Organic light-emitting diode display panel and production method thereof

A technology for light-emitting diodes and display panels, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, and can solve problems such as poor display of OLED display panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

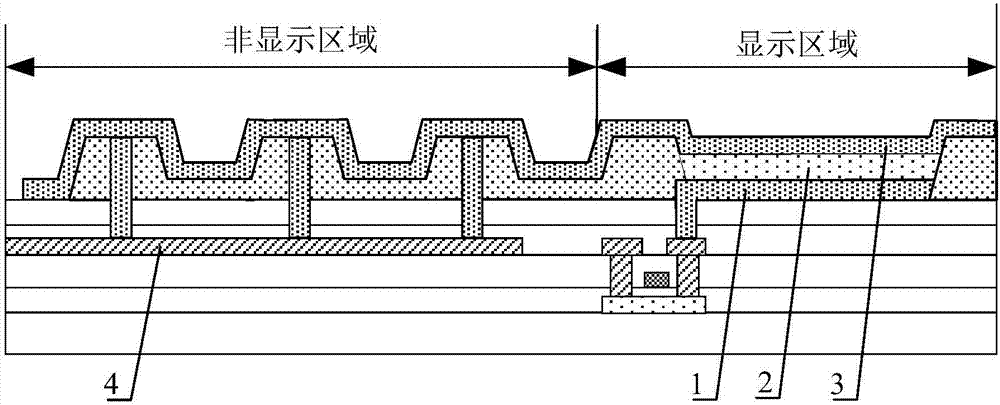

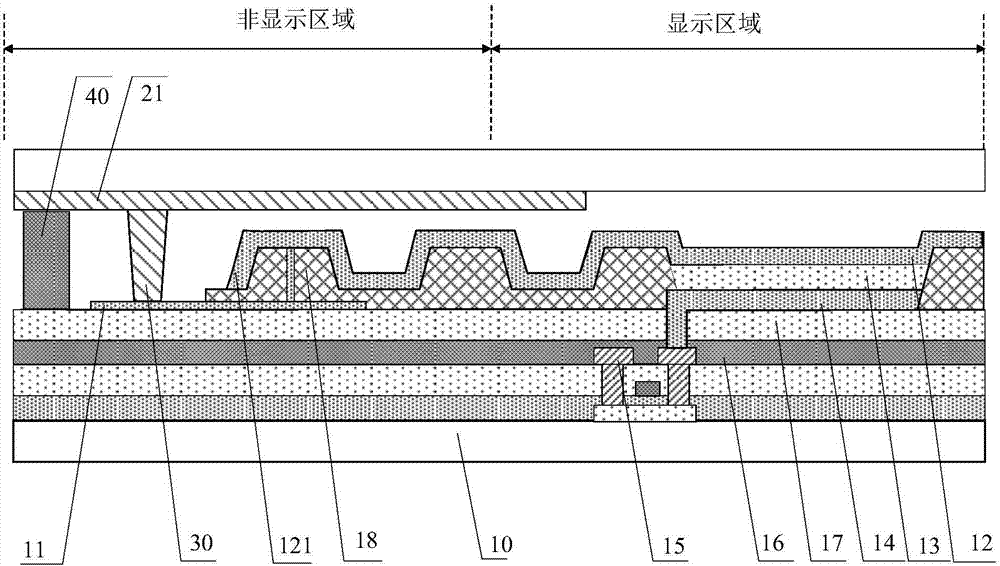

[0061] figure 2 A schematic structural diagram of an OLED display panel provided in Embodiment 1 of the present invention, as shown in figure 2 As shown, the OLED display panel provided by the embodiment of the present invention includes: a first substrate and a second substrate oppositely arranged; the first substrate includes a first lead 11 connected to a cathode 12; the second substrate includes a second lead 11 connected to a peripheral circuit. Lead wire 21 ; the first lead wire 11 is connected to the second lead wire 21 through the connecting portion.

[0062] In this embodiment, the first substrate is an array substrate, and the second substrate is a color filter substrate. It should be understood that the first substrate includes a base 10, and the base 10 includes a display area and a non-display area around the display area. The first substrate It also includes: a thin film transistor 15 arranged on the substrate 10 in the display area, a passivation layer 16 and a...

Embodiment 2

[0076] Based on the above inventive concept, image 3 A schematic structural diagram of an OLED display panel provided in Embodiment 2 of the present invention, as shown in image 3 As shown, the OLED display panel provided by the embodiment of the present invention includes: a first substrate and a second substrate oppositely arranged; the first substrate includes a first lead 11 connected to a cathode 12; the second substrate includes a second lead 11 connected to a peripheral circuit. Lead wire 21 ; the first lead wire 11 is connected to the second lead wire 21 through the connecting portion.

[0077] In this embodiment, the first substrate is an array substrate, and the second substrate is a color filter substrate. It should be understood that the first substrate includes a base 10, and the base 10 includes a display area and a non-display area around the display area. The first substrate It also includes: a thin film transistor 15 arranged on the substrate 10 in the disp...

Embodiment 3

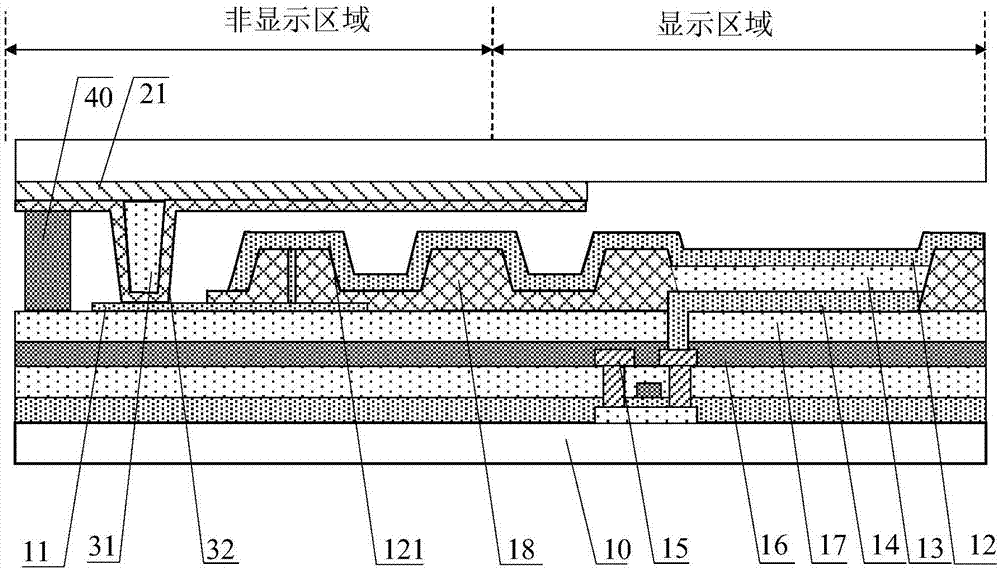

[0092] Based on the above inventive concept, Figure 4 A schematic structural diagram of the OLED display panel provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the OLED display panel provided by the embodiment of the present invention includes: a first substrate and a second substrate oppositely arranged; the first substrate includes a first lead 11 connected to a cathode 12; the second substrate includes a second lead 11 connected to a peripheral circuit. Lead wire 21 ; the first lead wire 11 is connected to the second lead wire 21 through the connecting portion.

[0093] In this embodiment, the first substrate is an array substrate, and the second substrate is a color filter substrate. It should be understood that the first substrate includes a base 10, and the base 10 includes a display area and a non-display area around the display area. The first substrate It also includes: a thin film transistor 15 arranged on the substrate 10 in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com