Patents

Literature

141results about How to "Experience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

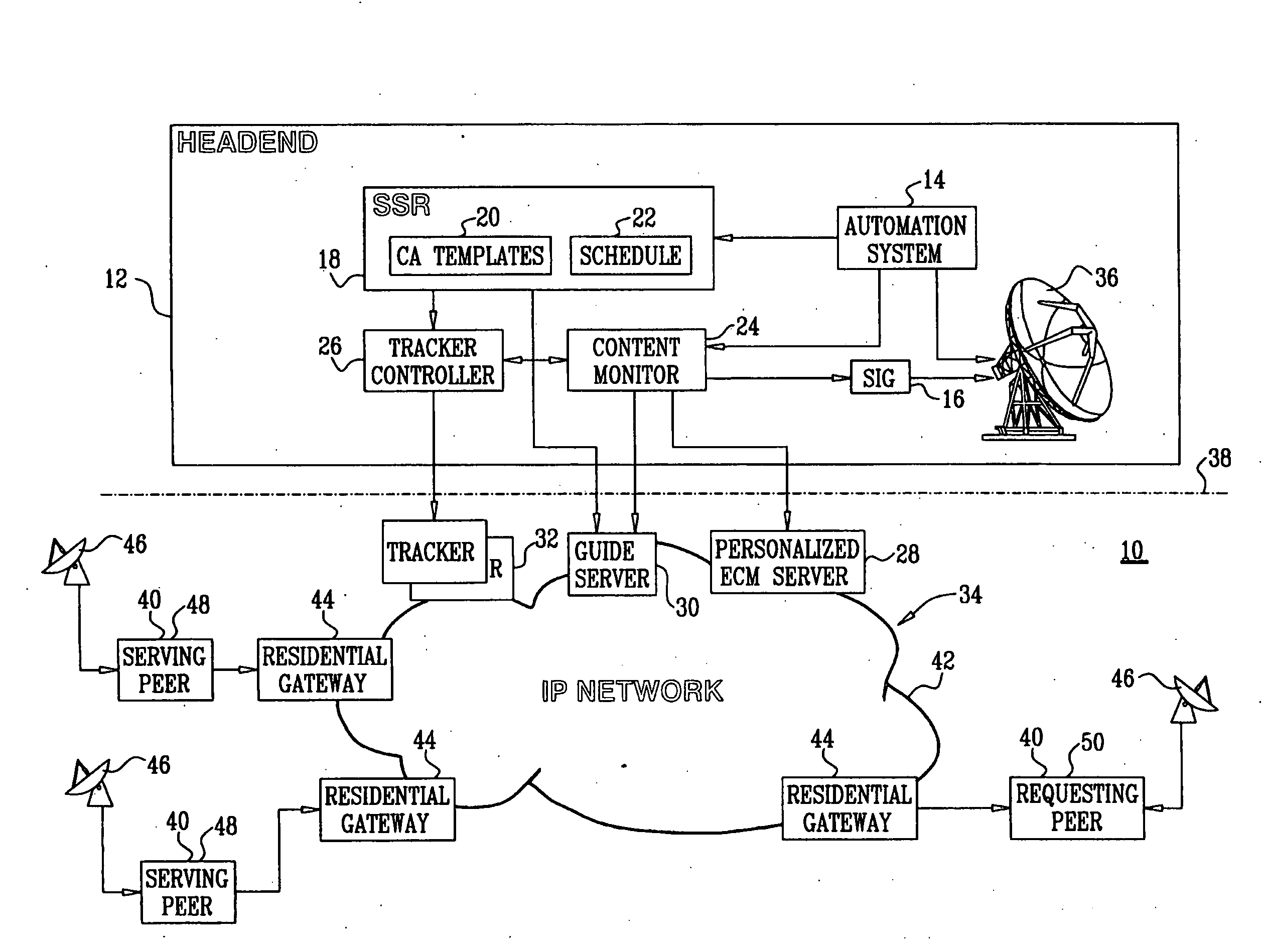

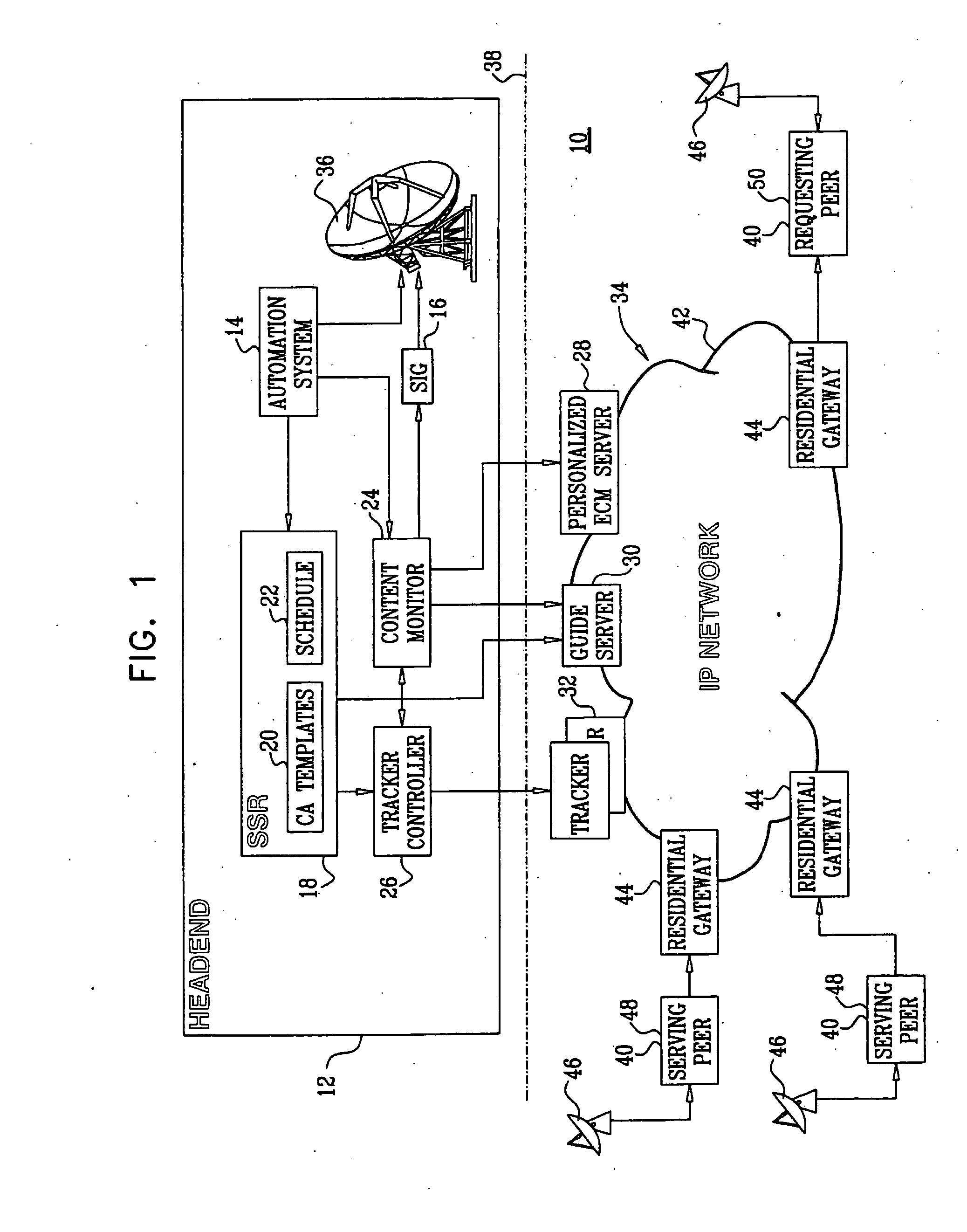

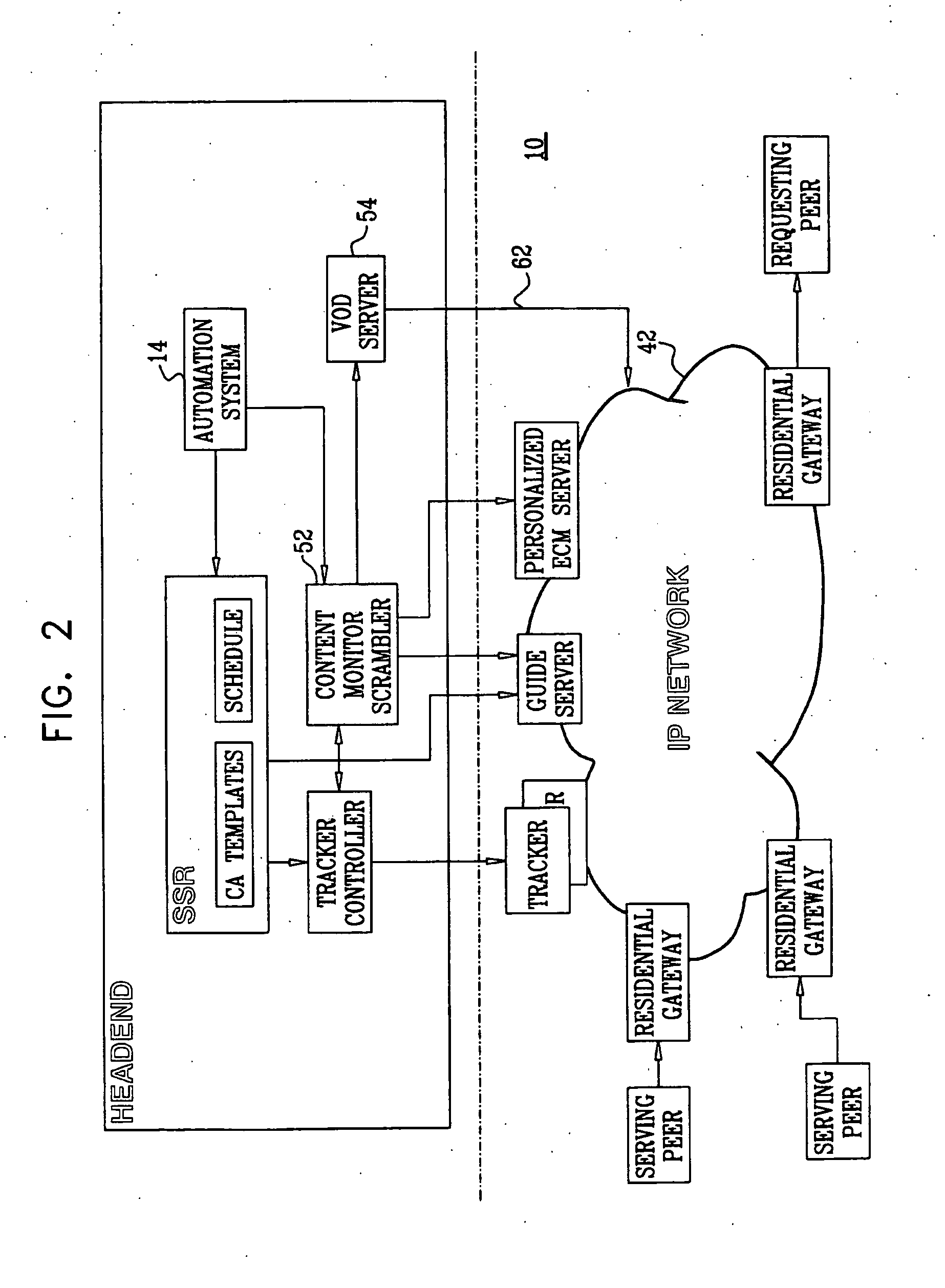

Peer- to- peer set-top box system

InactiveUS20090300673A1Easy to shareDecreasing download bandwidthTelevision system detailsColor television detailsContent sharingMetadata

A content sharing system, for implementation in a requesting peer, to receive at least a part of a chunk from a serving peer, the chunk being part of a content item, the requesting peer being operationally connected to a plurality of peers including the serving peer via a communications network, the content item being media content originally broadcast in a media stream by a Headend to at least some of the peers, the system including a metadata module to receive chunk metadata identifying the location of the chunk based on an identifier in the media stream originally broadcast by the Headend, a content transfer module to request the at least part of the chunk from the serving peer based on the chunk metadata, and receive the at least part of the chunk from the serving peer. Related apparatus and methods are also described.

Owner:CISCO TECH INC

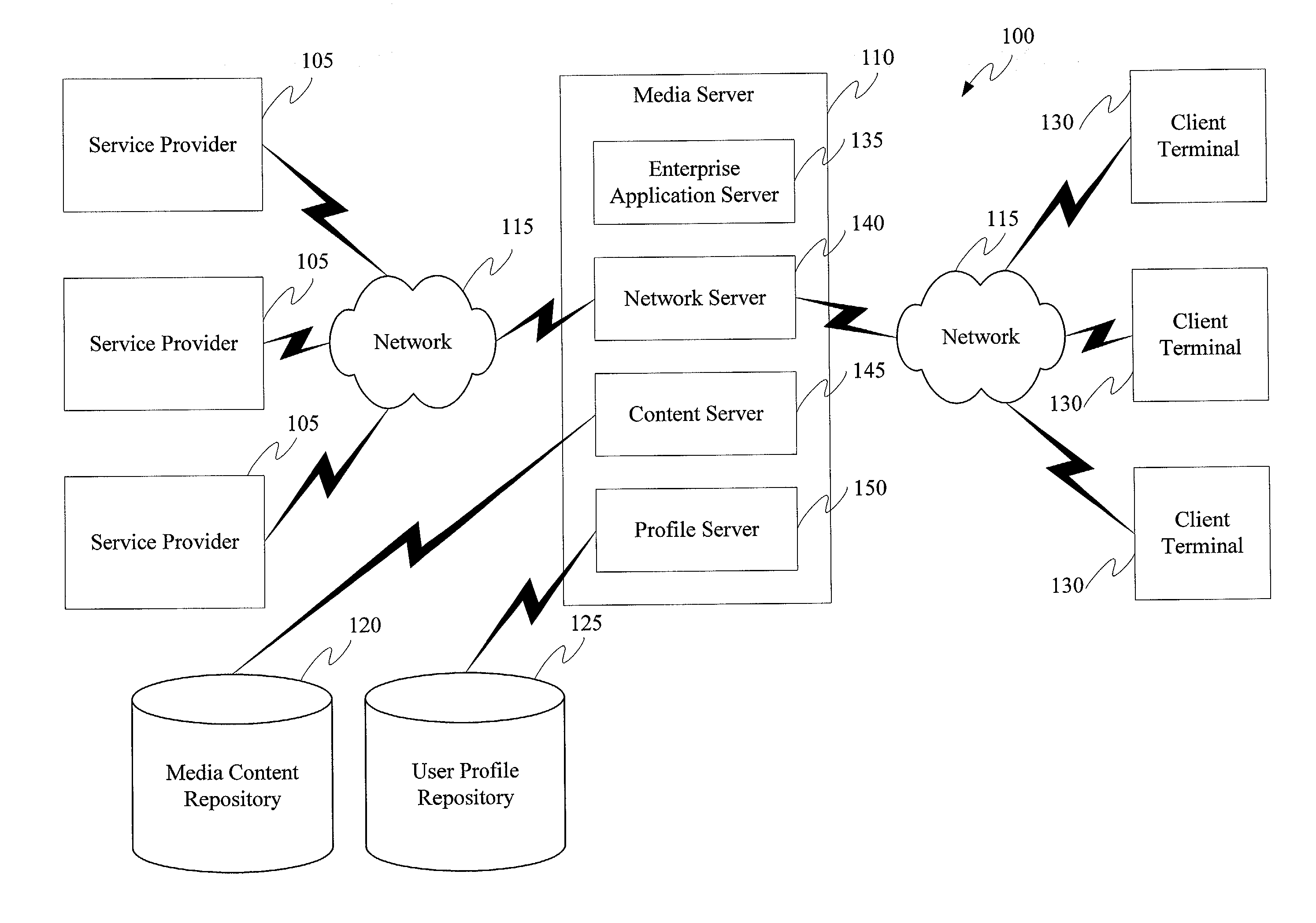

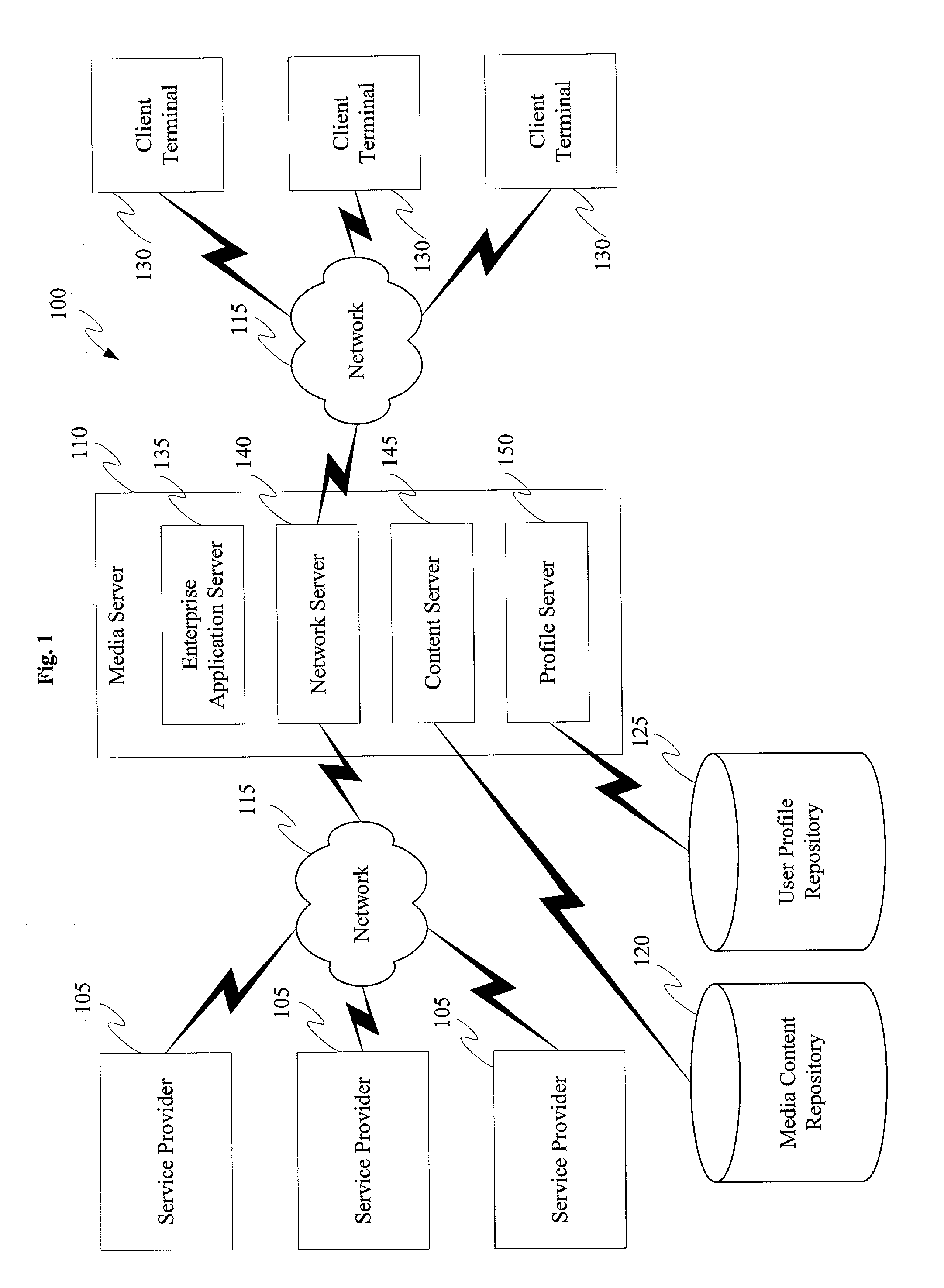

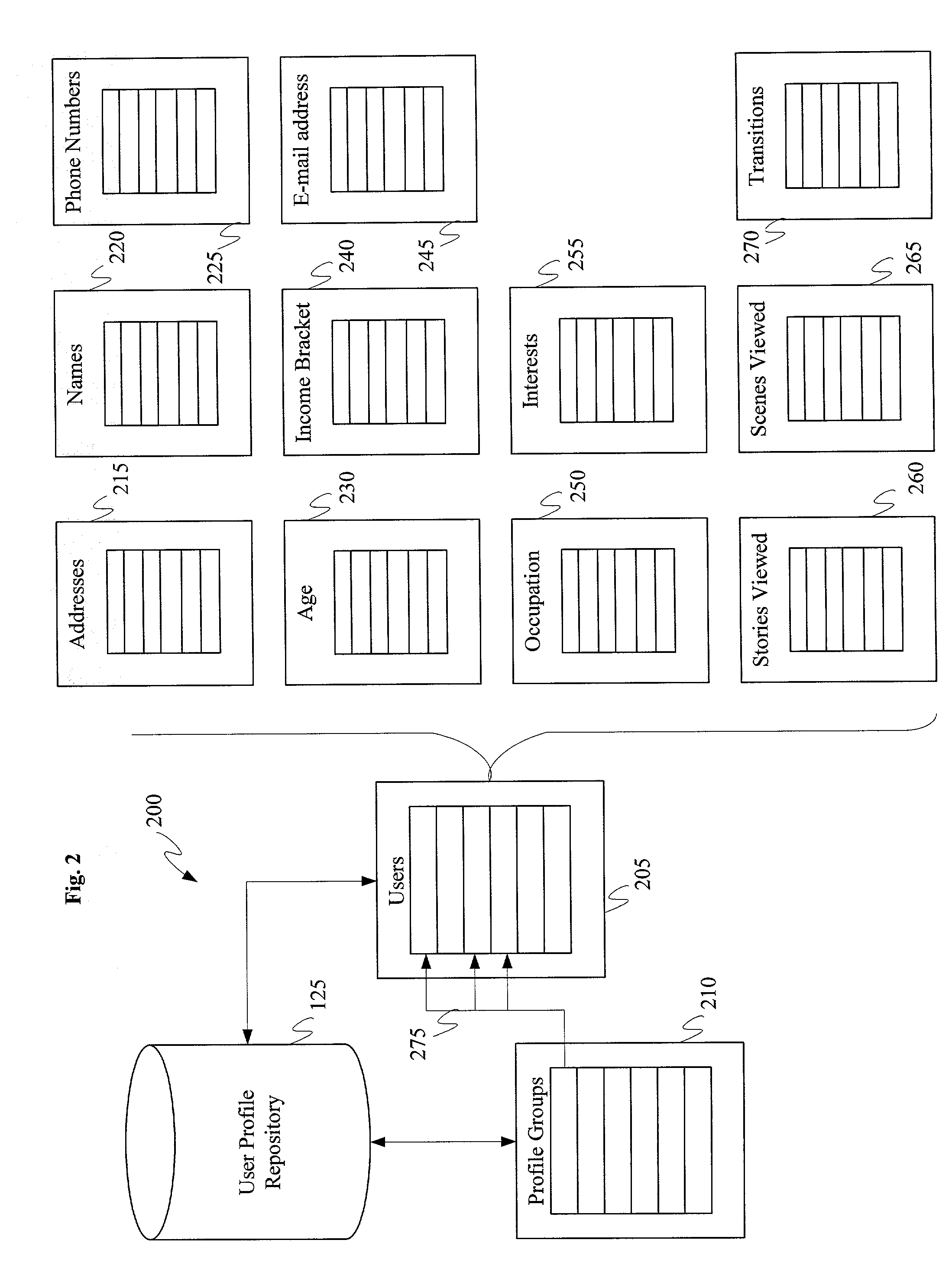

Method and apparatus for providing interactive media presentation

InactiveUS7114170B2Facilitate communicationEfficient use ofTelevision system detailsAnalogue secracy/subscription systemsInteractive contentWeb service

A method and system for presenting interactive and non-interactive media content to a client computer over a computer network. The system can combine discrete, continuous and interactive media into a single scene that is presented to the client computer. The system allows the presentation to be highly configurable and may therefore customize the presentation for a specific user. User profile information may be stored in an repository associated with the system. This information may be used to customize the presentation to suit the specific needs of a user or to notify the user when a presentation of interest to the user is available. Furthermore, information about a user's interaction with a particular presentation may be stored in the repository so that a presentation can adapt “on-the-fly” to suit the specific needs of a user. In addition, information regarding web services that are available on the Internet may be integrated with other interactive content in a presentation that is provided to a user. The system and method may also utilize an open-source computing platform so that presentations can be transmitted and displayed on a wide variety of client terminals.

Owner:NEORIS USA

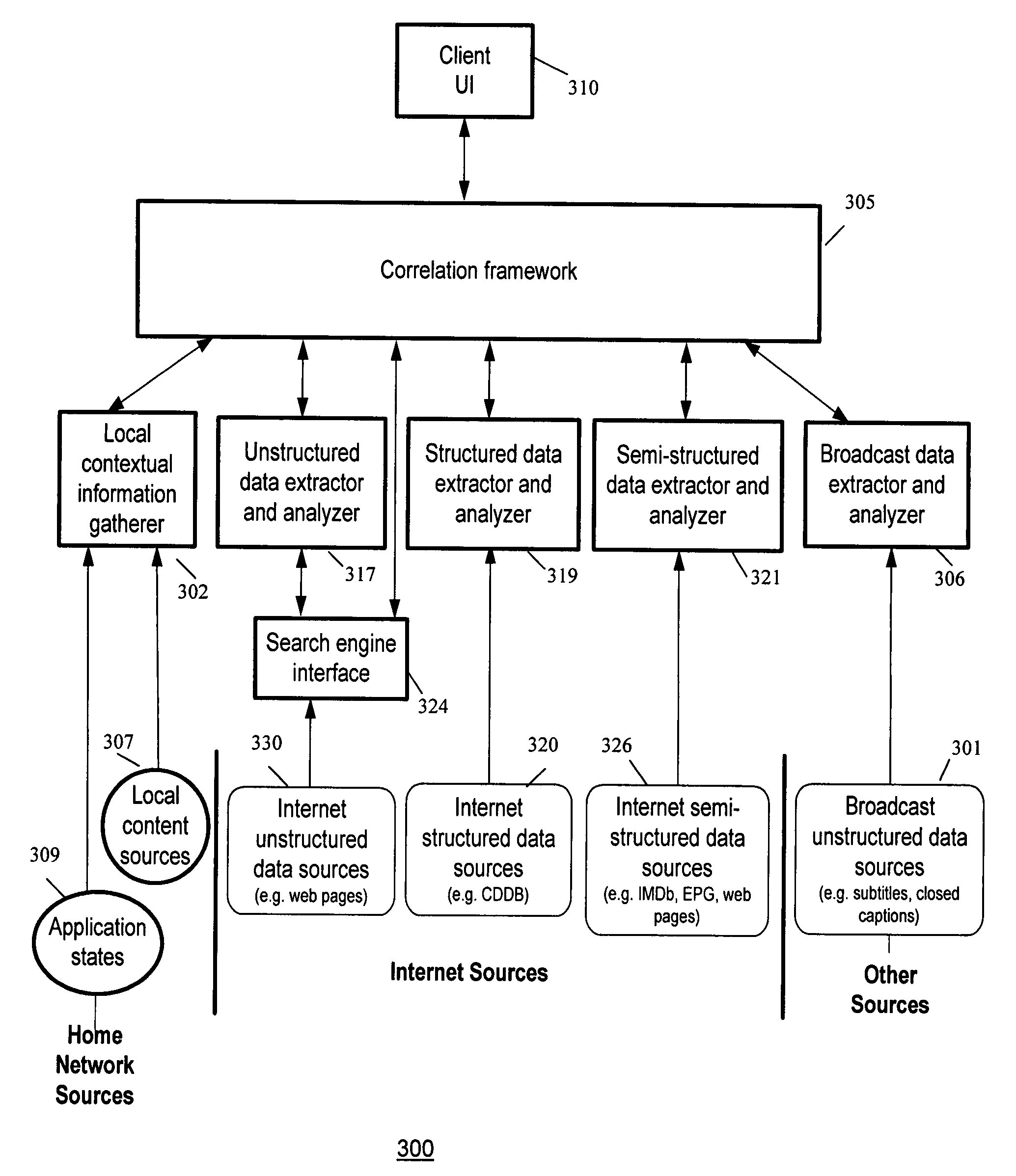

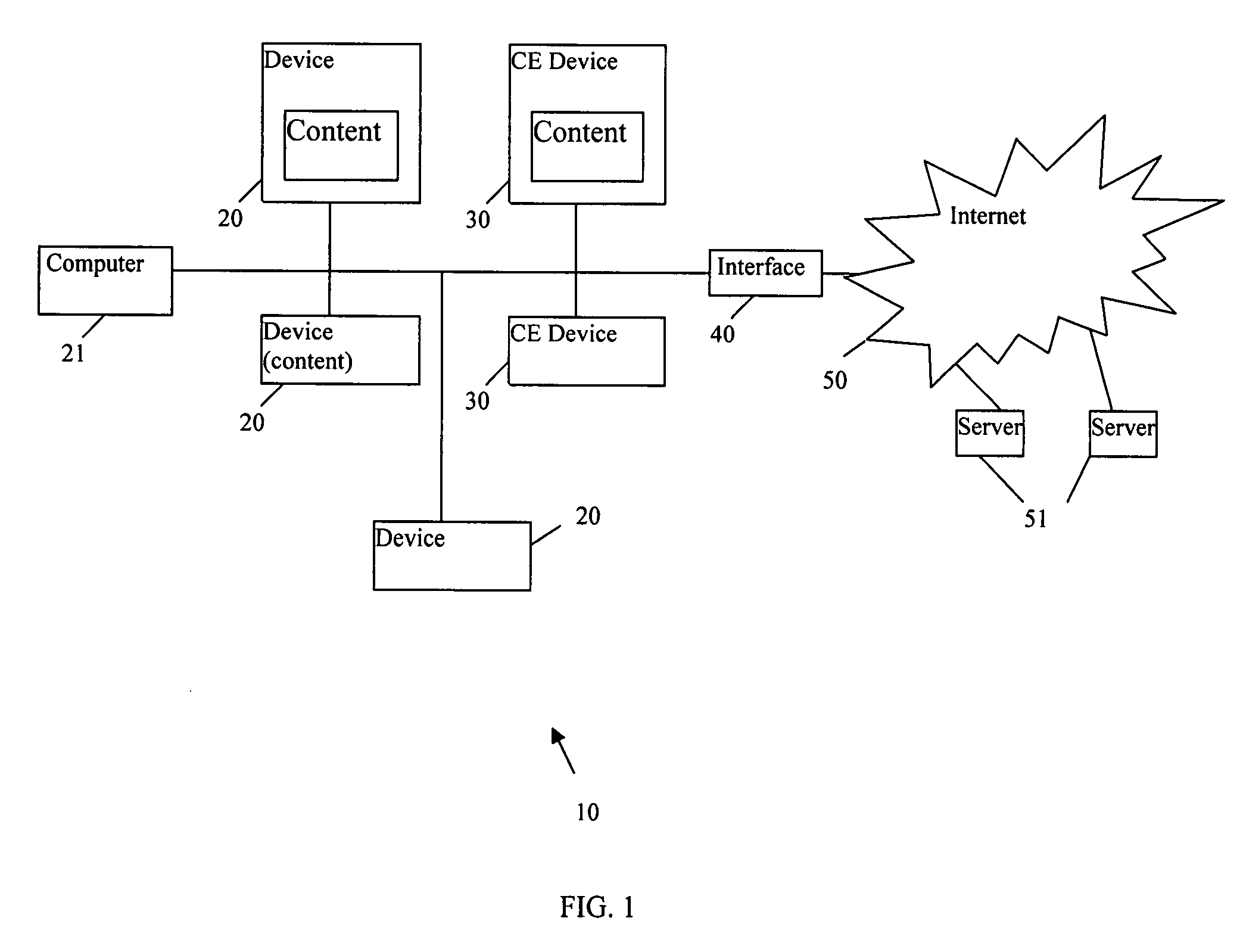

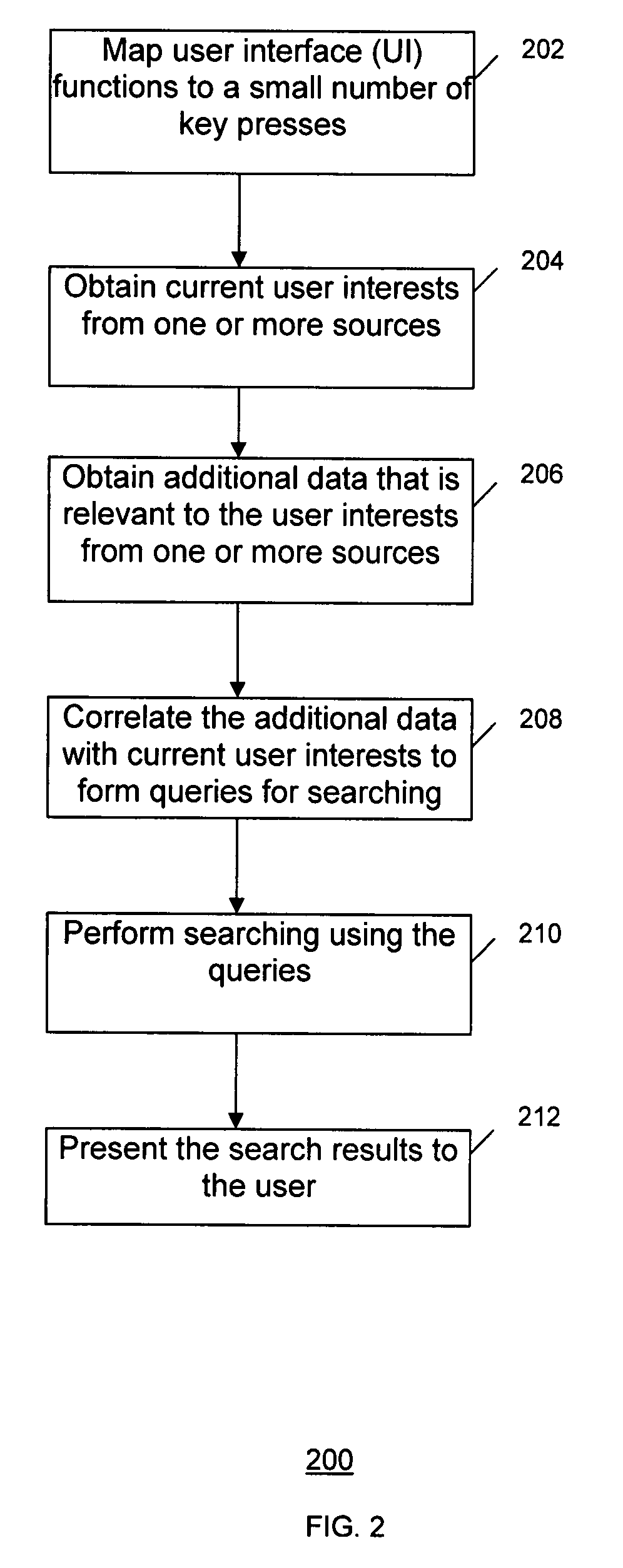

Method and system for providing relevant information to a user of a device in a local network

InactiveUS20080288641A1Minimization requirementsExperienceDigital data information retrievalDigital computer detailsRelevant informationInformation gain

A method and system for providing information to a user of a device on a local network is provided. This involves obtaining information about current user activity on the local network, obtaining contextual information about current user activity on the local network and obtaining additional information interrelated to the contextual information and the user activity information. Then correlations are identified between the additional information, the contextual information and the user activity information. The correlations are used in forming a query to search for information related to the current user activity, to provide to the user.

Owner:SAMSUNG ELECTRONICS CO LTD

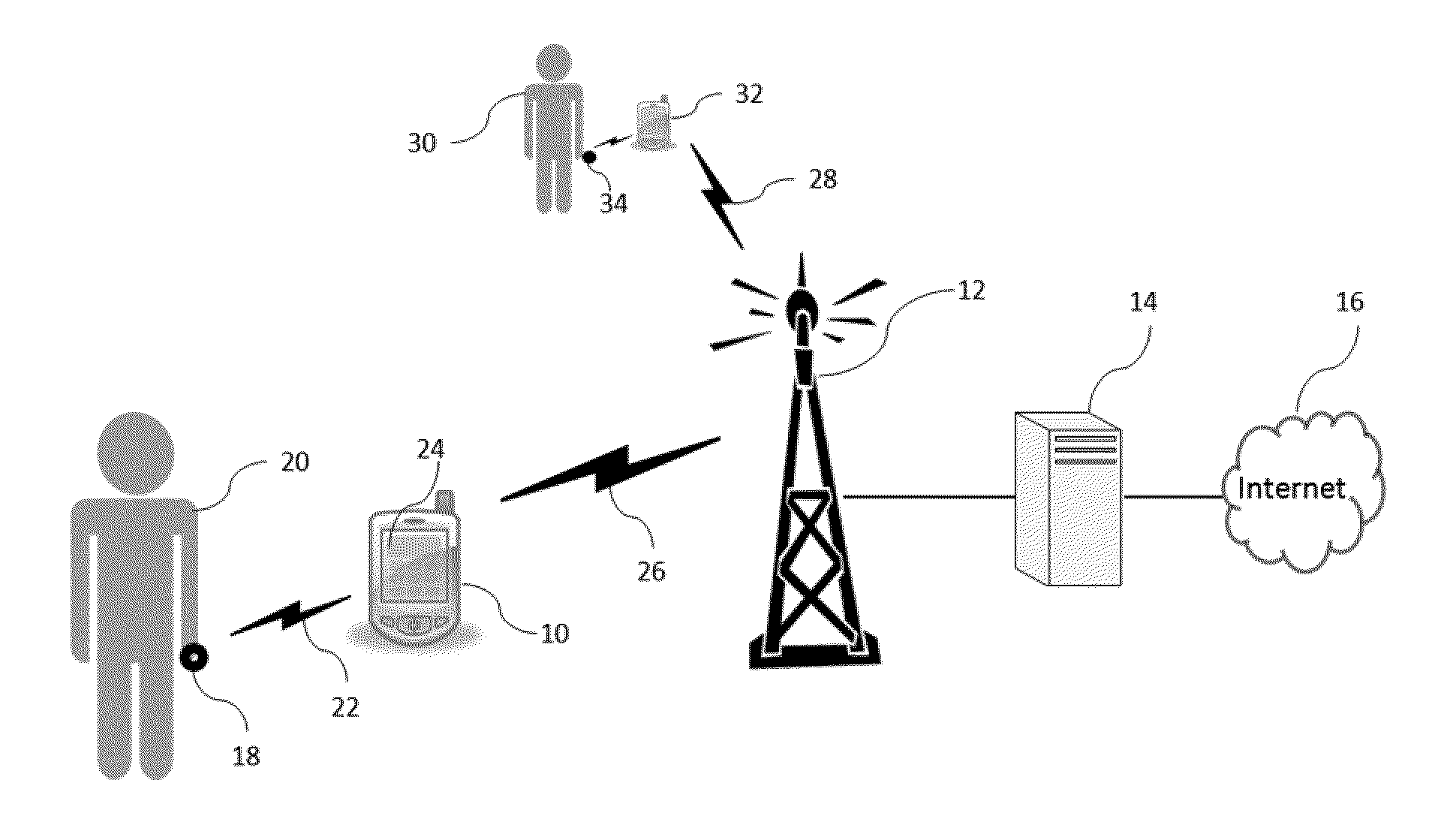

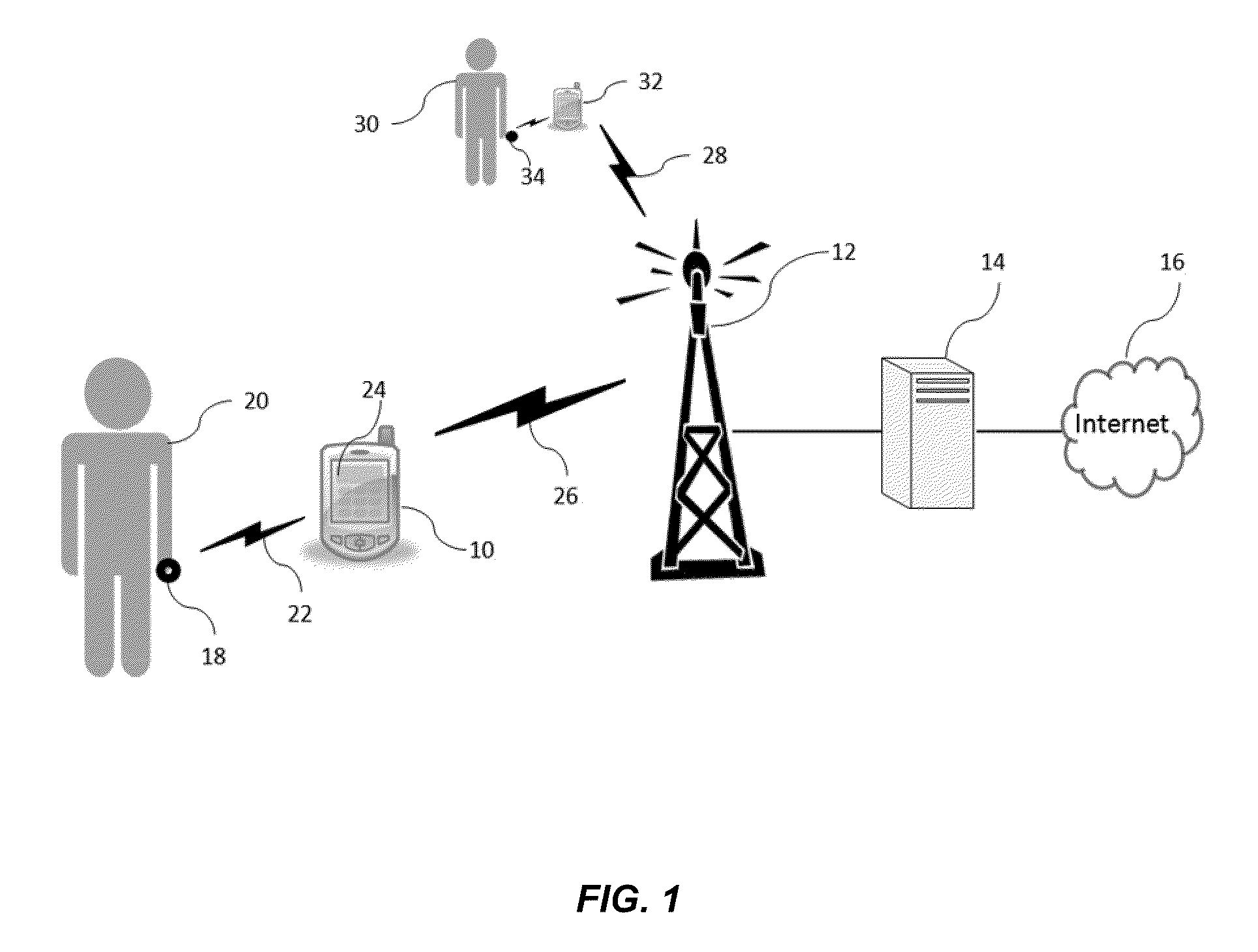

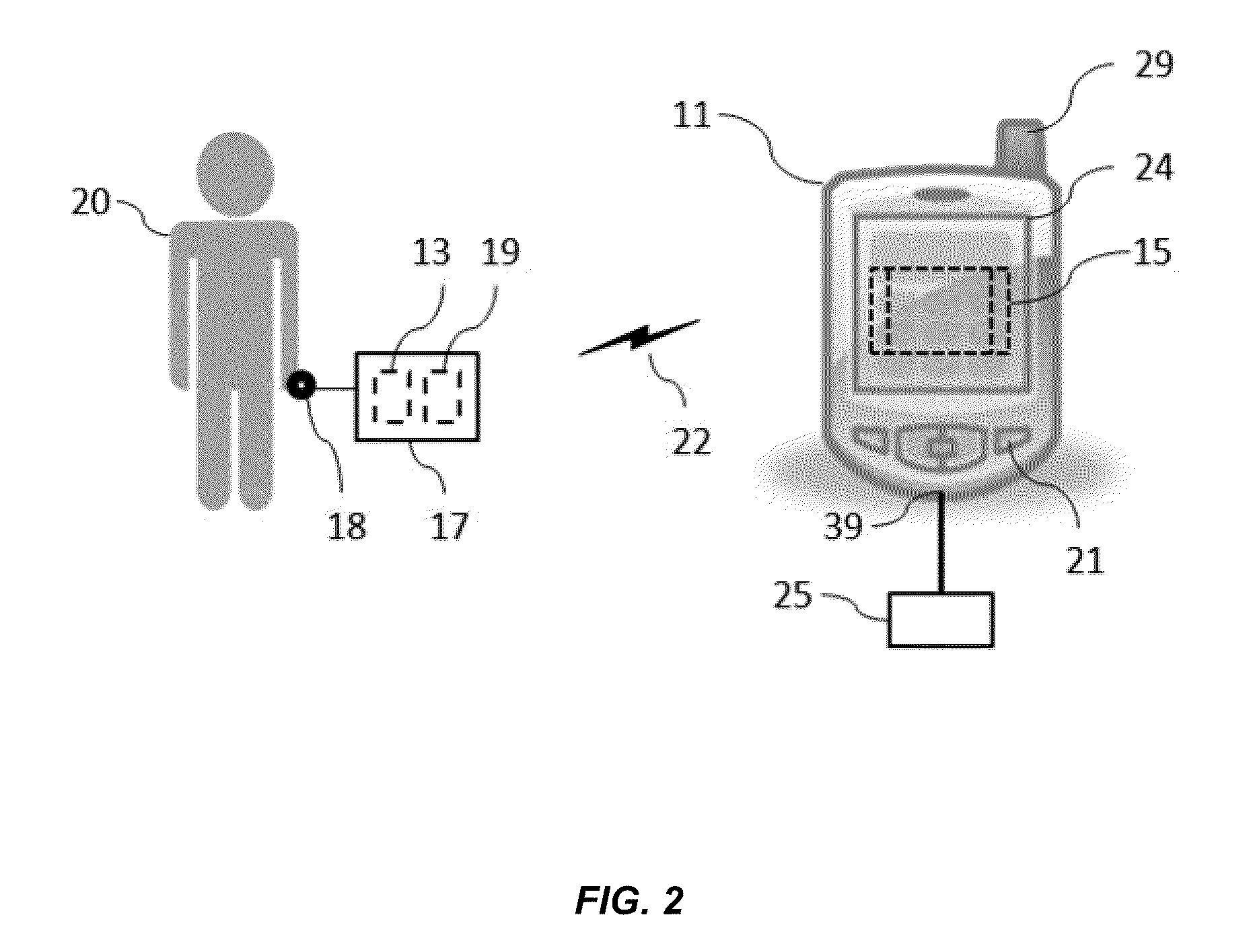

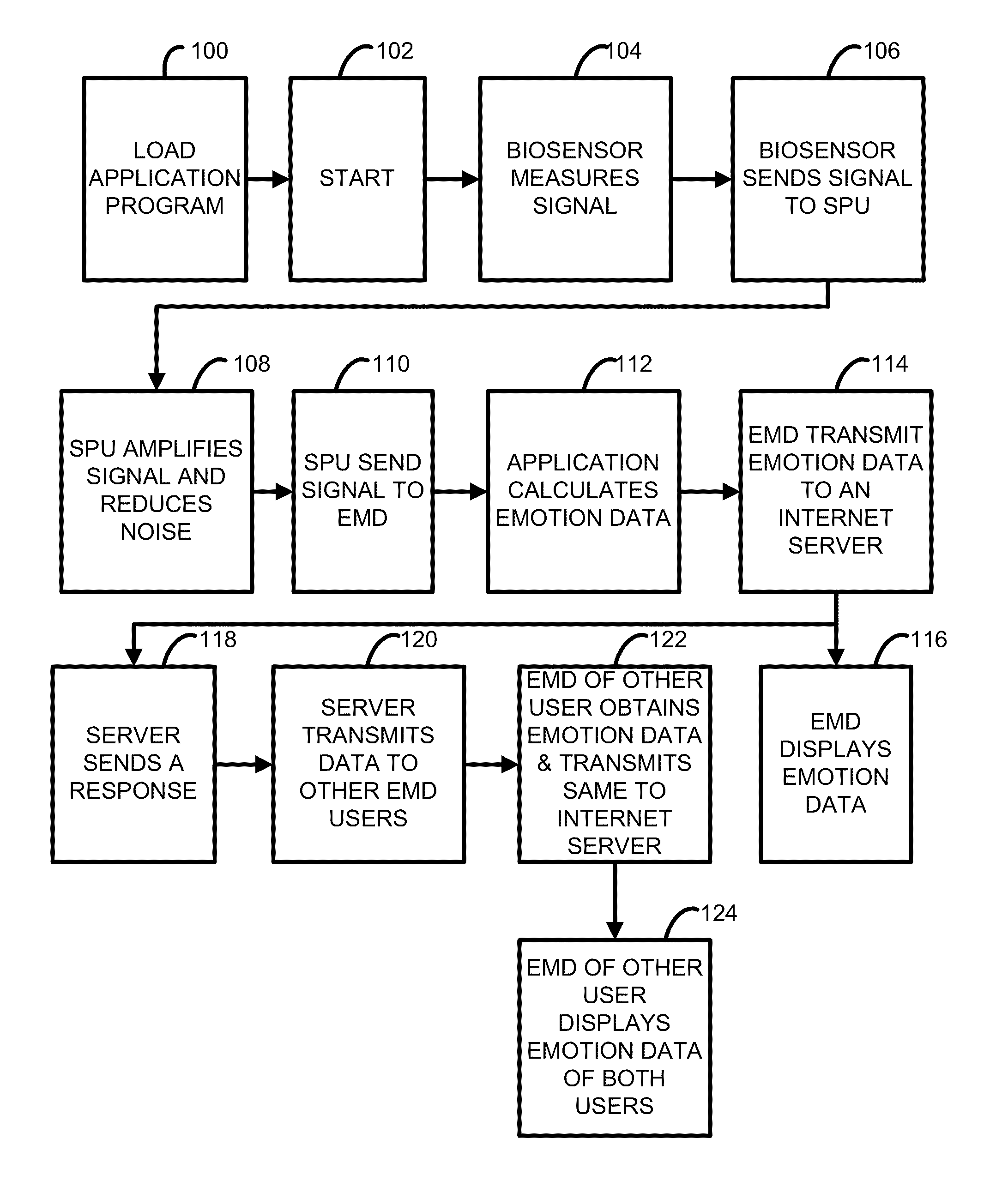

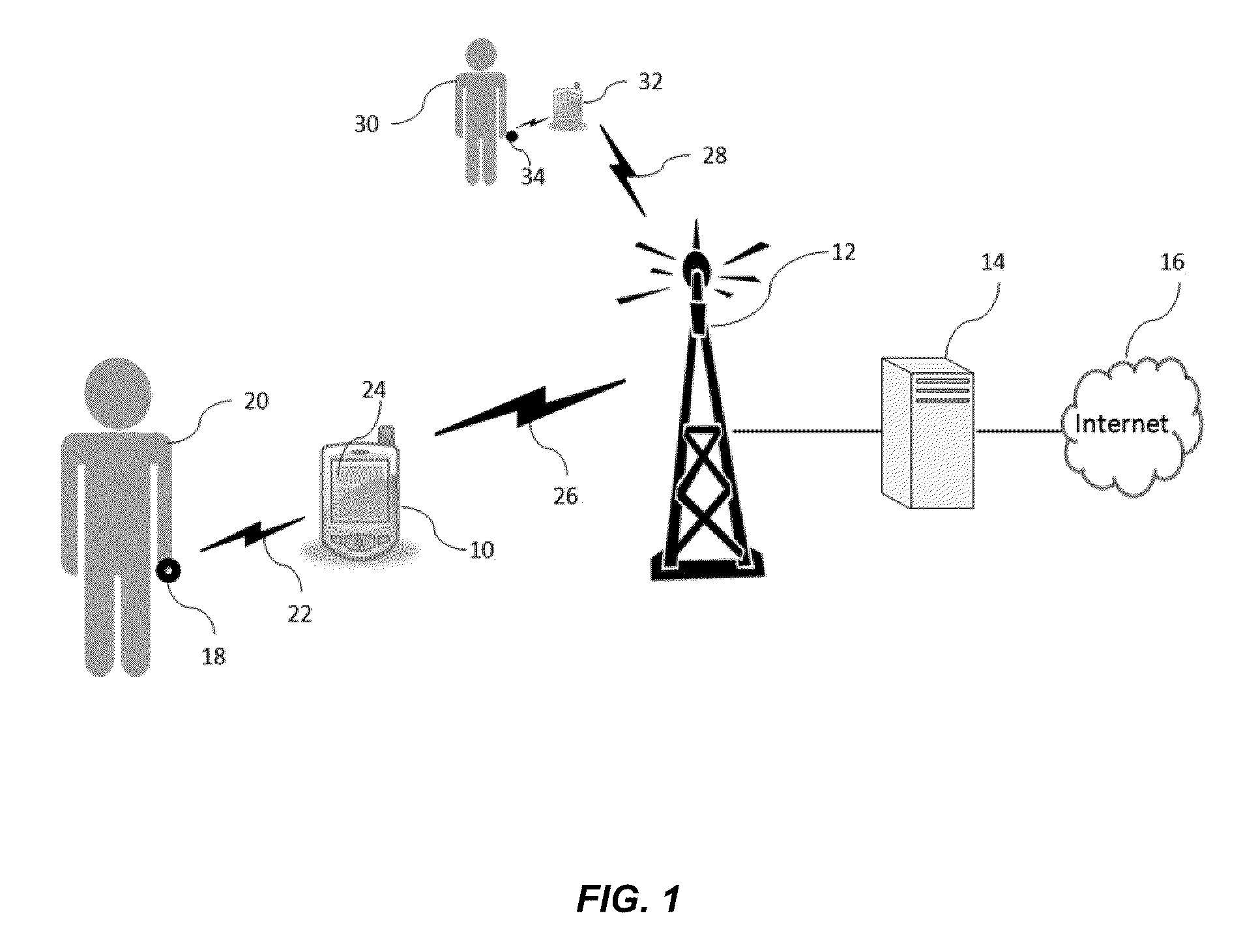

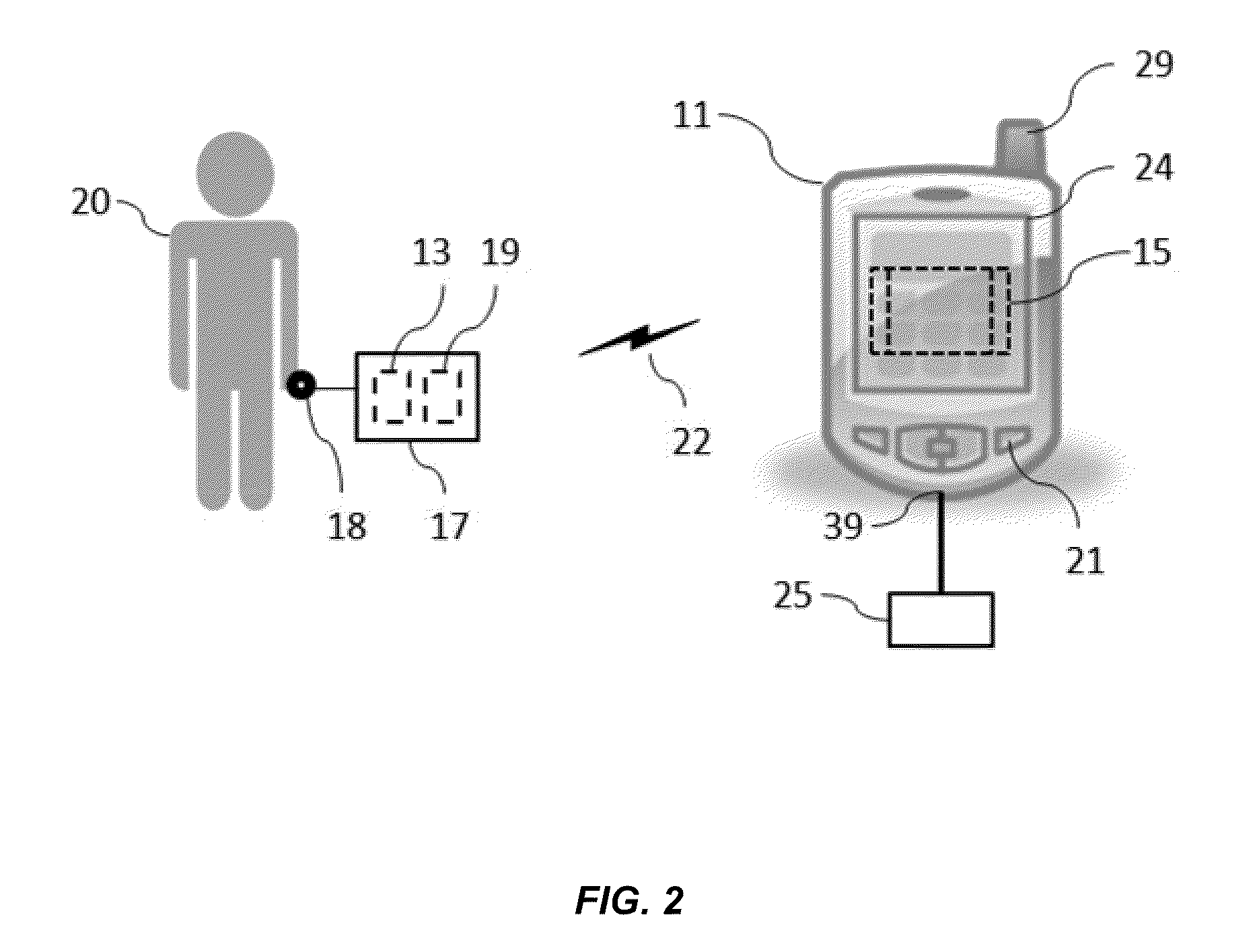

Method and apparatus for monitoring emotion in an interactive network

ActiveUS20110300847A1Easy to detectEasy to monitorService provisioningMedical automated diagnosisWide areaEmotional arousal

Embodiments of the invention provide a method, devices, and system for monitoring and sharing emotion-related data from one or more persons connected via the internet. An emotion monitoring device (EMD) measures physiological signals obtained from biosensors and computes emotion states relating to emotional arousal and valence. Various signal processing methods are employed to reduce artifact and improve the detection of emotional states. The EMD communicates the emotion data to an internet server via a wireless network. The internet server transmits the emotion data to other persons equipped with an EMD. Their emotion data similarly is obtained and shared with others. The networked emotion data can used to enrich online, community experiences such as games and social networks. An implementation of an EMD based on a smart phone enables emotion data to be monitored in wide area, mobile environment. The biosensors can be integrated into the casing or a cover for the mobile phone.

Owner:THE VISTA GRP LLC

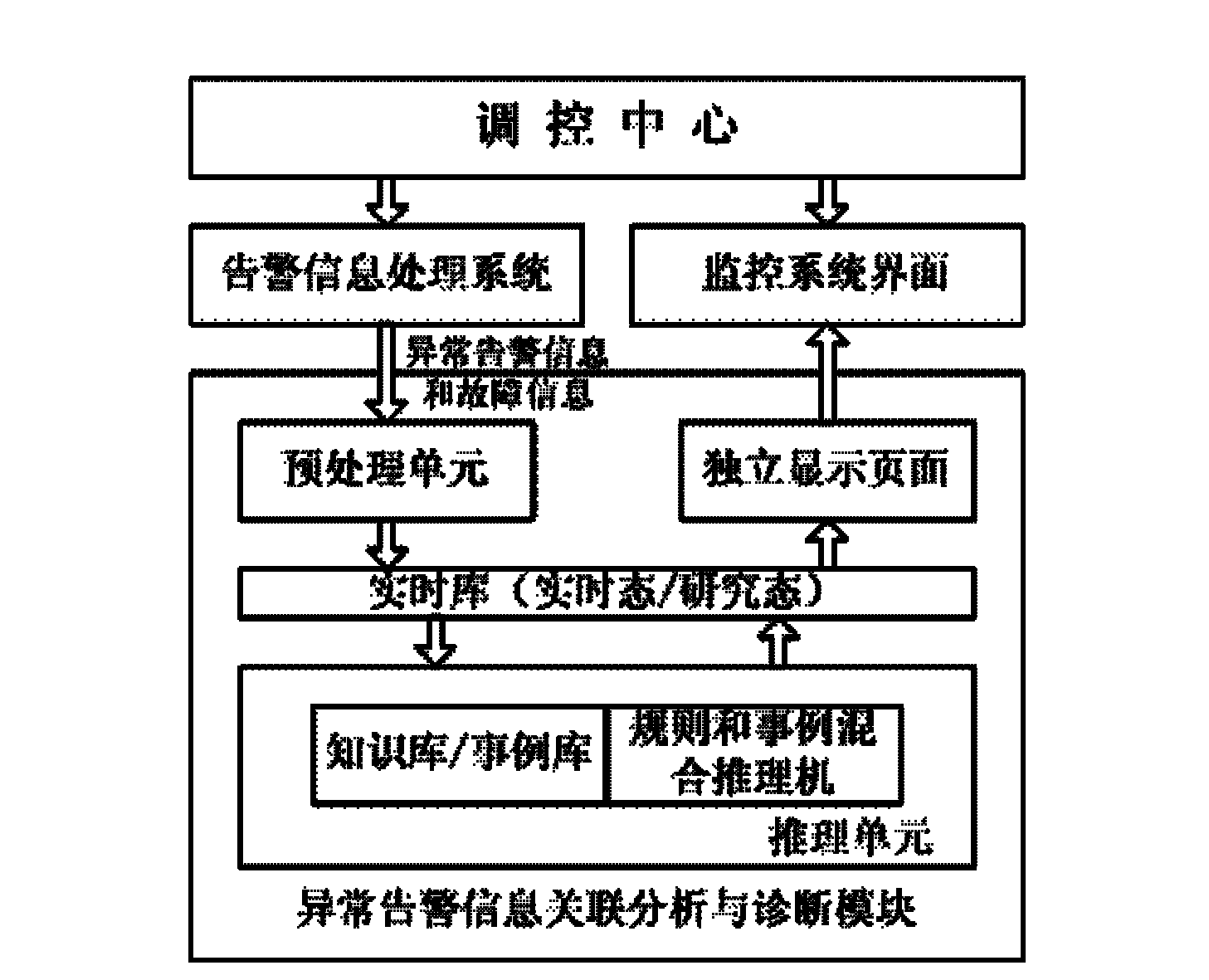

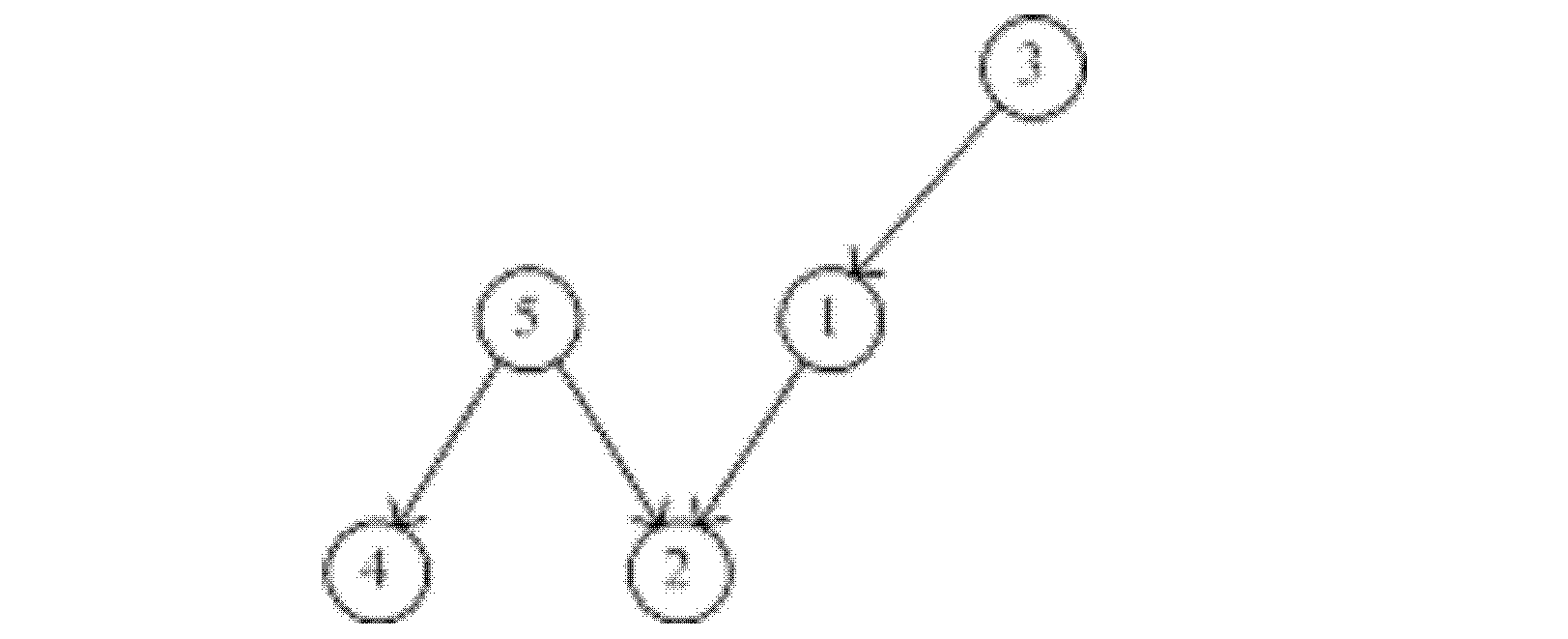

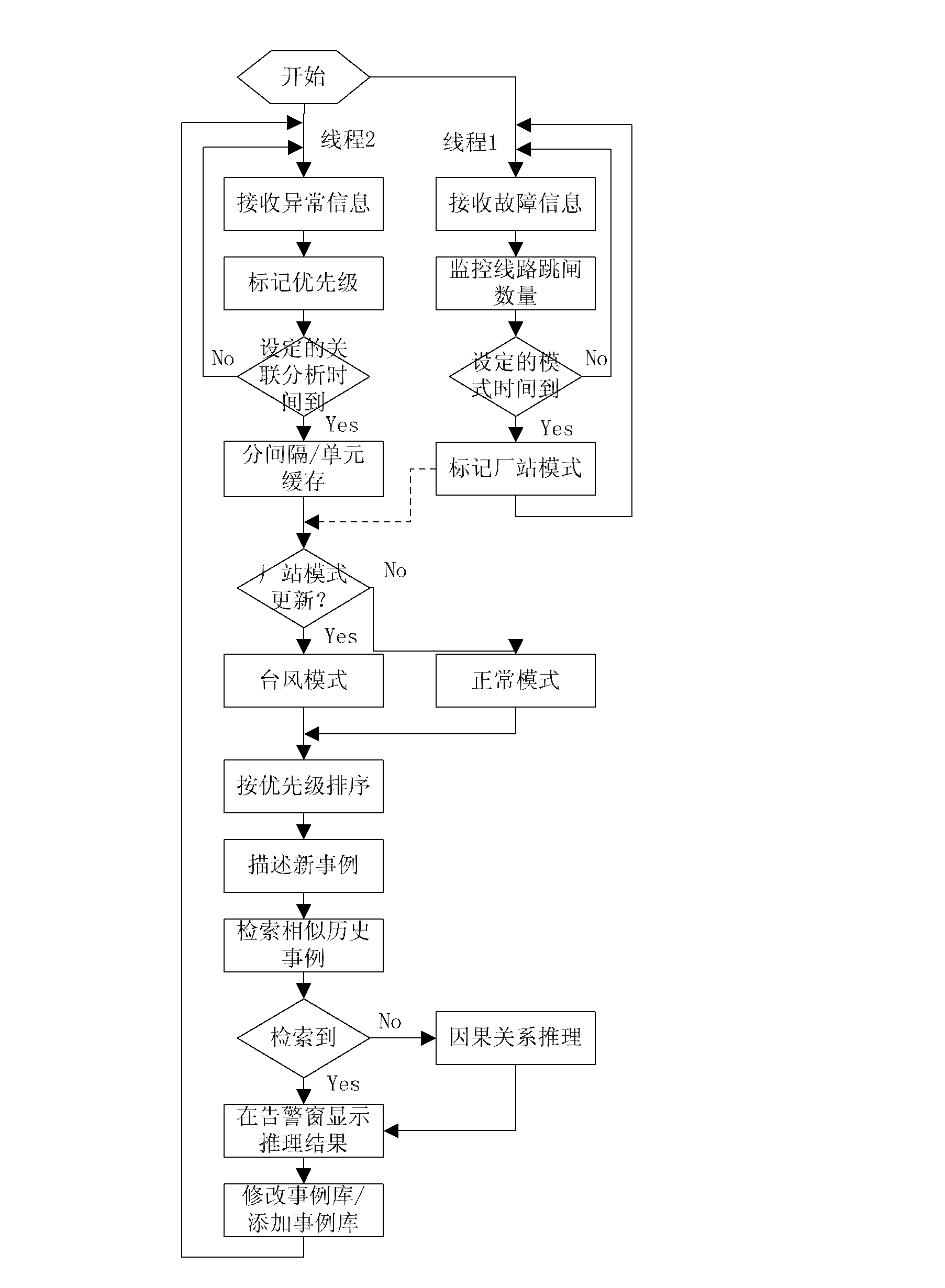

District power network equipment abnormal alarm signal association analysis and diagnosis method

InactiveCN102638100AIntegrity guaranteedGuarantee authenticityCircuit arrangementsInformation processingPower system scheduling

The invention discloses a district power network equipment abnormal alarm signal association analysis and diagnosis method in the field of automation of scheduling of electric power systems. According to the method disclosed by the invention, the weather situation of a plant station region at which abnormal alarm information is located can be automatically identified so as to determine the information processing mode. The method disclosed by the invention has the beneficial effects that by realizing intelligent association analysis and auxiliary decision making of the equipment abnormal alarm information under the real-time state, and performing playback on historical alarm information and performing real-time treatment on manual set information under the research state, the abnormal treatment time is greatly reduced, the incidence of accidents is reduced, a real-time, rich and intelligent auxiliary decision-making support is provided for regulation and control staff, and the safe, high-quality, economical and stable operation of an electric fence is further ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

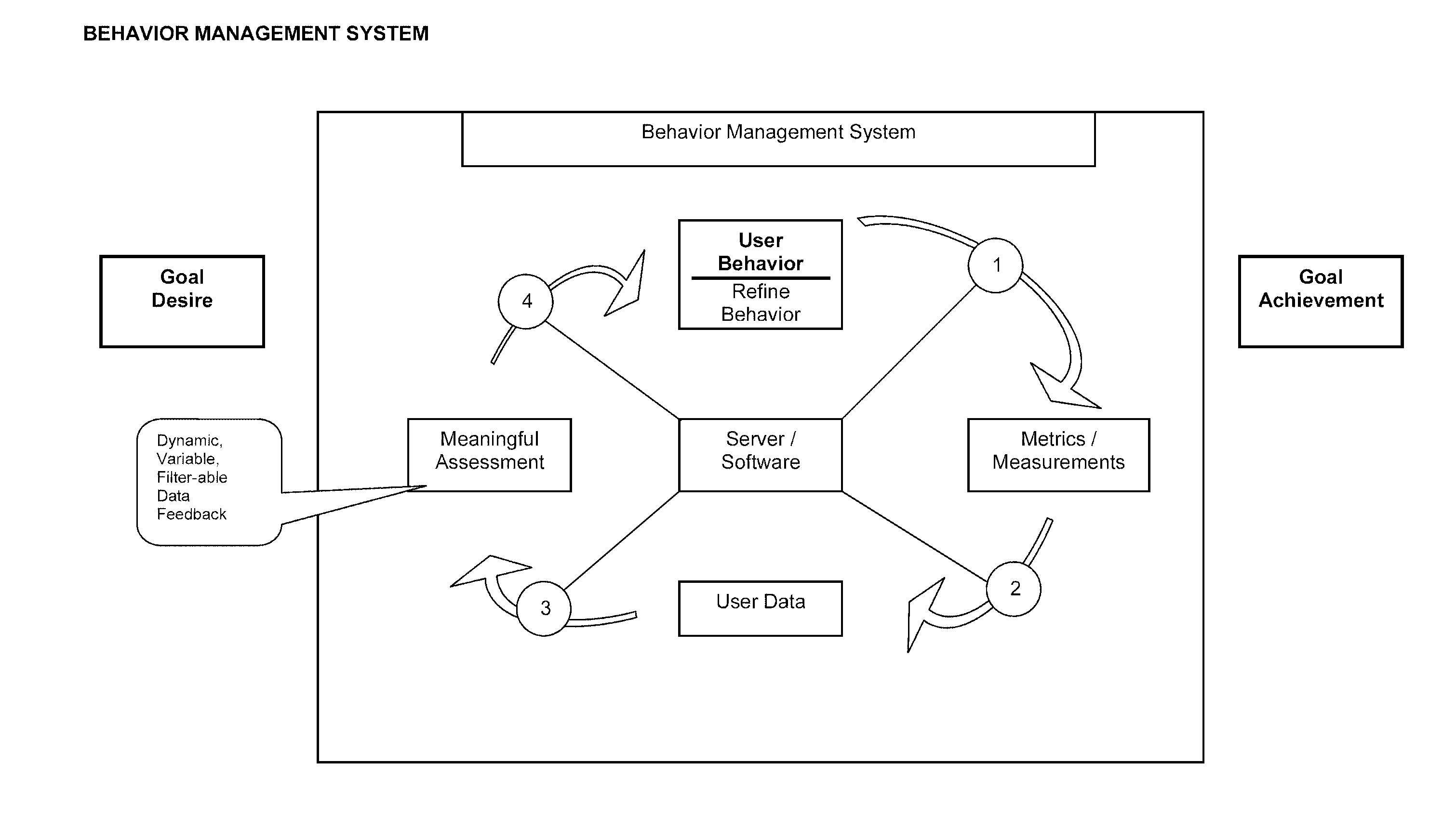

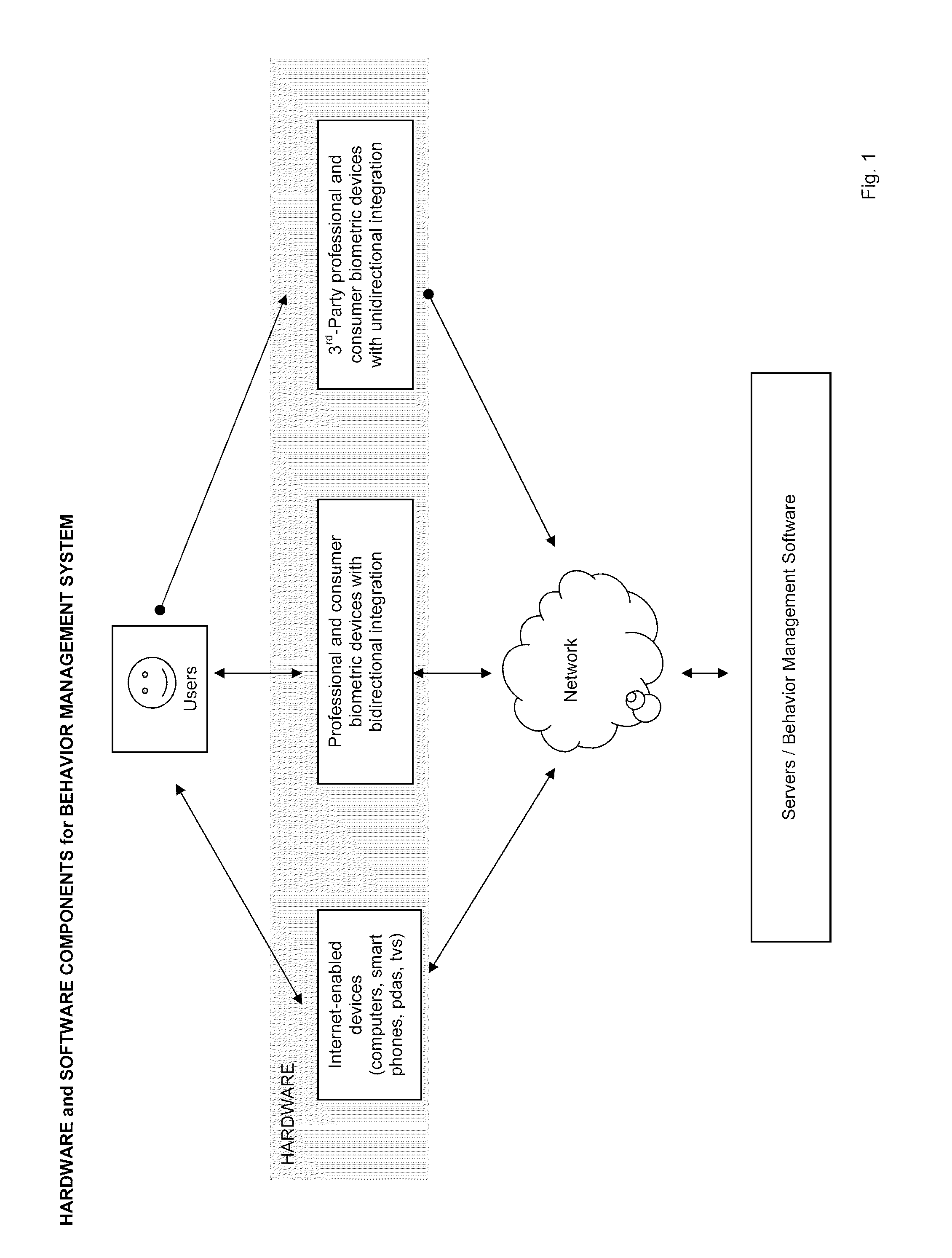

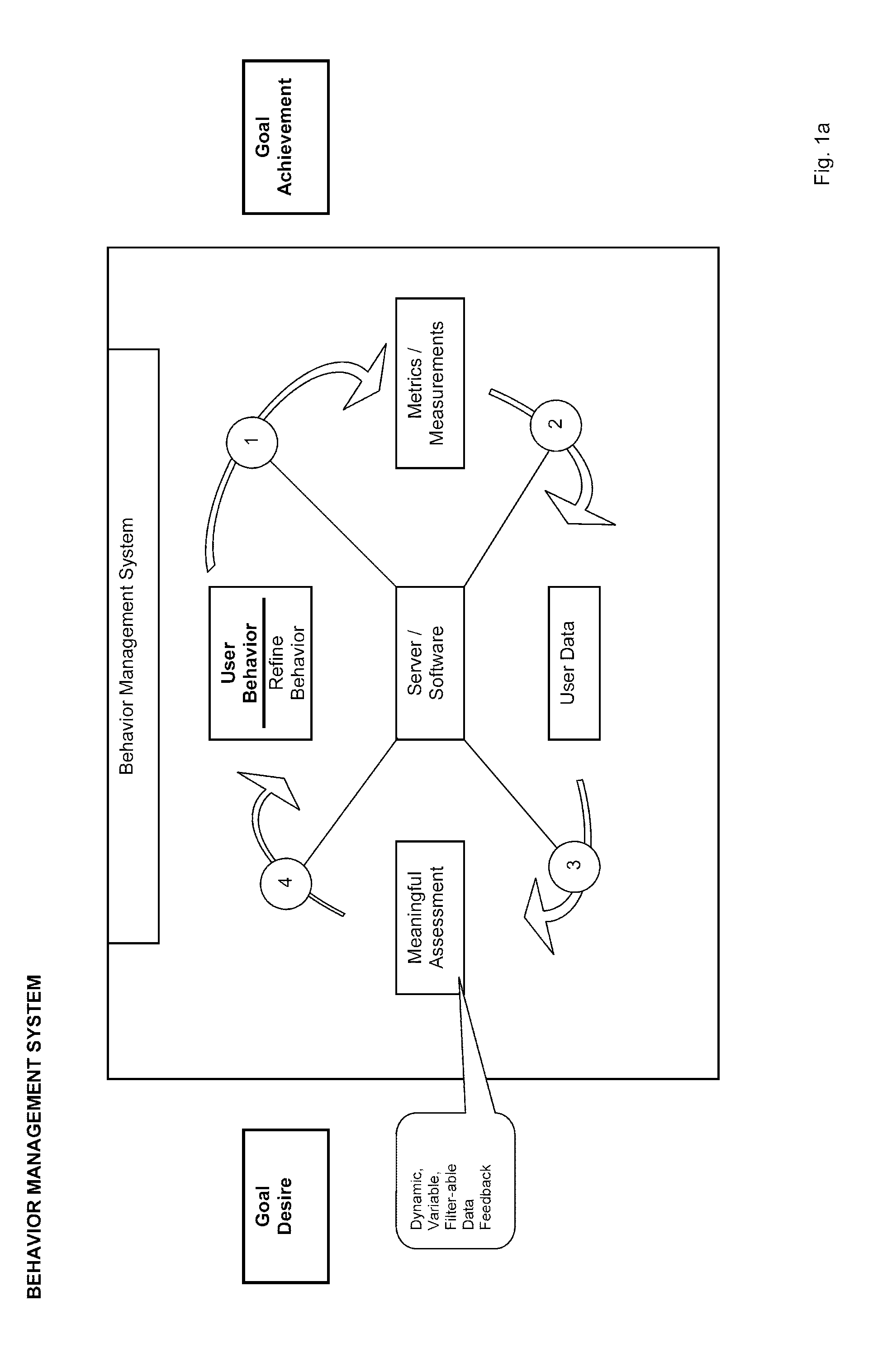

Metrics assessment system for health, fitness and lifestyle behavioral management

ActiveUS20100227302A1Great feedback ratioRaise the ratioPhysical therapies and activitiesMental therapiesComputer scienceLifestyle behavior

A software and hardware system is described that enables effective lifestyle management by providing a dynamic assessment of a user's physical and behavioral metrics via a high feedback ratio interface.

Owner:FAT STATZ BODYSPEX

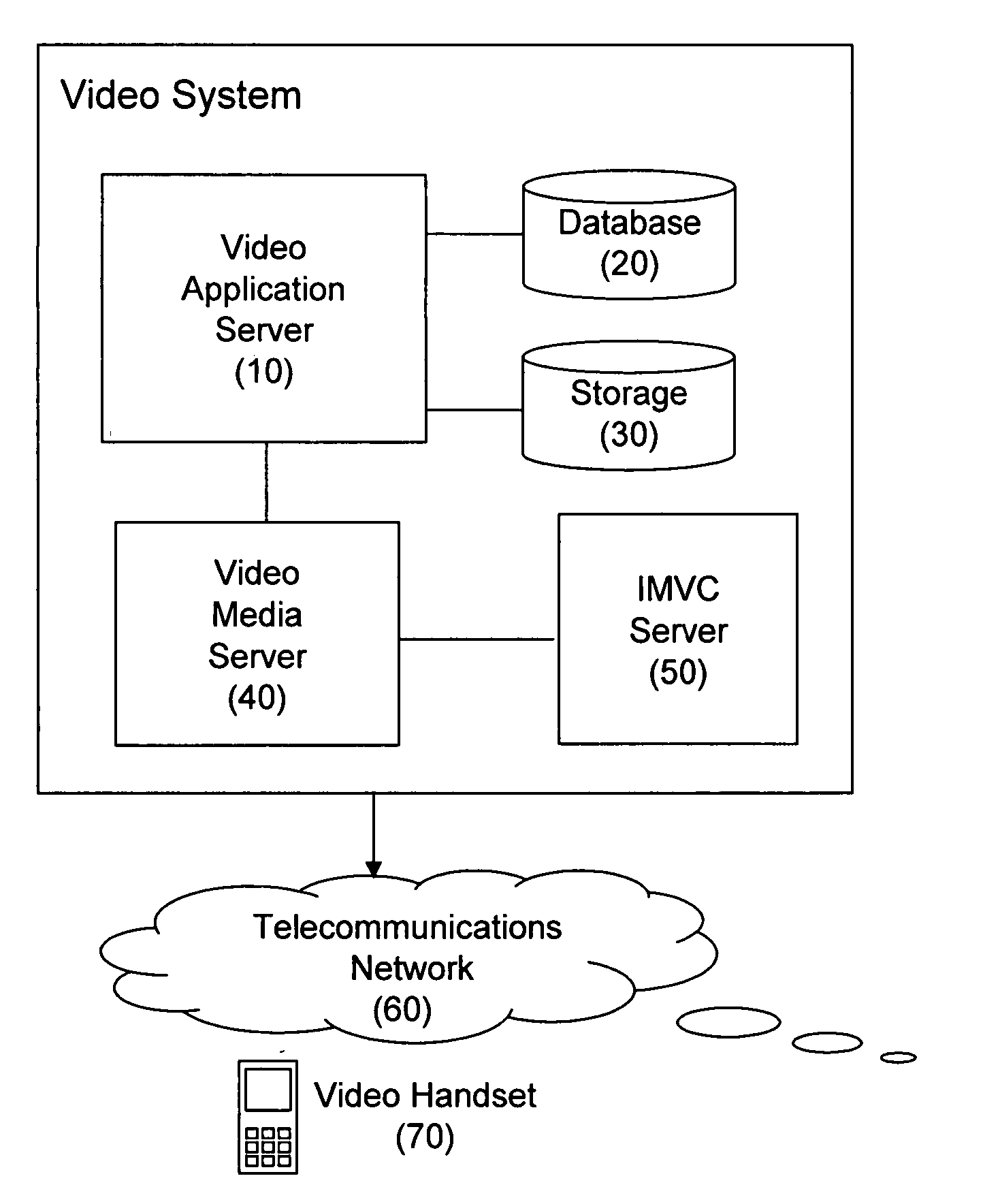

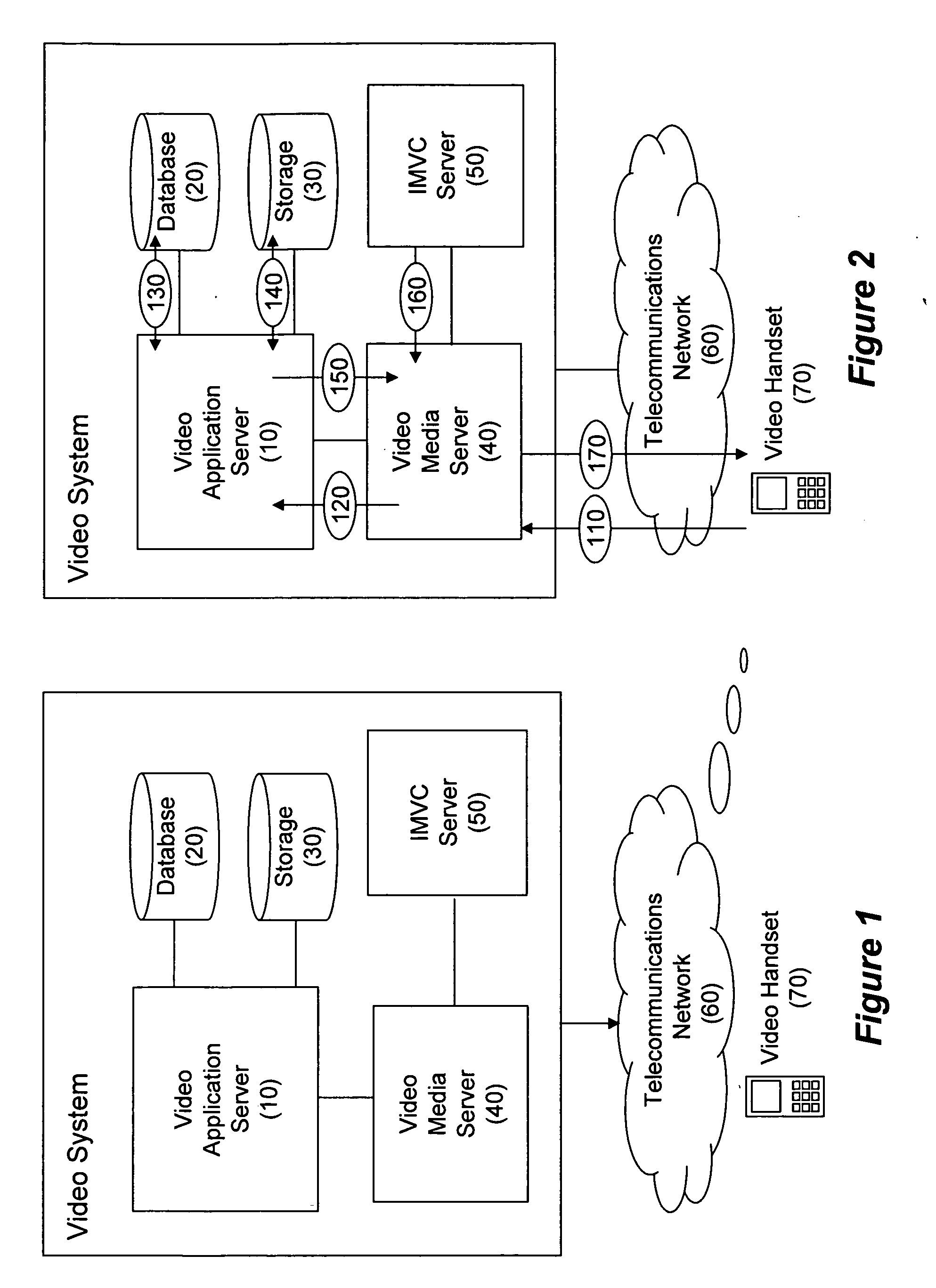

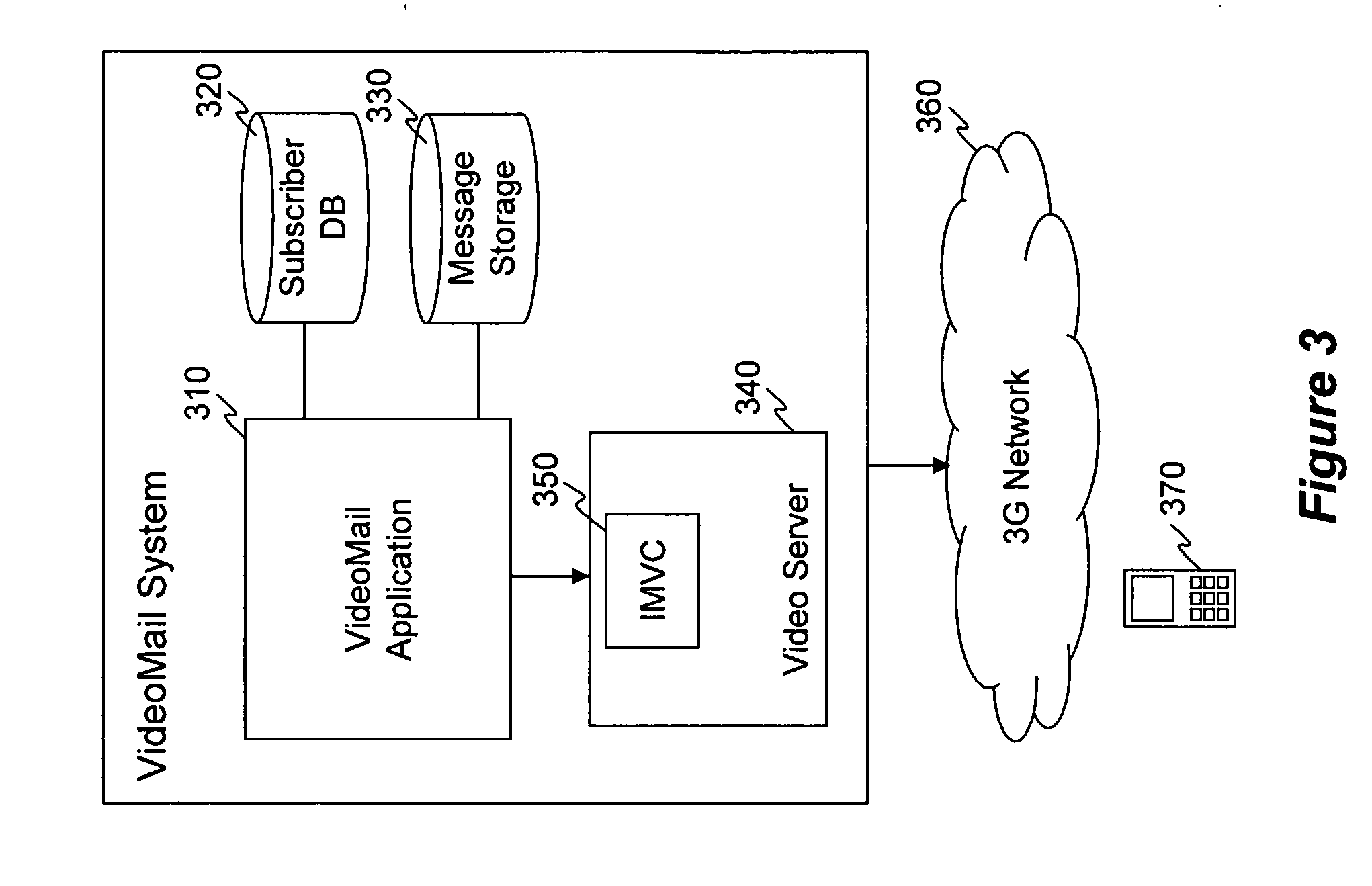

System and method for multimedia-to-video conversion to enhance real-time mobile video services

ActiveUS20070216761A1Good serviceExperienceTwo-way working systemsTransmissionTelecommunications networkCommunications system

A communication system converting multimedia data of enhanced services into video stream for transmission to a user's handset communication device. The system includes a database storing therein users profile data; a mailbox system storing therein users mailboxes and capable of storing messages in audio and video formats; an application server managing data storage and retrieval from the database and storage; a multimedia to video converter, receiving multimedia data and converting it into a video streams corresponding to a pre-selected template; an access server providing the multimedia data to the multimedia to video converter and receiving therefrom the video stream, and transmitting the video stream onto a telecommunication network.

Owner:COMVERSE

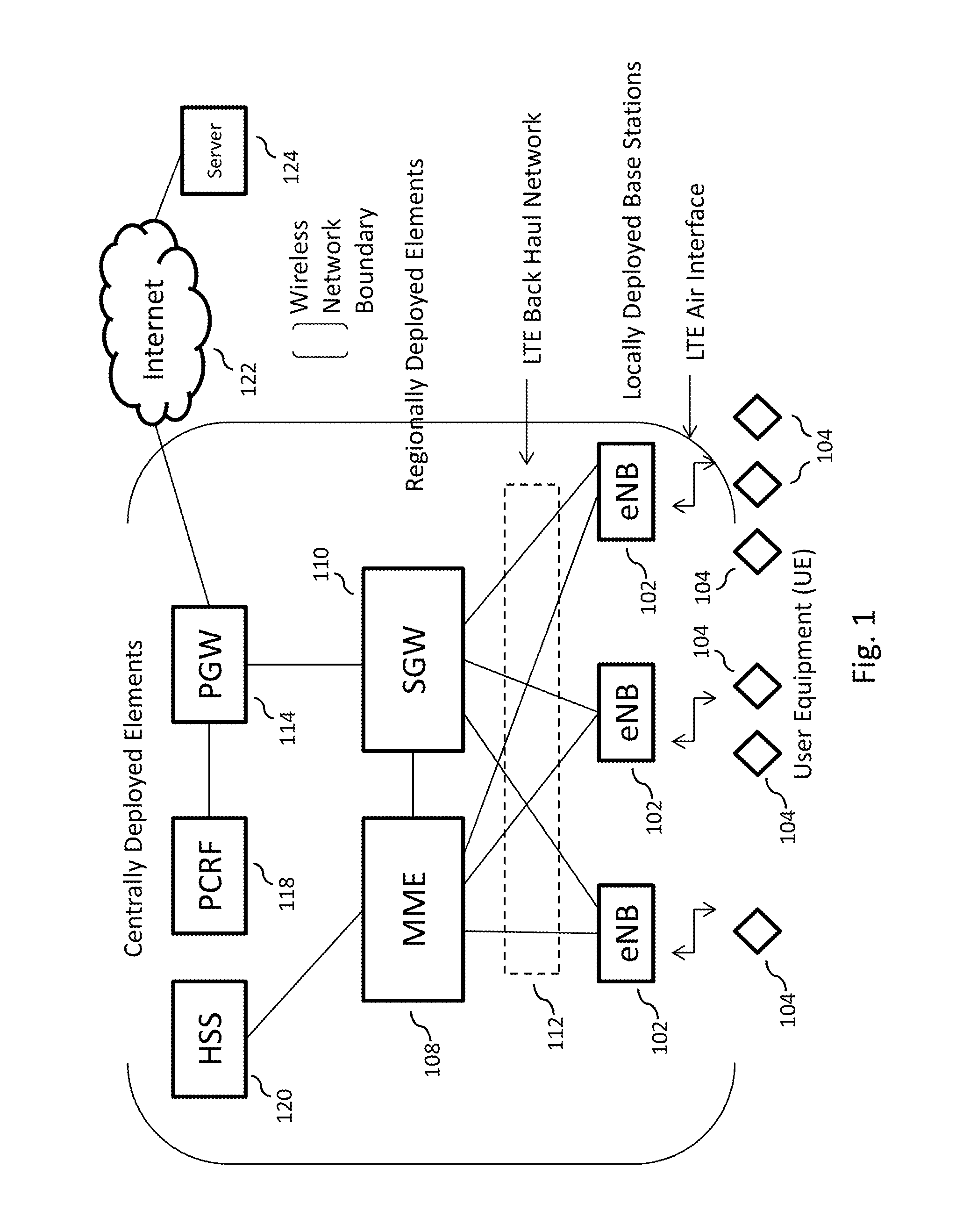

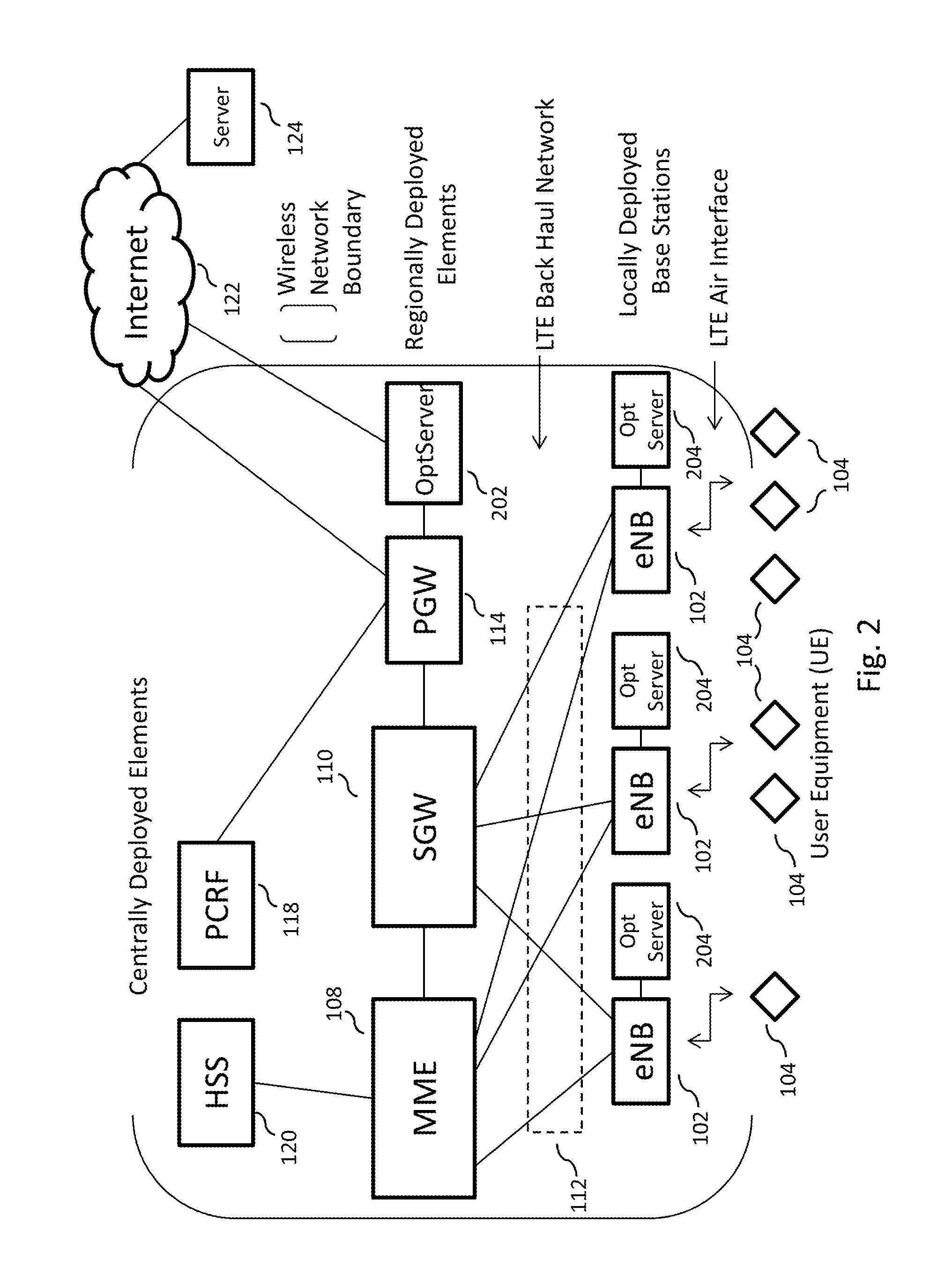

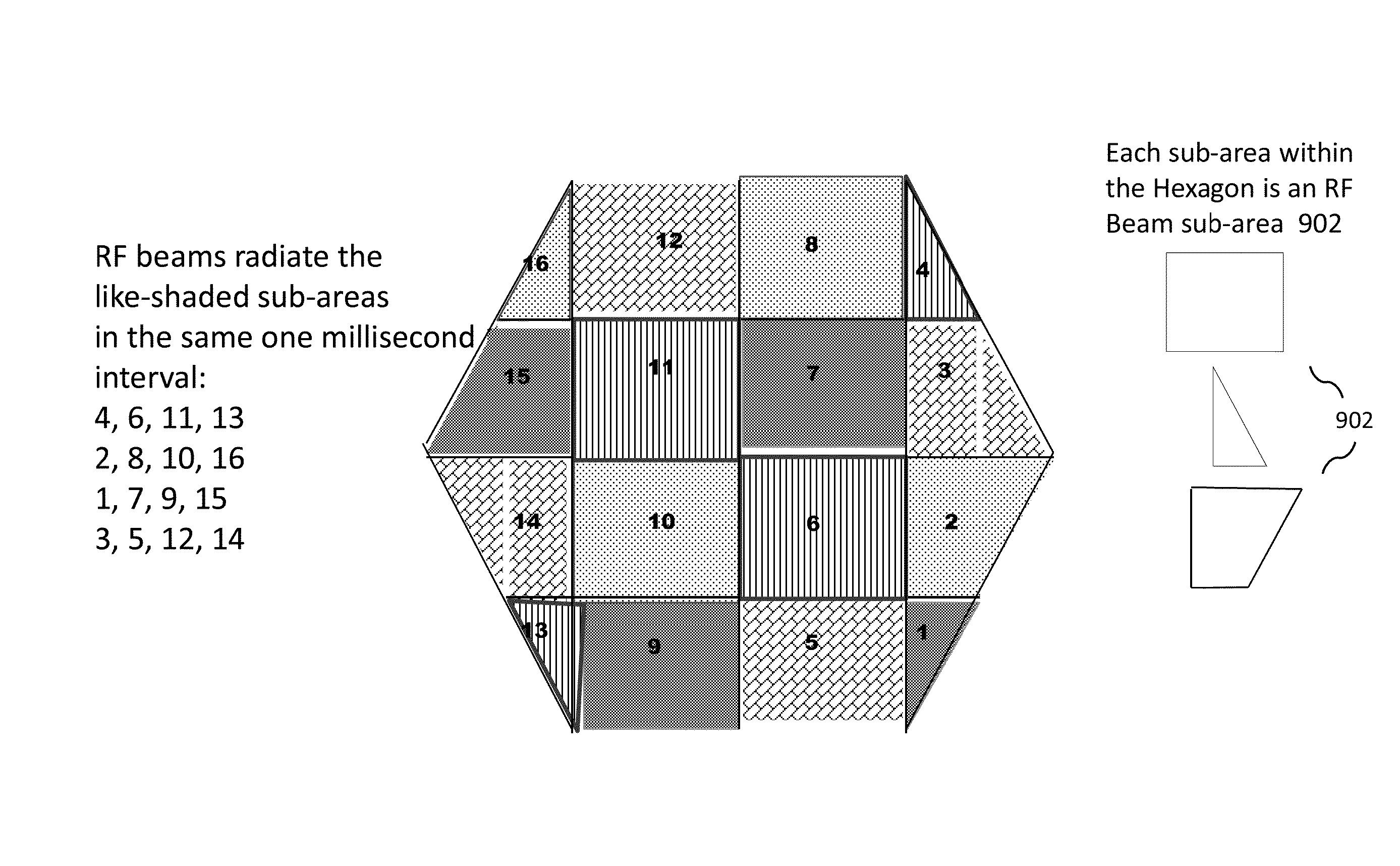

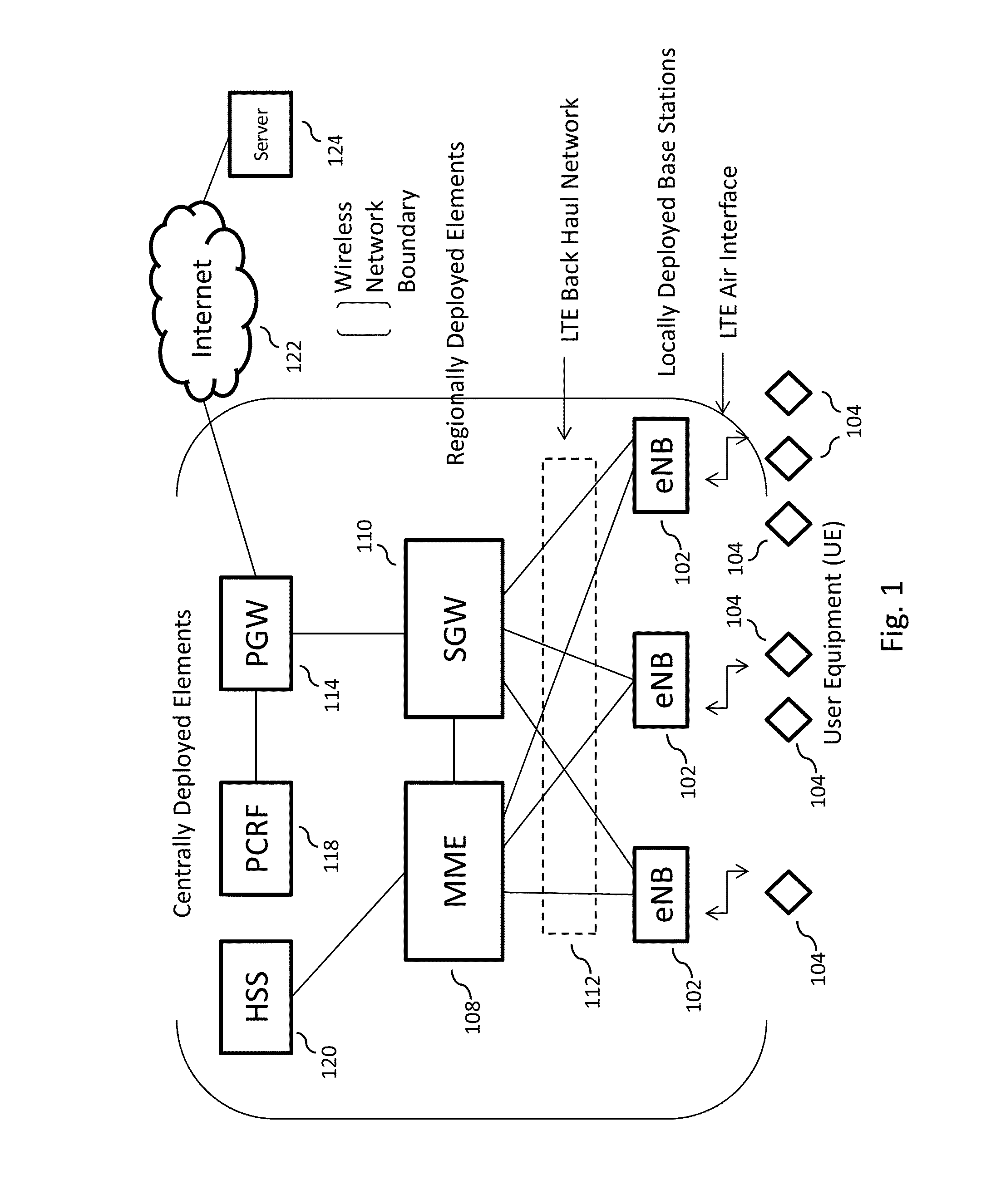

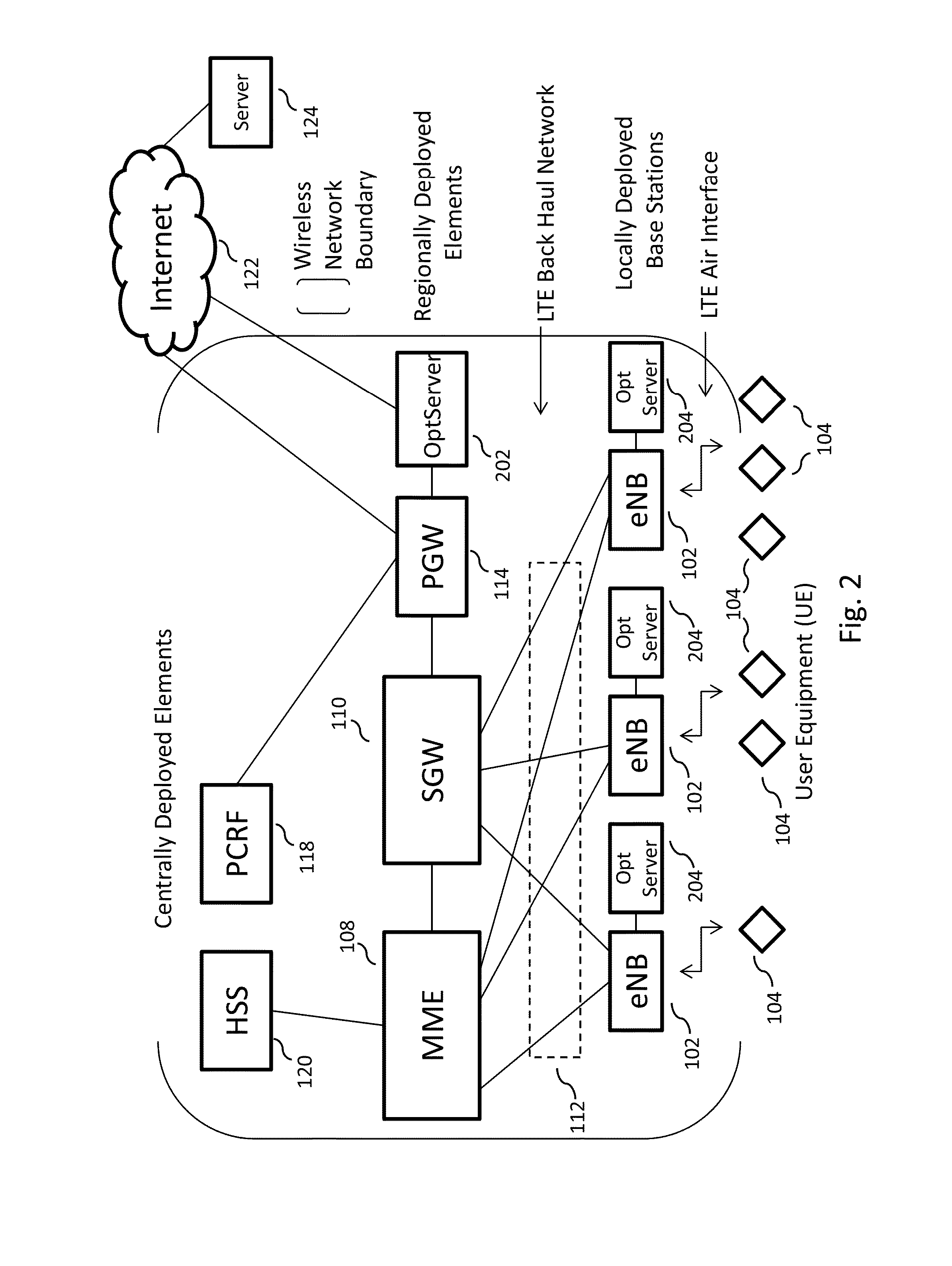

Efficient reduction of inter-cell interference using RF agile beam forming techniques

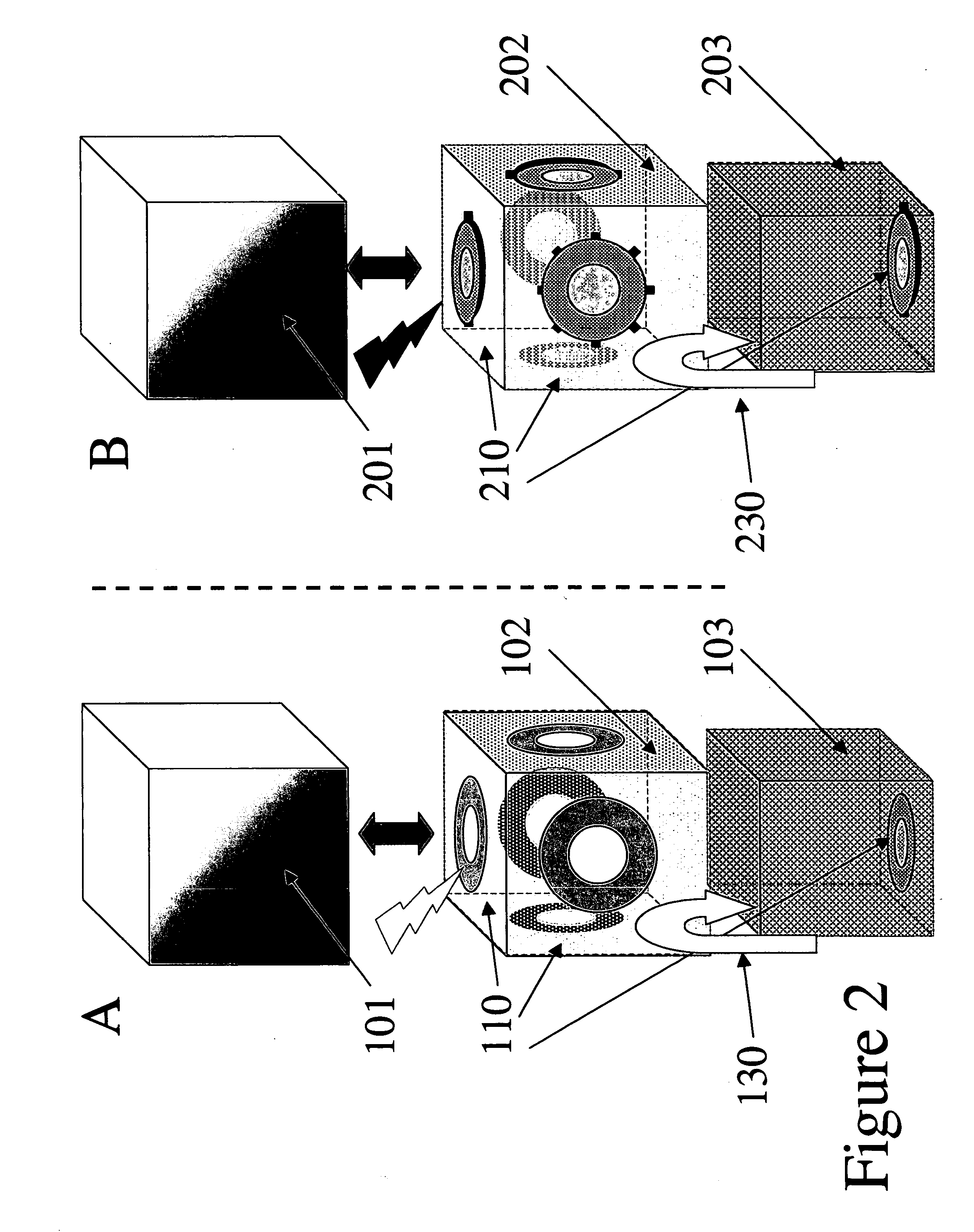

ActiveUS20140010129A1Low data rateExperienceTime-division multiplexFrequency-division multiplexCell to cell communicationData rate

In embodiments of the present disclosure improved capabilities are described for reducing inter-cell interference in a large area broadband LTE wireless network utilizing RF agile beam forming antennas, where the reduced inter-cell interference is realized by arranging the sets of rotating RF beams in each cell such that adjacent RF beam sub-areas in the same or in different cells are not illuminated at the same time. The reduction in inter-cell interference results in reduced interference noise for users located near the edges of cells, thereby allowing them to be assigned higher data rates. Also, the same set of sub-carriers can be assigned by adjacent cells to users located in the RF beam sub-areas at the cell boundaries, thereby allowing the complete set of LTE sub-carriers to be assigned to any user at any time, without requiring additional cell-to-cell communications.

Owner:ALL PURPOSE NETWORKS INC

Method and apparatus for monitoring emotion in an interactive network

ActiveUS8700009B2Improve detection and monitoringReduce artifactsService provisioningSpecial service for subscribersEmotional arousalData shipping

Embodiments of the invention provide a method, devices, and system for monitoring and sharing emotion-related data from one or more persons connected via the internet. An emotion monitoring device (EMD) measures physiological signals obtained from biosensors and computes emotion states relating to emotional arousal and valence. Various signal processing methods are employed to reduce artifact and improve the detection of emotional states. The EMD communicates the emotion data to an internet server via a wireless network. The internet server transmits the emotion data to other persons equipped with an EMD. Their emotion data similarly is obtained and shared with others. The networked emotion data can used to enrich online, community experiences such as games and social networks. An implementation of an EMD based on a smart phone enables emotion data to be monitored in wide area, mobile environment. The biosensors can be integrated into the casing or a cover for the mobile phone.

Owner:THE VISTA GRP LLC

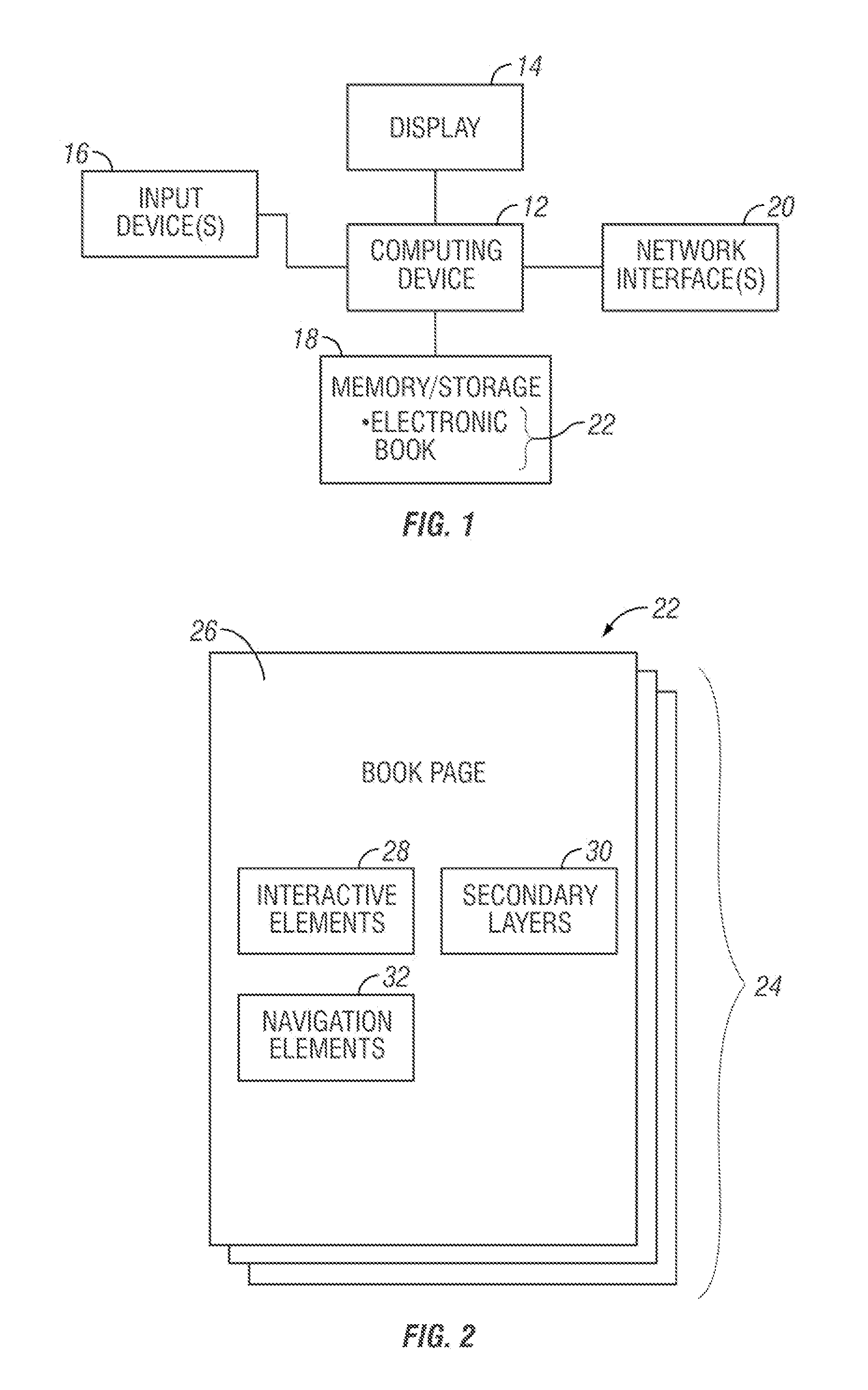

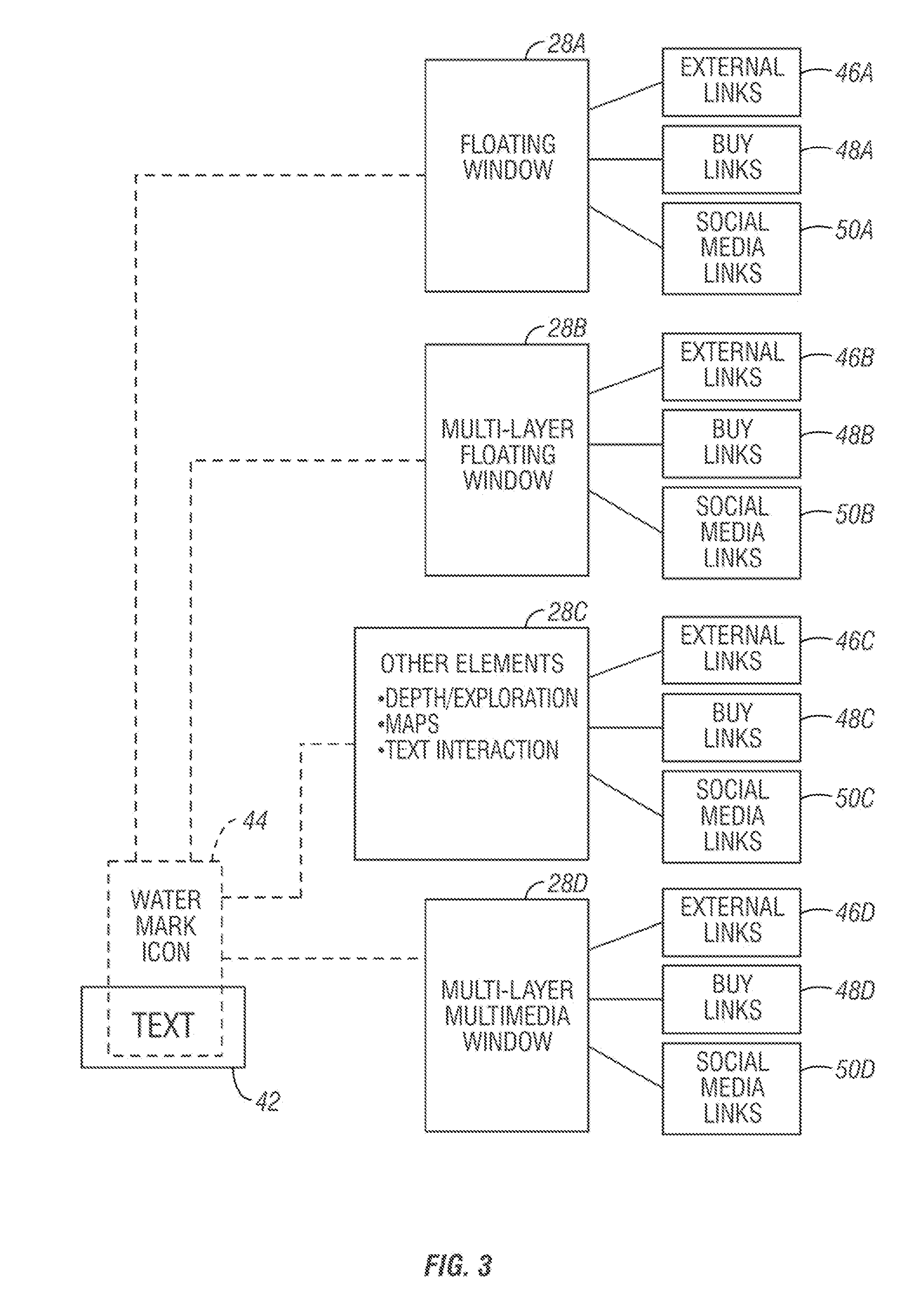

Interactive electronic book

ActiveUS20130104072A1Enhanced experienceEnrich experienceDigital computer detailsCathode-ray tube indicatorsInteractive contentDisplay device

A computer-storage media having computer executable instructions embodied thereon that, when executed on a computing device perform a method for providing an interactive electronic book, the method including providing a user interface for the interactive electronic book, the user interface including representations of pages to display on a display associated with the computing device, providing on one of the representations of the pages of the user interface a watermark icon of an interactive element to display on the display associated with the computing device, associating the watermark icon of interactive content with interactive content, the watermark icon being indicative of presence of the interactive content and a content type for the interactive content, and wherein the user interface further provides for accessing the interactive content by selecting the watermark icon of the interactive content and without navigating away from the pages on which the watermark icon is present.

Owner:HAVARD AMANDA MEREDITH

Dice that recognize the values of their own throws and transmit them to computers, with applications to electronic and casino games

InactiveUS20050215312A1ExperienceSmall modificationLottery apparatusVideo gamesElectricityEngineering

Dice are disclosed that detect their state, i.e., their own value once at rest, using for instance gravity, piezoelectricity, or photoelectric cells that are assigned to all faces to recognize the lower face. Said dice preferably transmit said state to a computer. Said computer may be the same that is used for the game that depends on the throw of the dice, or may be used mostly for display as for some casino games. Electricity is used in the die to let it determine its own state and transmit it. Economical protocols of transmission are used such as Bluetooth. Such dice may securely send alerts whenever deviations from a fair distribution of the outcomes is detected and can monitor small modifications of their balance to maintain their fairness. Part or all of the teaching can be realized as MEMS (micro electro-mechanical systems) or NEMS (nano electromechanical systems) modifications of usual dice.

Owner:TRESSER YUVAL ARIE +1

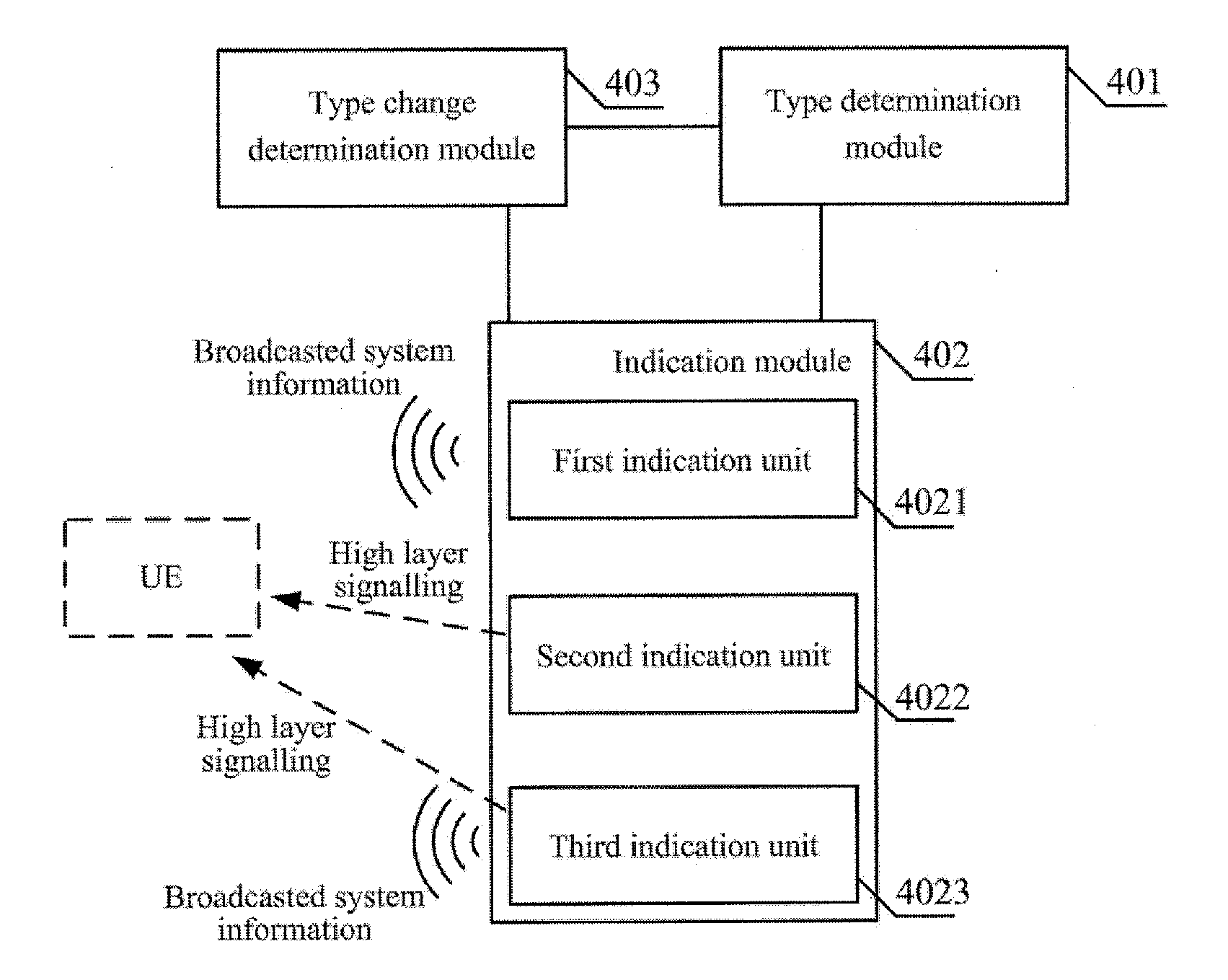

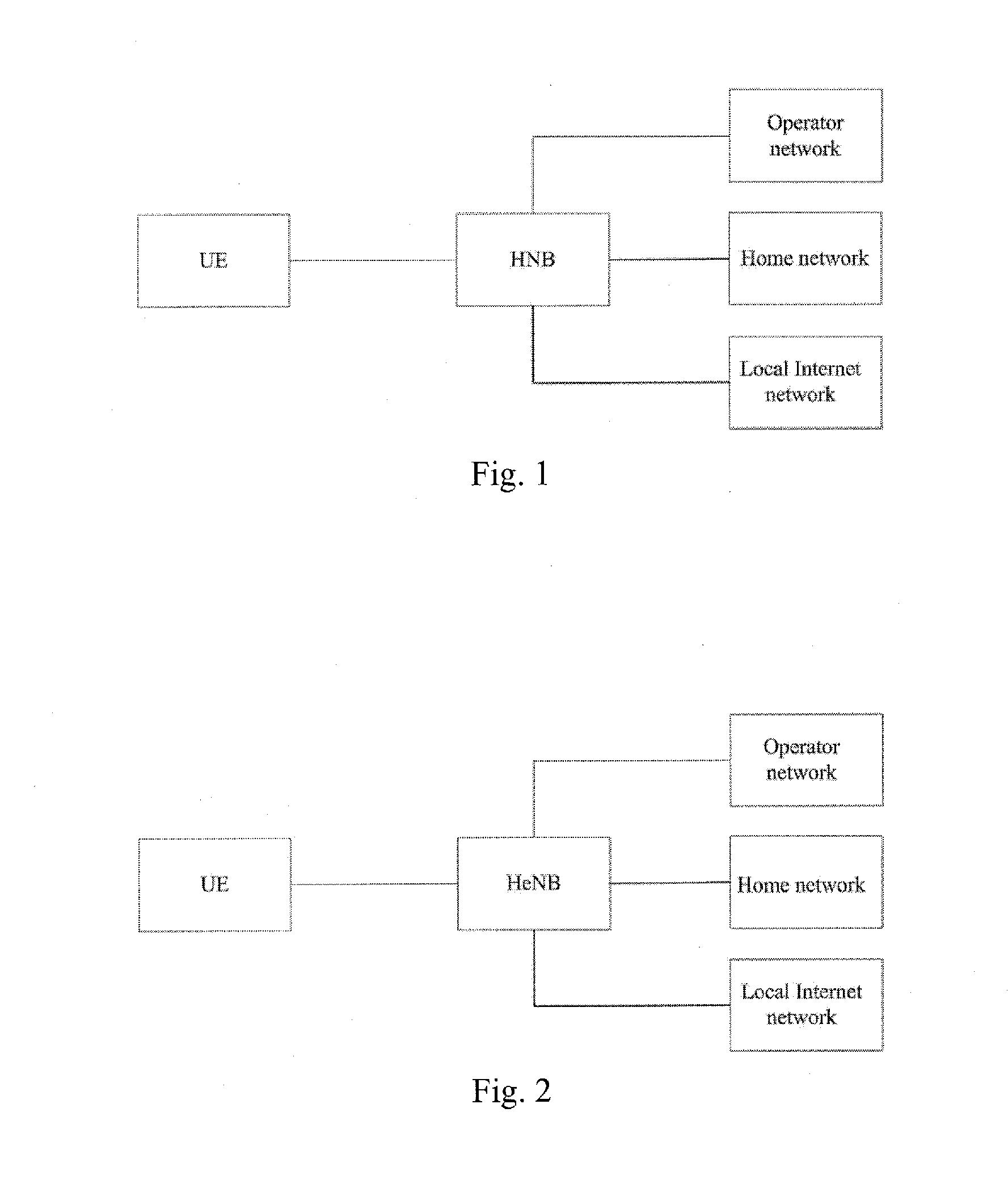

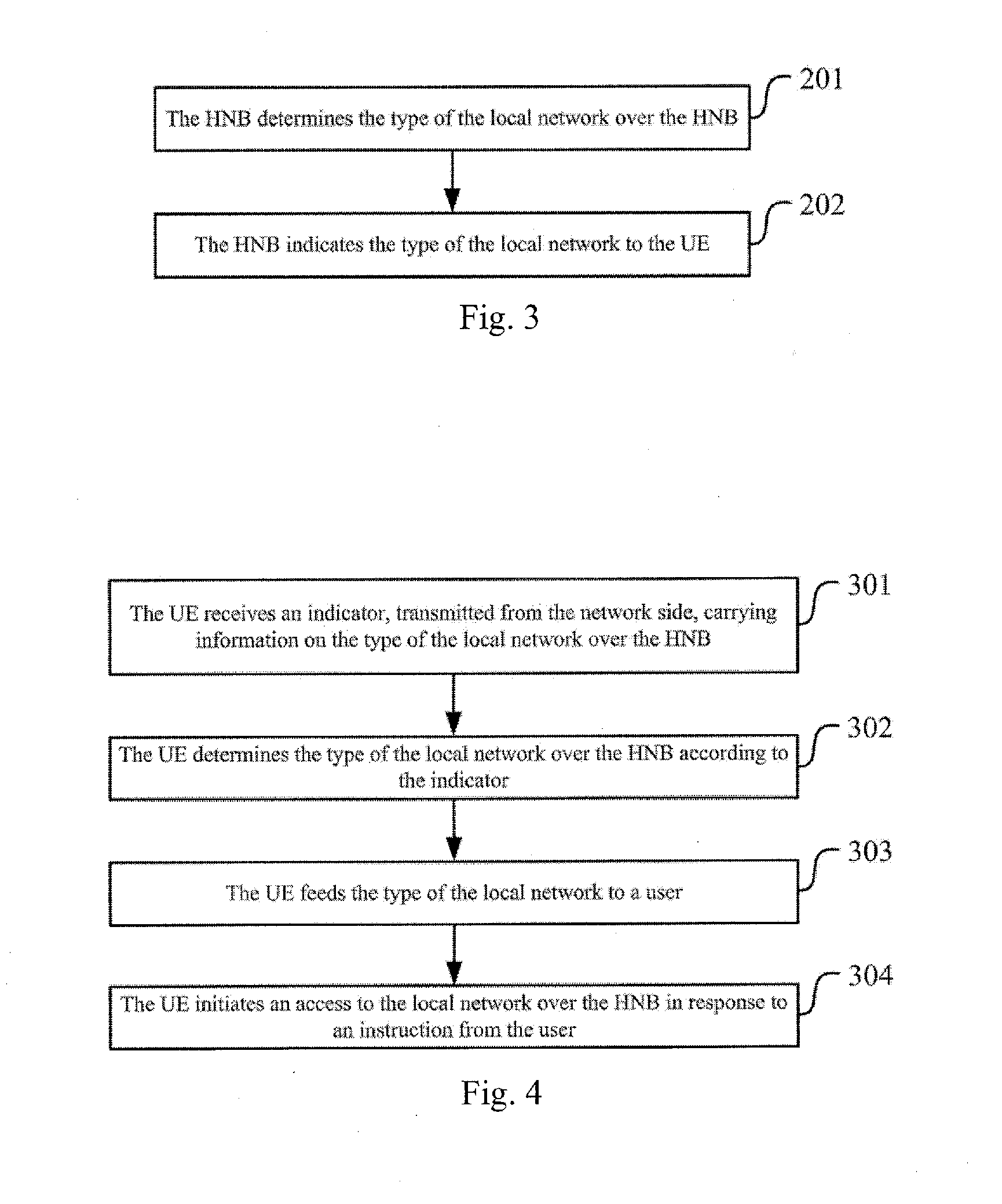

Method and device for processing type of local network over base station

The present application discloses a method and an equipment for processing the local network type of a base station (BS). The method comprises: when a BS has determined its local network type, it indicates to a user equipment (UE) said local network type; and when the UE receives the indication carrying said local network type of the BS, it can determine, according to said indication, the local network type of the BS. The present application solves the problem of a user being unable to acquire the type of network connected to a BS and accordingly being unable to determine the corresponding connection means, and enriches user experience.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Efficient reduction of inter-cell interference using RF agile beam forming techniques

ActiveUS9125064B2Low data rateExperienceSpatial transmit diversityFrequency-division multiplexCell to cell communicationData rate

In embodiments of the present disclosure improved capabilities are described for reducing inter-cell interference in a large area broadband LTE wireless network utilizing RF agile beam forming antennas, where the reduced inter-cell interference is realized by arranging the sets of rotating RF beams in each cell such that adjacent RF beam sub-areas in the same or in different cells are not illuminated at the same time. The reduction in inter-cell interference results in reduced interference noise for users located near the edges of cells, thereby allowing them to be assigned higher data rates. Also, the same set of sub-carriers can be assigned by adjacent cells to users located in the RF beam sub-areas at the cell boundaries, thereby allowing the complete set of LTE sub-carriers to be assigned to any user at any time, without requiring additional cell-to-cell communications.

Owner:ALL PURPOSE NETWORKS INC

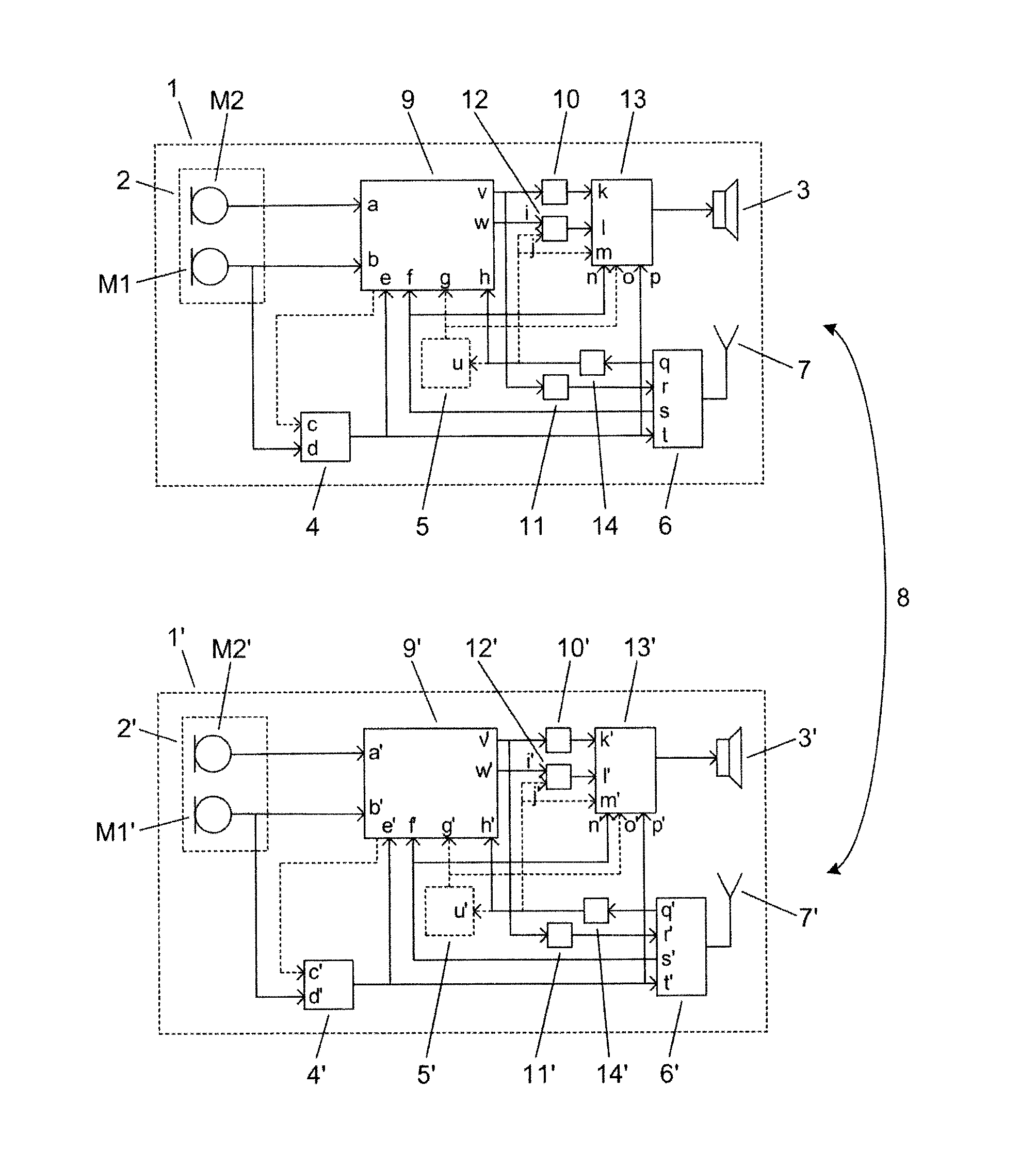

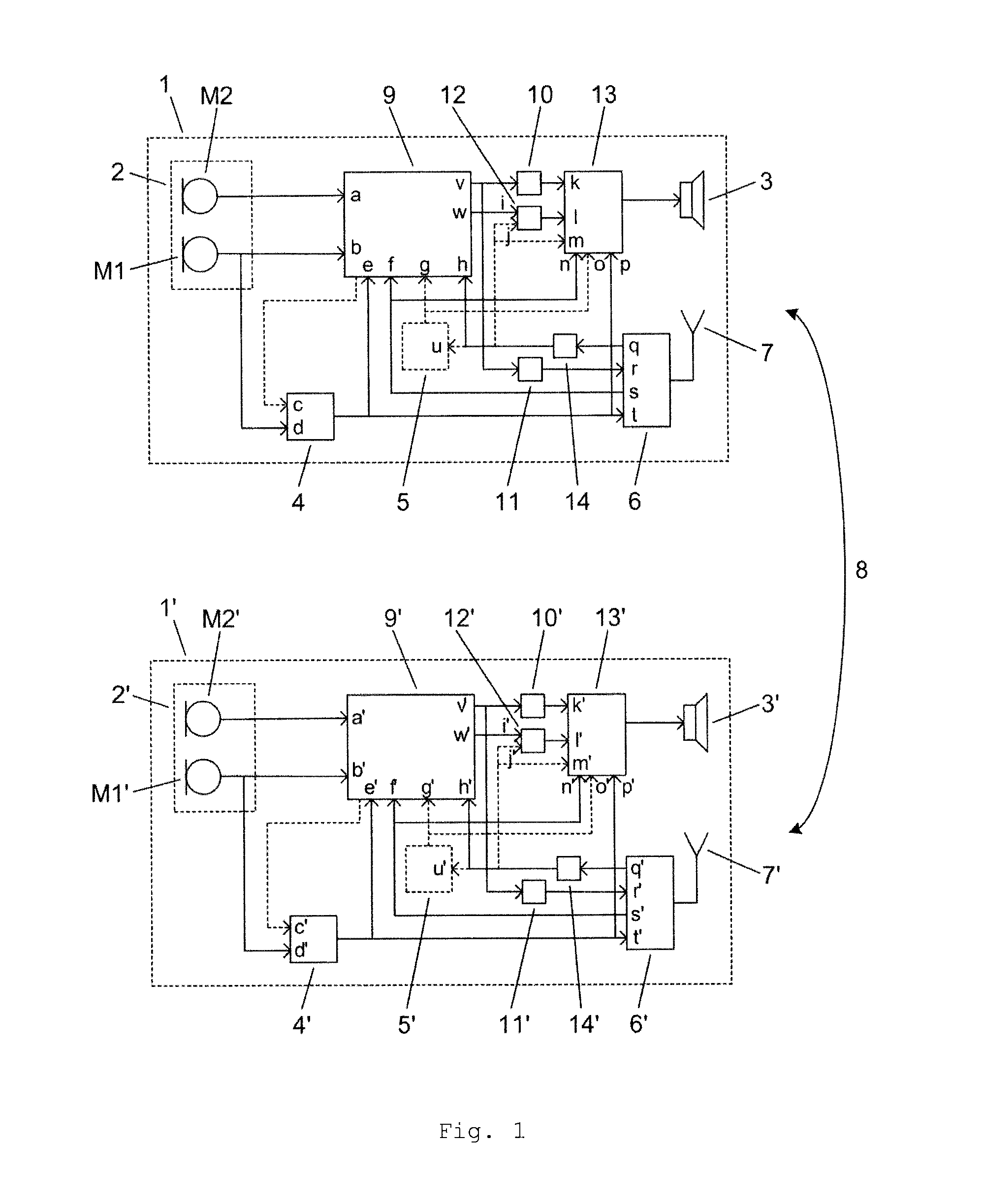

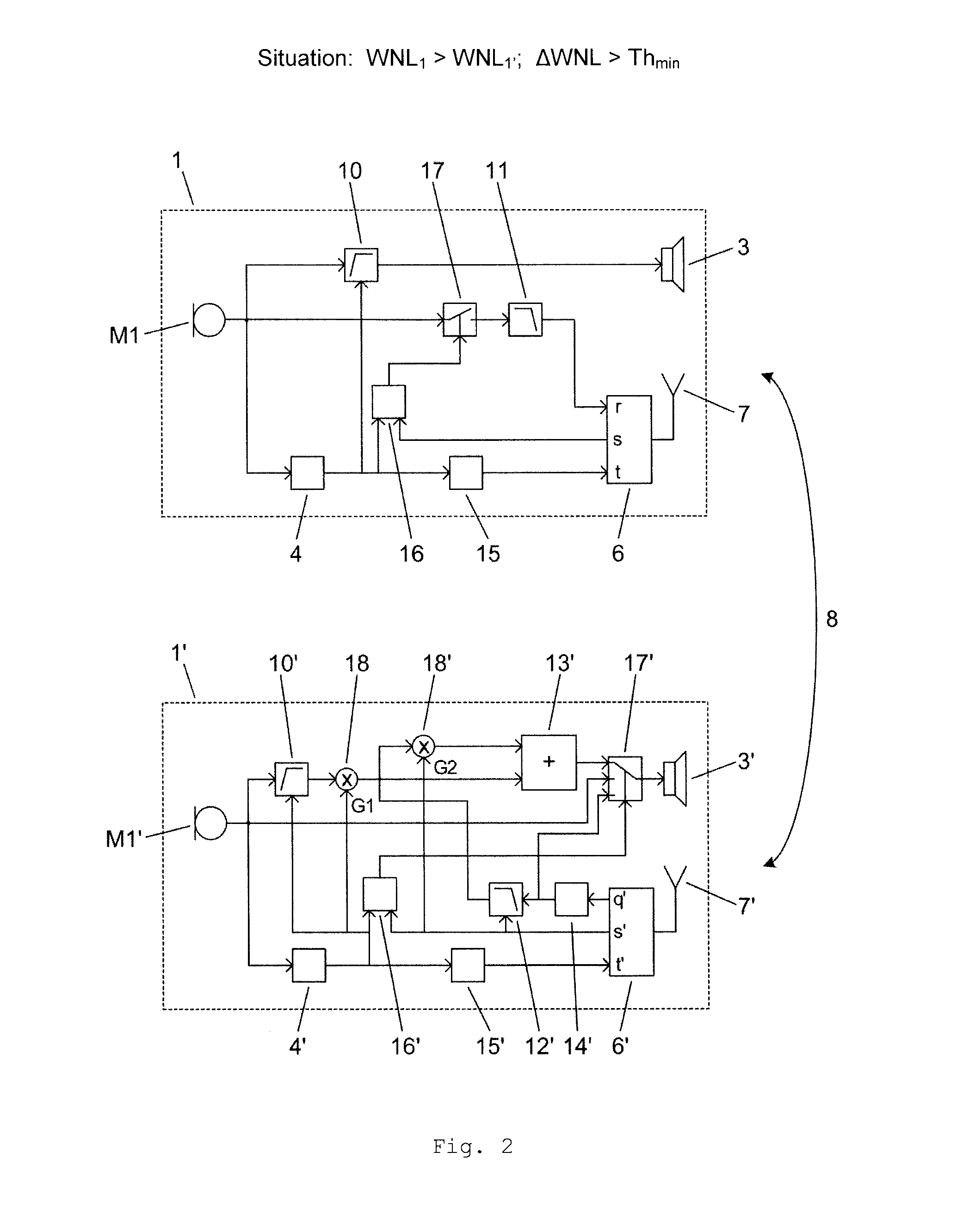

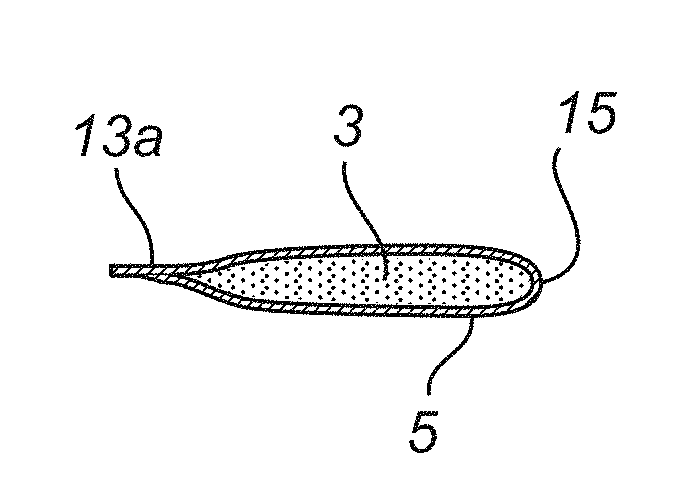

Method for operating a binaural hearing system and binaural hearing system

ActiveUS20150249892A1Improves hearing perceptionReduce adverse effectsDeaf-aid setsEngineeringHearing perception

The present invention proposes a method for operating a binaural hearing system with two hearing devices (1, 1′) operationally interconnected by means of a bidirectional link (8) which improves hearing perception in windy listening situations. The method comprises determining the level of wind noise present at each of the two hearing devices (1, 1′) and sending the audio signal picked-up at the first hearing device (1) to the second hearing device (1′) via the link (8) and then providing an output signal derived from the received signal to the electrical-to-mechanical output converter (3′) of the second hearing device (1′) if the level of wind noise at the second hearing device (1′) exceeds the level of wind noise at the first hearing device (1) by a pre-set threshold value. Furthermore, a binaural hearing system capable of performing such a method is given.

Owner:SONOVA AG

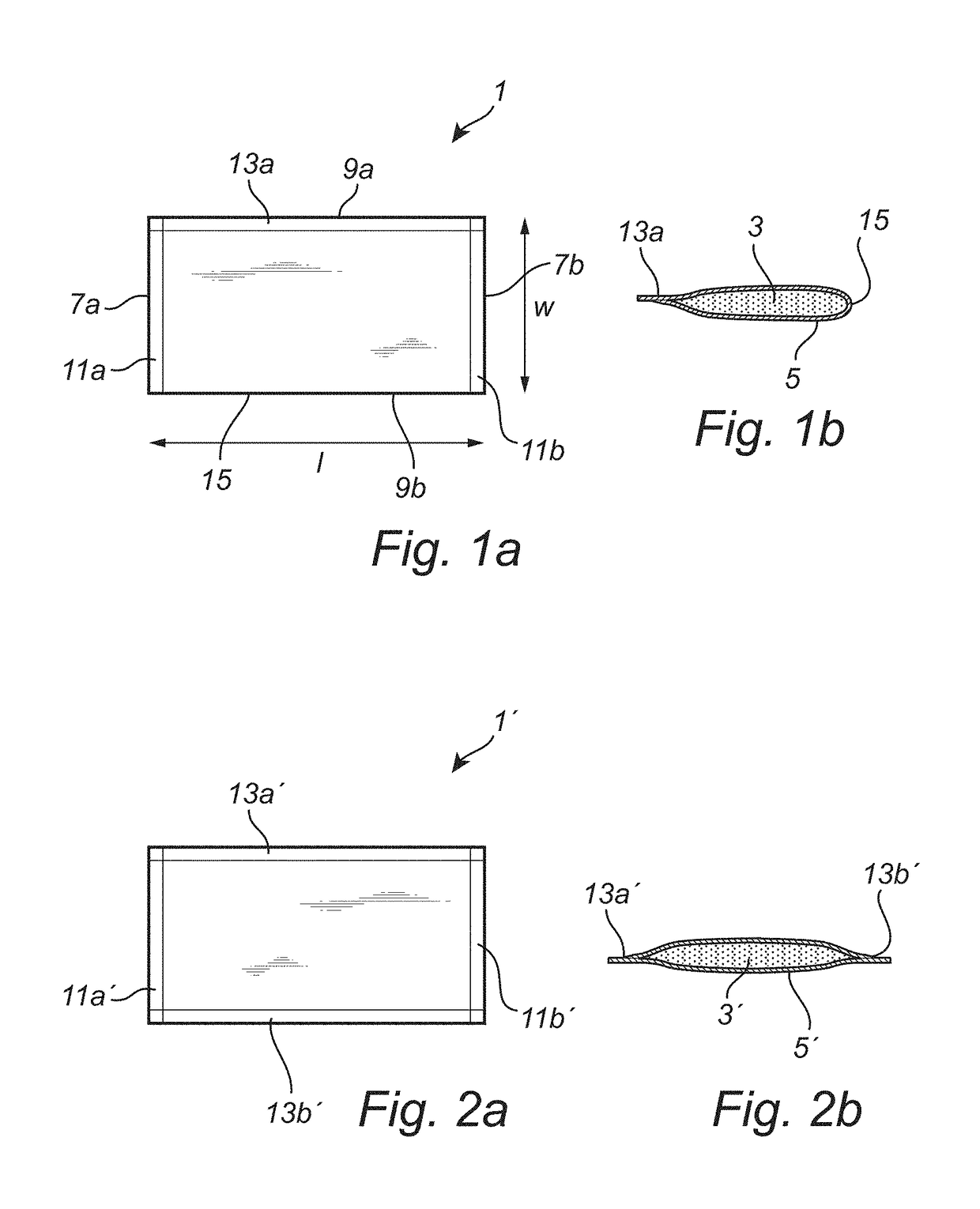

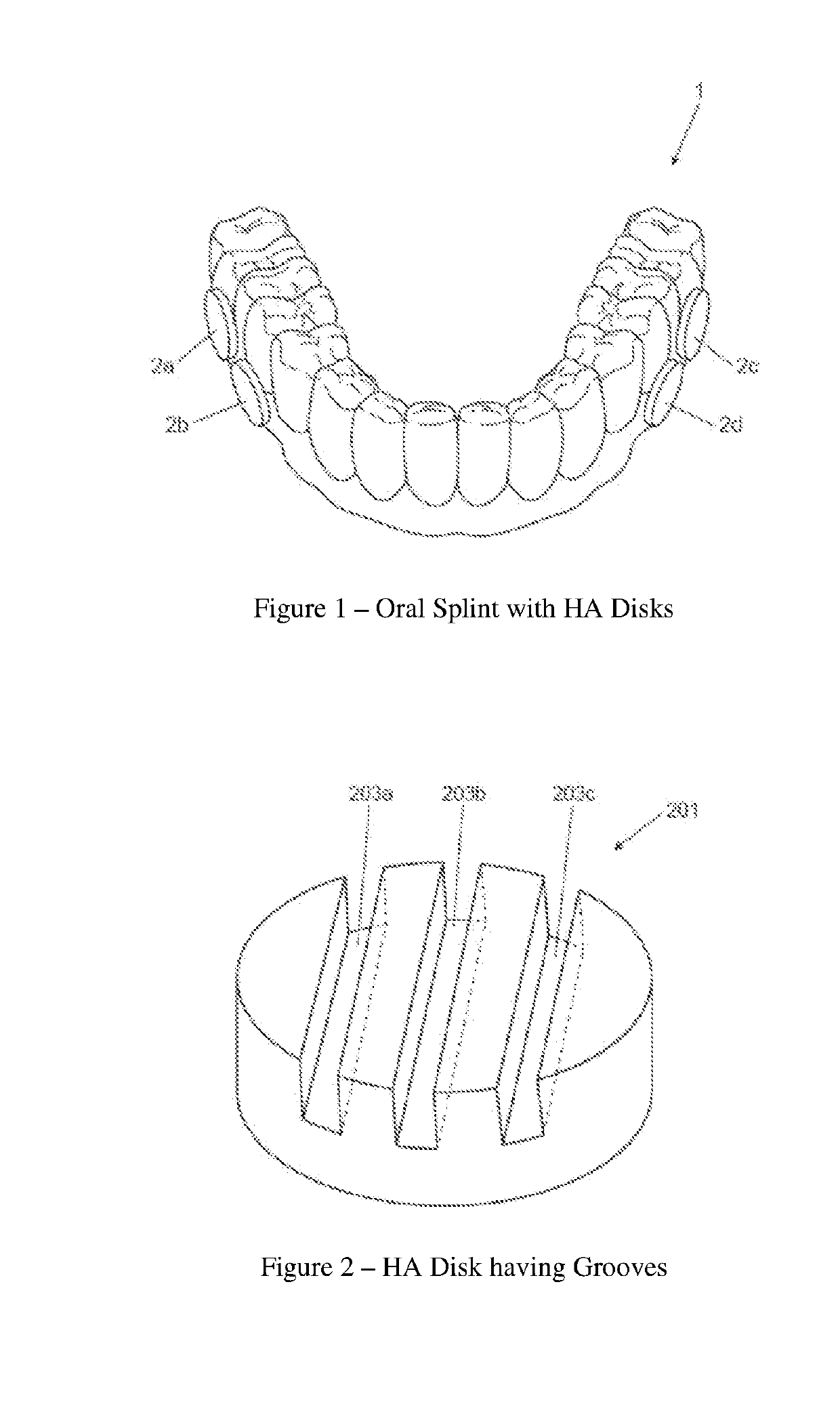

Chewable and deformable oral pouched snuff product

InactiveUS20180153211A1Decrease seal widthReduce the amount requiredTobacco treatmentTobacco devicesFilling materialsPolyamide

The present disclosure relates to an oral pouched snuff product and a method for its production. The oral pouched snuff product comprises a filling material and a saliva-permeable pouch enclosing the filling material, the saliva-permeable pouch comprising at least one elongated seal and the saliva-permeable pouch comprising a mesh material being elastic in at least one direction and comprising fibres of thermoplastic polyamide, wherein the at least one elongated seal has a seal strength of at least 0.10 N / mm as measured in dry state as well as in wet state. The at least one elongated seal may be an ultrasonically provided weld.

Owner:SWEDISH MATCH NORTH EURO

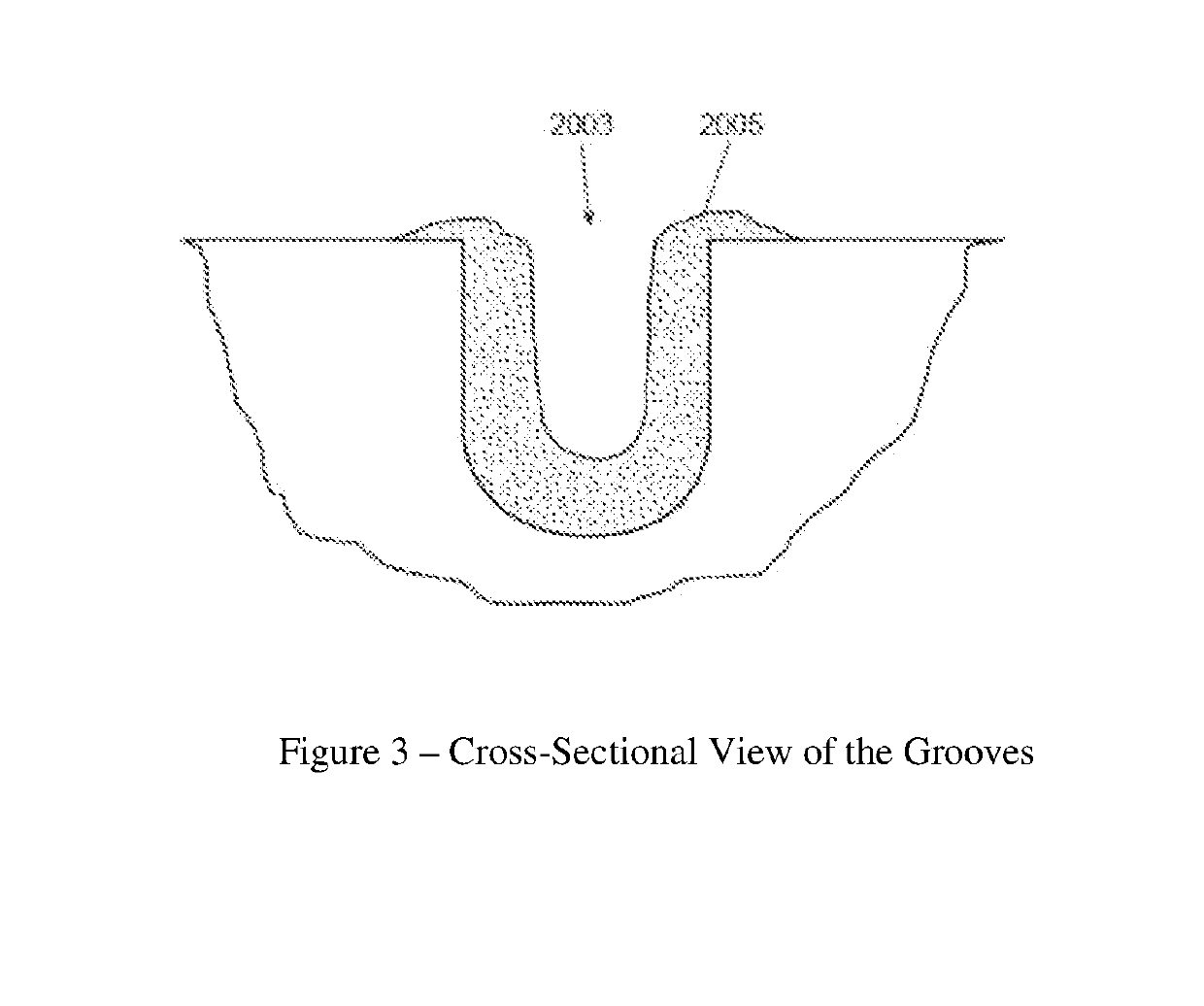

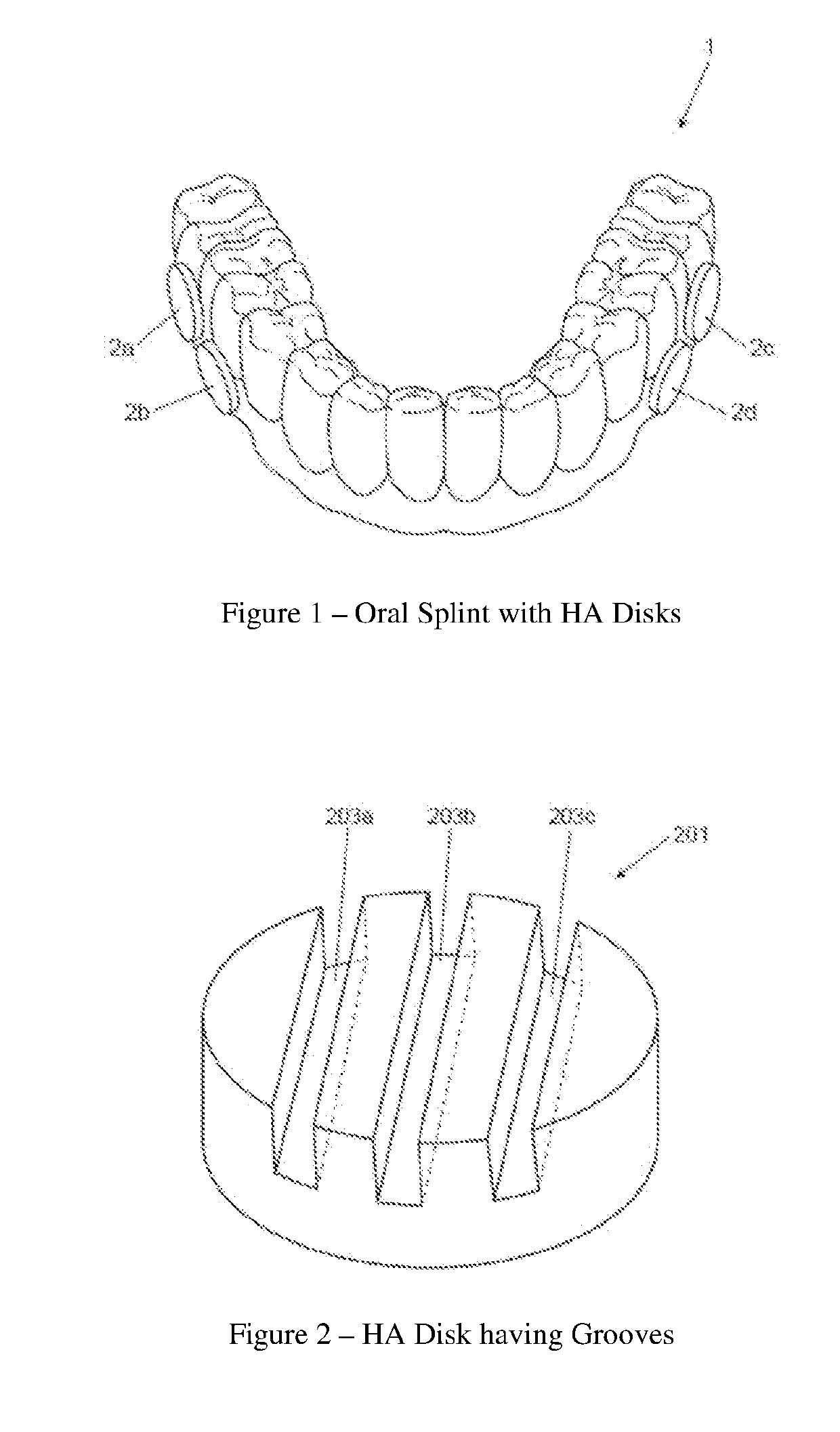

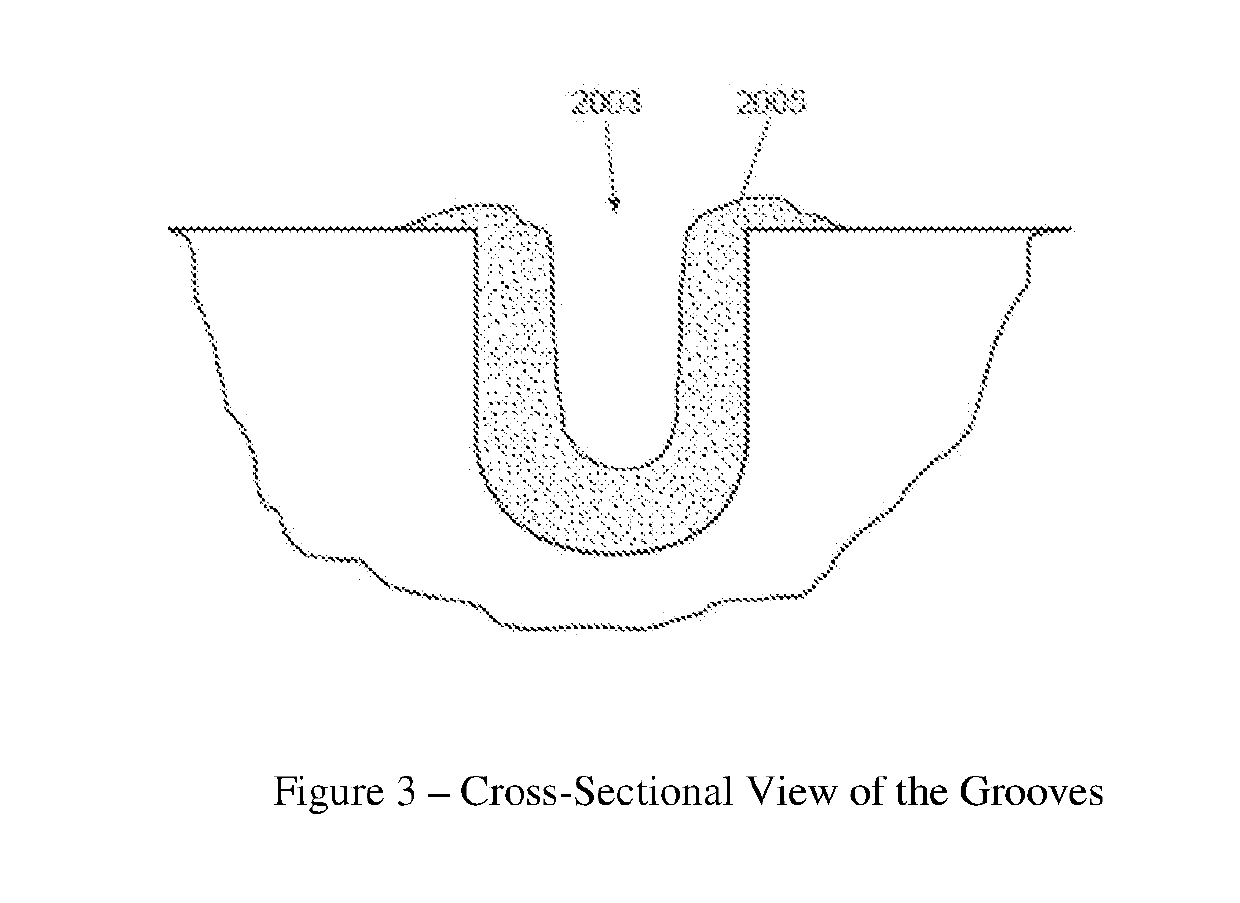

Oral care compositions for promoting gum health

ActiveUS20190298636A1Improved Gum Health benefitDeep penetrationCosmetic preparationsToilet preparationsMedicineChewing gum

Oral care compositions comprising an amino acid and stannous ion source, especially in the absence of zinc ion source, are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

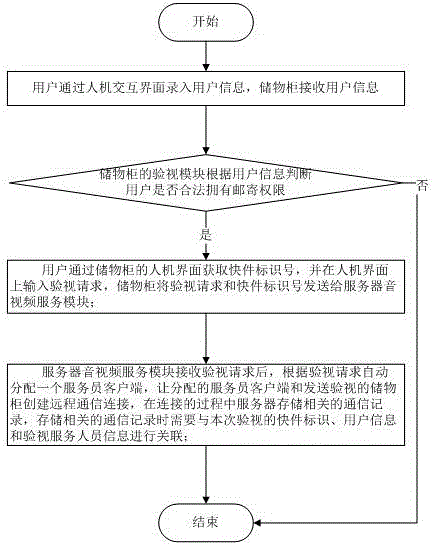

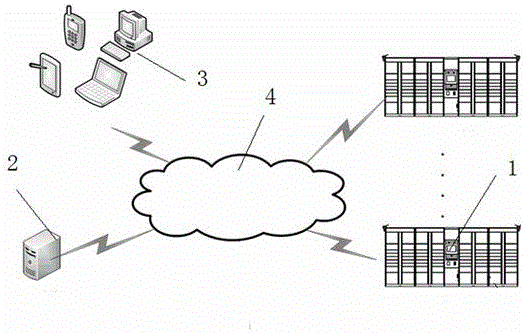

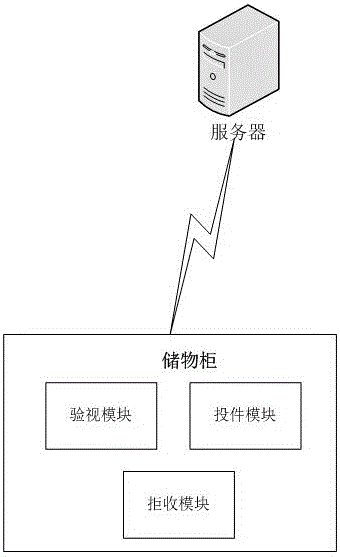

Storage cabinet inspection system and storage cabinet inspection method

ActiveCN105719403AExperienceLow probability of error detectionApparatus for meter-controlled dispensingTransmissionComputer hardwareControl unit

The invention discloses a storage cabinet inspection system and a storage cabinet inspection method. The storage cabinet inspection system comprises a server, a plurality of storage cabinets and a plurality of waiter clients, wherein each storage cabinet comprises a central control unit, a camera and a plurality of box compartments; and the central control unit comprises a mail delivery module and an inspection module. The waiter clients remotely inspect whether mails meet delivery requirements or not, so that the labor consumption is reduced while couriers and senders perform inspection personally, the mail sending time of the senders is shortened, and mail sending of the senders is facilitated.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

Oral care compositions for promoting gum health

ActiveUS20190298634A1Deep penetrationAdd depthCosmetic preparationsToilet preparationsCitrullineMedicine

Oral care compositions comprising citrulline and stannous ion source with a specific pH range are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Oral care compositions for promoting gum health

ActiveUS20190298620A1Deep penetrationAdd depthCosmetic preparationsImpression capsMouth careMedicine

Oral care compositions comprising an acidic amino acid and stannous ion source are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Commissioning method of bypass-free wet desulphurization system of coal-fired unit by means of tiny-oil ignition

ActiveCN102620275AGuaranteed Synchronous Secure BootReasonable durationDispersed particle separationBoiler controlWater treatment systemWastewater

The invention discloses a commissioning method of a bypass-free wet desulphurization system of a large coal-fired unit by means of tiny-oil ignition. A unified formed commissioning method of a hot commissioning specific to bypass-free desulphurization systems does not exist at present. The commissioning method comprises two stages of a cold commissioning and the hot commissioning, the commissioning of a desulphurization process water system and a desulphurization waste water treatment system is required to be completed before the hot commissioning is started, the desulphurization waste water treatment system is used for receiving and processing waste water produced by a desulphurization system, commissioning steps and methods of the rest branch systems are identical to those of corresponding branch systems of a wet desulphurization system with a bypass, and start operation steps in the stage of the hot commissioning are properly adjusted. According to the commissioning method of the bypass-free wet desulphurization system of the coal-fired unit by means of tiny-oil ignition, the cold and hot commissioning processes are adjusted so that the problems existing in a bypass-free system during the hot commissioning are avoided, and the construction period is further reasonably arranged so that the synchronous safe starting of the desulphurization system and a main generator unit is guaranteed.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Oral care compositions for promoting gum health

ActiveUS20190298635A1Improved Gum Health benefitDeep penetrationCosmetic preparationsToilet preparationsNeutral Amino AcidsMedicine

Oral care compositions comprising a neutral amino acid and stannous ion source are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

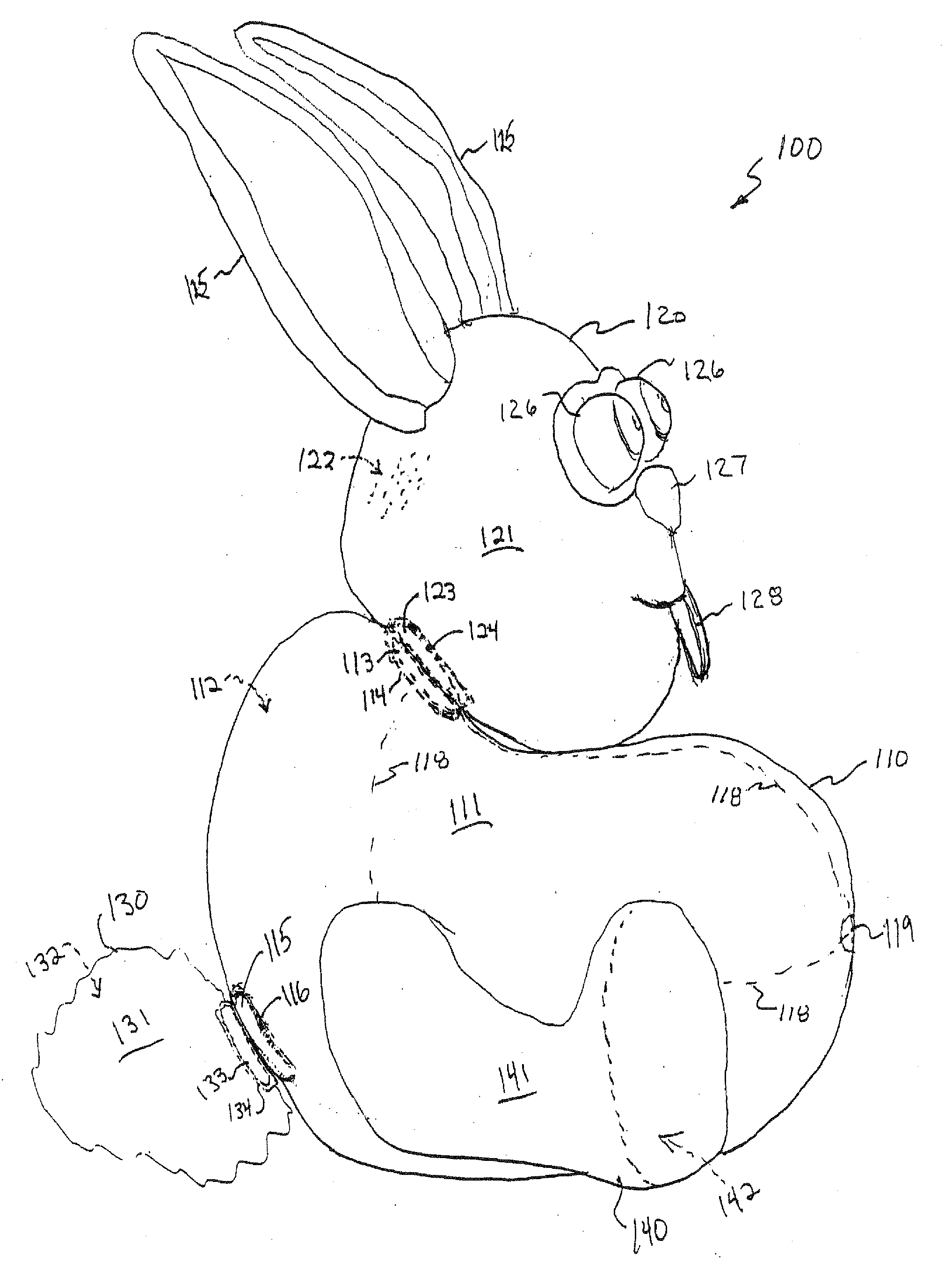

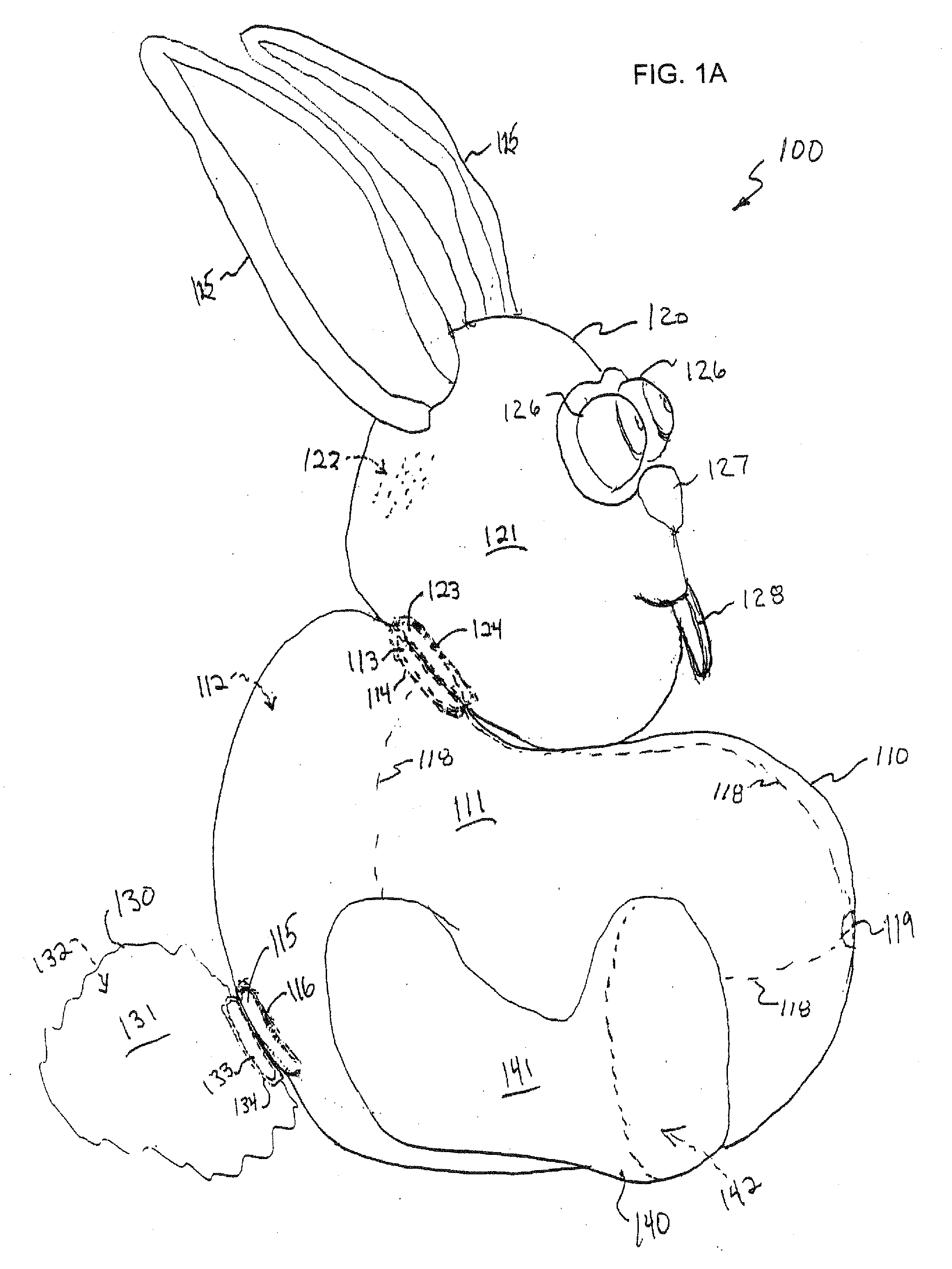

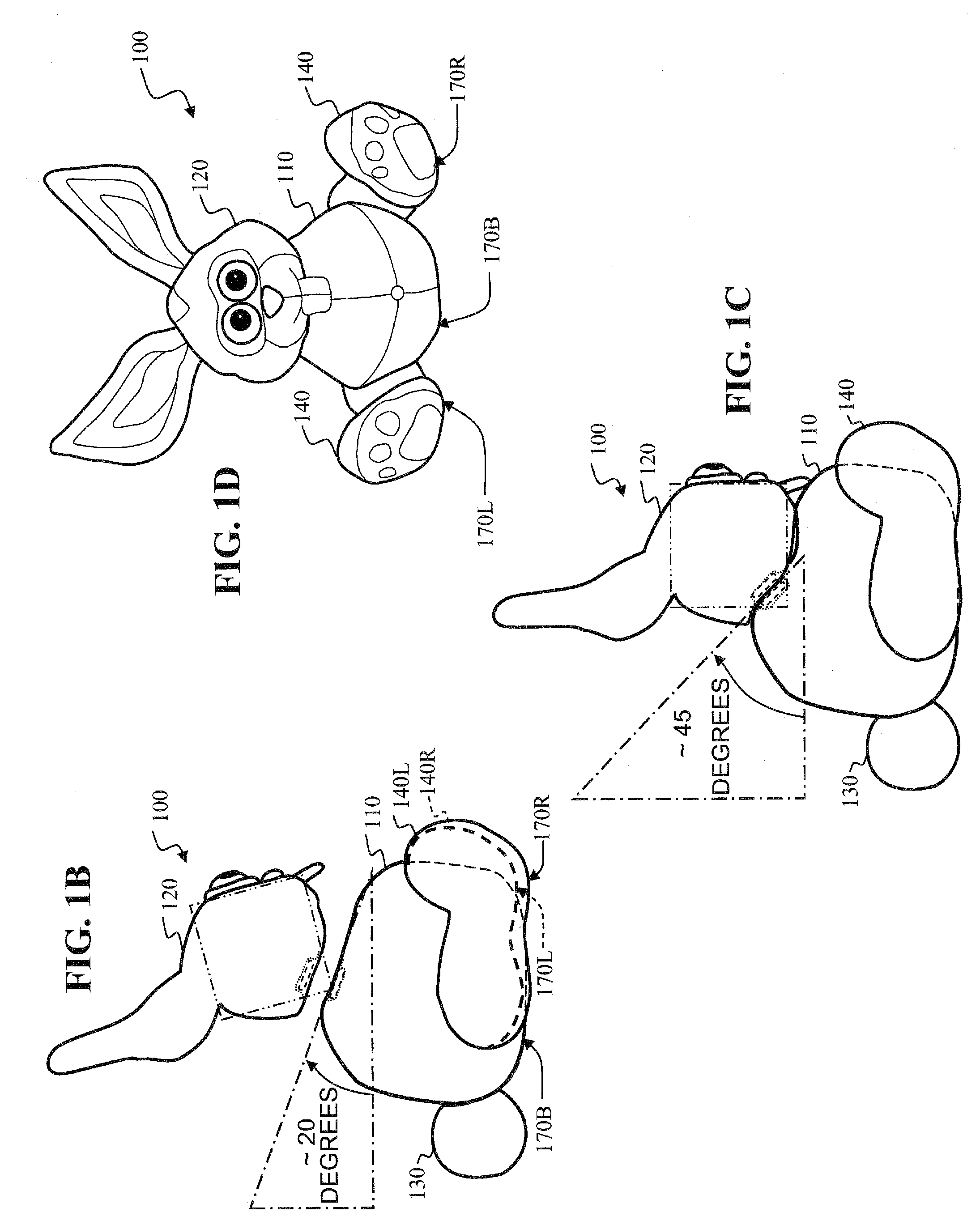

Stuffed toy with embedded magnets and related method

A stuffed toy and method for removably attaching appendages. The appendages are magnetically attached using permanent magnets embedded beneath the stuffed toy fabric. In some embodiments, the appendages include such parts as a head, legs, arms, trunk, tail, or other toy body parts. The magnetically attached toy appendages are removable, reattachable, and interchangeable between toys or in some embodiments, to different positions on the same toy. In other embodiments, the head attaches only to a head position on the body, and the tail attaches only to a tail position on the body. In some embodiments, the body is shaped to provide an additional support structure to help hold the head in a desired position.

Owner:SWT ACQUISITION LLC

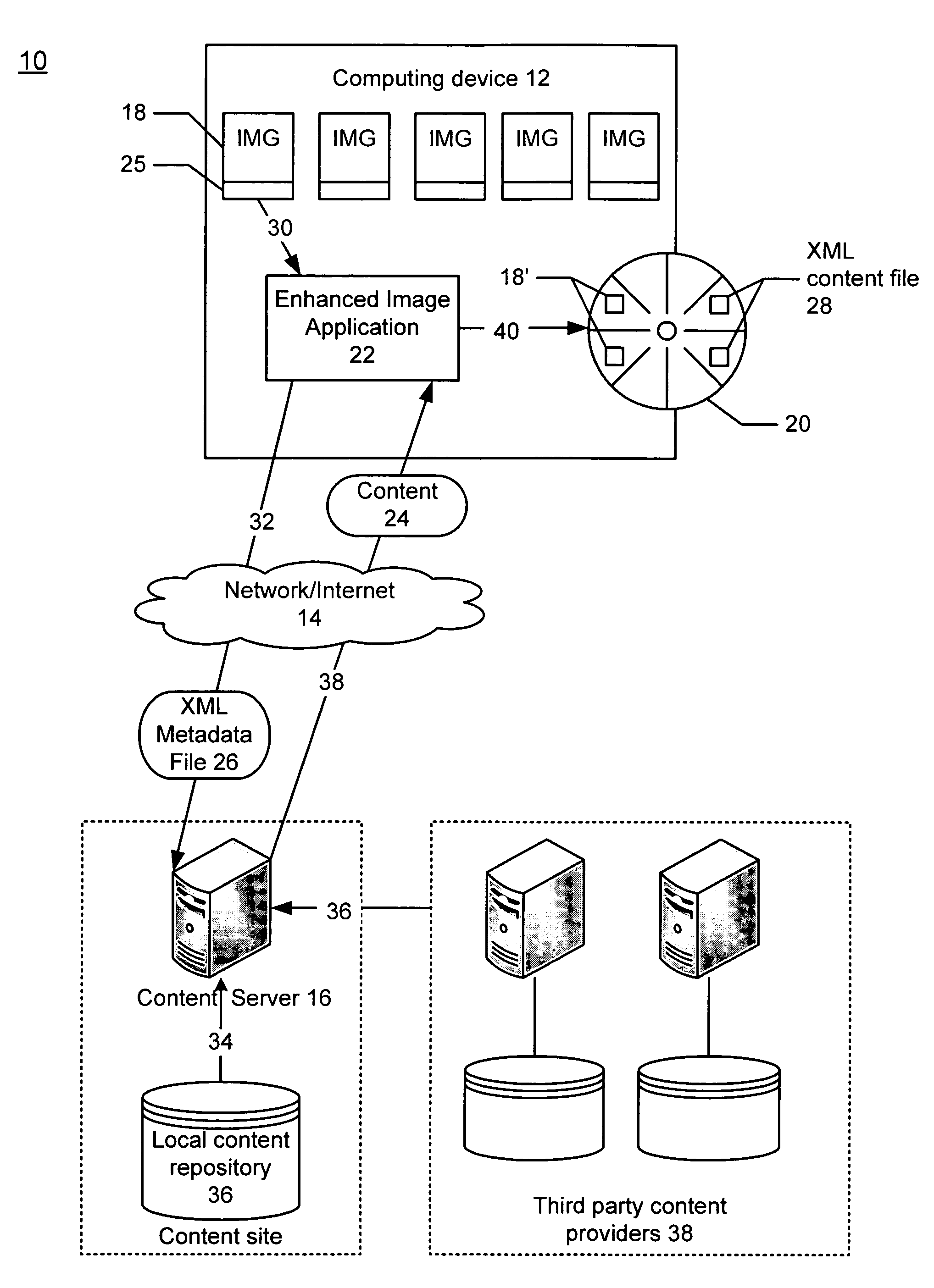

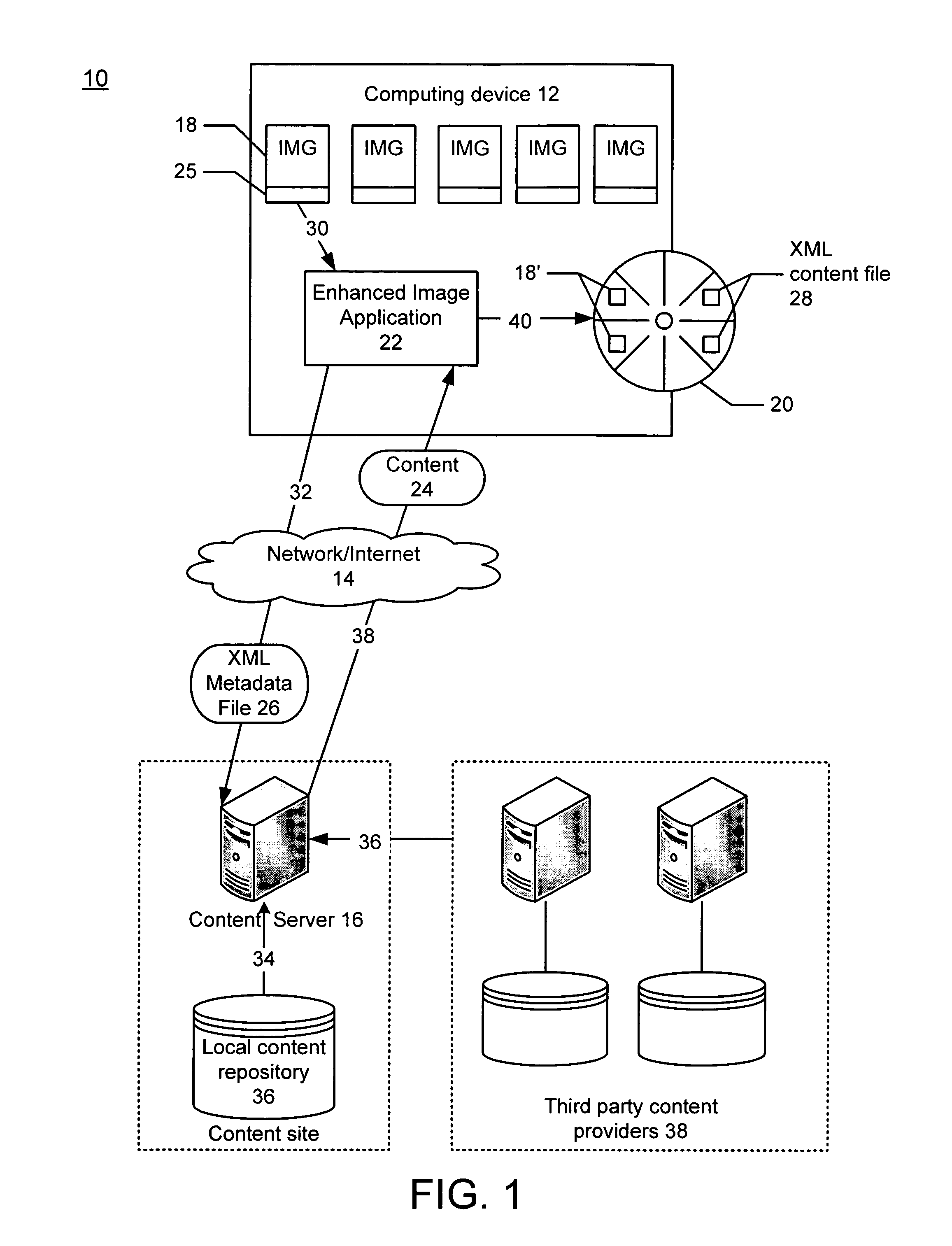

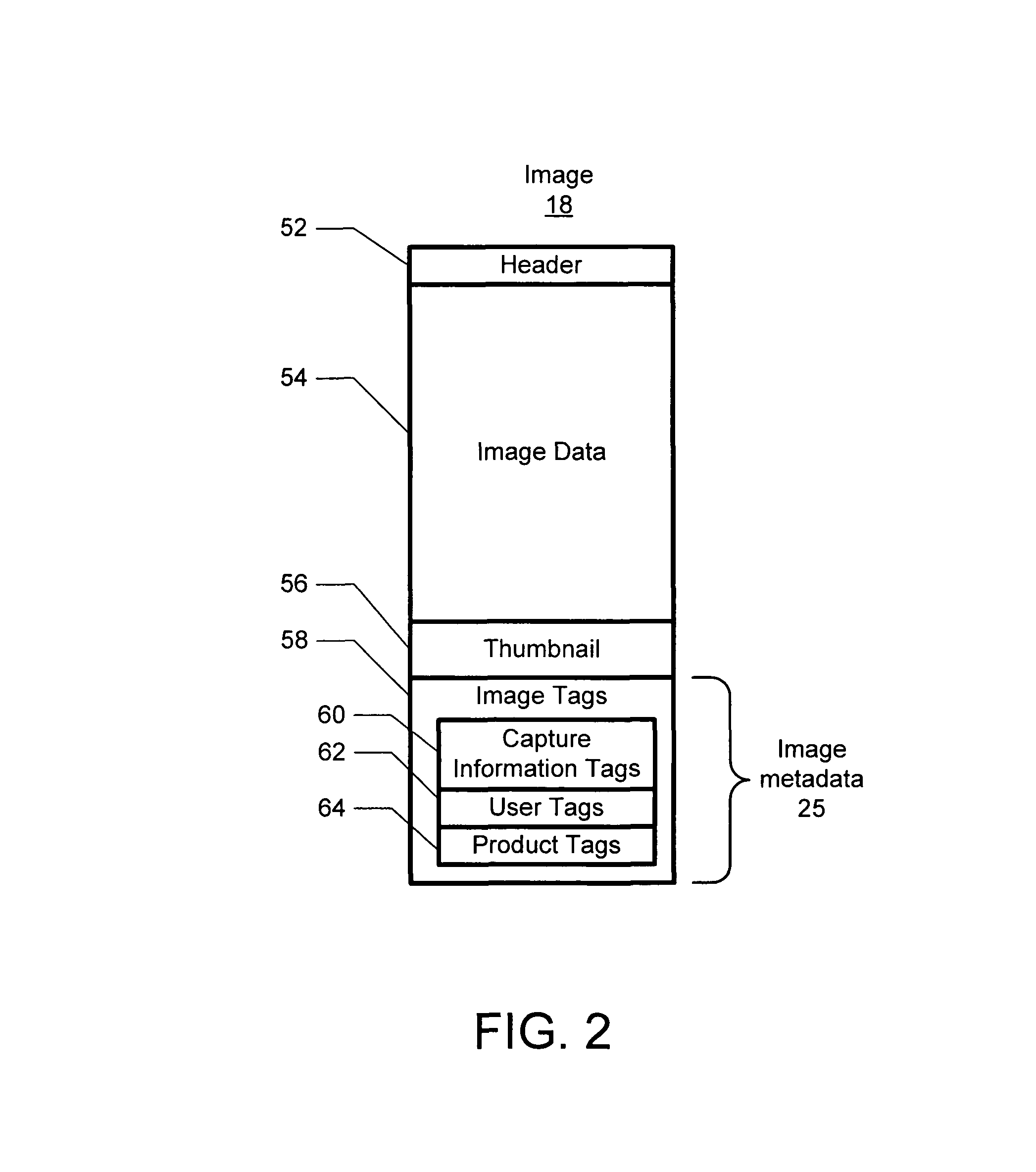

Associating external content with a digital image

InactiveUS8527492B1ExperienceEnhanced informationDigital data processing detailsStill image data indexingDigital imageMetadata

A method and system is provided for associating external content with a digital image. Aspects of the method and system include extracting metadata from the digital image; using the extracted metadata to query an online content server to retrieve content related to the digital image through at least one attribute of the extracted metadata; in response to receiving the content returned by the content server, associating the content with the digital image; and using the content when an operation is performed on the digital image.

Owner:QURIO HLDG

Traditional Chinese medicine formula for treating acute or chronic gastritis and preparation method

InactiveCN101190314AEasy to takeExperienceDigestive systemGranular deliveryOfficinalisBILE REFLUX GASTRITIS

The invention discloses a Chinese medicine prescription for treating acute and chronic gastritis and the preparation method thereof, which is prepared by ten Chinese medicines of raw rhizoma atractylodis, cortex magnoliae officinalis, citrus chachiensis hortorum, raw liquoric root, fried white paeony root, raw malt, dandelion, cablin potchouli herb, sepium and common bletilla pseudobulb, etc. The raw medicines are matched with excipient and corrective to be prepared into granular formulation or micro-pills; the invention can treat acute and chronic superficial gastritis, erosive gastritis, bile reflux gastritis and duodenal bulbar inflammation and so on by oral administration. The invention has the efficacies of regulating the middle warmer, driving the stomach, promoting qi and stopping pain.

Owner:曹明成

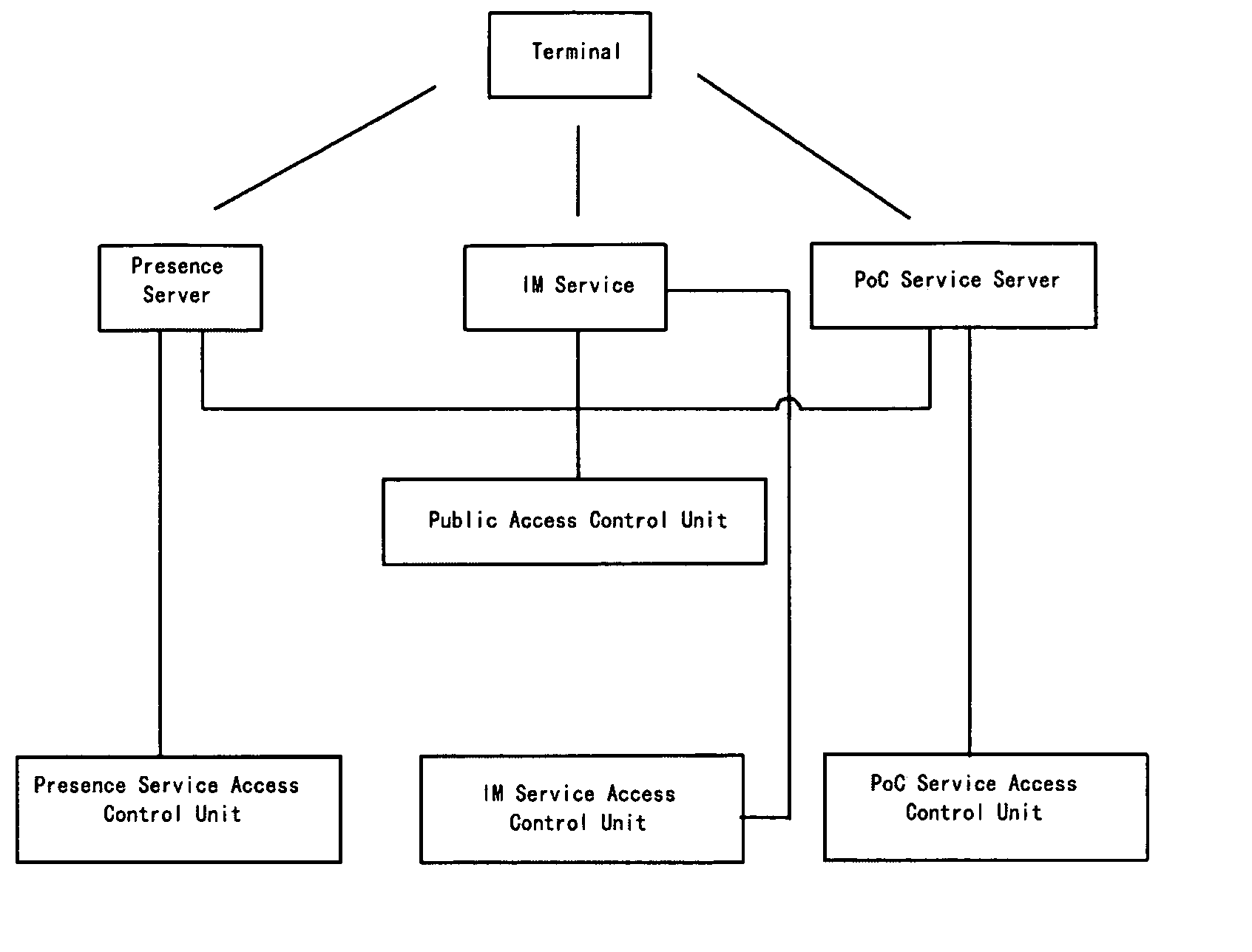

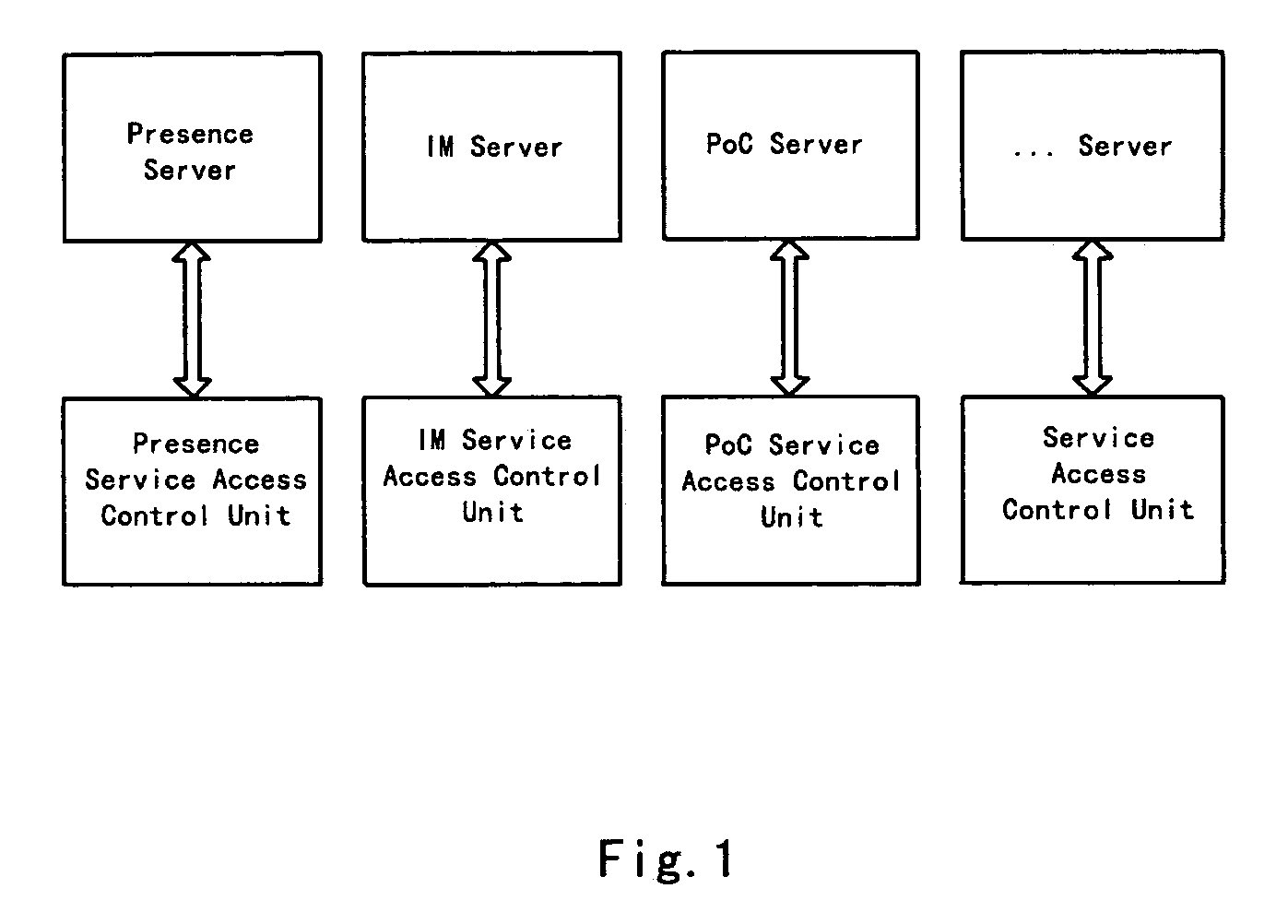

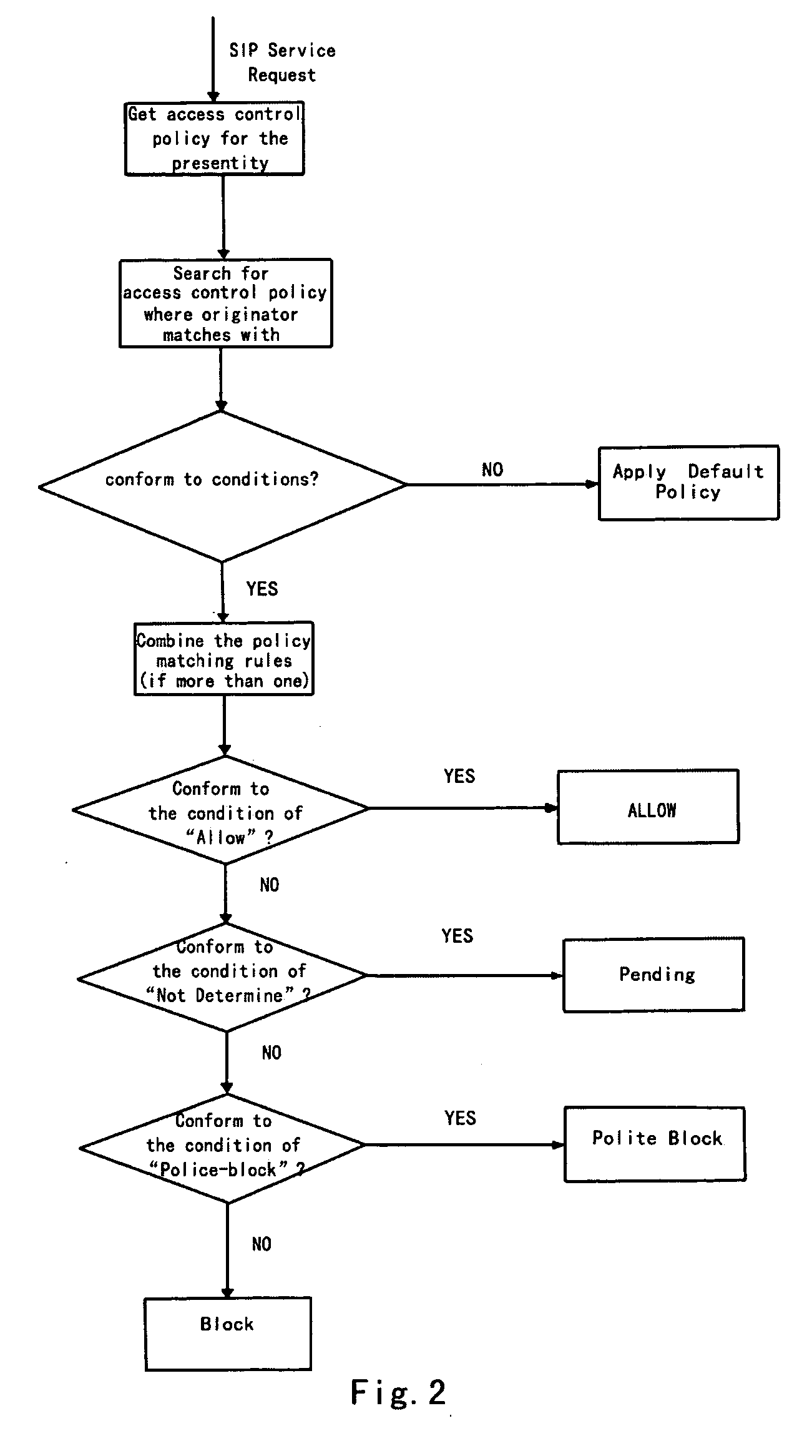

Data service system and access control method

InactiveUS20070123226A1Enrich experienceExperienceSpecial service for subscribersComputer security arrangementsService systemAuthorization

A data service system and a method for access control. The data service system includes a plurality of service servers, through which terminals subscribe relevant services. The system further includes a public access control unit, which is connected to the plurality of service servers, in which the public access control information is set; the service server is used to obtain an authorization result of the service request and perform access control for the service according to the authorization result; the authorization result comprises the result of authorization for the service request from the terminal according to the public access control information. By using the data service system and access control method of the present invention, when a user subscribes a new service, it may be directly configured to use public access control list strategy to make all-in-one setup for certain public policies, and thus enrich the user's experience.

Owner:HUAWEI TECH CO LTD

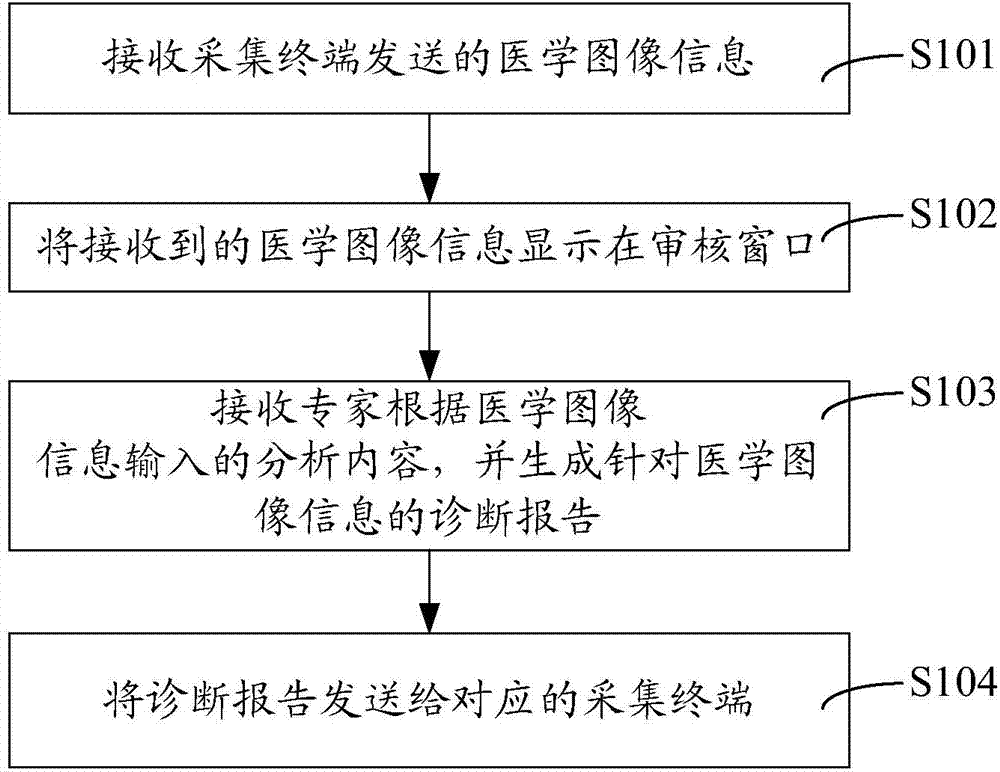

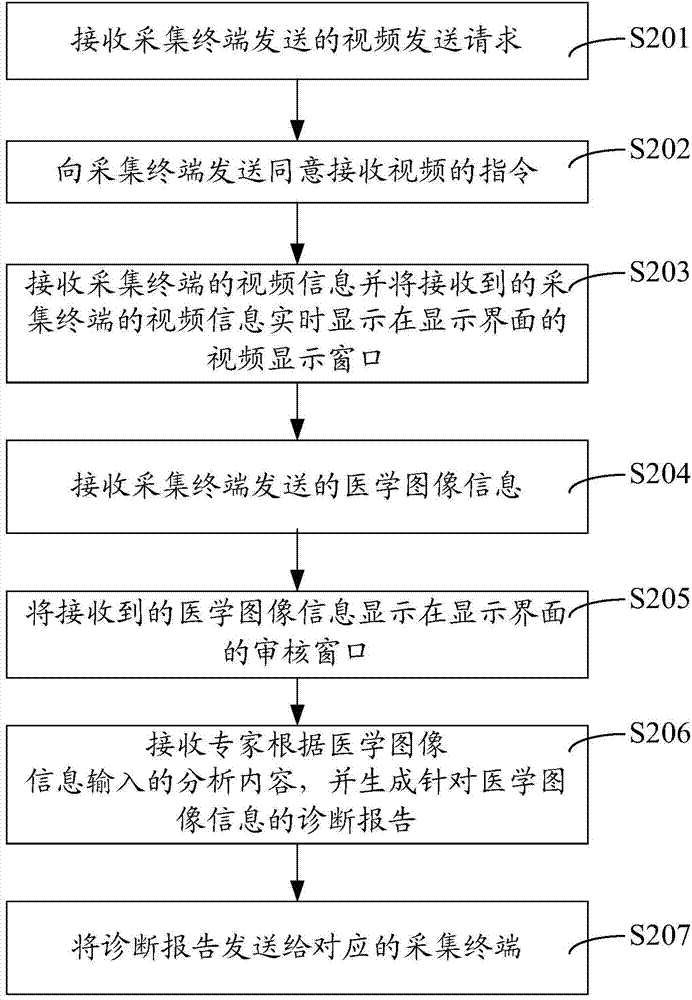

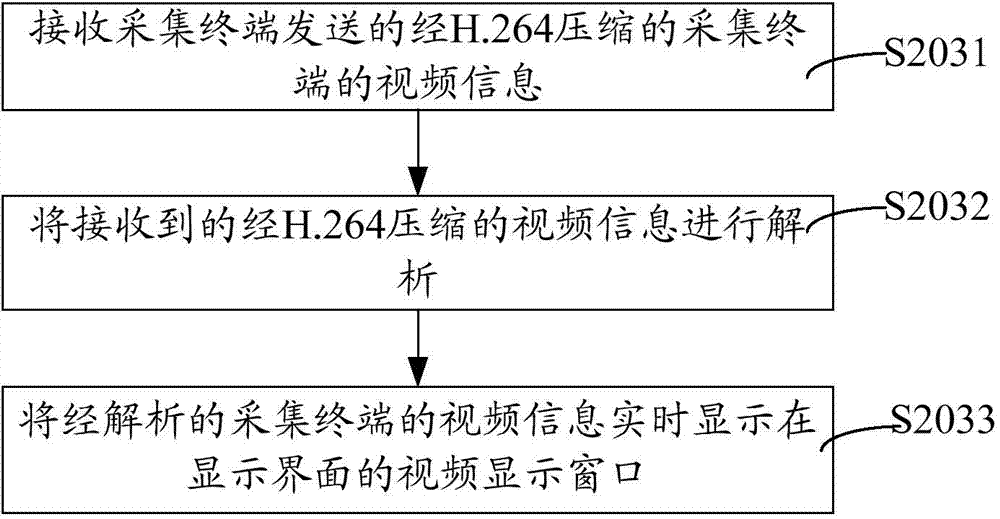

Remote diagnosis method, diagnosis terminal, acquisition terminal and system

InactiveCN104519324AExperienceSave time and energyClosed circuit television systemsSpecial data processing applicationsMedical emergencyComputer hardware

The invention provides a remote diagnosis method, a diagnosis terminal, an acquisition terminal and a system. The remote diagnosis method comprises the following steps of receiving medical image information transmitted by the acquisition terminal, displaying the received medical image information on a review window of a display interface, receiving analysis contents input by an expert according to the medical image information, generating a diagnosis report specific to the medical image information, and transmitting the diagnosis report to the corresponding acquisition terminal. Patients in remote regions with a lower medical level can obtain accurate diagnosis from the experienced expert by virtue of the remote diagnosis method, and the method has no spatial limitation. Further, since the remote diagnosis can be realized, the patients in the remote regions do not need to spend time and money in going out for seeing a doctor for the purpose of the accurate diagnosis, and the time and energy of the patients are saved.

Owner:AVE SCI & TECH CO LTD

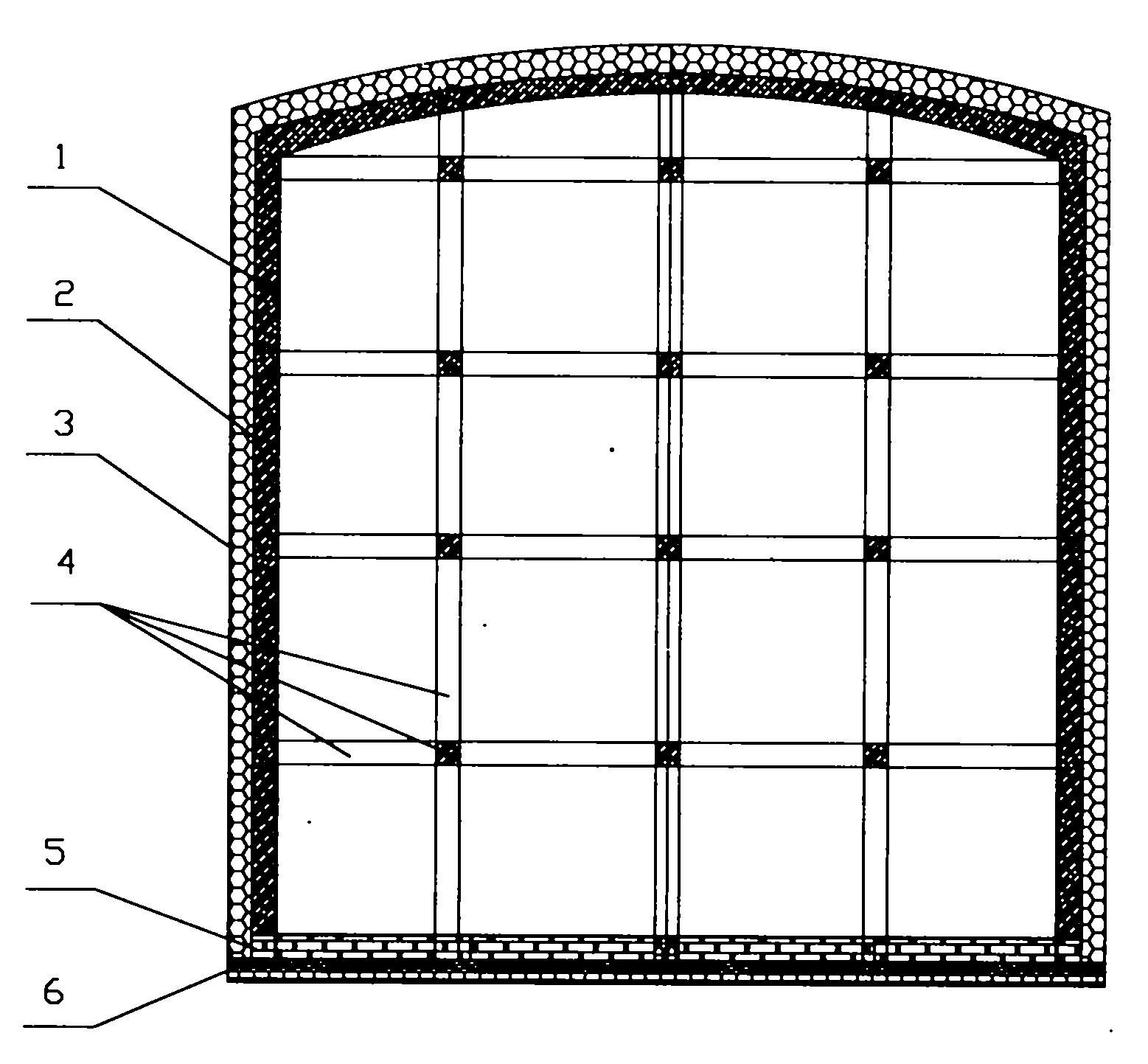

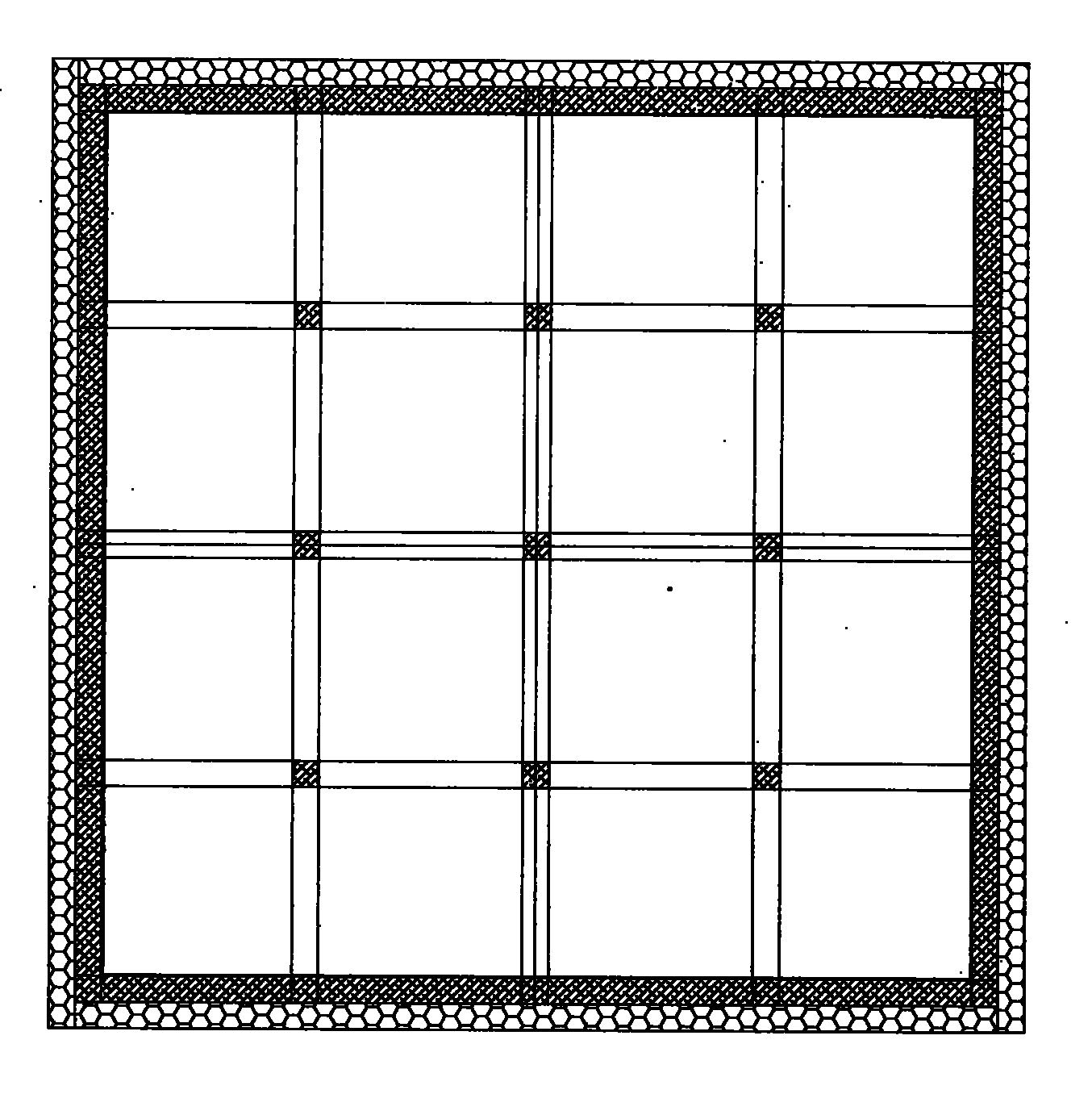

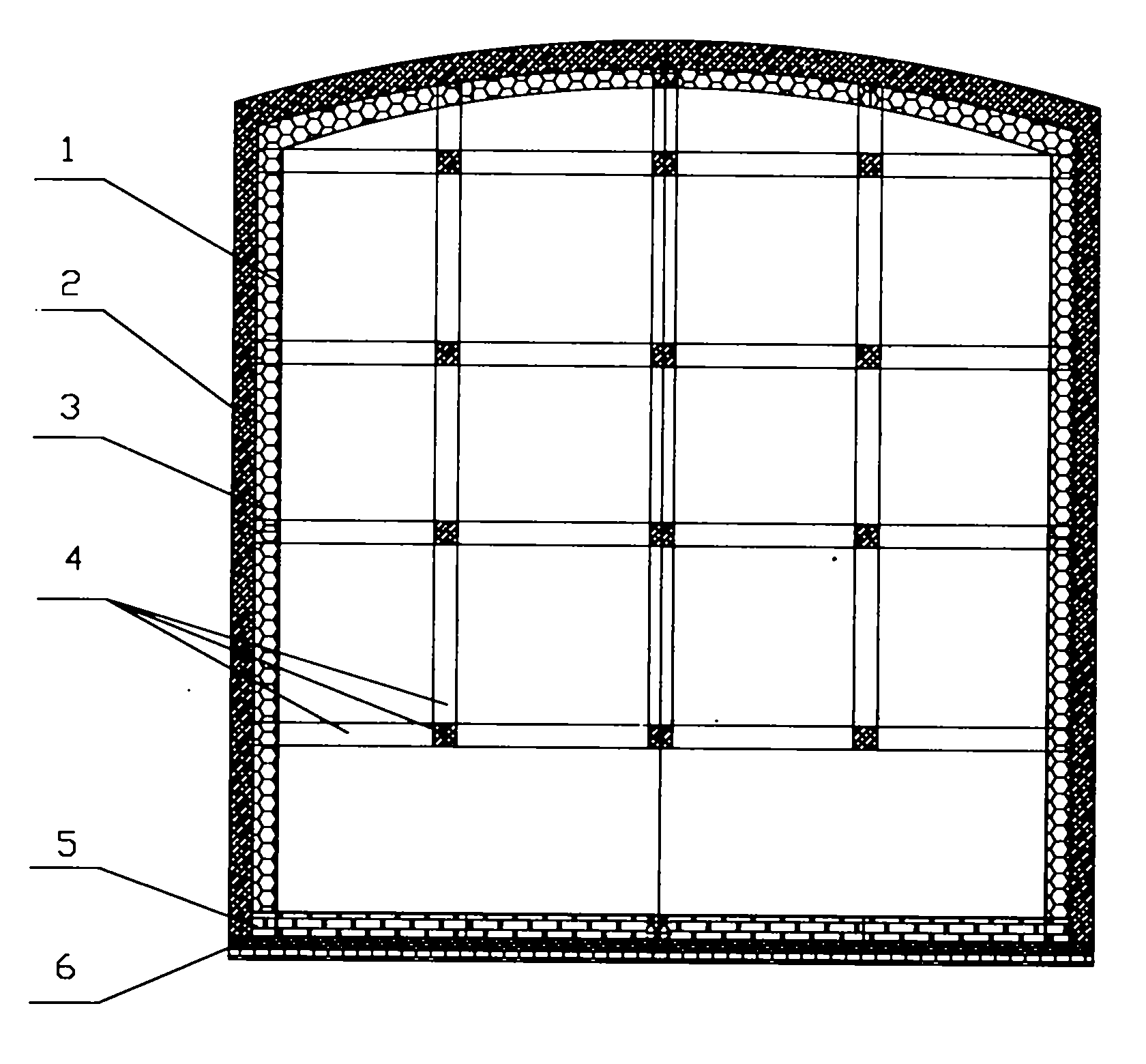

Design and manufacturing of ultra-large rectangular or oblong-shaped LNG storage tank

Design and manufacturing of an ultra-large rectangular or oblong-shaped LNG storage tank are characterized in that the cross section of a tank body of the LNG storage tank is rectangular or in the shape of an oblong, a stressed layer of the tank wall is made of pre-stressed reinforced concrete in a blocked mode or in an integrated mode, longitudinal, transverse and vertical three-direction pre-stressed reinforced concrete beam frames are arranged in the wall of the tank, a top cover of the tank is in the shape of a one-way arc face or a flat top or a slope, and the top cover of the tank is supported on stand columns. A heat-preserving layer is arranged on an outer layer or an inner layer, or both the inner layer and the outer layer are respectively provided with a heat-preserving layer. A material containing layer is an inner coating layer or an inner adhering layer, or the material containing layer is composed of both the inner coating layer and the inner adhering layer, the inner coating layer is made of anti-leakage, anti-frost crack and anti-corrosion coating, the inner adhering layer is made of low-temperature nickel steel, stainless steel, ceramic or low-temperature-resistant plastic boards, and therefore the high-difficulty design and the high-difficulty manufacturing of the ultra-large LNG tank are converted into design and manufacturing of a large conventional pre-stressed reinforced concrete building, successful and rich experience is achieved in both the design and the manufacturing of the large conventional pre-stressed reinforced concrete building by people, people only need to pay attention to selection and utilization of ultra-low-temperature materials, and the design can guarantee that pressure in a 200000m<3>-400000m<3> LNG storage tank can reach 3mpa. The cost for the design and the manufacturing is several times smaller than that of an existing LNG storage tank, and stress, stability, anti-disaster performance and borne inner pressure of the designed and manufactured LNG storage tank are several times higher than those of the LNG storage tank in existing design.

Owner:重庆宇冠数控科技有限公司

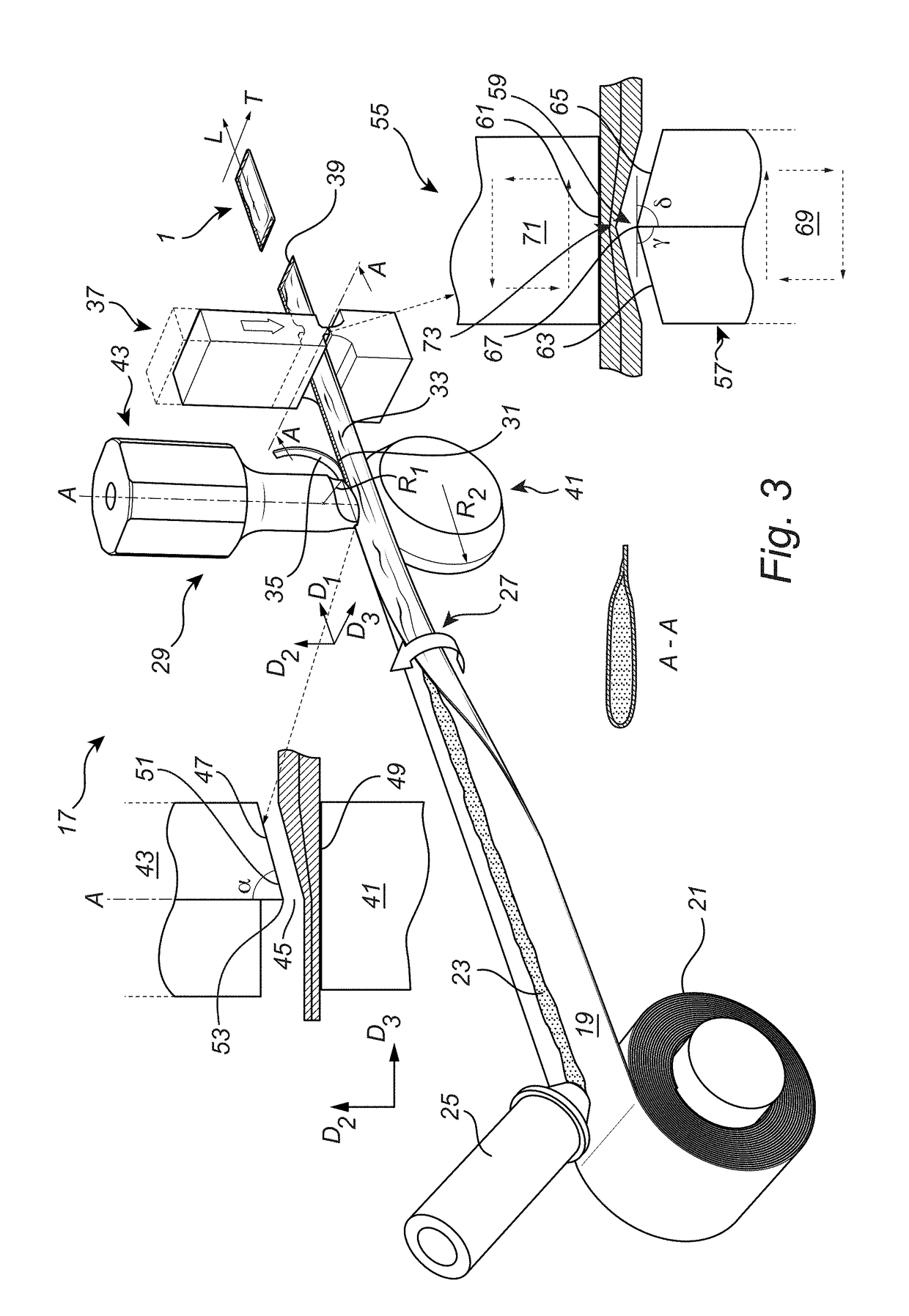

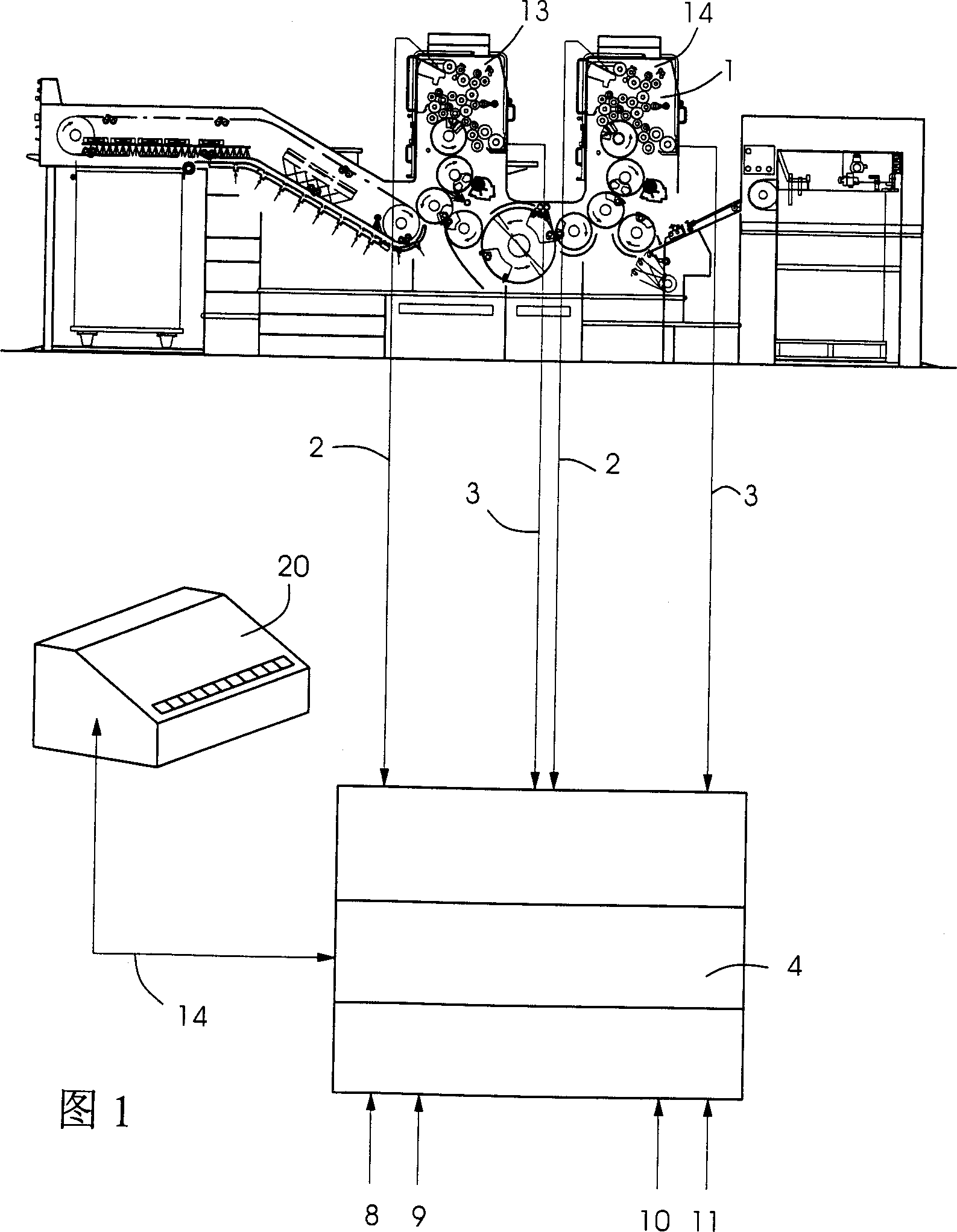

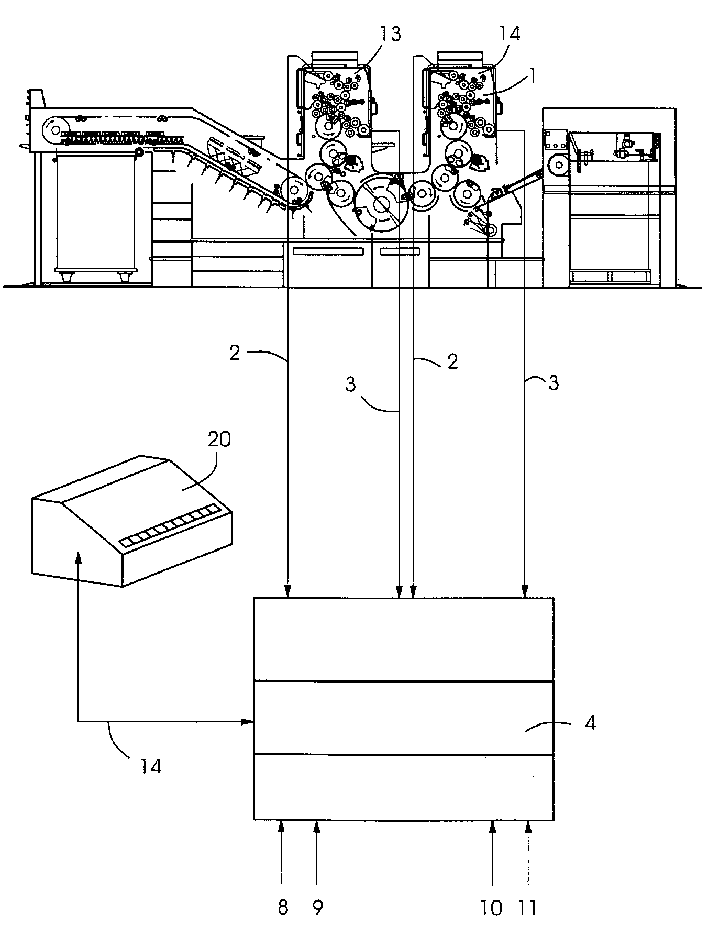

Method for regulating printing technical parameters of printing machine and other parameters related to printing process

InactiveCN1367079AGuaranteed smooth receptionNo difficulty readingPrinting press partsDigital output to print unitsBarcode readerComputer engineering

A method for setting machine settings for a printing machine at a time selected from before and during printing of a printed product on a printing machine, includes providing for one of an operator of the printing press and a pressman to evaluate a printed result of a printed product produced in one of a production printing and a proof printing, and resetting the machine settings, if necessary; in dependence upon an enabling signal, storing prescribed input variables and machine settings, which define a print job, in a control system belonging to the printing machine; and applying the stored values for influencing future settings of the printing machine, even for other print jobs; a printing machine for performing the method; and a material for printing with the printing machine.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

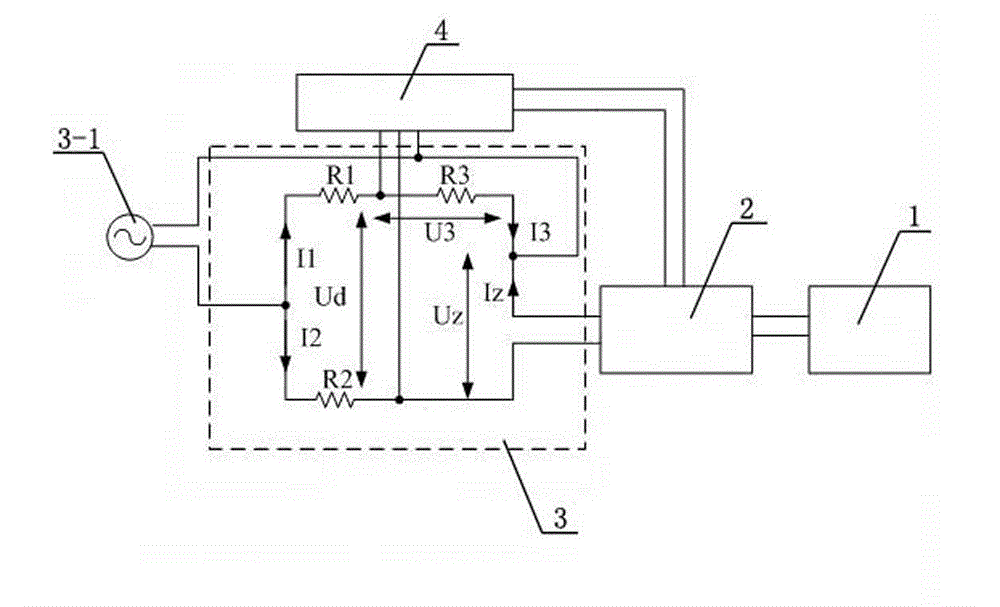

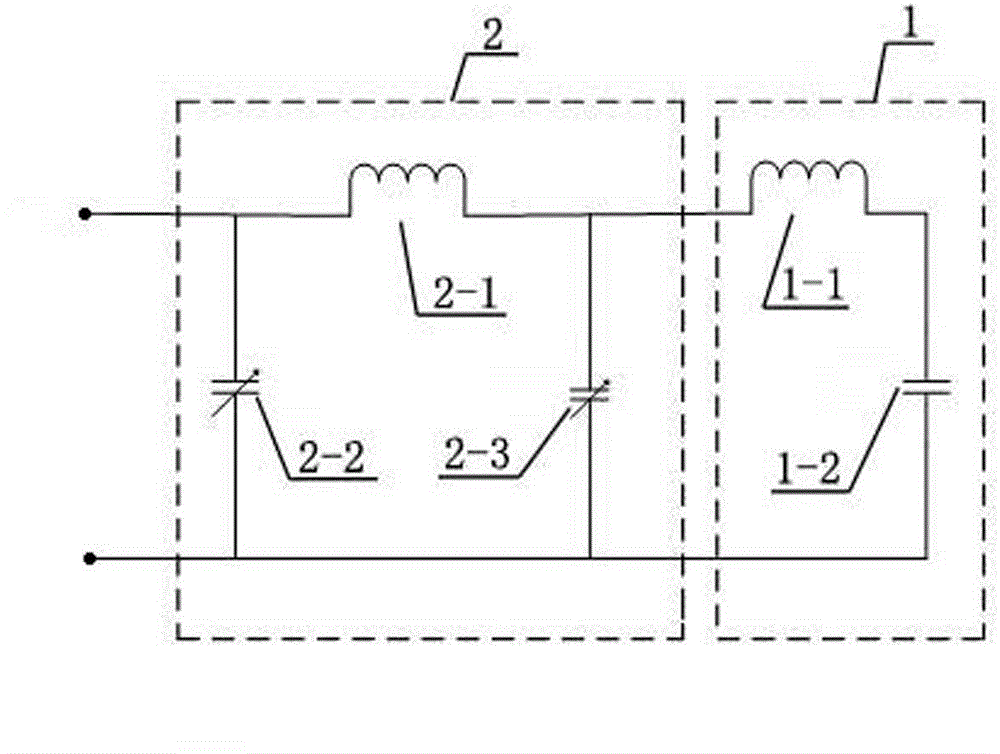

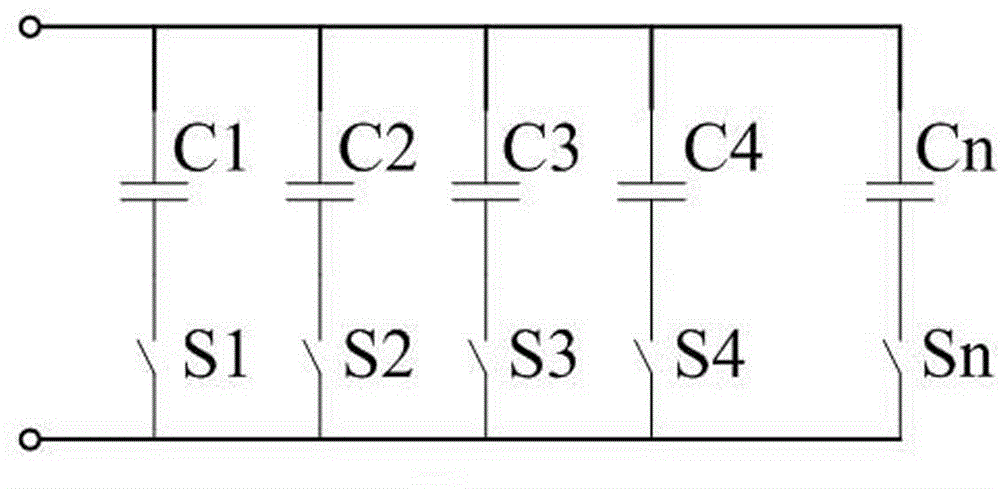

Intelligent impedance matching device of LC resonant antenna

InactiveCN103338018AReduce configurationIngenious designMultiple-port networksCapacitanceAntenna impedance

The invention relates to an intelligent impedance matching device of an LC resonant antenna. With the intelligent impedance matching device adopted, problems such as manual matching, long time matching, complicated process and low precision in an existing antenna impedance matching method can be solved. The intelligent impedance matching device includes the LC resonant antenna, an adjustable matching circuit unit, a test circuit unit and a micro controller; a planar spiral inductor and a parallel plate capacitor are connected in series so as to form the LC resonant antenna; the adjustable matching circuit unit includes an inductor, a first adjustable capacitor array and a second adjustable capacitor array which are in pi-shaped impedance matching network connection; the test circuit unit includes a signal generator; a Wheatstone bridge is connected between two ends of the signal generator; and four bridge arms of the Wheatstone bridge respectively are a first resistor, a second resistor, a third resistor and the adjustable matching circuit unit. The intelligent impedance matching device of the invention has the advantages of high matching efficiency, short matching time, simple matching process, high matching precision and low cost, and can be greatly adaptive to the development of some handheld RF devices.

Owner:ZHONGBEI UNIV

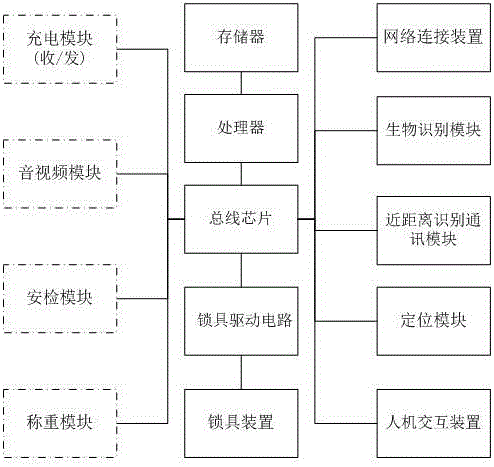

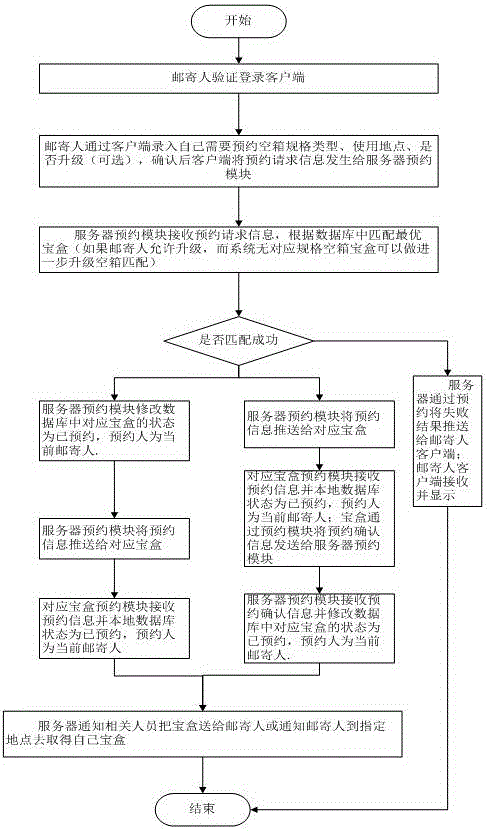

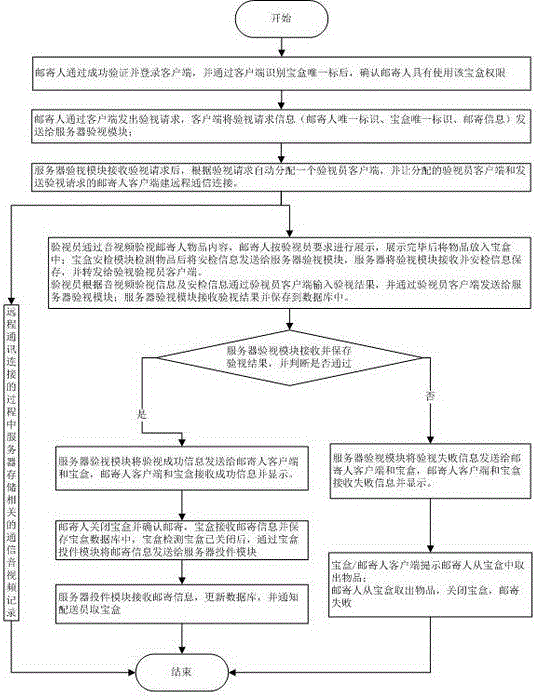

Treasure box mailing system and method

InactiveCN106203899AImprove securityCommunication is convenient and simpleApparatus for meter-controlled dispensingIndividual entry/exit registersWorkloadData library

The invention discloses a treasure box mailing system and method. The mailing system comprises a client, a treasure box and a server, the client and the treasure box communicate with the server via the network, the server comprises a user module, a mail inspection module, a mail sending module, a mail taking module and a database, and the treasure box comprises a safety check module, an audio and video module and a treasure box database. The mailing method comprises a treasure box booking step, a mail sending step and a mail taking step, and remote inspection is needed when a mail is sent. According to the invention, onsite inspection is not needed when the fast mail is sent, convenience is provided for senders, and the workload of delivery staff is reduced at the same time.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com