High-power LED heat-dissipation packaging structure

A packaging structure, high-power technology, applied in cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of luminous efficiency decline, luminous yellow/blue spots, poor consistency, etc., and reach the contact surface Reduce, increase heat dissipation performance, and avoid the effect of increasing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

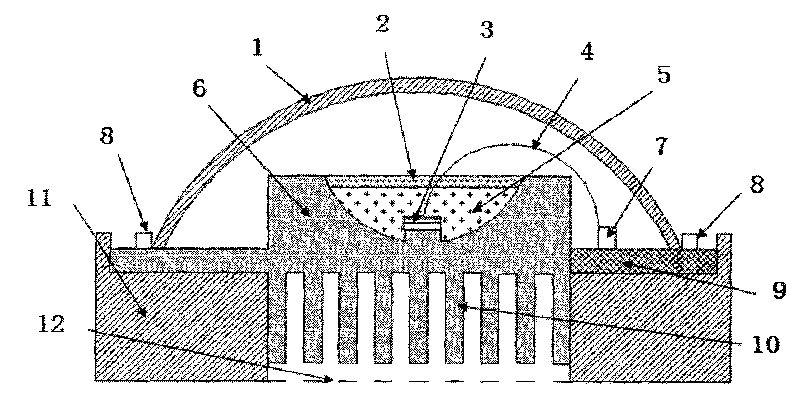

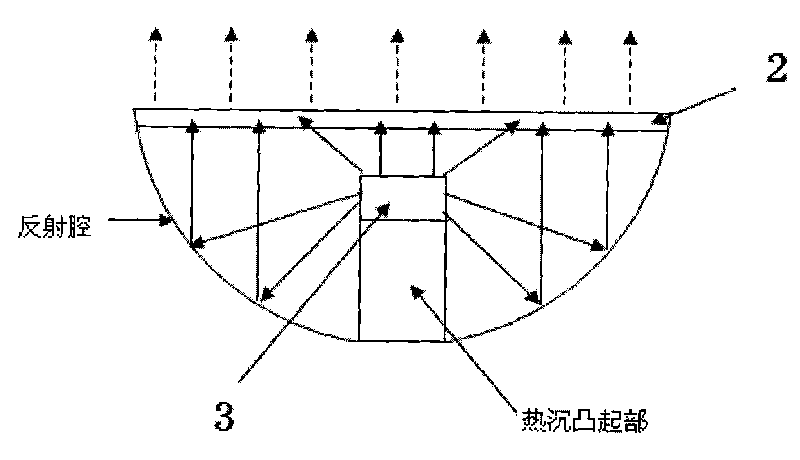

[0024] Example 1 as figure 1 As shown, the high-power LED heat dissipation packaging structure includes an aluminum heat sink 6 and a chip 3 arranged in the concave cavity of the aluminum heat sink 6. The anode of the LED chip 3 is connected to the internal terminal 7 through a gold wire 4, and the internal terminal 7 7 is connected to the external terminal 8 through the printed circuit board 9, and the lens 1 is potted on the aluminum heat sink 6 including the LED chip 3; wherein, the aluminum heat sink 6 has an inverted T-shaped structure and extends along its lower side There is a scaly heat sink 10 integrated with the aluminum heat sink 6, and a printed circuit board 9 is connected to the extension arm of the aluminum heat sink 6. The center of the aluminum heat sink 6 is provided with a hemispherical concave cavity, and the LED chip 3 Mounted on the boss on the bottom surface of the semi-spherical concave cavity in the center of the aluminum heat sink 6, the flexible sili...

Embodiment 2

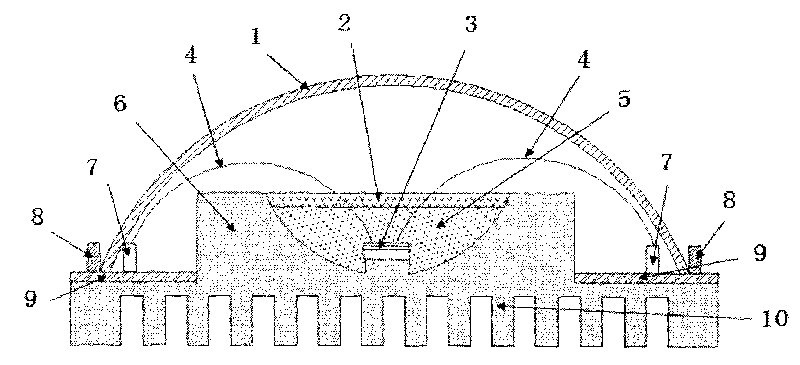

[0033] Example 2 as figure 2 As shown, the framework of this structure is substantially the same as that of Embodiment 1, except that a scale-shaped heat sink 10 integrally structured with the aluminum heat sink 6 extends below the inverted T-shaped aluminum heat sink 6 . There is no need to set up the plastic bracket 11 , the structure is simpler than that of Embodiment 1, and the link of the plastic bracket is omitted, and the fin-shaped structure at the bottom is conducive to the rapid dissipation of heat. Its heat dissipation effect is better than that of embodiment 1, but the difference is that its cost will be greater than that of embodiment 1.

[0034] The aluminum heat sink 6 of this structure is a double-arm structure, and the connection method of the upper end surfaces of the two arms is different from that of embodiment 1. The aluminum heat sink 6 of the double-arm structure and the scaly heat sink 10 of the integral structure of the aluminum heat sink 6 are vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com