Integrated double concrete supplying and pouring system and supplying method

A concrete and one-piece technology, which is applied in construction, building structure, and building material processing, can solve the problems of increasing labor costs, affecting building quality, and poor thermal insulation effects, so as to reduce material residue and avoid spillage and leakage , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

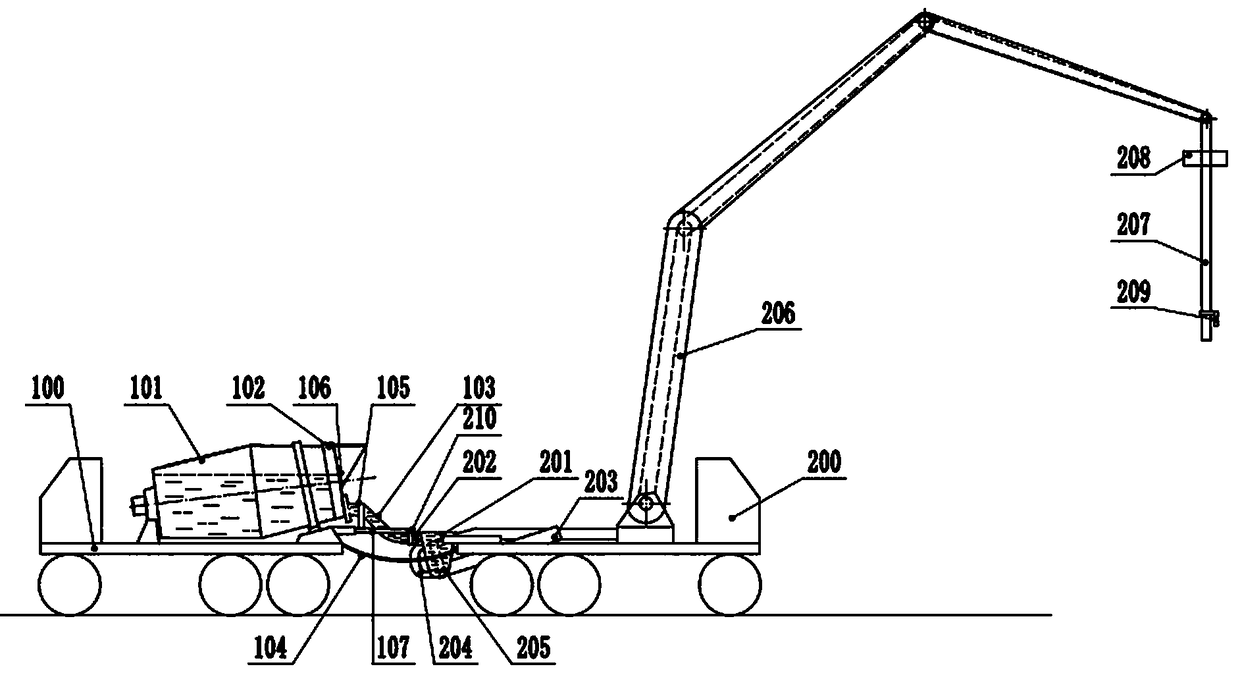

[0027] Such as figure 1 , an integrated duplex concrete supply pouring system, including a mixer truck 100 and a pump truck 200.

[0028] The mixer truck 100 has a mixing bucket 101 that rotates relative to the mixer truck 100 body and a sealing end cover 102 that is installed on the mixer truck 100 body and is positioned at the rear side of the mixing bucket 101. The mixer truck 100 is also provided with a The rotary sealing device between the sealing end cover 102 and the rear end of the mixing bucket 101 is used to prevent concrete from leaking from between the sealing end cover 102 and the mixing bucket 101. The structure of the rotary sealing device can refer to the authorized publication number CN102029940B The rotary sealing mechanism in the Chinese invention patent "concrete mixer truck with rotary sealing of the inlet and outlet of the mixing drum" can also adopt other structural forms; the sealing end cover 102 is provided with a discharge port.

[0029] The mixing ...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the front end of the mixing drum 101 is driven to a certain height along the axial direction by the tilting drive mechanism arranged on the mixer truck 100 to ensure that the discharge end of the mixing drum 101 has sufficient The height of the liquid level ensures the initial pressure and sufficient supply of concrete feed. In the case of using the tilting drive mechanism, the adjustment of the liquid level by the agitation controller may not be used, or the function of the agitation controller to adjust the liquid level may be retained, and the two are coordinated. The rest of the two embodiments are the same.

[0048] One of the common structures of the tilting drive mechanism: the mixing drum and the end cover are placed on a rotating frame, the rear end of the rotating frame is hinged with the vehicle body or sub-frame, and a hydraulic cylinder is also provided. One end of the hydraulic cylinder It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com