Multi-connected turbine cutting device and cutting method

A cutting device and multi-unit technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, manufacturing tools, etc., can solve the problems of low cutting efficiency, poor cutting precision, troublesome operation, etc., and achieve high cutting efficiency, Good clamping adaptability and good automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

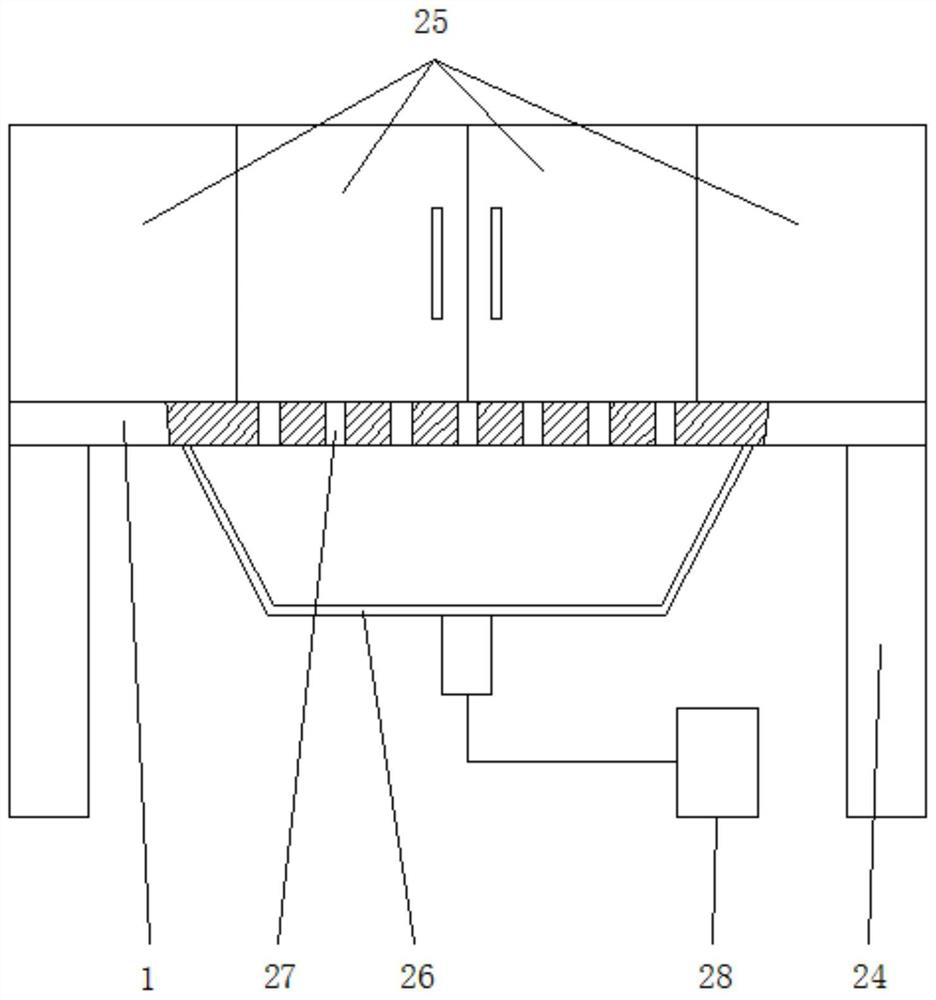

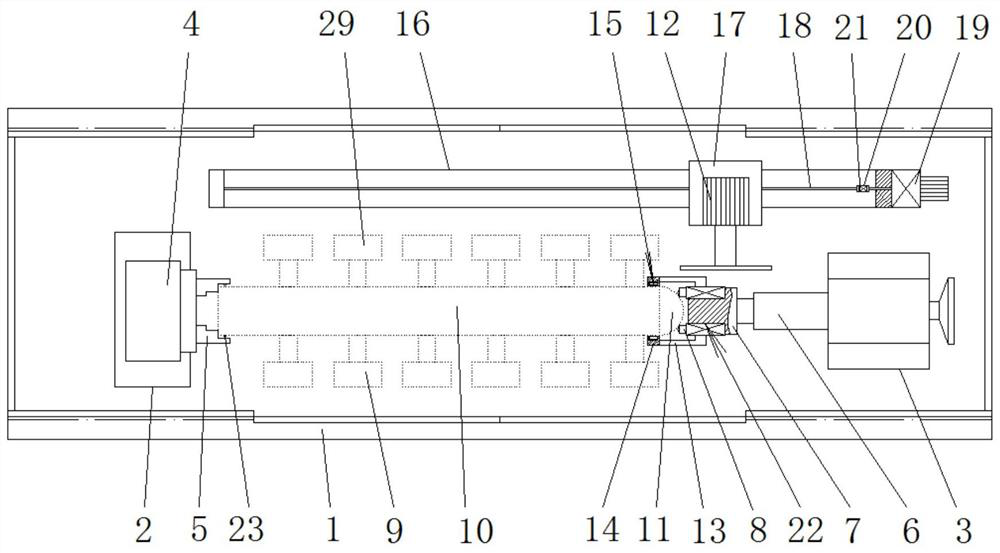

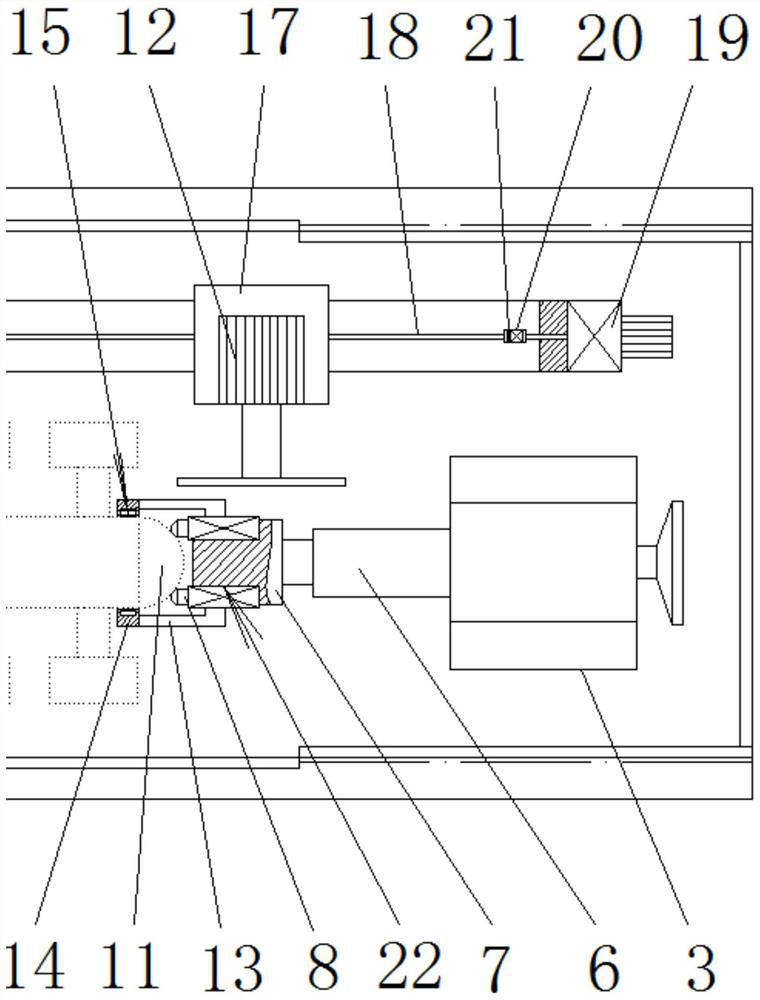

[0034] Such as Figures 1 to 4Shown is an embodiment of a multi-conjoined turbine cutting device of the present invention, including a workpiece positioning and fixing tool and a grinding wheel moving cutting tool, and the workpiece positioning and fixing tool includes a base plate 1 and a left base arranged on the base plate 1 2 and the right base 3, the left base 2 is equipped with an index plate 4 facing the direction of the right base 3, the index plate 4 is equipped with a three-jaw self-centering chuck 5, the right A telescopic sleeve 6 pointing to the direction of the left base 2 is installed on the base 3, and a rotating thimble 7 is installed on the front end of the telescopic sleeve 6, and the rotating thimble 7 is a modified type rotating thimble, and the modified type rotates The front end of the thimble is flattened and three floating support cylinders 8 are installed at the outer circumference of the front end of the rotating thimble 7, and the front end of the f...

Embodiment 2

[0047] A kind of cutting method that adopts the multiple conjoined turbine cutting device of embodiment 1, comprises the steps:

[0048] (1) workpiece installation: open the combined movable transparent shield 25, and carry out the clamping of the workpiece; The claw self-centering chuck 5 clamps the outer circle of the flat end of the intermediate shaft of the multi-joint turbine 9, and finally passes through the three floating support cylinders 8 to the ball end of the intermediate shaft of the multi-joint turbine 9 11 The surface of the blank realizes three-point floating resistance and locking; wherein, when clamping the outer circle of the spherical end 11 of the intermediate shaft of the multi-connected turbine 9, the spherical end 11 of the intermediate shaft of the multi-connected turbine 9 The outer circle is inserted into the inner hole of the annular hollow air ring 15, and the inner hole of the annular hollow air ring 15 is uniformly shrunk by filling the annular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com