Patents

Literature

50results about How to "Sufficient feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

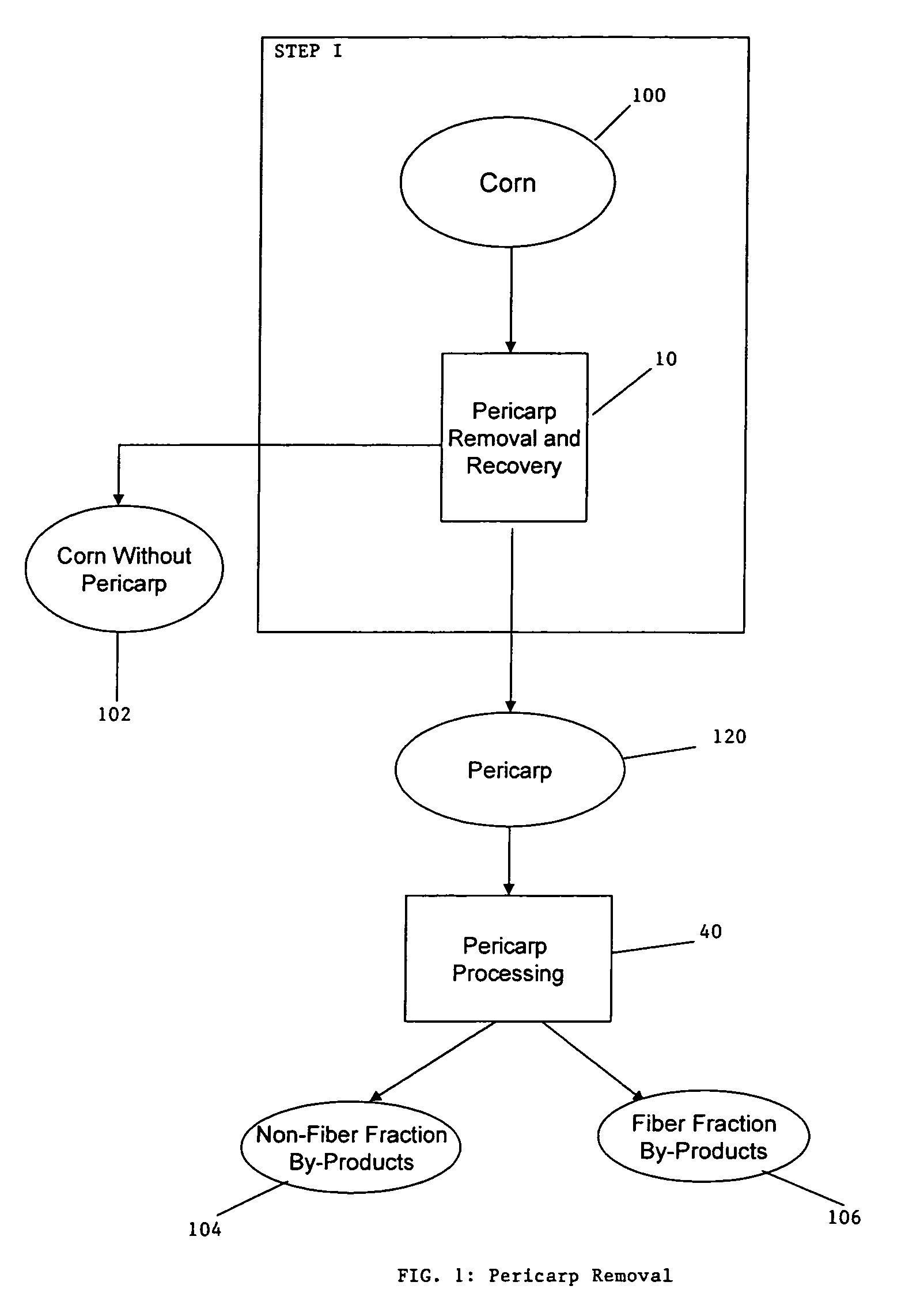

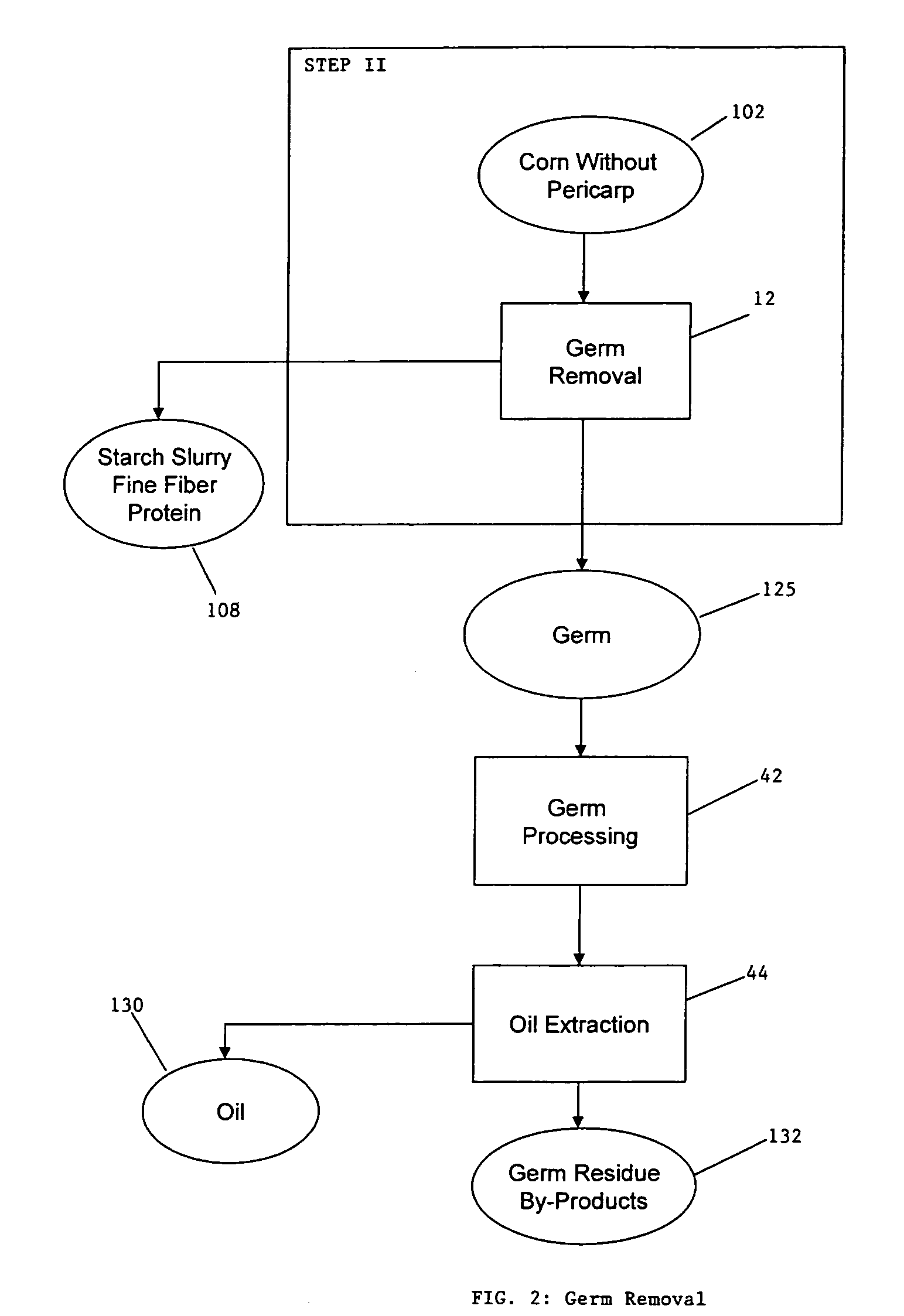

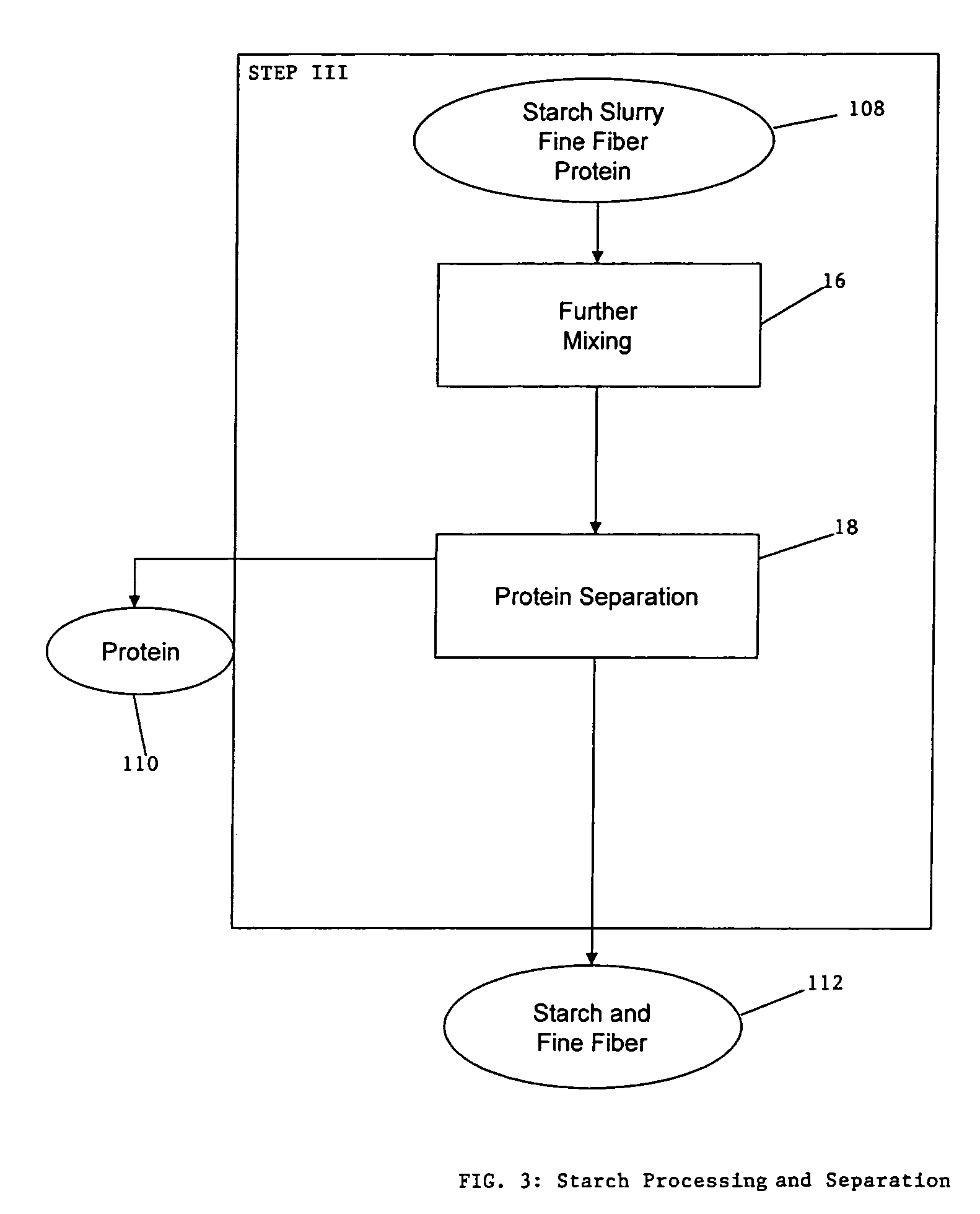

Process for the production of animal feed and ethanol and novel animal feed

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

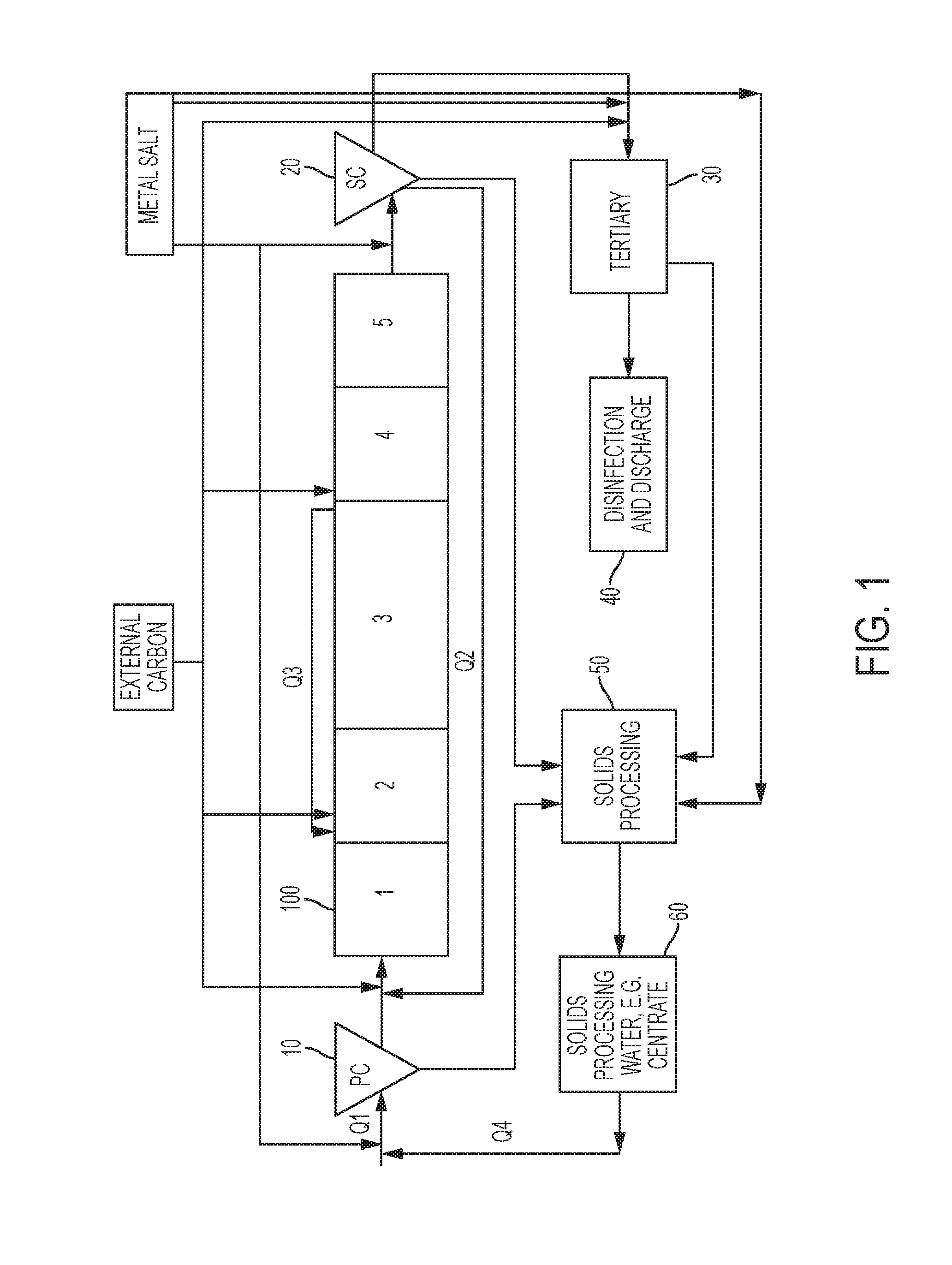

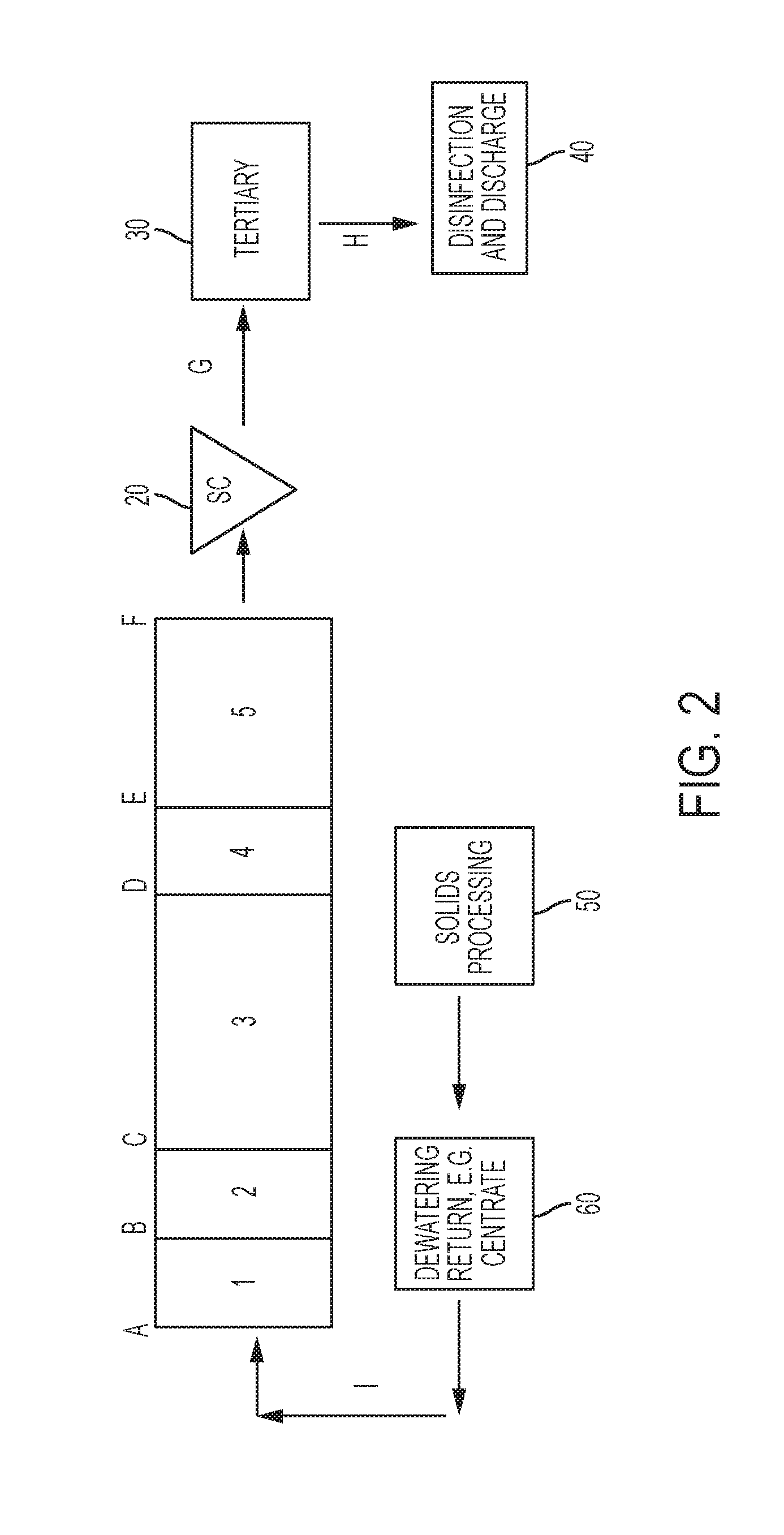

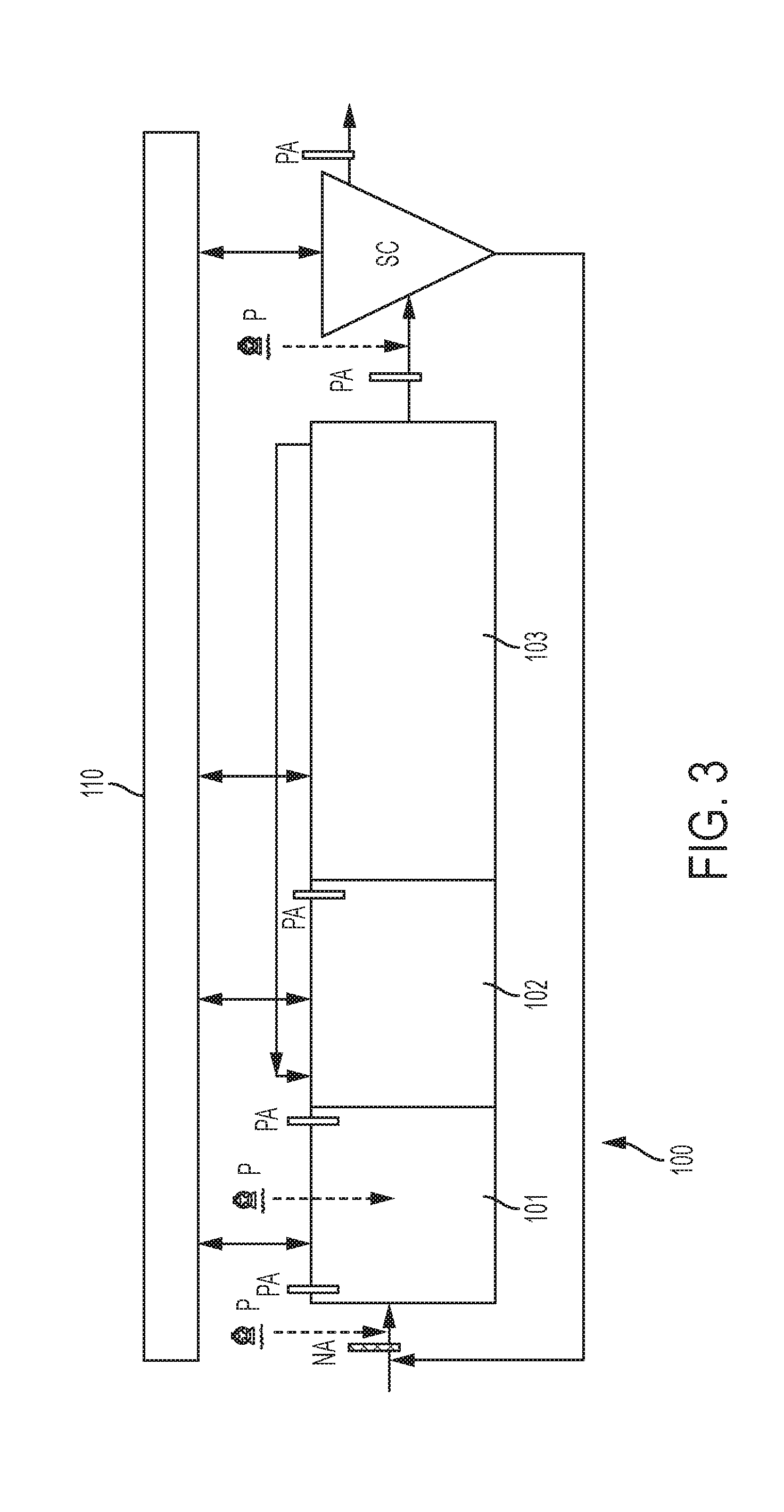

Control system for nitrogen and phosphorus removal

ActiveUS20160272519A1Enhanced biological phosphorus removalPreventing enhanced biological phosphorus removalWater treatment parameter controlBiological treatment regulationControl signalChemical compound

A central controller is used in a treatment method and system for removing at least one of nitrogen or phosphorus from wastewater. Based on data received from a plurality of sensors, each of which is coupled to a component of a wastewater treatment system, a control signal is sent from the central controller to at least one chemical delivery system, which dispenses at least one chemical compound into the wastewater in an amount effective to reduce the level of nitrogen or phosphorus in the wastewater.

Owner:ENVIRONMENTAL OPERATING SOLUTIONS

Artificial hybridization and breeding method for male Paralichthys dentatus and female summer flounder

InactiveCN1843100ALarge variationRich typeClimate change adaptationPisciculture and aquariaAquatic productProviding material

The invention belongs to field of fish breeding and aquaculture, which in detail relates to a method of artificial crossing with summer-bothus and tooth-Bothus and breeding. It comprises following steps: (1) taking summer-bothus as male parent and tooth-bothus as female parent, reinforcing the nutrient and environmental condition to promote simultaneous gonadal maturity, getting mature sperm and ovum; (2) crossing fertilized ovum and hatching; (3) culturing the hybrid body and young fish; (4) providing systematic bait in culturing period. The invention not only provides material for deseription improvement for bothus and soles, but also the lies foundation of adding a new breeding species for sea fish cultivating.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

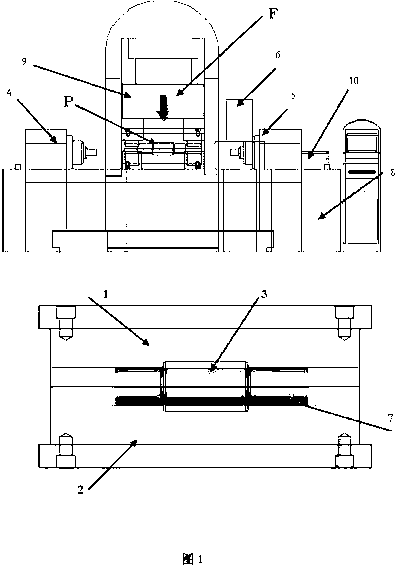

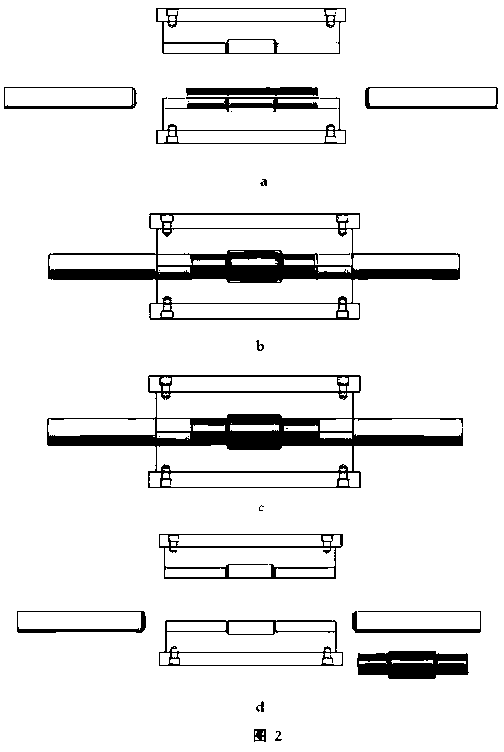

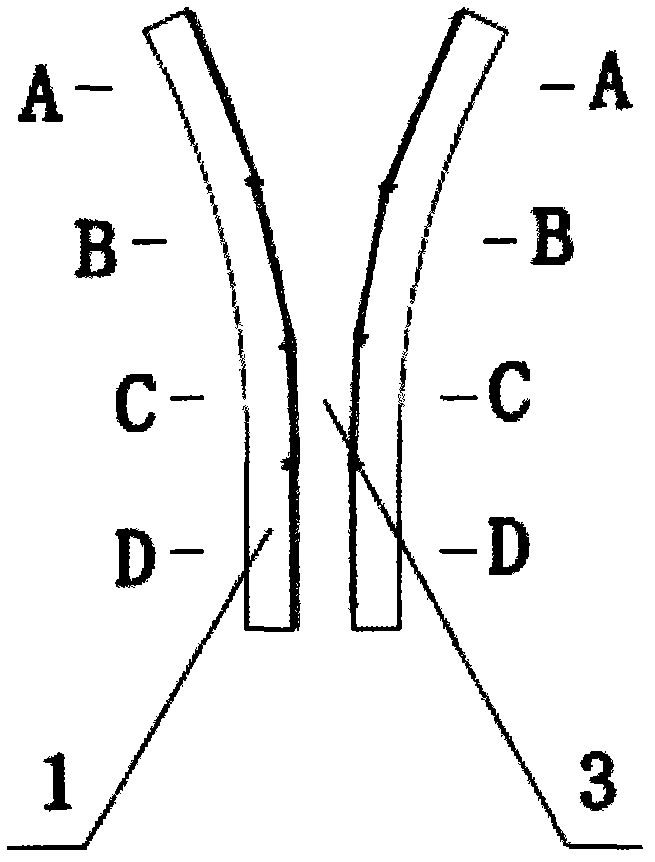

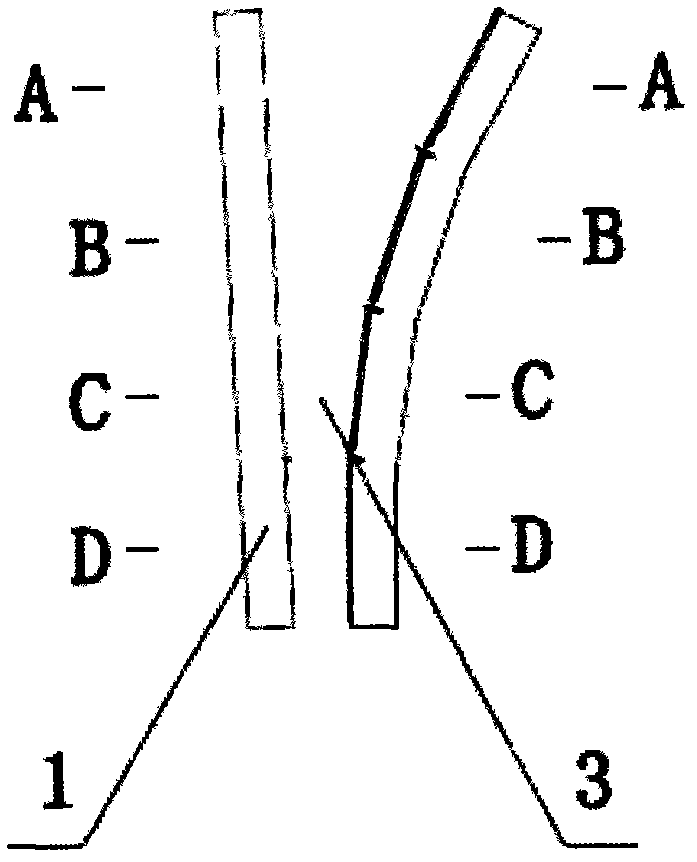

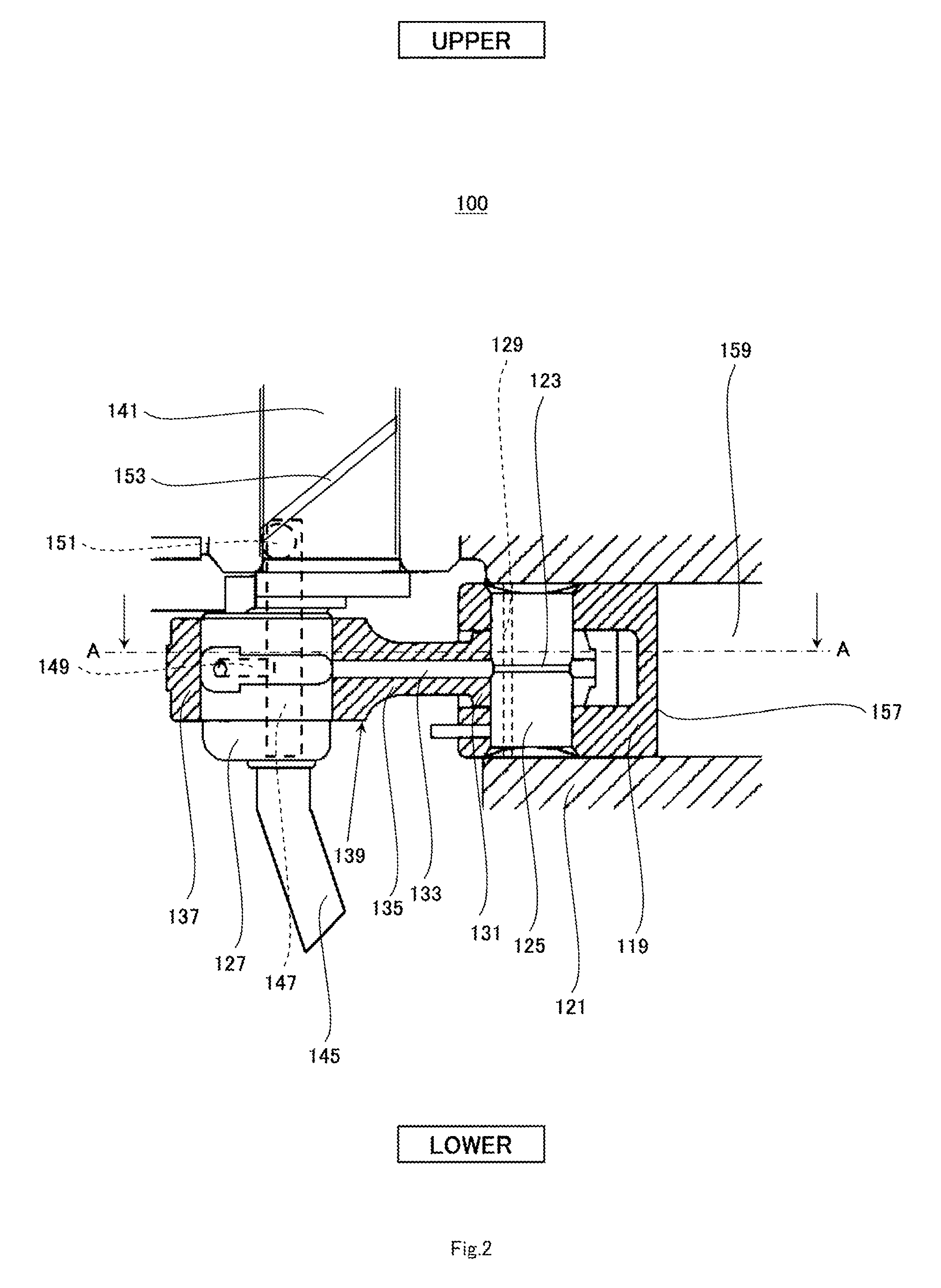

Variable-mold-clamping-force pipe internal high-pressure forming device and method

ActiveCN103212619AReduced pressure holding performance requirementsSmall tonnageEngineeringAxial force

The invention relates to a variable-mold-clamping-force pipe internal high-pressure forming method, which comprises the steps that after an upper mold and a lower mold are clamped, forming media with certain pressure is filled into a mold cavity, pushing heads on a left side and a right side simultaneously push pipe blanks into the mold cavity from the left side and the right side, the pipe blanks are pressed into the mold cavity to be formed through internal pressurization and axial force application and material compensation under the joint effect of the pressure of the forming media and the material compensation of the pushing heads, and finally the pipe blanks are in fit with the mold cavity to realize part formation. Since different mold clamping forces are adopted at different stages, the defects that the pressure required by the traditional constant-mold-clamping-force tube internal high-pressure forming method is high, the requirements on machine performance, mold performance, sealing performance and mold lubricating performance are high, the machine cost is high, the situation of mold lifting is apt to occur, the part forming pressure is high, large-deformation complex parts cannot be formed, the working efficiency is low and the like are overcome.

Owner:NINGBO POWER PRECISION HYDRAULIC MACHINERY

Flaky feed for feeding Geometridae insects

InactiveCN101953438AShiny freshSufficient feedAnimal feeding stuffAccessory food factorsYeastSucrose

The invention relates to a flaky feed for feeding Geometridae insects, which comprises the following components in parts by weight: 120-160 parts of wheat germ powder, 25-35 parts of soybean meal, 12-18 parts of yeast powder, 10-14 parts of cane sugar, 2.4-4 parts of preservative, 2-6 parts of ascorbic acid and 2-6 parts of vitamin. The flaky feed can greatly improve the feeding level and shorten the feeding time, and the life cycle duration of the flaky feed tends to be identical with that in the nature, thus achieving the purpose of artificial feeding in a large scale.

Owner:茂名市林业科学研究所

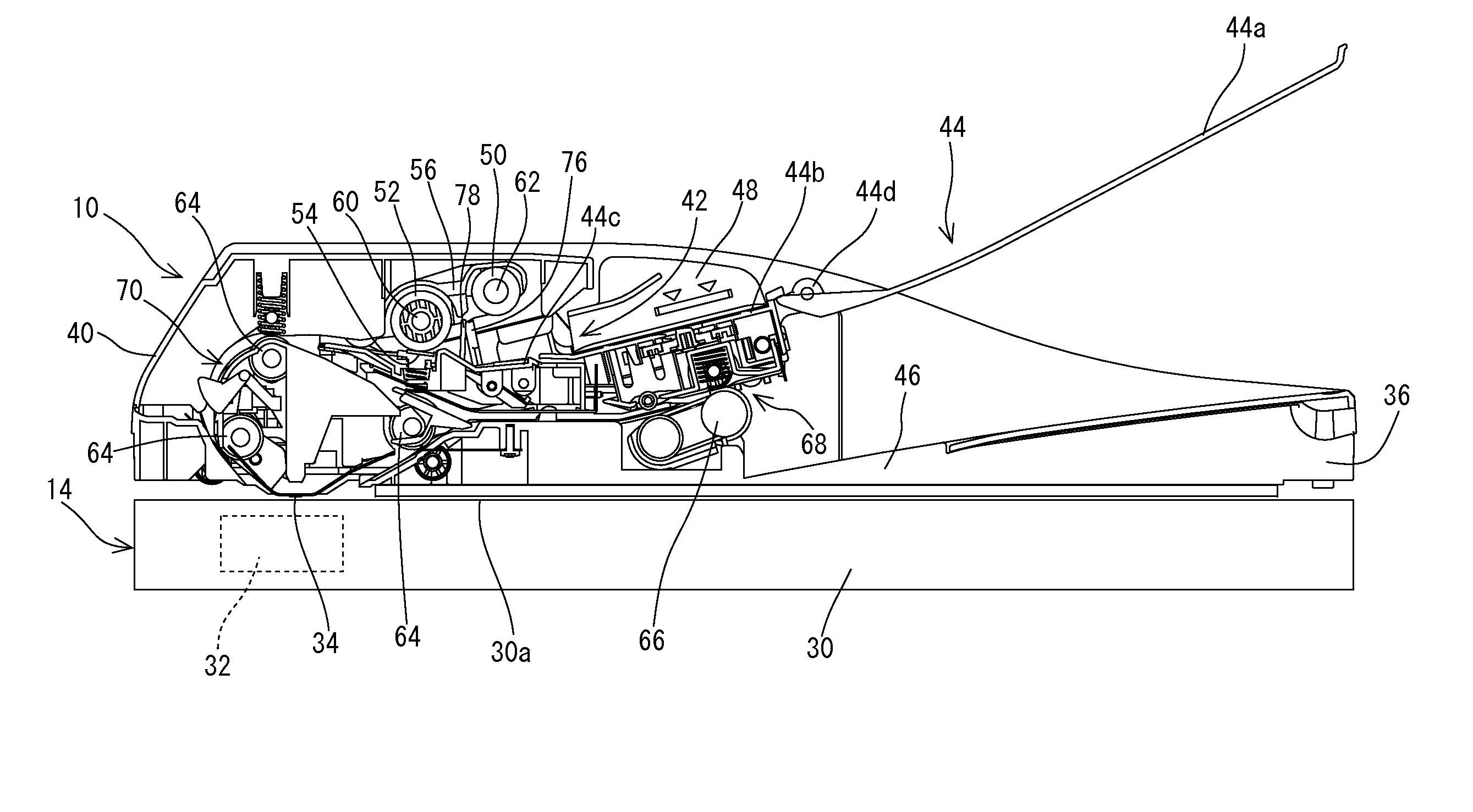

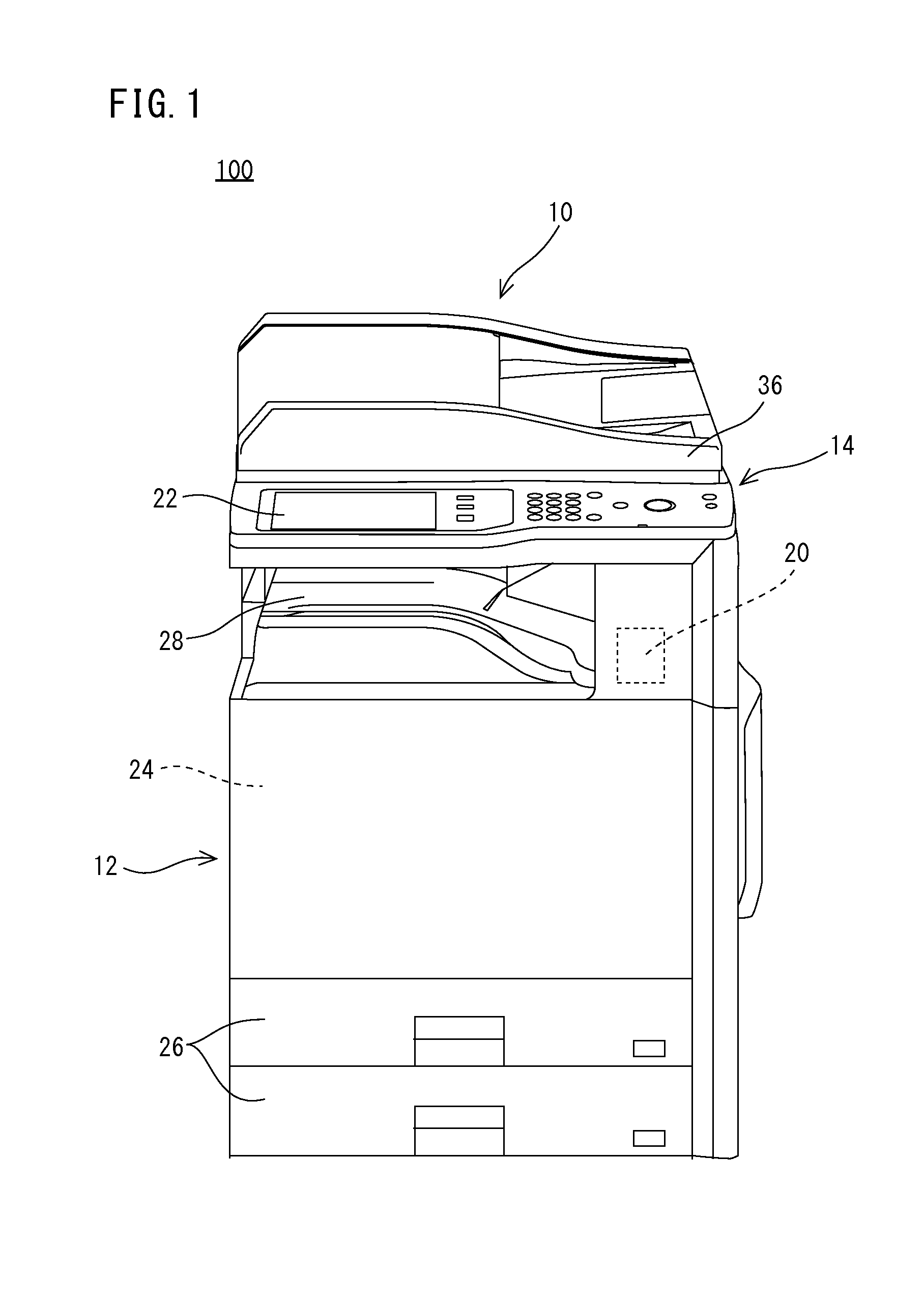

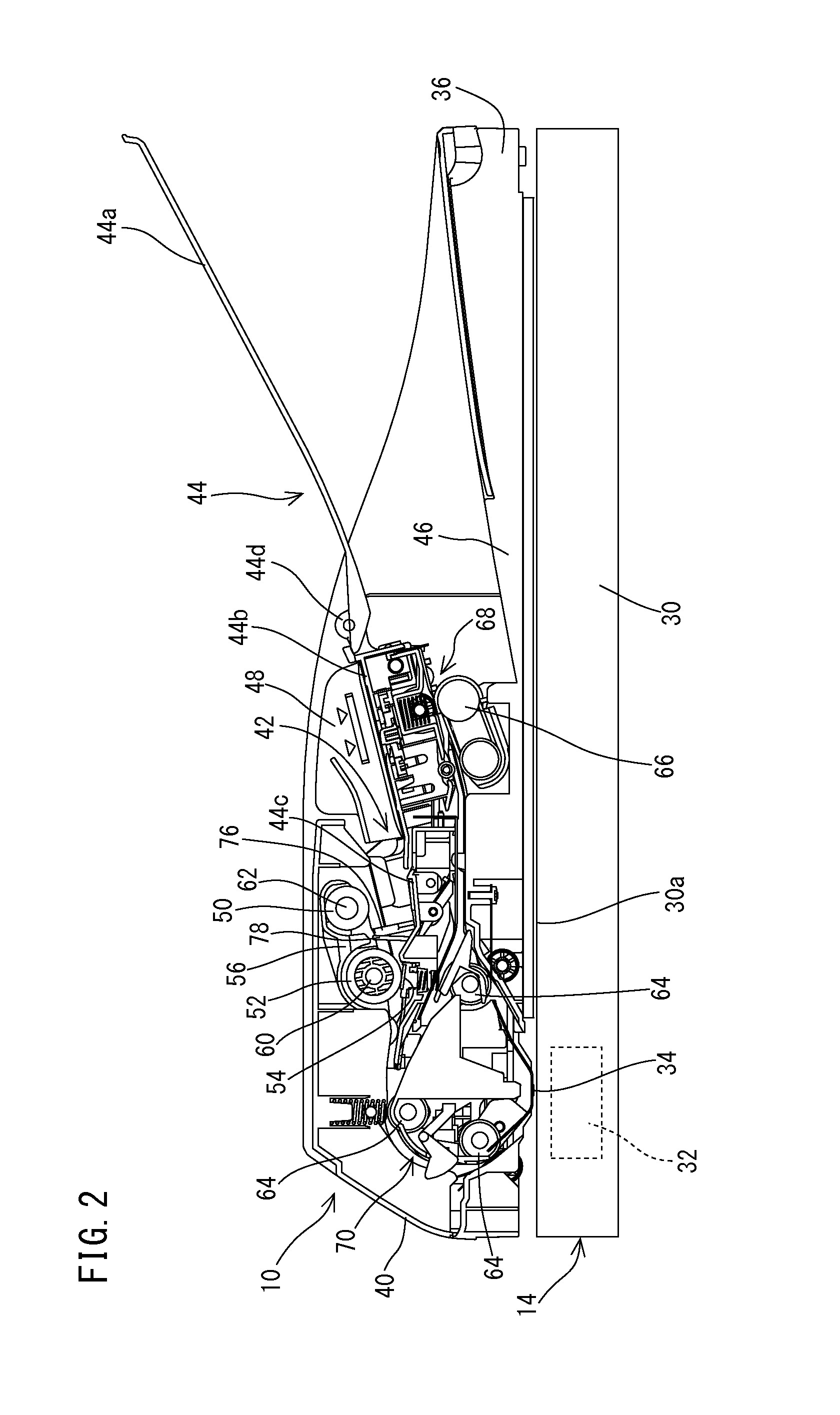

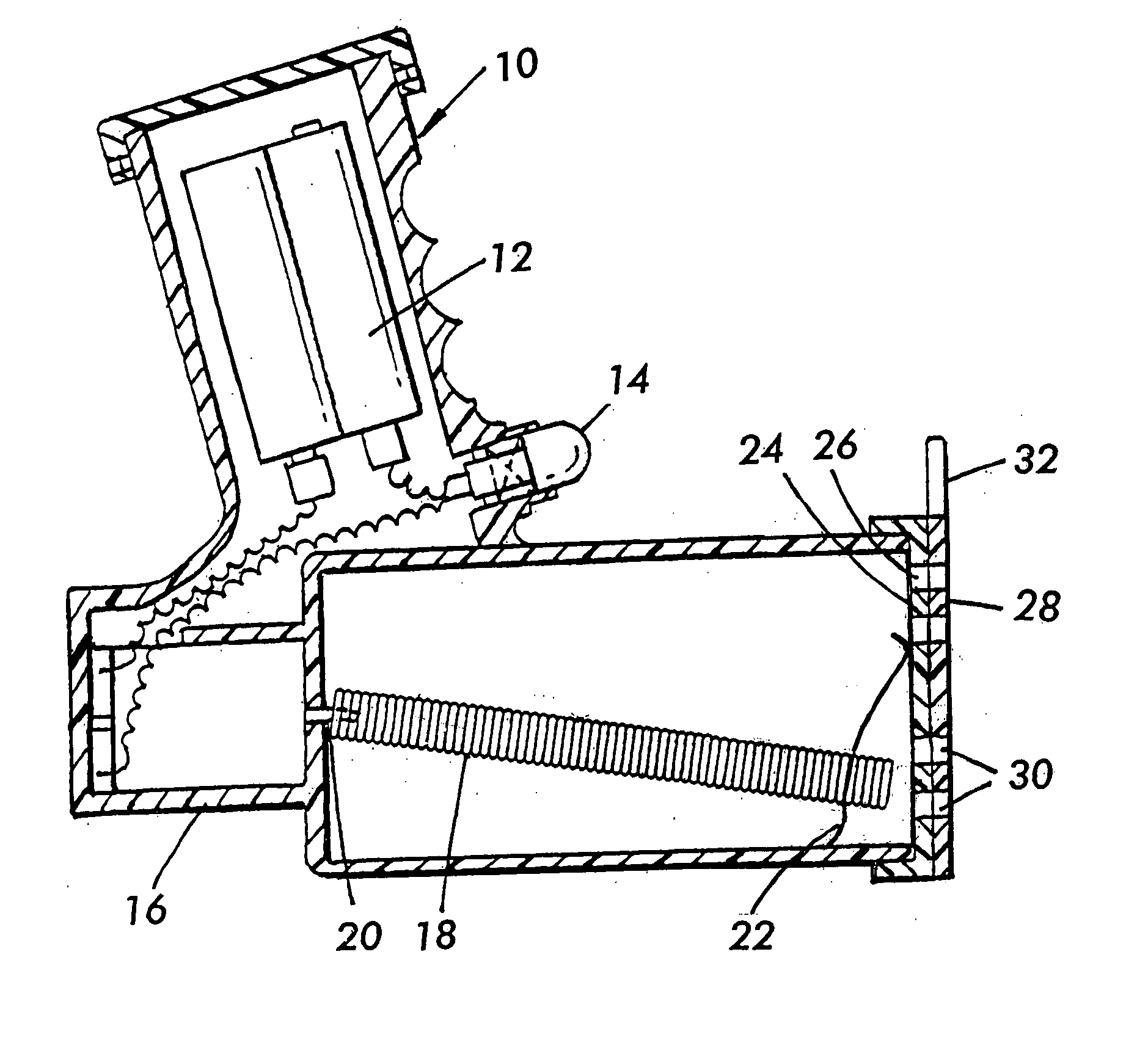

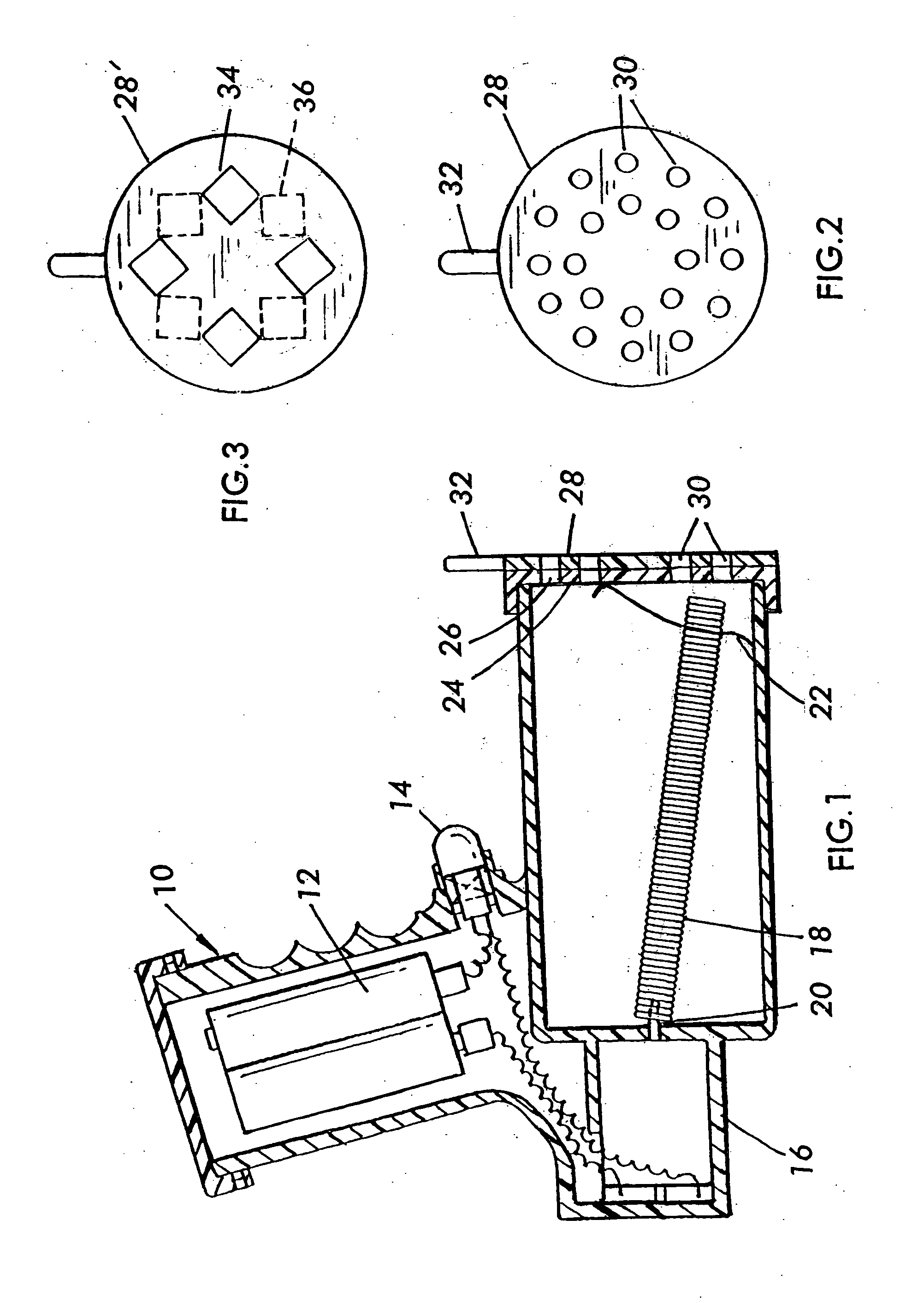

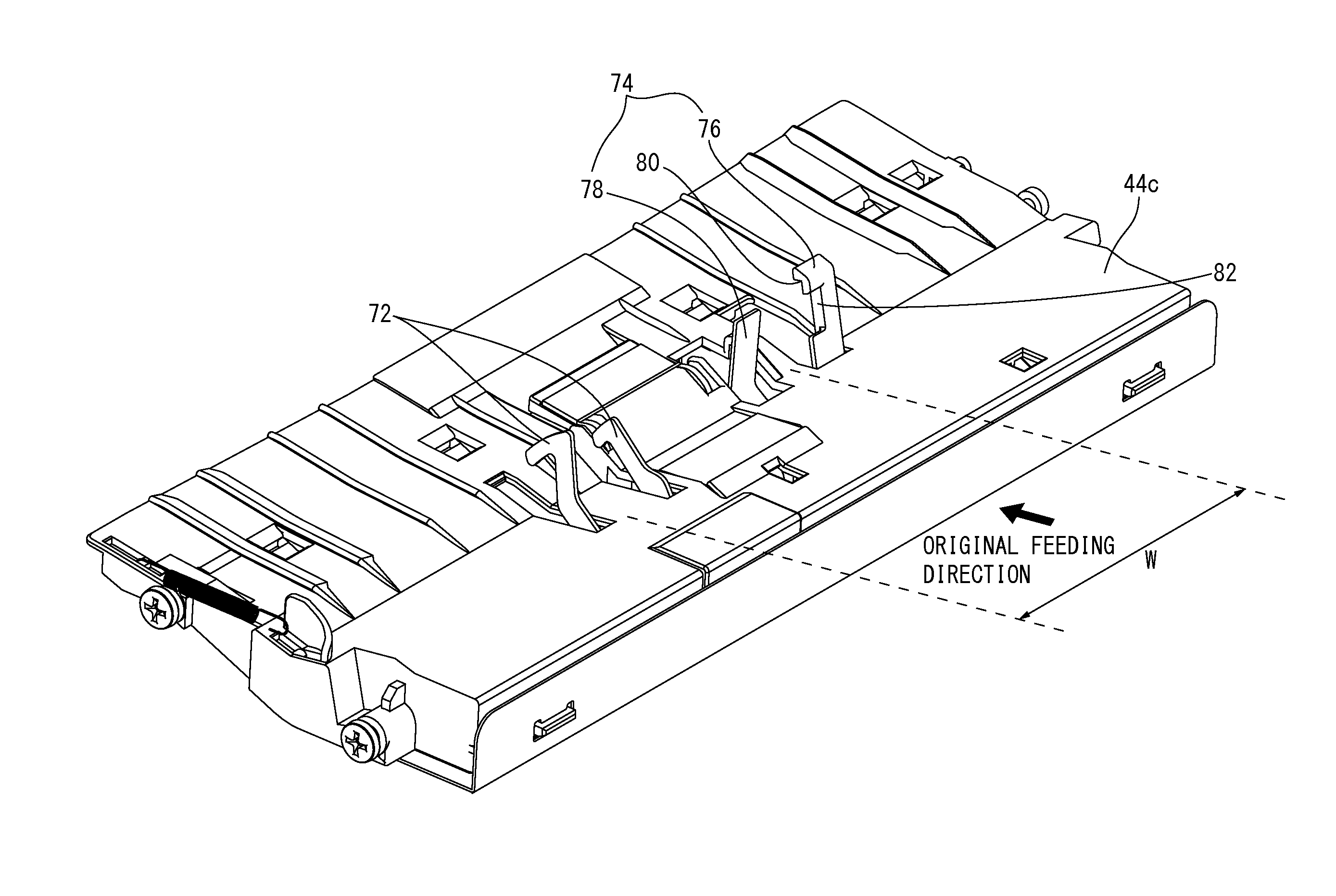

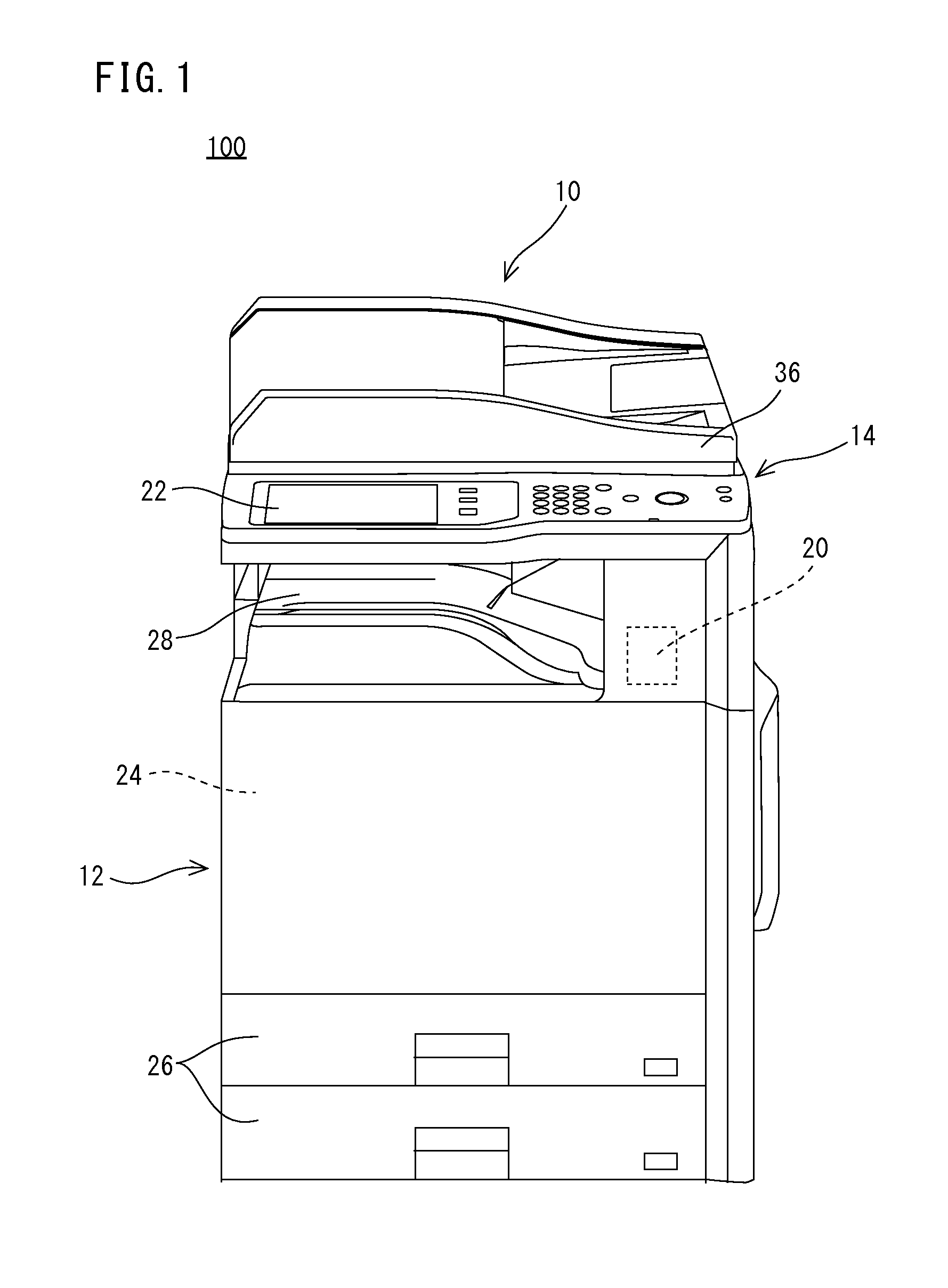

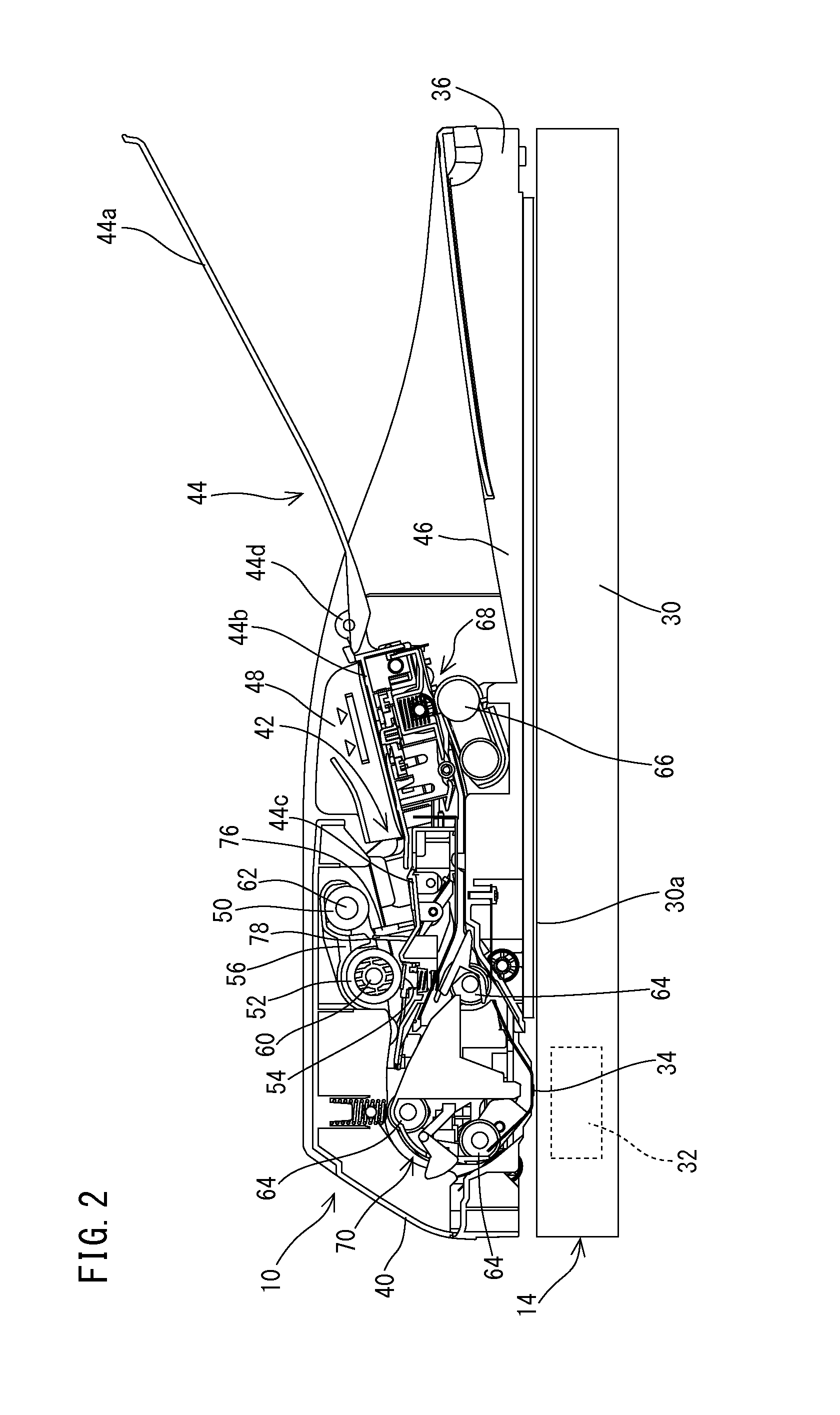

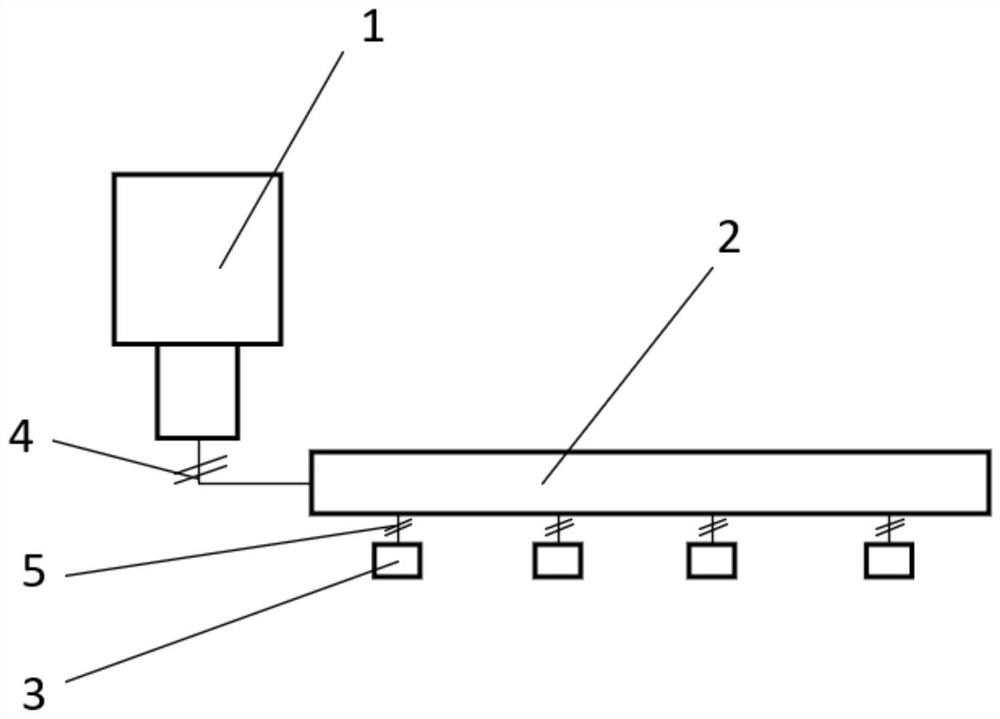

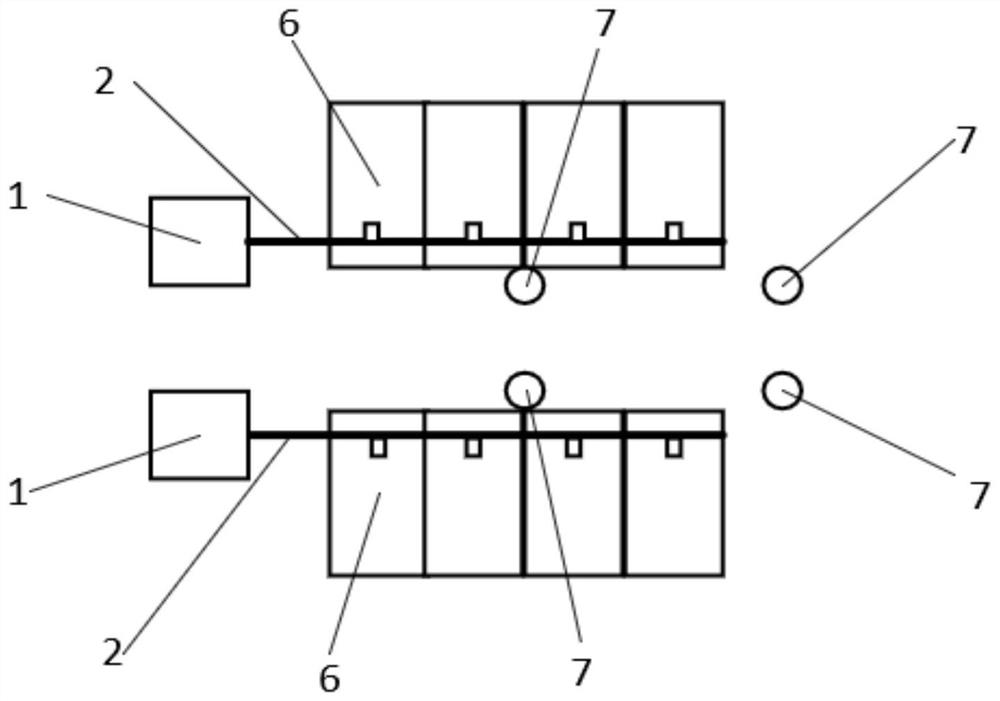

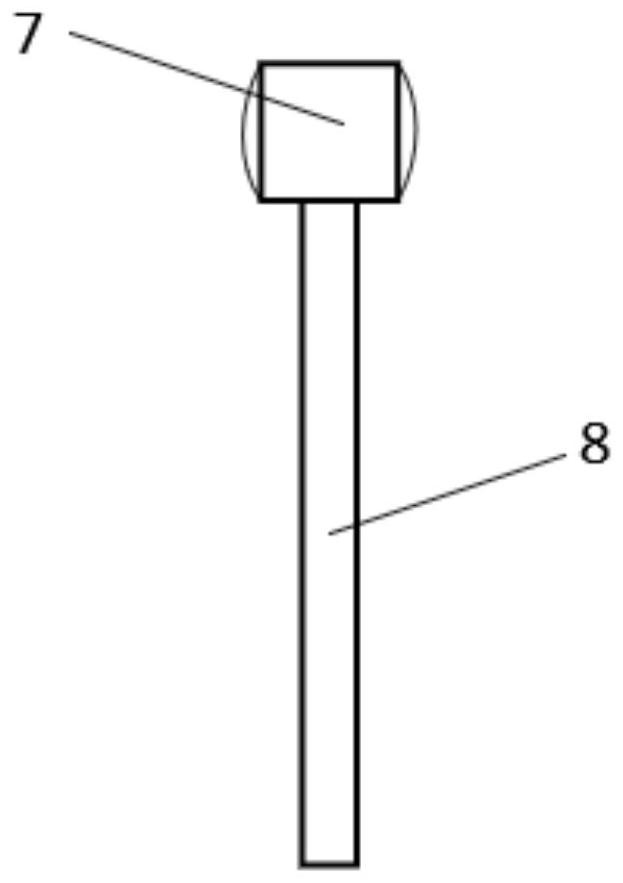

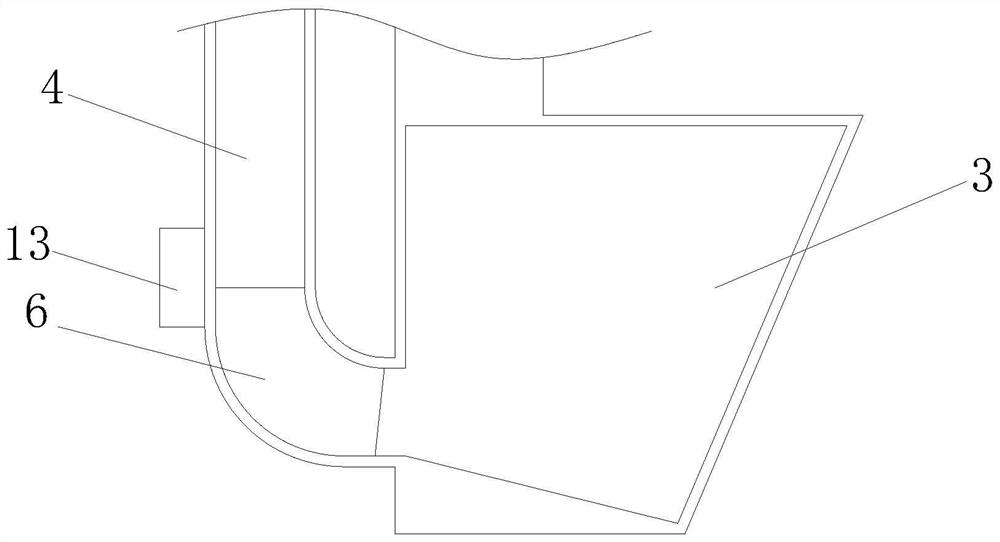

Paper feed apparatus, image reading apparatus comprising paper feed apparatus, and image forming apparatus comprising image reading apparatus

ActiveUS20140374984A1Easy to shapeSufficient feedRegistering devicesArticle feedersImage formationPulp and paper industry

A paper feed apparatus includes a paper feeding portion that sends-out a paper placed in a paper placing tray, and is used in an image forming apparatus such as a multifunction machine. The paper feed apparatus comprises a first regulating portion and a second regulating portion that are arranged in the vicinity of a downstream side of a paper feeding position by the paper feeding portion. The first regulating portion is arranged outside a second width paper passage area to regulate a movement of a first width paper such as A4 paper placed in the paper placing tray toward a feeding direction. On the other hand, the second regulating portion is arranged inside the second width paper passage area to regulate a movement of a second width paper such as a name card placed in the paper placing tray toward a feeding direction. Since there are provided with the first regulating portion and the second regulating portion that are arranged outside and inside the second width paper passage area, the second width paper such as a name card can be adequately fed in addition to the first width paper such as A4 paper.

Owner:SHARP KK

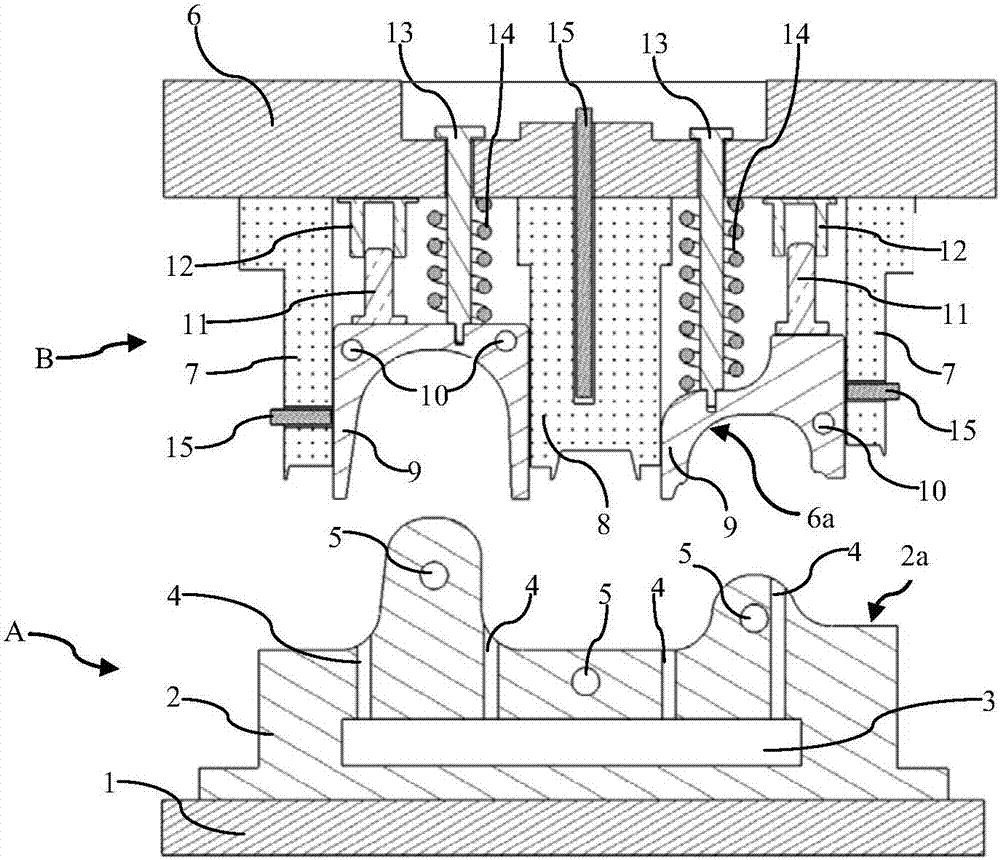

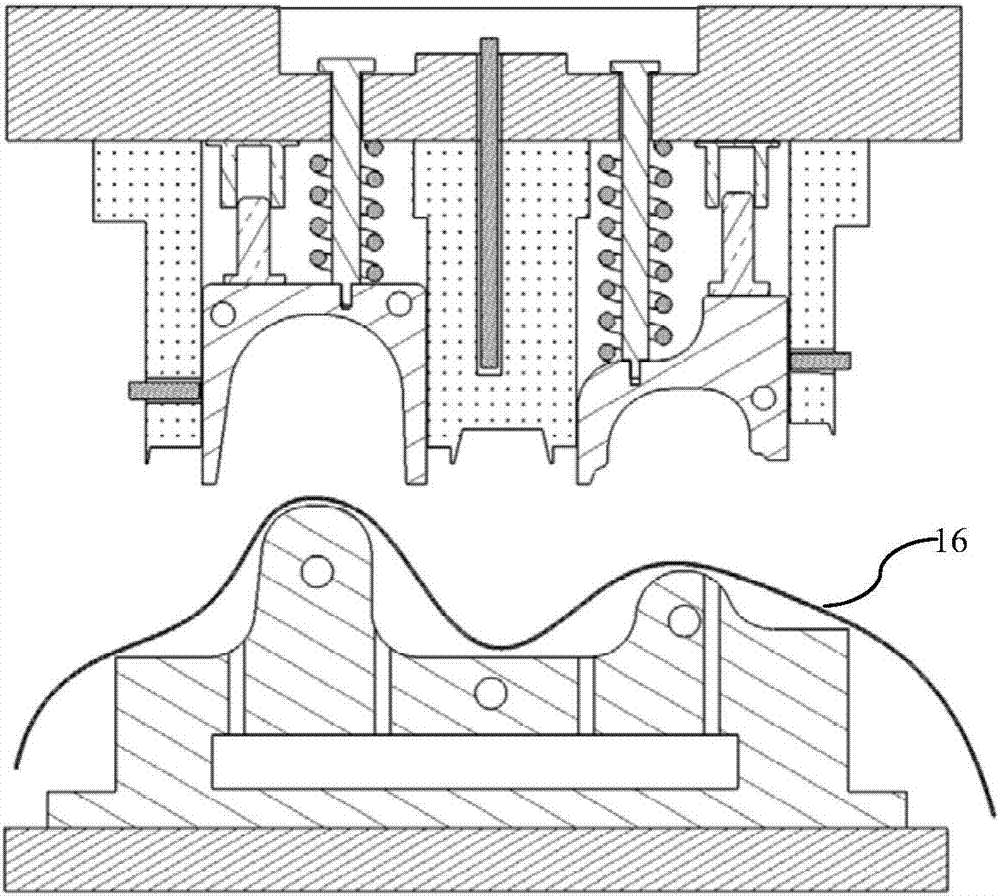

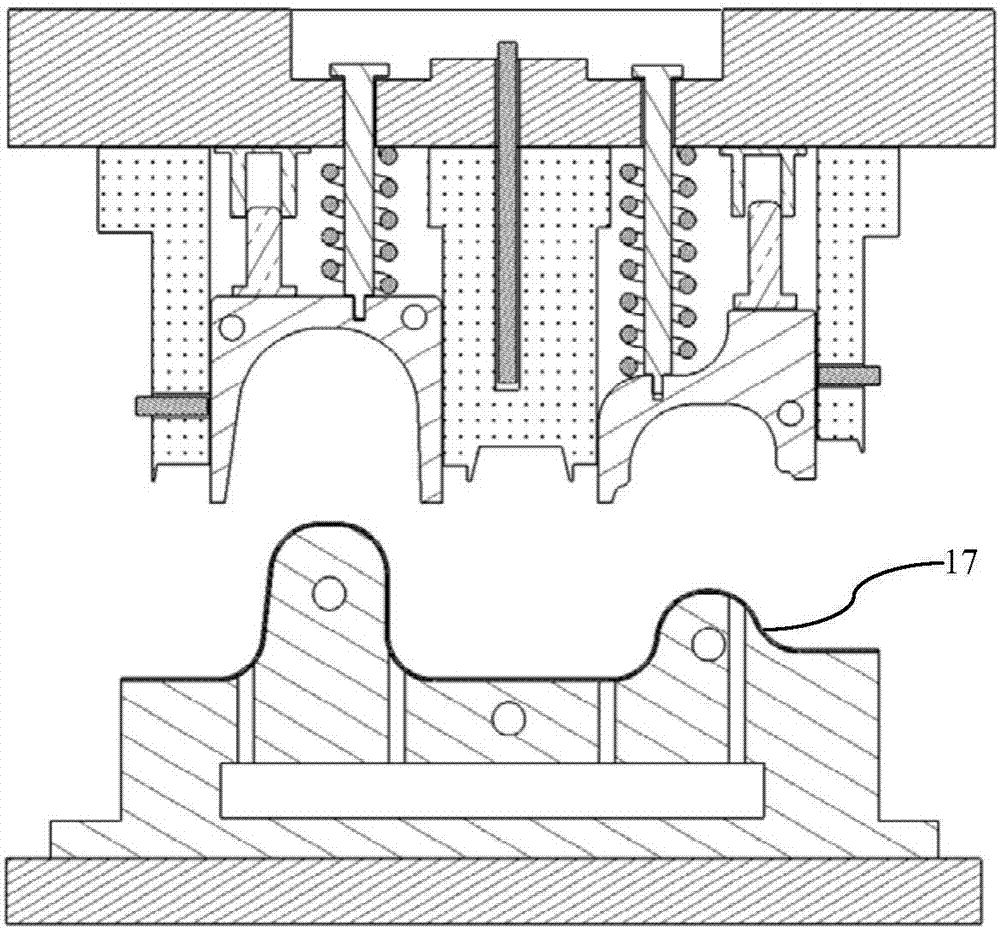

Mold and method for manufacturing automotive sound-insulation pads

ActiveCN107443715APlay a protective effectSufficient feedDomestic articlesInsulation layerMaterials science

The invention relates to a mold and method for manufacturing automotive sound-insulation pads. The mold comprises a fixed mold and a movable mold which are opposite to each other, wherein the fixed mold comprises a fixed mold body; the fixed mold body is provided with a first molded surface which faces the movable mold; a sound-insulation layer which is placed on the first molded surface can be formed in a vacuum adsorption manner; the movable mold comprises a movable mold body, a pressing plate and a trimming cutter; the pressing plate is movably arranged on the movable mold body; the trimming cutter is fixedly arranged on the movable mold body; in the direction, which is opposite to the movable mold, of the fixed mold, a region covered by the projection of the first molded surface to the movable mold is a second molded surface; the trimming cutter is positioned on the periphery of the second molded surface; after being heated, the trimming cutter is used for trimming the edge of a sound-insulation pad after the sound-insulation pad is subjected to mould pressing to form a sound-insulation pad with the required profile. In a process of manufacturing sound-insulation pads by using the mold, the circumstance that sound-absorbing cotton is broken due to incomplete filling and poor drawability of the sound-absorbing cotton in the whole process is avoided.

Owner:SAIC MOTOR

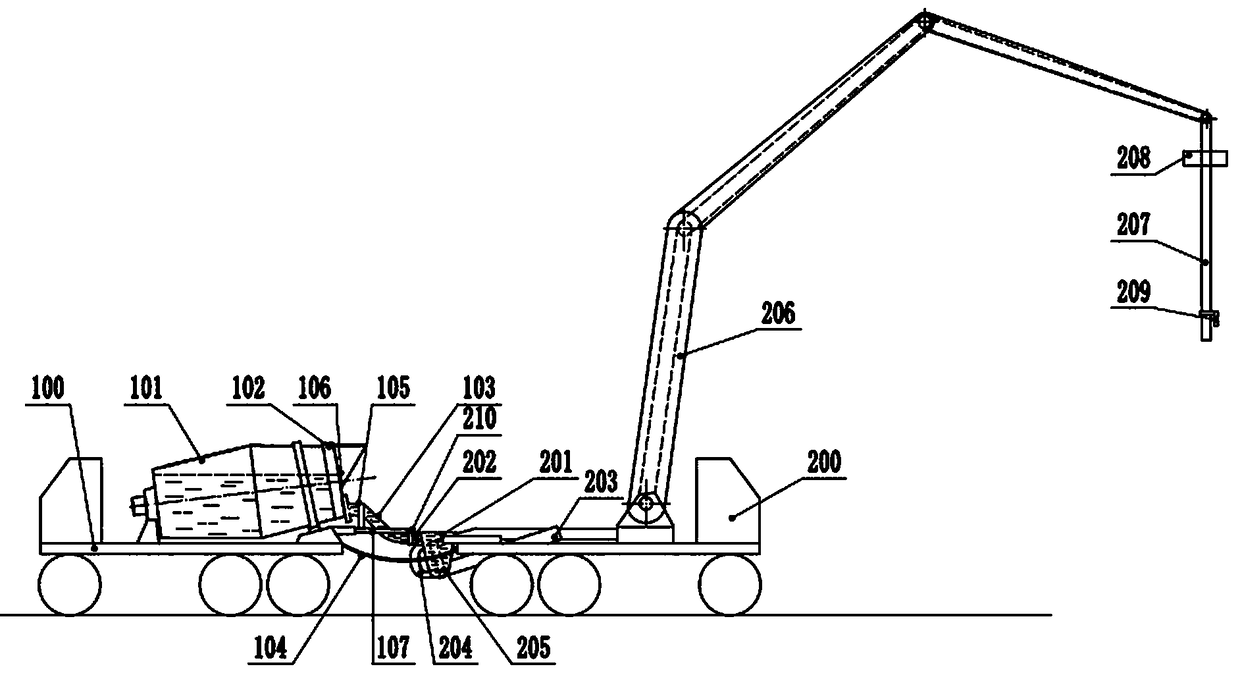

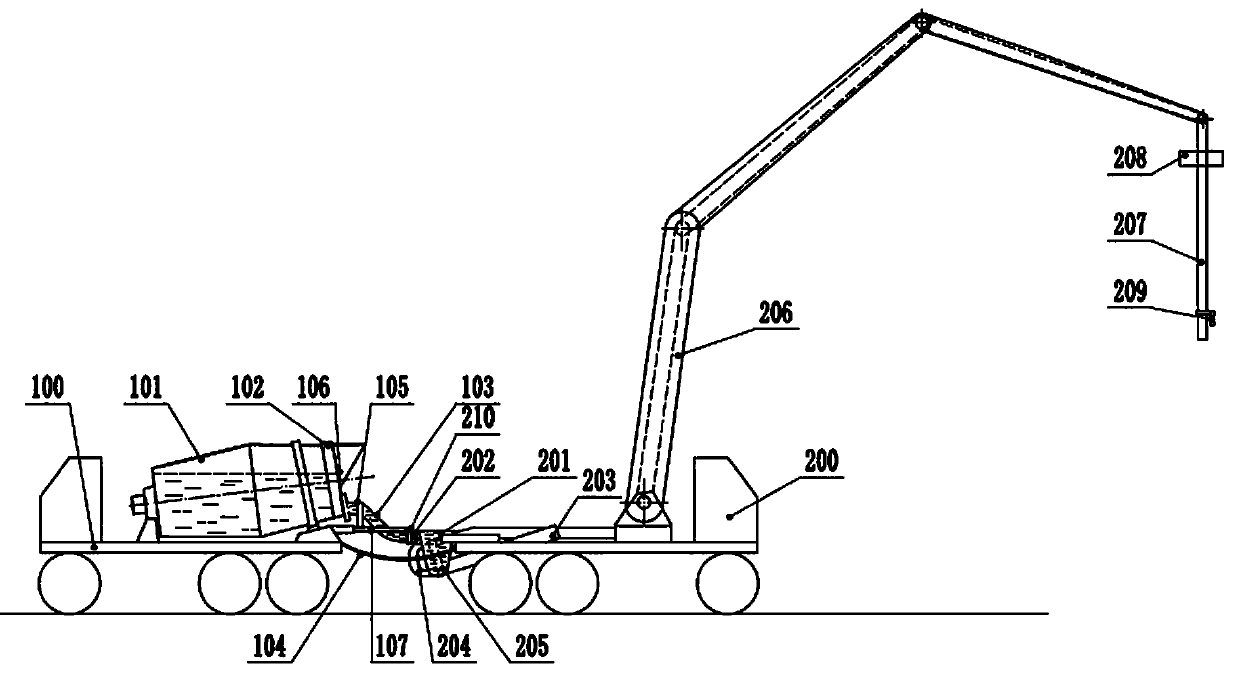

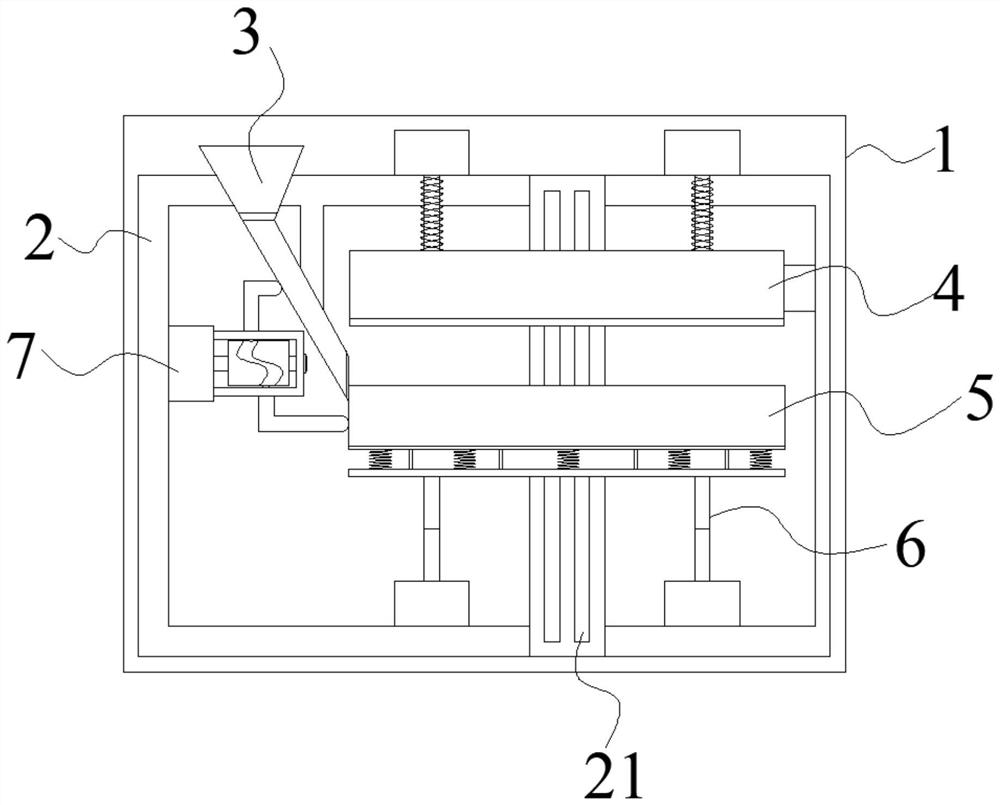

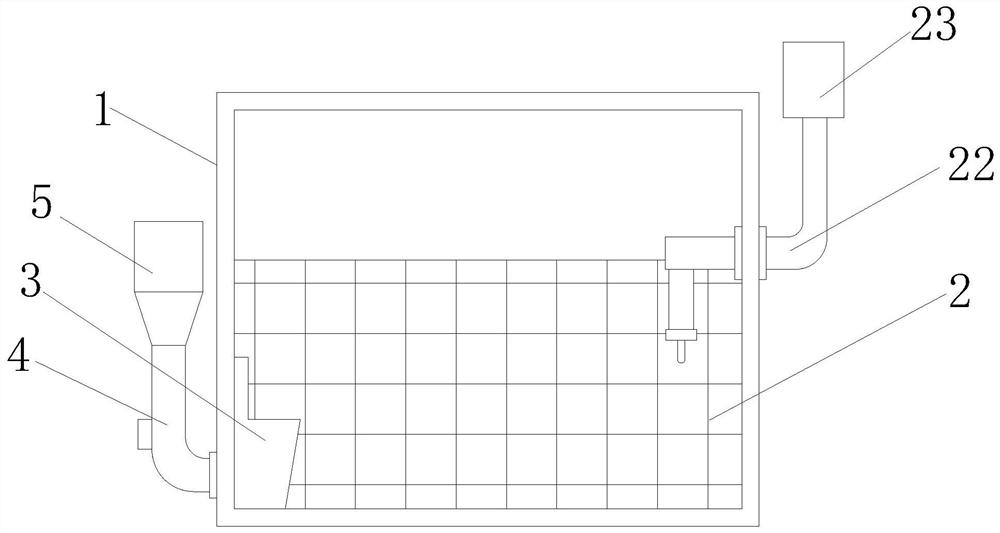

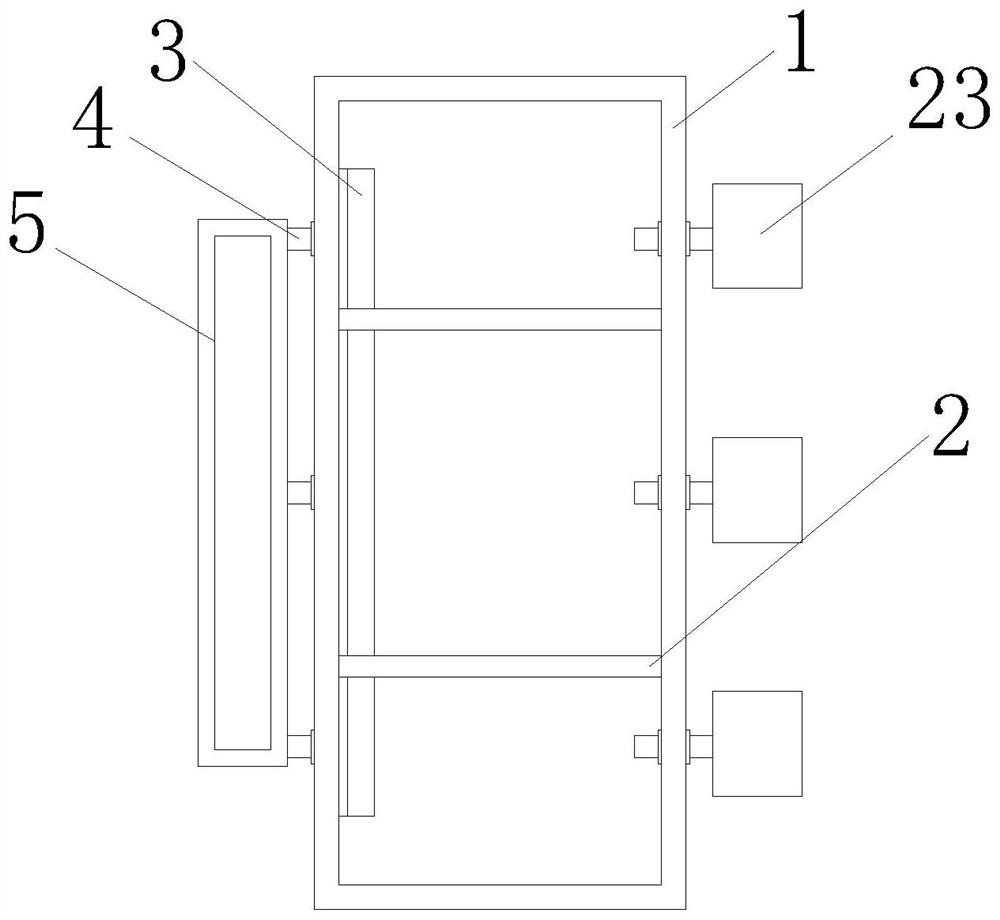

Integrated double concrete supplying and pouring system and supplying method

ActiveCN108331351AReduce volumeAvoid spillingBuilding material handlingThermal insulationEvaporation

The invention discloses an integrated double concrete supplying and pouring system and supplying method. The supplying system comprises a stirring truck and a pump truck, wherein the stirring truck isprovided with a stirring barrel and a sealing end cover, the pump vehicle comprises a closed supplying system, the stirring truck and the pump truck are communicated through a closed supplying pipe and a feeding pipe, so that a communicated concrete fluid with pressure difference is formed, and concrete in a receiving hopper of the pump truck is endowed with lasting supplying pressure. Integratedand concentrated control of the stirring truck and the pump truck is realized by connecting operating systems of the stirring truck and the pump truck. Integrated and automatic operation of the stirring truck and the pump truck is convenient to realize, the concrete pouring construction efficiency is improved, water adding in the pumping position due to concrete water evaporation and slump loss is also avoided, the concrete quality is ensured, overflow leakage of the concrete at the receiving hopper is eradicated, the thermal insulation effect is improved, and the purpose of continuous concrete supply to the pump truck under certain pressure conditions is achieved.

Owner:盛富春

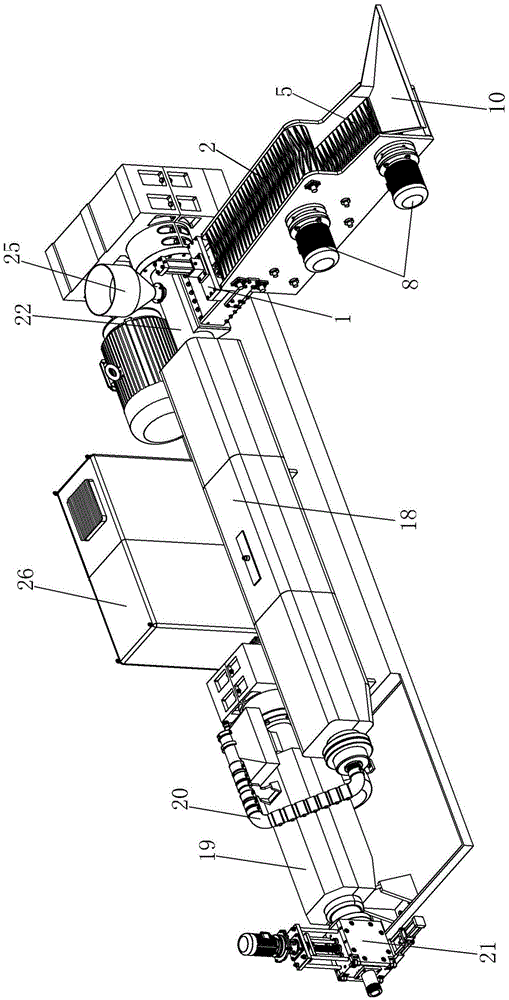

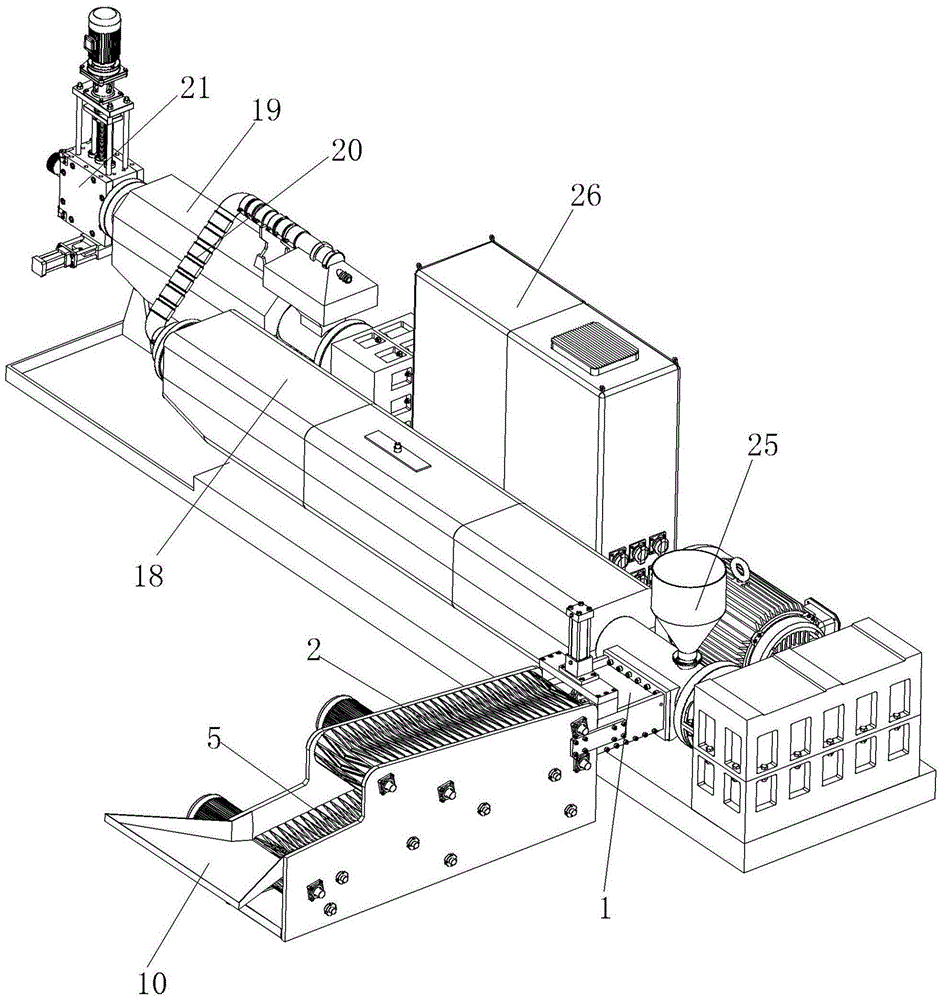

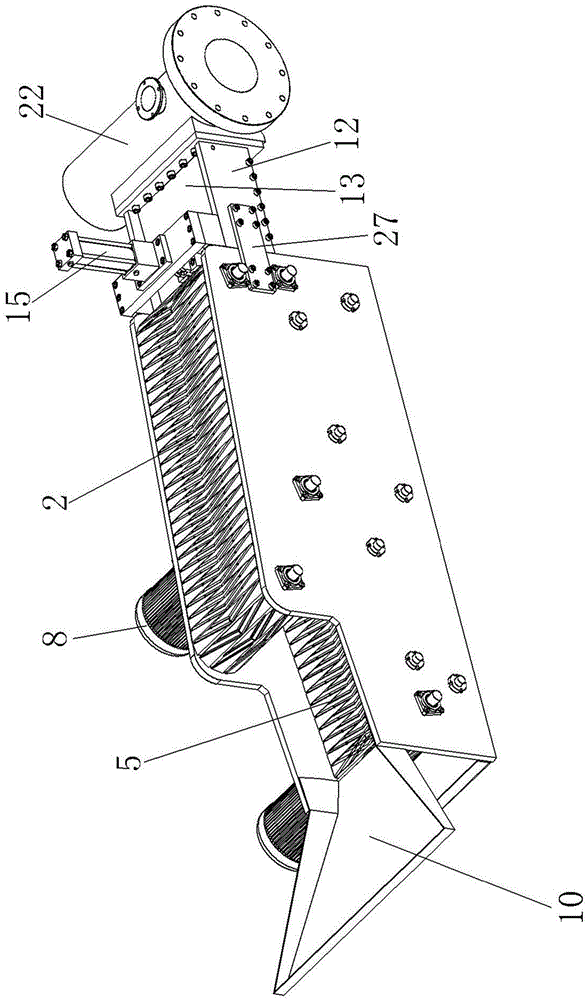

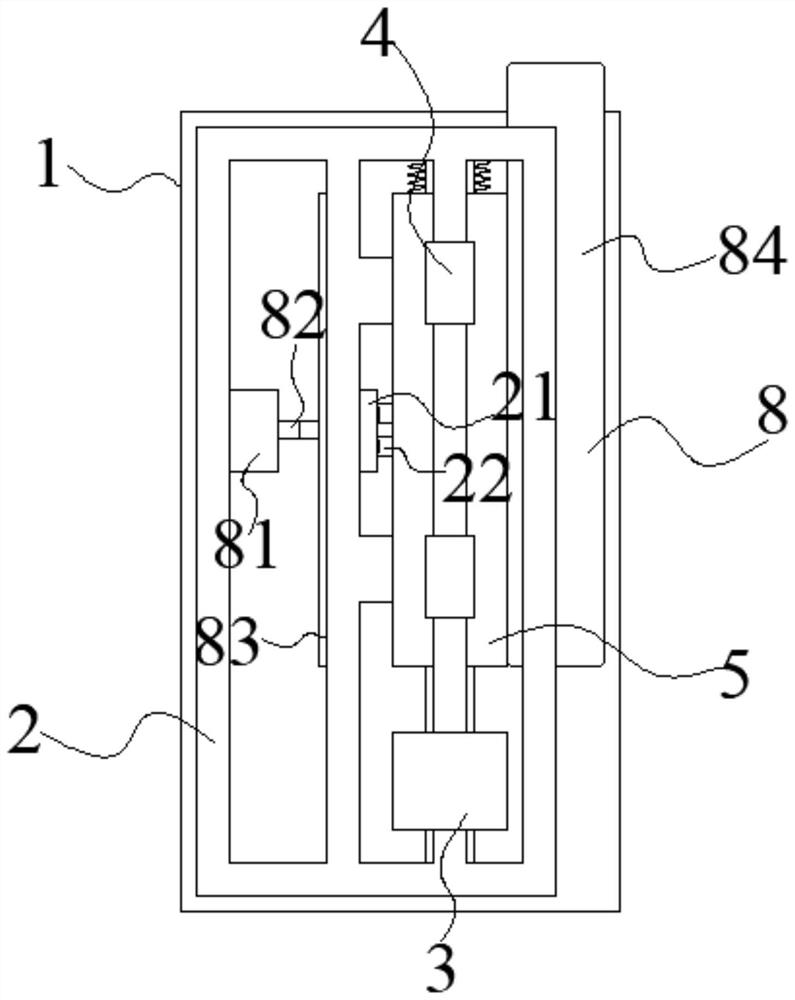

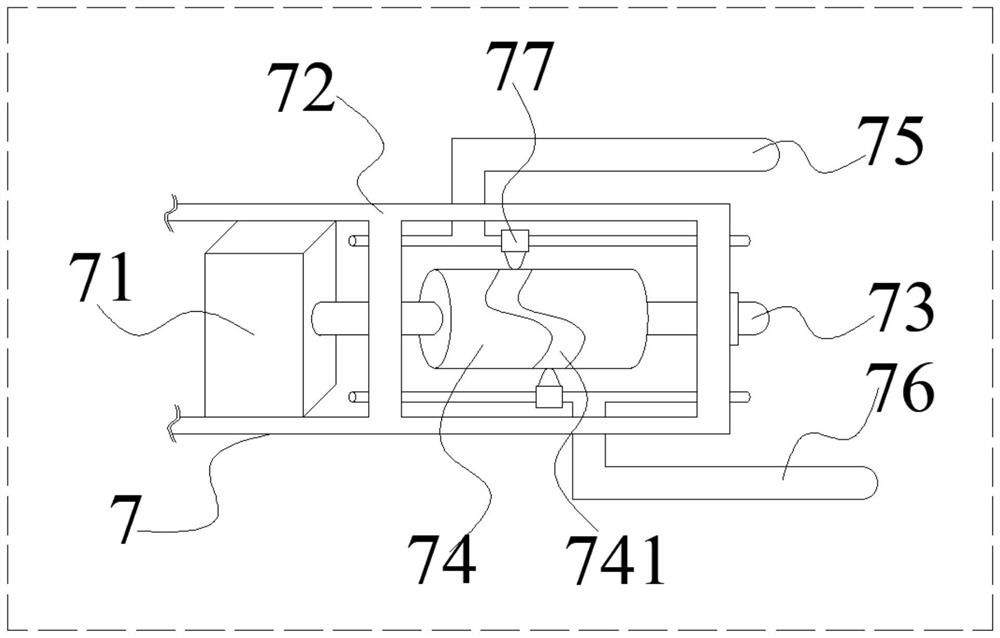

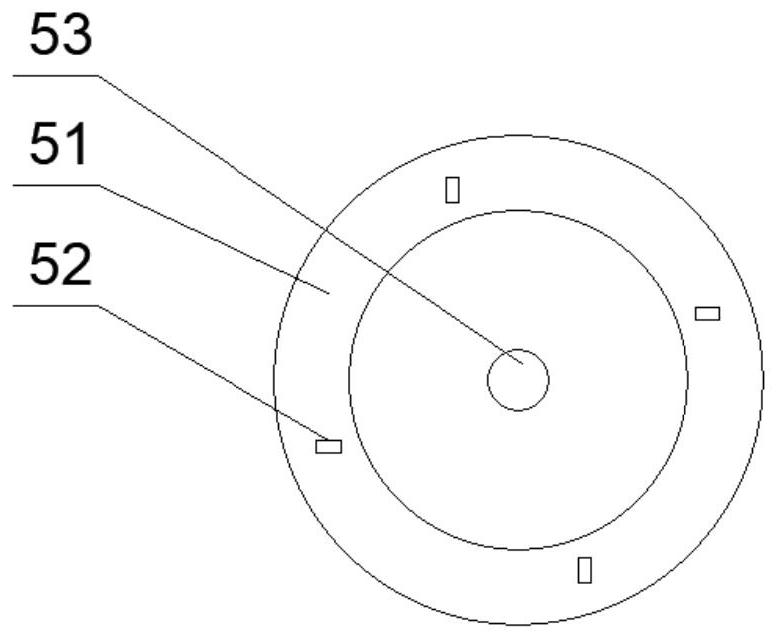

Automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine

ActiveCN105619641AOutstanding and Beneficial Technical EffectsRealize automatic dehydrationCoatingsEngineeringDehydration

The invention belongs to the field of pelletizer equipment, in particular to an automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine. The automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine comprises a pelletizer set, and also comprises a crawler-type dehydration and feed device and a secondary extrusion and feed device; the crawler-type dehydration and feed device comprises two sets of extrusion conveyer belts and driving mechanisms a separately used for driving the two sets of extrusion conveyer belts to drive; the two sets of extrusion conveyer belts are arranged top and bottom oppositely; a top extrusion conveyer belt a comprises an extrusion face and a feed face; the extrusion face and a bottom extrusion conveyer belt b are oppositely arranged and form an extrusion passage; an angle formed between the feed face and the extrusion face is an obtuse angle; the discharge end of the extrusion conveyer belt b is connected with the feed end of the secondary extrusion and feed device; and the discharge end of the secondary extrusion and feed device is connected with the feed port of the pelletizer set. The automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine disclosed by the invention has the advantages of being simple in structure, convenient to use, high in production efficiency and automation degree, reduced in amount of labor and fast in feed rate, and being capable of saving electric quantity and reducing occupied area.

Owner:ZHEJIANG LEENY TECH

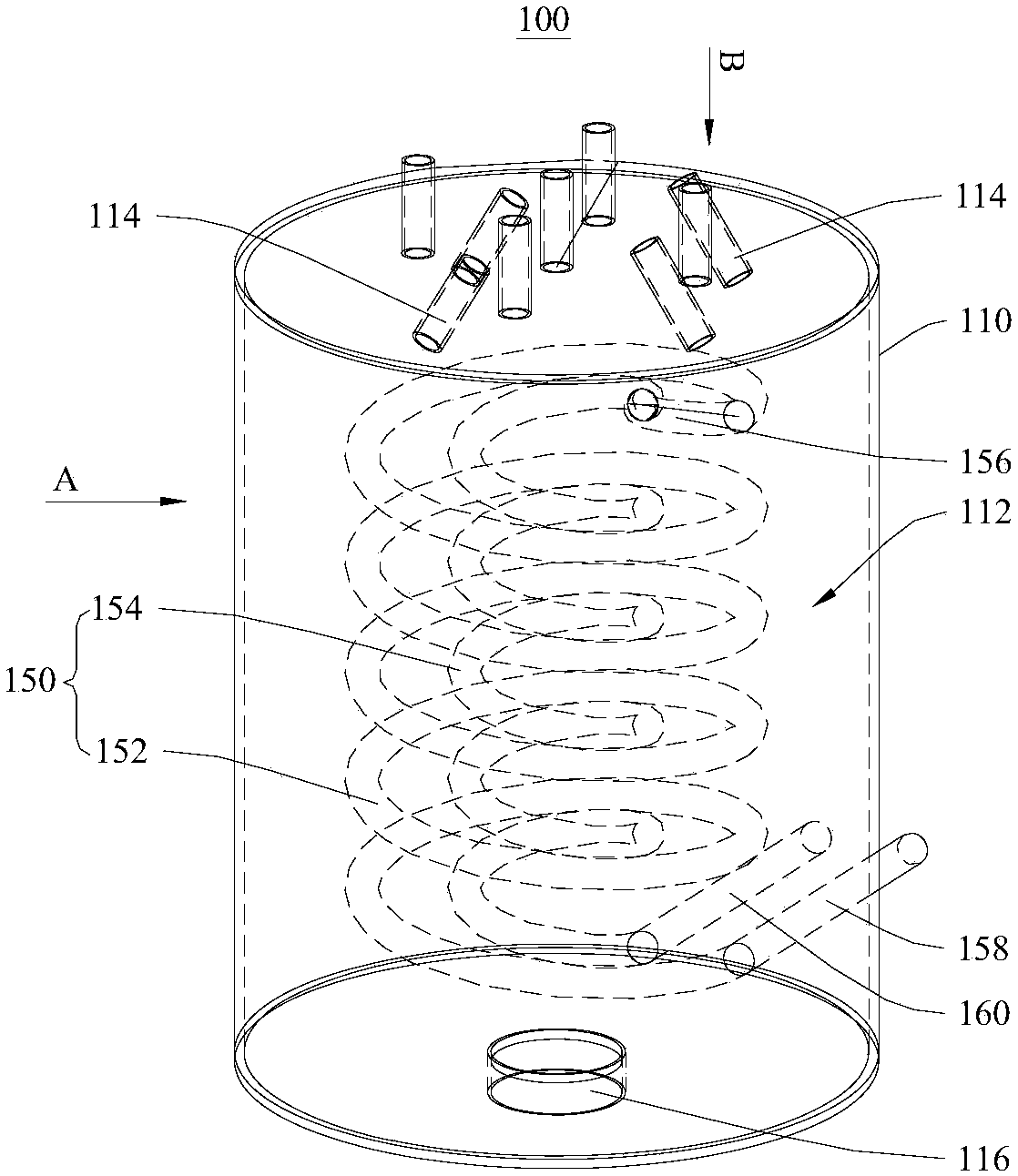

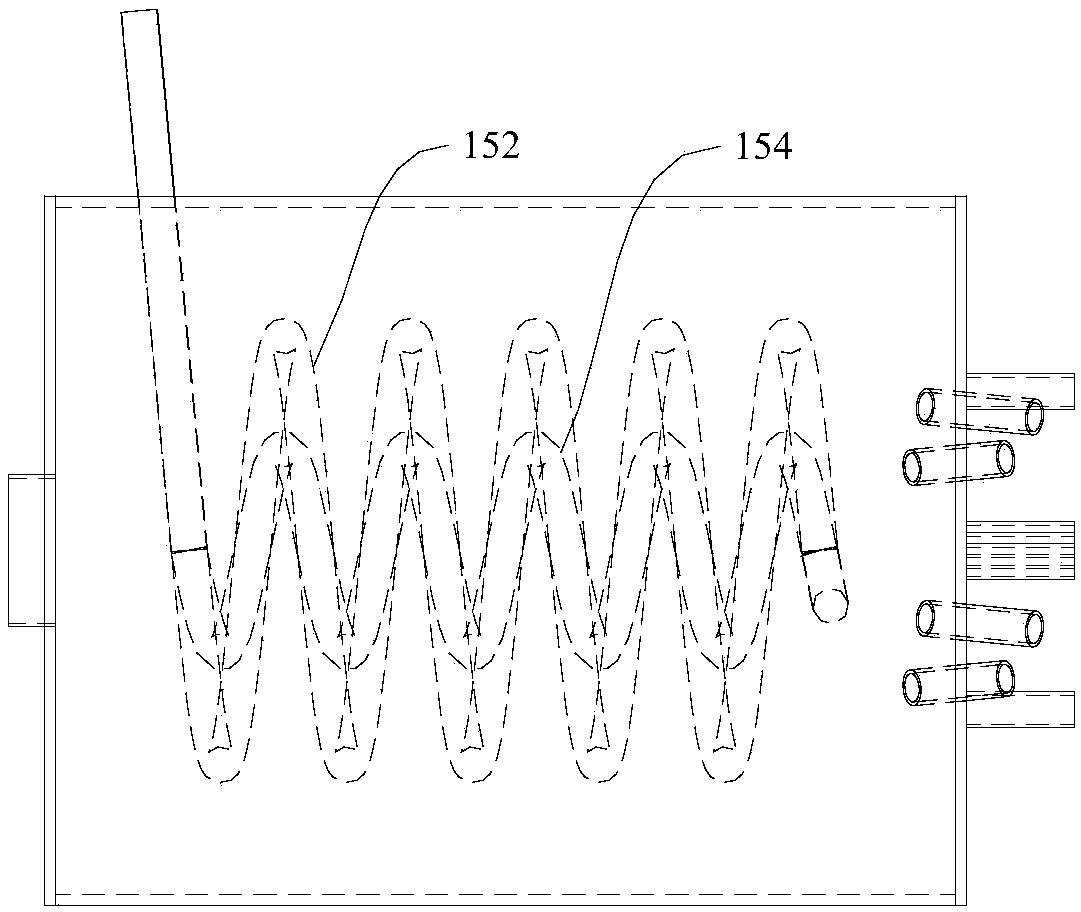

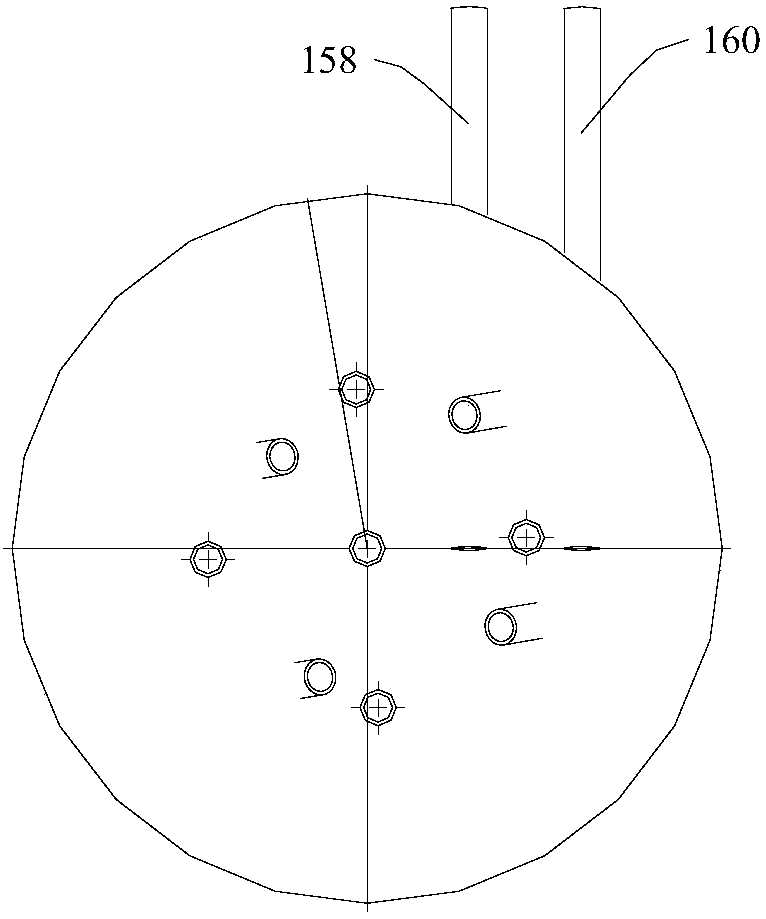

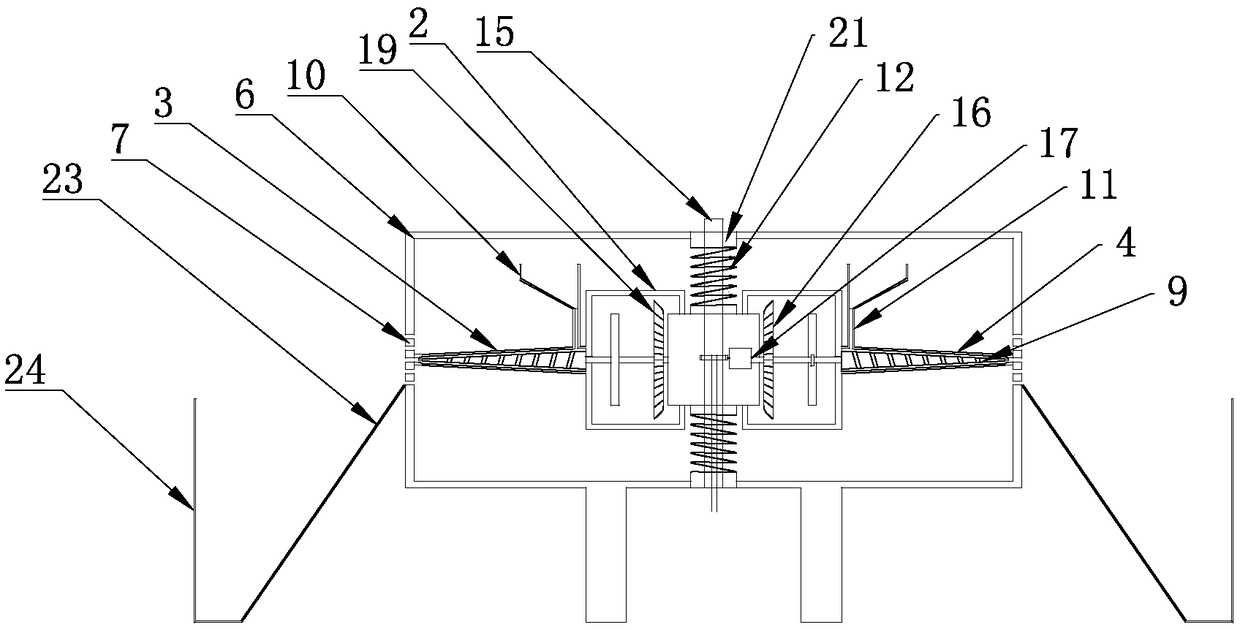

Micro-reactor and chemical industry production system

PendingCN108014730AEasy feedingEasy dischargeChemical/physical/physico-chemical microreactorsMicroreactorChemical industry

The invention provides a micro-reactor and a chemical industry production system, and relates to the field of chemical reaction equipment. The micro-reactor comprises a barrel body, and also comprisesa reaction pipe, wherein the barrel body defines an accommodating hollow cavity; a feeding pipe is mounted on the barrel body and is mutually communicated with the accommodating hollow cavity; the reaction pipe is arranged in the accommodating hollow cavity in a spiral form; two ends of the reaction pipe penetrate both through the barrel body and extend to the outer side of the barrel body. By spiral coiling, coiling length of the reaction pipe in the same space is increased, so that the heat exchange area of a heat exchange medium and a reaction material can be increased by the reaction pipeunder a limited space condition, and the heat exchange efficiency is improved; meanwhile, by the spiral coiling, a mass transfer effect of fluid in the reaction pipe can be further improved, the masstransfer effect and a heat transfer effect are improved at the same time, so that the reaction uniformity of the reaction material is higher, and the reaction yield is higher. The invention also provides the chemical industry production system including the micro-reactor. According to the chemical industry production system disclosed by the invention, by utilizing high-efficient heat exchange ability of the micro-reactor, the aim of improving the production efficiency and the production ability can be fully fulfilled.

Owner:SHANDONG HIMILE CHEM TECH

Particulate dispenser

InactiveUS20050252456A1Sufficient feedUniform sizeClimate change adaptationPisciculture and aquariaParticulatesEngineering

A particulate dispenser includes a housing for receiving particulate matter, such as fish food, to be dispensed, the housing having a perforated end through which the particulate matter may be discharged and an agitator for rotation within the housing. The agitator agitates the particulate matter, and sweeps the particulate matter against the perforated end, thereby forcing the particulate matter through the perforations.

Owner:MAG LIFE

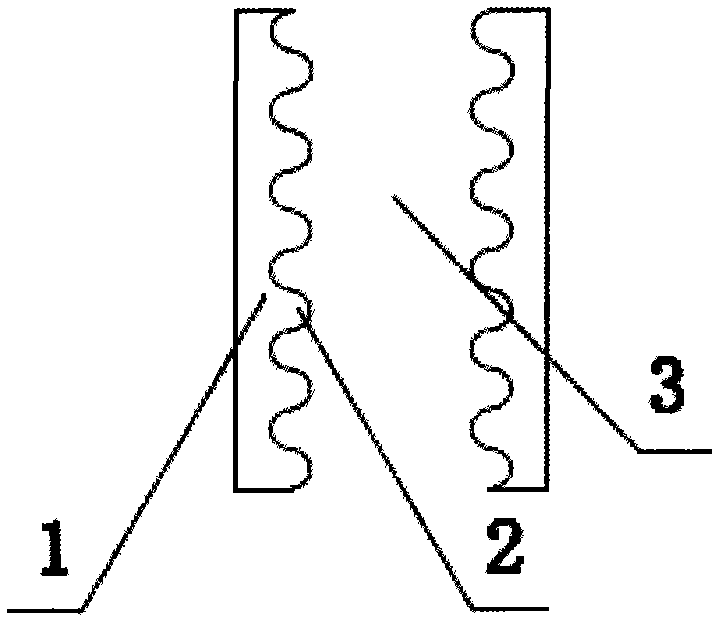

Crushing pair with superfine crushing function and implementation method of superfine crushing function thereof

The invention discloses a crushing pair with a superfine crushing function and an implementation method of a superfine crushing function thereof. The crushing pair comprises two jaw plates which are oppositely arranged to form an at least two-level step structure type crushing cavity, wherein the step structure type crushing cavity formed by the opposite working surfaces of the two jaw plates is gradually reduced step by step from top to bottom and forms an angle-step type structure, and the working surfaces of the two jaw plates of the final-level crushing cavity at the lower end in the step structure type crushing cavity are of a long and narrow structure. The remarkable functional characteristic of the crushing pair disclosed by the invention is to realize a supernormal and superfine crushing function. By improving the matched crusher structure, single-machine direct crushing for sand production and even crushing for powder production can be realized.

Owner:义乌市凌丰知识产权服务有限公司

Artificial hybridization and breeding method for male Paralichthys dentatus and female summer flounder

InactiveCN100355337CLarge variationRich typeClimate change adaptationPisciculture and aquariaAquatic productProviding material

The invention belongs to field of fish breeding and aquaculture, which in detail relates to a method of artificial crossing with summer-bothus and tooth-Bothus and breeding. It comprises following steps: (1) taking summer-bothus as male parent and tooth-bothus as female parent, reinforcing the nutrient and environmental condition to promote simultaneous gonadal maturity, getting mature sperm and ovum; (2) crossing fertilized ovum and hatching; (3) culturing the hybrid body and young fish; (4) providing systematic bait in culturing period. The invention not only provides material for deseription improvement for bothus and soles, but also the lies foundation of adding a new breeding species for sea fish cultivating.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Casting flow coating device with warning function

InactiveCN105108047AGuaranteed purityGuarantee the quality of sprayingFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a casting flow coating device with a warning function. The casting flow coating device comprises a spraying workbench, a filter device, a charging tank, a water pump and a spray gun, wherein a funnel-shaped paint recycling device is arranged in the spraying workbench; the upper end surface of the paint recycling device is parallel to the upper end surface of the spraying workbench; the lower end of the paint recycling device is communicated with the charging tank through a first pipeline; the filter device is arranged at a communicated part of the paint recycling device and the first pipeline; a charging hole is formed in the upper end of the charging tank; the water pump is arranged at one side, far from the first pipeline, of the charging tank; a feeding hole of the water pump is communicated with the charging tank; a discharging hole of the water pump is communicated with the spray gun through a second pipeline; the spray gun is arranged above the spraying workbench; a formaldehyde detector, a master control system and an alarm are arranged on the side wall of the spraying workbench; and the formaldehyde detector, the master control system and the alarm are sequentially connected through a circuit. Compared with the prior art, the casting flow coating device can warn the formaldehyde concentration, can improve the spraying efficiency and can improve the spraying quality.

Owner:廖子贵

Method for straw treatment and resource utilization

InactiveCN108739676APromotes thorough mixingLoose base materialCuttersAnimal husbandryRice strawCoupling system

The invention discloses a method for straw treatment and resource utilization, and belongs to the field of waste treatment. The method is based on a technology of treating organic straw by using earthworms, aims at the problems of large yield and difficult treatment of corncob, rice bran and rice straw. According to the method, a microorganism-earthworm coupling system is used for treating the straw, an efficient biological treatment system for crop straw is constructed, the degradation capacity of a microbial agent and earthworms is fully exerted, the microbial agent and the earthworms complement each other and overcome the defects that incineration, compost, ammonification and the like take a long time, occupy a large area, have odors, and generate secondary pollution to the environment;and many beneficial products such as (1) earthworm bodies and (2) earthworm excrement, wherein the earthworm bodies contain high-quality protein, can be ate, serve as livestock fodder, be used as medicine and be used for producing cosmetics; the earthworm can be used as a fertilizer, can be used as a soil improver and biological deodorizer after being processed, so that the resource utilization of the organic straw is achieved, and the method has good environmental benefits, economic benefits and broad application prospects.

Owner:宜兴市天石饲料有限公司 +2

Paper feed apparatus, image reading apparatus comprising paper feed apparatus, and image forming apparatus comprising image reading apparatus

ActiveUS9266691B2Sufficient feedRegistering devicesArticle feedersImage formationPulp and paper industry

Owner:SHARP KK

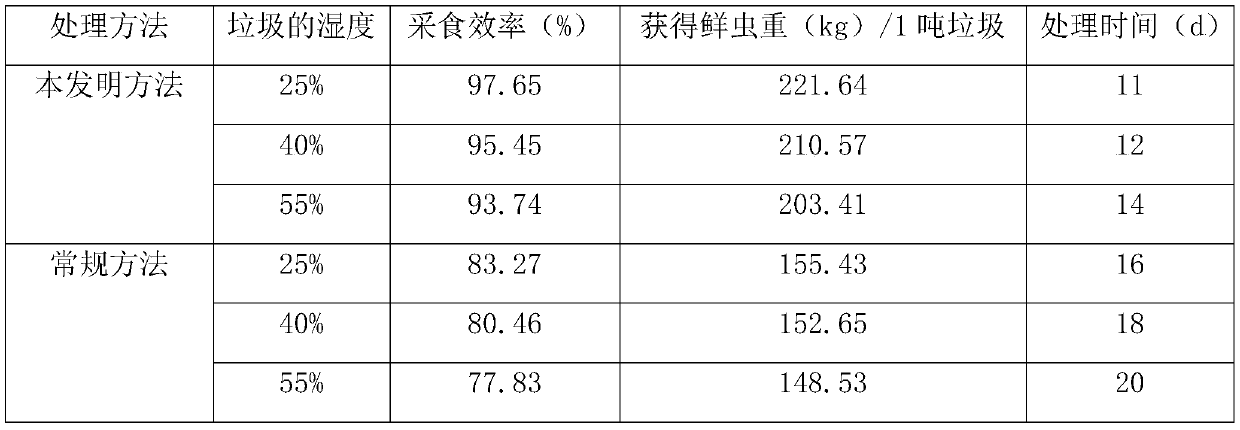

Method for adjusting and controlling feeding of raw materials to hermetia illucens larvae

The invention belongs to the technical field of hermetia illucens breeding, and particularly relates to a method for adjusting and controlling feeding of raw materials to hermetia illucens larvae. According to the characteristic that the hermetia illucens larvae are photophobic, the hermetia illucens larvae are stimulated through illumination, and when illumination of which the illumination intensity is higher than a certain illumination intensity is given, the hermetia illucens larvae enter the raw materials so as to take in the raw materials from inside to outside; when illumination of whichthe illumination intensity is lower than a certain illumination intensity is given or illumination does not exist at all, the hermetia illucens larvae climb out from the raw materials and take in theraw materials from outside to inside; and therefore, through adjusting different illumination intensities, the hermetia illucens larvae are forced to change intake positions and the depth of the rawmaterials, and the purpose of improving raw material intake efficiency is finally achieved.

Owner:GUANGZHOU UNIQUE BIOTECH CO LTD +1

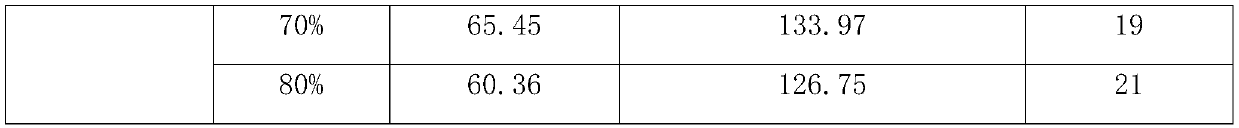

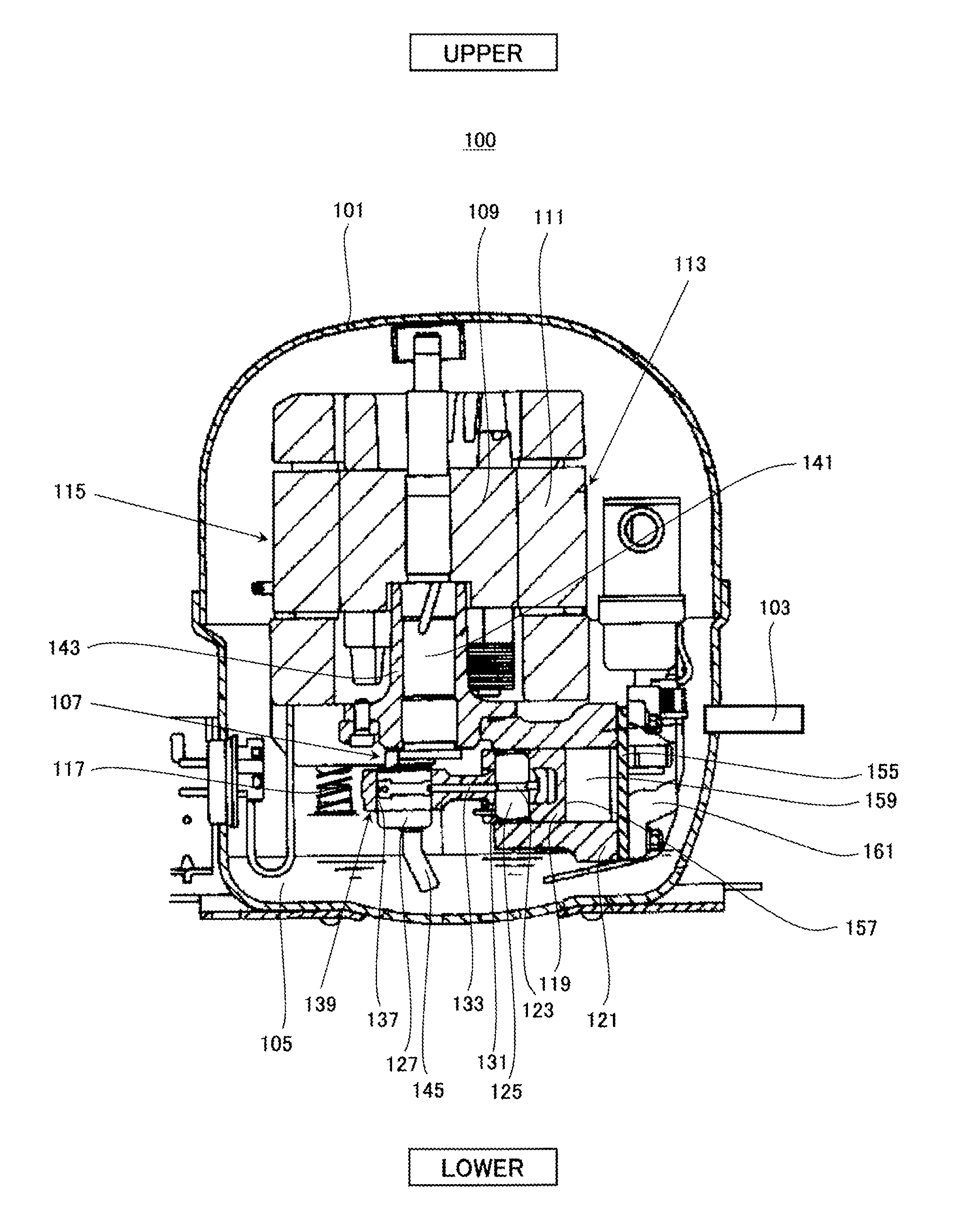

Refrigerant compressor

ActiveUS20130121809A1Inhibit wearImprove reliabilityPositive displacement pump componentsPump controlCouplingEngineering

A refrigerant compressor comprises an electric element; a compression element; and a sealed container; wherein the compression element includes: a crankpin; a piston pin; and a connecting rod having a large hole portion into which the crankpin is inserted, a small hole portion in which the piston pin is rotatably disposed, and a coupling rod portion; wherein an oil guide hole is provided in the coupling rod portion of the connecting rod such that the large hole portion and the small hole portion are communicated with each other via the oil guide hole; a circular first groove is provided on an outer peripheral surface of the piston pin such that the first groove communicates with the oil guide hole; and a second groove extending in a center axis direction of the piston pin is provided in a first region of the small hole portion of the connecting rod.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

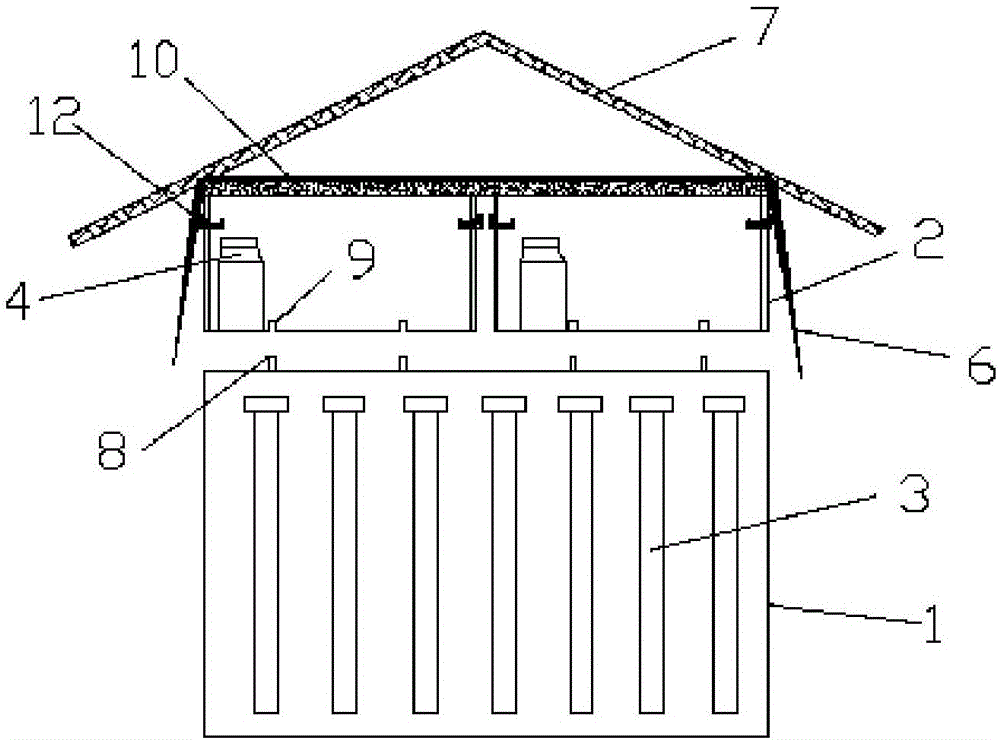

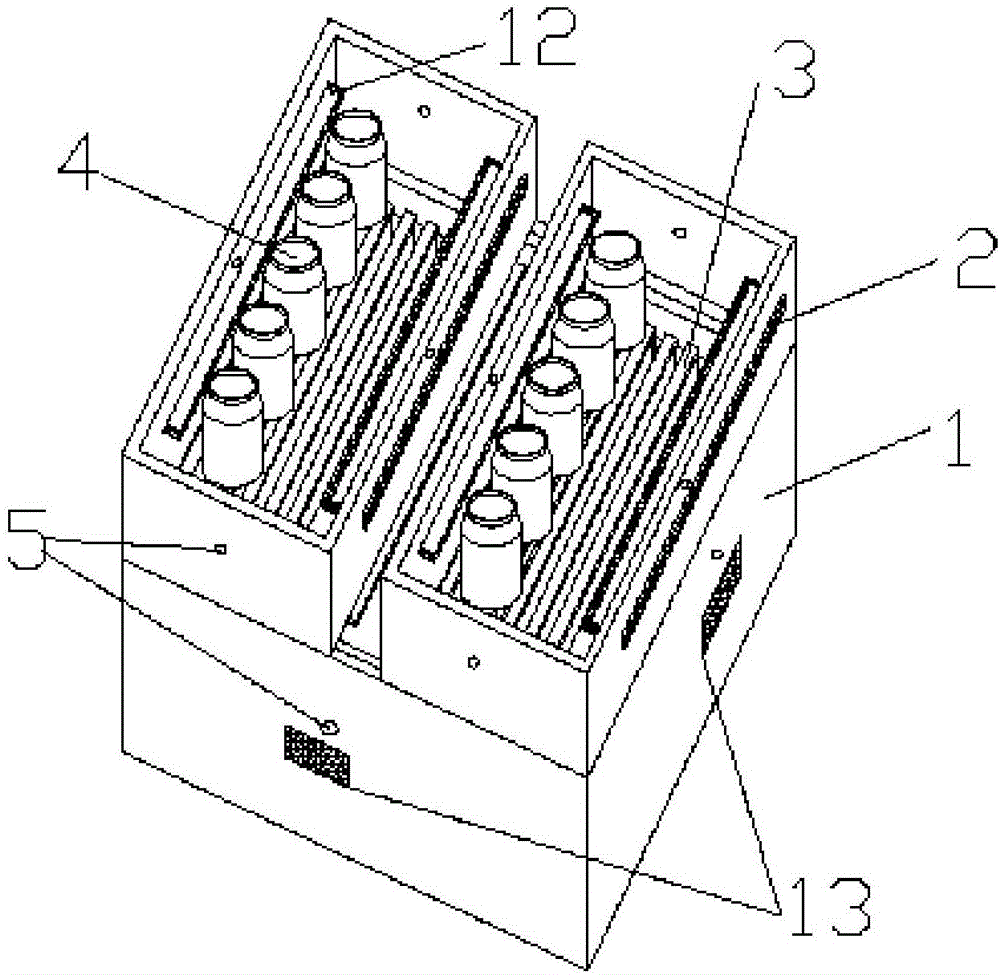

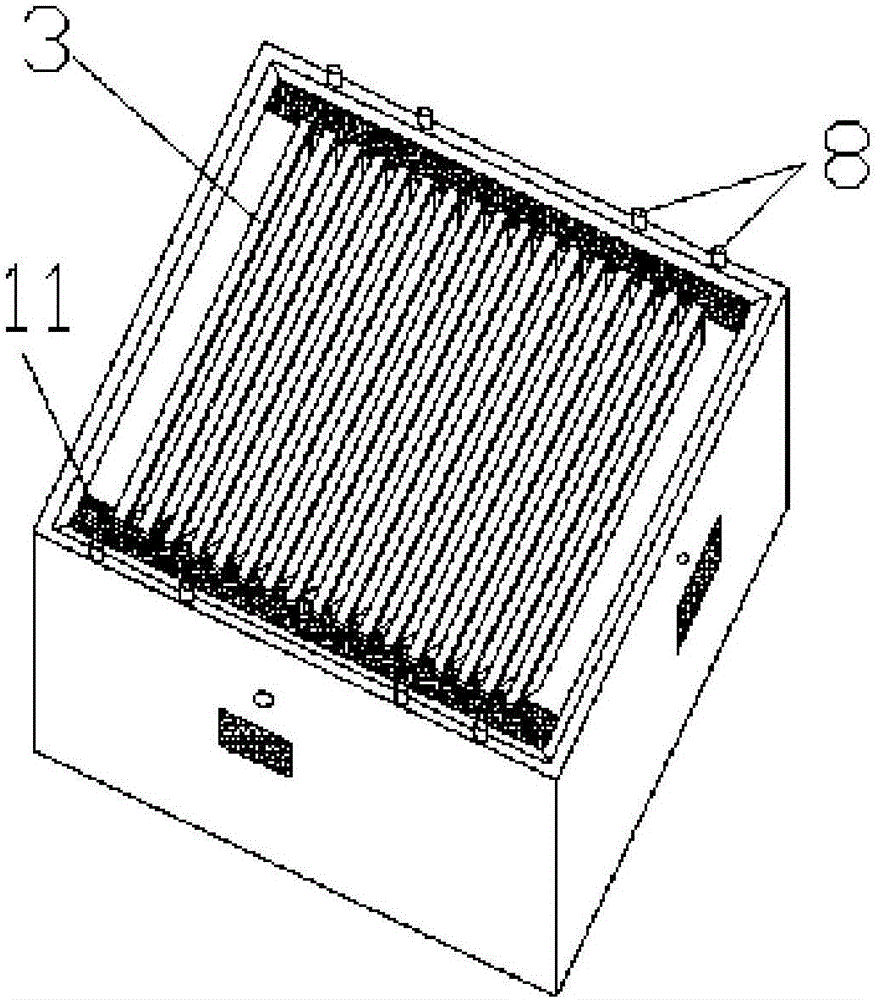

Beehive

The invention provides a beehive and belongs to the technical field of beehive manufacturing. The beehive comprises a main body, auxiliary bodies and a case cover, wherein honeycombs are inserted into the main body; the honeycombs are supported in the case body via supporting plates with grooves; the auxiliary bodies are arranged over the main body side by side and connected with the main body via positioning pins and positioning holes; inlets / outlets are formed in each side surface of the main body and the auxiliary bodies; ventilating ports are arranged in each side surface of the beehive main body; feeding grooves are formed in the side surfaces of the beehive auxiliary bodies; the feeding grooves can be inserted into the auxiliary body cavities from the external side surfaces of the auxiliary bodies; hoppers are all disposed in the auxiliary body cavities; and the feeding grooves are arranged under the inlets / outlets. The beehive has great ventilating property and can conveniently feed bees; the beehive can directly collect canned bee nests; work efficiency can be improved for bees; and the bee survival rate can be enhanced.

Owner:莫仁告

Feeding detection system

InactiveCN112825795AGood feed supplyQuality improvementAnimal feeding devicesAvicultureAnimal scienceNutrition

The invention relates to a feeding detection system. According to the feeding detection system, the feed feeding amount is preliminarily determined according to the age and the body type of livestock and poultry, the feed feeding amount is adjusted in real time according to the daily exercise amount of the livestock and poultry before feeding each time is carried out, an intelligent real-time identification system determines relational data of nutrition demand quantity of the livestock and poultry at different age stages, a central control processor controls feed ingredients and controls feed feeding according to the nutritional ingredient requirements of the intelligent real-time identification system, a feedback system collects biological information of the livestock and poultry in real time and transmits the obtained information to the central control processor, and therefore the whole process is automatically controlled, it is guaranteed that the feeding amount of feed is sufficient, meanwhile, the feed can be saved, and the breeding cost is reduced.

Owner:余姚市谐丰模塑有限公司

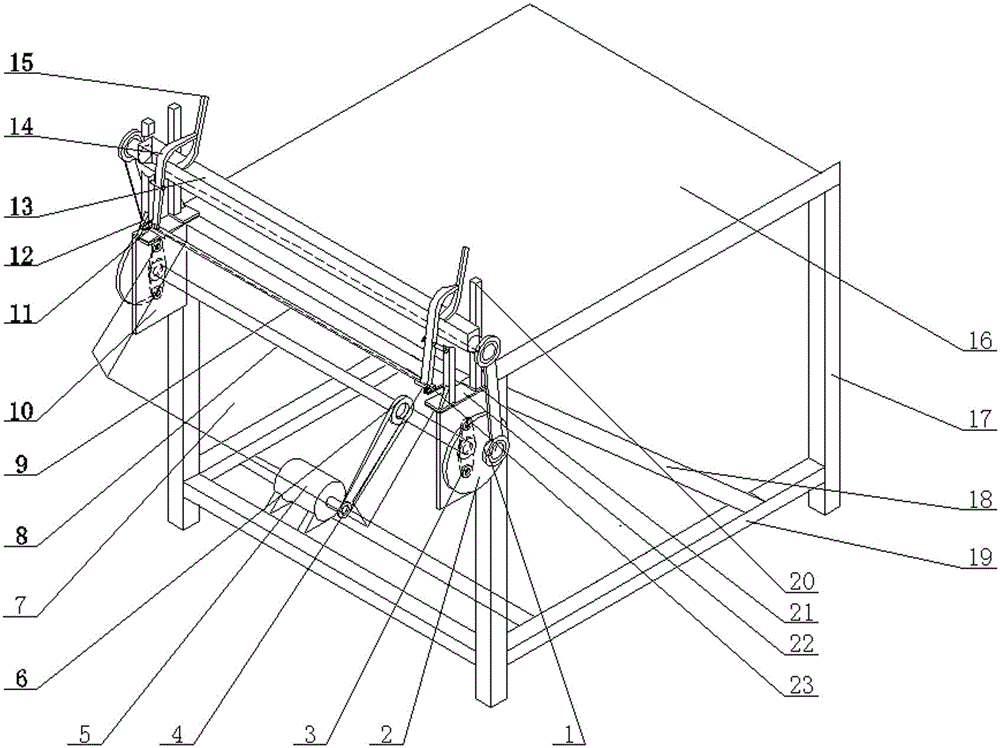

Device for cutting frozen meat loaves

The invention discloses a device for cutting frozen meat loaves. The device comprises rocker arm rods, rotating plates, flange plates, an electric motor rotating wheel, an electric motor, a rotating wheel, a rotating shaft, a baffle, vertical supporting plates, a cutter, a working table, supporting legs, balanced supports, stand columns, supporting plates and the like. The working table is fixed through the supporting legs. The electric motor is arranged on the two balanced supports. The rotating plates are arranged on the vertical supporting plates. One end of each rocker arm rod is arranged on the corresponding rotating plate in a hinged manner, and the other end of each rocker arm rod is connected with the cutter in a hinged manner. The cutter is limited by the stand columns to move leftwards and rightwards. The rotating shaft is connected with the rotating plates. The rotating wheel on the rotating shaft is connected with the electric motor rotating wheel. The electric motor drives the rotating shaft to move. The rotating shaft drives the rotating plates to rotate. The rotating plates drive the rocker arm rods, and therefore the rocker arm rods can make the cutter reciprocate in the vertical face. The device can conveniently cut frozen meat into the meat loaves, overcomes the defect that the frozen meat loaves are hard and difficult to cut, improves the frozen meat cutting efficiency, and is suitable for cutting frozen meat in livestock farms to manufacture fodder.

Owner:韦有任

Compound feed capable of promoting growth of nibea albiflora

InactiveCN107373208APromote absorptionFast growthFood processingClimate change adaptationDiseaseBiotechnology

The invention discloses compound feed capable of promoting growth of nibea albiflora. The compound feed is prepared from raw materials in parts by weight as follows: 25-45 parts of plant-source protein feed, 60-80 parts of wheat, 10-20 parts of blood worm powder, 4-8 parts of fermented feather powder, 20-40 parts of pine needle powder, 8-16 parts of fermented straw, 10-20 parts of yeast protein meal, 2-4 parts of montmorillonite, 2-4 parts of monocalcium phosphate, 18-22 parts of a digestion promoter and 3-6 parts of sweet potato powder. The proposed compound feed capable of promoting growth of nibea albiflora can effectively improve intestinal flora of the nibea albiflora, promote digestive absorption and strengthen the physique and realizes the effect on preventing diseases; the nibea albiflora has good absorption effect and grows fast.

Owner:合肥申仁养殖有限公司

Integrated duplex concrete supply pouring system and supply method

ActiveCN108331351BReduce volumeAvoid spillingBuilding material handlingWireless transmissionControl system

Owner:盛富春

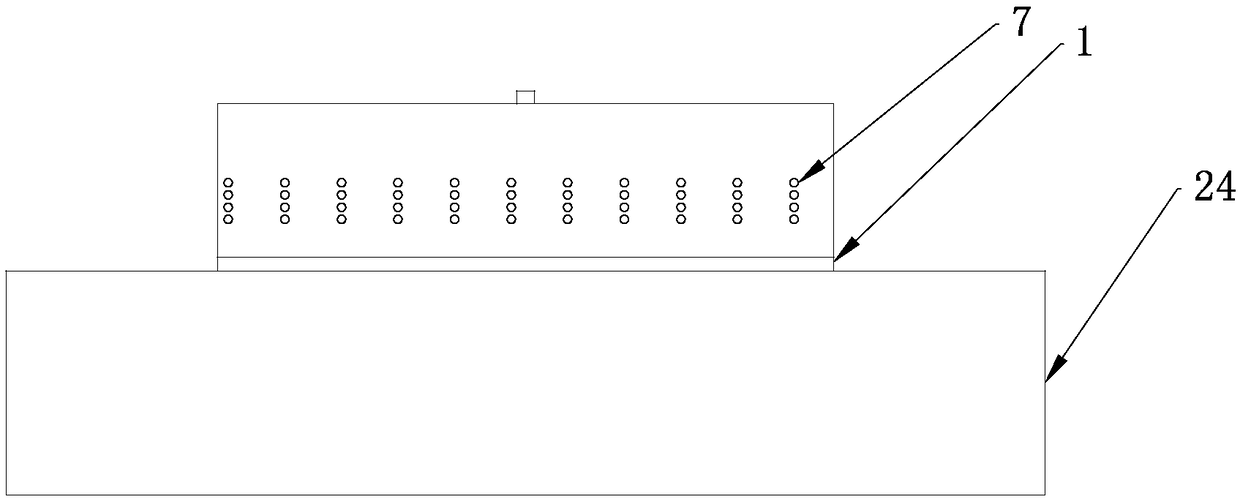

Sawdust compressing device

ActiveCN108972827ASufficient feedImprove firmnessWood working apparatusDomestic articlesGear wheelDrive motor

The invention discloses a sawdust compressing device. The sawdust compressing device comprises a machine body frame, a drive device and extruding devices, wherein the drive device and the extruding devices are arranged in the machine body frame. The drive device comprises a mounting base, a drive motor, a gear set, eccentric wheels, a linkage bearing and spring parts. A rotary shaft is verticallyarranged on each side face of the circumference of the mounting base, the eccentric wheels and the gear set are coaxially fixed to the rotary shafts, and an output shaft of the drive motor is fixedlyconnected with one rotary shaft. In the using process, the drive motor drives the rotary shafts to rotate, the rotary shafts drive extruding screws to rotate to extrude compressed sawdust, extruding force and friction heat are continuously generated in the compression process, lignin in the sawdust has the effect of a binder, sawdust rods are formed in extruding barrels, through the transmission effect of the gear set, the other rotary shafts are driven to rotate to drive the extruding devices to extrude the sawdust, multi-station synchronous operation is achieved, and the production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

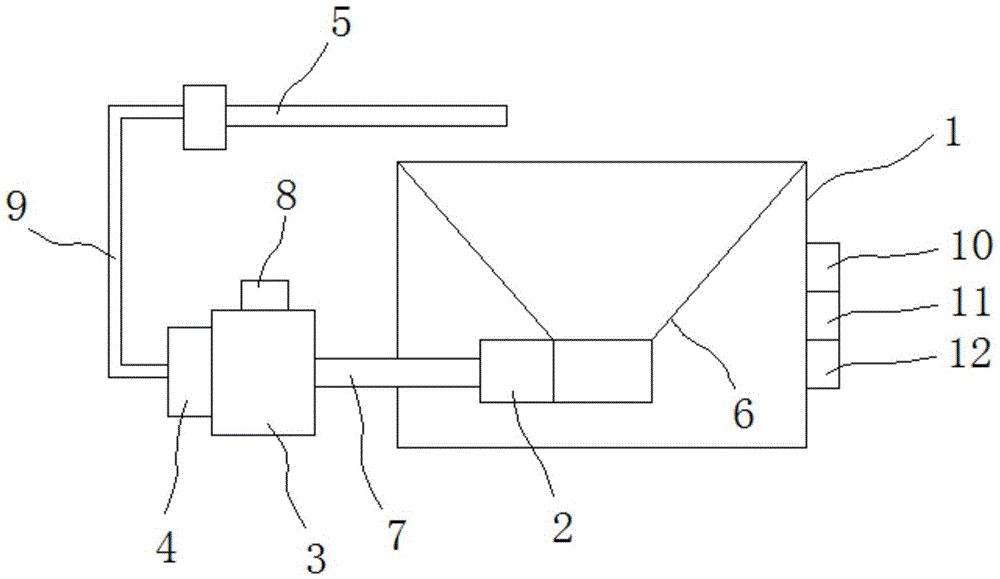

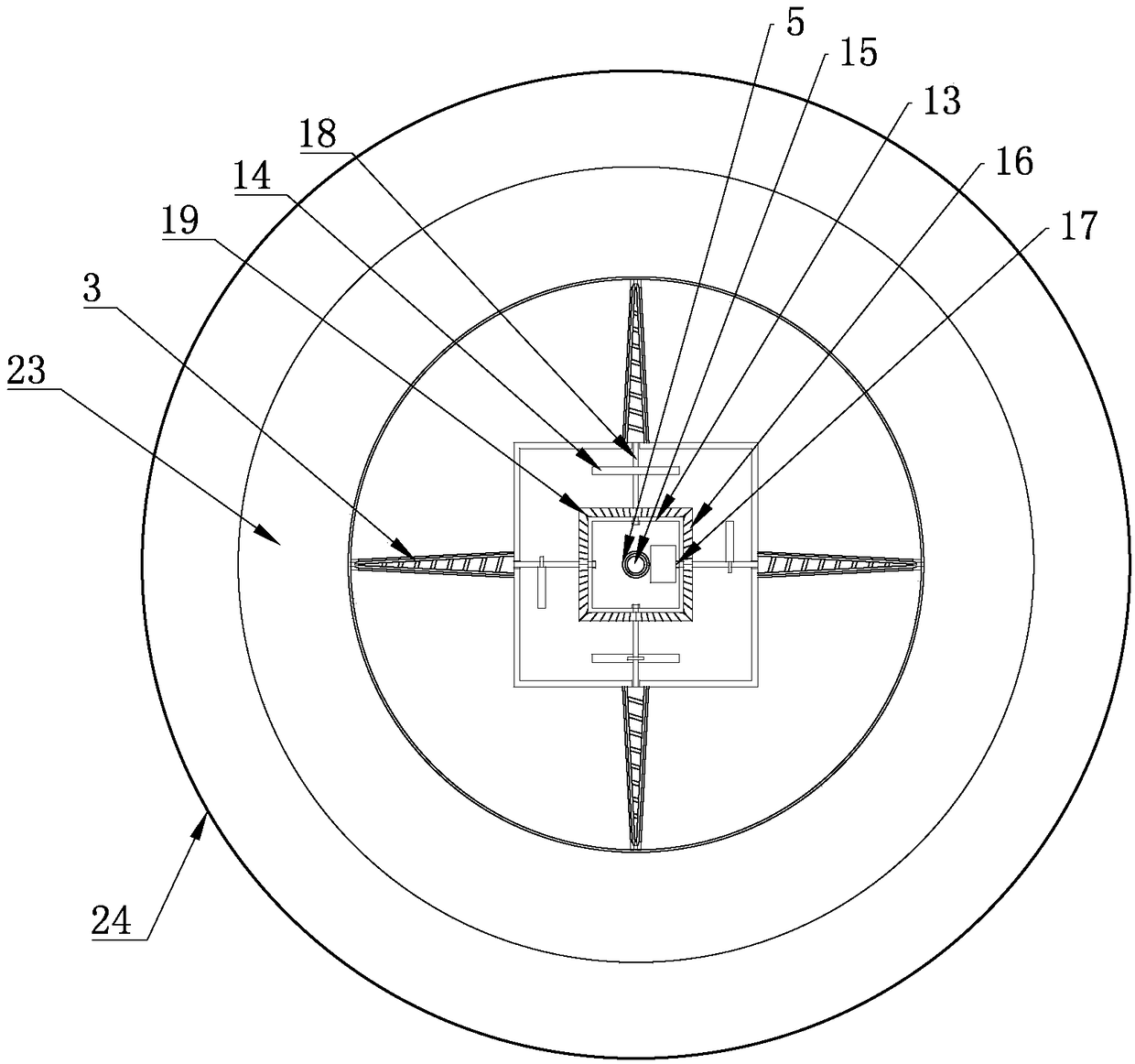

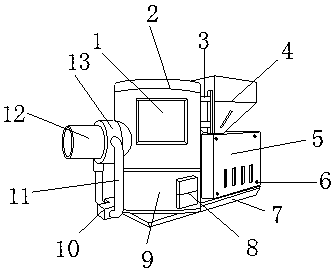

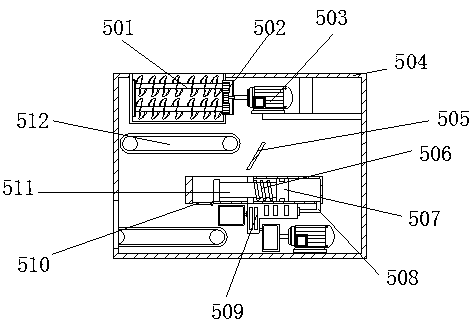

Biomass multistage cyclone burner

PendingCN110469844APromote combustionSufficient feedSolid fuel combustionGrain treatmentsCycloneCombustion chamber

The invention discloses a biomass multistage cyclone burner. The biomass multistage cyclone burner structurally comprises a visible window, an upper sealing cover, a supporting frame, a feeding hopper, a processor, fixing screws, a base, a sealing plate, a combustion chamber, a pipeline fixing block and a pipeline. According to the biomass multistage cyclone burner, a motor in a shell of the biomass multistage cyclone burner is started to drive a smashing rod to rotate to smash raw materials, and then the raw materials are driven by a driver to reach an extruding rod below a sliding channel; and hydraulic oil is sucked from an oil tank through a hydraulic pump, the hydraulic oil is transferred to the position below a piston block through a guide pipe to extrude and push the piston block, so that an extruding rod moves. Therefore, the raw materials on a torsional spring plate are extruded, and when the raw materials reach certain weight, a torsional spring can be automatically opened, and the raw materials are driven by the driver to be combusted in the combustion chamber. By improving the structure of the equipment, when the biomass multistage cyclone burner is used, the smashed raw materials can be extrude-formed, the raw materials are more convenient to burn, and feeding is more sufficient.

Owner:江苏台安迪环保科技有限公司

Quick forming and slitting integrated equipment for sintered brick production

ActiveCN112339071AReduce frictional energy lossUniform compactnessMouldsFeeding arrangmentsBrickStructural engineering

The invention discloses quick forming and slitting integrated equipment for sintered brick production. The equipment comprises an equipment body, a rack, a feeding mechanism, an extrusion forming mechanism, a die cavity, a slitting mechanism, a shaking mechanism and supplying mechanisms, wherein the rack is located in the equipment body, the feeding mechanism is fixedly welded to the rack and is located on one side of the extrusion forming mechanism, the extrusion forming mechanism is arranged at the upper end of the rack, the die cavity is hollow and is fixed to the rack, the die cavity is formed right below the extrusion forming mechanism in a horizontal direction, the slitting mechanism is arranged right below the die cavity in parallel, the bottom end of the slitting mechanism is fixedly connected to the rack, one end of the shaking mechanism is fixed to the rack and the other end of the shaking mechanism is in contact with the feeding mechanism and the side wall of the die cavity,separately, the supplying mechanisms are distributed on two sides of the die cavity, the feeding mechanism comprises a feeding hopper, a feeding pipe and a spiral pipe, the feeding pipe is arranged obliquely, the upper end of the feeding pipe is connected to the bottom end of the feeding hopper, an opening in the other end of the feeding pipe is formed vertically, and the spiral pipe is arrangedin the feeding pipe in a penetrating manner.

Owner:宜兴市鼎诚建筑陶瓷有限公司

A feeding box for laying hen breeding that is convenient for timing and quantitative input of feed

ActiveCN110859141BImprove survival rateSituations to avoid deathBird housingsAnimal scienceEngineering

The invention discloses a feeding box for laying hen breeding which is convenient for timing and quantitative feeding of feed. The present invention comprises a box body, the interior of the box body is fixedly installed with a partition net, the side wall of the box body is fixedly installed with a food trough, the side wall of the food tank is connected with a conveying pipe, the top of the conveying pipe is connected with a storage tank, and the conveying pipe The internal fixed installation quantitative cylinder. In the present invention, the laying hen chicks are placed in the space surrounded by the partition net, and through the control of the external control device, the filler in the dosing cylinder is pushed to move the connecting rod inside the dosing cylinder, and the feed inside the dosing cylinder is pushed into the trough Among them, by placing the young chicks separately, it not only helps to avoid the occurrence of food competition, but also through regular and quantitative supplementation of feed to ensure sufficient food, which helps to improve the survival rate of young chicks. In addition, when supplementing feed, through Feeding is carried out by stacking upwards from the bottom of the trough, which reduces noise pollution and avoids the death of young chicks caused by stress.

Owner:常德市中晟农牧有限公司

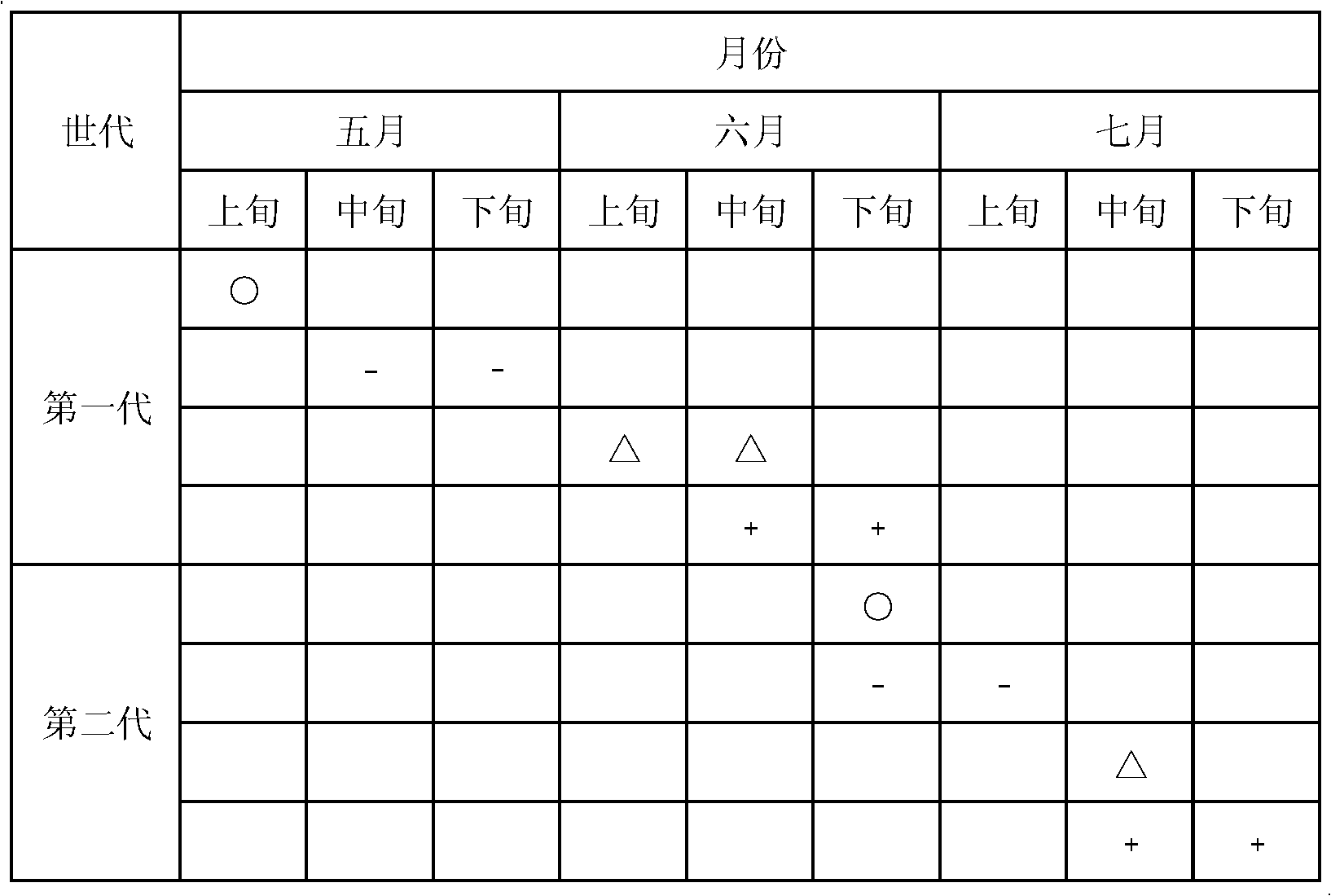

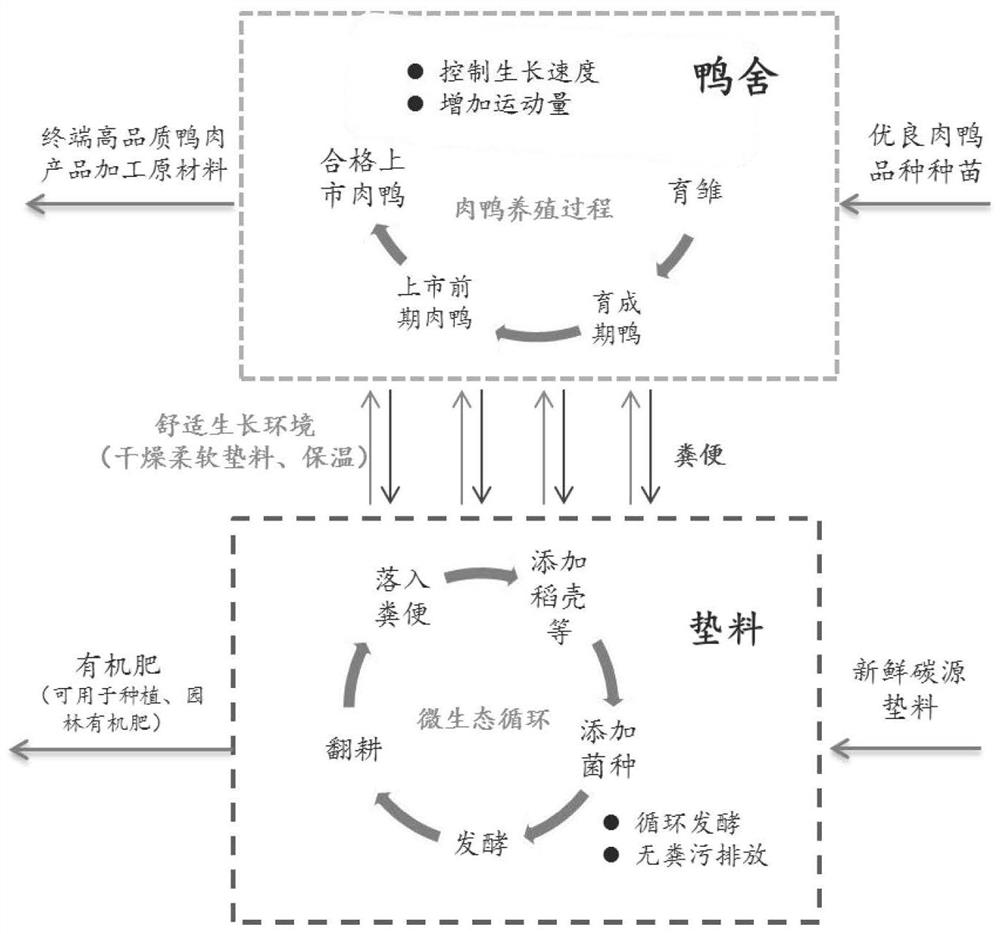

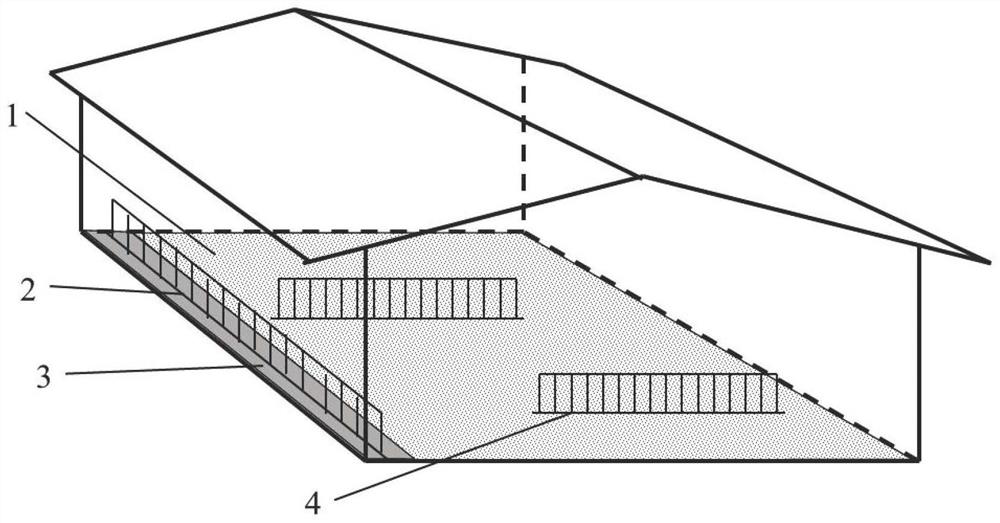

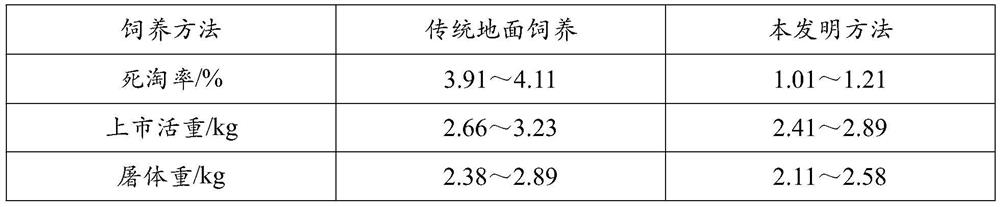

An environmentally friendly breeding method for improving the quality of meat ducks

An environmentally friendly breeding method to improve the quality of meat ducks. First, mix sawdust and rice husks and adjust the water to make litter; second, use thermal umbrellas to adjust the temperature throughout the brooding period, and adjust the temperature according to the age of the ducks. Adjust the stocking density and feeding amount of ducklings accordingly; in the growing period, in addition to the same adjustment of stocking density and feeding amount, it also involves adding dry-scattered strains to the litter, plowing the litter, and adjusting water. Circular fermentation of litter; Finally, in the early stage of listing, by limiting the stocking density and feeding amount, and carrying out sampling and weighing, the meat ducks will reach the predetermined target when they are released. The method of the invention can improve the quality of the meat duck, reduce the death rate of the meat duck, effectively solve environmental problems such as manure treatment and waste water discharge, ensure the appearance of the meat duck to be clean, and improve the breeding efficiency.

Owner:四川省畜牧总站 +1

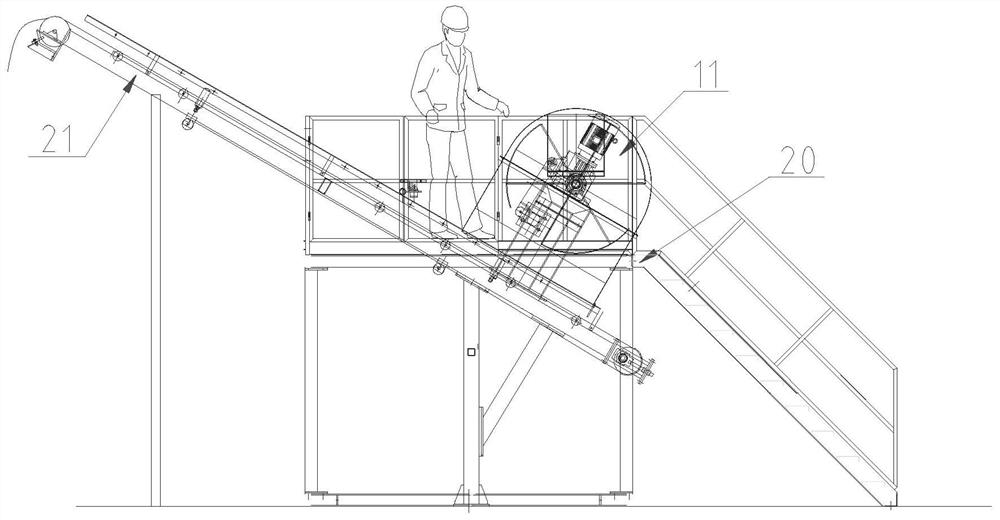

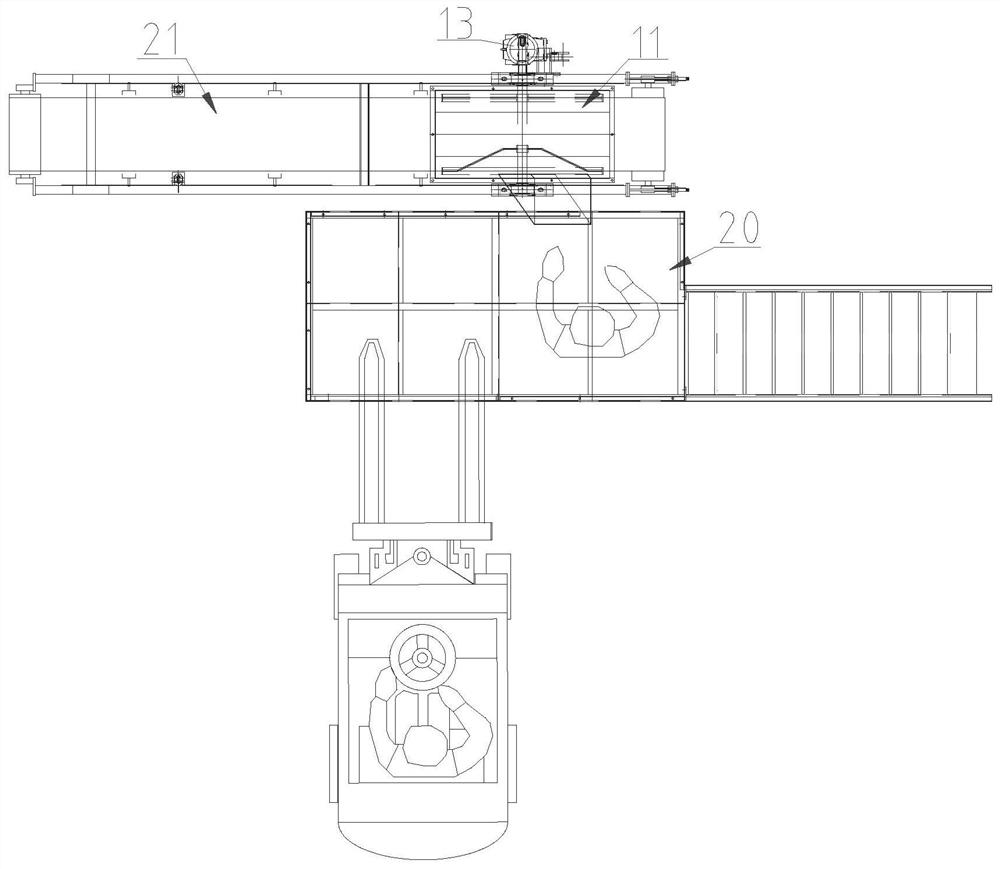

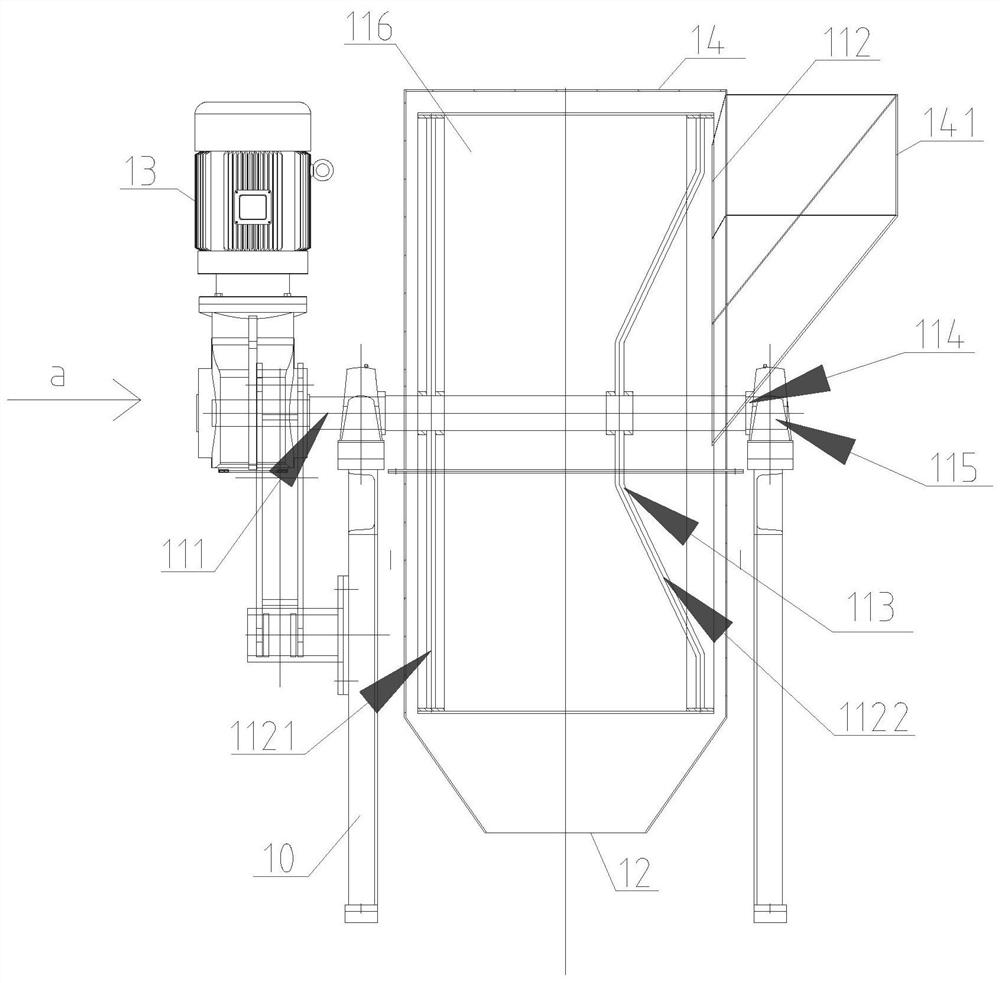

Drum-type steel fiber uniform distribution device and steel fiber distribution platform

The invention discloses a drum-type steel fiber uniform distribution device. The drum-type steel fiber uniform distribution device comprises supporting legs, a drum, a lower box body and a motor, wherein a feeding hole is formed in the top end of the lower box body; a discharging hole is formed in the bottom end of the lower box body; the drum comprises a rotating shaft, a supporting rod group, a supporting steel ring and a screen; one end of the rotating shaft is matched with the power output end of the motor; the supporting rod group comprises a plurality of supporting rods; one end of each supporting rod is fixedly connected with the rotating shaft, and the other end of each supporting rod is fixedly connected with the supporting steel ring; an annular partition plate is arranged on the drum; and the peripheral side of the outer ring of the annular partition plate is connected with the supporting steel ring. The invention also discloses a steel fiber distribution platform. The steel fiber distribution platform comprises the drum-type steel fiber uniform distribution device, a feeding platform supporting frame and a belt conveyor conveying device, wherein the drum-type steel fiber uniform distribution device is arranged on the feeding platform supporting frame; and the belt conveyor conveying device is positioned on the lower portion of the discharging hole. According to the device, the problem that the uniformity of steel fibers cannot be effectively controlled during traditional manual feeding is solved, and the production quality of concrete is effectively guaranteed.

Owner:SHANTUI JANEOO MACHINERY

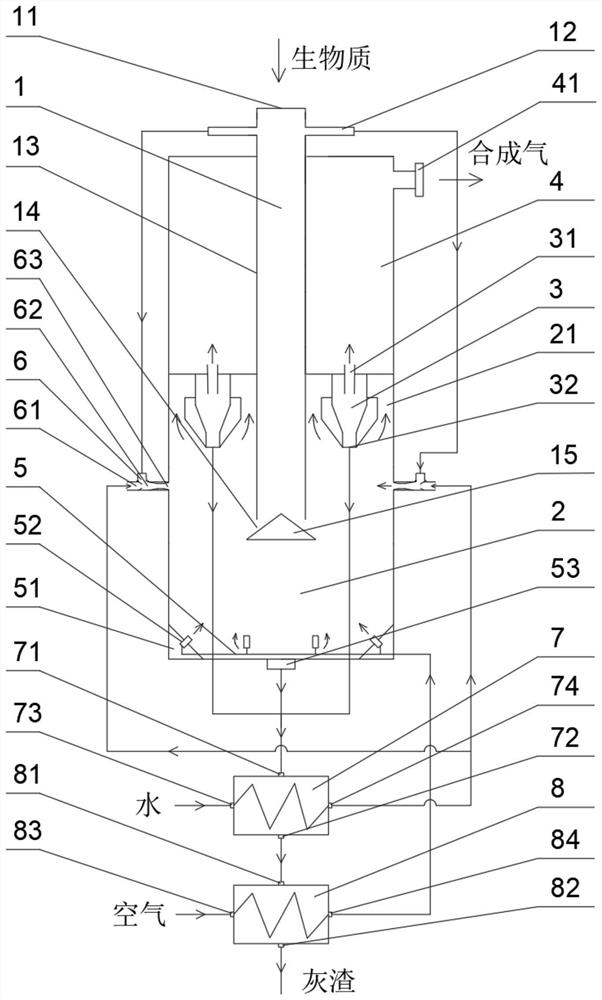

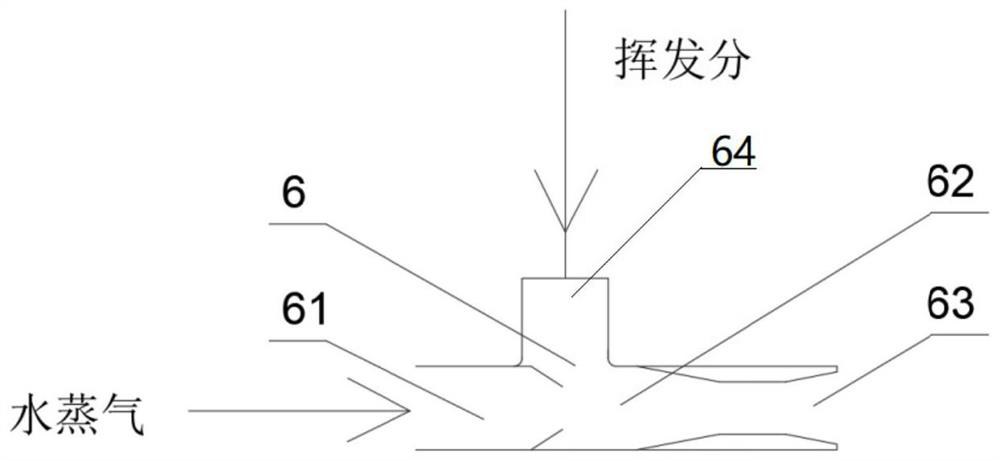

Device for preparing synthesis gas from biomass

ActiveCN114479953AGuaranteed continuitySimple preparation processGasification processes detailsCombustible gas productionSyngasBiomass

The invention provides a device for preparing synthesis gas from biomass, and belongs to the field of biomass utilization. The device comprises a pyrolysis chamber as well as a heat exchange chamber and a graded gasification chamber which are arranged outside the pyrolysis chamber in a sleeving manner, a biomass feed port and a volatile component outlet are formed in the top end of the pyrolysis chamber, and a solid product outlet is formed in the bottom end of the pyrolysis chamber; a synthesis gas outlet is formed in the upper part of the heat exchange chamber, and the lower part of the heat exchange chamber is connected with the grading gasification chamber through a gas-solid separator; the two sides of the grading gasification chamber are connected with a gas mixer, meanwhile, a tangential air distributor is arranged below the grading gasification chamber, and the position where the gas mixer is connected with the grading gasification chamber is located above a solid product outlet, so that the grading gasification chamber is divided into a reforming area and a preliminary gasification area. According to the invention, baking pyrolysis, graded gasification and waste heat utilization are realized through three relatively independent spaces, the continuity of an object and the stability of a reaction are ensured, reaction conditions such as atmosphere and temperature are conveniently and accurately controlled, and a preparation process of clean synthesis gas is simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com