Six-freedom-degree heavy loading vehicle used for conveying and installing heavy components

A technology of degrees of freedom and components, which is applied to vehicles used for freight, vehicles used to carry long goods, transportation and packaging, etc., can solve the problems of low installation accuracy, low efficiency of transportation and installation, and can not be realized. The effect of saving construction costs and solving special installation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

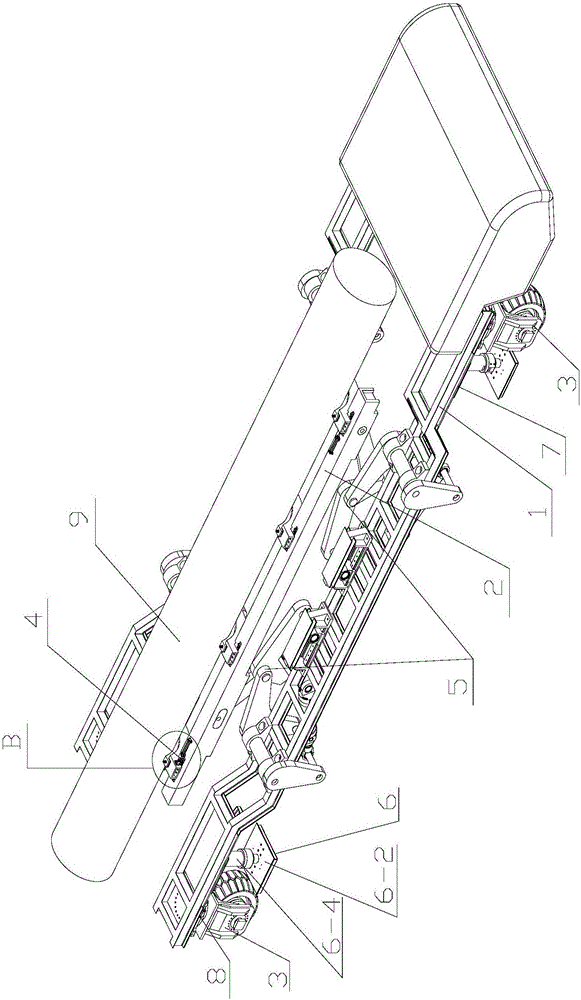

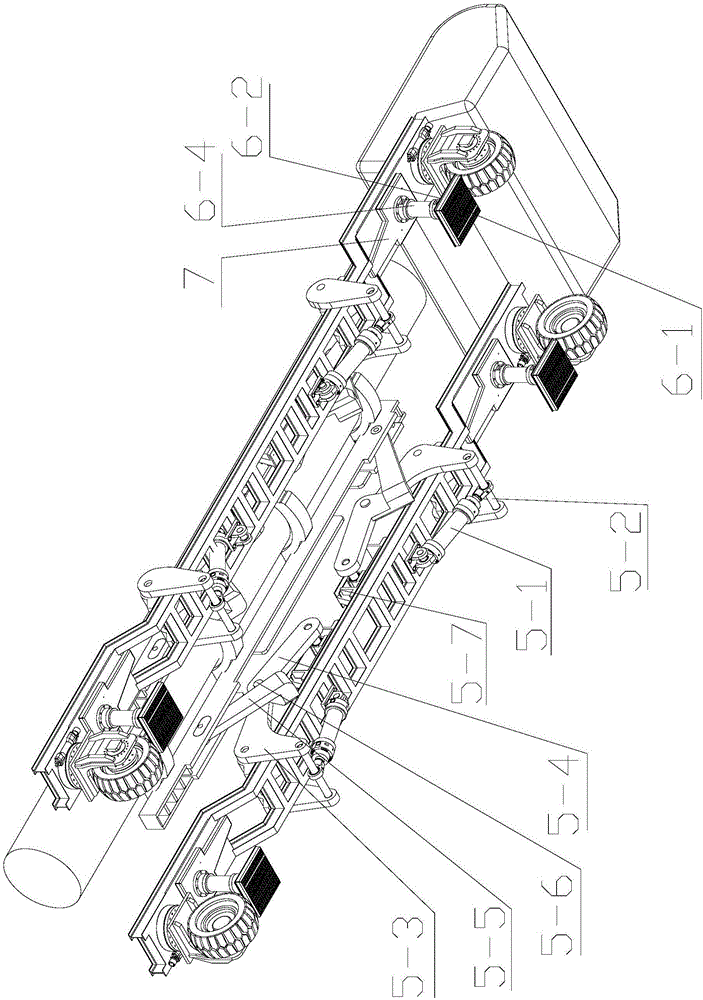

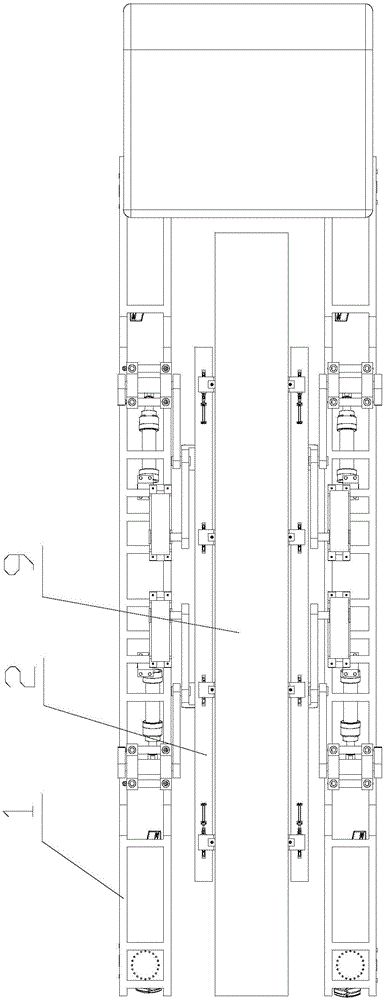

[0036] In this embodiment, a six-degree-of-freedom heavy-duty vehicle for transporting and installing heavy components, such as figure 1 , figure 2 or image 3 As shown, it includes a U-shaped vehicle frame 1 and a bracket platform 2. The bracket platform is arranged on the U-shaped vehicle frame. The bottom of the U-shaped vehicle frame is provided with a walking wheel mechanism 3. XZ plane rotation mechanism (see Figure 5 ), a Z-axis translation mechanism 5 is provided between the bracket translation and the U-shaped frame, and the U-shaped frame is provided with an X-axis translation mechanism 6, an XY plane rotation mechanism 7 and a YZ plane rotation mechanism 8. Among them, the X-axis translation mechanism, the Y-axis translation mechanism, the Z-axis translation mechanism, the XY plane rotation mechanism, the XZ plane rotation mechanism and the YZ plane rotation mechanism are all fine-tuning mechanisms, which are used to adjust the U-shaped frame or bracket platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com