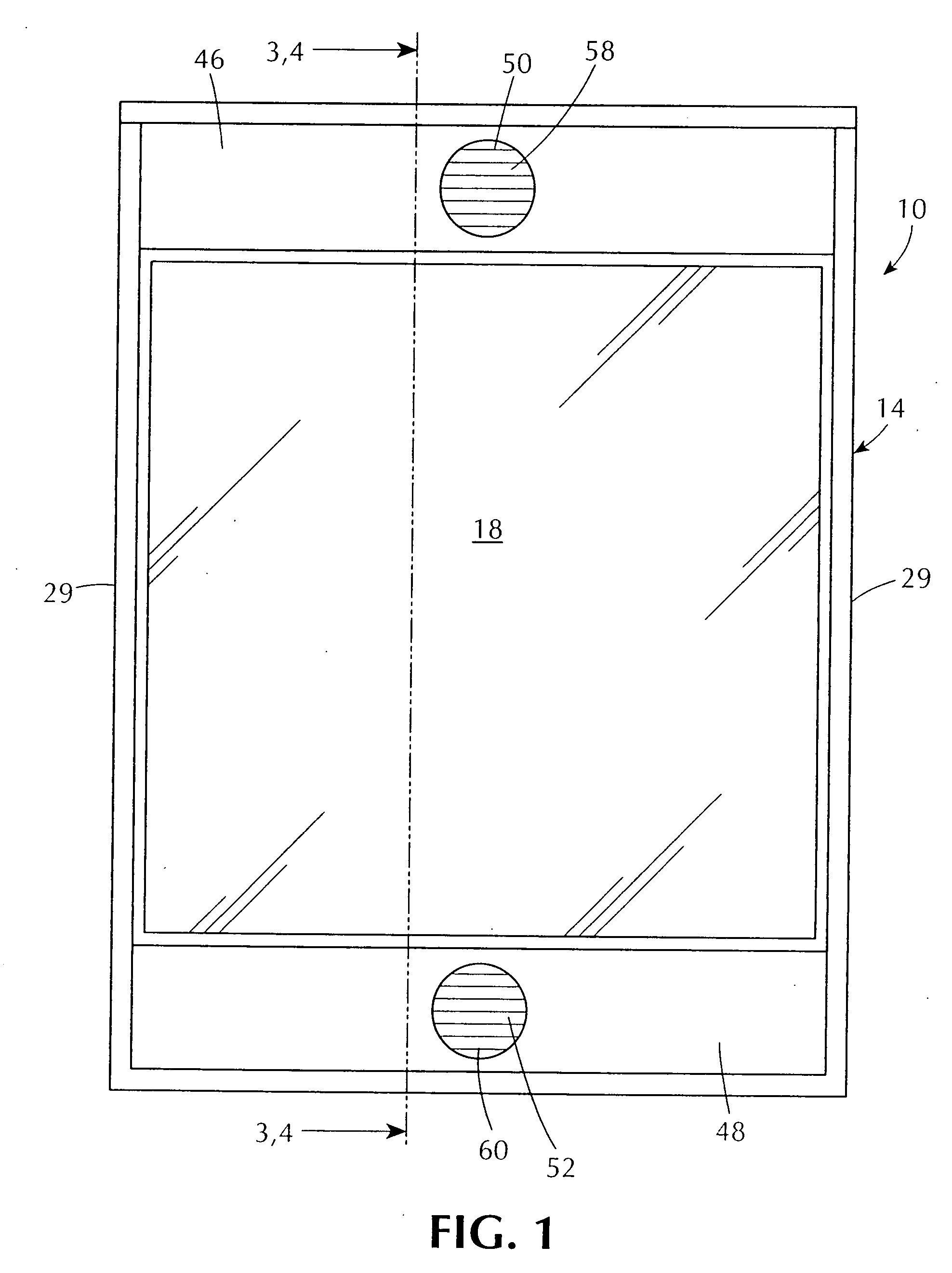

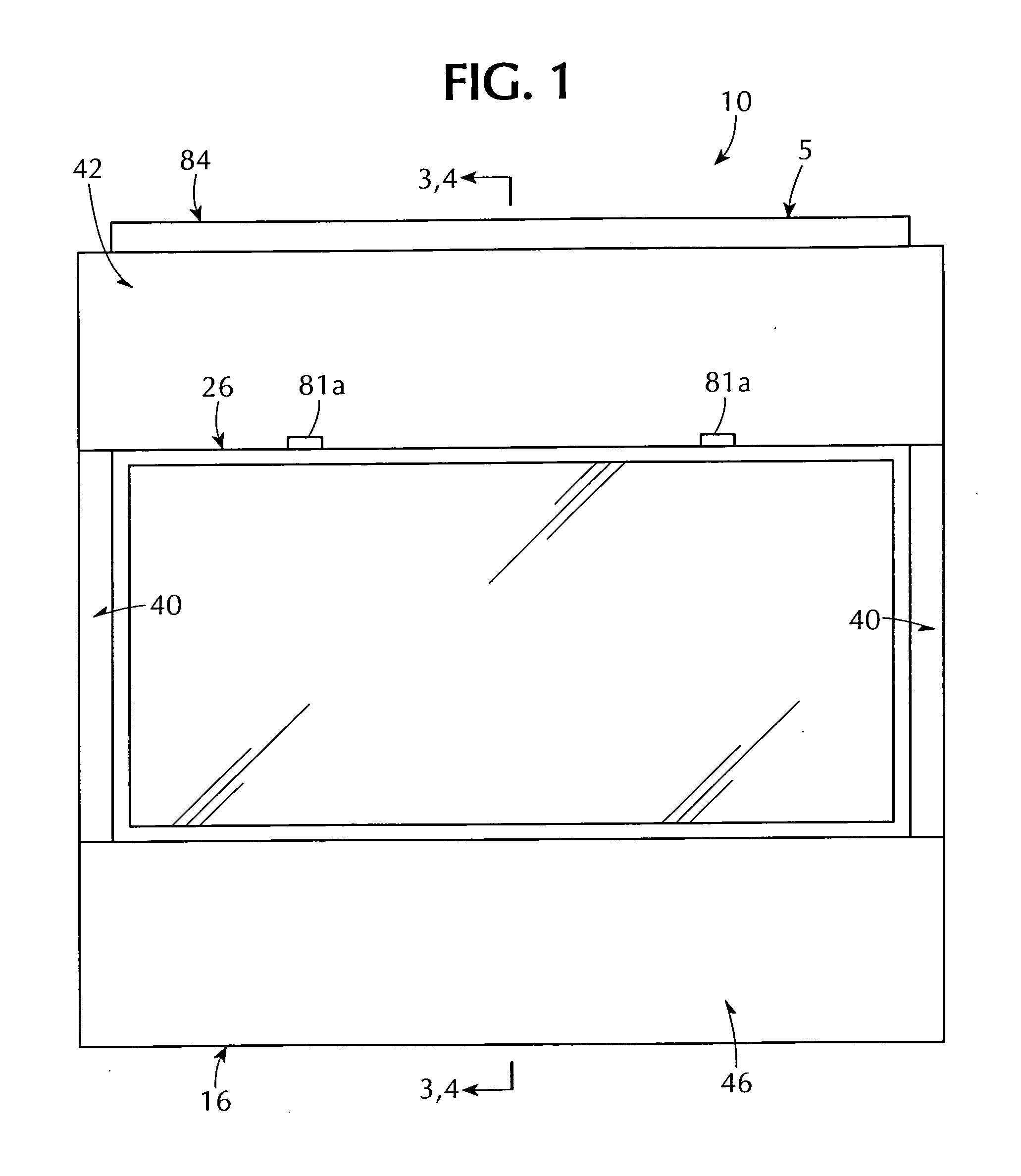

Window for absorbing sunlight heat in warm weather that otherwise would flow uncontrolled therethrough and discharging the sunlight heat to the atmosphere while permitting relatively unobstructed vision therethrough and passing the sunlight heat in cold weather therethrough for thermal warming

InactiveUS20070289231A1Absorption of heatPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringSunlight

A window for absorbing sunlight heat in warm weather that otherwise would flow uncontrolled therethrough and discharging the sunlight heat to the atmosphere while permitting relatively unobstructed vision therethrough and passing the sunlight heat in cold weather therethrough for thermal warming. The window includes a frame, an inner pane, an outer pane, and a heat sink. The inner pane is pivotally mounted to the frame. The outer pane is affixed to the frame and spaced from the inner pane so as to form a space therebetween. The heat sink is rotatably mounted to the frame and has an extended position in which the heat sink occupies coextensively the space for absorbing the sunlight heat in the warm weather that otherwise would flow uncontrolled therethrough and discharging the sunlight heat to the atmosphere while permitting relatively unobstructed vision therethrough, and a retracted position in which the heat sink does not occupy coextensively the space for passing the sunlight heat in the cold weather therethrough for thermal warming.

Owner:NEVINS ROBERT L

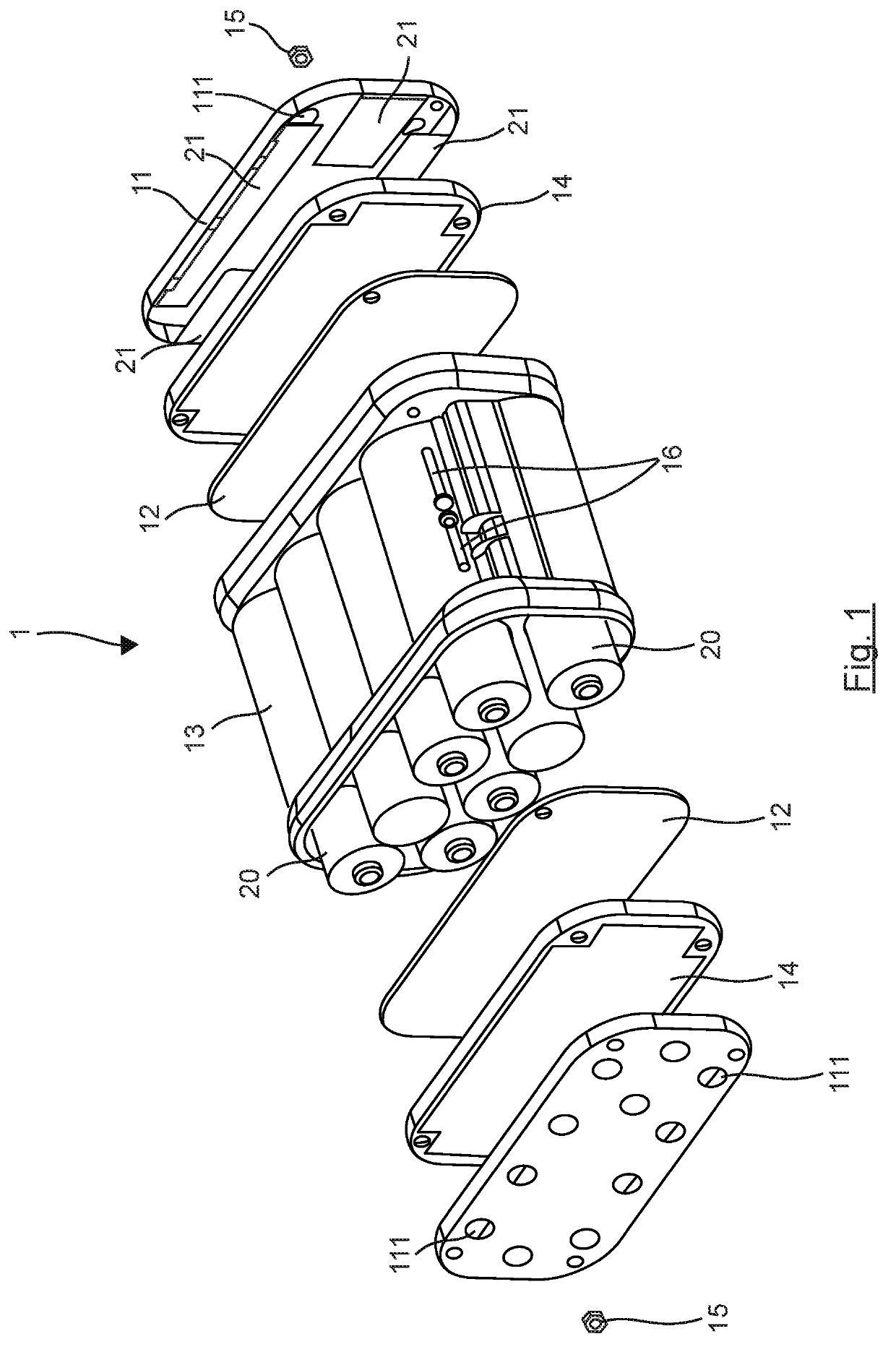

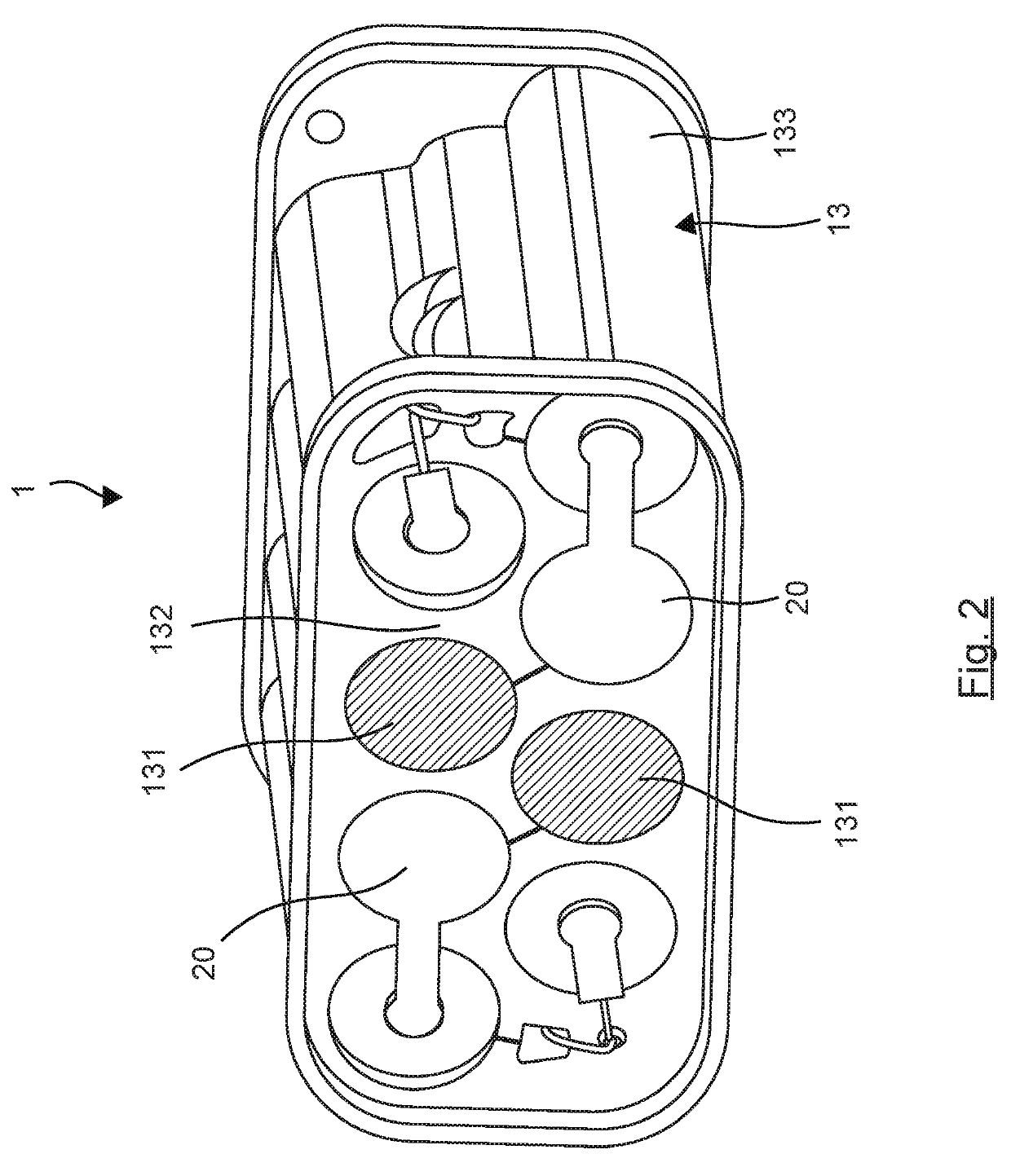

Battery pack for a distress beacon

ActiveUS20190252652A1Reduce the temperatureHinders its propagationCell lids/coversAircraft black boxesMetallic materialsMechanical engineering

A battery pack includes a plurality of electrical energy storage cells positioned in a parallel layout in a protective casing. The protective casing has a peripheral wall and is closed at two opposite ends by a lid. Each of the lids has at least one venting hole for gases that that can form inside the protective casing, and at least one layer of metallic material, through which the gases are intended to flow, is disposed between the internal face of each of the lids and the cells.

Owner:OROLIA LTD

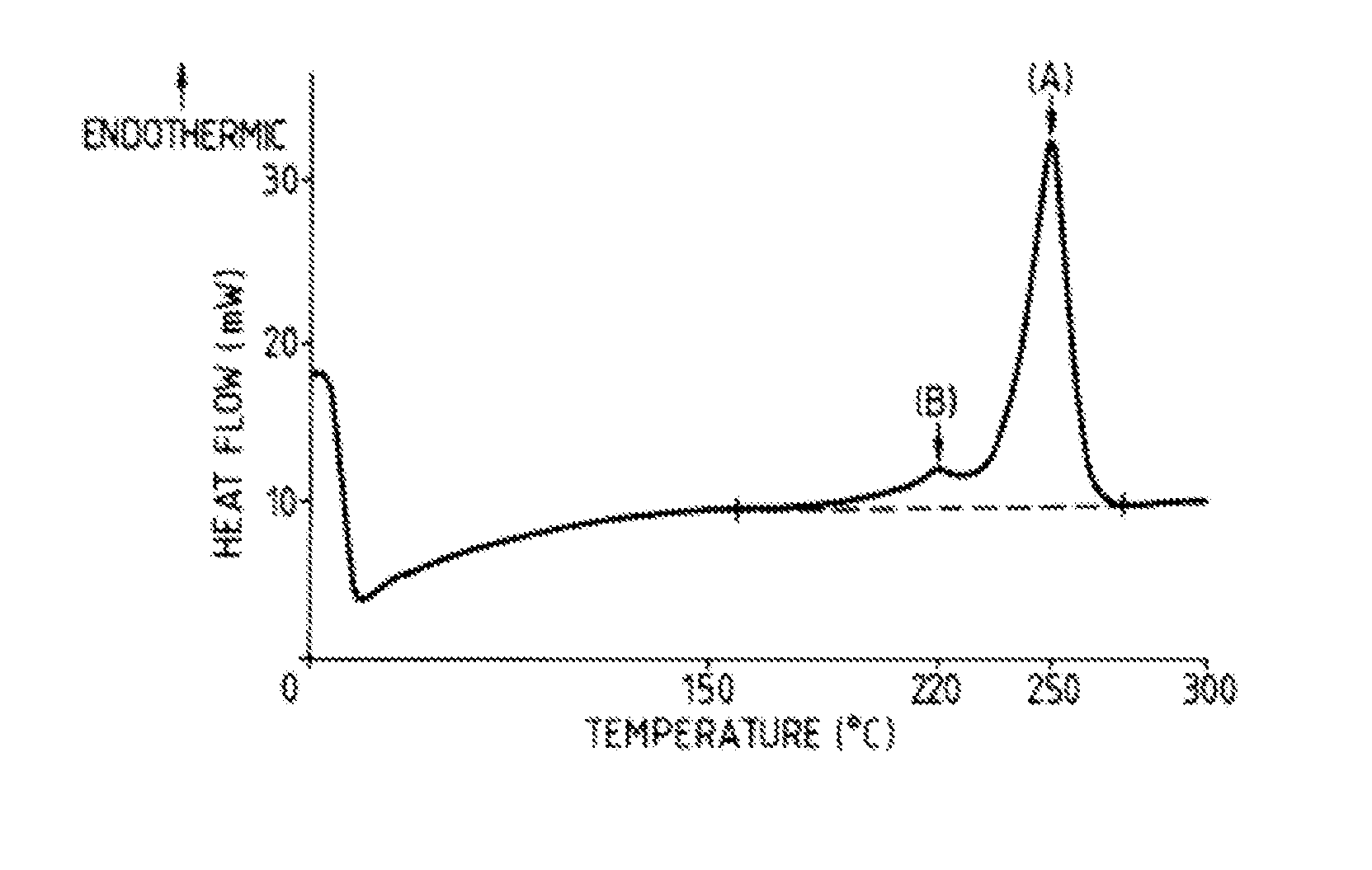

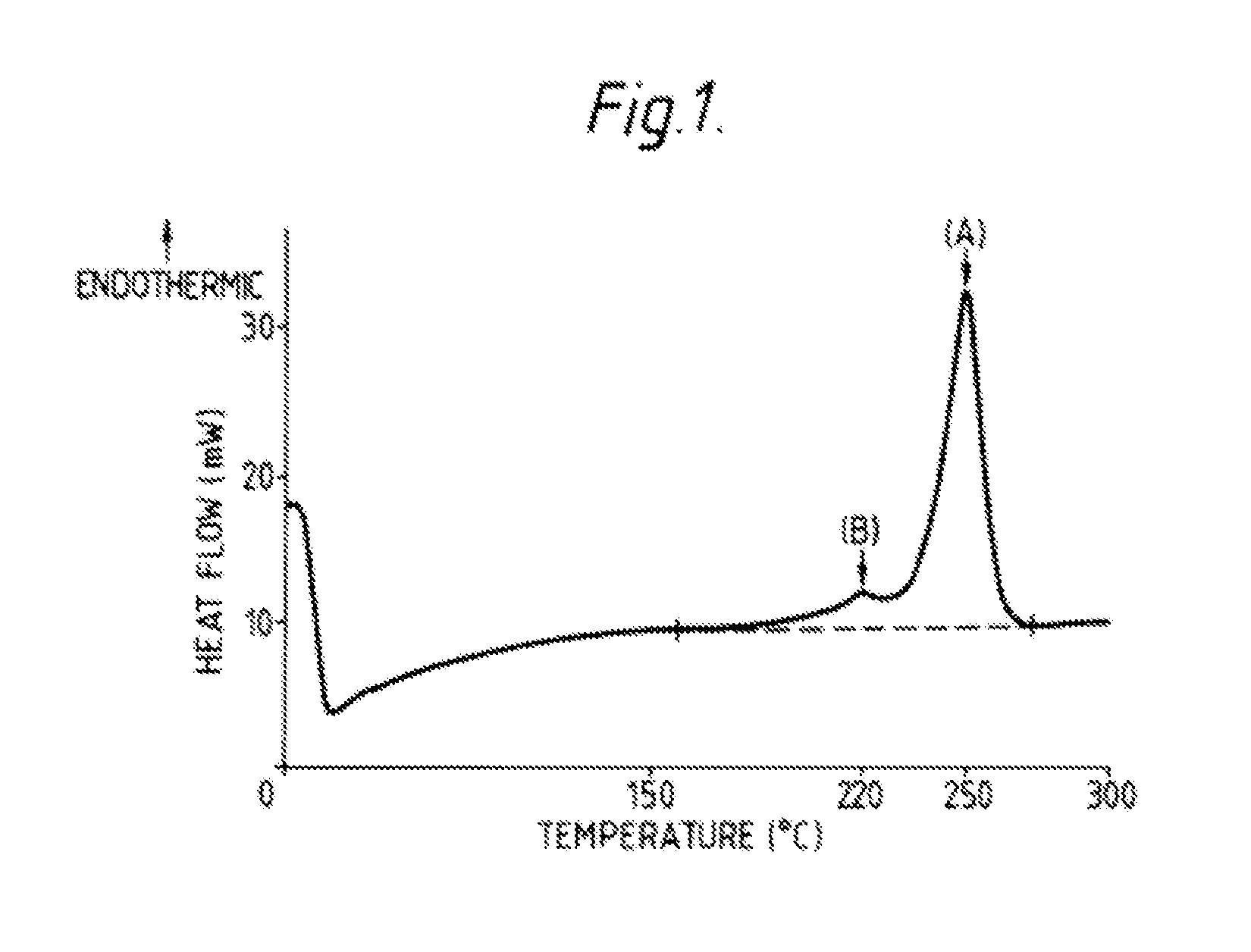

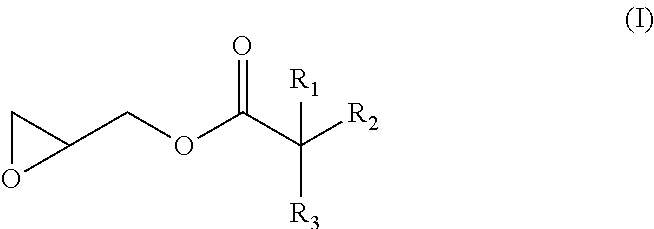

Hydrolysis resistant polyester films

InactiveUS20150151474A1Increase production capacityImprove hydrolytic stabilitySynthetic resin layered productsLaminationPolyesterEnd-group

A biaxially oriented polyester film comprising polyester and at least one hydrolysis stabiliser selected from a glycidyl ester of a branched monocarboxylic acid, wherein the monocarboxylic acid has from 5 to 50 carbon atoms, wherein said hydrolysis stabiliser is present in the film in the form of its reaction product with at least some of the end-groups of said polyester, and wherein said reaction product is obtained by the reaction of the hydrolysis stabiliser with the end-groups of the polyester in the presence of a metal cation selected from the group consisting of Group I and Group II metal cations.

Owner:DUPONT TEIJIN FILMS U S LLP

Electric equipment in which heat being dissipated through superficial temperature maintaining member and exchanging fluid

InactiveUS20120099277A1Heat dissipationAbsorption of heatTransformers/inductances coolingHeat storage plantsEngineeringSecondary side

The present invention relates to a heat exchange device equipped with a primary fluid circulation loop and a secondary fluid circulation loop and installed between an electrical equipment and a superficial temperature maintaining member, such that the heat generated by the electrical equipment is transmitted by a primary side fluid of the heat exchange device, and a secondary side fluid passes through a heat equalizer installed in the superficial temperature maintaining member so as to dissipate heat through the superficial temperature maintaining member.

Owner:YANG TAI HER

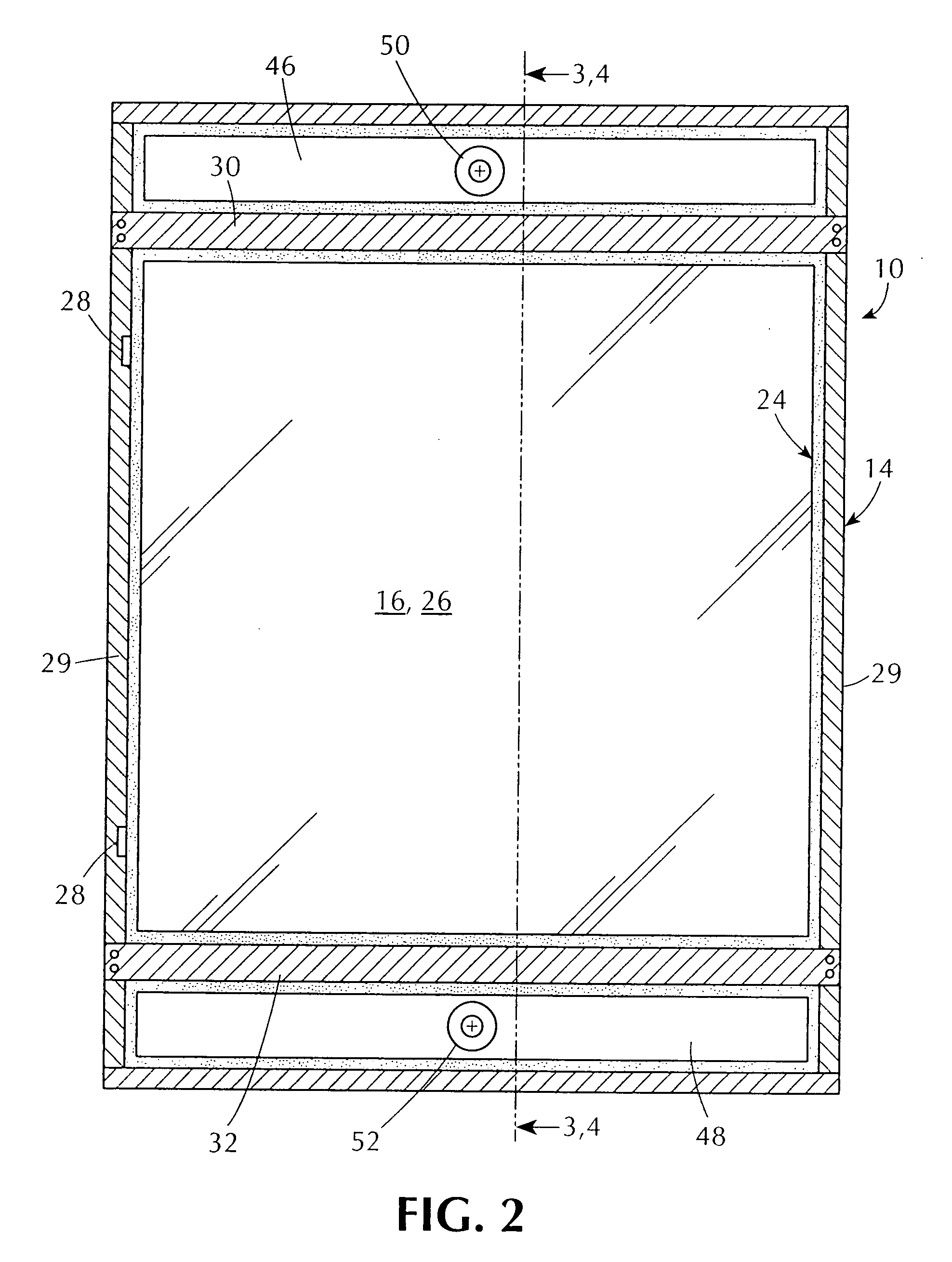

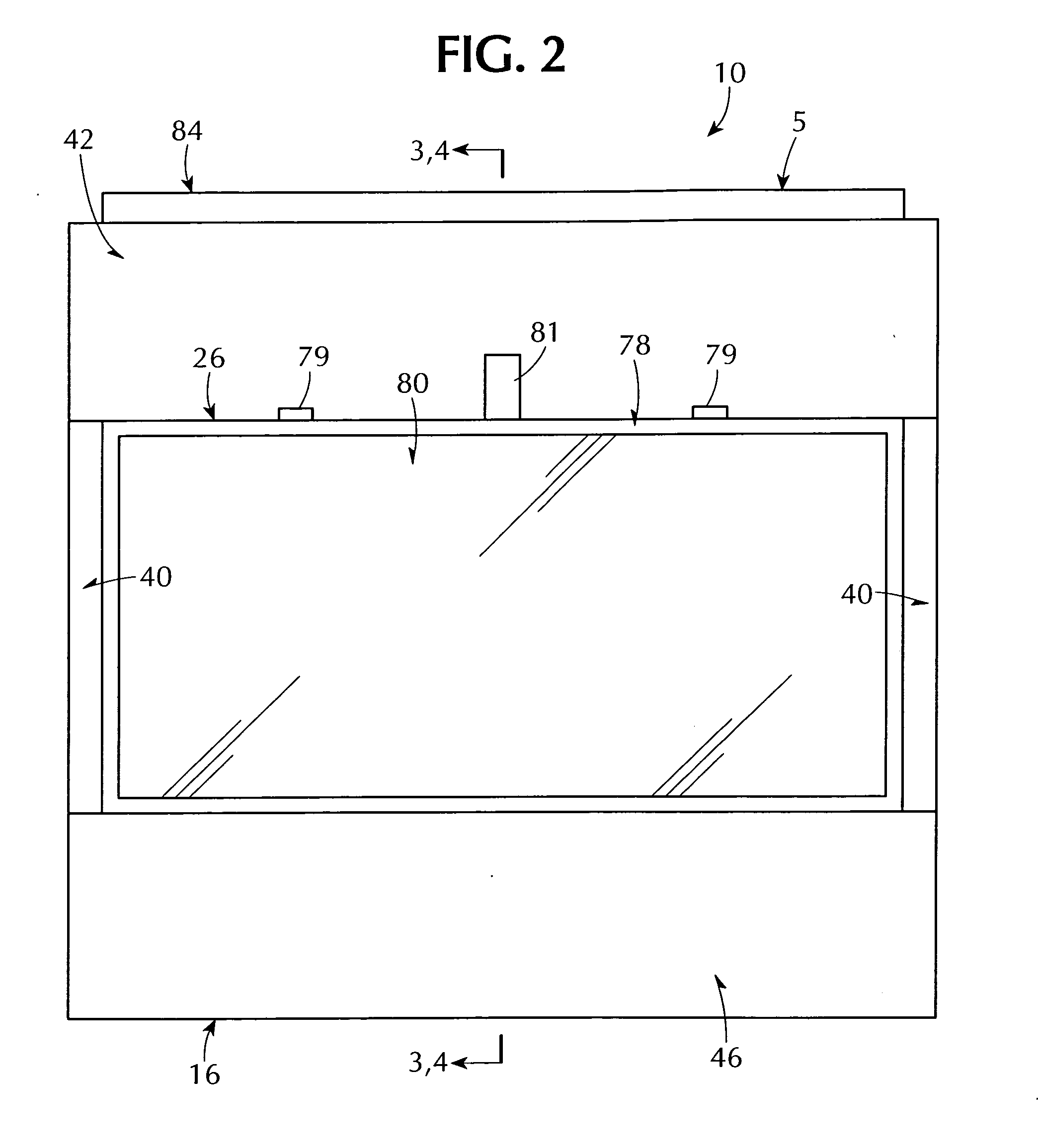

Tri-vent awning window

InactiveUS20110277386A1Absorption of heatPhotovoltaic supportsSolar heating energyEngineeringCold weather

A tri-vent awning window for absorbing sunlight heat in warm weather that otherwise would flow uncontrolled therethrough and discharging the sunlight heat to the atmosphere while permitting relatively unobstructed vision therethrough and passing the sunlight heat in cold weather therethrough for thermal warming. The tri-vent awning window includes a frame, an inner pane, an outer pane, and a heat sink. The inner pane is replaceably mounted to the frame so as to form a first vent. The outer pane is pivotally mounted to the frame so as to form a second vent, and is spaced from the inner pane so as to form a space therebetween. The heat sink is removably mounted to the frame, in the space, and when removed, creates a passive solar application. The inner pane has an in-place position and the outer pane has an open position during which in the warm weather the sunlight heat hits the heat sink and passes therethrough and rises by convection. The inner pane has a removed position and the outer pane has a closed position during which in the cold weather the interior sunlight heat is circulated from the space.

Owner:NEVINS ROBERT L

Fire Extinguishing Composition Comprising Alcohol Phenol Compound and Derivative Thereof

ActiveUS20160332014A1Composition be efficientSafer and efficient fire-extinguishingFire extinguisherPhenol CompoundCombustion

Owner:NANO FIRE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com