Work fixture for glass mould machining

A technology for glass molds and fixtures, applied in the field of fixtures, can solve problems such as affecting the smoothness of the mold cavity, damage to the glass mold, affecting the transparency of the glass container, etc., to ensure the quality and efficiency of engraving, convenient and fast operation, and good clamping The effect of fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

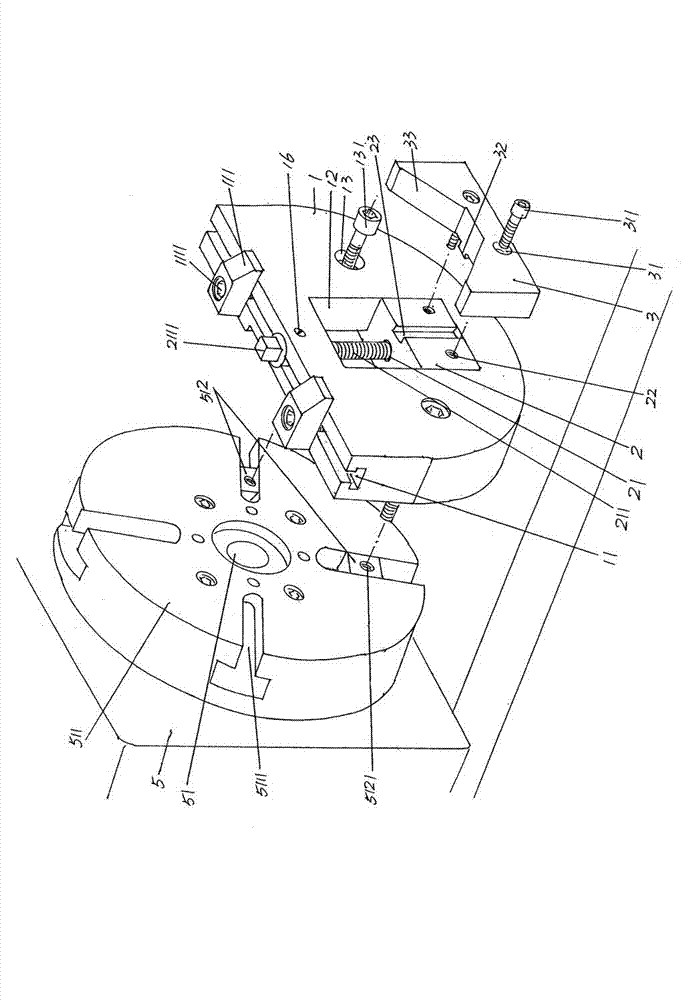

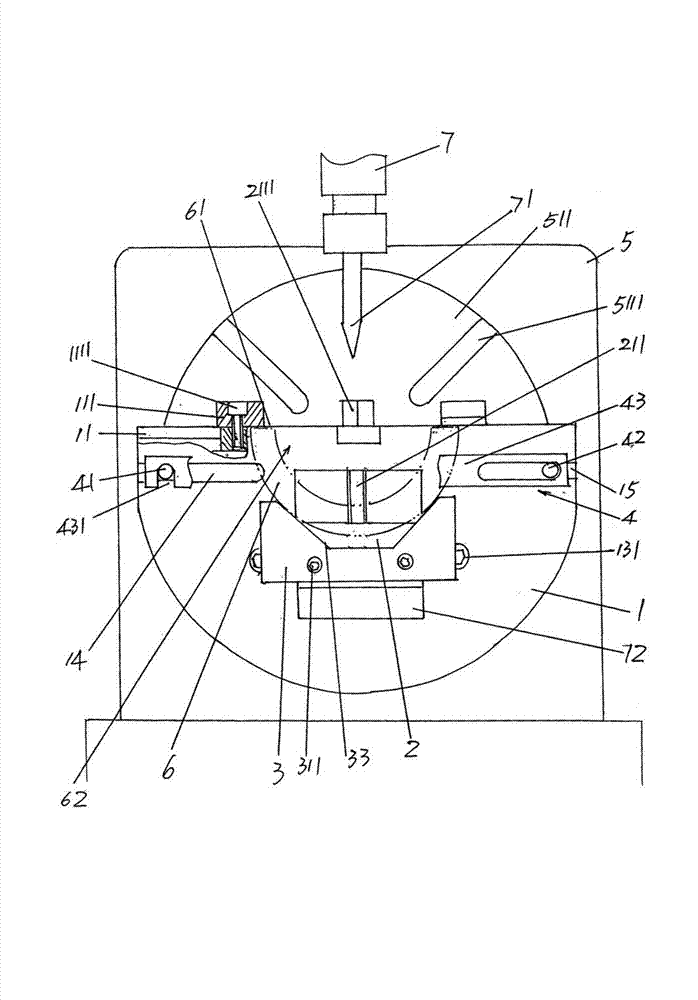

[0022] Please see figure 1 , in order to facilitate the understanding of the public, the applicant in figure 1 The machine tool 5 is also shown in the figure, and a chuck 511 is fixed on the main shaft 51 of the machine tool 5. According to known common sense, a chuck groove 5111 is opened on the chuck 511, and the number of chuck grooves 5111 is usually four and the cross-section The shape is T-shaped, and the adjacent chuck grooves 5111 are in a 90° relationship with each other. Each chuck groove 5111 is equipped with a T-shaped nut 512 , and each T-shaped nut 512 has a nut hole 5121 .

[0023] The overall shape of the base 1 as the technical solution provided by the present invention is in the shape of a semicircle. The shape of the semicircle can also be called a horseshoe. The so-called horseshoe refers to a shape in which three sides form a U shape and one side is a straight line. On the surface of one side of the base 1, that is, the side facing upward under the...

Embodiment 2

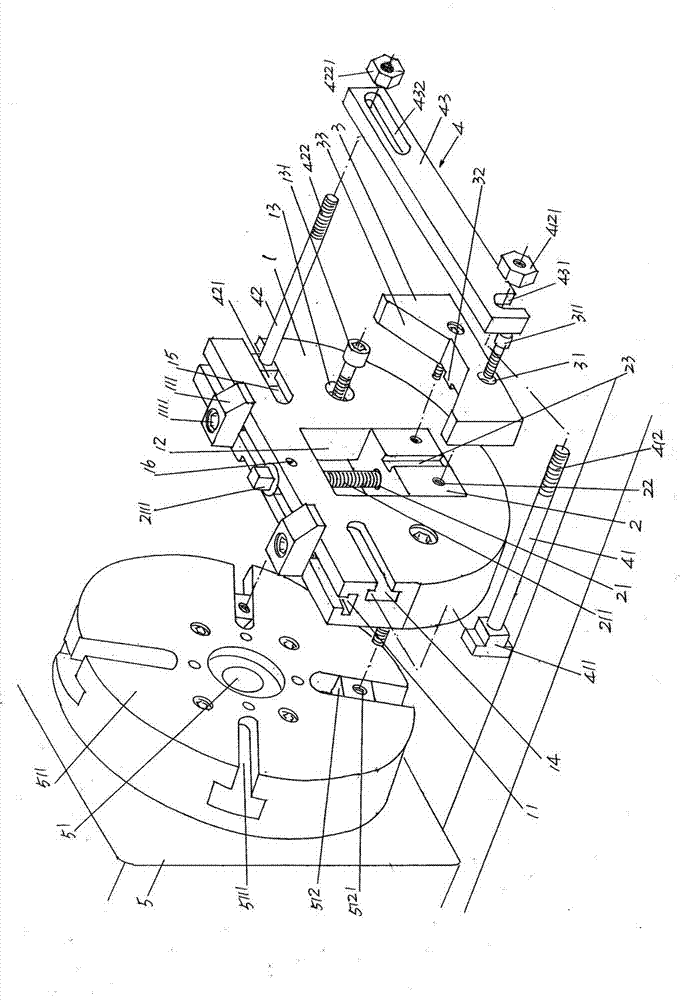

[0030] Please see figure 2 , because there are differences in the varieties of the glass mold tool 6, for example, the length of the glass mold 6 used for forming glass cans is relatively short, so the structure of embodiment 1 can be competent for reliable clamping of this type of glass mold 6, while for The length of the glass mold 6 of the glass container such as molding red wine bottle or title height is relatively long or claims higher, therefore, figure 2 The structure shown can be flexibly dealt with.

[0031] Depend on figure 2 As shown, on the side of the base 1 facing the support module 3 and at positions corresponding to each other in a horizontal state ( figure 2 The position shown is taken as an example) there is a first guide chute 14 and a second guide chute 15, wherein: the first guide chute 14 is located on one side of the sliding chamber 12 of the bracket module fixing seat mentioned in Embodiment 1 , while the second guide chute 15 is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com