Construction device capable of blanking mixed materials of block-shaped waste concrete

A technology for waste concrete and construction equipment, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of repeated transportation up and down, labor-intensive, long operation time, etc., to facilitate pouring, improve pouring efficiency, Use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the drawings and examples, but the implementation of the present invention is not limited thereto.

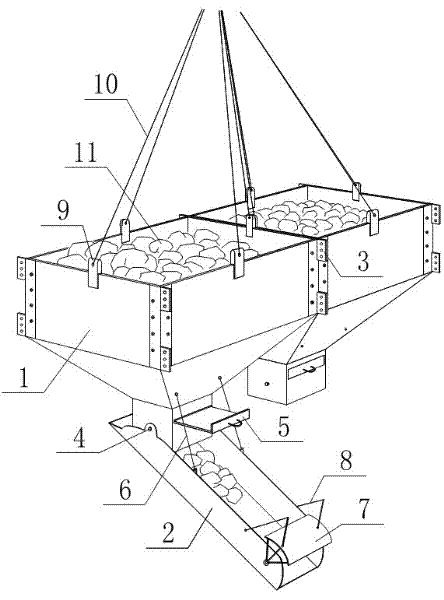

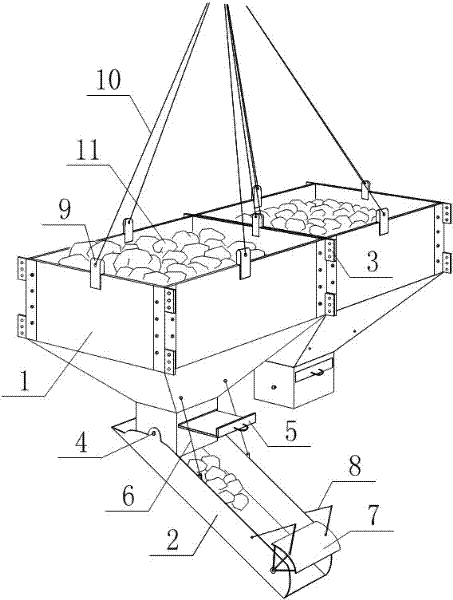

[0024] Such as figure 1 As shown, the mixing and unloading construction device for block-type waste concrete is mainly composed of a row-type hopper 1, an aqueduct 2, and an ear plate 3; the ear plate 3 is located at the corner of the hopper, and the hoppers are connected by the ear plate 3 to form a row-type Hopper 1; the upper part of the hopper is provided with lifting lugs 9, the lifting lugs 9 are connected with the wire rope 10 of the lifting equipment, the hopper is filled with block-shaped waste concrete 11, and the lower part of the hopper is equipped with drawer-type baffles 5; the aqueduct 2 is hung by 4 round hinges Connected to the bottom of the hopper, the inclination angle of the aqueduct 2 can be changed with the adjustment of the extension and contrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com