Patents

Literature

401results about How to "Poor contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

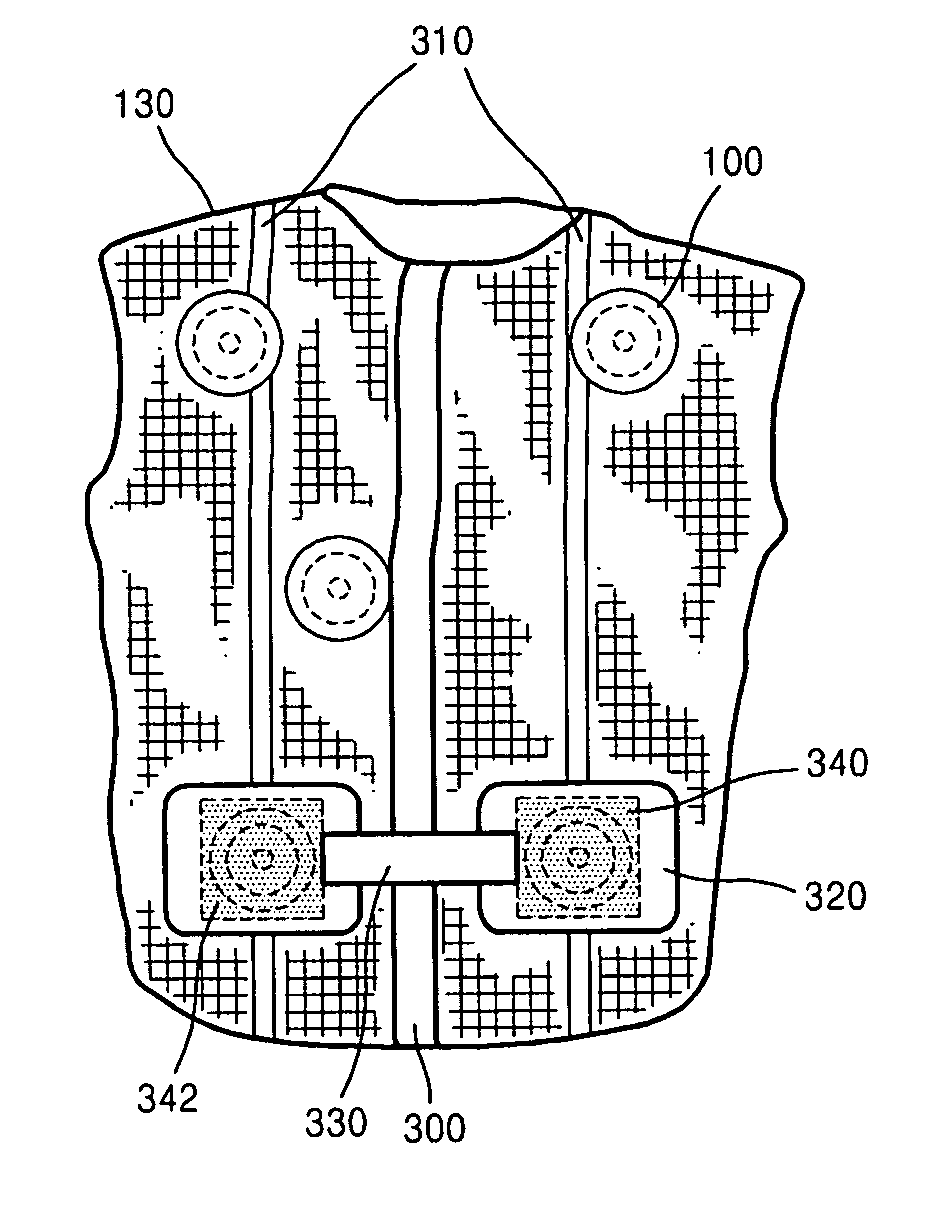

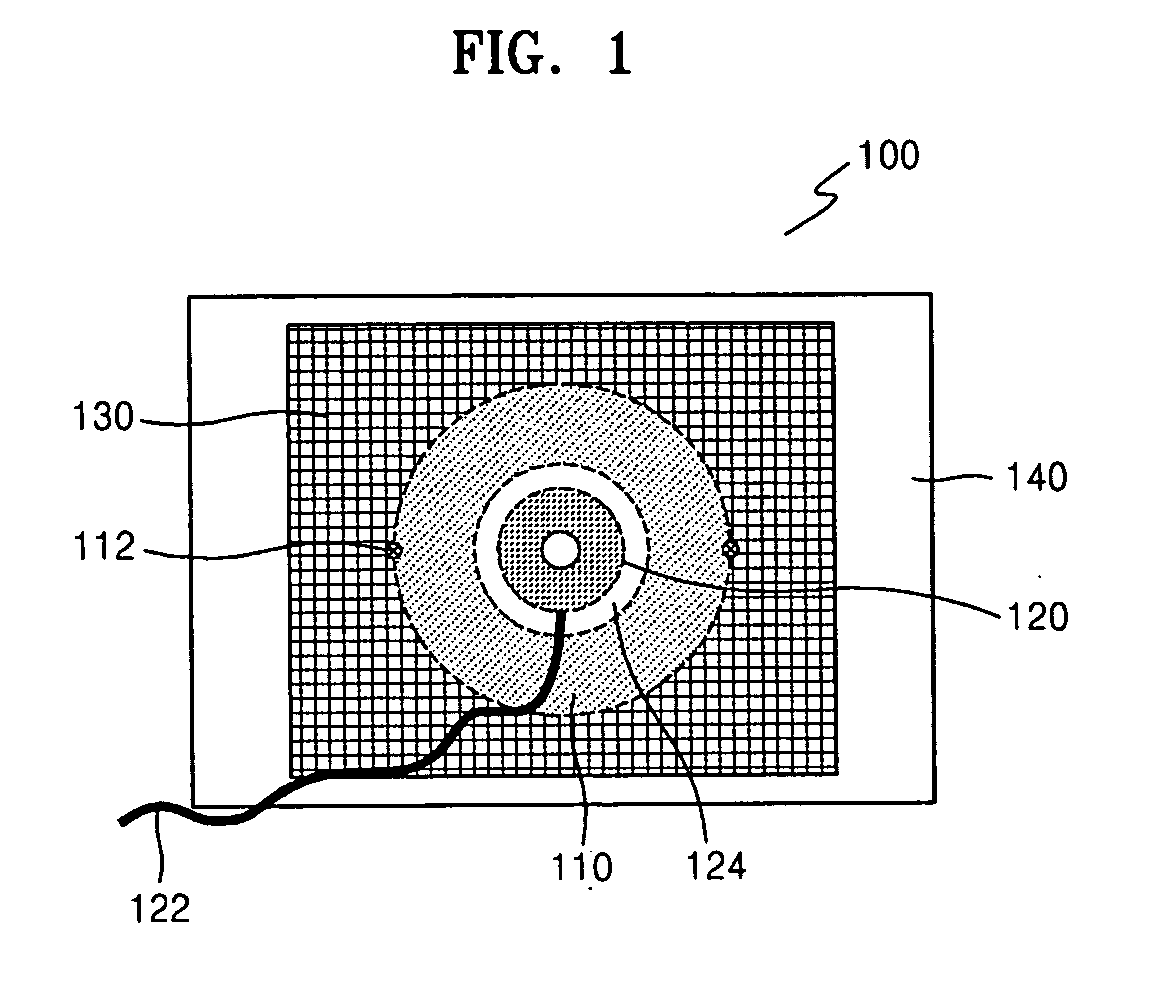

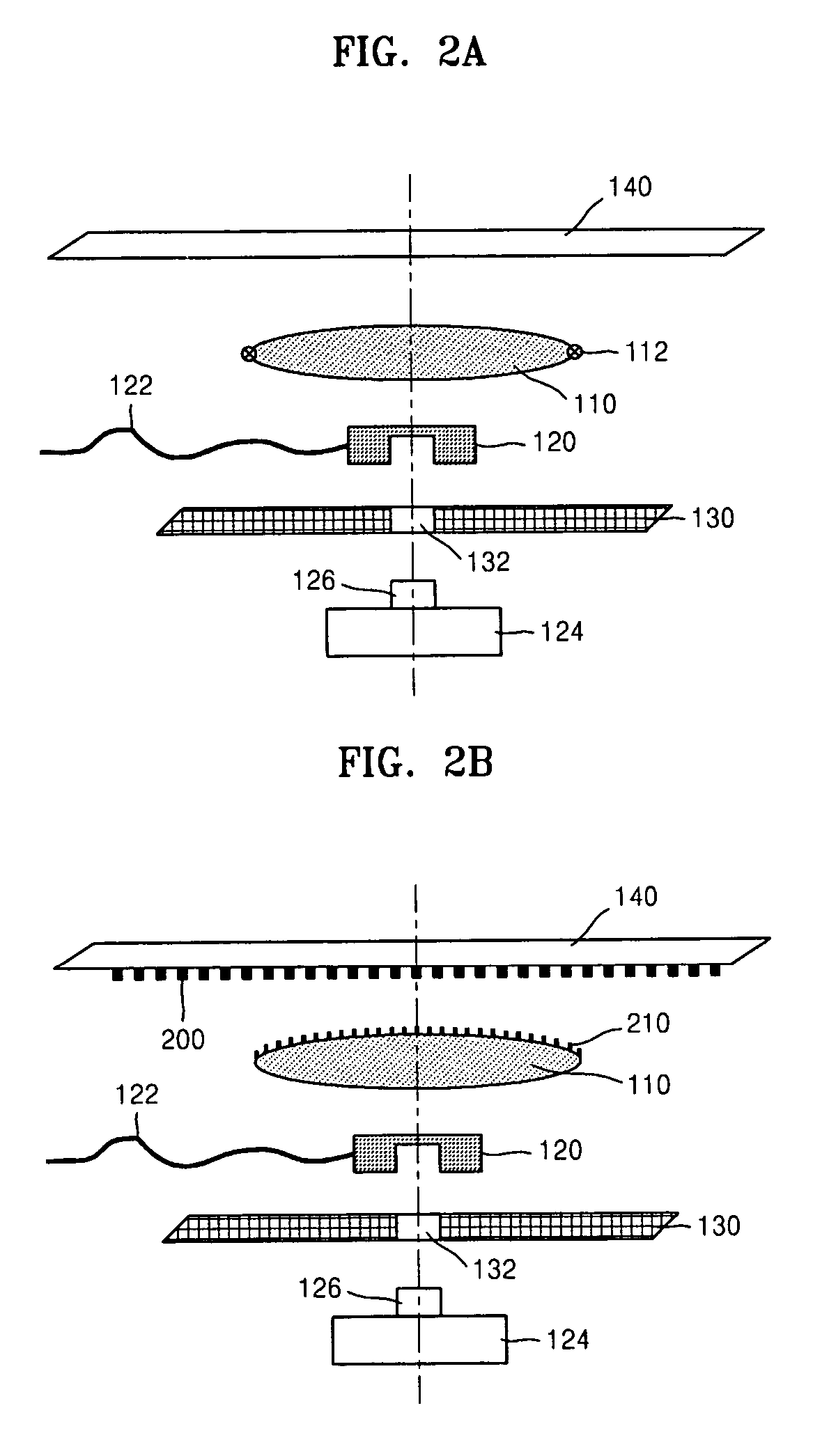

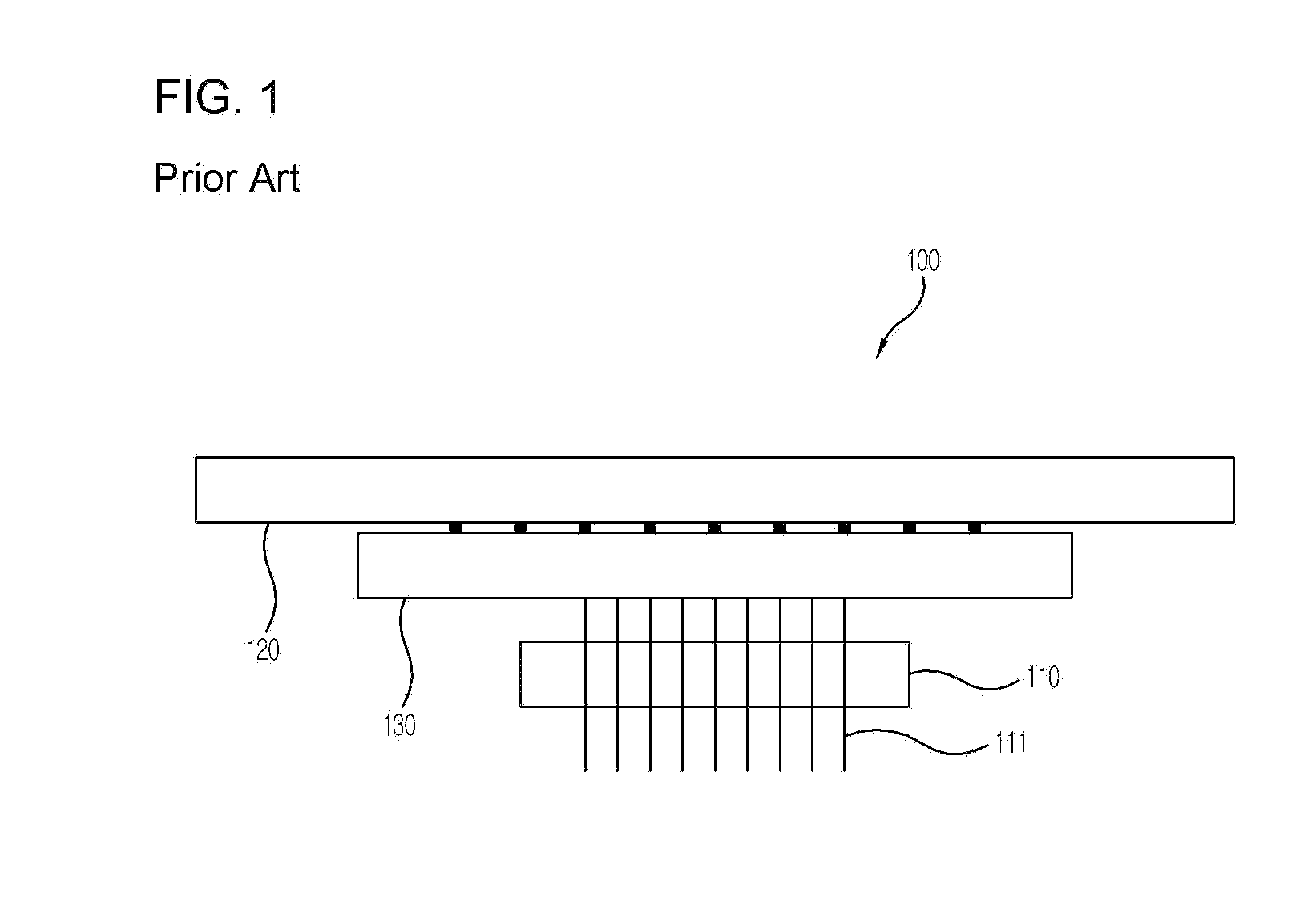

Garment for measuring physiological signal

Provided is a garment for measuring a physiological signal. The garment includes: an inner layer made of an elastic mesh fabric; a physiological signal measuring electrode including a connector connected to an external line and an electrode having a protrusion and measuring a physiological signal, the protrusion of the electrode passing through a mesh of the inner layer and engaging with the connector to be attached to the inner layer; and a compressing cushion interposed between an outer layer and the inner layer and compressing the physiological signal measuring electrode to a human body. Accordingly, poor contact between the physiological signal measuring electrode and the human body can be prevented and noise generated when measuring the physiological signal can be reduced.

Owner:RYU CHANG YONG +5

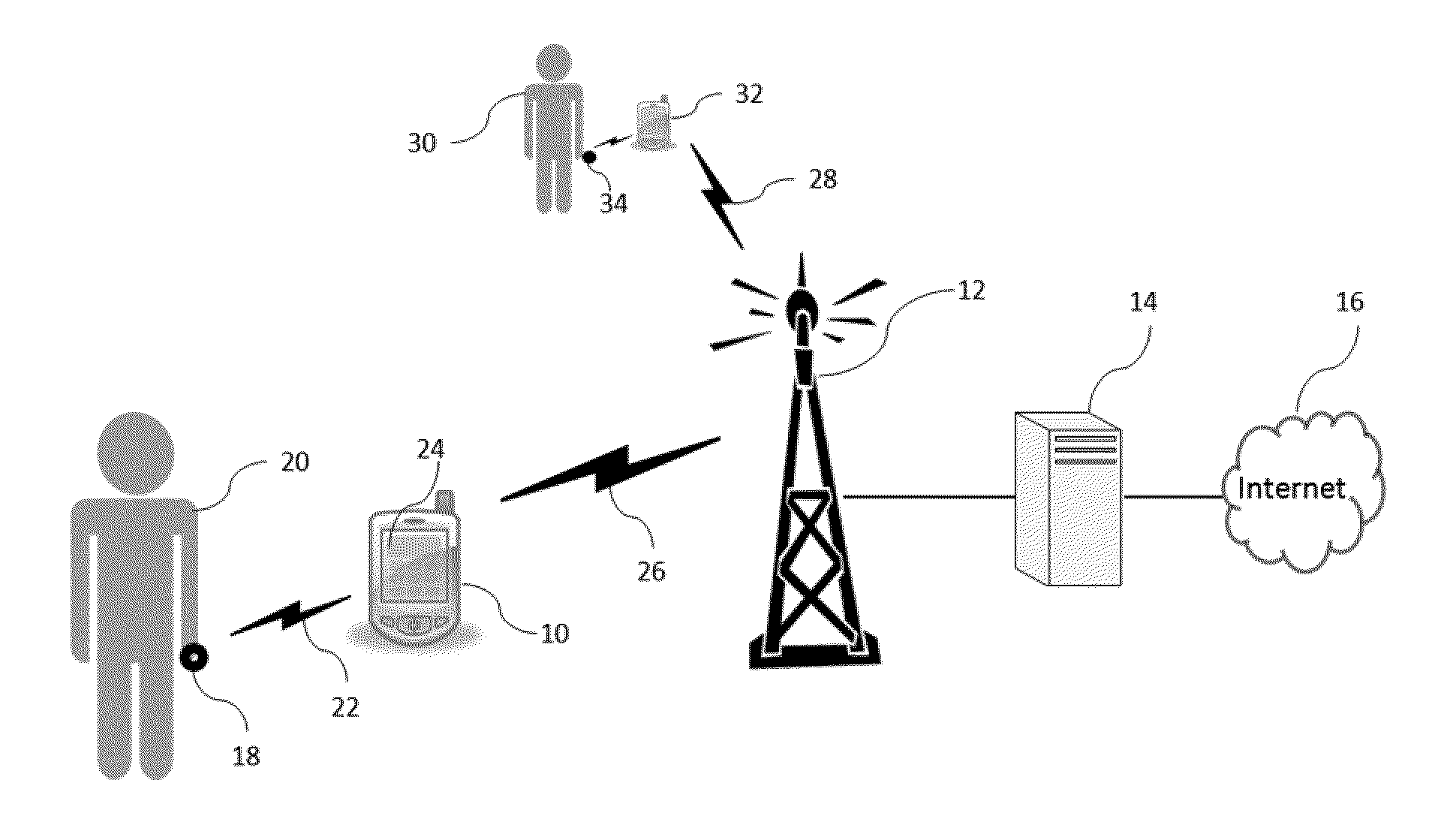

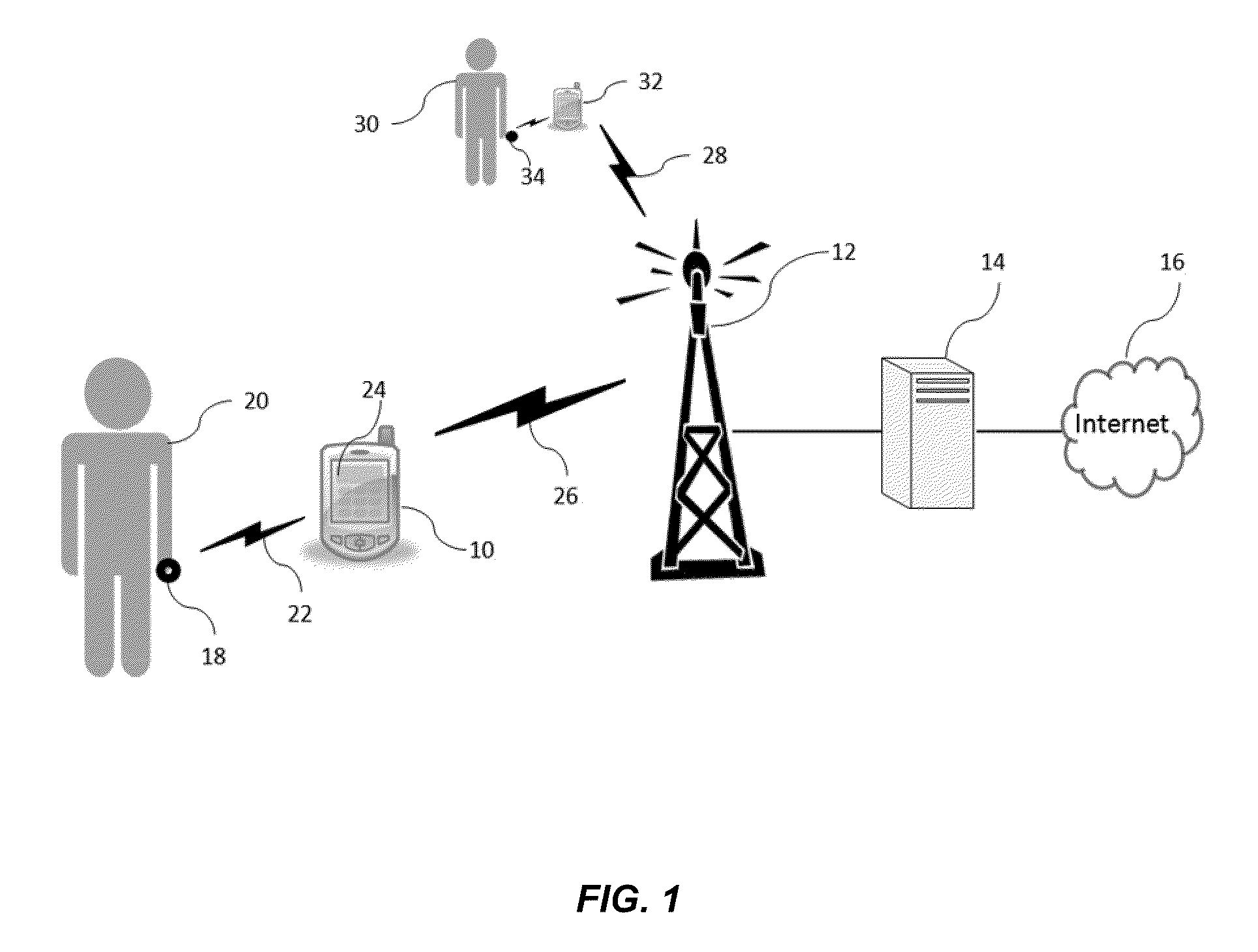

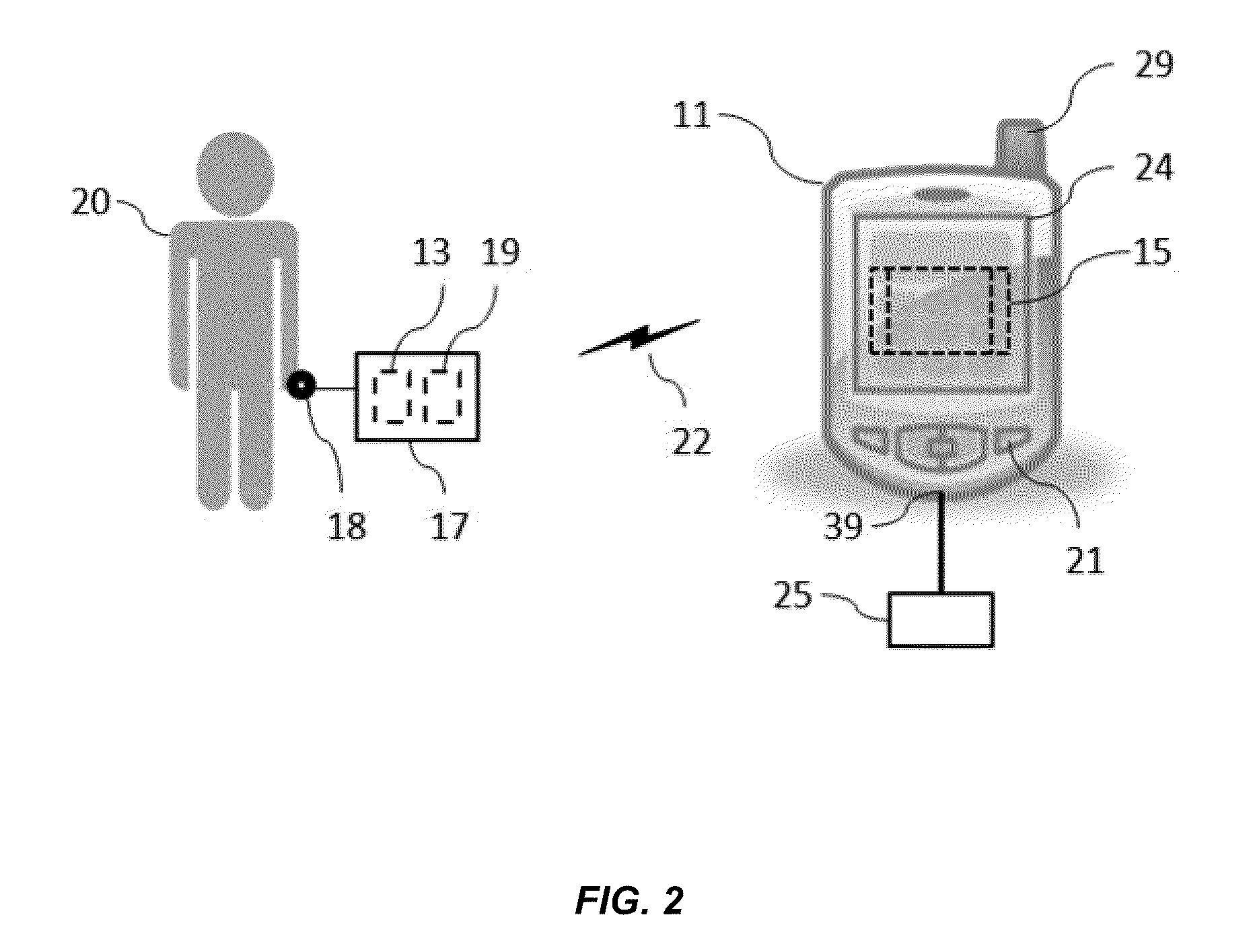

Method and apparatus for monitoring emotion in an interactive network

ActiveUS20110300847A1Easy to detectEasy to monitorService provisioningMedical automated diagnosisWide areaEmotional arousal

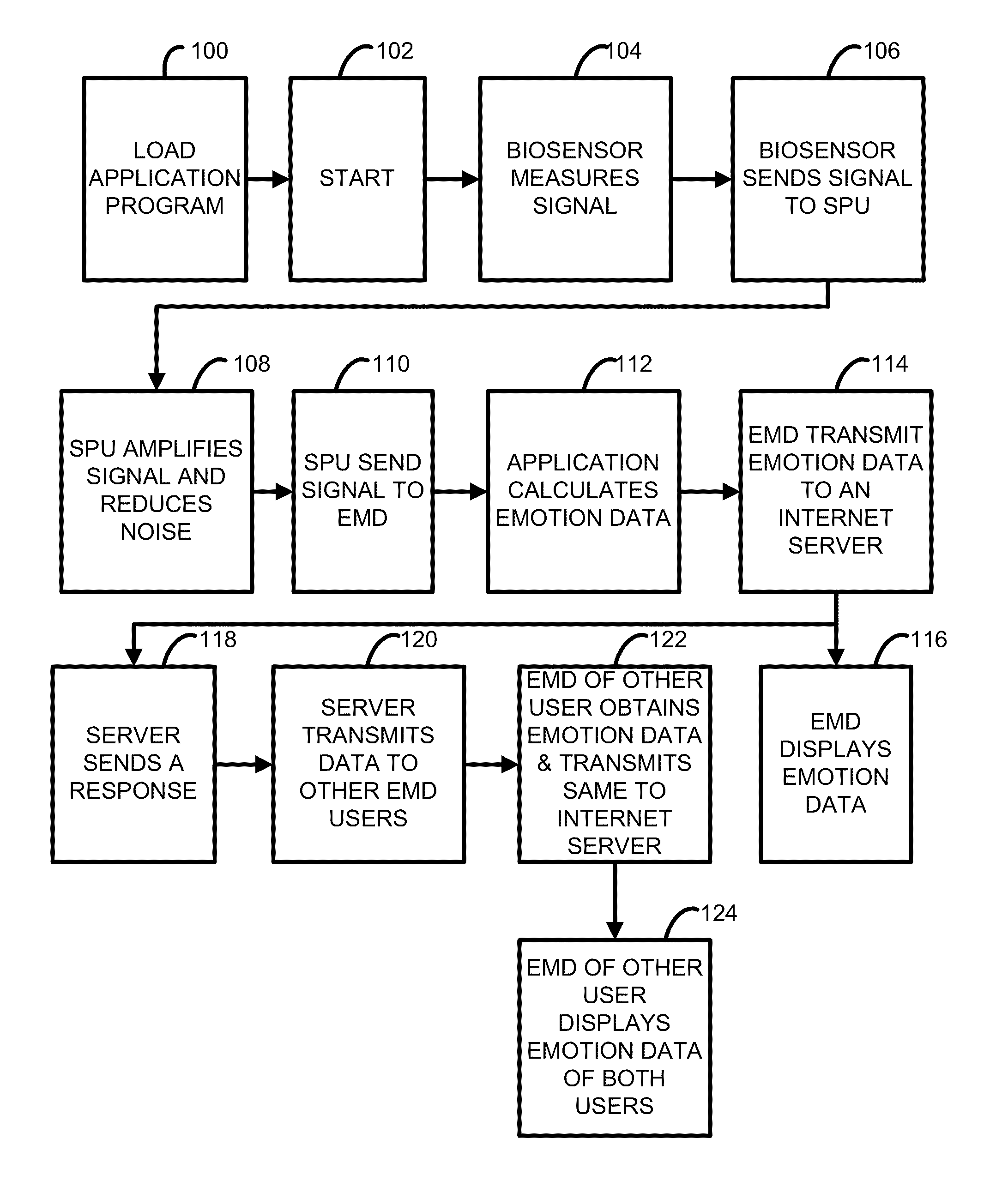

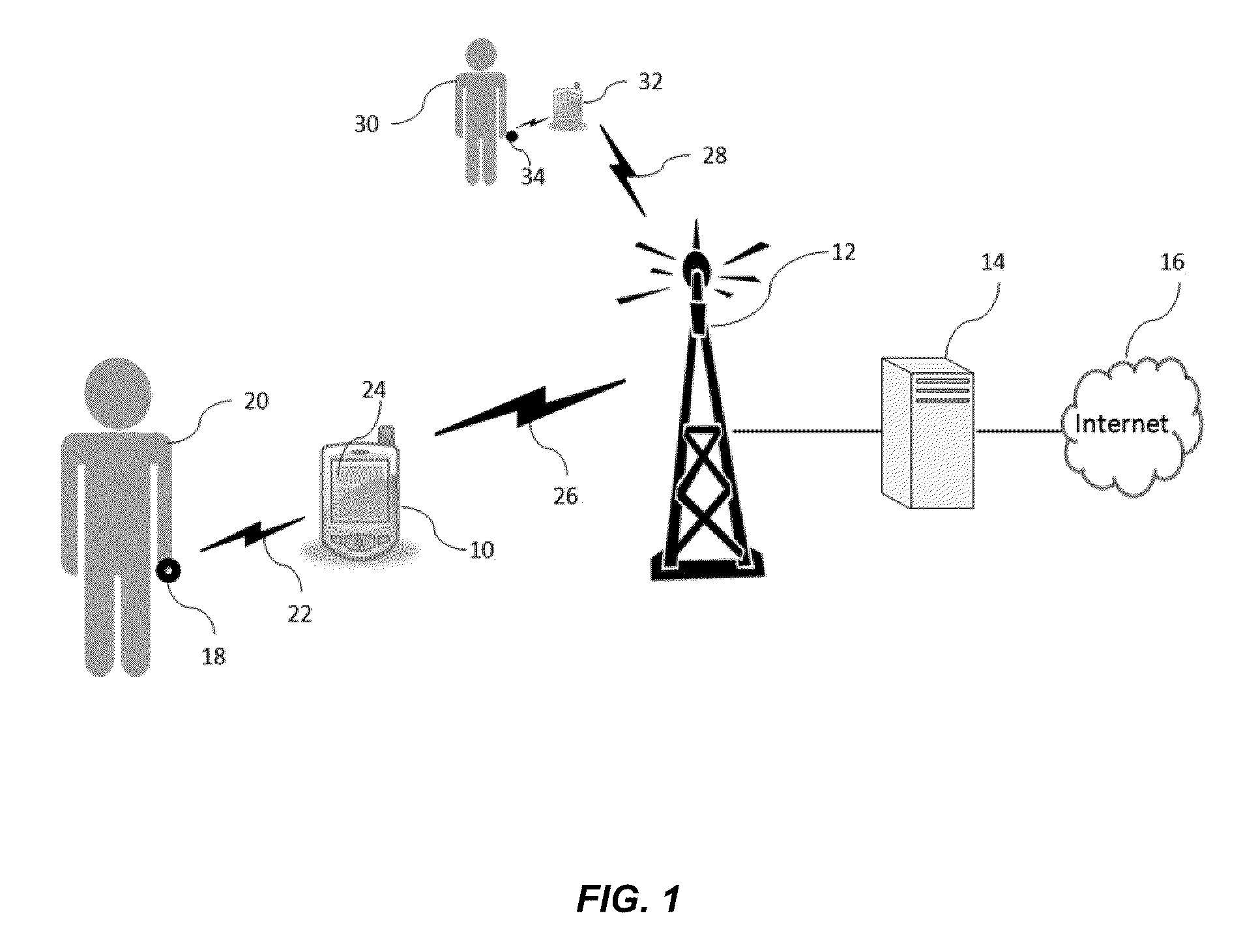

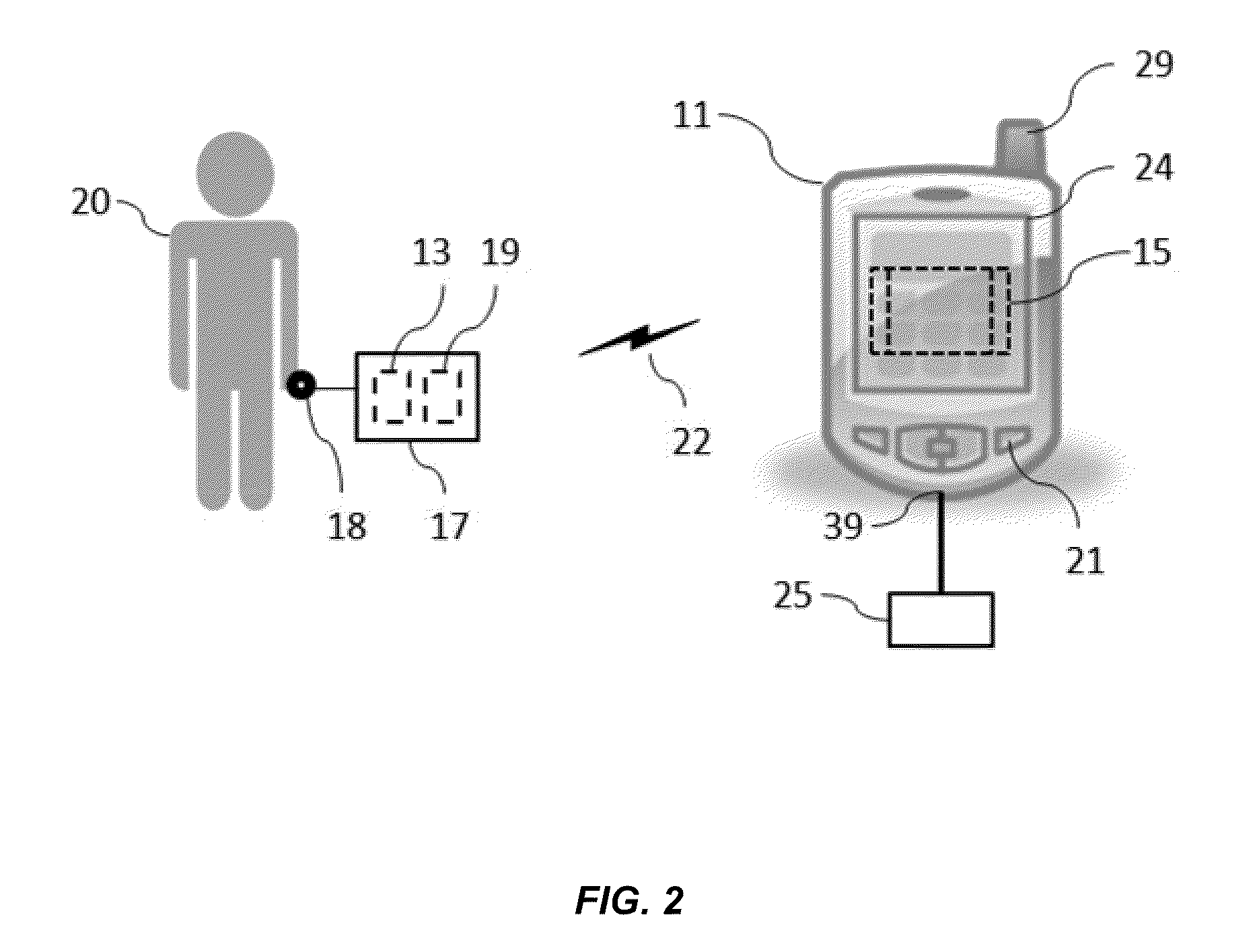

Embodiments of the invention provide a method, devices, and system for monitoring and sharing emotion-related data from one or more persons connected via the internet. An emotion monitoring device (EMD) measures physiological signals obtained from biosensors and computes emotion states relating to emotional arousal and valence. Various signal processing methods are employed to reduce artifact and improve the detection of emotional states. The EMD communicates the emotion data to an internet server via a wireless network. The internet server transmits the emotion data to other persons equipped with an EMD. Their emotion data similarly is obtained and shared with others. The networked emotion data can used to enrich online, community experiences such as games and social networks. An implementation of an EMD based on a smart phone enables emotion data to be monitored in wide area, mobile environment. The biosensors can be integrated into the casing or a cover for the mobile phone.

Owner:THE VISTA GRP LLC

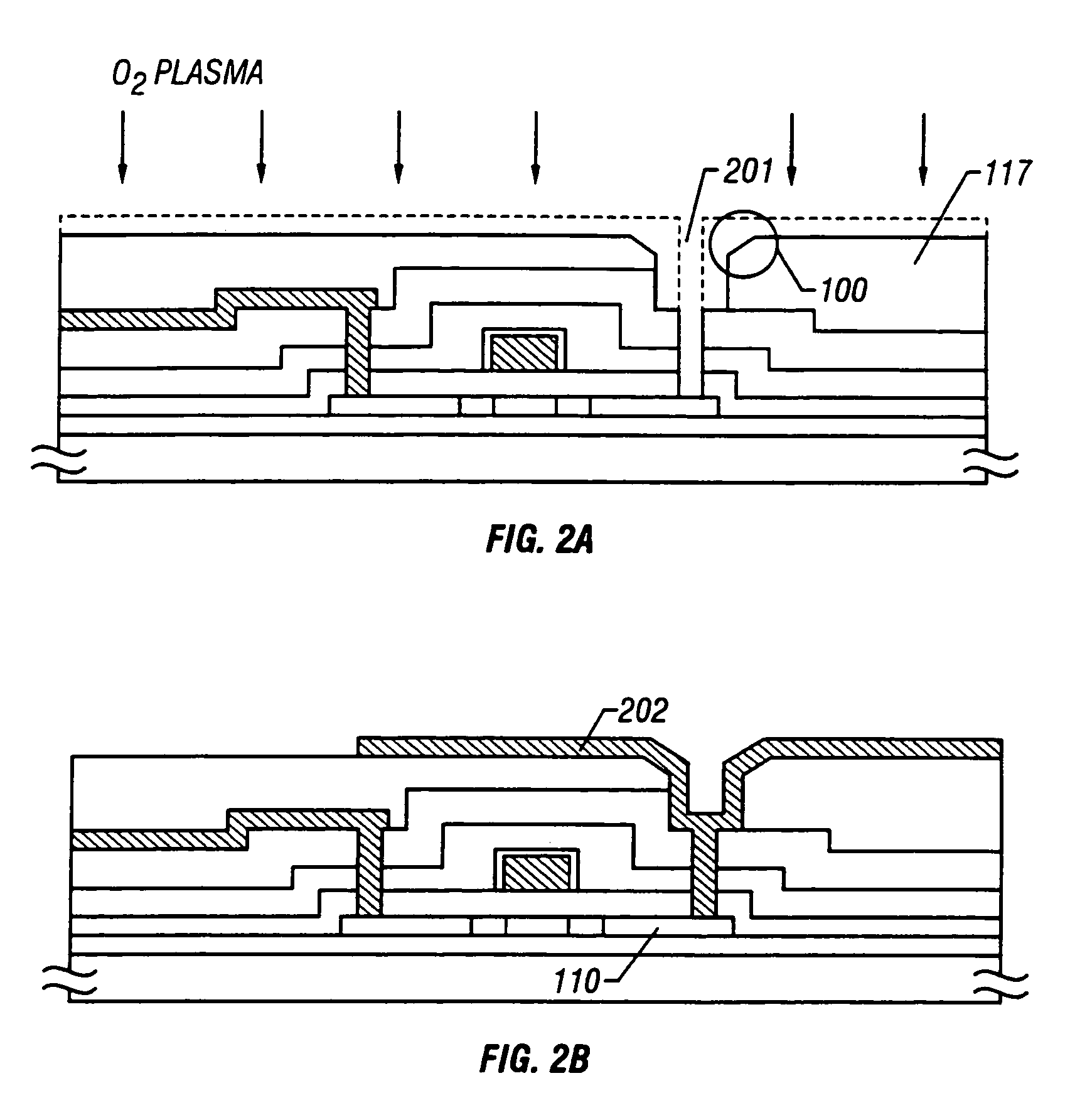

Fabricating a tapered hole incorporating a resinous silicon containing film

Owner:SEMICON ENERGY LAB CO LTD

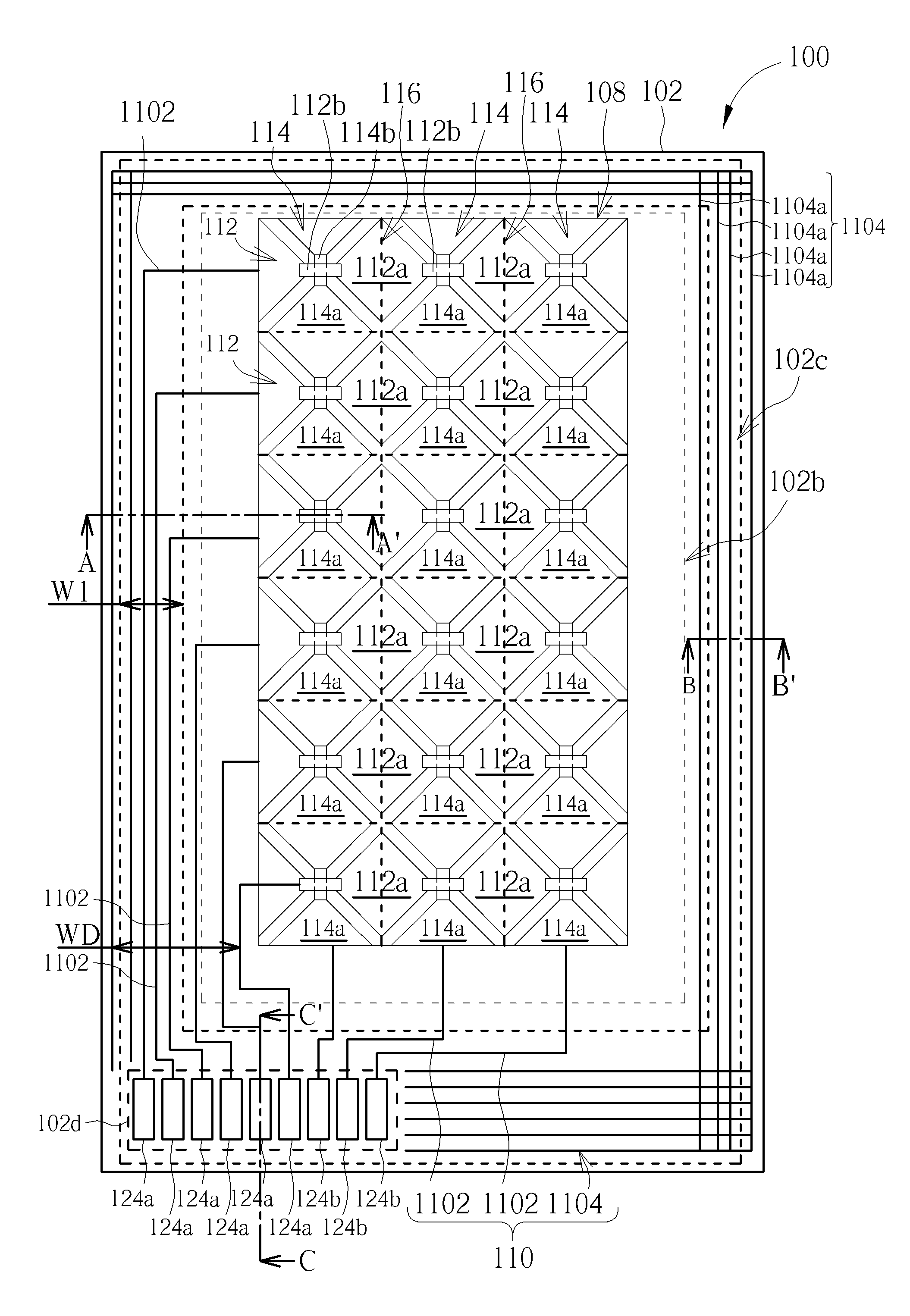

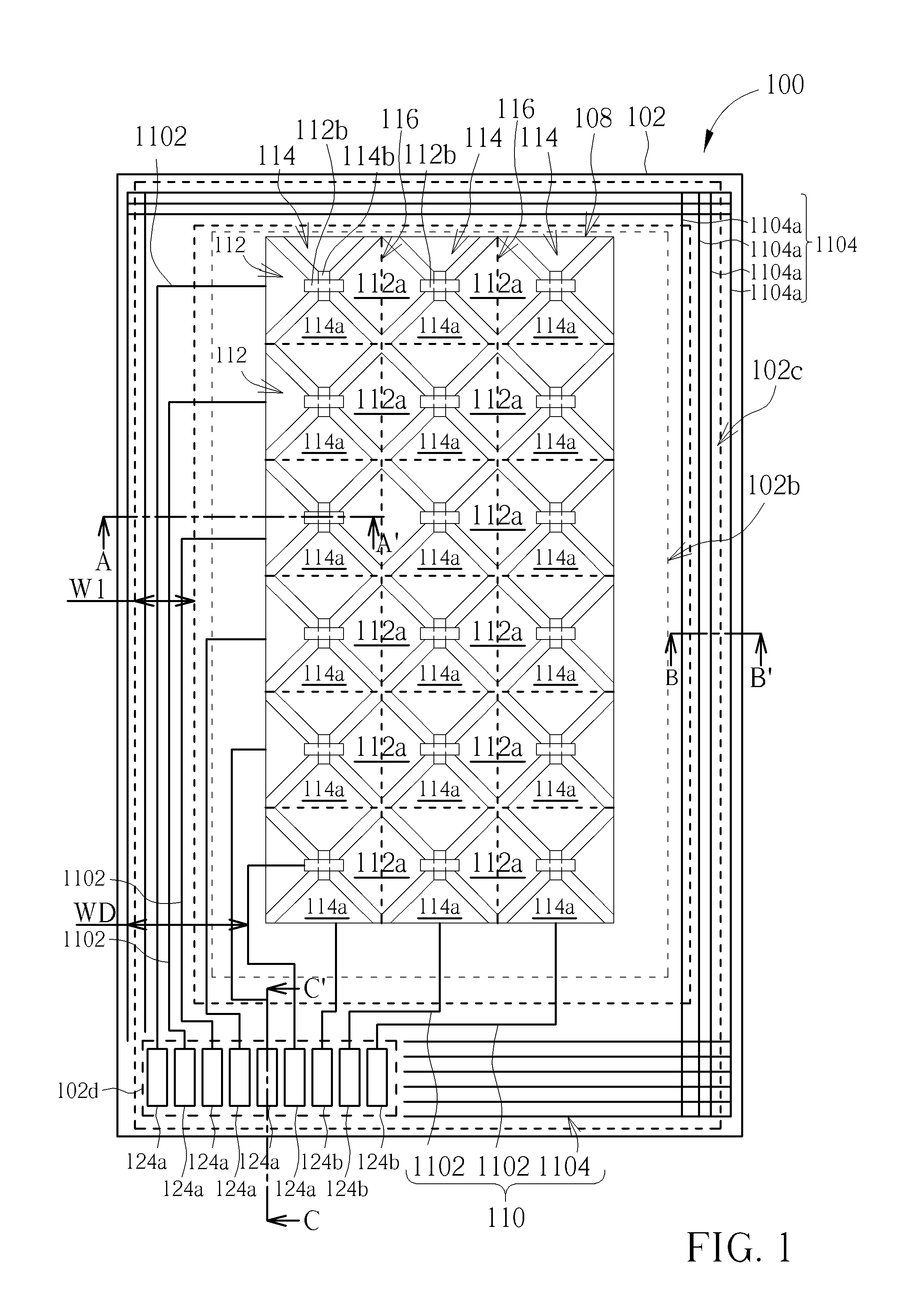

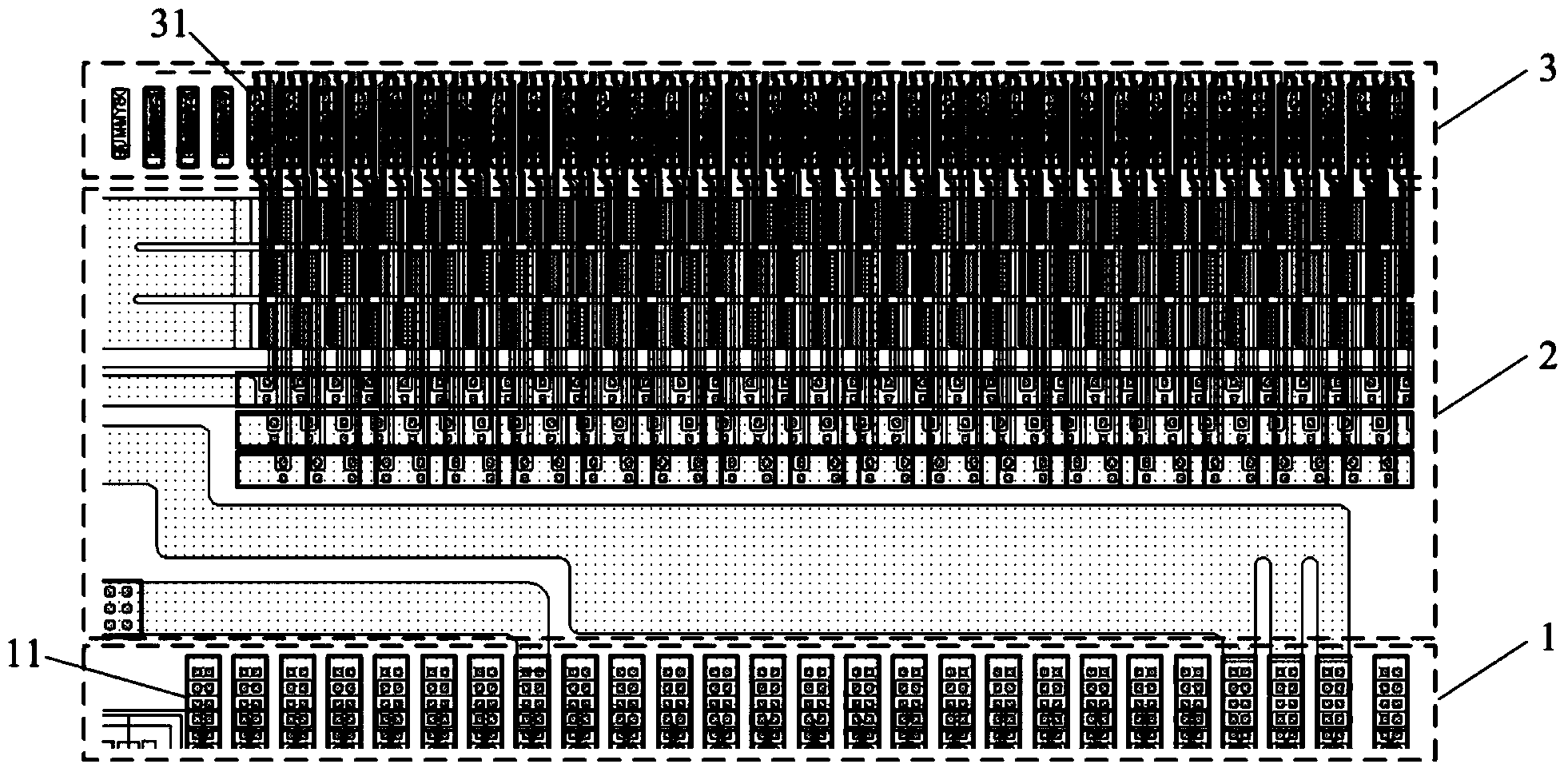

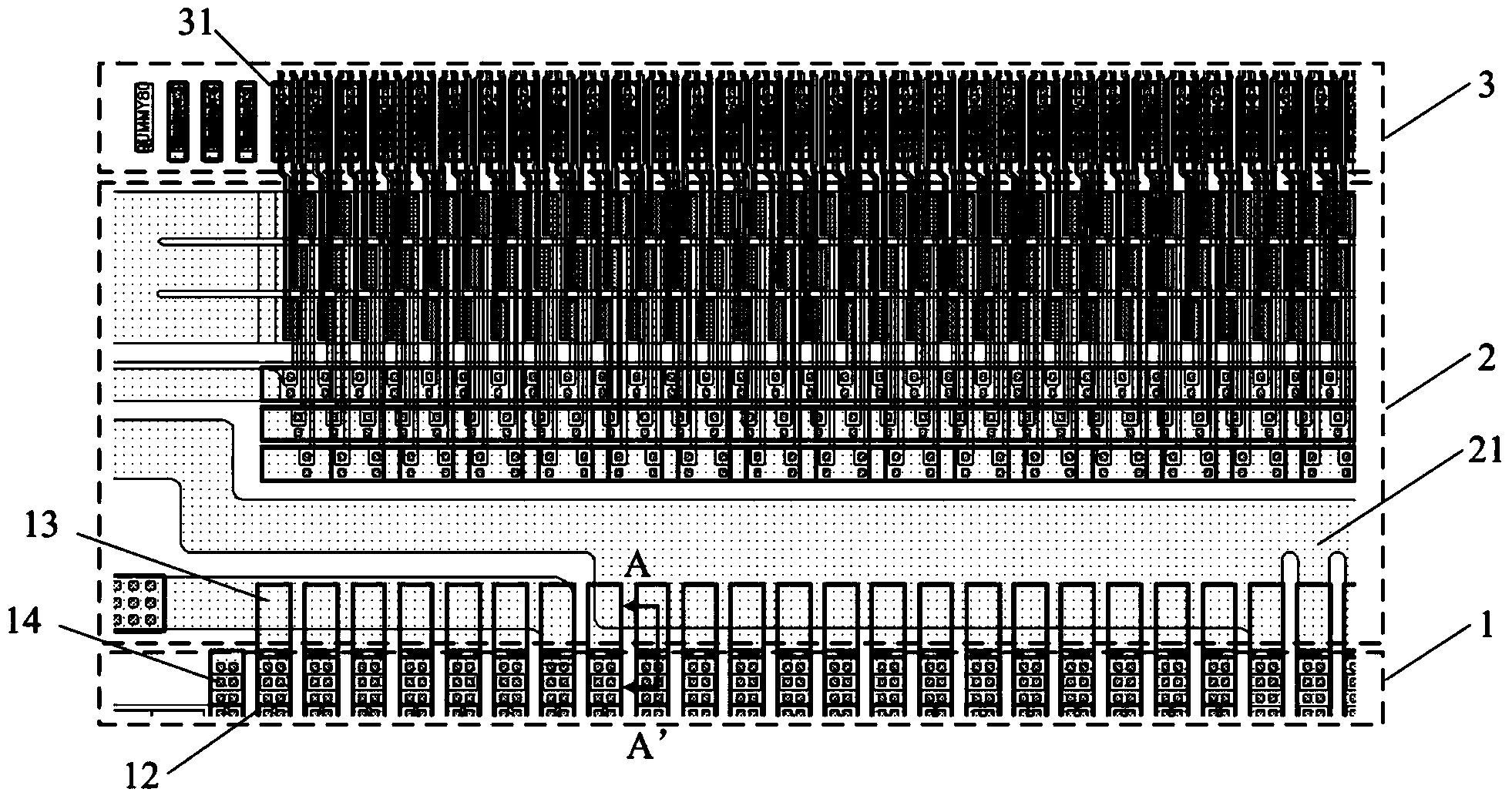

Touch sensing display panel and touch sensing liquid crystal display panel

ActiveUS20130314625A1ContactSmooth connectionNon-linear opticsInput/output processes for data processingAuxiliary electrodeLiquid-crystal display

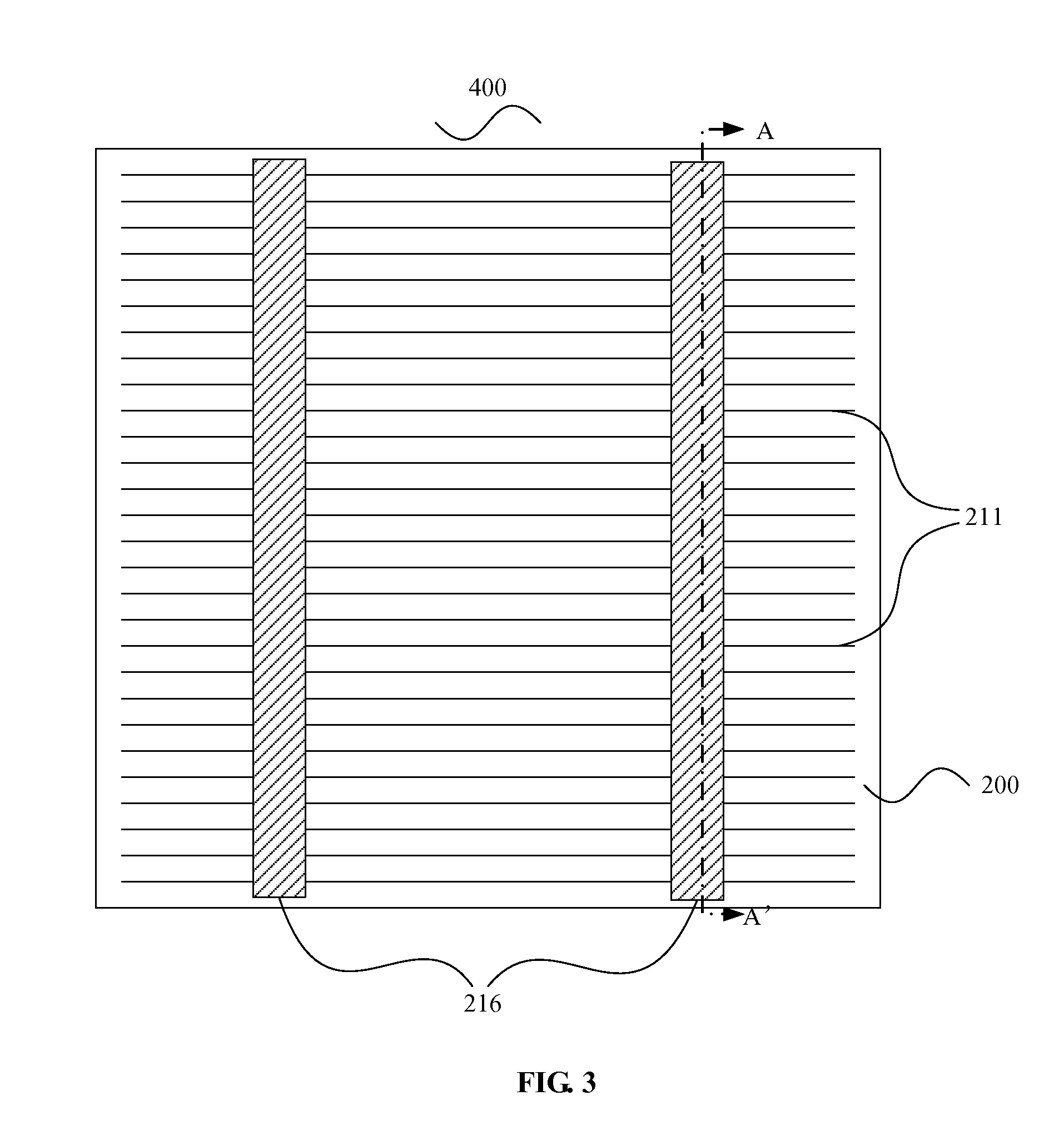

A touch sensing display panel includes a first substrate, a second substrate, a touch sensing device, a patterned electrode layer, an insulating layer, and a sealant. The first substrate has a touch sensing region, and a sealant region surrounding the touch sensing region. The touch sensing device is disposed on an inner surface of the first substrate in the touch sensing region. The patterned electrode layer is disposed on the inner surface of the substrate in the sealant region, and the patterned electrode layer includes a plurality of connecting lines electrically connected to a touch sensing device, and an auxiliary electrode. The auxiliary electrode is not directly electrically connected to the connecting lines and the touch sensing device. The sealant is disposed between the first substrate and the second substrate in the sealant region, and at least one of the connecting lines and the auxiliary electrode overlap the sealant.

Owner:AU OPTRONICS CORP

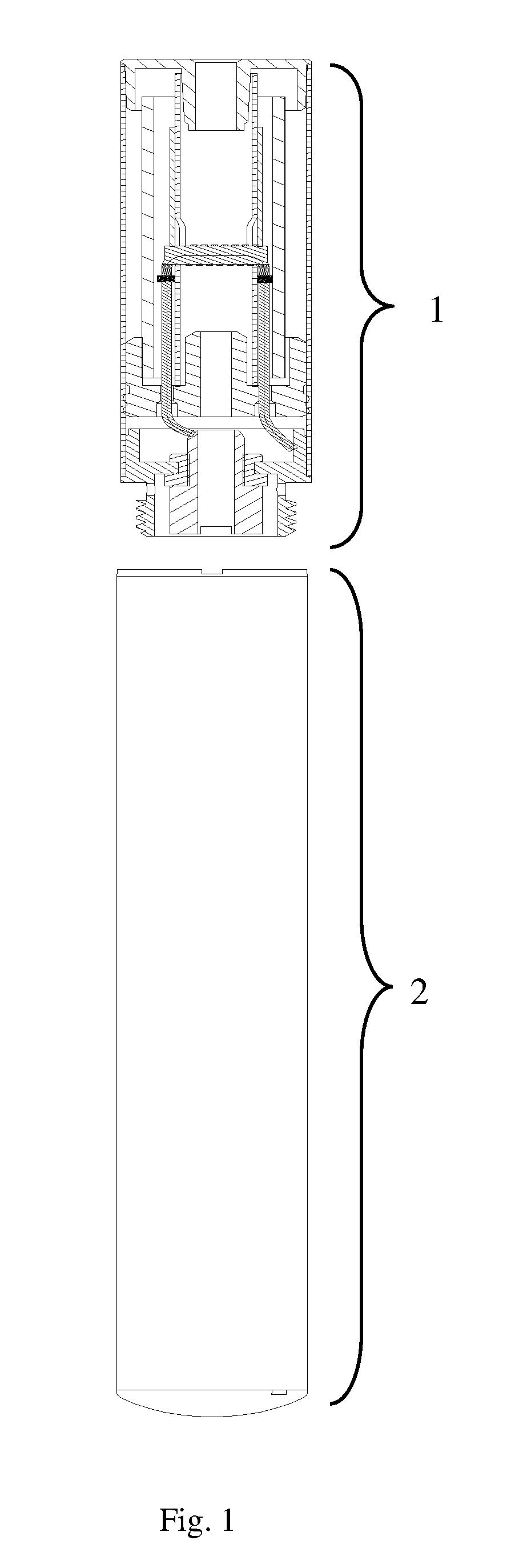

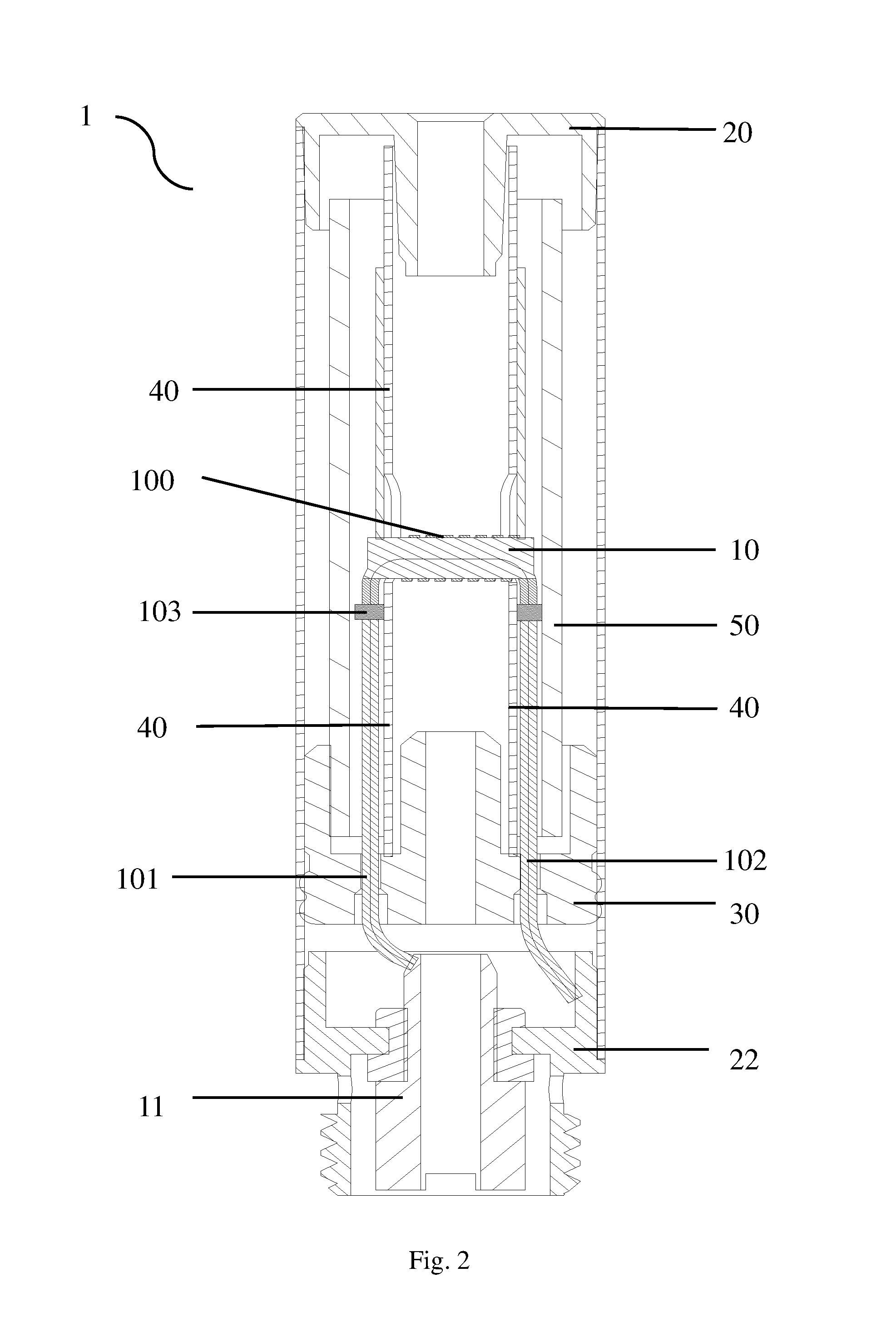

Atomization assembly and electronic cigarette

InactiveUS20160198768A1Amount is small and easilyPoor contactTobacco devicesHand ironEngineeringElectronic cigarette

An atomization assembly and an electronic cigarette with the atomization assembly. The atomization assembly comprises an oil guide member, a heating member wound round on the oil guide member, and a first electrically-conductive connecting member and a second electrically-conductive connecting member are being connected with two ends of the heating member respectively; the heating member includes at least one plane, and one plane in the at least one plane is attached to and wound towards an outside surface of the oil guide member with a close fit. Since the heating member is designed with at least one plane and the plane is wound towards an outer surface of the oil guide member, the contact area between the heating member and the oil guide member is increased so that the amount of atomization generated per unit time is improved, the atomization effect is improved, and user experience is enhanced.

Owner:KIMREE HI TECH

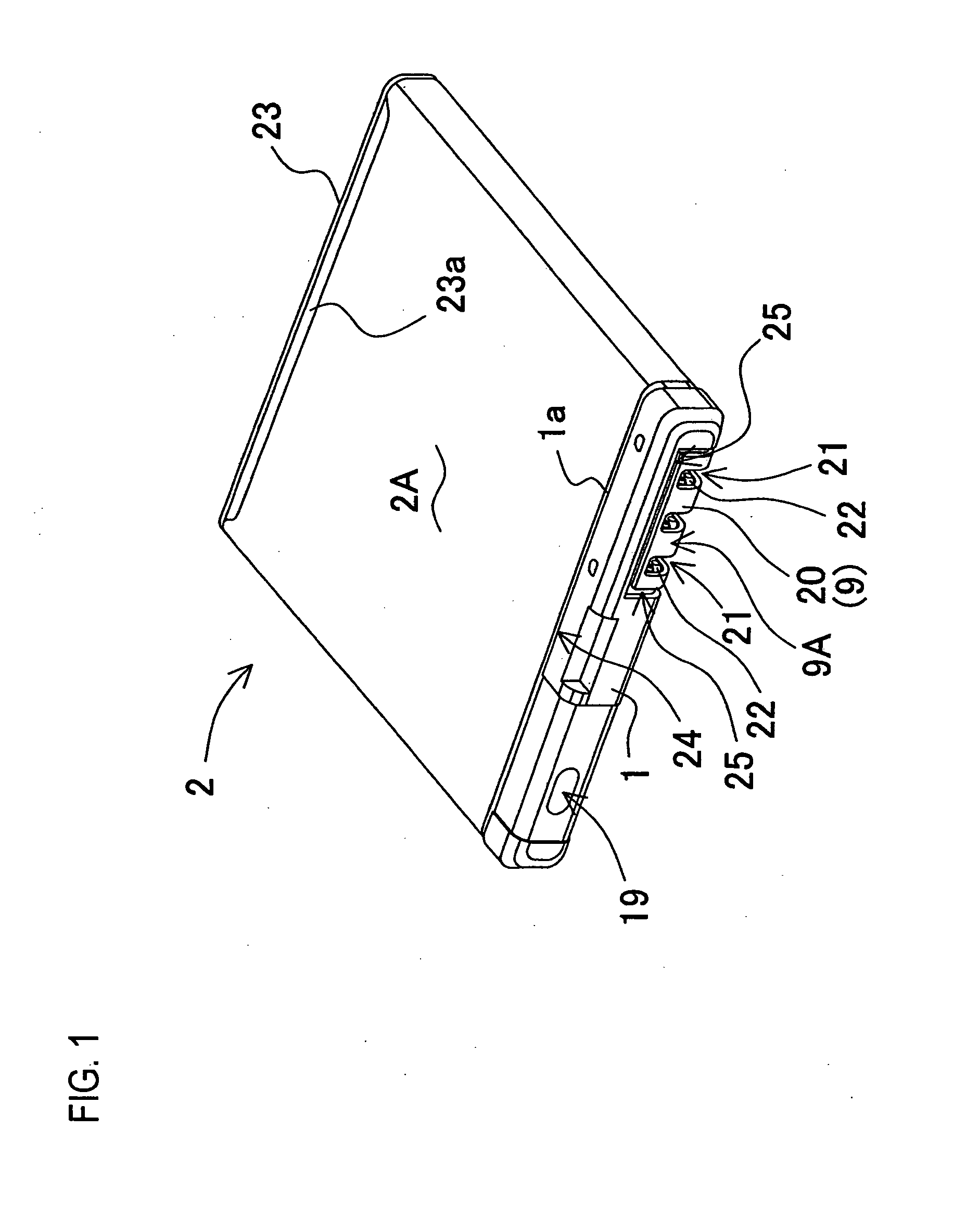

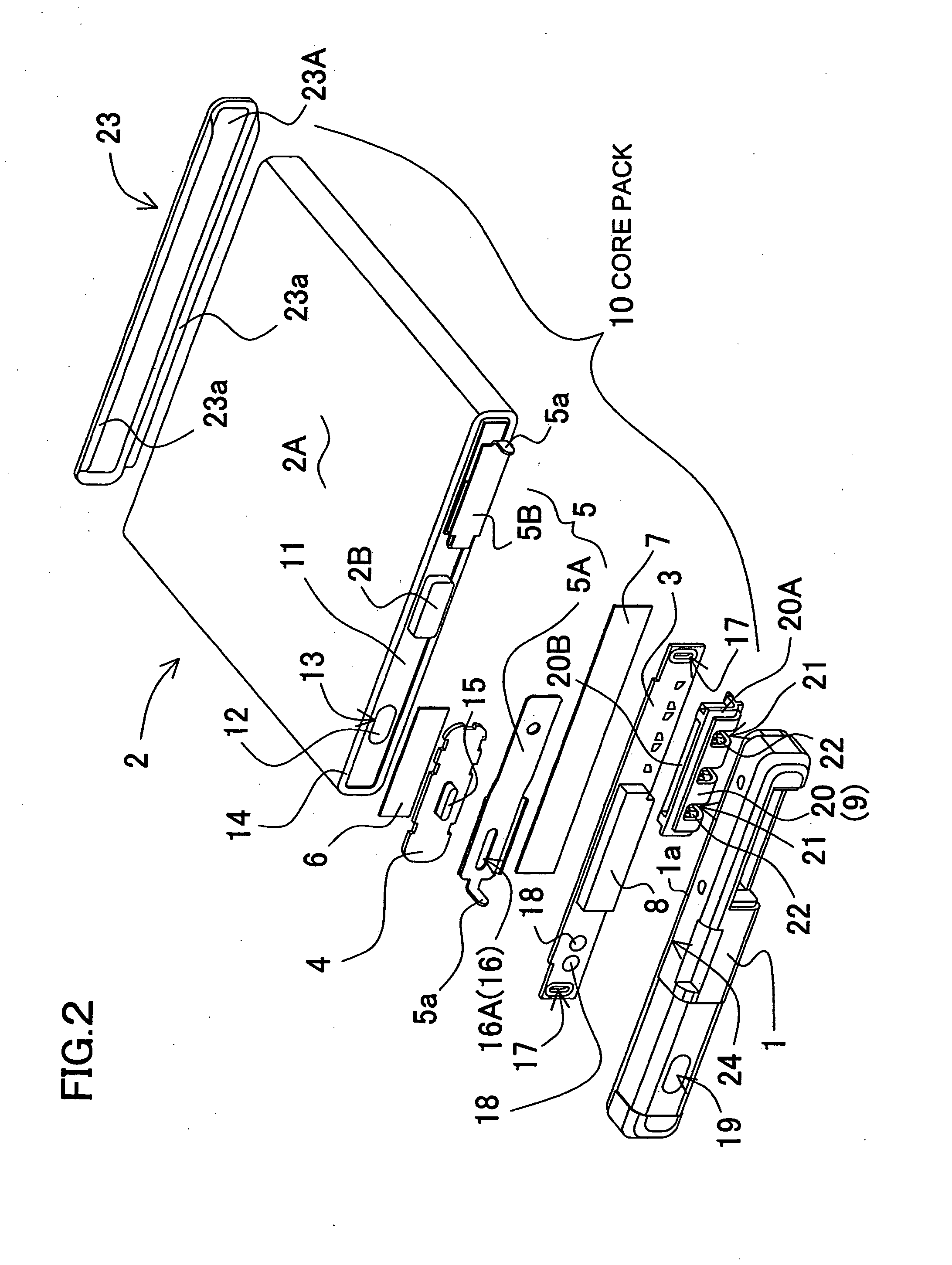

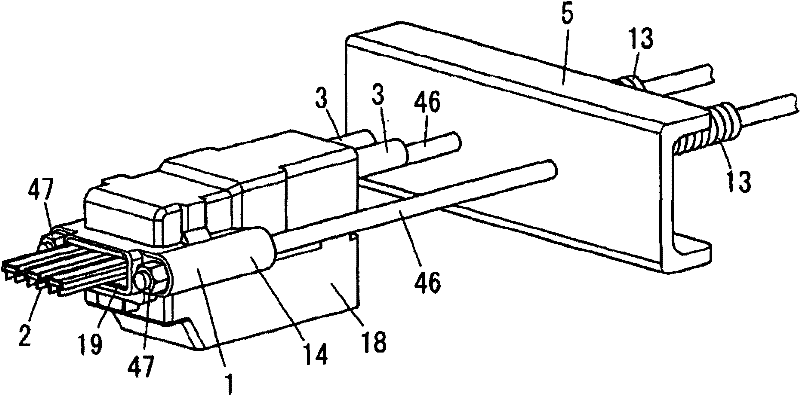

Battery pack

InactiveUS20080152994A1Avoid overwritingPoor contactBatteries circuit arrangementsFinal product manufacturePlastic materialsEngineering

In a battery pack, a battery core pack having a connector is inserted into a resin molded portion which is formed of a plastic material. The battery core pack includes a rechargeable unit cell, a circuit board electrically connected to the unit cell, and a connector fixed to the circuit board. The connector incorporates a contact point in a connector casing which is formed of an insulation material, and the connector casing is inserted into the resin molded portion so as to partially appear to a surface of the resin molded portion. Further, the battery pack is provided with a sealing groove at a boundary between the connector casing and the resin molded portion, along a peripheral edge of an exposed portion of the connector, appearing outside the resin molded portion.

Owner:SANYO ELECTRIC CO LTD

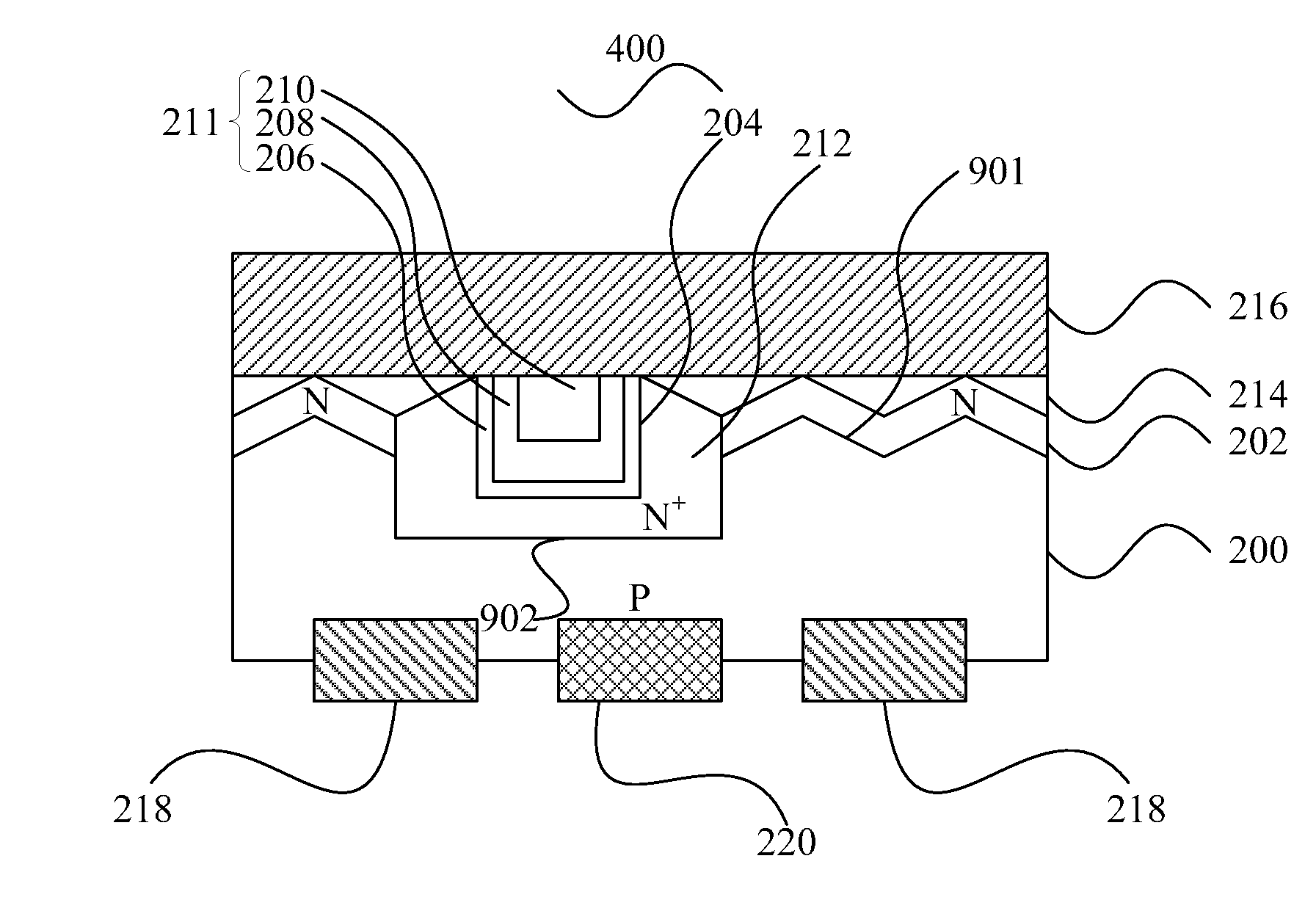

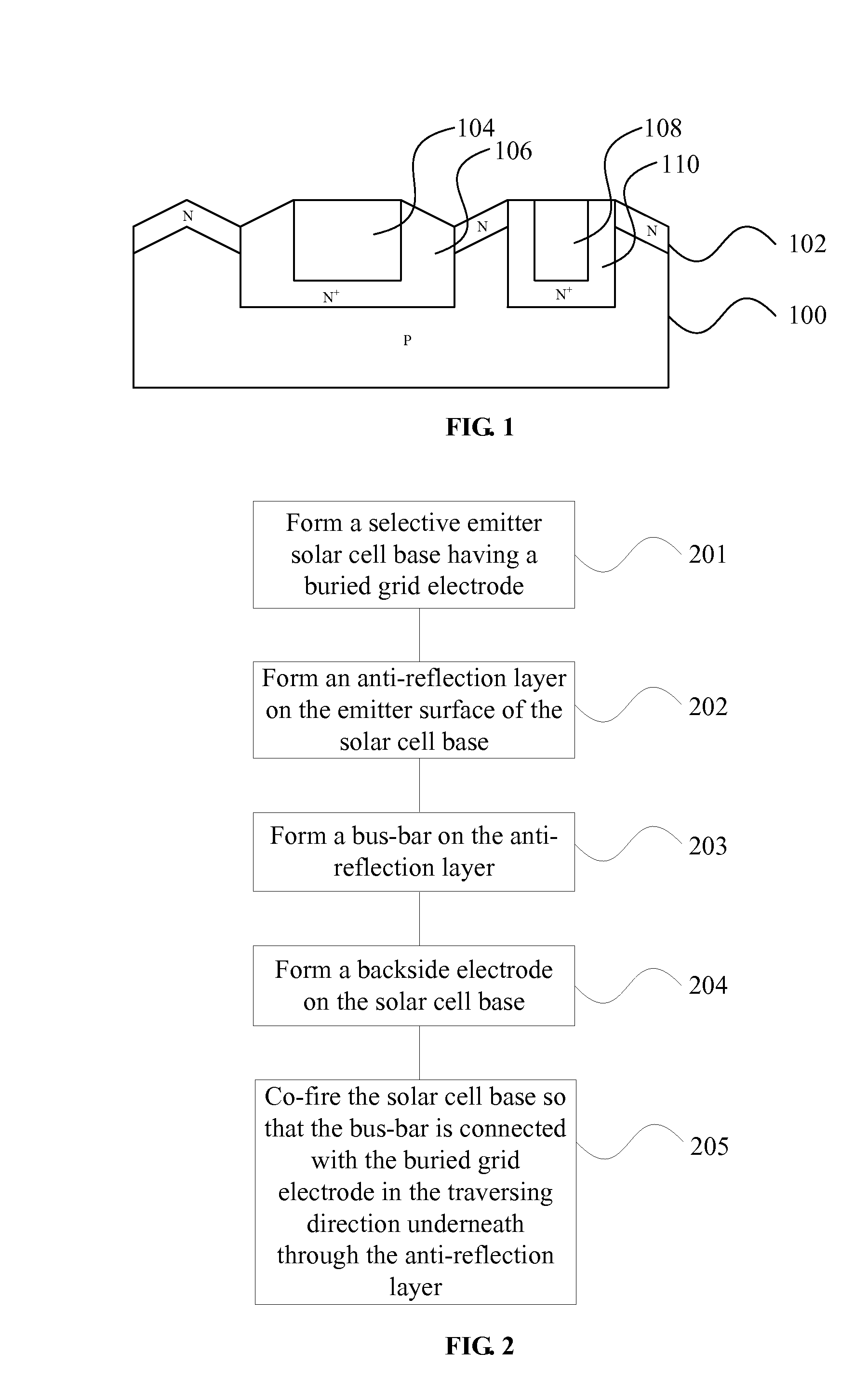

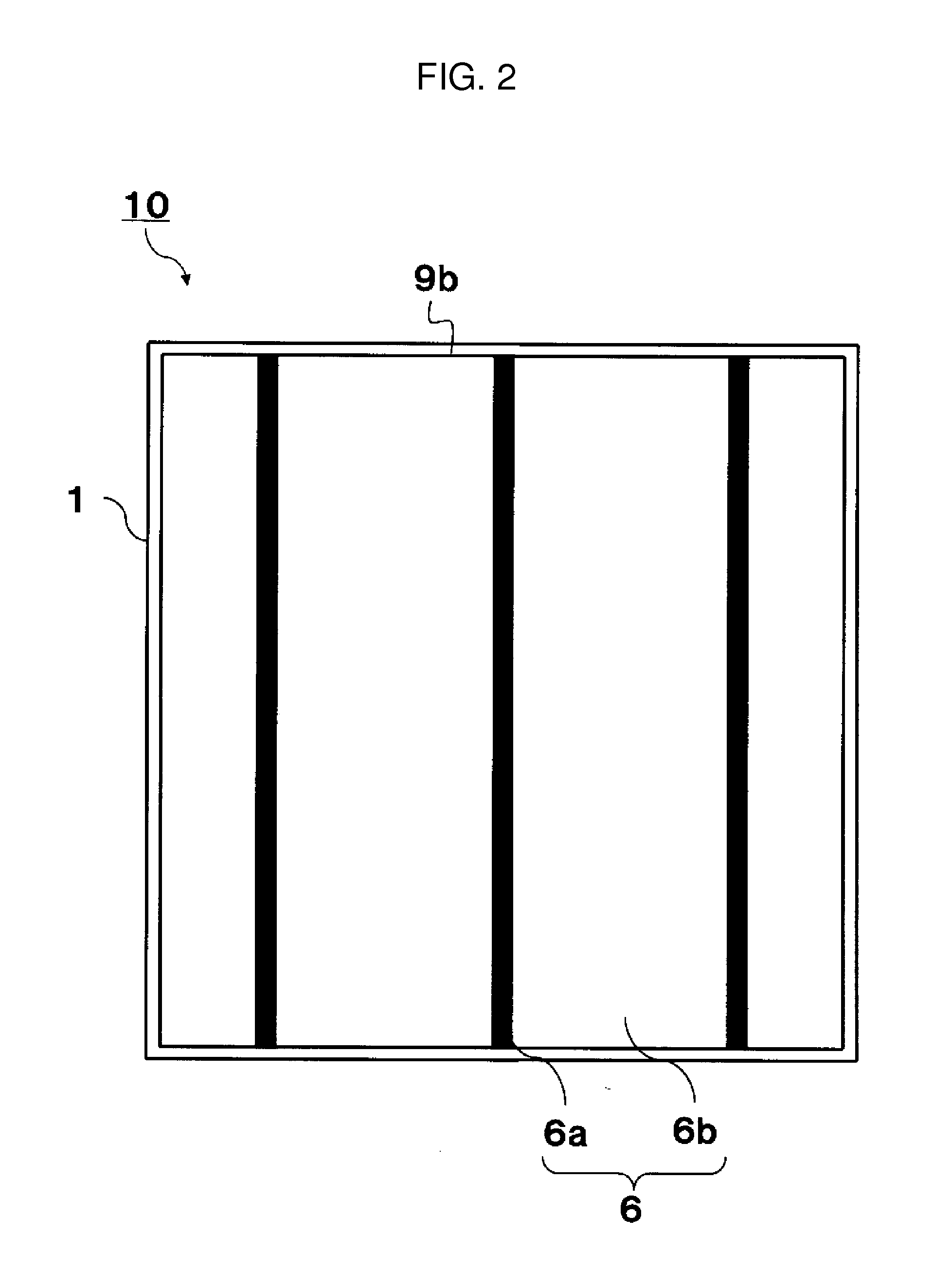

Selective Emitter Solar Cell and Fabrication Method Thereof

InactiveUS20100037952A1Improve conversion efficiencyReduce widthFinal product manufactureSemiconductor/solid-state device manufacturingTO-18Solar cell

A fabrication method of a selective emitter solar cell, including: forming a selective emitter solar cell base having a buried grid electrode; forming an anti-reflection layer on the emitter surface of the solar cell base; forming a bus-bar on the anti-reflection layer; and connecting the buried grid electrode with the bus-bar in the traversing direction underneath through the anti-reflection layer. Accordingly, the invention provides a selective emitter solar cell. With the method of the invention, emitters and bus-bars are made separately, the width of the emitters can be reduced according to actual needs, the area that is unnecessarily taken may be reduced, the effective area for a solar cell panel to receive sunlight may be increased. The invention improves conversion efficiency of a selective emitter solar cell panel from 16.5% to 18% or more.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Method and apparatus for monitoring emotion in an interactive network

ActiveUS8700009B2Improve detection and monitoringReduce artifactsService provisioningSpecial service for subscribersEmotional arousalData shipping

Embodiments of the invention provide a method, devices, and system for monitoring and sharing emotion-related data from one or more persons connected via the internet. An emotion monitoring device (EMD) measures physiological signals obtained from biosensors and computes emotion states relating to emotional arousal and valence. Various signal processing methods are employed to reduce artifact and improve the detection of emotional states. The EMD communicates the emotion data to an internet server via a wireless network. The internet server transmits the emotion data to other persons equipped with an EMD. Their emotion data similarly is obtained and shared with others. The networked emotion data can used to enrich online, community experiences such as games and social networks. An implementation of an EMD based on a smart phone enables emotion data to be monitored in wide area, mobile environment. The biosensors can be integrated into the casing or a cover for the mobile phone.

Owner:THE VISTA GRP LLC

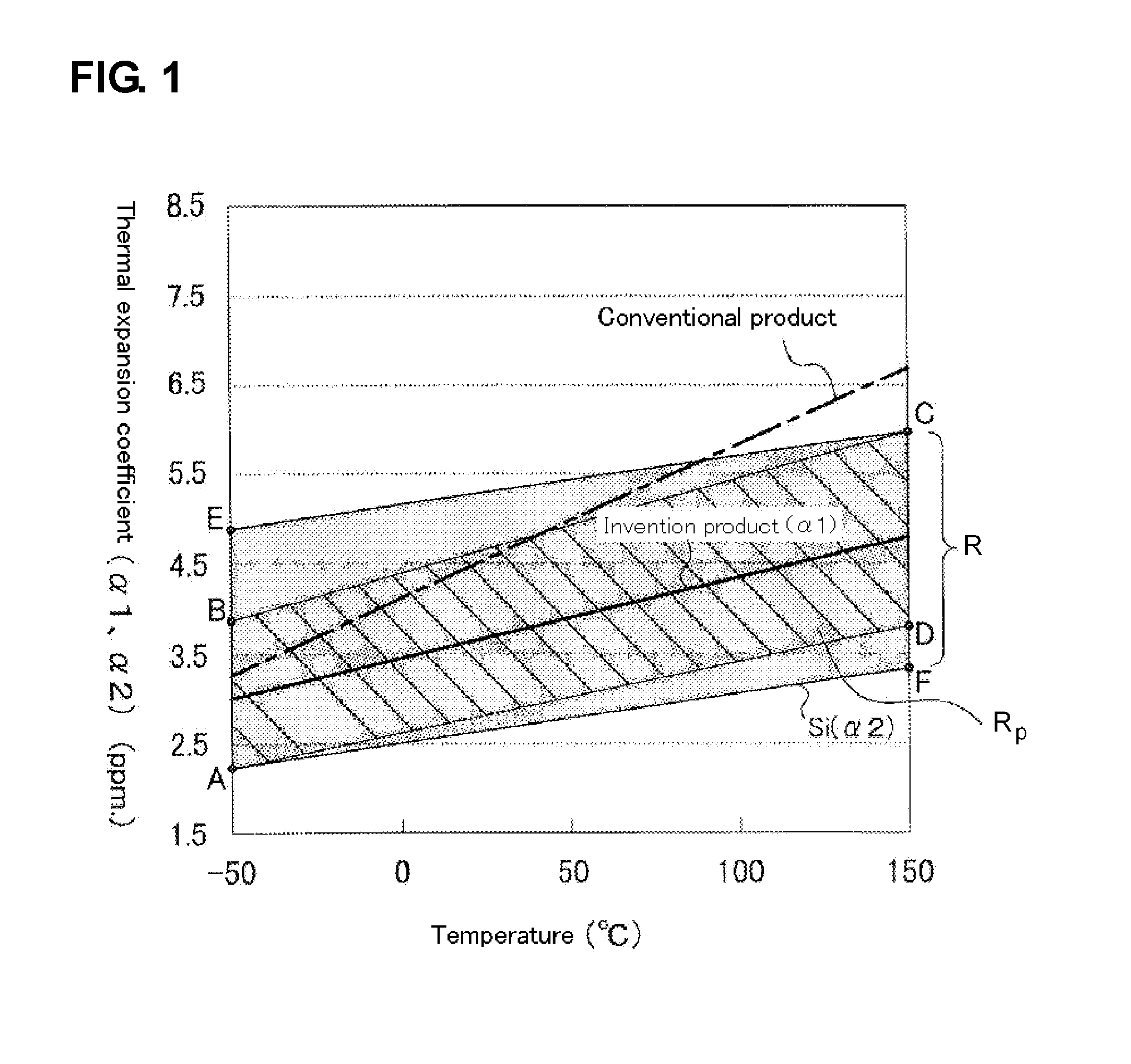

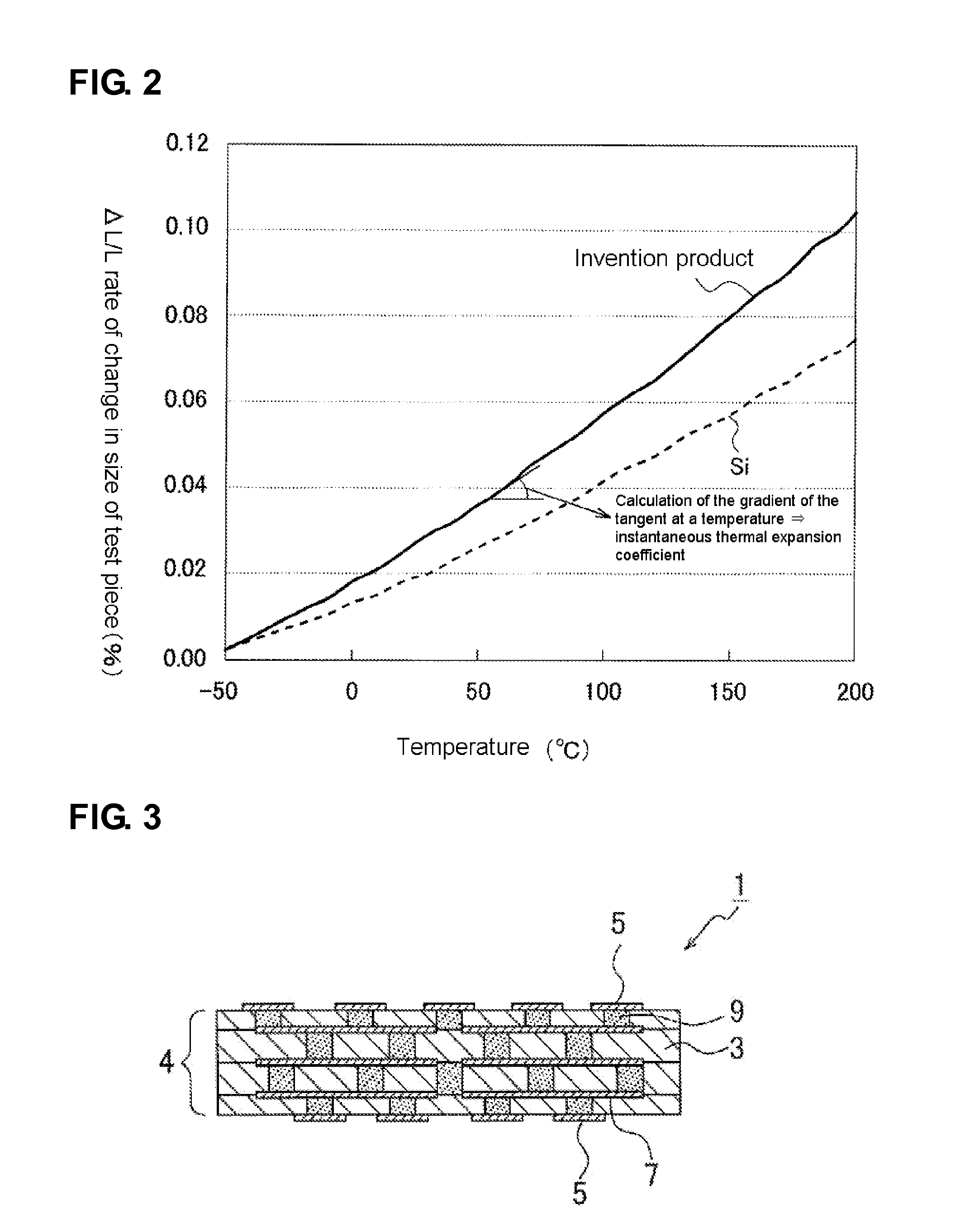

Electrical inspection substrate unit and manufacturing method therefore

ActiveUS20090321114A1Improve electrical reliabilityHigh mechanical strengthElectrical measurement instrument detailsPrinted circuit aspectsAlkali metal oxideMullite

Owner:NGK SPARK PLUG CO LTD

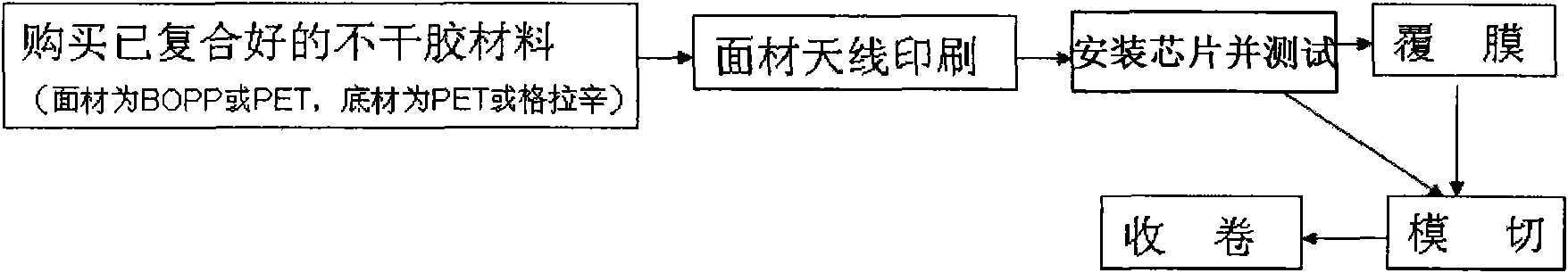

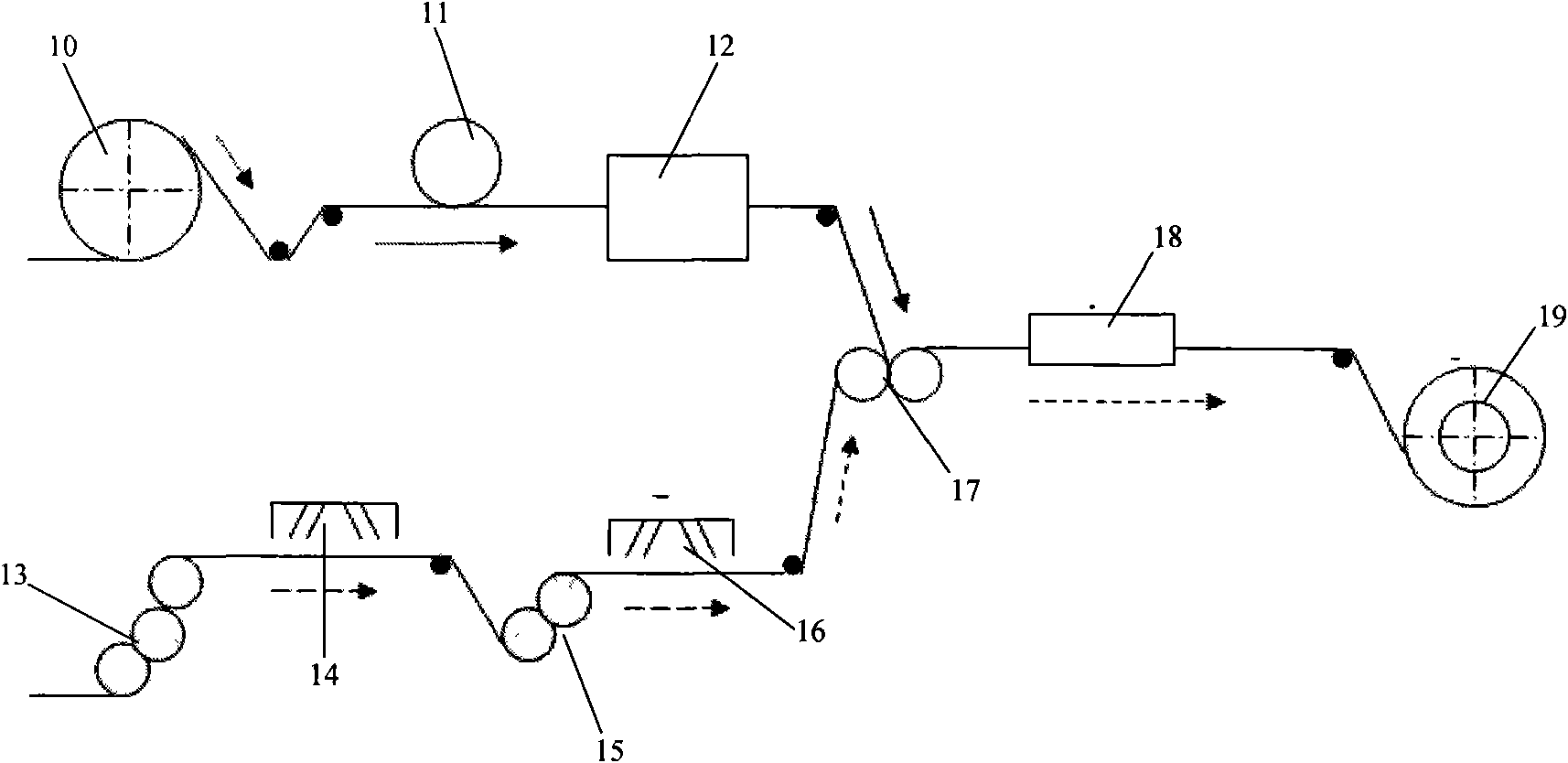

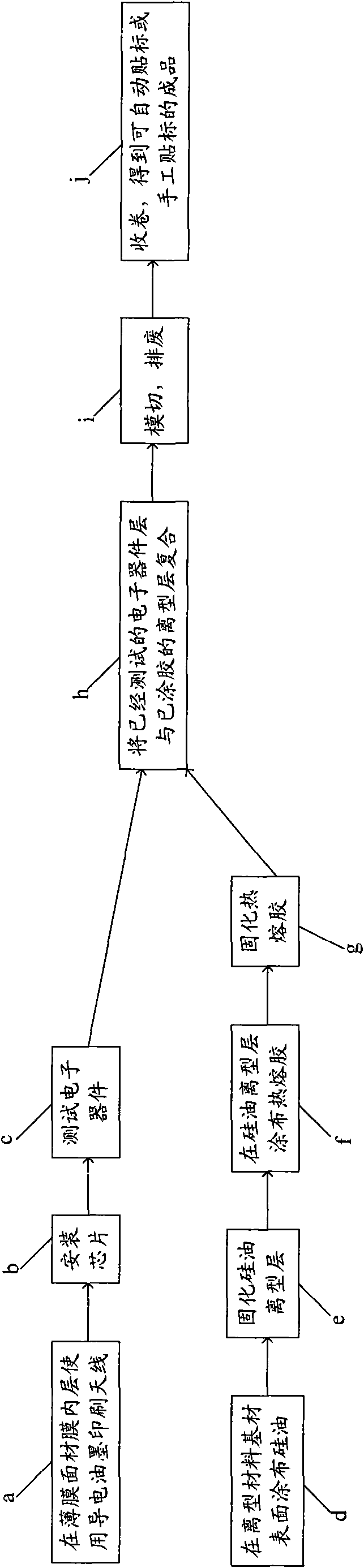

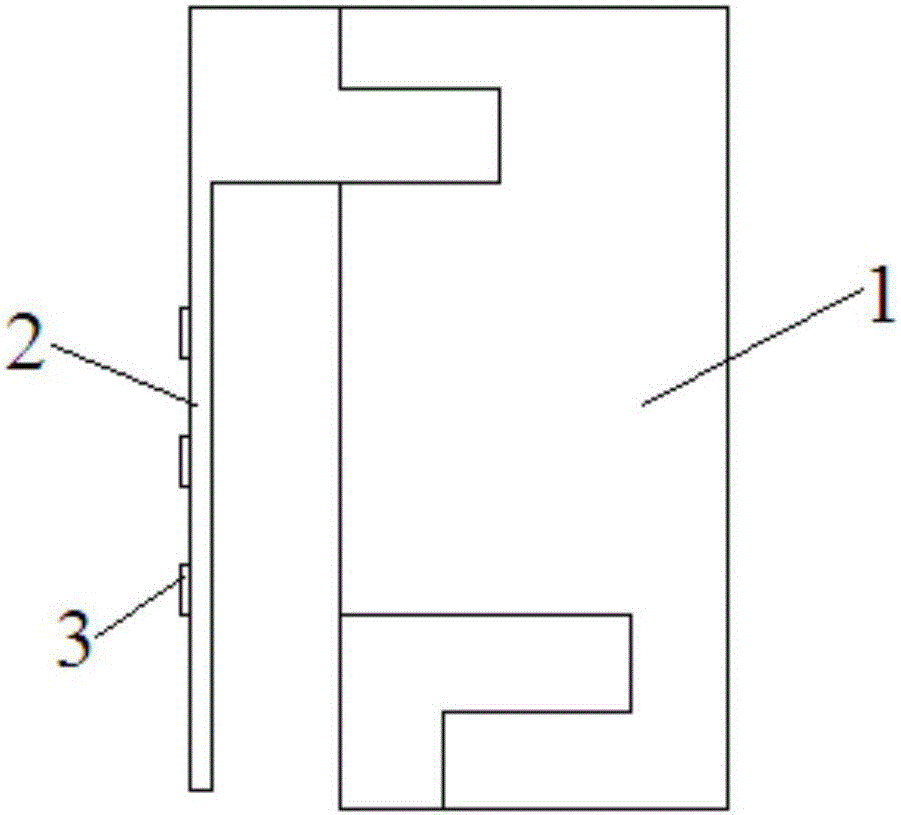

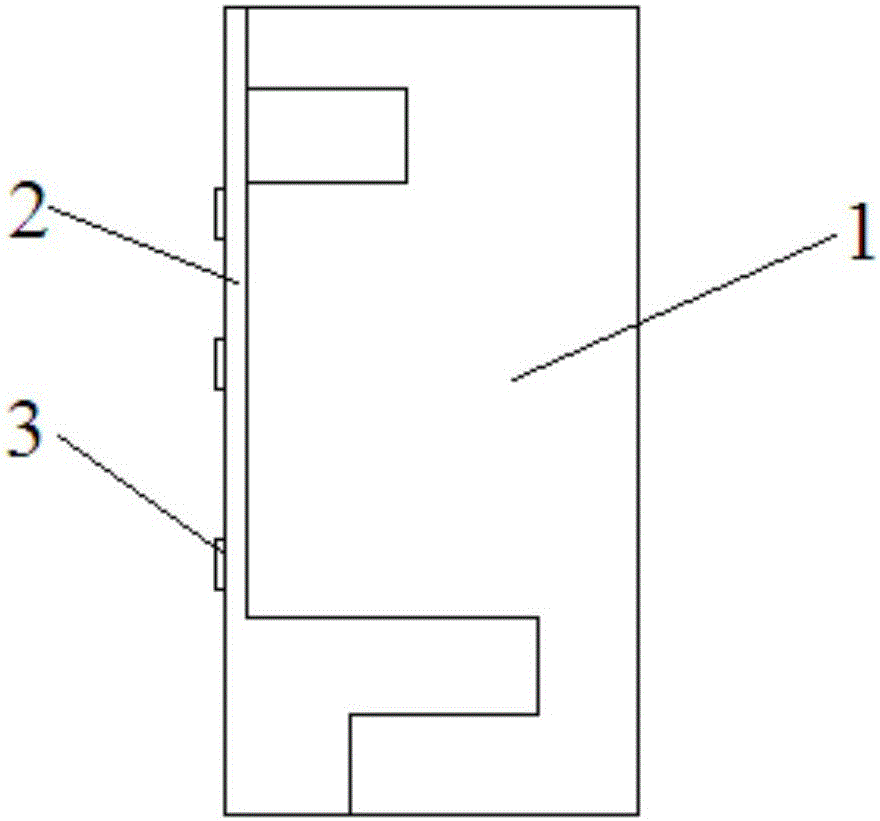

Manufacturing method and system of radio frequency self-adhesive label

ActiveCN101877072AAvoid scratchesPrevent oxidationSemiconductor/solid-state device manufacturingRecord carriers used with machinesEngineeringSilicone oil

The invention relates to a manufacturing method and a system of a radio frequency self-adhesive label, and the manufacturing method of the radio frequency self-adhesive label comprises the following steps: a) using conductive ink to print an antenna on an inner layer of a surface material film of a thin film; b) mounting a chip; c) testing an electronic device; d) coating silicone oil on the surface of a release material substrate; e) curing a silicone oil release layer; f) coating hot melt adhesive on the silicone oil release layer; g) curing the hot melt adhesive; h) compounding the tested electronic device layer with the release layer coated with the adhesive; i) carrying out die cutting and waste discharge; and j) taking up and obtaining a finished product which can be stuck automatically or manually. The manufacturing method of the radio frequency self-adhesive label can meet the technical requirements of the market on the radio frequency self-adhesive label, has significant advantages in the aspects of manufacturing efficiency, product yield, durability and economy, and can solve the shortcomings of the existing process, and the popularization of the manufacturing method of the radio frequency self-adhesive label is conductive to the wide applications of the radio frequency technology.

Owner:浙江龙游道明光学有限公司

Suspension-type mobile socket

ActiveCN105048232ASimple structureReduce volumeCoupling contact membersTwo-part coupling devicesElectrical conductorEngineering

Owner:SHANUTEC (SHANGHAI) CO LTD

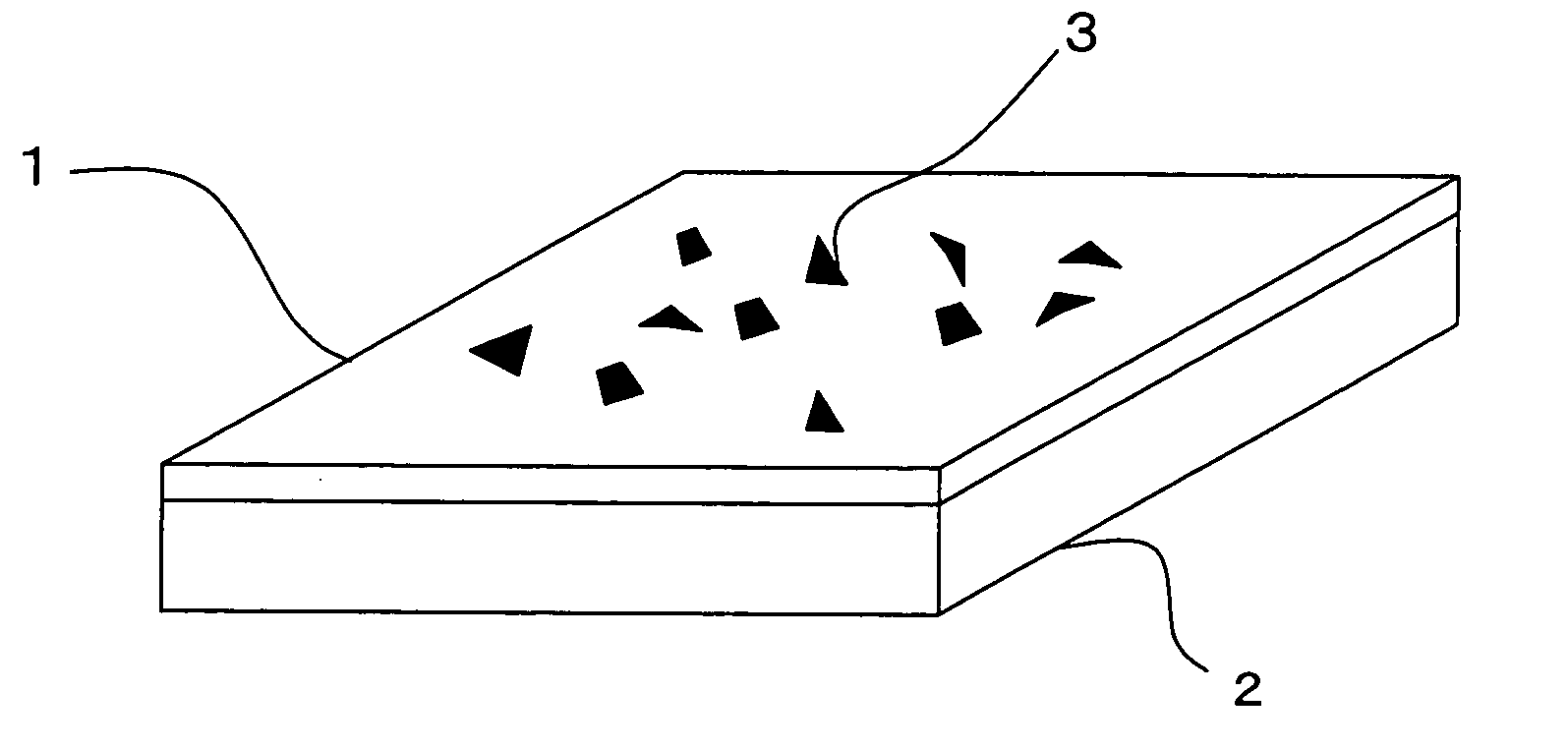

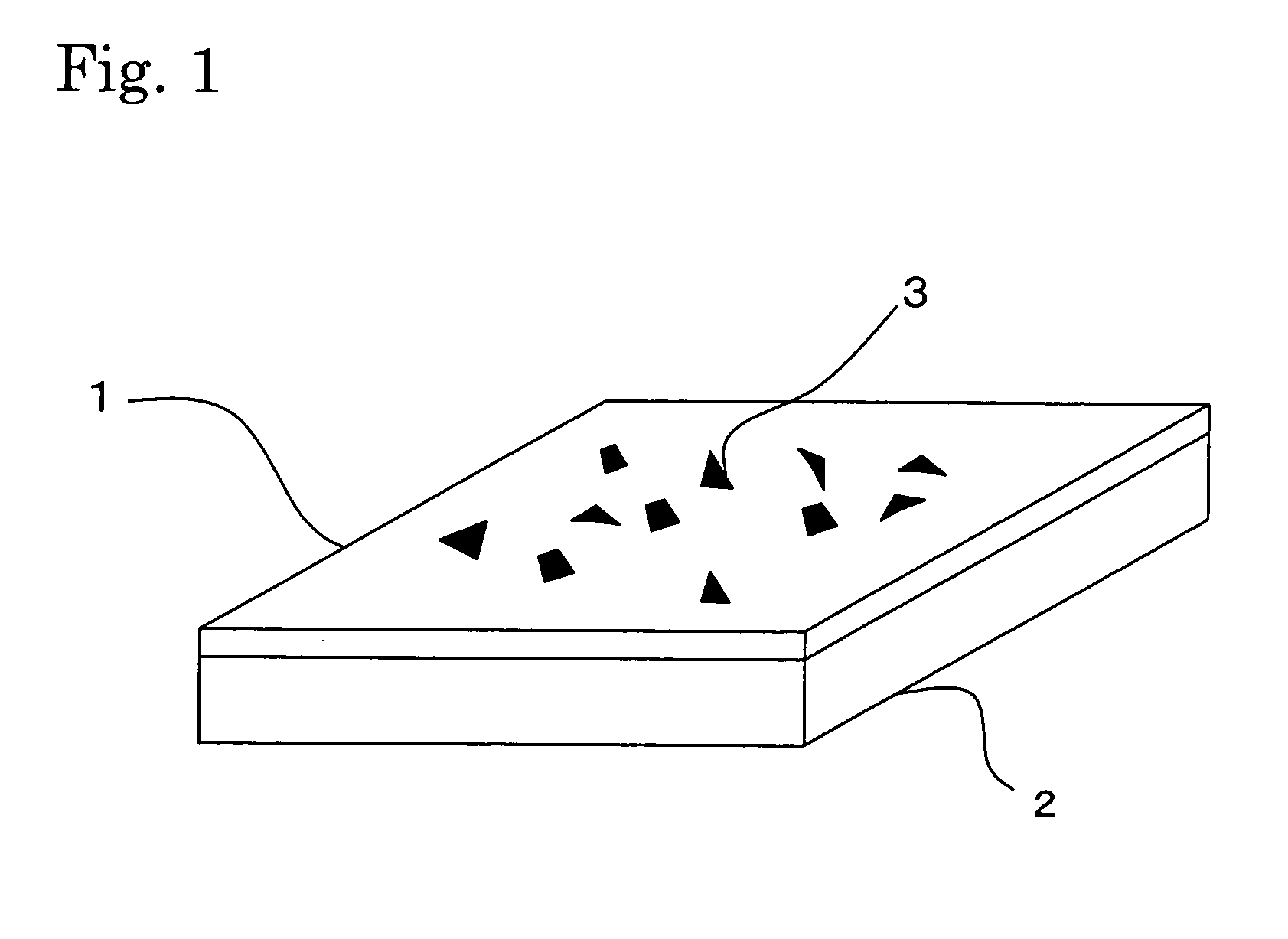

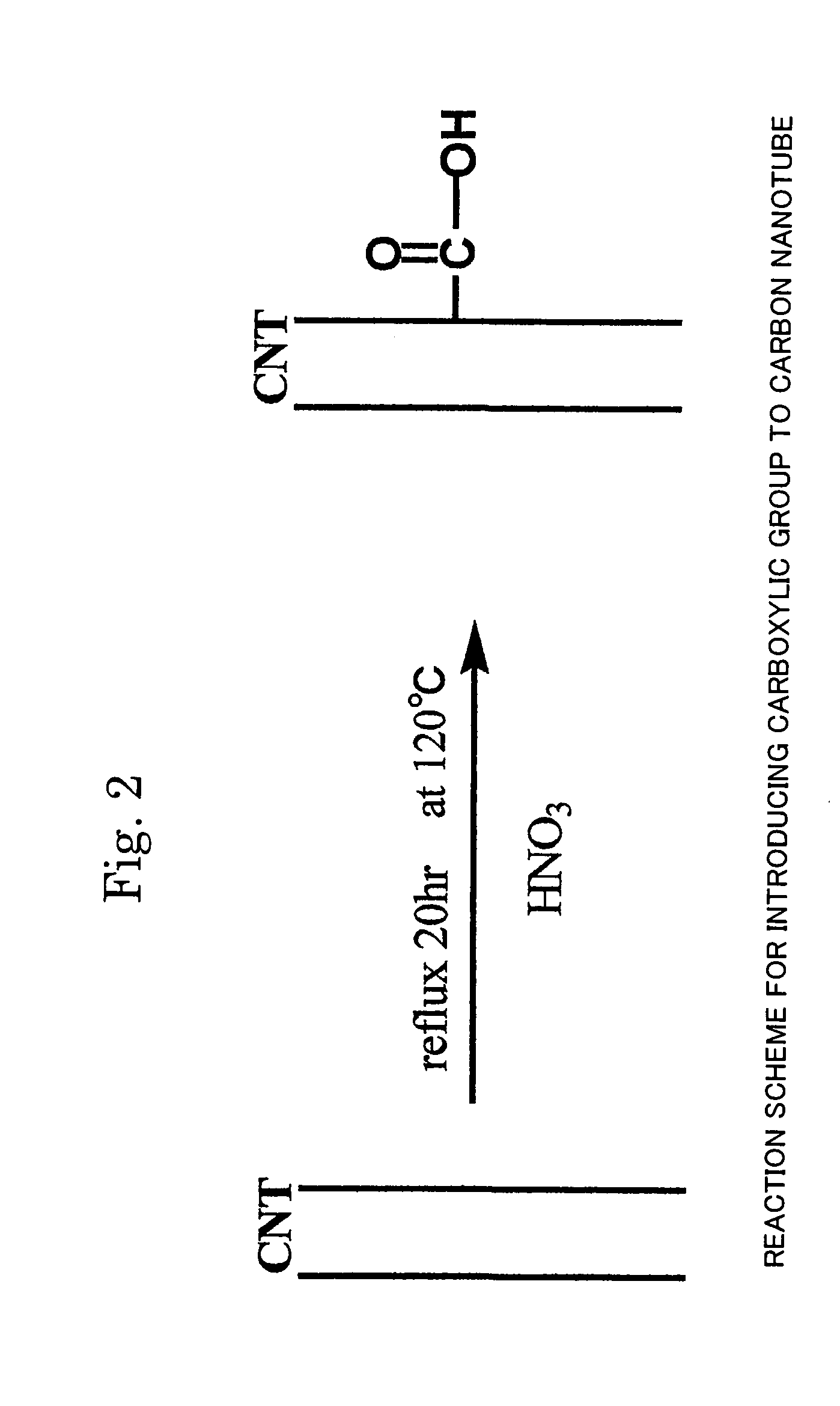

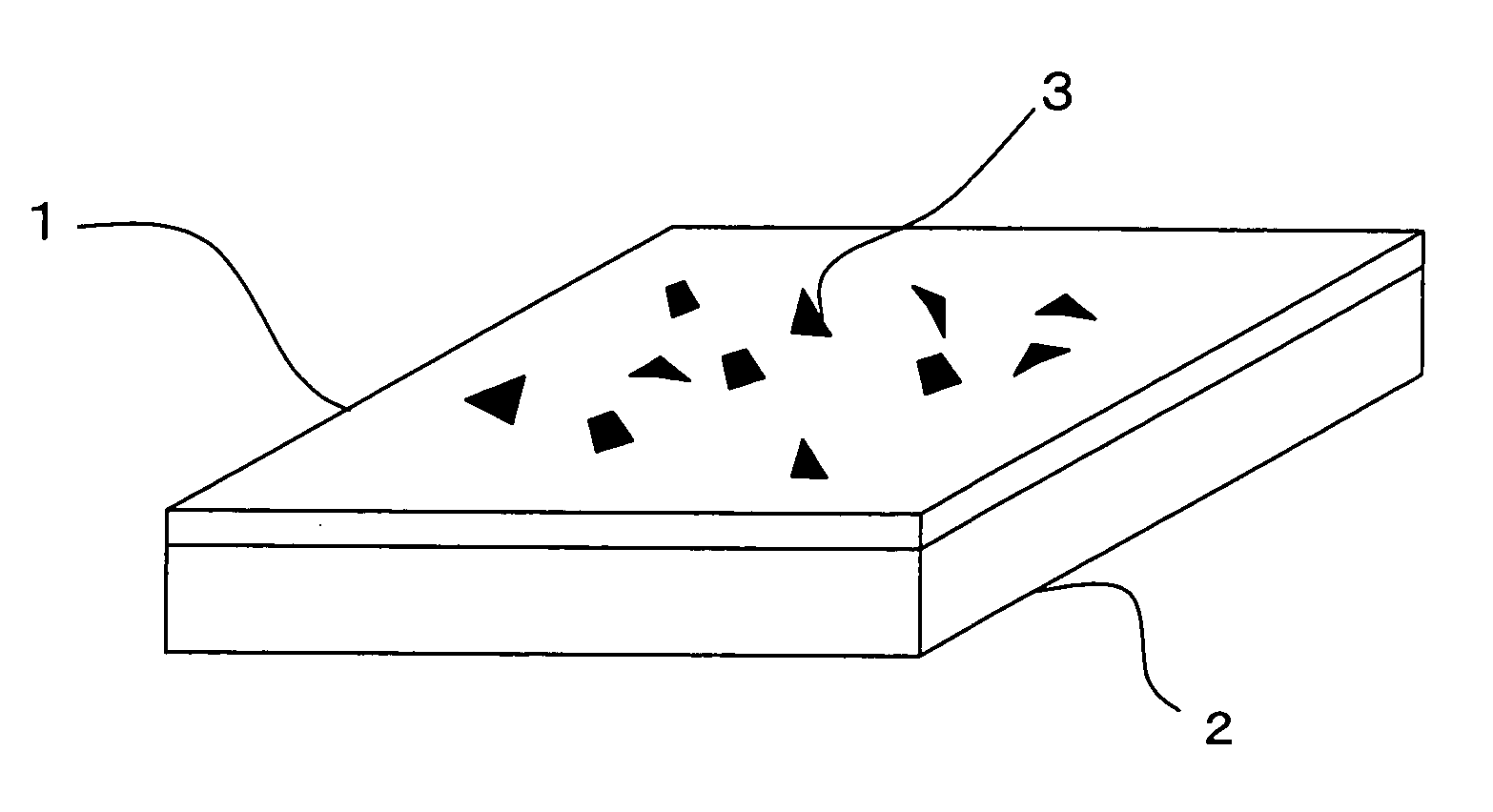

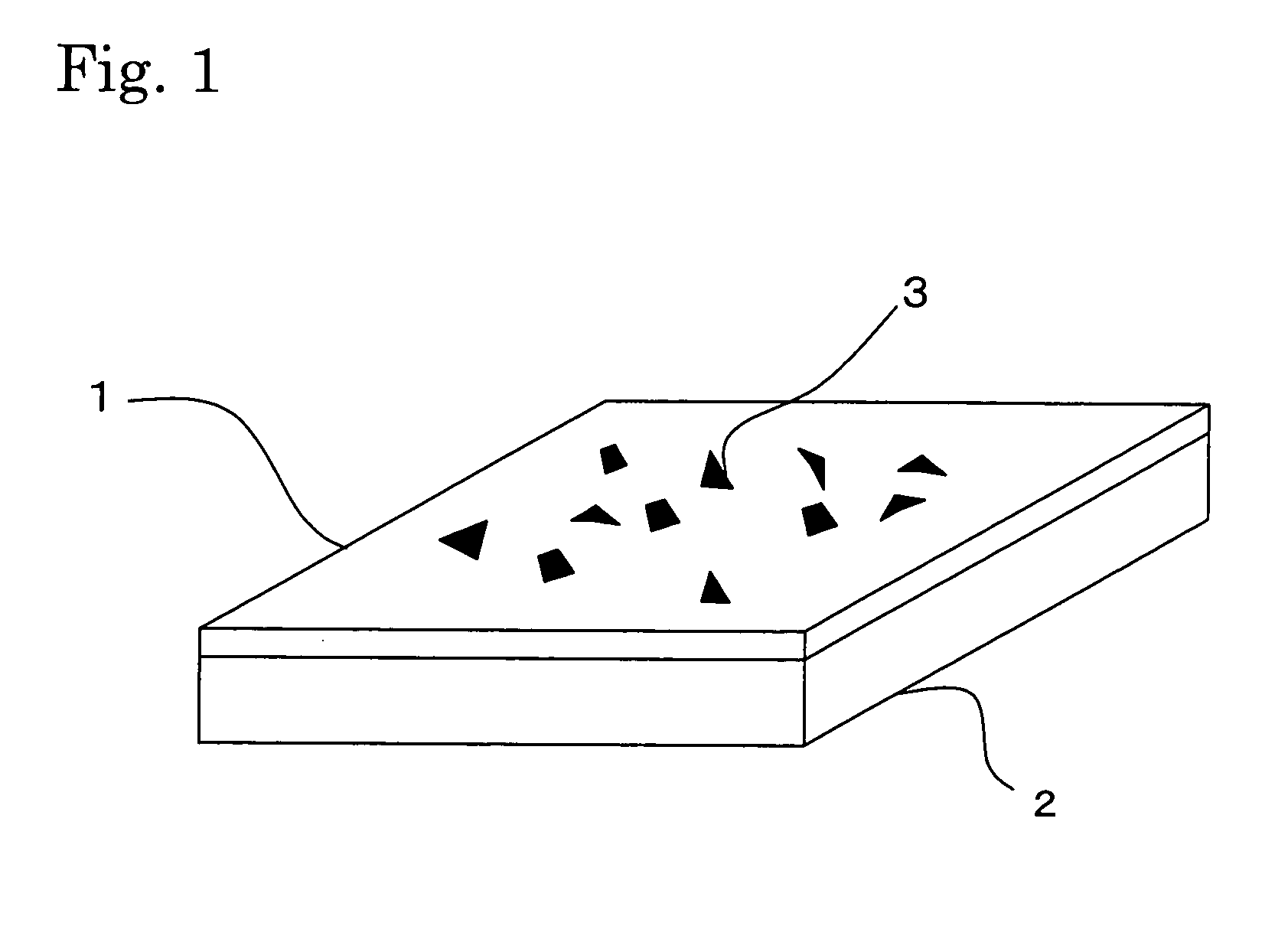

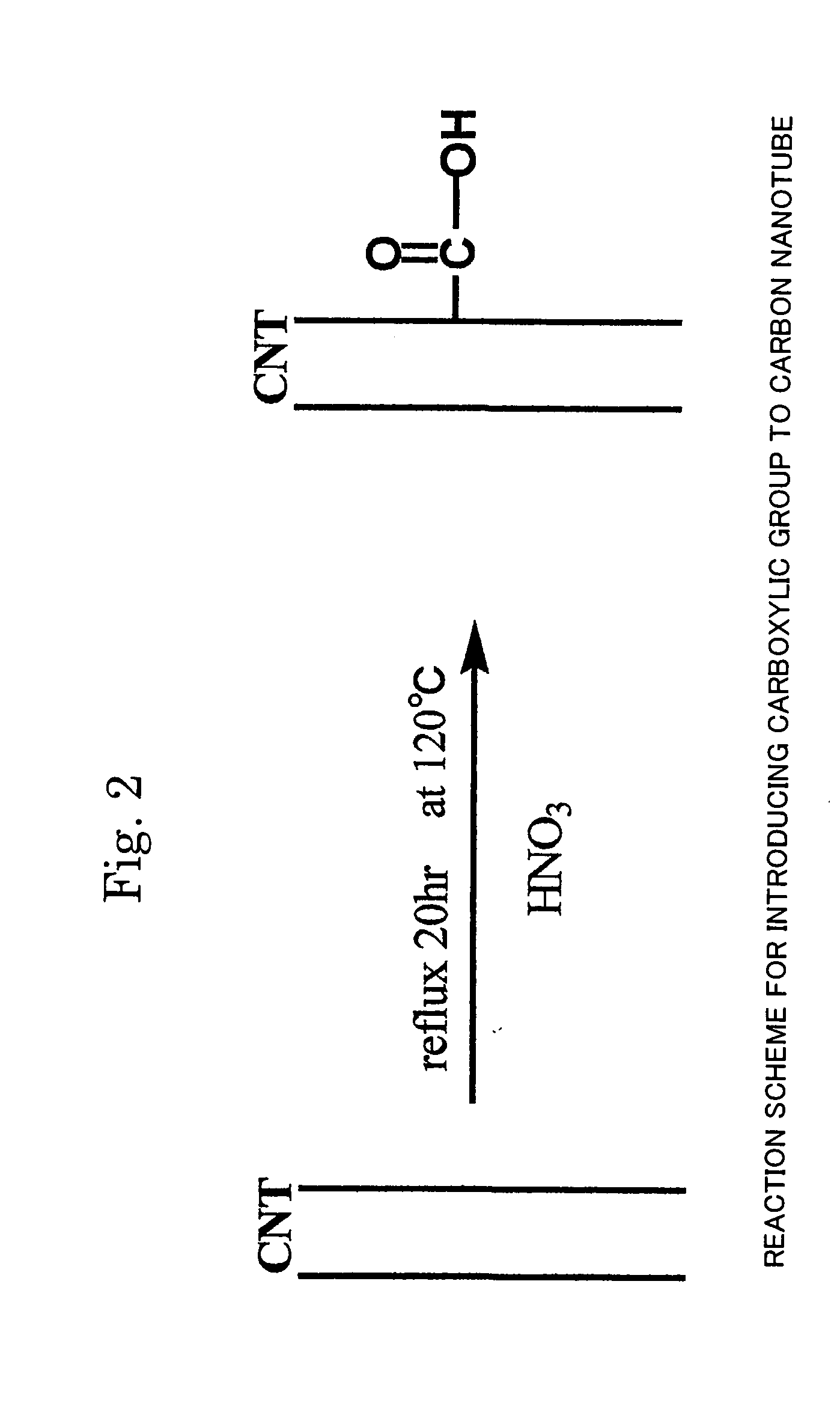

Gas decomposing unit, electrode for a fuel cell, and method of manufacturing the gas decomposing unit

InactiveUS7081429B2High mechanical strengthDeterioration of catalytic activityMaterial nanotechnologyGas treatmentCross-linkChemical Linkage

Provided are a gas decomposing unit and an electrode for a fuel cell capable of stably supporting a gas decomposing catalyst. A gas decomposing unit and an electrode for a fuel cell each including: a carbon nanotube structure having a mesh structure in which functional groups bonded to plural carbon nanotubes are chemically bonded to mutually cross-link the plural carbon nanotubes; and a gas decomposing catalyst supported on the carbon nanotube structure. A method of manufacturing a gas decomposing unit characterized by including: an applying step of applying, to the surface of a substrate, a solution containing plural carbon nanotubes to which functional groups are bonded; a cross-linking step of chemically bonding the functional groups to build a mesh structure in which the plural carbon nanotubes mutually cross-link; and a supporting step of forming the carbon nanotube structure supporting a gas decomposing catalyst.

Owner:FUJIFILM BUSINESS INNOVATION CORP

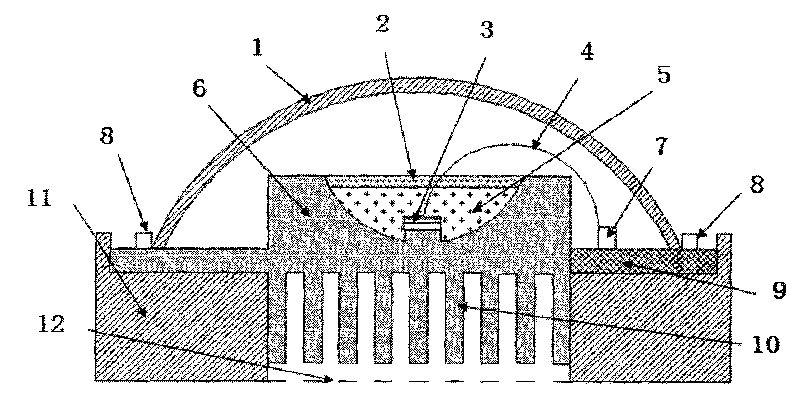

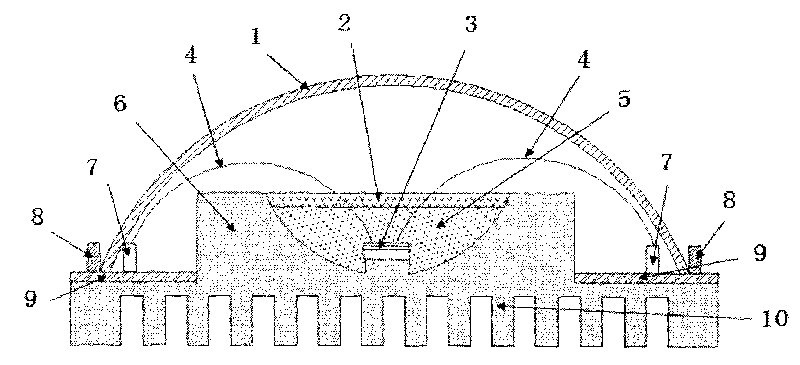

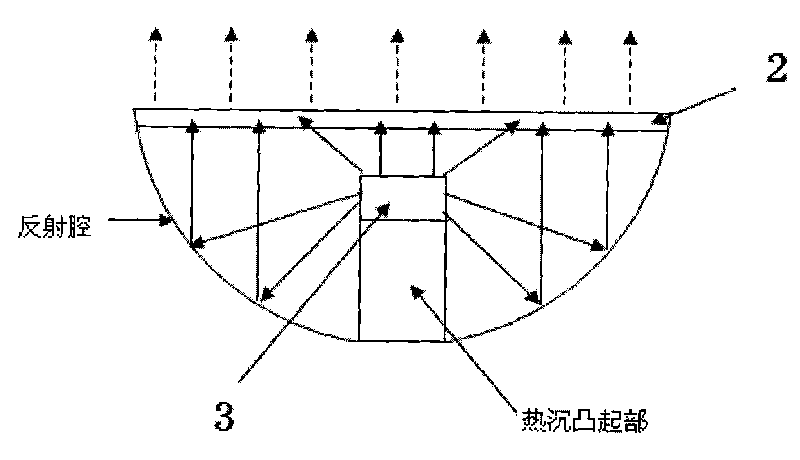

High-power LED heat-dissipation packaging structure

InactiveCN101696790AAvoid thermal quenchingImprove external quantum efficiencyPoint-like light sourceLighting heating/cooling arrangementsFluorescenceInverted t

The invention relates to a high-power LED packaging structure. The packaging structure is characterized in that an aluminum heat sink (6) is in the structure of an inverted T; a scalelike heat-dissipation plate (10) integrated with the aluminum heat sink (6) extends under the aluminum heat sink; an extending arm of the aluminum heat sink (6) is connected with a printed circuit board (9), the center of the aluminum heat sink (6) is provided with a semi-spherical surface concave cavity; a chip (3) is adhered to a lug boss on the inner bottom surface of the semi-spherical surface concave cavity; flexible silica gel (5) is packaged inside the semi-spherical surface concave cavity comprising the chip (3); and the top surface of the flexible silica gel (5) is coated with a fluorescent powder layer (2). The high-power LED packaging structure ensures that the heat of an LED can be dissipated quickly, thereby increasing the light-emitting stability and service life of high-power LEDs.

Owner:IRICO

Gas decomposing unit, electrode for a fuel cell, and method of manufacturing the gas decomposing unit

InactiveUS20050090388A1Stable chemical structureLengthMaterial nanotechnologyGas treatmentCross-linkFuel cells

Provided are a gas decomposing unit and an electrode for a fuel cell capable of stably supporting a gas decomposing catalyst. A gas decomposing unit and an electrode for a fuel cell each including: a carbon nanotube structure having a mesh structure in which functional groups bonded to plural carbon nanotubes are chemically bonded to mutually cross-link the plural carbon nanotubes; and a gas decomposing catalyst supported on the carbon nanotube structure. A method of manufacturing a gas decomposing unit characterized by including: an applying step of applying, to the surface of a substrate, a solution containing plural carbon nanotubes to which functional groups are bonded; a cross-linking step of chemically bonding the functional groups to build a mesh structure in which the plural carbon nanotubes mutually cross-link; and a supporting step of forming the carbon nanotube structure supporting a gas decomposing catalyst.

Owner:FUJIFILM BUSINESS INNOVATION CORP

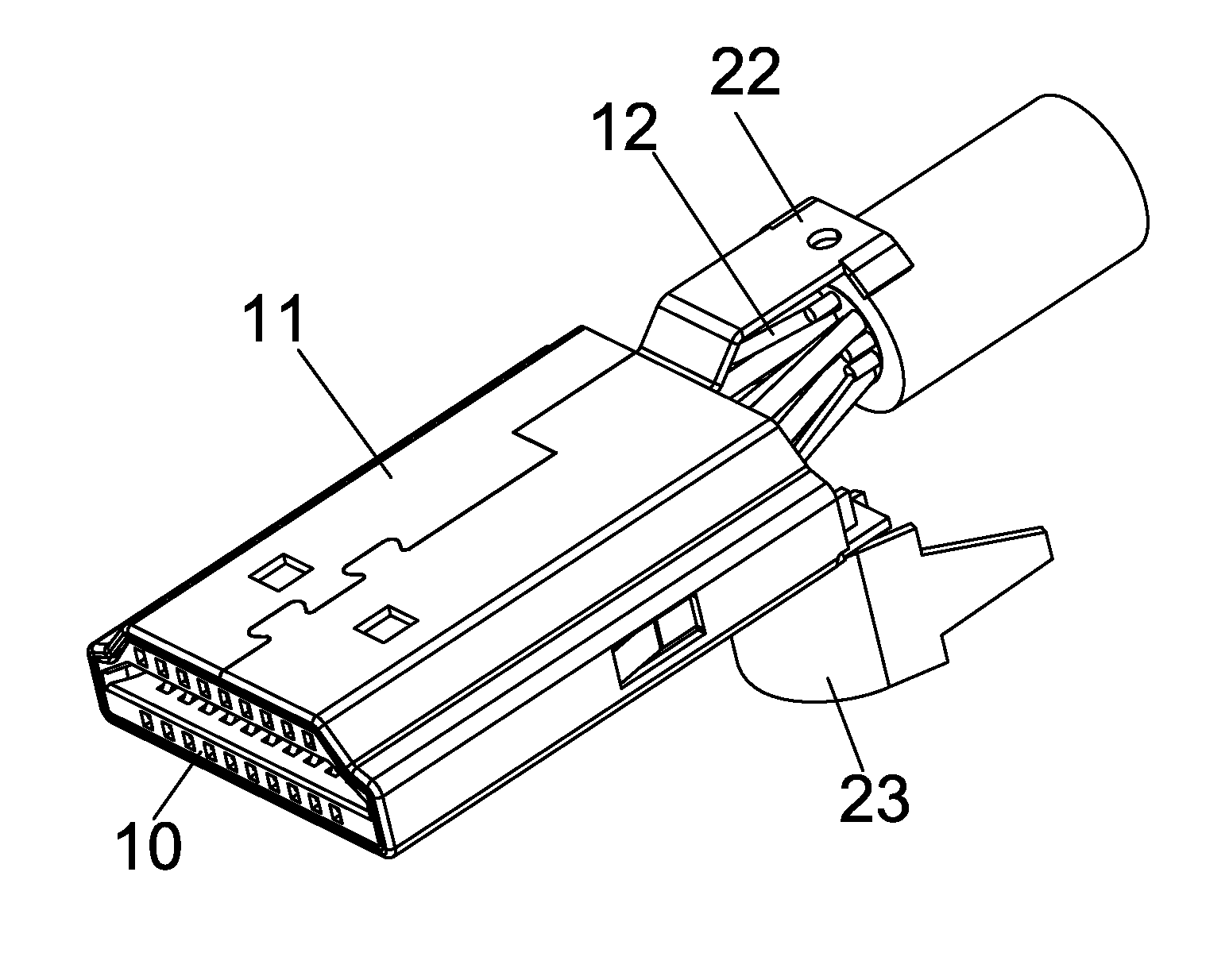

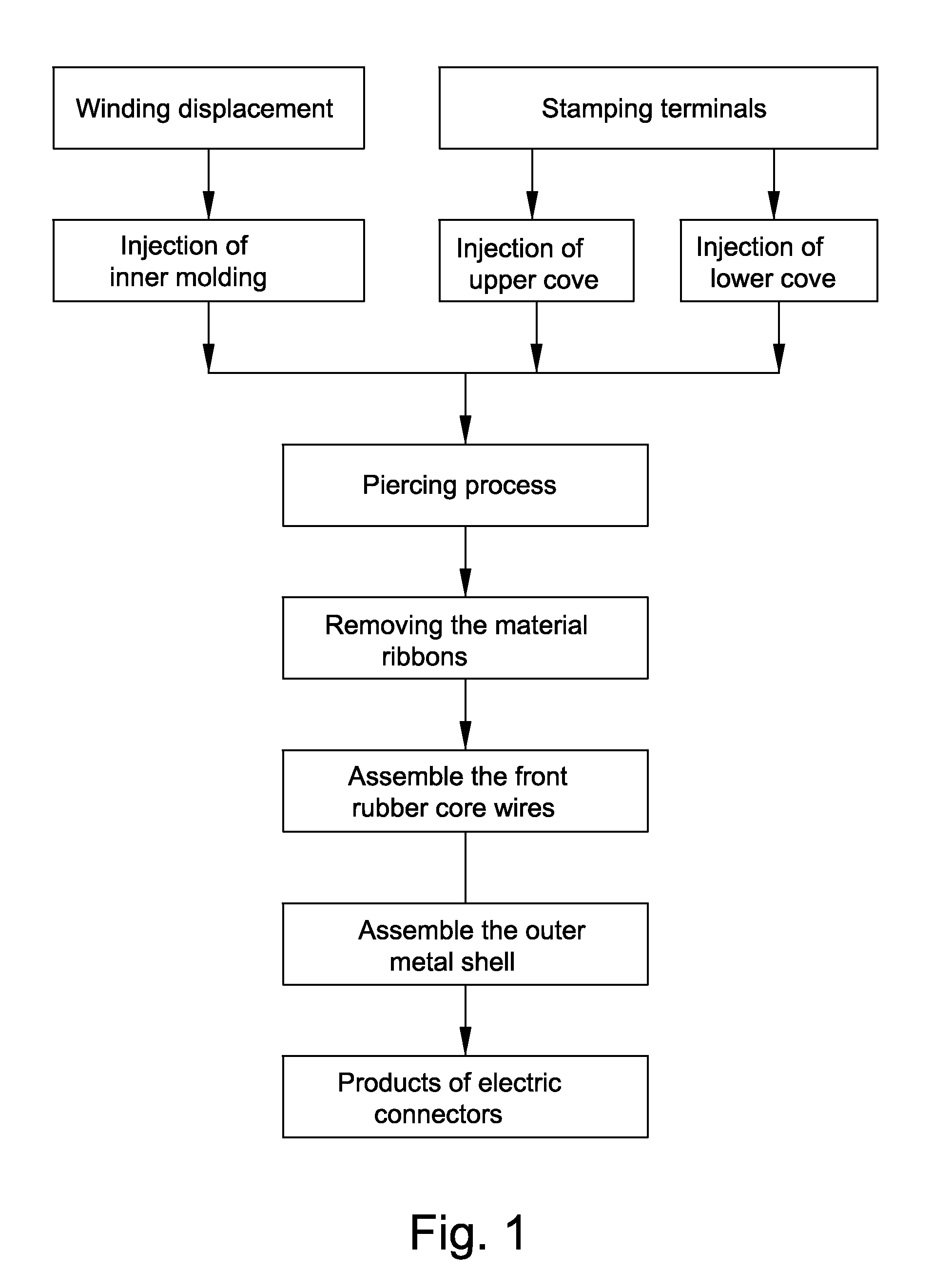

Piercing Terminal, Electric Connector and Their Production Process

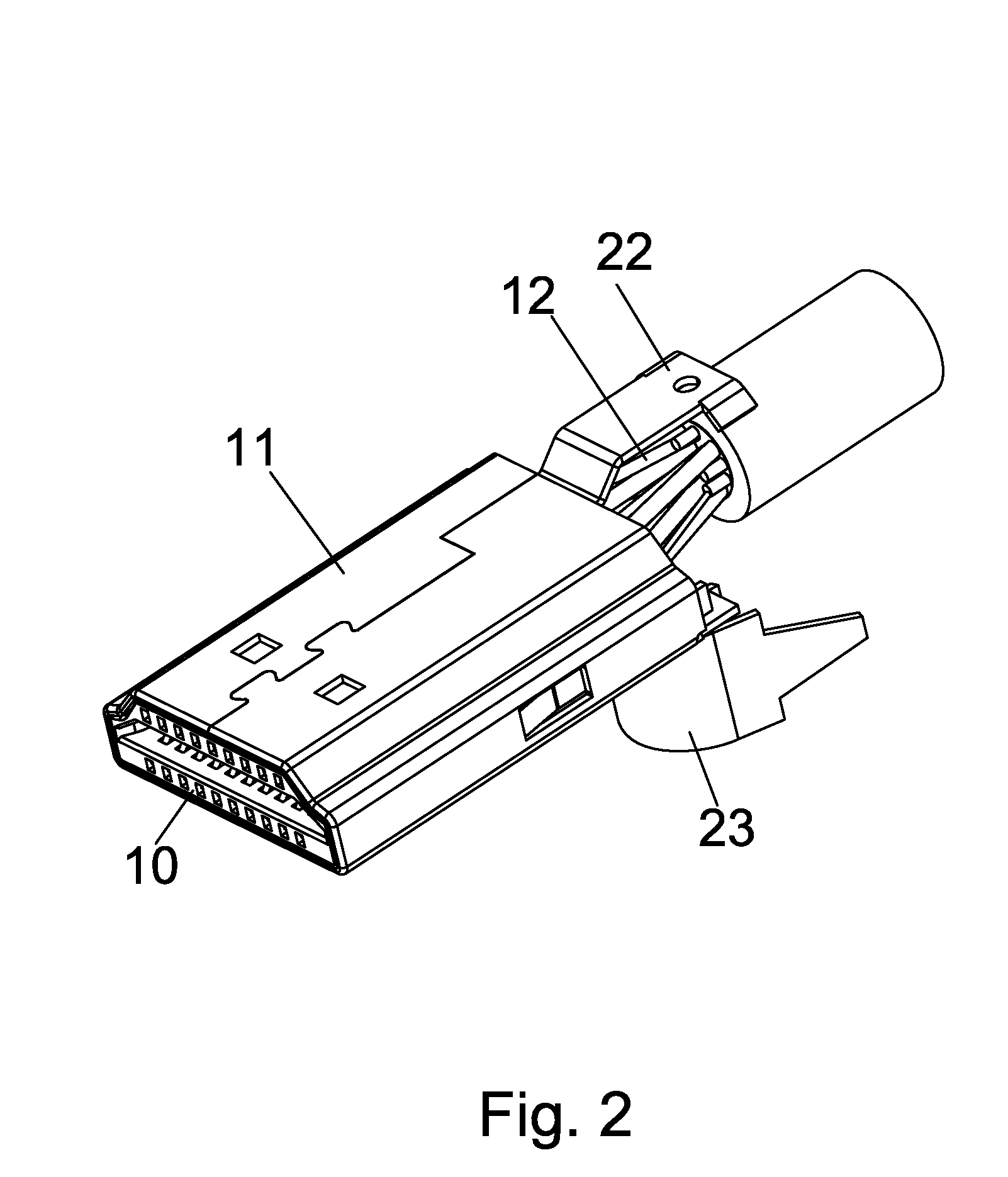

InactiveUS20100178794A1Low electric resistanceVarious problemContact member manufacturingContact member cases/bases manufactureElectricityHDMI

This invention is about the electric connector and its processing technique. More specifically, it involves terminals with puncture structure, electric connector and their processing technique. The processing technique herein includes stamping terminal processing, winding displacement processing, injection upper cover, injecting lower cover, piercing processing, removal of material ribbon, front glue chip assembly, assembly of outer metal shell. Among them, the upper cover and lower cover are injected and molded in the middle and rear of the corresponding terminals in array. The processing technique has tackled the problems as unstable contact, poor contact, high electric resistance and micromation which cannot be solved by the current existing electric connector. There should be at least two tusks whose tips are intertwined molded in the electric connector of piercing terminal. The tusks are the pyramid shape with a cambered surface in the inner side; it reduces the electric resistance of electric connector. The upper and lower covers of piercing HDMI electric connector are respectively molded in the arrayed terminals. The rear end of the terminal has molded piercing tusk. The electric connector has become smaller and lighter, improving its performance in every aspect significantly.

Owner:HSU CHING JEN

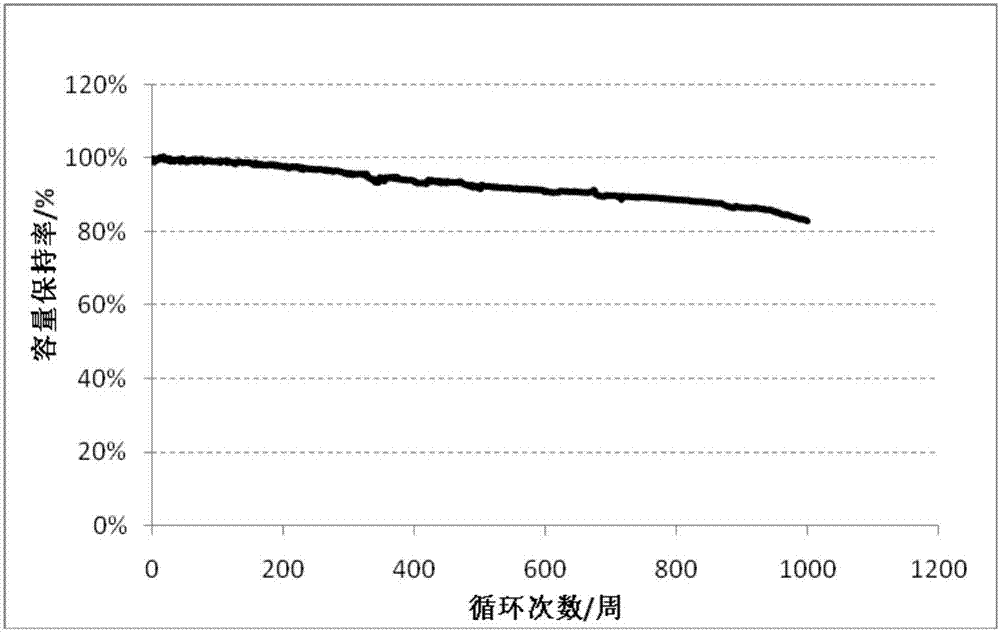

A negative electrode active material for a lithium ion battery, a preparing method thereof, a negative electrode plate of the lithium ion battery and the lithium ion battery

InactiveCN107482173AIncrease energy densityImprove cycle lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh energyBlack phosphorus

A negative electrode active material for a lithium ion battery is provided. The active material includes a composite formed by connecting a carbon material and black phosphorus through C-P bonds. The carbon material and the black phosphorus in the active material form the C-P bonds, thus ensuring tight contact between the carbon material and the black phosphorus in charge-discharge processes, and avoiding bad contact with the carbon material and a current collector when the black phosphorus is expanded. In addition, the carbon material is high in flexibility so that expansion of the black phosphorus can be relieved in the aspect of volume. The invention also provides a preparing method of the active material. The method includes mixing the carbon material and the black phosphorus, and then subjecting the mixture to ball milling at a ball milling speed of 300-700 r / min for 10-20 h, wherein the carbon material and the black phosphorus are connected through the C-P bonds to form the composite, and then the active material is formed. The method is simple and easy to operate. The invention also provides a negative electrode plate of the lithium ion battery and the lithium ion battery. The lithium ion battery has extremely high energy density and long cyclic lifetime.

Owner:SHENZHEN UNIV

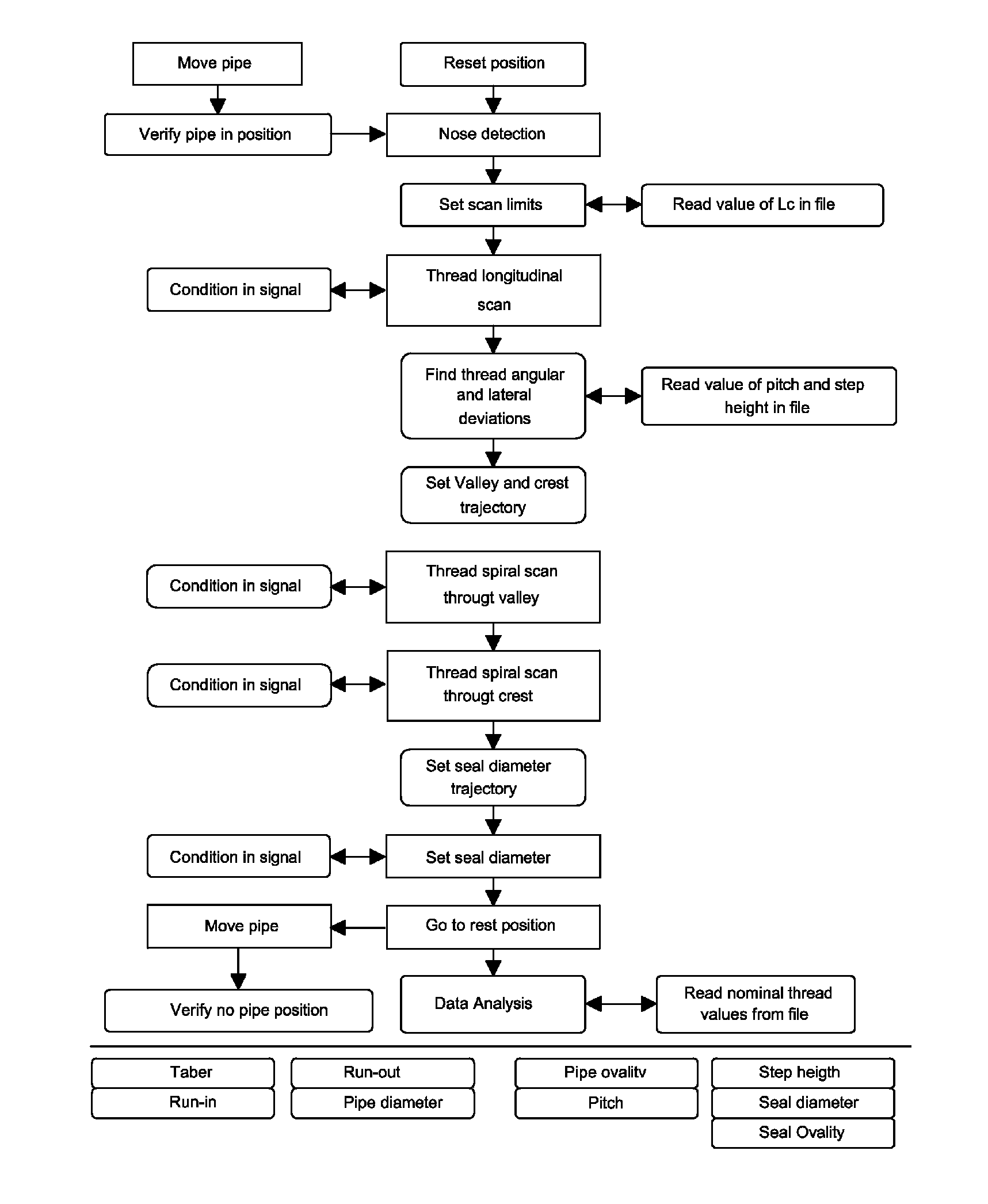

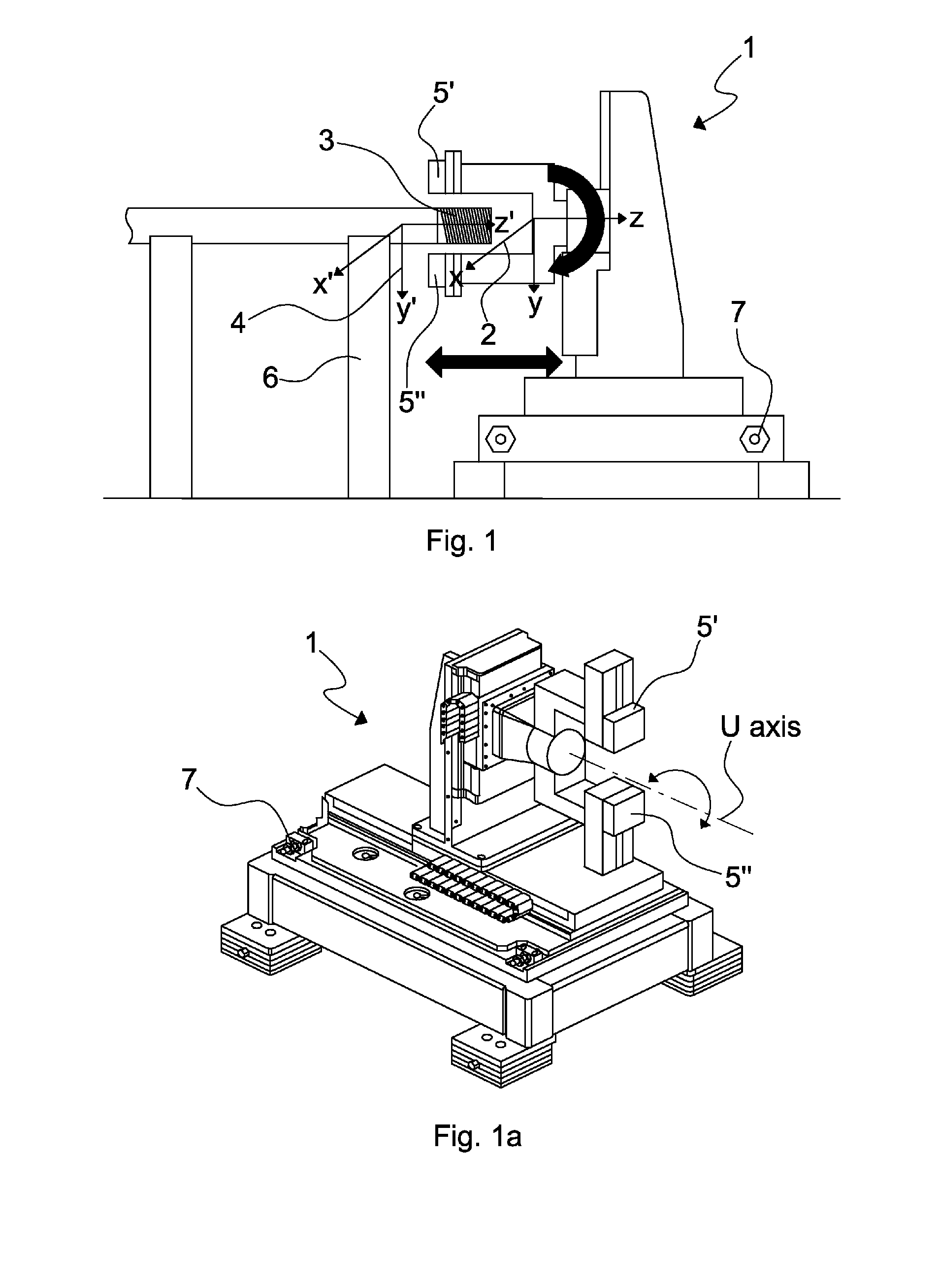

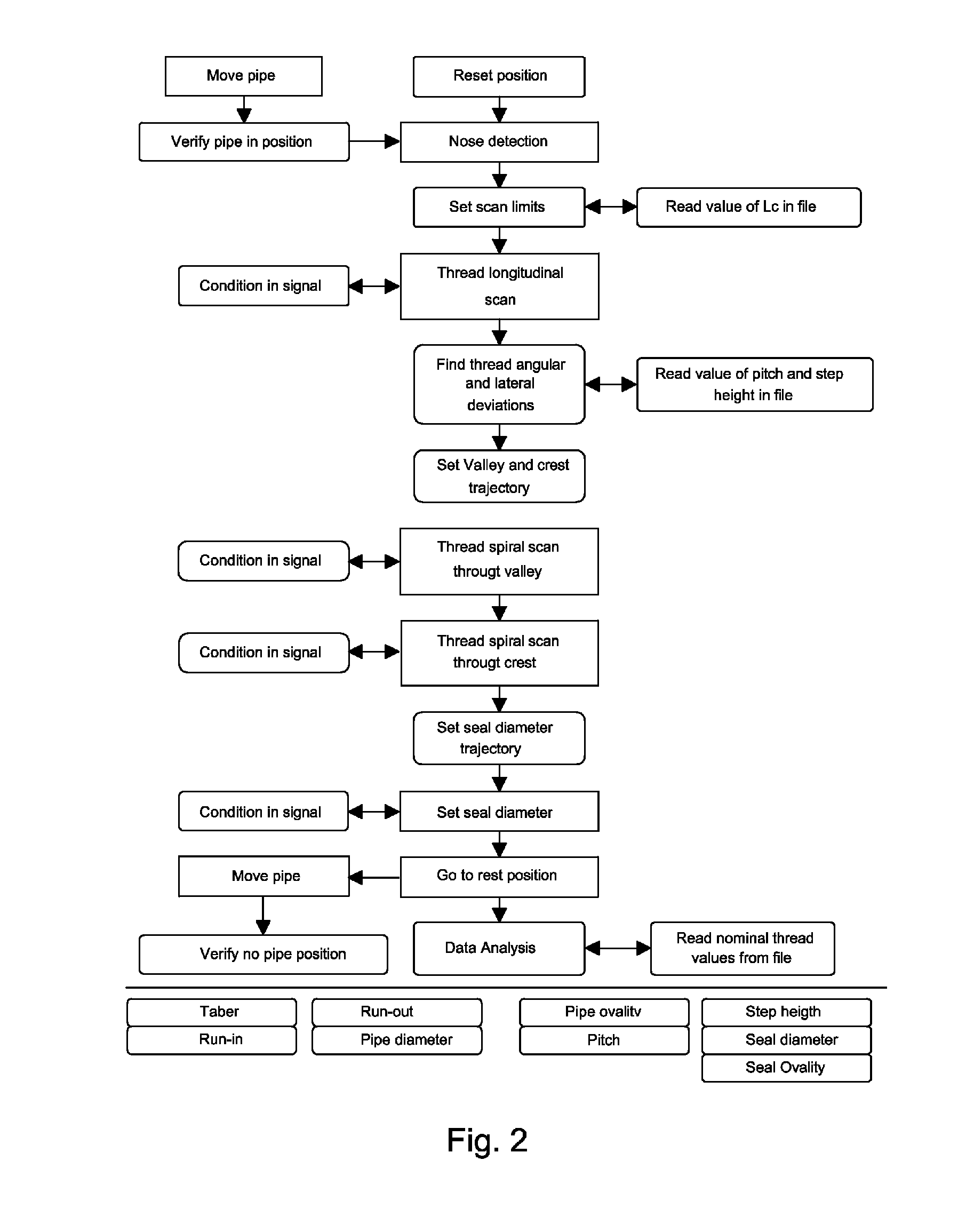

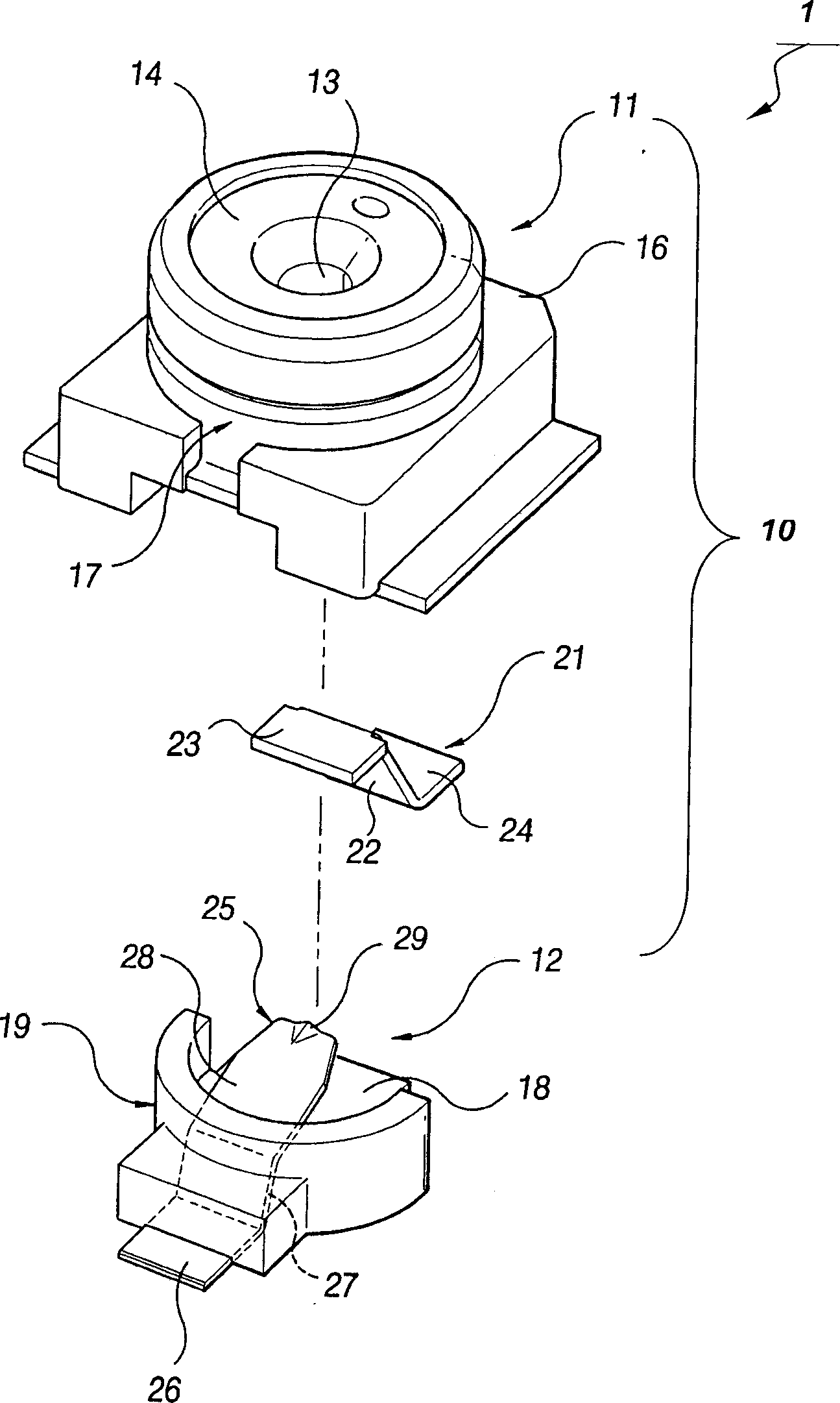

Measurement method and device for thread parameters

ActiveUS20110238199A1Accurate and automatically performed and non-contact inspectionPoor contactUsing optical meansSpecial data processing applicationsMeasurement deviceMeasurement point

A measurement method for thread parameters for a threaded object (3), by means of a measurement device (1) defining a spatial reference system (X, Y, Z) incorporating an optical sensor (5) to retrieve the shape of the threaded object, and defining a spatial reference system (X′, Y′, Z′), the measurement device (1) having a computer to assemble a first matrix that describes the quadratic form representing the threaded object in the spatial reference system (X, Y, Z), thus providing the relationship between the two spatial reference systems. The method comprises the steps of:a) predefining at least one trajectory of the at least one optical sensor (5) on the threaded object, along which measurement points are selected such that the matrix evaluated on these values satisfies the condition that it has maximum rank,b) performing a first scanning operation by the at least one optical sensor (5) along said at least one trajectory and retrieving data of the predefined measurement points,c) feeding these data to the first matrix and calculating an axes transformation matrix relating the first spatial reference system with the second spatial reference system for defining the relative position of the threaded object with respect to the second spatial reference system,d) using the axes transformation matrix to convert all data retrieved from the second spatial reference system to the first spatial reference system.

Owner:TENARIS CONNECTIONS

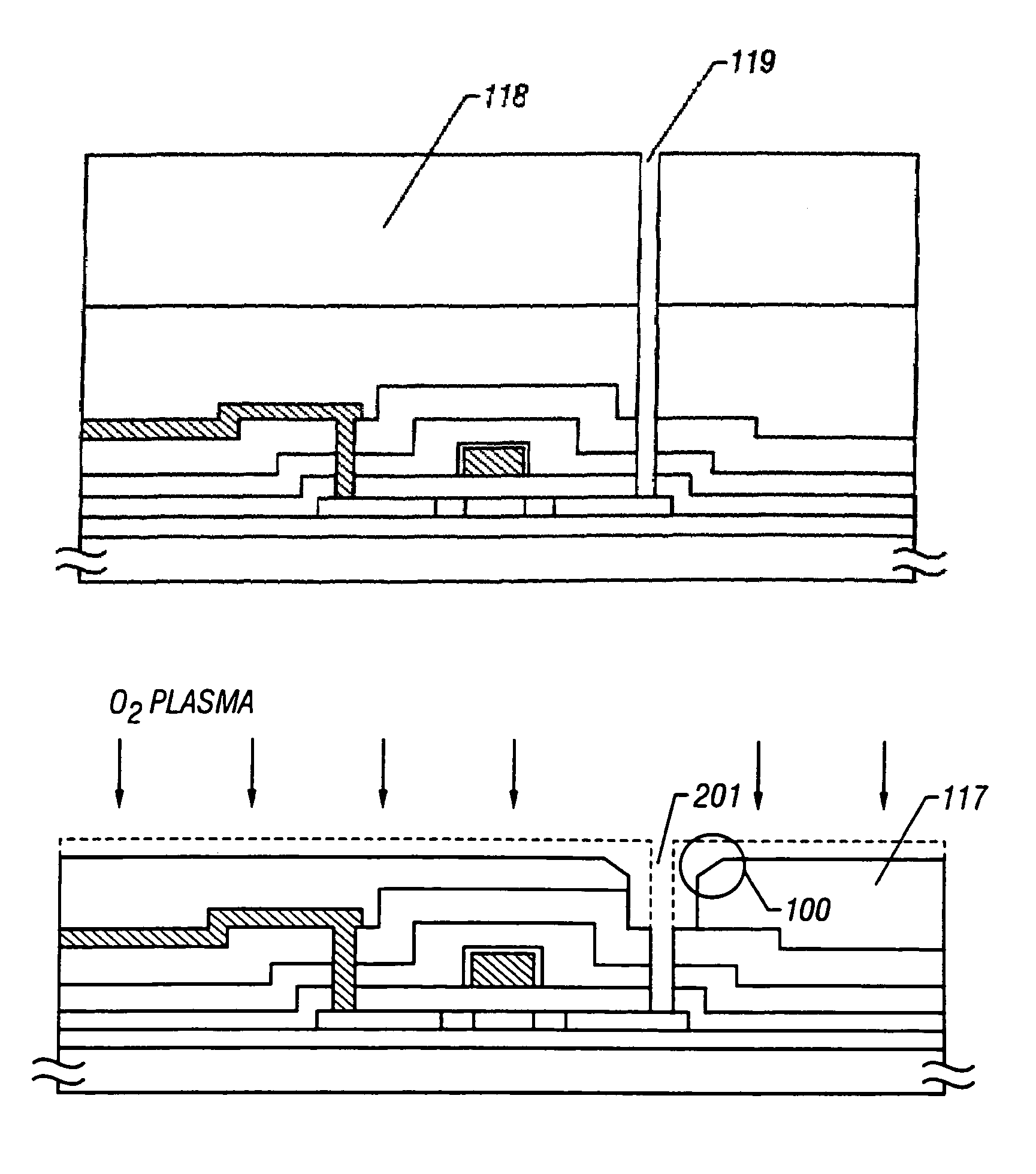

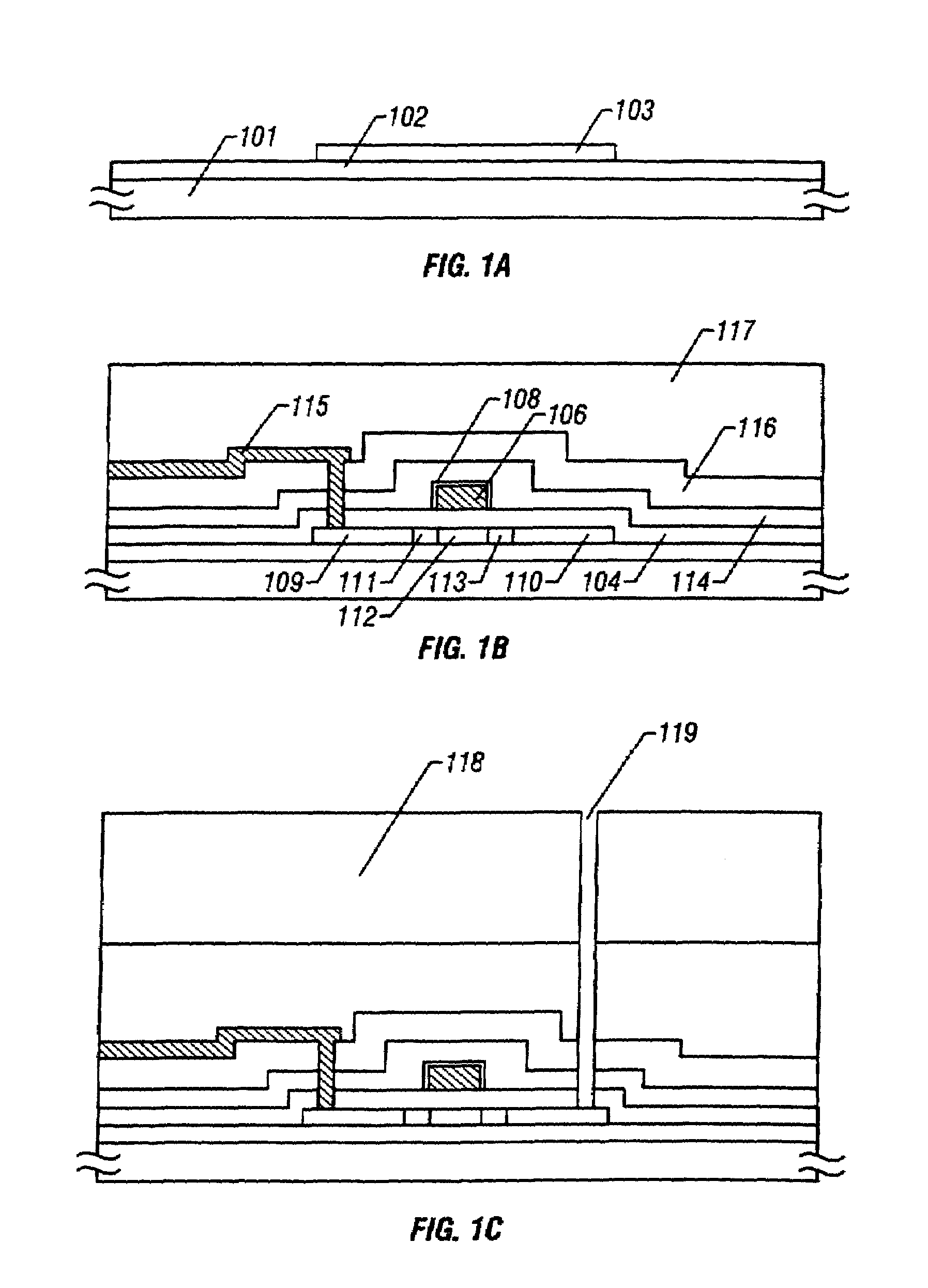

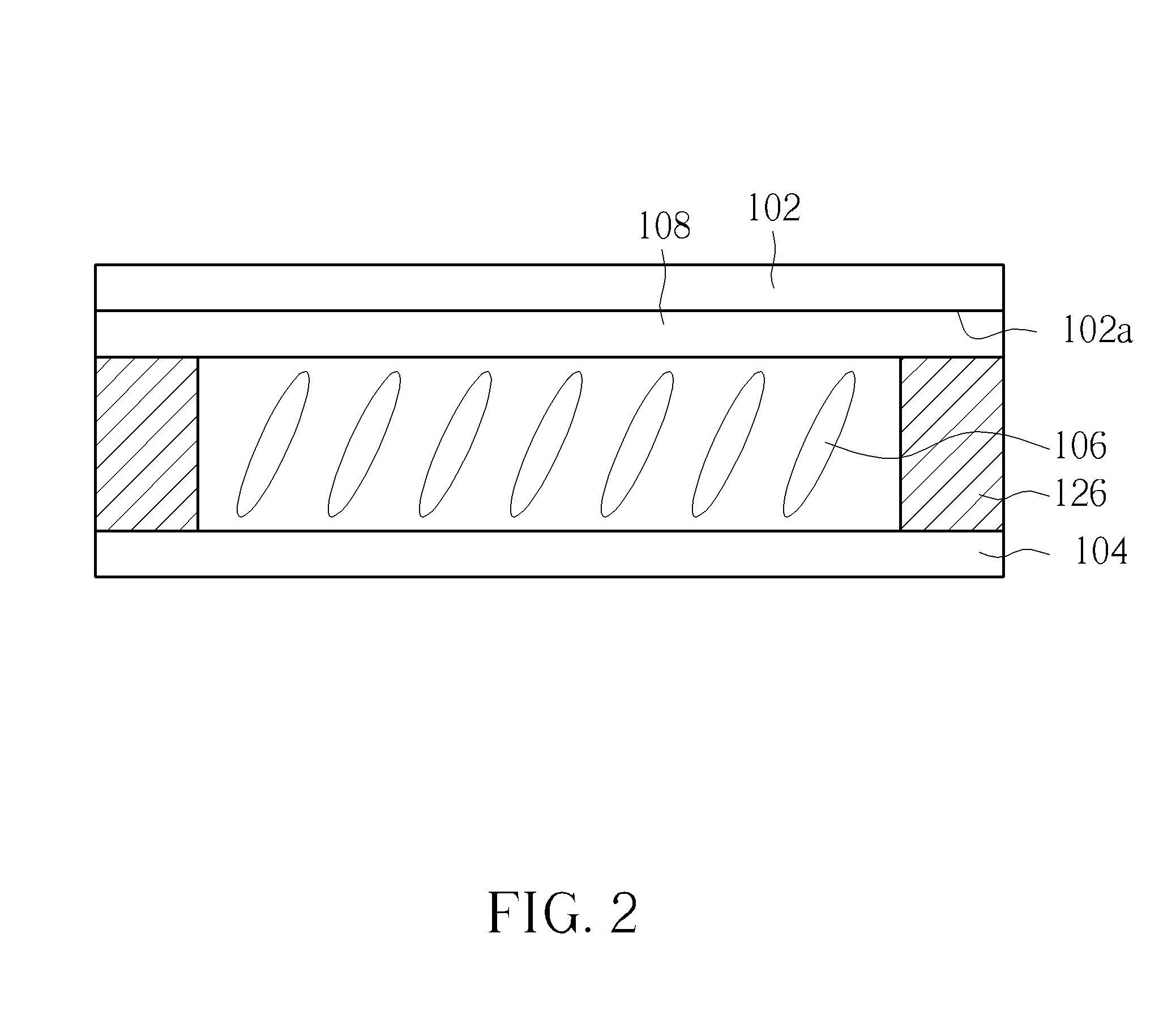

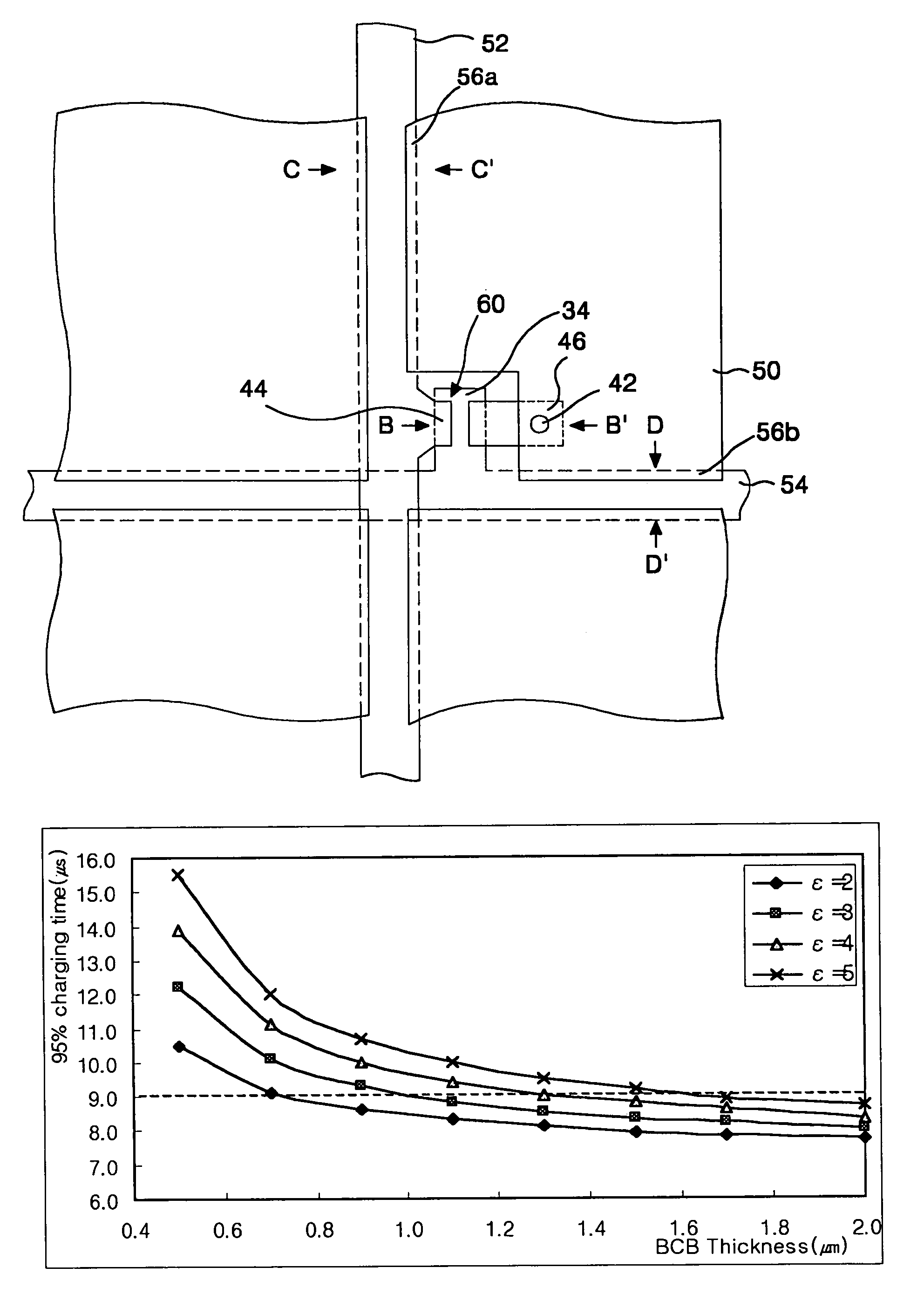

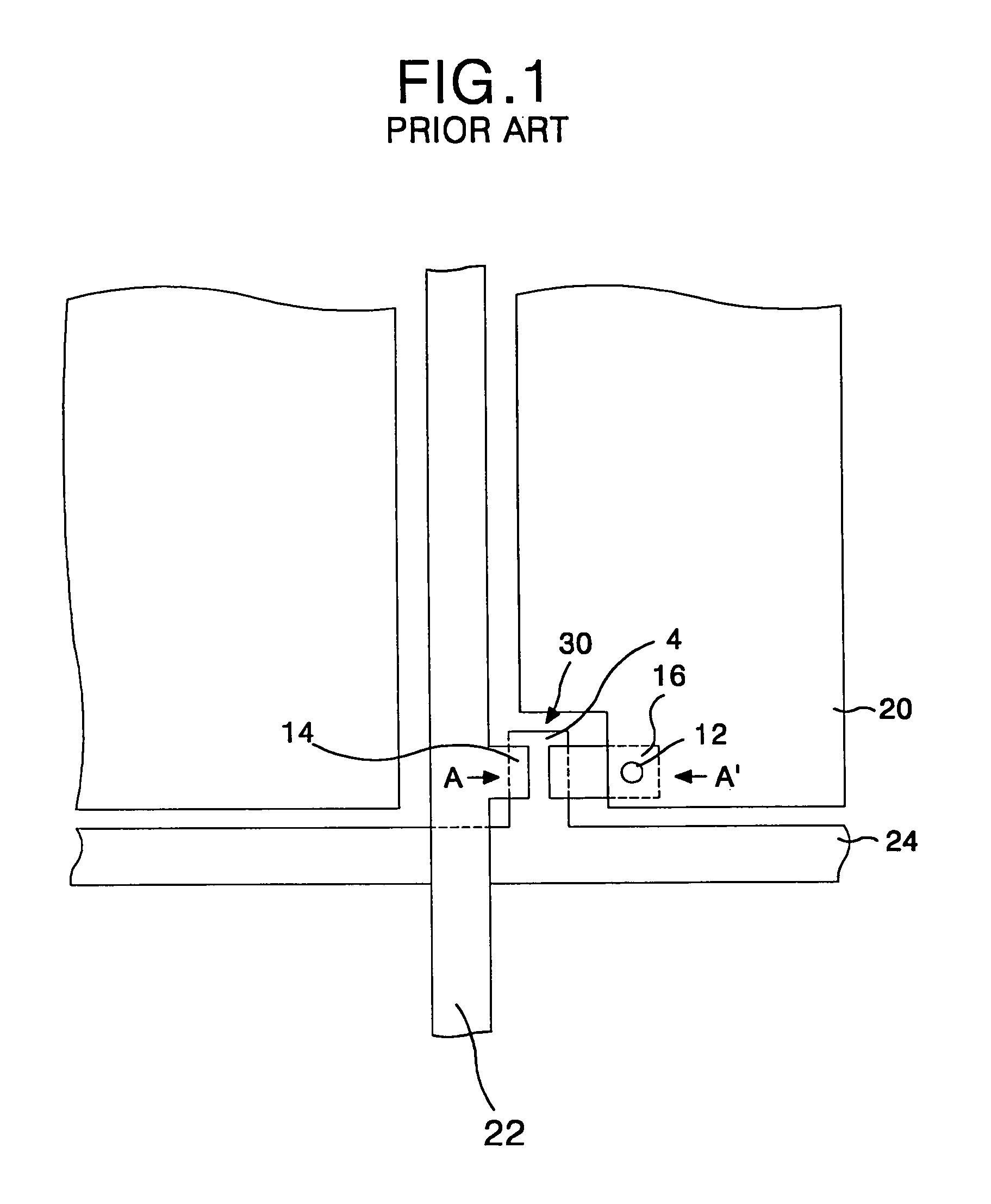

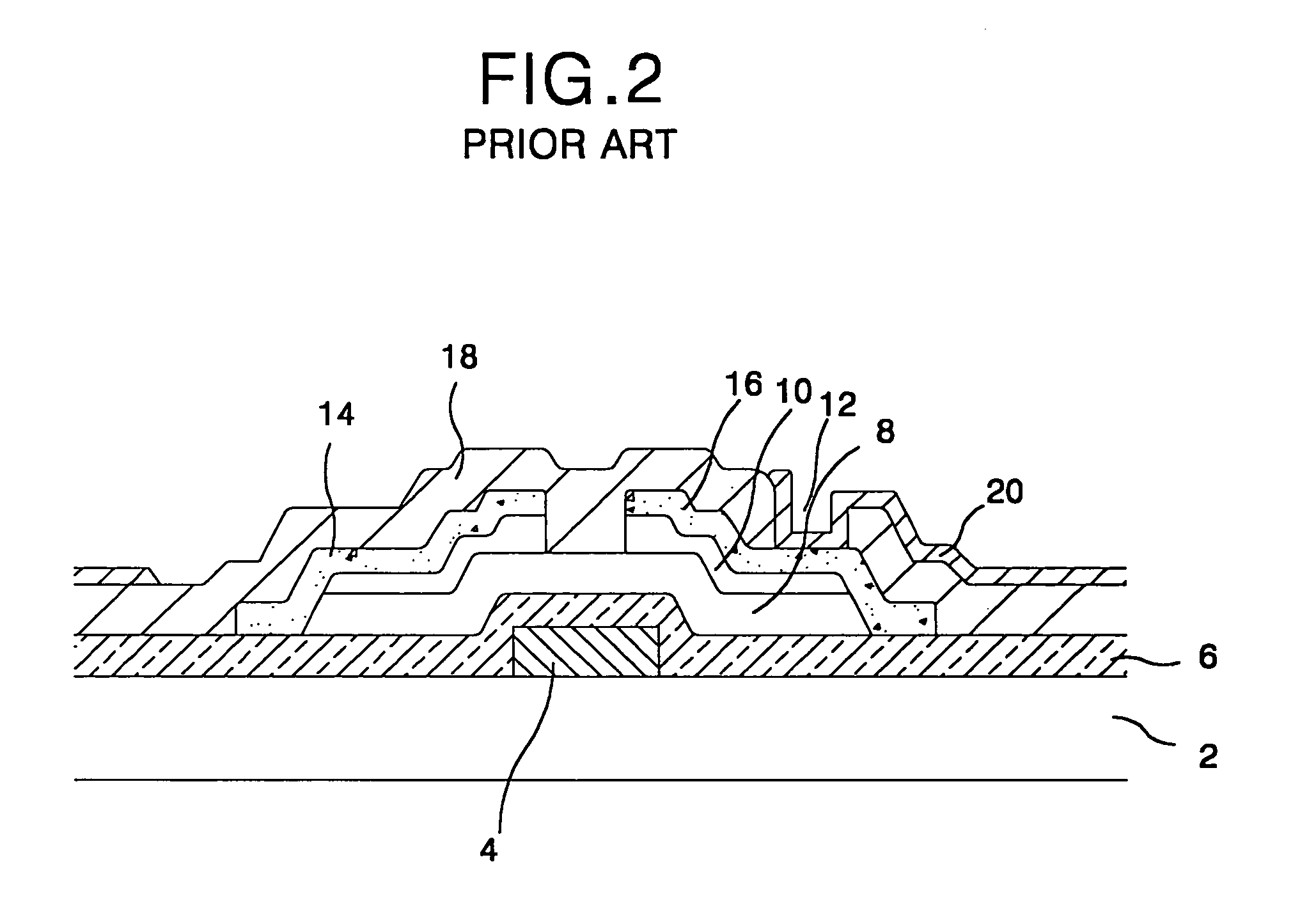

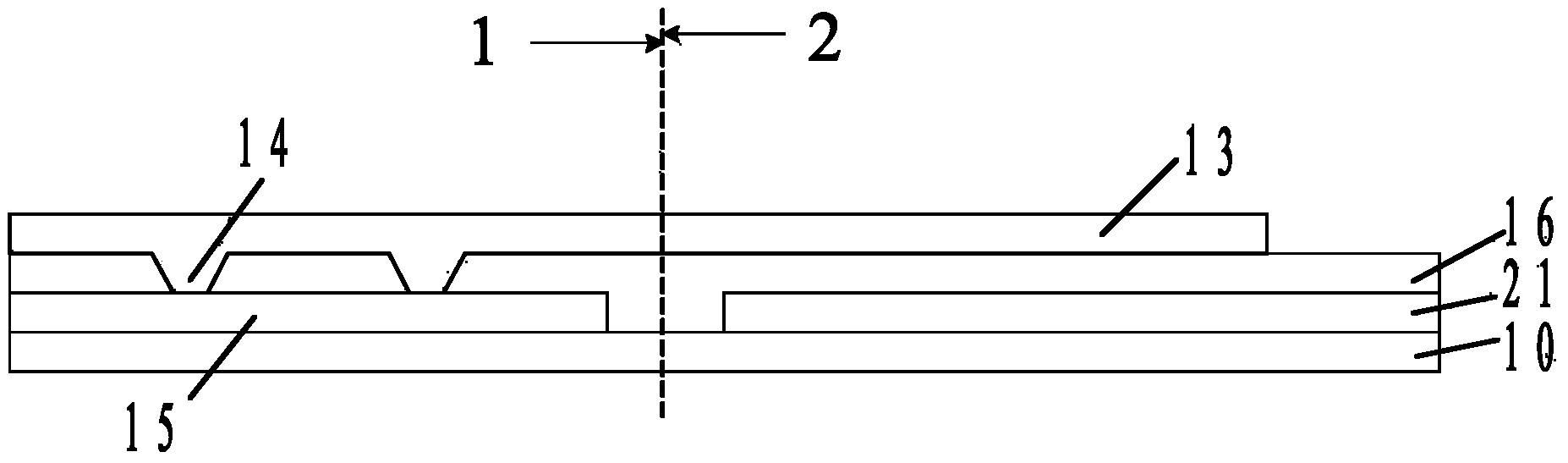

Liquid crystal display device and method of fabricating the same

InactiveUS6970221B1Reduce signal delayPoor contactTransistorNon-linear opticsPhysicsLiquid-crystal display

A liquid crystal display device and a method of fabricating the same that is capable of speeding up a data charge time in a liquid crystal pixel cell in a liquid crystal display device with a high aperture ratio overlapping a pixel electrode and a signal wiring. In the device, a thickness and a dielectric constant of the organic insulating film are set such that a signal delay at the gate line and the data line can be reduced.

Owner:LG DISPLAY CO LTD

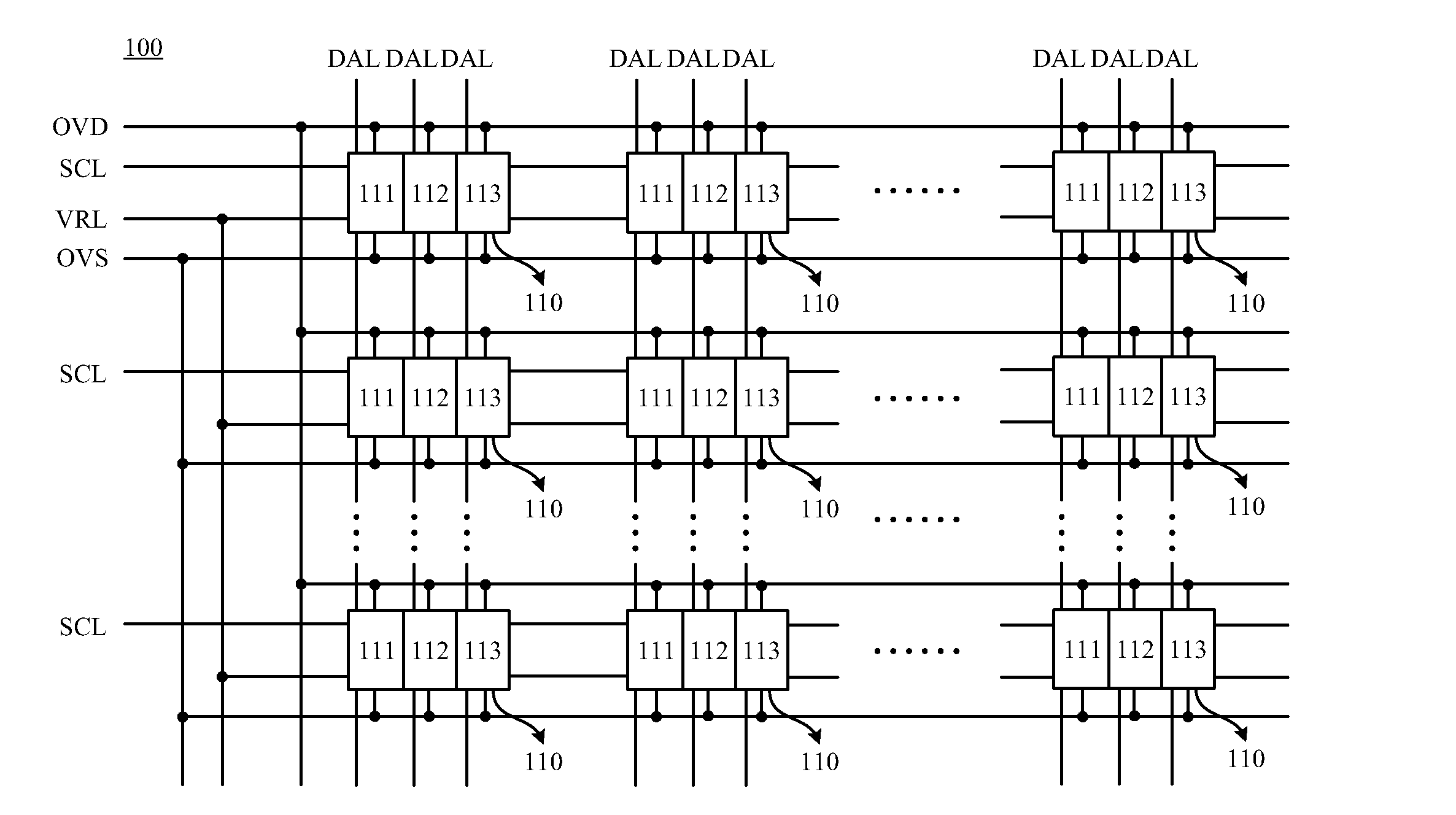

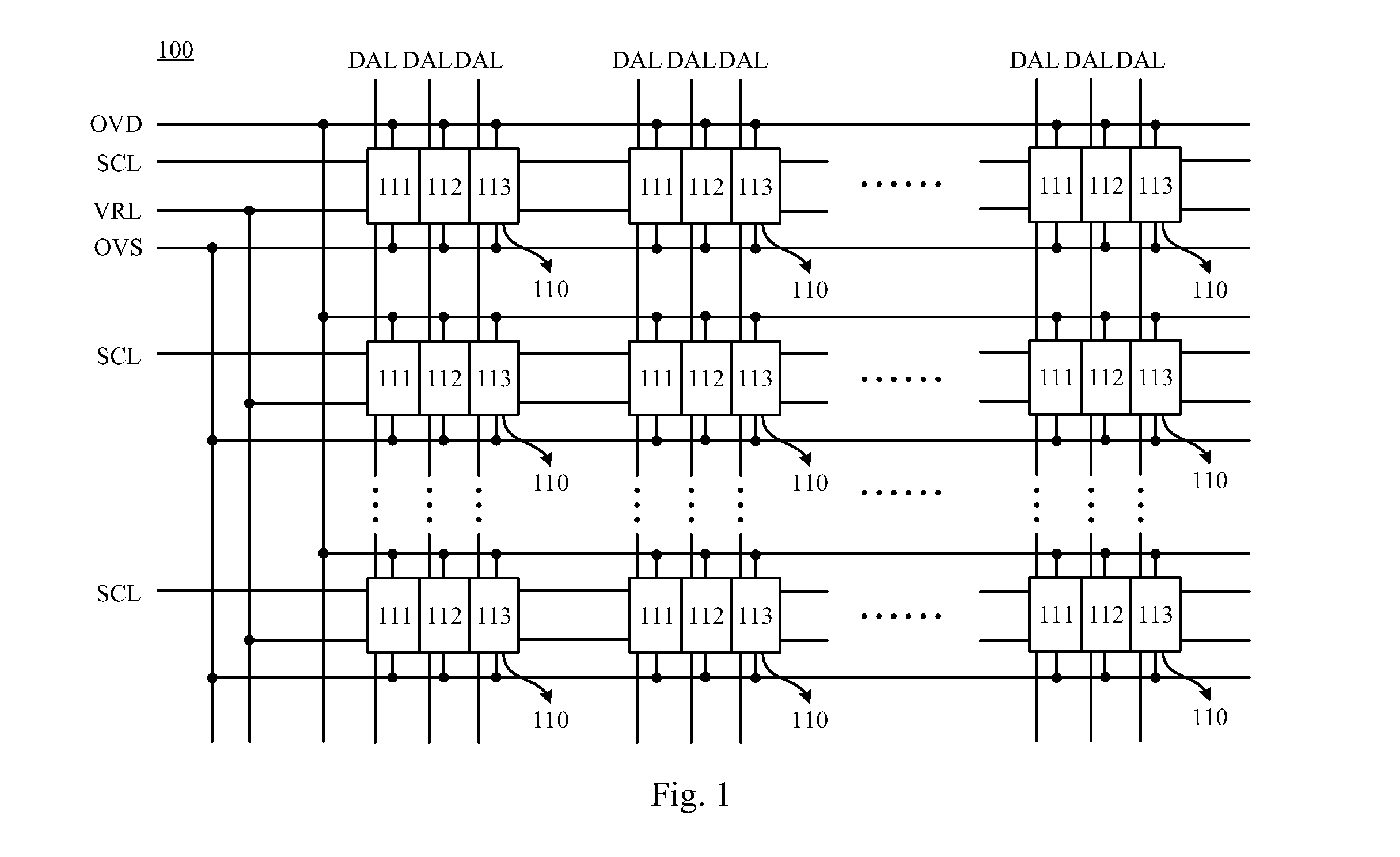

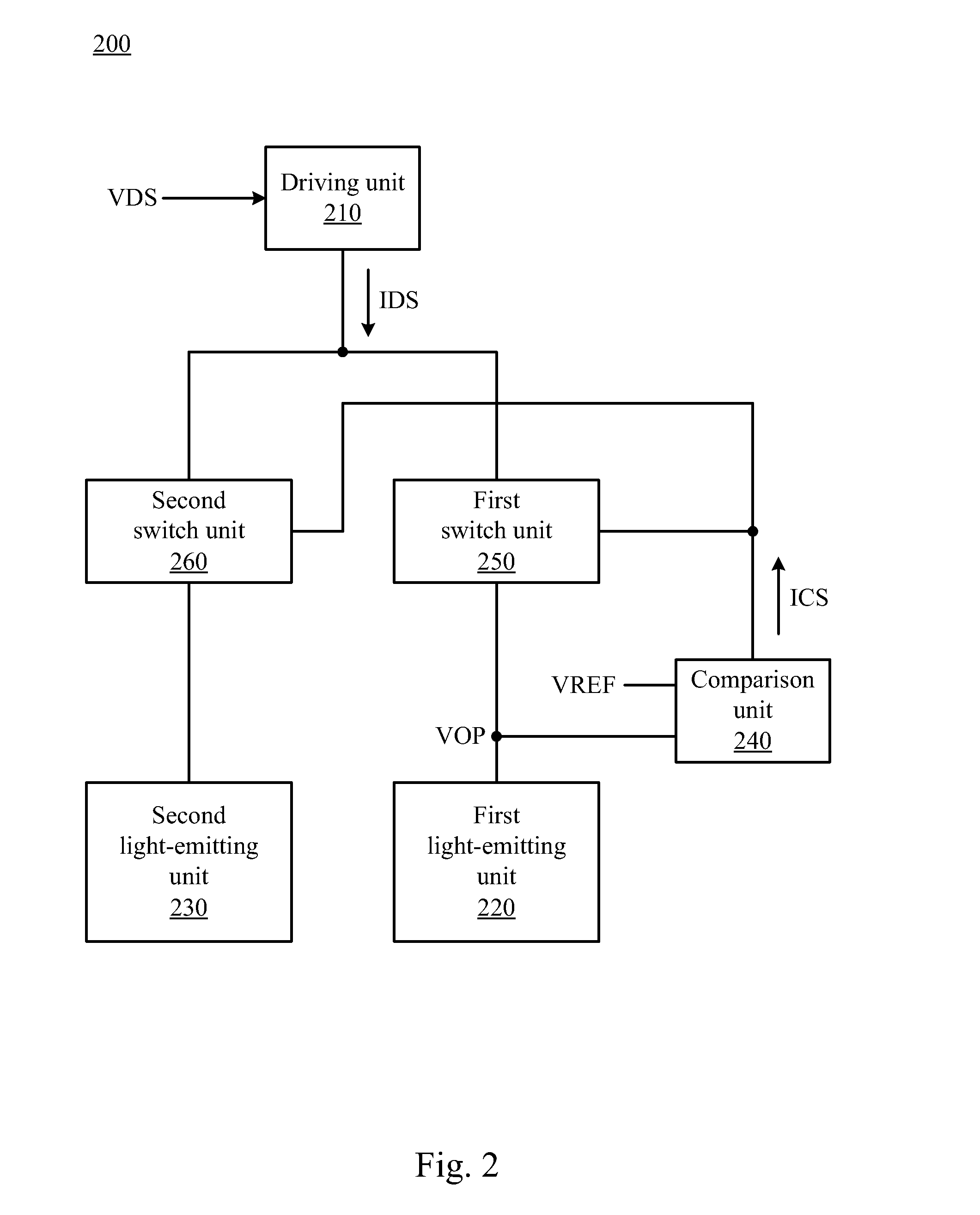

Display and sub-pixel driving method therein

ActiveUS20150339975A1Simple structureThin thicknessCathode-ray tube indicatorsElectric light circuit arrangementDriving currentPower flow

A display and a sub-pixel driving method therein are provided. The display includes a data line and a sub-pixel. The data line is configured to provide a data voltage signal. The sub-pixel includes a driving unit, a first light-emitting unit and a second light-emitting unit. The driving unit is configured to generate a driving current according to the data voltage signal. The first light-emitting unit is configured to emit light by the driving current and generate an operating voltage according to the driving current. The second light-emitting unit is selectively substituted for the first light-emitting unit to emit light according to a variation of the operating voltage.

Owner:AU OPTRONICS CORP

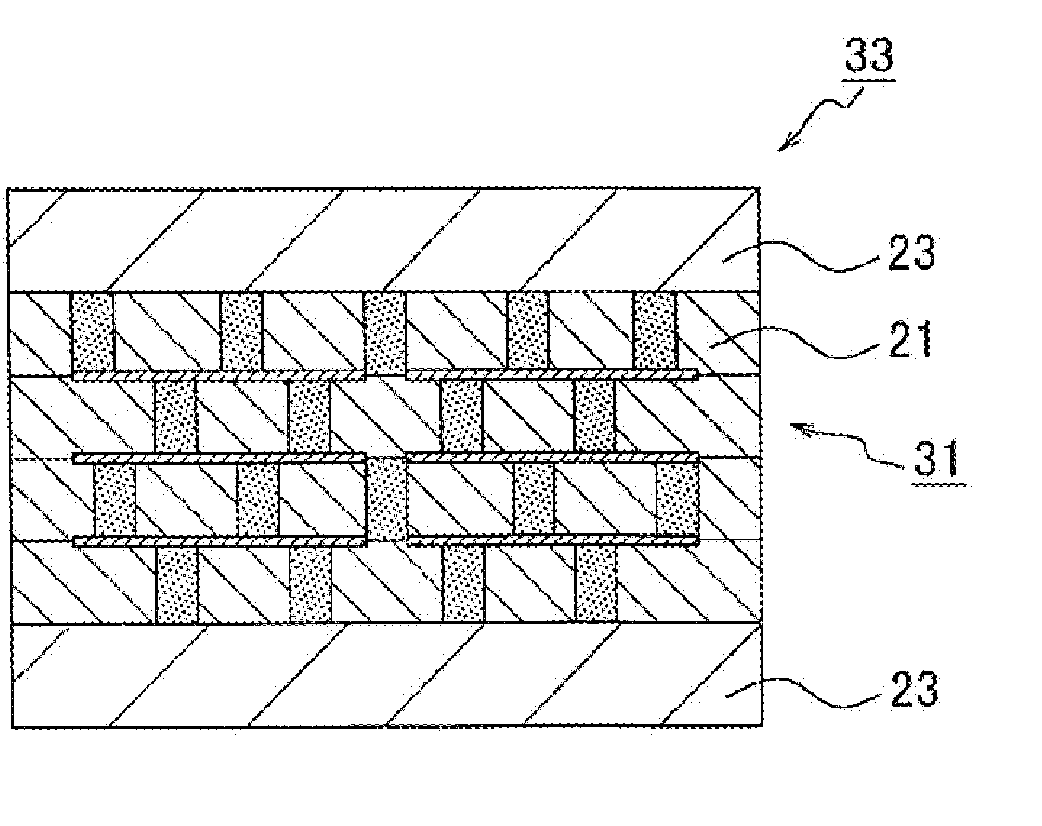

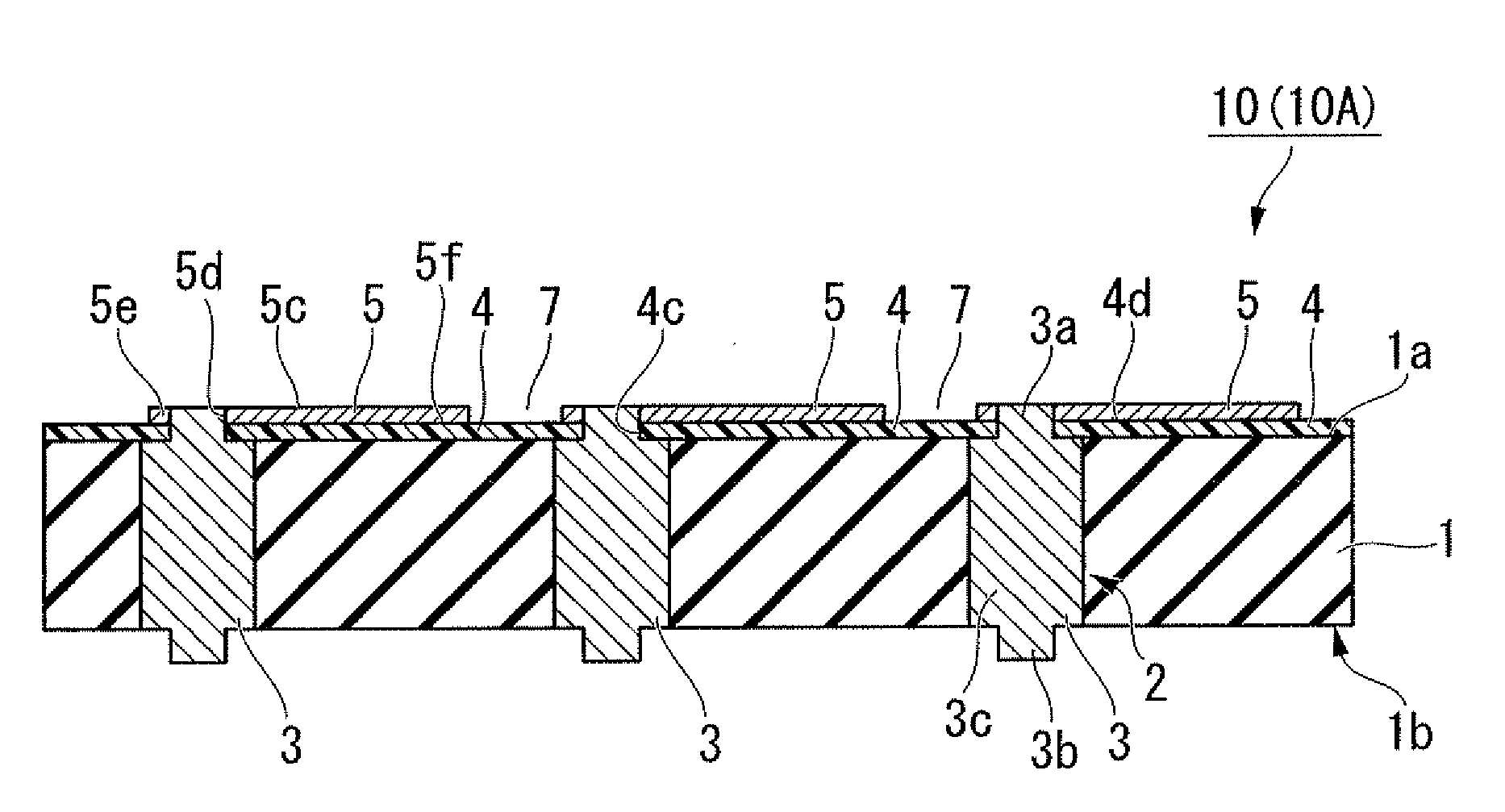

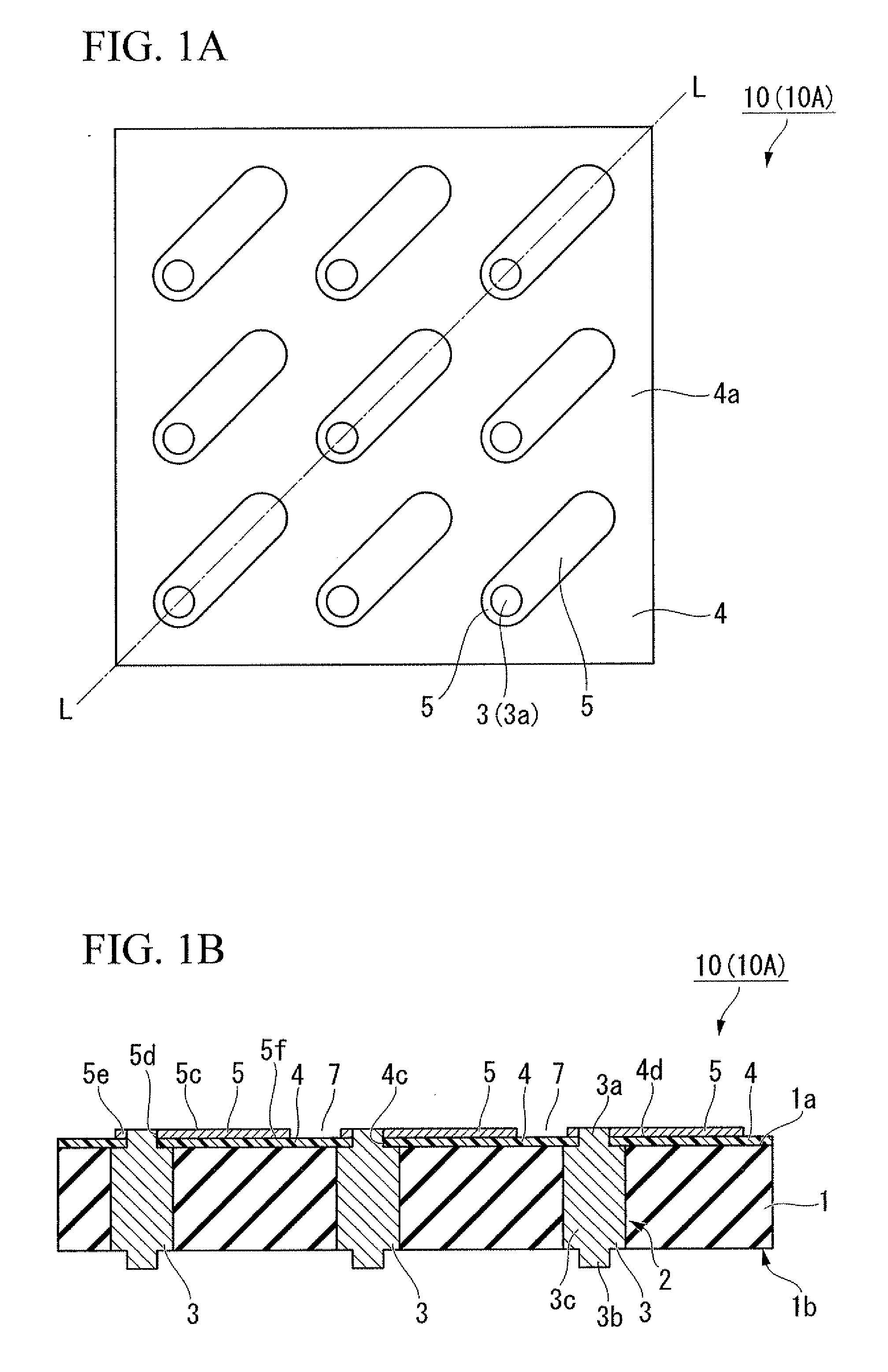

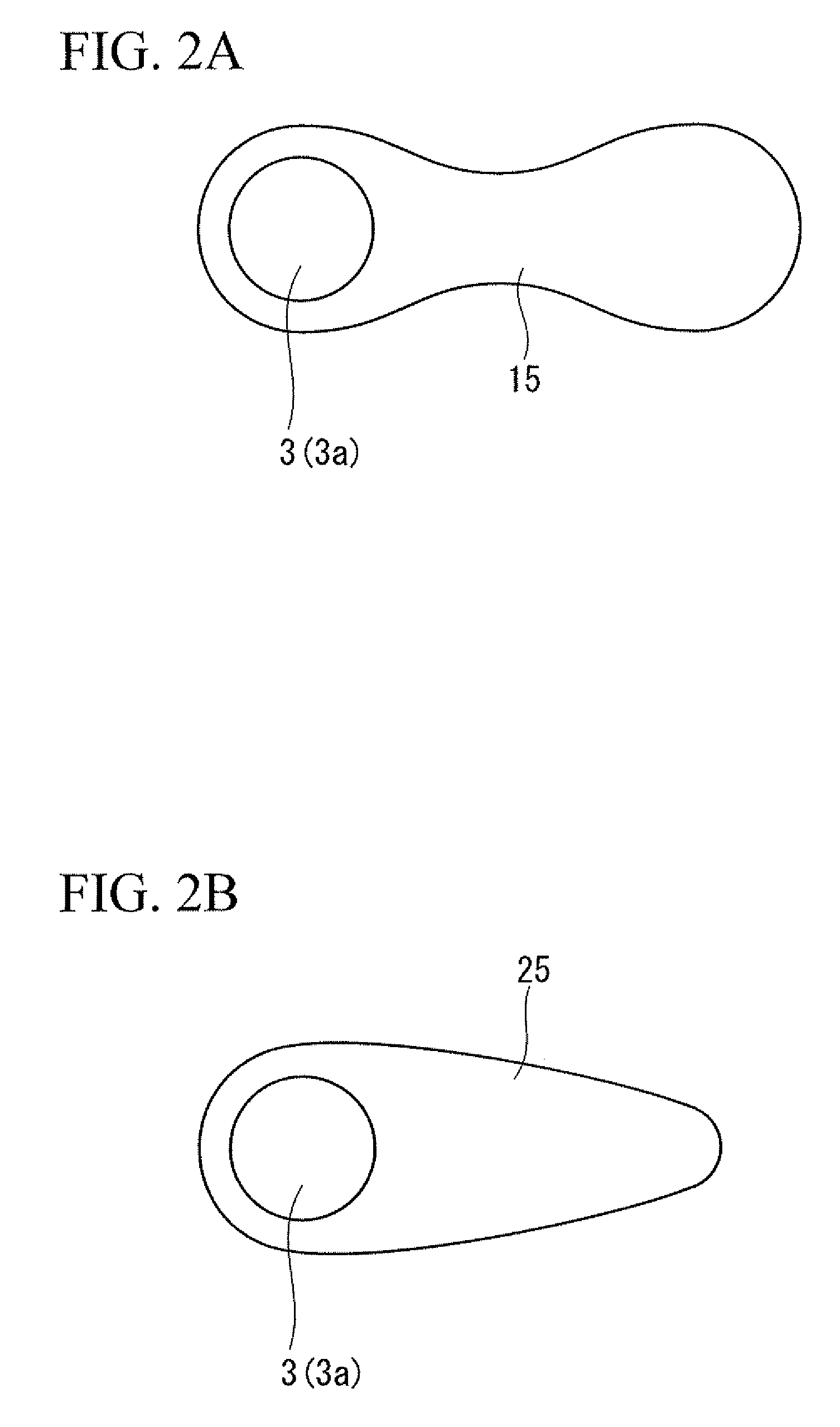

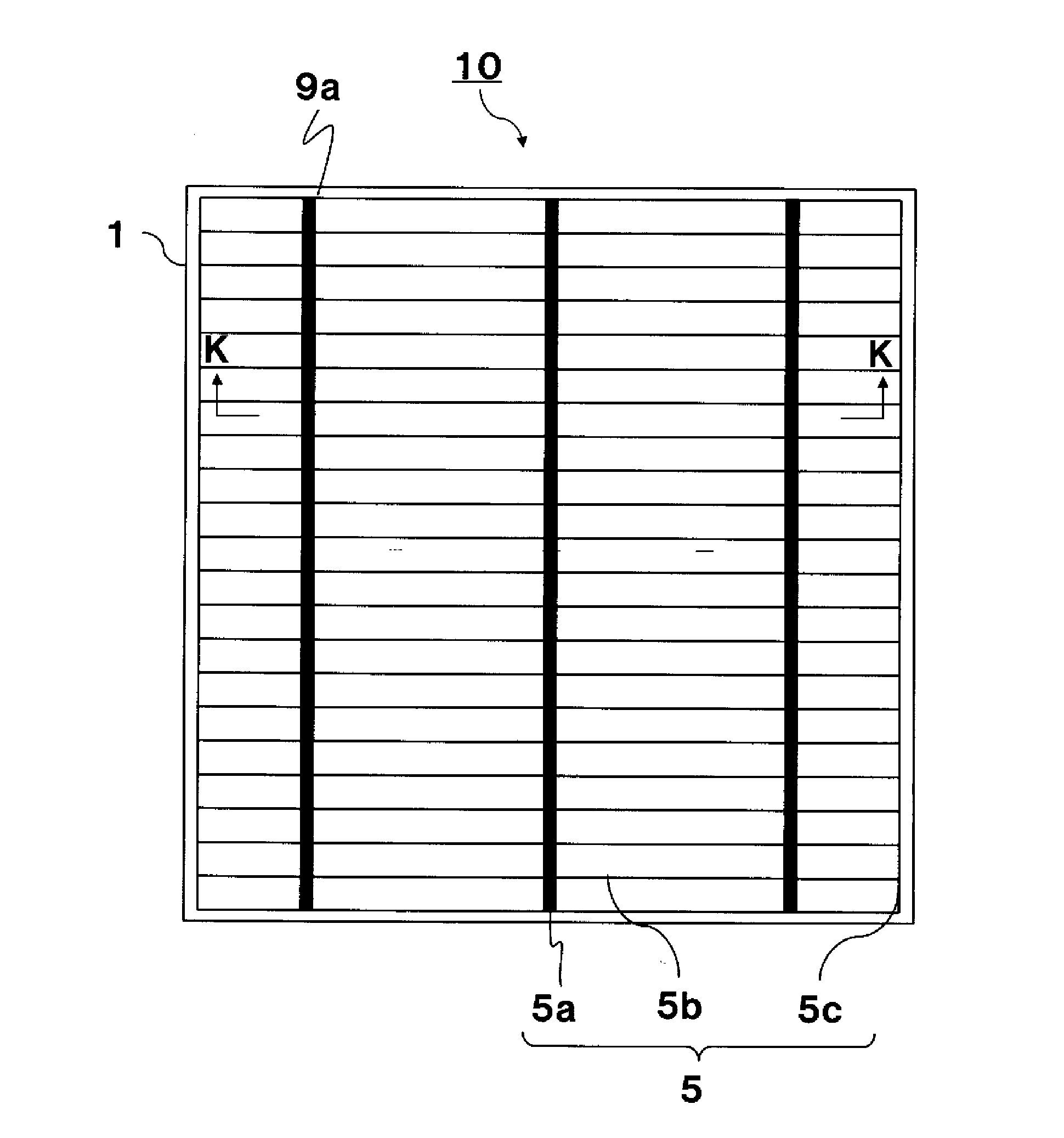

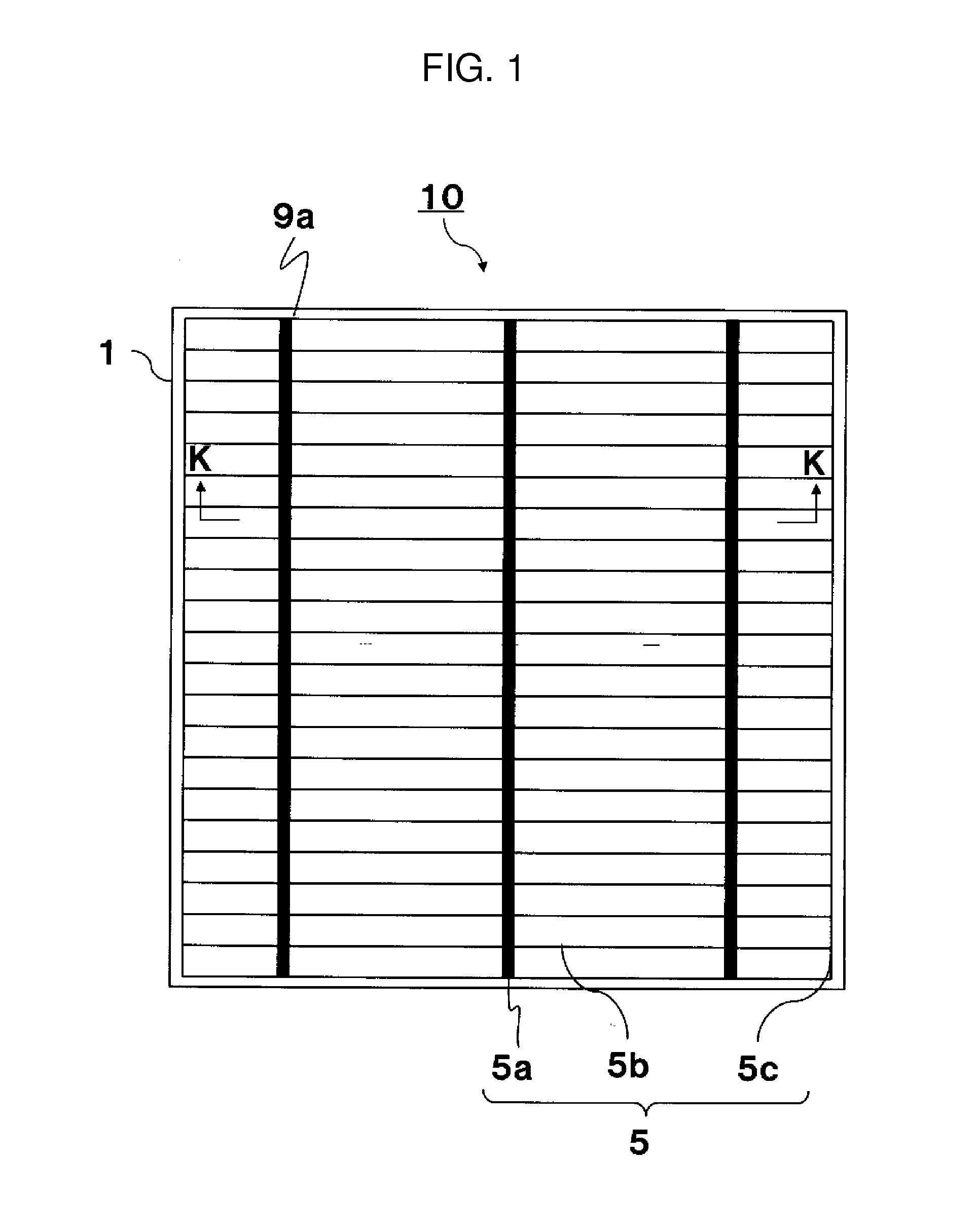

Electronic component mounting board, method for manufacturing the same and electronic circuit unit

InactiveUS20090242242A1Sufficient contact pressureReduce contact resistancePrinted circuit assemblingPrinted circuit detailsElectronic componentElectronic circuit

An electronic component mounting board, including: a substrate base made of a flat-plate-like elastic body, the substrate base having a plurality of through-holes in a manner spaced a predetermined distance apart from each other; conductive members, each of which has a main unit portion filled in the through-hole, the main unit portion having a first protrusion portion and a second protrusion portion respectively on a first end and a second end thereof, with the first protrusion portion arranged so as to protrude from a first surface of the substrate base and the second protrusion portion arranged so as to protrude from a second surface of the substrate base; a flexible substrate that is arranged on the first surface of the substrate base and that has first opening portions for penetration of the first protrusion portions; and a plurality of oval electrodes arranged on the substrate, each of which has a second opening portion for penetration of the first protrusion portion, in which the electrodes are arranged in a manner spaced apart from each other, and each of the second opening portions is formed on a first end side of each of the electrodes.

Owner:THE FUJIKURA CABLE WORKS LTD

Conductive paste for use in photovoltaic cell and method of producing photovoltaic cell element using the same

ActiveUS20130203206A1Poor contactReduce crackingConductive materialSemiconductor/solid-state device manufacturingConductive pasteFrit

A conductive paste for a photovoltaic cell and a method for producing the photovoltaic cell are disclosed. The conductive paste includes a silver powder, glass frit and a sintering inhibitor that suppresses sintering of the silver powder. The sintering inhibitor contains at least one substance selected from aluminum oxide, silicon oxide and silicon carbide. The method includes forming a first anti-reflective layer on a first region of a main surface of a semiconductor substrate; forming a second anti-reflection layer on a second region of the main surface which is different from the first region; coating the electrically conductive paste onto the second anti-reflective layer on the second anti-reflection layer; and forming a surface electrode in the second region by reacting the second anti-reflection layer with the electrically conductive paste at an elevated temperature.

Owner:KYOCERA CORP

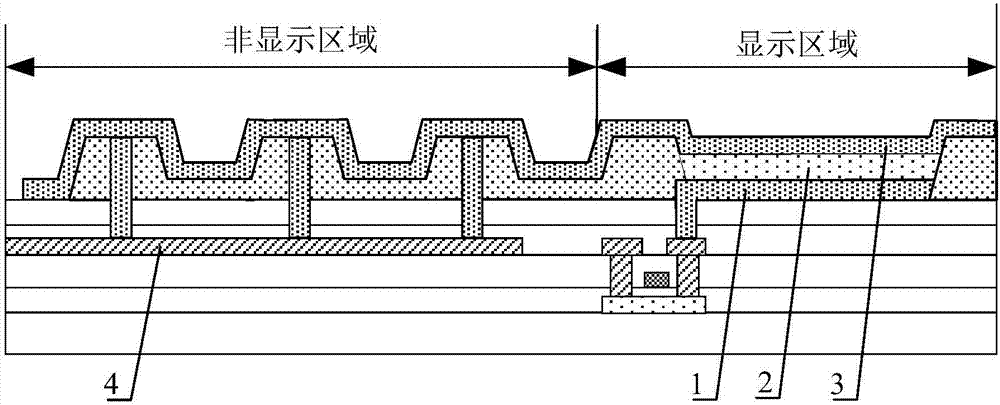

Organic light-emitting diode display panel and production method thereof

ActiveCN107302016APoor contactShow clearlySolid-state devicesSemiconductor/solid-state device manufacturingPeripheralSurface plate

The embodiment of the invention discloses an organic light-emitting diode display panel and a production method thereof. The organic light-emitting diode display panel comprises a first substrate and a second substrate which are oppositely arranged, wherein the first substrate comprises a first lead wire connected with a negative electrode; the second substrate comprises a second lead wire connected with a peripheral circuit; the first lead wire is connected with the second lead wire through a connecting part. According to the technical scheme adopted by the invention, the negative electrode is connected with the peripheral circuit through the first lead wire, the connecting part and the second lead wire, the first lead wire is arranged on the first substrate and the second lead wire is arranged on the second substrate, so that the first lead wire and the second lead wire are difficult to break, poor contact, caused by easy breakage of the lead wires, between the negative electrode and the peripheral circuit in the prior art is avoided, good contact between the negative electrode and the peripheral circuit is ensured, and thus good display of the OLED (organic light-emitting diode) display panel is achieved.

Owner:BOE TECH GRP CO LTD

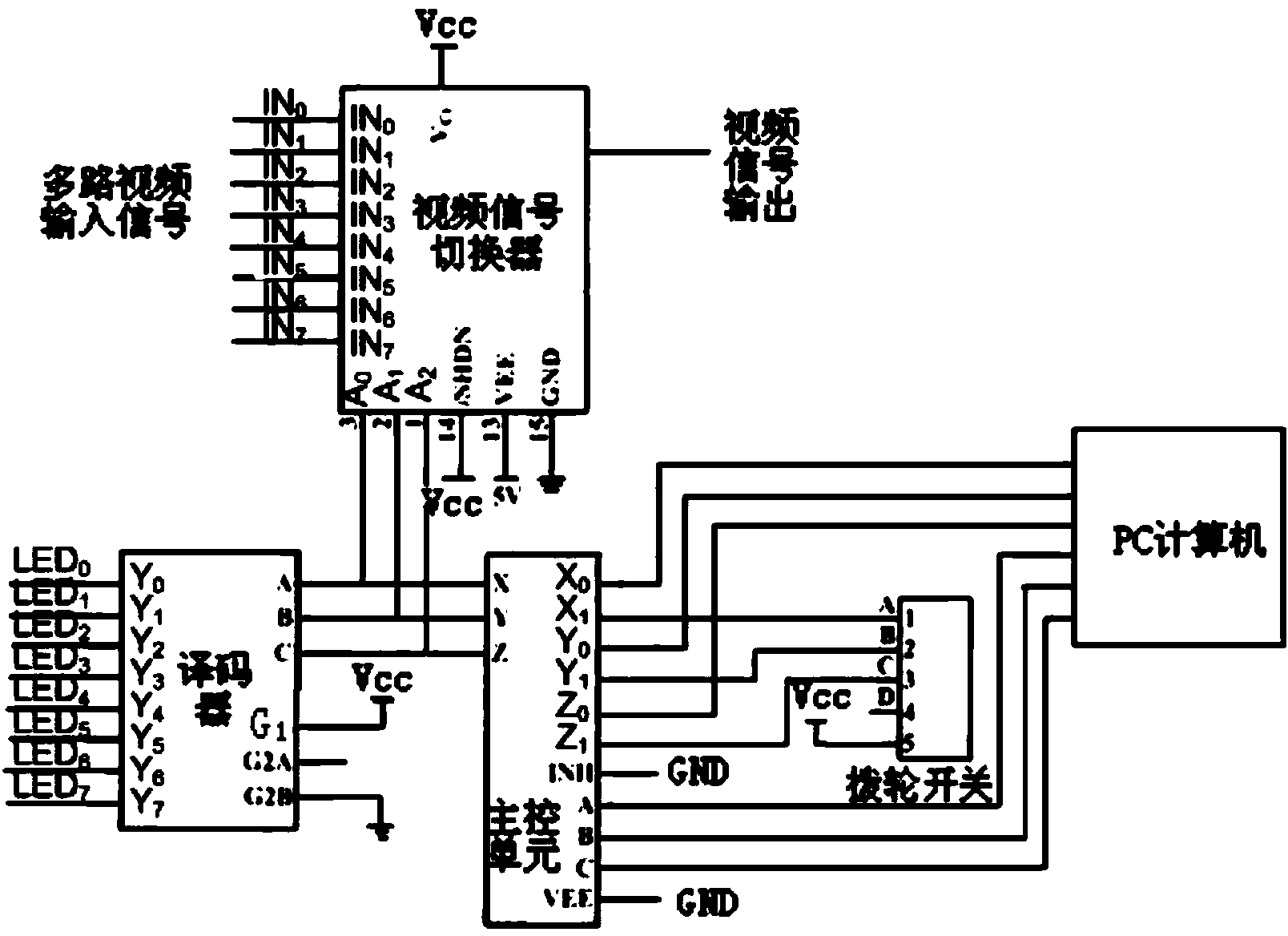

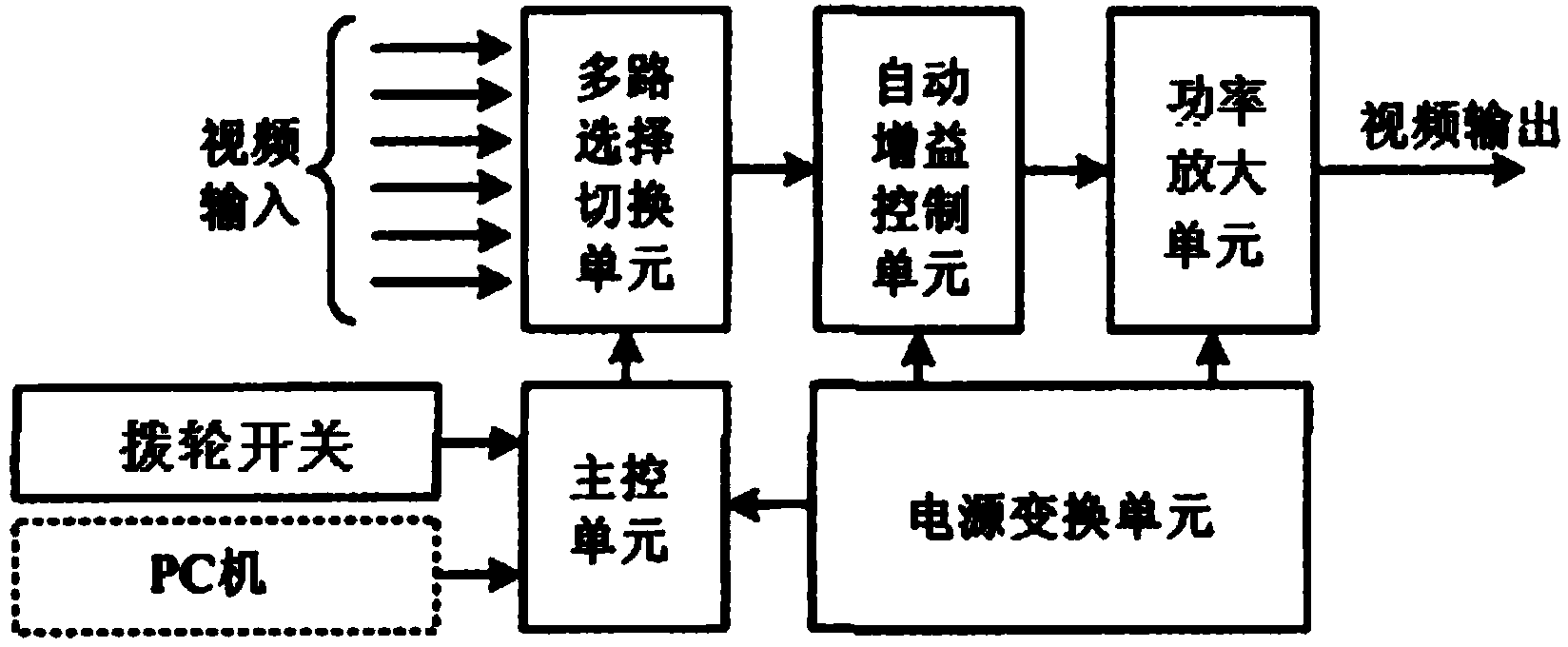

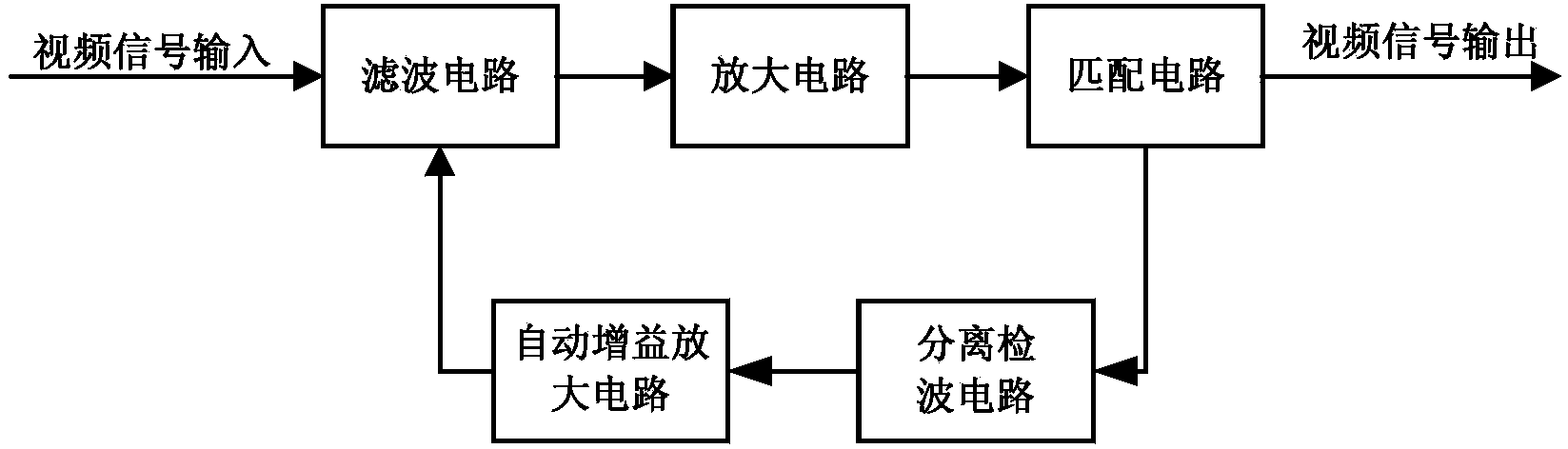

Unmanned aerial vehicle multiplex video switching device

ActiveCN103647907AReduce areaReduce distributed capacitanceTelevision system detailsColor television detailsMultiplexingCapacitance

The invention discloses an unmanned aerial vehicle multiplex video switching device. According to the multiplex video switching device, a main control unit is controlled with a thumb wheel switch or an industrial personal computer so as to cause the main control unit to drive a multiplex switching unit, so the input not only can be switched to the output, and but also can be outputted to different output channels according to a certain time sequence, and a power amplification circuit is designed in the circuit for video output signals at the same time, so the distributed capacitance can be effectively reduced, the circuit board area can be reduced and the operation of the whole system is more stable. The multiplex switching unit of the invention adopts a eight-channel video high-speed multiplexing chip produced by the MAX company, the switching time is 40ns, and compared with a multiplex mechanical switch of a passive switching device, the large contact noise problem occurring in the switching process does not exist, and the poor contact problem also does not exist.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

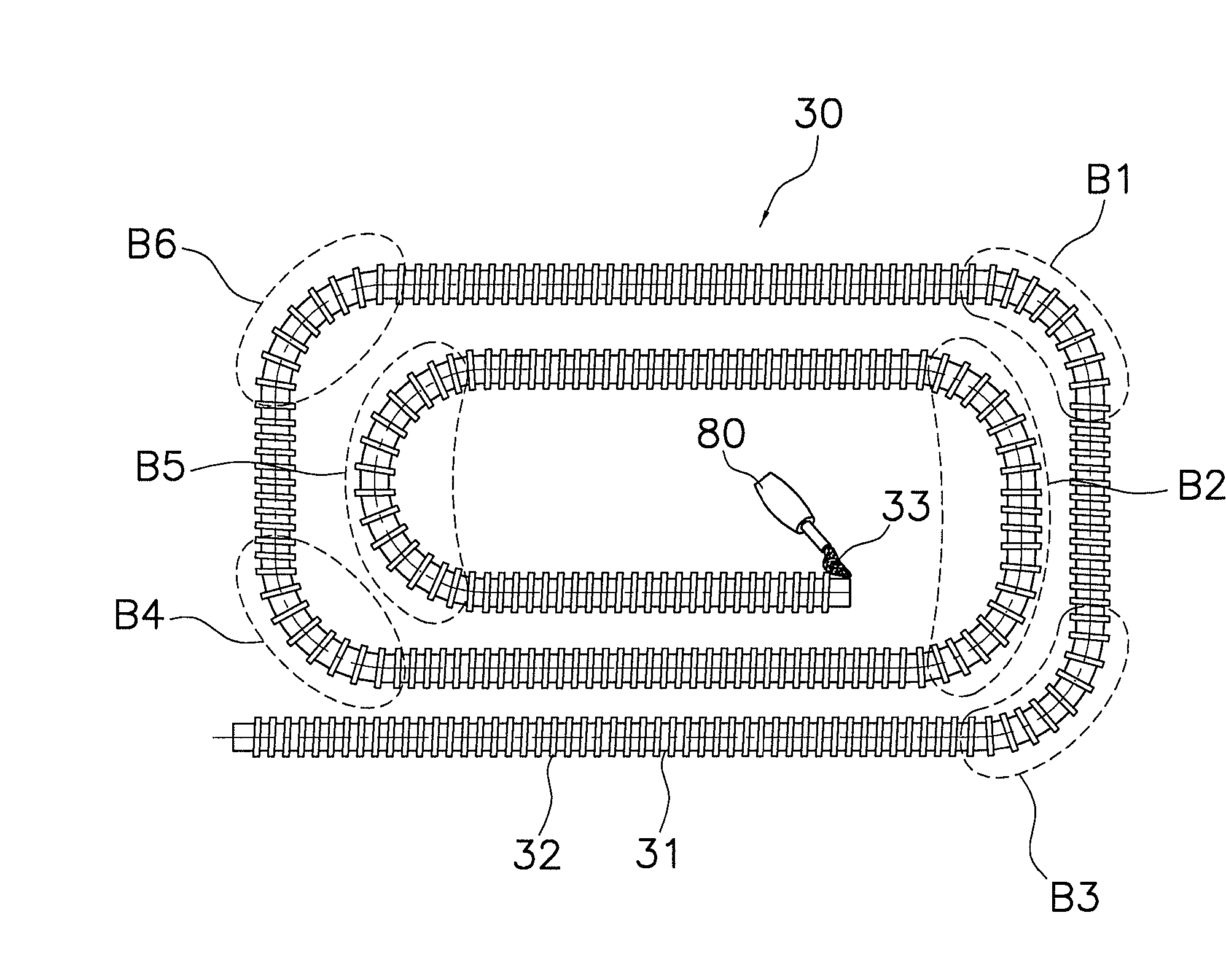

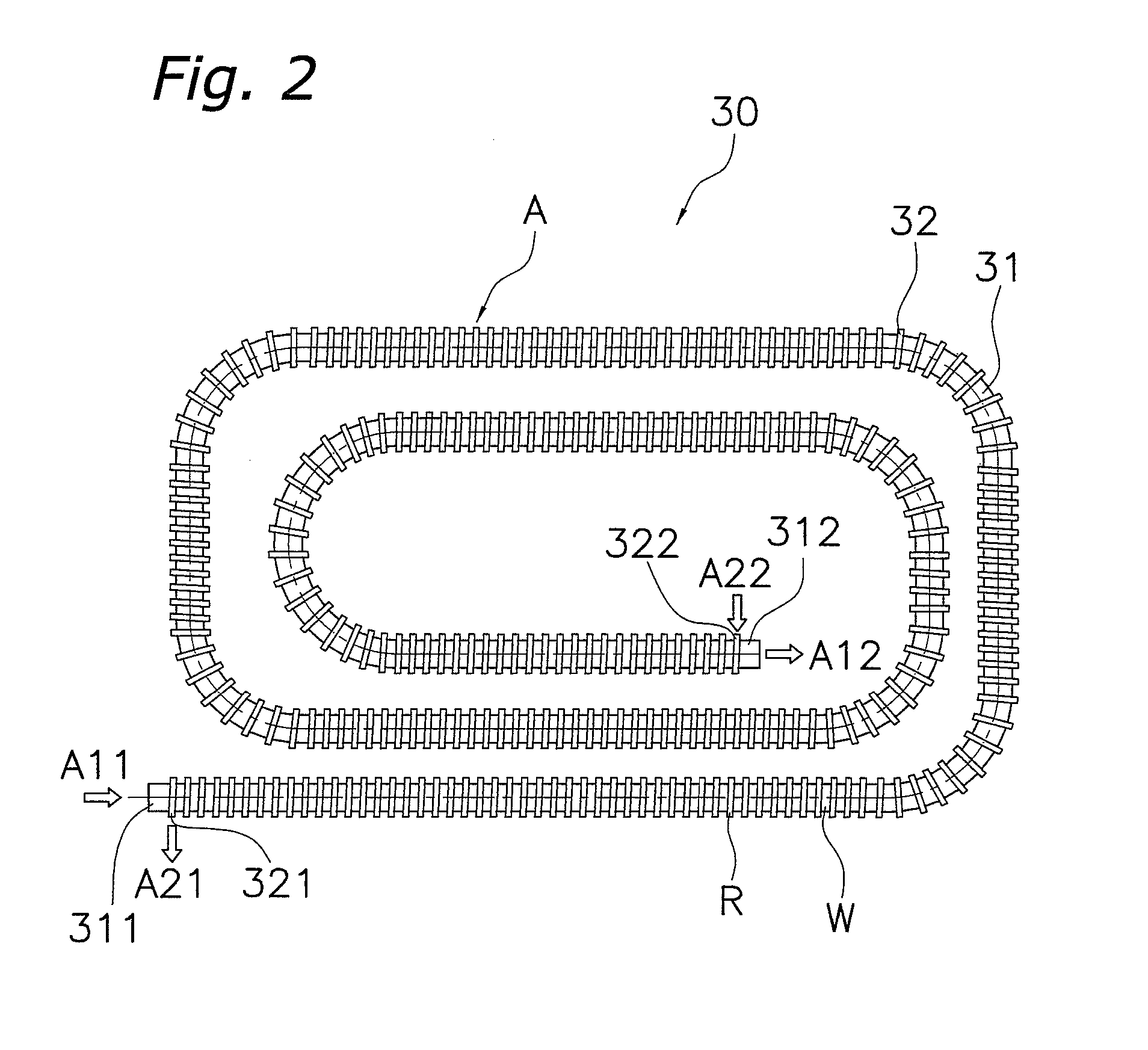

Heat exchanger

InactiveUS20090071639A1Improve heat transfer performanceLarge breakageHeat pumpsHeat exhanger conduitsEngineeringHeat exchanger

The outer surface of a core pipe 31 is pressed so as to form projections 313 on the inner surface of the core pipe 31, and a winding pipe 32 is helically wound around the outer circumference of the core pipe 31. Subsequently, the core pipe 31 and the winding pipe 32 are bent together, and brazing is performed. As a result, the outer surface of the winding pipe 32 is in contact with the outer surface of the core pipe 31 without any gap therebetween at a bending center portion (D), and the outer surface of the winding pipe (32) is bonded to the outer surface of the core pipe (31) by a brazing material (33) at the bending center portion (D) of the bent part C-C.

Owner:DAIKIN IND LTD

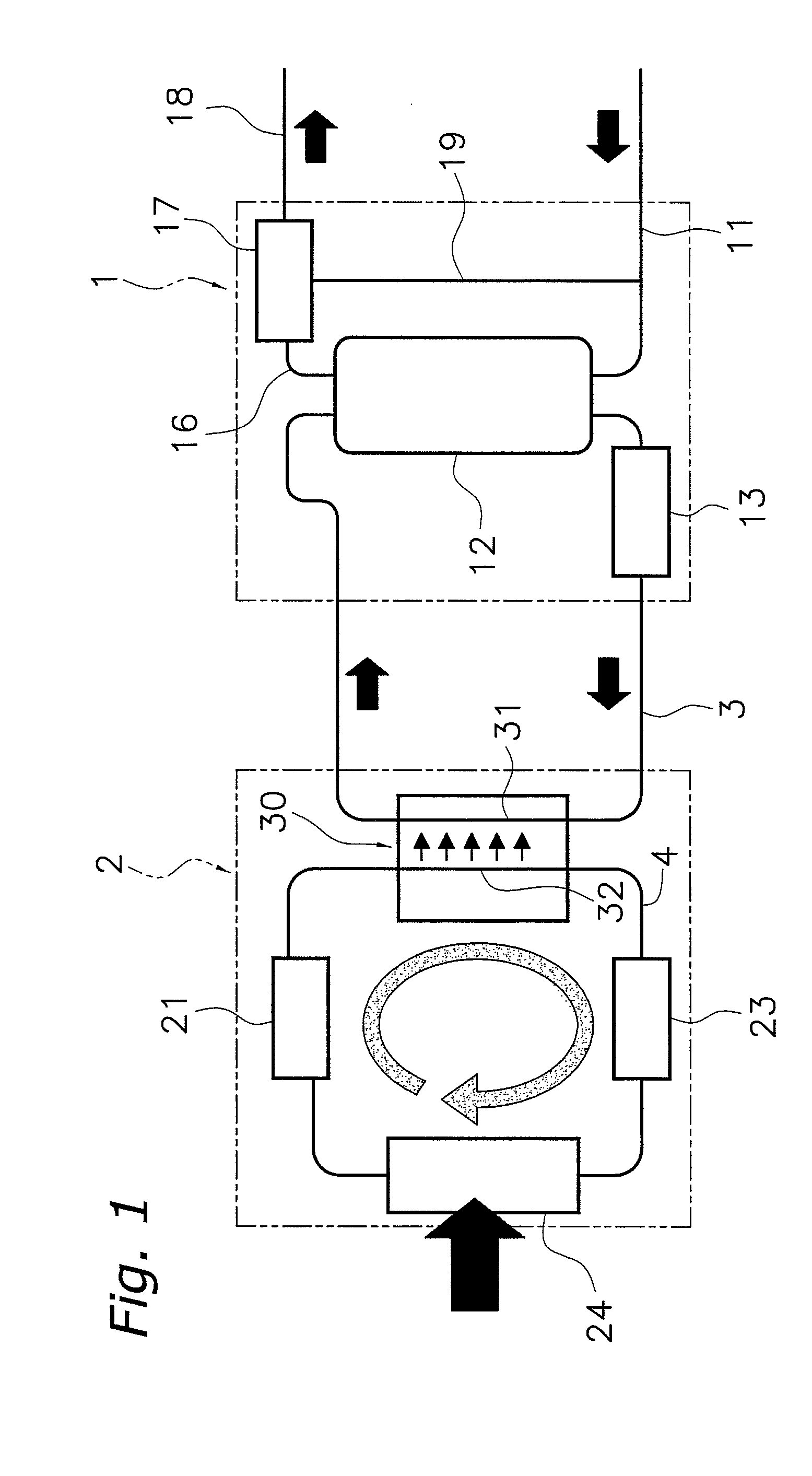

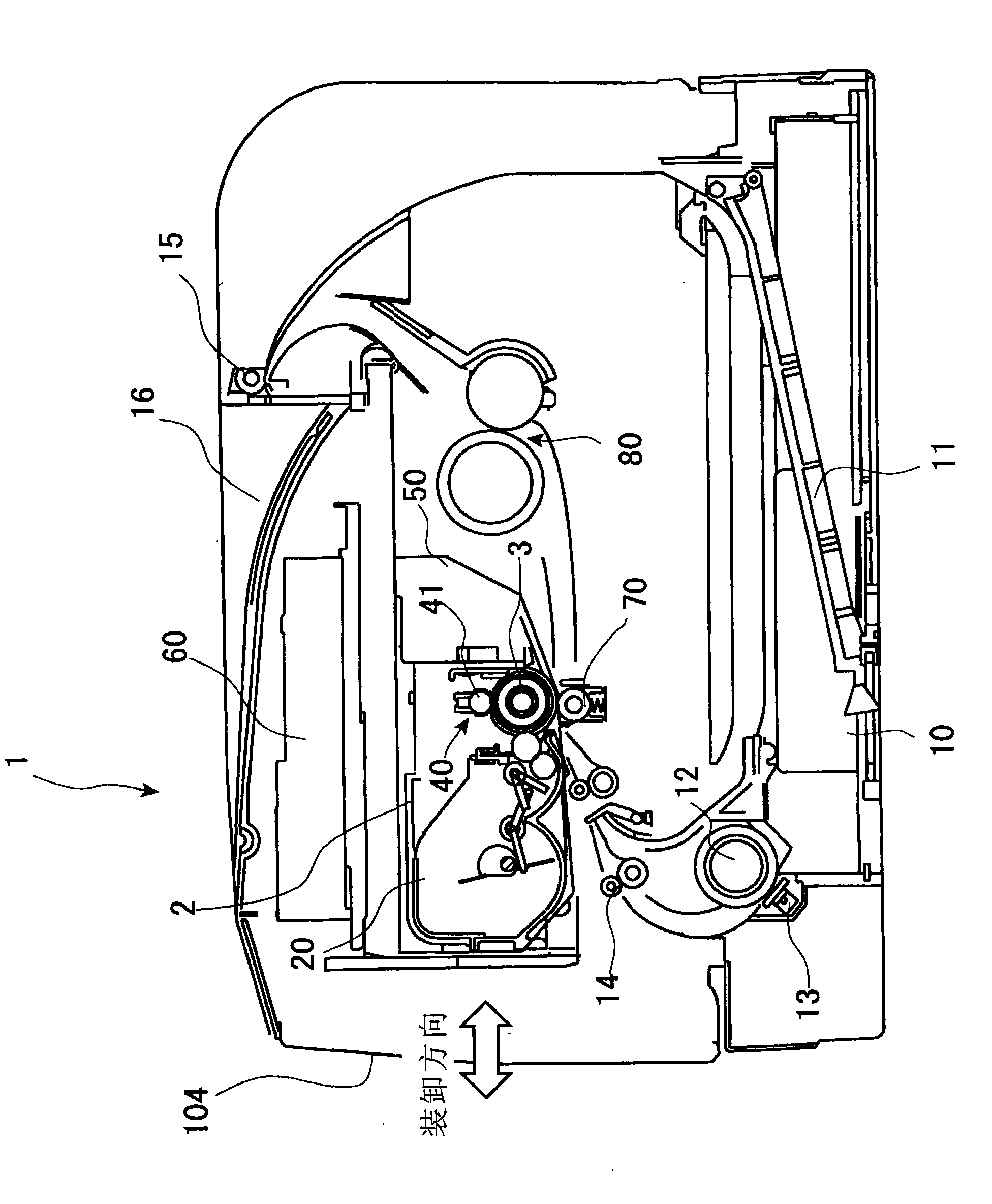

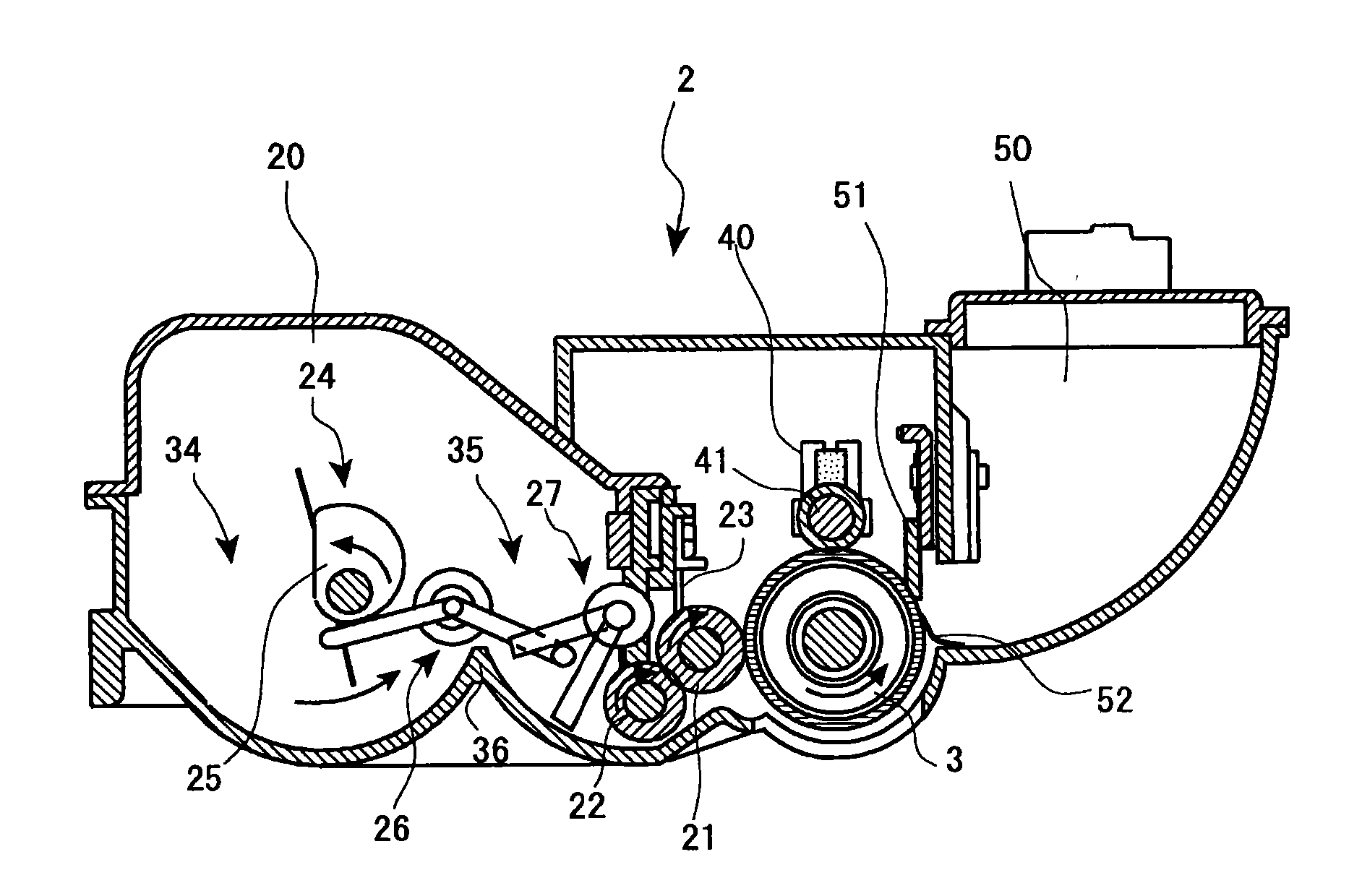

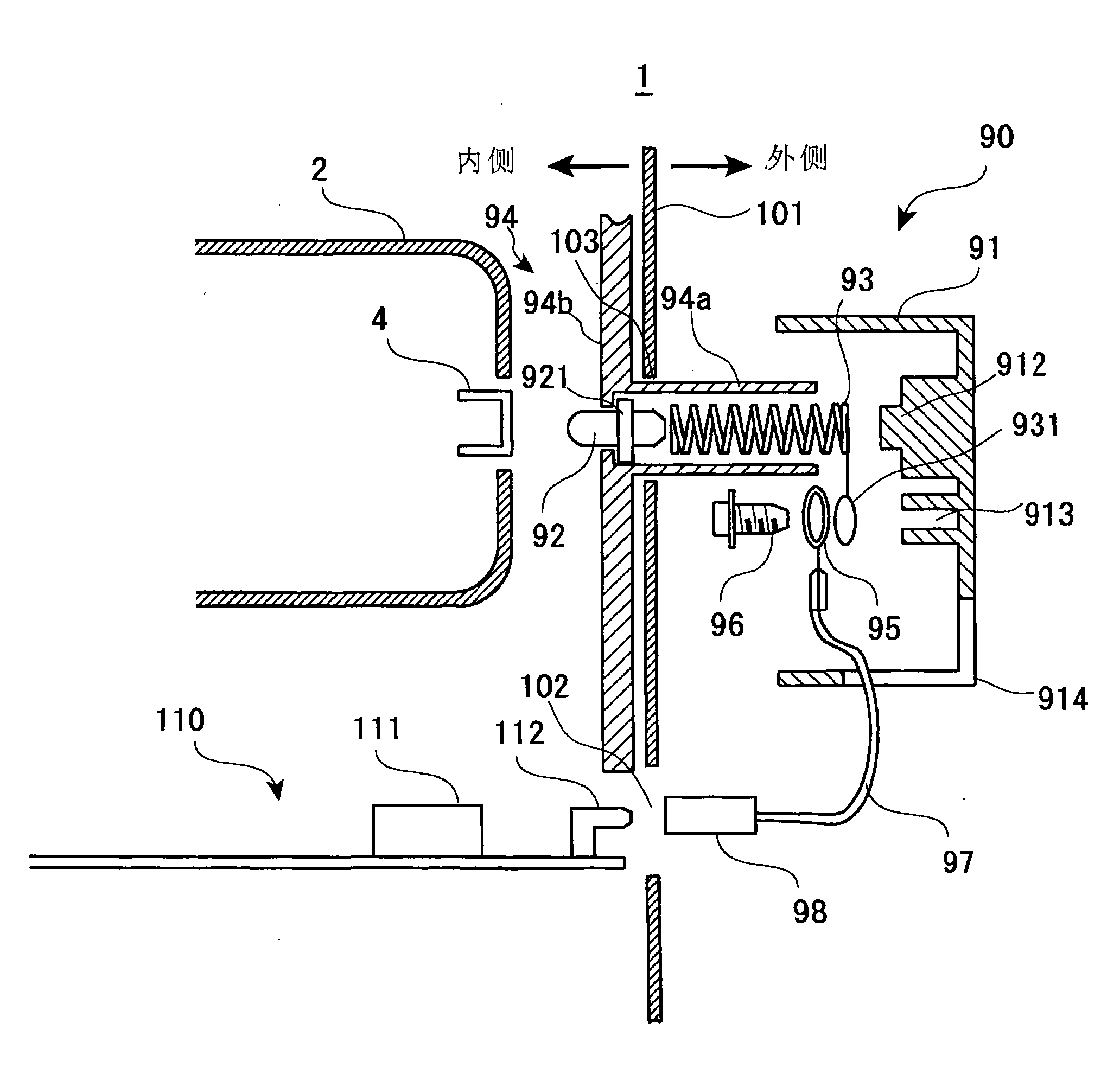

Power supply circuit, image forming device, power panel and processing unit

InactiveCN101673890APoor contactEasy loading and unloadingCoupling contact membersElectrographic process apparatusElectrical and Electronics engineeringEngineering

The invention provides a power panel with convenient assembly and disassembly, and further provides an image forming device not capable of generating poor connection among the power panel, an image carrier, a current-carrying device, a processing unit and the like. The method is characterized in that: a contact terminal (4) is arranged on a lateral surface of the processing unit (2); a contact terminal (92) on the body side is arranged at a position contacted with the contact terminal (4); the contact terminal (92) on the body side can be positioned in a displacing way along a direction vertical to a moving direction of the processing unit (2), and retreats in the direction vertical to the moving direction corresponding to the stress when moving from the processing unit (2) by attaching to the processing unit through a spring (93); and when the processing unit (2) is being mounted, the processing unit is connected with the contact terminal (4) on the processing unit side in a pressingway.

Owner:RICOH KK

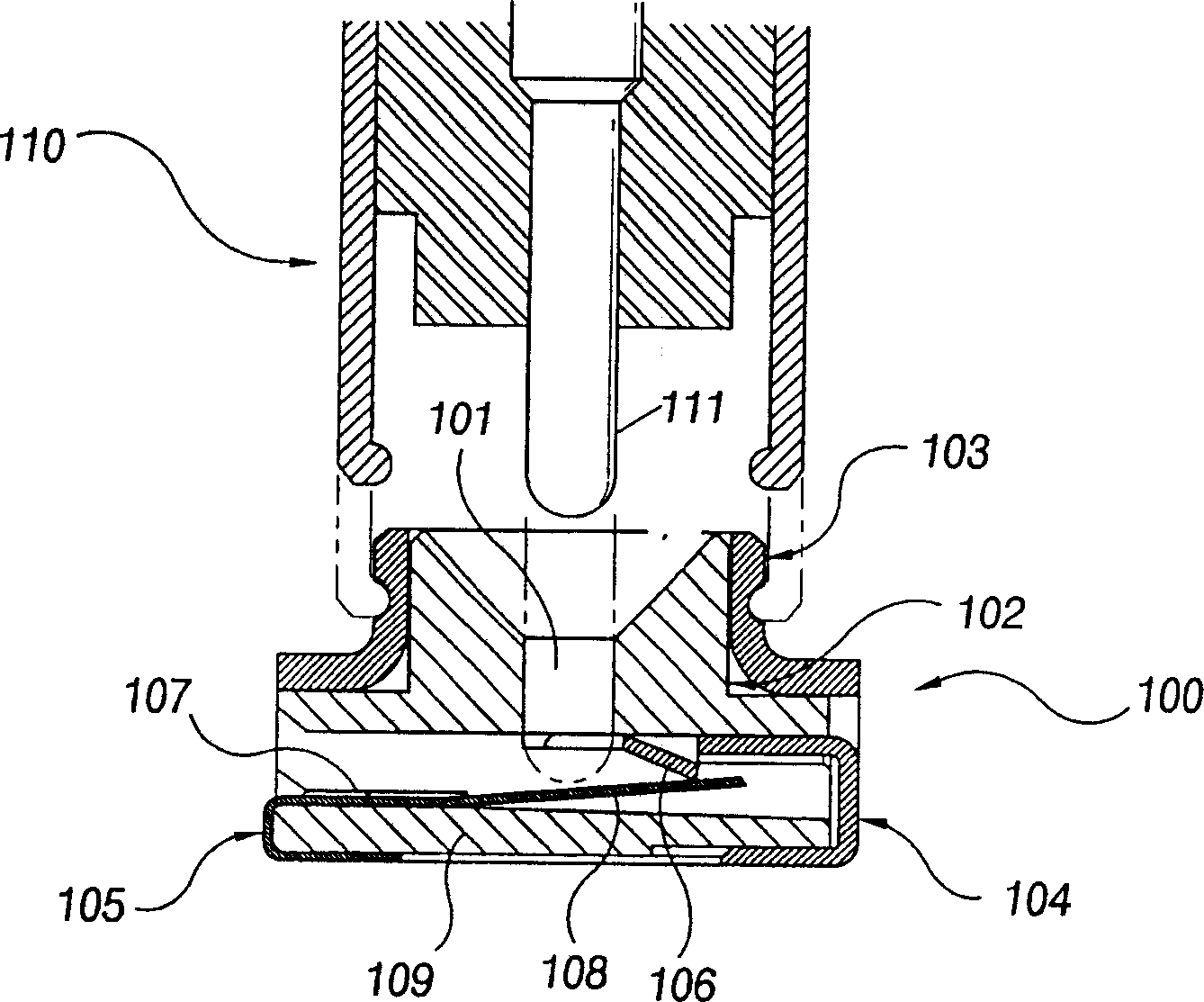

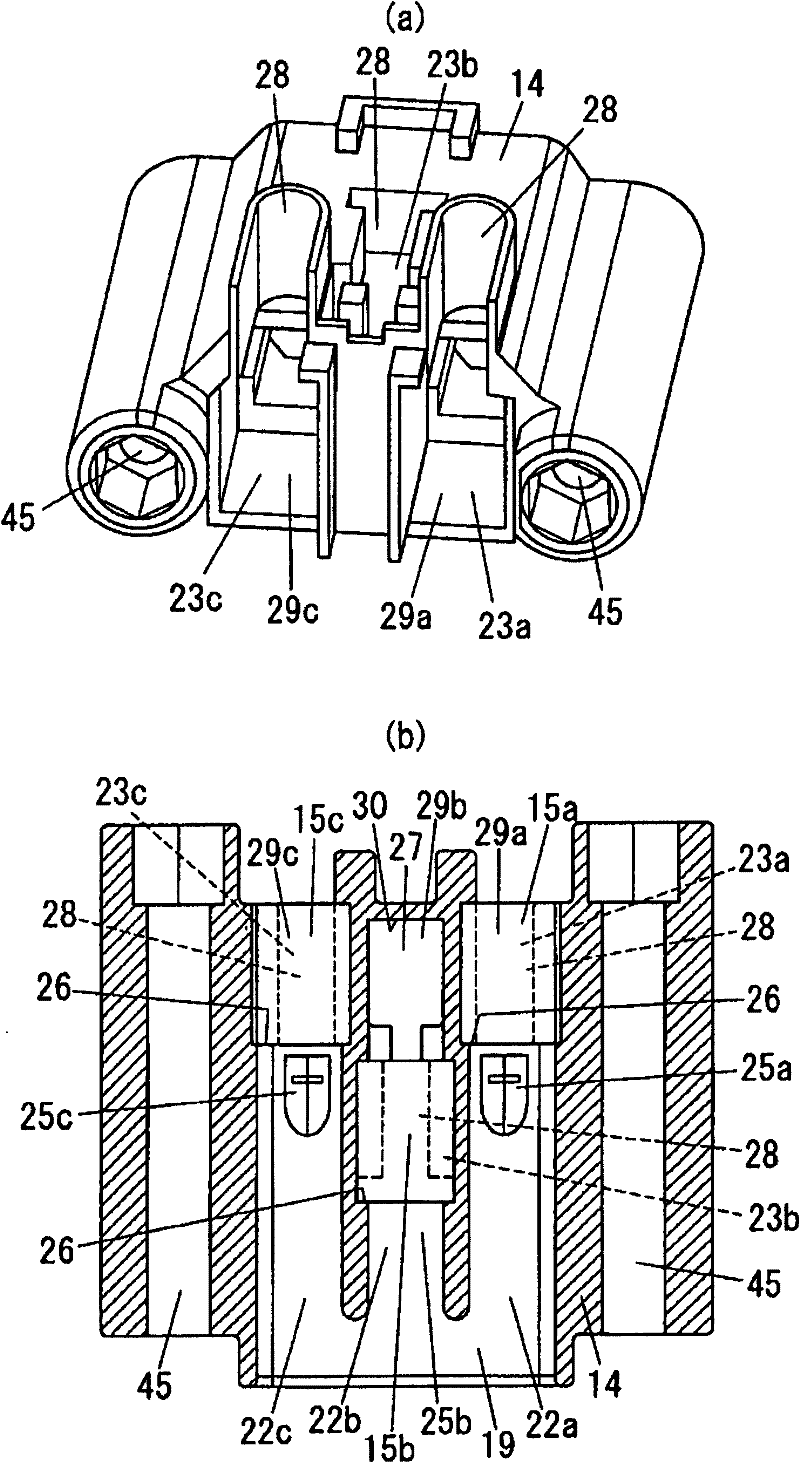

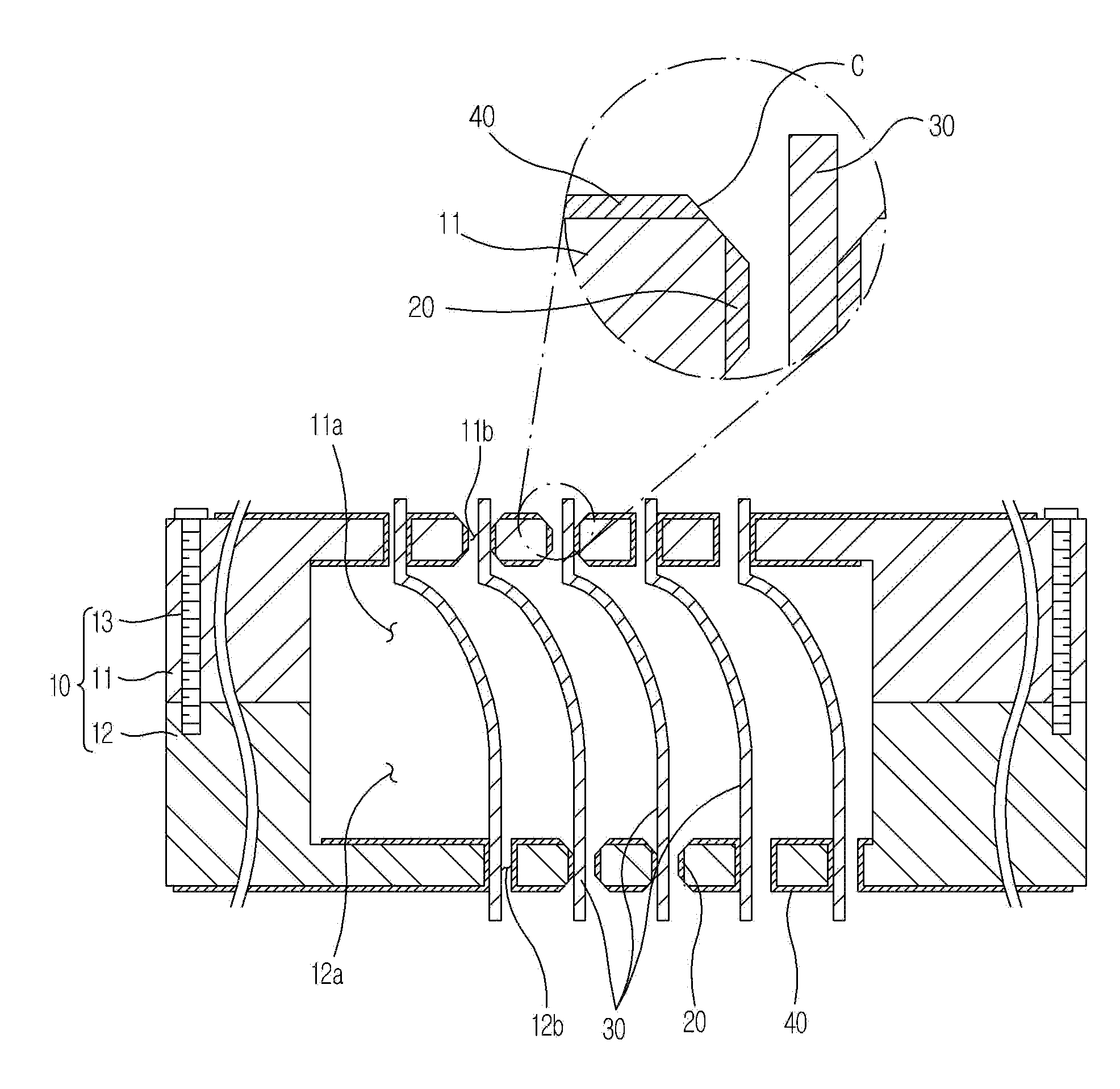

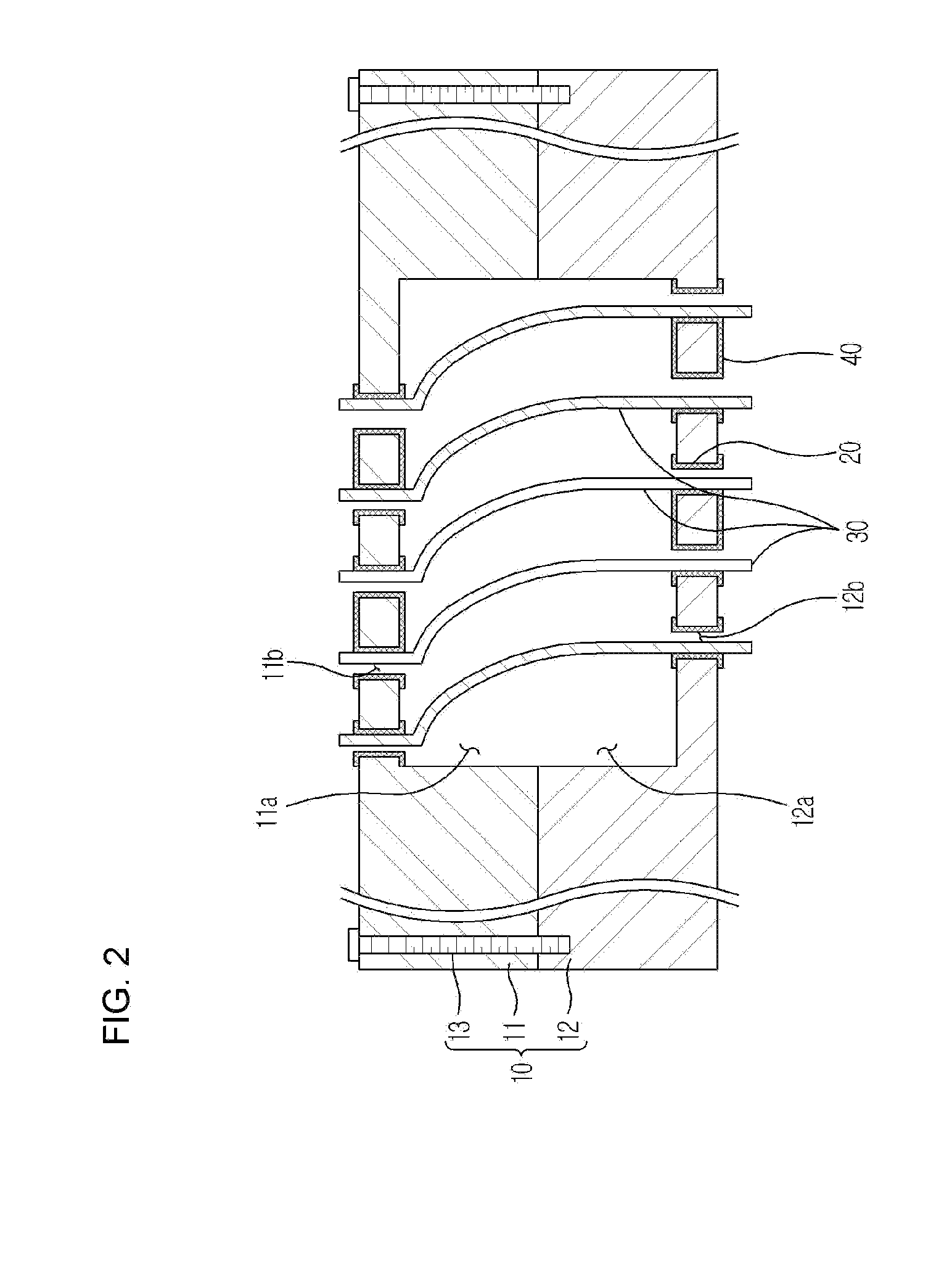

Coaxial connector with RF switch

InactiveCN1722542AAvoid it happening againGuaranteed stabilityTwo pole connectionsCoupling device detailsElectrical conductorRF switch

The present invention relates to coaxial connector with an RF switch. In particular, a housing 10 covered with an external conductor 17 is composed of upper and lower housings 11 and 12 . A fixed terminal 21 connected to an RF circuit is insert molded in the upper housing 11 , and a movable terminal 25 that is selectively brought into contact with the fixed terminal 21 is insert molded in the lower housing 12 . The movable terminal 25 comprises a fixed portion 26 fixed to the lower housing 12 ; a waist portion 27 extending upwardly from the fixed portion 26 at a first angle alpha1 and molded to the lower housing 12 ; and an elastic piece 28 bent from the tip end of the waist portion 27 at a second angle alpha2, extending into a space 15 of the housing, and being contact with the fixed terminal 21.

Owner:HTEC

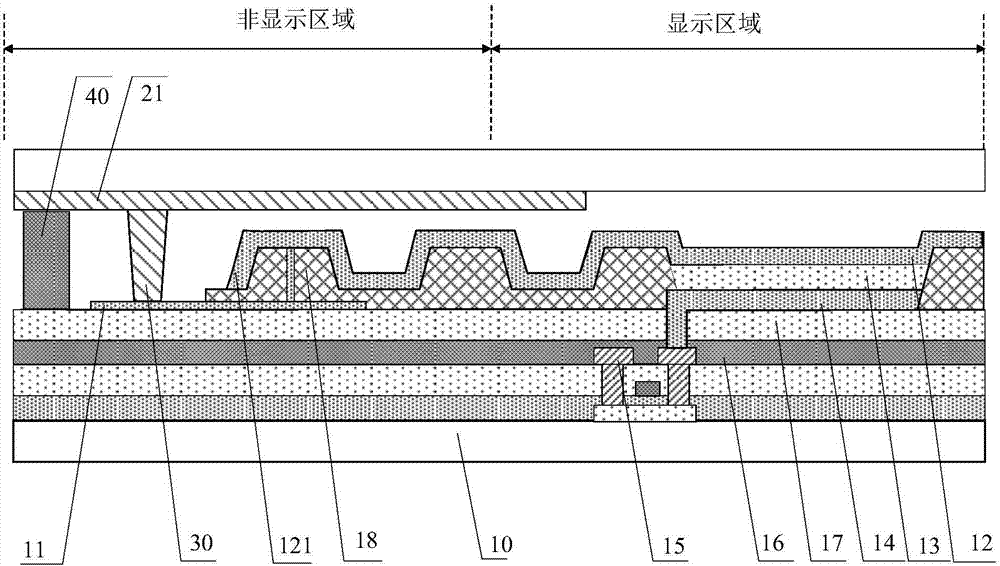

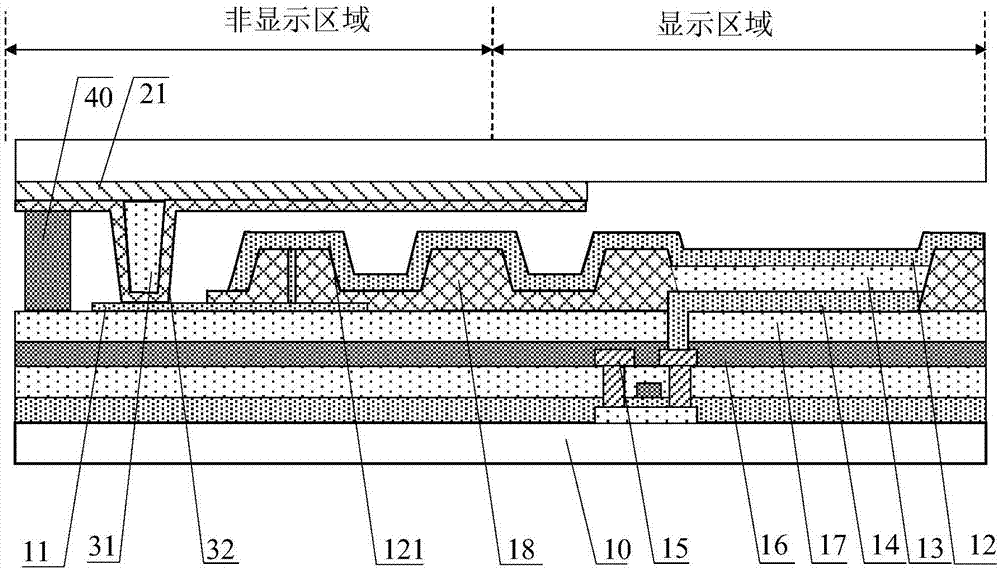

Array substrate, display device and manufacture method of the array substrate

ActiveCN104064567APoor contactAvoid the risk of short circuitsSolid-state devicesNon-linear opticsPhysicsDisplay device

The invention discloses an array substrate, a display device and a manufacture method of the array substrate. The array substrate comprises an IC crimping region including an IC region and a terminal region arranged on one side of the IC region and near an edge of the array substrate. The terminal region is provided with a plurality of transmission terminals. The IC region comprises a conductor layer, a first insulating layer, a separating layer and a second insulating layer stacked one by one. Each transmission terminal comprises a first conductive layer which is arranged on the second insulating layer and extends from the terminal region to the IC region. The separating layer is arranged in the IC region and at least overlaps with the first conductive layers extending to the IC region. When a small-size IC chip is adopted, contact failure between the IC chip and the terminals of the array substrate can be prevented. Meanwhile, short circuit risks between the first conductive layers and the conductor layer can be avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

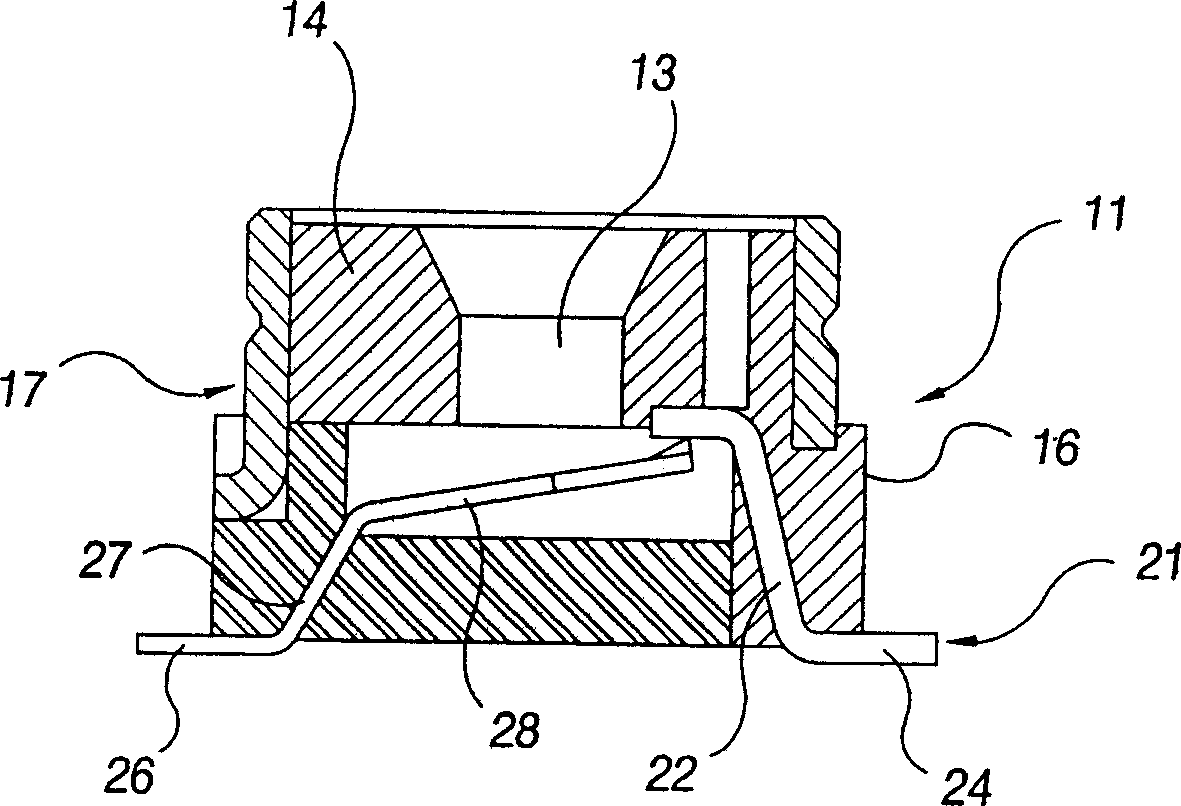

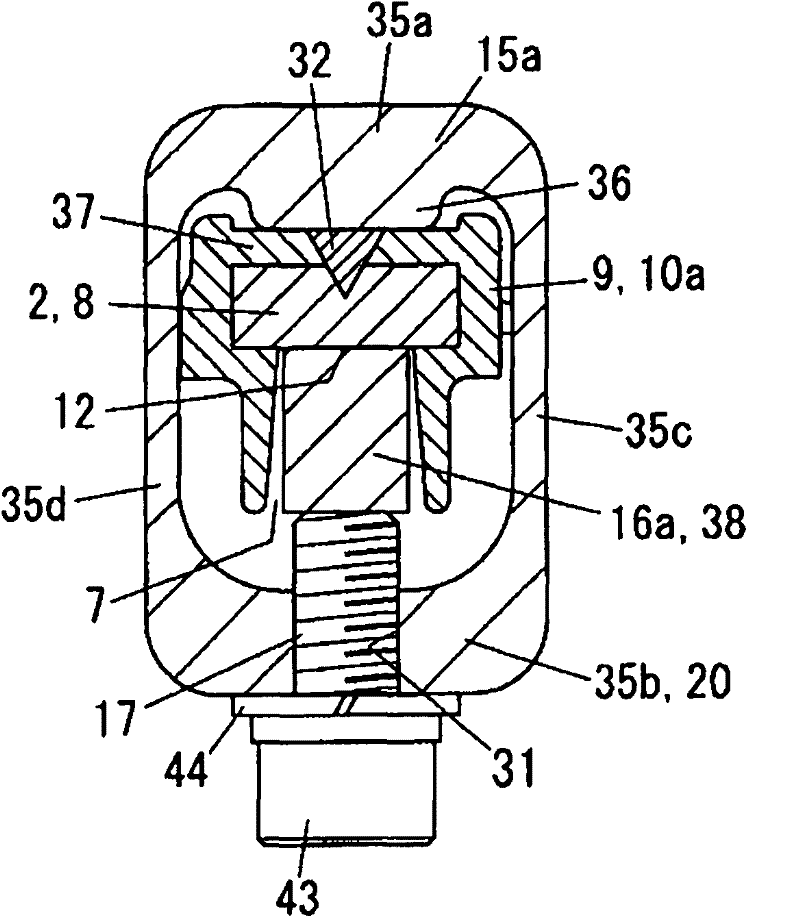

Connector

ActiveCN102394394AReduce laborPoor contactNon-rotary current collectorTrolley linesElectrical conductorEngineering

The present invention provides a connector which can reduce labor amount in processing for stripping out conductor of overhead insulated wire and can prevent inferior contact between terminals and the conductor of the overhead insulated wire. Terminals (16a-16c) which can connect electric wires (3) are provided with contact parts (38). The contact parts contact with an exposed surface (12) which is exposed from a slot opening (7) of sheath parts (10a-10c) of the overhead insulated wire (2). The connector is provided with a pressing component (17) which directly presses the contact parts (38) from an opposite side of the conductor (8) to the side of the conductor (8).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

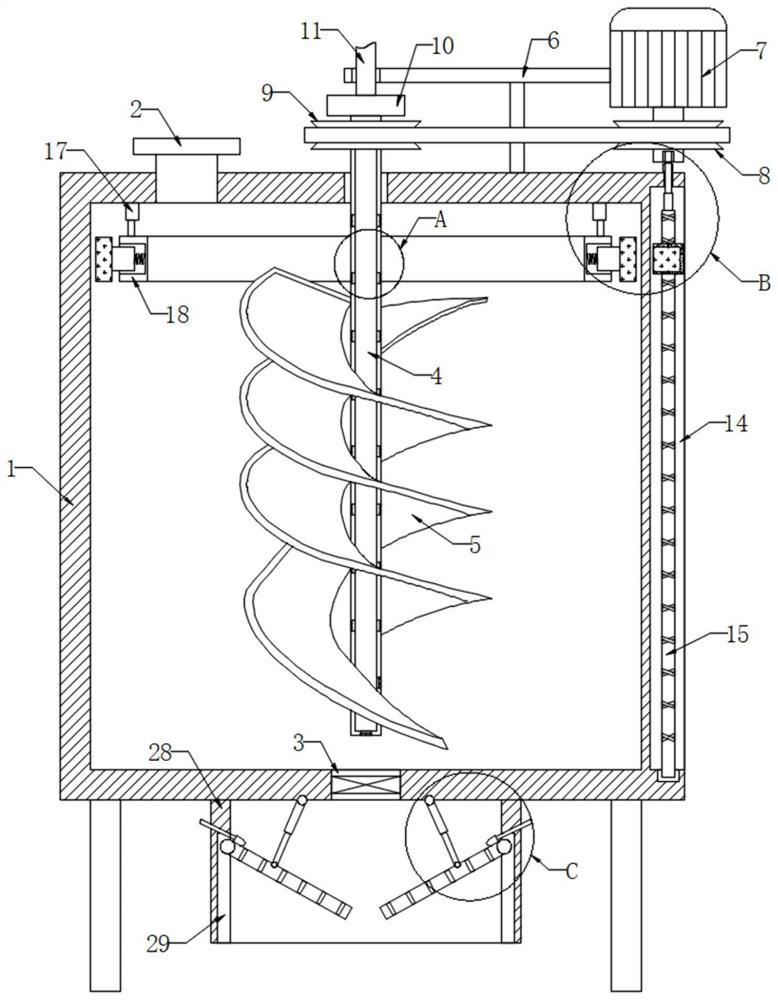

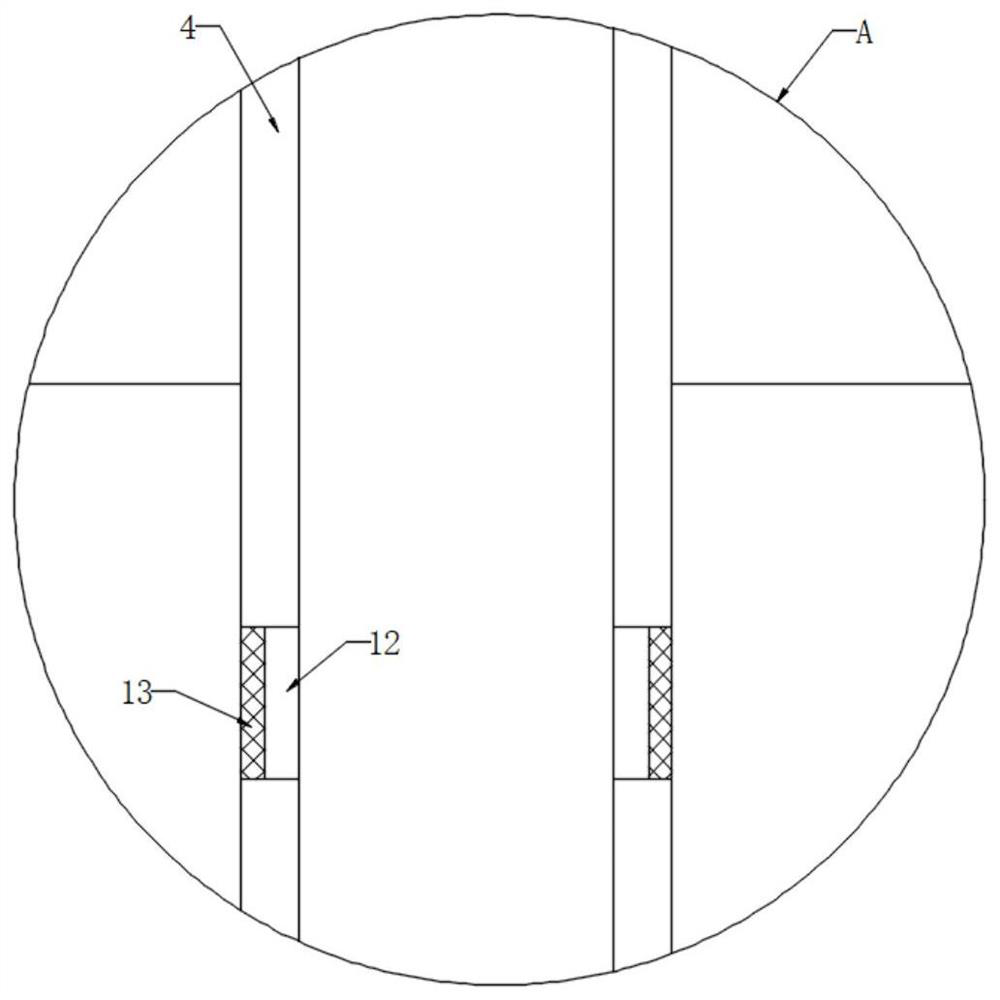

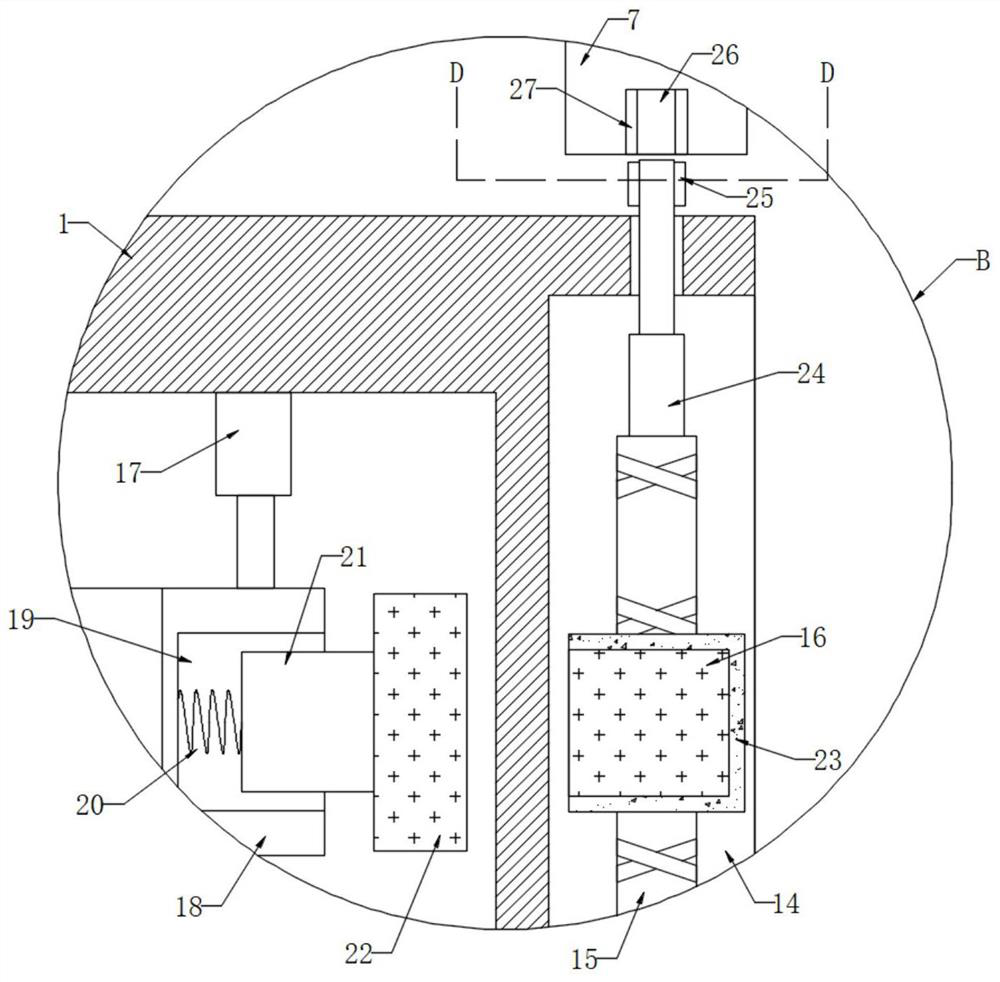

Self-cleaning mortar mixer

InactiveCN111873175AEasy to cleanAffectHollow article cleaningCement mixing apparatusBLENDER/MIXERStructural engineering

One or more embodiments of the invention provide a self-cleaning mortar mixer which comprises a mixing box. A hollow rotating shaft is rotatably connected to the top in the mixing box, mixing blades are fixedly connected to the side wall of the hollow rotating shaft, and the upper end of the hollow rotating shaft penetrates through the upper end of the mixing box and extends to the outside of themixing box. The upper end of the hollow rotating shaft is fixedly connected with a rotating connector, the upper end of the rotating connector is fixedly connected with a water inlet pipe, and water spraying openings are evenly formed in the side wall of the hollow rotating shaft. According to the self-cleaning mortar mixer, water is sprayed into the hollow rotating shaft through the water inlet pipe and is rapidly sprayed out from the water spraying openings, residual mortar on the mixing blades and the inner wall of the mixing box is cleaned, and the cleaning effect is excellent; a magneticsliding block moves up and down on the inner wall of a sliding groove through rotation of a reciprocating lead screw, and the magnetic sliding block drives a scraping plate to move up and down on theinner wall of the mixing box; and the residual mortar on the inner wall of the mixing box is scraped up and down, so that the mortar on the inner wall of the mixing box is prevented from influencing the subsequent use of the mixer, and the labor force is reduced.

Owner:WUHU INST OF TECH

Semiconductor testing apparatus

ActiveUS20150198632A1Enhancement in various characteristicImprove reliabilityElectrical measurement instrument detailsIndividual semiconductor device testingElectricityHigh frequency

Provided is a semiconductor testing apparatus that a testing pin is rendered to electrically connect to another testing pin or an external substrate through a conductive layer formed in the guide hole, so that it results in enhancement in various characteristics such as poor electrical contact of the testing pin, space efficiency, noise, and high frequency characteristics, thereby improving reliability in testing results.

Owner:WILLTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com