A negative electrode active material for a lithium ion battery, a preparing method thereof, a negative electrode plate of the lithium ion battery and the lithium ion battery

A negative electrode active material, lithium-ion battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, batteries, etc., can solve the problems of battery capacity attenuation, active material and conductive agent, poor contact of current collector, etc., and achieve long cycle life , The preparation method is simple and easy to operate, and the effect of alleviating the swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A second aspect of the embodiment of the present invention provides a method for preparing a negative electrode active material for a lithium ion battery, including:

[0033] The carbon material and black phosphorus are mixed and then ball-milled, the ball-milling speed is 300r / min-700r / min, the ball-milling time is 10h-20h, the carbon material and the black phosphorus are connected by C-P bond to form a complex, that is, lithium ions are obtained A negative electrode active material for a battery; the negative electrode active material for a lithium ion battery includes a composite formed by connecting a carbon material and black phosphorus through C-P bonds.

[0034] In an embodiment of the present invention, the black phosphorus and carbon materials are ball milled under an inert atmosphere. Optionally, black phosphorus and carbon material are added together into a high energy ball mill for ball milling.

[0035] In the embodiment of the present invention, the mass ...

Embodiment 1

[0051] A preparation method of a negative electrode active material for a lithium ion battery, comprising:

[0052] Orthorhombic black phosphorus and artificial graphite were added to a high-energy ball mill at a weight ratio of 7:3, and the ball mill speed was adjusted to 500 r / min.

[0053] The 18650 battery is made according to the conventional method, wherein the negative electrode active material includes a composite formed by ball-milled orthorhombic black phosphorus and artificial graphite balls, the positive electrode active material is lithium cobalt oxide, the electrolyte in the electrolyte is lithium hexafluorophosphate, and the solvent is ethylene carbonate and diethyl carbonate, the additive is vinylene carbonate, and the diaphragm material is polyethylene.

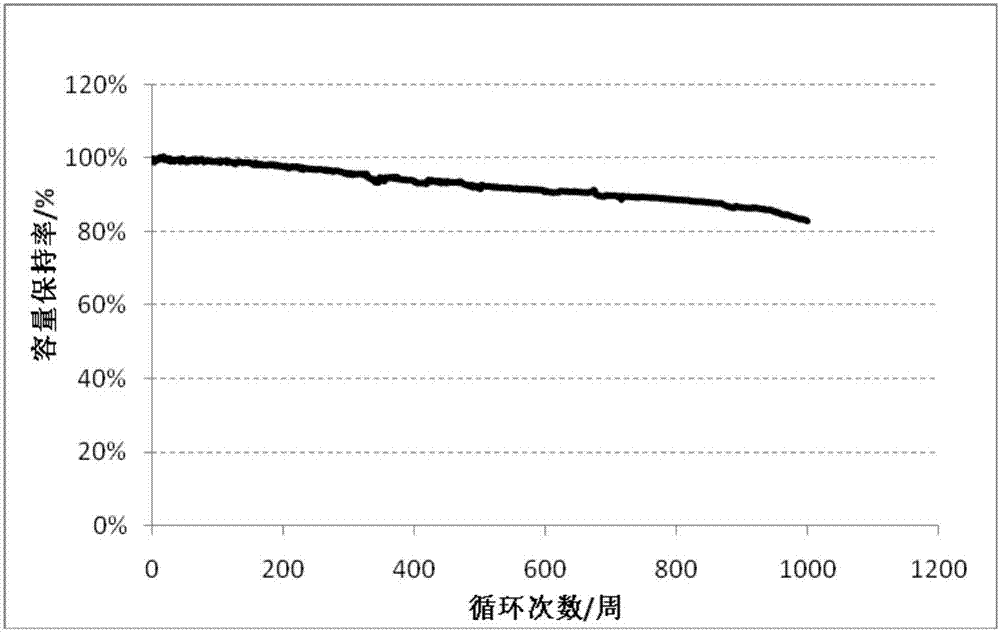

[0054] The battery prepared in Example 1 is tested for performance, and the energy density of the battery is 620wh / L. The cycle performance results are as follows: figure 1 shown, figure 1 It is the cycle c...

Embodiment 2

[0056] A preparation method of a negative electrode active material for a lithium ion battery, comprising:

[0057] Orthorhombic black phosphorus and graphene were added to a high-energy ball mill at a weight ratio of 8:2, the ball mill speed was adjusted to 700 r / min, and the ball mill was taken out after 18 hours to obtain a negative electrode active material for a lithium ion battery.

[0058] 523450 type flexible packaging battery was made according to the conventional method, wherein the negative electrode material comprises a compound formed by ball-milled orthorhombic black phosphorus and graphene, the positive electrode active material is a nickel-cobalt-aluminum ternary material, the electrolyte in the electrolyte is lithium hexafluorophosphate, and the solvent It is ethylene carbonate, dimethyl carbonate and diethyl carbonate, the additives are vinylene carbonate, fluoroethylene carbonate and propane sultone, and the diaphragm material is polypropylene.

[0059] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com