Steel form jumbo with main structure capable of passing conventional sections, and implementation method thereof

A technology of steel formwork trolley and main structure, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of high labor intensity, inconvenient construction, large disassembly and assembly workload, etc., and achieves less manpower and ensures work safety. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

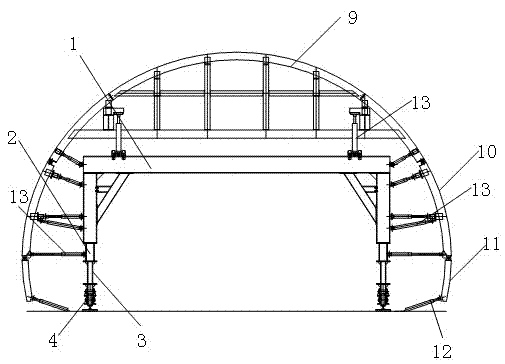

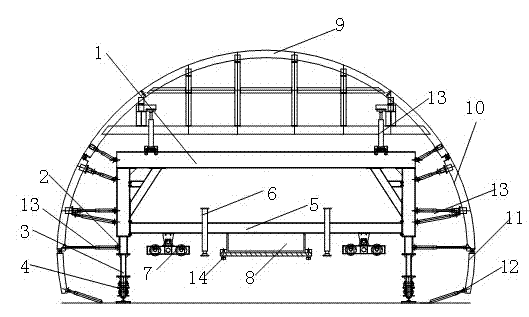

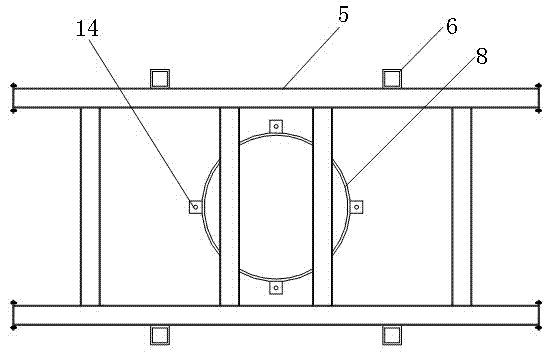

[0043] In the prior art, the method of passing the conventional section of the steel mold trolley is to disassemble and assemble the template and reduce the span of the gantry, so as to reduce the volume of the entire steel mold trolley and make it match the conventional section. This method has the advantages of low efficiency, high labor intensity and safety. Defects such as high risk. In order to overcome the defects of the prior art, this embodiment provides a steel mold trolley whose main structure can pass through a conventional section as a whole, such as Figures 1 to 4 As shown, the difference between this design and the prior art is that the main structure of the steel mold trolley is basically unchanged, such as dismantling, and the main structure of the steel mold trolley is used as a whole to pass through a conventional section. Specifically, the steel formwork trolley mainly includes a main structure and a working traveling device 4; wherein, the main structure s...

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is that when the conventional section that the steel mold trolley needs to pass through is relatively large, the enlarged section is basically equivalent to the conventional section. Therefore, only part of the steel mold trolley needs to be adjusted. The specific method is: the height difference between the main structure of the trolley and the ground can be adjusted through the height adjustment column, and then supplemented by the removal of part of the formwork, such as the bottom mold and / or side mold, the steel mold trolley can be realized. Through the purpose of regular section, the construction efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com