Clamp structure used for eccentricity molding machining of glass mold

A glass mold and eccentric technology, which is applied in the field of fixtures, can solve the problems of glass mold eccentric molding quality, increased difficulty of management, and increased cost of eccentric fixtures, etc., to achieve good clamping adaptability and good generalization , the effect of concise overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

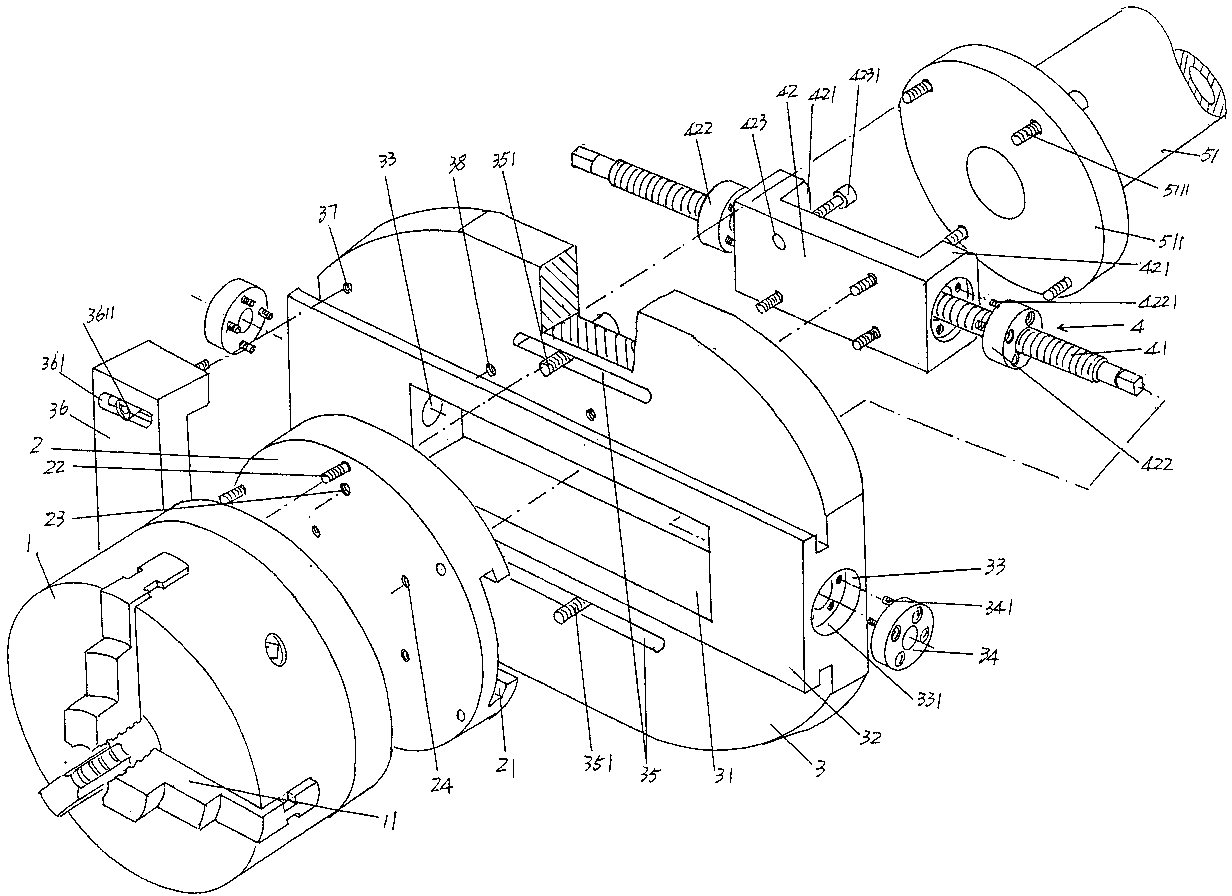

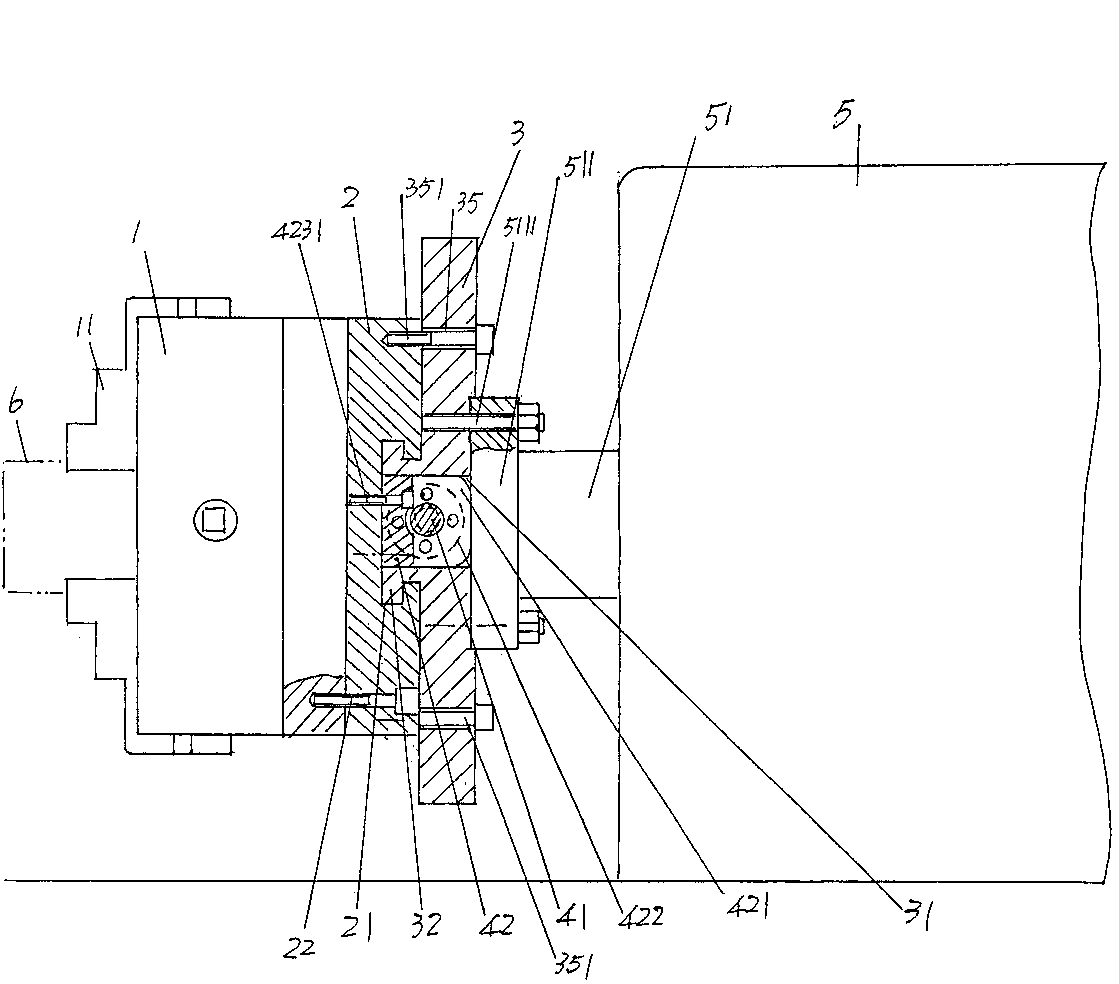

[0021] See figure 1 and figure 2 , for the convenience of the public's understanding, the applicant shows the lathe spindle 51 of the headstock 5 of the CNC lathe in the figure, and a spindle disk 511 is formed on the end face of the lathe spindle 51, on the spindle disk 511 and around the spindle disk A group of spindle disc connecting screws 5111 are arranged at intervals in the circumferential direction of the spindle disc 511 .

[0022] The following description is aimed at the parts that constitute the clamp structure system for the eccentric molding of the glass mold of the present invention. A jaw plate 1 is provided, and the side facing outwards in the use state of the jaw plate 1 is the back One set of jaws 11 is provided on one side of the connection plate 2, and the number of the set of jaws 11 is three. Since the structure and function of the jaw plate 1 belong to the known technology, the applicant will not repeat them here.

[0023] Provide a connection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com