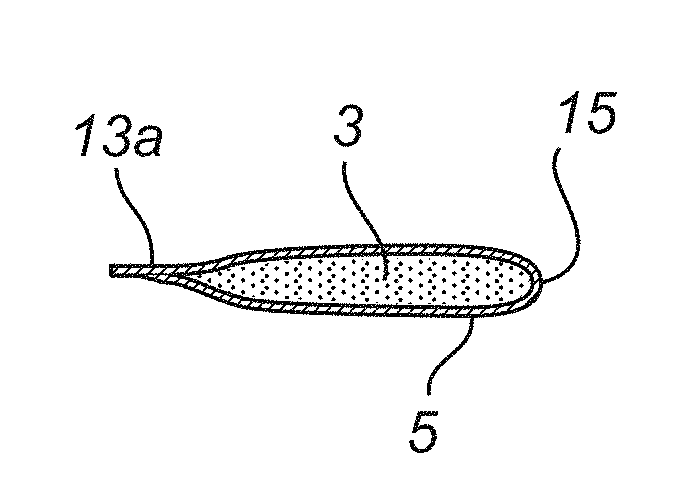

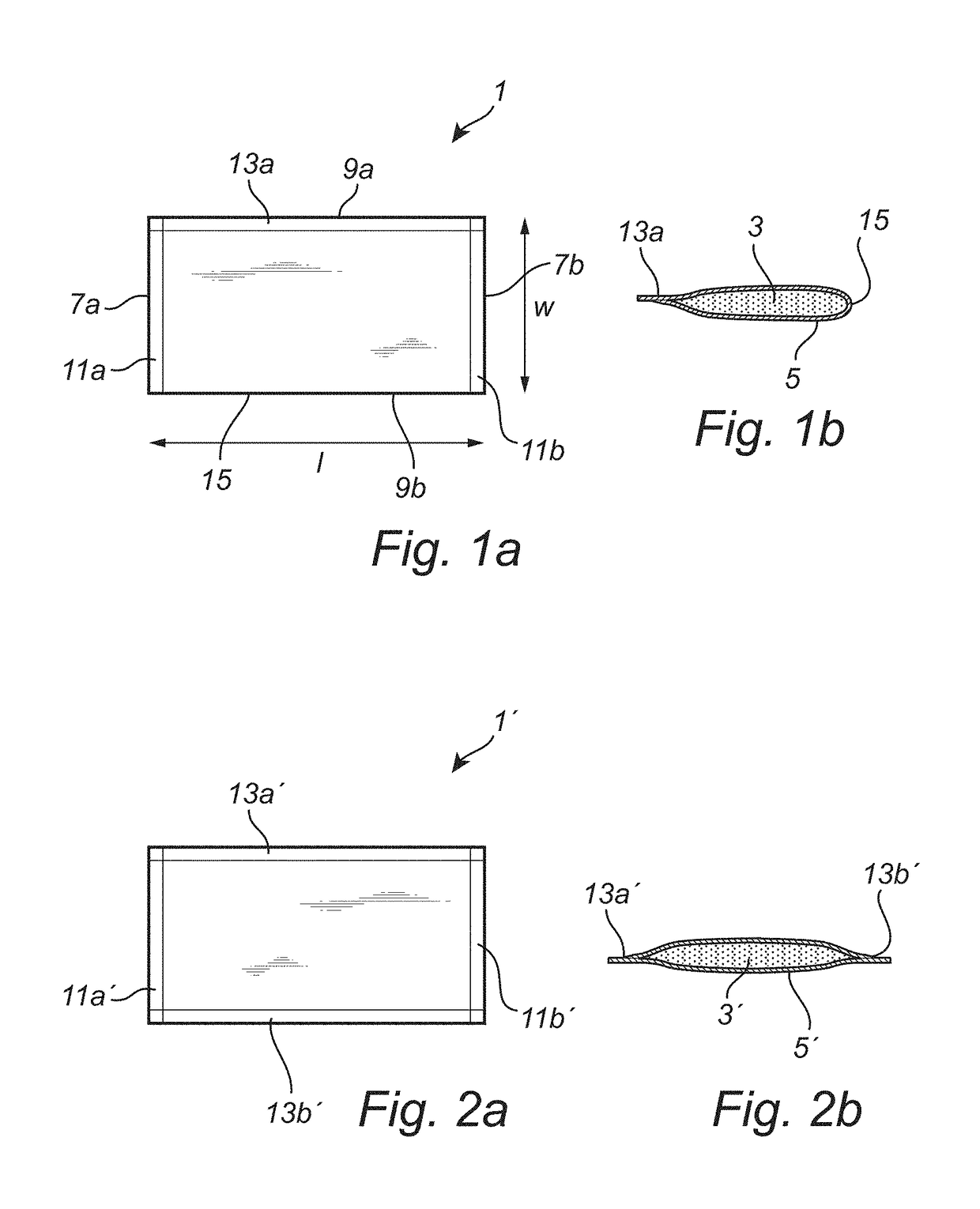

Chewable and deformable oral pouched snuff product

a snuff product and mouth technology, applied in the field of mouth pouched snuff products, can solve the problems of increasing time consumption, reducing the amount of pouch material required, and reducing the seal width. , the effect of reducing the amount of pouch material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

nt of Seal Strength Resulting from Heat-Melt Welding and Ultrasonic Welding

[0213]The elastic mesh material as well as the nonwoven reference material was heat-melt welded and ultrasonically welded and the seal strength of the resulting samples was measured.

Heat-Melt Welding

[0214]A strip of the nonwoven reference material having a length of about 1 m in the machine direction, MD, of the material and a width of 4 cm in the cross direction, CD, of the material was cut out. The strip was double-folded to obtain a two-layered material, which was about 4 cm×50 cm.

[0215]The two layers of the double-folded strip were welded to each other along the CD direction as well as along the MD direction of the material in a HS-2 laboratory heat sealer from RDM equipment. The dimensions of upper and lower seal bars were 50 mm×5 mm. The seal bars were applied such that the 50 mm direction was perpendicular to the length direction of the double-folded strip.

[0216]The upper seal bar was heated to about 3...

example 2

o Withstand Aggressive Flavors Known to Affect Seal Strength

[0248]Samples of the ultrasonically welded and the heat melt welded elastic mesh material and the nonwoven reference material prepared as described in Example 1, were placed in a first compartment of a two-compartment container. A flavor (in oil form) known to impair seal strength was placed in the other compartment. The flavor is also known to dissolve the binder present in nonwoven material normally used and thereby impair the tensile strength thereof.

[0249]The container was thereafter closed and the samples were stored in the container for two days (about 48 hours). Thereafter, the seal strength of each sample was measured.

[0250]The results (average values of 10 measurements for seal strength and average values of 5 measurements for tensile strength) are presented in Table 1. Standard deviation is included in Table 2 for the seal strength measurements.

TABLE 2Elastic meshReferencematerial after 2material after 2ParameterU...

example 3

ion of Seal Strength Upon Storage of Oral Pouched Snuff Product

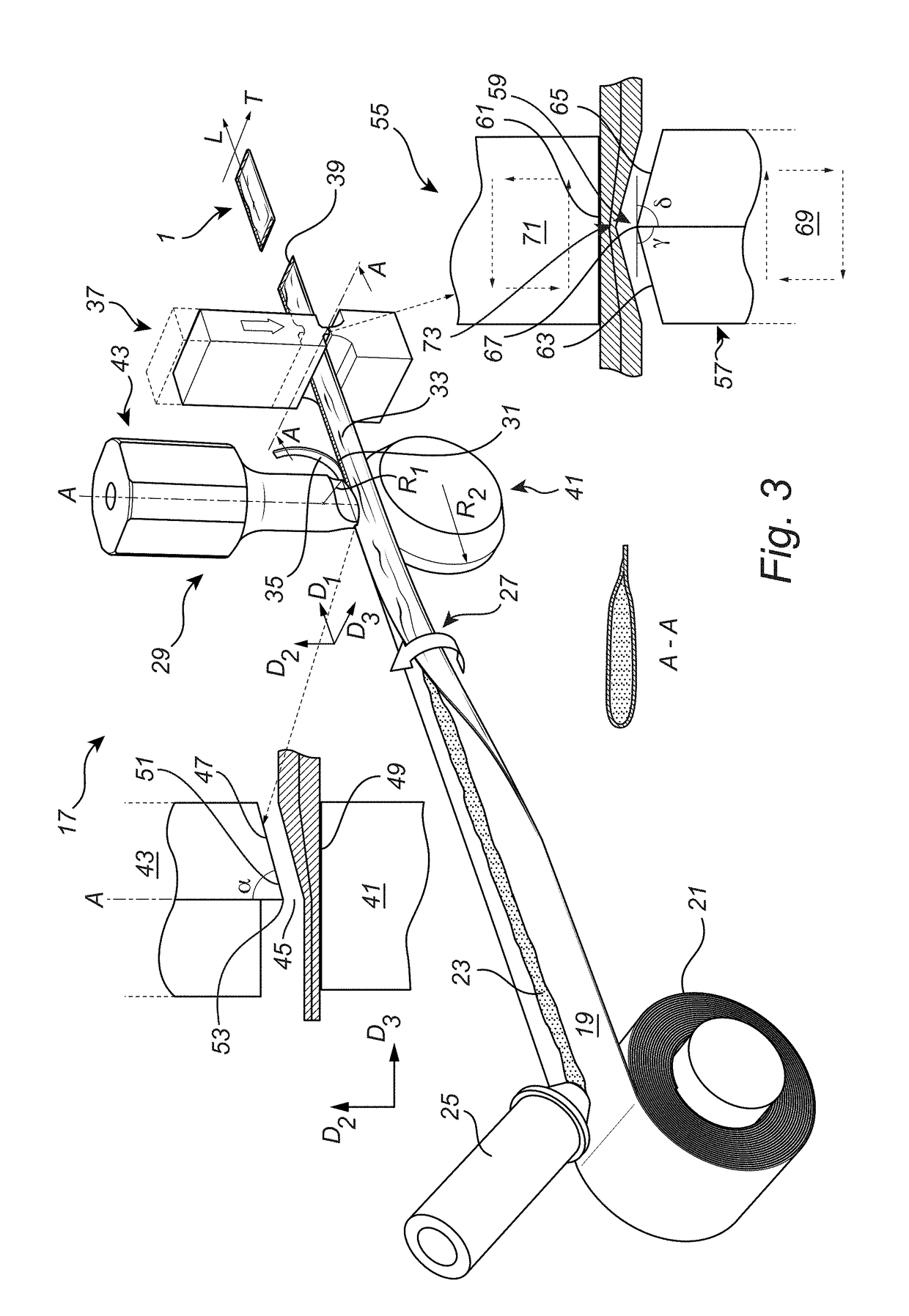

[0252]A tobacco composition (snus composition), having moisture content of about 50-60% w / w, such as 56% w / w, based on the total weight of the composition, is portion-packed in pouches of the elastic mesh material of Example 1 using the herein disclosed arrangement utilizing ultrasonic welding for sealing the pouches.

[0253]The same tobacco composition is also portion-packed in pouches of the nonwoven reference material of Example 1 using conventional portion-packing apparatus utilizing heat melt welding for sealing the pouches.

[0254]The seal strength of some of the resulting oral pouched snus products is measured. Some of the resulting pouched snus products are stored in a refrigerator for about 3 weeks. Thereafter, the seal strength of the stored products is measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com