Automobile manufacturing MES data acquisition system based on industrial Internet

A data acquisition system, industrial Internet technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as inability to add hardware, lack of field equipment data acquisition, and data messy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

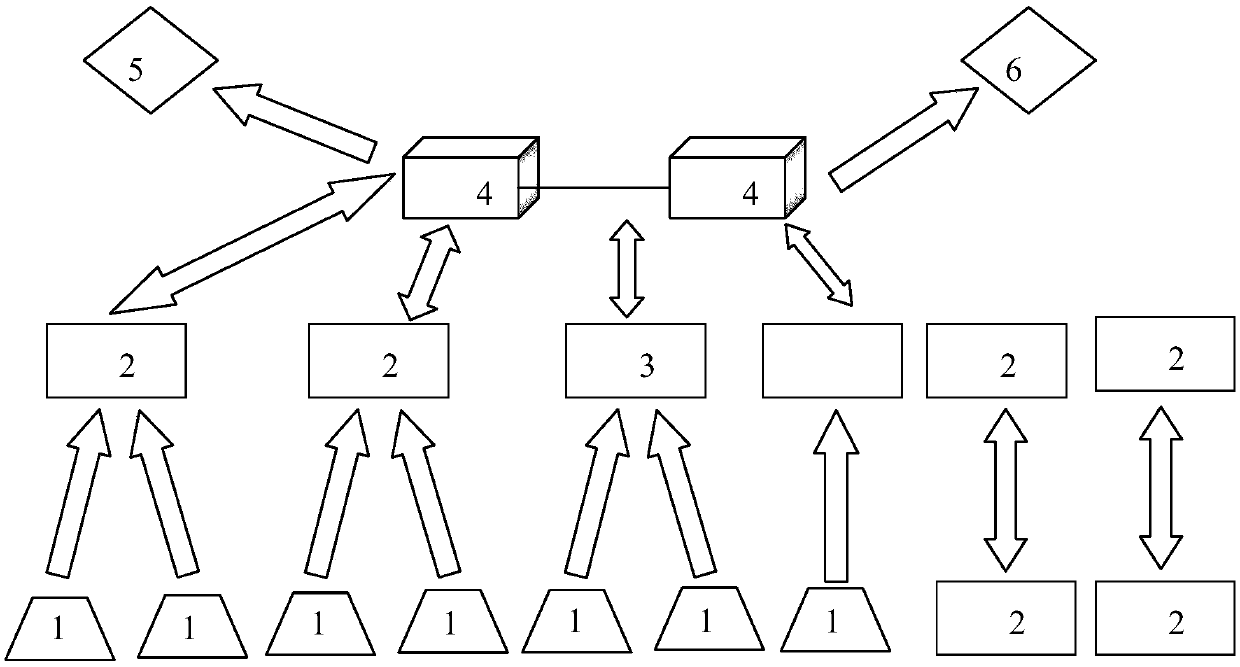

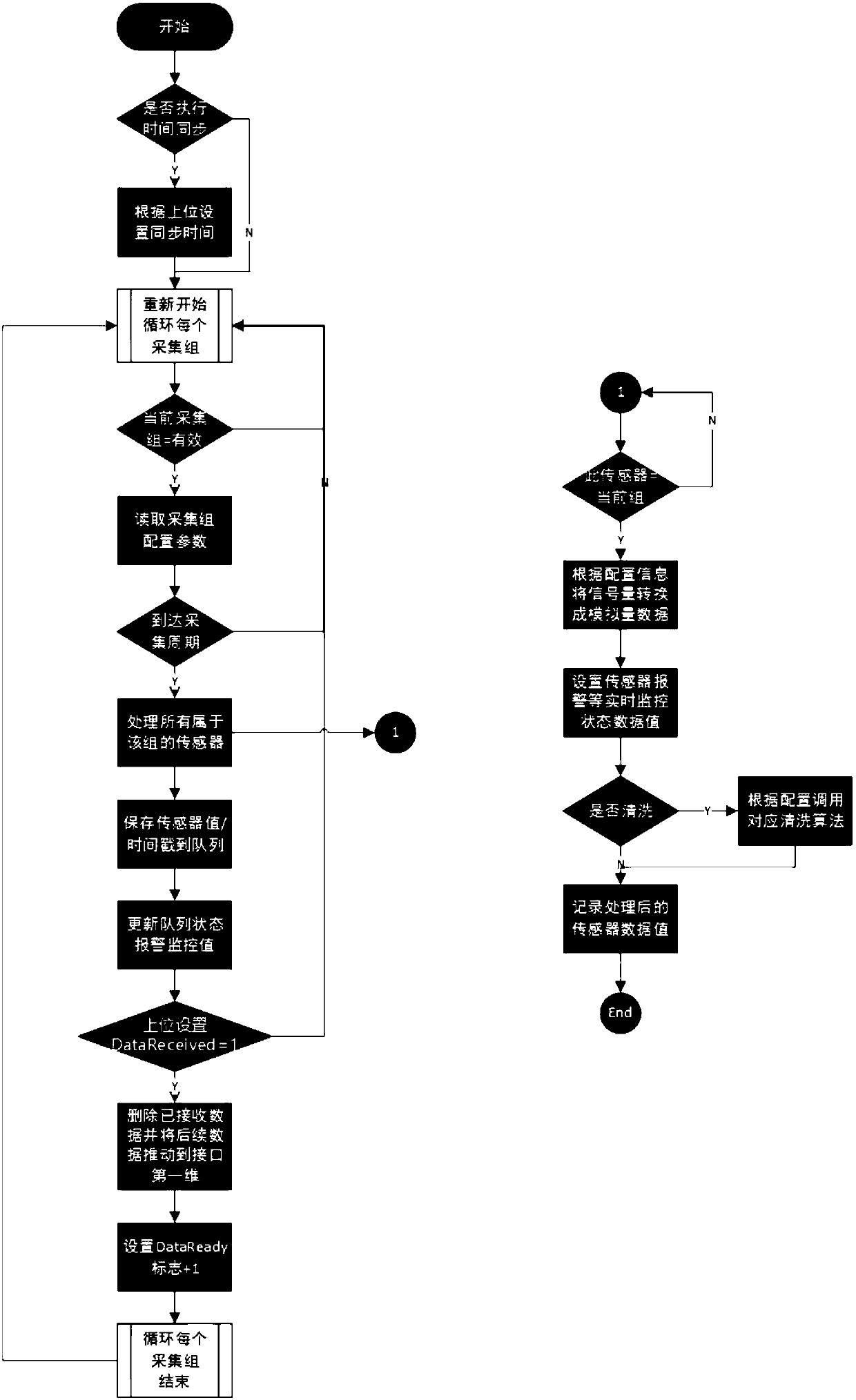

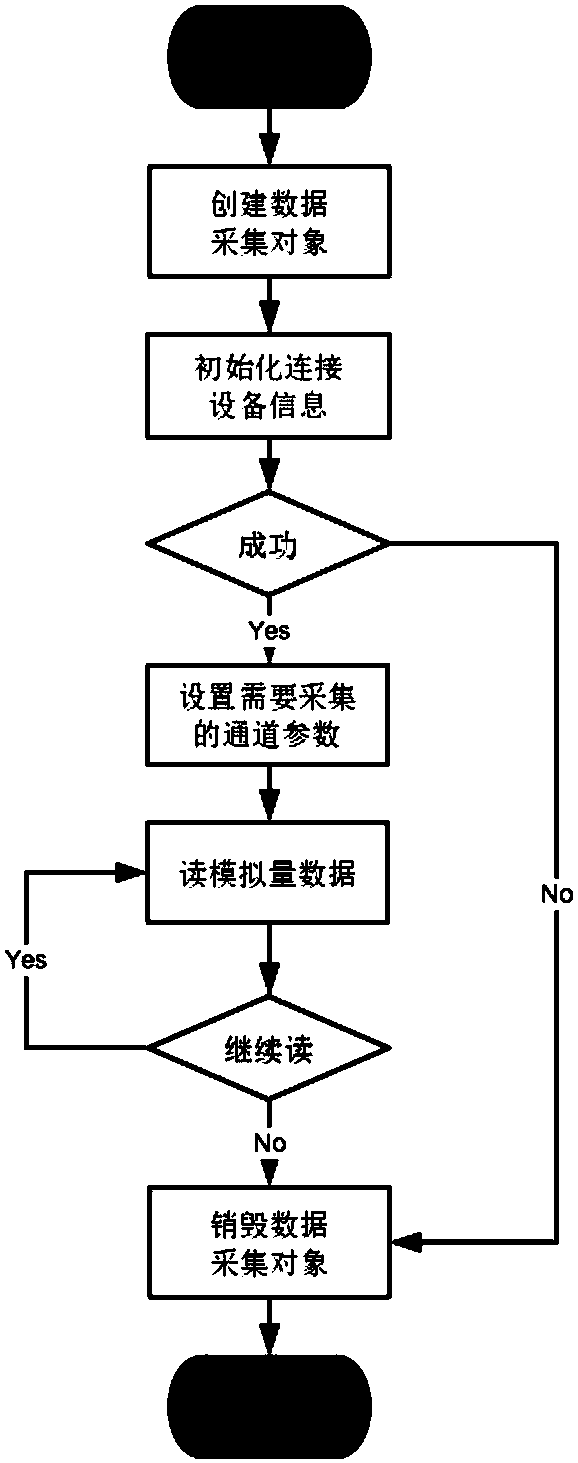

[0045] A preferred embodiment of the present invention provides an MES data acquisition system for automobile manufacturing based on the Industrial Internet, including data acquisition and data transmission, and the data acquisition includes sensor data acquisition, high-speed acquisition card data acquisition, and data from PLC to PLC Acquisition, data acquisition from PLC to PC; the data transmission is set to transmit the data collected by the data to the big data platform. The production site server calls WebAPI through Ethernet, and uploads real-time / timed data to the acquisition server of the large database platform according to the specified interface template.

[0046] like figure 1 As shown, the framework of an MES data acquisition system for automobile manufacturing based on the Industrial Internet includes data acquisition and data transmission. Data acquisition includes data collected by sensor 1 and transmitted to PLC2 through signal lines / AI modules or Modbus bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com