Carrier and light-emitting device

A light-emitting device and carrier technology, applied in the field of lighting, can solve problems such as poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the present application, all the embodiments, implementations and features of the present application can be combined with each other under the condition of no contradiction or conflict. In this application, conventional equipment, devices, components, etc., can be purchased commercially, or can be self-made according to the content disclosed in this application. In this application, in order to highlight the key points of this application, some conventional operations, equipment, devices, and components are omitted or simply described.

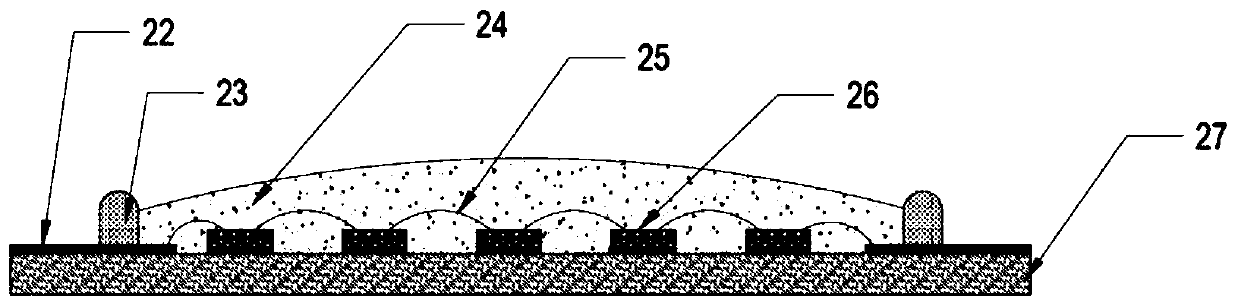

[0034] COB LED refers to a light-emitting diode device in which the chip is directly bonded and packaged on the entire substrate. There are multiple LED chips on the substrate of the device, which are integrated together for packaging. COB LED can be used to solve the problem of manufacturing high-power LED lamps through low-power chips, so it is widely used in bulbs, spotlights, downlights, fluorescent lamps, street lamps, high ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com