A kind of composite fluorescent ceramic material and preparation method thereof

A technology of fluorescent ceramics and synthesis methods, which is applied to luminescent materials, heat exchange materials, chemical instruments and methods, etc., can solve the problem of low efficiency of fluorescent materials absorbing and converting blue light, thermal quenching, poor thermal shock resistance of fluorescent materials, etc. problems, to achieve excellent luminescence thermal stability and physical and mechanical properties, reduce production and preparation costs, and improve thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

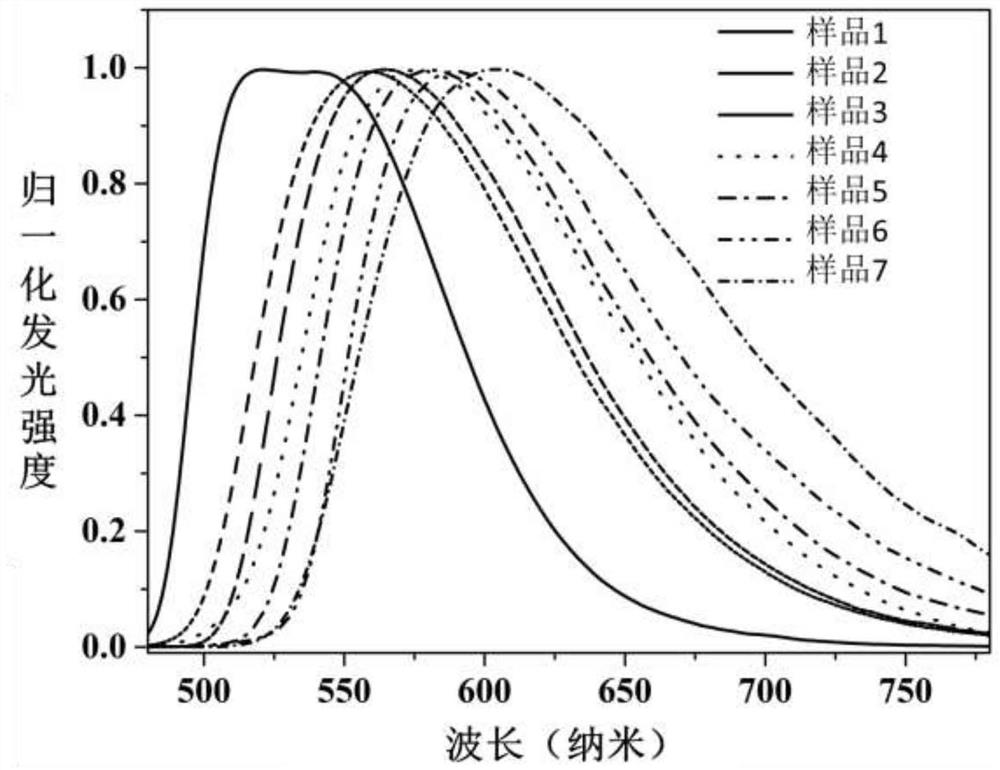

[0042] A chemical composition is xY 2 o 3 -yLu 2 o 3 -zAl 2 o 3 -mSiO 2 -nMgO-pCe 2 o 3 A series of components of fluorescent ceramic materials are as follows:

[0043]

[0044] (1) Calculate the amount of each oxide substance by 100% mol, weigh Y respectively 2 o 3 , Lu 2 o 3 , Al 2 o 3 , SiO 2 , MgO, Ce 2 o 3 corresponding to the amount of substance. Use a grinding tank to add zirconia balls, and use absolute ethanol as the grinding medium for grinding and mixing until the average particle size of the powder is less than 1 μm;

[0045] (2) The obtained slurry is dried and sieved, and the sieved powder is kept at 1000°C in the air for 2 hours to remove the organic matter in the powder; after the obtained powder is sieved, it is molded with a uniaxial mold, and 4Mpa is applied Keep the pressure for 2 minutes, after the pressure is released and sealed, press it again in the cold isostatic pressing equipment to obtain the green body, the pressure is 200MPa, ...

Embodiment 2

[0050] A chemical composition of 10% Y 2 o 3 -8.725%Lu 2 o 3 -21.25%Al 2 o 3 -10% SiO2 2 -10%MgO-0.025%Tb 2 o 3 The preparation method of the fluorescent ceramic material is as follows:

[0051] (1) Calculate the amount of each oxide substance by 100% mol, weigh Y respectively 2 o 3 : 10% mol, Lu 2 o 3 :8.725%mol, Al 2 o 3 : 21.25% mol, SiO 2 : 10% mol, MgO: 10% mol, Tb 2 o 3 : 0.025% mol. Use a grinding tank to add zirconia balls, and use absolute ethanol as the grinding medium for grinding and mixing until the average particle size of the powder is less than 1 μm;

[0052] (2) The obtained slurry is dried and sieved, and the sieved powder is kept at 1000°C in the air for 2 hours to remove the organic matter in the powder; after the obtained powder is sieved, it is molded with a uniaxial mold, and 4Mpa is applied Keep the pressure for 2 minutes, after the pressure is released and sealed, press it again in the cold isostatic pressing equipment to obtain the g...

Embodiment 3

[0057] A chemical composition of 10% Y 2 o 3 -8.7%Lu 2 o 3 -16.25% Al 2 o 3 -15% SiO2 2 -15%MgO-0.05%Ce 2 o 3 The preparation method of the fluorescent ceramic material is as follows:

[0058] (1) Calculate the amount of each oxide substance according to 100% mol, and weigh Y 2 o 3 :-10%mol, Lu 2 o 3 : -18.7% mol, Al 2 o 3 : -16.25% mol, SiO 2 :-15%mol, MgO:-15%mol, Ce 2 o 3 : -0.05% mol. Use a grinding tank to add zirconia balls, and use absolute ethanol as the grinding medium to grind and mix until the average particle size of the powder is about 300nm;

[0059] (2) Dry and sieve the obtained slurry, heat the sieved powder in air at 850° C. for 2 hours to remove organic matter in the powder; sieve the obtained powder and wait for sintering for use;

[0060] (3) Put the ceramics in a muffle furnace for sintering. Start from room temperature with a heating rate of 5°C / min to 1200°C and keep it for 2 hours, then raise the temperature to 1680°C at 2°C / min and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com