Fast-setting castable for main runner for COREX furnace and production technology thereof

A castable and process technology, applied in the field of quick-drying castables in the main trench of COREX furnace, can solve the problems of waste of resources, affecting production, spalling, etc., and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The particle size and mass percentage of each component are:

[0085] Fused dense corundum 5-8mm: 12%;

[0086] Brown corundum 3~5mm: 22%;

[0087] Tabular alumina 1~3mm: 20%;

[0088] Activated alumina powder <3um: 14%;

[0089] Silicon carbide 1~3mm: 8%;

[0090] 320 mesh silicon carbide 0.048mm: 12%;

[0091] Spherical asphalt: 5%;

[0092] Metal magnesium powder: 1%;

[0093] Sodium hexametaphosphate: 0.8%;

[0094] Lithium carbonate: 0.4%;

[0095] Polyethylene organic fiber: 2.8%;

[0096] Silicon fume: 2%.

[0097] Such a ratio is suitable for use as a castable in the manufacture of new trenches, with strong thermal shock resistance and good erosion resistance.

Embodiment 2

[0099] The particle size and mass percentage of each component are:

[0100] Fused dense corundum 5-8mm: 15%;

[0101] Brown corundum 3~5mm: 20%;

[0102] Tabular alumina 1~3mm: 20%;

[0103] Activated alumina powder <3um: 12%;

[0104] Silicon carbide 1~3mm: 9%;

[0105] 320 mesh silicon carbide 0.048mm: 11%;

[0106] Spherical asphalt: 3.3%;

[0107] Metal aluminum powder: 1%;

[0108] Sodium hexametaphosphate: 1%;

[0109] Lithium carbonate: 0.7%;

[0110] Polyethylene organic fiber: 4%;

[0111] Silicon fume: 3%.

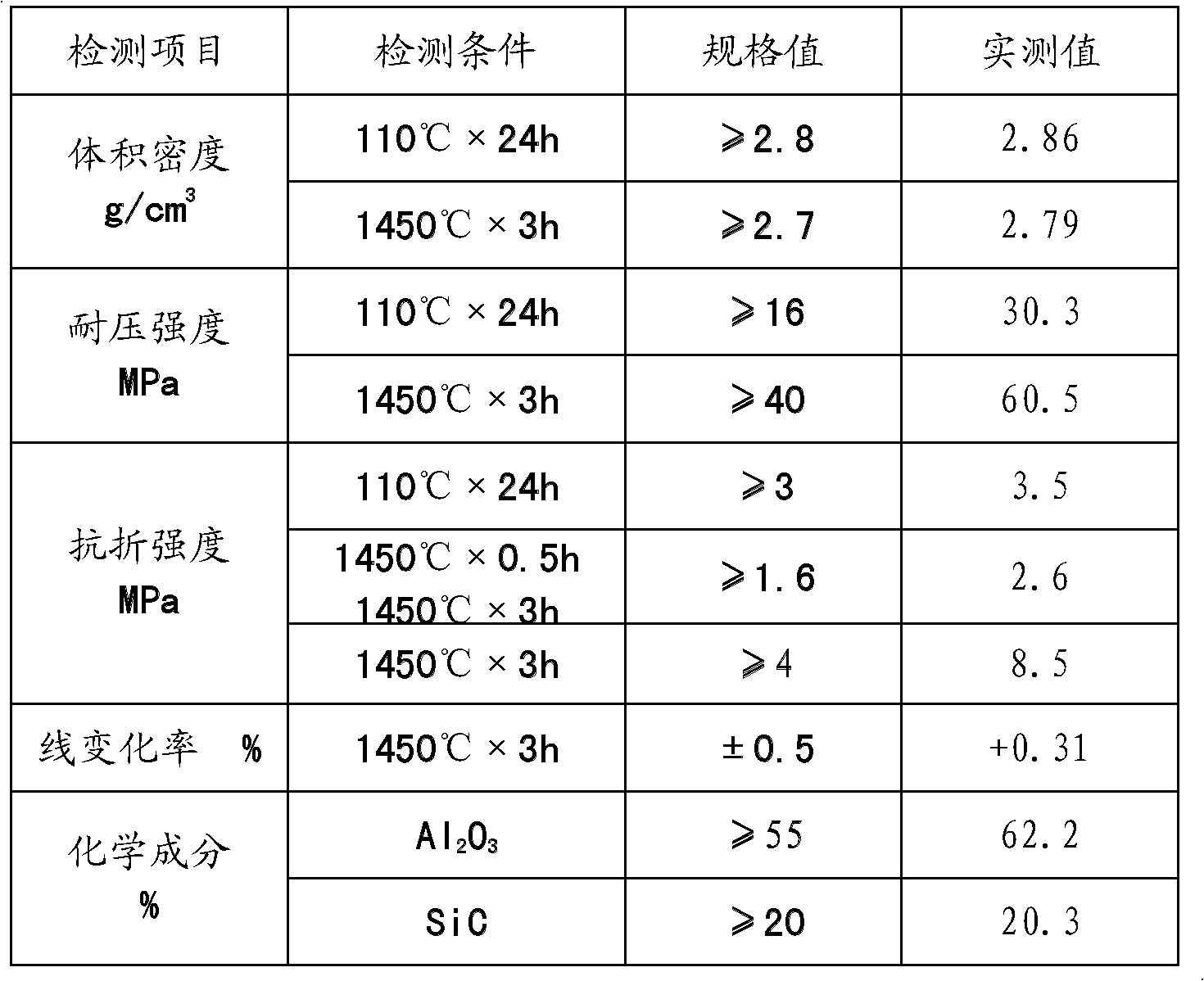

[0112] This kind of ratio has good explosion-proof effect, more lithium carbonate, and strong quick-drying ability, so it is more suitable as a repair material. The following table is the performance index that the present invention reaches:

[0113]

[0114] It can be seen that the effect of the present invention is higher than the national requirement.

[0115] The present invention also relates to a process for producing quick-drying castables ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com