Commissioning method of bypass-free wet desulphurization system of coal-fired unit by means of tiny-oil ignition

A technology of wet desulfurization and coal-fired units, applied in control systems, separation methods, chemical instruments and methods, etc., can solve problems such as plate deformation, secondary pollution, and plate condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

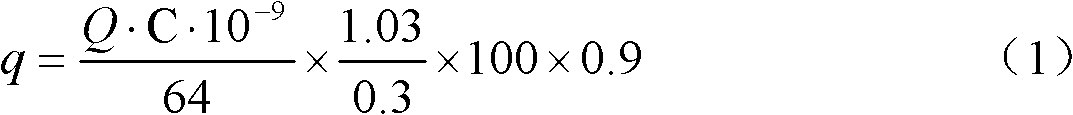

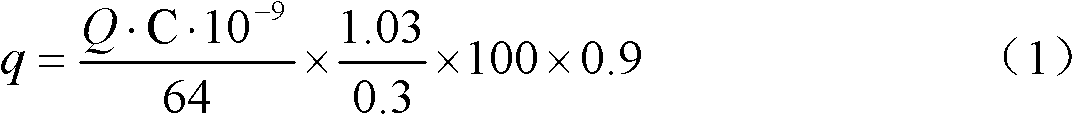

Image

Examples

Embodiment Construction

[0033] The commissioning of the non-bypass wet desulfurization system of coal-fired units is divided into two stages: cold state commissioning and hot state commissioning. In the cold state commissioning stage, it is mainly to pay attention that the desulfurization process water system and the desulfurization wastewater treatment system need to be commissioned in advance. The desulfurization wastewater treatment system is used to receive and treat the waste water generated by the desulfurization system. Because in the hot state commissioning, the system will discharge waste water during the startup stage of the unit. The debugging of other systems is the same as that of the monomer and sub-systems with bypass system.

[0034] A. Cold debugging method and sequence

[0035] The main tasks of the cold state commissioning stage are the individual commissioning of each equipment and the trial operation of the subsystems. It is worth noting that since there is no bypass flue, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com