Automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine

A technology of forced feeding and integrated machine, applied in the direction of coating, etc., can solve the problems of complex production process, low production efficiency, and high power consumption, and achieve the effect of simplifying processing technology, improving production efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

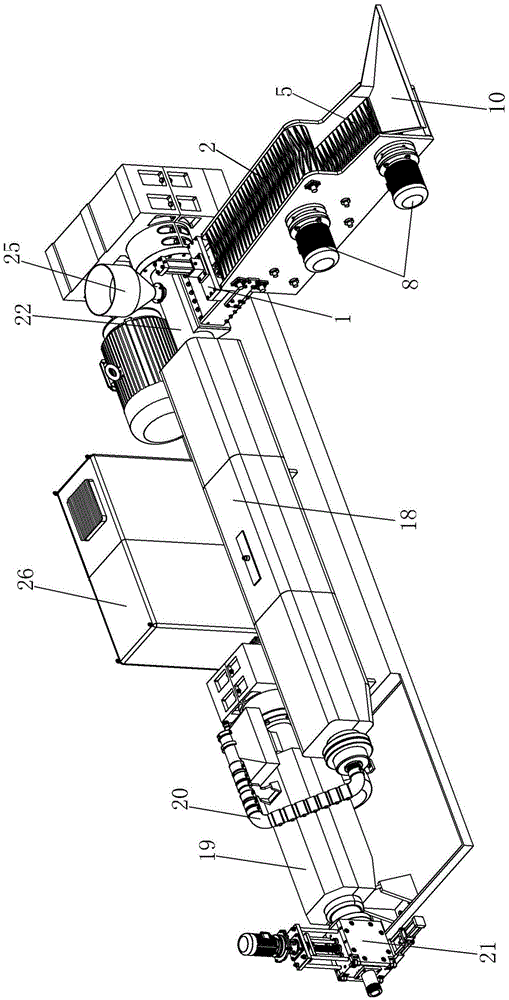

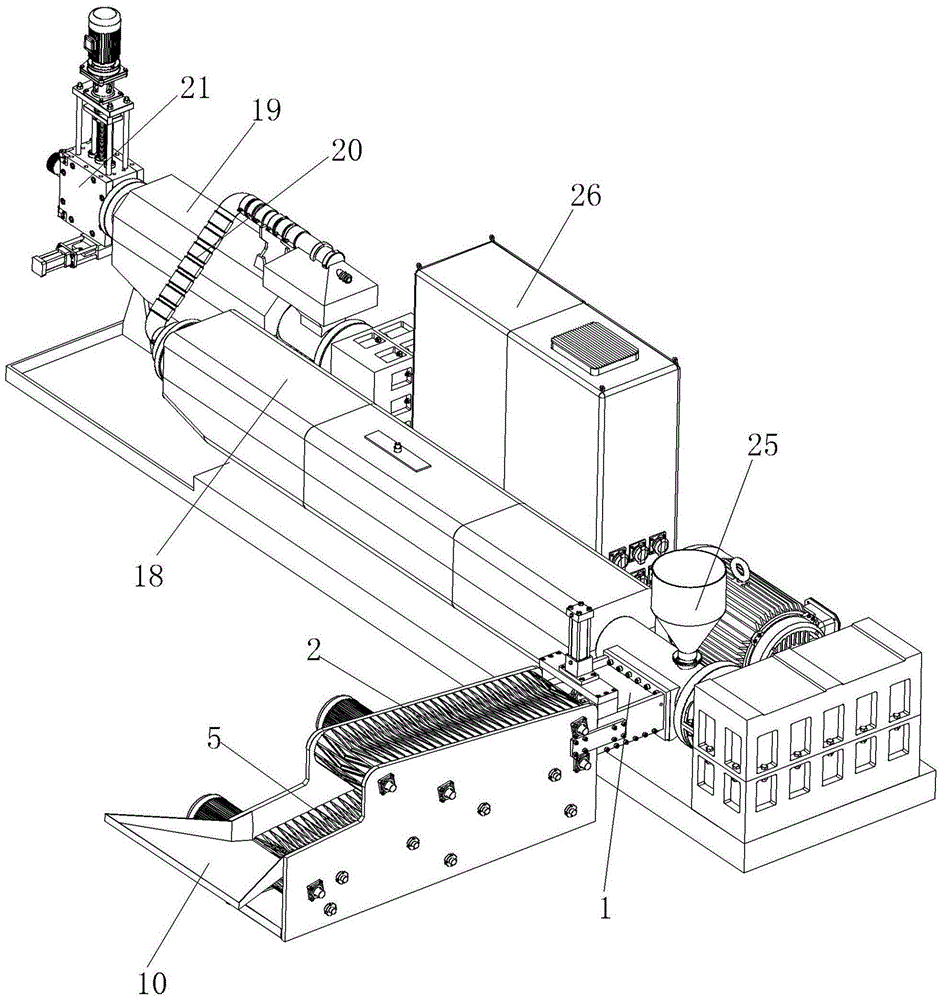

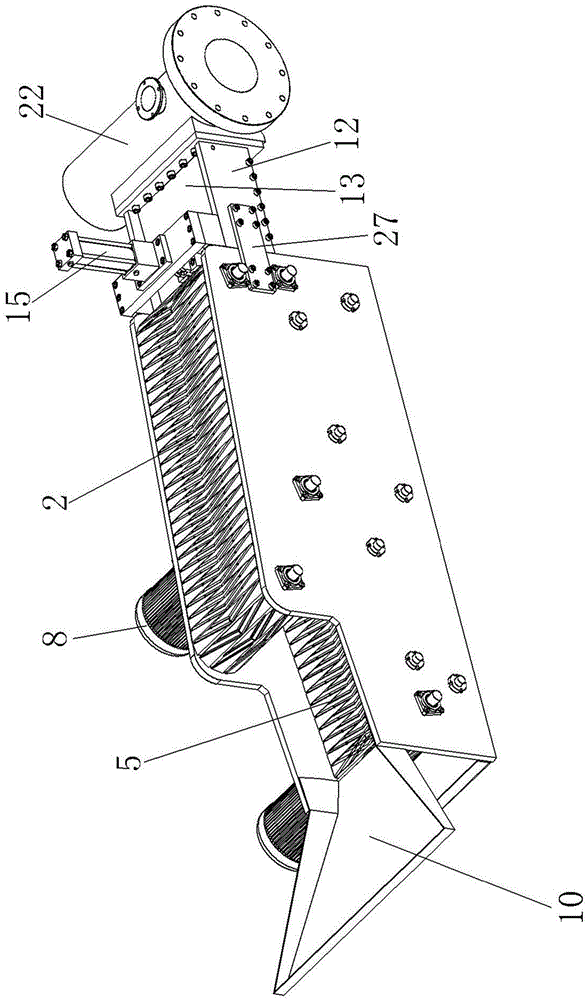

[0042] A high-efficiency mold material granulation integrated machine with automatic dehydration and feeding, including a granulation unit, a crawler dehydration feeding device and a secondary extrusion feeding device 1, the crawler dehydration feeding device includes two sets of extrusion conveyor belts And the driving mechanism a that respectively drives two sets of extrusion conveyor belt transmission, the two sets of extrusion conveyor belts are arranged up and down opposite to each other, the upper extrusion conveyor belt a2 includes an extrusion surface 3 and a feeding surface 4, and the extrusion surface 3 and the lower extrusion conveyor belt b5 The extrusion channel 6 is relatively arranged and formed. The size of the extrusion channel 6 can be adjusted according to the needs. The angle formed by the feeding surface and the extrusion surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com