Patents

Literature

187results about How to "Promotes thorough mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

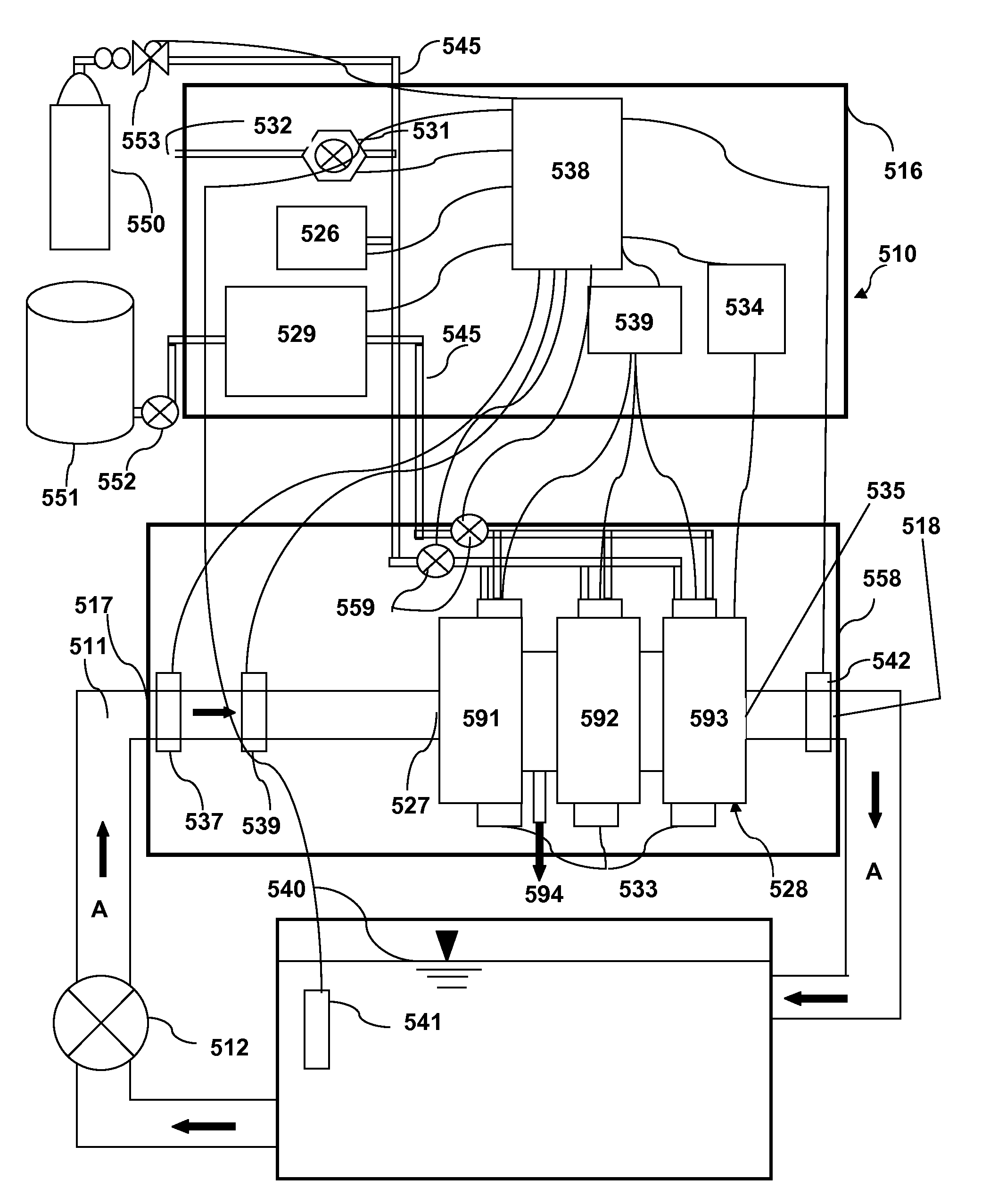

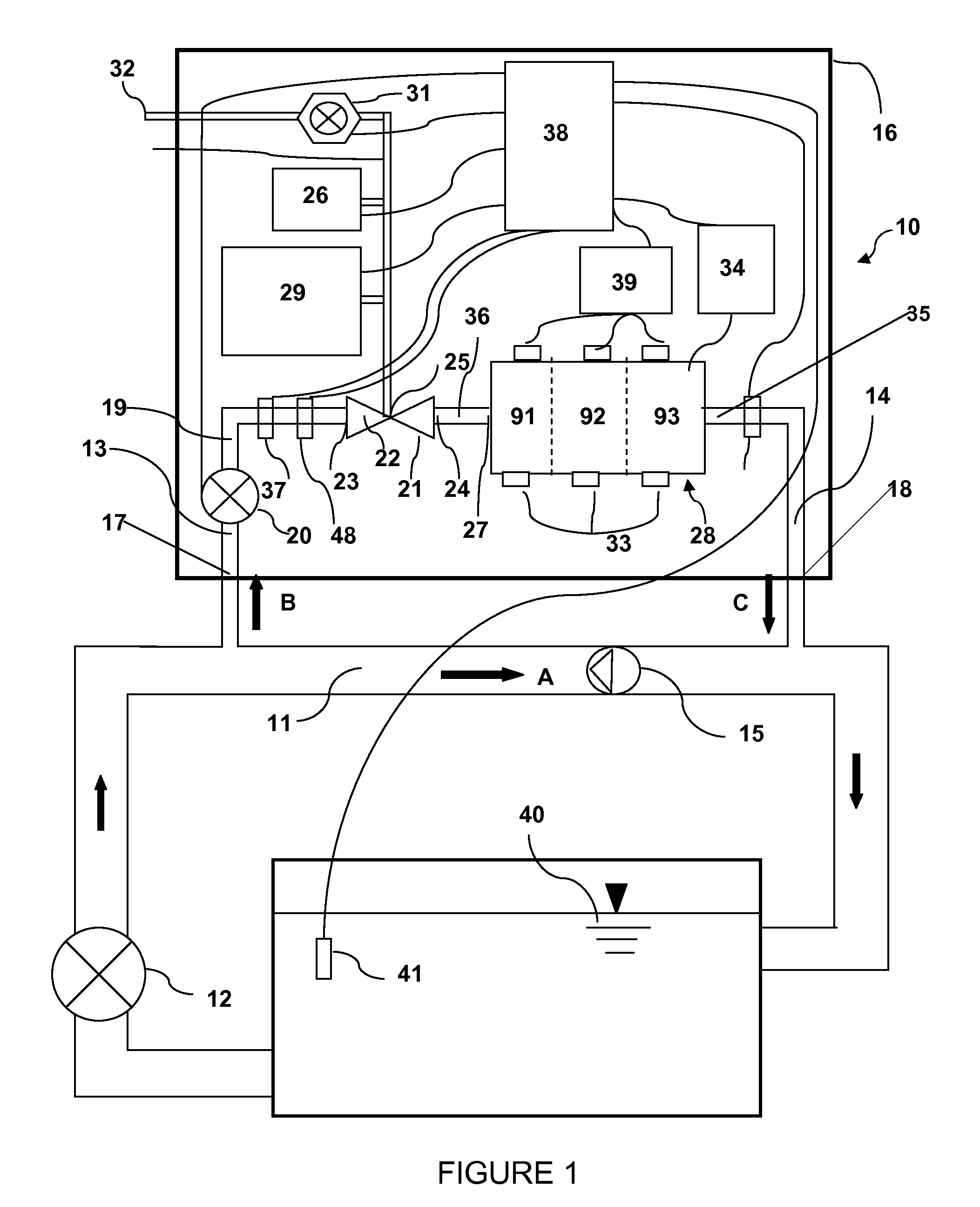

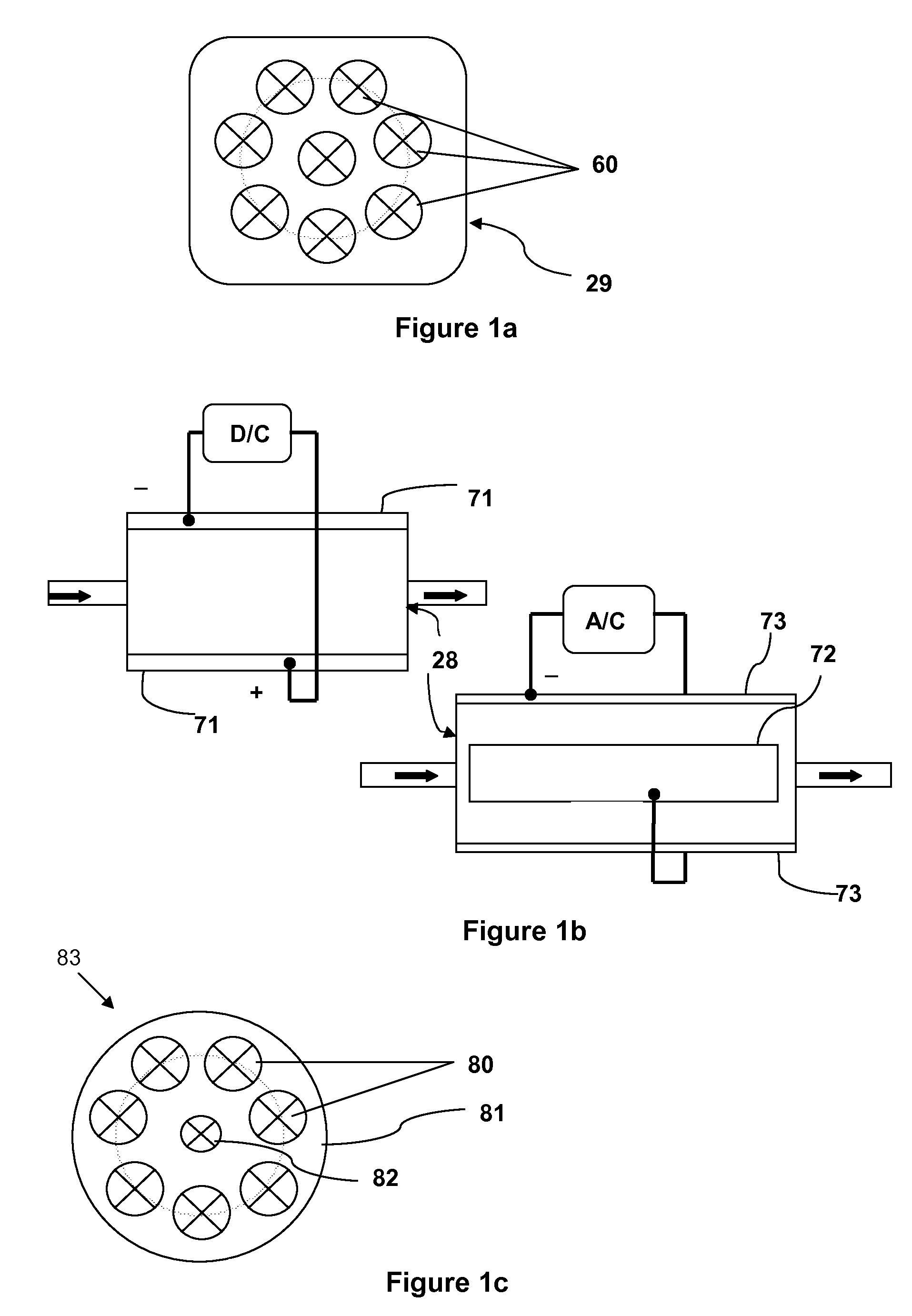

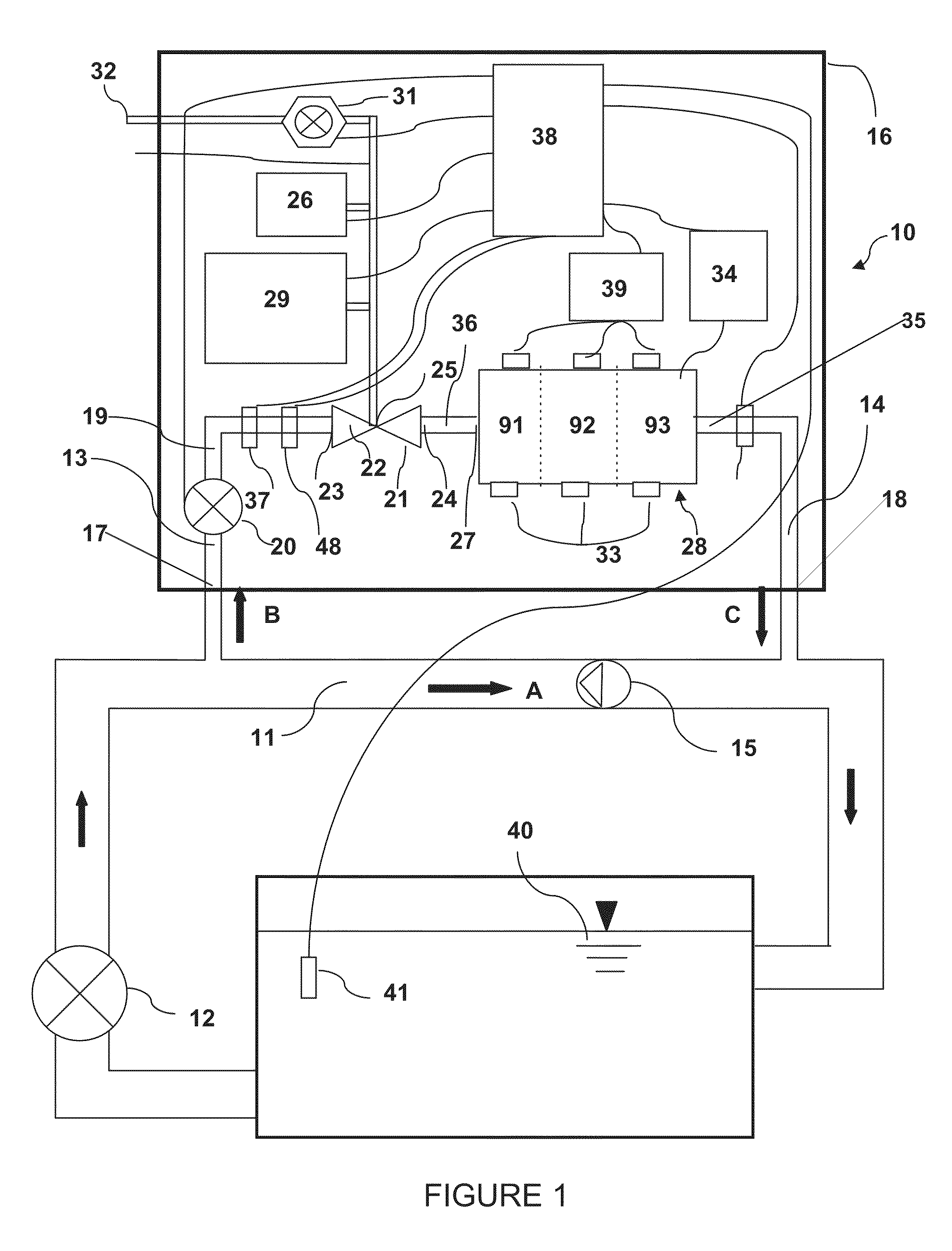

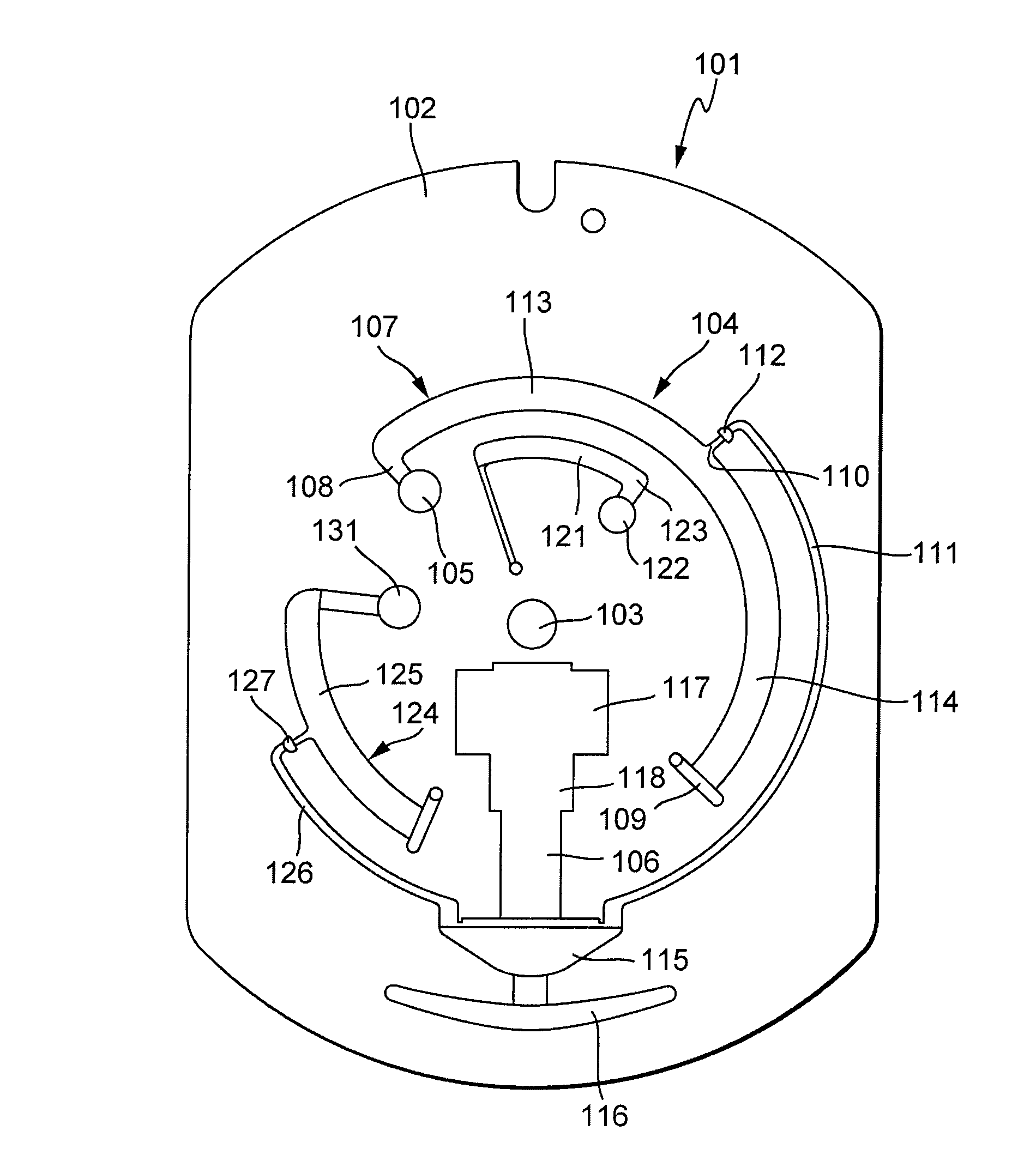

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS20110024361A1Prevent precipitationReduce maintenance costsFrom normal temperature solutionsLiquid separation by electricityEnvironmental chemistrySet point

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

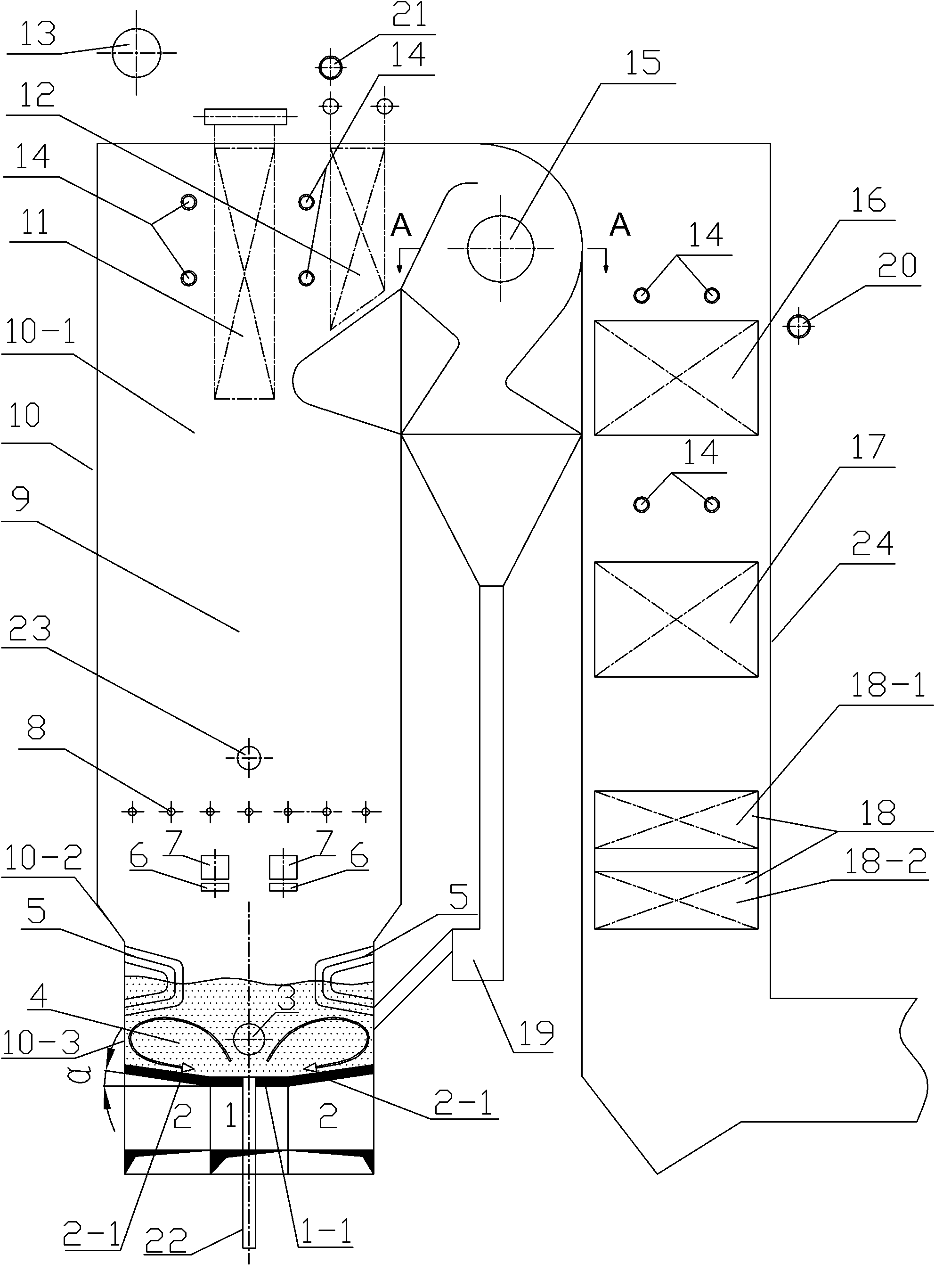

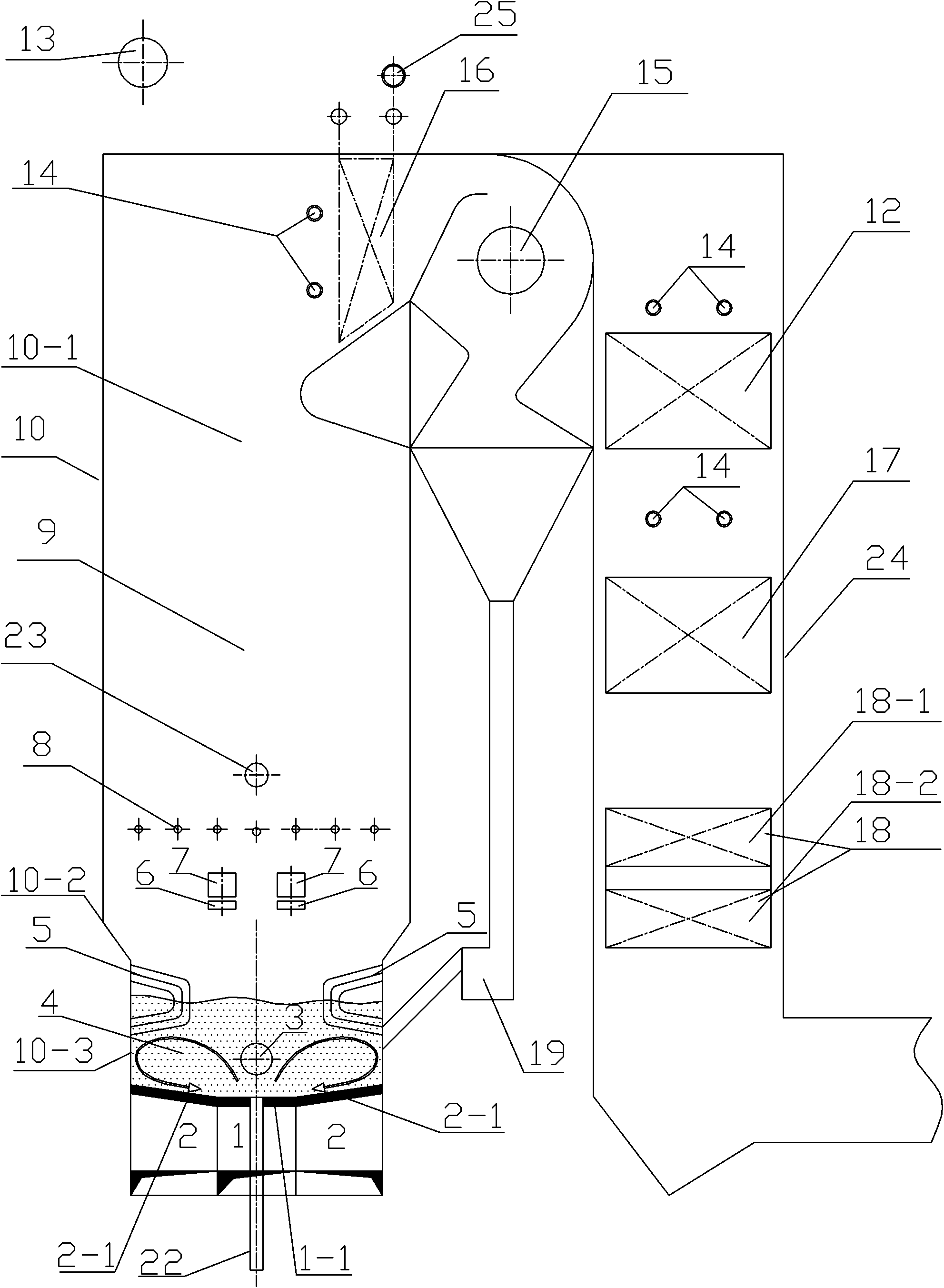

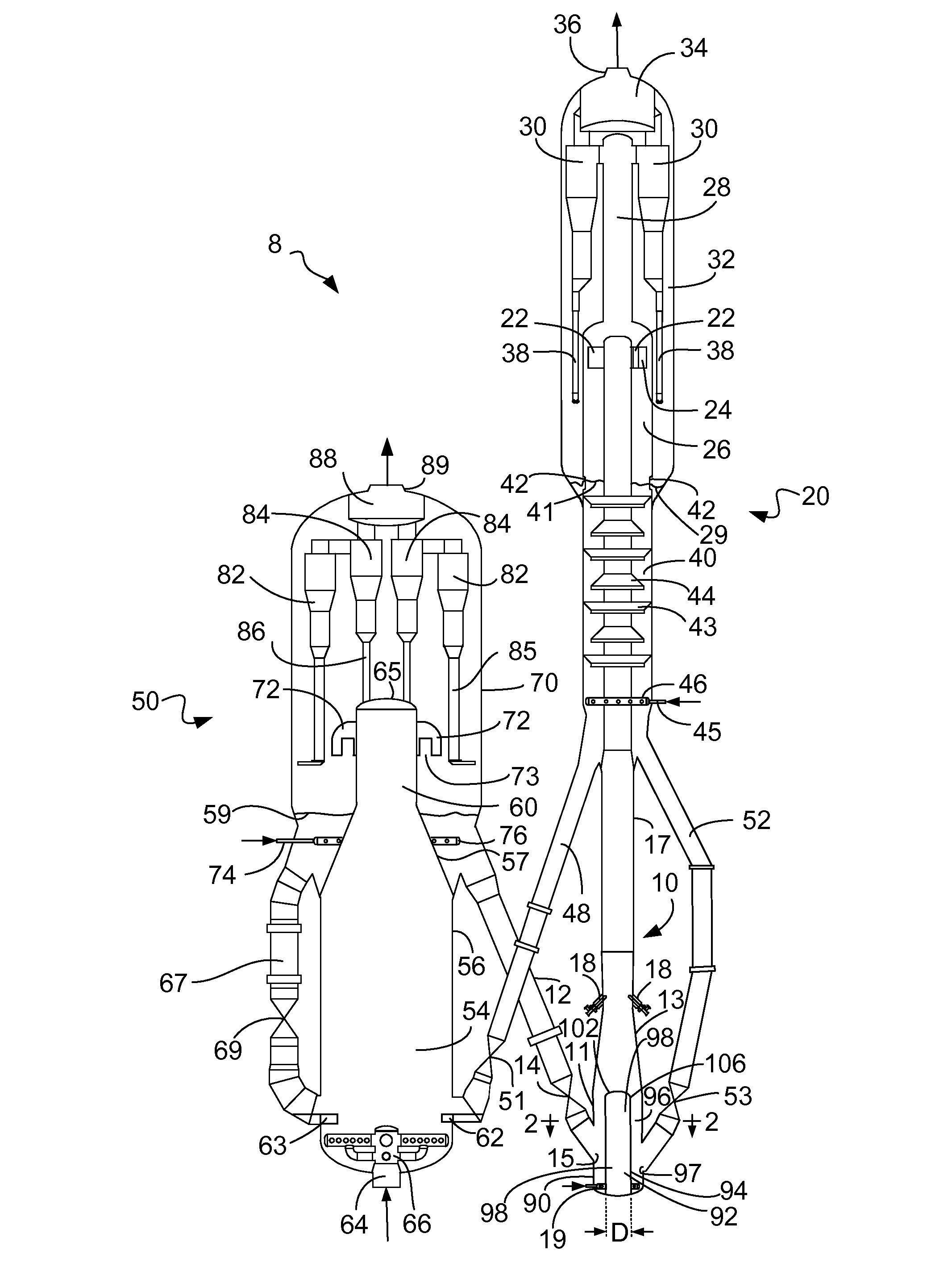

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

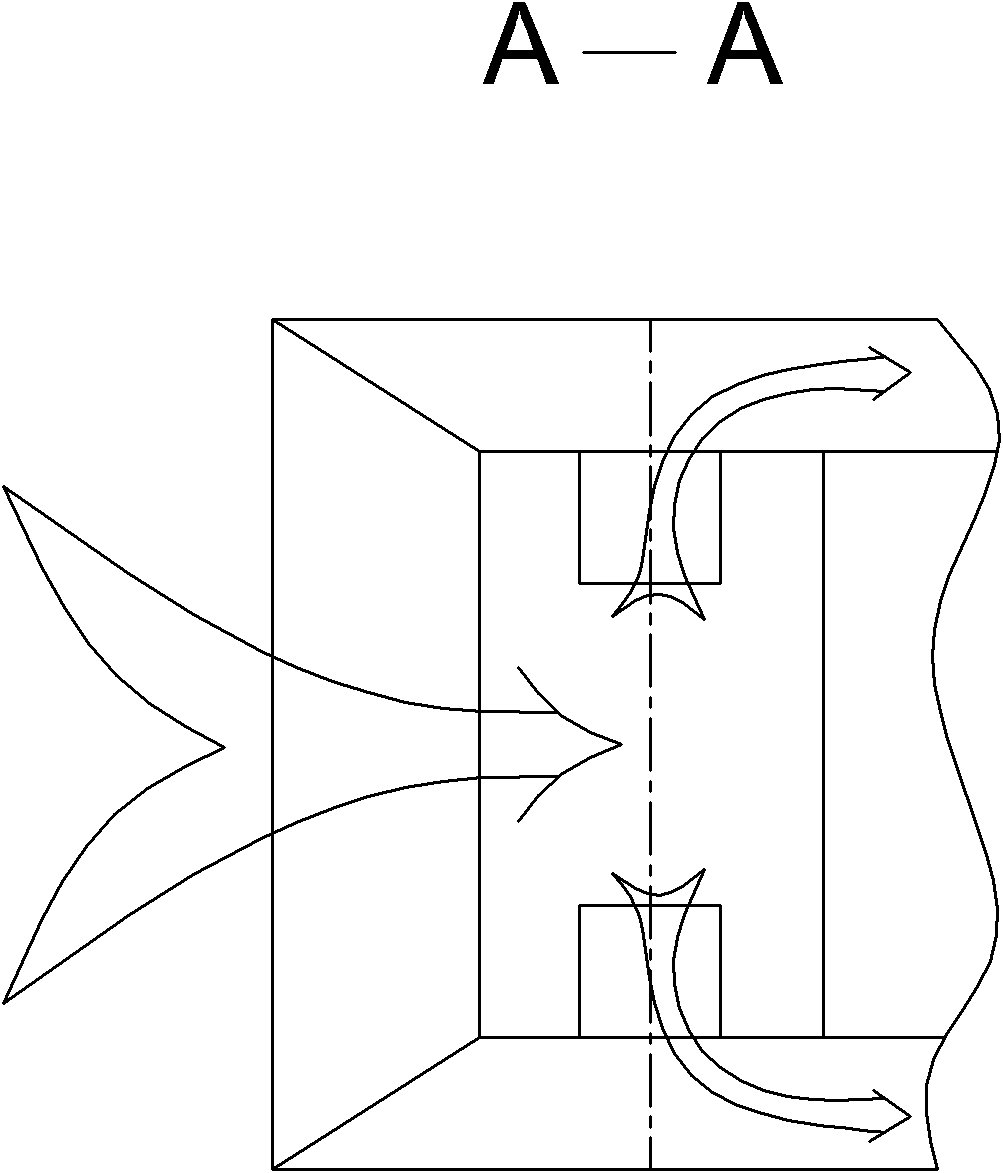

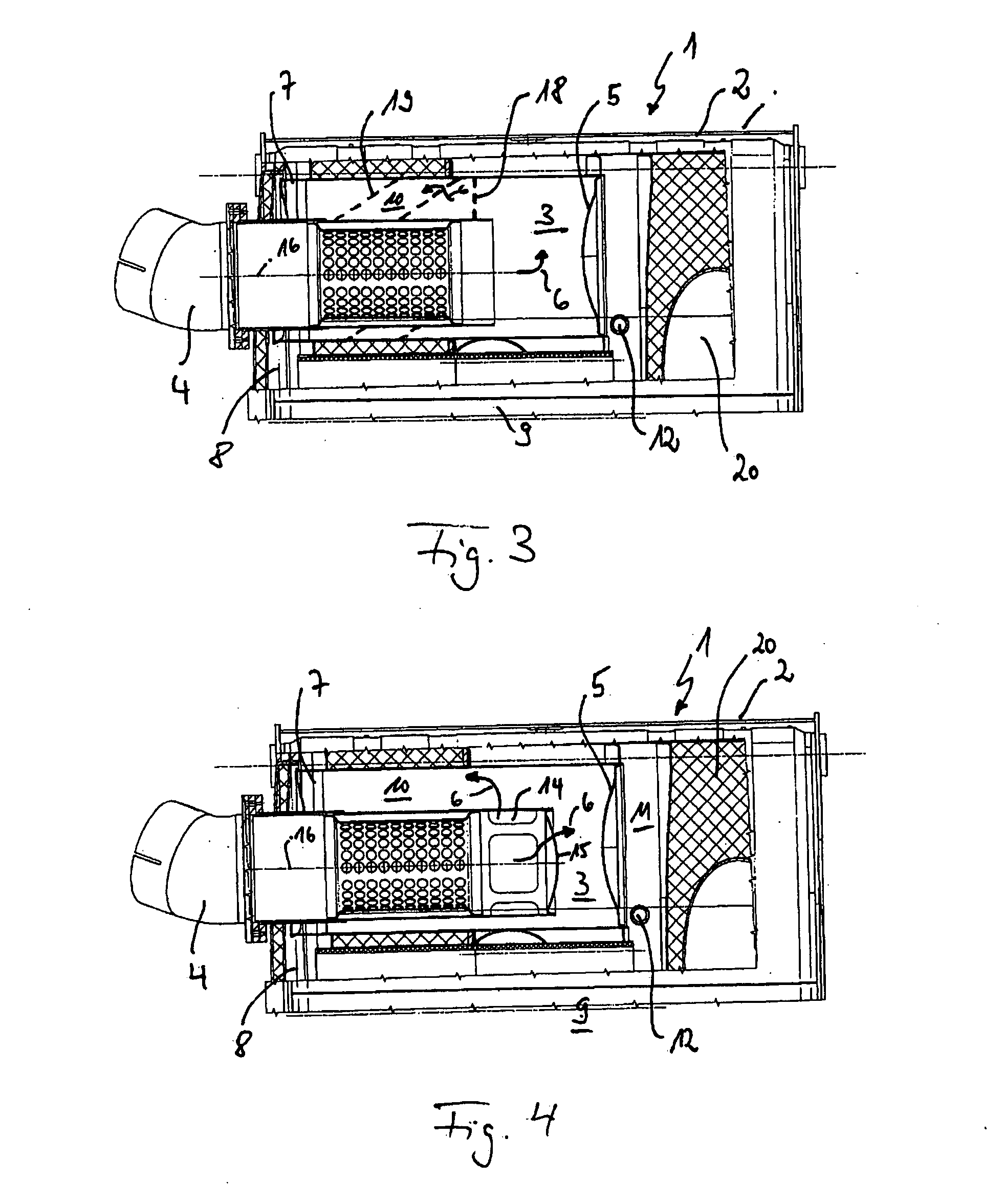

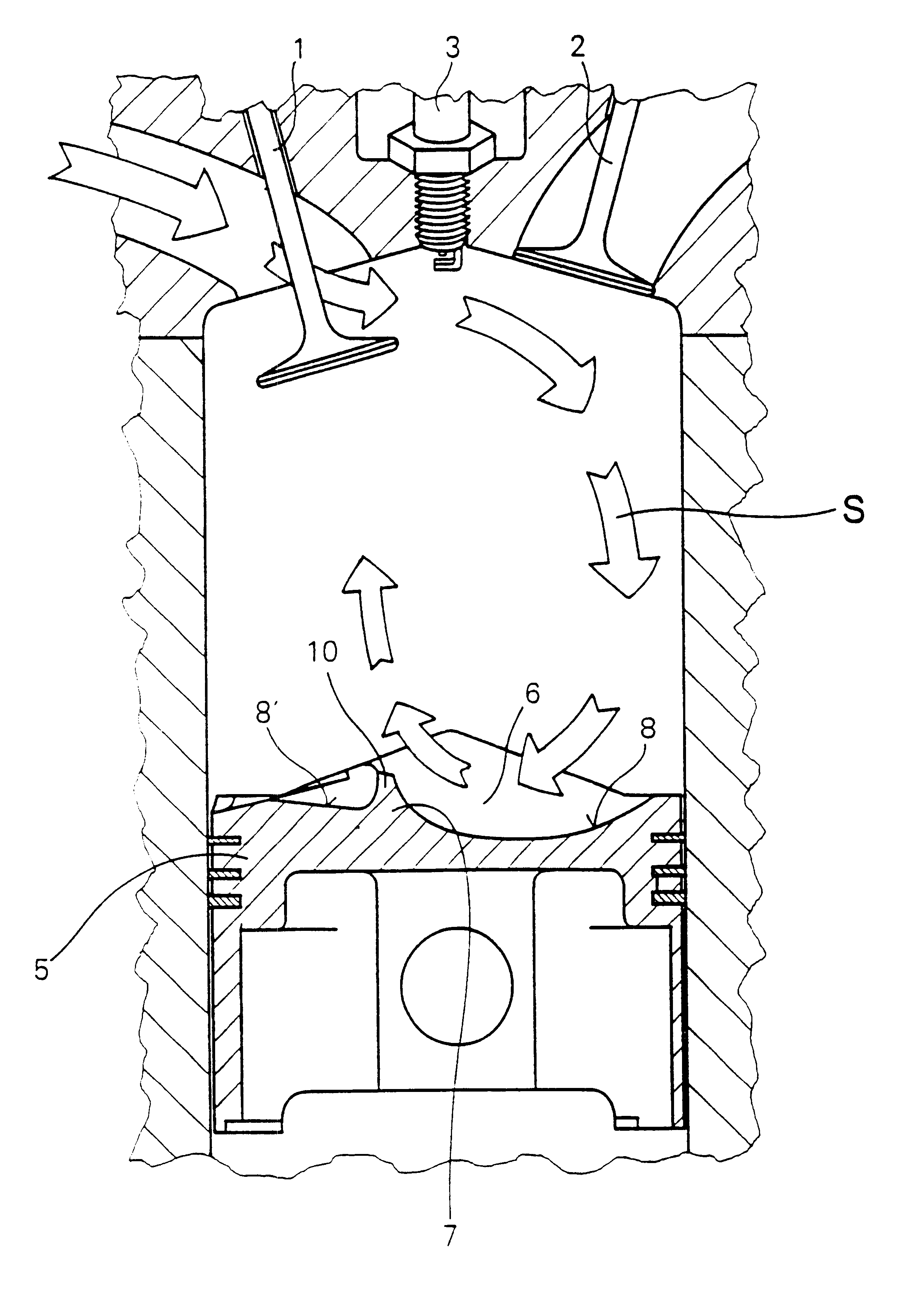

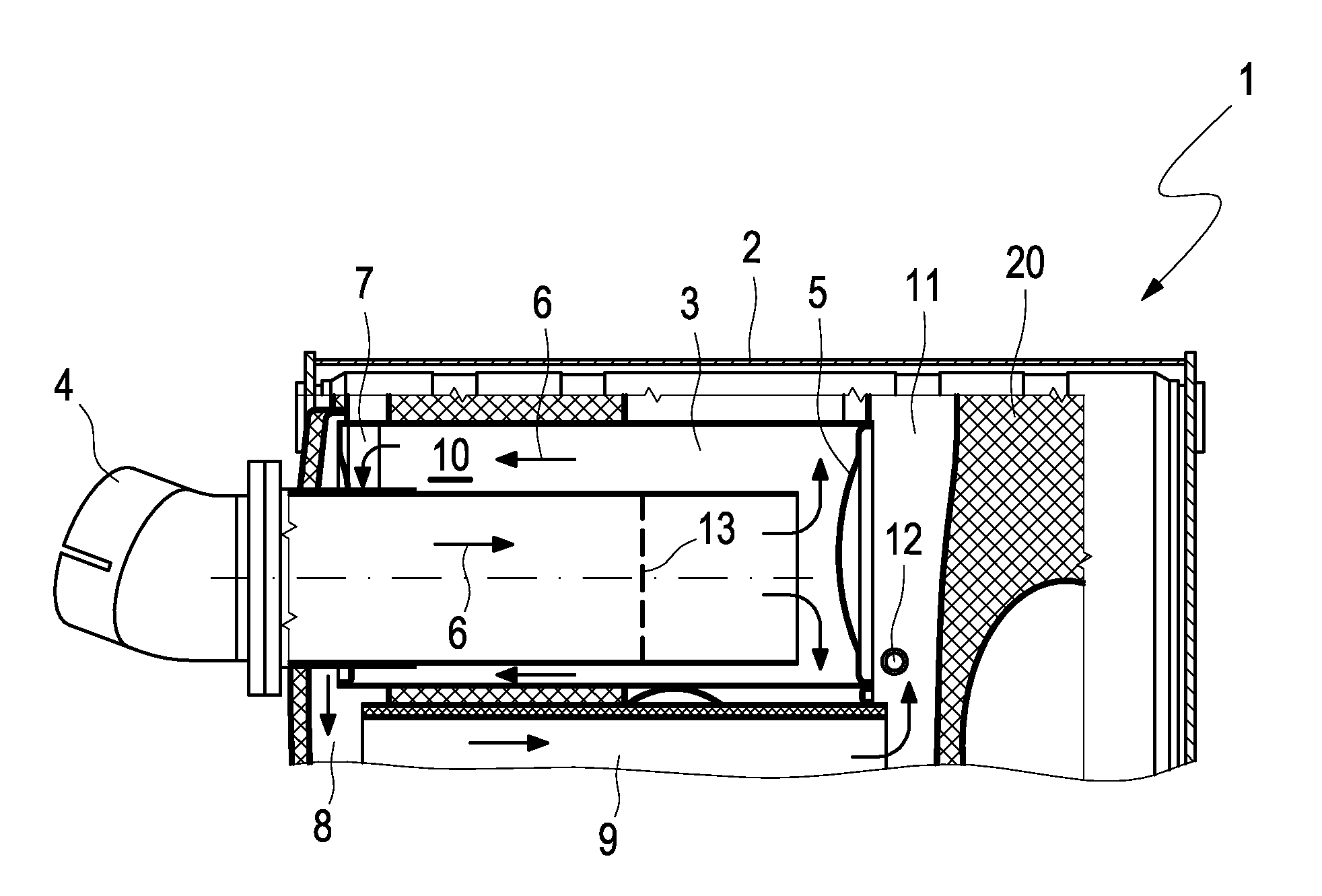

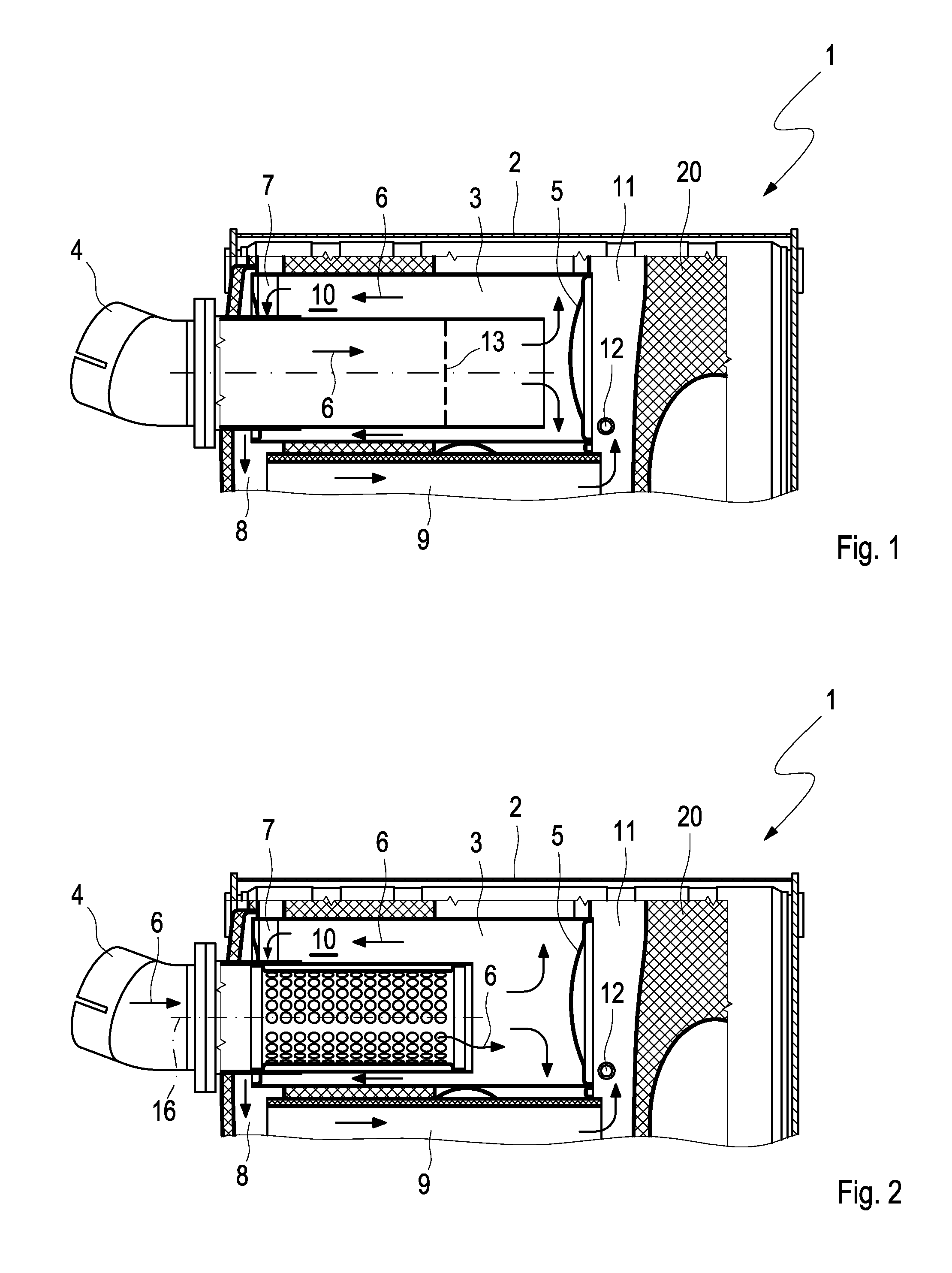

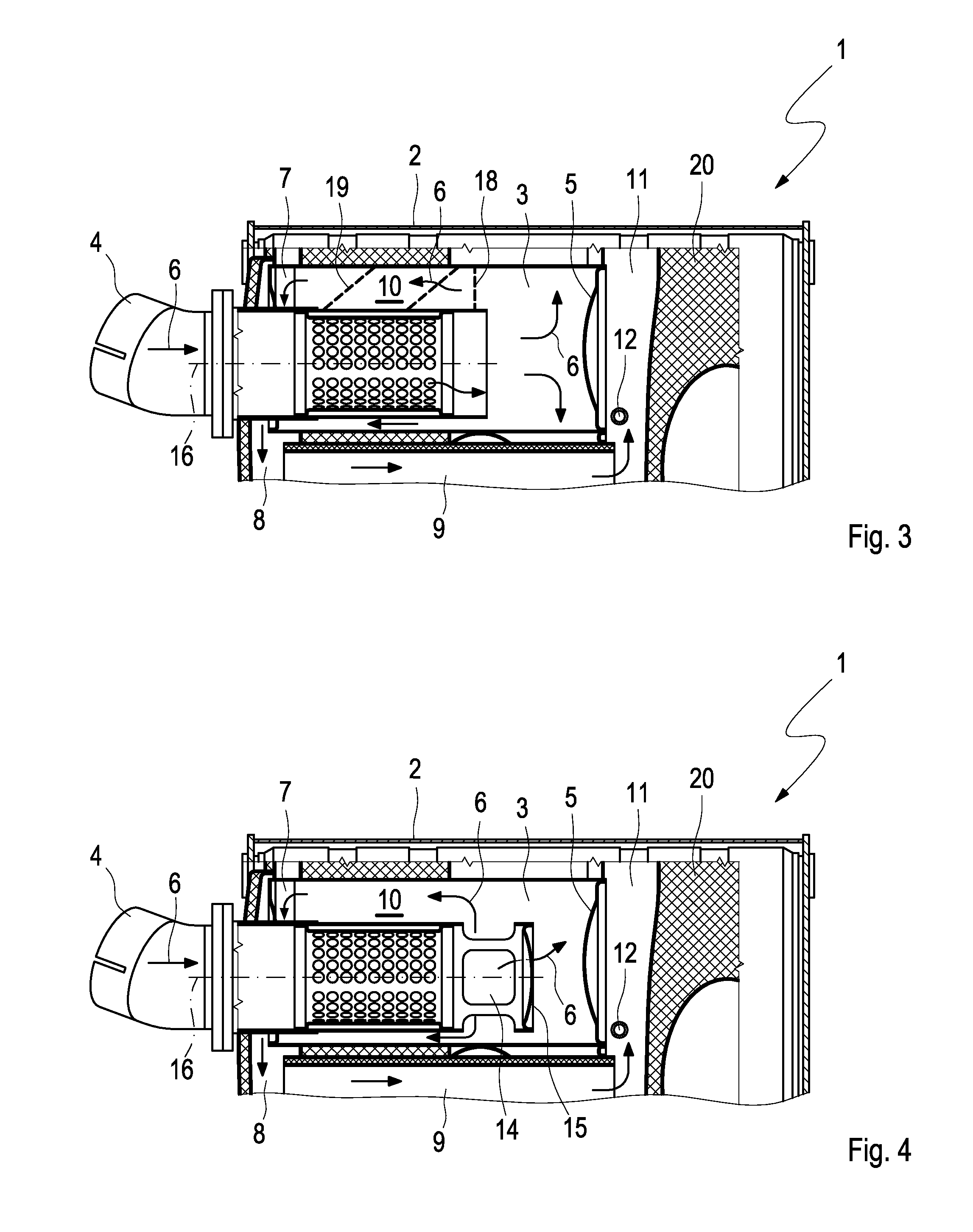

Exhaust gas aftertreatment device for an internal combustion engine

ActiveUS20070289294A1Good and thorough mixingWell and thorough mixingInternal combustion piston enginesSilencing apparatusExhaust fumesAfter treatment

The invention relates to an exhaust gas after-treatment device for an internal combustion engine, including a housing into which an exhaust pipe that opens into a mixing chamber penetrates. The mixing chamber is shaped as a pot and reverses a direction of flow of the incoming exhaust gas whereby it returns the exhaust gas radially outside of the exhaust pipe. An open end of the pot-shaped mixing chamber opens into a collecting space which is designed so that it supplies the exhaust gas to at least one downstream SCR catalytic converter.

Owner:PUREM GMBH

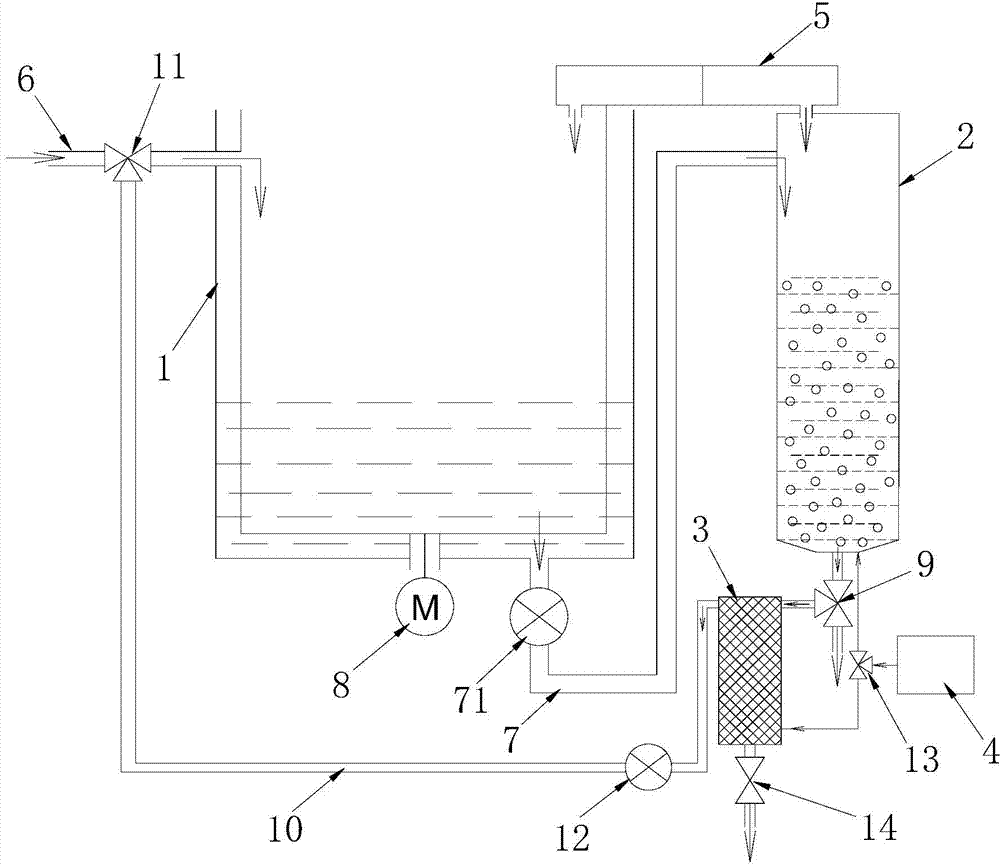

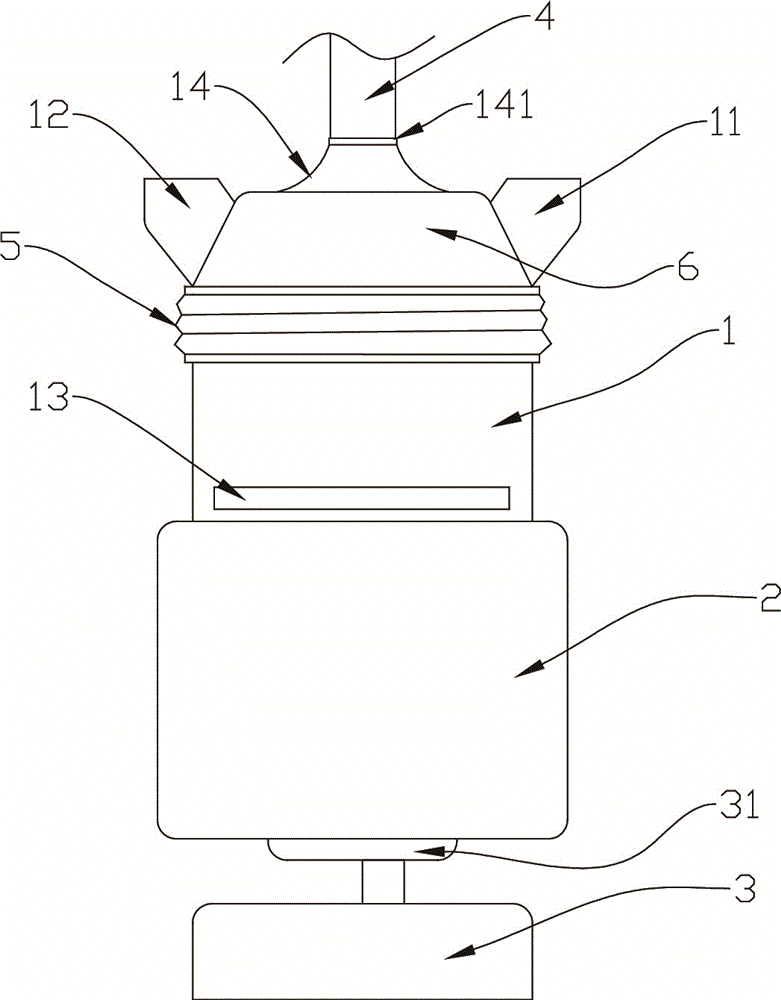

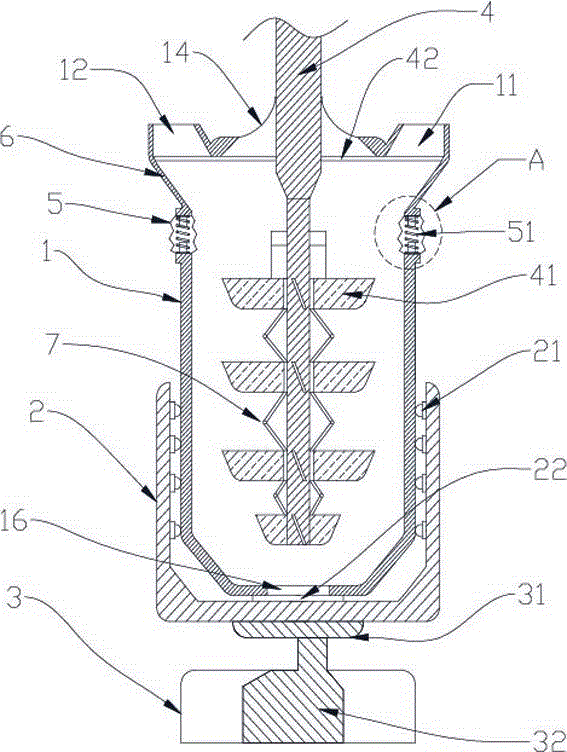

Flocculation washing machine

ActiveCN104514122ARealize self-cleaningBlow evenlyOther washing machinesTextiles and paperFlocculationFilter effect

The invention discloses a flocculation washing machine. The flocculation washing machine comprises an outer barrel, a flocculation unit and a filtering unit which are circularly communicated in a sequence through pipelines. The washing machine further comprises an air pump which is respectively communicated with the flocculation unit and the filtering unit. According to the flocculation washing machine, air generated by the air pump is conveyed into a flocculation container through the same air pump so as to generate a mass of bubbles in the water into the flocculation container, thus the water fully flow to enable fully mixing of a flocculant and washed water to achieve flocculation reaction; in addition, the air exhausted by the air pump can be conveyed into a filtering container during washing a filtering unit to generate bubbles to drive water in the filtering container to fully flow as well as generating an instantaneous impact force to act on the surface of a filtering screen, so as to separate dirt attached on the surface of the filtering screen, and as a result, the filtering effect of the filtering screen can be improved. The flocculation washing machine is high in automation degree and simple in structure and saves the production cost.

Owner:HAIER GROUP TECHN R&D CENT +1

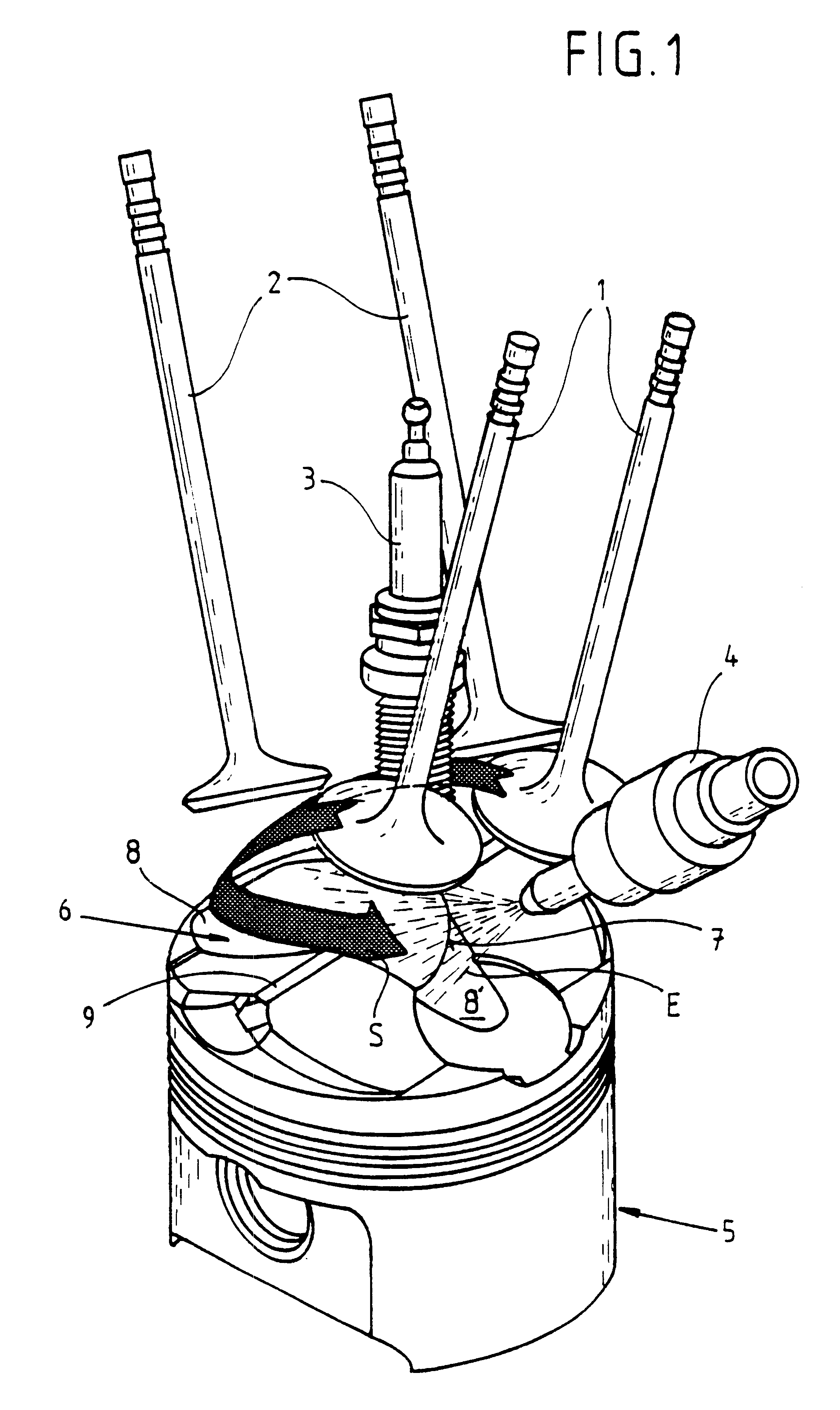

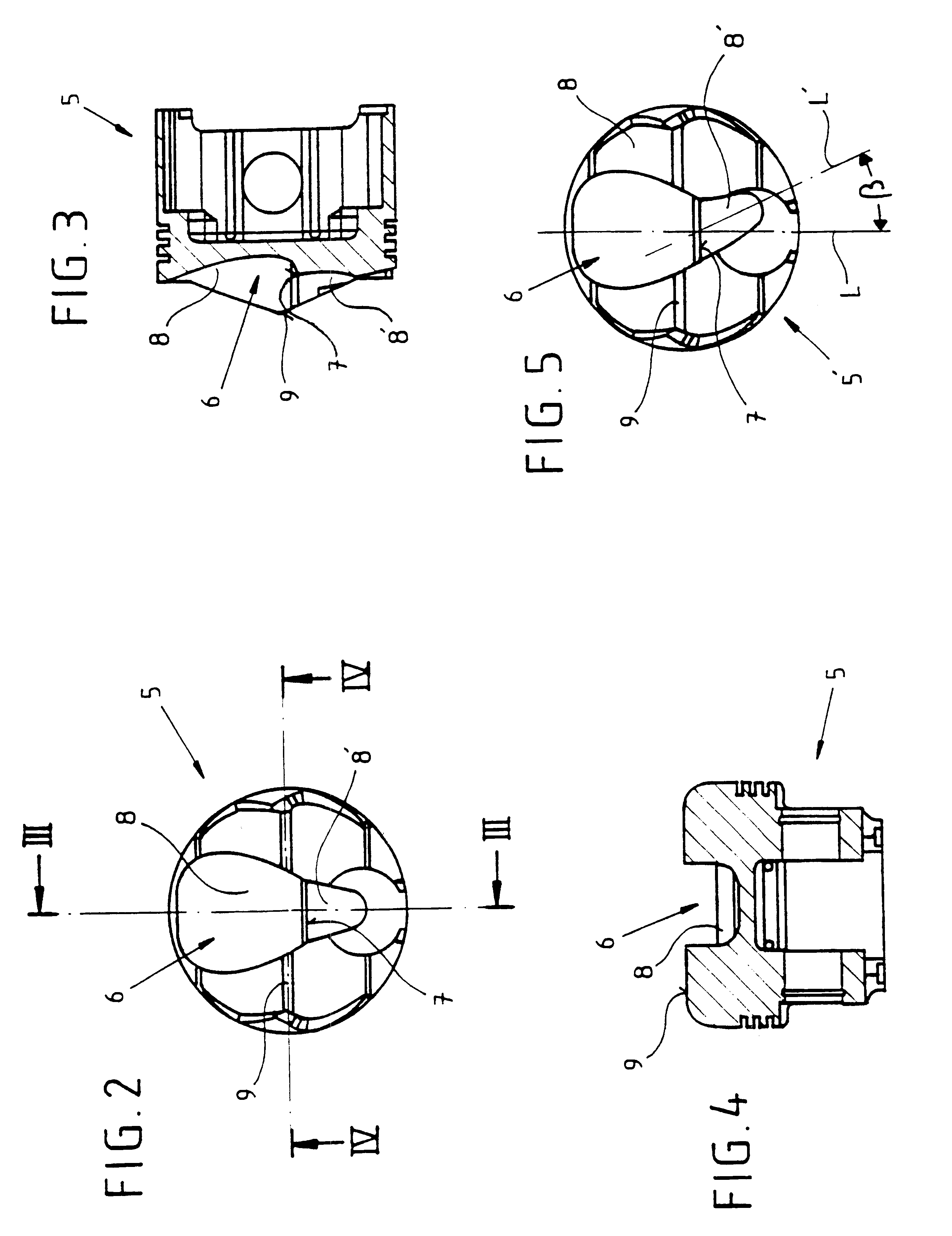

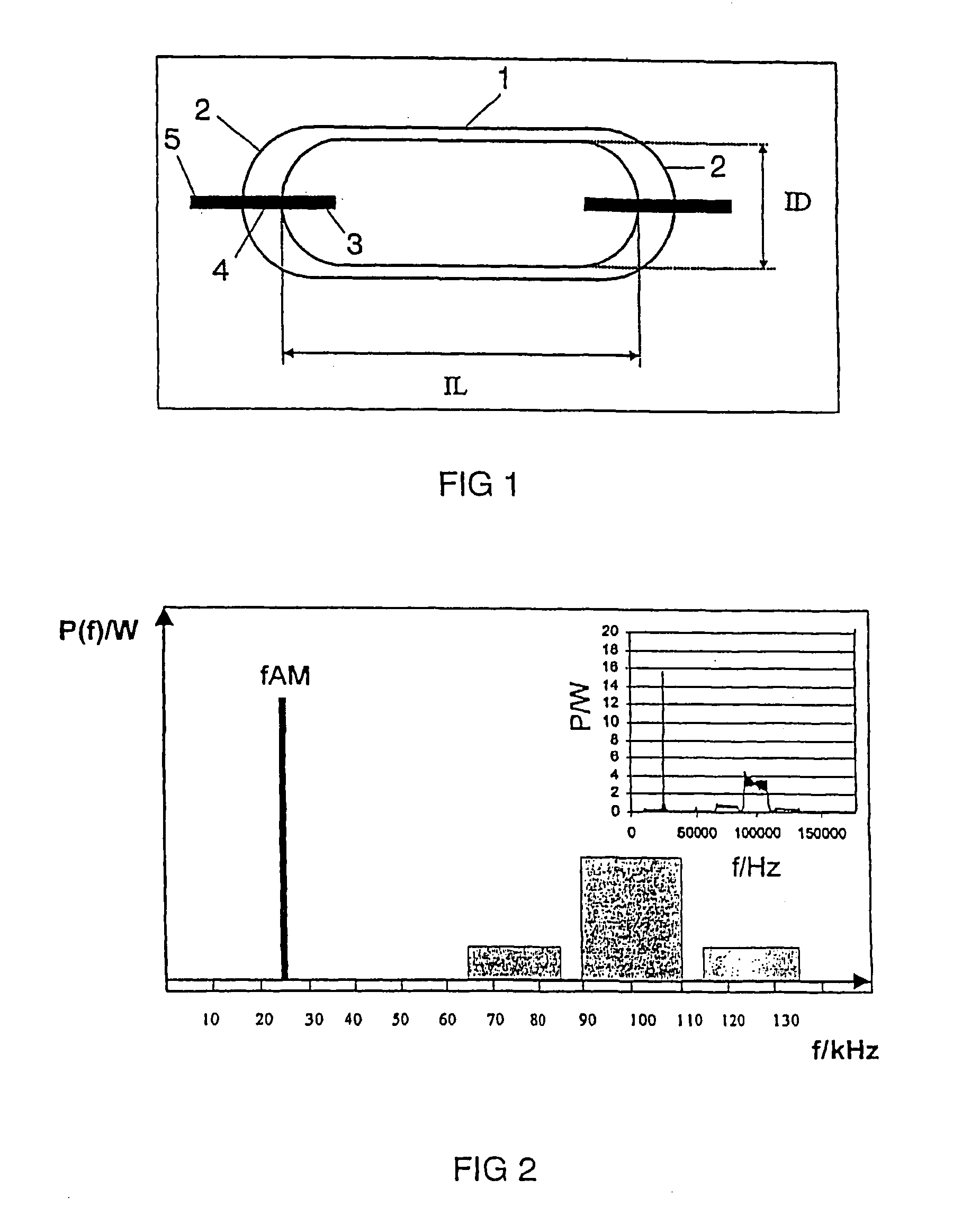

Direct injection internal combustion engine

InactiveUS6378490B1Reduce fuel consumptionLow exhaust emissionInternal combustion piston enginesCylinder headsVertical projectionCombustion chamber

The invention relates to an internal combustion engine with direct fuel injection comprising at least two adjacent inlet valves (1) per cylinder, a number of outlet valves (2), an essentially coaxial spark plug (3), an injection valve (4) and a piston (5,5'). The aim of the inventive engine is to provide an improved mixture preparation which is characterized by low fuel consumption and low exhaust emissions. To this end, the injection valve (4) is arranged between two of the adjacent inlet valves (1) and the section of the cylinder wall adjacent to said inlet valves (1). in addition, the piston (5,5') has a longitudinally extended combustion chamber cavity (6), whereby the combustion chamber cavity (6) essentially extends along the front surface of the piston (5,5') in the direction of the vertical projection of an injection stream (E) exiting from the injection valve (4). Said cavity also comprises a step (7) which essentially runs in a transversal direction.

Owner:AUDI AG

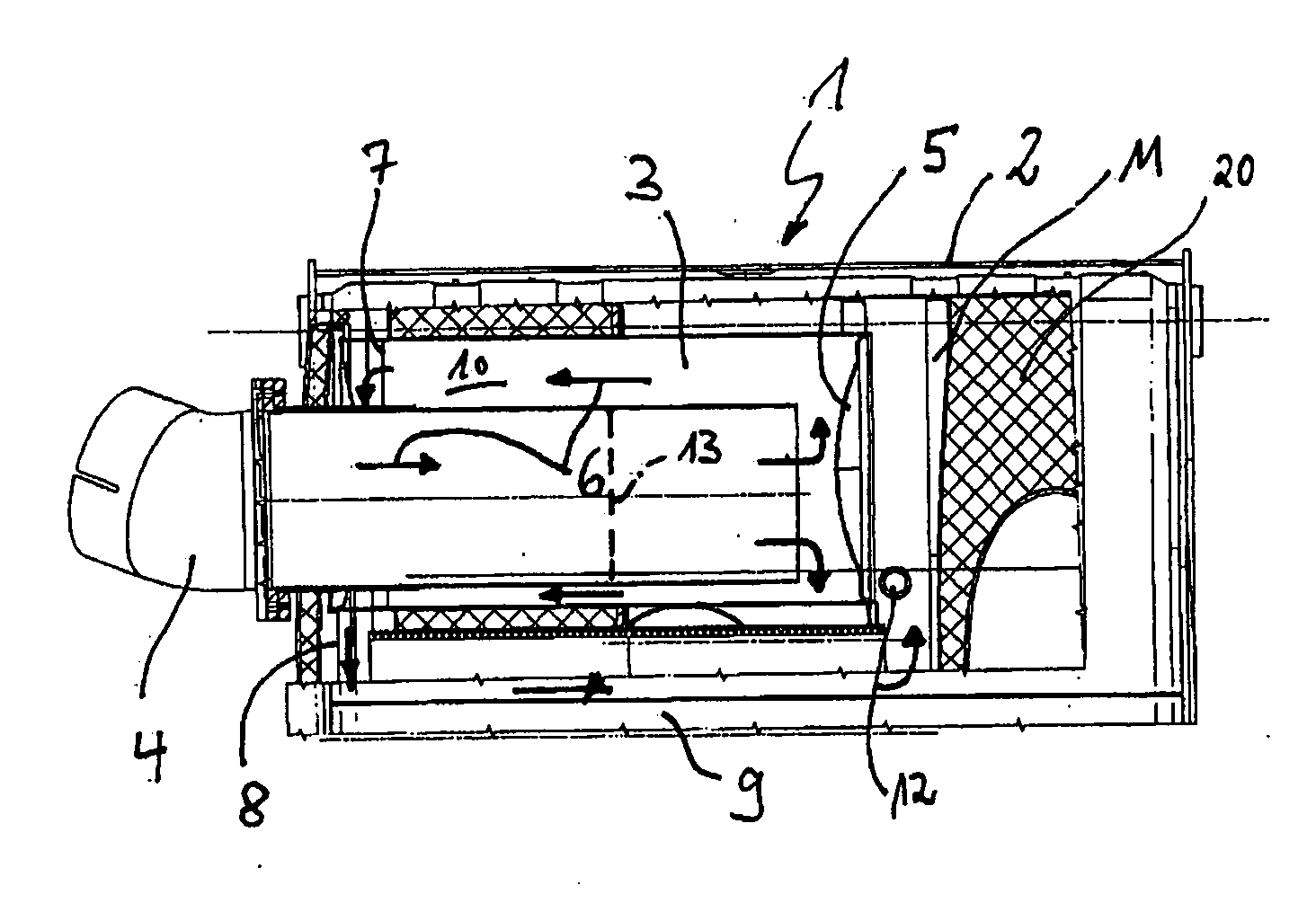

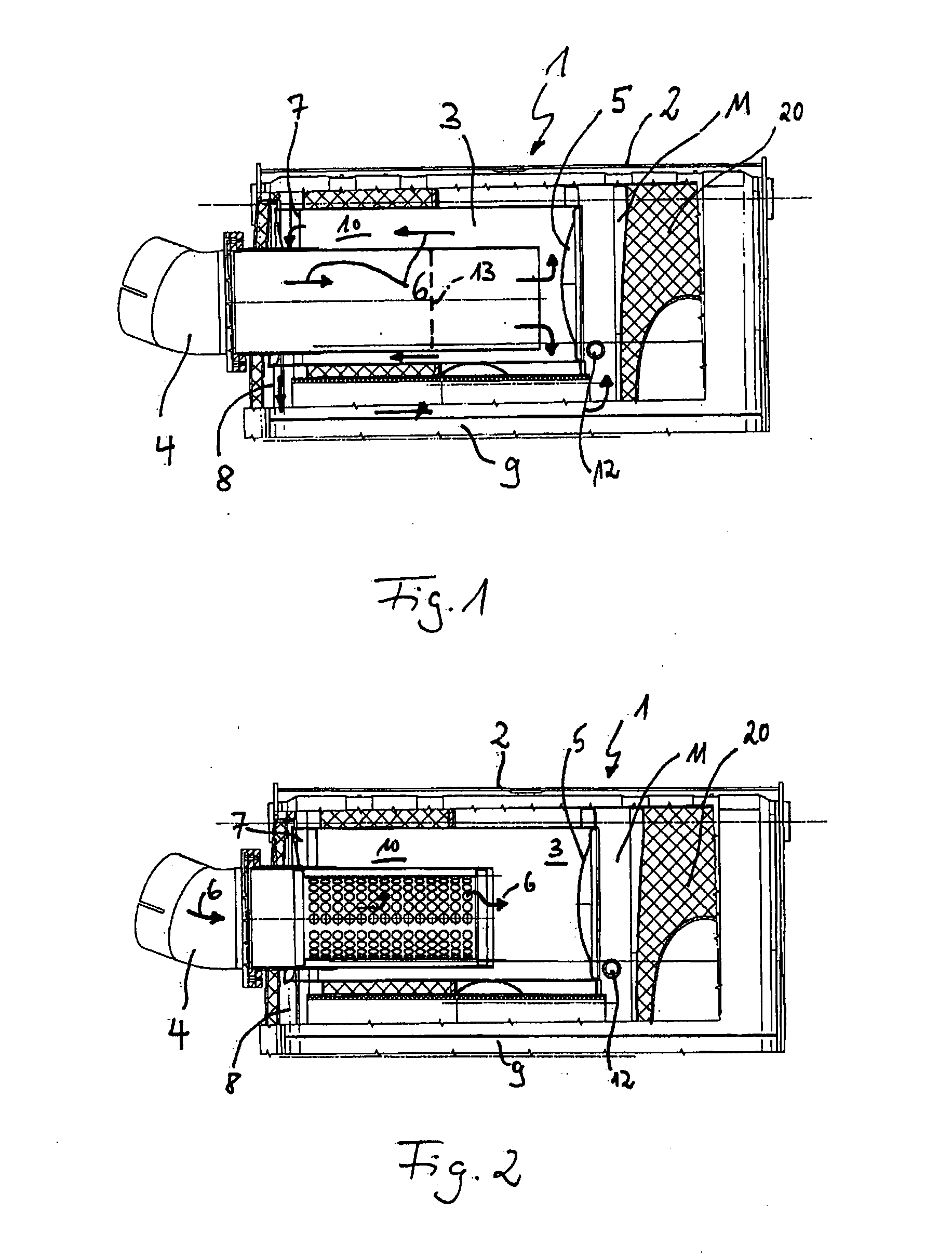

Device and method for processing food items

ActiveUS10667639B2Close reliableAvoid pollutionSteam cooking vesselsThermodynamicsProcess engineering

A device for processing food items arranged in a receptacle includes a steam-generating unit for generating steam, and a steam supply unit, which is connected to the steam-generating unit, for supplying steam to the receptacle. The steam supply unit has a steam probe having at least one steam-dispensing opening, and also has a steam probe stroke drive for a stroke movement of the steam probe along a stroke axis.

Owner:CAROGUSTO AG

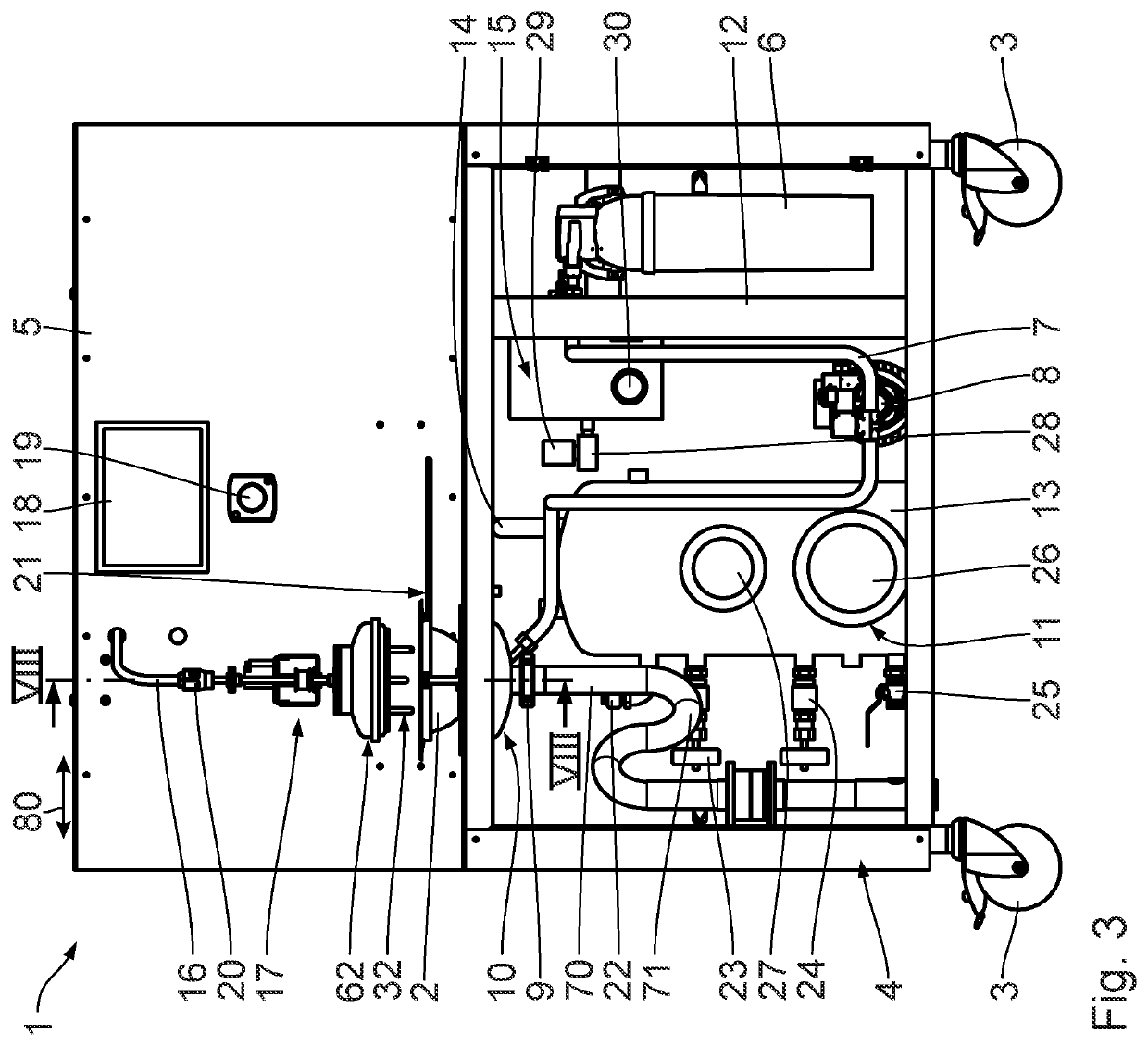

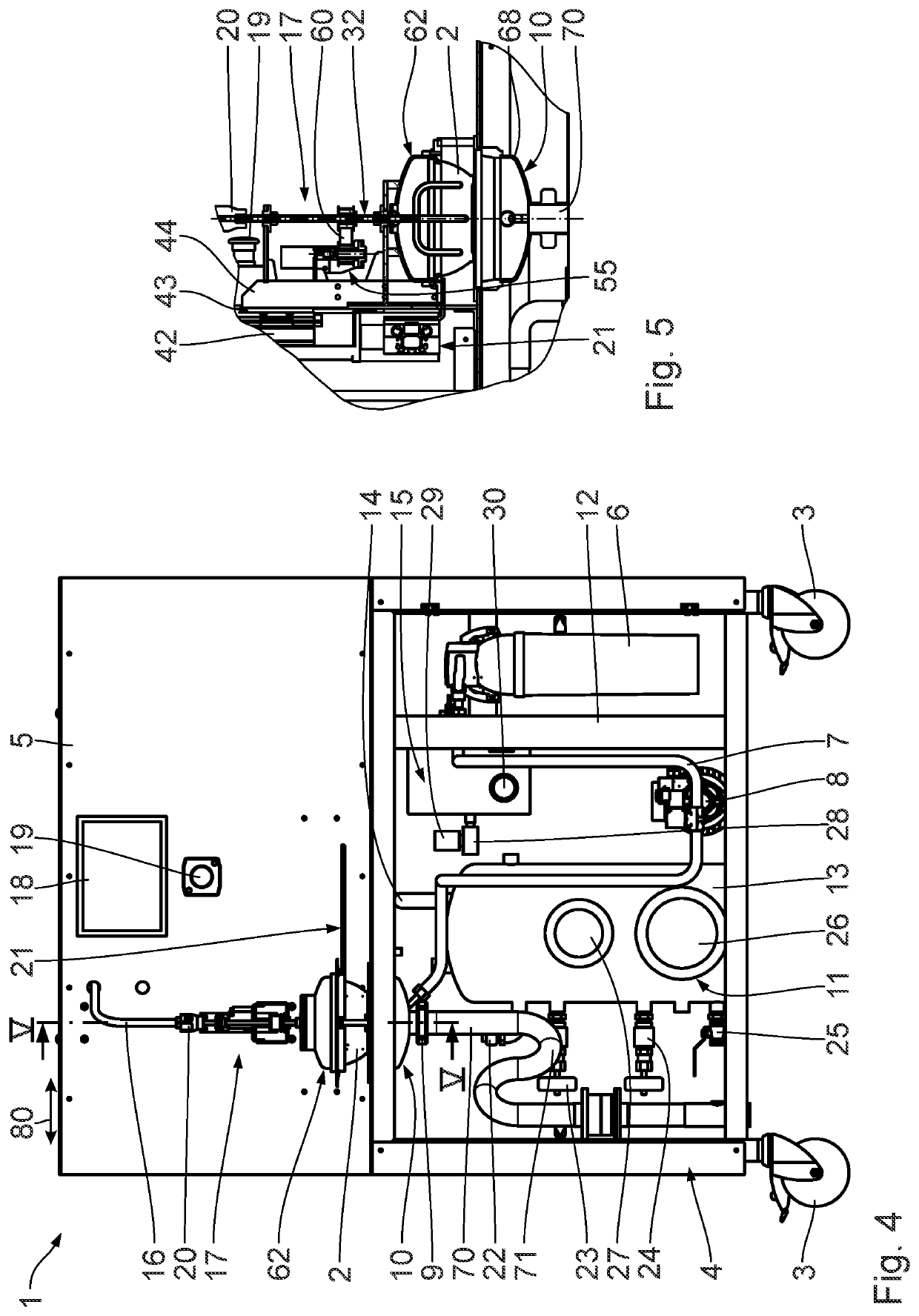

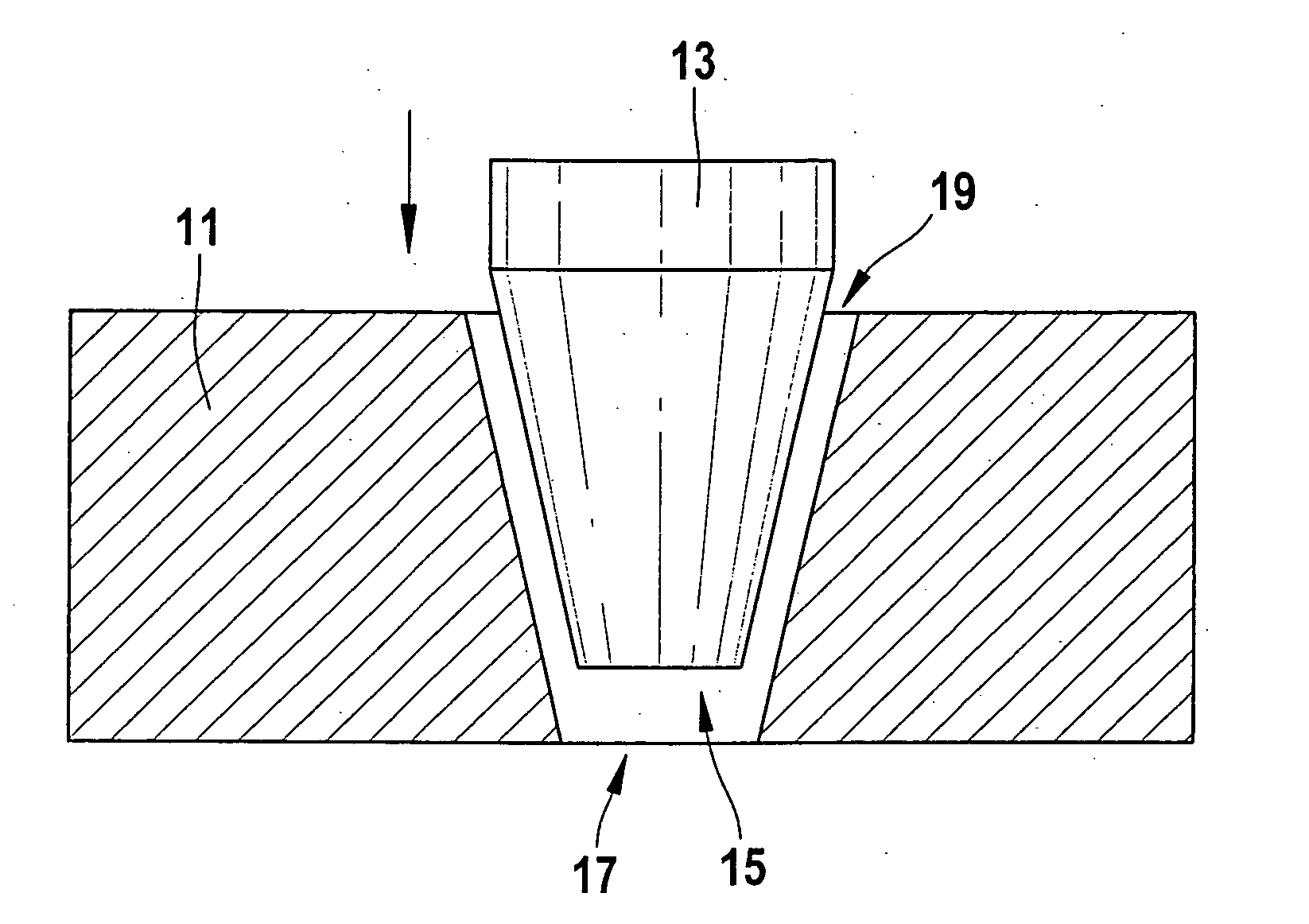

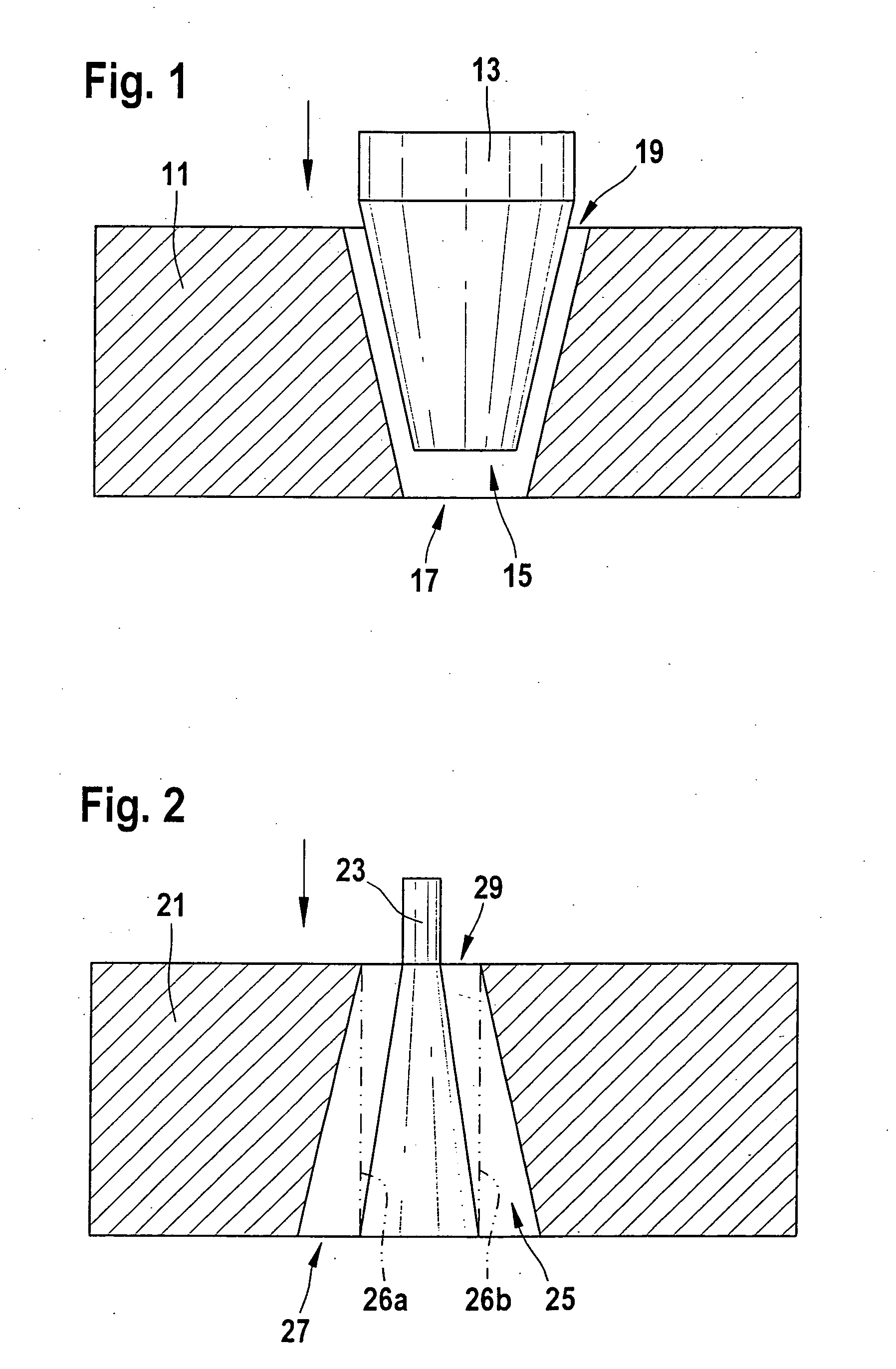

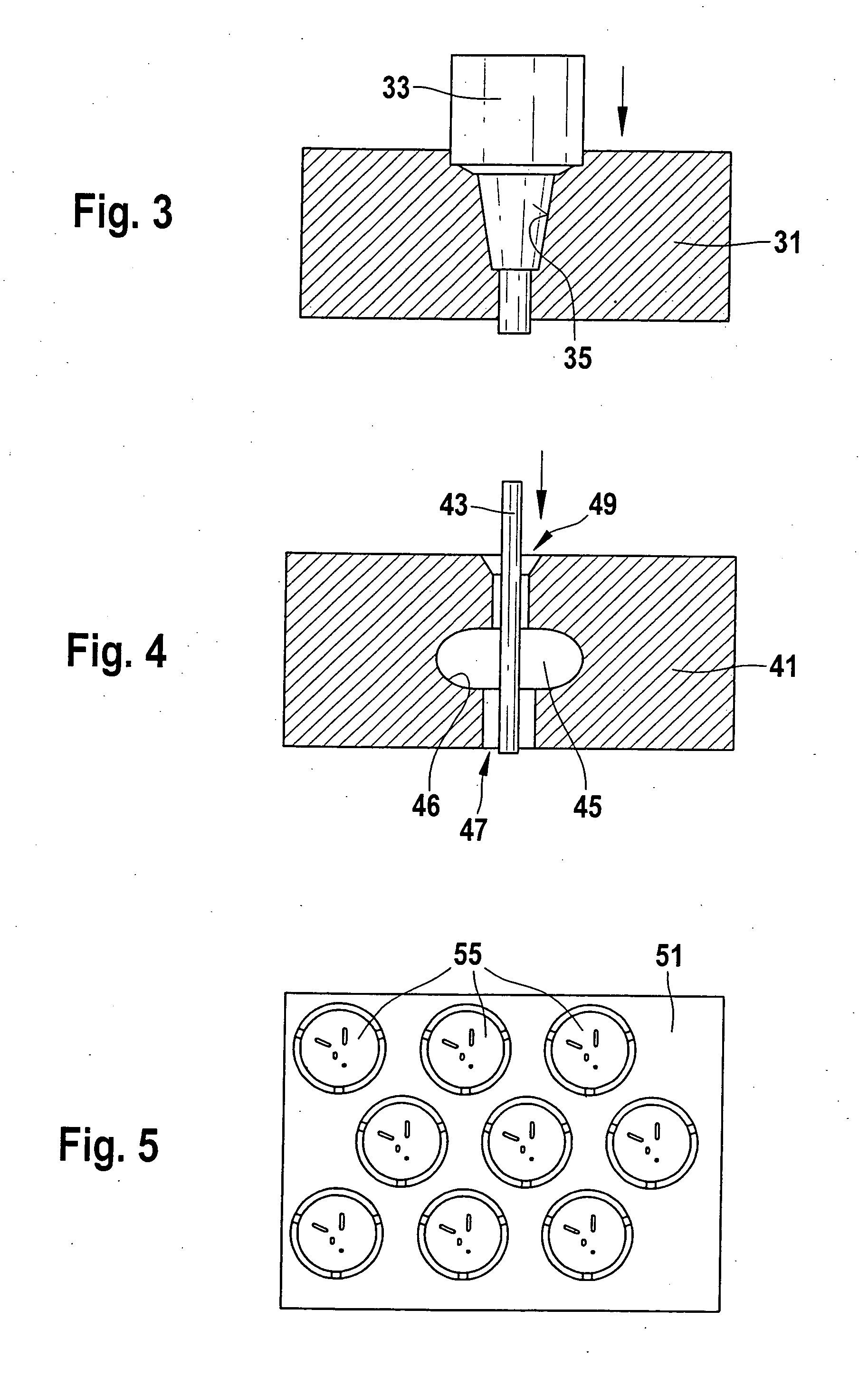

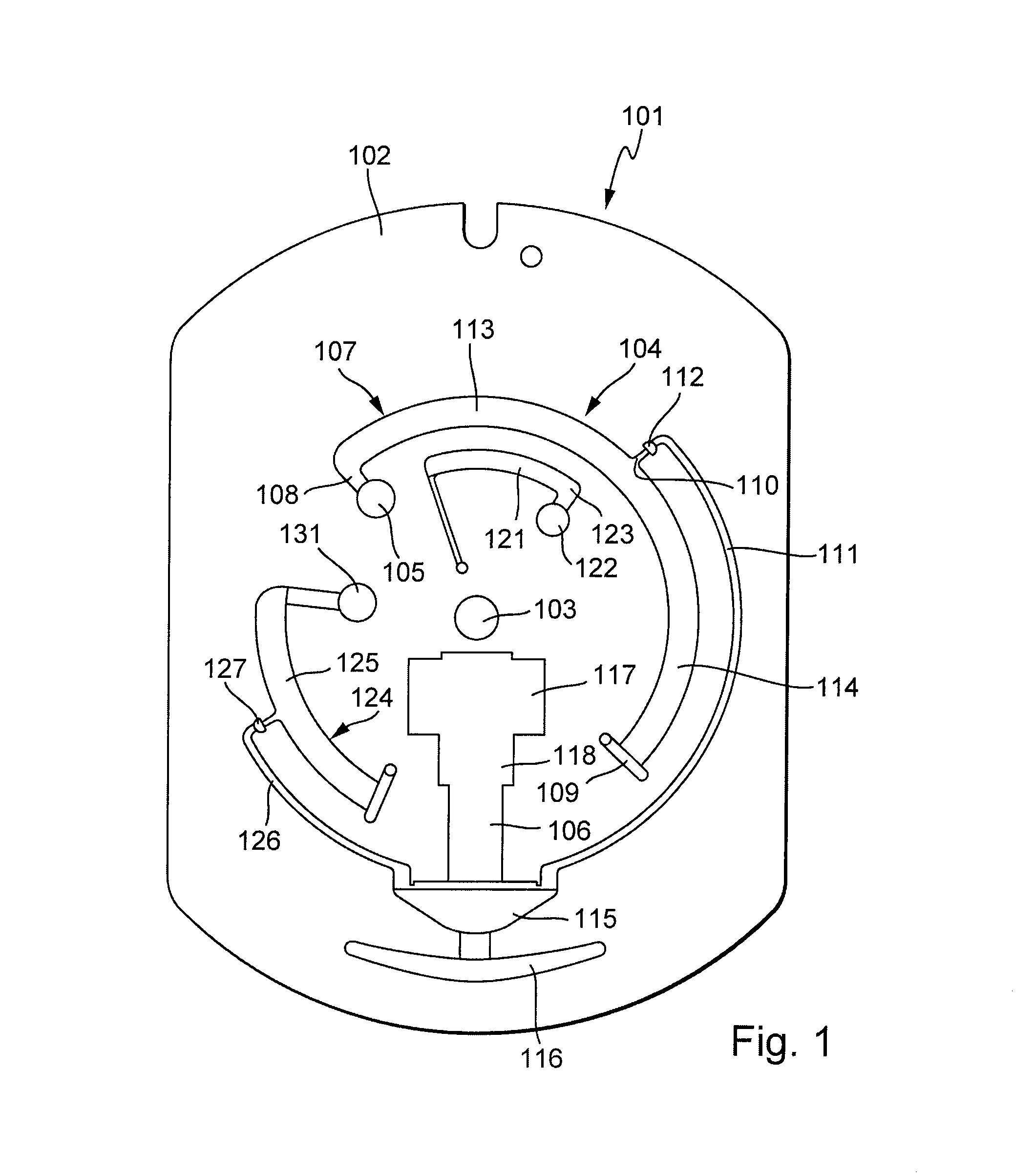

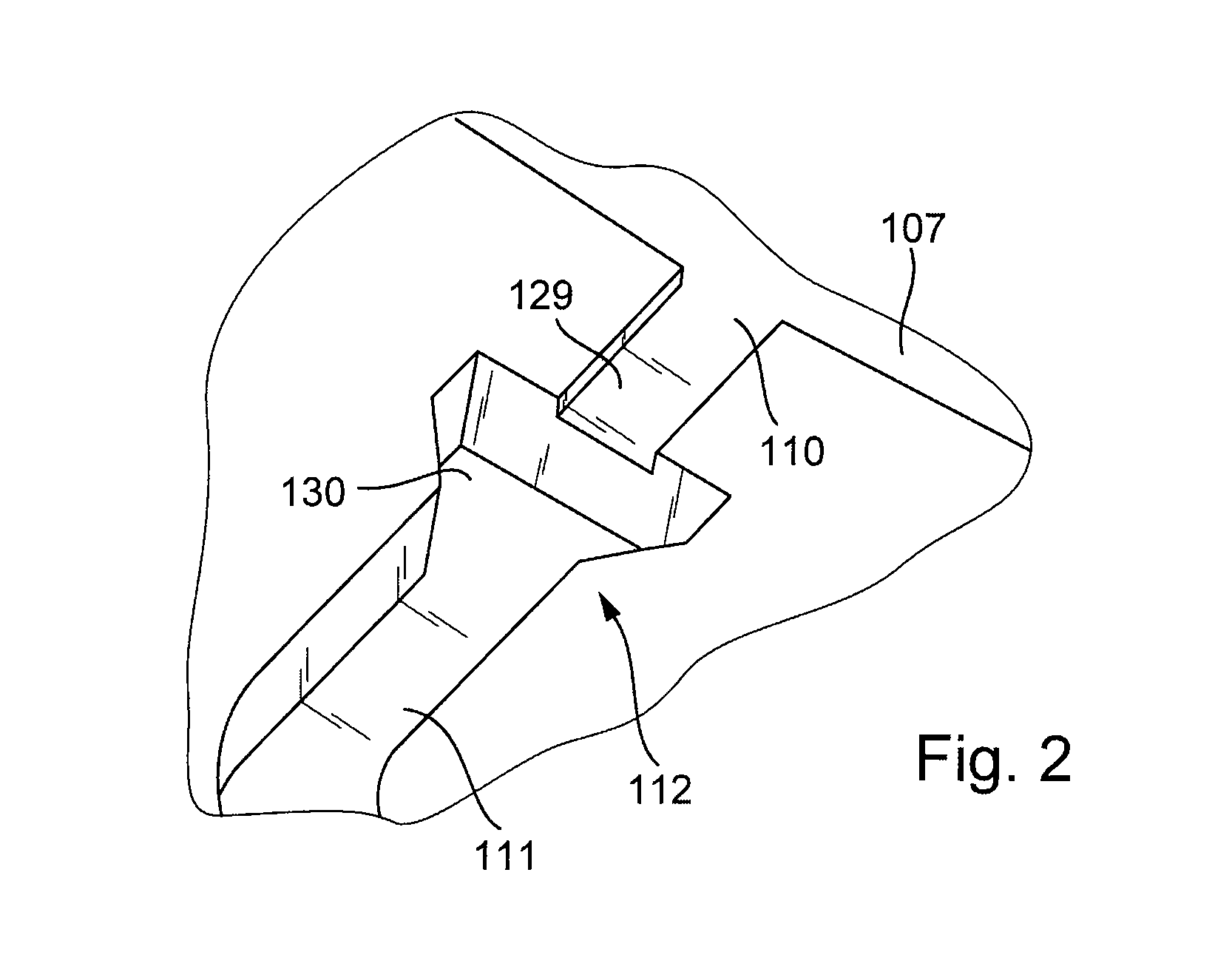

Method and device for removing metallic material of a workpiece

InactiveUS20050133378A1Good removal effectPromotes thorough mixingElectrolysis componentsMachining electric circuitsMetallic materialsBiomedical engineering

A method for removing metallic material of a workpiece, using the flow of current between an electrode and the workpiece in the presence of an electrolyte. In this context, a relative movement occurs between the electrode and the workpiece as a function of time. In addition, it is provided that at least one further process parameter be regulated and / or changed as a function of time.

Owner:ROBERT BOSCH GMBH

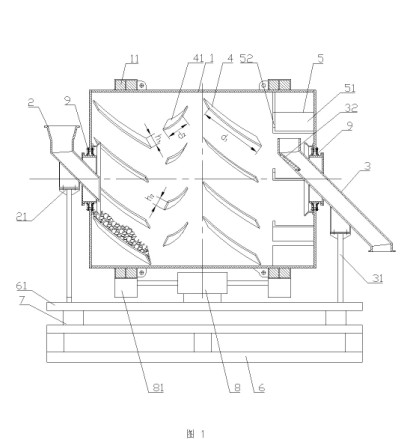

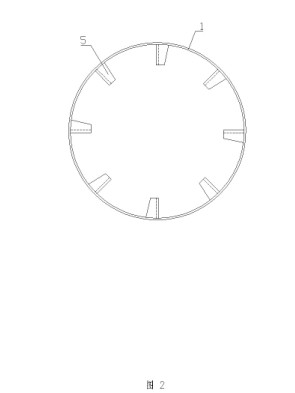

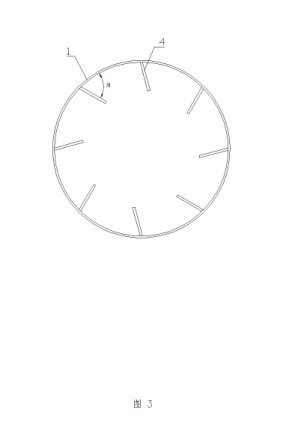

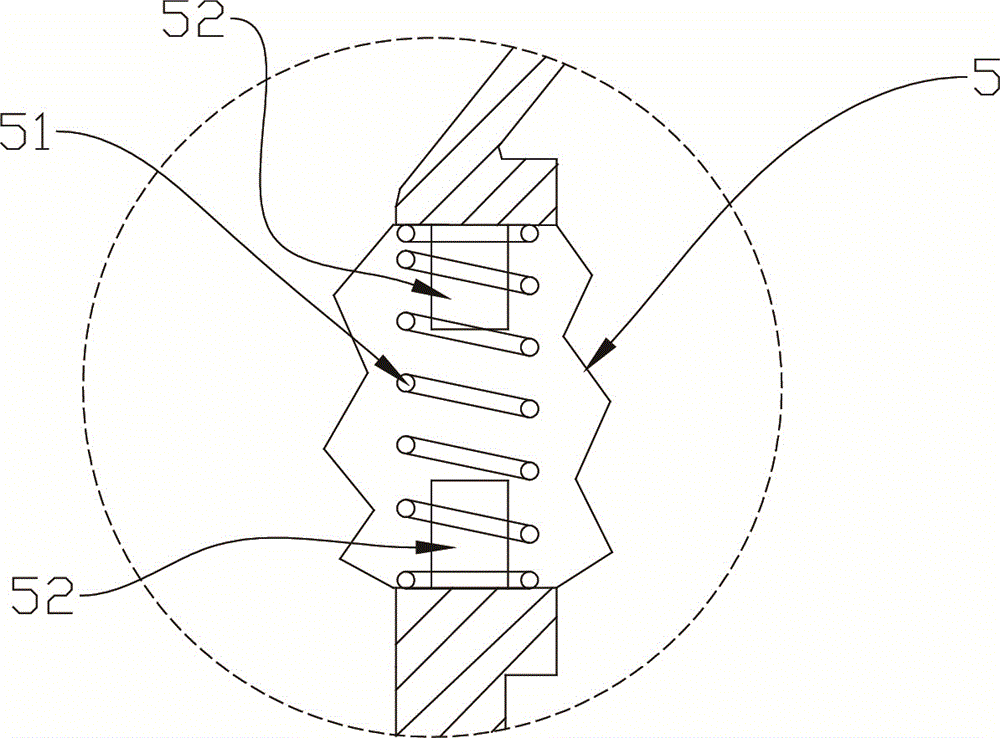

Rubber mixing machine

The invention discloses a rubber mixing machine. The rubber mixing machine comprises a control device and a mixing cylinder which is arranged on a supporting base, wherein a driving device used for driving the mixing cylinder to rotate is arranged on the supporting base; a material inlet and a material outlet are respectively formed at the two ends of the mixing cylinder; a feeding device is arranged at the material inlet; a discharging device is arranged at the material outlet; the driving device, the feeding device and the discharging device are respectively connected with the control device; material mixing blade wings arranged along a feeding spiral direction are respectively arranged in the inner wall of the mixing cylinder; an acute angle material accommodating angle is formed between the material mixing blade wings and the inner wall of the mixing cylinder; and a material stirring hopper is distributed on the inner wall of the mixing cylinder, positioned in the end of the material outlet. Before standard rubber blocks are subjected to banburying and after the standard rubber blocks produced in different batches are cut into small rubber blocks, the small rubber blocks can be fully mixed and homogenized, the production quality is improved, and the energy consumption is reduced.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Exhaust gas aftertreatment device for an internal combustion engine

ActiveUS8220253B2Promotes thorough mixingReduction of the nitrogen oxidesInternal combustion piston enginesSilencing apparatusAfter treatmentExternal combustion engine

The invention relates to an exhaust gas after-treatment device for an internal combustion engine, including a housing into which an exhaust pipe that opens into a mixing chamber penetrates. The mixing chamber is shaped as a pot and reverses a direction of flow of the incoming exhaust gas whereby it returns the exhaust gas radially outside of the exhaust pipe. An open end of the pot-shaped mixing chamber opens into a collecting space which is designed so that it supplies the exhaust gas to at least one downstream SCR catalytic converter.

Owner:PUREM GMBH

Skin cream

InactiveUS6861062B2Promotes thorough mixingReduce wrinklesCosmetic preparationsBiocideWrinkle skinAdditive ingredient

A skin cream is presented which reduces wrinkles upon topical application to the skin. The main ingredients of the composition include water and a xanthine based compound composition which is mixed together in a first vessel and a glycerin composition heated in a second vessel. The three components of the active ingredient are mixed carefully, making sure that any precipitate produced is remixed into the solution. After heating and mixing the components, the entire composition is cooled with care being taken to push any precipitate back into solution to ensure an even distribution of all of the components. The active ingredient thus produced may be combined with a suitable pharmaceutical vehicle to provide the topical wrinkle reducing moisturizing and protecting composition. The composition is topically applied to the effected area over a period of days or months in order to reduce or entirely eliminate wrinkles and dryness from the skin. The final active ingredient may also be used for other applications.

Owner:VICTOR SILVA

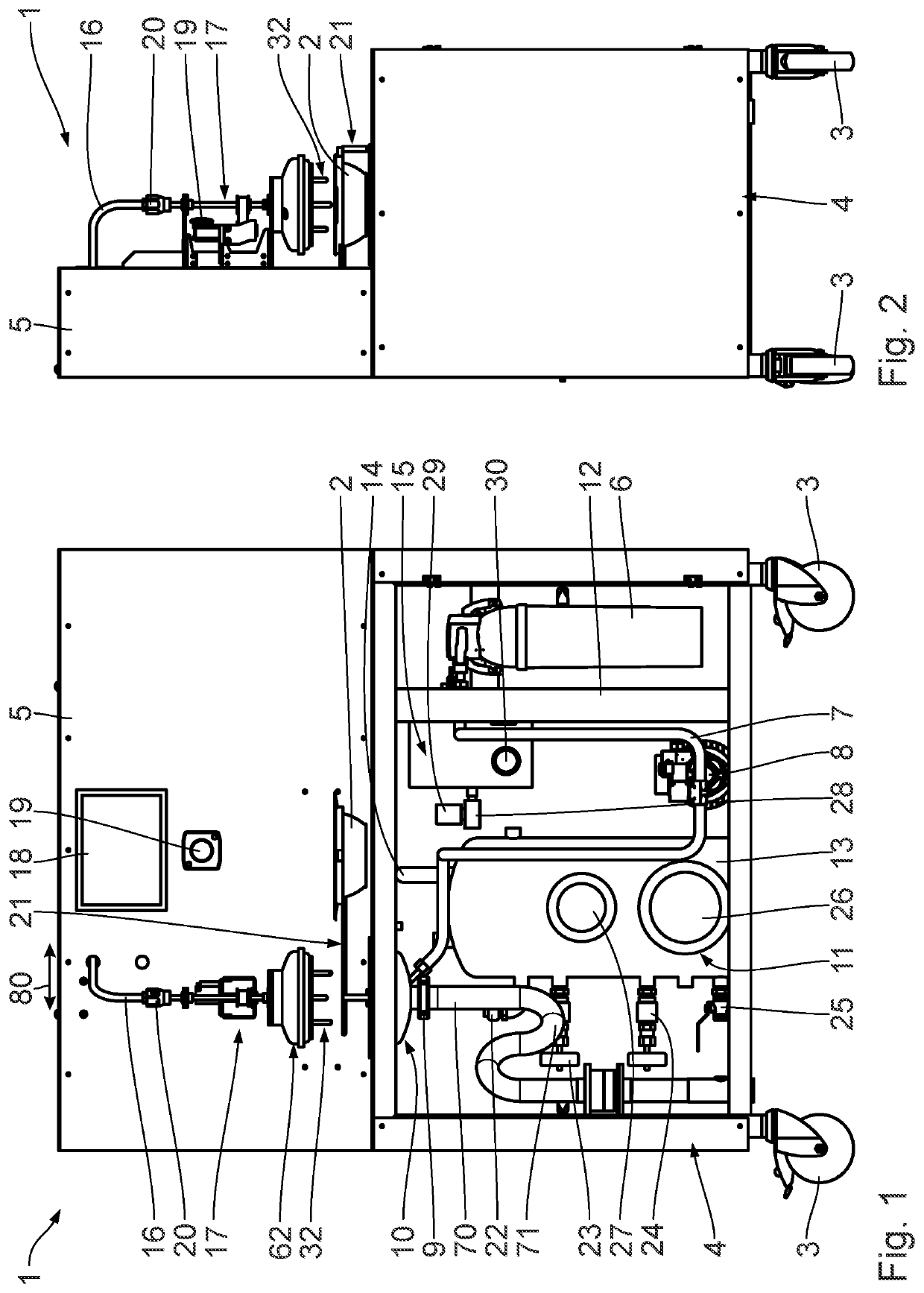

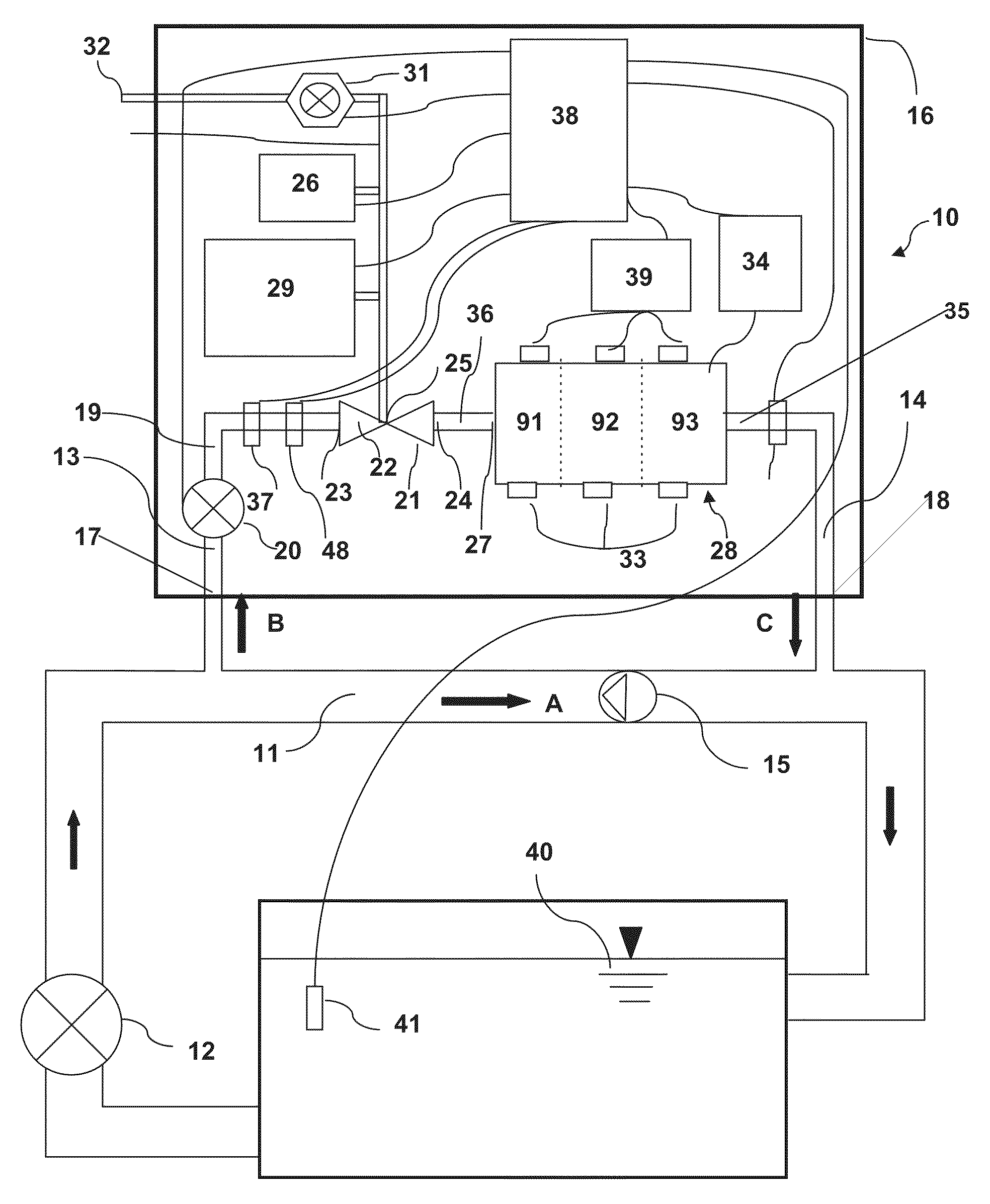

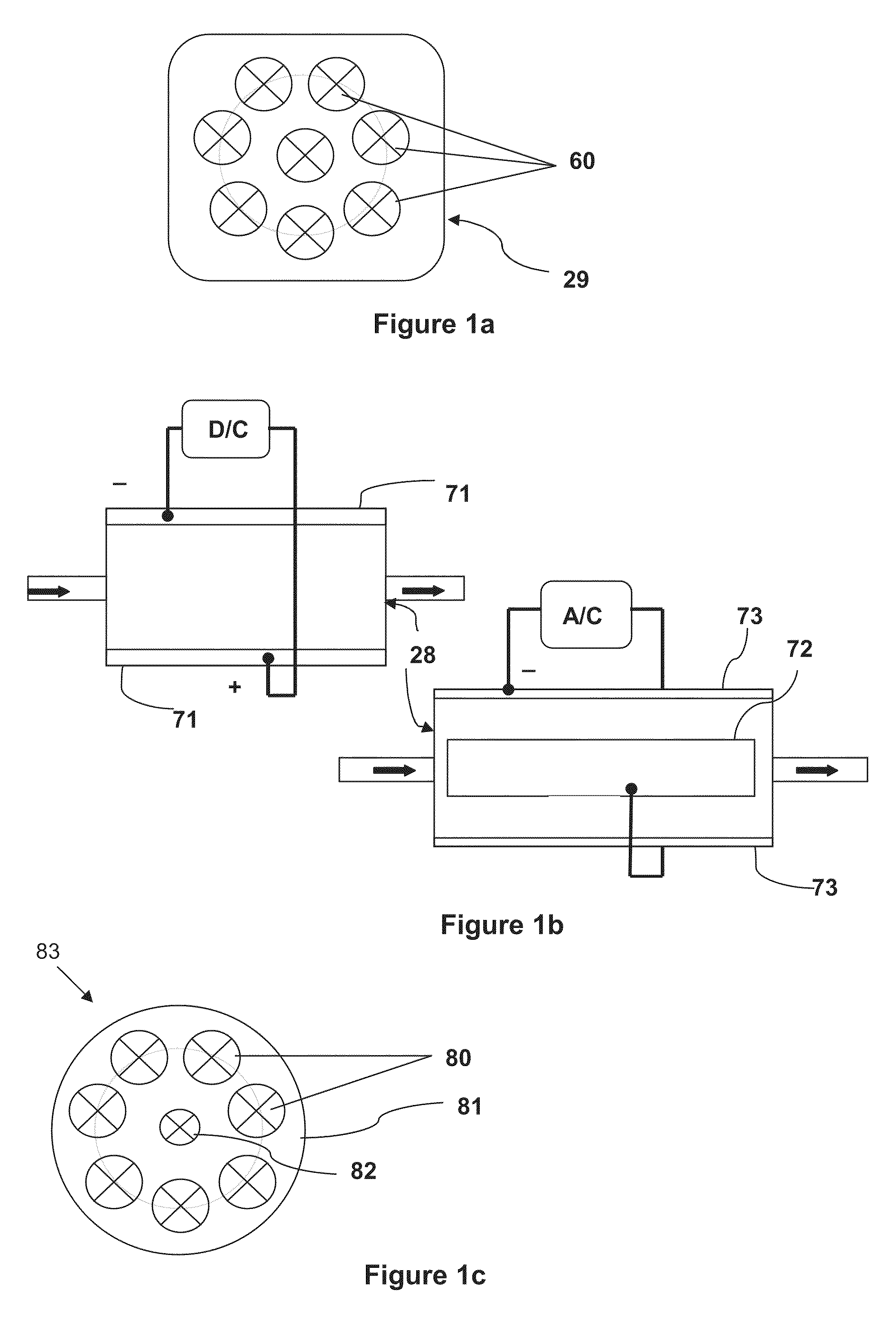

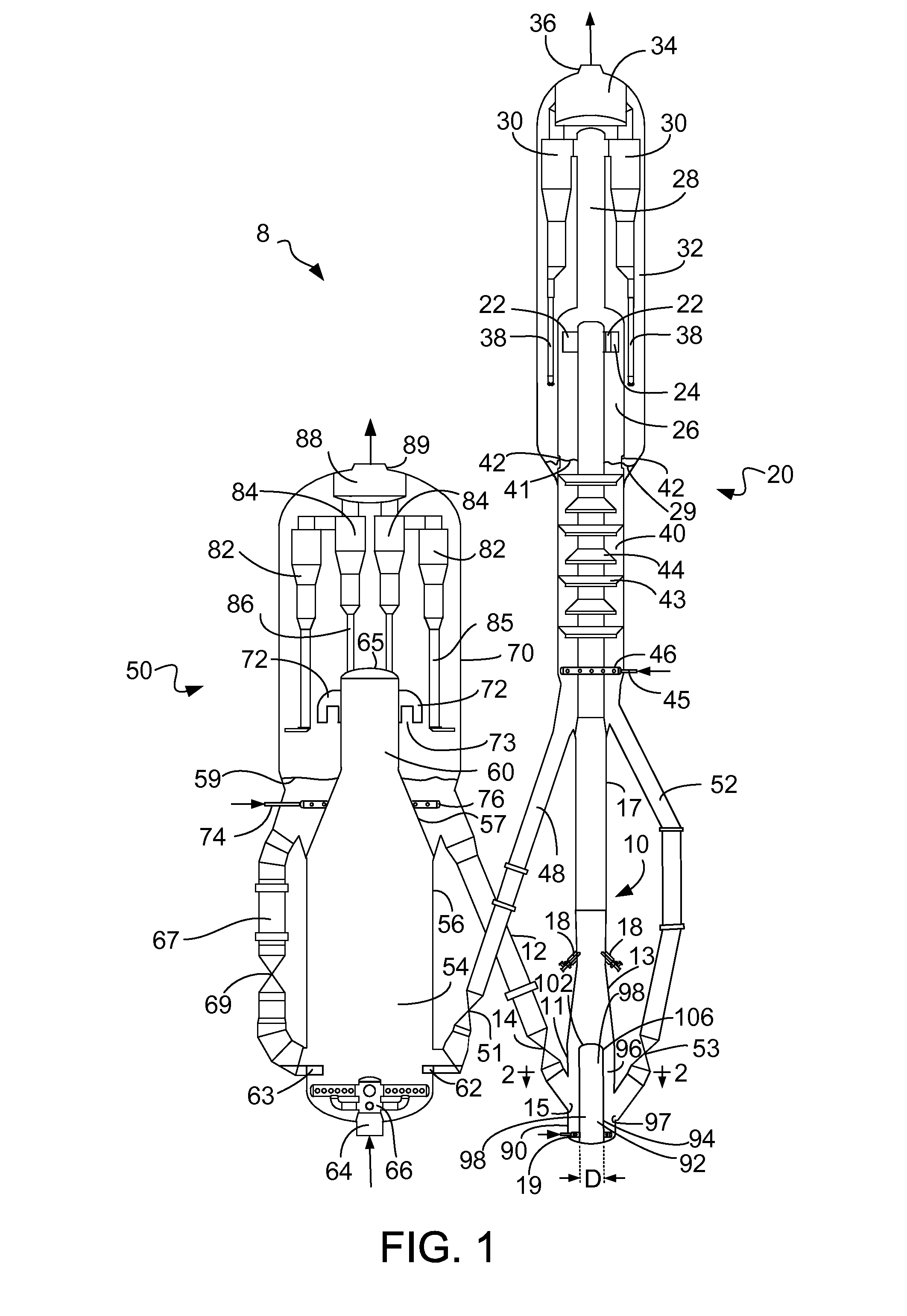

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS8999173B2Promotes thorough mixingFacilitate chemical reactionsLiquid separation by electricityIsotope separationTotal dissolved solidsWater source

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

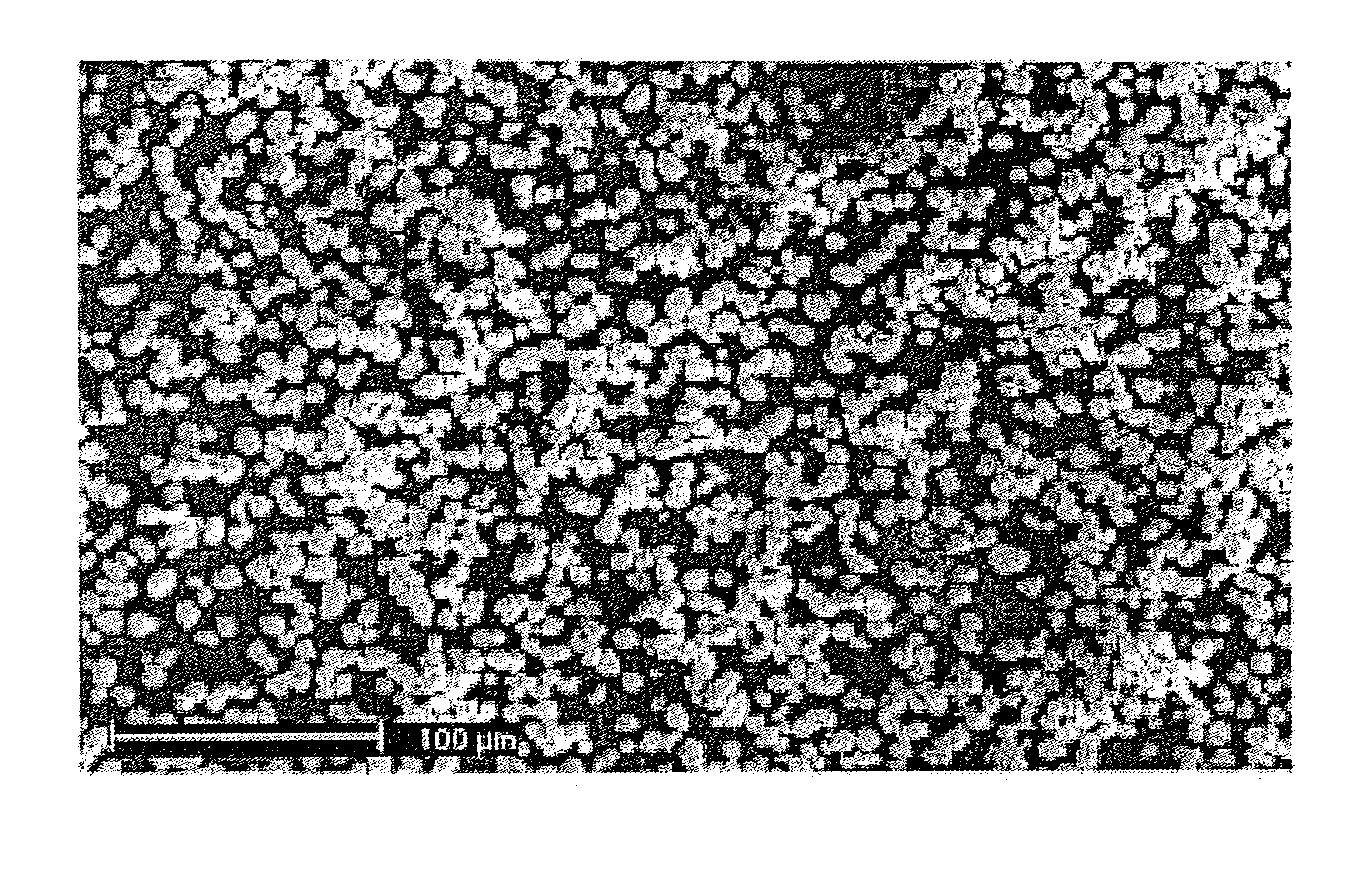

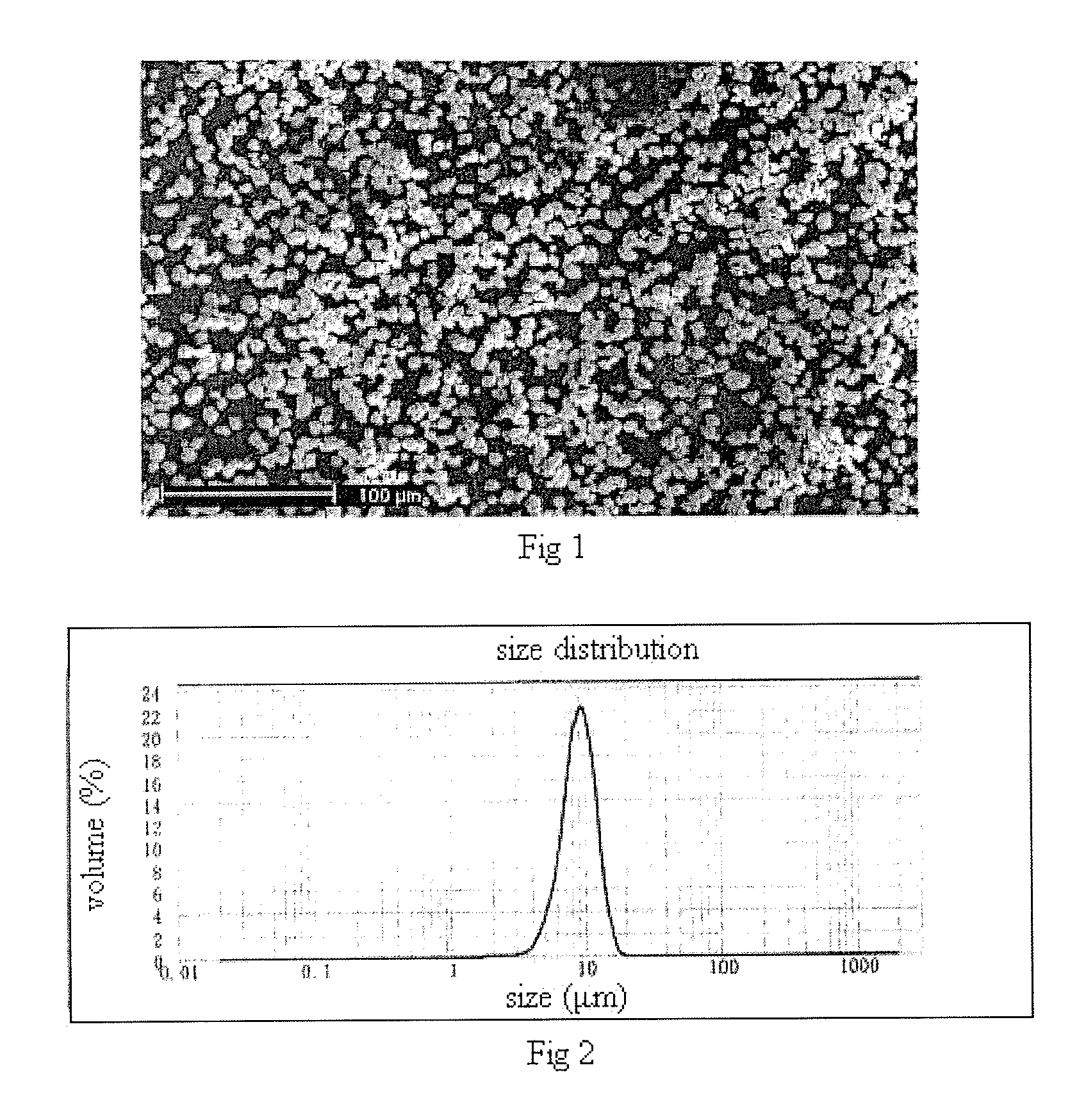

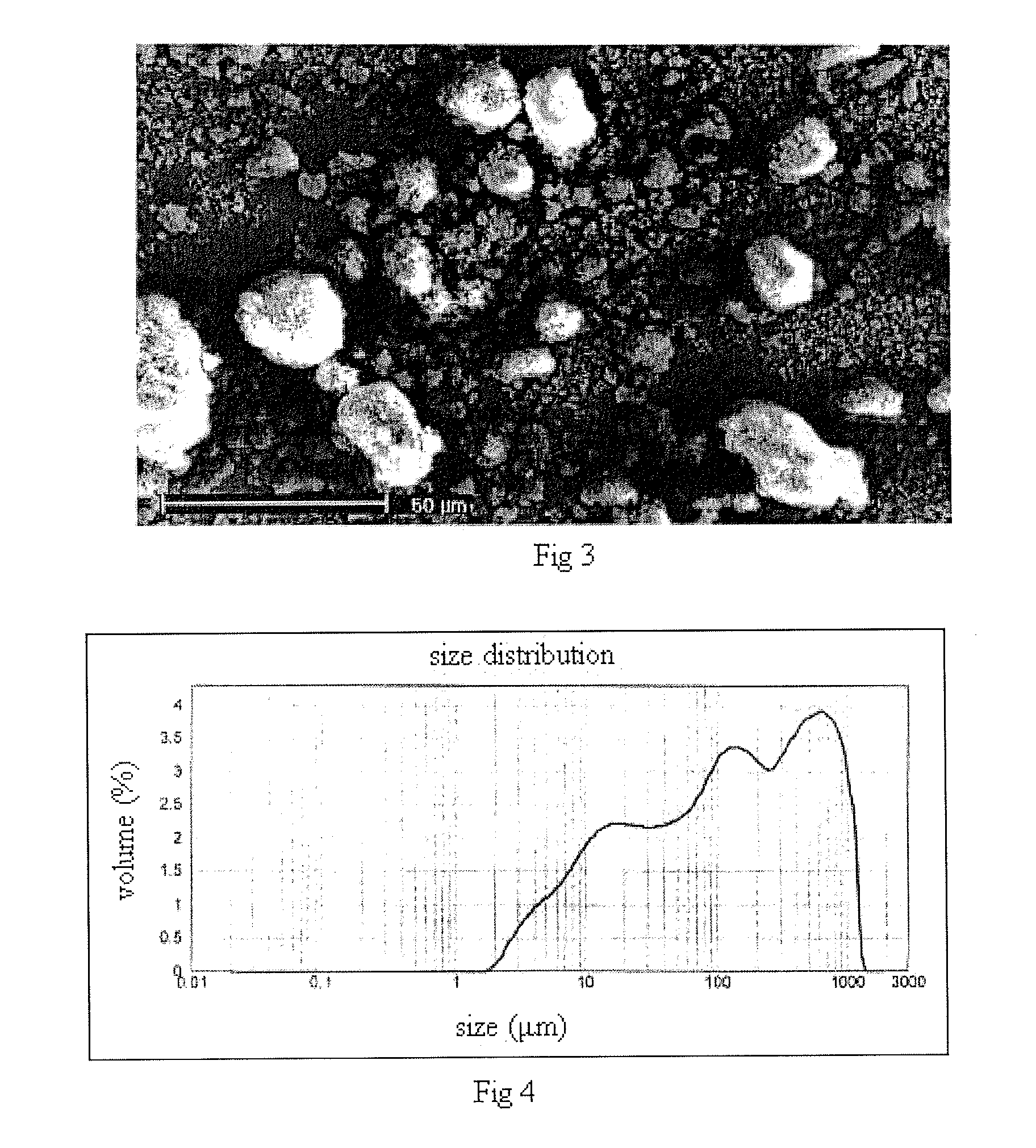

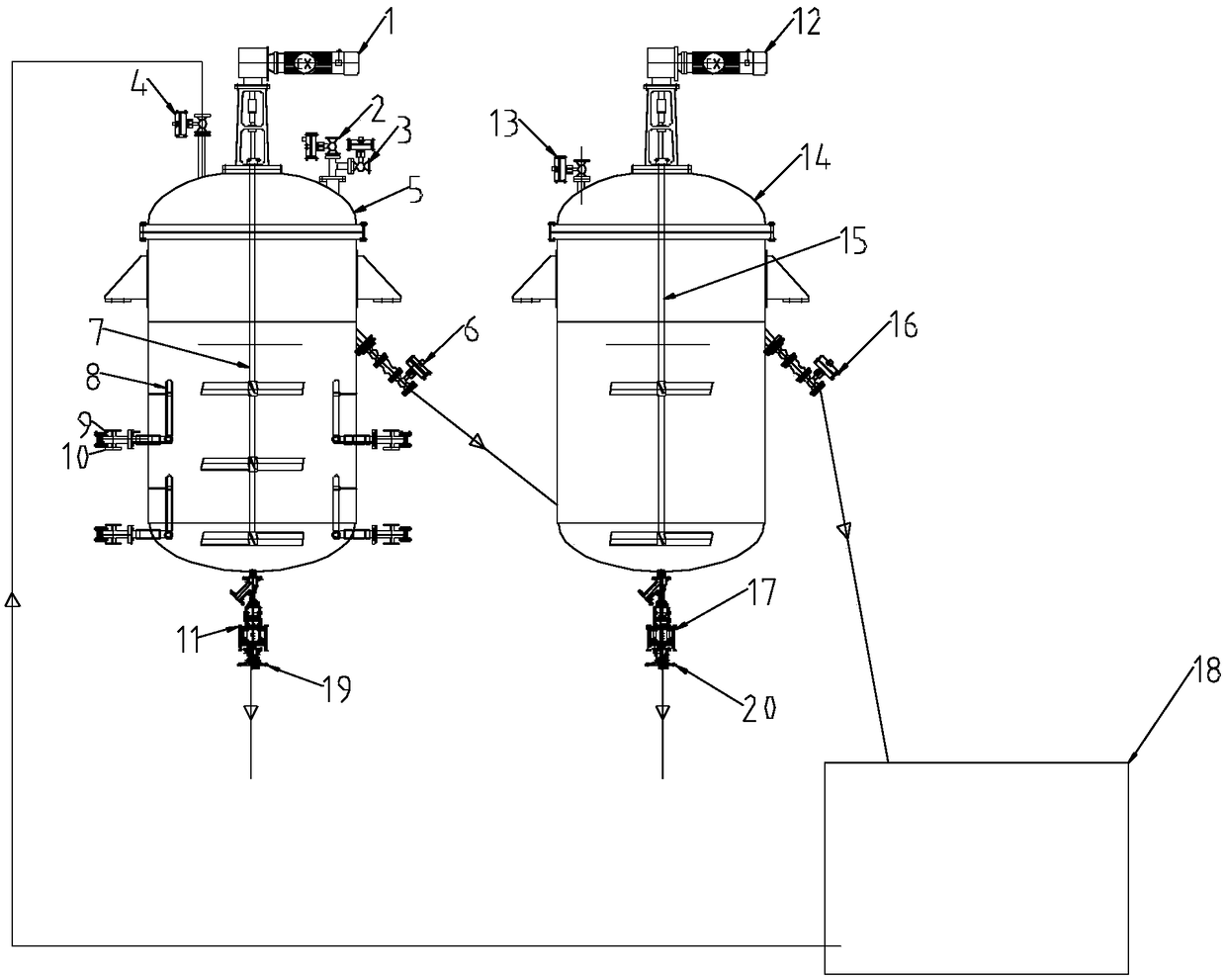

Catalyst component for polymerization of olefin and preparation method

ActiveUS9068025B2Improve responseHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOctenePolybutadiene

The present invention relates to a catalyst component for olefin polymerization, which comprises the reaction product of at least one organo-magnesium compound, at least one titanium-containing compound, at least one hydroxyl group-containing compound, at least one chlorine-containing organo-aluminum, boron, phosphorus or silicon compound, and at least one polybutadiene block copolymer. The catalyst component of the present invention has well-shaped particles, and a narrow particle size distribution; a polymerization reaction of olefins with the catalyst component produces well-shaped polymer particles with a high bulk density (BD) and an excellent comprehensive catalytic performance. The present invention also relates to a preparation method for said catalyst component and the application thereof, particularly in the homopolymerization and copolymerization of olefins such as ethylene, propylene, butene, hexene and octene.

Owner:CHINA PETROCHEMICAL CORP +1

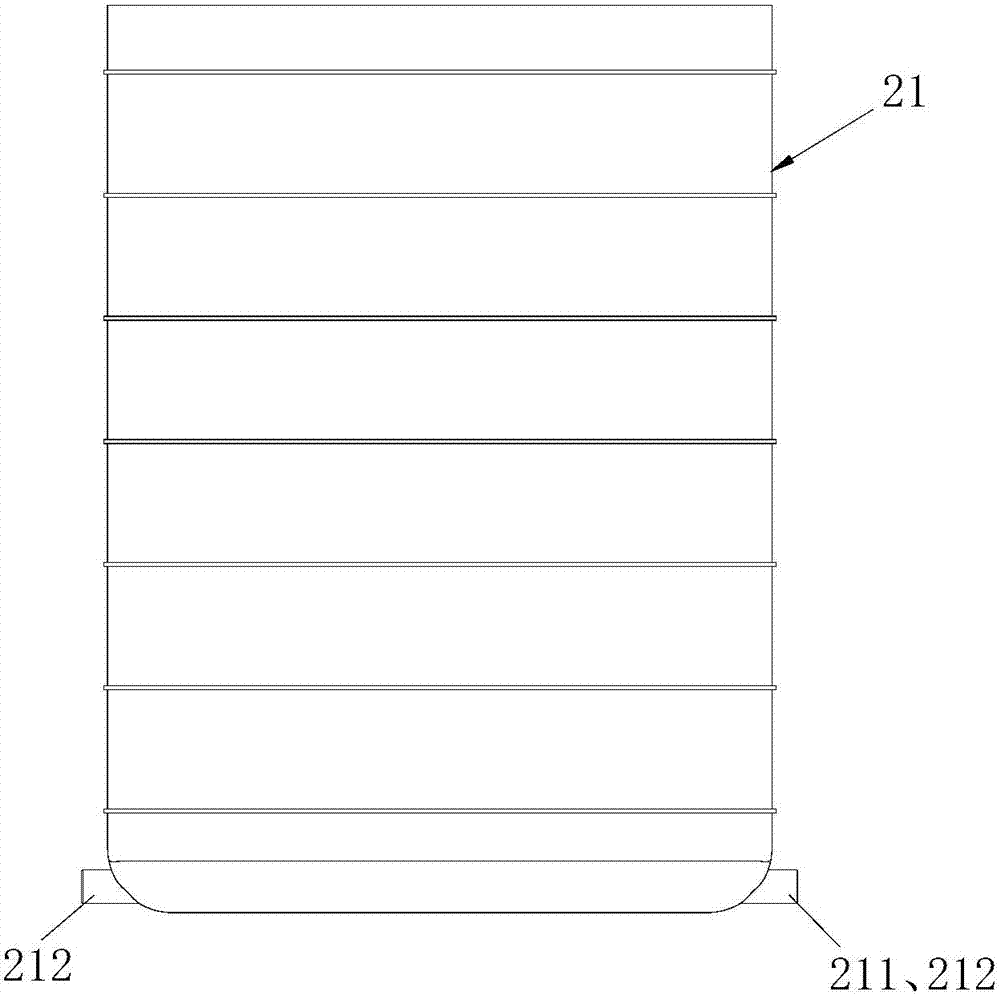

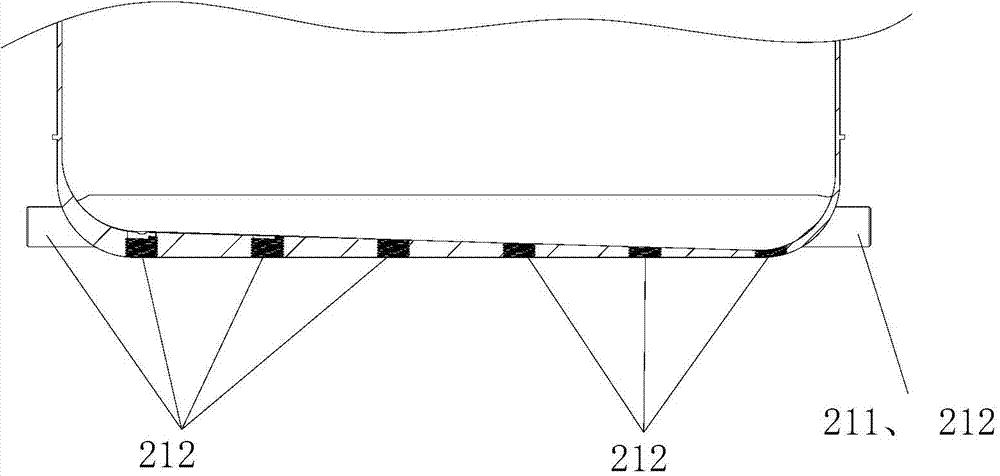

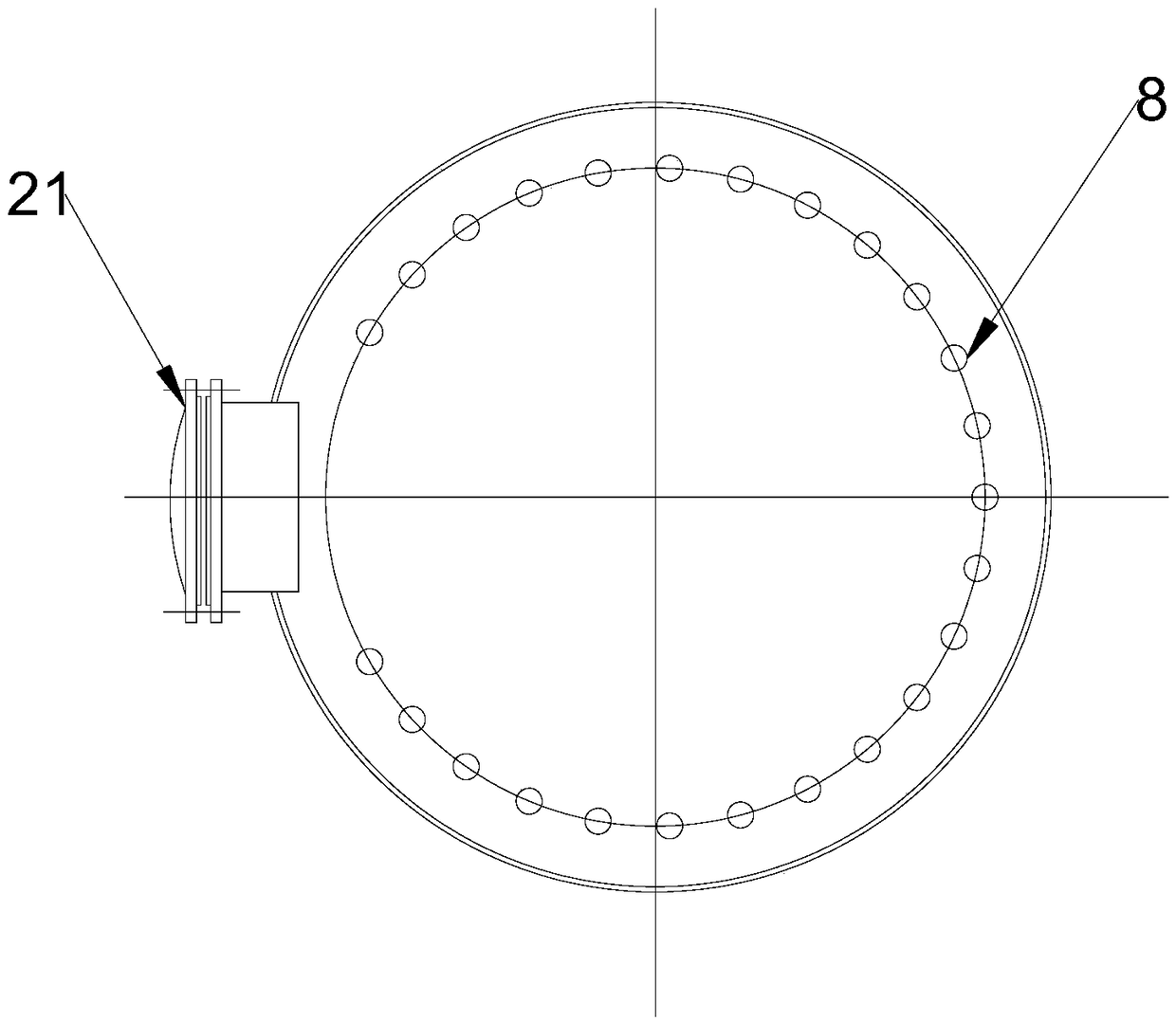

Novel filtering and concentrating device and main reaction kettle device

PendingCN109382058ASolve layeringAchieve reuseChemical/physical/physico-chemical stationary reactorsStationary filtering element filtersNitrogenPulp and paper industry

The invention discloses a novel filtering and concentrating device and a main reaction kettle device. The novel filtering and concentrating device comprises a cylinder body A, a cylinder body B, a gear motor A, a gear motor B, a stirring paddle A and a stirring paddle B, and further comprises a drain valve A, a drain valve B, a final concentrated product outlet A and a final concentrated product outlet B, wherein the gear motor A and the gear motor B are arranged at the top ends of the cylinder body A and the cylinder body B, the stirring paddle A and the stirring paddle B are arranged in theinner parts of the cylinder body A and the cylinder body B, the drain valve A and the drain valve B are arranged at the bottom ends of the cylinder body A and the cylinder body B; a nitrogen inlet, aregenerated liquid inlet and a spraying water inlet are arranged at the top end of the cylinder body A, an annular filter element is arranged on the inner wall of the cylinder body A, a back flushingport and a clear liquid outlet connected with the bottom part of the filter element and a filtered concentrated liquid outlet connected with a main reaction kettle are arranged on the side wall of thecylinder body A, a raw material feed port is arranged at the top end of the cylinder body B, an overflow port is arranged on the side wall of the cylinder body B and communicates with a middle tank,and the middle tank communicates with the top part of the filtering and concentrating device. The structure design of the novel filtering and concentrating device is more advanced and more reasonable,the mounting, dismounting and maintaining are simple and convenient, the problems of layering, shaking, sealing and the like of material liquid are effectively solved, and the filtering fineness is higher.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for producing superphosphate and compound fertilizer thereof by means of concentrated acid slag powder method

InactiveCN103086338AReduce corrosionReduce or eliminate the introductionSuperphosphatesPhosphorus compoundsPowder methodSlag

The invention discloses a method for producing superphosphate and a compound fertilizer of the superphosphate by means of concentrated acid powder slag method, and belongs to the field of agricultural fertilizer. The superphosphates compound fertilizer is directly prepared by subjecting the mixing process of concentrated sulfuric acid and phosphorite to mechanical stirring and grinding force and organically combining the preparation and neutralization pretreatment of the superphosphate and the preparation of the compound fertilizer, complex process flow is prevented, production efficiency is improved, and production cost is reduced.

Owner:ZHENGZHOU UNIV

Microfluidic element for thoroughly mixing a liquid with a reagent

ActiveUS20130196447A1Promotes thorough mixingMixing methodsTransportation and packagingAnalyteEngineering

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

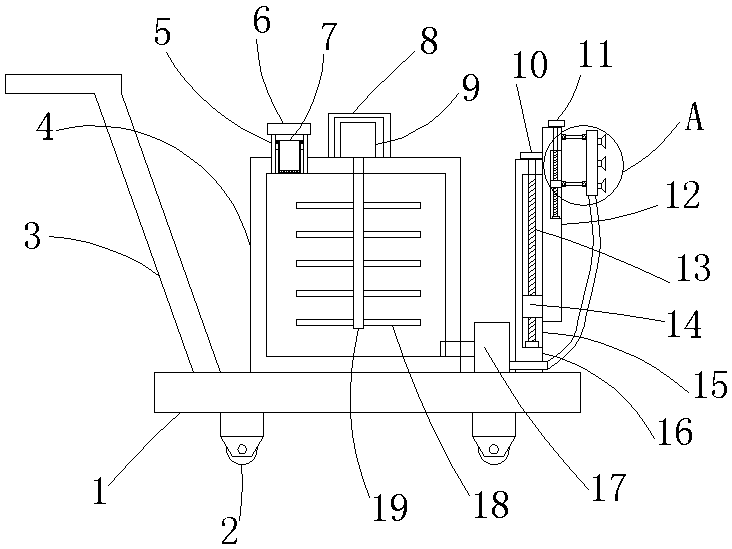

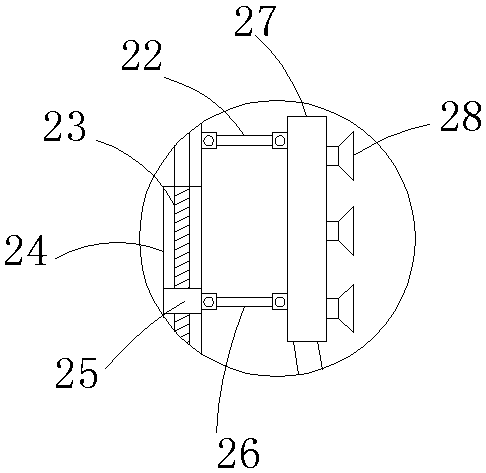

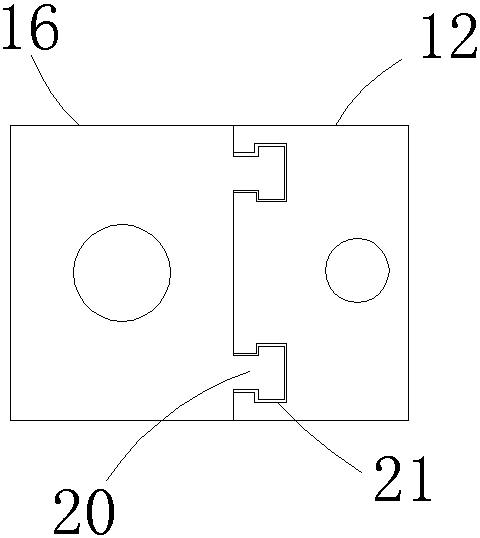

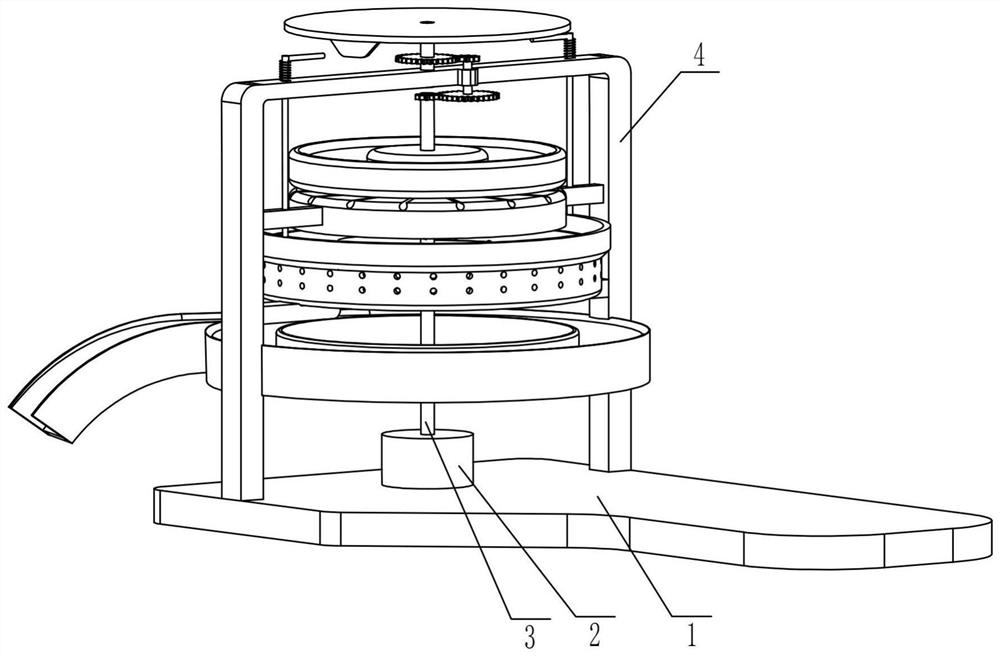

Enriched selenium plant nutrient and mixing device thereof

ActiveCN104557295AGuaranteed normal growthProcess stabilitySuperphosphatesTransportation and packagingBiologyNutrient

The invention discloses an enriched selenium plant nutrient. The enriched selenium plant nutrient comprises the following ingredients by weight proportion: 25-30% of dried cow dung, 25-30% of dried straw powders, 30-38% of attapulgite, 5-7% of selenium sources, 2-3% of potassium phosphate, 2-3% of calcium superphosphate and 2-3% of plant ash. The invention further provides a mixing device used for mixing the enriched selenium plant nutrient. The enriched selenium plant nutrient and the mixing device have the following benefits: 1) the enriched selenium plant nutrient has the good slow-release effect, and is convenient for long-term preservation; 2) the mixing device can realize the automatic addition of different powders in batches at intervals, avoids the trouble and cost of manual operation, reduces powders adhered on the inner wall of a tank body through vibration, and is low in noise during operation, simple in structure and convenient to dismount and replace.

Owner:NINGBO ZHONGJING BIOLOGICAL TECH

Spraying device for plant protection

InactiveCN109329255AEasy to filterEasy height adjustmentRotary stirring mixersTransportation and packagingEngineeringThreaded rod

The invention belongs to the field of agriculture, and particularly relates to a spraying device for plant protection. In order to solve the problems that existing liquid medicine is mixed unevenly and the spraying height is not convenient to adjust, the device comprises a base, universal wheels are installed at the bottom of the base, a handrail, a water tank, a pump machine and a stand column are arranged at the top of the base, a water inlet pipe, a motor, a rotating shaft and stirring blades are arranged on the water tank, a first sliding groove, a guide rail, a first threaded rod and a first movable block are arranged in the stand column, a movable column is slidably connected to the guide rail, a second sliding groove is formed in the movable column, a second threaded rod and a second movable block are arranged inside the second sliding groove, a hose is connected to the water outlet end of the pump machine, a connecting pipe is connected to the other end of the hose, a first connecting rod is hinged between the connecting pipe and the movable column, and a second connecting rod is hinged between the second movable block and a connecting pipe. Liquid medicine can be sufficiently mixed, the spraying height and angle are convenient to adjust, the working efficiency is effectively improved, and the labor intensity of workers is lowered.

Owner:郑州浩普信息技术有限公司

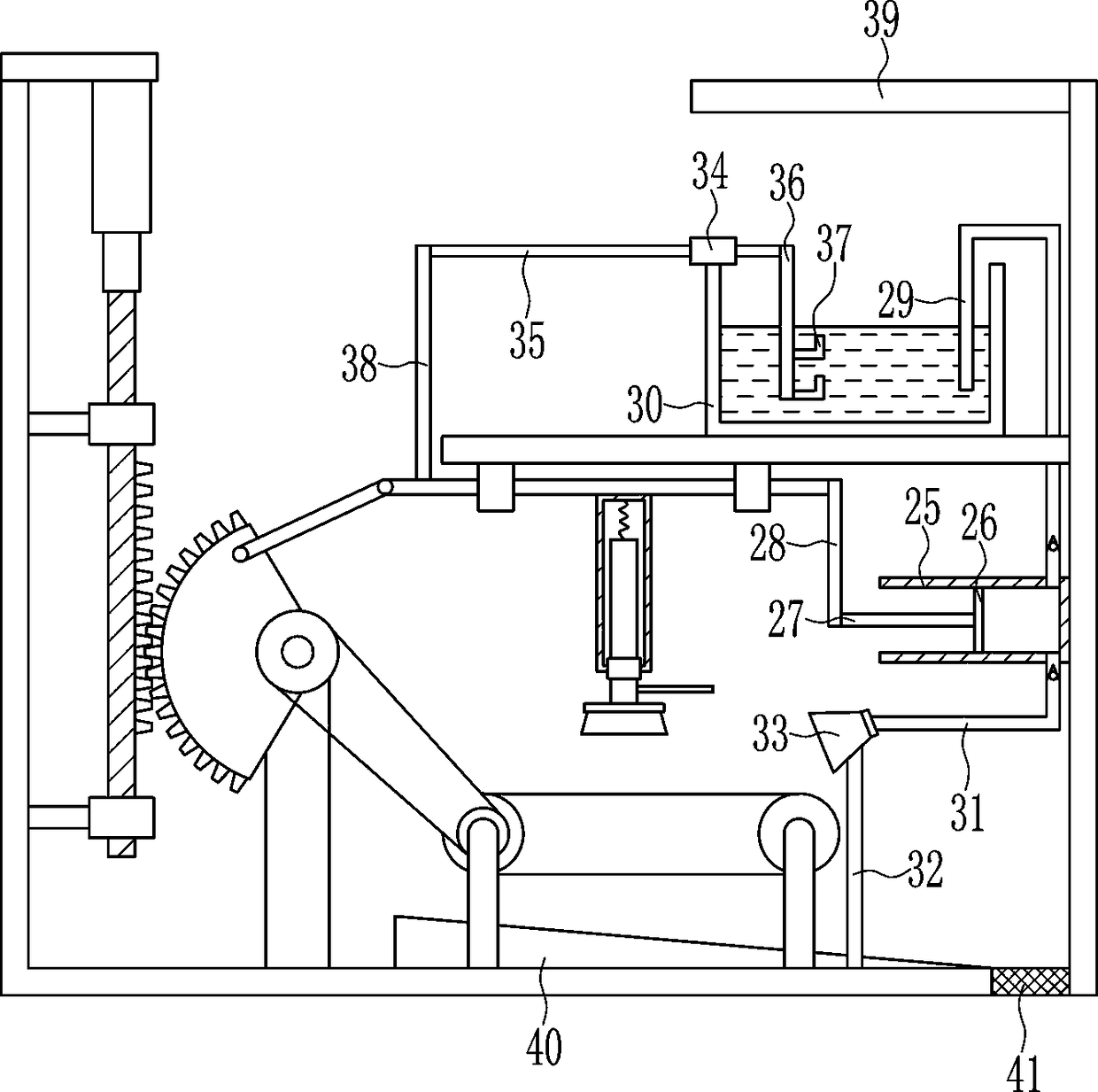

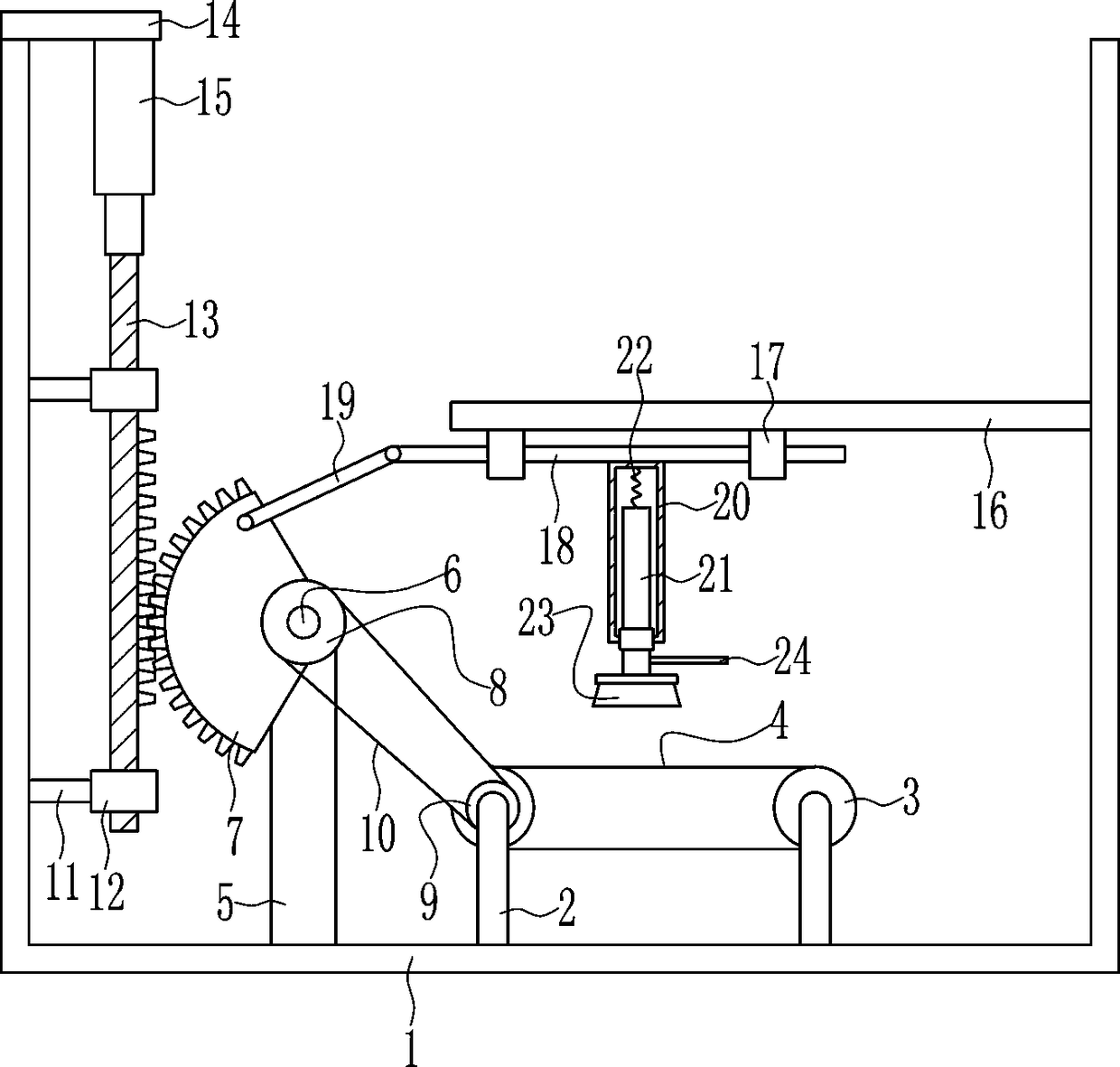

Mechanical tile surface cement brushing-away equipment for construction

ActiveCN108499920AEffective flushingEasy to useCleaning using toolsCleaning using liquidsDrive wheelEngineering

The invention relates to brushing equipment, in particular to mechanical tile surface cement brushing-away equipment for construction. By means of the mechanical tile surface cement brushing-away equipment for construction, oxalic acid left on surfaces of brushed tiles can be washed away conveniently, and water for washing can be drained in time. The mechanical tile surface cement brushing-away equipment for construction comprises a mounting frame, first supporting rods, driven wheels, a conveying belt, a second supporting rod, a rotary shaft, a sector gear, a first belt wheel, a second belt wheel, a flat belt, third supporting rods and the like, wherein the first supporting rods are arranged at the bottom of the interior of the mounting frame in a bilateral symmetry mode. The oxalic acidleft on the surfaces of the tiles is effectively washed away by washing the surfaces of the tiles, thus, workers can directly use the washed tiles, and the working efficiency of the workers is improved.

Owner:新疆广益天成建设工程有限公司

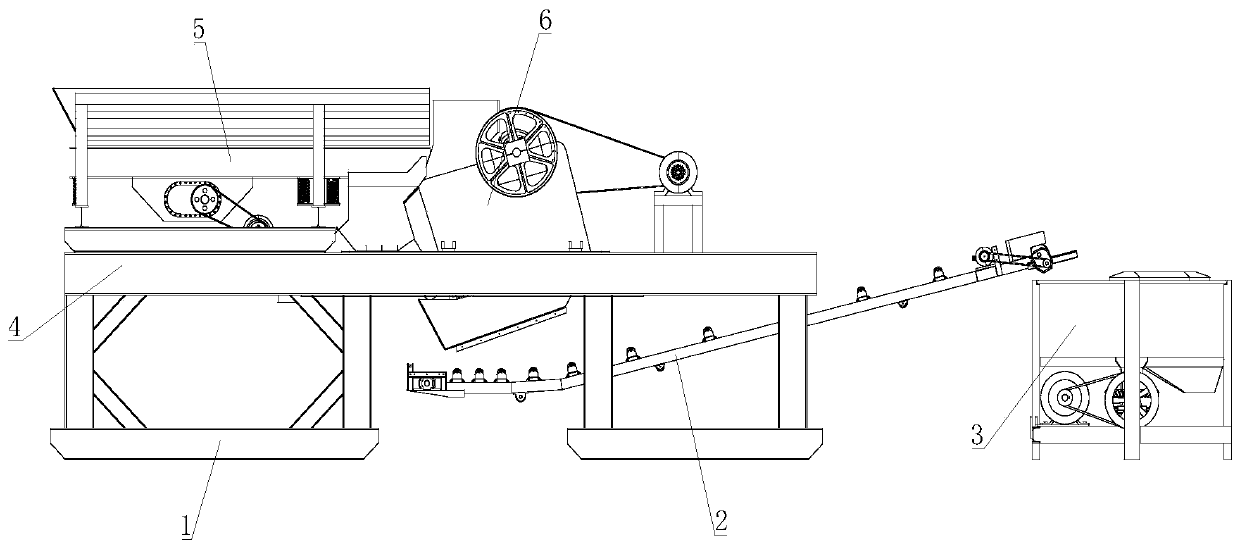

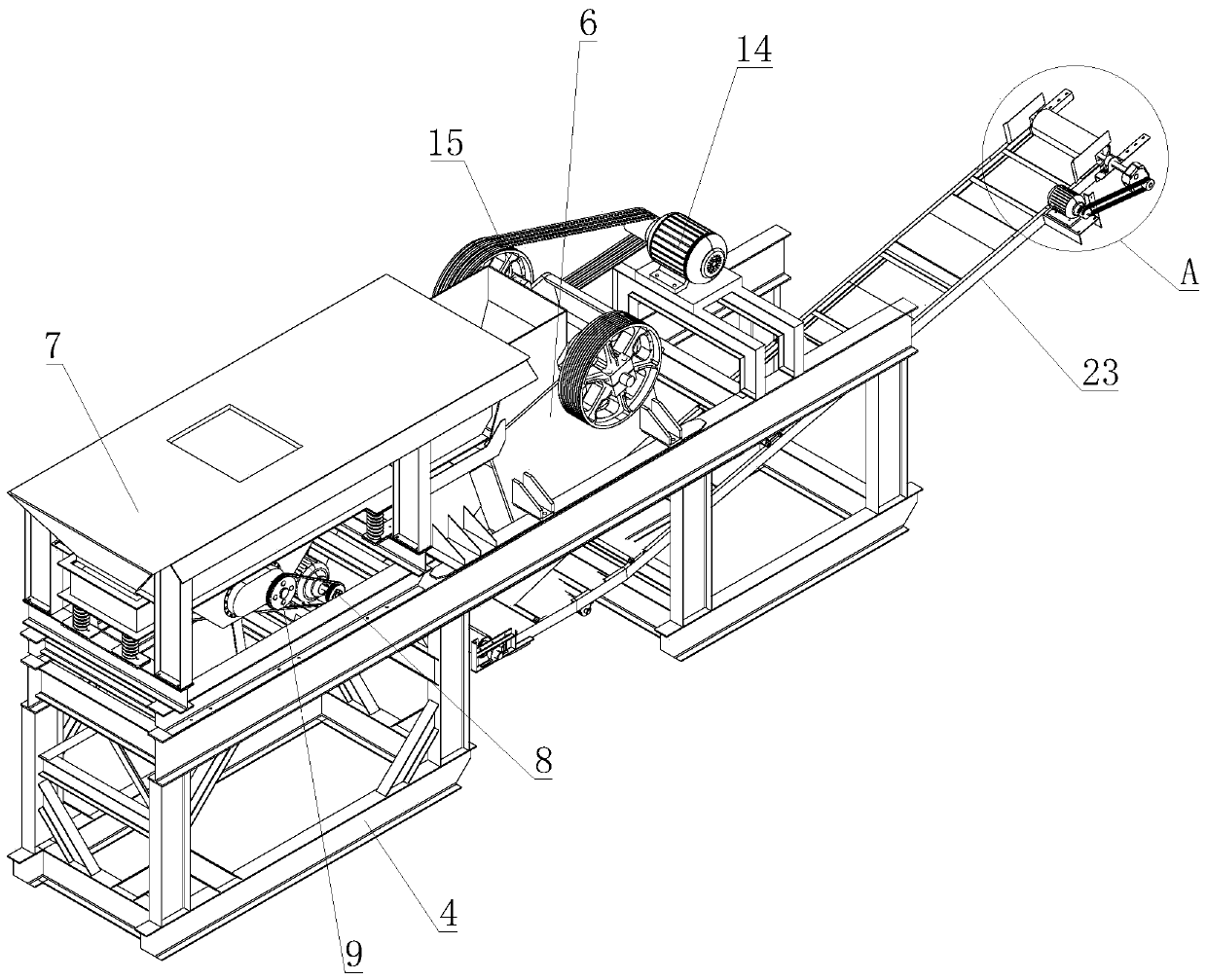

Method for preparing novel sintered brick from construction waste

InactiveCN111484263AQuality assuranceReduce processing stepsTransportation and packagingRotary stirring mixersBrick kilnRaw material

The invention discloses a method for preparing a novel sintered brick from construction waste, which comprises the following steps: 1. collecting construction waste, and removing impurities from the construction waste for later use; 2, the construction waste is thrown into a crushing mechanism to be crushed, and the construction waste obtained after extrusion crushing falls into a conveying mechanism through a discharging hopper; the crushed construction waste is conveyed into a mixing mechanism through the conveying mechanism; 3, water is added into the sintered brick mixed raw material, stirring is carried out to form brick body pug, and the brick body pug is prepared into a sintered brick blank; and step 4, the sintered brick blank is put into a brick kiln for roasting, drying and shaping are carried out, according to the novel sintered brick preparation device, construction waste and sintered brick raw materials are stirred and mixed through a second mixing frame, meanwhile, a first mixing frame rotates while rotating around a rotary disc, the sintered brick preparation raw materials can be fully mixed and stirred to be uniform, and therefore the quality is better when the rawmaterials are used for preparing sintered bricks.

Owner:深圳市俊隆环保科技有限公司

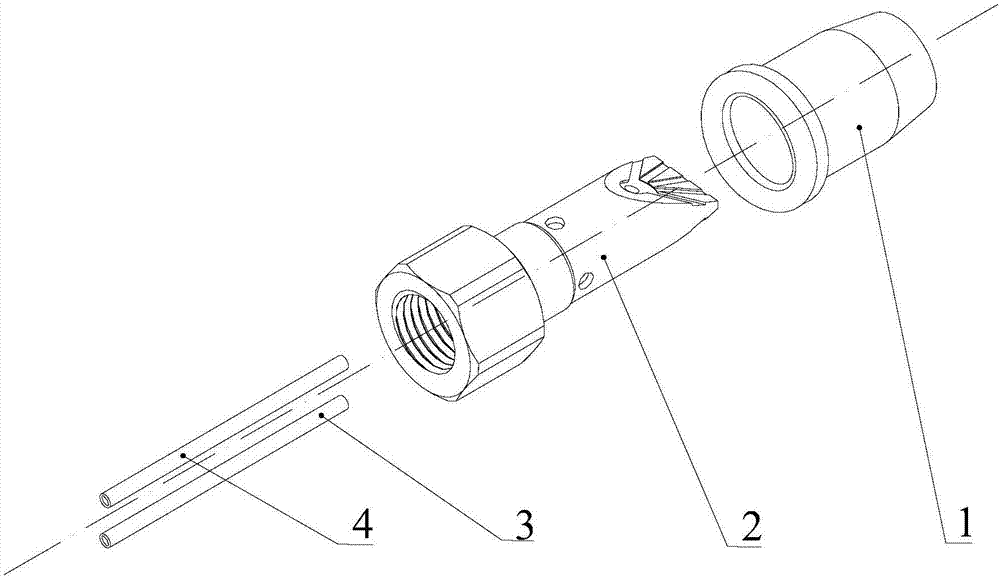

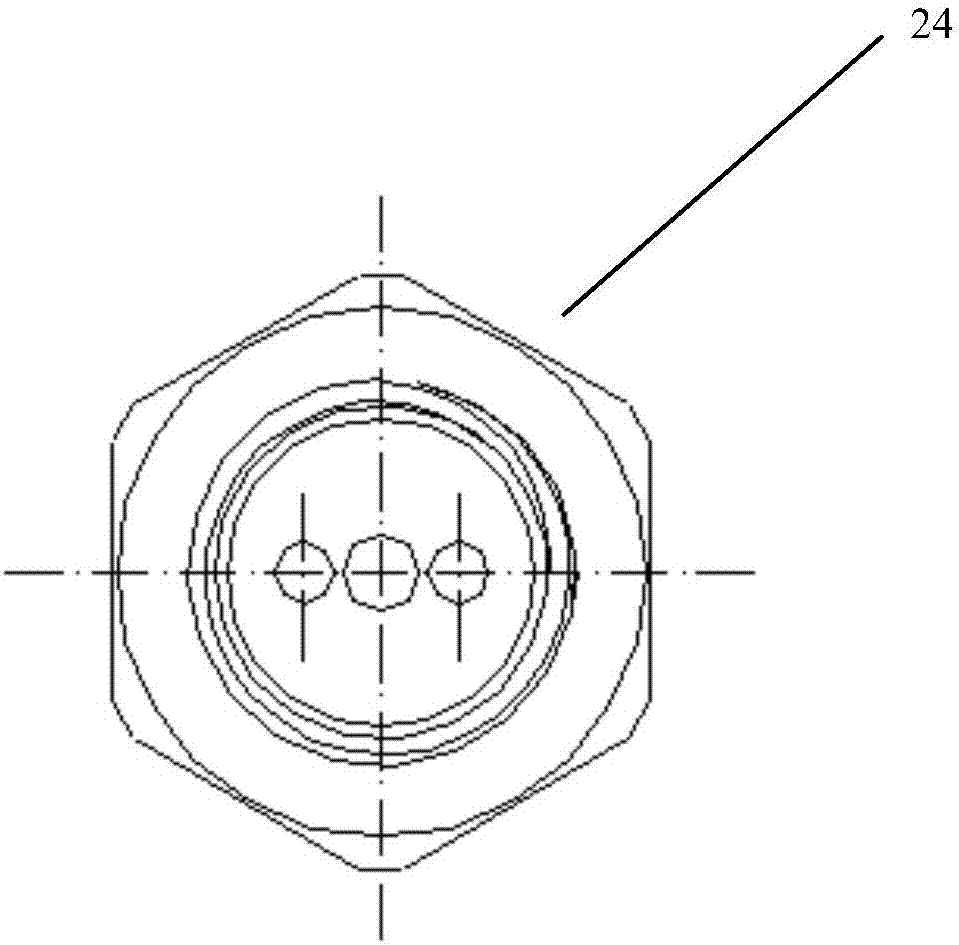

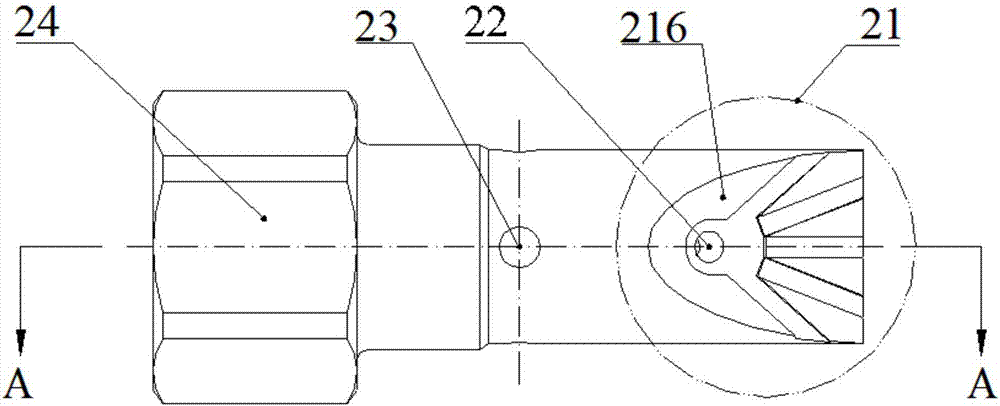

Energy saving nozzle of minimum quantity lubrication system

ActiveCN107042165AUniform liquid supplyImprove cooling and lubrication effectSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention provides an energy saving nozzle of a minimum quantity lubrication system. The energy saving nozzle of the minimum quantity lubrication system is characterized by comprising an embedding ring and a nozzle body; the embedding ring is embedded on the outer side of the nozzle body, totally or partially covers the surface of the nozzle body, and is in clearance fit with the nozzle body; an air cavity and at least two fluid channels are formed in the nozzle body; an air hole and a hole for penetrating through the internal of the nozzle body are formed in the surface of the nozzle body; a guide groove unit is arranged on the surface of the nozzle body; and with a liquid hole as a starting point, the guide groove unit is multiple symmetric guide groove bodies scattered on the surface of the nozzle body. The nozzle structure generates fan-shaped spray to spray to a cutting area, so that the supply problem of minimum quantity lubrication cutting liquid with a machining mode as linear contact is preferably solved, the liquid supply to the cutting area is uniform, and the cooling lubrication performance of minimum quantity lubrication is improved.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH +1

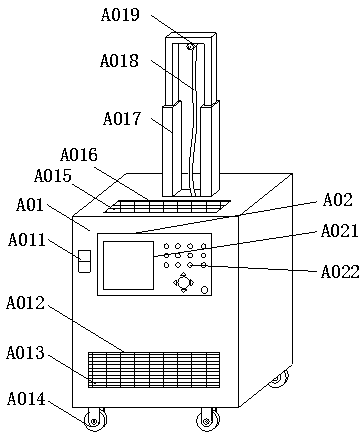

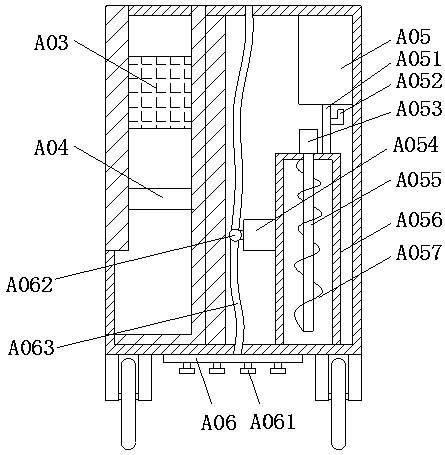

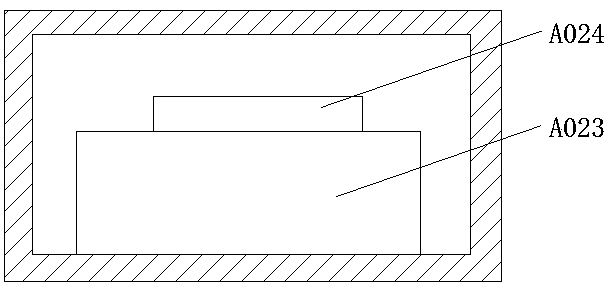

Indoor air purification equipment with disinfectant spray function

InactiveCN107860073ATo achieve the purification effectImprove purification efficiencyMechanical apparatusLighting and heating apparatusMicrocontrollerMicrocomputer

The invention discloses indoor air purification equipment with a disinfectant spray function. The indoor air purification equipment comprises a purification equipment body, wherein air inlet holes areformed in the purification equipment body, a first dust screen is installed on the air inlet holes, moving wheels are installed at the bottom of the purification equipment body, air outlet holes areformed in the top of the purification equipment body, a second dust screen is installed in the air outlet holes, telescopic rods are installed at the top of the purification equipment body, and a spray gun is installed on the telescopic rods. Sensors are embedded in the purification equipment body and comprise a temperature sensor and a humidity sensor, a control panel is installed on one side ofthe sensors, a display screen is installed on the control panel, operating buttons are installed on one side of the display screen, a circuit mainboard is installed in the control panel, and a singlechip microcomputer is installed on the circuit mainboard. The purification equipment is compact in structure and convenient to use.

Owner:李文来

Preparation method of rice paste

InactiveCN104872540AIncrease surface areaImprove water absorptionFood ingredient functionsFood preparationEngineeringCooking process

The invention relates to a preparation method of rice paste. The method comprises the following steps: (a) a crushing stage, wherein a crushing container, a heating element, a motor and a tool are arranged, the heating element is used for heating the crushing container, the tool is located in the crushing container, the motor is used for driving the tool to rotate, materials and water are added to the crushing container, the motor is used for driving the tool to rotate and crush the materials to be in a small particle state, and the retention rate of the materials on a 2.5mm sieve is 60%-80%; (b) a ripening stage, namely heating the water and the materials after the crushing stage by the heating element until the materials are cured; and (c) a crushing and homogenizing stage, namely driving the tool to rotate and crush the water and the materials into the rice paste by the motor after a cooking stage. Therefore, the condition that cereals enter the cooking stage with certain particle sizes is ensured; on one hand, the anti-paste effect can be put into play in the cooking process; and on the other hand, the hygroscopic property is increased by enlarging the superficial area of the materials, and the phenomena of pasted surface and hard middle heart are not generated in the cooking process.

Owner:JOYOUNG CO LTD

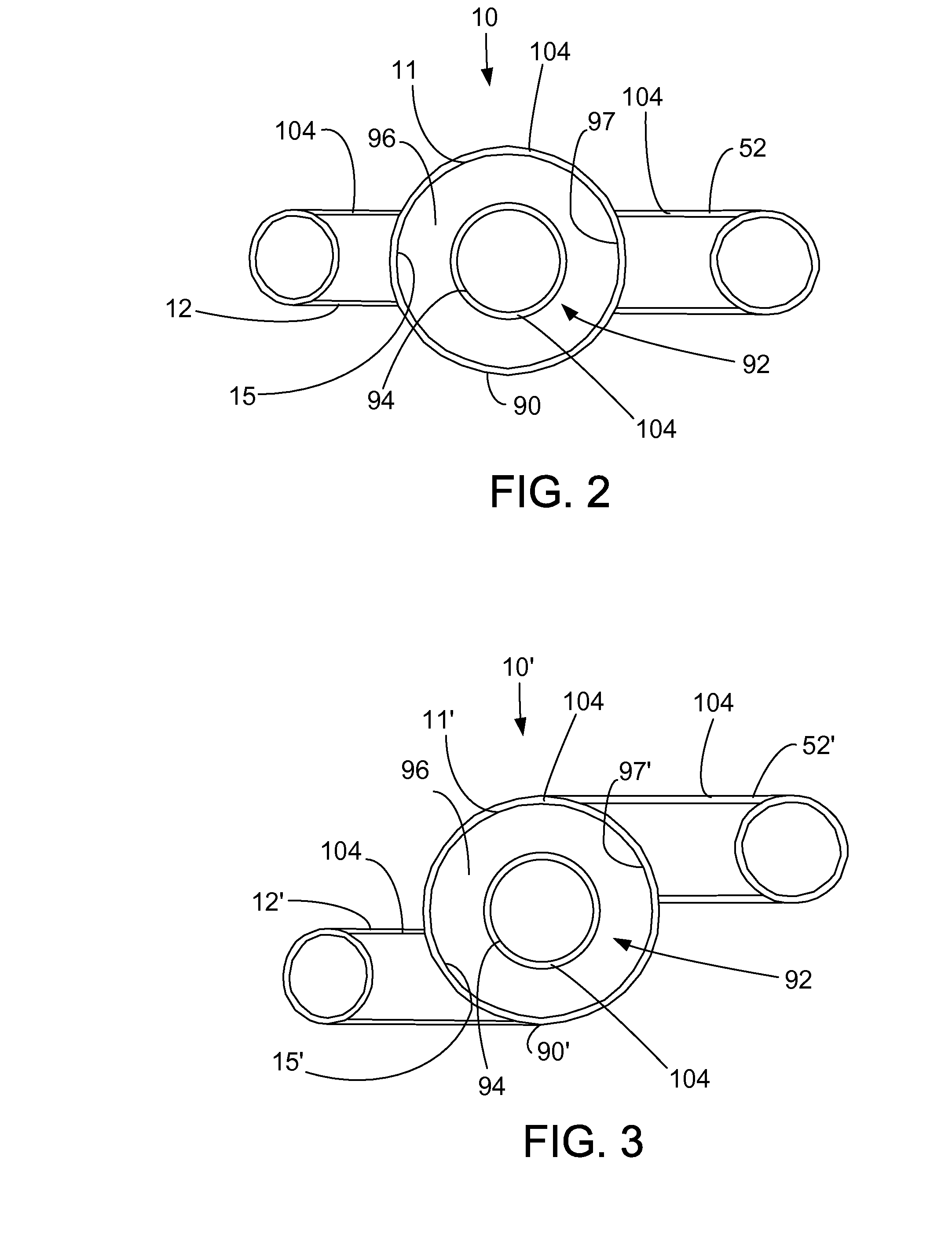

Process and apparatus for mixing two streams of catalyst

ActiveUS20130250717A1Lower height requirementWell mixedCatalytic crackingMolecular sieve catalystsPolymer science

Owner:UOP LLC

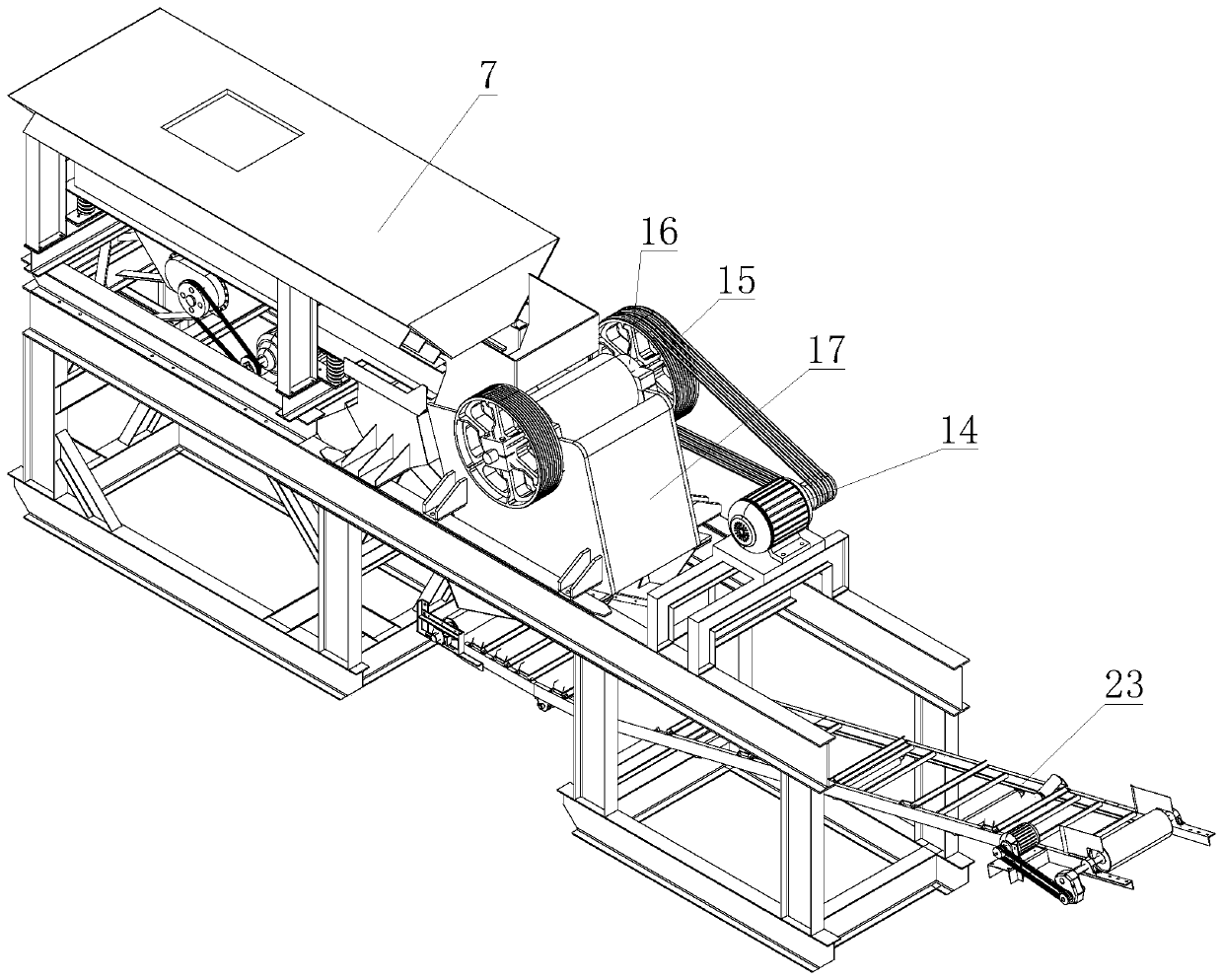

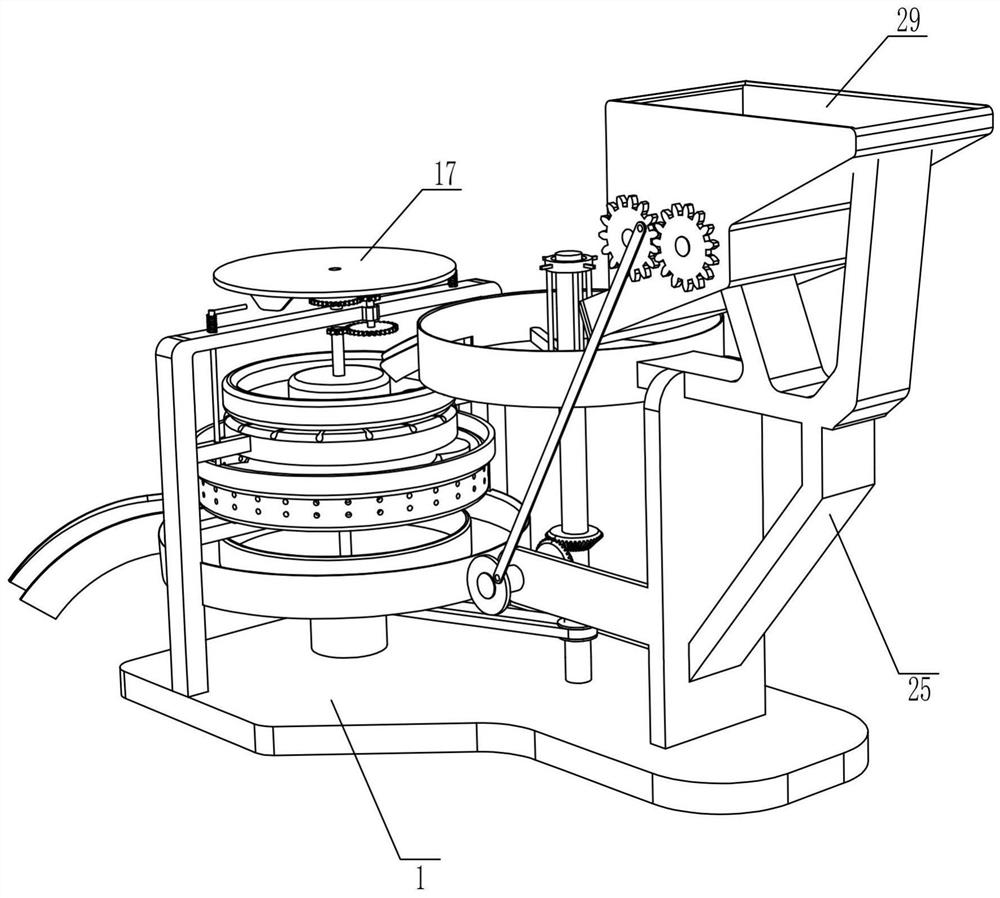

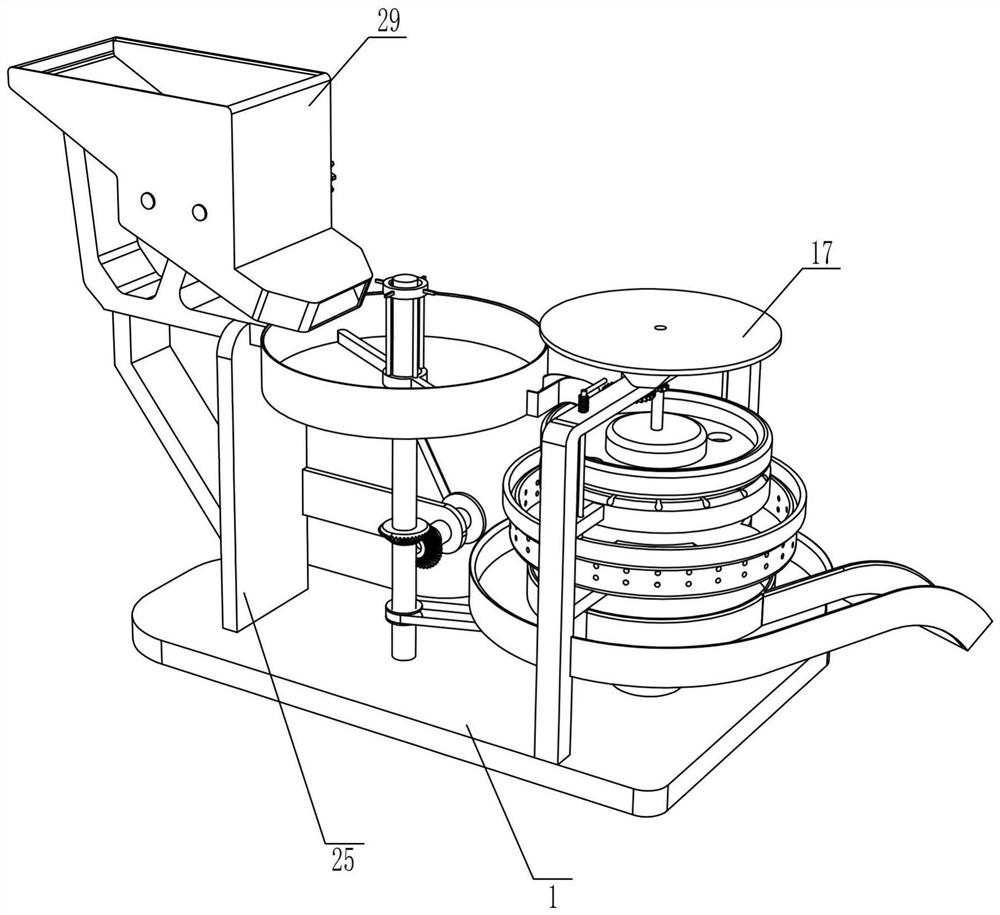

Efficient production and manufacturing machine for granulated feed

InactiveCN111802674AEnsure safetyPromotes thorough mixingFeeding-stuffCocoaMolding machineElectric machinery

The invention relates to the technical field of feed production, and particularly relates to an efficient production and manufacturing machine for granulated feed. The efficient production and manufacturing machine for the granulated feed can automatically crush feed raw materials, heat and sterilize the feed raw materials, grind the feed raw materials into powder to be quickly formed and not prone to being broken, and finally cut the feed raw materials into the granulated feed, and the feed production efficiency is improved. The efficient production and manufacturing machine for the granulated feed comprises a base, a motor, a first rotating shaft, a supporting frame, a first rotating disc, a discharging frame and a forming mechanism, wherein the motor is fixedly installed on the base, and one end of the first rotating shaft is fixedly connected with the output end of the motor. According to the efficient production and manufacturing machine for the granulated feed, a crushing mechanism and a heating mechanism are arranged, the feed raw materials can be automatically crushed, and therefore various materials can be fully mixed conveniently; and the materials are heated and sterilized, infectious microbes in the materials are killed, and then the safety of the feed is guaranteed.

Owner:李玲

Method for producing high temperature nickel-metal hydride battery

ActiveCN102544509AImprove high temperature performanceReduce usageFinal product manufactureLead-acid accumulator electrodesRare-earth elementMetallurgy

The invention discloses a method for producing a high temperature nickel-metal hydride battery. The method comprises the steps of preparing gamma-CoOOH powder, producing anode, preparing electrolyte, selecting a diaphragm, winding and the like. In the method, gamma-CoOOH powder is used as an additive to be filled in the anode, and a polypropylene diaphragm subjected to grafting or fluoridation treatment is adopted as the battery diaphragm, thereby effectively improving the high temperature performance of the nickel-metal hydride battery, avoiding the use of rare earth elements, and further greatly reducing the production cost (the cost of the additive is saved by 20 percent).

Owner:QUANZHOU JINTION ELECTRONICS

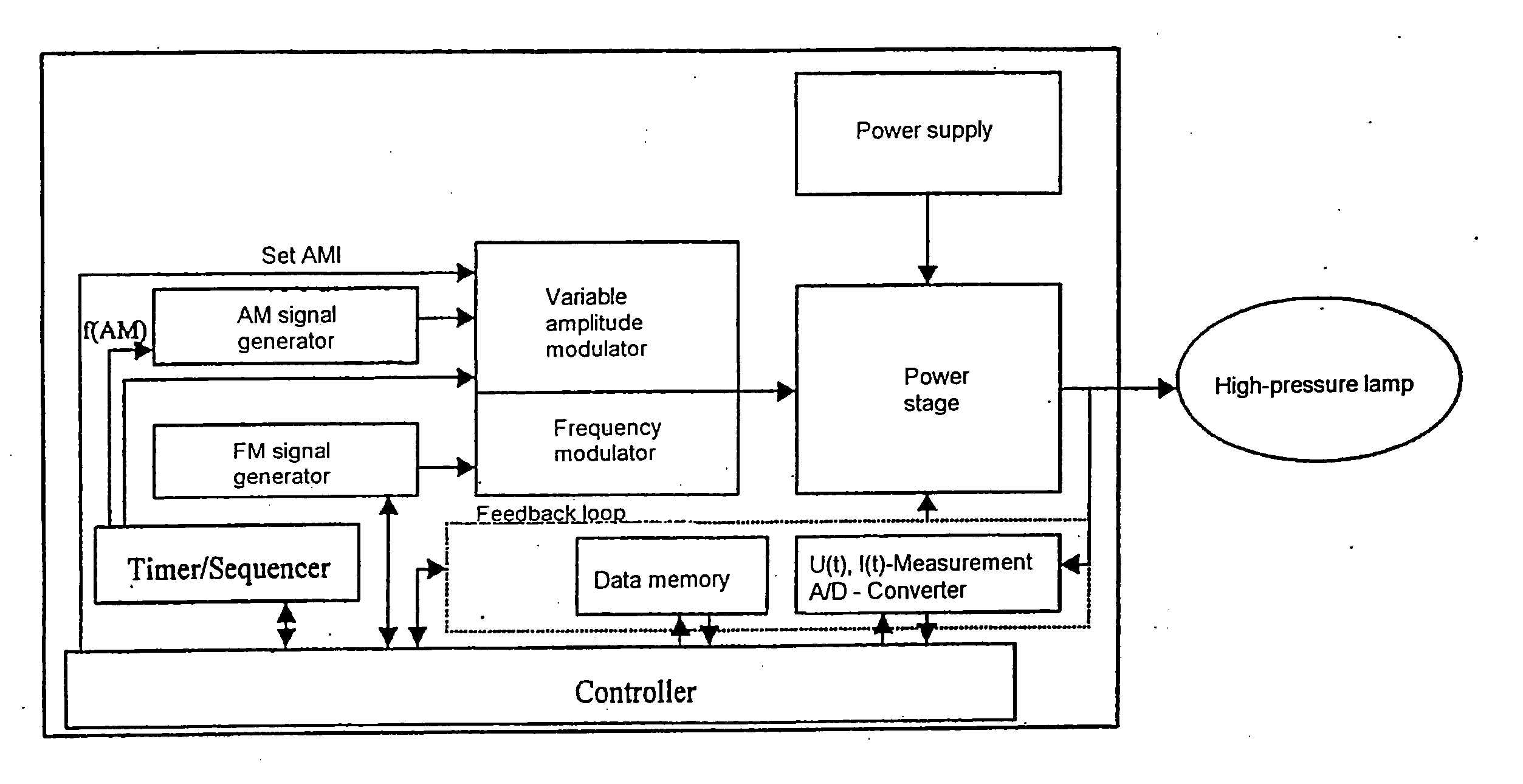

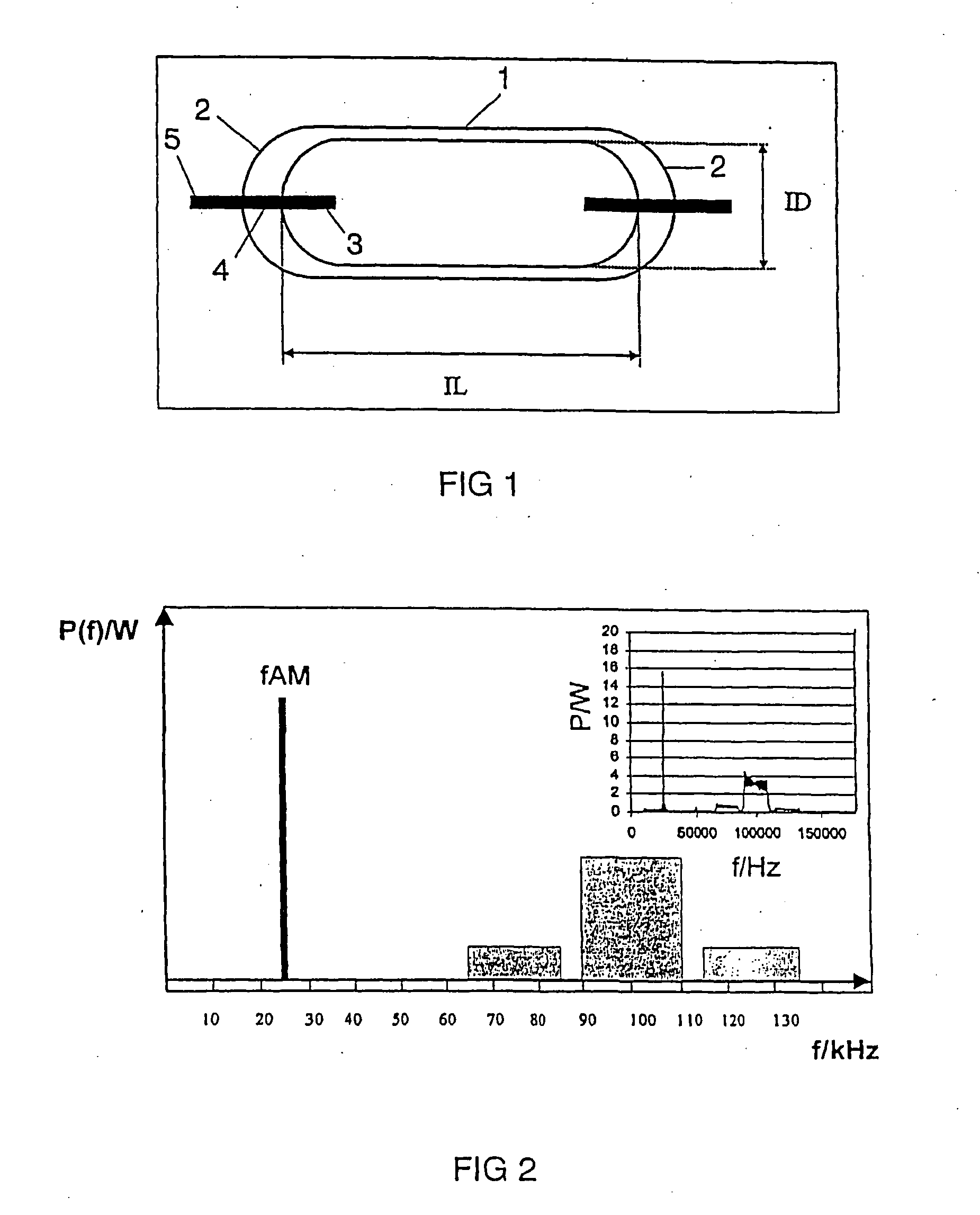

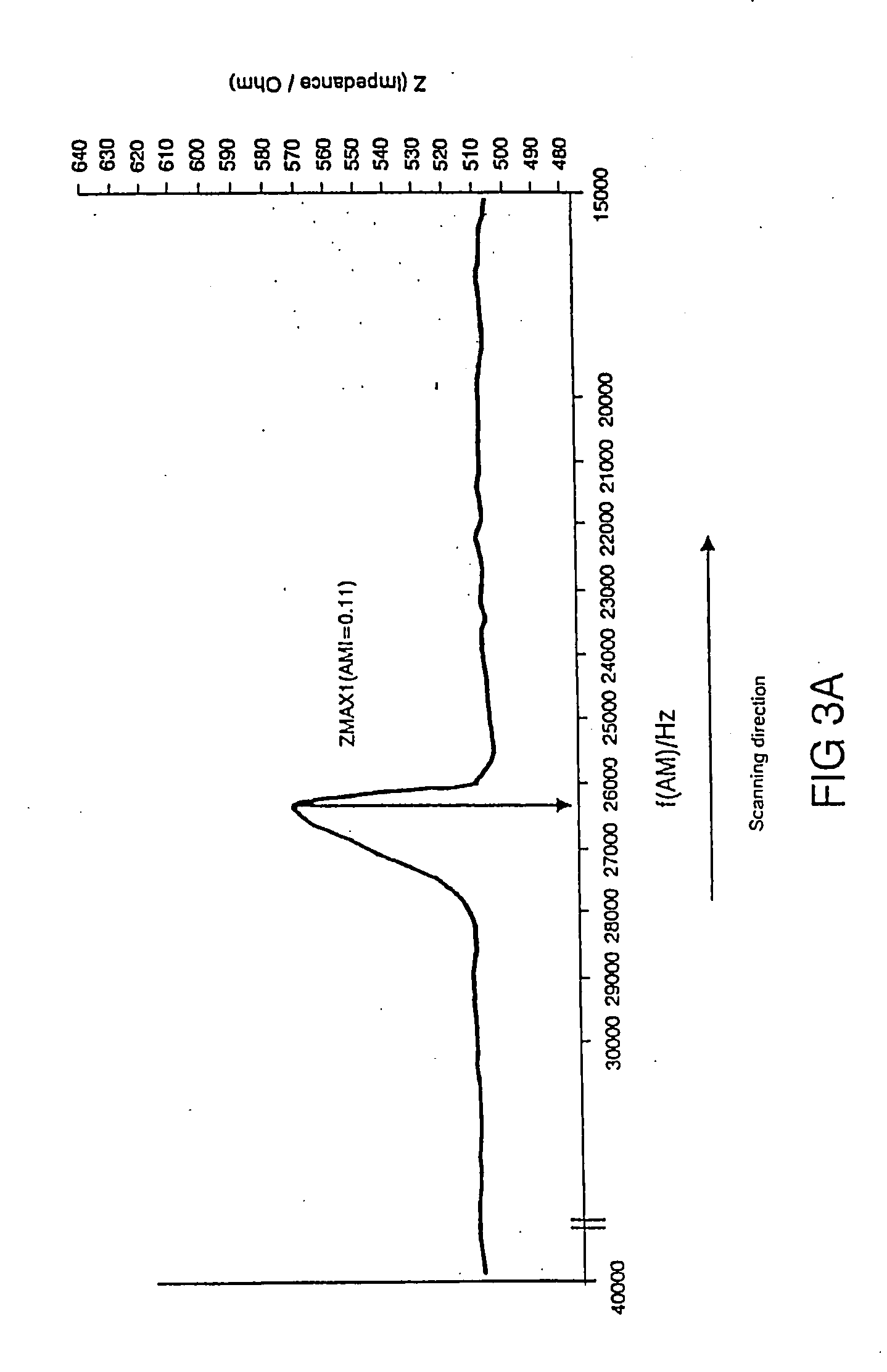

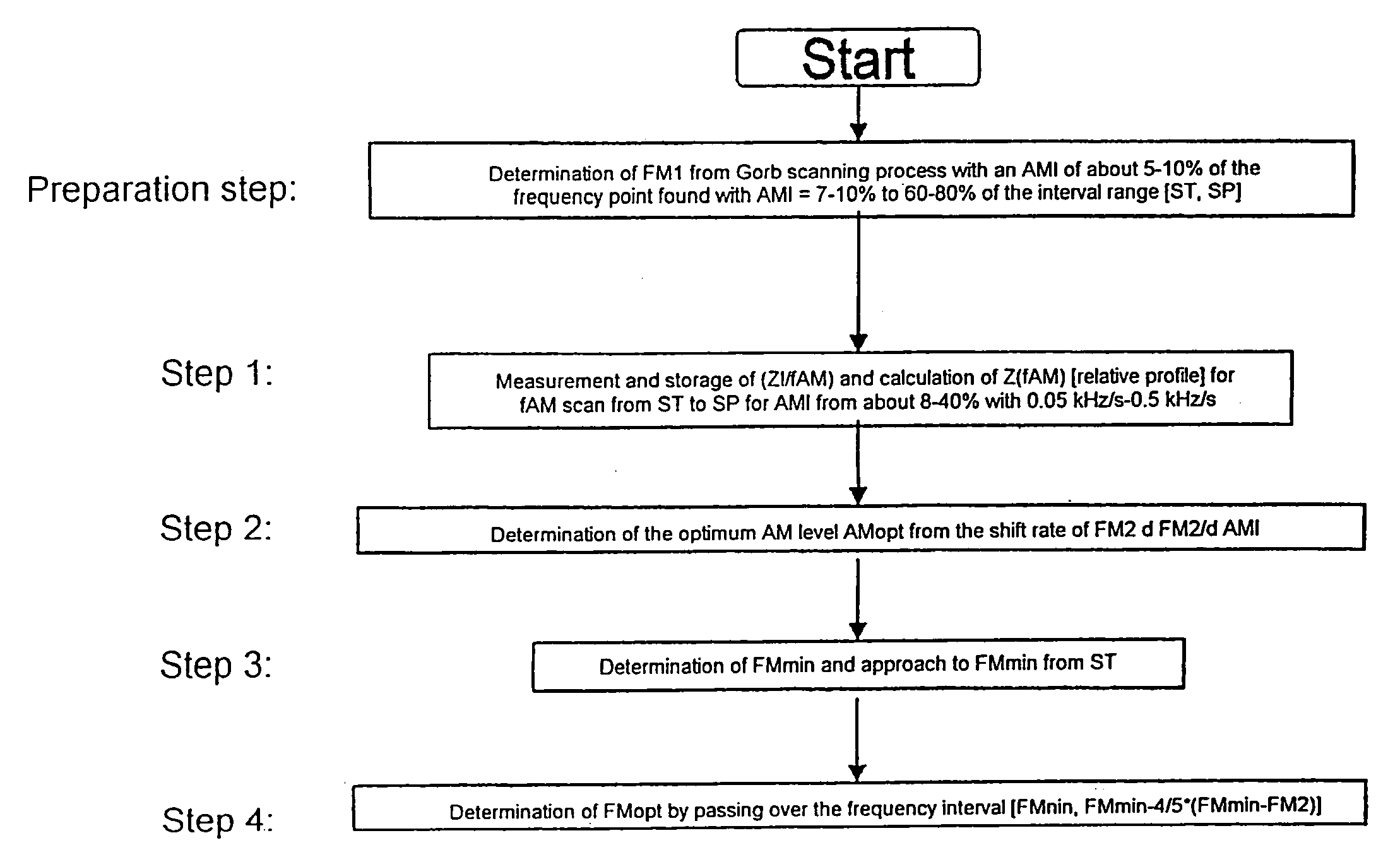

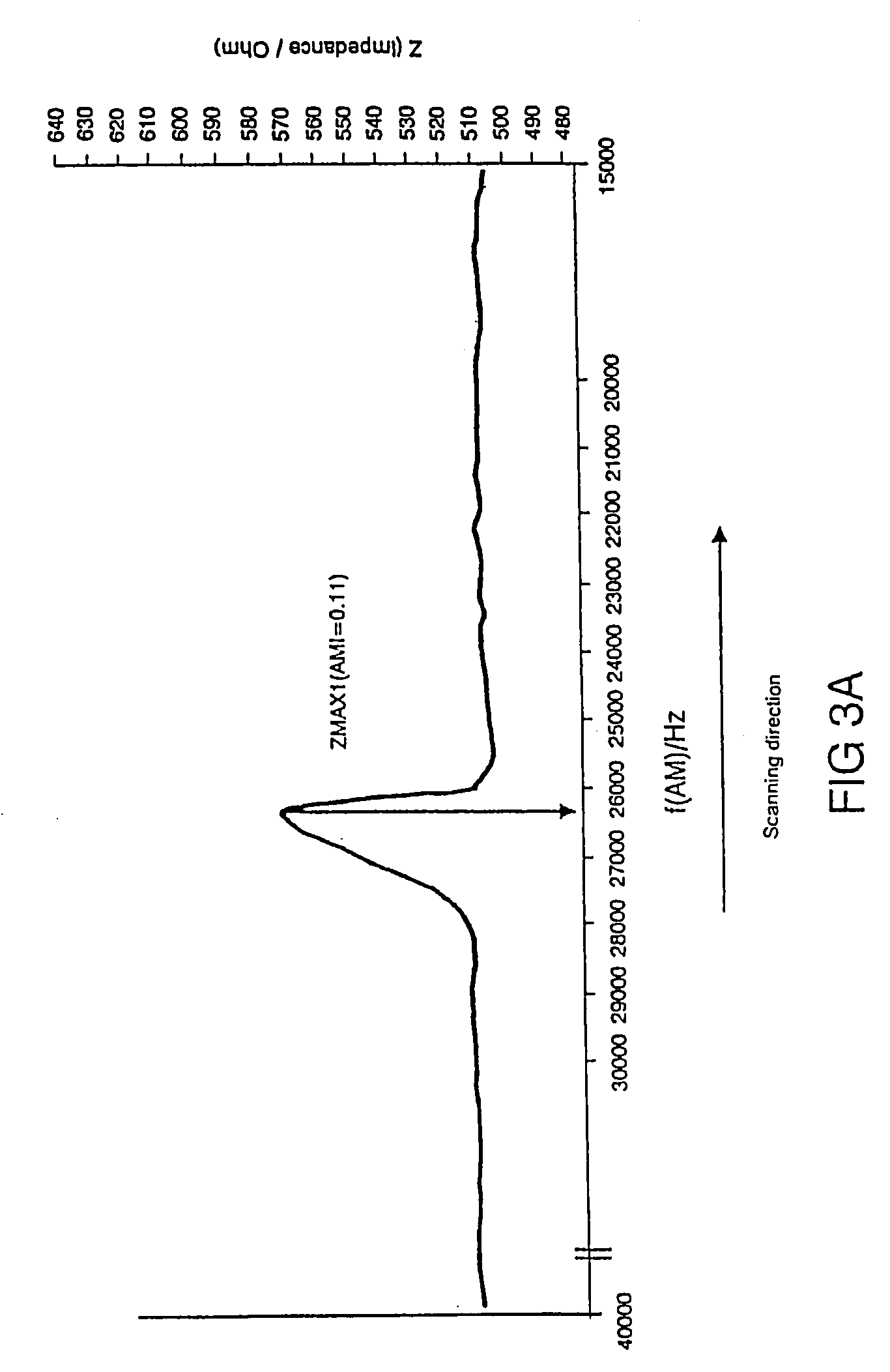

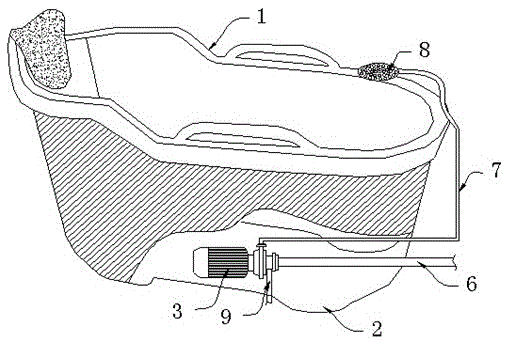

Operating method, electronic ballast and system for resonant operation of high pressure lamps in the longitudinal mode

InactiveUS20050168176A1Promotes thorough mixingInhibit coloringGas discharge lampsElectric light circuit arrangementHigh pressureLongitudinal mode

Operating method, electronic ballast and system for resonant operation of high-pressure lamps in the longitudinal mode The operating method is based on the simultaneous use of FM and AM and is distinguished by passing through a number of steps which are used to find an optimum frequency for the AM and, in addition, to define an optimum AM level. An electronic ballast which has a memory module which can be overwritten is used for implementation.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

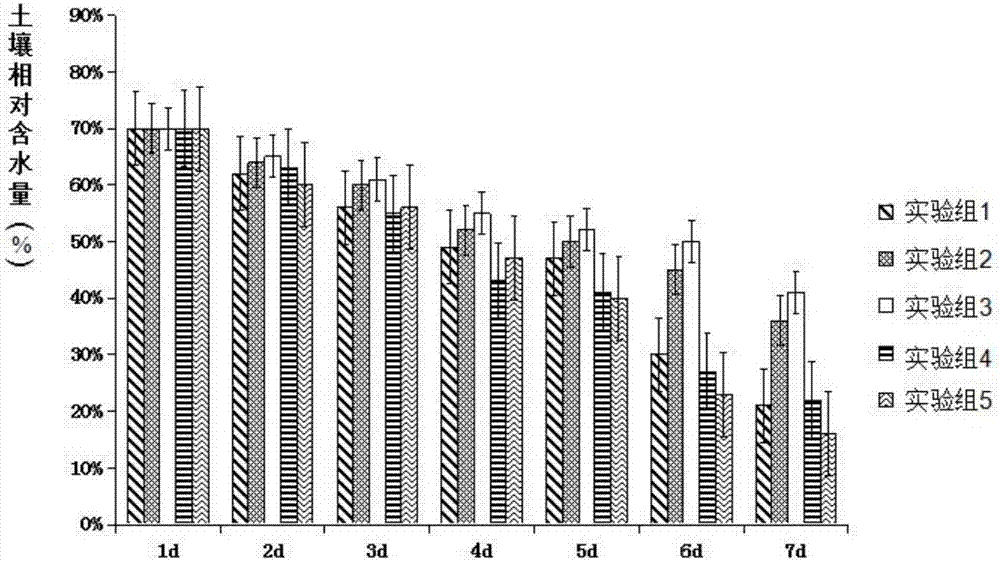

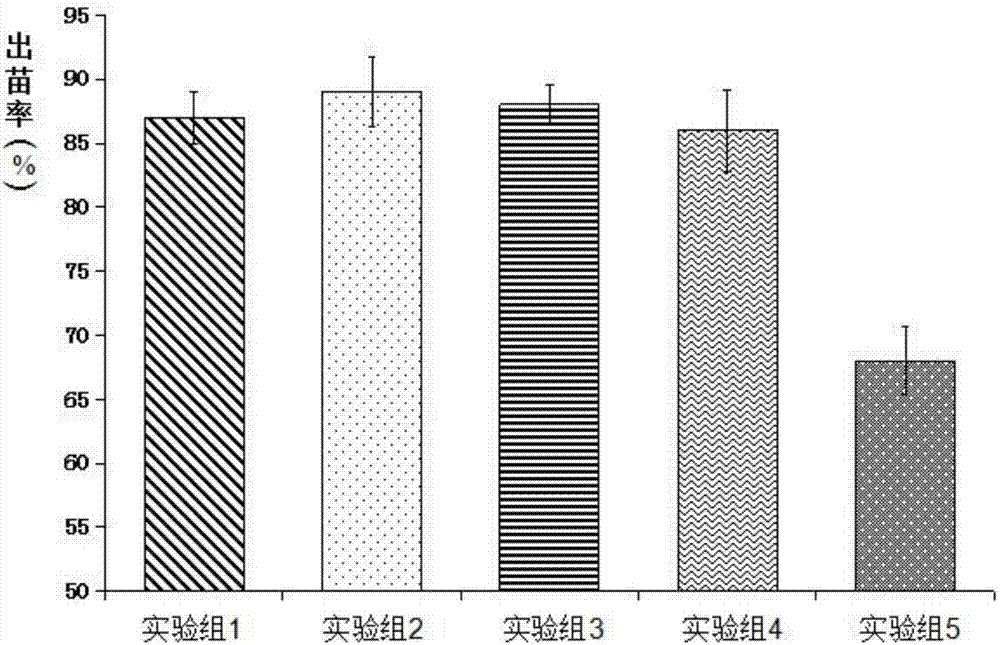

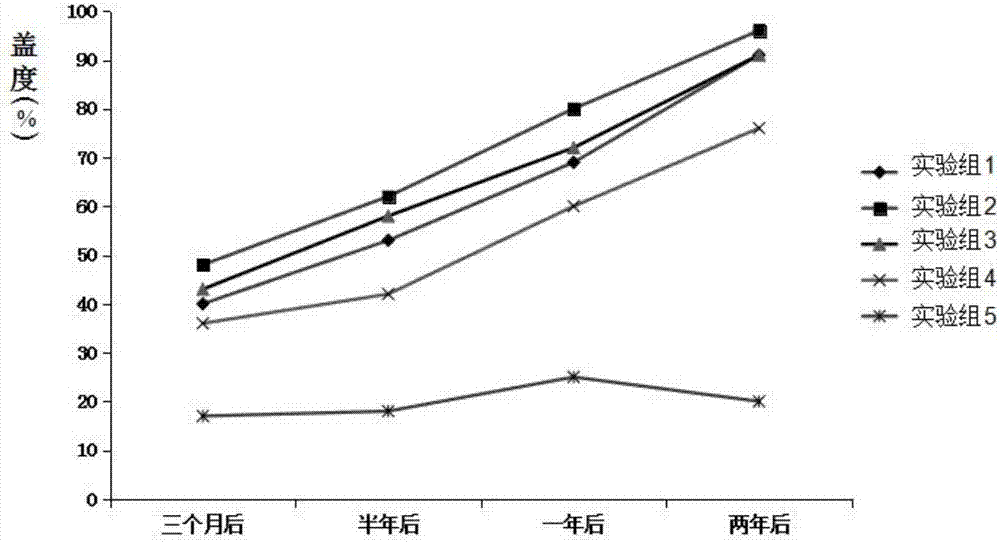

Spray seeding matrix for regreening of bare side slope adapted to soil in arid and semi-arid zones and preparation method of spray seeding matrix

InactiveCN106866230AReduce chappingImprove fertilityGrowth substratesCulture mediaFiberSodium Bentonite

The invention relates to the technical field of environment protection and greening of side slopes, and provides a spray seedling matrix for regreening of bare side slope adapted to soil in arid and semi-arid zones and a preparation method of the spray seeding matrix. The spray seedling matrix provided by the invention is prepared from the following raw materials in parts by weight: 25 to 40 parts of composted organic wastes, 30 to 40 parts of side slope loess, 5 to 15 parts of kaolin, 0.5-0.8 part of potassium fulvate, 5 to 15 parts of bentonite clay, 3 to 4 parts of flour sticky glue and 5 to 10 parts of plant fibers. According to the spray seedling matrix, intensive aboveground parts and developed root systems of plants can be quickly formed on the long-term arid and bare side slope, regreening of the side slope can be effectively carried out, the soil is consolidated, and surface runoff and soil washing can be prevented and controlled. The preparation method provided by the invention comprises the steps of mixing the composted organic wastes, the side slope loess, the kaolin, the potassium fulvate and the bentonite clay and pulverizing into particles; then mixing the particles with the plant fibers to obtain a mixture; successively, adding water and stirring the mixture to form a viscous state; then mixing the viscous product with the flour sticky glue. The preparation method has the advantages of simple technology, strong operability and benefit to industrial production.

Owner:LANZHOU UNIVERSITY

Operating method, electronic ballast and system for resonant operation of high pressure lamps in the longitudinal mode

InactiveUS7157867B2Promotes thorough mixingInhibit coloringGas discharge lampsElectric light circuit arrangementEngineeringHigh pressure

The operating method is based on the simultaneous use of FM and AM and is distinguished by passing through a number of steps which are used to find an optimum frequency for the AM and, in addition, to define an optimum AM level. An electronic ballast which has a memory module which can be overwritten is used for implementation.

Owner:PATENT TREUHAND GESELLSCHAFT FUER ELECTRIC GLUEHLAMPEN M B H

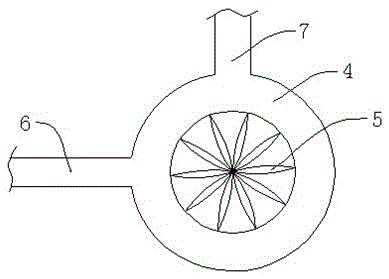

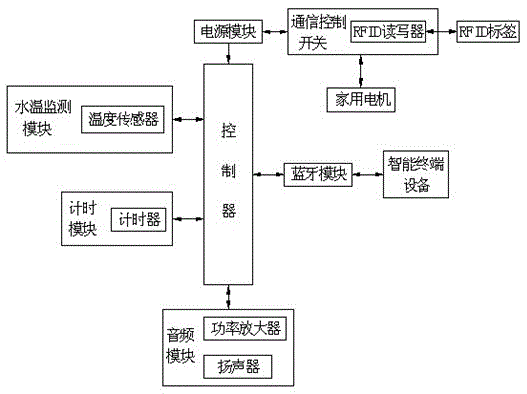

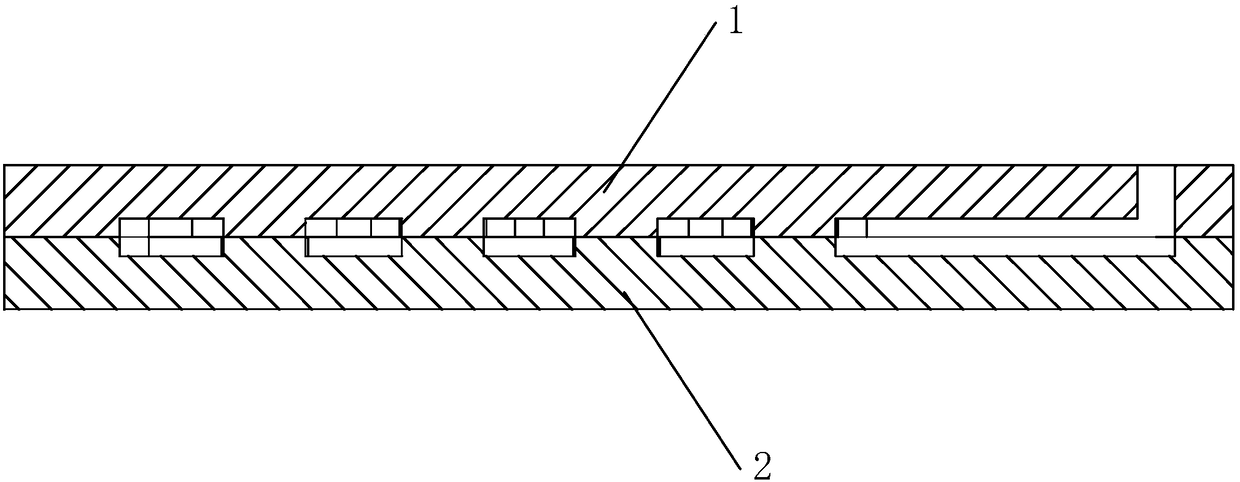

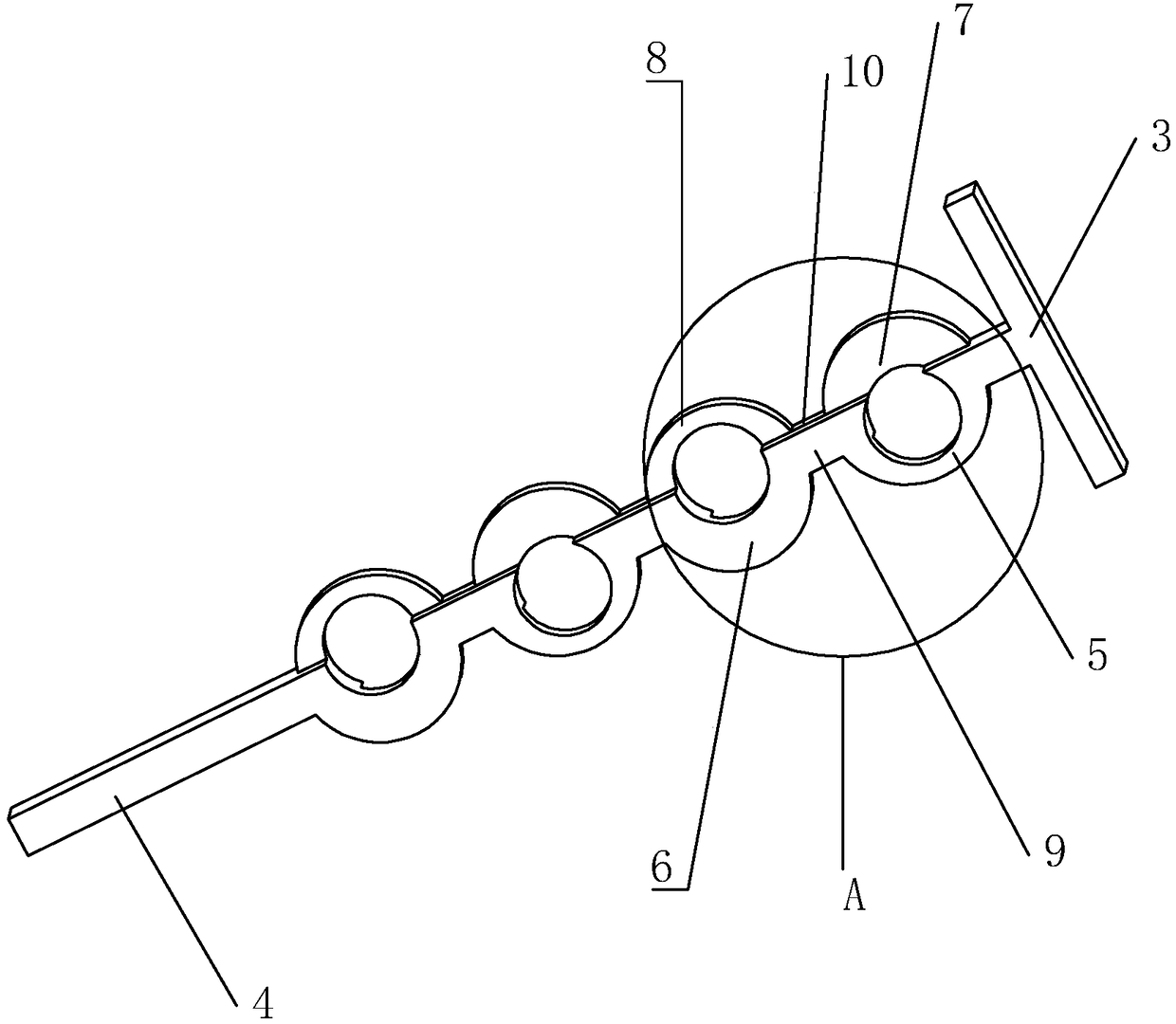

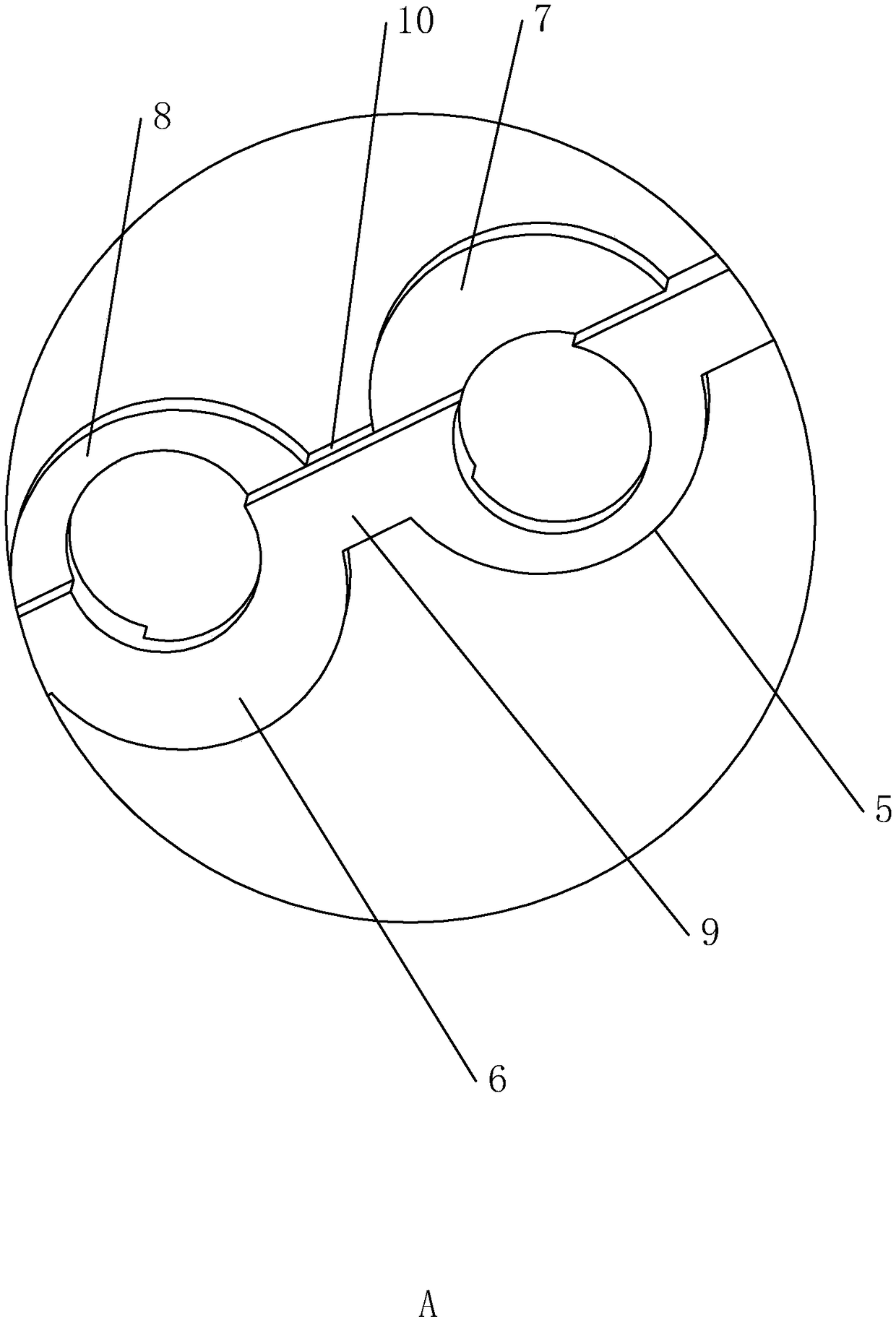

Wooden shower bucket with micro-bubble function

The invention provides a wooden shower bucket with a micro-bubble function. The wooden shower bucket comprises a wooden bucket body. The wooden shower bucket is characterized in that an interlayer cavity is formed in the bottom of the wooden bucket body; a micro-bubble generator is arranged in the interlayer cavity; the micro-bubble generator comprises a household motor and a water cutting room which is connected with the household motor; an air diffusion impeller which is integrally connected with the output shaft of the household motor is arranged in the water cutting room; a water inlet pipeline and a water outlet pipeline which are communicated with the water cutting room are respectively arranged in the water cutting room; an air inlet pipeline which is communicated with the outside is connected with one side of the water inlet pipeline; the water outlet pipeline extends outside the interlayer cavity and is connected with an external shower head. By adoption of the wooden shower bucket, air and water can be effectively and uniformly mixed, and thus a great amount of micro-bubbles can be generated.

Owner:SUZHOU HUANGZHANGMEIZU IND DESIGN

3D asymmetric division and combination structure passive type micromixer

PendingCN108201848AIncrease contact areaImprove the mixing effectTransportation and packagingMixersMixed flowEngineering

The invention relates to a 3D asymmetric division and combination structure passive type micromixer. According to the 3D asymmetric division and combination structure passive type micromixer, an uppermatrix and a lower matrix are combined firmly; a matrix is provided with a runner through etching; the runner comprises an inlet runner, circular mixing units, an outlet runner, and a straight runner; each circular mixing unit is composed of a large circular runner, a small circular runner, and a straight runner unit; the circular mixing units are arranged between the straight runner and the outlet runner in series; the straight runner and the outlet runner are arranged to be collinear; the annular mixing units are arranged along the axis direction at equal intervals; liquid is introduced into the runner through a runner inlet, separation of mixed flow is induced because of interface abrupt change in entering into the circular mixing units, a part fluid enters into a circular runner, andlaminar flow diffusion states are maintained, and another part fluid flows along the vertical direction, secondary flow and eddy generation, and flow line disturbance are caused because of the abruptreduction of the width when the fluid enters into the circular runner, in fluid separation and combination, collision and extrusion of the two fluid parts are caused because of the convection, so thatfull contact of the two fluid parts is realized.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com