Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

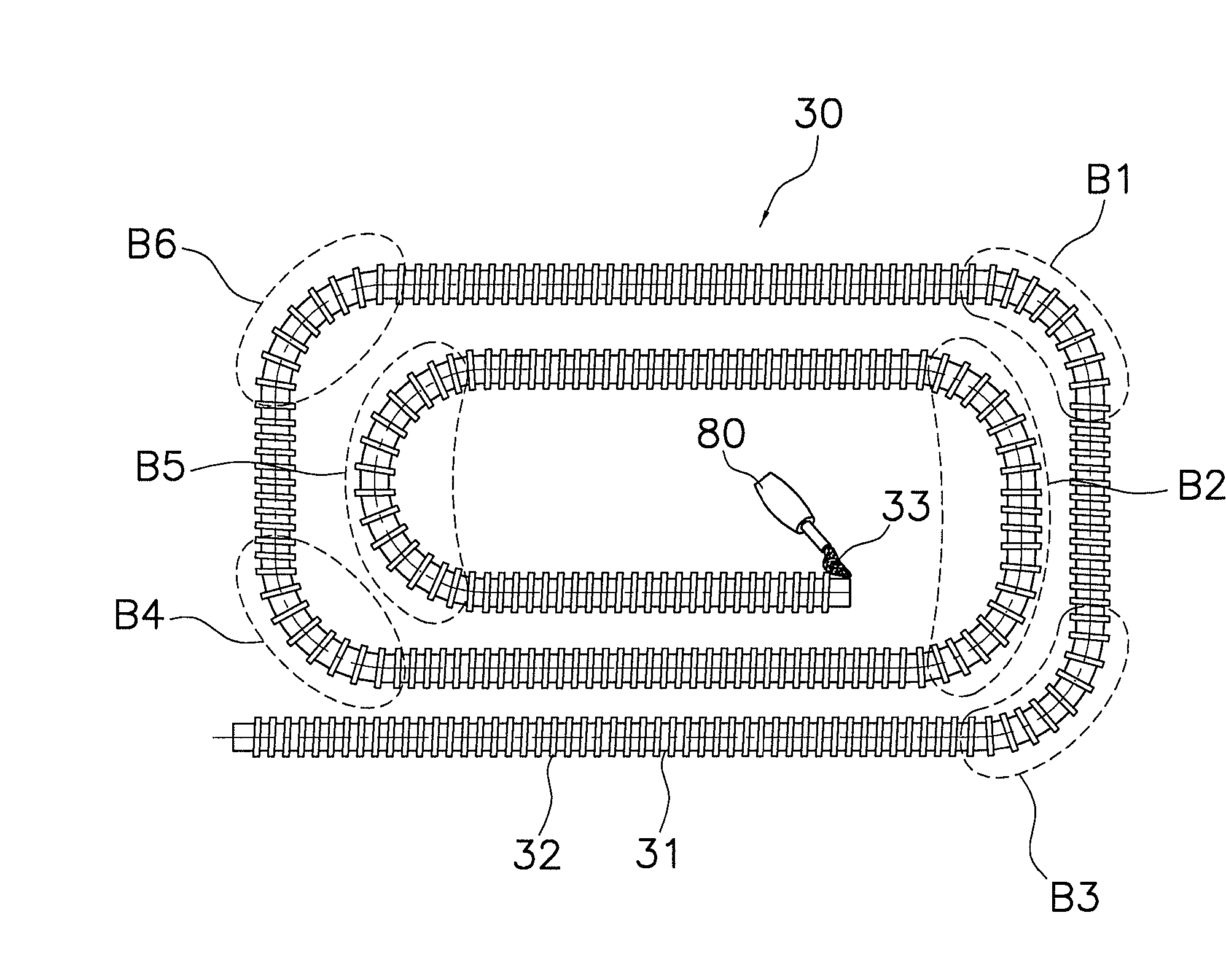

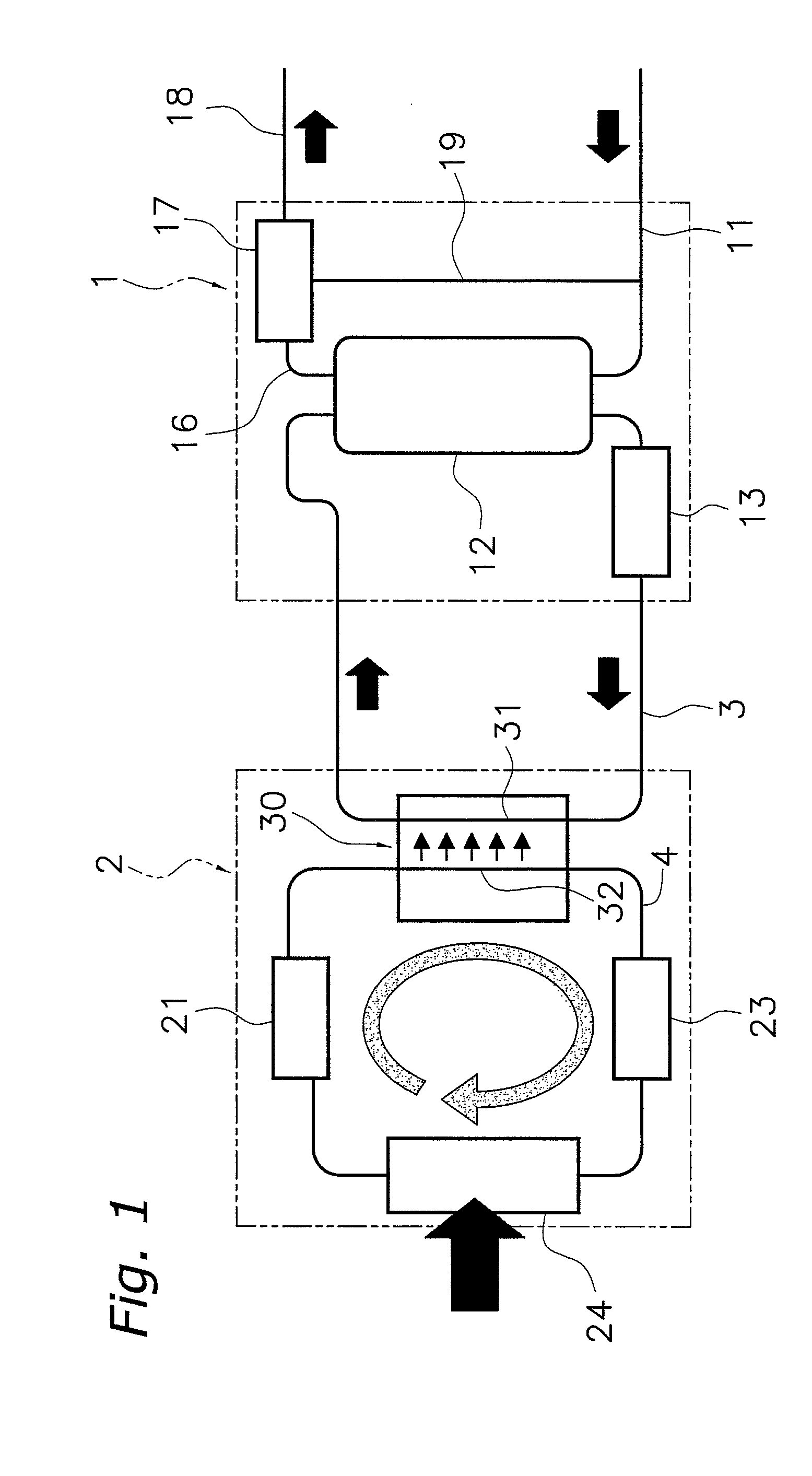

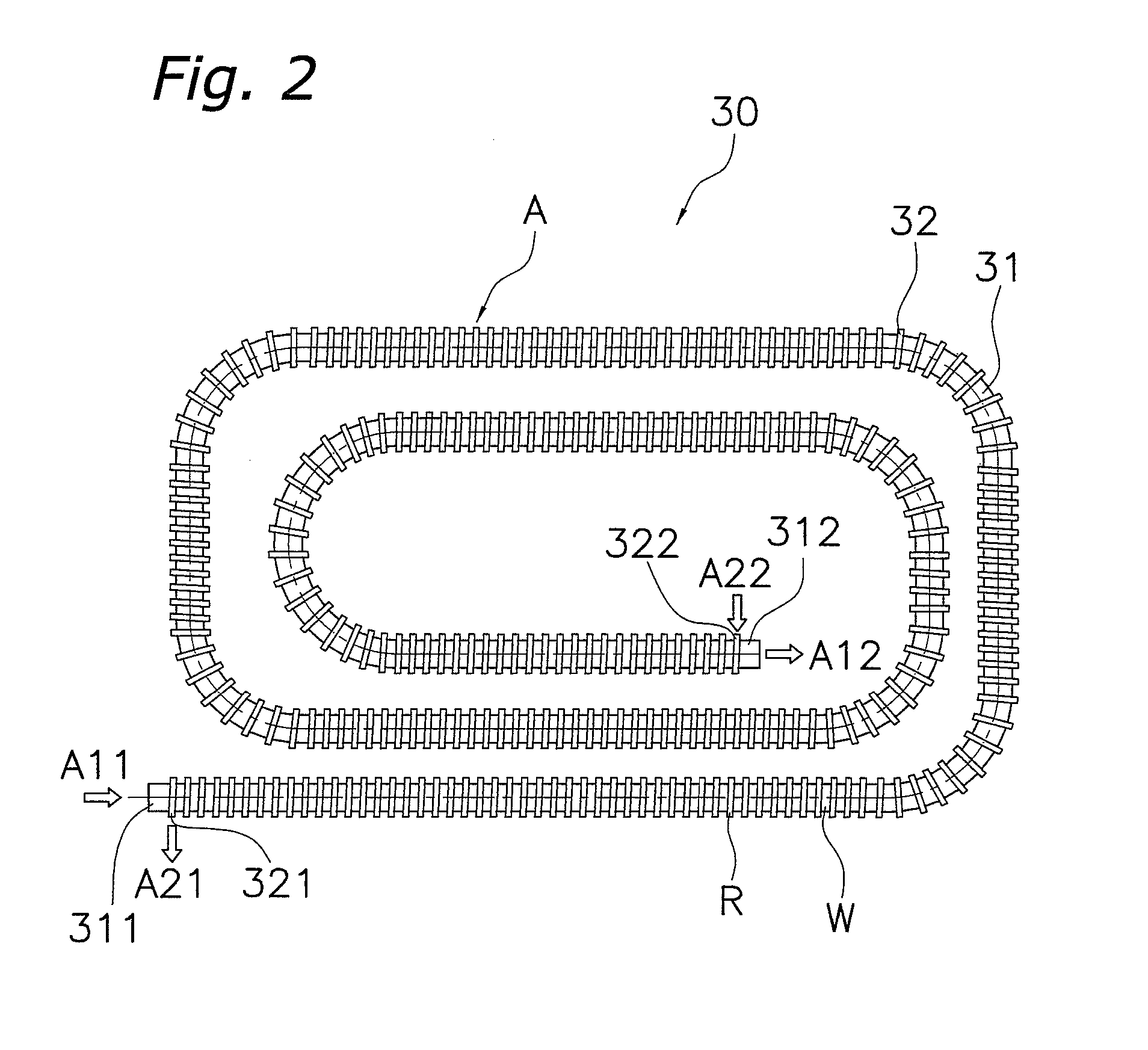

[0028]The heat exchanger according to the present invention will now be described based on the attached drawings and the embodiments. FIG. 1 is a schematic diagram of a heat pump water heater in which a heat exchanger of the present invention is employed. In the heat pump water heater shown in FIG. 1, water is heated in a single pass from about 10° C. to about 90° C. over a long time of period in order to efficiently use low-cost nighttime electric power. Here, the heat pump water heater includes a hot water supply unit 1, and a heat pump unit 2. The following are successively coupled in the hot water supply unit 1: a service water pipe 11, a hot water storage tank 12, a water circulation pump 13, a water supply pipe 3, a core pipe 31 that constitutes a water heat exchanger 30, a hot water pipe 16, a mixing valve 17, and a hot water supply pipe 18. Here, service water is supplied from the water supply pipe 11 to the hot water storage tank 12. Low temperature water is supplied by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com